Automatic welding device for aluminum alloy longitudinal joints

An automatic welding and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of high thermal conductivity, heat loss and slow speed of aluminum alloy materials, achieve prolonged cooling and solidification, prevent heat loss, The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

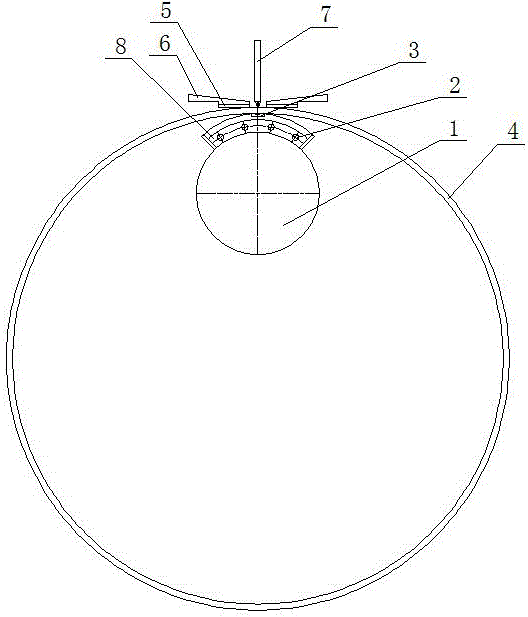

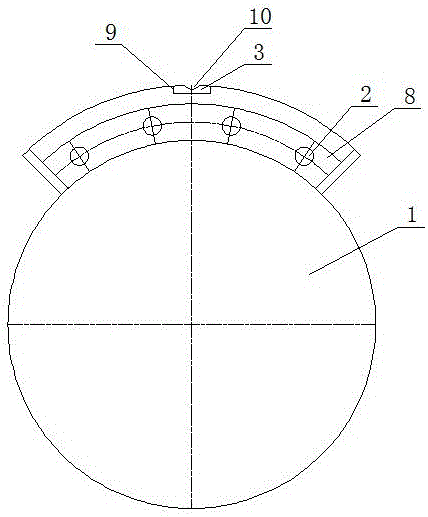

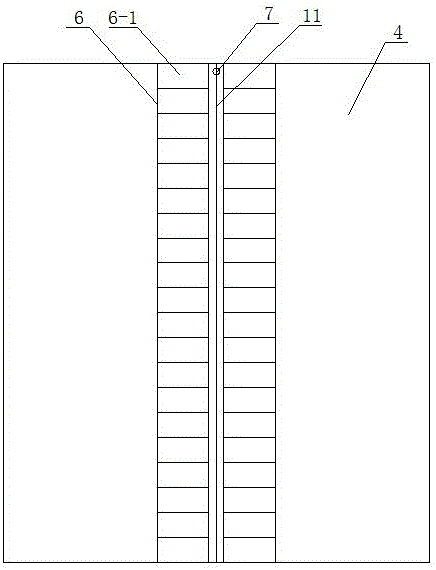

[0015] Such as figure 1 As shown in -3, the aluminum alloy longitudinal seam automatic welding device includes a mandrel 1 installed on the welding device frame, the axial direction of the mandrel 1 is consistent with the length direction of the longitudinal seam 11 of the workpiece 4, and the mandrel 1 is set on the 4 Below the longitudinal seam 11, an arc-shaped steel pipe 8 is arranged on the upper surface of the mandrel 1, and four electric heating pipes 2 are inserted in the arc-shaped steel pipe 8, and the four electric heating pipes 2 are evenly distributed along the arc direction of the arc-shaped steel pipe 8. . The upper surface of the arc-shaped steel pipe 8 is connected with a liner 3 , and the upper surface of the arc-shaped steel pipe 8 is provided with a liner installation groove 9 along the length direction, and the liner 3 is arranged in the liner installation groove 9 . A welding seam forming groove 10 is arranged on the upper surface of the pad 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com