Patents

Literature

1188results about How to "Efficient conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

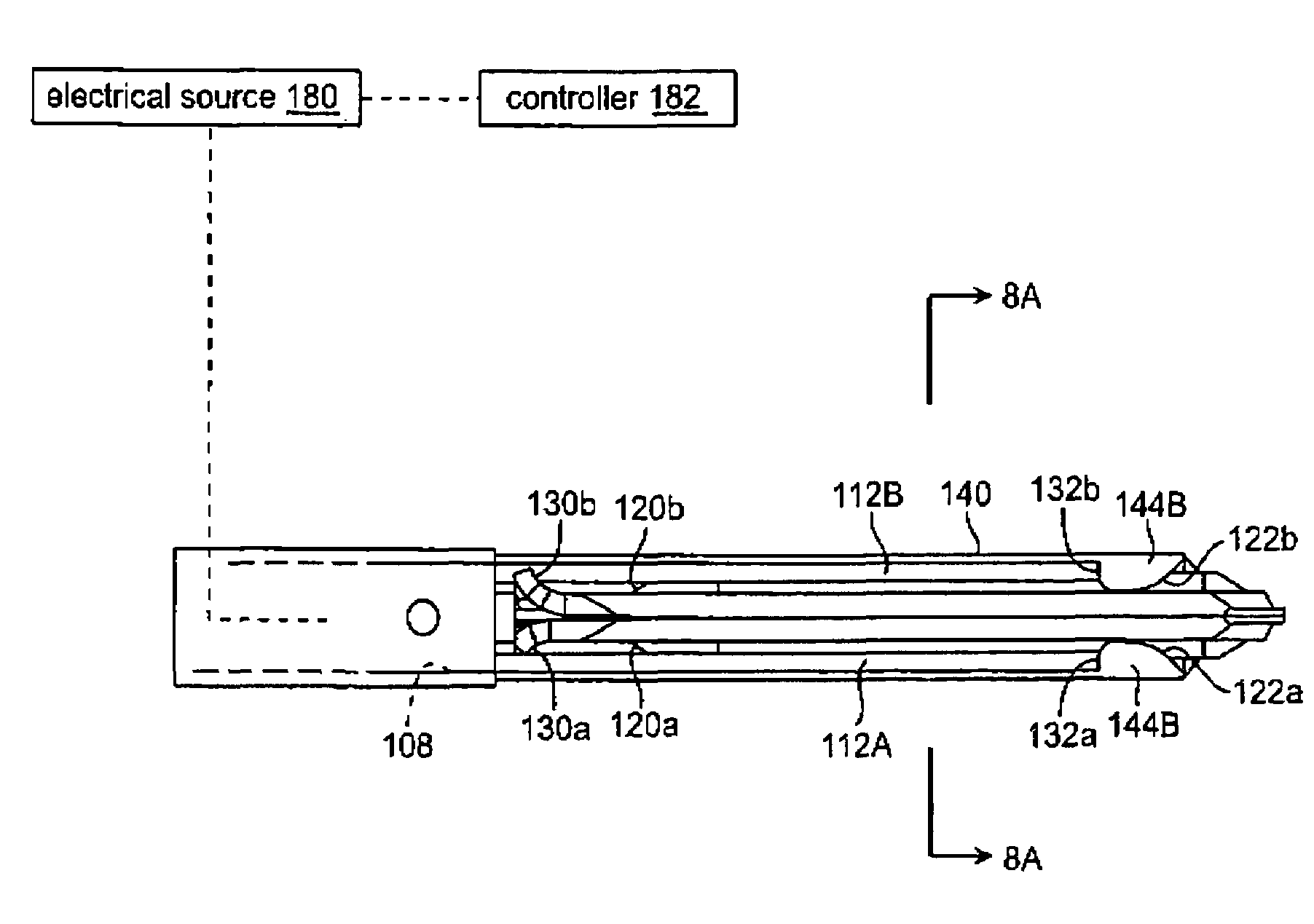

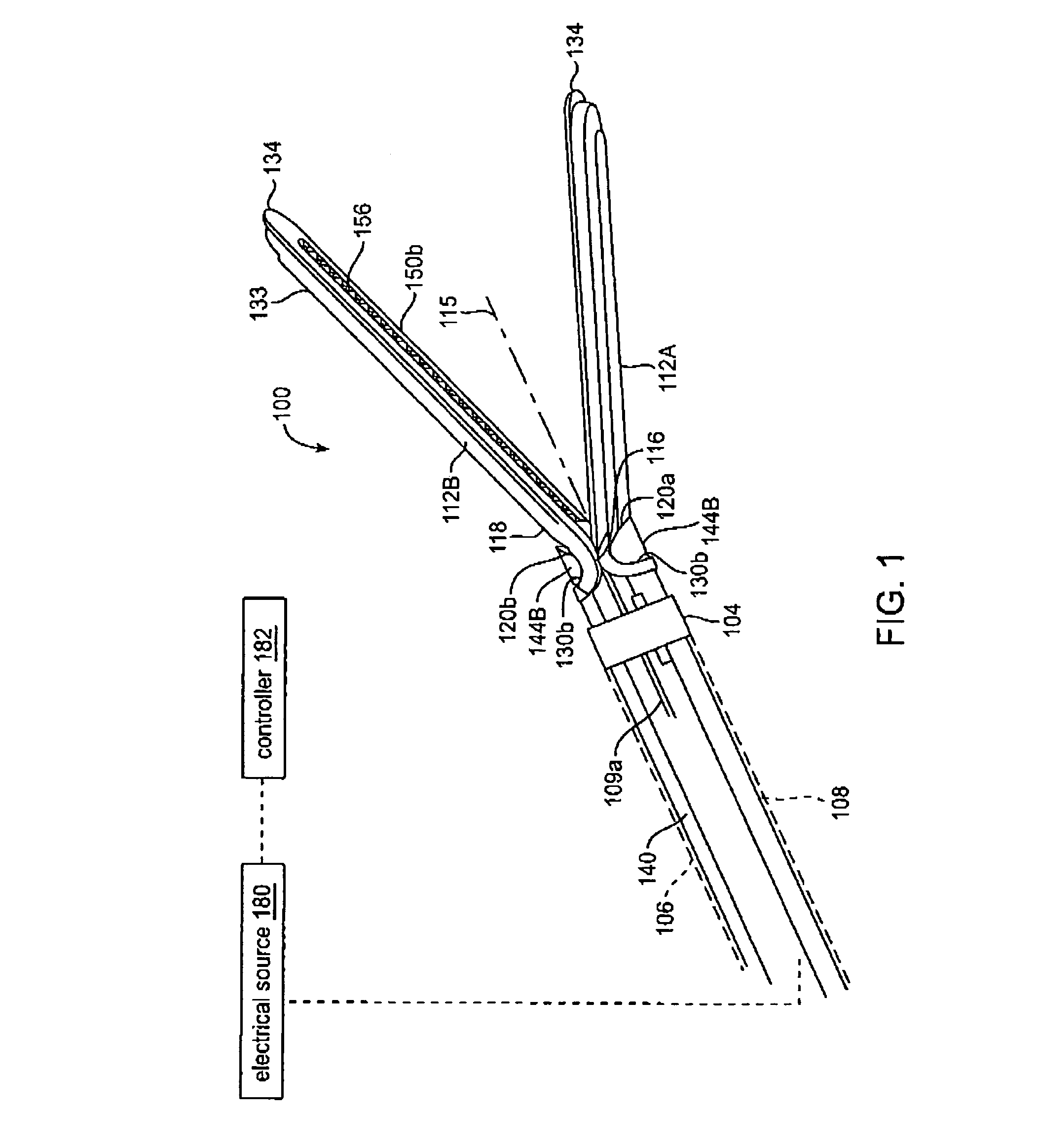

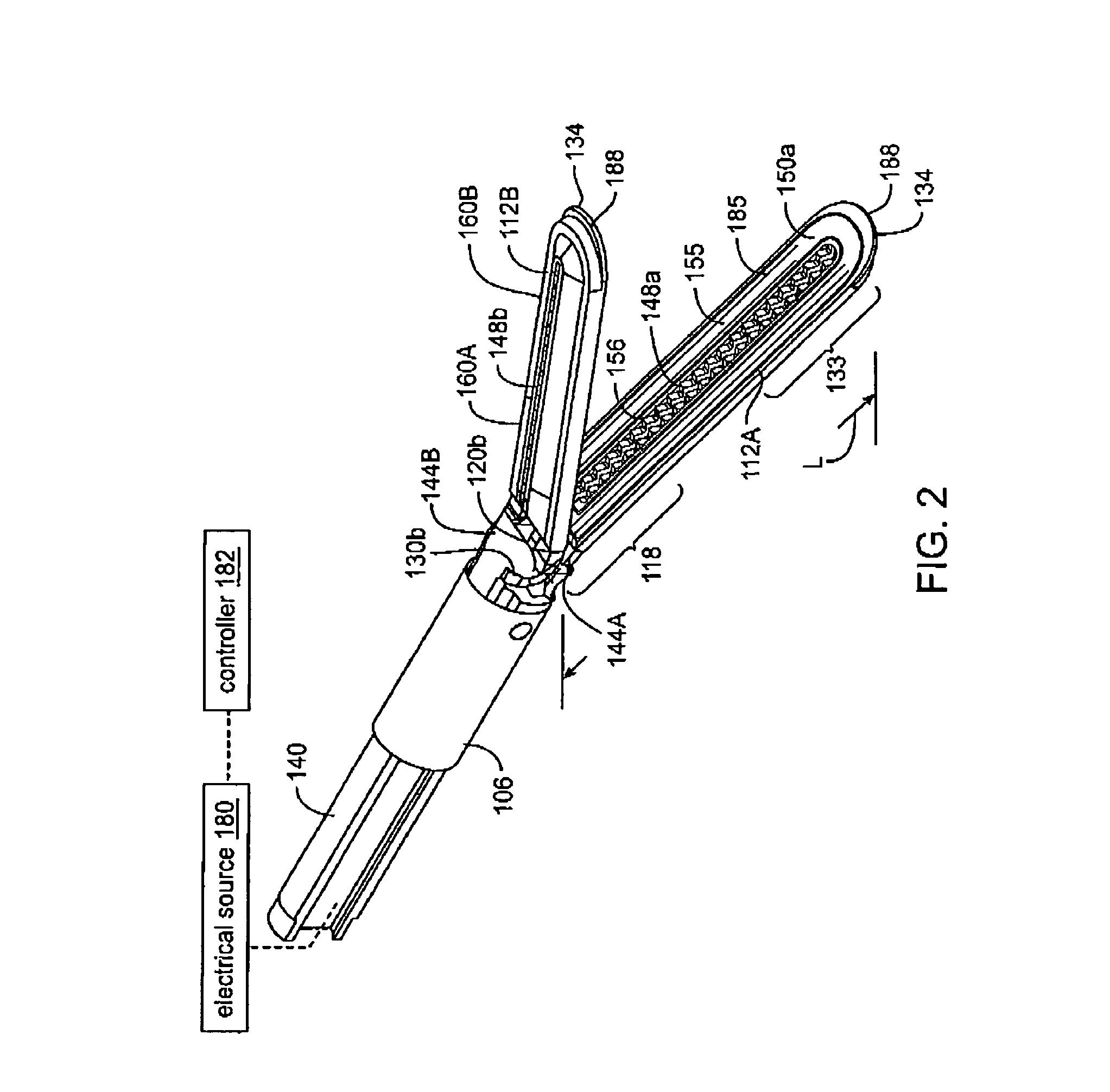

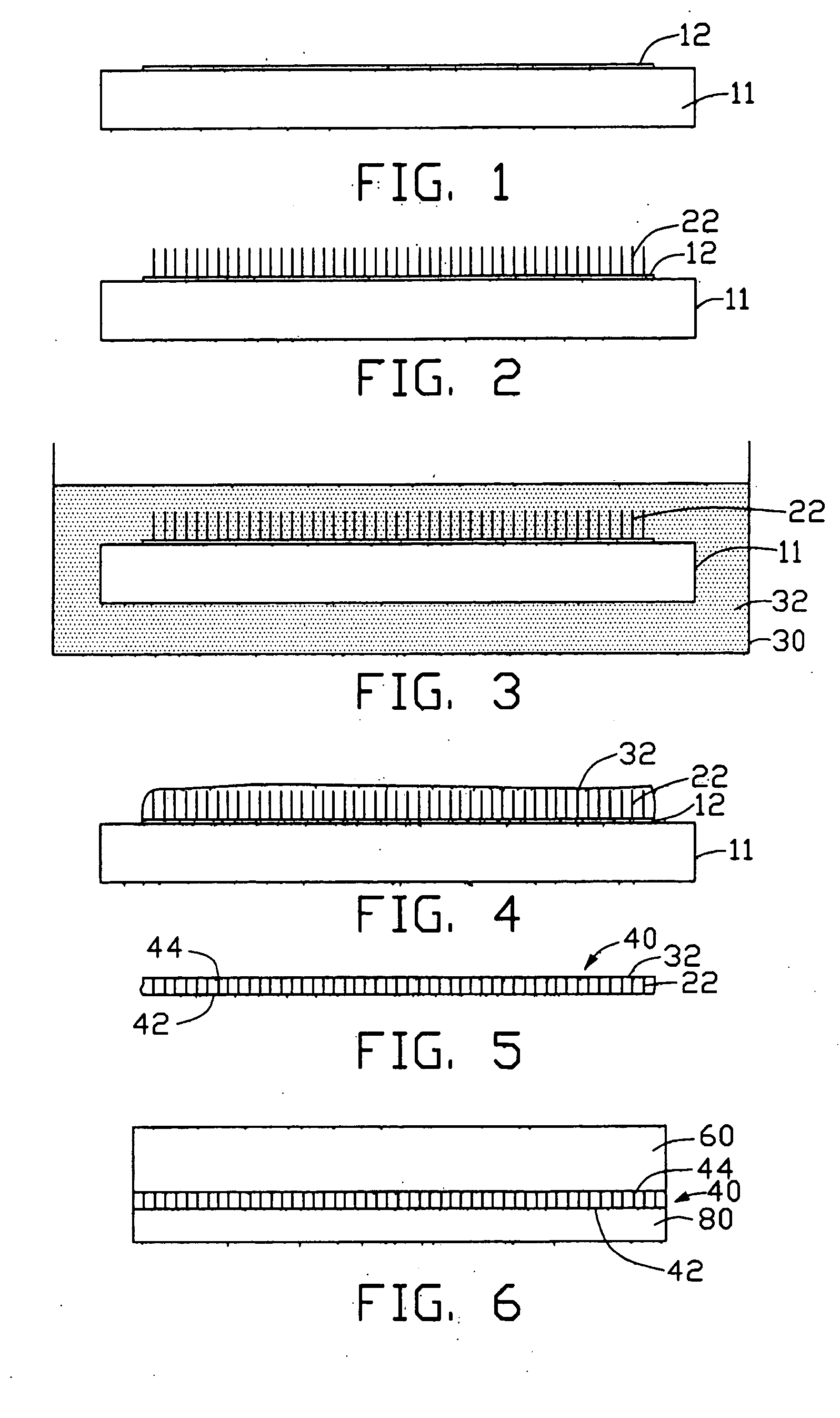

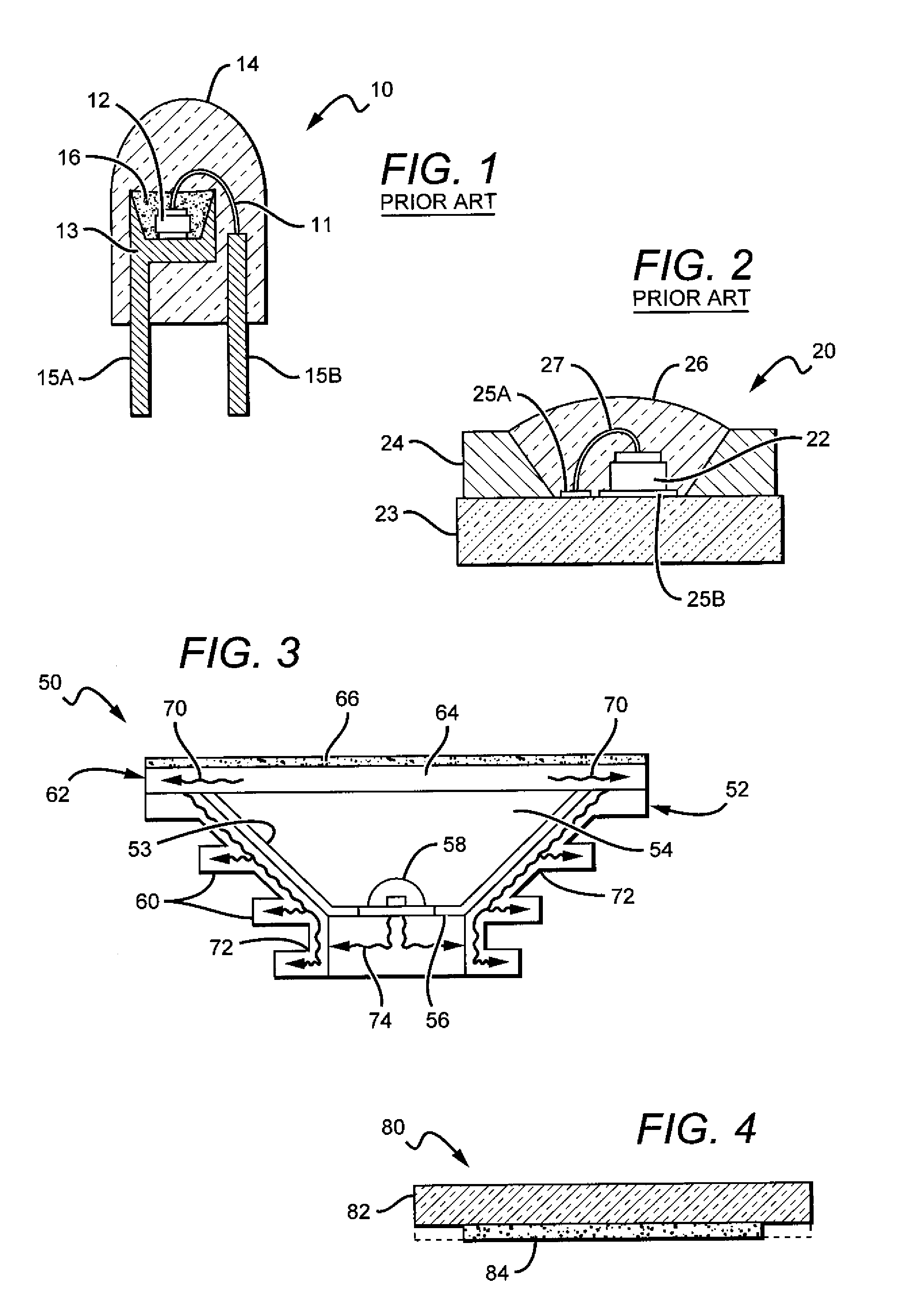

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

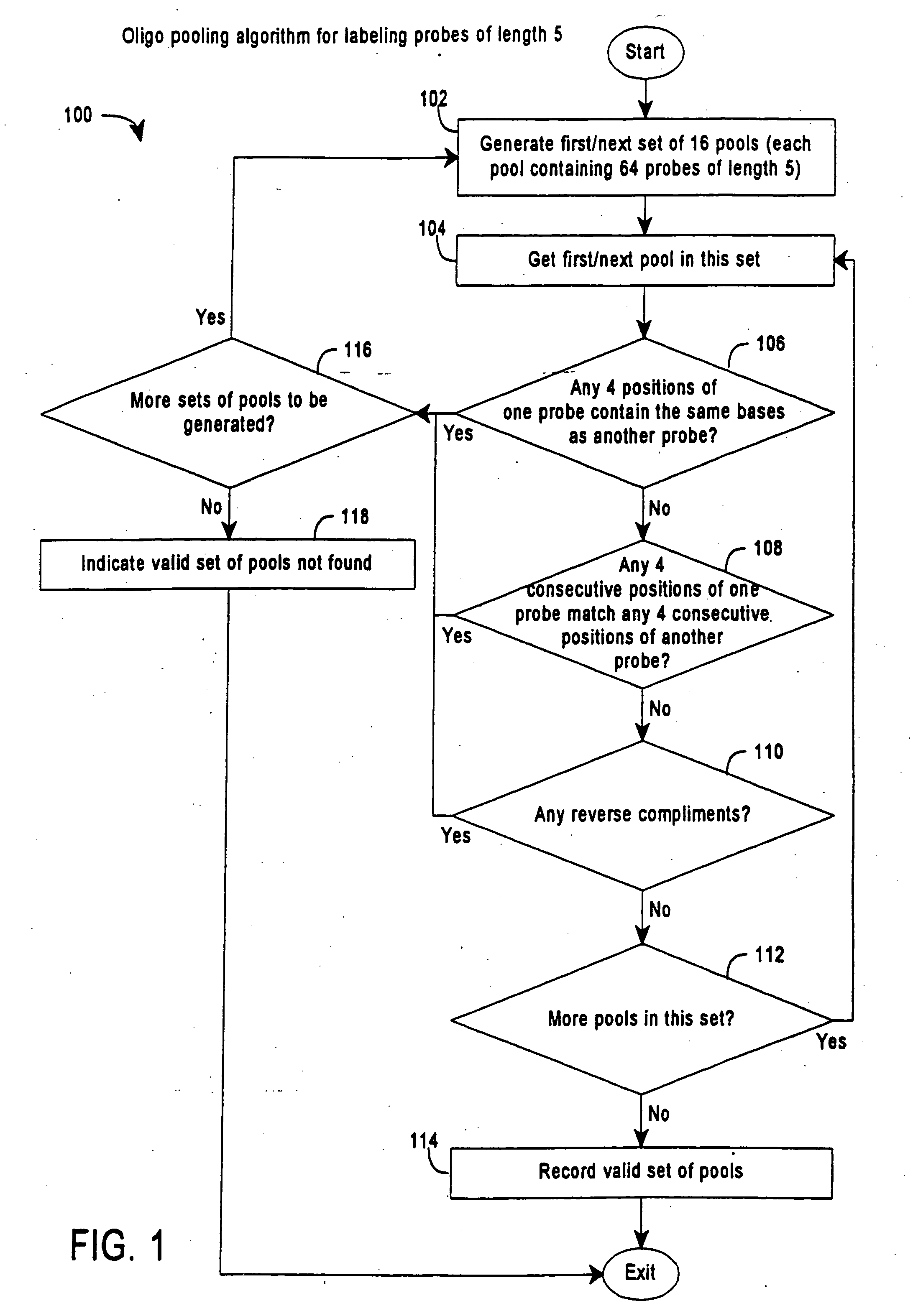

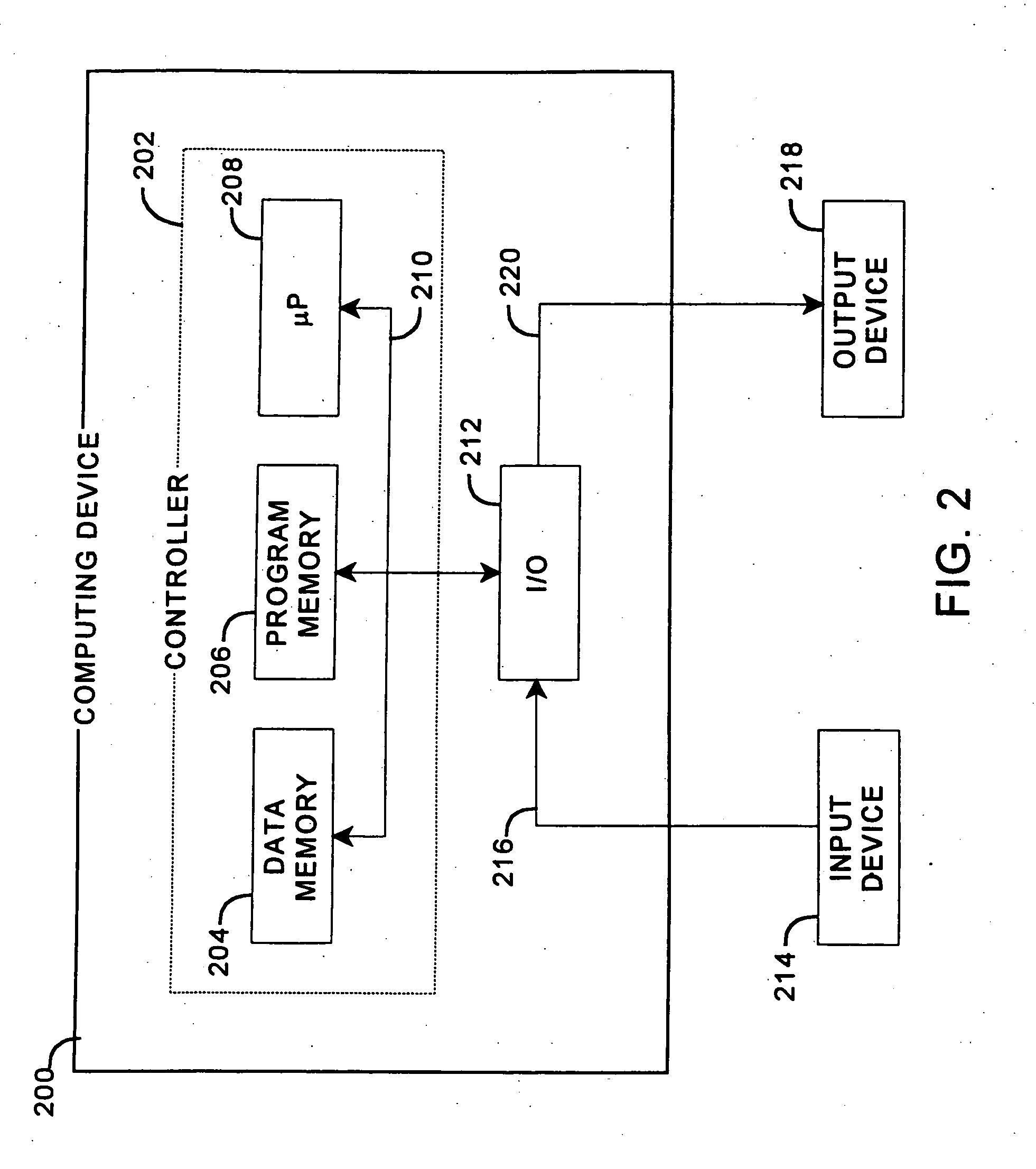

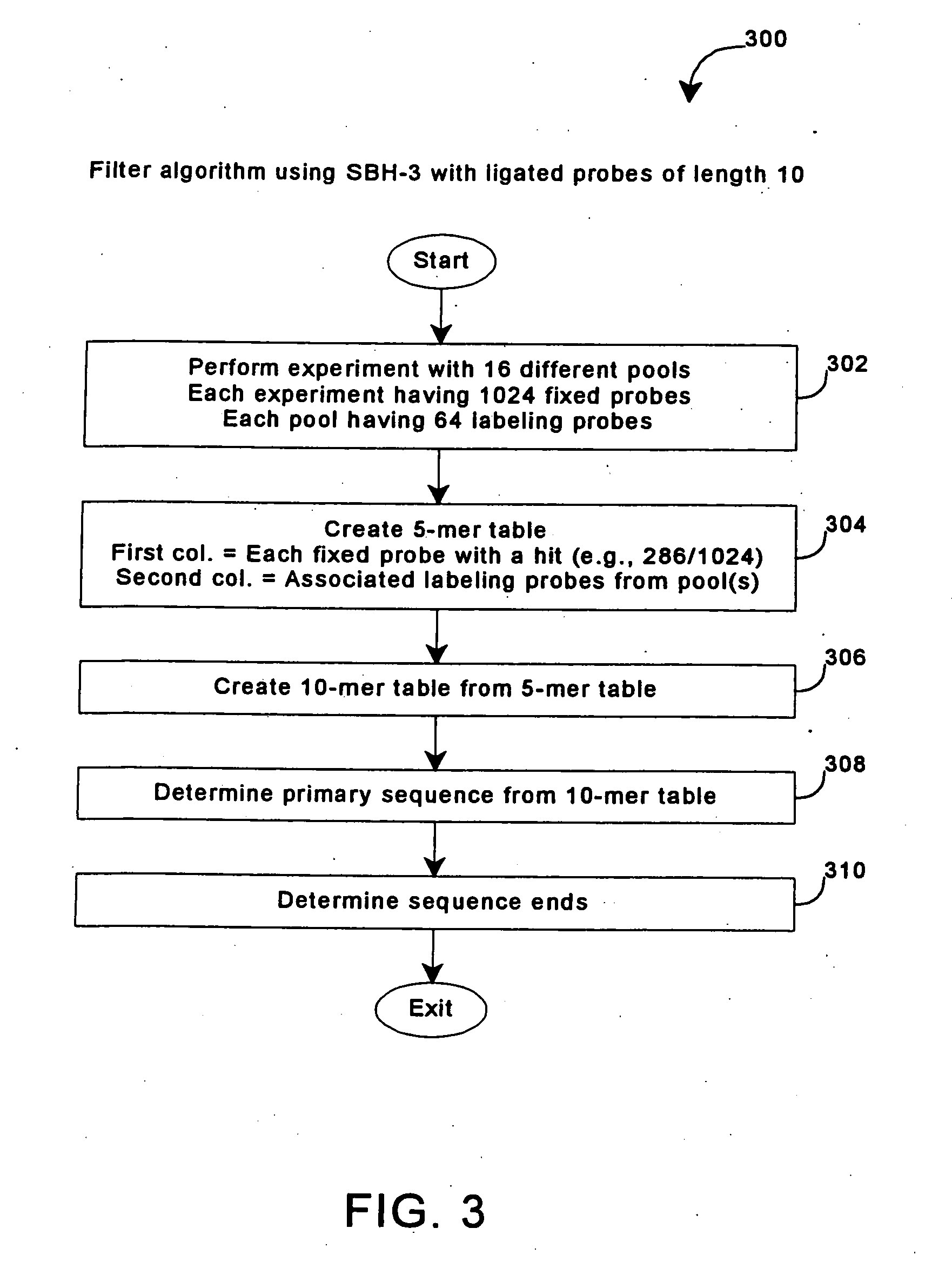

Enhanced sequencing by hybridization using pools of probes

InactiveUS20050191656A1Enhances SBH methodReduce redundancySugar derivativesMicrobiological testing/measurementNucleic acid sequencingNucleic acid sequence

The invention provides methods for sequencing by hybridization (SBH) using pools of probes that allow greater efficiency in conducting SBH by reducing the number of separate measurements of hybridization signals required to identify each particular nucleotide in a target nucleic acid sequence. The invention also provides pools and sets of pools of probes, as well as methods of generating pools of probes.

Owner:COMPLETE GENOMICS INC

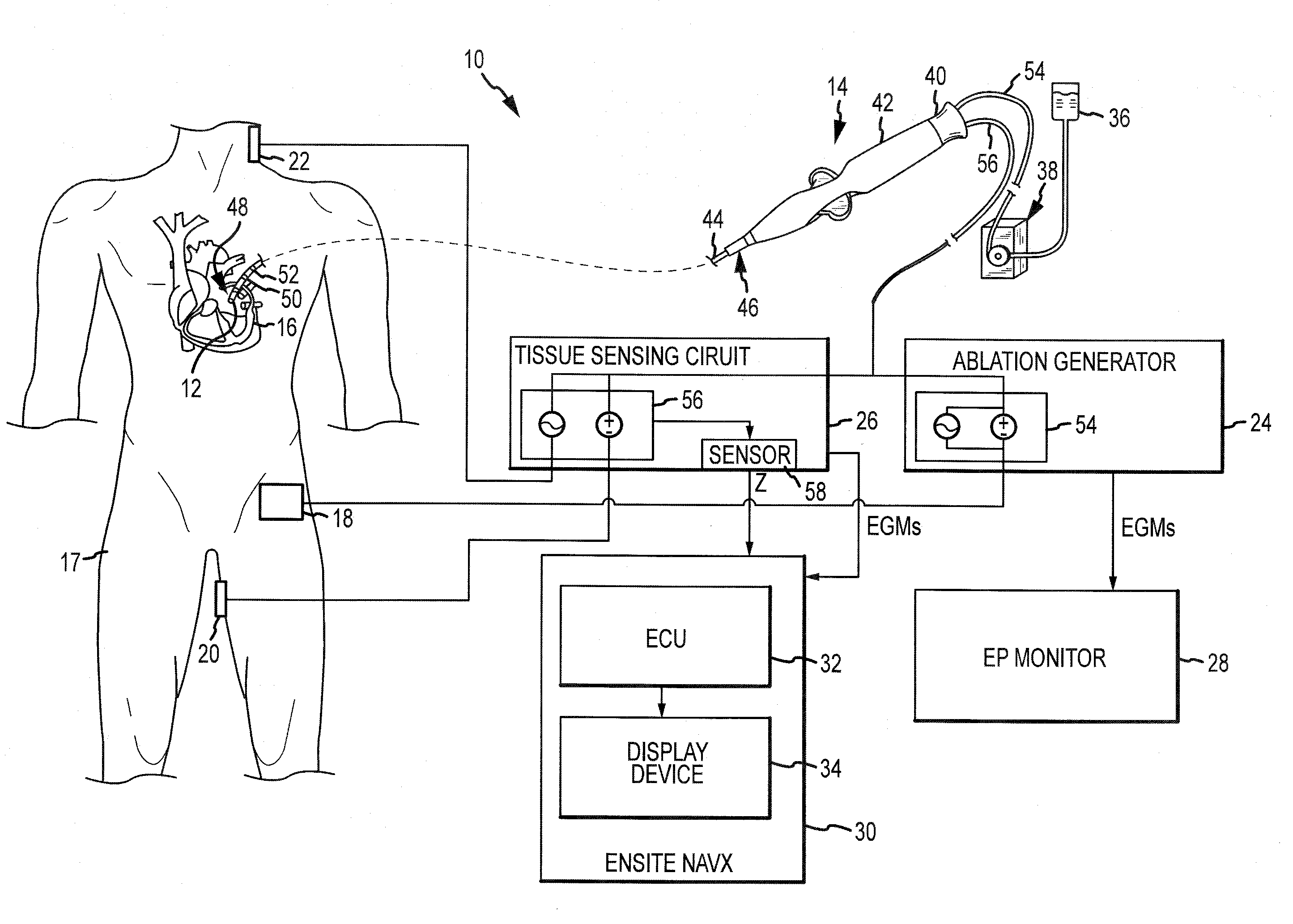

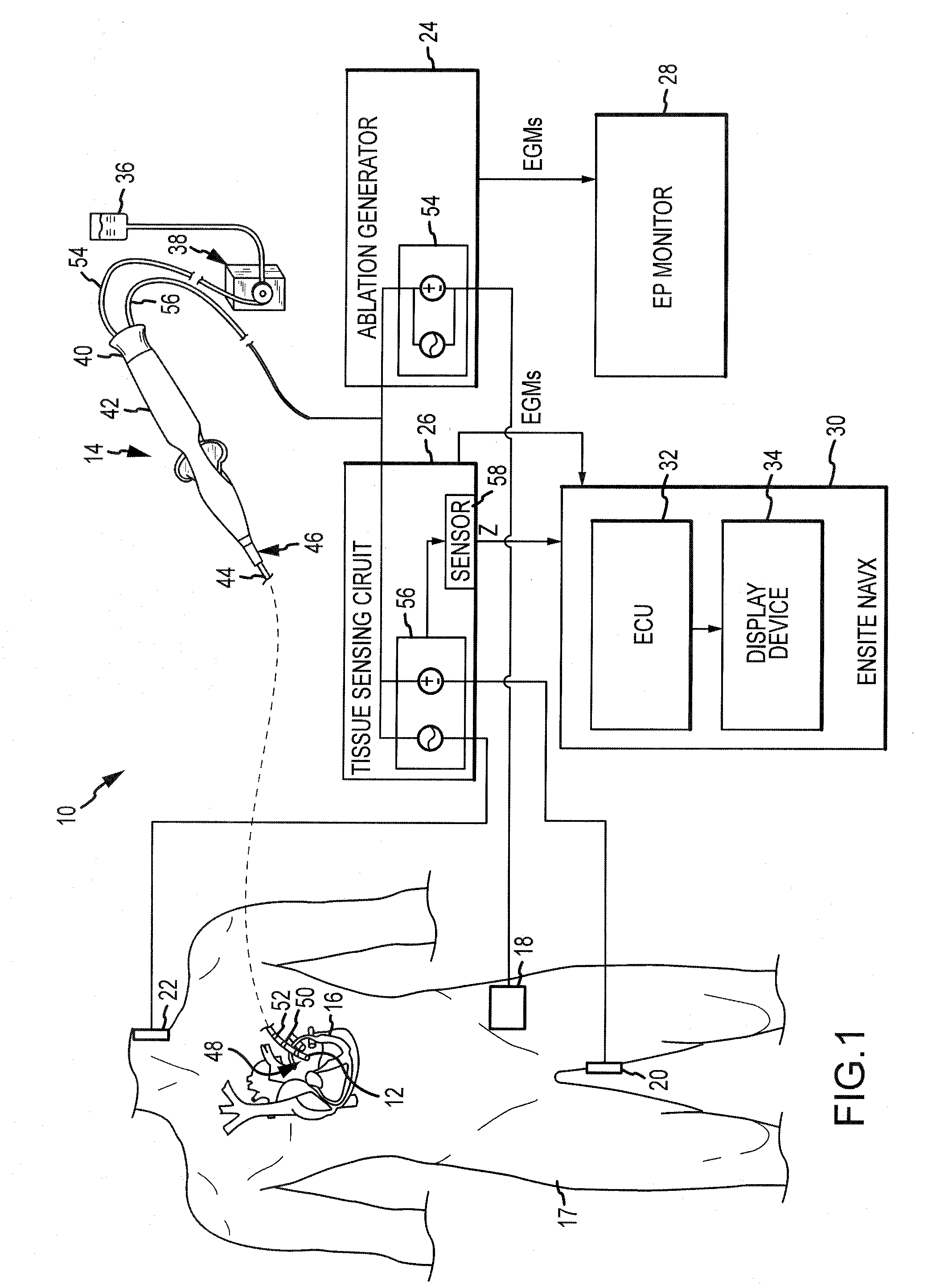

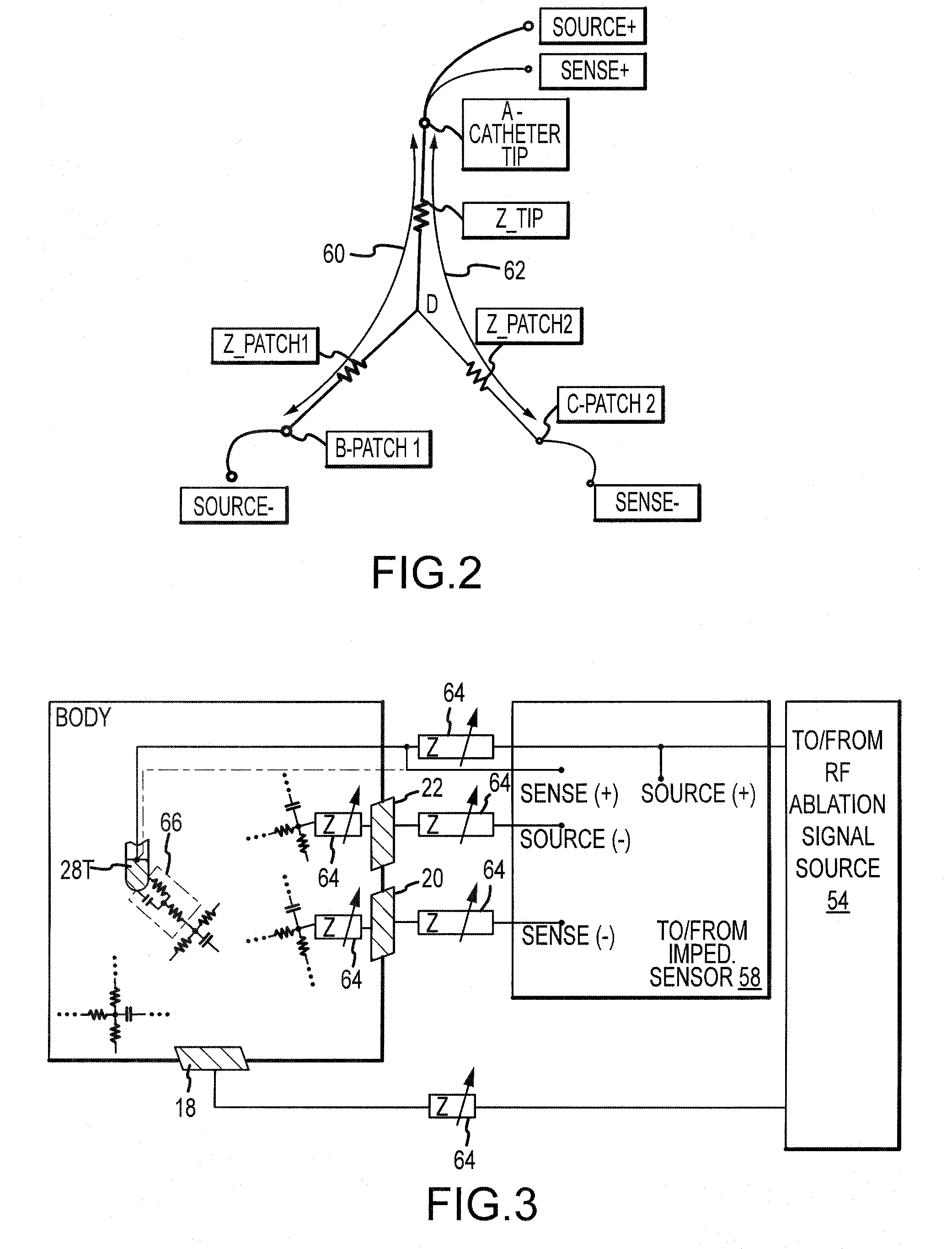

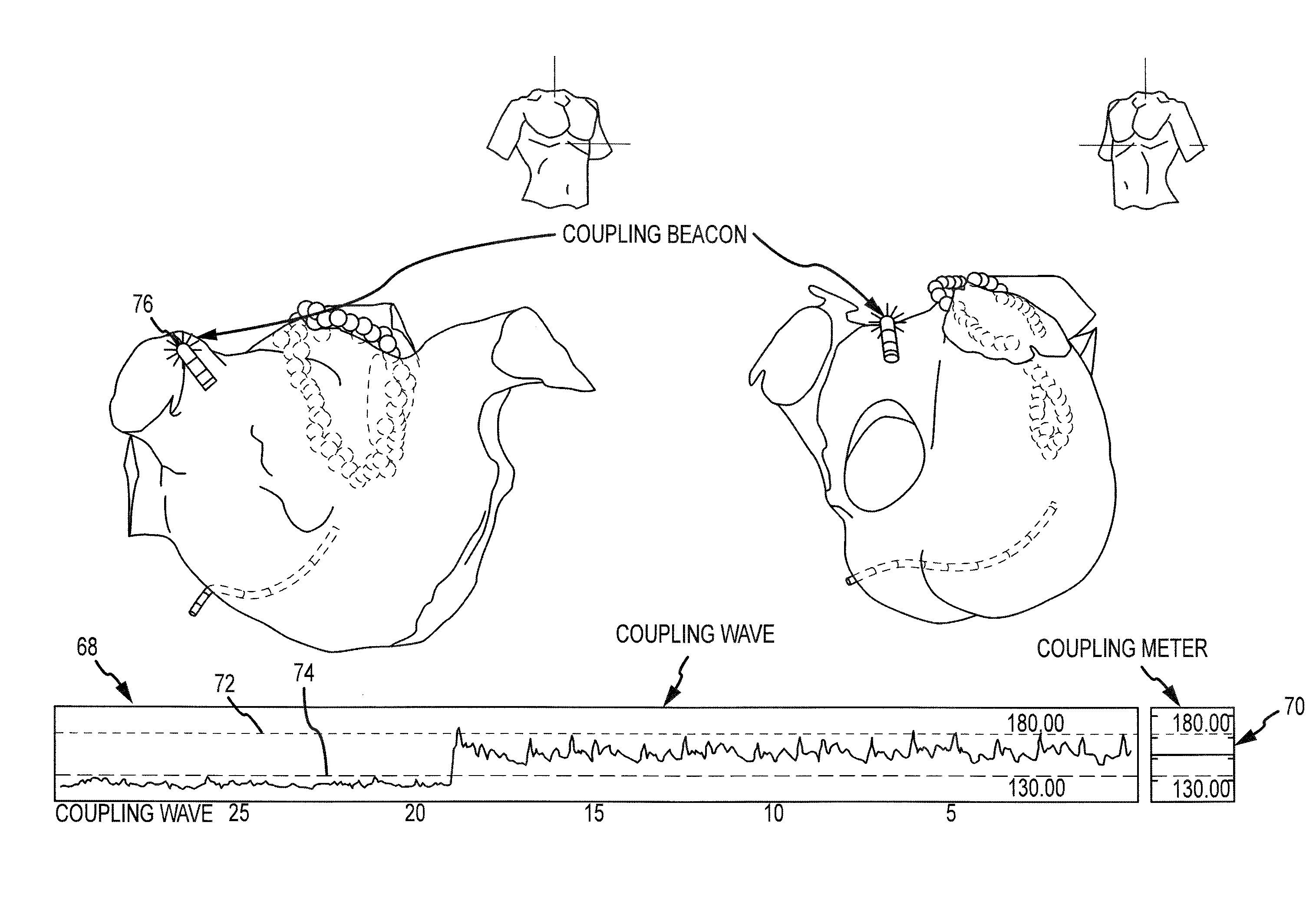

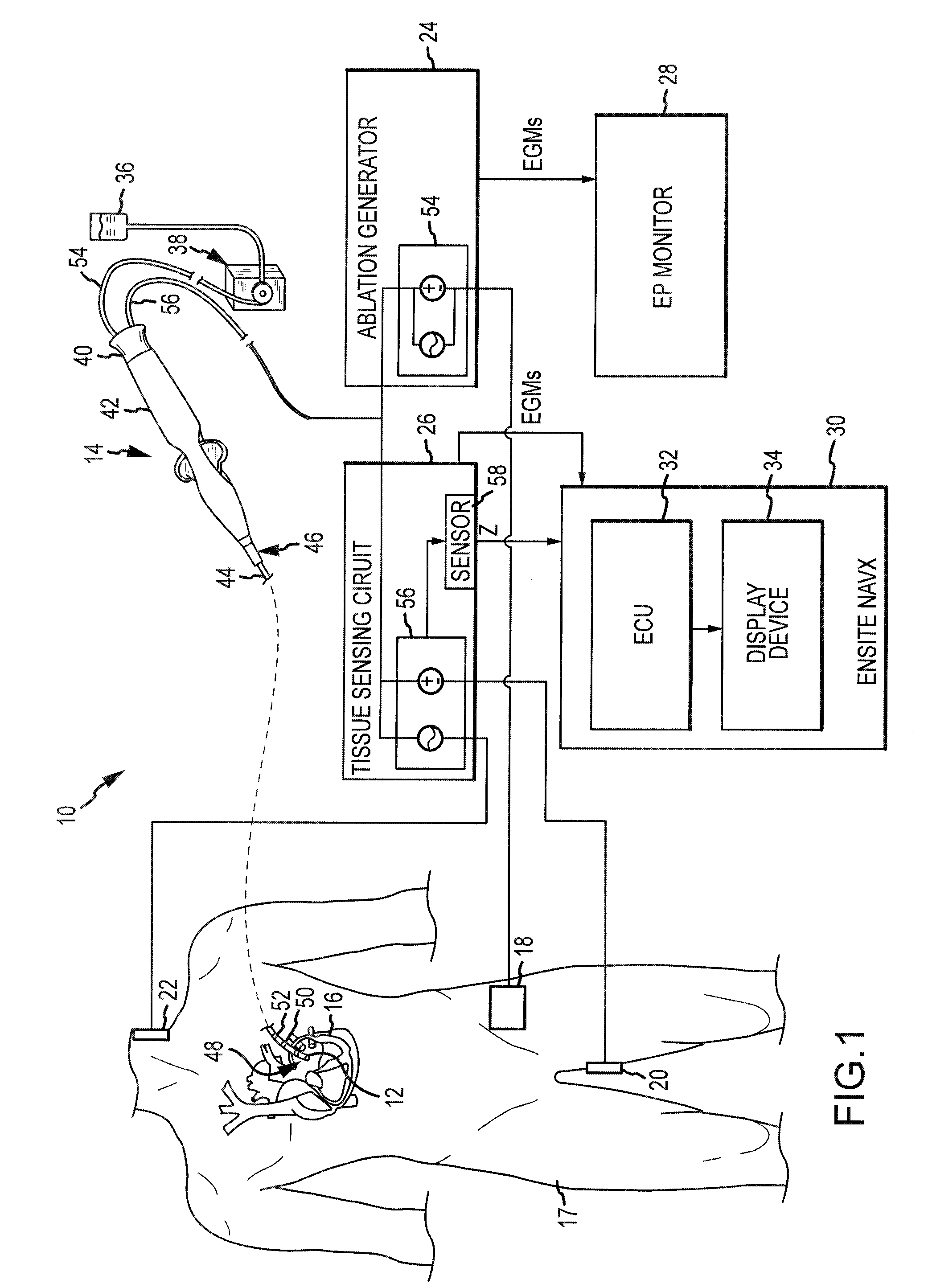

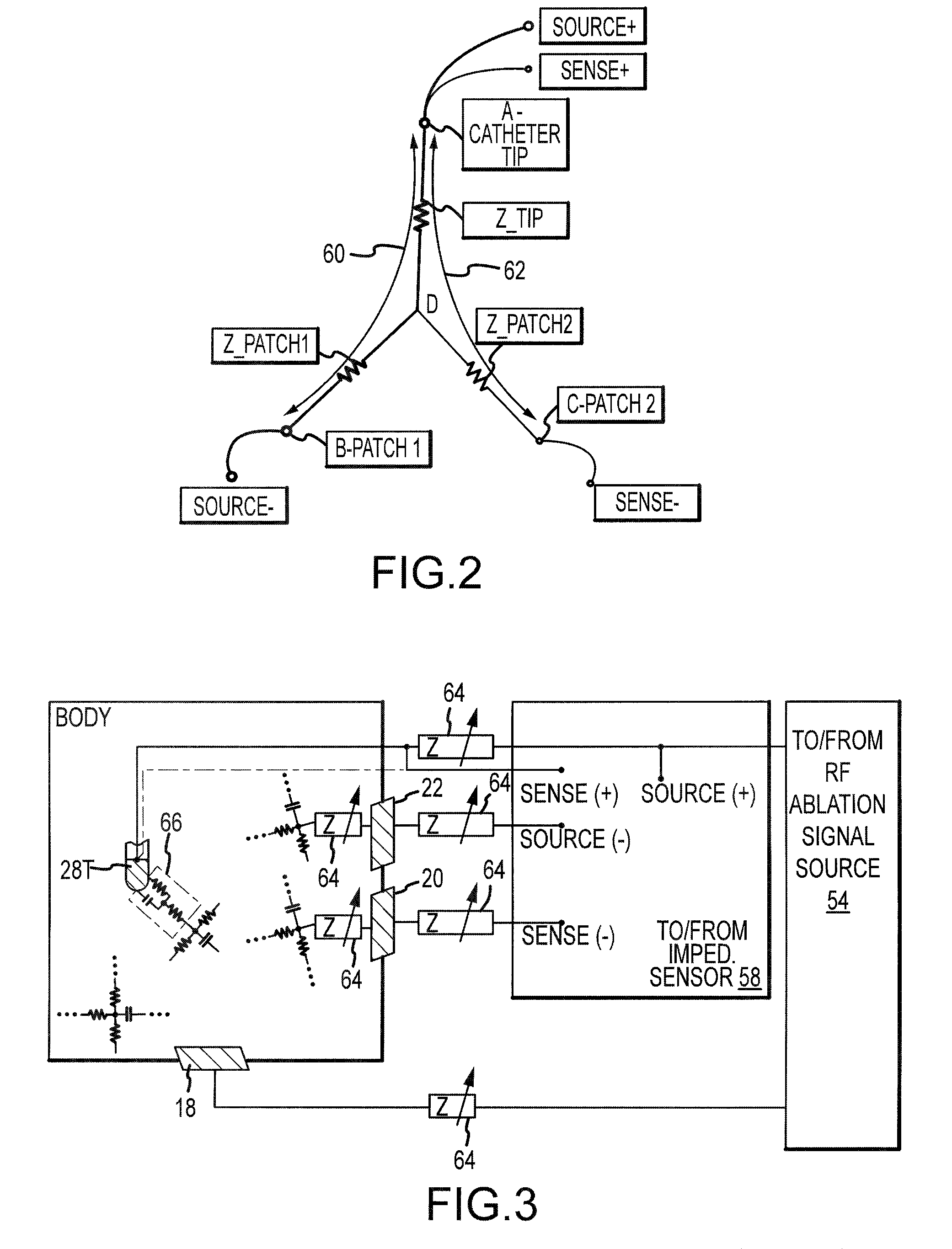

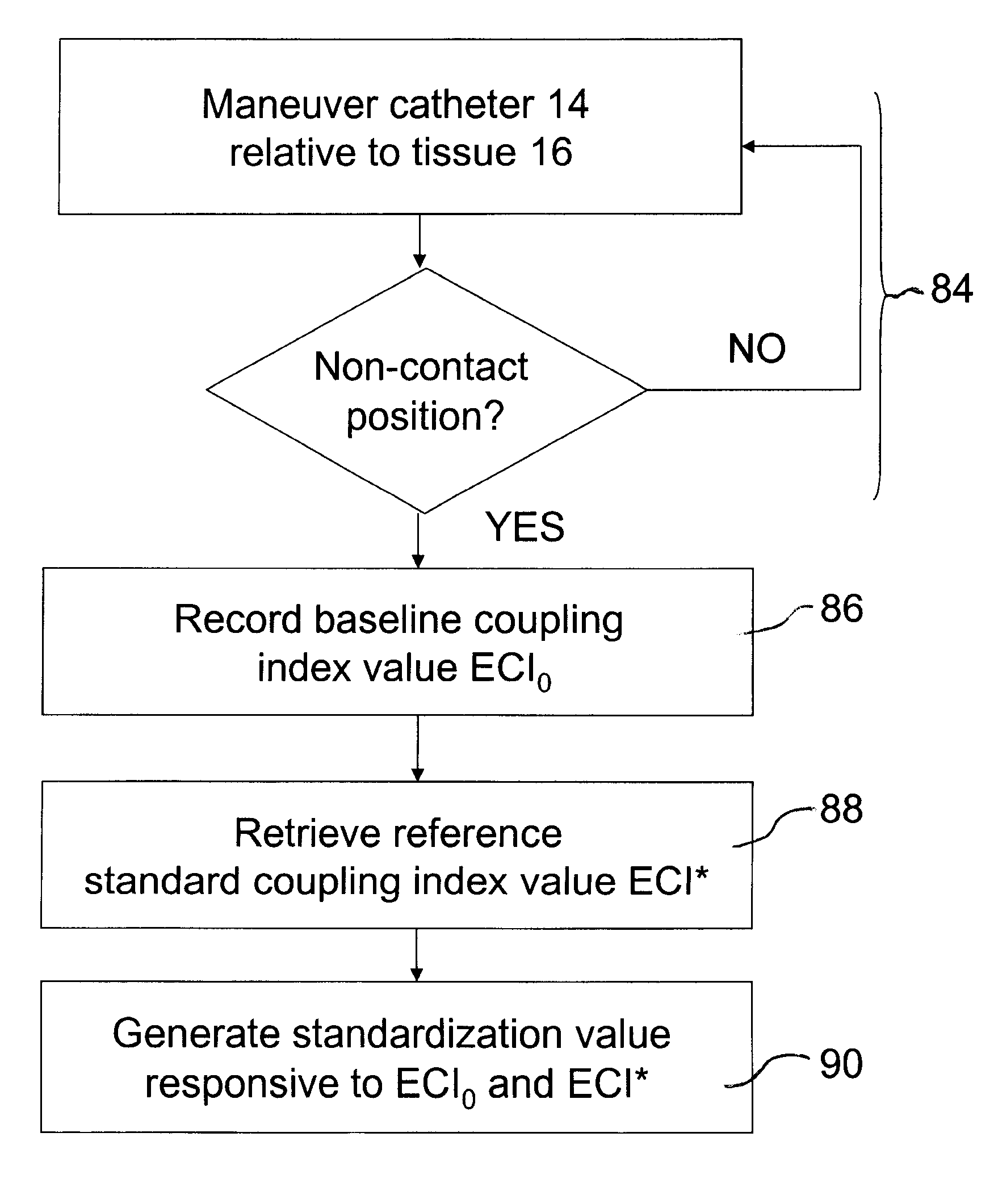

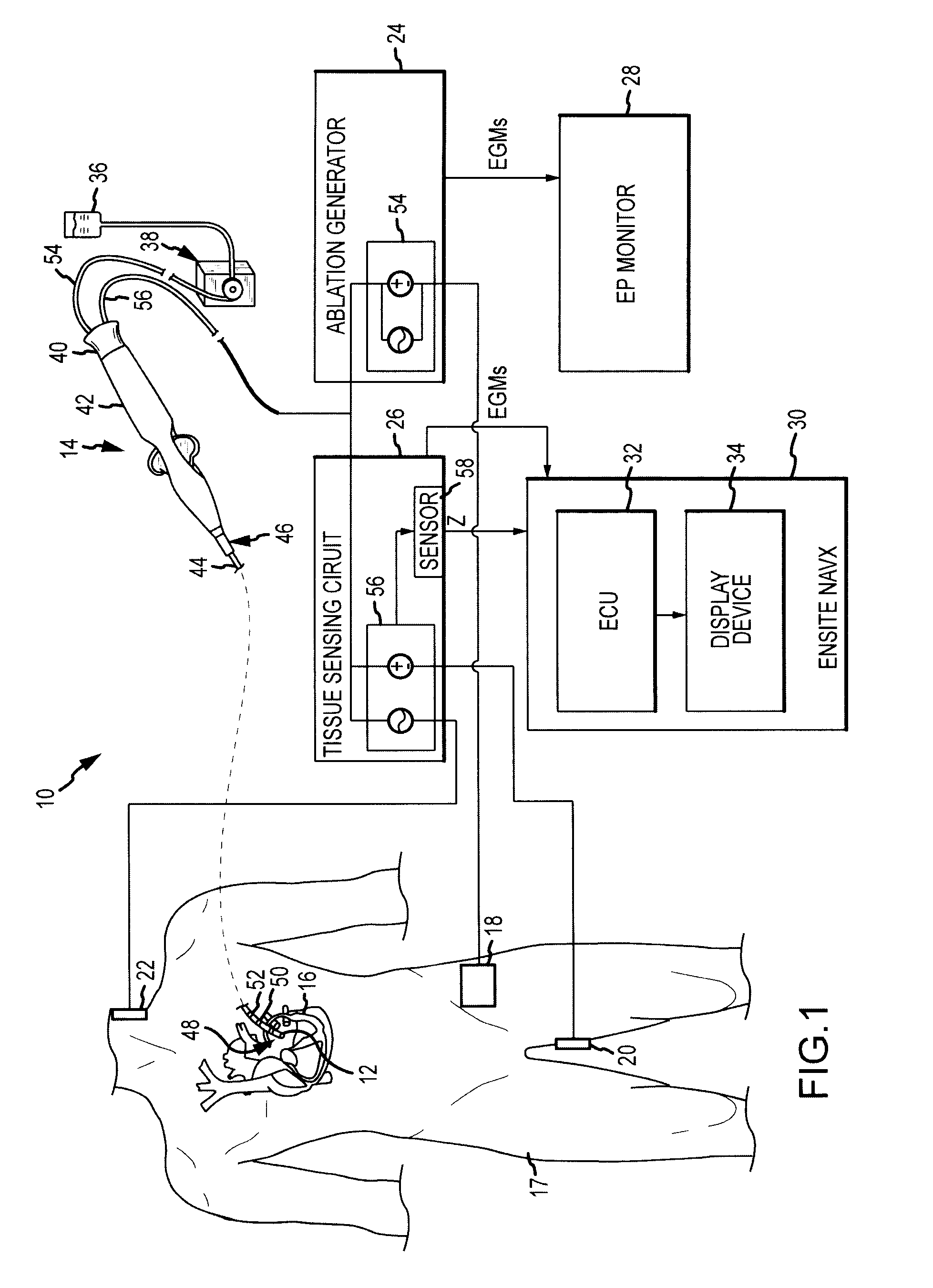

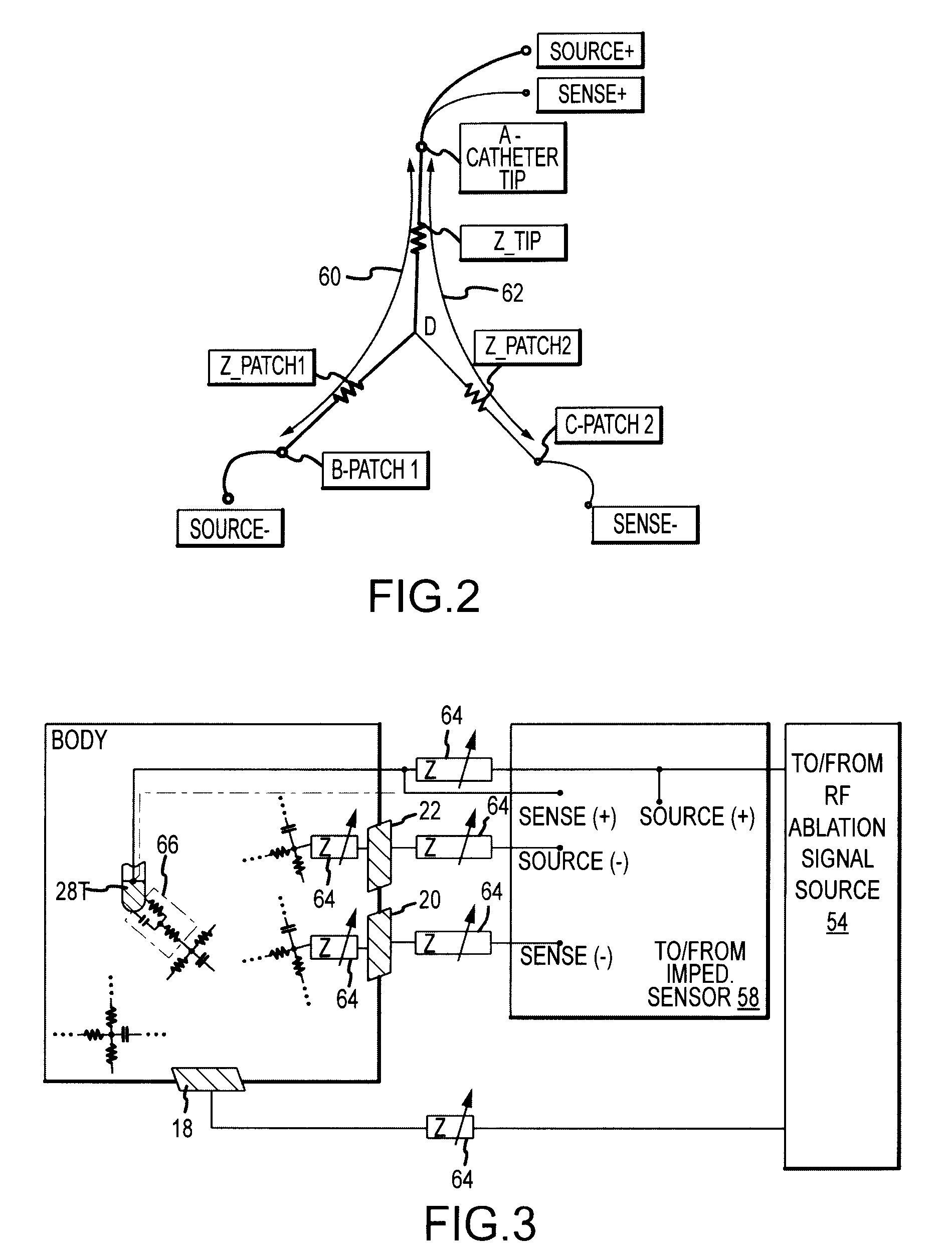

System and Method for Assessing Coupling Between an Electrode and Tissue

ActiveUS20090163904A1Good assessmentEasy interpretation and correlationResistance/reactance/impedenceCatheterEngineeringPhase angle

A system and method for assessing a degree of coupling between an electrode and tissue in a body is provided. Values for first and second components of a complex impedance (e.g., resistance and reactance or impedance magnitude and phase angle) between the electrode and the tissue are obtained. From these values, a coupling index is calculated that that is indicative of a degree of coupling between the electrode and the tissue. The coupling index may be displayed to a clinician in a variety of ways to indicate the degree of coupling to the clinician. The system and method find particular application in ablation of tissue by permitting a clinician to create lesions in the tissue more effectively and safely.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

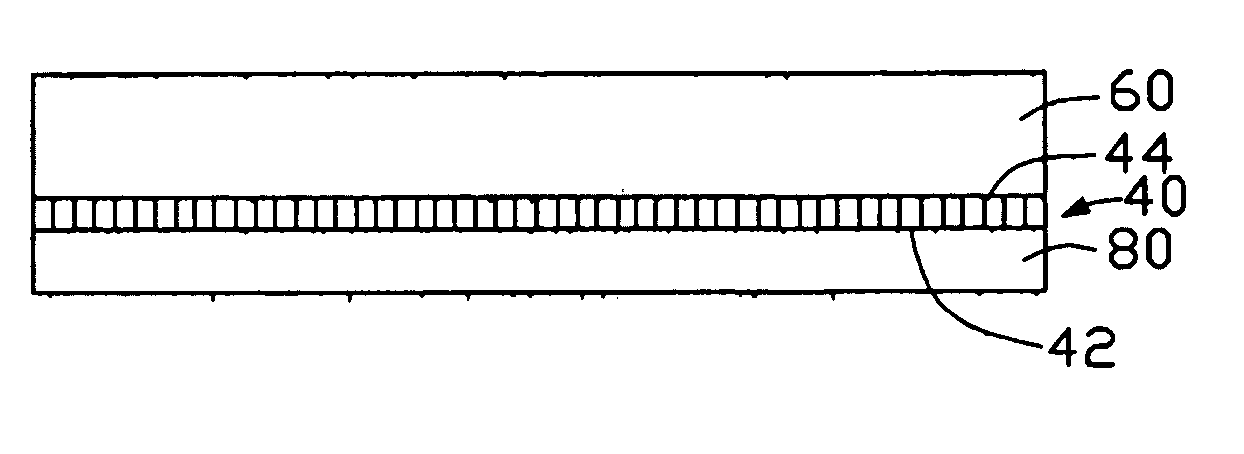

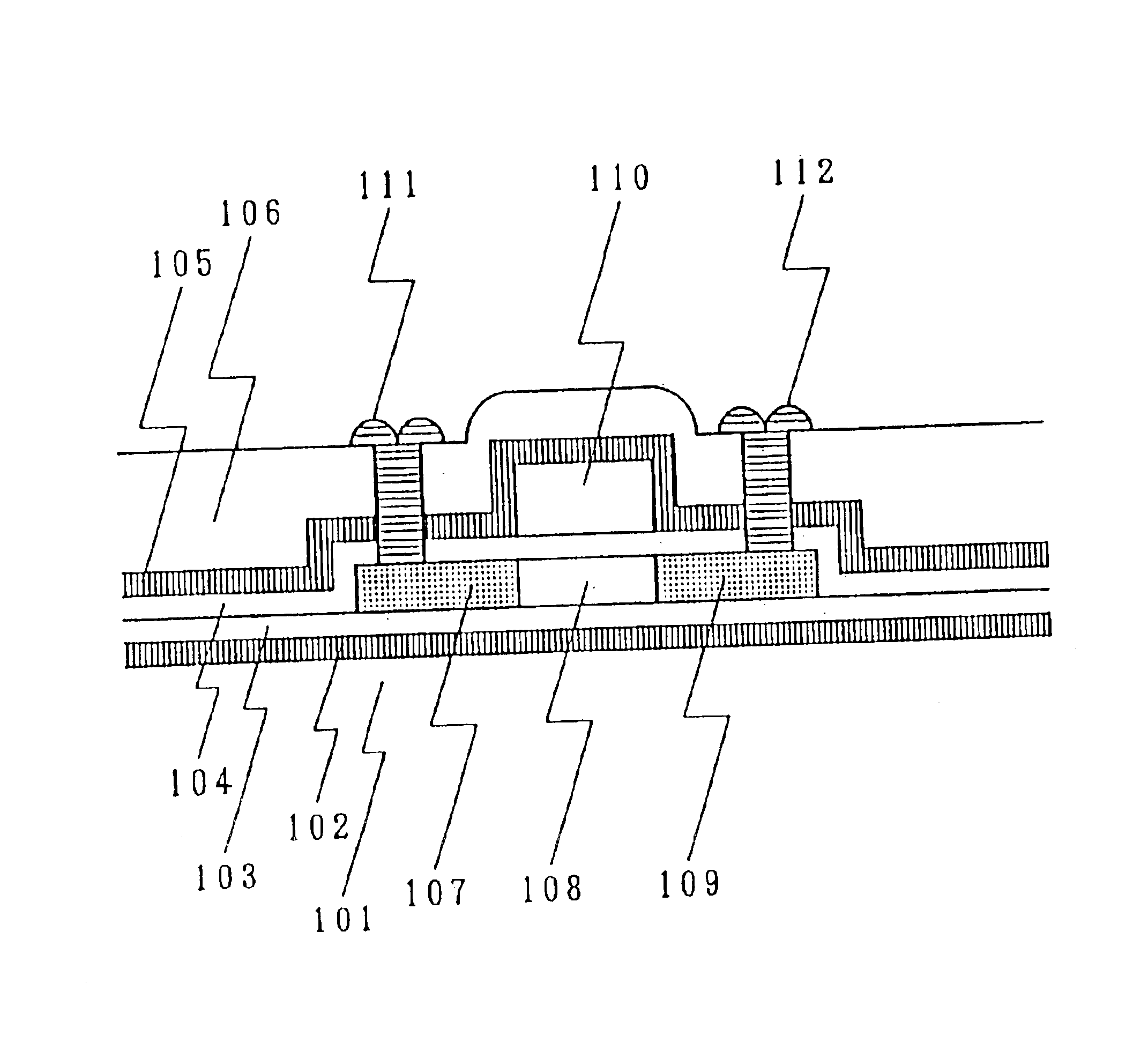

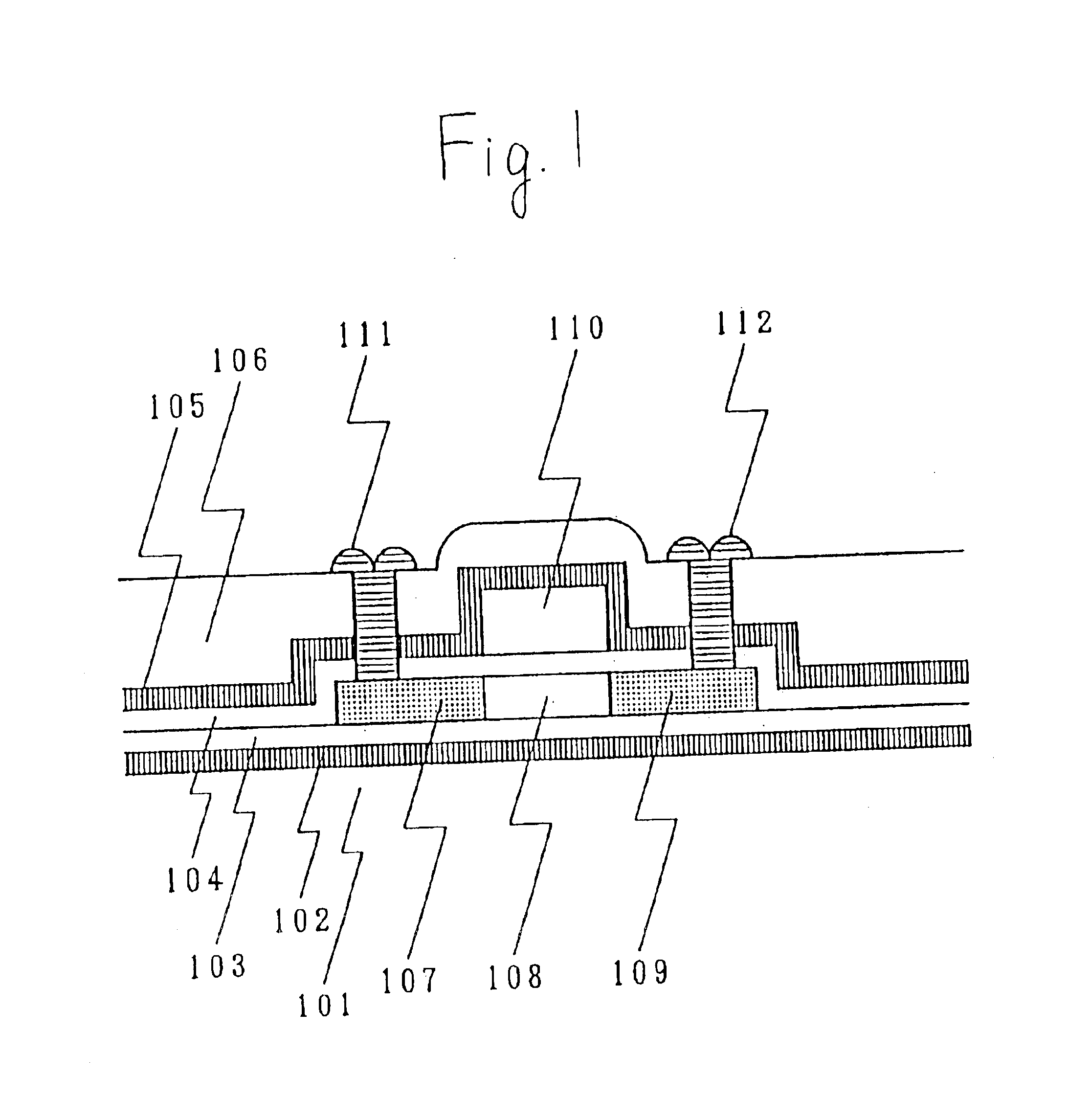

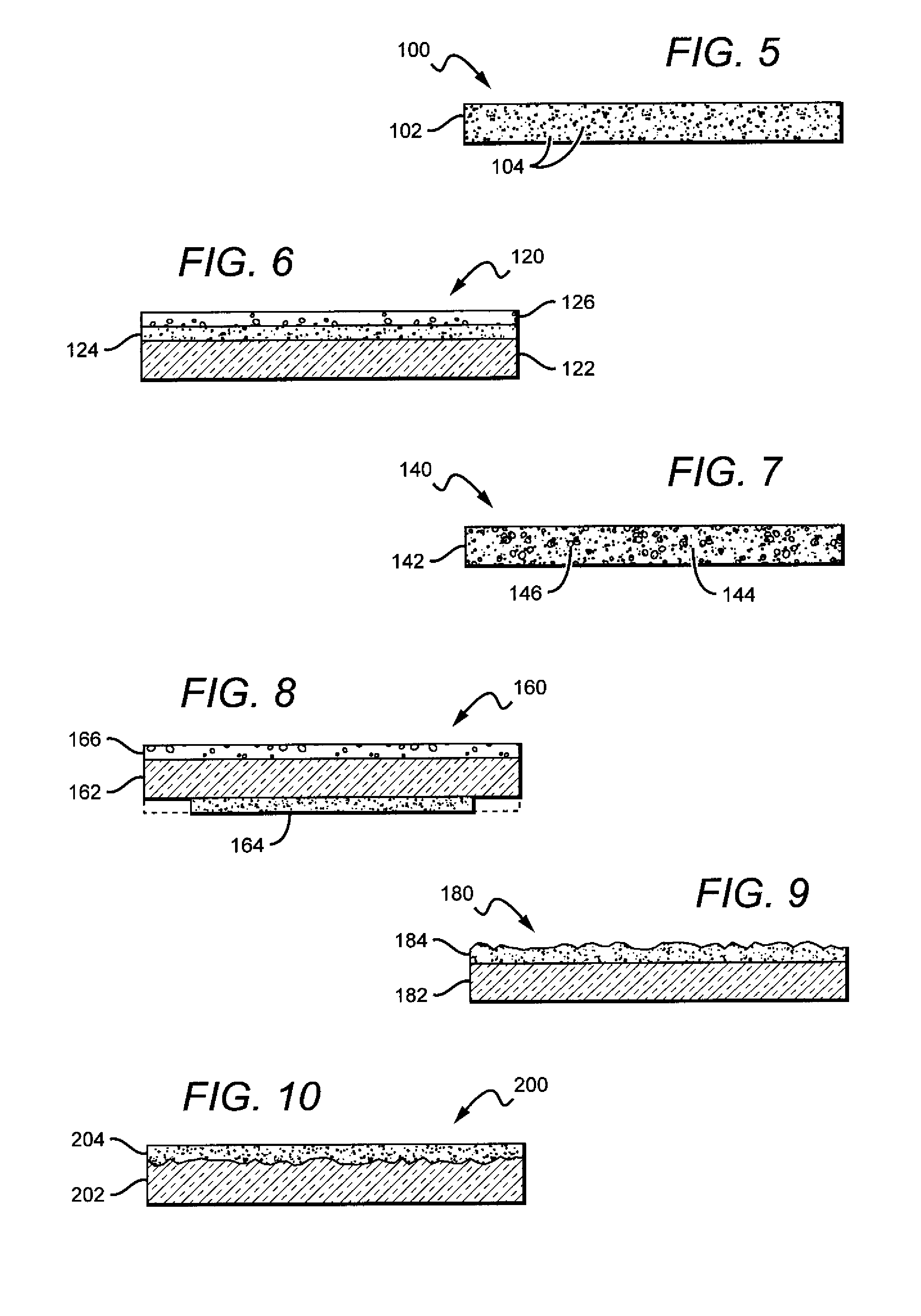

Thermal interface material and method for manufacturing same

ActiveUS20050167647A1Reduce thicknessSmall resistanceMaterial nanotechnologySemiconductor/solid-state device detailsLiquid stateCarbon nanotube

A thermal interface material (40) includes a macromolecular material (32), and a plurality of carbon nanotubes (22) embedded in the macromolecular material uniformly. The thermal interface material includes a first surface (42) and an opposite second surface (44). Each carbon nanotube is open at both ends thereof, and extends from the first surface to the second surface of the thermal interface material. A method for manufacturing the thermal interface material includes the steps of: (a) forming an array of carbon nanotubes on a substrate; (b) submerging the carbon nanotubes in a liquid macromolecular material; (c) solidifying the liquid macromolecular material; and (d) cutting the solidified liquid macromolecular material to obtain the thermal interface material with the carbon nanotubes secured therein.

Owner:TSINGHUA UNIV +1

System and method for assessing coupling between an electrode and tissue

ActiveUS8449535B2Easy interpretation and correlationBetter assessmentResistance/reactance/impedenceCatheterElectrical resistance and conductanceCoupling

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

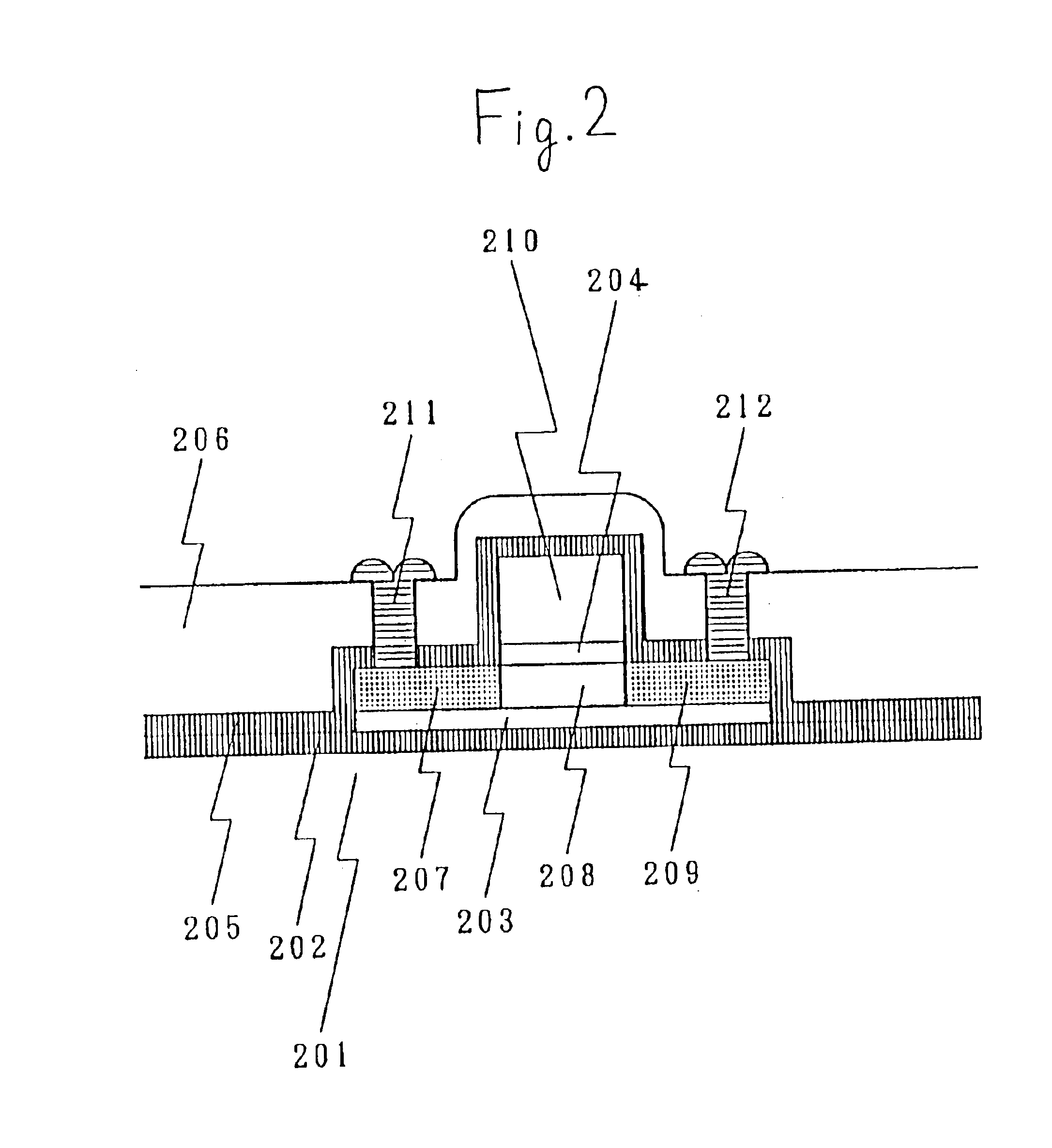

Thin film transistor

InactiveUS6849872B1Intuitive effectInhibit deteriorationTransistorSolid-state devicesNitrideSemiconductor device

An improved type thin film semiconductor device and a method for forming the same are described. That is, in a thin film semiconductor device such as TFT formed on an insulating substrate, it is possible to prevent the intrusion of a mobile ion from a substrate or other parts, by forming the first blocking film comprising a silicon nitride, an aluminum oxide, an aluminum nitride, a tantalum oxide, and the like, under the semiconductor device through an insulating film used in a buffering, and then, by forming the second blocking film on TFT, and further, by covering TFT with the first and second blocking films.

Owner:SEMICON ENERGY LAB CO LTD

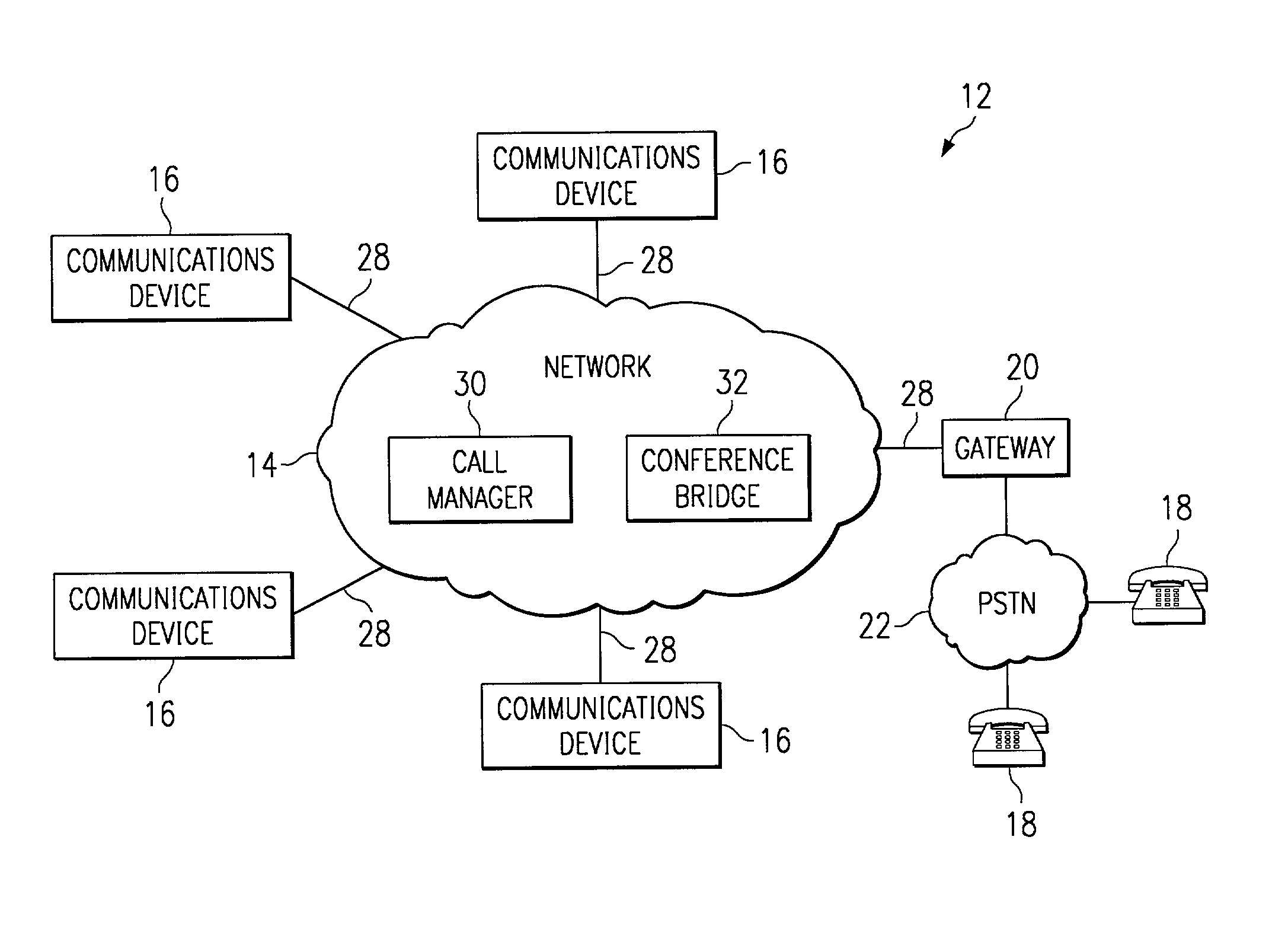

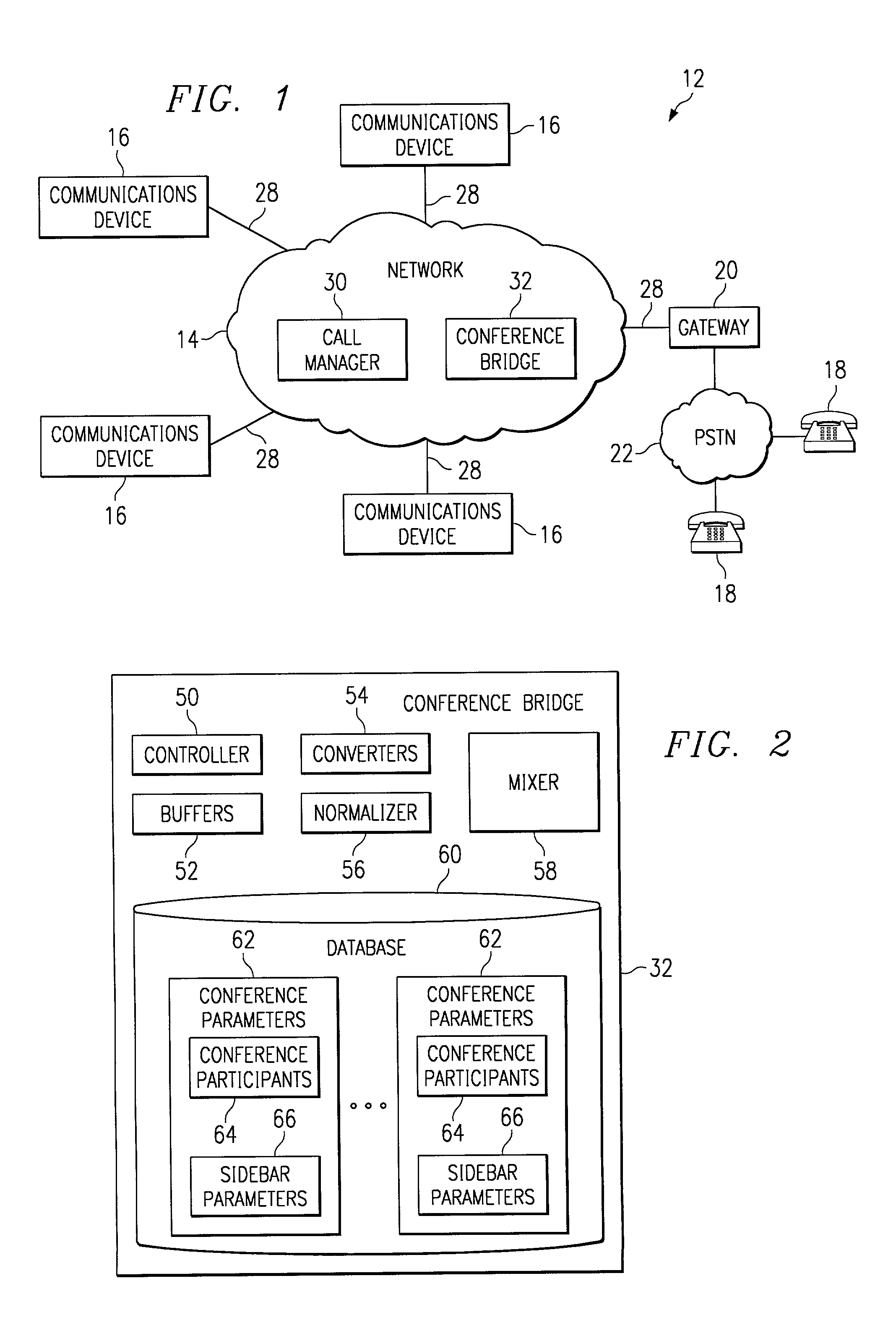

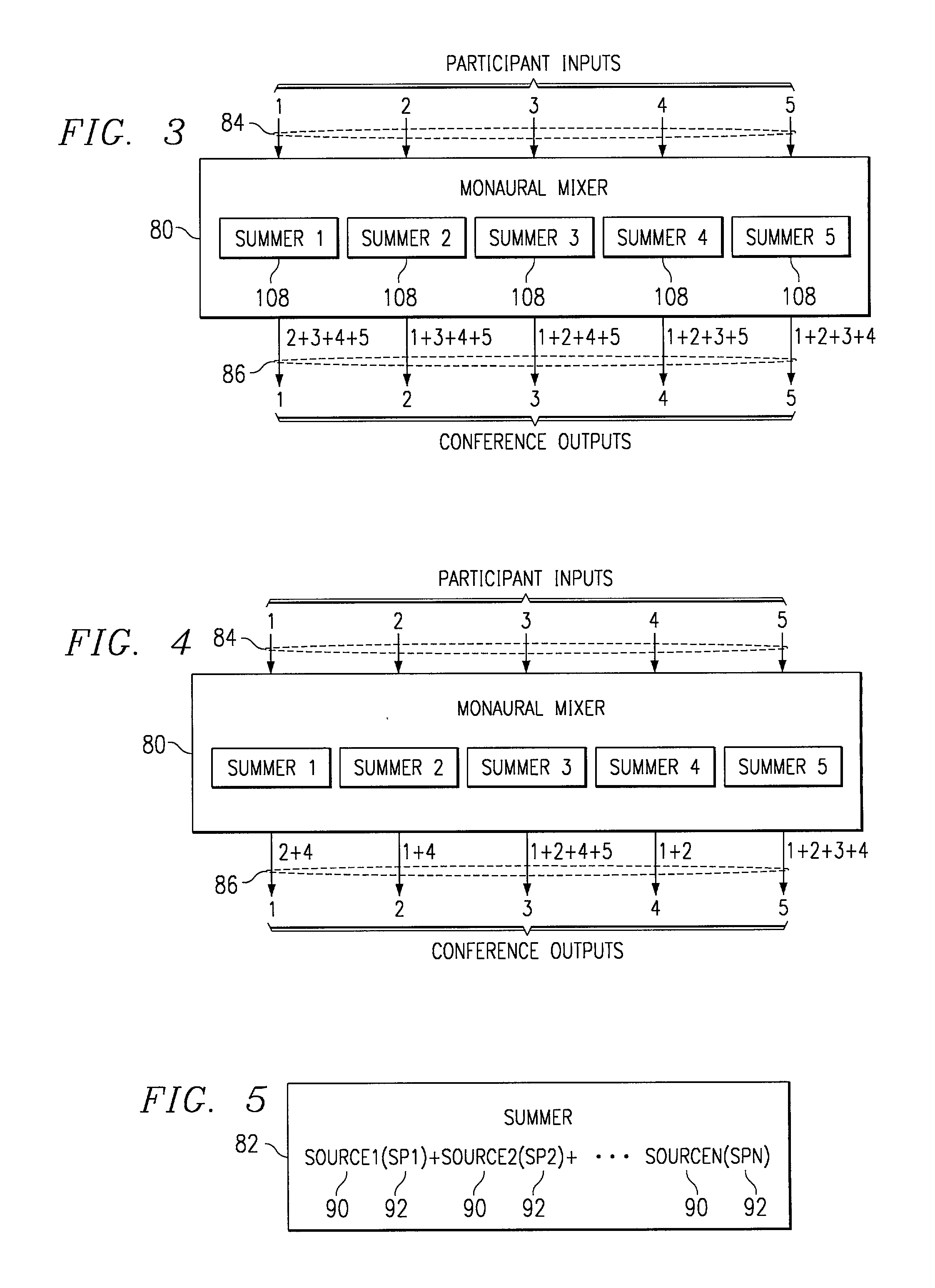

Method and system for participant control of privacy during multiparty communication sessions

ActiveUS7058168B1Eliminate and reduce disadvantageEliminate and reduce and problemMultiplex system selection arrangementsSpecial service provision for substationComputer networkMultiparty communication

A method and system for participant control of privacy during a multiparty communication session includes receiving a request from a first participant to a multiparty communication connection for a sidebar between the first participant and a second participant to the multiparty communication connection. The sidebar is provided by at least substantially eliminating voice streams generated by the first participant and the second participant from conference output streams generated for a set of remaining participants to the multiparty communication connection.

Owner:CISCO TECH INC

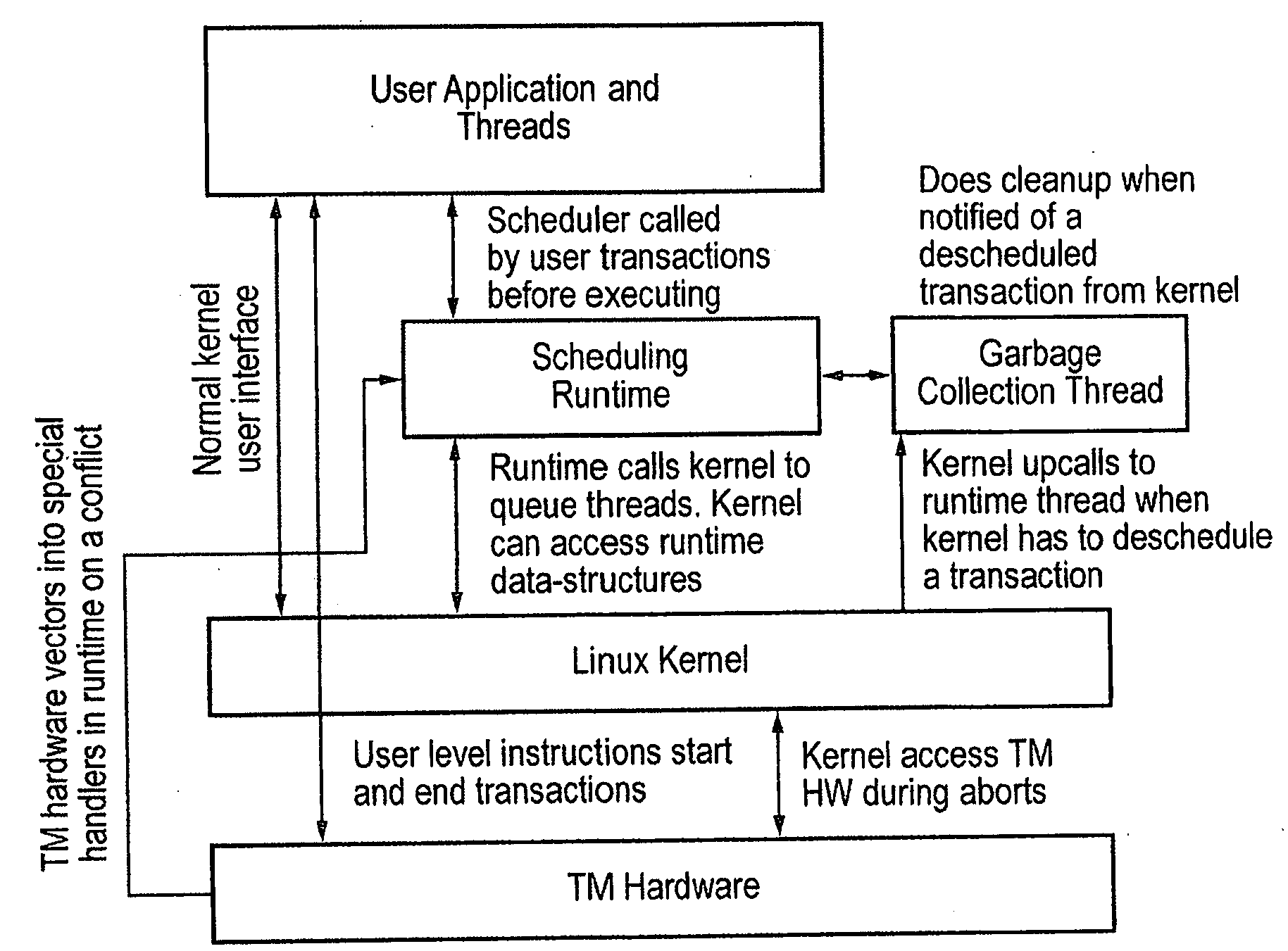

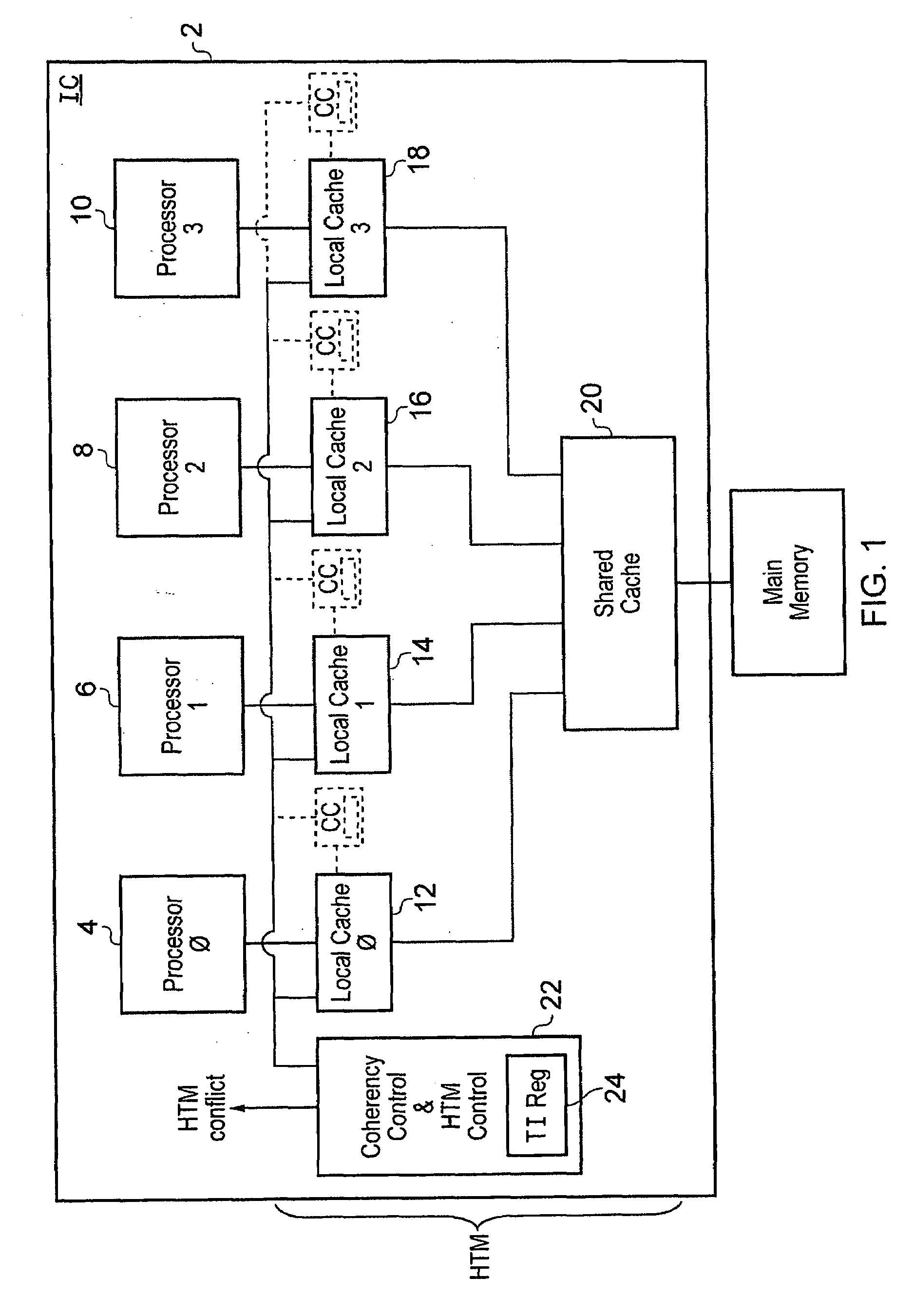

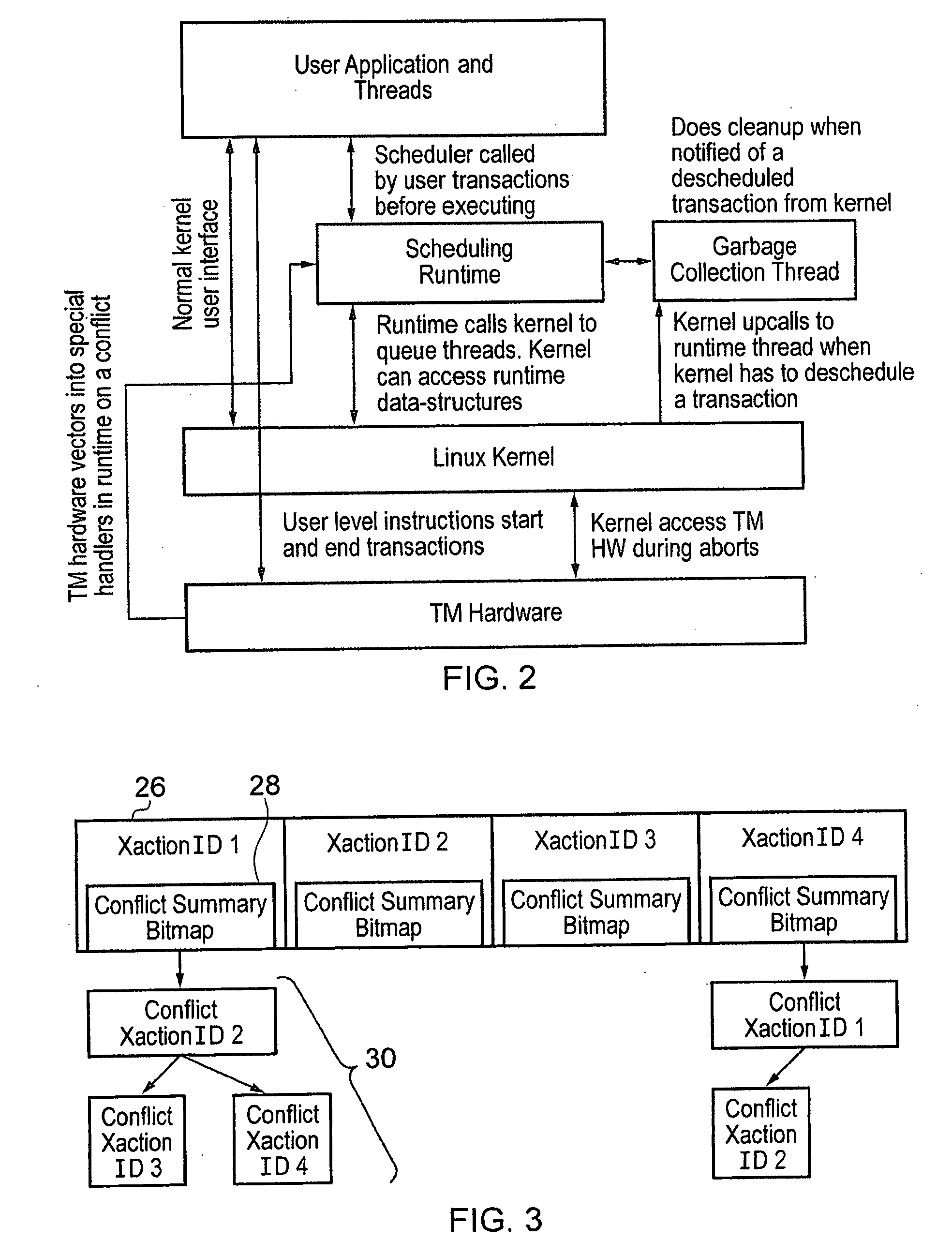

Contention management for a hardware transactional memory

InactiveUS20090138890A1Reduce storage overheadImprove performanceMemory architecture accessing/allocationMemory systemsConsistency controlComputer science

A hardware transactional memory 12, 14, 16, 18, 20 is provided within a multiprocessor 4, 6, 8, 10 system with coherency control and hardware transaction memory control circuitry 22 that serves to at least partially manage the scheduling of processing transactions in dependence upon conflict data 26, 28, 30. The conflict data characterises previously encountered conflicts between processing transactions. The scheduling is performed such that a candidate processing transaction will not be scheduled if the conflict data indicates that one of the already running processing transactions has previously conflicted with the candidate processing transaction.

Owner:RGT UNIV OF MICHIGAN +1

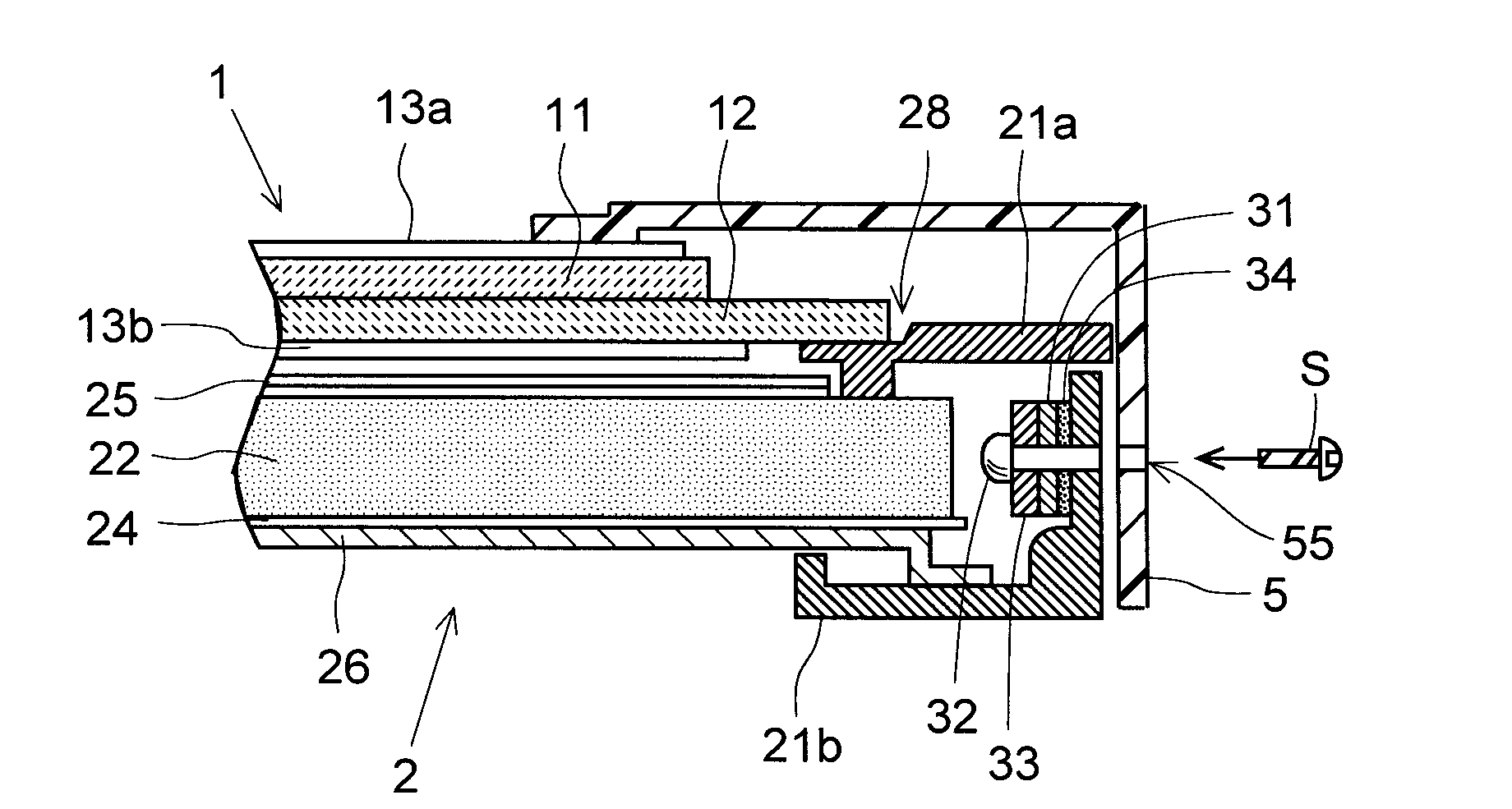

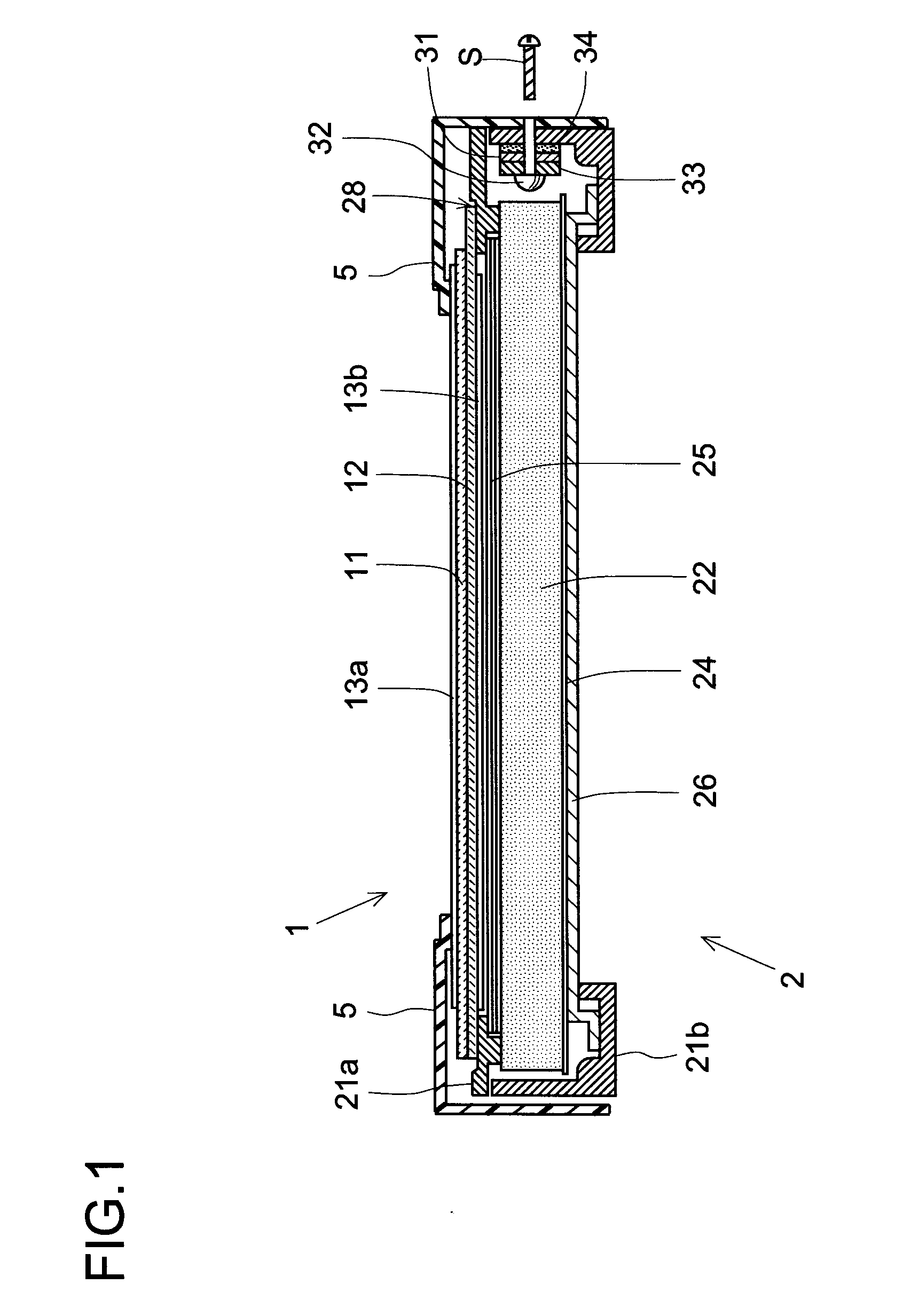

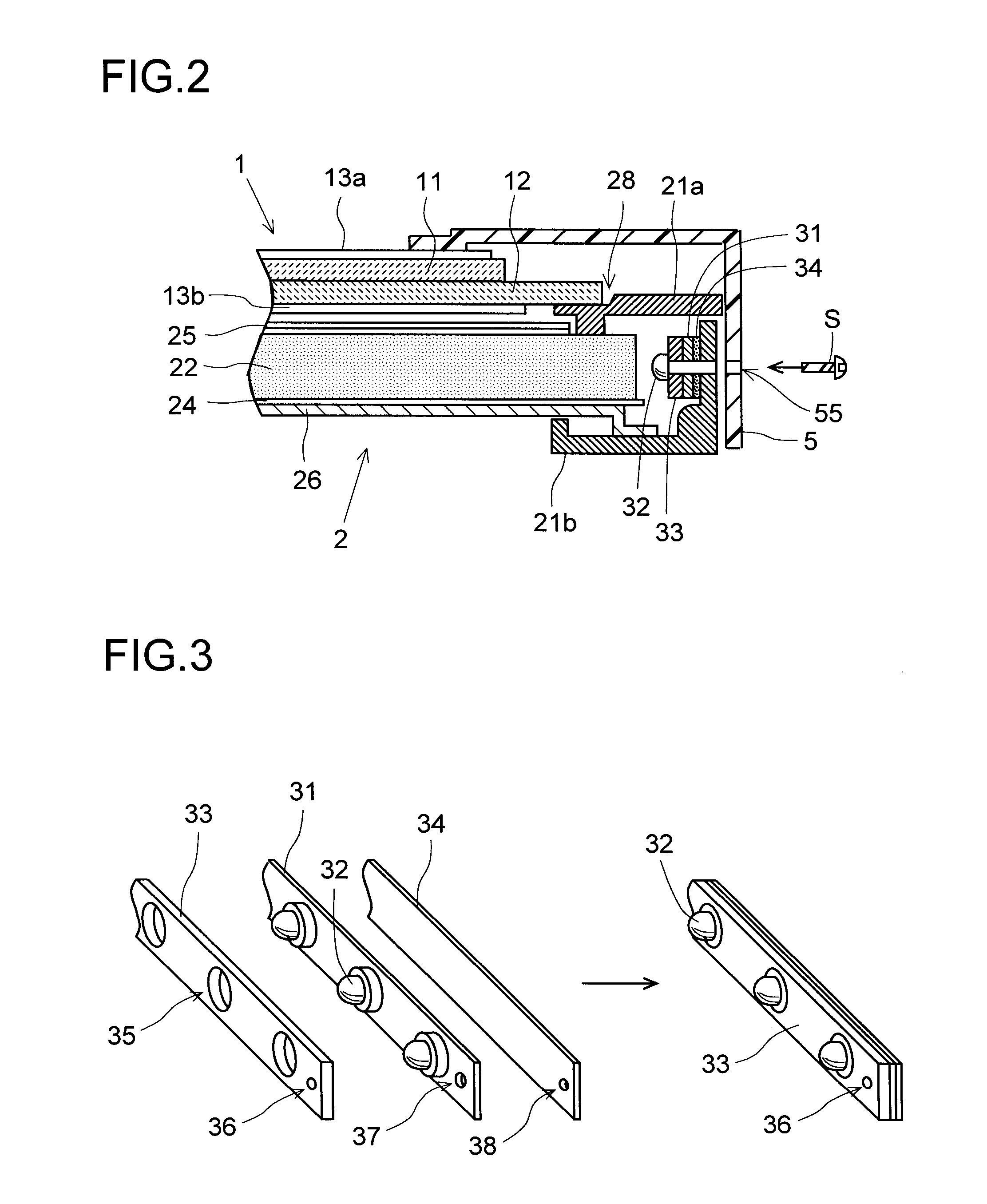

Backlight device and flat display using it

ActiveUS20100073959A1Long life timeEfficient conduction of heatLighting heating/cooling arrangementsOptical light guidesFlat panel displayEngineering

An FPC (31) on which LEDs (32) are mounted at predetermined intervals in the longitudinal direction is secured to a lower chassis (21b) used also as a heat-dissipating plate through an elastic heat conductive sheet (34). With a retaining plate (33) is overlapped on the mounting surface of the FPC (31), a screw (S) is inserted into the retaining plate (33) from the outside of a bezel (5) to fix the retaining plate. Furthermore, the FPC (31) is held between the retaining plate (33) and the lower chassis (21b).

Owner:SHARP KK

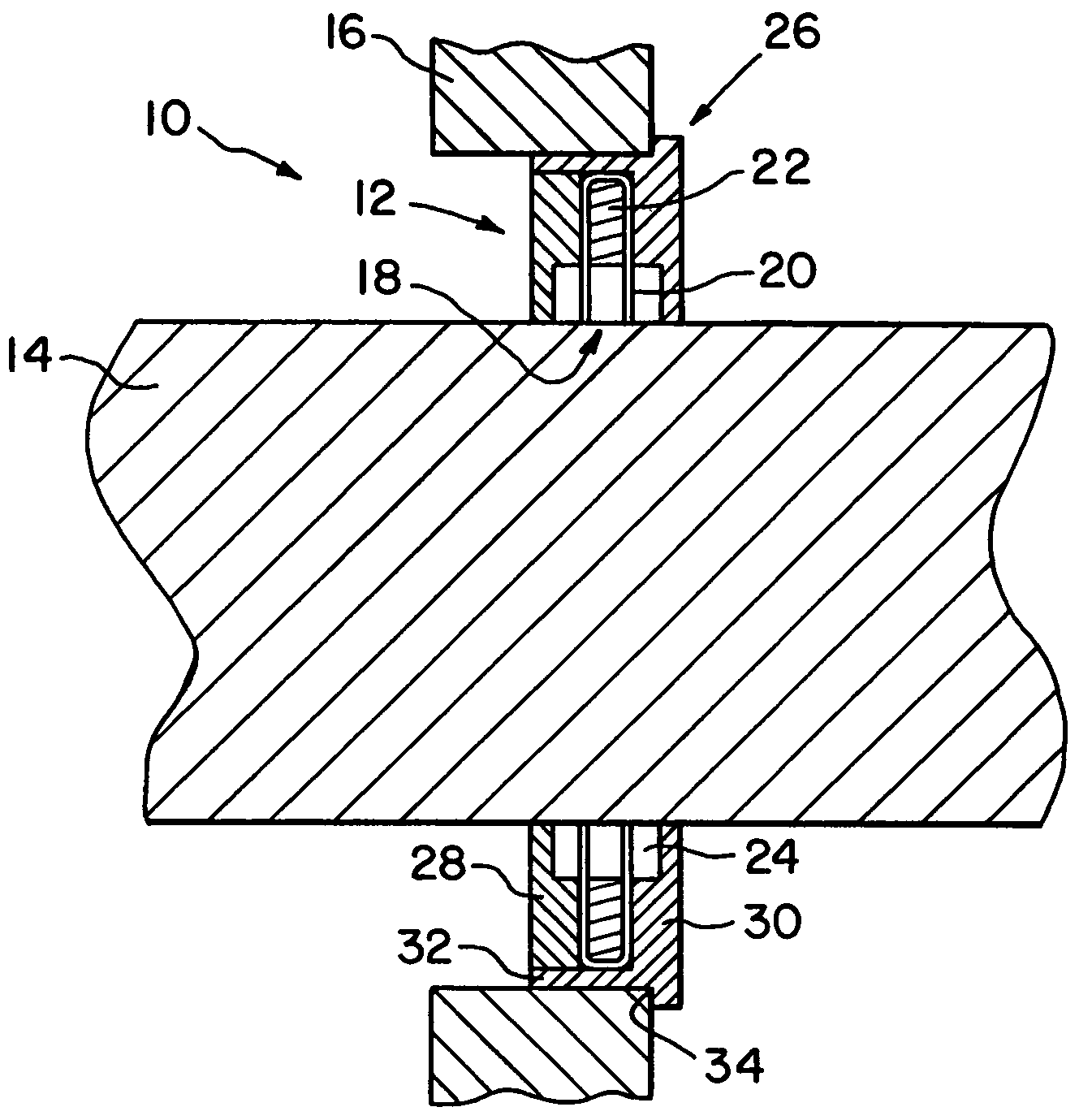

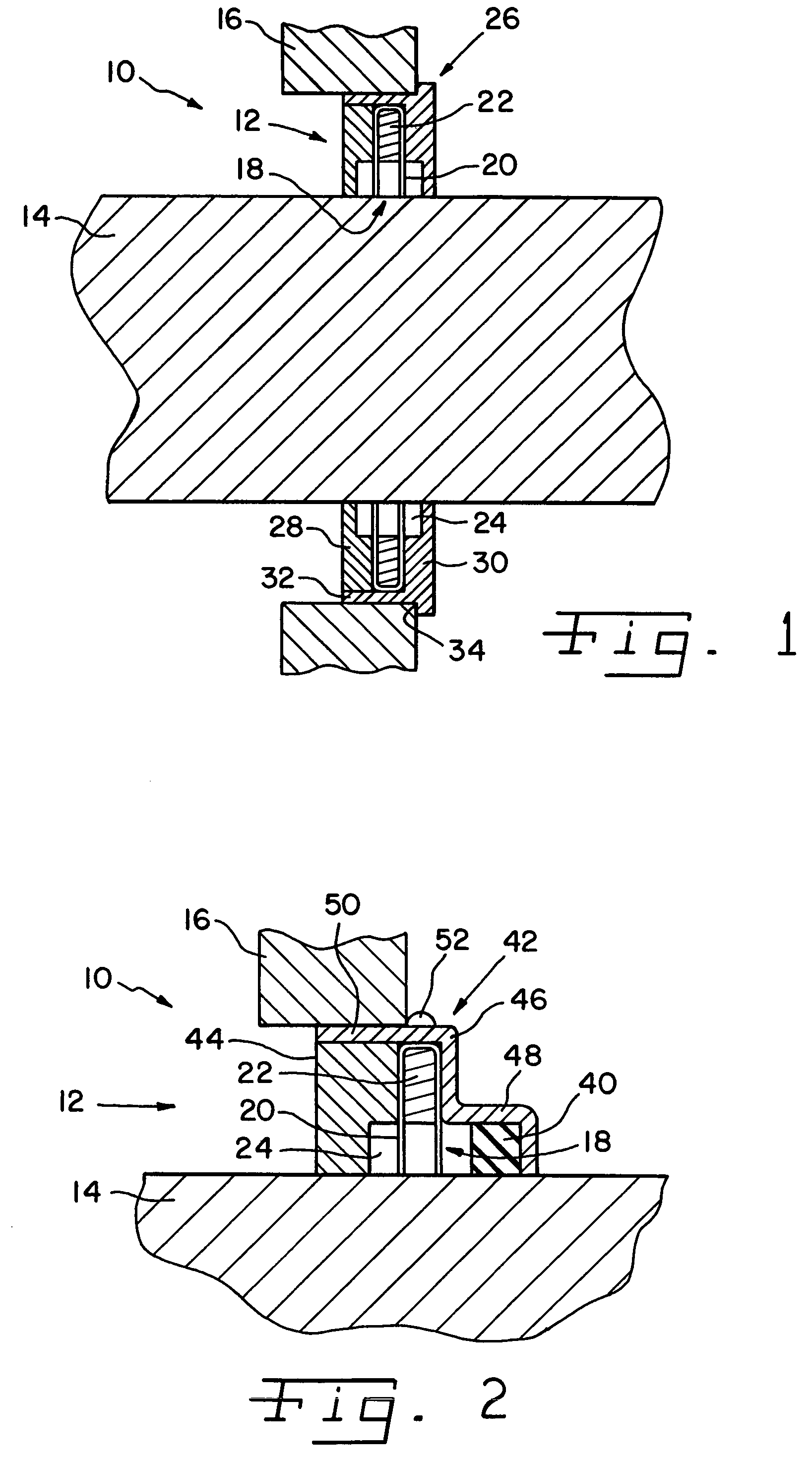

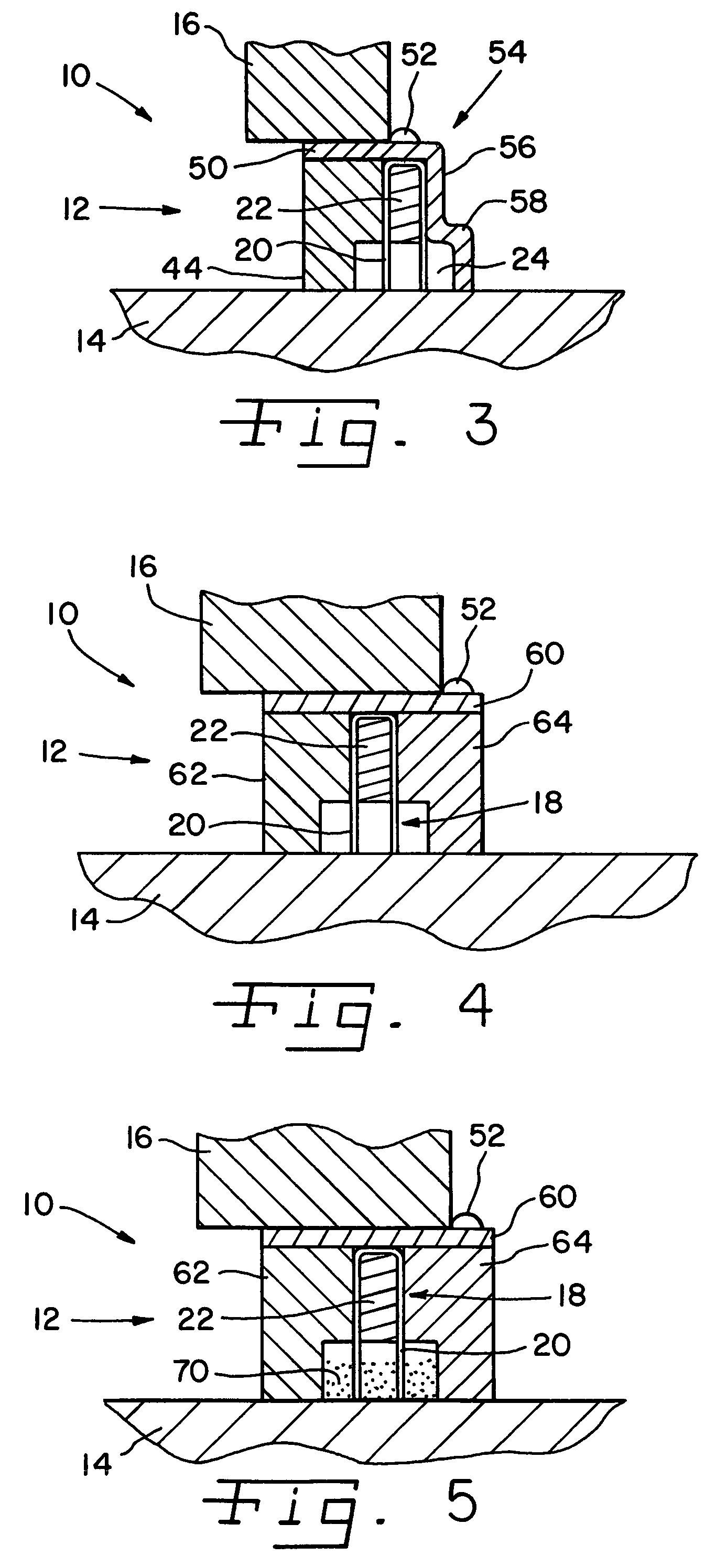

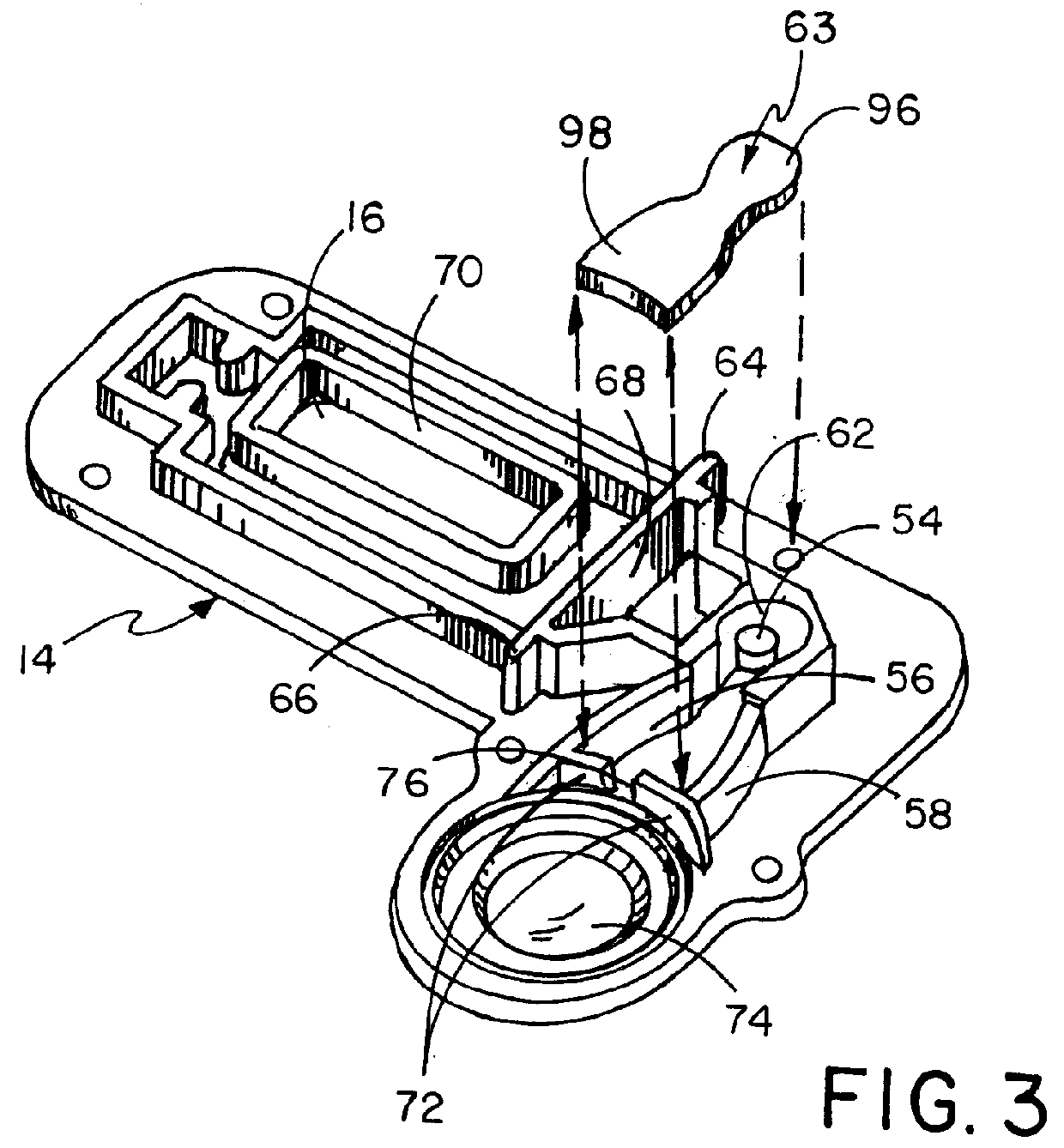

Grounding brush for mitigating electrical current on motor shafts

ActiveUS7193836B2Reduce shaft currentEfficient assemblyAssociation with grounding devicesEmergency protective arrangement detailsElectric machineClassical mechanics

A grounding brush for mitigating static electric charge on a motor shaft includes a plurality of filaments secured to an annular frame around the shaft, with tips of the filaments disposed in a channel defined by the frame. Conductive powder can be provided in the channel to improve current flow from the shaft to the filaments.

Owner:ILLINOIS TOOL WORKS INC

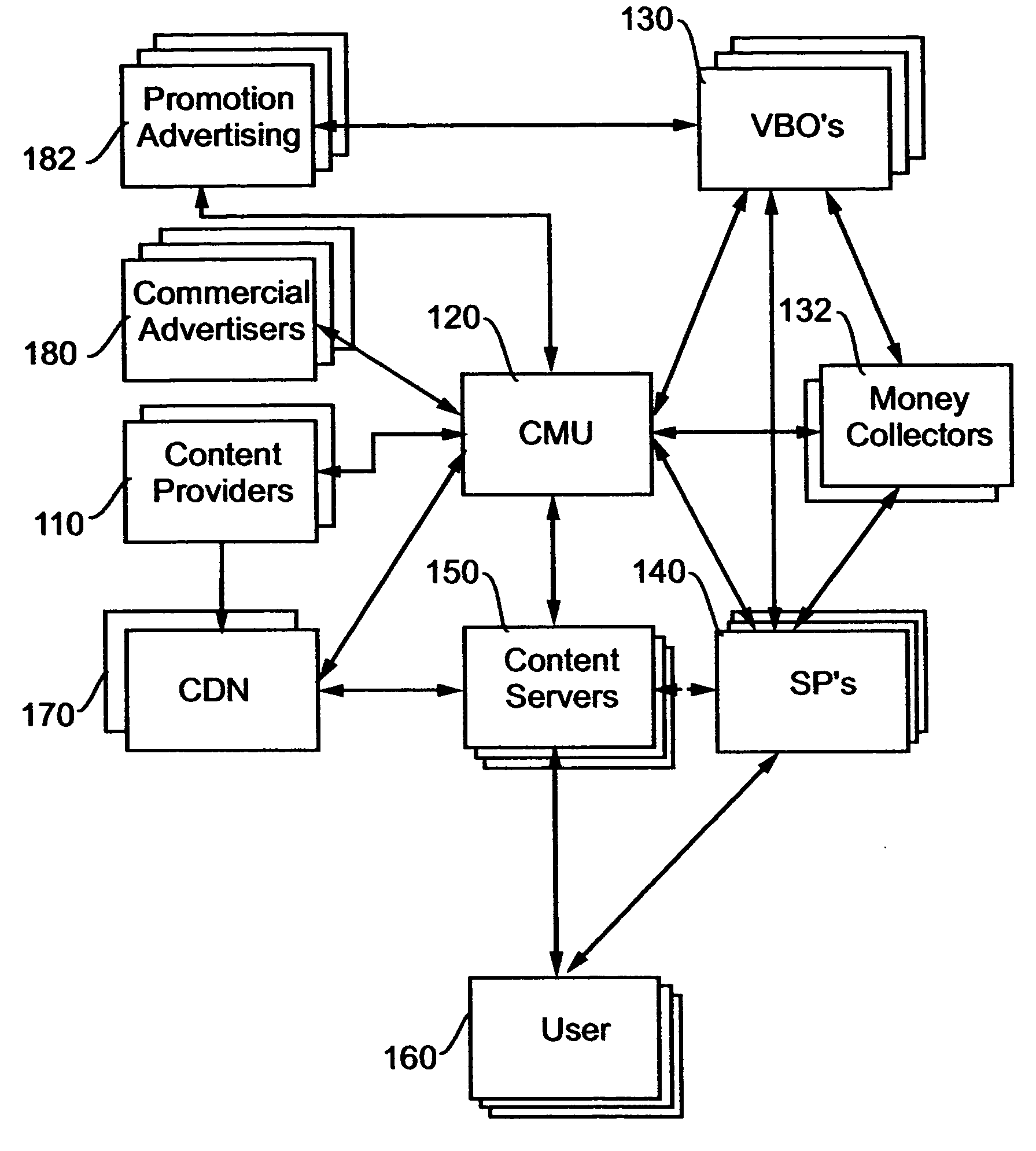

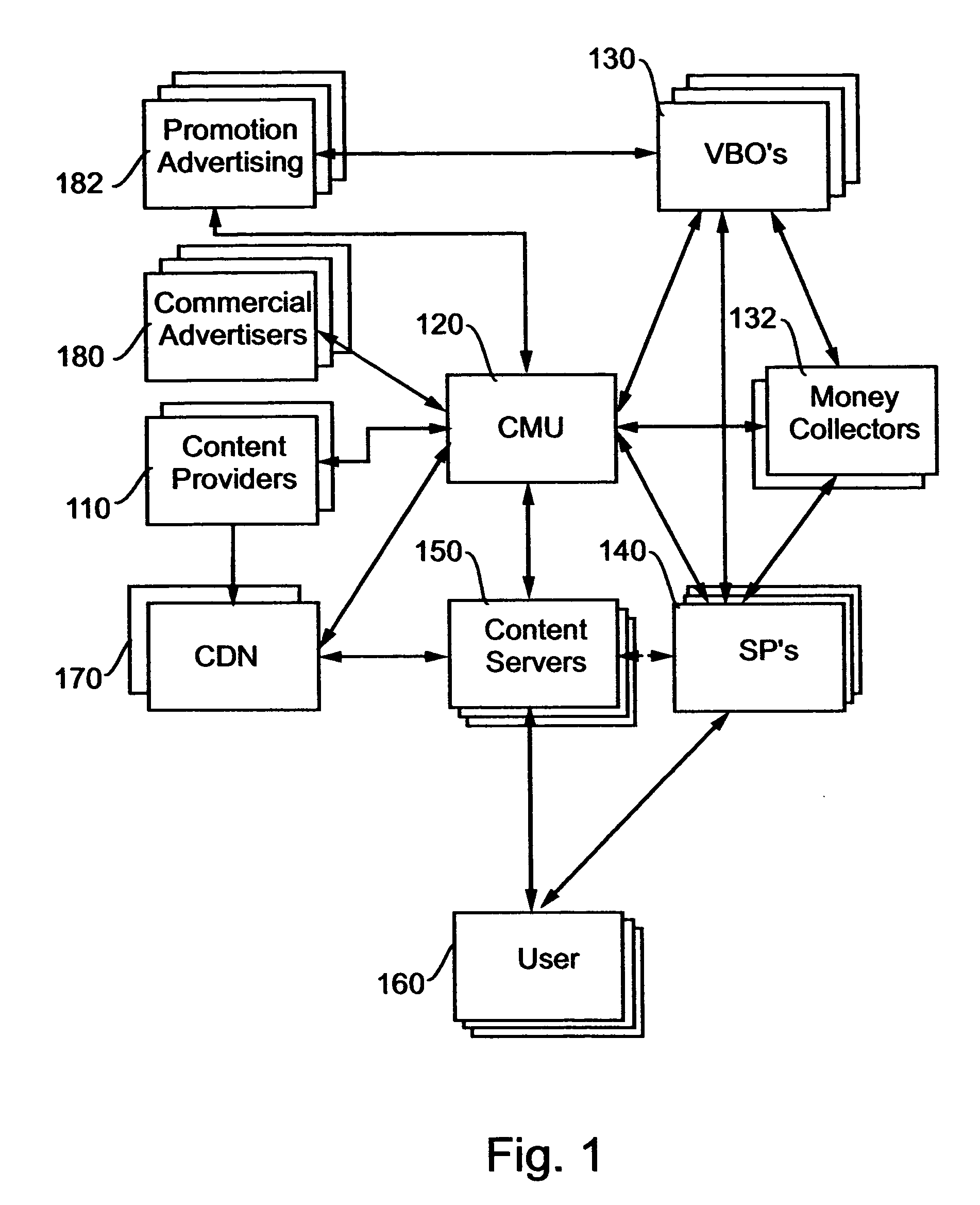

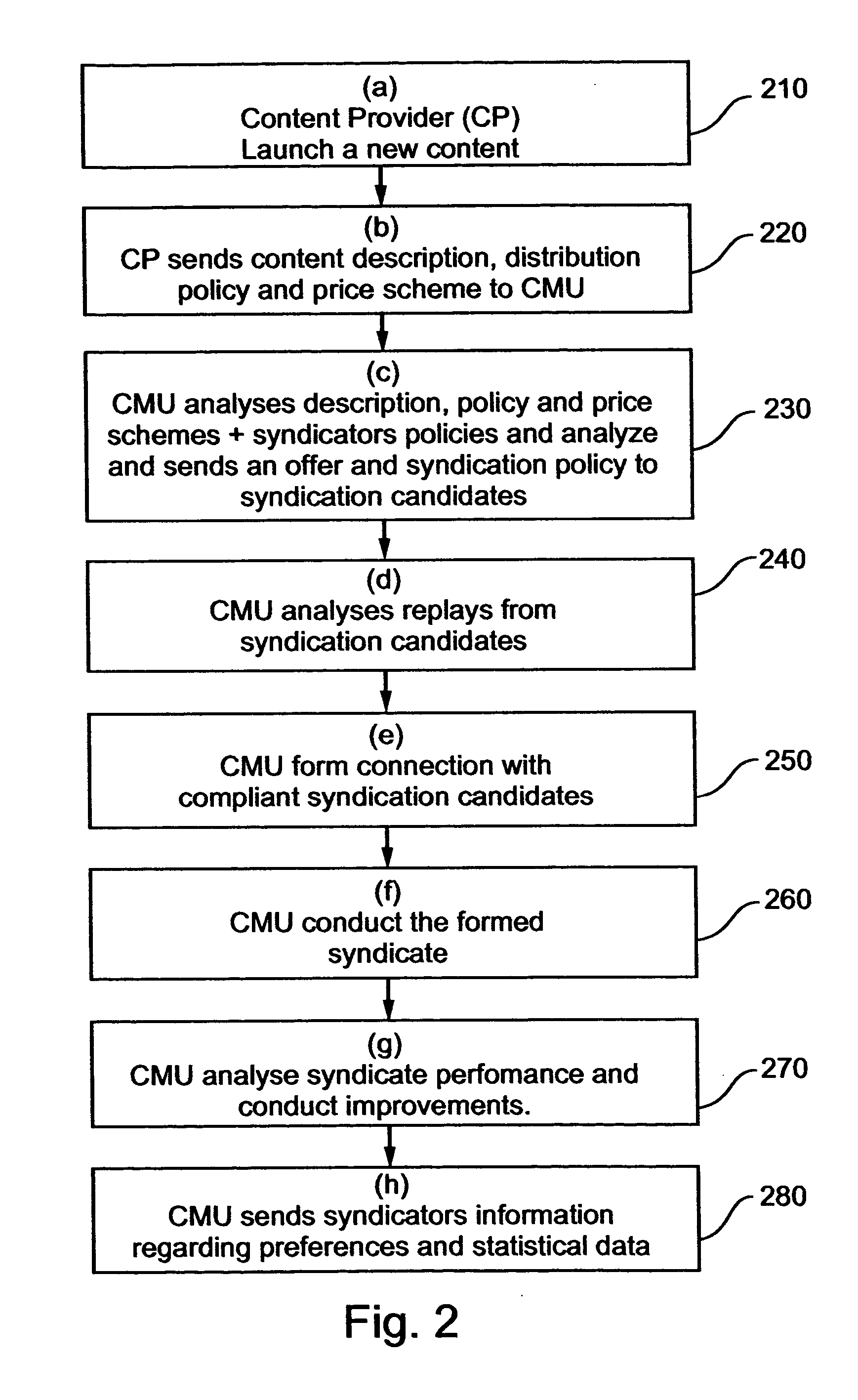

Method and system for creation, management and analysis of distribution syndicates

InactiveUS20060242072A1Efficient conductionComputer security arrangementsMarketingDigital contentNumber content

A method of distributing digital content or service over a communication network is provided. The method is effected by: (a) analyzing a request for distribution of the digital content or service; (b) generating a policy associated with the digital content or service; and (c) assembling a distribution syndicate of distribution entities, the distribution entities being selected according to the policy associated with distribution of the digital content or service, the distribution syndicate being for distributing the digital content or service over the communication network.

Owner:PORTAUTHORITY TECH LLC

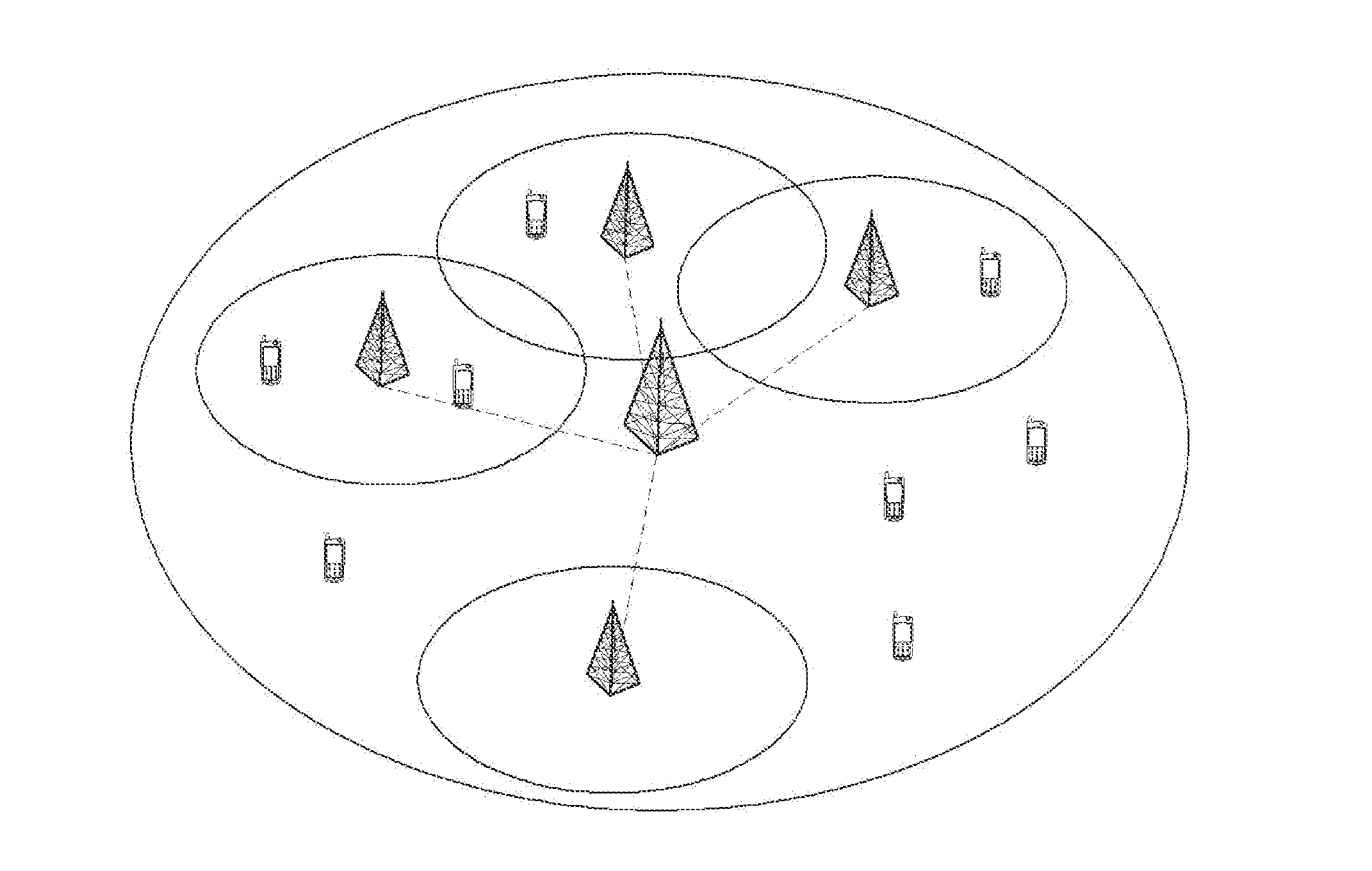

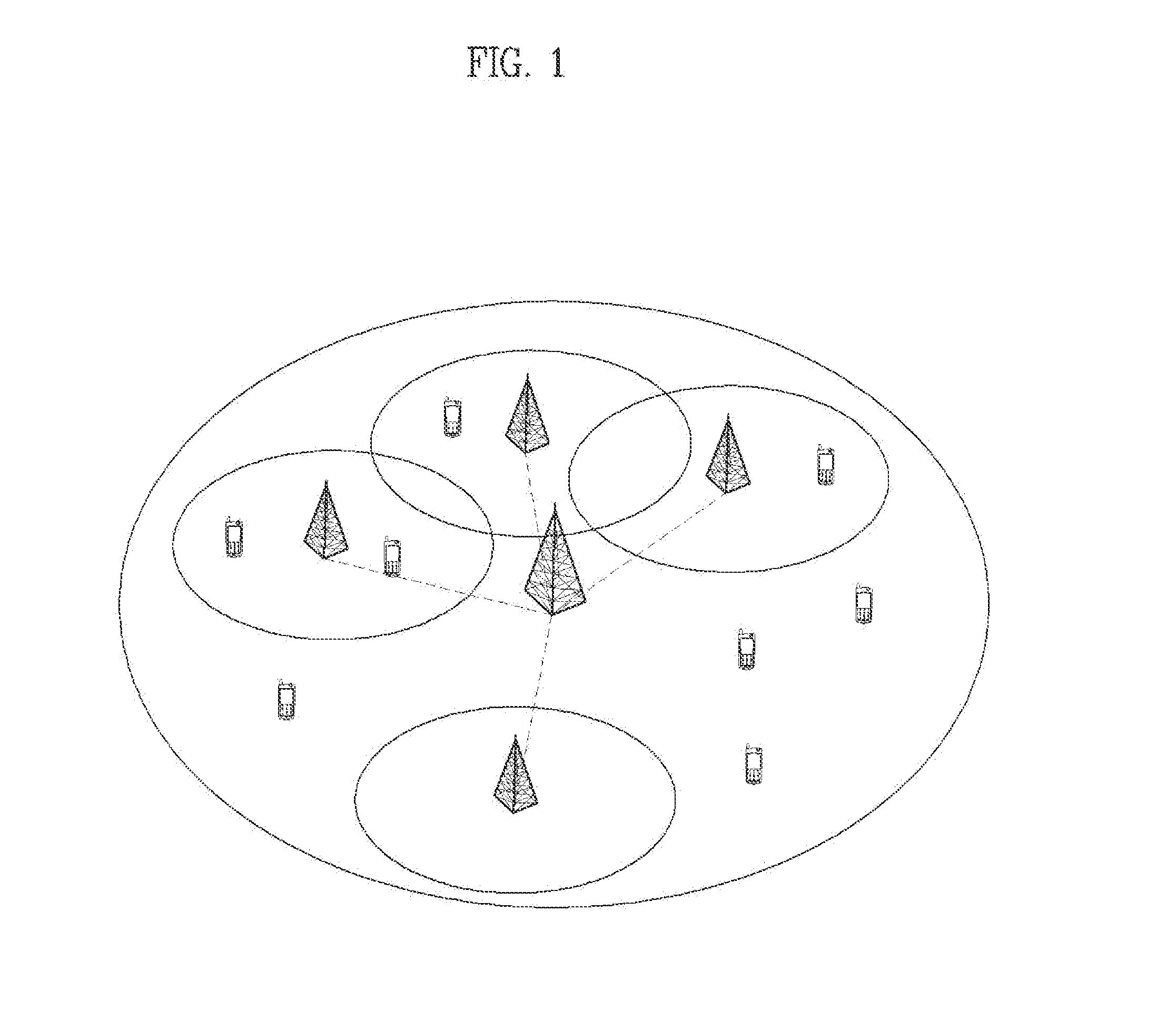

Method of allocating resource for relay

InactiveUS20120113884A1Efficient conductionReduce in quantityFrequency-division multiplex detailsBroadcast transmission systemsControl channelPhysical control

A method for wireless backhaul communication between a base station and a relay is disclosed. The base station enables a physical control channel to be set up, separately from the terminal that is used to transmit control information to each relay and the physical downlink control channel that has been set up. The base station can transmit data to the relay based on this control information. In a special embodiment, physical downlink control channel transmissions can be minimized by prescribing in advance the transmission of control information between the base station and the relay.

Owner:LG ELECTRONICS INC

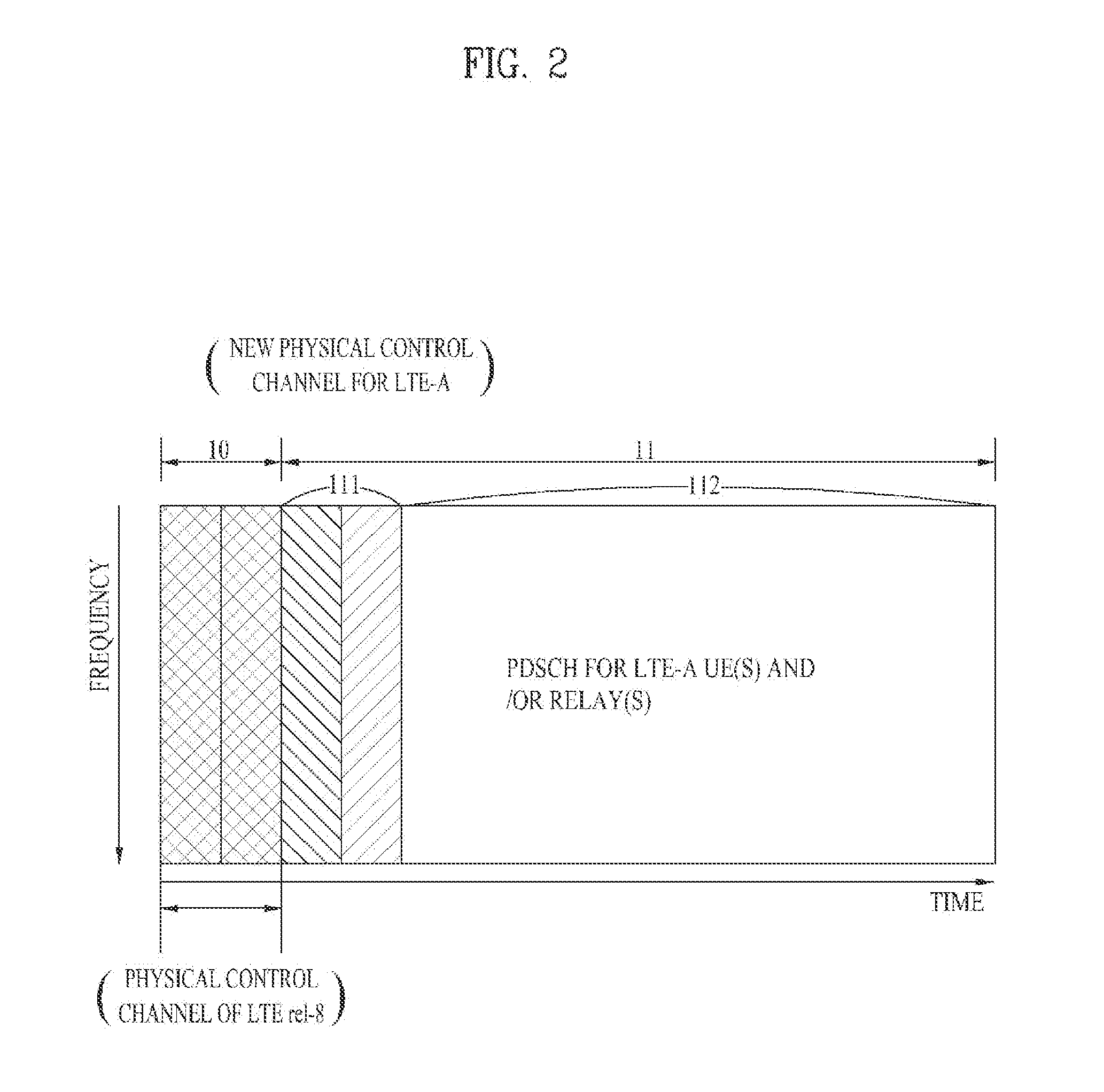

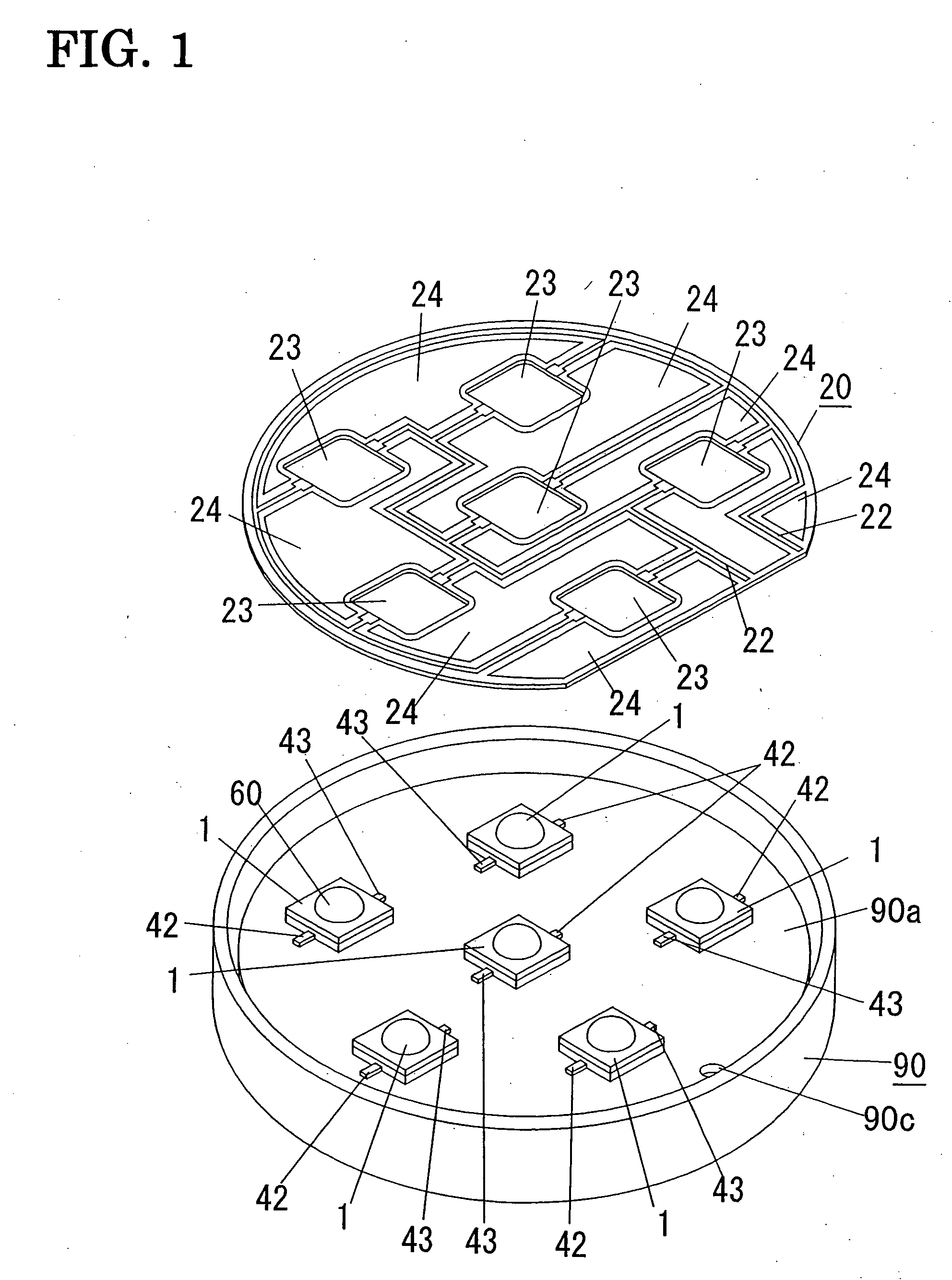

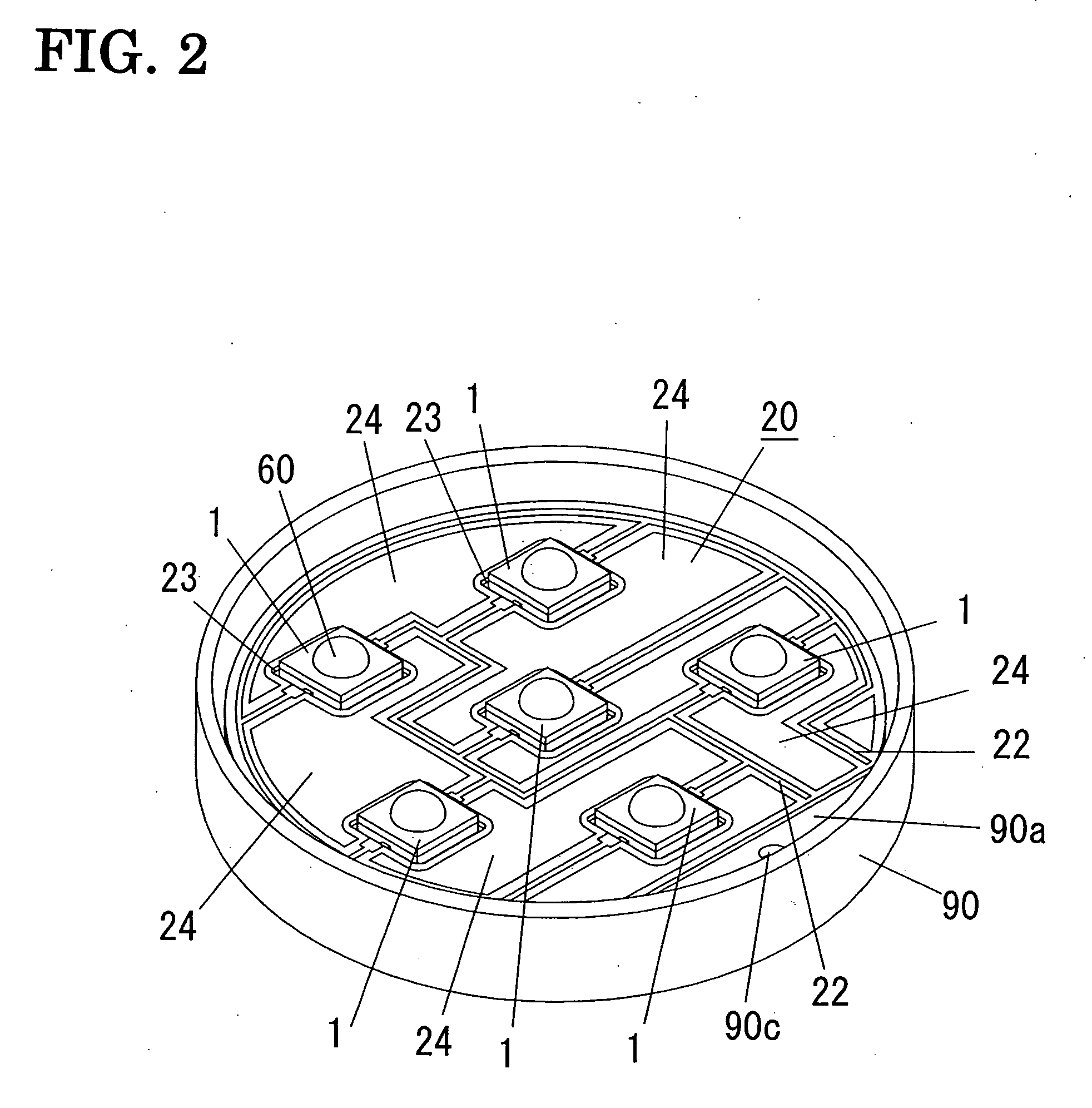

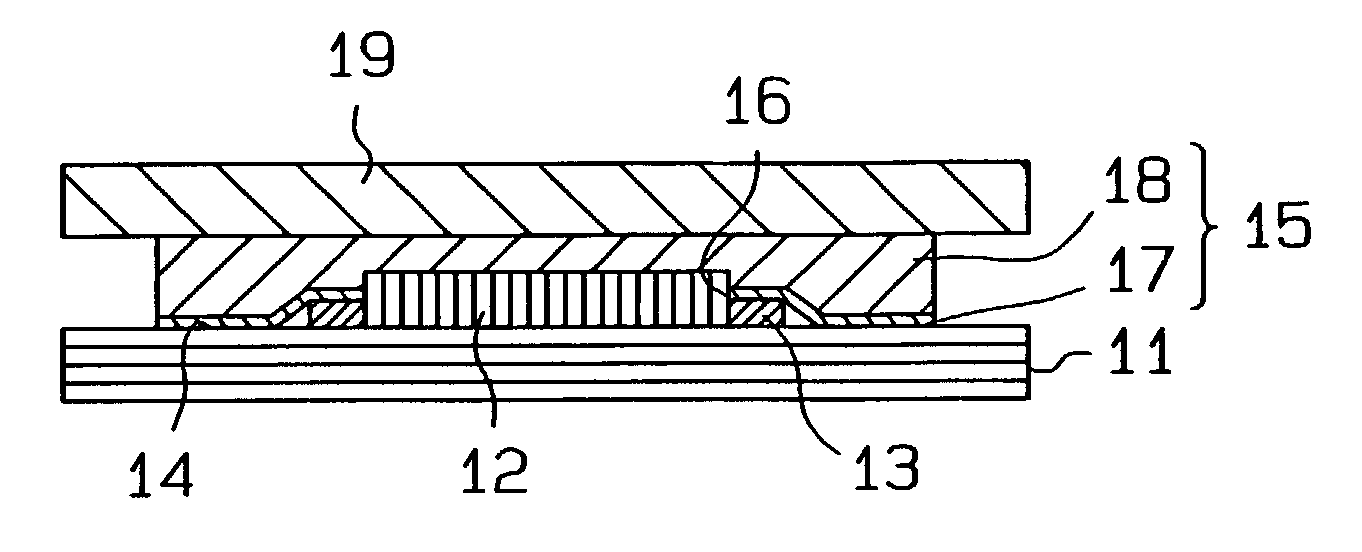

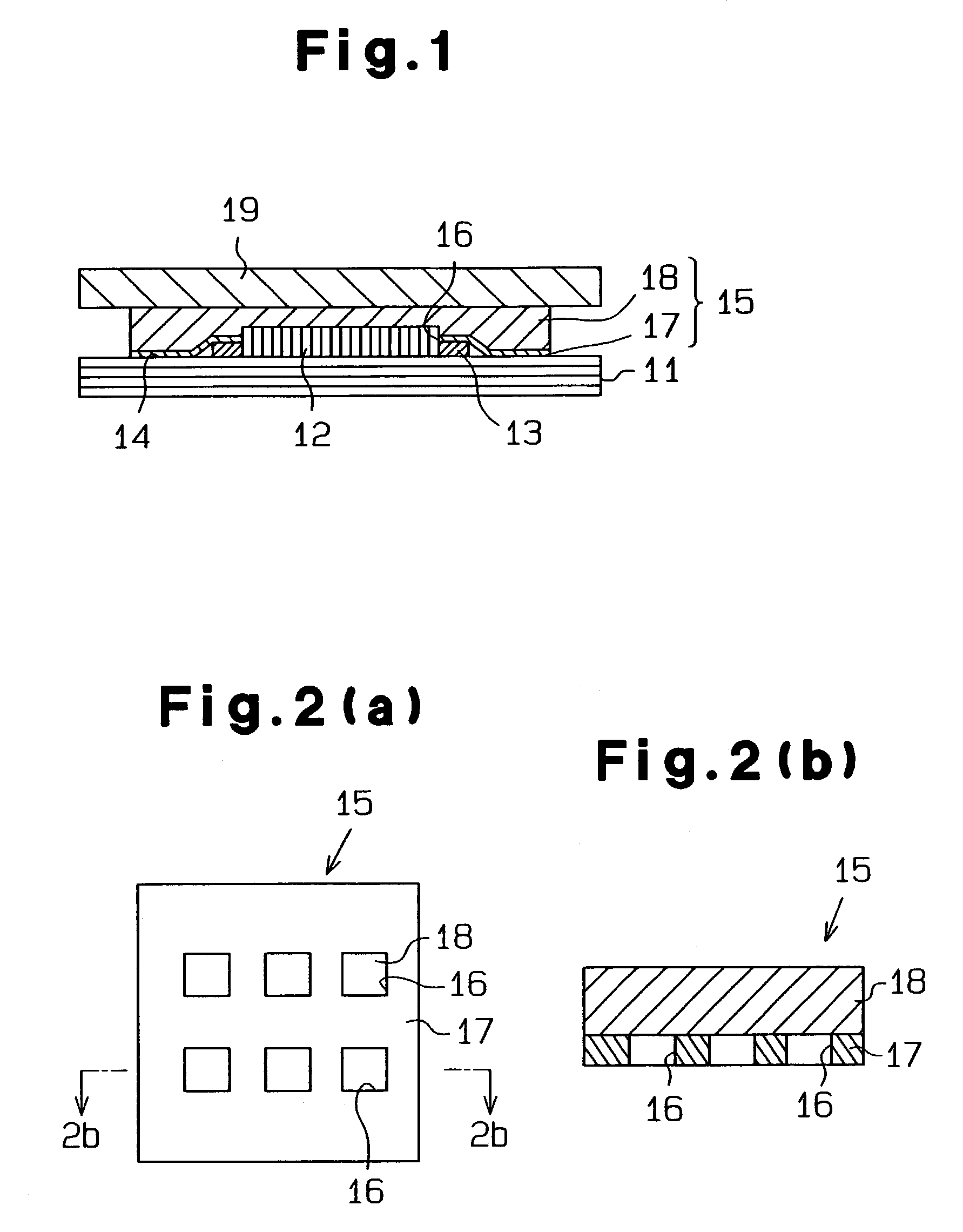

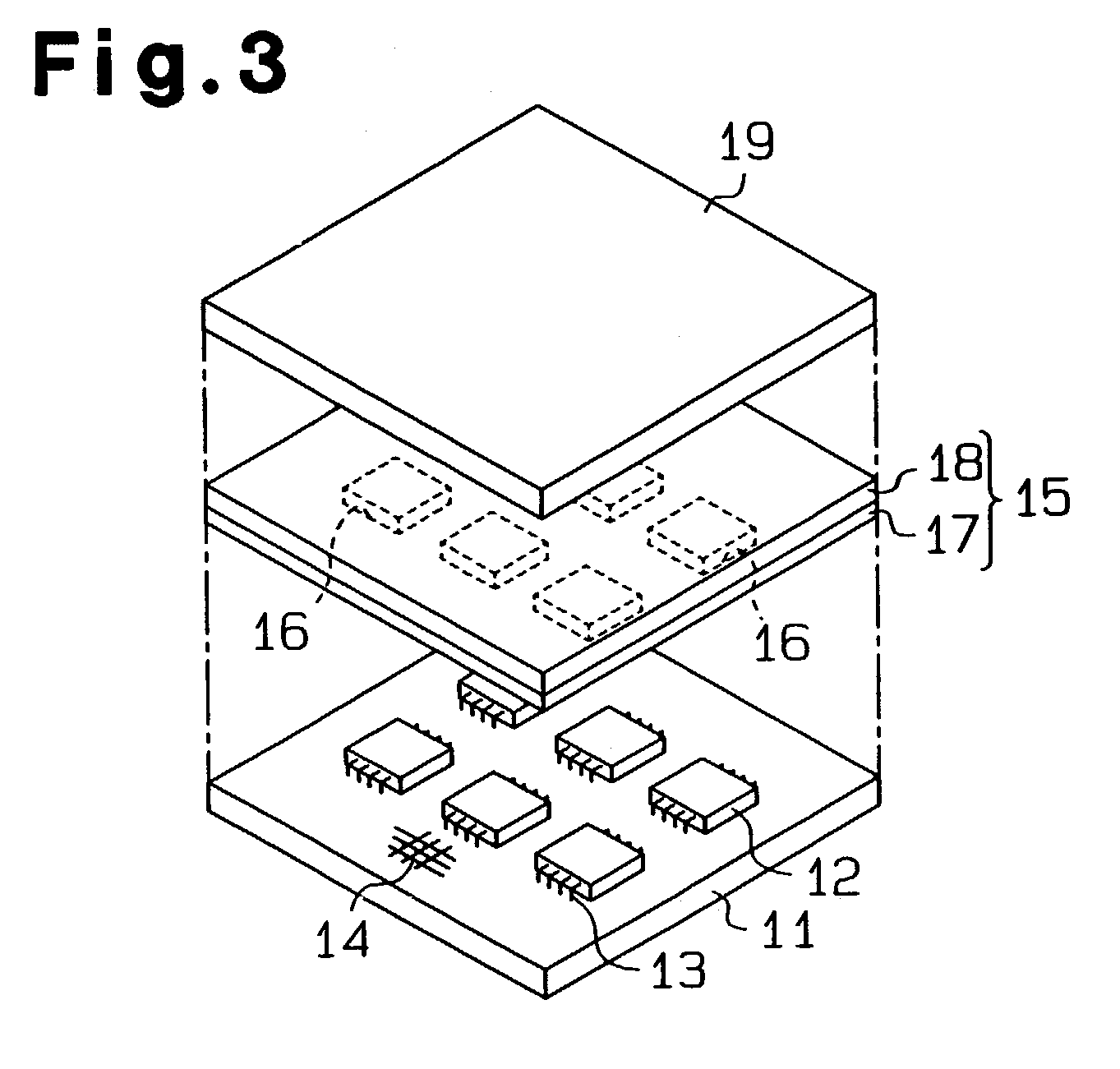

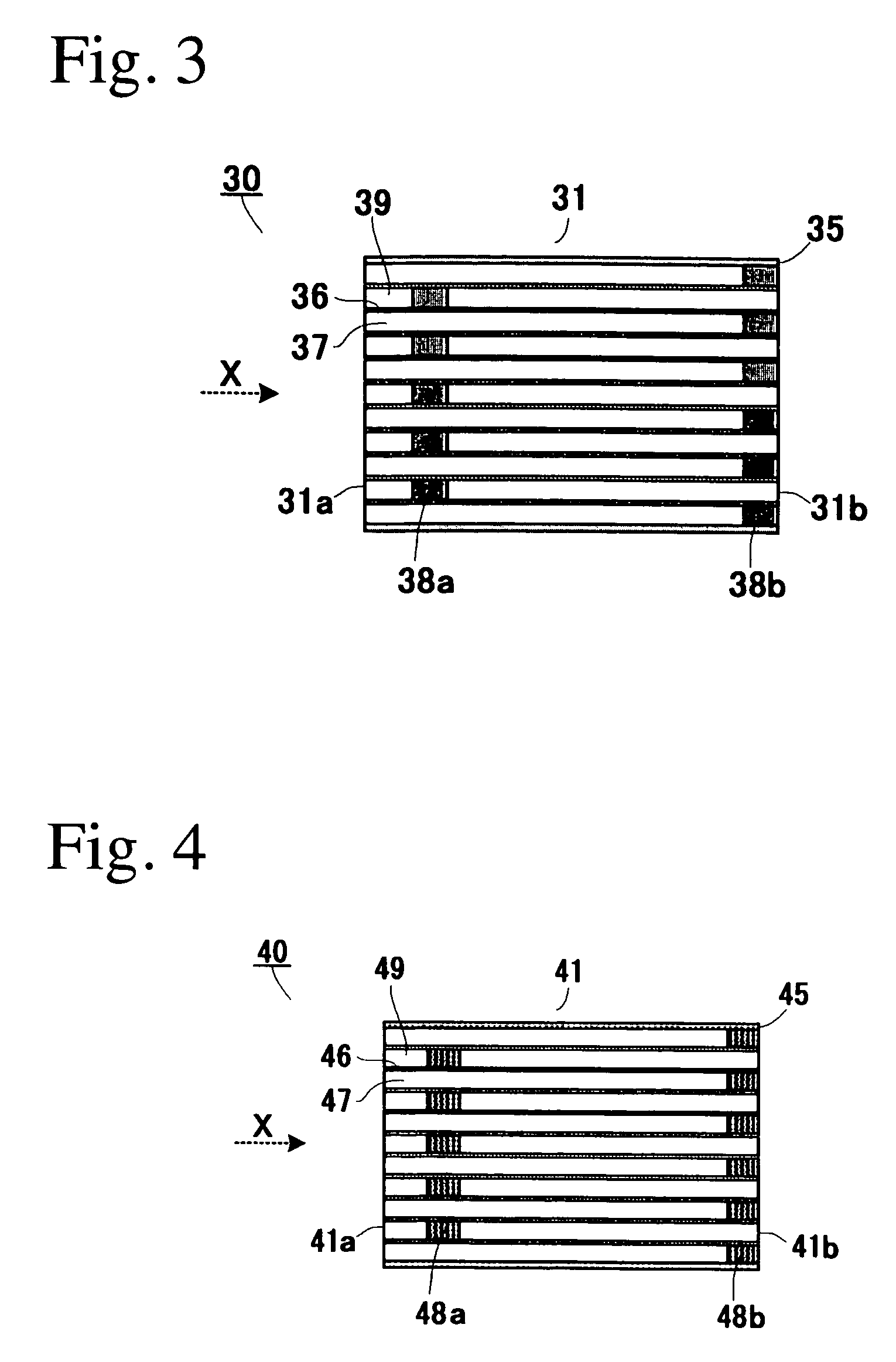

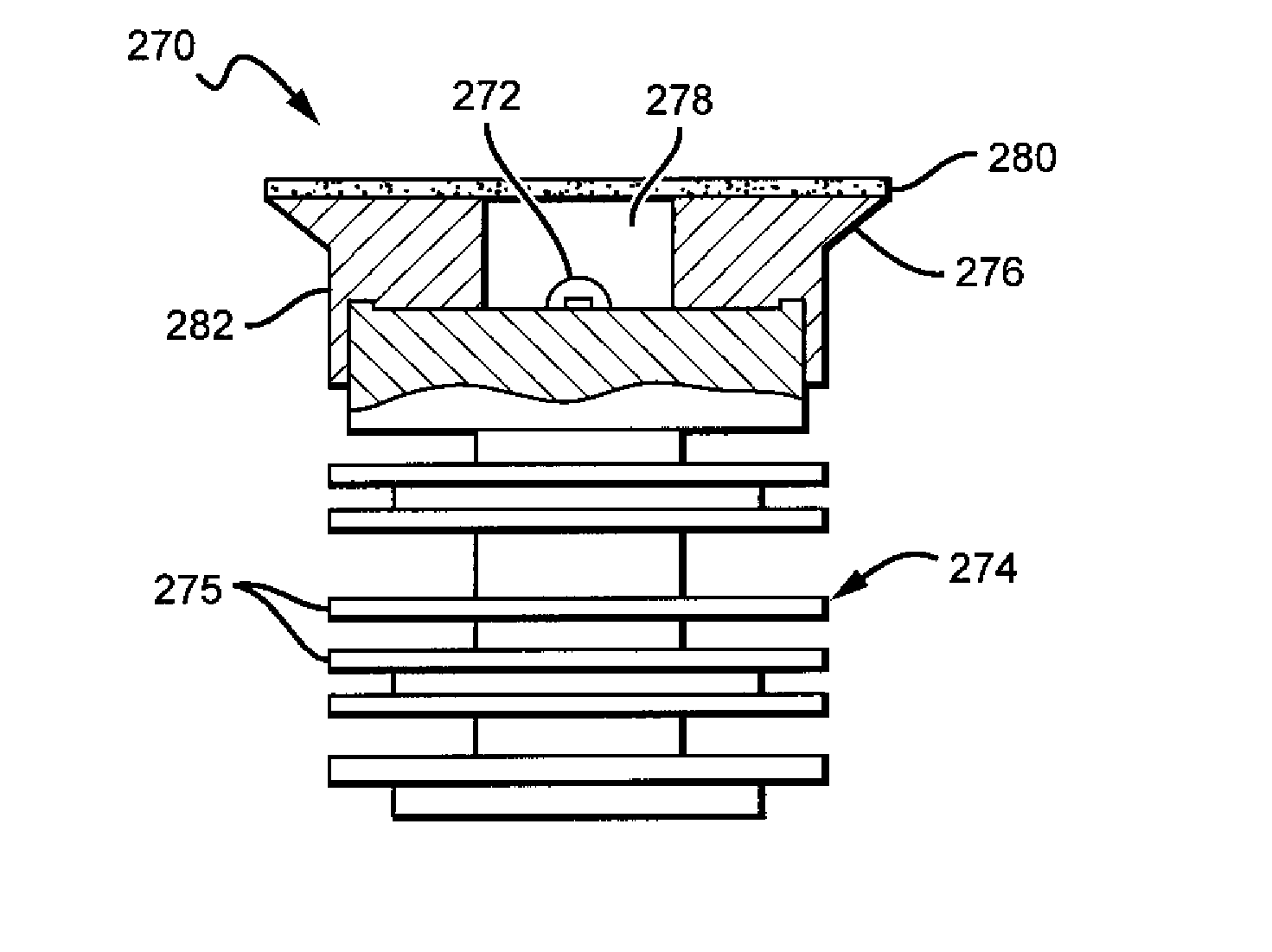

Lighting Apparatus With Leds

ActiveUS20090046456A1Inhibit temperature riseLow costPoint-like light sourcePortable electric lightingLight equipmentEffect light

A lighting apparatus with LED includes a metal-made main body 90; a plurality of LED chip units 1 each including an LED chip and a pair of lead terminals 42, 43 electrically connected to electrodes of the LED chip; and a dielectric layer 80 disposed between the main body 90 and each LED chip unit 1 for making electrical insulation therebetween as well as bond the same. The circuit board 20 is formed with a plurality of windows 23 through which the individual LED chip units 1 extend respectively with the lead terminals held in electrical contact with the circuit pattern of the circuit board at the circumference of the window, each of the LED chip units being thermally coupled at its bottom face with the main body 90 through the dielectric layer 80, and the heat generated in the LED chip is conducted to the main body through the dielectric layer without passing through the circuit board.

Owner:MATSUSHITA ELECTRIC WORKS LTD

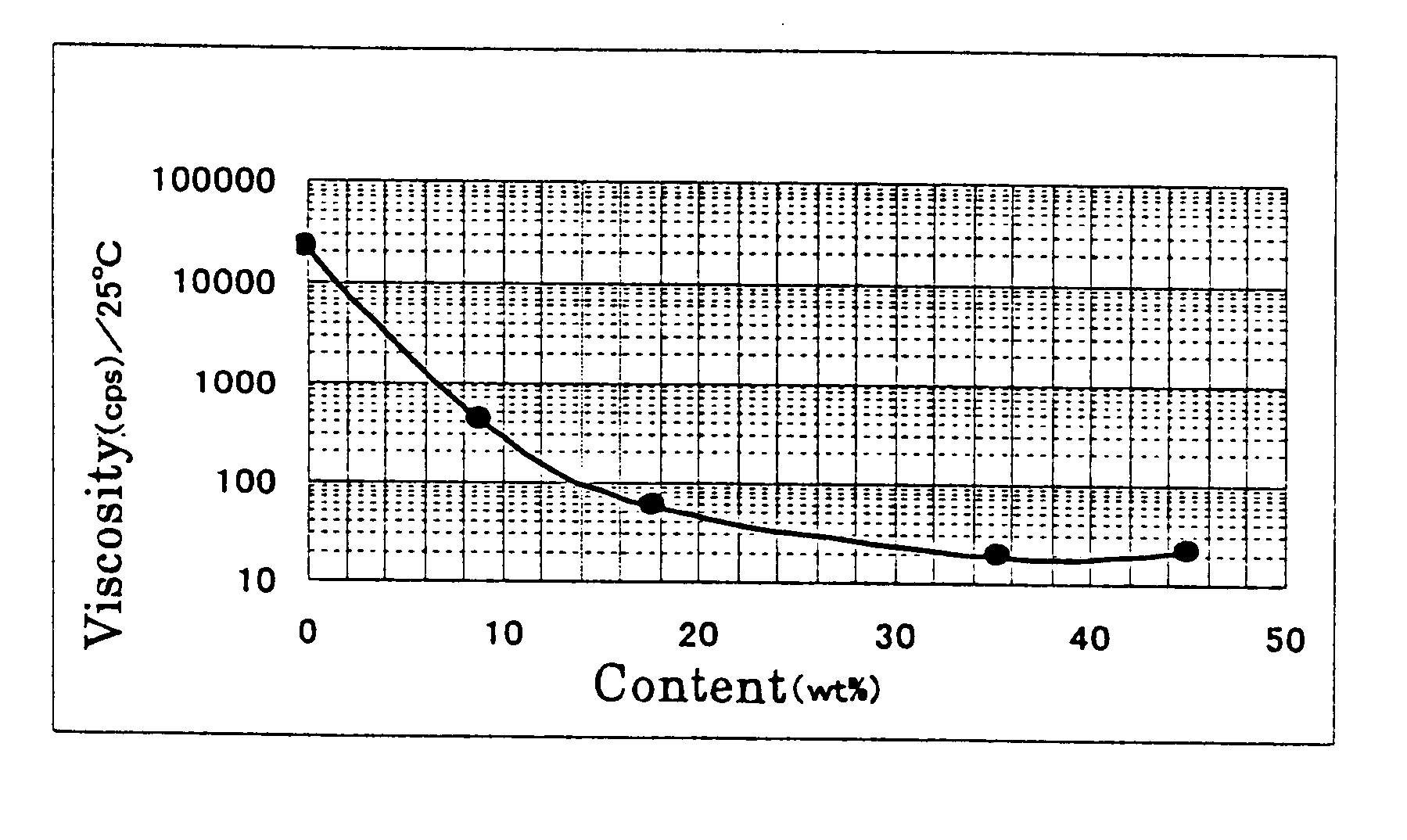

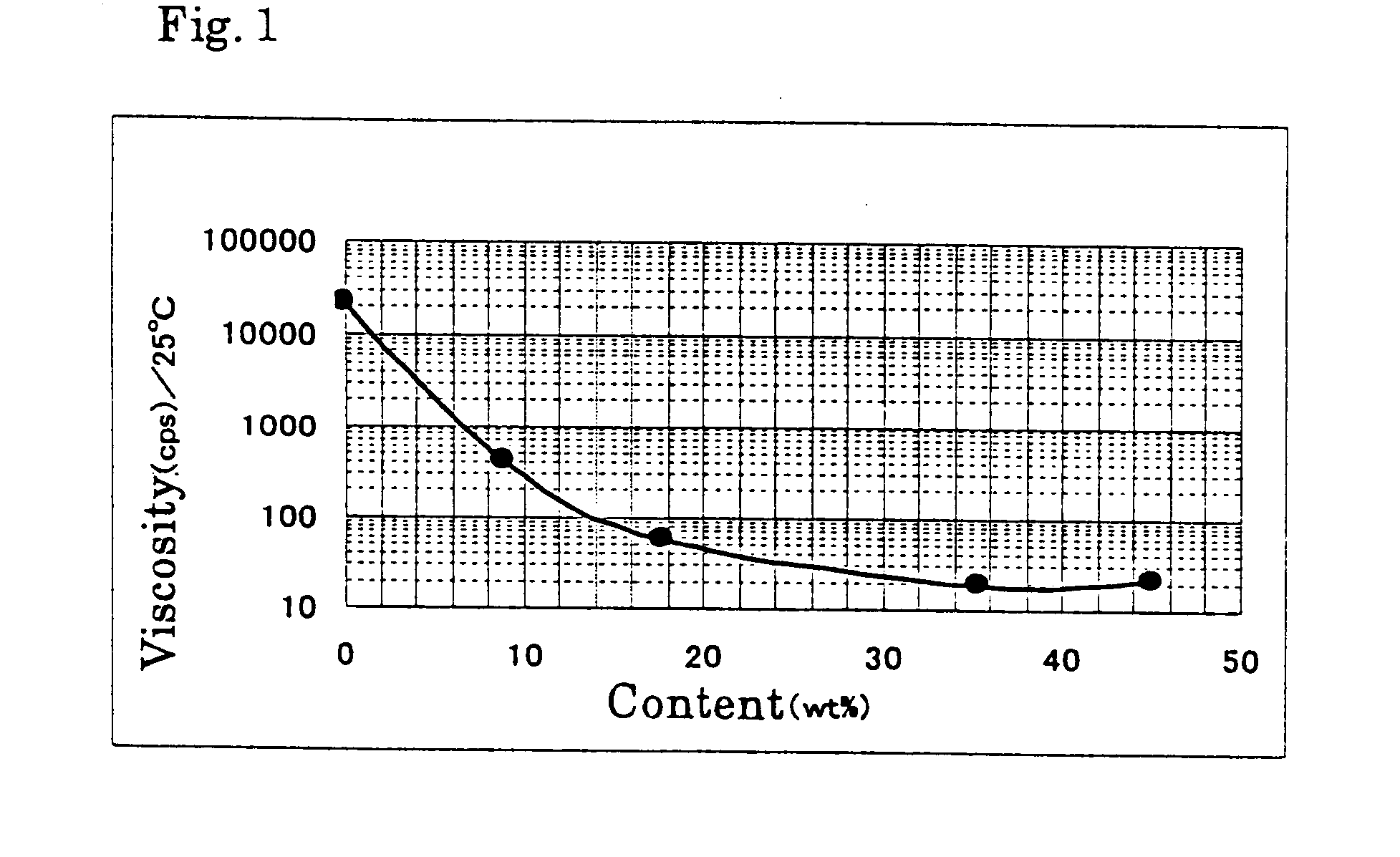

Method for preparing N-long chain acyl neutral amino acid

InactiveUS6703517B2Efficient conductionLow viscosityCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlanine

A method for preparing a highly purified N-long chain acyl neutral amino acid for use of a detergent and the like in a simple and convenient manner and in a high yield by reacting a neutral amino acid such as glycine, gamma-aminobutyric acid, and alanine, with a saturated or unsaturated fatty acid halide having 8 to 22 carbon atoms, wherein the reaction is performed in a mixture of water and one or more kinds of hydrophilic organic solvents selected from the group consisting of acetone, acetonitrile, a secondary alcohol having 3 or 4 carbon atoms, and a tertiary alcohol having 4 carbon atoms such as isopropanol, sec-butanol, and tert-butanol in the presence of a base.

Owner:AJINOMOTO CO INC

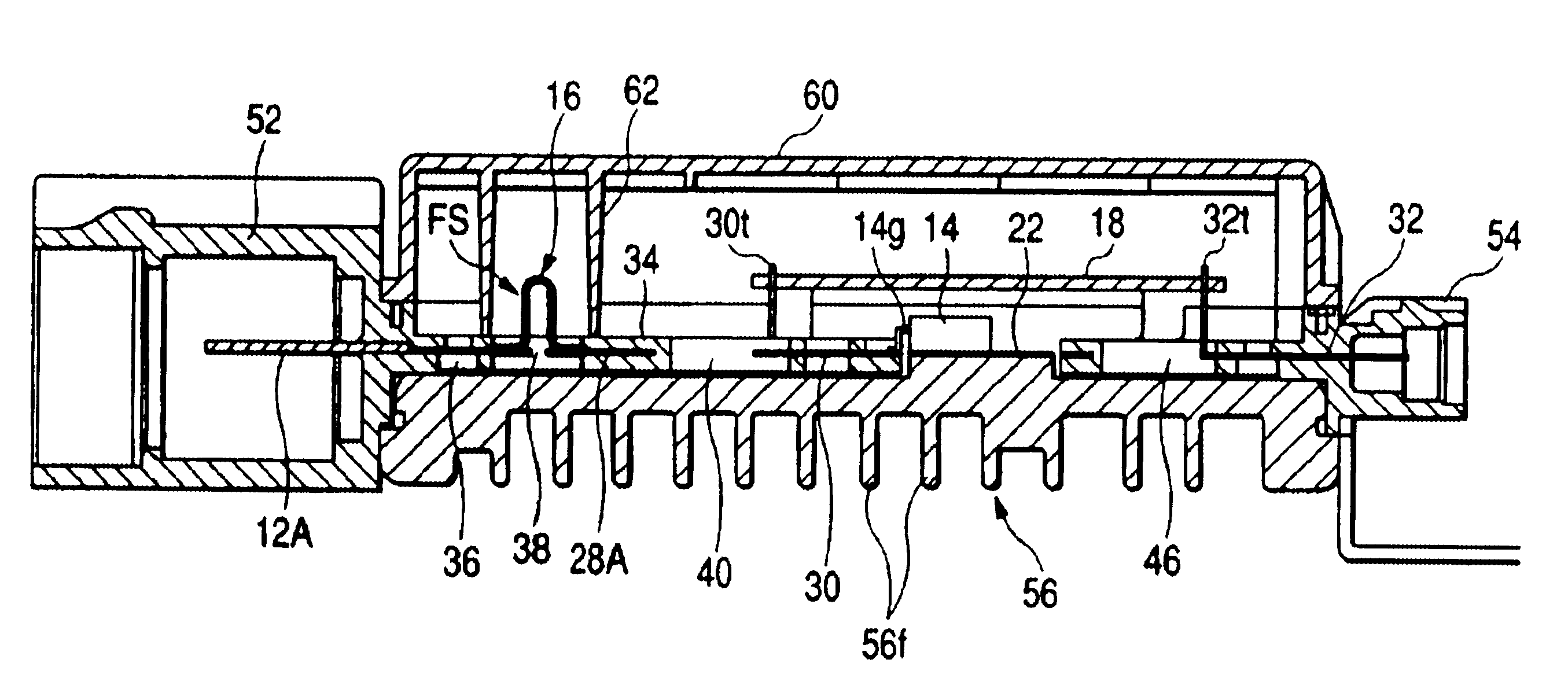

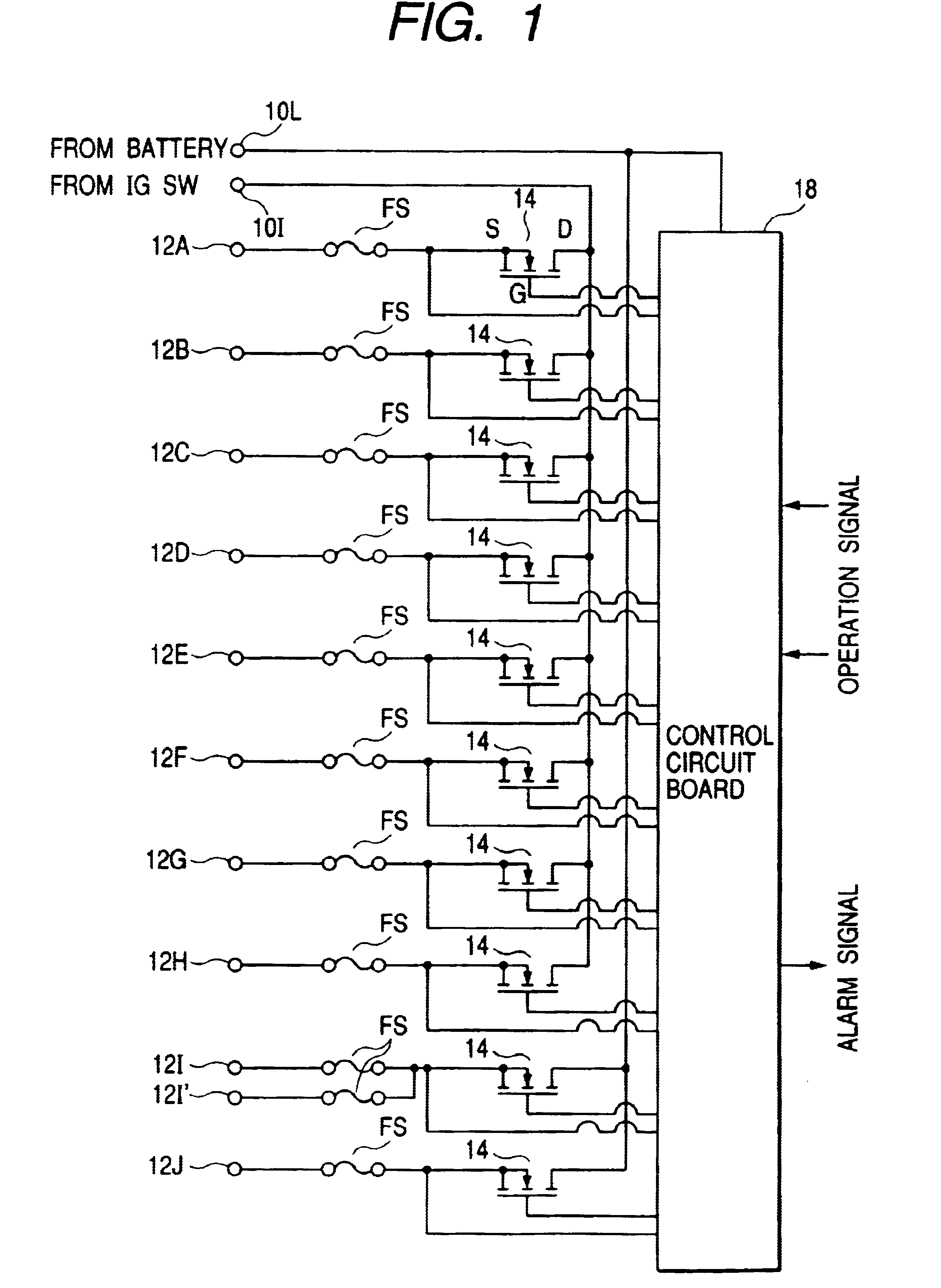

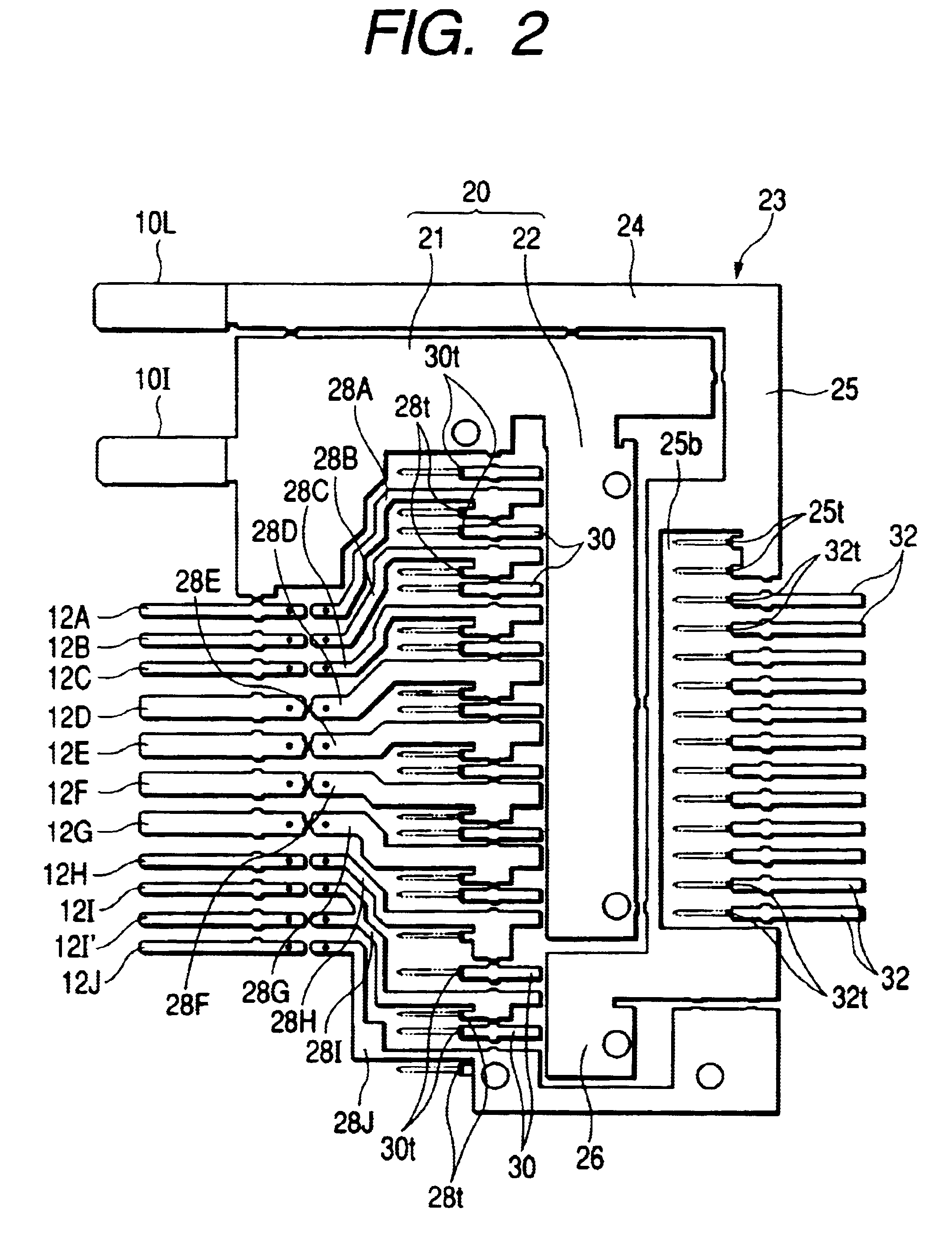

Power distributor for a vehicle and production method thereof

InactiveUS6724627B2Simple structureAssembly precisionSemiconductor/solid-state device detailsSolid-state devicesPunchingDistributor

In the power distributor using a semiconductor switching element, input terminals 10I and 10L, output terminals 12A-12J, connected to the element, and more preferably, the board terminals 30 and 32, are structured by a metallic plate, and arranged on the same plane perpendicular to the plate thickness. The metallic plate can be integrated by the resin mold, thereby the structure can be greatly simplified. The metallic plate can be produced by a greatly simple method by which, after the punching out of the metallic plate and the molding of the resin mold, a predetermined portion of the metallic plate is cut and the semiconductor switching element is mounted, and it can contribute to also the reduction of the cost.

Owner:AUTONETWORKS TECH LTD +2

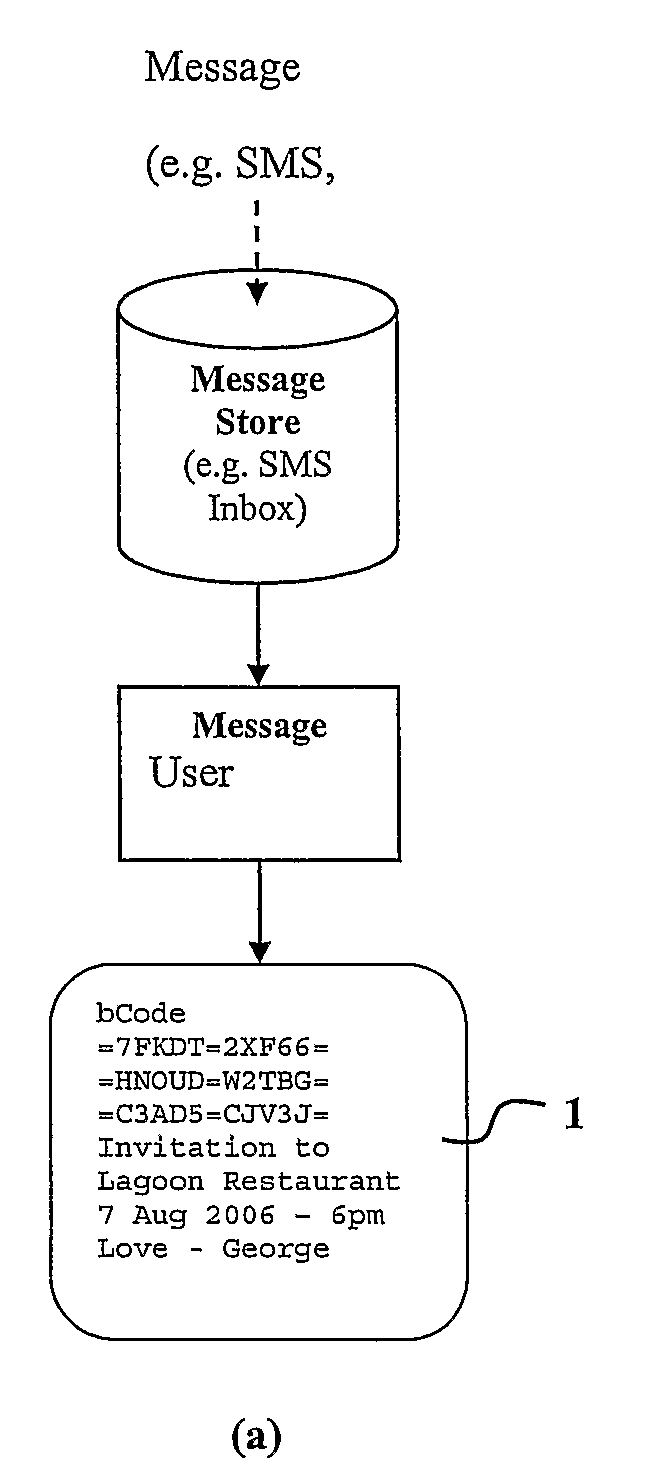

Distributed electronic commerce system, method and apparatus

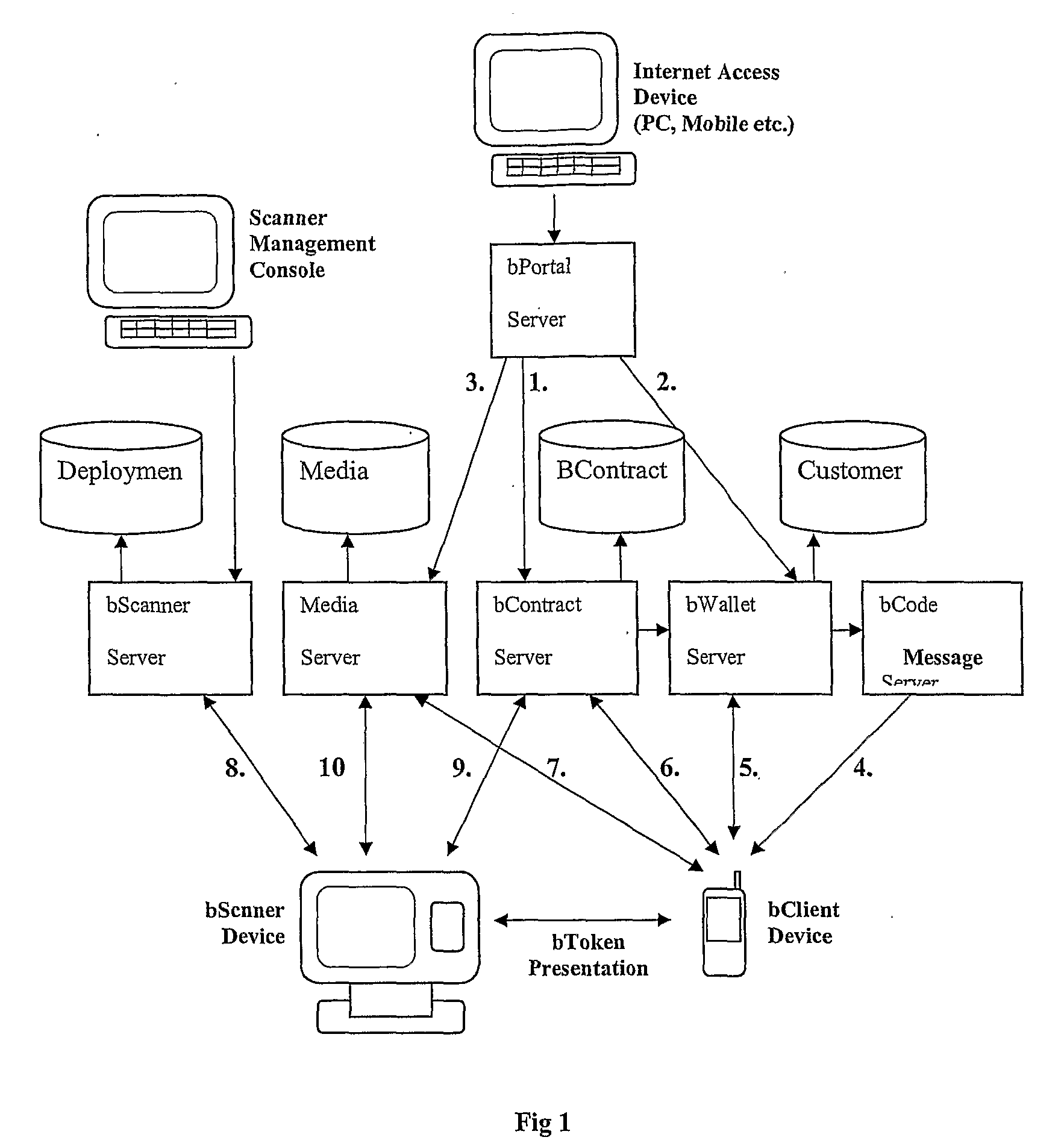

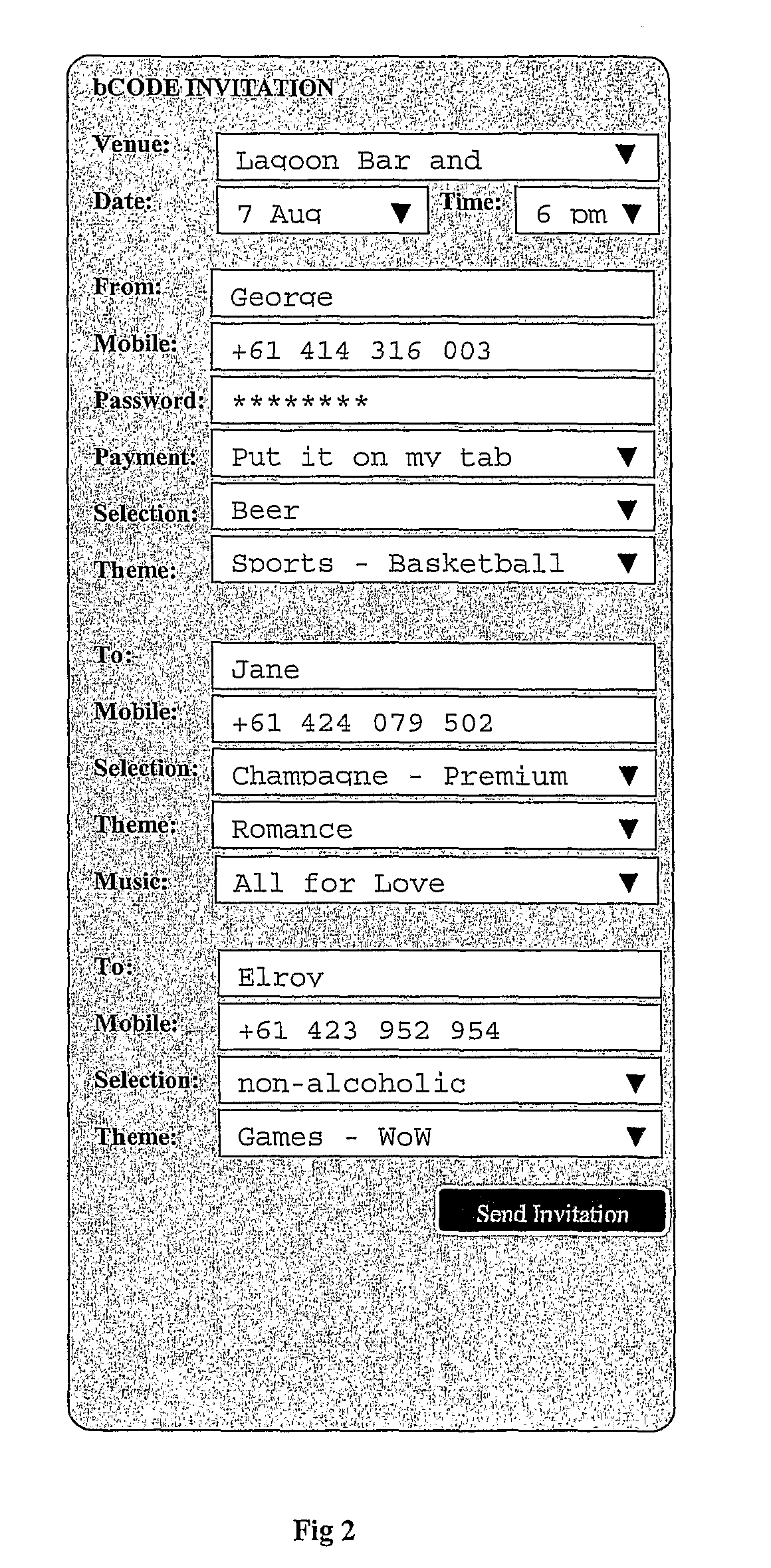

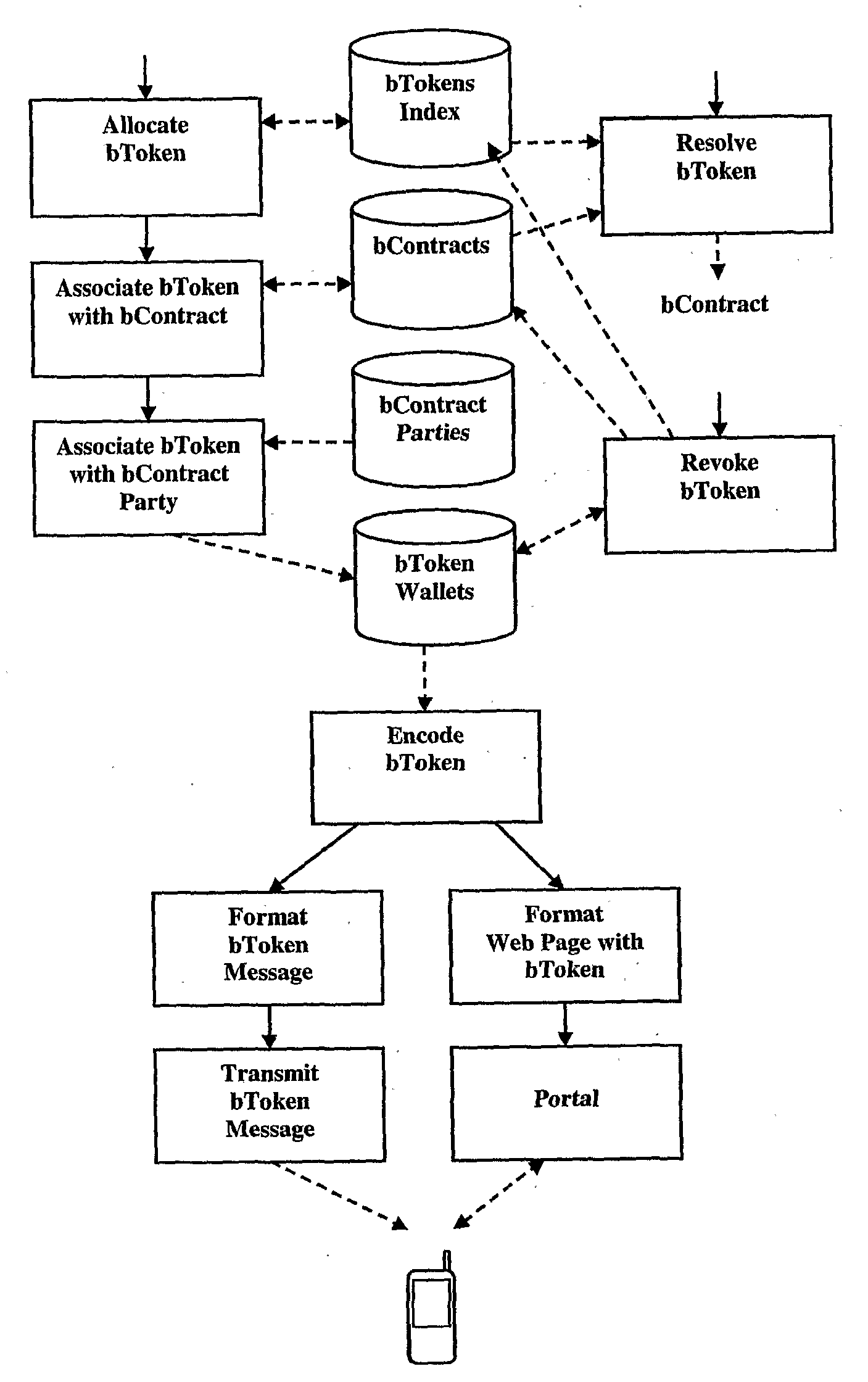

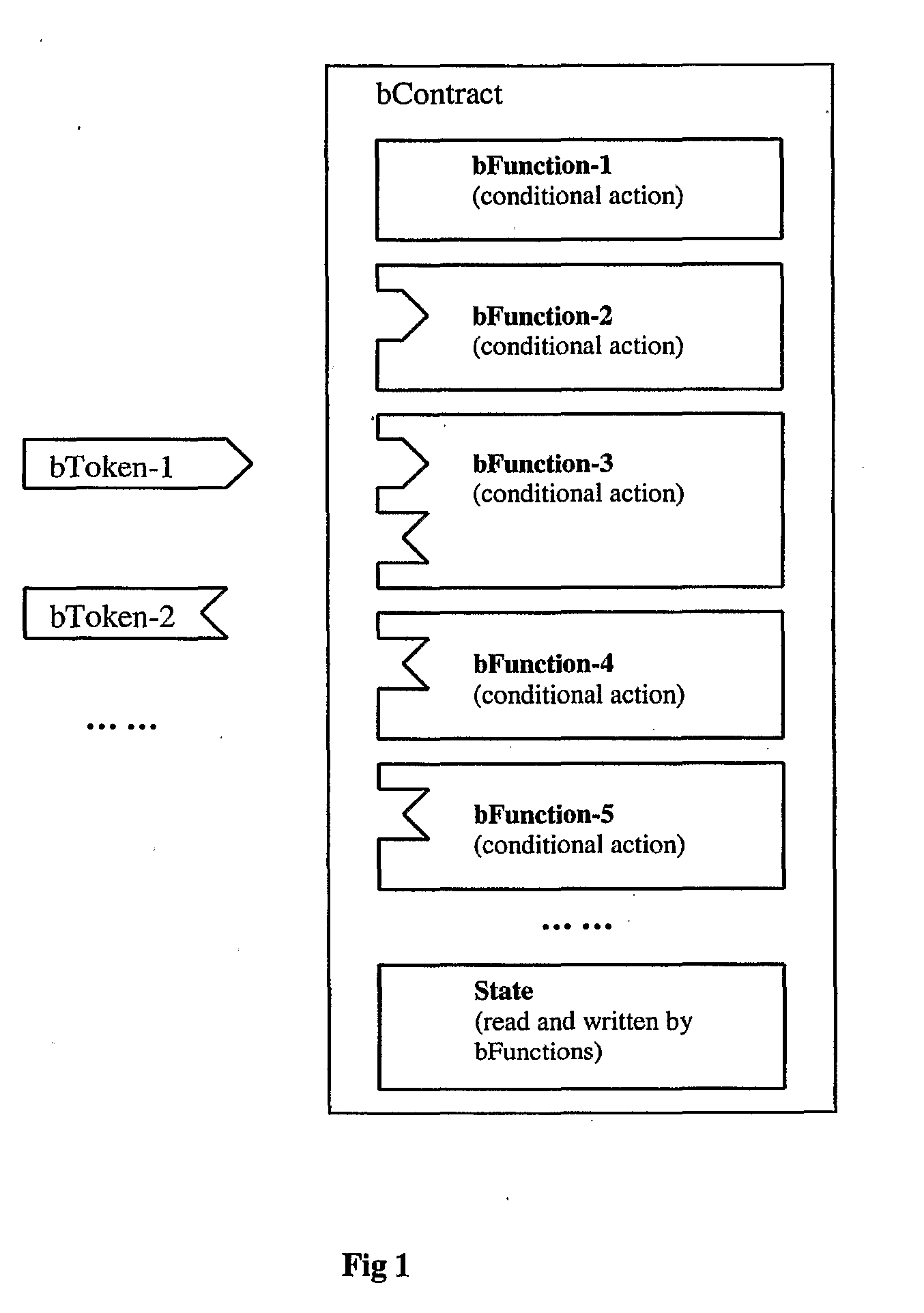

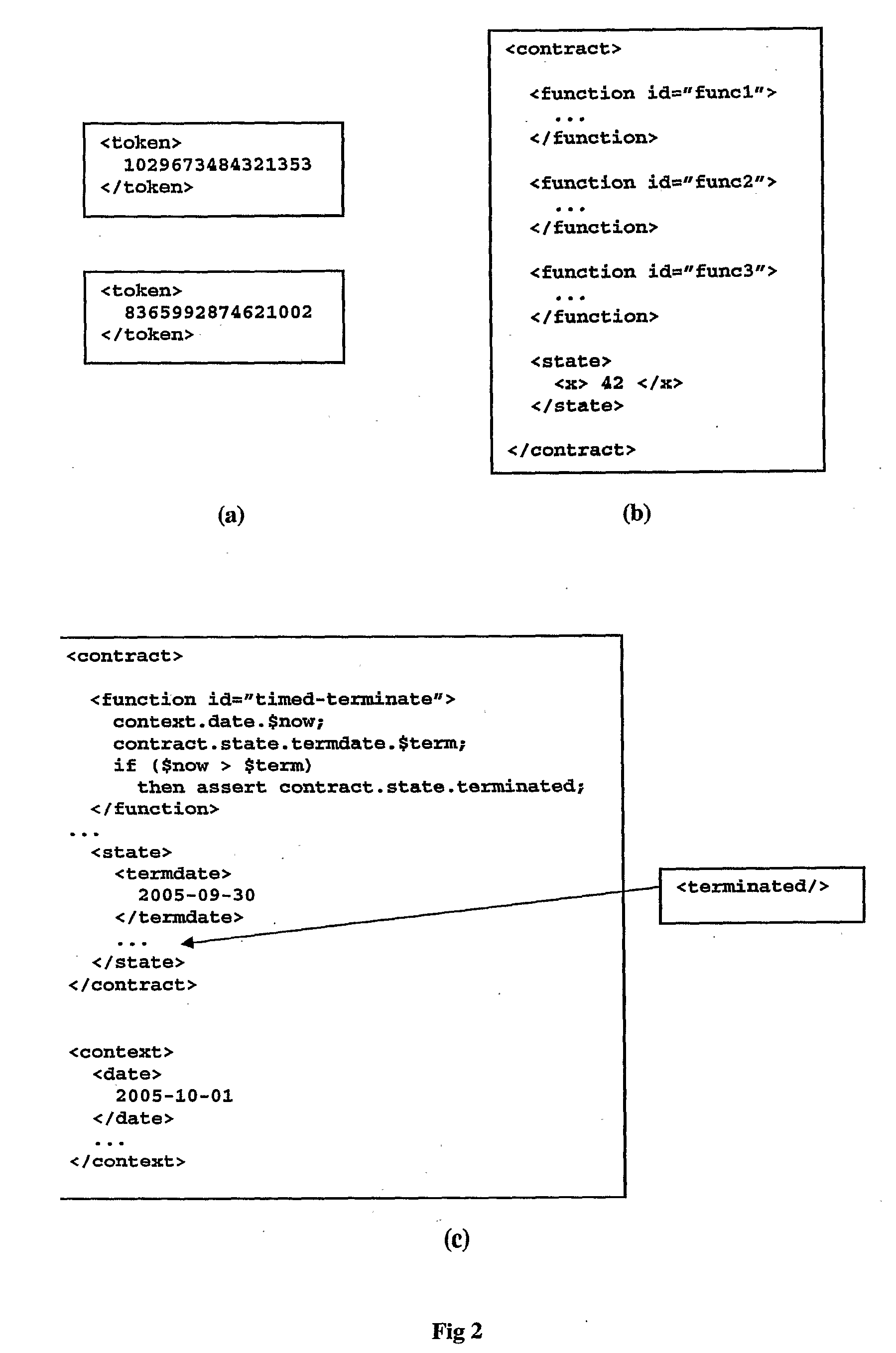

InactiveUS20100063892A1Efficiently executedGood and more responsive user experienceComplete banking machinesTelephonic communicationClient-sideDigital object

A method for constructing electronic commerce services and conducting electronic commerce transactions is disclosed. The method is illustrated by instantiating and storing the electronic contract on a server; issuing and transmitting a token message to one or more contracting party's client device. Using a processor to intercept the token message and contact the server to retrieve the electronic contract associated with the token message; and downloading or uploading digital media as instructed by the electronic contract. The method is based on the uniform, highly expressive representation of electronic contracts as digital objects. A system based on a distributed object architecture that implements the method is also described. The architecture enables the execution of the promises encoded as part of an electronic contract to be executed on any device that implements an electronic contract interpreter mechanism.

Owner:BCODE

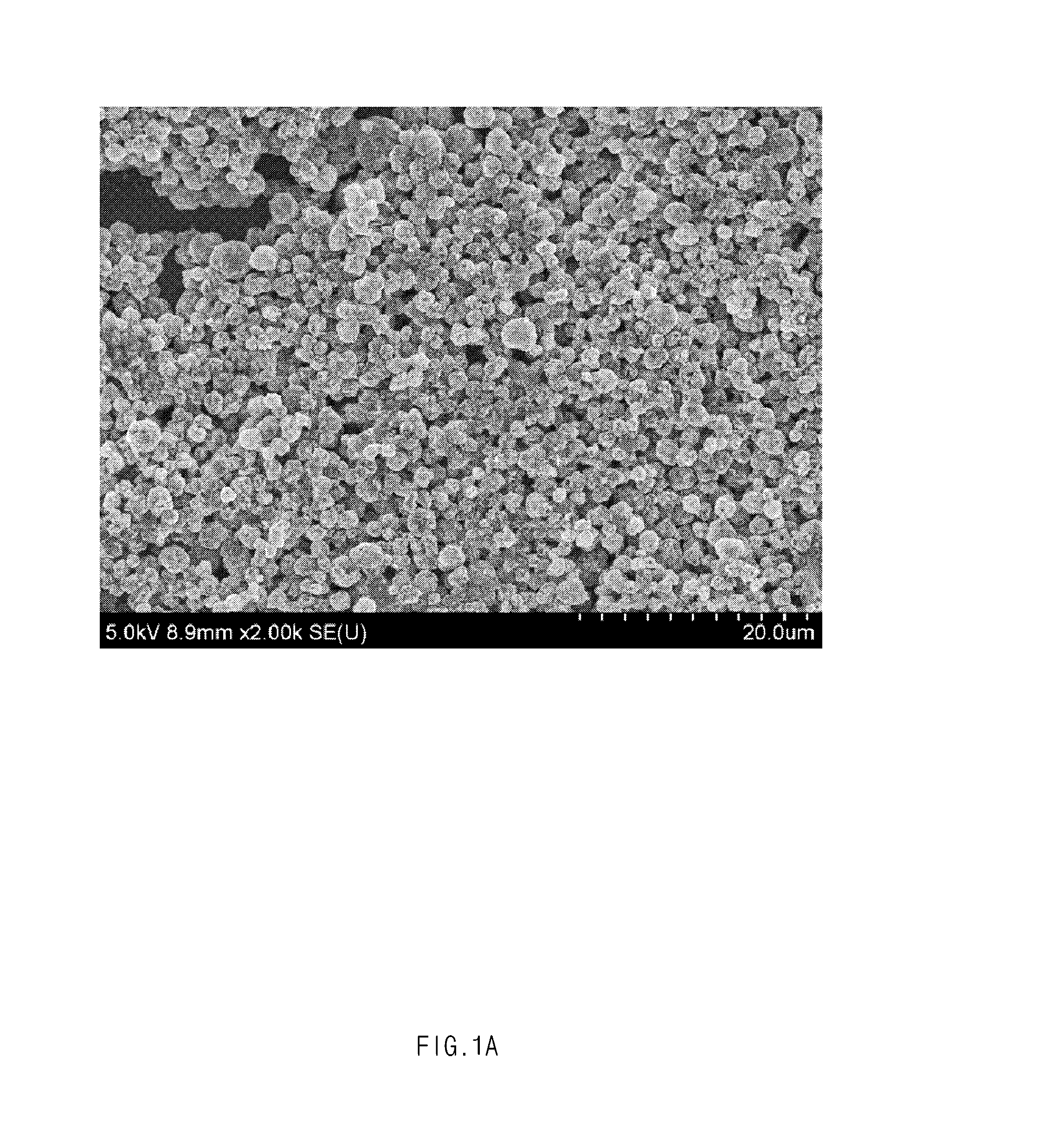

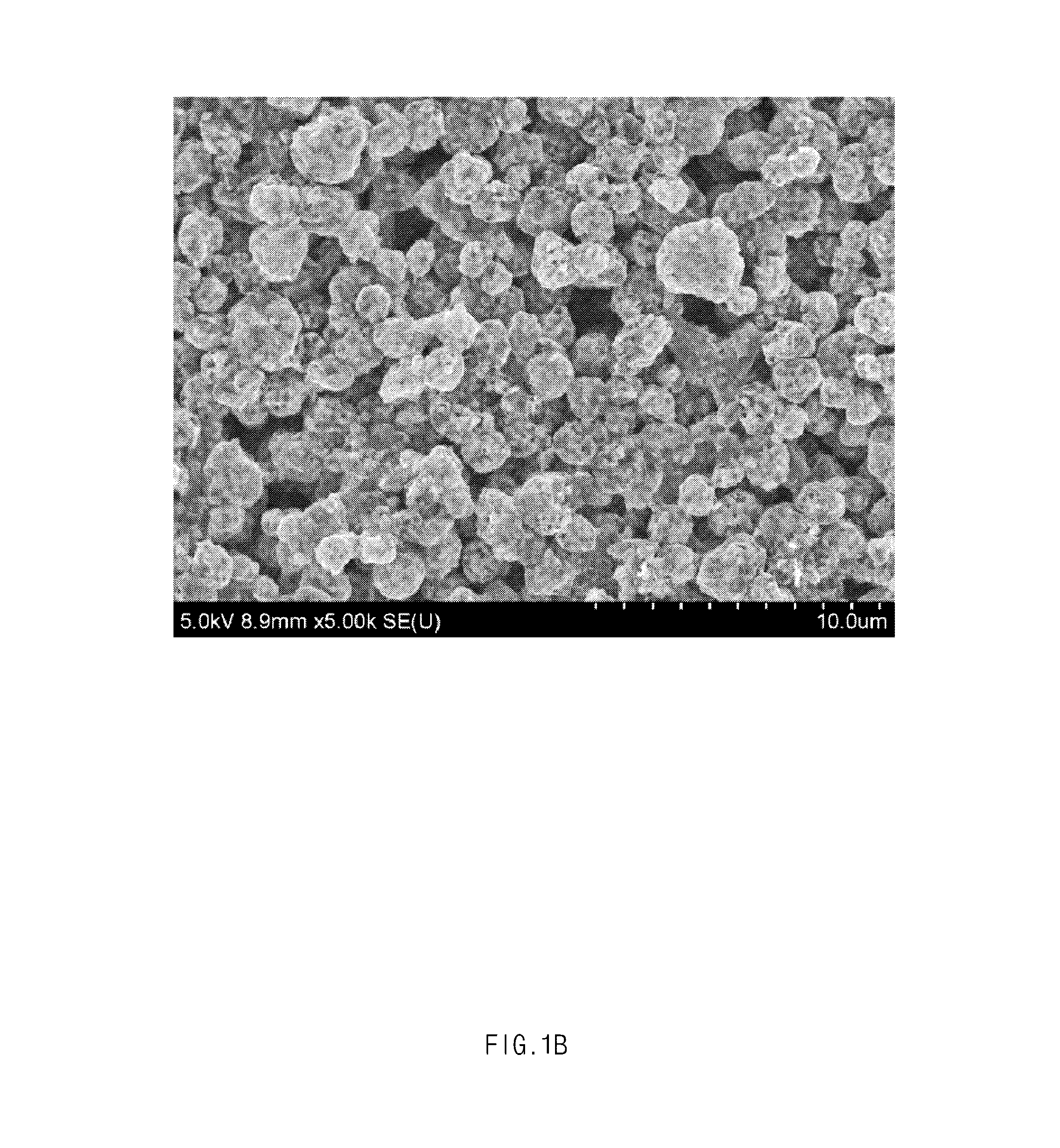

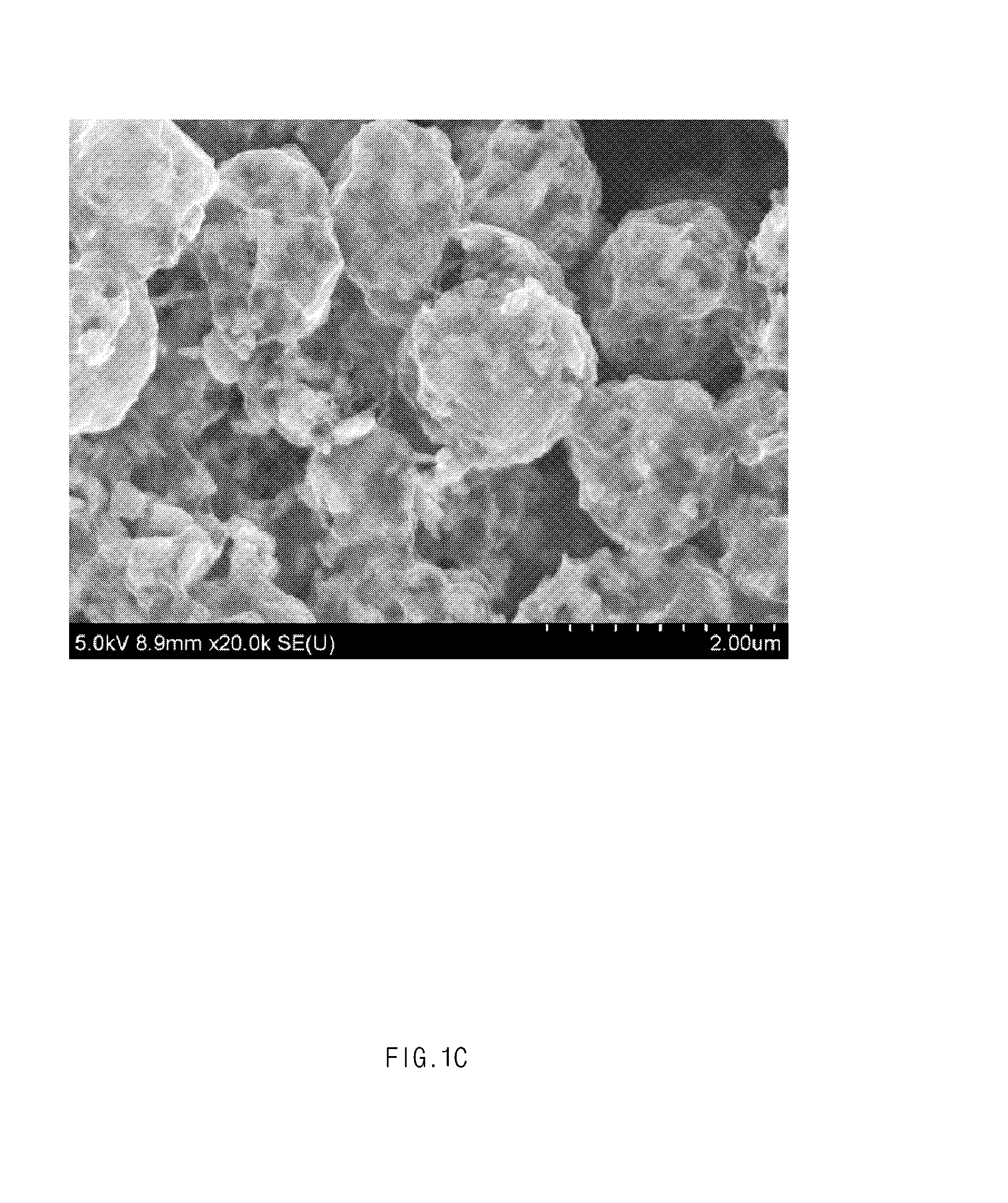

Graphene-coated porous silicon-carbon composite and method of manufacturing the same

ActiveUS20170047584A1Good electrical propertiesGood electrical conductivityElectrode thermal treatmentNegative electrodesSilicon particleCarbon composites

Provided are a porous silicon-carbon composite, which includes a core including a plurality of active particles, a conductive material formed on at least a portion of surfaces of the active particles, first pores, and second pores, and a first shell layer which is coated on the core and includes graphene, wherein the active particles include a plurality of silicon particles, silicon oxide particles, or a combination thereof, the first pores are present in the core and are formed by agglomeration of the plurality of active particles, and the second pores are irregularly dispersed and present in the core, has an average particle diameter smaller than an average particle diameter of the active particles, and are spherical, a method of manufacturing the same, and a negative electrode and a lithium secondary battery including the porous silicon-carbon composite.

Owner:LG ENERGY SOLUTION LTD

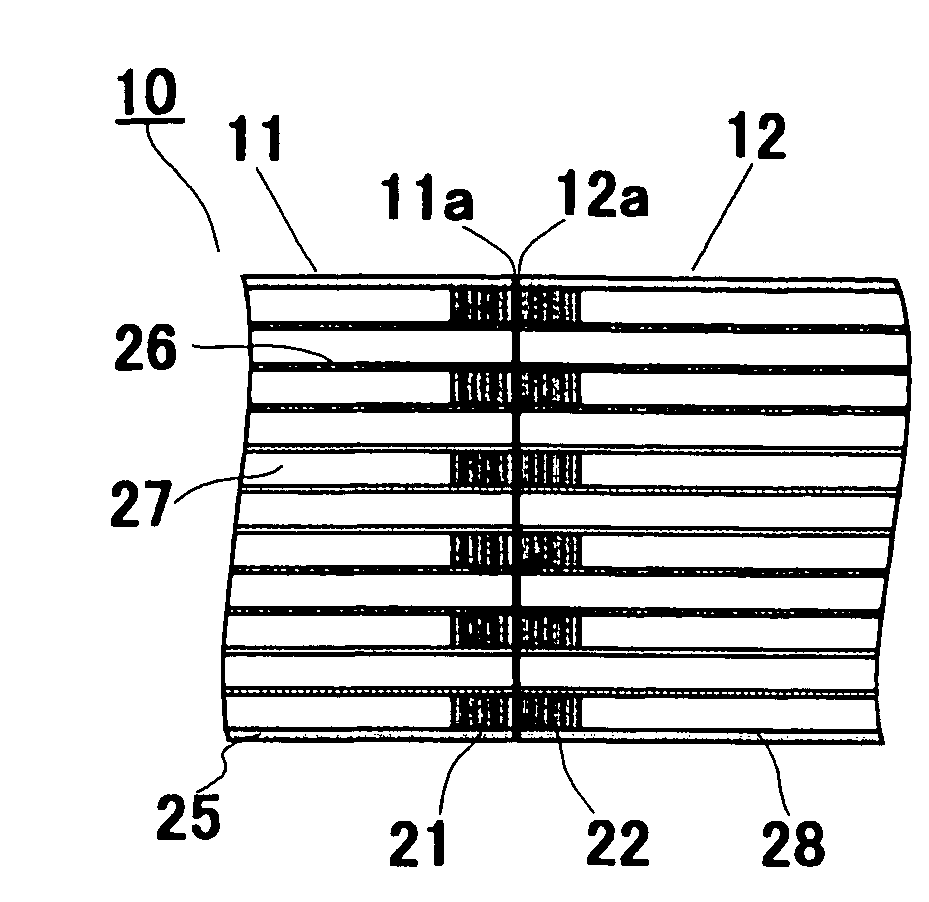

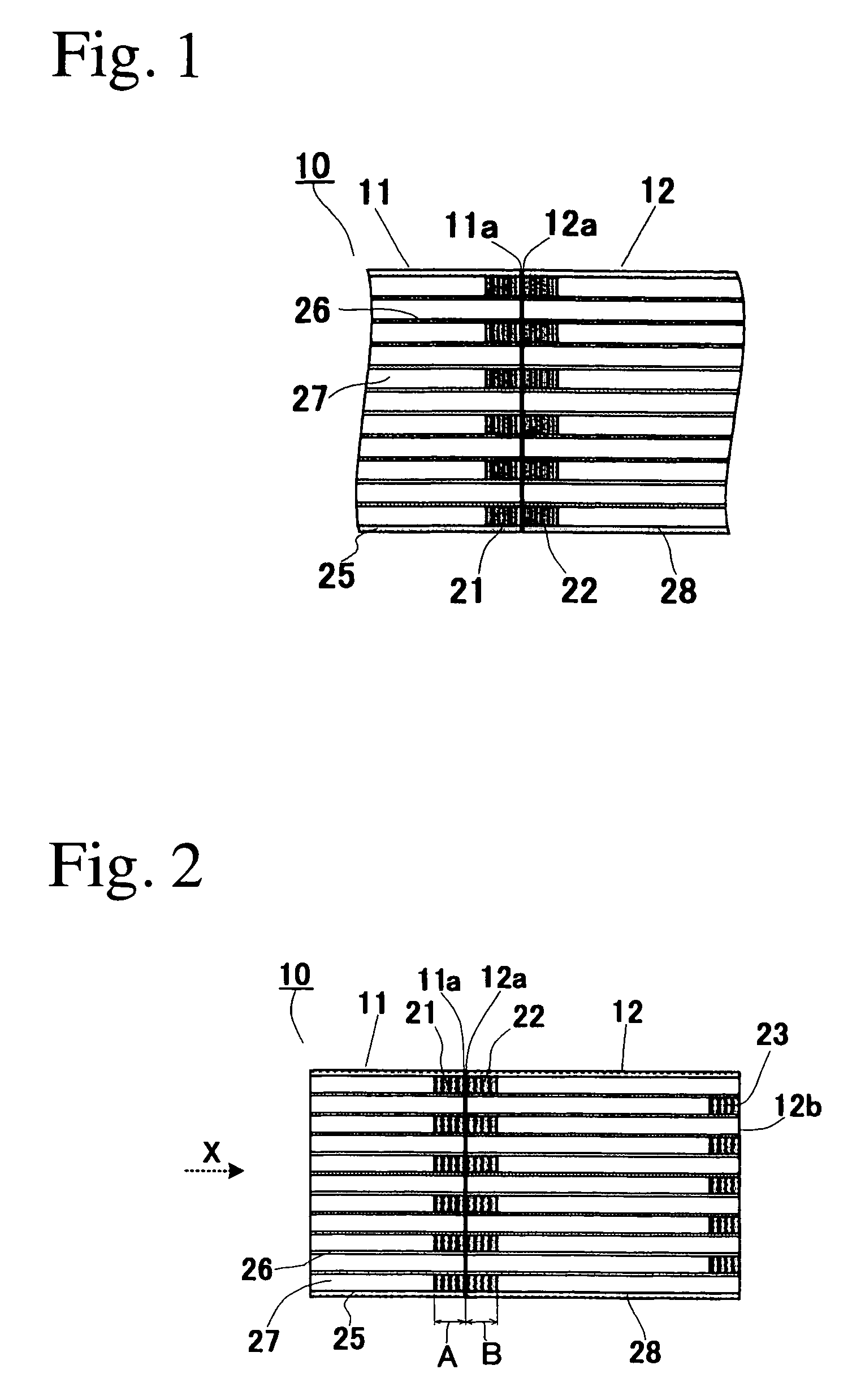

Method for cooling electronic components and thermally conductive sheet for use therewith

InactiveUS7094459B2Efficient conductionLayered productsSemiconductor/solid-state device detailsInsulation layerElectronic component

A thermally conductive sheet includes a thermally conductive layer and an insulation layer laminated onto the thermally conductive layer. The thermally conductive layer includes matrix containing thermally conductive filler having an electrical conductivity. The insulation layer contains thermally conductive filler having an insulating property. The thermally conductive sheet is disposed so that the insulation layer covers the terminal of the electronic component and the electric circuit. At this time, the thermally conductive layer covers and closely contacts with the insulation layer and the electronic component. The heat generated by the electronic component is conducted to a cooling member through the thermally conductive layer and is ultimately dissipated.

Owner:POLYMATECH CO LTD

Electronic Commerce System, Method and Apparatus

InactiveUS20090125387A1Conveniently formEfficiently conductAdvertisementsReservationsOperating systemE-commerce

An electronic commerce method that includes publishing an offer for a product or service, receiving the published offer and conditionally accepting the offer, and forwarding the conditional acceptance to a matching processor to request the product or service. The matching processor receives the conditional acceptance by the matching processor, determines whether conditions present in the conditional acceptance can be fulfilled, and forwards at least one option for acceptance. The at least one option for selection is displayed and the user, selects any one of the at least one options. Upon selection, a token is provided to the user. The token is configured to be used to redeem the service or product, be transferable to another user device, or to be stored for future redemption of the product or service.

Owner:MOBILE TECH HLDG LTD +1

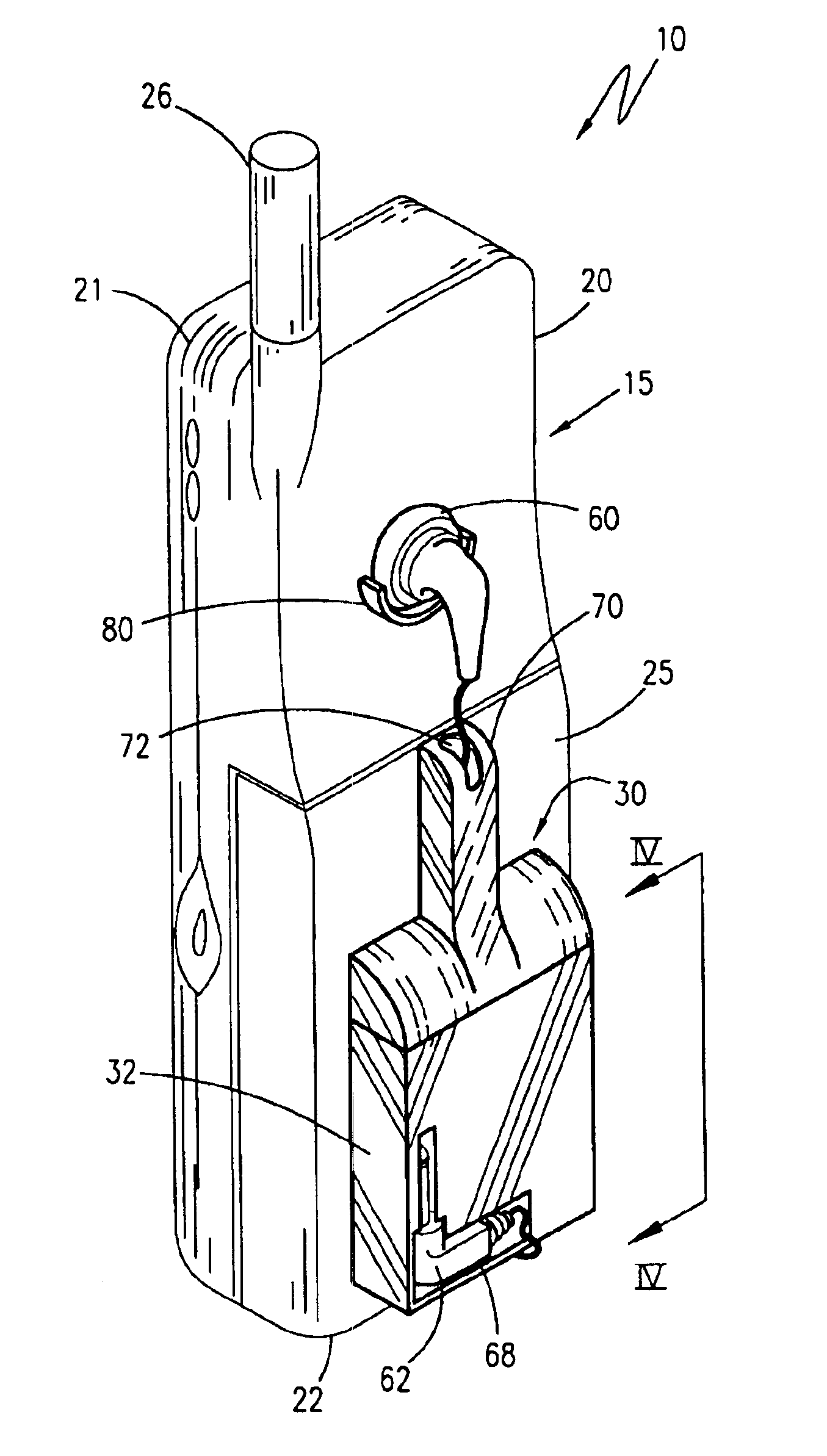

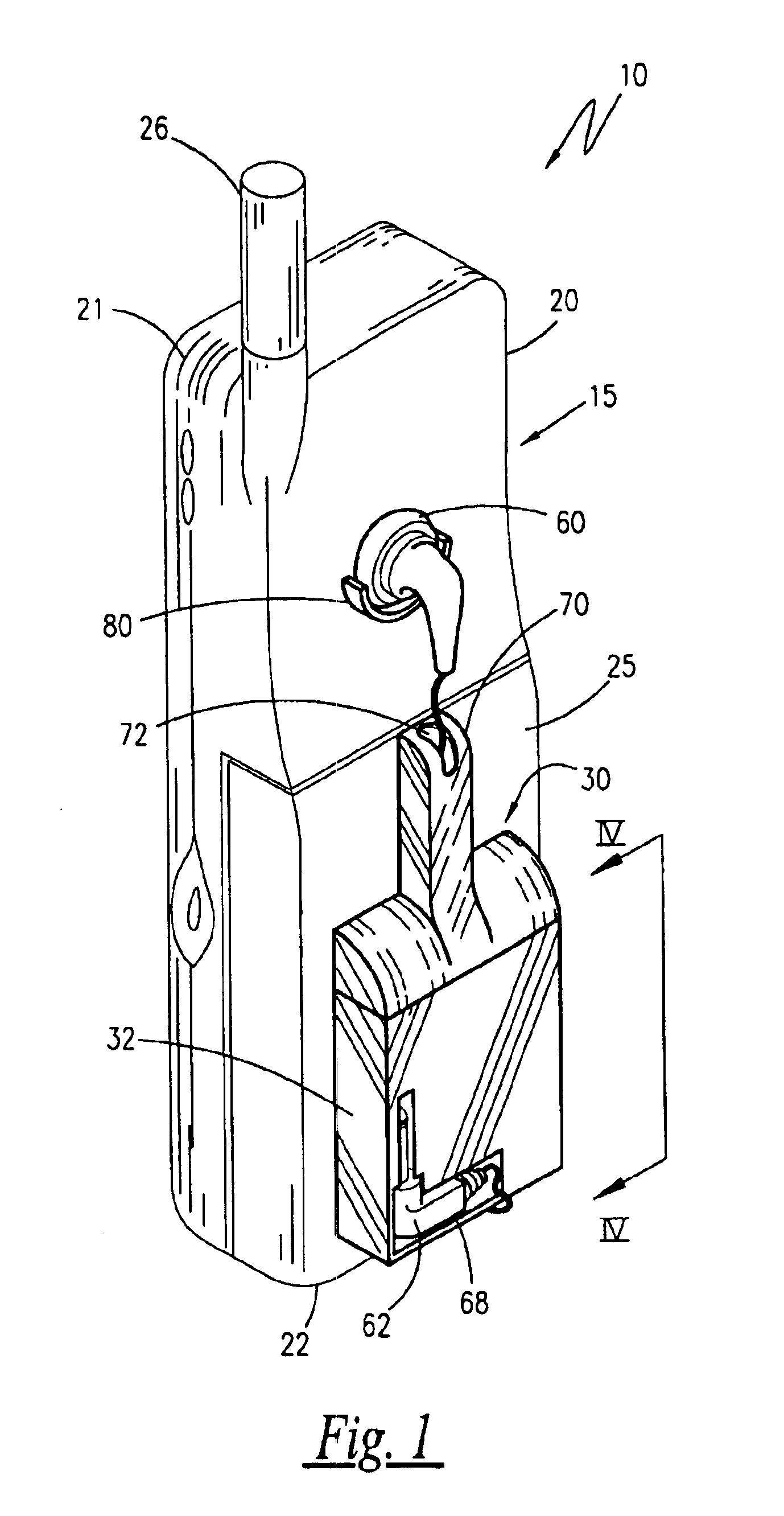

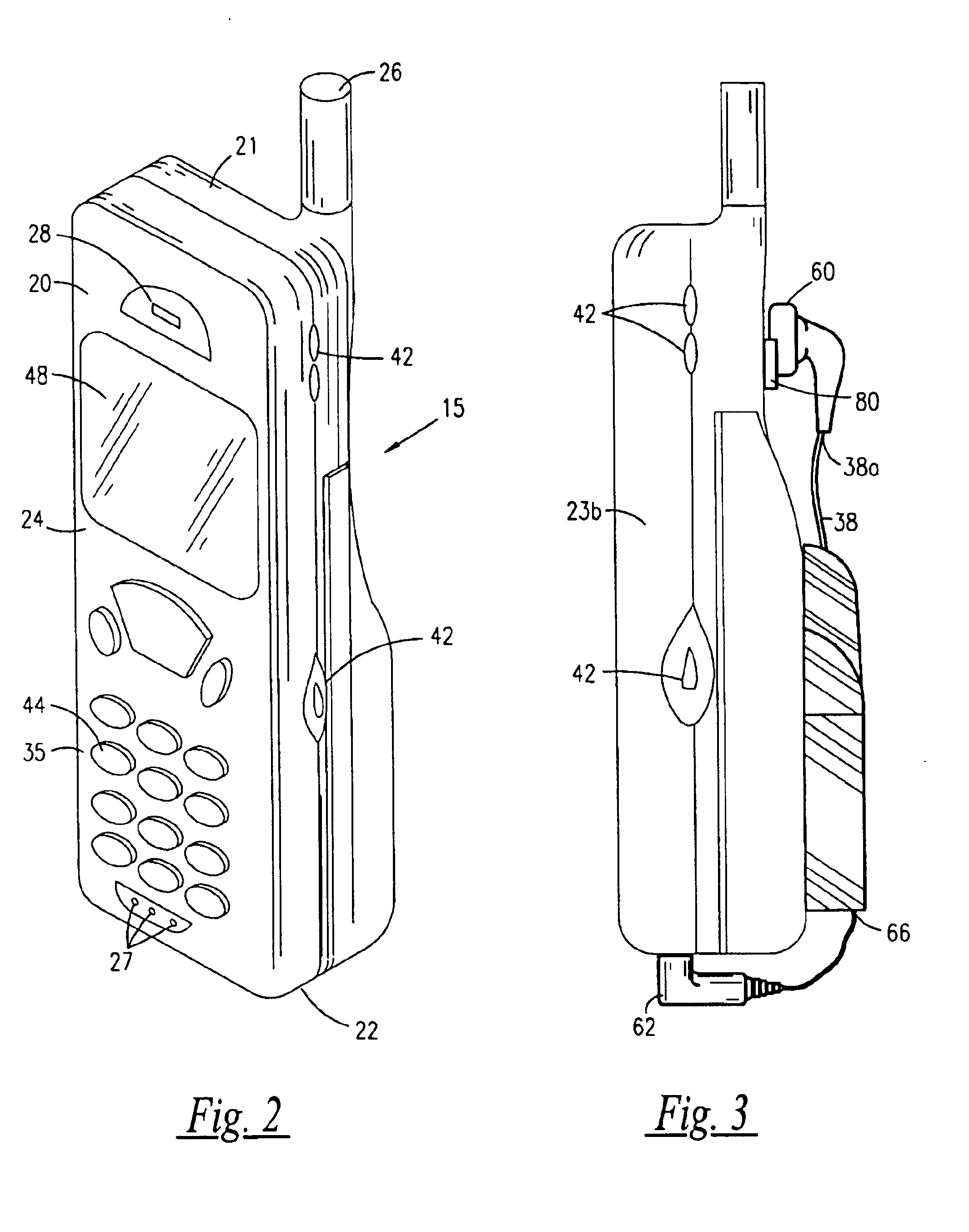

Cellular communication device with integral headset retraction assembly

InactiveUS6712304B1Convenience constraintsEasy to reinforceSubstation speech amplifiersTelephone set constructionsHeadphonesCommunication device

A cellular communication phone with integral headset retraction device is provided. The headset retraction device is integrally molded to a lower portion of the rear side of the phone. The headset retraction device includes a housing which serves to store a cable reel having a cable retracting mechanism and an electrical conducting cable. The electrical conducting cable includes a micro-sized microphone connected between an audio receiver earpiece and an auxiliary plug connector. An auxiliary plug storage receptacle is provided in order to prevent free suspension of the auxiliary plug connector. A cable guidance column is provided to aid in directing the electrical conducting cable into the retraction housing when being wound therein. An earpiece retention jacket is disclosed for supporting the audio receiver earpiece.

Owner:TAYLOR CHAD DYLAN

System and method for assessing coupling between an electrode and tissue

ActiveUS8406866B2Easy interpretation and correlationBetter assessmentDiagnostic recording/measuringSensorsElectrical resistance and conductanceCoupling

A system and method for assessing a degree of coupling between an electrode and tissue in a body is provided. Values for first and second components of a complex impedance (e.g., resistance and reactance or impedance magnitude and phase angle) between the electrode and the tissue are obtained. These values are used together with a standardization value indicative of a deviation from a reference standard by a parameter associated with at least one of the body, the electrode and another component of the system to calculate a coupling index that is indicative of a degree of coupling between the electrode and the tissue. The coupling index may be displayed to a clinician in a variety of ways to indicate the degree of coupling to the clinician. The system and method find particular application in ablation of tissue by permitting a clinician to create lesions in the tissue more effectively and safely.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

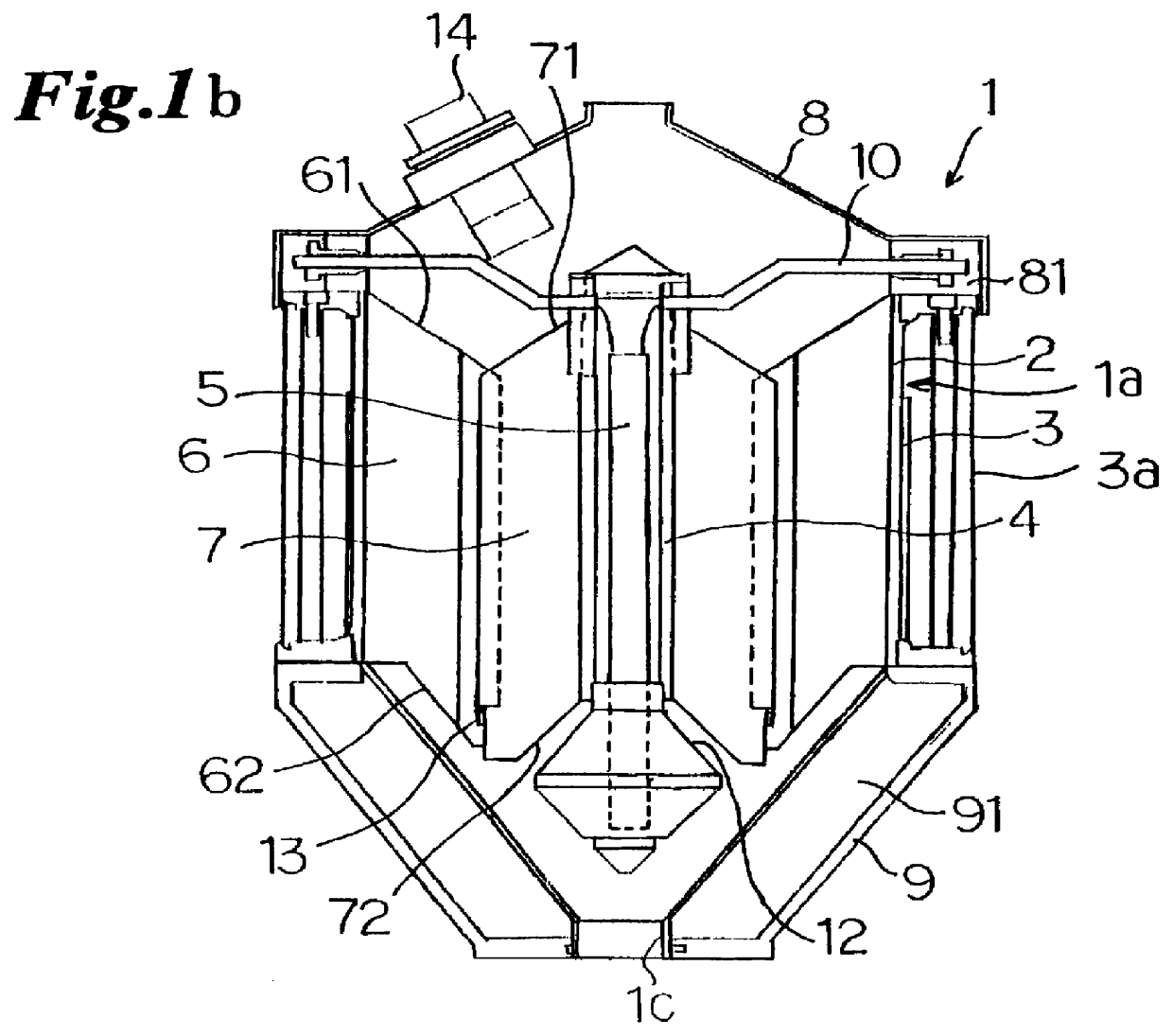

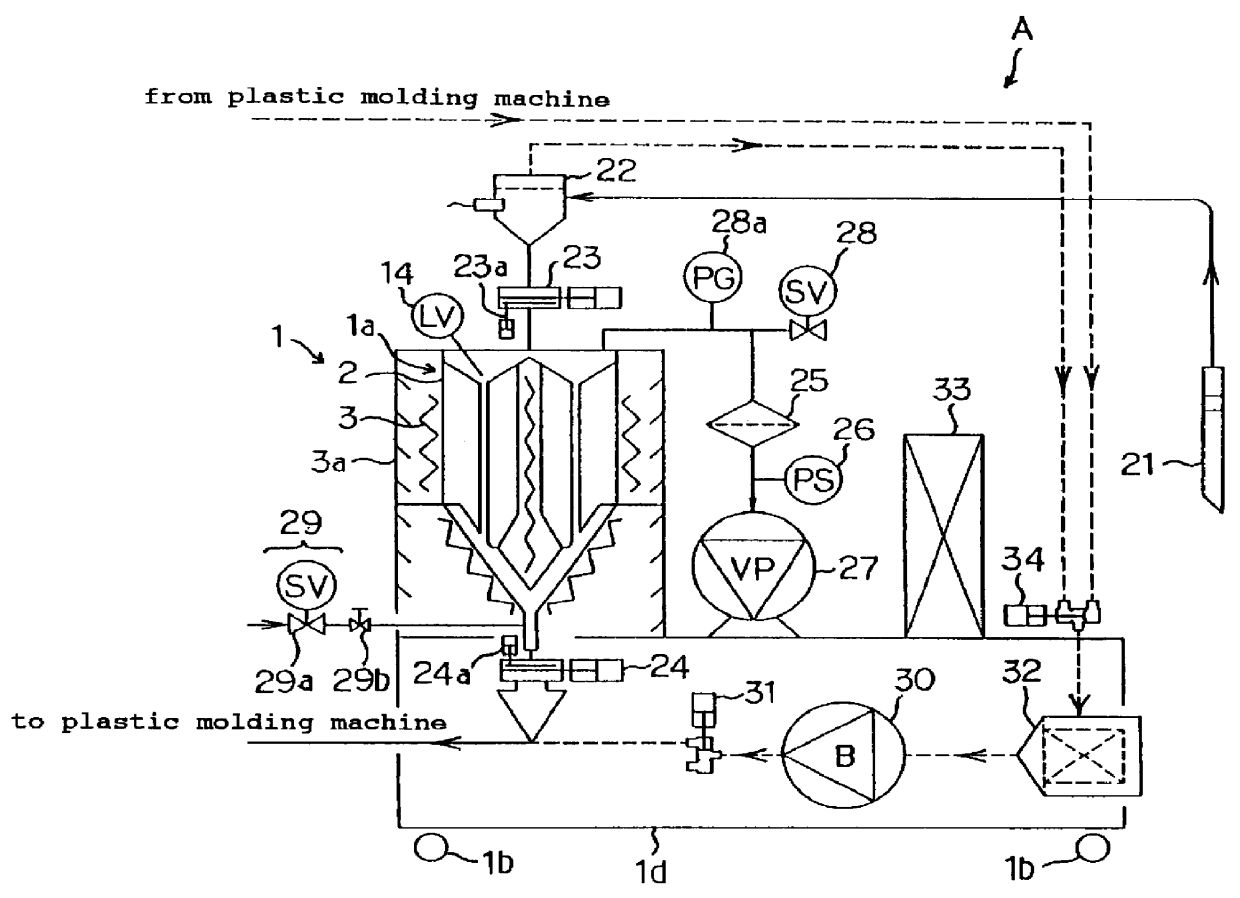

Vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material

InactiveUS6163976AEfficient conductionImprove heating efficiencyDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

A vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material such as a pelletized or powdered resin or the like, provided with a drying hopper connected to an evacuating means having at its bottom a material discharge valve, and provided with a material collector communicating with the drying hopper via a material feeding valve above the drying hopper for collecting the powdered material therein. The apparatus comprises a double constructed drying hopper having a cylindrical main body made of a high heat conductivity material provided on its inner peripheral surface with plural fins, which define compartment walls, projecting inwardly and provided on its outer peripheral surface with a heating means surrounding the cylindrical main body. The main body is outwardly enclosed with a heat insulation wall, and comprises an outer air inlet for introducing outer air thereinto, a material sensor for detecting amount of the material stored in the hopper, and an evacuating means connected to the main body.

Owner:MATSUI MFG

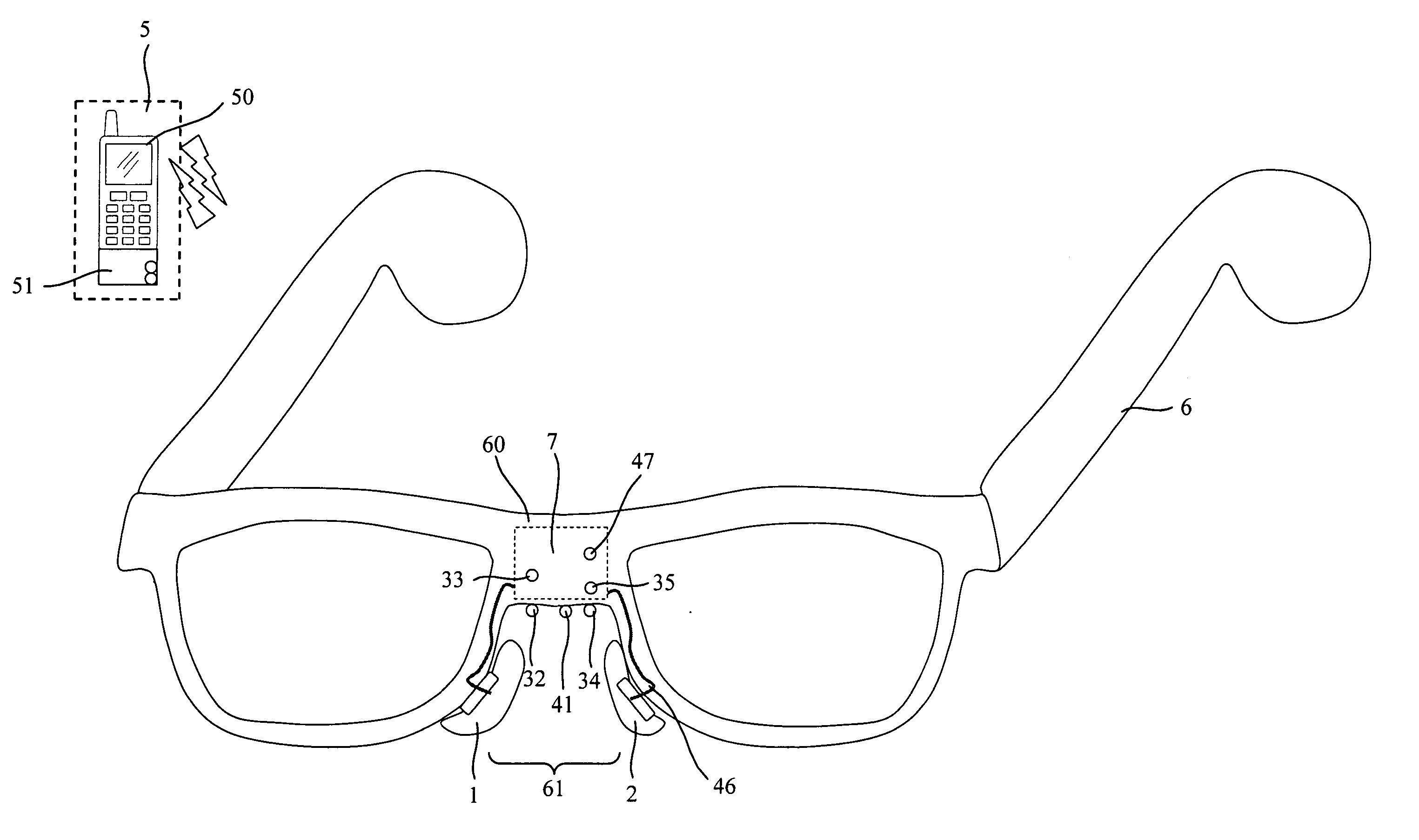

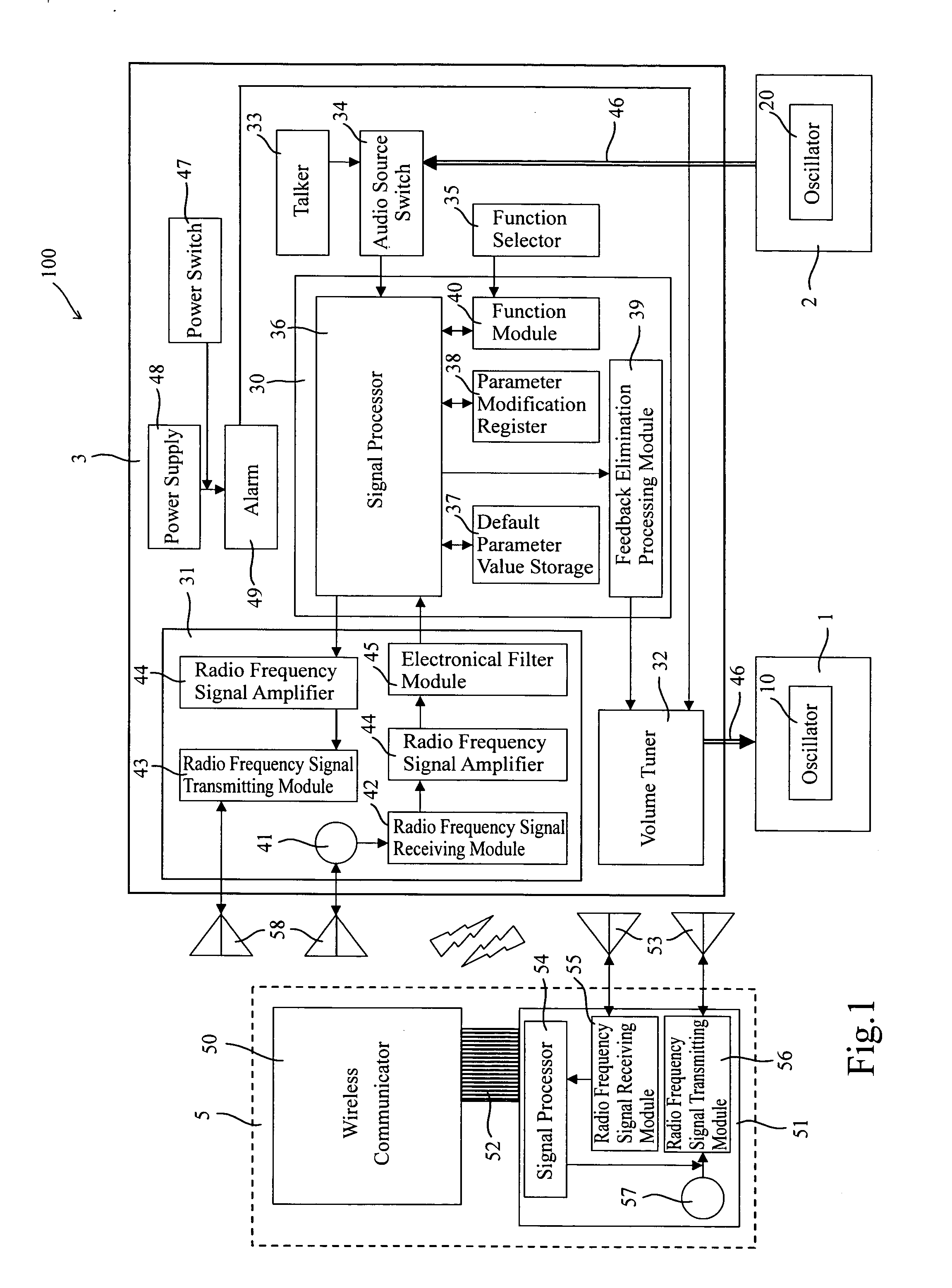

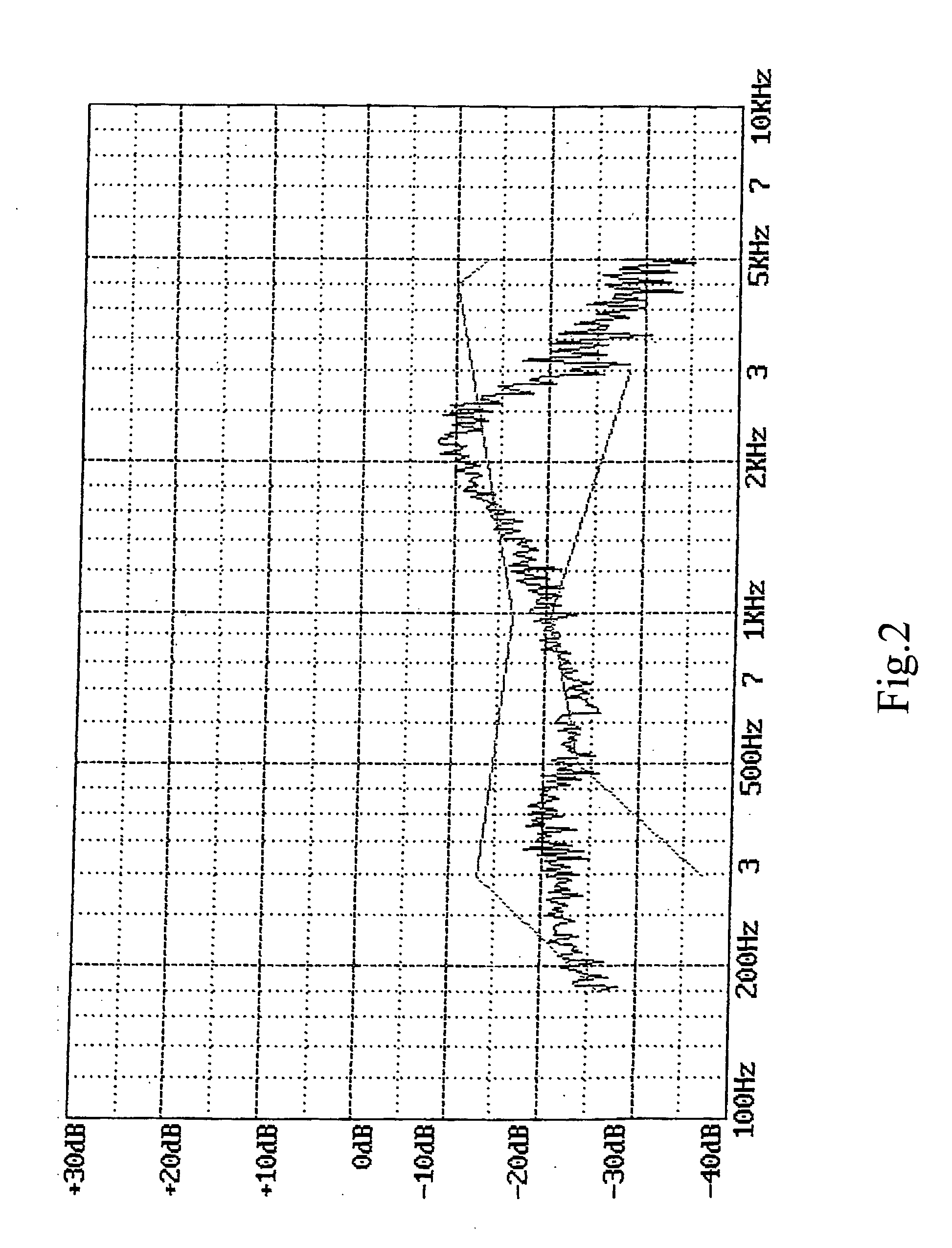

Nasal bone conduction wireless communication transmitting device

InactiveUS20050286734A1Reducing feedback soundEfficient conductionNon-optical adjunctsBone conduction transducer hearing devicesNasal cavityResonance

The nasal bone conduction wireless communication transmitting device of the present invention comprises a bone conduction inputting device; a wireless communication transmitting device electrically connected to the bone conduction inputting device; a bone conduction outputting device having a second oscillator; and a carrier device for supporting those abovementioned devices. The invention is characterized by that the carrier device is a carrier provided on the nose for making the bone conduction outputting device and the bone conduction inputting device supported by it closely touching the skin of the nasal bone, and making the oscillating wave of the bone conduction outputting device being sent to the ear via the nasal bone conduction after the resonance in the nasal cavity; and converting the sound provided through the nasal conduction resonance by the bone conduction inputting device into an electrical wave, and then transmitting it to the wireless communication transmitting device for signaling.

Owner:VICTORION TECH CO LTD

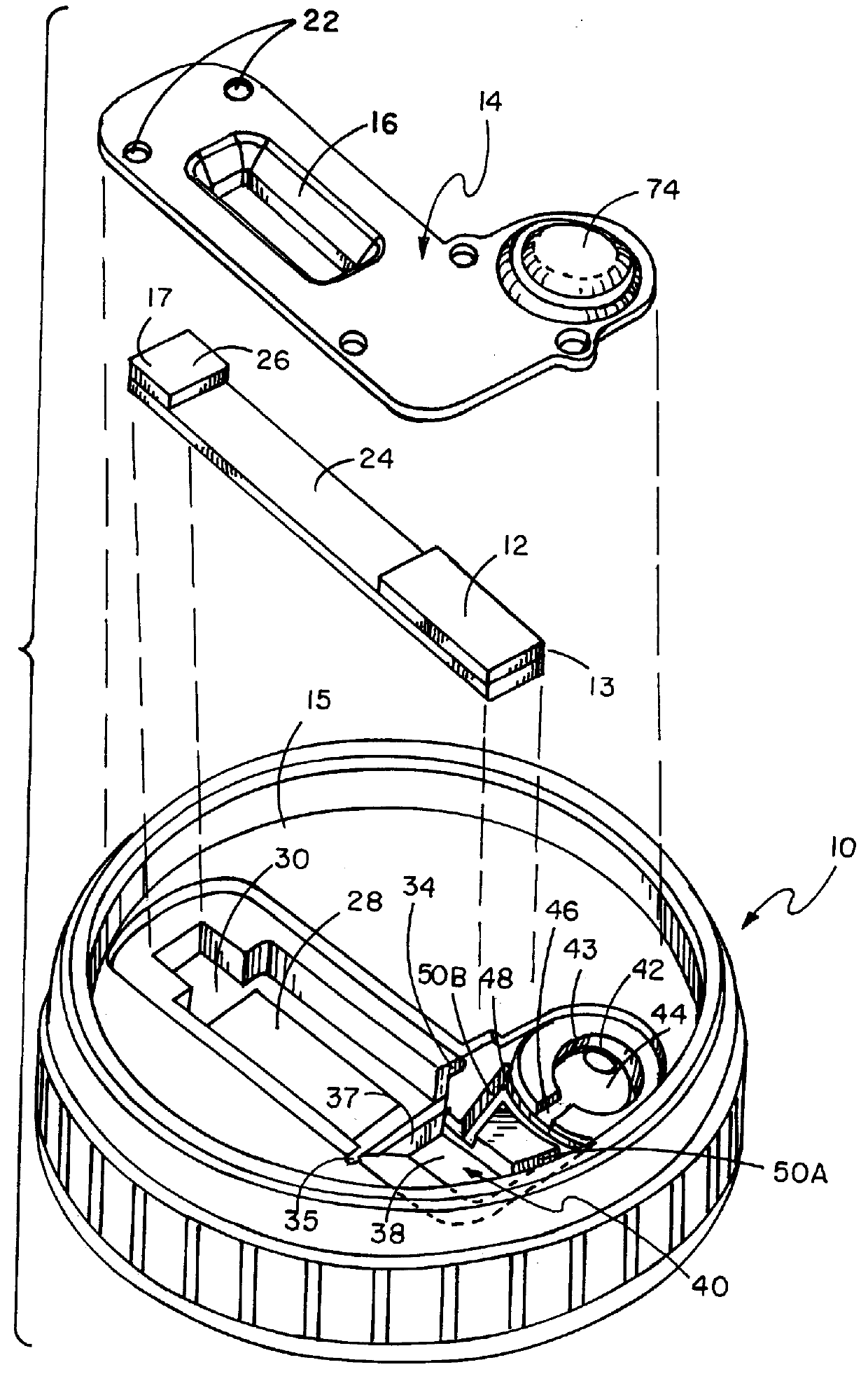

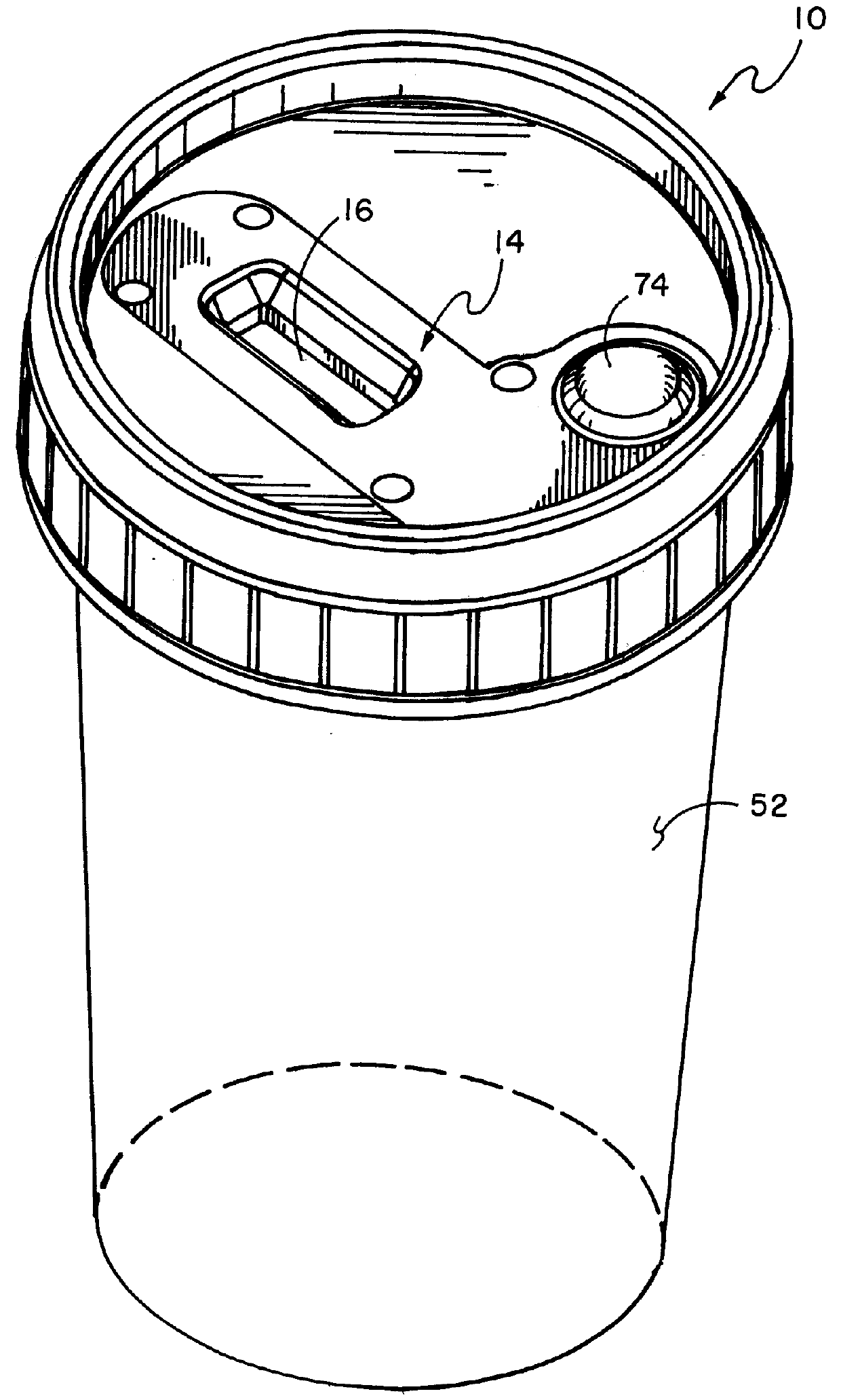

One-step test device

InactiveUS6074606AEfficient conductionAnalysis using chemical indicatorsSurgeryEngineeringColor changes

An improved test device for the testing of a fluid having a cup and a cover lid, such cover lid having a reagent test strip chamber containing a reagent test strip, a fluid receipt chamber, a fluid channel containing a fluid-passing pad and a fluid contact chamber. An actuation cover with a window defined therein is positioned over the regent test strip chamber, fluid receipt chamber, fluid contact chamber, such window positioned over the color change area of the reagent test strip. The actuation cover forms a fluid-tight seal around a first end of the reagent test strip which protrudes into the fluid contact chamber. After the cup is filled with fluid and the cover lid is positioned thereon, the cup is inverted, causing fluid to flow into the fluid receipt chamber through an aperture in said cover lid. When the test device is turned upright, the fluid drains from the bottom of the fluid receipt chamber, through the pad, down the fluid channel and into the fluid contact chamber where it comes in contact with the protruding first end of the reagent test strip, such fluid to be drawn along the reagent test strip to accomplish the desired test to cause the appropriate color change to appear on such reagent test strip visible through the window in the actuation cover. An actuation button on the actuation cover can aid in some embodiments to draw fluid into the fluid receipt chamber. In other embodiments a valve, when actuated, can open the fluid receipt chamber to receive the fluid to be tested when the cup is inverted.

Owner:SAYLES PHILIP W

Ceramic honeycomb filter and its production method

InactiveUS7578864B2Efficient conductionCombination devicesAuxillary pretreatmentHoneycomb structureMaterials science

A ceramic honeycomb filter comprising pluralities of ceramic honeycomb structures each having large numbers of flow paths partitioned by cell walls, which are bonded in the direction of the flow paths, predetermined flow paths being sealed by plugs, plugs formed at one end of at least one honeycomb structure being bonded to at least part of plugs formed at one end of a honeycomb structure adjacent to the end of this honeycomb structure.

Owner:HITACHI METALS LTD

Method of Producing Propylene Containing Biomass-Origin Carbon

InactiveUS20080312485A1Quality improvementSwitch-over frequencyMolecular sieve catalystsBiofuelsButeneDecomposition

Ethanol obtained from ordinary biomass resources contains many impurities other than water and these impurities themselves or their decomposition products contaminate ethylene when the ethylene is produced by a dehydration reaction, whereby the activity of metathesis catalyst is adversely affected. A method for producing propylene of the present invention is characterized in that the ethanol obtained from biomass is converted to ethylene by a dehydration reaction, the ethylene is separated from the generated water, the separated ethylene is purified by adsorption in an adsorption tower filled with an adsorbent, and then a metathesis reaction is carried out along with a raw material containing n-butene. With the present invention, propylene having biomass-derived carbon and reduced-environmental burden can be efficiently produced without lowering the catalysis activity.

Owner:MITSUI CHEM INC

LED lamp incorporating remote phosphor with heat dissipation features

ActiveUS20110215701A1Reduce and eliminate spreadEfficient and reliablePlanar light sourcesPoint-like light sourcePhosphorLED lamp

An LED lamp or bulb is disclosed that comprises a light source, a heat sink structure and a remote planar phosphor carrier having at least one conversion material. The phosphor carrier can be remote to the light sources and mounted to the heat sink so that heat from the phosphor carrier spreads into the heat sink. The phosphor carrier can comprise a thermally conductive transparent material and a phosphor layer, with an LED based light source mounted to the heat sink such that light from the light source passes through the phosphor carrier. At least some of the LED light is converted by the phosphor carrier, with some lamp embodiments emitting a white light combination of LED and phosphor light. The phosphor arranged according to the present invention can operate at lower temperature to thereby operate at greater phosphor conversion efficiency and with reduced heat related damage to the phosphor.

Owner:IDEAL IND LIGHTING LLC

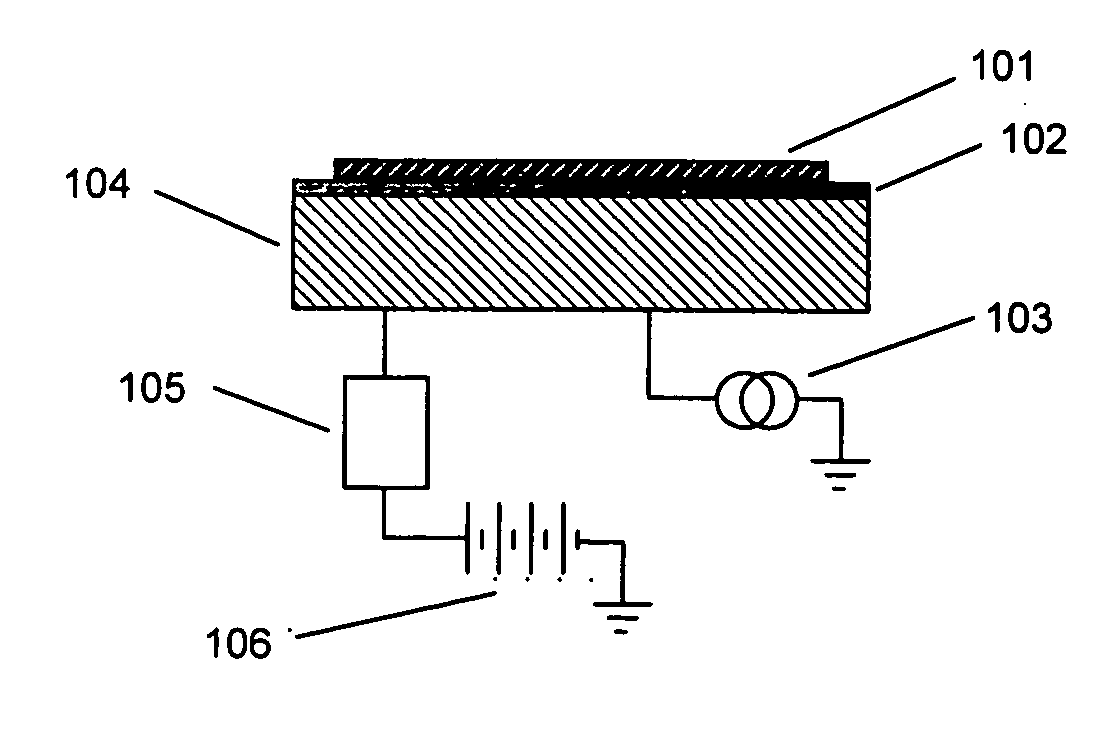

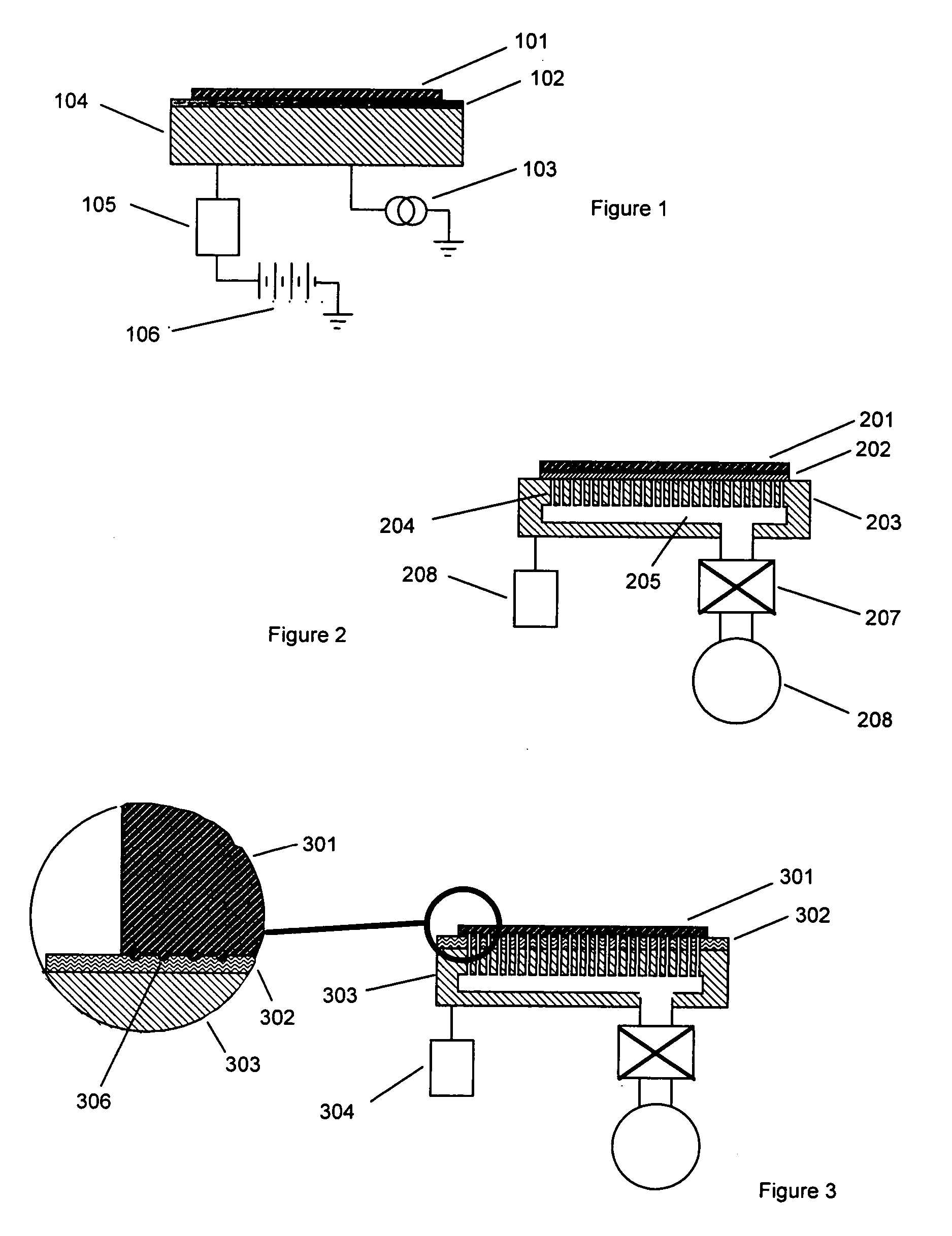

Clamp for holding and efficiently removing heat from workpieces

InactiveUS20050036267A1Effectively safely clampIncrease resistanceSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsEtchingCelsius Degree

The invention described in this disclosure is an apparatus and method for clamping semiconductor wafers or other substrates or workpieces during etching, CVD, or surface modification processes. The purpose of the invention is to achieve improved heat transfer during processing between the wafer / substrate and a temperature controlled pedestal used for supporting it in the process chamber. The typical level of process heat put into the wafer during plasma-based etching or deposition processes will be up to about 10 Watts per centimeter squared while the maximum acceptable temperature differential between wafer / substrate and pedestal is less than about 100 Celsius. In such low gas pressure environments typical for plasma-based processes, the heat removal from the wafer / substrate by gaseous conduction may be inadequate to meet requirements. This invention achieves excellent heat transfer to the pedestal from the wafer / substrate when there is a thin, resilient, electrically insulating layer (tape) bonded to the wafer / substrate or the pedestal. Wafer / substrate clamping for improved process heat removal is achieved by a combination of vacuum clamping of the wafer / substrate beginning prior to evacuation of the processing chamber, along with or followed by electrostatic clamping of the wafer / substrate which continues during processing. The invention also permits the wafer / substrate to be rapidly and safely released from the electrostatic clamping when the chamber is returned to atmospheric pressure by a providing a slight pressure increase, above atmospheric pressure, between wafer and pedestal. The pedestal may have some roughening or narrow grooves on the wafer clamping surface, and some small holes from its surface leading to an evacuated plenum or channel within the pedestal. Alternatively, the pedestal may have a layer of a porous metal extending from its surface down to the evacuated channel or plenum which permits gas to be evacuated. These structures allow vacuum pumping of gas that might otherwise be trapped between the insulating layer and the pedestal. When a wafer / substrate is placed on the pedestal by loading at atmospheric pressure, vacuum pumping through the pedestal is commenced. This causes the workpiece to be pressed to the pedestal clamping surface with approximately atmospheric pressure compressing the soft layer against its clamping surface. This provides sufficient contact of the soft layer with the pedestal to greatly improve heat transfer from the wafer / substrate to the pedestal. A voltage is applied to the pedestal, beginning any time after the wafer is on the pedestal, to further clamp the wafer electrostatically. As the processing chamber is then pumped down to operating pressure for processing the electrostatic clamping voltage maintains sufficient pressure of the wafer / substrate against the pedestal to maintain the heat conductive contact between the soft layer and the pedestal. This permits good heat conduction to be maintained during the low pressure plasma-based etching or CVD processing. Following processing when the wafer / substrate is to be removed it may be rapidly de-clamped from the electrostatic clamping by application of a slight over-atmospheric pressure in the reservoir or pumping channels within the pedestal.

Owner:SAVAS STEPHEN EDWARD +1

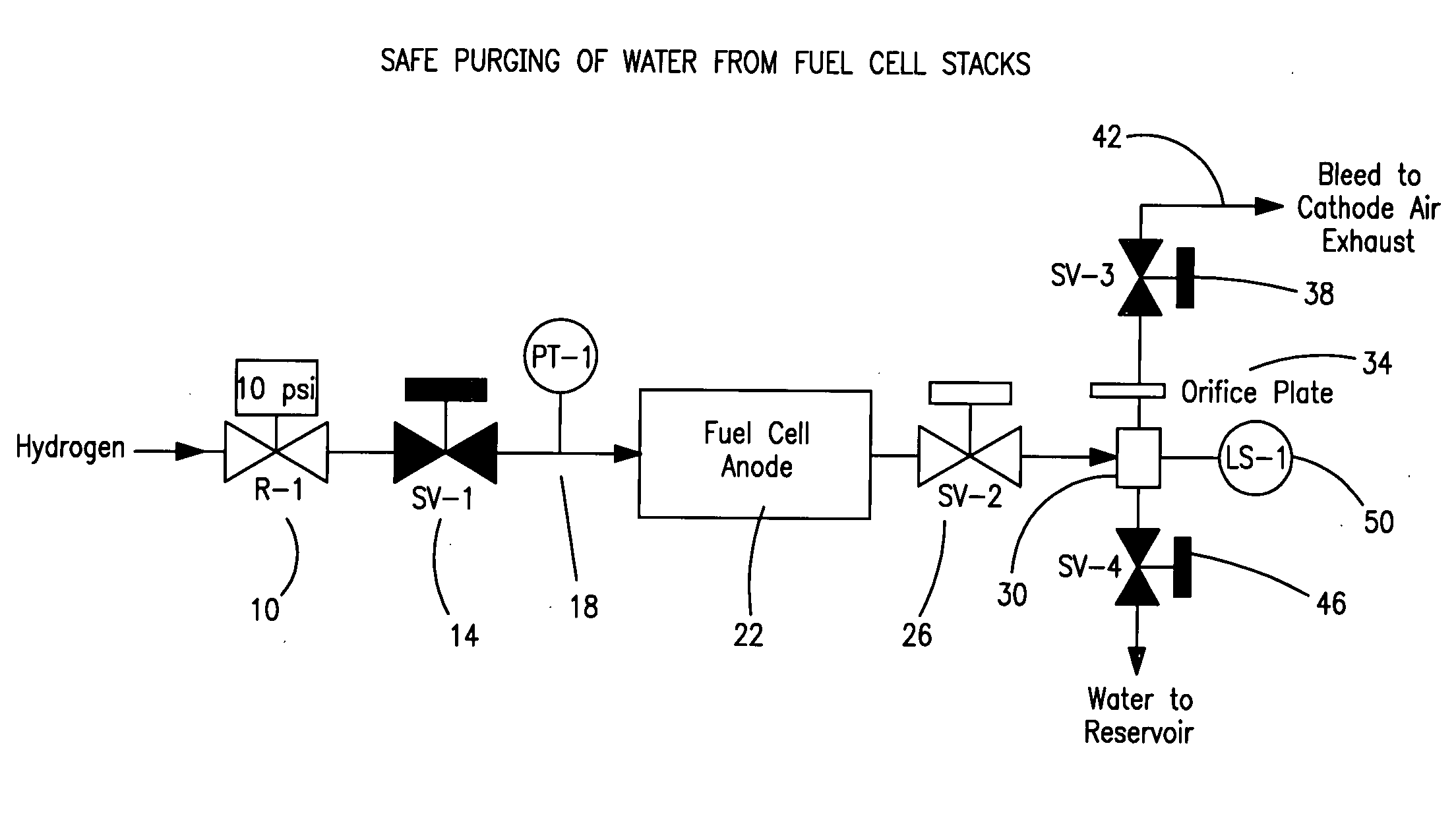

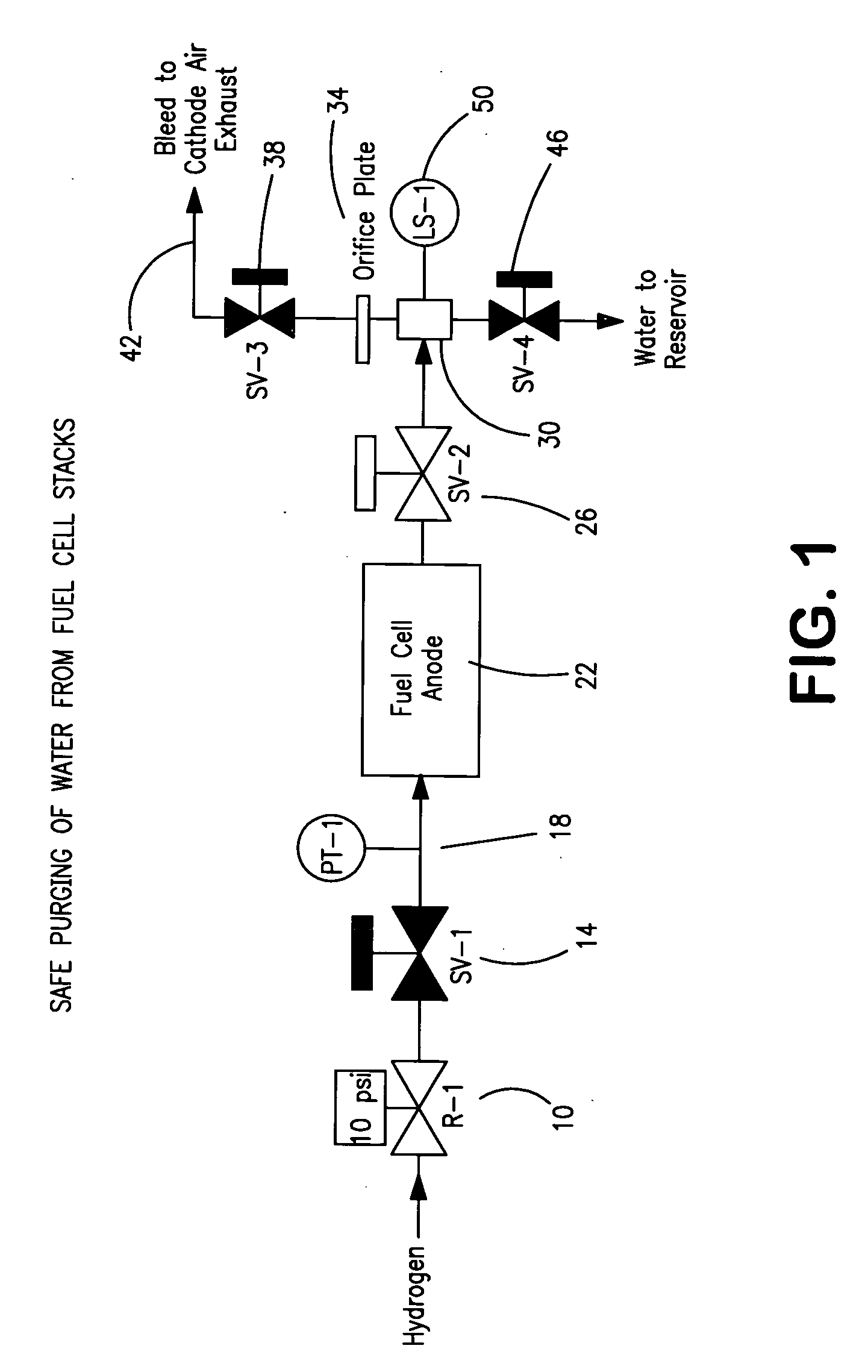

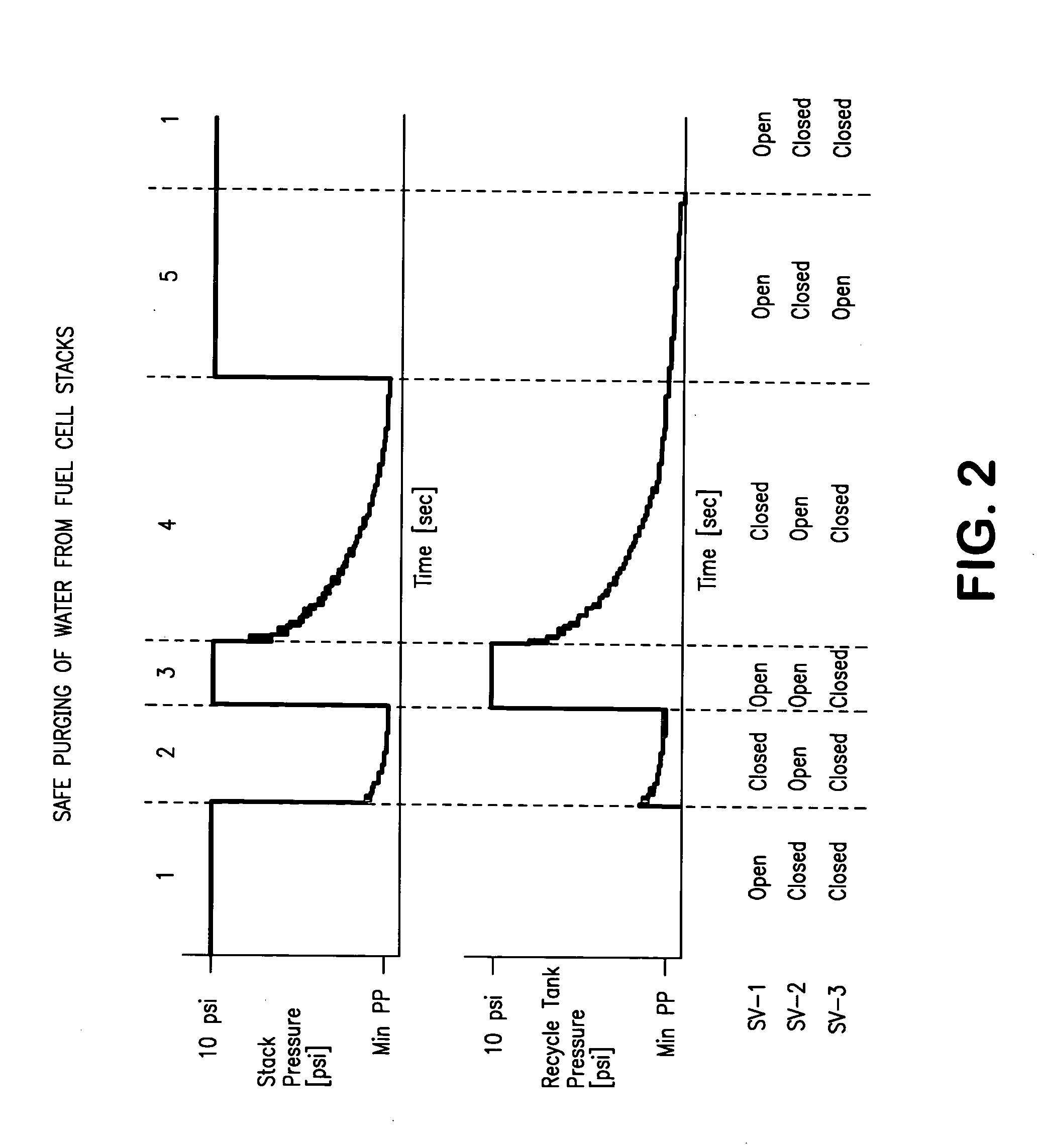

Safe purging of water from fuel cell stacks

InactiveUS20050142400A1Inhibition releaseLittle hydrogen lossReactant parameters controlFuel cellsHydrogen

Methods and devices are provided for purging fuel cells of water and accumulated non-reactive gases whereby the systems are constructed to dilute any emitted hydrogen below its inflammability limit for increased safety.

Owner:NUVERA FUEL CELLS

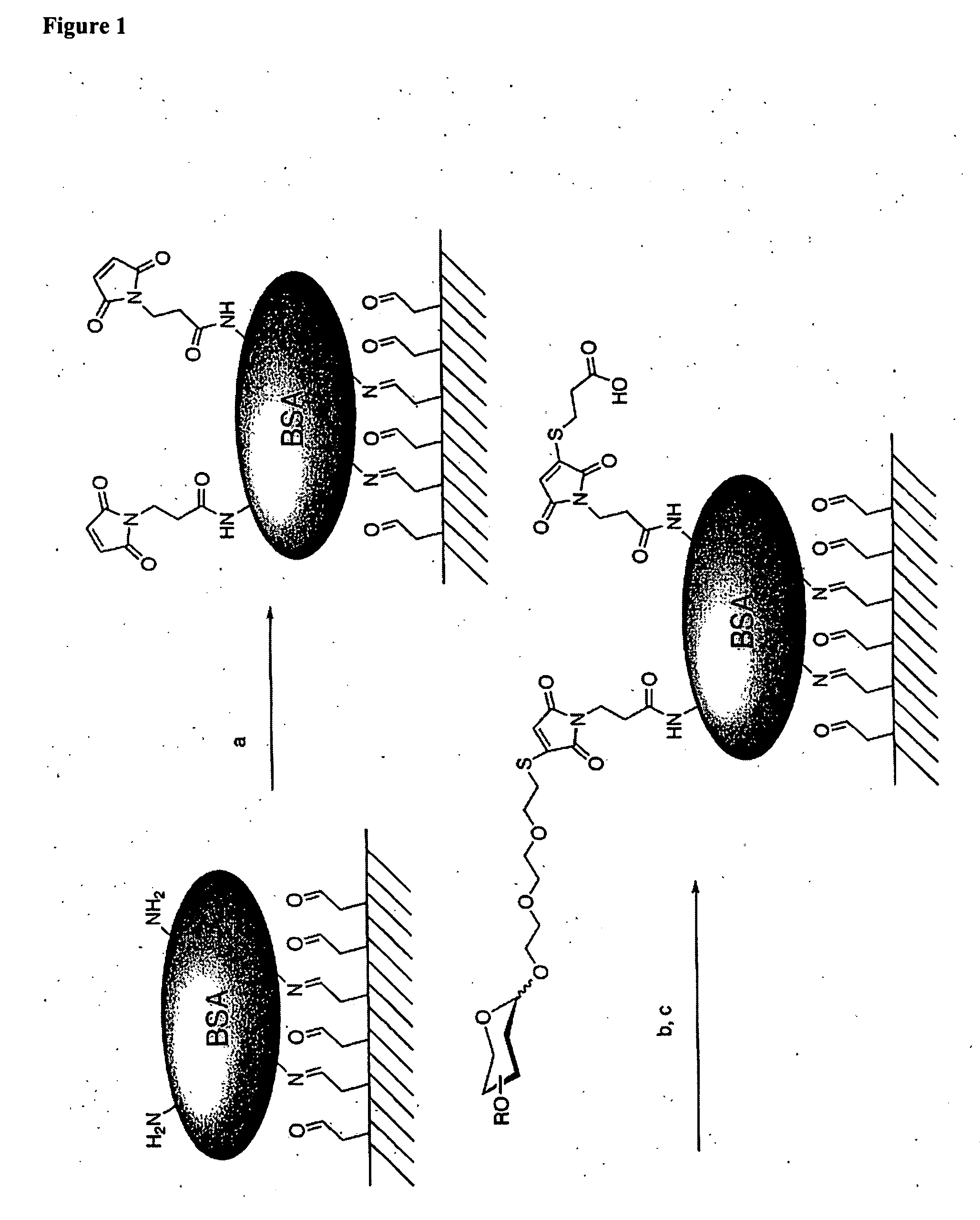

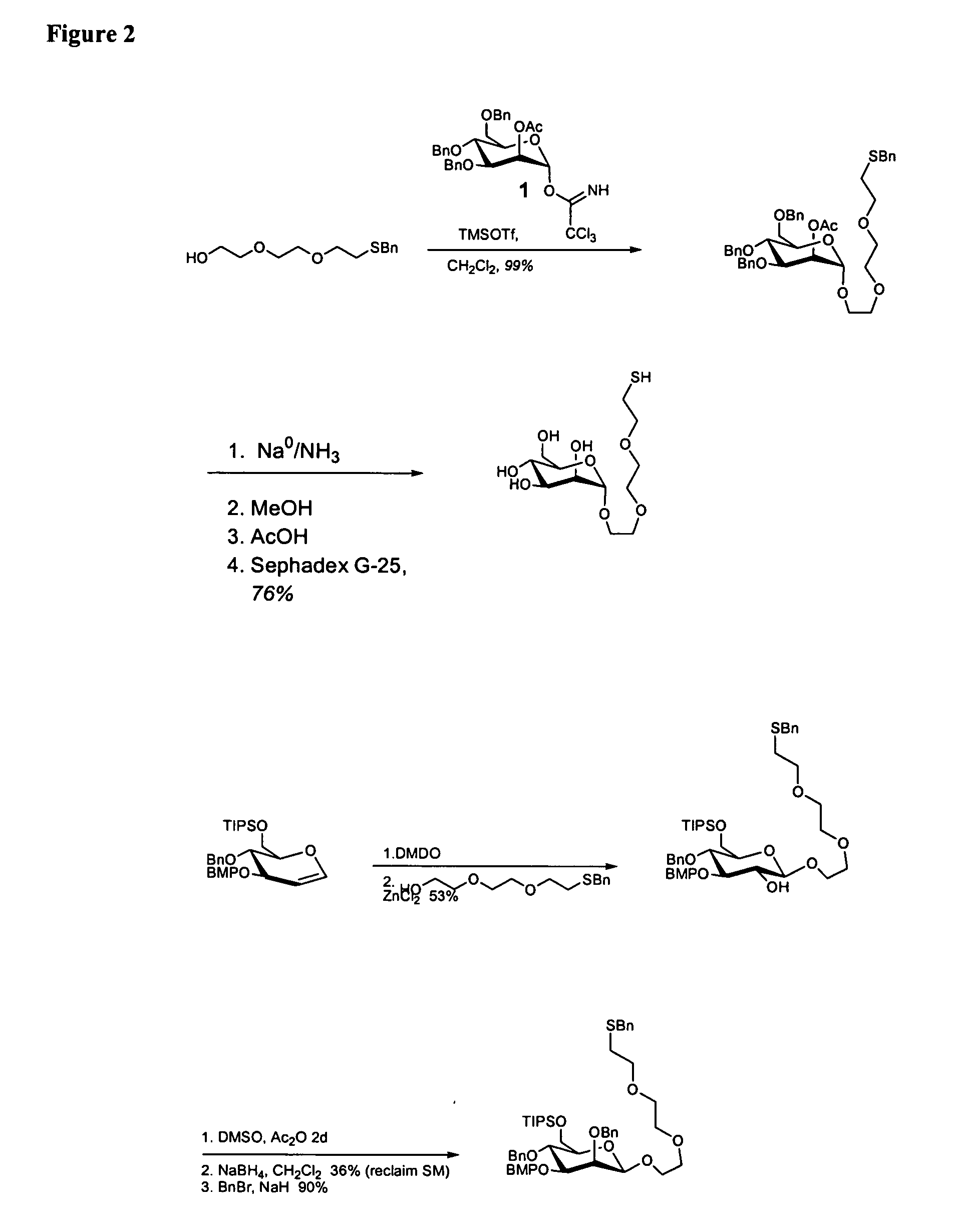

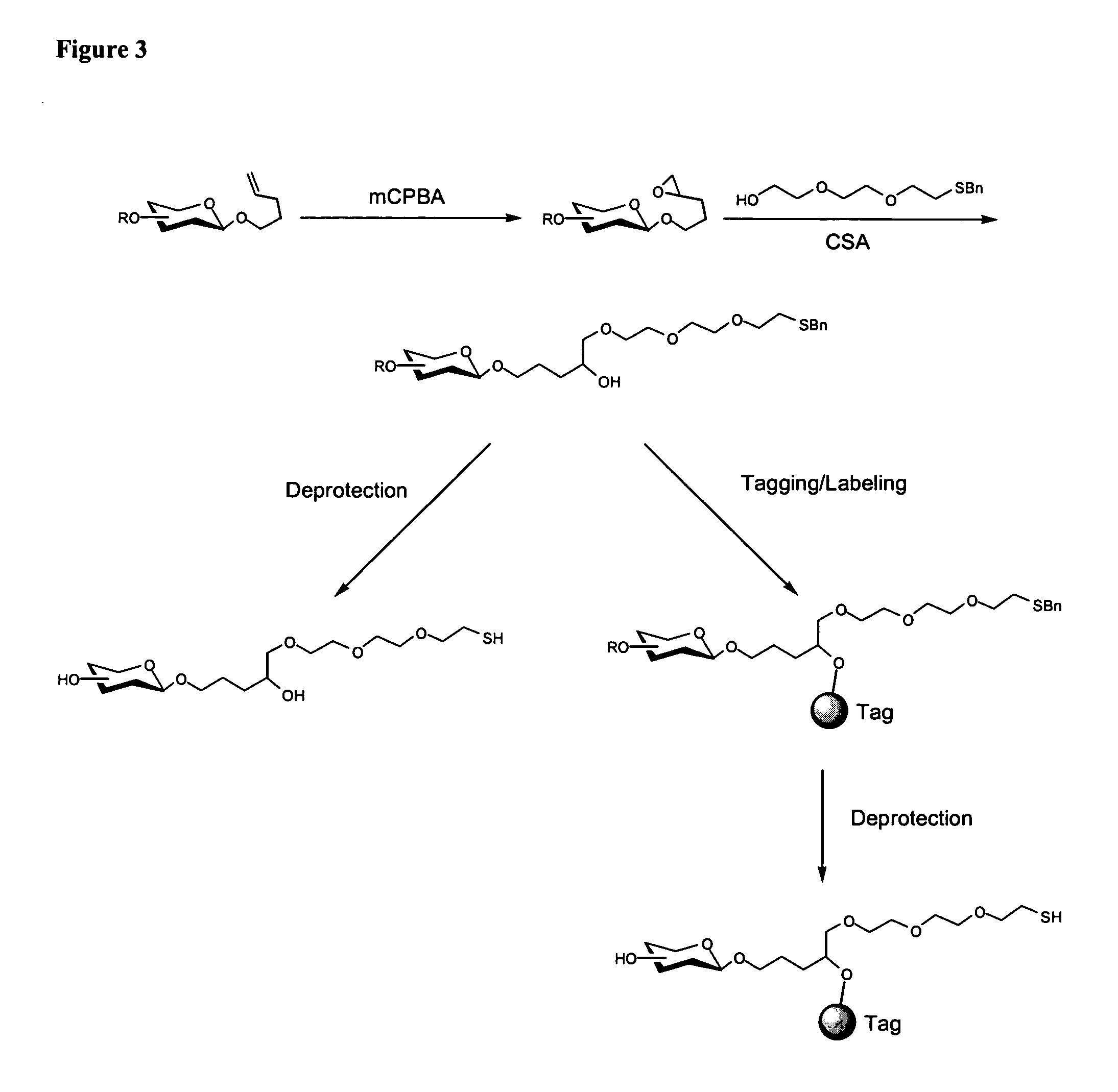

Microarrays and microspheres comprising oligosaccharides, complex carbohydrates or glycoproteins

InactiveUS20050221337A1Efficient conductionAvoid huge wasteBioreactor/fermenter combinationsBiological substance pretreatmentsMicrosphereCompound (substance)

One aspect of the present invention relates to an array, comprising a plurality of spots on a solid support, wherein each spot independently comprises a substrate attached to said solid support, wherein each substrate attached to said solid support is independently a carbohydrate-containing molecule. A second aspect of the present invention relates to a method of preparing such an array of carbohydrate-containing molecules. A third aspect of the present invention relates to a method to detect the interaction of a carbohydrate with a binding molecule.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com