Patents

Literature

762 results about "Soft layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

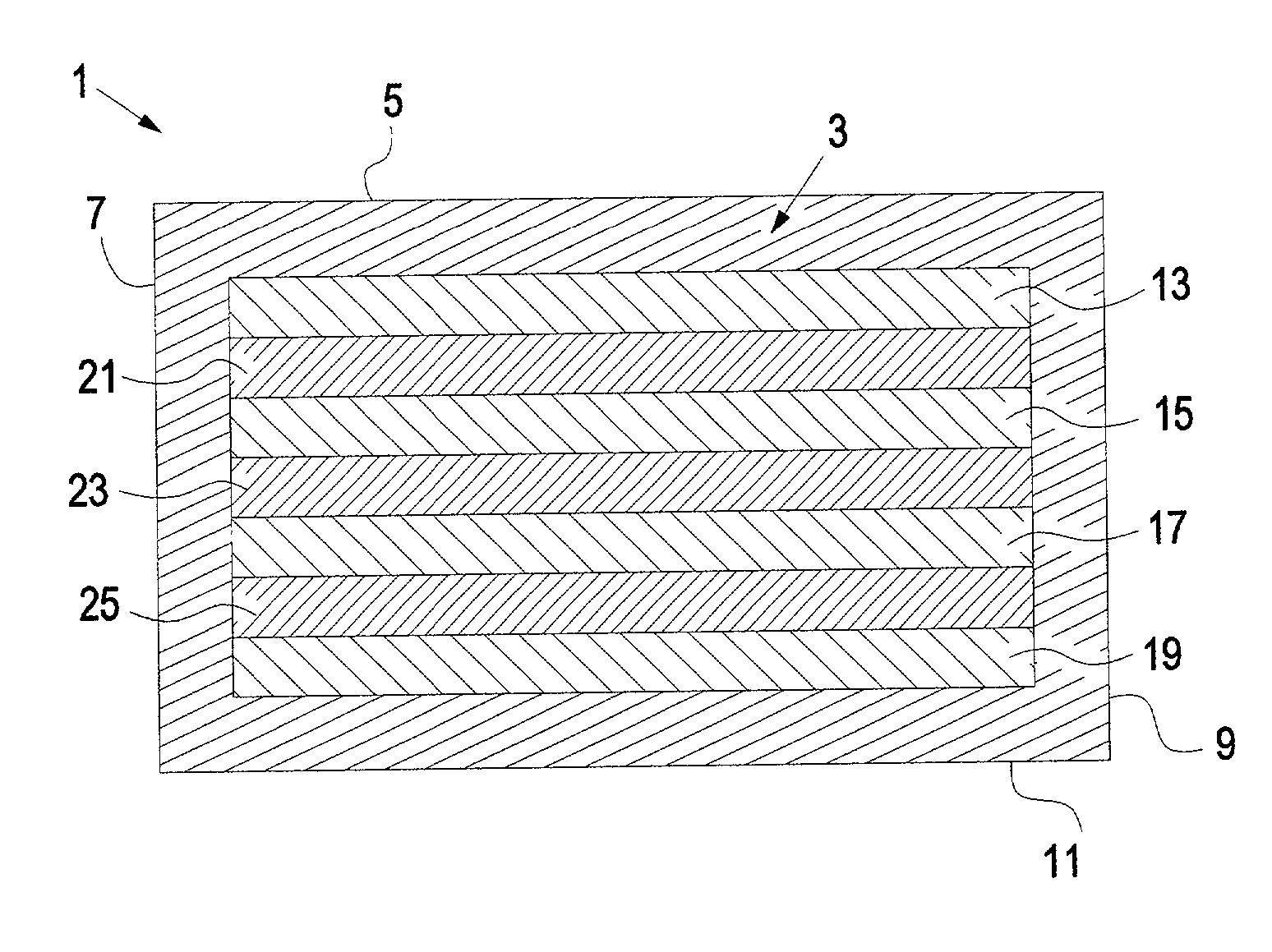

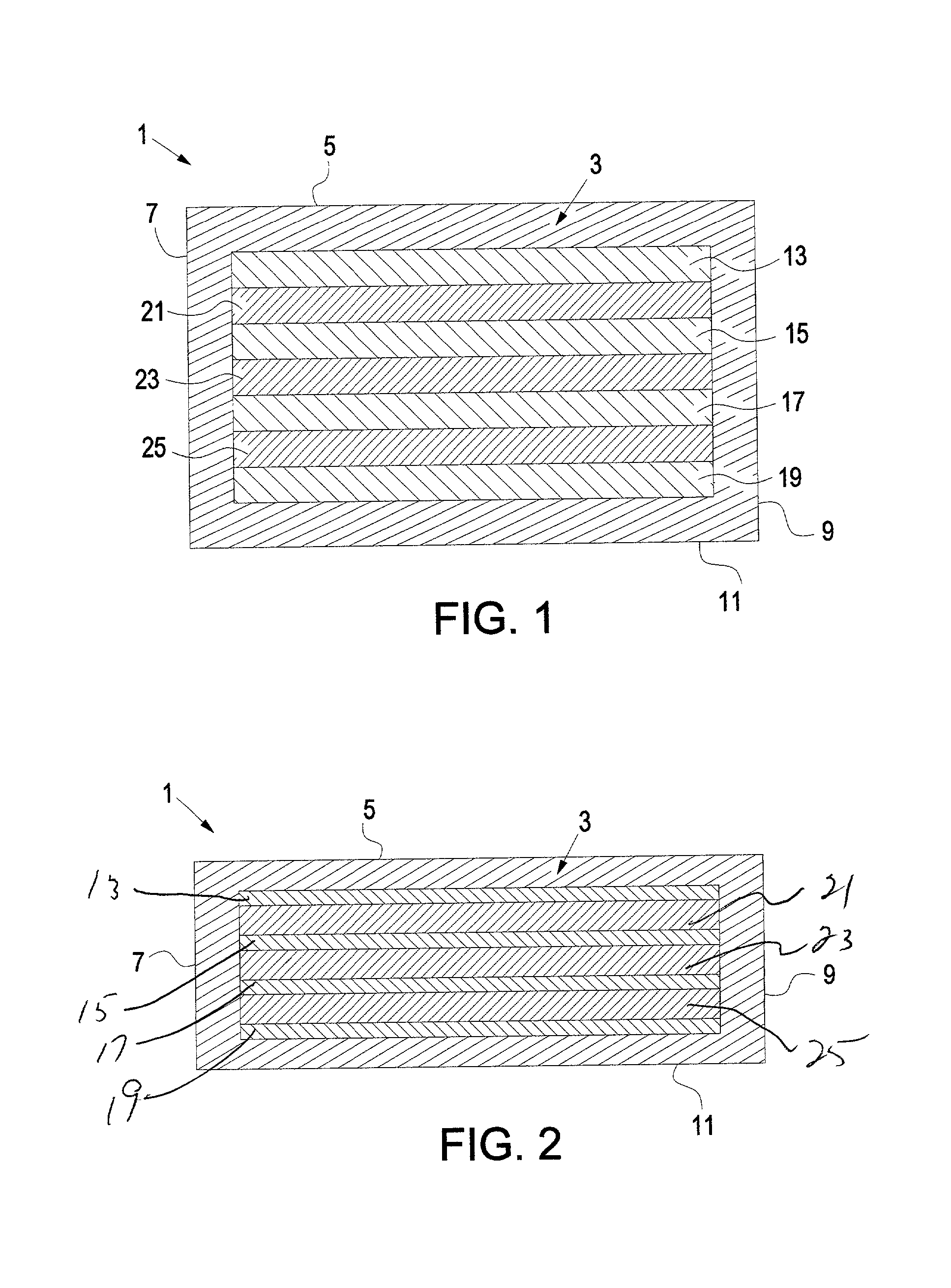

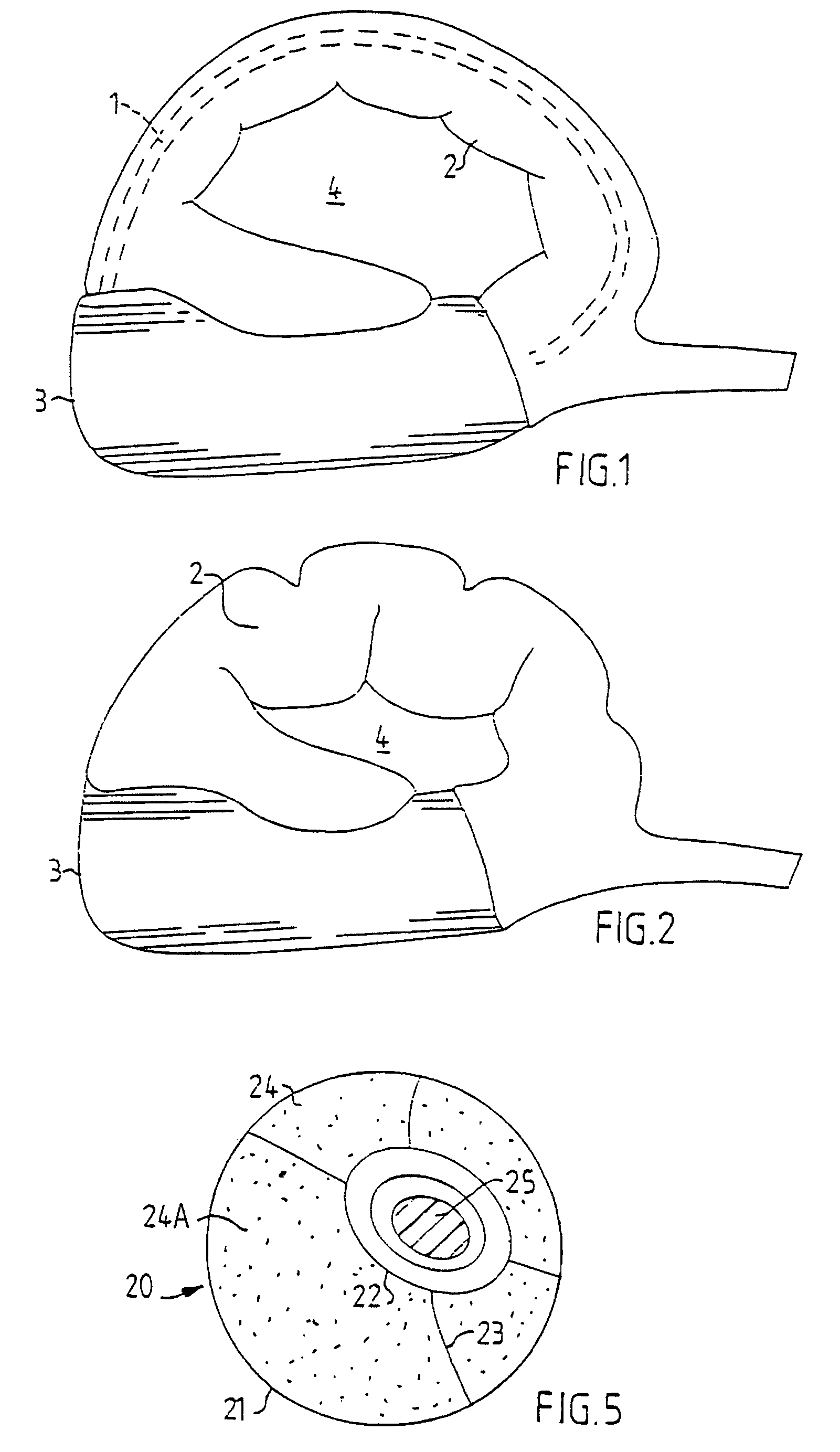

Hydrogel-based prosthetic device for replaceing at least a part of the nucleus of a spinal disc

InactiveUS6726721B2Limited to componentMaximal flattening during dehydrationSpinal implantsTissue regenerationSoft layerProsthesis

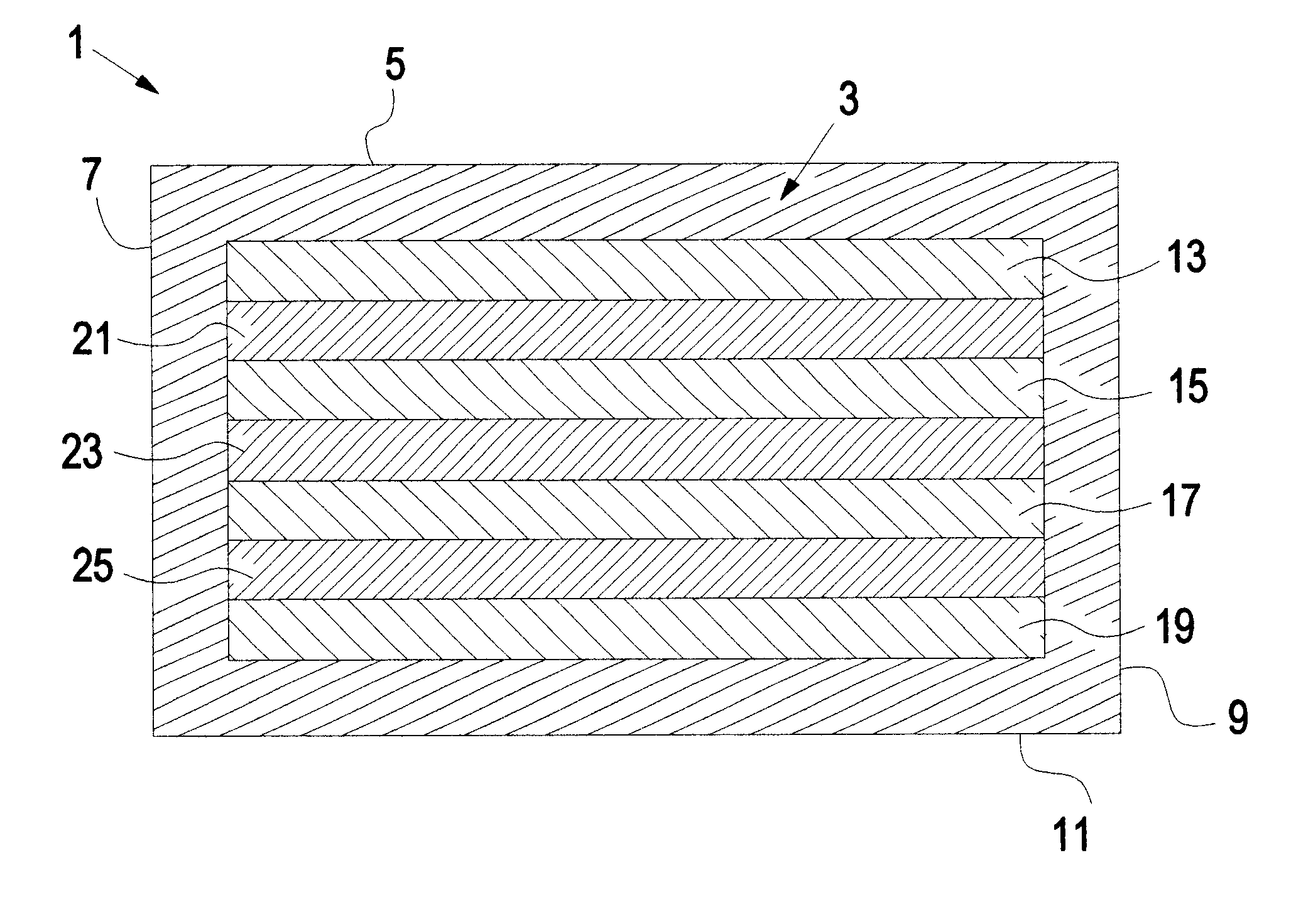

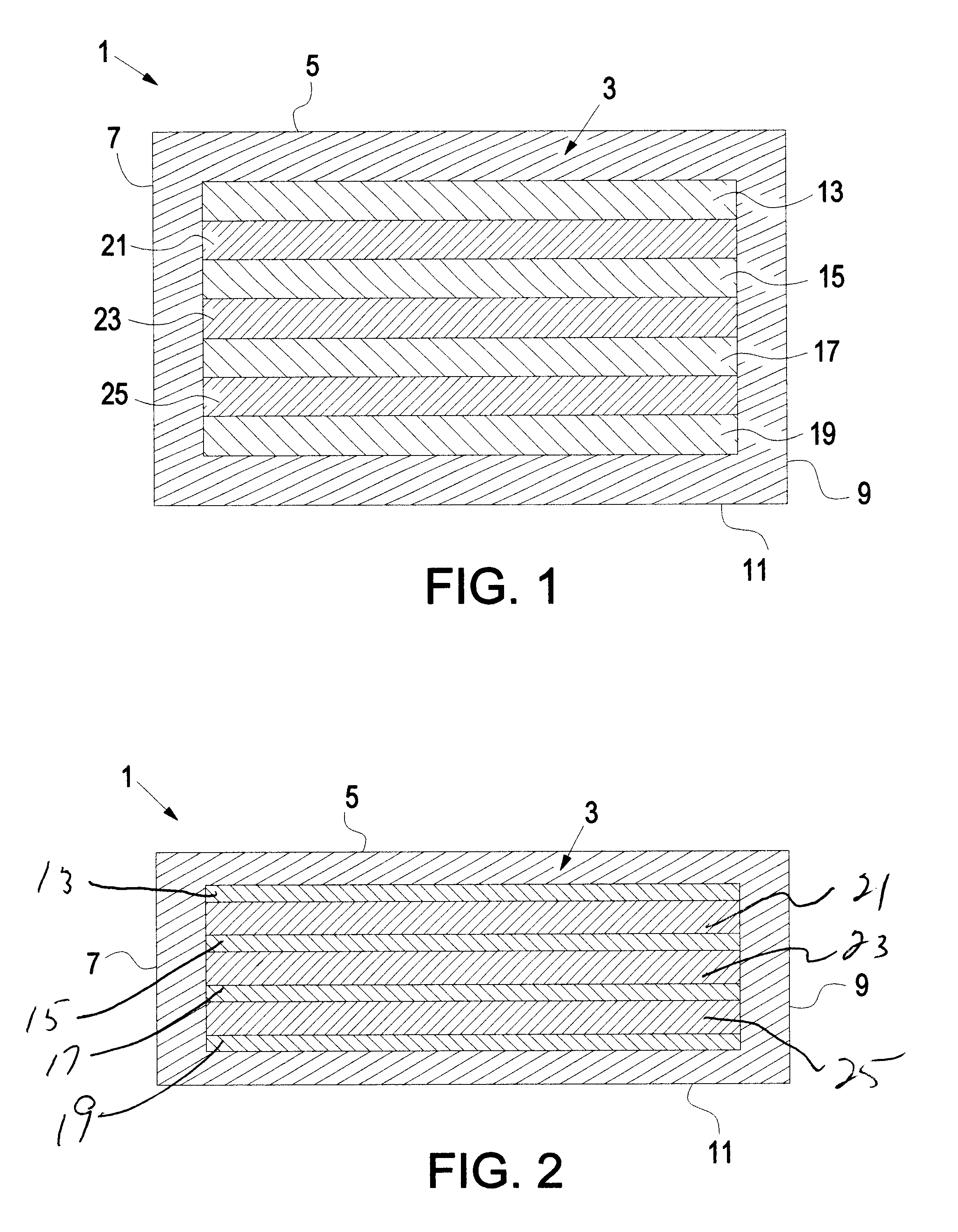

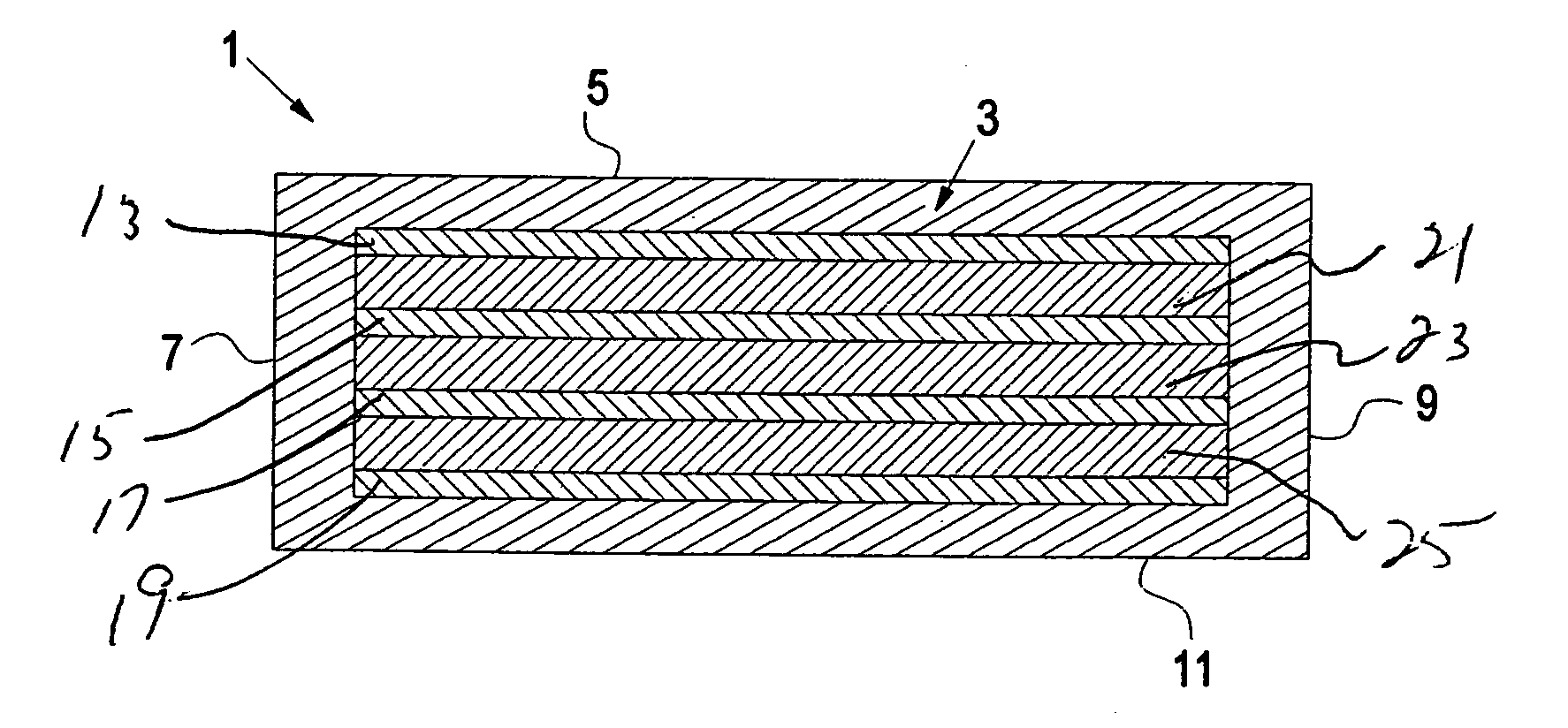

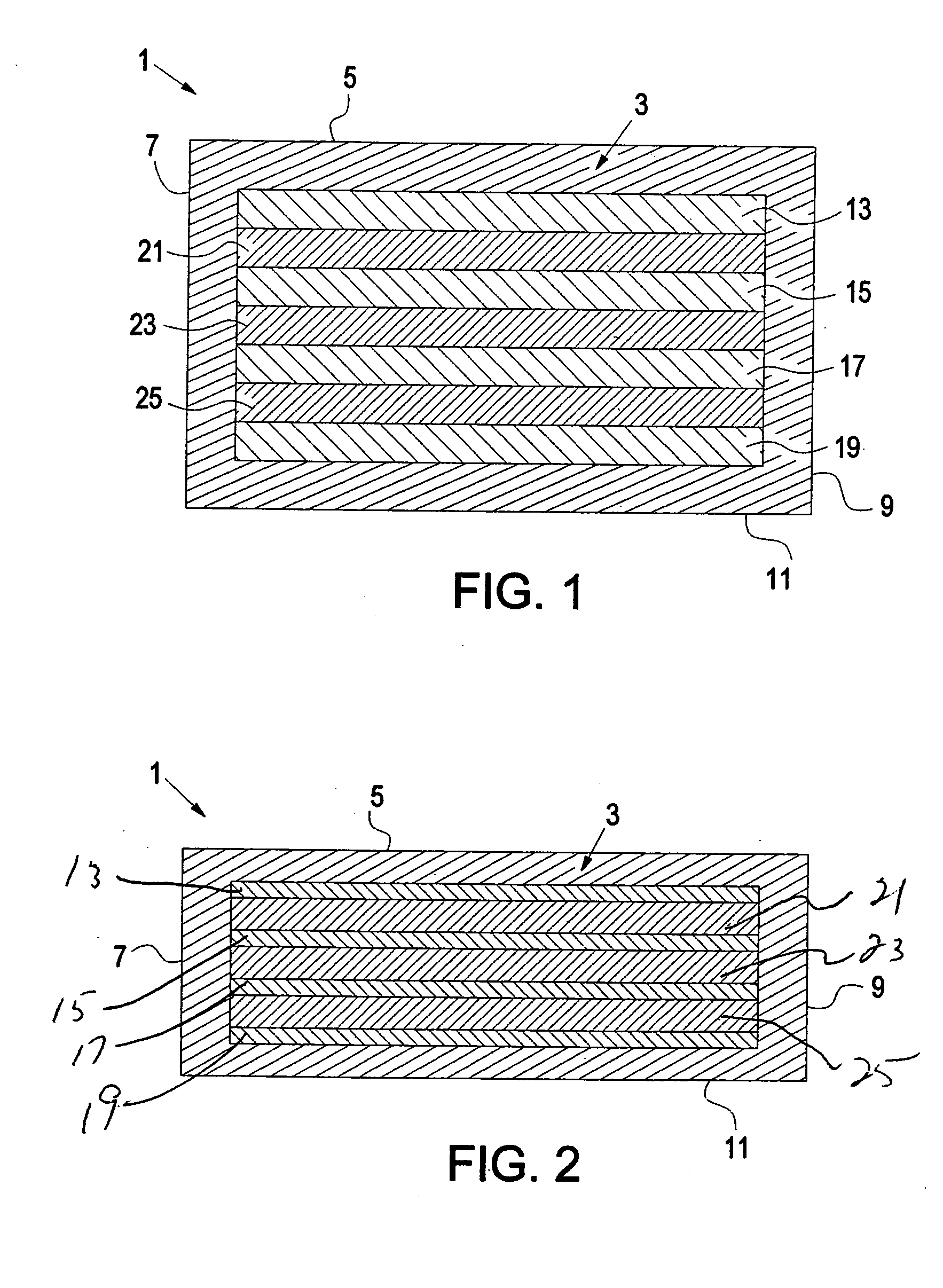

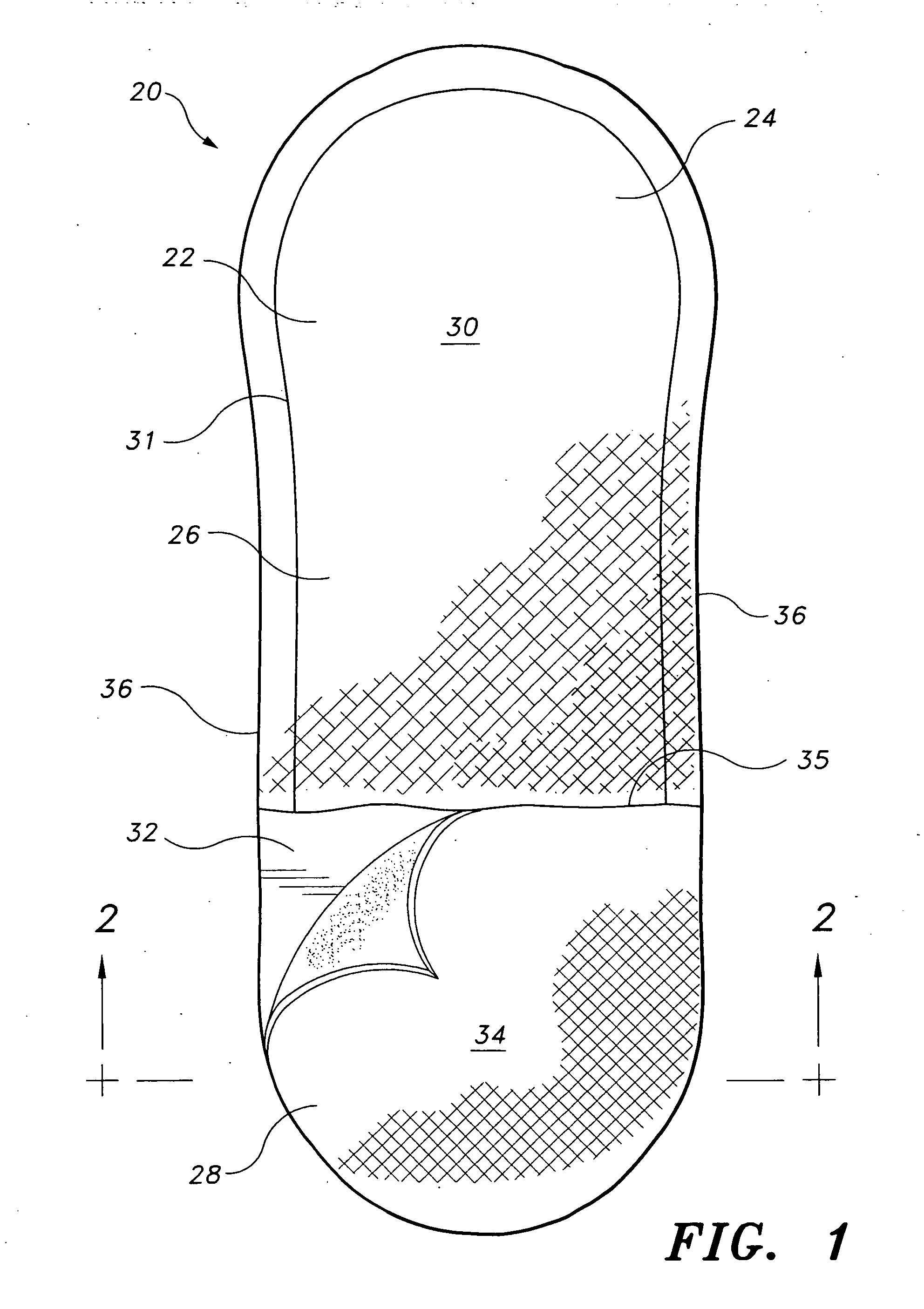

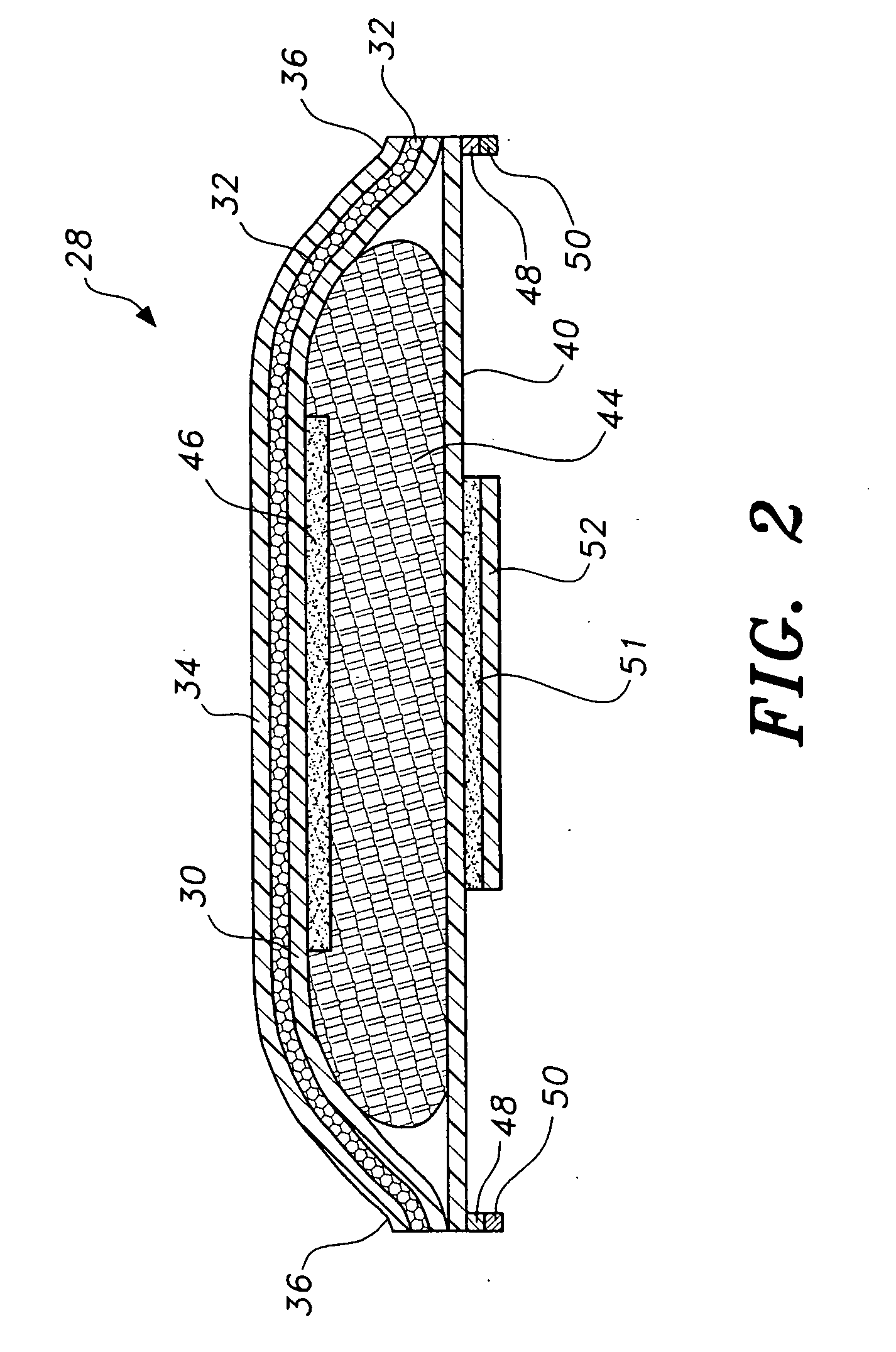

The present invention is a prosthetic for replacement of at least a part of the nucleus of a intravertebral disc. The prosthetic device is composed of at least two essentially parallel soft layers of an elastically deformable hydrogel and at least one rigid layer, the rigid layer having less compressibility than the soft layers, being adjacent to the soft layers, parallel to them, and firmly attached to them. In some embodiments, the soft layers have the same thickness and composition. Typically, the prosthesis has more than one rigid layer and these rigid layers have the same thickness and composition. The number of soft layers is usually one more than the number of rigid layers, with, e.g., at least three soft layers.

Owner:REPLICATION MEDICAL

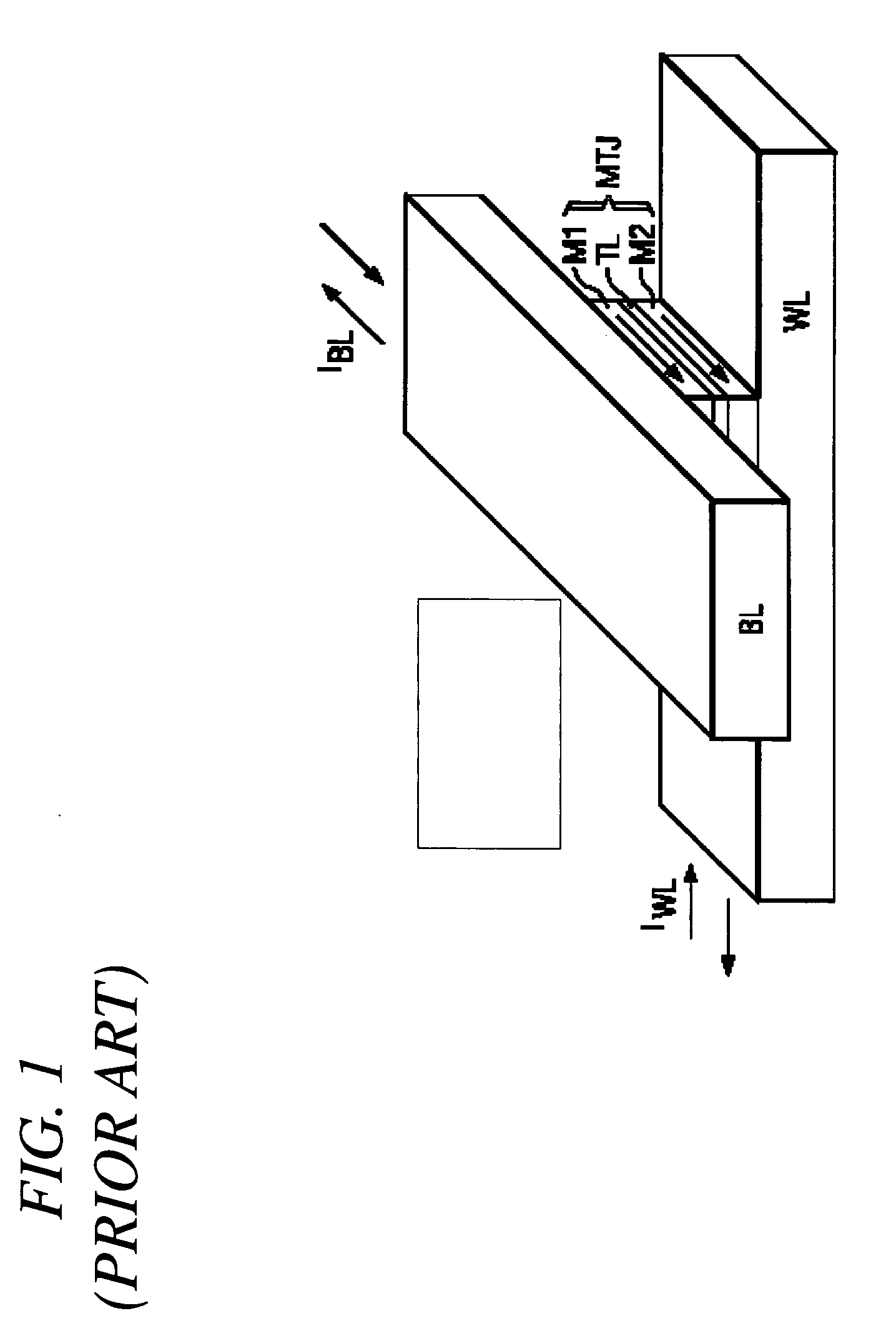

Method for making a nano-stamp and for forming, with the stamp, nano-size elements on a substrate

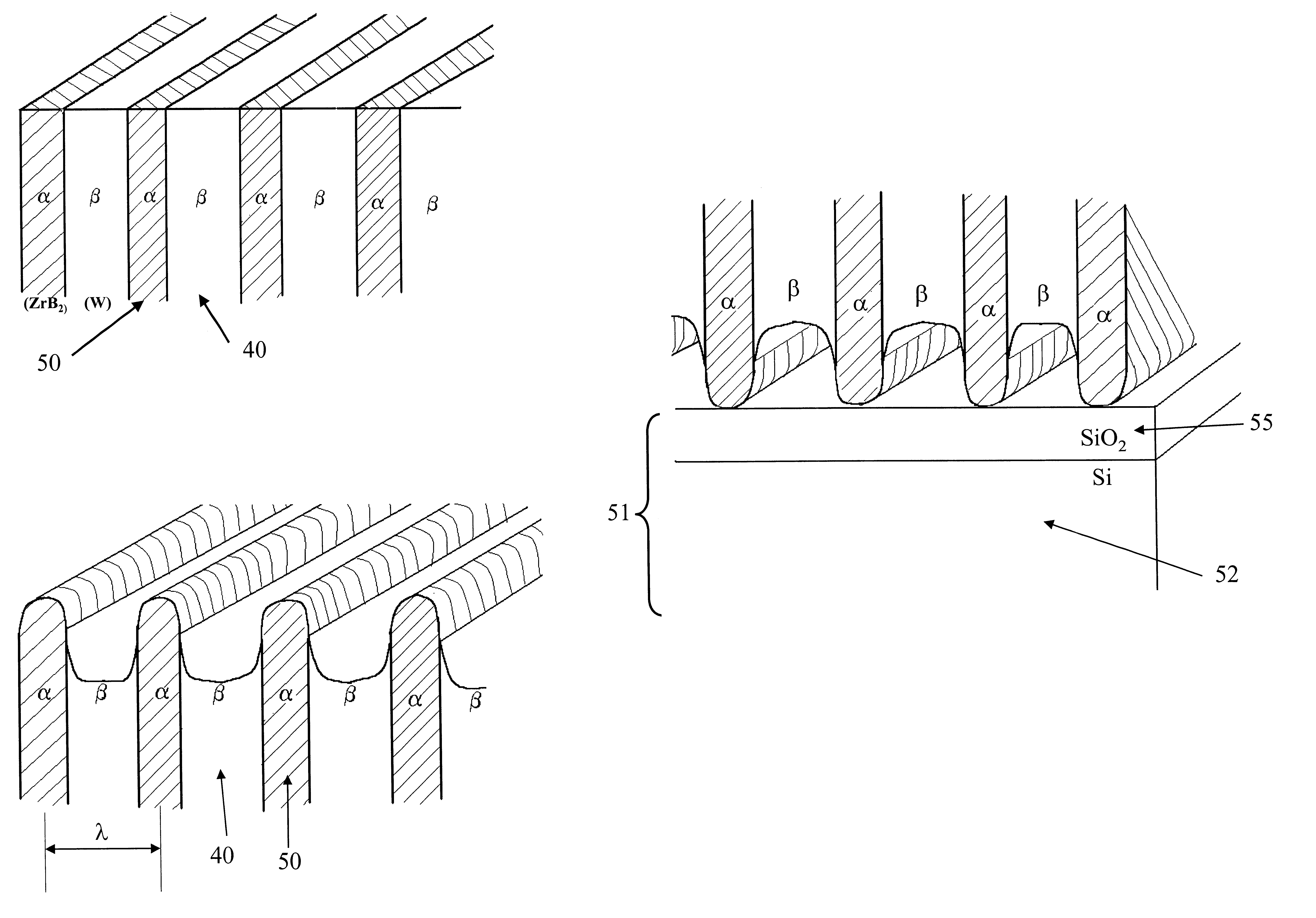

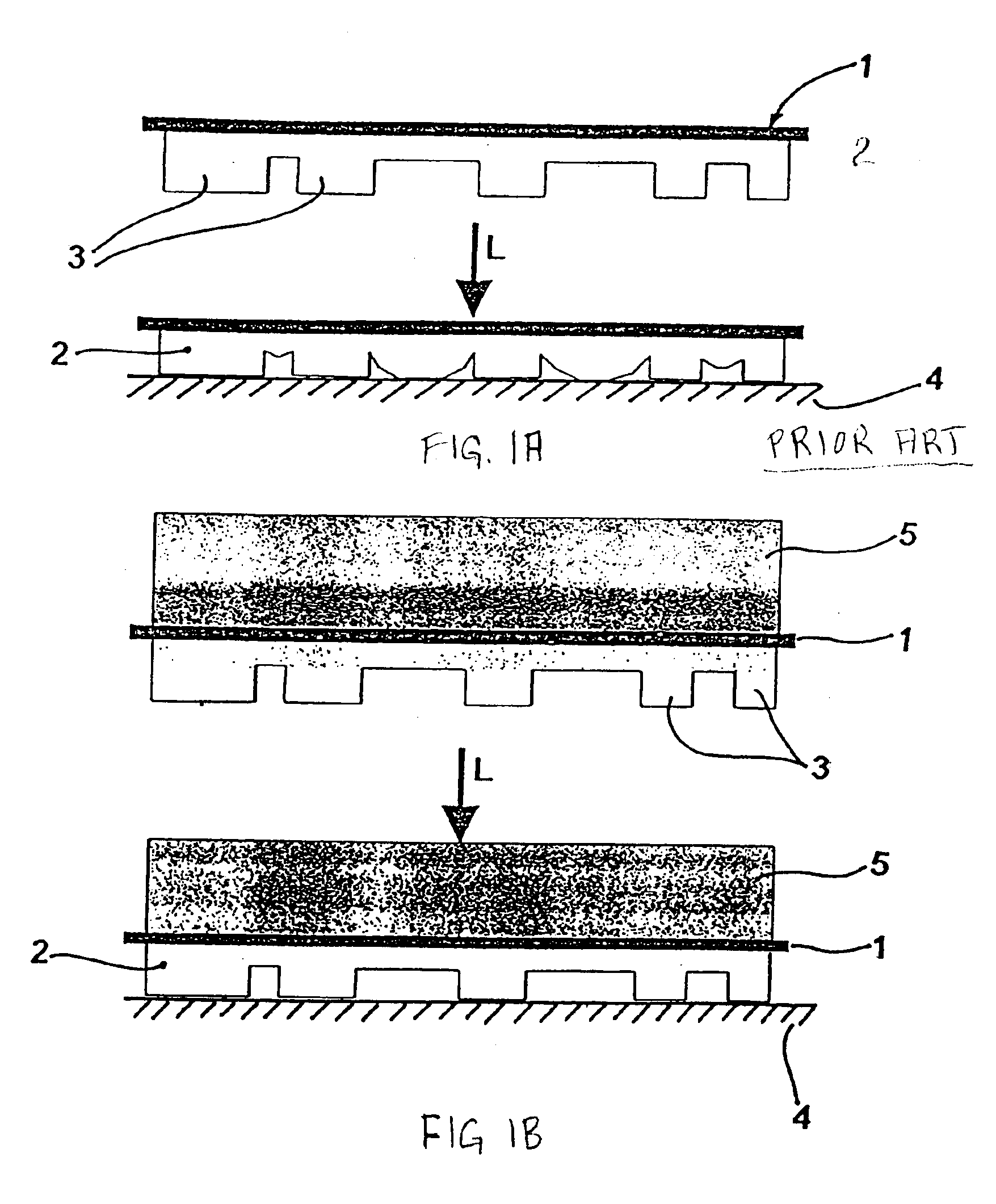

The stamping process and a method of fabrication of nano-stamps with characteristic dimensions below 1 nm and up to 100 nm intended for usage in making patterns of characteristic dimensions the same as those of the nano-stamp on surface of a substrate is provided. In the process a very hard stamp is fabricated by first depositing alternating layers of two materials, one of which has very high hardness, on some sacrificial substrate via PVD, CVD or any other deposition procedure that produces alternating layers of selected thickness, from sub 1 nm to above 100 nm. The layered film is then polished to an atomically smooth finish perpendicular to the plane of the layers and etched to produce dips in the softer layers. These steps produce a grid of parallel elevations and valleys on the etched surface, which now can be used as a stamp to stamp out patterns on a substrate of lower hardness than the hardness of the elevated layers. If the substrate is stamped twice with a turning of the stamp 90 degrees between first and second stampings, a square pattern of elevations or hills and valleys is formed, which can be used for magnetic memory storage by subsequently sputtering magnetic material on the tops of the elevations or hills.

Owner:VIGIL THOMAS R +1

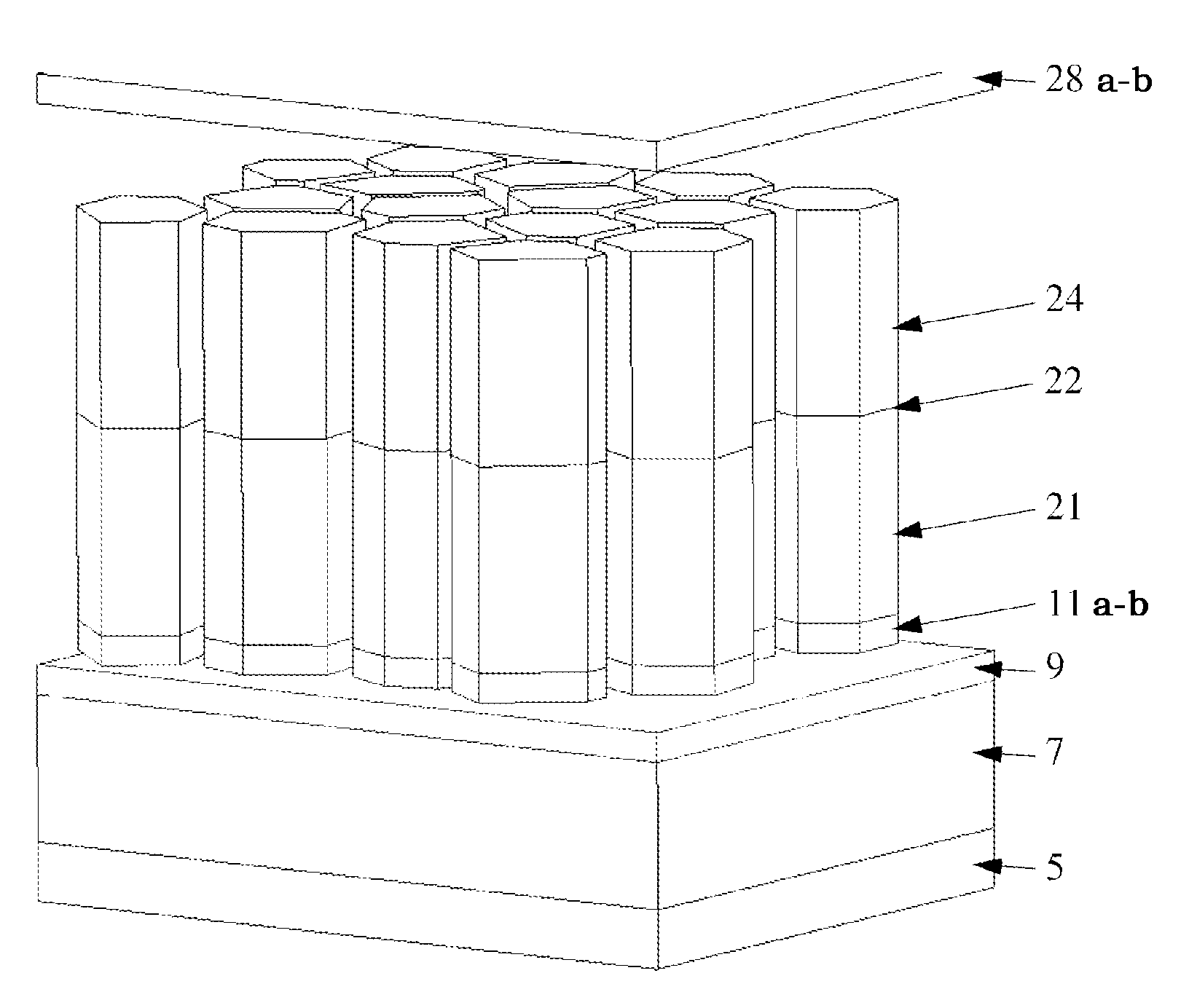

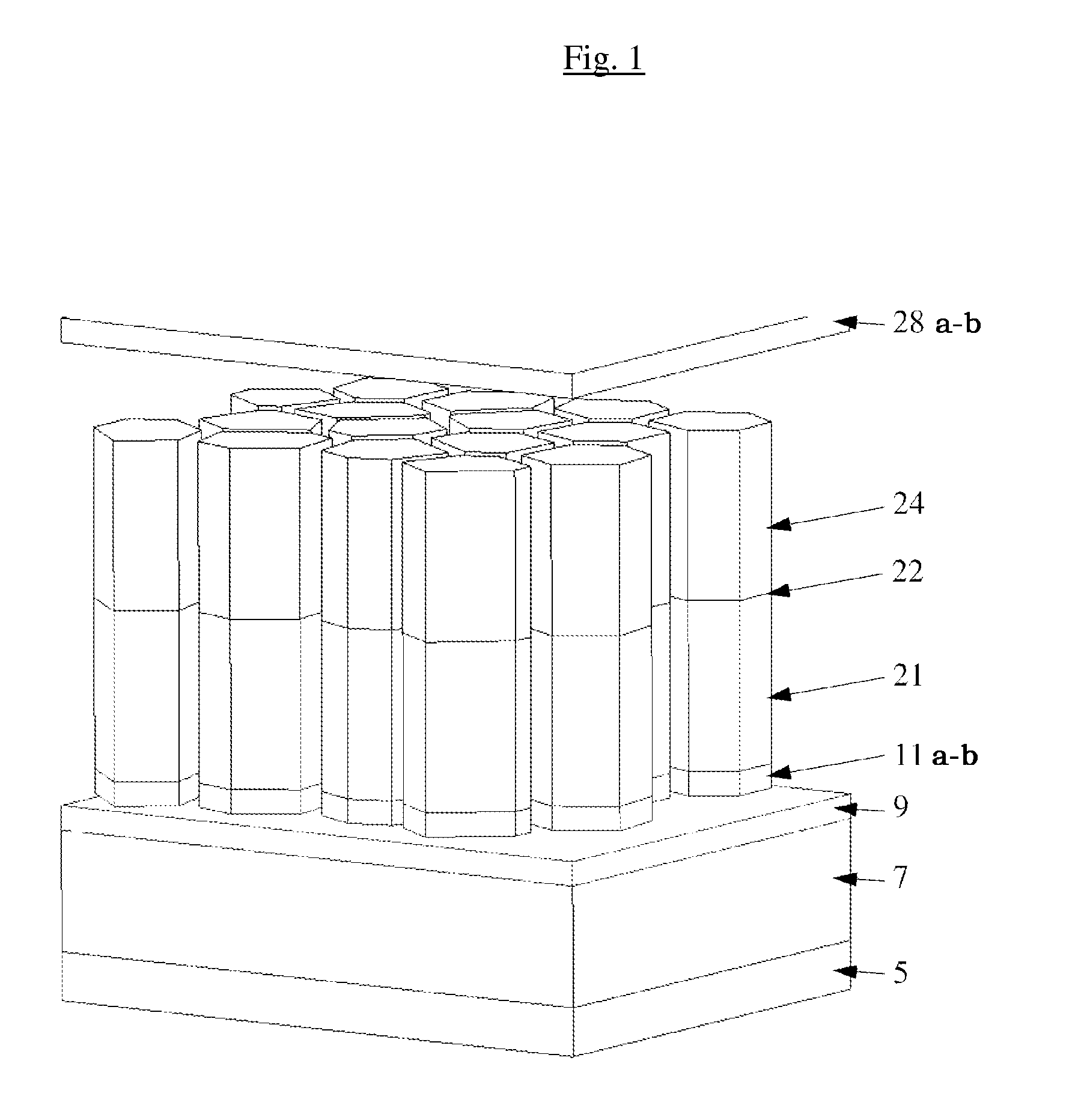

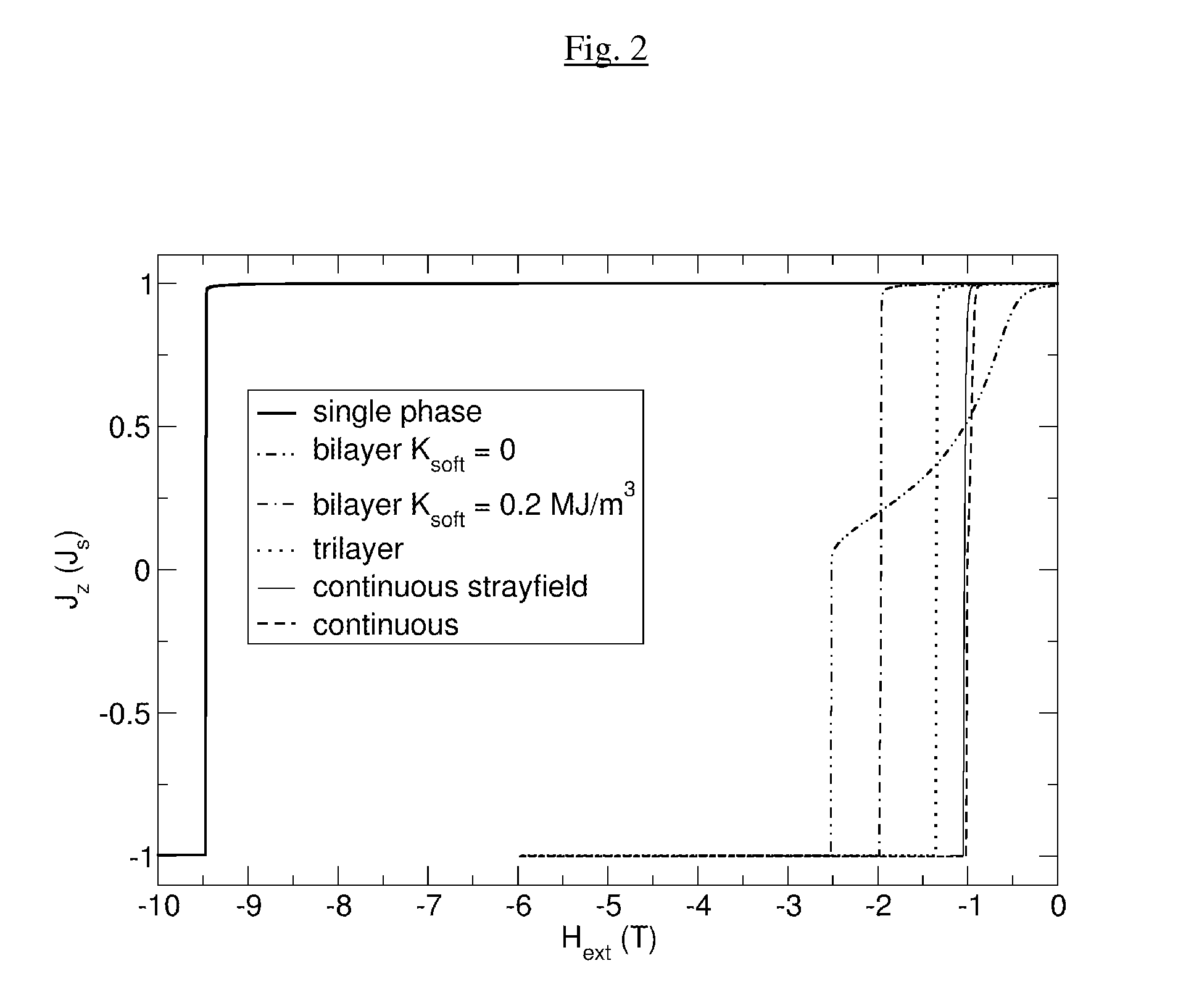

Multilayer Exchange Spring Recording Media

ActiveUS20070292720A1Coercive field can also be increasedCoercive field is reducedNanomagnetismMagnetic measurementsSoft layerMagnetic storage

A multilayer exchange spring recording media consists of a magnetically hard magnetic storage layer strongly exchange coupled to a softer nucleation host. The strong exchange coupling can be through a coupling layer or direct. The hard magnetic storage layer has a strong perpendicular anisotropy. The nucleation host consists of one or more ferromagnetic coupled layers. For a multilayer nucleation host the anisotropy increases from layer to layer. The anisotropy in the softest layer of the nucleation host can be two times smaller than that of the hard magnetic storage layer. The lateral exchange between the grains is small. The nucleation host decreases the coercive field significantly while keeping the energy barrier of the hard layer almost unchanged. The coercive field of the total structure depends on one over number of layers in the nucleation host. The invention proposes a recording media that overcomes the writeability problem of perpendicular recording media.

Owner:MR TECH GMBH

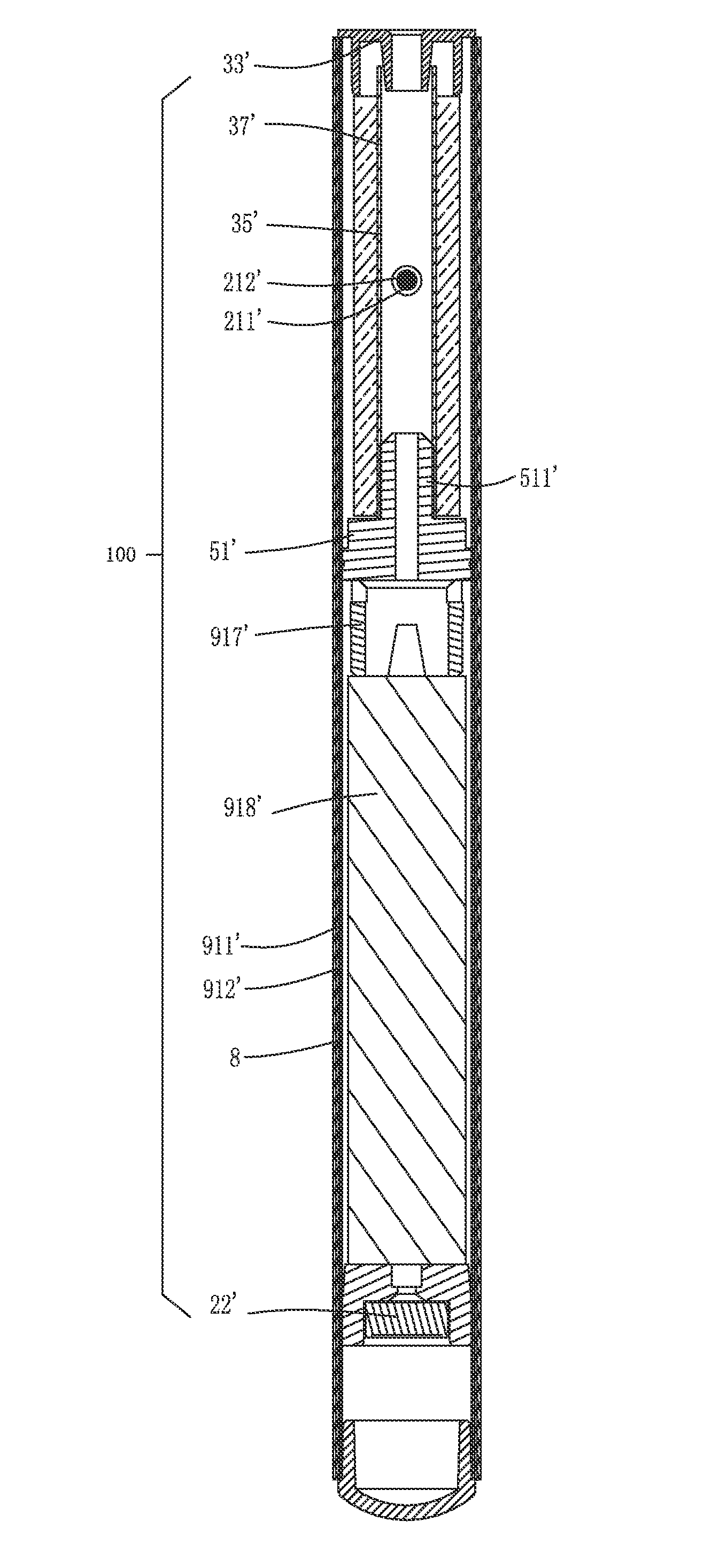

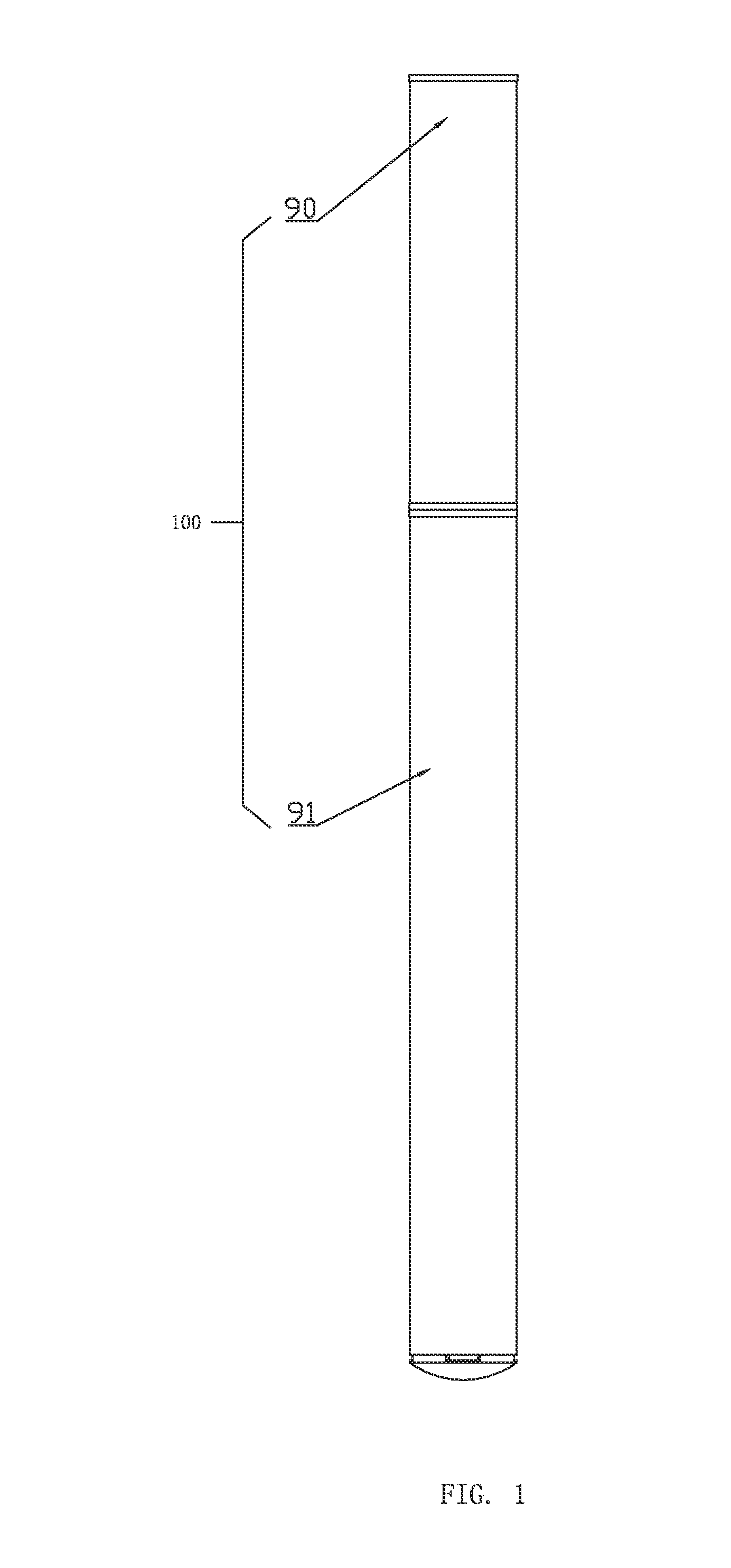

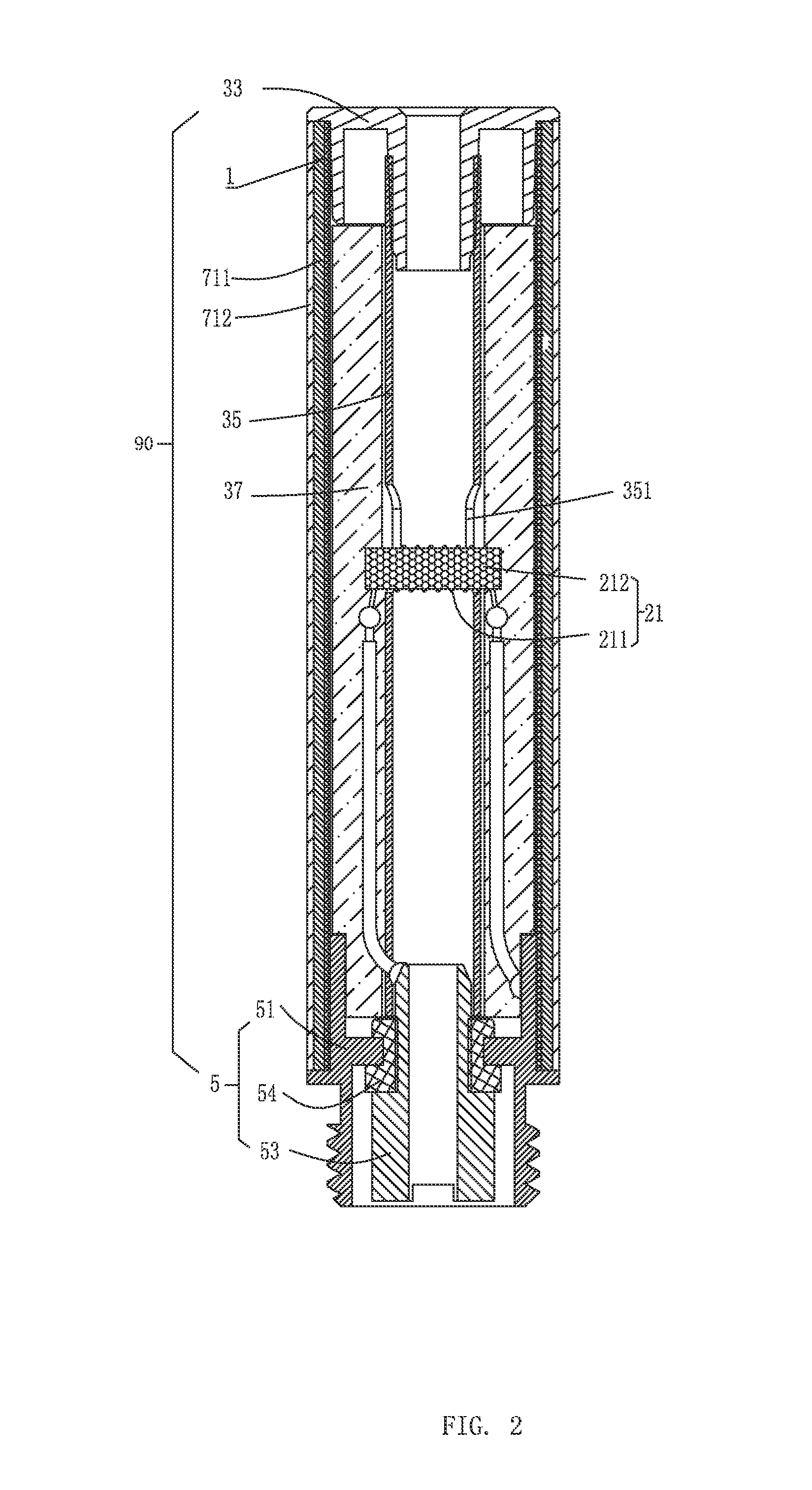

Electronic cigarette

InactiveUS20150128970A1Feel goodIncrease flexibilityTobacco pipesTobacco devicesSoft layerElectronic cigarette

The invention is related to an electronic cigarette, including an outer shell; at least two soft layers are fitted around the outer shell and wrap the outer shell therein; the outer shell therein has a liquid storage component, an atomizer and a power supply; one end of the outer shell is set with a mouthpiece cover; the outer shell therein is further set with an liquid isolation component; the liquid storage component is disposed in a closed space enclosed by the mouthpiece cover, part of the outer shell and the liquid isolation component; inner wall of the liquid storage component is set with a conduit supporting the liquid storage component, the conduit is respectively communicated with the mouthpiece cover and the liquid isolation component; the atomizer is fixedly supported in the conduit. The electronic cigarette offers favorable feeling to touch and mouth, a simple structure, and quick and convenient assembly.

Owner:KIMREE HI TECH

Hydrogel-based prosthetic device for replaceing at least a part of the nucleus of a spinal disc

InactiveUS20030055506A1Prevent surface shrinkageSmall surface areaSpinal implantsTissue regenerationSoft layerWater vapor

The present invention is a prosthetic for replacement of at least a part of the nucleus of a intravertebral disc. The prosthetic device is composed of at least two essentially parallel soft layers of an elastically deformable hydrogel and at least one rigid layer, the rigid layer having less compressibility than the soft layers, being adjacent to the soft layers, parallel to them, and firmly attached to them. In some embodiments, the soft layers have the same thickness and composition. Typically, the prosthesis has more than one rigid layer and these rigid layers have the same thickness and composition. The number of soft layers is usually one more than the number of rigid layers, with, e.g., at least three soft layers. The invention also includes a method of prosthesis production, which involves prefabricating soft and rigid layers; stacking at least two prefabricated soft and at least one prefabricated rigid layer in a parallel fashion into their final form, and, permitting the layers to firmly connect to one another by mutual interaction. In this method, at least one type of the layers is prefabricated in the dehydrated state, which is done by dehydrating stretched foil in an apparatus preventing its contraction and thereby decreasing its area. There is at least partial dehydration of the prosthesis under pressure applied in a direction tangent to the planes of the layers. In preferred embodiments, while in the state of almost full dehydration, is sterilized using ionizing radiation or a gaseous chemical agent, after which it is partially rehydrated within the sterile wrapper using water vapor.

Owner:REPLICATION MEDICAL

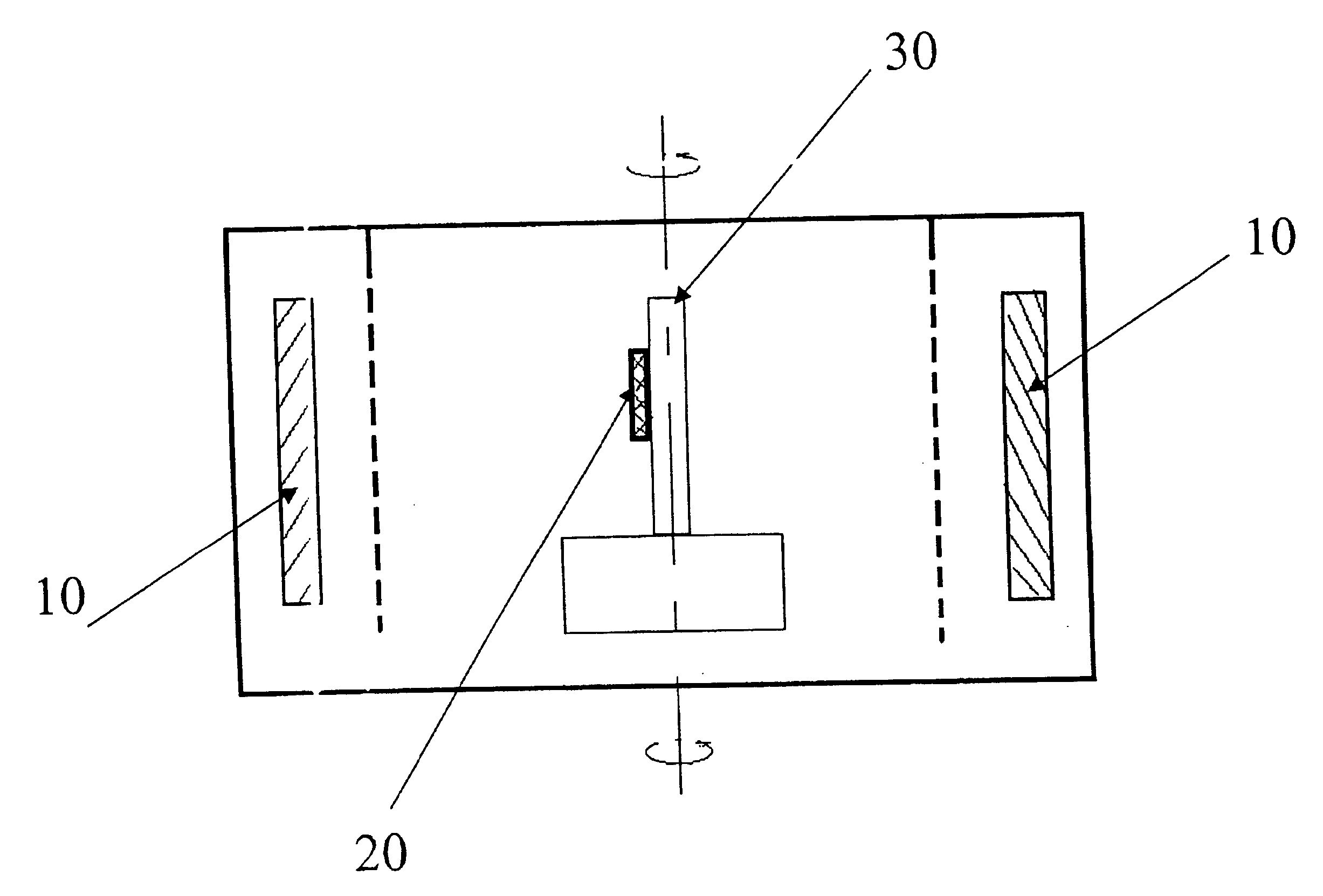

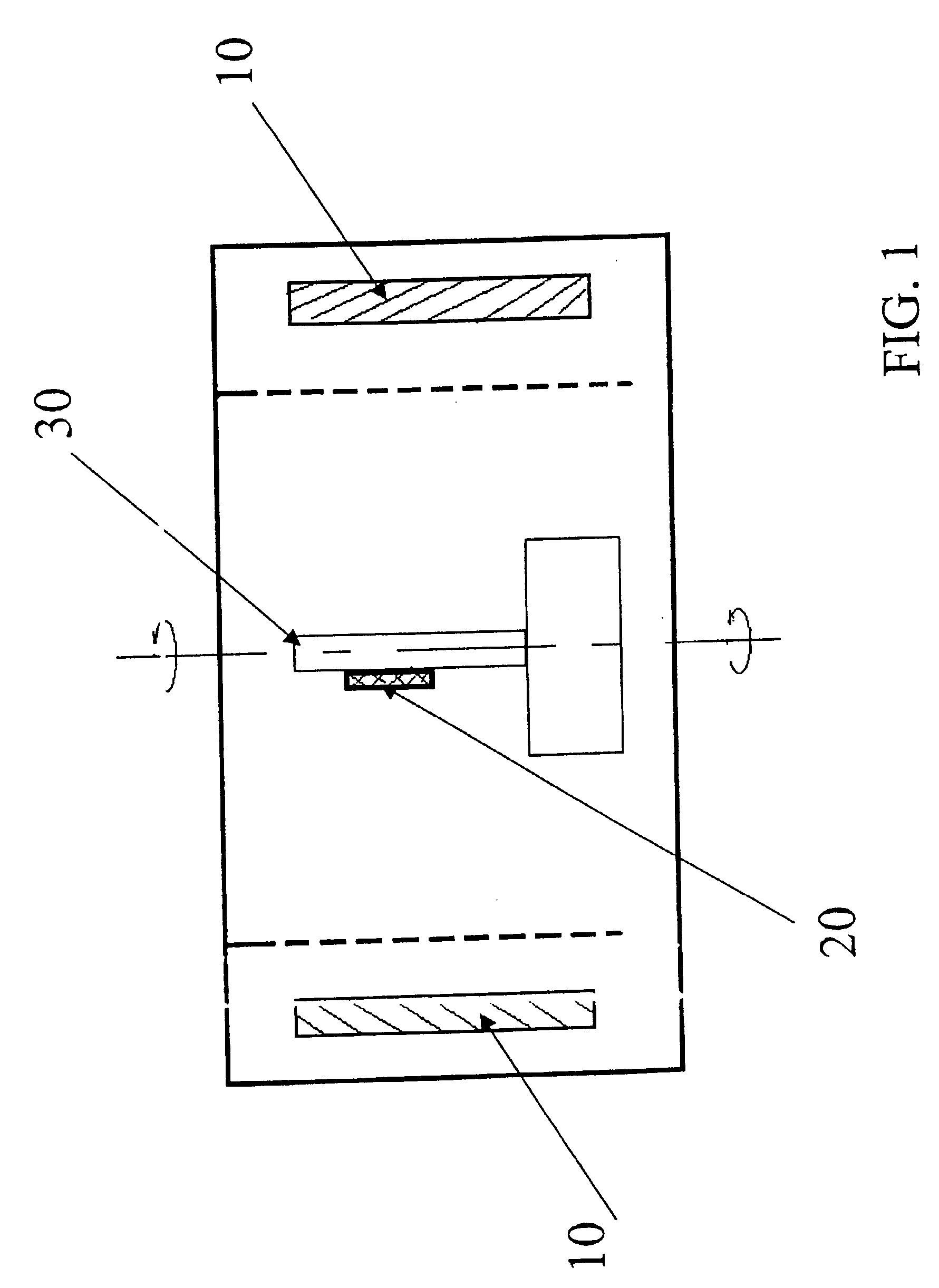

Clamp for holding and efficiently removing heat from workpieces

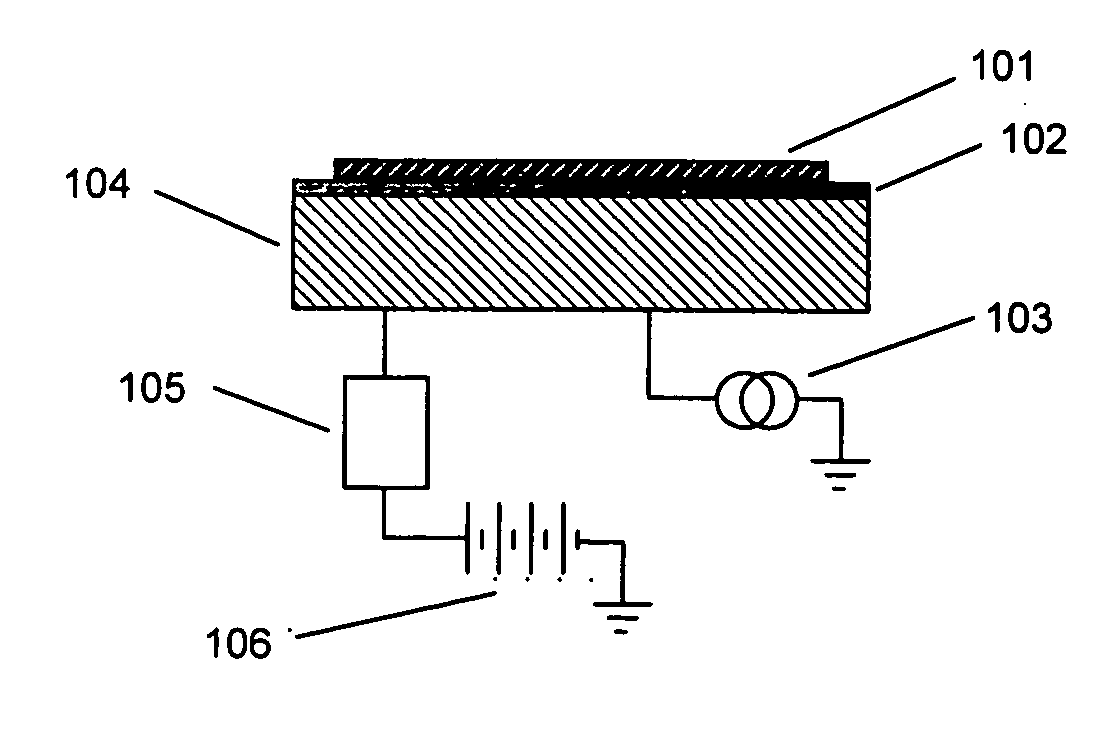

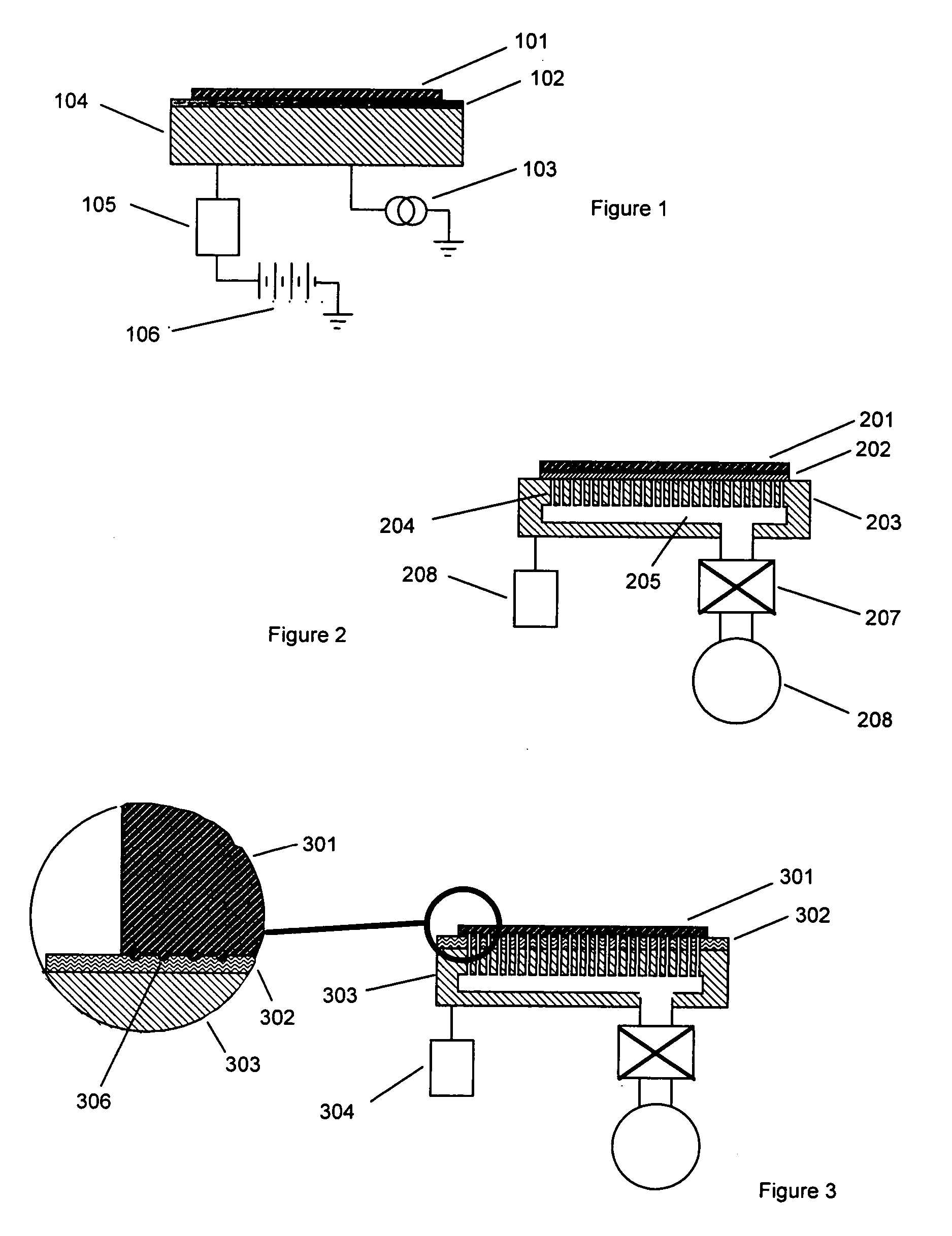

InactiveUS20050036267A1Effectively safely clampIncrease resistanceSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsEtchingCelsius Degree

The invention described in this disclosure is an apparatus and method for clamping semiconductor wafers or other substrates or workpieces during etching, CVD, or surface modification processes. The purpose of the invention is to achieve improved heat transfer during processing between the wafer / substrate and a temperature controlled pedestal used for supporting it in the process chamber. The typical level of process heat put into the wafer during plasma-based etching or deposition processes will be up to about 10 Watts per centimeter squared while the maximum acceptable temperature differential between wafer / substrate and pedestal is less than about 100 Celsius. In such low gas pressure environments typical for plasma-based processes, the heat removal from the wafer / substrate by gaseous conduction may be inadequate to meet requirements. This invention achieves excellent heat transfer to the pedestal from the wafer / substrate when there is a thin, resilient, electrically insulating layer (tape) bonded to the wafer / substrate or the pedestal. Wafer / substrate clamping for improved process heat removal is achieved by a combination of vacuum clamping of the wafer / substrate beginning prior to evacuation of the processing chamber, along with or followed by electrostatic clamping of the wafer / substrate which continues during processing. The invention also permits the wafer / substrate to be rapidly and safely released from the electrostatic clamping when the chamber is returned to atmospheric pressure by a providing a slight pressure increase, above atmospheric pressure, between wafer and pedestal. The pedestal may have some roughening or narrow grooves on the wafer clamping surface, and some small holes from its surface leading to an evacuated plenum or channel within the pedestal. Alternatively, the pedestal may have a layer of a porous metal extending from its surface down to the evacuated channel or plenum which permits gas to be evacuated. These structures allow vacuum pumping of gas that might otherwise be trapped between the insulating layer and the pedestal. When a wafer / substrate is placed on the pedestal by loading at atmospheric pressure, vacuum pumping through the pedestal is commenced. This causes the workpiece to be pressed to the pedestal clamping surface with approximately atmospheric pressure compressing the soft layer against its clamping surface. This provides sufficient contact of the soft layer with the pedestal to greatly improve heat transfer from the wafer / substrate to the pedestal. A voltage is applied to the pedestal, beginning any time after the wafer is on the pedestal, to further clamp the wafer electrostatically. As the processing chamber is then pumped down to operating pressure for processing the electrostatic clamping voltage maintains sufficient pressure of the wafer / substrate against the pedestal to maintain the heat conductive contact between the soft layer and the pedestal. This permits good heat conduction to be maintained during the low pressure plasma-based etching or CVD processing. Following processing when the wafer / substrate is to be removed it may be rapidly de-clamped from the electrostatic clamping by application of a slight over-atmospheric pressure in the reservoir or pumping channels within the pedestal.

Owner:SAVAS STEPHEN EDWARD +1

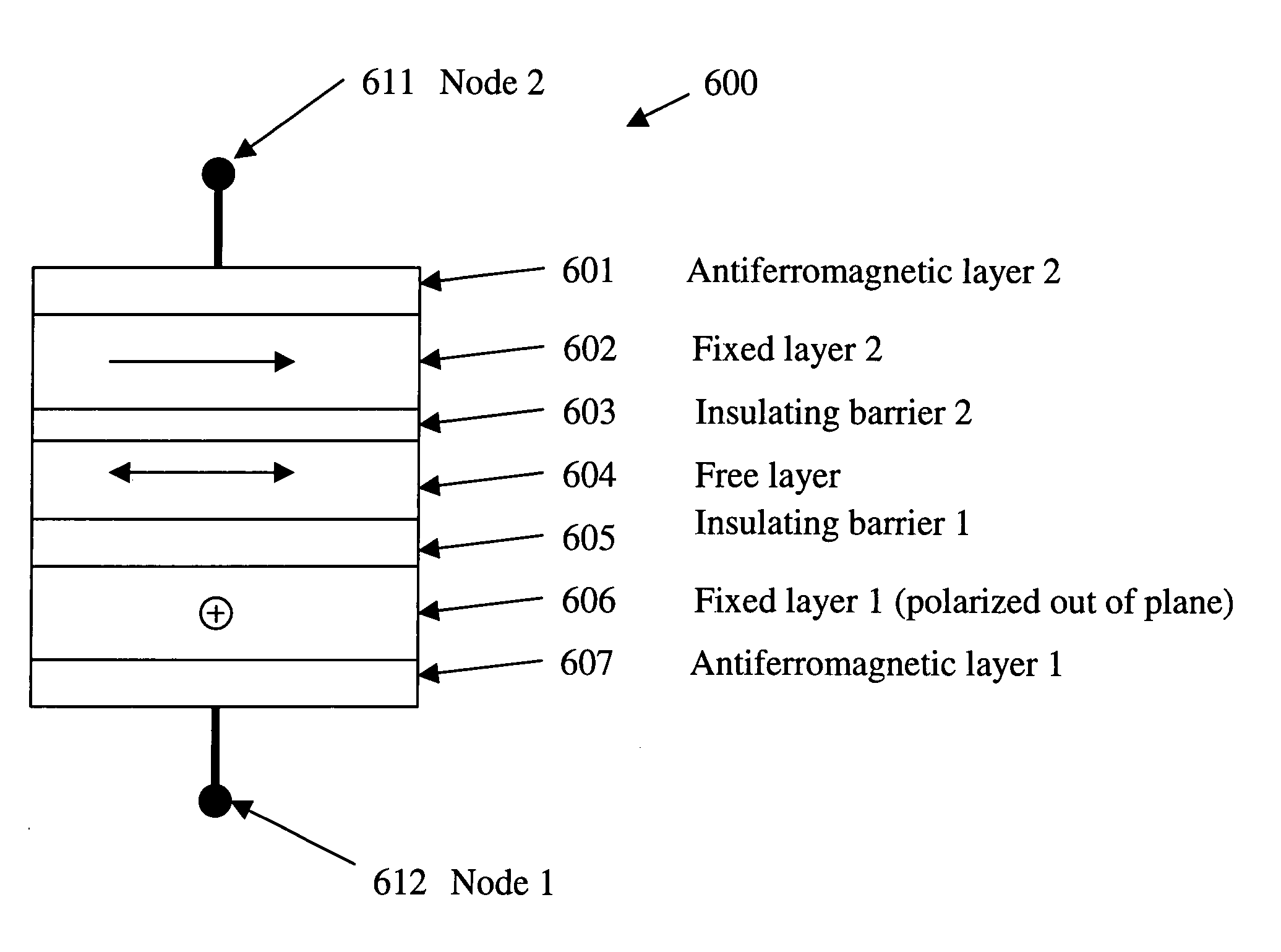

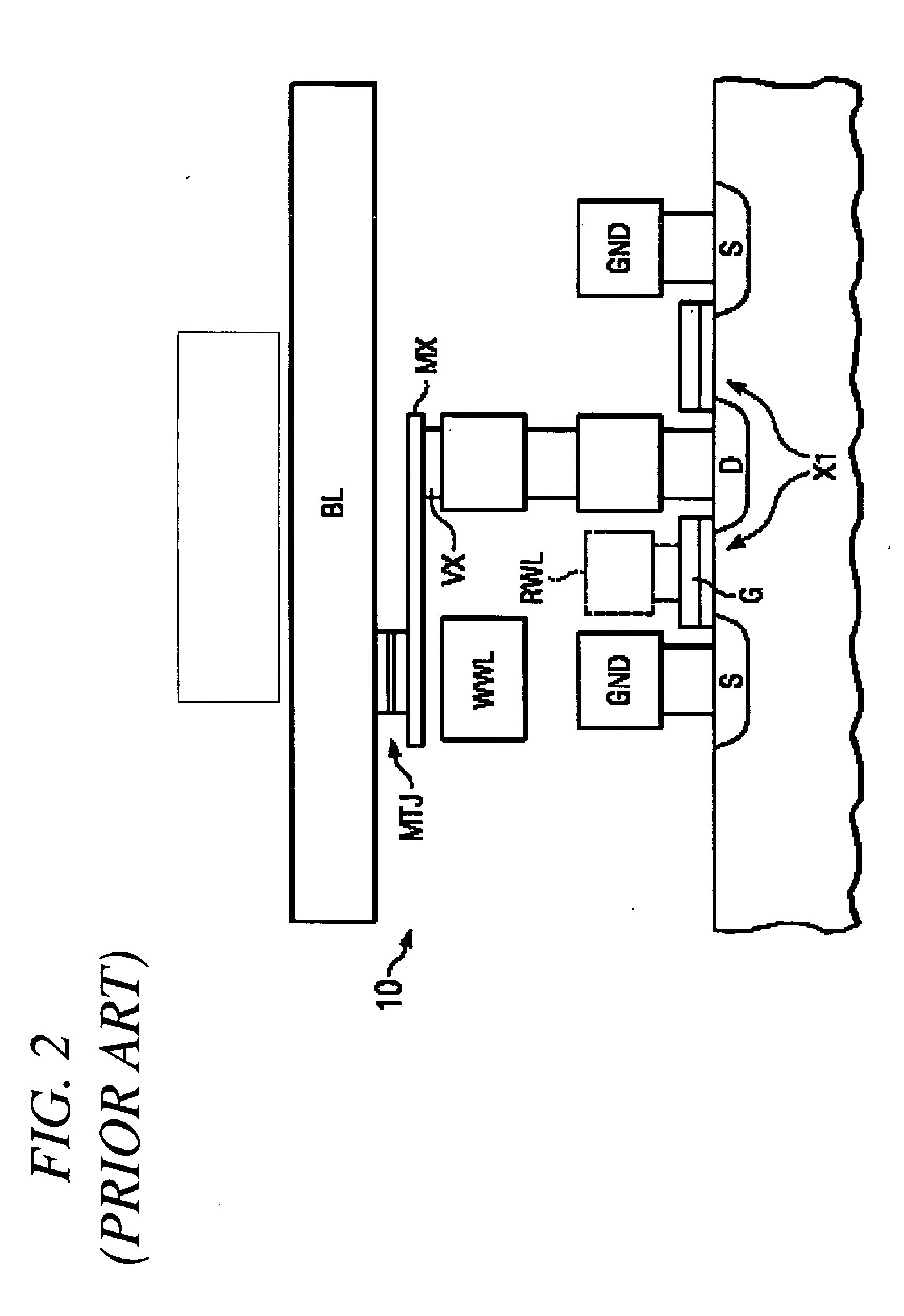

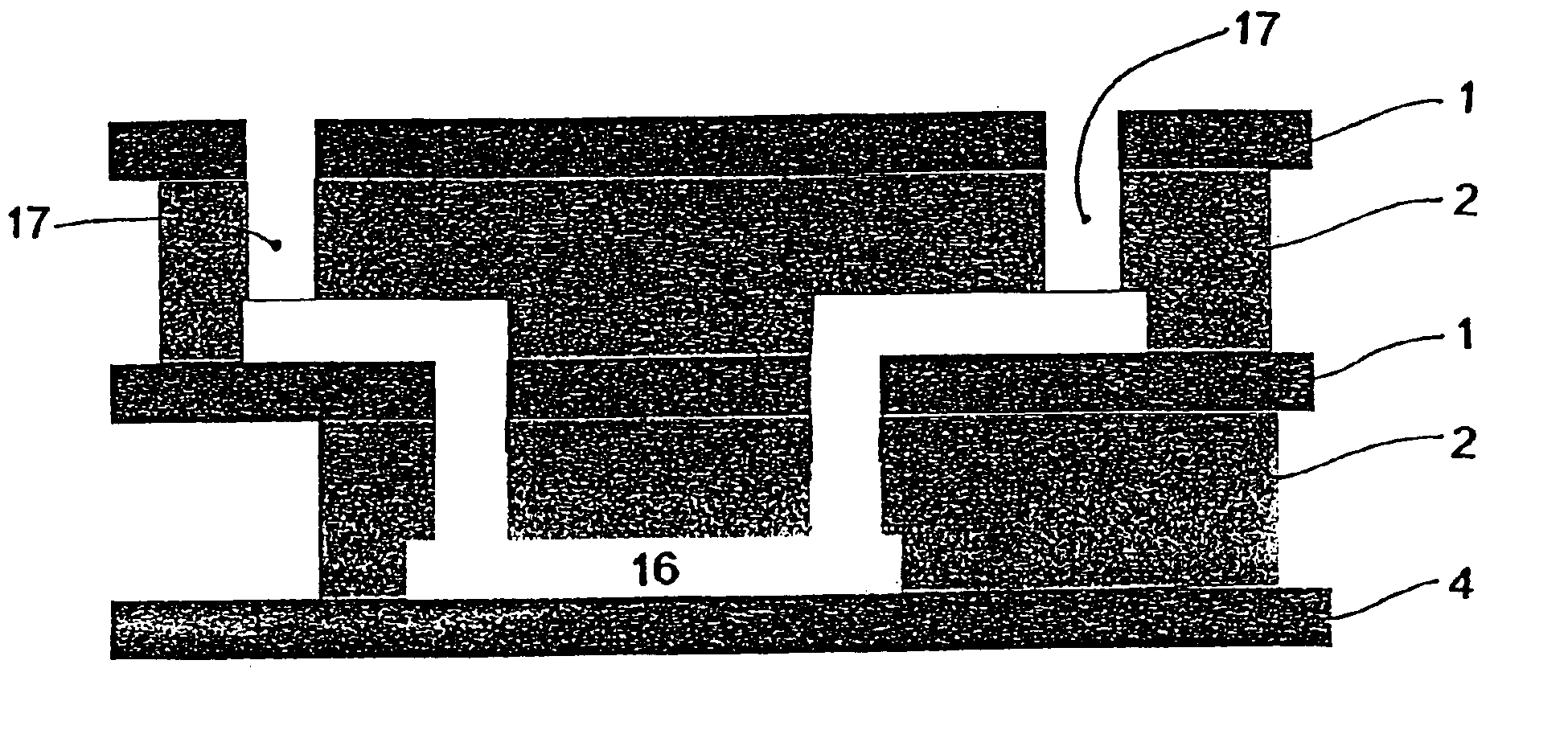

Read out scheme for several bits in a single MRAM soft layer

InactiveUS20060013039A1Increase memory densityReduce manufacturing costSemiconductor/solid-state device manufacturingDigital storageSoft layerElectrical resistance and conductance

A magnetic tunnel junction (MTJ) device is configured to store at least two bits of data in a single cell utilizing the variable resistance characteristic of a MTJ. The MTJ includes a soft and two fixed magnetic layers with fixed field directions oriented in perpendicular directions. The soft magnetic layer is separated from the fixed layers by insulating layers preferably with different thicknesses, or with different material compositions. The resulting junction resistance can exhibit at least four distinct resistance values dependent on the magnetic orientation of the free magnetic layer. The cell is configured using a pattern with four lobes to store two bits, and eight lobes to store three bits. The resulting cell can be used to provide a fast, non-volatile magnetic random access memory (MRAM) with high density and no need to rewrite stored data after they are read, or as a fast galvanic isolator.

Owner:INFINEON TECH AG

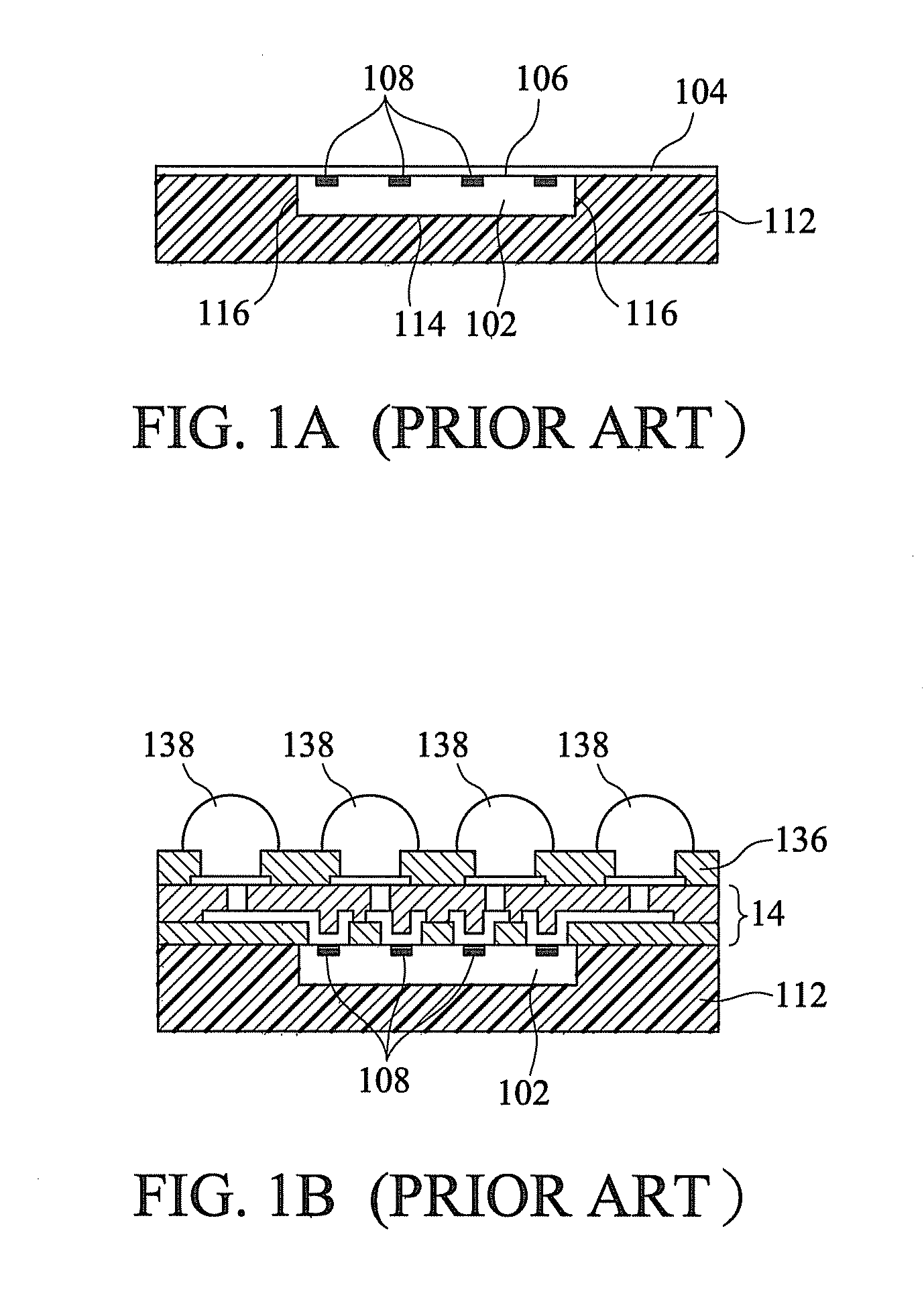

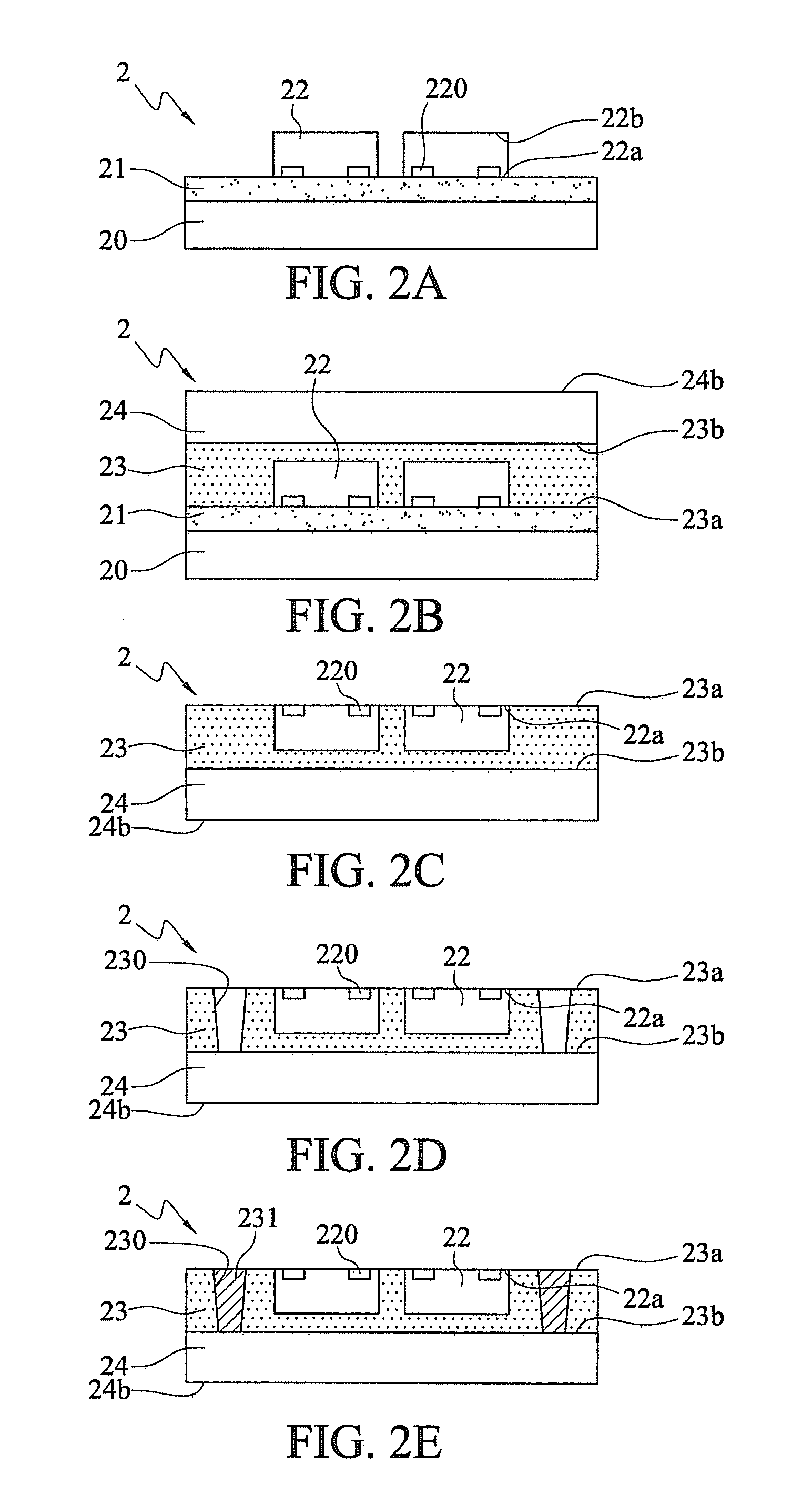

Printed circuit board reinforcement structure and integrated circuit package using the same

InactiveUS8059384B2Reduce thicknessMaintain rigidityMake-and-break ignitionPrinted electric component incorporationSoft layerSurface mounting

A printed circuit board reinforcement structure for a printed circuit board receiving a plurality of surface mounting devices, and an integrated circuit package using the same. The structure includes a hard layer having one or more openings formed at areas corresponding to one or more surface mounting devices with a thickness exceeding a predetermined thickness; and a soft layer bonded to a side of the hard layer so that the soft layer can accommodate the protrusion of the surface mounting devices. The structure prevents defects of a printed circuit board, such as deformation, fracture or the like, while substantially reducing the size of a package by applying a reinforcement structure to a thin printed circuit board, thereby reinforcing the rigidity (mechanical strength) of the thin printed circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD

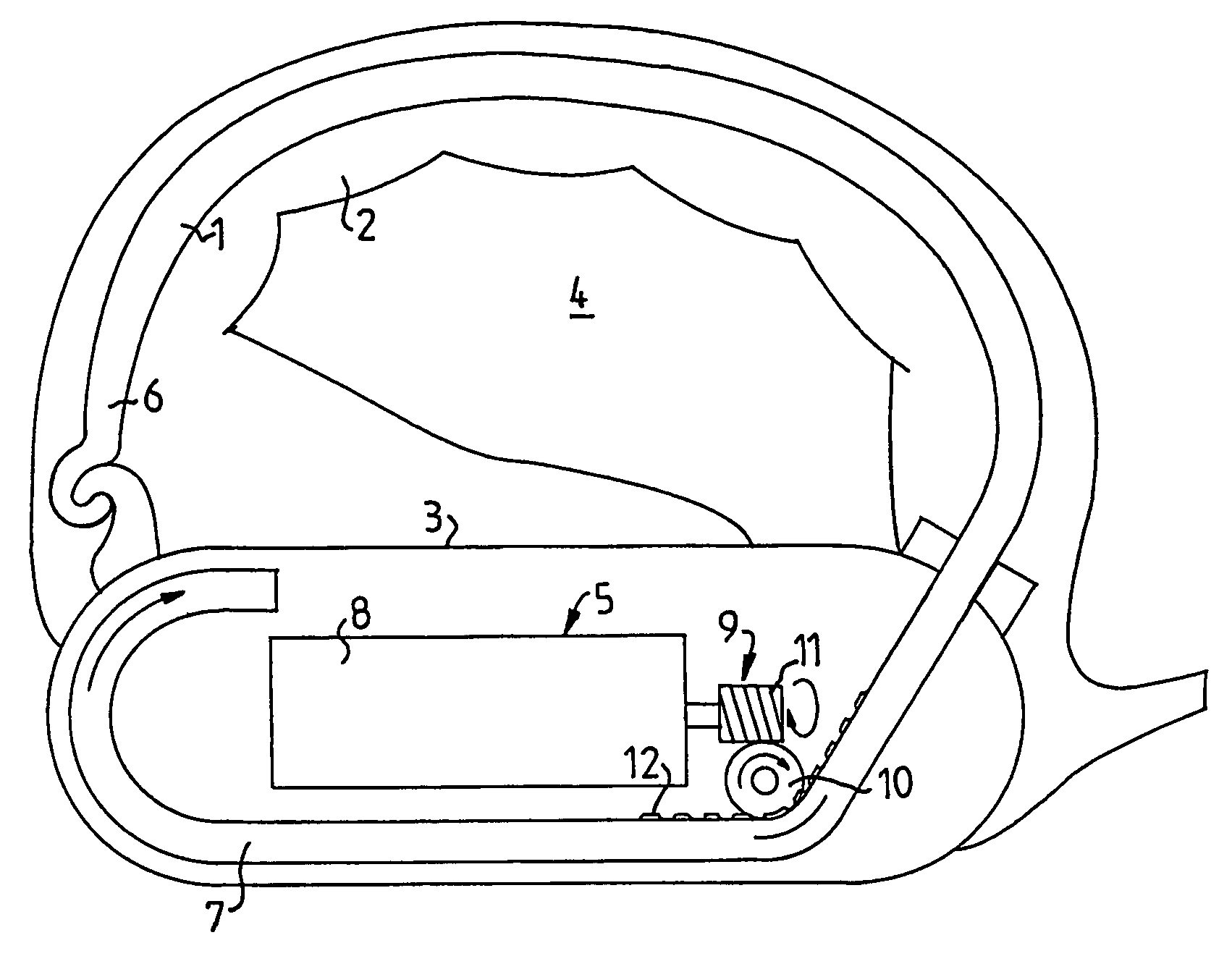

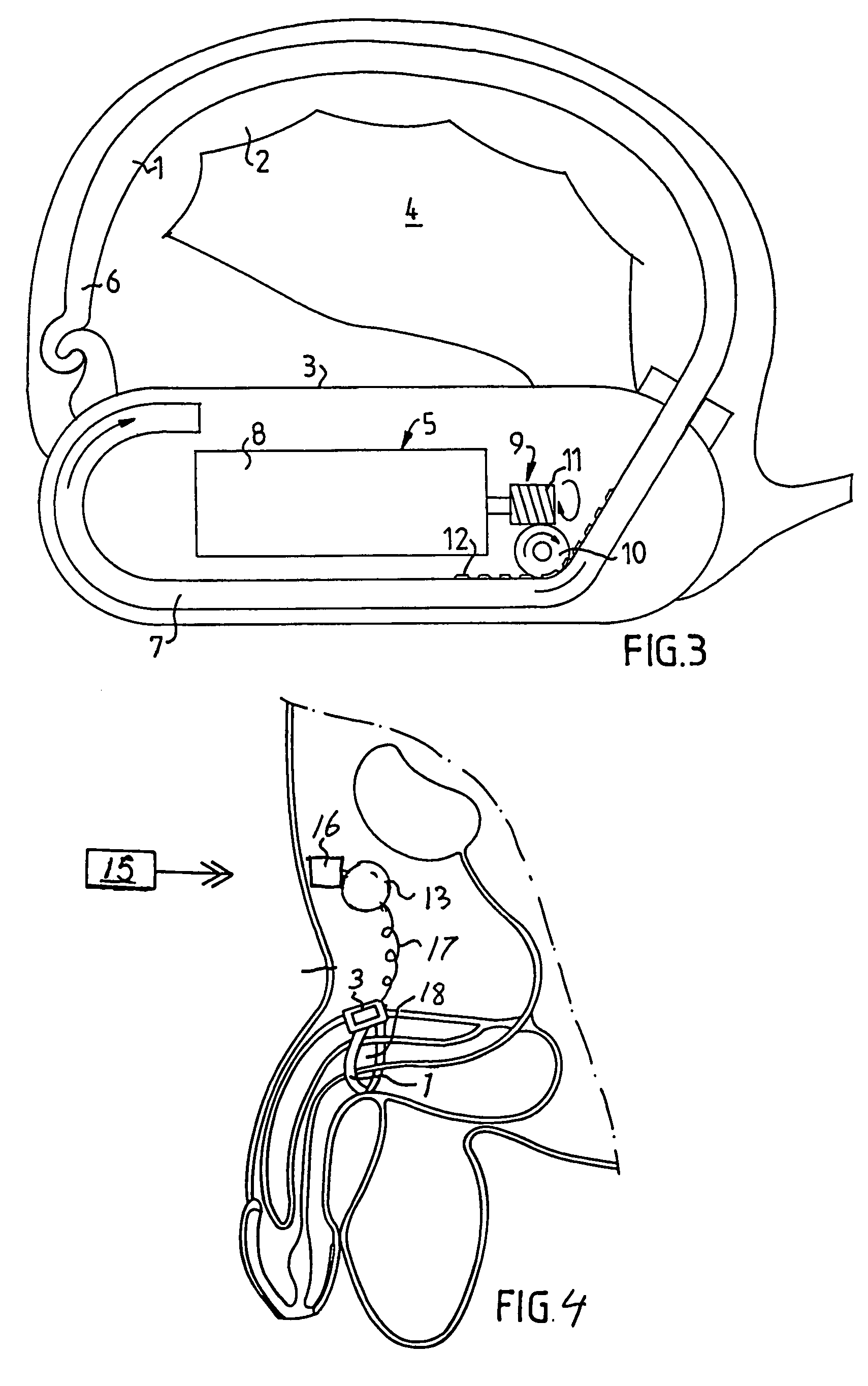

Careful impotence treatment apparatus

InactiveUS7207936B2Constrict the penile tissueIncreased constrictionPenis support devicesNon-surgical orthopedic devicesMale Sexual ImpotenceSoft layer

A male sexual impotence treatment apparatus includes an elongate adjustable constriction member extending in a loop around a male patient's penile tissue or the prolongation thereof. An adjustment device adjusts the longitudinal extension of the constriction member in the loop to temporarily constrict the penile tissue or the prolongation thereof to restrict the penile exit blood flow to achieve erection. A layer of a soft viscoelastic material is applied on the constriction member such that it is located between the constriction member and the patient's penile tissue or the prolongation thereof at least along a portion of the constriction member to protect the penile tissue or the prolongation thereof from being eroded by the constriction member. The layer has an inwardly directed radial extension in the loop such that, when the adjustment device is operated to decrease the longitudinal extension of the constriction member in the loop, the soft layer is forced to expand radially inwardly in the loop causing a corresponding increased constriction of the penile tissue or the prolongation thereof.

Owner:POTENTICA +1

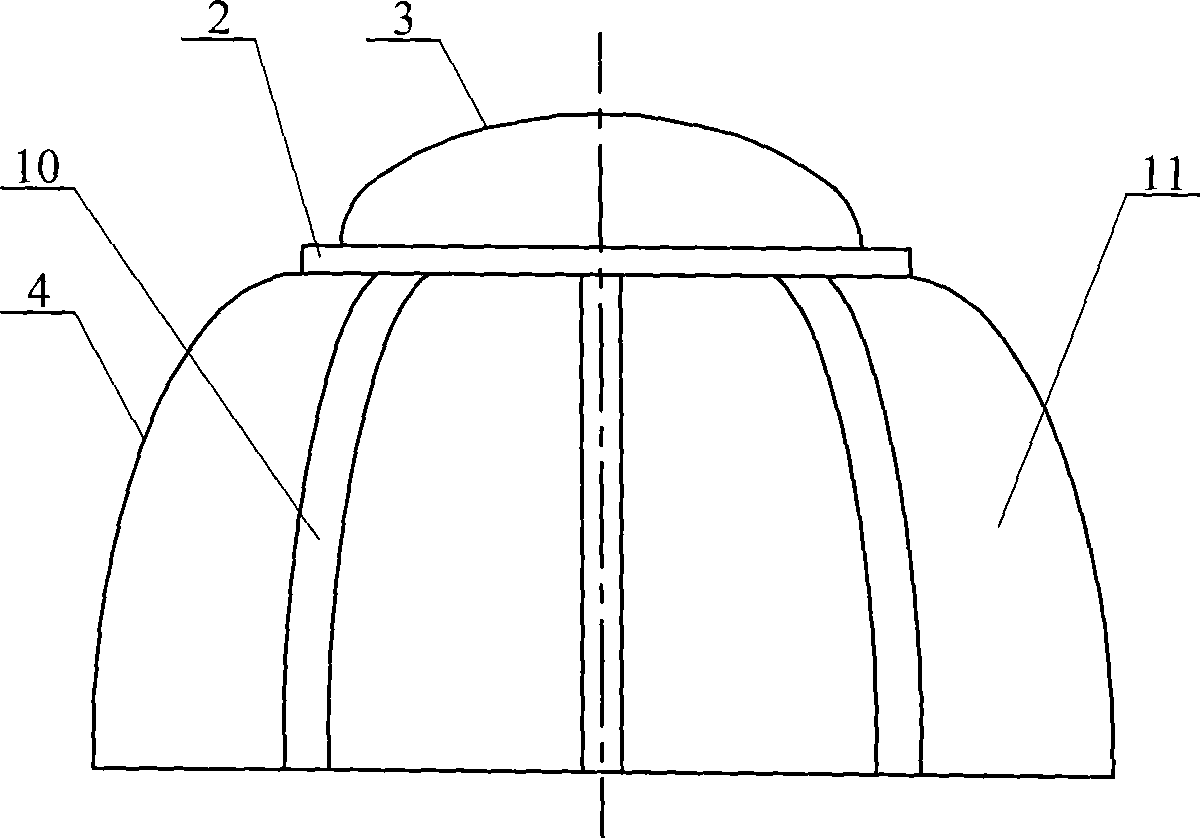

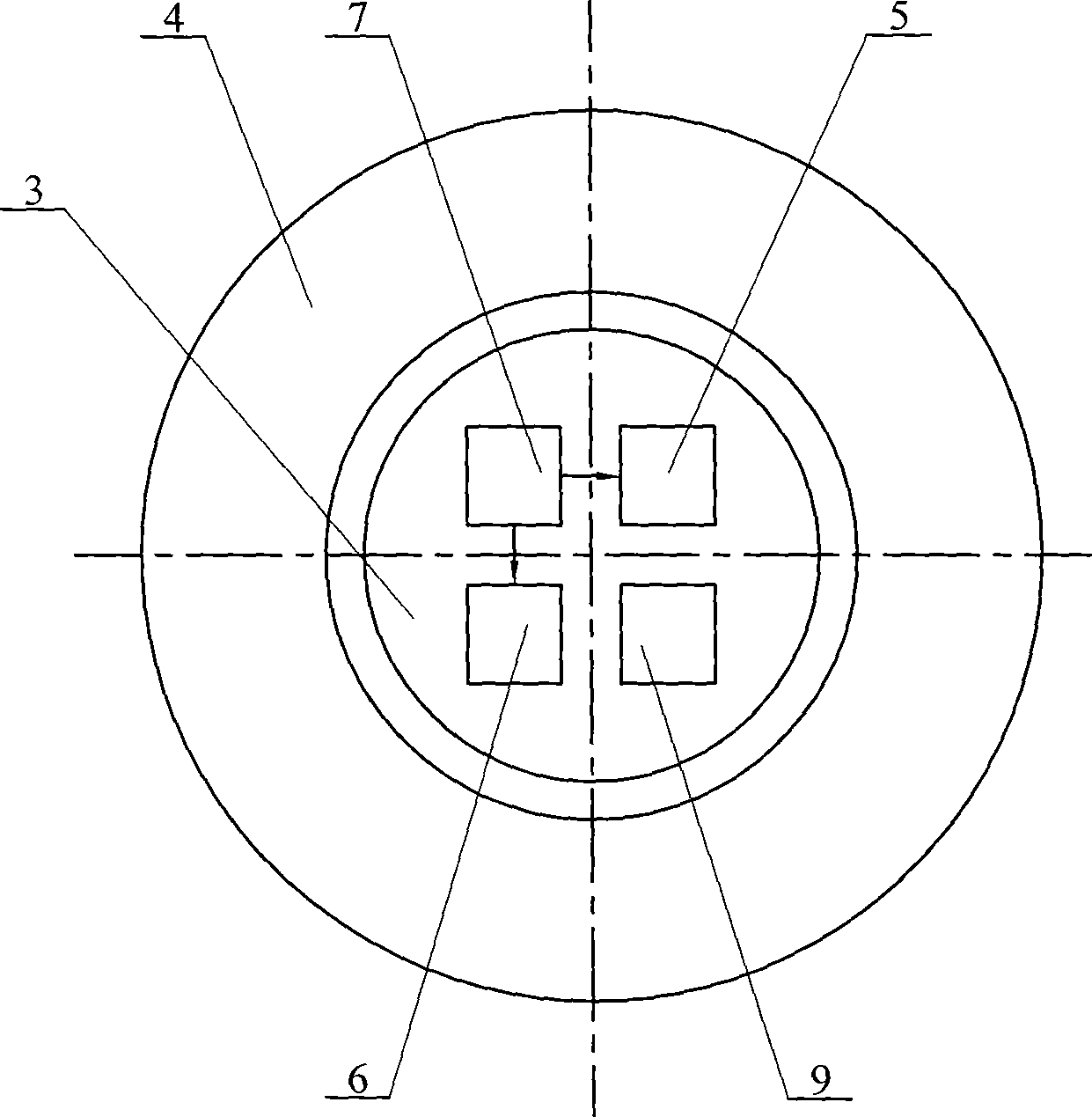

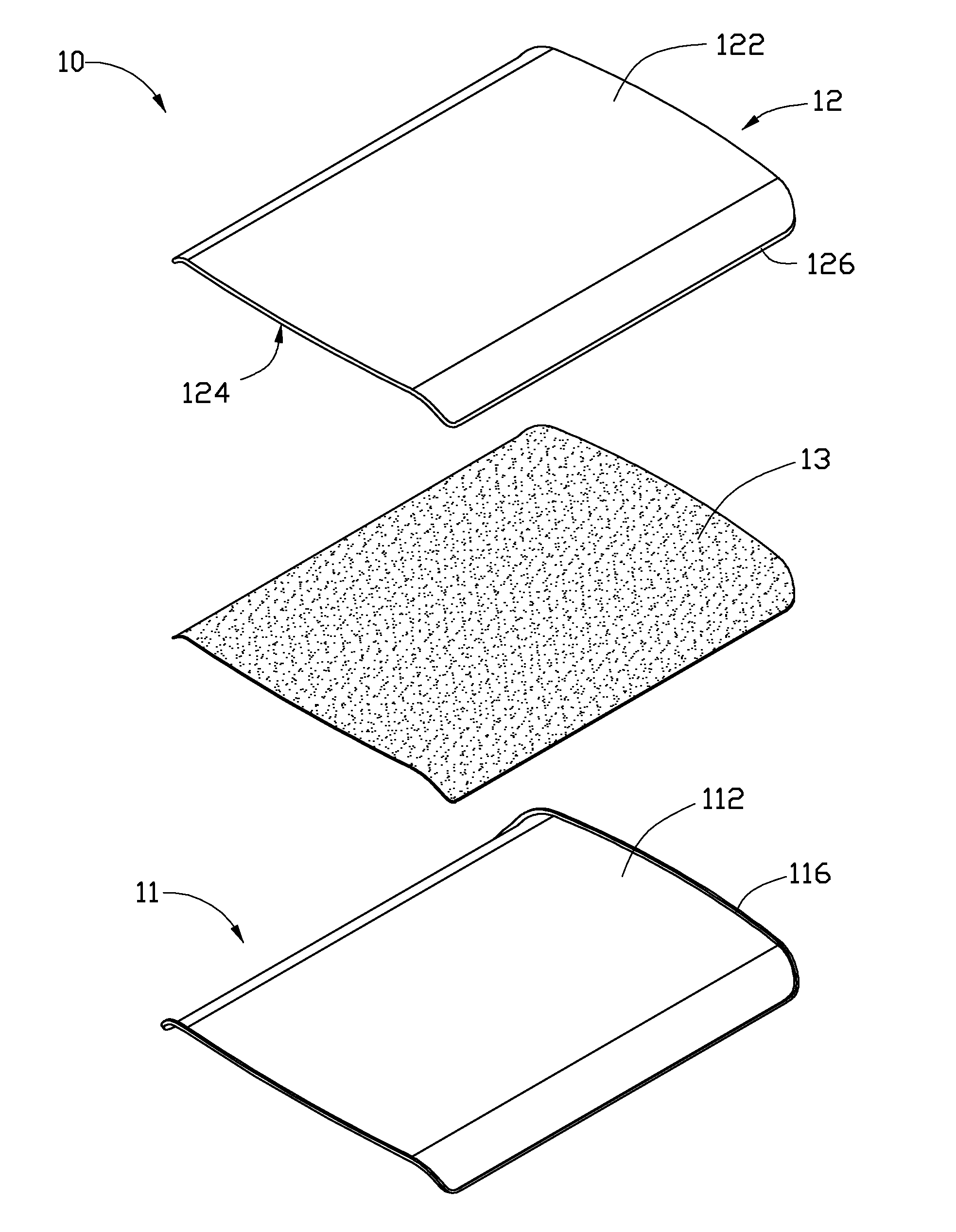

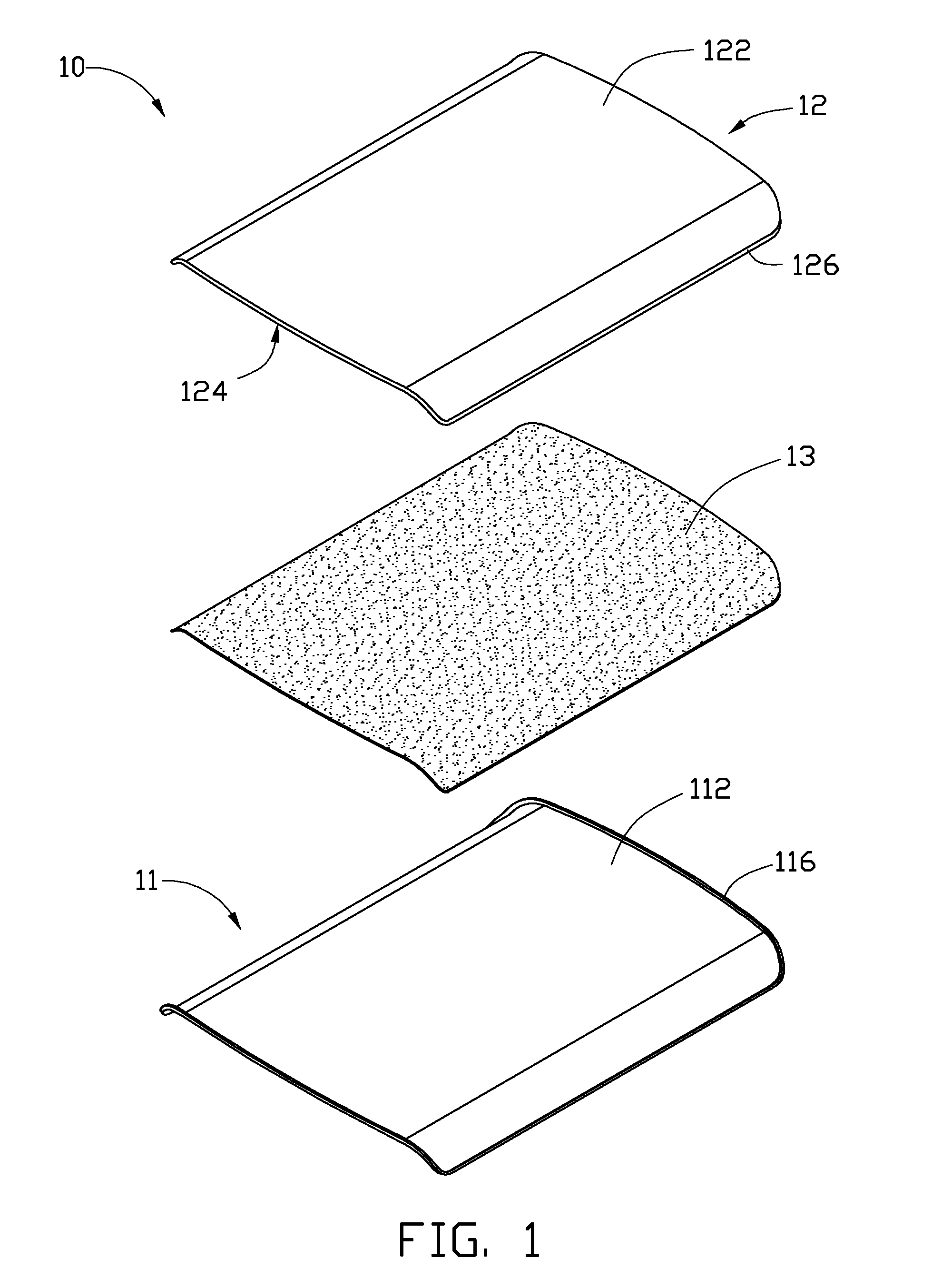

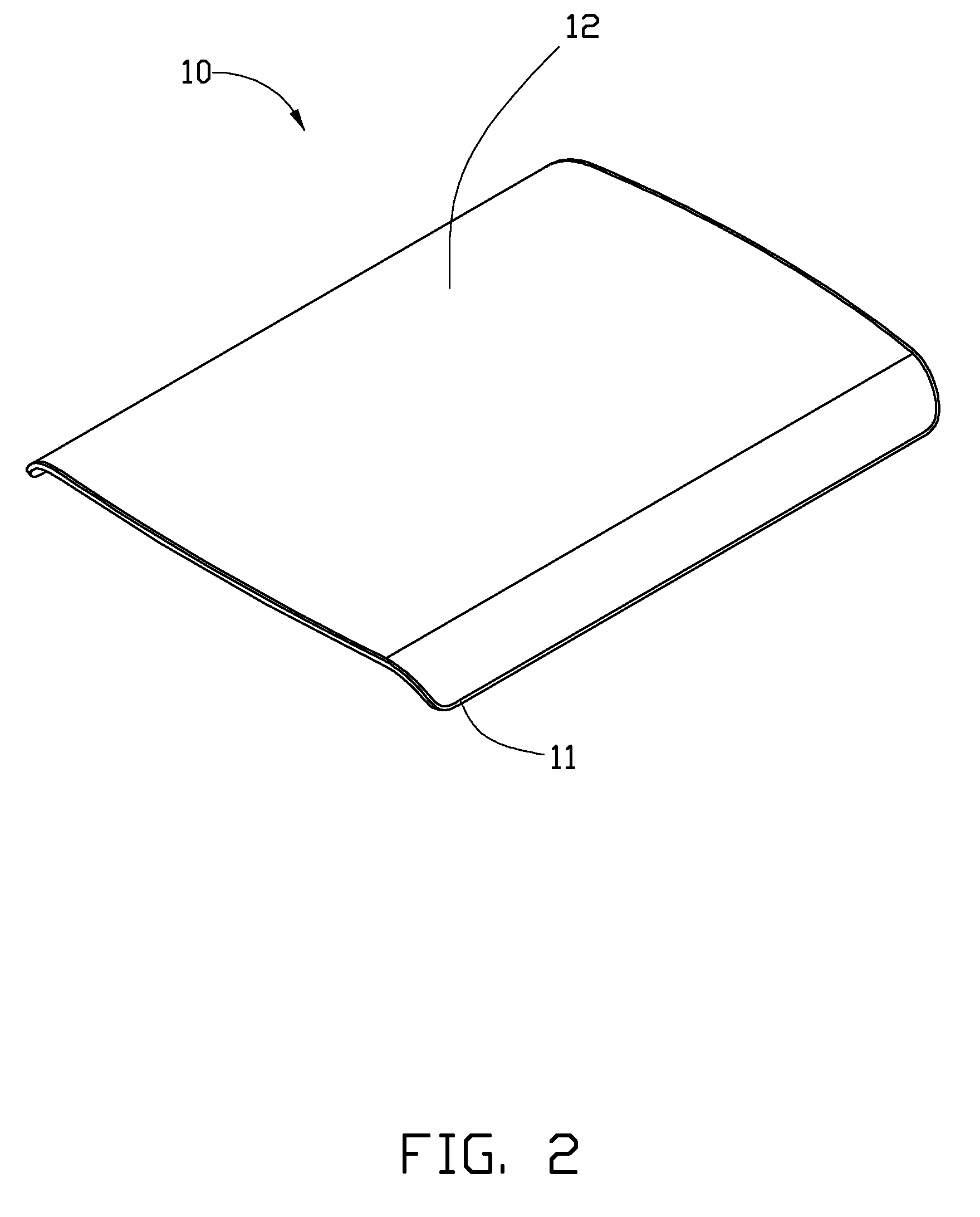

Bionics machine acaleph driven by shape-memory alloy wire

InactiveCN101391650AChange frequencyChange rangePropulsive elements of non-rotary typeSoft layerElastomer

The invention discloses a biomimetic mechanical jellyfish that is driven by shape memory alloy wires, relates to a biomimetic mechanical jellyfish and aims at solving the problems that the existing biomimetic mechanical jellyfishes only simulate jellyfish actions, do not cover devices such as a drive device and the like, and have complex structure and the biomimetic effect that is totally different with the action principle of real jellyfishes. The biomimetic mechanical jellyfish has following structure: an action unit (10) consists of the shape memory alloy wires (12), an elastic body (13), a coating skin (15) and a substrate (16), the substrate (16) and the shape memory alloy wires (12) are fixedly arranged on the elastic body (13), the action unit (10) is coated inside an umbrella-like soft layer (11), the coating skin (15) covers outside the shape memory alloy wires (12), the substrate (16) and a sealing cover (3) are fixedly connected with a supporting body (2), a power source (7), a control device (5), a communication device (6) and a sinking and floating control device (9) are fixedly arranged on the supporting body (2), and the power source (7) provides electricity respectively to the control device (5), the communication device (6) and the shape memory alloy wires (12). The biomimetic mechanical jellyfish has simple structure, lightness, low production cost, large action range and good biomimetic effect.

Owner:HARBIN INST OF TECH

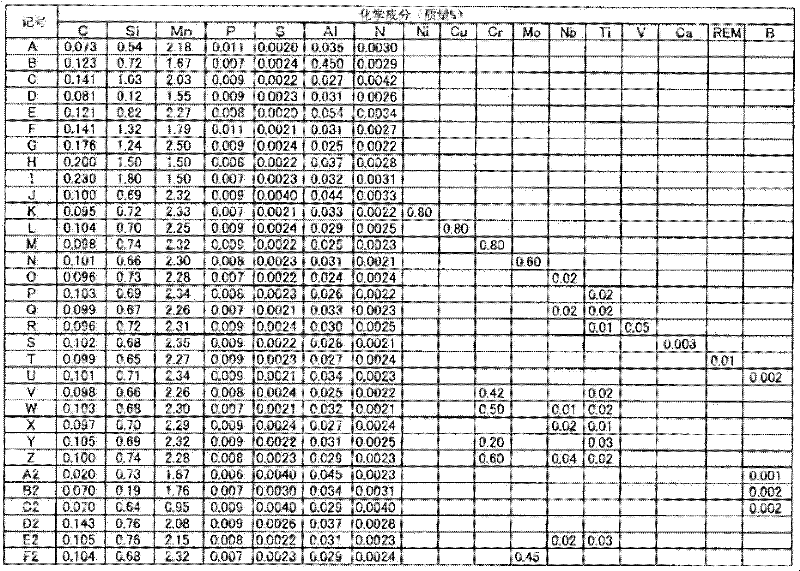

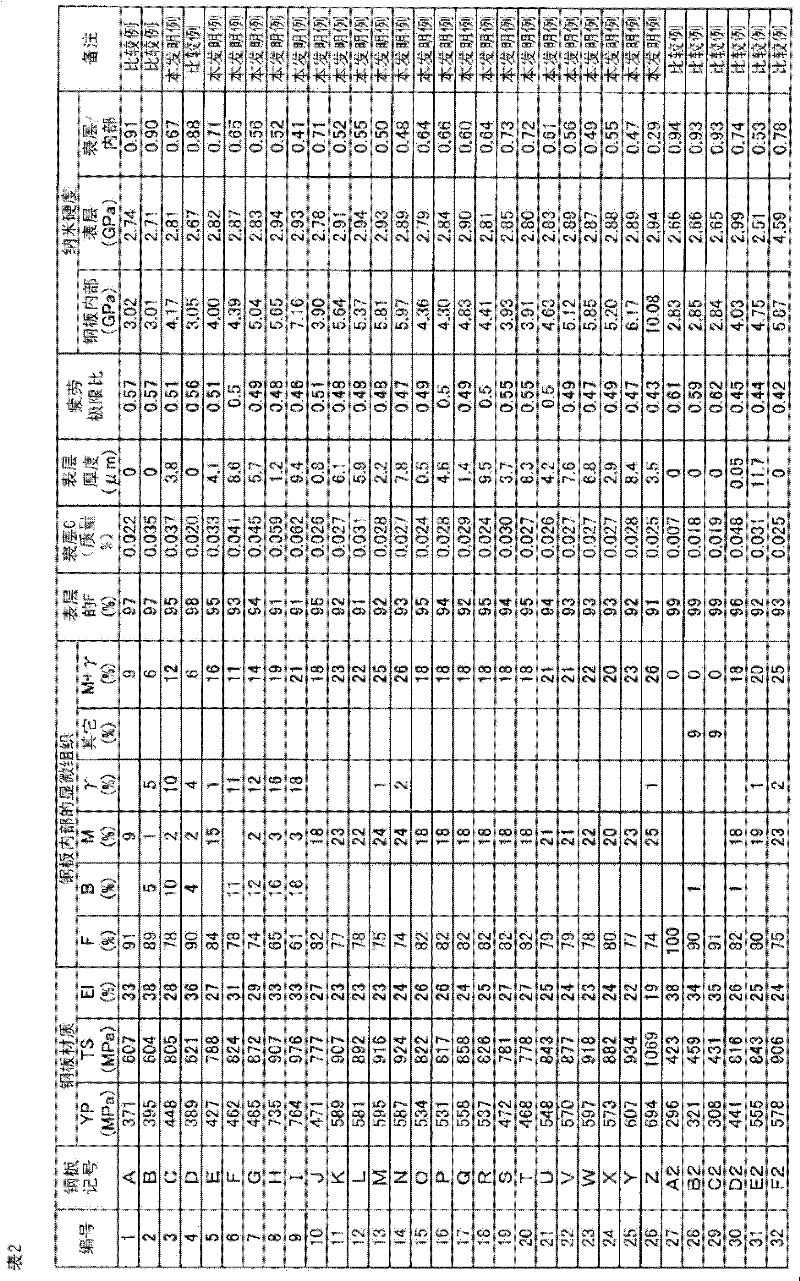

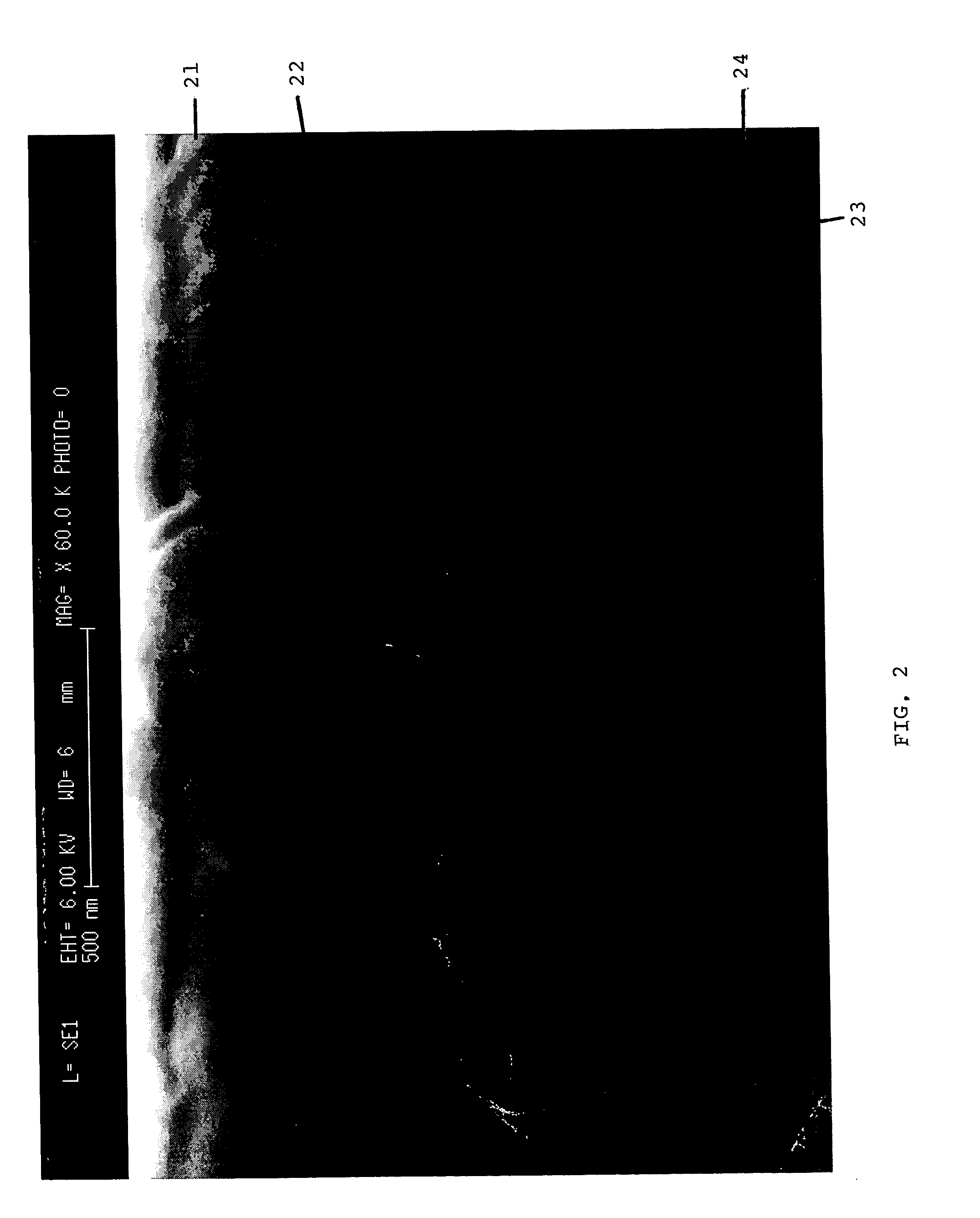

High-strength hot-dip galvanized steel sheet and process for producing same

ActiveCN102482753AImprove fatigue durabilityExcellent resistance to hydrogen embrittlementHot-dipping/immersion processesFurnace typesSoft layerHigh intensity

Disclosed is a hot-dip galvanized steel sheet which comprises a steel sheet part and a deposit formed on the surface of the steel sheet part and has a tensile strength of 770 MPa or higher, wherein the deposit is a zinc layer formed by hot-dip plating or an alloyed zinc layer formed by hot-dip plating, the steel sheet part comprises a soft layer, which is in direct contact with the deposit, and an inner layer, which is the part other than the soft layer, and the thickness (D) of the soft layer is 0.001 to 5% of the thickness (t) of the steel sheet part. In a cross-section along the thickness direction of the steel sheet part, when the hardness of the soft layer measured by a nanoindentation method is expressed by H1 and the representative hardness of the steel sheet part measured by the nanoindentation method is expressed by Ha, then H1 is 5-75% of Ha.

Owner:NIPPON STEEL CORP

Housing for electronic device and method for making the same

InactiveUS20110048755A1Lamination ancillary operationsDecorative surface effectsSoft layerEngineering

A housing for electronic device, comprising: a metal substrate, the substrate having a bonding surface, a peripheral edge, and a ridge protruding from the peripheral edge and surrounding the bonding surface; a soft layer soft to the touch, the soft layer having an edge; and an adhesive layer located between the bonding surface of the substrate and the soft layer, thereby bonding the soft layer to the substrate, the ridge of the substrate blocking the edge of the soft layer. A method for making the present housing is also provided.

Owner:FIH (HONG KONG) LTD

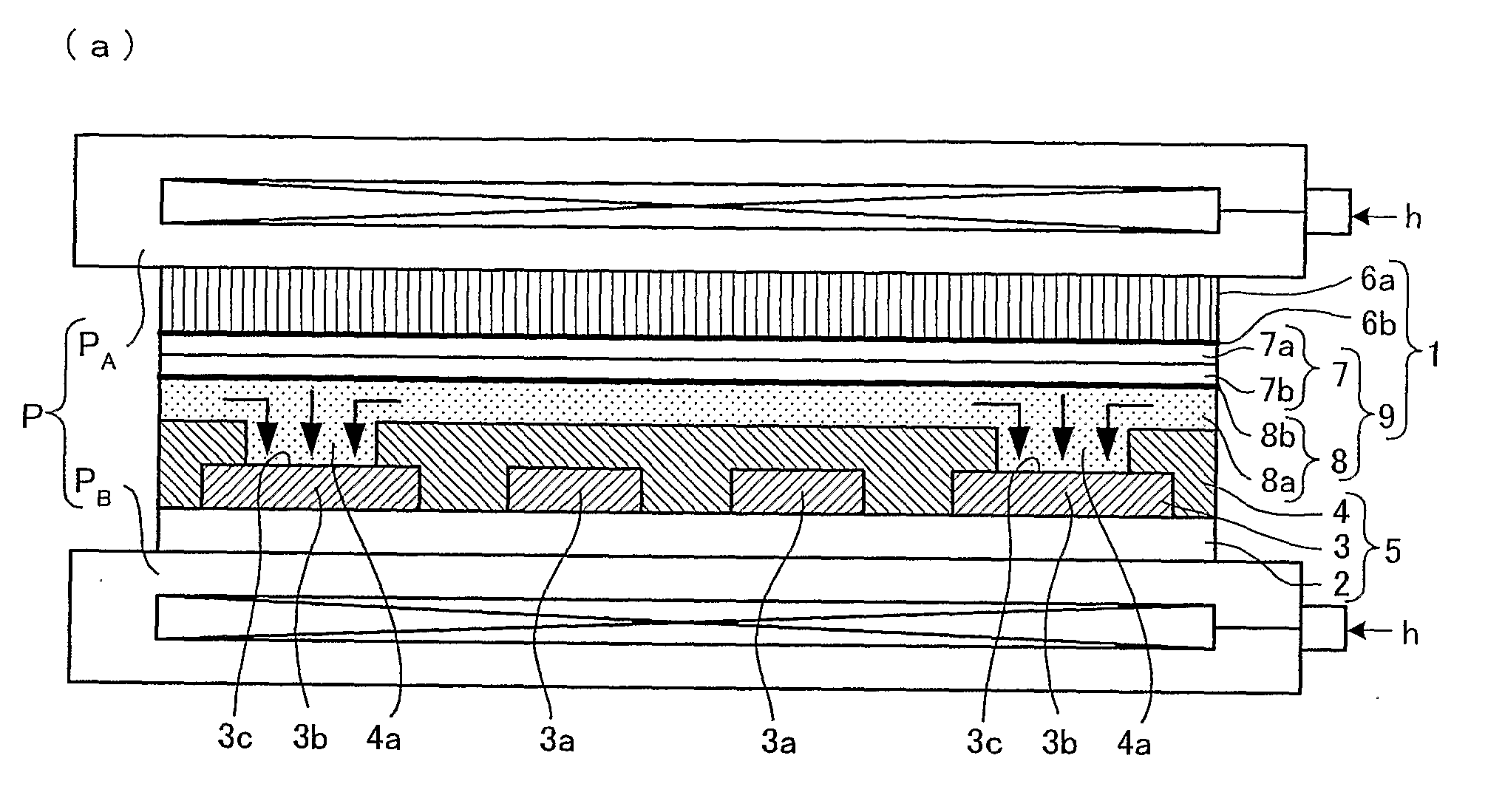

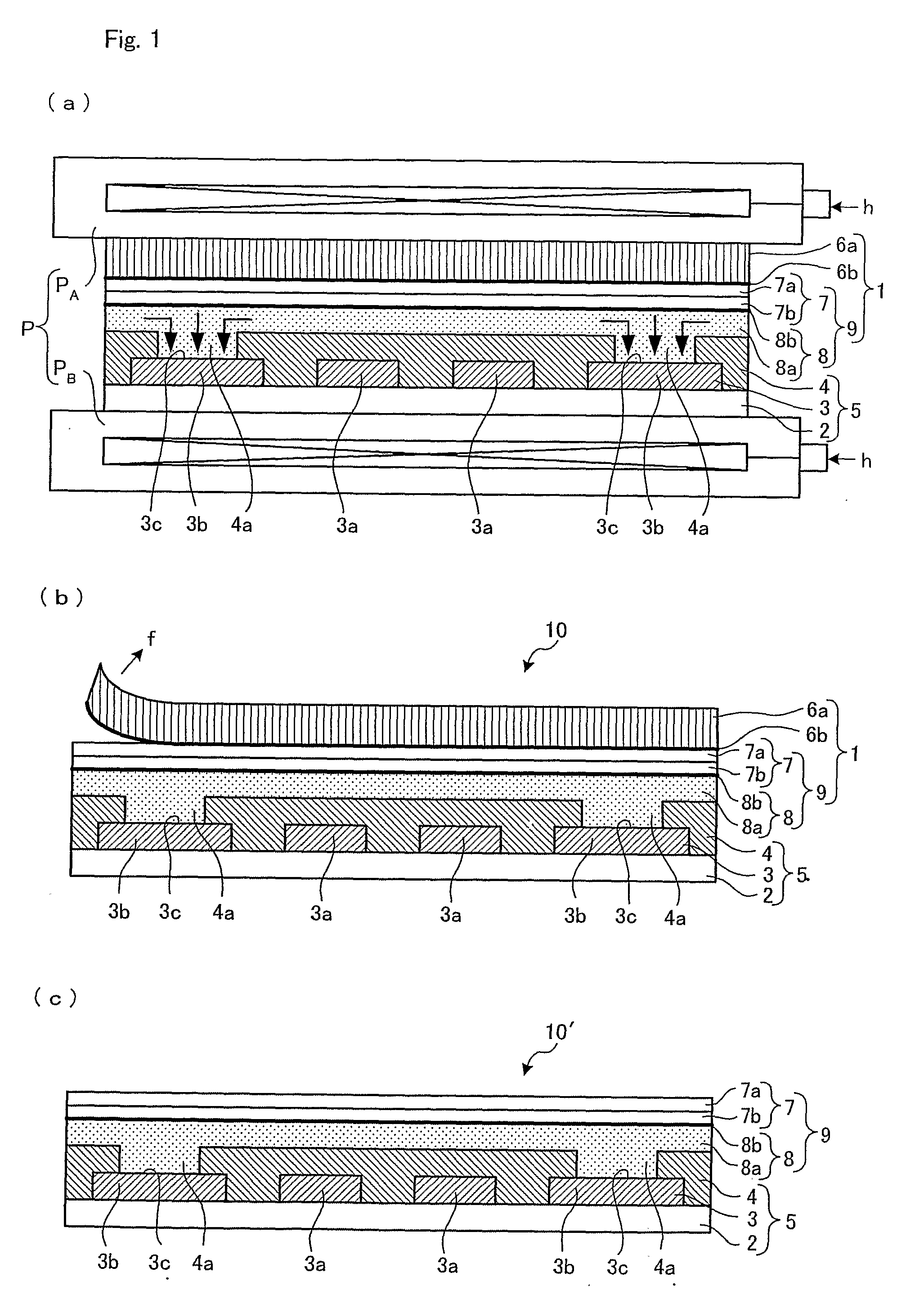

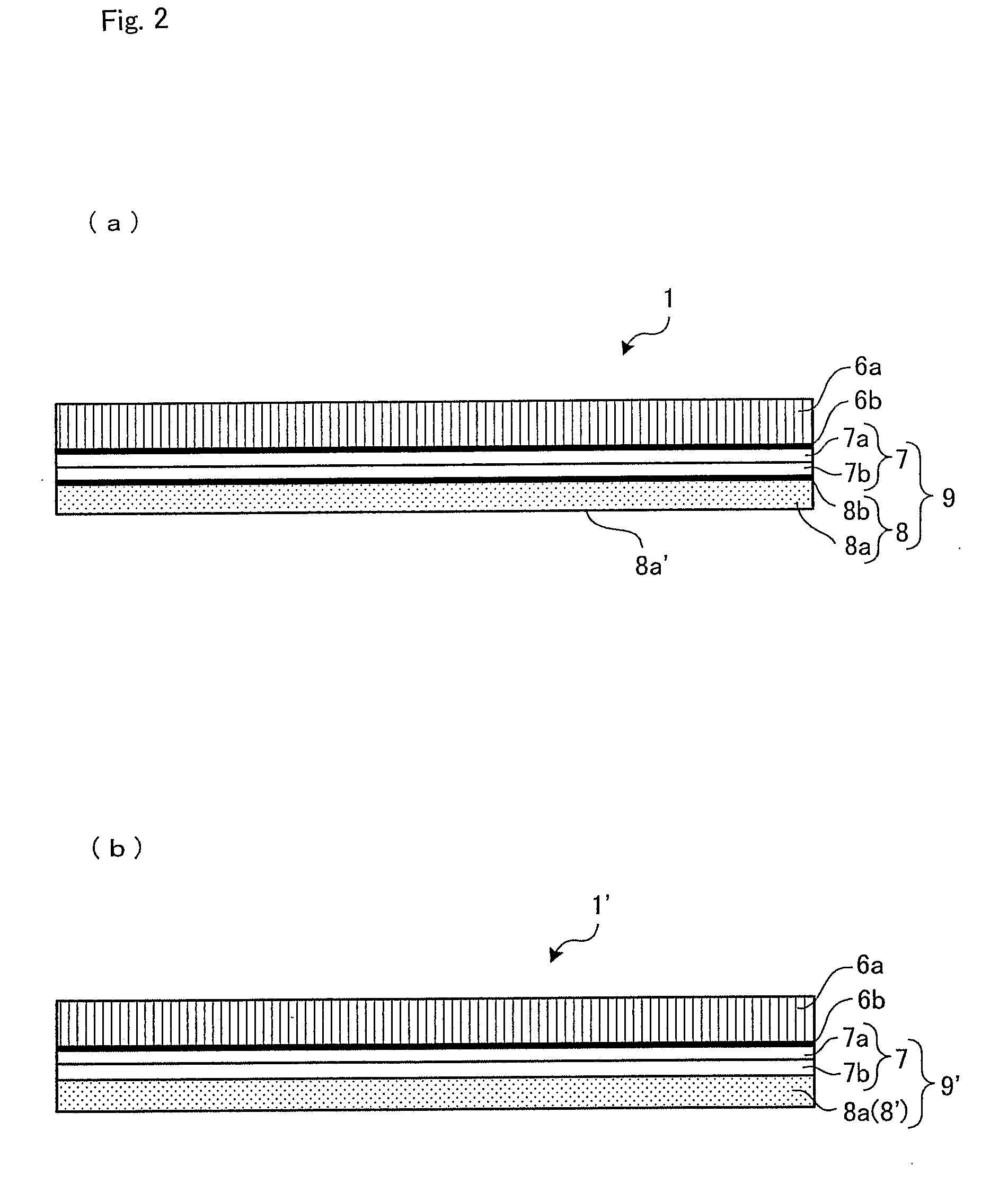

Shielding film, shielded printed circuit board, shielded flexible printed circuit board, method of manufacturing shielding film, and method of manufacturing shielded printed circuit board

ActiveUS20090038839A1Excellent abrasion resistance and blocking resistanceNo crackMagnetic/electric field screeningCross-talk/noise/interference reductionSoft layerEngineering

The invention includes a shielding film, which does not have breakage of a metal layer, and has excellent abrasion resistance and blocking resistance, and does not crack. The cover film 7 is provided on one surface of a separation film 6a, and an adhesive layer 8a is formed on the surface of the cover film 7 opposite to the separation film 6a via the metal layer. The cover film 7 has at least one hard layer 7a and at least one soft layer 7b, and the surface of the cover film 7 facing the separation film 6a is composed of the hard layer 7a.

Owner:NIPPON MEKTRON LTD +1

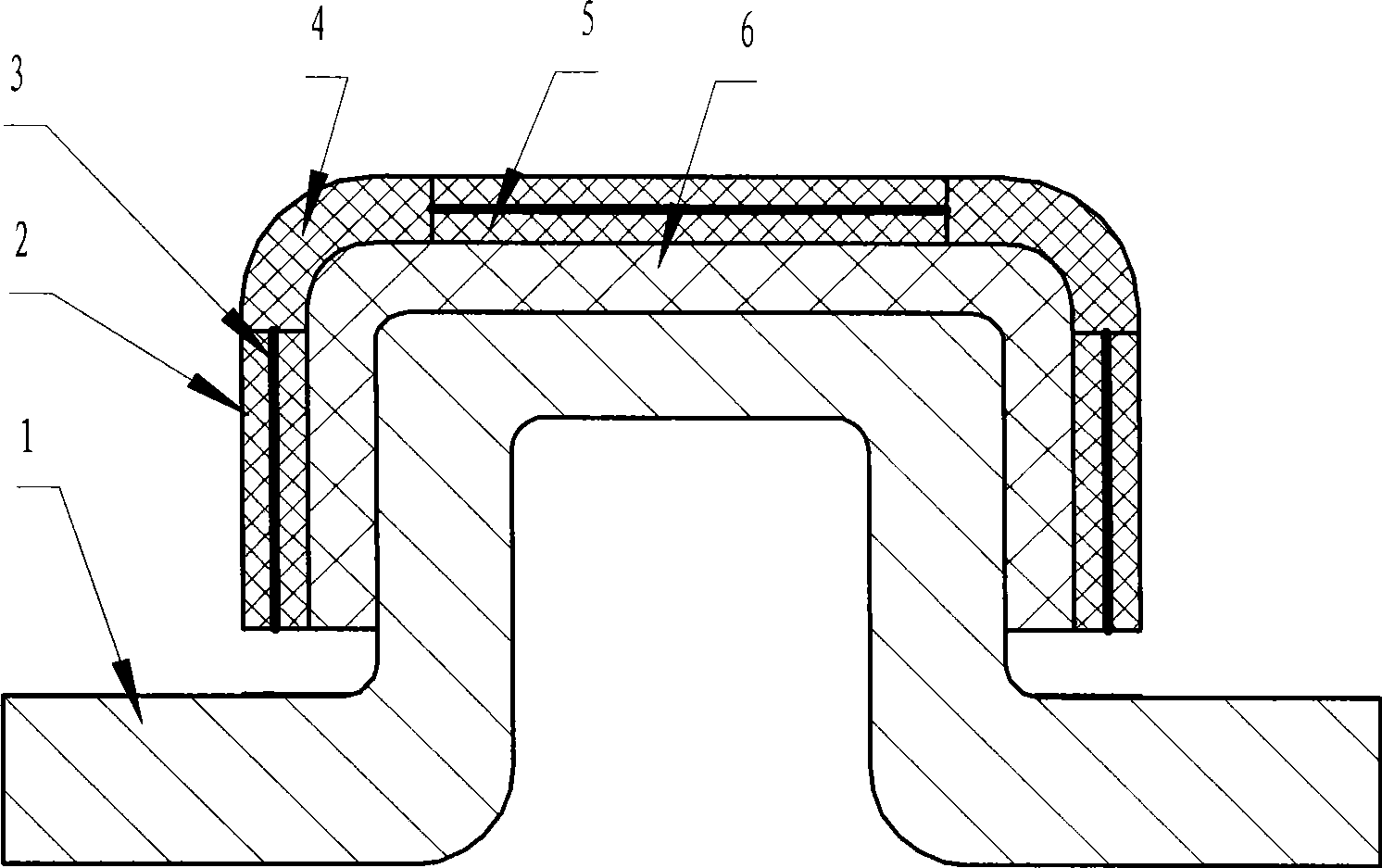

Curing formation method for non-flat plate composite product and shaping mould

The invention discloses a curing forming method and a forming die used for a non-slab composite material part. The method comprises the steps as follows: composite material part blank is arranged on a rigid die body which has the same shape with the processing shape and gluing and layer-paving are carried out according to the required dimension; after the layer-paving is finished, the composite material part blank is arranged on the rigid die body; furthermore, surfaces with plane are provided with elastic soft layers; corner pure rubber layers which are connected with elastic soft layer joint seams are arranged at corner profile so as to form a soft die surface; subsequently, vacuum bag auxiliary material is arranged on the soft die surface so as to prepare the vacuum bag curing forming composite material part. By the flexible soft die consisting of rubber-fabrics, the method arranges the composite material part blank on the surface of the soft die after the layer-paving is finished; the method for preparing the vacuum bag curing forming part solves the surface quality problems in the prior art that the non-die surface of the bag-pressing forming composite material part is crapy, accidented and has no gloss and the like, and improves the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

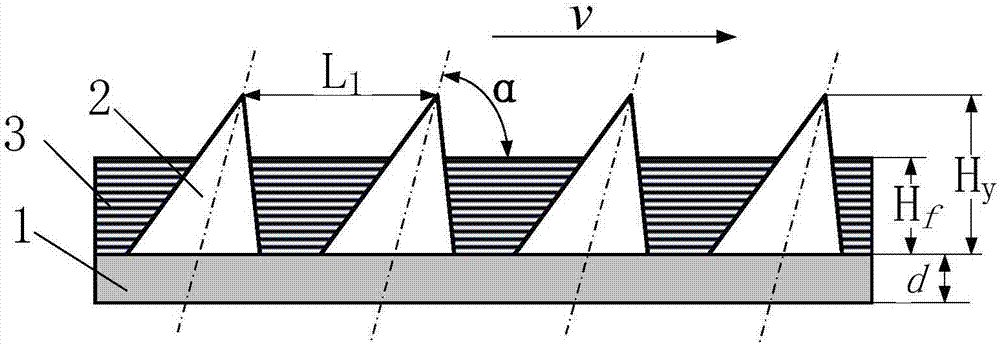

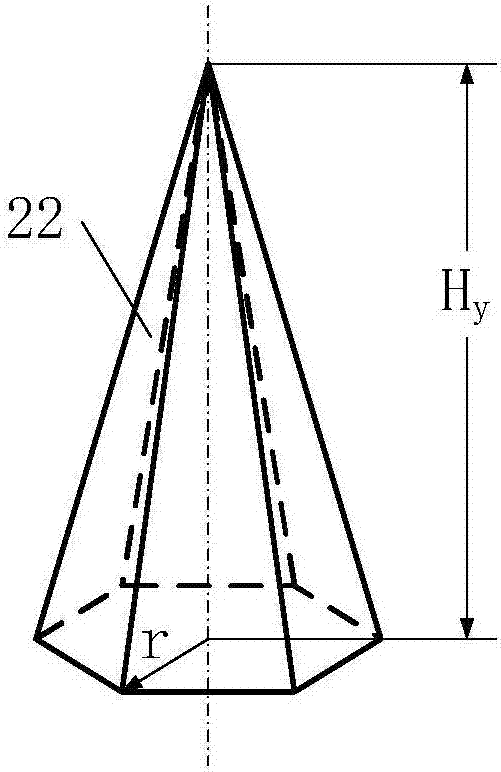

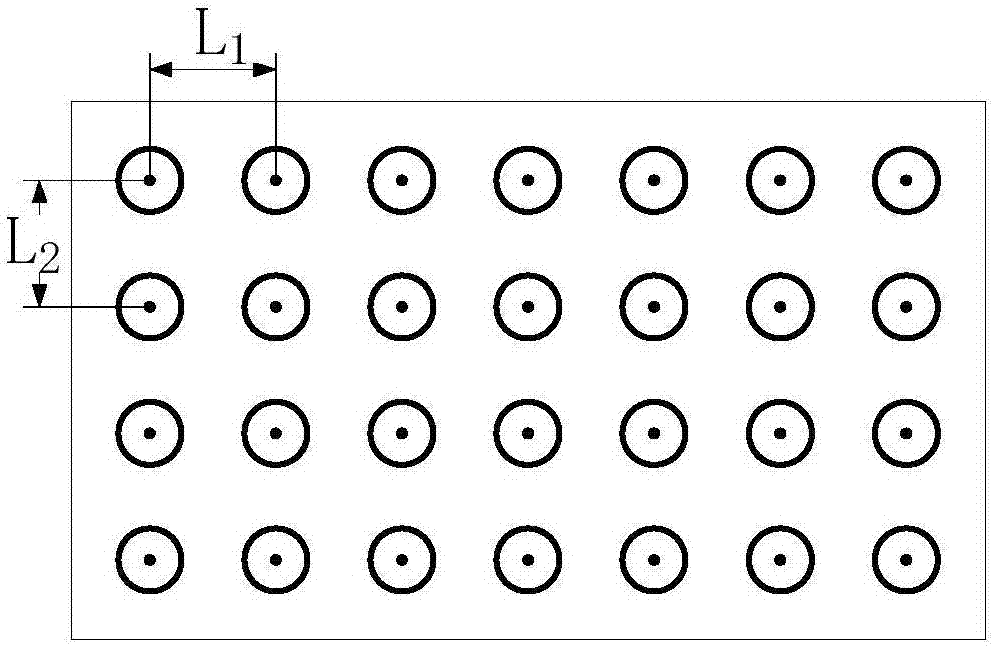

Underwater drag-reduction surface simulating scarfskin morphology of puffer and preparation method

InactiveCN106945782AImprove structural performanceVersatile and reliable manufacturing processesWatercraft hull designFluid dynamicsBasementSoft layer

The invention discloses an underwater drag-reduction surface simulating scarfskin morphology of a puffer and a preparation method. The underwater drag-reduction surface simulating the scarfskin morphology of the puffer comprises a basement, hard drag reduction elements, and soft cover layers, wherein a plurality of hard drag reduction elements are distributed on the basement, the soft cover layers are filled among the hard drag reduction elements, and the hard drag reduction elements are tightly attached to the joint surface of the basement and the hard drag reduction elements. By adoption of the tapered or columnar hard drag reduction elements, the underwater drag-reduction surface simulating the scarfskin morphology of the puffer is different from the existing rib-shaped groove structure; and the soft layers are covered on the basement and form the rigid-flexible drag reduction surface which can form adaptive variations with differences of water velocity on the surface and fit with the scarfskin properties of the puffer better.

Owner:JIANGSU UNIV OF SCI & TECH

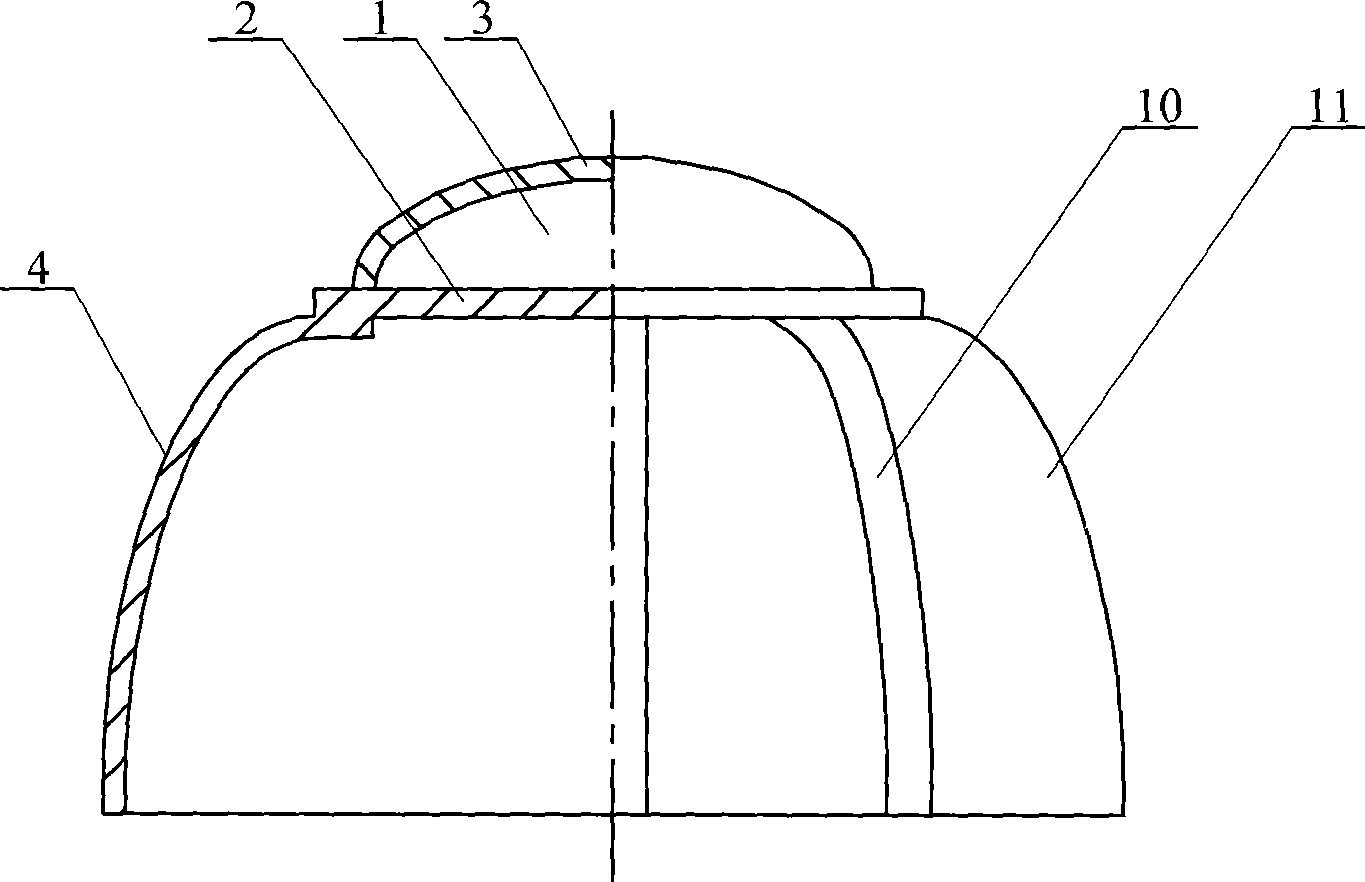

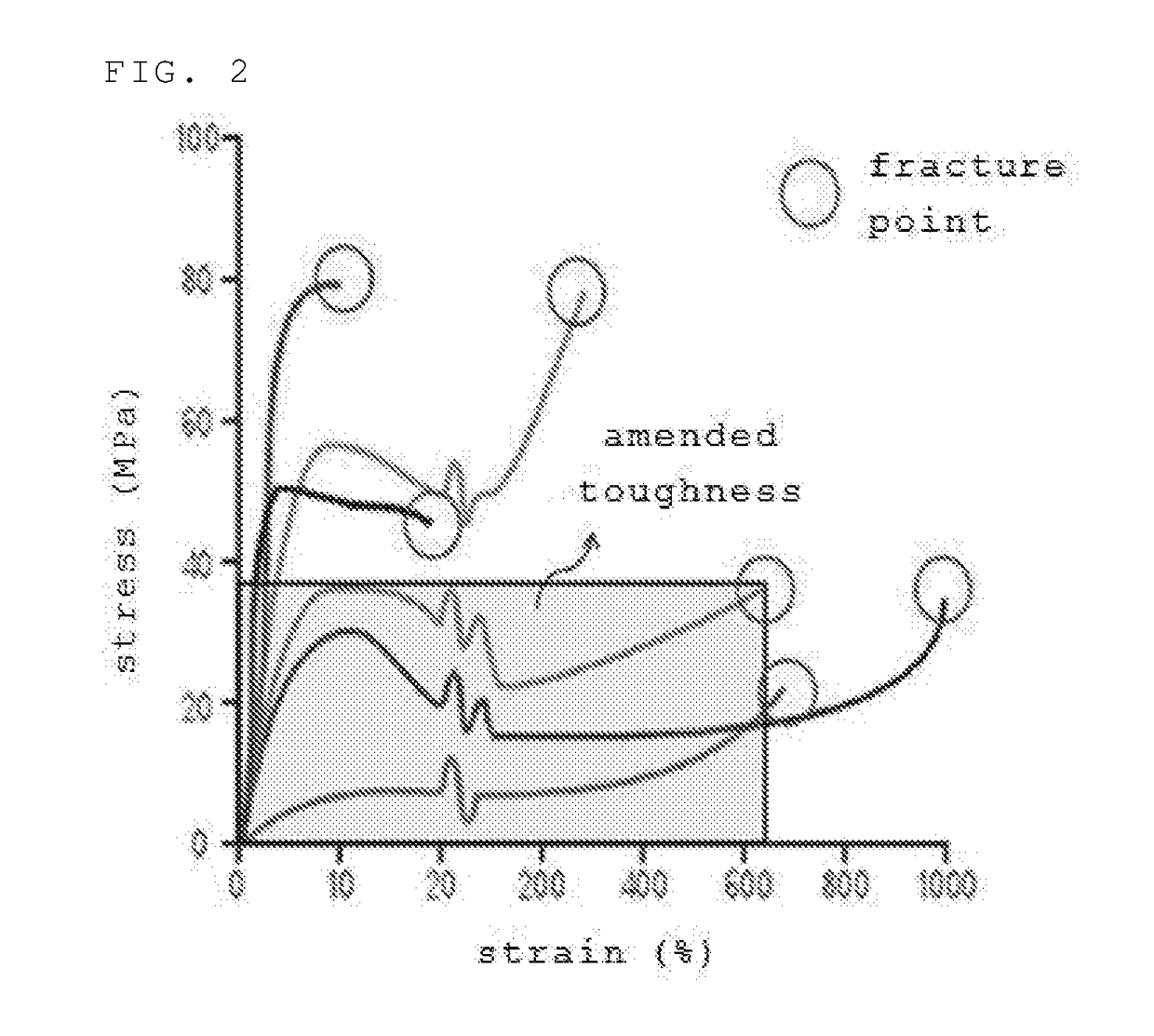

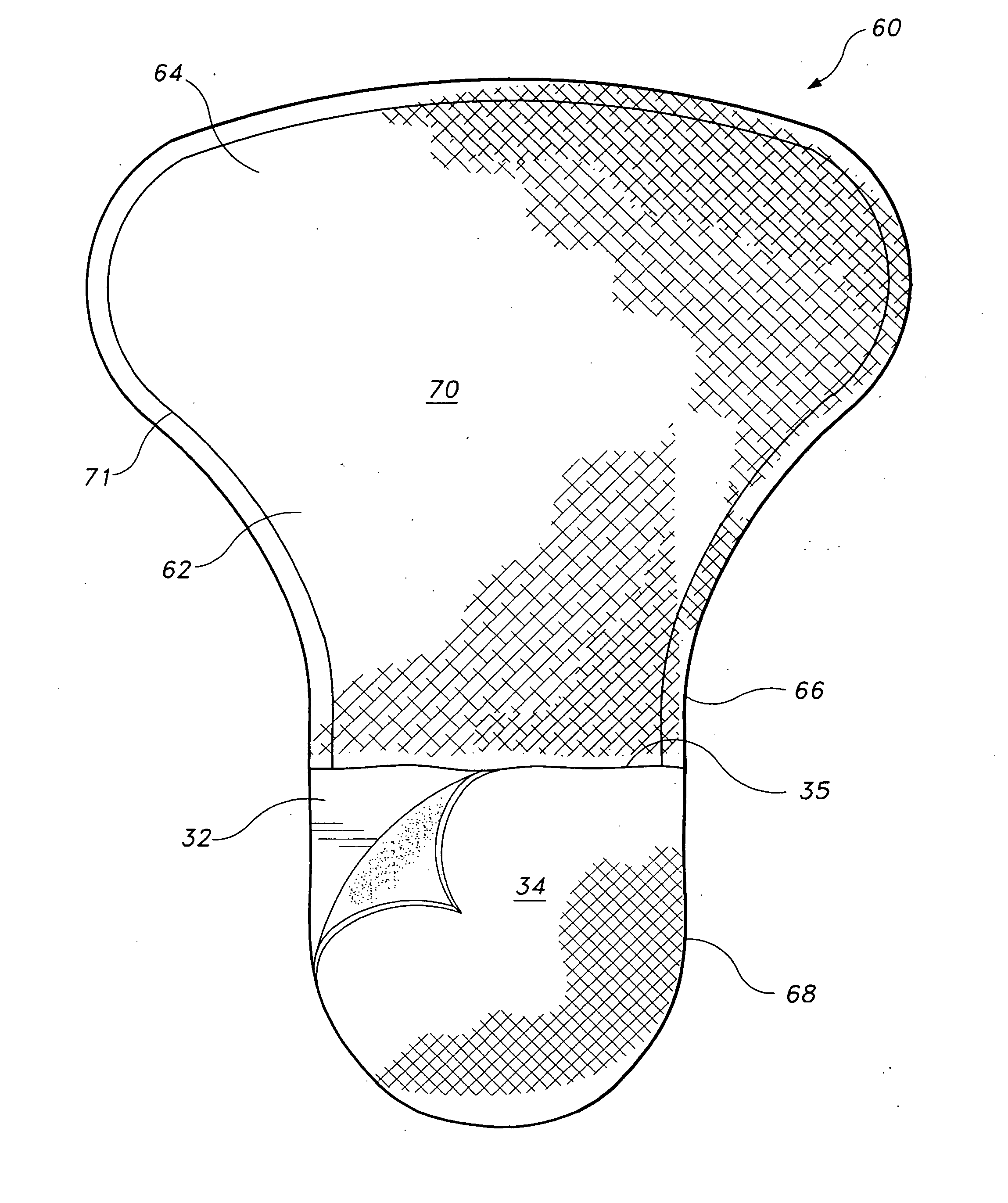

Hydrogel-based prosthetic device for replacing at least a part of the nucleus of a spinal disc

InactiveUS20050171611A1Limited to componentMaximal flattening during dehydrationCeramic shaping apparatusSpinal implantsSoft layerMedicine

The present invention is a prosthetic for replacement of at least a part of the nucleus of a intravertebral disc. The prosthetic device is composed of at least two essentially parallel soft layers of an elastically deformable hydrogel and at least one rigid layer, the rigid layer having less compressibility than the soft layers, being adjacent to the soft layers, parallel to them, and firmly attached to them. In some embodiments, the soft layers have the same thickness and composition. Typically, the prosthesis has more than one rigid layer and these rigid layers have the same thickness and composition. The number of soft layers is usually one more than the number of rigid layers, with, e.g., at least three soft layers. The invention also includes a method of prosthesis production, which involves prefabricating soft and rigid layers; stacking at least two prefabricated soft and at least one prefabricated rigid layer in a parallel fashion into their final form, and, permitting the layers to firmly connect to one another by mutual interaction. In this method, at least one type of the layers is prefabricated in the dehydrated state, which is done by dehydrating stretched foil in an apparatus preventing its contraction and thereby decreasing its area. There is at least partial dehydration of the prosthesis under pressure applied in a direction tangent to the planes of the layers. In preferred embodiments, while in the state of almost full dehydration, is sterilized using ionizing radiation or a gaseous chemical agent, after which it is partially rehydrated within the sterile wrapper using water vapor.

Owner:REPLICATION MEDICAL

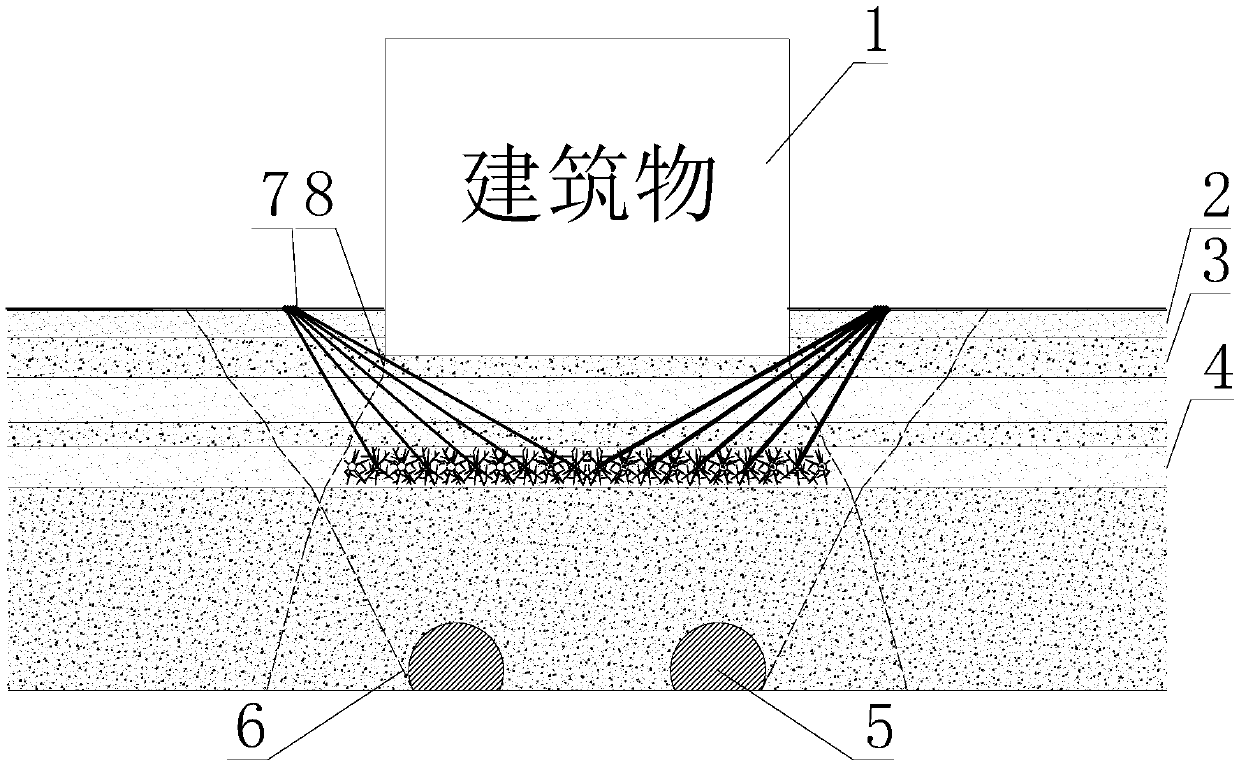

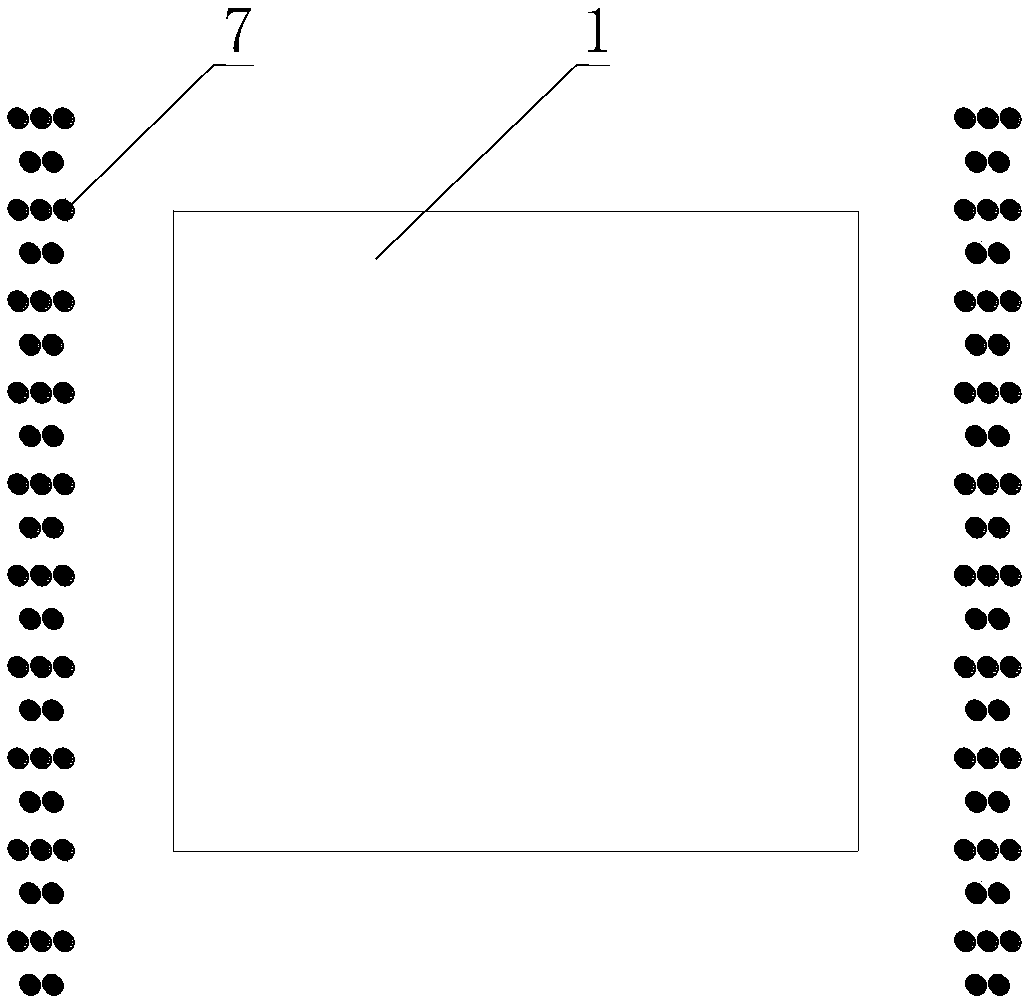

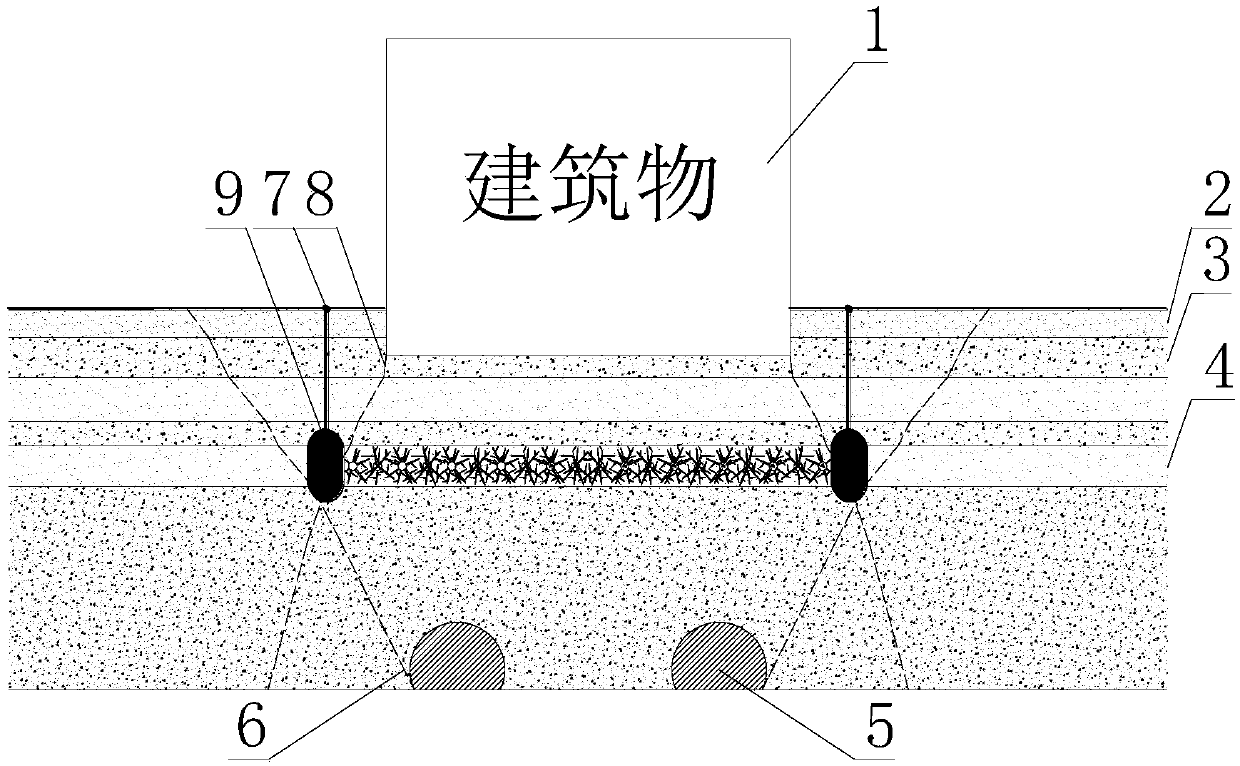

Soft rock strata grouting elevating method compensating for building settlement caused by subway tunnel under crossing

The invention discloses a soft rock strata grouting elevating method compensating for building settlement caused by subway tunnel under crossing, and aims at the treating the earth surface building settlement disease caused by subway tunnel construction. The method comprises the steps that firstly, elevating grouting soft layer selection is conducted; secondly, soft layer pre-strengthening is conducted; thirdly, soft layer escape stop curtain construction is conducted; and fourthly, soft layer grouting elevating is conducted, and it is ensured that the building settlement value and the settlement difference do not exceed the allowed value. Through the technology that ring-direction grouting is conducted on the periphery of a soft layer to construct a stratum escape stop curtain, damage tothe native foundation due to the grouting elevating construction is avoided, and the requirement for elevating grouting equipment is effectively lowered; and the grouted soft layer is prevented from sliding and escaping towards the periphery under the load action of an overlying strata and the earth surface building, and the construction technology compensating for subway tunnel under crossing building settlement based on soft layer grouting elevating is developed.

Owner:HUNAN UNIV

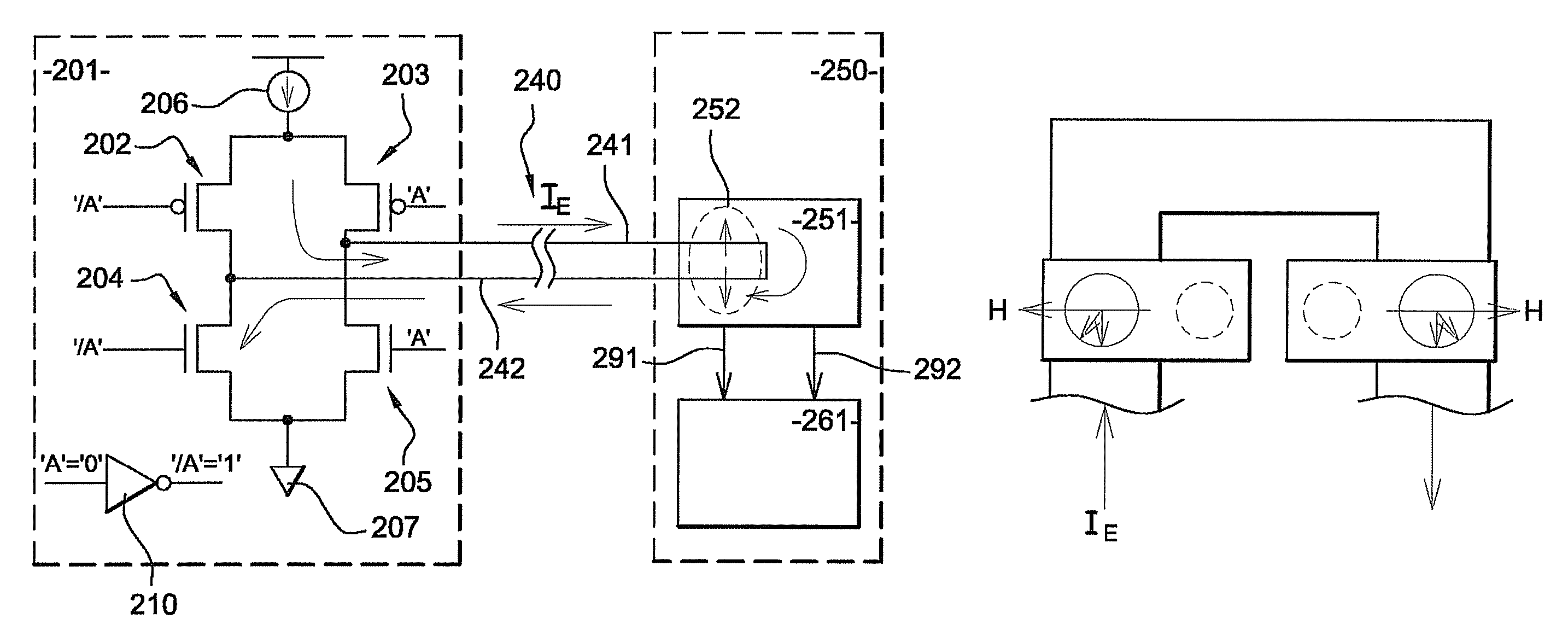

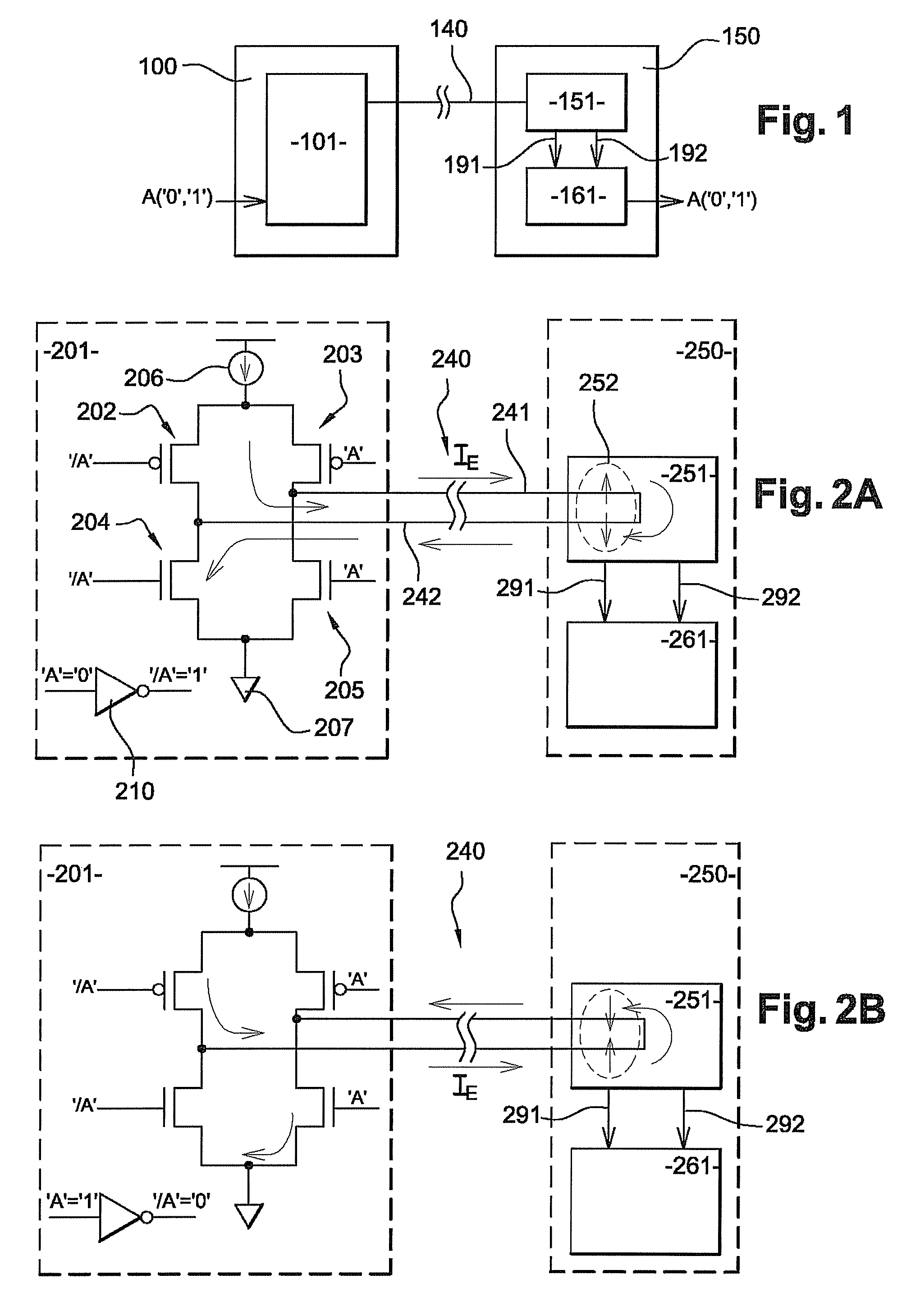

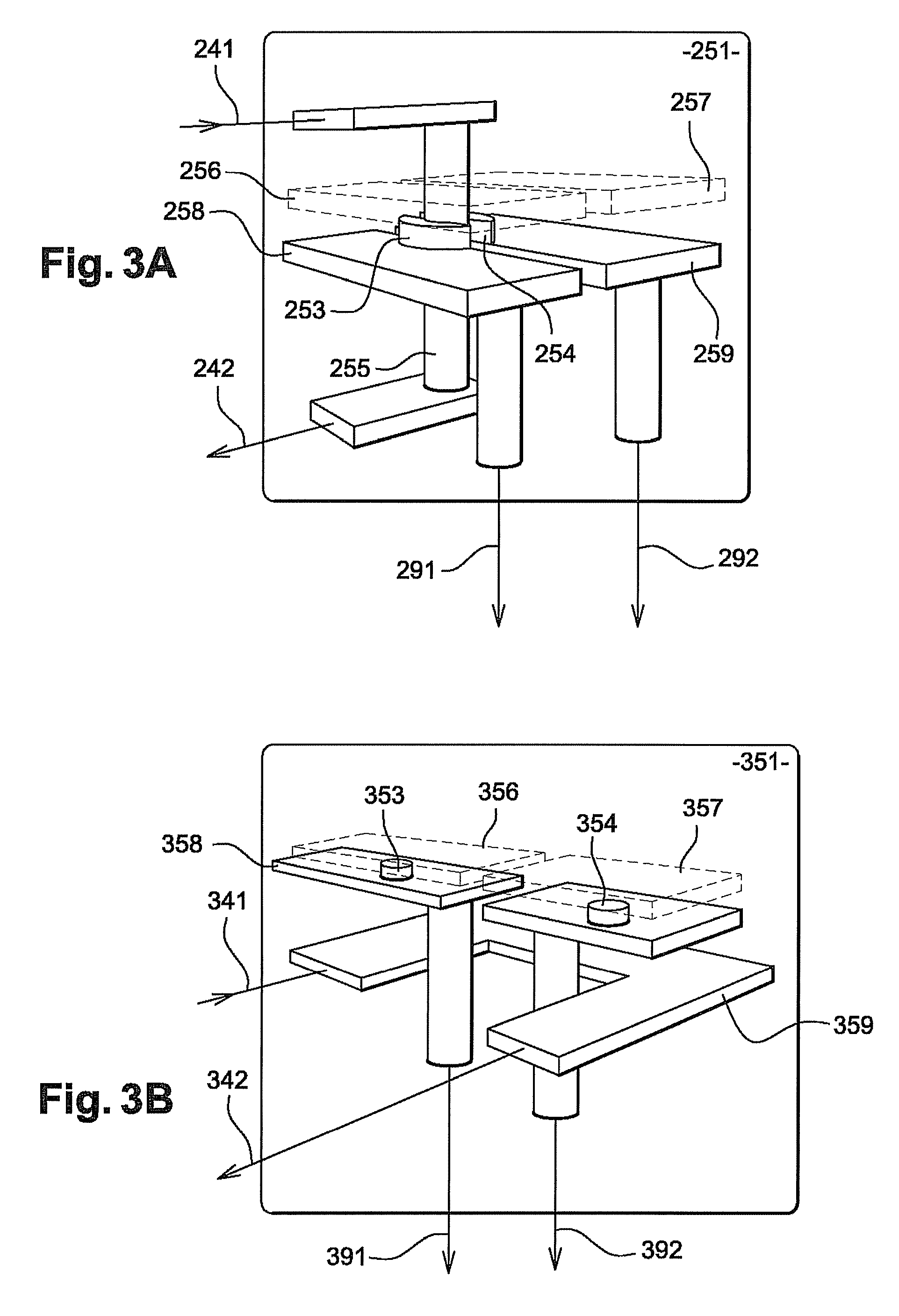

Electronic device for the transport of numerical information

InactiveUS7944231B2Maximise variationReduce areaReliability increasing modificationsSolid-state devicesElectricityElectrical resistance and conductance

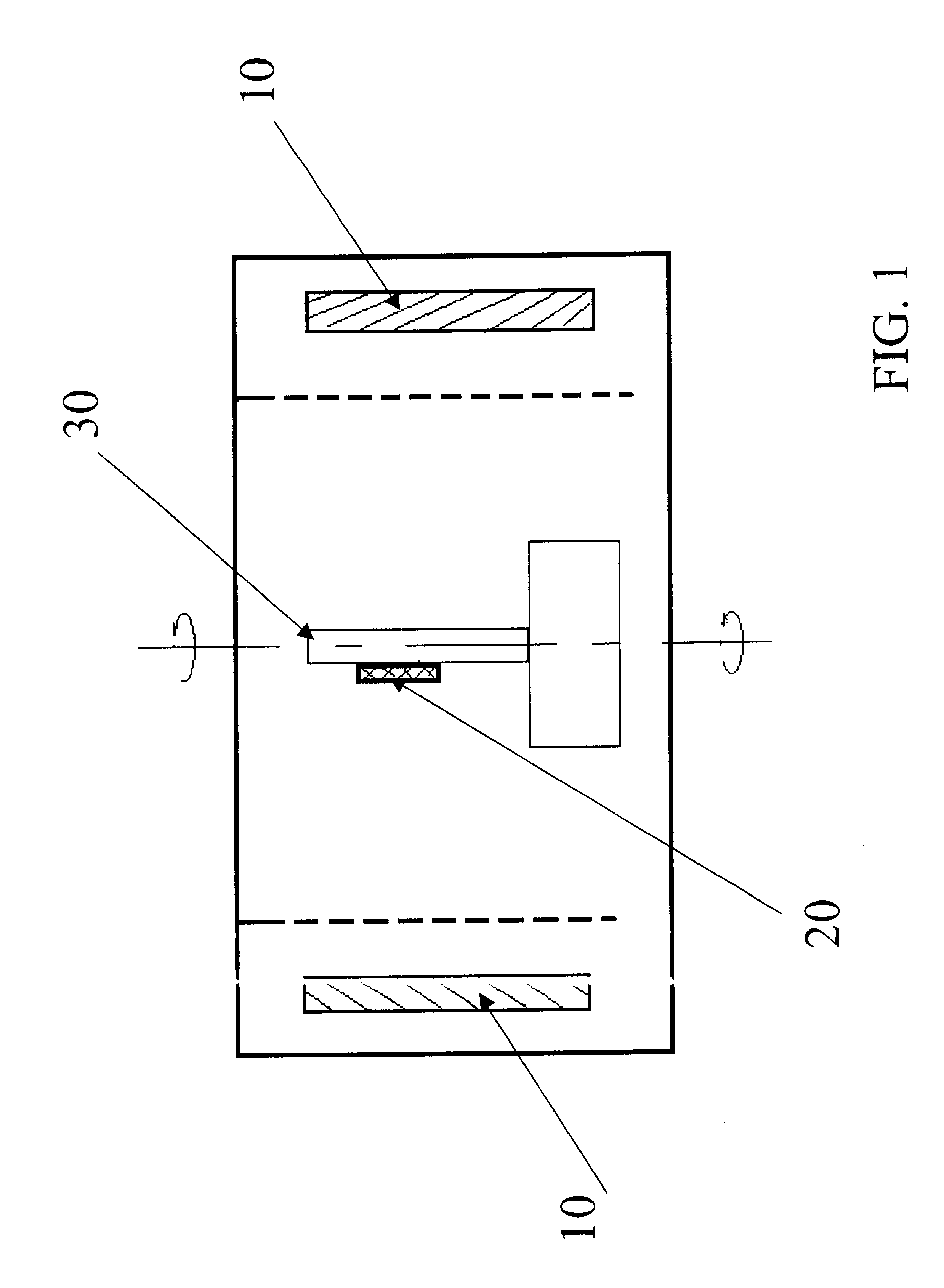

An electronic device designed to transport digital information (“0”, “1”) over long distances, including a transmitter generating current pulses and at least one assembly of receivers converting the received current pulses into logic pulses which are compatible with the operation of standard electronic logic circuits. Each receiver includes a pair of magnetoresistive stacks containing at least one hard ferromagnetic layer and one soft ferromagnetic layer separated by a non-ferromagnetic interlayer, the hard layer of each of the magnetoresistive stacks being pinned in a magnetic orientation perpendicular to an easy-magnetization axis which is used as a reference for the soft layer of the same stack. The soft layer of each magnetoresistive stack has a magnetic orientation which can be modulated by the magnetic field generated by current pulses delivered by the transmitter so as to cause modification of the transverse resistance of the stack sufficient to trigger an electrical signal.

Owner:CENT NAT DE LA RECH SCI 15

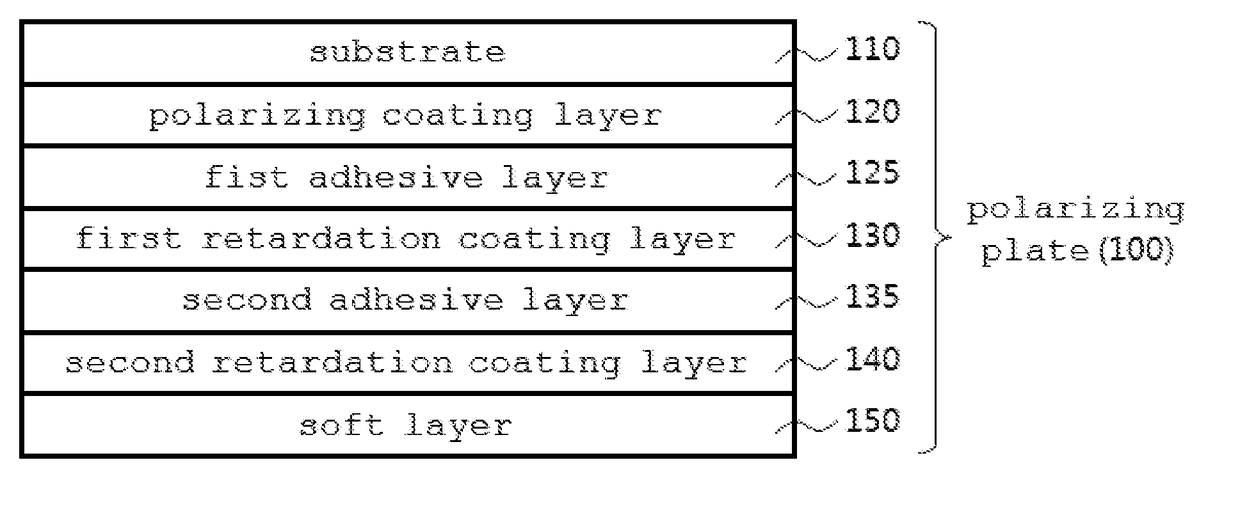

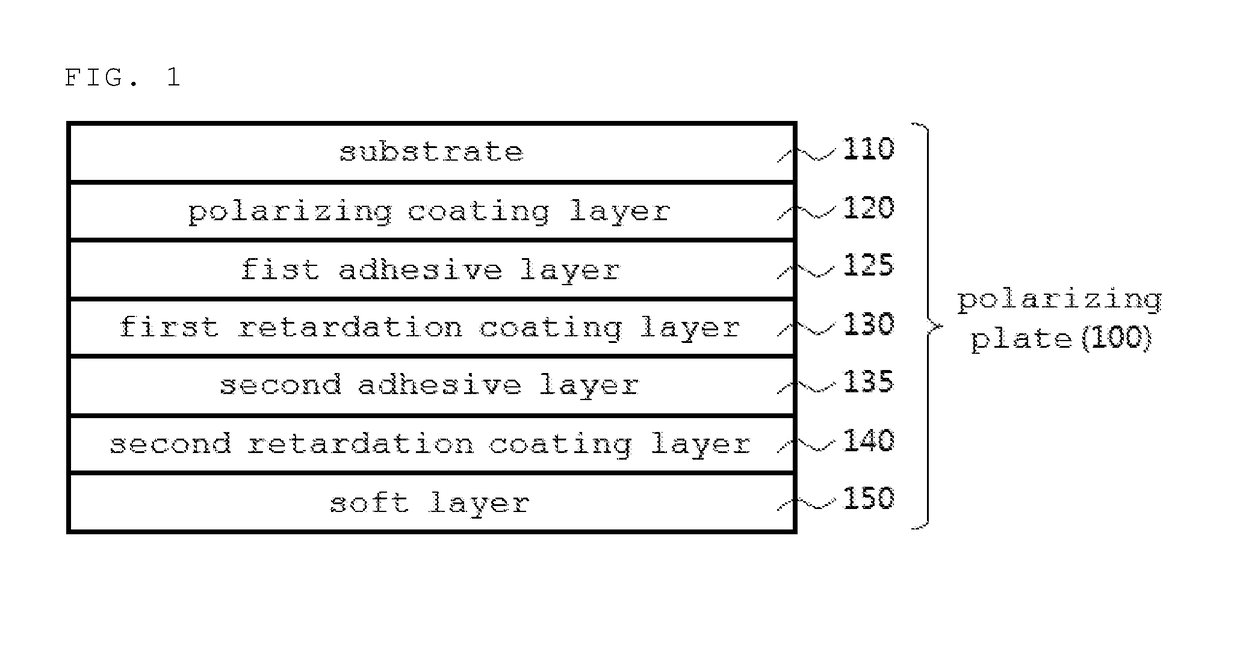

Polarizing plate and image display device comprising the same

ActiveUS20180059300A1Improve bending resistanceEasy to useLayered productsOptical articlesSoft layerDisplay device

The present invention provides a polarizing plate comprising a substrate, a polarizing coating layer formed on one side of the substrate, a first adhesive layer formed on the polarizing coating layer, a first retardation coating layer formed on the first adhesive layer, a second adhesive layer formed on the first retardation coating layer, a second retardation coating layer formed on the second adhesive layer, and a soft layer formed on the second retardation coating layer, wherein, the soft layer has an amended toughness of 1,000 to 40,000 MPa·%. The polarizing plate according to the present invention has excellent bending resistance and thus can be effectively used for a flexible display.

Owner:DONGWOO FINE CHEM CO LTD

Disposable incontinence napkin for men

The disposable incontinence napkin for men is an elongated sanitary napkin having a liquid permeable top layer that faces the pubic area in use, a liquid impermeable bottom layer that faces the undergarment in use, and an absorbent middle layer disposed between the top and bottom layers for absorbing urine. The sanitary napkin has an anterior portion that overlies the base of the penis and upper pubic area, a posterior portion that overlies the scrotum, and a medial portion extending between the anterior and posterior portions. A posterior shield of liquid impermeable material covers the posterior portion of the top layer, and a soft layer of cotton is disposed over the posterior shield. Adhesive strips disposed on the bottom layer adhere the sanitary napkin to the undergarment and prevent bunching of the napkin.

Owner:ALLETABEE GEORGE

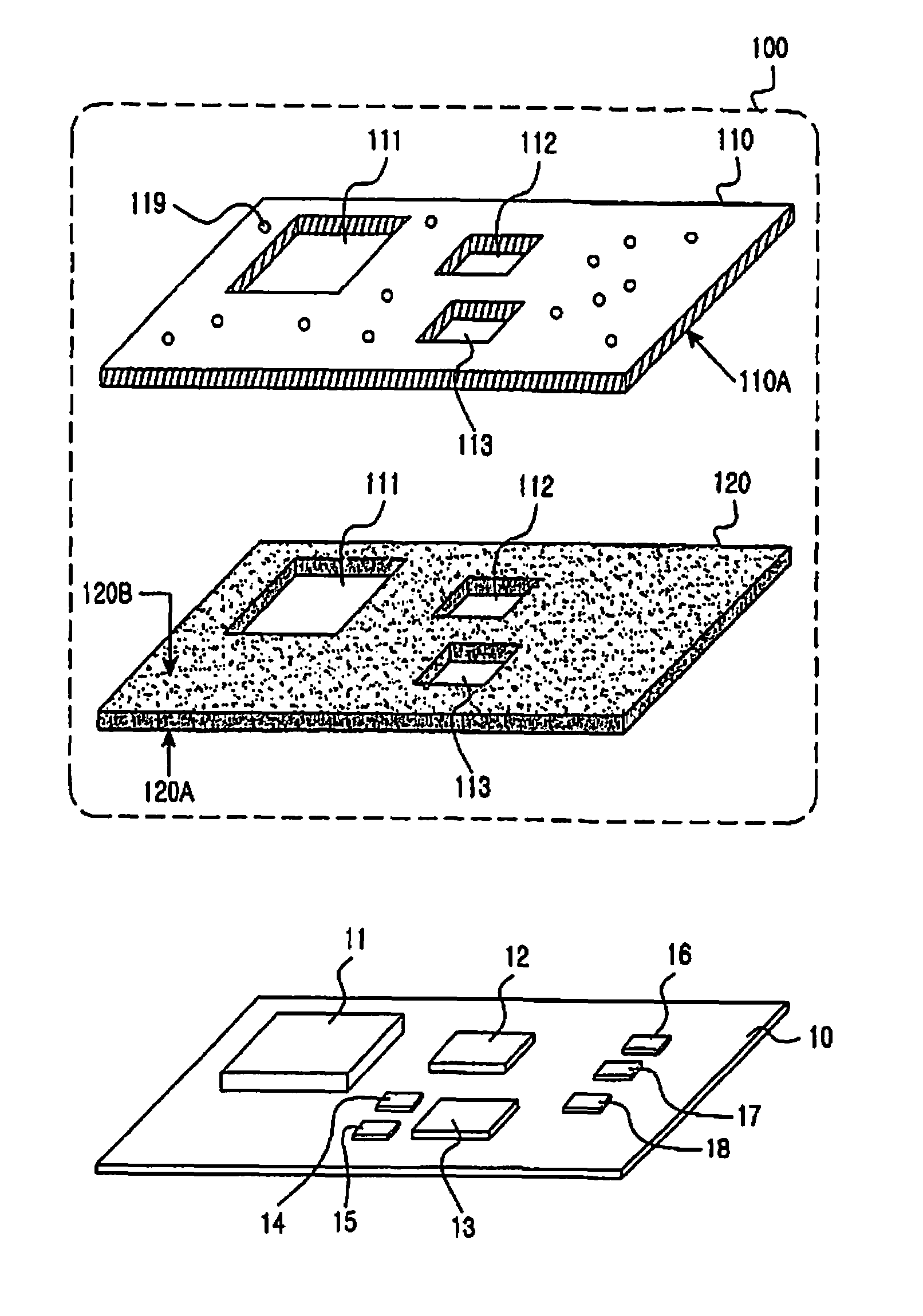

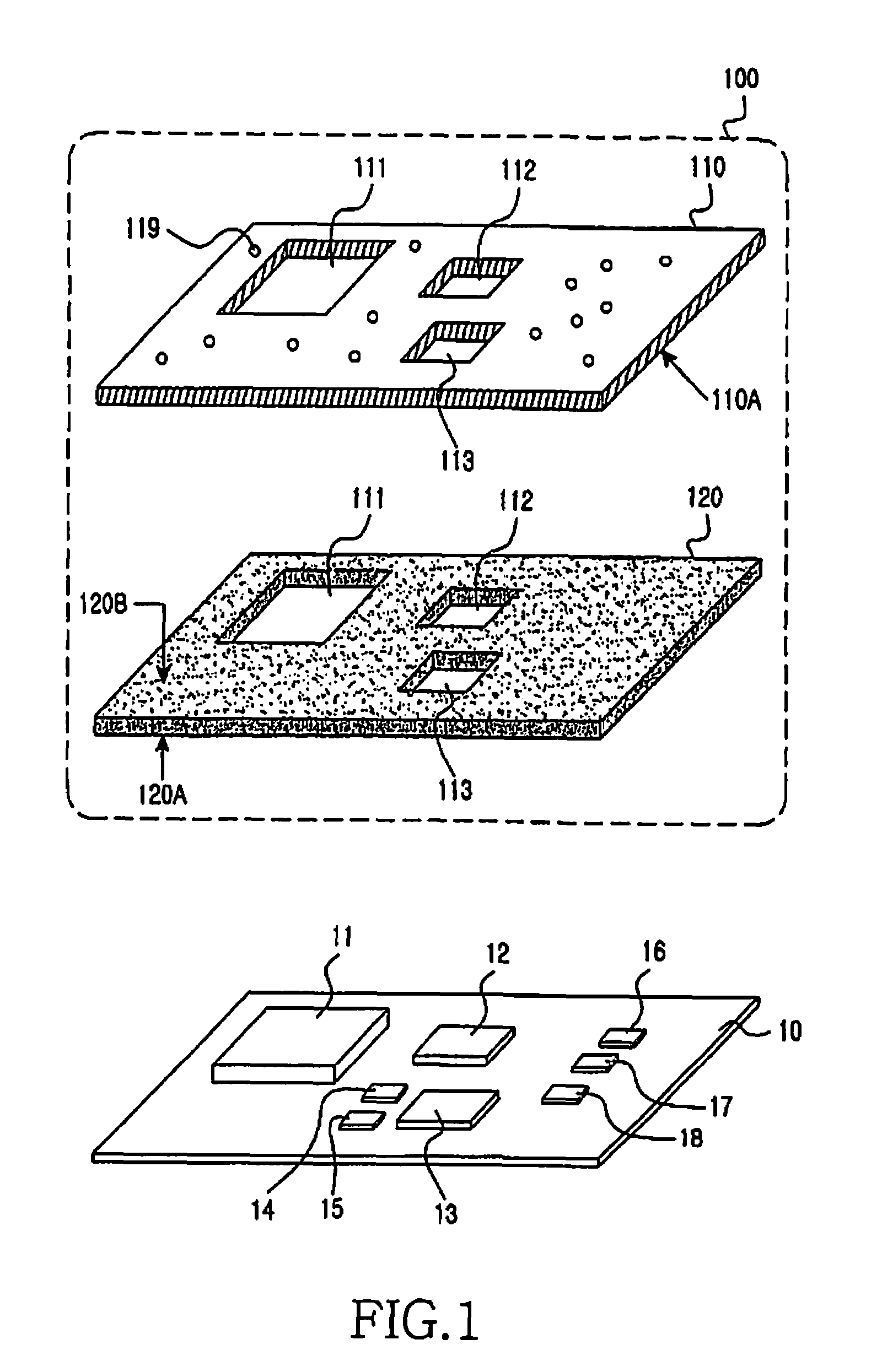

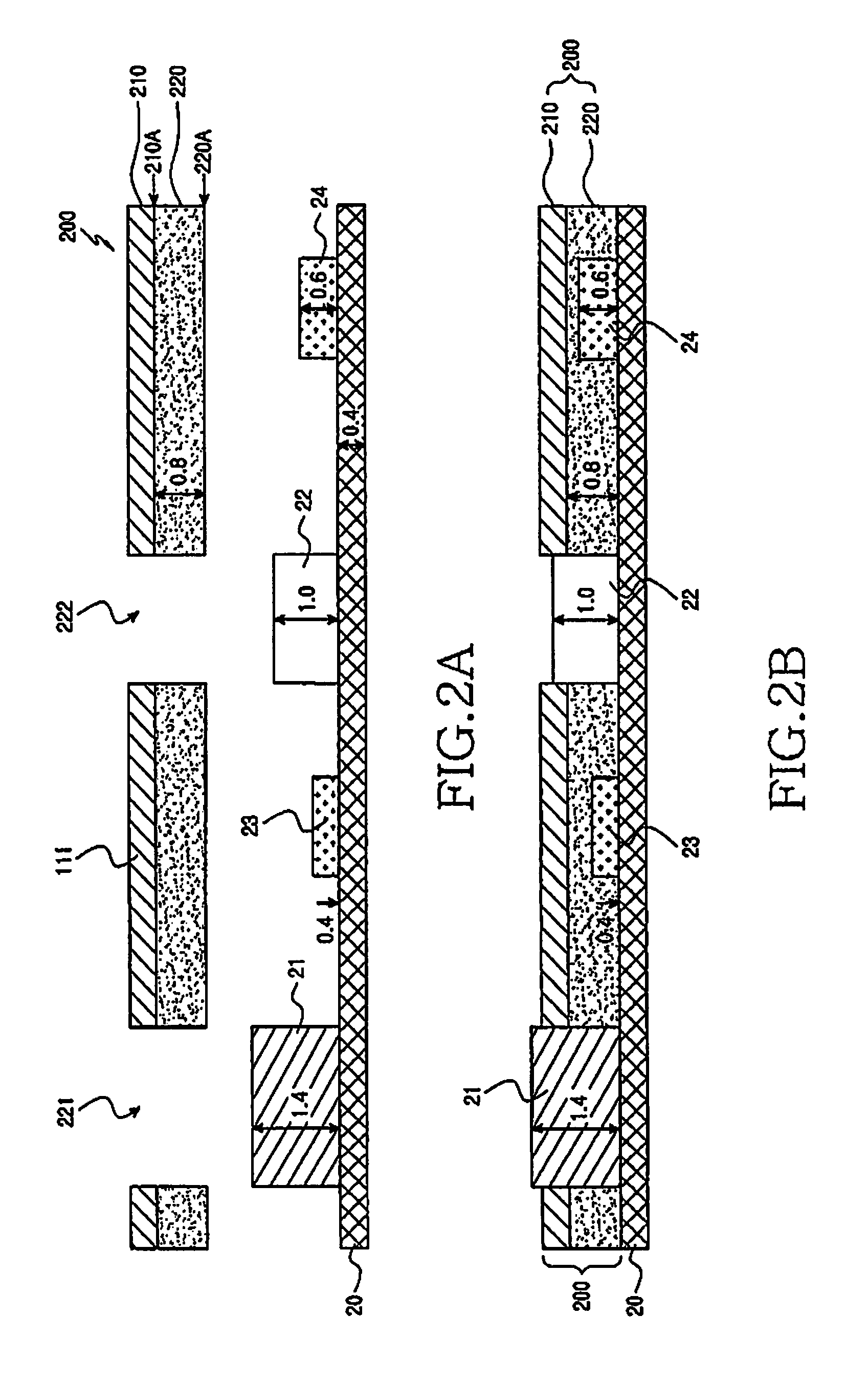

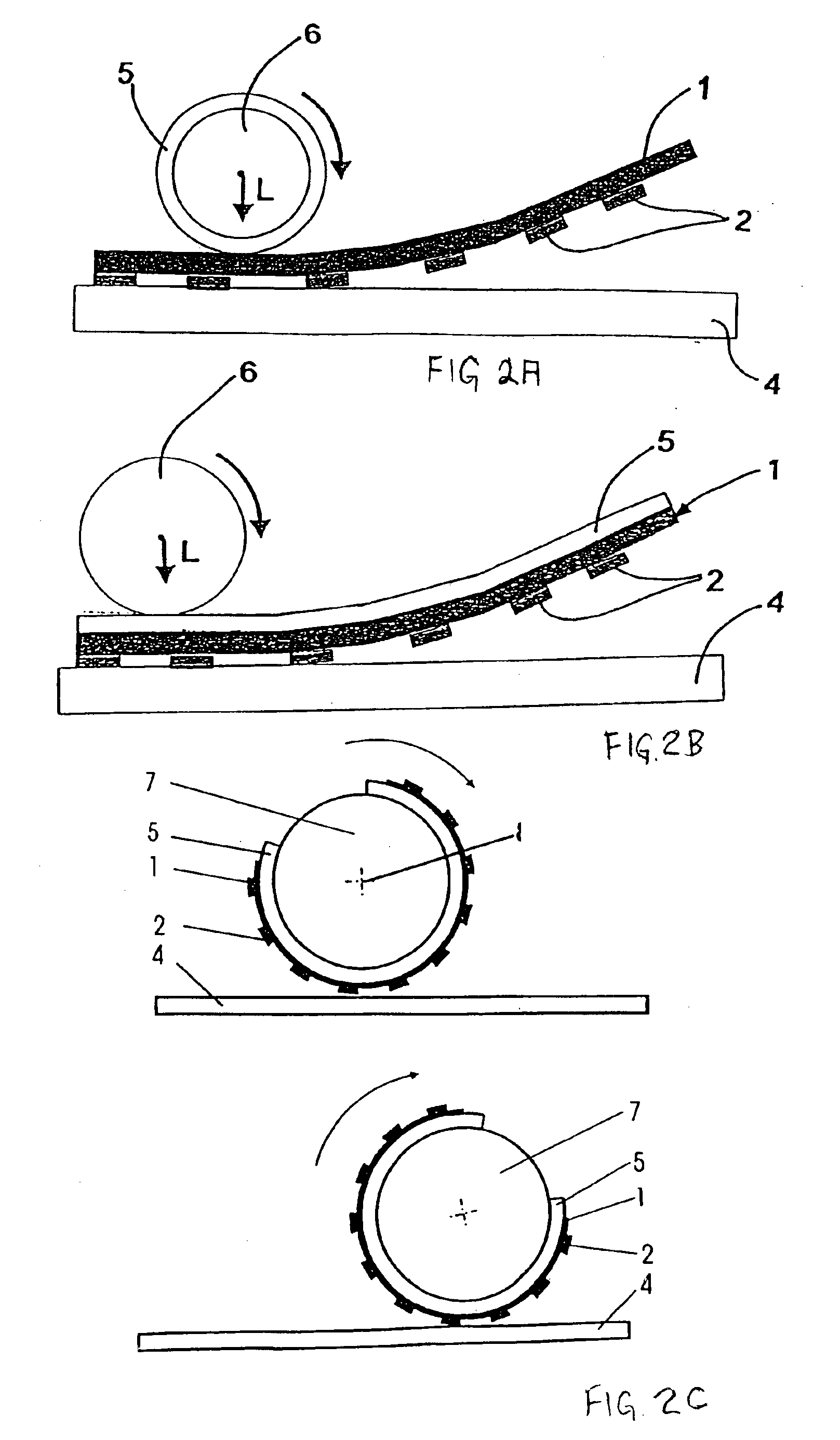

Stamp device for printing a pattern on a surface of a substrate

InactiveUS6976424B2Thin layerIncrease frictionDecorative surface effectsNanoinformaticsSoft layerSoft materials

A stamp device for printing a pattern on a surface of a substrate having a two-sided rigid carrier layer providing on its first side a patterned layer made of a first material and being combined on its second side with a soft layer made of a softer material than that of the first material.

Owner:IBM CORP

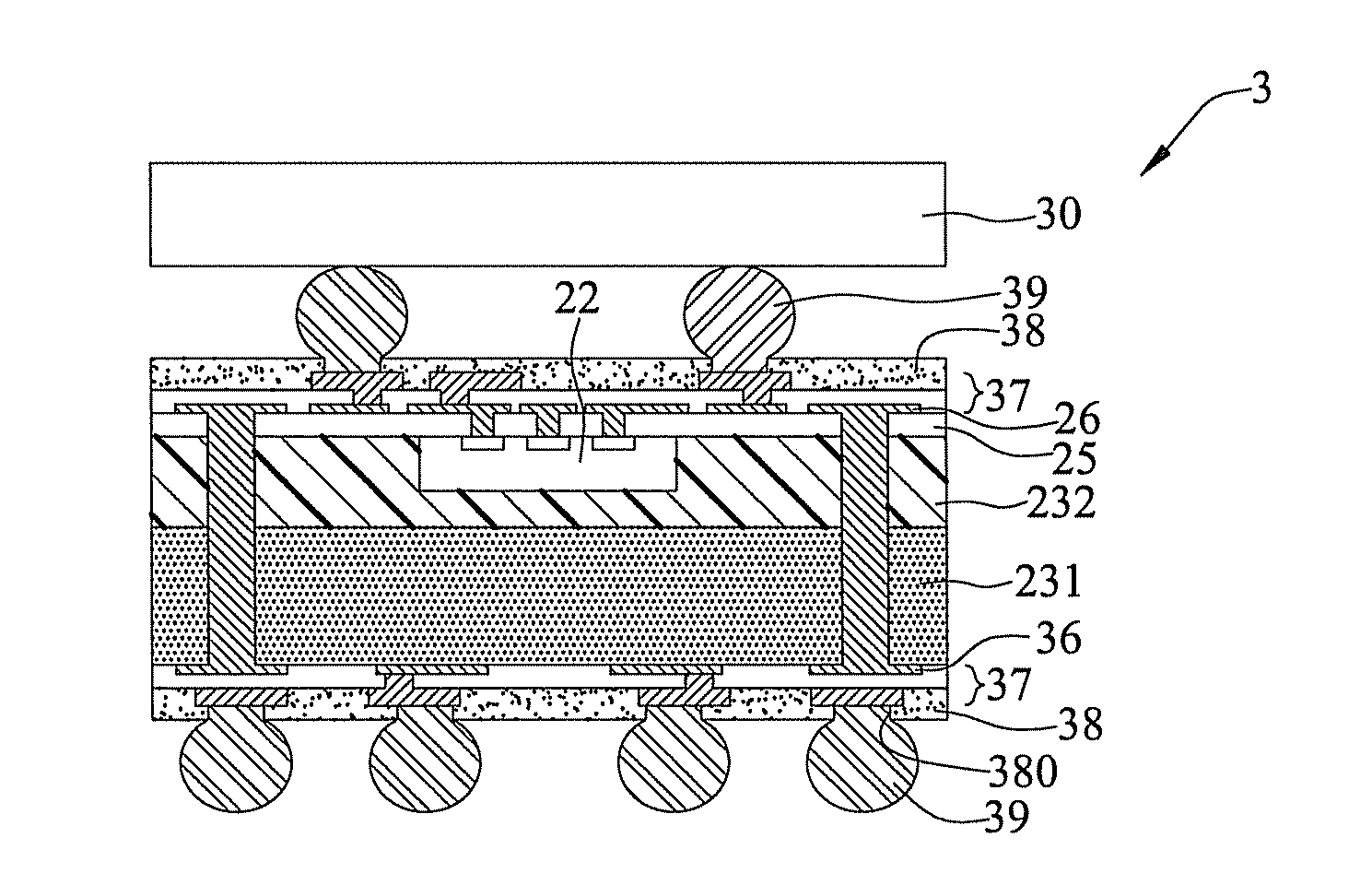

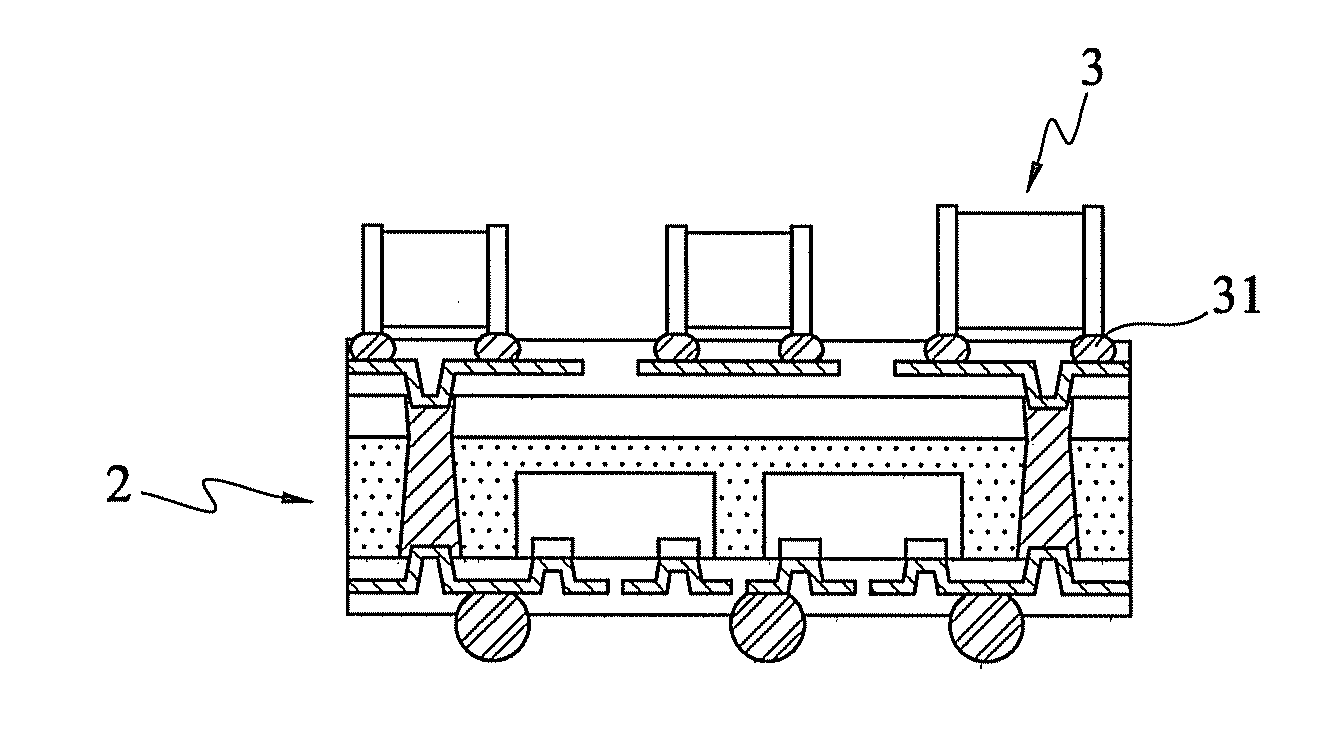

Chip scale package and fabrication method thereof

ActiveUS20120018870A1Avoid residueSolve the real problemSemiconductor/solid-state device detailsSolid-state devicesSoft layerRedistribution layer

A fabrication method of a chip scale package includes: disposing a chip on a carrier board and embedding the chip into a composite board having a hard layer and a soft layer; and removing the carrier board so as to perform a redistribution layer (RDL) process, thereby solving the conventional problems caused by directly attaching the chip on an adhesive film, such as film-softening caused by heat, encapsulant overflow, chip deviation and contamination, etc., all of which may result in poor electrical connection between the wiring layer and the chip electrode pads in the subsequent RDL process and even waste products as a result.

Owner:SILICONWARE PRECISION IND CO LTD

Method for making a nano-stamp and for forming, with the stamp, nano-size elements on a substrate

The stamping process and a method of fabrication of nano-stamps with characteristic dimensions below 1 nm and up to 0.1 micron intended for usage in making patterns of characteristic dimensions same as those of the nano-stamp on surface of a substrate is provided. In the process a very hard stamp is fabricated by first depositing alternating layers of two materials, one of which has very high hardness, on some sacrificial substrate via PVD, CVD or any other deposition procedure that produces alternating layers of selected thickness, from sub 1 nm to above 100 nm. The layered film is then polished to atomically smooth finish perpendicular to the plane of the layers and etched to produce dips in the softer layers These steps produce a grid of parallel elevations and valleys on the etched surface, which now can be used as a mold to stamp out patterns on a substrate of lower hardness than the hardness of the elevated layers. If the substrate is stamped twice with turning of the stamp 90 degrees between first and second stampings, a square pattern of hills and valleys is formed, which can be used for magnetic memory storage by subsequently sputtering magnetic material on the tops of the elevations or hills.

Owner:PECHENIK ALEXANDER

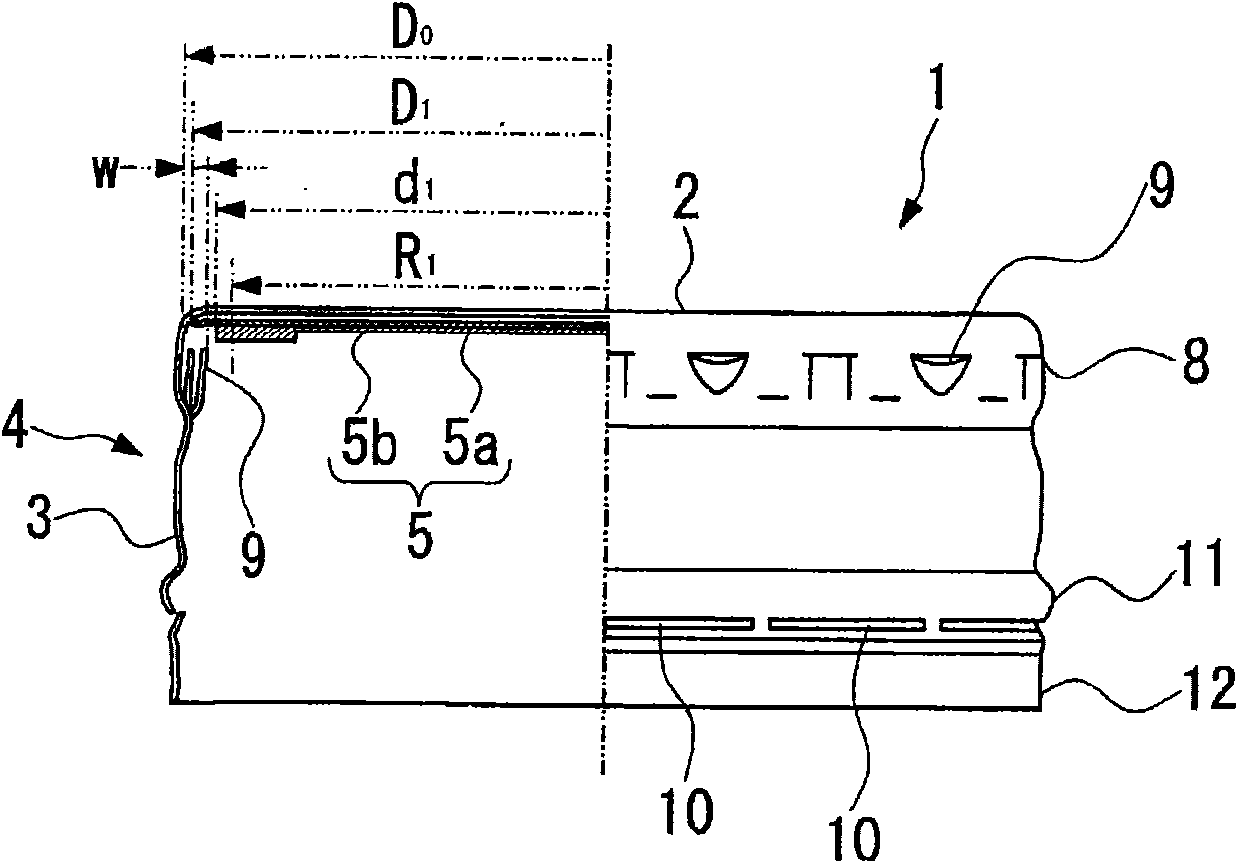

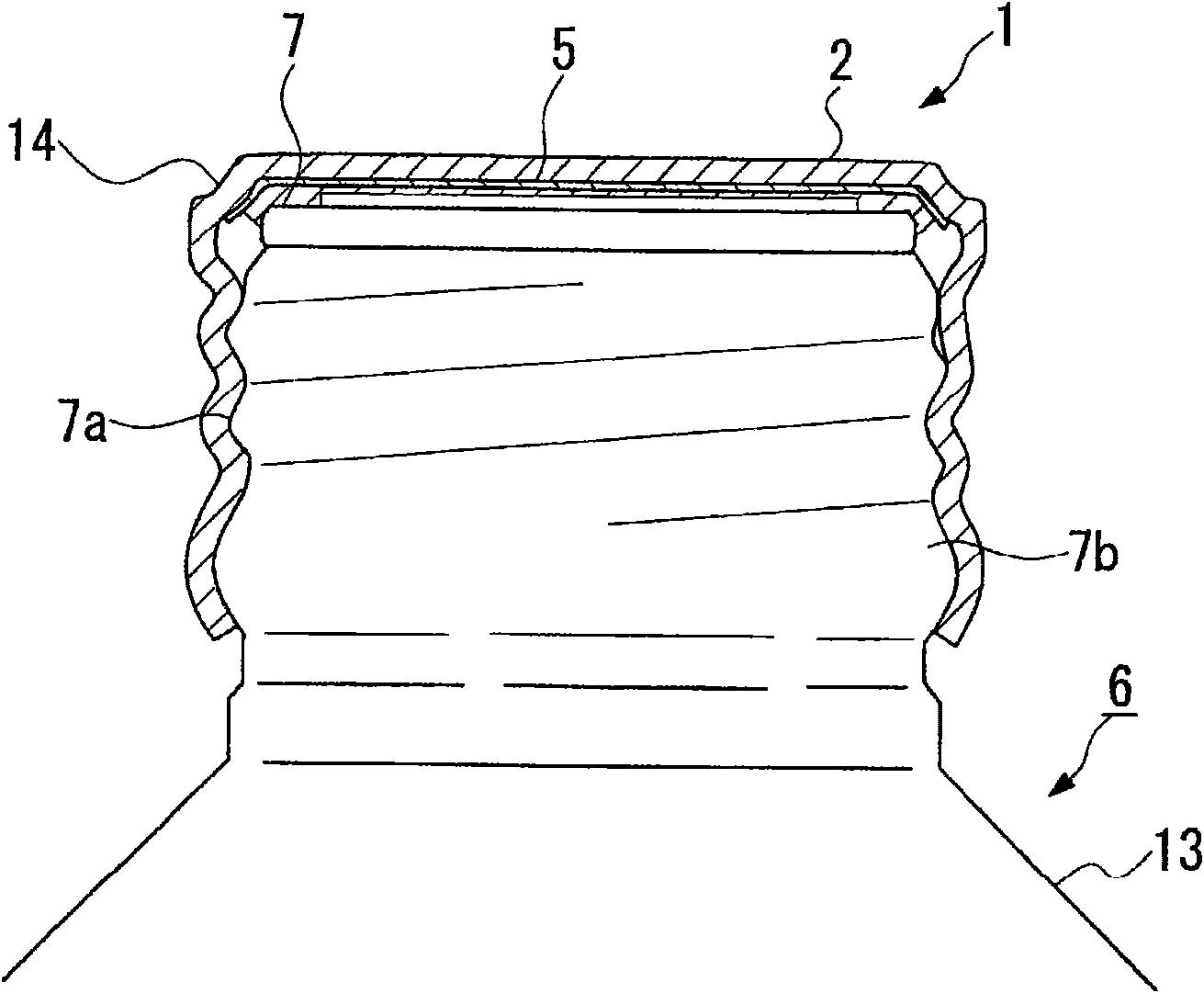

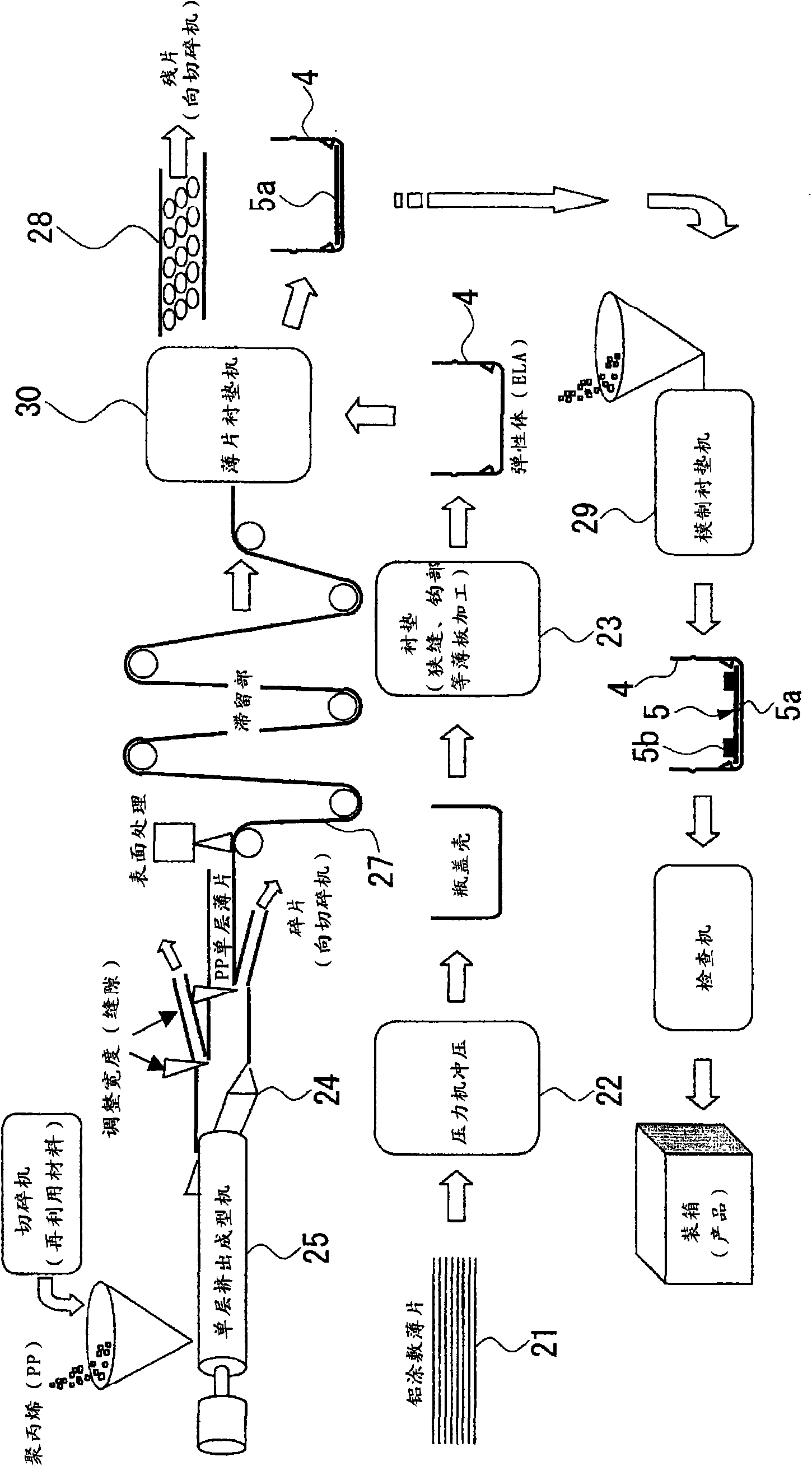

Liner-provided cap and cap-provided threaded container

ActiveCN101891031AHigh suitability for installationSmall unseal torque valueCapsClosure capsSoft layerEngineering

The present invention discloses a liner-provided cap and a cap-provided threaded container. The liner-provided cap for sealing the mouthpiece of the threaded container includes the cap shell (4) consisting of the top plate (2) and the tubular peripheral wall section (3) that hangs from the peripheral edge of the top plate (2), and the synthetic resin liner (5) provided on the inner surface of the top plate (2). The liner (5) includes the disk-shaped rigid sheet (5a) disposed in contact with the inner surface of the top plate (2), and the soft layer (5b) that is laminated to the rigid sheet (5a) and is more flexible than the rigid sheet (5a). The soft layer (5b) is concentric with the rigid sheet (5a) and is formed in an annular or disk shape with a diameter smaller than that of the rigid sheet (5a) so that the soft layer (5b) can be brought into contact with at least the mouthpiece.

Owner:UNIVERSAL CAN CORP

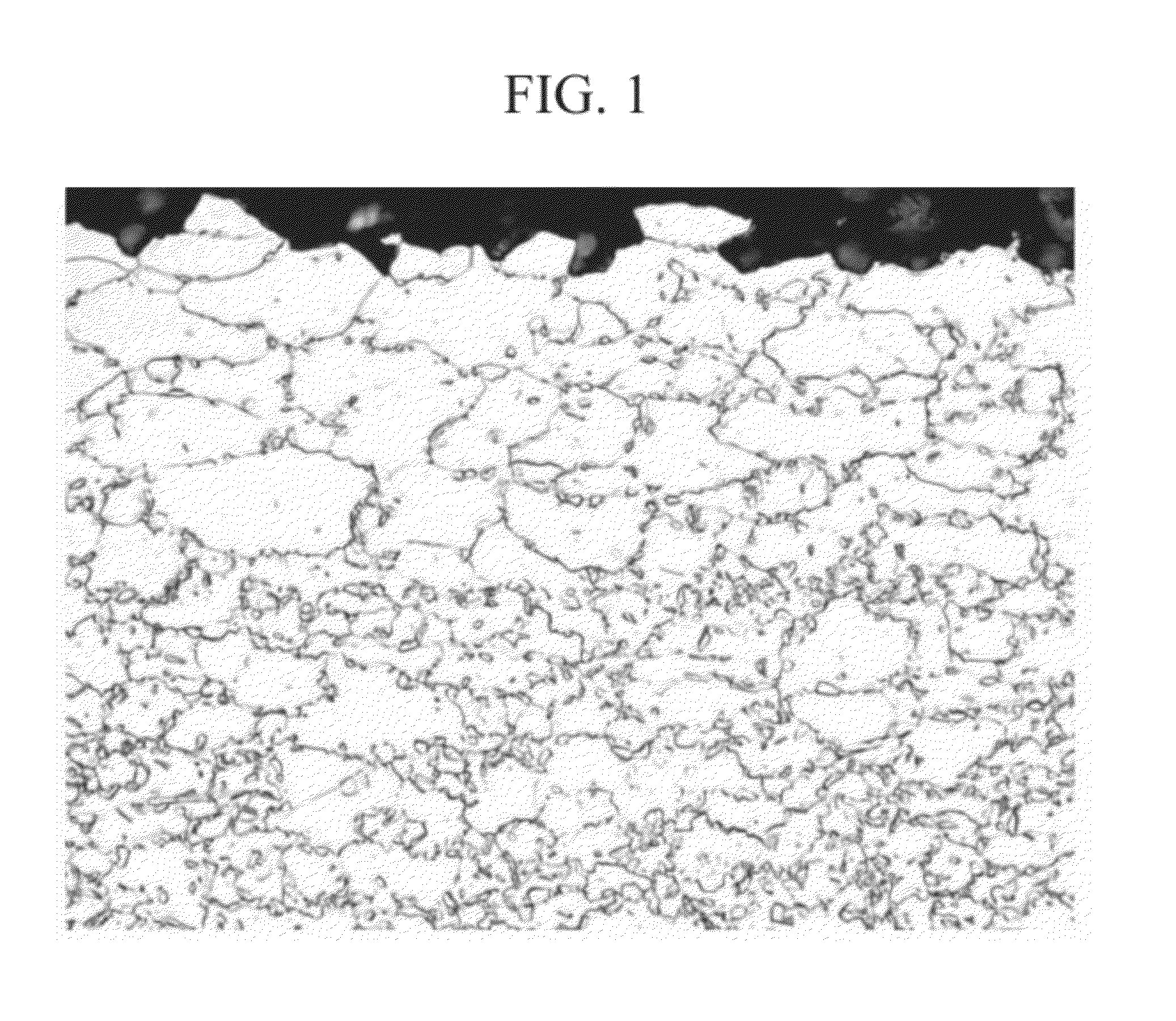

High-strength galvanized steel sheet and method of manufacturing the same

ActiveUS20120152411A1Improve fatigue durabilityImprove bending performanceHot-dipping/immersion processesFurnace typesSoft layerHigh intensity

Provided is a galvanized steel sheet having a tensile strength of 770 MPa or more including a steel sheet portion, and a plated layer formed on the surface of the steel sheet portion, in which the plated layer is a galvanized plated layer or an galvannealed plated layer, the steel sheet portion has a soft layer that directly adjoins the interface with the plated layer and an inside layer that is other than the soft layer, the thickness D of soft layer is 0.001% to 5% of thickness t of the steel sheet portion, and, when the hardness of the soft layer measured by nano-indentation method is indicated by H1, and the representative hardness of the steel sheet portion measured by the nano-indentation method is indicated by Ha in cross section that goes along the thickness direction of the steel sheet portion, H1 is 5% to 75% of Ha.

Owner:NIPPON STEEL CORP

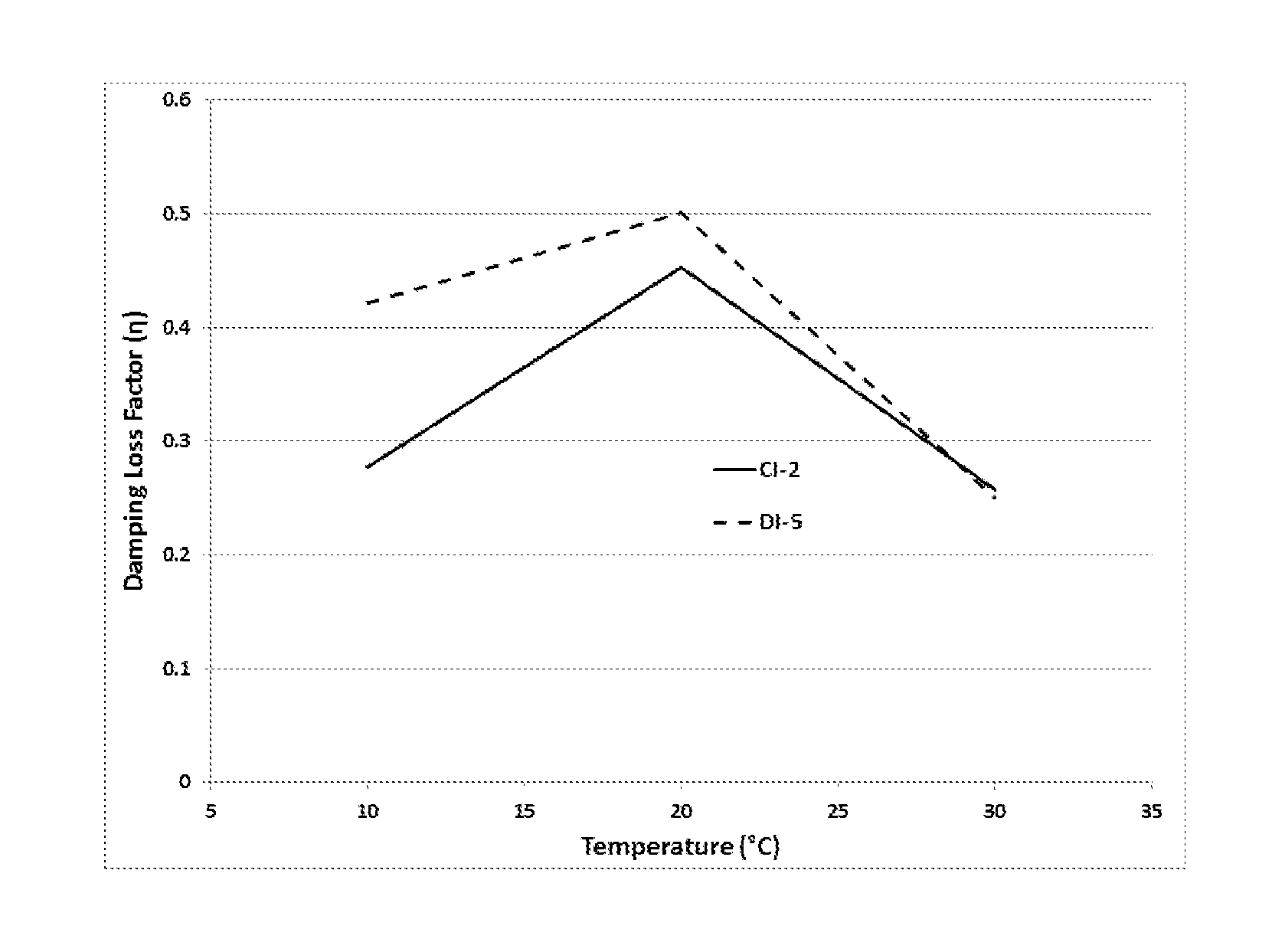

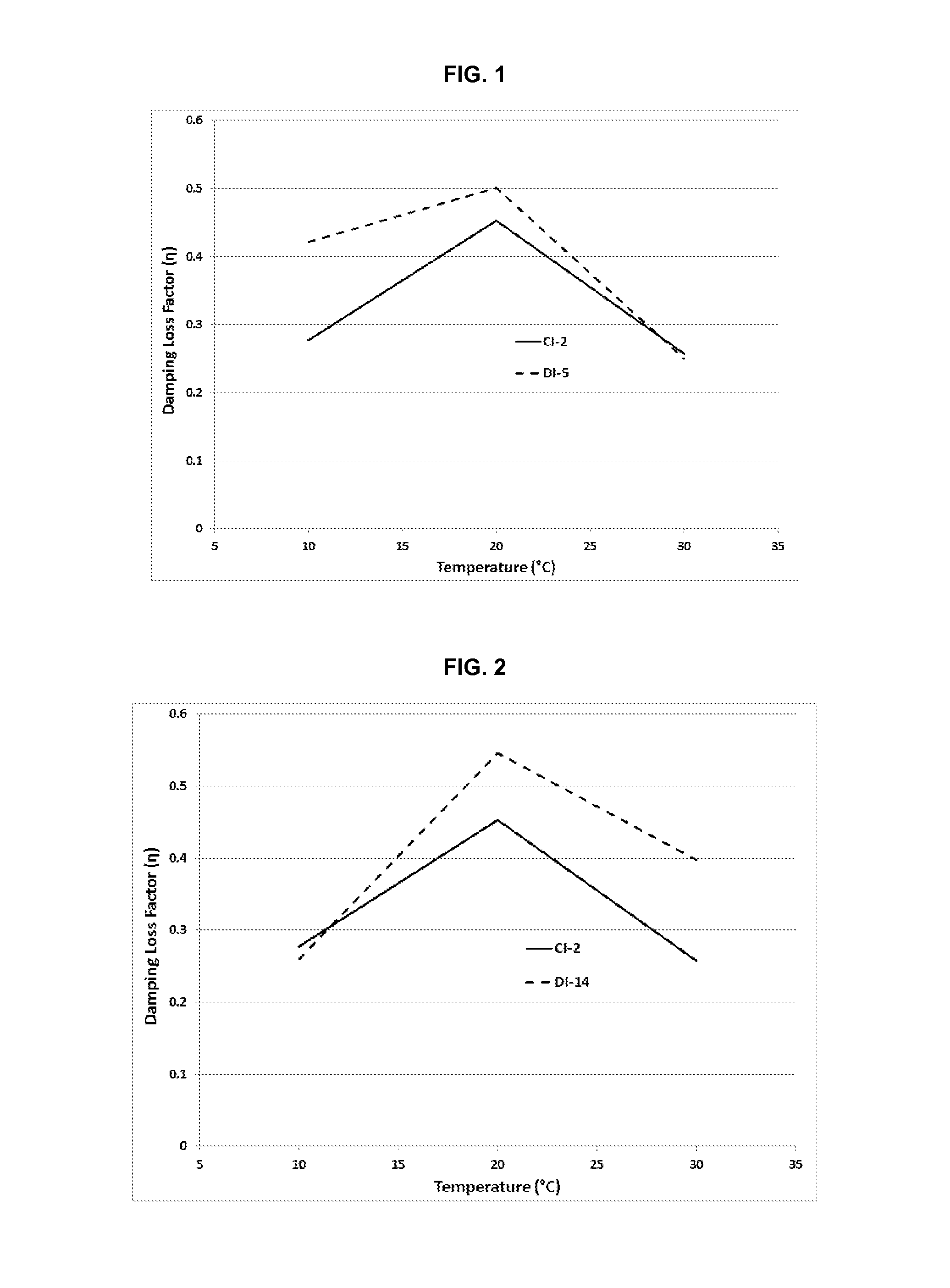

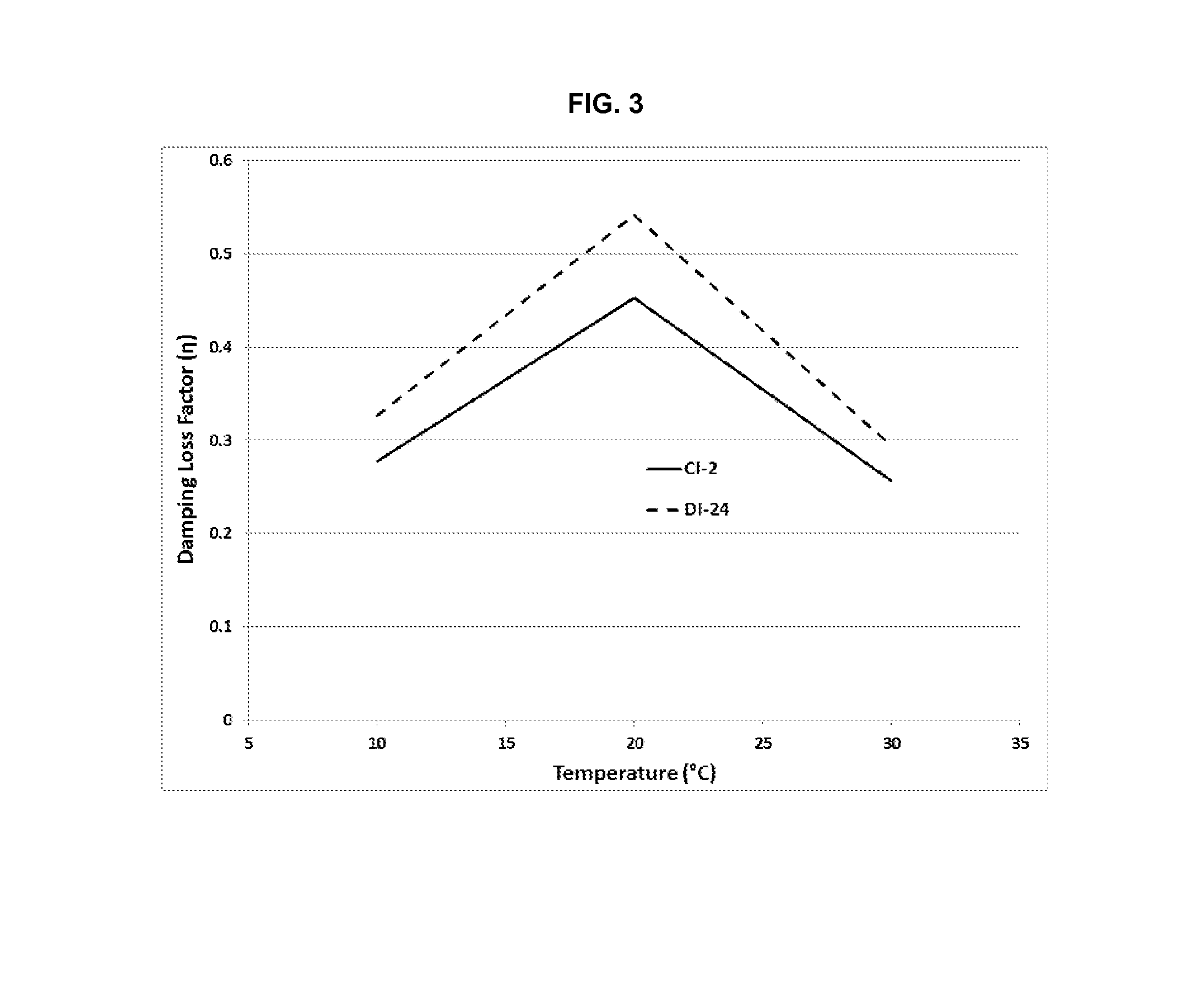

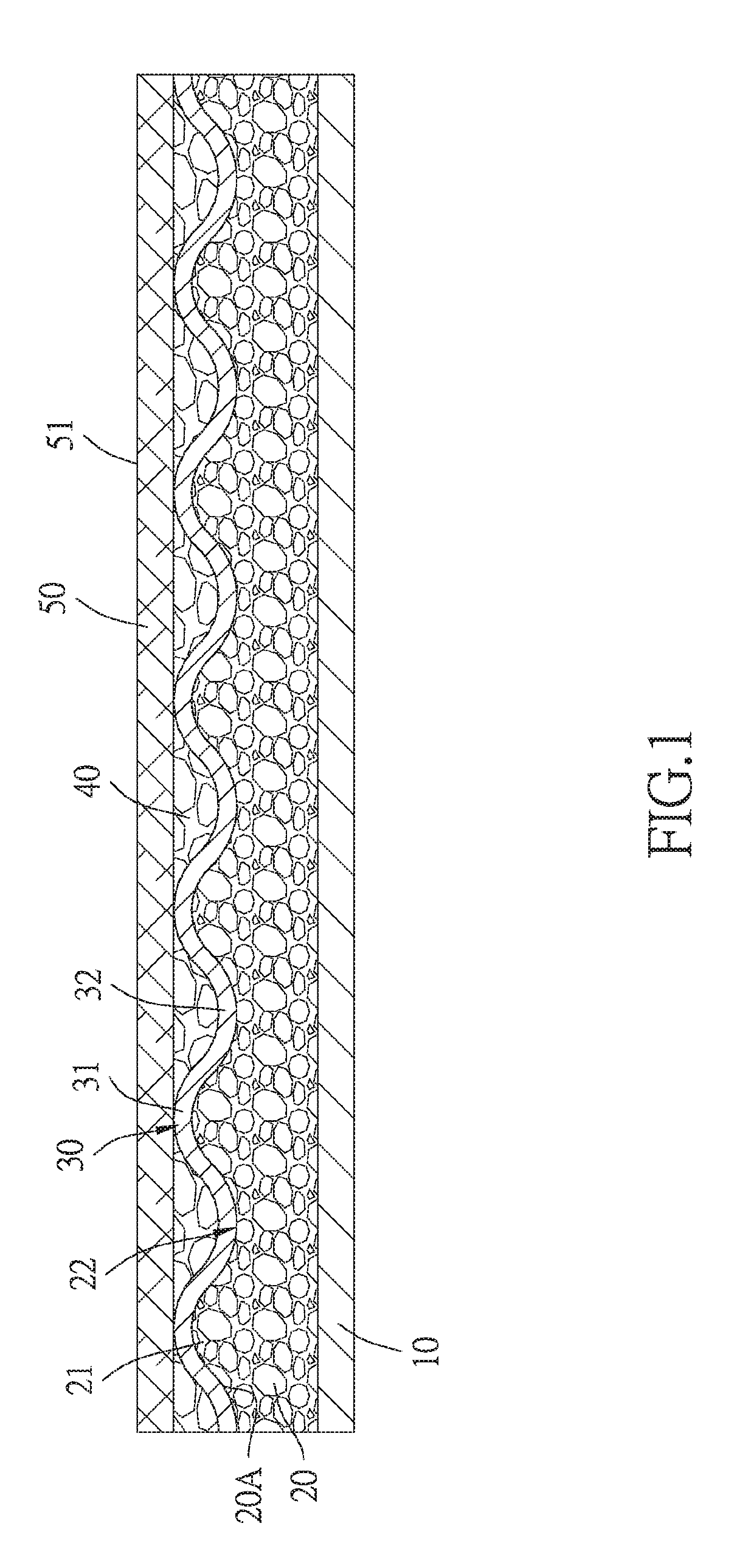

Multilayer interlayer having sound damping properties over a broad temperature range

ActiveUS20160111077A1Improve sound insulationWallsSynthetic resin layered productsSoft layerPlasticizer

A polymer interlayer having improved sound insulation is disclosed. The polymer interlayer comprises at least one soft layer wherein the soft layer comprises: a first poly(vinyl butyral) resin having a first residual hydroxyl content and a first glass transition temperature (Tg); a second poly(vinyl butyral) resin having a second residual hydroxyl content and a second glass transition temperature (Tg), wherein the difference between the first residual hydroxyl content and the second residual hydroxyl content is at least 1.0 weight percent; wherein the difference between the first glass transition temperature (Tg) the second glass transition temperature (Tg) is at least 1.5° C.; and a plasticizer; at least one stiffer layer comprising a third poly(vinyl butyral resin) having a third residual hydroxyl content; and a plasticizer, wherein the polymer interlayer has a damping loss factor (q) (as measured by Mechanical Impedance Measurement according to ISO 16940) of at least about 0.16 measured at two or more different temperatures selected from 10° C., 20° C. and 30° C.

Owner:SOLUTIA INC

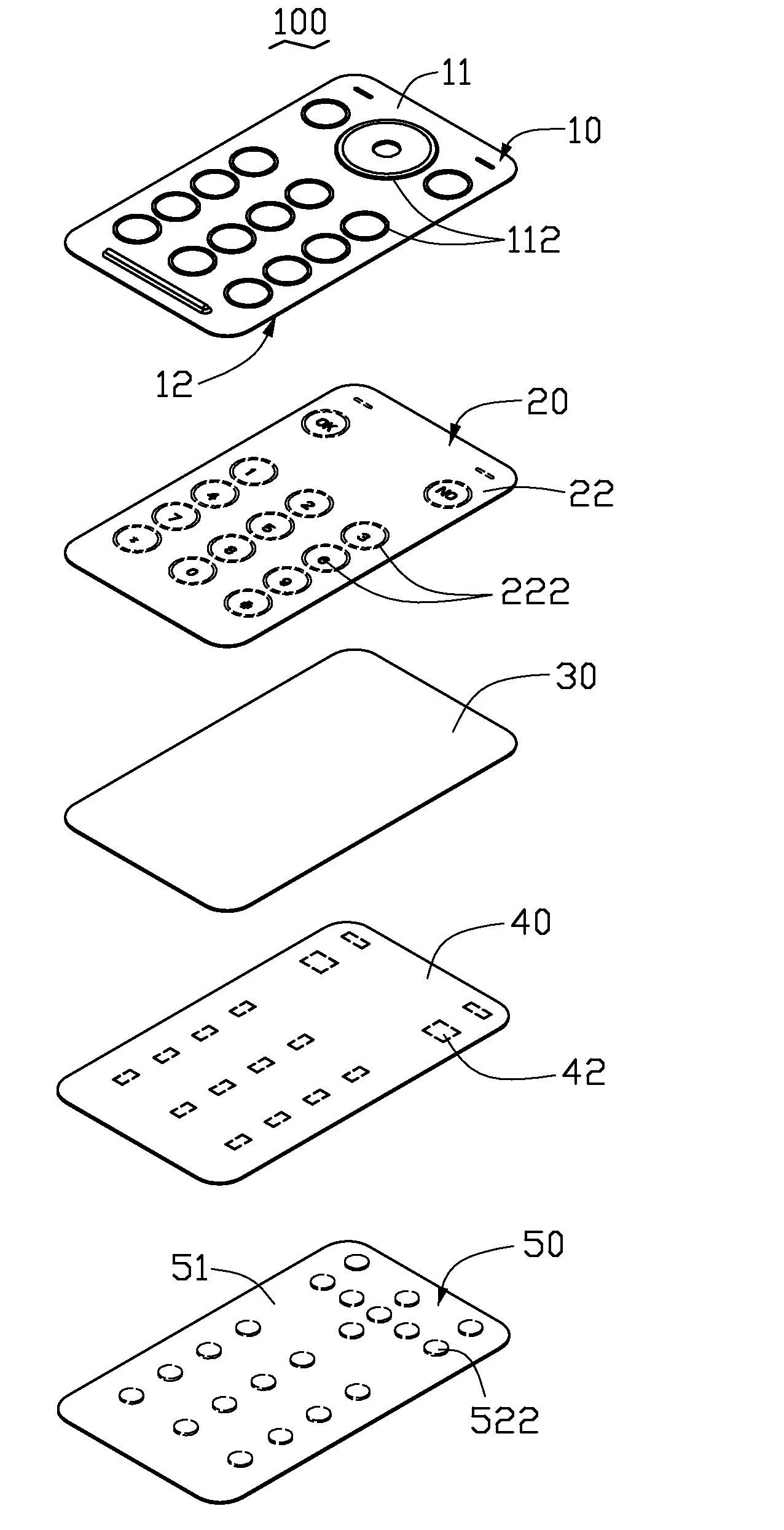

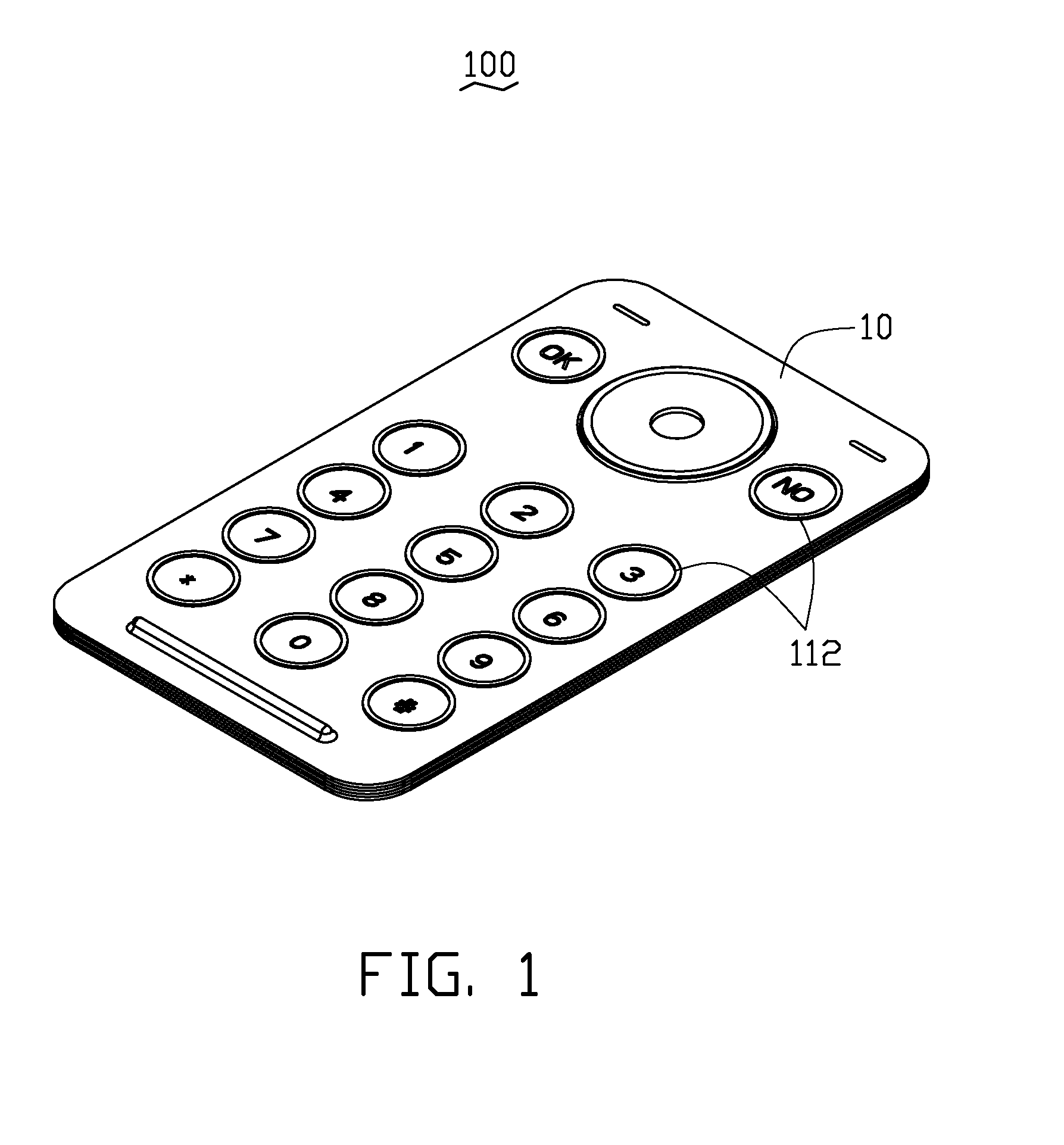

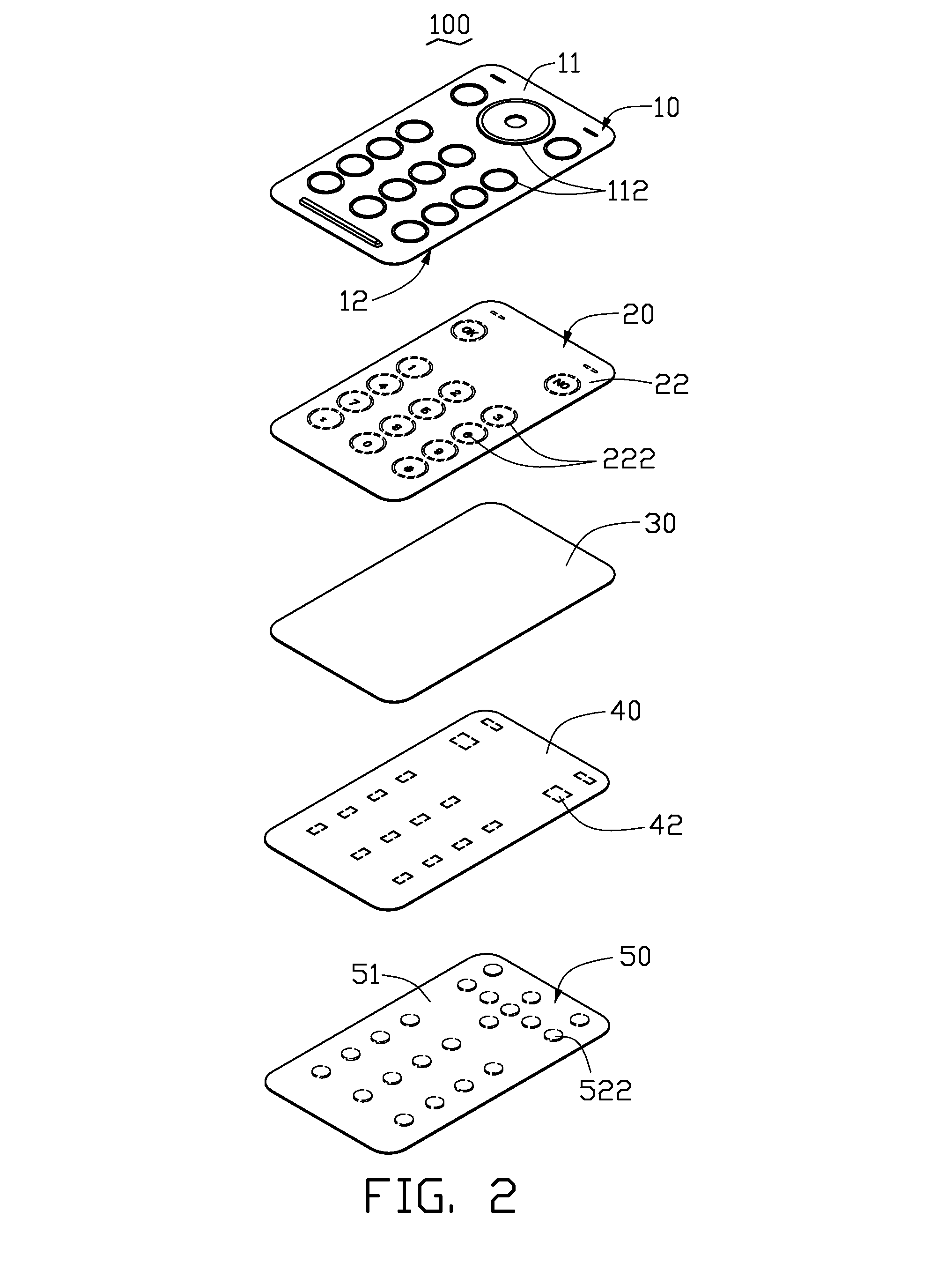

Keypad assembly for electronic device

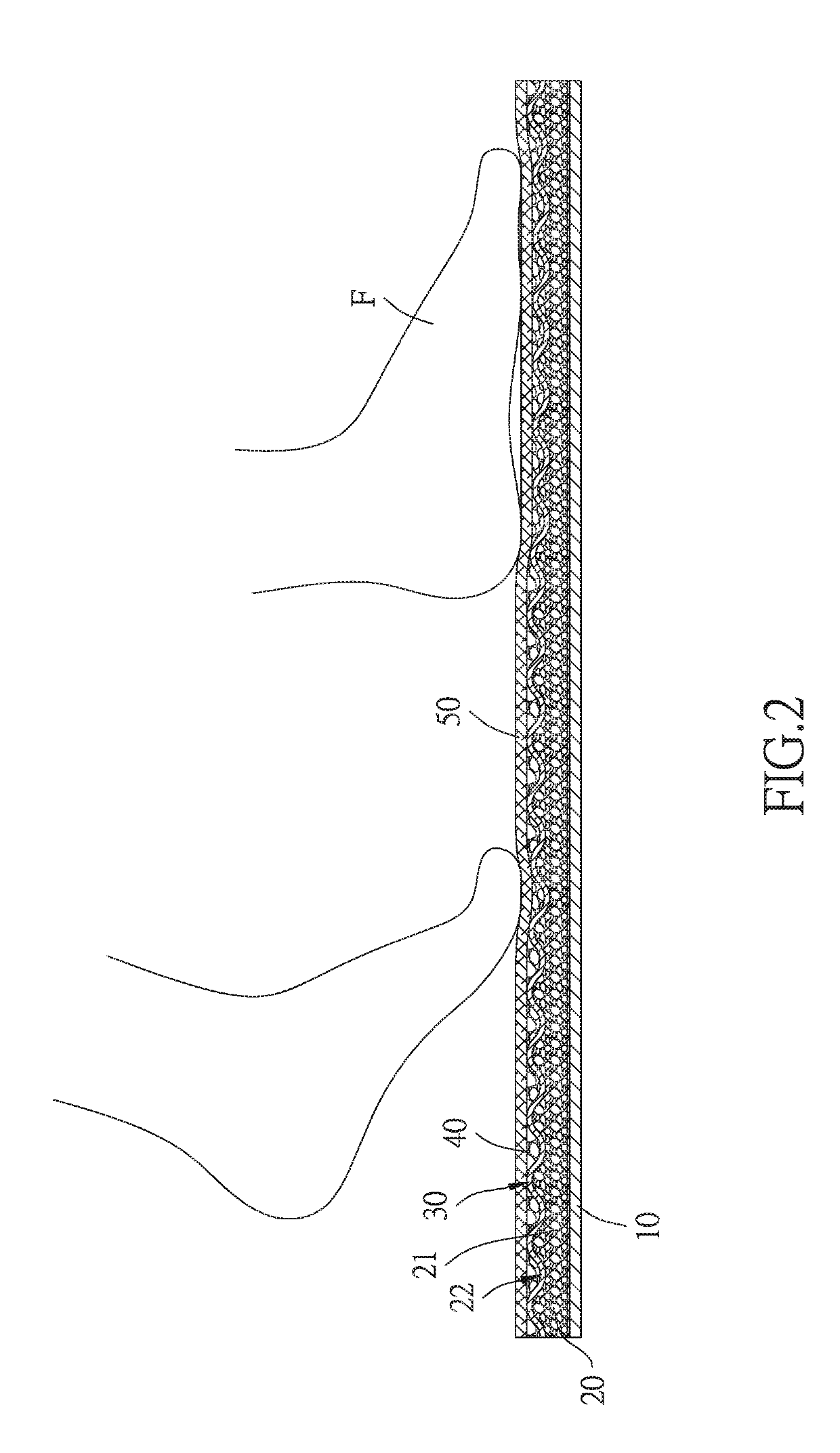

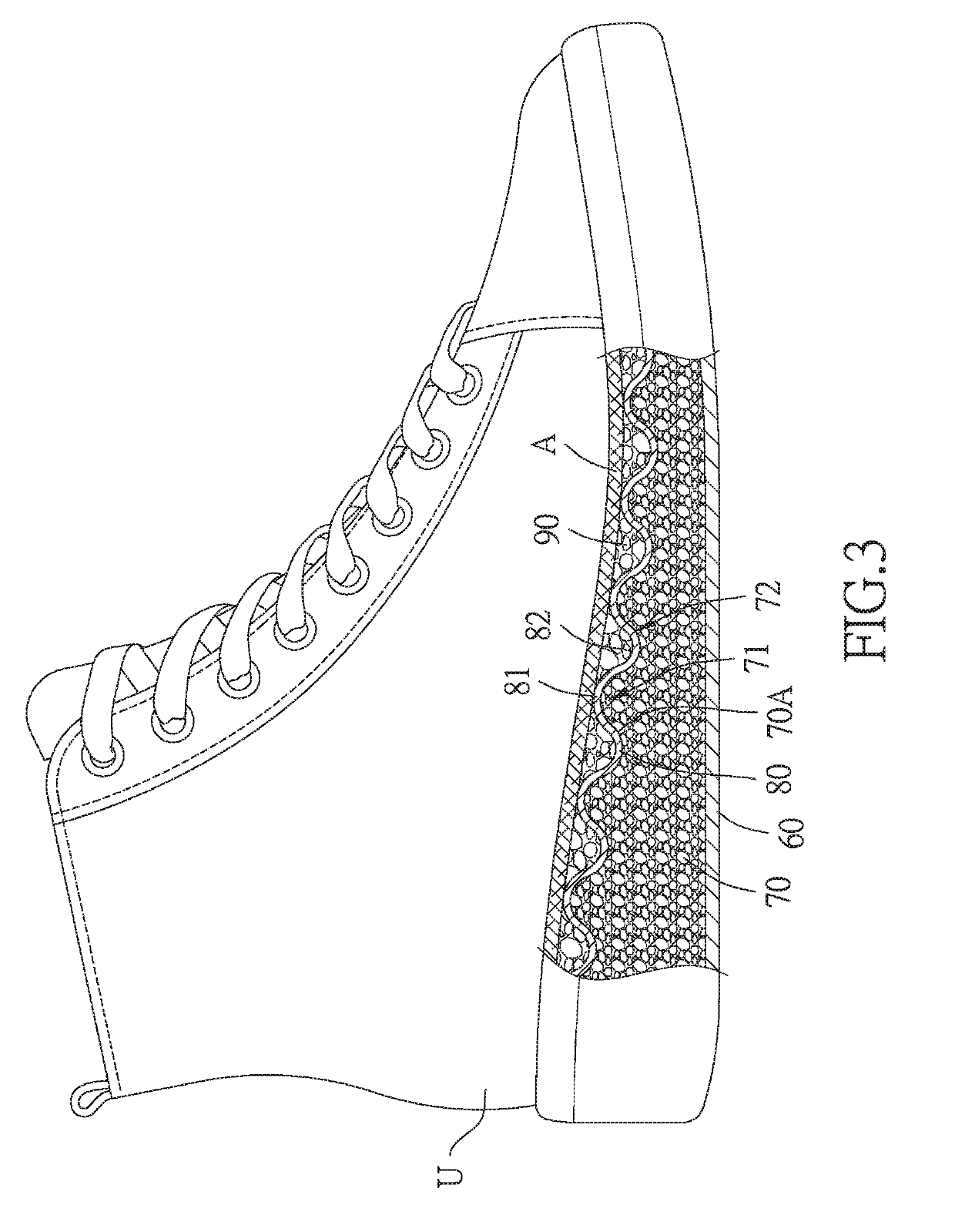

A keypad assembly (100) includes a first soft layer (10), a stiff layer (20) mounted to the first soft layer, an optical layer (40) located under the stiff layer, and a second soft layer (50) mounted to the optical layer. The first soft layer has at least one protrusion (112) formed thereon. The stiff layer has at least one icon (222) formed thereon. The at least one icon corresponds to the at least one protrusion. The optical layer has at least one focusing unit (42) formed thereon. The at least one focusing unit corresponds to the at least one icon. The second soft layer has at least one switch point (522). The at least one switch point corresponds to the at least one protrusion.

Owner:CHI MEI COMM SYST INC

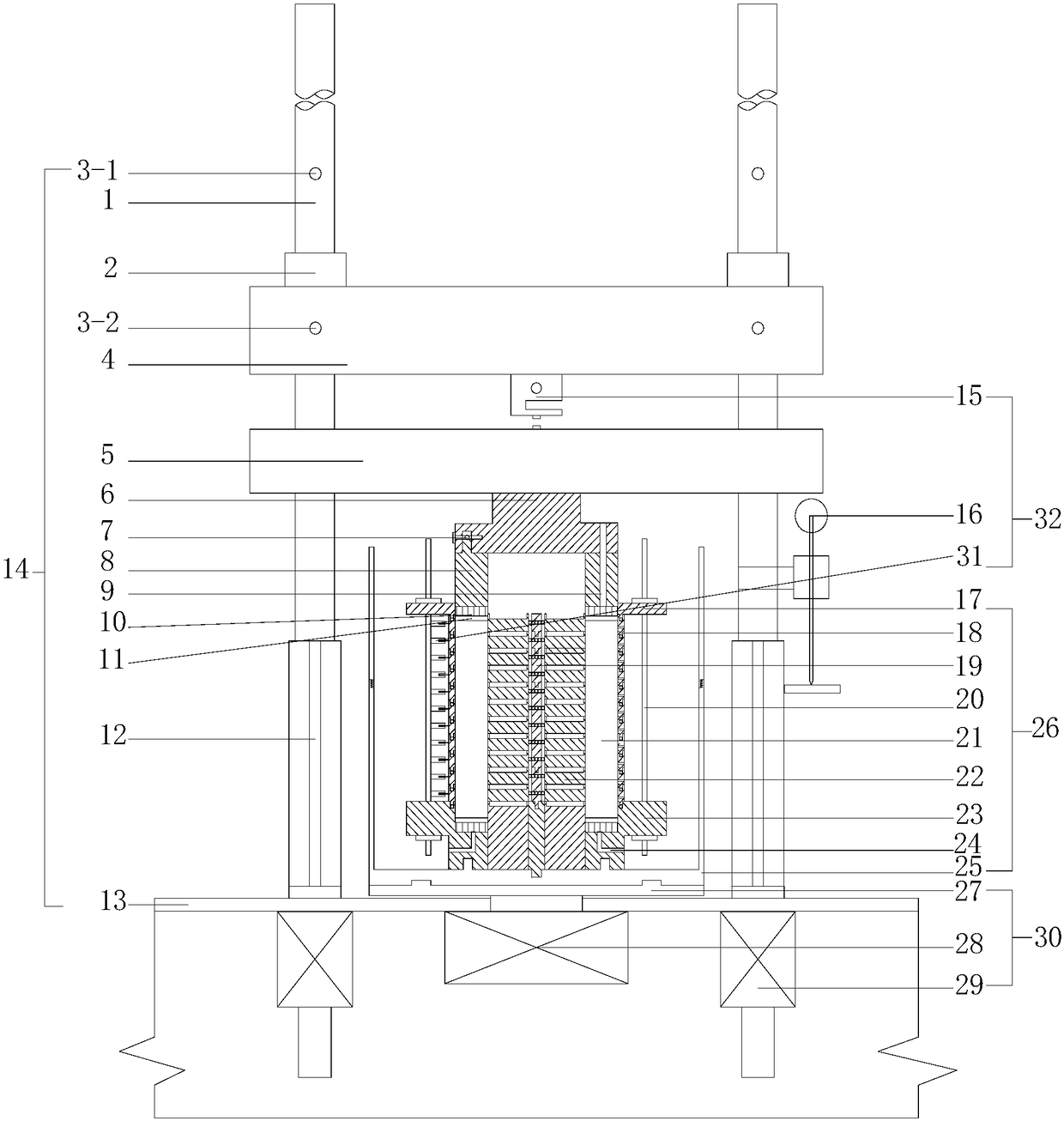

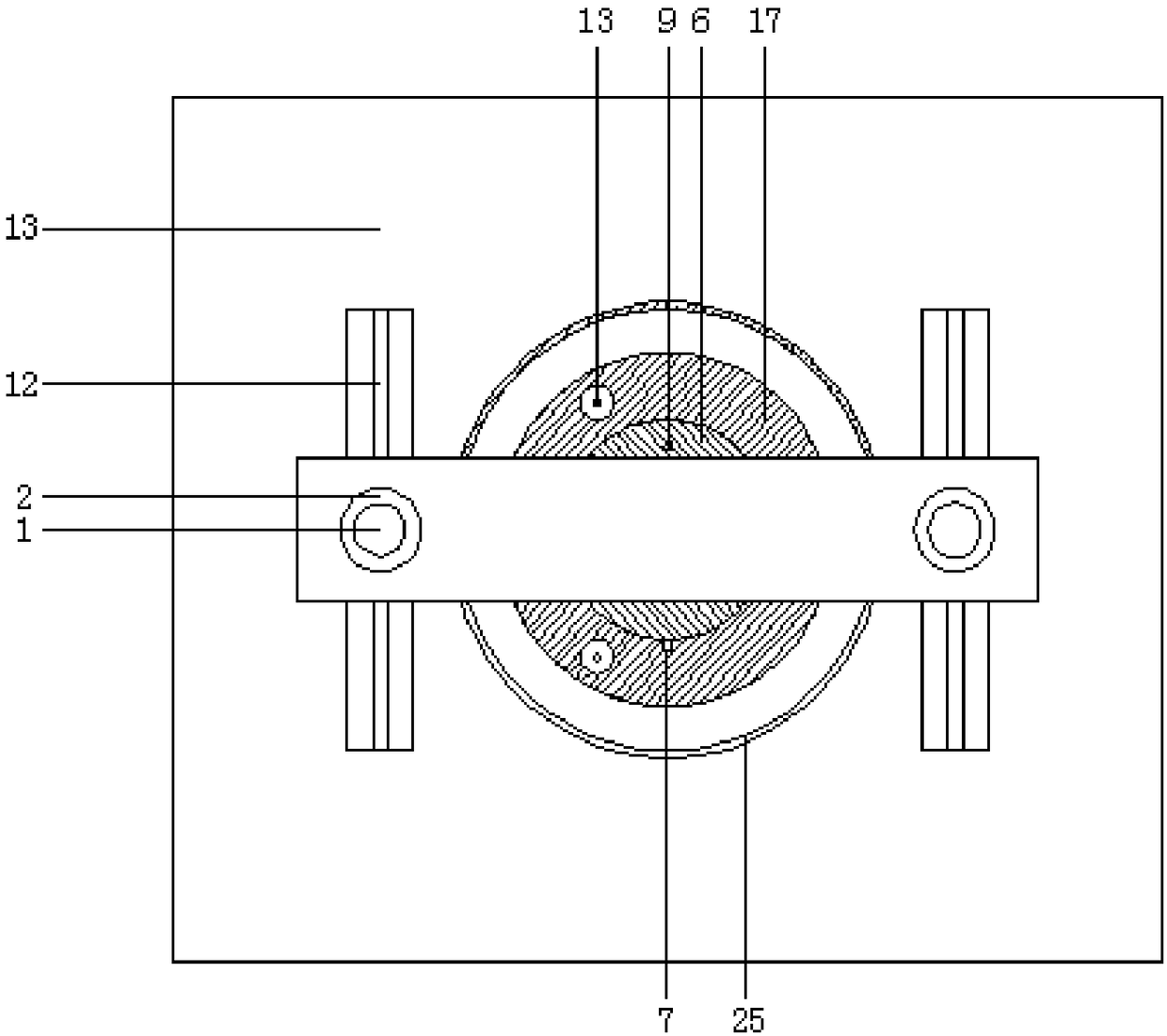

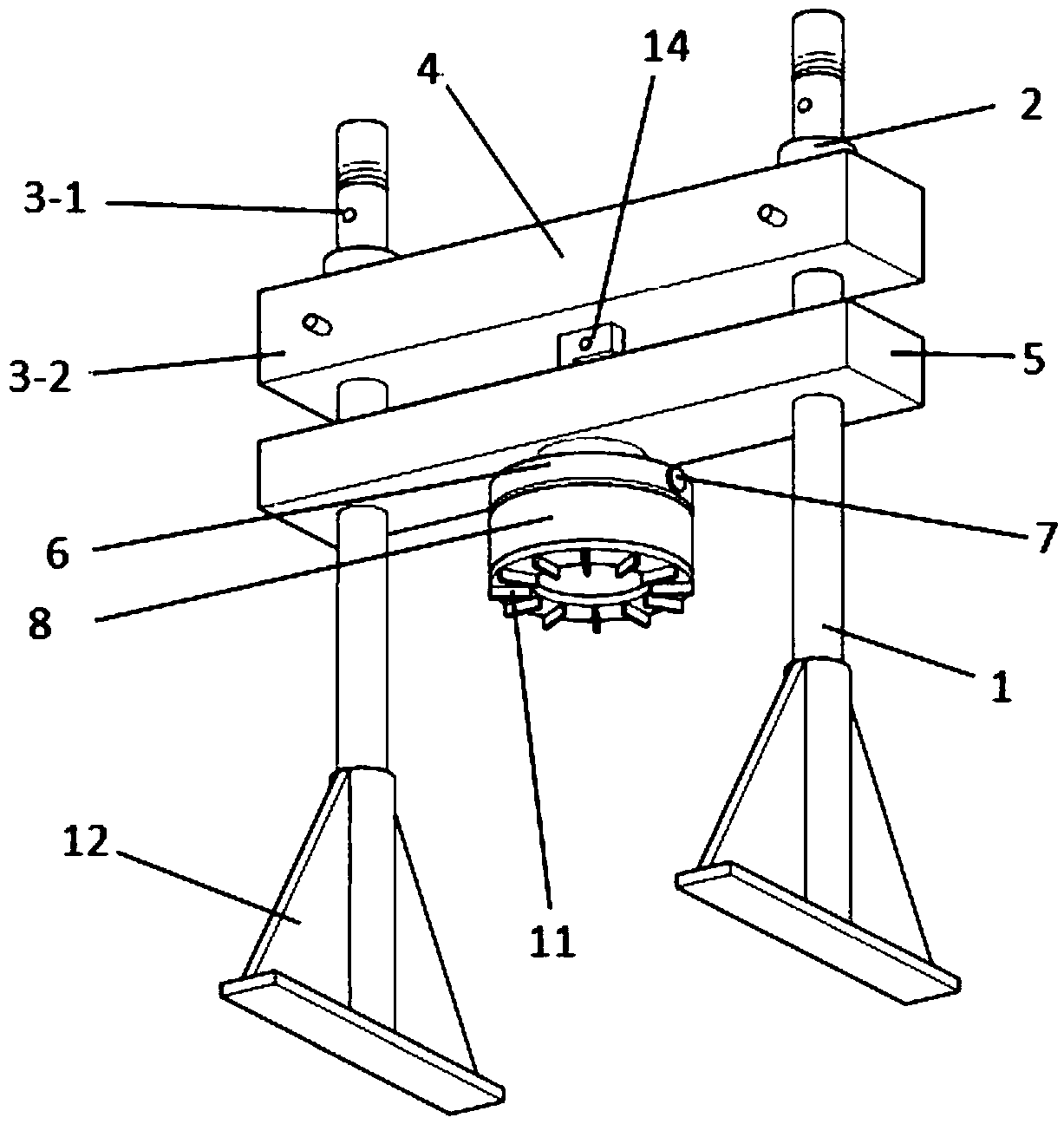

Overlaying-ring ring shear apparatus as well as overlaying ring shear test

PendingCN108225945AAutomate operationThe test process is simple and simpleMaterial strength using steady shearing forcesSoft layerTest sample

The invention belongs to the field of geotechnical test and deformation simulation, and particularly relates to an overlaying-ring ring shear apparatus and an overlaying ring shear test for continuouslarge-displacement shear deformation characteristic research of soil and complicated structural soil deformation simulation. The overlaying-ring ring shear apparatus comprises a vertical pressurizingmechanism, a twisting mechanism, a vertical assisting pressure applying mechanism and an overlaying ring shear box mechanism; the overlaying ring shear box mechanism is arranged on the twisting mechanism and can be driven by the twisting mechanism to rotate; the vertical pressurizing mechanism can apply vertical pressure to the overlaying ring shear box mechanism by virtue of the vertical assisting pressure applying mechanism; the limitless deformation ring-shaped shear of different geotechnical test samples of different heights can be performed, and the test sample is enabled to have certainfreedom and continuity in the deformation process; and the overlaying-ring ring shear apparatus can also be used for researching a deformation law of different material contact surfaces, simulating long-distance deformation of the complicated structural soil landslide as well as searching soft layers.

Owner:FUJIAN GEOLOGICAL ENG SURVEY INST

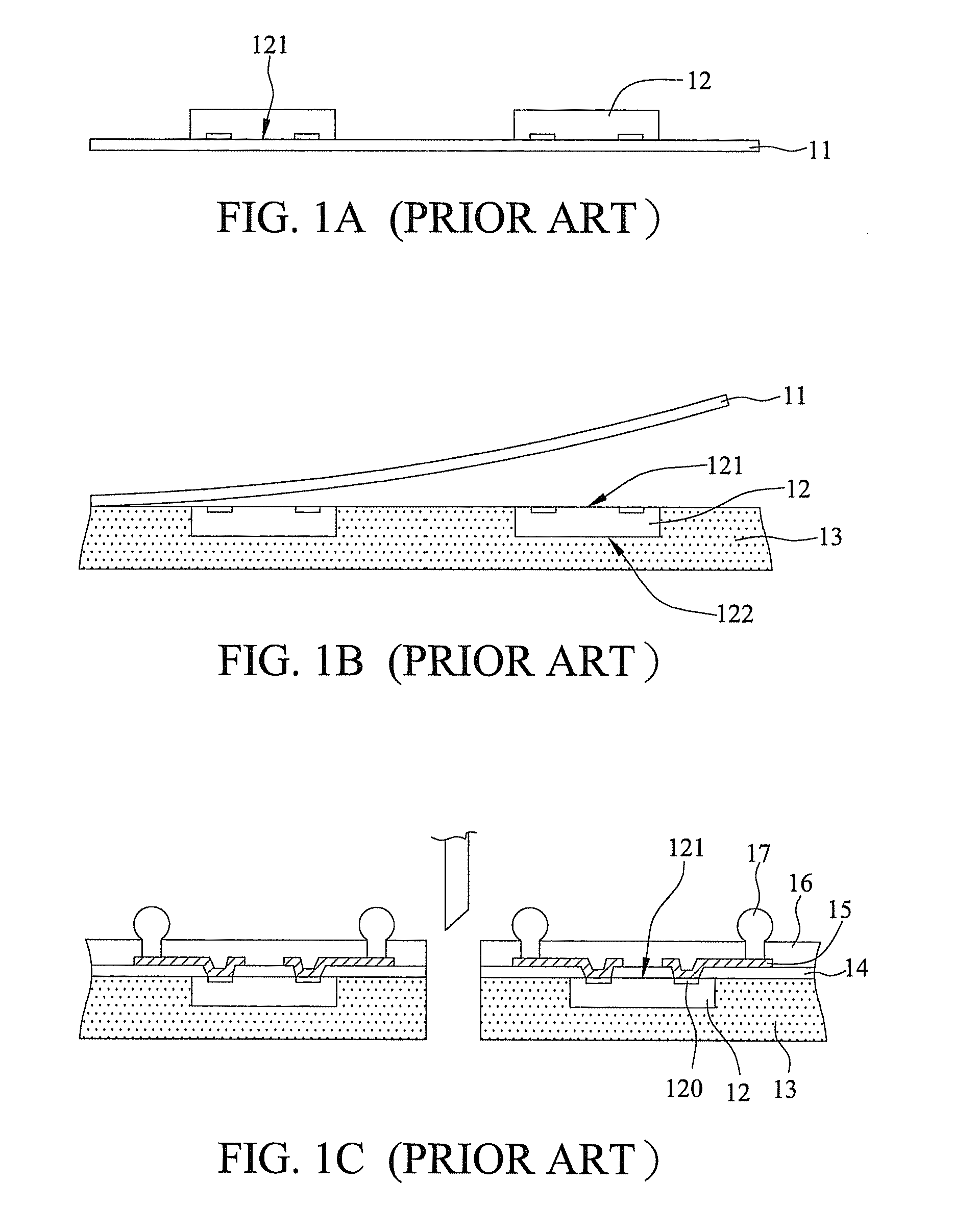

Semiconductor package and method of fabricating the same

InactiveUS20140042638A1Avoid warpingSemiconductor/solid-state device detailsSolid-state devicesSoft layerSemiconductor package

A semiconductor package is provided, which includes: a soft layer having opposite first and second surfaces and first conductive through hole vias; a chip embedded in the soft layer and having an active surface exposed from the first surface of the soft layer; a support layer formed on the second surface of the soft layer and having second conductive through hole vias in electrical connection with the first conductive through hole vias; a first RDL structure formed on the first surface of the soft layer and electrically connected to the active surface of the chip; and a second RDL structure formed on the support layer and electrically connected to the first RDL structure through the first and second conductive through hole vias. The invention prevents package warpage by providing the support layer, and allows disposing of other packages or electronic elements by electrically connecting the RDL structures through the conductive through hole vias.

Owner:SILICONWARE PRECISION IND CO LTD

Mat structure and sole structure

A sole structure includes: an anti-skid layer, a rigid layer, an elastic piece and a soft layer which are superimposed upon one another. With the characteristic of the elastic piece being elastically deformable, a rebounding force can be produced to act on the foot to stimulate the ligaments and muscles of the foot, which consequently corrects the flatfoot.

Owner:HI MAX INNOVATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com