Patents

Literature

165results about How to "Fix unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

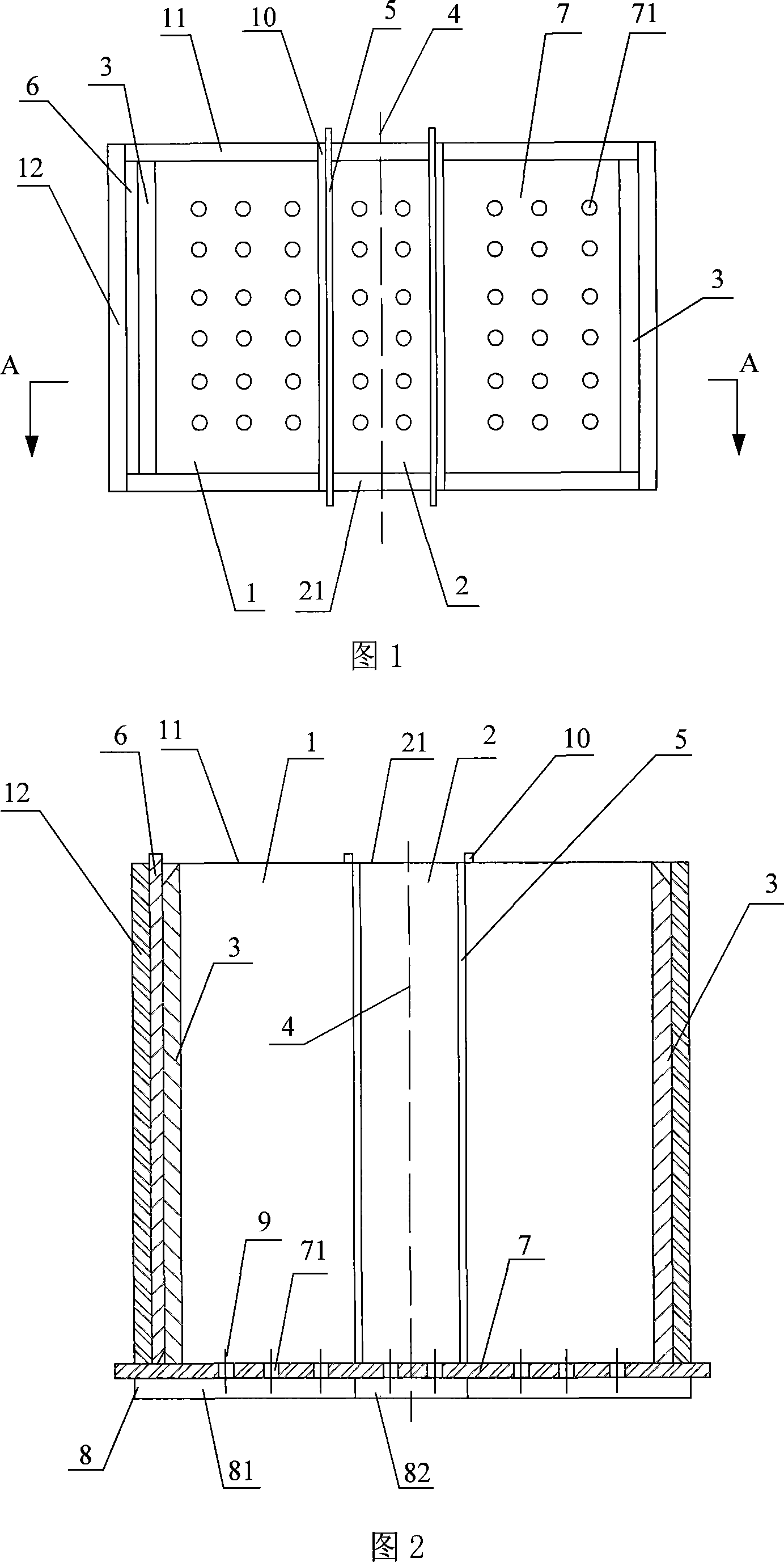

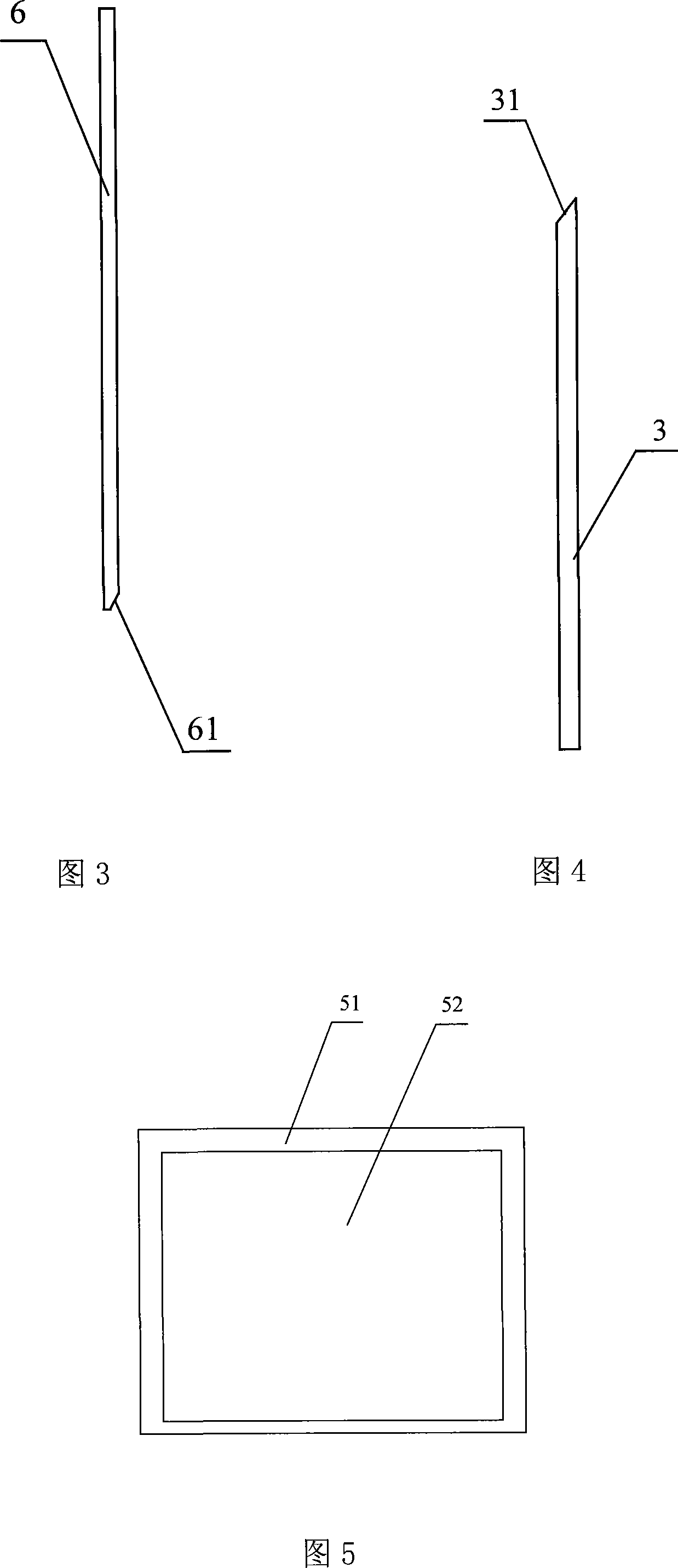

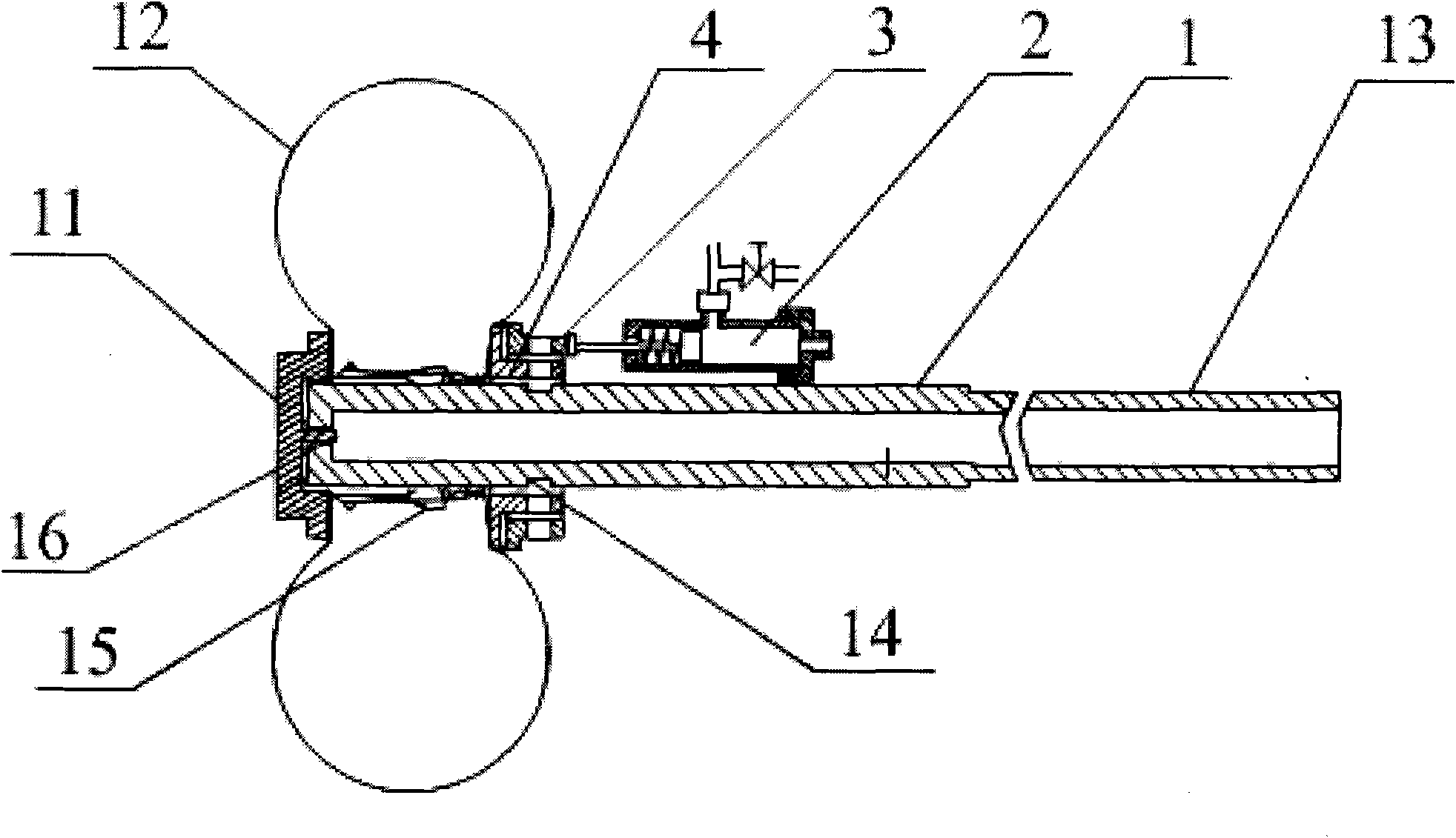

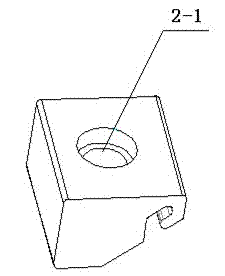

Plants root box culturing device used for rhizosphere soil sampling

InactiveCN101082547AEasy accessSimplified methodWithdrawing sample devicesPreparing sample for investigationPlant rootsEngineering

The invention discloses a kind of plant root box culture equipment used in rhizosphere oil sample which includes a removable block body and in the block body grip lays two pieces of root room separation mesh piece so it slips the block body into one medial cell and two side cells; at the bottom of block body sets up a guide water board with a hole on it and the locelle irrigation bottom cut locates under the guide water board and at one end of the guide water line locates in the locelle irrigation bottom cut and the other end locates in the cavity of block body through the guide water hole; the side cell sets up a inner lining board slipping in the side cell and the plug board may lay between the inner lining board and the block body and the inner lining board parallels with the center line of the plug board. Adopt the invention's equipment can sampling the different distance oil convenience and accurately.

Owner:ZHEJIANG UNIV

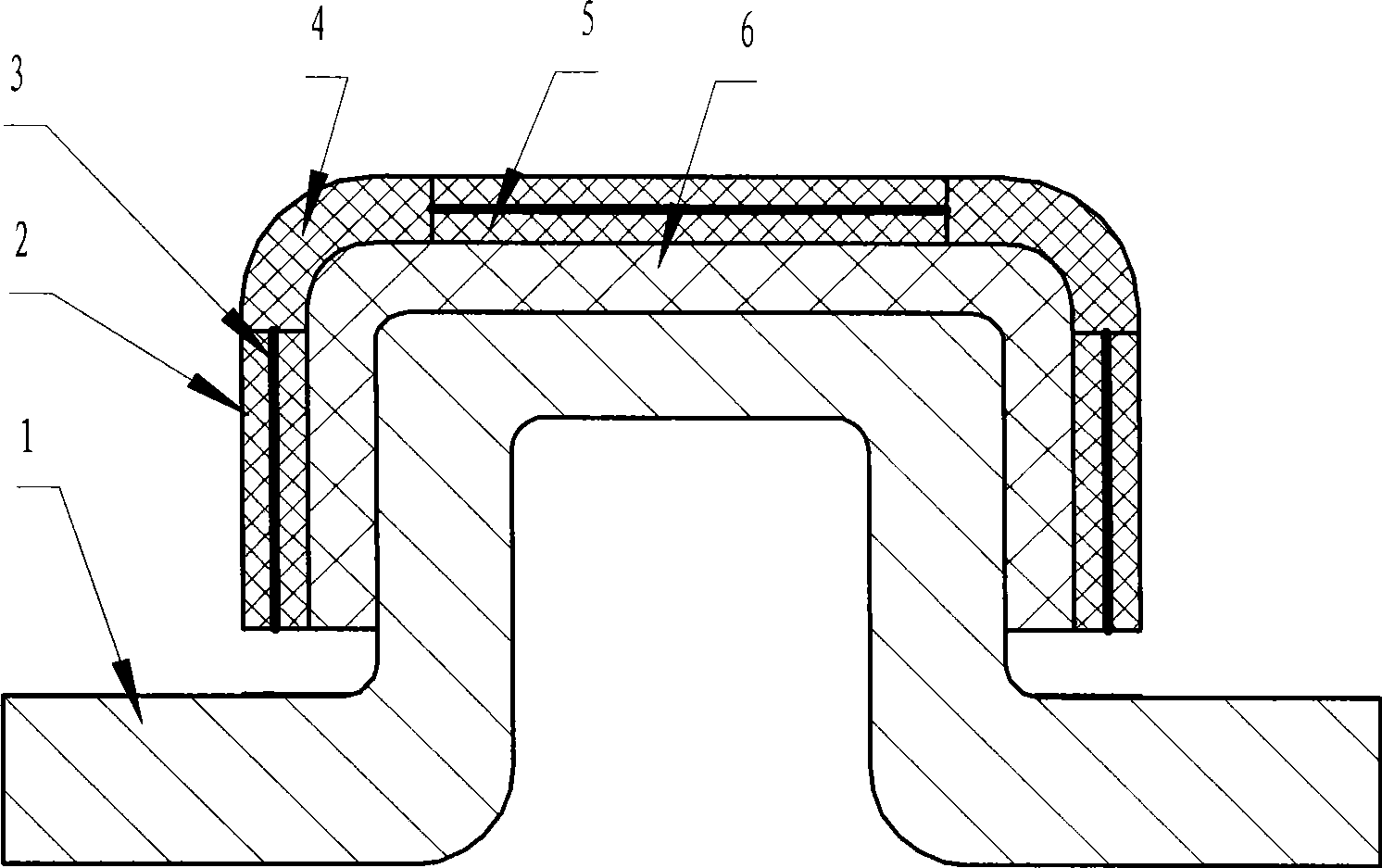

Curing formation method for non-flat plate composite product and shaping mould

The invention discloses a curing forming method and a forming die used for a non-slab composite material part. The method comprises the steps as follows: composite material part blank is arranged on a rigid die body which has the same shape with the processing shape and gluing and layer-paving are carried out according to the required dimension; after the layer-paving is finished, the composite material part blank is arranged on the rigid die body; furthermore, surfaces with plane are provided with elastic soft layers; corner pure rubber layers which are connected with elastic soft layer joint seams are arranged at corner profile so as to form a soft die surface; subsequently, vacuum bag auxiliary material is arranged on the soft die surface so as to prepare the vacuum bag curing forming composite material part. By the flexible soft die consisting of rubber-fabrics, the method arranges the composite material part blank on the surface of the soft die after the layer-paving is finished; the method for preparing the vacuum bag curing forming part solves the surface quality problems in the prior art that the non-die surface of the bag-pressing forming composite material part is crapy, accidented and has no gloss and the like, and improves the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

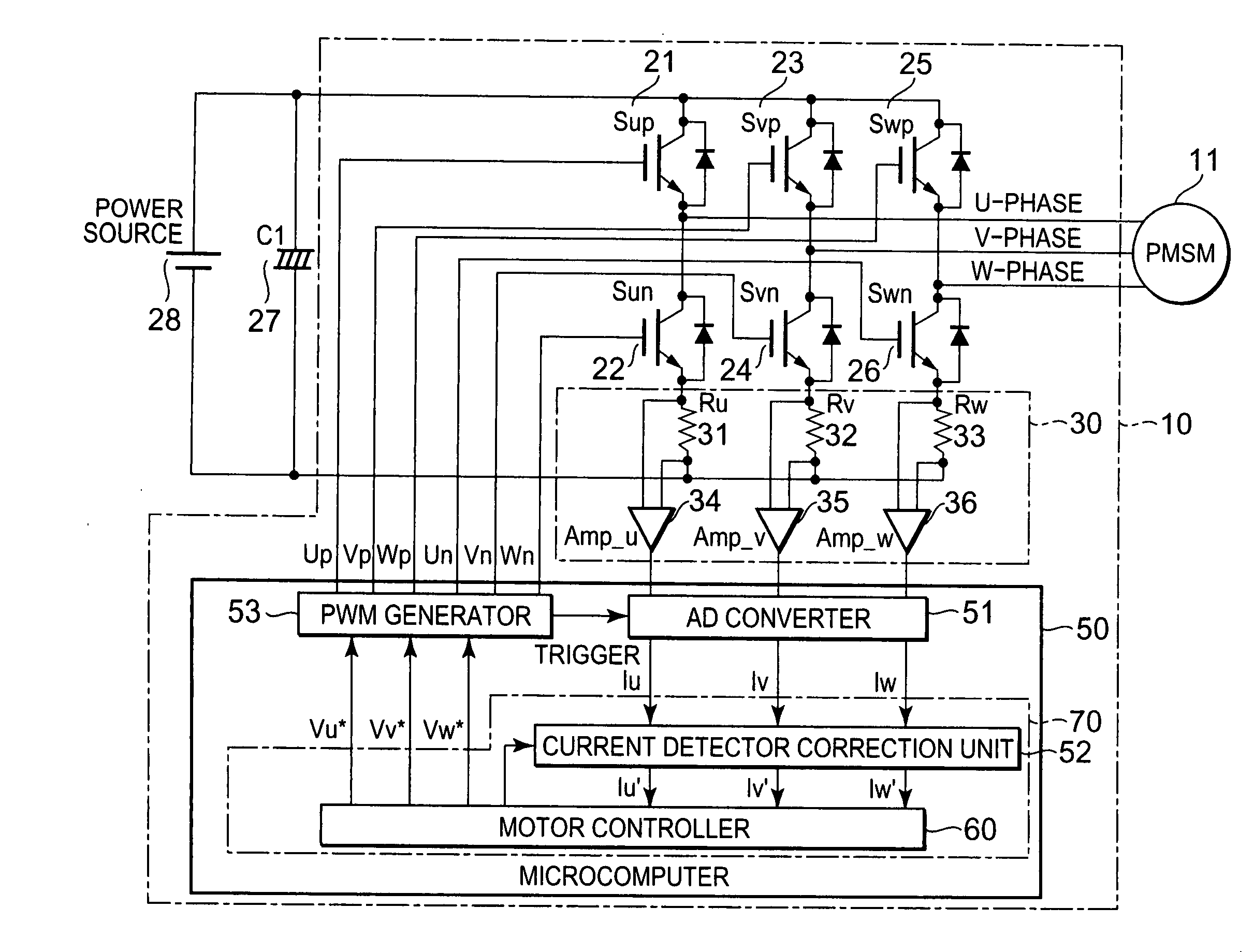

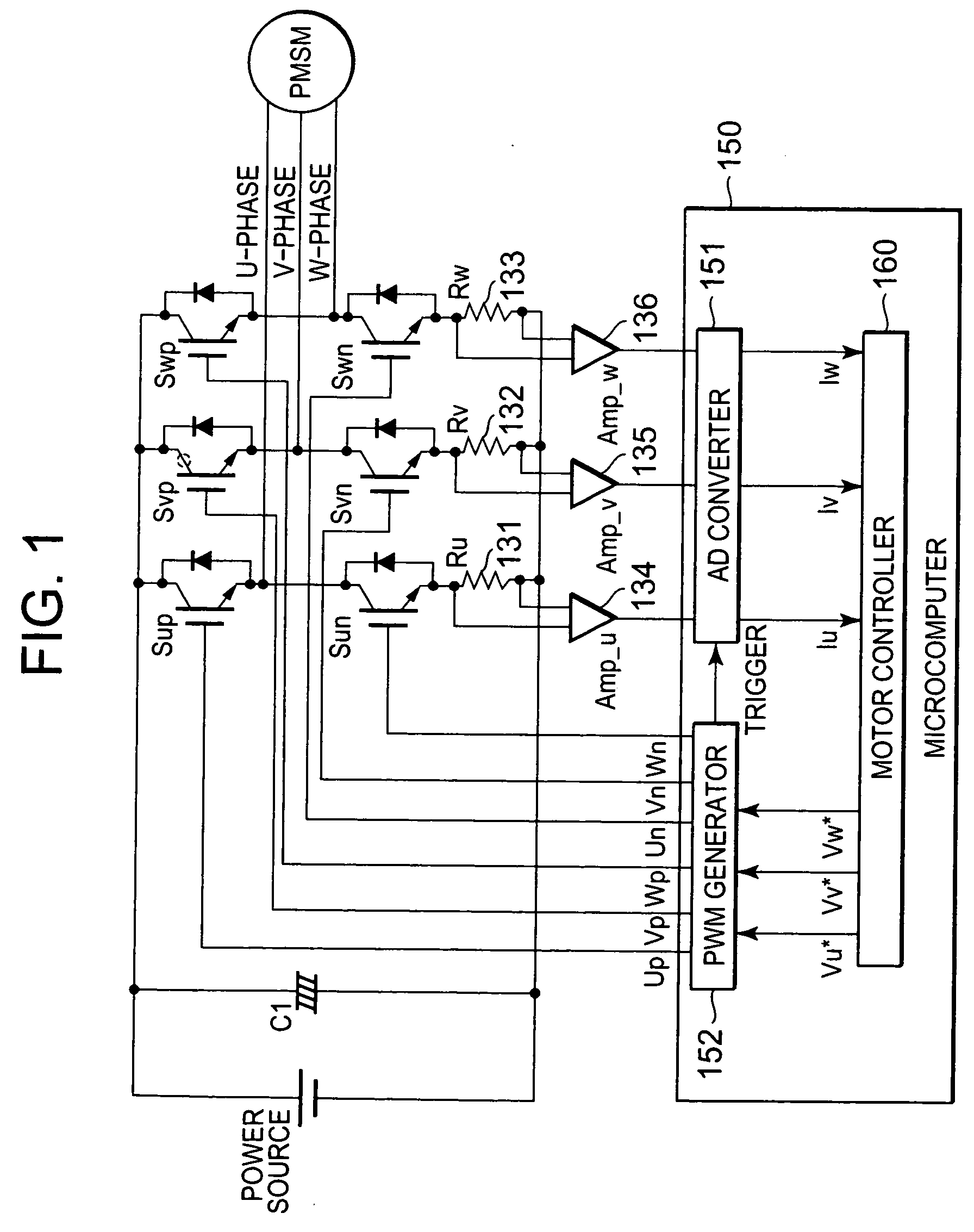

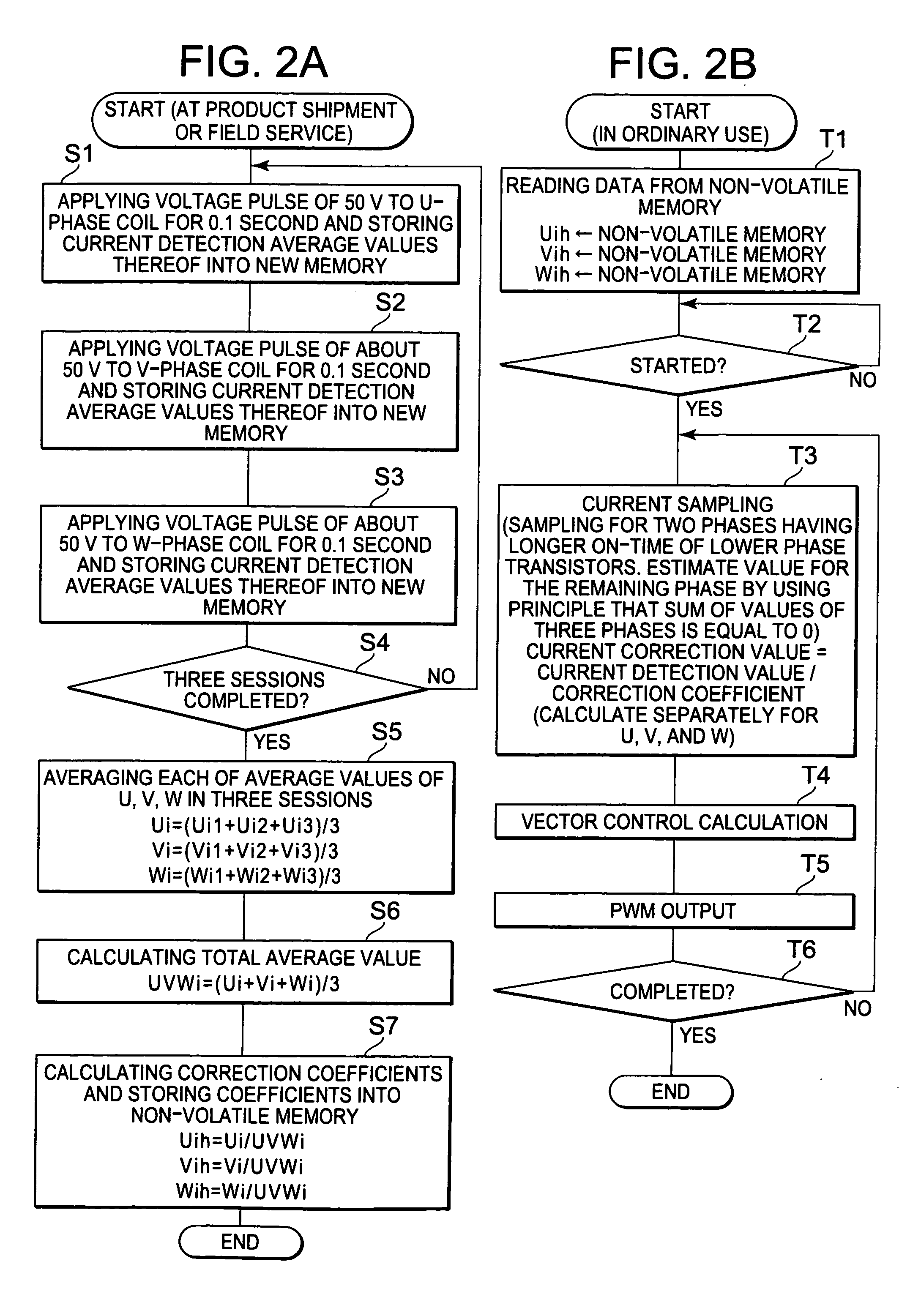

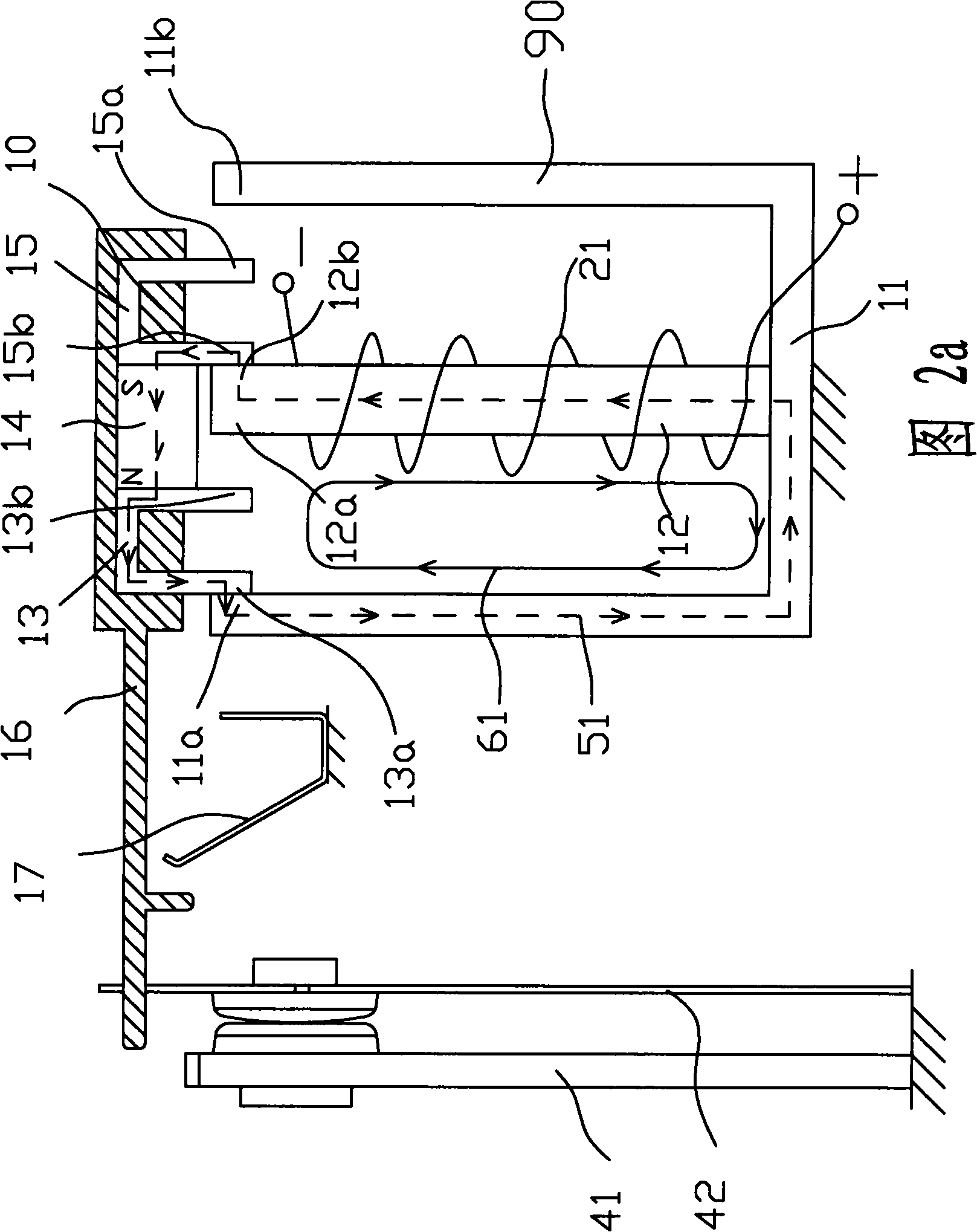

Inverter apparatus and a semiconductor device used for the same

ActiveUS20080265829A1Low costIncrease torqueSingle-phase induction motor startersDC motor speed/torque controlThree-phaseSemiconductor

FIGS. 4A and 4B are principle diagrams for correcting deviations among current detectors of a three-phase motor 19 in an inverter apparatus of the present invention, which includes bidirectional switching elements 13 to 18. FIG. 4C shows on and off states of switches in the cases of FIGS. 4A and 4B, in which 1 and 0 mean on- and off-states, respectively. The states shown in FIGS. 4A and 4B are alternately repeated by controlling the switches, and measurement for correcting the deviations among the current detectors are obtained in the state shown in FIG. 4B. Specifically, in FIG. 4B, currents having the same amplitude flow on a U phase and a V phase. Accordingly, a difference in the measured data represents a difference in performances of the current detectors. In the state of normal use, the inverter apparatus is operated by correcting detected current values based on the measurement data.

Owner:RENESAS ELECTRONICS CORP

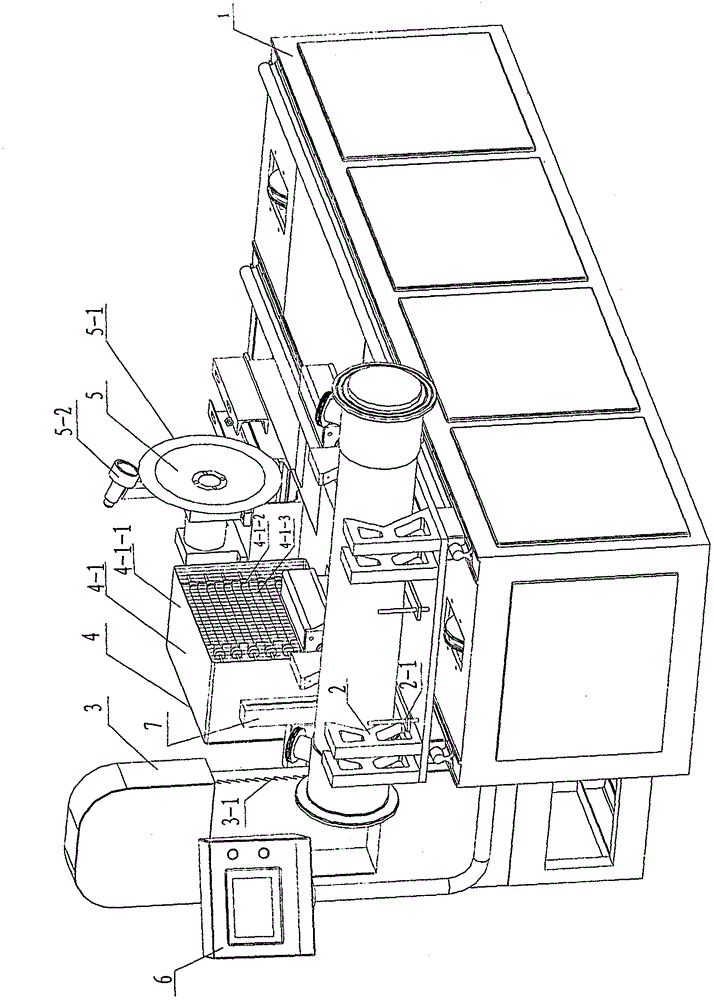

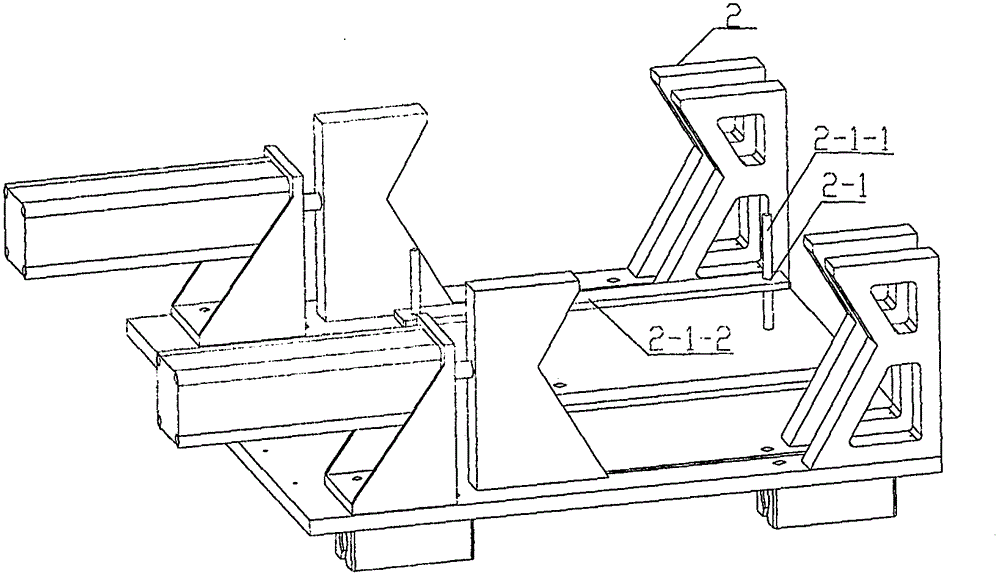

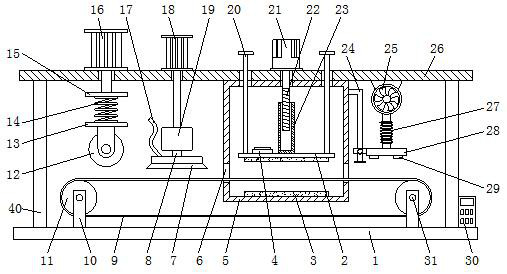

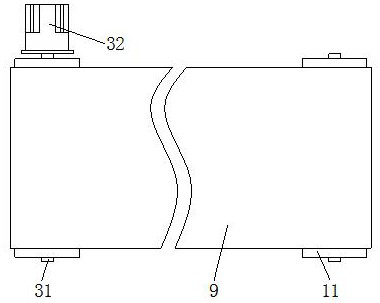

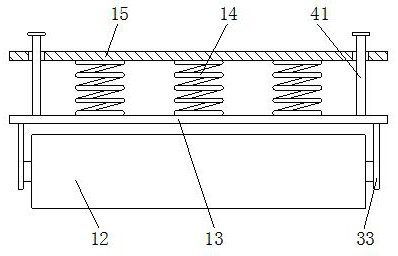

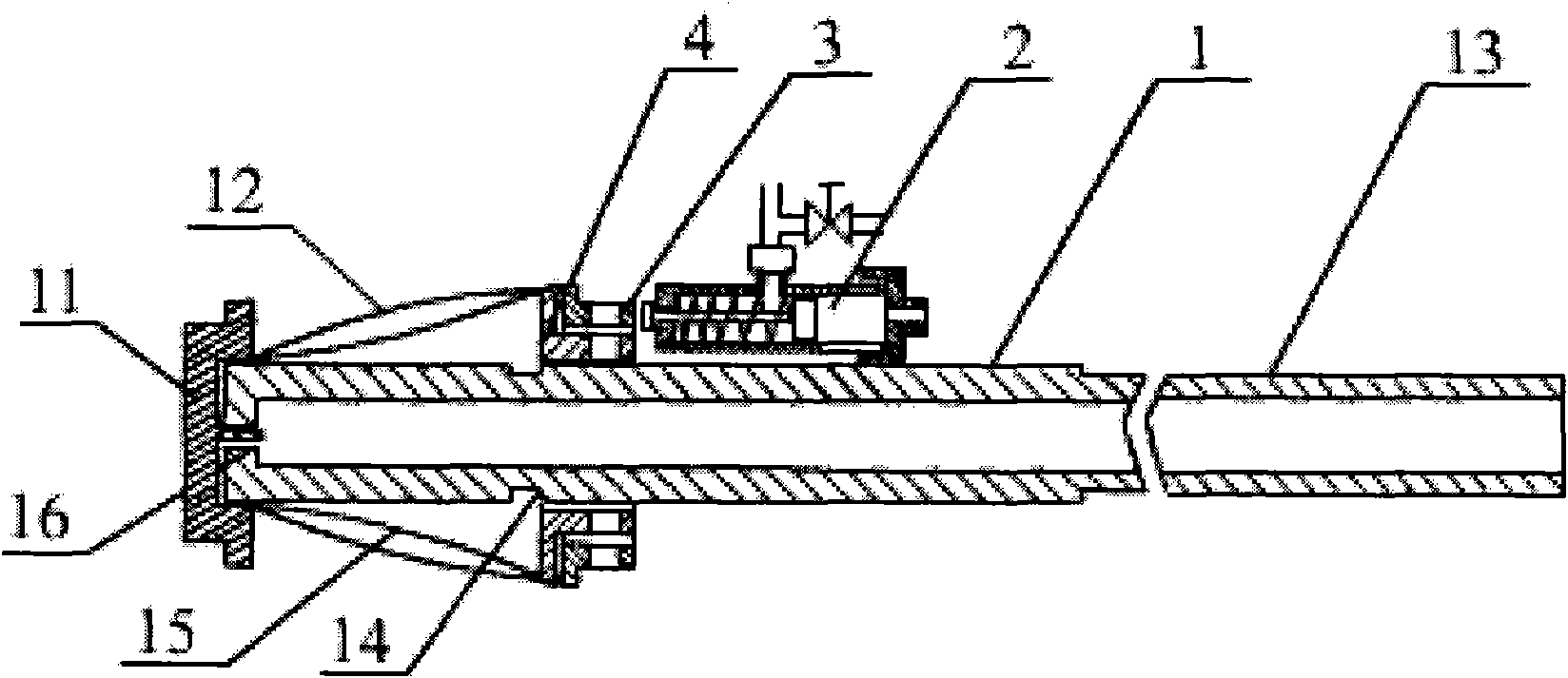

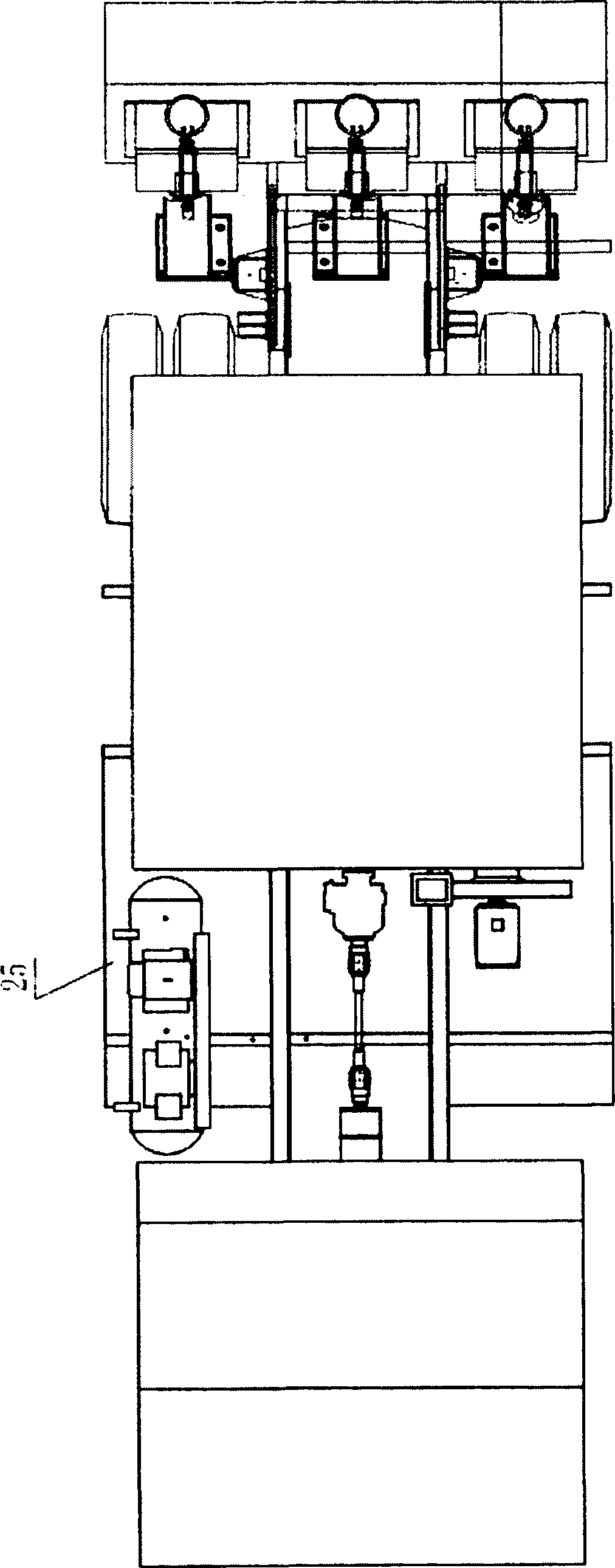

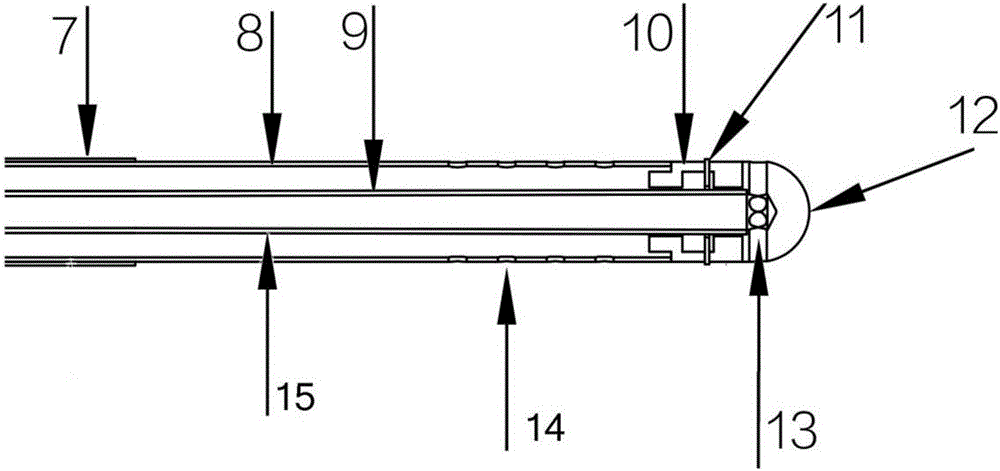

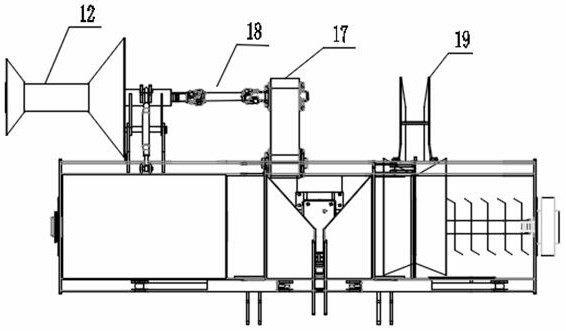

Multifunctional ultrafiltration membrane module cutter

InactiveCN102744742AImprove cutting efficiencyHigh speedMetal working apparatusBiochemical engineeringOperational safety

The invention relates to the technical field of ultrafiltration membrane machining equipment, in particular to a multifunctional ultrafiltration membrane module cutter. The multifunctional ultrafiltration membrane module cutter is provided with a frame with a slide rail; a movable clamping device used for clamping an ultrafiltration membrane module is arranged on the frame; and a rough cutting device, a heating device and a fine cutting device, which are capable of roughly cutting, heating and finely cutting the ultrafiltration membrane module in the clamping device in sequence when the clamping device advances to a certain position, are arranged on one side of the frame. Through the adoption of the technology, technical problems of low efficiency, uneven cutting end surface, easiness for plugging a hole, potential safety hazards in operation and so on of the traditional manual cutting are solved; high production efficiency, even cutting end surface, no blockage of the hole, good use effect and long service life of an ultrafiltration membrane as well as simplicity and convenience in operation are achieved; and the potential safety hazards in operation are lowered.

Owner:施吉中

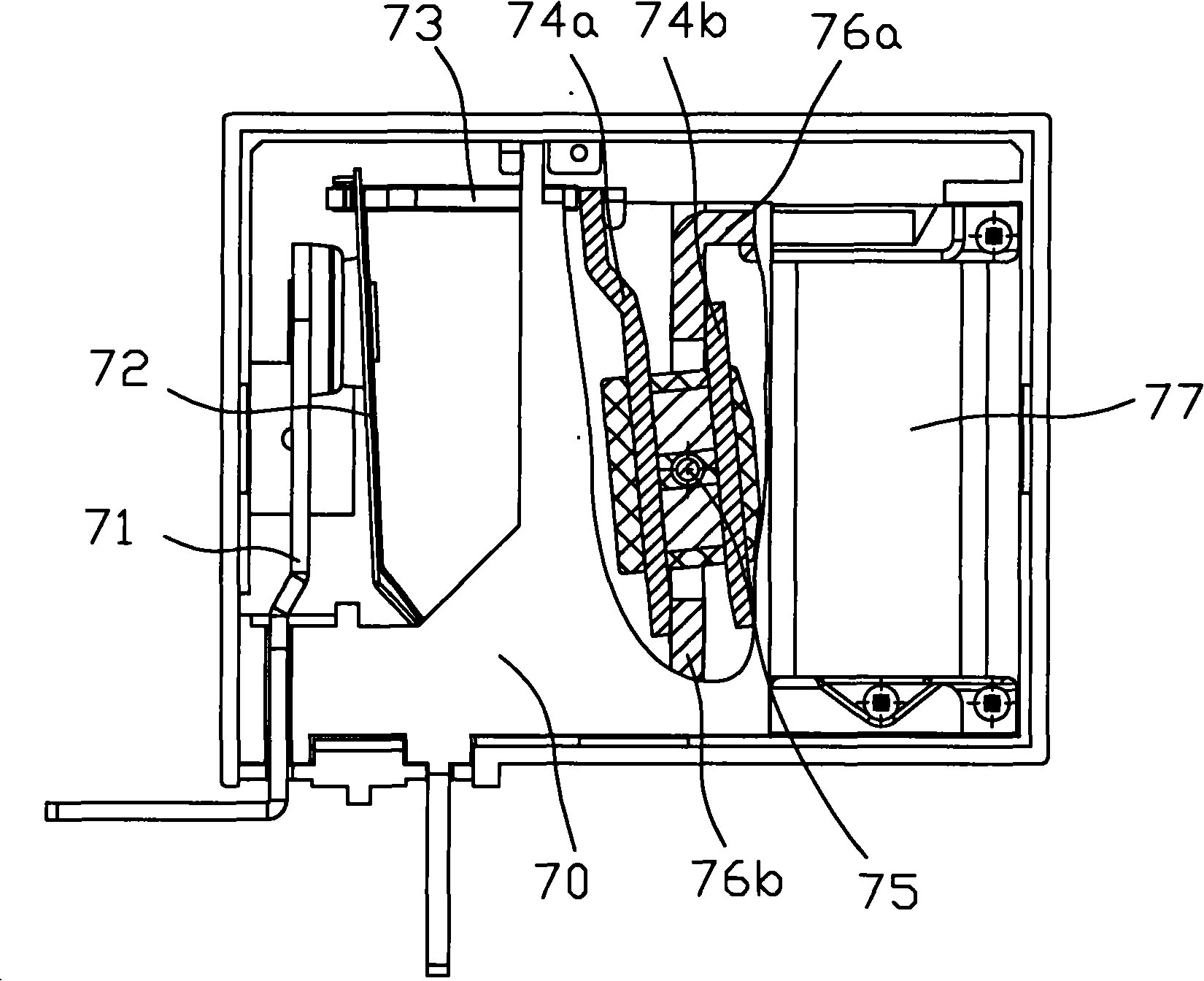

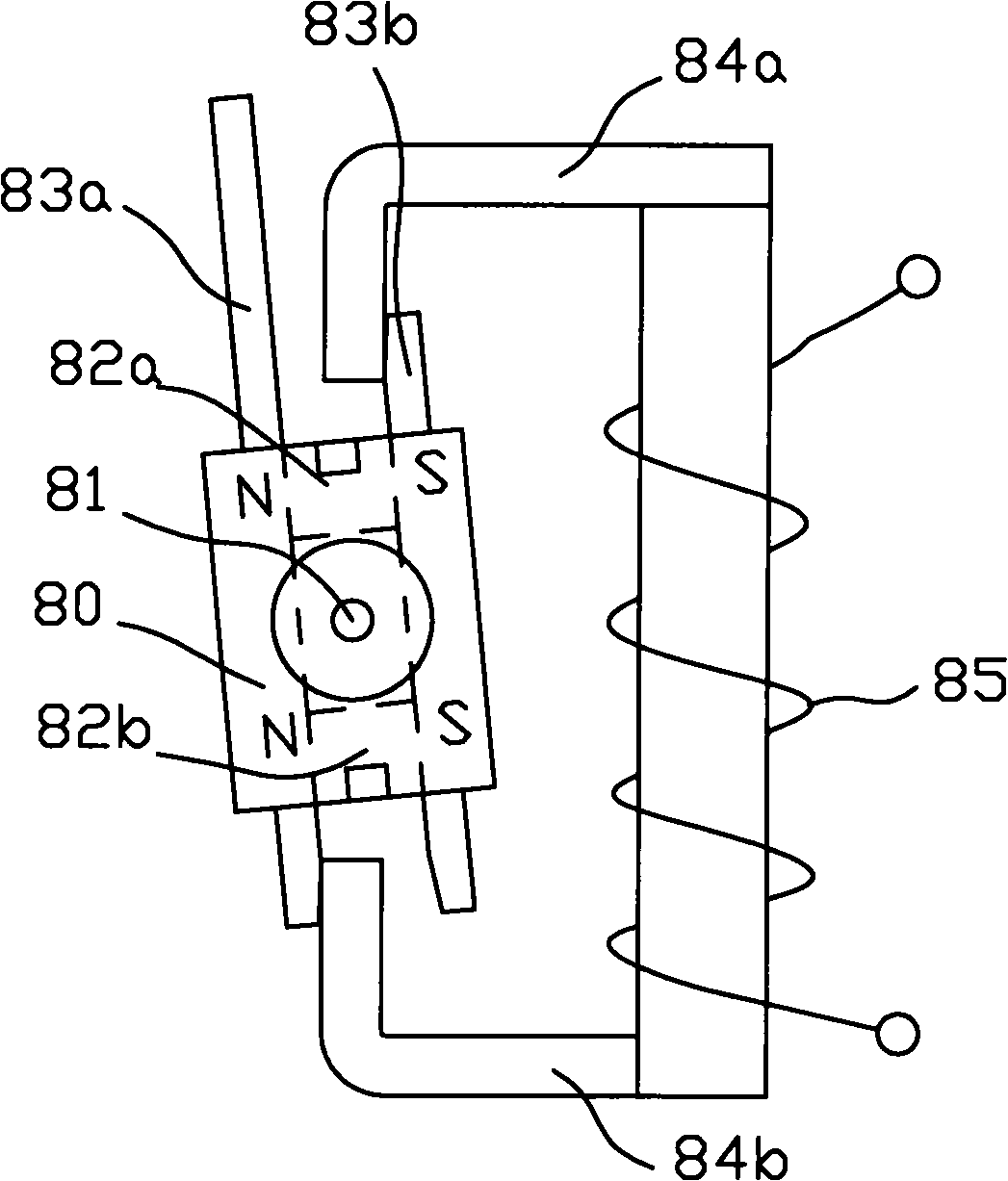

Magnet retaining relay

InactiveCN101335156AImprove stabilityReduce manufacturing difficultyElectromagnetic relay detailsNon-polarised relaysCounterforceRelay

The invention discloses a magnetic latching relay comprising a magnetic circuit part, a contact part and a counterforce reed. The magnetic circuit part is composed of a coil, an E-shaped static magnetizer component and a moveable magnetizer component; the coil is wound on the static magnetizer component and a movable magnetizer component comprises a magnetic steel and a movable magnetizer arranged at the both sides of the magnetic steel with the same structure, the E-shaped static magnetizer component is formed by connecting two magnetizers and at lease one magnetizer is provided with a U-shaped structure. The magnetic circuit takes the shape of 'two squares stacked vertically', solves the problem of unevenness of magnetic circuit contact surface and enhances the stability of product performance; the static magnetizer of the magnetic circuit part adopts the U-shaped structure, and the movable magnetizer adopts two same U-shaped or similar structures; therefore, the manufacture difficulty of parts and assemble difficulty and precision of components are reduced, the counterforce reed causes the absorbing counterforce of the relay in working state to be balanced, thus enhancing the reliability.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

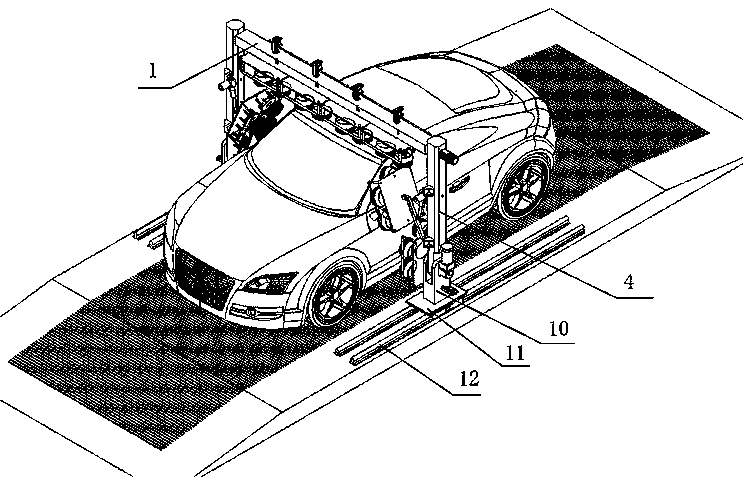

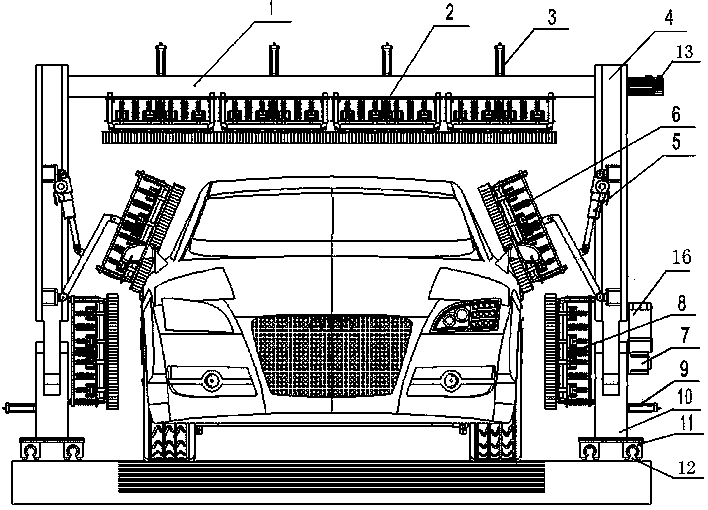

Gantry swing arm type automatic vehicle cleaning mechanism

PendingCN107685717AReduce volumeImprove cleanlinessCleaning apparatus for vehicle exteriorsStructural engineeringControl theory

The invention discloses a gantry swing arm type automatic vehicle cleaning mechanism which comprises fixing guide rails, movable sliders, swing arm supports, gantry swing arms and a gantry transversebeam. The fixing guide rails are arranged on the ground, the movable sliders can slide on the fixing guide rails in the front-back directions, the swing arm supports are fixed onto the movable sliders, the gantry swing arms are arranged on the swing arm supports and are connected with the swing arm supports by connecting shafts, and the gantry transverse beam is arranged on the two gantry swing arms and is connected with the gantry swing arms by shafts; bottom electric push rods are arranged on the swing arm supports, and bottom cleaning devices are arranged at the front ends of the bottom electric push rods. The gantry swing arm type automatic vehicle cleaning mechanism has the advantages that the gantry swing arm type automatic vehicle cleaning mechanism is of a gantry structure, two side arms of a gantry can swing, accordingly, the gantry swing arm type automatic vehicle cleaning mechanism can be easily matched with vehicle shapes, and vehicles can be efficiently automatically cleaned in a high-quality manner; the gantry swing arm type automatic vehicle cleaning mechanism is small in occupied area, simple in integral structure and quite suitable for popularization and utilization.

Owner:HEBEI BOYI GONGJI SCI & TECH DEV CO LTD

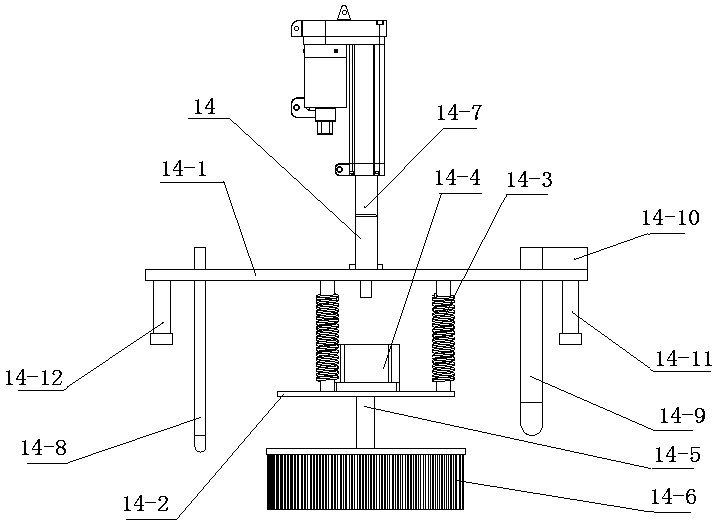

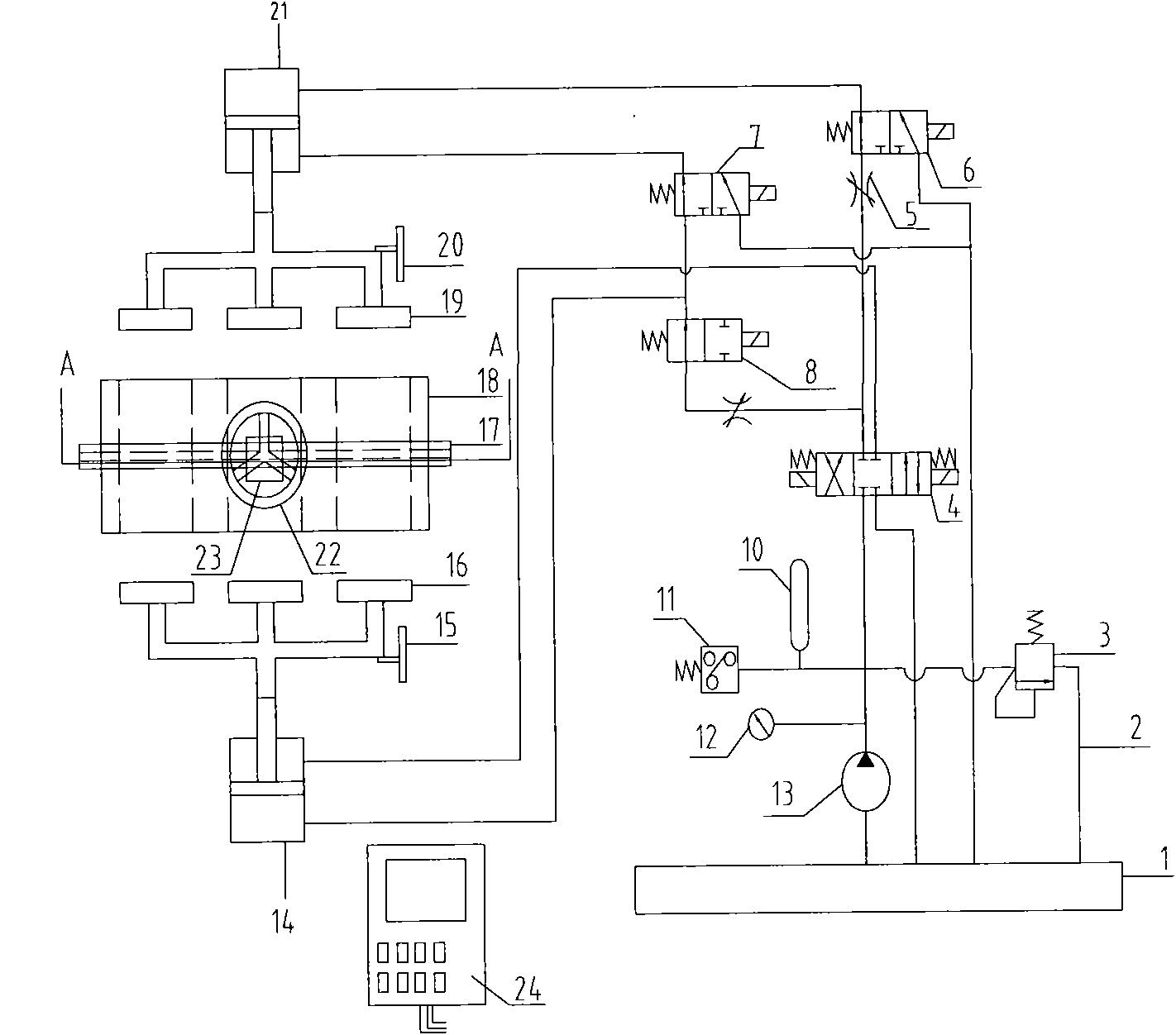

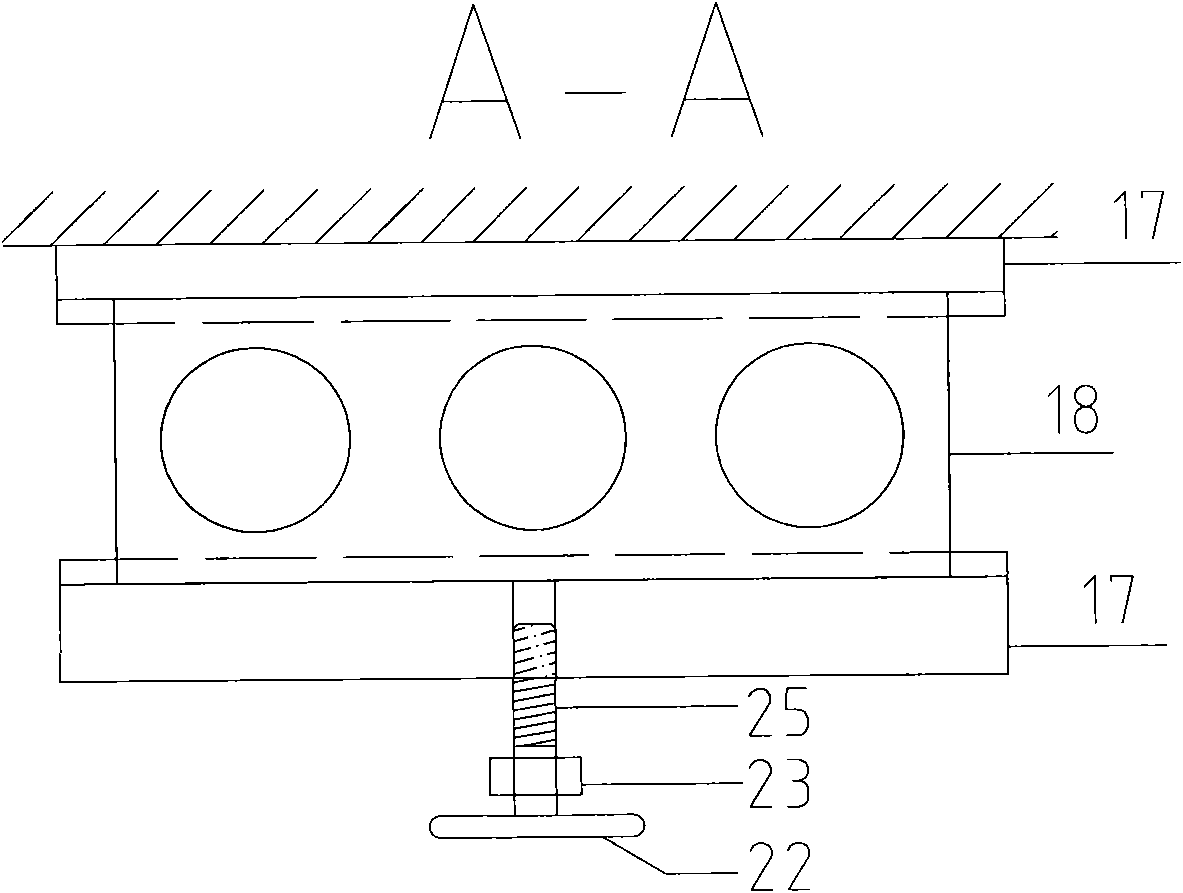

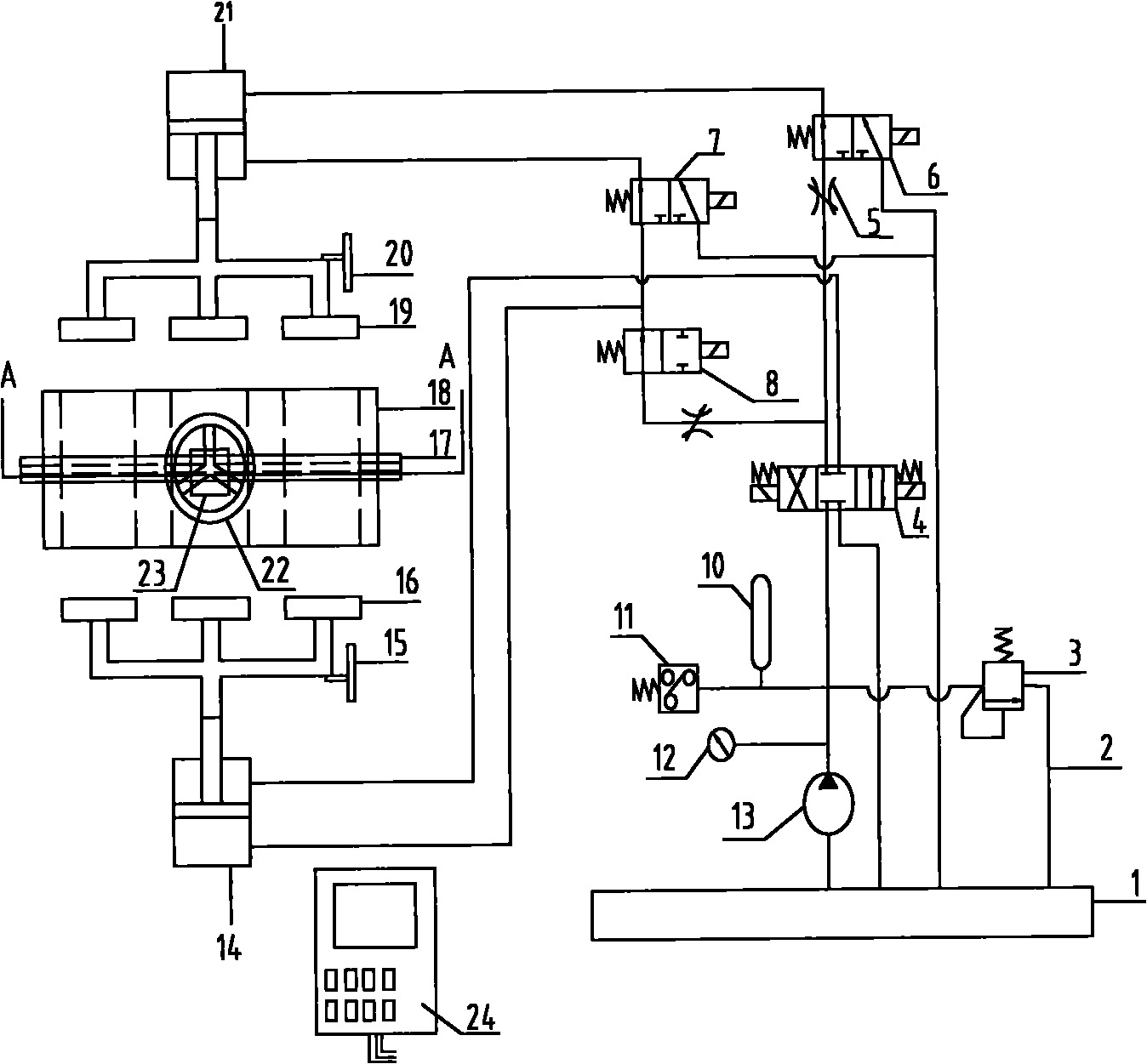

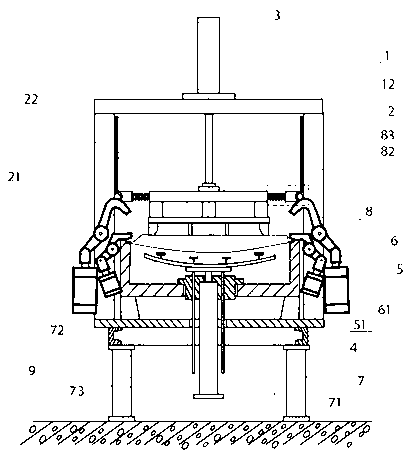

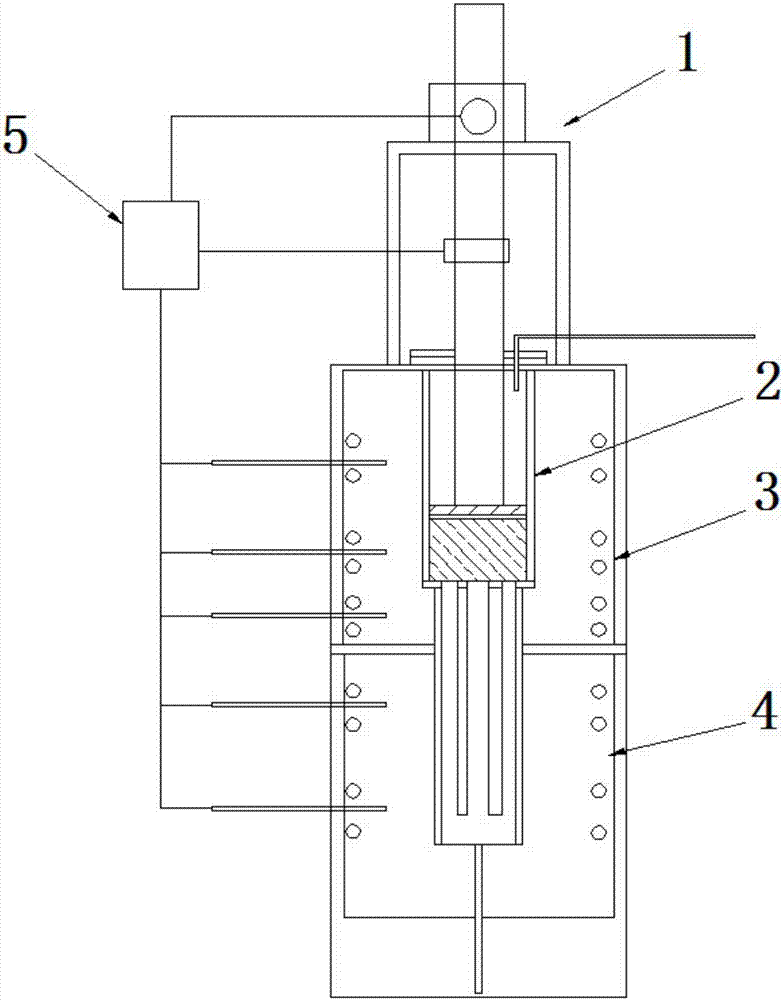

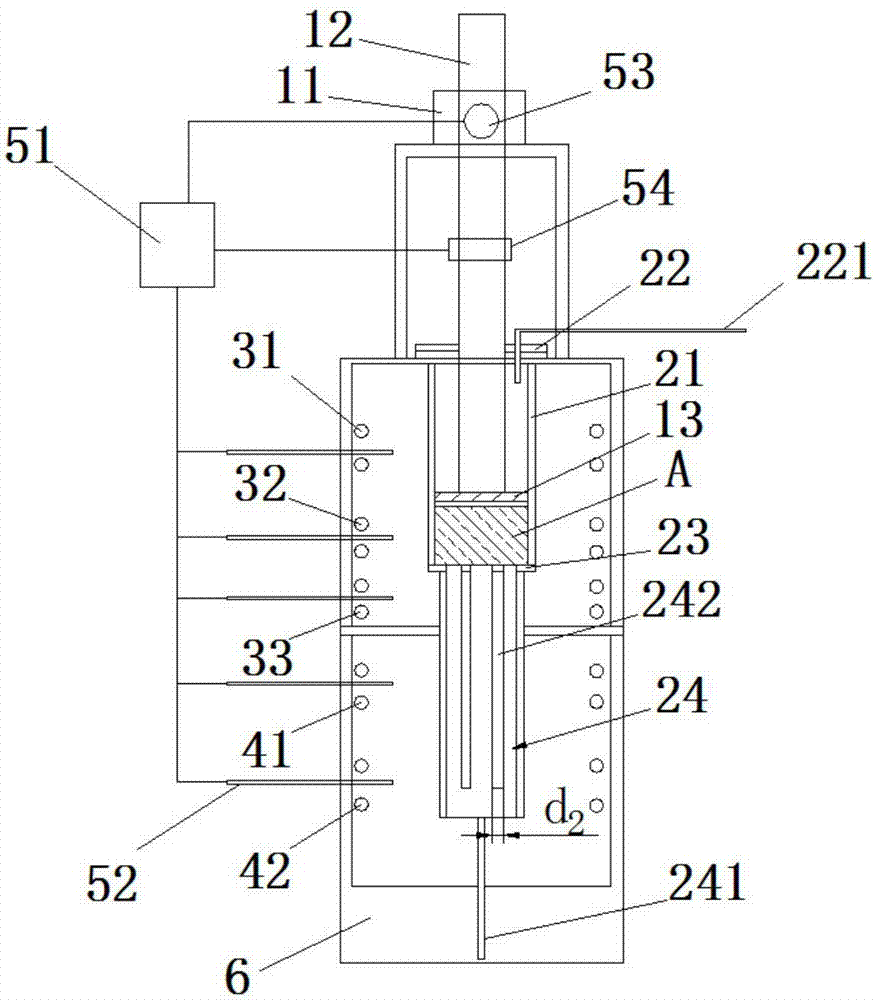

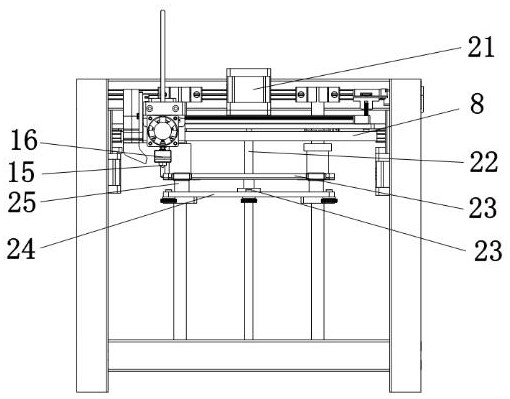

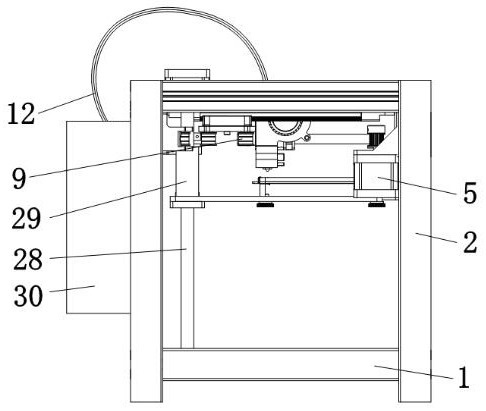

Sample preparing and demoulding integrated instrument

InactiveCN101863075AControl automatic demouldingAddressing inhomogeneityDischarging arrangementHigh densityEngineering

The invention discloses a sample preparing and demoulding integrated instrument. The integrated instrument at least comprises a driving mechanism, a transmission mechanism, a base and a material loading die which is arranged on the base, wherein an upper pressure plate is arranged above the material loading die; a lower pressure plate is arranged below the material loading die; and both the upper pressure plate and the lower pressure plate are connected with the transmission mechanism. The integrated instrument has the advantages of capability of preparing a plurality of test pieces at the same time, and realizing a mode of bidirectional vertical pressurization, simple operation and using, certain automation degree, convenient maintaining, capability of preparing geotechnical samples with higher density and uniform water content, and high efficiency of sample preparation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Mask and production method thereof

ActiveCN101650526ALarge inclinationDecrease the inclinationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPhotoresist

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Automobile door taping machine

InactiveCN103157711ASmooth hemmingReduce noiseShaping toolsMetal-working feeding devicesEngineeringCar door

The invention discloses an automobile door taping machine. A pre-taping module and a taping module of the automobile door taping machine are provided with working faces which are matched with automobile door pre-taping molded surfaces. Two ends of the pre-taping module and two ends of the taping module are provided with rotary shafts respectively. The rotary shafts are arranged on bearing blocks which are arranged at two ends of each edge of a die block. The pre-taping module and the taping module are respectively driven by a first actuating device and a second actuating device and rotate around the rotary shafts of the pre-taping module and the taping module. The pre-taping module and the taping module are arranged in a separating mode and are controlled by independent actuating devices, so that the whole structure is reasonable, dismantling becomes convenient, and mold repairing quantity of the pre-taping module and the taping module is greatly reduced. Due to the fact that a rolling mechanism which guides a clamping device to move up and down and can adjust gaps automatically is arranged on the clamping device, work of the clamping device is stable and reliable, a chattering phenomenon generated when the clamping device works is restrained effectively, and positioning error is reduced.

Owner:戴崇强

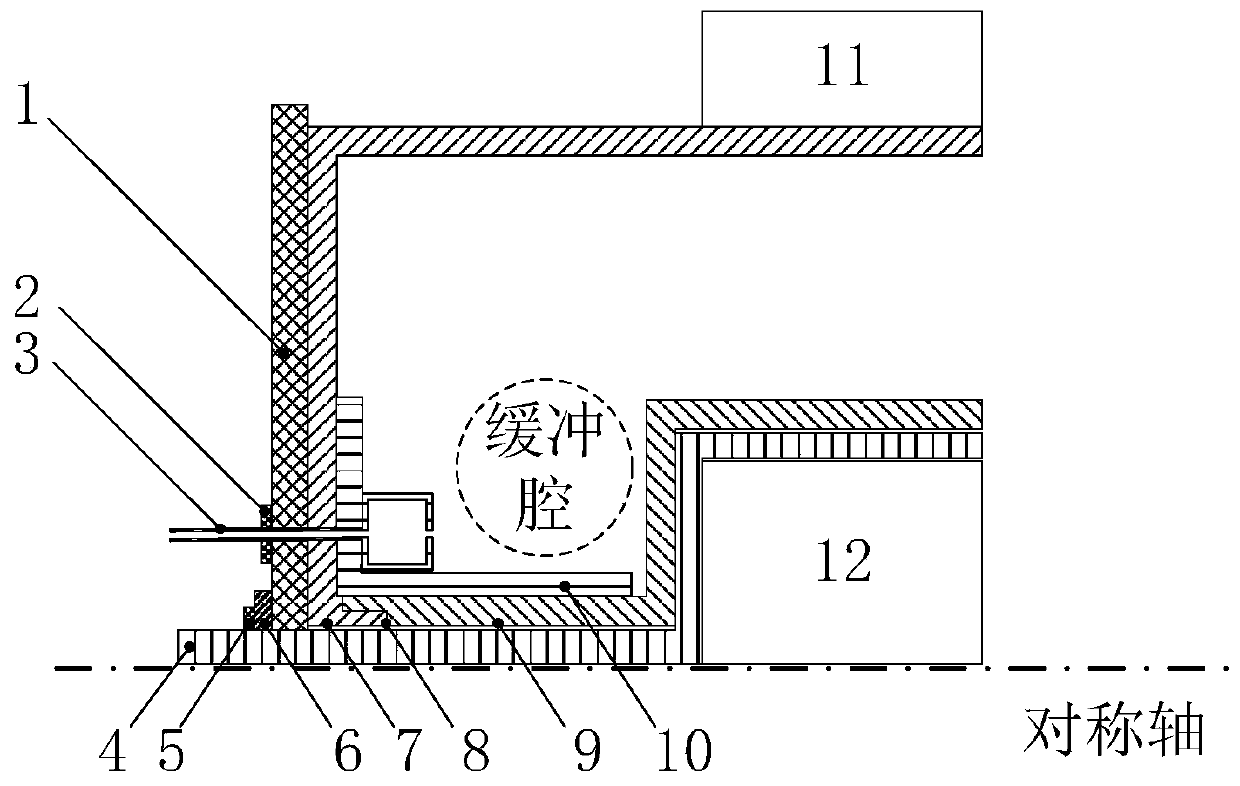

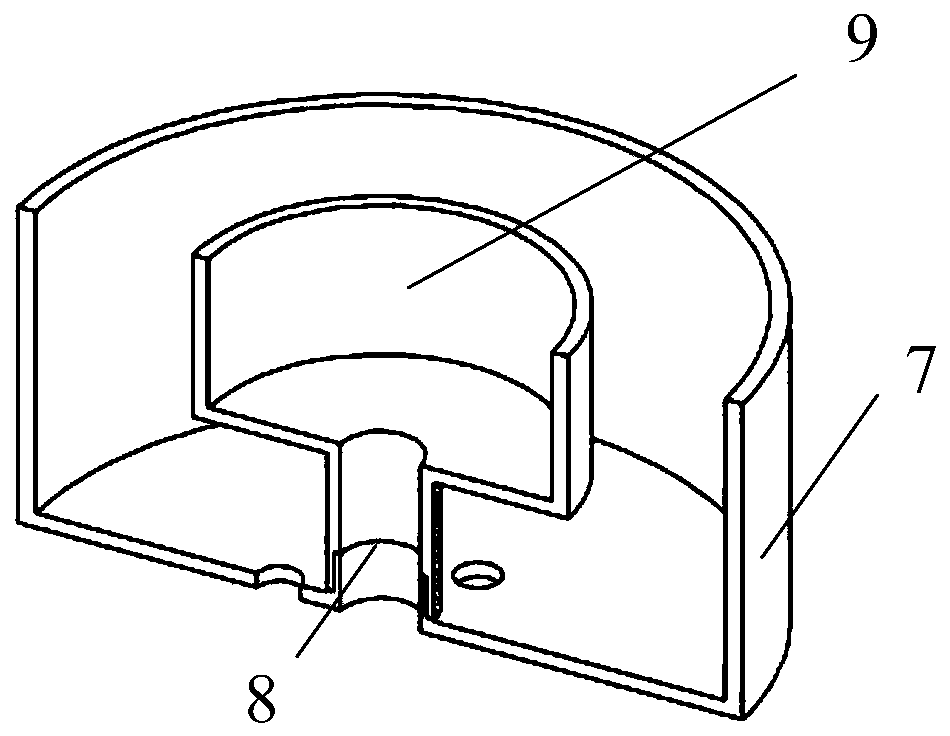

Hall thruster with novel buffer cavity

ActiveCN111219305AHigh energy productIncrease gas densityMachines/enginesUsing plasmaPhysicsEngineering

The invention discloses a Hall thruster with a novel buffer cavity, and belongs to the technical field of Hall thrusters. The Hall thruster with the novel buffer cavity solves the problems that in thecase of an existing low-power Hall thruster, due to the fact that the size is too small, gas density and homogenization degree are not high. An inner ceramic screen and an outer ceramic screen of theHall thruster with the novel buffer cavity are of an inside-and-outside nested cylindrical structure, a radial gap and an axial gap are formed between the inner ceramic screen and the outer ceramic screen, so that a buffer cavity structure between the inner ceramic screen and the outer ceramic screen is formed, an anode and the outer ceramic screen are fixedly mounted on a bottom plate through agas distributor and a nut, an inner permanent magnet is fixedly mounted in the inner ceramic screen through a permanent magnet support, and is fixedly mounted on the bottom plate through a fixing nut,and an outer permanent magnet is mounted on the outer side of the outer ceramic screen in a sleeving mode. A discharge channel of the Hall thruster with the novel buffer cavity is formed by insertingthe outer ceramic screen and the inner ceramic screen, the buffer cavity is formed at the area between the outer ceramic screen and the inner ceramic screen, a gas motion path is enlarged through thenovel buffer cavity structure, and gas is more sufficiently homogenized.

Owner:HARBIN INST OF TECH

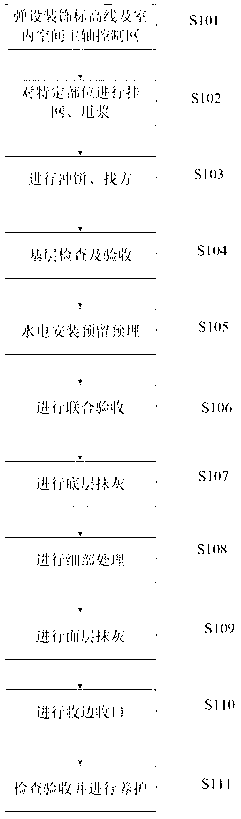

Interior wall plastering construction method

ActiveCN103321393AControl hollowing and crackingFix unevennessBuilding constructionsElectricitySlurry

The invention provides an interior wall plastering construction method. The method includes: a) setting a decoration elevation line and an indoor spatial main axis control network; b) hanging a continuous steel mesh at a specific position, and then performing slurry throwing and broom finish treatment on a wall base layer; c) controlling the thickness of wall ash cakes, and after cake flushing construction is finished, remeasuring the spatial size and squareness of a room; d) performing complete inspection and acceptance on the wall base layer, pretreating portions with structural deviations exceeding construction requirements; e) performing water and electricity installation, reservation and embedding according to a designed comprehensive wiring pattern; f) performing combined inspection and acceptance on the steps; g) performing bottom layer plastering; h) performing detail treatment; i) performing face layer plastering; j) performing edging and closing; and k) performing inspection, acceptance and maintenance. By the method, hollowing and cracking of plastered surfaces, detail quality and installing and embedding of boxes can be controlled beneficially, and quality and attractiveness of finished surfaces of plastering are improved effectively.

Owner:MCC NORTHEAST CONSTR SHENYANG ENGTECH CO LTD +1

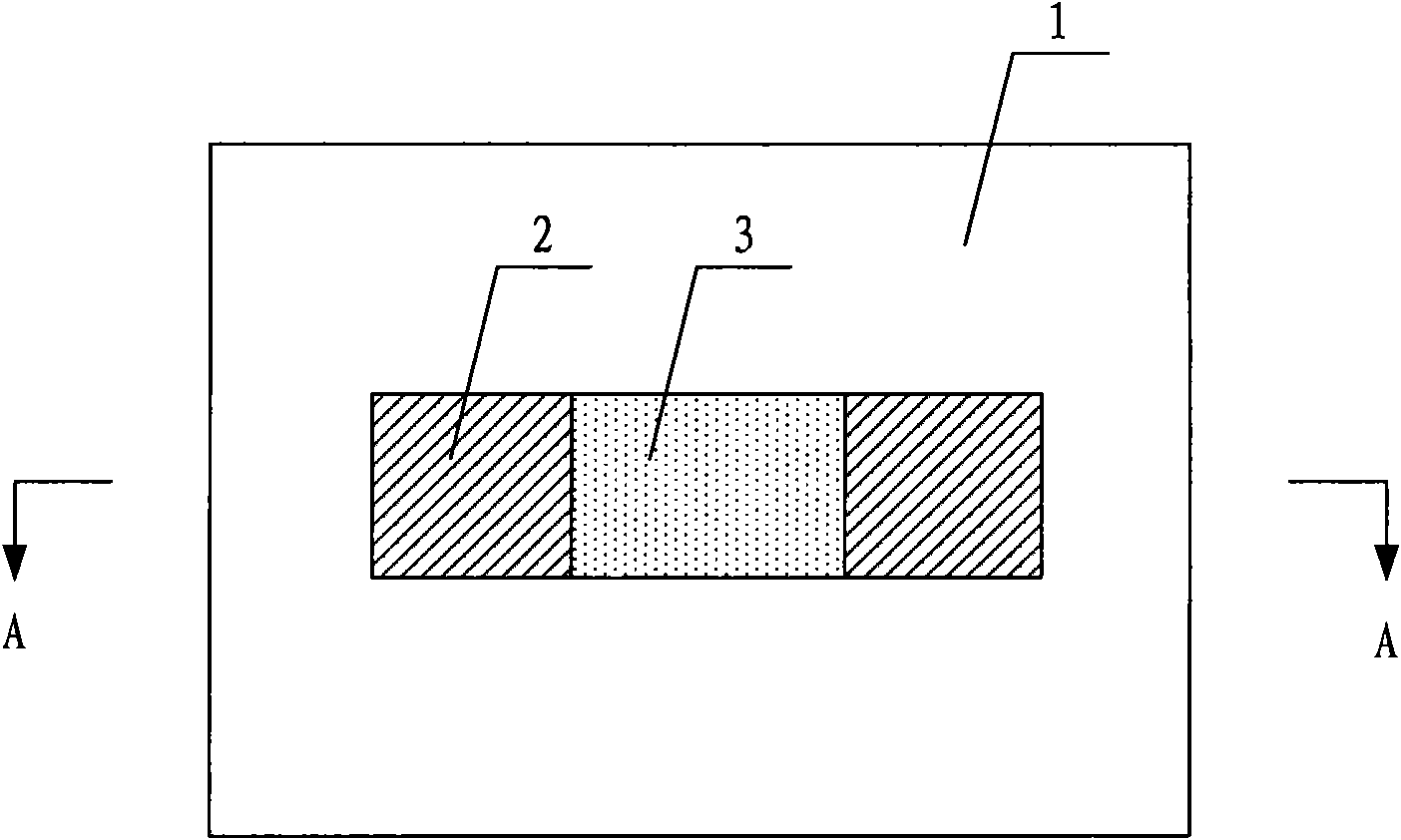

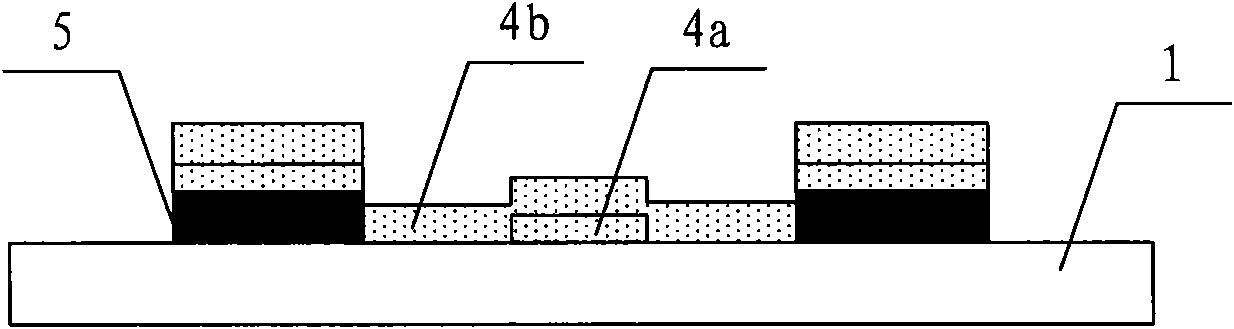

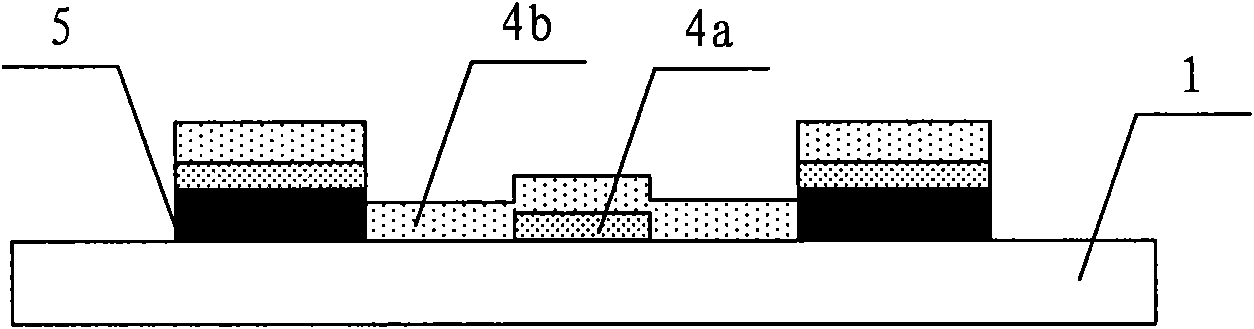

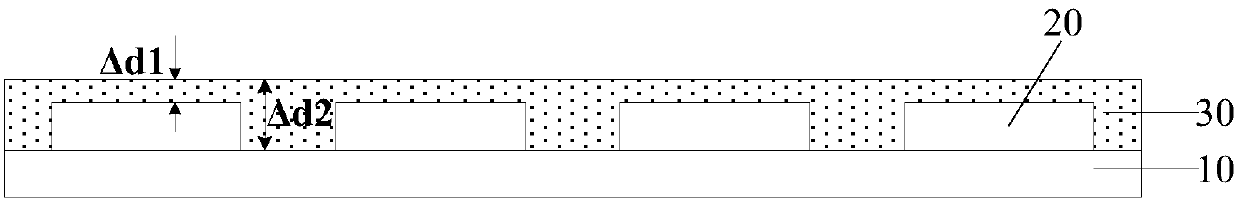

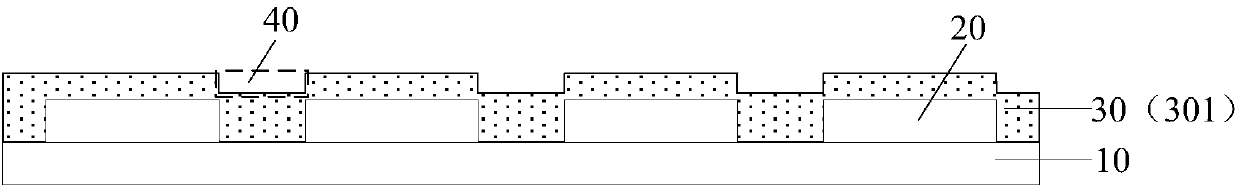

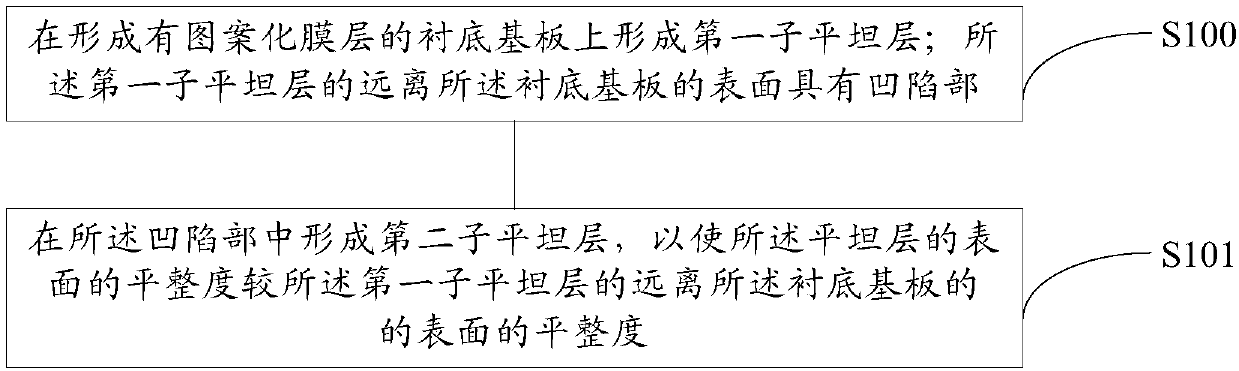

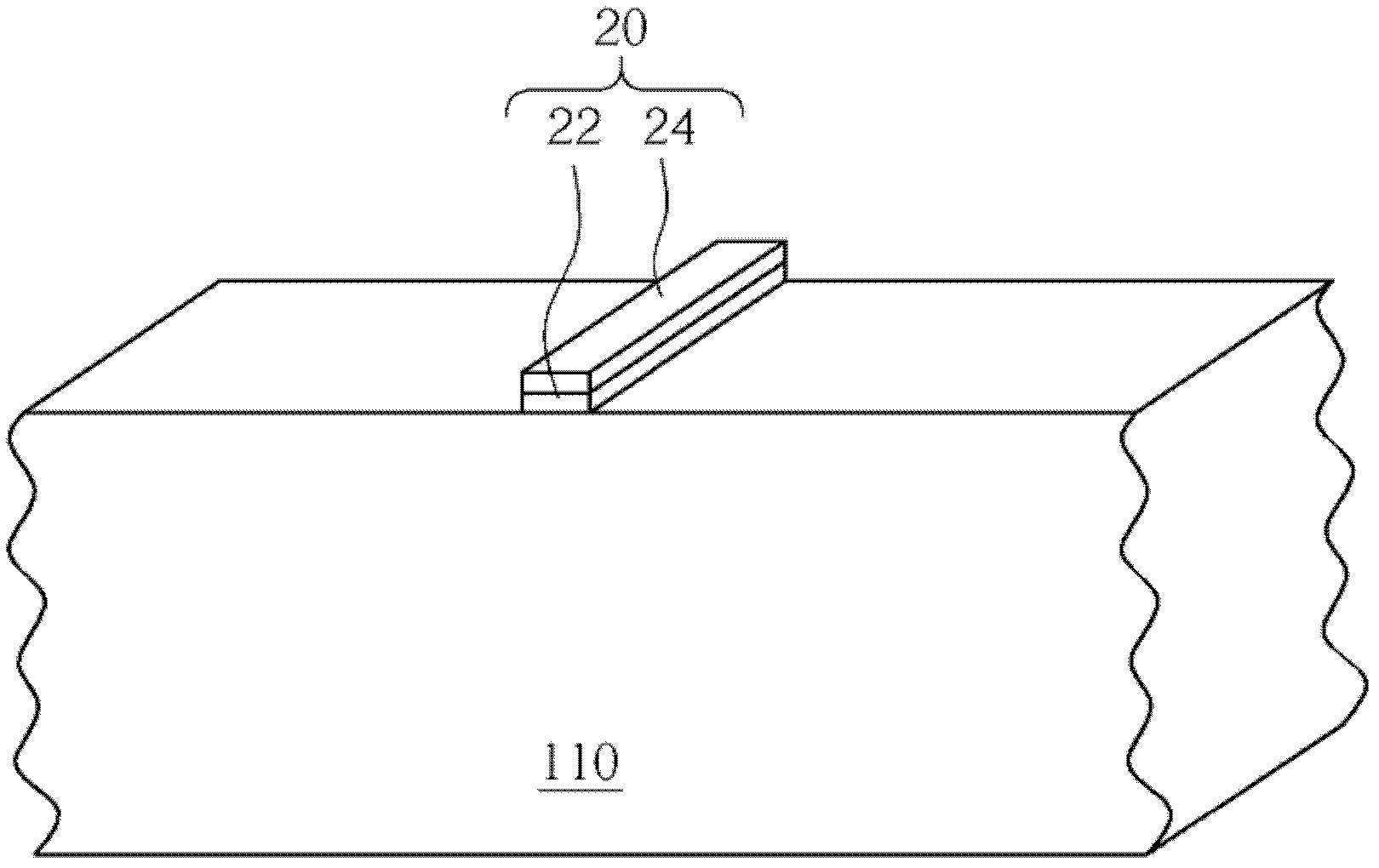

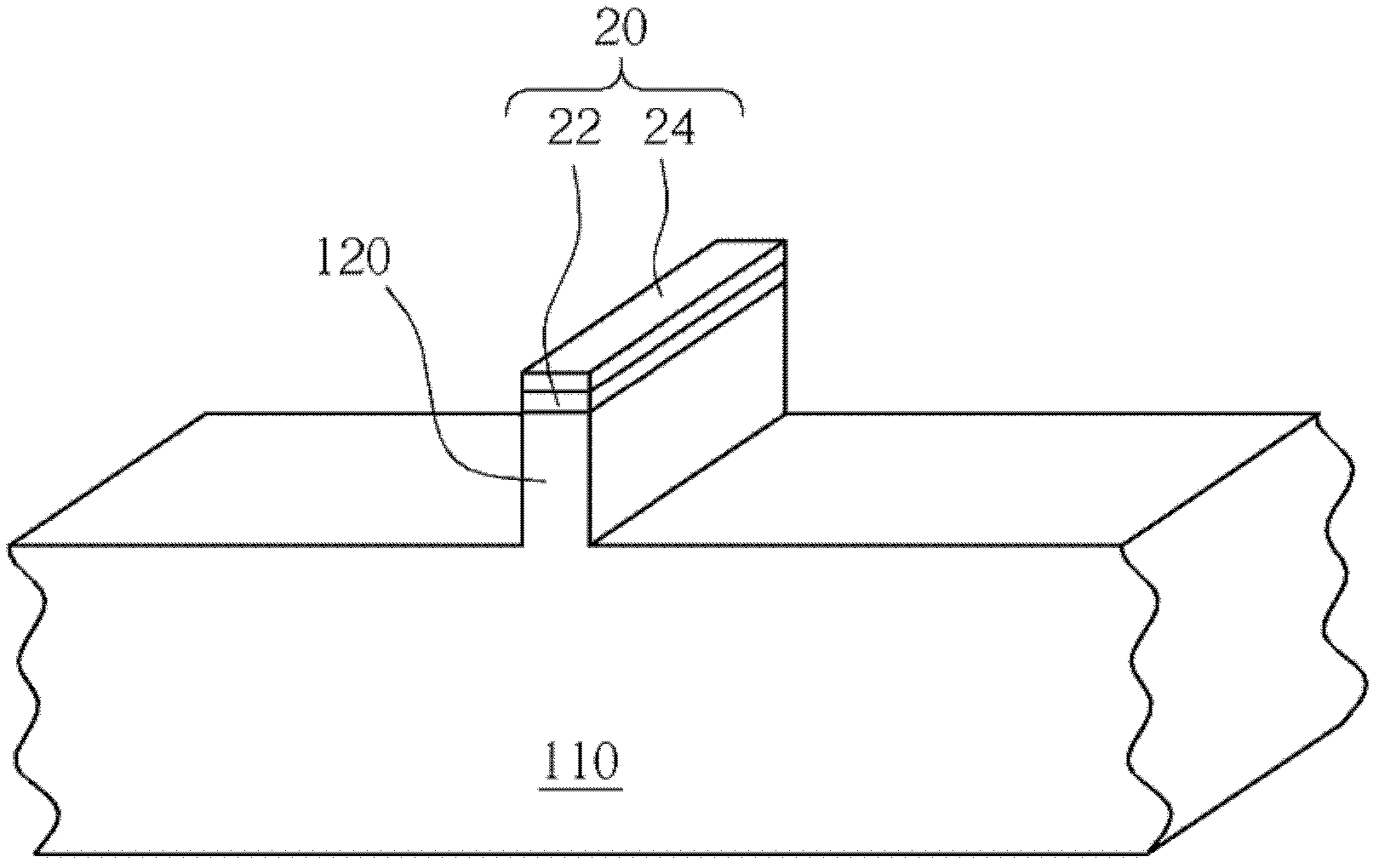

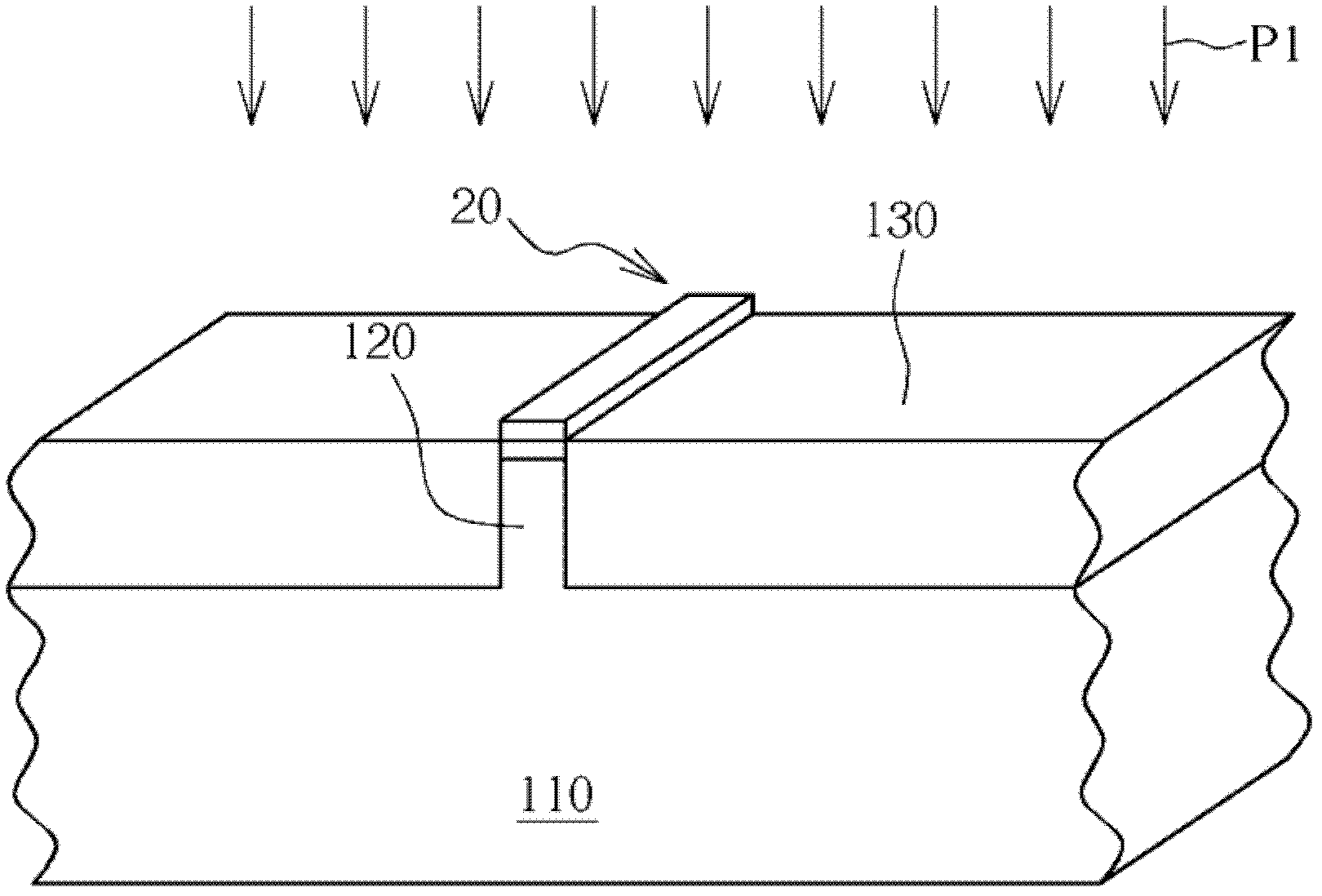

Substrate, preparation method thereof, display panel and display device

ActiveCN107731872AImprove flatnessFix unevennessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The embodiment of the invention provides a substrate, a preparation method thereof, a display panel and a display device, relates to the technical field of display, and is used for solving the problemthat a flat layer is rugged in the manufacturing process. The preparation method comprises the following steps: forming the flat layer, wherein the step of forming the flat layer comprises forming afirst sublayer on a substrate on which a patterned film is formed, wherein the surface, away from the substrate, of the first sublayer is provided with a concave part; and forming a second sublayer inthe concave part so that the flatness of the surface of the flat layer is higher than that of the surface, away from the substrate, of the first sublayer. The preparation method is used for forming the flat layer.

Owner:BOE TECH GRP CO LTD +1

Printing device and printing method

InactiveCN112208195AImprove drying effectHigh quality printed productsPlaten pressesPrinting press partsElectric machineryPrinting ink

The invention discloses a printing device and a printing method. The printing device comprises a bottom plate, wherein vertical plates are fixedly connected to the front sides and the rear sides of the left side and the right side of the top of the bottom plate; rotating rods are movably connected to the tops between the opposite sides of the front sides and the rear sides of the vertical plates;and the surfaces of the rotating rods are fixedly sleeved with rotating rollers. Through cooperative use of an electric heating plate, a temperature sensor, a heat preservation shell, a printing plate, a conveying belt, a pressing roller, a buffer spring, a first cylinder, a second cylinder, a third motor, a first threaded rod, a threaded barrel, a fan, a telescopic hose, a flat pipe, an air outlet pipe, a controller, a second motor, a threaded sleeve and a second threaded rod, the problems that disorder phenomenon occurs during printing since the phenomenon that printing paper is uneven oftenoccurs in the printing process of an existing printing device, meanwhile, printing ink cannot be rapidly dried after printing, and the situation that the printing ink moves easily occurs and then theprinting quality is affected if wind power drying is directly conducted are solved.

Owner:姚祖武

Process for producing semiconductor

ActiveCN103035517AFix bugsFix unevennessSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The invention discloses a process for producing a semiconductor. The method comprises steps of providing a substrate, forming at least one fin-shaped structure on the substrate and an oxide layer on the position of the substrate, which is except the fin-shaped structure, conducting a heat treatment production process and enabling the side wall of part of the fin-shaped structure to form a melted layer.

Owner:UNITED MICROELECTRONICS CORP

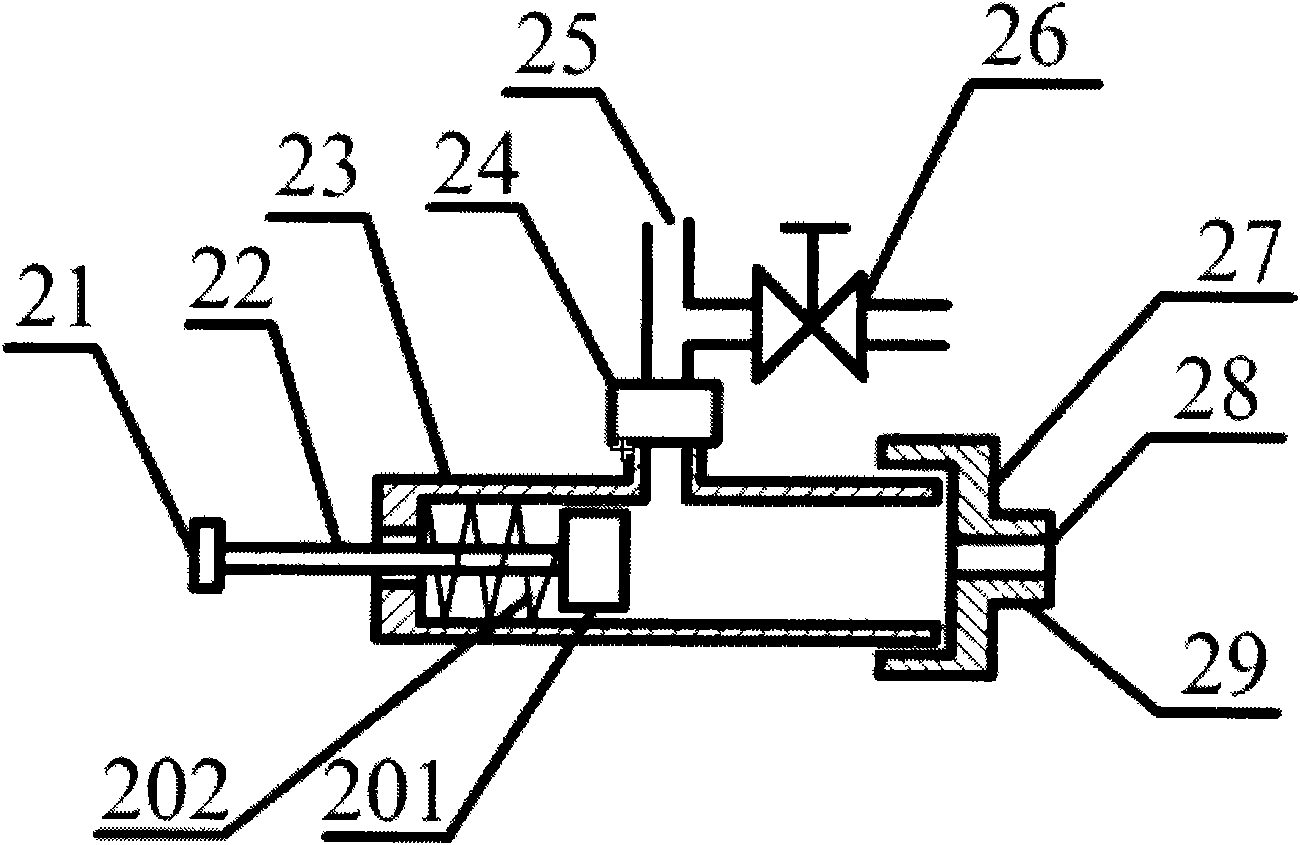

Outboard inflatable plugging air bag

The invention relates to an outboard inflatable plugging air bag, which consists of a master rod kit, a high-pressure air controller, an air bag seat, an air bag, a positioning pin, a supporting device and a high-pressure air container, wherein the master rod kit consists of a master rod and an end cover; the master rod is a pipe fitting with a sealed end, and the center of the sealing end is provided with a screw hole; the high-pressure air controller consists of a body, a top rod system, a check valve, a blowoff valve and a stuffy cover; the air bag seat consists of a master piece of the airbag seat and an accessory of the air bag seat, and the air bag seat is sleeved on the master rod and can make axial movement on the master rod; the air bag is divided into an inner layer and an outerlayer; when not being inflated, the air bag is in a cylindrical shape, and a sealing air bag space is formed between the two layers; the positioning pin consists of a positioning pin tongue, a positioning pin seat, a positioning pin spring, a positioning pin pull ring and a positioning pin substrate; and the supporting device consists of a handle, a supporting rod, a cross rod and a chuck. The outboard inflatable plugging air bag is suitable for the plugging after various ships are damaged, and thus, the outboard inflatable plugging air bag can support the ships reliably after the ships are plugged.

Owner:王晓勇

Glass rod material preparation method and preparation device

The invention relates to a glass rod material preparation method and a glass rod material preparation device. The glass rod material preparation method comprises the following steps: (a) putting a material into a material barrel; (b) feeding protection gas into the material barrel, a forming mold and a collimating mold; (c) controlling a heating unit to perform heating, preserving the heat till the temperature in the heating unit reaches softening temperature Ts of the material, controlling an annealing unit to be heated, and preserving the heat till the temperature in the annealing unit reaches annealing temperature of the material; (d) extruding the softened material, wherein after passing through the material barrel and being prepared into a rod material through the forming mold, the material enters the collimating mold; (e) enabling the heating unit to stop heating, naturally cooling the heating unit, preserving the heat of the annealing unit, and after the annealing unit is subjected to heat preservation for T, naturally cooling the annealing unit; and (f) after the annealing unit is cooled, taking out the material, and collimating and forming the material through the collimating mold, thus preparing the glass rod material. The forming mold is detachable, thus facilitating production of glass rod materials with different sizes; and furthermore, one forming mold can be provided with multiple through holes, so that the glass rod material production efficiency is improved.

Owner:NINGBO SUNNY INFRARED TECH COMPANY

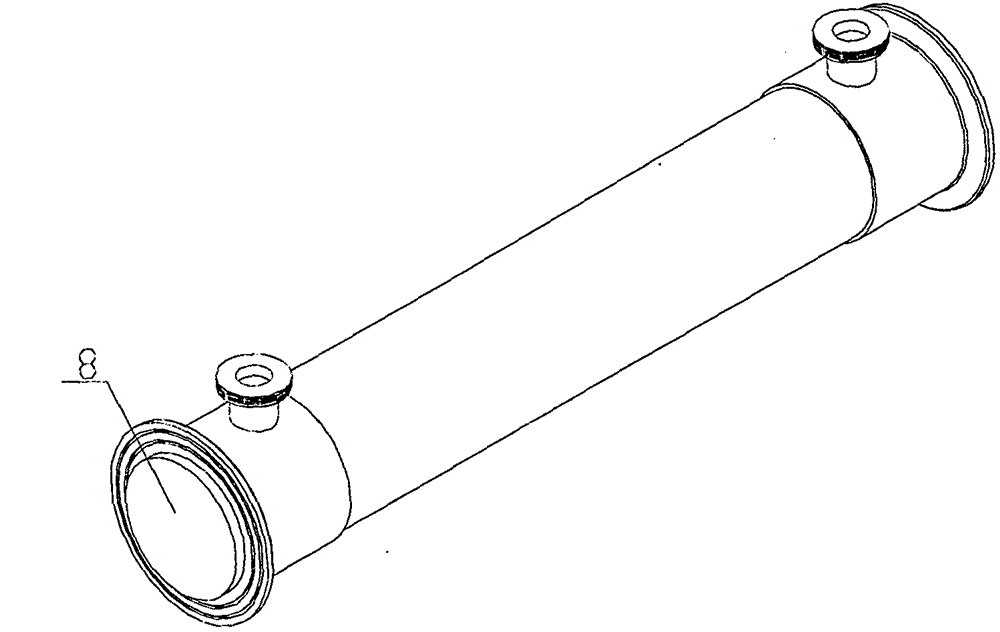

Static pouring column type membrane component and machining method thereof

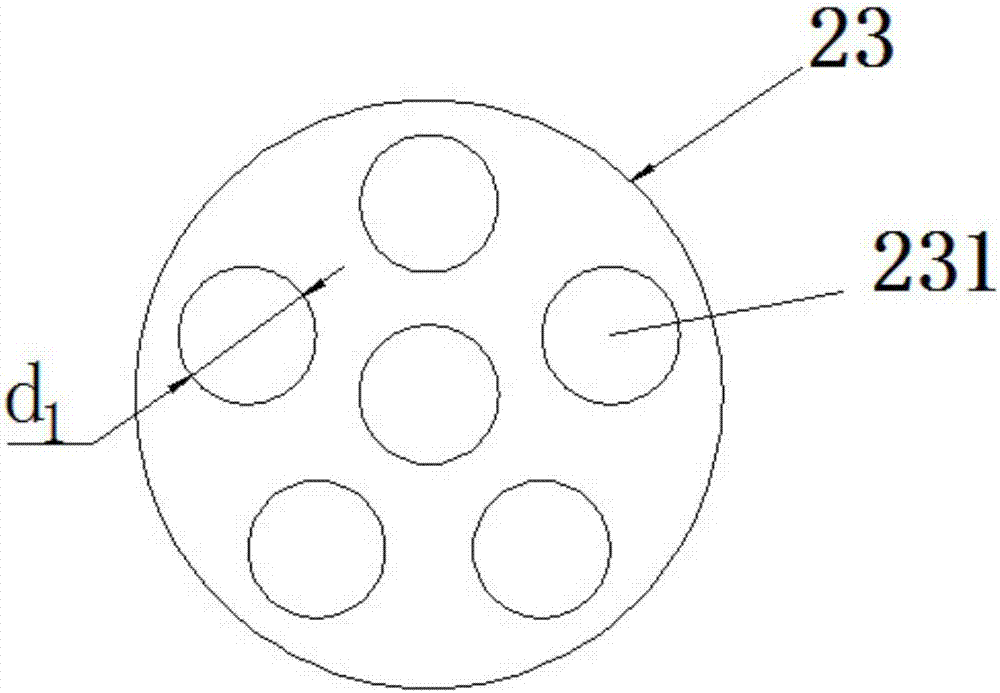

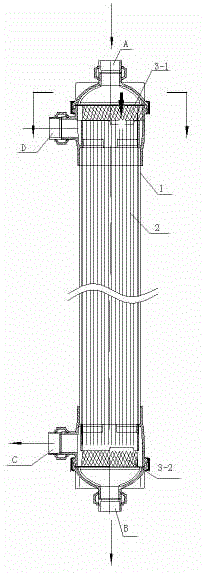

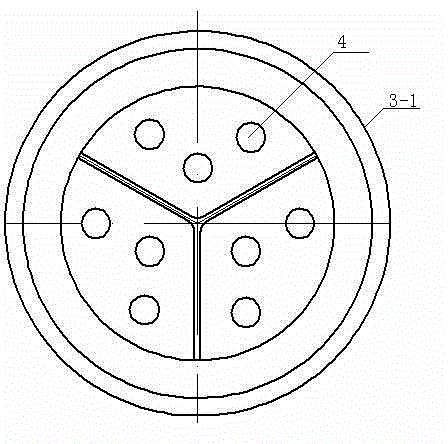

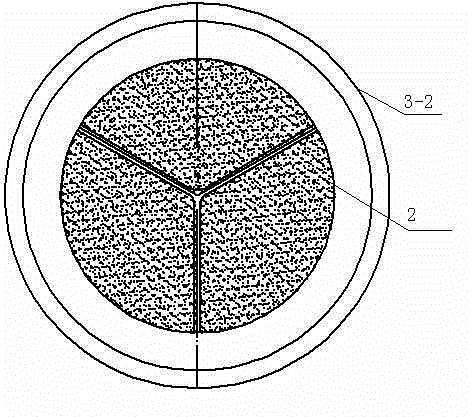

InactiveCN104524977AHigh bonding strengthNo bendSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWire cuttingWater processing

The invention relates to a water processing device and a machining method of the water processing device, in particular to a static pouring column type membrane component and a machining method of the static pouring column type membrane component. The membrane comprises a shell, membrane wires, a water inlet, a water outlet, a spare opening and a concentrated solution outlet. The water inlet and the water outlet are provided with resin ends. The water processing device and the machining method are characterized in that the resin at the resin ends is flexible resin and fixes the two ends of the membrane wires, the diameter of water inlet holes ranges from 8 mm to 20 mm, and the number of water inlet holes ranges from 5 to 20. The machining method of the membrane component includes the steps of membrane wire drying, membrane wire fixing, membrane wire cutting, membrane wire pouring and resin solidification. The membrane wires of the column type membrane component are evenly distributed, firmly fixed at the ends and not prone to damage, and the membrane wire utilization rate and the long service life of the membrane component are effectively guaranteed; by means of the machining method, the problems that the membrane wires are unevenly distributed, high in number adjustment difficulty and unsmooth and not straight are solved effectively, and effective input and output of original water are guaranteed.

Owner:SHANDONG ZHAOJIN MOTIAN

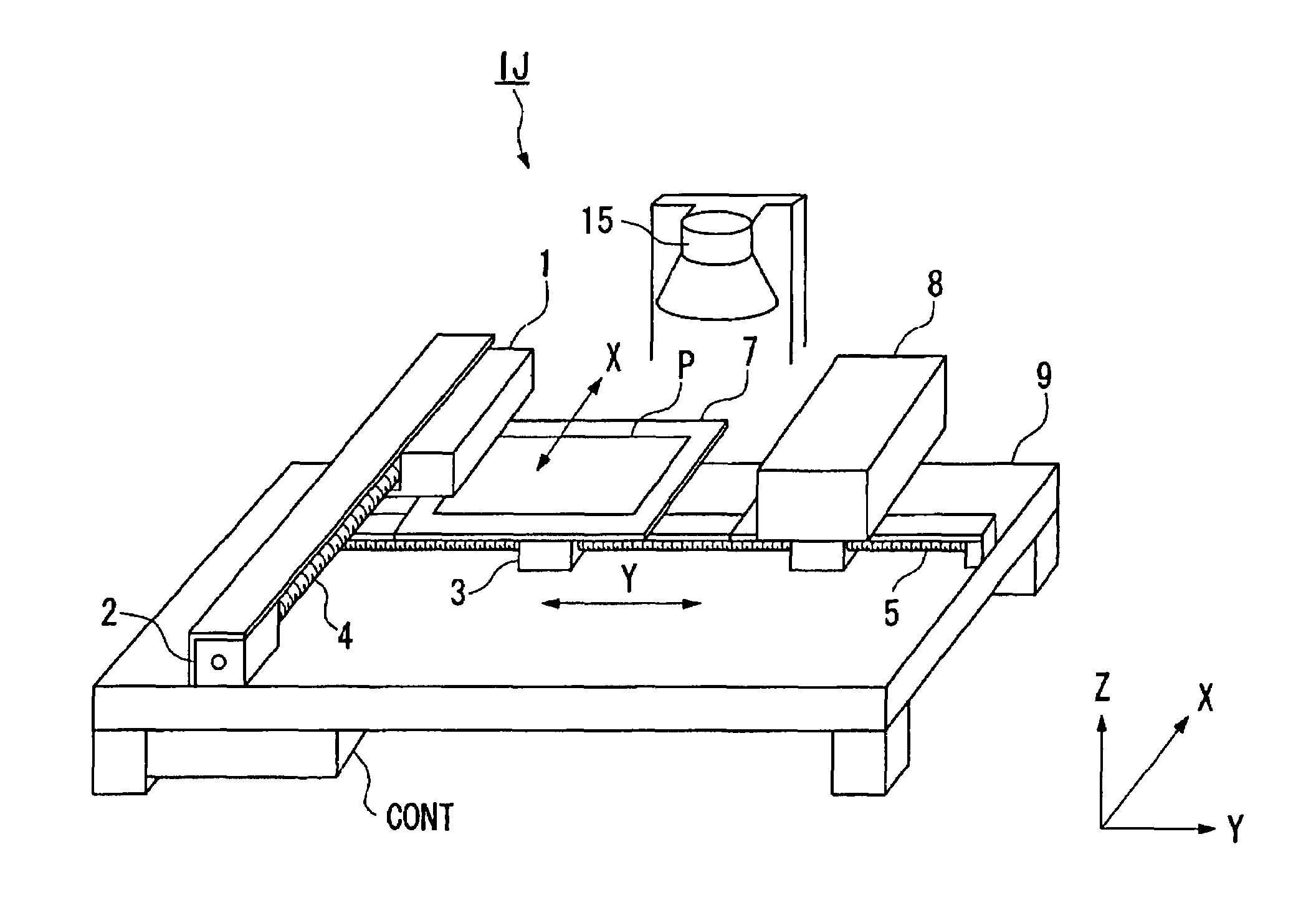

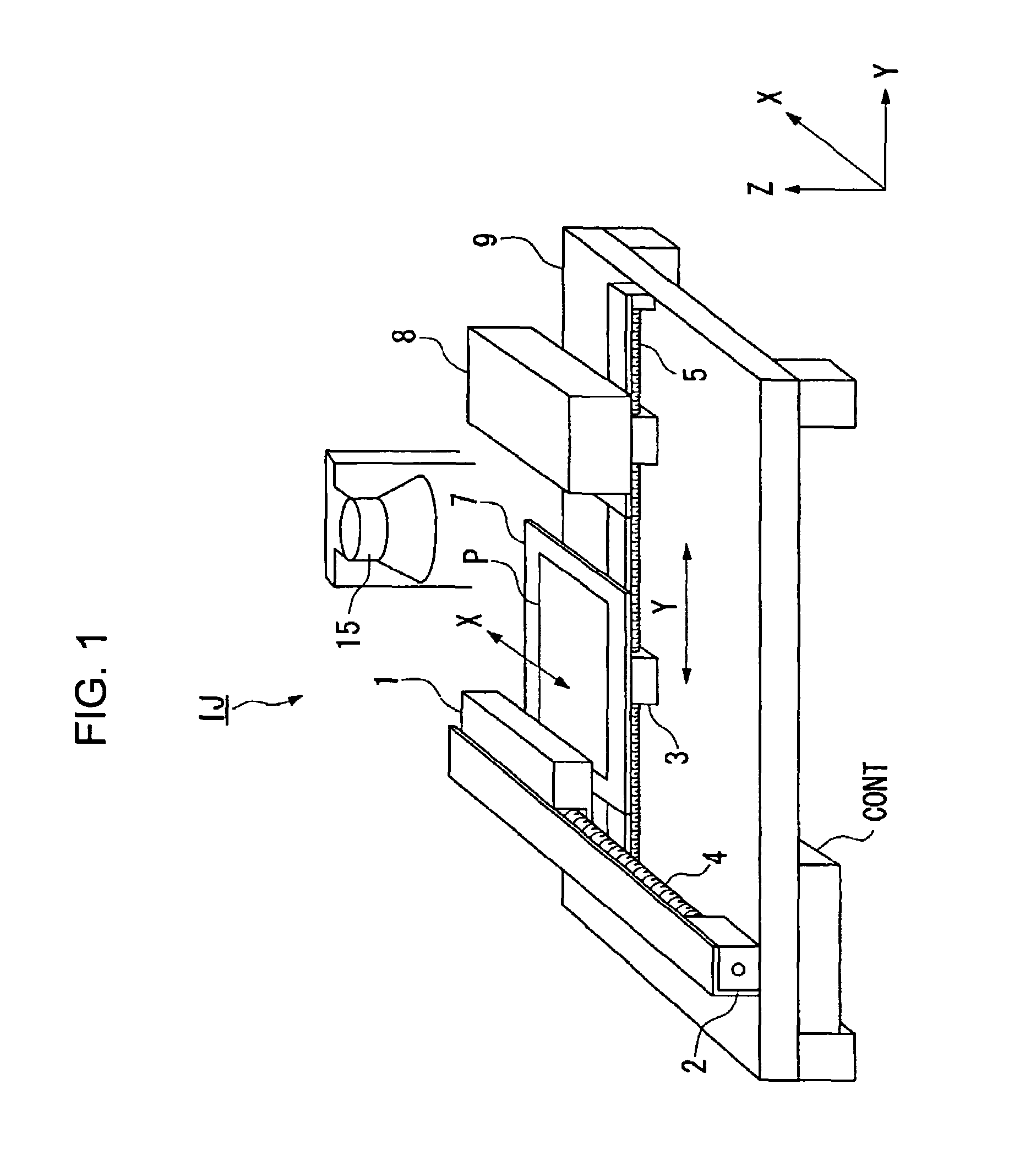

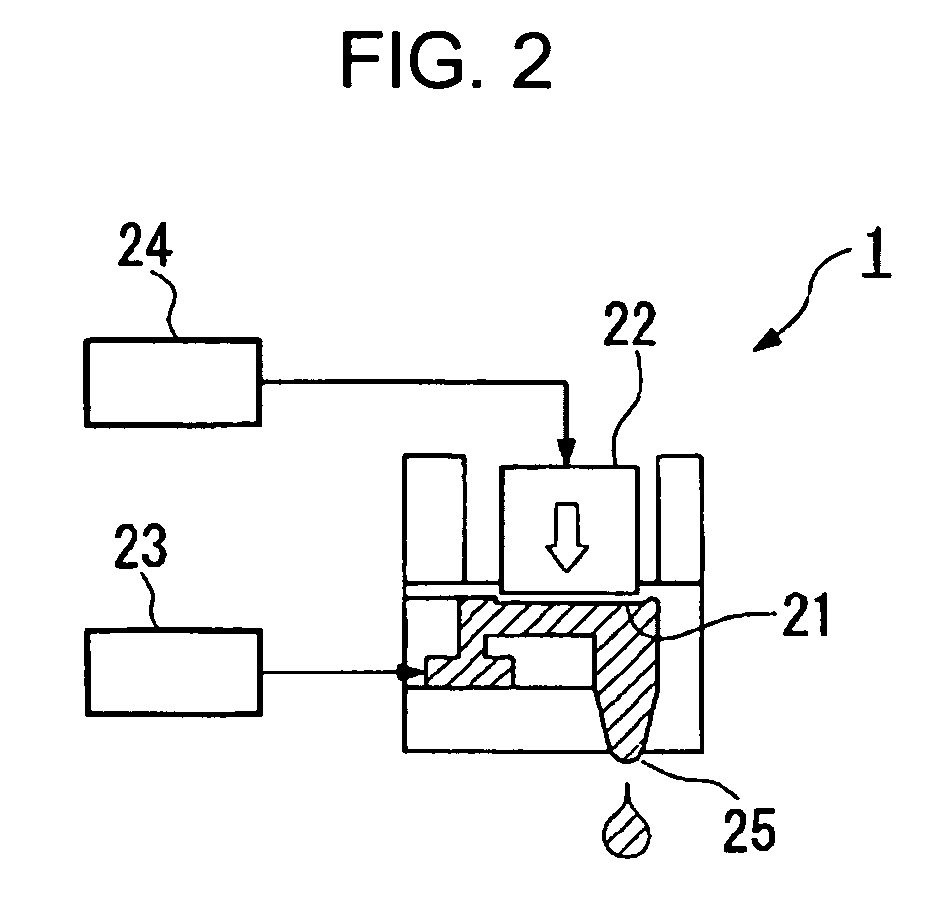

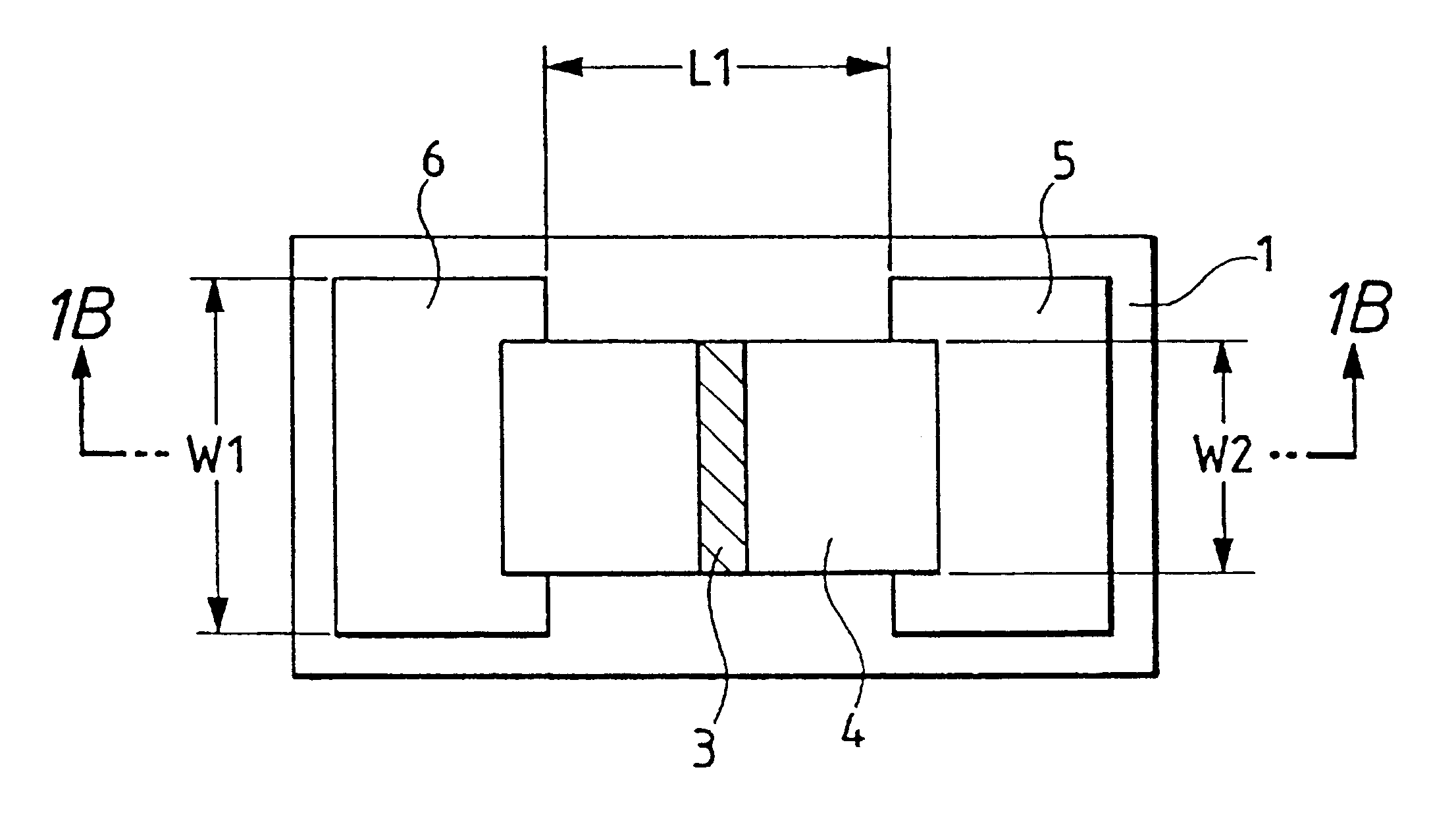

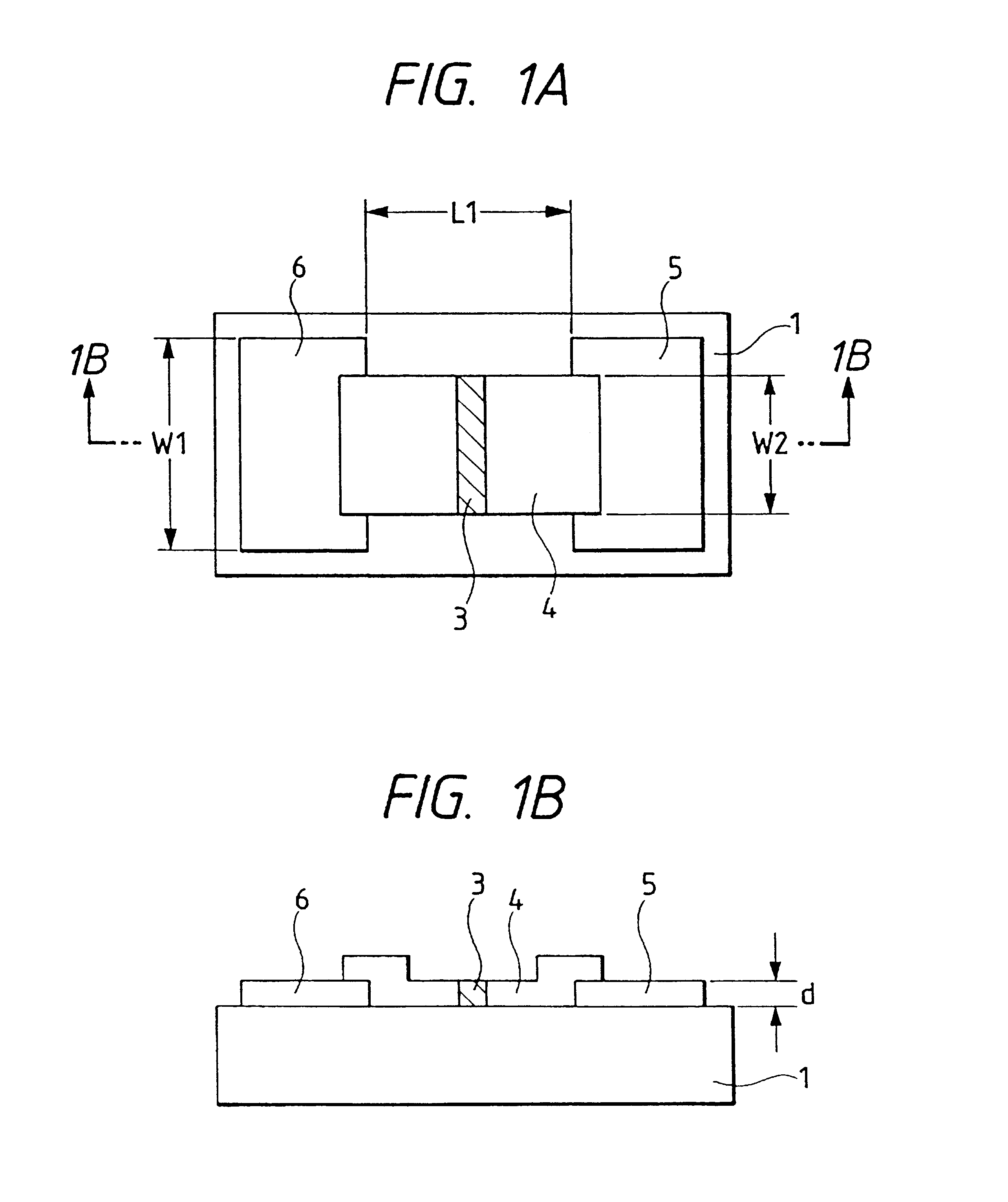

Device, method of manufacturing the same, electro-optic device, and electronic equipment

InactiveUS7326460B2Uniform thicknessUnevenness of electric propertySemiconductor/solid-state device detailsElectric lighting sourcesEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

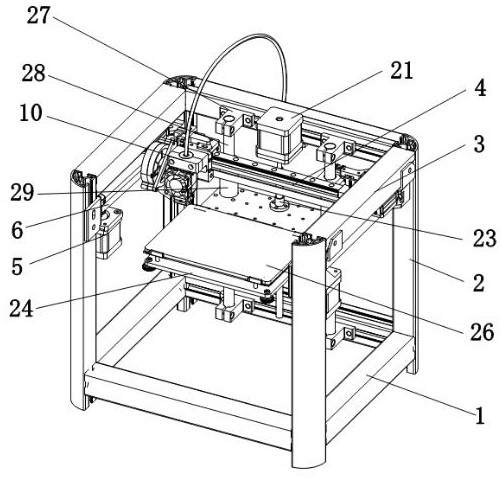

3D printer

ActiveCN112959657ASolve precise controlHigh movement accuracyManufacturing heating elements3D object support structuresThermal dilatationComputer printing

The invention relates to the technical field of printing equipment, in particular to a 3D printer which comprises a bottom frame. Multiple sets of vertical frames are arranged at the top of the bottom frame, a top frame is arranged between any two vertical frames, a cross beam is arranged between the top frames through a Y-axis controller, and an X-axis controller on the outer surface of the cross beam is slidably connected with a printing device; and a bottom plate is arranged at one side of each top frame through a Z-axis controller, the printing device comprises a booster, a raw material pipe is slidably connected into the booster, a heating cavity is formed in the bottom of the booster, the bottom of the heating cavity communicates with a flowing cavity, and a temperature sensor is arranged in the flowing cavity and used for detecting the internal temperature of the flowing cavity. According to the 3D printer, the current value of an electromagnet is controlled to change a gap between a heat-resistant magnetic ball and a spray head and change the volume of a molten material flowing out of the spray head, the material thermal expansion principle is combined, the material volume is increased when the temperature rises, the needed shape and volume are obtained after cooling, the printing effect is good, and the printing precision is high.

Owner:深圳市俩棵树科技有限公司

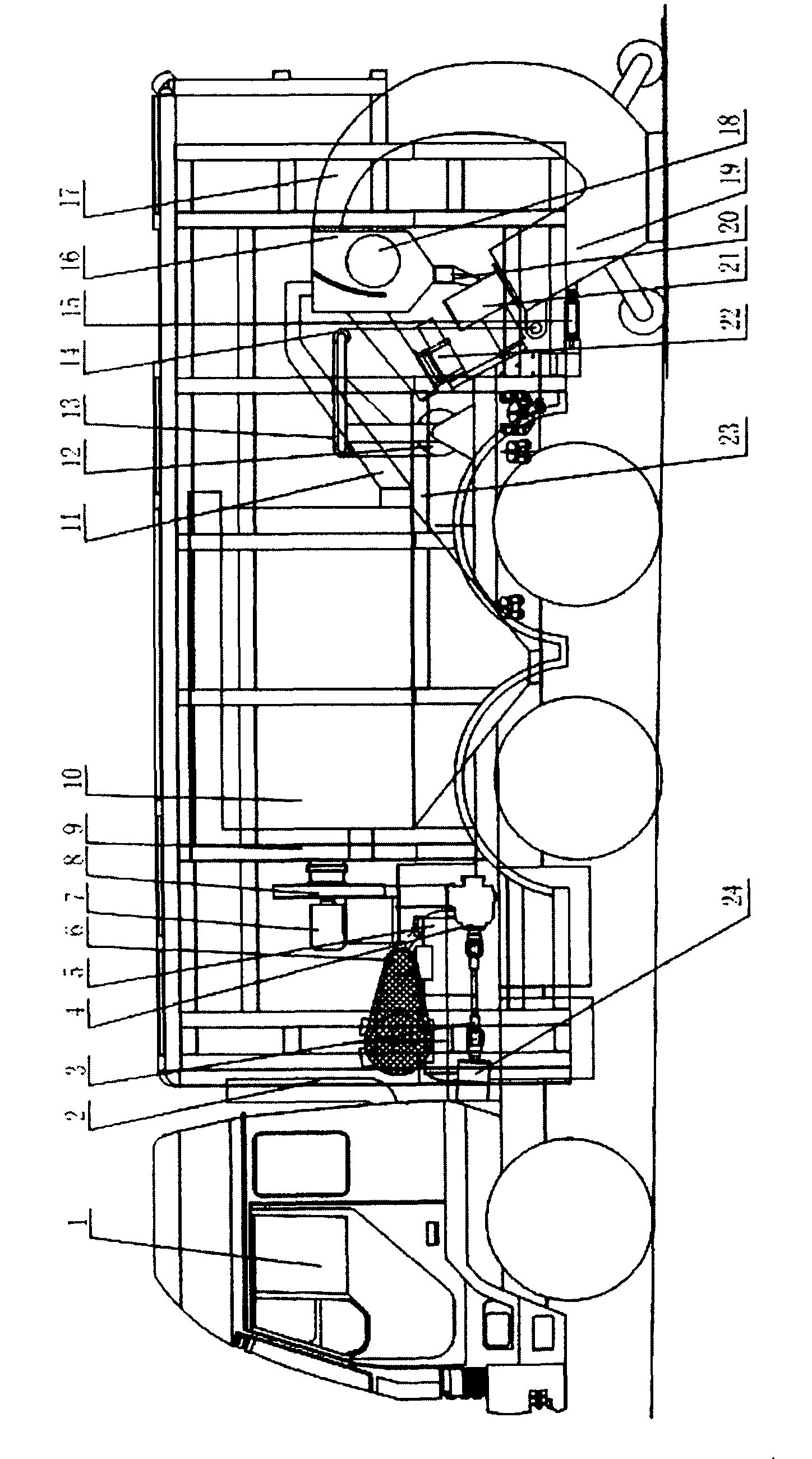

Environment-friendly high-technology road-surface technological equipment

The invention discloses environment-friendly high-technology road-surface technological equipment. The environment-friendly high-technology road-surface technological equipment comprises an automobile body with a vehicle chassis, a carriage and an automobile head, and is characterized by further comprising a road-surface dust striking device and a dust removal device. The road-surface dust striking device is composed of an impeller head, an impeller head motor, a material distribution cabin and a recovery channel, wherein the impeller head, the impeller head motor, the material distribution cabin and the recovery channel are arranged on the automobile chassis; the material distribution cabin is communicated with the impeller head fixed on an impeller head box; the impeller head is further connected with the impeller head motor; the impeller head box is communicated with the material distribution cabin through the recovery channel; the dust removal device is composed of a dust removal box communicated with the material distribution cabin and a negative-pressure generator connected with the dust removal box; the negative-pressure generator is composed of a draught fan motor, an induced draft fan and an air suction box connected with the dust removal box; the induced draft fan is connected with the draught fan motor, and is communicated with the air suction box. The environment-friendly high-technology road-surface technological equipment effectively solves the problem that dust bonded on a road surface and hard to clean can not be cleaned easily.

Owner:青岛亨泰来机械科技有限公司

Solution for fabrication of electron-emitting devices, manufacture method of electron-emitting devices, and manufacture method of image-forming apparatus

InactiveUSRE37896E1Fix unevennessElectric discharge tubesGroup 8/9/10/18 element organic compoundsCarboxylic saltMethod of images

In a solution for forming electron-emitting regions of electron-emitting devices, the solution contains a metal carboxylate expressed by the following general formula (I), an organic solvent <DEL-S DATE="20021029" ID="DEL-S-00001" / >and / or<DEL-E ID="DEL-S-00001" / > <INS-S DATE="20021029" ID="INS-S-00001" / >, and <INS-E ID="INS-S-00001" / >water;where k=<DEL-S DATE="20021029" ID="DEL-S-00002" / >numeral from<DEL-E ID="DEL-S-00002" / > 1 <DEL-S DATE="20021029" ID="DEL-S-00003" / >to 4<DEL-E ID="DEL-S-00003" / > , m=<INS-S DATE="20021029" ID="INS-S-00002" / >a <INS-E ID="INS-S-00002" / >numeral from 1 to 4, and <DEL-S DATE="20021029" ID="DEL-S-00004" / >R=CnX2n+1-k<DEL-E ID="DEL-S-00004" / > <INS-S DATE="20021029" ID="INS-S-00003" / >R=CnX2n+2-k <INS-E ID="INS-S-00003" / >where X=<INS-S DATE="20021029" ID="INS-S-00004" / >a <INS-E ID="INS-S-00004" / >hydrogen or halogen <DEL-S DATE="20021029" ID="DEL-S-00005" / >(total number of hydrogen and halogen atoms is 2n+1)<DEL-E ID="DEL-S-00005" / > , n=<INS-S DATE="20021029" ID="INS-S-00005" / >an <INS-E ID="INS-S-00005" / >integer from 0 to 30, and M=<INS-S DATE="20021029" ID="INS-S-00006" / >a <INS-E ID="INS-S-00006" / >metal<INS-S DATE="20021029" ID="INS-S-00007" / >, wherein the organic solvent is a carboxylic ester having the same carboxylic group as R(COO)k expressed in the general formula (I)<INS-E ID="INS-S-00007" / >. In a manufacture method of electron-emitting devices each provided between electrodes with a conductive film including an electron-emitting region, a process of forming the conductive film includes a step of coating and calcining the above solution. An image-forming apparatus is manufactured by using the electron-emitting devices. Variations in sheet resistance values of electron-emitting region-forming thin films and characteristics of the electron-emitting devices are reduced.

Owner:CANON KK

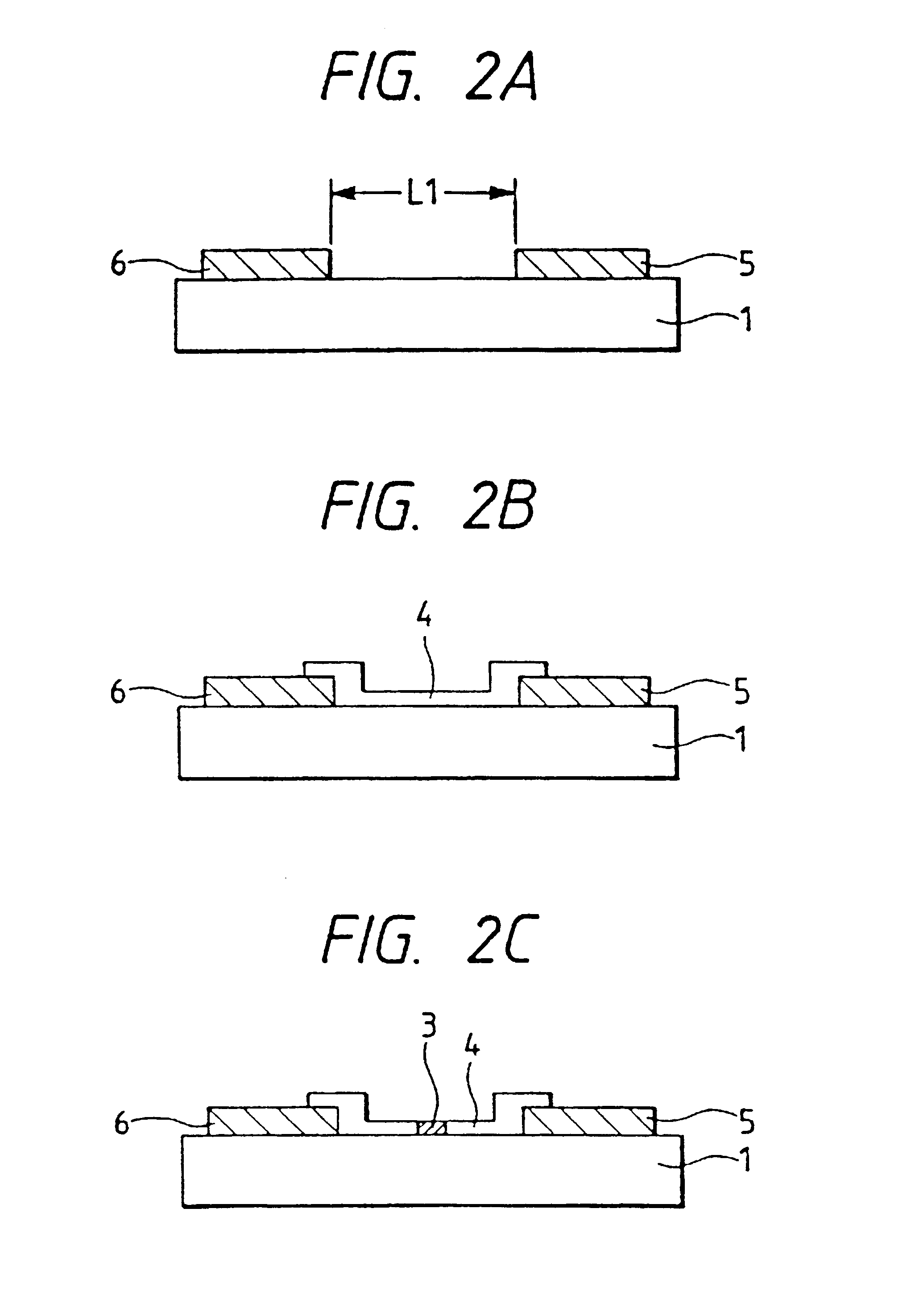

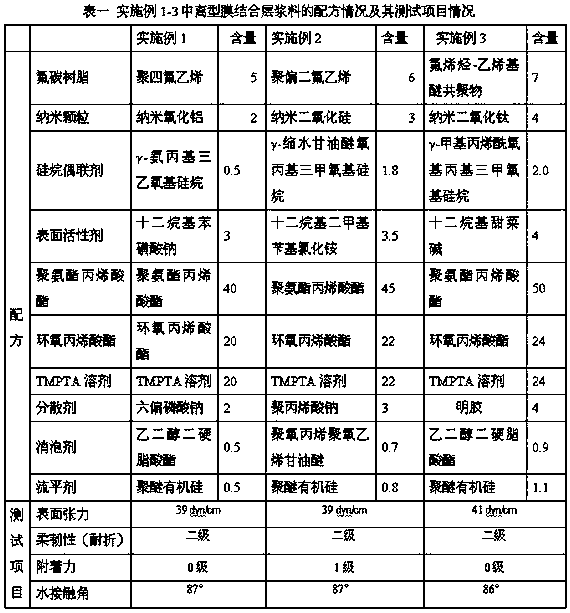

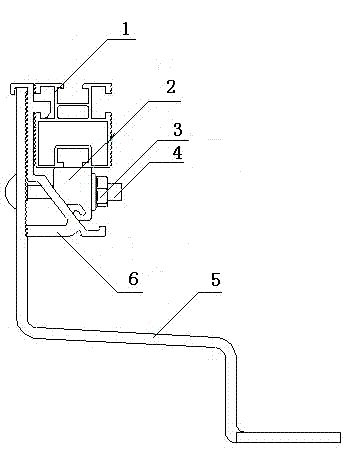

Liposuction cutter

ActiveCN105854095ATo achieve the effect of liposuctionReduce area ratioInstrument handpiecesMedical devicesLiposuctionPlasma generator

A liposuction cutter comprises a liposuction tool bit and a handle, wherein the liposuction tool bit is mounted on the handle, and comprises an inner metal pipe and an outer metal pipe; a cavity is formed between the inner metal pipe and the outer metal pipe; a water inlet pipe is communicated to the end, near the handle, of the inner metal pipe; a metal sheet serving as an electrode is mounted at the other end of the inner metal pipe; a water suction pipe is communicated to the end, near the handle, of the outer metal pipe; both the inner metal pipe and the outer metal pipe are connected with conducting wires; the conducting wires are connected to a generation electrode of a plasma generator. Through the adoption of the liposuction cutter, the problems that the efficiency of mashing fat in an inserting and pulling manner in the conventional medical technology is low, and postoperative skin is bumpy due to non-uniform liposuction are solved.

Owner:CHENGDU MECHAN ELECTRONICS TECH

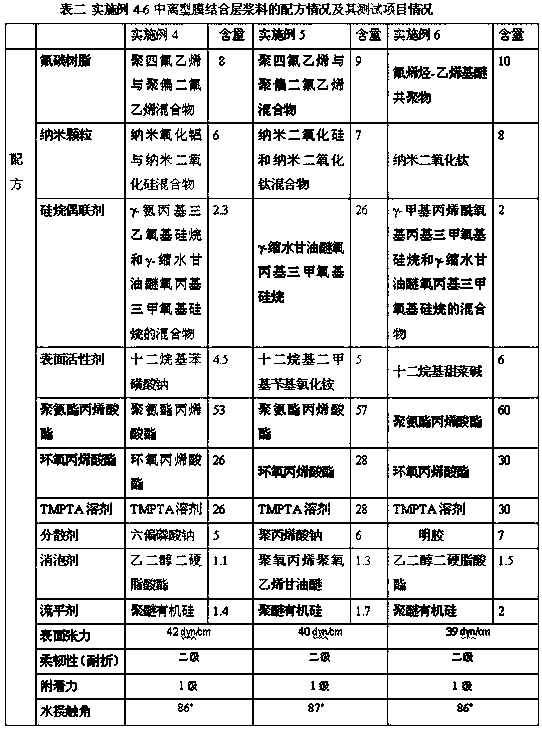

Formula of binding layer slurry used for release film of synthetic leather and preparation method of the binding layer slurry

ActiveCN107603458AImprove adhesionGood flexibilityPolyurea/polyurethane coatingsTextiles and paperSlurrySolvent

The invention discloses a formula of binding layer slurry used for a release film of synthetic leather and a preparation method of the binding layer slurry. The binding layer slurry includes, by weight, 5-10 parts of fluorocarbon resin, 2-8 parts of nano-particles, 0.5-2 parts of a silane coupling agent, 3-6 parts of a surfactant, 40-60 parts of polyurethane acrylate, 20-30 parts of epoxy acrylate, 20-30 parts of a TMPTA solvent, 2-7 parts of a dispersant, 0.5-1.5 parts of a defoamer, and 0.5-2 parts of a flatting agent. By means of the raw materials, which are cooperated with each other, in the formula, a binding layer has excellent adhesion force and flexibility, and can solve problems of an uneven and non-uniform coating surface when the surface of a base material is coated with a release agent directly. In addition, the binding layer is mainly used for improving combination between the base material and a release layer by being applied between the base material and the release layer and improving the performance of the release layer during production of the release film.

Owner:南京盛凯新材料有限公司

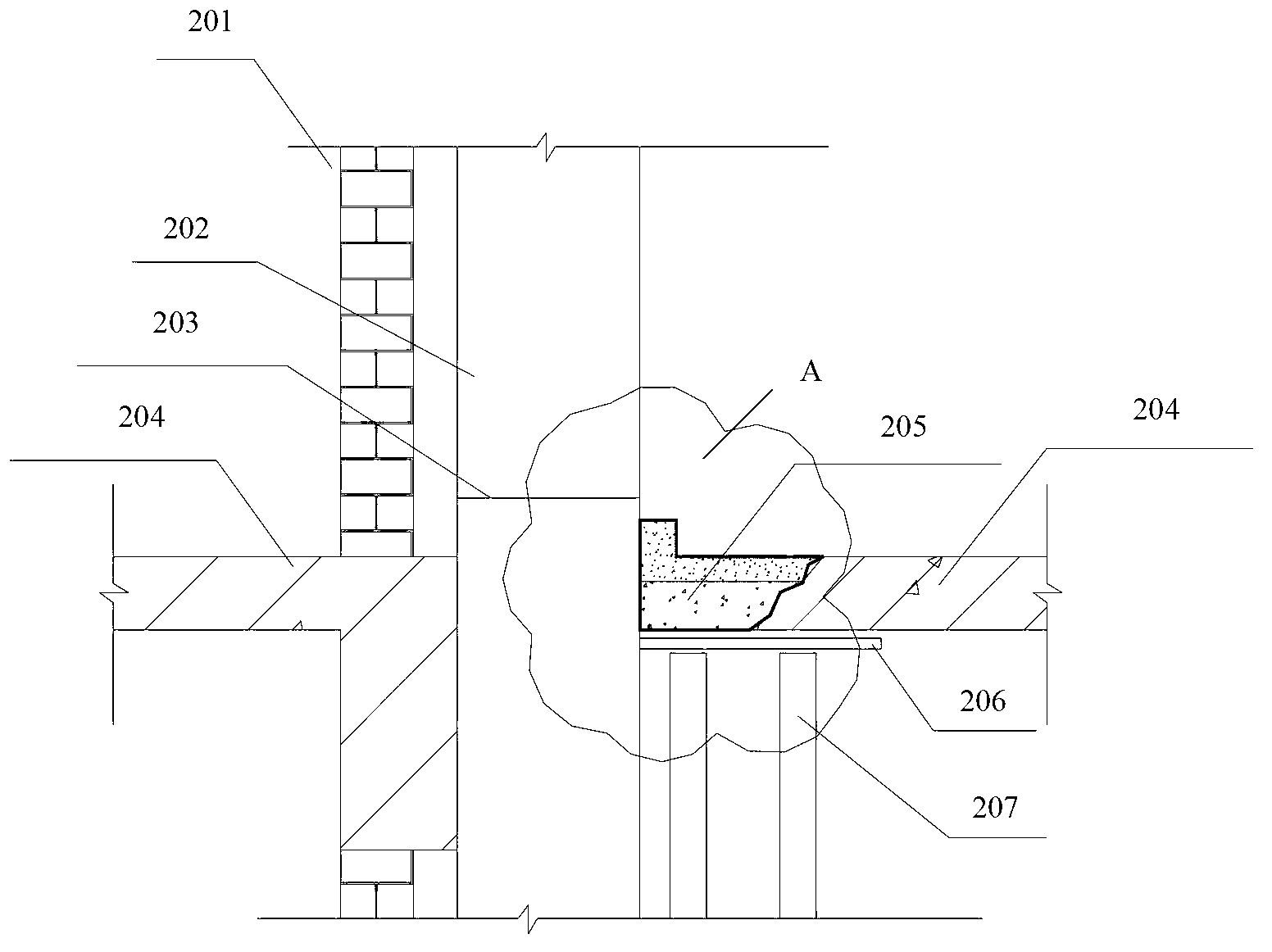

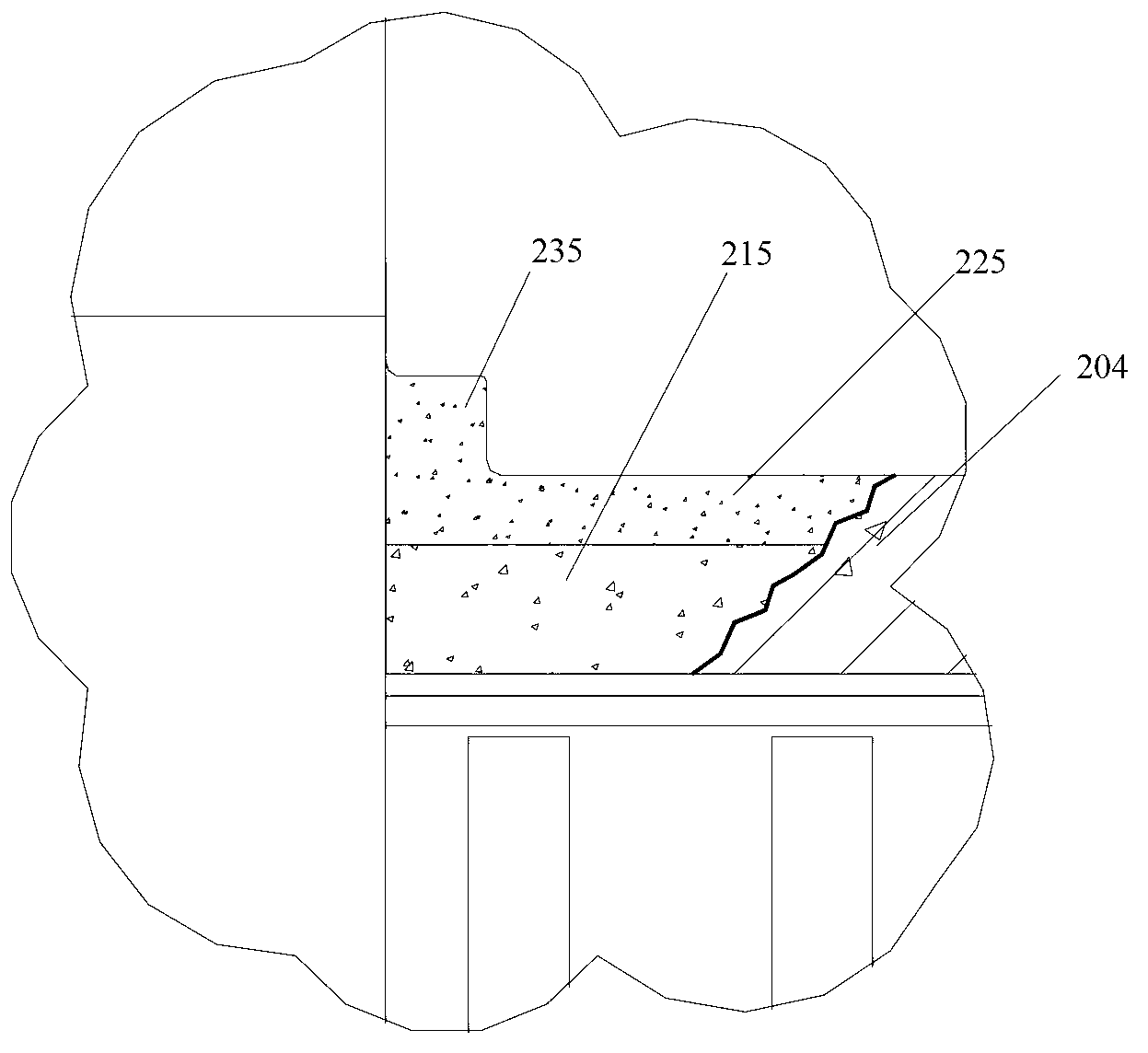

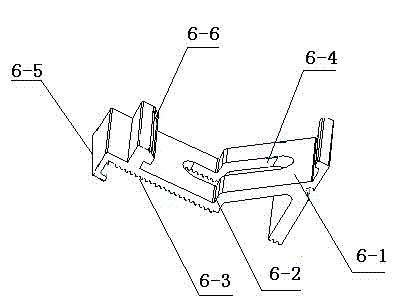

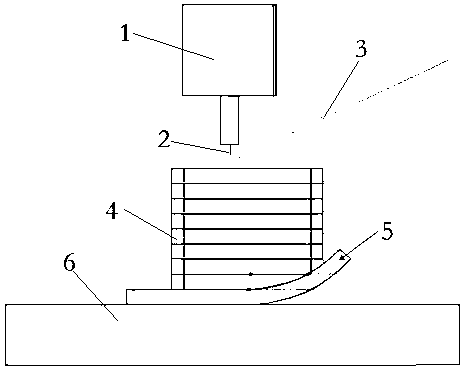

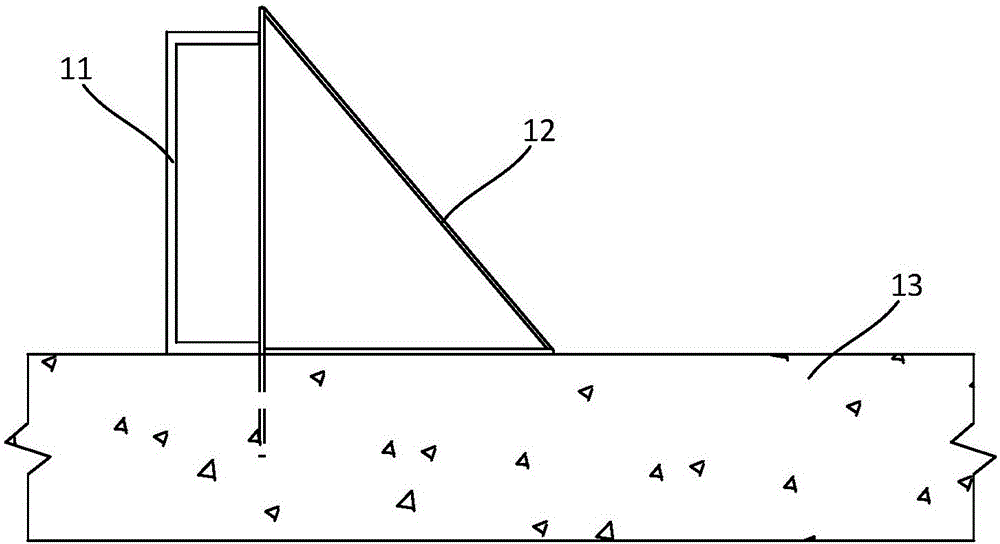

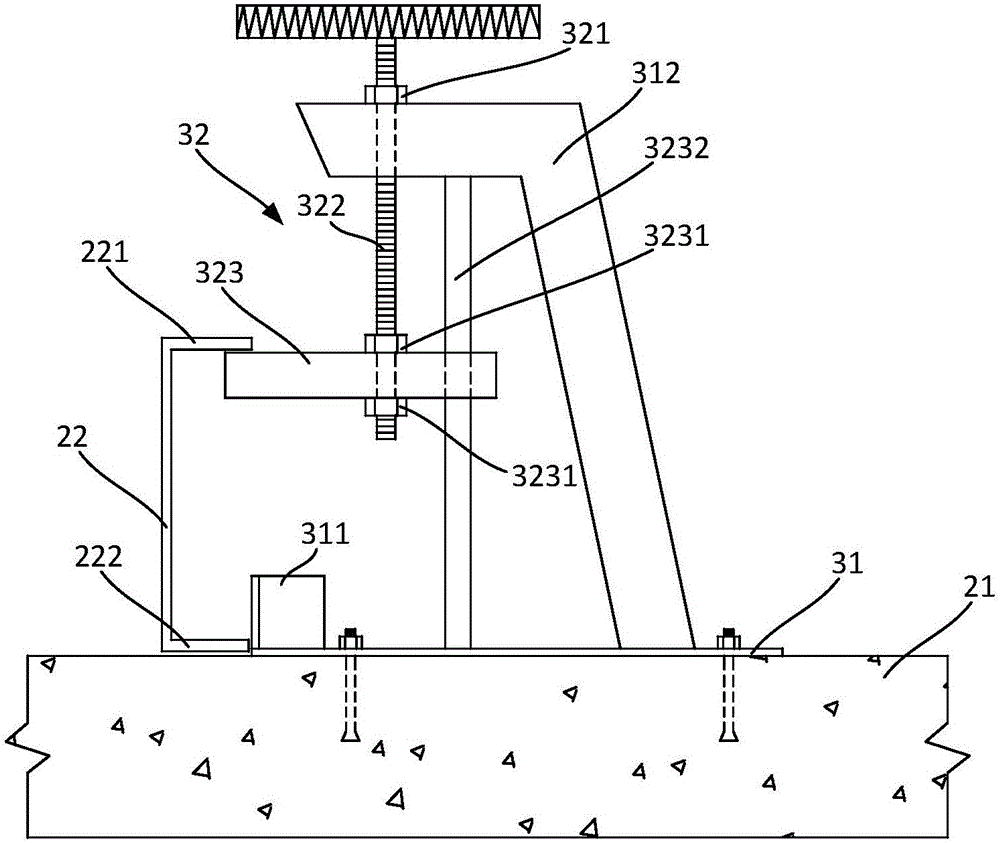

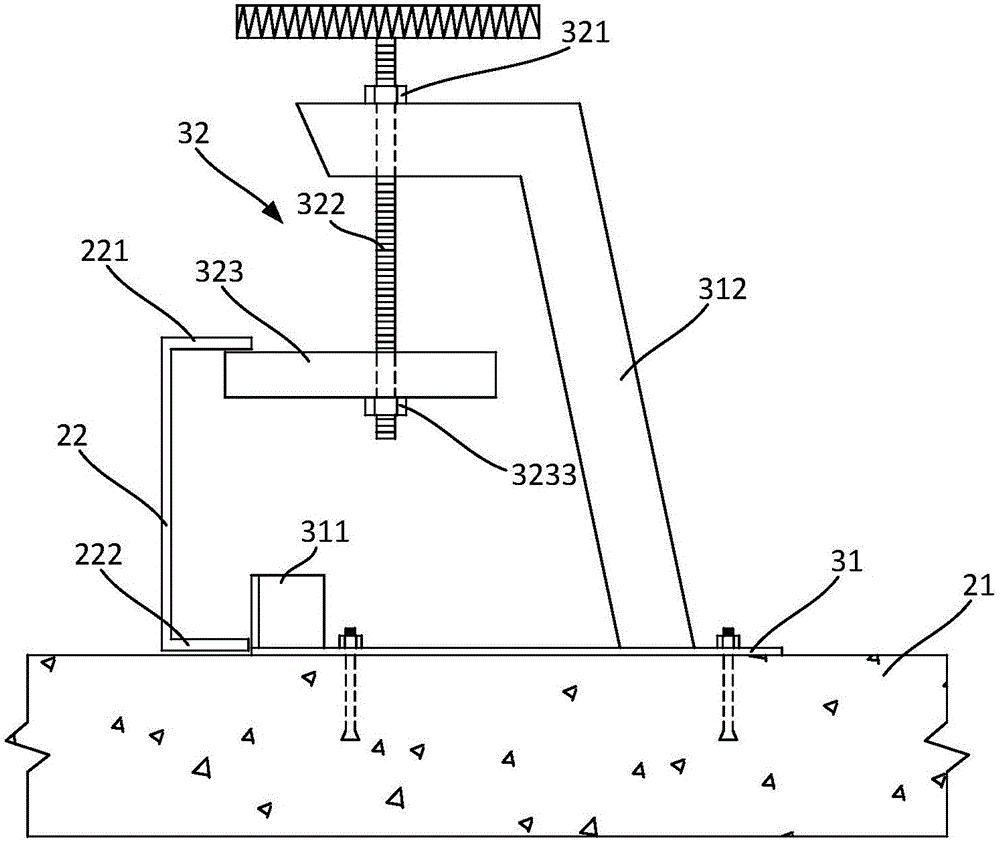

Side surface fast mounting mechanism for photovoltaic bracket

InactiveCN102891198AHeight adjustableFix unevennessPhotovoltaic supportsPhotovoltaic energy generationEngineeringMechanical engineering

The invention discloses a side surface fast mounting mechanism for a photovoltaic bracket. The side surface fast mounting mechanism comprises an inclined plane pressure block, an inclined plane base, a connecting piece, a bolt and a nut, wherein hanging hooks are arranged on the two sides of the upper part of the inclined plane base, and the inclined plane base is mounted on the connecting piece through the hanging hooks; the inclined plane pressure block is placed on the inclined plane of the inclined plane base, a stepped hole is formed in the inclined plane pressure block, and a spring is placed in the stepped hole; a waist-shaped hole is formed in the position of the inclined plane base, which corresponds to the connecting piece; and the bolt sequentially penetrates through the connecting piece, the inclined plane base, the inclined plane pressure block and the spring, and the upper end of the bolt is connected with the nut. The side surface fast mounting mechanism disclosed by the invention is simple in structure, low in cost and fast and convenient in mounting process; a spring structure is adopted for realizing fast mounting of the inclined plane pressure block in a preset position, so that the inclined plane pressure block can be conveniently and reasonably clamped into a groove of a guide track, the spring in a locked state can be finally compressed into a countersunk hole, and the reliability and aesthetics in locking can be ensured; the square-neck bolt and the nut are adopted, thereby effectively preventing the following rotation and improving the mounting efficiency; and a side-surface fast mounting piece base can realize adjustability in height during the mounting process, thereby solving the problem that a roof is uneven during actual mounting.

Owner:SAMIL POWER

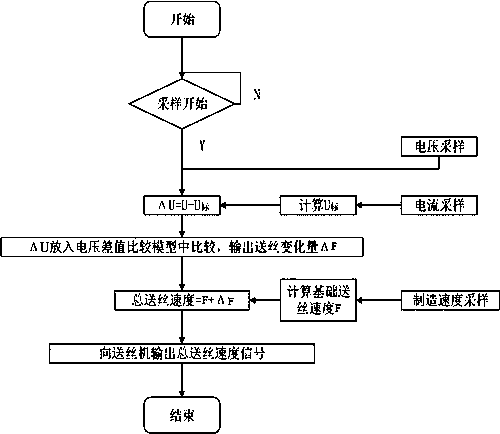

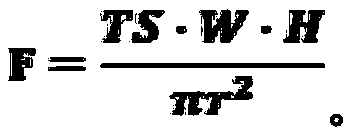

Method of controlling arc length of additive manufacturing arc and flatness of end face of formed part

ActiveCN109128177ASolve control problemsSettle compensationAdditive manufacturing apparatusEngineeringLinear regression

The invention discloses a method of controlling arc length of additive manufacturing arc and flatness of the end face of a formed part. The method includes the following steps that a relation functionbetween wire feeding speed F and additive manufacturing speed TS is established; on TIG arc additive manufacturing platform, single pass and single layer welding are conducted without change of the arc length, recorded welding current and voltage are fitting processed to obtain a linear regression equation of welding current and standard voltage; the voltage difference delta U between the voltageand the standard voltage is calculated, relationship between the delta U and delta F is obtained; and the relation function between the wire feeding speed F and the additive manufacturing speed TS isused for calculating the theoretical wire feeding speed F corresponding to the manufacturing speed TS of different additive, and transferring the signal to a wire feeding machine, the actual wire feeding speed output by the wire feeding machine for is equal to F + delta F. According to the method of controlling arc length of additive manufacturing arc and flatness of the end face of the formed part, the effective control and compensation of the arc length can be realized by using the system, the arc length is always kept within a reasonable range, the flatness of the end face and the formingquality of the formed part are greatly improved.

Owner:LIYANG JIANGNAN DRYER MFG

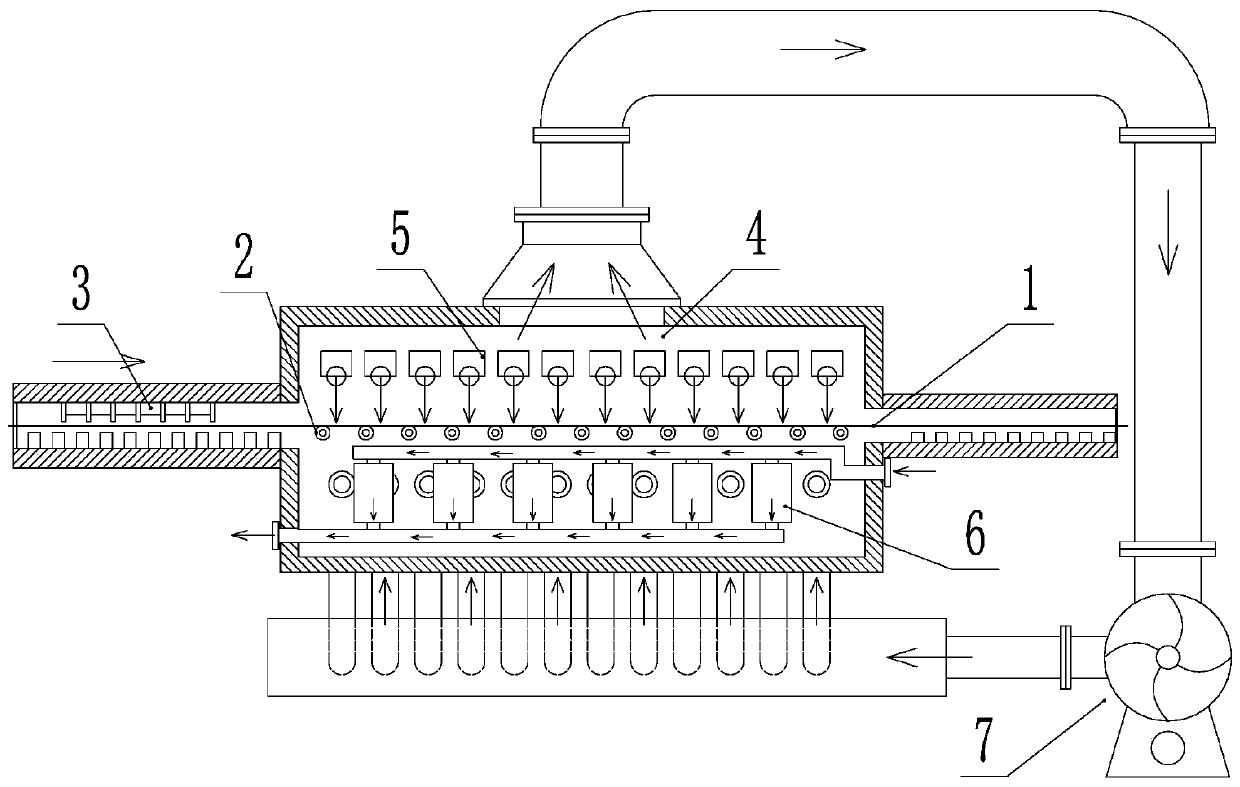

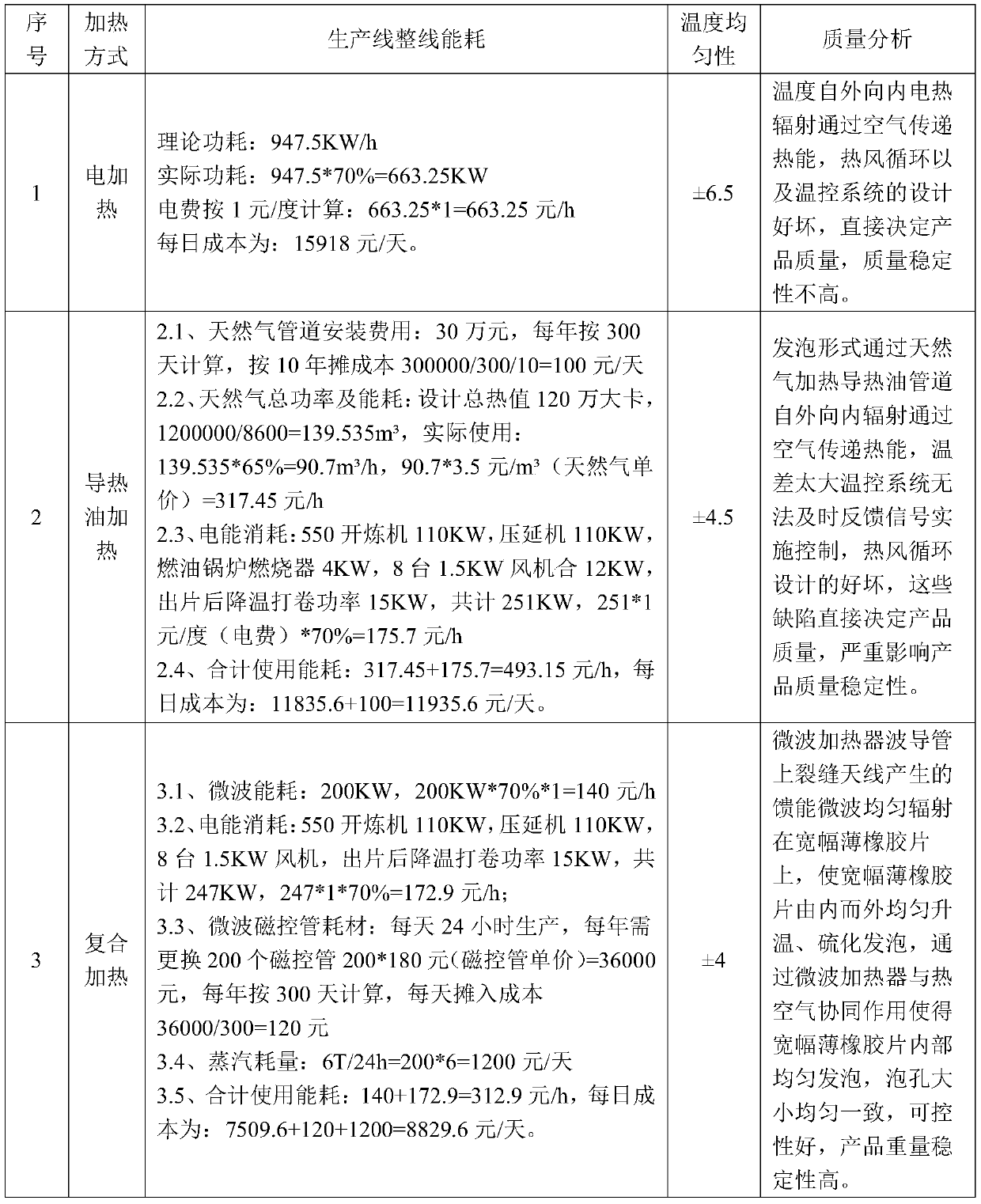

Wide-width thin rubber sheet foaming technology based on infrared ray, steam and microwave composite heating

The invention discloses a wide-width thin rubber sheet foaming technology based on infrared ray, steam and microwave composite heating. The technology comprises the following steps that step A, rubber, a foaming agent and a vulcanizing agent are mixed, and pressing is performed through a calender to form a wide-width thin rubber sheet; step B, air in a foaming furnace is heated through a steam radiator, so that the temperatures in the furnace are evenly distributed; step C, the wide-width thin rubber sheet is conveyed into the foaming furnace for heating, an infrared heating pipe of a feedingsegment is heated, so that the surface layer is quickly cured and formed, and under the combined effect of energy feedback microwaves radiated by a leaky antenna on a microwave heater wave guide pipeand air hot in the foaming furnace, the thin rubber sheet is evenly heated, vulcanized and foamed from inside to outside; step D, after foaming is completed, discharging is conducted. The invention aims at providing the wide-width thin rubber sheet foaming technology based on infrared ray, steam and microwave composite heating. According to the foaming technology, the wide-width thin rubber sheetis heated and foamed from inside to outside, the labor efficiency is improved, energy is saved, and the product qualification rate is guaranteed.

Owner:JIHUA 3517 RUBBER PROD +1

Reinforcing tool and method for templates in cast-in-situ ground surface layer

InactiveCN106499156AEasy to adjustHigh adjustment accuracyBuilding constructionsSurface layerCushion

The invention relates to a reinforcing tool for templates in a cast-in-situ ground surface layer. The reinforcing tool includes a base, wherein an end of the base is fixedly provided with a limiting member pressed against the bottom of a template, and a support is arranged on the base; and an adjustment assembly which is arranged on the support, wherein the adjustment assembly can adjust the height along the support and support an upper flange plate of the template so as to adjust the elevation of the upper flange plate. The reinforcing tool can limit horizontal displacement of the template by making the limiting member be pressed against the template, and can adjust the elevation of the template by the adjustment assembly so as to make the elevation of the template in a horizontal state, and then can ensure the flatness of a surface of a surface layer. The reinforcing tool is convenient and fast to adjust and operate, and can save time and effort relative the wood bar elevating method; the adjustment accuracy of the adjustment assembly is high; uneven elevation of a top surface of the template due to an uneven cushion layer or ground can be overcome; and the reinforcing tool can be reused, and can save cost.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Double-shot injection molding method for sundries box of automobile auxiliary console

The invention discloses a double-shot injection molding method for a sundries box of an automobile auxiliary console. The method comprises the following steps: mounting an injection molding die; pre-heating a double-shot injection molding machine; carrying out injection molding on hard rubber after the hard rubber and soft rubber are baked to ensure that the temperature of a material storage barrel of the hard rubber PC / ABS is 180 to 250 DEG C, the temperature of hot runner is 250 to 280 DEG C, and the holding pressure is 60 to 90Mpa, completing hard rubber injection molding and then carrying out soft rubber injection molding; completing the double-shot injection molding on the sundries box of the automobile auxiliary console when the temperature of a material storage barrel of the soft rubber TPU is 130 to 220 DEG C and the holding pressure is 60 to 90Mpa. The double-shot injection molding method has the advantages that the process is simple and is easy to realize. The shrinkage rate of the hard rubber adopts a low value of about 3%, so that plastic rubber expansion coefficients caused by the high temperature of the mould are eliminated, when the soft rubber injection molding for twice is carried out, the mould and a plastic rubber piece have suitable pressure, so that a parting surface of the mould is tightly adhered to the plastic rubber piece, and the damage caused by pressing due to heat expansion of the plastic rubber piece is unlikely happened.

Owner:锦州希尔达汽车零部件有限公司

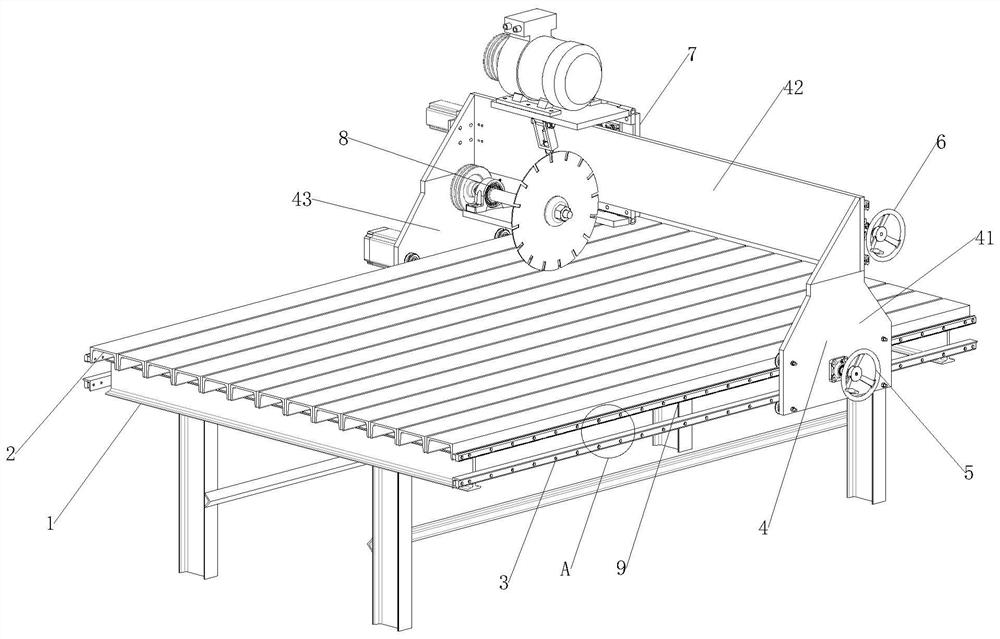

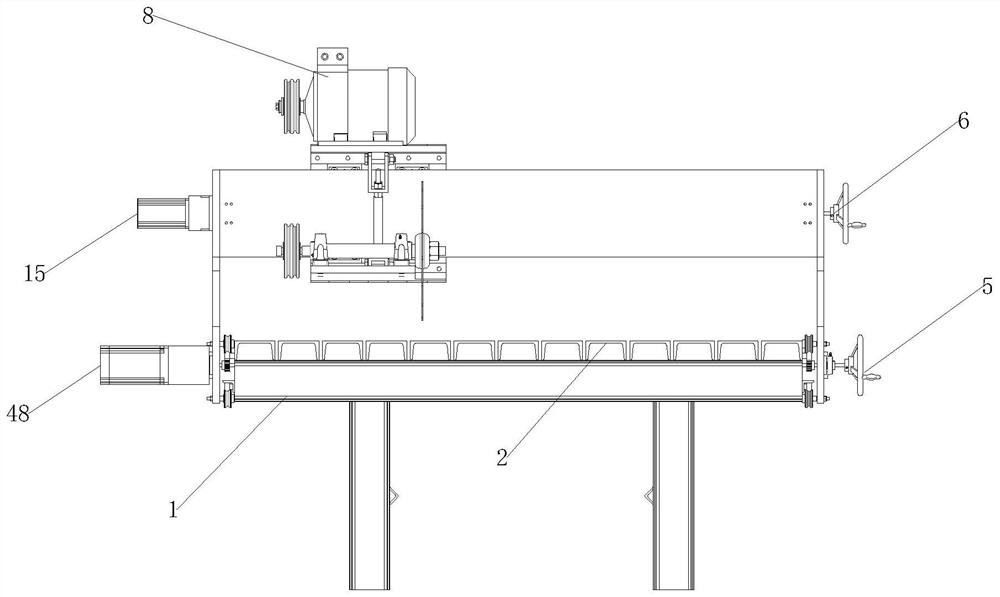

Autoclaved aerated board processing equipment and processing method thereof

InactiveCN111976035AFix unevennessSolve the problem of uneven cutting edgesWorking accessoriesStone-like material working toolsGas cylinderElectric machinery

The invention discloses autoclaved aerated board processing equipment and a processing method thereof, and belongs to the technical field of cutting equipment. The autoclaved aerated board processingequipment comprises a base, a first movable base, a second movable base and a cutting device, wherein the first movable base is connected onto the base; the second movable base is connected onto the first movable base; the cutting device is fixedly connected onto the second movable base; a group of cutting partitioning boards, which are uniformly arranged on the base, is fixedly connected on the base; a first slide rail is arranged on the base; a second slide rail is arranged on the base; the lower end of the second slide rail is equipped with a rack; first mounting holes are formed in the first slide rail and the second slide rail; the cutting device comprises a first board, a second board, a third board, a hinge, a first motor, a first rotary shaft and a cutting plate; and a first gas cylinder comprises a gas cylinder body, a first hinged base and a second hinged base; and the first hinged base is fixedly connected to the bottom end of the gas cylinder body. The autoclaved aerated board processing equipment solves the problem that cut edges of autoclaved aerated boards in the prior art are unflat.

Owner:ZHEJIANG SONT BUILDING MATERIAL

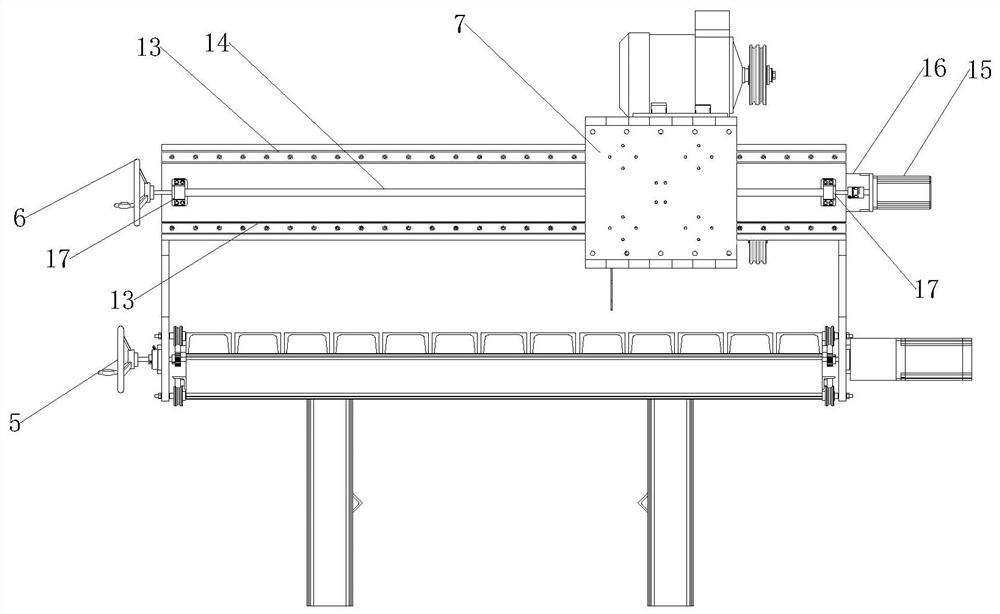

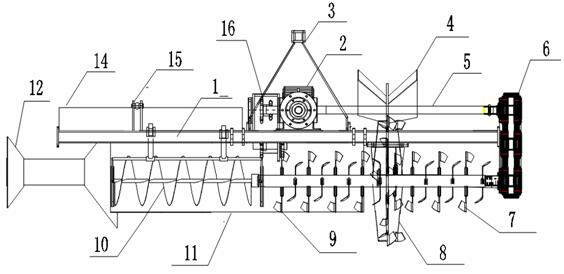

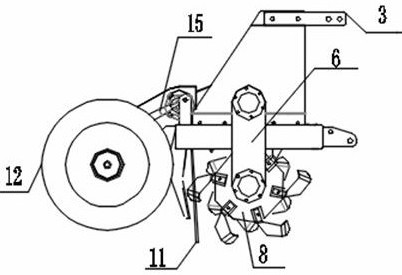

Ridging and ditching integrated machine

ActiveCN112655290AFix unevennessGuaranteed flatnessSpadesAgricultural machinesAgricultural engineeringStructural engineering

The invention discloses a ridging and ditching integrated machine which comprises a rack and is characterized in that a middle gear box is installed on the rack, a rotating shaft is arranged below the rack, the middle gear box transmits one path of power to a side gear box, the side gear box transmits the power to the rotating shaft, a rotary blade, a ditching cutter head and a soil leveling cutter are sequentially installed on the rotating shaft from right to left, the tail end of the rotating shaft drives a screw conveyor, the screw conveyor is fixed to the rack through an oil cylinder, and the other path of power of the middle gearbox is transmitted to a ridger; and a rear soil baffle is installed behind the ditching cutter head, the soil leveling cutter and the screw conveyor, a hood is further installed on the rack, a soil flying plate is arranged above the ditching cutter head, a soil dividing plate is arranged behind the ditching cutter head, and the ridger is located behind the side edge of the screw conveyor. The ridging and ditching integrated machine integrally designs ditching and ridging and has the advantages that fields ditched and ridged through the machine are located on the same horizontal plane, the problem that the fields are uneven after different agricultural machines work is solved, and the middle screw conveyor can convey redundant ditched soil to ridging ends, so that reasonable matching operation between machines can be well achieved.

Owner:LIANYUNGANG SHUANGYA MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com