Multifunctional ultrafiltration membrane module cutter

A technology of ultrafiltration membrane and cutting machine, which is applied in the direction of metal processing, etc. It can solve the problems of uneven cutting end surface, unsafe operation, and easy blockage of the port, so as to achieve the advantages of no hole blocking on the cutting end surface, high degree of mechanization, and reduced working intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

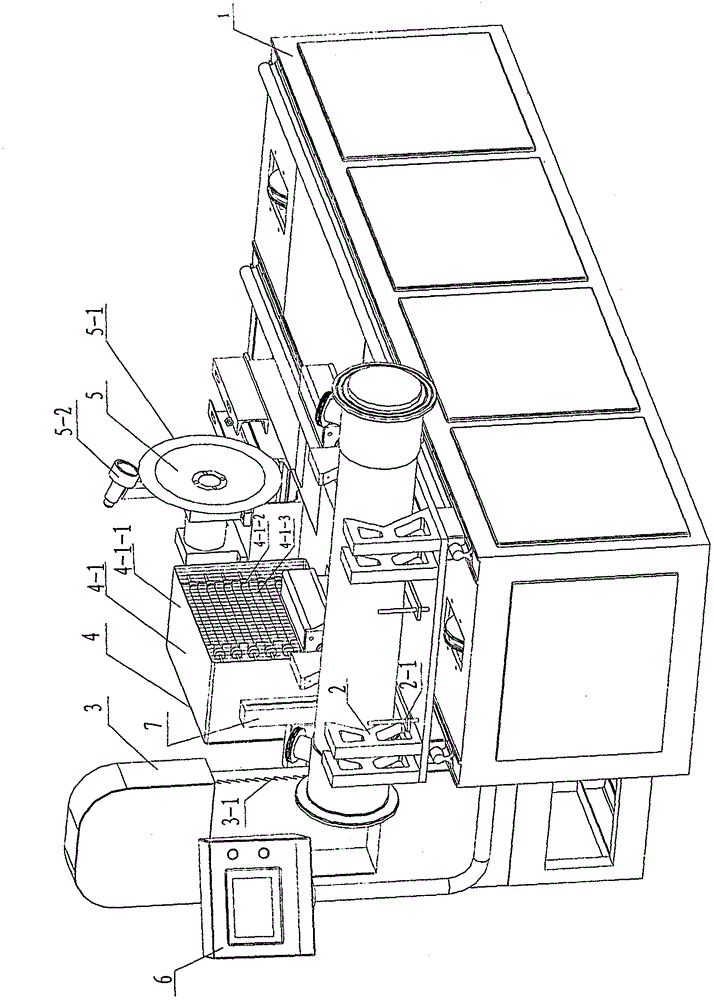

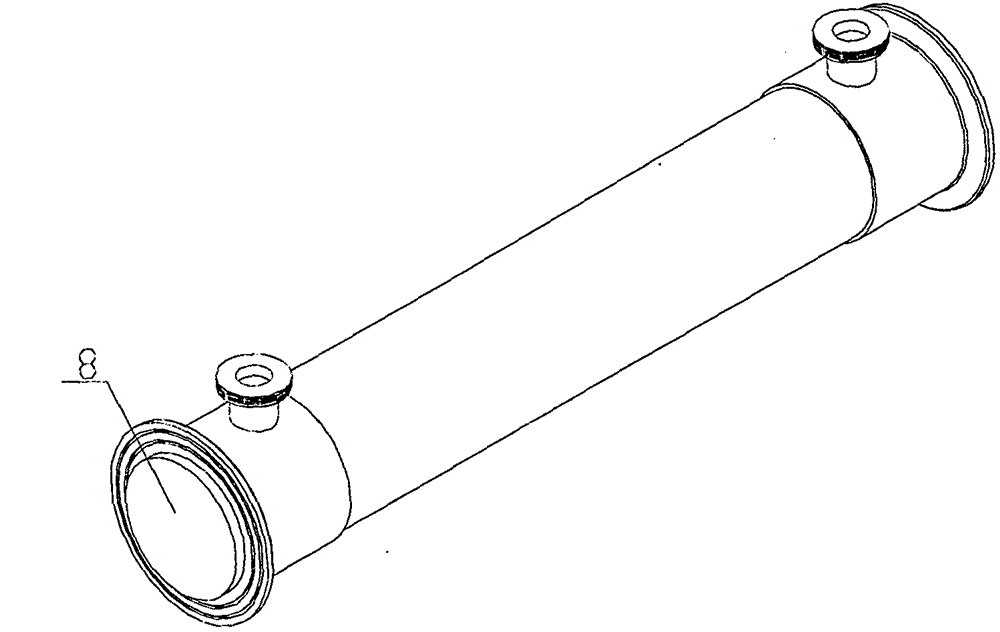

[0029] Such as Figure 1-3 As shown, a multi-functional ultrafiltration membrane module cutting machine, especially a cutting machine suitable for column ultrafiltration membrane modules, has a frame 1 with slide rails, and a movable frame 1 is set to fix the ultrafiltration membrane. The clamping device 2 of the membrane module, one side of the frame 1 is equipped with a device that can sequentially rough cut and heat the ultrafiltration membrane module in the clamping device 2 when the clamping device 2 advances to a certain position , rough cutting device 3 for fine cutting, heating device 4, and fine cutting device 5. The frame 1 is also provided with a human-machine interface device 6 connected to the PLC for the operator to input commands and display operating parameters, and the human-machine interface device 6 is a touch screen.

[0030] There is also a dust suction port 7 between the rough cutting device 3 and the heating device 4, which is used to remove the powder ...

Embodiment 2

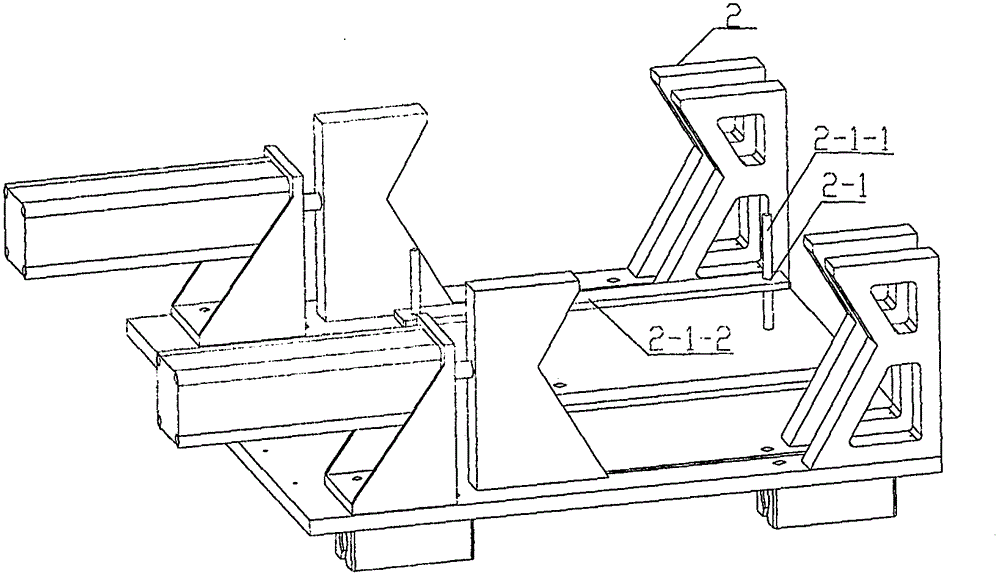

[0035] Such as Figure 4-5 As shown, a multifunctional ultrafiltration membrane module cutting machine, especially a cutting machine suitable for curtain ultrafiltration membrane modules, has a frame 1 with slide rails, and a movable frame 1 is set on the frame 1 to fix the ultrafiltration membrane module. The clamping device 2 of the membrane module, one side of the frame 1 is equipped with a device that can sequentially rough cut and heat the ultrafiltration membrane module in the clamping device 2 when the clamping device 2 advances to a certain position , rough cutting device 3 for fine cutting, heating device 4, and fine cutting device 5. The frame 1 is also provided with a human-machine interface device 6 connected to the PLC for the operator to input commands and display operating parameters, and the human-machine interface device 6 is a touch screen.

[0036] The rough cutting device 3 is a circular saw 3-2, the heating device 4 is an infrared heating box 4-1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com