Horizontal diamond wire cutting machine tool

A wire cutting machine tool and diamond sand technology, which is applied in metal processing, stone processing tools, stone processing equipment, etc., can solve the problems of difficult clamping and easy breakage, and achieve simple clamping, not easy to break, and multi-directional cutting efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

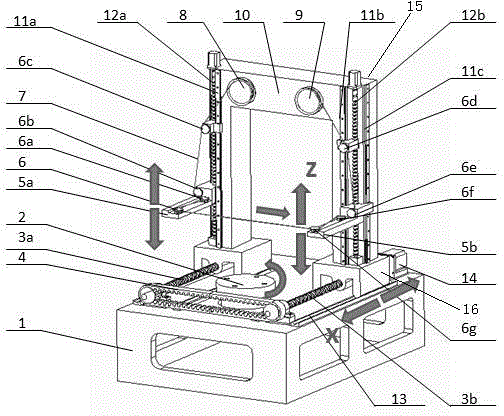

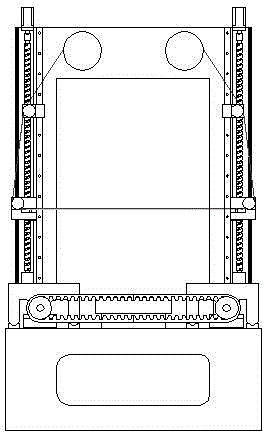

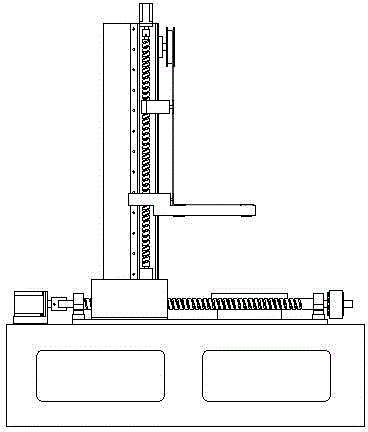

[0018] Such as figure 1 , 2 shown.

[0019] A horizontal diamond sand wire cutting machine tool, which includes a bed 1, a gantry mobile connected to the X guide rails 13 on both sides of the bed 1, the gantry is formed by connecting a beam 10, a left column and a right column, The left column and the lower end of the right column are connected with the X-axis screw rods 3a, 3b through screw nuts, and one end of the screw rods 3a, 3b is connected with a synchronous toothed belt 4; driven by ball screws 12a, 12b The left column and the right column are respectively installed on the X-direction slide block, and the guide rails 11a, 11b, 11c are respectively installed on the left column and the right column; On the Z-direction slider driven by the ball screw 12a, 12b, the tension adjustment wheel 6b and the guide wheels 6, 6a are installed on the extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com