Automatic die-changing processing equipment

A technology for processing equipment and automatic mold change, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of troublesome mold replacement, low work efficiency, and many equipment occupations, so as to avoid interference, improve processing efficiency, and facilitate The effect of clamping the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

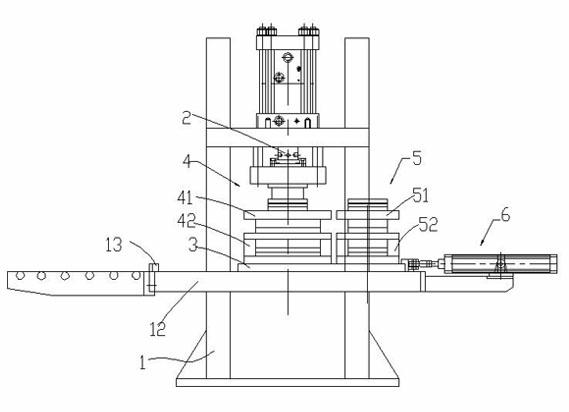

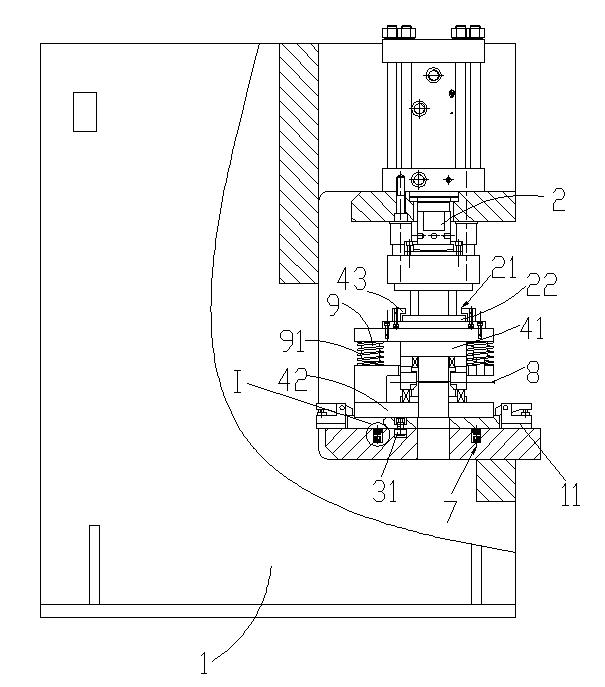

[0023] attached figure 1 The positional relationship between up and down shown in is corresponding to the positional relationship of "up" and "down" described in the manual. figure 1 The left and right directions in the manual refer to the "horizontal" described in the manual. figure 1 The up and down direction in is the "vertical" described in the manual.

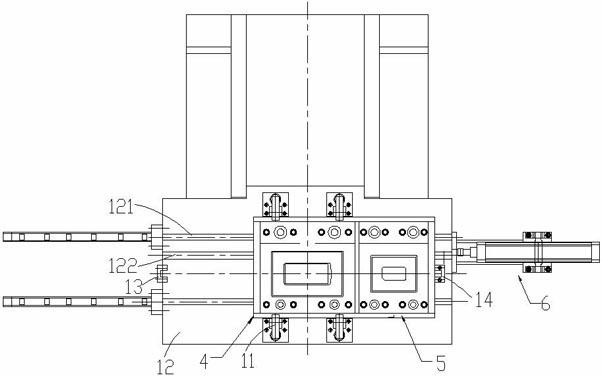

[0024] In this embodiment, a punch press is taken as an example to illustrate the working principle of the present invention. Such as Figure 1-3 As shown, a processing equipment for automatic mold change includes a frame 1, a punch 2 that can be lifted and lowered on the frame, a workbench 3, and at least two horizontally arranged on the workbench 3 4,5 on the mold. The frame 1 is provided with a bearing platform 12 for fixing the workbench 3. Generally speaking, the bearing platform 12 refers to the bed surface of a punching machine.

[0025] as attached figure 2 , 4 As shown, a pair of storage grooves 121 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com