High cavitation, low tonnage rubber mold machine and method

A technology for injection molds and injection molds, which is applied in the direction of forming pressure heads, etc., and can solve problems such as loss and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

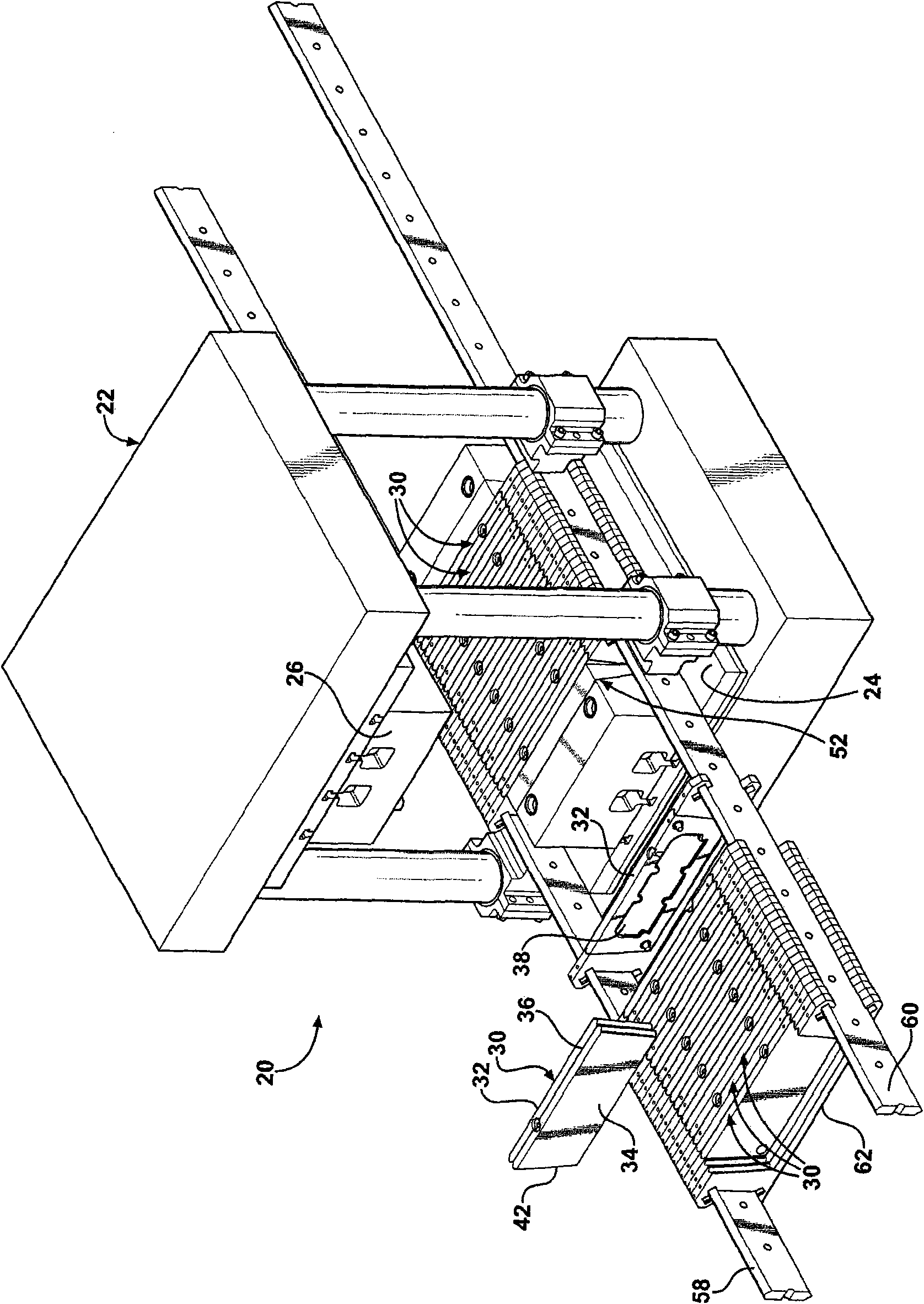

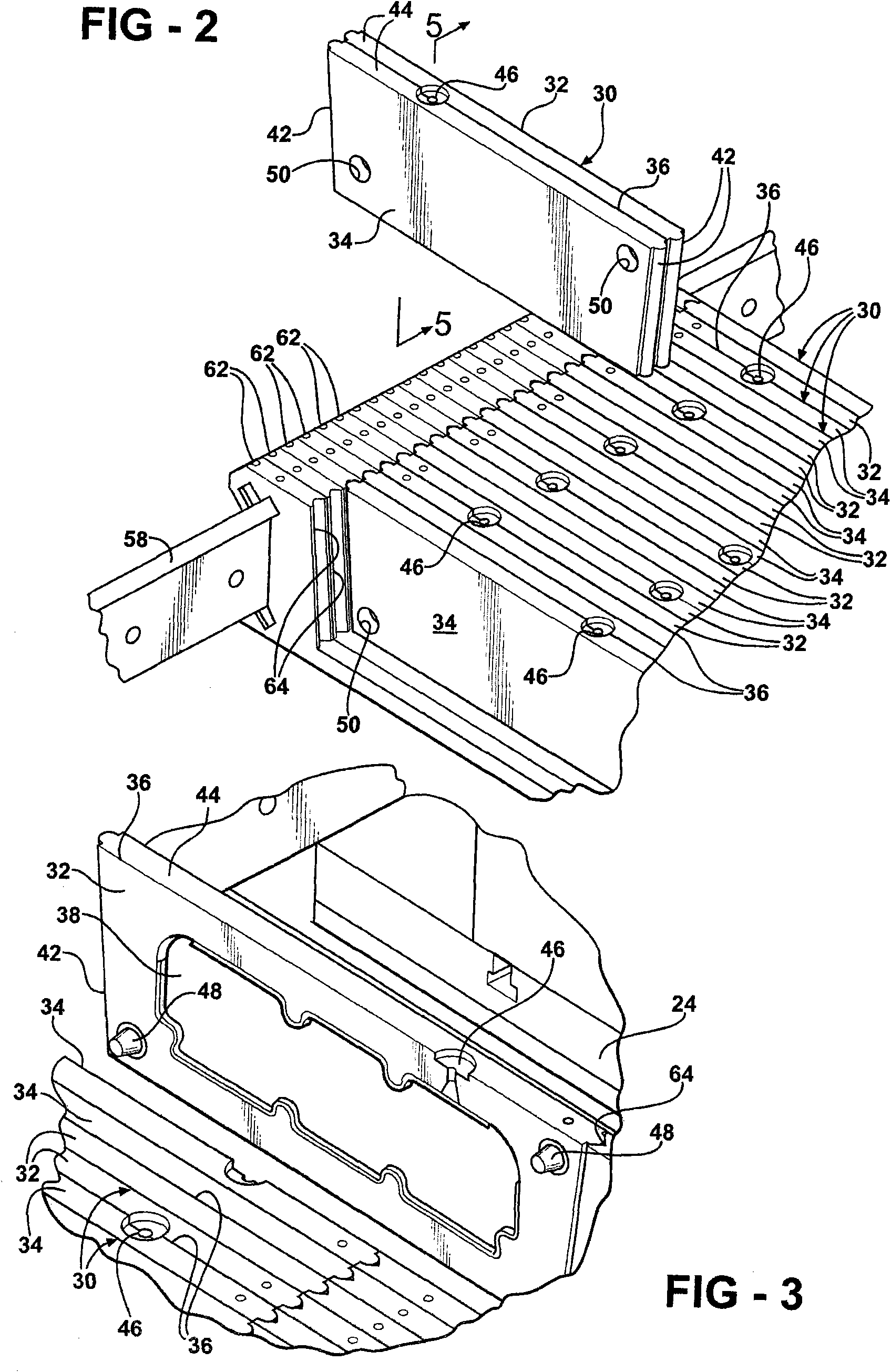

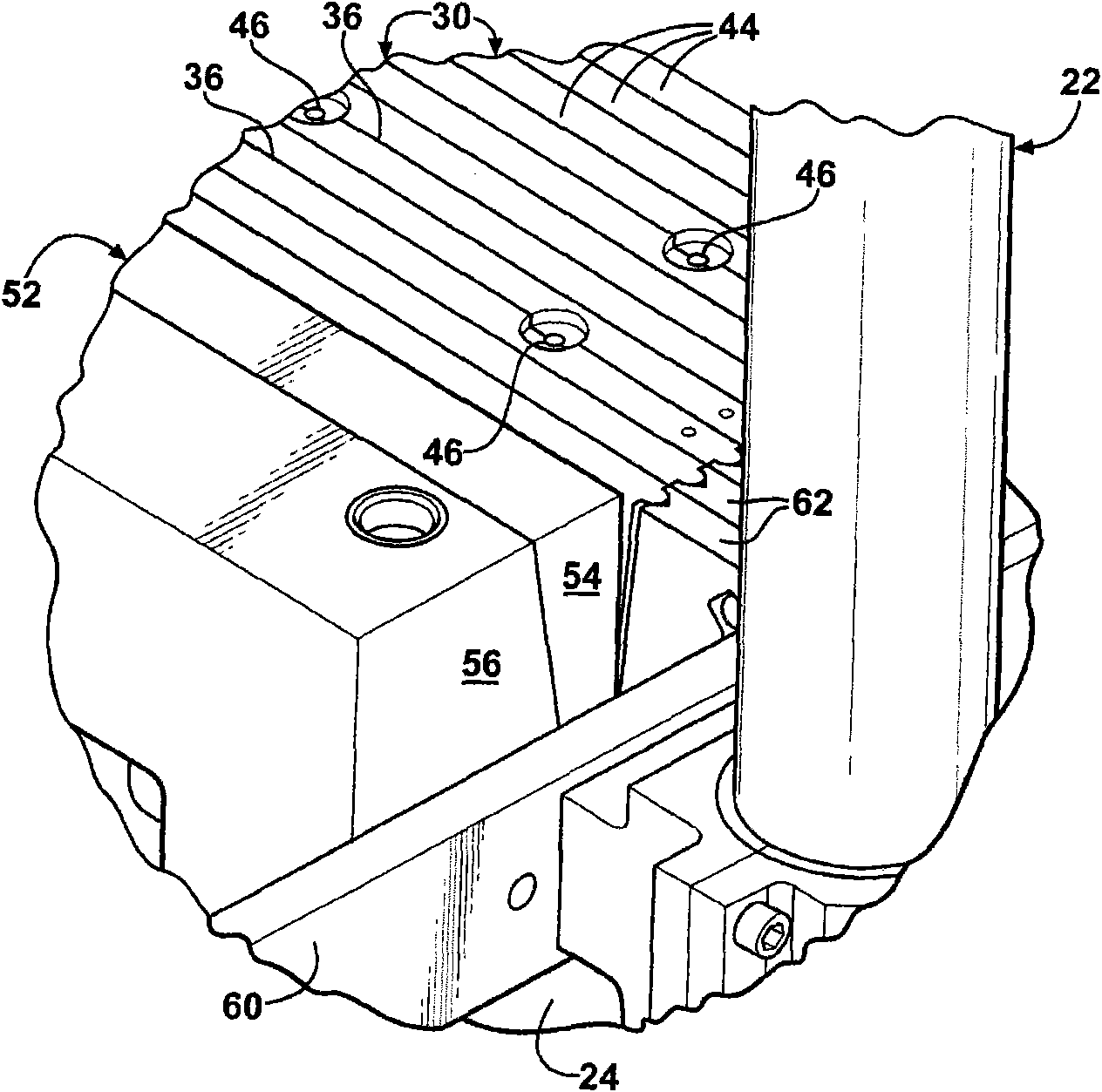

[0020] As shown in the drawings, wherein in all the drawings, the same numerals represent the same or corresponding components, a rubber injection molding apparatus for simultaneously molding multiple workpieces in separate molds by a single press is shown at 20 Show. A rubber injection molding press, generally indicated at 22, includes a press bed 24 and a vertically oriented press slide 26 which supports reciprocating motion on a vertical path toward and away from a press bed 24. The press slide 26 can be equipped with multiple heaters, runner system 28 and nozzles, as shown in Figures 6 and 7, to distribute the molten rubber to multiple molds at the appropriate time in the molding cycle.

[0021] A plurality of separate and independent injection molds, generally indicated at 30, are distributed within the pressure zone, for example, between the press 24 and the press slide 26, or as described alternatively, between the Within the path of the reciprocating motion of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com