Patents

Literature

1703results about "Shaping press ram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

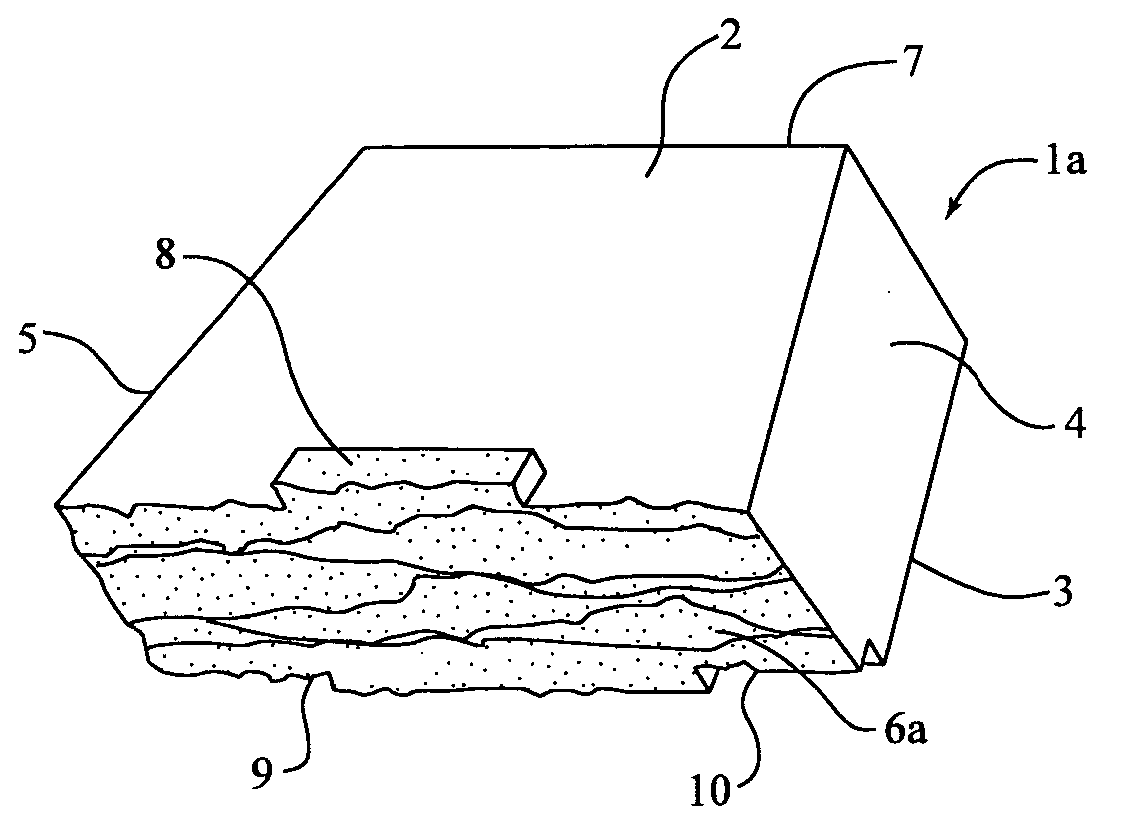

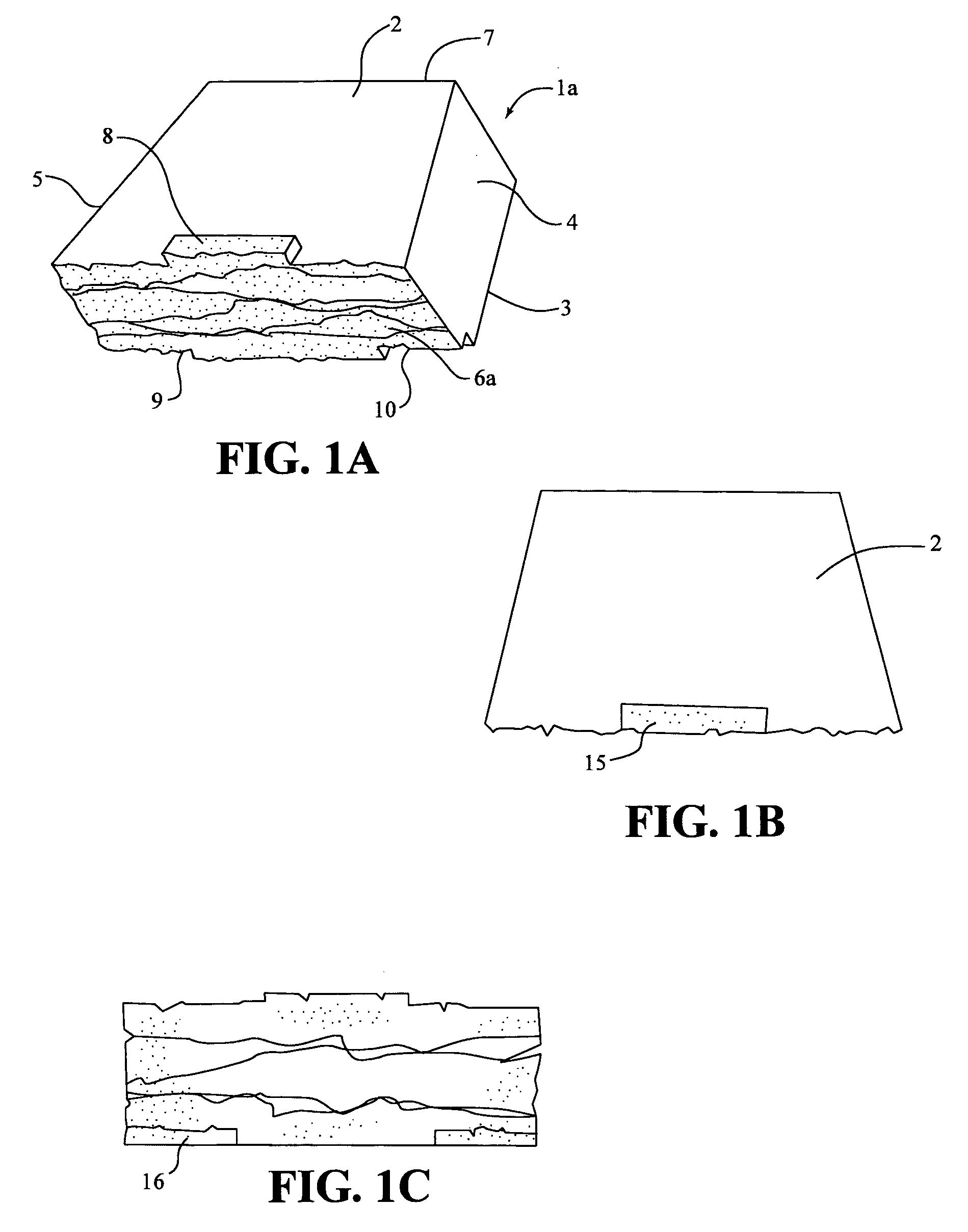

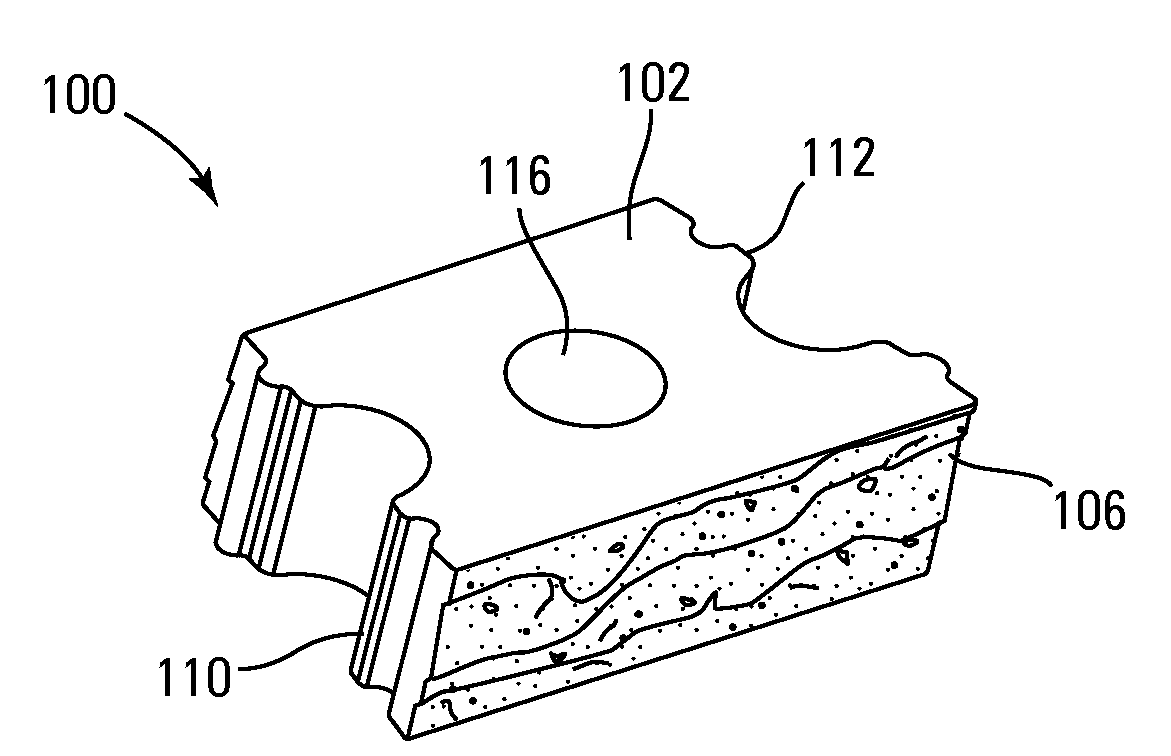

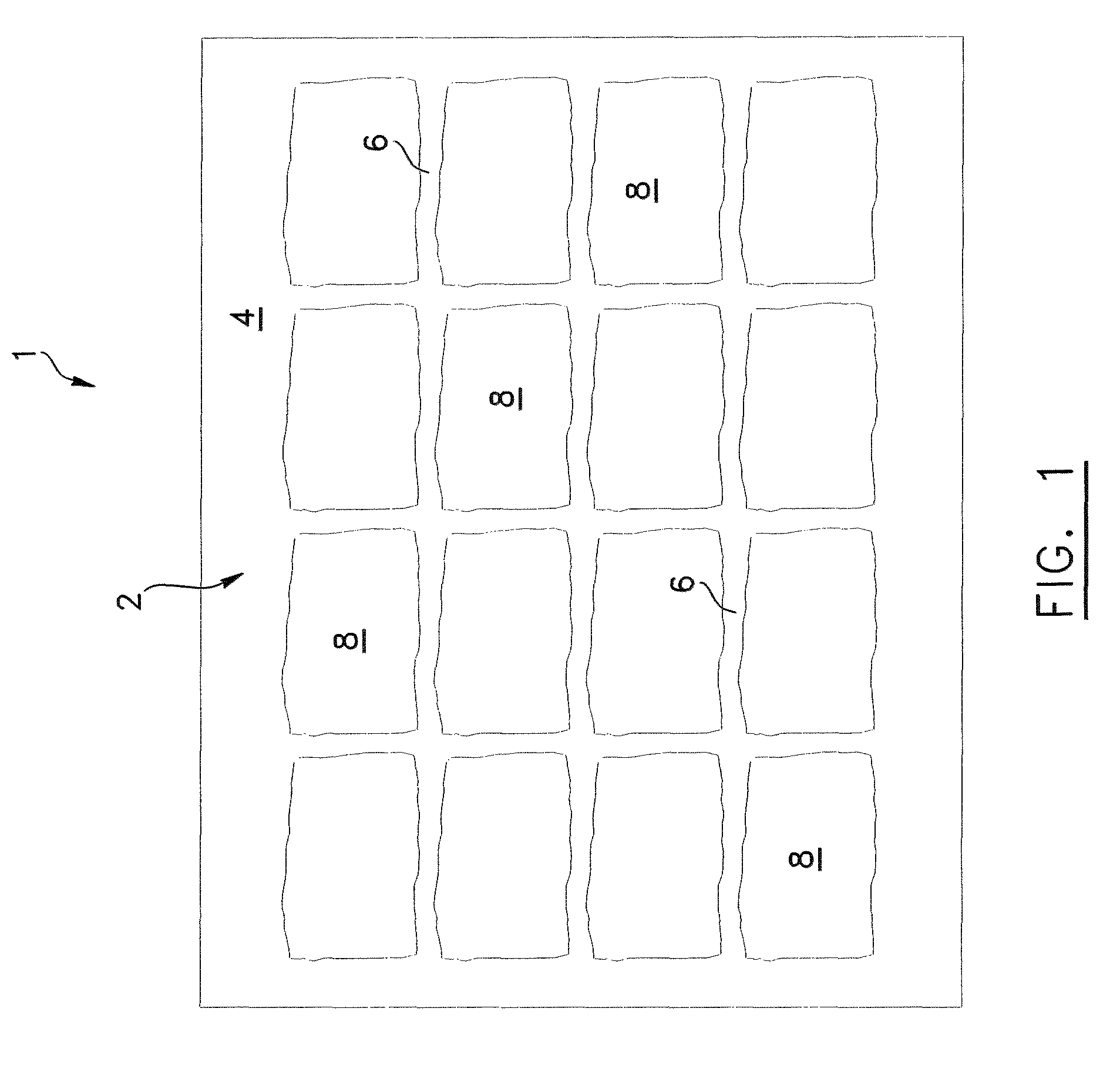

Retaining wall block with face connection

Single and multiple retaining wall blocks and block systems are disclosed. The blocks are provided with a face connection system which includes at least one front lip extending from a top surface of the block and a bottom channel formed into a front face and bottom surface of the block. The front lips have a length which is less than the width of the blocks.

Owner:CONTECH TECH

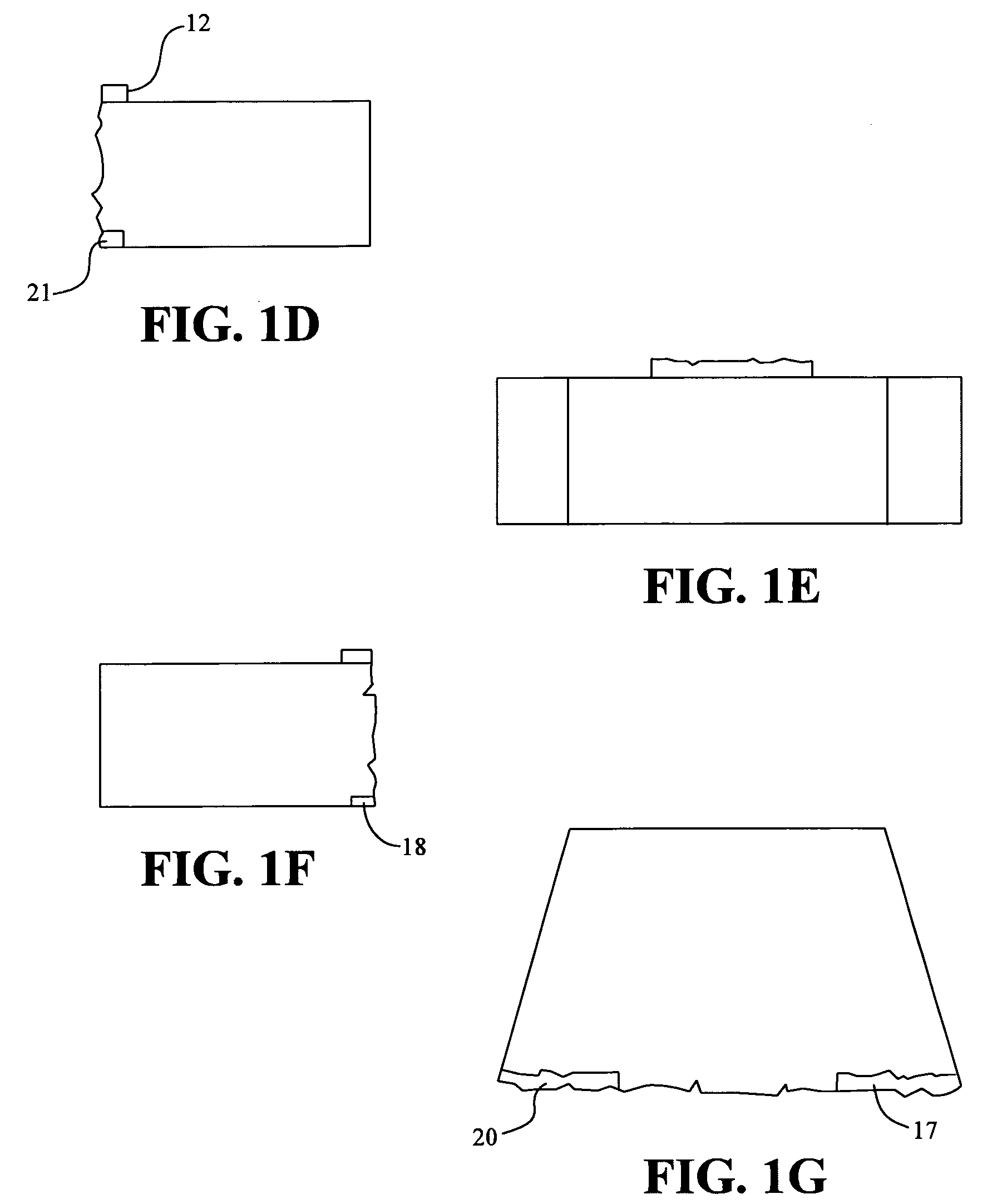

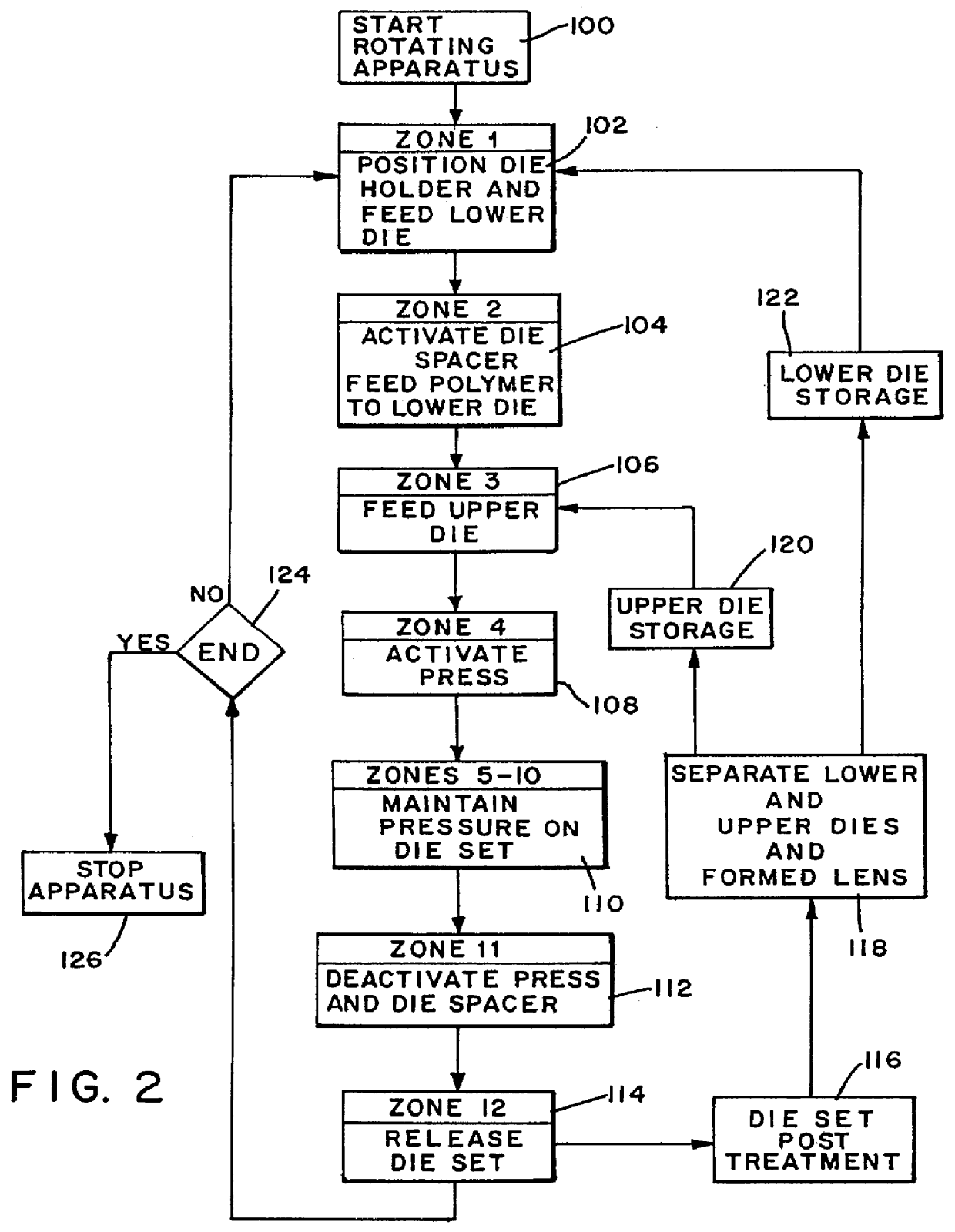

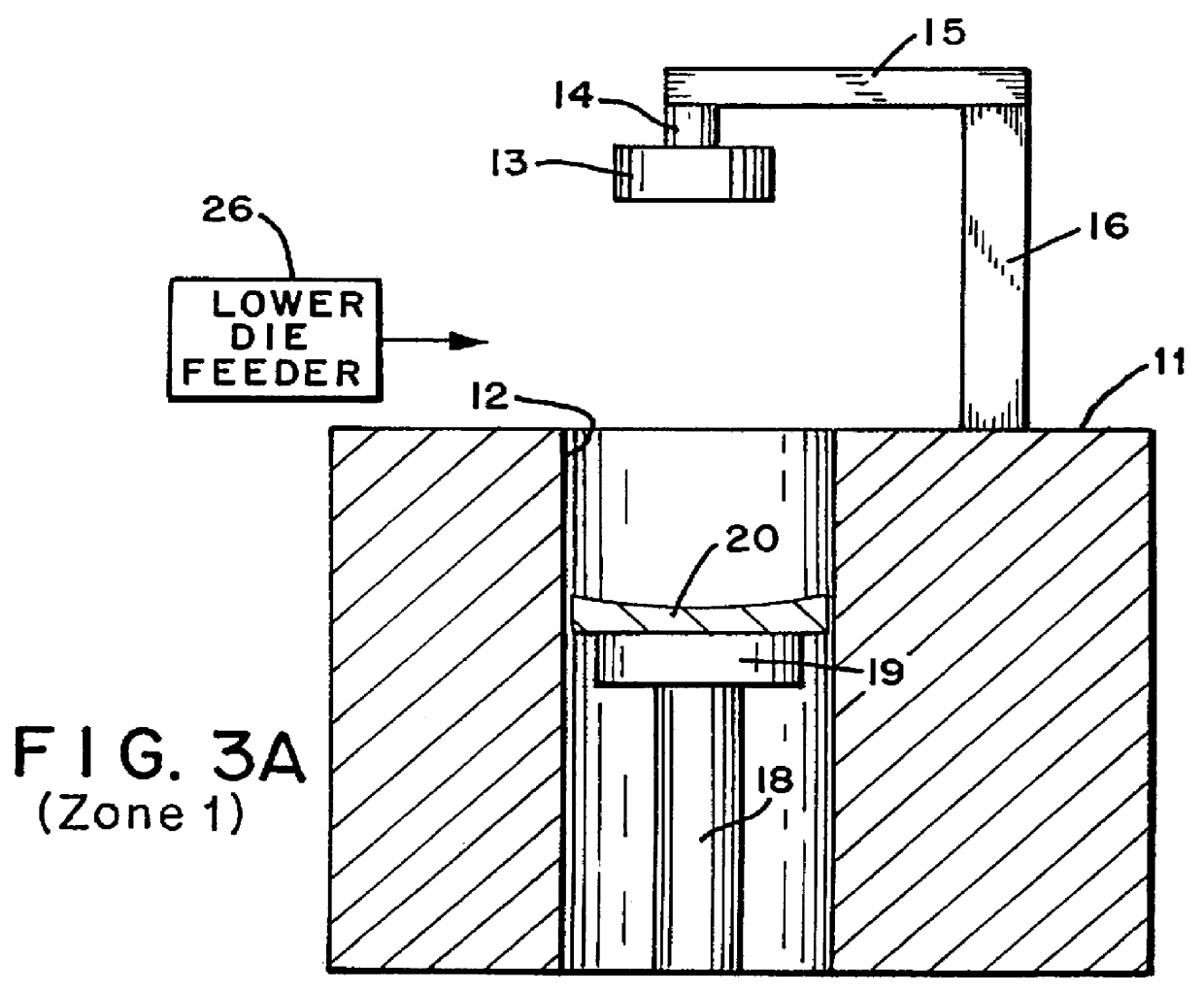

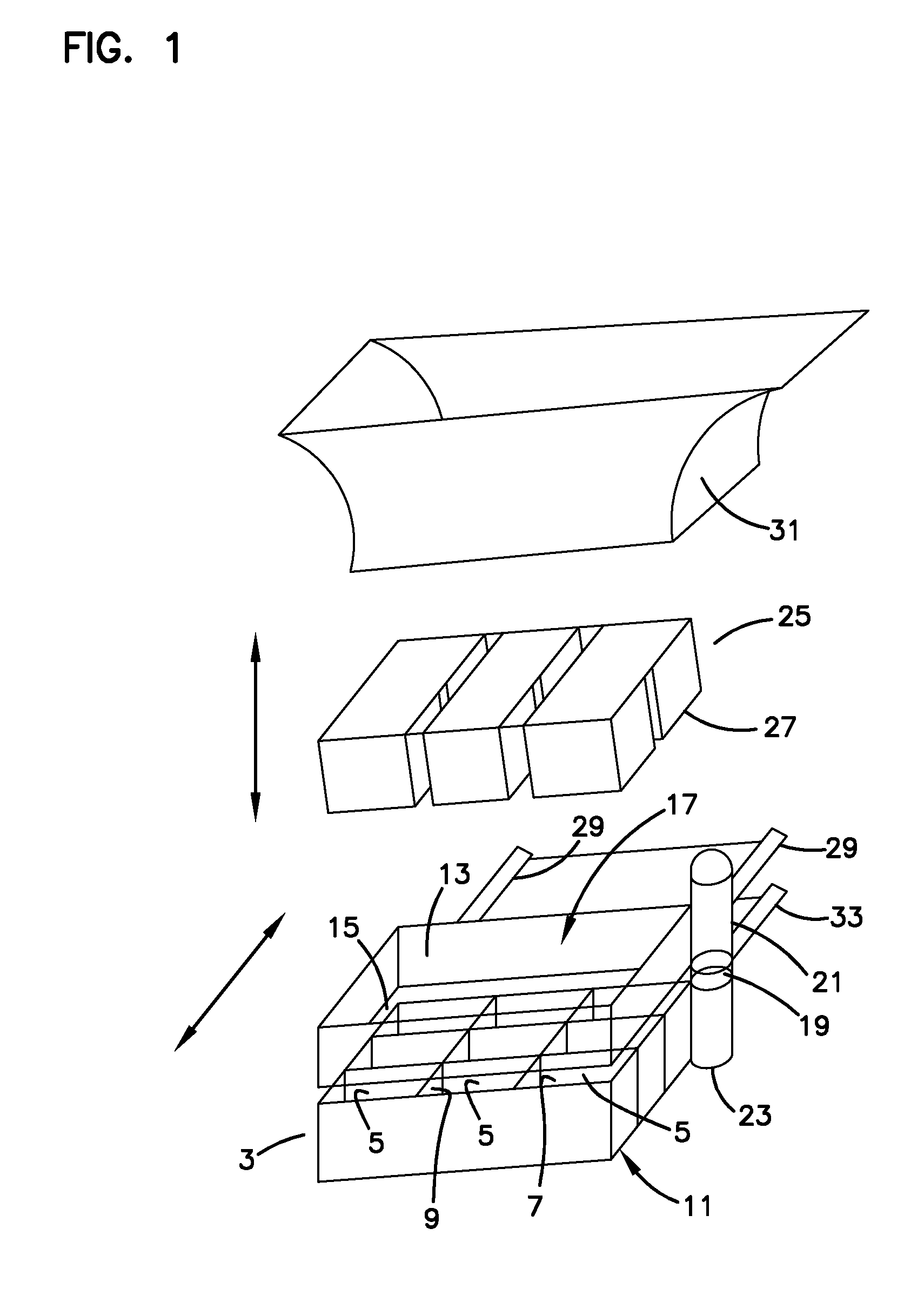

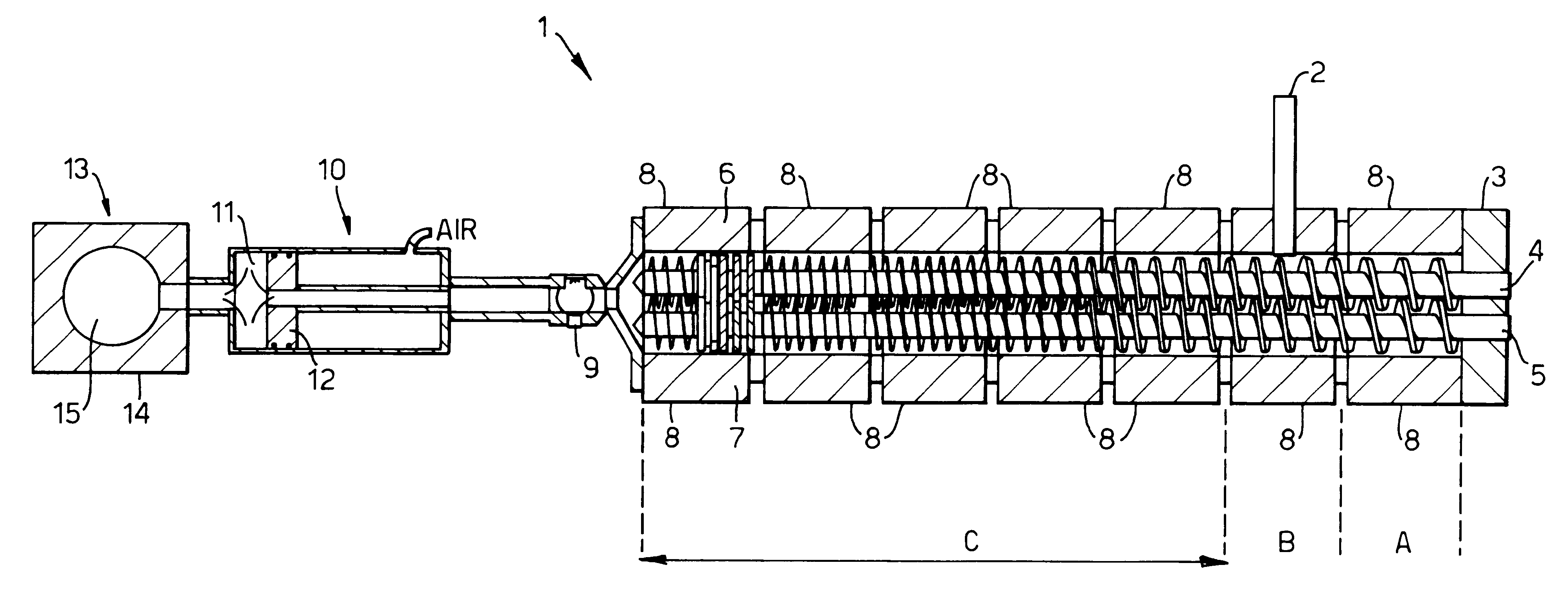

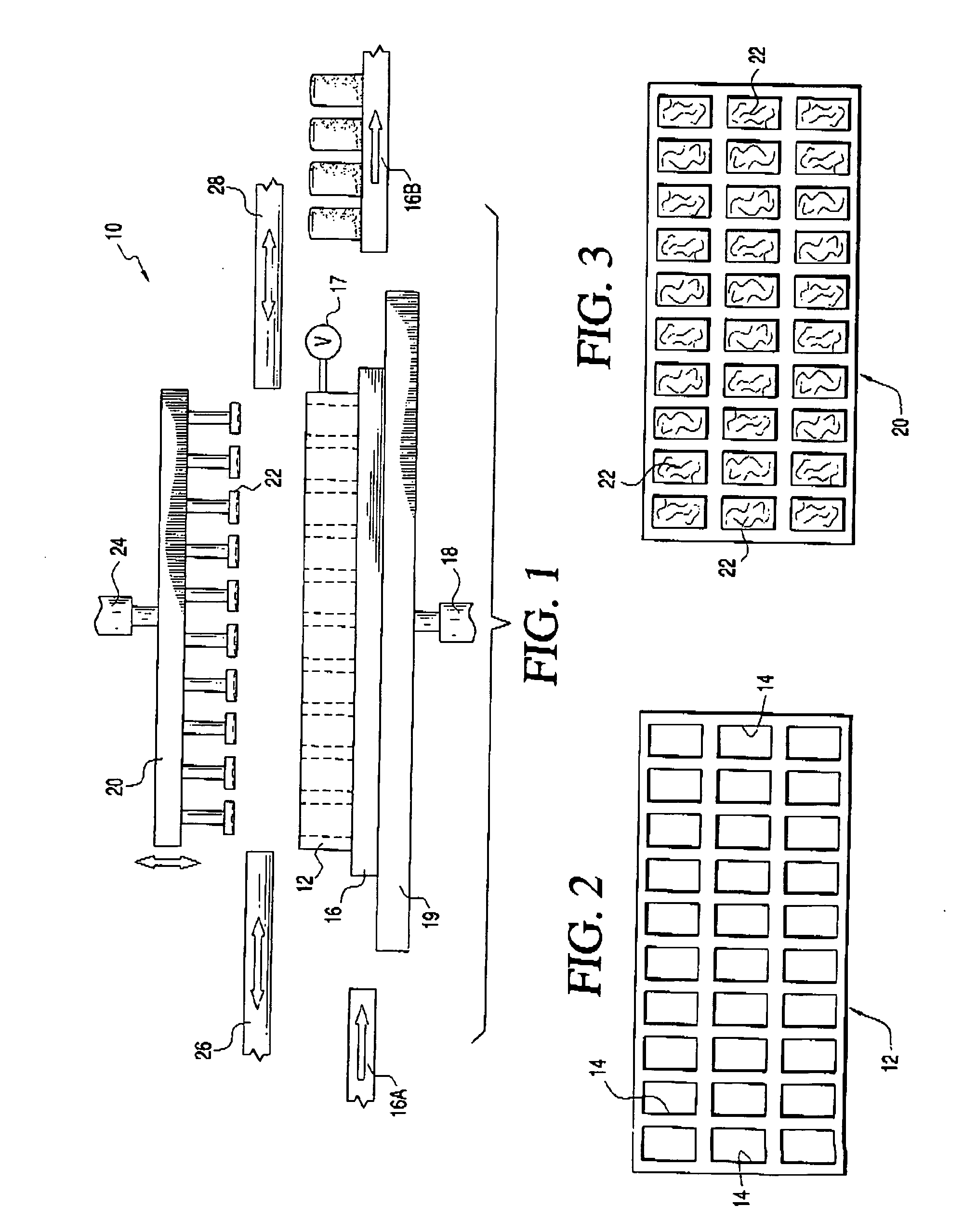

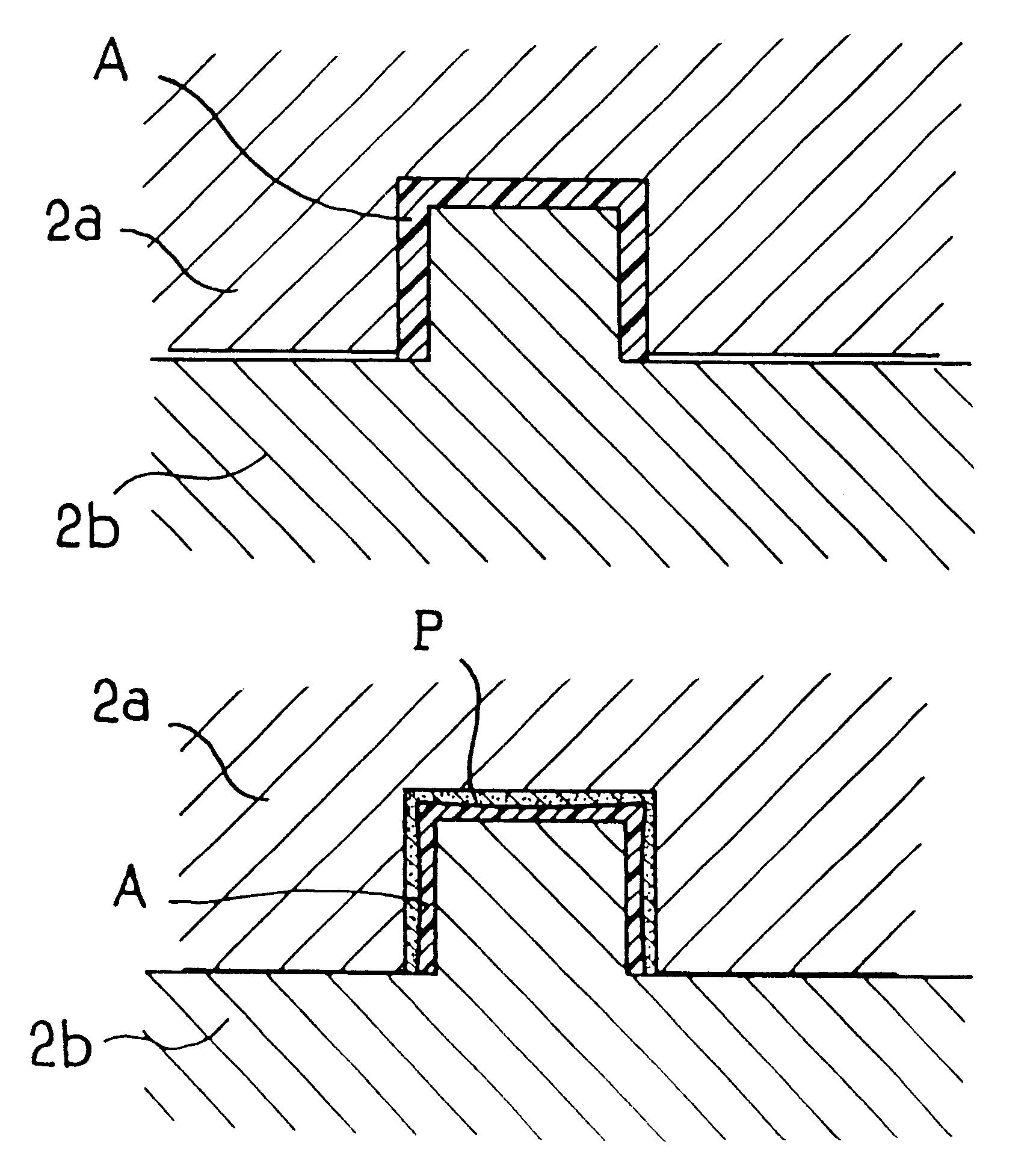

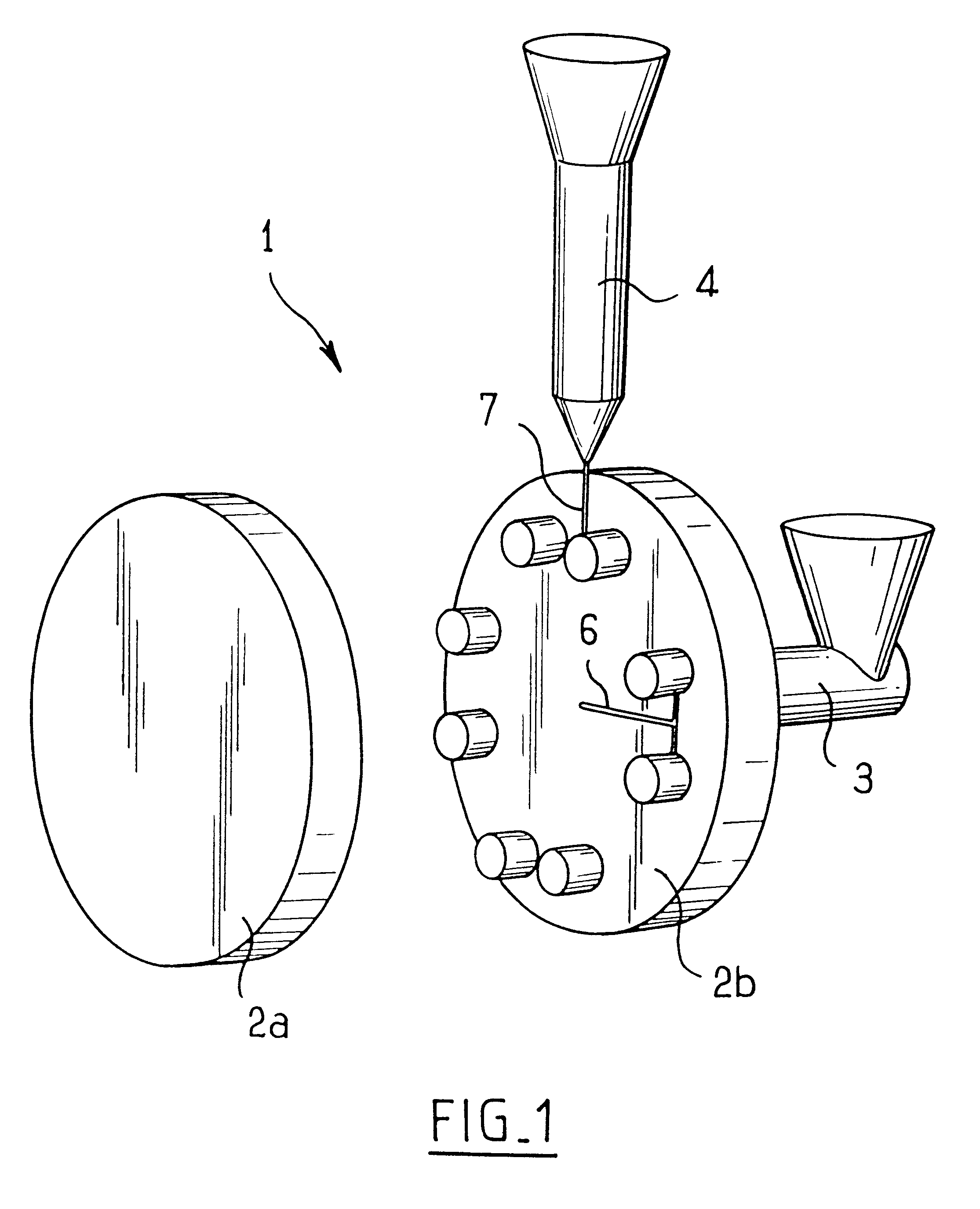

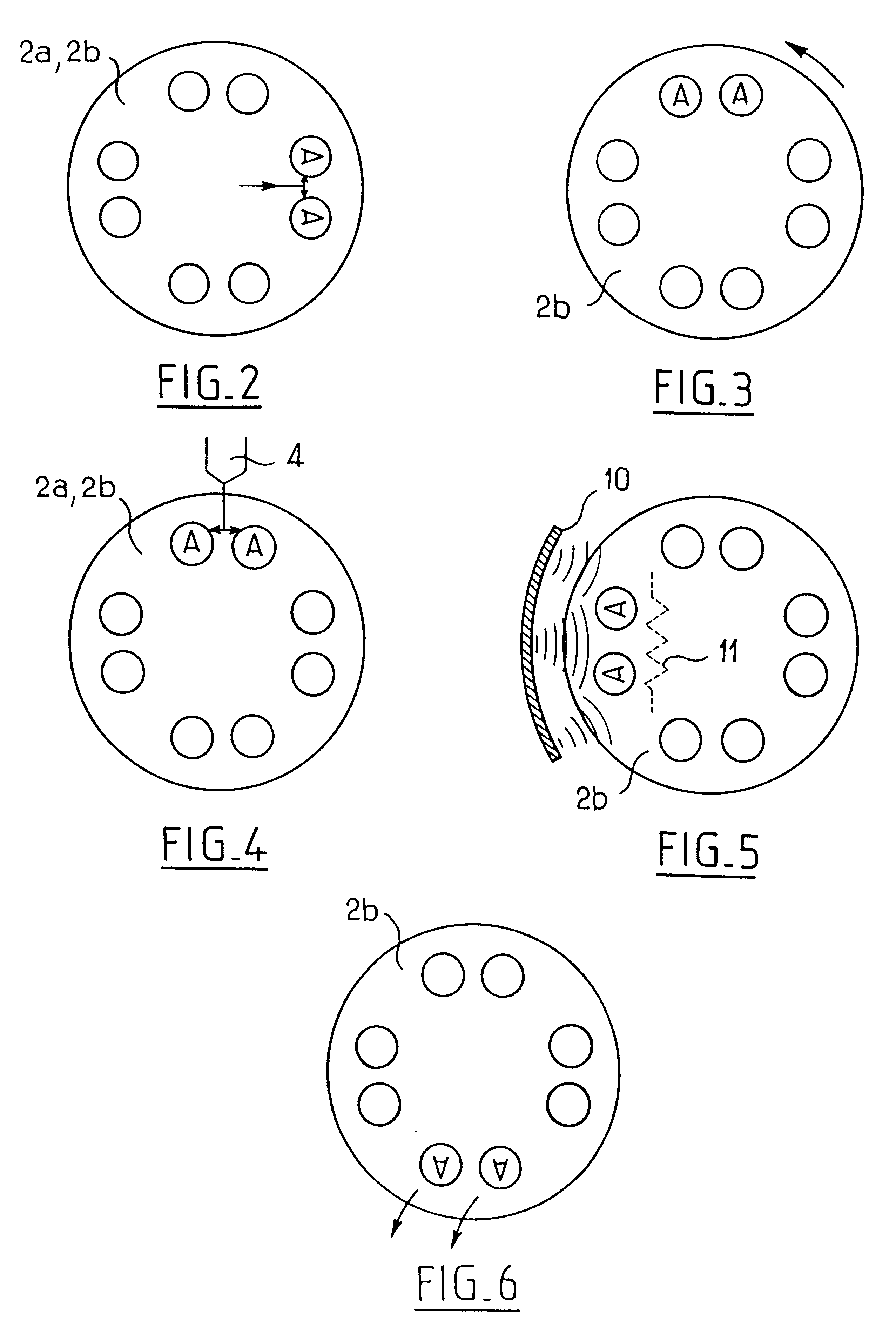

Continuous extrusion-compression molding process for making optical articles

InactiveUS6042754AEasy to processLong lastingRecord carriersConfectioneryCompression moldingShell molding

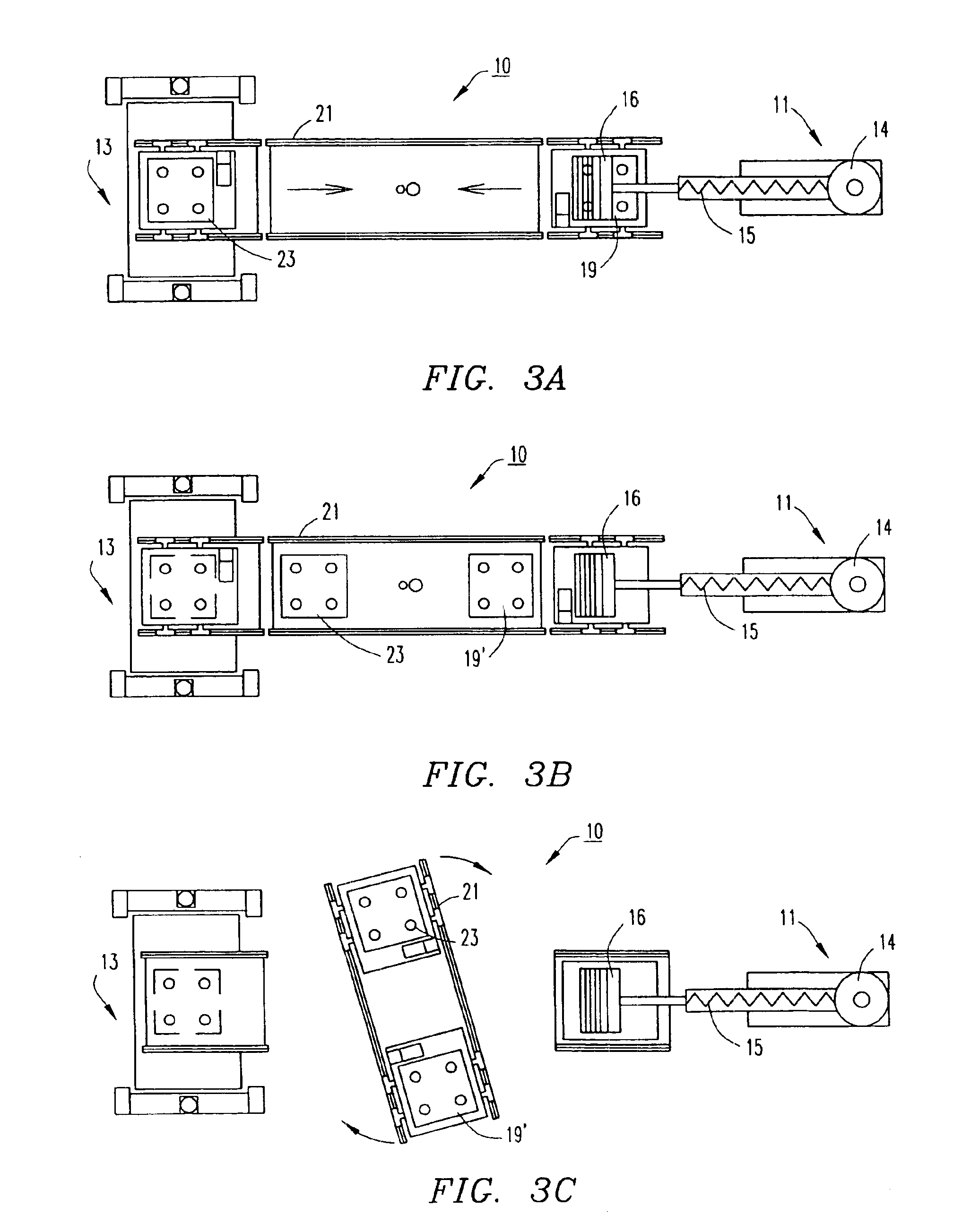

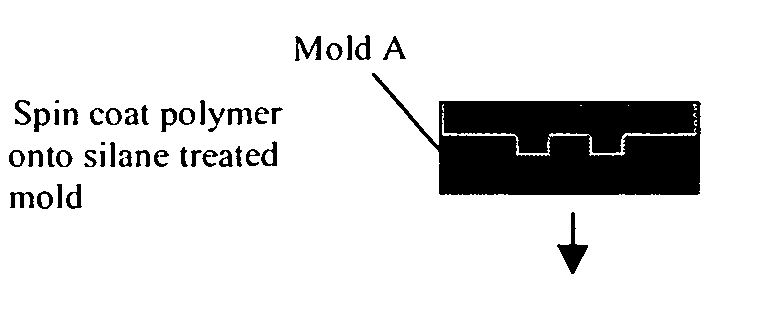

The present invention relates to making optical articles such as opthalmic lenses by molding and, in particular, to using a continuous extrusion-compression molding method to make plastic lenses whereby a polymer melt is fed from an extruder or melting apparatus to a first die of a plurality of rotating or conveyed sequentially processed compression die sets comprising a first die and a second die. The die sets are positioned on die supports on a rotating turntable or conveying system, the lenses formed by compressing the die sets with pressing means associated with each die support, the lenses separated from the dies and the dies recycled to die loading and the melt feed step of the process and the process repeated until the desired number of lenses or other optical articles such as compact disk substrates are produced.

Owner:FOREVER VISION

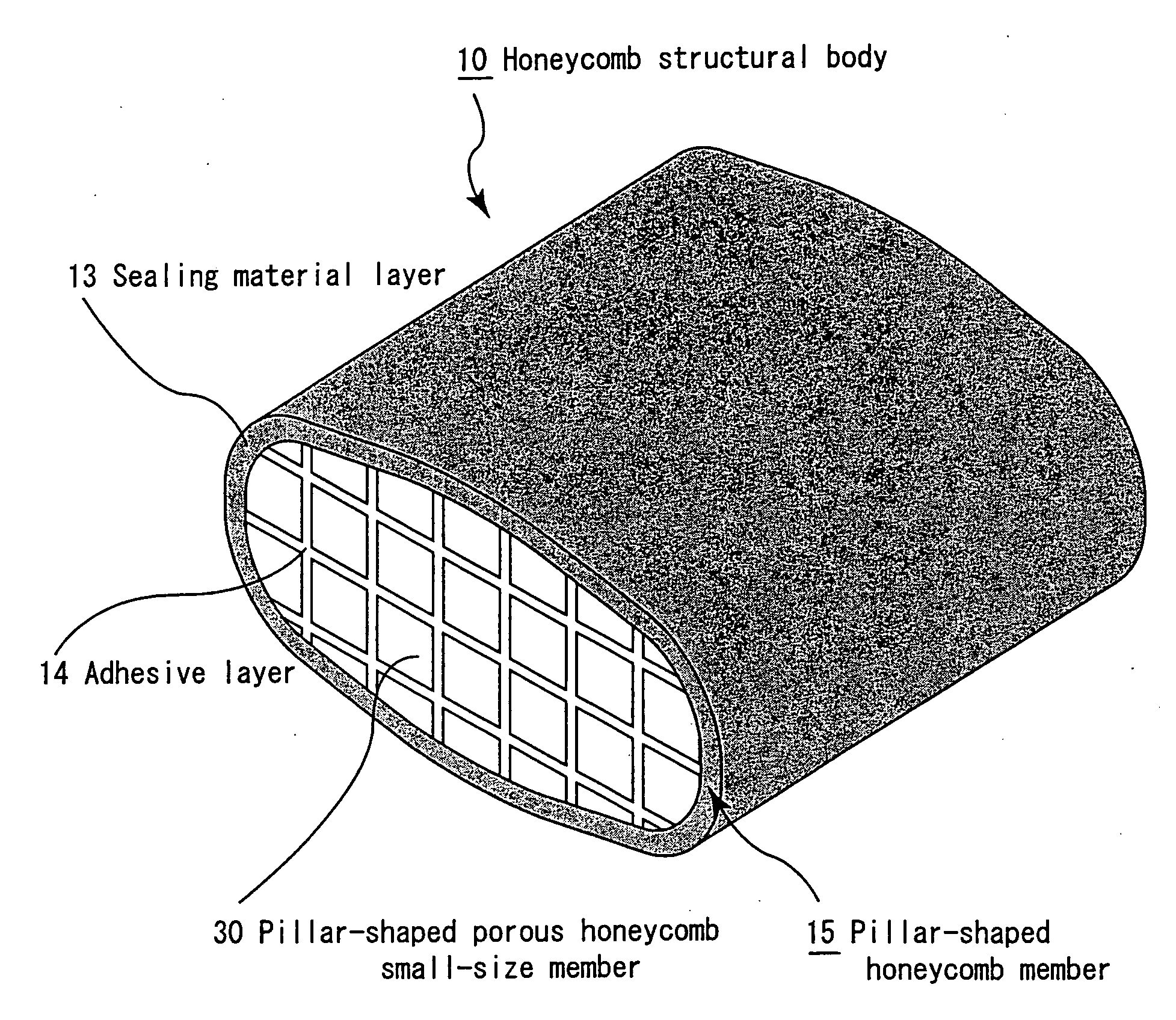

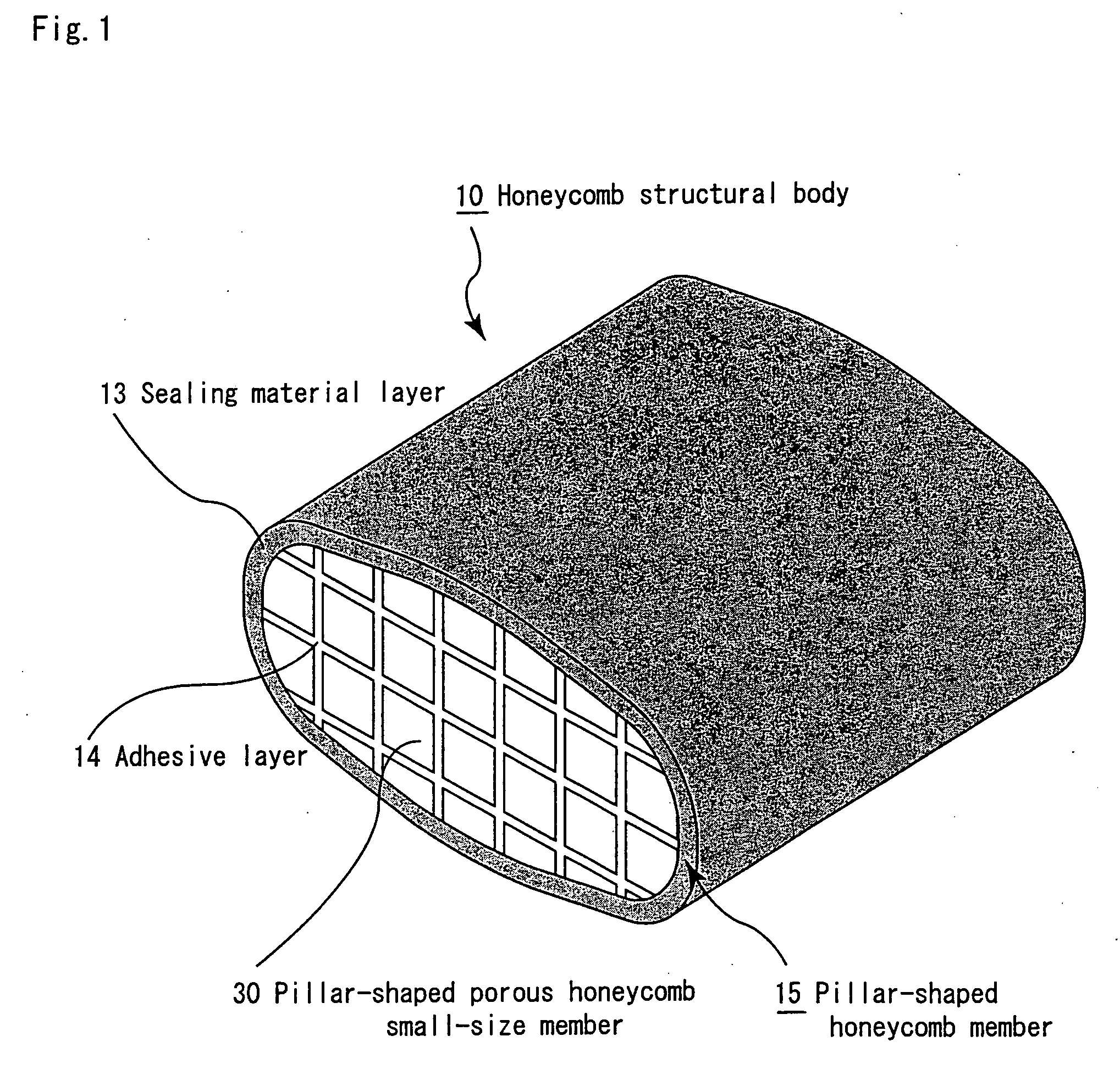

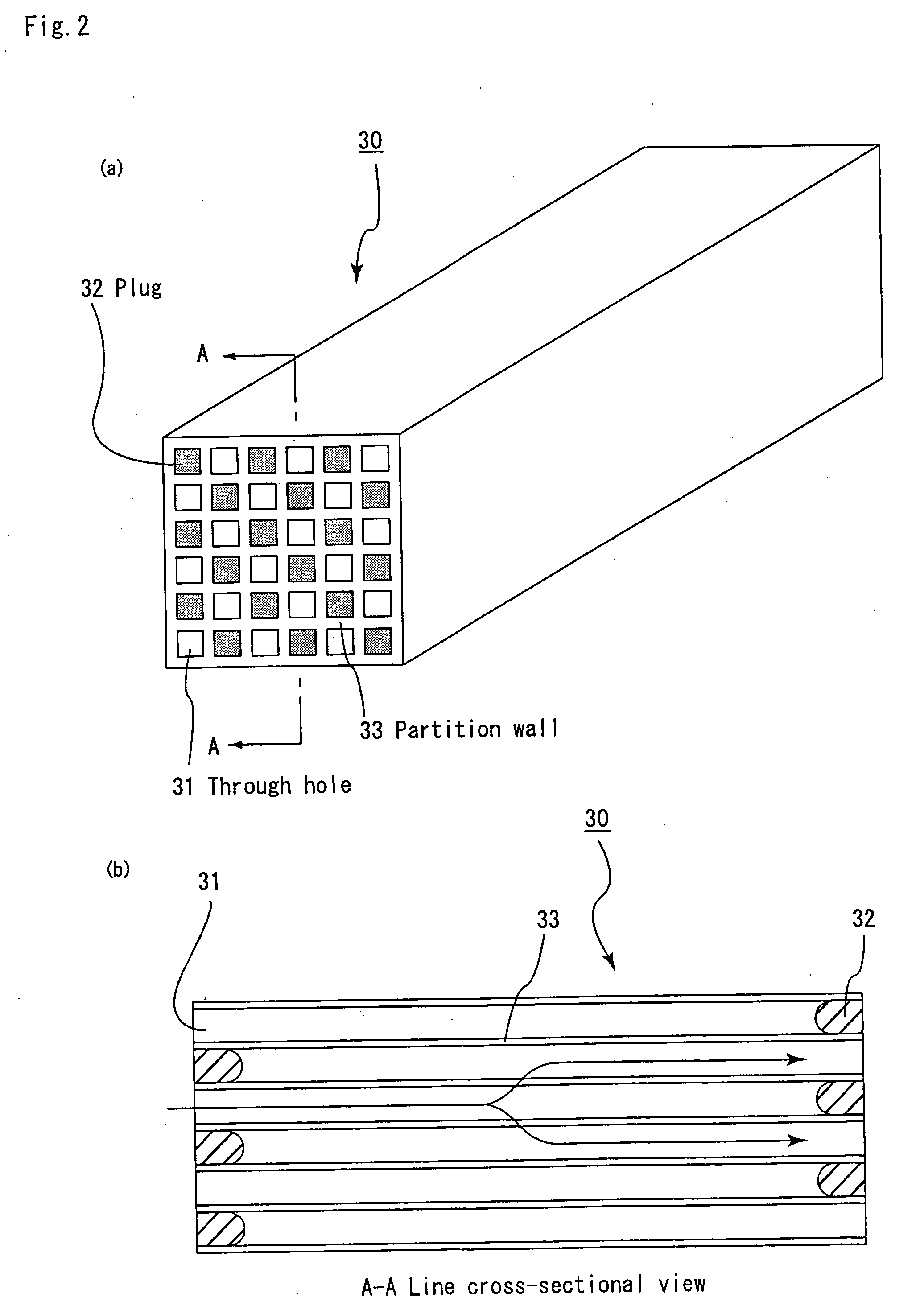

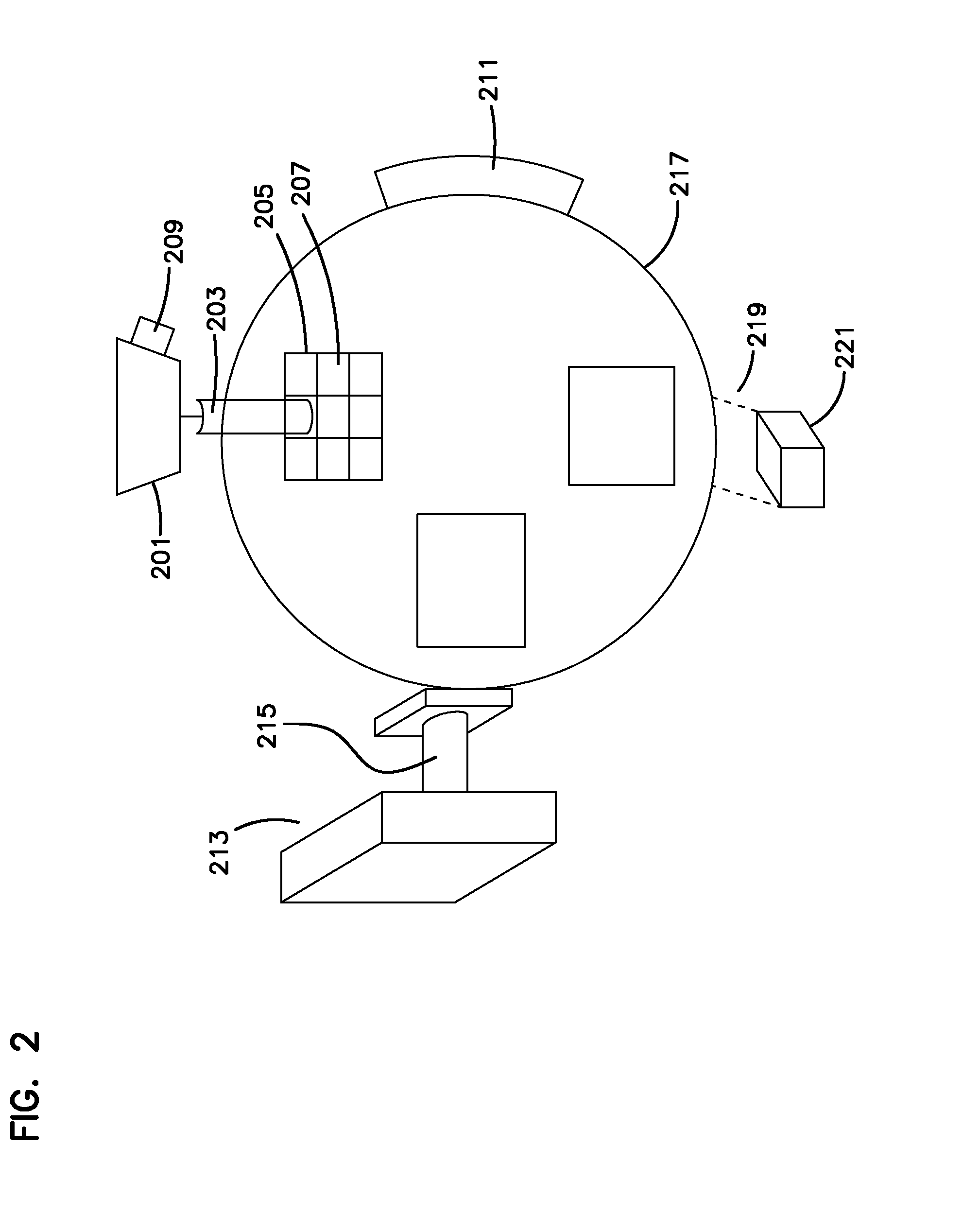

Manufacturing method of honeycomb structural body, and sealing material

ActiveUS20070126160A1Improve assembly effectAvoid separationExhaust apparatusConfectioneryHoneycomb structureRaw material

An object of the present invention is to provide a manufacturing method of a honeycomb structural body which makes the profile of a cross section perpendicular to the length direction thereof less likely to generate dispersion, and also makes the thickness of its sealing material layer thinner, and a sealing material that is suitably used in the manufacturing method of the honeycomb structural body. According to the present invention, the manufacturing method of a honeycomb structural body with a sealing material layer formed on the peripheral portion of a pillar-shaped porous honeycomb member includes a sealing material applying step of applying a paste-like sealing material, which is a raw material of the sealing material layer, onto a circumferential face of the pillar-shaped porous honeycomb member, and a scraping step of fitting a ring-shaped scraper, which can be brought into contact with the circumferential face of the pillar-shaped porous honeycomb member so as to slide thereon, to the pillar-shaped porous honeycomb member and moving said ring-shaped scraper in the length direction, thereby expanding the paste-like sealing material applied onto the circumferential face of the pillar-shaped porous honeycomb member so as to spread over the entire circumferential face of the pillar-shaped porous honeycomb member.

Owner:IBIDEN CO LTD

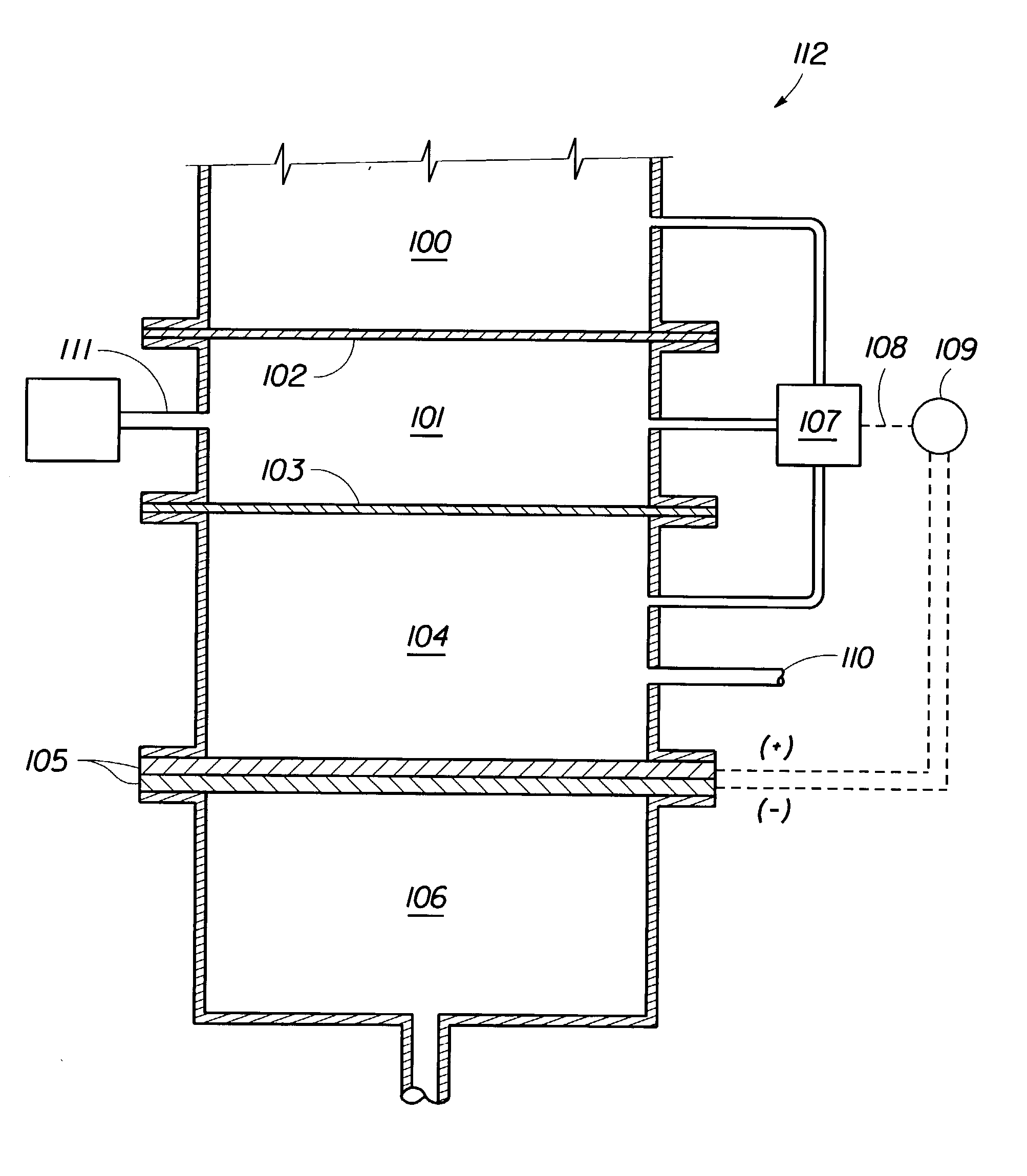

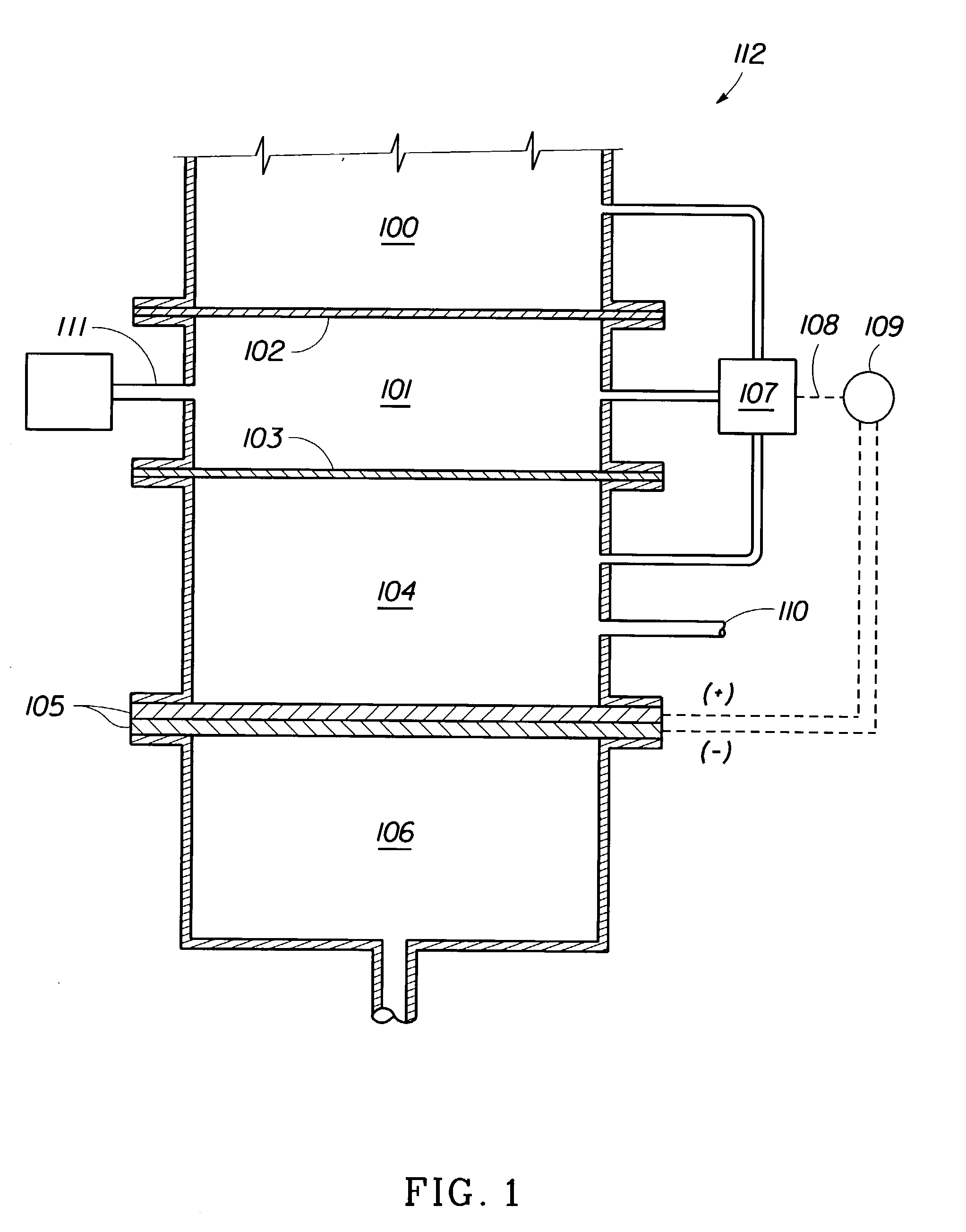

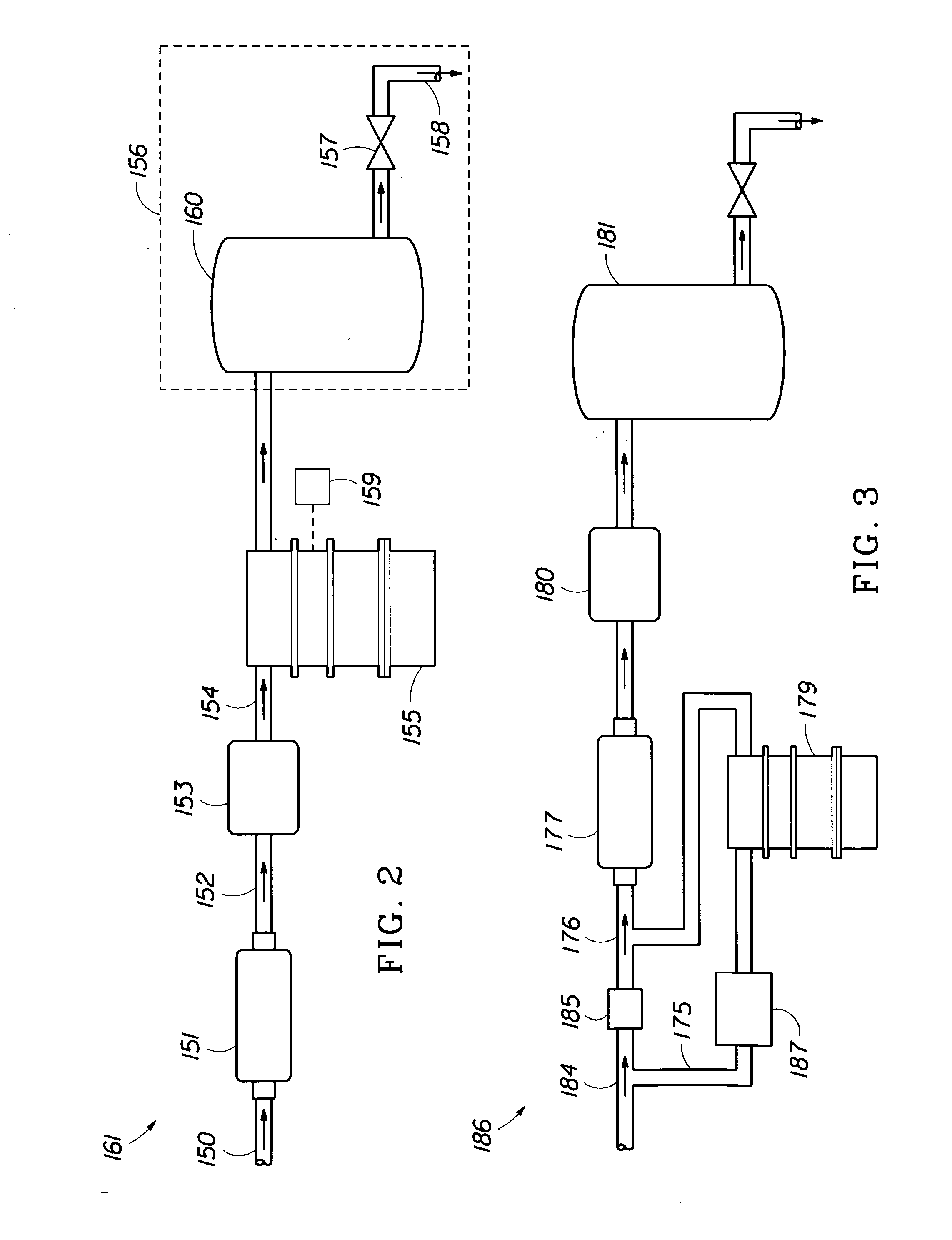

Microorganism control of point of use potable water sources

InactiveUS20030080467A1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesMedical equipmentWater source

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

Pressed, self-solidifying, solid cleaning compositions and methods of making them

ActiveUS8889048B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringAdhesive bonding

The present invention relates to a method of making a solid cleaning composition. The method can include pressing and / or vibrating a flowable solid of a self-solidifying cleaning composition. For a self-solidifying cleaning composition, pressing and / or vibrating a flowable solid determines the shape and density of the solid but is not required for forming a solid. The method can employ a concrete block machine for pressing and / or vibrating. The present invention also relates to a solid cleaning composition made by the method and to solid cleaning compositions including particles bound together by a binding agent.

Owner:ECOLAB USA INC

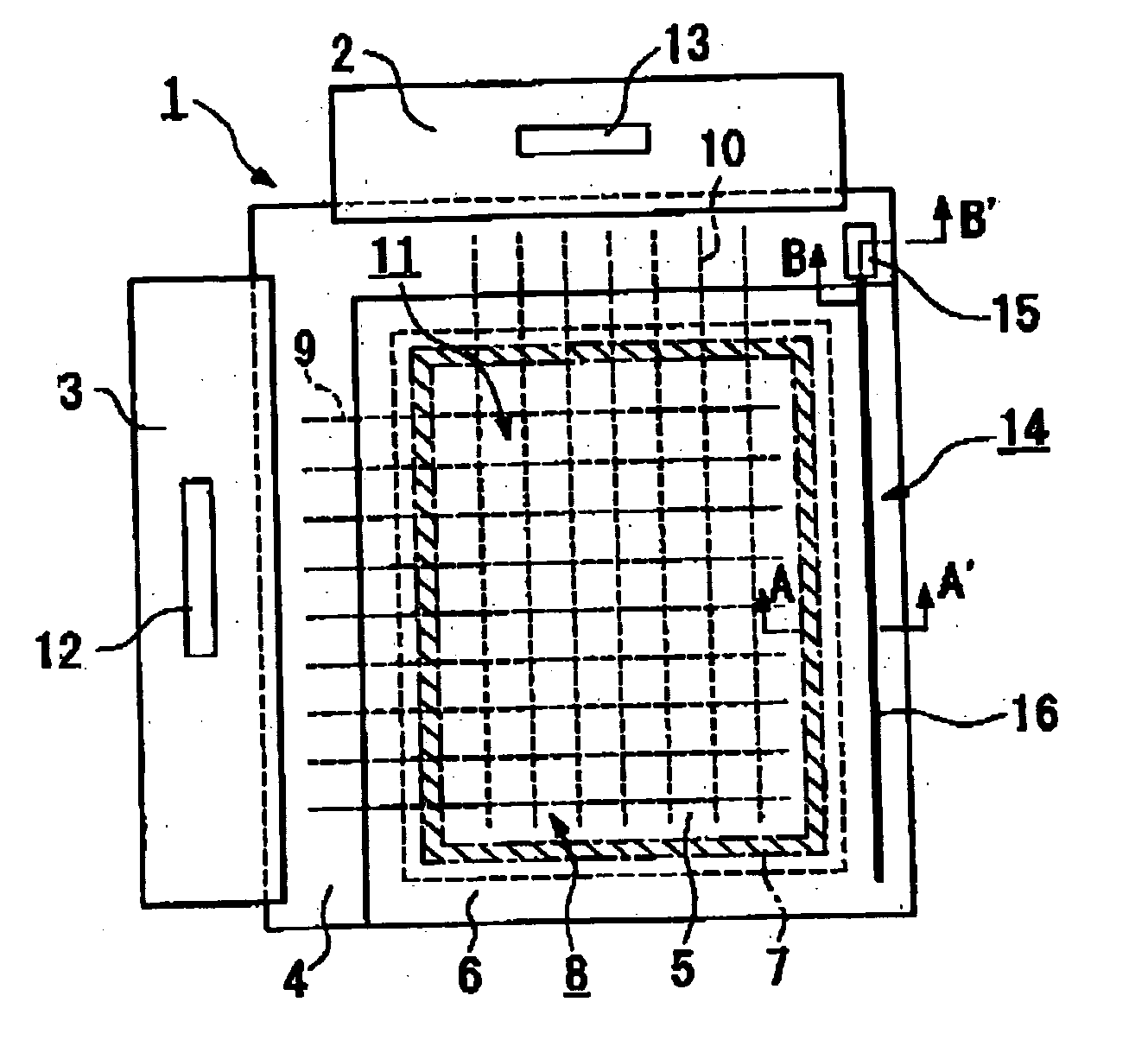

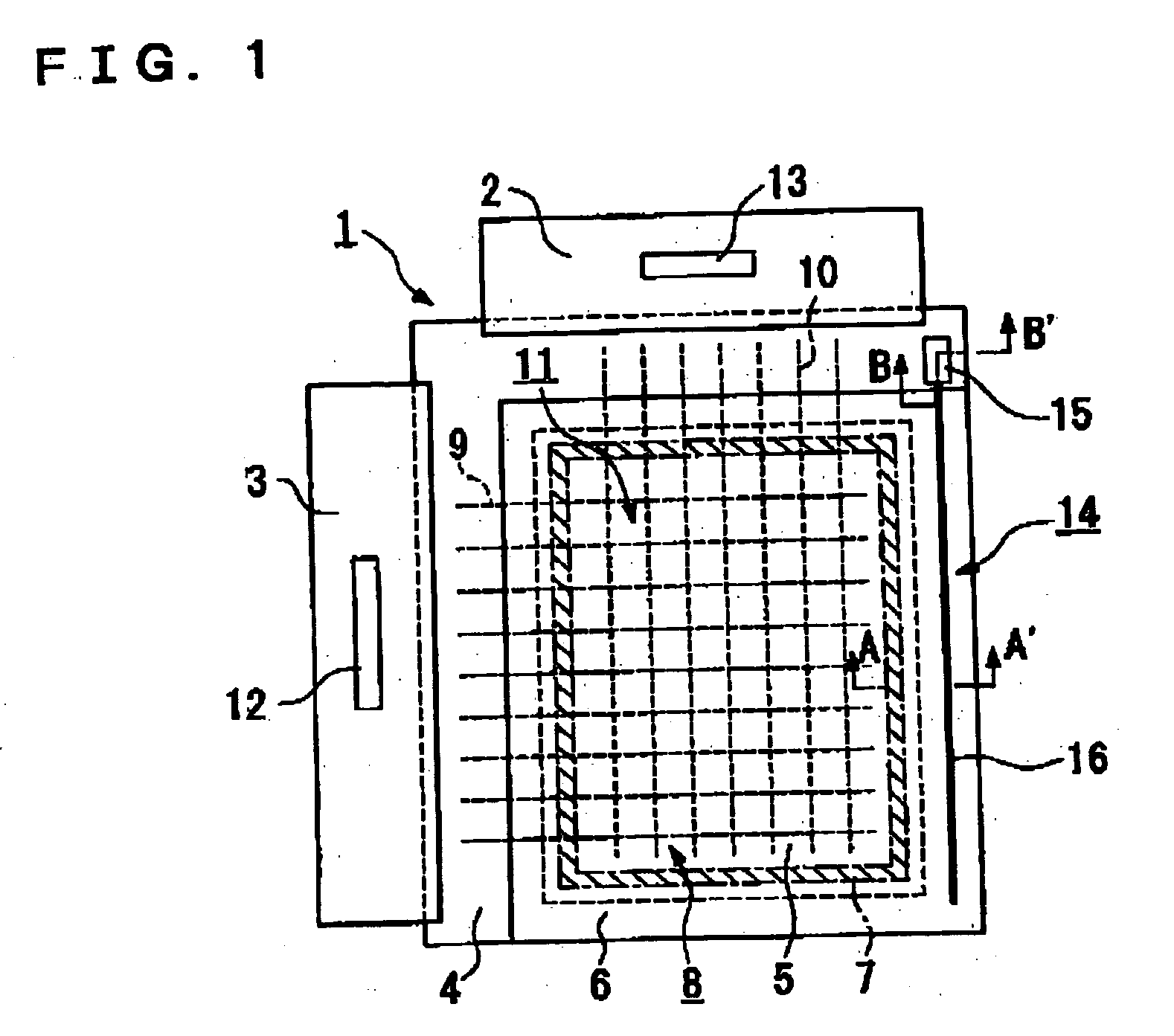

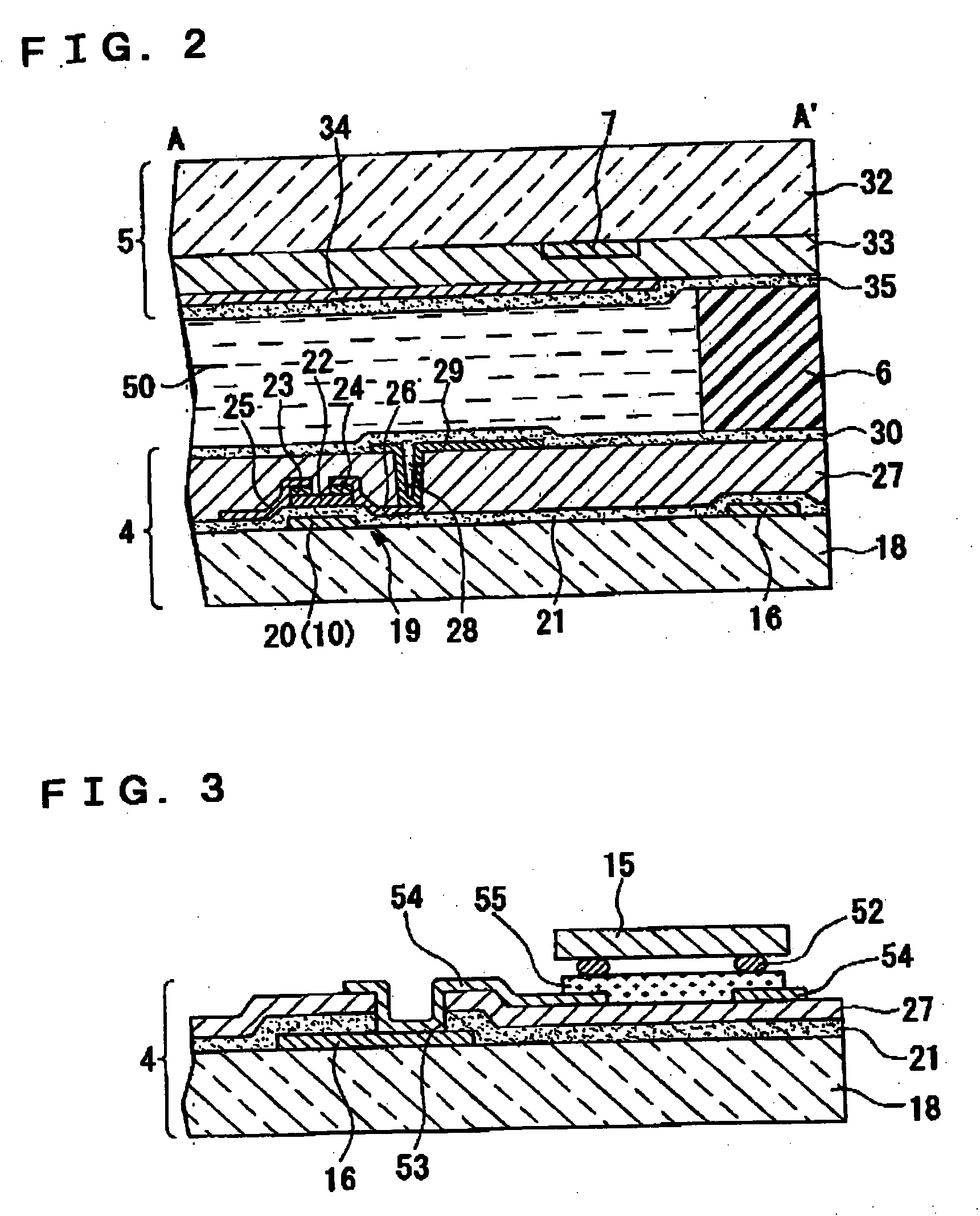

Display device and electronic apparatus

ActiveUS20040189625A1Simple structureReduce amount of effort and timeMouldsSolid-state devicesElectrical conductorDisplay device

To provide a display device and an electronic apparatus including a radio communication device, such as an IC tag, which do not need a special space to attach the IC tag and is capable of reducing the amount of time and effort required for attaching the IC tag, a display device including a radio communication device having at least one substrate provided with a display unit and display-unit-driving wiring lines 9 and 10, a communication integrated-circuit unit, and an antenna is provided. At least a part of the antenna is formed on the substrate and formed of a conductor formed in the same layer as a conductor that constitute the display unit or conductors that constitute the display-unit-driving wiring lines.

Owner:BOE TECH GRP CO LTD

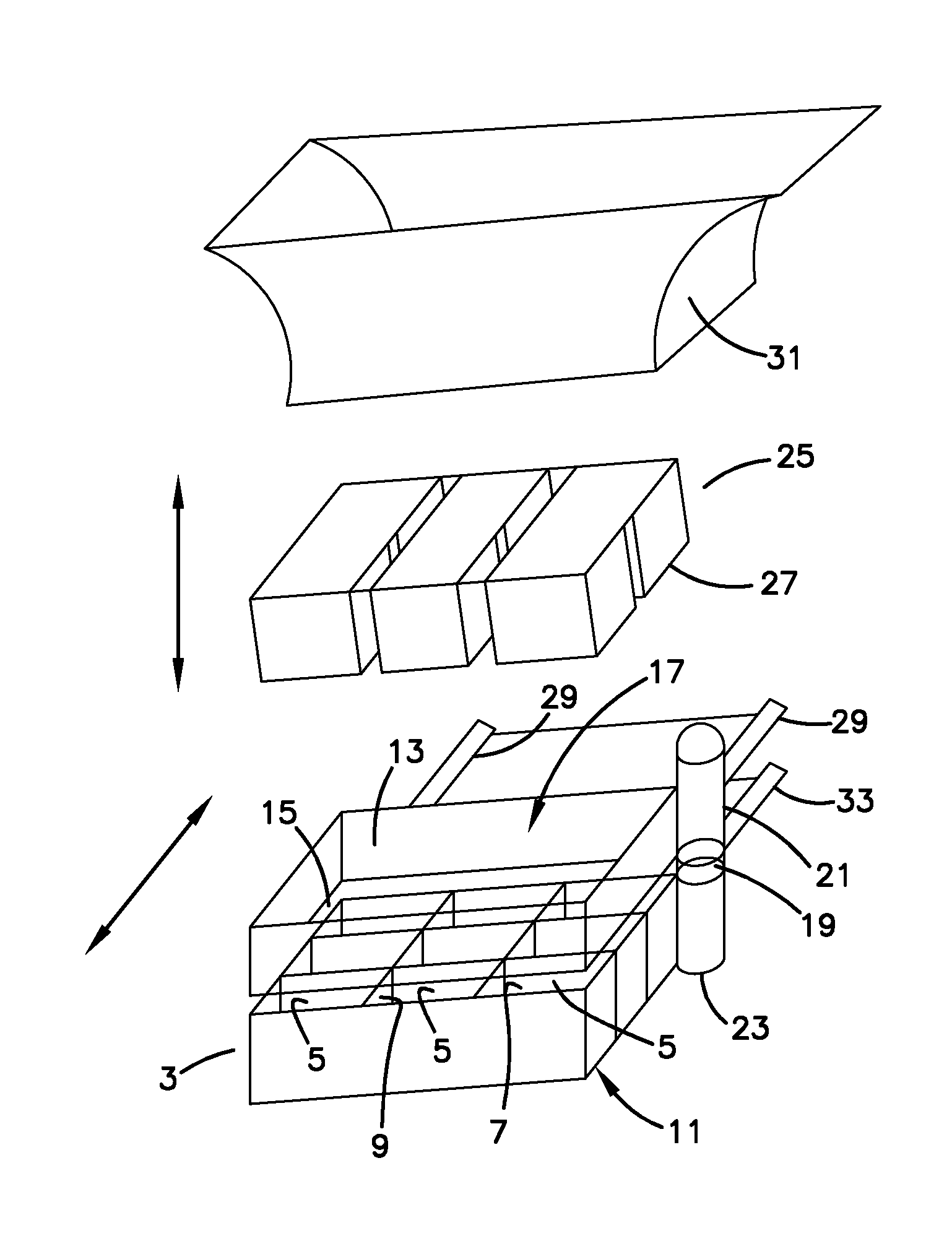

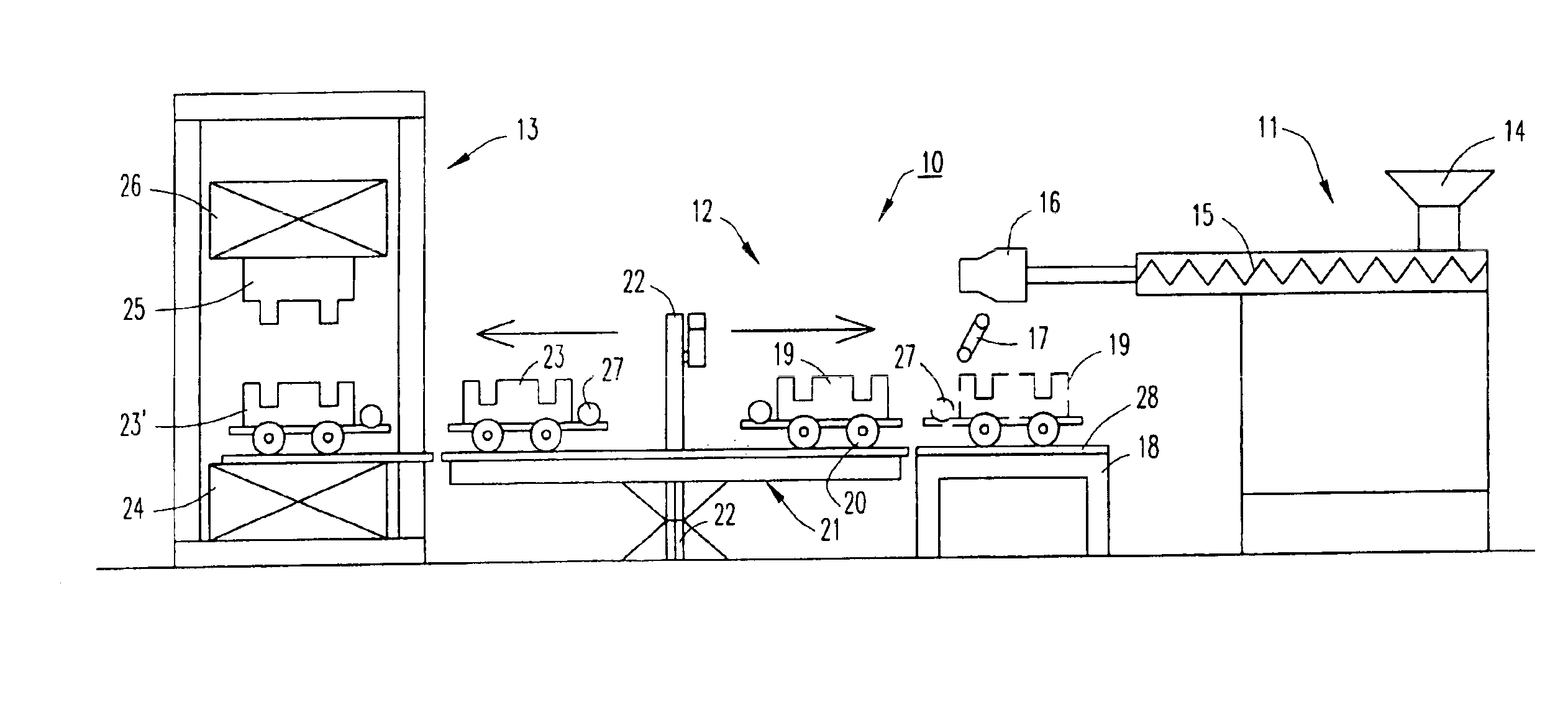

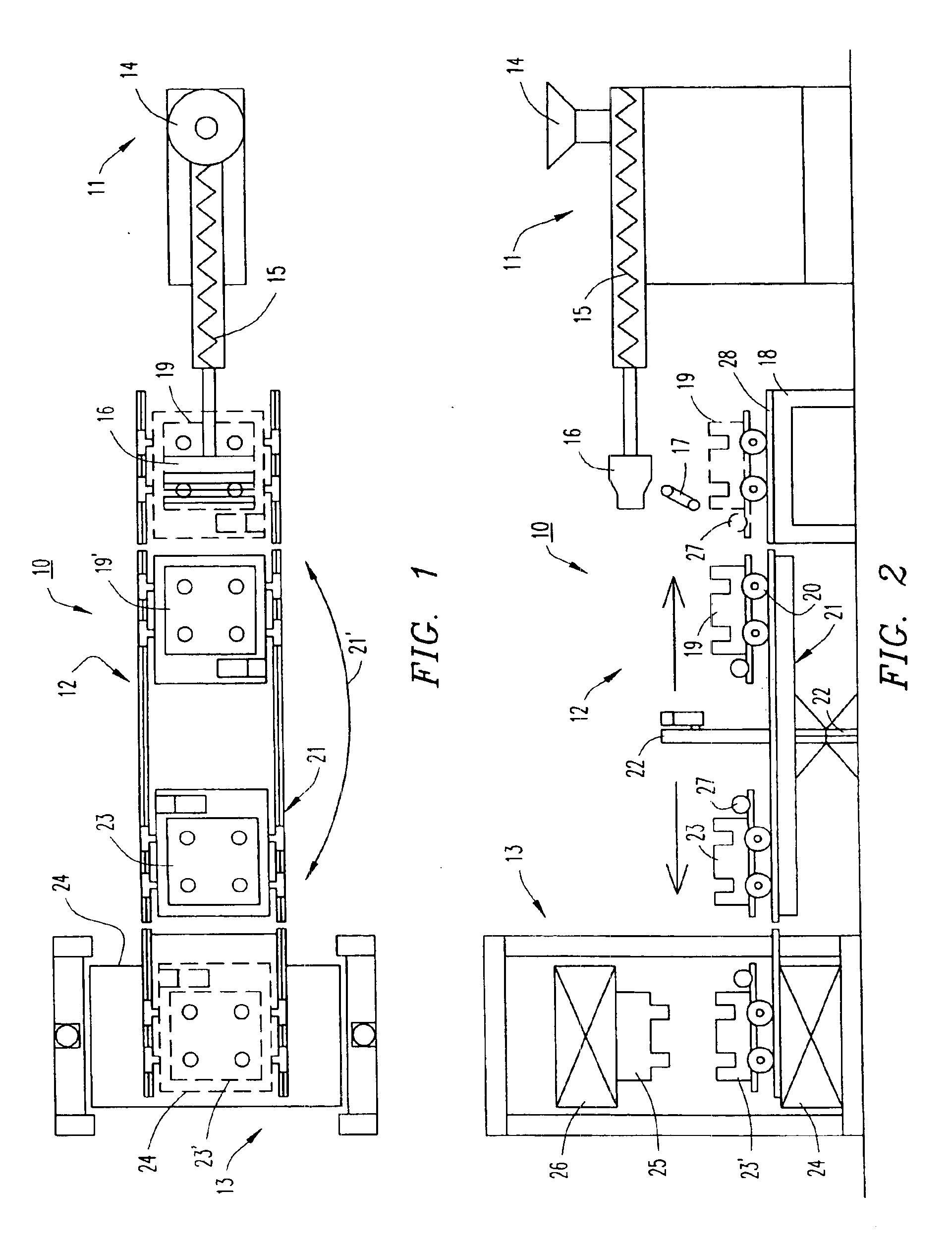

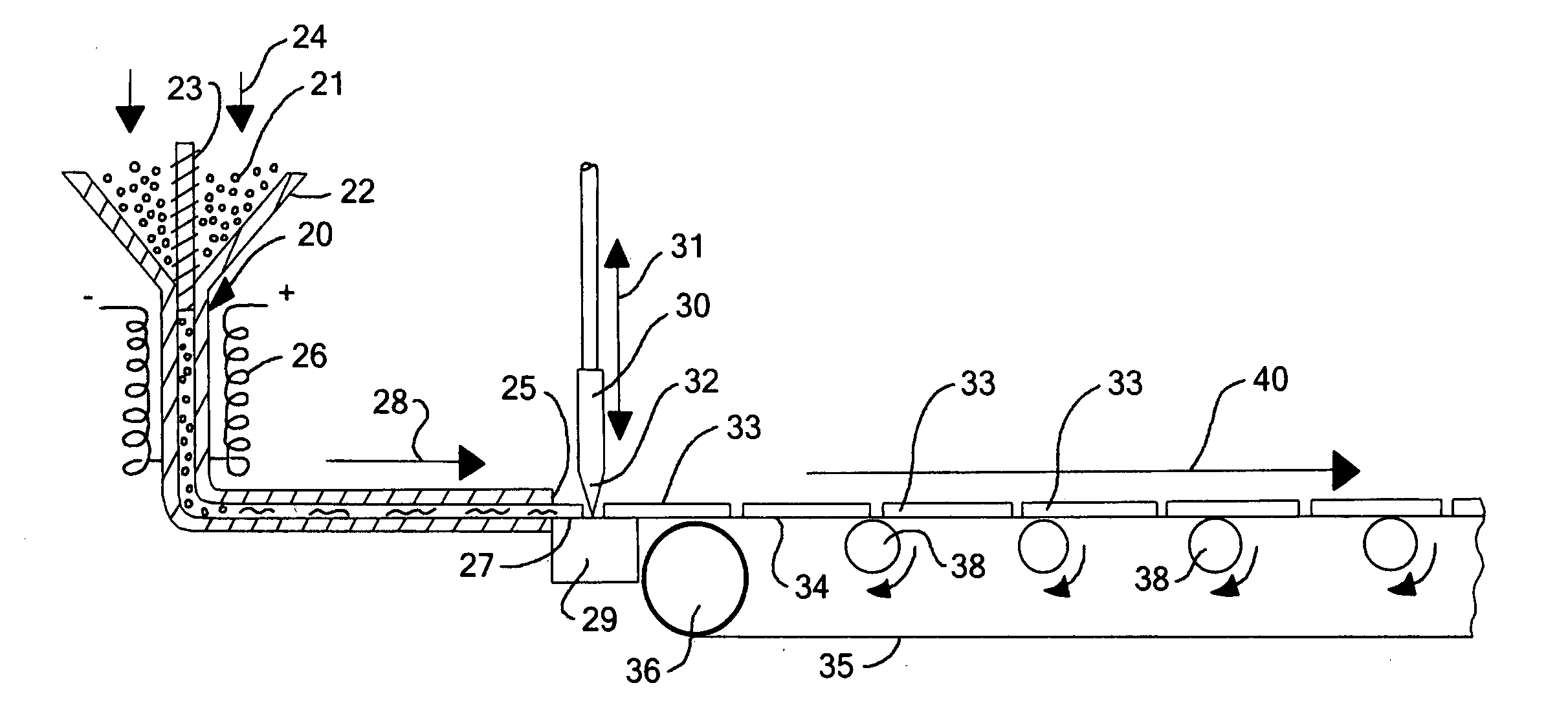

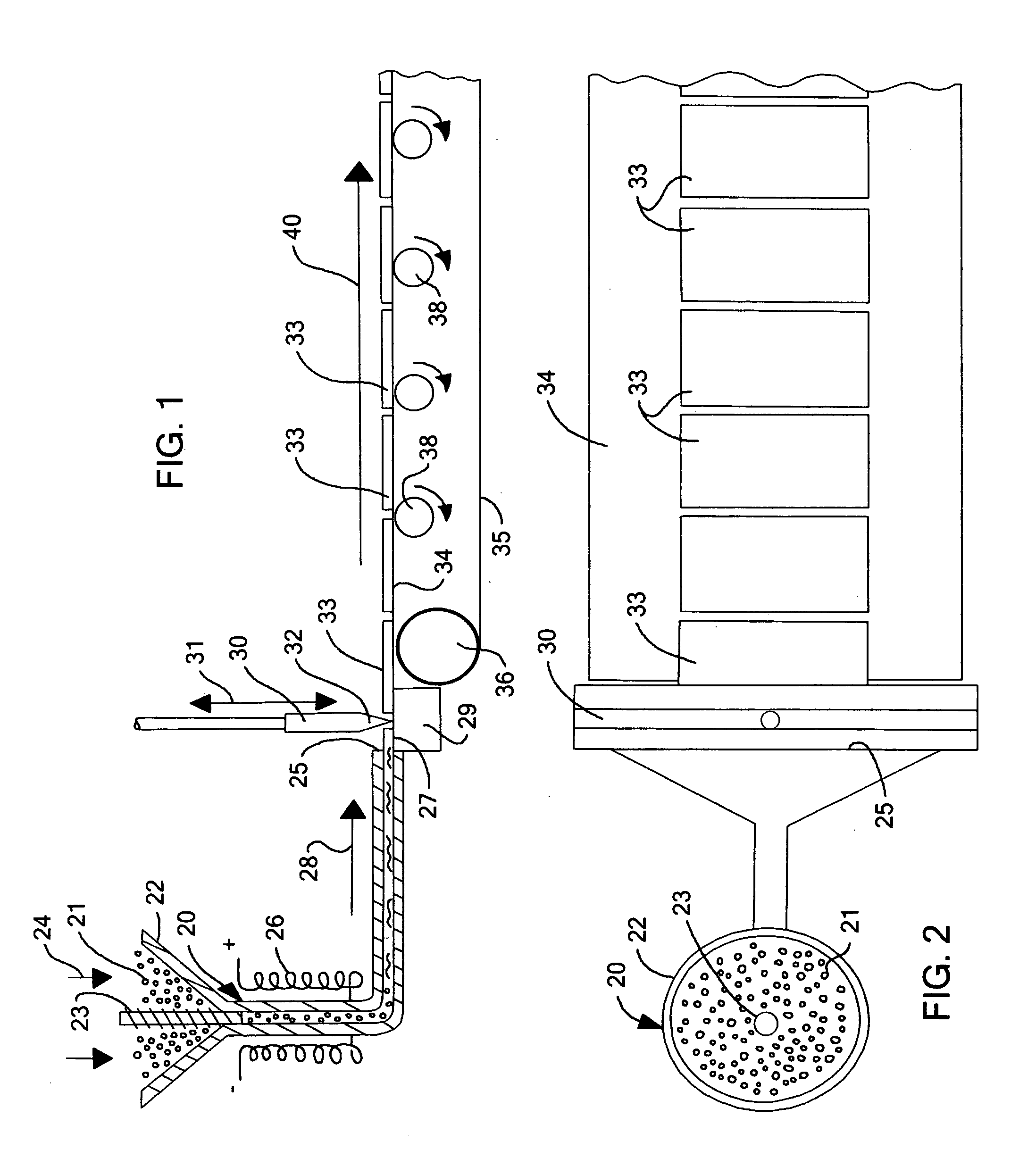

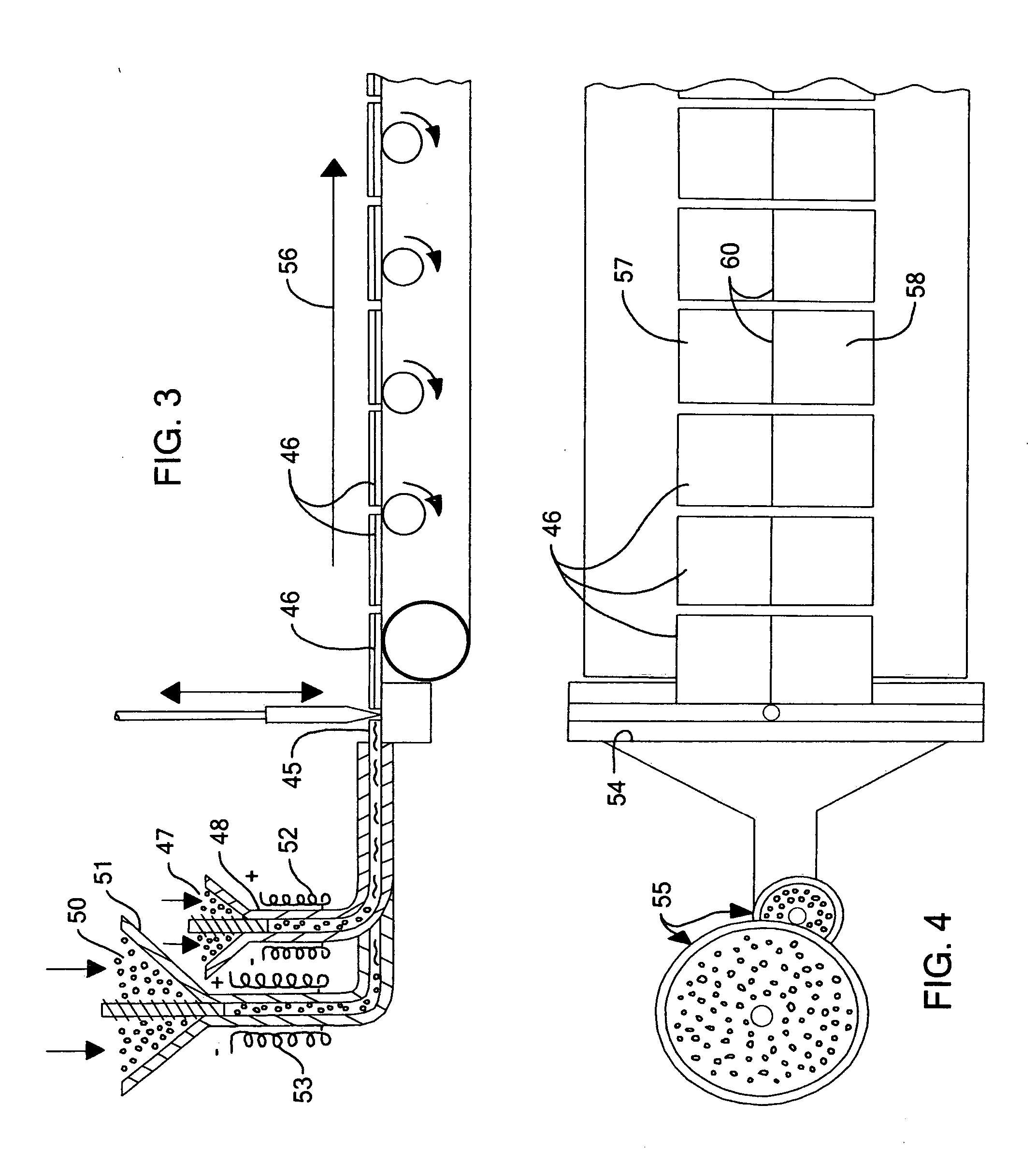

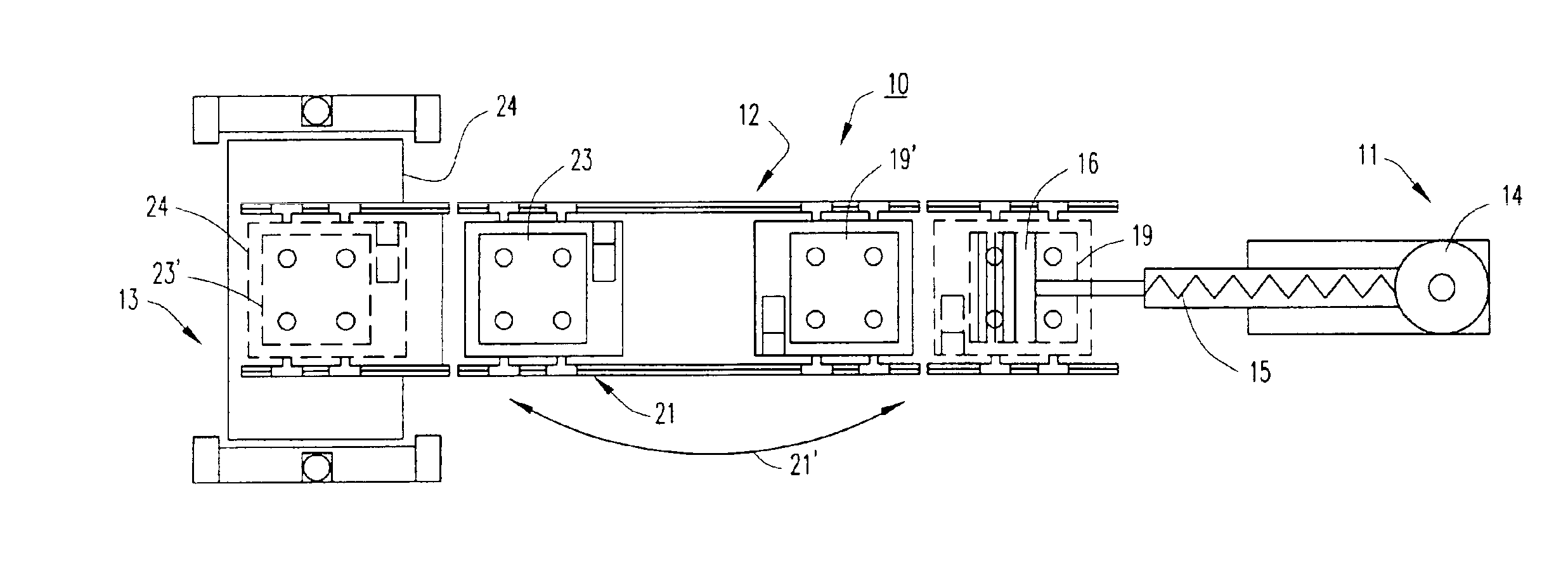

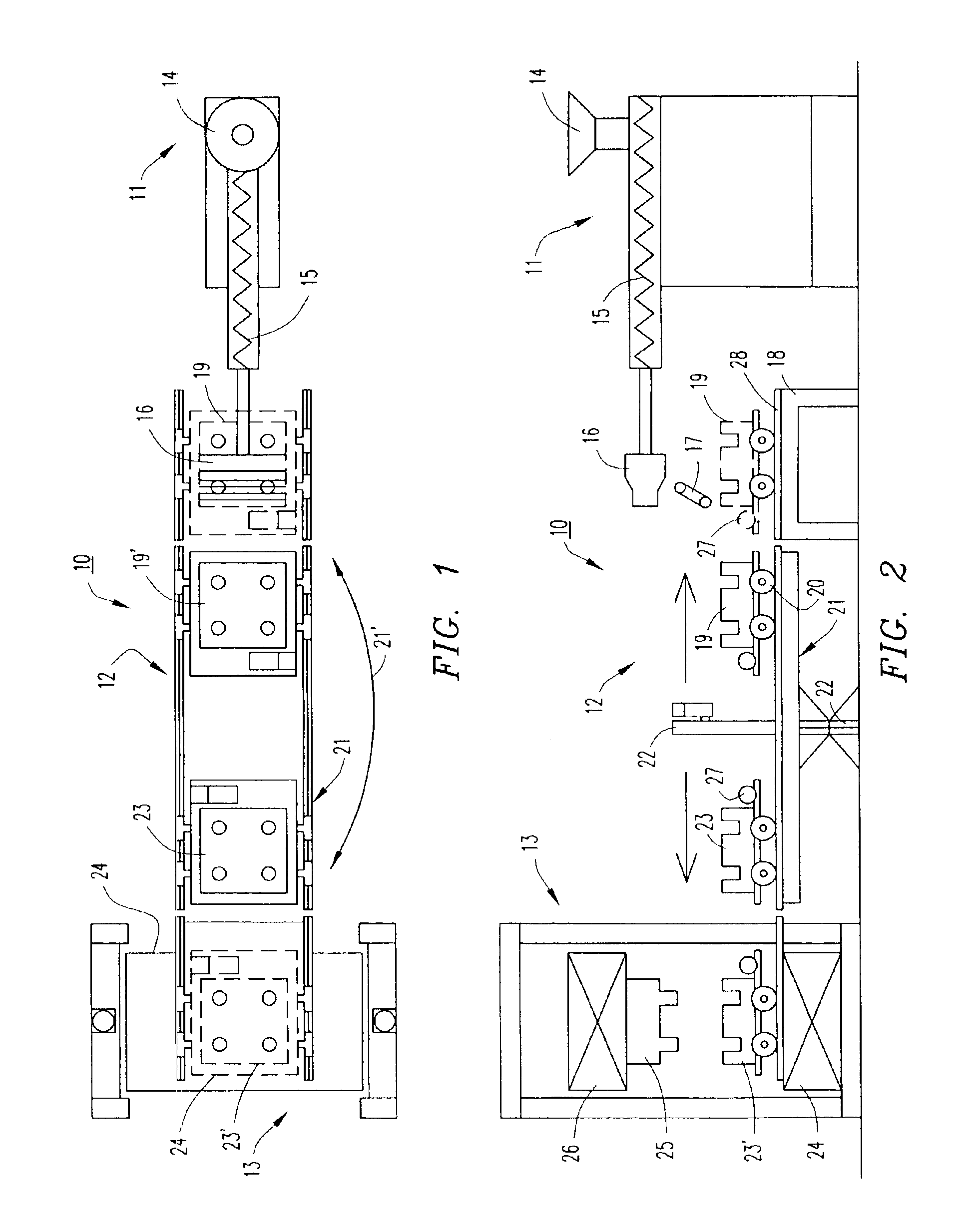

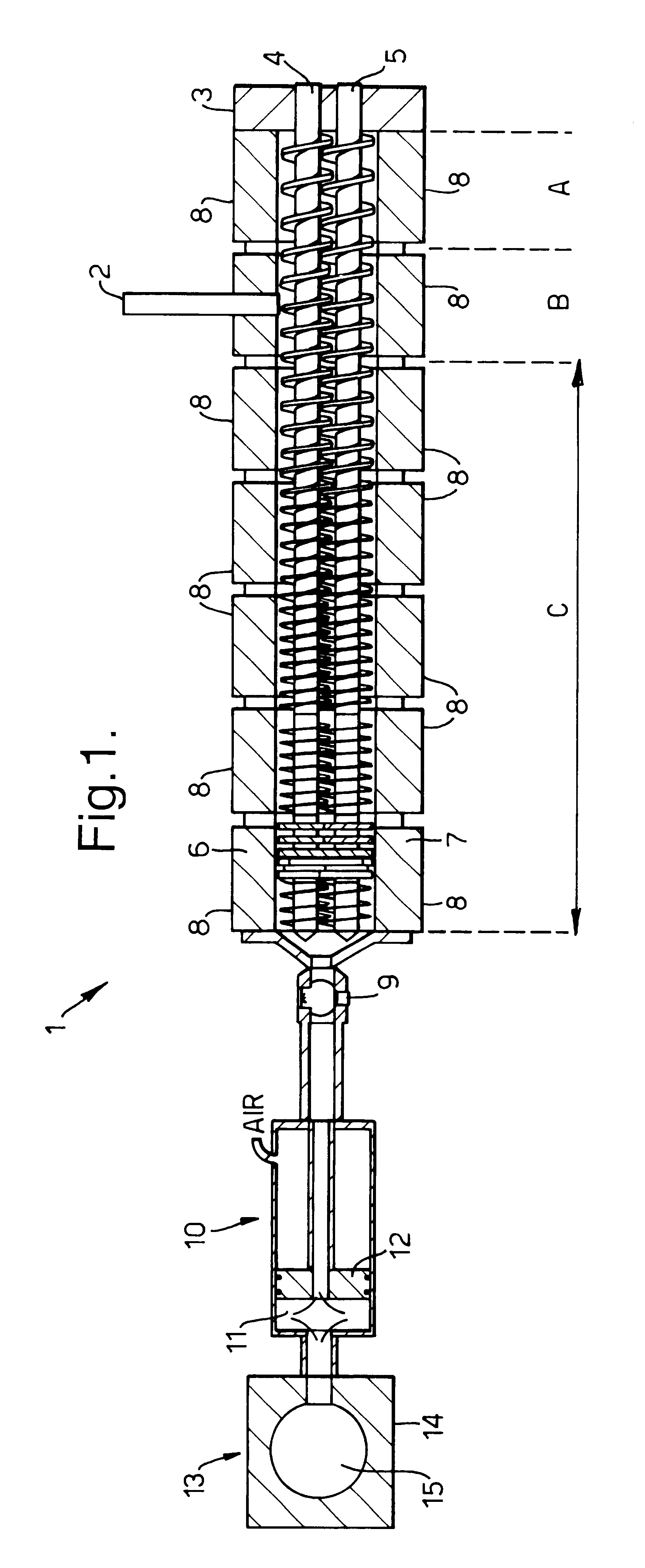

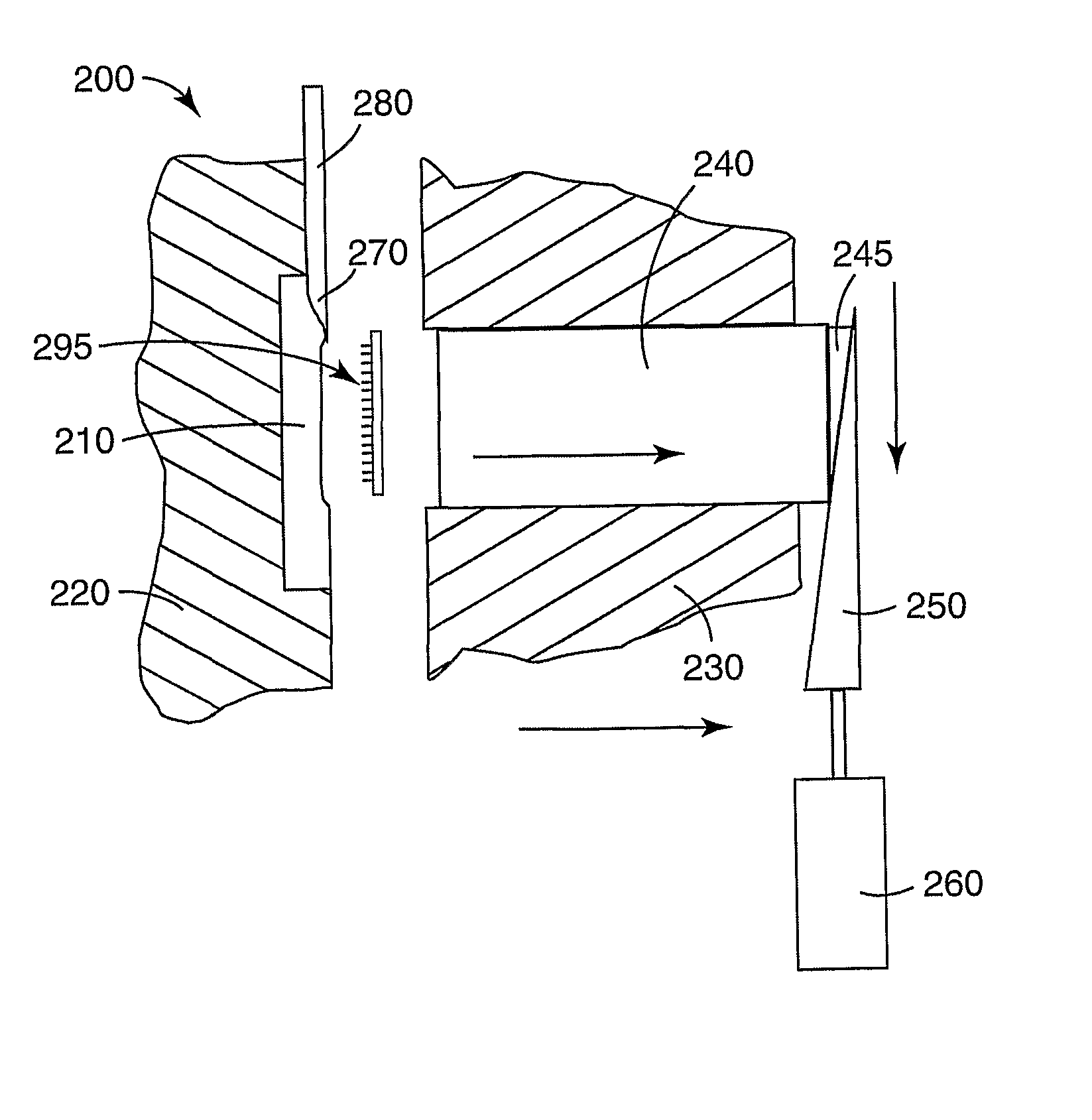

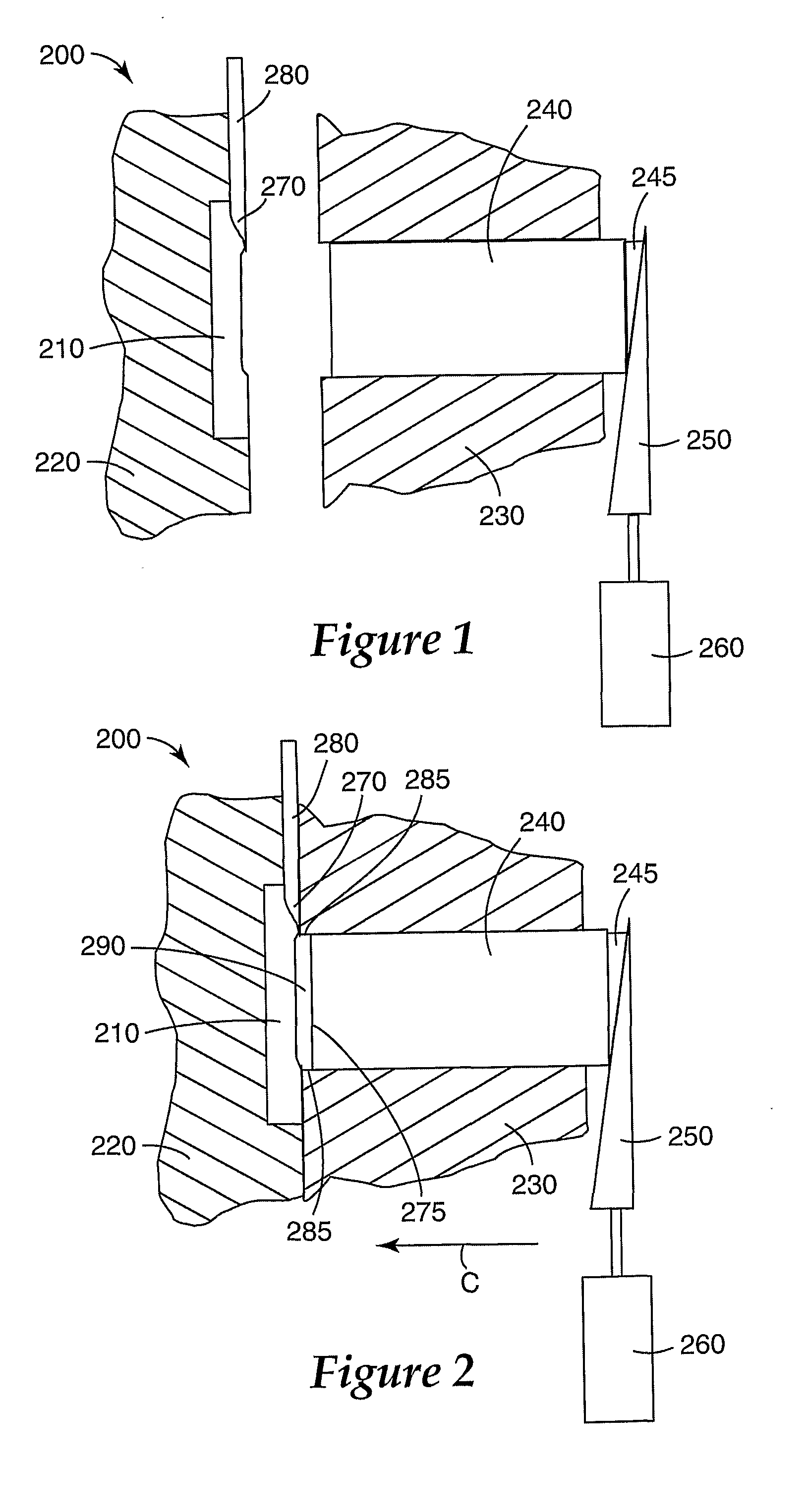

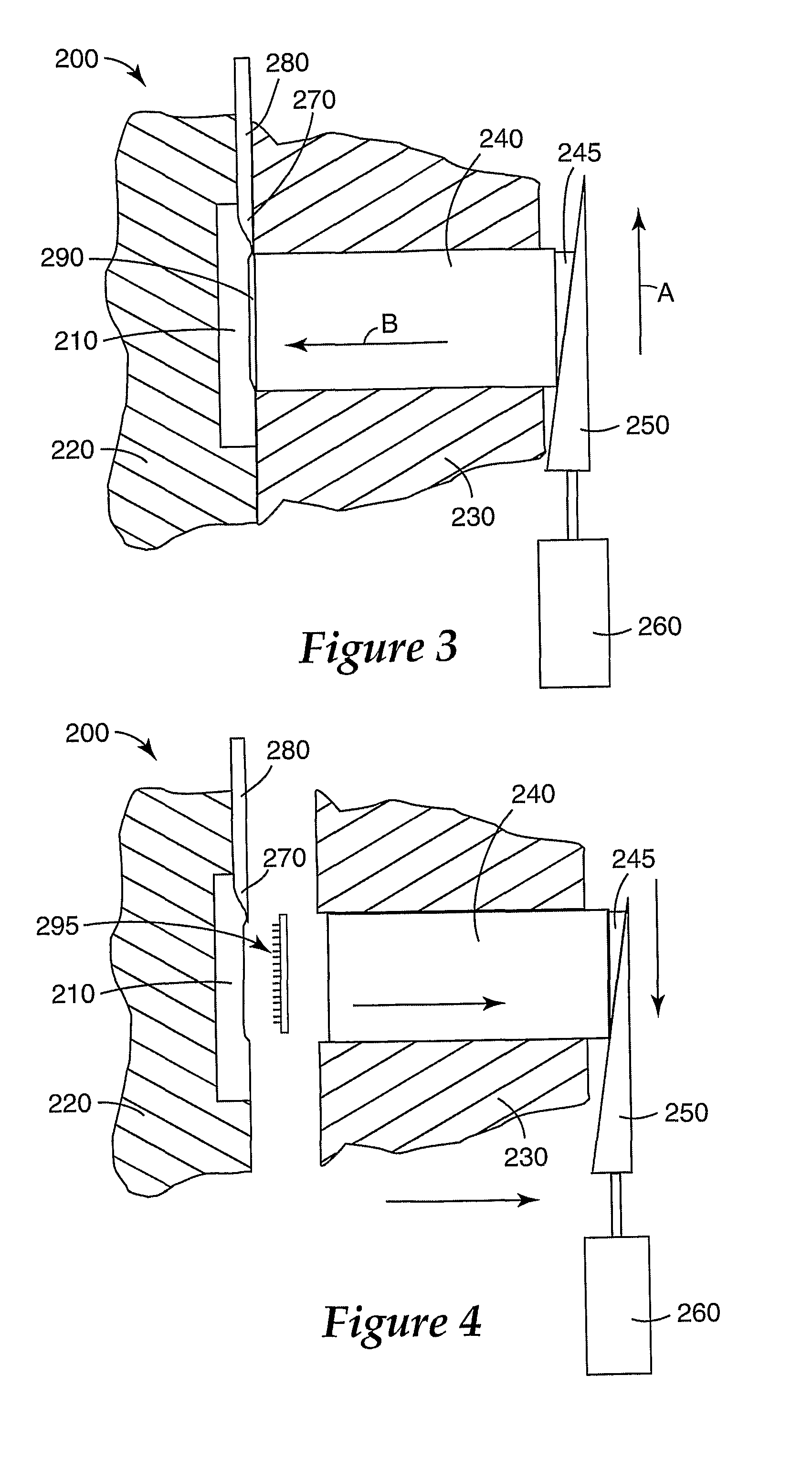

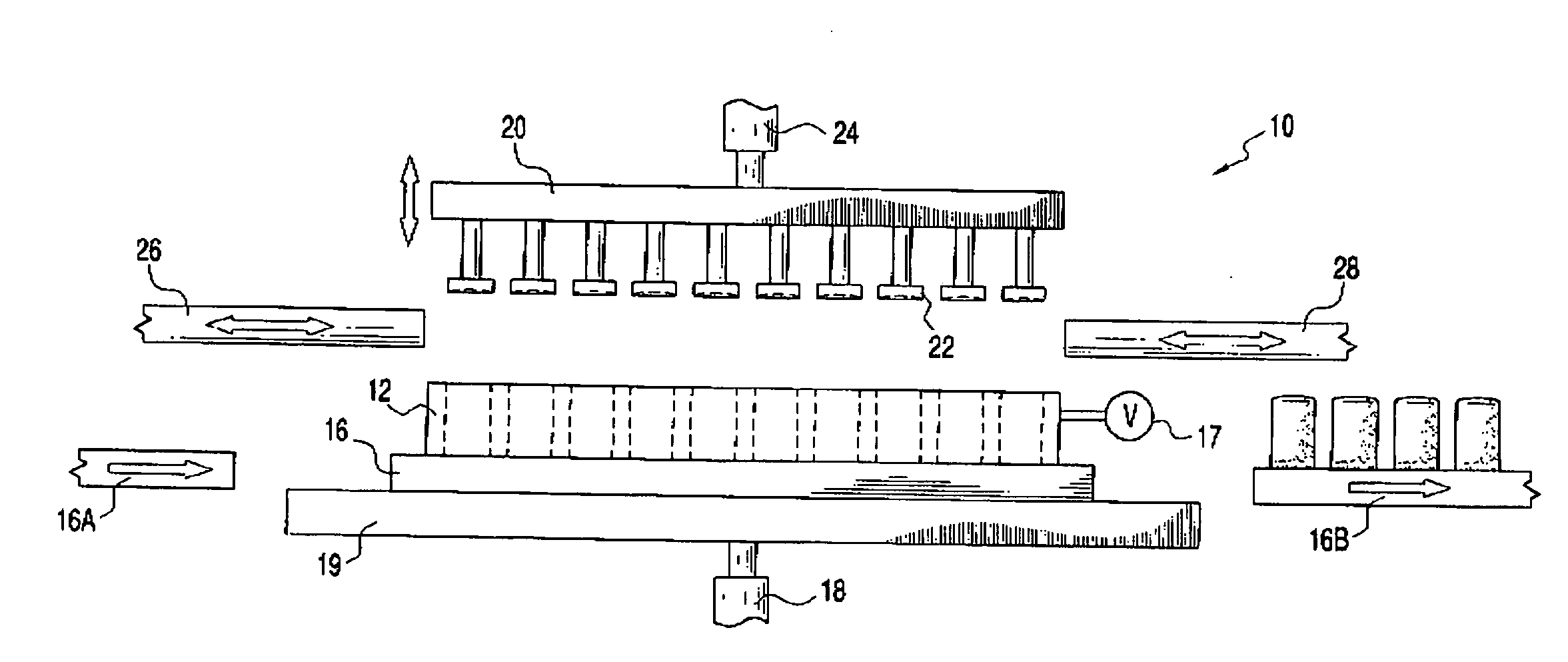

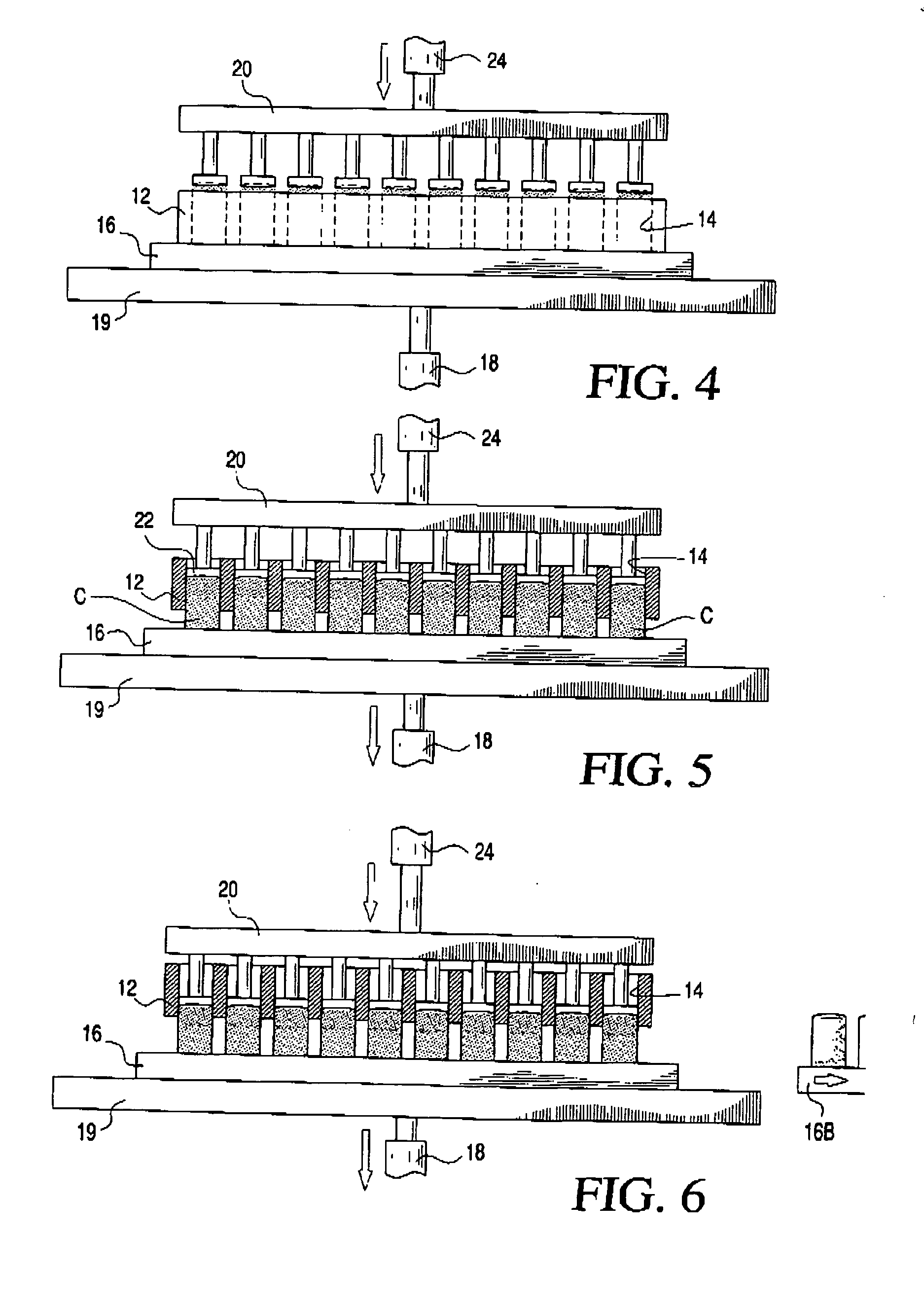

Thermoplastic molding process and apparatus

InactiveUS6900547B2Promote formationLow rateSemiconductor/solid-state device detailsConfectioneryFiberLower upper

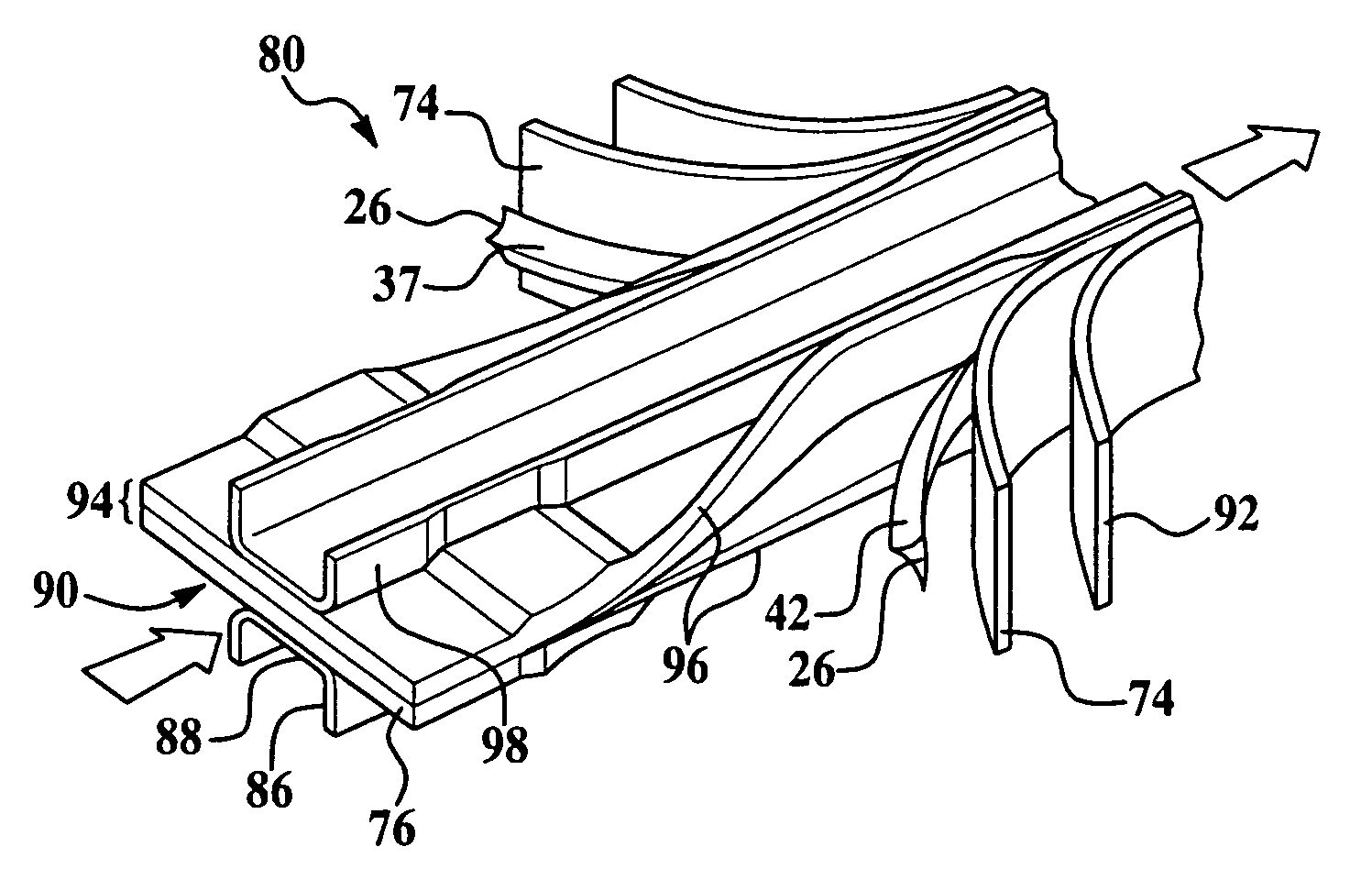

A system and method for forming an article from thermoplastic material and fiber. The method includes heating thermoplastic material to form a molten thermoplastic material for blending with the fiber. The molten thermoplastic material is blended with the fibers to form a molten composite material having a concentration of fiber by weight. The molten composite material may then be extruded through dynamic dies to deliver discrete controlled material that is gravitated onto a lower portion of a mold. The lower portion of the mold may be moved in space and time while receiving the flow of composite material to deposit a predetermined quantity of molten composite material thereon conforming to mold cavities of the lower and an upper portion of the mold. The upper portion of the mold may be pressed against the predetermined quantity of molten composite material and closing on the lower portion of the mold to form the article.

Owner:D&D MFG LLC

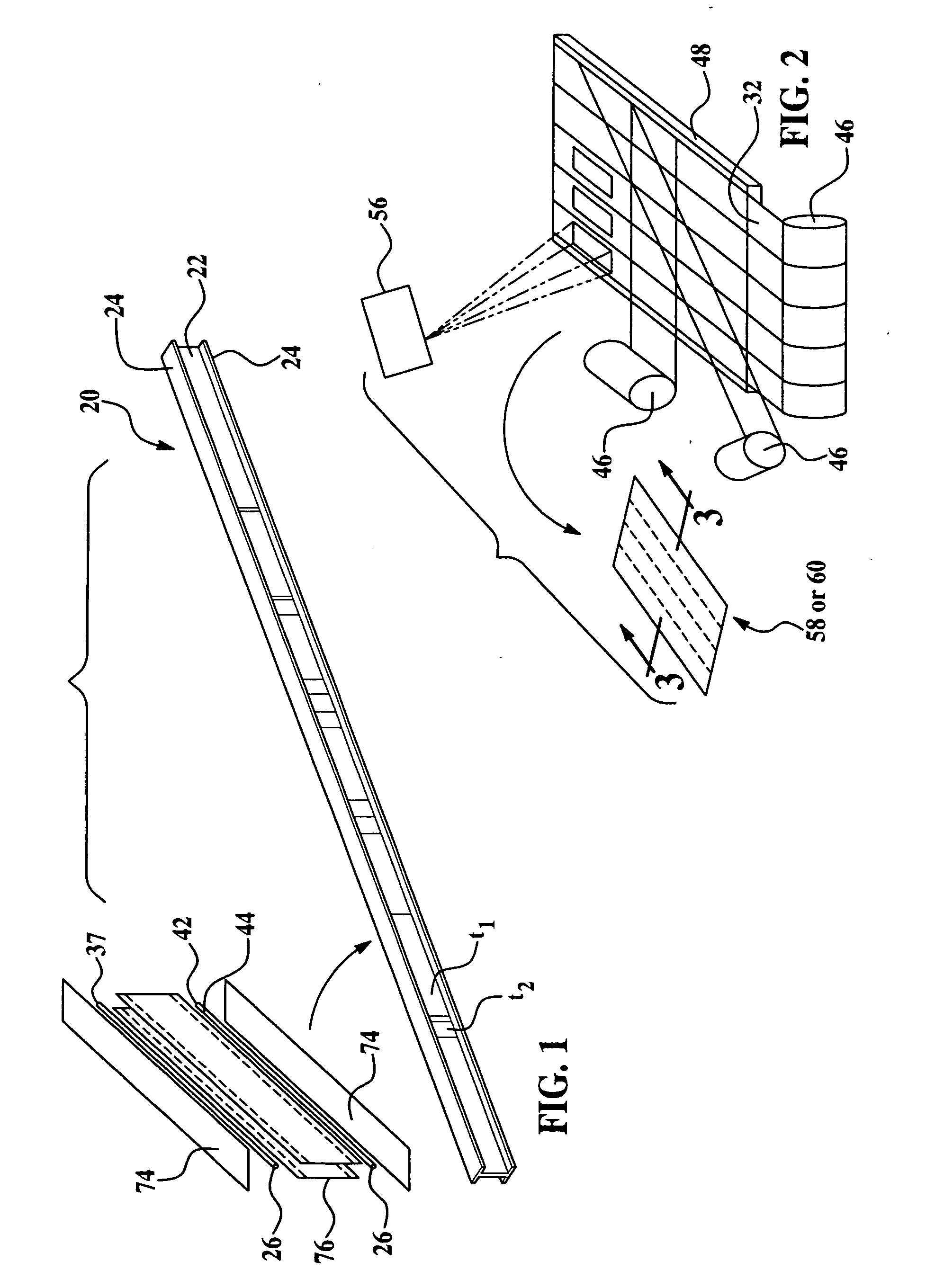

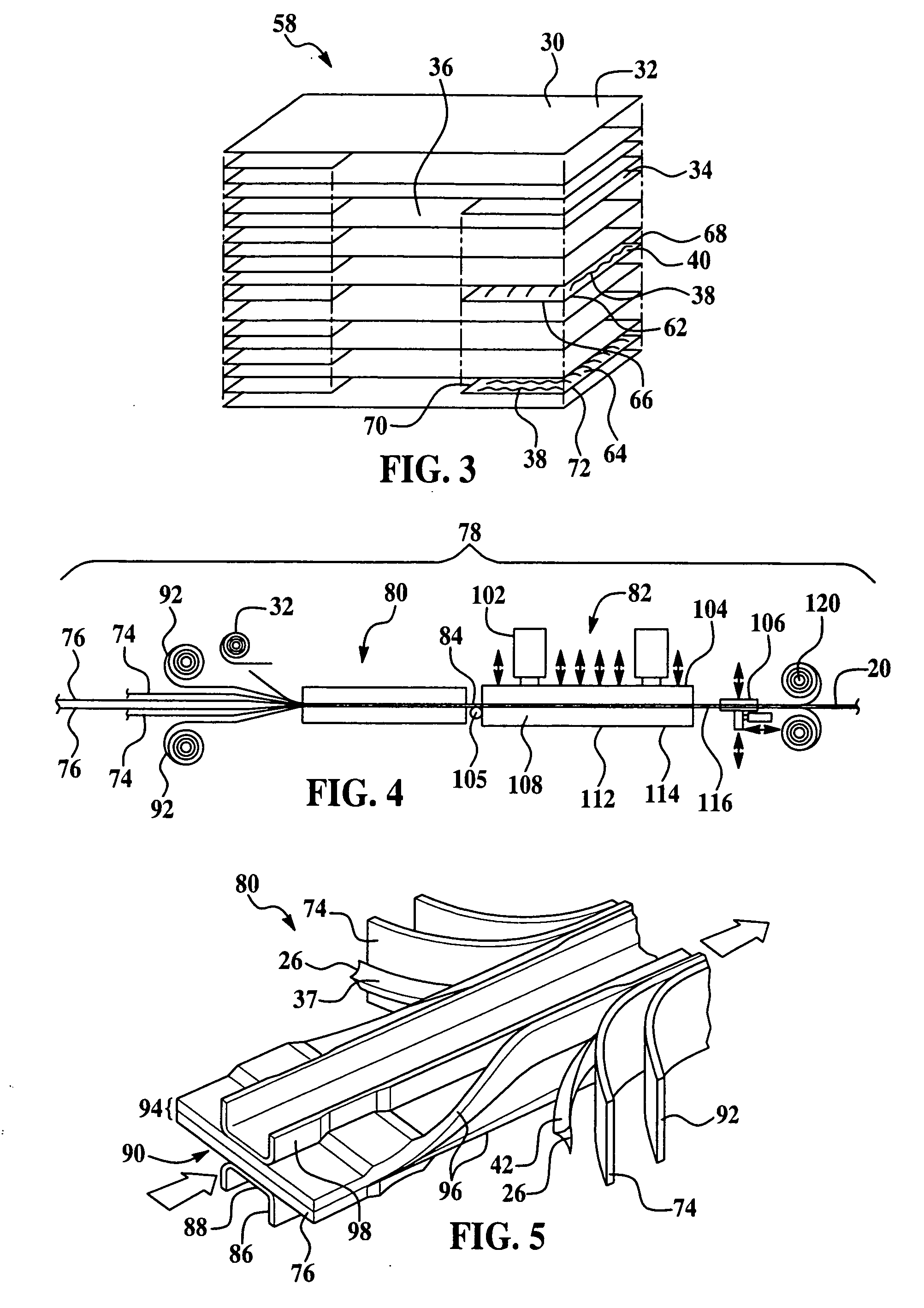

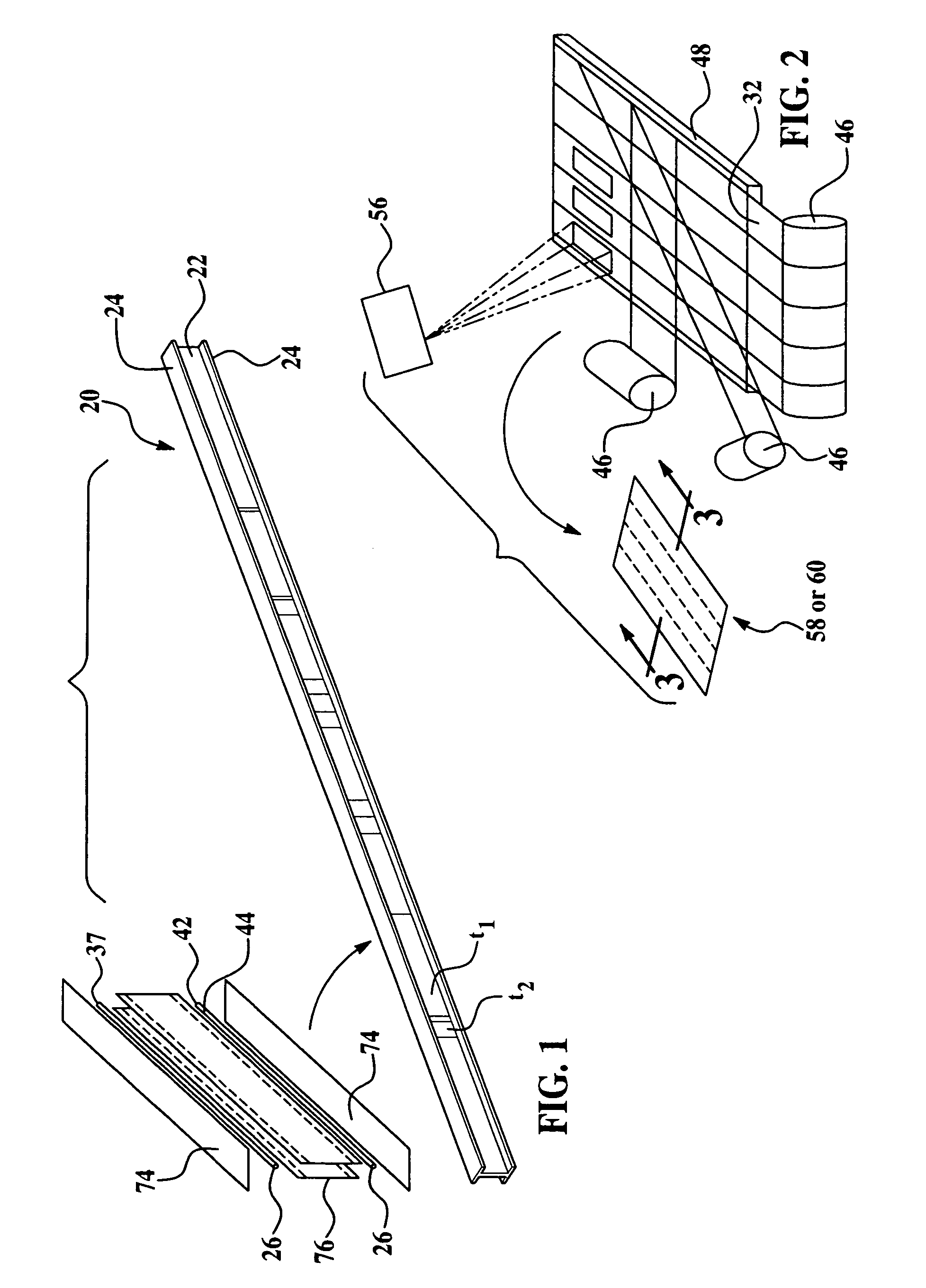

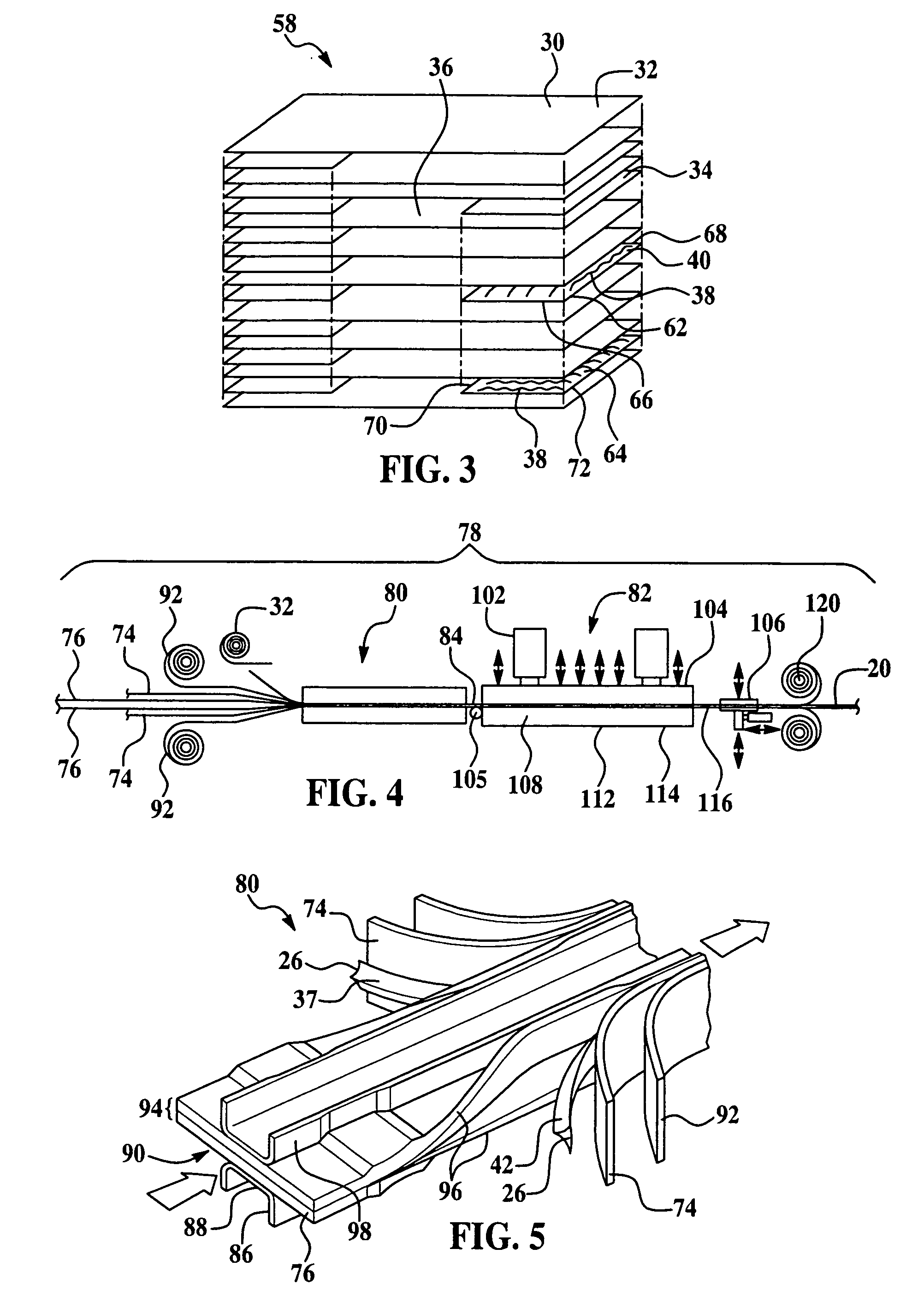

Method for fabricating curved thermoplastic composite parts

ActiveUS20070175575A1Mechanical working/deformationWood working apparatusEngineeringThermoplastic composites

A fabrication method of forming curved thermoplastic composite laminate parts with tailored and varying thickness in a continuous process. Automated equipment or hand lay-up are used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

Process of and apparatus for making a shingle, and shingle made thereby

InactiveUS20060029775A1Shorten the timeMouldsConfectioneryBiomedical engineeringThermoplastic materials

A process and apparatus for making a shingle, together with the shingle made thereby, is provided, in which one or more thermoplastic materials are extruded or co-extruded to form an extrudate, with the extrudate being cut into a preliminary shingle shape, which is allowed to dissipate heat, and then is delivered to a compression mold, wherein the preliminary shingle shape is compression molded to substantially its final dimensions and is then discharged from the mold and allowed to cool.

Owner:CERTAINTEED CORP

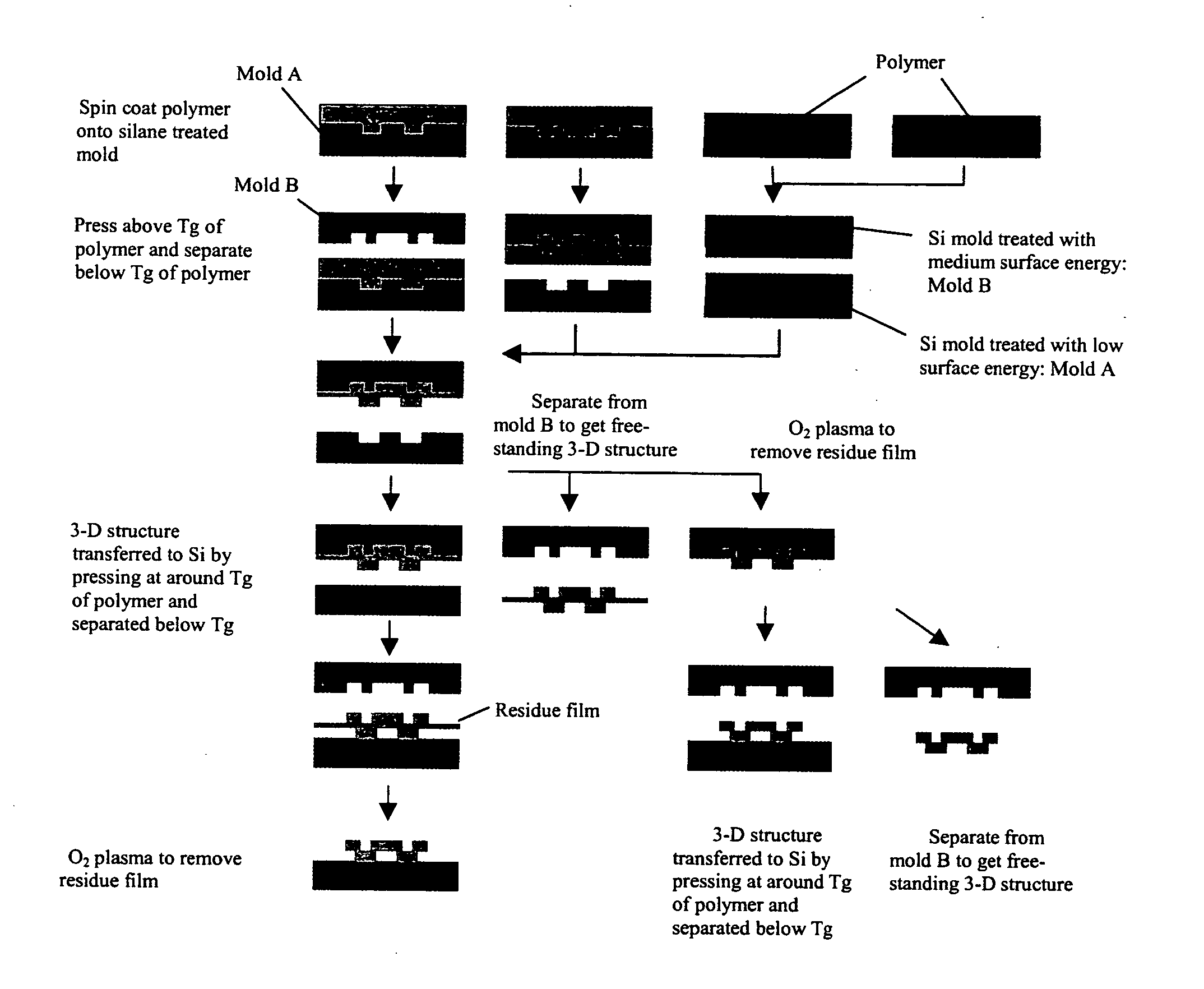

Method of imprinting shadow mask nanostructures for display pixel segregation

InactiveUS20050258571A1Easy to separateRemove heatNanostructure manufactureDecorative surface effectsVitrificationDisplay device

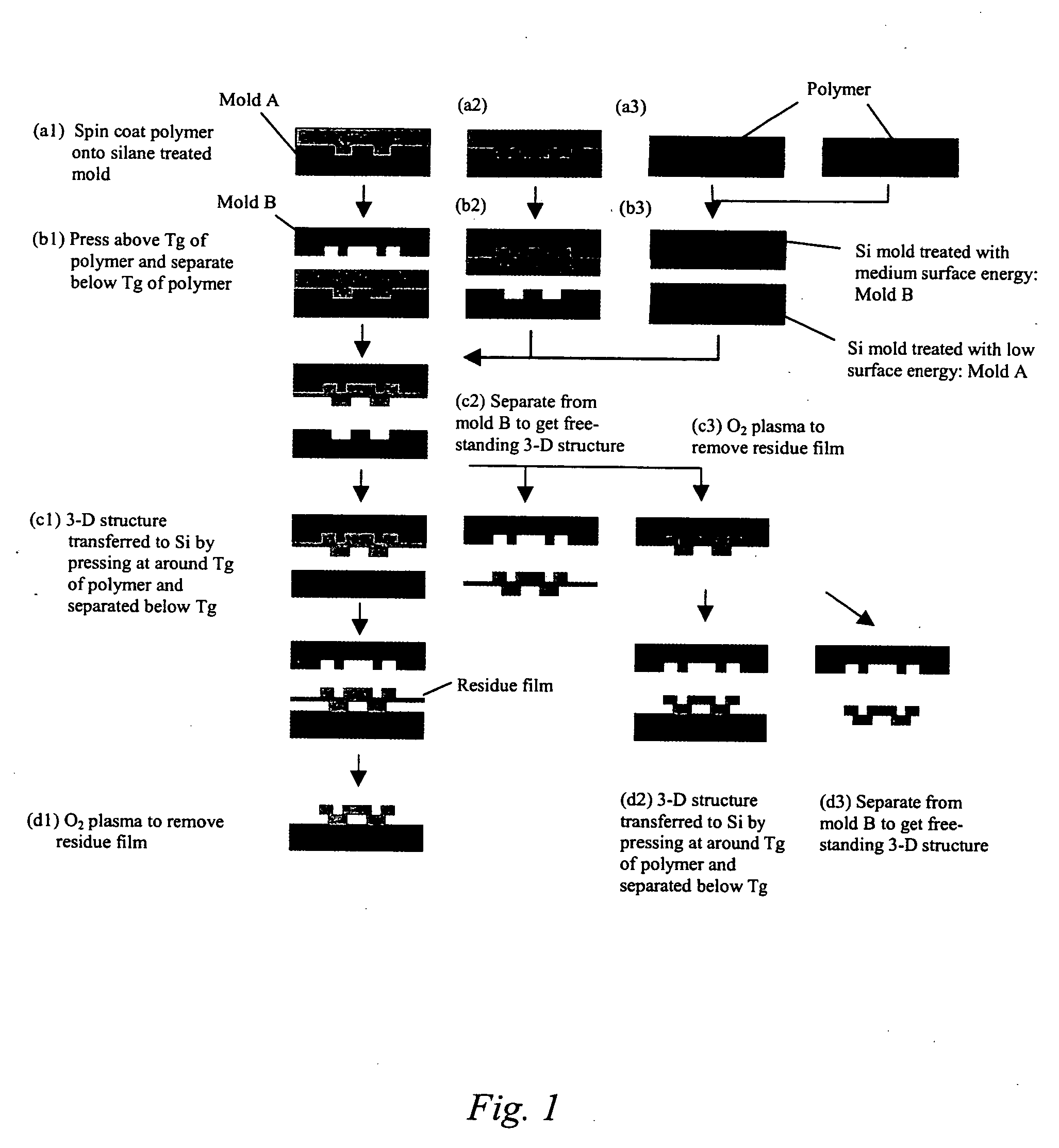

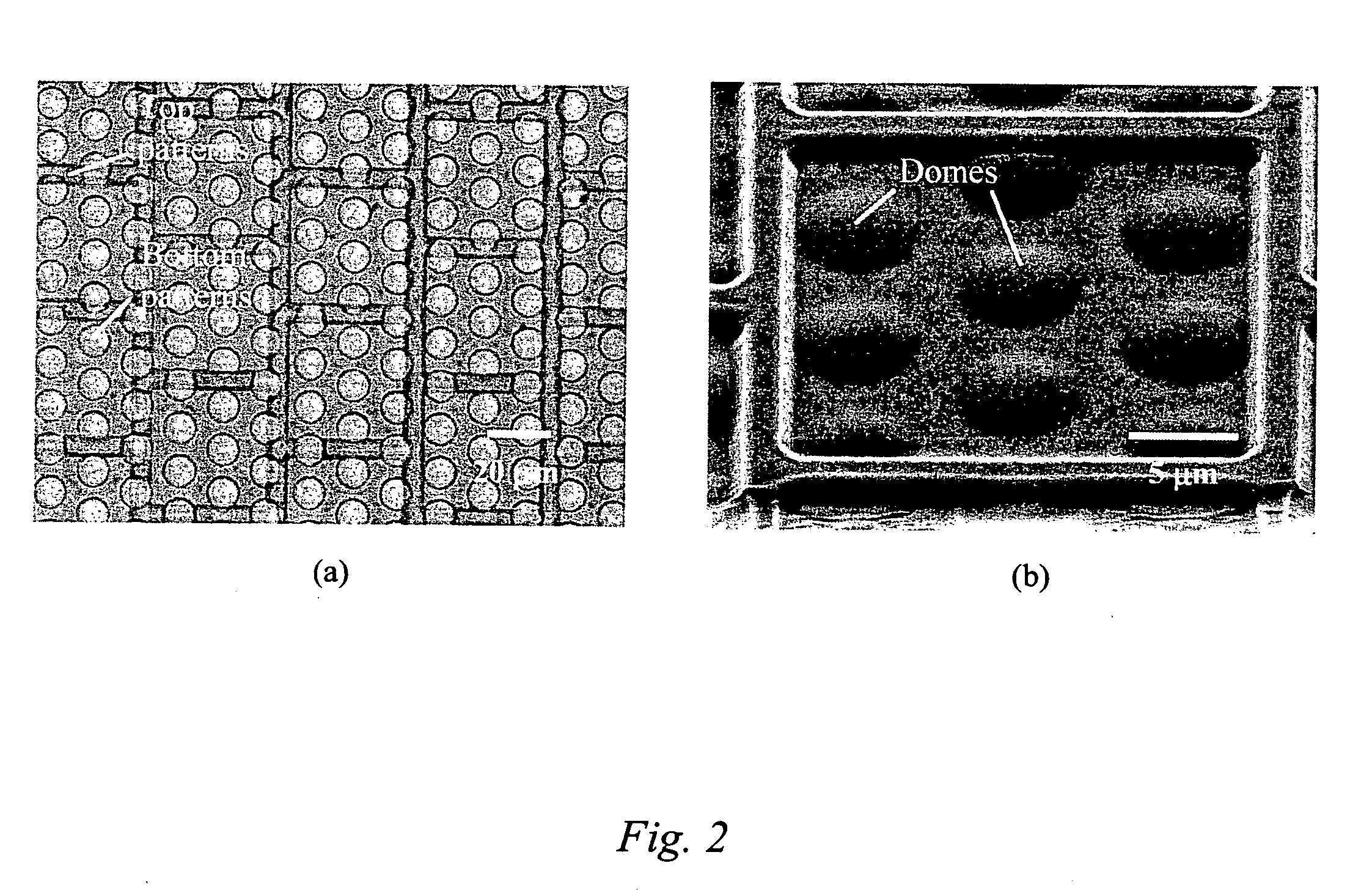

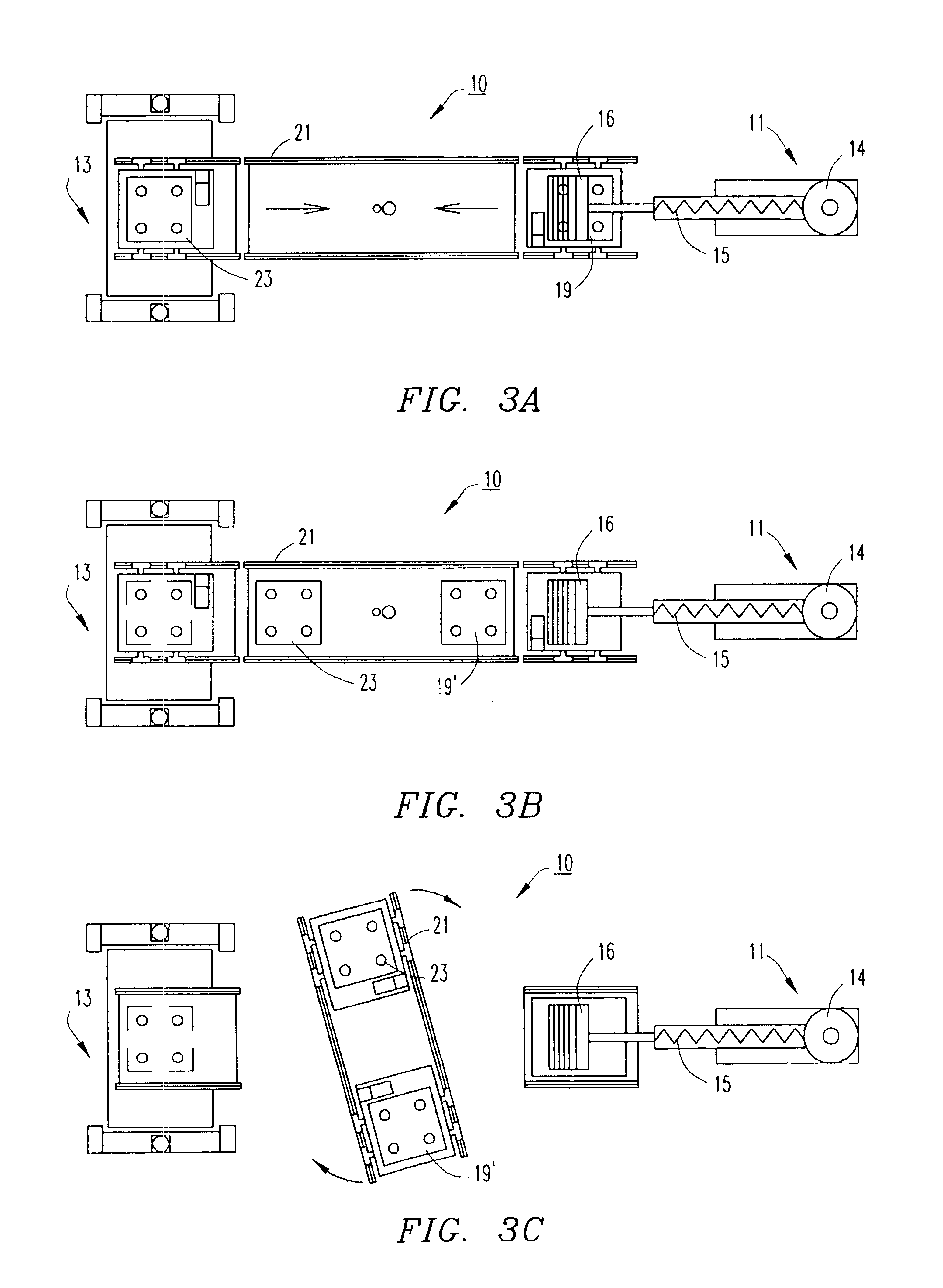

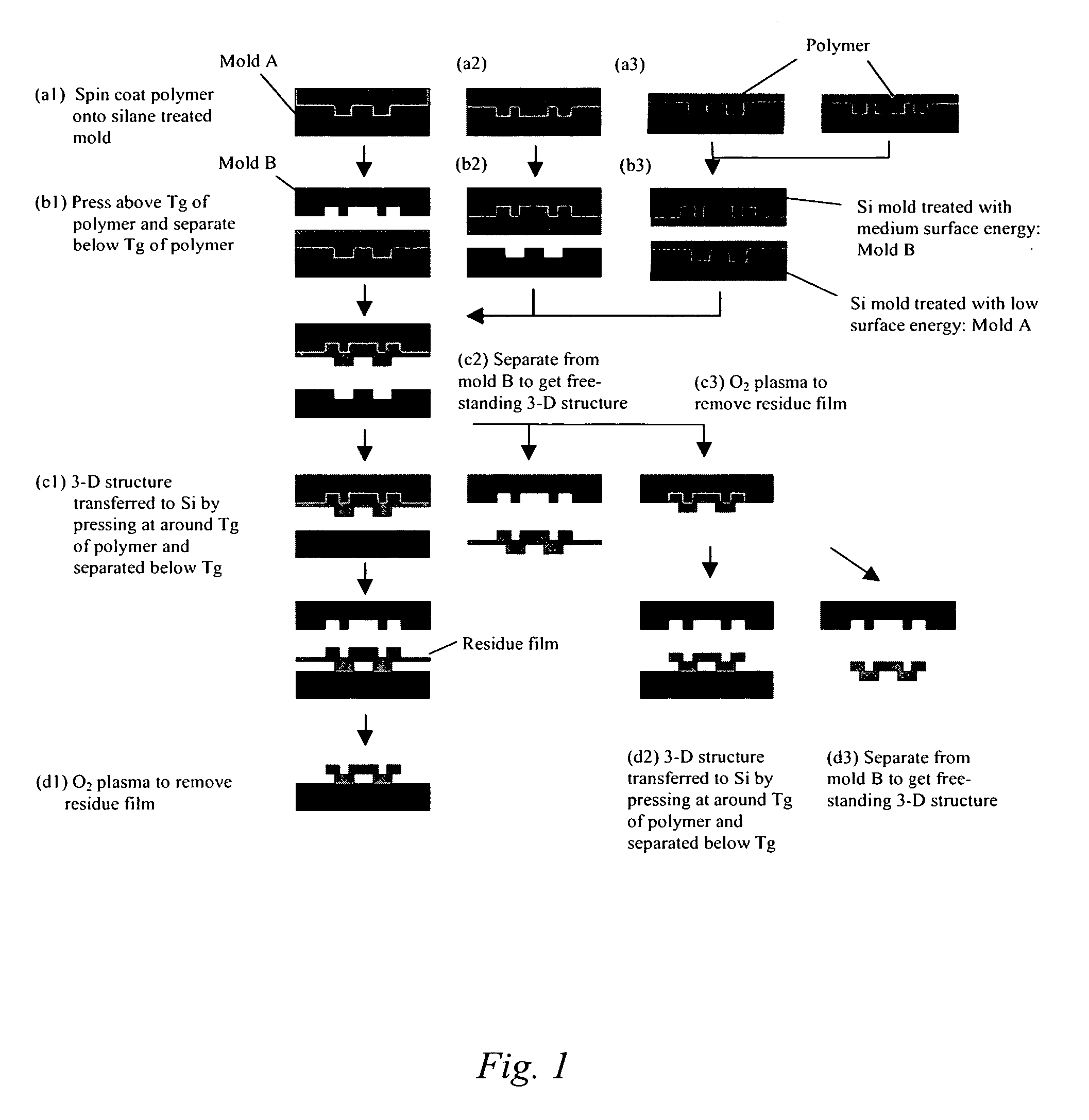

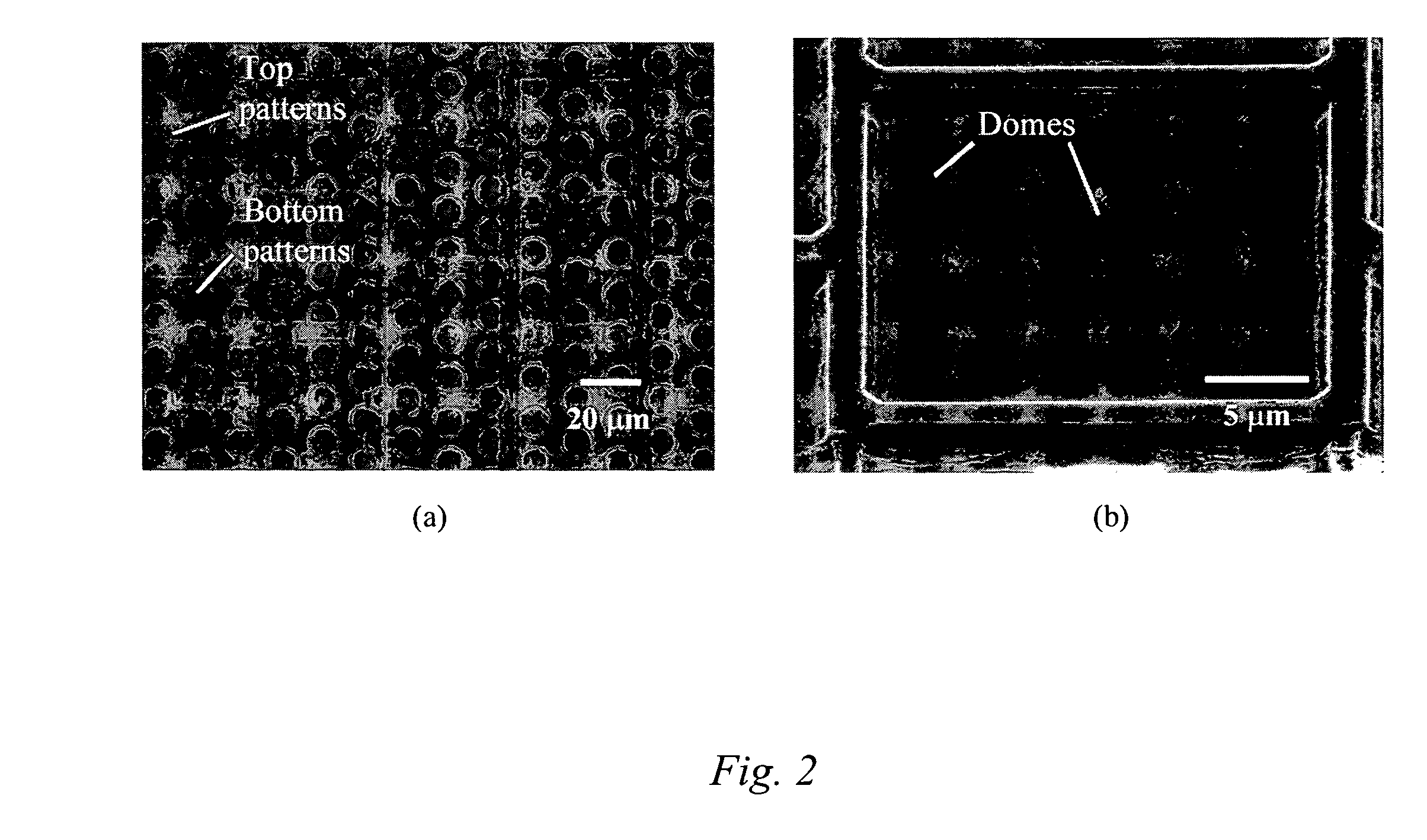

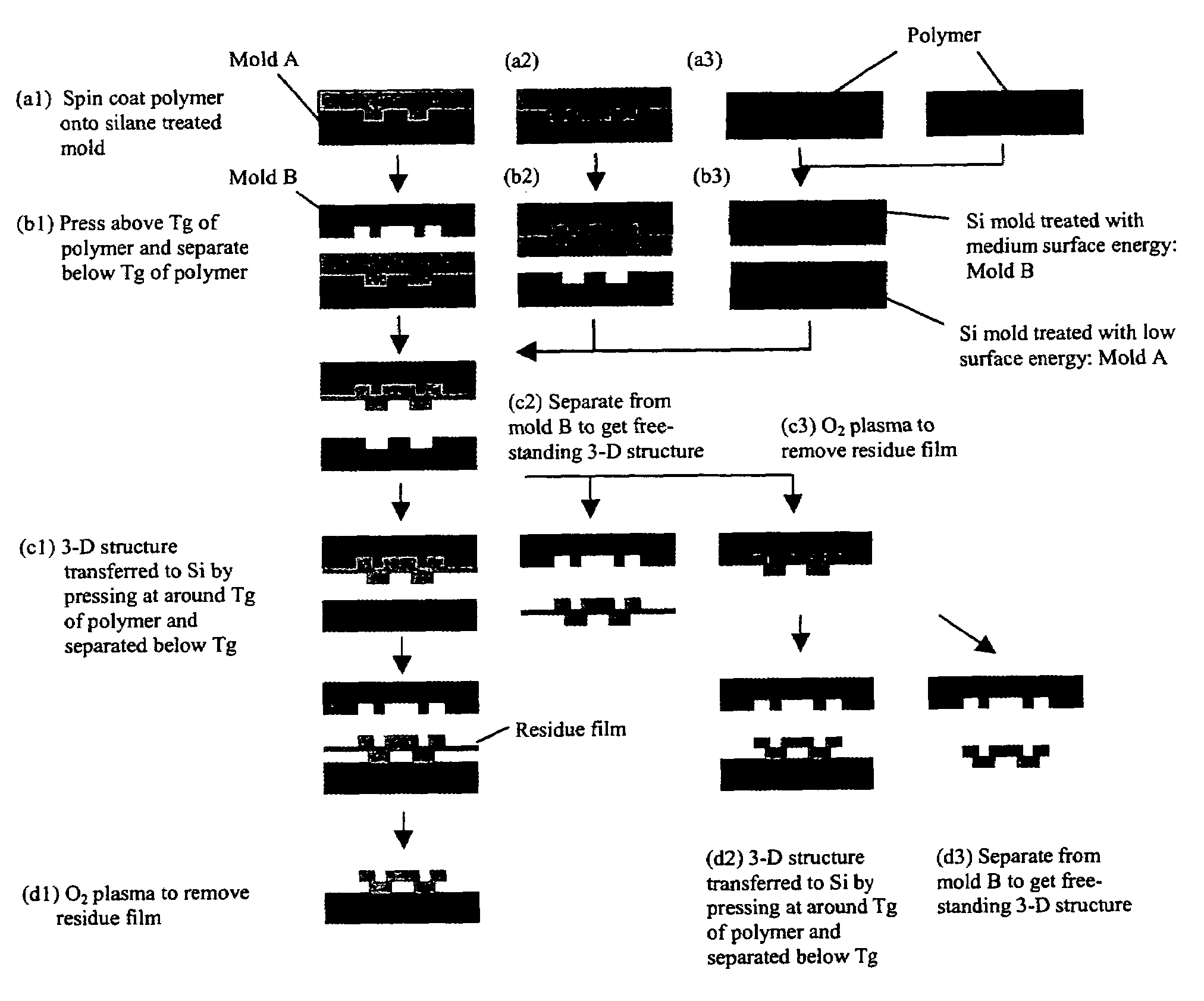

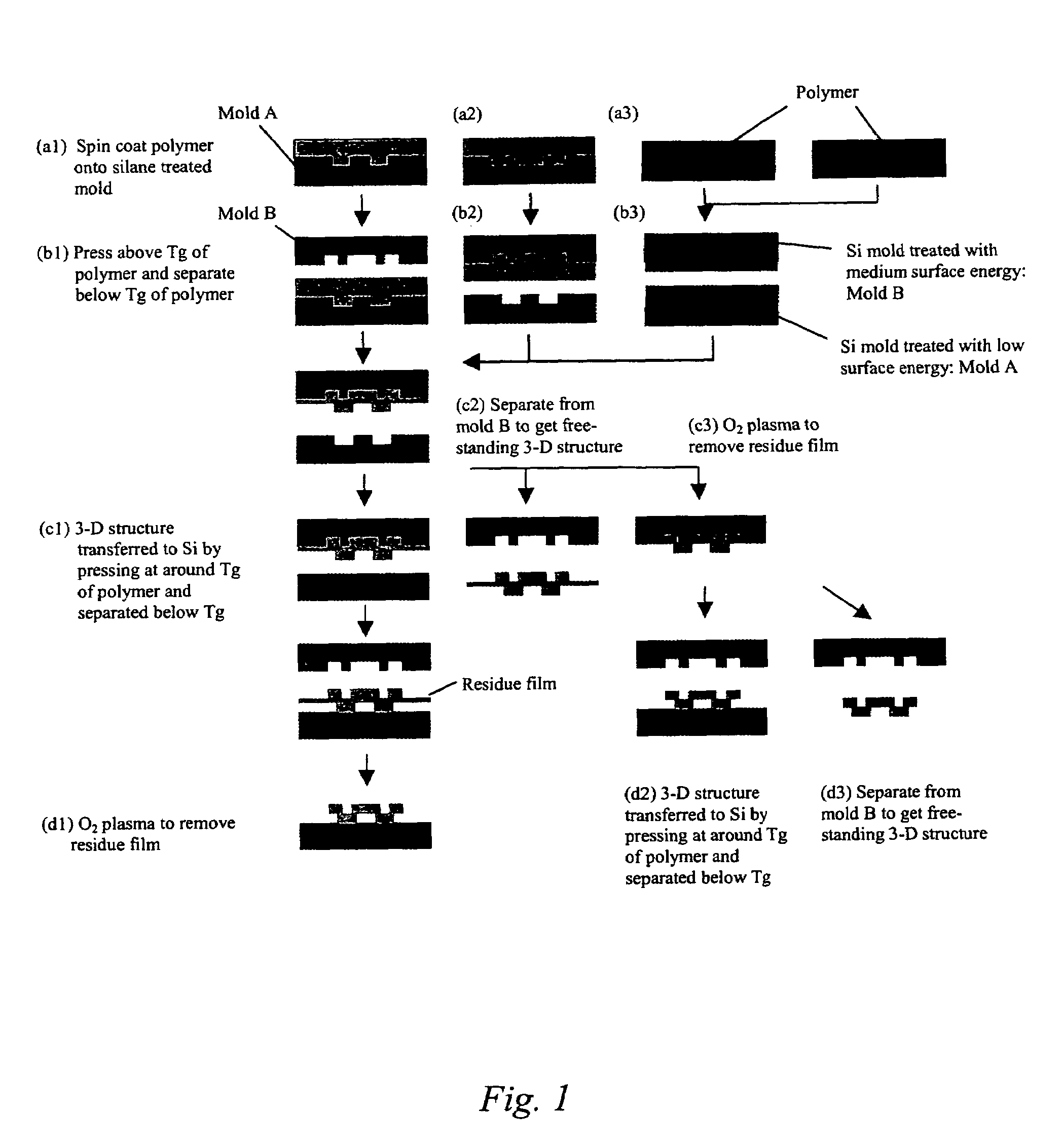

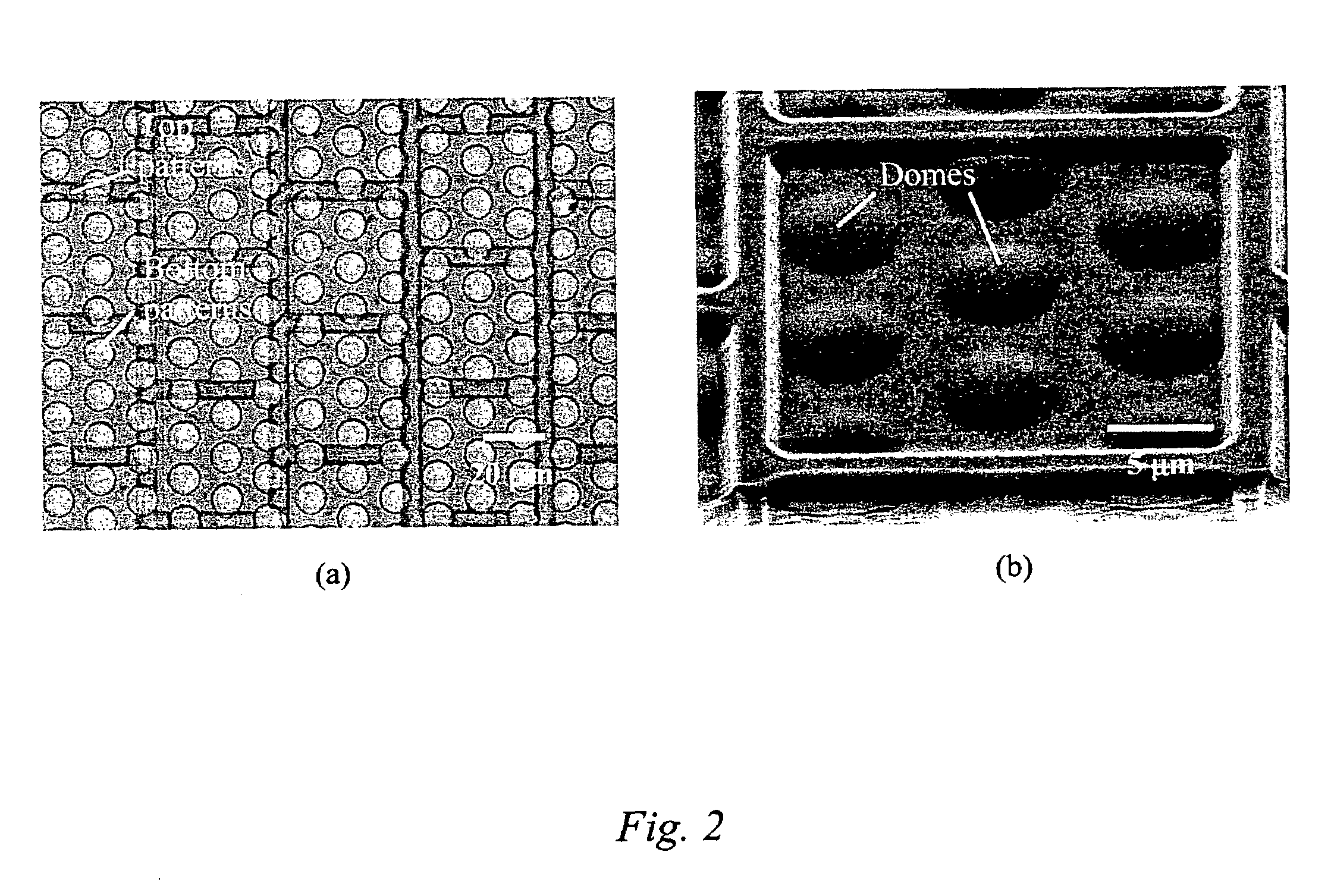

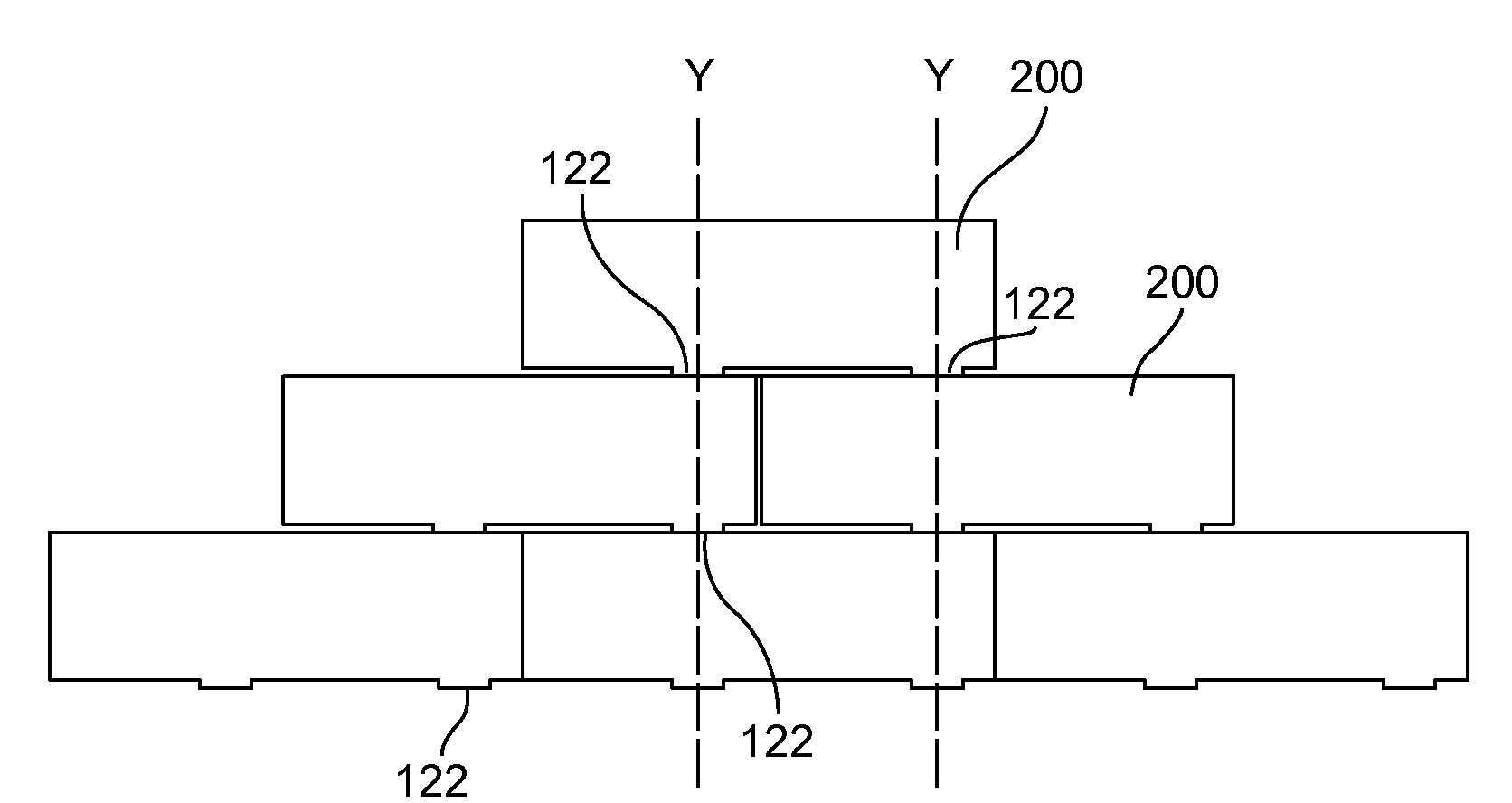

The present invention is directed to micro- and nano-scale imprinting methods and the use of such methods to fabricate supported and / or free-standing 3-D micro- and / or nano-structures of polymeric, ceramic, and / or metallic materials, particularly for pixel segregation in OLED-based displays. In some embodiments, a duo-mold approach is employed in the fabrication of these structures. In such methods, surface treatments are employed to impart differential surface energies to different molds and / or different parts of the mold(s). Such surface treatments permit the formation of three-dimensional (3-D) structures through imprinting and the transfer of such structures to a substrate. In some or other embodiments, such surface treatments and variation in glass transition temperature of the polymers used can facilitate separation of the 3-D structures from the molds to form free-standing micro- and / or nano-structures individually and / or in a film. In some or other embodiments, a “latch-on” assembly technique is utilized to form supported and / or free-standing stacked micro- and / or nano-structures that enable the assembly of polymers without a glass transition temperature and eliminate the heating required to assemble thermoplastic polymers.

Owner:AGENCY FOR SCI TECH & RES

Thermoplastic molding process and apparatus

A system and method for forming an article from thermoplastic material and fiber. The method includes heating thermoplastic material to form a molten thermoplastic material for blending with the fiber. The molten thermoplastic material is blended with the fibers to form a molten composite material having a concentration of fiber by weight. The molten composite material may then be extruded through dynamic dies to deliver discrete controlled material that is gravitated onto a lower portion of a mold. The lower portion of the mold may be moved in space and time while receiving the flow of composite material to deposit a predetermined quantity of molten composite material thereon conforming to mold cavities of the lower and an upper portion of the mold. The upper portion of the mold may be pressed against the predetermined quantity of molten composite material and closing on the lower portion of the mold to form the article.

Owner:D&D MFG LLC

Imprinting of supported and free-standing 3-D micro- or nano-structures

InactiveUS20050258570A1Easy to separateRemove heatNanostructure manufactureLayered productsVitrificationMetallic materials

The present invention is directed to micro- and nano-scale imprinting methods and the use of such methods to fabricate supported and / or free-standing 3-D micro- and / or nano-structures of polymeric, ceramic, and / or metallic materials. In some embodiments, a duo-mold approach is employed in the fabrication of these structures. In such methods, surface treatments are employed to impart differential surface energies to different molds and / or different parts of the mold(s). Such surface treatments permit the formation of three-dimensional (3-D) structures through imprinting and the transfer of such structures to a substrate. In some or other embodiments, such surface treatments and variation in glass transition temperature of the polymers used can facilitate separation of the 3-D structures from the molds to form free-standing micro- and / or nano-structures individually and / or in a film. In some or other embodiments, a “latch-on” assembly technique is utilized to form supported and / or free-standing stacked micro- and / or nano-structures that enable the assembly of polymers without a glass transition temperature and eliminate the heating required to assemble thermoplastic polymers.

Owner:AGENCY FOR SCI TECH & RES +1

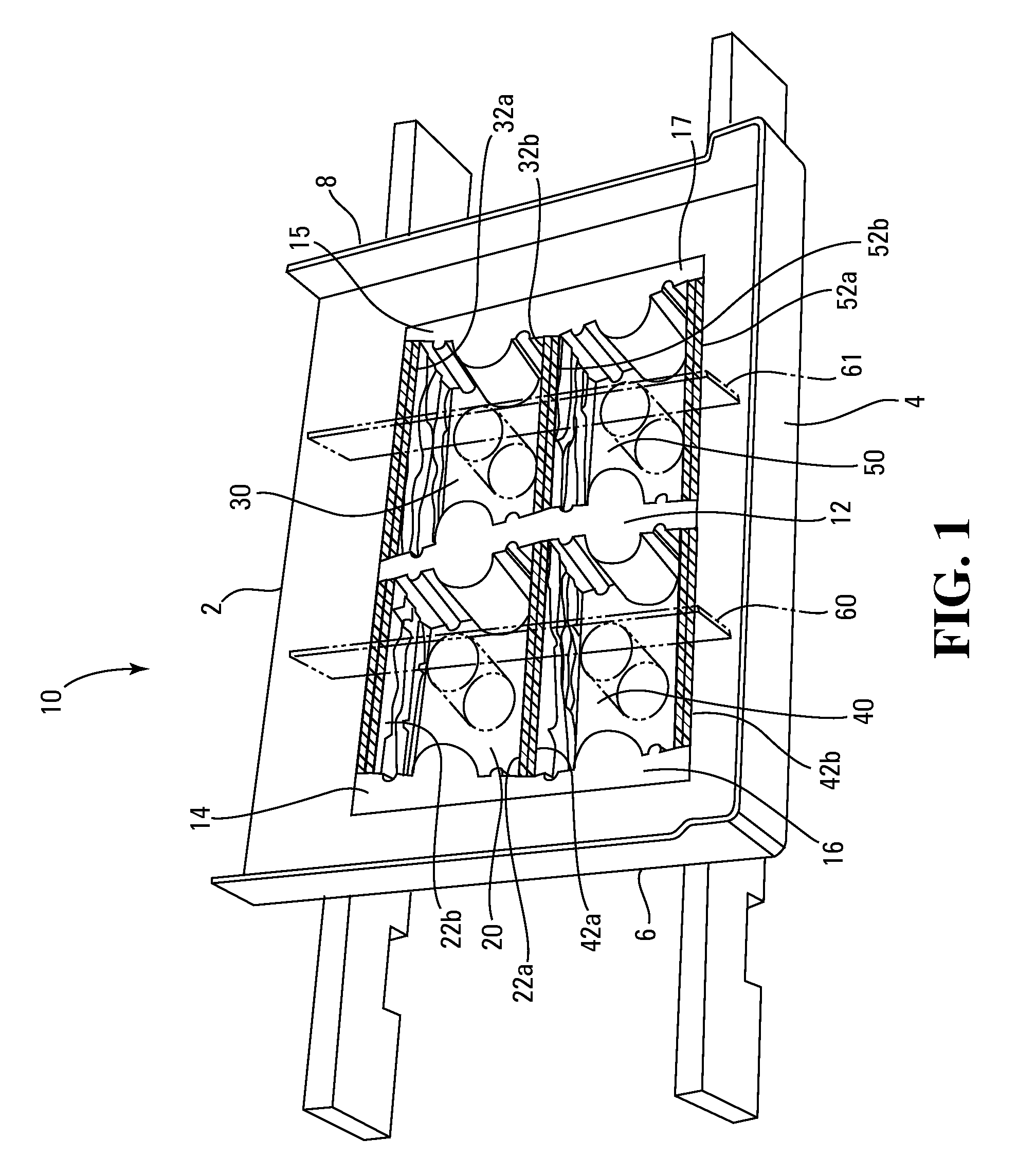

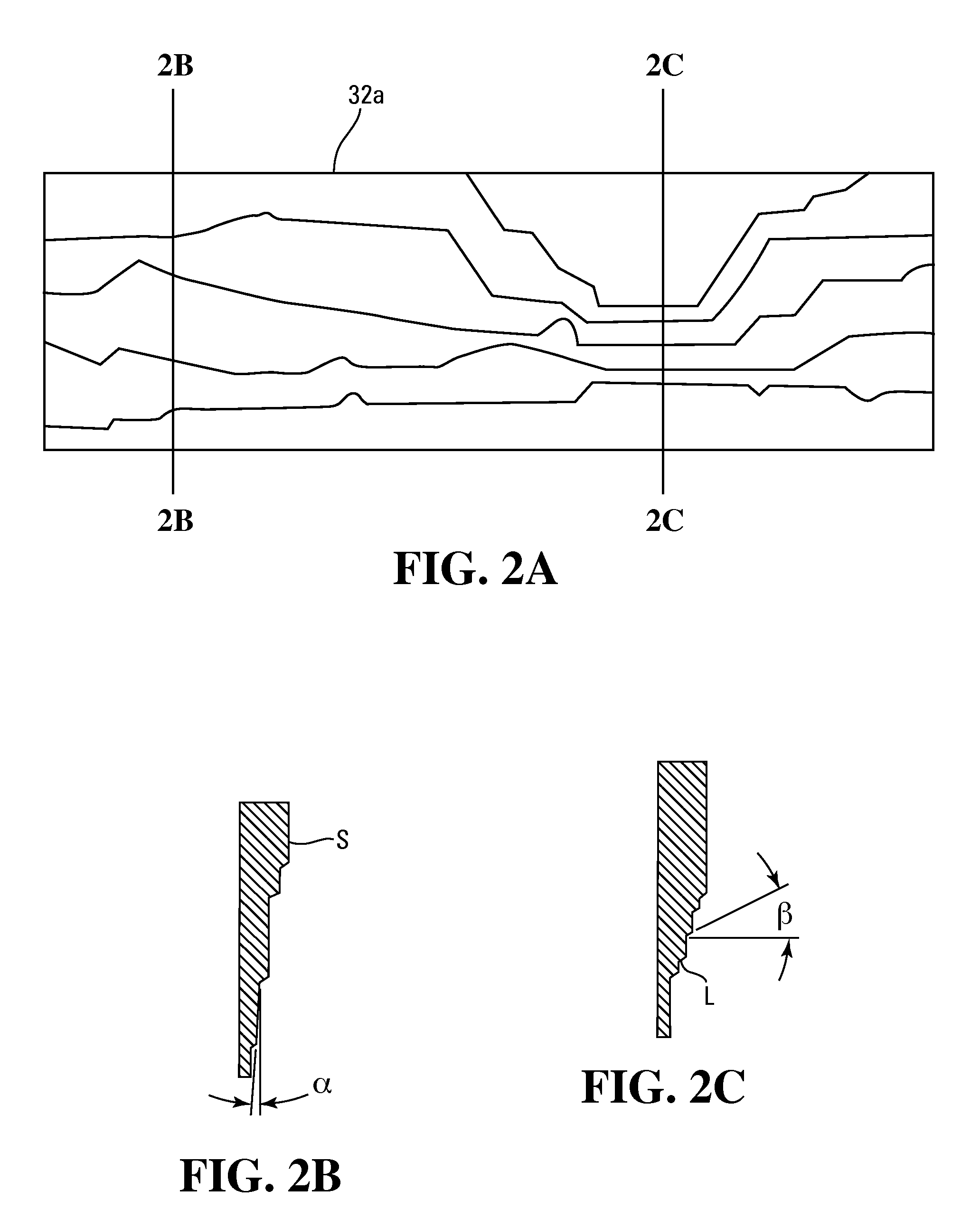

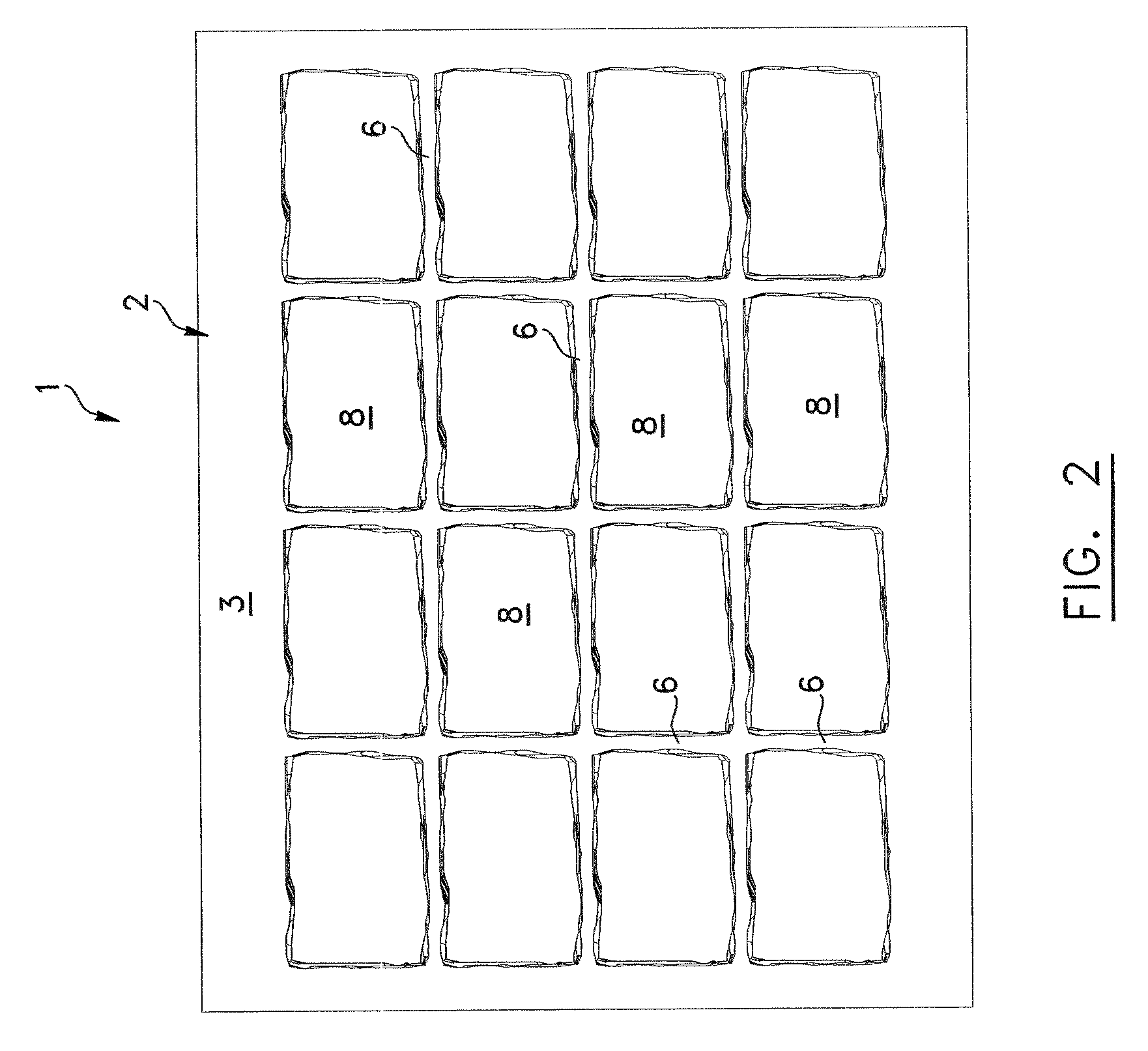

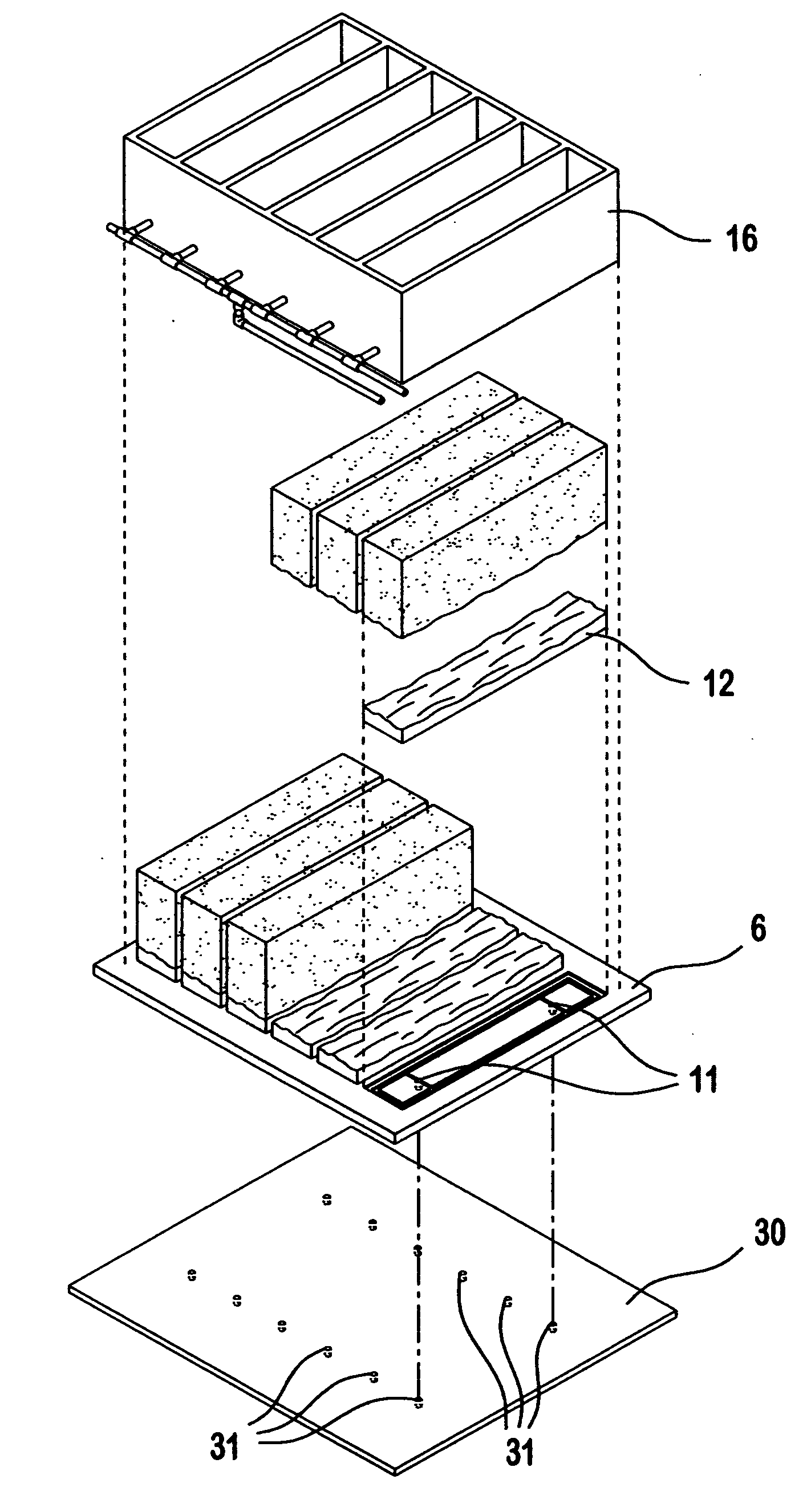

Mold box and method of manufacturing a block

The present invention relates a mold box method of manufacturing a block, and a wall block with a stepped-back strata and ledges imprinted on one or more faces of the block. A mold box is provided with a block face liner that is machine cut to create a particular strata and ledge pattern that is widest at the top of the liner and steps back over a plurality of planes to a narrower width at the bottom of the liner. Masonry material is allowed to form in the mold box around the liner to produce the strata and ledges imprint onto one or more faces of the block. The invention also relates to the mold box, multiple embodiments of the block face liner with differing strata and ledge patterns, and to blocks formed in the mold box and methods of constructing walls with the blocks.

Owner:KEYSTONE RETAINING WALL SYST

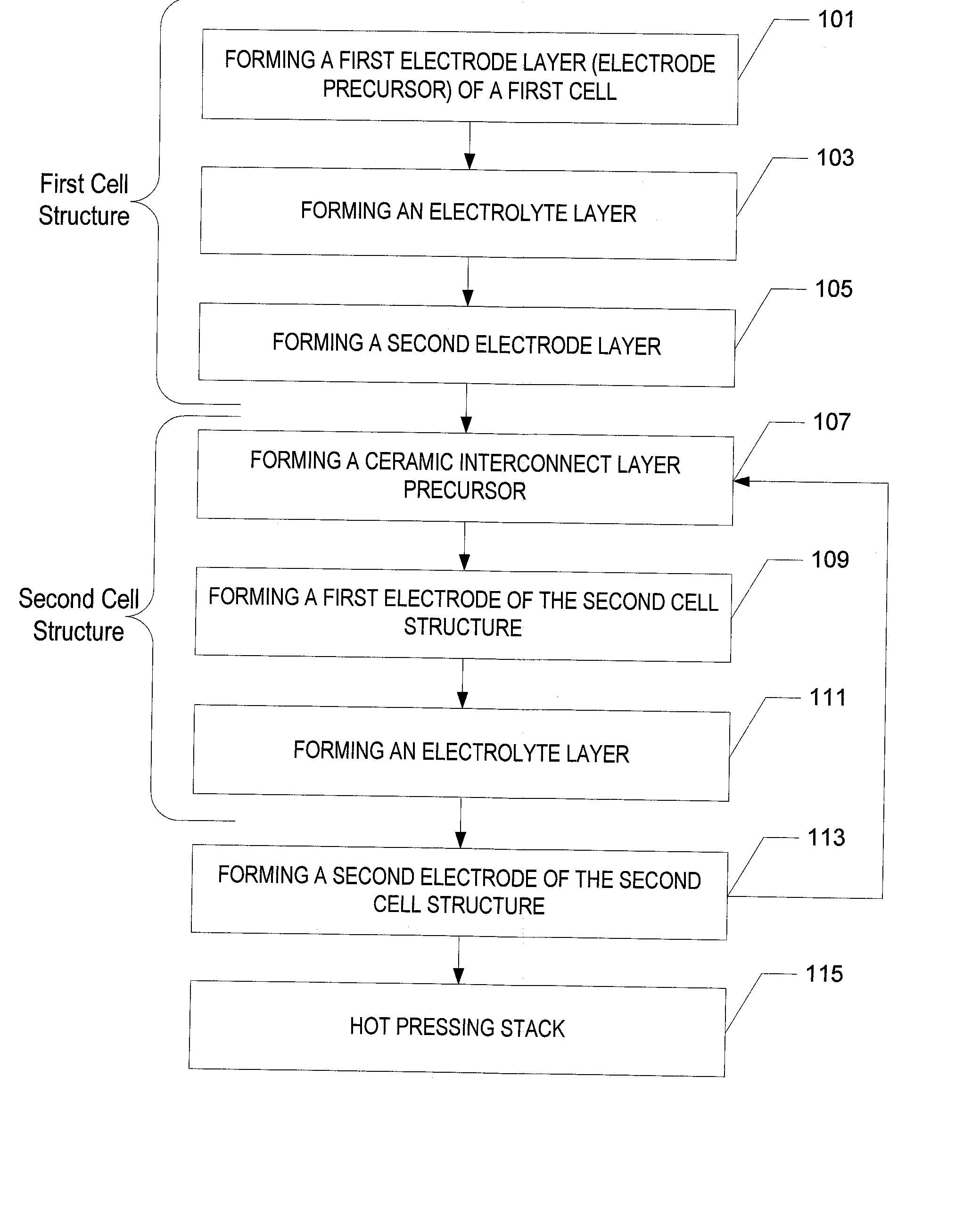

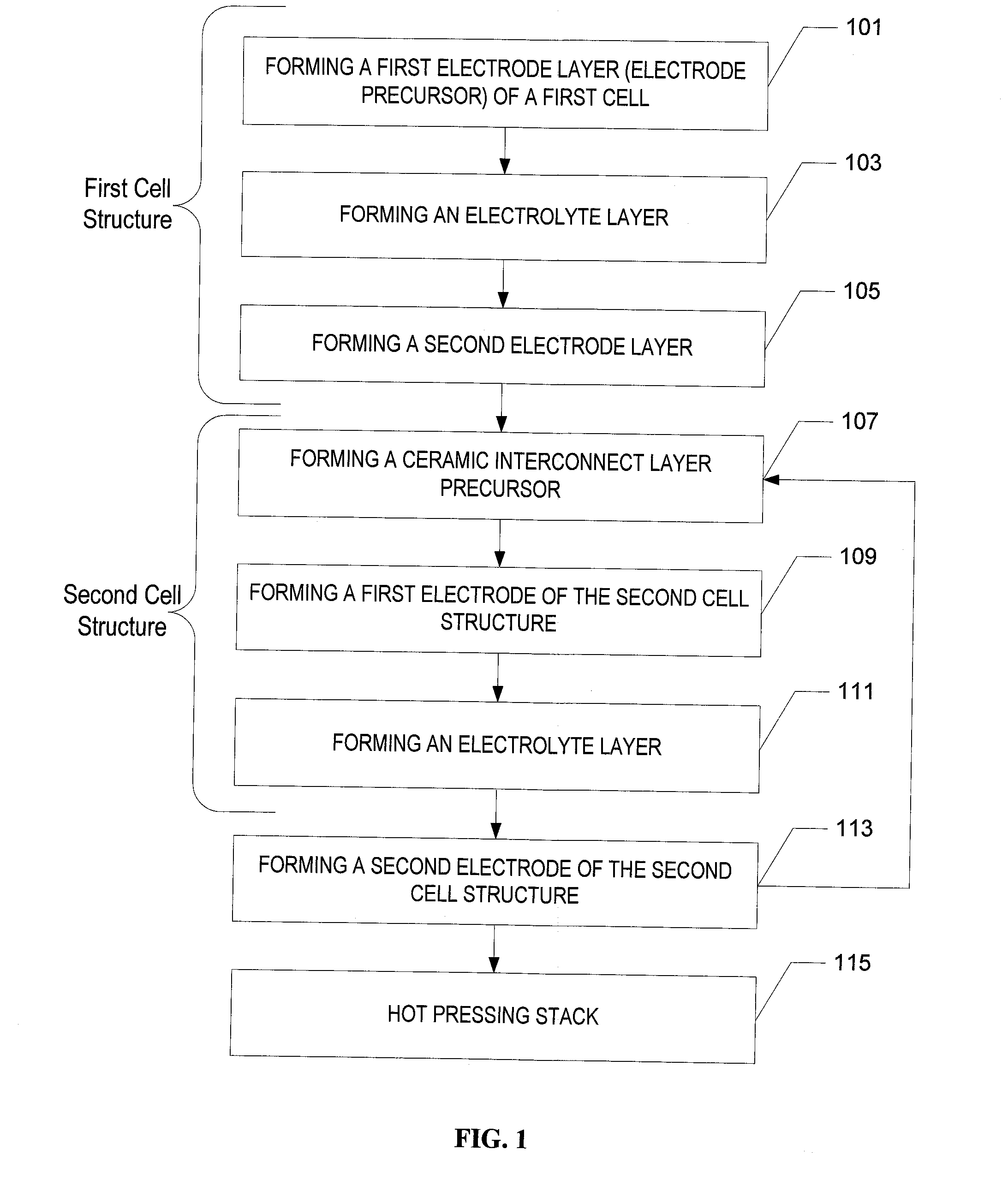

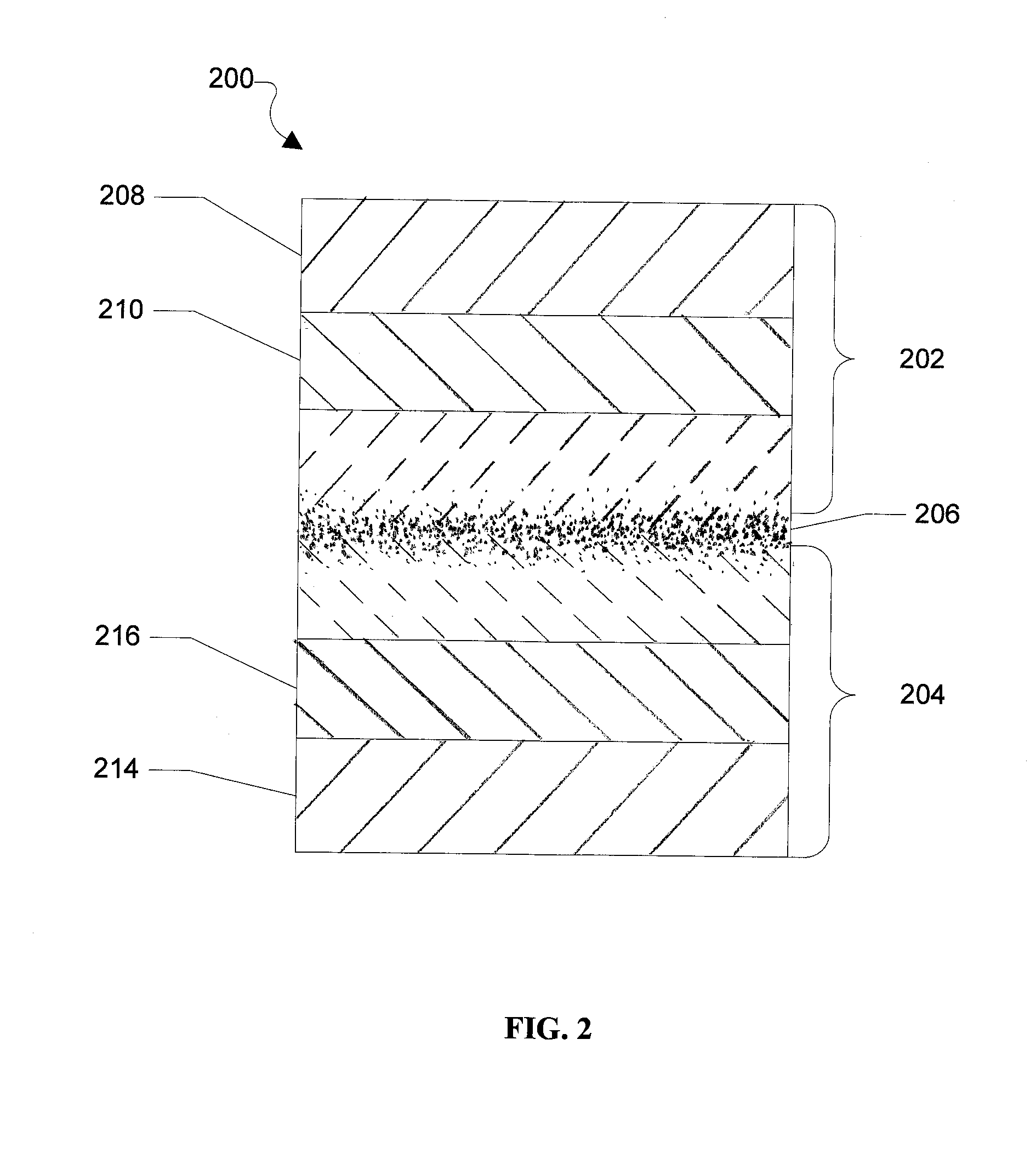

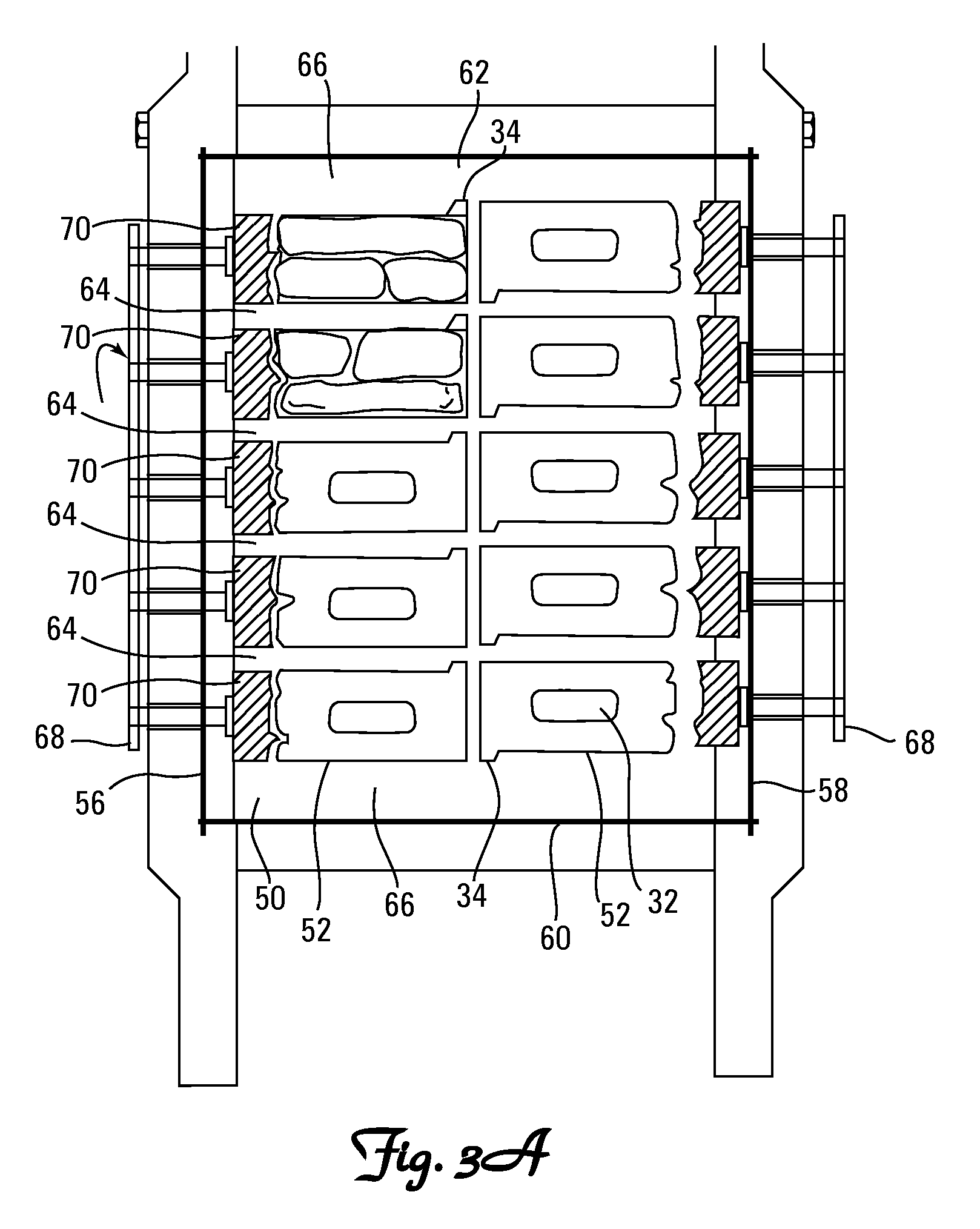

SOFC stack having a high temperature bonded ceramic interconnect and method for making same

ActiveUS20070237999A1High-temperature bondingFuel cells groupingCell electrodesMetallurgyElectrolyte

The present disclosure is directed to an integrated SOFC stack including, a first cell having a cathode layer, an electrolyte layer overlying the cathode layer, and an anode layer overlying the electrolyte layer. The SOFC stack also includes a second cell having a cathode layer, an electrolyte layer overlying the cathode layer, and an anode overlying the electrolyte layer. The SOFC stack further includes a ceramic interconnect layer between the first cell and the second cell, the ceramic interconnect layer having a first high temperature bonding region along the interfacial region between the first cell and the ceramic interconnect layer. The ceramic interconnect layer also includes a second high temperature bonding region along the interfacial region between the second cell and the ceramic interconnect layer.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

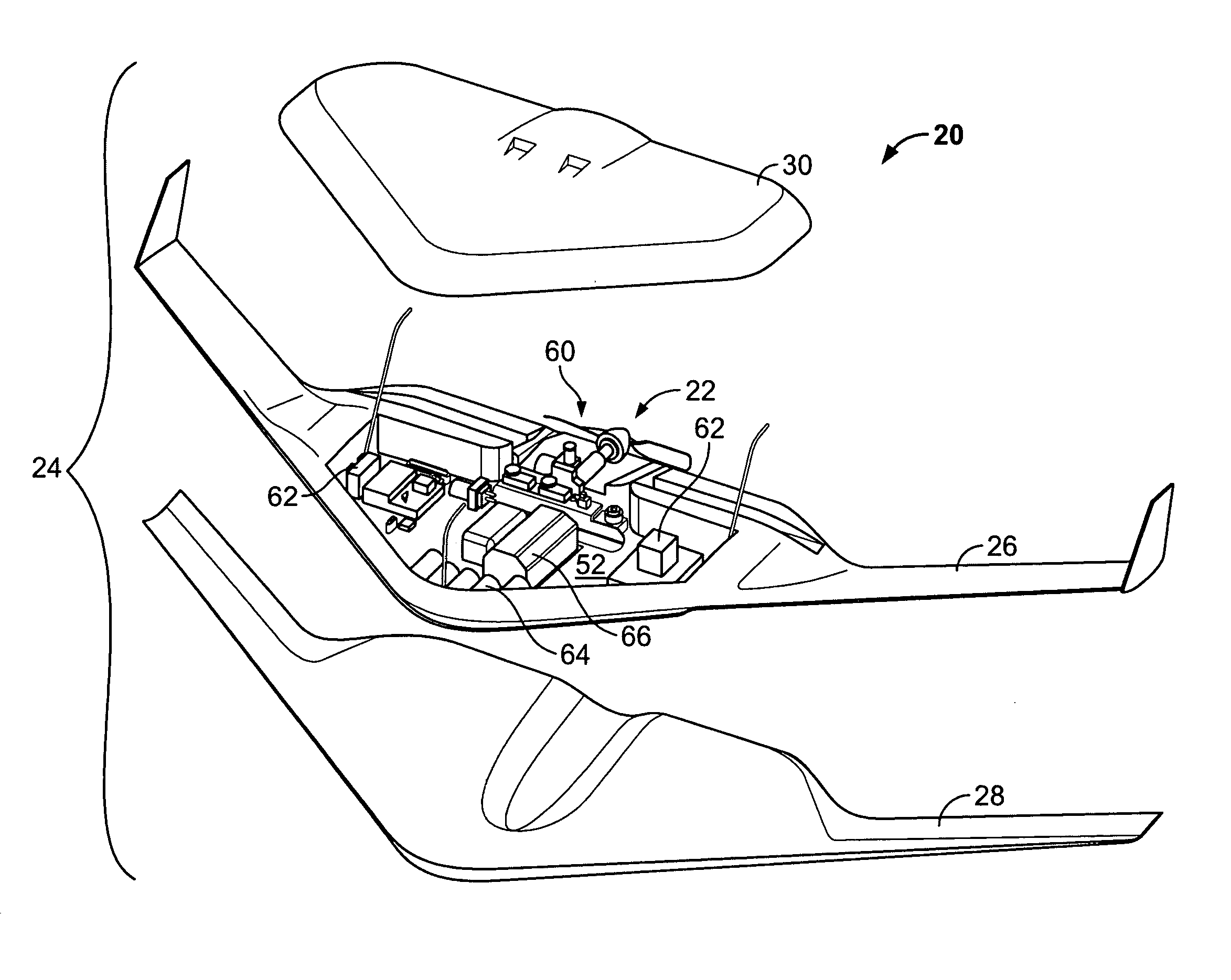

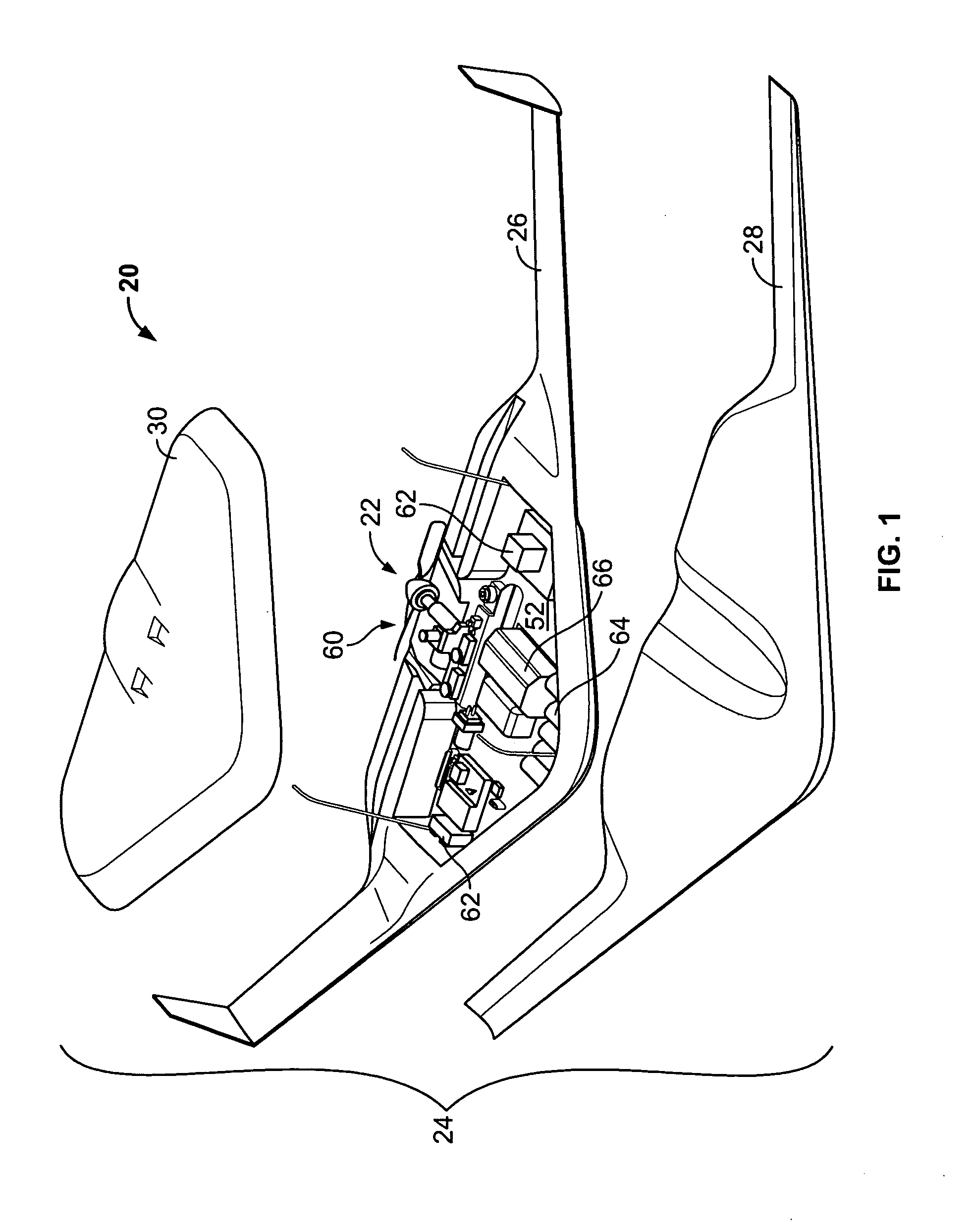

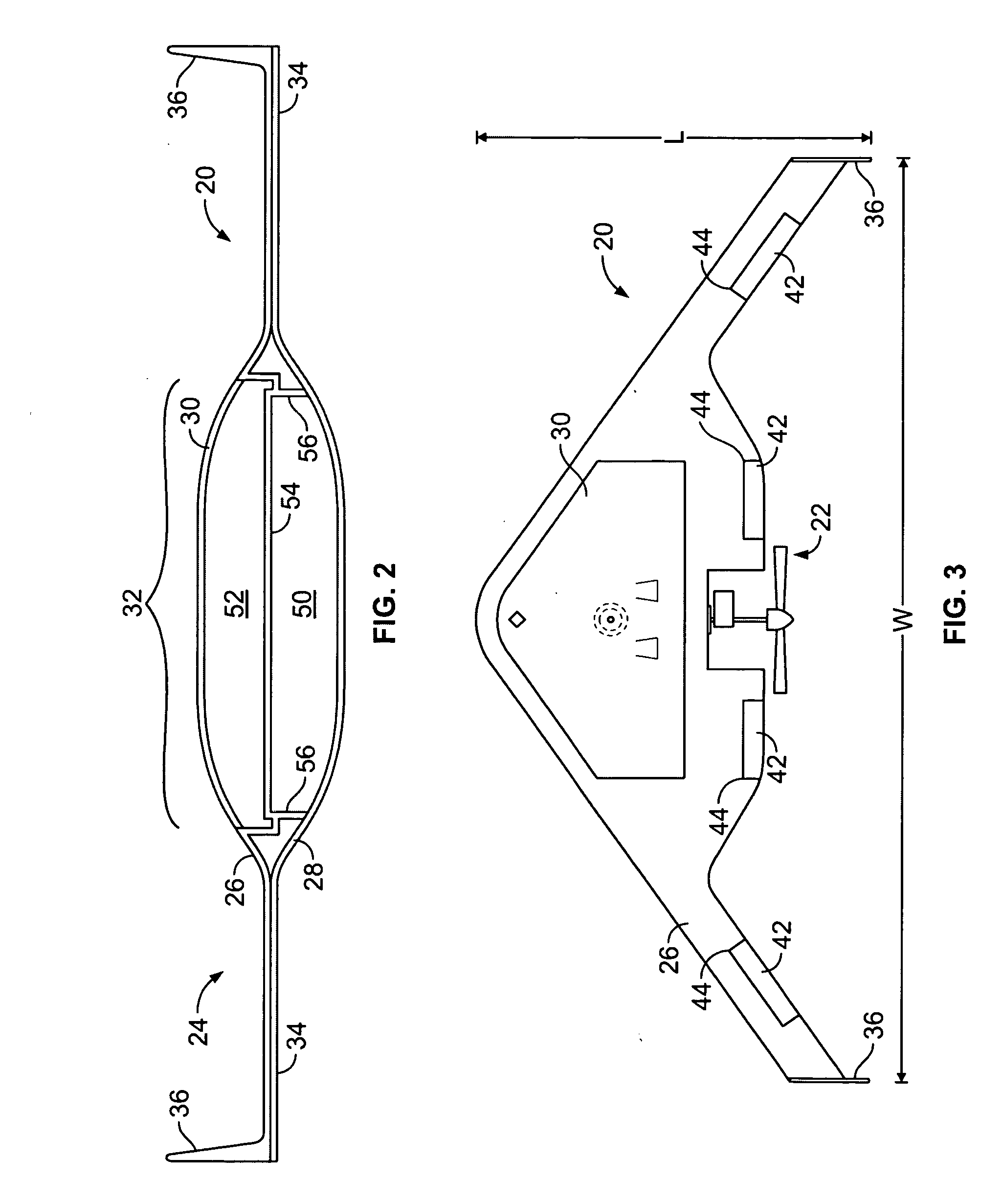

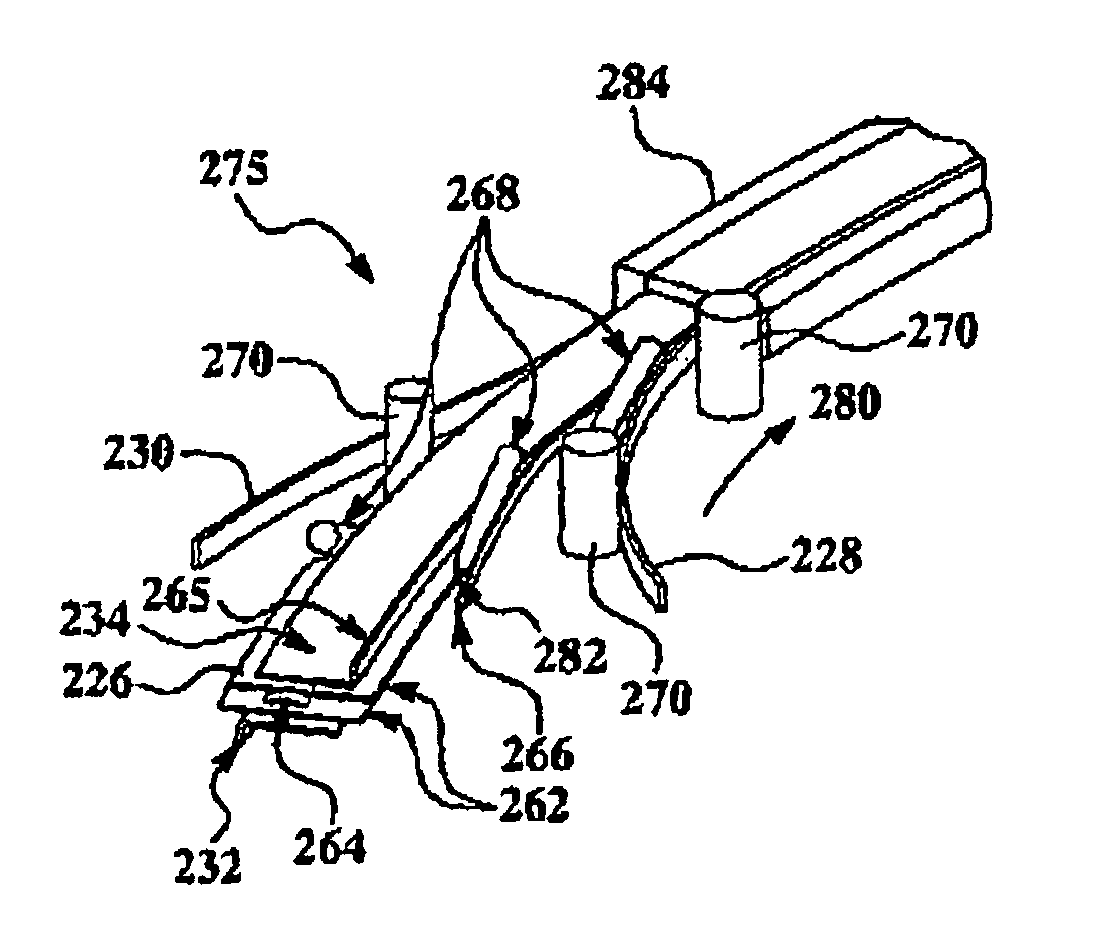

Unmanned aerial vehicle and launch assembly

ActiveUS20090134273A1Cost-effective to useCost-effective to manufactureUnmanned aerial vehiclesLaunching/towing gearFuel tankUncrewed vehicle

An unmanned aerial vehicle (UAV) is provided, that is cost effective to use and manufacture and that includes a low count of component parts, allowing mission planners to use the UAVs in a disposable manner. The UAV includes an airframe having a central body and wings extending from the central body, defining an interior cavity. The airframe includes an upper and a lower shell, each configured of a unitary piece of plastic. The upper and lower shells have walls among them that define a fuel tank and a payload bay in a stacked configuration. The airframe can further include a payload cover configured to enclose the payload bay and to contribute to the central body of the airframe. A launch assembly is also provided. In a first configuration, a launch assembly is provided, that includes a container for housing multiple UAVs and a deployment mechanism that initiates rapid ejection of the UAVs from the container. In a second configuration, a launch assembly is provided, that includes an elastic tether connecting a UAV to an accelerated mass for gentle acceleration to flight speed under a stable tow.

Owner:NORTHROP GRUMMAN SYST CORP

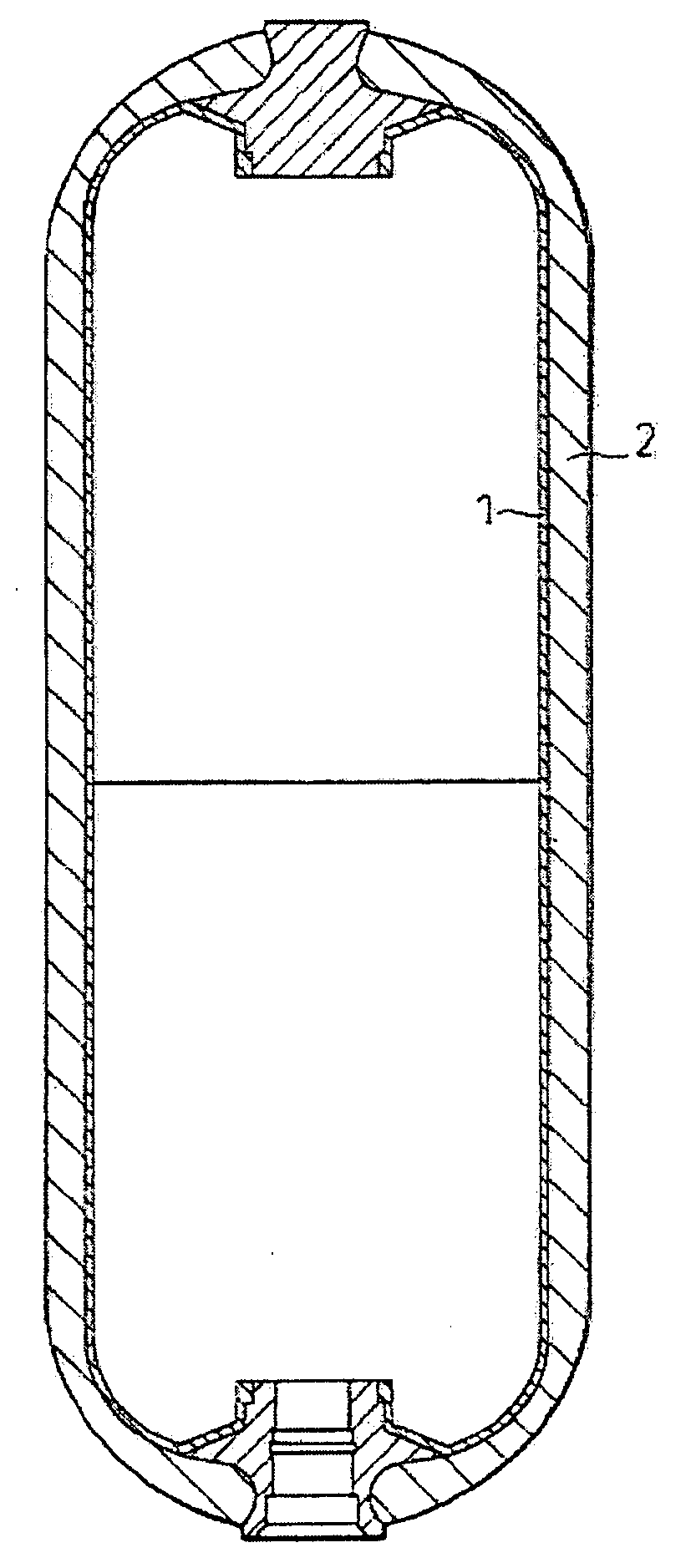

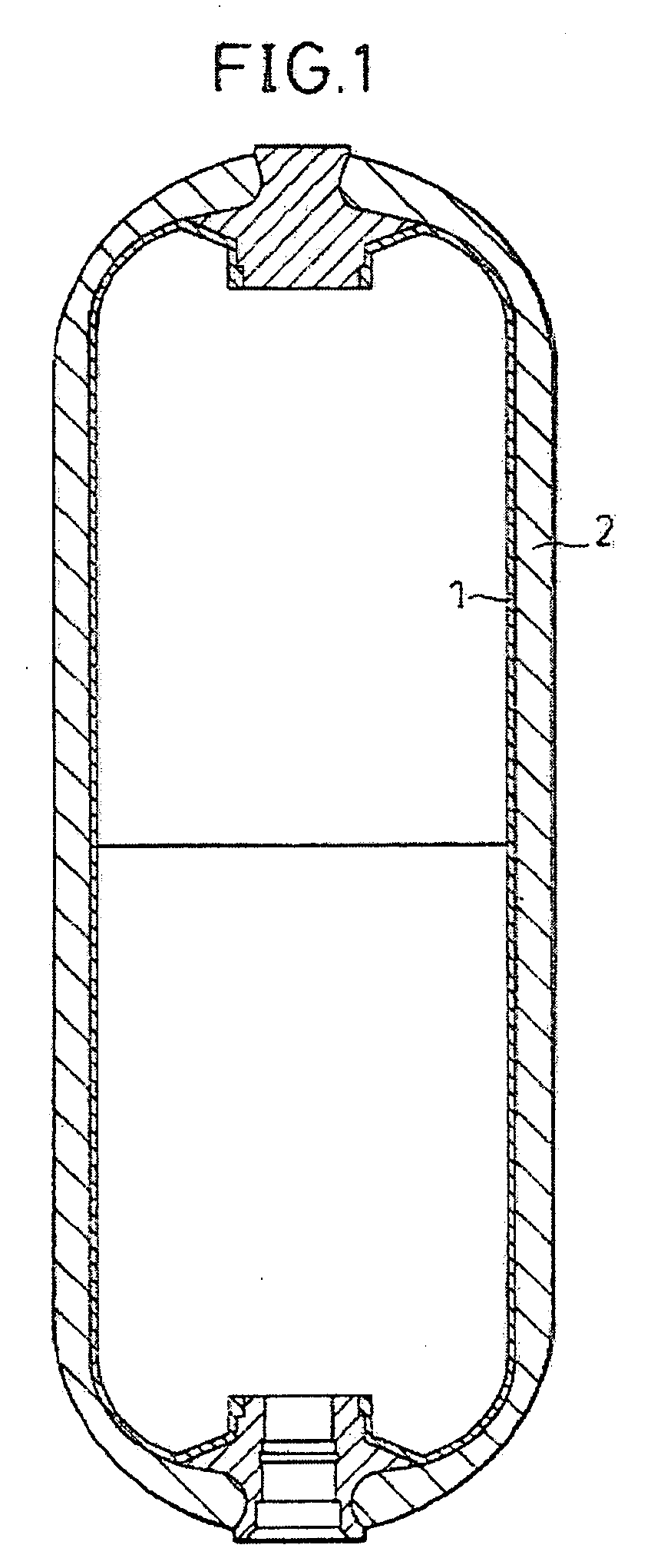

Hydrogen tank liner material and hydrogen tank liner

ActiveUS20090203845A1Improve impact resistanceSuitable for useVessel mounting detailsVessel manufacturingAlpha-olefinHydrogen tank

A hydrogen tank liner material comprises a polyamide resin composition which comprises (A) a polyamide resin at 85-40 wt %, (B) a copolyamide at 5-30 wt % and (C) an impact-resistant material at 10-30 wt % with respect to the total weight of the polyamide resin composition. Preferably, the (B) copolyamide is PA6 / 66 and the (C) impact-resistant material is an acid-modified ethylene / α-olefin-based copolymer. A hydrogen tank liner material with excellent gas barrier properties and superior impact resistance even at low temperatures is obtained.

Owner:UBE CORP +1

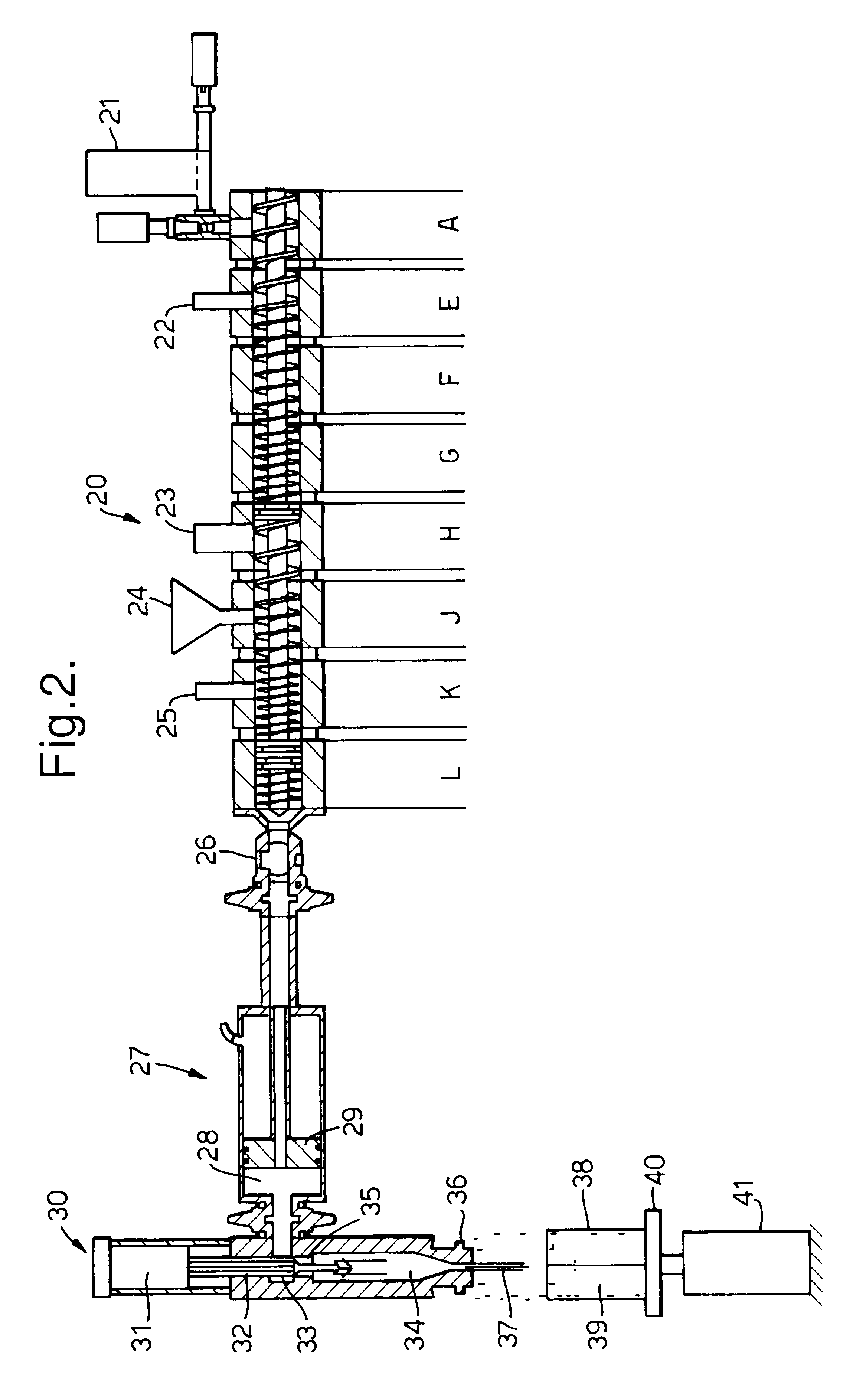

Process and apparatus for the production of a deodorant or antiperspirant composition

InactiveUS6338840B1Quicker and easy to control temperatureLess heat lossCosmetic preparationsToilet preparationsParticulatesActive agent

In a first aspect, a process for forming deodorant or antiperspirant sticks by continuously forming a mobile composition for dispensing into containers or molds at a rate matched with the rate at which it is dispensed, and in other aspects a process in which a mobile deodorant or antiperspirant composition is dispensed by injection molding, i.e. a process in which the deodorant or antiperspirant composition is dispensed under pressure. The composition at the time of injection moulding is preferably either in the vicinity of its regular set temperature, particularly in the range of about 0-3° C. below the regular set temperature and / or partially structured at the time of its delivery it into a container or mold. The deodorant or antiperspirant composition is preferably continuously produced in a screw extruder, especially a twin screw extruder, which is controlled to deliver the composition in a substantially semi-solid state, at a temperature close to its regular set temperature and is injected into the container or barrel at a pressure at the point of injection that is often greater than 15 psi. and in many instances from 200 to 400 psi in the injection head. Apparatus for forming deodorant or antiperspirant sticks by injection molding is also described. The combined process offers benefits for incorporating sensitive ingredients and ameliorating sedimentation of particulates such as particulate antiperspirant actives.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

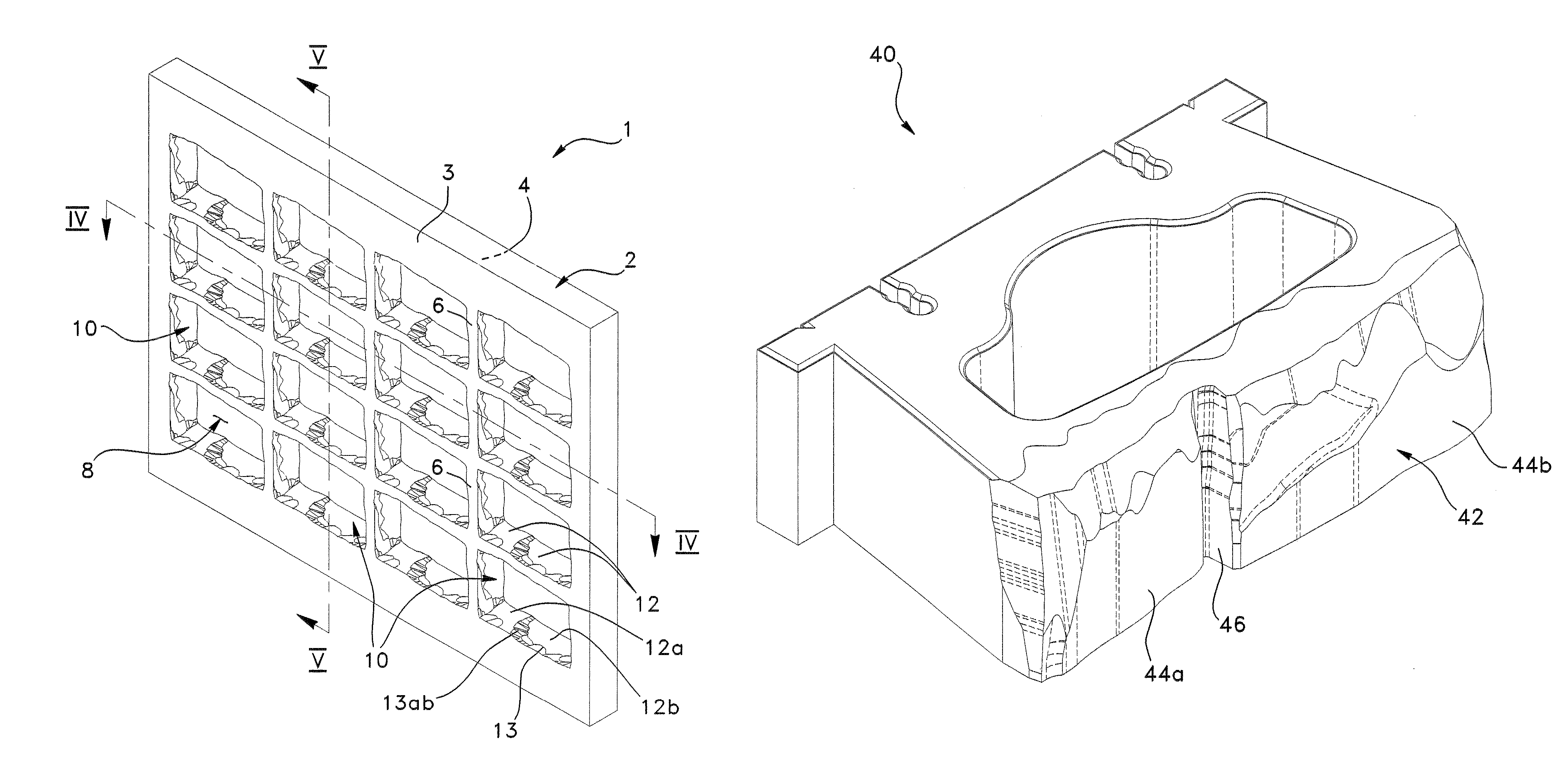

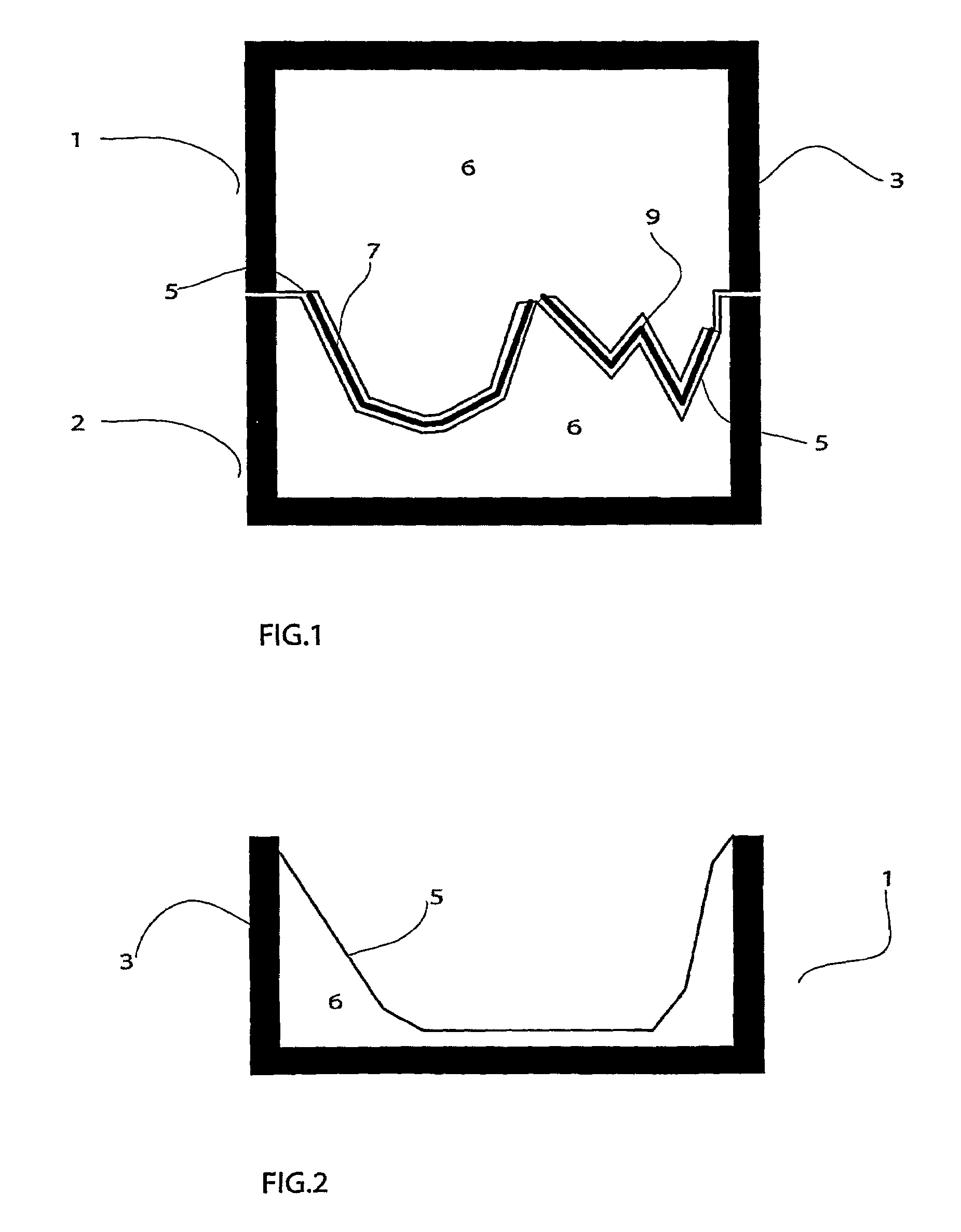

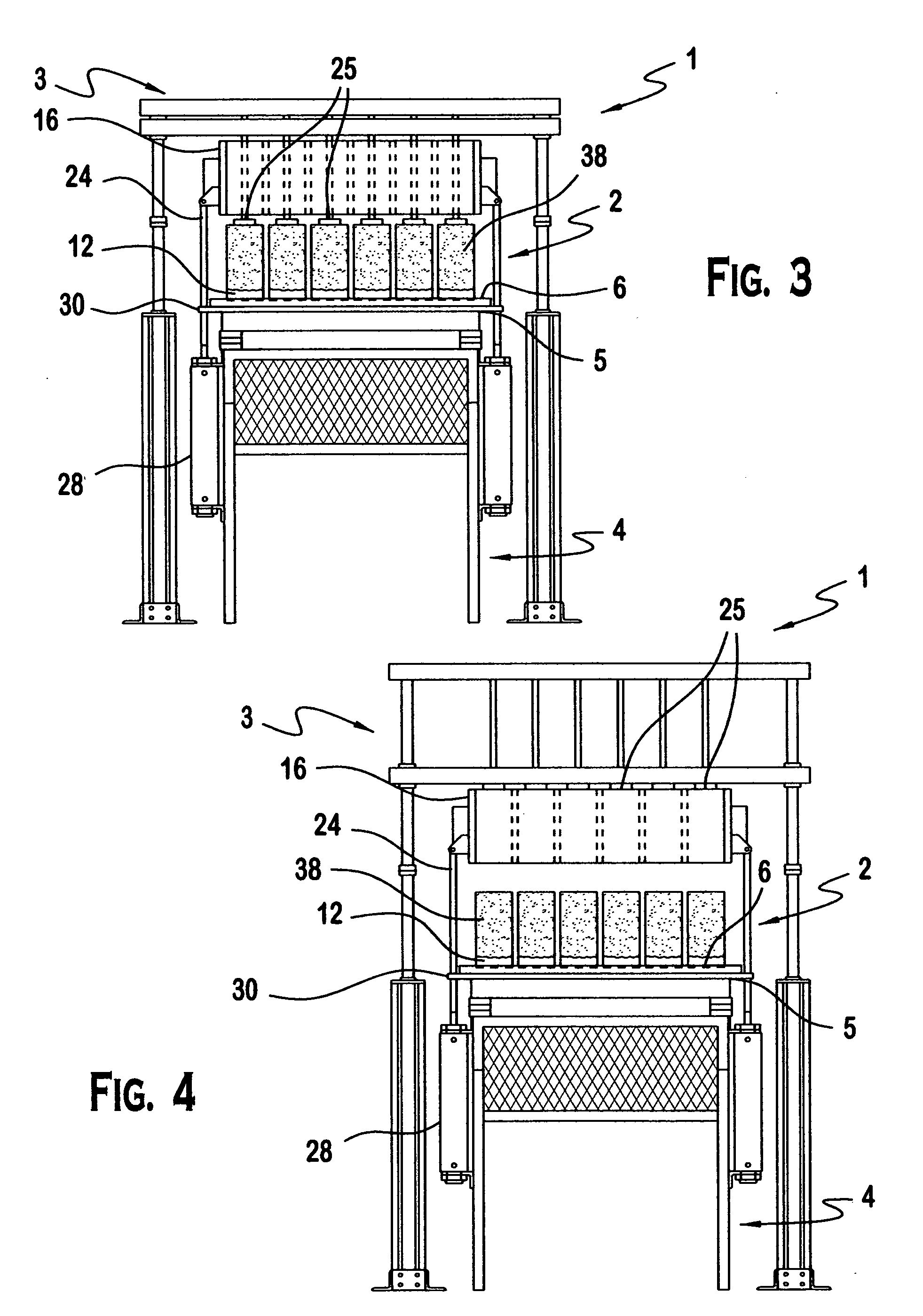

Molding apparatus for producing dry cast products having textured side surfaces

ActiveUS8101113B2Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

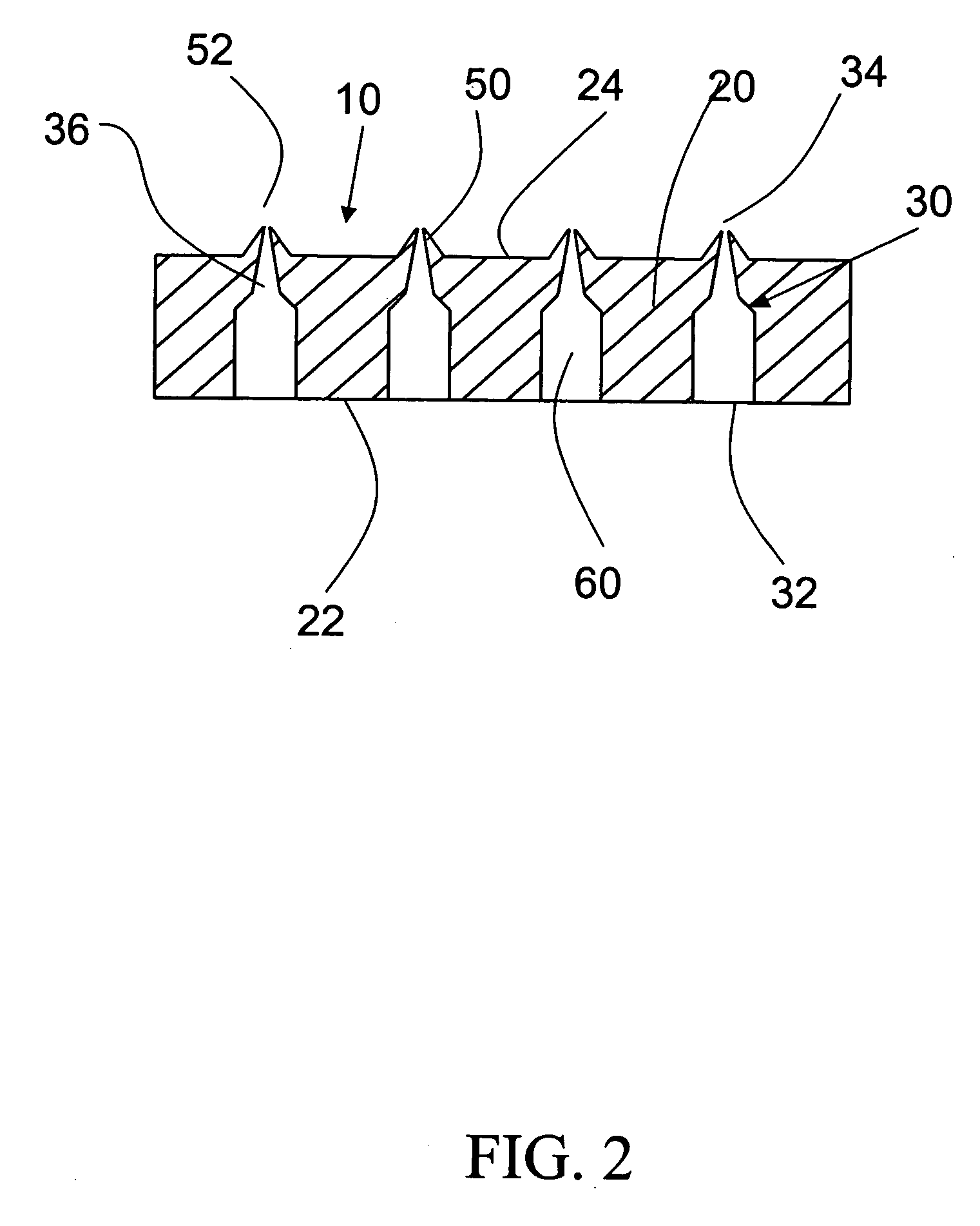

Method Of Molding A Microneedle

InactiveUS20080088066A1Simple molding processReliably producedMicroneedlesMedical devicesReciprocating motionMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

Method of imprinting shadow mask nanostructures for display pixel segregation

InactiveUS7615179B2Easy to separateRemove heatNanostructure manufactureDecorative surface effectsVitrificationDisplay device

The present invention is directed to micro- and nano-scale imprinting methods and the use of such methods to fabricate supported and / or free-standing 3-D micro- and / or nano-structures of polymeric, ceramic, and / or metallic materials, particularly for pixel segregation in OLED-based displays. In some embodiments, a duo-mold approach is employed in the fabrication of these structures. In such methods, surface treatments are employed to impart differential surface energies to different molds and / or different parts of the mold(s). Such surface treatments permit the formation of three-dimensional (3-D) structures through imprinting and the transfer of such structures to a substrate. In some or other embodiments, such surface treatments and variation in glass transition temperature of the polymers used can facilitate separation of the 3-D structures from the molds to form free-standing micro- and / or nano-structures individually and / or in a film. In some or other embodiments, a “latch-on” assembly technique is utilized to form supported and / or free-standing stacked micro- and / or nano-structures that enable the assembly of polymers without a glass transition temperature and eliminate the heating required to assemble thermoplastic polymers.

Owner:AGENCY FOR SCI TECH & RES

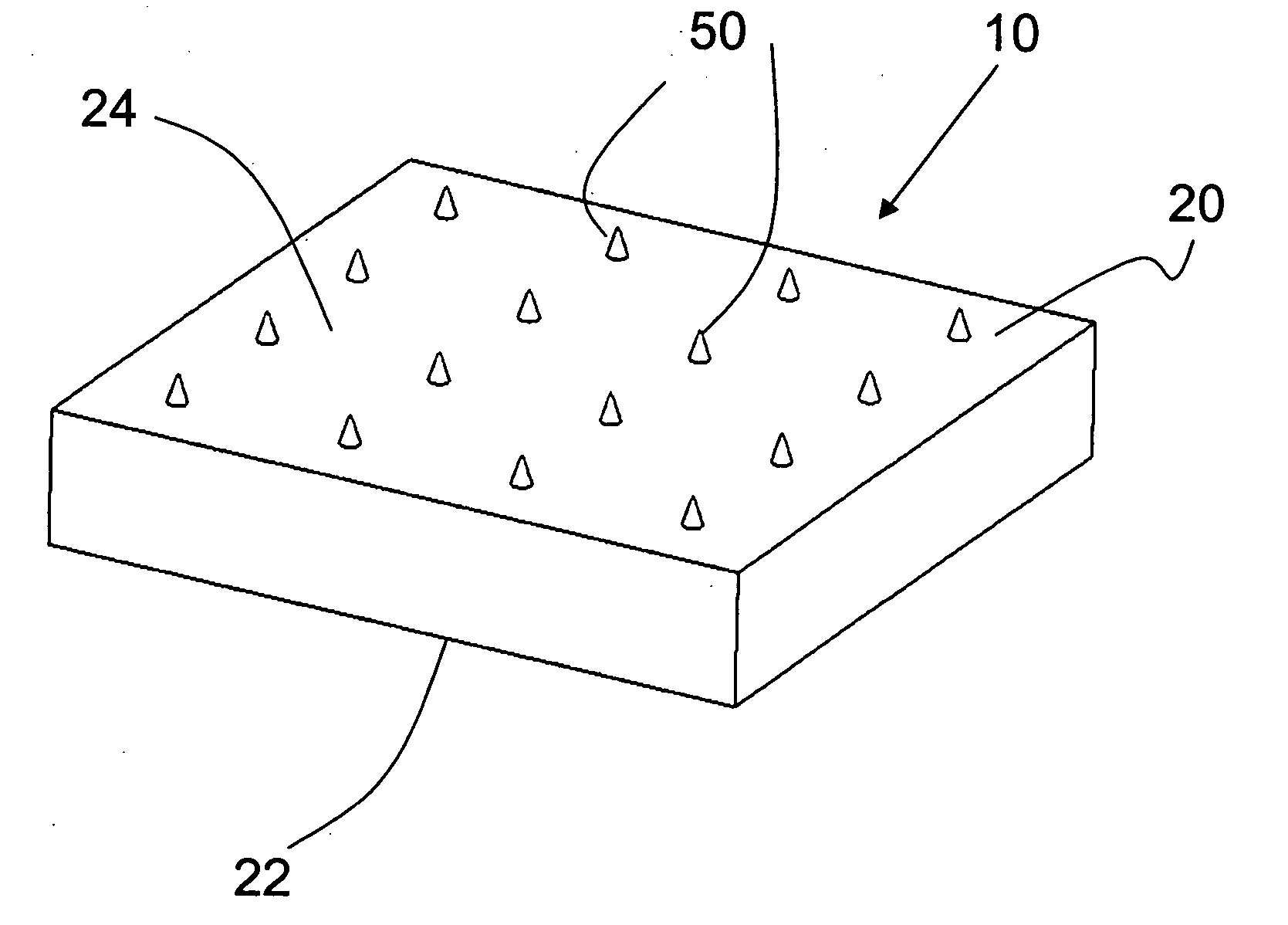

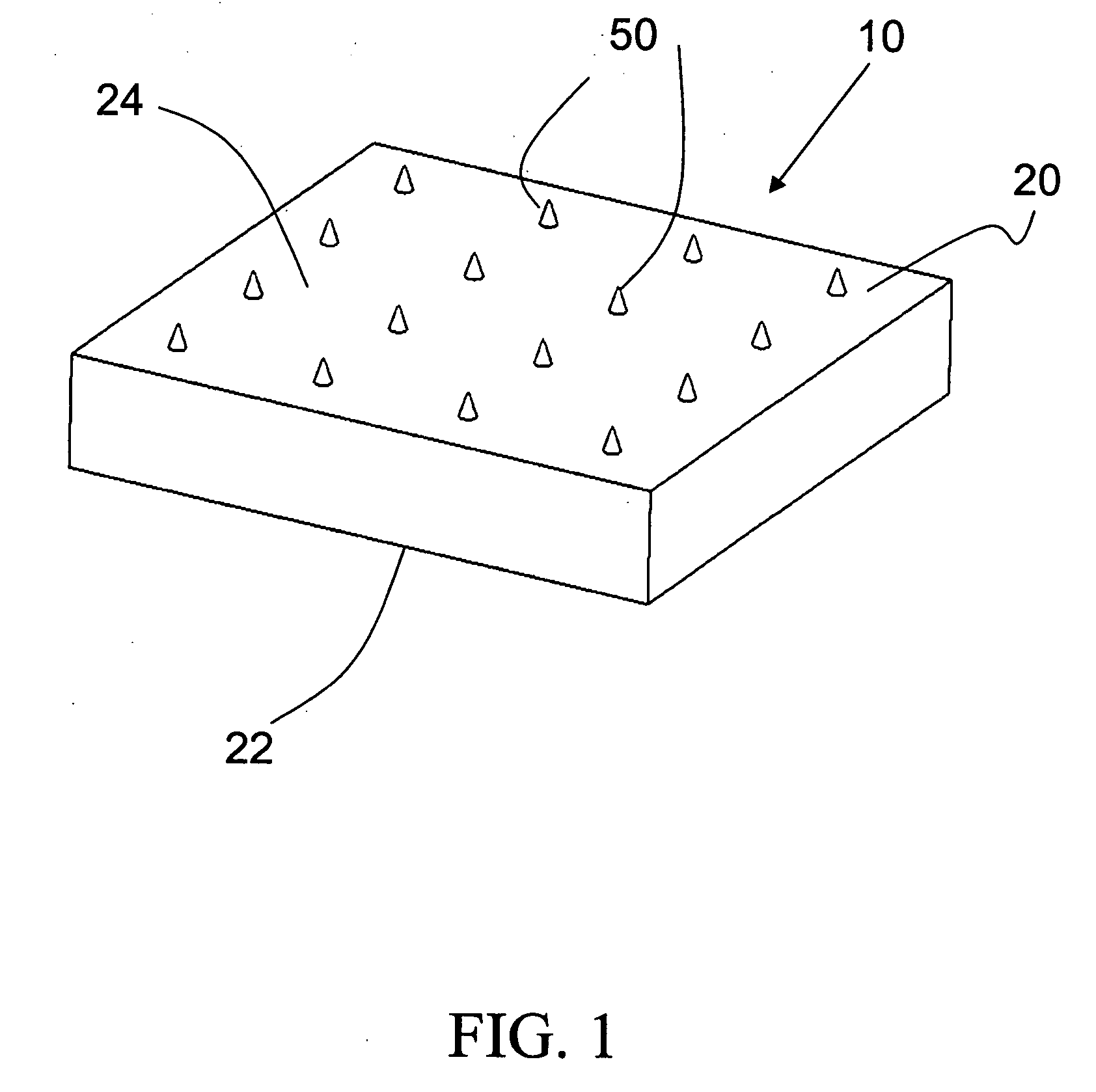

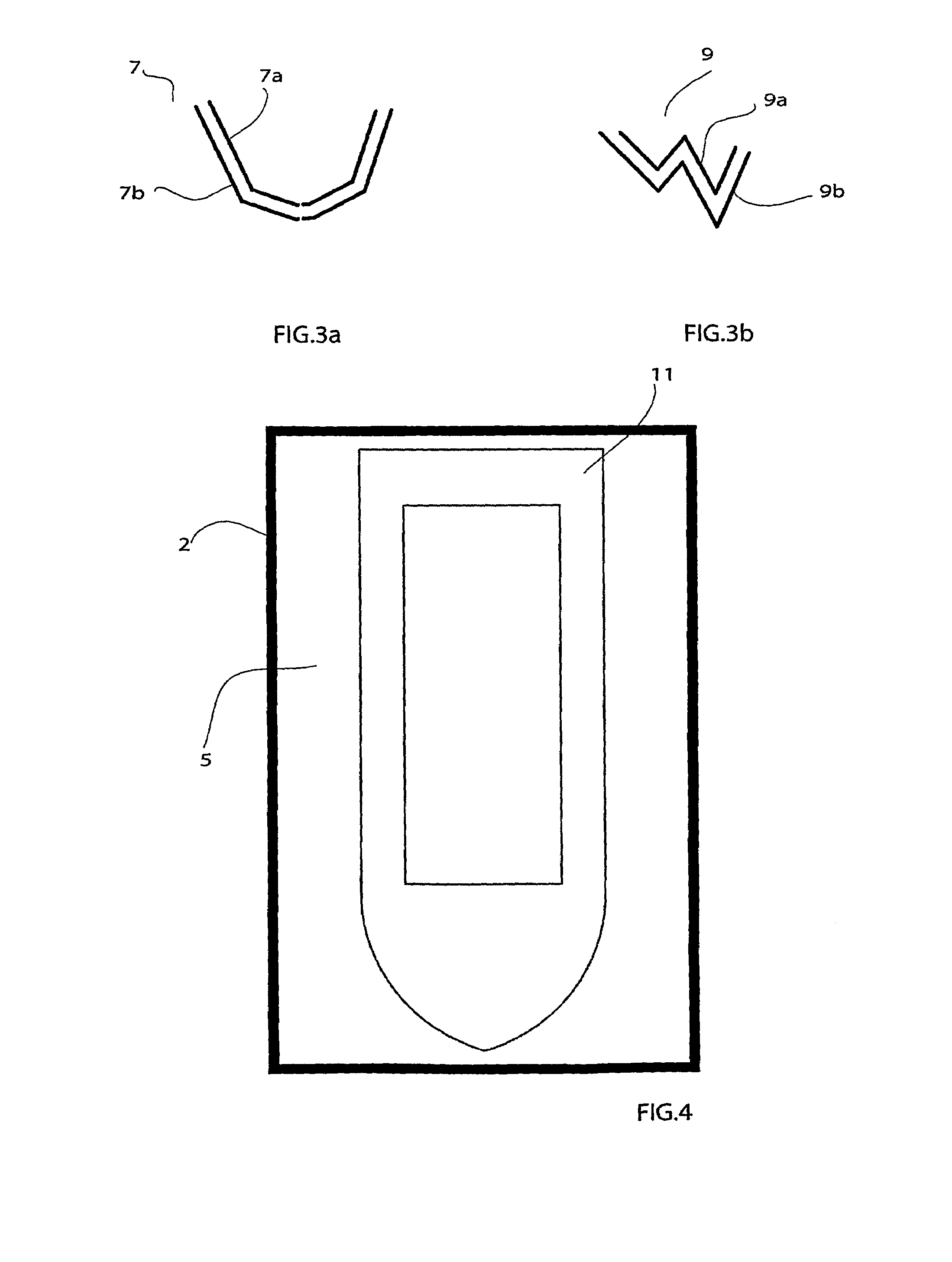

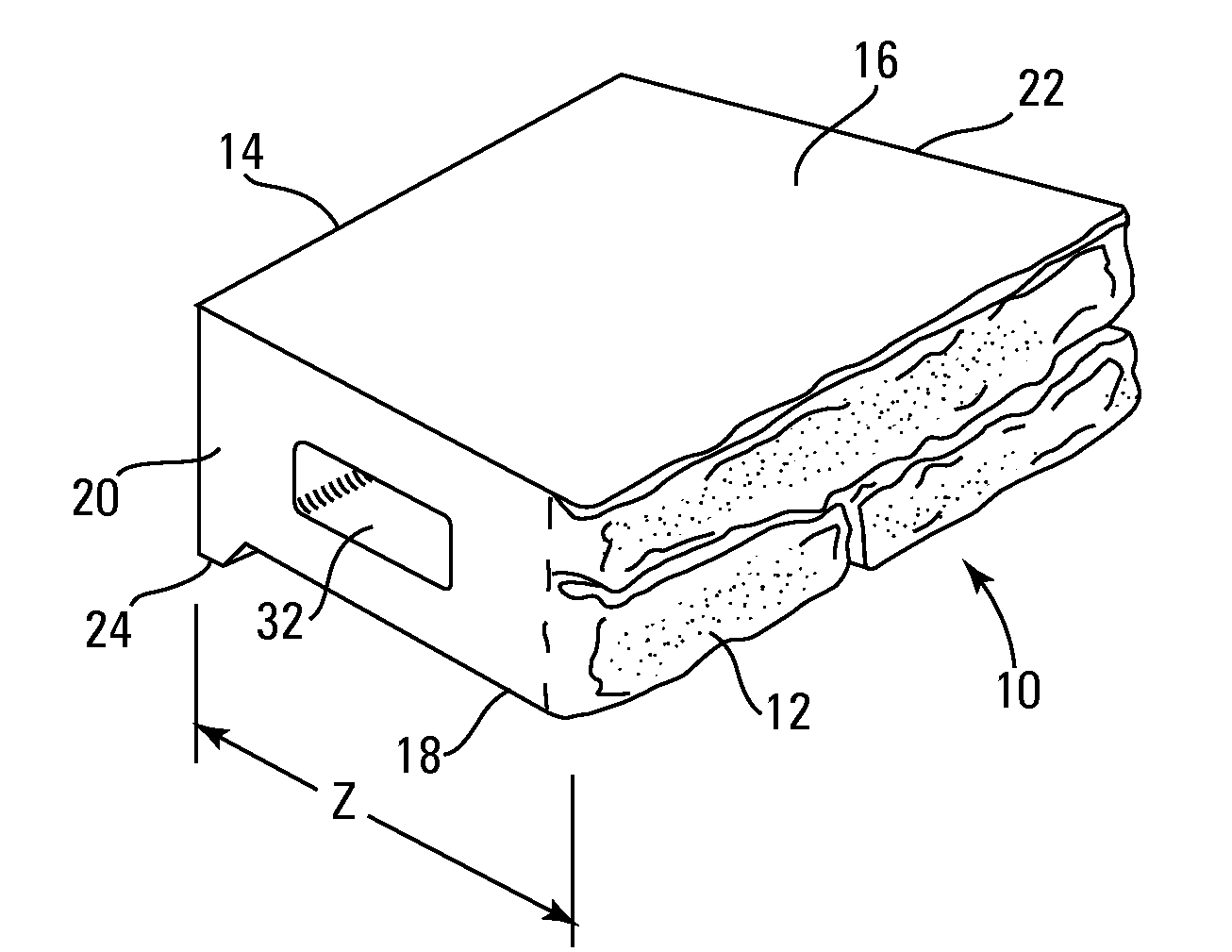

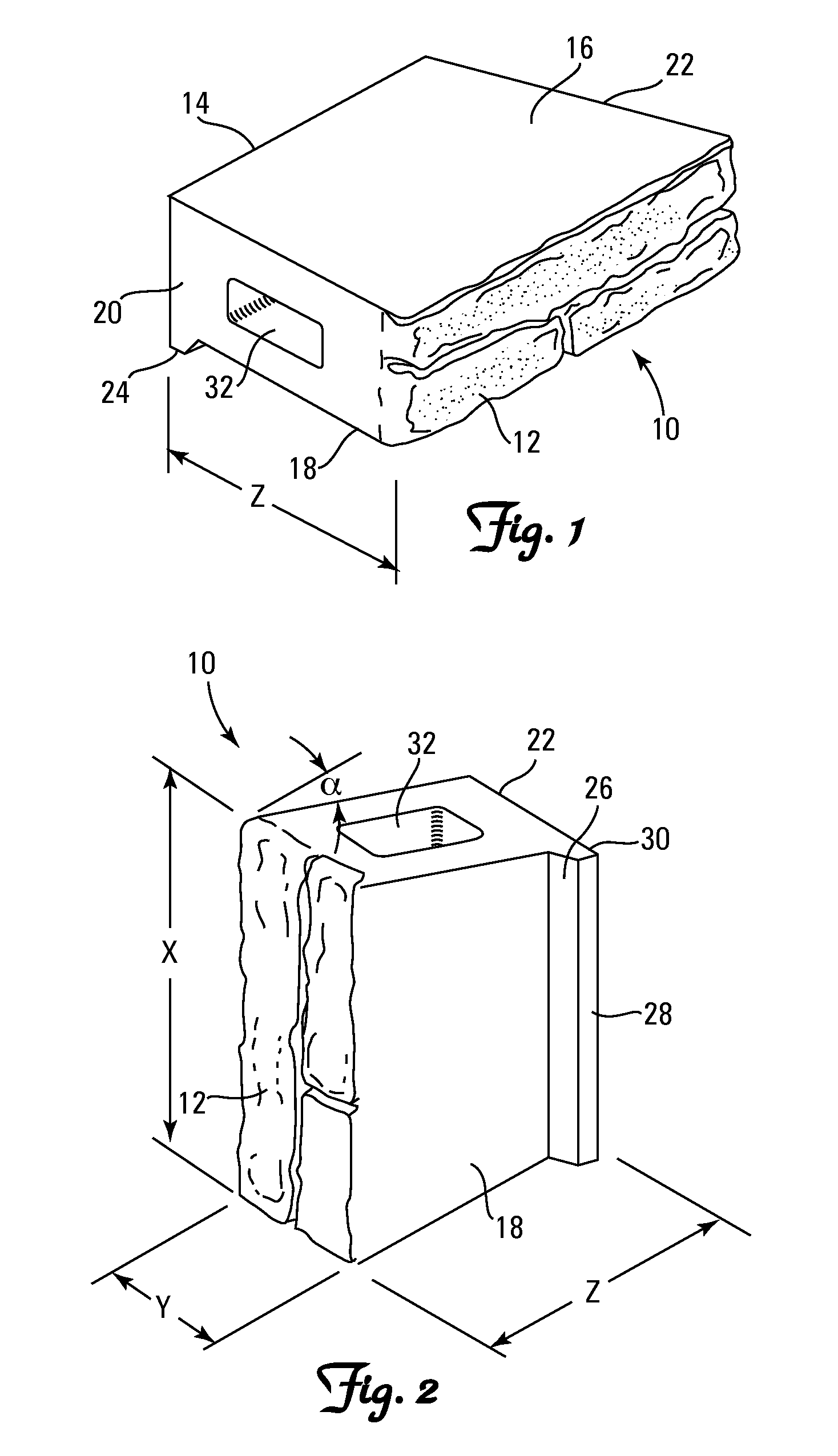

Wall block with weight bearing pads and method of producing wall blocks

A wall block having at least one weight bearing pad on an upper or lower surface of the block and a compression head and methods of making the block and making walls with the block.

Owner:KEYSTONE RETAINING WALL SYST

Microfluidic array devices and methods of manufacture thereof

InactiveUS20060103051A1OpenHigh degreeAdditive manufacturing apparatusDecorative surface effectsEngineeringInjection moulding

Microfluidic nozzle array devices are provided with the body of each device having at least one nozzle extending outwardly from one surface of the body. The microfluidic nozzle array devices are fabricated using an injection molding process and find particular utility in a wide range of applications, including but not limited to nanospray / electrospray applications, mass spectrometer applications, optical spectrometry applications, spotting applications (i.e., DNA or protein array), etc. Manufactured nozzles can include sealed nozzle apexes which are subsequently opened by focusing energy from an energy source on the sealed apex resulting in the opening of the nozzle channel.

Owner:PHOENIX S&T

Paving block and molding process therefor

InactiveUS20070216058A1Produce multipleHigh strengthConfectionerySweetmeatsEngineeringUltimate tensile strength

A paving block that closely resembles a used mined cobblestone. The blocks are manufactured by a bi-layer concept that is subjected to processes that cause the layers to structurally integrate. The process and composition permit the mass production of blocks having independent top topographies that emulate the surfaces of original cobblestones and with a comparable strength.

Owner:ECOLOGICA CARMELO

Method and apparatus for manufacturing painted or varnished parts out of molded plastics material

InactiveUS6558599B1Solve the real problemMouldsDomestic articlesShell moldingThermoplastic materials

A method of making a painted part out of molded thermoplastic material, the method including making the part to be painted by a method of molding thermoplastic material in the cavity of a mold; allowing the part made in this way to cool at least on the surface, cooling being accompanied by shrinkage, and being performed by opening the mold that was used to make the part that is to be painted; and injecting paint around the part in a cavity of a mold having the same shape as the mold cavity that was used for molding the thermoplastic material.

Owner:LOREAL SA

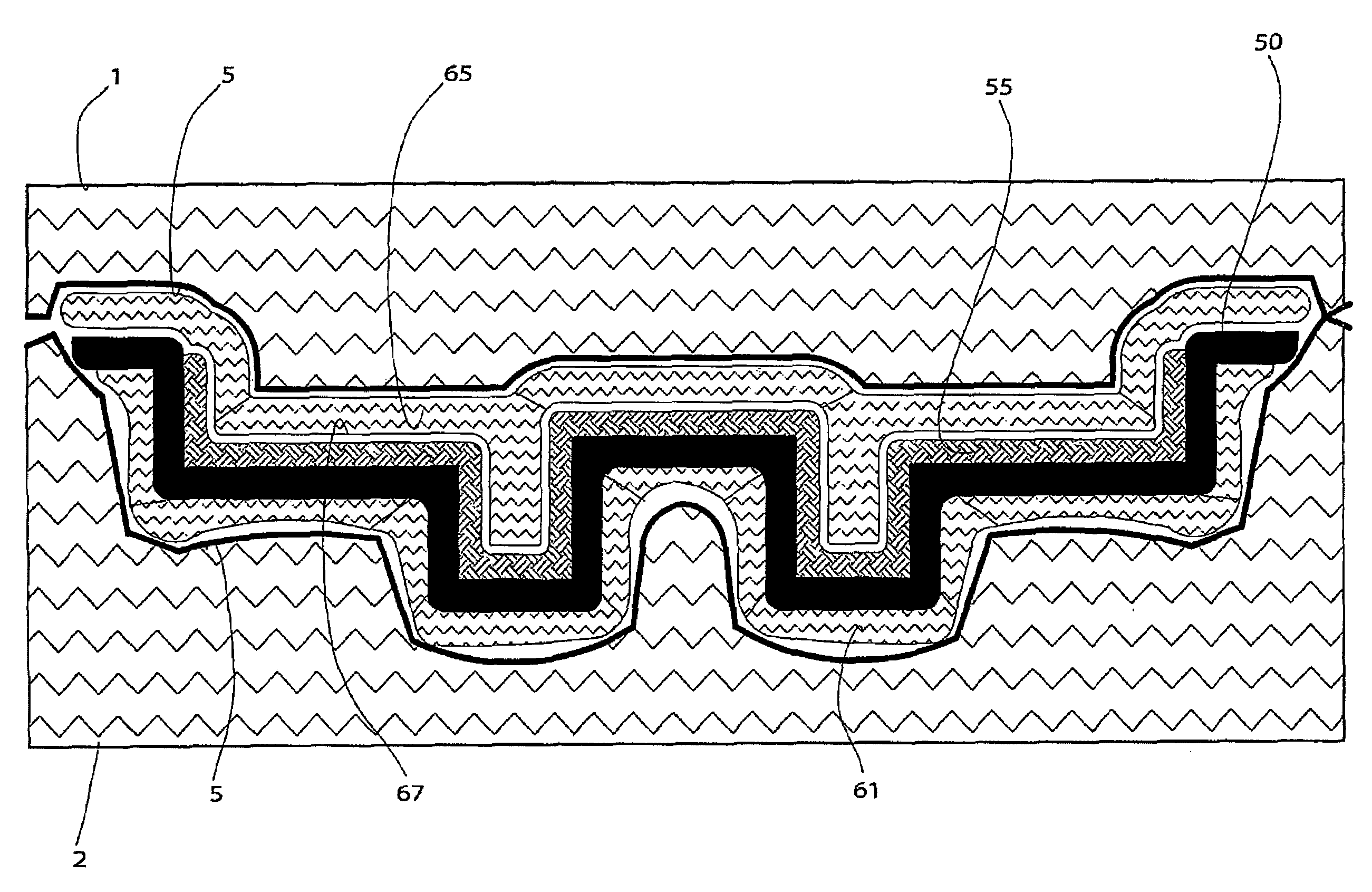

Composite and metal component production, forming and bonding system

A system for producing composite or bonded metal components including: first and second pressure chambers, each pressure chamber having an elastically deformable chamber wall; means for circulating fluid at an elevated temperature and pressure through each said pressure chamber; and at least one mould assembly including at least one separate mould section providing a mould cavity within which a composite or bonded metal lay-up can be located; wherein when the system is in use, the pressure chambers are held together with the elastically deformable chamber walls located in opposing relation, the at least one mould assembly containing a said lay-up being accomodated between the chamber walls while fluid at elevated temperature and pressure is circulated through each pressure chamber such that the lay-up can be compressed and cured or formed.

Owner:QUICKSTEP TECH

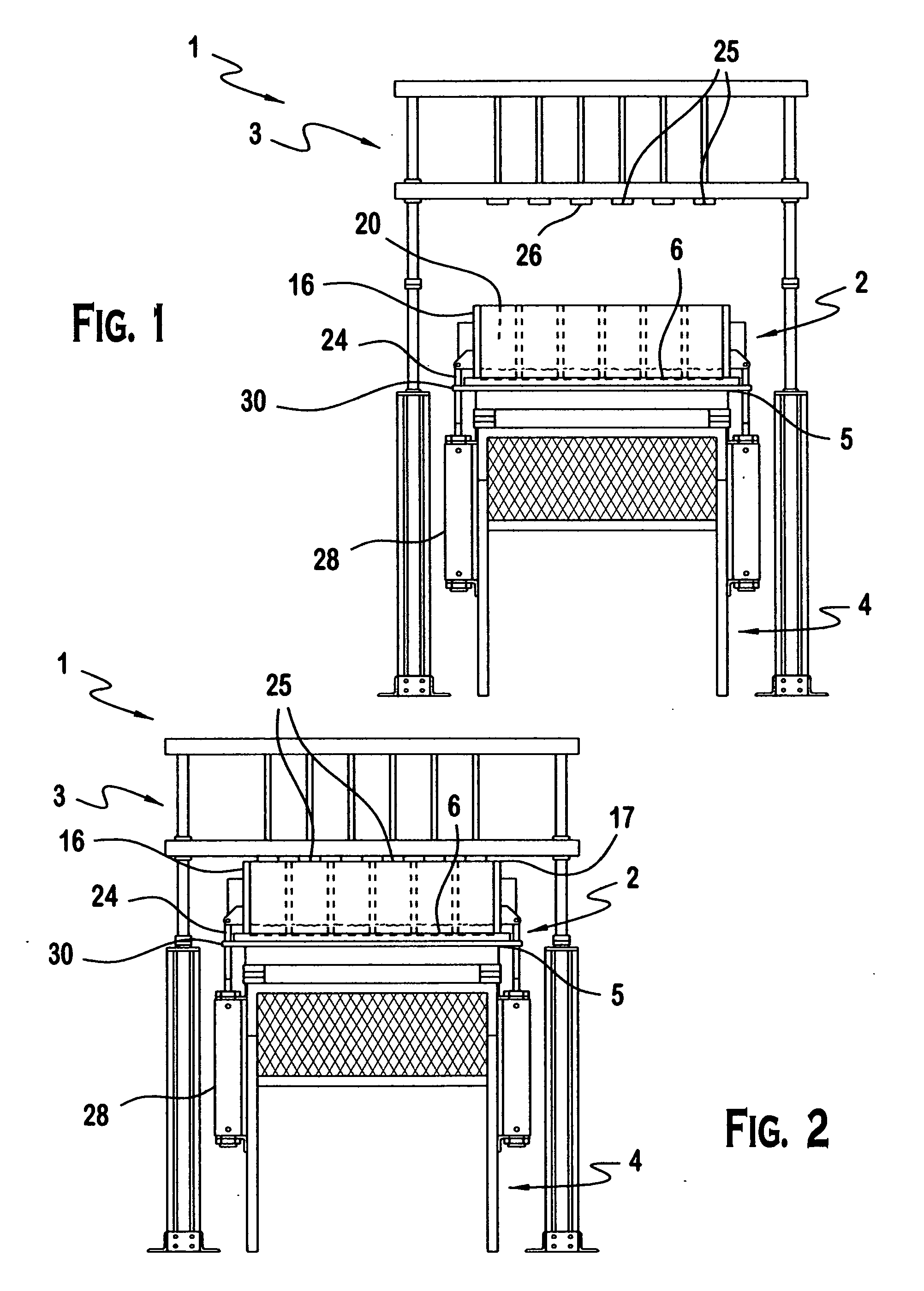

Concrete block making machine and method

A method for manufacturing decorative concrete blocks for decorative garden walls is presented, along with a machine suitable for practicing the method.

Owner:FIREDMAN DOUGLAS KELLER +1

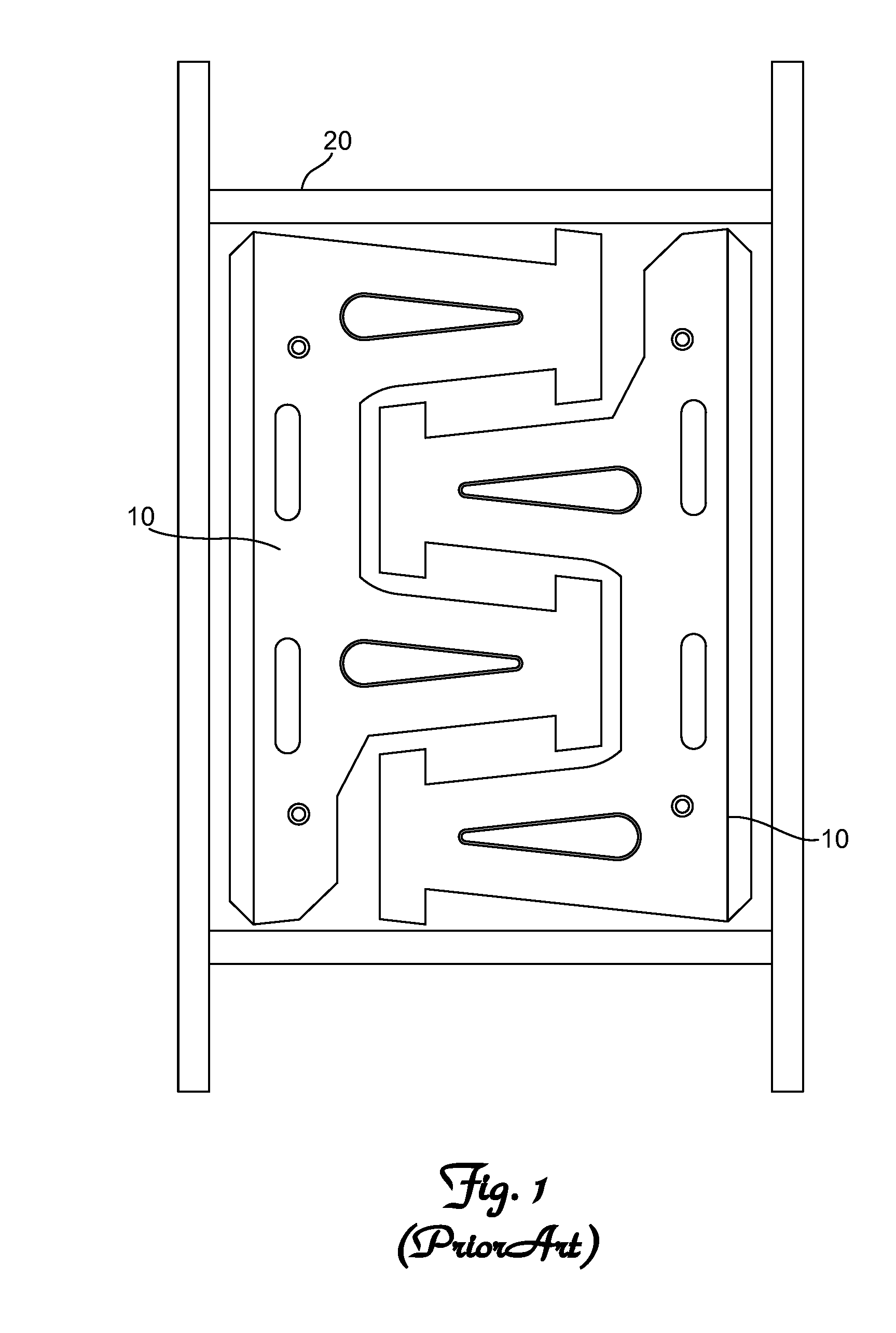

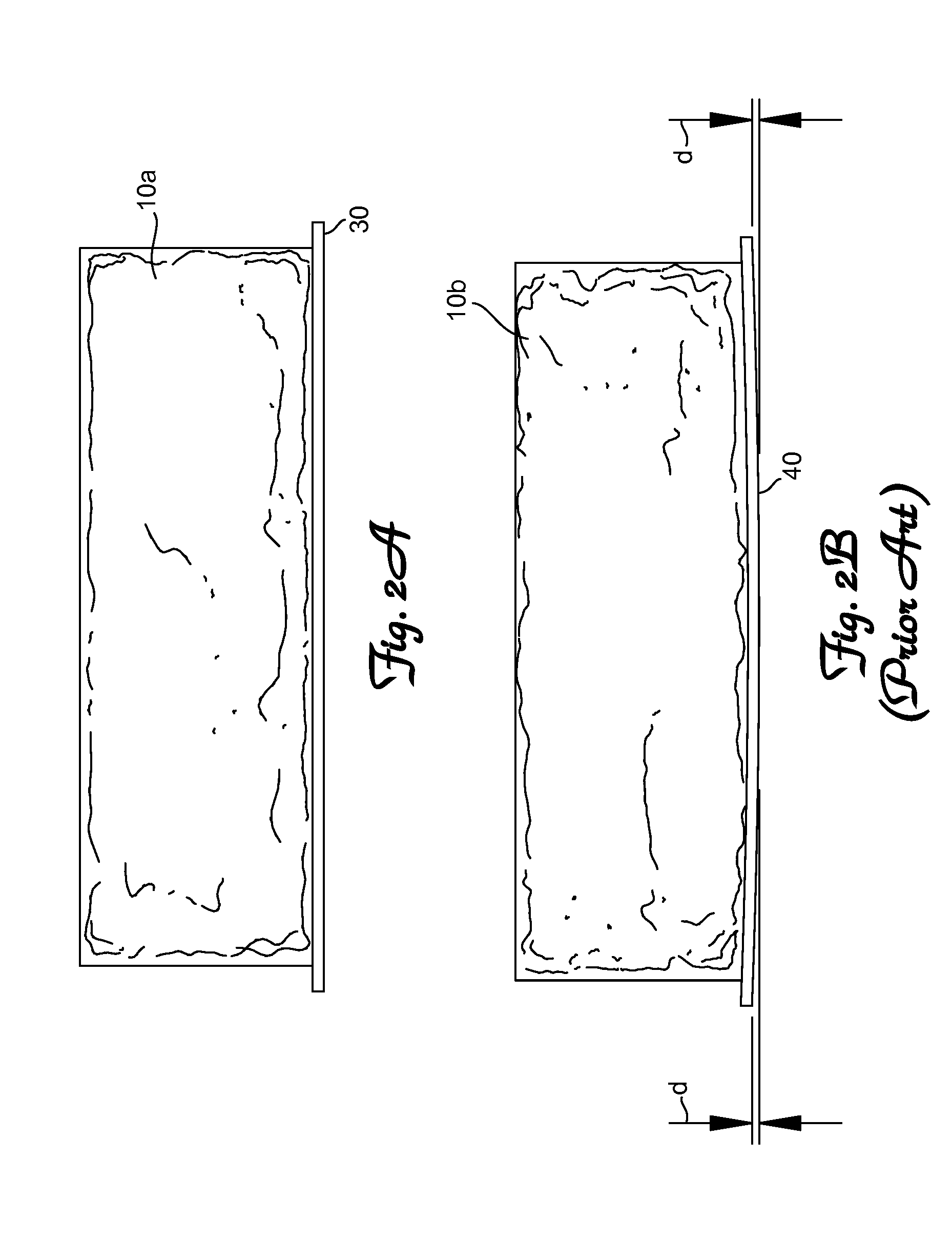

Retaining wall block

A retaining wall block having a rear flange and a mold box and method of making the block. The mold box is configured with a mold cavity that includes a vertical flange forming cavity extending from the top of the mold box to the bottom of the mold box.

Owner:KEYSTONE RETAINING WALL SYST

Method for fabricating curved thermoplastic composite parts

ActiveUS8333858B2Mechanical working/deformationWood working apparatusVarying thicknessThermoplastic composites

A fabrication method of forming curved thermoplastic composite laminate parts with tailored and varying thickness in a continuous process. Automated equipment or hand lay-up are used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

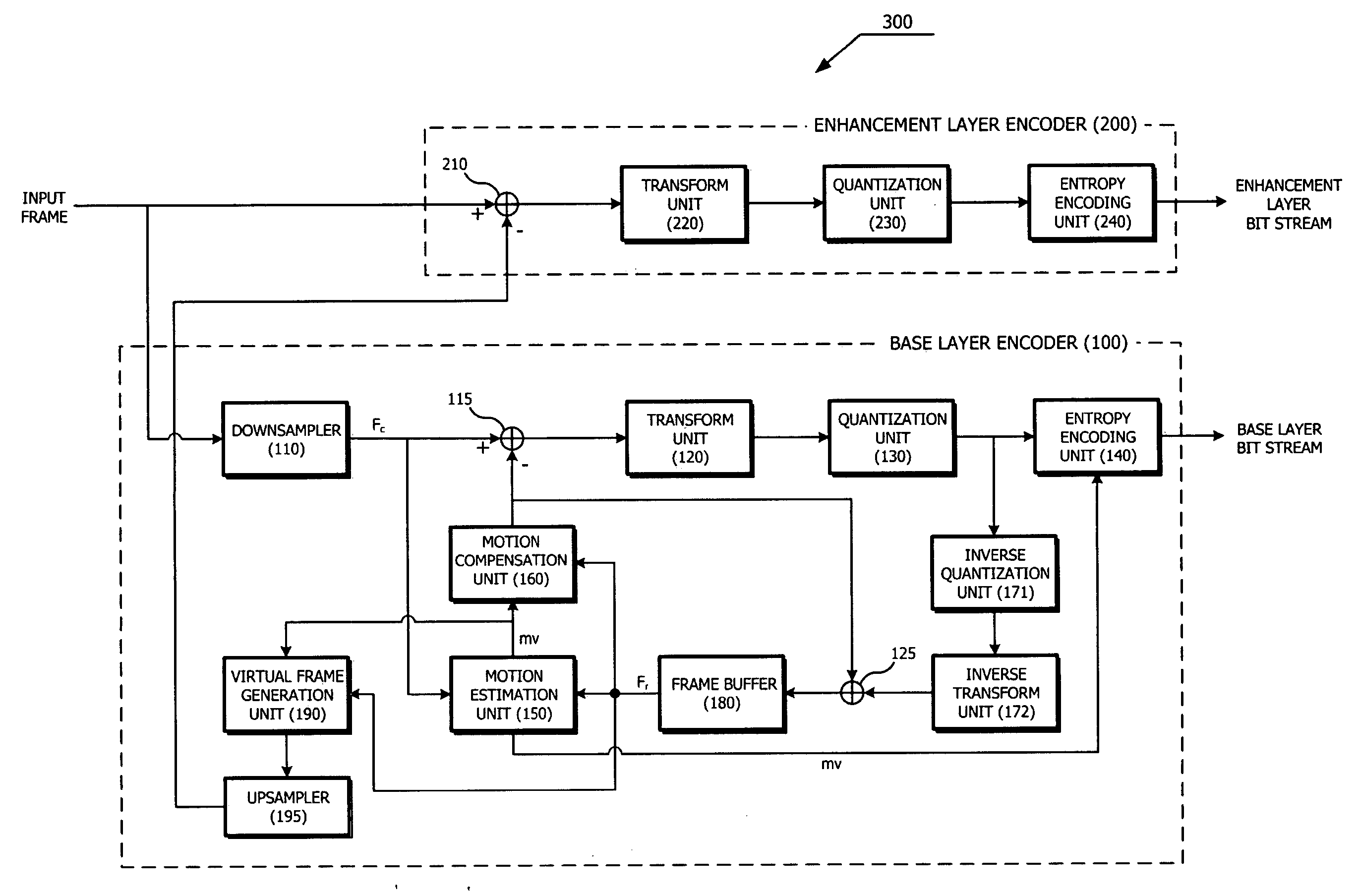

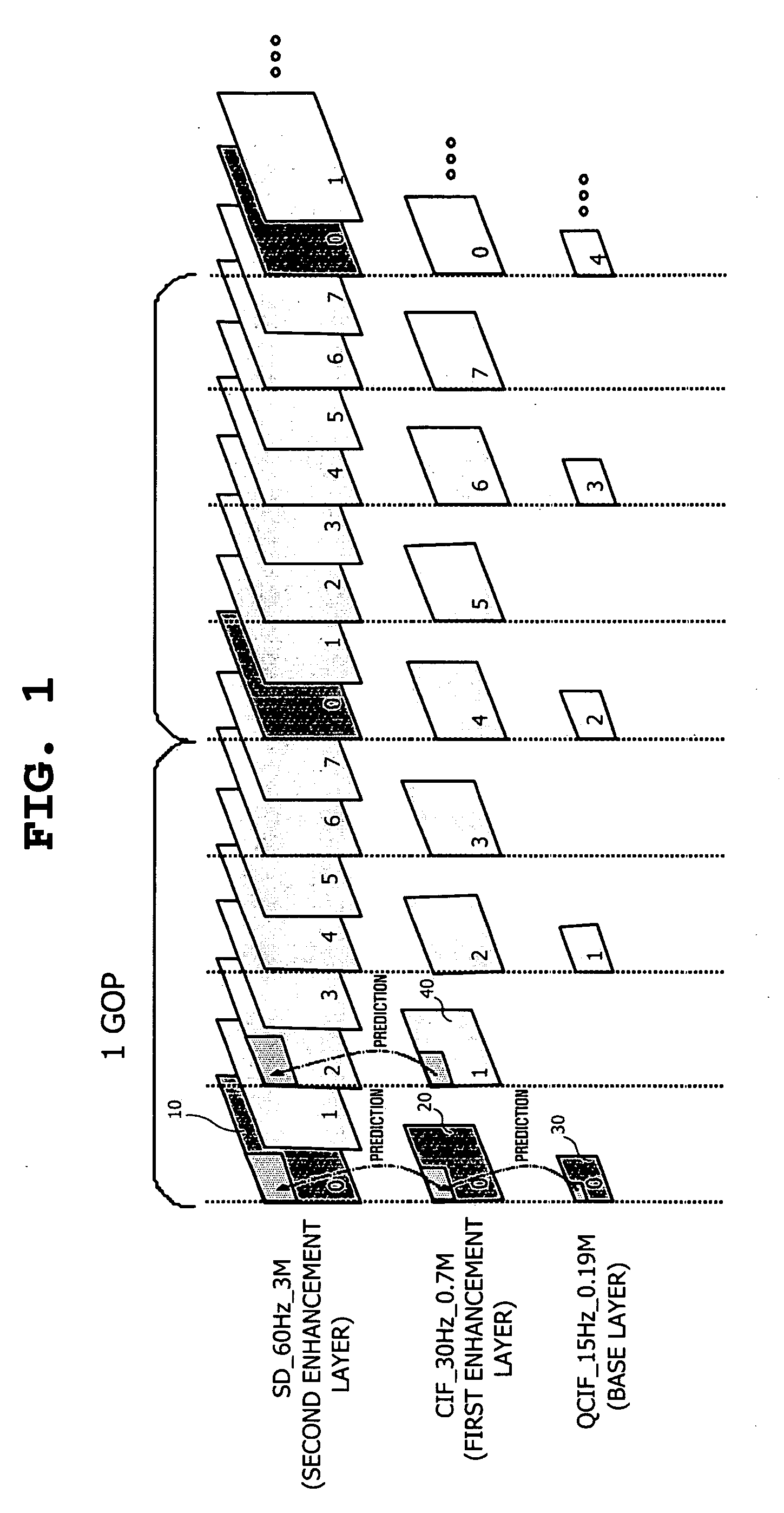

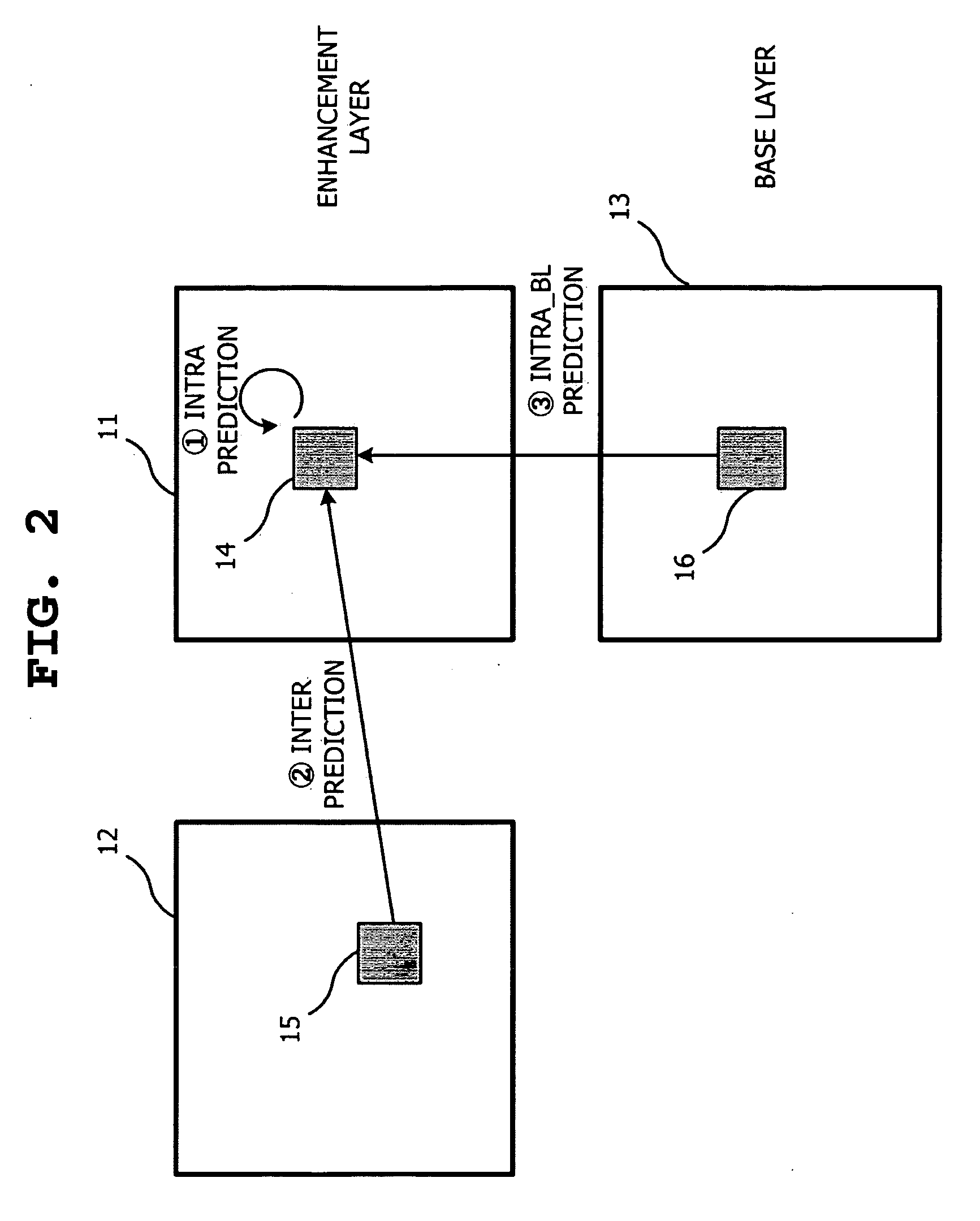

Video coding method and apparatus for efficiently predicting unsynchronized frame

InactiveUS20060165303A1Improve performanceMouldsCharacter and pattern recognitionMotion vectorVideo encoding

A multi-layered video encoding method is provided wherein motion estimation is performed by using one of two frames of a lower layer temporally closest to an unsynchronized frame of a current layer as a reference frame. A virtual base layer frame at the same temporal location as that of the unsynchronized frame is generated using a motion vector obtained as a result of the motion estimation and the reference frame. The generated virtual base layer frame is subtracted from the unsynchronized frame to generate a difference, and the difference is encoded.

Owner:SAMSUNG ELECTRONICS CO LTD

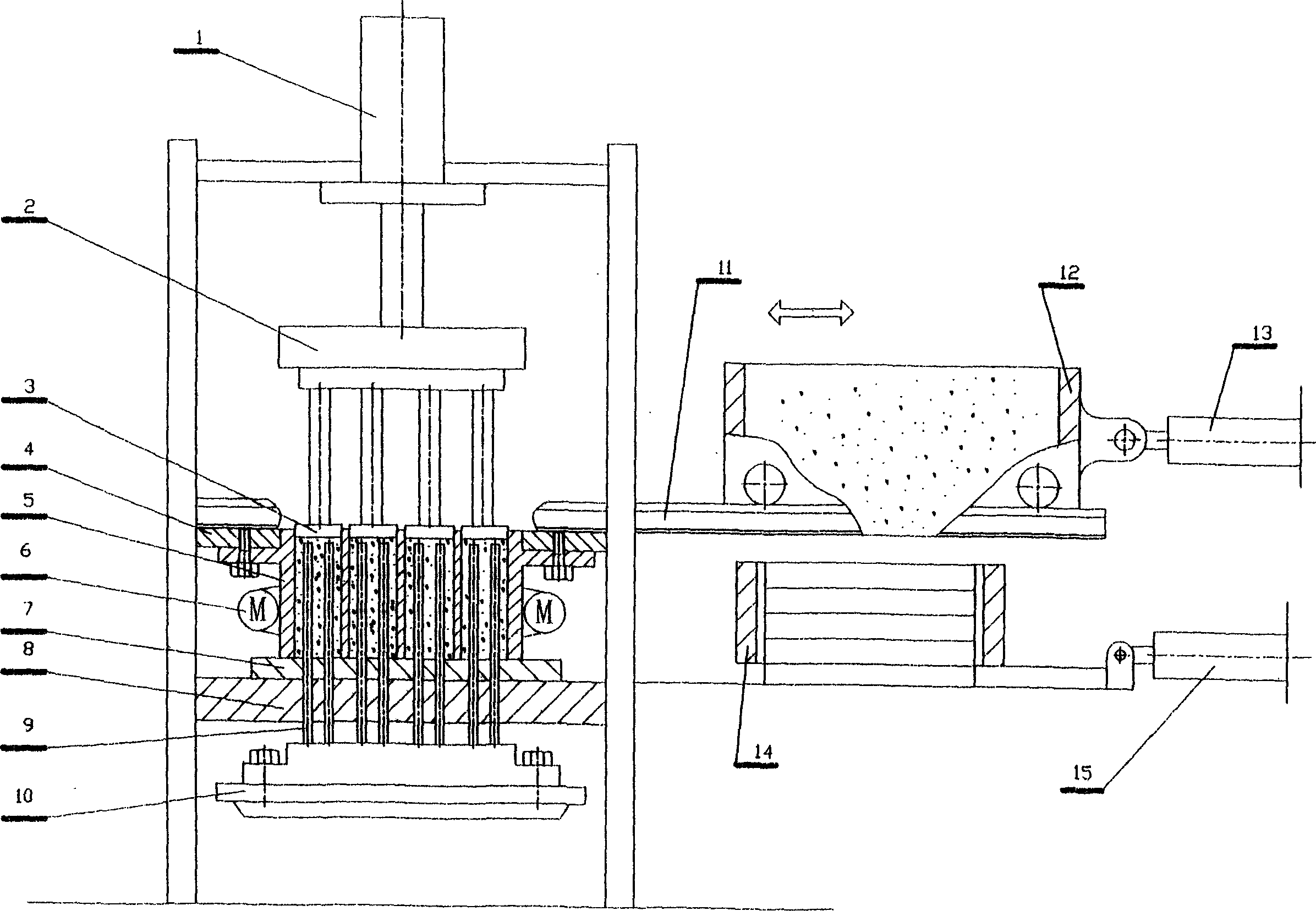

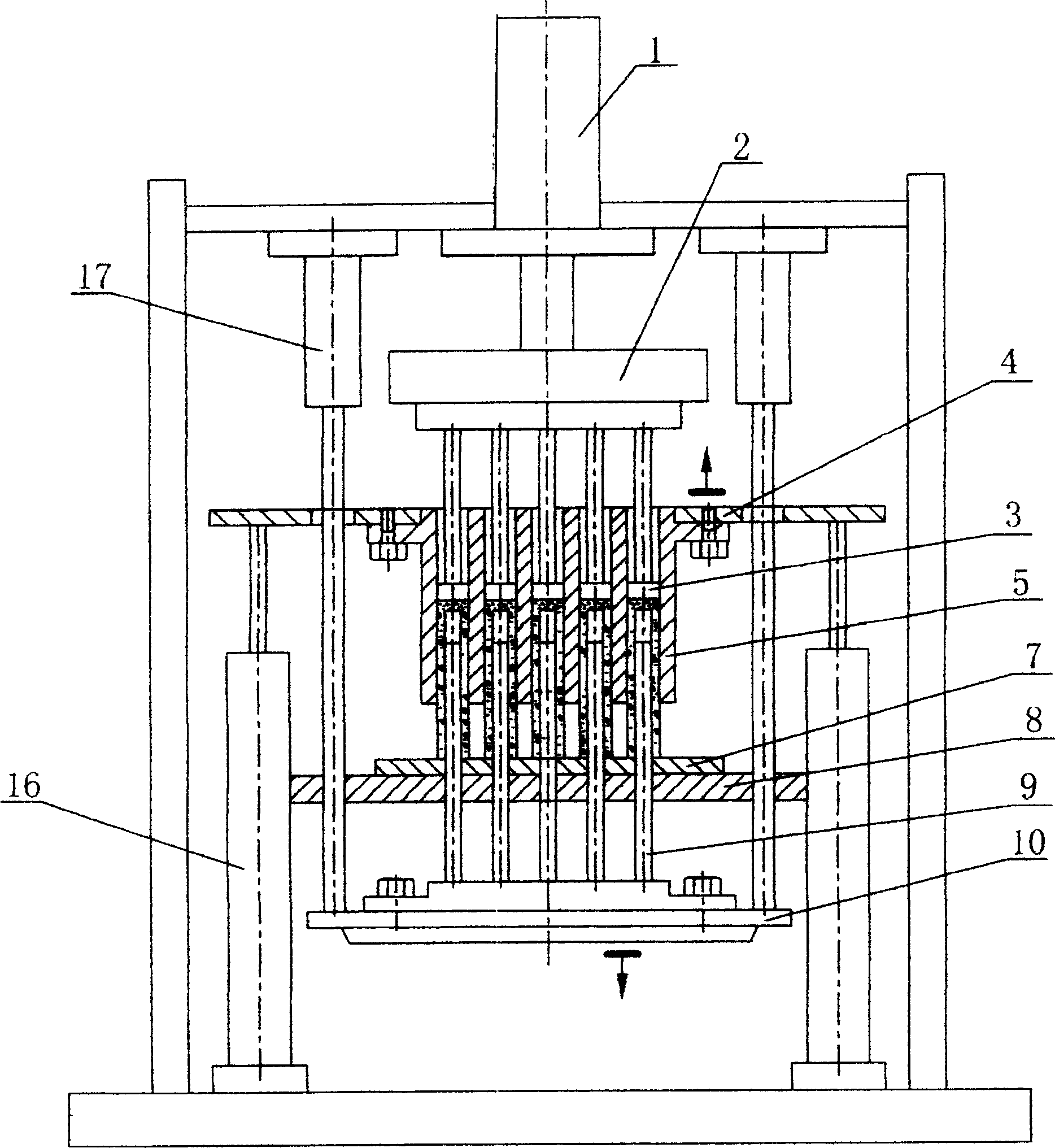

Automatic shaping method and equipment for load-bearing hollow brick

InactiveCN1657251ALiberate labor intensitySpeed up the flowDischarging arrangementMouldsBrickEngineering

A method for automatically shaping the load-bearing hollow brick includes such steps as preparing concrete, stirring, filling in mould, inserting core mould while vibrating, hydraulic pressing, and demoulding. Its apparatus is composed of electric power control box, control mechanism, motor, concrete preparing system, shaping system, feeding unit, and discharging unit.

Owner:广西金瓯建材机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com