Patents

Literature

92 results about "Decorative concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decorative concrete is the use of concrete as not simply a utilitarian medium for construction but as an aesthetic enhancement to a structure, while still serving its function as an integral part of the building itself such as floors, walls, driveways, and patios.

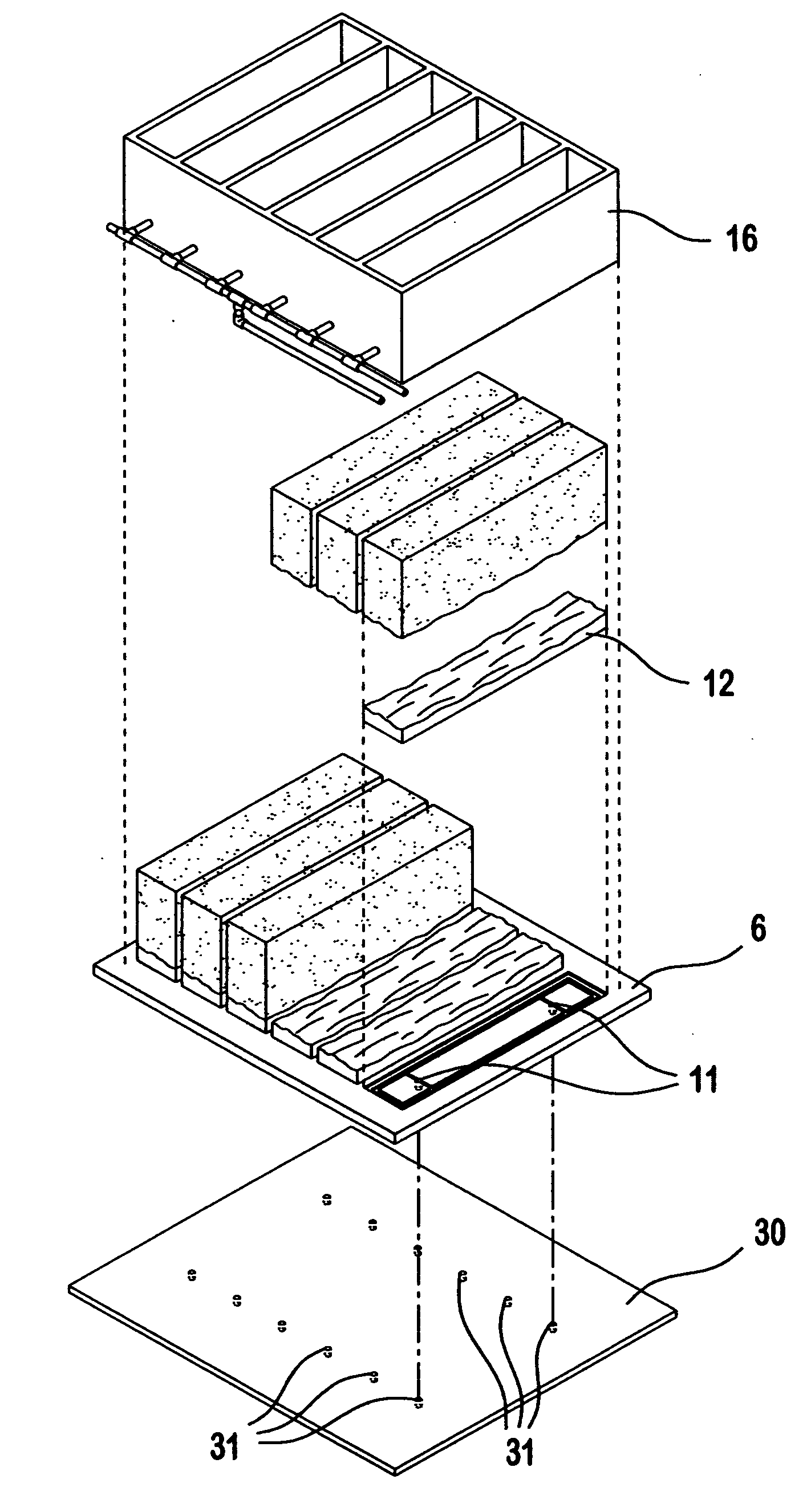

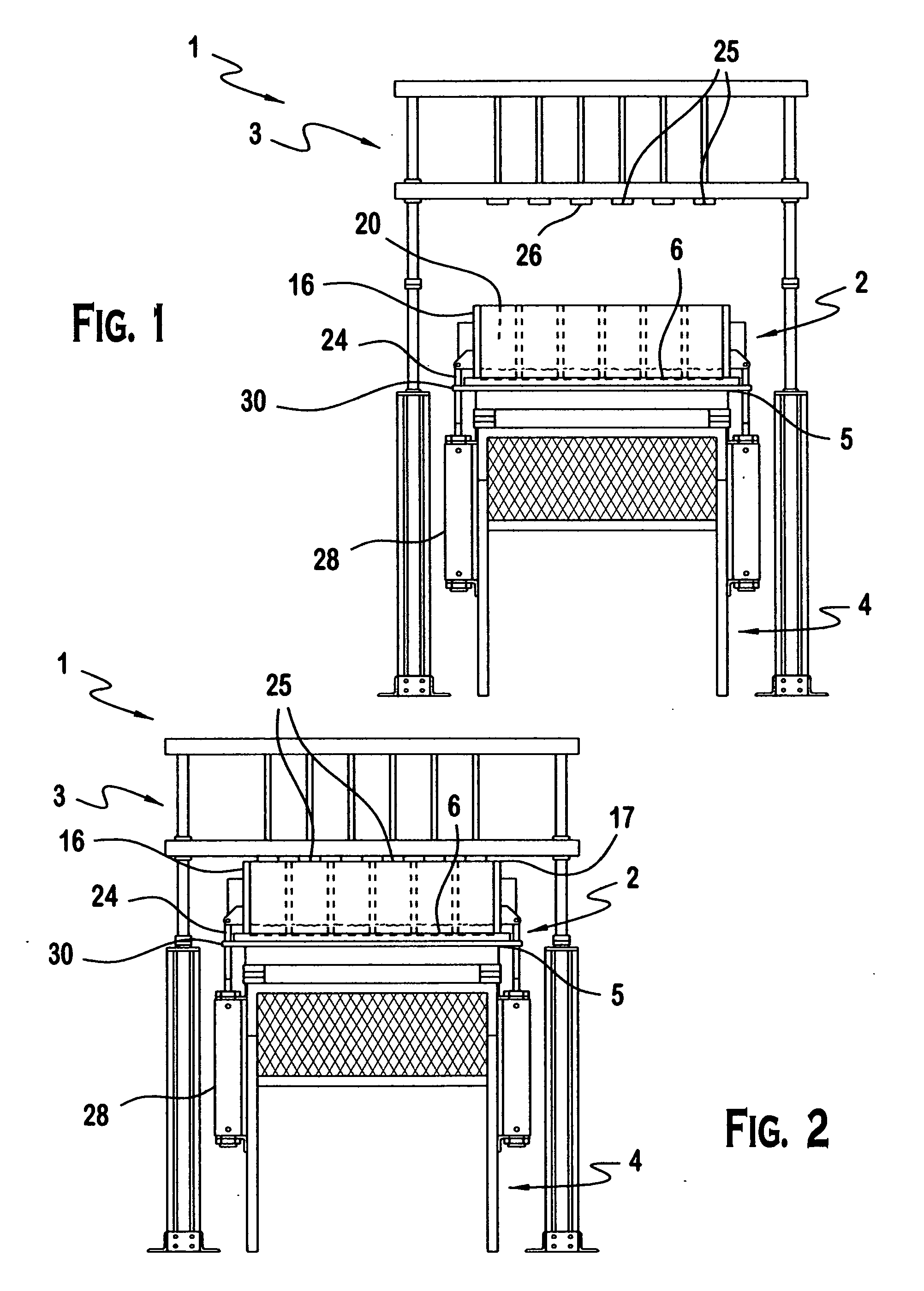

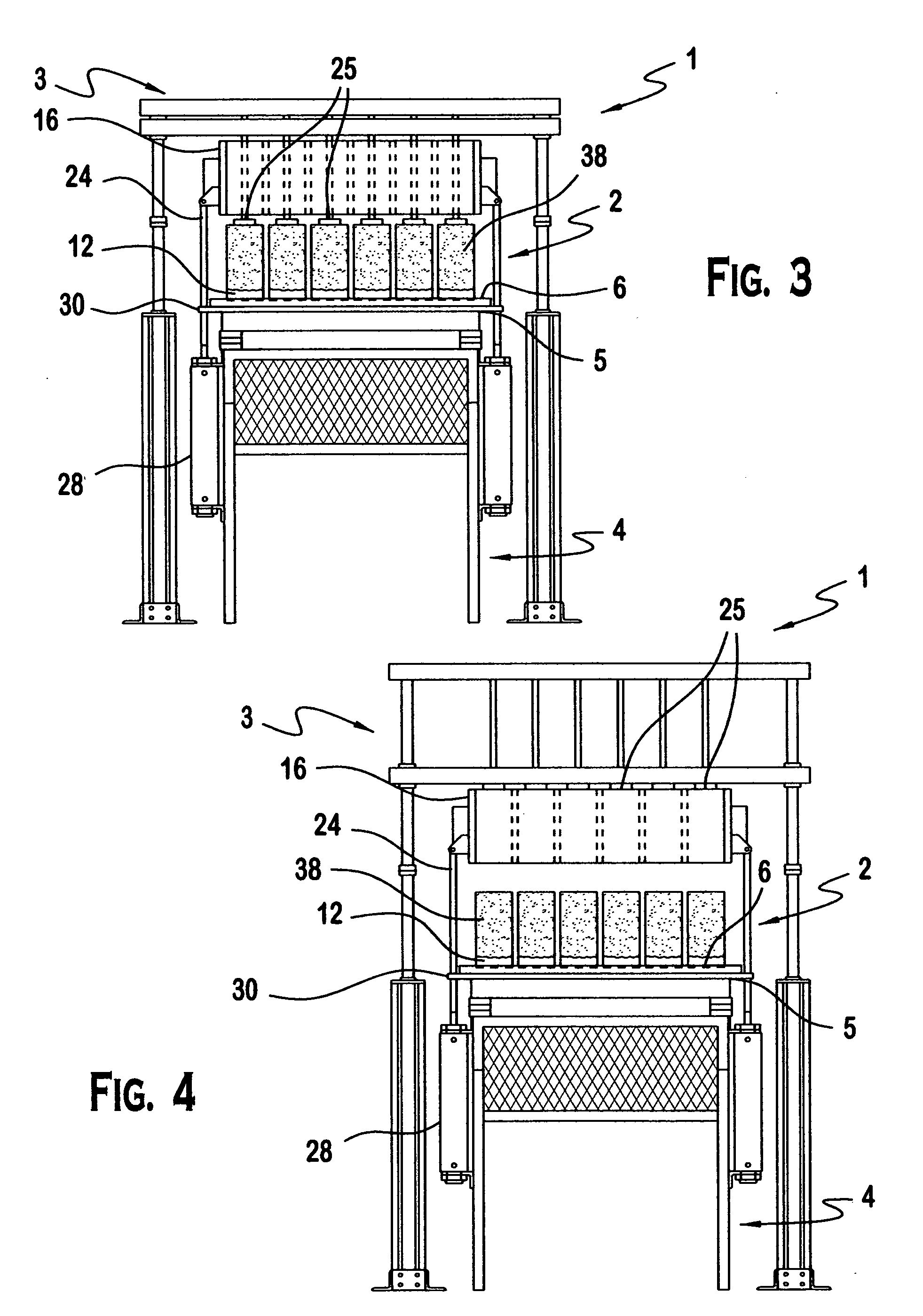

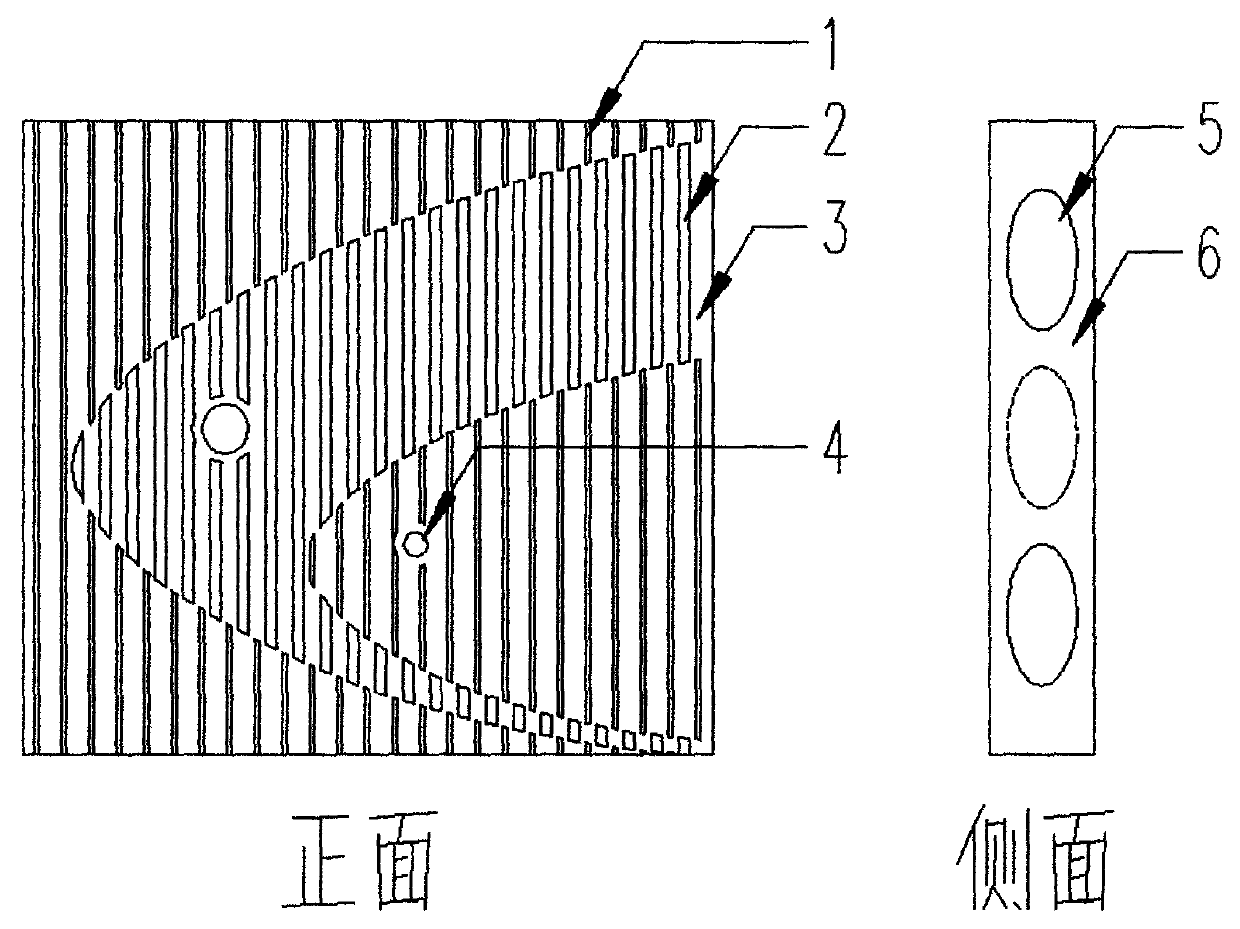

Concrete block making machine and method

A method for manufacturing decorative concrete blocks for decorative garden walls is presented, along with a machine suitable for practicing the method.

Owner:FIREDMAN DOUGLAS KELLER +1

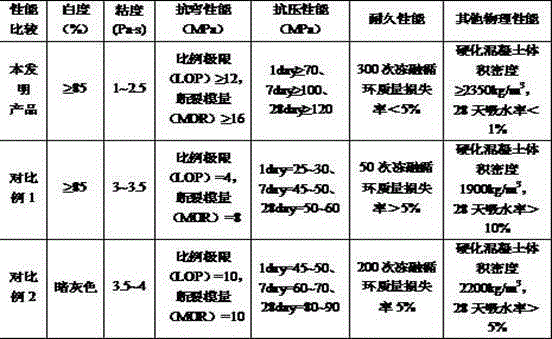

Ultra-high-performance decorative concrete and preparation method thereof

InactiveCN108264289AWide variety of sourcesConducive to ecological green sustainable developmentFiberSuperplasticizer

The invention discloses ultra-high-performance decorative concrete and a preparation method thereof. The concrete consists of cement, industrial waste residues, fine aggregates, pigment, a defoamer, ahigh-efficiency water reducing agent, water and fibers. The prepared ultra-high-performance decorative concrete uses an active mineral additive and thus has good grain composition, the mechanical property of the ultra-high-performance decorative concrete is good, the appearance color can also be adjusted randomly, and the decorative concrete has certain decorative and artistic effect while beingused as a load-bearing structure; the prepared ultra-high-performance decorative concrete has excellent mechanical property, durability, decorative property, artistry and construction property; and plasticity of the concrete and constitutional features of the material are fully utilized, appropriate measures are taken during forming of walls and components, and therefore, the surfaces of the wallsand the components have decorative lines, patterns, textures, qualities and colors.

Owner:NANJING UNIV OF SCI & TECH

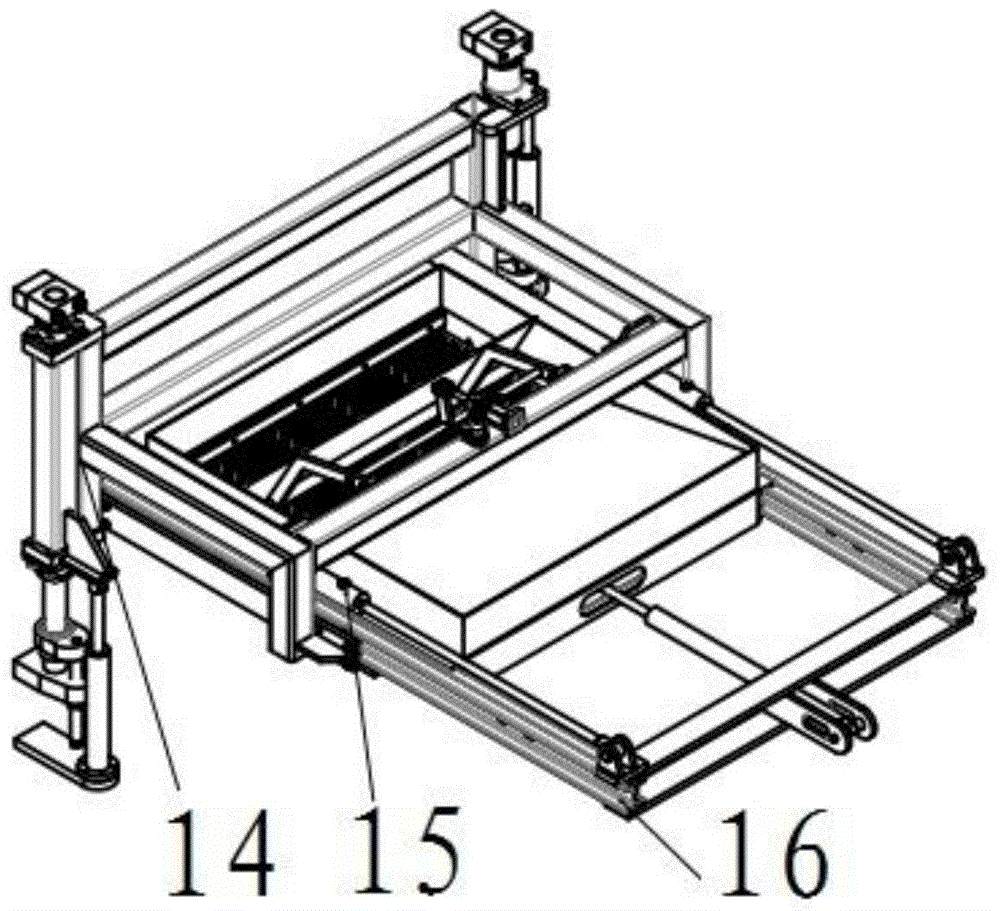

Decorative concrete light-transmitting plate and manufacturing method thereof

The invention discloses a decorative concrete light-transmitting plate and a manufacturing method thereof. The method comprises the following steps: step A, designing and arranging an effect modeling pattern of the concrete light-transmitting plate according to the use range and the style and selecting light transmission bodies and concrete polymer materials; step B, selecting the required light transmission body according to the designed modeling pattern and accurately positioning the light transmission body; selecting a modeling pattern designing, processing and positioning way of the light transmission body as required and accurately processing a wedge plate or a mold for positioning by using a numerical control carving machine; step C, preparing corresponding concrete polymer gel materials according to different decorative effects, pouring the uniformly-stirred concrete polymer gel materials in the mold for fixing the light transmission body to mold and finally performing demolding and post-processing. The decorative concrete light-transmitting plate not only has the physical properties of texture, grains, high strength and the like of decorative concrete, but also has the decorative effects of transparency, decorative light transmission and day-lighting of a natural stone composite light-transmitting plate, a light-transmitting stone light-transmitting plate and the like; the two kinds of effects are combined together.

Owner:GUANGZHOU SHEUNGYU CIVIL ENG & ARCHITECTURE

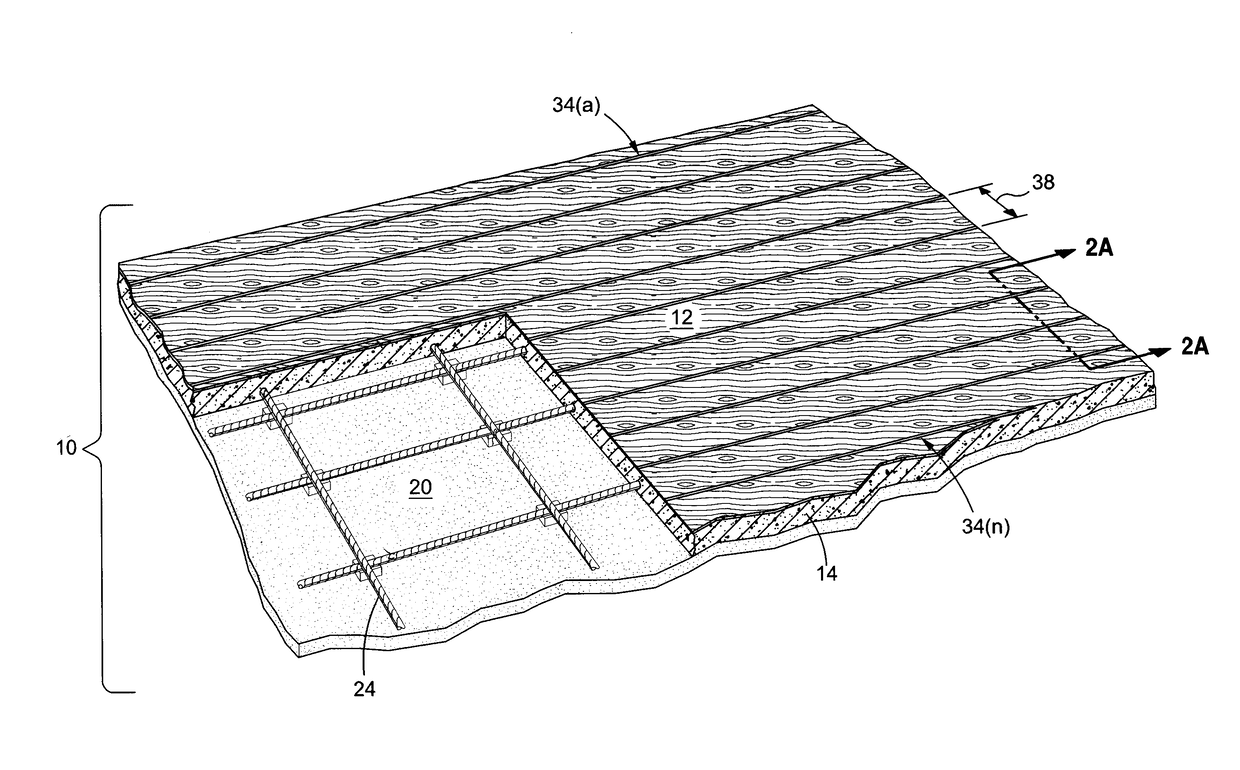

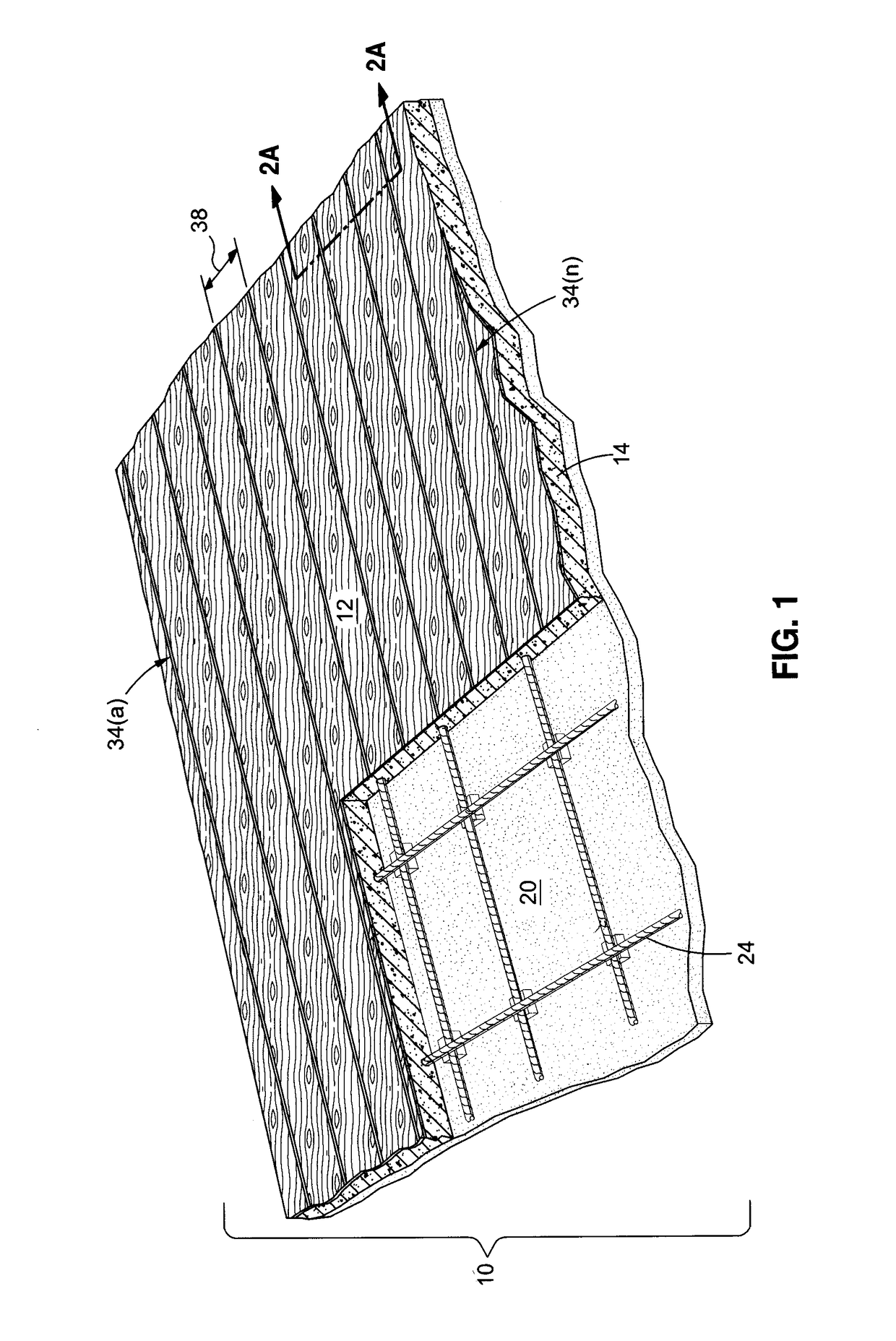

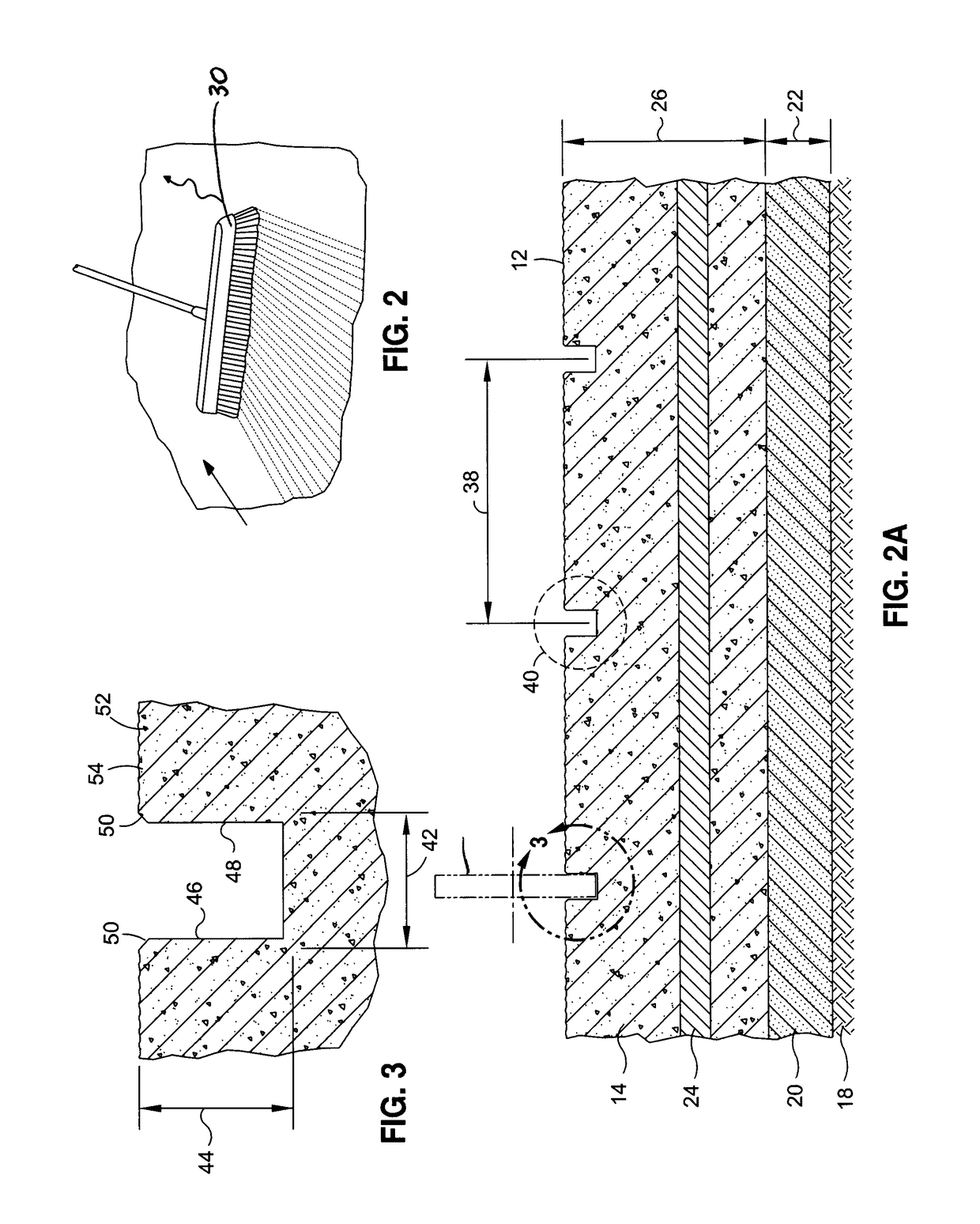

Decorative concrete and method of installing the same

A decorative concrete product and method of making the same is provided. The concrete surface carries a unique textural and visual decorative pattern that is troweled over the uncured surface. The decorative pattern strategically conceals any imperfections in the concrete surface. A decorative finishing tool is utilized to create a unique and consistent pattern throughout the exposed surface of the concrete. Unique visual patterns may include any aesthetic design including wood grain, or lightly finished honed or cut stone. The decorative finishing tool may be configured so that varying textures and contours may consistently be imprinted throughout the concrete. Advantageously, the cured concrete retains the durability of a concrete surface while carrying a visually and texturally appealing appearance.

Owner:SHAW CRAFTSMEN CONCRETE LLC

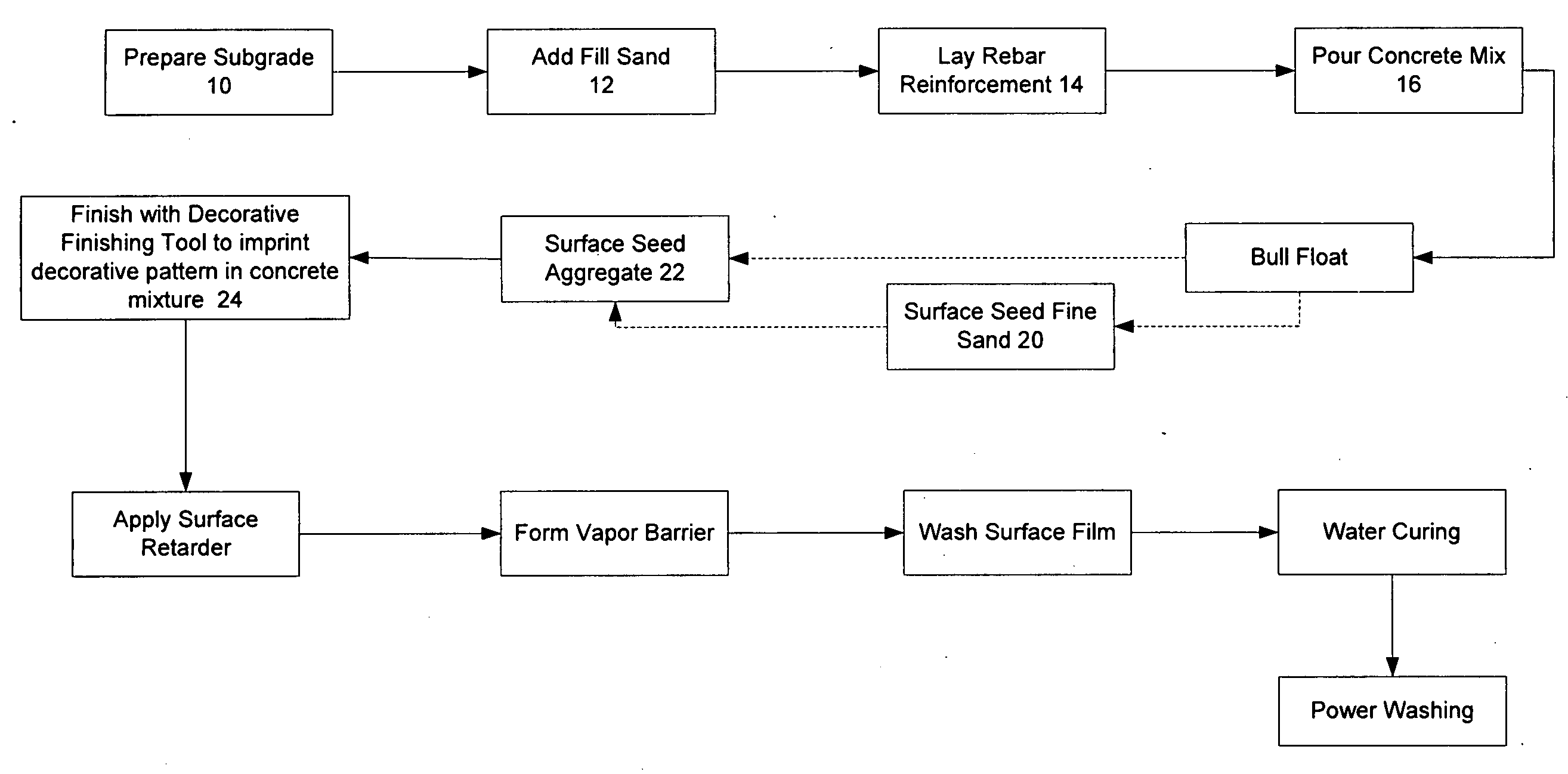

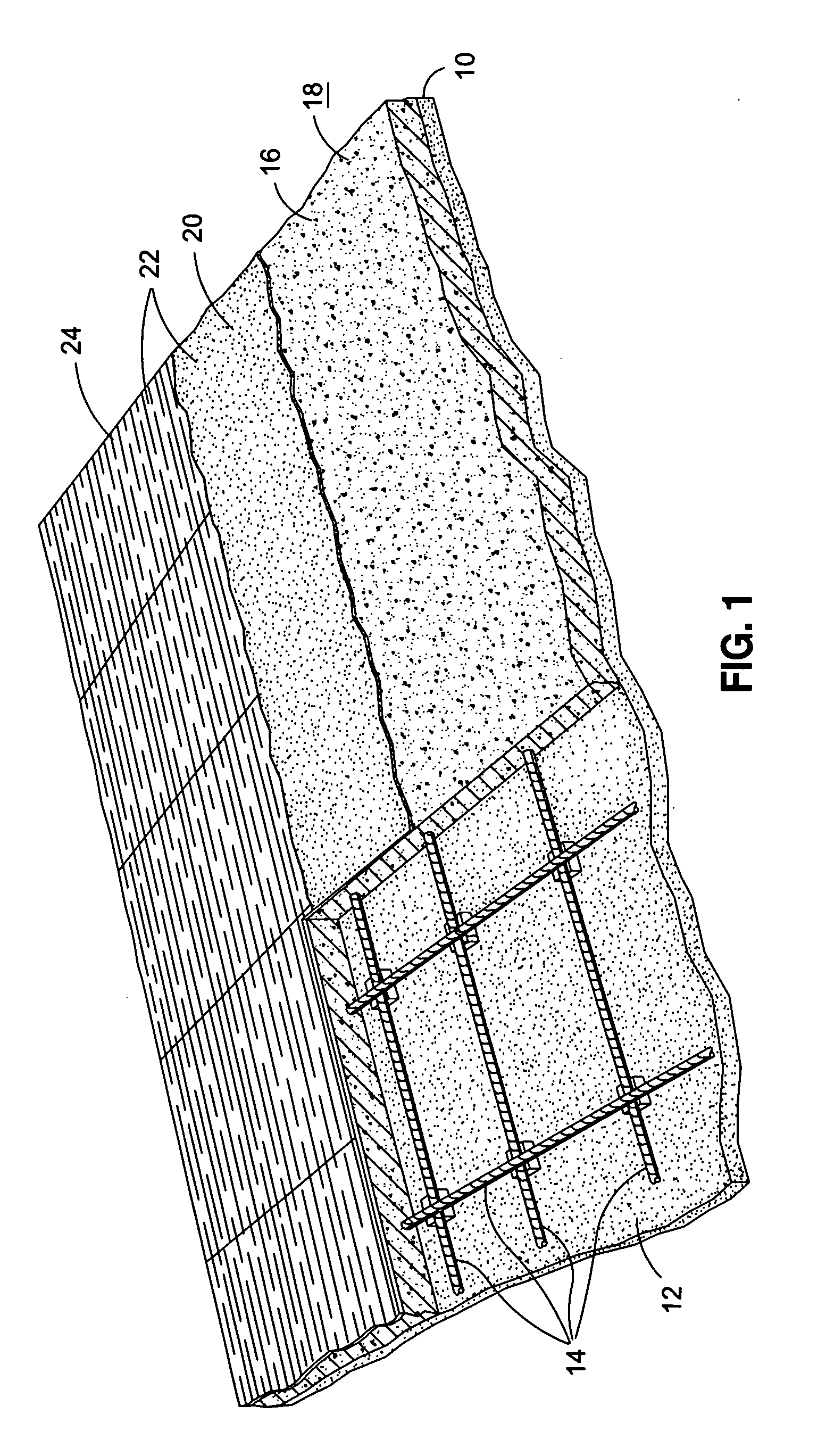

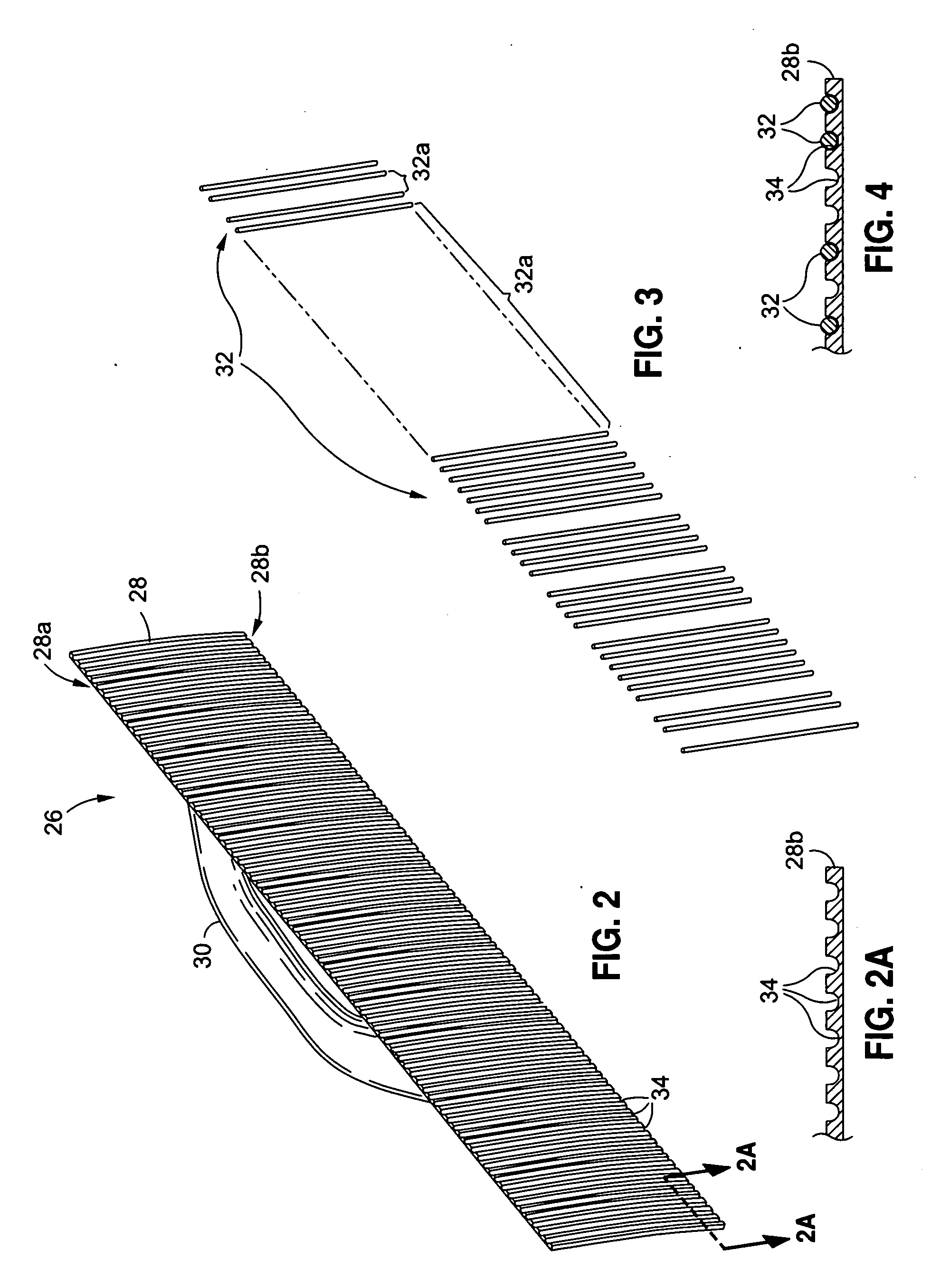

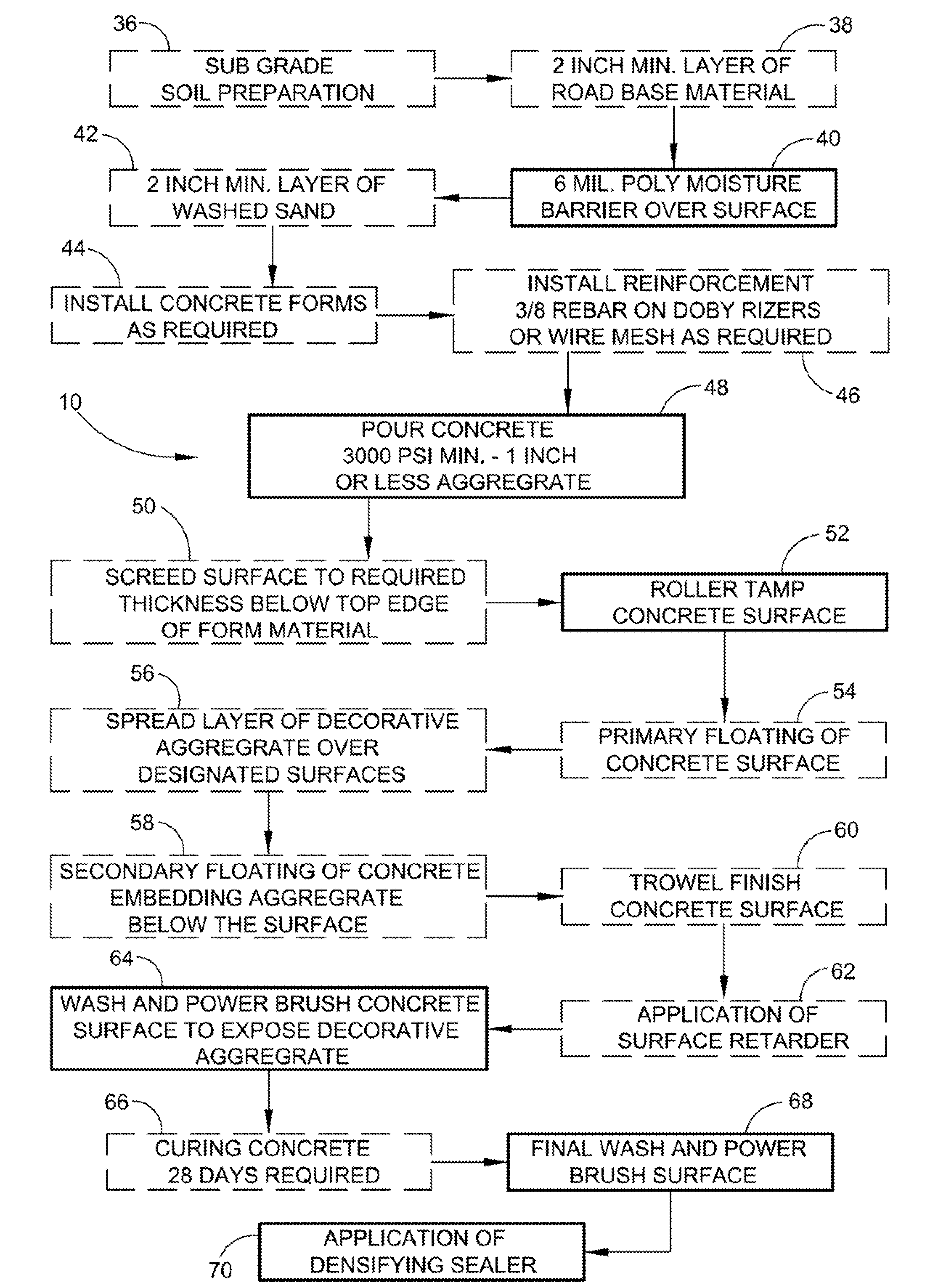

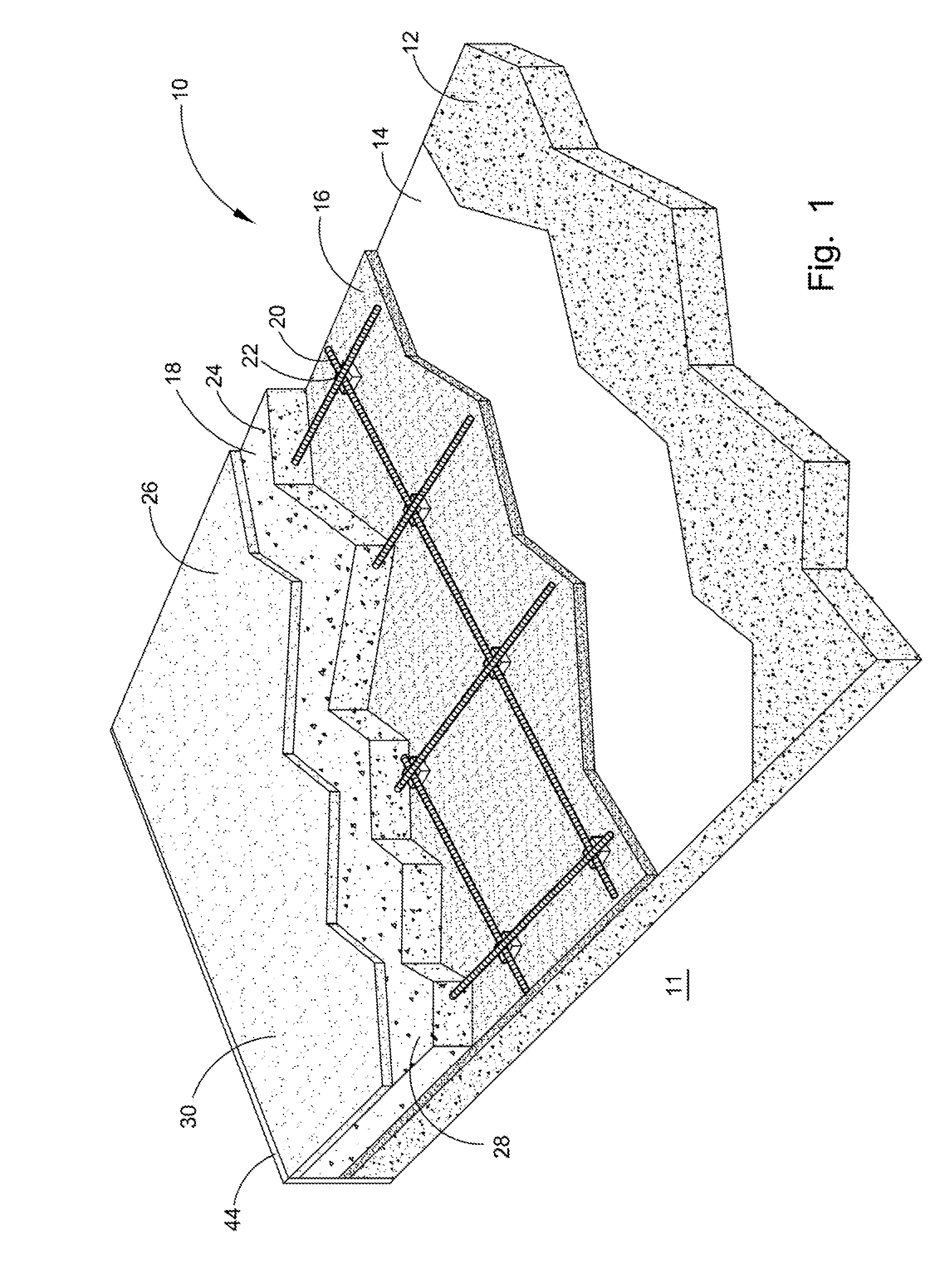

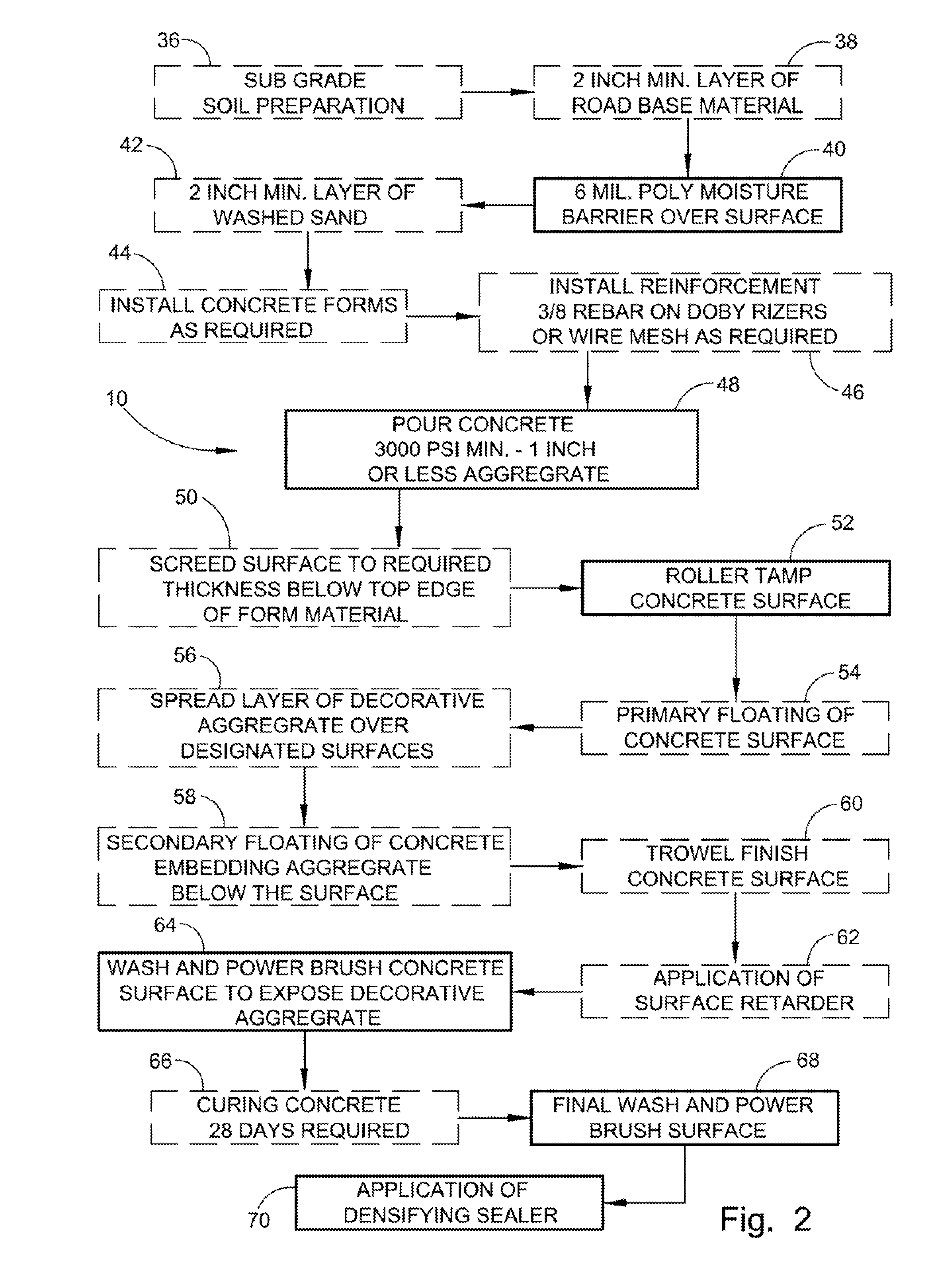

Decorative aggregate concrete surface preparation process

InactiveUS20140000214A1Increases adhesion potentialReduces the potential for shrinkageIn situ pavingsBuilding repairsWood veneerPolypropylene

The present invention is directed to a process of creating a decorative aggregate concrete surface. The preparation includes washed decorative aggregate surfaces using a variety of decorative aggregate materials imbedded within a standard concrete mix having a one inch maximum aggregate. A 6-mil polypropylene sheet Visqueen material covered with a two-inch layer of sand is used directly below the concrete to retard the curing time. Roller tamping is used to move the large aggregate below the surface of the concrete material. Power brushes are then used to expose the decorative aggregate prior to the final process of applying a densifing sealer. This process has been designed to reduce installation time, as well as overall labor and material costs.

Owner:VASQUEZ JR RICARDO +1

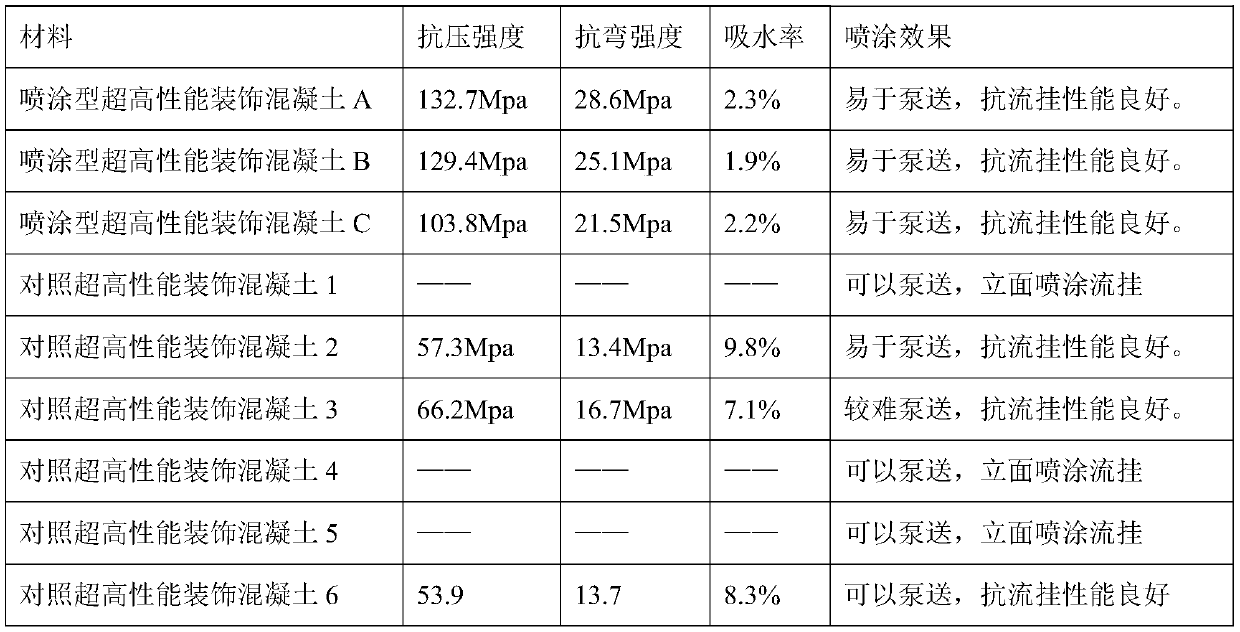

Spray-type ultrahigh-performance decorative concrete material and preparation method thereof

ActiveCN110342875AHigh compressive strengthImprove flexural strengthMechanical propertyMaterials science

The invention provides a spray-type ultrahigh-performance decorative concrete material and a preparation method thereof, and relates to the technical field of building materials. The concrete materialis prepared from the following raw materials: 800-1300 parts of cement, 100-300 parts of a mineral admixture, 400-600 parts of quartz sand of 15-20 meshes, 300-400 parts of quartz sand of 45-50 meshes, 200-400 parts of quartz powder of 400-500 meshes, 50-150 parts of an expansive agent, 6-15 parts of a water reducing agent, 5-25 parts of an early strength agent, 1-2.5 parts of a defoamer, 5-20 parts of a polymer emulsion, 8-20 parts of bentonite, 0.1-0.4 part of hydroxyethyl cellulose, 0.02-0.1 part of starch ether, 70-110 parts of alkali-resistant glass fiber, 0-10 parts of pigment and 90-160 parts of water. The ultrahigh-performance decorative concrete material has high mechanical properties, can be sprayed for construction, and has easy pump transfer and spray and good anti-sagging performance.

Owner:江苏澄筑建筑科技有限公司

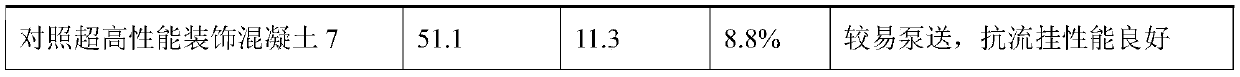

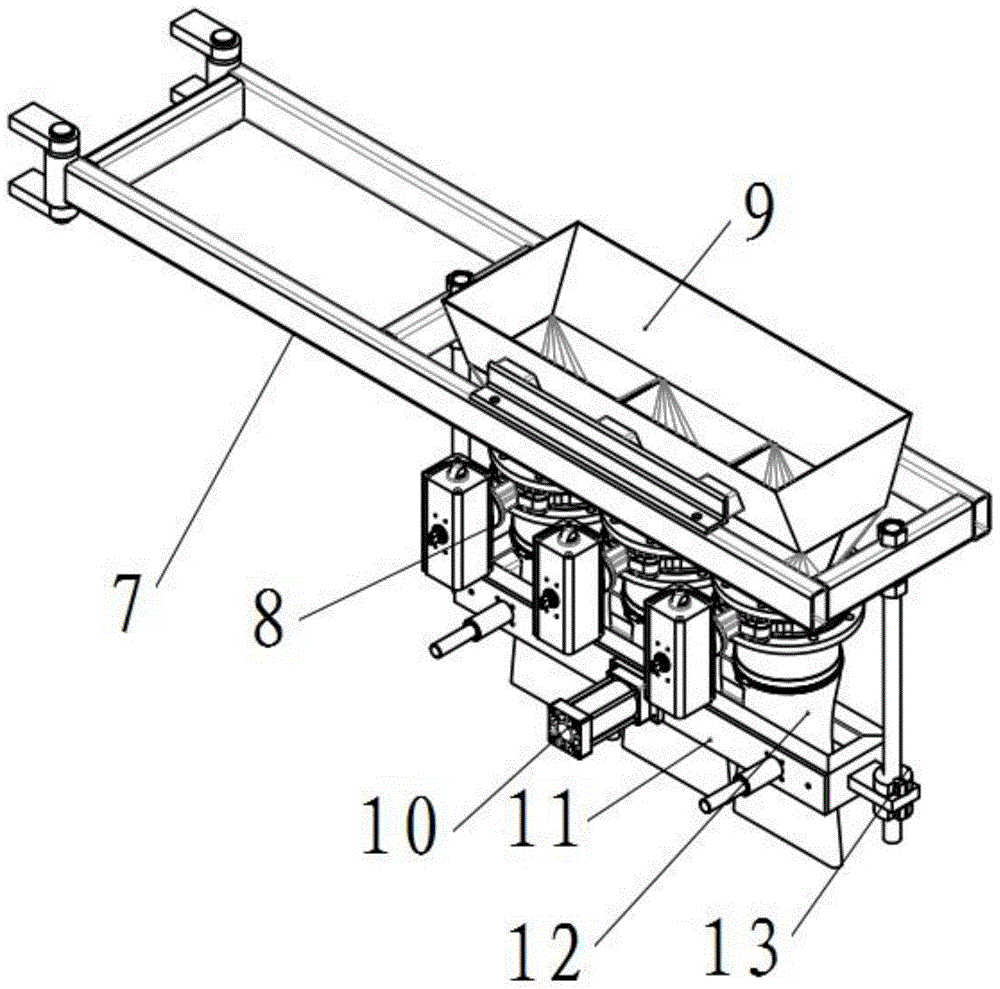

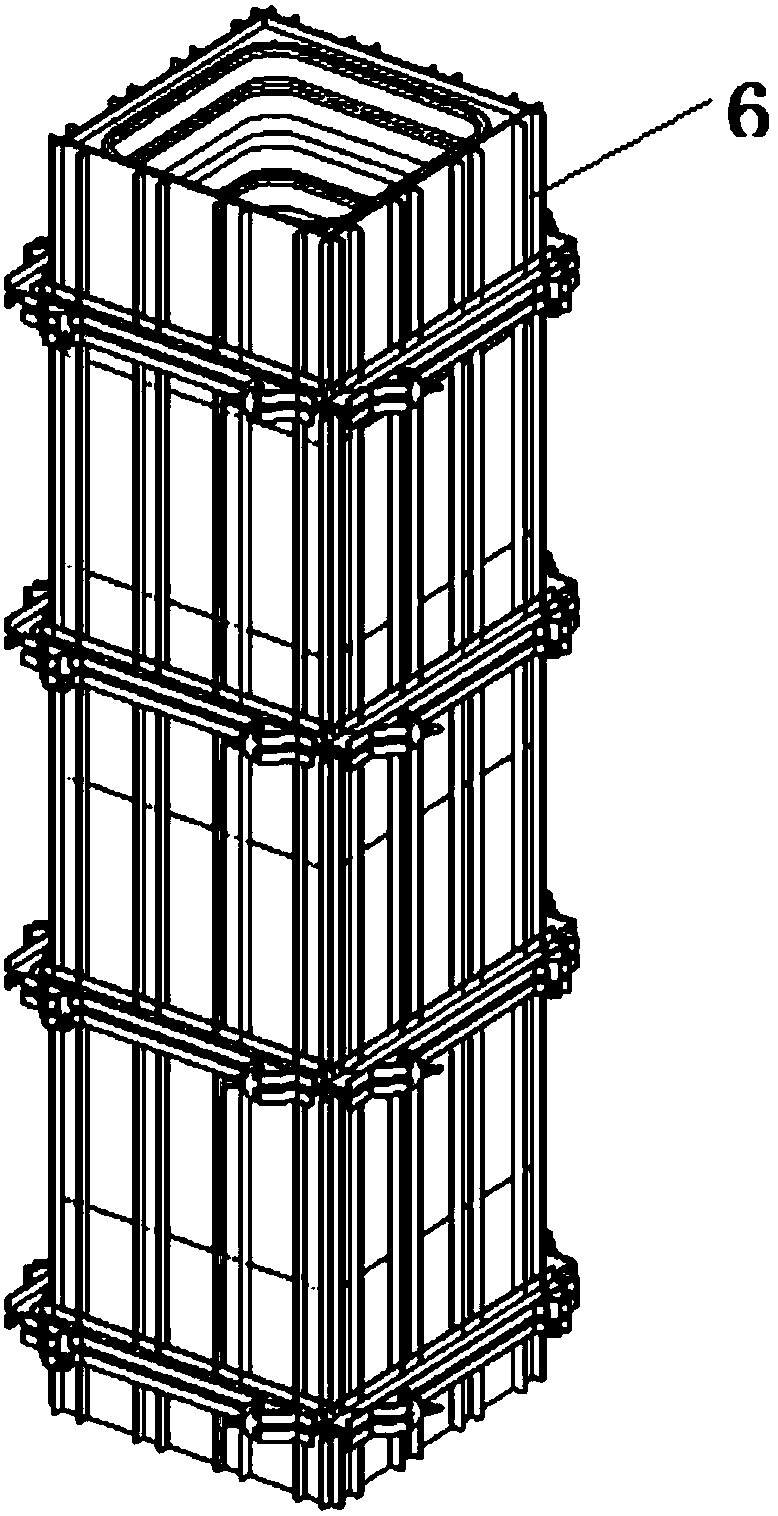

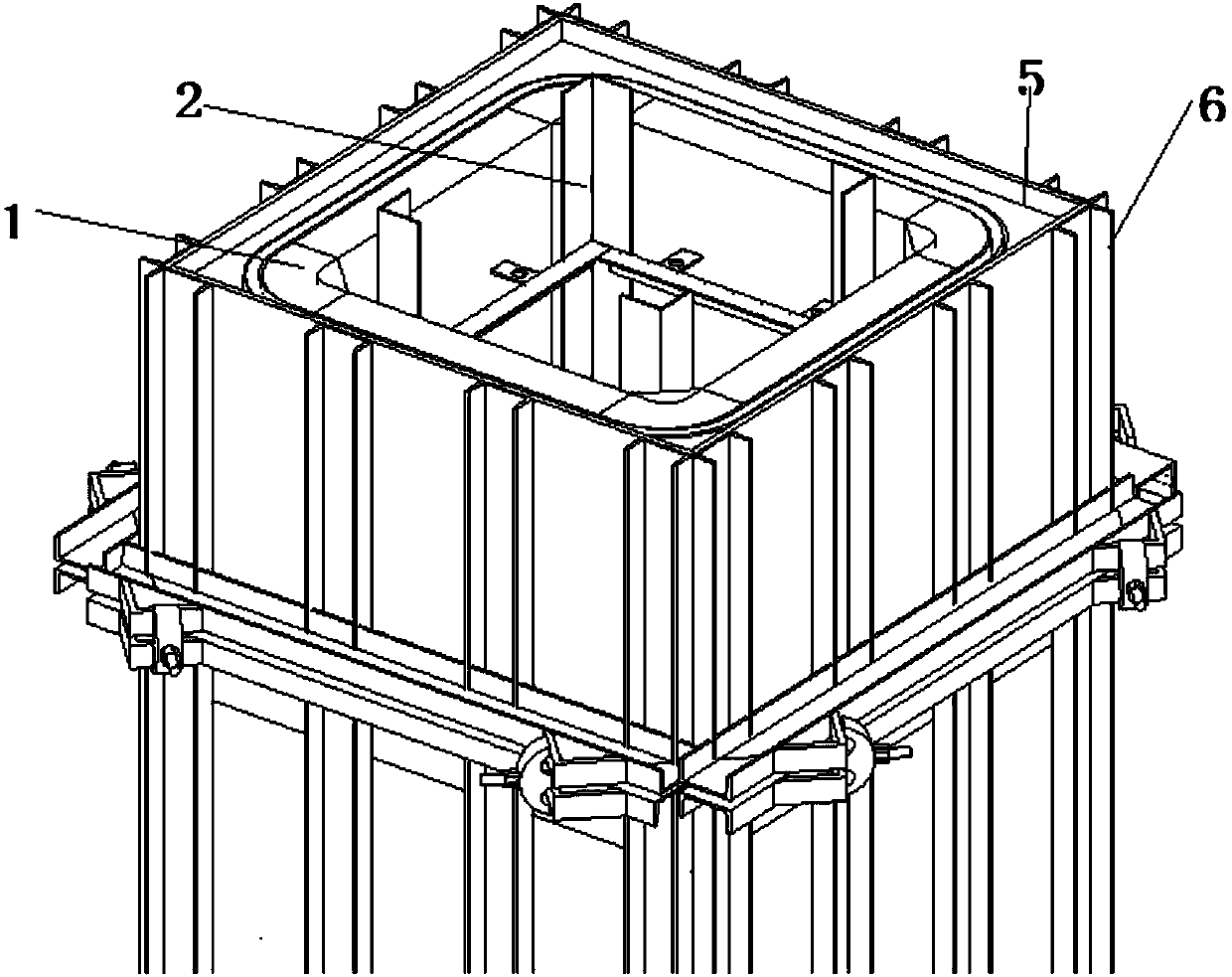

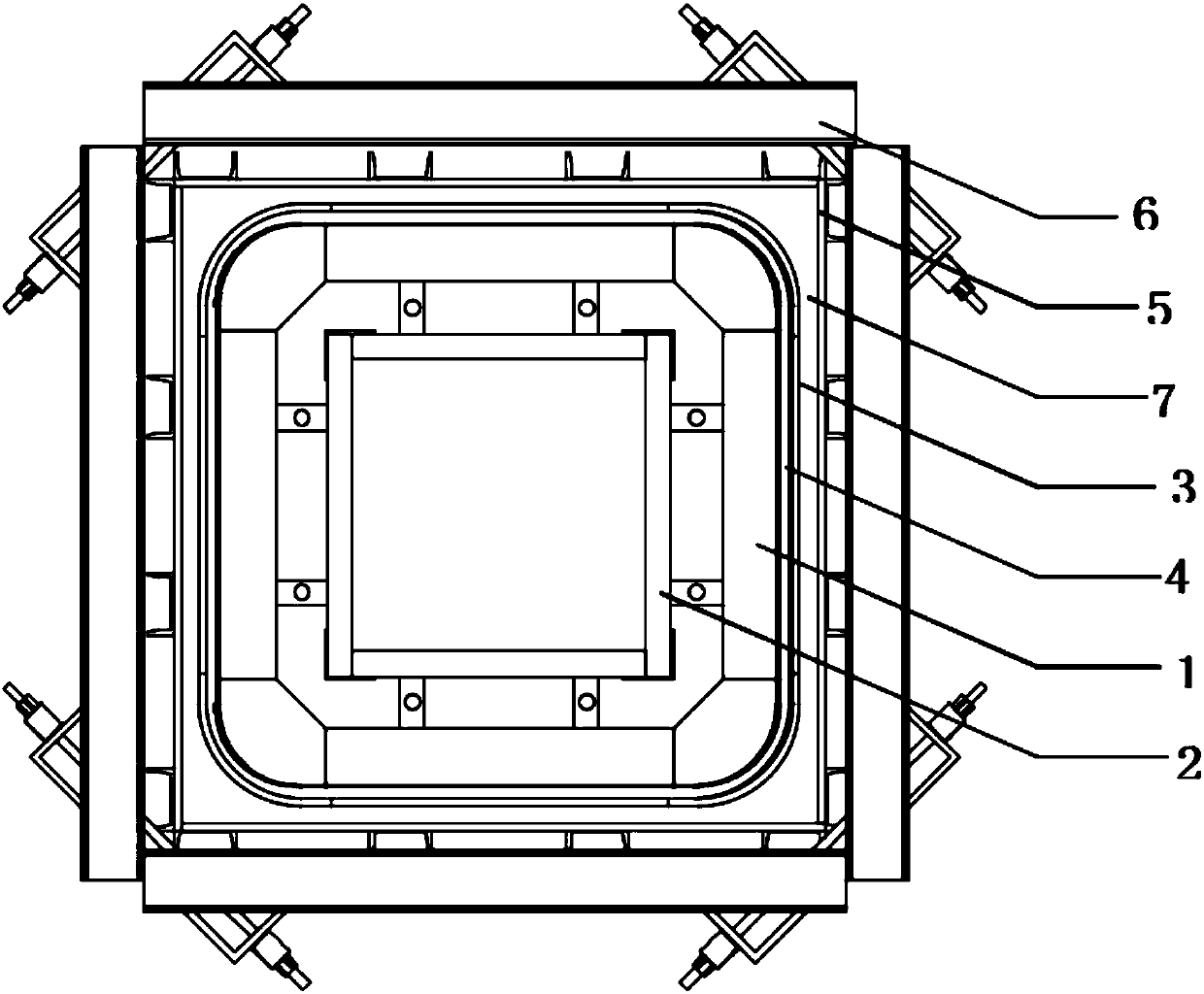

High-compactness concrete product molding machine

InactiveCN104552596AImprove compactnessHigh strengthCeramic shaping apparatusHigh strength concreteSocial benefits

The invention discloses a high-compactness concrete product molding machine. The machine comprises a bracket I, wherein the upper end of the brake I is provided with a vacuum vibration molding device; the front end of the vacuum vibration molding device is provided with a matching quantitative feeder; the lower end of the quantitative feeder is provided with a spreading surface material distributing machine; a matching bottom material distributing device is arranged at the rear end of the spreading fabric distributing machine and on the lower side of the vacuum vibration molding device; a steel mesh automatic laying device is arranged at the front end of the bottom material distributing device and at the lower end of the spreading surface material distributing machine; the front of the steel mesh laying device is provided with a matching brick receiver. The machine has the beneficial effects that high-compactness high-strength concrete products can be produced by using a vibration compression molding principle; particularly the conventional casting process is changed, the natural stone imitation concrete products are mechanically produced on a large scale, and extremely high economic benefit and social benefit are realized; the products are more compact, higher in strength, delicate, bright and clean in appearance and can be further deep-processed into decorative concrete products.

Owner:BEIJING REIT TECH DEV

Decorative concrete for building external envelope structure and preparation method thereof

The invention discloses a decorative concrete for building external envelope structures and a preparation method thereof. The decorative concrete is suitable for building external wall decoration, internal wall decoration and artistic sculptures and the like. The decorative concrete is composed of white Portland cement, low-viscosity decorative powder, ultrafine non-continuously-grading sand and a solution with addition of fibers in certain doping quantity. The decorative concrete can reach 50-100 years in service life, can achieve free regulation of colors, and satisfies the requirements in the aspects of strength, durability, decorative property, artistry, application property, self maintenance and the like.

Owner:江苏倍立达新材料科技有限公司

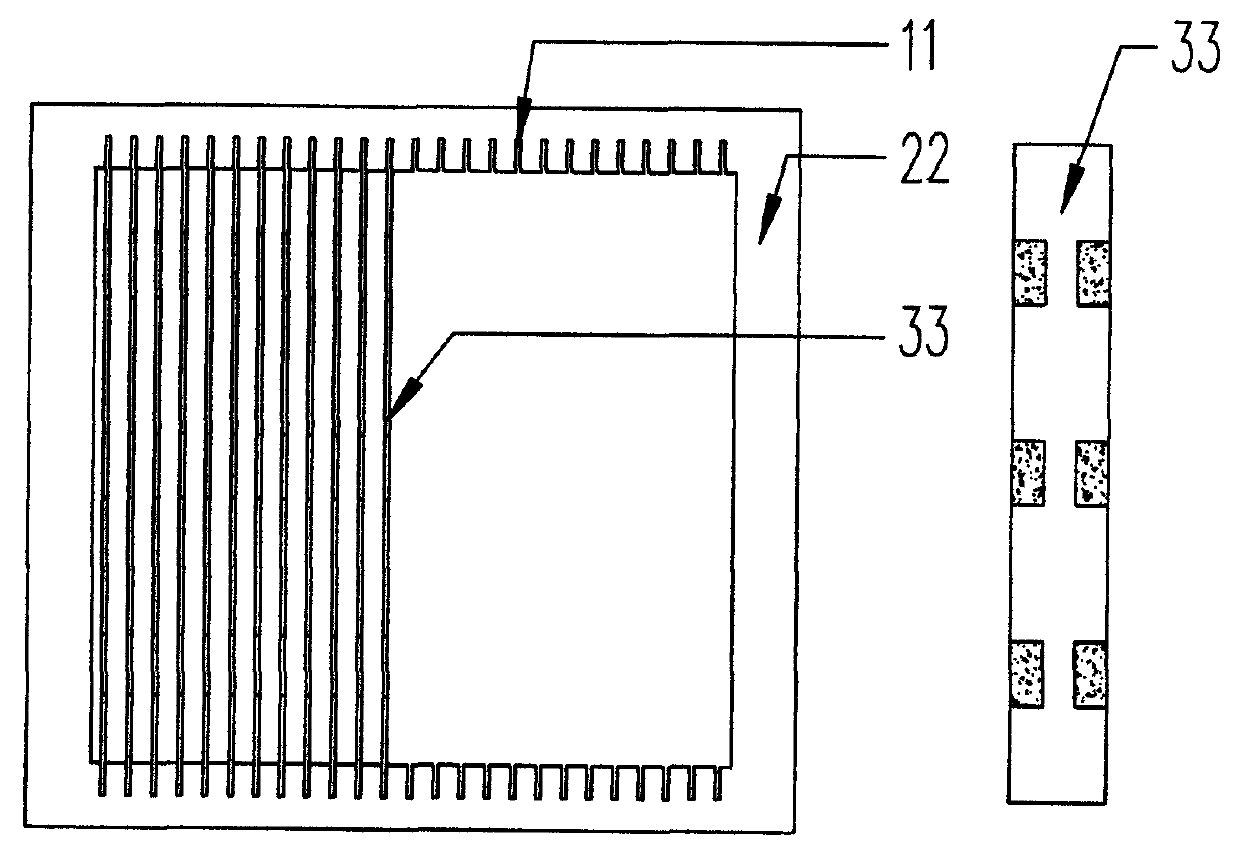

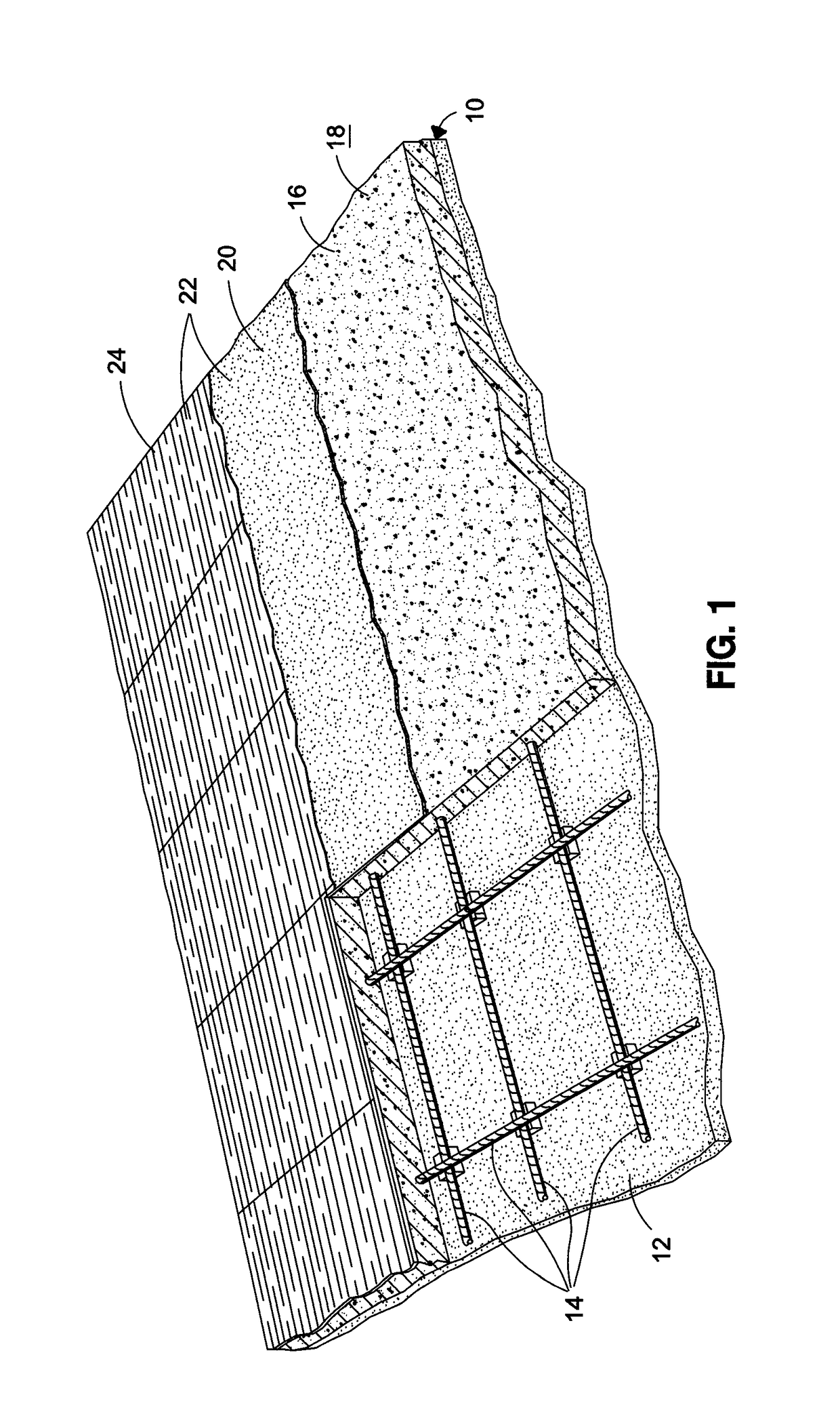

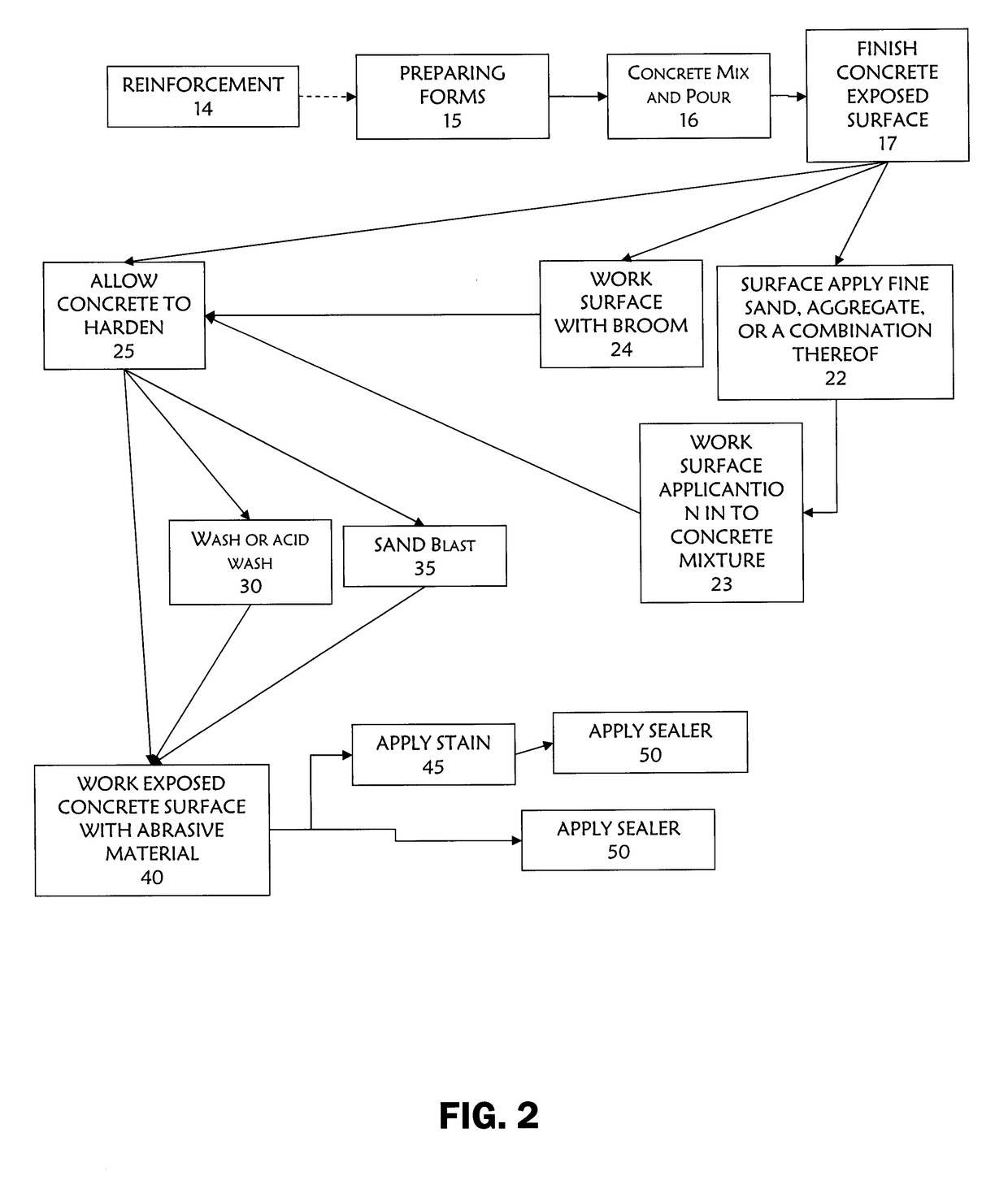

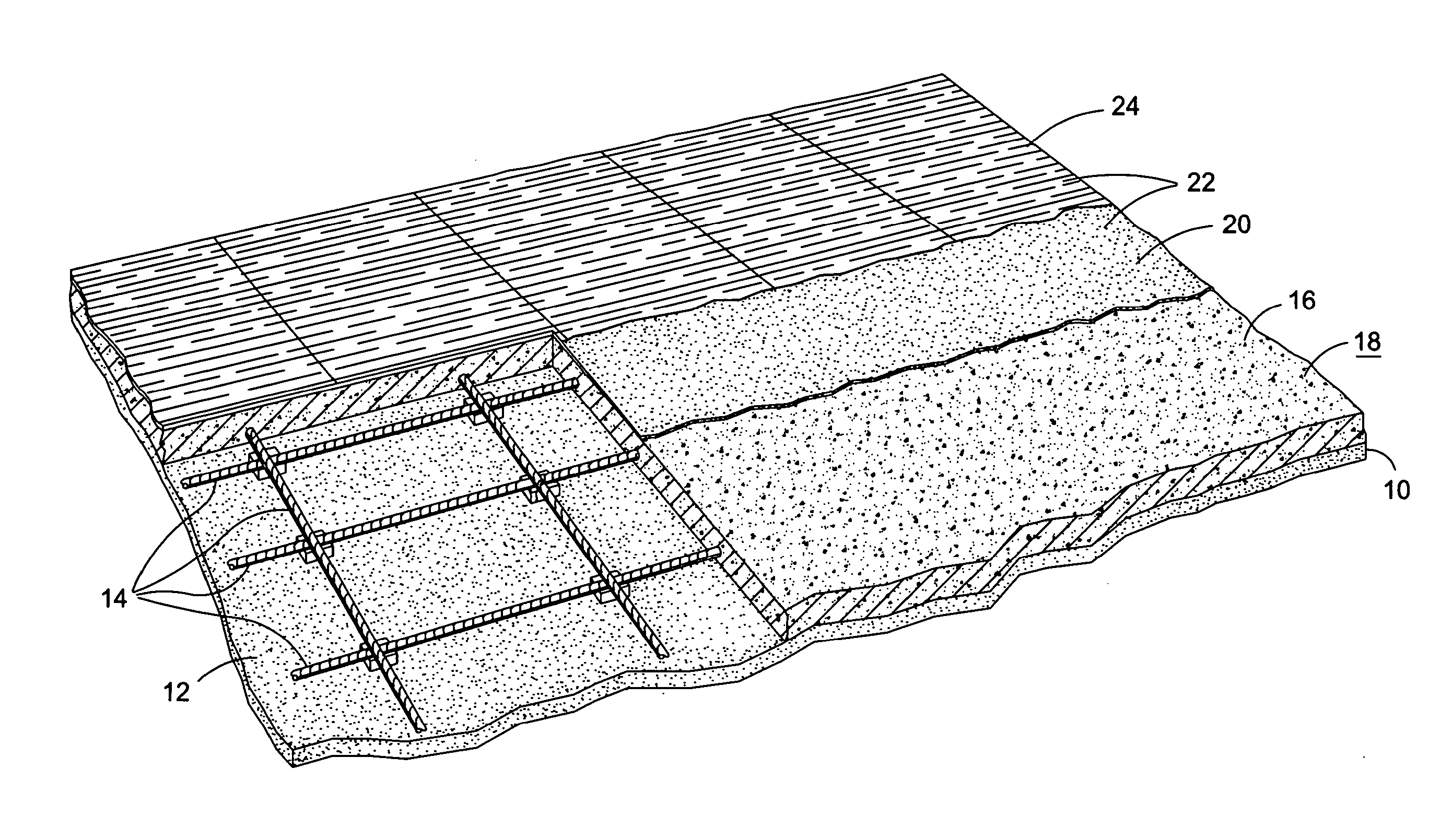

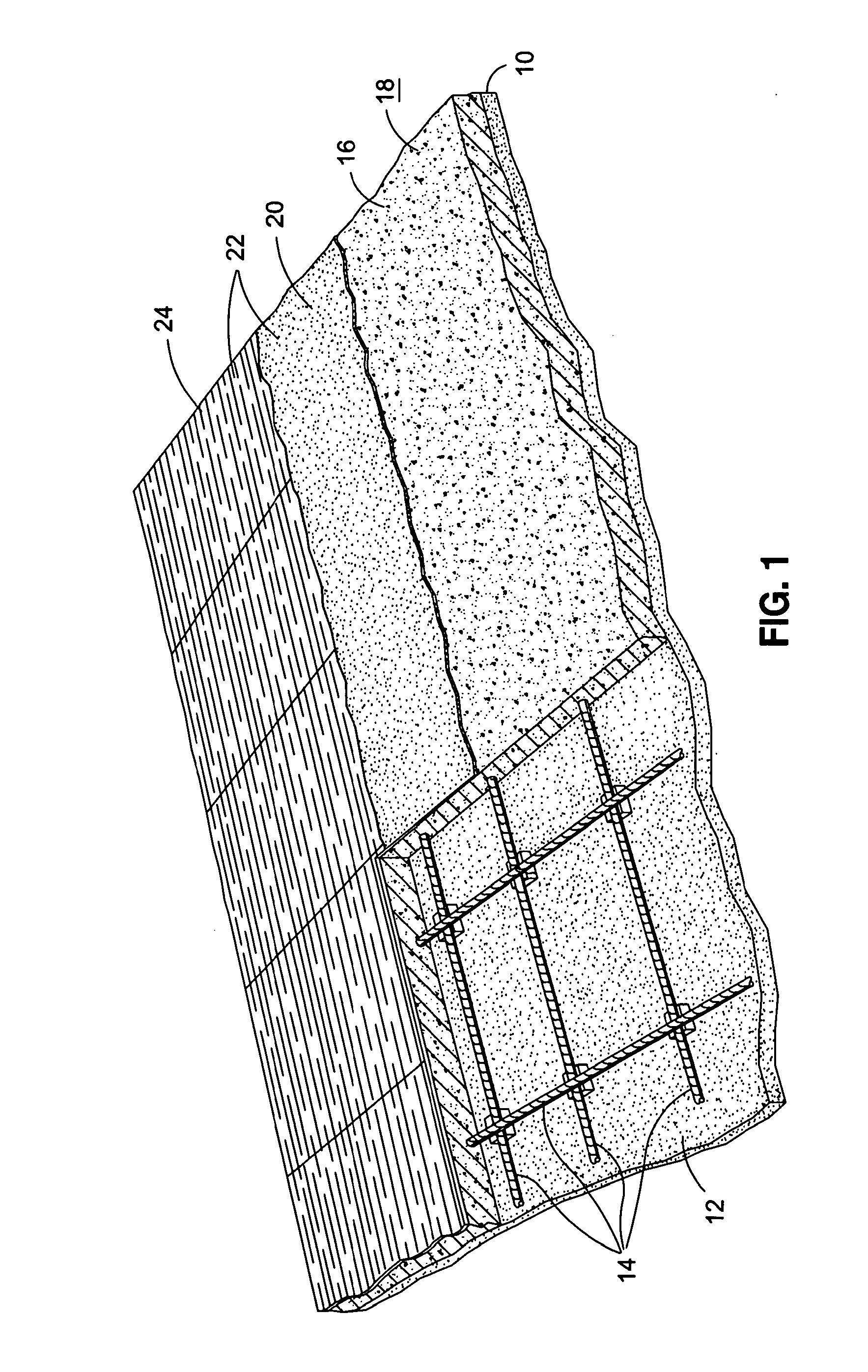

Decorative concrete with uniform surface and method of forming the same

InactiveUS20170298626A1Uniform finishImprove uniformityConstruction materialDomestic articlesMachined surfaceMaterials science

A decorative concrete with a very uniform finish surface and a method of fabricating the same is disclosed. A concrete mixture is poured over a subgrade which defines an exposed surface. The exposed surface is finished with any of several techniques, and the surface is then worked with an abrasive material, and additional techniques are used to color and seal the concrete.

Owner:SHAW & SONS

Decorative concrete and method of installing the same

A decorative concrete product and method of making the same is provided. The concrete surface carries a unique textural and visual decorative pattern that is troweled over the uncured surface. The decorative pattern strategically conceals any imperfections in the concrete surface. A decorative finishing tool is utilized to create a unique and consistent pattern throughout the exposed surface of the concrete. Unique visual patterns may include any aesthetic design including wood grain, or lightly finished honed or cut stone. The decorative finishing tool may be configured so that varying textures and contours may consistently be imprinted throughout the concrete. Advantageously, the cured concrete retains the durability of a concrete surface while carrying a visually and texturally appealing appearance.

Owner:SHAW CRAFTSMEN CONCRETE LLC

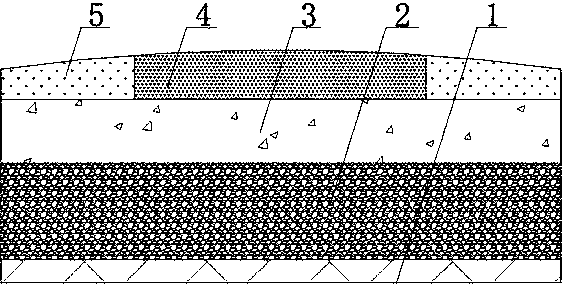

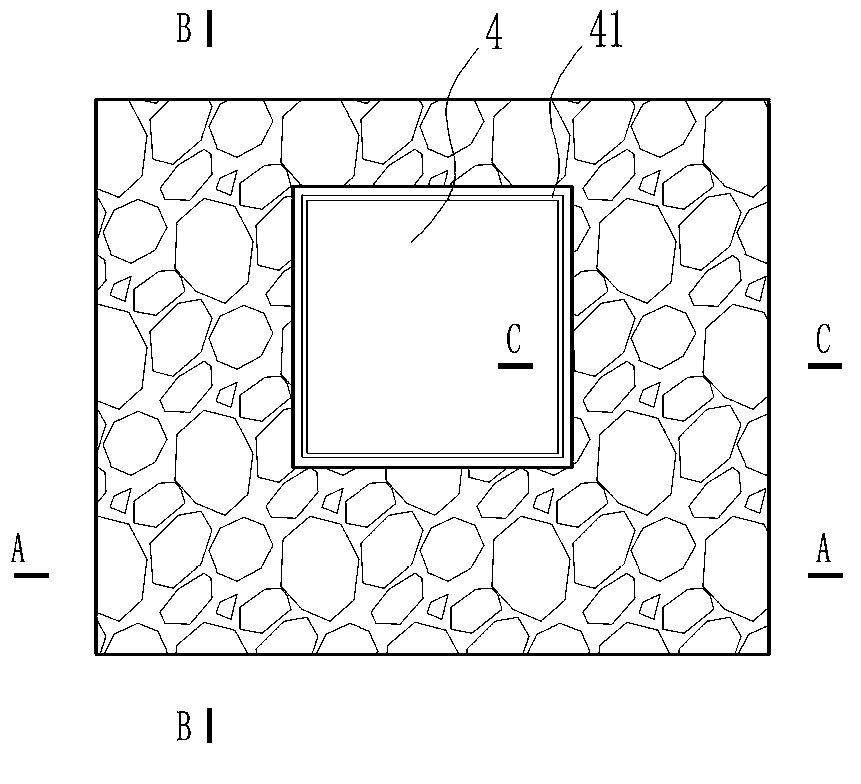

Decorative concrete floor structure and manufacturing method thereof

ActiveCN103806356AImprove bearing capacityExquisite structureIn situ pavingsClimate change adaptationSurface layerCarrying capacity

The invention discloses a decorative concrete floor structure and a manufacturing method thereof. The decorative concrete floor structure is formed by lamellar pavement. The decorative concrete floor structure is characterized in that a lamellar structure is sequentially composed of a plain oil rolling base layer, a graded broken stone layer, a sand-free macro-porous pervious concrete layer and a decorative concrete surface layer from bottom to top, wherein the decorative concrete surface layer is divided into three parts along the driving direction; the distances from the two sides to a roadside are the same and are 300-500mm; a colored pervious concrete surface layers is paved on the decorative concrete surface layer; the residual part is a middle part and is internally paved with an aggregate-exposed natural colored stone concrete surface layer; a part from the middle line of the aggregate-exposed natural colored stone concrete surface layer to the two sides and a part from the colored stone concrete surface layer to the roadside are inclined downwards and the slope is 1%-2%. The road surface is attractive in appearance, anti-skidding and pervious; meanwhile, the decorative concrete floor structure has green functions of high carrying capacity, good durability and the like; rainwater can rapidly permeate to supplement underground water; the decorative concrete floor structure is applied to places including side pavements, roadways and the like of landscape garden paths, parking lots, fire fighting accesses, municipal side roads, residential districts, villa districts and the like.

Owner:BEIJING XI AO XING YE GARDEN LANDSCAPE ENG

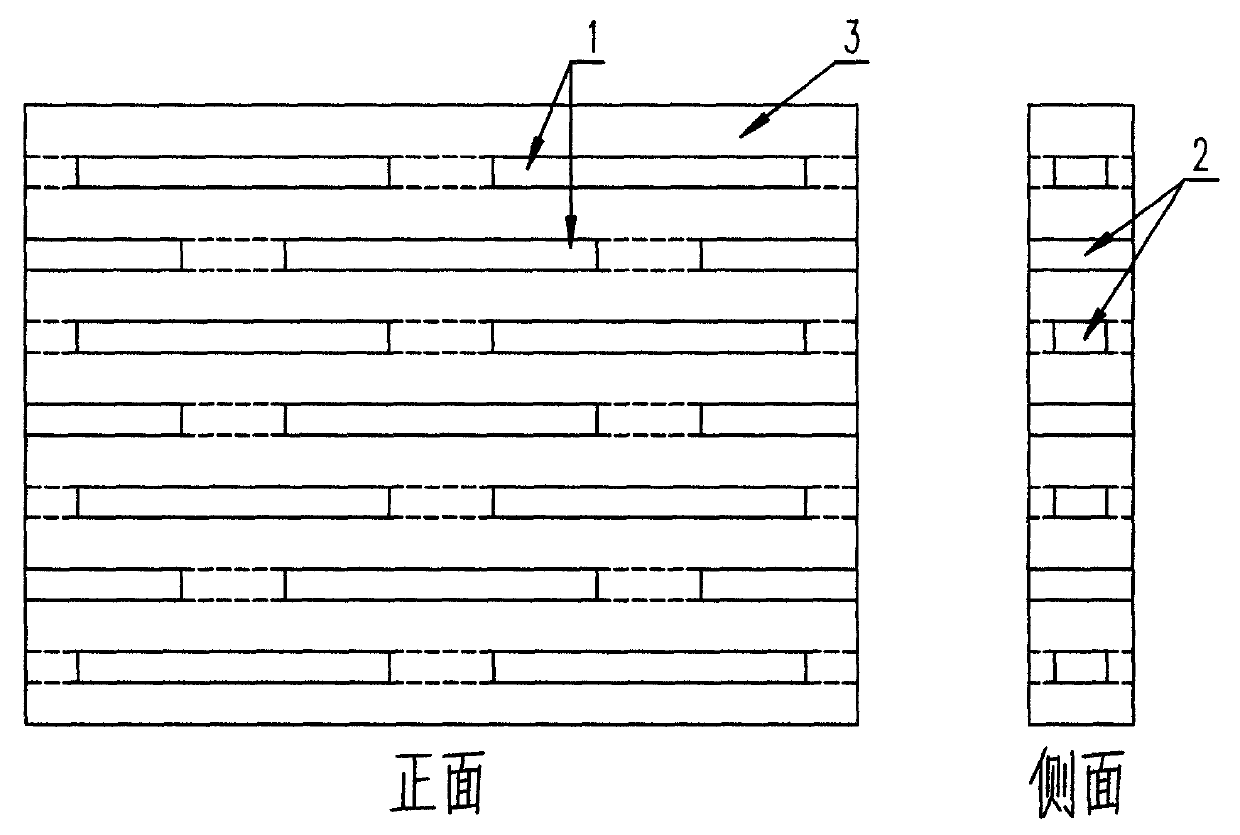

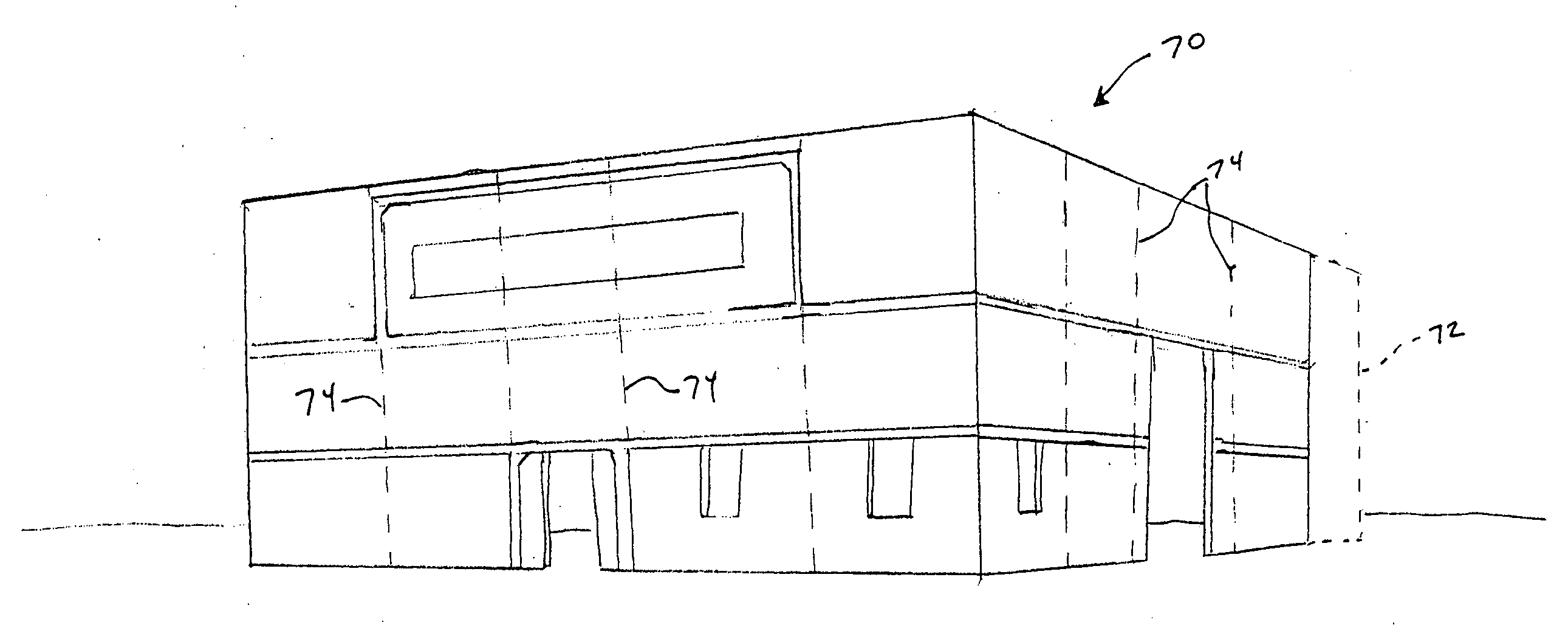

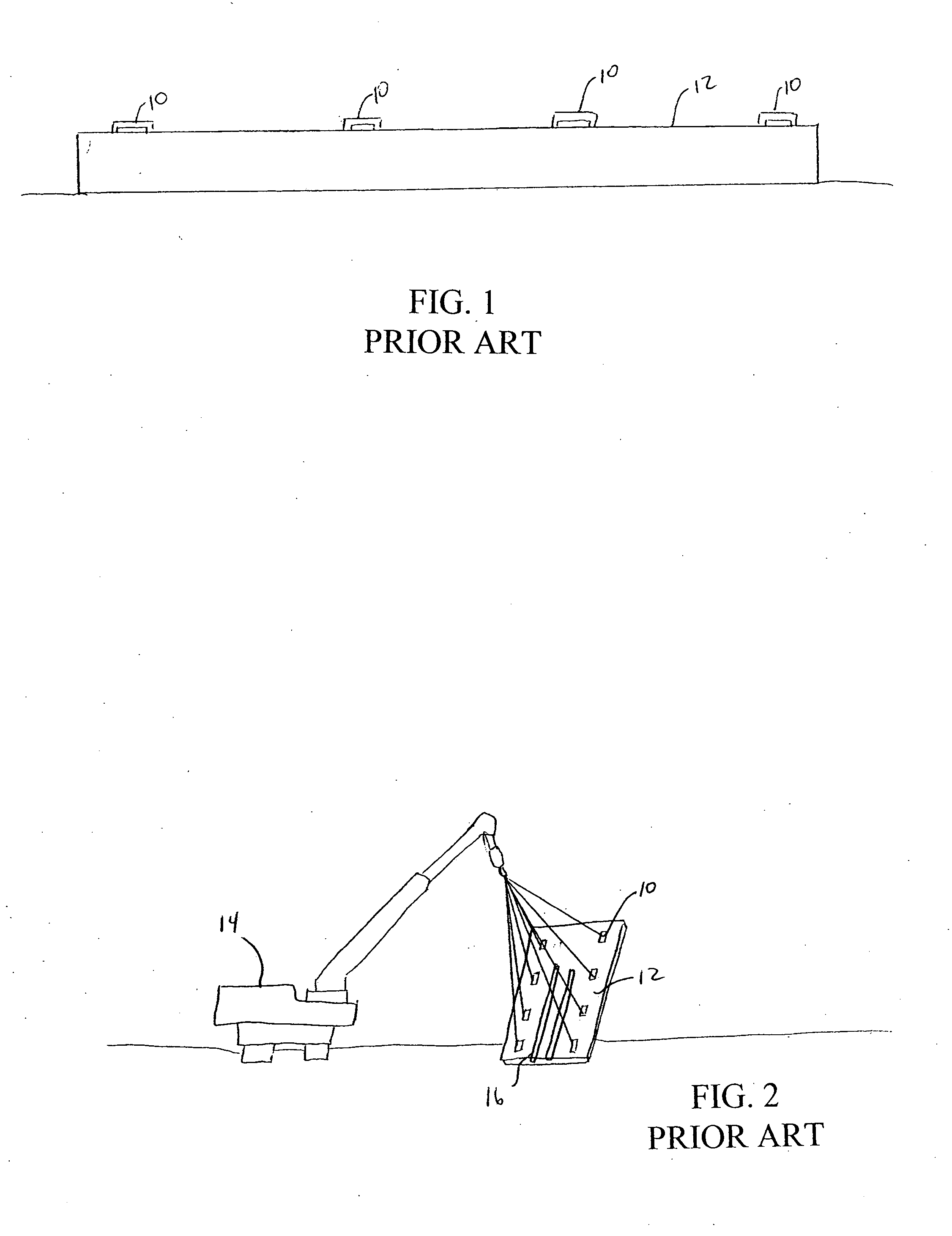

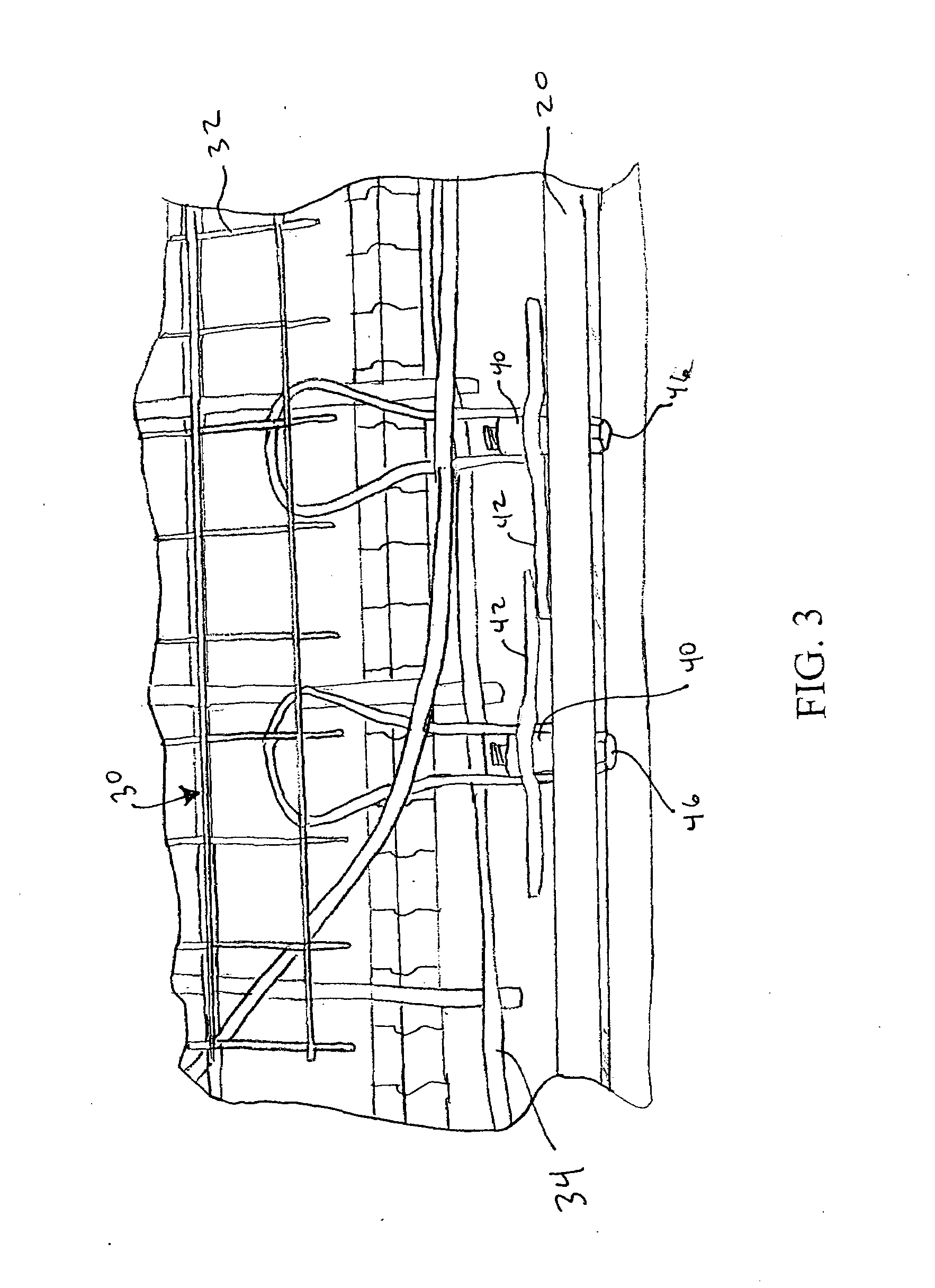

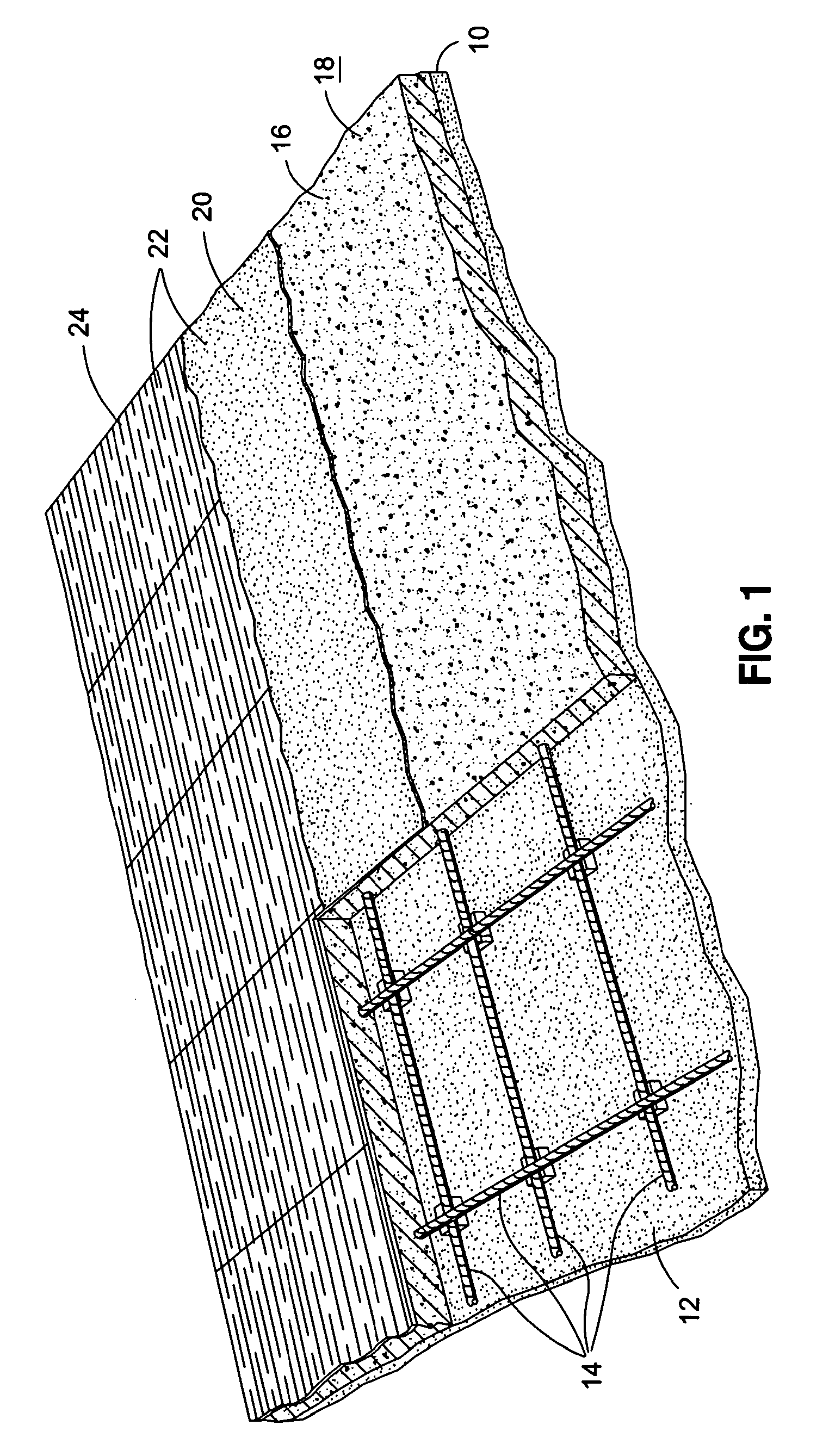

Method of forming a decorative concrete wall

InactiveUS20070234664A1Fast constructionLow costConstruction materialStructural engineeringDecorative concrete

A method of constructing a concrete wall. A mold form is placed upon on a surface at a construction site. A support structure is placed into the mold form and concrete is poured around the support structure within the mold form to form a concrete panel. The upward facing surface of the poured panel is altered with one or more of a color, a texture, and a pattern to form a decorative concrete panel while the panel lies on the ground. The decorative concrete panel is then lifted into an upright position by a crane connected to lifting inserts of the panel. The lifting inserts are desirably located at a side or top end of the panel and not in the decorative surface.

Owner:MATTHEW TUCKER KENNETH

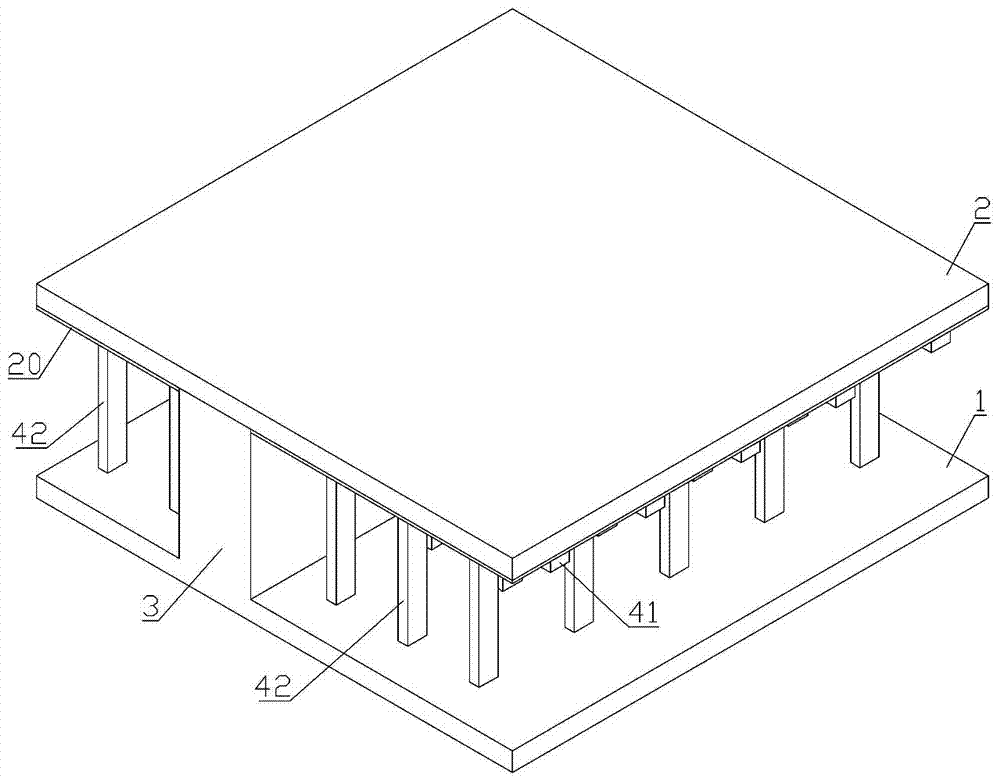

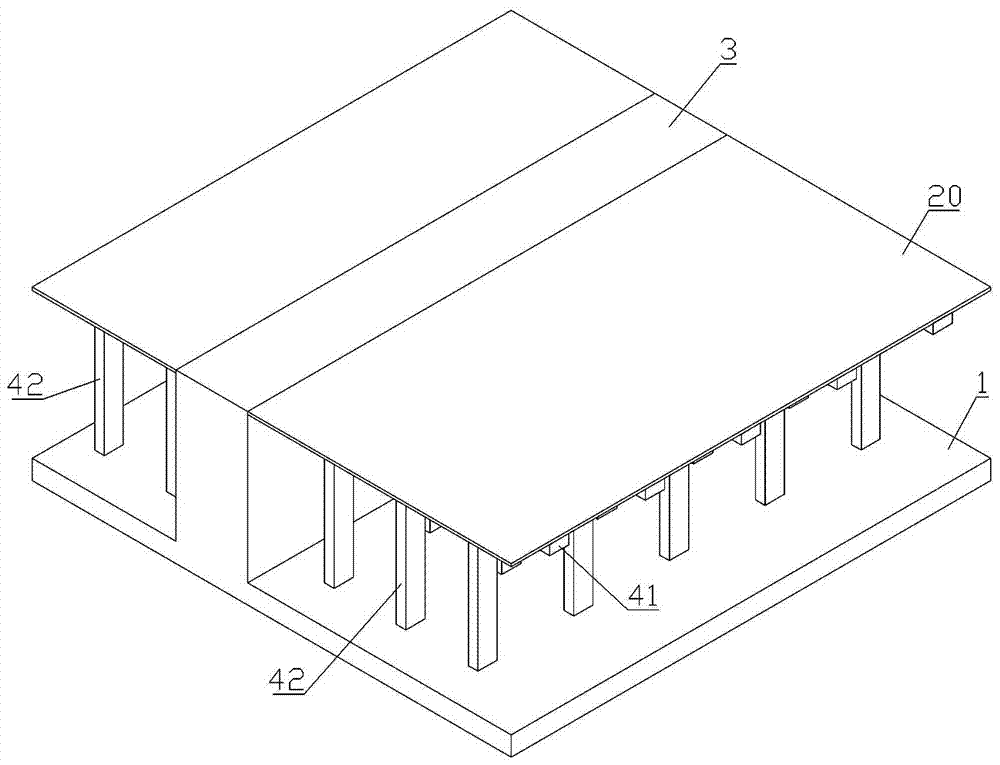

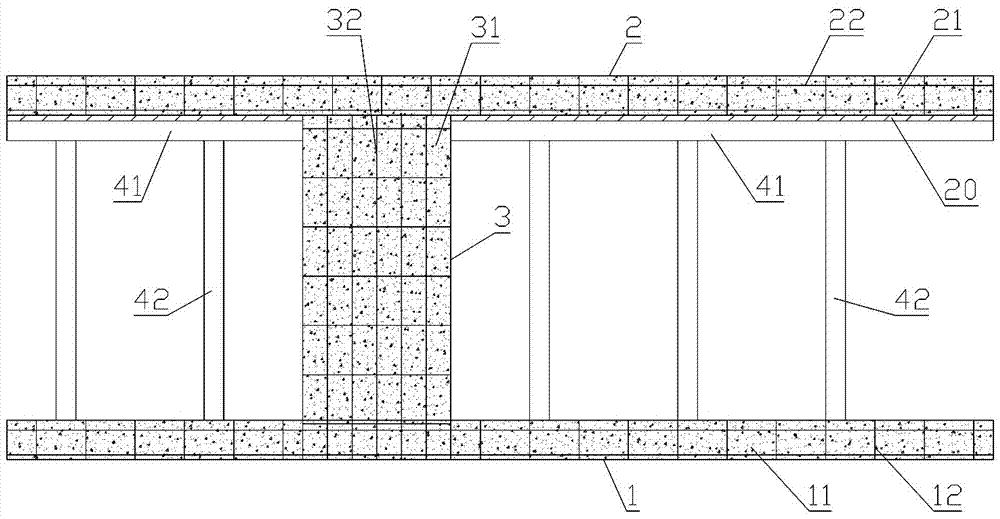

Concrete hollow double-layer floor and construction method thereof

PendingCN106939663AReduce construction costsShorten the construction periodFloorsBuilding material handlingSupporting systemFalsework

The invention discloses a concrete hollow double-layer floor. The concrete hollow double-layer floor comprises a lower laminated plate, an upper laminated plate and a structural beam, which are all of reinforced concrete structures, especially, the lower laminated plate, the upper laminated plate and the structural beam define a mould cavity; the structural beam and the lower laminated plate are continuously formed integer structure; and an upper laminated plate template and a laminated timber supporting frame are arranged in the mould cavity. The concrete hollow double-layer floor is convenient in construction, is low in manufacturing cost and is good in perception effect. The invention also discloses a construction method for the concrete hollow double-layer floor, and the construction method comprises the following steps: 1, constructing a scaffold supporting system; 2, constructing a lower laminated plate template; 3, hoisting structural beam reinforcement; 4, spreading lower laminated plate reinforcement; 5, mounting a beam side template; 6, pouring the lower laminated plate concrete and the structural beam concrete; 7, dismounting the beam side template; 8, constructing the laminated timber supporting frame and the upper laminated plate template; 9, spreading upper laminated plate reinforcement; 10, pouring upper laminated plate concrete; and 11, dismounting the lower laminated plate template. The method has the characteristics of low construction cost, short construction period and firm structure, and is very suitable for bare concrete decorated floors.

Owner:广东省第四建筑工程有限公司

Manufacturing method of multi-hook-face decorative concrete formwork

The invention discloses a manufacturing method of a multi-hook-face decorative concrete formwork. The manufacturing method comprises the following steps that 1, a flowerpot column is duplicated in a proportion of 1:1, and a case mould is manufactured; 2, the case mould which is manufactured in the step 1 is installed on a case mould framework; 3, a steel lining mould is arranged on the outer portion of the case mould which is installed in the step 2 in a sleeving mode; 4, silica gel is poured into a clearance between the case mould and the steel lining mould; 5, after the silica gel is solidified, a timber formwork reinforcing system is arranged on the outer side of the steel lining mould; 6, foamed concrete is poured into the position between the steel lining mould and the timber formworkreinforcing system, and a composite formwork system is formed; and 7, after the strength of the foamed concrete reaches the design requirements, the case mould is dismantled from the interior, and manufacturing is completed. According to the manufacturing method, constructors can complete manufacturing of various irregular-surface decorative concrete formworks which have a plurality of hook facesand are in special shapes and the like according to the design requirements, the decorative design fineness after forming is high, and the whole body is showed without an abutted seam.

Owner:CHINA RAILWAY CONSTR GROUP

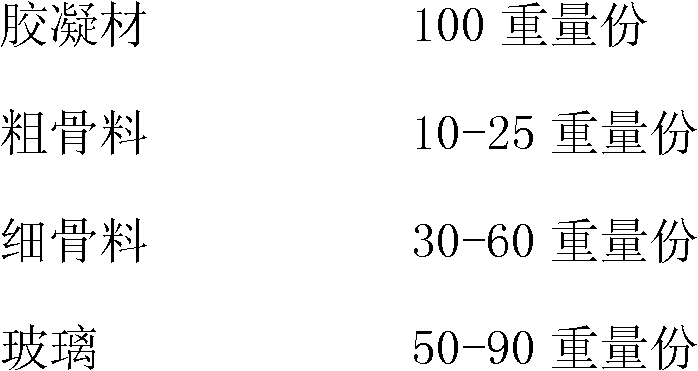

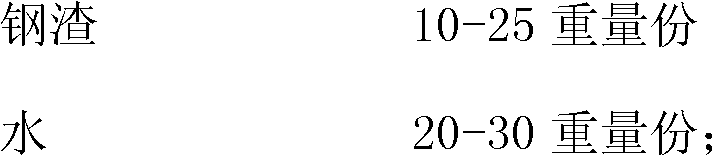

High-strength glass decorative steel slag concrete prefabricated art stone and manufacture method thereof

ActiveCN102182130AOvercome strengthOvercome flashy and other shortcomingsSingle unit pavingsCeramic shaping apparatusSlagAdditional values

The invention provides high-strength glass decorative steel slag concrete prefabricated art stone which comprises the following raw material components in parts by weight: 100 parts of gelatinizing material, 10-25 parts of rough aggregate, 30-60 parts of fine aggregate, 50-90 parts of glass, 10-25 parts of steel slag and 20-30 parts of water. The strength grade of the glass decorative steel slag concrete prefabricated art stone is above Cc40. The invention overcomes the defects of low strength, garishness, and the like of the common decorative concrete products and changes the rigid and ugly visual effect of the common steel slag concrete products; the manufactured glass decorative concrete prefabricated art stone has dynamic and fashionable aesthetic effect, and greatly improved mechanical performance and anti-skidding performance. In addition, the invention also provides a high-additional value recycling path for steel slag solid wastes and waste and old glass.

Owner:MCC BAOSTEEL TECH SERVICE +1

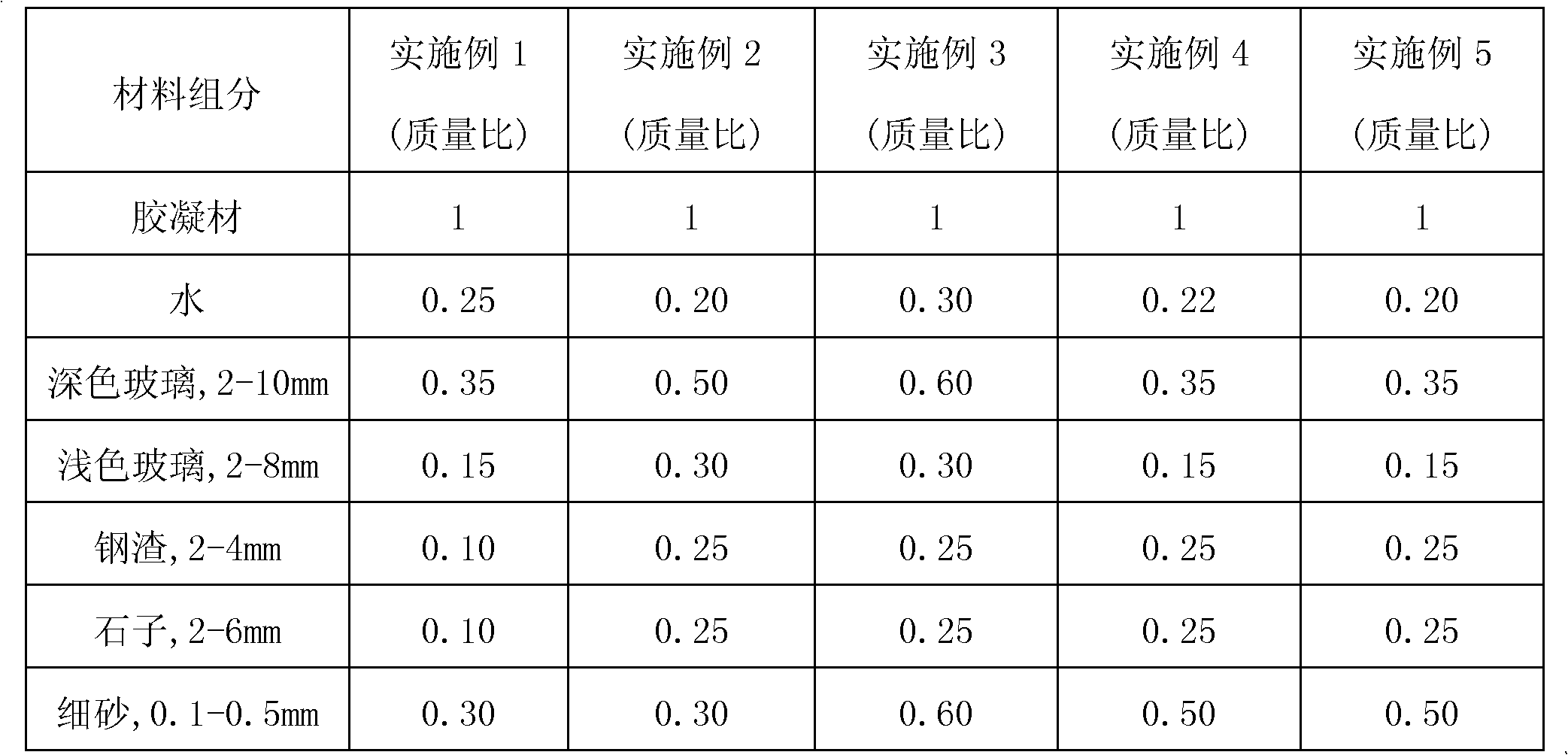

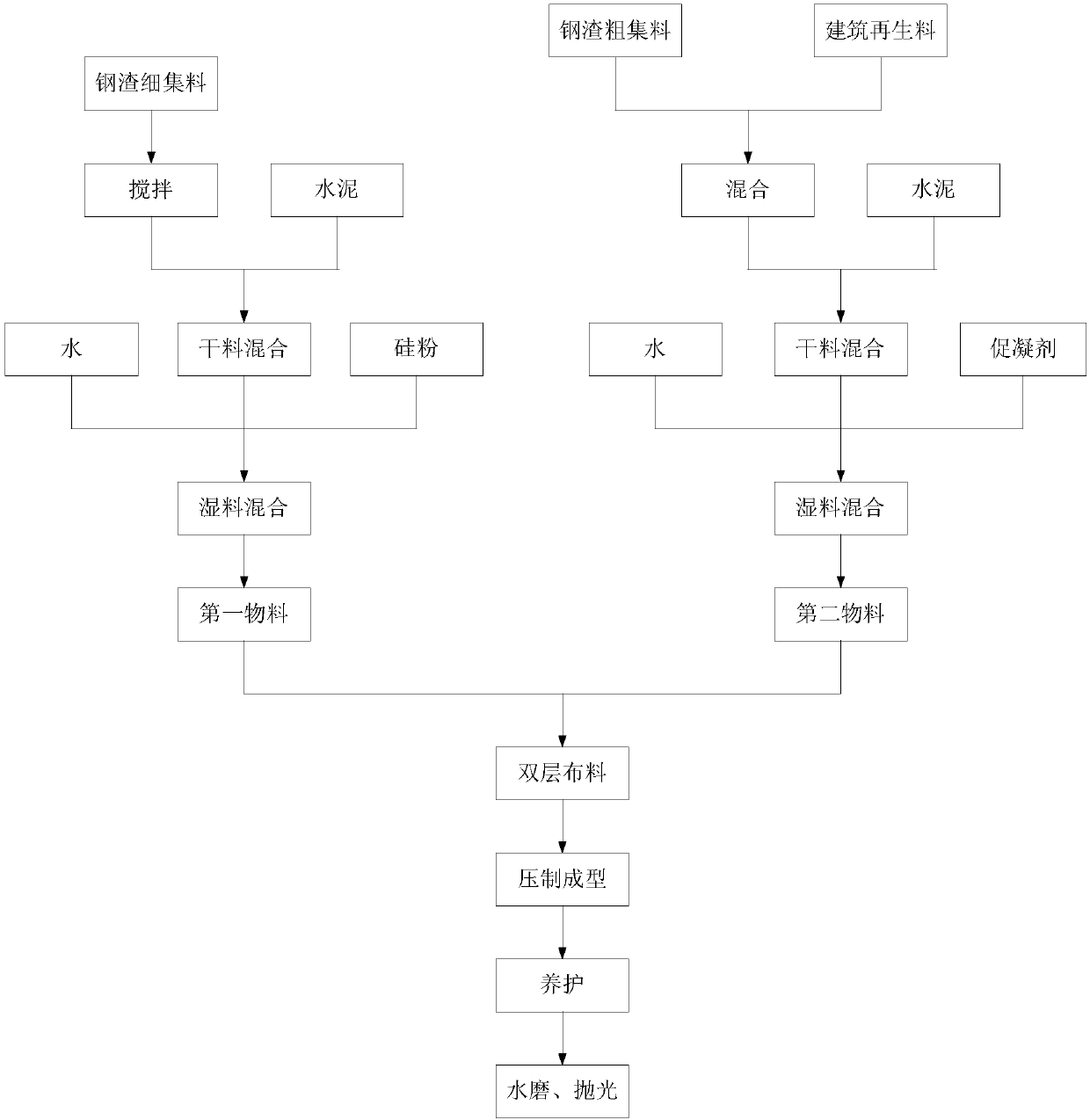

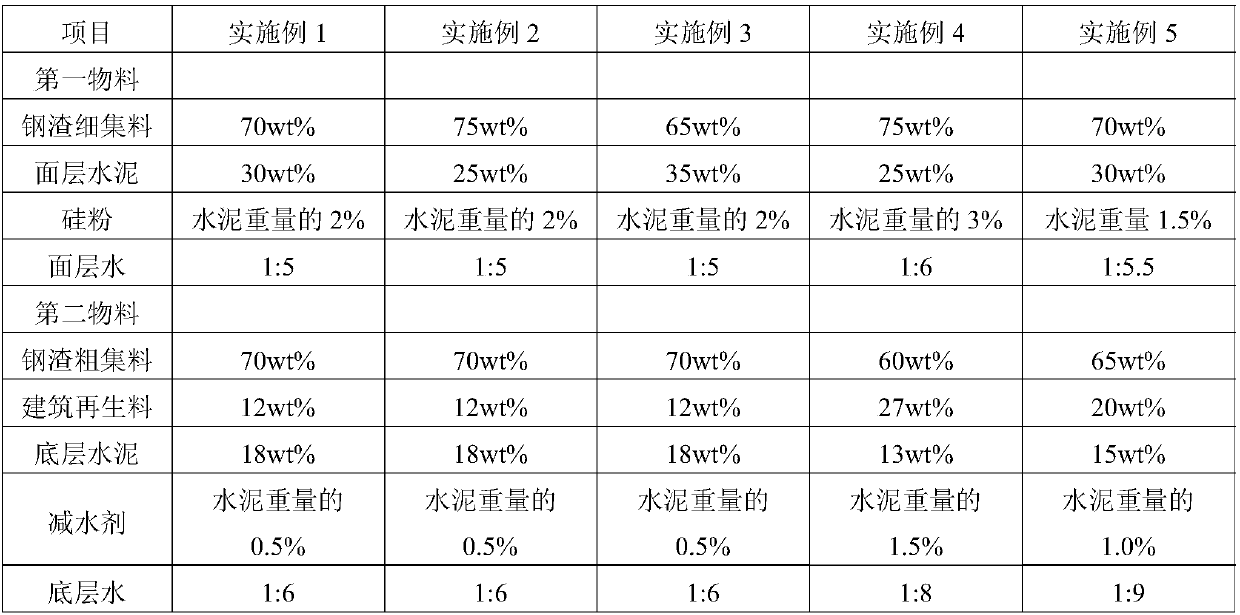

Decorative pavement product and preparation method thereof

The invention provides a decorative pavement product. The product comprises a surface layer and a bottom layer in sequence from top to bottom, wherein the surface layer comprises a surface material and surface-layer water, the surface material comprises the following components in percent by weight: fine steel aggregate 60-80% and surface-layer cement 20-40%, and a proper amount of the surface-layer water is added; and the bottom layer includes a bottom material and bottom-layer water, the bottom material comprises the following components in percent by weight: steel slag coarse aggregate 55-75%, building recycled material 10-30%, and bottom-layer cement 10-20%, and a proper amount of the bottom-layer water is added. The invention further provides a preparation method of the decorative pavement product. The decorative pavement product and the preparation method thereof provided by the invention overcome the disadvantages of ordinary decorative concrete products such as low strength andspeciosity, and at the same time changes the unsightly visual effect of common steel slag concrete products. The prepared decorative product has the advantages of high gloss, seepage resistance, fashion and good mechanical properties.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Precast side fascia with decorative concrete surface layer and manufacturing method thereof

The invention discloses a precast side fascia with a decorative concrete surface layer. The precast side fascia comprises an inner cement fiberboard, a sandwich insulating layer and a ribbed outer concrete plate and is characterized in that the ribbed outer concrete plate comprises reinforcing ribs and a surface plate; an outer surface of the surface plate is a colorized concrete surface layer with textures; and the sandwich insulating layer is filled between the reinforcing ribs. The precast side fascia provided by the invention adopts the colorized concrete molded exterior facing and has a low price, multiple types of surface textures, thin thickness of outer concrete, light self-weight, no risk of exterior facing spalling and good resistance.

Owner:杨众 +1

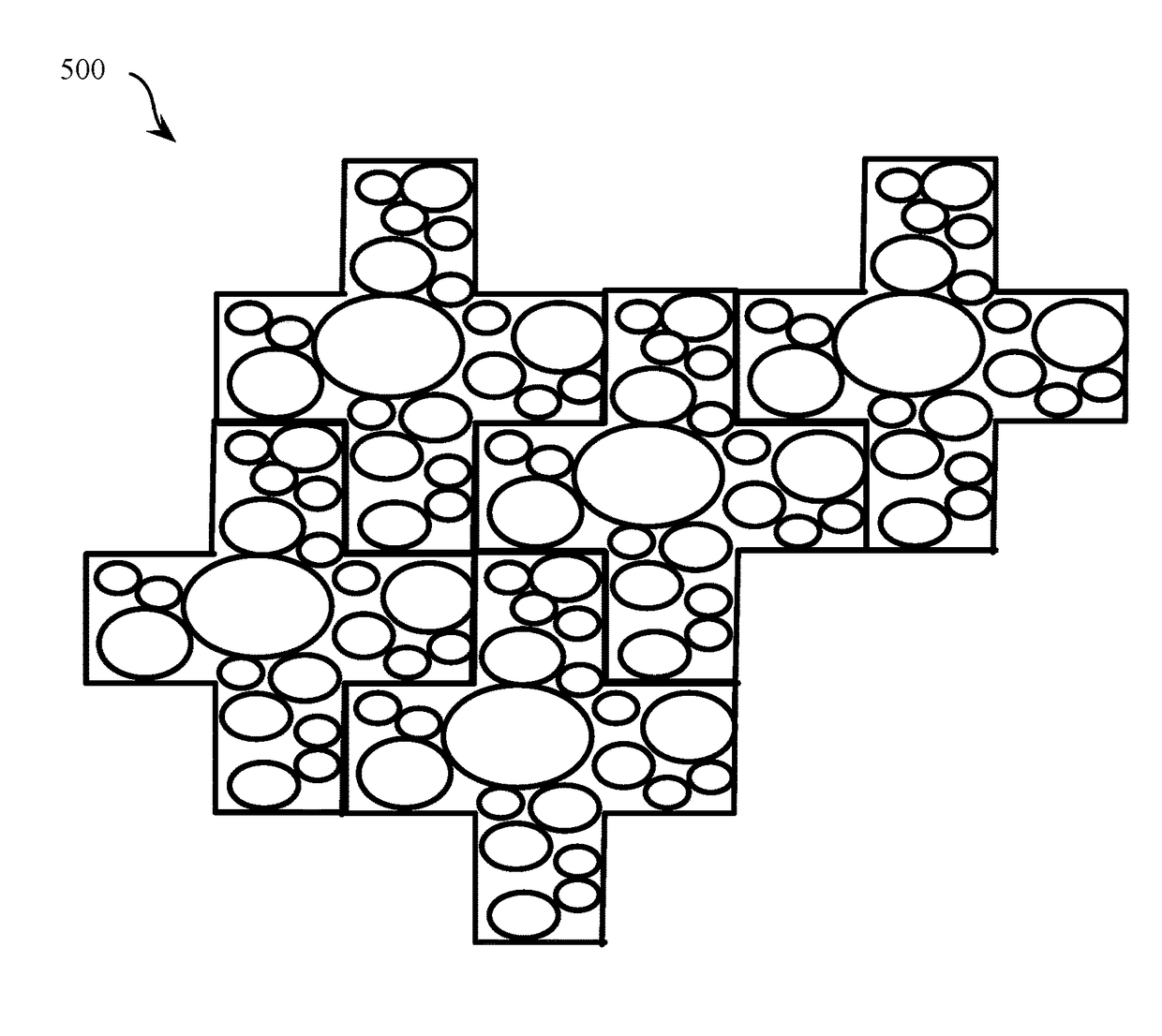

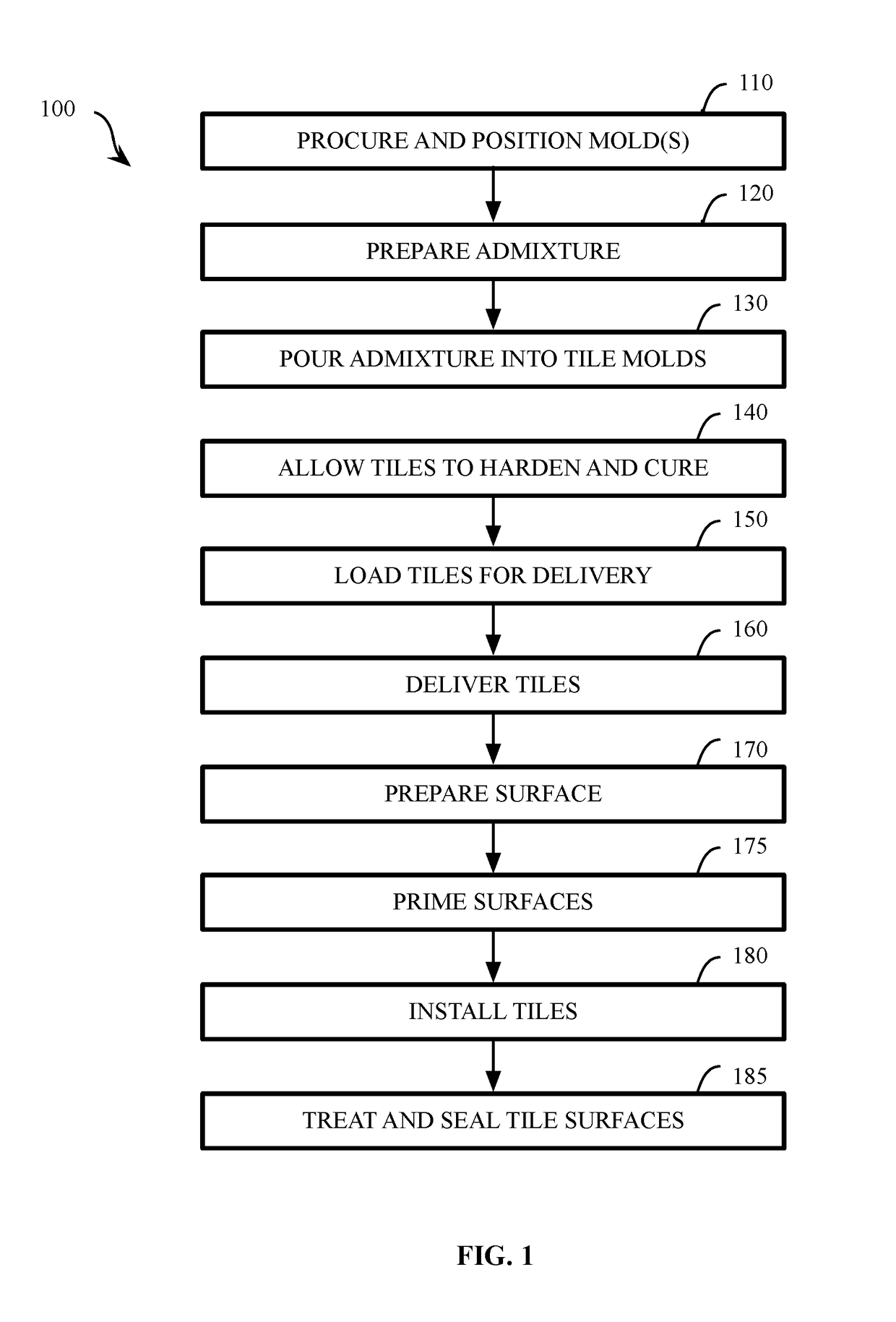

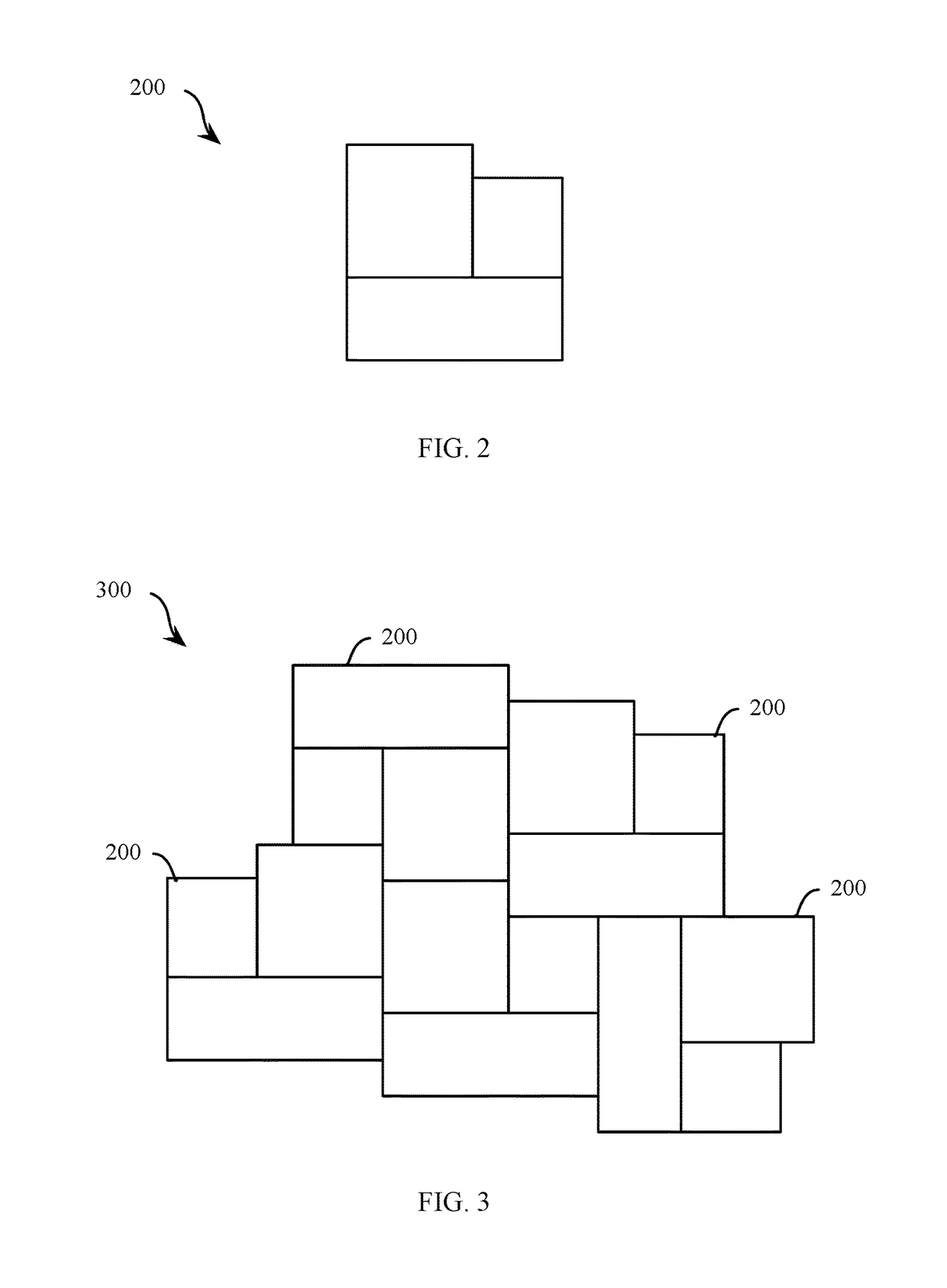

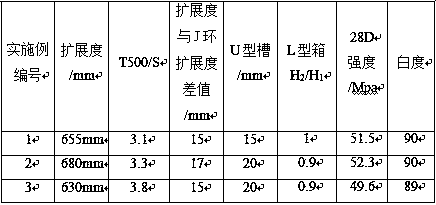

System and method for installing tile

InactiveUS9909322B1Reduce and minimize occurrenceNone provides advantagesCovering/liningsMouldsAdhesiveDecorative concrete

A system and method for installing tile includes the use of fasteners and washers that are installed into the interstitial gaps of the tiles or installed through the face of the tile. The washers and fasteners create a downward pressure on the tiles to align the edges of the tiles and to ensure that the tiles conform to the surface to which they are applied, thereby significantly reducing or minimizing the occurrence of gaps or voids between the installation surface and the tiles. Once the tiles are fixed in position and the adhesive has set or cured, the washers and fasteners are removed and the interstitial spaces or gaps between the tiles is grouted and the tile can be painted or stained. Additionally, the method of manufacturing decorative concrete tiles uses flexible rubber molds to achieve a variety of unique shapes, patterns, and textures.

Owner:SADLEIR GERALD

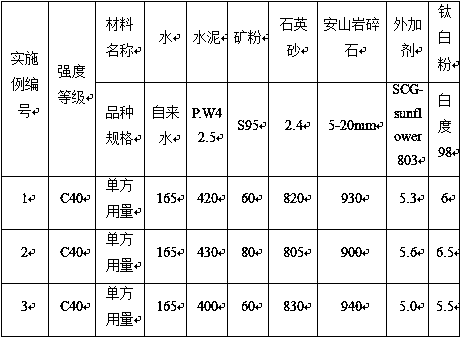

White self-compacting C40-pumping fair-faced concrete

The invention discloses white self-compacting C40-pumping fair-faced concrete including the components of: 350-430 kg / m<3> of cement, 50-80 kg / m<3> of slag micropowder, 790-830 kg / m<3> of quartz sand,5-6 kg / m<3> of additives, 155-165 kg / m<3> of blending water, 5-8 kg / m<3> of TiO2 pigment and 900-940 kg / m<3> of crushed andesite rock. The concrete has the performances of high flowability and self-compacting effect of regular self-compacting concrete and has a pure-white appearance that does not change along with time. The product also has the surface performances of fair-faced concrete, is lessin bubbles and has homogeneous color, so that the product has great application value in the field of decorative concrete. The concrete can serve as a structural concrete base material in an integrated shaping manner, is free of decoration on concrete surface, can save coatings and reduce manpower cost, and satisfies the green-construction idea in our country.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

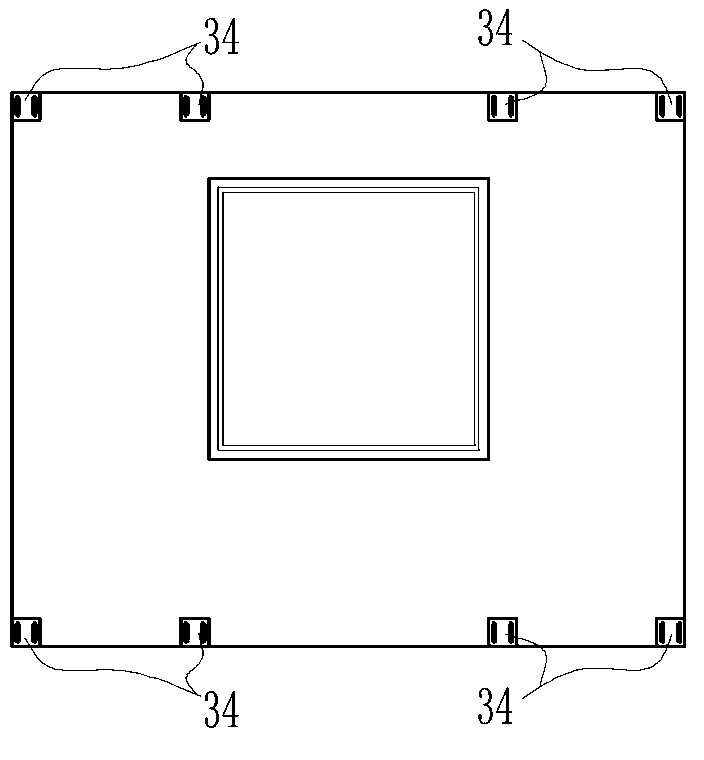

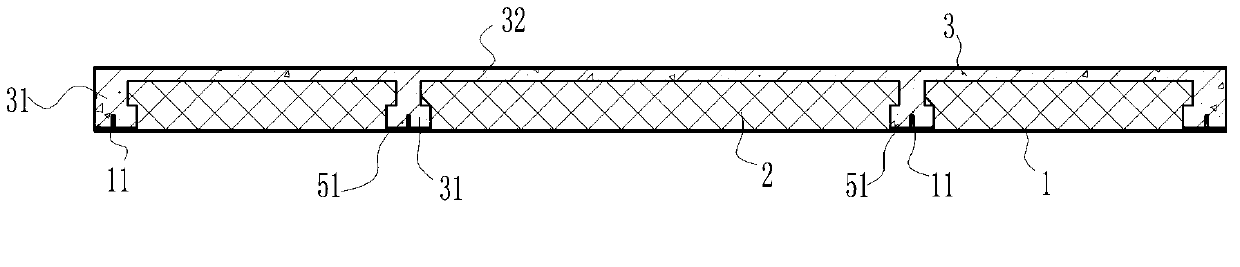

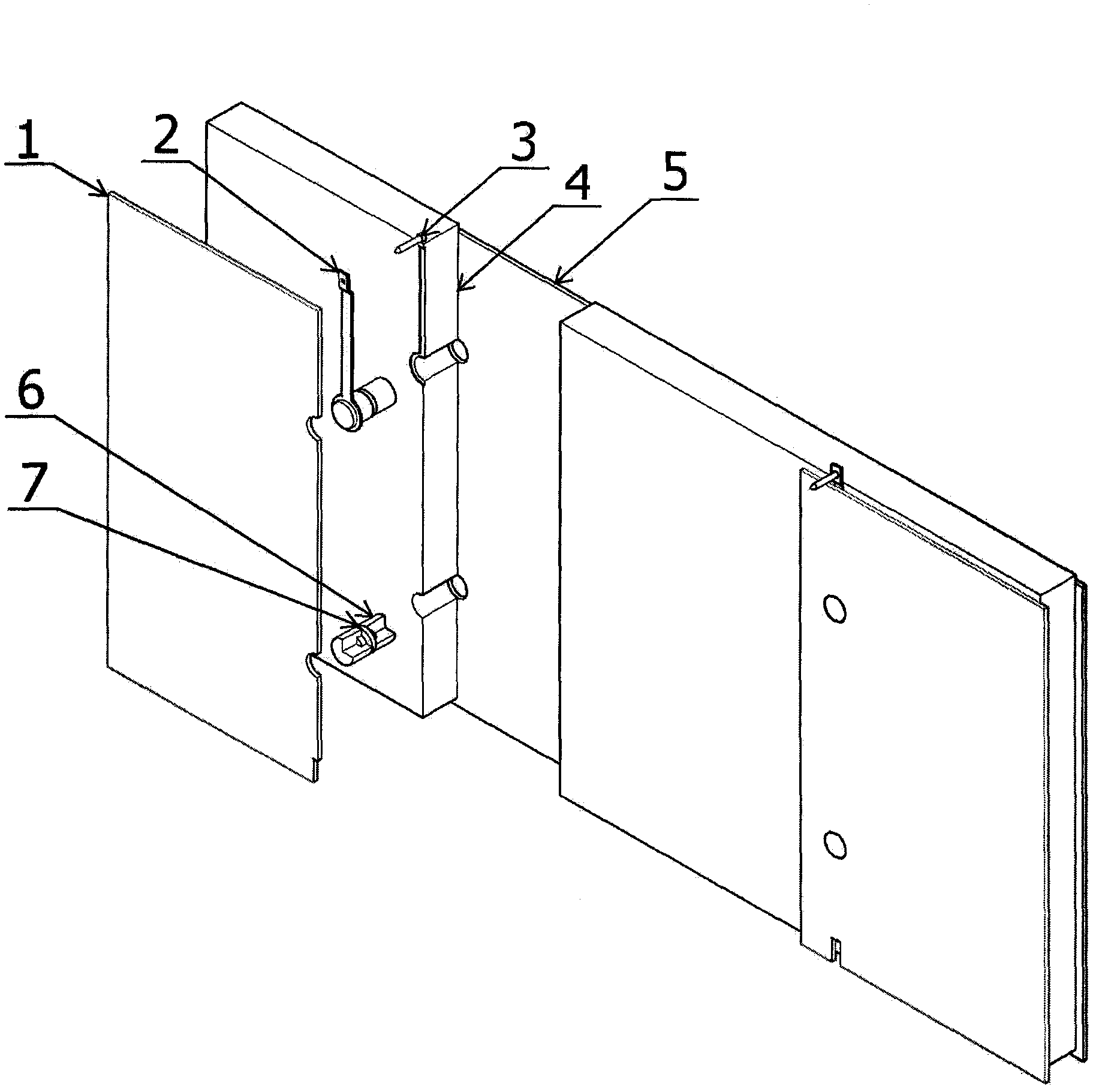

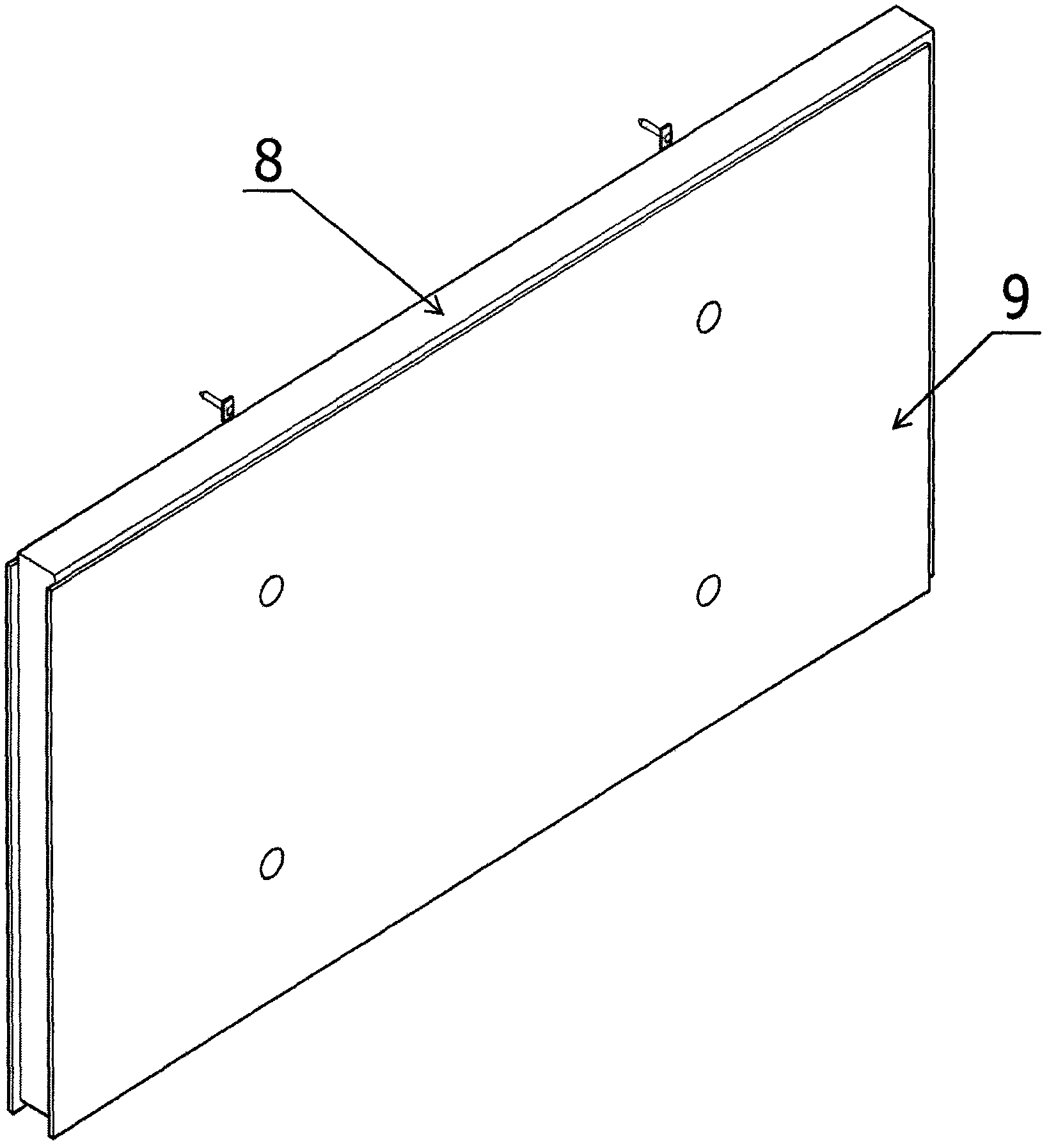

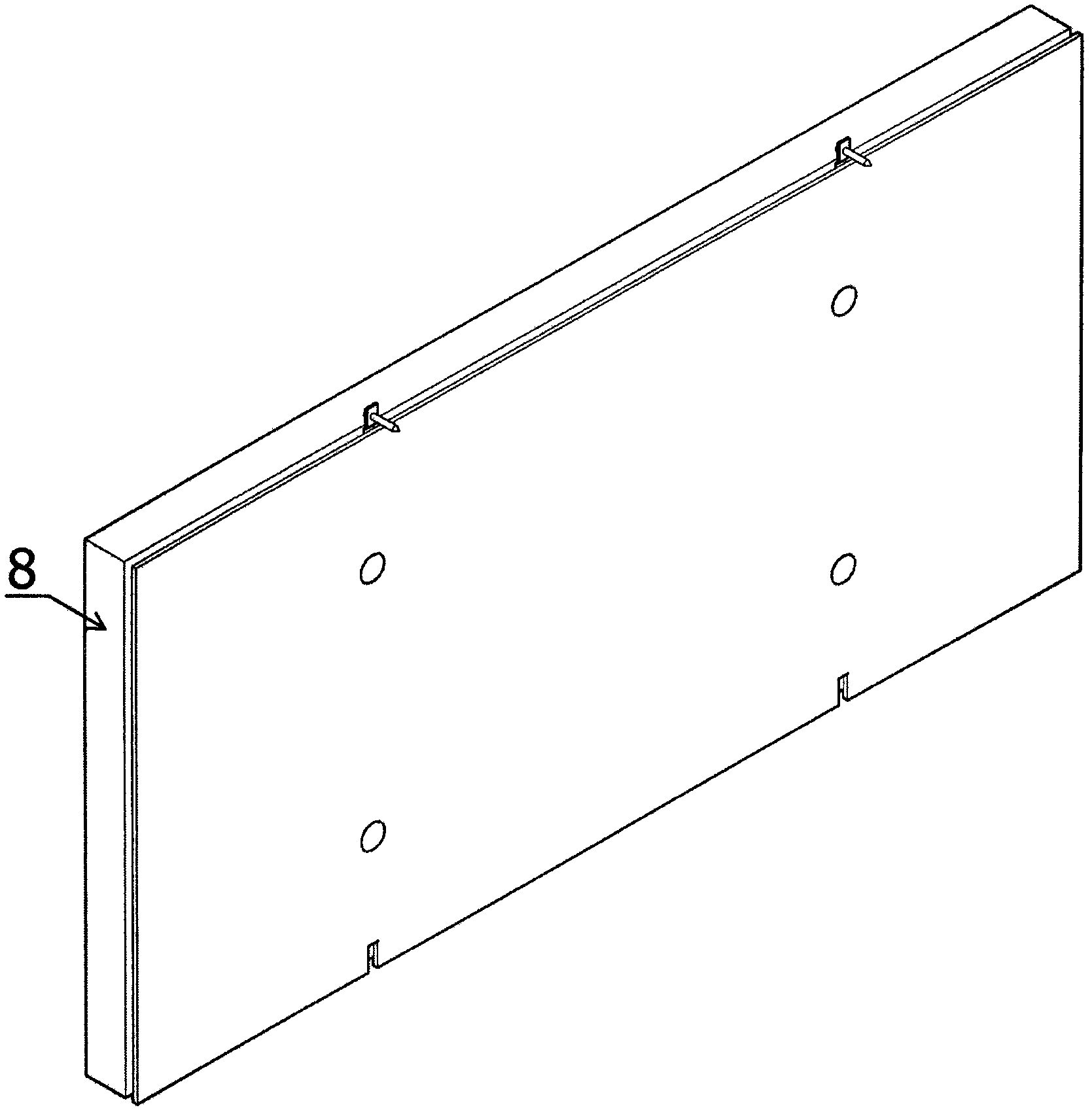

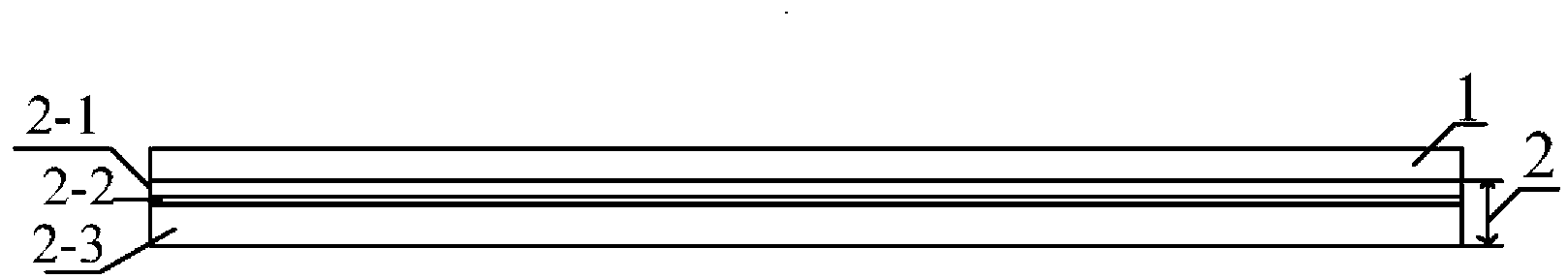

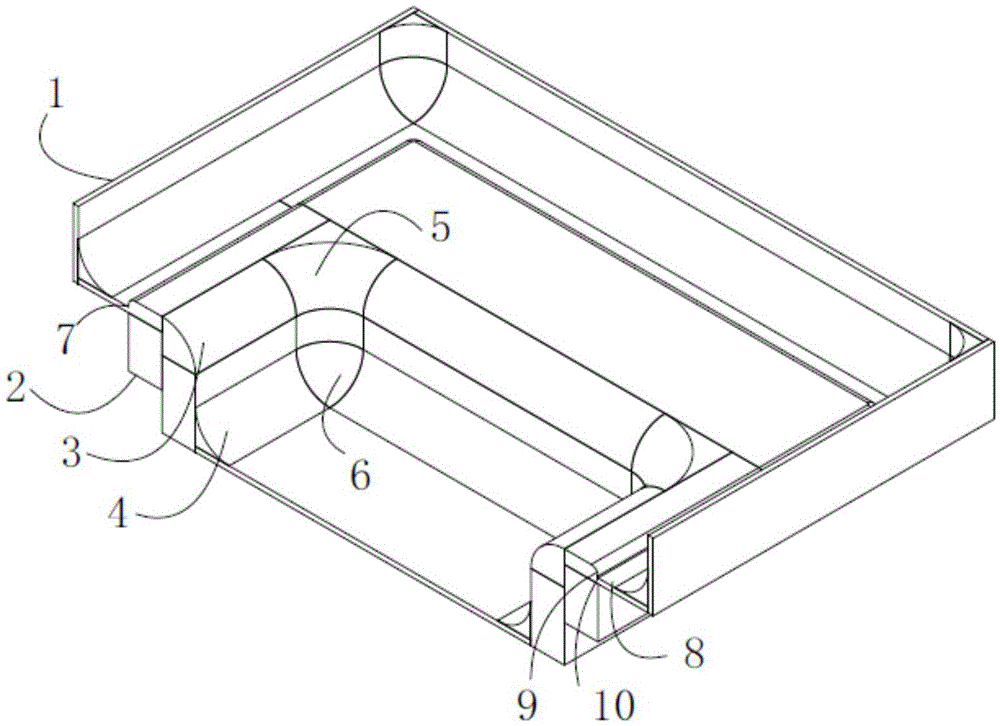

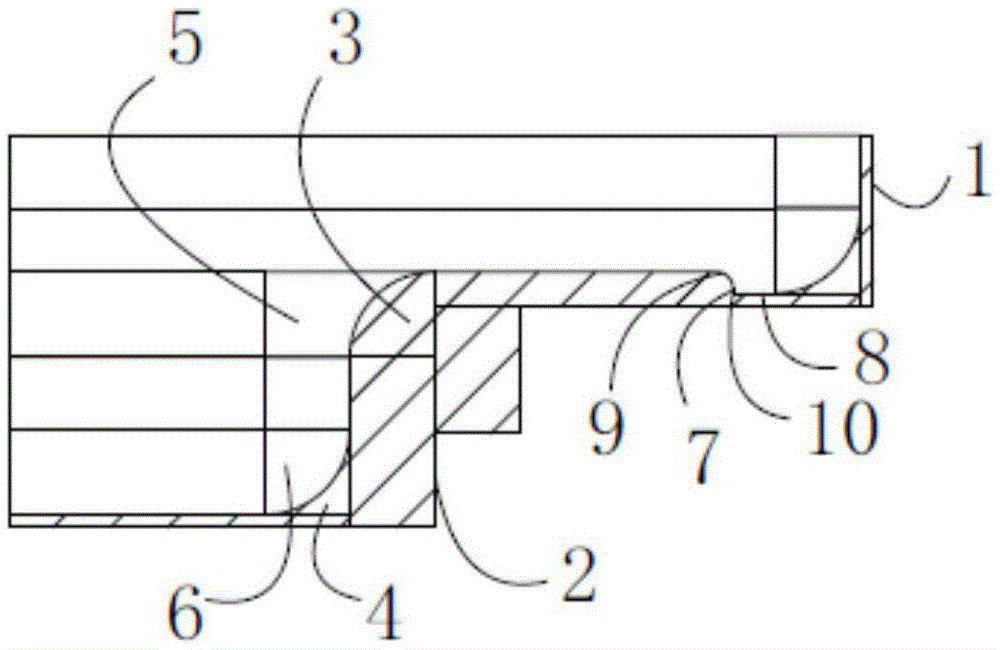

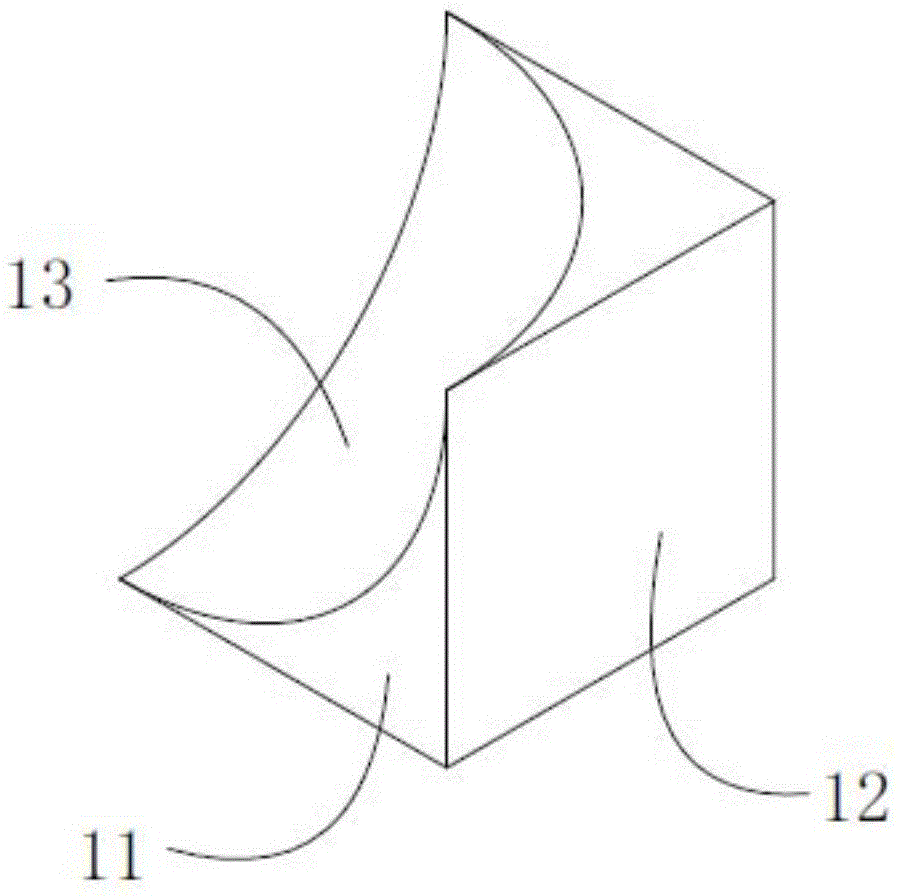

Fiber Concrete Sandwich Insulation Decorative Panel

The invention relates to a thermal insulating material for buildings, and in particular relates to a fibre concrete sandwiched thermal insulating decorative plate which comprises a panel, a back plate and a core plate. Holes are correspondingly formed on the panel, the back plate and the core plate; the core plate is bonded between the panel and the back plate; a broken bridge component penetrates through the holes to be fixed in the middle of the core plate; a broken bridge shearing-resistant connecting component is formed by a poured anchor plug and the broken bridge component; and the panel, the back plate and the core plate are fixedly connected into one to form the main body of the thermal insulating decorative plate. A hole-containing hanger is fixed in the main body of the thermal insulating decorative plate; the hanger is sleeved to the broken bridge shearing-resistant connecting component; seals are fixedly attached to the four sides of the main body of the thermal insulatingdecorative plate; and a veneer is fixedly attached to the panel of the thermal insulating decorative plate. The materials used for the fibre concrete sandwiched thermal insulating decorative plate all are incombustible materials, so that the fireproof performance of the thermal insulation system is obviously improved. Besides, the integrated space stress of the plate is scientific, safe and reliable, and the thermal insulation system is prevented from creeping.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

Preparation technology of fair-faced concrete and preparation method of special admixture

The invention relates to a preparation technology of fair-faced concrete and a preparation method of a special admixture. The fair-faced concrete is prepared from the following components: water, cement, fly ash, mineral powder, medium sand, gravels, a dispersing agent, a defoaming agent, an air entraining agent and a water reducing agent. The fair-faced concrete has good apparent effects; by utilizing molding effects of the concrete, a decorative effect can be realized, and secondary finishing and decorating of partial molded concrete are eliminated; the fair-faced concrete is often used as decorative concrete and has the characteristics of small color difference and the like; the cured and molded concrete has the advantages of no obvious color difference in surface color and unique texture; the fair-faced concrete has the advantages of flat and smooth surface, uniform color, angular property, no damage or pollution, good environmental affinity and close to nature when being used forengineering construction.

Owner:成都精准混凝土有限公司

Decorative concrete and method of installing the same

A decorative concrete product and method of making the same is provided. The concrete surface carries a unique textural and visual decorative pattern that is troweled over the uncured surface. The decorative pattern strategically conceals any imperfections in the concrete surface. A decorative finishing tool is utilized to create a unique and consistent pattern throughout the exposed surface of the concrete. Unique visual patterns may include any aesthetic design including wood grain, or lightly finished honed or cut stone. The decorative finishing tool may be configured so that varying textures and contours may consistently be imprinted throughout the concrete. Advantageously, the cured concrete retains the durability of a concrete surface while carrying a visually and texturally appealing appearance.

Owner:SHAW CRAFTSMEN CONCRETE LLC

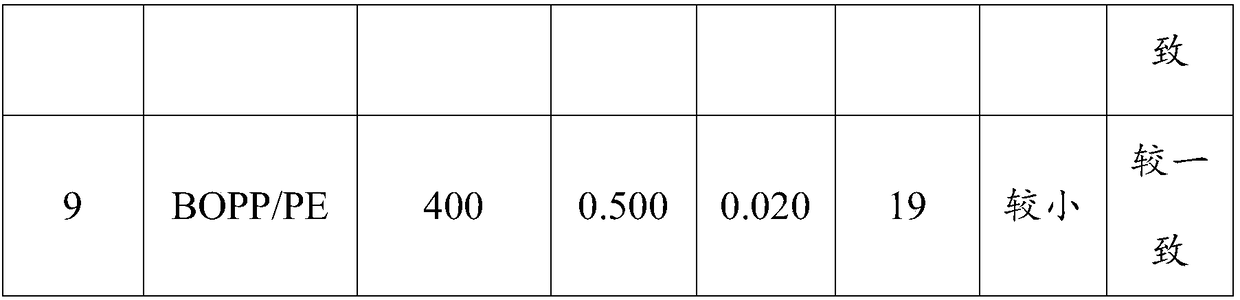

Method for manufacturing decorative concrete product

ActiveCN108274589APromote formationClear and precise linesMouldsSurface patternPulp and paper industry

Owner:HUBEI UNIV OF TECH

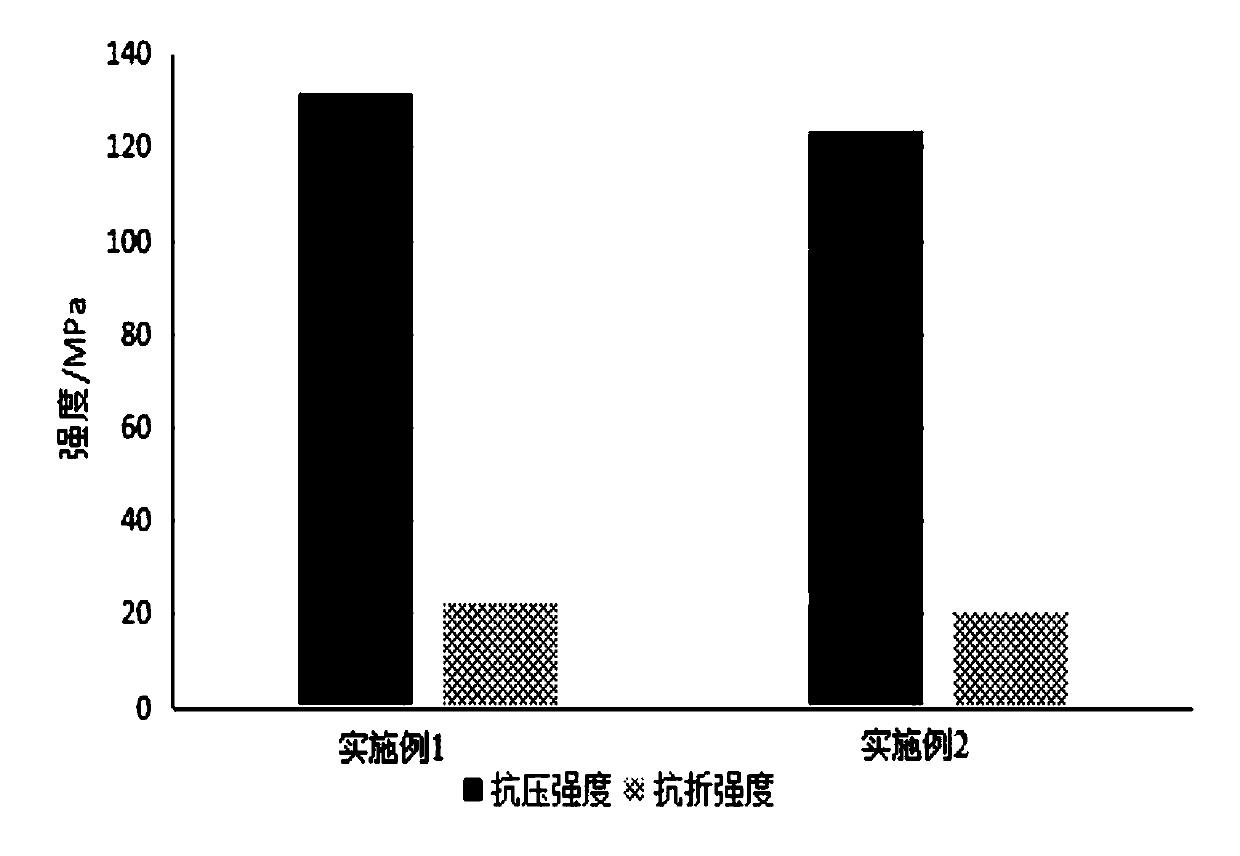

Fair-faced structure decorative concrete and preparation method thereof

The invention discloses fair-faced structure decorative concrete which is prepared from the following raw materials in parts by mass: 1 part of a cementing material, 1.0 to 1.5 parts of aggregate, 0.02 to 0.045 part of fiber, 0.01 to 0.0135 part of an additive and 0.2 to 0.3 part of water. According to the fair-faced structure decorative concrete, the compressive strength is larger than or equal to 120 MPa, the bending strength is larger than or equal to 20 MPa, the drying shrinkage value is smaller than or equal to 300*10<-6>, the free shrinkage value is smaller than or equal to 650*10<-6>, the expansion degree is 650-750 mm, and the formed concrete is consistent in color and luster and is green-grey in color. The fair-faced structure decorative concrete meets the requirements of structural performance, decorative performance, aesthetic performance and industrial construction performance, can be formed at a time, eliminates plastering, decoration, protection and other process links, reduces the operation intensity, saves materials, and conforms to the characteristic of green construction.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Covering-type decorative concrete and construction method thereof

The invention provides covering-type decorative concrete and a construction method thereof. The covering-type decorative concrete comprises, by weight, 30-40% of portland cement, 3-8% of a polymer, 0-5% of organic fibers, 0-5% of an inorganic pigment, 0-1% of an additive and 41-67% of an inorganic mineral filler. The decorative concrete is polymer-modified cement mortar, can be directly used as a covering layer with thickness of 5 millimeters to several centimeters on the existing concrete base and has a uniform structure and high plasticity. The covering-type decorative concrete can form different decorative patterns such as stone, wood, brick and tile patterns with white or various colors by different molds. Through a special-purpose coloring agent, daedal color effects are obtained.

Owner:惠州市斐尔创新材料有限公司

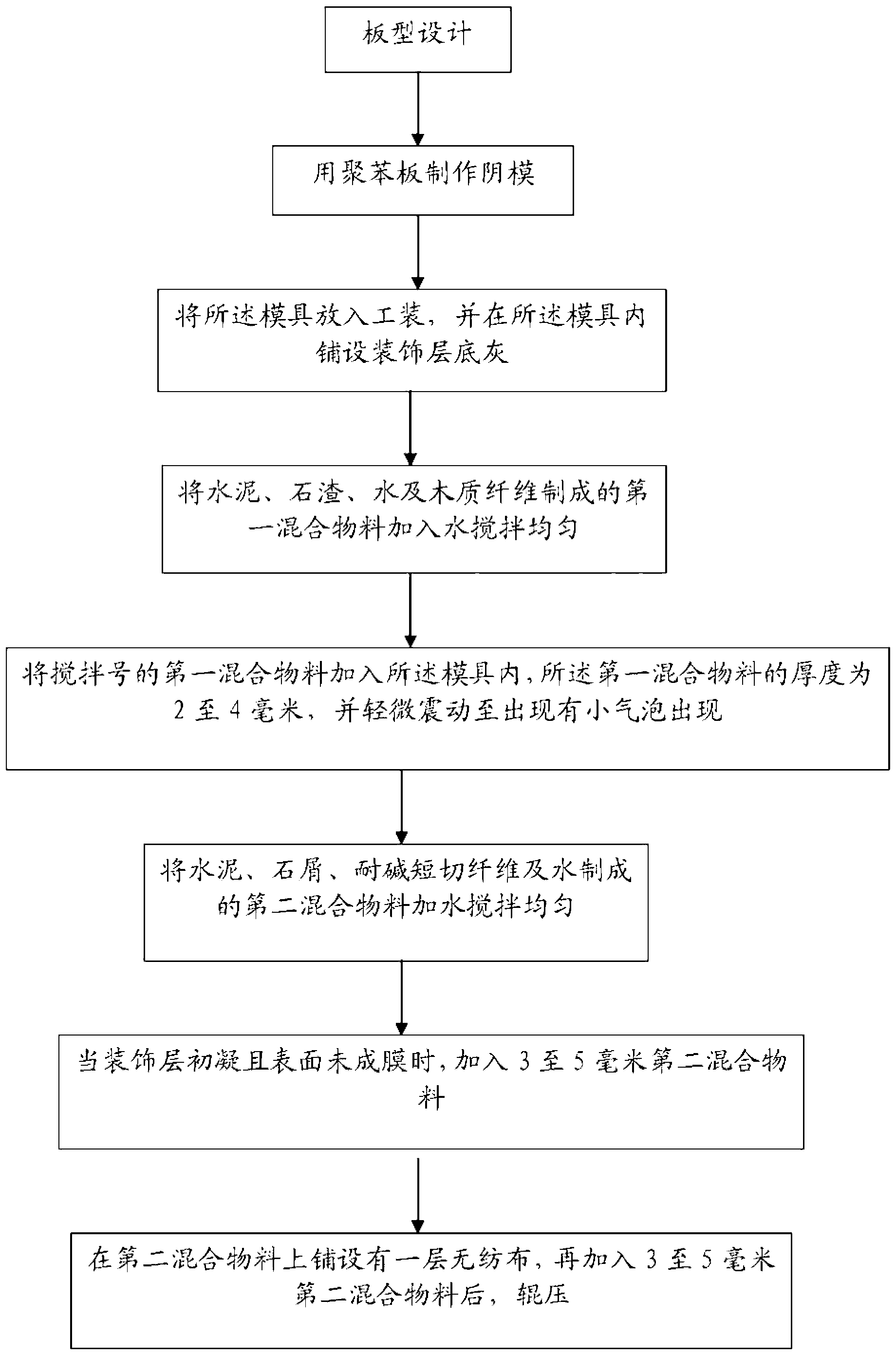

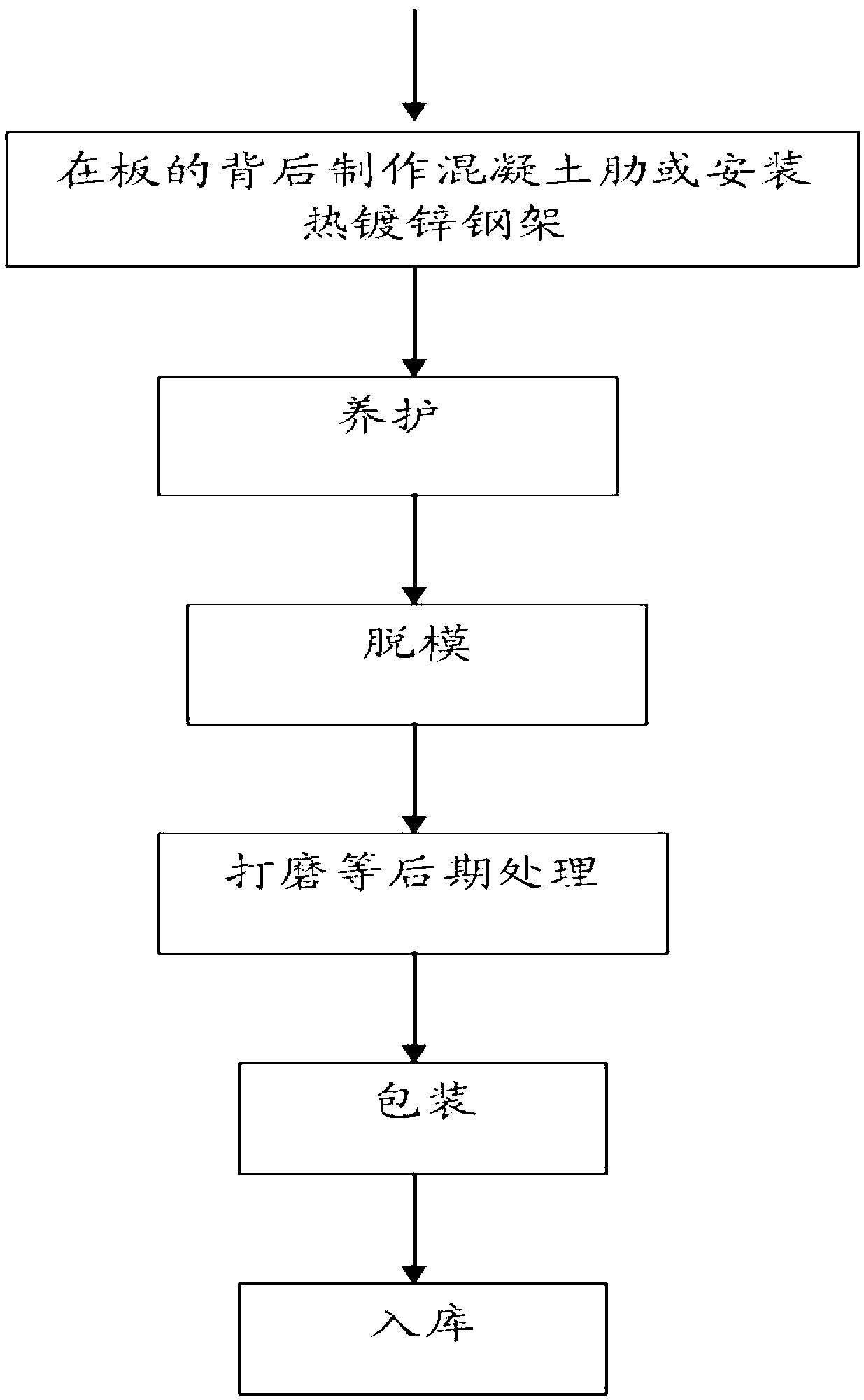

Method for manufacturing decorative concrete light-weight wallboard

The invention relates to a method for manufacturing a decorative concrete light-weight wallboard and the decorative concrete light-weight wallboard manufactured through the method. The decorative concrete light-weight wallboard comprises a decorative layer and a structure layer, wherein cement rock ballast slurry or cement stone chip slurry is solidified and then the surface is polished to form the decorative layer, the structure layer is composed of a first cement fiber layer, a non-woven fabric layer and a second cement fiber layer all of which are sequentially arranged, and the first cement fiber layer is tightly connected with the decorative layer. The non-woven fabric layer is additionally arranged in the structure layer and has the characteristics of being soft, tensile, smooth and the like, a corresponding bending-resistant property is provided when a chisel groove is formed in the structure layer, and therefore the thickness of the structure layer can be reduced and the size is small. Due to the mutual cooperation of the cement fiber layers and the non-woven fabric layer, not only is high compression-resistant intensity kept, but also the tensile intensity and impact-resistant intensity are increased. Due to the fact that the cement rock ballast slurry or the cement stone chip slurry is solidified and then the surface is polished to form the decorative layer, the decorative layer has the texture of stone, and is free of spraying coatings on the surface, firm and durable, and attractive in appearance.

Owner:张宝贵

Decorative concrete overhanging eave formwork

The invention provides a decorative concrete overhanging eave formwork. The decorative concrete overhanging eave formwork comprises baffles, keels, internal corner wood strips, external corner wood strips and a support, wherein the baffles surround an overhanging eave with concrete to be poured. Internal corner connecting parts are arranged at the joints, at corners, of the internal corner wood strips, external corner connecting parts are arranged at the joints, at the corners, of the external corner wood strips, and a boss groove is formed in the outer side of the position where a water drip is reserved. Thus, the decorative concrete overhanging eave formwork is simple in structure and convenient to use, one-time forming at the corners on three sides can be achieved, and the surface of the concrete overhanging eave can be smooth.

Owner:CHANGXING ZHONGHAI CONSTR ENG CO LTD

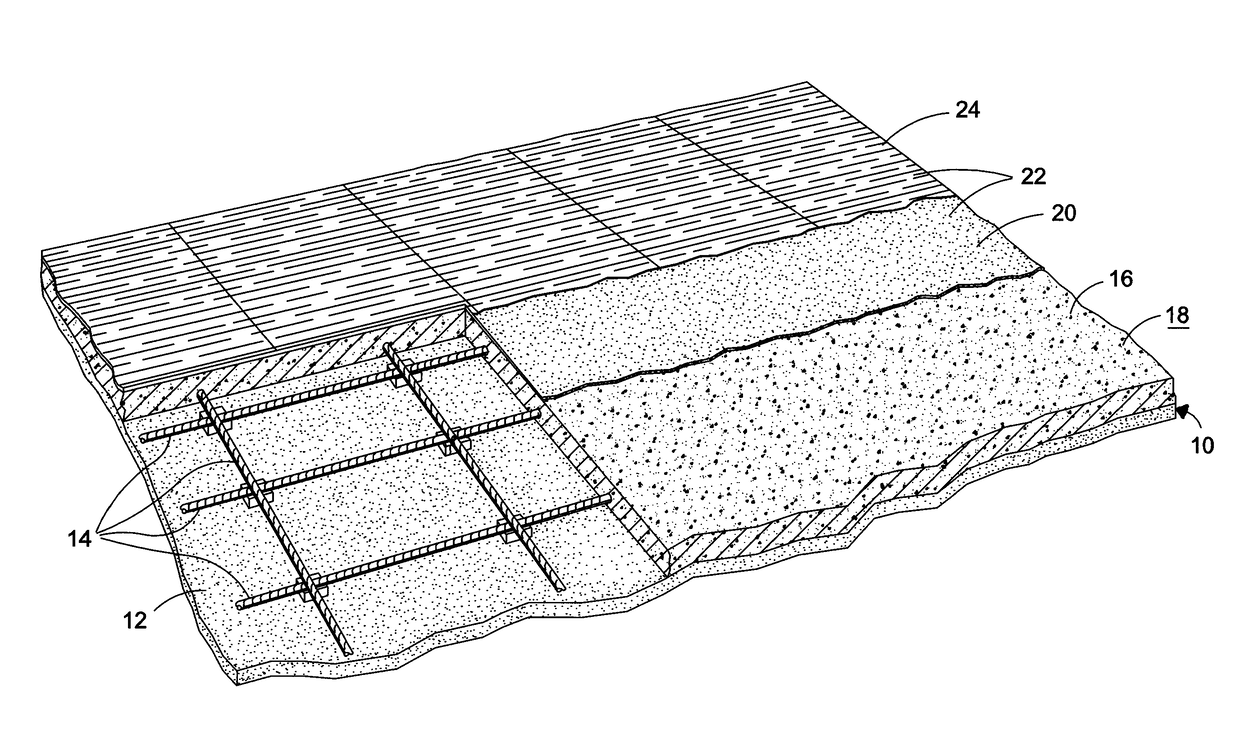

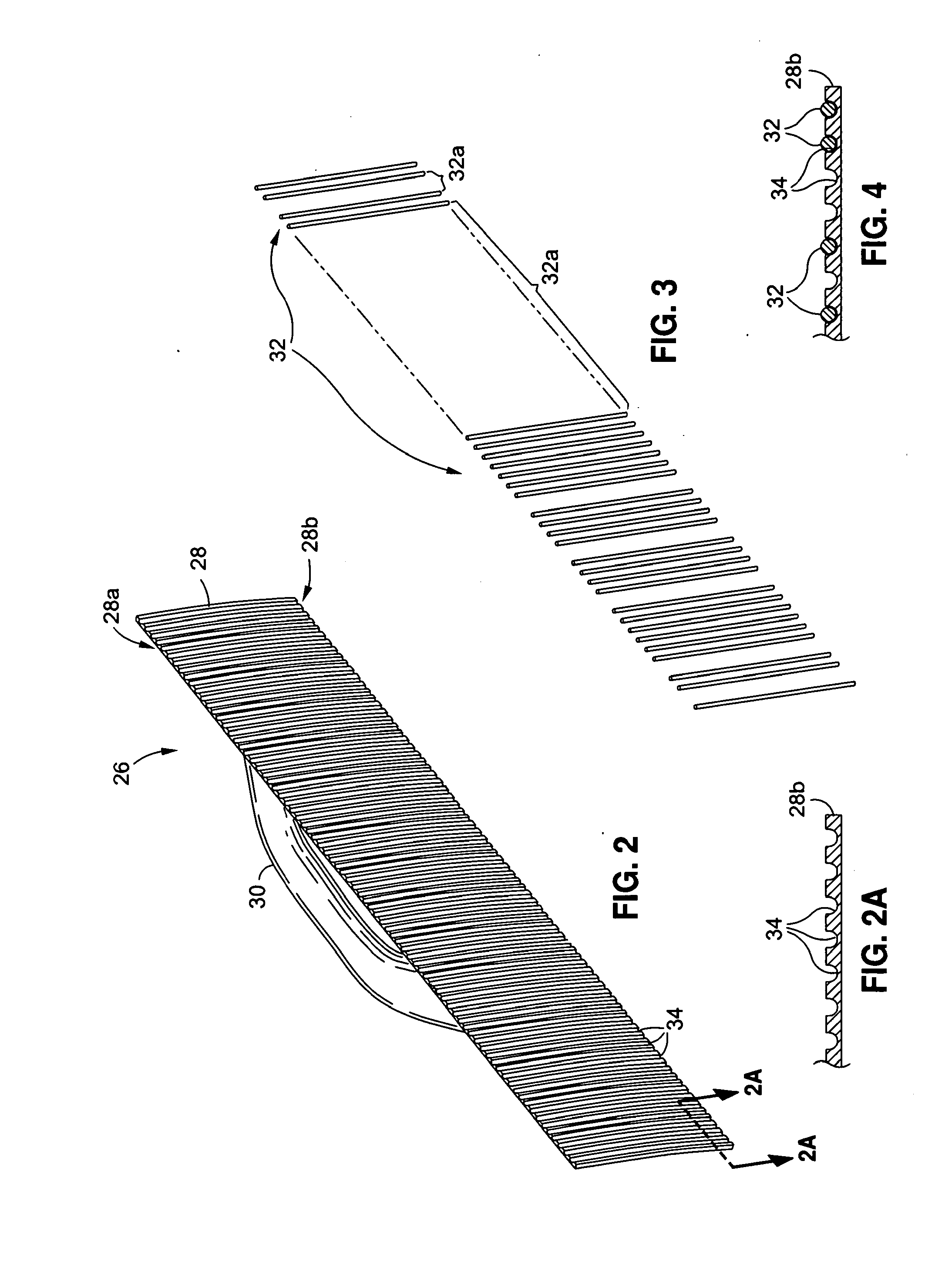

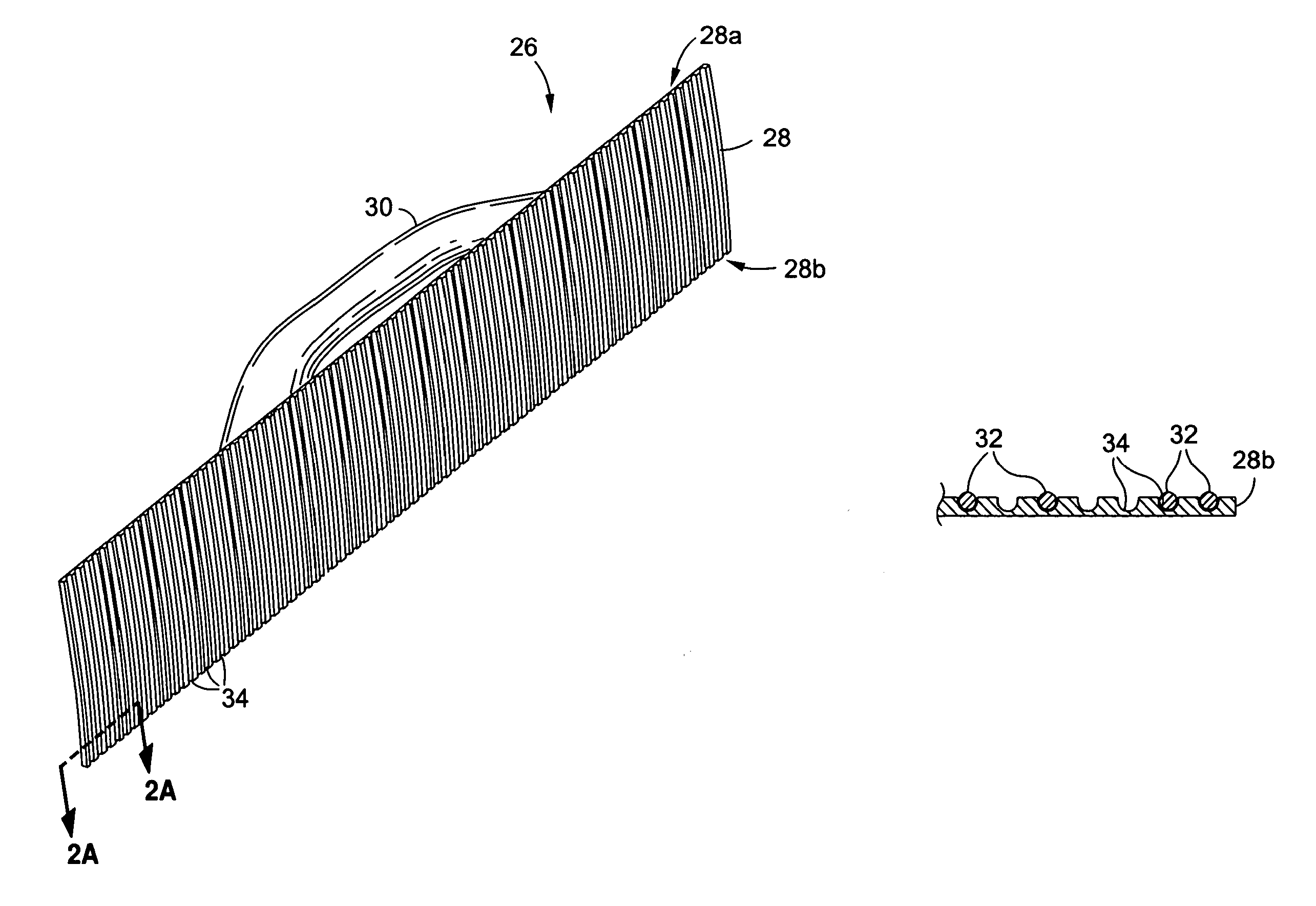

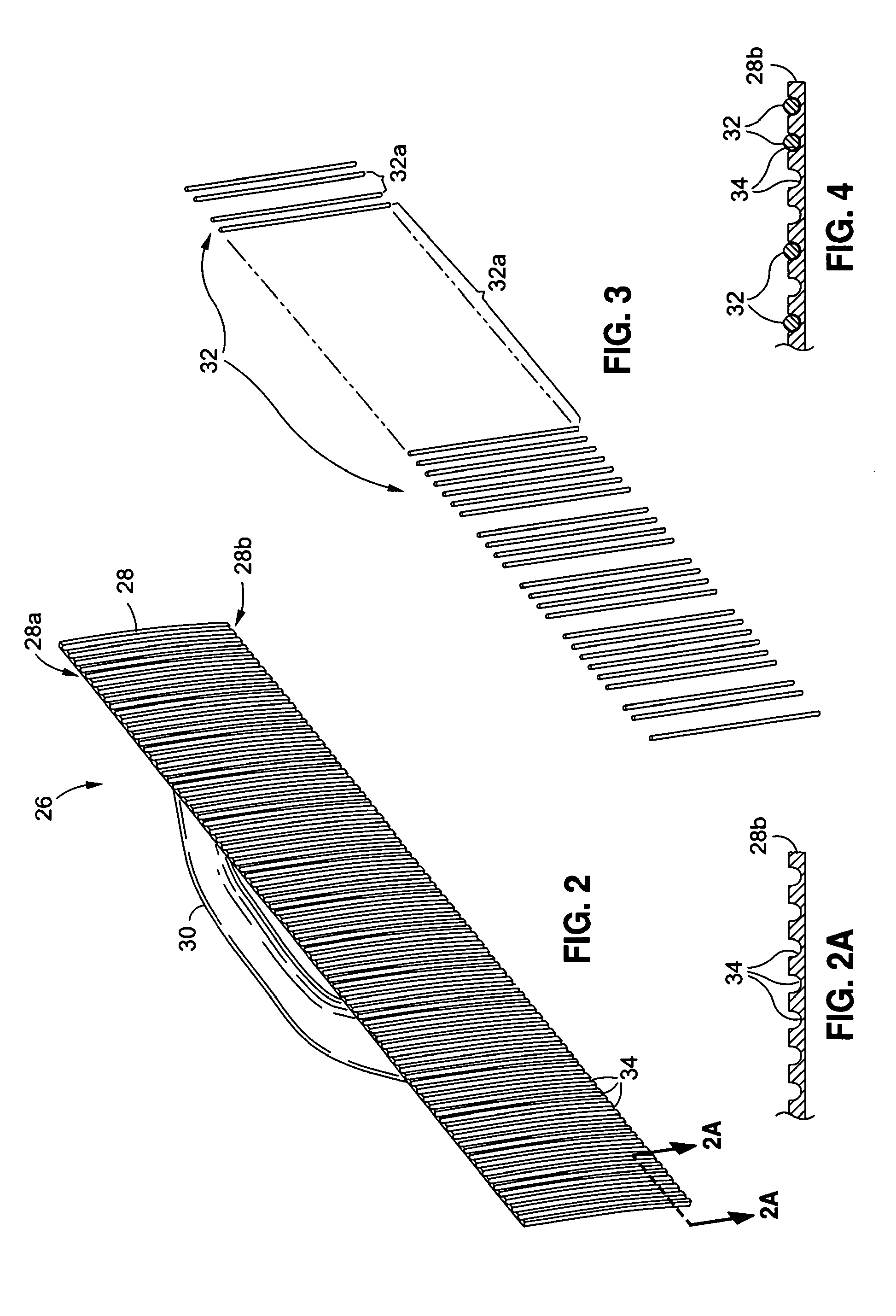

Decorative concrete simulating natural wood and method of forming the same

InactiveUS20170166001A1Improve aestheticsMore cost-effectivelyConstruction materialNatural patternsEngineeringBroom

A decorative concrete structure simulating natural wood and a method of fabricating the same is disclosed. A concrete mixture is poured over a subgrade which defines an exposed surface. The exposed surface is swept with a broom, saw cut, and optionally stained, and sealed to simulate aesthetic appearance of the natural wood.

Owner:SHAW & SONS

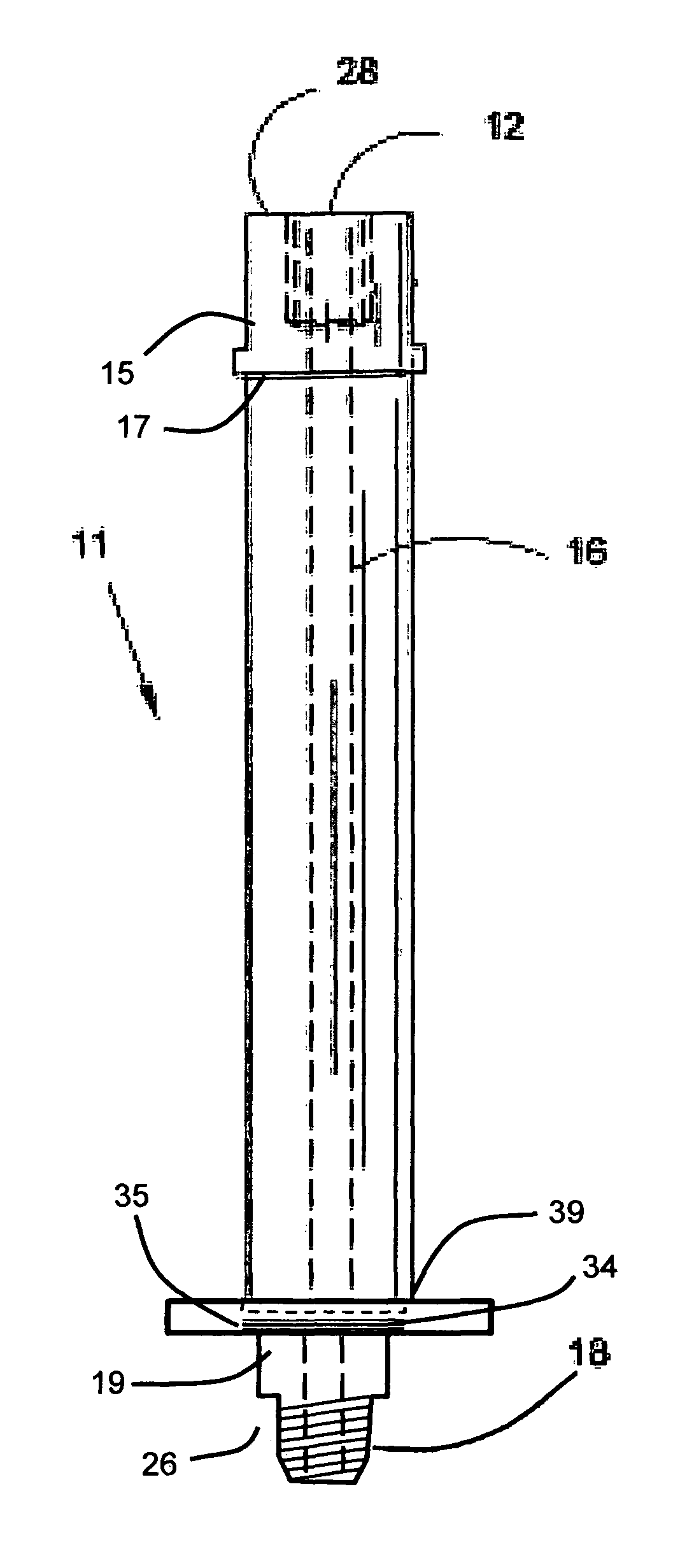

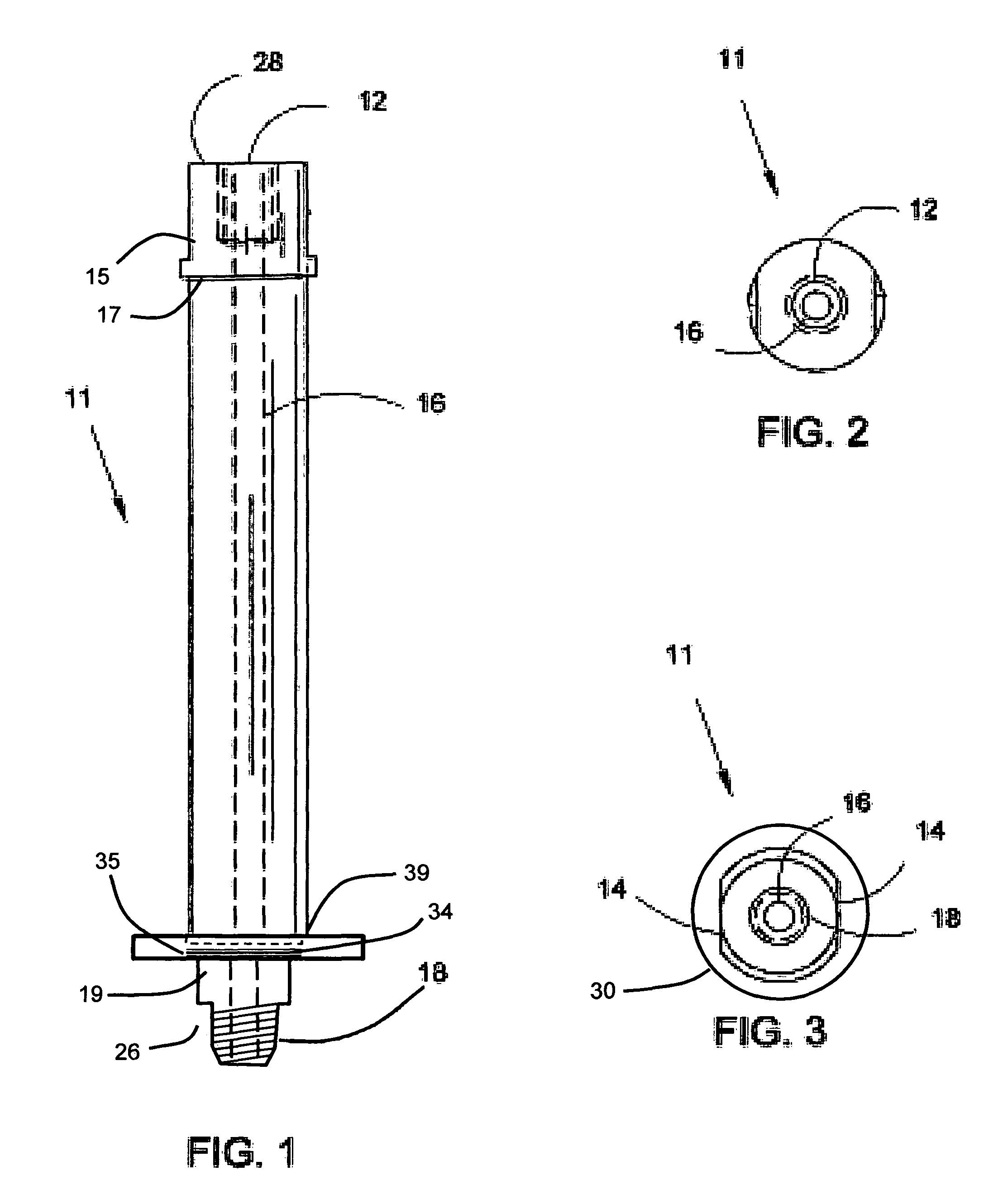

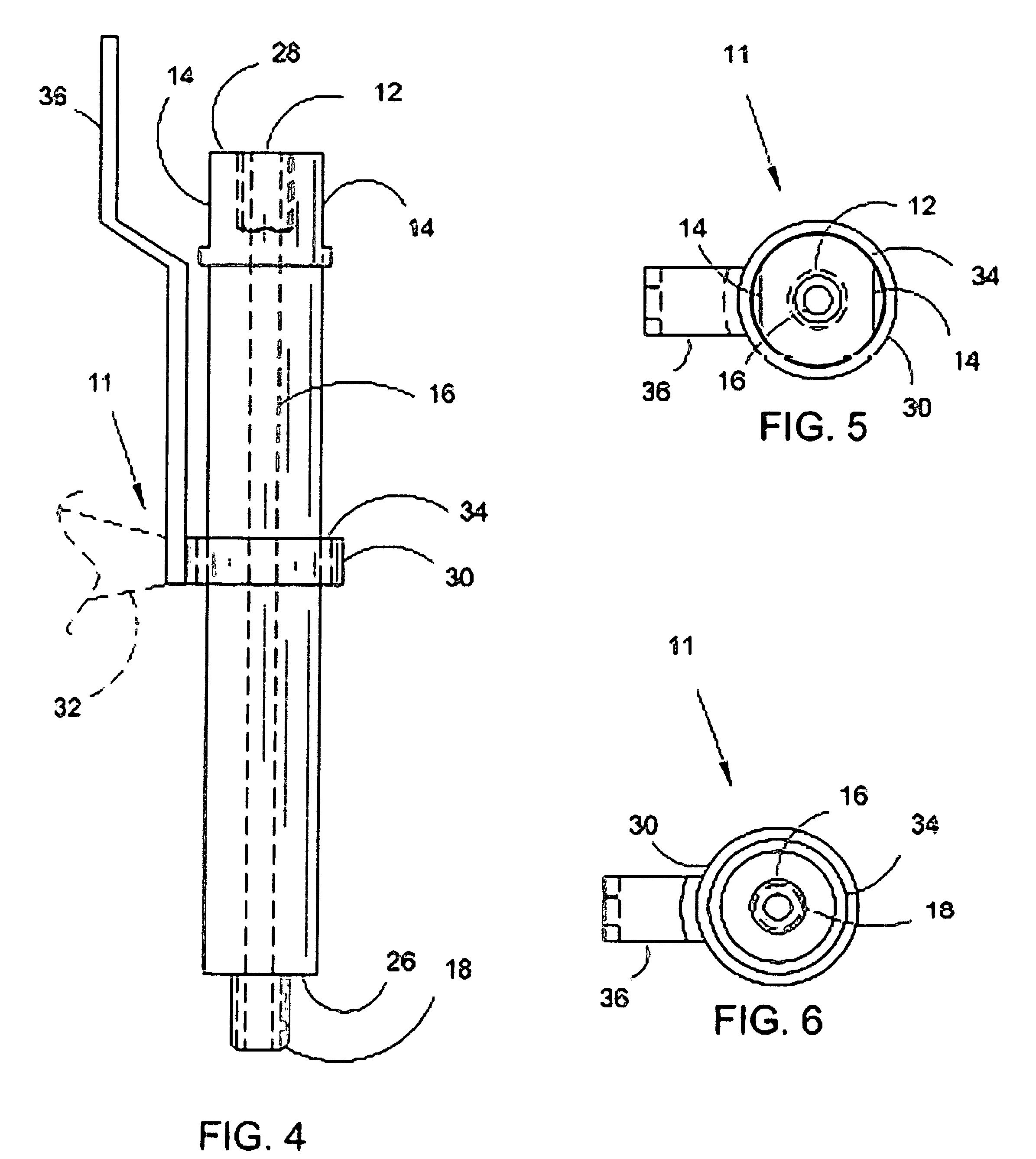

Concrete polishing extension

A Concrete Polishing Extension device for treating hardened concrete surfaces and more specifically interior surfaces of countertop sinks made from decorative concrete. The extension device has features for use with grinding deep, contoured surfaces of concrete. The preferred embodiment is comprised of an extended shaft with connection features and other features; a containment cap; a means to connect cap to shaft; an external sleeve that encircles the shaft; a slip ring collar; a means to connect external sleeve to slip ring collar; a bearing such as a thrust bearing; means to connect slip ring collar to bearing; and a means of the extended shaft used to contain bearing, slip ring collar and sleeve assembly. The device has a distal end with means to removably attach to a standard driver and a proximal end with means to removably attach to engage a standard grinding head.

Owner:KROMPACK BRIAN JAMES

Decorative Concrete Topping Process

Described herein is a method for preparing decorative concrete top ping which overcomes the limitations associated with epoxy Terrazzo floors. Specifically, the decorative concrete topping mixture described herein has a low crack potential, high strength and durability, much longer working time, thereby allowing for the material to be mixed in larger quantities and simplifying application. A binder composition made of Portland cement and pozzolanic materials is mixed with an decorative aggregate and other additives before pumping the concrete topping mixture onto a subfloor and allowing the concrete topping mixture to cure.

Owner:SKARB HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com