Patents

Literature

147 results about "Large aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus of on demand business activity management using business performance management loops

InactiveUS20060111921A1Overcome limitationsImprove management abilityCash registersResourcesGranularityBusiness activities

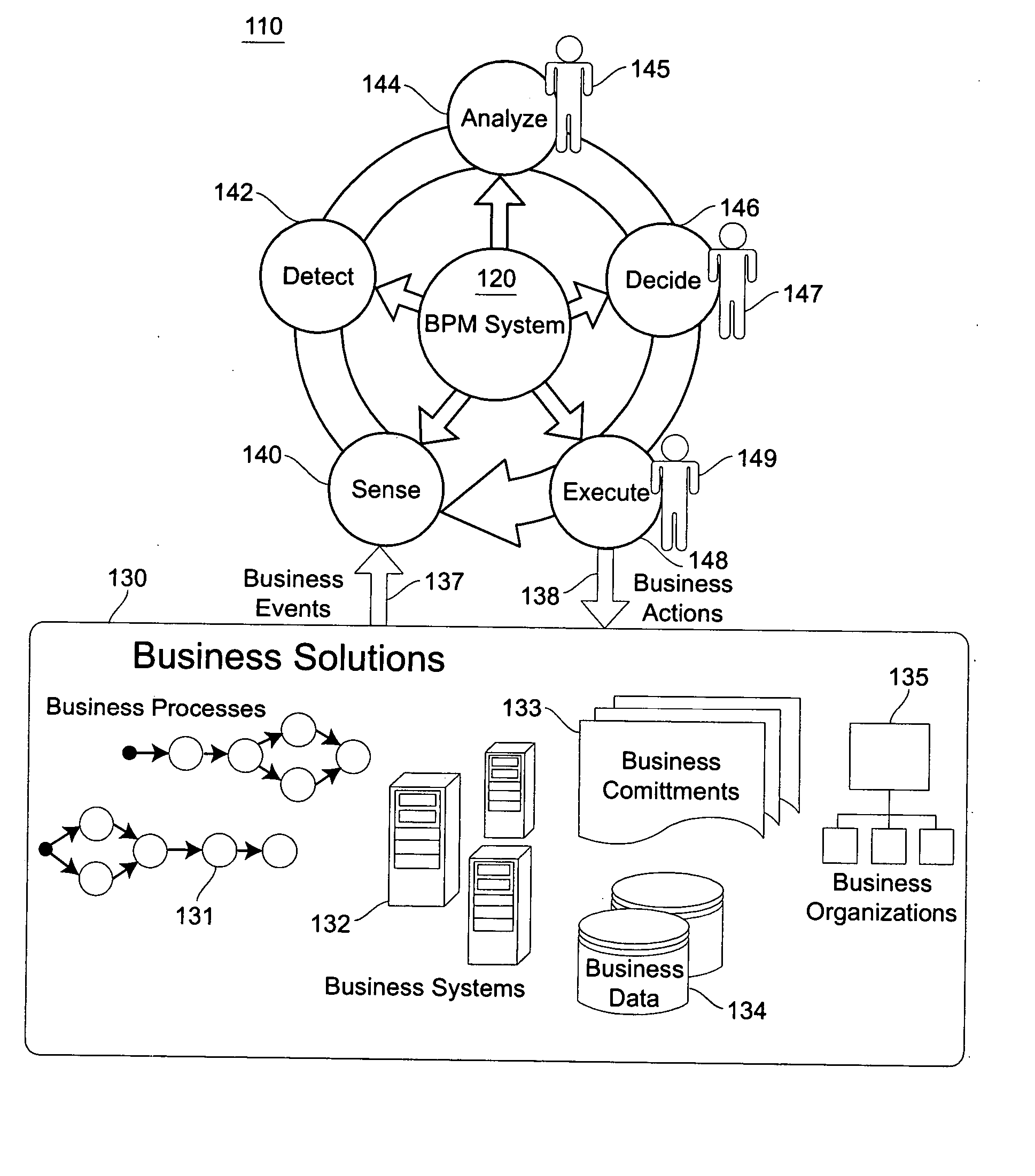

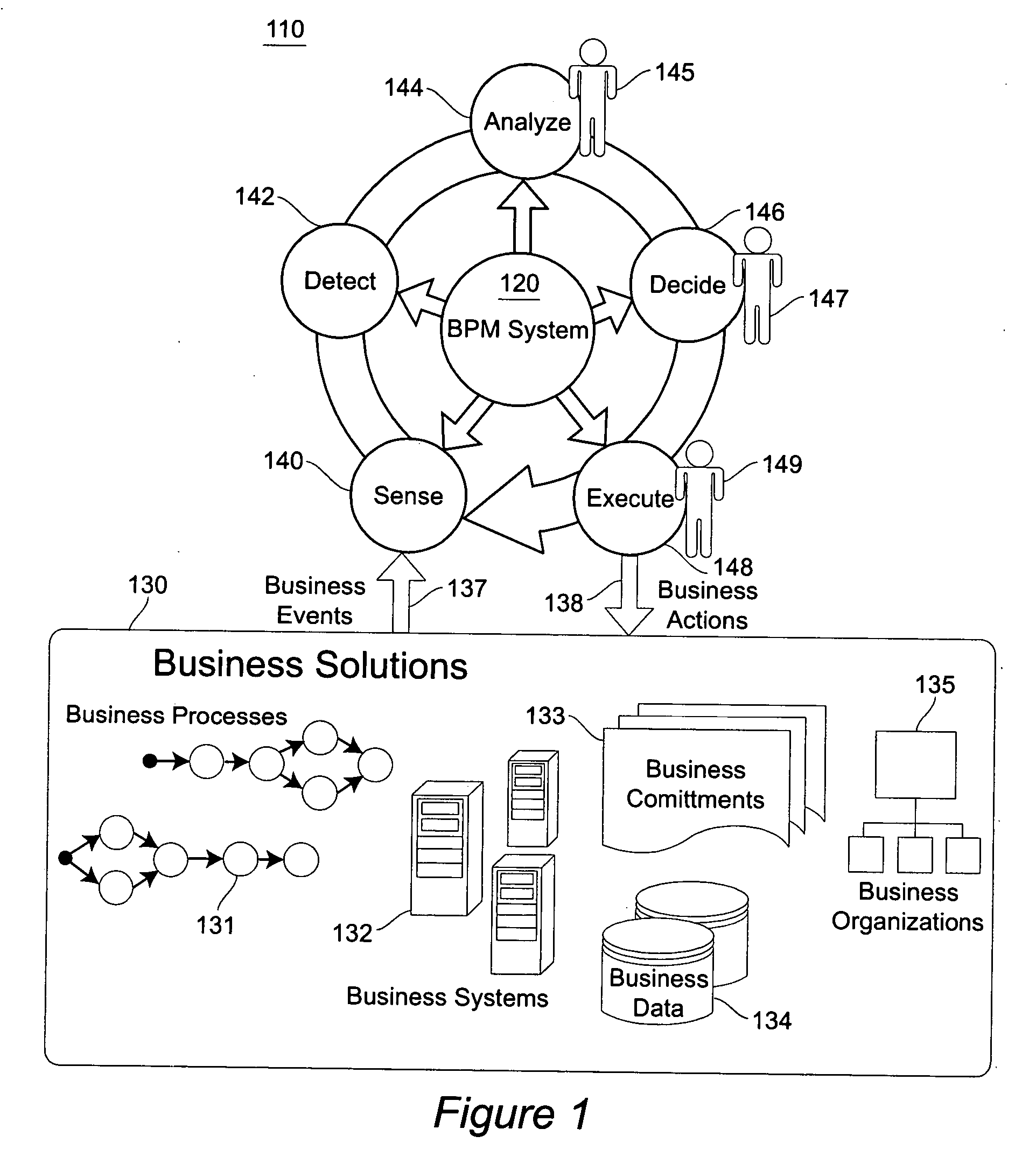

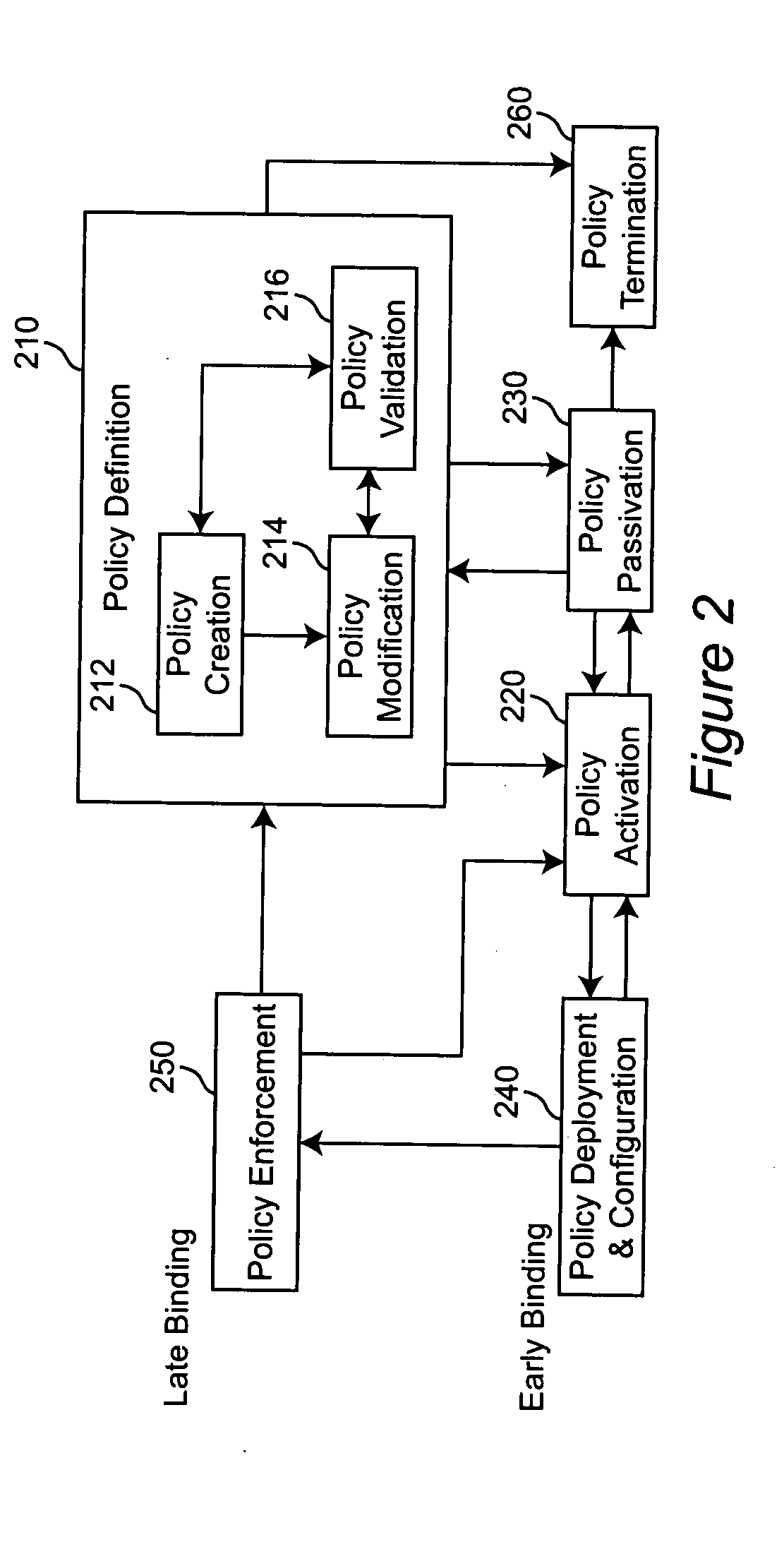

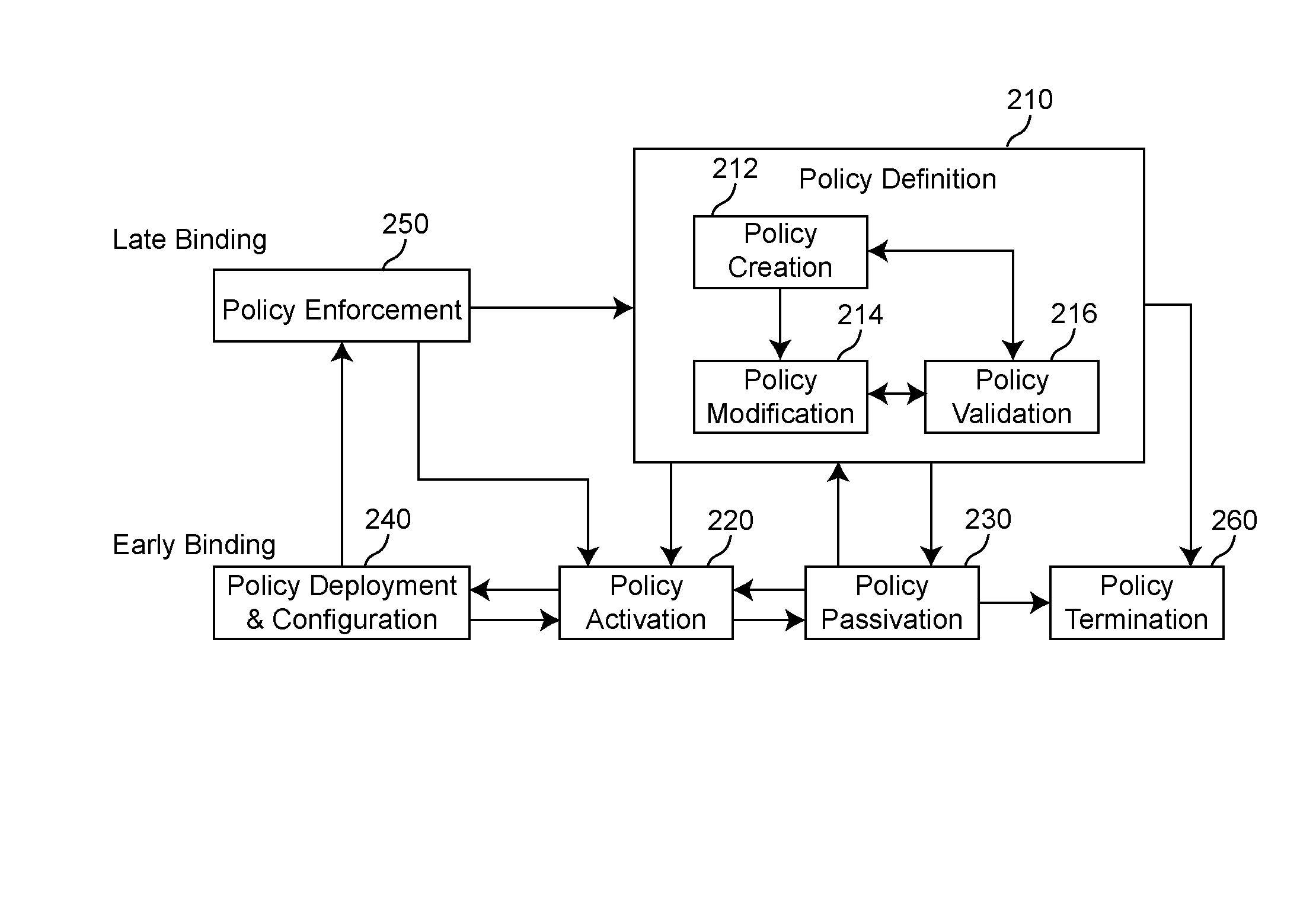

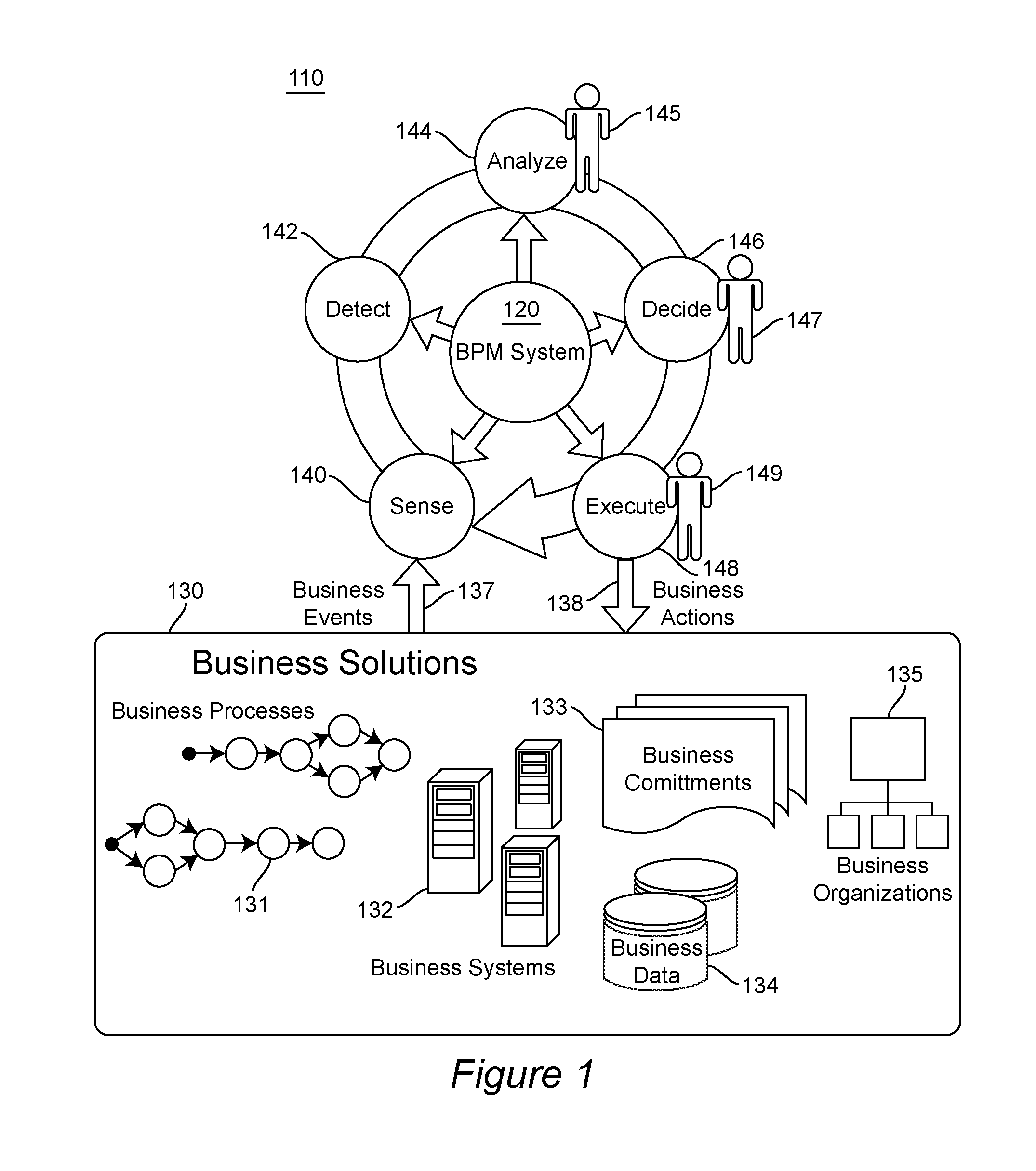

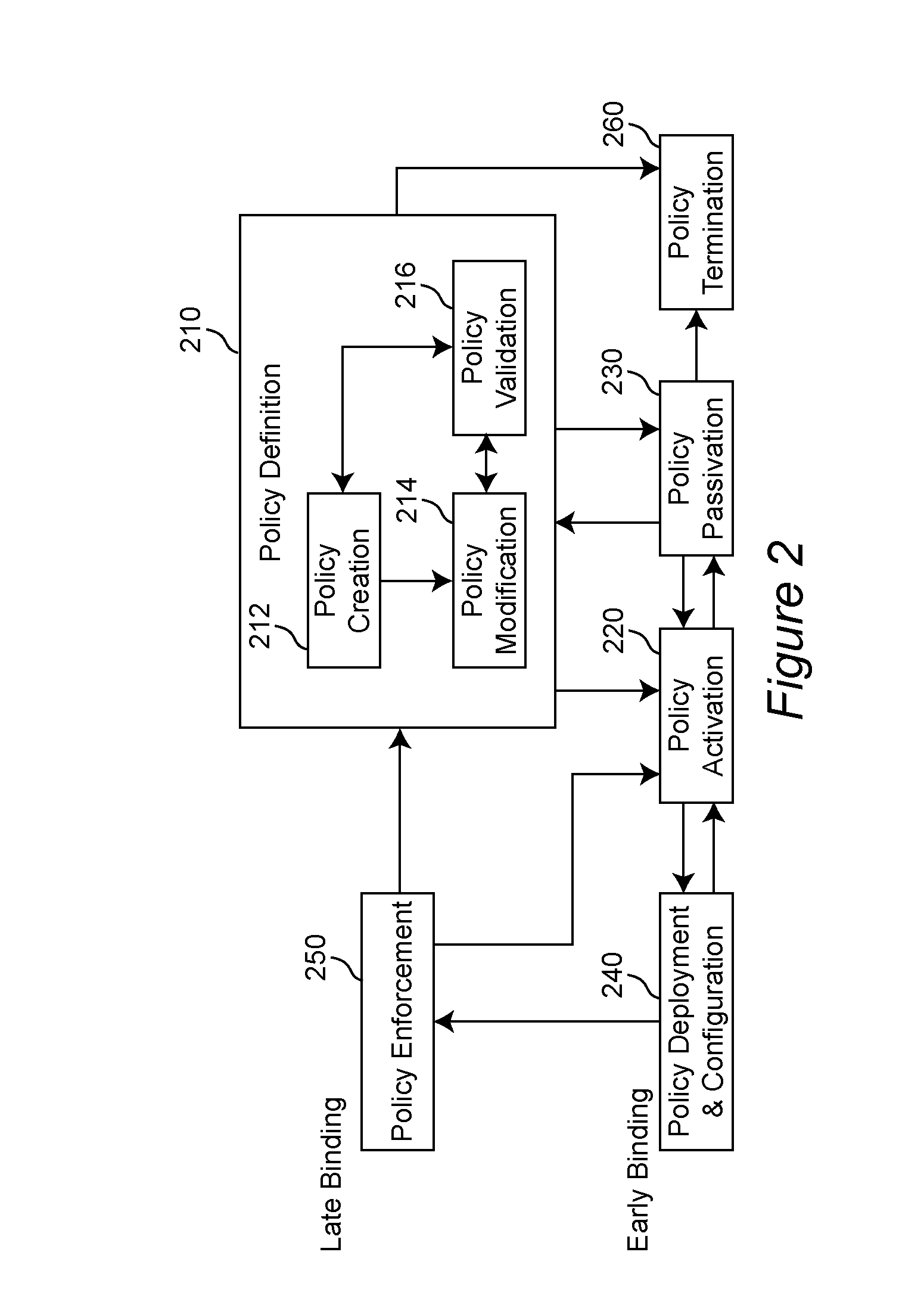

An architecture, system, and method are provided for a commitment loop solution for on demand business activity management. A Business Performance Management (BPM) loop is defined as a set of nodes each relating to different tasks for processing performance management trigger data generated by a business entity in real time, where the beginning or sensing element of the loop is triggered by a token (representing a business event from a business process) and the ending or executing element provides a business action to be implemented by the business entity. The token is passed from node to node sequentially in a particular order around the loop. Processing of the data represented by the token is governed by policies, which can be changed dynamically and follow a life cycle. On demand business activity management of larger aggregates of business entities (i.e. enterprises and value chains) is achieved by extending this architecture by building upon the BPM loops of the component entities to form a BPM net, adding nodes as necessary. This architecture, system and method can be implemented at multiple levels of granularity from operational or tactical business activities to enterprise wide strategic activities.

Owner:IBM CORP

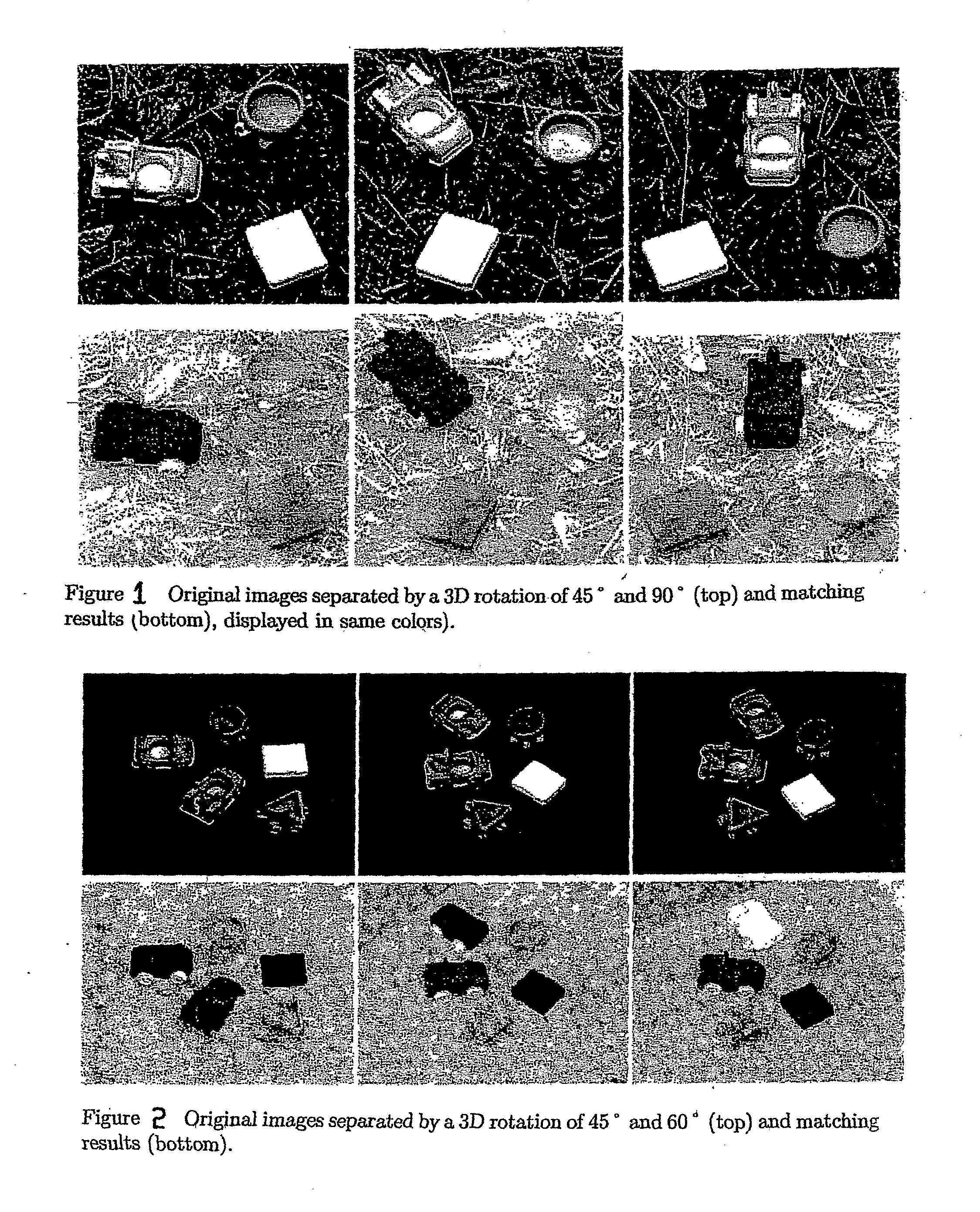

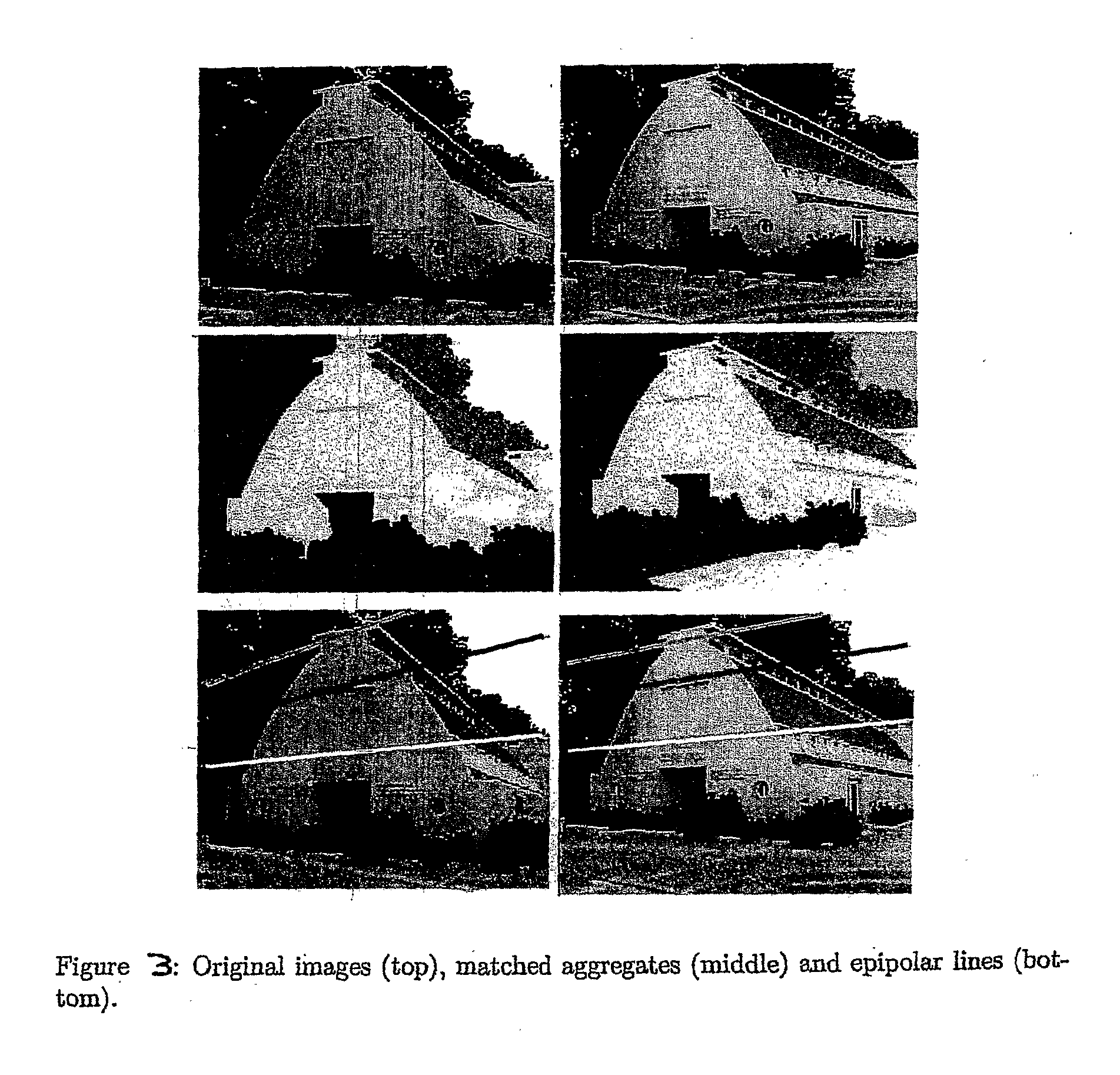

Method and apparatus for matching portions of input images

InactiveUS20070185946A1Overcome difficultiesLinear complexityImage enhancementTelevision system detailsAmbiguityImage segmentation

A method and apparatus for finding correspondence between portions of two images that first subjects the two images to segmentation by weighted aggregation (10), then constructs directed acylic graphs (16,18) from the output of the segmentation by weighted aggregation to obtain hierarchical graphs of aggregates (20,22), and finally applies a maximally weighted subgraph isomorphism to the hierarchical graphs of aggregates to find matches between them (24). Two algorithms are described; one seeks a one-to-one matching between regions, and the other computes a soft matching, in which is an aggregate may have more than one corresponding aggregate. A method and apparatus for image segmentation based on motion cues. Motion provides a strong cue for segmentation. The method begins with local, ambiguous optical flow measurements. It uses a process of aggregation to resolve the ambiguities and reach reliable estimates of the motion. In addition, as the process of aggregation proceeds and larger aggregates are identified, it employs a progressively more complex model to describe the motion. In particular, the method proceeds by recovering translational motion at fine levels, through affine transformation at intermediate levels, to 3D motion (described by a fundamental matrix) at the coarsest levels. Finally, the method is integrated with a segmentation method that uses intensity cues. The utility of the method is demonstrated on both random dot and real motion sequences.

Owner:YEDA RES & DEV CO LTD

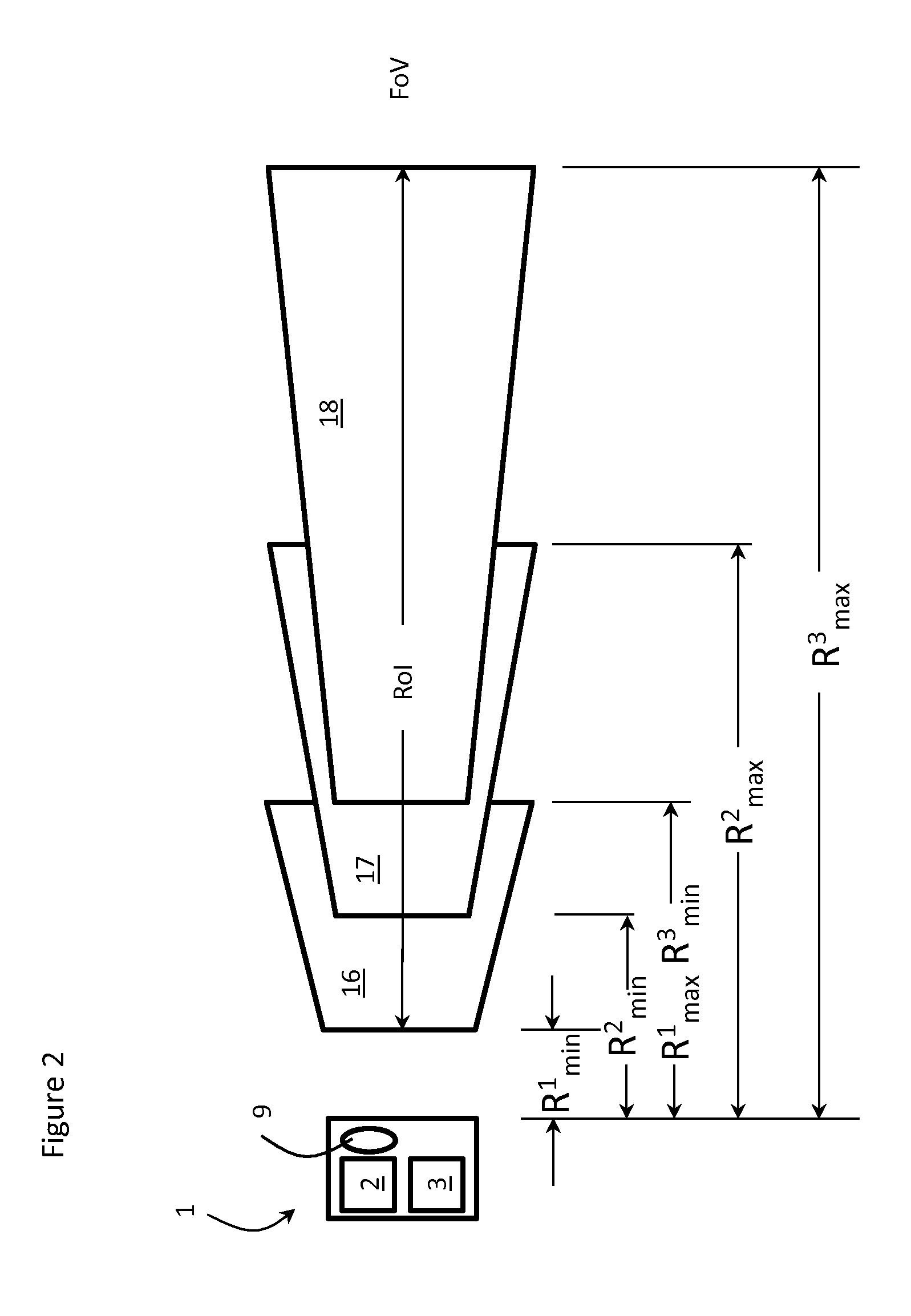

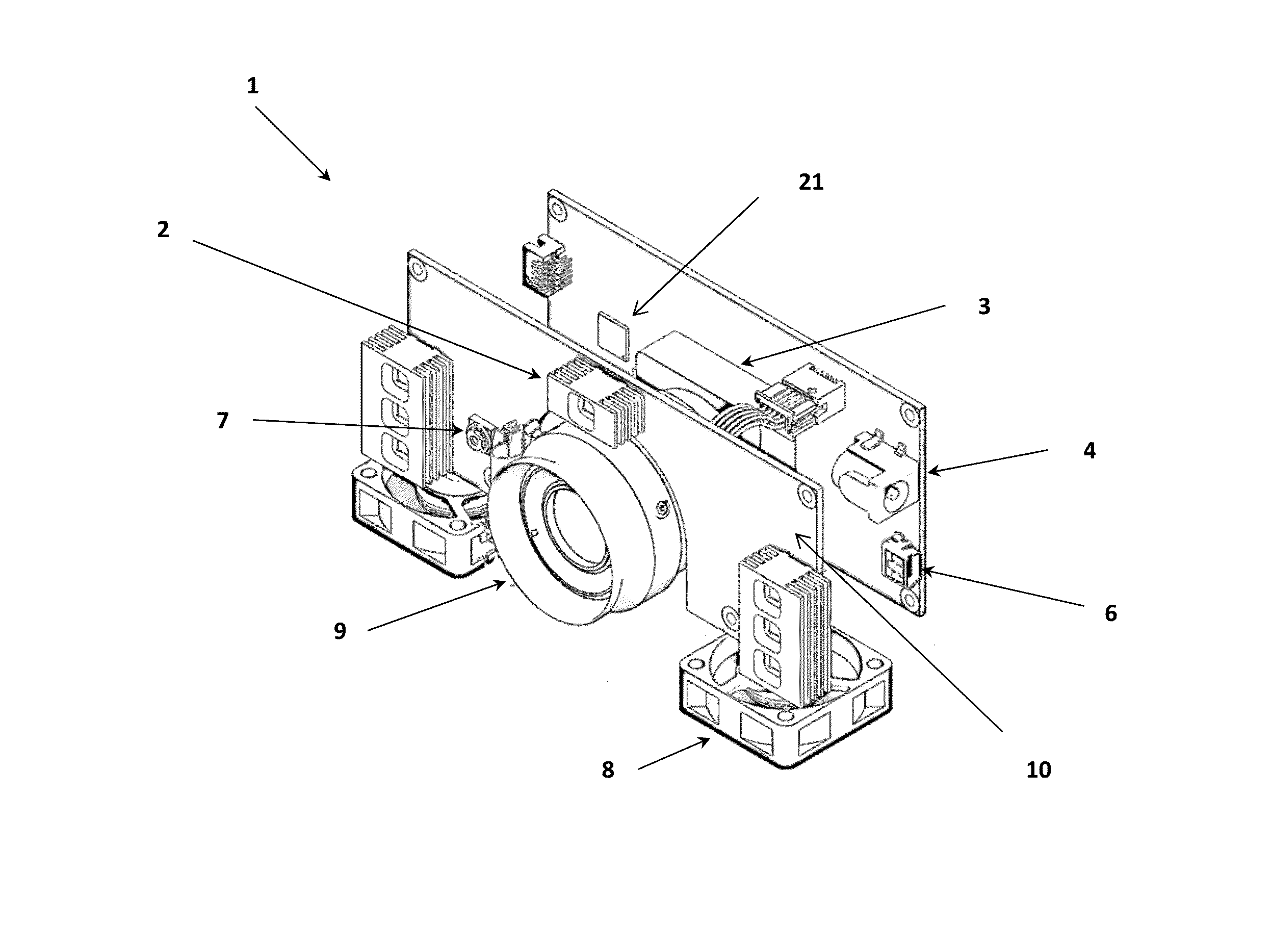

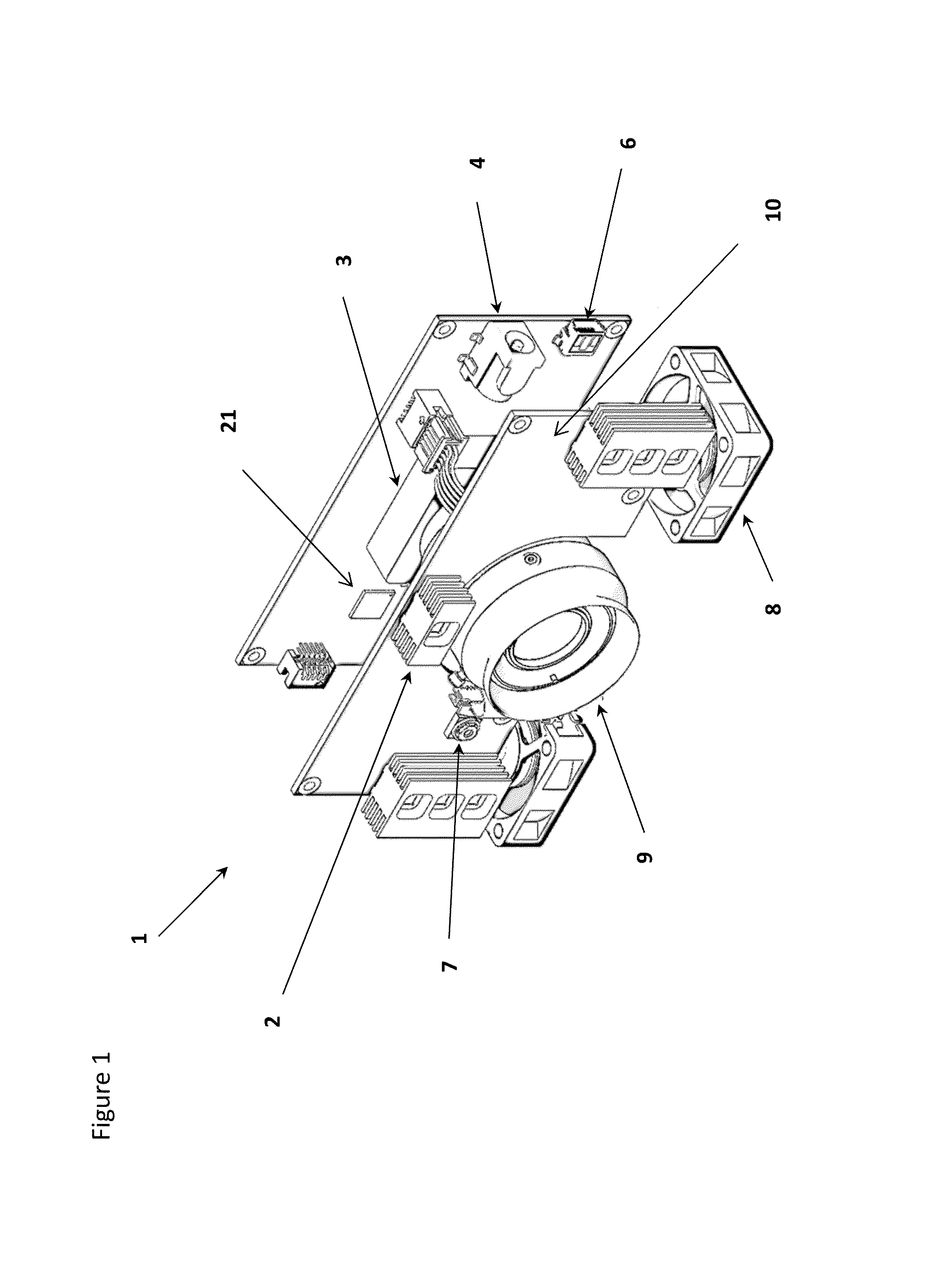

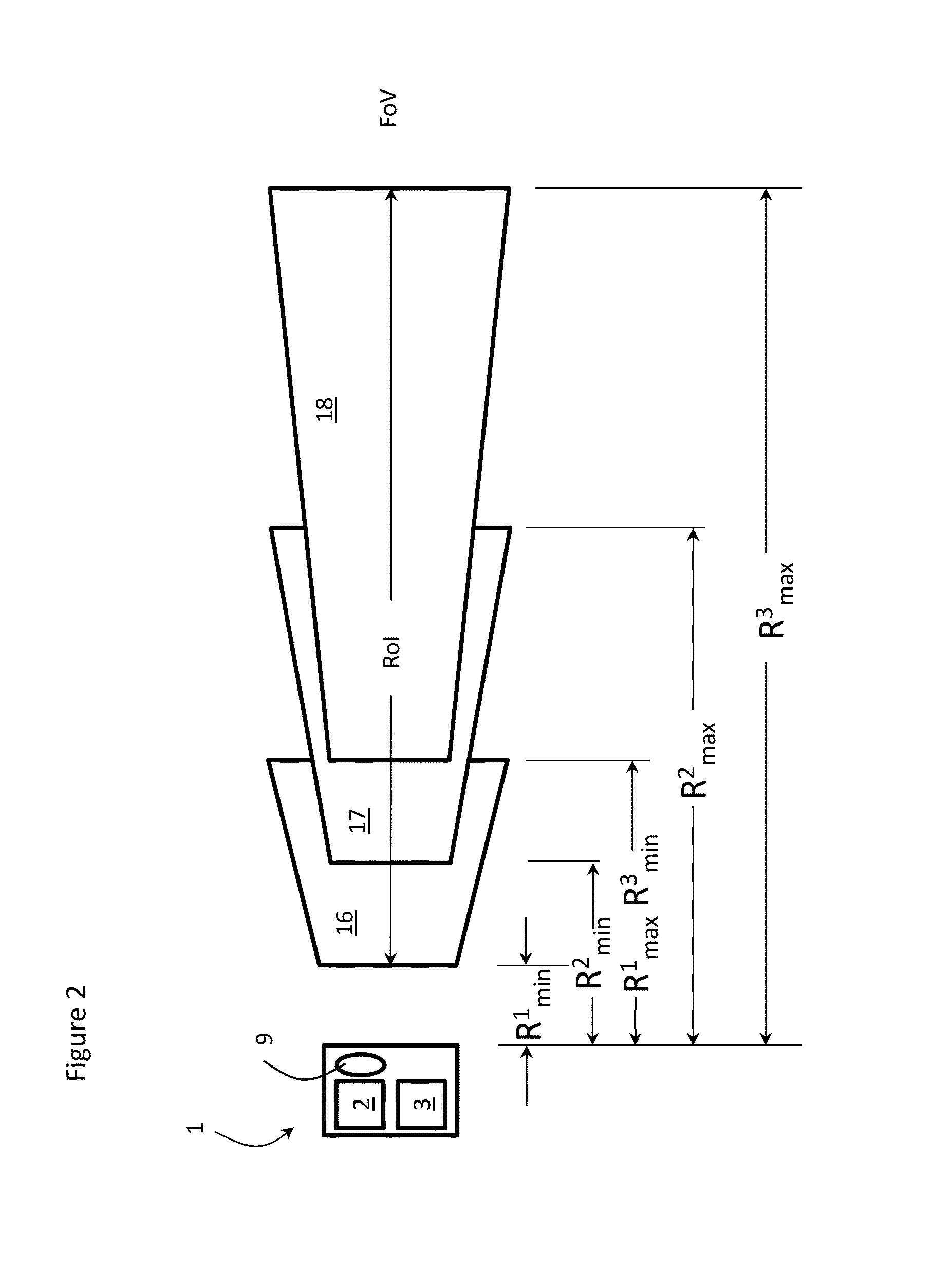

High dynamic range & depth of field depth camera

ActiveUS20130201288A1Add depthImprove dynamic rangeElectromagnetic wave reradiationSteroscopic systemsObject motionFrame time

In order to maximize the dynamic range and depth of field for a depth camera used in a time of flight system, the light source is modulated at a plurality of different frequencies, a plurality of different peak optical powers, a plurality of integration subperiods, a plurality of lens foci, aperture and zoom settings during each camera frame time. The different sets of settings effectively create subrange volumes of interest within a larger aggregate volume of interest, each having their own frequency, peak optical power, lens aperture, lens zoom and lens focus products consistent with the distance, object reflectivity, object motion, field of view, etc. requirements of various ranging applications.

Owner:LUMENTUM OPERATIONS LLC

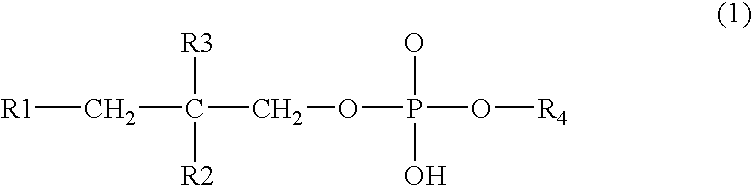

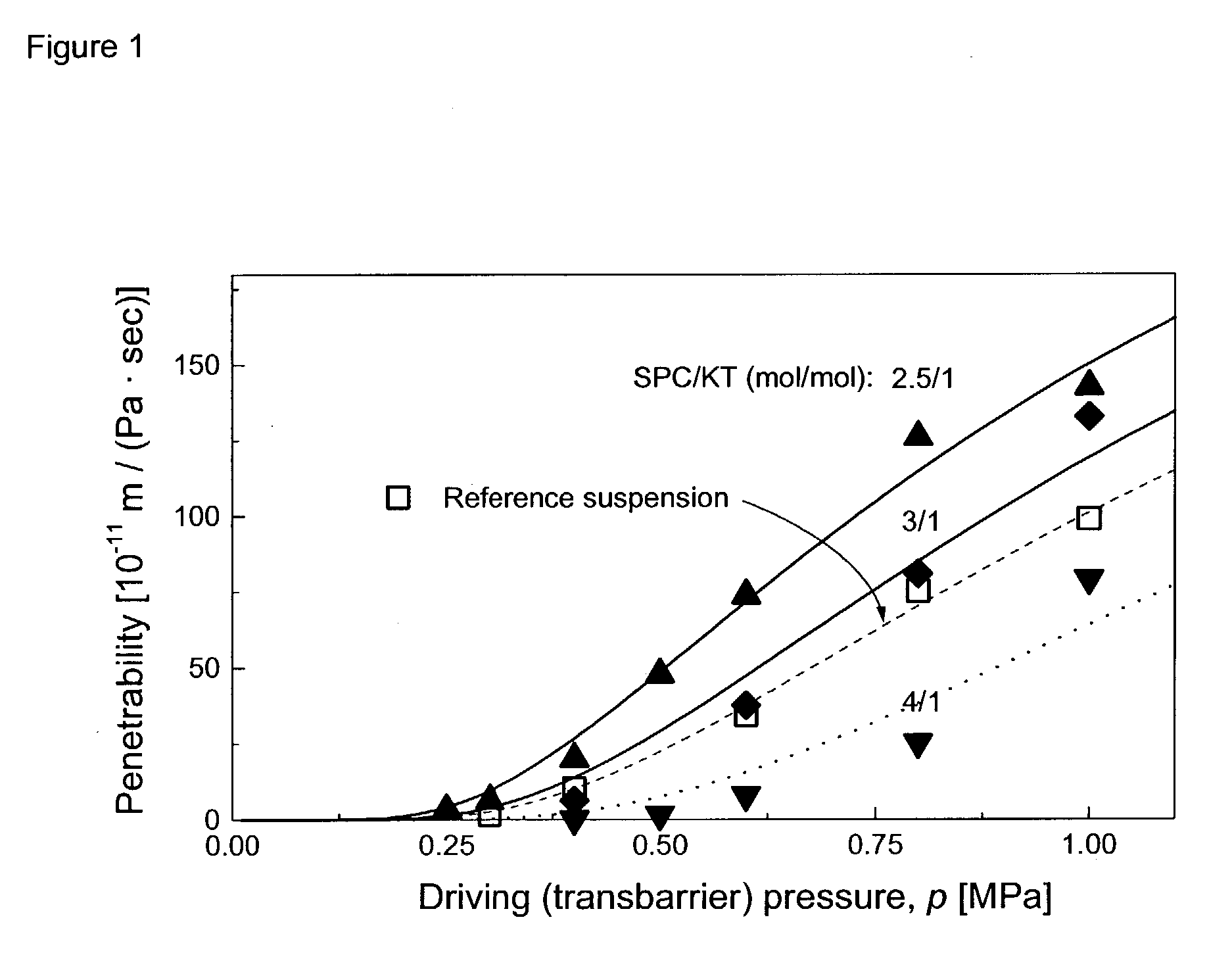

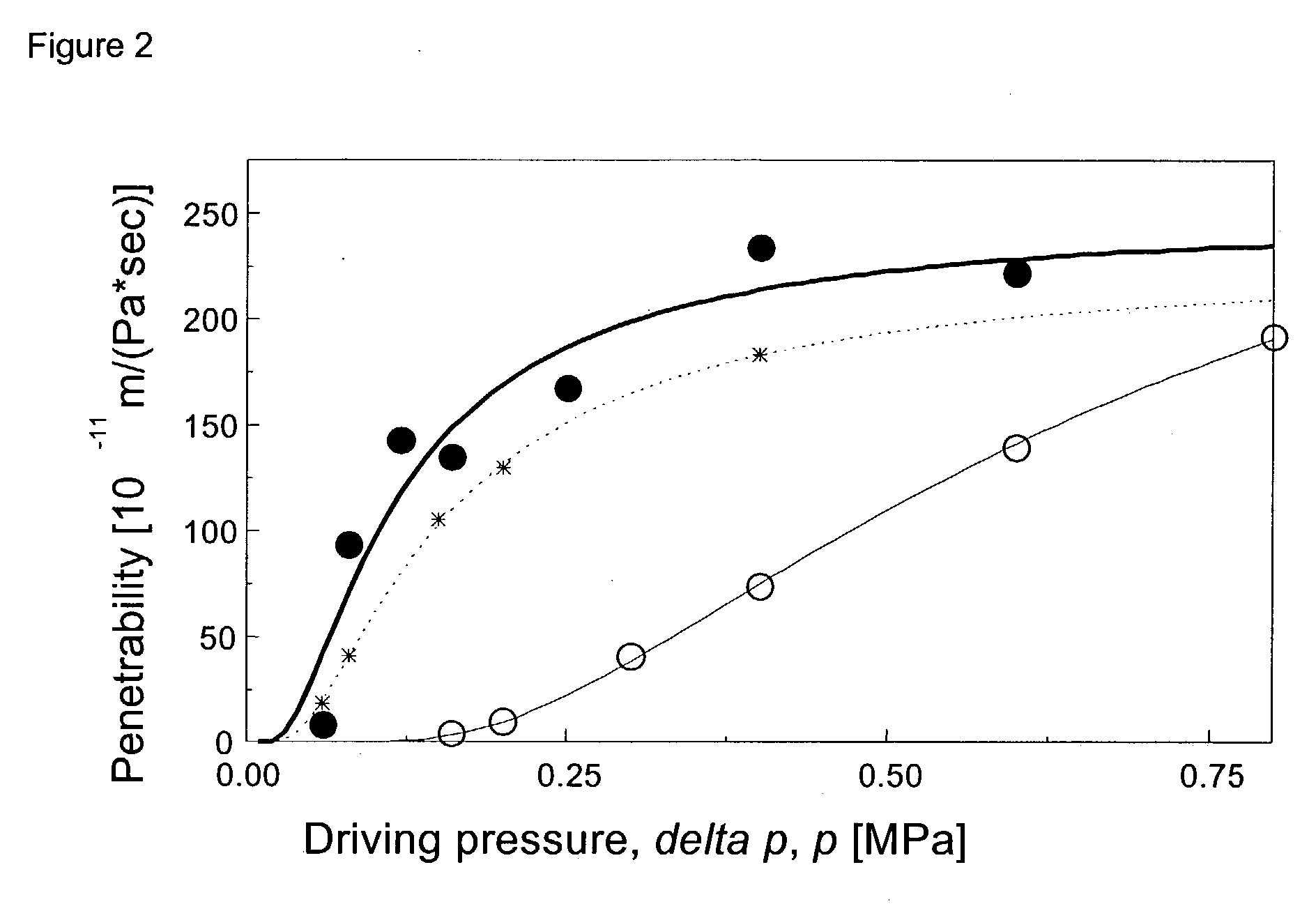

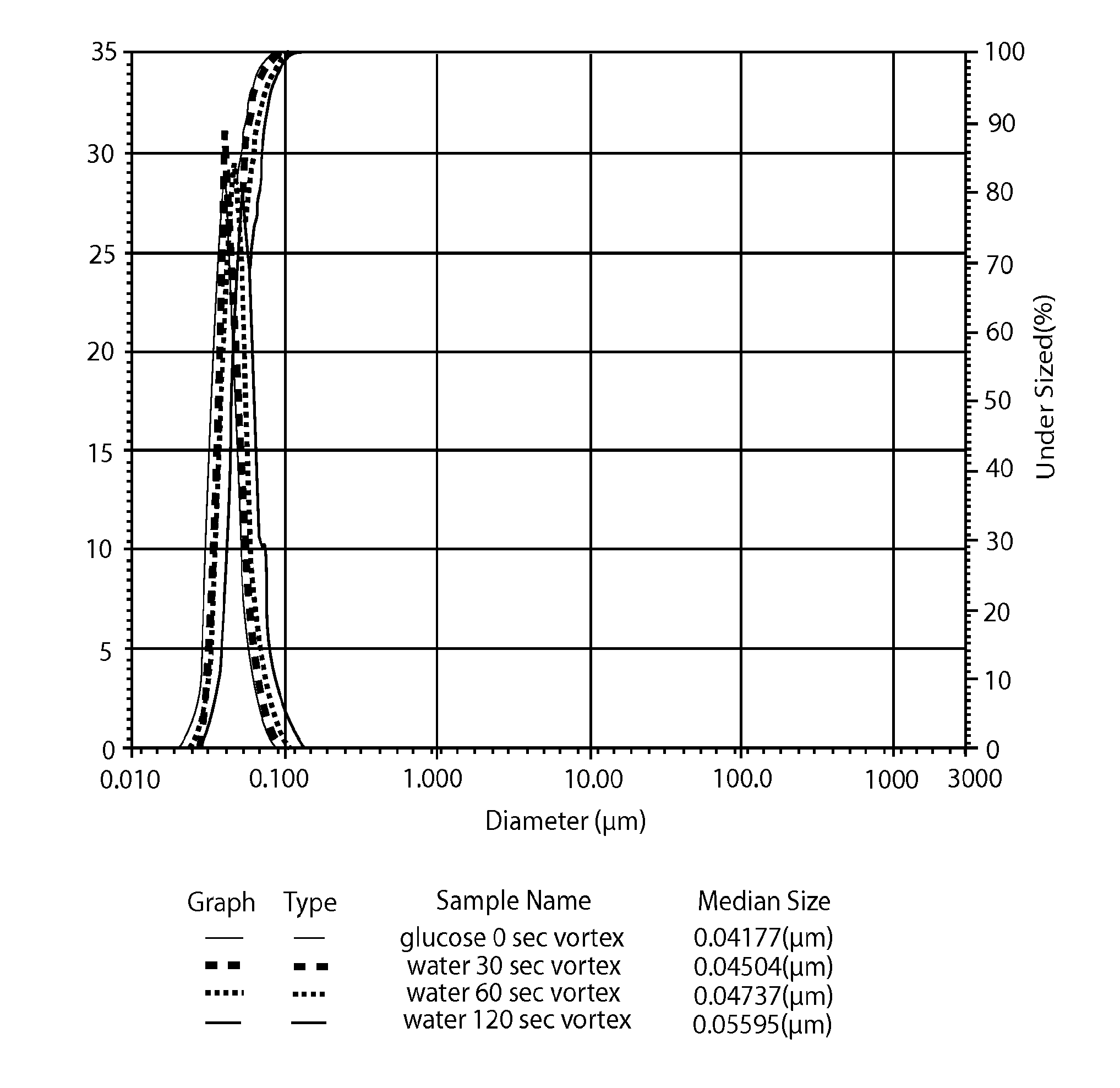

NSAID formulations, based on highly adaptable aggregates, for improved transport through barriers and topical drug delivery

The invention describes novel formulations of nonsteroidal anti-inflammatory drugs (NSAIDs) based on complex aggregates with at least three amphipatic components suspended in a suitable, e.g. pharmaceutically acceptable, polar liquid medium. A suitably ionised NSAID is one of the two, amongst said three, components that tends to destabilise lipid membranes, the other system component with such activity being typically a surfactant. In contrast, the remaining amongst said at least three amphipatic components typically forms a stable lipid membrane on it's own. An essential characteristics of the resulting, relatively large, aggregates is an improved ability to penetrate pores, in a semi-permeable barrier, at least 30%, and often much smaller than the average diameter of the complex aggregate. This enables said aggregates to mediate NSAID transport through semi-permeable barriers including mammalian skin. As a result of the skin penetration by NSAID loaded large aggregates, the drug delivered transcutaneously with such carriers gets deeper into the tissue than the corresponding NSAID from a solution on the skin surface. This is believed to be due to the special ability of suitable large carriers to bypass the local sink of blood capillaries at the epidermal-dermal junction in the skin. The carrier-mediated delivery of locally applied NSAIDs thus allows therapy of deep tissues under the drug administration site, which is medically highly desirable.

Owner:IDEA AG

Method and apparatus of on demand business activity management using business performance management loops

Owner:INT BUSINESS MASCH CORP

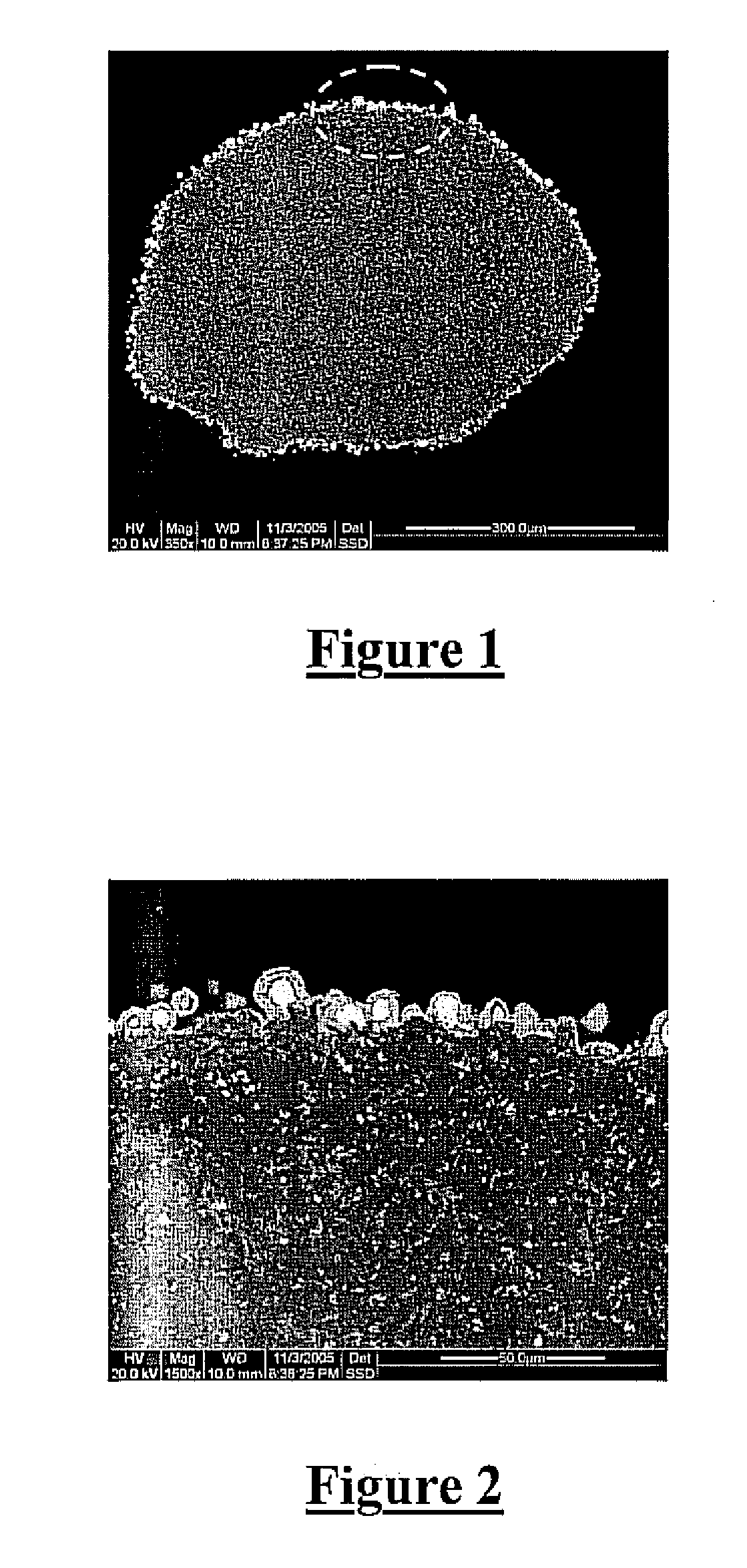

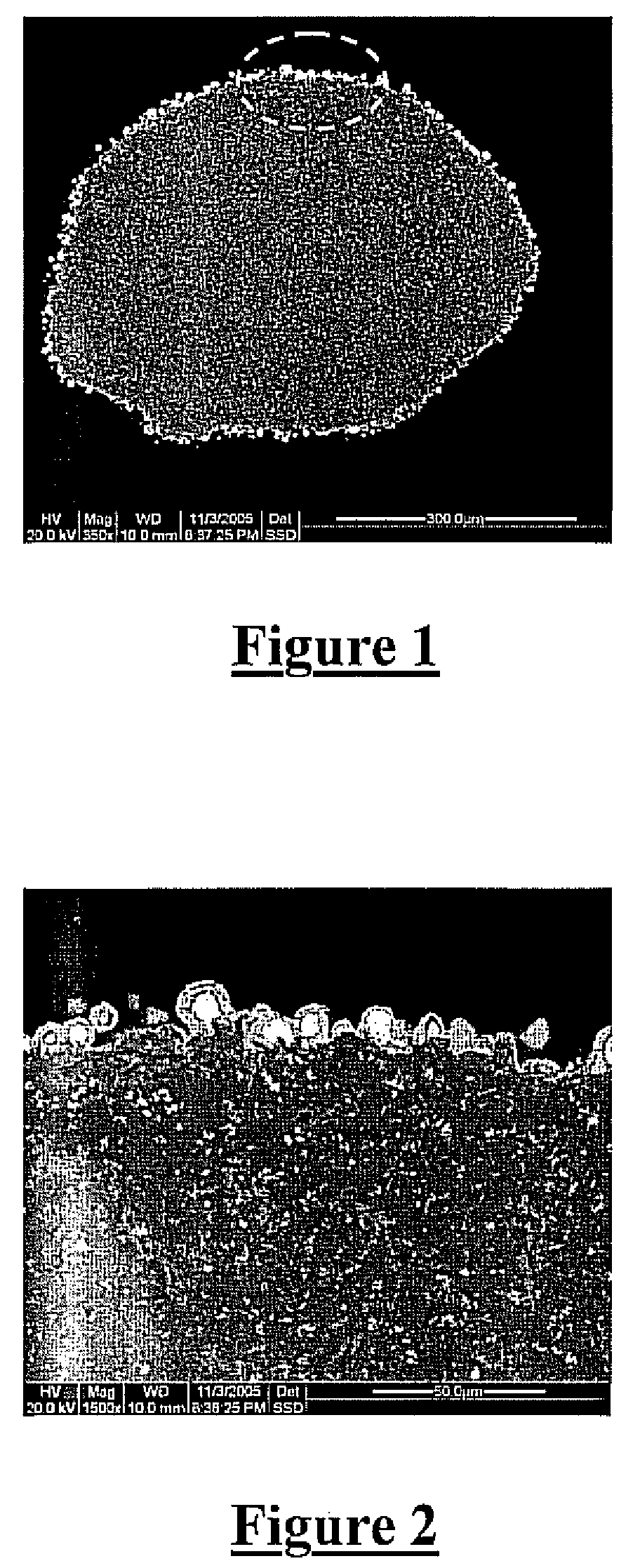

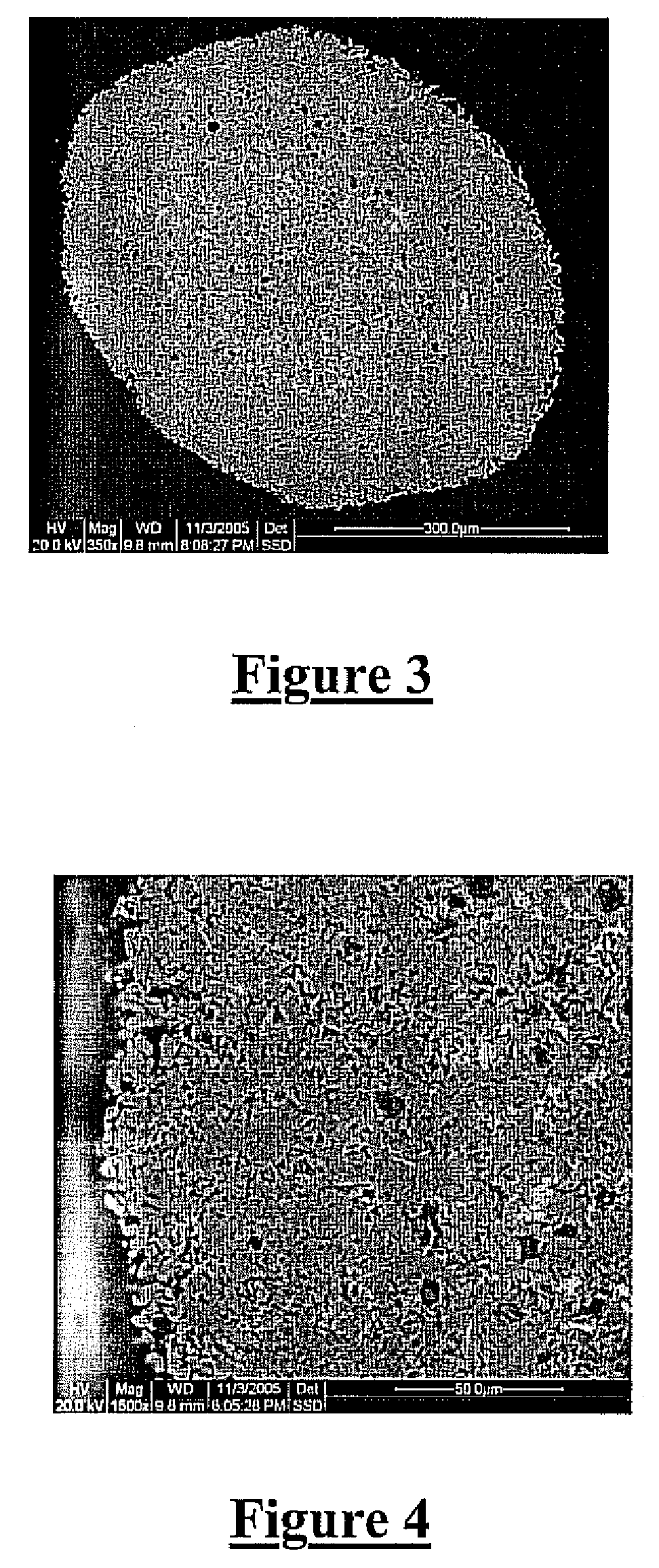

Material having a controlled microstructure, core-shell macrostructure, and method for its fabrication

Disclosed is a method for making a material having a controlled microstructure, the method including providing particles of a ceramic mineral material, the particles having a metal oxide dopant therein. The particles of the ceramic mineral material are consolidated into larger aggregates of a size relevant to the desired application using standard industrial mixing and pelletizing technology. The aggregates are heated under reducing conditions so that at least part of the dopant is reduced to form a transient, metastable liquid phase among the particles. The liquid phase includes at least part of the reduced dopant and promotes sintering of the particles and forms islands of reduced metal within the material and on the surface of the aggregates. Following heating of the aggregates under reducing conditions, the aggregates are heated under oxidizing conditions such that the islands of reduced metal are oxidized and / or go into solid solution within the particles, thereby creating voids within and form a shell thereon the particles.

Owner:CARBO CERAMICS +1

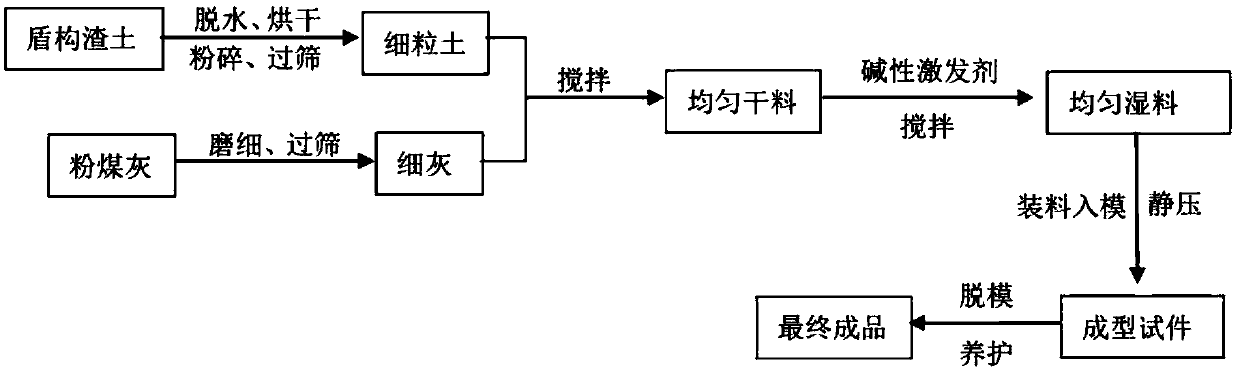

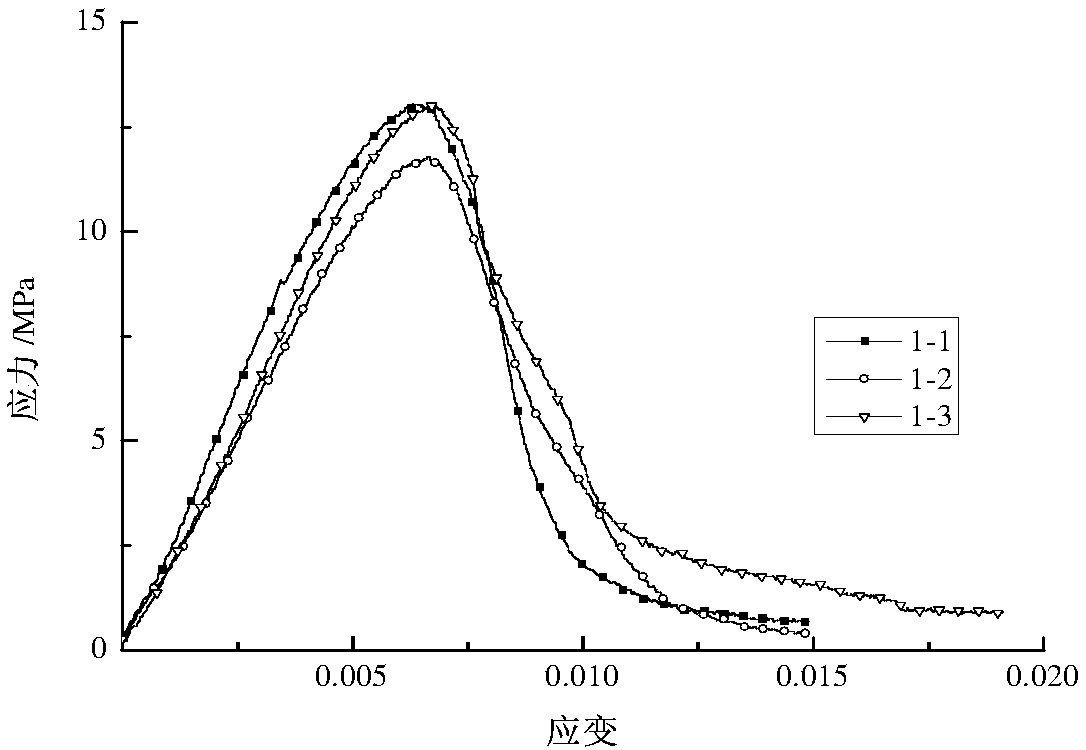

Geopolymer and preparation method and application thereof

ActiveCN108046669ALow permeability coefficientHigh strengthCement productionGeopolymerUltimate tensile strength

The invention discloses a geopolymer and a preparation method and application thereof. The geopolymer is at least prepared from fly ash, shield muck and an alkaline activator. The main component of the shield muck is clay, and the mass ratio of the fly ash to the dried shield muck is (1-2):3; the mass ratio of a mixture of the fly ash and the dried shield muck to the alkaline activator is 1:(0.14-0.18). According to the geopolymer, the high-mud-content shield muck is subjected to recycling application, and the preparation raw materials do not include any type of traditional cementing materialssuch as cement and lime, so that large carbon emission is avoided, and the cost is low. The geopolymer is high in strength and good in water resistance. The preparation method of the geopolymer includes the steps that the alkaline activator is added into the mixture of the fly ash and the shield muck through spraying to avoid large aggregates; the mixed wet material is tightly pressed in a mold,so that a geopolymer test piece has relatively high strength and water resistance.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

High dynamic range and depth of field depth camera

Owner:LUMENTUM OPERATIONS LLC

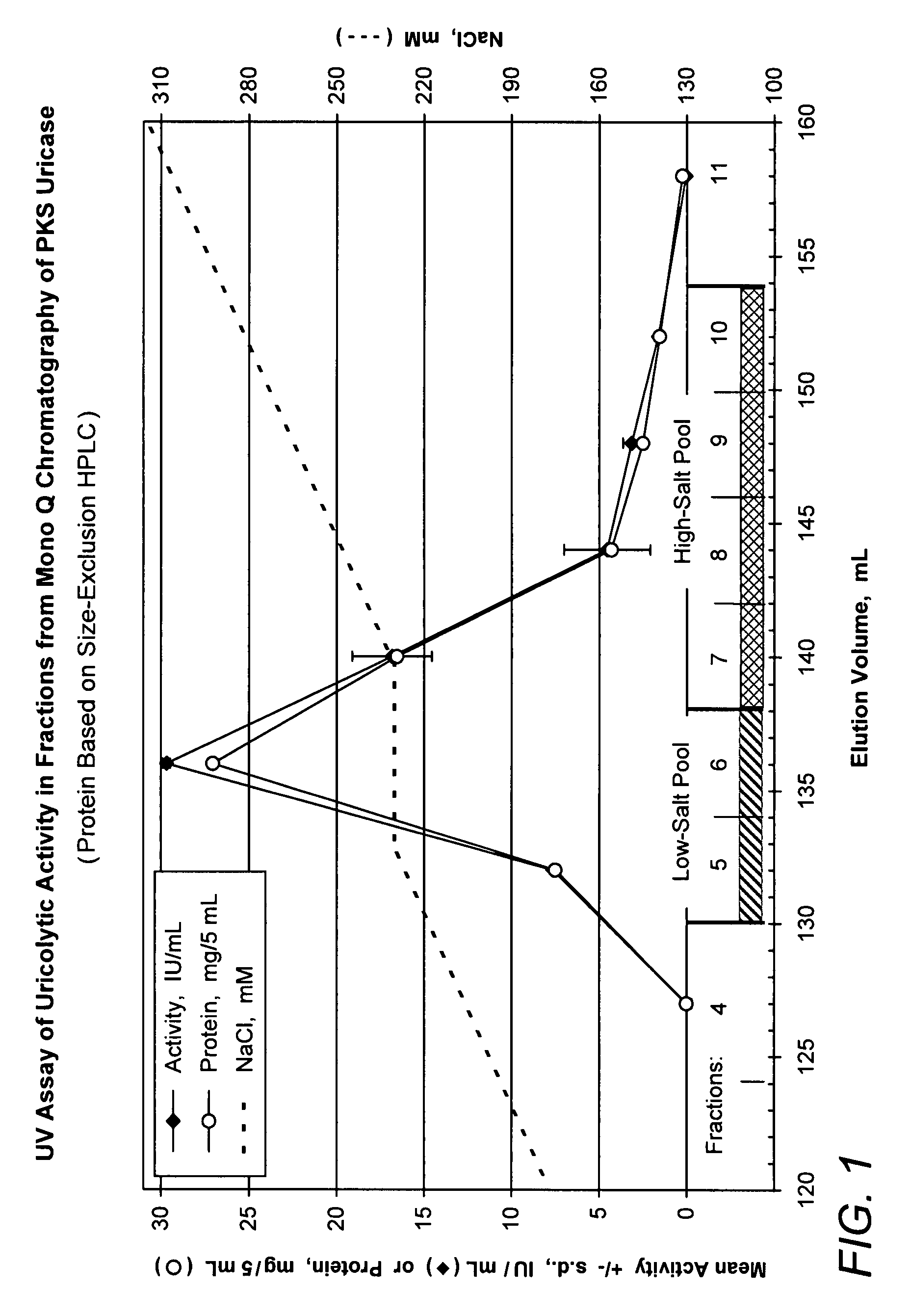

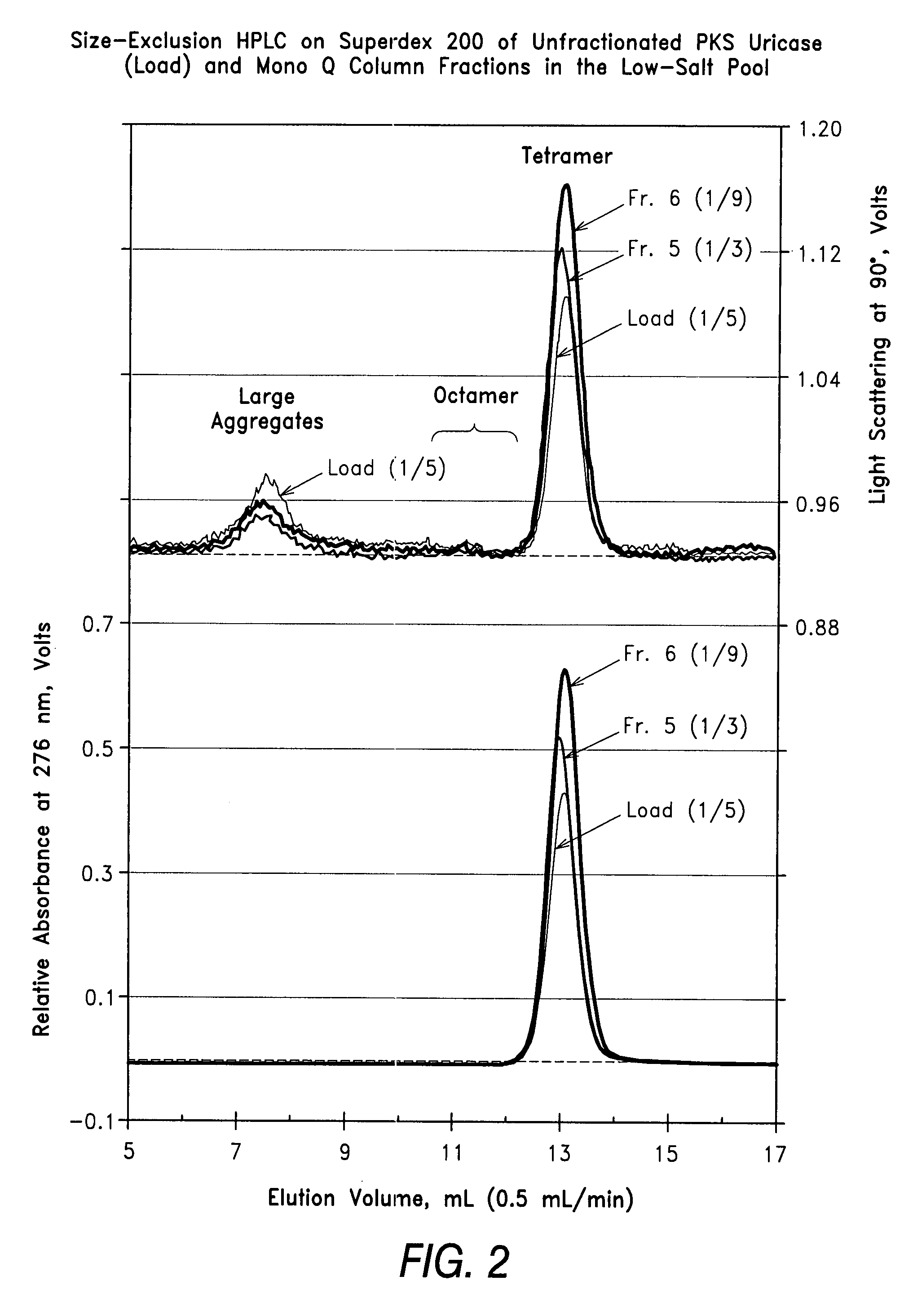

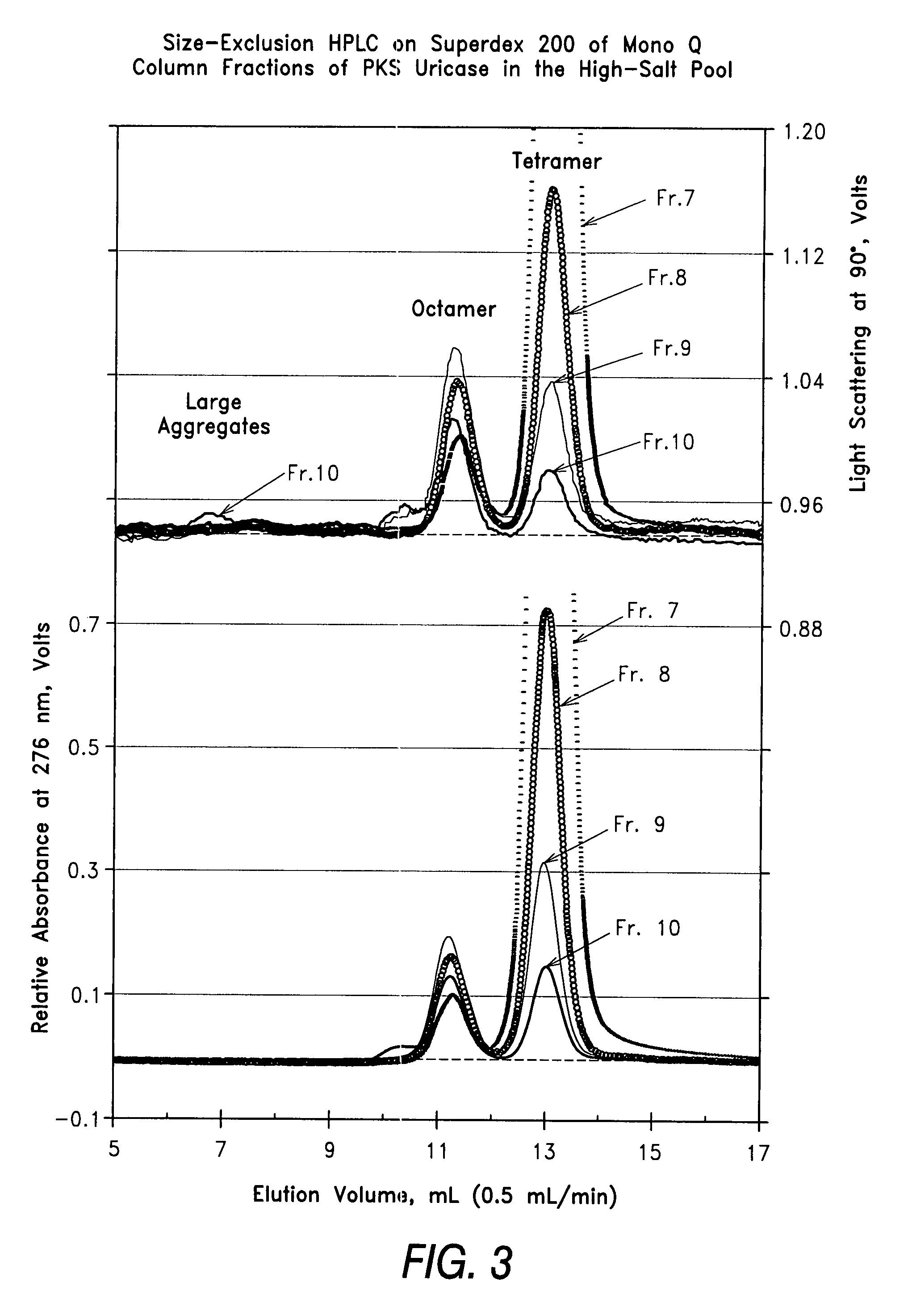

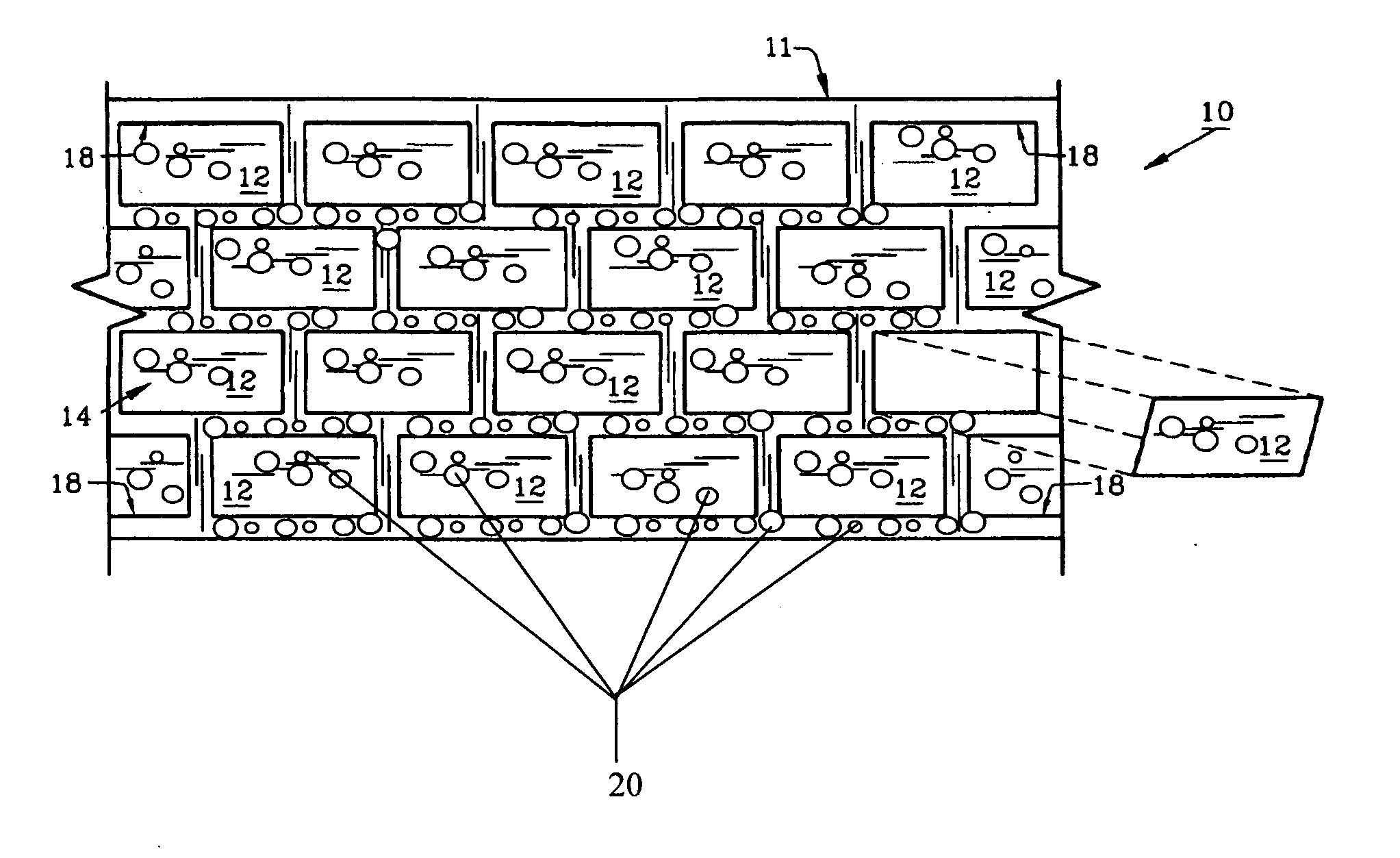

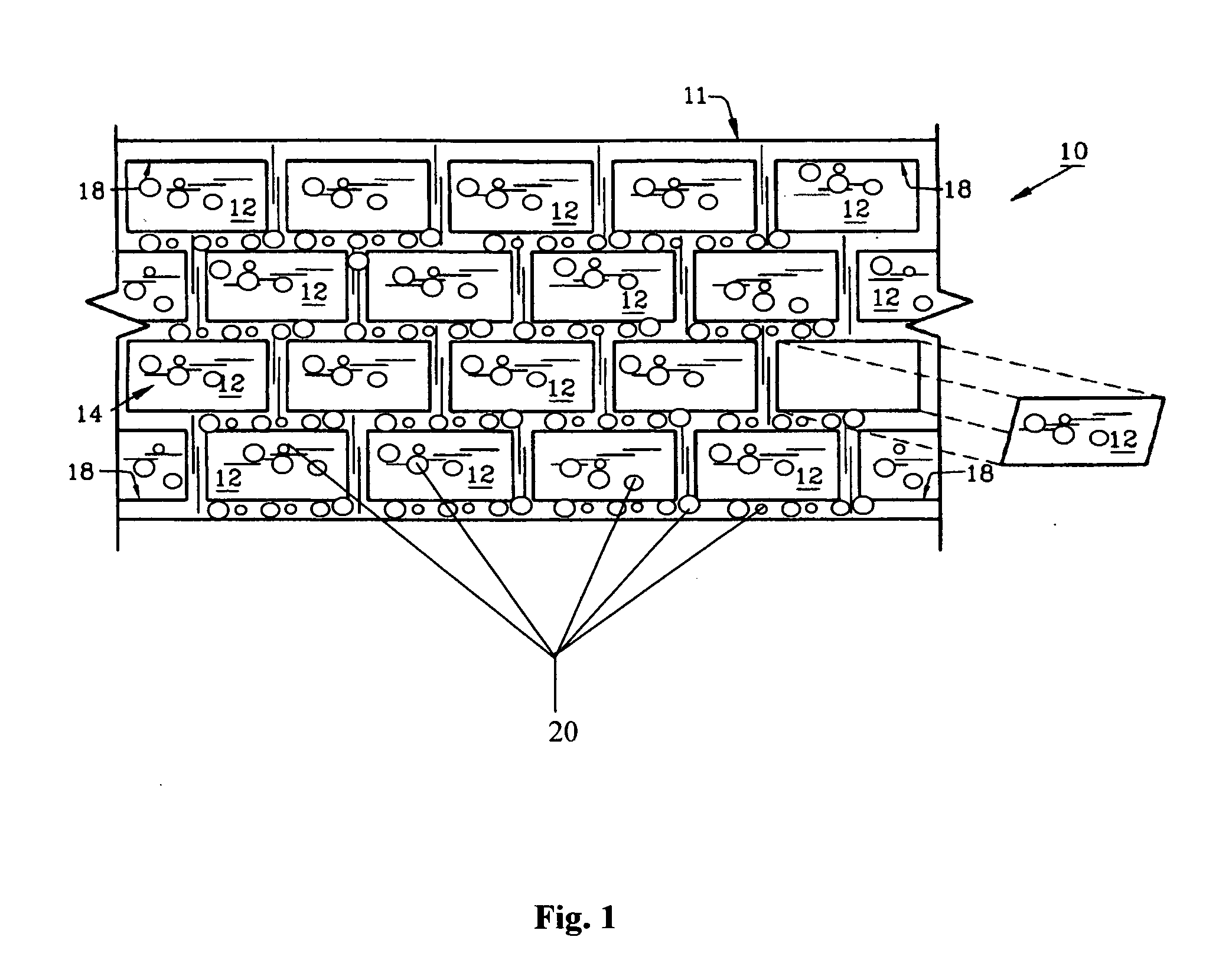

Aggregate-free urate oxidase for preparation of non-immunogenic polymer conjugates

A naturally occurring or recombinant protein, especially a mutein of porcine urate oxidase (uricase), that is essentially free of large aggregates can be rendered substantially non-immunogenic by conjugation with a sufficiently small number of strands of polymer such that the bioactivity of the protein is essentially retained in the conjugate. Such conjugates are unusually well suited for treatment of chronic conditions because they are less likely to induce the formation of antibodies and / or accelerated clearance than are similar conjugates prepared from protein preparations containing traces of large aggregates.

Owner:HORIZON THERAPEUTICS USA INC +1

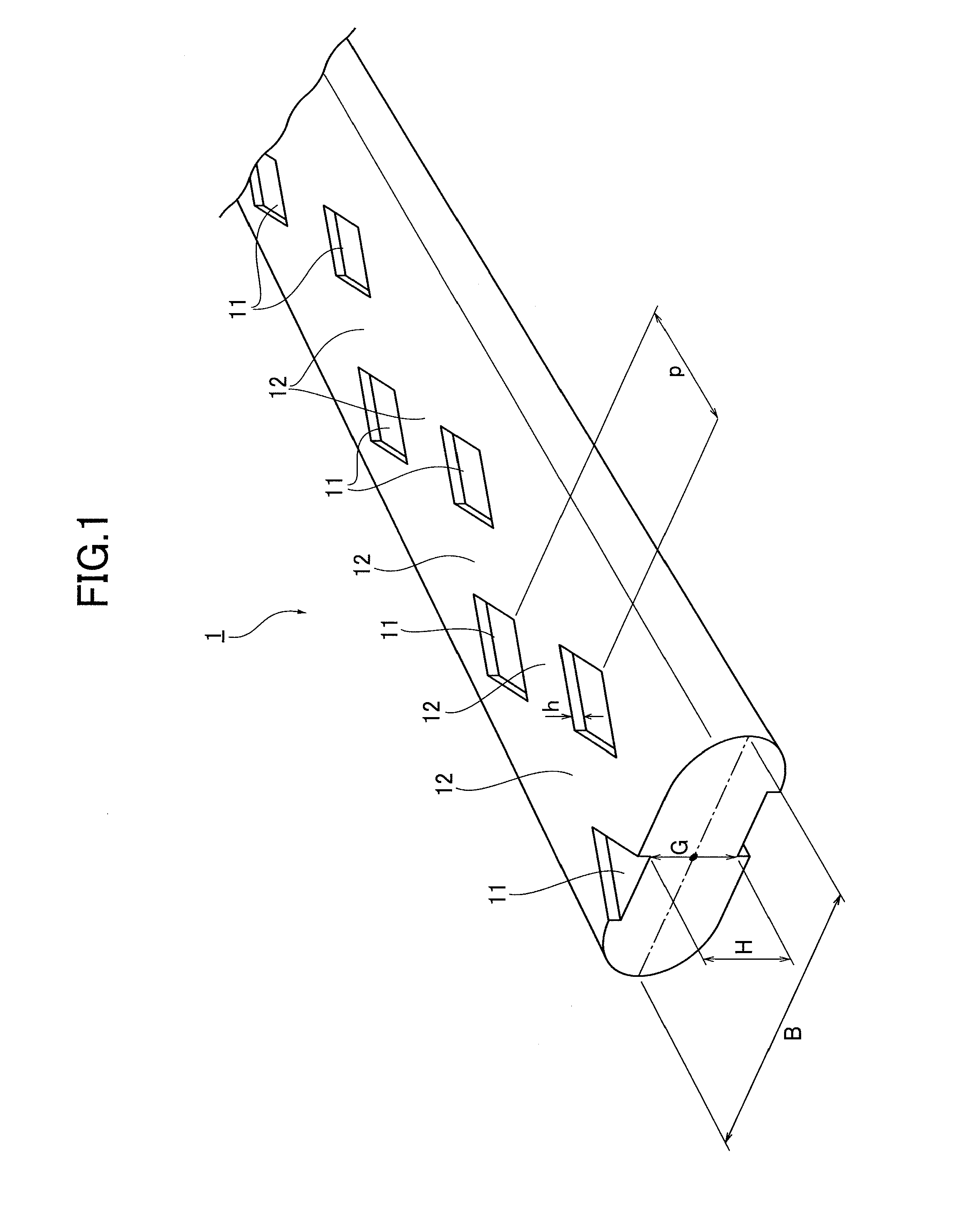

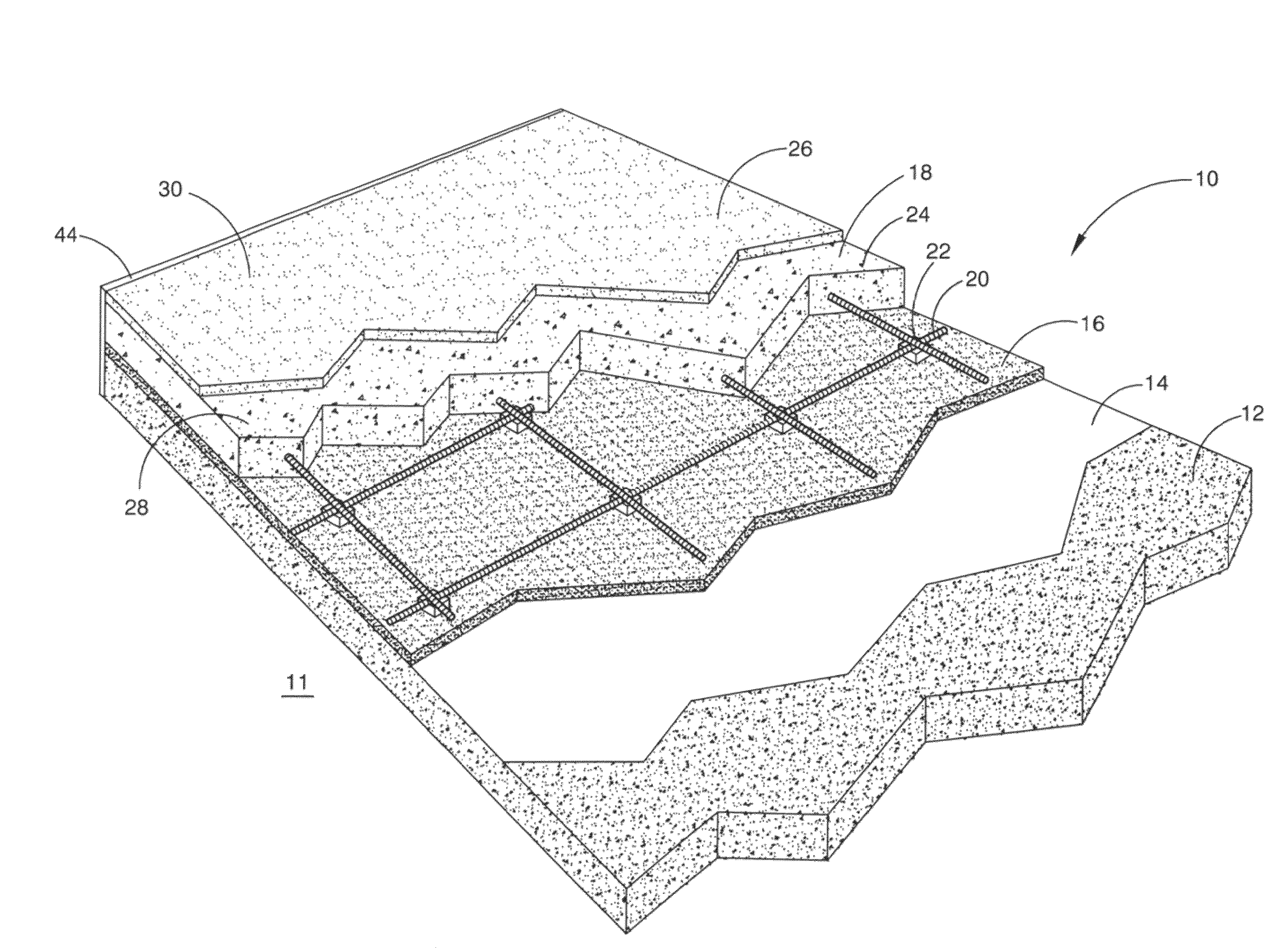

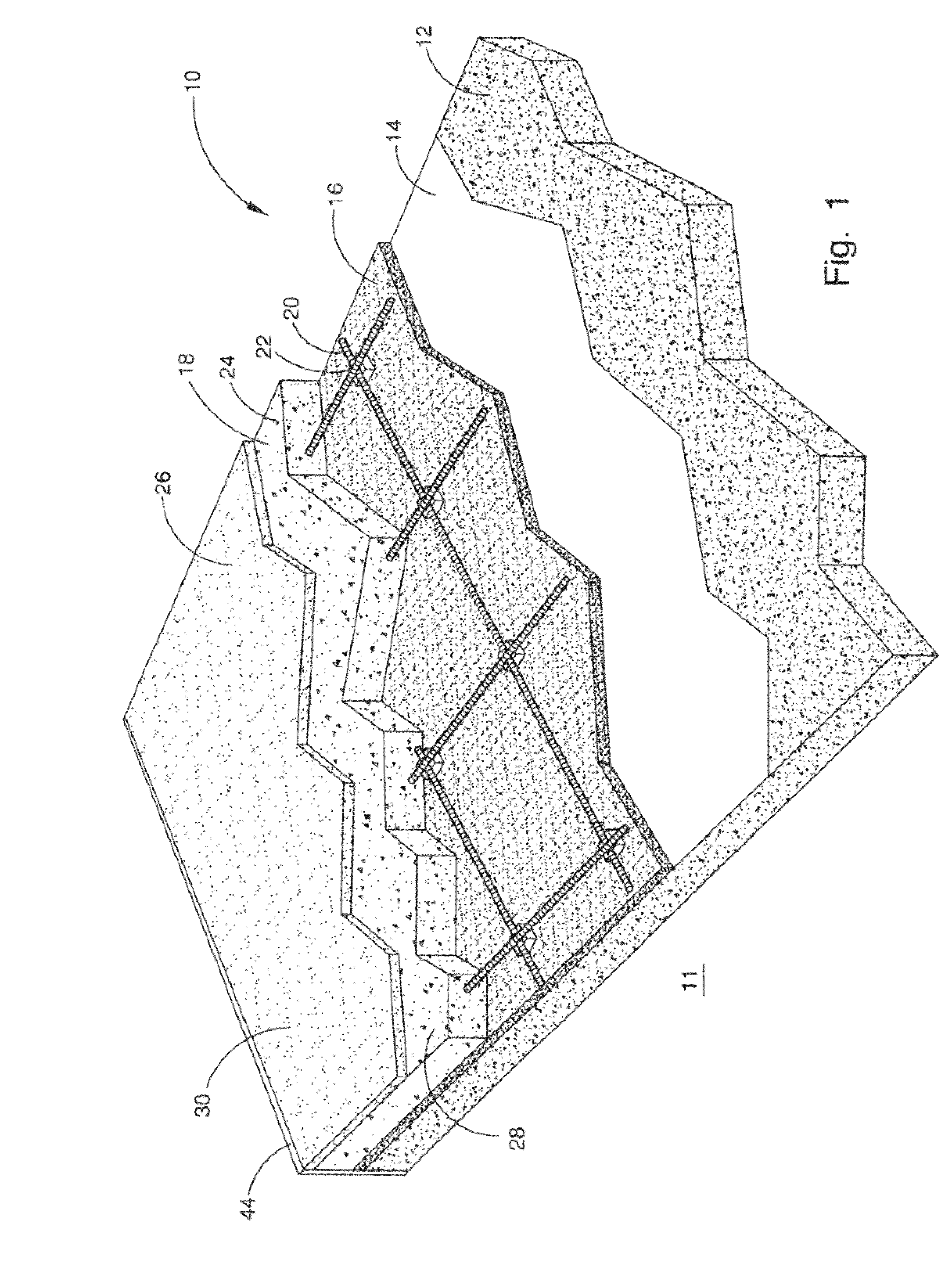

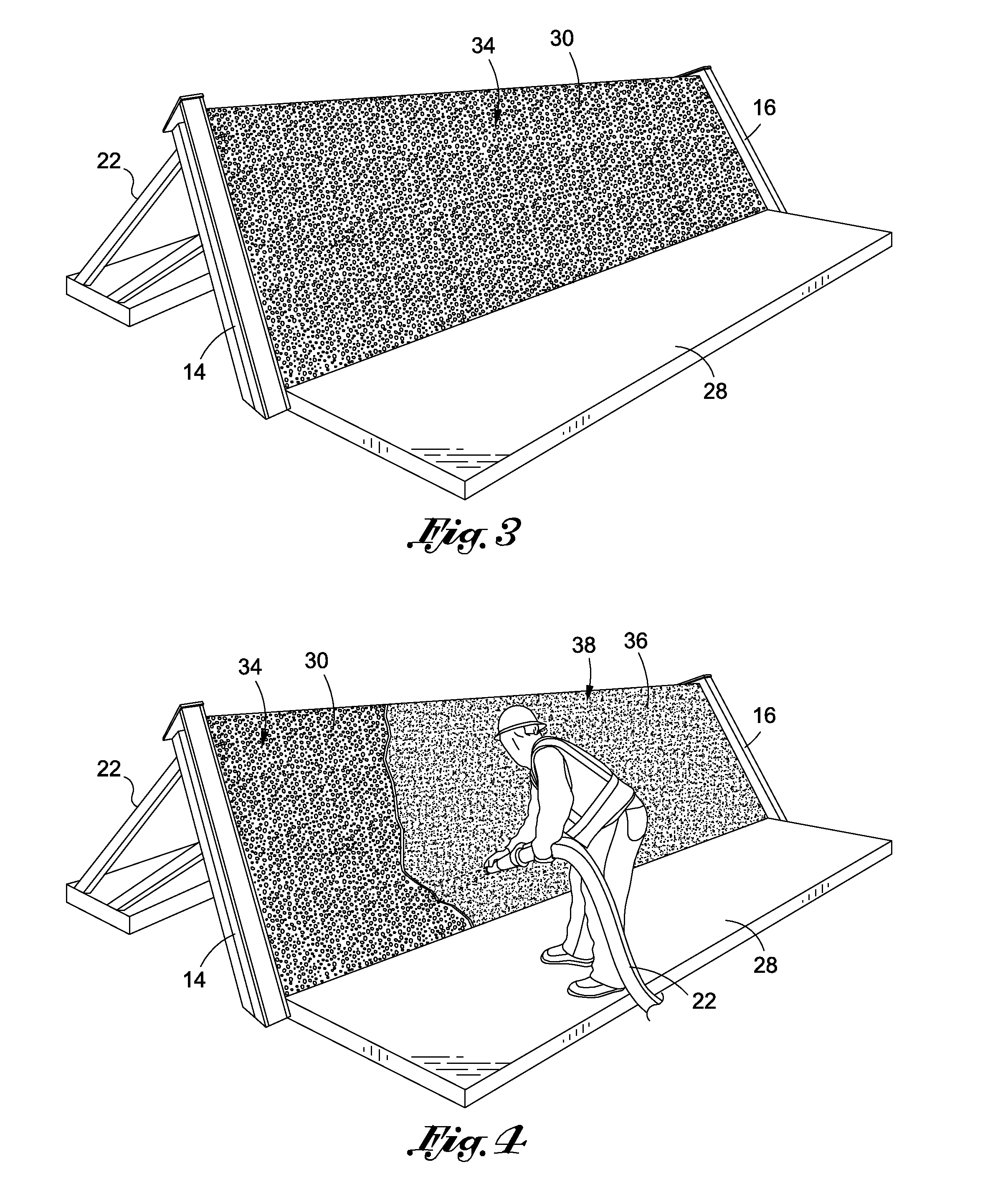

Preformed thermoplastic pavement marking and method utilizing large aggregate for improved long term skid resistance and reduced tire tracking

ActiveUS20110123770A1Labor savingShorten the timeTraffic signalsTextiles and paperThermoplasticEngineering

The present disclosure describes a preformed or in some cases a hot applied thermoplastic marking composition comprising a planar top surface portion and a planar bottom surface portion that are coplanar to each other, wherein said bottom surface portion is directly applied to a substrate via application of heat or pressure or both heat and pressure and wherein said top surface portion comprises an intermix that exits throughout said thermoplastic composition and includes large grit size aggregate in the range of about 8 to about 20 mesh or grit size, thereby reducing or eliminating tire tracking while also improving long-term skid resistance.

Owner:ENNIS FLINT INC

Fiber reinforced cement based mixed material

ActiveUS20140326168A1Small amount of shrinkageRapid early strength developmentSolid waste managementChemical admixturePolymer science

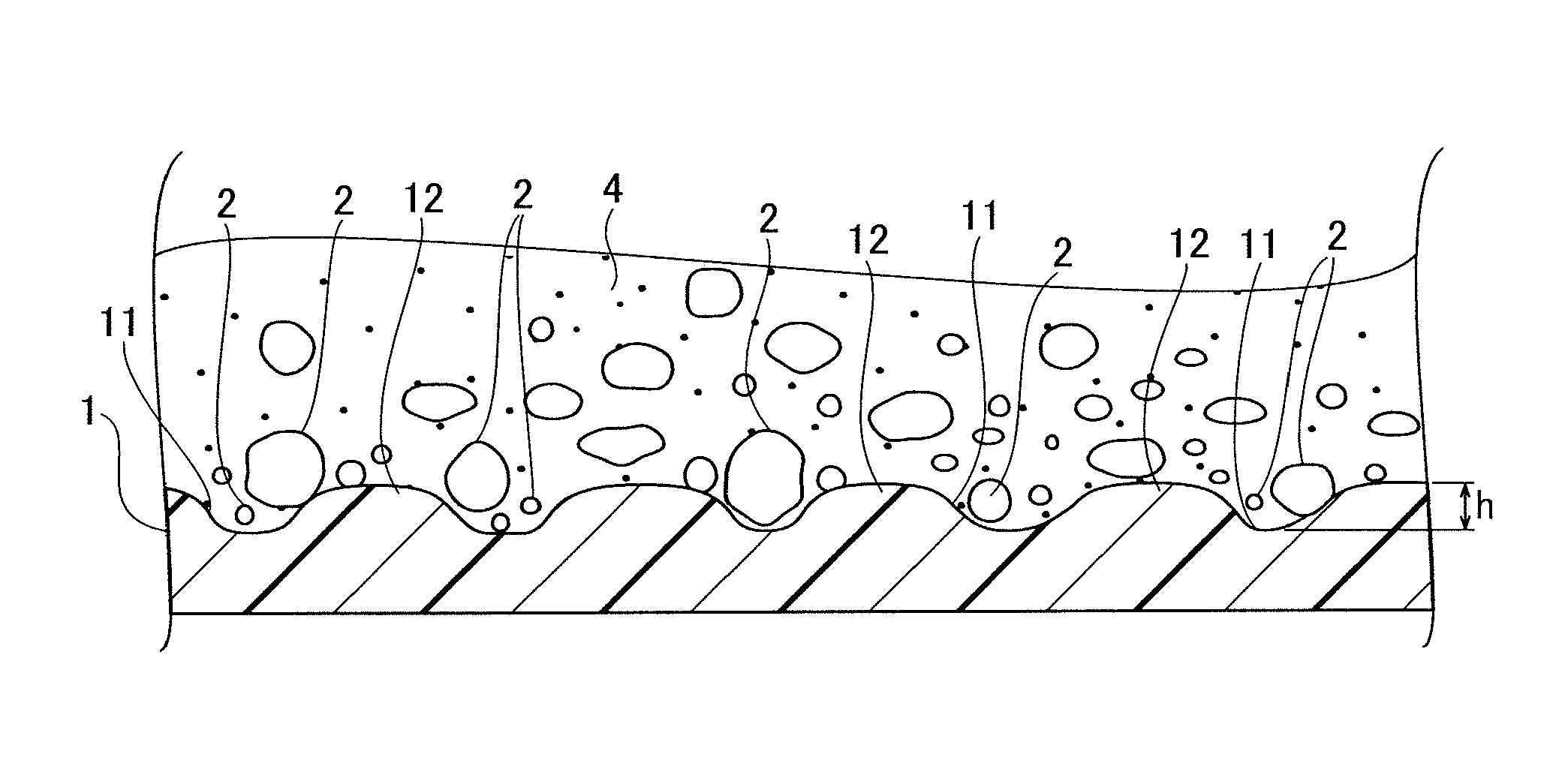

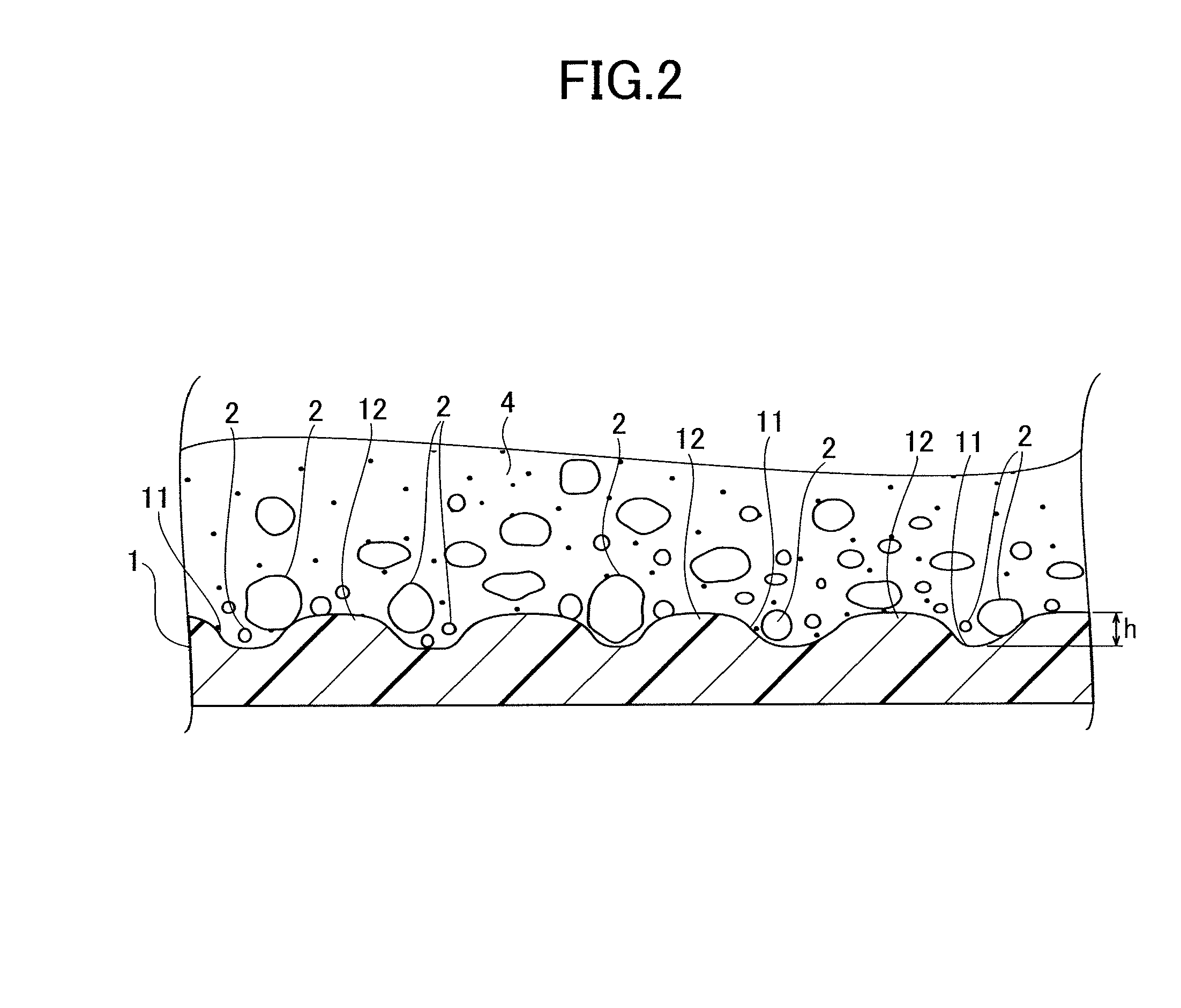

Provided is a fiber reinforced cement based mixed material having high tensile strength and high toughness, the mixed material comprising a cementitious composition with fast development of early strength; a small hydration heat temperature; and a small shrinkage during curing. The fiber reinforced cement based mixed material contains 100 wt. parts of cement, 5-30 wt. parts of silica fume, 30-80 wt. parts of at least one pozzolanic material excluding the silica fume, 5-25 wt. parts of limestone powder, at least one chemical admixture, water, 70-150 wt. parts of aggregate having a largest aggregate diameter of 1.2-3.5 mm, and fibers, wherein at least some of the fibers comprise a fiber having asperities formed in the surface, the fiber having asperities being formed such that a ratio (h / H) of a depth h of each of recessed portions among the asperities to a smallest cross-sectional diameter H thereof is 0.05-0.8.

Owner:TAISEI CORP

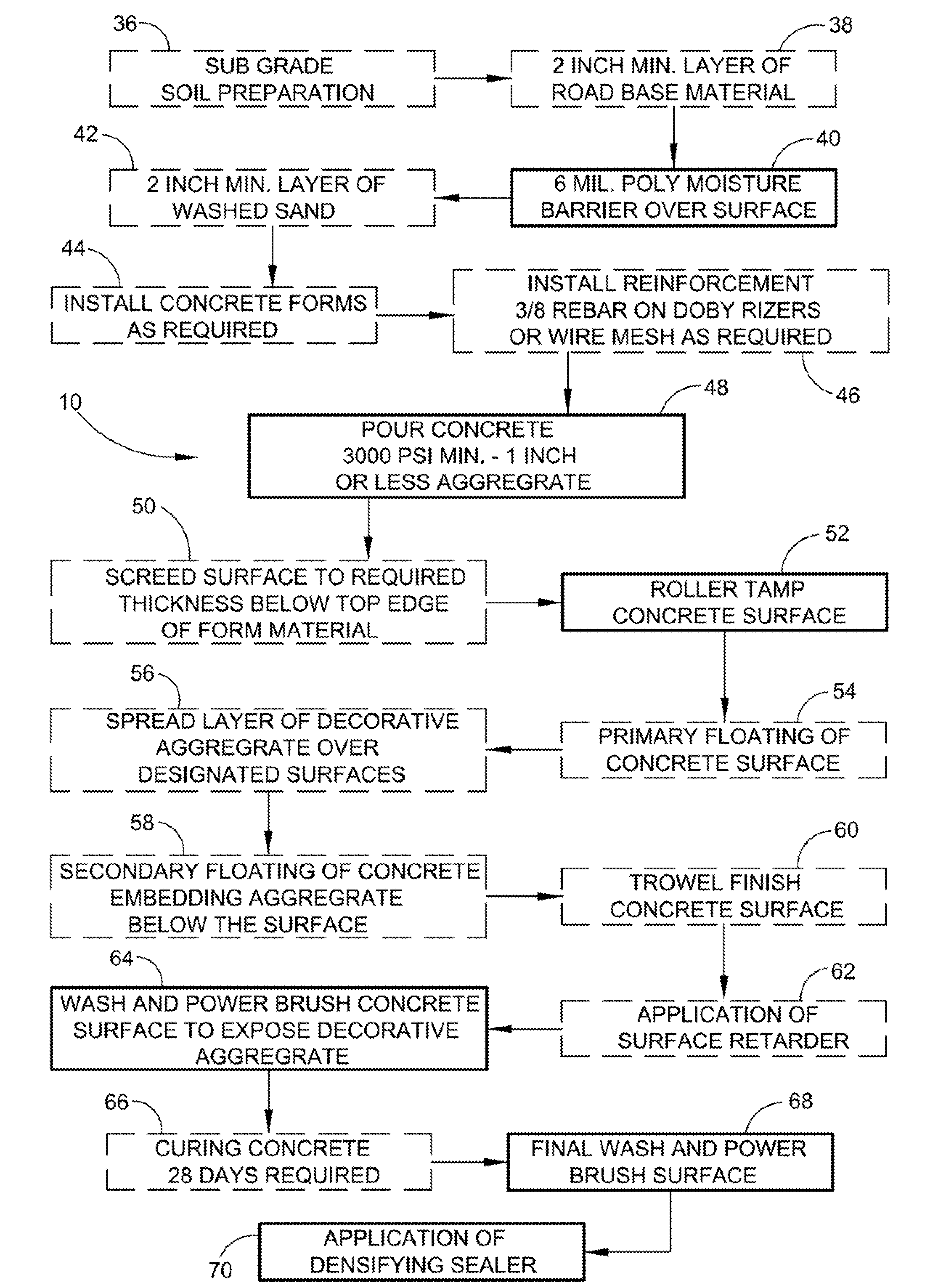

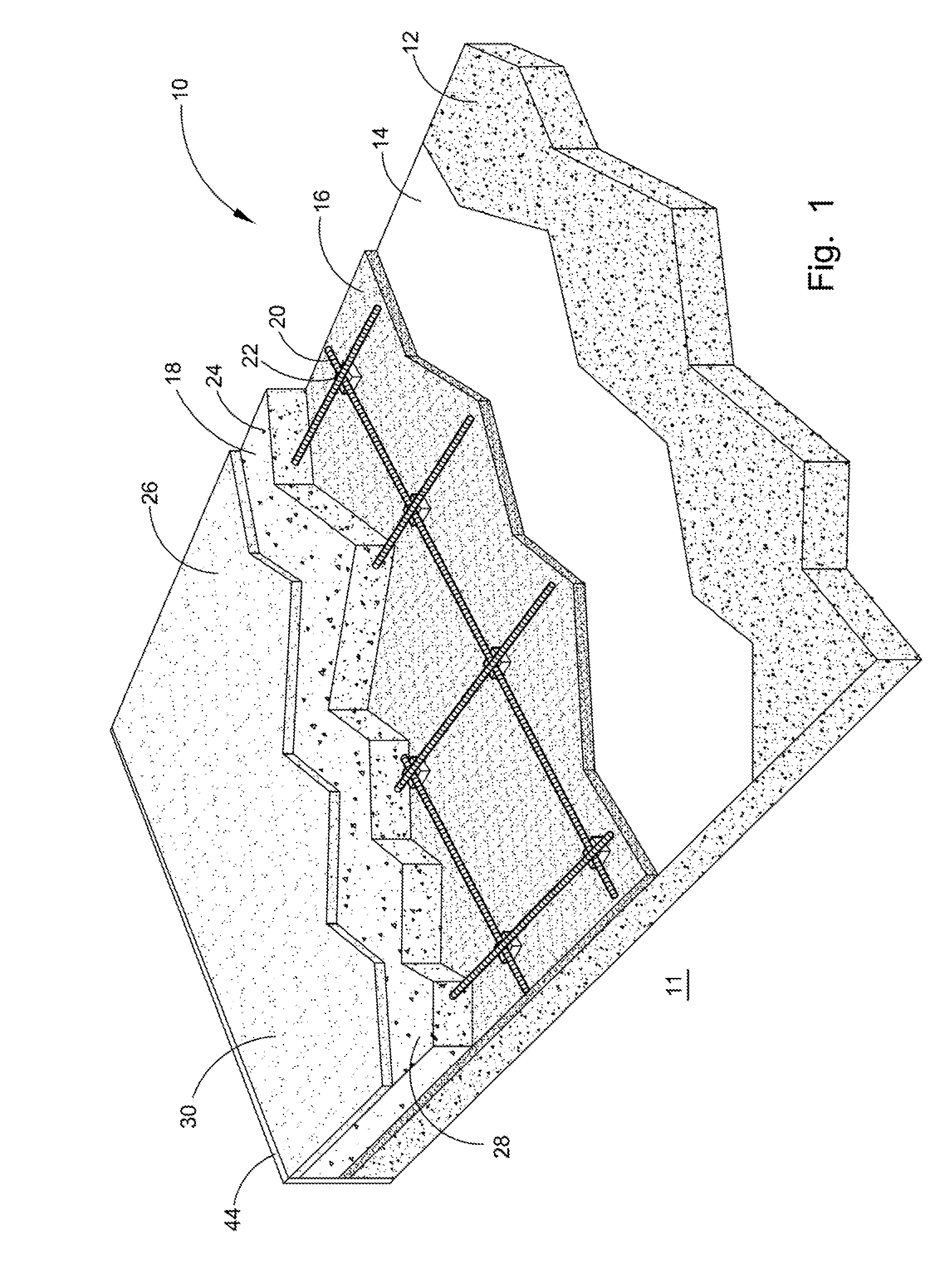

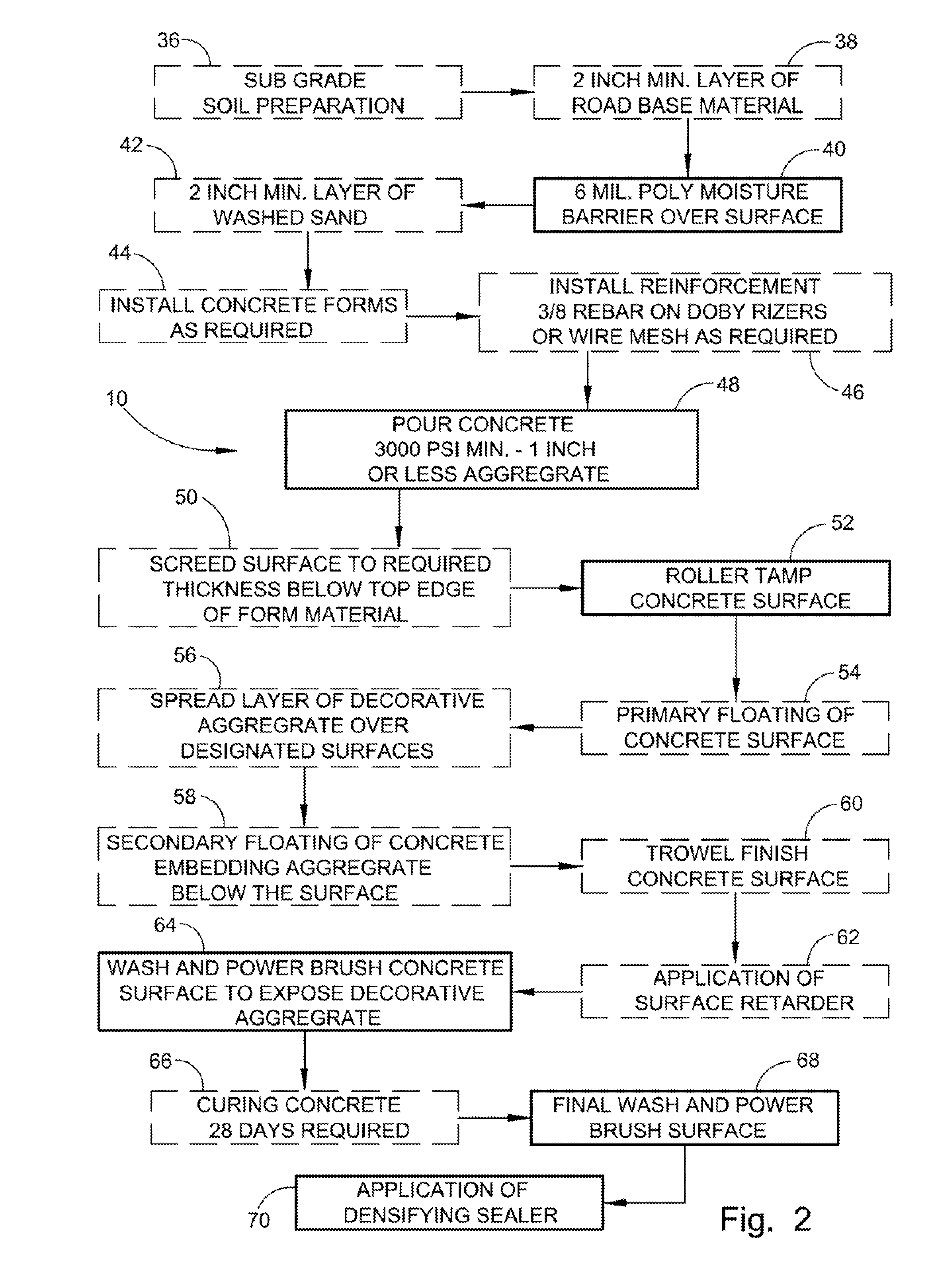

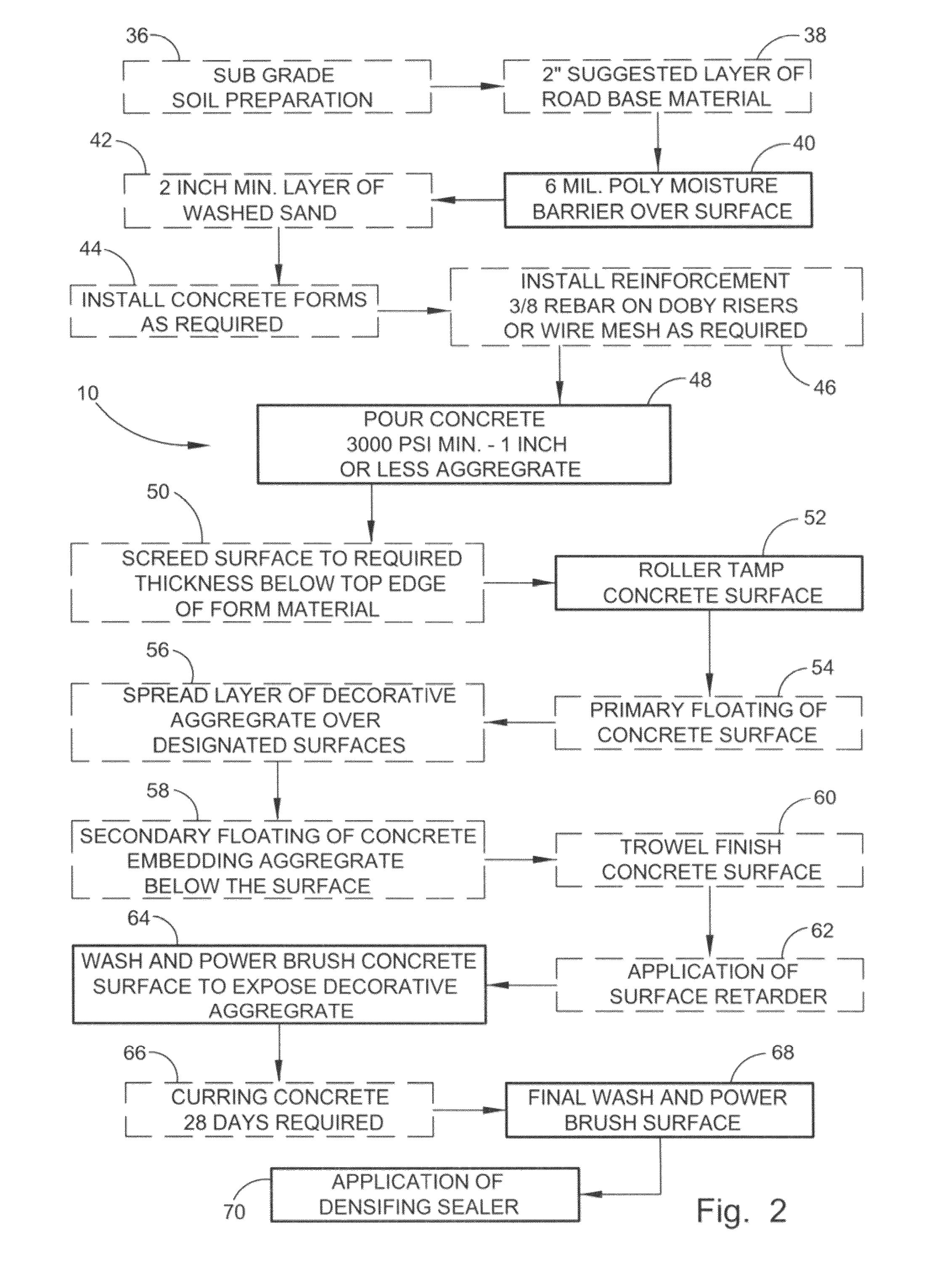

Decorative aggregate concrete surface preparation process

InactiveUS20140000214A1Increases adhesion potentialReduces the potential for shrinkageIn situ pavingsBuilding repairsWood veneerPolypropylene

The present invention is directed to a process of creating a decorative aggregate concrete surface. The preparation includes washed decorative aggregate surfaces using a variety of decorative aggregate materials imbedded within a standard concrete mix having a one inch maximum aggregate. A 6-mil polypropylene sheet Visqueen material covered with a two-inch layer of sand is used directly below the concrete to retard the curing time. Roller tamping is used to move the large aggregate below the surface of the concrete material. Power brushes are then used to expose the decorative aggregate prior to the final process of applying a densifing sealer. This process has been designed to reduce installation time, as well as overall labor and material costs.

Owner:VASQUEZ JR RICARDO +1

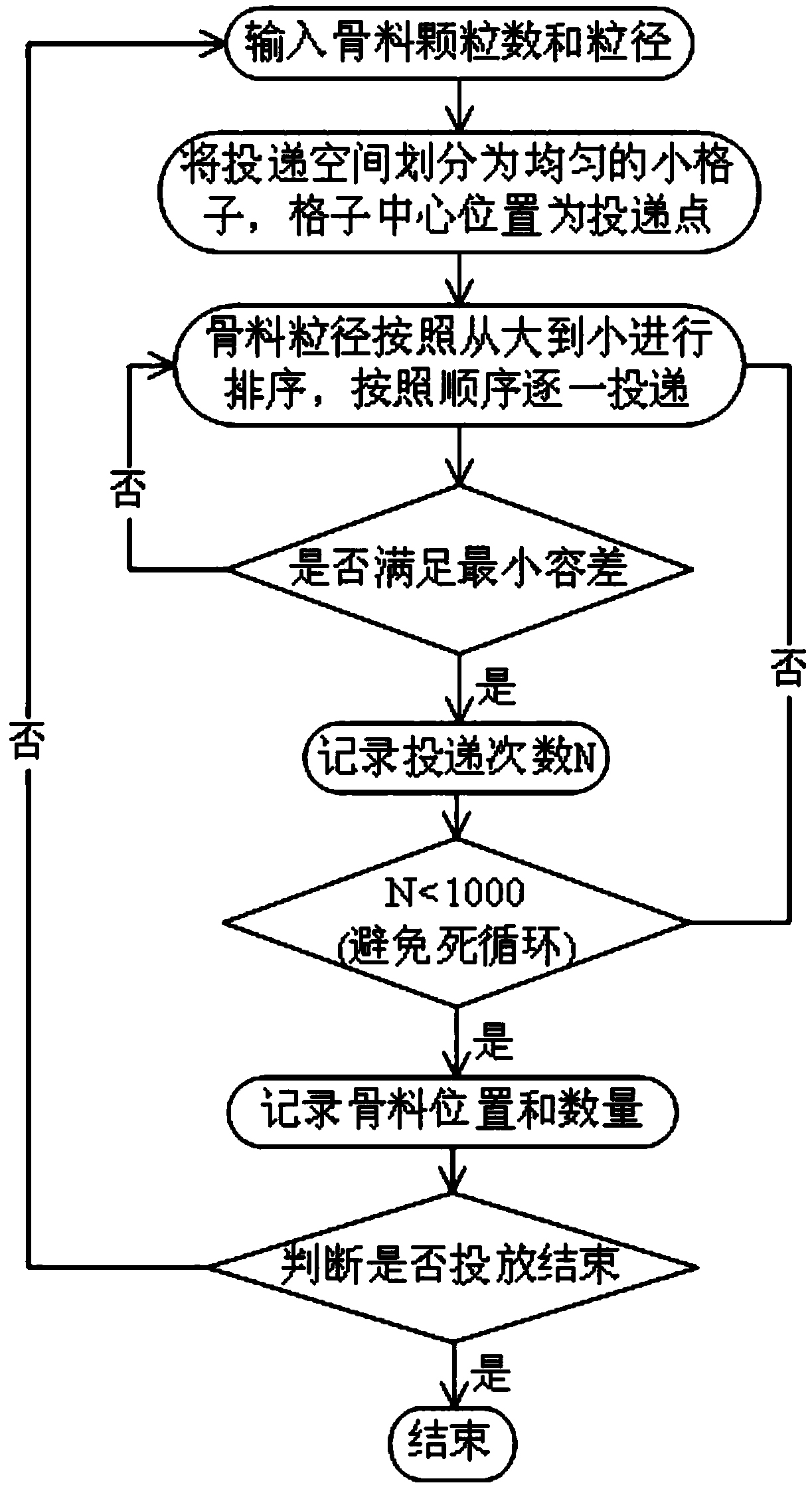

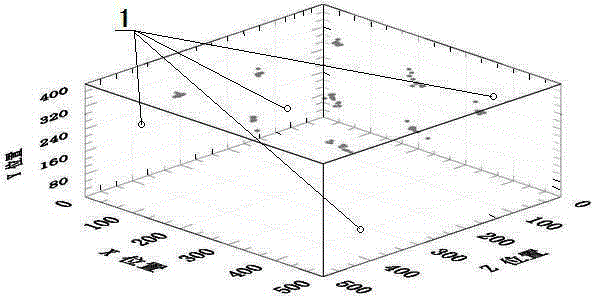

Method of constructing recycled concrete three-dimensional random spherical aggregate model based on Python

InactiveCN108334676ASatisfy the requirement of generating randomnessMesostructure conforms toGeometric CADDesign optimisation/simulationArray data structureSpatial partition

The invention discloses a method of constructing a recycled concrete three-dimensional random spherical aggregate model based on Python, comprising: defining an array to store diameter, coordinate andvolume parameters; inputting basic parameters, including aggregate content, model dimensions, and aggregate microscopic size; building inside, a particle size distribution function and a random function; randomly generating a floating point number from particle sizes d1 to d2 to obtain a random number within a required range; grading the particle sizes; dividing a deployment space into uniform small cells, deploying from the large aggregate particle size to the small aggregate particle size, randomly generating deployment positions, and performing circulating deployment to obtain a satisfactory aggregate model; subjecting spherical aggregates to plane translation to obtain an outer interface region, old hardened mortar and an inner interface region. The model is a damage plasticity modelin ABAQUS software; the parameter values are stored in the array mat; the model is saved; the method that has higher speed and efficiency is provided for researches on numerical simulation of recycledconcrete.

Owner:XIAN UNIV OF TECH

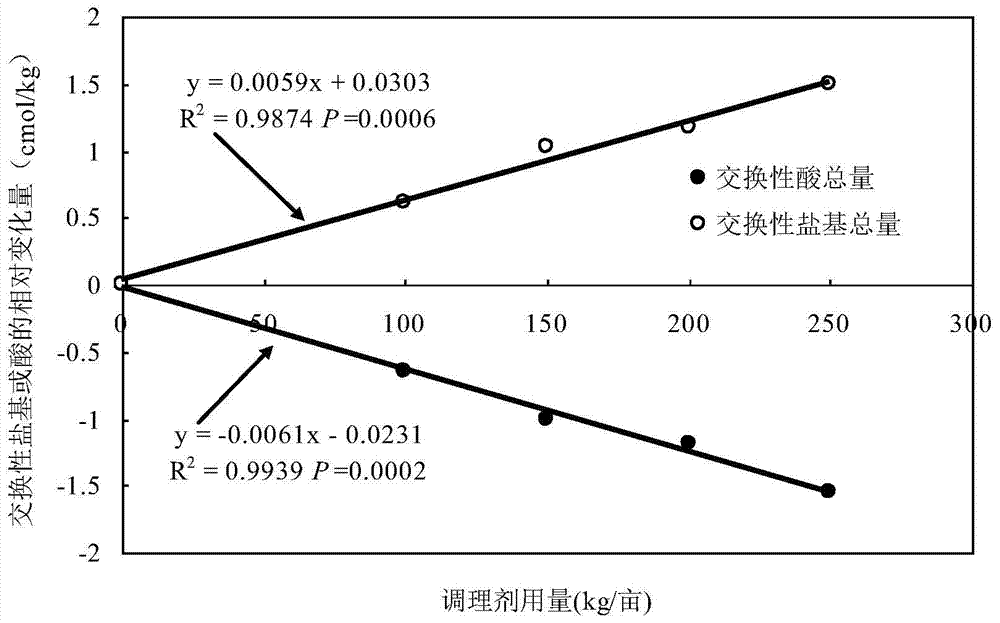

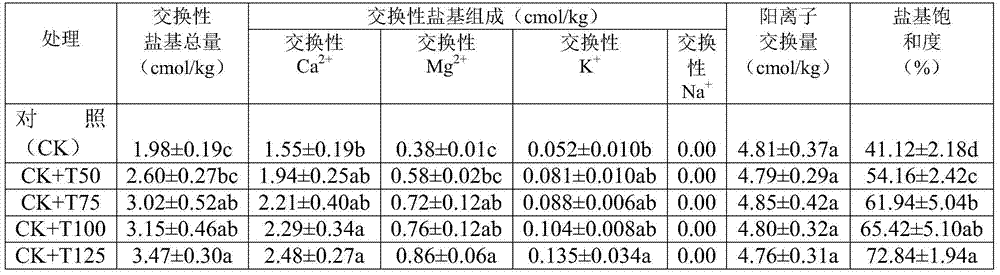

Granular southern paddy field acid soil conditioner using rice husk as matrix

ActiveCN107418586ALight weightHigh porosityAgriculture tools and machinesOther chemical processesSoil porosityHydrolysis

The invention provides a granular southern paddy field acid soil conditioner using rice husk as a matrix, wherein the raw materials comprise 25-38% of carbonized rice hull, 10-20% of rice hull silicon-alkali, 14-25% of fly ash, 28-40% of silicon-calcium-magnesium-phosphorus-potassium fertilizer, and 2-8% of polyacrylamide. According to the present invention, the conditioner can obviously reduce the bulk density of the soil, can increase the soil porosity and the proportion of large aggregates, can effectively prevent soil from hardening, and can provide a large amount of Ca<2+>, Mg<2+>, K<+> and other salt-based ions so as to perform equal exchange with H<+>, Al<3+> and other acid forming ions adsorbed by soil colloids, wherein the exchanged H<+> and the Al<3+> are neutralized and precipitated with the OH<-> carried by the conditioner and the OH<-> released by the active silicon hydrolysis, such that the problems of acidity and toxicity of paddy field acid soil are fundamentally solved.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

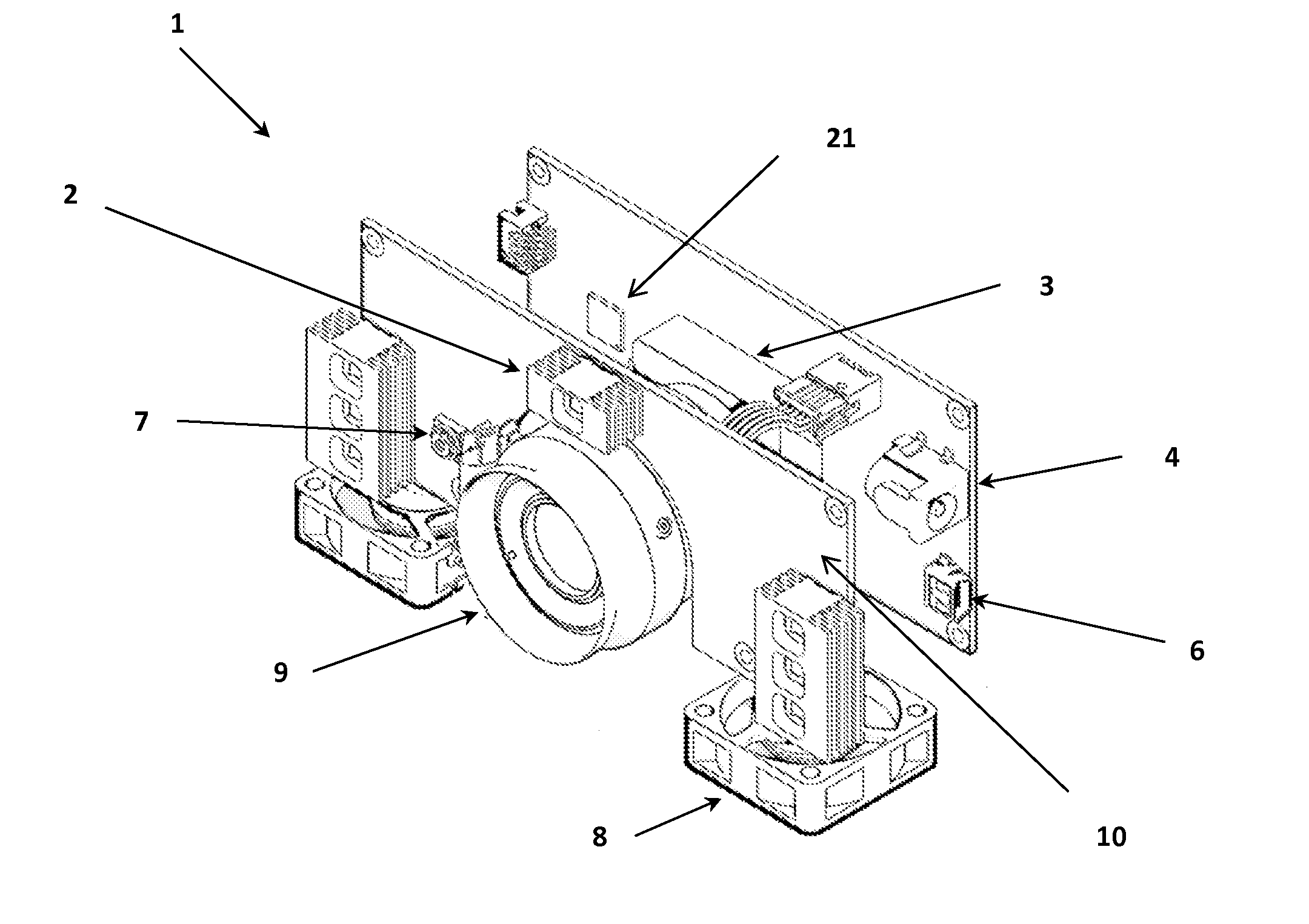

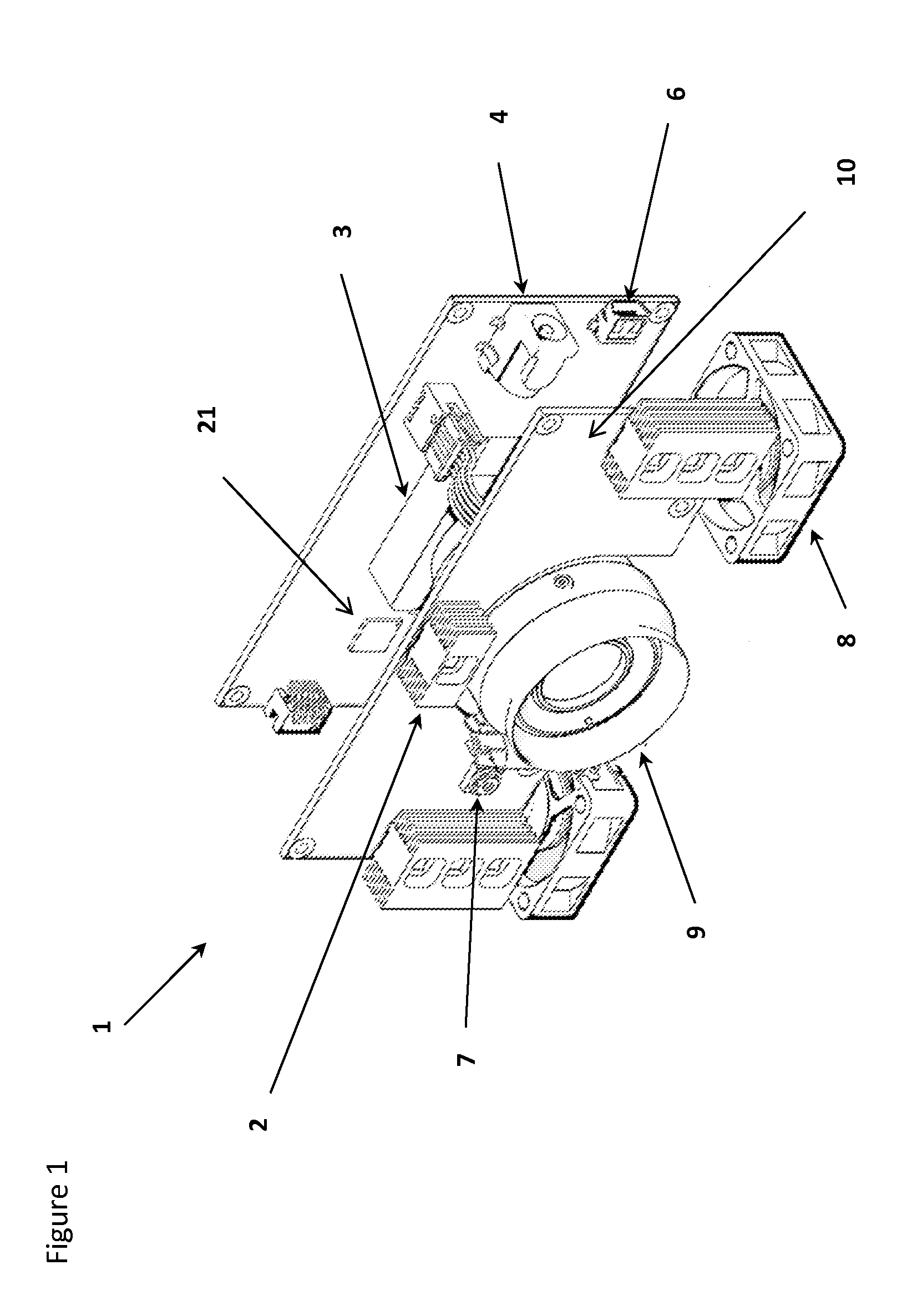

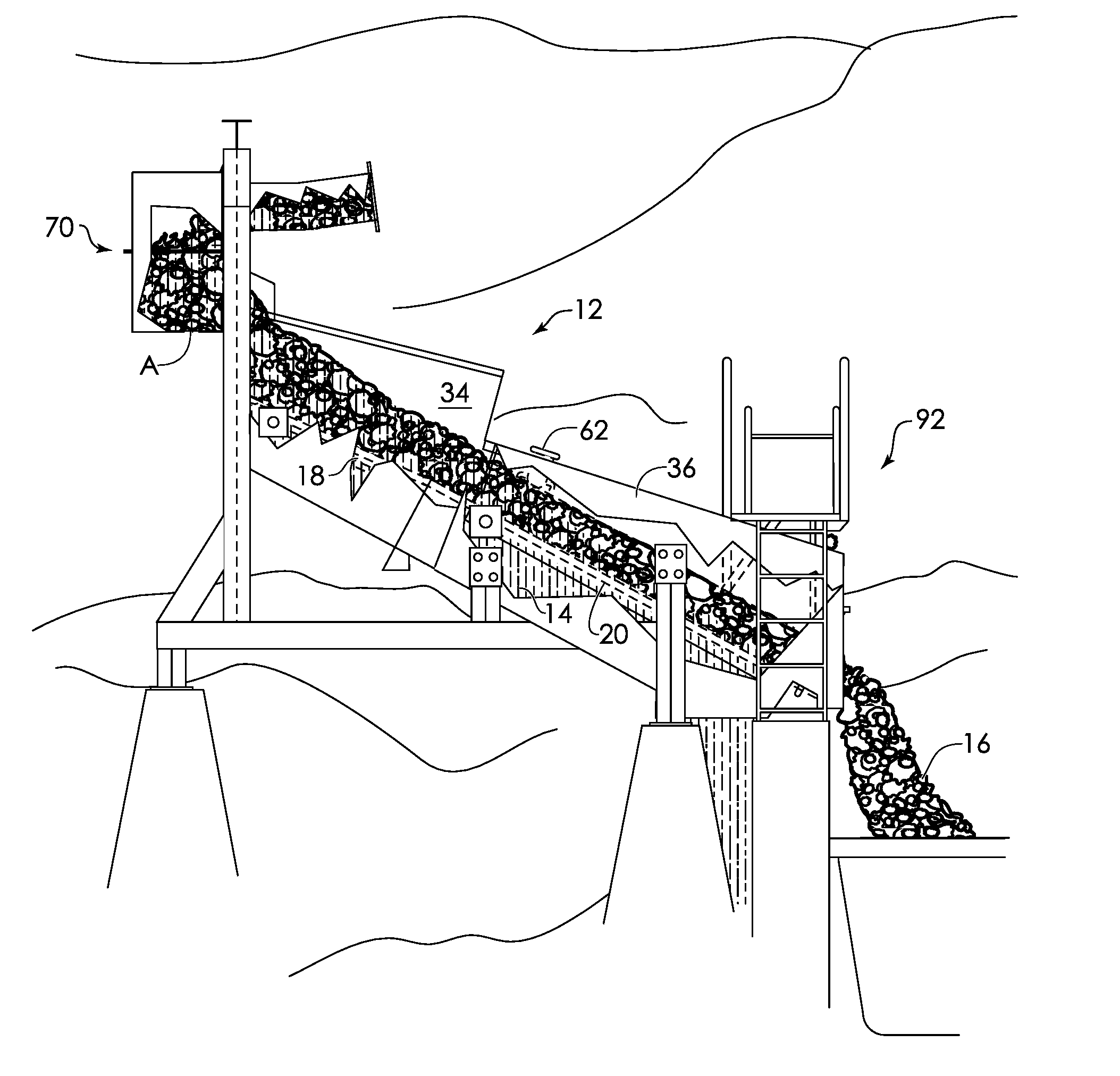

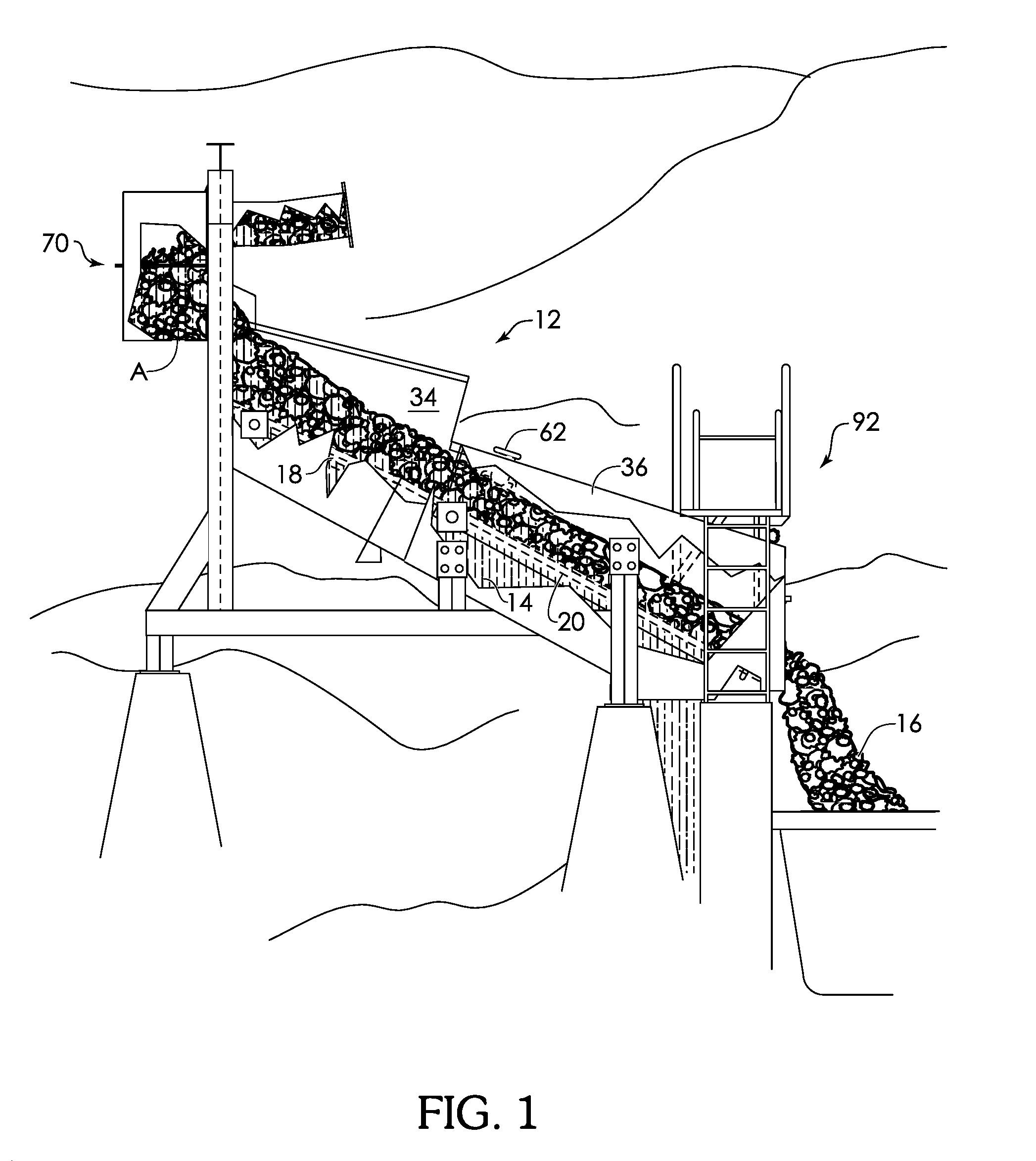

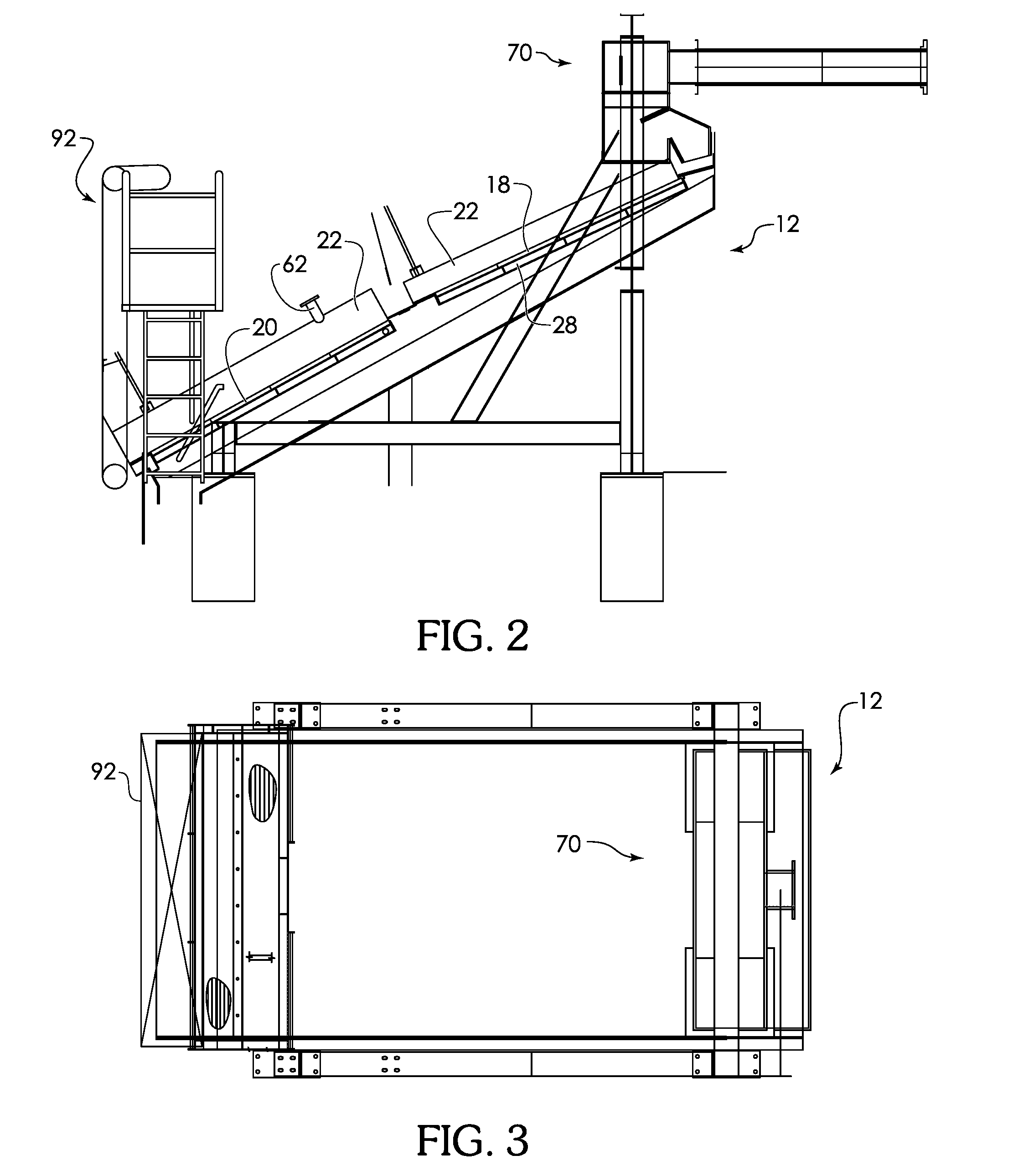

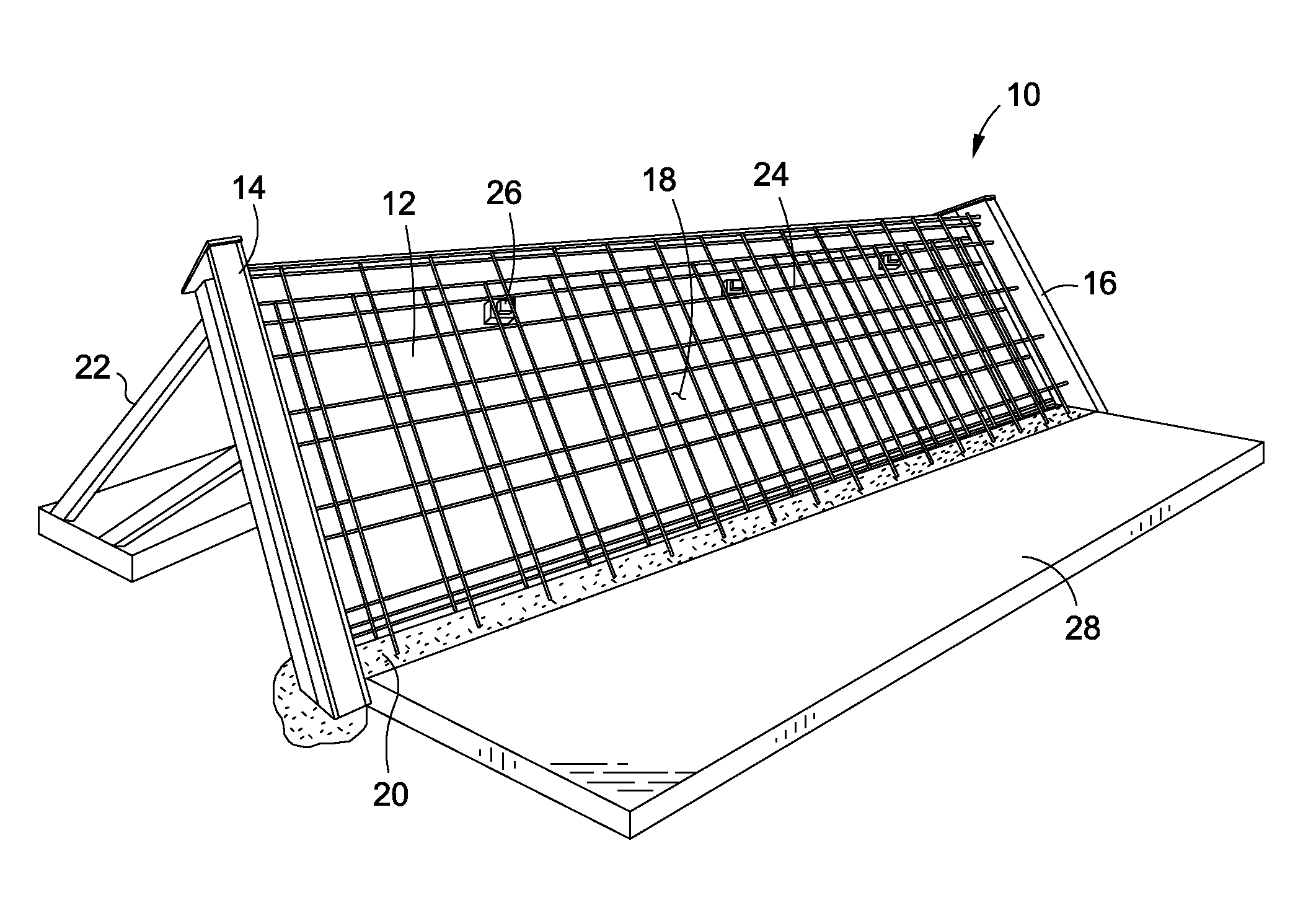

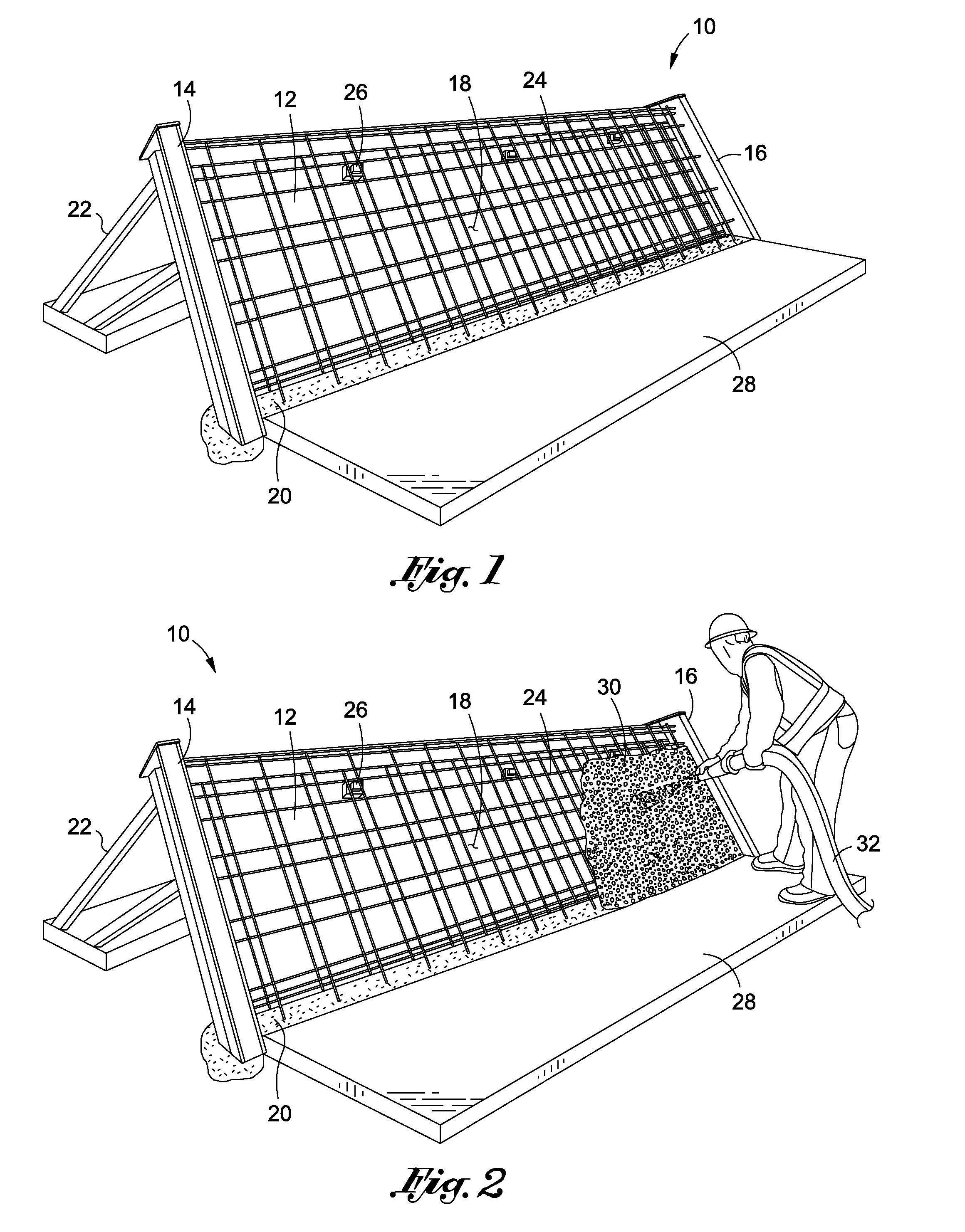

Screening apparatus

ActiveUS8636150B1Improve securityElimination of electrical or vibrating springsSievingScreeningMechanical engineeringLarge aggregate

An upper deck in a top flume before a lower deck in a bottom flume, each deck is adjustable from form about 10 to about 70 degrees, or from about 20 to about 45 degrees, and has a frame divided into a grid containing blank or screen panels that have openings to selectively permit smaller aggregate to pass through, while larger aggregates pass over the screens. The top flume has an opening for feeding the larger aggregates to the top of the deck adjacent the flume, and a bottom with an opening for feeding smaller aggregates under the deck. The bottom flume has an upstream side with an opening at the bottom to receive the smaller aggregates from the upstream adjacent flume and a downstream side having an opening adjacent the bottom of the side to discharge the larger aggregates, and the bottom has an opening it discharge the smaller aggregates.

Owner:DEWAR OF VIRGINIA

Decorative aggregate concrete surface preparation process

InactiveUS20090277127A1Increases adhesion potentialReduces the potential for shrinkageIn situ pavingsBuilding repairsPolypropyleneThin sheet

The present invention is directed to a process of creating a decorative aggregate concrete surface on both a slab on grade installation and a podium deck or topping slab installation. The preparation includes washed decorative aggregate surfaces using a variety of decorative aggregate materials imbedded within a standard concrete mix having a one inch maximum aggregate. A 6-mil polypropylene sheet 435 Visqueen material covered with a two-inch layer of sand is used directly below the concrete to retard the curing time. Roller tamping is used to move the large aggregate below the surface of the concrete material. Power brushes are then used to expose the decorative aggregate prior to the final process of applying a densifing sealer. This process has been designed to reduce installation time, as well as overall labor and material costs.

Owner:SINGLE EAGLE

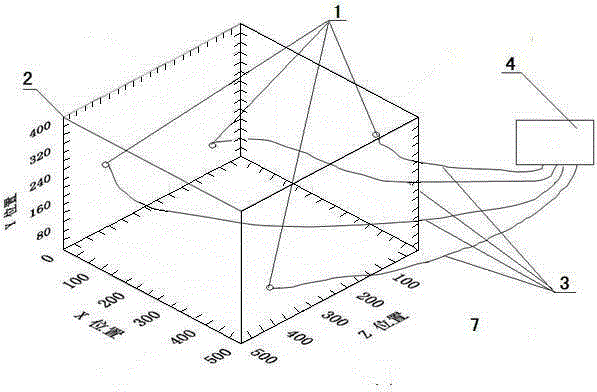

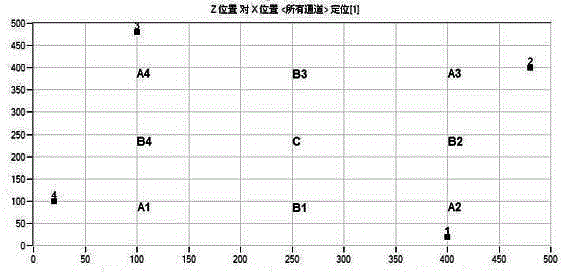

Accurate positioning method for concrete crack

InactiveCN104569159AEasy to operateReasonable structureMaterial analysis using acoustic emission techniquesEpoxyAcoustic emission

The invention relates to an accurate positioning method for a concrete crack. The method comprises the following steps: acoustic emission sensors (1) are packaged by epoxy resin, subjected to waterproofing work, buried in a concrete (2) structure as large aggregate, and connected with acoustic emission monitoring equipment (4) through coaxial screened cables (3); the acoustic emission monitoring equipment (4) is used for recording and analyzing acoustic emission source information, locates the position of a particular acoustic emission source (a crack) according to a received acoustic emission signal, and observes the developing and variation trend of the acoustic emission source (the crack); a cardinal point O is selected; the particular coordinate positions of the four acoustic emission sensors (1) are determined by taking the cardinal point O as datum; the acoustic emission sensors (1) are arranged in the concrete (2), and are led out to the acoustic emission monitoring equipment (4) through the coaxial screened cables (3) respectively. The accurate positioning method is accurate in positioning of a concrete crack, and reduces omissive and false positioning to the maximum extent.

Owner:UNIV OF JINAN

Backfill earth construction method by using premixed flow state solidified earth

A backfill earth construction method by using premixed flow state solidified earth comprises the following steps that earth in a natural state is backfilled to a construction site where backfill earthis required; premixed curing agent slurry is poured into the backfill earth, and the slurry is higher than the backfilled earth by a certain height to form gravity momentum, so that the slurry permeates into the backfilled earth under action of the self-gravity; and the situation that whether the slurry permeates into the bottom of the earth or not is detected, if the earth is not fully permeatedby the slurry, and the curing agent slurry is supplemented and poured to continue permeating and / or a mixing device is used for mixing in the part without being fully permeated. Alternatively, the method comprises the following steps that the earth body is input to a mixer, at the same time, the mixed curing agent slurry is also added to the mixer for full blending, crushing and mixing accordingto the predetermined proportion to form premixed flow state solidified earth; the premixed flow state solidified earth is conveyed to a backfilled earth construction site through a pump or a tanker for backfill operation; and large aggregate is thrown into the premixed flow state solidified earth during the backfill operation process. According to the two methods, the earth excavated by the project can be utilized to the utter most and most rapidly, the construction speed is high, the cost is low, and the quality is reliable.

Owner:王继忠

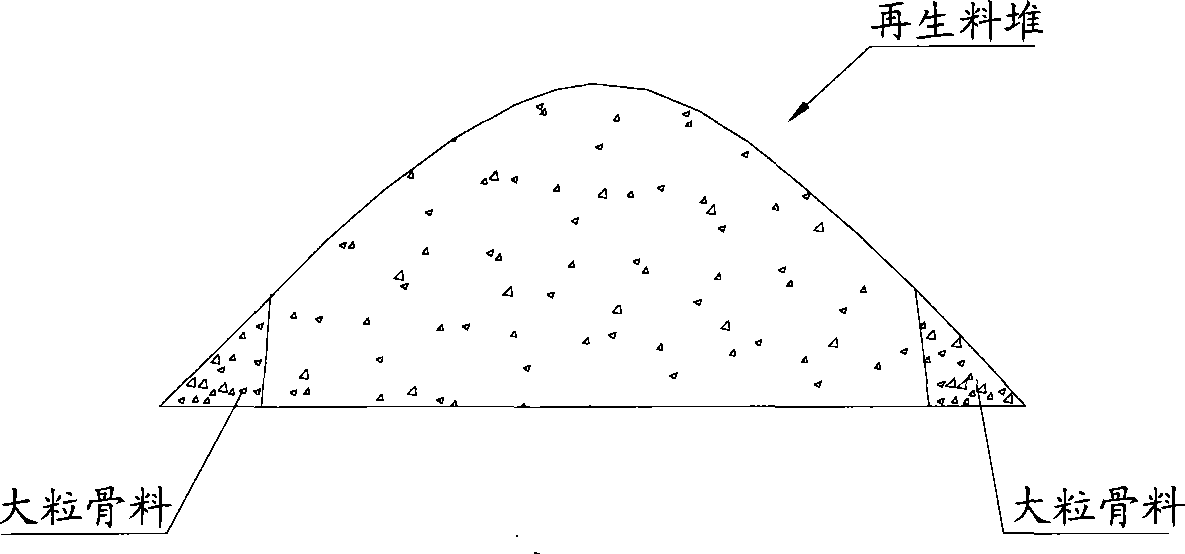

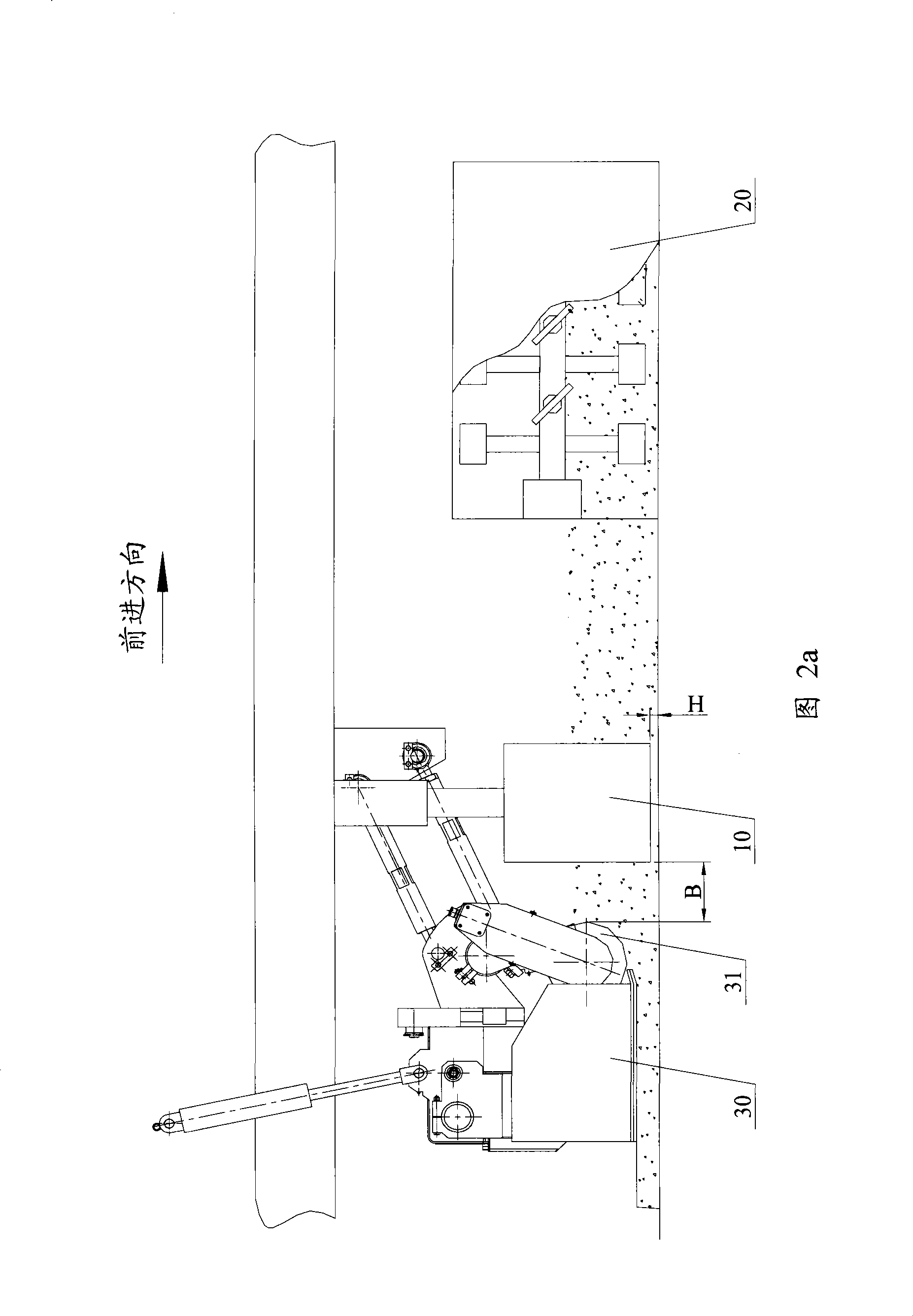

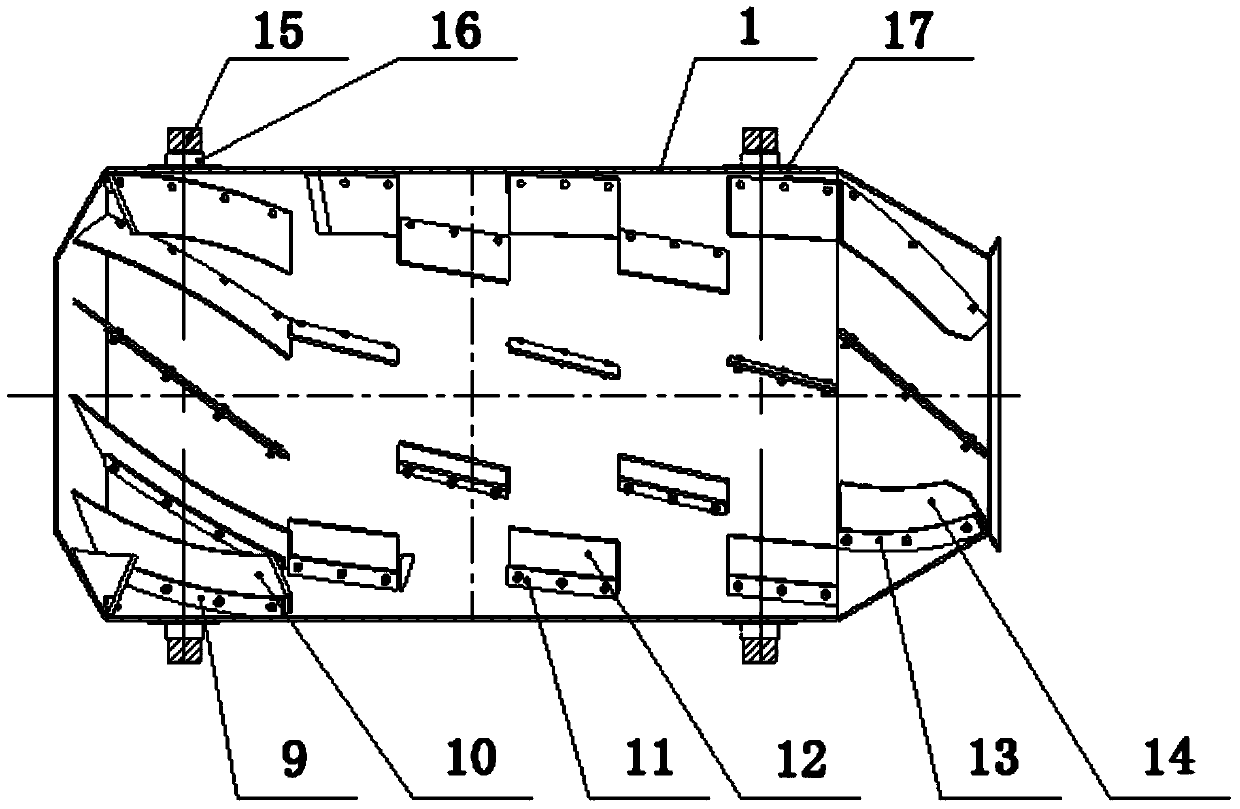

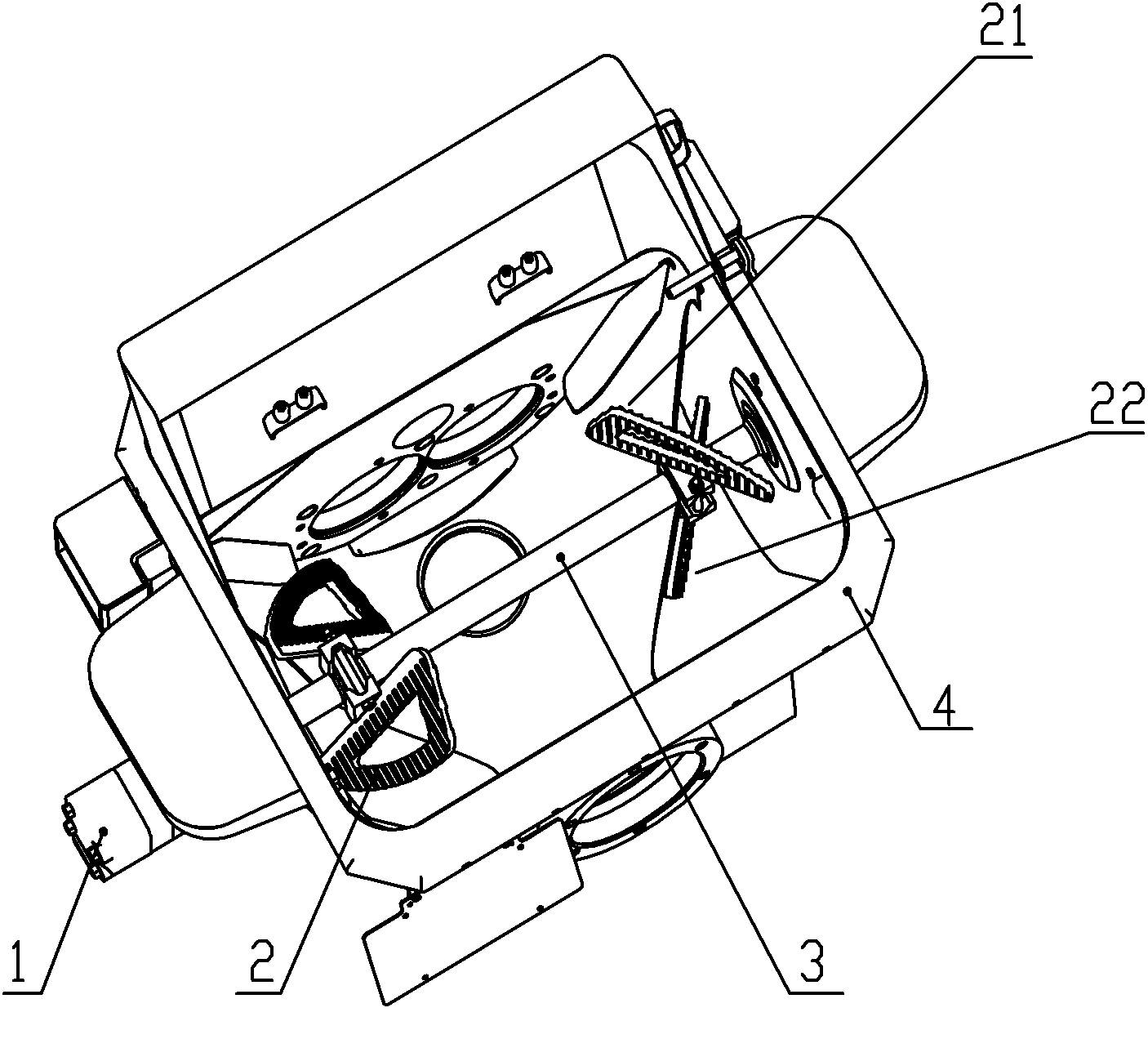

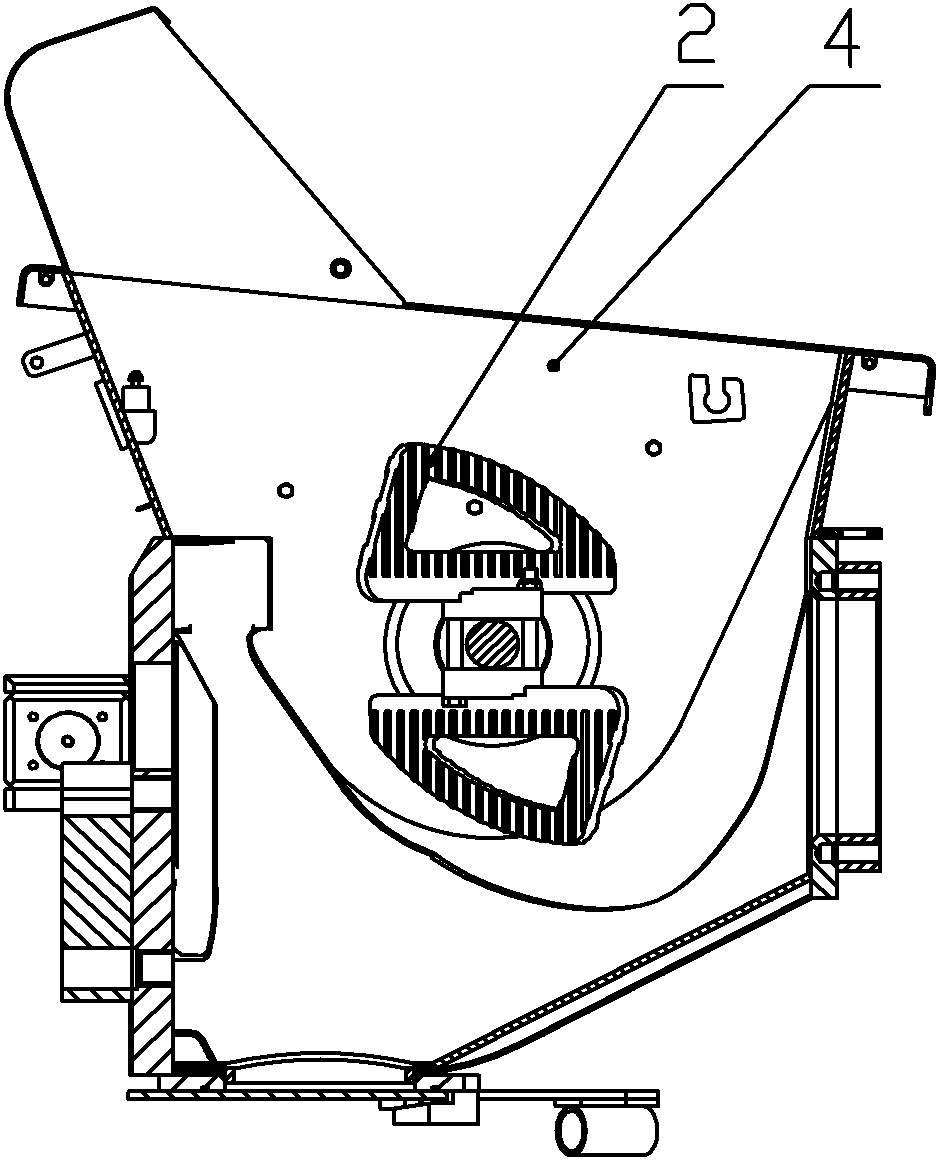

Asphalt pavement on-site heat recoveryremixer

InactiveCN101392495AImprove adaptabilityIncrease flexibilityRoads maintainenceRoad surfaceMiddle line

The invention discloses an on-the-spot thermal regenerative asphalt remixer of an asphalt road. A segregation-eliminating device containing a plurality of blades is arranged between a mixing device and a spreading device, and firstly passes the regenerative stock pile and turning over the mixture at the two sides of the stock pile along with the proceeding of the whole machine; the ground clearance of the lower edge of the blade is less than half of the maximum aggregate size of the regenerative mixture to fully actuate the large aggregate at the most bottom of the regenerative stock; the distance between the rear edge of the blade and the spreading device is less than 1m, a spiral distributing device of the spreading device that is adjacent closely after the isolation-removing device enters the regenerative stock pile which eliminates segregation, thus being capable of effectively avoiding that the segregation occurs again to the regenerative stock pile, the segregation of which is eliminated; the segregation-eliminating device is symmetrically arranged at the left side and right side of the longitudinal central line, and the distance between the outer edges at the left side and the right side of the blade is 0.5-3.0m so as to satisfy the requirement of different width of the regenerative stock pile. The segregation-eliminating device of the invention can also be applied to the ordinary spreading machine.

Owner:ZOOMLION HEAVY IND CO LTD

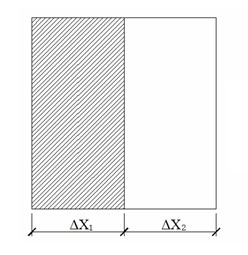

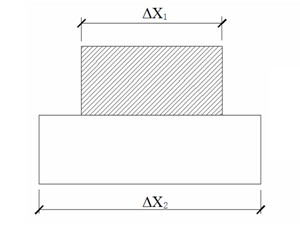

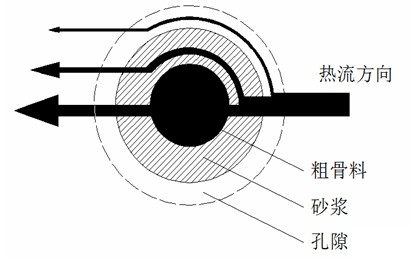

Construction method of a predictive model for thermal expansion coefficient of fully graded large aggregate concrete in hardening stage

InactiveCN102297876AFit closelySimplify measurement difficultyMaterial thermal coefficient of expansionThermal expansionMaterials science

The invention discloses a construction method for a thermal expansion coefficient prediction model of complete size grading large aggregate concrete in a hardening phase. According to the invention, the thermal expansion coefficient of the complete size grading large aggregate concrete in the hardening phase and a material composing the concrete are researched, the complete size grading large aggregate concrete can be treated as an aggregation of apertures, a mortar and a crude aggregate, and the thermal expansion coefficient of the complete size grading large aggregate concrete in the hardening phase is predicted according to thermal expansion coefficients of all components. The concrete construction method for the thermal expansion coefficient prediction model of the complete size grading large aggregate concrete in the hardening phase comprises steps of establishing a series model of the thermal expansion coefficient, establishing a parallel model of the thermal expansion coefficient, and establishing the thermal expansion coefficient model based on the series model and the parallel model. The prediction model can well characterize the law of the relation between the thermal expansion coefficient of the complete size grading large aggregate concrete and the thermal expansion coefficients of the materials.

Owner:HOHAI UNIV

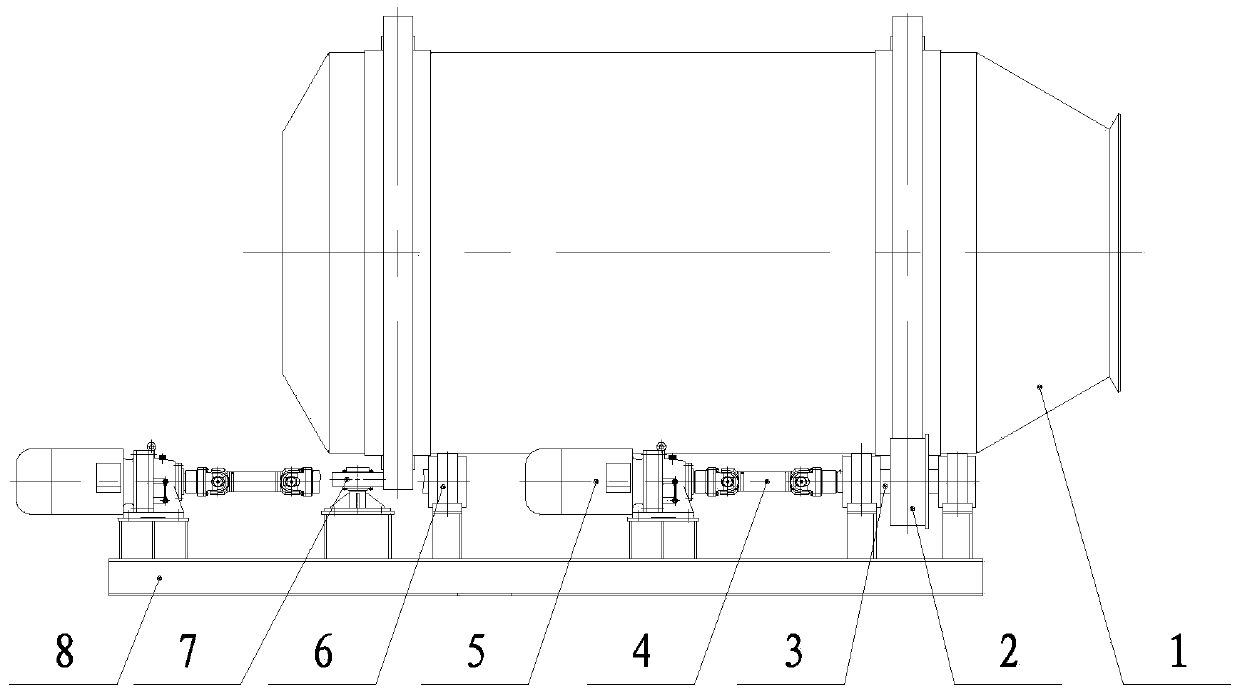

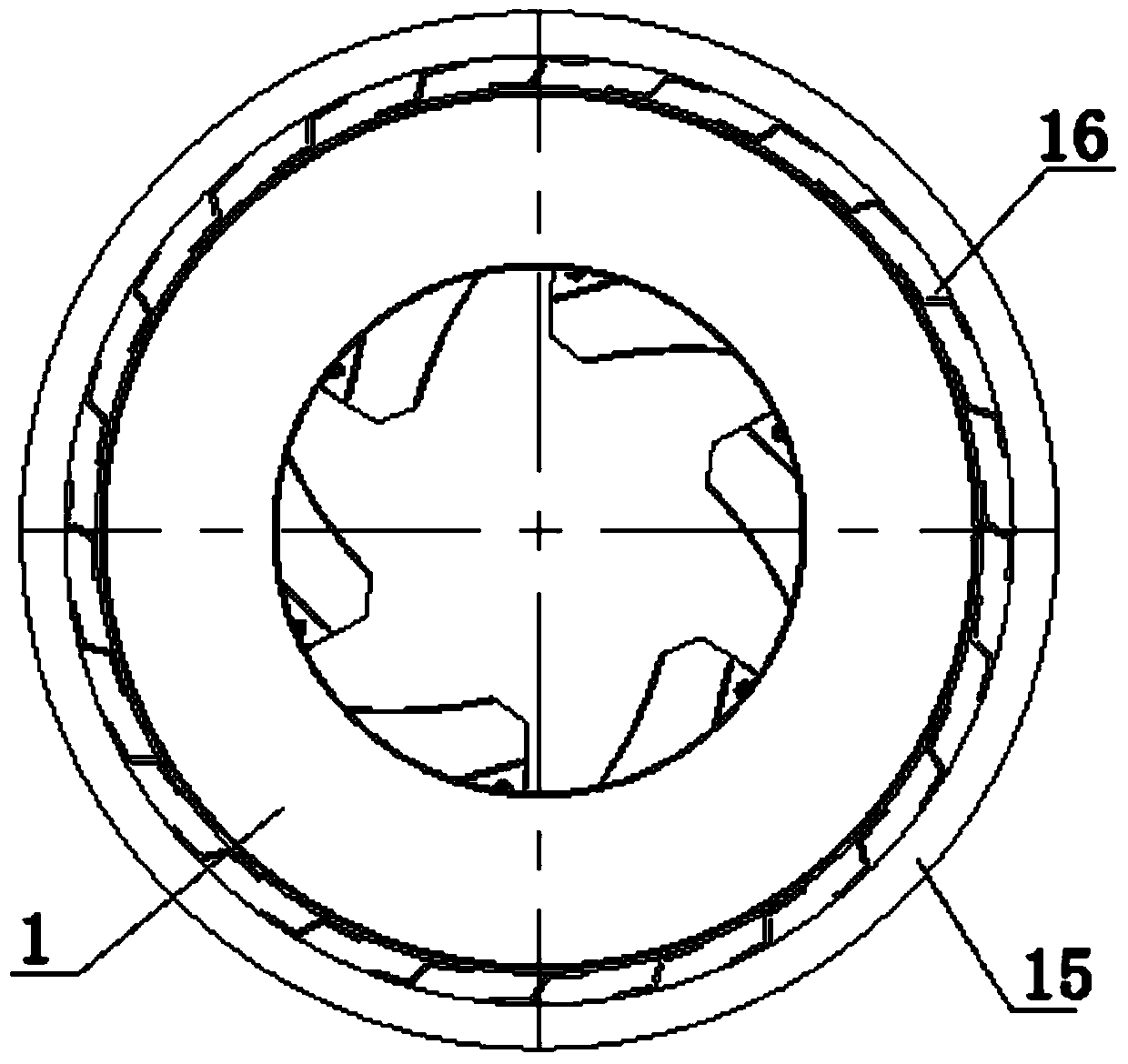

Continuous rotary mixer and using method thereof

ActiveCN103432938ALarge particle sizeEasy to manufactureRotating receptacle mixersTransportation and packagingCouplingDrive shaft

The invention relates to a continuous rotary mixer and a using method thereof. The rotary mixer comprises a base, a cylinder body, a riding wheel, transmission shafts, reducers, a catch wheel, wheel belts and Z-shaped plates, wherein a reinforcing ring is fixedly connected with the outer wall of the cylinder body; the wheel belts are fixed through the Z-shaped plates uniformly fixed on the reinforcing ring; the riding wheel is connected with the corresponding transmission shaft, props against the wheel belts and drives the cylinder body to rotate around the mandrel of the riding wheel; the transmission shafts are driven by the reducers through couplings and are adjusted in coaxiality through the couplings; the catch wheel fixed on the base props against the side walls of the wheel belts to limit the axial position of the cylinder body. The rotary mixer has the advantages of being easy and quick to mount and move and low in cost as not having a foundation, being reasonable in structural design, convenient to manufacture, uniform in stirring, high in yield and low in power consumption, and ensuring a large aggregate size.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +3

Ultrafine processing method of molybdenum disulfide powder

InactiveCN1724594ASolve the "anti-coarse" phenomenonGood broken effectPigment physical treatmentSlurryBall mill

The invention relates to a method to manufacture molybdenum disulfide powder. The process includes the following steps: adding ball mill medium, large aggregate molybdenum disulfide powder, disperse liquid into high power whisking burnishing-machine to take waterproof pulverization; drying the slurry by blast dryer; and taking the second pulverization on the ball mill. The invention solves the problem of returning to coarse phenomenon of superfine powder existing in drying process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Material having a controlled microstructure, core-shell macrostructure, and method for its fabrication

Disclosed is a method for making a material having a controlled microstructure, the method including providing particles of a ceramic mineral material, the particles having a metal oxide dopant therein. The particles of the ceramic mineral material are consolidated into larger aggregates of a size relevant to the desired application using standard industrial mixing and pelletizing technology. The aggregates are heated under reducing conditions so that at least part of the dopant is reduced to form a transient, metastable liquid phase among the particles. The liquid phase includes at least part of the reduced dopant and promotes sintering of the particles and forms islands of reduced metal within the material and on the surface of the aggregates. Following heating of the aggregates under reducing conditions, the aggregates are heated under oxidizing conditions such that the islands of reduced metal are oxidized and / or go into solid solution within the particles, thereby creating voids within and form a shell thereon the particles.

Owner:CARBO CERAMICS +1

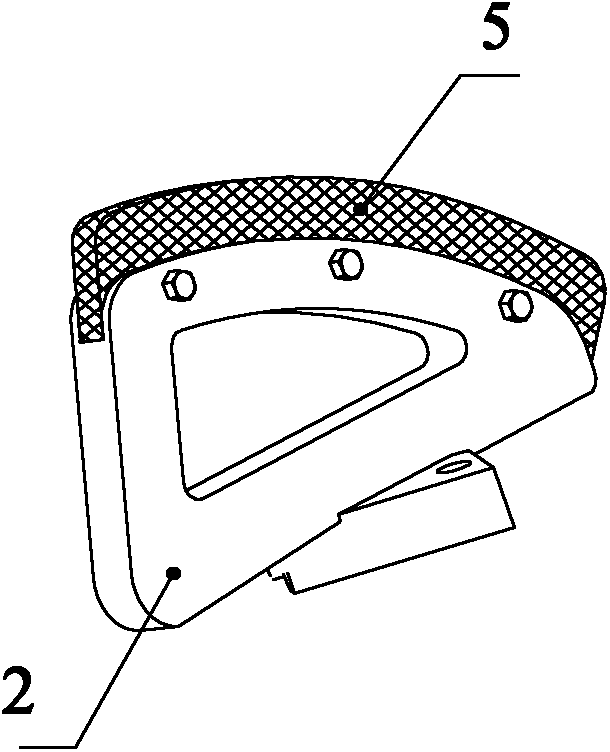

Novel elastic stirring blade for concrete hopper

ActiveCN103101112AExtended service lifeSimple structureCement mixing apparatusConstruction aggregateFlange

The invention relates to a novel elastic stirring blade for a concrete hopper. The concrete hopper is internally provided with a stirring shaft which is driven to rotate by a stirring motor. The stirring blade is arranged on the stirring shaft, and the stirring blade is provided with an elastic flange at least on the outer edge facing one side of the concrete hopper. As the elastic flange is employed in the invention, when larger aggregate is stuck between the stirring blade and the concrete hopper, the elastic flange deforms to let the aggregate pass, so that the aggregate cannot be jammed deadly, and no damage can be brought about on the hopper and stirring equipment. In addition, with the invention, a traditional rigid contact relation existing between stirring blades, aggregate and a hopper inner wall when they contact simultaneously is also improved, and the service life of the hopper is improved. Also, the novel elastic stirring blade provided in the invention has the beneficial effects of simple structure, low cost, obvious effect and the like.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

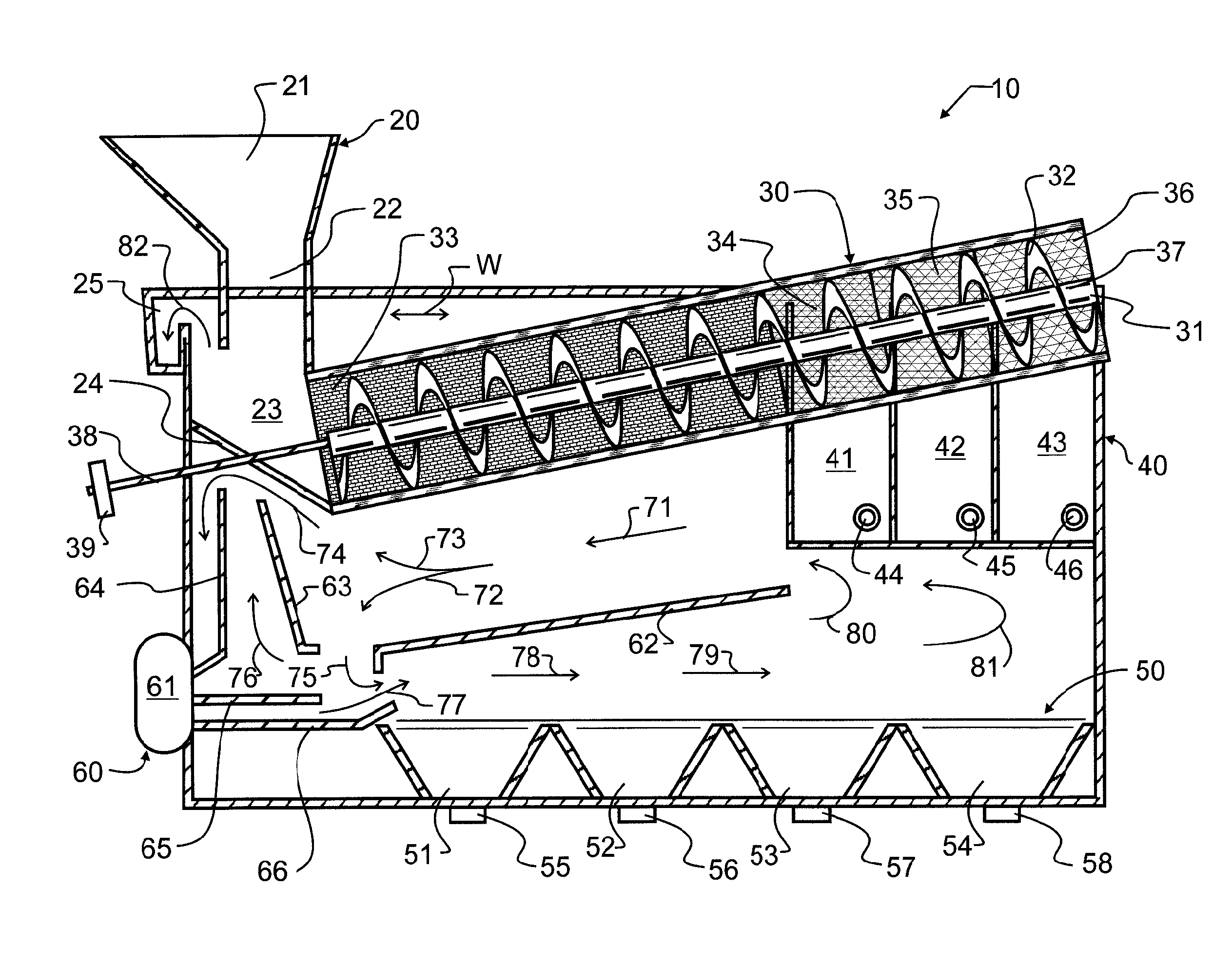

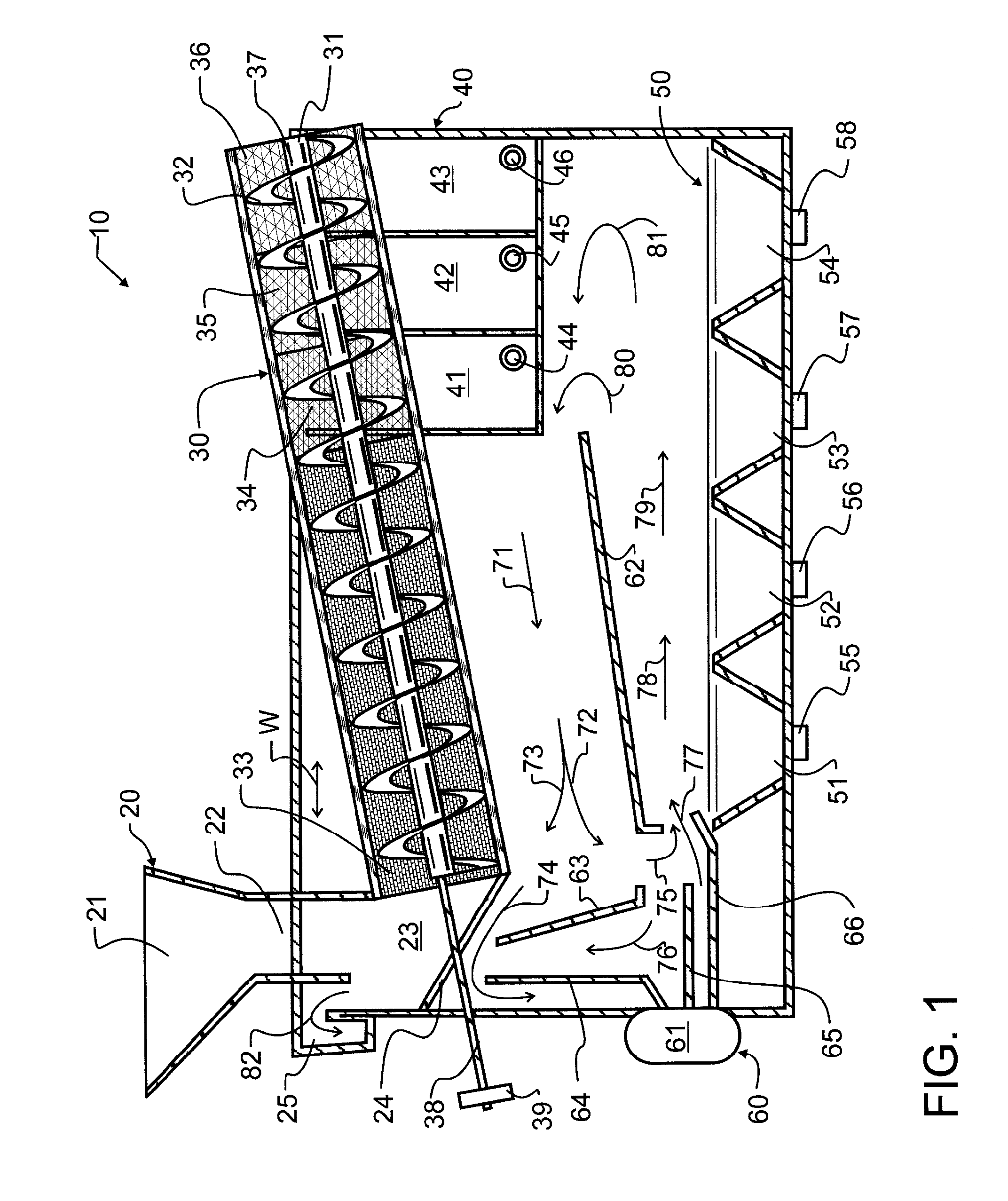

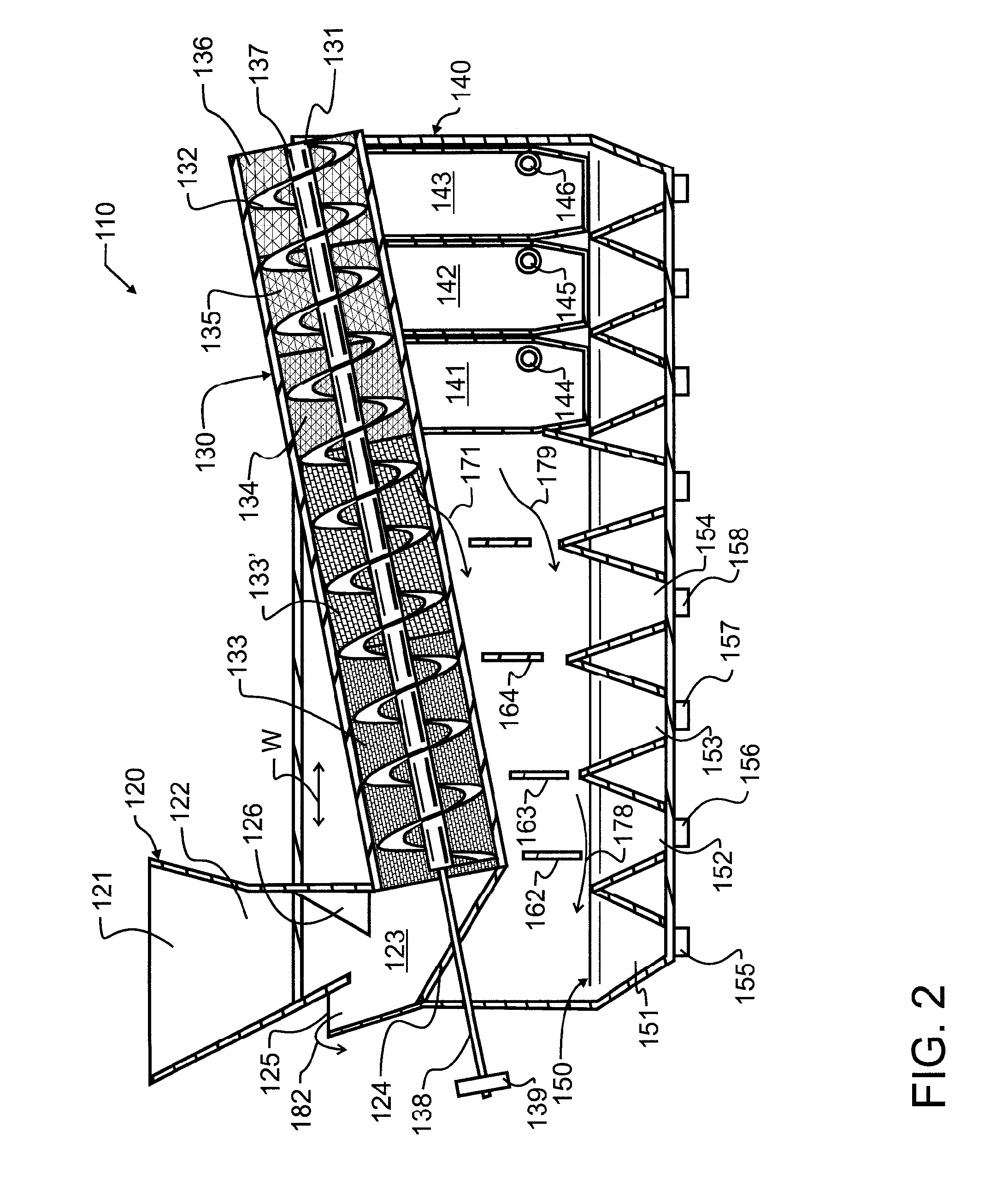

Rotary aggregate washing and classification system

InactiveUS8381916B2Quickly and efficiently classifyPromote formationSievingScreeningCounter flowWater flow

An aggregate washing and classification system incorporates into a water-filled receptacle a sand classifier and one or more rotating augers. The augers are wrapped with screens or perforated walls that are fixed relative to the augers. The size of the perforations may be chosen to selectively sift particular sizes of gravel and rock, and if the perforations increase in size along the length of the augers, either continuously or discontinuously, the material which passes through the perforations will likewise increase in size with greater travel through the auger passageway. Consequently, a set of rock bins may be provided adjacent to the auger outlet, for collecting various sizes of larger aggregate, such as washed rocks. Sand will typically be permitted to pass through the screen perforations near the aggregate inlet. Once outside of the auger and screens, the sand will drop directly into a sand classifier, which is conveniently located directly below the augers and adjacent to the material inlet. Fresh water is pumped into the bottoms of the rock bins, and flows counter to the aggregate passing through the augers. The counter-flow keeps the rock bins clean, and the flow of water adjacent and counter to the material inlet is used to extract and discharge low-density matter from the aggregate inlet. The entire system is desirably incorporated into a single land vehicle for transport to aggregate sources, such as gravel pits and the like, where the finest grades of aggregate may be rapidly prepared.

Owner:BOSSEN PAUL W

Method and finish for concrete walls

Owner:SHAW CRAFTSMEN CONCRETE LLC

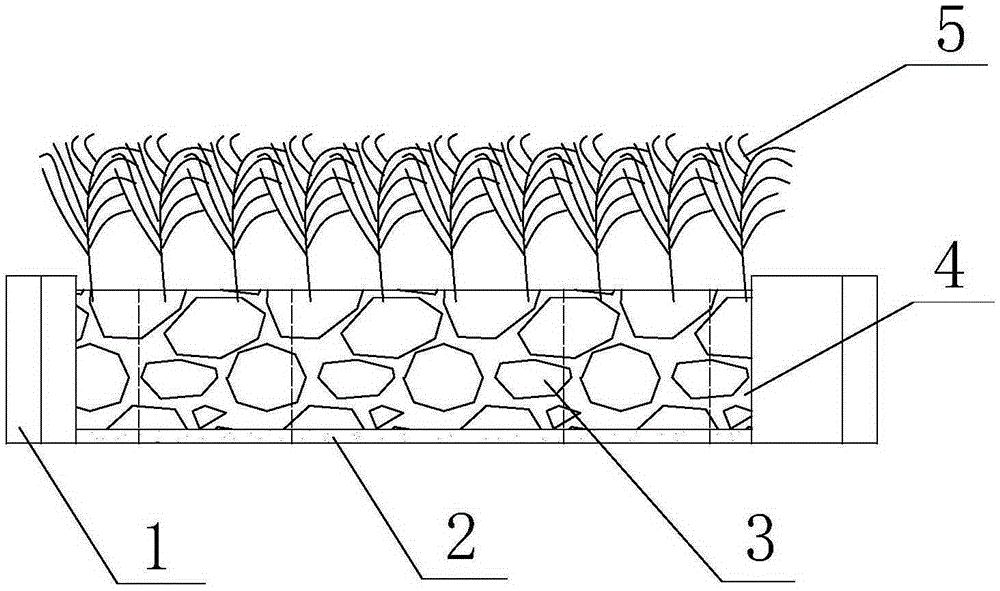

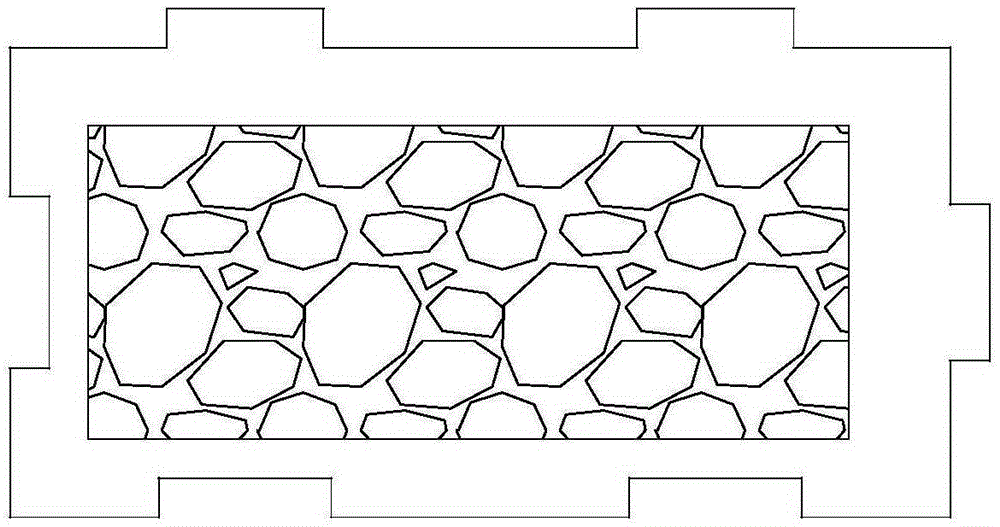

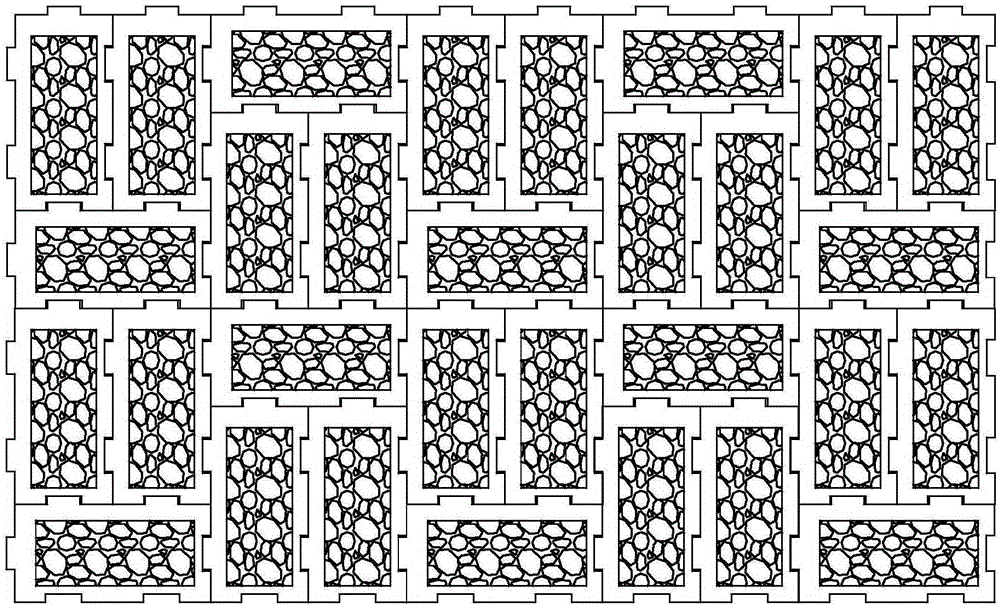

Ecological concrete building block similar to sponge and preparation method thereof

InactiveCN105239532AImprove structural strengthHigh water retention and high permeabilityRoof covering using tiles/slatesSingle unit pavingsUnderwaterPlant growth

The invention provides an ecological concrete building block similar to a sponge. The ecological concrete building block similar to the sponge has multiple features of being high in water permeability, water retention and intensity, suitable for growth of animals and plants, capable of being self-locked and engaged and the like. The ecological concrete building block similar to the sponge is composed of a concrete frame with concave and convex grooves, a phenolic aldehyde water retention cushion layer, large aggregate non-fine concrete and composite nutrient soil. The concrete frame with the concave and convex grooves is filled with the large aggregate non-fine concrete; pores and the surface of the large aggregate non-fine concrete are filled with the composite nutrient soil; the phenolic aldehyde water retention cushion layer is laid at the bottom of the large aggregate non-fine concrete. The phenolic aldehyde water retention cushion layer at the bottom has the high water retention and high water permeability, can store water for need of growth of the plants when rain is small or water conservation is needed at ordinary times, and can be pervious to water rapidly when rainstorms happen or rain is large. The internally filled large aggregate non-fine concrete has good water permeability and air permeability, the communicated pores are suitable for rotting growth of the plants, and the ecological concrete building block can provide a multiply and habitat environment for aquatic animals when applied to the underwater.

Owner:福建启鹏生态科技有限公司 +1

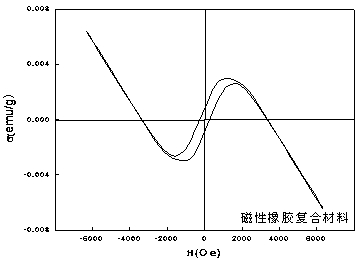

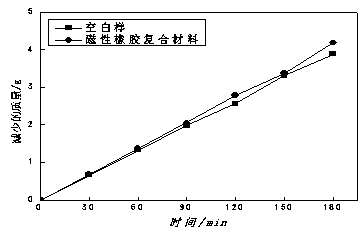

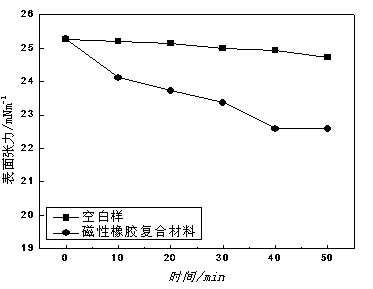

Magnetic fuel-saving rubber composite material

InactiveCN103627051AWith magnetic radiation propertiesImprove fuel saving effectEnvironmental energyRubber material

A magnetic fuel-saving rubber composite material relates to a rubber material and comprises components of butadiene-acrylonitrile rubber, a chloroprene rubber adhesive, zinc white, stearic acid, an antideteriorant 4010NA, an antideteriorant RD, a coumarone, dioctyl phthalate, carbon black, a magnetic material, brimstone, a promoter M, and a promoter PZ. The magnetic fuel saving rubber composite material is prepared through the steps of plastifying, mixing, vulcanizing and the like. The magnetic fuel saving rubber composite material provided by the invention has the benefits of enabling an oil delivery pipeline to have a magnetic radiation performance, enabling fuel oil molecules to become small aggregate structures from a large aggregate structure by using a magnetic line to smash the clustering states of fuel oil molecules, and enabling the fuel oil molecules to be activated so as to change physical chemical property thereof, thereby being helpful to sufficient burning of fuel oil, improving the fuel-saving performance of an engine and also reducing contaminant emission. The magnetic fuel saving rubber composite material is in favour of energy conservation and environment protection. Therefore, the magnetic fuel-saving rubber composite material has a stronger promotion and application value. The magnetic fuel saving rubber composite material belongs to products of green environmental energy saving facilities on the aspects of rubber industry and is used on the aspect of automobile fuel saving.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Stable non-aggregating nucleic acid lipid particle formulations

ActiveUS9415109B2Improve stabilityInhibit aggregationMicroencapsulation basedGenetic material ingredientsLipid particleNanoparticle

The present invention relates to stable lipid nanoparticle pharmaceutical formulations which are substantially free of large aggregates (e.g., aggregates greater than 1 μm in size) and include a substantially non-ionic medium.

Owner:ALNYLAM PHARMA INC

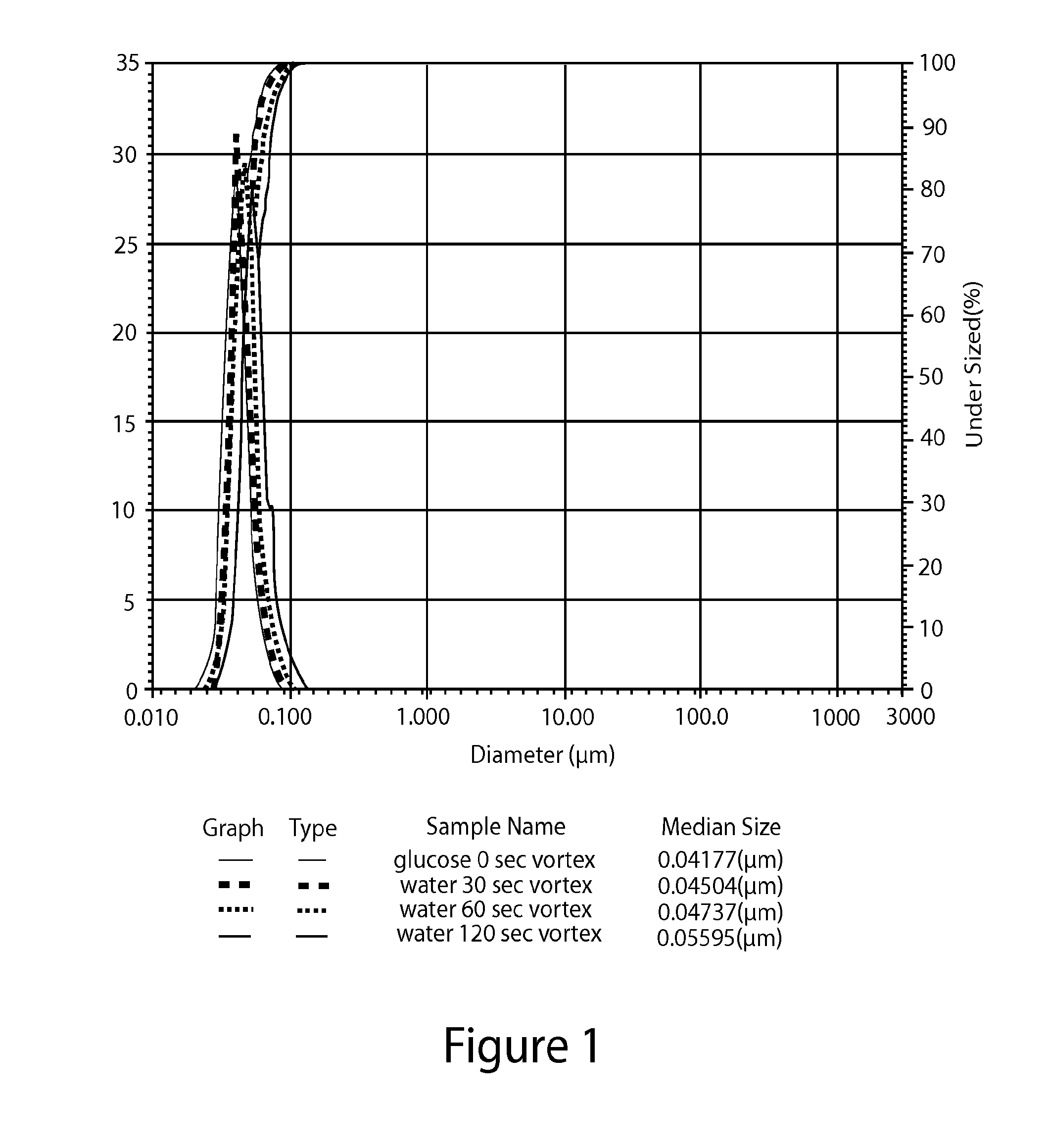

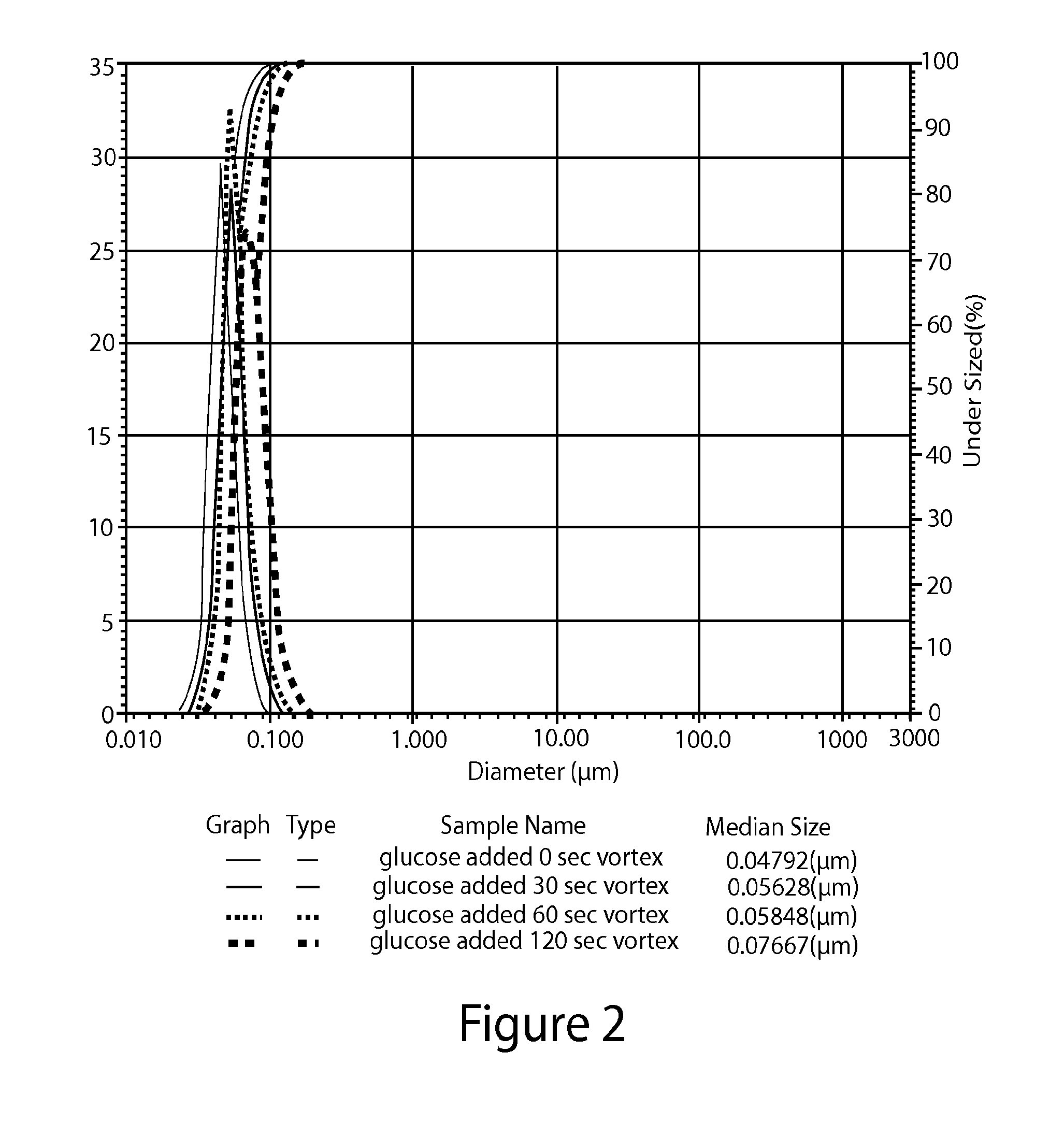

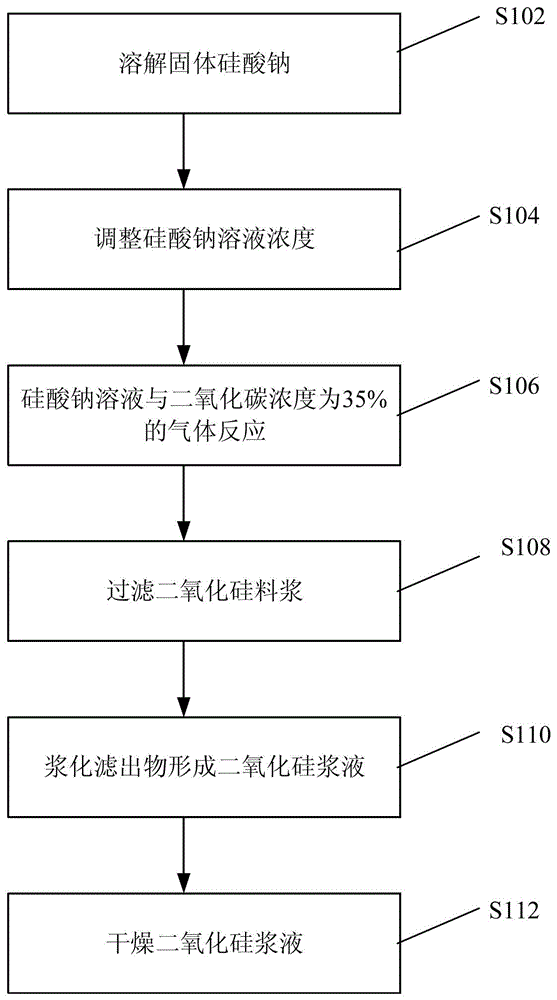

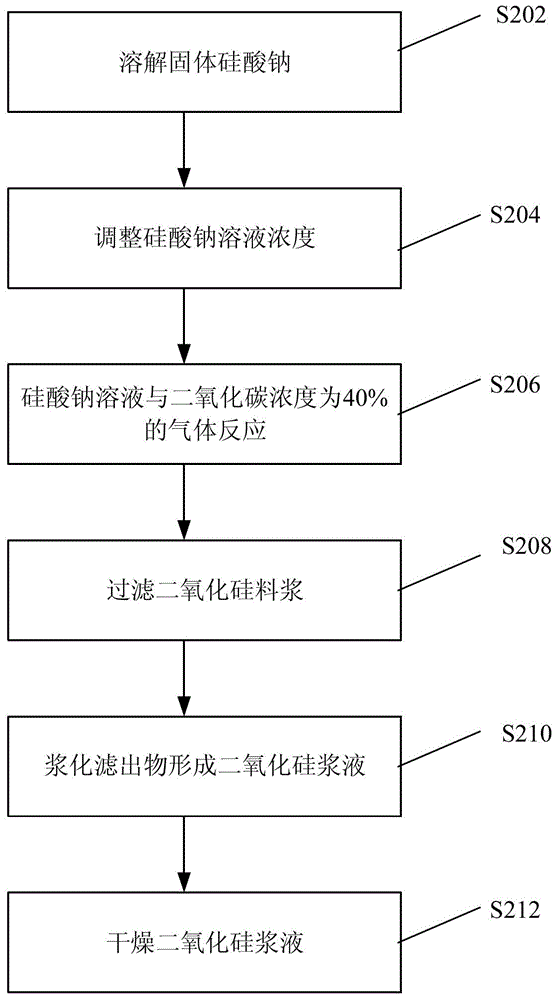

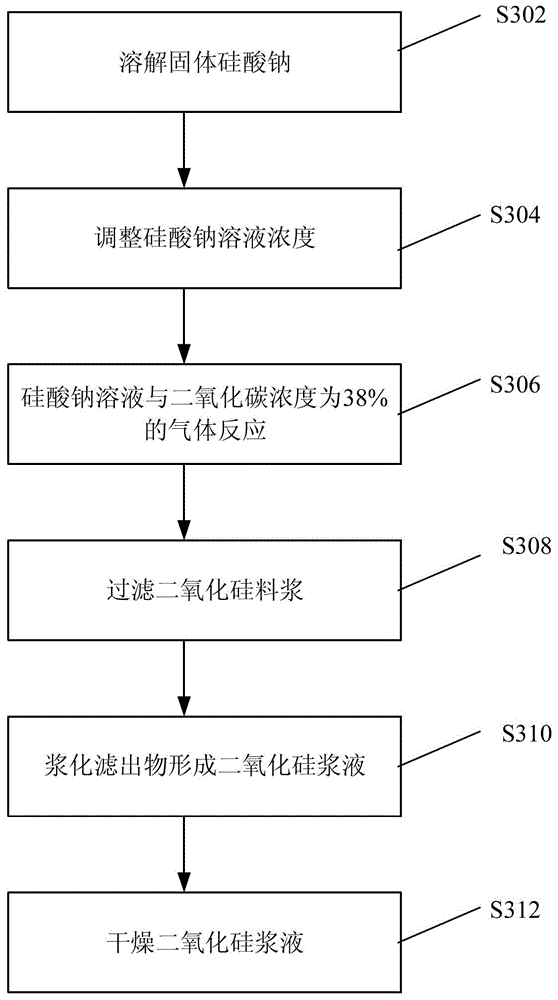

Preparation method of silicon dioxide

ActiveCN104418332ALarge particle sizeUniform particle size distributionSilicaHigh concentrationSlurry

The invention provides a preparation method of silicon dioxide, namely, method for preparing the silicon dioxide by carbon dioxide method, and the method comprises the following steps: process gas bubbles with uniform diameter are dispersed into a sodium silicon solution for reaction of the sodium silicon solution and carbon dioxide to produce silicon dioxide slurry, wherein the process gas contains carbon dioxide; the silicon dioxide slurry is filtered to obtain filtrate; the filtrate is pulpified to obtain silicon dioxide pulp liquid; and the silicon dioxide pulp liquid is dried. Silicon dioxide particles prepared by the method are proper in particle size and uniform in particle size distribution, the number of large aggregates is decreased significantly and the content of fine powder is greatly reduced. In addition, initial gas containing carbon dioxide is purified to obtain the process gas with high concentration of carbon dioxide, the process gas with high concentration of carbon dioxide is used as a reaction raw material, the production cost is reduced, and the production efficiency is improved.

Owner:QUECHEN SILICON CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com