Magnetic fuel-saving rubber composite material

A technology of composite materials and magnetic materials, which is applied in the field of magnetic fuel-saving rubber composite materials, can solve the problems of high cost, short magnetization lines, and incomplete magnetization, and achieve the effects of improving fuel-saving performance, saving environmental protection, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The magnetic fuel-saving rubber composite material prepared by the applied method is tested in accordance with the following rubber formula scheme.

[0020] name Dosage (phr) Nitrile rubber80 Neoprene20 Zinc oxide5 Stearic acid1 Anti-aging agent 4010NA1 Anti-aging agent RD1.5 Gumalon5 Organic iron1 Dioctyl phthalate10 Carbon black50 sulfur2 Accelerator M2 Promoter pz 1

[0021] Table 2: Basic performance characterization of magnetic fuel-saving rubber

[0022]

[0023] According to the national standard GB / T528-1998, a tensile test was carried out on the sample, the tensile speed was 500mm / min, and the room temperature.

[0024] According to the national standard GB / T2941, the hot air aging test of vulcanized rubber was carried out.

[0025] The liquid resistance test of vulcanized rubber was carried out according to the national standard GB / T1690-92.

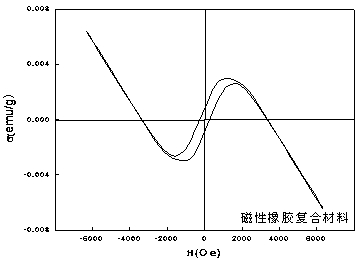

[0026] Hysteresis loop HH-15 vibration sample magnetometer for testing.

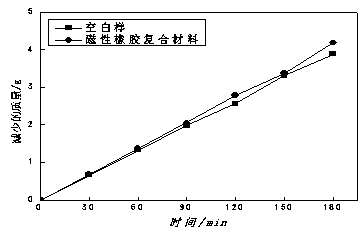

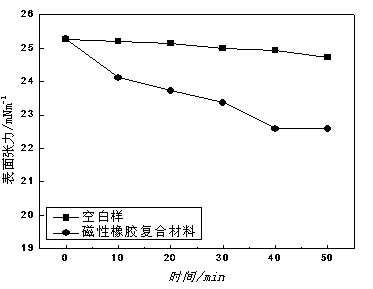

[0027] The fuel vapority is measured i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com