Patents

Literature

55 results about "Small aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

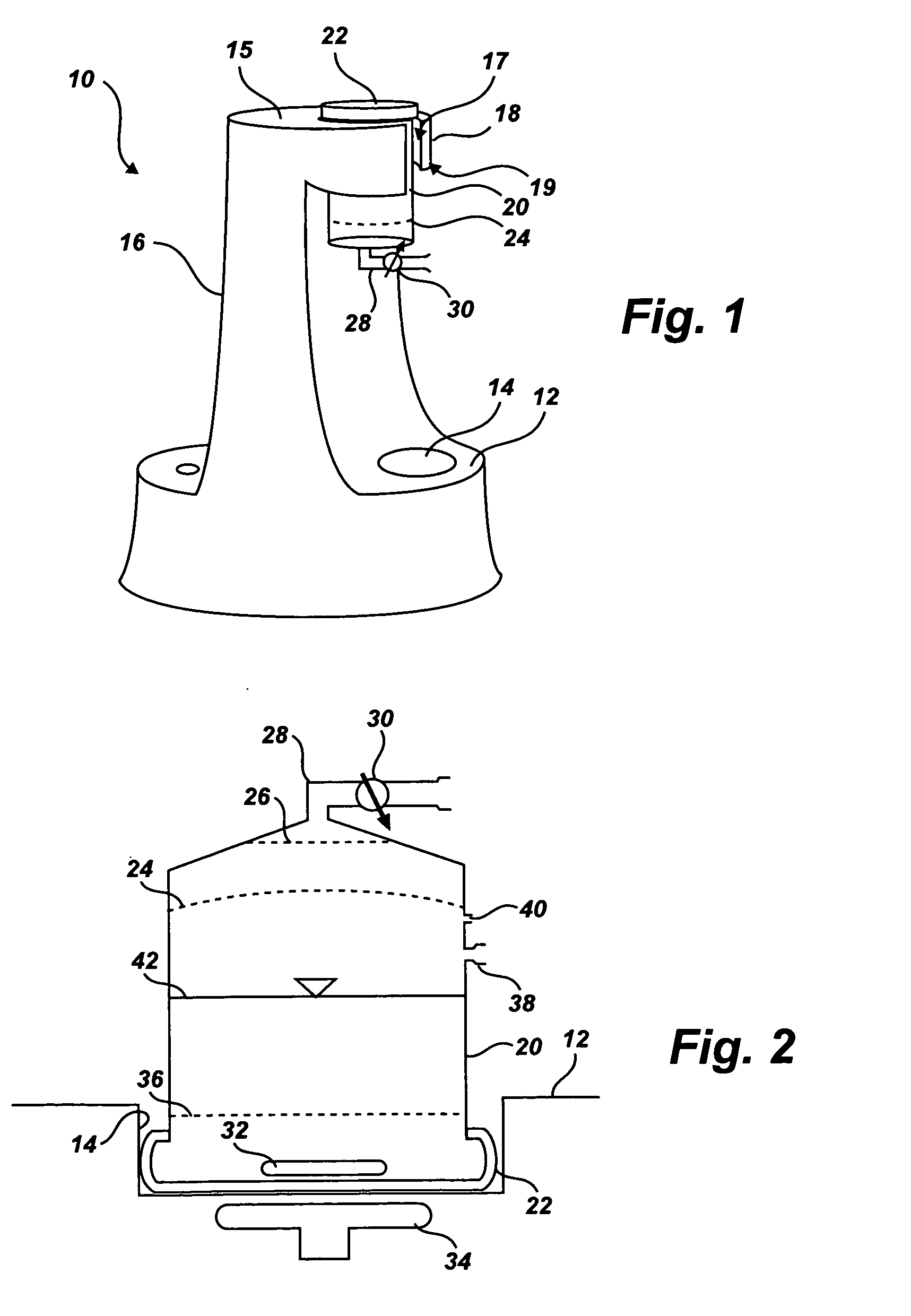

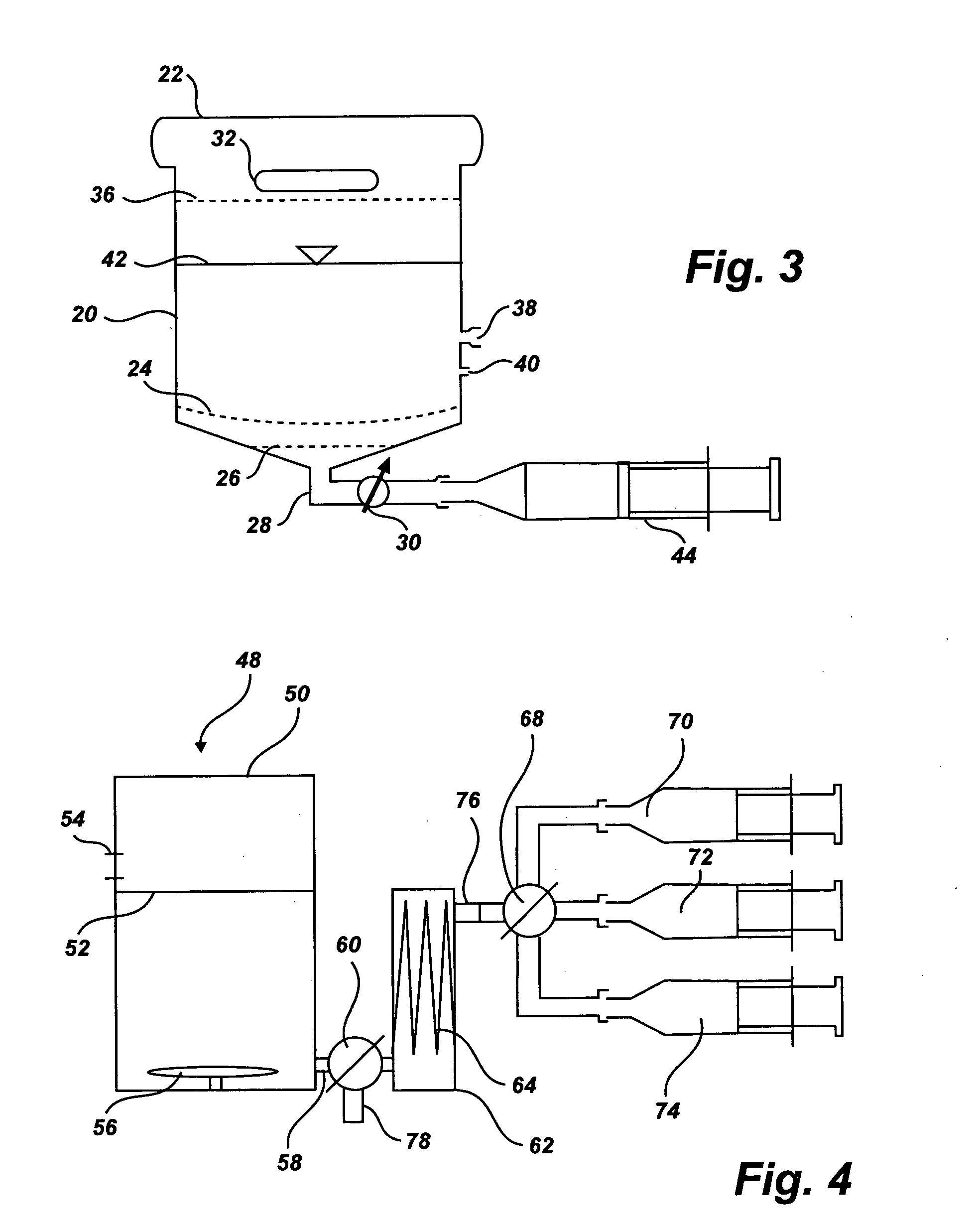

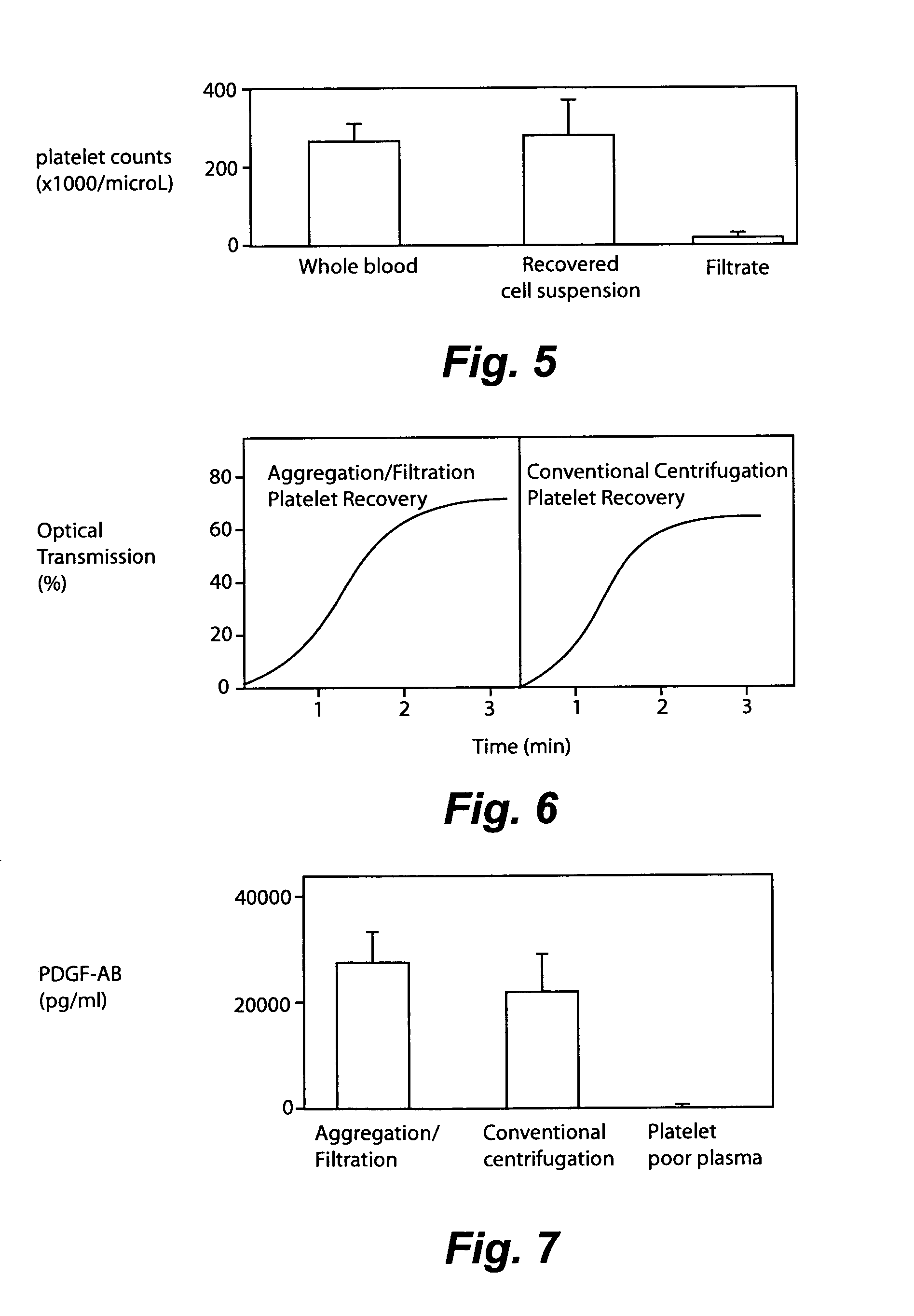

Separation of platelets from whole blood for use as a healant

InactiveUS7011852B2Rapidly and conveniently and cost-effectively harvestEliminate useSurgical adhesivesMammal material medical ingredientsFiltrationBlood plasma

Owner:MOHAMMAD S FAZAL +1

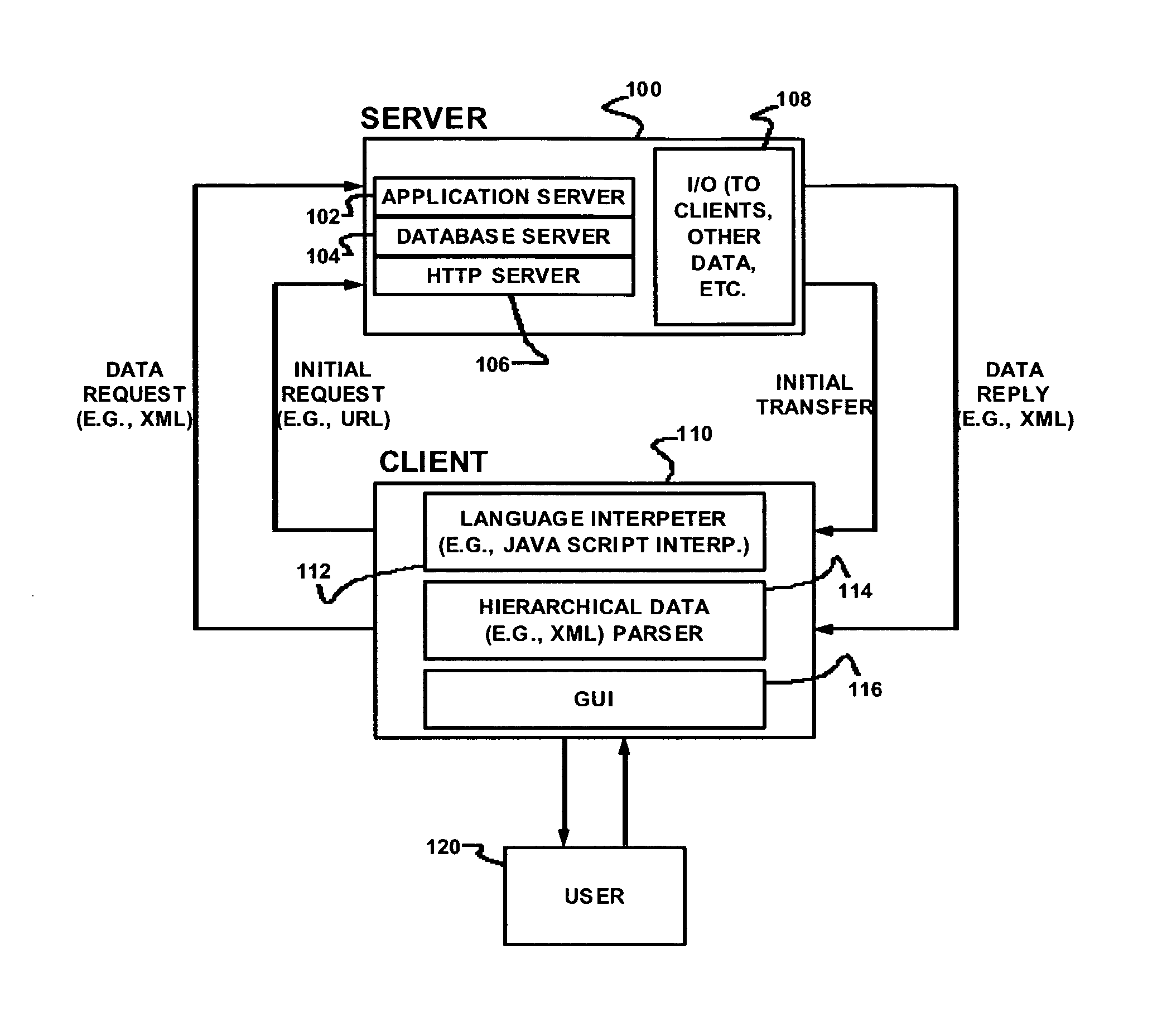

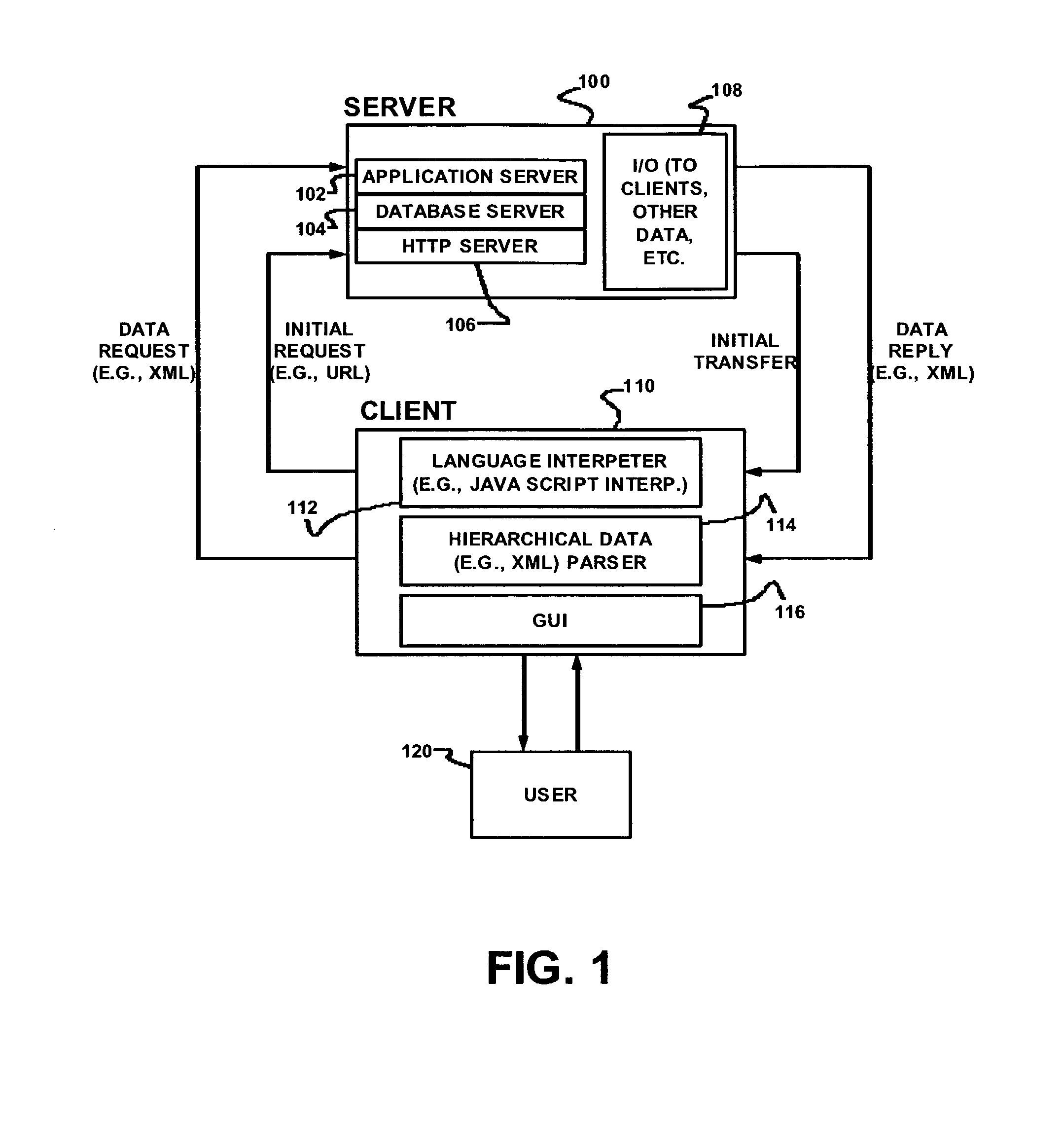

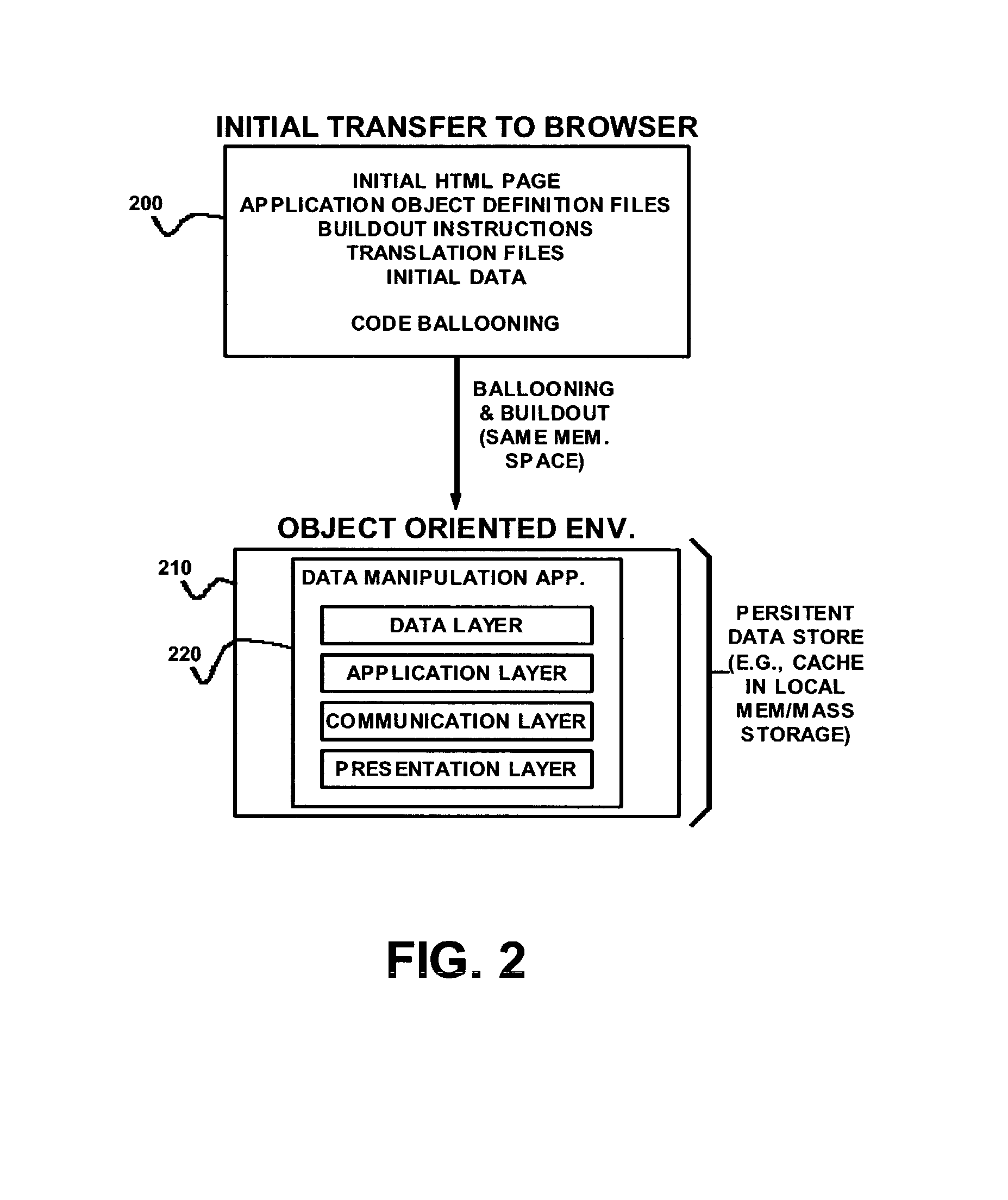

Delivery of data and formatting information to allow client-side manipulation

ActiveUS8136109B1A large amountSoftware designProgram loading/initiatingInterpreted languageWeb browser

Delivering data and formatting information includes delivering object definition files from a server to a client; generating definitions and object instantiations at a client using JavaScript or another simple browser-interpreted language, for objects relating to data modeling and presentation; and presenting data using those objects at the client, using a web browser without a separate runtime environment or application plug-in, but maintaining substantial state at the web browser regarding the data itself and the format for its presentation. Definition files are modified to provide object properties consistent with a full object-oriented language, including for example hierarchical inheritance of object properties. Code ballooning generates definitions and individual instantiations, with the effect that a very large amount of DHTML, or another markup or presentation definition language for use with the application, can be generated from relatively small aggregate size of definition files communicated from the server to the client.

Owner:CLOUD SOFTWARE GRP INC

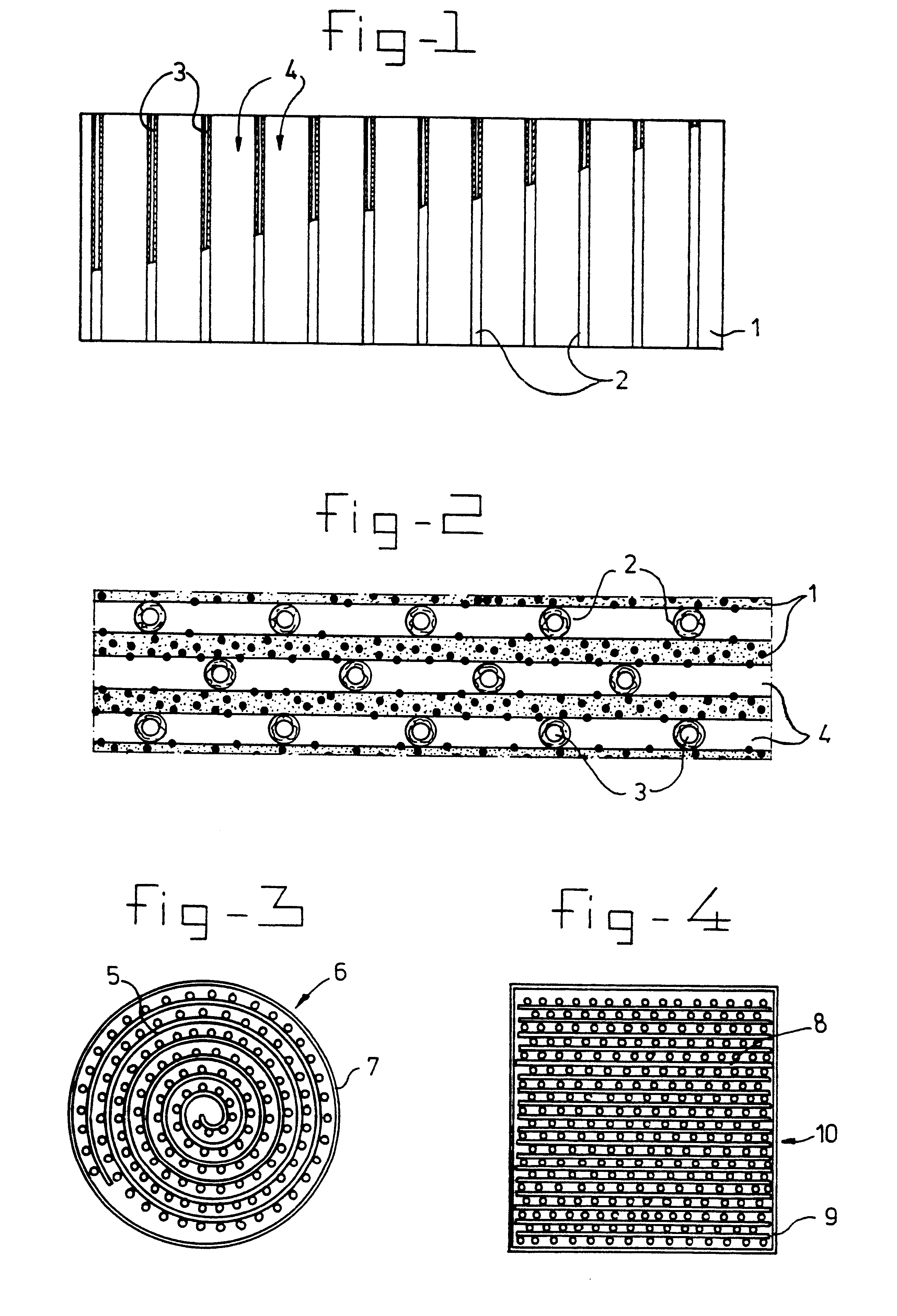

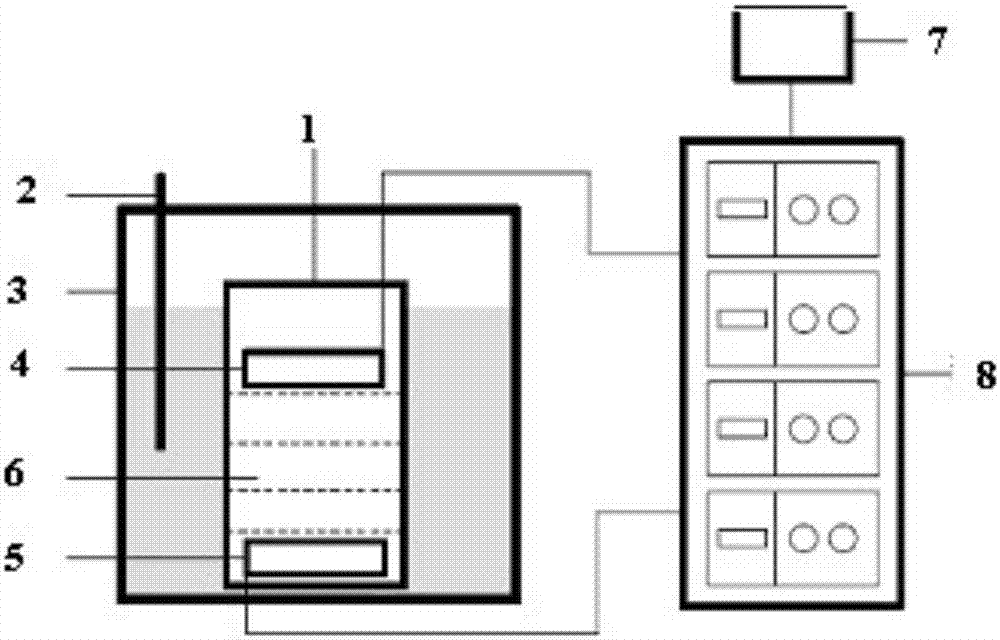

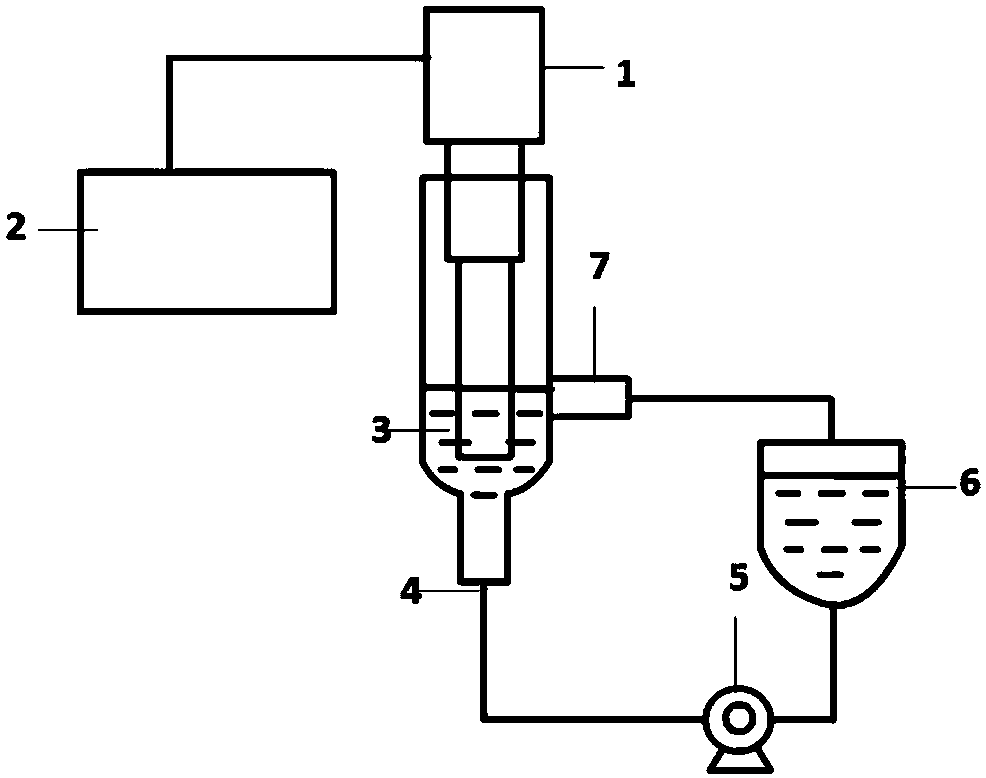

Bio-artificial organ containing a matrix having hollow fibers for supplying gaseous oxygen

InactiveUS6372495B1Practical to useBioreactor/fermenter combinationsBiological substance pretreatmentsHollow fibreFiber

A bio-artificial organ system is provided comprising a wall surrounding a space which has a solid support for cell cultivation. The space includes a there dimensional matrix in the form of a highly porous sheet or mat and including a physiologically acceptable network of fibers or an open-pore foam structure; hydrophobic hollow fibers permeable to gaseous oxygen or gaseous carbon dioxide evenly distributed through the three dimensional matrix material and arranged in parallel running from one end of the matrix material to the other end of the matrix material. Cells obtained from organs are present in the extra fiber space for culture wherein the cells are provided with sufficient oxygenation and are maintained as small aggregates with three dimensional attachment.

Owner:ACADEMISCH ZIEKENHUIS BIJ DE UNIV VAN AMSTERDAM ACADEMISCH MEDISCH CENT +1

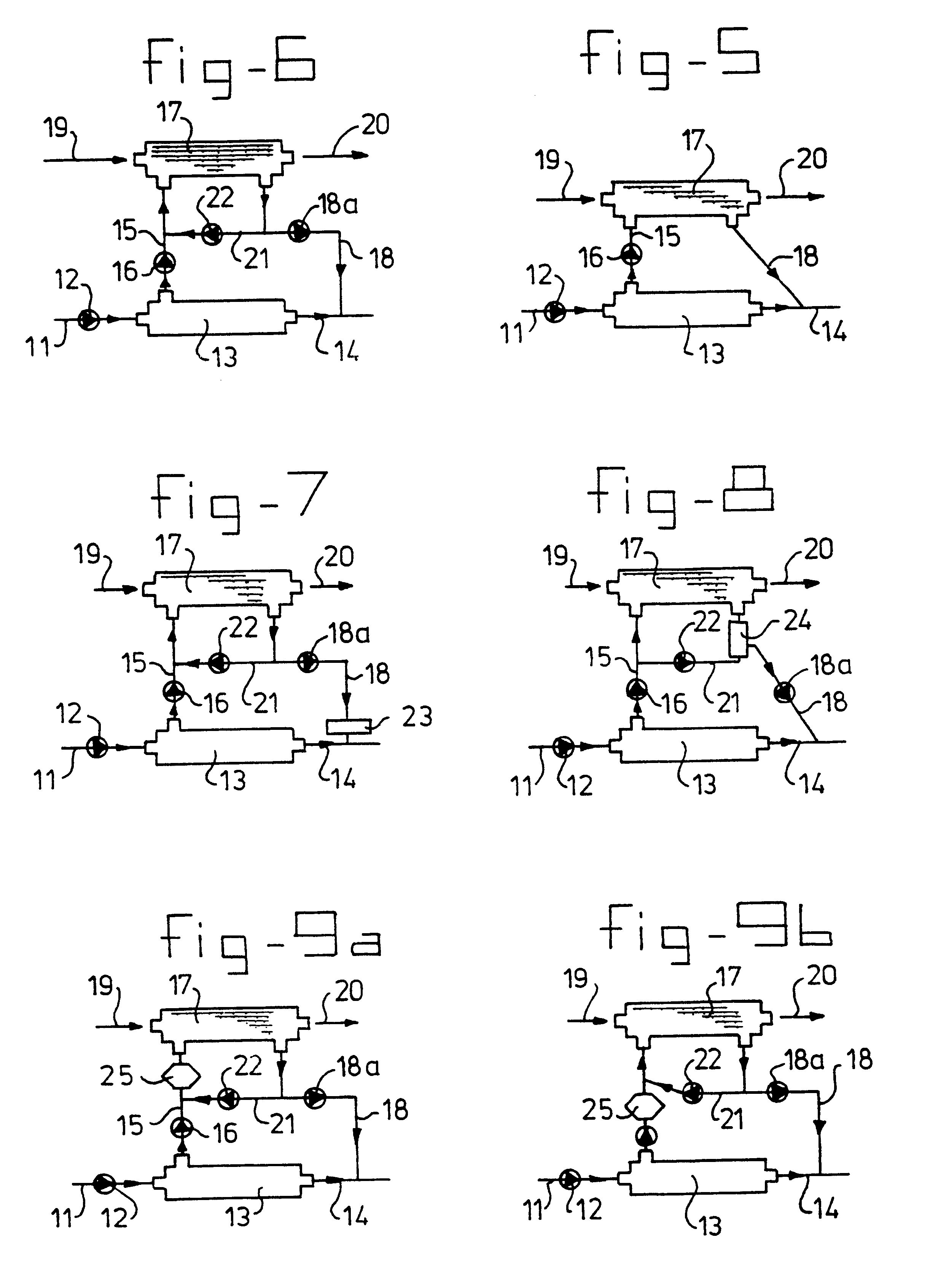

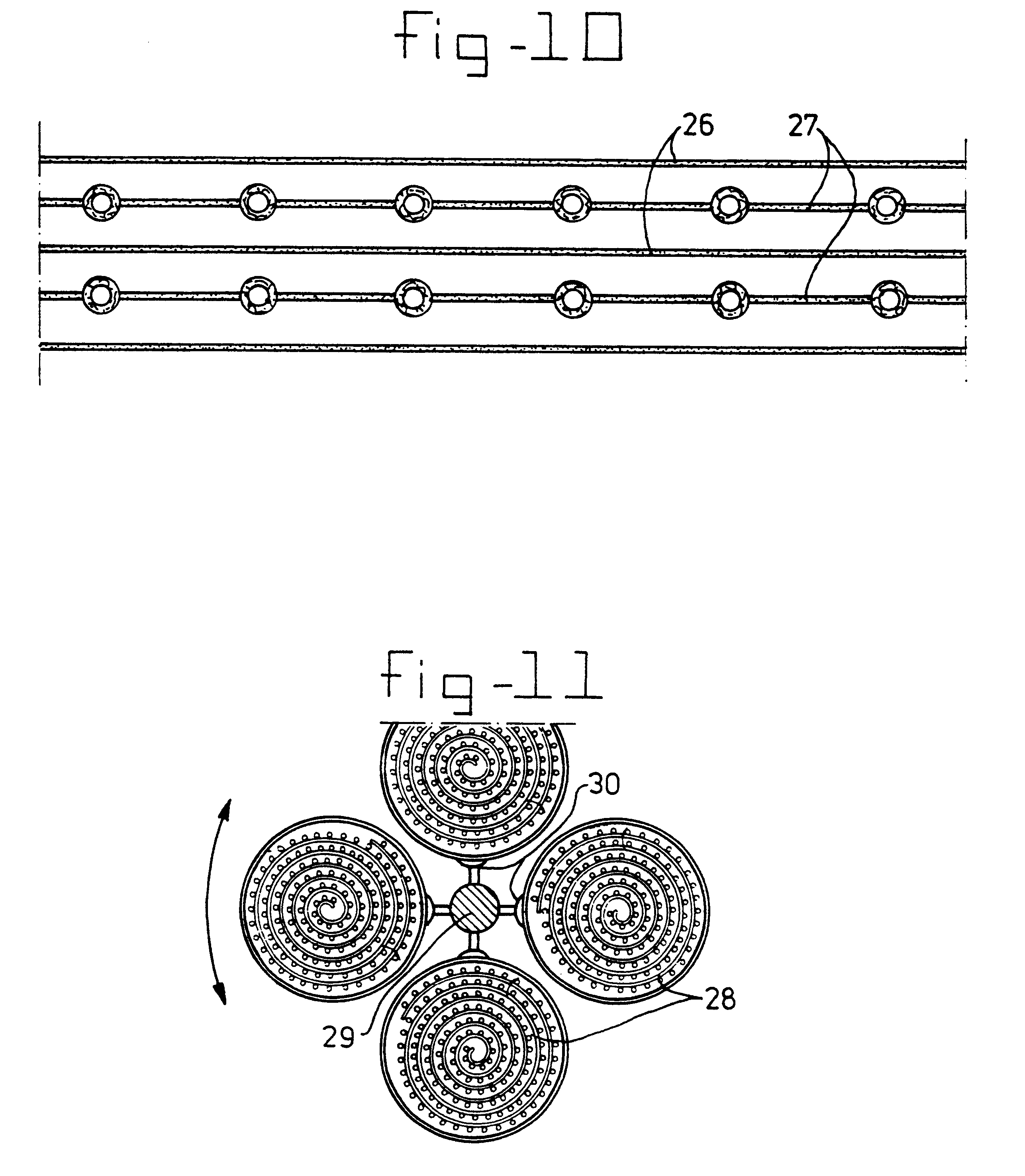

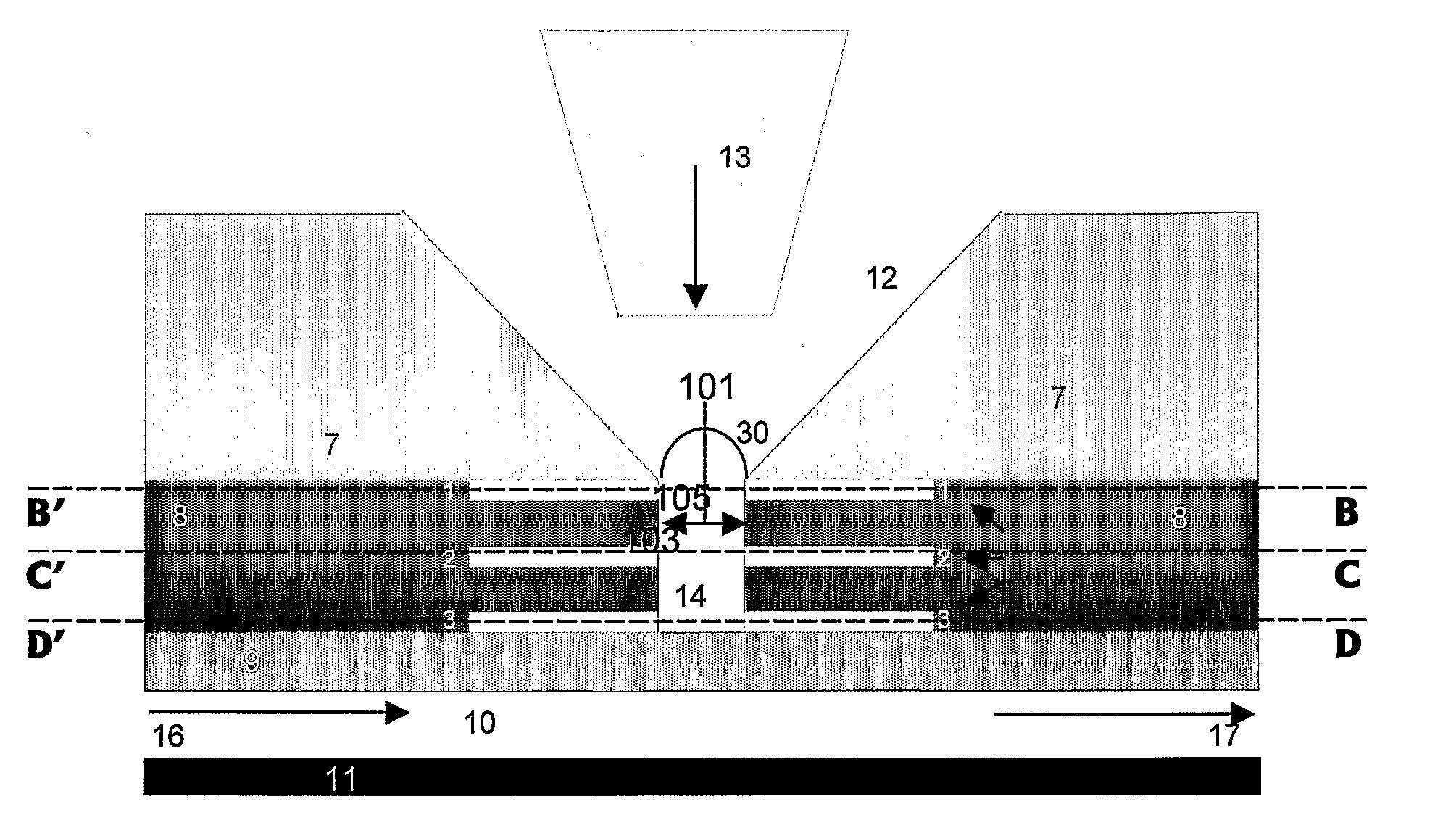

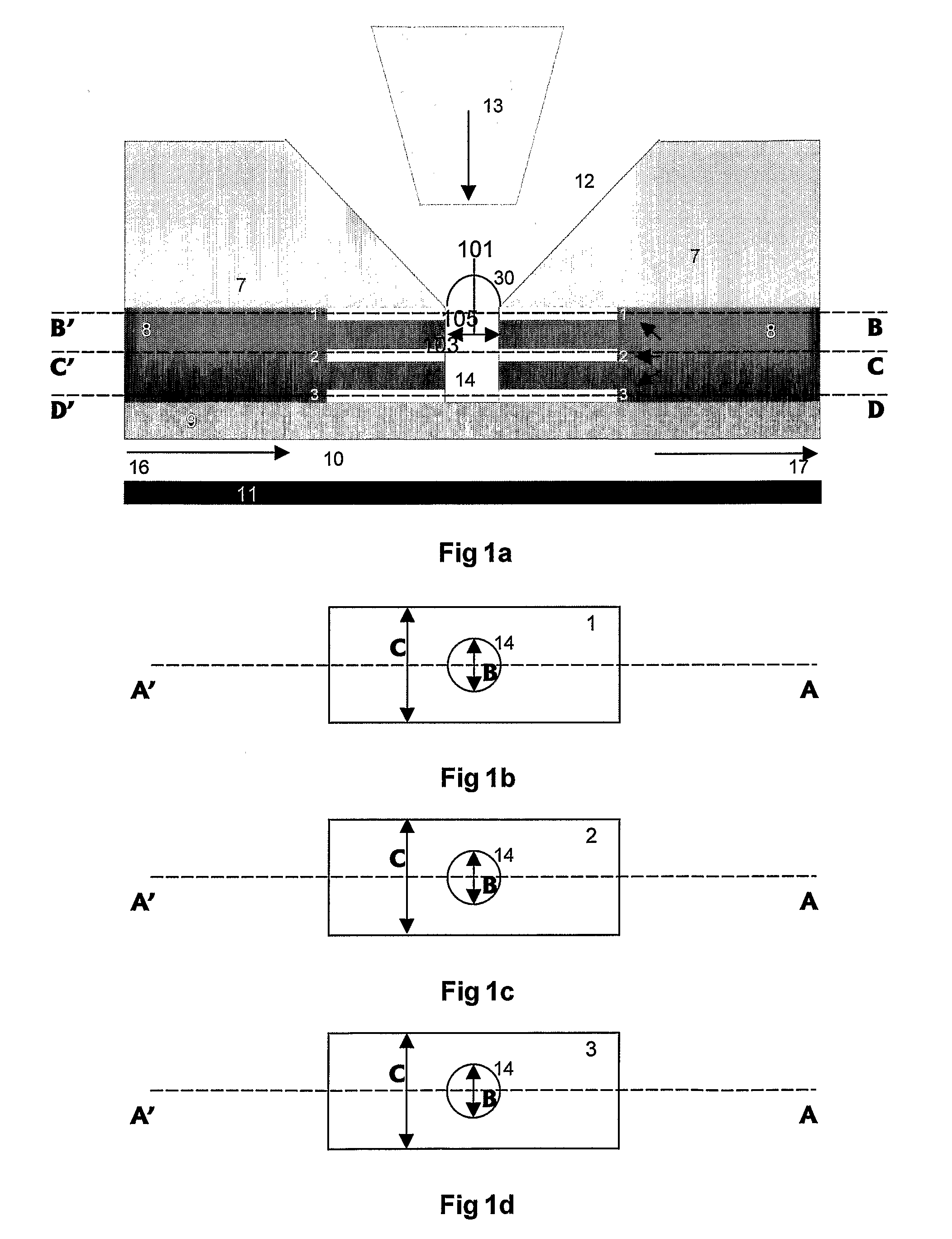

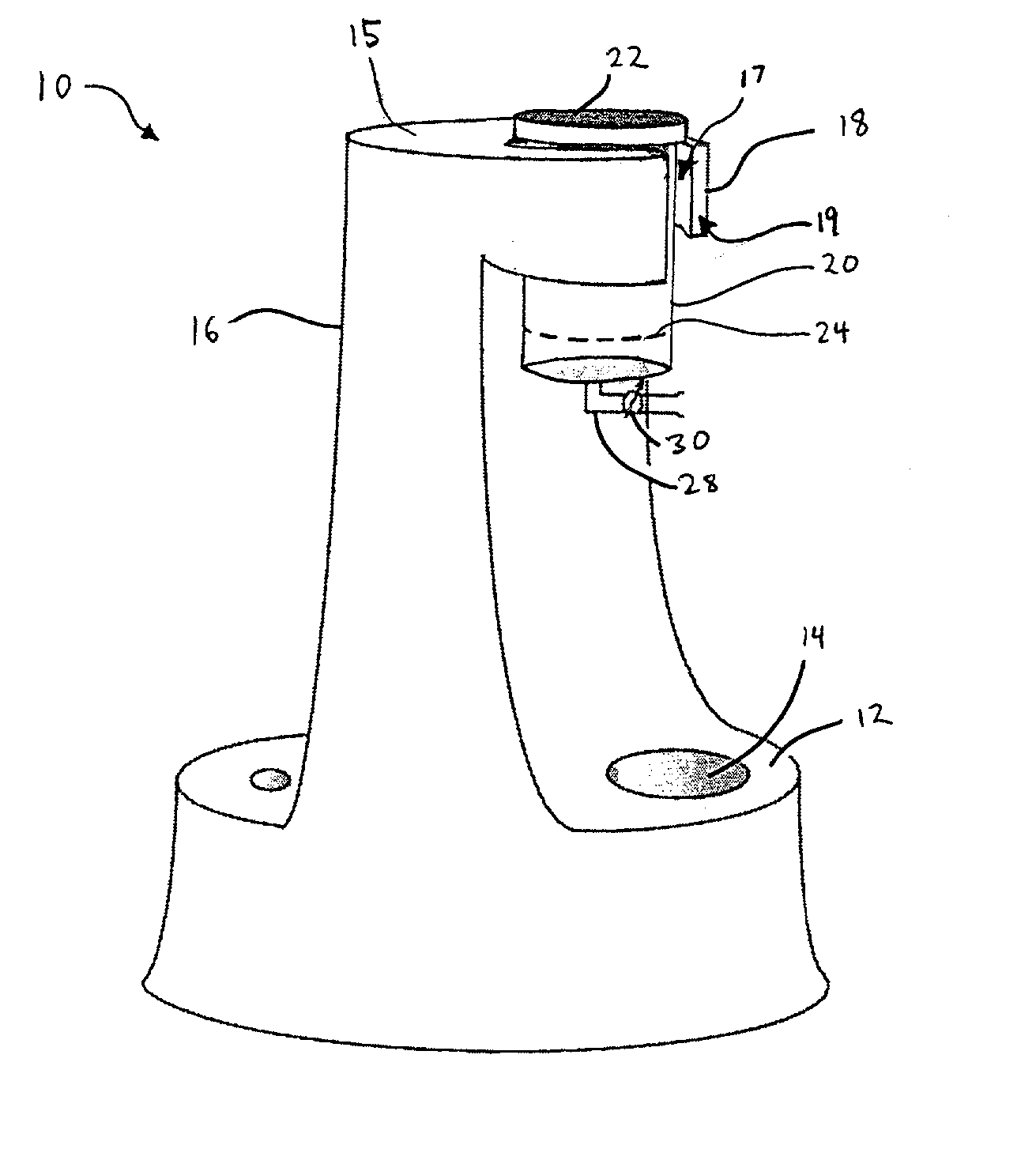

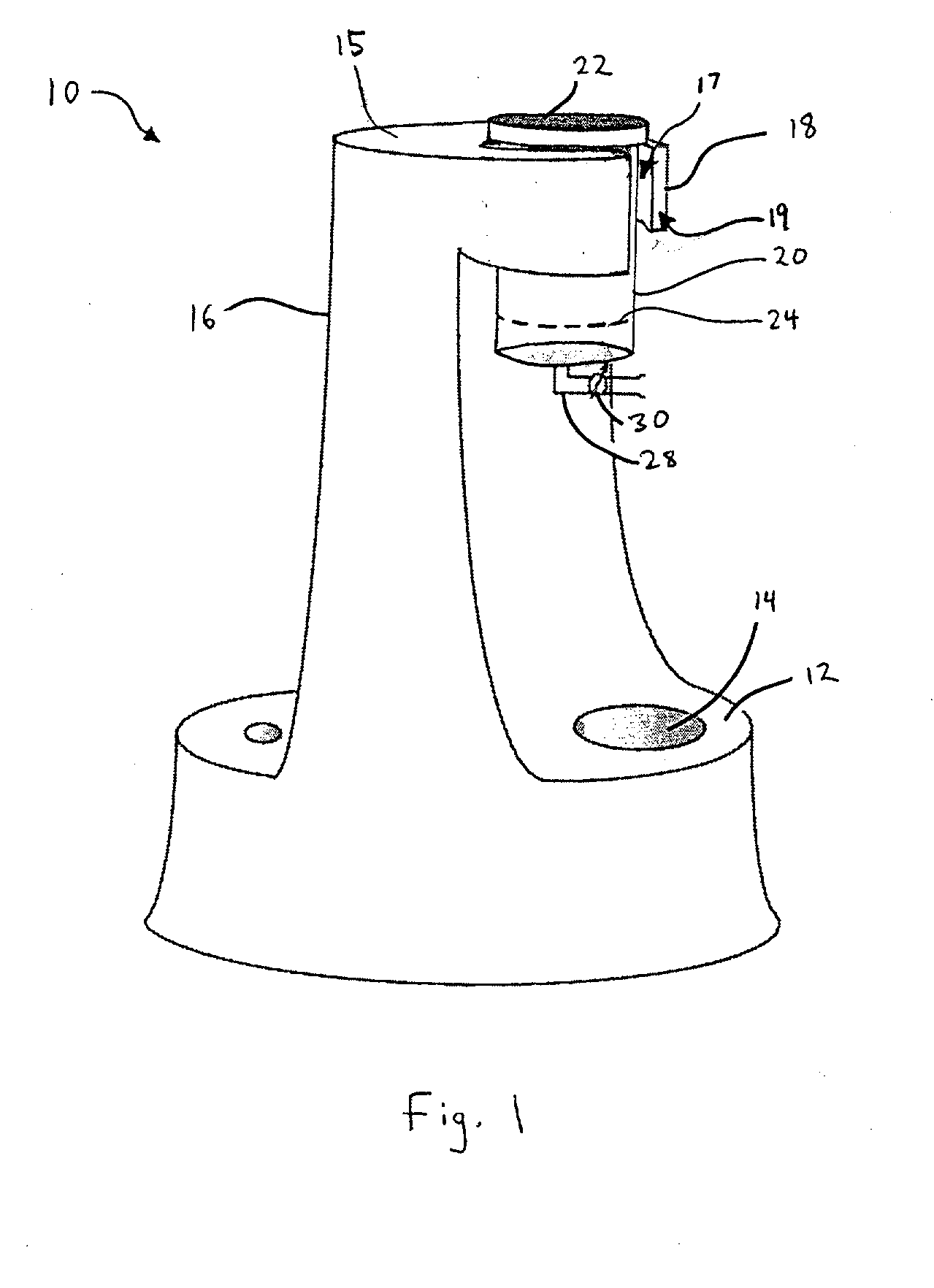

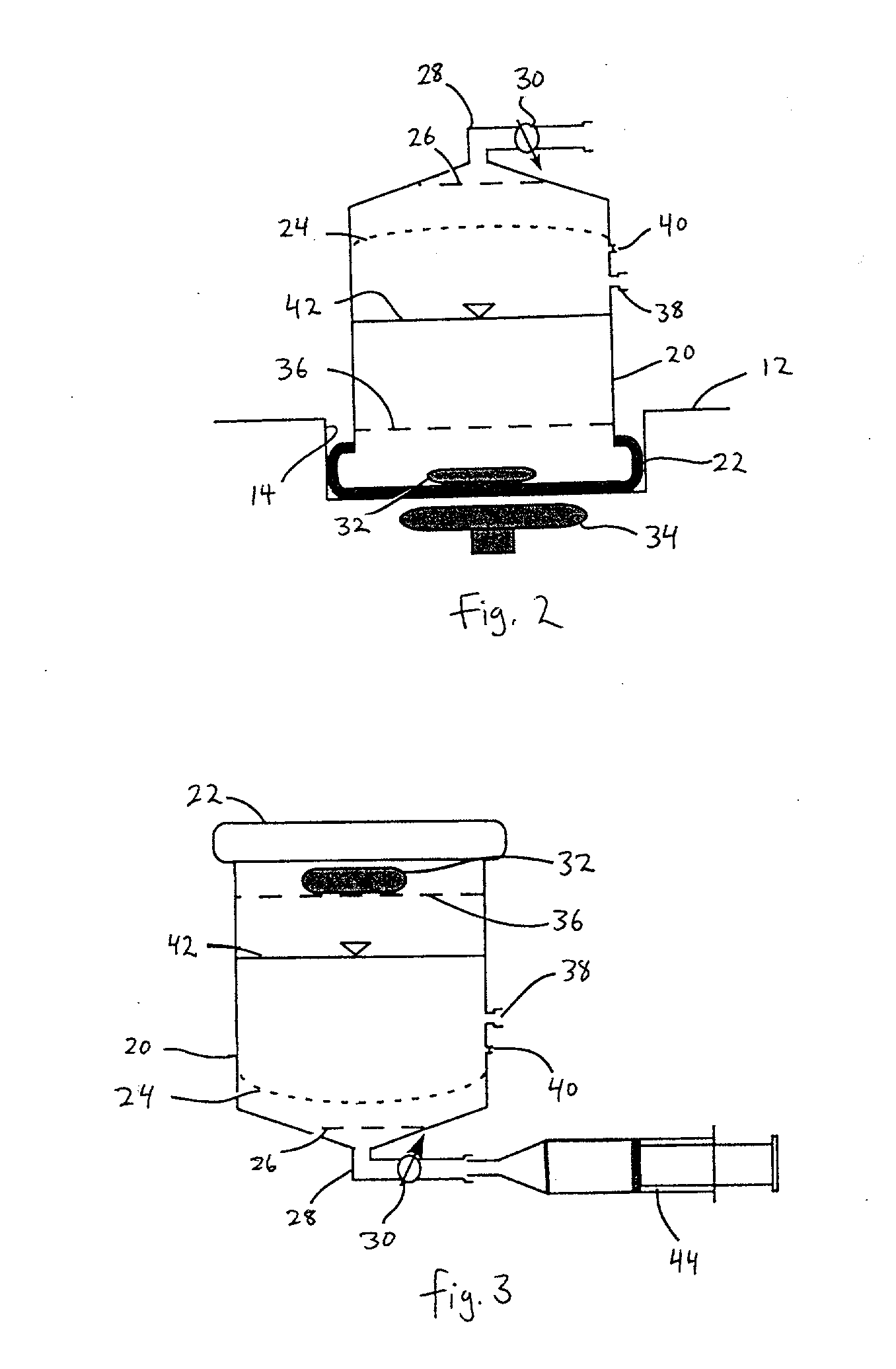

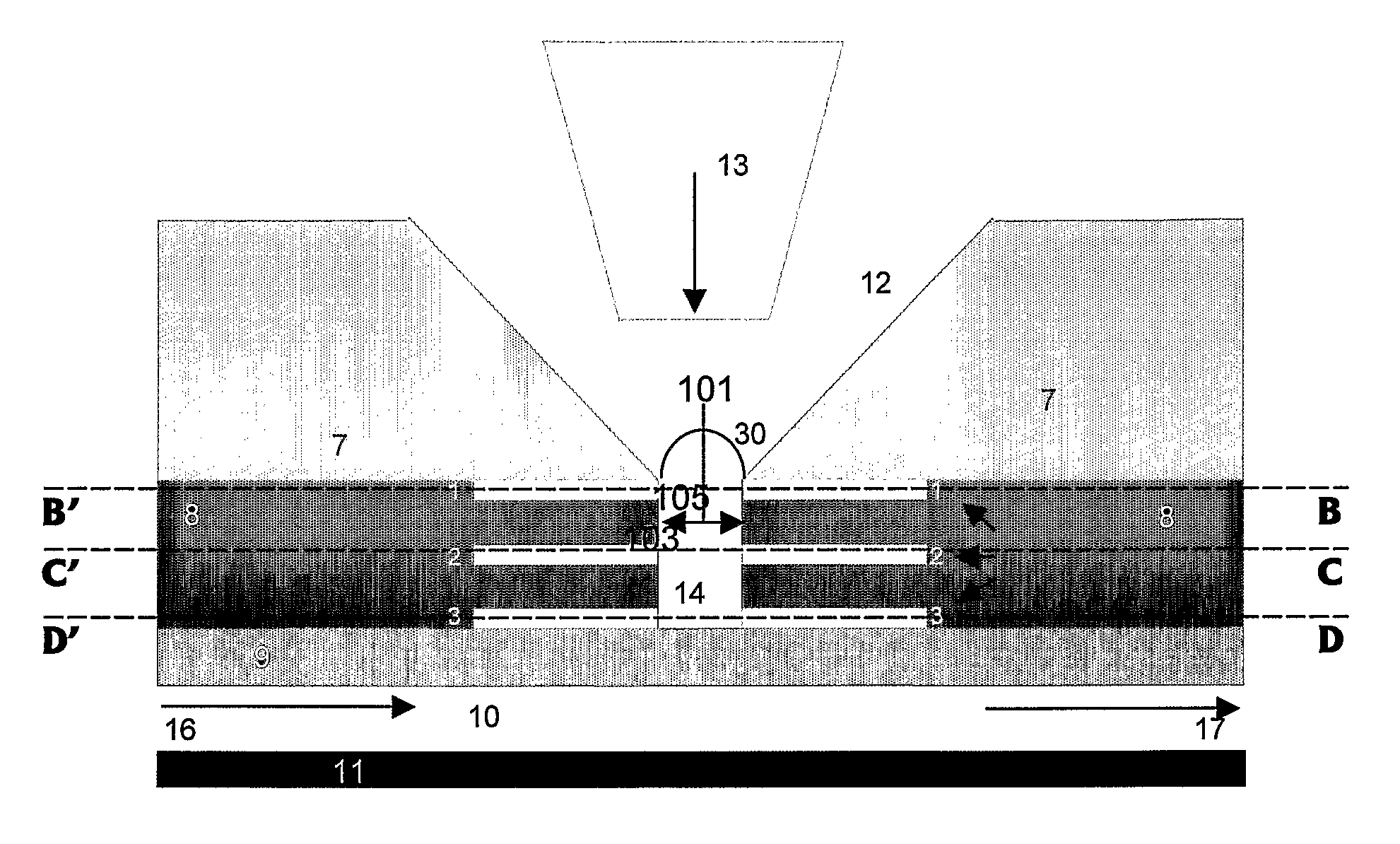

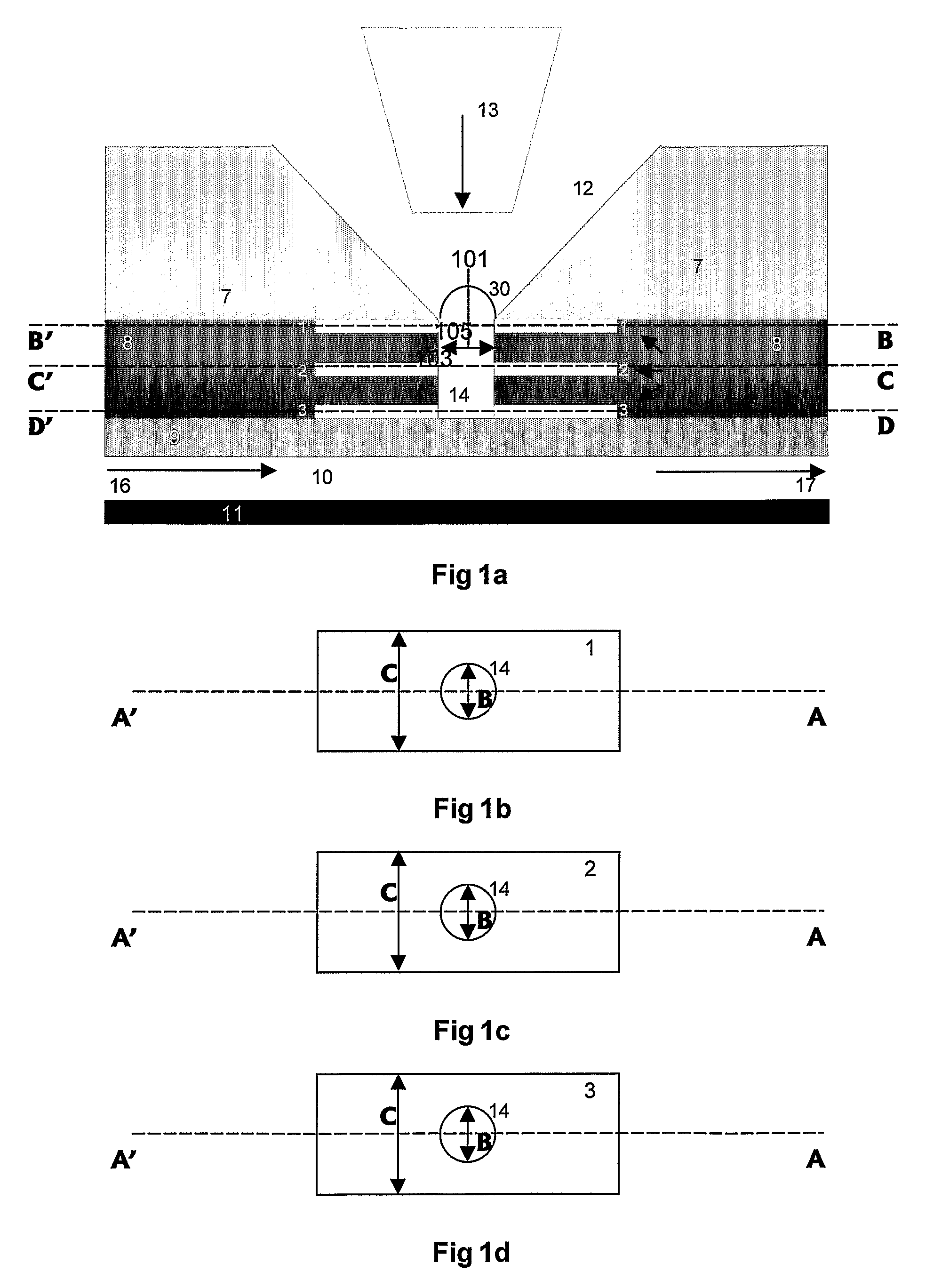

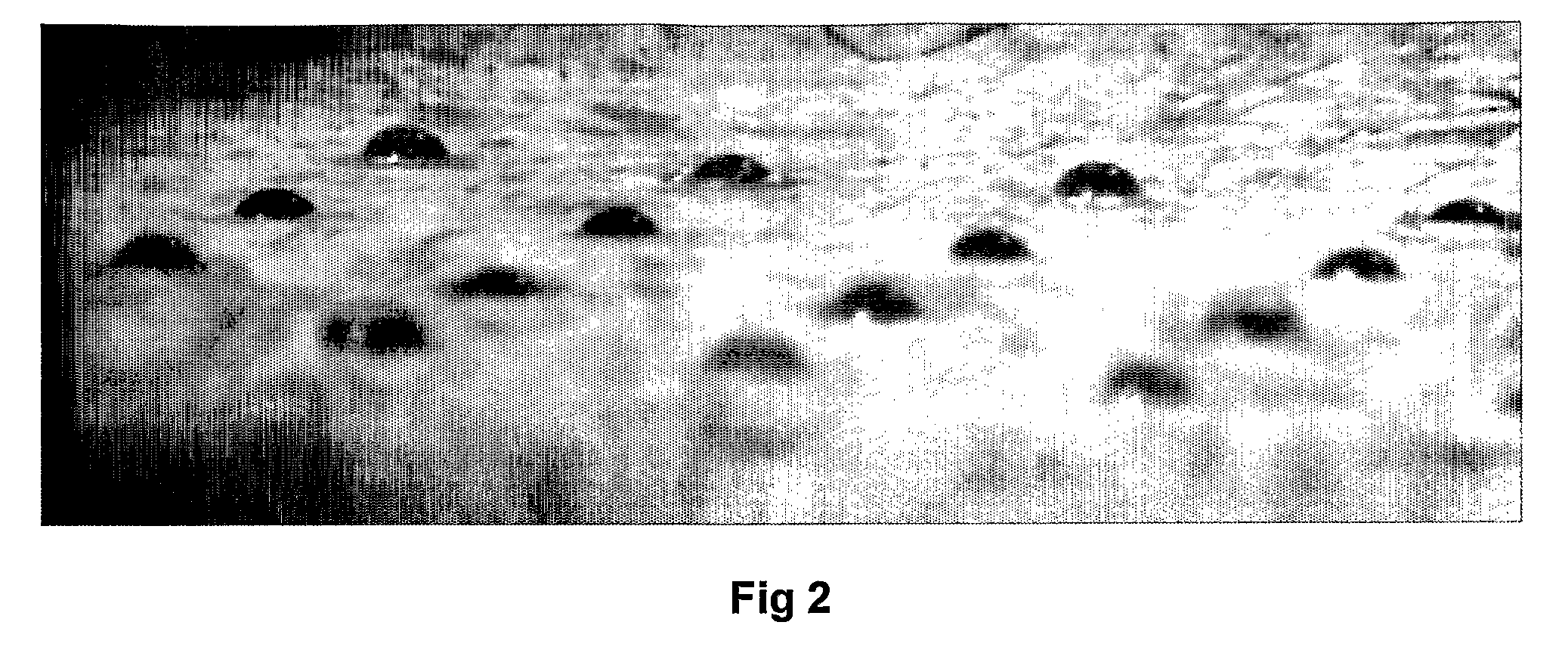

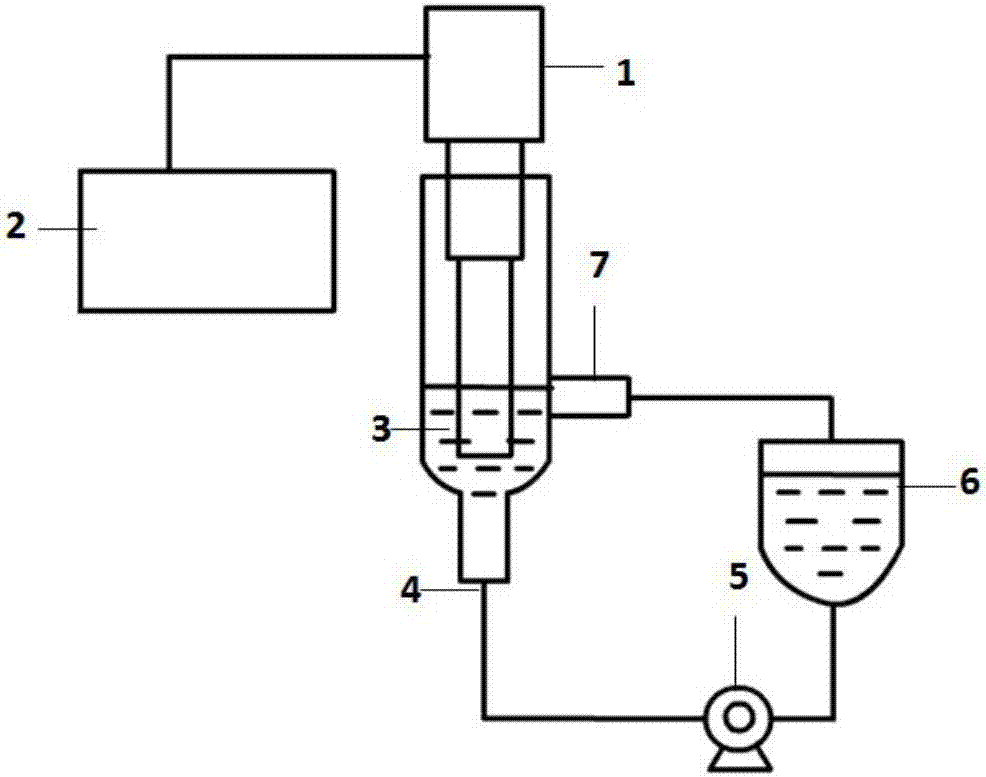

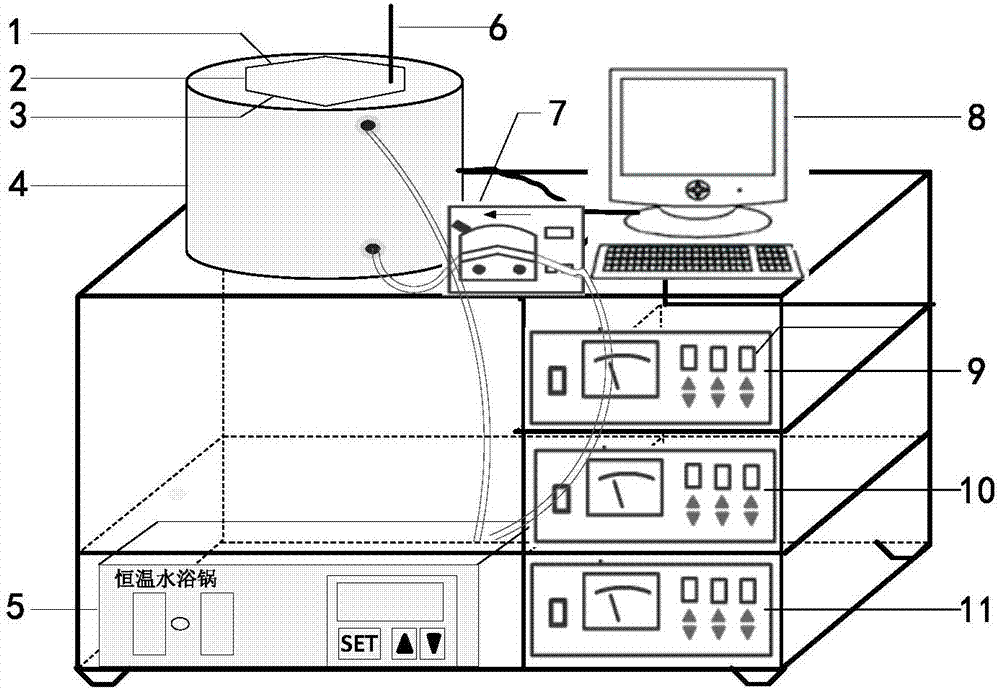

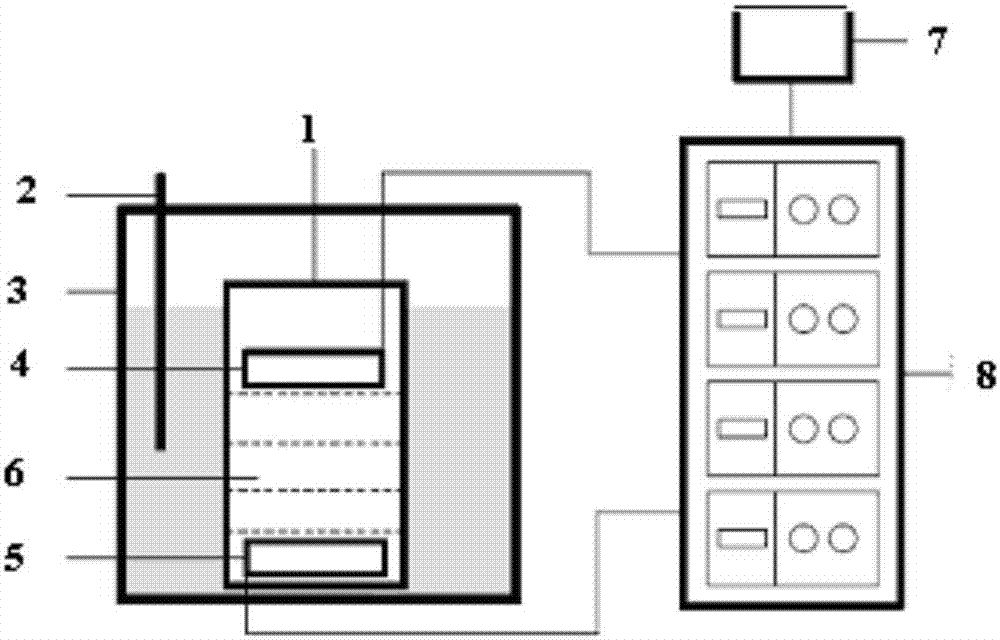

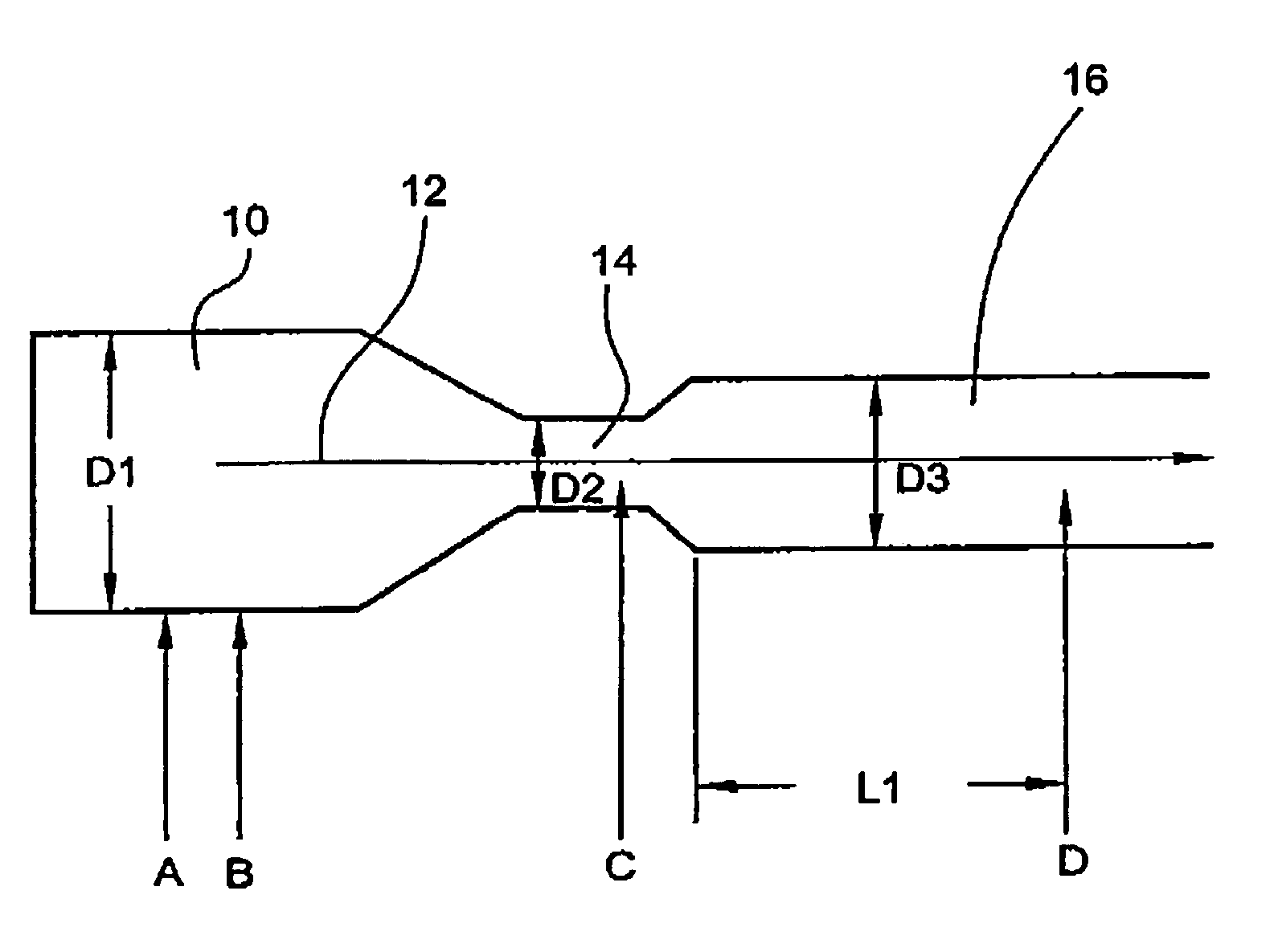

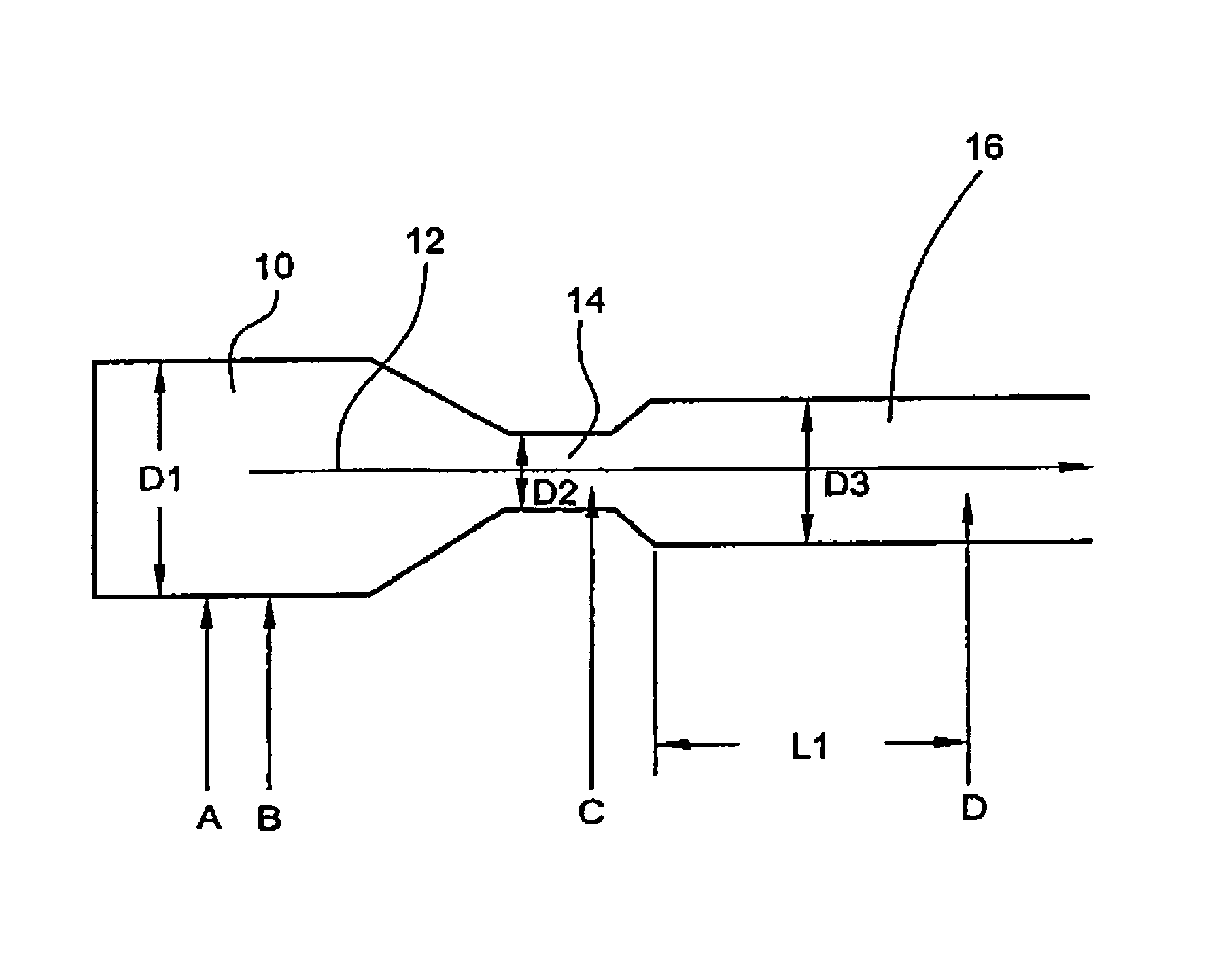

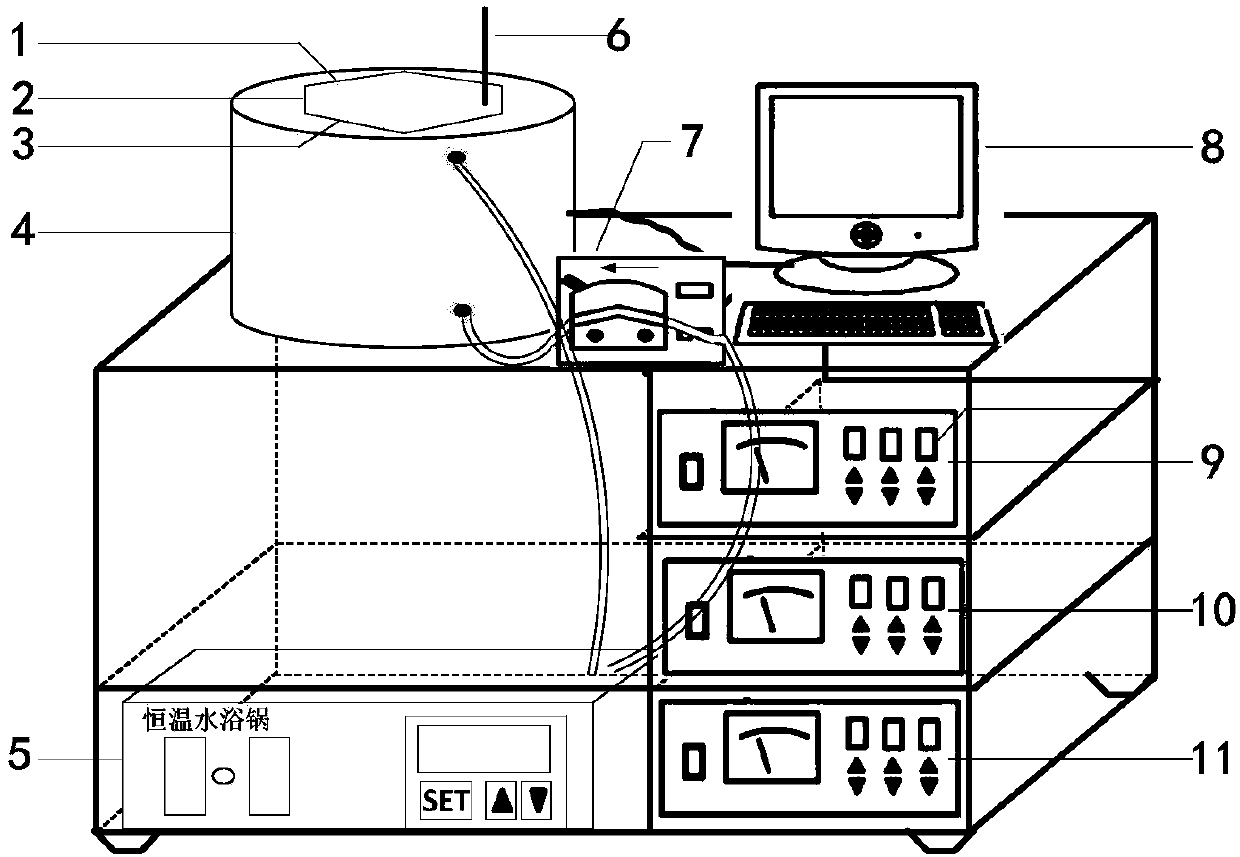

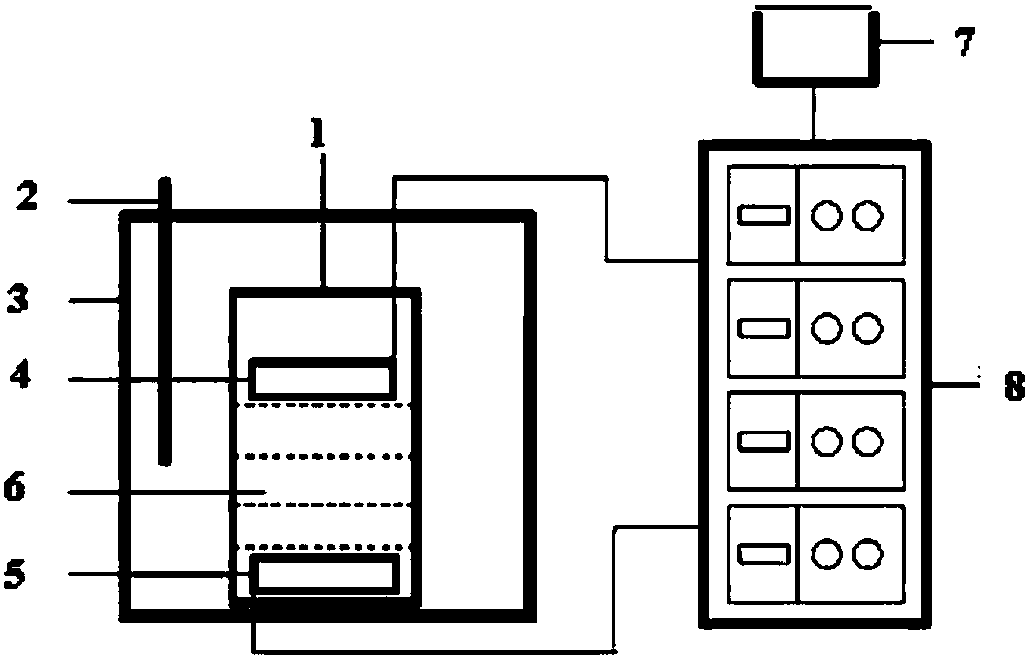

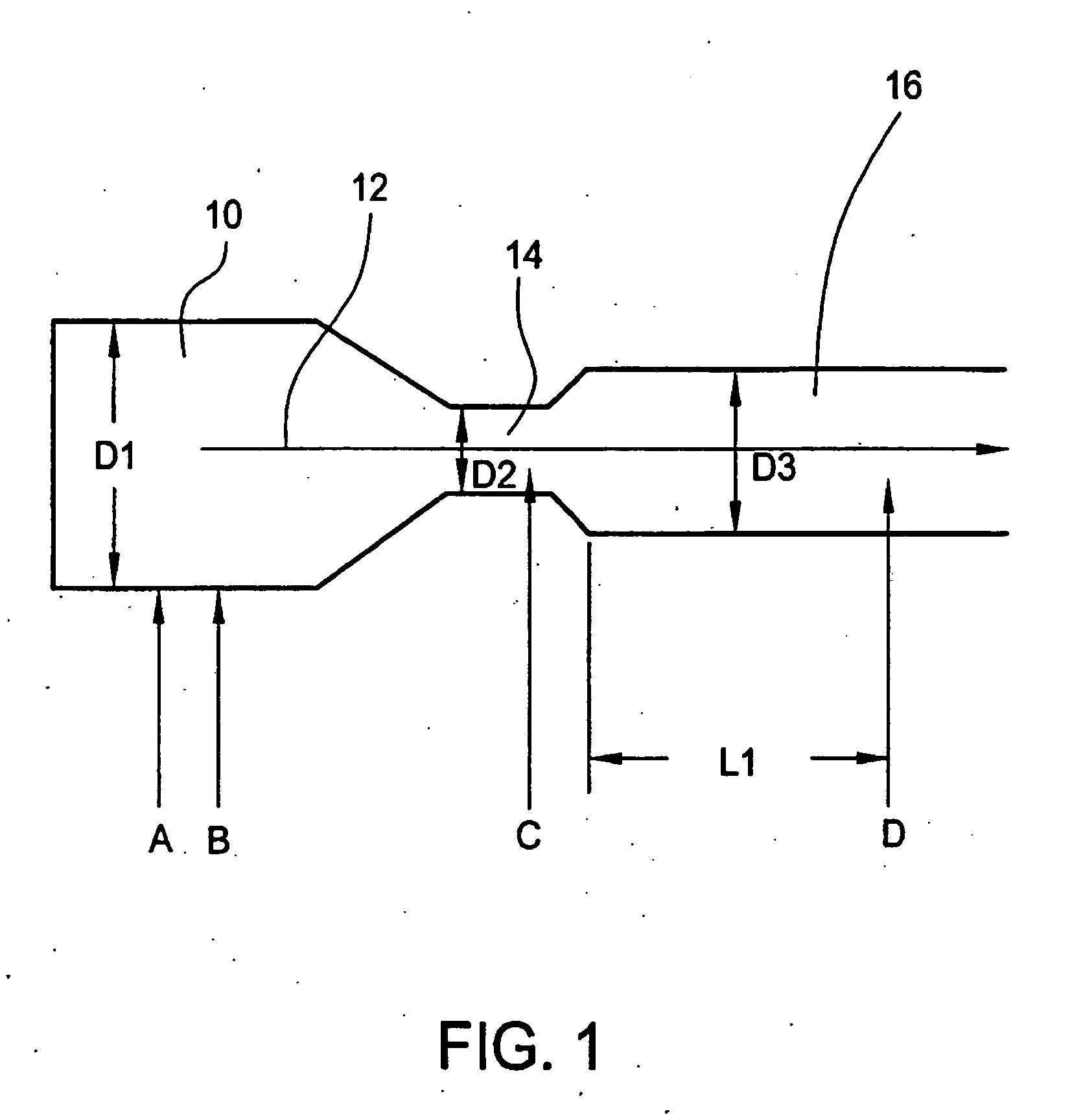

Method and apparatus for manipulating single cells and small aggregates thereof

ActiveUS20090288963A1High voltageDielectrophoresisElectrostatic separatorsEngineeringDielectrophoresis

A well, in particular an open well (14) with an upper end having a vertical axis (101), for containing a liquid and particles contained within said liquid, characterized by comprising at least two manipulation electrodes (1, 2, 3, 31, 32, 36, 17, 40, 41) able to be powered by electrical voltages, in particular alternating electrical voltages, so as to manoeuvre particles within the well by means of the dielectrophoretic effect. A platform comprising a plurality of wells as described above and a method for using said well.

Owner:CELLPLY SRL

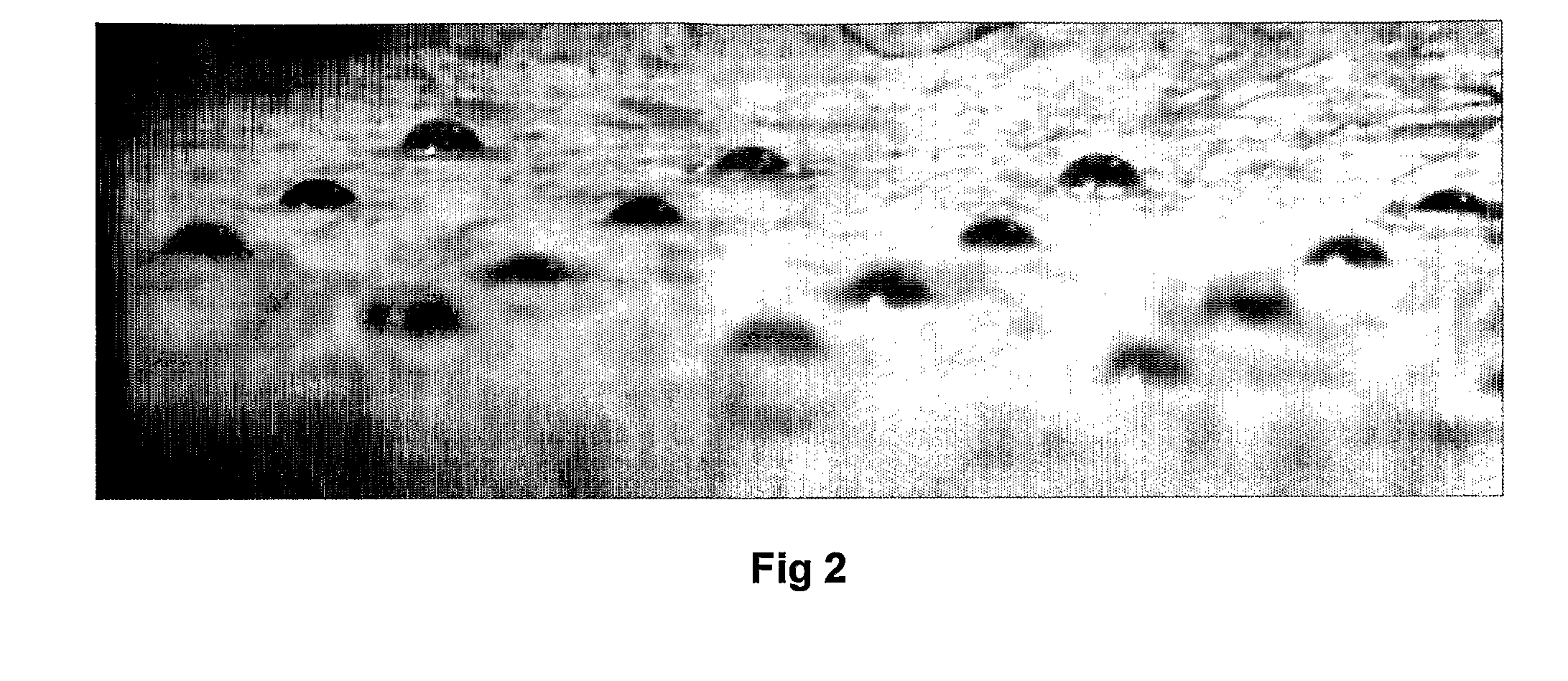

Separation of platelets from whole blood for use as a healant

InactiveUS20020179537A1Prevent substantial premature releaseImmediate growth factor treatmentSurgical adhesivesDead animal preservationFiltrationBlood plasma

A method is described for separating, retrieving and concentrating platelets from whole blood relying on aggregation of the platelets followed by filtration. This method eliminates the need of a centrifuge for separating said cells from blood. To obtain cellular concentrates of platelets, blood is mixed with compatible agents that will aggregate cells while retaining contained growth factors. The resulting aggregates can then be separated from blood by filtration. If desired, the filter-captured aggregates are subject to a brief washing cycle where they are washed clean of residual aggregating agent, plasma, and red cells. Aggregates can then be partly or wholly deaggregated and the cells retrieved. The result is a suspension of cells and small aggregates with therapeutic levels of concentrated blood cells with included growth factors that are available for delivery to a wound site. A device that accomplishes the aforementioned process is also described.

Owner:MOHAMMAD S FAZAL +1

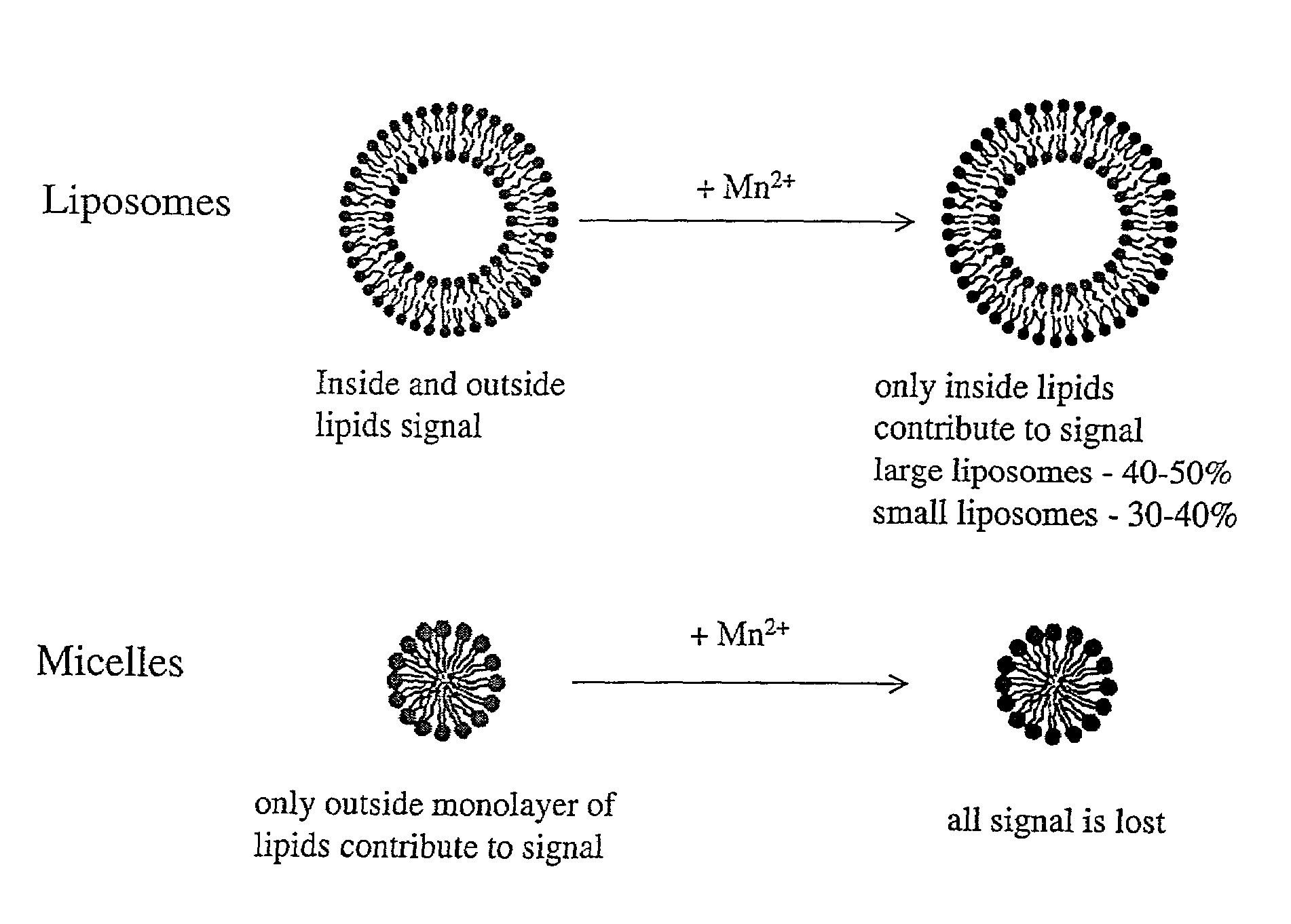

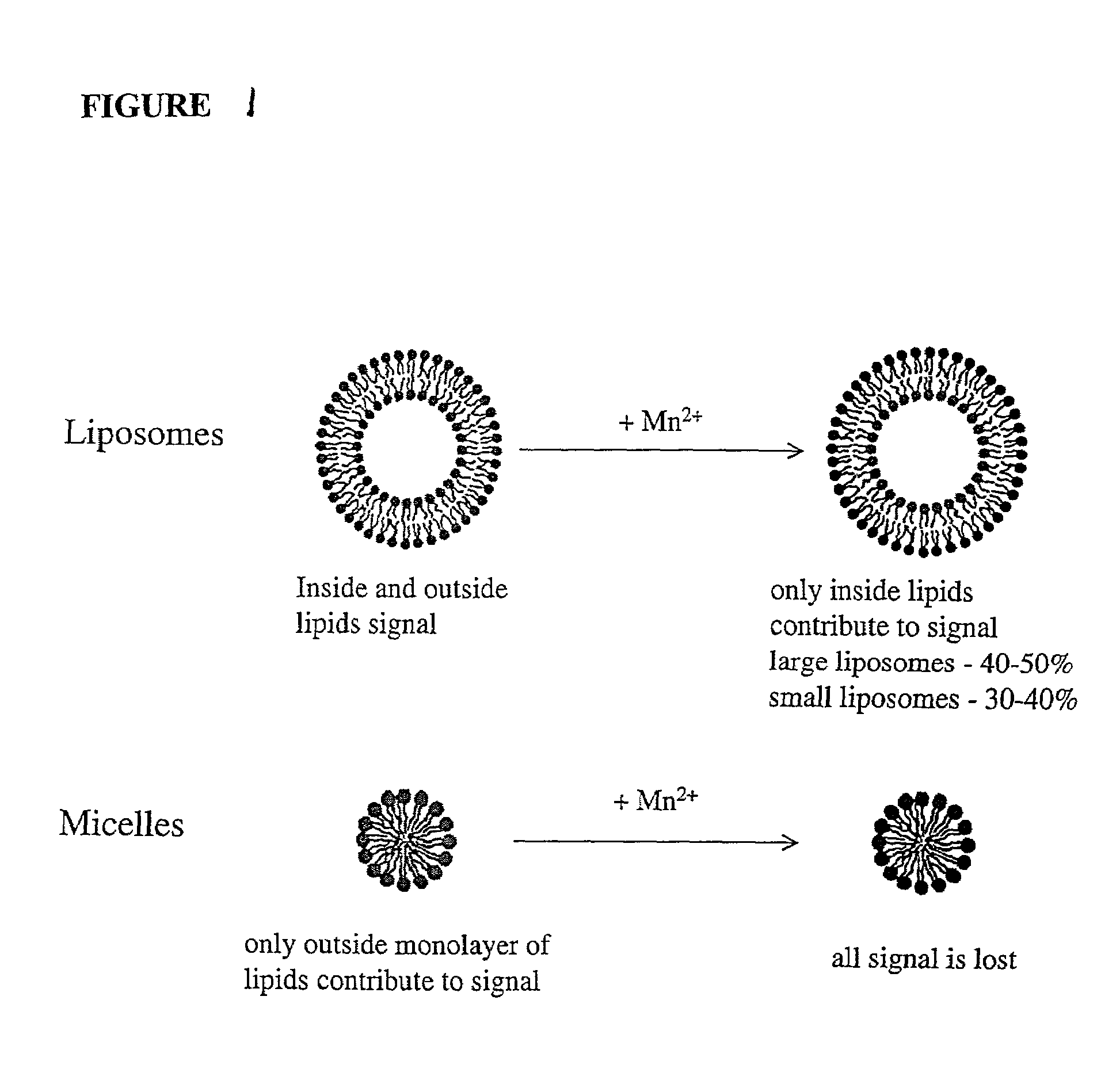

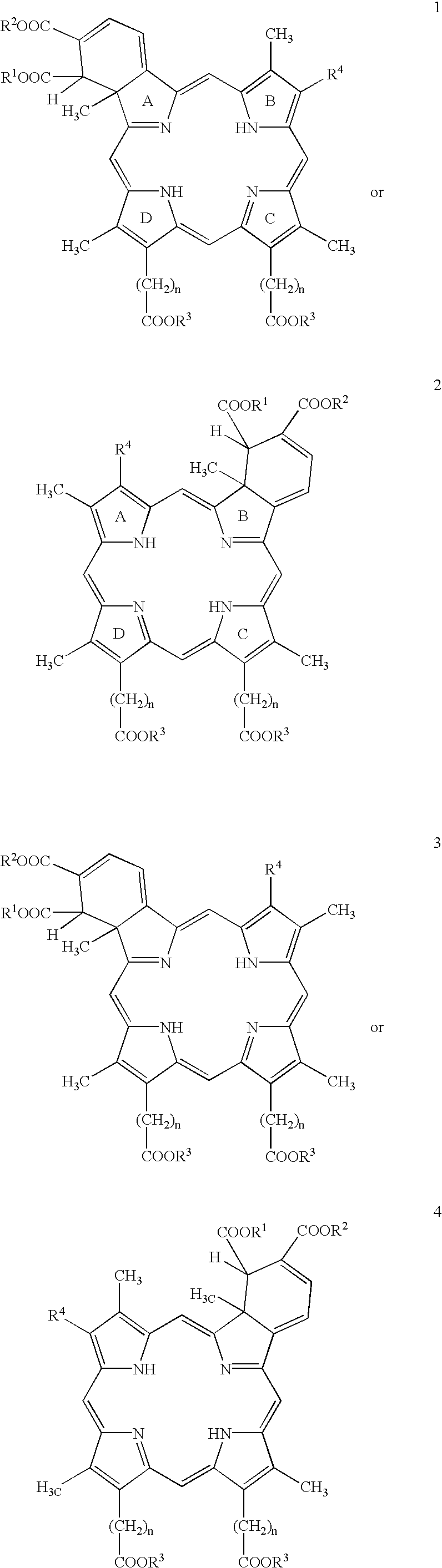

Drug delivery system for hydrophobic drugs

Compositions comprising microaggregates containing hydrophobic drugs, as well as methods for their production, are described. Such microaggregates may include micelle structures or combinations thereof with liposomes, and constitute an effective delivery vehicle for a hydrophobic agent. Methods for microaggregate production include the use of preferred lipid compounds and processing conditions favoring the production of small aggregates for improved filter sterilization.

Owner:VALEANT PHARMA INT

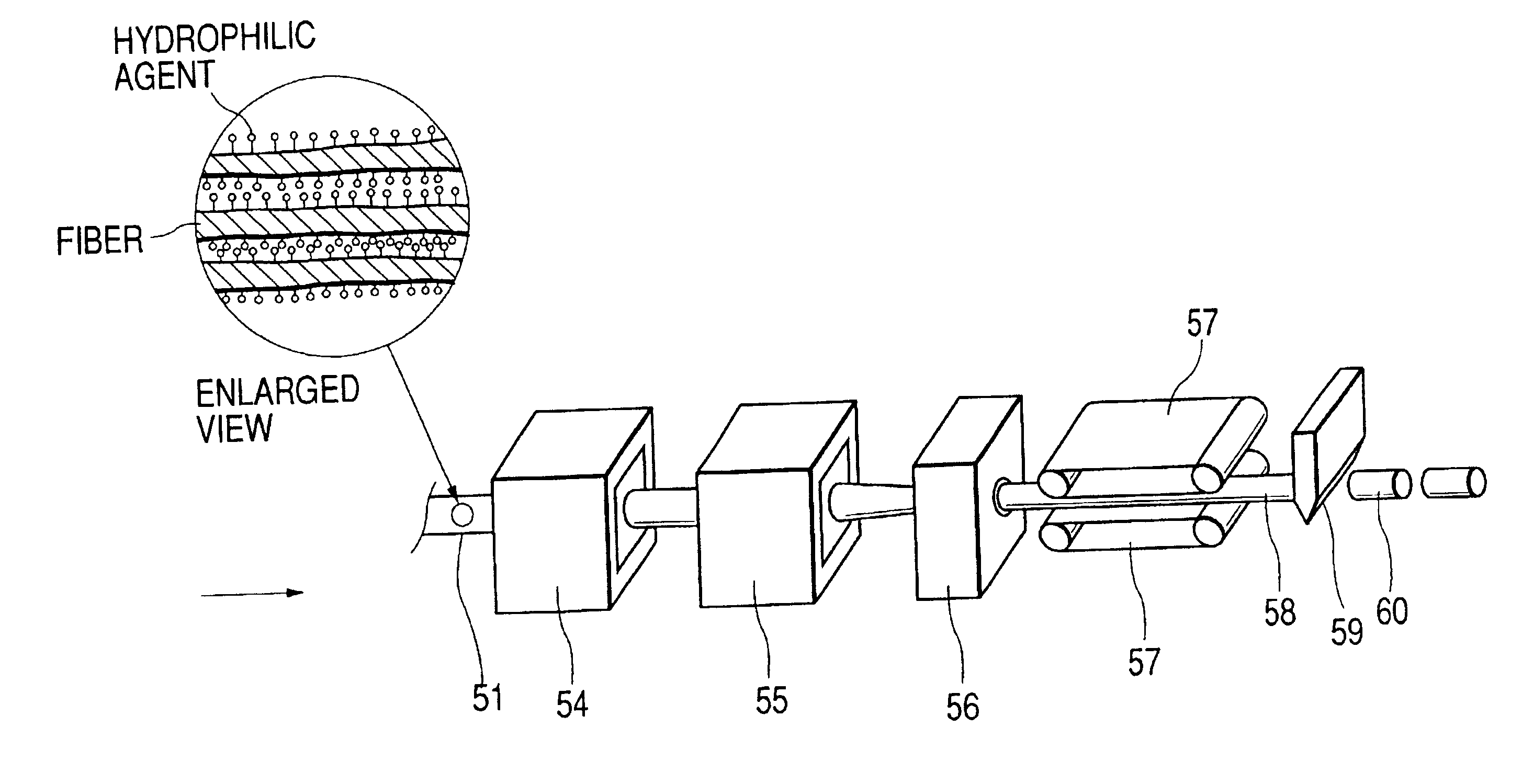

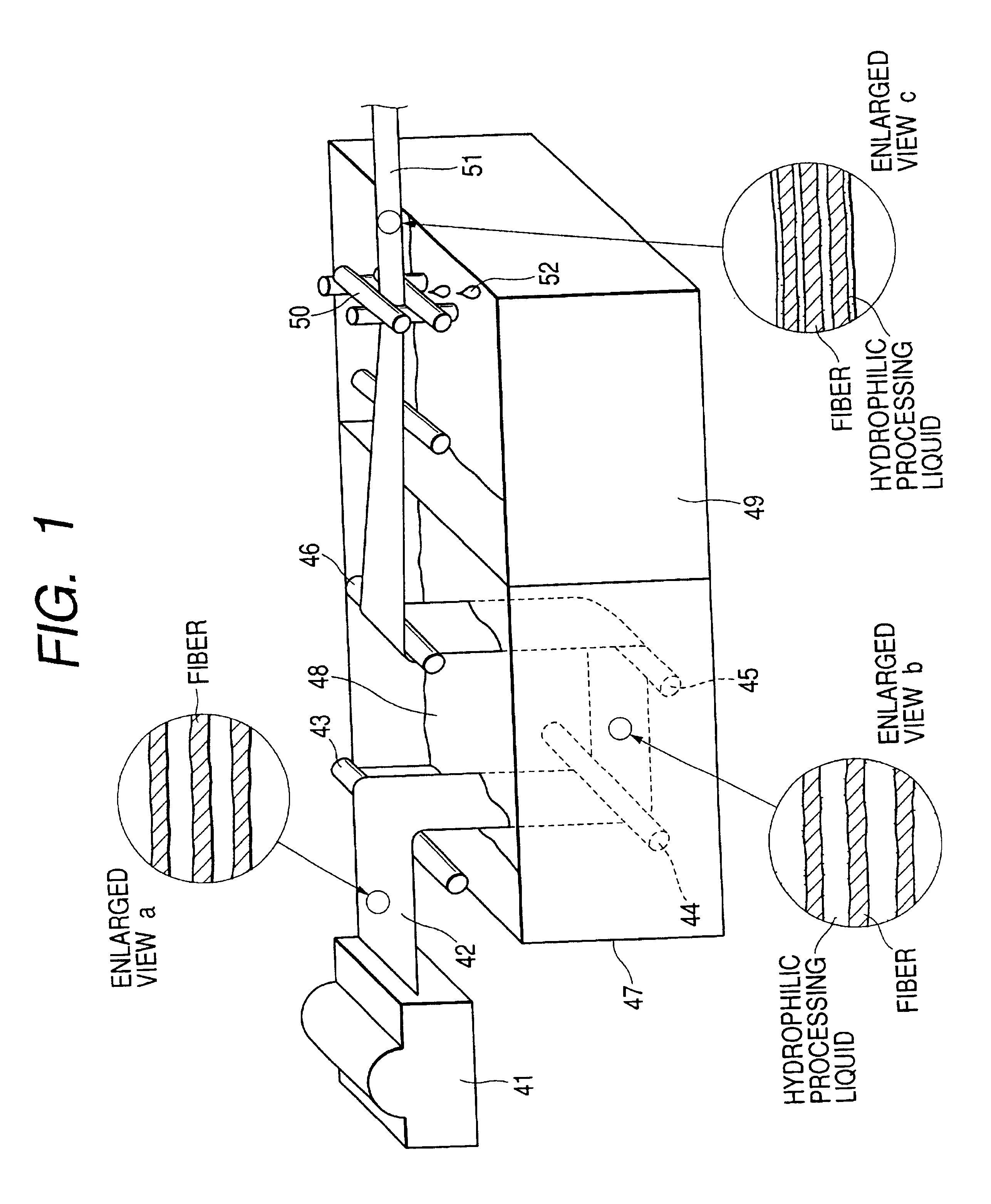

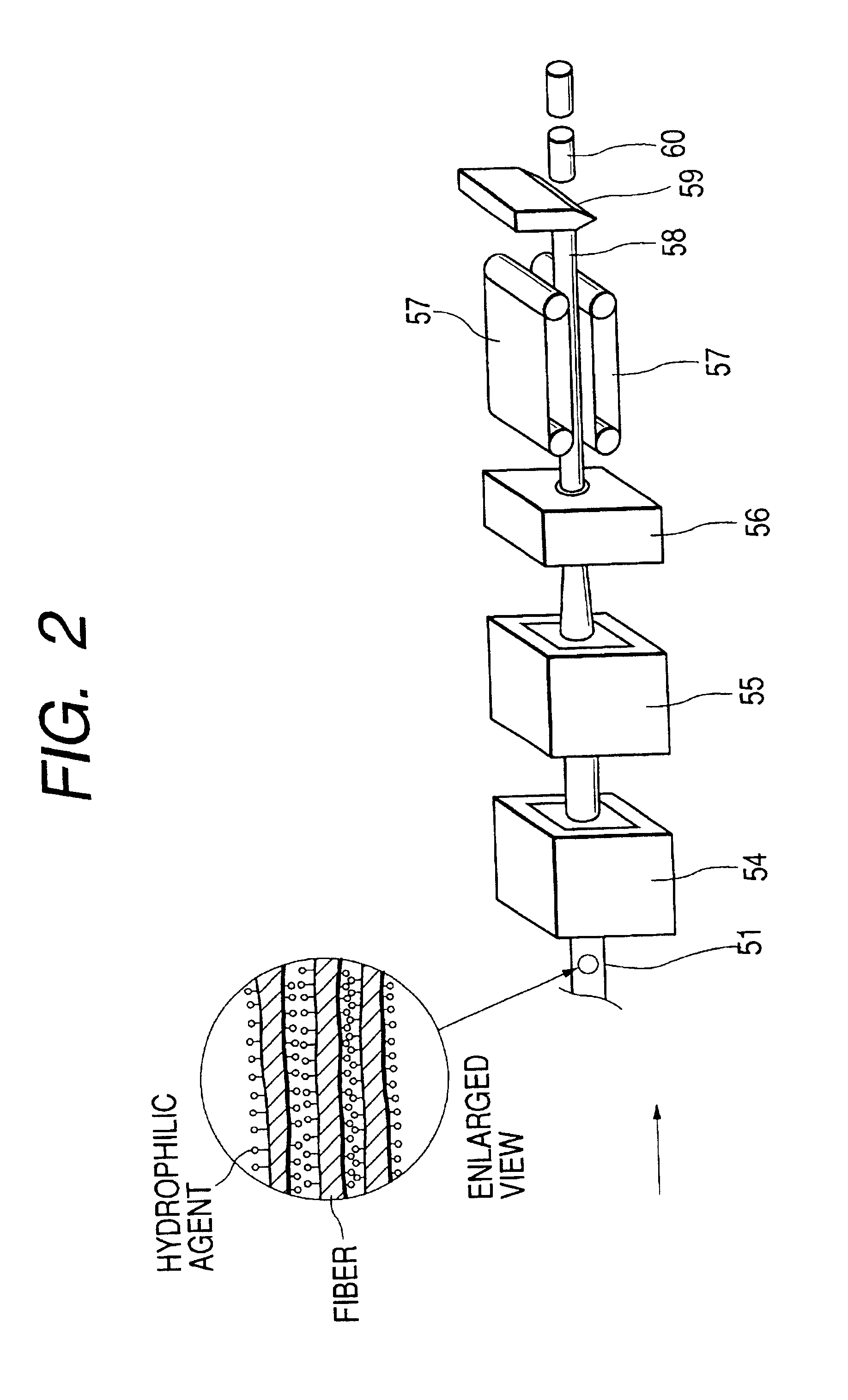

Method for manufacturing fiber aggregate, fiber aggregate, and liquid container using such fiber aggregate

InactiveUS6863762B2Enhancing uniform propertySmall stepMechanical working/deformationWood working apparatusSurface layerSingle fiber

A method for manufacturing a fiber aggregate formed by fiber having reforming surface comprises the steps of providing a fiber surface having thermoplastic resin at least on the surface layer thereof with a hydrophilic processing liquid containing polymer having a first portion with more hydrophilic group than the surface, and a second portion having interfacial energy different from that of the hydrophilic group, and interfacial energy substantially equal to the surface energy of the fiber; orientating the second portion toward the fiber surface, while orientating polymer to the side different from the surface of the first group; and forming a fiber absorber by heating the fiber having the reformed surface in the step of orientating polymer to thermally bond the contact points of fibers themselves. With this method of manufacture, it becomes possible to enhance the uniform property of the fiber aggregate still more, which is formed subsequent to making the property of such fiber aggregate uniform per unit of single fiber or small aggregate existing in any one of stages before the formation thereof.

Owner:CANON KK

Method and apparatus for manipulating single cells and small aggregates thereof

A well, in particular an open well (14) with an upper end having a vertical axis (101), for containing a liquid and particles contained within said liquid, characterized by comprising at least two manipulation electrodes (1, 2, 3, 31, 32, 36, 17, 40, 41) able to be powered by electrical voltages, in particular alternating electrical voltages, so as to manoeuvre particles within the well by means of the dielectrophoretic effect. A platform comprising a plurality of wells as described above and a method for using said well.

Owner:CELLPLY SRL

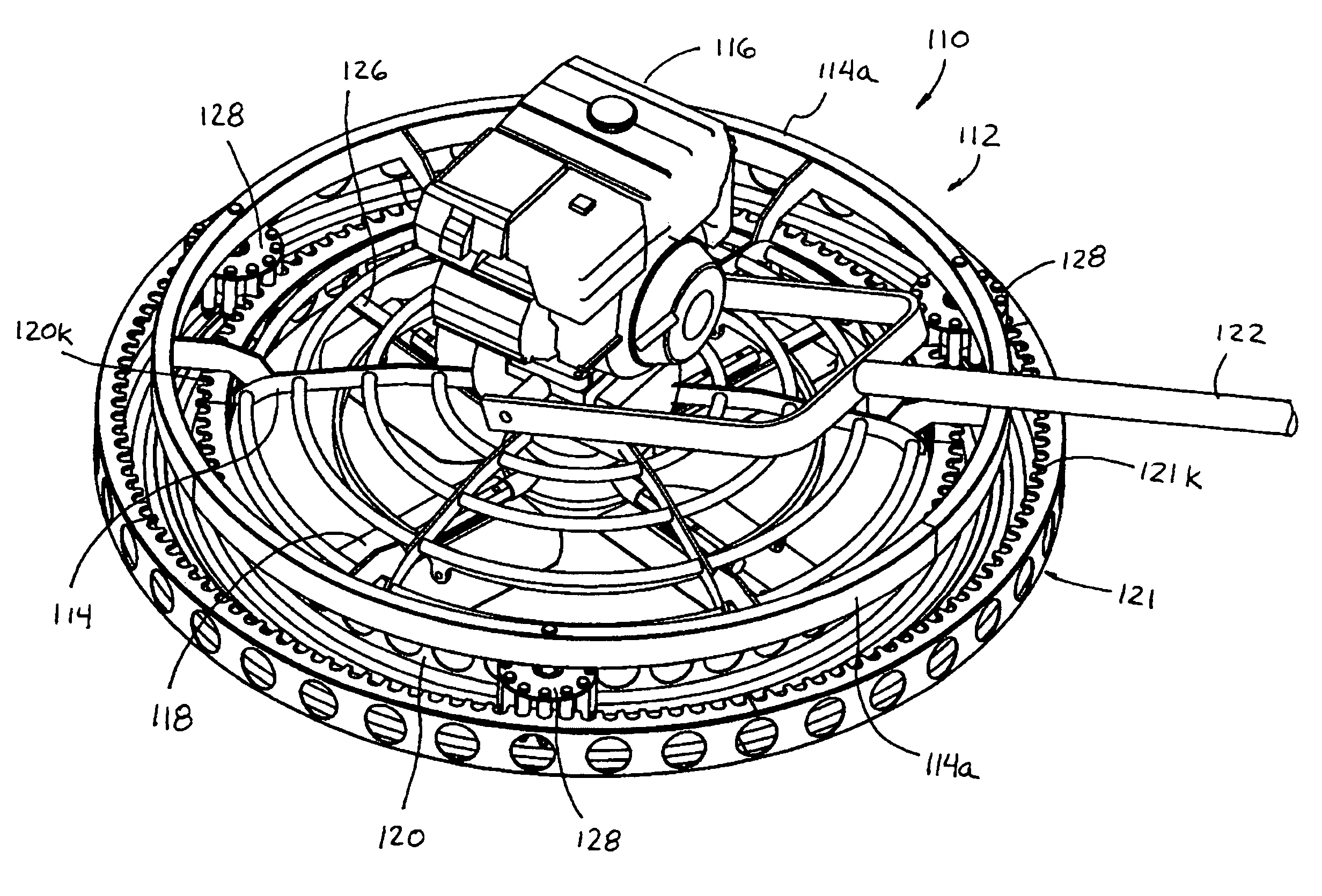

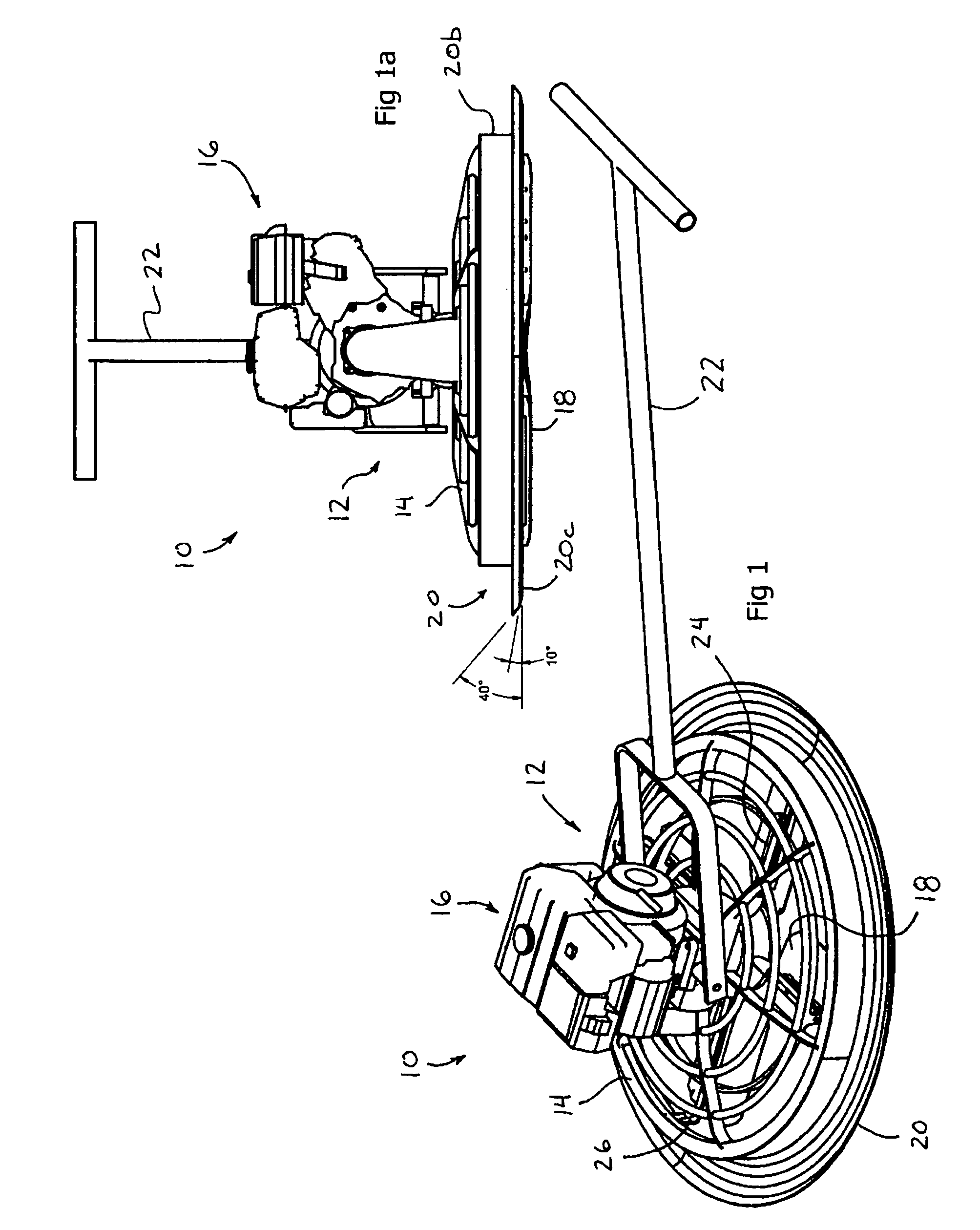

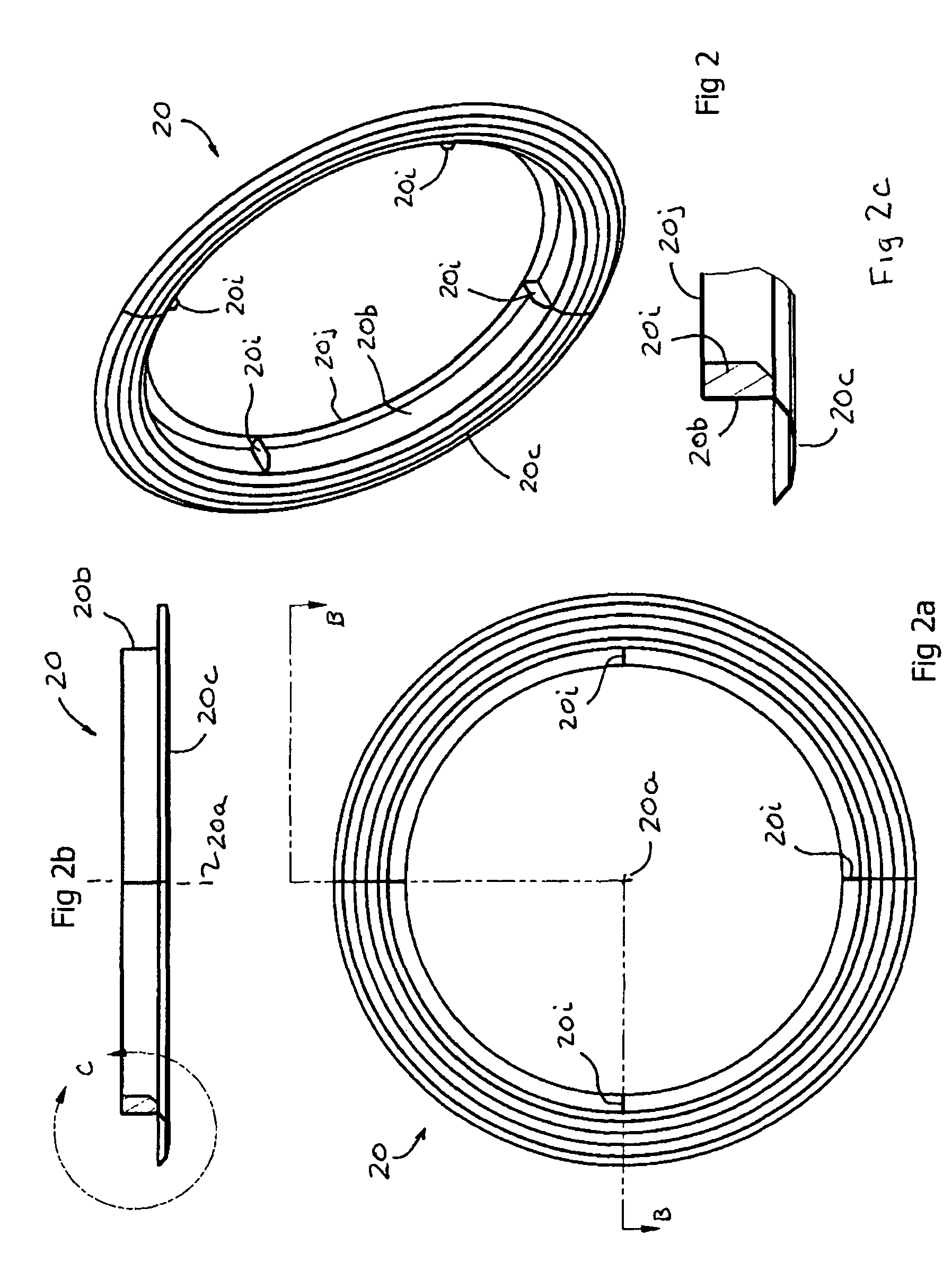

Concrete finishing apparatus

ActiveUS7891906B2High degree-flatness and smoothnessQuality improvementIn situ pavingsBuilding constructionsCement pasteConstruction aggregate

A concrete finishing apparatus and method for smoothing and flattening partially set-up concrete to a close-tolerance surface includes a movable unit that is movable and supported at a partially set-up concrete surface and at least one rotatable ring finishing member mounted to the movable unit. The rotatable ring finishing member is positioned at the concrete surface and rotatable to engage and finish the surface of the partially set-up concrete to a higher quality, closer-tolerance flat and level concrete floor surface. The apparatus may include a pair of rotatable ring finishing members that may be rotatable in opposite directions to enhance the floating and finishing processes and to transport any cement paste, sand, small aggregate, or concrete mix residue forward with the rotatable ring finishing members working surfaces to cut high areas and fill in any low areas as the concrete finishing apparatus moves over the partially set-up concrete.

Owner:SOMERO ENTERPRISES INC

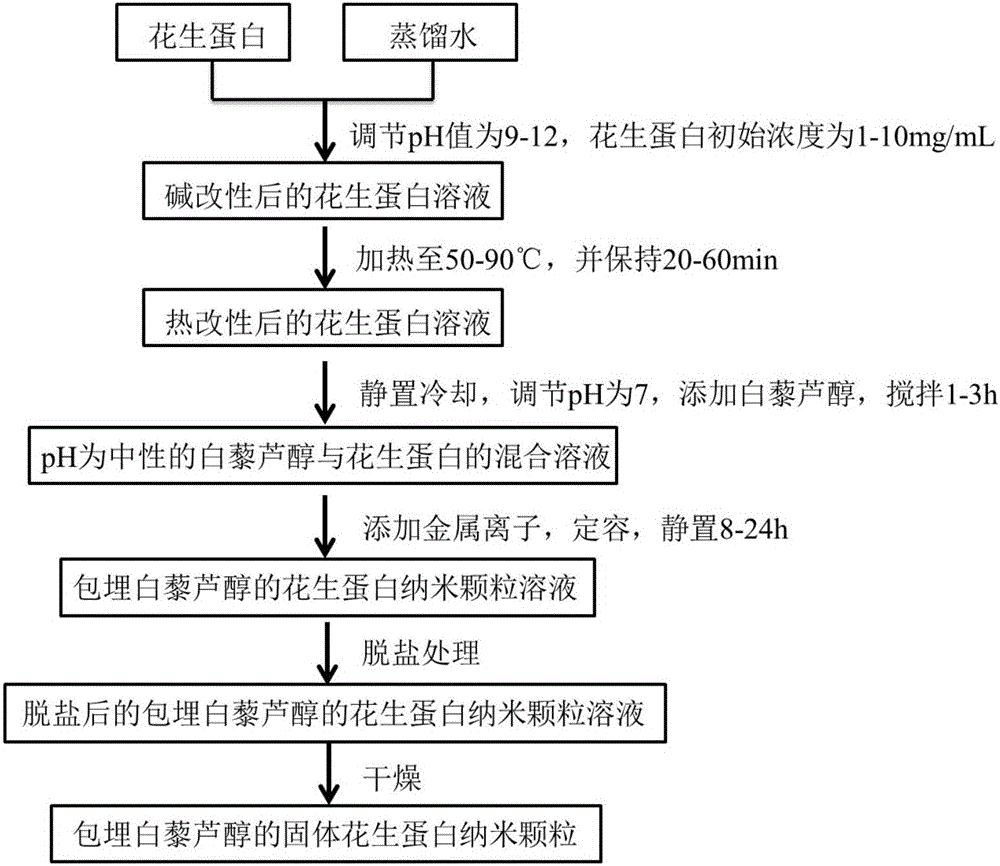

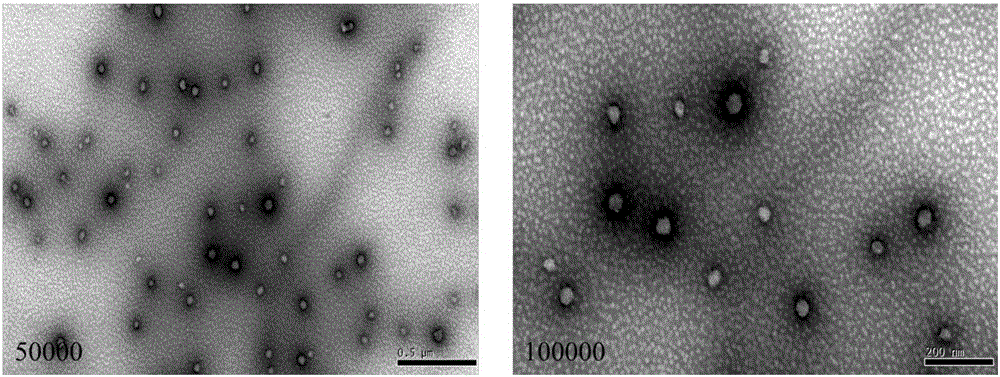

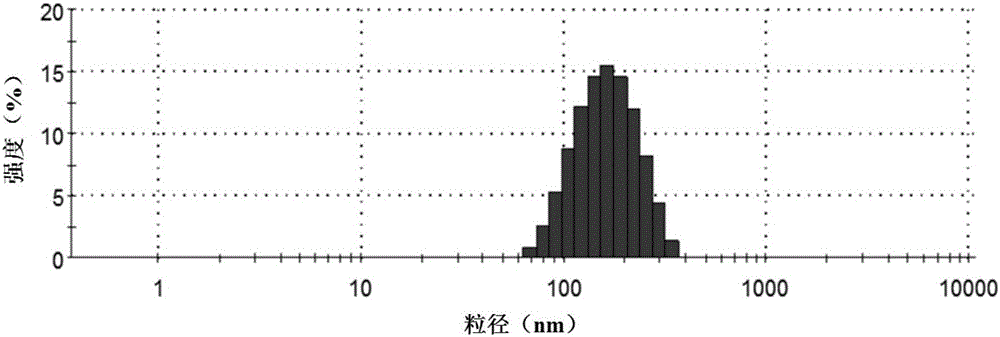

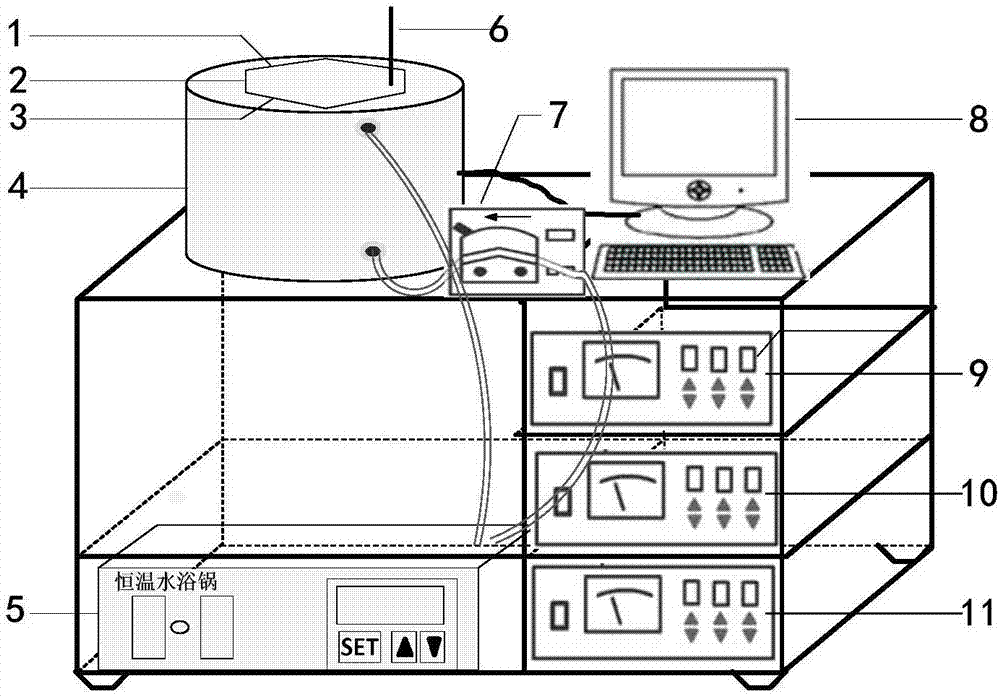

Resveratrol embedded peanut protein nano-particles and preparation method thereof

ActiveCN105709238AIncrease added valueEfficient use ofCosmetic preparationsHydroxy compound active ingredientsProtein moleculesNanoparticle

The invention relates to nano-particles and particularly discloses resveratrol embedded peanut protein nano-particles and a preparation method thereof. According to the nano-particles, resveratrol serves as a core, and modified peanut protein with the quaternary structure opened serves as a shell. According to the preparation method, peanut protein is separated out and extracted from peanut meal by means of alkali solution and acid isolation, the quaternary structure is opened after peanut protein is subjected to alkali modification and thermal modification, active groups are exposed, peanut protein is mixed with resveratrol, peanut protein molecules form small aggregates by means of metal ion induction, and then all the aggregates are promoted to form the resveratrol embedded peanut protein nano-particles through hydrophobic interaction. The peanut meal is used as a raw material, peanut protein in the peanut meal is separated out and extracted and used as a raw material for preparing the resveratrol embedded peanut protein nano-particles, it is beneficial for comprehensive utilization of peanut byproducts, and meanwhile the added value of the peanut meal is increased.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

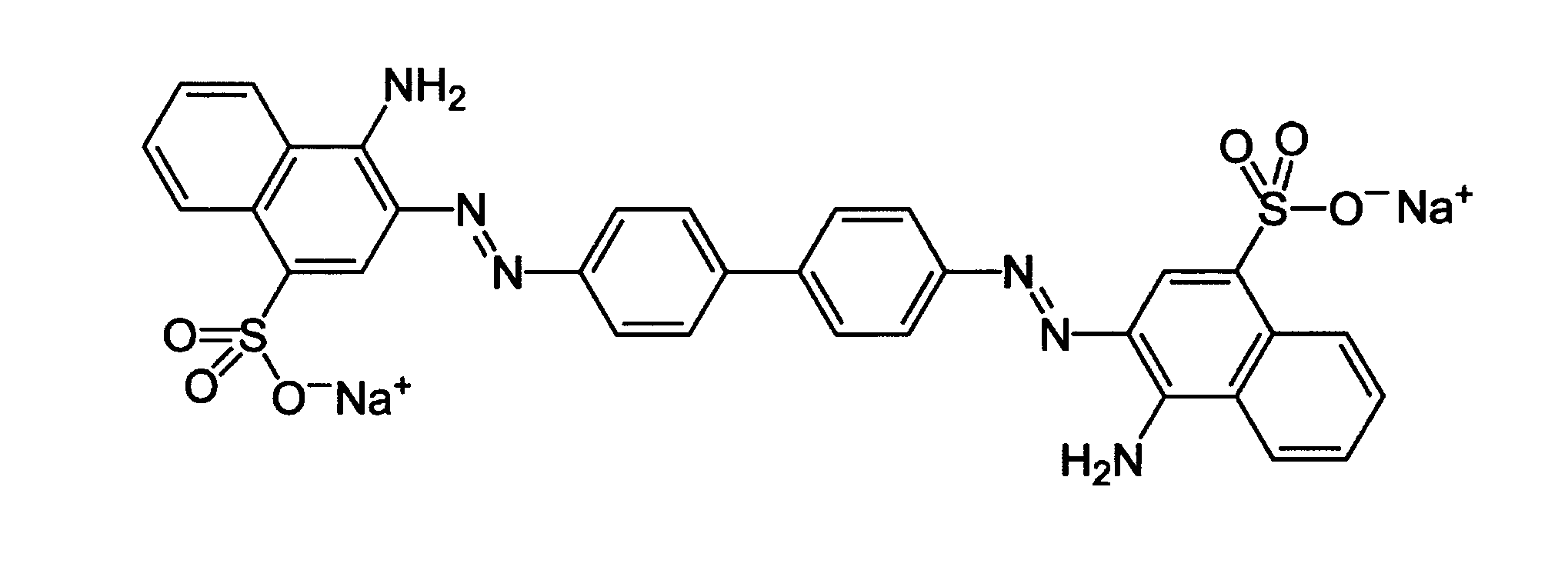

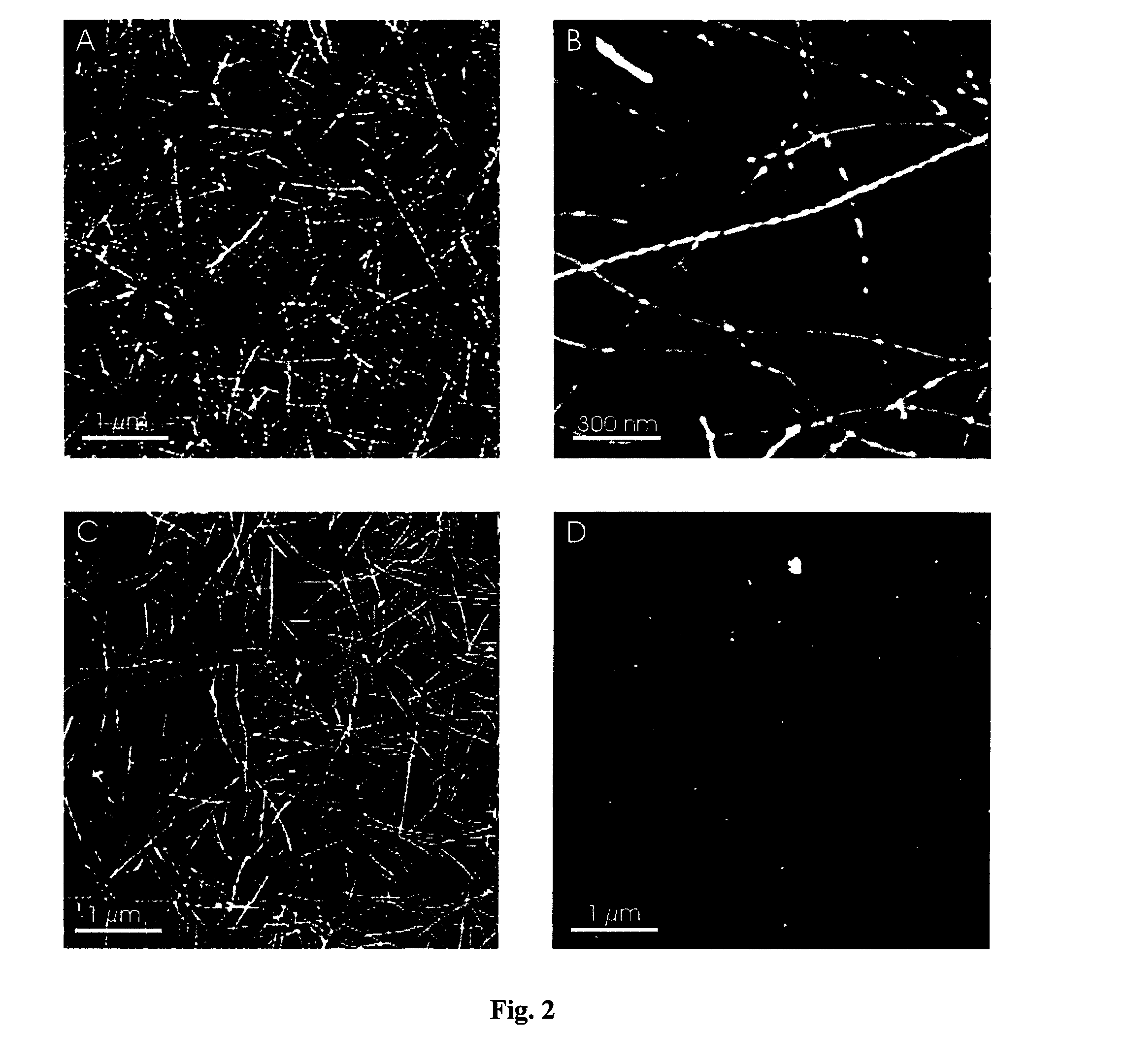

Compositions and methods for removal or destruction of amyloid fibril or amyloid adhesin comprising aggregates

InactiveUS20130115257A1Reduce riskFacilitate communicationAntibacterial agentsOrganic active ingredientsHuntingtons choreaAmyloid beta

Methods and compositions for treating biofilms and diseases associated with amyloidosis such as Alzheimer's, Parkinson's and Huntington's disease, and Type 2 diabetes, by destroying amyloid fibrils in a two-step treatment are disclosed. The first step consists of binding to the amyloid fibril an intercalating molecule with a negatively charged group such as Congo red. The second step consists of adding metal ions, such as silver, gold(I), copper(I), palladium or lead ions or metal colloids of silver or gold, which destabilize the amyloid-dye complex. This process results in a disintegration of the fibril into peptide monomers and small aggregates of monomers.

Owner:KATHOLIEKE UNIV LEUVEN

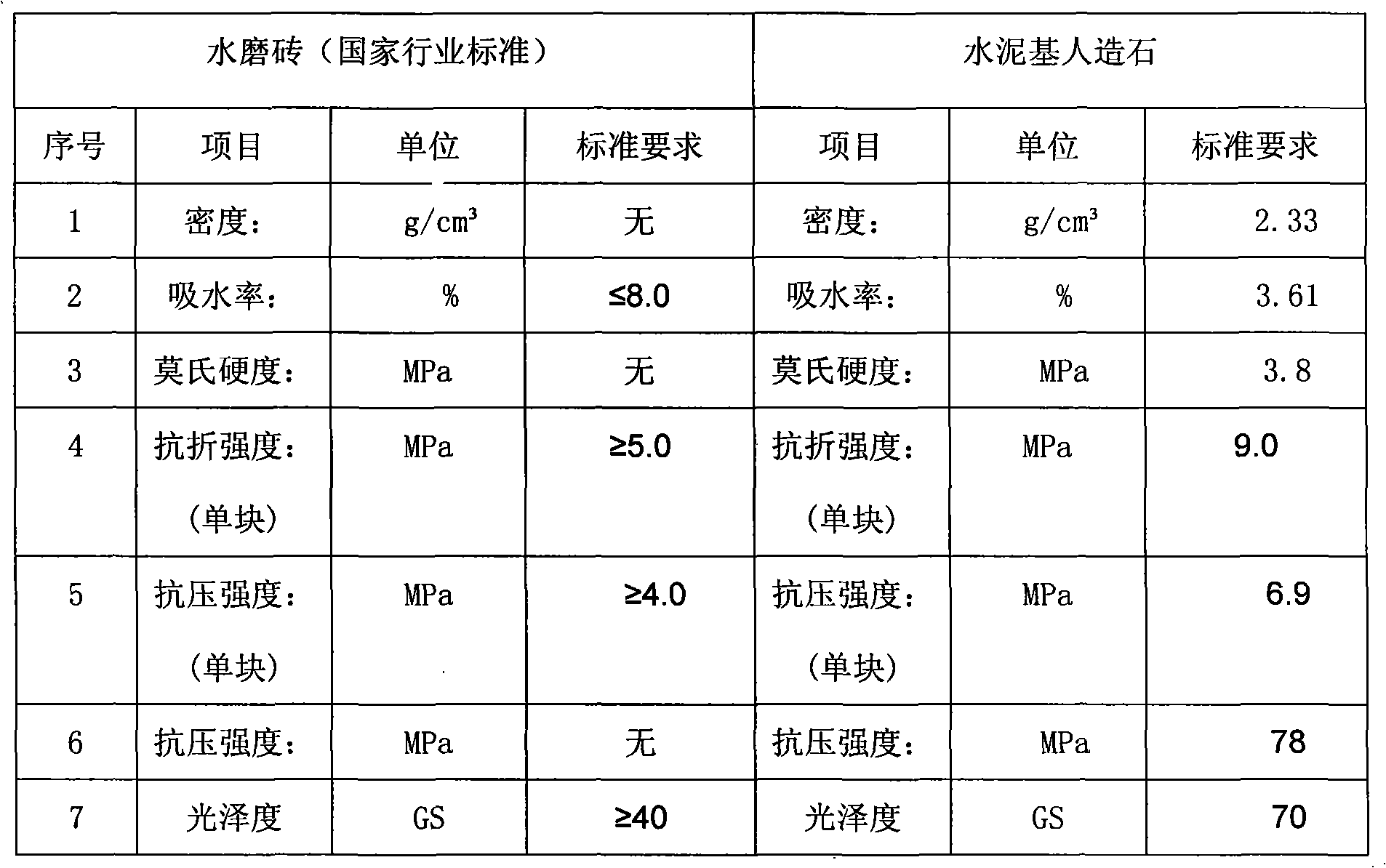

Cement-based artificial stone and production process thereof

The invention discloses a cement-based artificial stone and a production process thereof. The process comprises the following steps of: mixing cement and road metal with particle size of 0 to 15mm in a mass ratio of 1:1.5-2.5, adding an SM high-efficiency water reducing agent, namely SM1013P high-efficiency active powder in an amount which is 0.3 to 0.5 percent of the mass of the cement, and a brightening agent in an amount which is 0.3 to 0.5 percent of the mass of the cement, uniformly mixing to form an initial mixture; adding water in an amount which is 5 to 15 percent of the mass of the initial mixture and uniformly stirring to form a mixture; and injecting the mixture into a casting mold for pressure casting, vibrating under the conditions of vacuum and high pressure of 8.17*10<6> to 14.97*10<6>Pa, briquetting and curing with water to obtain the cement-based artificial stone. The cement-based artificial stone has the advantages of uniform patterns and colors, no deformation, fastness, skid resistance, wear resistance, rich third dimension, high level, elegant appearance, capability of manufacturing varieties with various colors and unequal large and small aggregates, simple curing (mopped by a wet mop for one time every day), and suitability to be paved on the indoor and outdoor ground and the ground of subway stations, market squares and the like.

Owner:云浮市泰利环保石材有限公司

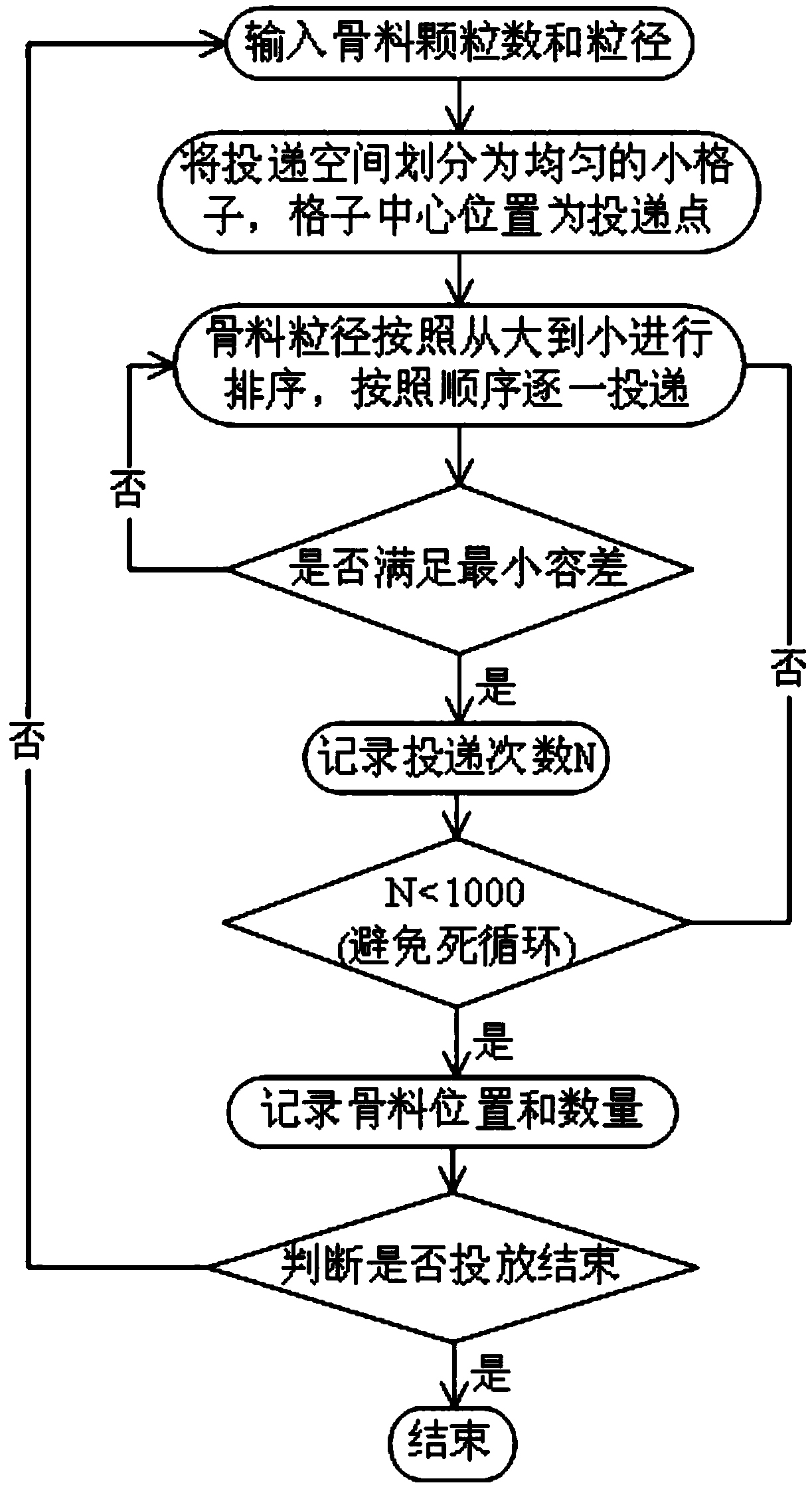

Method of constructing recycled concrete three-dimensional random spherical aggregate model based on Python

InactiveCN108334676ASatisfy the requirement of generating randomnessMesostructure conforms toGeometric CADDesign optimisation/simulationArray data structureSpatial partition

The invention discloses a method of constructing a recycled concrete three-dimensional random spherical aggregate model based on Python, comprising: defining an array to store diameter, coordinate andvolume parameters; inputting basic parameters, including aggregate content, model dimensions, and aggregate microscopic size; building inside, a particle size distribution function and a random function; randomly generating a floating point number from particle sizes d1 to d2 to obtain a random number within a required range; grading the particle sizes; dividing a deployment space into uniform small cells, deploying from the large aggregate particle size to the small aggregate particle size, randomly generating deployment positions, and performing circulating deployment to obtain a satisfactory aggregate model; subjecting spherical aggregates to plane translation to obtain an outer interface region, old hardened mortar and an inner interface region. The model is a damage plasticity modelin ABAQUS software; the parameter values are stored in the array mat; the model is saved; the method that has higher speed and efficiency is provided for researches on numerical simulation of recycledconcrete.

Owner:XIAN UNIV OF TECH

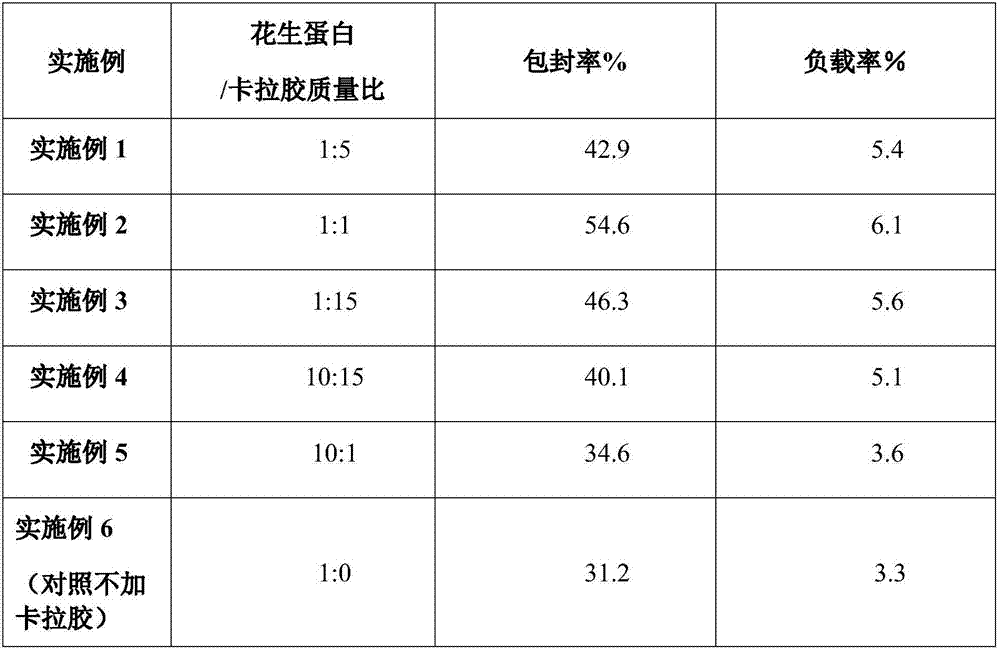

Ultrasonic preparation method of peanut protein/polysaccharide composite particle and functional food application

InactiveCN107298863AImprove stabilityGood biocompatibilityOrganic active ingredientsCosmetic preparationsCarrageenanBULK ACTIVE INGREDIENT

The invention discloses an ultrasonic preparation method of a peanut protein / polysaccharide composite particle and functional food application, and relates to the technical field of functional food microcapsules. The peanut protein / polysaccharide composite particle is prepared from the following raw materials in parts by weight: 1-10 parts of peanut protein, and 1-15 parts of carrageenan. The carrageenan is added into the peanut protein, the advanced structure of the peanut protein is changed, the structure of the peanut protein is opened, an active group is exposed, and besides, the protein and the polysaccharide form a small aggregate, so that various aggregates form the composite particle through hydrophobic interaction, and the foundation is provided for embedding a biological active ingredient. In the process of embedding a tea polyphenol by using the peanut protein / polysaccharide composite particle, the sweep frequency ultrasonic processing technique or the multi-mode ultrasonic technique is used, the physical force of the ultrasonic wave promotes the crosslinking of the protein and the polysaccharide to form the aggregate, so that the various aggregates are promoted to form the composite particle through hydrophobic interaction, and the foundation is provided for embedding the biological active ingredient.

Owner:JIANGSU UNIV

Zein-chitosan composite agglomerate and multi-mode ultrasonic preparation method

PendingCN106942703AChange the high-level structureLow priceFood scienceBULK ACTIVE INGREDIENTActive ingredient

The invention discloses a zein-chitosan composite agglomerate and a multi-mode ultrasonic preparation method, and belongs to the technical field of food embedding. The zein-chitosan composite agglomerate is prepared from the following raw materials in parts by weight: 1-10 parts of zein, and 1-2.5 parts of chitosan. According to the invention, the chitosan is added into the zein so as to change high-level structure of the zein, and thus, the structure of the zein is opened up and the active groups are exposed; and small aggregates form by proteins and polysaccharides, so that hydrophobic interaction of the aggregates are promoted so as to form nanometer particles, and thus, basis is provided for bio-active ingredient embedding. Moreover, a multi-mode ultrasonic treatment technology is used during the preparation process of the zein-chitosan composite agglomerate embedding resveratrol according to the invention so as to promote cross-linking of the protein and the polysaccharides to form agglomerates by a physical method, so that hydrophobic interaction of the aggregates are promoted so as to form nanometer particles, and thus, basis is provided for bio-active ingredient embedding.

Owner:JIANGSU UNIV

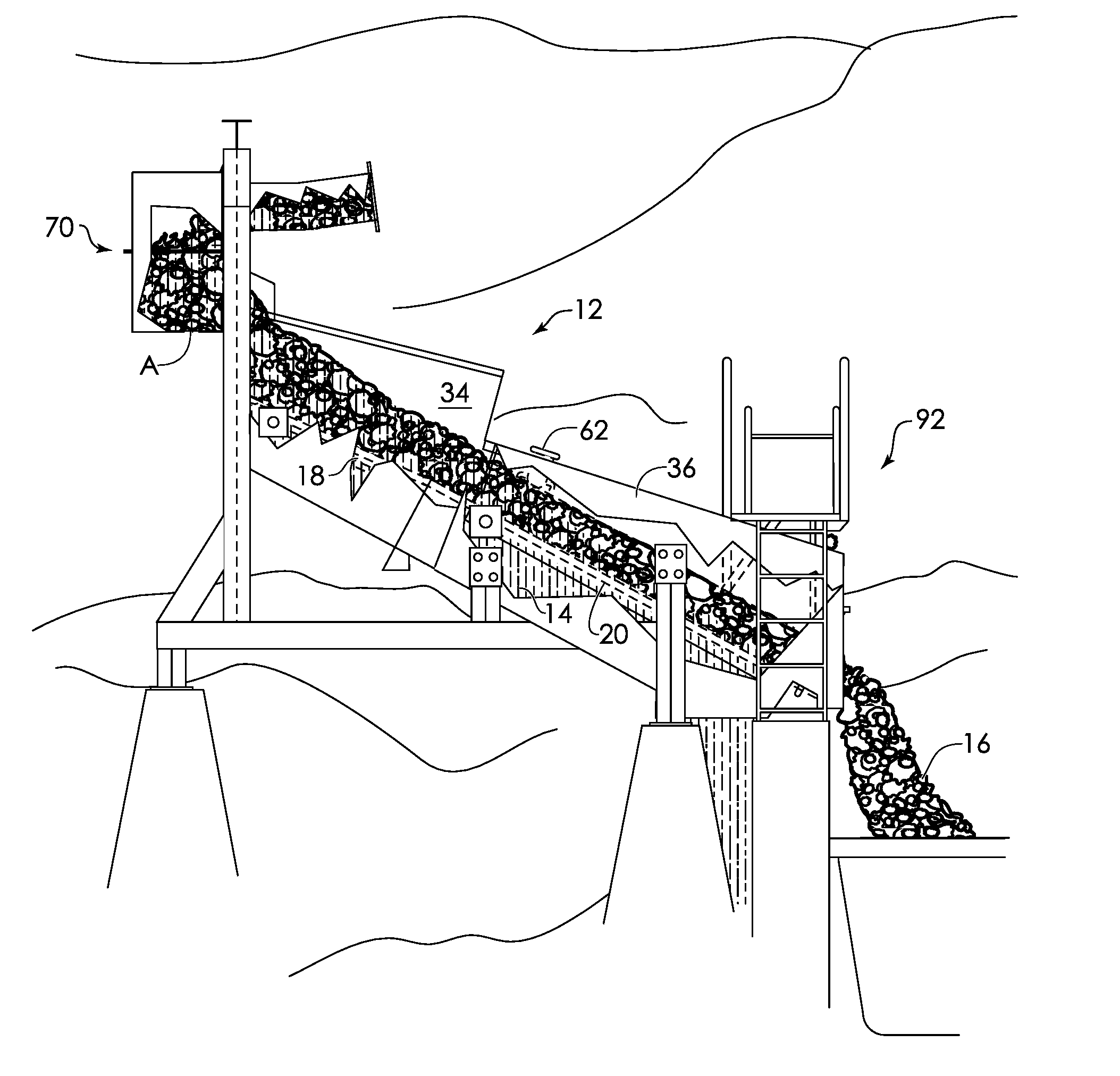

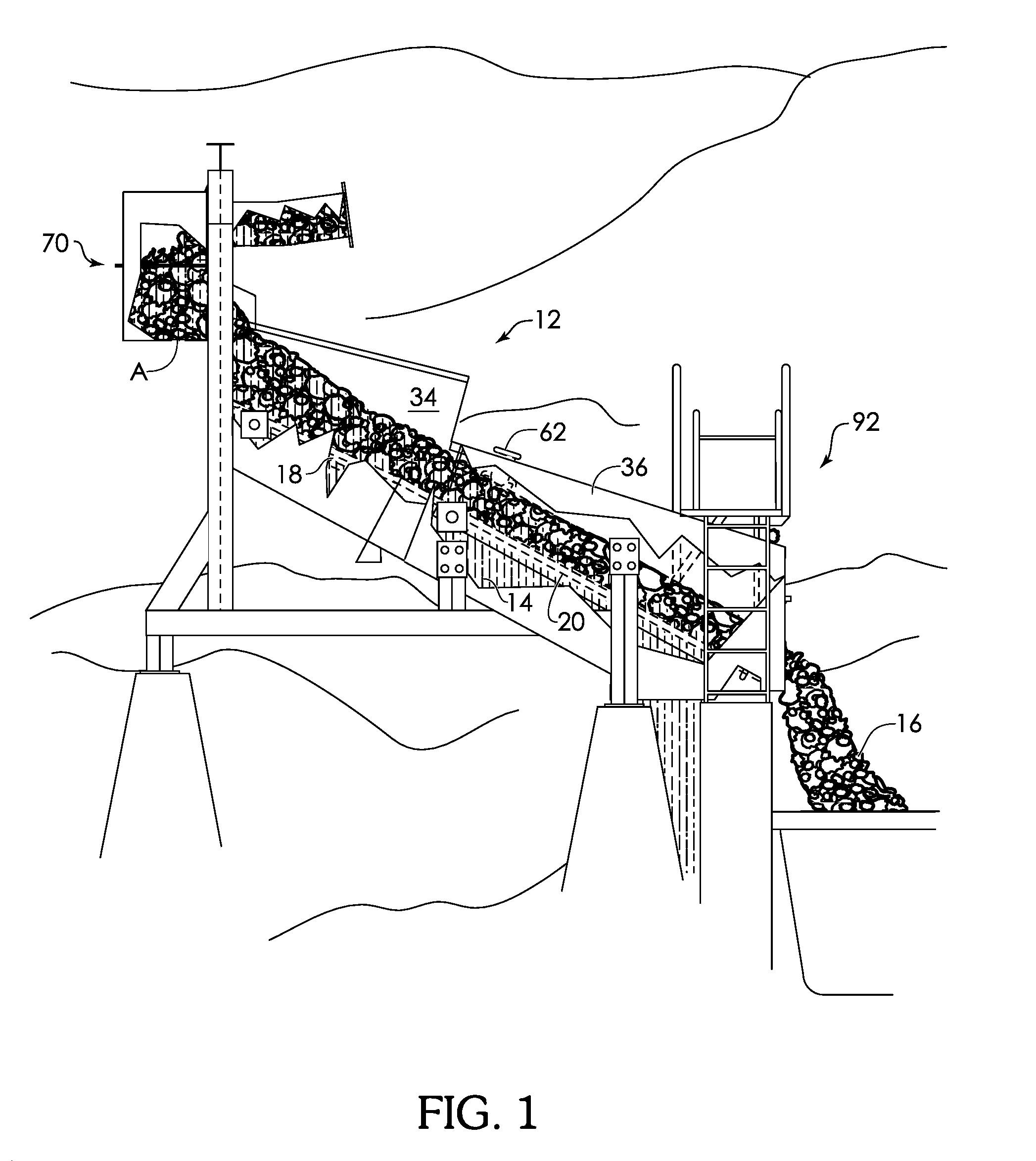

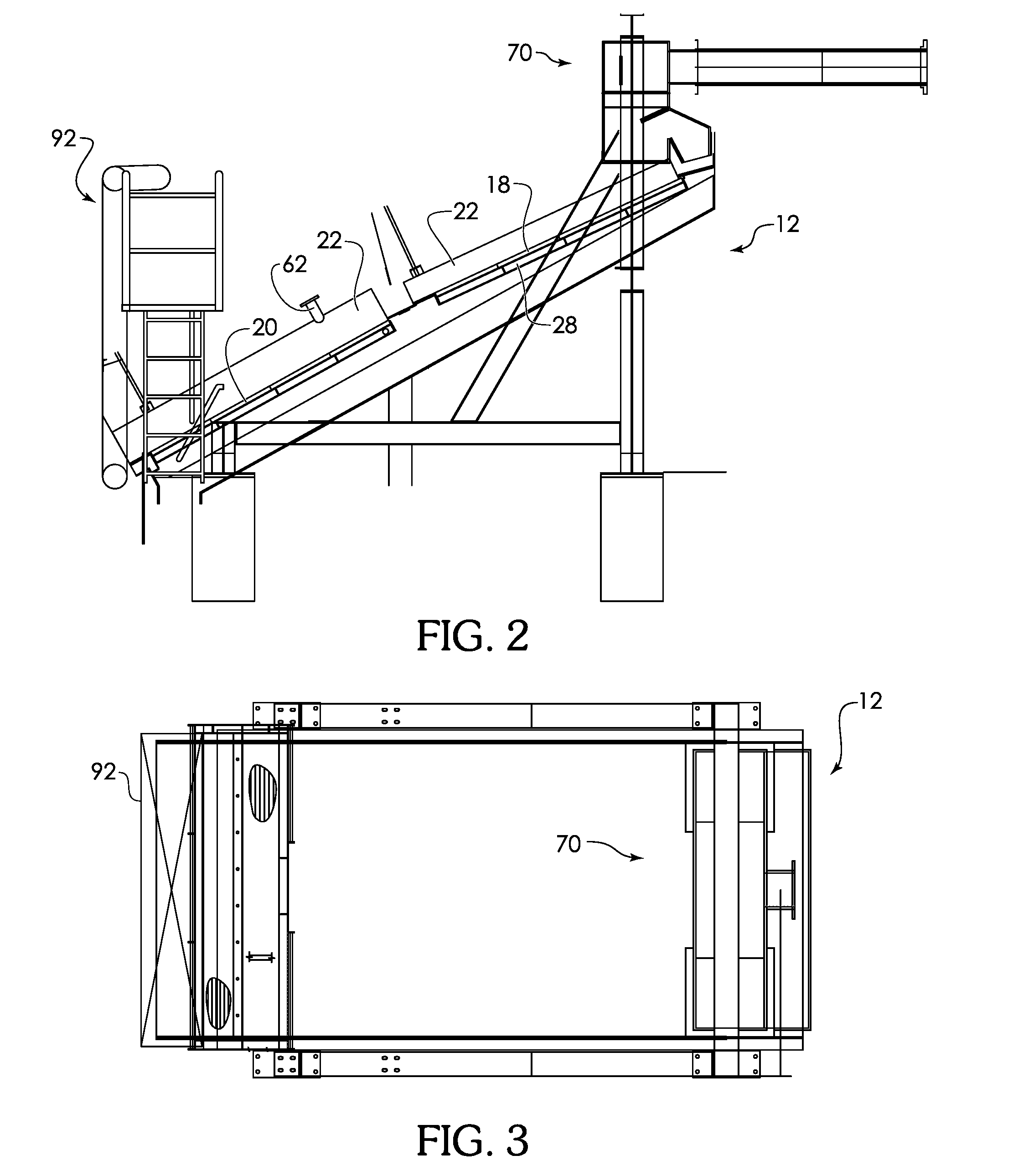

Screening apparatus

ActiveUS8636150B1Improve securityElimination of electrical or vibrating springsSievingScreeningMechanical engineeringLarge aggregate

An upper deck in a top flume before a lower deck in a bottom flume, each deck is adjustable from form about 10 to about 70 degrees, or from about 20 to about 45 degrees, and has a frame divided into a grid containing blank or screen panels that have openings to selectively permit smaller aggregate to pass through, while larger aggregates pass over the screens. The top flume has an opening for feeding the larger aggregates to the top of the deck adjacent the flume, and a bottom with an opening for feeding smaller aggregates under the deck. The bottom flume has an upstream side with an opening at the bottom to receive the smaller aggregates from the upstream adjacent flume and a downstream side having an opening adjacent the bottom of the side to discharge the larger aggregates, and the bottom has an opening it discharge the smaller aggregates.

Owner:DEWAR OF VIRGINIA

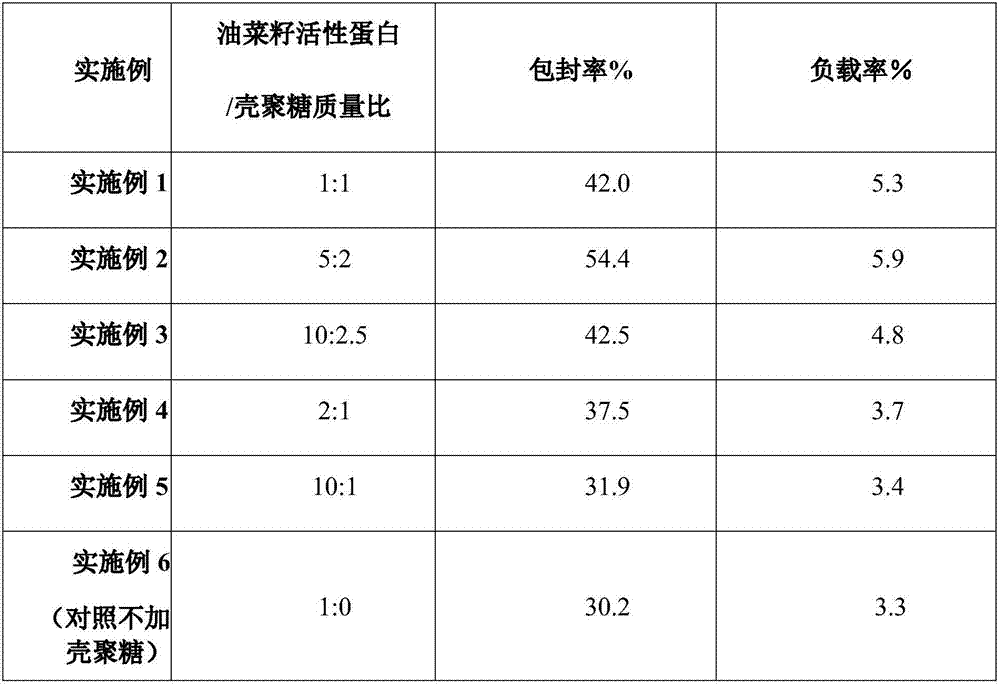

Frequency-sweeping ultrasonic preparation method of rapeseed protein-chitosan nanoparticles

InactiveCN107298773AChange the high-level structurePromote cross-linking intoMaterial nanotechnologyChitosan nanoparticlesRapeseed

The invention discloses a frequency-sweeping ultrasonic preparation method of rapeseed protein-chitosan nanoparticles, and relates to the technical field of composite nanoparticles of functional food. The rapeseed protein-chitosan nanoparticles are prepared from the following raw materials in parts by weight: 2-10 parts of active rapeseed protein and 1-2.5 parts of chitosan. The chitosan is added into the active rapeseed protein to change the advanced structure of the active rapeseed protein, so that the structure thereof is opened to expose active groups; meanwhile, the protein and polysaccharide form small aggregates, so that formation of the nanoparticles by the aggregates through hydrophobic interaction is promoted, and a foundation is laid for embedding a bioactive component. In the preparation process of the curcumin-embedded active rapeseed protein-chitosan composite nanoparticles, by a frequency-sweeping ultrasonic processing technology, cross-linking of the protein and the polysaccharide into the aggregates is promoted through the physical force of ultrasonic, so that the formation of the nanoparticles by the aggregates through the hydrophobic interaction is promoted and the foundation is laid for embedding the bioactive component.

Owner:JIANGSU UNIV

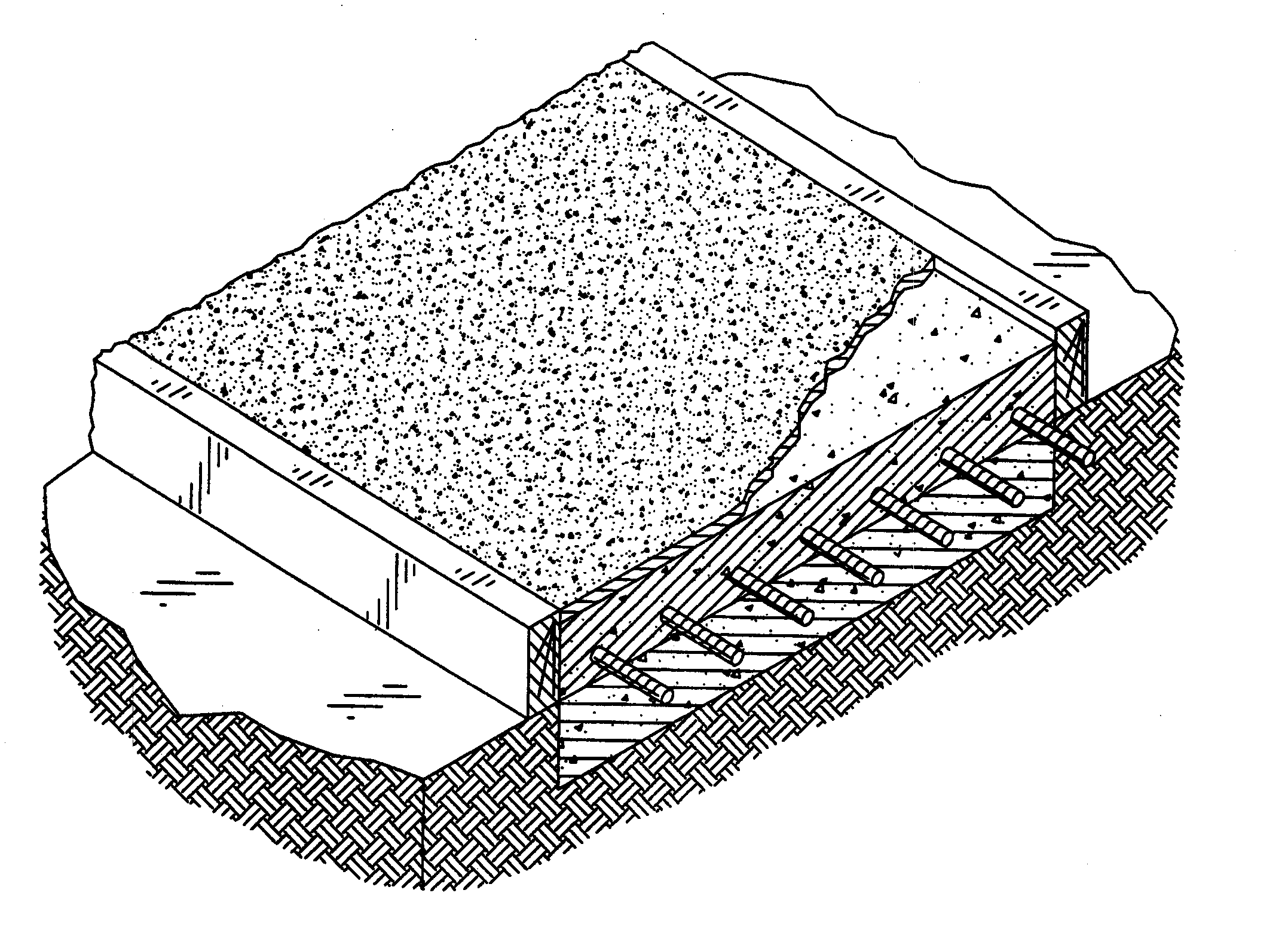

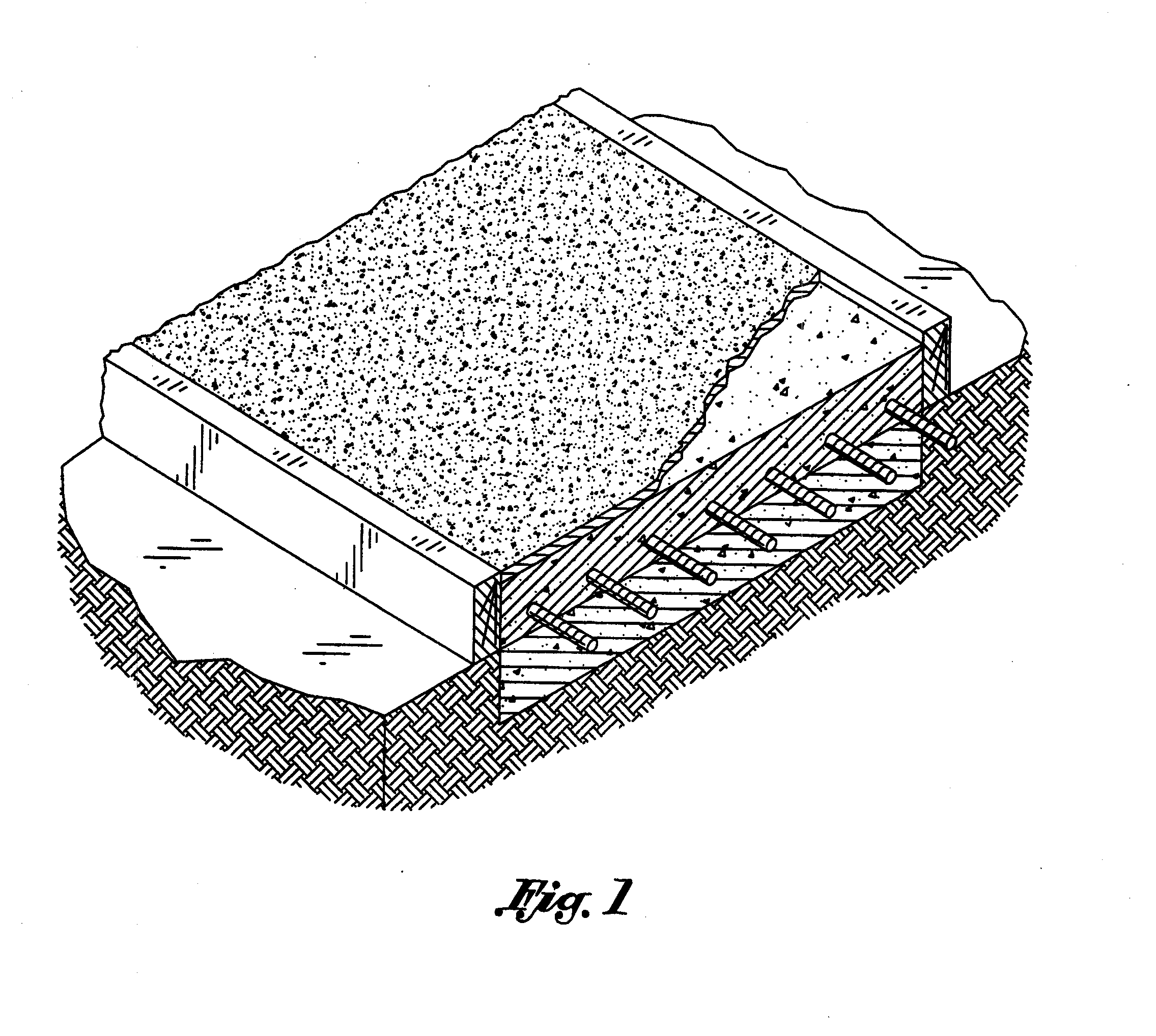

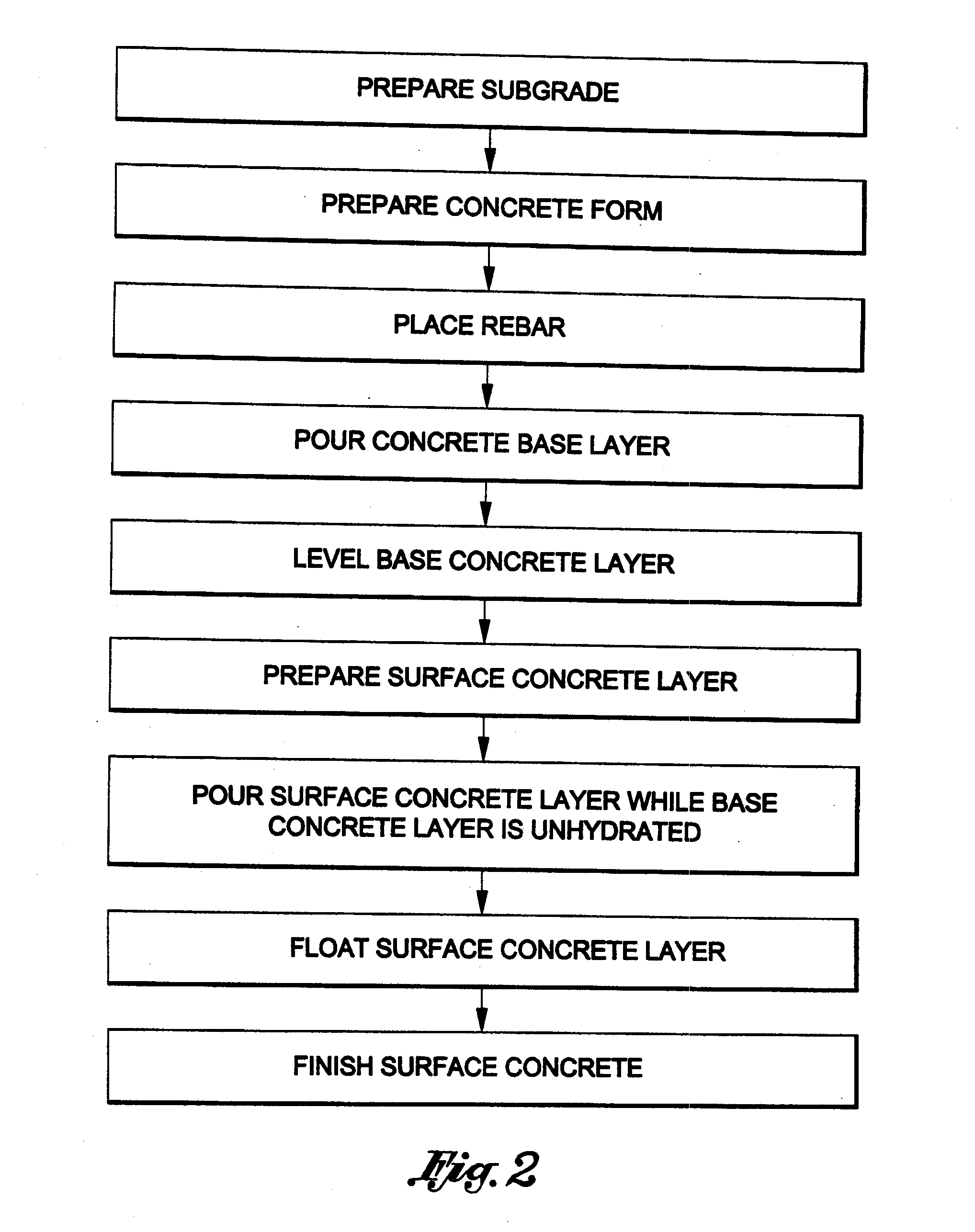

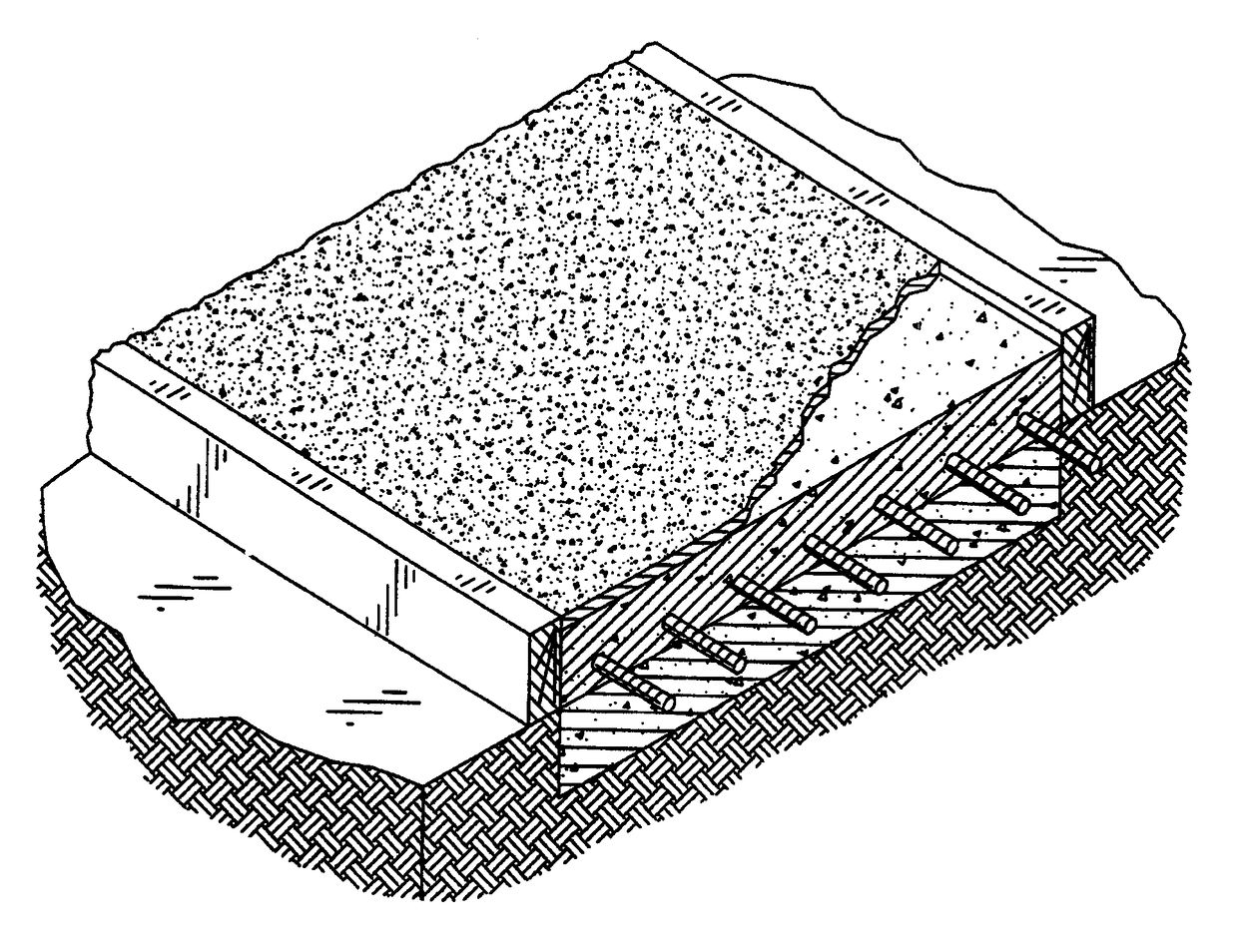

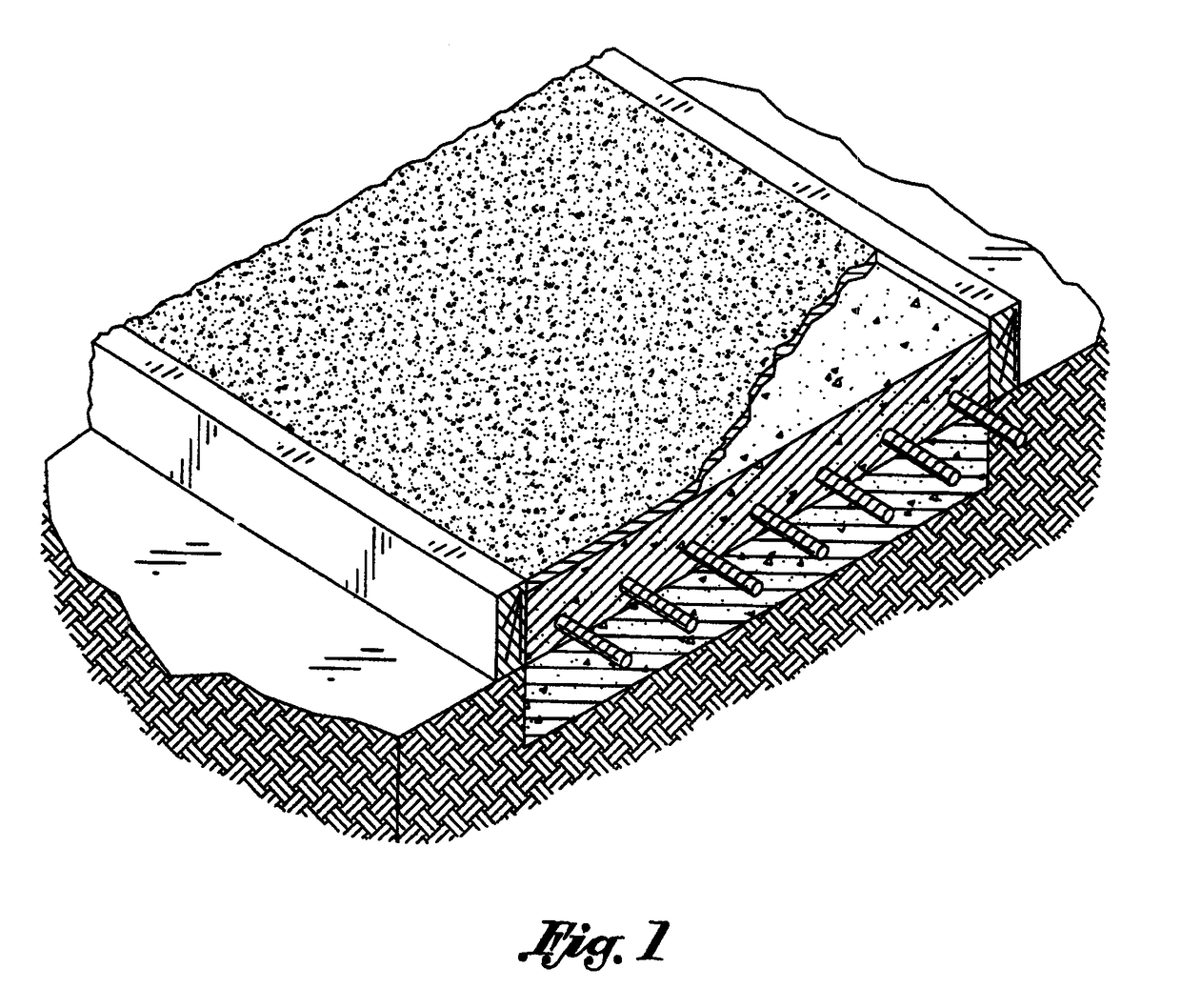

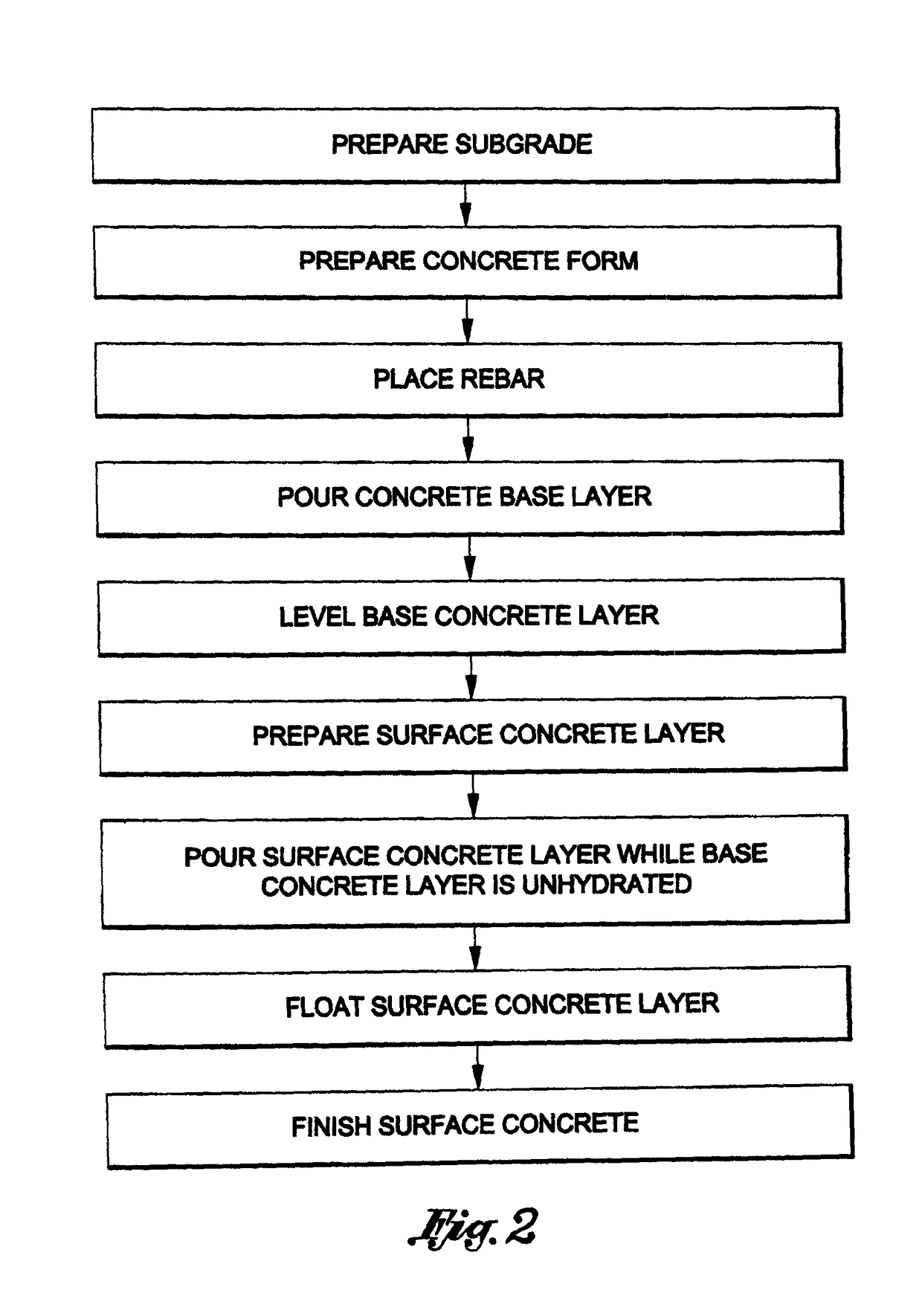

Architectural concrete and method of forming the same

InactiveUS20150052842A1Provide durabilityProvide strengthConstruction materialMouldsUltimate tensile strengthMaterials science

Owner:SHAW & SONS

Fumed metal oxide particles and process for producing the same

The invention provides a process for producing fumed metal oxide particles comprising providing a stream of a liquid feedstock comprising a volatizable, non-halogenated metal oxide precursor, providing a stream of a combustion gas having a linear velocity sufficient to atomize and combust or pyrolyze the liquid feedstock, and injecting the stream of the liquid feedstock into the stream of combustion gas to form a reaction mixture such that the liquid feedstock is atomized and subjected to a sufficient temperature and residence time in the combination gas stream for fumed metal oxide particles to form before the combustion gas temperature is reduced below the solidifying temperature of the metal oxide particle. The invention further provides fumed silica particles having a relatively small aggregate size and / or narrow aggregate size distribution.

Owner:CABOT CORP

Architectural concrete and method of forming the same

ActiveUS9695602B2Provide durabilityProvide strengthConstruction materialFloorsUltimate tensile strengthMaterials science

Owner:SHAW & SONS

Ultrasonic preparation method of rapeseed protein microcapsule and application of rapeseed protein microcapsule as functional food

InactiveCN107114799AImprove stabilityGood biocompatibilityFood ingredientsOrganic solventActive protein

The invention discloses an ultrasonic preparation method of a rapeseed protein microcapsule and application of the rapeseed protein microcapsule as functional food, and relates to the technical field of functional food microcapsules. The rapeseed protein microcapsule is prepared from the following raw materials in parts by weight: 10 to 25 parts of rapeseed active protein and 1 to 5 parts of curcumin. Counter-current ultrasonic waves and sweep-frequency ultrasonic waves are applied during a process of embedding the curcumin in the rapeseed active protein, the advanced structure of the rapeseed active protein is changed, the structure of the rapeseed active protein is opened, active groups are exposed, and small aggregates are formed by protein, so that all aggregates are facilitated to form microcapsules through hydrophobic interaction, and the basis is provided for embedding bioactive components. According to the ultrasonic preparation method of the rapeseed active protein microcapsule in which the curcumin is embedded, disclosed by the invention, the technological operation is simple, an organic solvent is not used in the preparation process, the ultrasonic preparation method is suitable for industrial production, the price of raw materials of the rapeseed active protein is cheap, and the preparation technology is simple.

Owner:JIANGSU UNIV

Nucleic acid antioxidant compositions, methods for obtaining such compositions and formulations thereof

InactiveUS20050019373A1Reduces rate of oxidative damageCosmetic preparationsBiocideLipid formationAqueous solution

Compositions containing purified nucleic acid wherein the nucleic acid acts as an antioxidant. Such compositions also include materials subject to oxidative damage such as antioxidants, vitamins, lipids, foods and pharmaceuticals. The invention also includes methods for preparing such compositions. These methods include dissolving the nucleic acid and a hydrophilic material in an aqueous solution, which may later be dried or further processed. Additionally, nucleic acid may be coupled with a molecule having hydrophobic and hydrophilic regions and then solubilized in a hydrophobic material. It may also be shaped into small aggregates and added to a hydrophobic material.

Owner:MATERIALS EVOLUTION & DEVMENT USA

Fumed metal oxide particles and process for producing the same

The invention provides a process for producing fumed metal oxide particles comprising providing a stream of a liquid feedstock comprising a volatizable, non-halogenated metal oxide precursor, providing a stream of a combustion gas having a linear velocity sufficient to atomize and combust or pyrolyze the liquid feedstock, and injecting the stream of the liquid feedstock into the stream of combustion gas to form a reaction mixture such that the liquid feedstock is atomized and subjected to a sufficient temperature and residence time in the combination gas stream for fumed metal oxide particles to form before the combustion gas temperature is reduced below the solidifying temperature of the metal oxide particle. The invention further provides fumed silica particles having a relatively small aggregate size and / or narrow aggregate size distribution.

Owner:CABOT CORP

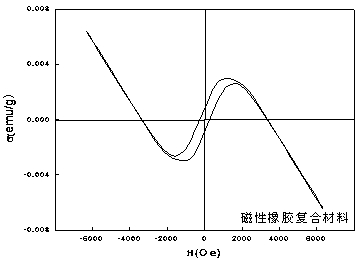

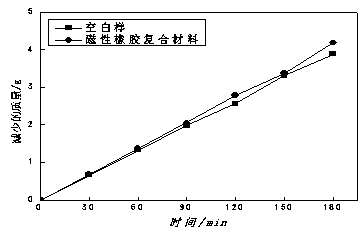

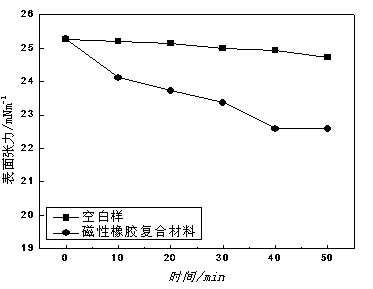

Magnetic fuel-saving rubber composite material

InactiveCN103627051AWith magnetic radiation propertiesImprove fuel saving effectEnvironmental energyRubber material

A magnetic fuel-saving rubber composite material relates to a rubber material and comprises components of butadiene-acrylonitrile rubber, a chloroprene rubber adhesive, zinc white, stearic acid, an antideteriorant 4010NA, an antideteriorant RD, a coumarone, dioctyl phthalate, carbon black, a magnetic material, brimstone, a promoter M, and a promoter PZ. The magnetic fuel saving rubber composite material is prepared through the steps of plastifying, mixing, vulcanizing and the like. The magnetic fuel saving rubber composite material provided by the invention has the benefits of enabling an oil delivery pipeline to have a magnetic radiation performance, enabling fuel oil molecules to become small aggregate structures from a large aggregate structure by using a magnetic line to smash the clustering states of fuel oil molecules, and enabling the fuel oil molecules to be activated so as to change physical chemical property thereof, thereby being helpful to sufficient burning of fuel oil, improving the fuel-saving performance of an engine and also reducing contaminant emission. The magnetic fuel saving rubber composite material is in favour of energy conservation and environment protection. Therefore, the magnetic fuel-saving rubber composite material has a stronger promotion and application value. The magnetic fuel saving rubber composite material belongs to products of green environmental energy saving facilities on the aspects of rubber industry and is used on the aspect of automobile fuel saving.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

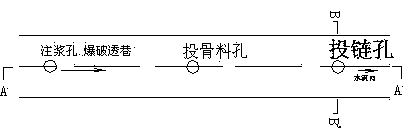

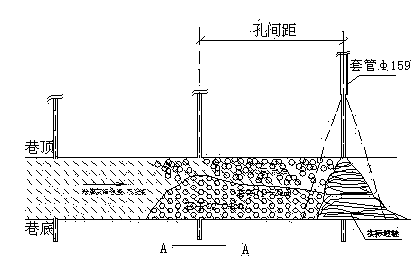

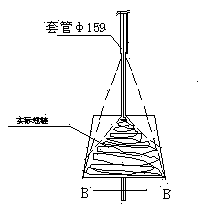

Underground tunnel large dynamic water plugging method

InactiveCN104047620ACompletely closedEasy to pile upUnderground chambersTunnel liningSmall aggregateDrill hole

The invention discloses an underground tunnel large dynamic water plugging method. The method comprises the steps that (1), the position, the direction and the specification shape of a tunnel are determined according to a tunnel design drawing; (2), a plurality of drill holes are drilled in a permeable tunnel on the ground in the direction of the tunnel and are spaced by a certain distance, and an orifice tube is arranged at the upper mouth of each drill hole; (3), aggregates are thrown into the permeable tunnel through any drill hole to determine the water bursting tunnel dynamic conditions, and the number of thrown iron chains is determined; (4), the iron chains are thrown into the permeable tunnel from the drill hole in the most downstream, and the iron chains are stacked to be in a mountain shape in the permeable tunnel; (5), large and small aggregates are thrown into the upstream drill holes sequentially from the drill hole adjoining to the most downstream, and the large and small aggregates and the iron chains form a filter framework until a water plugging curtain is formed; (6), after the water plugging curtain is built, the permeable tunnel is grouted from the drill hole in the most upstream and then burst water can be plugged; (7), the iron chains can be lifted out after grout is solidified. The method has the advantages that water is plugged fast and materials are saved.

Owner:JIZHONG ENERGY FENGFENG GRP

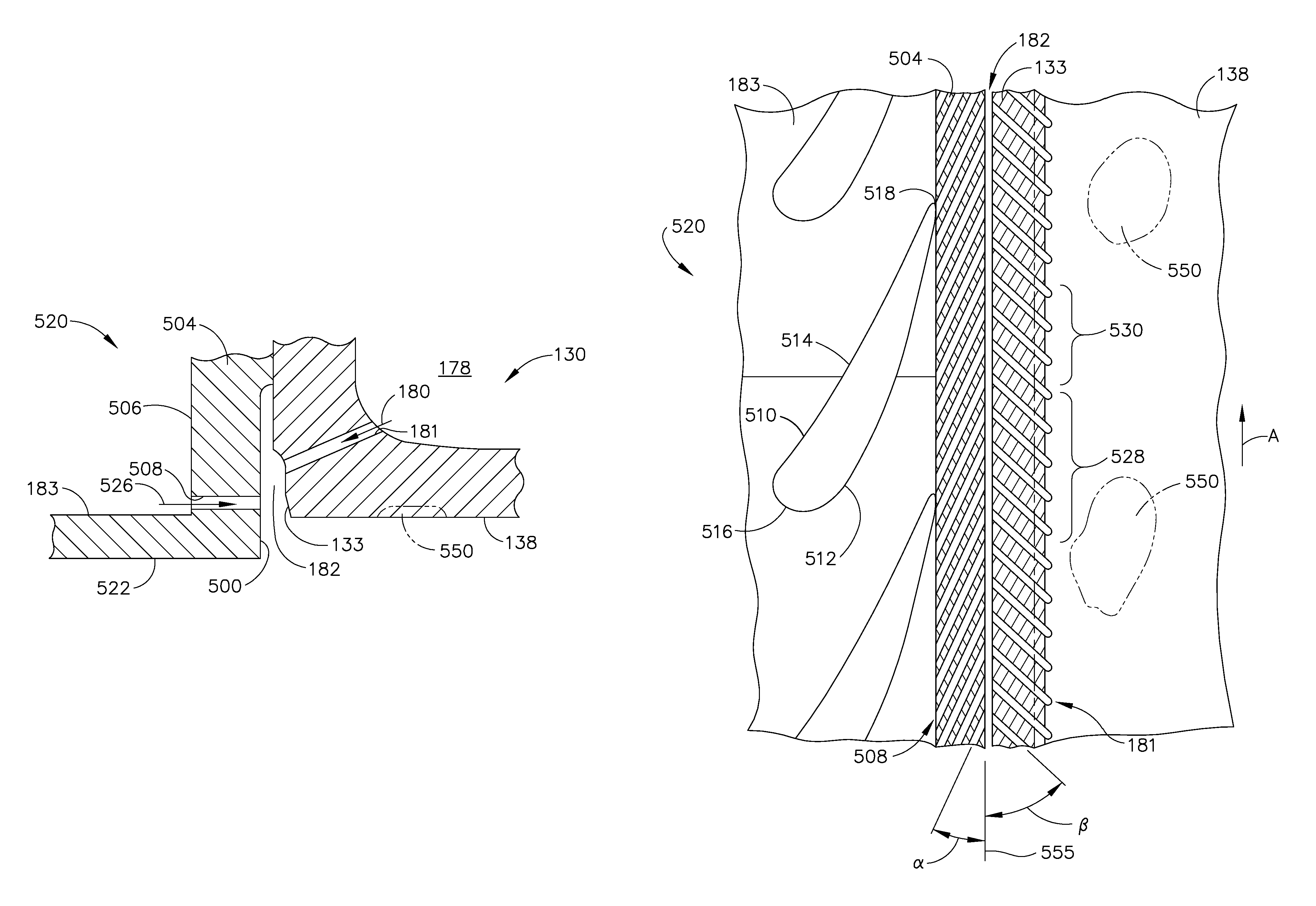

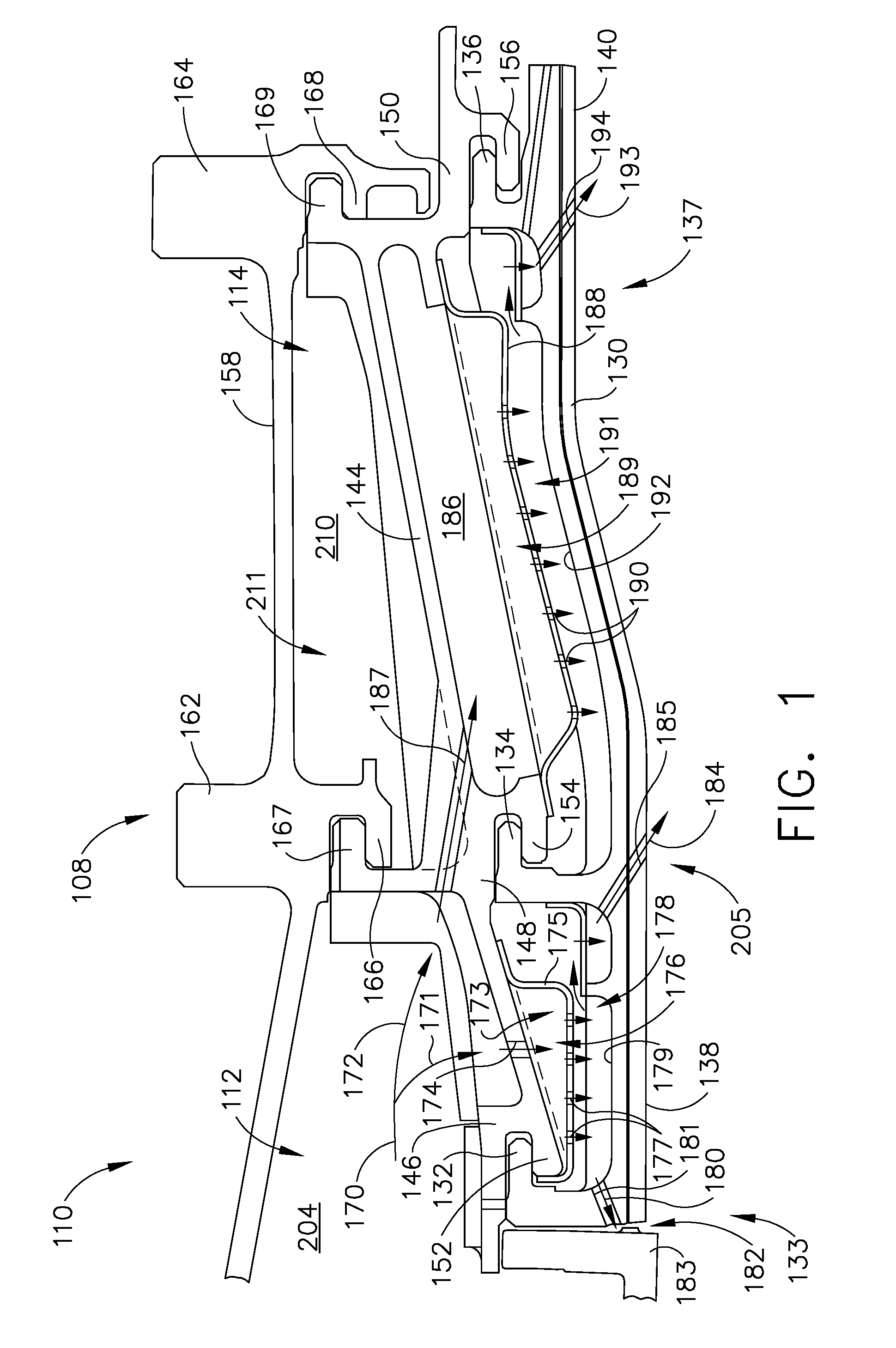

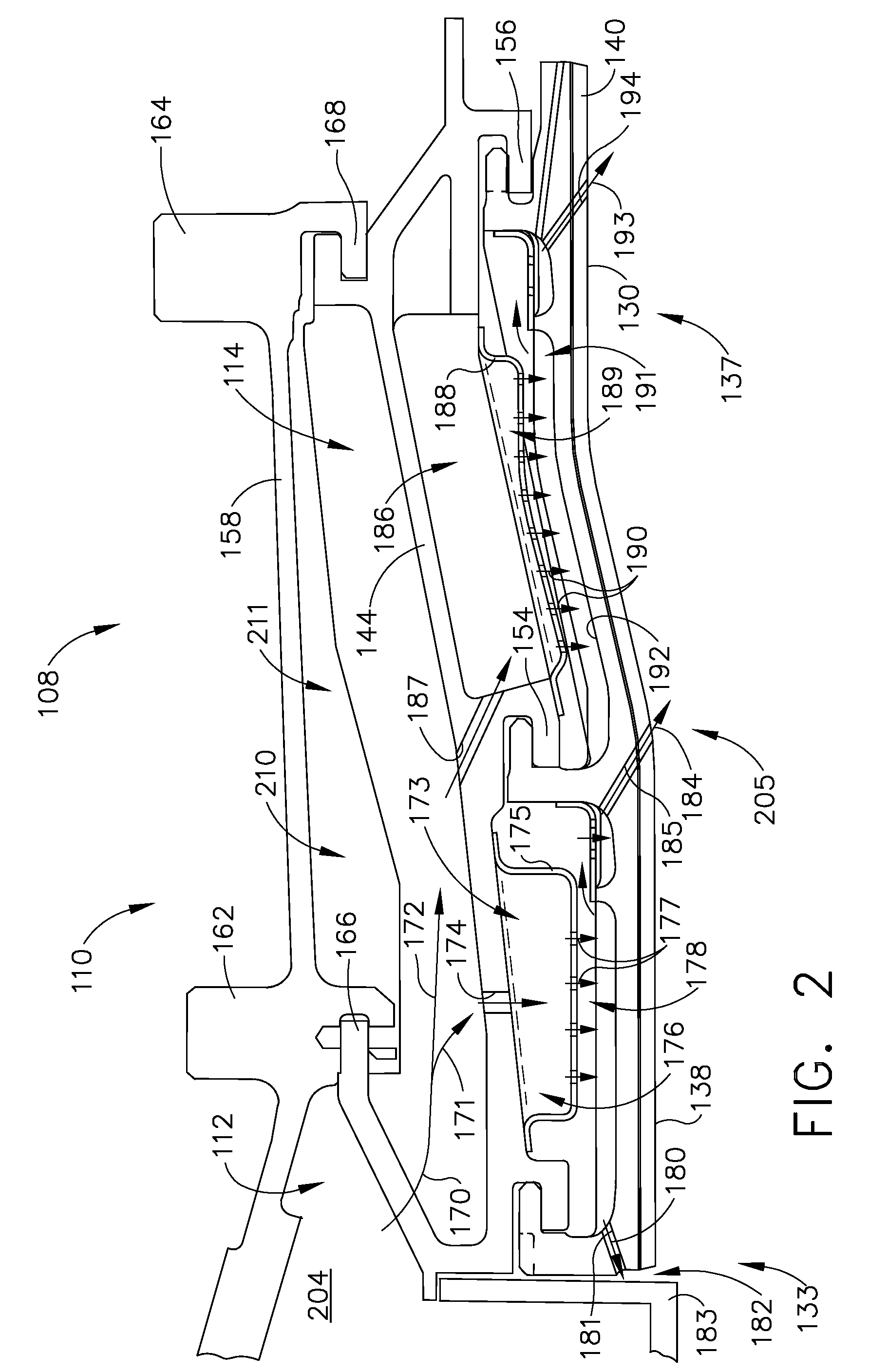

Method and system to facilitate enhanced local cooling of turbine engines

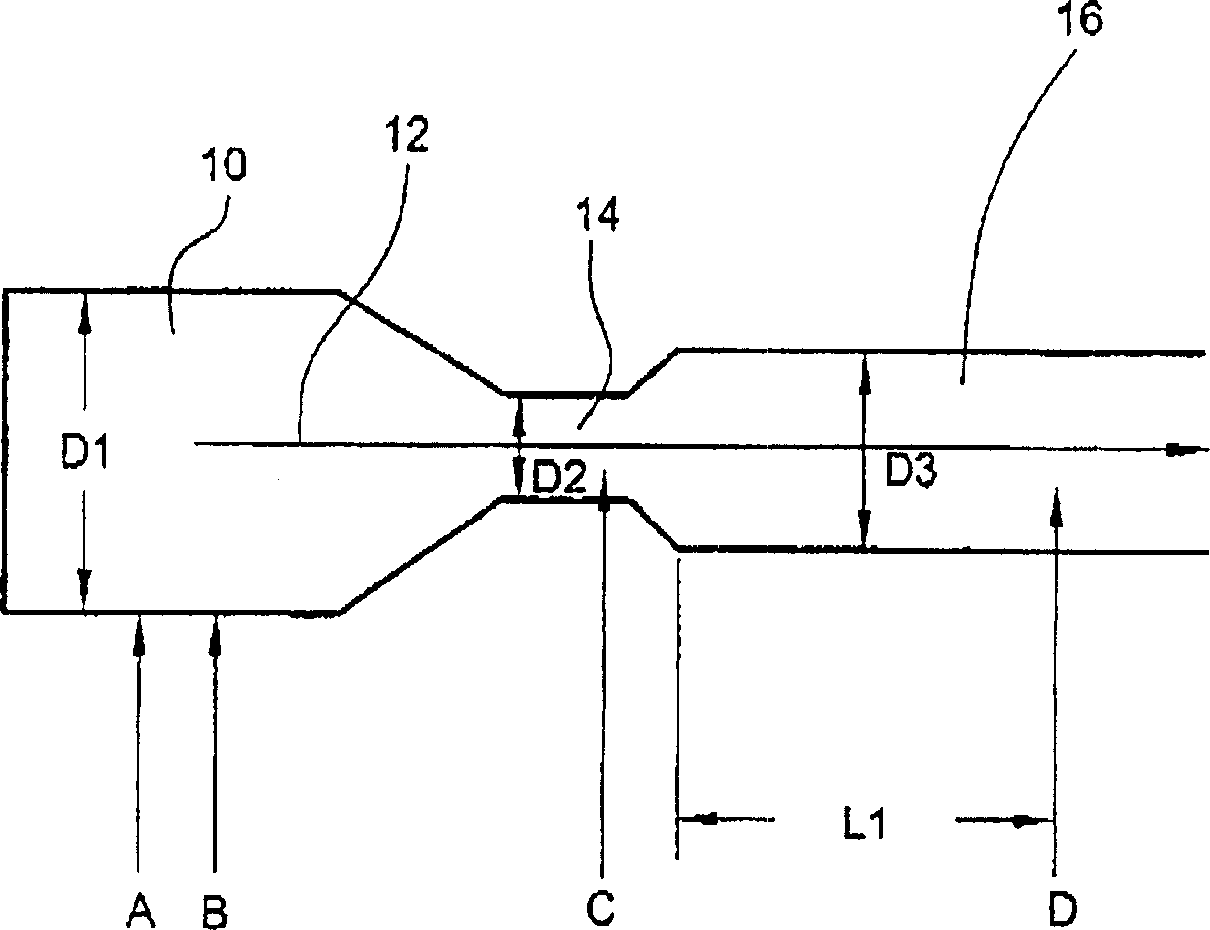

A method of assembling a gas turbine engine is provided. The method includes coupling at least one turbine nozzle segment within the gas turbine engine. The at least one turbine nozzle segment includes at least one airfoil vane extending between an inner band and an outer band that includes an aft flange and a radial inner surface. The method also includes coupling at least one turbine shroud segment downstream from the at least one turbine nozzle segment, wherein the at least one turbine shroud segment includes a leading edge and a radial inner surface, coupling a cooling fluid source in flow communication with the at least one turbine nozzle segment such that cooling fluid channeled to each turbine nozzle outer band aft flange is directed at an oblique discharge angle towards the leading edge of the at least one turbine shroud segment, and channeling the cooling fluid through at least a first group of cooling openings having a larger aggregate cross-sectional area and a second group of cooling openings having a smaller aggregate cross-sectional area to facilitate preferential cooling of the turbine shroud.

Owner:GENERAL ELECTRIC CO

Fumed metal oxide particles and process for producing the same

The invention provides a process for producing fumed metal oxide particles comprising providing a stream of a liquid feedstock comprising a volatizable, non-halogenated metal oxide precursor, providing a stream of a combustion gas having a linear velocity sufficient to atomize and combust or pyrolyze the liquid feedstock, and injecting the stream of the liquid feedstock into the stream of combustion gas to form a reaction mixture such that the liquid feedstock is atomized and subjected to a sufficient temperature and residence time in the combination gas stream for fumed metal oxide particles to form before the combustion gas temperature is reduced below the solidifying temperature of the metal oxide particle. The invention further provides fumed silica particles having a relatively small aggregate size and / or narrow aggregate size distribution.

Owner:CABOT CORP

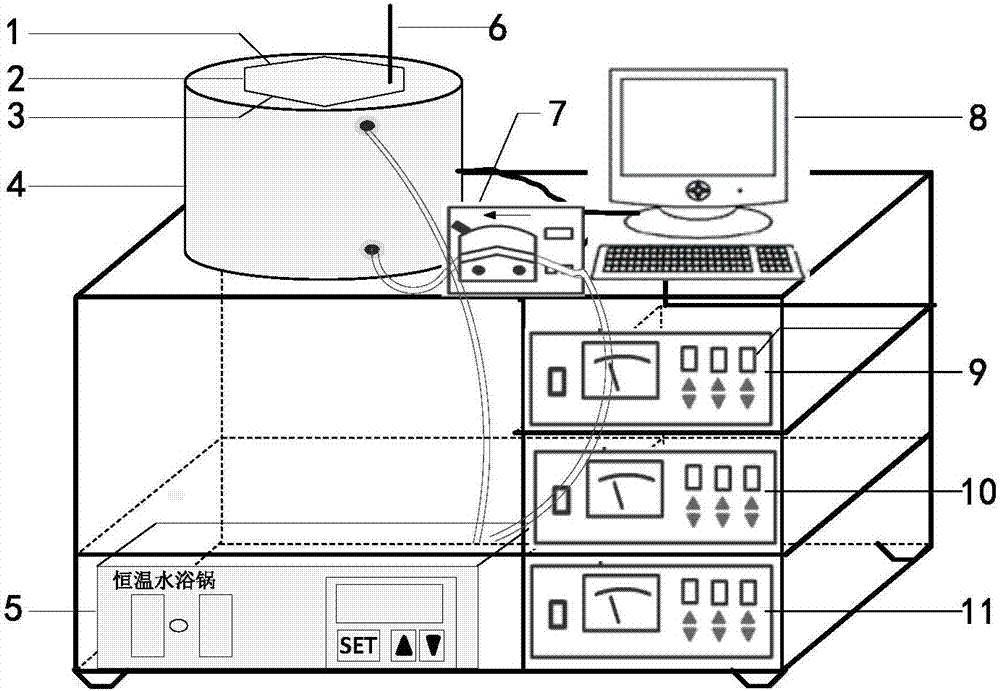

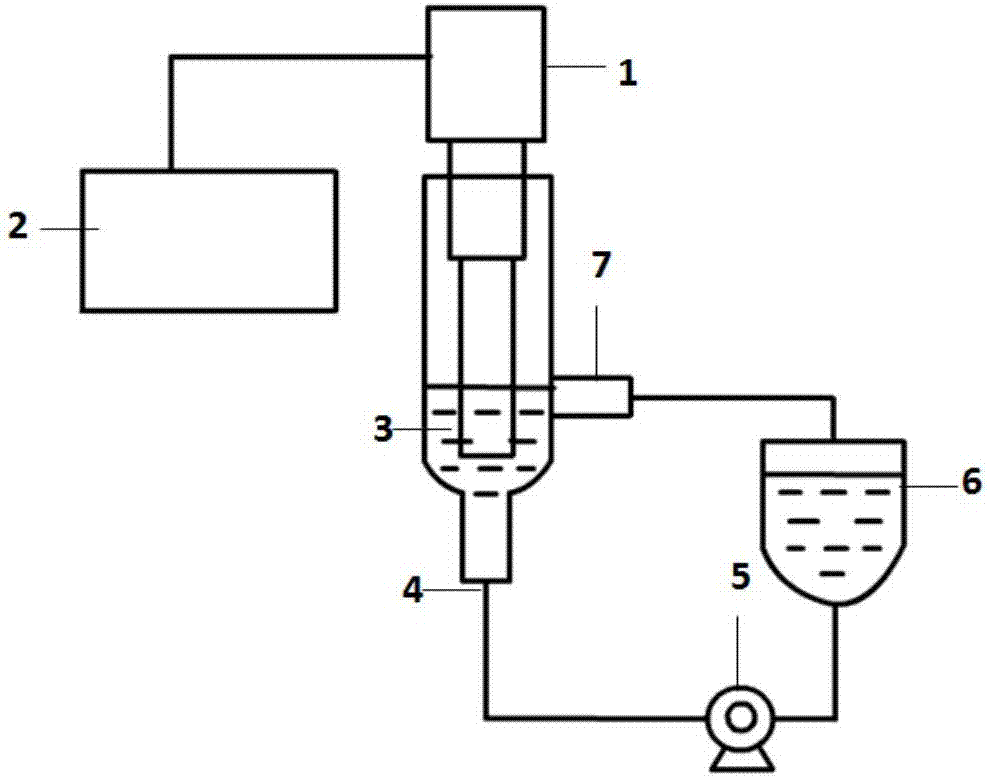

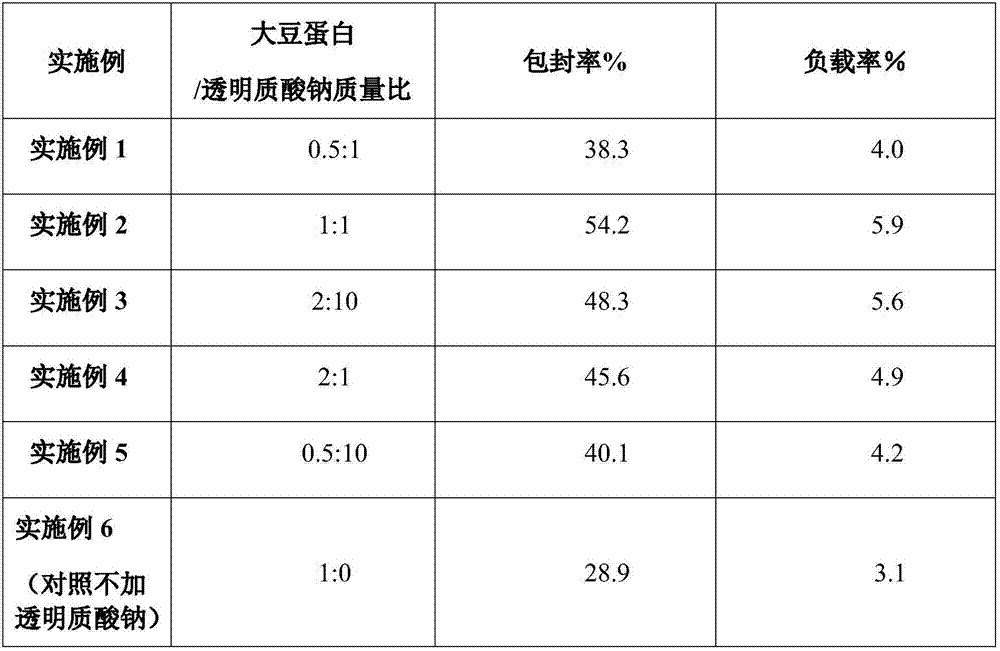

Ultrasonic preparation method of soybean protein-polysaccharides complex as well as application of functional food

The invention discloses an ultrasonic preparation method of a soybean protein-polysaccharides complex as well as application of functional food, and relates to the technical field of preparation of functional food complexes. The soybean protein-polysaccharides complex is prepared from the following raw materials in parts by weight: 0.5 to 2 parts of soybean protein and 1 to 10 parts of sodium hyaluronate. The sodium hyaluronate is added into the soybean protein, and a high-level structure of the soybean protein is changed, so that the structure is opened, and an active group is exposed; meanwhile, protein and polysaccharides are formed into small aggregates to promote all the aggregates to be formed into gel through a hydrophobic interaction effect and provide a basis for embedding bioactive ingredients. According to the ultrasonic preparation method of the soybean protein-polysaccharides complex disclosed by the invention, in a process of embedding xanthophylls by utilizing the soybean protein-polysaccharides complex, a counterflow ultrasonic treatment technology or a multi-mode ultrasonic technology is adopted, cross-linking of the proteins and the polysaccharides into the aggregates is promoted through ultrasonic physical force, so that all aggregates are promoted to form the complex through the hydrophobic interaction effect, and a basis is provided for embedding the biological active ingredients.

Owner:JIANGSU UNIV

Method for recycling damaged cement concrete pavement to form road base

The invention discloses a method for recycling a damaged cement concrete pavement to form a road base. The method comprises the following steps: crushing the damaged cement concrete pavement to obtain recyclable aggregates; (2) sieving the recyclable aggregates to obtain waste concrete powder and recyclable big and small aggregates; and then preparing a gel material through the waste concrete powder; and (3) mixing the obtained gel material and the recyclable big and small aggregates to prepare the recyclable concrete; and preparing the base of the damaged concrete pavement with the recyclable concrete according to related standards. The method has the beneficial effects that the problem of recycling waste concrete produced by the damaged cement concrete pavement can be solved; natural stone and cement are decreased to use; and the environmental pollution is reduced.

Owner:SOUTHEAST UNIV

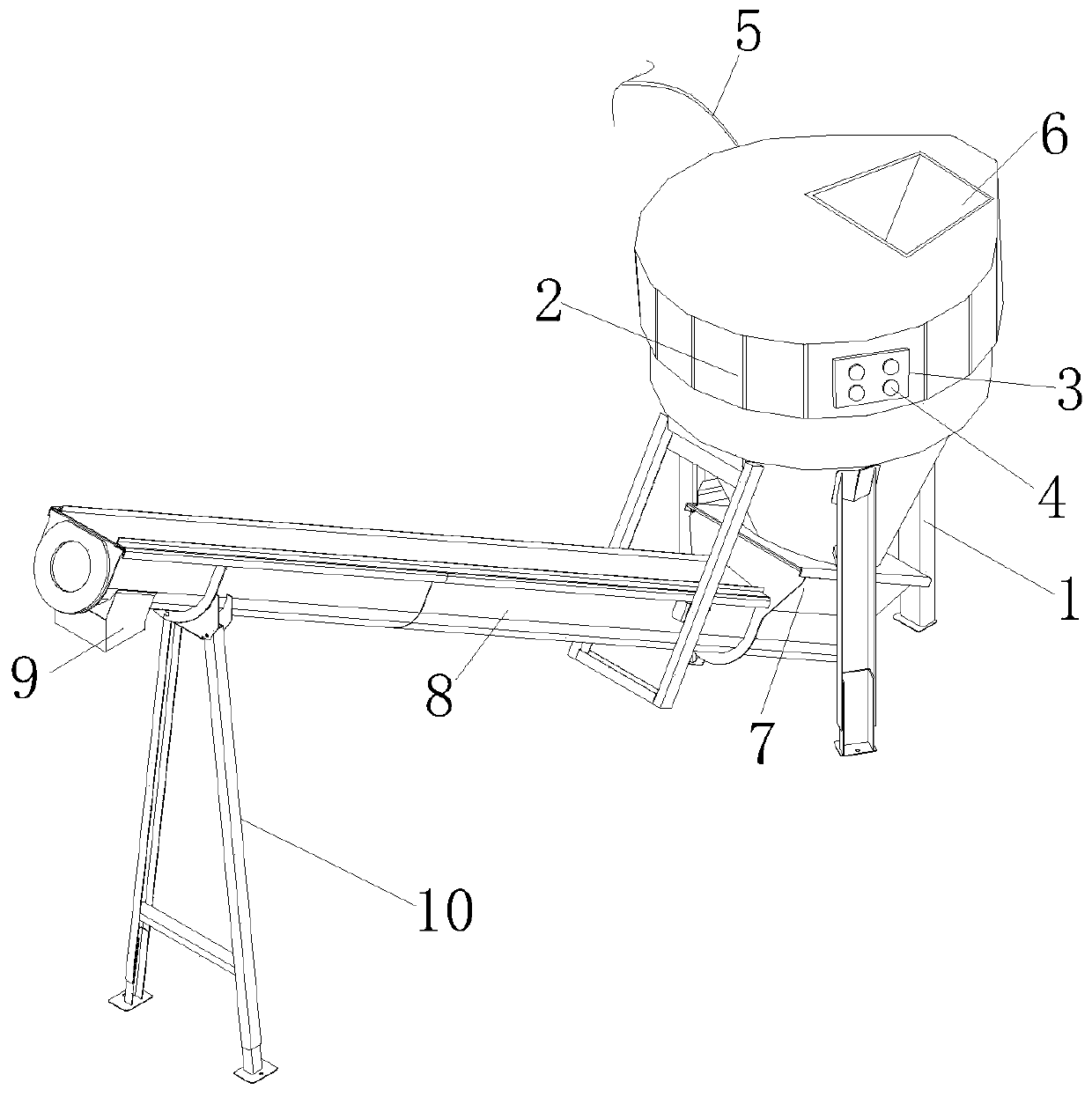

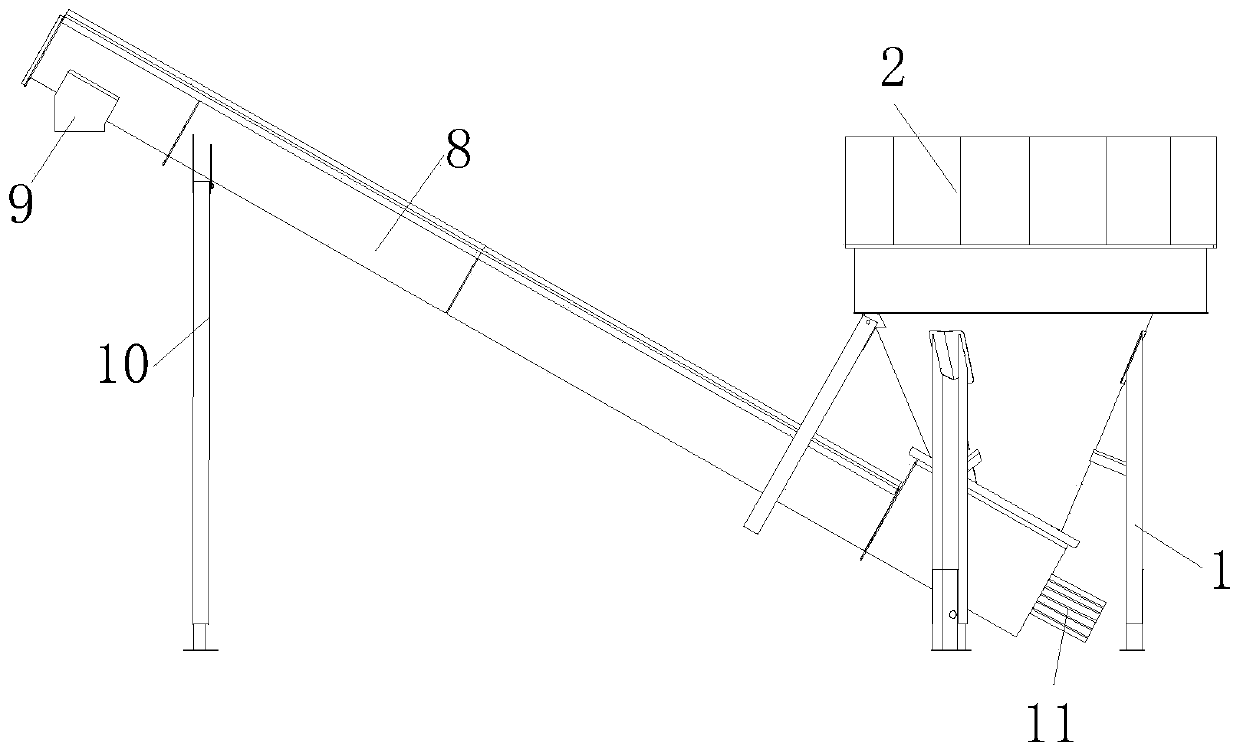

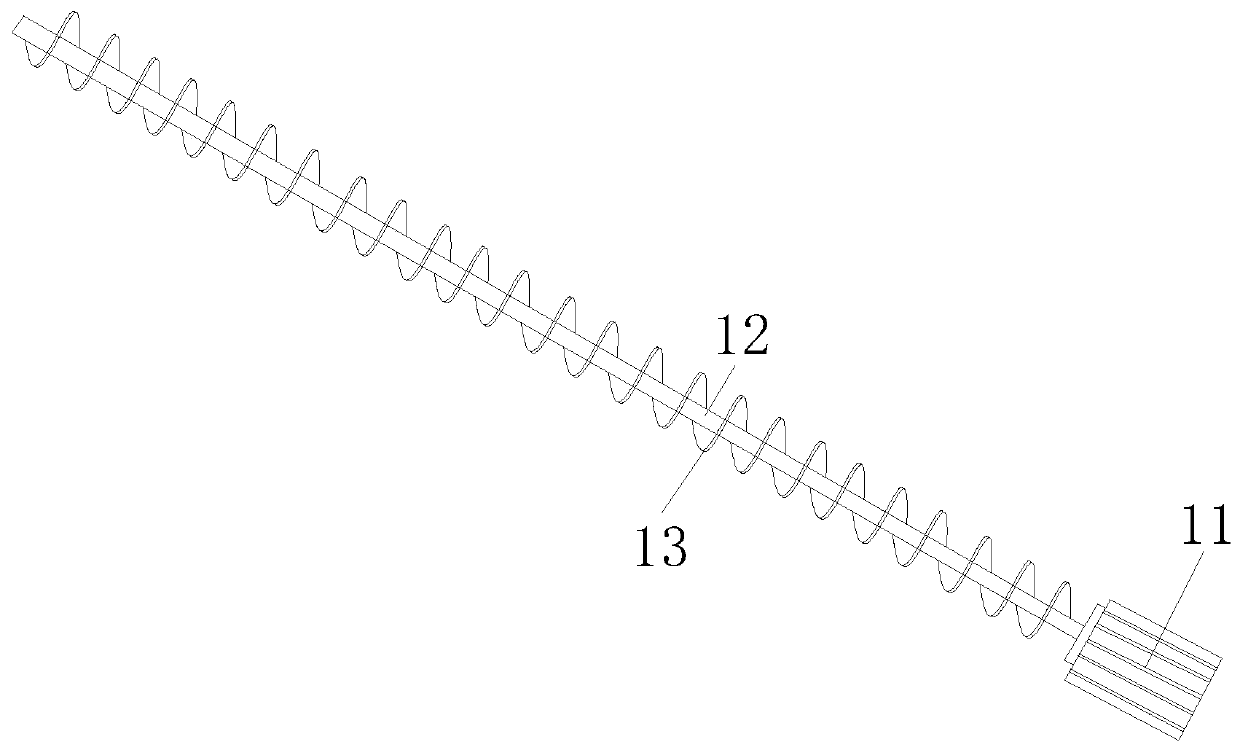

Aggregate crushing and conveying device for construction

The invention discloses an aggregate crushing and conveying device for construction. The aggregate crushing and conveying device comprises a multi-stage crushing and screening device. According to theaggregate crushing and conveying device, a screening mechanism is arranged inside a crushing frame, during swinging of a second crank, a second movable rod is driven to swing, the second movable roddrives a swing plate to swing accordingly, and a screening screen screens aggregates, so that the small aggregates are discharged through the bottom of the screening screen, and the large aggregates are discharged to the inner side of a secondary crushing mechanism for secondary crushing to achieve the advantage of rapid screening of the aggregates; and the secondary crushing mechanism is arrangedin the crushing frame, a rotary disc rotates and drives a belt pulley to rotate through a driving belt, so that the belt pulley drives a first sliding block to reciprocate up and down, and the firstsliding block drives a second sliding block to move left and right through a second connecting handle, so that the second sliding block drives a broken toothed plate to reciprocate back and forth on the inner side of a diversion baffle through a receiving rod to conduct secondary crushing on the discharged aggregates, and the advantage of secondary crushing of the aggregates is achieved.

Owner:姚伟鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com