Patents

Literature

138results about How to "Easy to pile up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorescent probe and preparation method thereof

ActiveCN106833623AStrong forceEasy to pile upOrganic chemistryFluorescence/phosphorescenceSolubilityDouble bond

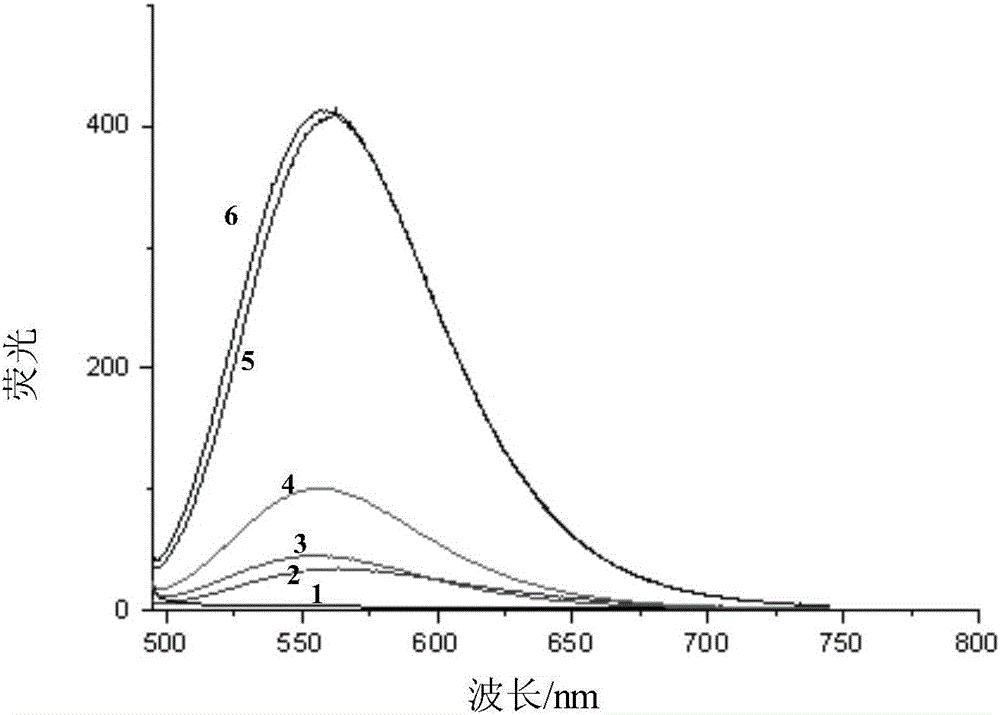

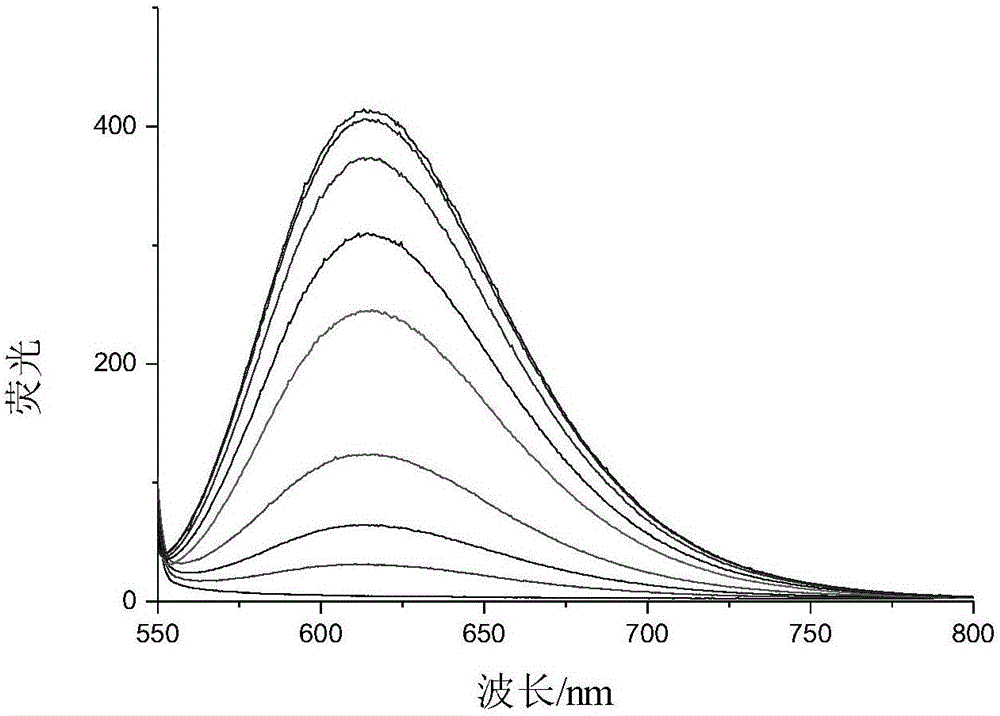

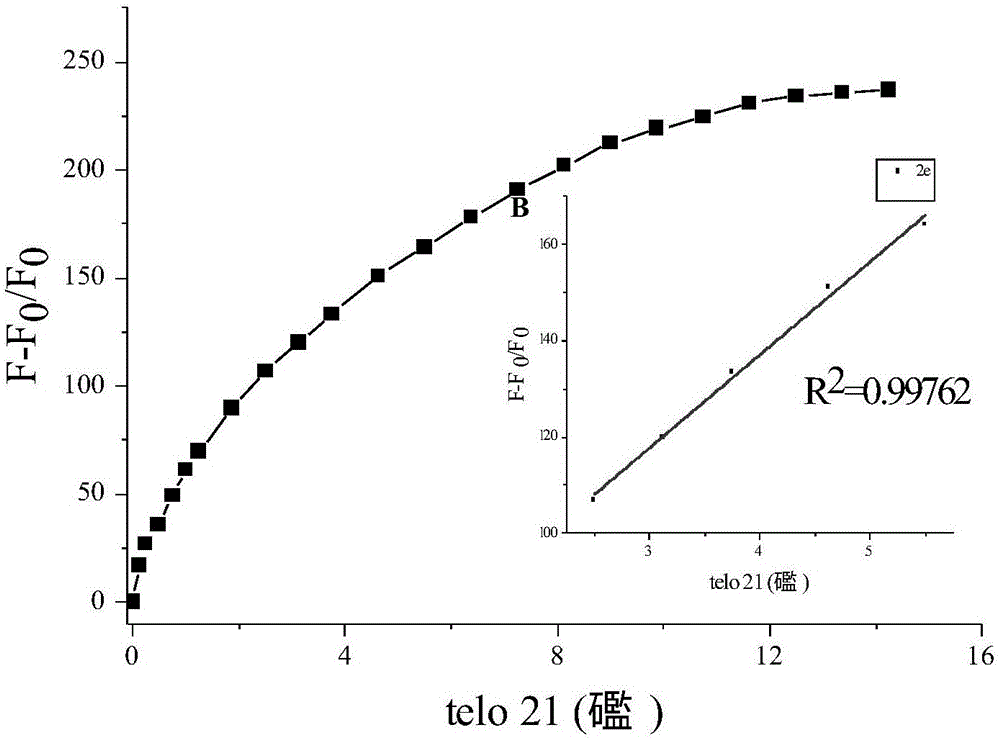

The invention provides a fluorescent probe represented by the formula (I), wherein R1 and R2 are independently selected from H or an aromatic vinyl group, and at least one of R1 and R2 is the aromatic vinyl group; R3 is selected from H, F, Cl, Br, OH, OCH3, N(CH3)2 or C1-C6 alkyl; and R4 is selected from C1-C6 alkyl. Compared with the prior art, because the fluorescent probe provided by the invention has a relatively large electronic conjugated system and plane, the intensity of the intramolecular charge transfer effect can affect the molecular fluorescence emission intensity; when the fluorescent probe and the G-quadruplex generate a specific action, the flexibility of intramolecular rotatable double bonds is restricted, the intramolecular charge transfer effect is enhanced, and the fluorescence is also enhanced significantly; moreover, the fluorescent probe provided by the invention has the advantages of low biotoxicity, phototoxicity and photobleaching property, good light stability, good water solubility and good cell membrane permeability.

Owner:GUANGDONG UNIV OF TECH

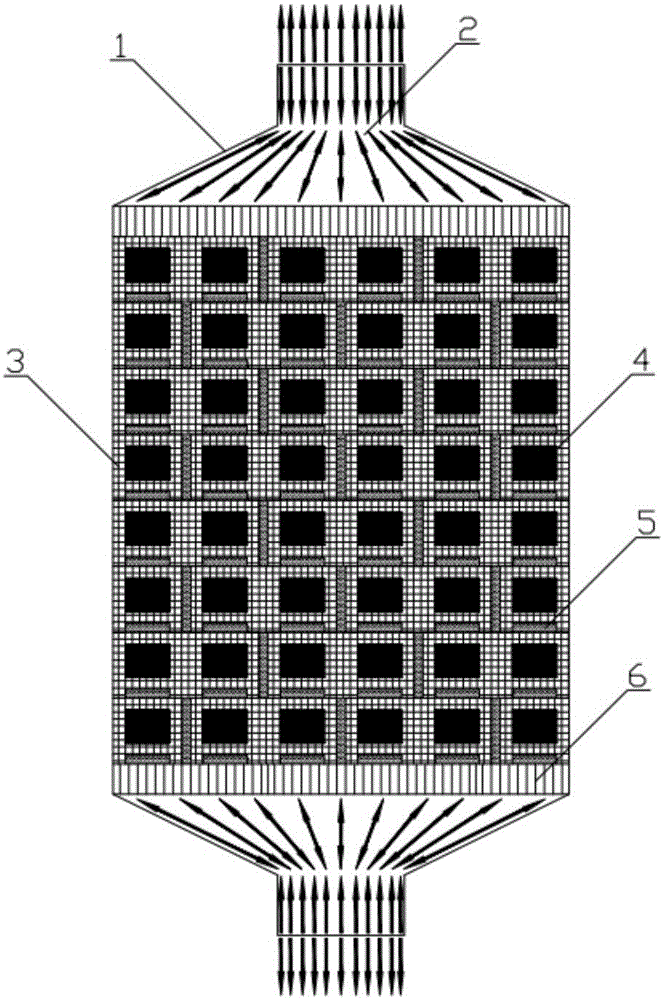

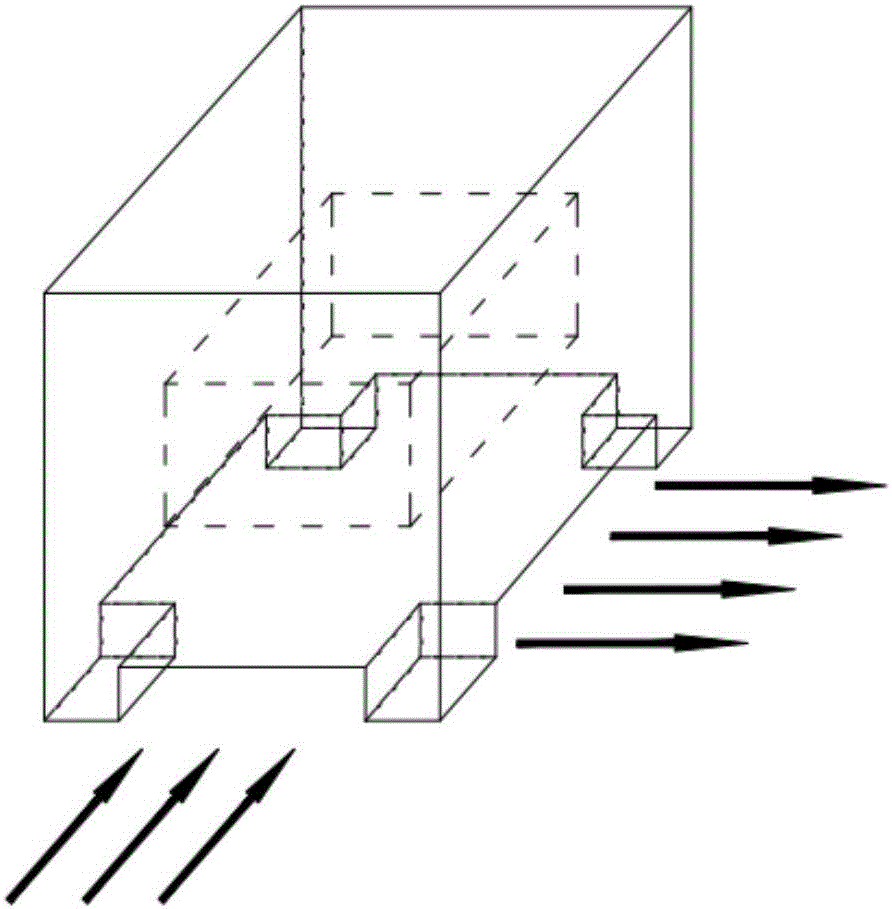

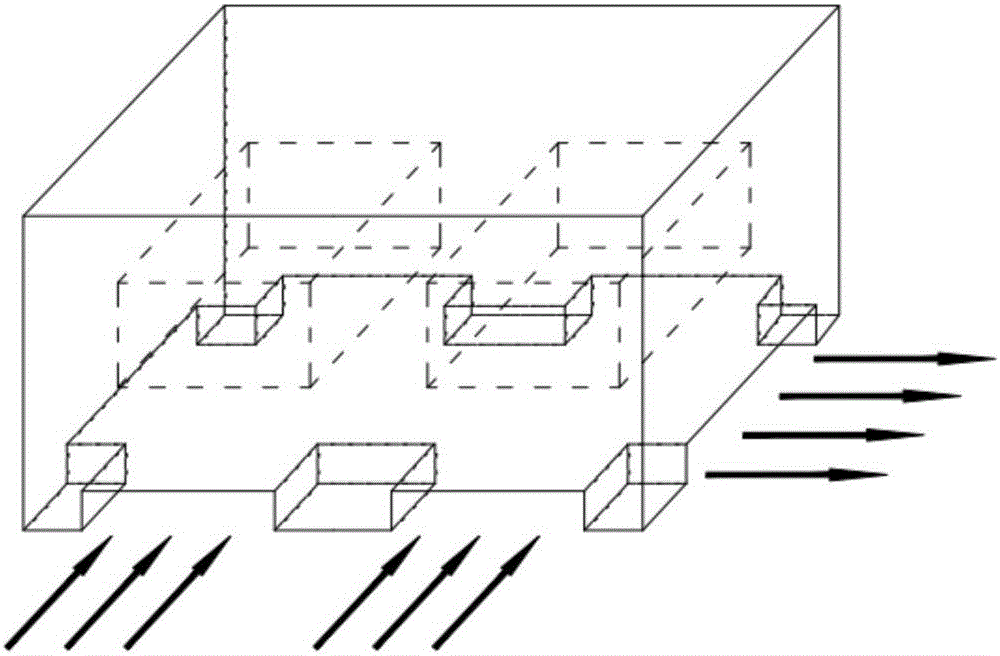

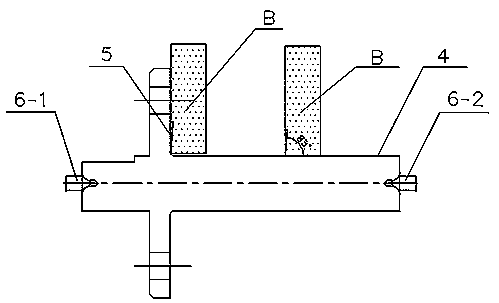

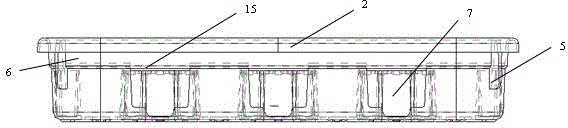

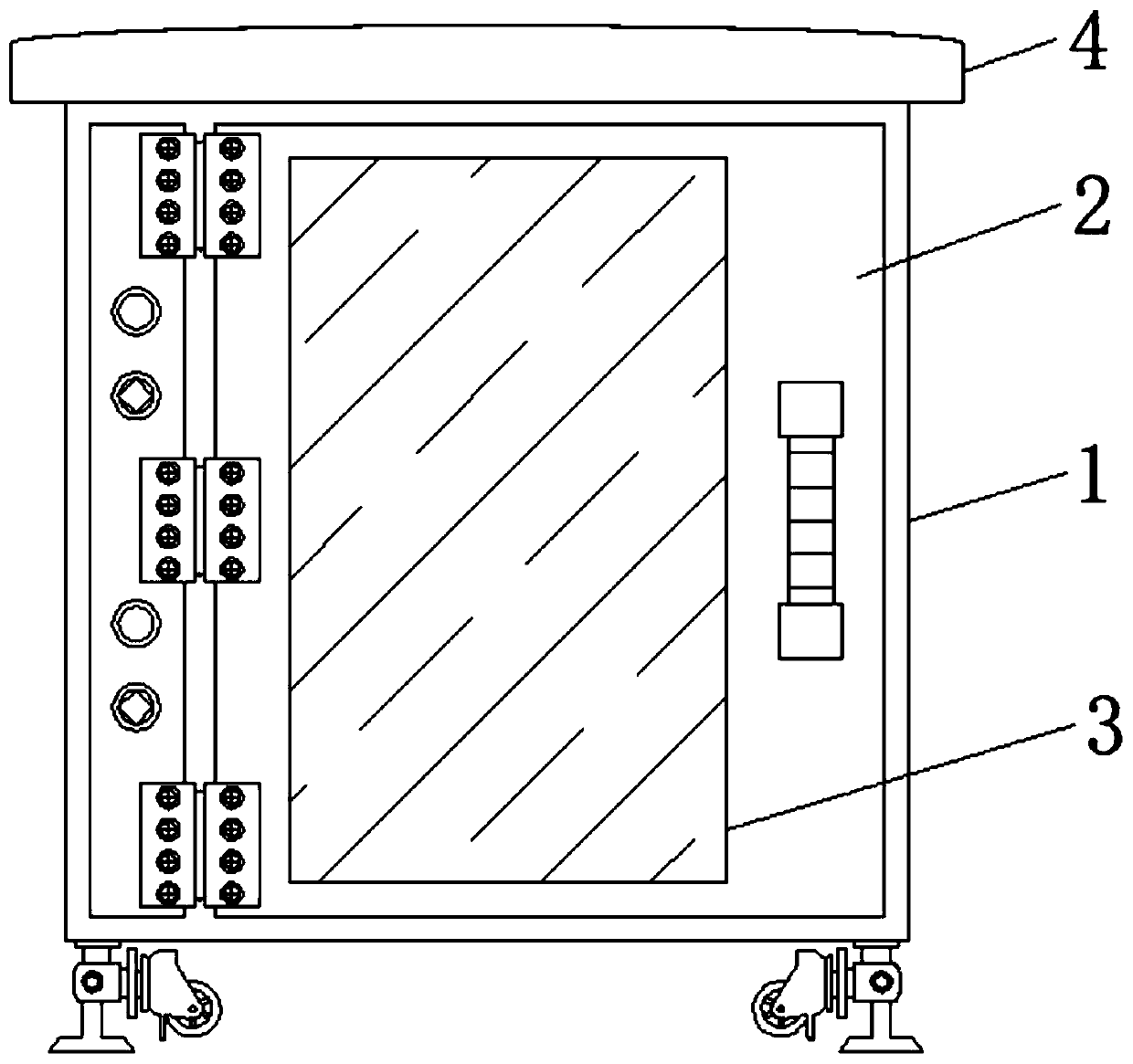

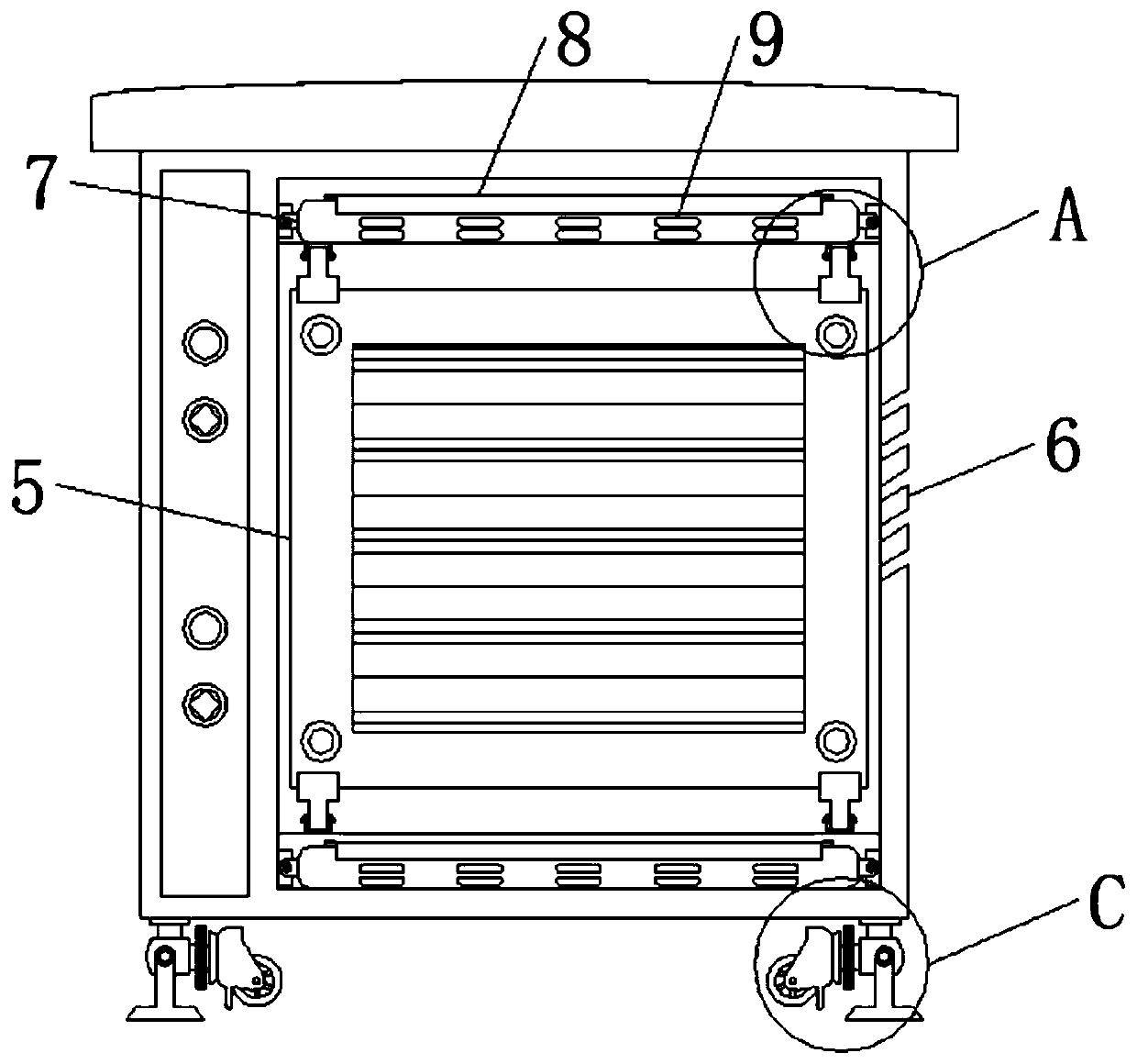

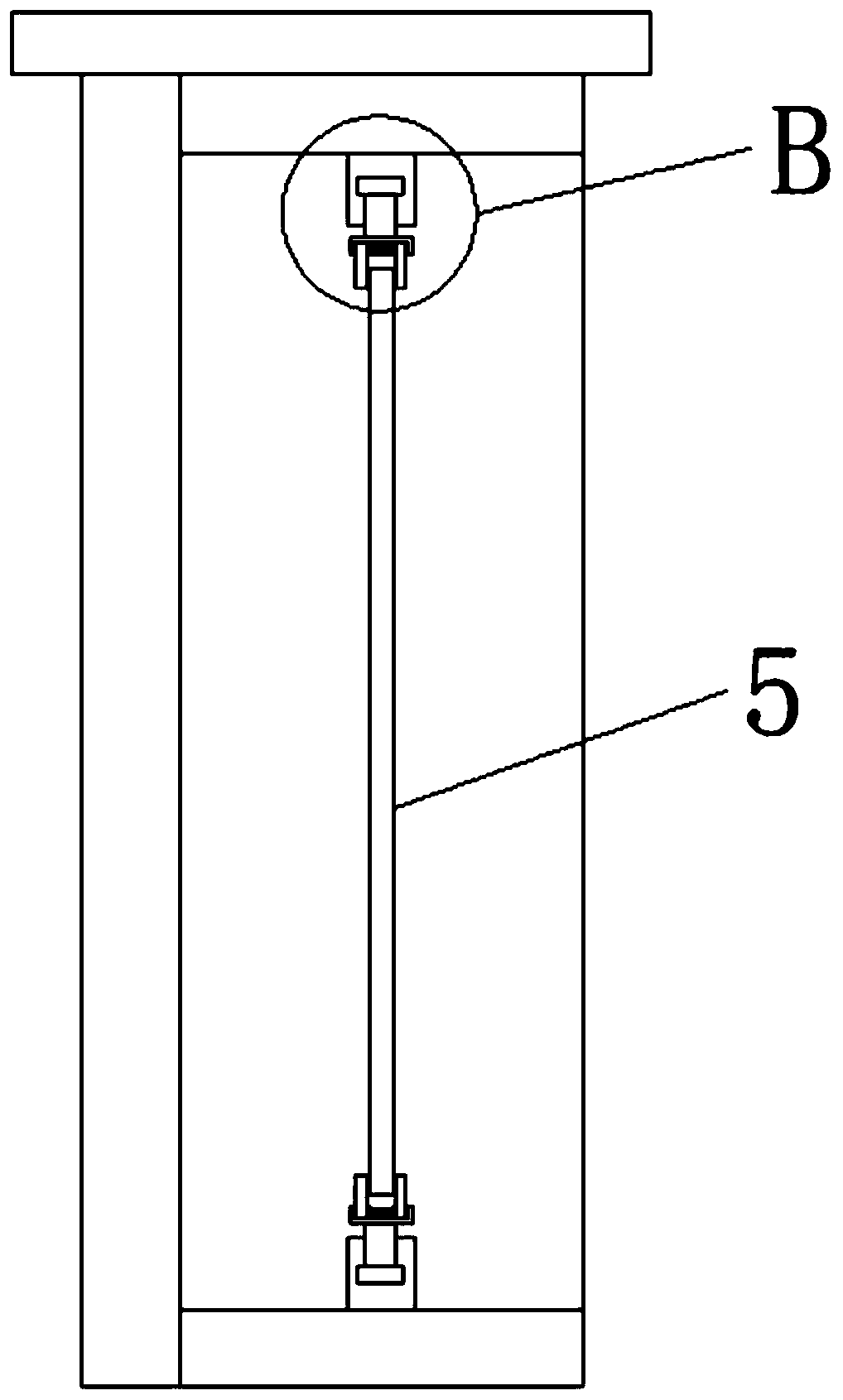

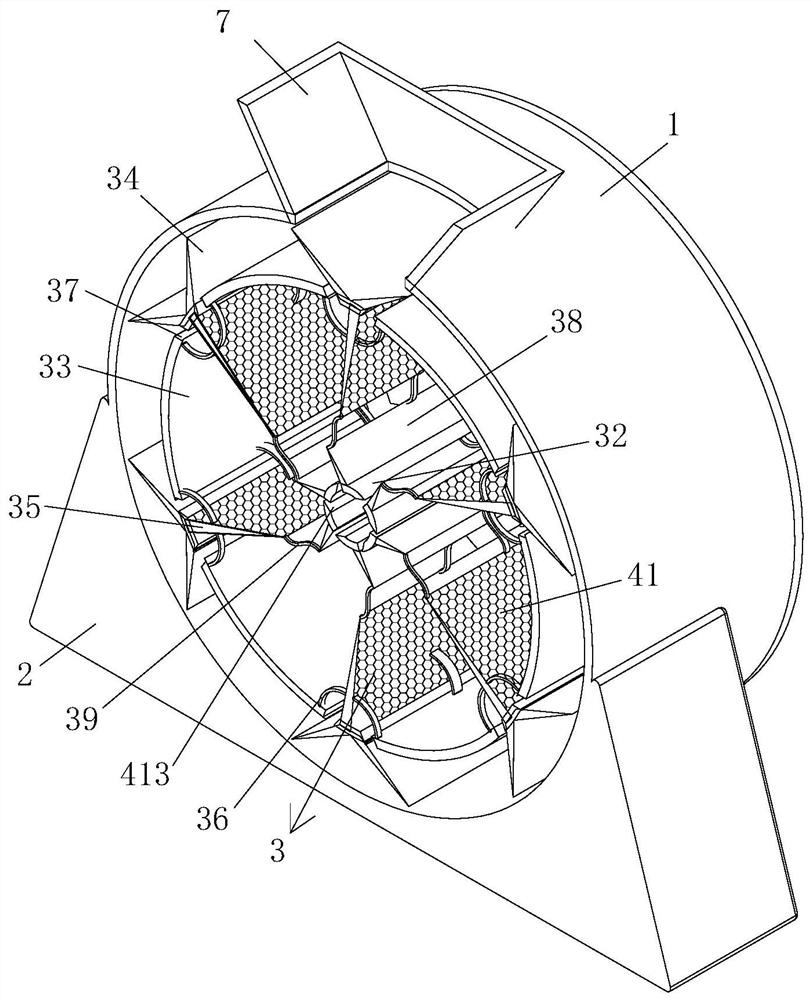

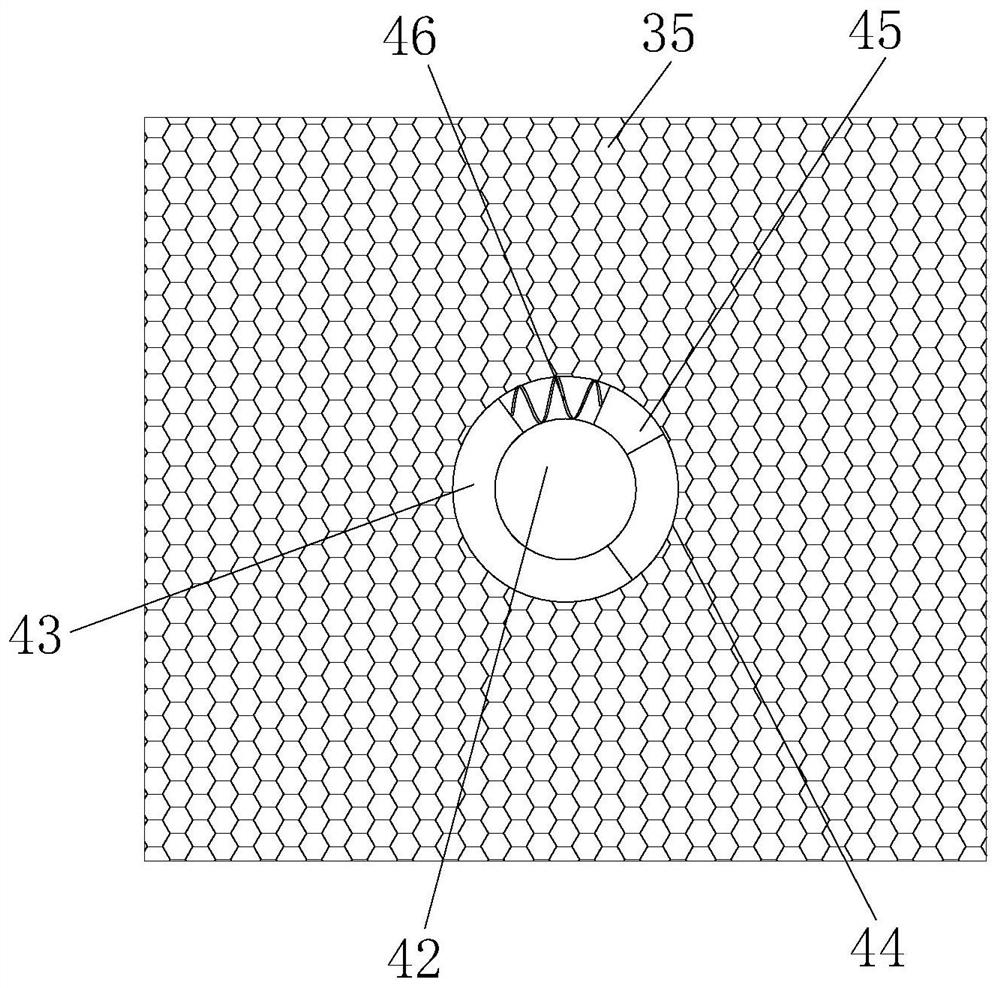

Modular cascaded heat storage device based on phase change heat storage unit and method thereof

ActiveCN106839850AImprove heat storage capacityEasy to pile upHeat storage plantsHot zoneProcess engineering

The invention discloses a modular cascaded heat storage device based on a phase change heat storage unit and a method thereof. The device comprises a device body, a phase change heat storage unit stacking system and input and output systems. The phase change heat storage unit stacking system is arranged in the device body, and the input and output systems are arranged at the upper and lower ends of the device body. The phase change heat storage unit stacking system comprises a plurality of phase change heat storage units, a supporting rack is arranged in the bottom of each of the phase change heat storage units to form a horizontal flowing channel of a heat exchange work medium, the phase change heat storage units are distributed in a cascaded manner in the device body according to the smelting points of the inner phase change materials, the internal portion of the unit is made from a phase change material, and a solid heat storage material wraps outside the unit. The heat storage flow of the system is as follows: a high-temperature fluid flows from a high temperature phase change heat storage area to a low temperature phase change heat storage area successively and finally flows out from the bottom of the device; on the contrary, a heat releasing flow is performed. The modular cascaded heat storage device disclosed by the invention is strong in heat storage capacity (heat can be stored and utilized in a cascaded manner), easy to stack in unit and amplify systematically and wide in application range.

Owner:SUN YAT SEN UNIV

Silicon oxide bonded silicon carbide material

InactiveCN105418086AReduce adverse effectsGood high temperature performanceCarbide siliconSilicon oxide

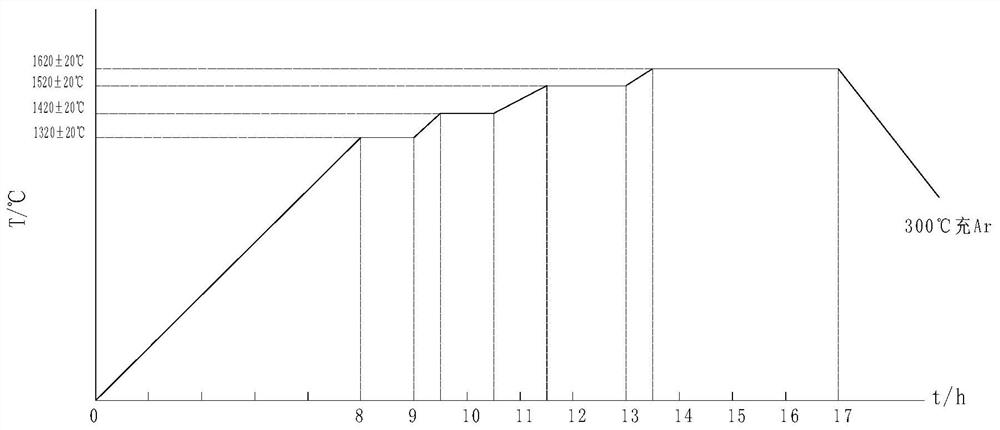

The invention belongs to the technical field of inorganic nonmetallic materials and discloses a silicon oxide bonded silicon carbide material. The silicon oxide bonded silicon carbide material is prepared from, by mass, 60-75% of silicon carbide particles, 18-30% of silicon carbide fine powder, 3-8% of silicon carbide micro powder, 1-3% of silica powder, and 0.3-1.5% of nano-silica, and the total mass percentage of the raw materials is 100%. Liquid phenolic resin serving as a binding agent is also added to the silicon oxide bonded silicon carbide material. The raw materials for preparing the silicon oxide bonded silicon carbide material are evenly mixed with liquid phenolic resin to generate pug, the pug is molded, dried and then sintered in a high-temperature kiln with the highest sintering temperature being 1350-1500 DEG C, then the product is cooled together with the kiln to be indoor temperature so that the silicon oxide bonded silicon carbide material can be obtained. The silicon oxide bonded silicon carbide material has the advantages of being high in purity, excellent in high-temperature performance and high in comprehensive performance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

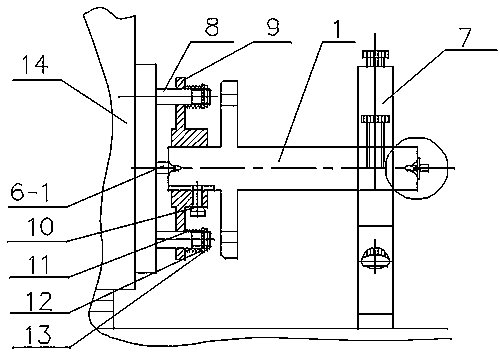

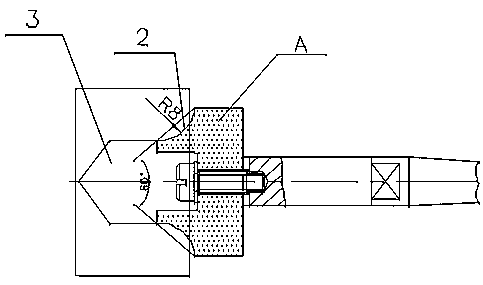

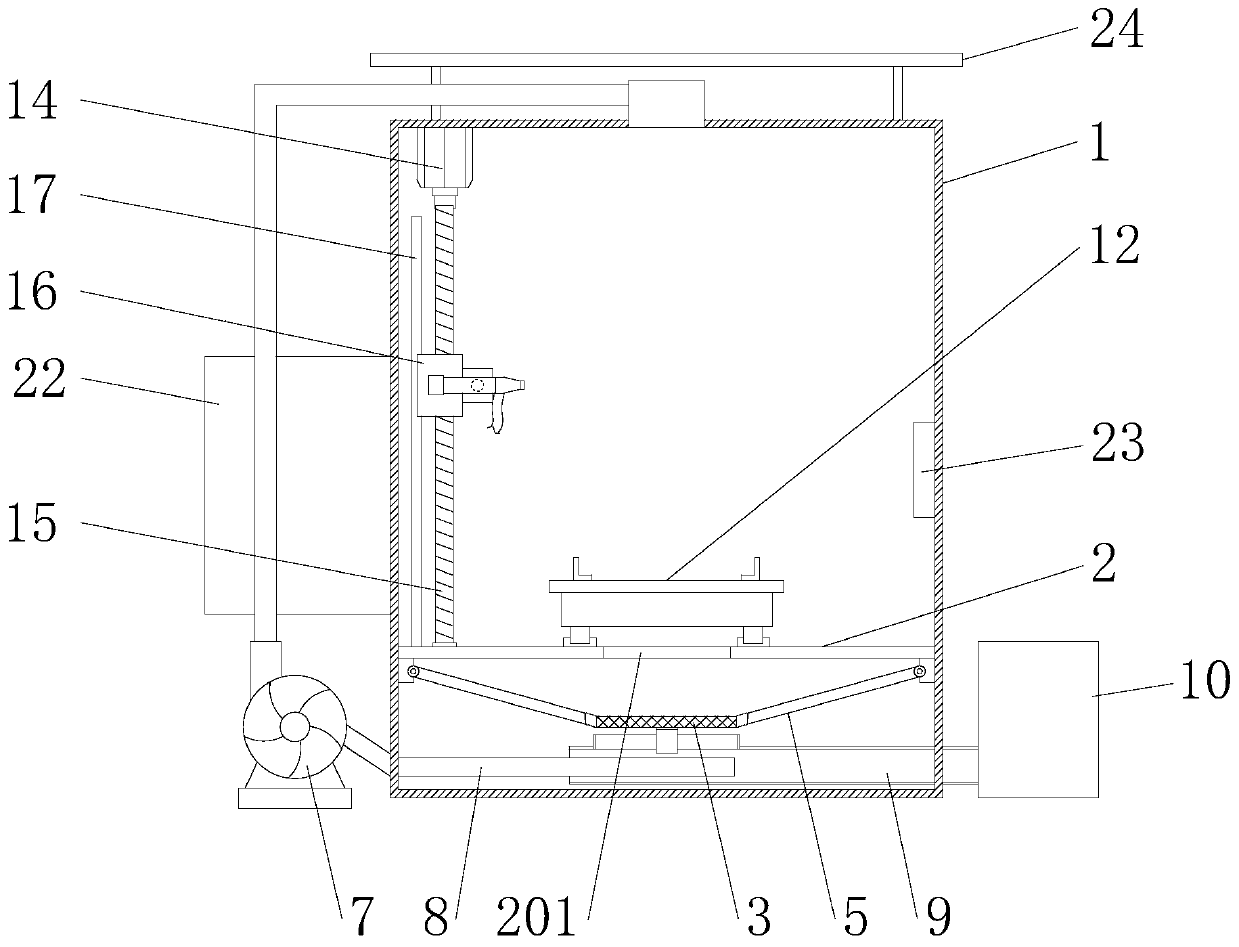

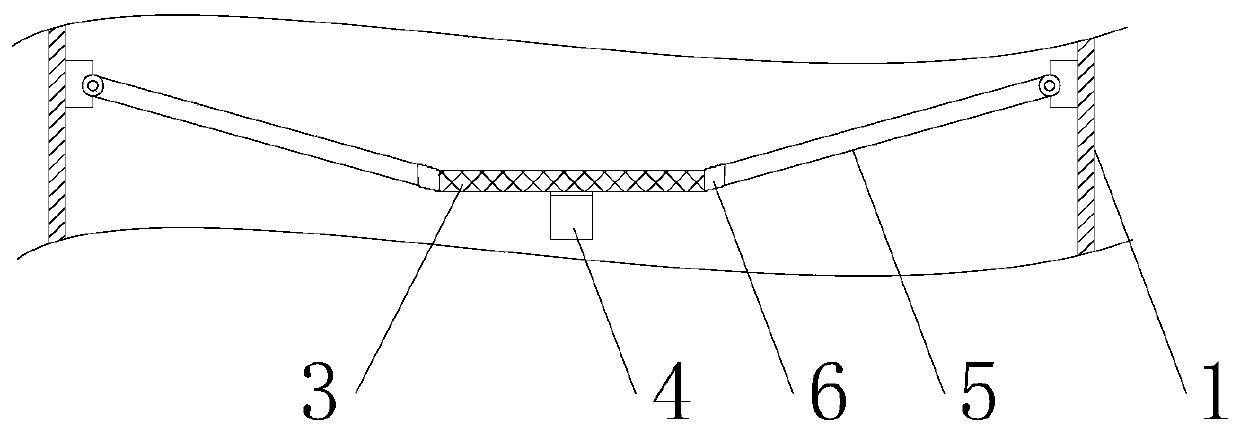

Grinding method for thin wall guide tube with tungsten carbide coating

InactiveCN109277885AEliminate the effects of processingCorrection of concentricity errorGrinding work supportsProcess systemsThin walled

The invention discloses a grinding method for a thin wall guide tube with a tungsten carbide coating and particularly relates to the grinding method for the thin wall guide tube with the tungsten carbide coating and a fixture. According to the grinding method for the fixture, the fixture is ground by operating a grinding machine, and the positioning accuracy of workpieces is improved; according tothe grinding method for the thin wall guide tube with the tungsten carbide coating, grinding machining process parameters are confirmed on base of the grinding technical requirements for the outer outline (an outer circle, a transition circle angle, an end face and an end face chamfer) of the thin wall guide tube with the tungsten carbide coating, and grinding process control is performed on theouter outline of the thin wall guide tube with the tungsten carbide coating; by means of the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture, the fact that the grinding machine, the fixture, a grinding wheel and the workpieces form a complete process system in grinding is realized, in this way, occurrence of the coating grinding quality problem of aluminum alloy sleeve type thin-wall parts of some type is completely eradicated, and the long-term practice test is performed, the qualified rate of the parts is increased, and the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture has reference significance in guiding production.

Owner:HARBIN UNIV OF SCI & TECH

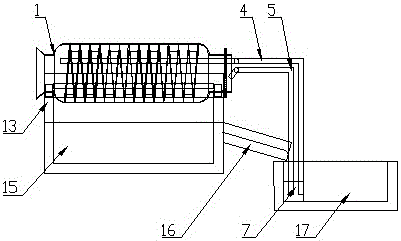

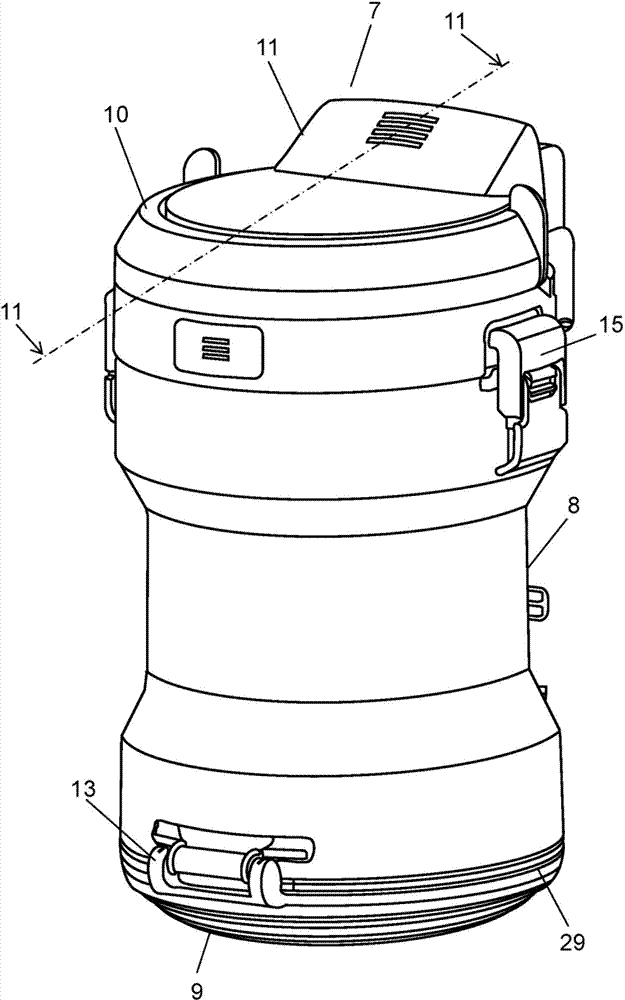

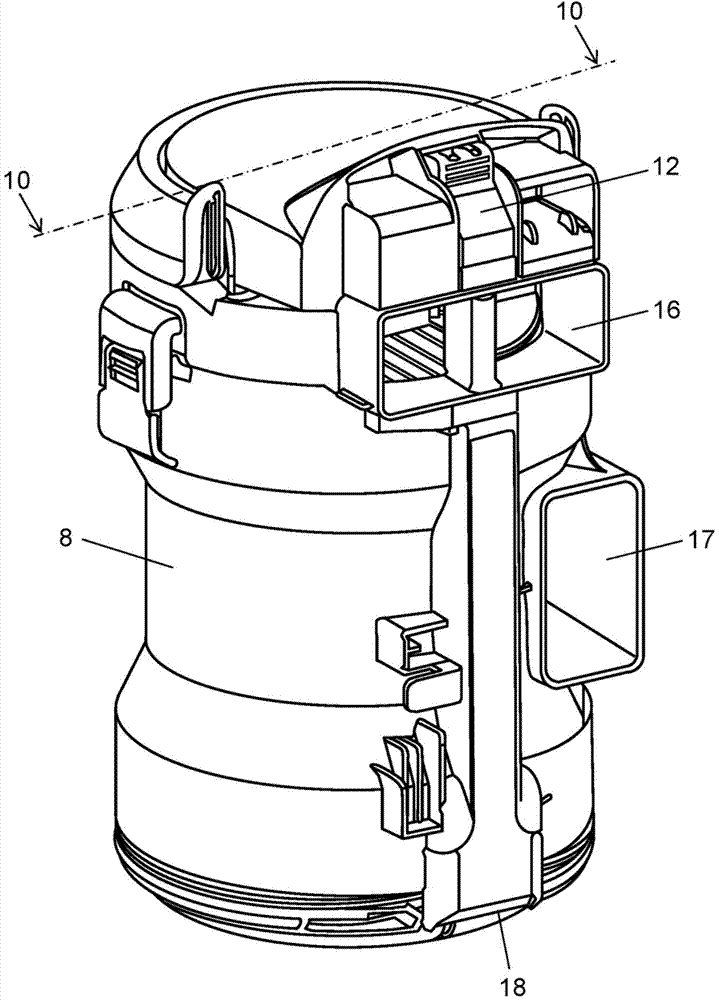

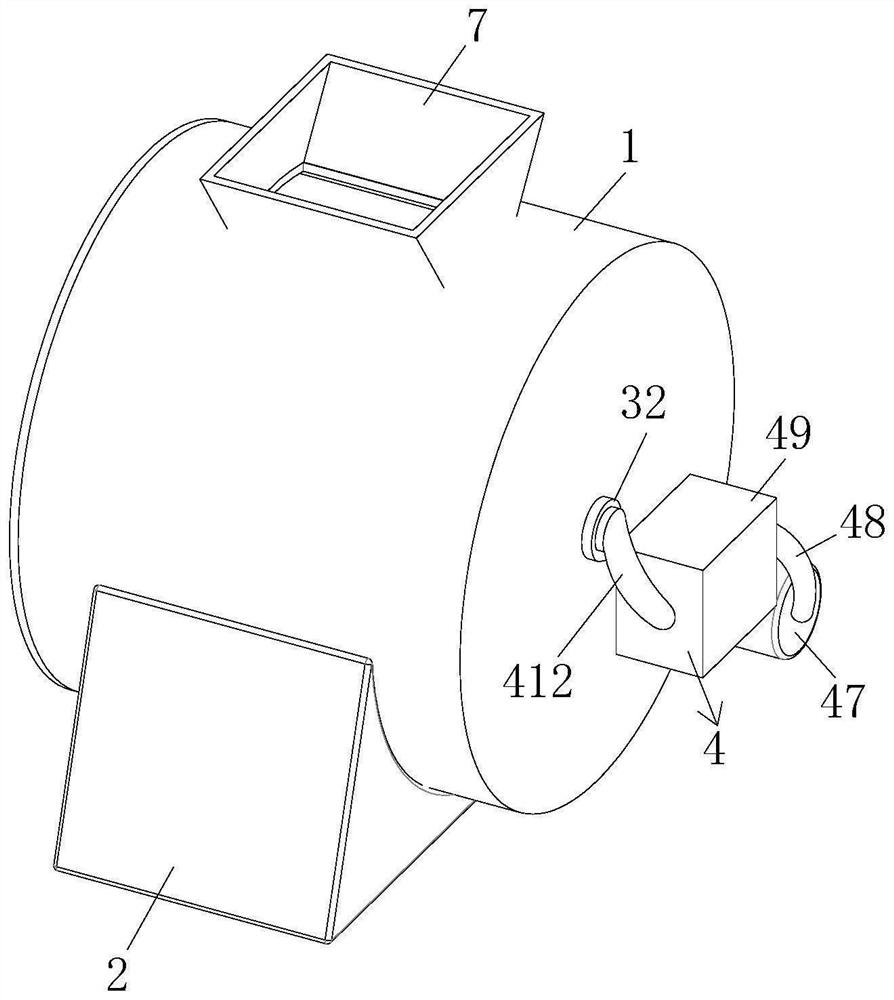

Drum type cullet cleaning system

The invention provides a drum type cullet cleaning system and relates to an industrial cleaning system. Through designing a drum, an internal spiral lifting and propelling device and a spraying device, the cullet cleaning system provided by the invention is green and environment-friendly and is thorough in cleaning. The drum type cullet cleaning system comprises the drum, an internal spiral propelling device, a material lifting board, a high-pressure circulating water spraying pipe I, a high-pressure circulating water spraying pipe II, a plurality of spraying nozzles, a water pump, a material inlet, a material outlet, an annular toothed ring, a circular track I, a circular track II, a drum bracket, a carrier roller, a water collecting sump, a flow guiding groove, a precipitating overflow tank impurity zone and a precipitating overflow tank clean water zone, wherein the internal spiral lifting and propelling device comprises the internal spiral propelling device and the material lifting board and is used for providing axial and circumferential tumbling motion for a material to be cleaned; and the spraying device comprises the high-pressure circulating water spraying pipe I, a plurality of spraying nozzles of the high-pressure circulating water spraying pipe I and the high-pressure circulating water spraying pipe II and is used for providing circulating spraying water with certain pressure for the material to be cleaned, and the circulating spraying water forms a specific spray cleaning area through the spraying nozzles of the spraying pipe I.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

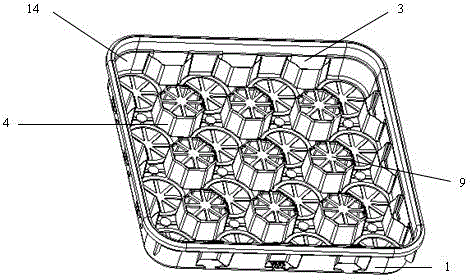

Fungal bottle basket and use method thereof in factory production

InactiveCN104885777AEasy to manageImprove labor efficiencyHorticultureEngineeringCordyceps militaris

The present invention discloses a fungal bottle basket and a use method thereof in factory production. The fungal bottle basket comprises a basket body, and the basket body comprises a basket wall and a basket bottom. The basket bottom comprises a plurality of first bottoms, a plurality of second bottoms and a plurality of third bottoms, wherein the first bottoms are used for arranging fungal bottles; protruding columns are arranged on the second bottoms and extend upwards from the second bottoms; spaces are formed between the first bottoms and the adjacent protruding columns or between the first bottoms and the adjacent protruding columns and ribs, and the side walls of the accommodated fungal bottles are in contact with the adjacent protruding columns or the adjacent protruding columns and ribs; the third bottoms are positioned between the first bottoms and the second bottoms. The fungal bottle basket has the characteristics of easiness for management, high labor efficiency, great anti-slip property, low contamination rate, convenience for stacking, no bed frame, safety, reliability, space saving and suitability for factory production of most cordyceps militaris.

Owner:山东美奥生物工程有限公司

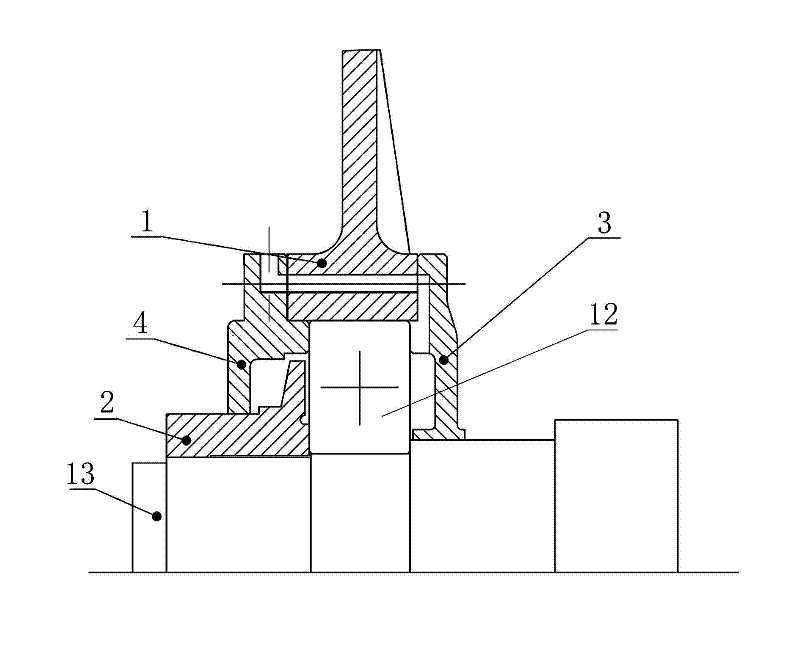

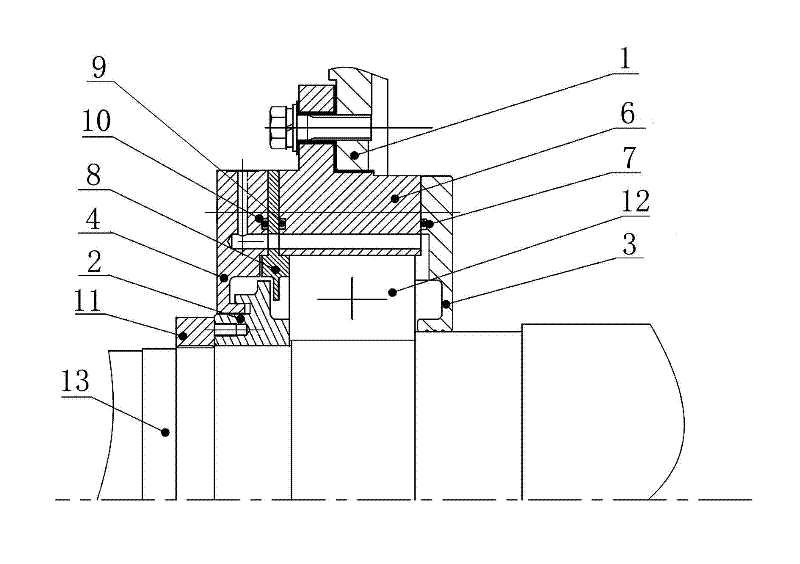

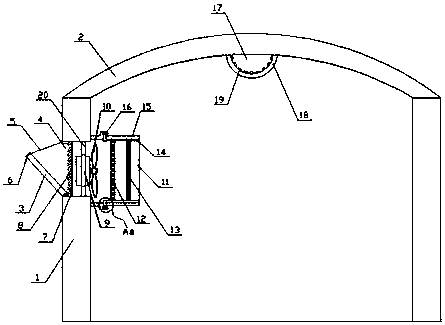

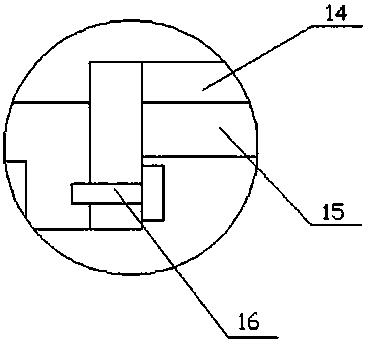

Motor bearing lubrication system

ActiveCN102510160APrevent leakagePrevent throwingSupports/enclosures/casingsForeign matterEngineering

The invention relates to a motor bearing lubrication structure, in particular to a motor bearing lubrication system. The motor bearing lubrication system solves the problem that lubricating grease always leaks and throws out, and is always accumulated in an outer bearing cover and external foreign matters are easy to enter the bearing when the traditional motor bearing lubrication structure is used. The motor bearing lubrication system comprises an end cover, a sealing ring, an inner bearing cover and an outer bearing cover, wherein the outer bearing cover is provided with a grease discharging hole; the inner side of the end cover is sheathed with a bearing chamber; the end surface of the outer side of the bearing chamber is provided with an oil deflector ring; a second O-shaped seal ringis installed between the end surface of the inner side of the oil deflector ring and the end surface of the outer side of the bearing chamber; and a labyrinth seal is arranged between the end surfaceof the outer side of the seal ring and the end surface of the inner side of the outer baring cover. According to the motor bearing lubrication system, the problem that the lubricating grease always leaks and throws out, and is always accumulated in the outer bearing cover and the external foreign matters are easy to enter the bearing when the traditional motor bearing lubrication structure is used can be effectively solved, and the motor bearing lubrication system is suitable for the motor bearing lubrication.

Owner:CRRC YONGJI ELECTRIC CO LTD

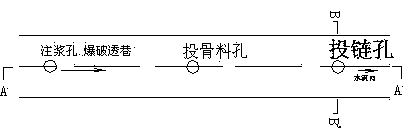

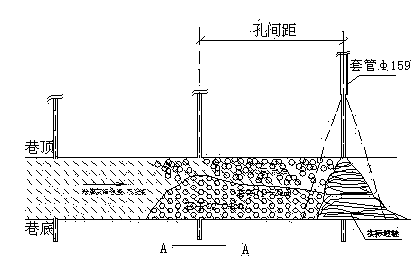

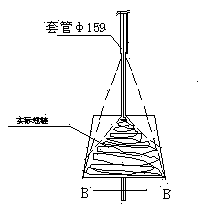

Underground tunnel large dynamic water plugging method

InactiveCN104047620ACompletely closedEasy to pile upUnderground chambersTunnel liningSmall aggregateDrill hole

The invention discloses an underground tunnel large dynamic water plugging method. The method comprises the steps that (1), the position, the direction and the specification shape of a tunnel are determined according to a tunnel design drawing; (2), a plurality of drill holes are drilled in a permeable tunnel on the ground in the direction of the tunnel and are spaced by a certain distance, and an orifice tube is arranged at the upper mouth of each drill hole; (3), aggregates are thrown into the permeable tunnel through any drill hole to determine the water bursting tunnel dynamic conditions, and the number of thrown iron chains is determined; (4), the iron chains are thrown into the permeable tunnel from the drill hole in the most downstream, and the iron chains are stacked to be in a mountain shape in the permeable tunnel; (5), large and small aggregates are thrown into the upstream drill holes sequentially from the drill hole adjoining to the most downstream, and the large and small aggregates and the iron chains form a filter framework until a water plugging curtain is formed; (6), after the water plugging curtain is built, the permeable tunnel is grouted from the drill hole in the most upstream and then burst water can be plugged; (7), the iron chains can be lifted out after grout is solidified. The method has the advantages that water is plugged fast and materials are saved.

Owner:JIZHONG ENERGY FENGFENG GRP

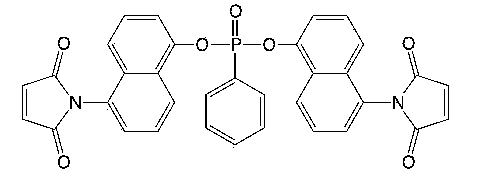

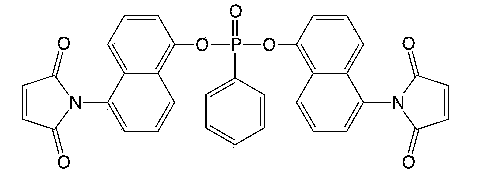

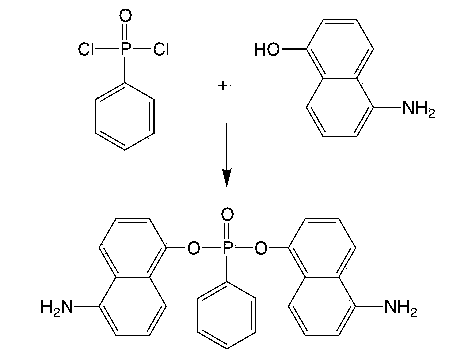

Flame-retardant heat-resistant bismaleimide resin and preparation method thereof

InactiveCN104193994AImprove flame retardant performanceLocal alignmentHeat resistanceLimiting oxygen index

The invention discloses flame-retardant heat-resistant bismaleimide resin and a preparation method thereof, belonging to the technical field of high performance thermosetting resin. According to the technical scheme, the flame-retardant heat-resistant bismaleimide resin is prepared from the following raw materials in parts by weight: 5-20 parts of phenylphosphonic dichloride, 21-52 parts of 1-amino-5-naphthol and 10-40 parts of maleic anhydride. The bismaleimide resin has a good molding technology and a cured product has high heat resistance and excellent flame retardance; the glass-transition temperature of the cured product reaches 370 DEG C, and the limit oxygen index reaches 48; benzyl di(5-amino) naphthoxy phosphonic acid is prepared by reaction between phenylphosphonic dichloride and excessive 1-amino-5-naphthol, and prepared benzyl di(5-amino) naphthoxy phosphonic acid is reacted with maleic anhydride to obtain the flame-retardant heat-resistant bismaleimide resin. The flame-retardant heat-resistant bismaleimide resin and the preparation method disclosed by the invention have the beneficial effects that the reaction is stable, the process condition is easy to control, unreacted raw materials can be recycled, and no three wastes are generated, so that the flame-retardant heat-resistant bismaleimide resin and the preparation method are suitable for industrialized production.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

Desilting device of water conservancy project

The invention discloses a desilting device of a water conservancy project. The desilting device of the water conservancy project comprises a turnover digging mechanism, a suction mechanism, a crushingmechanism and a sludge containing box, wherein the turnover digging mechanism comprises a pair of L-shaped supports which are vertically arranged and a rotating column which is horizontally arrangedin the axial direction; the suction mechanism comprises a suction cover and a stone filter screen arranged in the suction cover, and the suction cover is a circular truncated cone structure which is small in upper part, large in lower part and communicates in the axial direction; the crushing mechanism comprises an outer shell, an inner shell positioned in the outer shell, and a cutter body arranged inside the inner shell; the sludge containing box comprises a lower box body and an upper box body, wherein the lower box body and the upper box body are in sealing connection, the lower box body and the upper box body are both cylindrical structures which are vertically arranged in an axial direction. According to the device, sludge can be thoroughly cleared, the large-particle pebble hard objects are prevented from damaging a waste water pump, a pipeline cannot be blocked, the fineness of the cleared sludge is uniform, the water content is low, and the desilting device is a preferred option for preparing fertilizer.

Owner:刘兴海

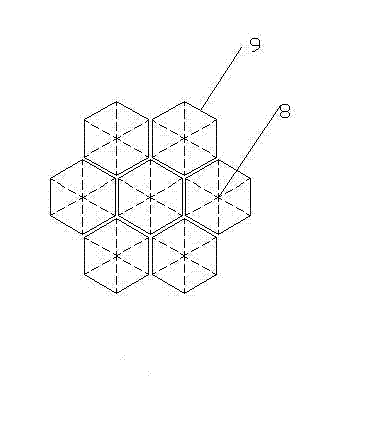

Secondary chromeplating process of printing round-net die

A secondary chromeplating process for a printing round-net die includes: plating nickel on a processed die blank, and performing first-time chromeplating and second-time chromeplating, wherein the first-time chromeplating solution is prepared by 240-350g / l of chromium trioxide, 2-10g / l of chromium sesquioxide, 2-5g / l of sulfuric acid and purified water; and the second-time chromeplating solution is prepared by 80-140g / l of chromium trioxide, 1-8g / l of chromium sesquioxide, 200-700mg / l of chloridion and purified water. A layer of chromate film is added on the first-time chromeplating surface of the die blank and firmly bonded in hexagonal net points of the die blank, when insulator glue is embedded in the hexagonal net points of the die blank, the chromate film can be well bonded, and glue dropping cannot be generated. The printing round-net die produced by the secondary chromeplating process is high in surface smoothness, long in service life, good in net evenness and high in poring rate and overcomes the shortcomings existing in the prior art.

Owner:江苏东方镍网有限公司

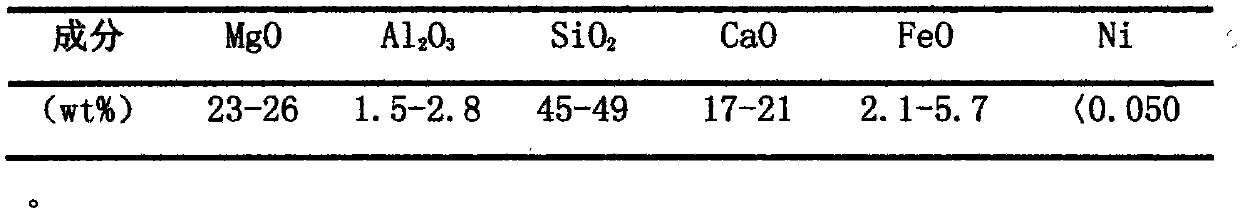

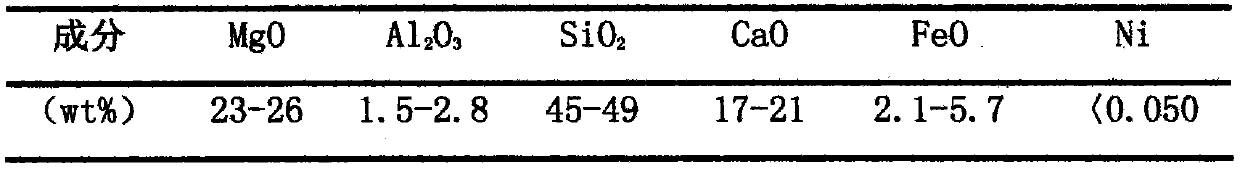

Method for preparing foamed ceramic from slag

InactiveCN104177117ALess types of raw materialsLow priceCeramic materials productionCeramicwareSlagCeramic

The invention discloses a method for preparing foamed ceramic from slag. The method comprises the following steps: by selecting nickel-smelting water-quenching slag (short for slag) discharged after refining ferronickel from laterite-nickel ore as a main raw material, adding a proper amount of kaolin and alumina powder; and preparing the foamed ceramic according to the following technological processes: sorting the nickel-smelting water-quenching slag; crushing; screening; weighing; adding the kaolin; adding the alumina powder; mixing the materials; molding; and sintering. The method is characterized in that the discharged quenched slag for smelting nickel after refining ferronickel by the laterite-nickel ore is selected as the main raw material, no foaming agent or template is utilized, holes which are even in distribution and controllable in size are formed in a sintering body by virtue of chemical reaction of the slag, the kaolin and the alumina powder at high temperature, and the foamed ceramic of mullite is finally prepared. The foamed ceramic has the advantages of high compressive strength, high hardness, uniform and beautiful color and low cost and is simple and convenient in pore size control, the slag is fully utilized, and the waste materials are changed into things of value.

Owner:HEBEI UNIV OF TECH

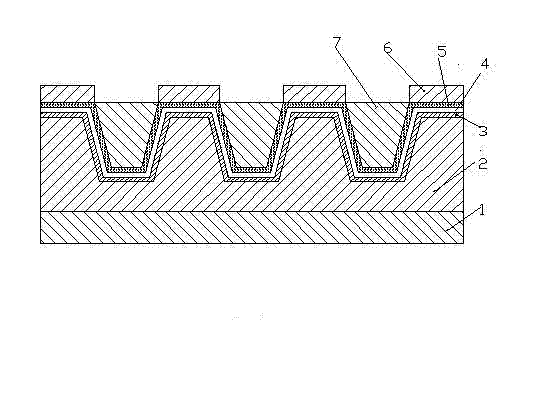

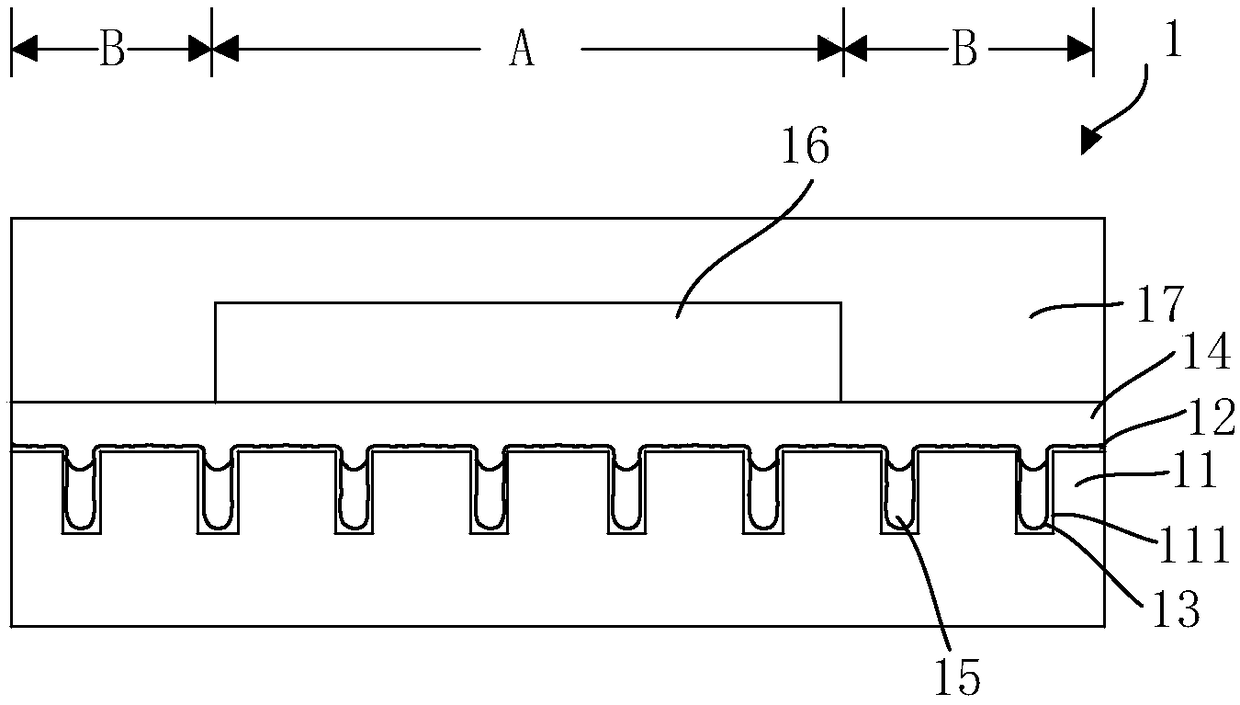

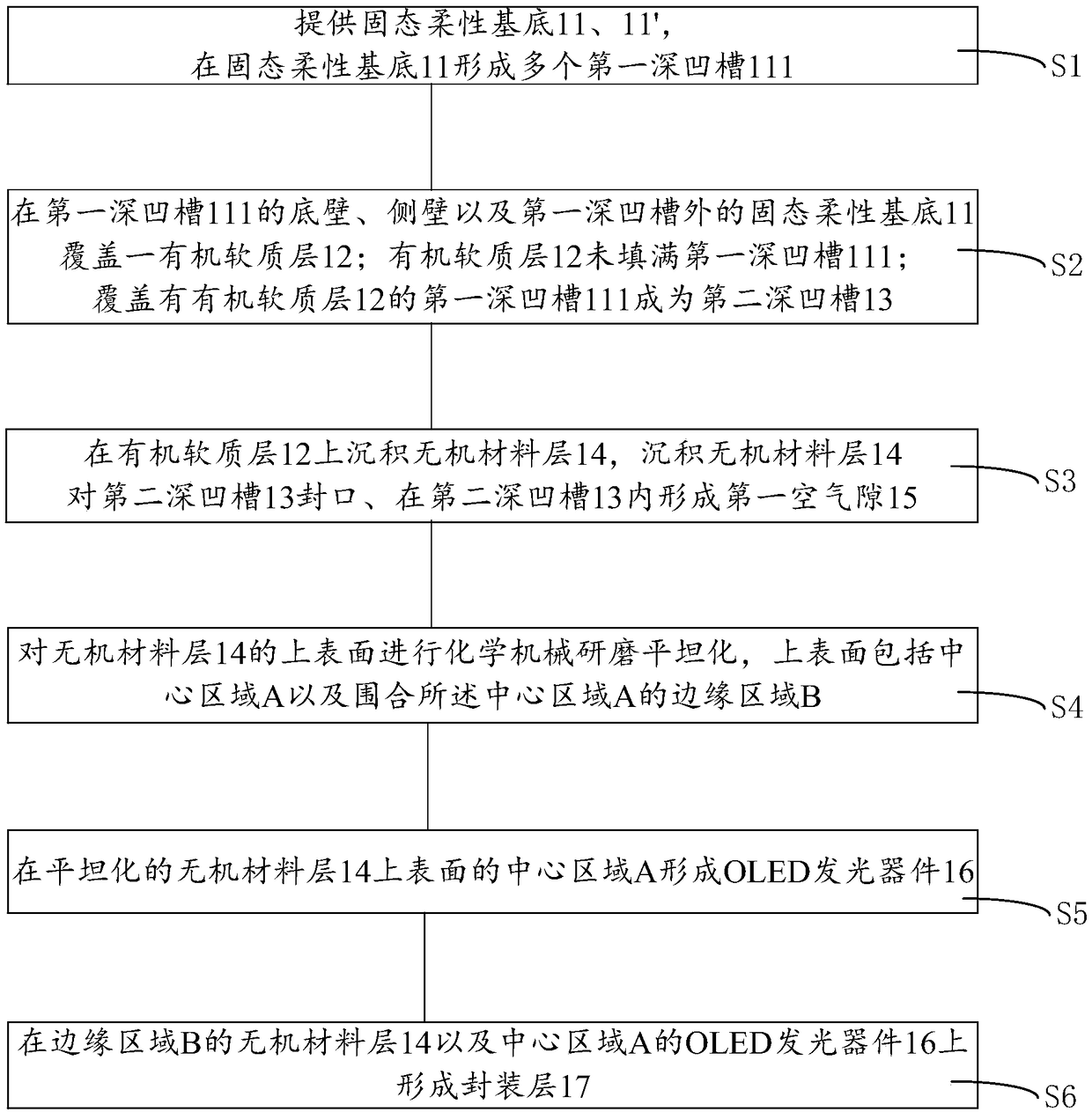

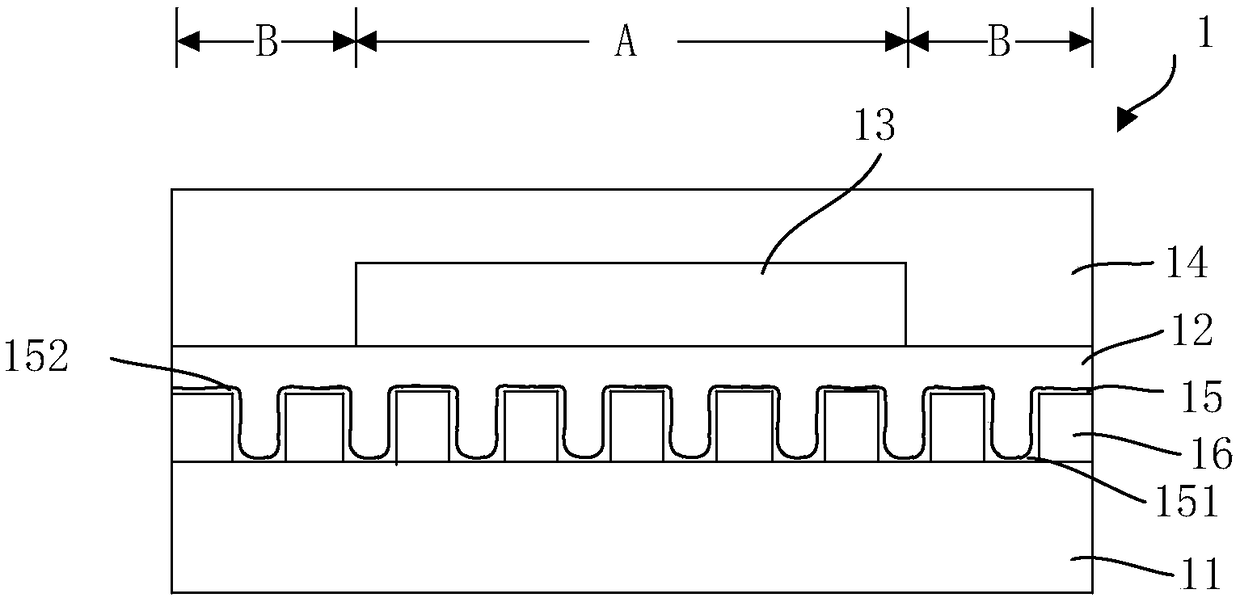

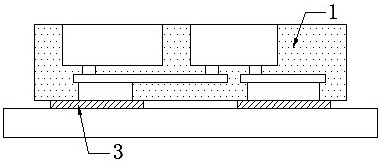

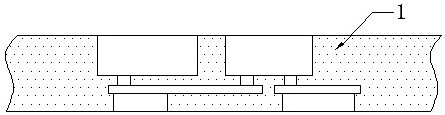

Diplsy device, Flexible OLED display panel and manufacturing method thereof

ActiveCN109273505AImprove bending performanceGood tensile propertiesSolid-state devicesSemiconductor devicesEngineeringSurface plate

The invention provides a display device, a flexible OLED display panel and a manufacturing method thereof, wherein a concave-convex undulating organic soft layer is fabricated by utilizing an uneven structure of a plurality of first deep grooves in a solid flexible substrate, and an air gap is formed between the organic soft layer and an inorganic material layer on the organic soft layer. The invention has the advantages that: firstly, a plurality of first deep grooves are made to remove part of the material of the solid flexible substrate, and the bending performance of the solid flexible substrate is improved; Secondly, the tensile property of the organic soft layer is better than that of the inorganic material, which can cushion the stress in the bending process of the OLED display panel. Third, the air gap provides the accommodation space for tensile or compressive strain of the soft material layer, and does not cause the stress transfer between the layers.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

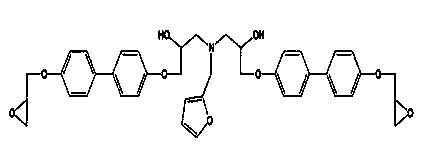

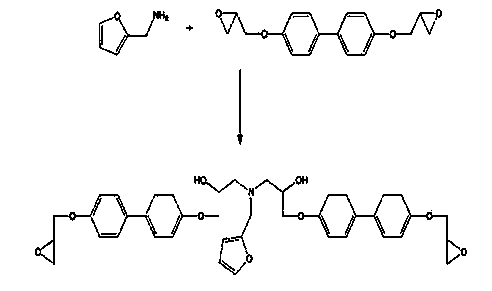

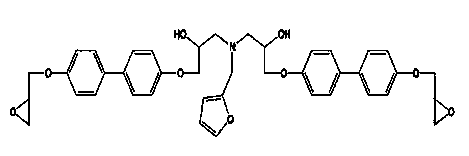

Self-healing functional epoxy resin containing biphenyl structure and preparation method of self-healing functional epoxy resin

The invention discloses a self-healing functional epoxy resin containing a biphenyl structure. The technical scheme of the invention is implemented through mixing formula amounts of 4,4'-biphenol, epichlorohydrin and a cosolvent at a temperature of 50-60 DEG C, adding a formula amount of phase transfer catalyst, uniformly mixing the obtained object so as to obtain a transparent solution, slowly adding a formula amount of sodium hydroxide to react for 1-6 h, after the reaction is completed, cooling and filtering the obtained product so as to remove generated sodium chloride, and carrying out water washing and reduced pressure distillation for removing unreacted epichlorohydrin and cosolvent, so that 4,4'-biphenol diglycidyl ether epoxy resin is obtained; and in parts by weight, dissolving 30-32 parts of the 4,4'-biphenol diglycidyl ether epoxy resin into 50-60 parts of a solvent, slowly adding 9-10 parts of furfuryl amine into a reaction container to react, and carrying out cooling and reduced pressure distillation on the obtained product so as to remove the solvent, thereby obtaining a biphenyl structure containing self-healing functional epoxy resin. The self-healing functional epoxy resin containing the biphenyl structure and the preparation method of the self-healing functional epoxy resin have the beneficial effects that obtained cured substances have the advantages of high toughness and good heat resistance, and can be used as a matrix of a high-performance composite material.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

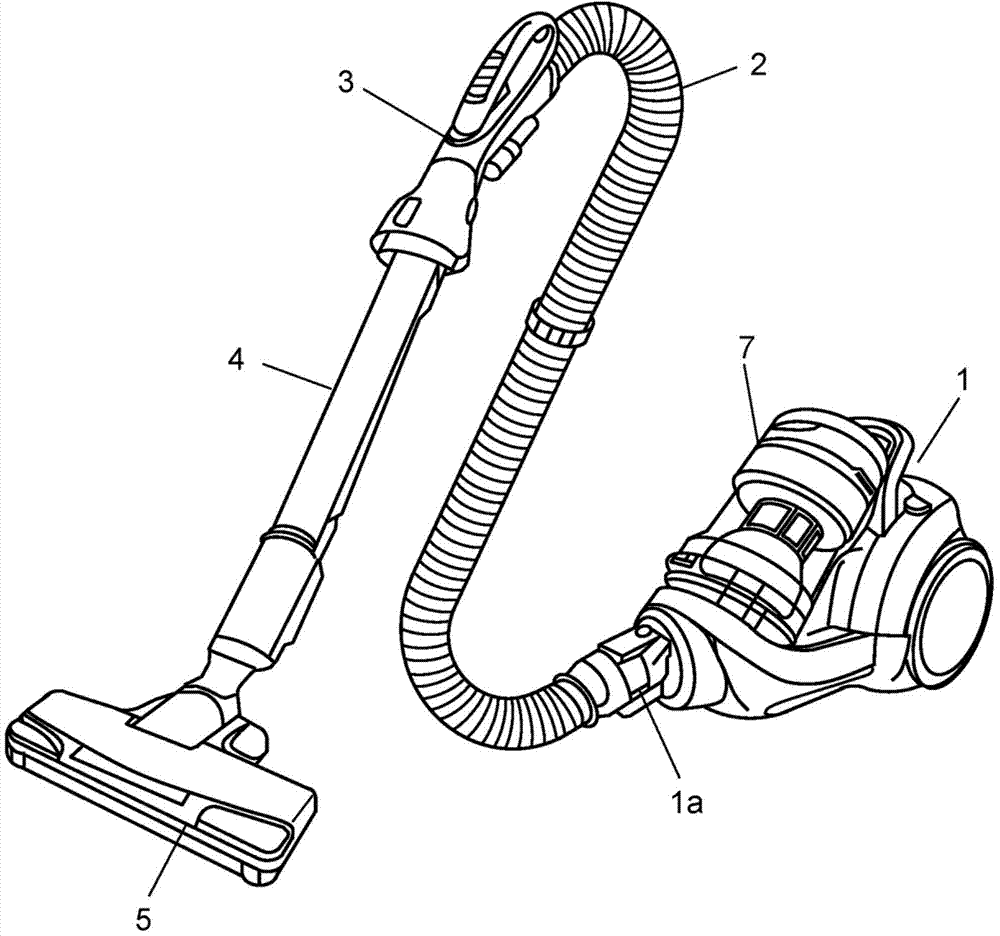

Electric dust collector

The invention provides an electric dust collector. A dust-collecting device of the electric dust collector comprises a structure configuring a primary filter (21) configured in the following manner: in the primary filter (21) provided with a plurality of through holes penetrating through an upstream side surface and a downstream side surface of the primary filter (21), a direction of a central axis and a forward direction of an outer side swirling airflow (61) flowing on the upstream side surface of the primary filter (21) form a second inclined angle which is downward inclined opposite to the forward direction. The central axis is a straight line of connecting an opening center of a first etching hole and an opening center of a second etching hole. Therefore, a declining swirling airflow (61) going toward a direction of a dust-collecting chamber (33) can be generated in the inner circumference of the primary filter (21), so that the dust can be prevented from flying; and blockage of the filter can be prevented.

Owner:PANASONIC CORP

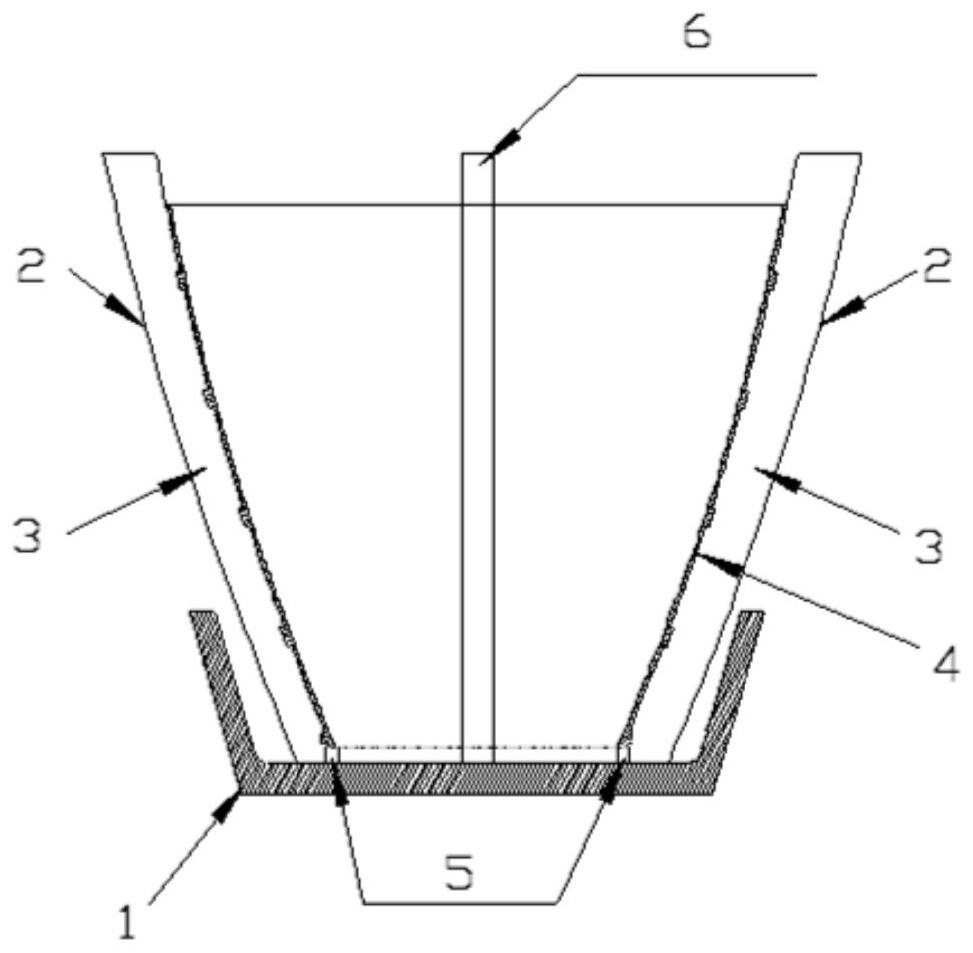

Melt siliconizing method for small-size circular-section ceramic-based composite material component

ActiveCN112341213AImprove the uniformity of modificationAvoid deformationCrucible furnacesCrucibleLiquid silicon

The invention relates to a melt siliconizing method for a small-size circular-section ceramic-based composite material component. The invention aims to solve problems that in the LSI process preparation process of a small-size circular-section ceramic matrix composite zero component, the internal and external density gradient difference is likely to be generated, the component density uniformity is poor, deformation is liable to happen, and bottom liquid silicon is liable to be accumulated and bonded. The method mainly comprises the steps of preparing a fused siliconizing tool, machining a small-size circular-section ceramic-based composite material component semi-finished product and preparing the small-size circular-section ceramic-based composite material component; wherein specifically, an inner mold of the small-size circular-section ceramic-based composite material component semi-finished product is filled with SiC sand; meanwhile, powder is packed into a gap, namely a powder filling area, formed between the outer wall of the small-size circular-section ceramic matrix composite component semi-finished product and the inner wall of the first crucible unit. Due to internal andexternal double-sided melt infiltration, the process effectively improves the modification uniformity.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Computer case capable of quickly disassembling computer mainboard

InactiveCN111103942AGood fixationImprove stabilityDigital processing power distributionLap jointProcess engineering

The invention discloses a computer case capable of quickly disassembling a computer mainboard. The computer case comprises a case main body, a computer mainboard and a desiccant box, the computer mainboard is in lap joint with the interior of the case main body; a drying agent box is fixedly connected to the top in the case main body; the top of the computer mainboard is fixedly connected with a mainboard fixing plate; a positioning bolt is connected to the top of the main board fixing plate in an embedded manner; the bottom end of the mainboard fixing plate is fixedly connected with a fixingrod; a spring is fixedly connected to the middle of the top of the fixing rod; a sealing cover is connected into the drying agent box in an embedded mode; the sealing cover can prevent the drying agent from flying out of the case in the moving process of the case; and the drying mechanism can play a role in drying the computer case. The service life of the case is prolonged, the moving mechanism ensures the stability of the case while facilitating movement of the case, and the mainboard fixing mechanism adopts a fixing mode which is convenient, rapid and good in stability, is suitable for being used in the computer case and has wide development prospects in the future.

Owner:杨墨涵

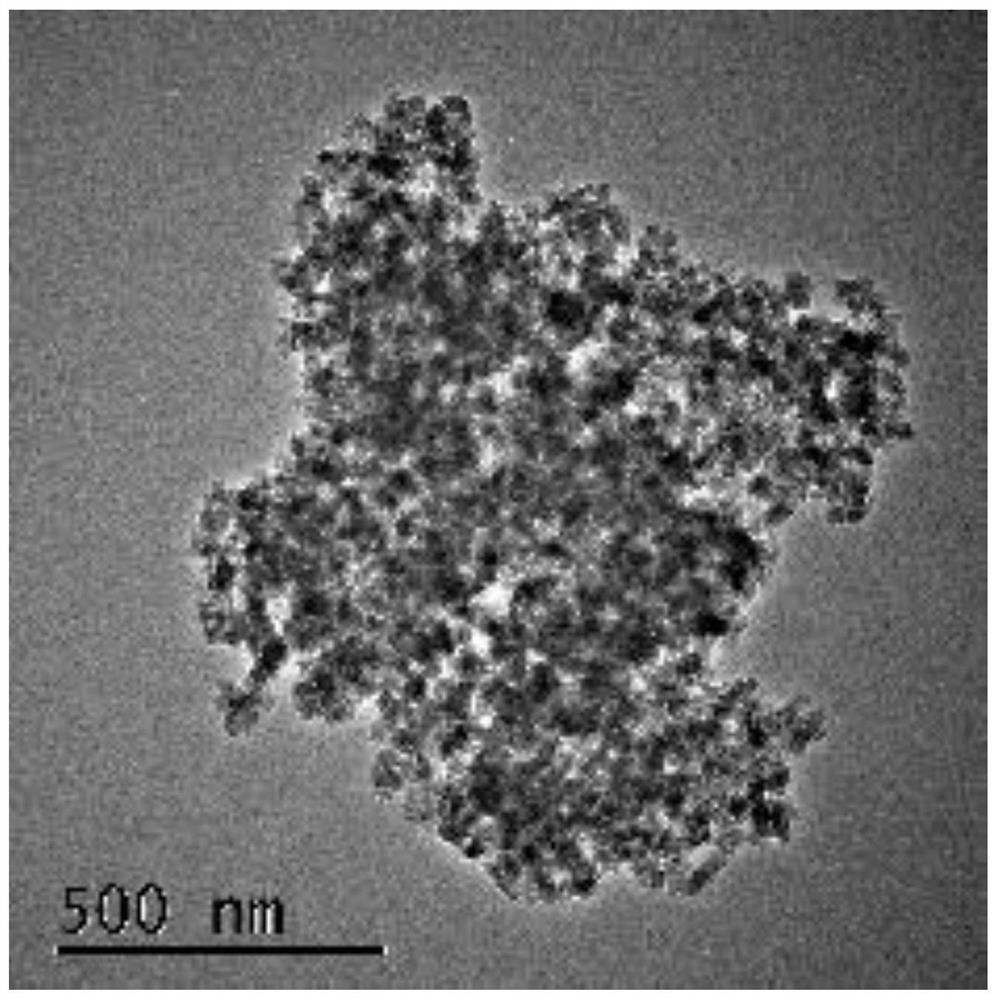

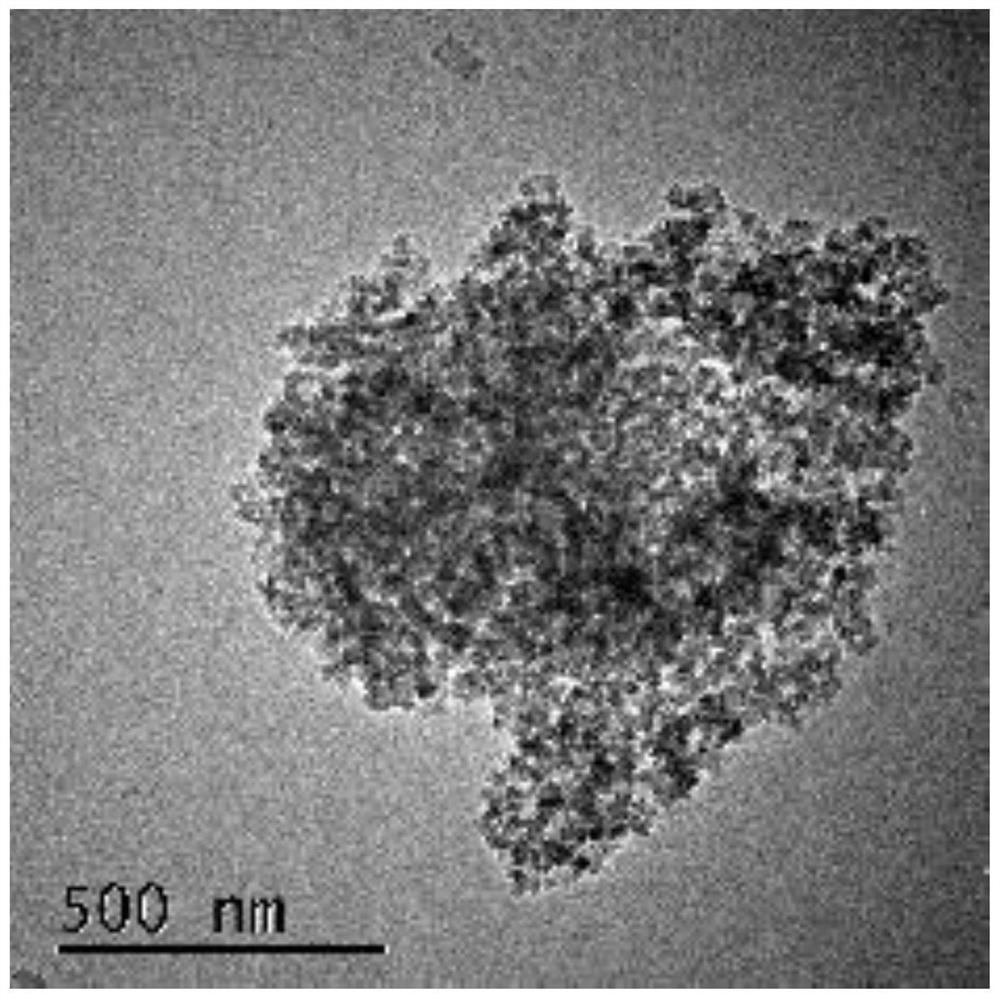

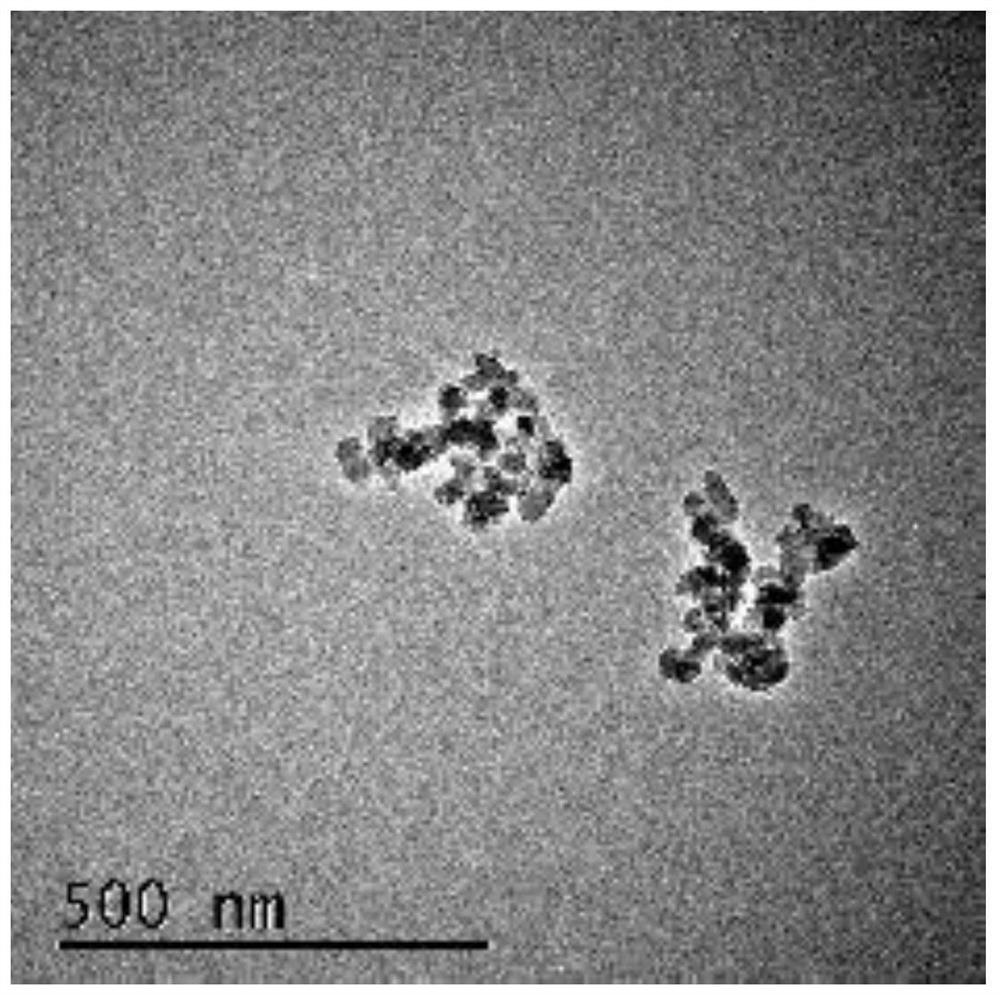

A kind of glass fiber ball bundle and preparation method thereof

The invention discloses a glass fiber ball bundle and a preparation method thereof. The preparation method comprises the following steps: 1, grinding and sorting waste printed circuit boards so as to obtain nonmetallic powder; 2, adding the nonmetallic powder into an inorganic acid, and reacting at the temperature of 50-95 DEG C for 8-40 hours; 3, filtering, and respectively collecting glass fiber powder solids and filtrate; 4, extracting the filtrate with an extraction agent so as to obtain the recycled epoxy resin; and 5, adding the glass fiber powder and the recycled epoxy resin into an organic amine solution while stirring according to a weight ratio of 100:(0.1-10), reacting at the temperature of 40-80 DEG C for 0.5-30 hours, and filtering, thereby obtaining the glass fiber ball bundle. According to the method disclosed by the invention, harm of the glass fiber powder on the human body in the process of recovering, treating and reutilizing the glass fibers is avoided, the recycled glass fiber ball bundle can serve as a carrier of catalysts, nanometer materials and other materials and can be directly prepared into a composite material, the condition that the performance is reduced due to a high temperature in the extrusion pelletizing process is avoided, and the glass fiber ball bundle has excellent application prospects.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

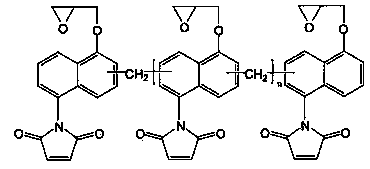

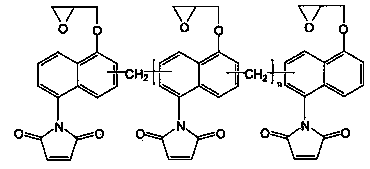

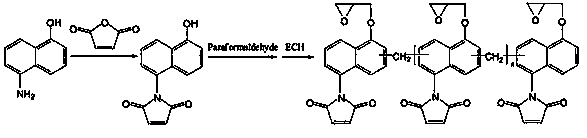

Dual-network crosslinked epoxy resin and preparation method thereof

The invention discloses a dual-network crosslinked epoxy resin. A preparation method of the dual-network crosslinked epoxy resin comprises the following steps: synthesizing 5-maleimide-1-naphthol by taking maleimide and 5-amino-1-naphthol as major raw materials; and reacting the obtained 5-maleimide-1-naphthol with paraformaldehyde, epoxy chloropropane and sodium hydroxide to obtain the dual-network crosslinked epoxy resin. The obtained epoxy resin contains an epoxy group and a maleimide group, and an epoxy loop-opening and imide polymerization dual-network crosslinked network can be formed in crosslinking and curing processes; and an obtained condensate has the characteristics of superior flame retardance and high heat resistance, and can be taken as a substrate of a high-performance composite material used in a high-temperature environment.

Owner:ANHUI SHANFU NEW MATERIAL TECH

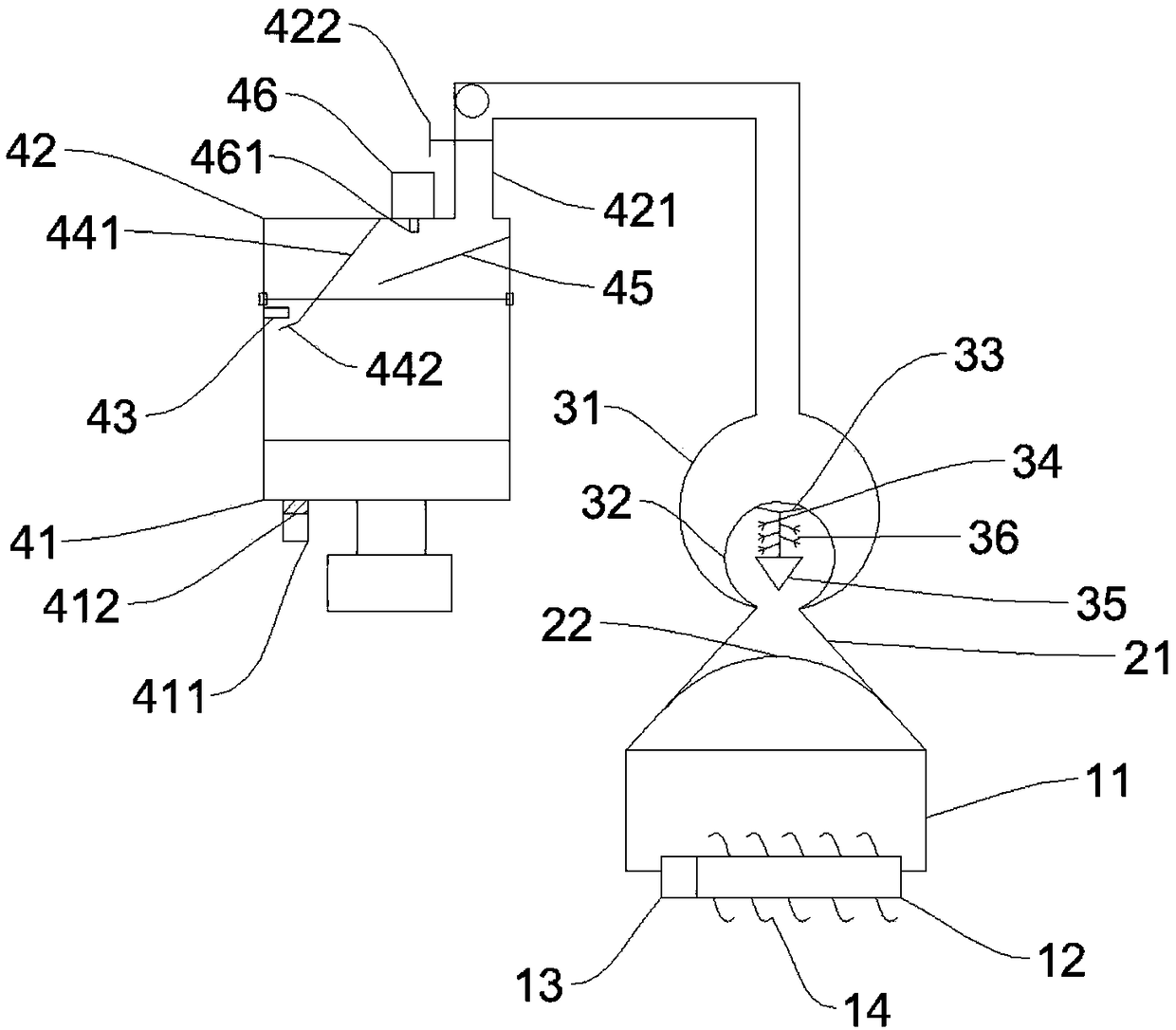

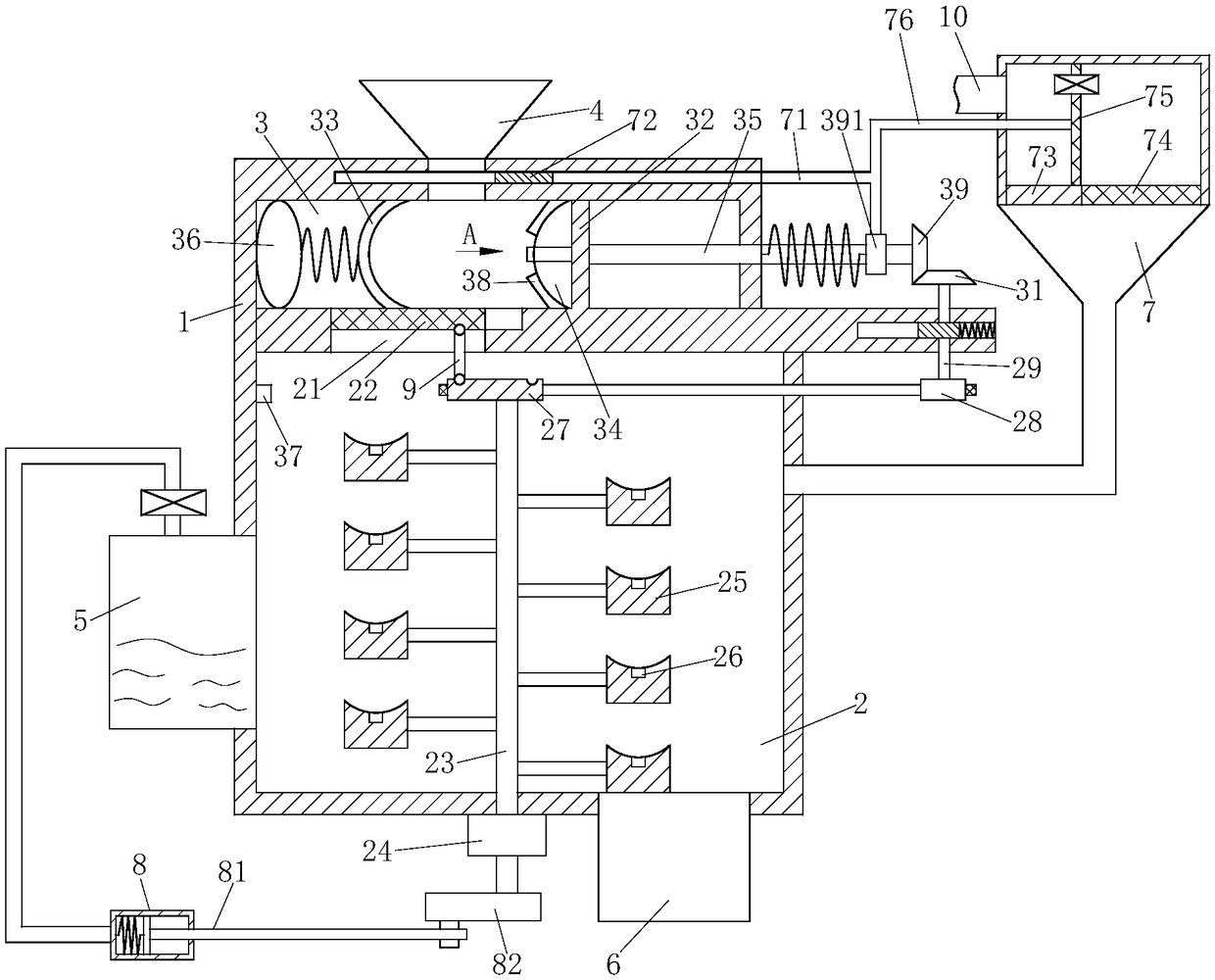

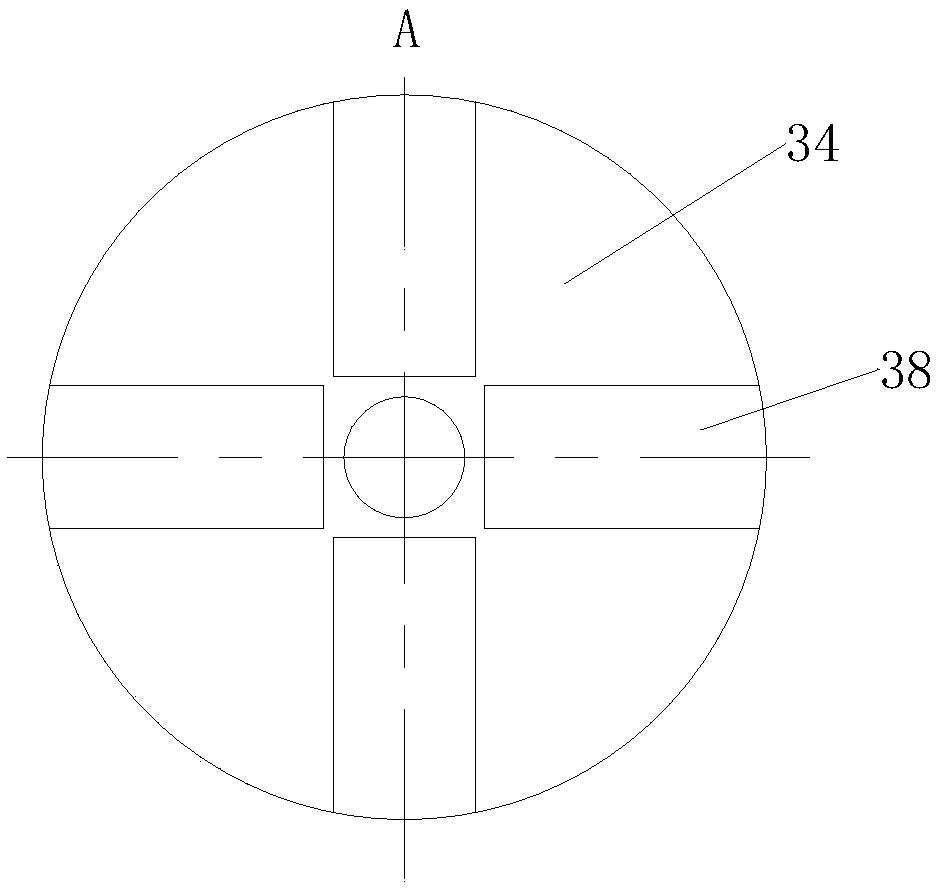

Coal chemical industry pyrolysis and gasification system

InactiveCN109022040AImprove combustion efficiencyTo achieve combustionCombustible gas productionCoal briquetteCombustion chamber

The invention belongs to the technical field of coal chemical industry, and concretely relates to a coal chemical industry pyrolysis and gasification system. The system comprises a shell, a combustionchamber and a grinding chamber; the grinding chamber is arranged in the top of the shell; a water tank is mounted at one side of the shell, a filtering tower is arranged at the other side of the shell, the filtering tower is communicated with the combustion chamber, and a first rotating rod and a spiral plate are arranged at the bottom of the combustion chamber; the top end of the first rotatingrod is fixedly connected with a cam; the cam is connected with a driven wheel through a belt, and the driven wheel is connected with a second bevel gear through a second rotating rod; a grinder is arranged in the grinding chamber, and a grinding block is arranged at one side of the grinding chamber; the bottom of the grinding block is connected with an airbag through a spring; a grinding head is arranged at the other side of the grinding chamber, and the grinding head is provided with circumferentially uniformly-distributed protrusions; the grinding head is connected with a first bevel gear through a first connecting rod; and a mounting block is arranged at one end of the first connecting rod. Coal briquettes are crushed by the grinder, and then are combusted, so the gasification efficiency of the coal briquettes is improved.

Owner:谢响玲

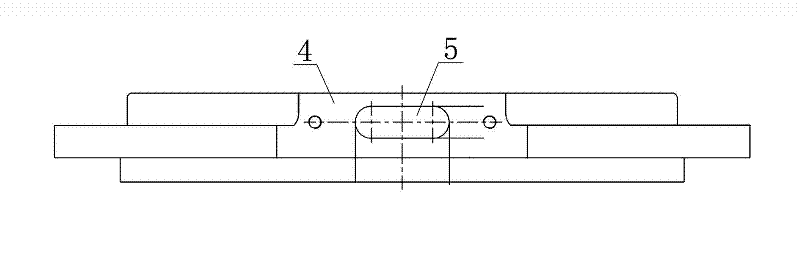

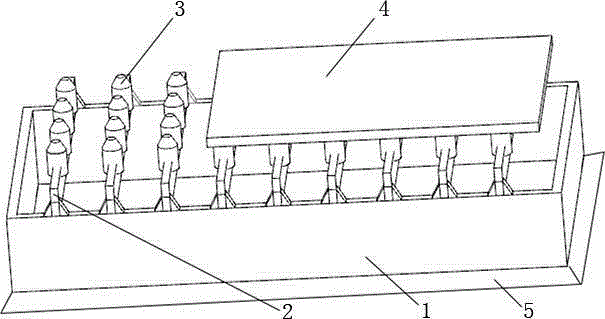

Replacement-free plate rib type steel plate flame cutting platform

InactiveCN105643047AEasy to pile upImprove cleanlinessWelding/soldering/cutting articlesMetal working apparatusEngineeringFlame cutting

The invention provides a replacement-free plate rib type steel plate flame cutting platform. The platform comprises a ground platform support frame; transverse steel plates and vertical steel plates are mounted on the ground platform support frame; multiple first clamping grooves are arranged on the vertical steel plates at equal intervals; transverse steel plates are arranged in the first clamping grooves, so that the transverse steel plates and the vertical steel plates form a latticed structure; multiple second clamping grooves are formed in the transverse steel plates; support pieces are mounted in the second clamping grooves, are cylinders with cones at the tops, and are clamped in the second clamping grooves through through grooves; the support pieces are arranged on the transverse steel plates in a lattice manner to form support planes; and the top ends of all the support pieces are positioned on the same horizontal plane. The platform is simple in structure, can use specificity of the support pieces for solving such problems as damage, lagging and tumor hanging in the steel plate cutting process of factories, reduces the replacement frequency of the support plates of the cutting platform, prolongs the service life of a cutting machine, and improves the production safety.

Owner:WUHAN YIYE STEEL STRUCTURE

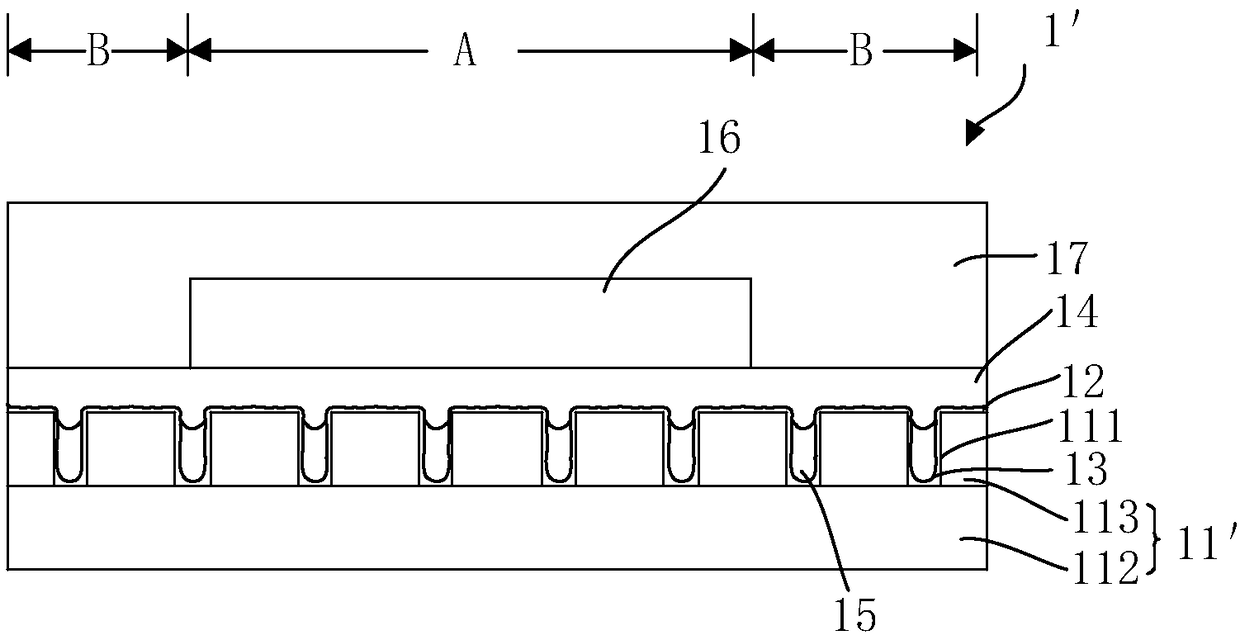

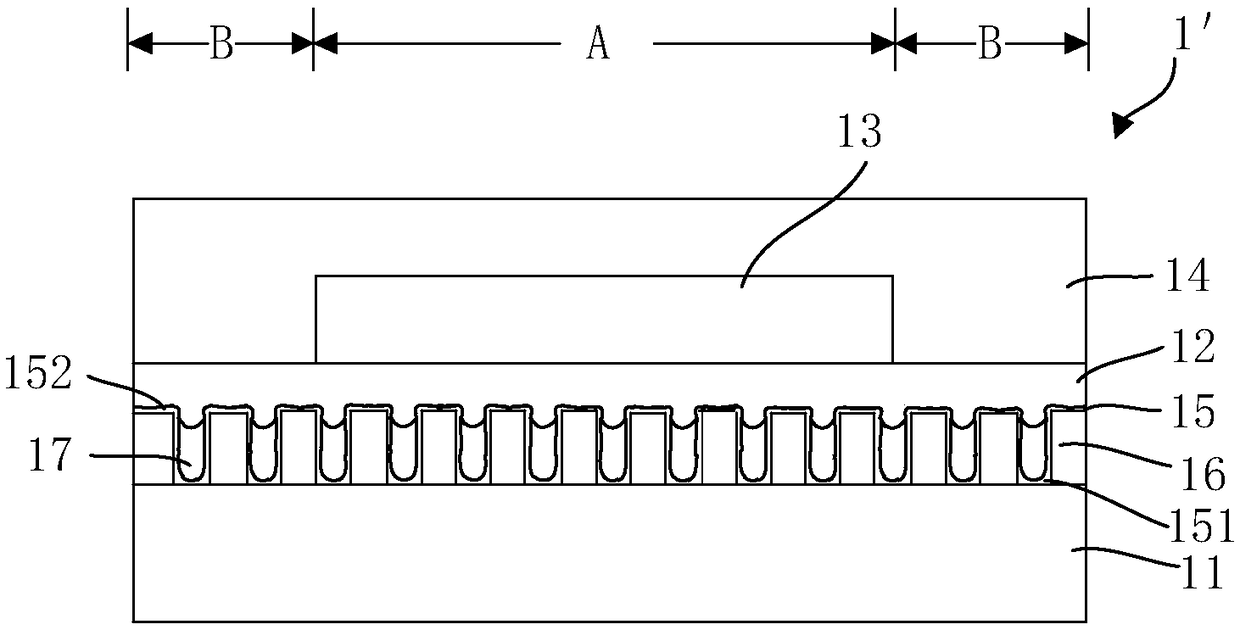

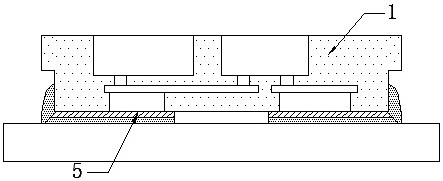

Display device, flexible OLED display panel and manufacturing method of flexible OLED display panel

ActiveCN109411620AGood tensile propertiesEasy to stretchFinal product manufactureSolid-state devicesWave shapeEngineering

The invention provides a display device, a flexible OLED display panel and a manufacturing method of the flexible OLED display panel. A wave-shaped organic soft layer is manufactured by utilizing an uneven structure of a plurality of strip-shaped sacrificial protrusions, then the strip-shaped sacrificial protrusions are removed, and an air gap is formed between the organic soft layer and a solid flexible substrate under the organic soft layer. The method has the advantages that 1, the tensile property of the organic soft layer is high relative to that of an inorganic material, so that the stress in the bending process of the OLED display panel can be buffered; 2, the organic soft layer is uneven, and compared with a planar structure, the stress in the OLED display panel with different curling degrees can be buffered; and 3, the air gap provides a containing space for the soft layer to stretch or compress the strain, so that stress transmission between the layers cannot be caused.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

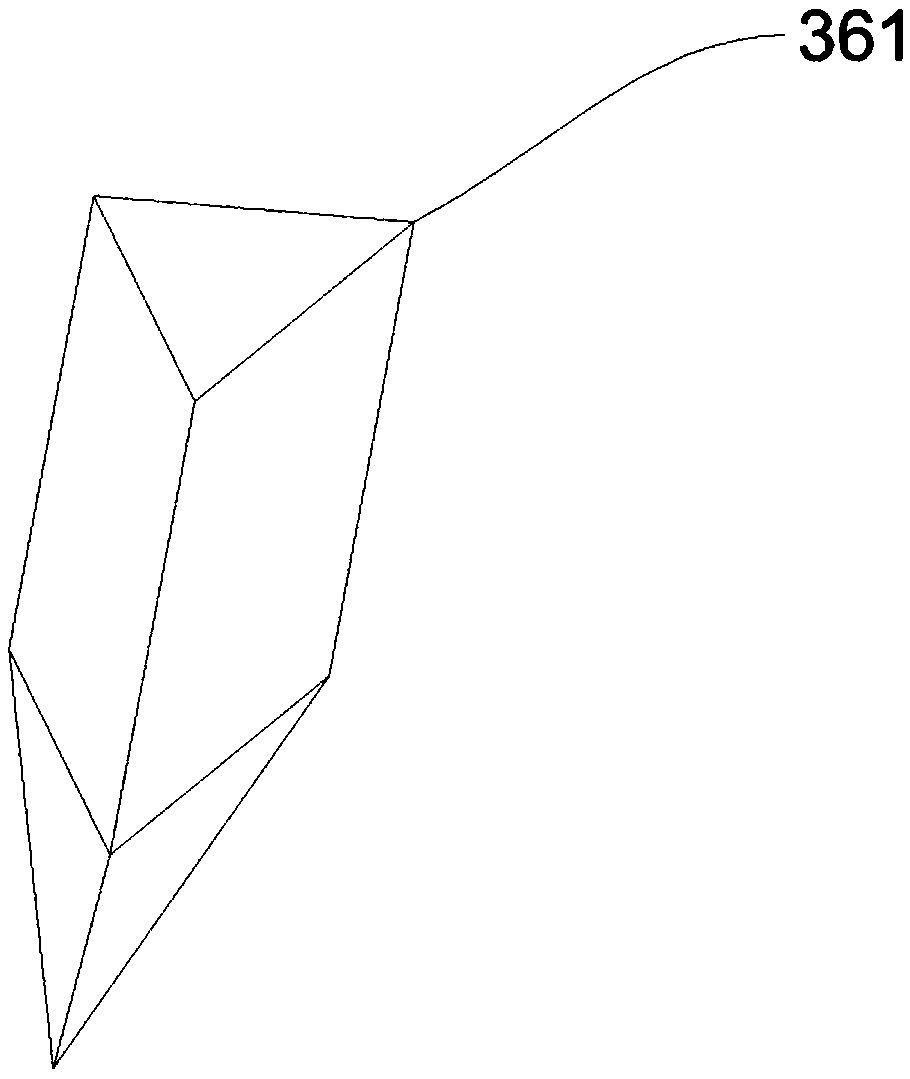

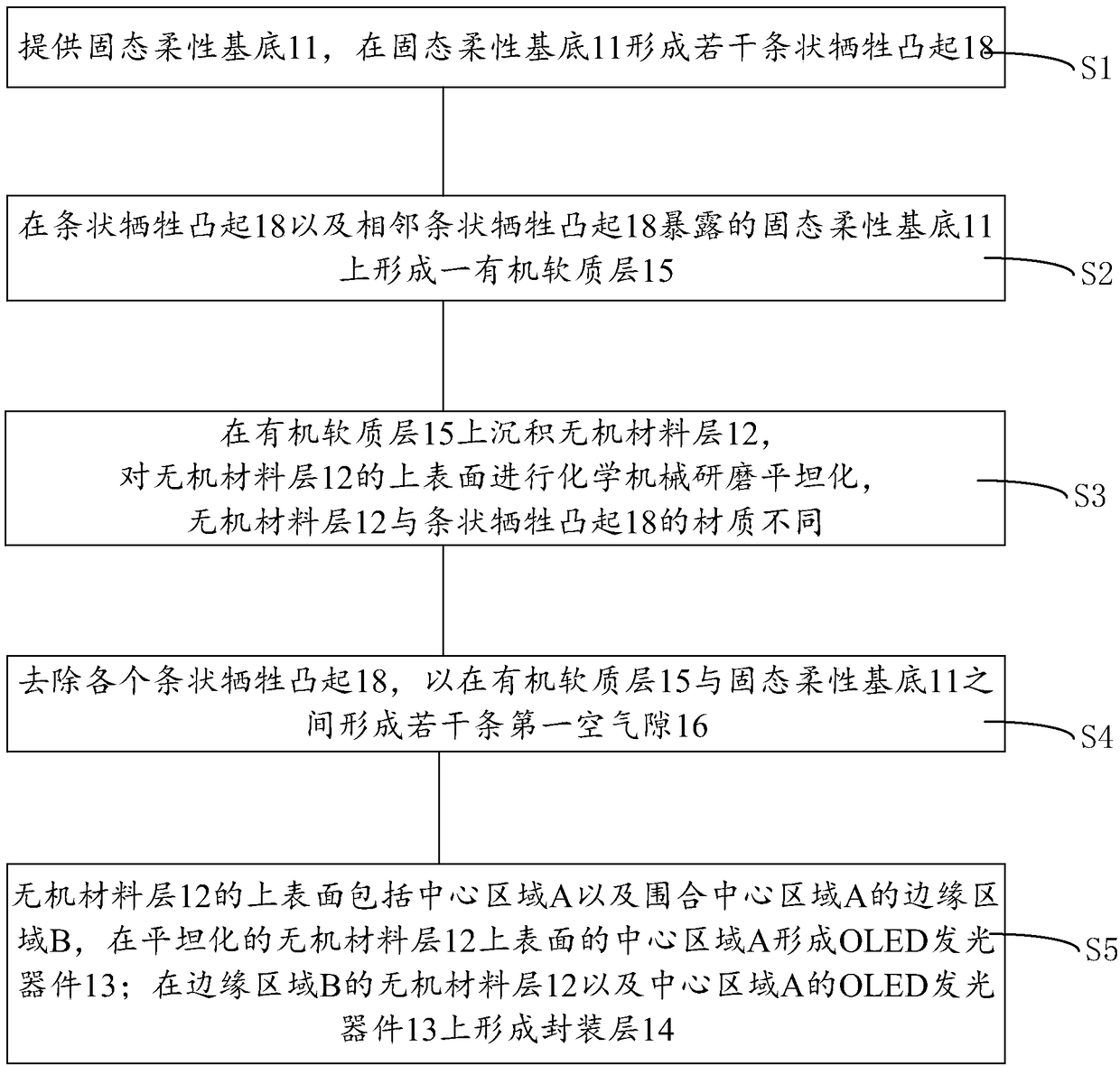

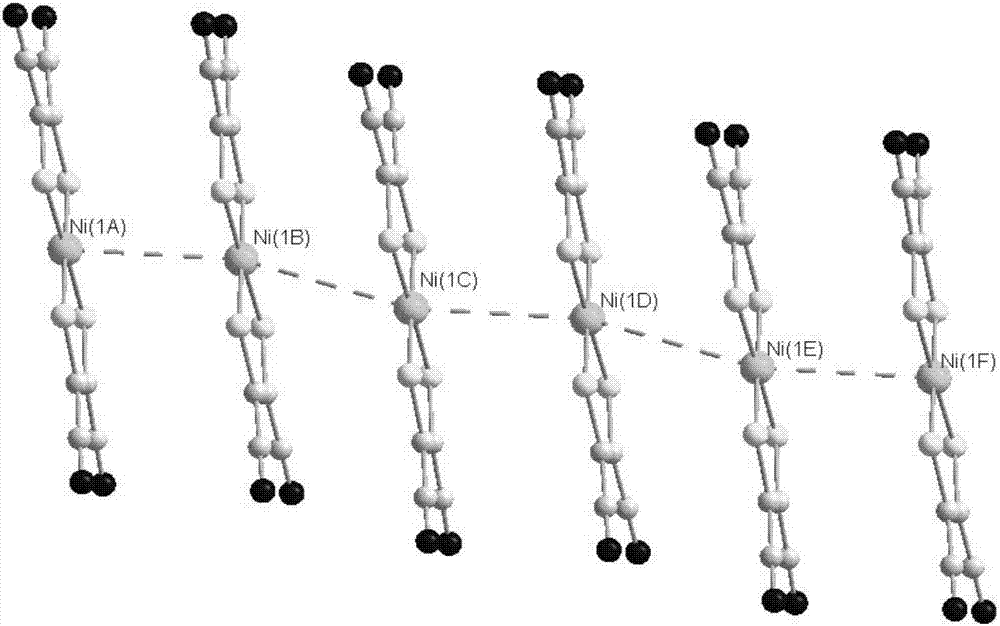

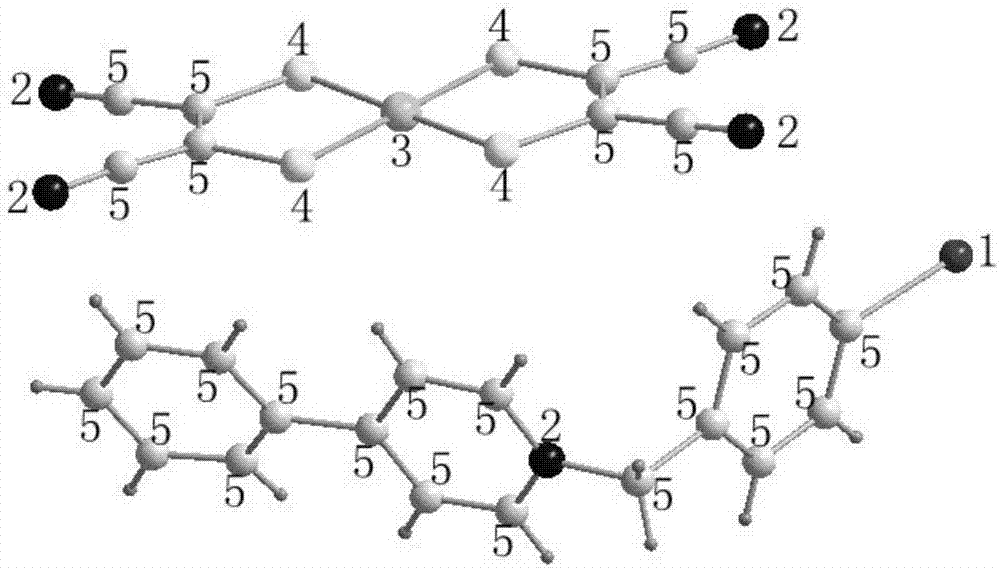

Coordination balance cationic salt, and magnet formed by metal dithiolene complex and preparation methods thereof

InactiveCN107021918AFacilitates electron transportGood for spin couplingNickel organic compoundsOrganic/organic-metallic materials magnetismCouplingReaction speed

The invention belongs to the field of functional materials, and particularly relates to a coordination balance cationic salt, and a magnet formed by a metal dithiolene complex and preparation methods thereof. The coordination balance cationic salt reacts with coordination anions to obtain the metal dithiolene complex; on one hand, the 4-iodobenzyl and 4-phenylpyridin in the coordination balance cation are respectively of a plane structure, the plane structures respectively have a symmetric axis, and are crossed at the connected carbon atom of 4-iodobenzyl and 4-phenylpyridin, and the whole inverted Y-shaped structure is formed; on the other hand, the coordination anion is of a plane structure, and the self-rotation density of the unpaired electrons is distributed on the whole anion skeleton. By adopting the structure, the magnet formed by the coordination balance cations and coordination anions is of an equal-spacing arrangement structure, the cations and anions are stacked into columns by lines, and the electron transmission and self-rotation coupling of the metal dithiolene complex are favorably performed. The magnet formed by the metal dithiolene complex has the advantages that the technology is simple, the control is easy, the reaction speed is quick, and the product purity is high.

Owner:NANJING XIAOZHUANG UNIV

Shot blasting room for metal plate machining

PendingCN110842794AEasy to pile upReduce wasteAbrasive machine appurtenancesAbrasive blasting machinesEngineeringStructural engineering

The invention relates to a shot blasting room for metal plate machining. The shot blasting room comprises a blasting room body, a grid plate is arranged on the bottom in the blasting room body, a shotblasting mechanism is arranged above the grid plate, a separation and dust collection mechanism is arranged below the grid plate, the separation and dust collection mechanism comprises a separation assembly and a dust collection assembly, the separation assembly comprises a filter net, a vibrator and two guide plates, the dust collection assembly comprises a fan, an air supply pipe, a dust discharge pipe and a collection box, and the shot blasting mechanism comprises a loading assembly and an adjusting assembly. In the shot blasting room for metal plate machining, the height and the angle ofa nozzle can be adjusted, different workpieces are subjected to automatic comprehensive shot blasting treatment, work is safer and efficient, the shot blasting quality is better, dust is prone to being stacked, wind is adopted for conveying dust, cleaning is efficient and convenient, effective shots can be separated and recycled, the raw material waste is reduced, and production cost is reduced.

Owner:苏州市金典精密制造有限公司

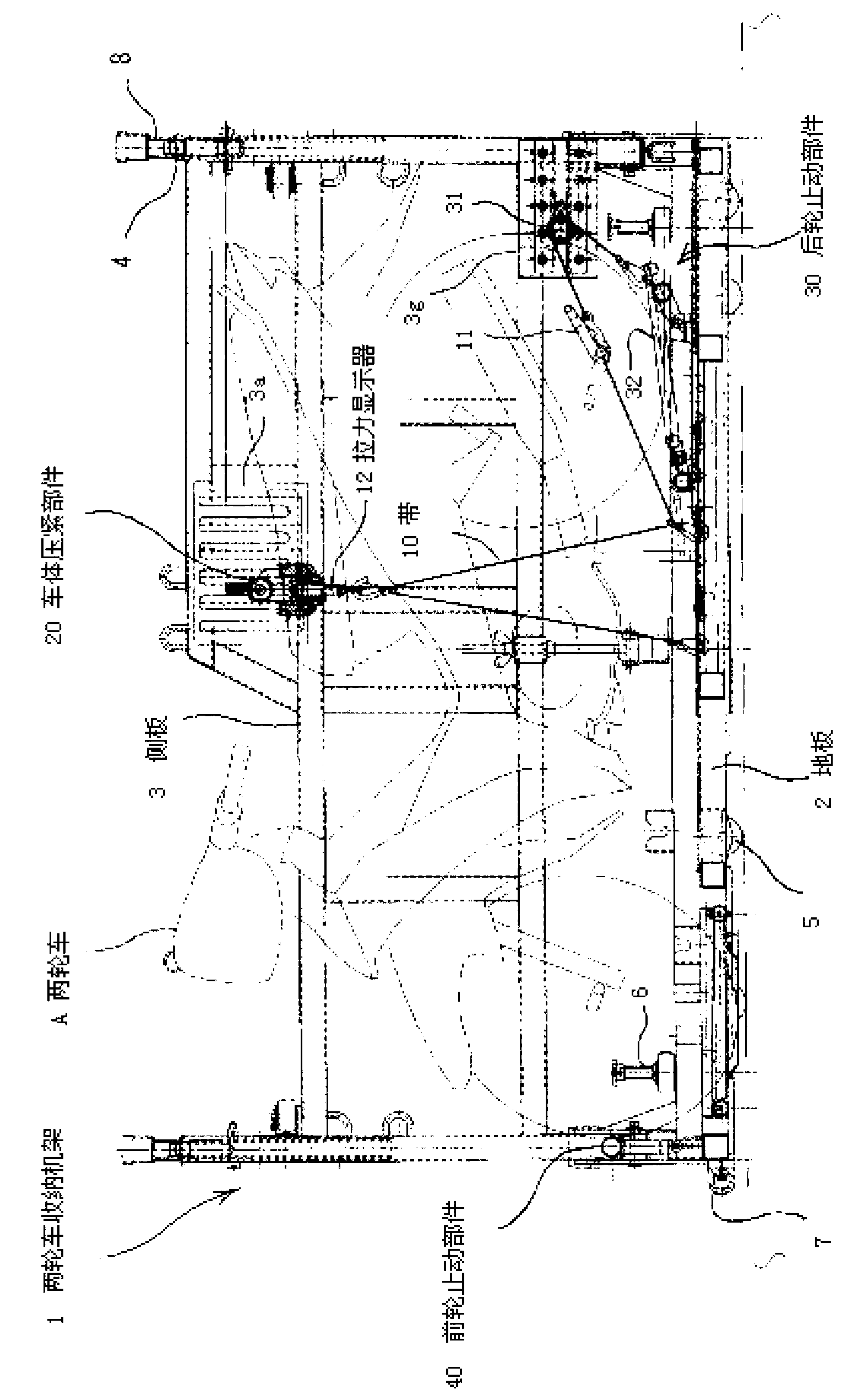

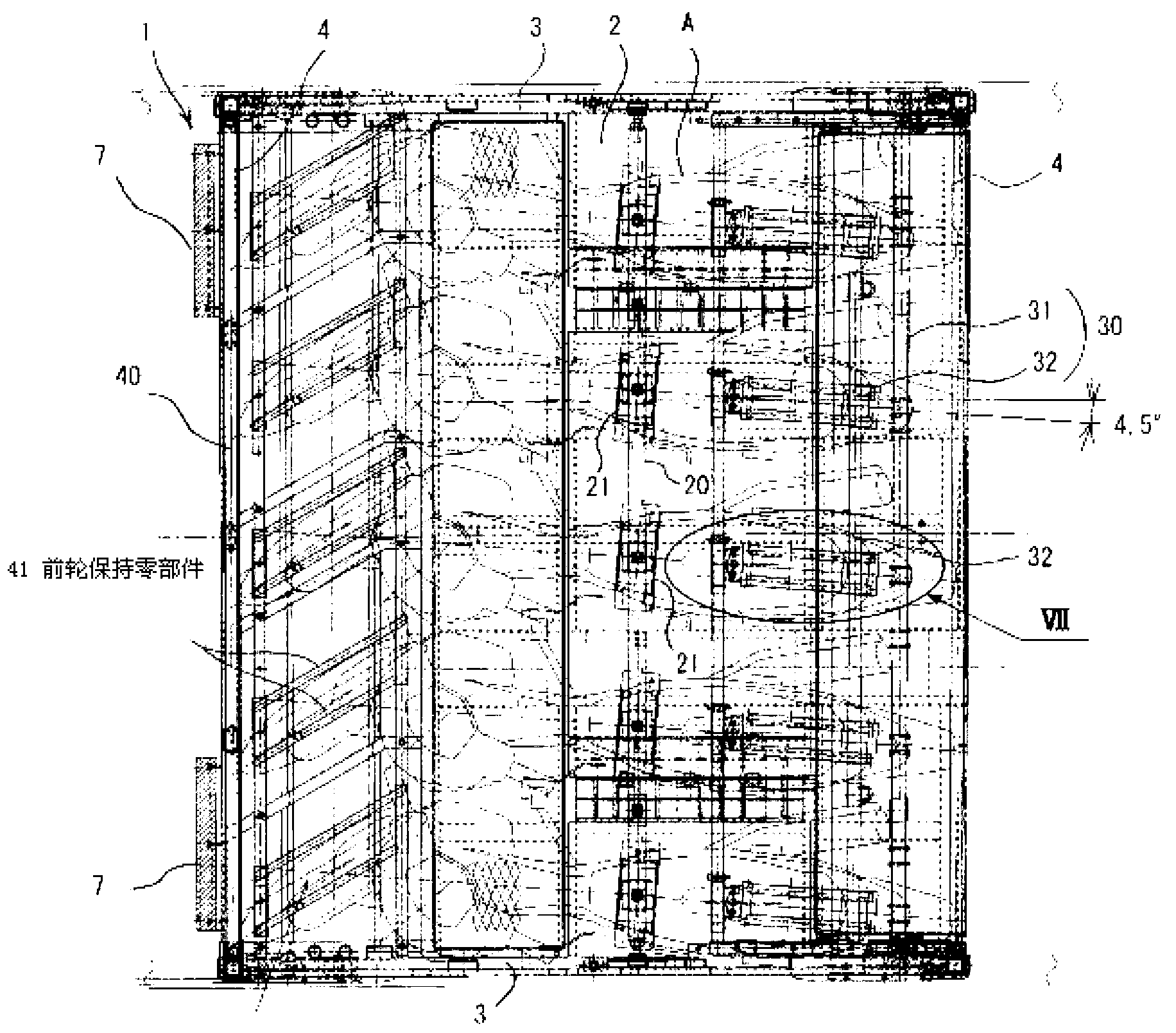

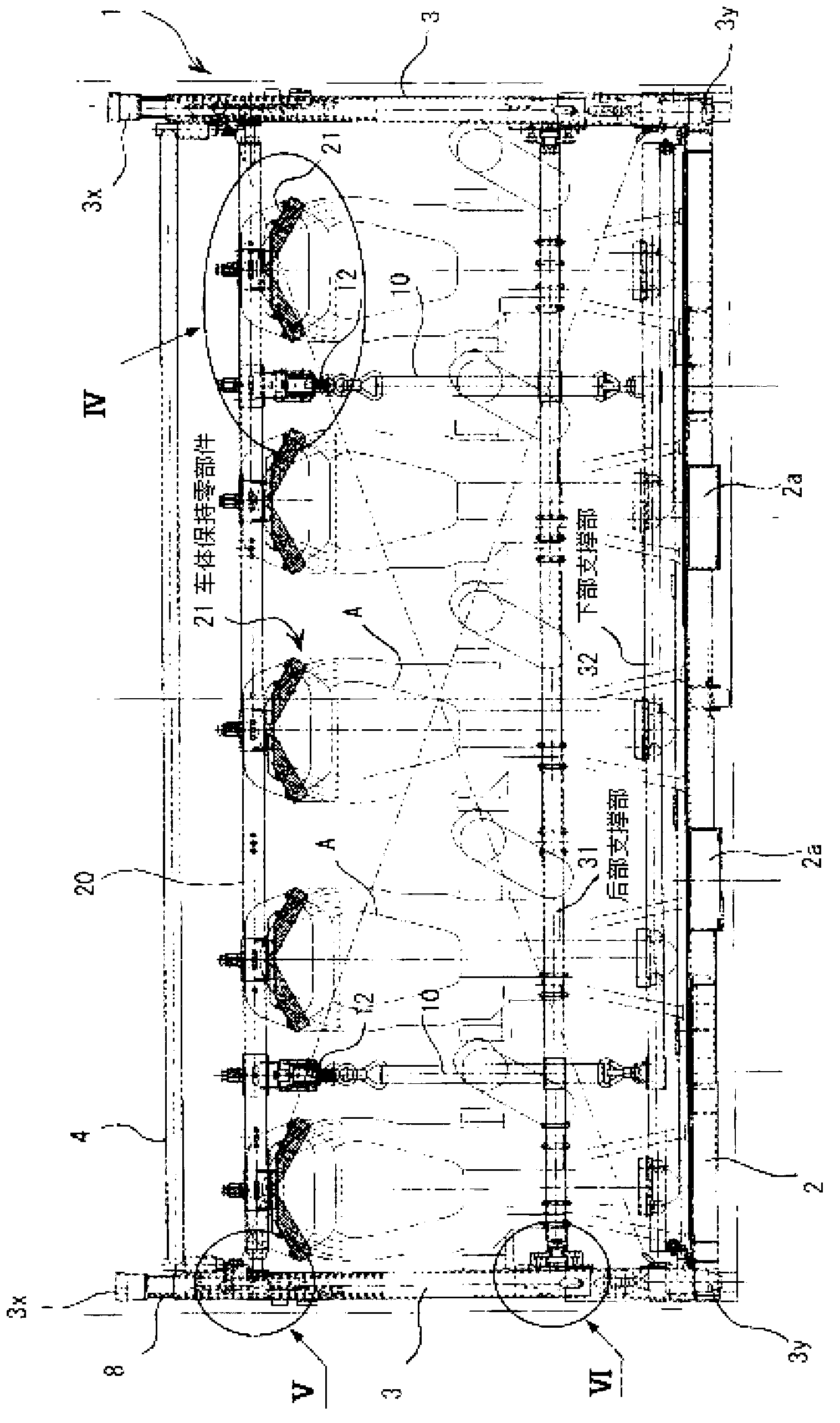

Securing device for transporting two-wheeled vehicle

InactiveCN103298713AEasy to fixFixed softPackaging vehiclesContainers for machinesEngineeringMechanical engineering

The purpose of the present invention is to provide a securing device for transporting a two-wheeled vehicle that reliably secures a two-wheeled vehicle during transport and lessens the mechanical burden of doing so, and that is compatible with two-wheeled vehicles differing in size and otherwise. The securing device secures a two-wheeled vehicle (A) to a floor (2) in order to transport the two-wheeled vehicle. A body holding member (20) that rests on the seat of the two-wheeled vehicle (A) is provided so as to be height adjustable, and a front wheel stop member (40) and a rear wheel stop member (30) that secure the position of the front wheel and the rear wheel are provided so that the front-to-back distance between the two members is adjustable. The floor (2) or members formed integrally therewith, the body holding member (20), and the rear wheel stop member (30) are connected via a continuous belt (10). Through adjustment of the length of the belt (10) the body holding member (20) presses the saddle from above and the front-to-back distance between the front wheel stop member (40) and the rear wheel stop member (30) is reduced and thus both members restrict the front-to-back direction positions of the front and rear wheels.

Owner:ROKKO ENG

Exposed welding leg of chip packaging body and processing method of exposed welding leg

ActiveCN114783888AEasy to pile upClear solderingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a chip packaging body exposed welding pin and a processing method thereof, and belongs to the technical field of semiconductor packaging, and the processing method comprises the following steps: after a packaging body is formed, forming a protruding welding pin on the packaging body before the packaging body is cut, so as to replace the step of forming the welding pin while forming a conductive layer group on the packaging body. Firstly, a plurality of cutting grooves are formed in a packaging body, each cutting groove is formed in the position of a cutting channel to be cut on the packaging body, each cutting groove is divided into two parts which are symmetrical left and right by the cutting channel, protruding weld legs are formed on the packaging body and in the cutting grooves, and the protruding weld legs comprise side weld legs and bottom weld legs. According to the packaging body, an original plate-shaped welding leg is changed into the L-shaped protruding welding leg wrapping the right-angle side of the packaging body, the forming sequence of the welding leg is changed, machining is convenient, tin climbing is obvious when the packaging body is welded, observation is convenient, and pseudo soldering is avoided.

Owner:HEFEI SMAT TECH CO LTD

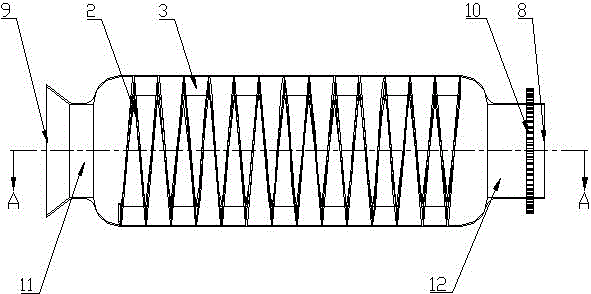

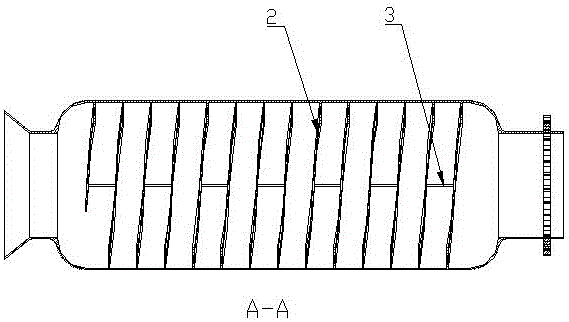

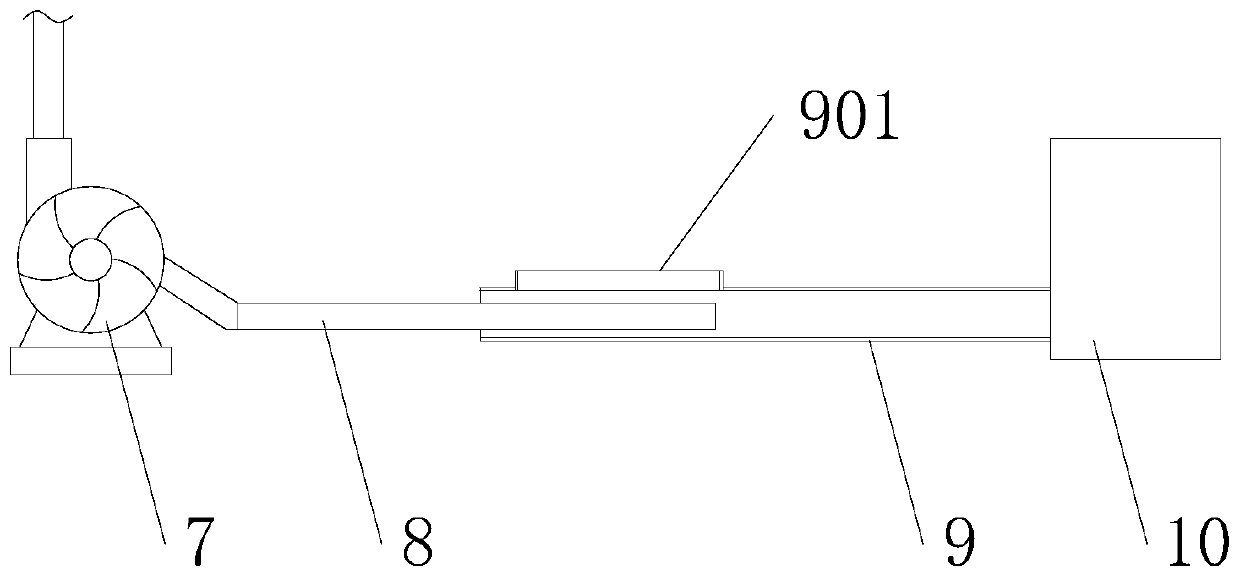

Coal particle drying device

InactiveCN113091421AImprove work efficiencyKeep dryGranular material dryingDrying gas arrangementsThermodynamicsCoal particle

The invention provides a coal particle drying device. The coal particle drying device comprises a drying cylinder for drying coal, a supporting base for supporting the drying cylinder, an inclined surface material turning mechanism for turning the coal and a uniform material screening mechanism, wherein the bottom of the drying cylinder is fixedly connected with the supporting base, the inclined surface material turning mechanism is arranged on the drying cylinder, and the uniform material screening mechanism is arranged on the drying cylinder and the inclined surface material turning mechanism. The invention relates to the field of coal processing. According to the coal particle drying device, a special structure which can facilitate uniform dispersion, improve the lift and turn the coal at various angles is designed according to the problems that in an existing coal drying process, the coal is prone to bonding, low in lift and not prone to turning, and thus, the problems that a common drying device difficultly uniformly turn the coal, the coal rolling amplitude is small, the coal is prone to accumulation, the lift in the cylinder is low, the coal drying is not uniform, and the drying efficiency of the coal is influenced to a certain extent are effectively solved.

Owner:沈晓军

Greenhouse with ventilating function

InactiveCN108283088AWith ventilation functionImprove securityDispersed particle filtrationTransportation and packagingImpellerFixed frame

The invention relates to a greenhouse with a ventilating function. The greenhouse comprises a wall body. A ceiling is arranged at the upper end of the wall body. A ventilating device is arranged on the wall body, and comprises a window plate arranged on the wall body. A vent hole is formed in the wall body and runs through the wall body. The lower side of the window plate is hinged to the lower edge of the vent hole. The outer edge of the window plate and the inner wall of the vent hole are each provided with a sealing elastic layer. Louver blades are arranged in the vent hole and provided with grids. A power channel is arranged in the vent hole. A motor and a fixing frame for fixing the motor are arranged in the power channel. An impeller is arranged at the output end of the motor. A filtering channel is connected with the power channel. A coarse filter screen and a fine filter screen are sequentially arranged on the filtering channel from outside to inside. A silent plate wraps the outer surface of the filtering channel. A flame-retardant plate wraps the outer surface of the silent plate. The greenhouse of the structure has a high ventilation property and high safety.

Owner:汪盛明

Synthetic method of metal organic framework

PendingCN113845662AImprove mass transfer efficiencyEasy access to each otherXylyleneMetal-organic framework

The invention relates to a metal organic framework material, in particular to a preparation method of the metal organic framework material, which comprises the following steps: (1) adding a metal zirconium salt and a dicarboxylic acid organic ligand into an aprotic polar solvent, and stirring the solution at room temperature until the solid is completely dissolved to obtain a solution I; (2) adding monocarboxyl organic acid into the solution I, and uniformly stirring the solution I to obtain a solution II; (3) adding water into the solution II to obtain a solution III; (4) adding a regulator into the solution III to obtain a solution IV, the regulator being one of xylene, trimethylbenzene or tetramethylbenzene; (5) controlling the temperature range of the solution IV to be 25-300 DEG C, and carrying out hydrothermal reaction; (6) after the reaction is finished, carrying out centrifugal separation, washing and drying to obtain a target product. Herein, the small-grain zirconium-based MOFs material can be successfully obtained by controlling the nucleation and crystallization rate of the metal ions and the organic ligands, so that the mass transfer efficiency of the microporous material is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Healthcare drink capable of losing weight

The invention belongs to the field of healthcare drinks, particularly relates to a healthcare drink capable of losing weight and provides a healthcare drink capable of decomposing fat and preventing fat accumulation to reduce fat and to lose weight. The healthcare drink is prepared from the following raw materials: green papaya, strawberry, radix bupleuri, lotus leaves, rhizoma alismatis, cassia seeds, pu'er tea, honey and spring water. The healthcare drink is prepared by the following methods of firstly extracting papaya enzyme from papaya; decocting and filtering Chinese herbal medicines in the raw materials to obtain a Chinese herbal medicine liquid, mixing the Chinese herbal medicine liquid with brewed pu'er tea and strawberry juice evenly, adding the extracted papaya enzyme at the ratio and carrying out seasoning through adding the honey and the spring water to prepare the healthcare drink capable of losing weight. Natural raw materials are adopted, so that the healthcare drink does not contain any feed additive, is unique in taste, healthy and nutrient, is rich in effective components of the papaya enzyme and multiple Chinese herbal medicines and has the healthcare efficacies of relaxing bowel, reducing fat and blood pressure and losing weight.

Owner:南陵县葛业协会

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com