Display device, flexible OLED display panel and manufacturing method of flexible OLED display panel

A display panel, flexible technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc. Good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

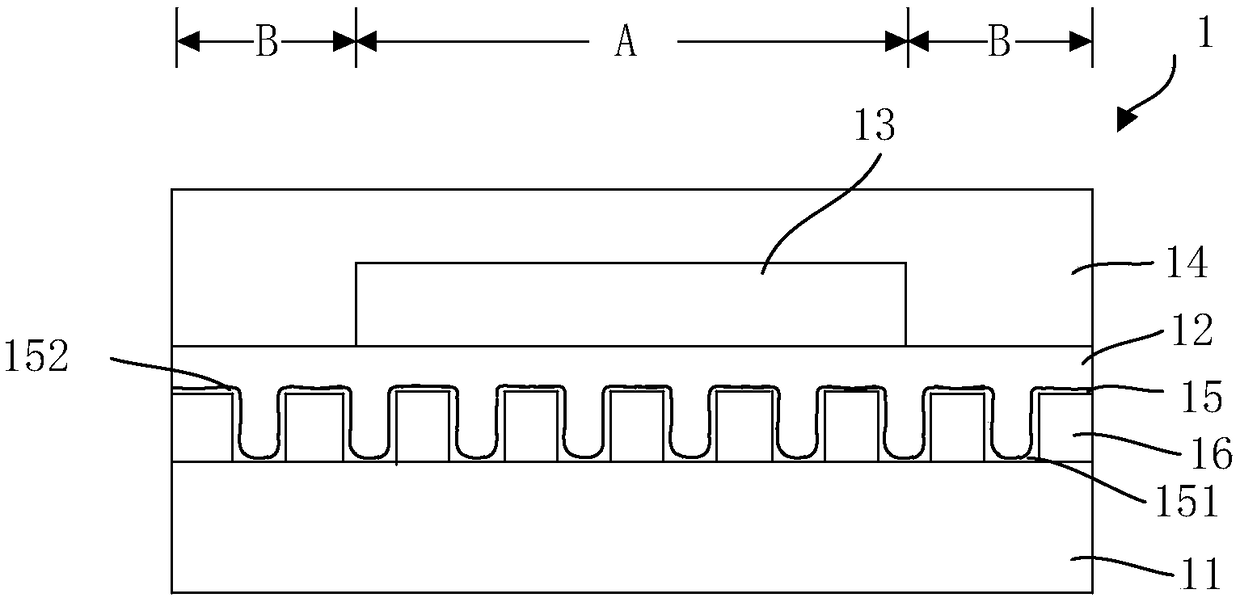

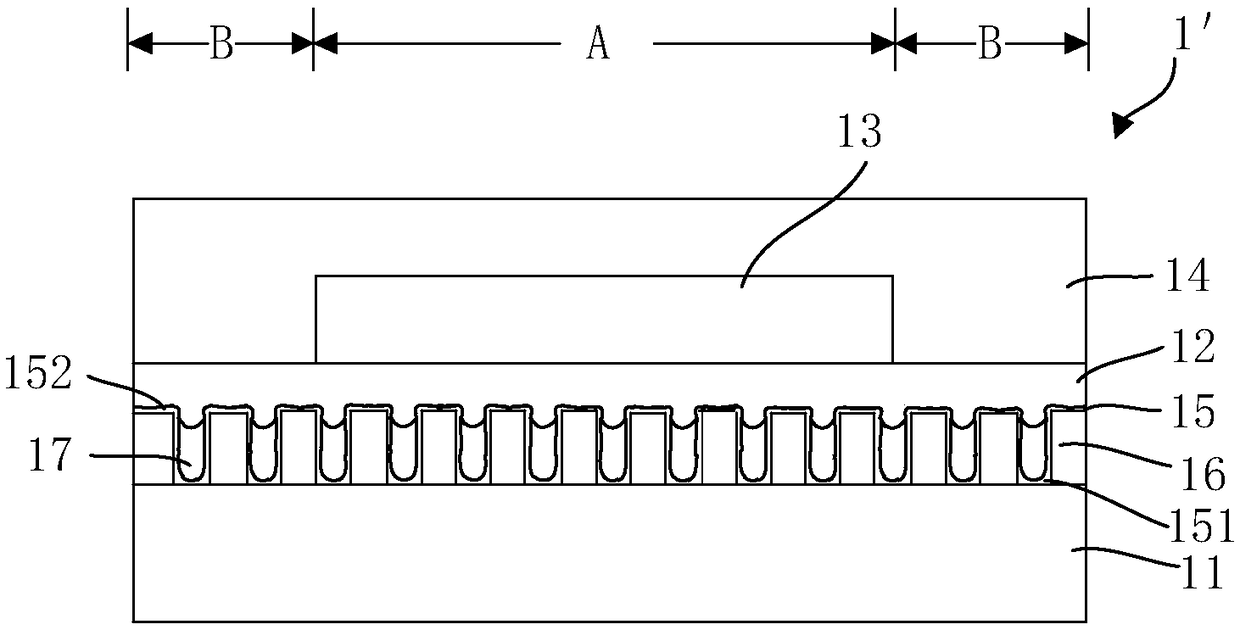

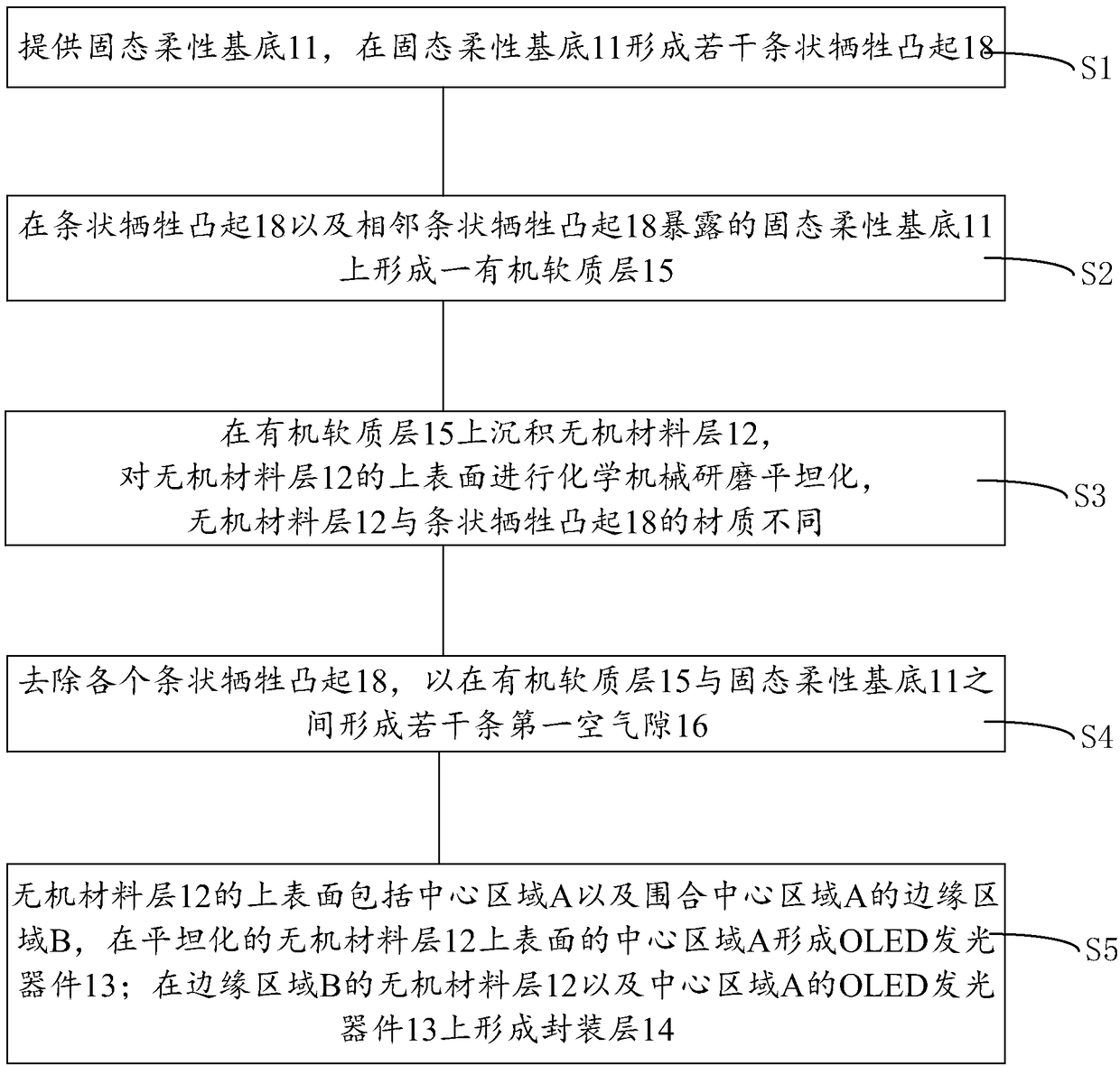

[0095] figure 1 It is a schematic structural diagram of a flexible OLED display panel in an embodiment of the present invention.

[0096] refer to figure 1 As shown, the flexible OLED display panel 1 includes:

[0097] a solid flexible substrate 11;

[0098] An inorganic material layer 12 located on the solid flexible substrate 11, the upper surface of the inorganic material layer 12 is flat, including a central area A and an edge area B surrounding the central area A;

[0099] An OLED light-emitting device 13 located in the central area A of the upper surface of the inorganic material layer 12;

[0100] An encapsulation layer 14 on the inorganic material layer 12 in the edge area B and the OLED light emitting device 13 in the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com