Anti-ultraviolet cold film for pallet-free packaging

A technology for packaging without trays, applied in the field of packaging materials, can solve the problems of easy deformation, no anti-ultraviolet effect, insufficient cold film strength, etc., and achieve the effects of strong wrapping, good tensile performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

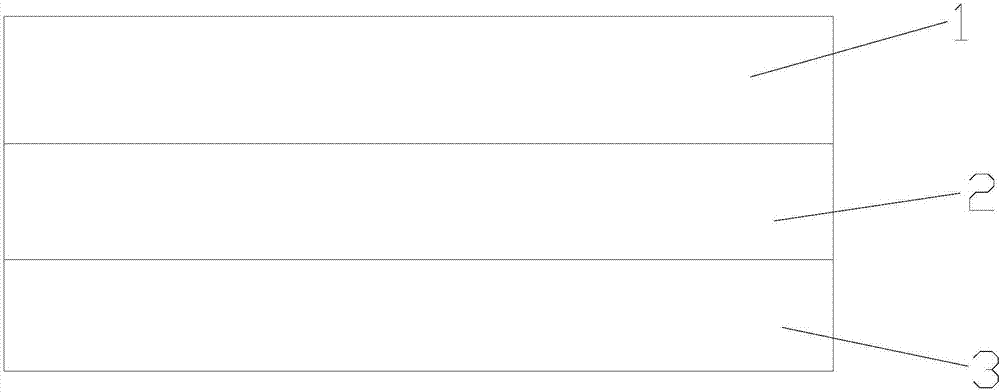

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0014] As shown in the figure, an embodiment of the cold film for anti-ultraviolet trayless packaging of the present invention is provided, which is sequentially co-extruded from the first layer 1, the second layer 2, and the third layer 3 materials. The first layer 1 material accounts for 20%-30%, the second layer 2 material accounts for 40%-60%, and the third layer 3 material accounts for 20%-30%;

[0015] In terms of mass fraction, the first layer of materials includes: metallocene raw materials accounting for 90%-95%, functional masterbatch accounting for 5%-10%;

[0016] In terms of mass fraction, the second layer of materials includes: ethylene-vinyl acetate copolymer raw materials accounted for 5%-95%, high-pressure raw materials accounted for 5%-15%, functional masterbatch accounted for 5%-10%;

[0017] In terms of mass fraction, the third layer of materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com