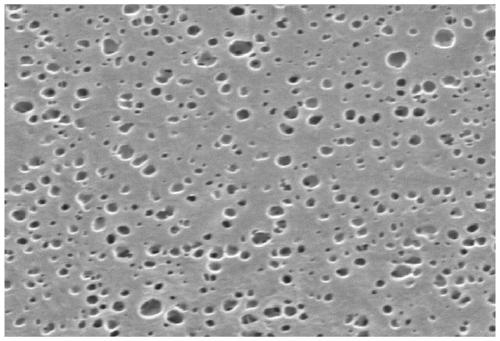

Patents

Literature

70results about How to "Good tensile properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel photo-irradiation induced self-repairing precious metal nano composite hydrogel and preparation method thereof

InactiveCN105949364AGood resistance to notch sensitivityGood tensile propertiesUnder-stimulationSelf repair

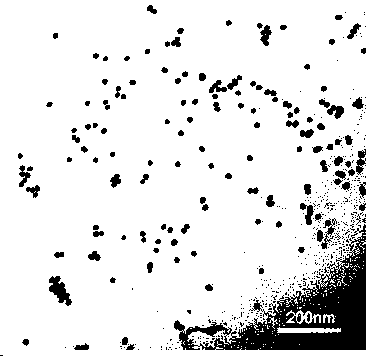

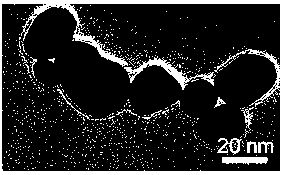

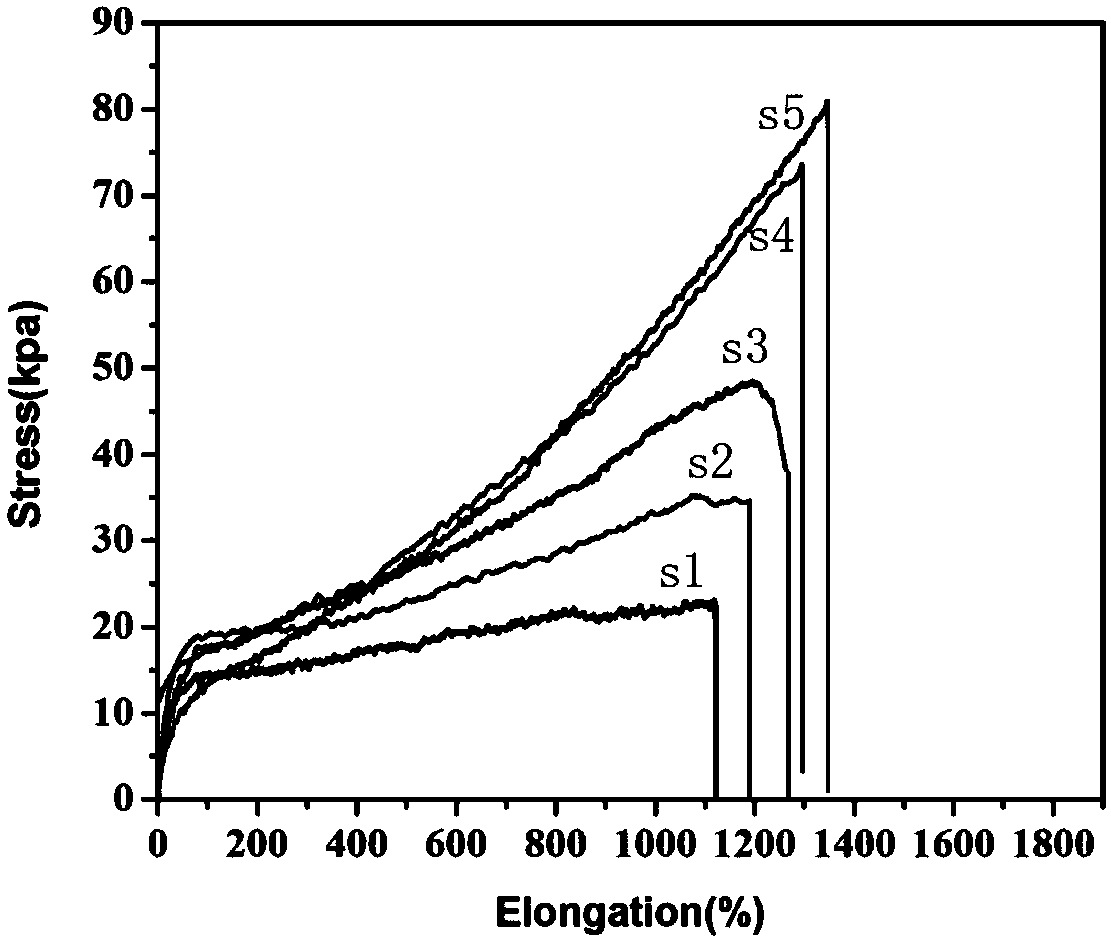

The invention discloses novel photo-irradiation induced self-repairing precious metal nano composite hydrogel. According to the hydrogel, a dynamic precious metal-sulfur coordination bond serves as a self-healing body which has a uniform mesh structure, that is, monomer has uniform polymerization reaction in the polymerization process, and accordingly the hydrogel has good stretchability and strength. The hydrogel has good notch sensitivity prevention capacity, that is, when notches or cracks exist in the surface of the hydrogel, hydrogel still has good stretchability. By means of the precious metal-sulfur coordination bond and good light-heat properties of precious metal, the hydrogel shows good self-repairing performance under stimulation of infrared laser.

Owner:HEFEI UNIV OF TECH

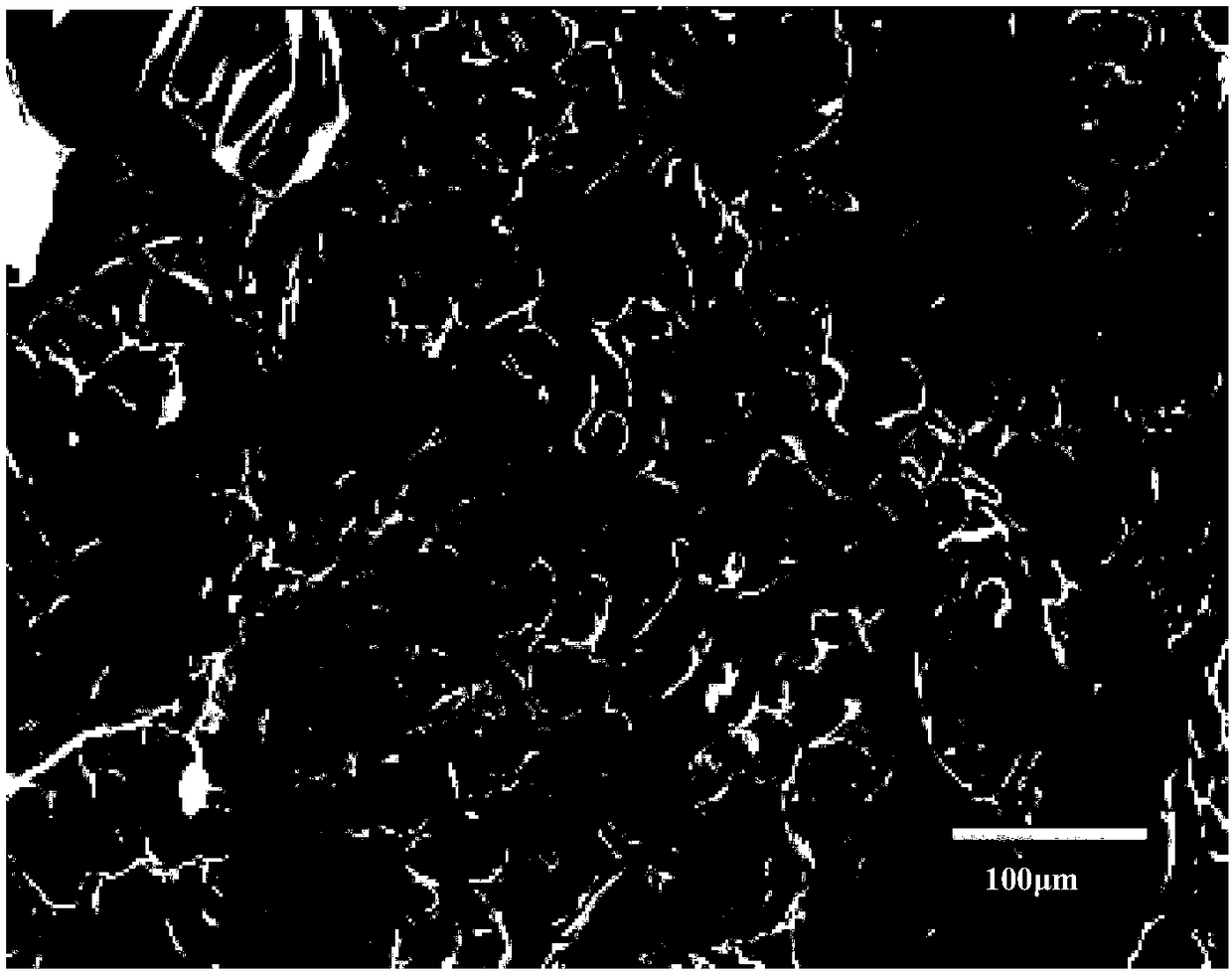

Method for preparing nano-fiber-based guided bone regeneration membrane

InactiveCN103611197AGood mechanical propertiesGood tensile propertiesSurgeryNon-woven fabricsElectrospinningChemistry

The invention relates to the preparation of a hydroxyapatite-grafted polylactide / polylactic acid-copolymerized glycolic acid electrospun nano-fiber-based guided bone regeneration membrane. The membrane is prepared from a mixture of HA-g-PLLA (hydroxyapatite-grafted poly-L-lactic acid) nanoparticles and PLGA (poly(L-co-glycolic acid) by an electrospinning method, i.e., the novel biodegradable guided bone regeneration membrane is constructed. Compared with PLGA and HAP / PLA fiber membranes, the prepared HA-g-PLLA / PLGA composite fiber membrane has the advantages that high mechanical performance is achieved, the adhesion and ductility of osteoblasts on the surface of the membrane are superior to those of the other composite membranes, and the HA-g-PLLA / PLGA composite fiber membrane has a broad application prospect in the treatment of guided bone regeneration.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

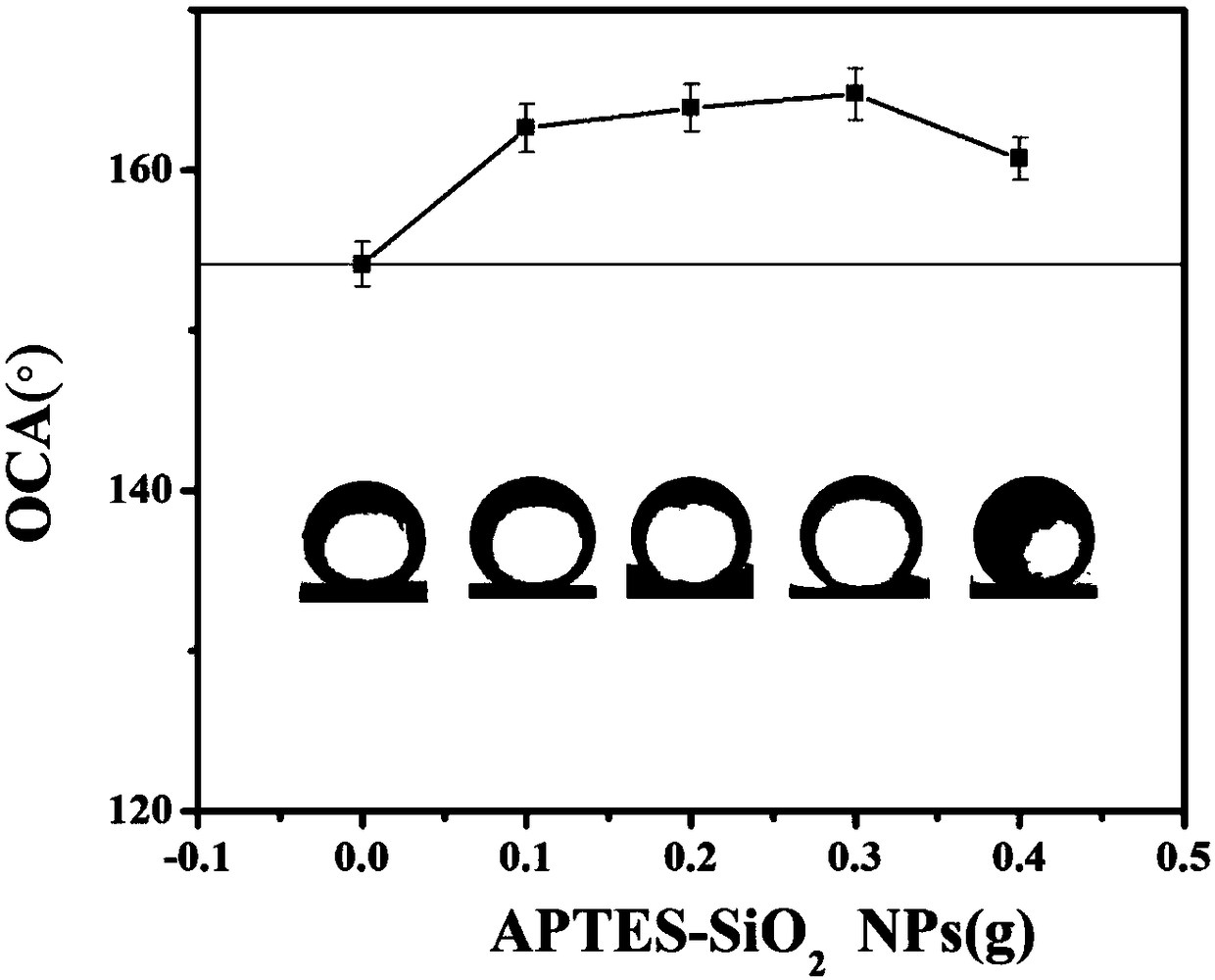

Double-network composite hydrogel, preparation method of double-network composite hydrogel and oil-water separator

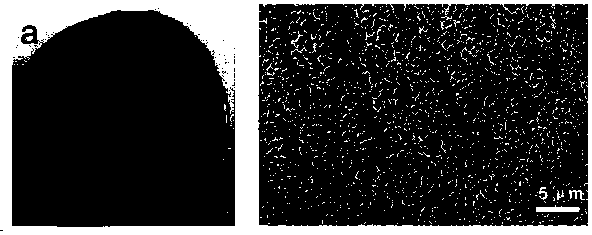

ActiveCN108164643AGood tensile propertiesLow self-healing effectLiquid separationChemistryComposite hydrogels

The invention relates to the field of materials, in particular to double-network composite hydrogel, a preparation method of the double-network composite hydrogel, and an oil-water separator. According to the method, an amino modified silicon dioxide nanoparticle, an acrylamide-acrylic acid copolymer and chitosan are cross-linked into a double-network structure by two pure physical effects of a hydrogen bond and an ionic bond; the double-network composite hydrogel has excellent tensile and underwater super-lipophobic properties, a certain self-repairing effect and a smaller swelling ratio; andthe oil-water separator prepared by coating a copper net with the double-network composite hydrogel is long in life and difficult to damage. The tensile strain of the double-network composite hydrogel is 1500-2000%; the tensile stress is 400-450kpa; a self-healing effect is obvious; the swelling ratio is smaller; and an underwater contact angle reaches 164 DEG. The separation efficiency of the oil-water separator on an oil-water mixture reaches 99.71%, and the hydrogel is an oil-water separation material with good development prospects.

Owner:HUBEI UNIV

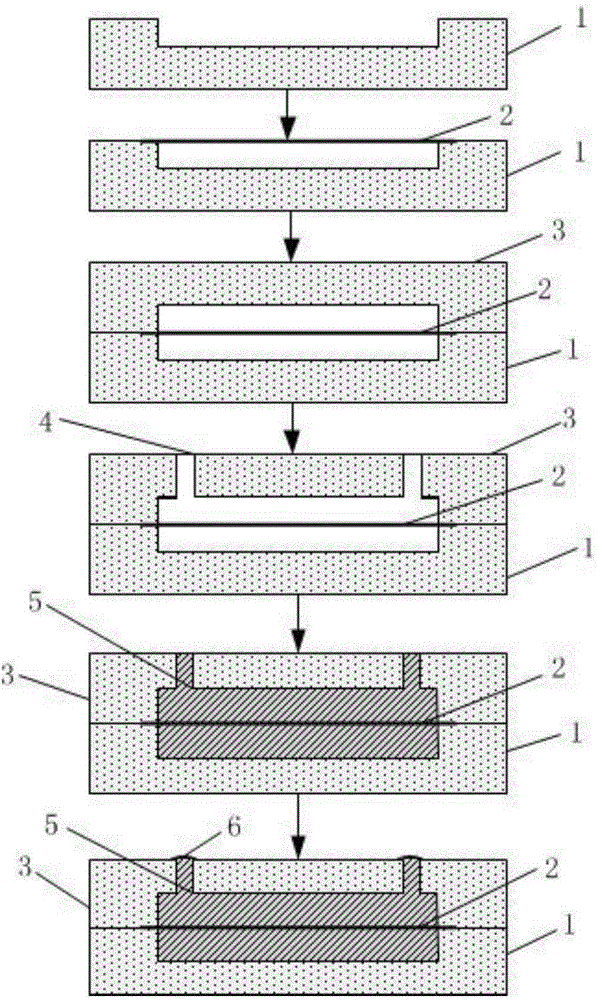

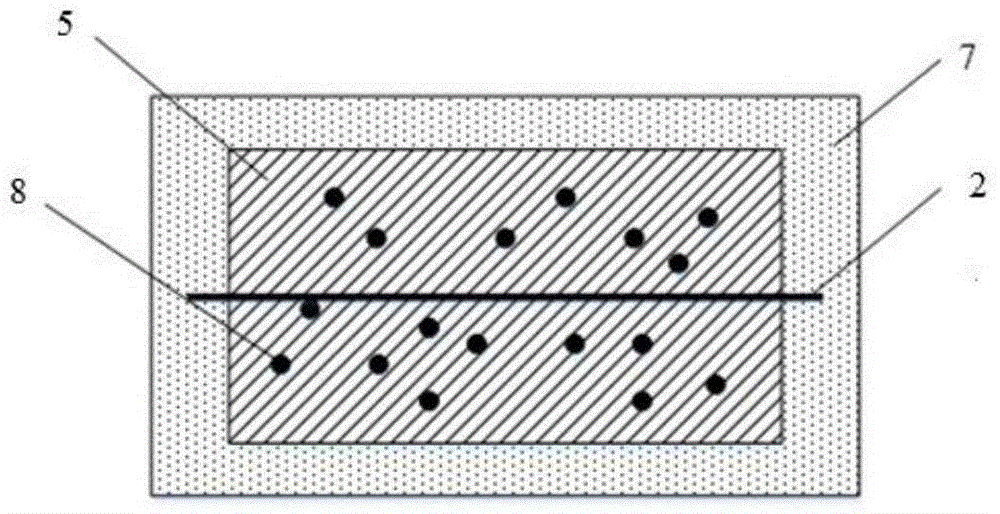

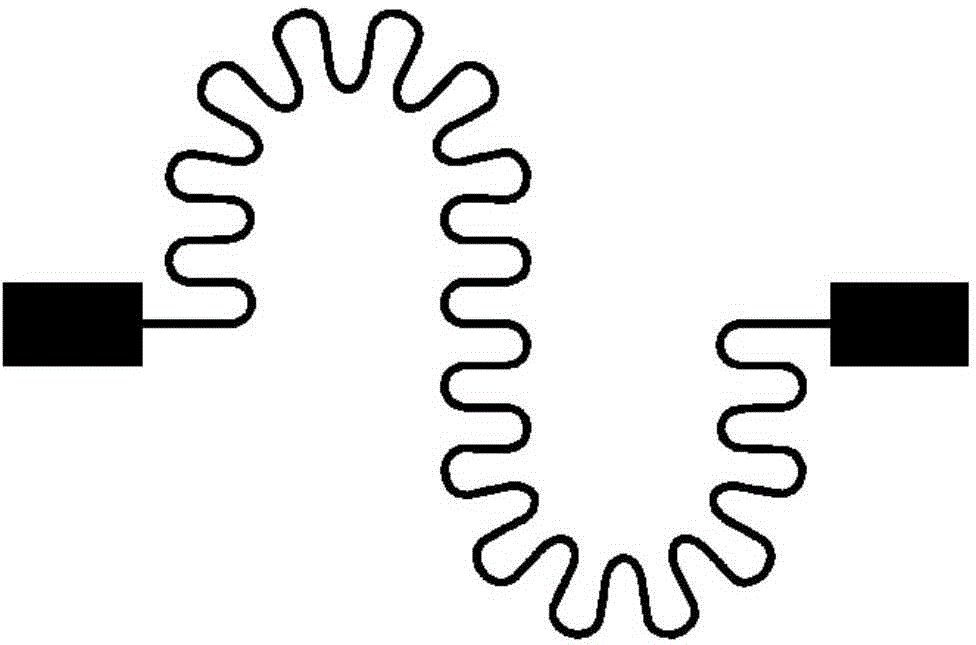

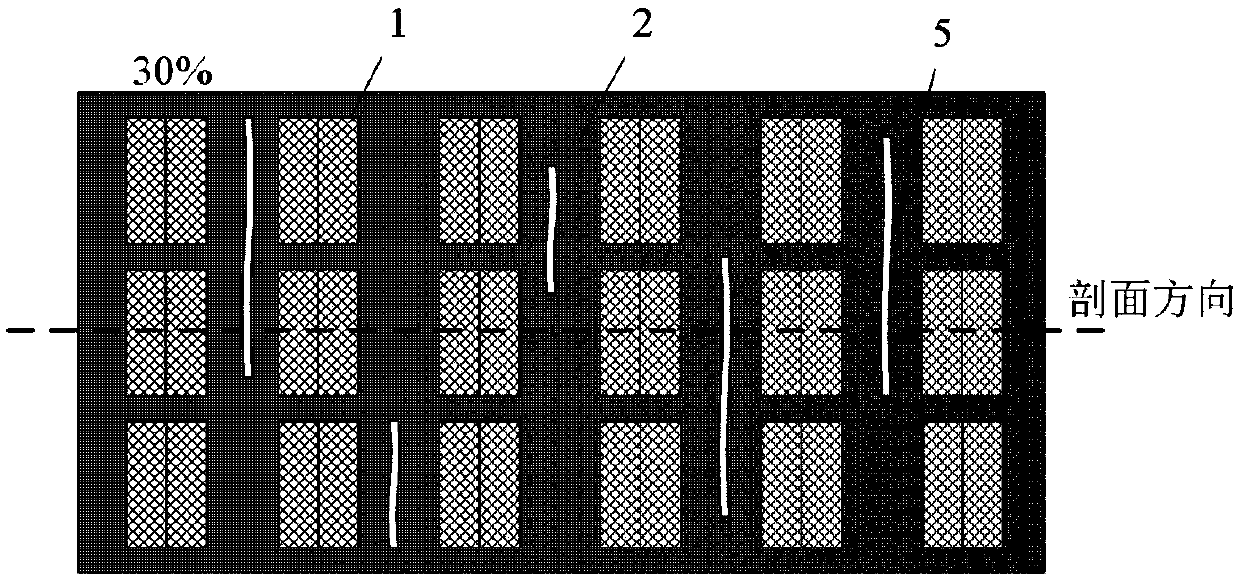

Flexible electronic fluid encapsulation method capable of improving ductility

ActiveCN104445055AImprove job stabilityGood tensile propertiesPrecision positioning equipmentDecorative surface effectsFlexible electronicsEngineering

The invention discloses a flexible electronic fluid encapsulation method capable of improving ductility. The flexible electronic fluid encapsulation method comprises the following steps: preparing an upper encapsulation structure and a lower encapsulation structure, wherein the two encapsulation structures are symmetrical and areas concavely extending are formed in central parts of the encapsulation structures; manufacturing a ductility interconnection structure which is of a curve structure with overall wavy distribution; correspondingly laminating the upper encapsulation structure and the lower encapsulation structure, and encapsulating the ductility interconnection structure in a hollow micro cavity; and finally, injecting insulation fluid into the micro cavity so that the micro cavity is filled with the insulation fluid and the ductility interconnection structure is coated, and therefore, the overall fluid encapsulation operation is completed. By virtue of the flexible electronic fluid encapsulation method capable of improving ductility, the tensile property of the interconnection structure can be remarkably improved; the phenomenon that the surface warps outwards is avoided; the quality can be controlled; meanwhile, the stability of the interconnection structure can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

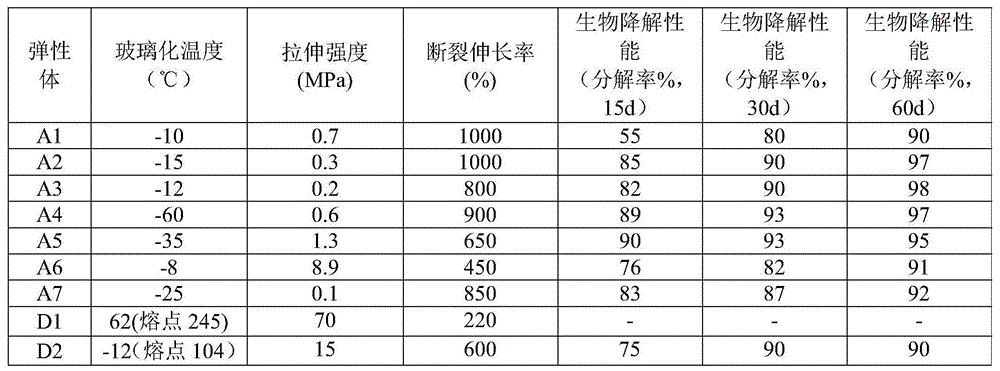

Polyester elastomer and preparation method thereof

InactiveCN105524259AGood tensile propertiesLower glass transition temperatureIsophthalic acidDicarboxylic acid

The invention discloses a polyester elastomer and a preparation method thereof. The method comprises the following steps: under condition of an esterification reaction and / or an ester interchange reaction, a dicarboxylic acid (ester) and dihydric alcohol-containing mixture is reacted; under condensation polymerization condition and existence of a polycondensation catalyst, the products after the esterification reaction and / or the ester interchange reaction; eherein, the dicarboxylic acid (ester) contains succinic acid (ester), isophthalic acid (ester) and terephthalic acid (ester), and dihydric alcohol contains glycol. The polyester elastomer has good biodegradability, has excellent stretching performance and rebound performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

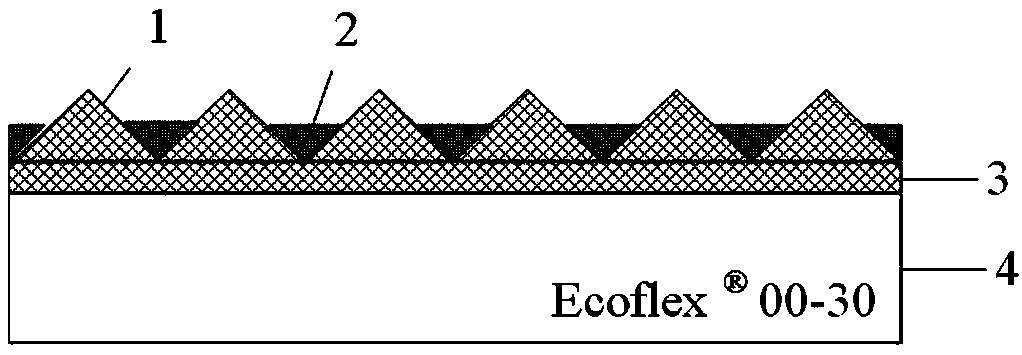

Flexible strain sensor based on carbon nano-tubes and preparation method thereof

ActiveCN109631742AHigh sensitivityGood tensile propertiesMaterial nanotechnologyNanosensorsStrain sensorCarbon nanotube

The invention discloses a flexible strain sensor based on carbon nano-tubes and a preparation method thereof. The flexible strain sensor comprises an epoxy resin layer, a composite layer and a multiwall carbon nano-tube layer; the composite layer is laid on an upper surface of the epoxy resin layer; the composite layer is provided with bulges in array distribution; the multi-wall carbon nano-tubelayer is laid among the bulges and connected with the adjacent bulges; the composite layer is made of the epoxy resin multi-wall carbon nano-tube composite material. The strain sensor has excellent sensitivity and wide measurement range; and meanwhile, the preparation method is simple and practicable.

Owner:SOUTHEAST UNIV

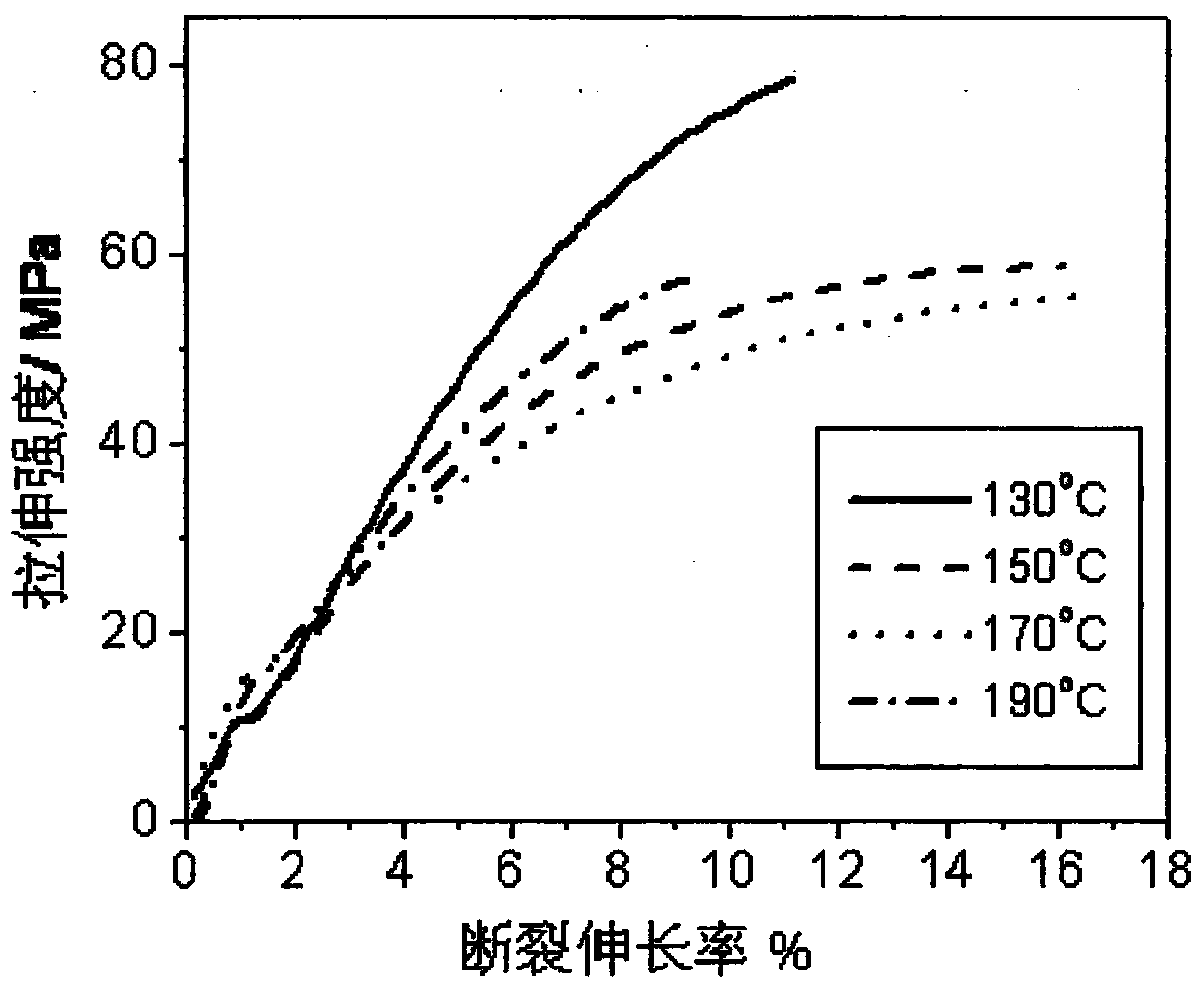

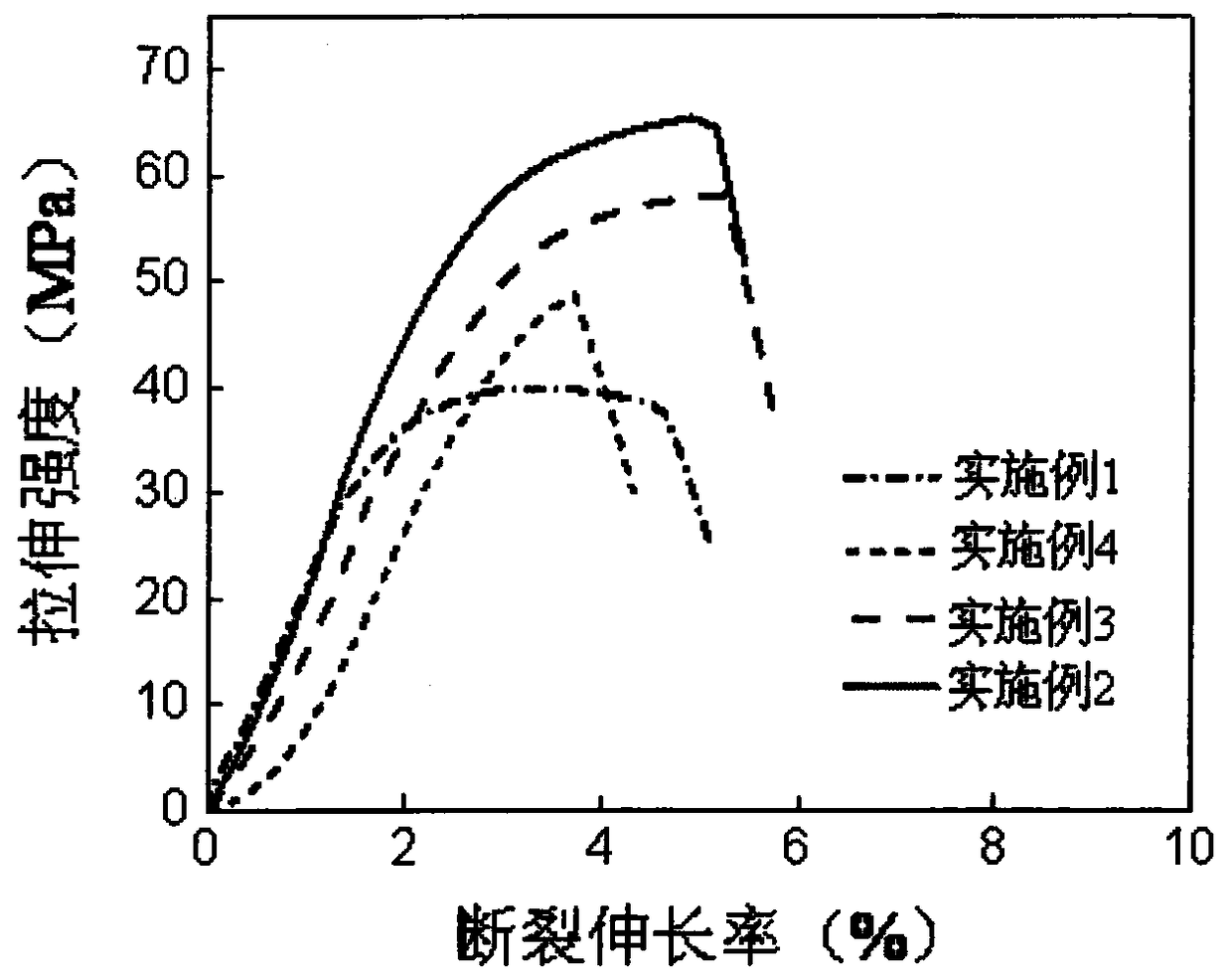

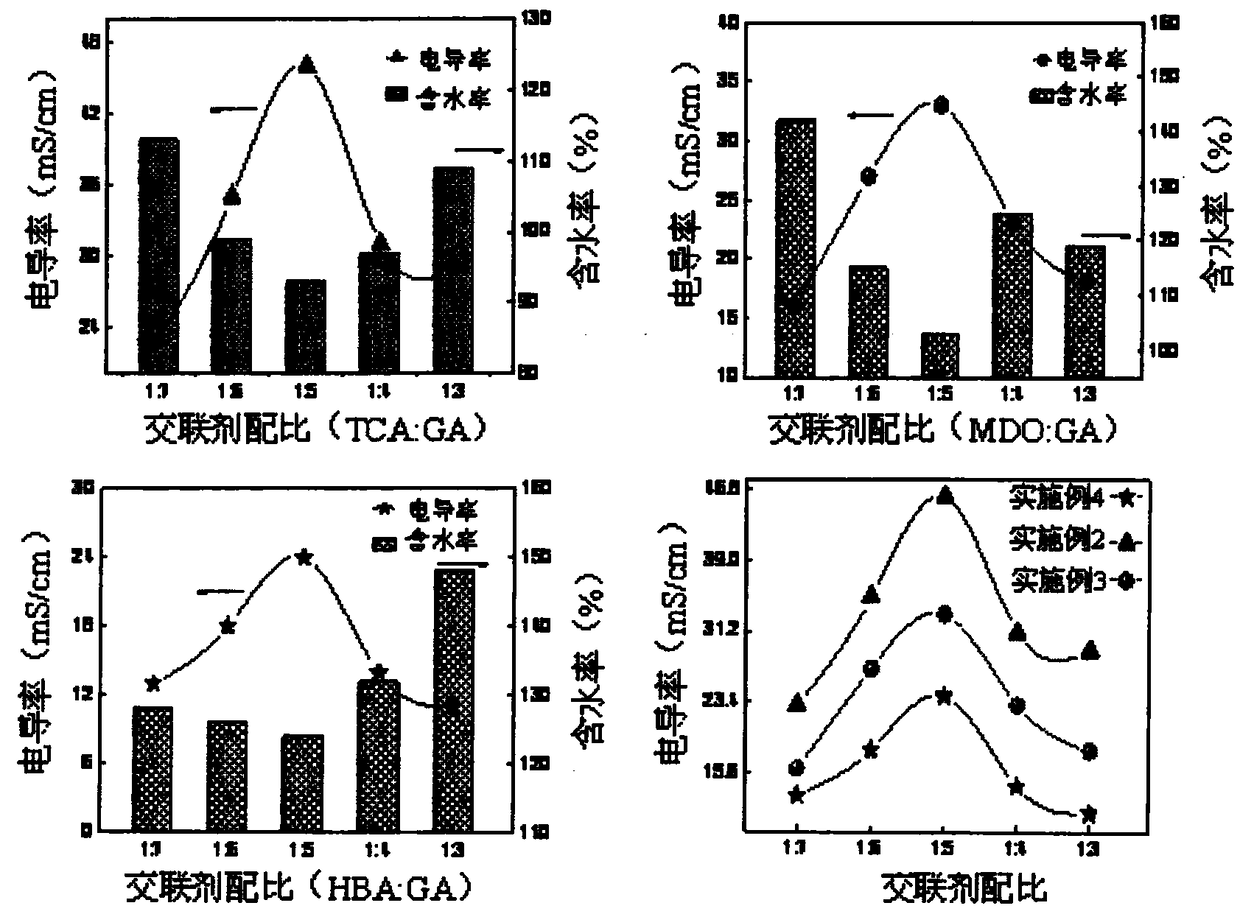

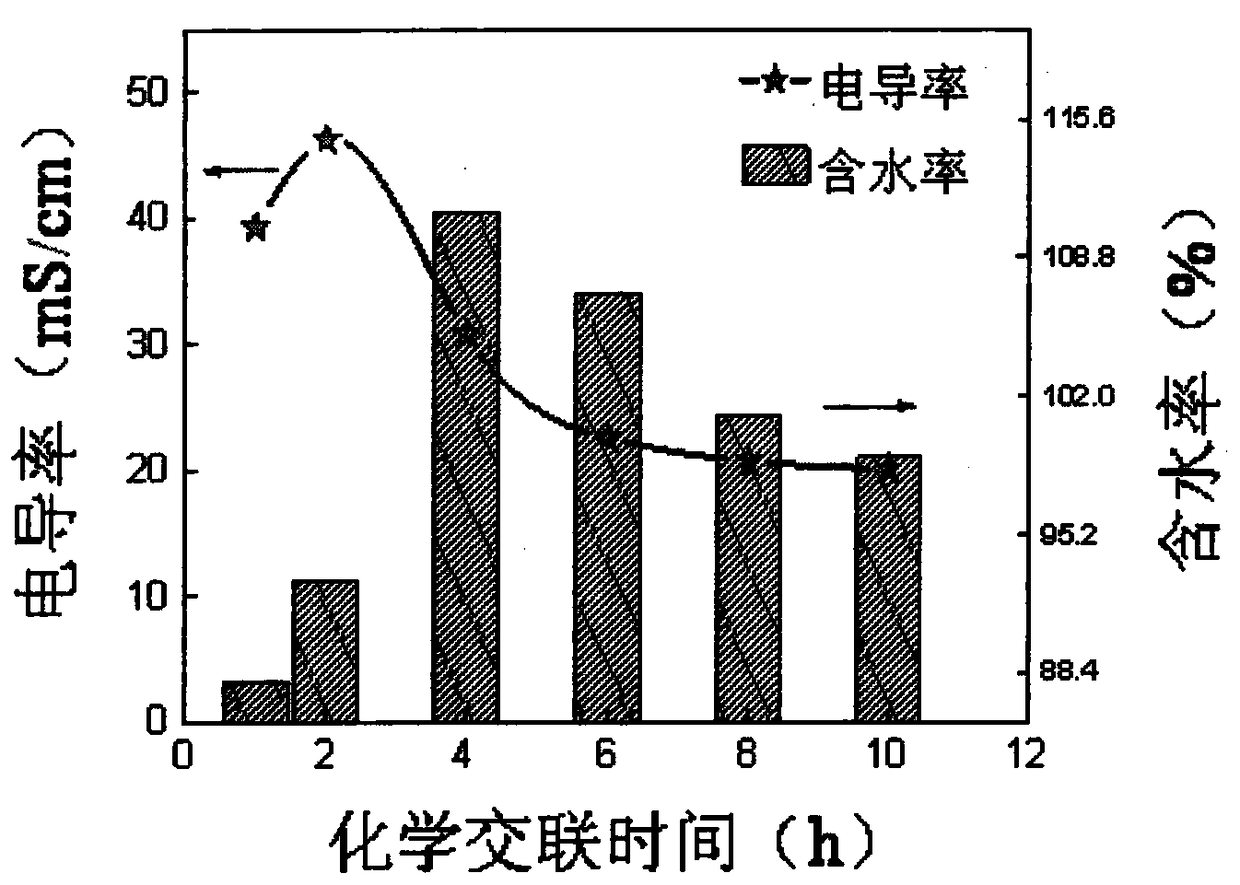

Alkaline anion-exchange composite membrane with high mechanical properties, and preparation and application thereof

InactiveCN104371128AGood tensile propertiesGood elongation at breakFinal product manufactureCell electrodesIonIon exchange

The invention relates to preparation and application of an alkaline anion-exchange composite membrane with high mechanical properties. The alkaline anion-exchange composite membrane with high mechanical properties comprises low-molecular-weight oxy water-soluble polyvinyl alcohol (PVA) and a polymer of quaternary-ammonium-group-containing water-soluble chlorinated-1-vinyl-3-methyl-1H-iminazole and 1-vinyl-2-pyrrolidone. The preparation method comprises the following steps: respectively dissolving oxy water-soluble PVA and quaternary-ammonium-group-containing Luviquat in deionized water to obtain a uniform mixed solution; carrying out vacuum filtration, pouring the filtrate into a plastic culture dish, and naturally drying to obtain a composite membrane; and carrying out thermophysical crosslinking on the composite membrane, carrying out chemical crosslinking, and finally, immersing in a KOH solution to carry out ion exchange. The preparation method has the advantages of accessible raw materials, low cost, no pollution, mild reaction conditions, short reaction time, simple and practical technique, high controllability and the like, and can easily implement large-scale production.

Owner:DONGHUA UNIV +1

High-strength binary cross-linked alkaline anion exchange composite film, preparation method and application

InactiveCN108997599AGood tensile propertiesImprove conductivityHybrid capacitor electrolytesFinal product manufactureIon exchangeWater soluble polymers

The invention discloses a high-strength binary cross-linked alkaline anion exchange composite film, a preparation method and an application of the composite film in electrochemical energy devices. Thecomposite film comprises hydroxyl-containing water-soluble polyvinyl alcohol and a water-soluble polymer containing quaternary ammonium groups. The preparation method comprises the following steps: preparing aqueous solutions from hydroxyl-containing water-soluble polyvinyl alcohol and the water-soluble polymer containing quaternary ammonium groups respectively; mixing the two solutions and pouring the mixed solution into a plastic culture dish, drying the mixed solution naturally to form a film and obtain the polymer film; stripping the polymer film from the culture dish, performing heat treatment for physical crosslinking, then performing chemical crosslinking, and finally immersing a product in a KOH solution for ion exchange. The alkaline anion exchange composite film has the advantages of being high in mechanical strength, good in conductivity, low in cost and environmental friendly, the preparation method is simple, has the advantages of mild reaction condition, short reaction time, high controllability and the like, and accordingly, large-scale production is facilitated.

Owner:DONGHUA UNIV

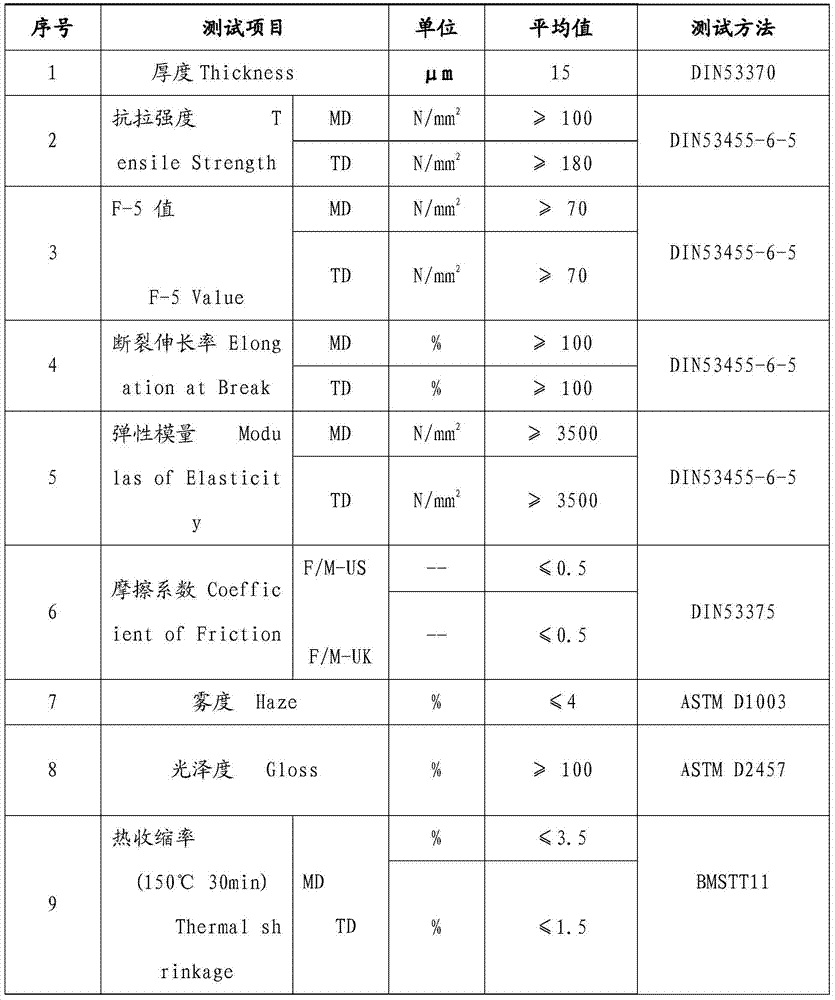

Directly-compoundable low-melting-point polyester thin film preparation method for laminated steel

ActiveCN103753932ALow melting pointGood tensile propertiesLamination ancillary operationsLaminationSolventChemistry

The invention discloses a directly-compoundable low-melting-point polyester thin film preparation method for laminated steel. A core-layer polyester slice is formed by mixing 60 to 80 mass percent of pure polyester slice with a melting point of 180 to 230 DEG C and 40 to 20 mass percent of silicon dioxide additive type polyester slice. In order to avoid the degradation of PET (polyethylene terephthalate) in a melting extrusion process, the core-layer polyester slice is crystallized and dried, wherein primary crystallization is carried out at 80 to 120 DEG C for 12 hours; secondary crystallization is carried out at 150 DEG C; the drying is carried out at 160 DEG C for not less than 6 hours. According to the preparation method, a polyester thin film has the advantages of low melting point, high tensile property, high machinability, resistance to high-temperature cooking, high barrier property, nontoxicity, anti-falling performance and the like, is used as an inner layer and an outer layer of a steel food and medicament can, and can be disinfected and sterilized at high temperature; in addition, the polyester thin film is free of adhesives and chemical solvents, so that safety in use can be ensured.

Owner:TIANJIN WANHUA CO LTD

Alumina based long fiber containing mullite crystal phase, and preparation method thereof

The invention relates to a preparation method for alumina based long fiber containing a mullite crystal phase. The preparation method comprises preparing a basic aluminum chloride sol, a precursor sol, a spinnable sol, original alumina based long fiber and the alumina based long fiber containing the mullite crystal phase, and has advantages of easy preparation and low cost. The prepared long fiber has advantages of long length, small diameter, high strength and good softness.

Owner:XI AN JIAOTONG UNIV

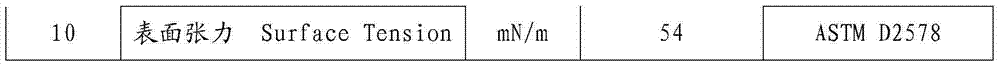

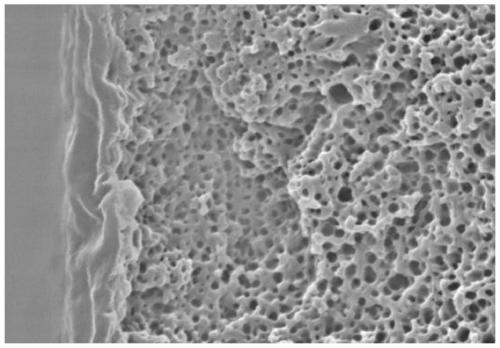

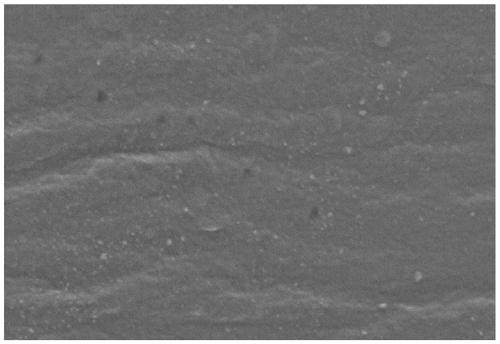

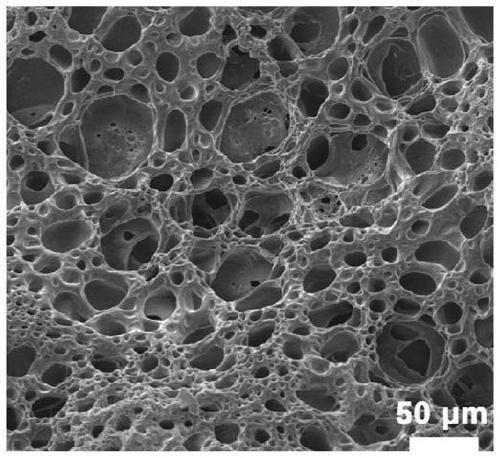

Asymmetric polyolefin degassing membrane and preparation method thereof

PendingCN111346520AGood tensile propertiesGood corrosion resistanceSemi-permeable membranesMembranesPolyolefinFilm material

The invention provides an asymmetric polyolefin degassing membrane which is provided with a porous support layer and a compact separation layer, wherein the average pore diameter of the support layeris 100-5000 nm, and the average pore diameter of the separation layer is 0.1-10 nm; the thickness of the separation layer is 0.5-5 [mu]m, and the thickness ratio of the separation layer to the supportlayer is 1:80-1:200. according to the asymmetric polyolefin film provided by the invention, the separation layer thickness is large, and the more proper thickness ratio of the separation layer to thesupport layer is realized; the polyolefin degassing film has better tensile property and remarkable corrosion resistance, liquid with low surface tension is effectively prevented from breaking through the film material, especially when the polyolefin degassing film is used for ink degassing, the breaking time is far longer than that of other polyolefin degassing films obtained by using solvent systems, and the service life of the polyolefin degassing film is greatly prolonged.

Owner:HANGZHOU COBETTER FILTRATION EQUIP

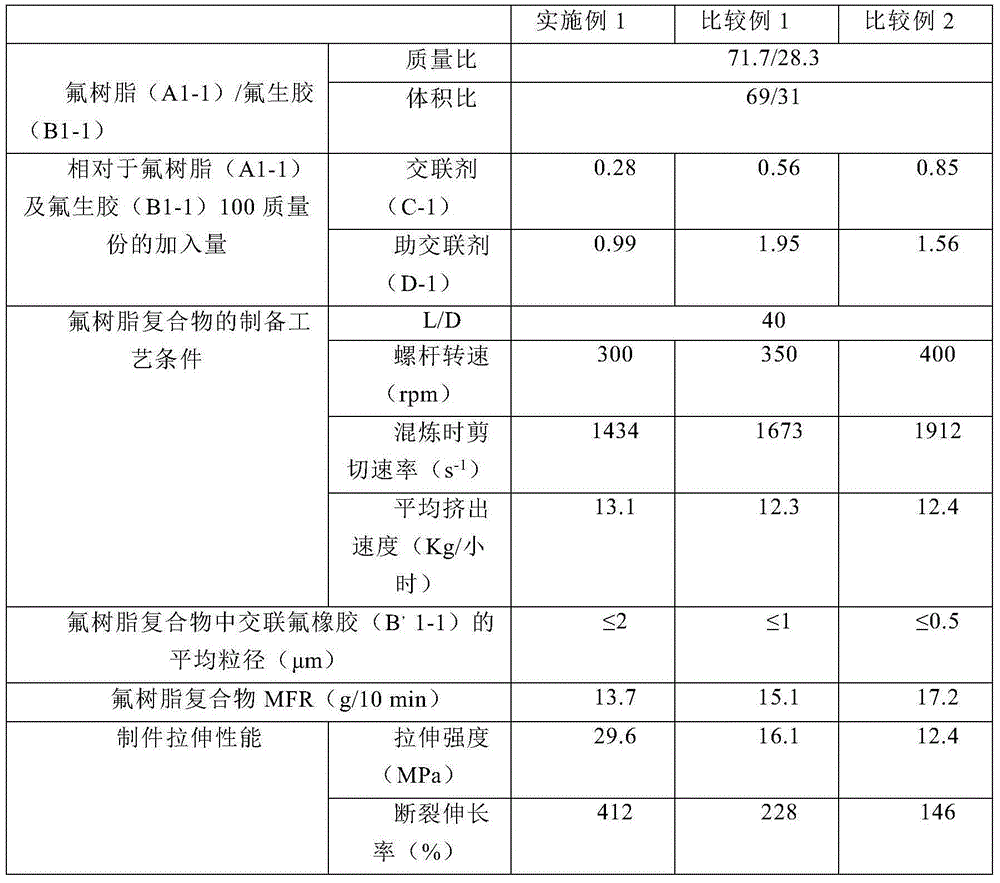

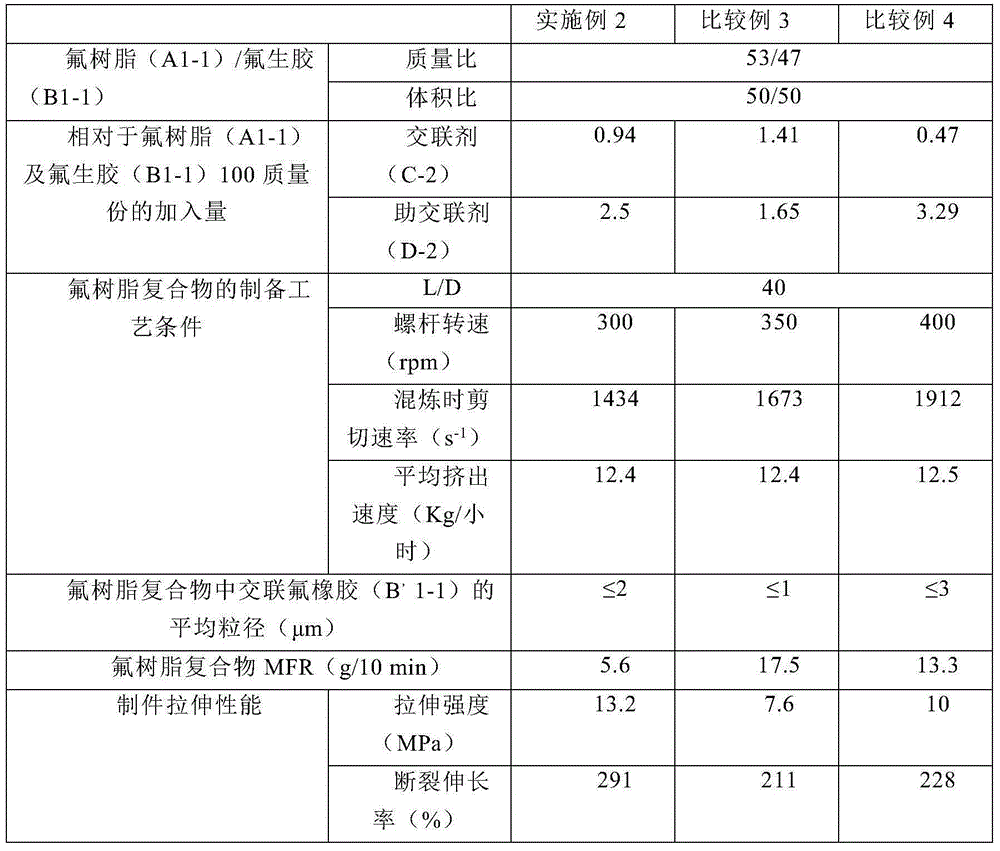

Preparation method of fluororesin composite, fluororesin composite and product produced by molding fluororesin composite

ActiveCN105082495AGood tensile propertiesEasy to stretchDomestic articlesCoatingsRaw rubberScrew speed

The invention relates to a preparation method of a fluororesin composite, the fluororesin composite obtained by the preparation method and a product. The preparation method of the fluororesin composite is a preparation method of a fluororesin (A) and crosslinked fluororubber (B') containing fluororesin composite, and comprises a process of mixing the fluororesin (A), fluorine raw rubber (B) and a crosslinking agent (C) in a twin-screw extruder. The mixing temperature of the twin-screw extruder is higher than a melting point of the fluororesin resin (A), the shearing rate of the twin-screw extruder is from 240s<-1> to 1600s<-1>, the average extrusion output of the twin-screw extruder is more than 10kg / h, and the ratio (L / D) of the length (L) to the outer diameter (D) of a screw of the twin-screw extruder is more than 20, and the screw speed of the twin-screw extruder is 50-700rpm.

Owner:SHANGHAI JIAO TONG UNIV +1

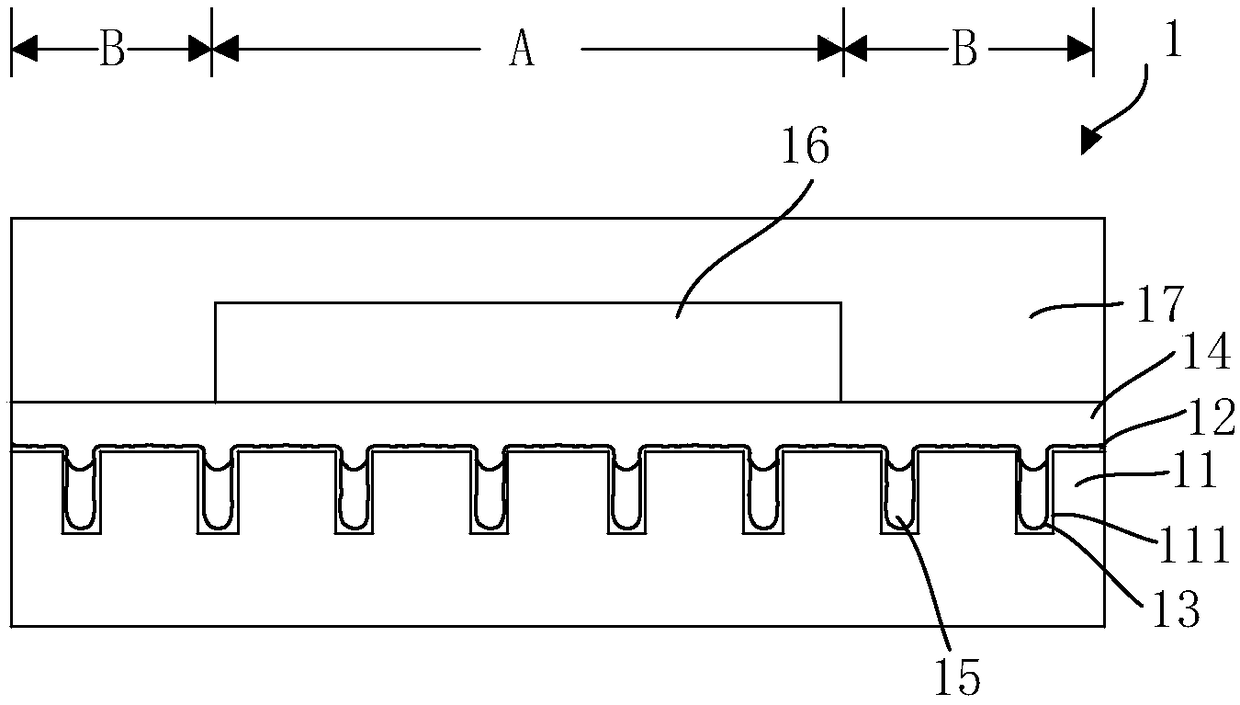

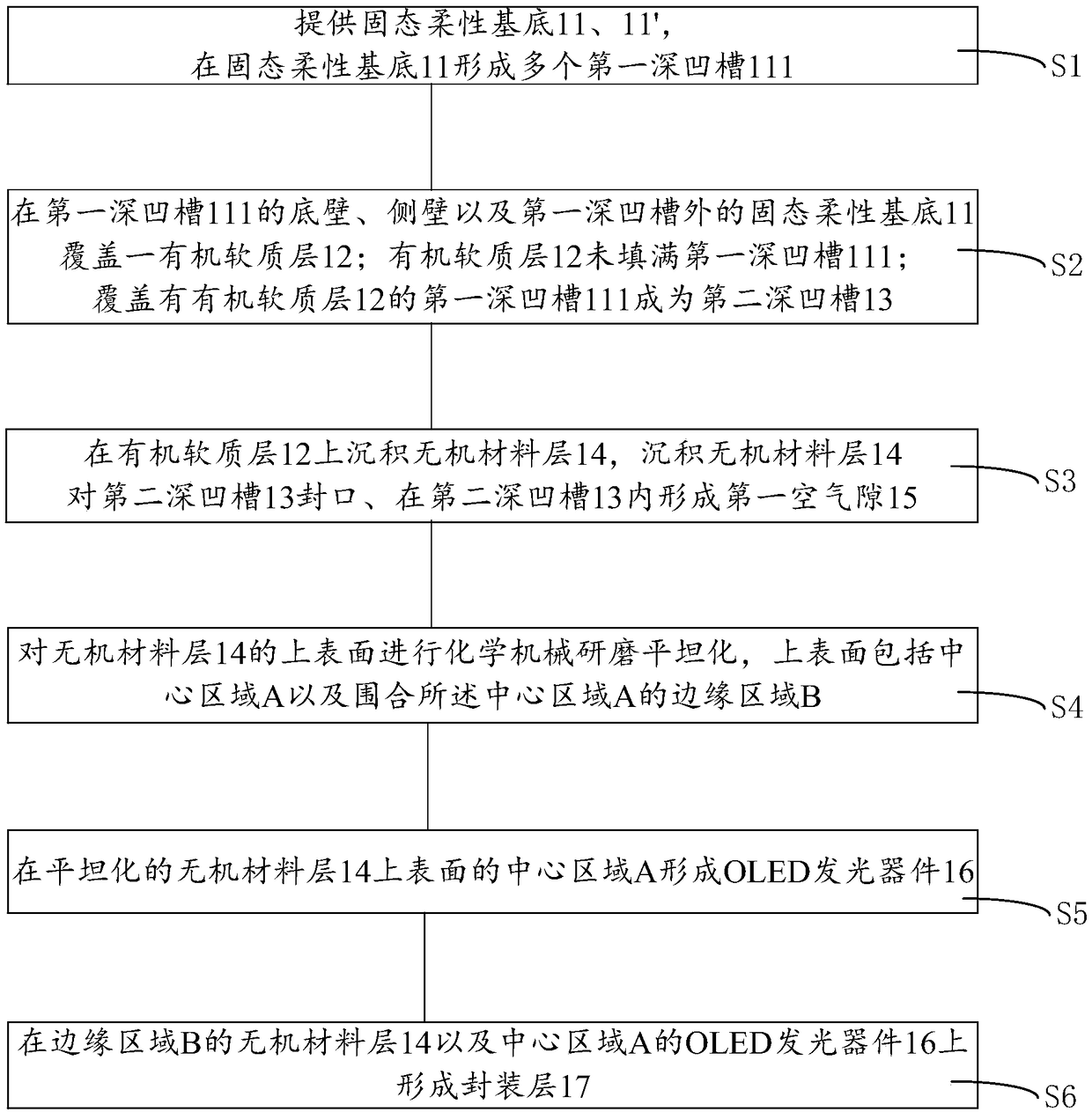

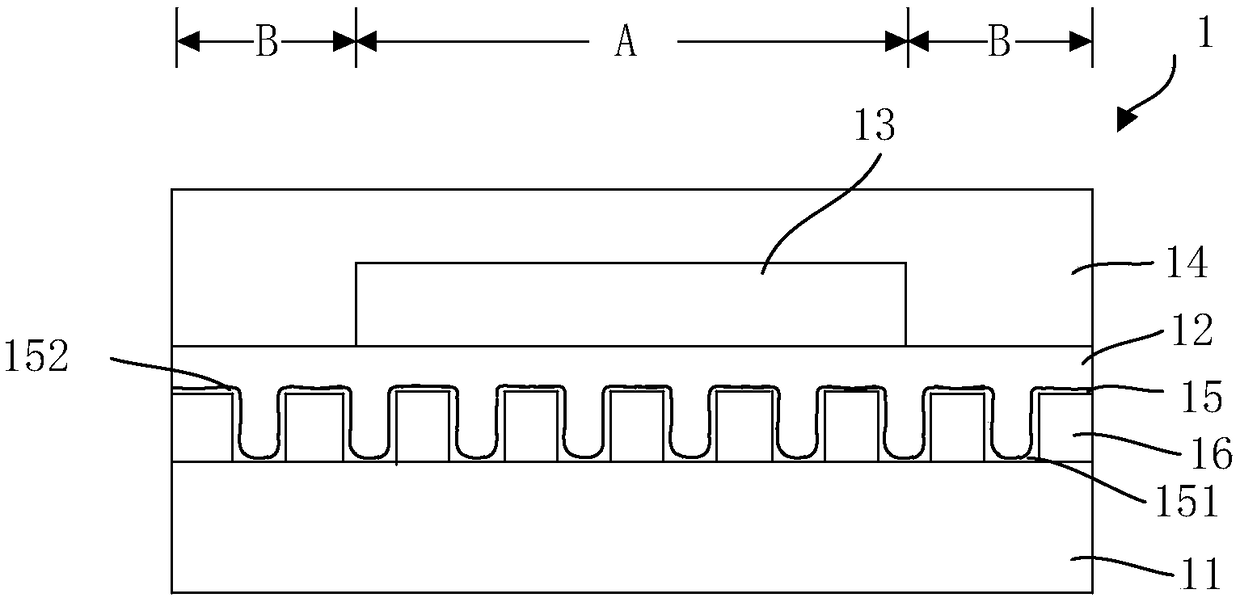

Diplsy device, Flexible OLED display panel and manufacturing method thereof

ActiveCN109273505AImprove bending performanceGood tensile propertiesSolid-state devicesSemiconductor devicesEngineeringSurface plate

The invention provides a display device, a flexible OLED display panel and a manufacturing method thereof, wherein a concave-convex undulating organic soft layer is fabricated by utilizing an uneven structure of a plurality of first deep grooves in a solid flexible substrate, and an air gap is formed between the organic soft layer and an inorganic material layer on the organic soft layer. The invention has the advantages that: firstly, a plurality of first deep grooves are made to remove part of the material of the solid flexible substrate, and the bending performance of the solid flexible substrate is improved; Secondly, the tensile property of the organic soft layer is better than that of the inorganic material, which can cushion the stress in the bending process of the OLED display panel. Third, the air gap provides the accommodation space for tensile or compressive strain of the soft material layer, and does not cause the stress transfer between the layers.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Bionic double-layer dressing and preparation method thereof

ActiveCN109481737AGood tensile propertiesExcellent semi-permeable barrierPharmaceutical delivery mechanismTissue regenerationIntestinal submucosaSmall intestine

The invention provides bionic double-layer dressing, comprising acellular animal intestinal submucosa and a gel layer crosslinked to the same. The acellular animal intestinal submucosa and the gel layer jointly form the bionic double-layer dressing in double-layer structure. Preparation steps include preparing the acellular animal intestinal submucosa, preparing powder of the acellular animal intestinal submucosa, preparing a solution of the acellular animal intestinal submucosa, preparing the bionic double-layer dressing; the solution of the acellular animal intestinal submucosa is mixed witha crosslinking liquid, the mixture is added to the surface of the acellular animal intestinal submucosa, and freezing and crosslinking are performed to obtain the bionic double-layer dressing. The bionic double-layer dressing has excellent tension resistance, has semipermeable barrier, can prevent moisture evaporation and bacterial penetration, is good for healing of a wound, and enables wound healing speed to be evidently increased, with the wound healing speed evidently increased on third to seventh day after surgery.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

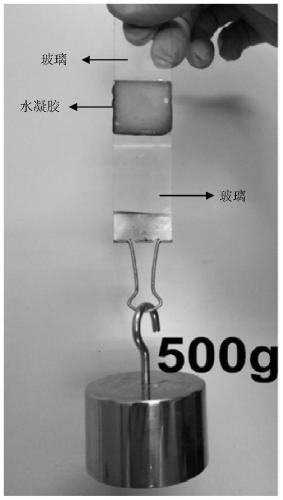

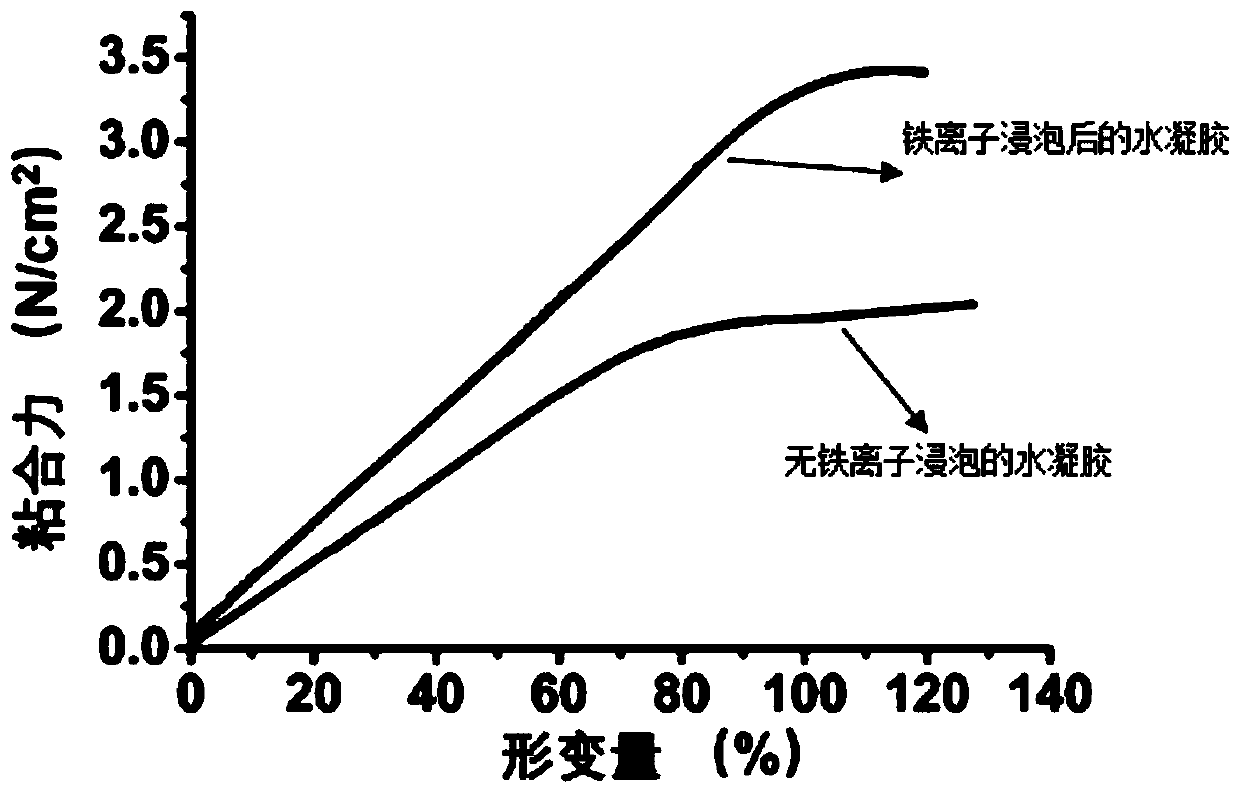

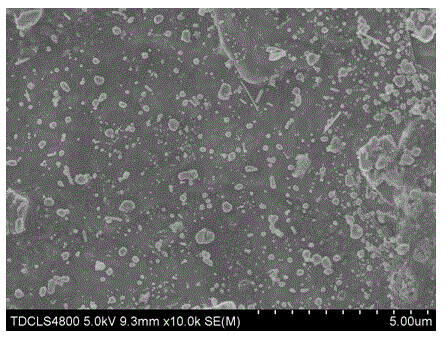

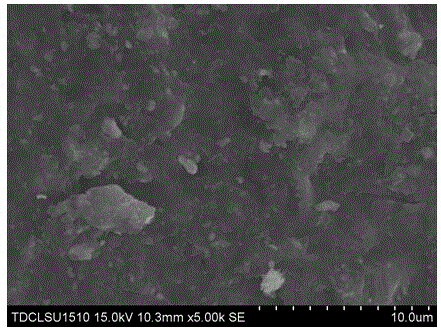

Self-healing injectable hydrogel, preparation method and application thereof

The invention belongs to the technical field of hydrogel adhesives, and discloses a self-healing injectable hydrogel, a preparation method and an application thereof. The method includes the followingsteps: (1) reacting chondroitin sulfate or chondroitin sulfate salt with an oxidant in water for subsequent treatment to obtain aldehyde chondroitin sulfate; (2) mixing the aldehyde chondroitin sulfate and gelatin in a solvent to obtain a hydrogel prepolymer solution; (3) mixing the hydrogel prepolymer solution with an Fe3+ solution to obtain the self-healing injectable hydrogel. According to themethod, through the combined use of chondroitin sulfate, gelatin and Fe3+, the prepared hydrogel has good biocompatibility, strong adhesiveness, rapid self-healing capability and injectability. The self-healing injectable hydrogel is applied in bio-adhesives, especially in medical bio-adhesives.

Owner:佛山市华健科创科技有限公司

High-impact transparent polyethylene film

InactiveCN104441891AGood impact resistanceGood tensile propertiesSynthetic resin layered productsCo extrusionImpact resistance

The invention discloses a high-impact transparent polyethylene film. The high-impact transparent polyethylene film is prepared by performing blow molding on 60-95 percent by weight of polyethylene and 40-5 percent by weight of metallocene polyethylene by virtue of a three-layer co-extrusion blow molding machine. The high-impact transparent polyethylene film is high in friction coefficient, high in heat seal strength, high in transparency, high in impact resistance and high in tensile property.

Owner:常熟市天娇塑业有限公司

Method for synthesizing Al-Cu alloy in situ by powder metallurgy

The invention discloses a method for synthesizing Al-Cu alloy in situ by powder metallurgy. The method comprises the following steps: firstly, obtaining a microscopic structure that copper nanoparticles are uniformly deposited on aluminum powder by an impregnation method, performing ball-milling for a relatively short time, uniformly dispersing copper and embedding dispersed copper into the aluminum powder; secondly, densifying the powder by a cold-pressing sintering or vacuum hot-pressing method to obtain a block material; finally, performing hot extrusion forming to obtain the Al-Cu alloy material. The method has the advantages that the Al-Cu alloy material is prepared by the method, and the mechanical property of the alloy material is superior to that of other powder metallurgy aluminum alloy material. Meanwhile, the method also can be popularized and applied to other metal powder so as to prepare different matrix alloy materials. Therefore, the method has a wide industrial application prospect.

Owner:TIANJIN UNIV

Fish scale protein-mesona chinensis glue-asparagus powder nutrient edible film and preparation method thereof

PendingCN109769920AGood tensile propertiesInhibition of growth and reproductionFlexible coversWrappersNutrientAmerican cranberry

The invention relates to fish scale protein-mesona chinensis glue-asparagus powder nutrient edible film and a preparation method thereof, and belongs to the technical field of food and medicine packaging. The fish scale protein-mesona chinensis glue-asparagus powder nutrient edible film is prepared by extracting collagen from oreochromis mossambicus scale, taking mesona chinensis glue, asparagus powder and cranberry fruit powder extracted and prepared from the roots, stems and leaves of mesona chinensis as base materials and adding sodium carboxymethylcellulose and glycerinum. The fish scale protein-mesona chinensis glue-asparagus powder nutrient edible film has the advantages that the technological process is simple, all the materials are harmless to the human body, and the edible film has nutritive value, has better antibacterial and antioxidant effects, can be completely degraded under the natural environment, and has no pollution to the environment.

Owner:JIANGNAN UNIV

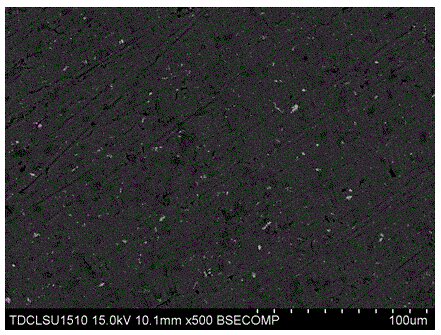

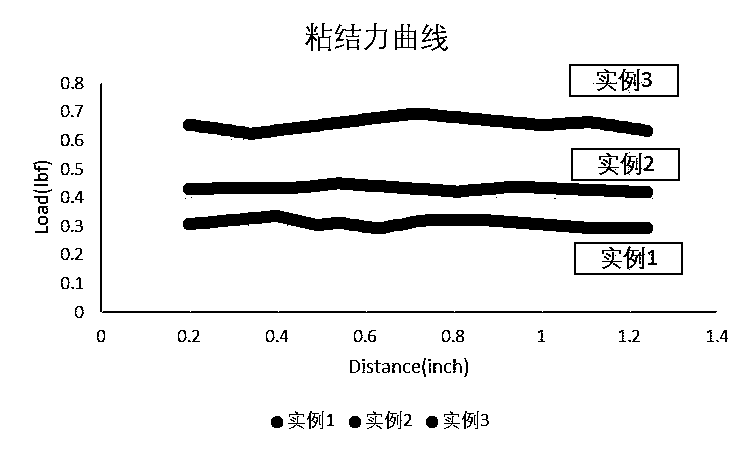

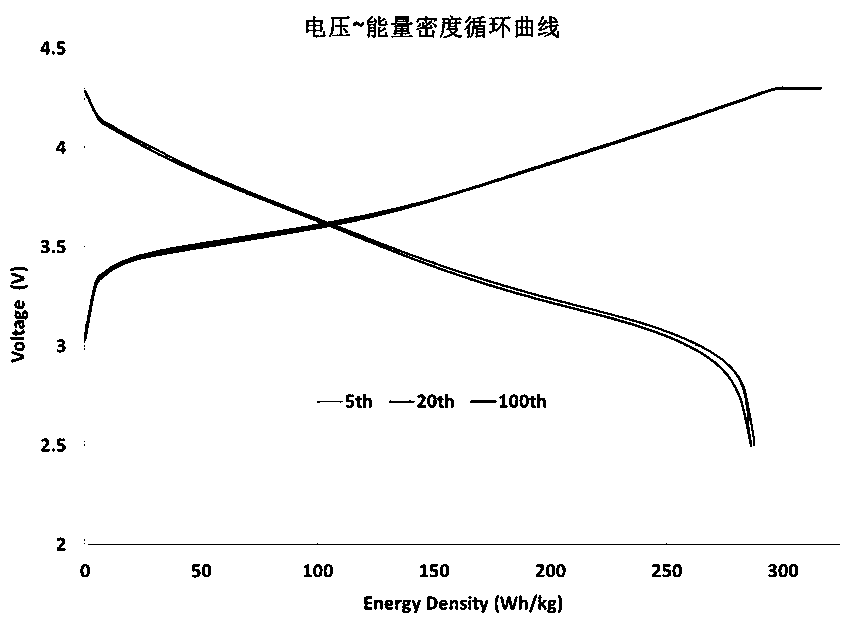

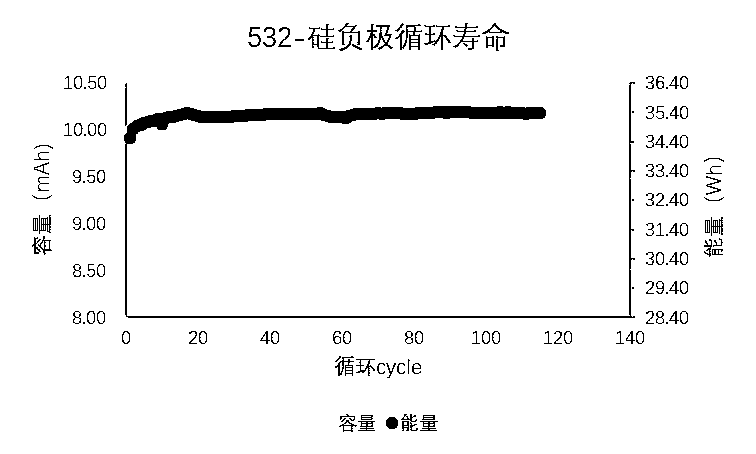

High-proportion silicon negative electrode aqueous composite binder and application thereof

InactiveCN111244454AGood tensile propertiesImprove bonding effectCell electrodesSecondary cellsCyclic stabilityAqueous solubility

The invention relates to a high-proportion silicon negative electrode aqueous composite binder, which is prepared by the following steps: mixing a polymer A, a polymer B and a polymer C into a negative electrode plate, and heating the negative electrode plate in vacuum, wherein the polymer A is water-soluble polyimide (PI), the polymer B is at least one of polyacrylic acid (PAA) or polymethylacrylic acid (PMAA), and the polymer C is water-soluble styrene-butadiene latex (SBR). T the aqueous composite binder combines good cohesiveness of PI, PAA (PMAA) and SBR, shows good tensile property, canform a cross-linked network after heating treatment, improves the bonding effect, can well adapt to expansion of the volume of the silicon negative electrode, and improves the cycling stability of thesilicon negative electrode.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

High-strength and deformation-resistant TPO waterproof coiled material and preparation method thereof

PendingCN114274620AGood tensile propertiesGood bendability at low temperatureRubber layered productsThermal treatmentHeat treated

The invention discloses a high-strength and deformation-resistant TPO waterproof roll. The waterproof roll structurally comprises a reinforcing layer, an upper TPO material layer, a fabric inner reinforcing layer and a lower TPO material layer from top to bottom. The invention further discloses a preparation method of the high-strength and deformation-resistant TPO waterproof coiled material. The preparation method comprises the steps of preparing the modified ethylene-1-hexene copolymer, preparing the reinforcing layer, preparing the TPO material layer and preparing the waterproof coiled material. The prepared waterproof coiled material is good in tensile property, the maximum tensile force is 953-960 N / cm, and the elongation at the maximum tensile force is 56-57%; the thermal treatment dimensional change rate of the waterproof coiled material prepared by the invention is 0.07-0.09%.

Owner:潍坊市璇宝防水材料有限公司

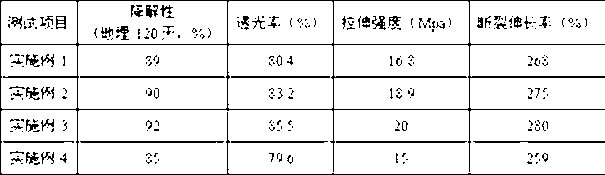

Biodegradable antibacterial plastic

The invention discloses a biodegradable antibacterial plastic. The biodegradable antibacterial plastic comprises the following raw materials: by weight, 60-70 parts of polyether sulfone resin, 10-20 parts of a modified resin, 20-35 of starch, 1-3 parts of a silane coupling agent, 1-5 parts of an antibacterial agent, 5-10 parts of a compatilizer, 1-2 parts of glycerol, 2-4 parts of a degrading promoter, 1-2 parts of carbon black, and 0.1-0.5 part of montan wax. The provided biodegradable antibacterial plastic has high degradability, good light transmittance, good tensile properties and good antibacterial effect due to addition of the antibacterial agent, and is environmentally friendly and healthy.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

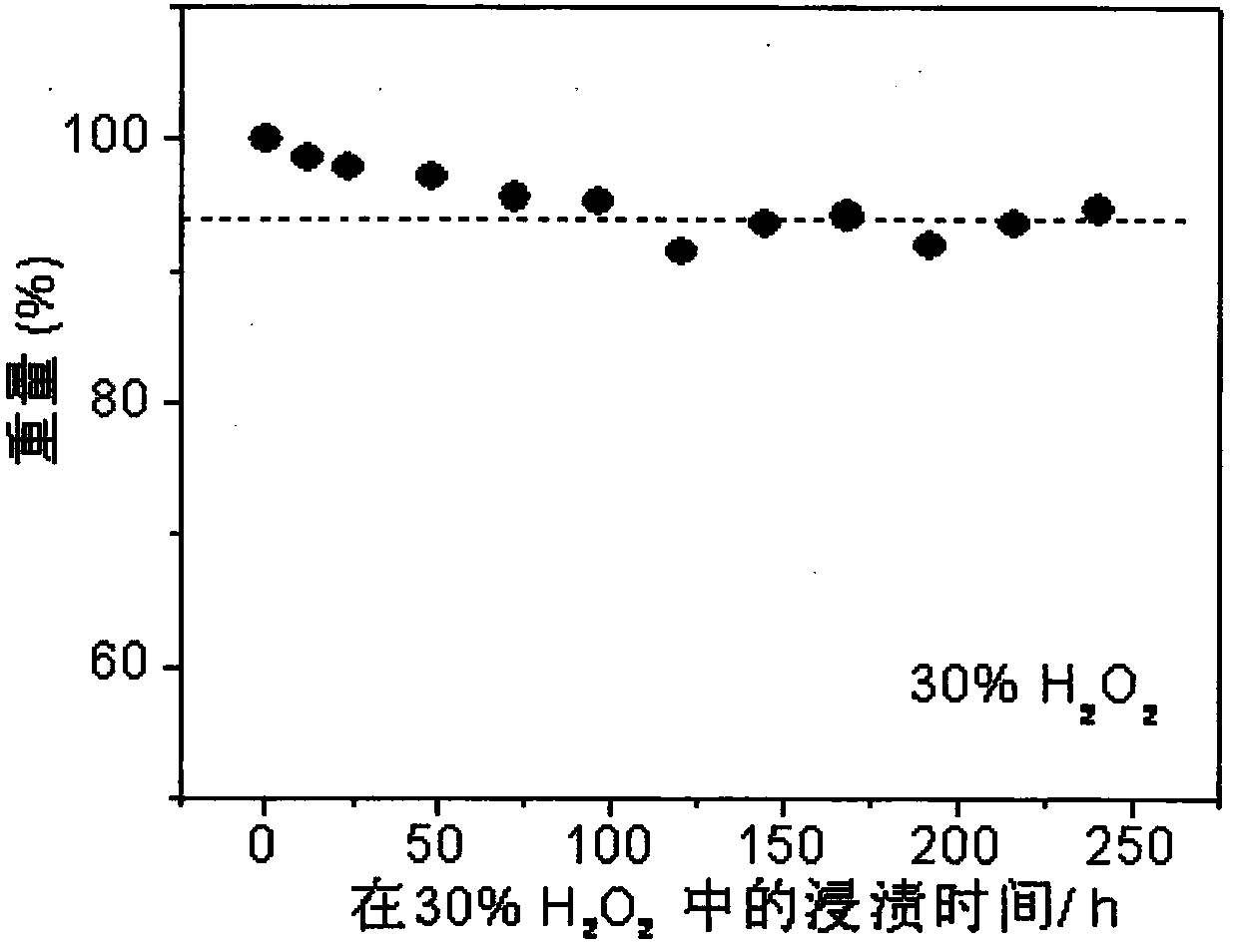

Fiberglass enhanced glass bead ceramsite foam concrete and preparation method and building block thereof

InactiveCN104844255AImproved tensile and compressive strengthGood tensile propertiesCement mixing apparatusCeramicwareHydrogen peroxideWater reducer

The invention relates to the technical field of concrete, and in particular to fiberglass enhanced glass bead ceramsite foam concrete and a preparation method and a building block thereof. The fiberglass enhanced glass bead ceramsite foam concrete comprises the following raw materials in parts by weight: cement, coal ash, glass beads, swelling ceramsite, fiberglass, water, hydrogen peroxide, water reducing agent, and manganese dioxide. Compared with ceramsite foam concrete prepared by a physical foaming method in the prior art, a tensile property and compressive strength of a building block prepared by using a raw material of the fiberglass enhanced glass bead ceramsite foam concrete are greatly improved, and the building block is not easily cracked or broken during cutting, so that the building block prepared by using the raw material of the fiberglass enhanced glass bead ceramsite foam concrete is good in tensile performance, high in compressive strength, low in shrinkage, not easily cracked, and good in water absorption and tenacity. .

Owner:XINJIANG AGRI UNIV

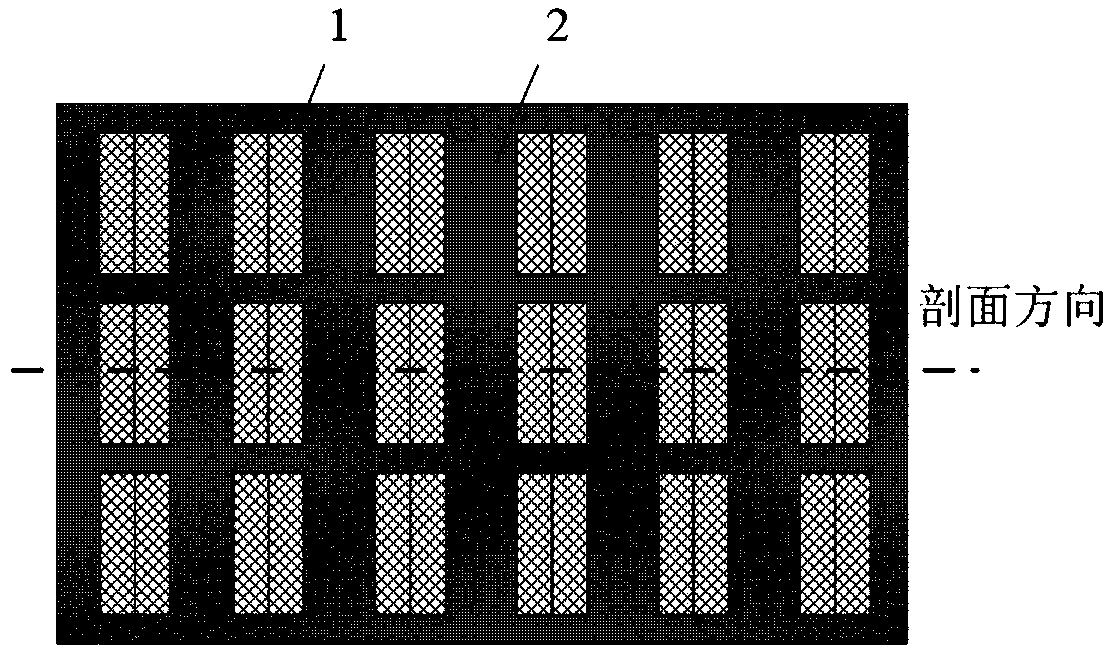

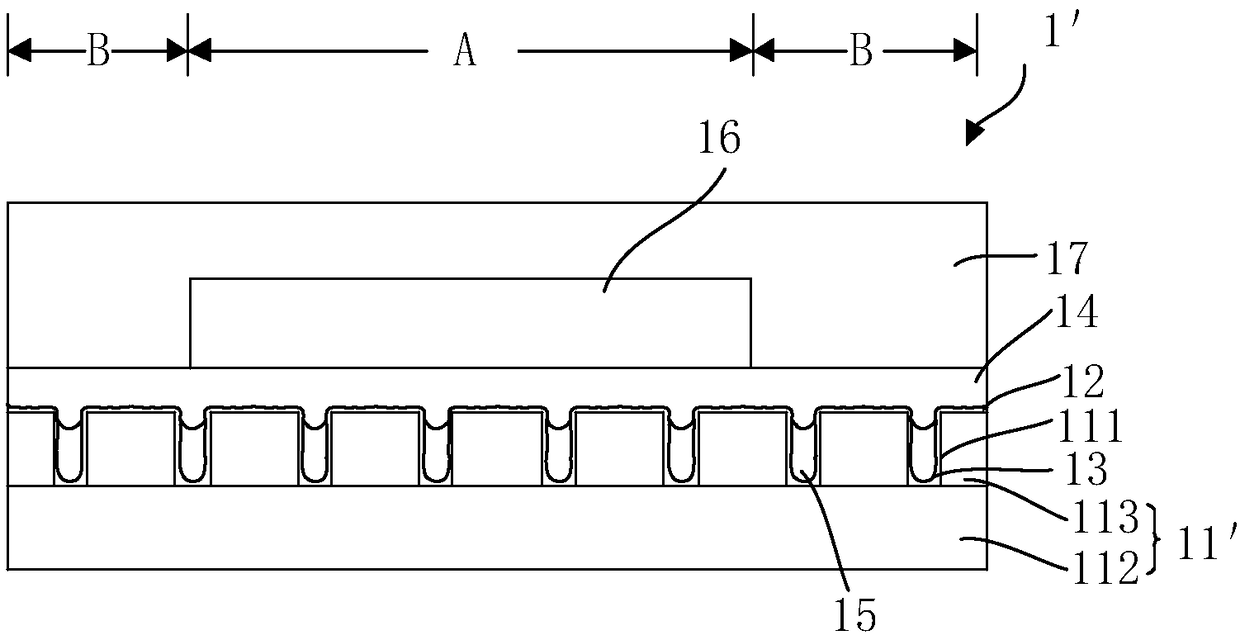

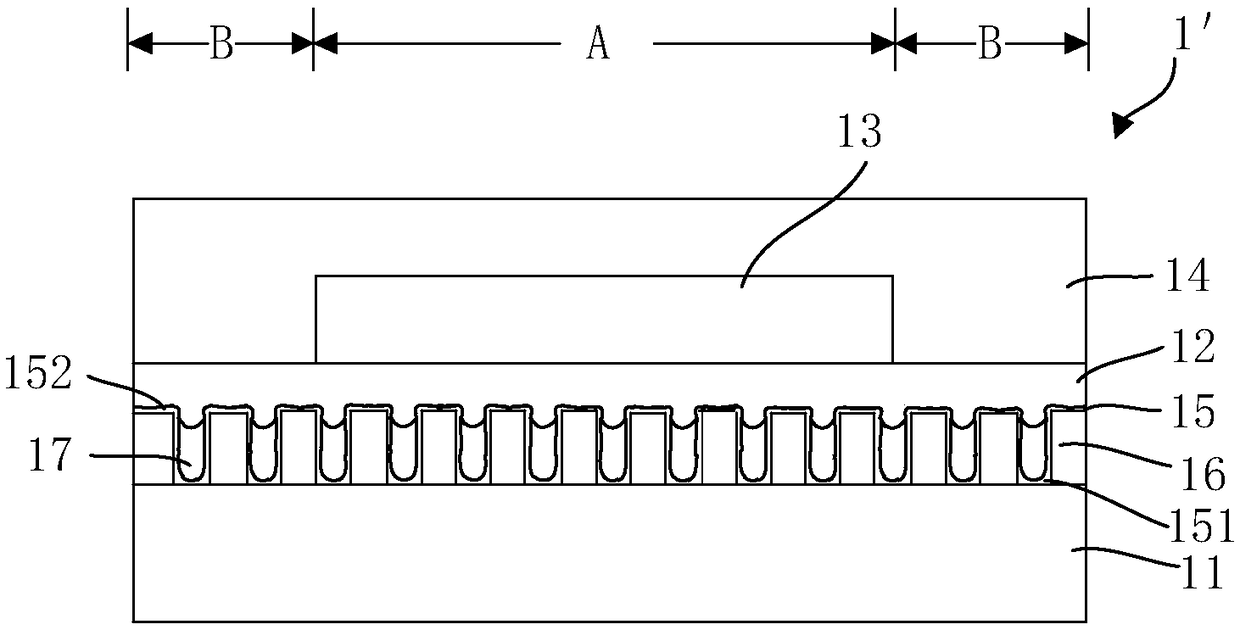

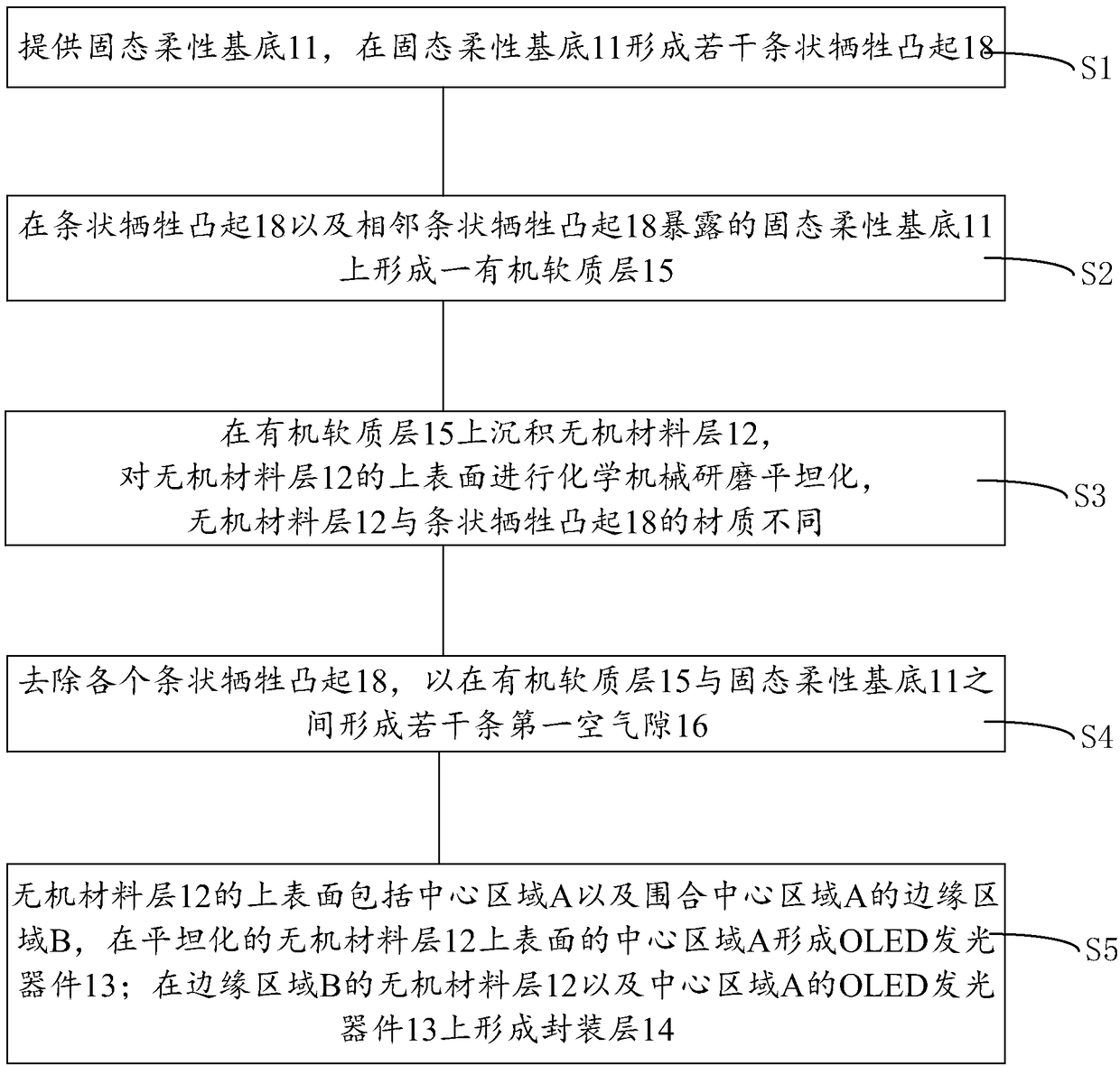

Display device, flexible OLED display panel and manufacturing method of flexible OLED display panel

ActiveCN109411620AGood tensile propertiesEasy to stretchFinal product manufactureSolid-state devicesWave shapeEngineering

The invention provides a display device, a flexible OLED display panel and a manufacturing method of the flexible OLED display panel. A wave-shaped organic soft layer is manufactured by utilizing an uneven structure of a plurality of strip-shaped sacrificial protrusions, then the strip-shaped sacrificial protrusions are removed, and an air gap is formed between the organic soft layer and a solid flexible substrate under the organic soft layer. The method has the advantages that 1, the tensile property of the organic soft layer is high relative to that of an inorganic material, so that the stress in the bending process of the OLED display panel can be buffered; 2, the organic soft layer is uneven, and compared with a planar structure, the stress in the OLED display panel with different curling degrees can be buffered; and 3, the air gap provides a containing space for the soft layer to stretch or compress the strain, so that stress transmission between the layers cannot be caused.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Reinforcing structure and method for concrete construction with local damage

InactiveCN104100101AGood tensile propertiesReduce tensile stressBarrages/weirsBuilding repairsSurface finishingComposite structure

The invention discloses a reinforcing structure and method for concrete construction with local damage. The reinforcing method includes the following steps of 1), subjecting a to-be-repaired part to surface treatment; 2), filling holes with mortar and plugging cracks; 3), fixing a fiber-woven net on a damaged area with a fixing and connecting piece; 4), spraying the polymer concrete mortar to the design thickness; 5), forming a fiber-woven net and mortar composited structure. Therefore, the advantages of two materials can be given to full play by utilizing the fiber-woven net and the polymer concrete mortar in combination, and bearing capacity and durability of the damaged concrete construction can be remarkably enhanced.

Owner:浙江固邦新材料有限公司 +1

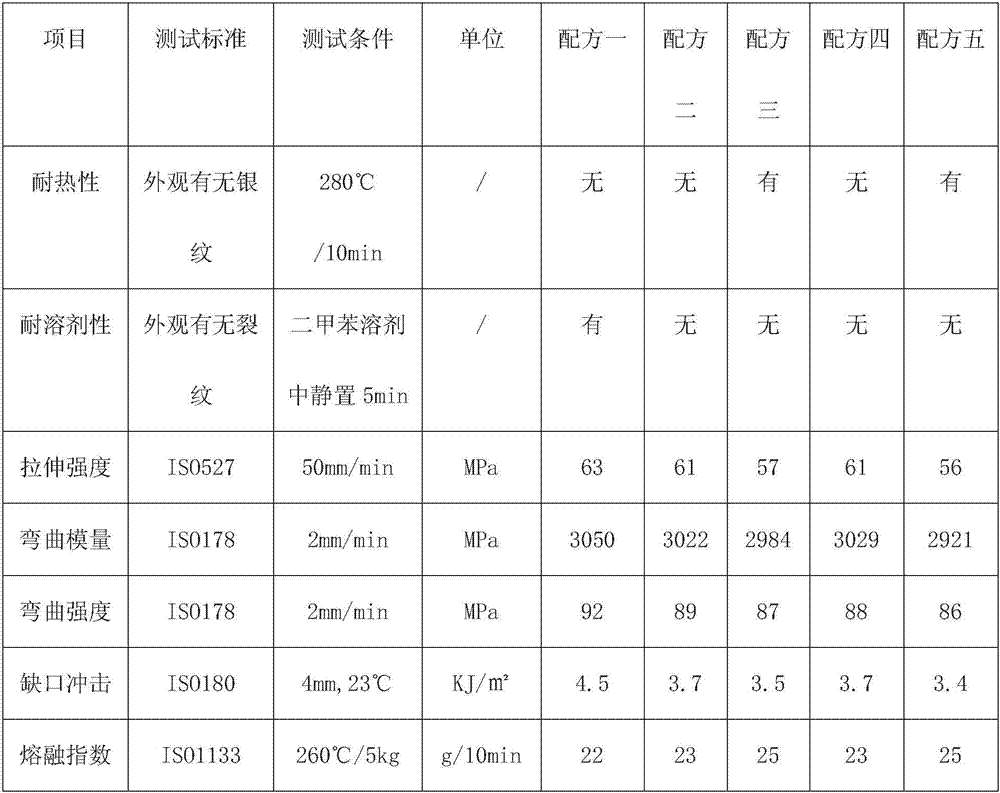

Heat-resistant and solvent-resistant PC/PET modified resin

InactiveCN106893298AExcellent heat and solvent resistanceGood tensile propertiesPolyethylene terephtalateMolten state

The invention discloses a heat-resistant and solvent-resistant PC / PET modified resin material. The heat-resistant and solvent-resistant PC / PET modified resin material is prepared by the following steps: adding 50 to 80 parts of PC, 10 to 40 parts of PET, 3 to 10 parts of mineral, 1 to 3 parts of a compatilizer and 0.2 to 1 part of an antioxidant into a stirring machine, dispersing uniformly, adding the mixture into an extruding machine, adjusting the temperature of the extruding machine to be 240 to 270 DEG C to convert the mixture into a melting state, mixing and extruding the mixture, and pelleting to obtain heat-resistant and solvent-resistant PC / PET modified granules. The heat-resistant and solvent-resistant PC / PET modified resin provided by the invention can be subjected to injection molding according to the flowability requirement, samples are prepared by extruding sheet materials or blowing molding and suction molding, and the material cost is reduced under the condition of guaranteeing various properties.

Owner:苏州井上高分子新材料有限公司

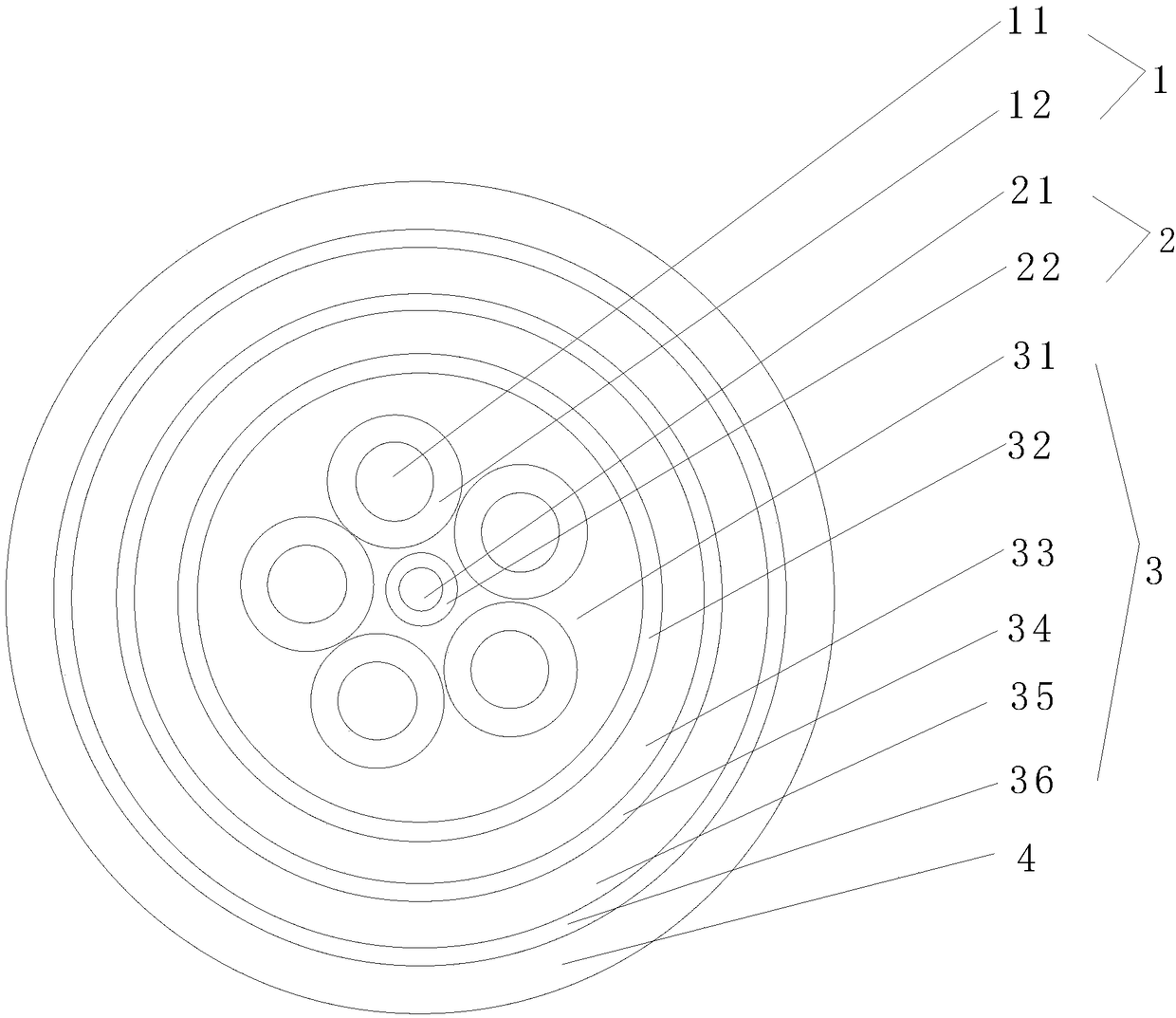

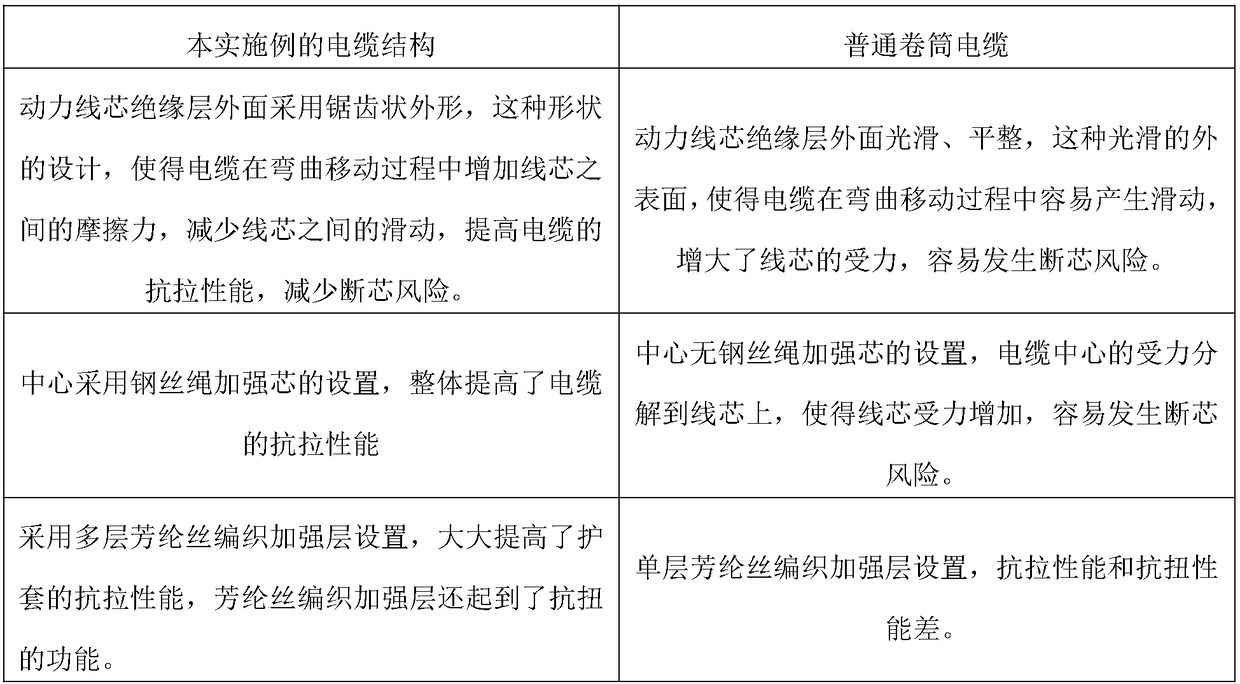

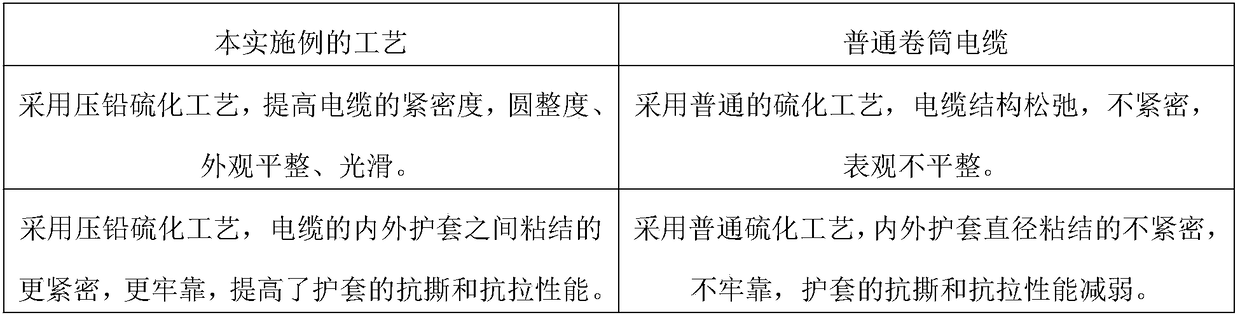

Smart energy port machine low-pressure roller cable and production process thereof

PendingCN108428499AReasonable cable structure designGood tensile propertiesPower cablesFlexible cablesYarnEngineering

The invention discloses a smart energy port machine low-pressure roller cable and a production process thereof. The cable is sequentially composed of a reinforcing core, power cable cores, a sheath reinforcing layer and an outer protection layer from inside to outside. The reinforcing core comprises a reinforcing core conductor and a reinforcing core insulating layer. The power cable cores are five strands of insulating wire cores and are wound around the outer side of the reinforcing core. Each strand of insulating wire core comprises a power cable core conductor and a power cable core insulating layer. The sheath reinforcing layer is sequentially composed of a first sheath layer, a first aramid fiber yarn woven reinforcing layer, a second sheath layer, a second aramid fiber yarn woven reinforcing layer, a third sheath layer and a third aramid fiber yarn woven reinforcing layer from inside to outside. The cable has the advantages of being reasonable in structural design, resistant tobending and winding, excellent in tensile performance and the like.

Owner:FAR EAST CABLE +2

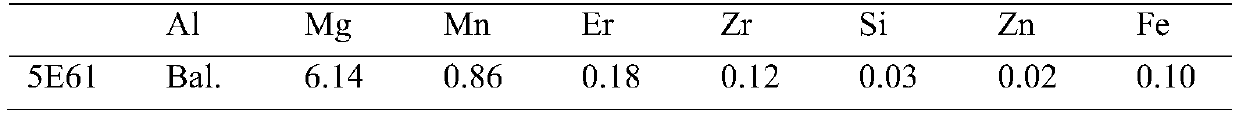

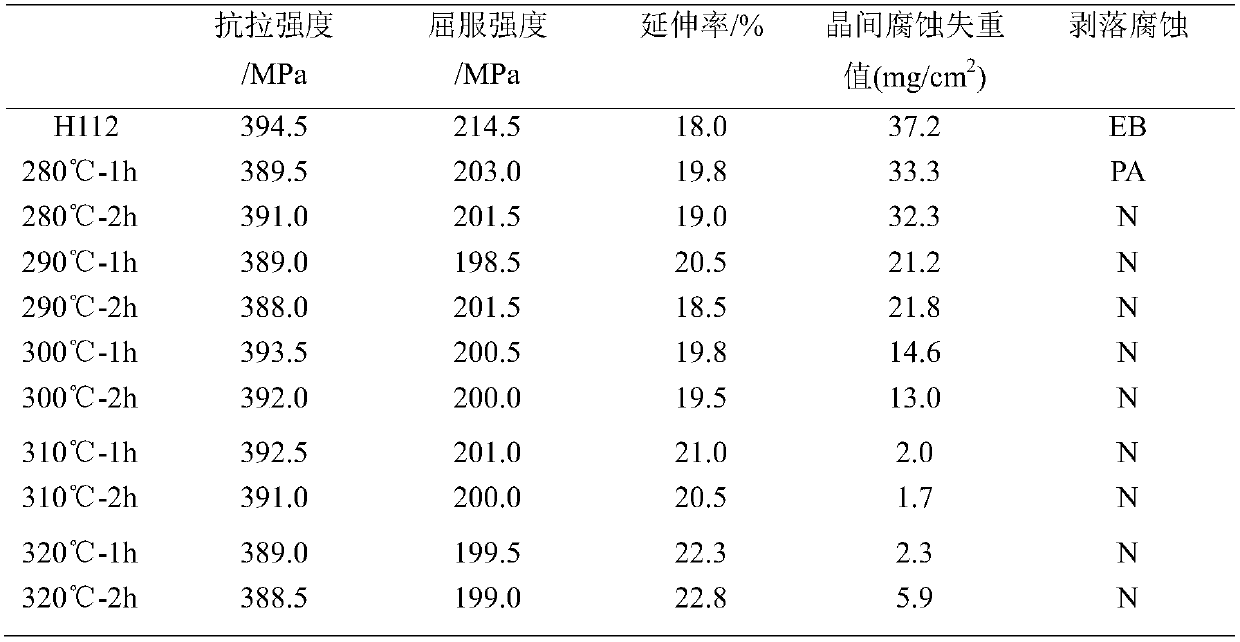

Thermal deformation and stabilization annealing process and material of Al-Mg-Mn-Er-Zr alloy

The invention relates to a thermal deformation and stabilization annealing process and a material of Al-Mg-Mn-Er-Zr alloy, and belongs to the technical field of metal materials. The Al-Mg-Mn-Er-Zr alloy is prepared from the following components: 5.5% to 6.5% of Mg, 0.7% to 1.1% of Mn, 0.02% to 0.3% of Er, 0.02% to 0.2% of Zr, less than 0.4% of Fe, less than 0.4% of Si, less than 0.1% of Cu, less than 0.2% of Zn and the balance of Al. Thermal deformation is performed on cast ingots at 250 DEG C to 300 DEG C, then stabilization annealing is performed, and the annealing temperature is 280 to 320DEG C.A plate prepared by adopting the process has good tensile property, and additionally, the corrosion resistance of the alloy is improved.

Owner:BEIJING UNIV OF TECH

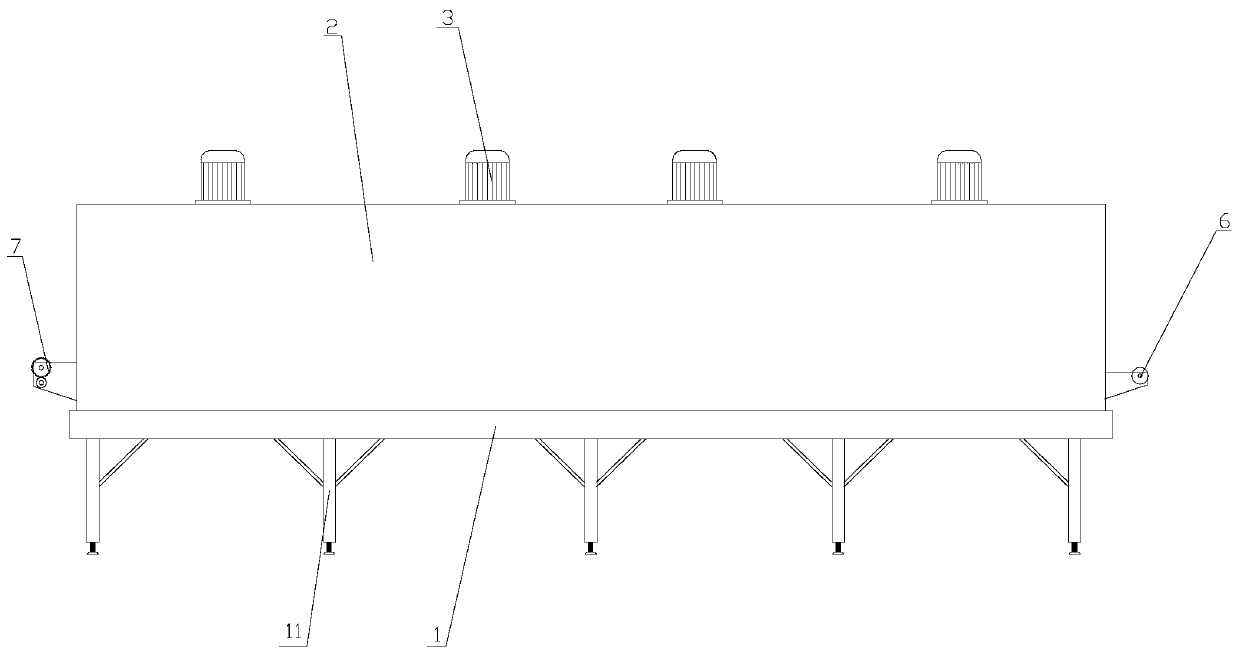

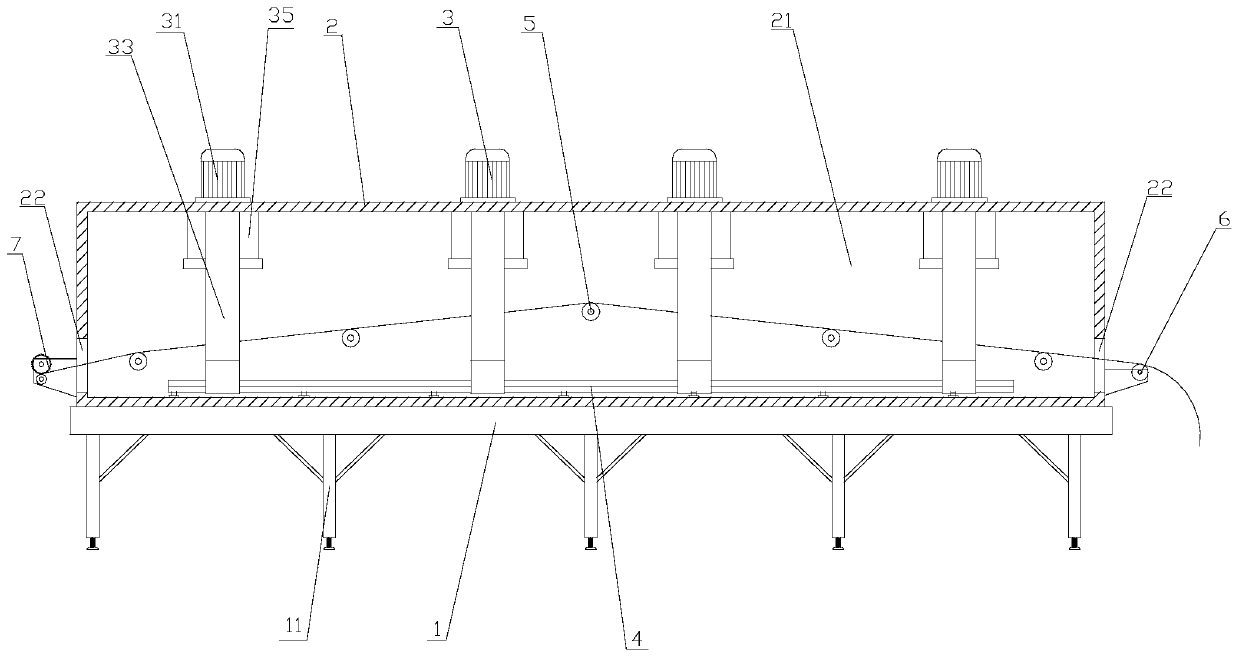

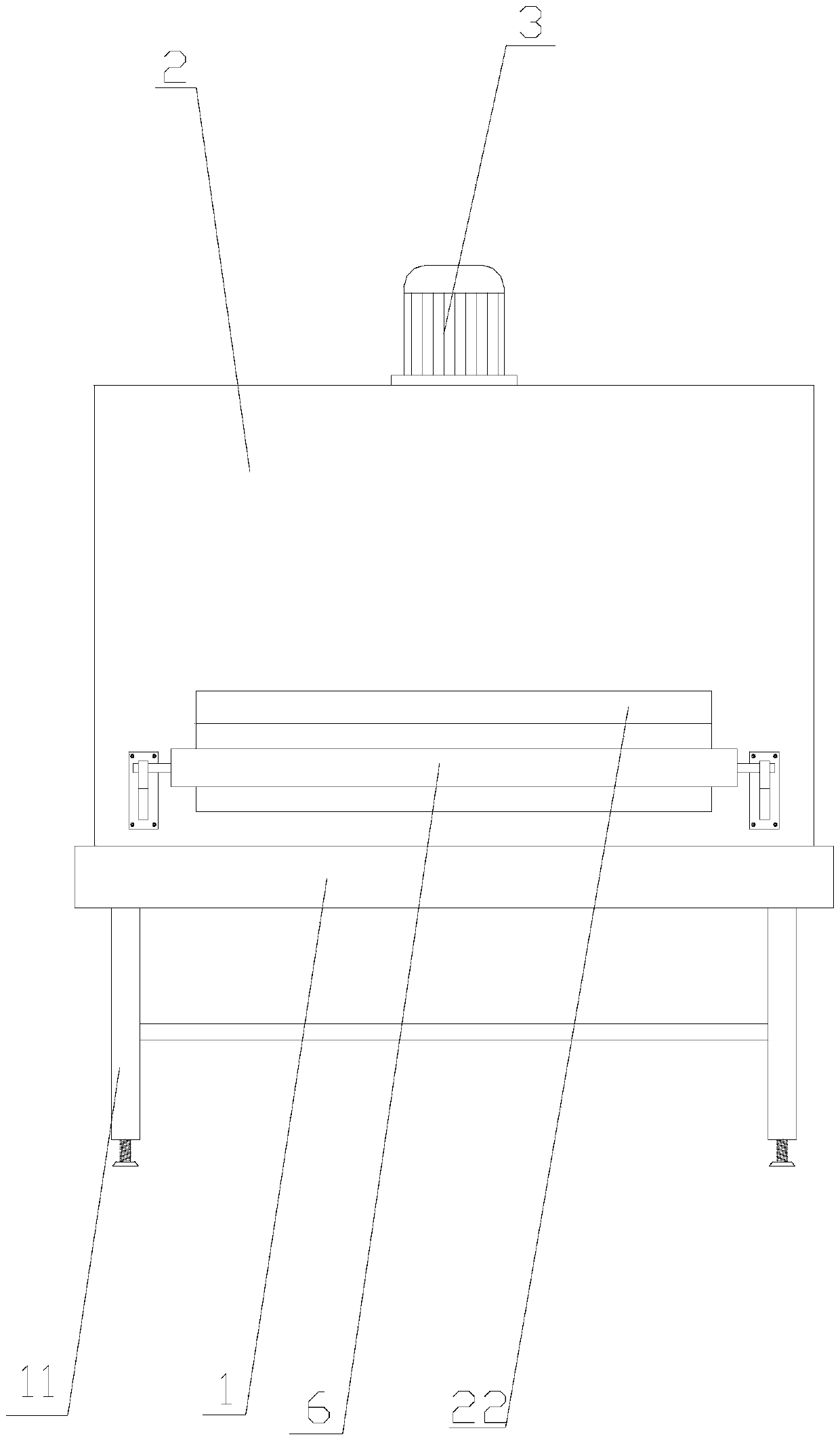

Hot air internal circulation type drying furnace for anti-static winding film with good tensile property

InactiveCN110314828AGood tensile propertiesReduce heat lossPretreated surfacesCoatingsAmbient airHeat losses

The invention discloses a hot air internal circulation type drying furnace for an anti-static winding film with good tensile property. The hot air internal circulation type drying furnace comprises arack, a drying furnace body, a plurality of hot air inner circulation devices, a heater, a plurality of conveying roller cylinders, a film inlet roller and a film outlet roller, the drying furnace body is transversely arranged at the upper end of the rack; a drying cavity is formed in the drying furnace body, the left side and the right side of the drying furnace body are respectively provided with a membrane inlet and a membrane outlet, the membrane inlet and the membrane outlet are respectively communicated with the drying cavity, a film inlet roller cylinder capable of being matched with the drying furnace body is arranged at the position, close to the film inlet opening, of the side edge of the drying furnace body. According to the hot air internal circulation type drying furnace, thehot air inner circulation device is arranged in the drying furnace, the heater is arranged at the bottom of the drying furnace, the heater is used for heating ambient air, the hot air inner circulation device conveys hot air to the upper end of the conveying roller and circulate continuously, the hot air is repeatedly used, so that the heat loss is reduced, the energy is saved, the cost is reduced, and the drying efficiency is higher.

Owner:浙江宏达包装科技股份有限公司

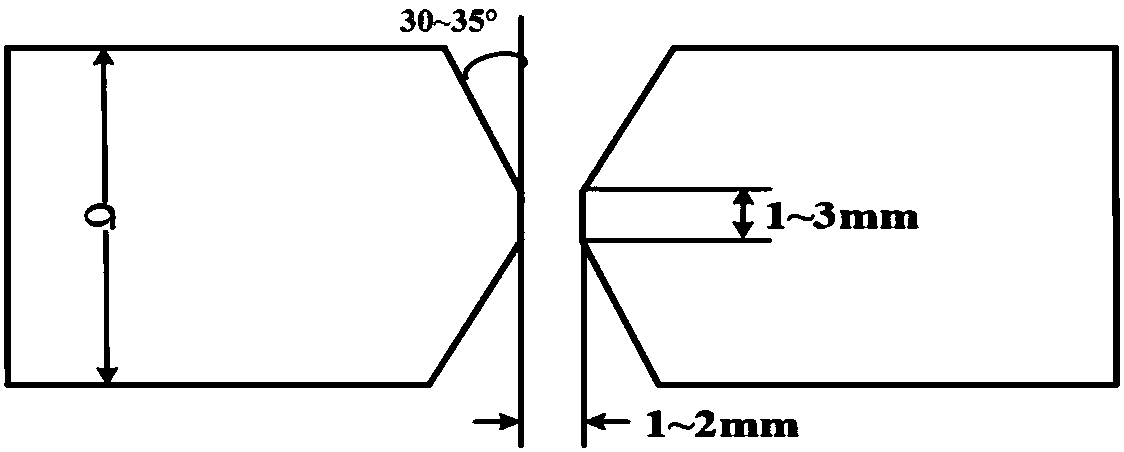

Gas shielded welding method for low-carbon Q420q bridge steel

InactiveCN108581136AGood tensile propertiesExcellent low temperature impact toughness and crack resistanceArc welding apparatusWelding/cutting media/materialsNational standardButt joint

The invention discloses a gas shielded welding method for low-carbon Q420q bridge steel, and belongs to the technical field of welding of medium-thickness plates of the bridge steel. The method comprises the following steps that 1), double-face V-shaped symmetric grooves are formed a double-butt-joint base material of a low-carbon Q420q bridge steel base material; 2), grinding and cleaning are carried out on the V-shaped symmetric grooves and the two sides of the V-shaped symmetric grooves; and 3), backing welding and filling welding are carried out under the protection of the mixed gas with 20% of CO2 and 80% of Ar. According to the method, by adopting the welding process technologies, the welding process without preheating carried out before welding and without heat treatment carried outafter welding for the manufacturing process of the low-carbon Q420q bridge steel medium-thickness plate structure under the new national standard requirement is achieved, the simple, high-efficiencyand economical welding mode in the construction process of the medium-thickness plates of the bridge steel is achieved, and the method has important significance in promotion of popularization of thenovel low-carbon bridge steel of the grade.

Owner:NORTHEASTERN UNIV

Anti-ultraviolet cold film for pallet-free packaging

InactiveCN107379699AHigh strengthGood tensile propertiesSynthetic resin layered productsHigh pressureEthylene-vinyl acetate

The invention discloses an anti-ultraviolet cold film for pallet-free packaging. The anti-ultraviolet cold film is prepared from 20%-30% by mass of a first-layer material, 40%-60% by mass of a second-layer material and 20%-30% by mass of a third-layer material by co-extruding in sequence, wherein the first-layer material comprises 90%-95% of raw metallocene and 5%-10% of functional masterbatch; the second-layer material comprises 5%-95% of raw EVA (ethylene vinyl acetate), 5%-15% of a raw high-pressure material and 5%-10% of the functional masterbatch; the third-layer material comprises 90%-95% of raw metallocene and 5%-10% of the functional masterbatch. The anti-ultraviolet cold film for pallet-free packaging is applicable to pallet-free packaging and is high in strength, good in tensile property, high in wrapping performance and not prone to deformation, a product can be prevented from bulging or being damaged during pallet-free packaging, and an anti-ultraviolet function can be realized by means of an added anti-ultraviolet agent.

Owner:ZHEJIANG BILI PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com