Asymmetric polyolefin degassing membrane and preparation method thereof

A technology of degassing membranes and polyolefins, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of insufficient stretching ratio of membrane materials, reduced membrane corrosion resistance, and easy leakage of liquid, etc., to achieve optimal mechanical Performance and anti-corrosion effect, excellent anti-corrosion performance, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

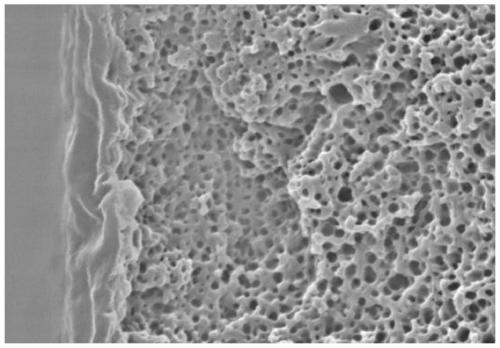

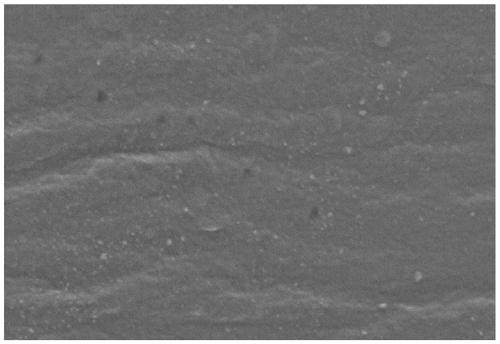

[0070] Embodiment 1 provides a kind of asymmetric poly(4-methyl-1-pentene) film, adopts following method to prepare:

[0071] S1, put 45wt% poly(4-methyl-1-pentene) into the twin-screw extruder, heat until plasticized, then add 38wt% methyl-12-hydroxystearic acid and 17wt% adipic acid Composed of dioctyl ester, stirred and mixed at 220°C to obtain a homogeneous casting solution;

[0072] S2, extruding the casting solution from a die with a temperature of 210° C. to obtain a formed film;

[0073] S3, the formed film is phase-separated through the air section with a length of 50mm, the phase-separation residence time is 45ms, the relative humidity of the air section is 50%, the temperature is 20°C, and it is wound at a speed of 60m / min, and the winding is completed. Then enter the quenching liquid for quenching for 3 hours, the quenching liquid is the solvent system used when preparing the casting film liquid, the quenching temperature is 80°C, and the film is obtained by quenc...

Embodiment 7

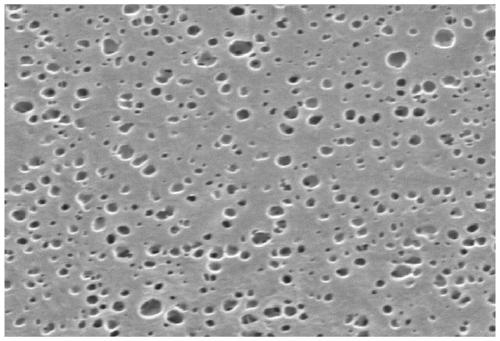

[0085] Embodiment 7 provides a kind of asymmetric polypropylene film, adopts following method to prepare:

[0086] S1, put 47wt% polypropylene into a twin-screw extruder, heat until plasticized, then add 35wt% dibutyl sebacate and 18wt% palm oil, stir and knead at 170°C to obtain a homogeneous casting Membrane fluid;

[0087] S2, extruding the casting solution from a die with a temperature of 165° C. to obtain a formed film;

[0088] S3, the formed film is phase-separated through the air section with a length of 50mm, the phase-separation residence time is 45ms, the relative humidity of the air section is 50%, the temperature is 20°C, and it is wound at a speed of 60m / min, and the winding is completed. Then enter the quenching liquid for quenching for 3 hours, the quenching liquid is the solvent system used when preparing the casting film liquid, the quenching temperature is 60 ° C, and the quenching obtains the raw film;

[0089] S4, extract the raw film with isopropanol at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com