Patents

Literature

116results about How to "Good tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

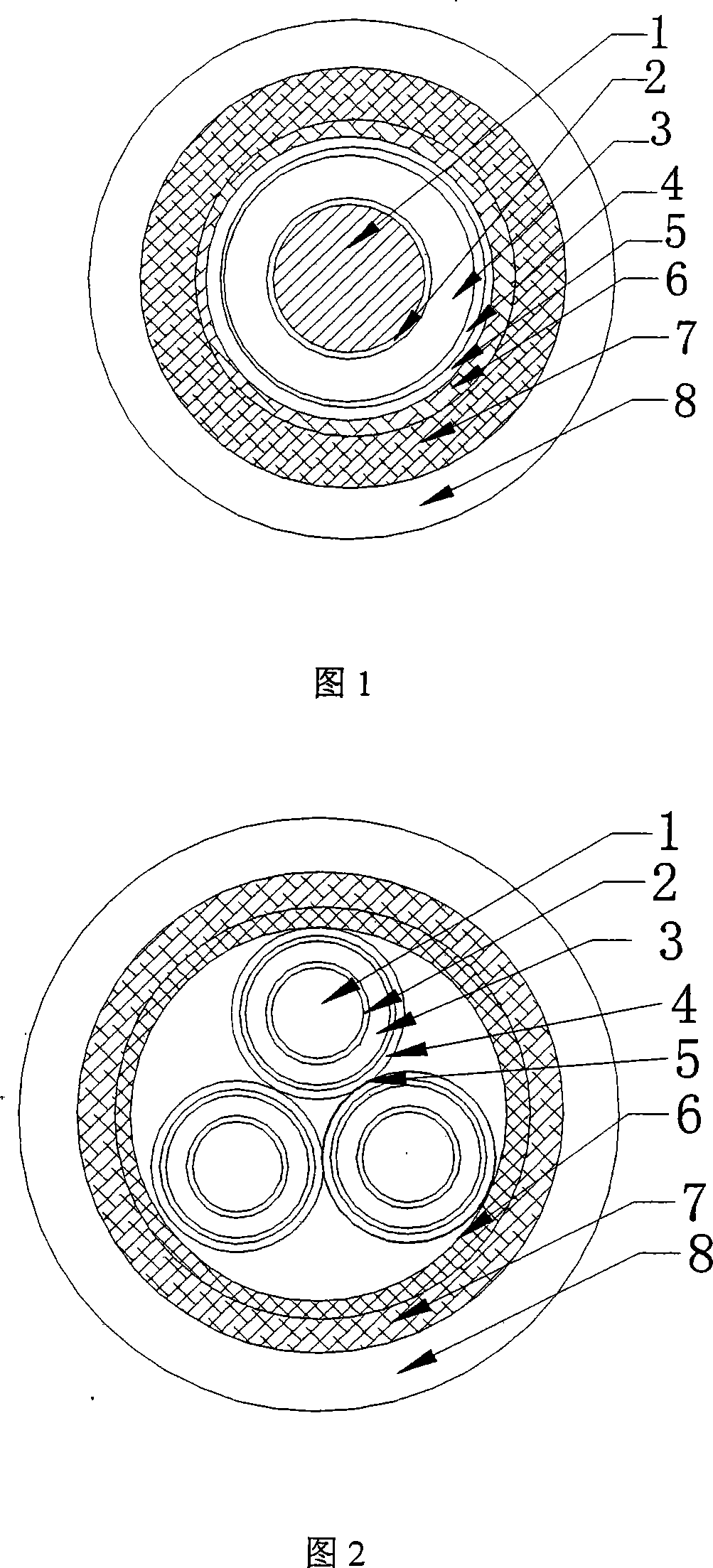

Medium-voltage fire-proof cable

ActiveCN101169993AGood tensile strengthGood fire and heat insulation performanceInsulated cablesInsulated conductorsThermal insulationCable transmission

The invention relates to a medium-voltage power transmission fire-resistant cable, which is characterized in that the outer fire-resistant layer of the medium-voltage cable core is made of fire-resistant inorganic fiber heat insulation layer on the inner side, and the outer side is a soft thermosetting elastomer for normal use. The composite fire-resistant and heat-insulating layer of the heat layer, the thermosetting elastomer, is composed of 30-50wt% silicon-based elastic material, 40-60wt% inorganic filler, 5-15wt% medium and low temperature frit, 4-10wt% vulcanizing agent, It is made by mixing extrusion molding and vulcanization. The composite fire-resistant and heat-insulating layer is a relatively soft sheath material when it is not exposed to flames, which can ensure good bending performance of the refractory structure in normal conditions, and quickly transforms into a shell-and-tube refractory and heat-insulating structure when it encounters fire or high temperature. In the fire-fighting environment, it can still maintain a certain period of time without being damaged, effectively preventing damage to the inner insulation caused by flames or high temperatures. When the flame temperature of the outer layer is 850°C, the temperature of the inner insulation surface is lower than 180°C. This fire-resistant and heat-insulating structure can be applied according to conventional cable production methods, and the production efficiency is extremely high.

Owner:FAR EAST CABLE +2

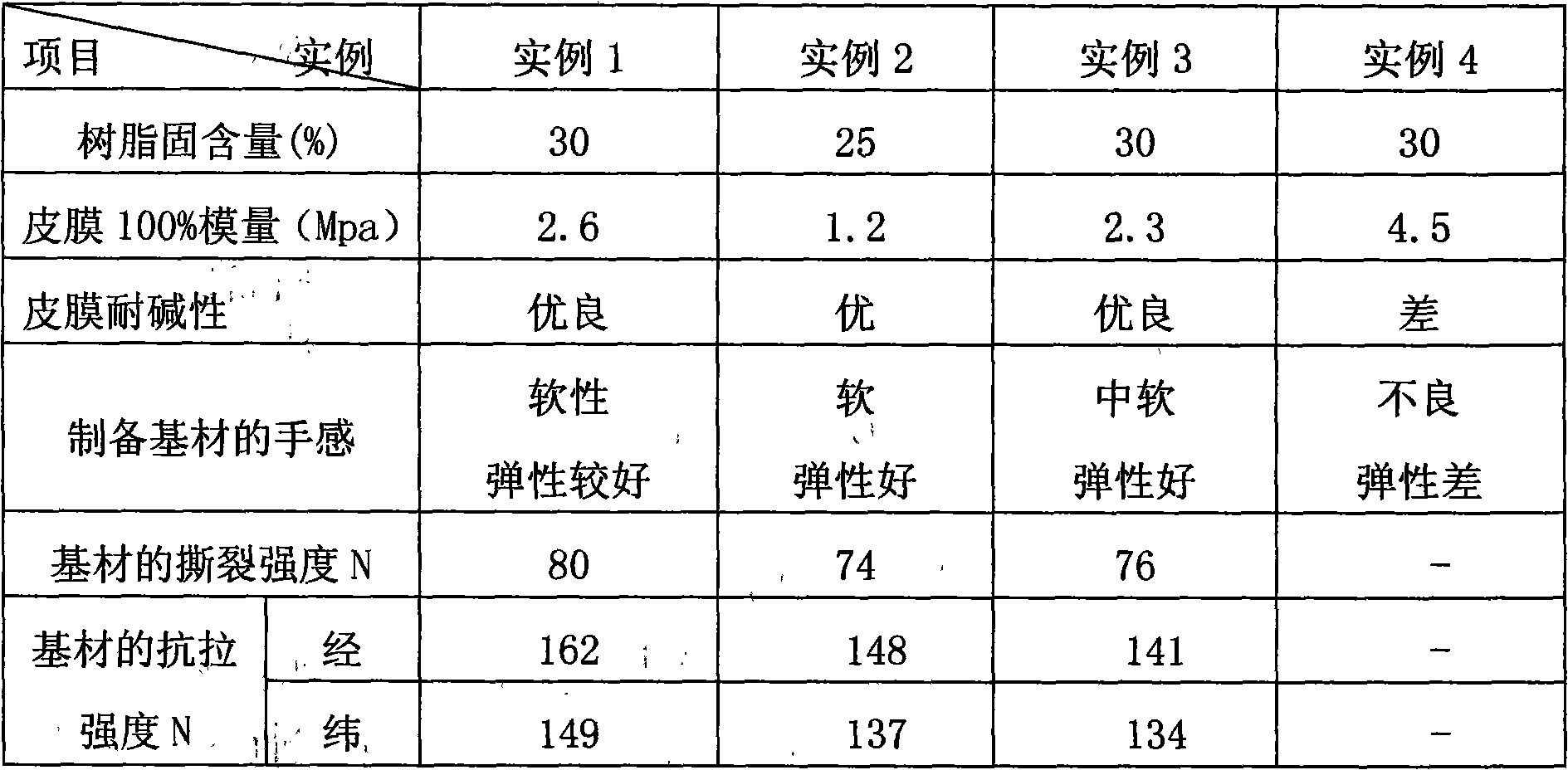

Waterborne polyurethane resin and preparation method of dipping sizing agent for synthetic leather base material

The invention relates to a preparation method of waterborne polyurethane dipping sizing agent for synthetic leather base material, belonging to the technical field of chemical products and a preparation method thereof. The preparation method is characterized in that diisocyanate, polyester polyol, polyether polyol and hydrophilic chain-extending agent carry out polymerization to generate prepolymer; the prepolymer is reacted with a neutralizer to carry out water dispersion emulsification to generate a waterborne polyurethane resin; and the waterborne polyurethane resin, wetting agent, thickener and stabilizer are reacted to generate synthetic leather base material dipping sizing agent. In the preparation method for synthesizing the leather base material dipping sizing agent by the waterborne polyurethane, synthetic leather and artificial leather base material manufactured after an ultrafine non-woven fabric is dipped in the dipping sizing agent have favorable performance, soft handle, favorable elasticity and stronger tear strength and tensile strength. In addition, the use and the discharge of organic solvent in a manufacture process is greatly reduced, the energy consumption and the environmental pollution is reduced to the maximum extent, and the invention has a wide popularization and application prospect.

Owner:烟台道成化学有限公司

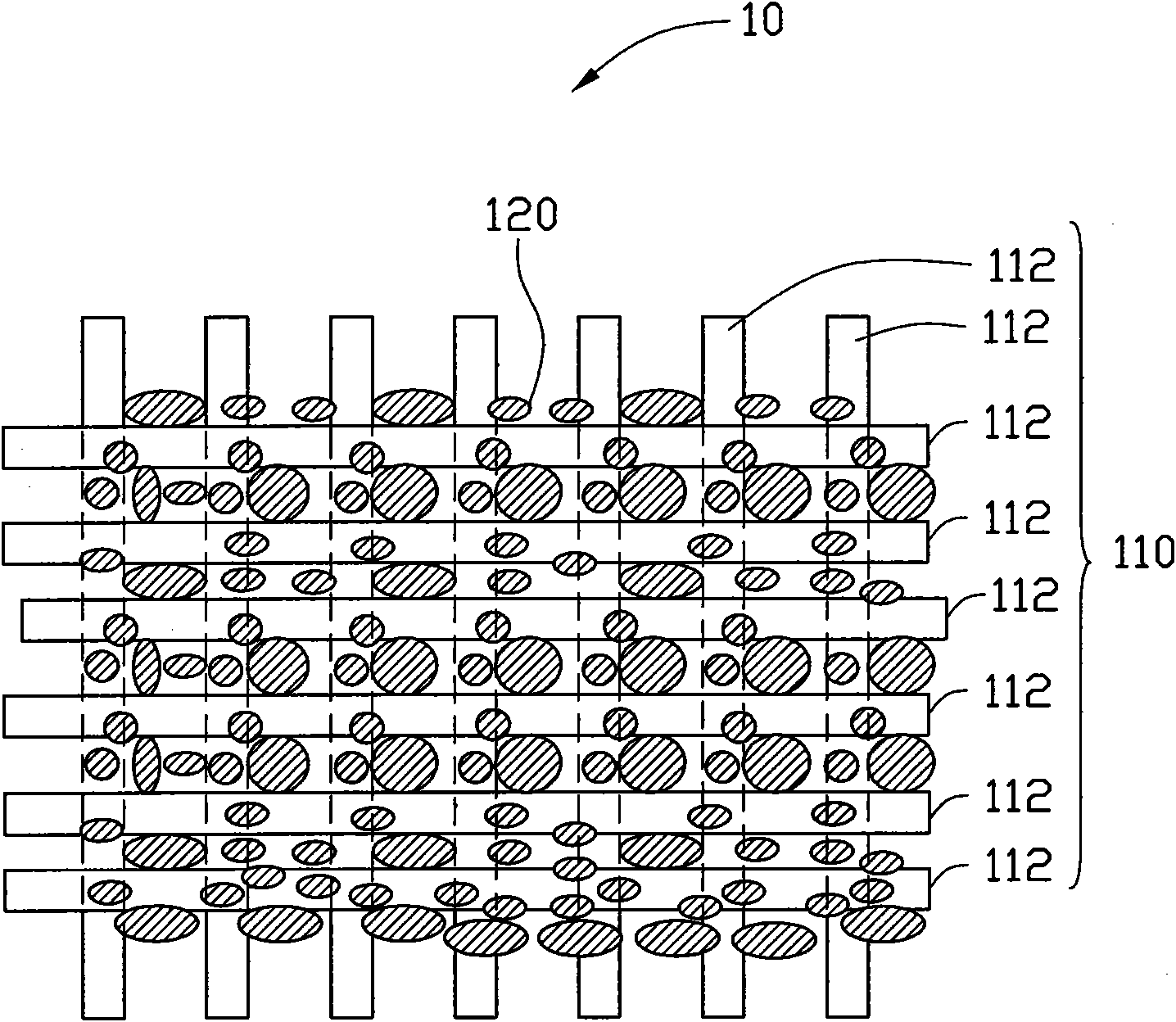

Carbon nano tube composite structure

ActiveCN102040212AGood tensile strengthGood Young's modulusMaterial nanotechnologyHybrid capacitor electrodesComposite structureYoung's modulus

The invention relates to a carbon nano tube composite structure which comprises a carbon nano tube structure and a reinforcement, wherein the carbon nano tube structure is a self-supporting structure consisting of a plurality of carbon nano tubes; and the reinforcement is arranged on the surface of the carbon nano tubes, and the adjacent carbon nano tubes are closely combined through the reinforcement. The carbon nano tube composite structure has better tensile strength and Young modulus.

Owner:TSINGHUA UNIV +1

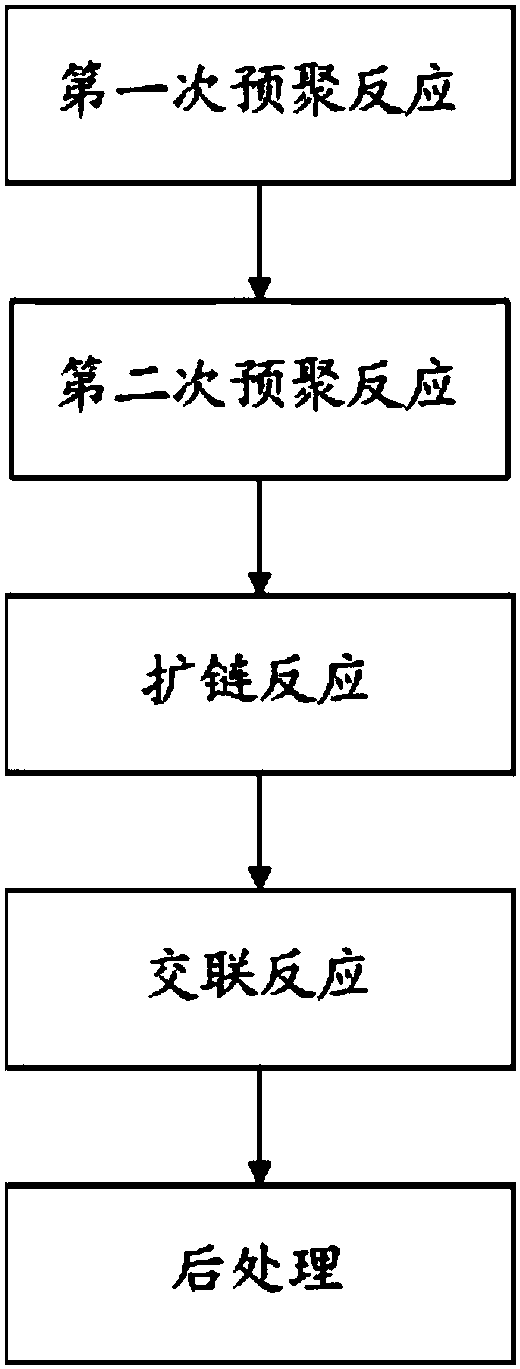

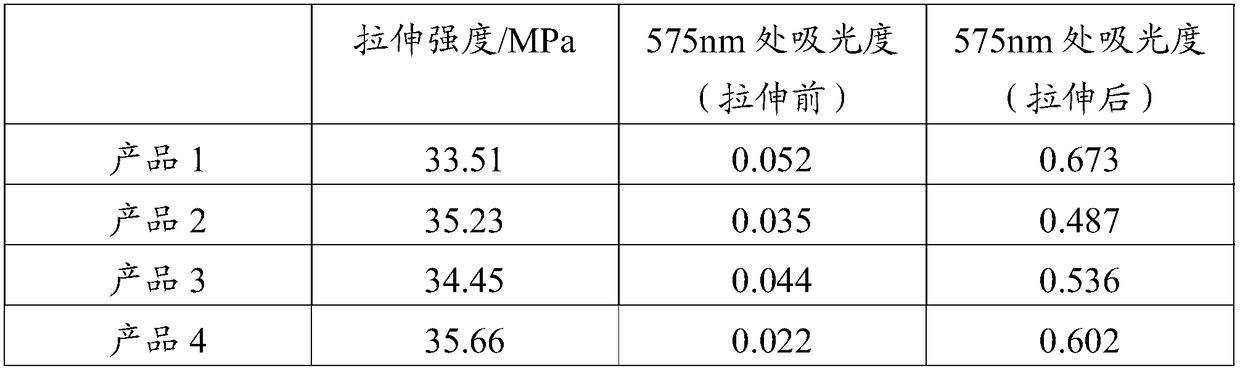

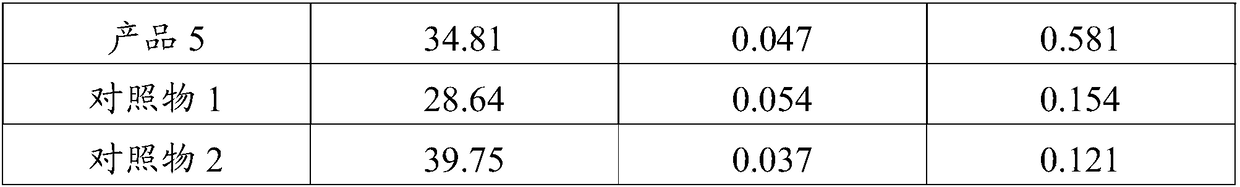

Composition as well as preparation method and application thereof to force-induced discoloration material field

The invention belongs to the technical field of functional polyurethane materials and in particular relates to a composition as well as a preparation method and application thereof to a force-induceddiscoloration material field. The invention provides the composition and the composition is prepared from the following raw materials: dihydroxyspiropyran, polyol, an organic amine type catalyst, diisocyanate, a chain extender and a crosslinking agent. The invention further provides the preparation method of the composition and also provides the application of the composition or a product obtainedby the preparation method to the force-induced discoloration material field. tensile experimental determination can show that color changes of the product prepared by the technical scheme are remarkable before and after stretching; meanwhile, the composition has good tensile strength and the tensile performance index is better than that of a reference substance. According to the composition as well as the preparation method and the application thereof to the force-induced discoloration material field, provided by the invention, the technical defects of a polyurethane based force-induced discoloration material in the prior art of poor force responsiveness and insensitive discoloration are solved.

Owner:GUANGDONG UNIV OF TECH

Flame-retardant thermoplastic vulcanized rubber material

InactiveCN106519460AGood tensile strengthImproved resistance to permanent deformation and processabilityCalciumFire resistance

The invention discloses a flame-retardant thermoplastic vulcanized rubber material. Raw materials of the flame-retardant thermoplastic vulcanized rubber material include ethylene propylene terpolymer, polypropylene, methyl-phenyl-vinyl silicone, montmorillonite, kaolin, cerium dioxide, white carbon black, zirconium oxide, aramid fiber, tetra-needle like ZnO whiskers, titanate coupling agent modified calcium sulfate whiskers, phenolic resin, pulverous coal, activated zinc oxide powder, nanosilicon dioxide, fire retardant, a vulcanizing agent, glutamic acid dithiocarbamic lanthanum, paraffin oil, an ultraviolet light absorber, an antioxidant and a lubricant. The flame-retardant thermoplastic vulcanized rubber material which is put forward has the beneficial effects of being high in strength, good in fire resistance, high in durability and good in tenacity.

Owner:安徽中翰高分子科技有限公司

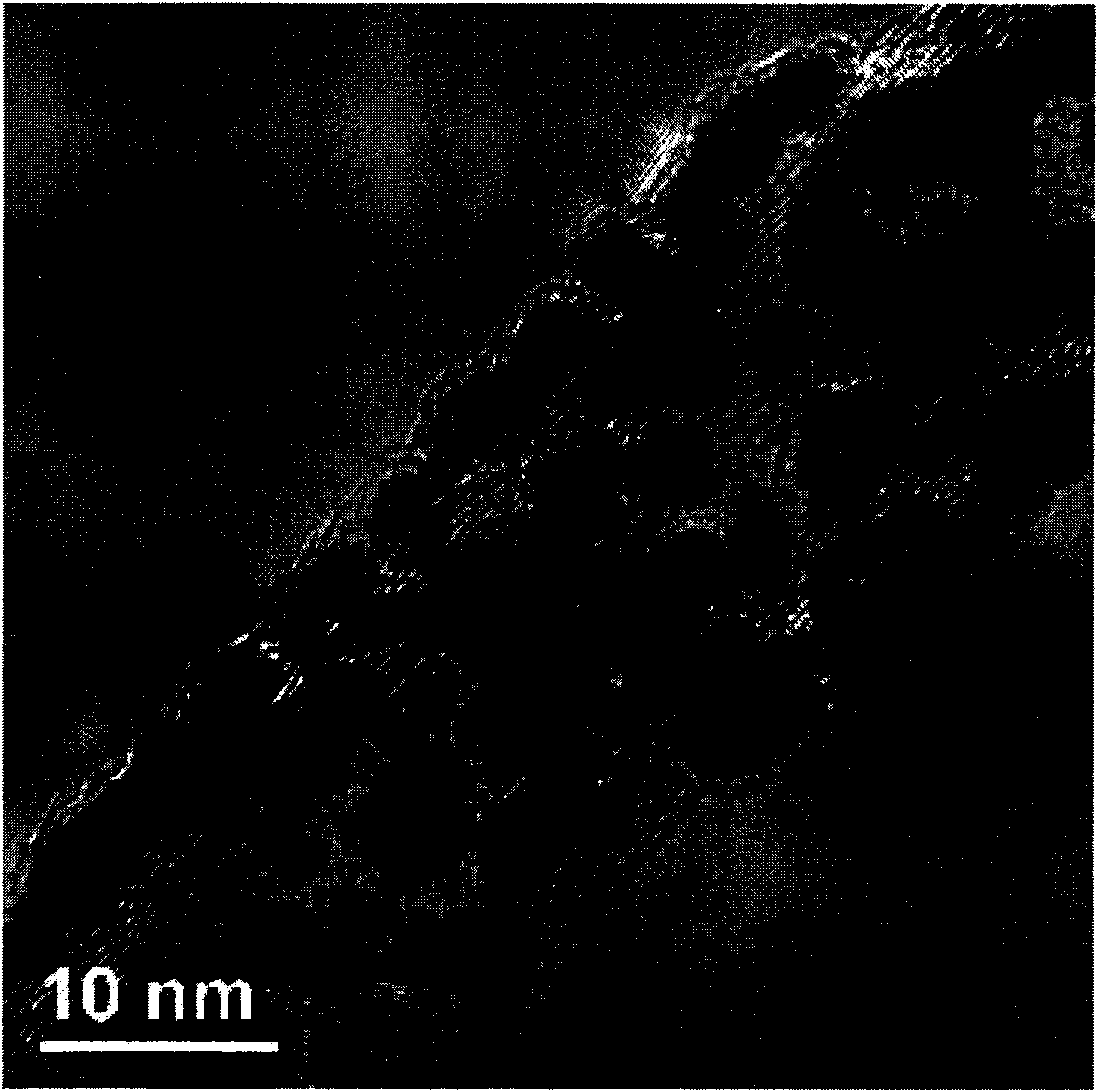

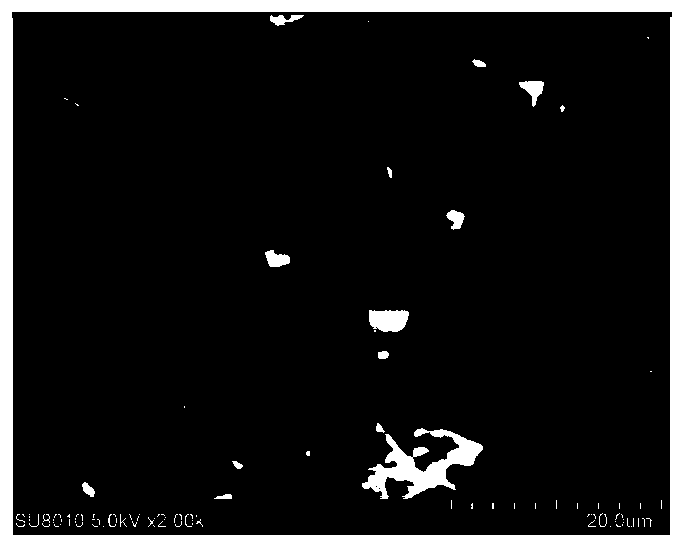

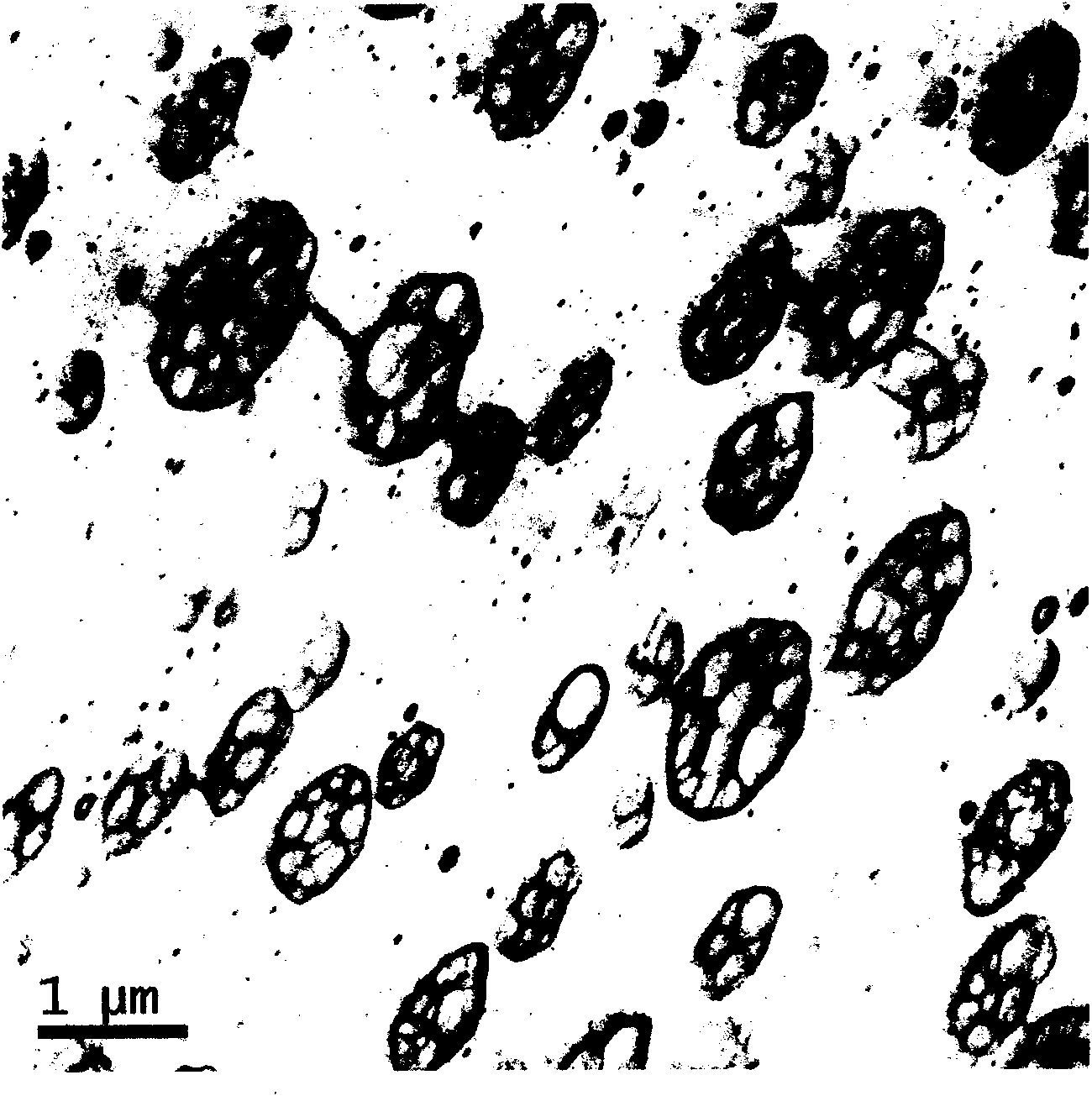

Modified wholly-vulcanised polyolefinic thermoplastic elastomer and its preparation method

The invention provides the modified fully vulcanizate polyolefin thermoplastic elastomers and its preparation method, and relates its technology field. , The fully vulcanizate polyolefin thermoplastic elastomers comprises the polyolefine resin, powder rubber and nano silicon dioxide. The said powder rubber is rubber particle possessing the crosslinked structure, the mean particle diameter of which is 20nm-1000nm, and the gelatin concent of which is 60wt% or more than 60wt%. The mean particle diameter of nano silicon dioxide is 1-100nm. The proportion by weight of powder rubber and polyolefin thermoplastic elastomers is 30í†70-75í† 25. The content of nano silicon dioxide is 0.5-10% of powder rubber. The powder rubber and inorganic particle are dispersed homogeneously in the polyolefin thermoplastic elastomers, so the fully vulcanizate polyolefin thermoplastic elastomers possesses good hot strength and wide application.

Owner:CHINA PETROLEUM & CHEM CORP +1

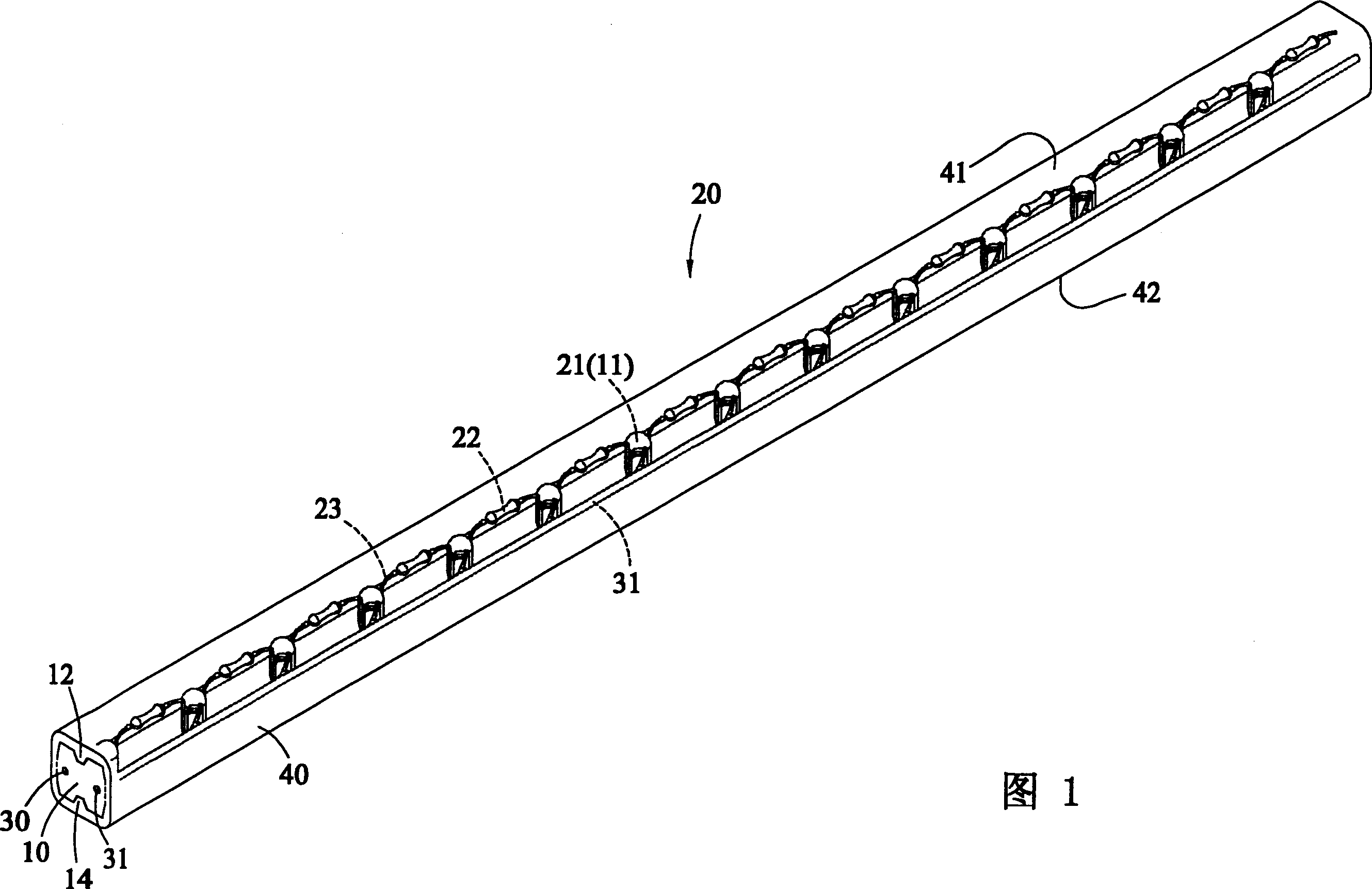

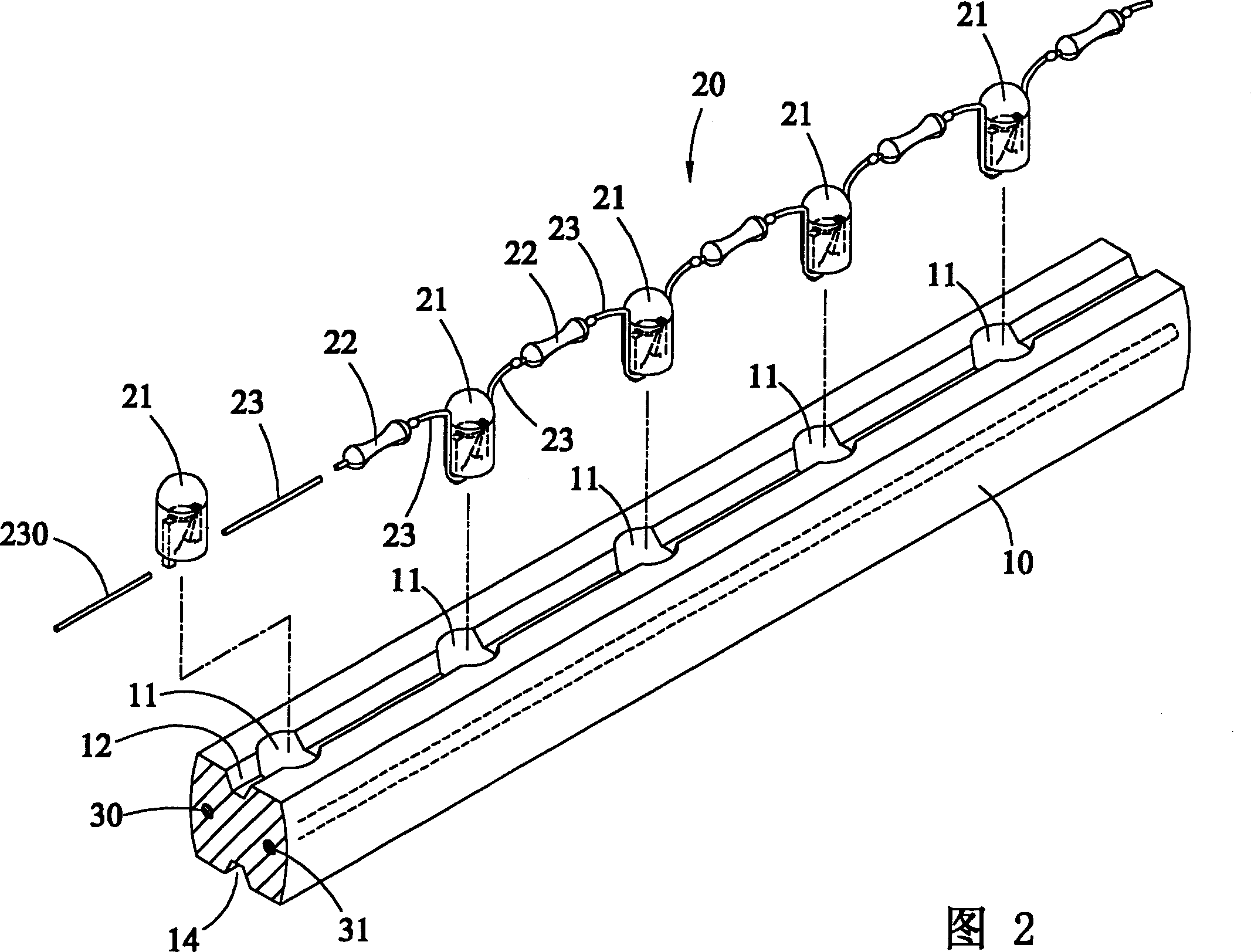

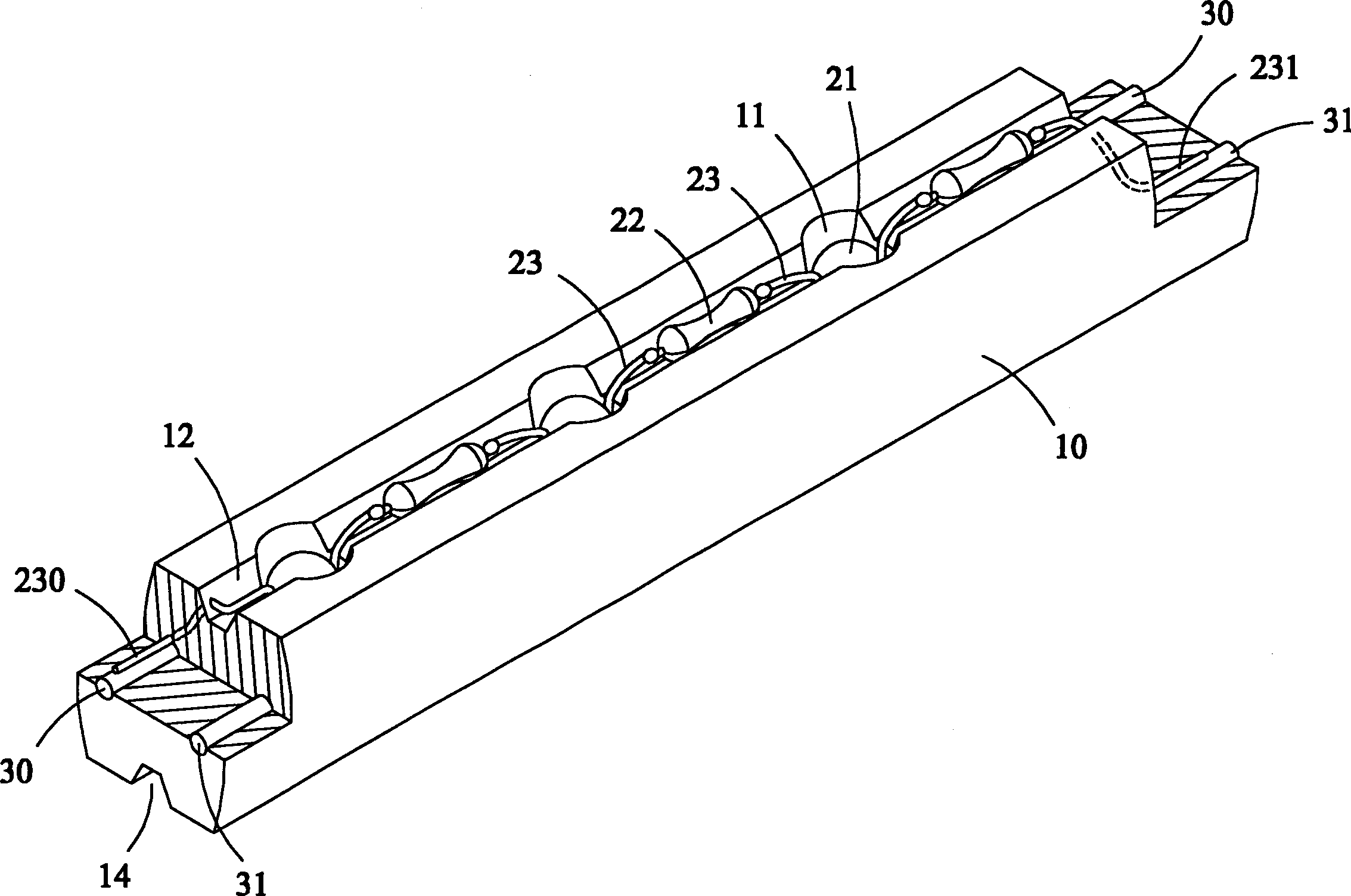

Flexiblel ight-emitting unit and its making process

InactiveCN1453499APoint to consistencyPlug-in fast and easyPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The flexible light-emitting unit includes one inner layer fixing seat, one LED lamp string, one pair of wires and one outer fixing body. Welded serially connected LED lamp string is inserted into the holes of the pre-formed inner fixing seat, connected to one pair of embedded wires electrically, pressed and coated with one outer fixing body. The said making process results in equidistantly laidlight sources and identical light source direction.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

High-density polyethylene double-wall corrugated tube

InactiveCN103554601AGood tensile strengthGood mechanical properties and anti-friction propertiesFlexible pipesRigid pipesEthyl phosphateKetone

The invention discloses a high-density polyethylene double-wall corrugated tube. The high-density polyethylene double-wall corrugated tube is characterized by comprising the following raw materials in parts by weight: 80 to 86 parts of high-density polyethylene, 2 to 3 parts of polycarbonate, 2 to 3 parts of tetradecanedioic acid, 1 to 2 parts of tartaric acid, 1 to 2 parts of octyl-isothiazolin-ketone, 0.5 to 1 part of tetramethylthiourea, 1 to 2 parts of N-ethyl-p / m-toluene sulfonamide, 4 to 5 parts of fluorite powder, 1 to 2 parts of monopotassium phosphate, 2 to 4 parts of poly-4-methyl-1-amylene, and 7 to 10 parts of composite filler. The corrugated tube disclosed by the invention has high tensile strength, high elongation at break and high notch impact strength, and also has high mechanical properties and anti-friction properties.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

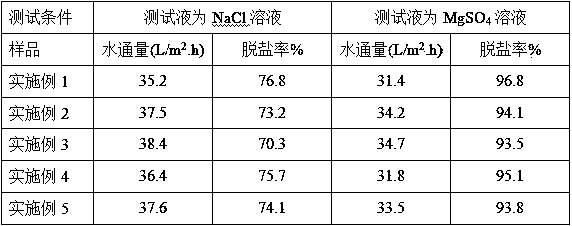

Preparation method of double-layer hollow fibrous nanofiltration membrane

InactiveCN108126528AEasy to prepareGood tensile strengthSemi-permeable membranesChemistryNanofiltration

The invention relates to a preparation method of a double-layer hollow fibrous nanofiltration membrane. The method comprises the following steps of a step (1), mixing and agitating a high-molecular polymer a, an organic solvent and a dispersant according to a certain proportion to form a uniform and stable membrane casting solution A, removing an air bubble in the membrane casting solution throughvacuum suction, and enabling to be for later use; a step (2), mixing and agitating a high-molecular polymer b, an organic solvent and a dispersant according to a certain proportion to form a uniformand stable membrane casting solution B, removing an air bubble in the membrane casting solution through the vacuum suction, and enabling to be for later use; a step (3), simultaneously ejecting the membrane casting solution A and the membrane casting solution B through a double-hole spinning nozzle under pressure driving, entering an outer gel bath in certain conditions of a core liquid flow velocity and an air section distance, and molding, so that the double-layer hollow fibrous nanofiltration membrane is obtained. The double-layer hollow fibrous nanofiltration membrane prepared by the method has favorable tensile strength; further, a membranous layer is uniform and stable, and the separation performance is favorable.

Owner:江苏向阳科技有限公司

Material for producing natural degradable deep-cavity thin-wall soft bottle for tableware and soft bottle thereof

InactiveCN101429328AGood glossGood tensile strengthFlexible coversWrappersSmokeLimiting oxygen index

The invention relates to a material for producing a soft bottle for natural degradable deep-cavity thin-walled tableware, and the soft bottle. The material consists of the following components in weight percentage: 85 to 90 percent of polylactic acid ester, 9 to 14 percent of polyethylene terephthalate, and the balance being additive of the polyethylene terephthalate. The soft bottle produced from the material has the characteristics of good glossiness, tensile strength and ductility, innocuity, no pungency, good biocompatibility, biodegradability and biological absorption and the like. The soft bottle does not pollute the environment and cannot distribute poison gas and cause pollution in combustion. The soft bottle has the advantages of higher limit oxygen index (LOI 24-29), good self extinguishing after ignition, low smoke development in combustion, better flame retardant property, and the same combustion value as that of paper incineration. The material is a sustainable ecological fiber. In the process of using the soft bottle, the advantages of health and innocuity, no need of cleaning, environmental protection, and natural degradation are achieved.

Owner:深圳市阳成世纪科技有限公司

Novel high-efficiency haze filtration silver nanowire net and MOFs composite porous fiber film material and preparation method thereof

ActiveCN110075815AImprove filtering effectGood tensile strengthGas treatmentOther chemical processesElectrospinningFilm material

The invention provides a preparation method of a novel high-efficiency haze filtration silver nanowire net and MOFs (metal-organic frameworks) composite porous fiber film material. The preparation method is characterized by comprising the following steps of preparation of silver nanowires, preparation of MOFs, preparation of a spinning precursor solution, preparation of a spinning solution, electrostatic spinning, preparation of suction filtration dispersing liquid and suction filtration and filming. The preparation method has the benefits that the preparation method of the novel high-efficiency haze filtration silver nanowire net and MOFs composite porous fiber film material prepares a composite fiber film by using the silver nanowires in certain diameters and the MOFs in certain particlesizes for doping; pore sizes of the fiber film formed by the spinning are used for filtration; at the same time, lower voltage is applied; particulates are collected by a remote electrostatic force of the silver nanowire; an filtration effect is improved; and since the silver nanowires have a sterilization function, the composite porous fiber film material can achieve a multifunctional haze filtration effect.

Owner:NORTHWEST UNIV

Polypropylene nanocomposites

InactiveUS20070093592A1Superior dimensional stabilityGood tensile strengthPolymer chemistryNanocomposite

The present invention relates to a polypropylene nanocomposite comprising (a) about 1 wt % to about 40 wt % of an acid- or acid anhydride-modified polypropylene; (b) about 0.1 wt % to about 50 wt % of an organically modified layered silicate; and (c) about 30 wt % to about 90 wt % of a nonpolar polypropylene, wherein the acid- or anhydride-modified polypropylene has a molecular weight that is lower than that of the nonpolar polypropylene, and wherein the polypropylene nanocomposite has a linear thermal expansion coefficient ranging from about 4×10−5 / ° C. to about 9×10−5 / ° C. The density and linear thermal expansion coefficient of these nanocomposites are, respectively, 10% to 20% and 20% to 40% less than conventional polypropylene composites and can be used to form durable molded products with superior dimensional stability, good tensile strength, good moldability, and high thermal resistance.

Owner:HYUNDAI MOTOR CO LTD

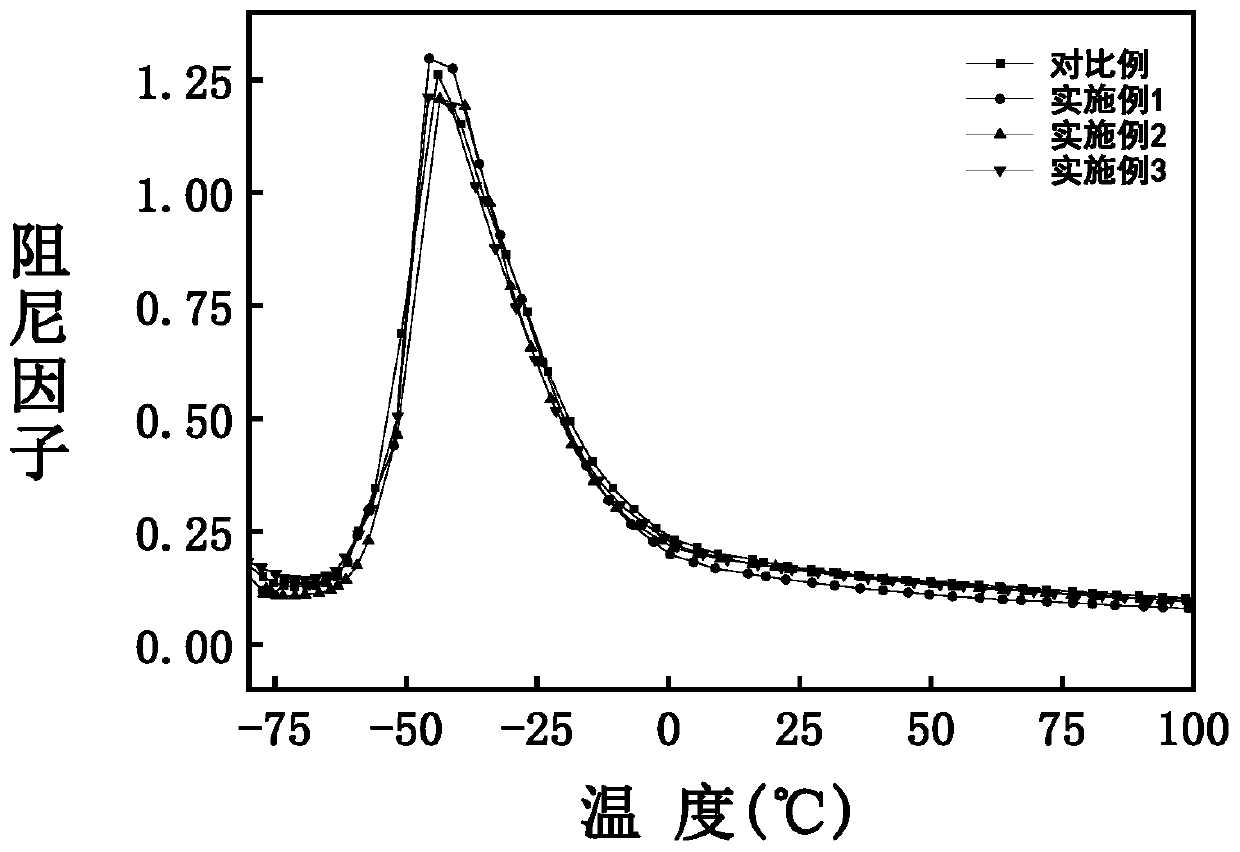

Automotive rubber material, preparation method and application thereof

The invention discloses an automotive rubber material, a preparation method and application thereof. The rubber material is prepared from the following raw materials in parts by weight: 70 to 110 parts of natural rubber, 5 to 45 parts of Eucommia ulmoides rubber, 20 to 60 parts of carbon black, 5 to 20 parts of white carbon black, 4 to 7 parts of a plasticizer, 1 to 5 parts of a coupling agent, 3to 8 parts of an anti-aging agent, 0.1 to 0.3 part of a scorch retarder, 5 to 7 parts of a vulcanizing activator, 1 to 1.5 parts of an accelerant and 2 to 4 parts of a vulcanizing agent. By using thecombination of natural rubber and Eucommia ulmoides rubber, the compound has the characteristics of excellent tensile strength, compressive strength, tension fatigue resistance, low heat generation rate and the like, and also has excellent flexural fatigue resistance.

Owner:DONGFENG MOTOR CORP HUBEI

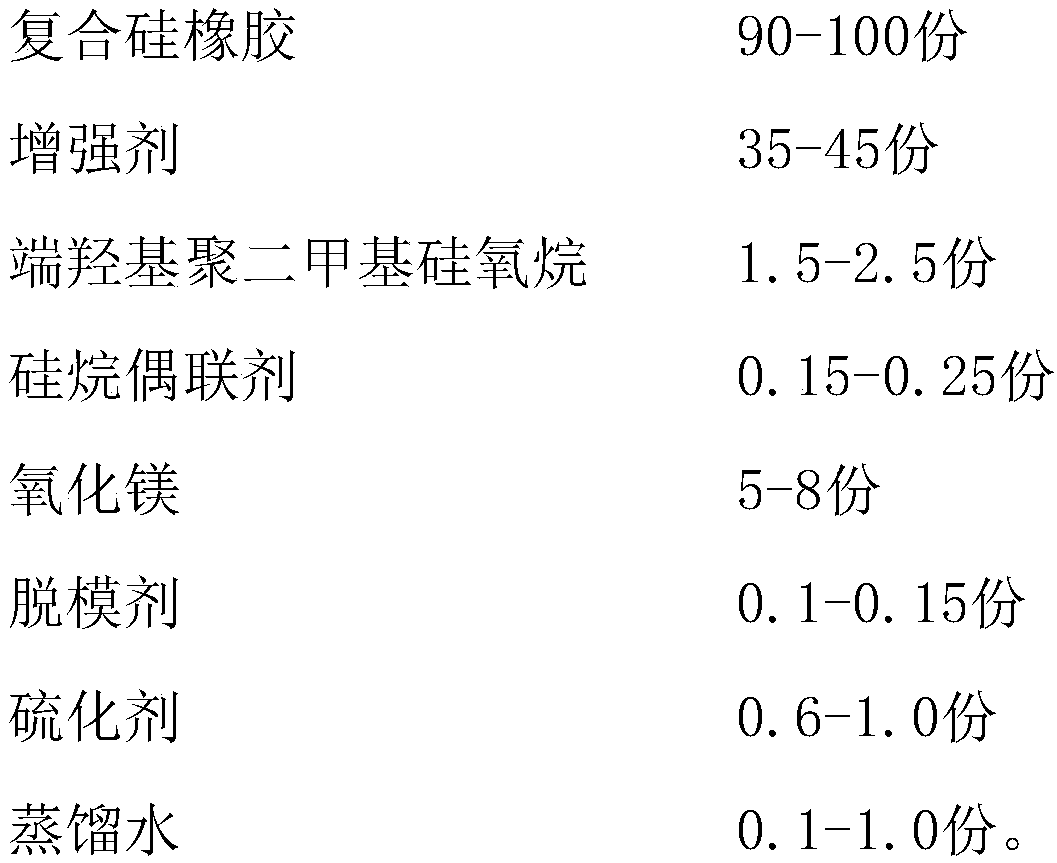

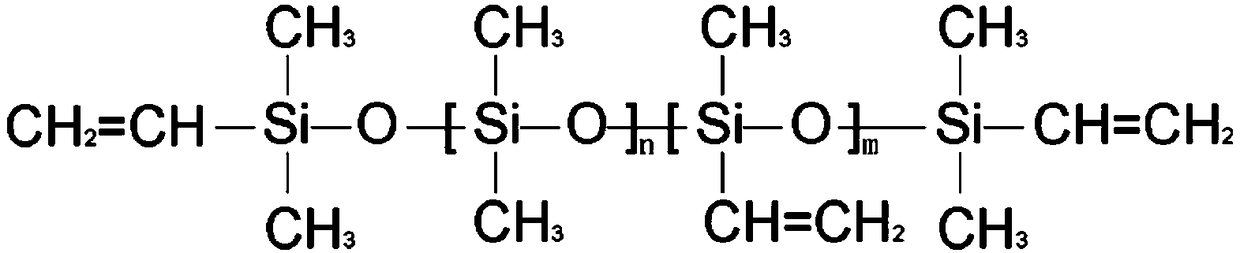

High-resilience silicone rubber and preparation method thereof

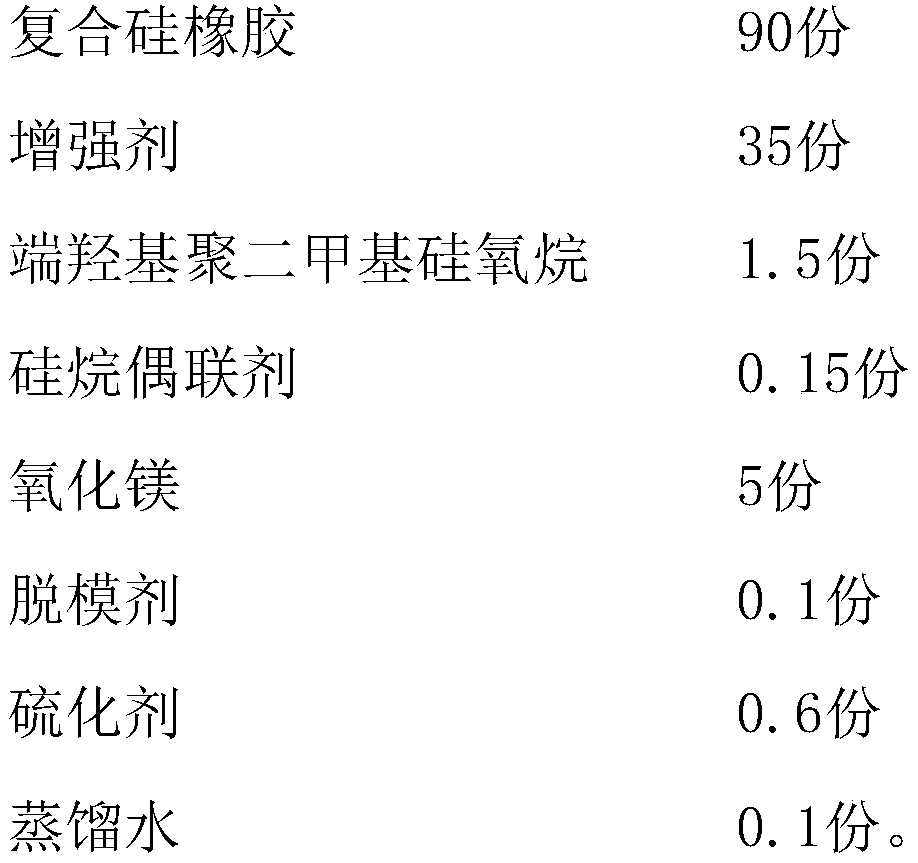

The invention relates to the technical field of silicone rubber, in particular to high-resilience silicone rubber and a preparation method thereof. The high-resilience silicone rubber comprises raw materials in parts by weight as follows: 90-100 parts of composite silicone rubber, 35-45 parts of a reinforcing agent, 1.5-2.5 parts of hydroxy-terminated polydimethylsiloxane, 0.15-0.25 parts of a silane coupling agent, 5-8 parts of magnesium oxide, 0.1-0.15 parts of a release agent, 0.6-1.0 part of a vulcanizing agent and 0.1-1.0 part of distilled water. By means of the materials such as the reinforcing agent, hydroxy-terminated polydimethylsiloxane, the silane coupling agent and the like, the prepared silicone rubber has high resilience rate and excellent resilience, further has the properties of better tensile strength, elongation at break, tear strength and the like, is high in mechanical strength and stability and has wide application range.

Owner:东莞市朗晟材料科技有限公司

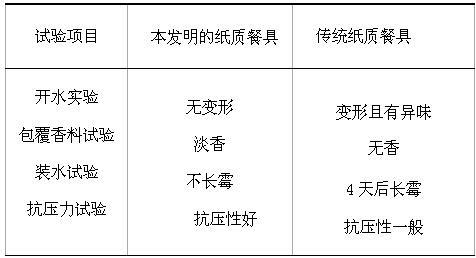

Water film on inner wall of paper tableware and preparation method thereof

InactiveCN101870775AStrong plasticityGood tensile strengthPaper coatingCoatingsCarrageenanPlasticizer

The invention provides a water film on an inner wall of paper tableware and a preparation method thereof. The water film on the inner wall of the paper tableware comprises the following raw materials in part by weight: 0.03 to 0.1 part of potassium sorbate, 0.05 to 0.15 part of emulsifier, 0.5 to 1 part of plasticizer, 0.2 to 0.3 part of stearic acid, 0.5 to 1.5 parts of konjac glucomannan esterified product, 0.5 to 2 parts of xanthan gum, 0.625 to 1 part of carrageenan, and 100 parts of water. The method comprises the following steps of: preparing film solution according to the raw material formula, and packaging the table ware after heating, centrifugally degassing, tableware filming, drying, samming and mellowing and sterilizing. The water film on the inner wall of the paper tableware has the advantages of no toxicity and obvious water resistance and capability of postponing transfer and diffusion of water, oil and other components in food; the konjac composite gel can coat a plurality of aromatic substances and improve the sensory quality of product; and the water film also has the advantages of water resistance, high temperature resistance, high mechanical performance, high flexibility, and no generation of harmful substances at high temperature or in the presence of oil.

Owner:FUJIAN AGRI & FORESTRY UNIV

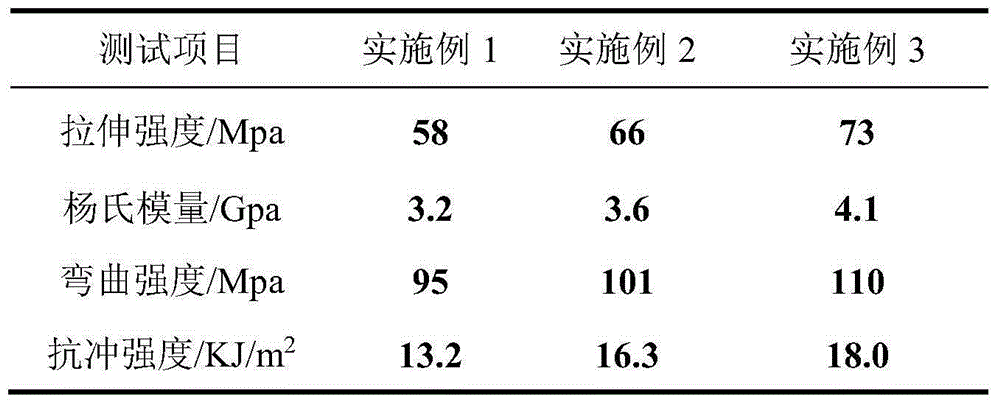

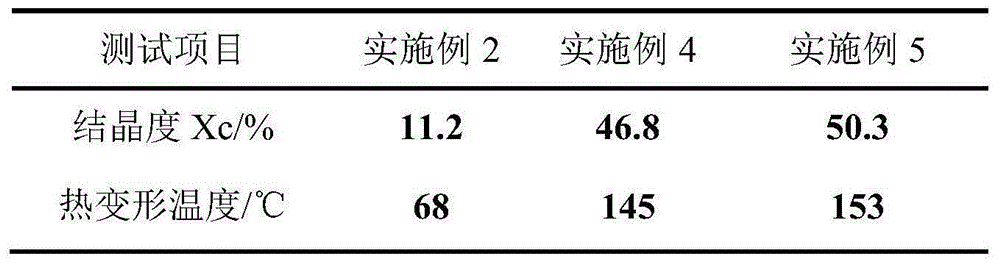

Full-biodegradation bacterial cellulose/polylactic acid composite material and preparing method thereof

The invention relates to a full-biodegradation bacterial cellulose / polylactic acid composite material and a preparing method thereof. The composite material is prepared from, by weight, 75 parts to 99 parts of polylactic acid, 1 part to 25 parts of bacterial cellulose and 1 part to 3 parts of coupling agents. The preparing method includes the steps that the polylactic acid and the bacterial cellulose are stirred to be mixed by weight, the coupling agents are added by weight, then the mixture is put into a mixing apparatus, the temperature is controlled to range from 170 DEG C to 220 DEG C, melt mixing is carried out, extruding and prilling are carried out, and premix particles are obtained; the premix particles are added into an injection molding machine or a compression molding machine, the temperature is controlled to range from 170 DEG C to 220 DEG C, the melting time is controlled to range from 2 min to 3 min, melt molding is carried out, and sample strips of the composite material are obtained; then drying treatment and heat treatment are carried out to increase the practical using temperature of the material. Compared with the prior art, the full-biodegradation bacterial cellulose / polylactic acid composite material and the preparing method thereof are simple in preparing technology, good in controllability, wide in raw material source and low in processing cost, and the prepared composite material is excellent in mechanical property, good in heat stability, capable of achieving full biodegradation in the natural environment and is environmentally friendly.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Mildew-preventing rubber

InactiveCN102977436AGood tensile strengthGood electrical insulationBuilding insulationsParaffin waxCarbon black

The invention discloses a mildew-preventing rubber which comprises the following components in parts by weight: 20-50 parts of chloroprene rubber, 30-60 parts of natural rubber, 2-5 parts of asphalt, 10-15 parts of magnesium stearate, 5-10 parts of magnesium oxide, 1-5 parts of clay powder, 20-40 parts of conductive carbon black, 5-8 parts of bi-lead tetraoxide and 1-5 parts of paraffin wax. Compared with the prior art, the mildew-preventing rubber has the advantages that the chloroprene rubber and the natural rubber are adopted as main raw materials, because the natural rubber has the characteristics of excellent tensile strength, good flexibility at low temperature and good electric insulation, the chloroprene rubber has the advantages of fire resistance, atmosphere corrosion resistance, mildew prevention, heat resistance and the like; the mildew preventing effect is greatly improved due to the addition of magnesium stearate; and excellent mechanical and physical properties are achieved.

Owner:JIAOZHOU FUTIAN CHEM ENG

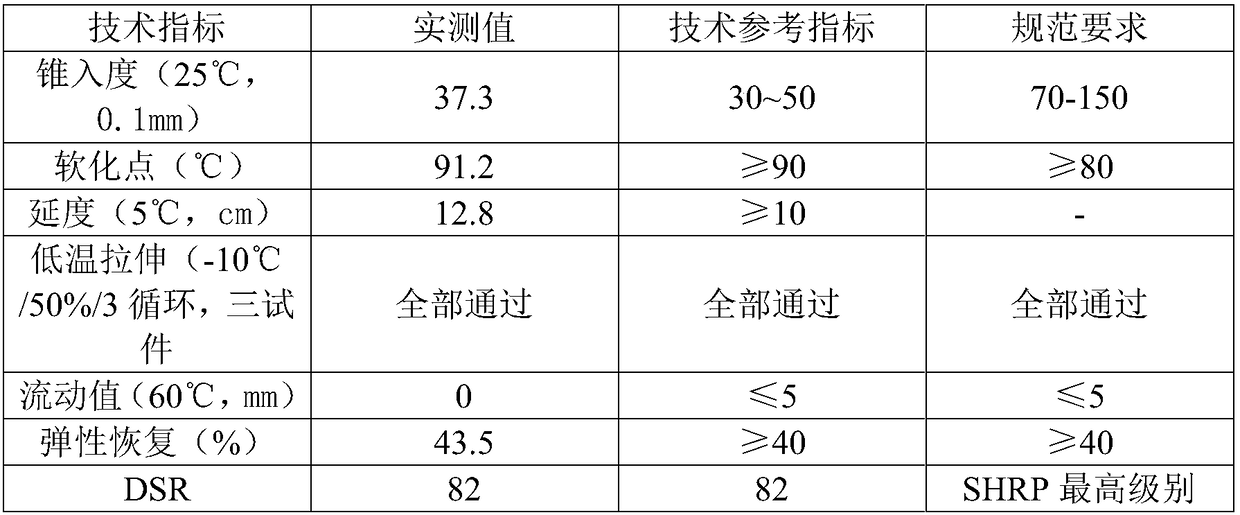

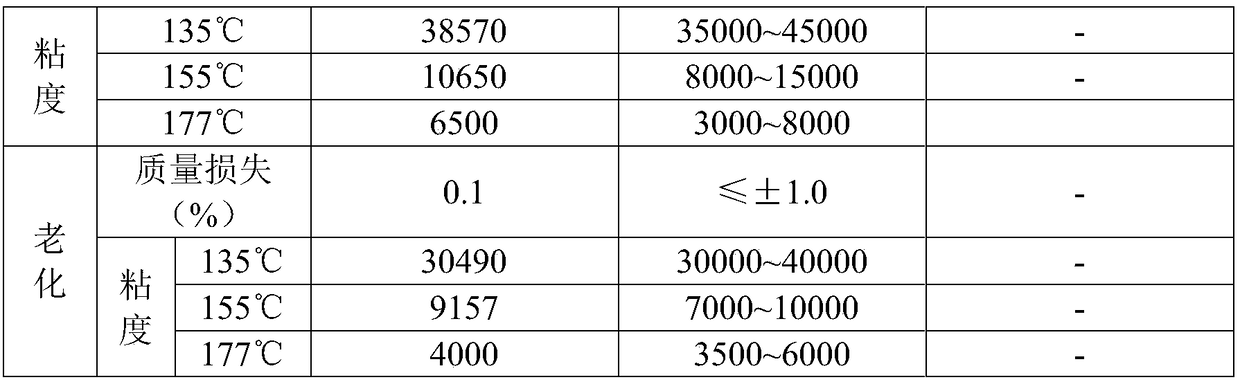

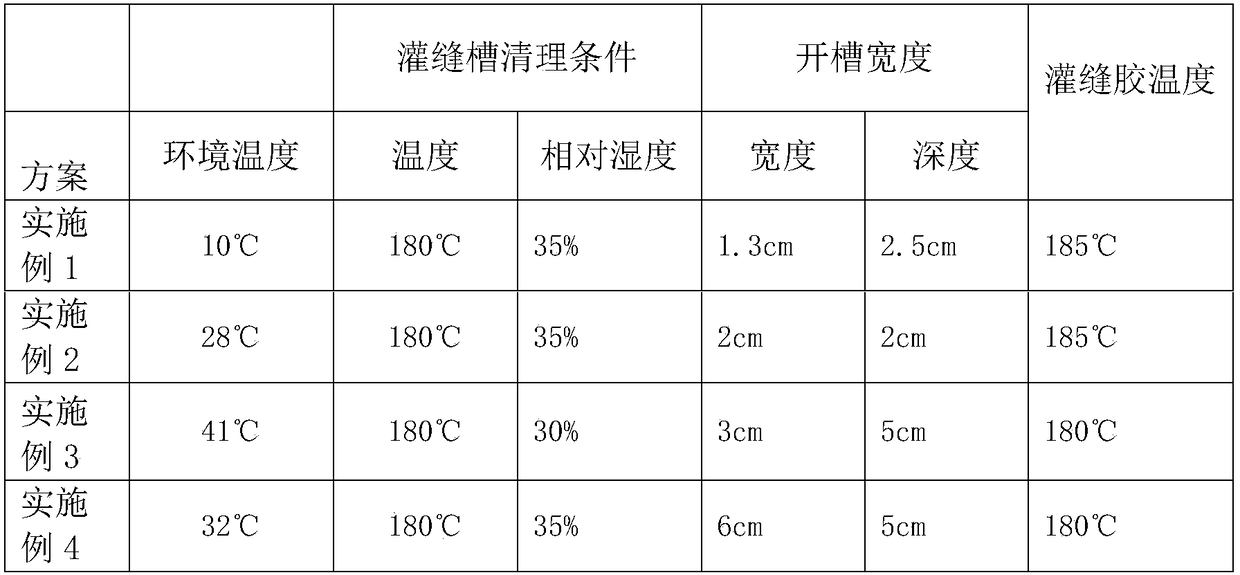

Joint-filling adhesive and road-joint repairing process applying same

InactiveCN108316116AGood acid and alkali resistanceGood tensile strengthMineral oil hydrocarbon copolymer adhesivesBituminous material adhesivesChemistryPetroleum

The invention discloses joint-filling adhesive and a road-joint repairing process applying the same. The joint-filling adhesive is characterized in that the joint-filling adhesive is prepared from themain components: petroleum asphalt, petroleum resin and alkyd resin with the proportion being (2-2.2):(1-1.5):(0.1-0.3), and in operation, the temperature is controlled to 180-195 DEG C all the time.A special hot-melting kettle provides high-temperature joint-filling adhesive in operation, the temperature is controlled to be 180-195 DEG C, and the mean temperature difference is within + / -3 DEG C, so that the complete filling of telescopic joints can be ensured; simultaneously, the joint-filling adhesive adopts petroleum asphalt, petroleum resin and alkyd resin as main components, the viscosity of the joint-filling adhesive can be controlled to be 360-390mPa.S, and the fluidity is better. The road-joint repairing process applying the joint-filling adhesive has the beneficial effects thatfast repairing for small joints of roads is realized, the service life of the road is prolonged, and the maintenance cost is reduced; simultaneously, due to dustless operation, the operation environment is greatly improved.

Owner:ZHONGSHAN YILUMEI ROAD MAINTENANCE TECH CO LTD

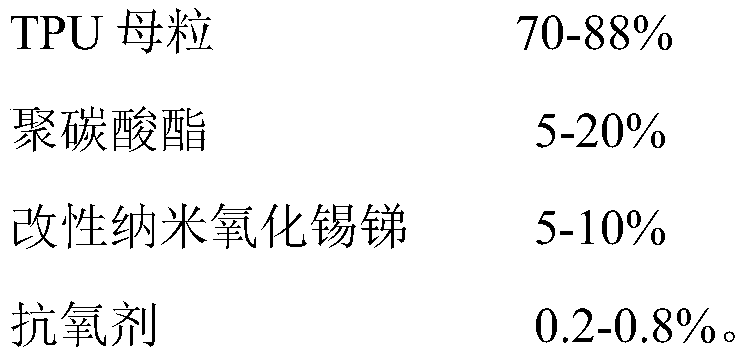

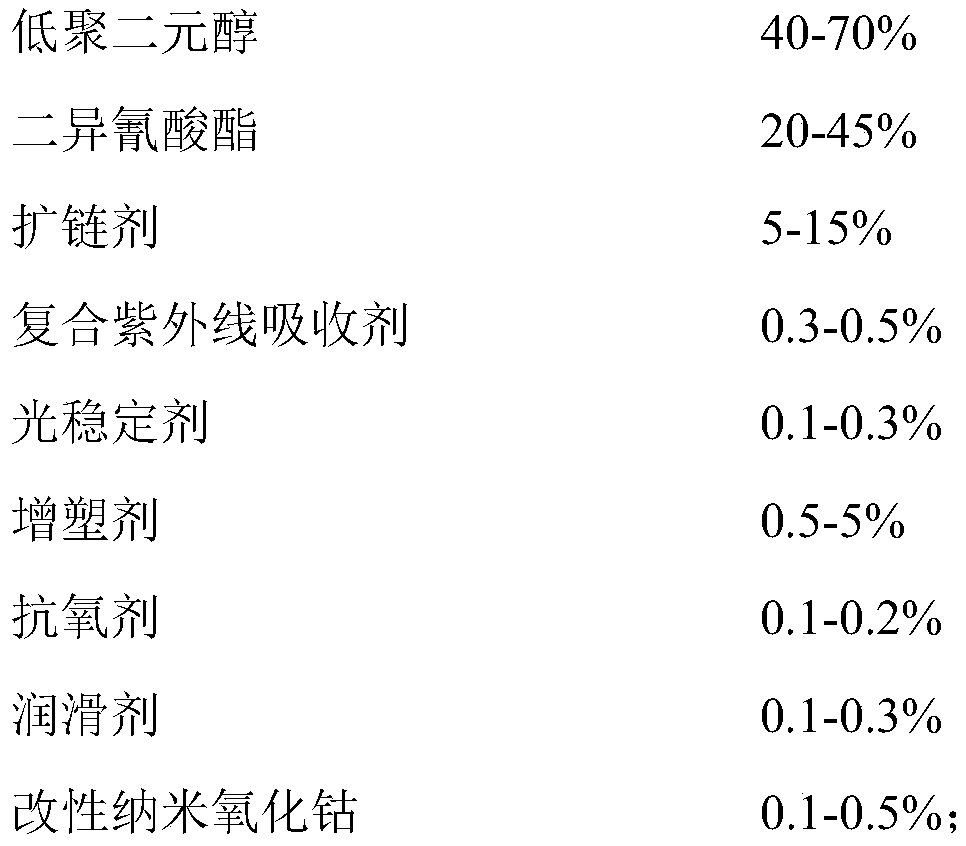

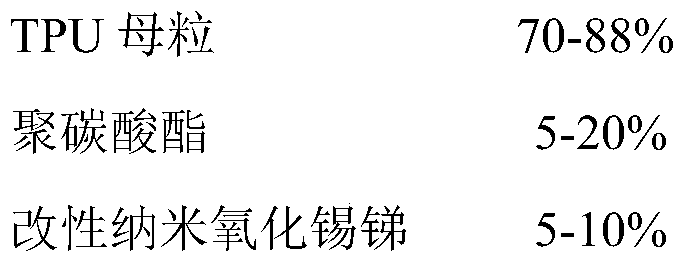

Explosion-proof heat-insulation TPU film for automobile glass, and preparation method thereof

The invention relates to the technical field of polyurethane synthetic materials, particularly to an explosion-proof heat-insulation TPU film for automobile glass, and a preparation method thereof. The explosion-proof heat-insulation TPU film is prepared from the following raw materials in percentage by mass: 70 to 88 percent of TPU master batch, 5 to 20 percent of polycarbonate, 5 to 10 percent of modified nano tin antimony oxide and 0.2 to 0.8 percent of an antioxidant. The explosion-proof heat-insulating TPU film of the invention has explosion-proof and scratch-resistant properties, is highin light transmittance and has heat-insulating and radiation-proof effects. The invention also provides a simple and feasible preparation method.

Owner:SHANDONG INOV POLYURETHANE

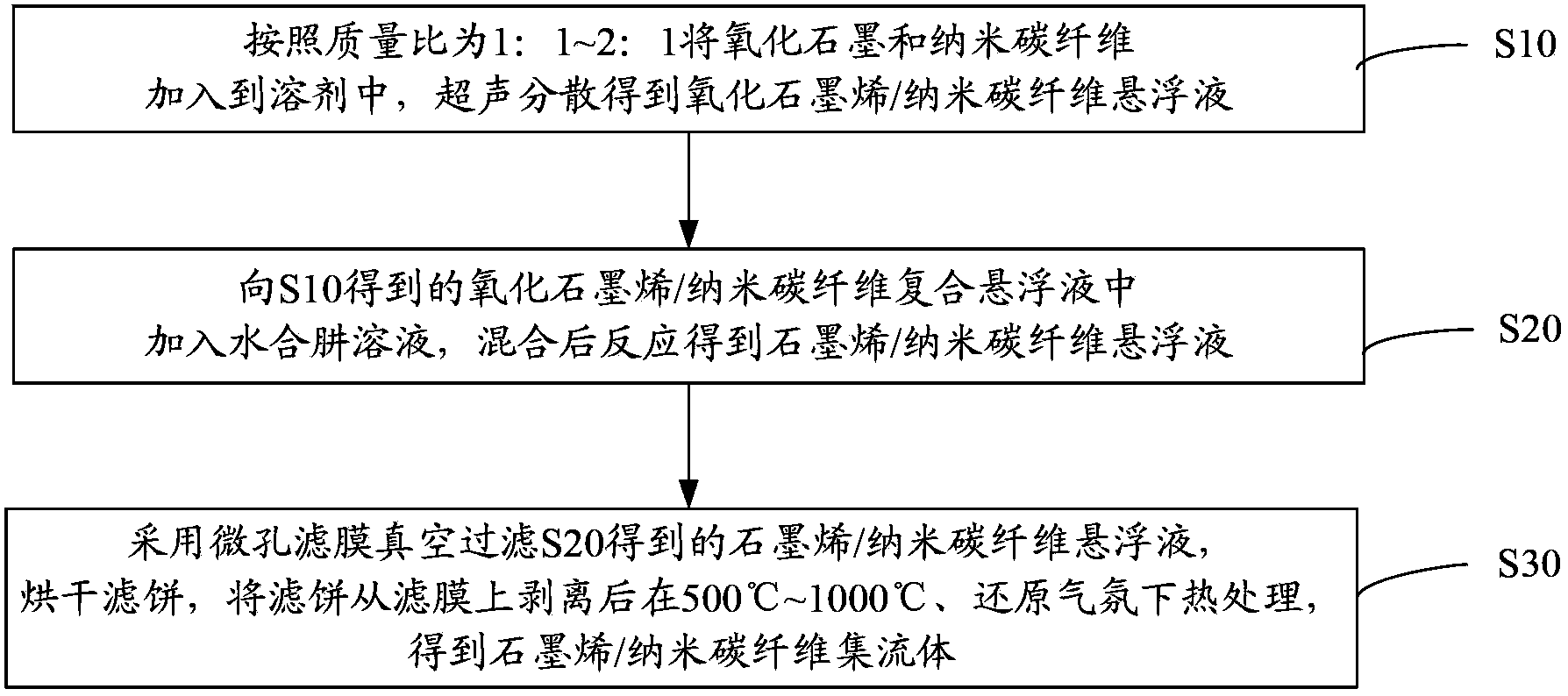

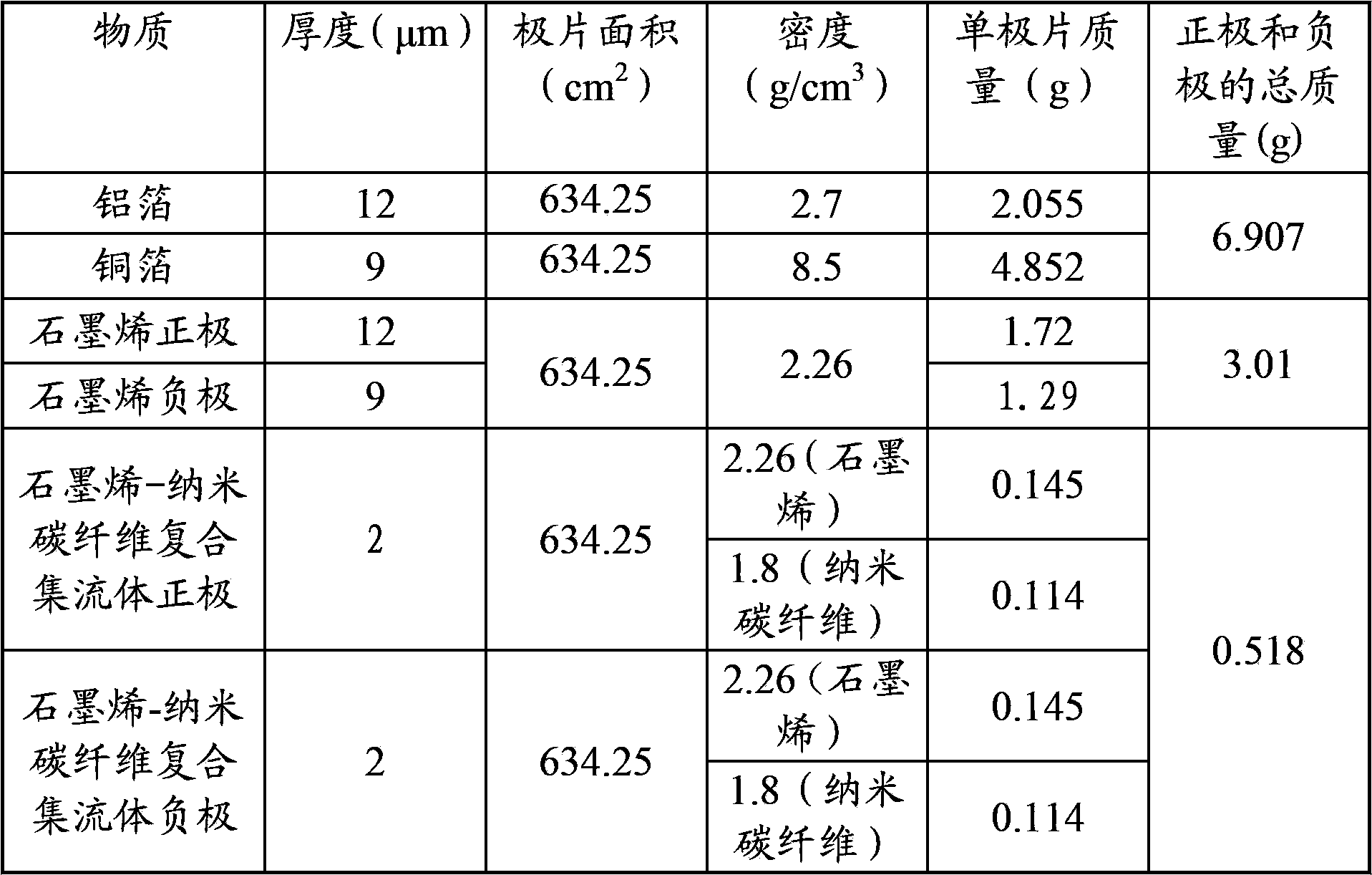

Preparation method for graphene-carbon nanofiber composite current collectors

InactiveCN103456501AHigh mechanical strengthGood tensile strengthCapacitor detailsSolventCvd graphene

The invention discloses a preparation method for graphene-carbon nanofiber composite current collectors. The preparation method includes the flowing steps: adding graphite oxide and carbon nanofibers into solvent to obtain graphene oxide-carbon nanofiber composite suspension liquid through ultrasonic dispersion, adding a hydrazine hydrate solution to obtain graphene-carbon nanofiber composite suspension liquid through reaction, performing vacuum filtration on the graphene-carbon nanofiber composite suspension liquid by a millipore filter membrane, drying filter cakes, and performing heat treatment on the fliter cakes in a reducing atmosphere at the temperature of 500 DEG C to 1000 DEG C after stripping the filter cakes from the filter membrane to obtain the graphene-carbon nanofiber composite current collectors. The carbon nanofibers are added into the graphene oxide suspension liquid, so that mechanical strength of the graphene-carbon nanofiber composite current collectors is improved. Compared with conventional preparation methods for the graphene current collectors, the preparation method has the advantage of capability of preparing the graphene-carbon nanofiber composite current collectors with good tensile strength.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

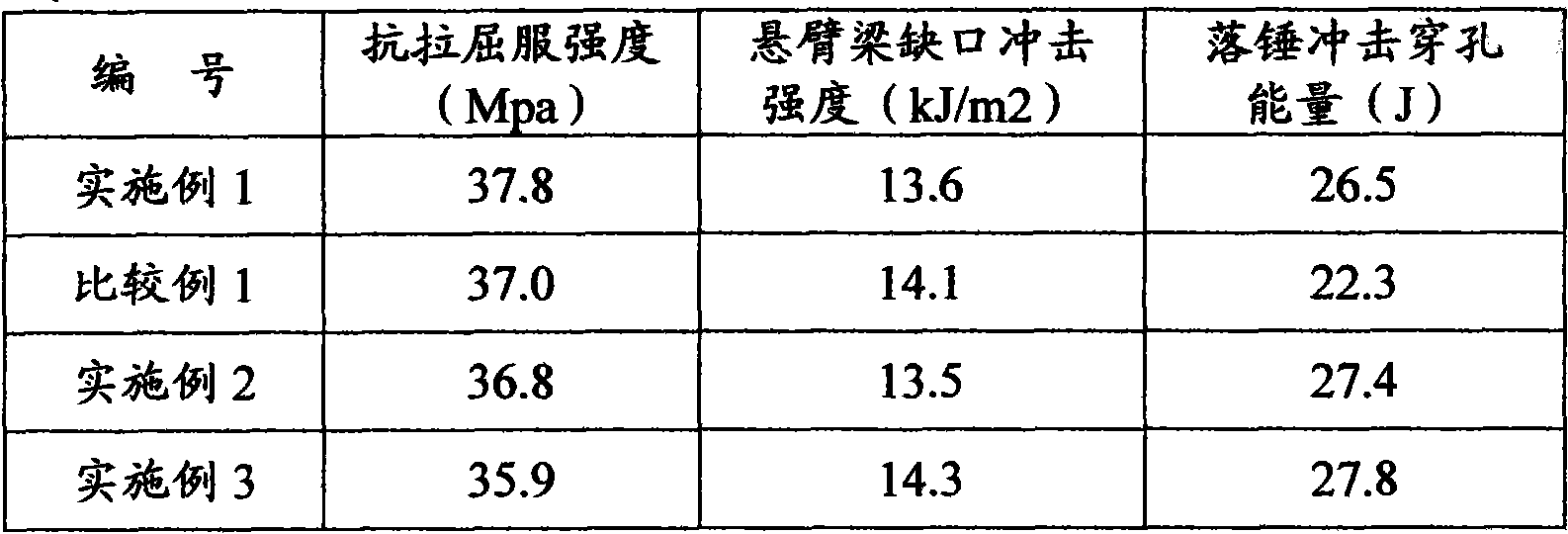

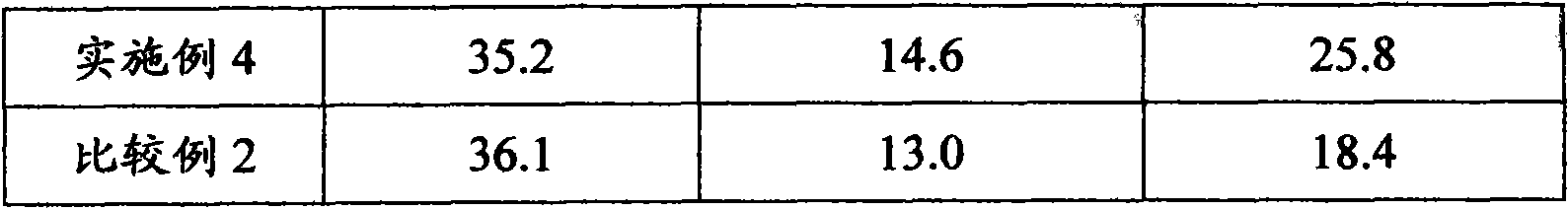

Compound rubber modified styrene series resin composition and preparation method thereof

The invention discloses a rubber modified styrene series resin composition. The total content of rubber is 1 to 40 weight percent, and the rubber consists of superfine powder rubber and polybutadiene rubber. The composition is prepared by the following method of: adding styrene series polymer monomer or styrene series polymer monomer and unsaturated monomer, the superfine powder rubber and the polybutadiene rubber into a reaction kettle, stirring the mixture uniformly, and then performing polymerization. The prepared compound rubber modified styrene series composition has the advantages of insulation, easiness in forming and processing, low moisture absorption and the like, and has good tensile strength, cracking resistance and breakdown resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing and molding manufacturing method of center shaft of special shaft sleeve for textile machinery by taking 5Cr2NiMoVSi magnesium alloy as material

InactiveCN103667834AGood tensile strengthExtended workpiece lifeShaftsFurnace typesQuenchingCorrosion

The invention relates to a processing and molding manufacturing method of a center shaft of a special shaft sleeve for textile machinery by taking 5Cr2NiMoVSi magnesium alloy as a material, and belongs to the technical field of textile machinery. The spinning rotor is achieved by the following procedures: forging a blank; annealing; mechanical roughening; finishing and forming; quenching and tempering at a high temperature; and renovating and polishing by a bench worker. The spinning rotor manufactured by the manufacturing method is easy to process, more reasonable in structure, good in abrasive resistance, good in mechanical property, longer in service life, good in airtightness, free of a lubricating grease overflow phenomenon, good in corrosion resistance, and good in inoxidizability, avoids pollution of a rubber covered roller and a cotton sliver, can ensure the lubricating requirements of a bearing, further prolongs the service life, and is applicable to high and low-speed textile machinery.

Owner:WUXI FUMEI LIGHT ALLOY TECH

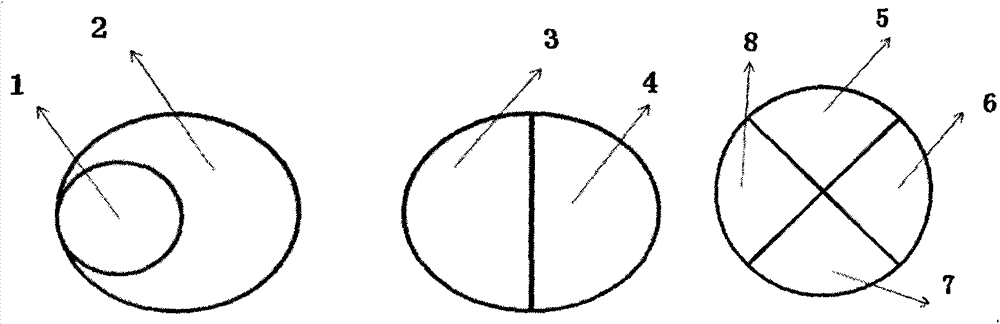

Crimping fiber elastic non-woven fabric and manufacturing method thereof

The invention discloses crimping fiber elastic non-woven fabric and a manufacturing method thereof. The cross section of each crimpled fiber contains two thermoplastic raw materials with different melting points, the two thermoplastic raw materials refer to polyisoprene and polyethylene, and the melting point deviation exceeds 100 DEG C. The two raw materials are distributed in the cross section direction according to a parallel structure or an eccentric core sheath structure or an orange section structure. A melt spinning tubular drafting technology is adopted, and in the fiber spinning process, for the reason that the heat shrinkable properties of the two raw materials are different, the fibers can be twisted in the cooling process. In the cooling drafting process, a high-speed rotating electrode is used for enabling a drafting tube with a thread structure to be rotated, the fibers are further driven to rotate, and accordingly high crimpiness fibers can be obtained. After the fibers are laid to form a net, the fibers are solidified to form the non-woven fabric through a needle-punched or hydroentangled technology. The crimping fiber elastic non-woven fabric has excellent elasticity and can be widely applied to the fields of medical treatment, sanitation, clothing, industry and the like.

Owner:JIAXING UNIV +1

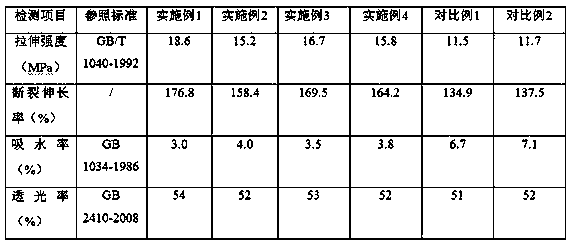

Environment-friendly BOPP flexible package film and preparation method thereof

InactiveCN108034209AGood tensile strengthSmall water absorptionPolypropyleneSodium carboxymethylcellulose

The invention discloses an environment-friendly BOPP flexible package film and a preparation method thereof. the package film is prepared from the following raw materials imparts by weight: 10-20 parts of polypropylene, 15-30 parts of polyhydroxyalkanoate, 5-10 parts of silk fibroin, 6-13 parts of carboxymethyl cellulose, 4-8 parts of chitosan, 4-8 parts of polycaprolactone, 5-12 parts of gliadin,3-7 parts of talcum powder, 4-10 parts of polylactic acid, 5-9 parts of butyl epoxy soyate, 3-6 parts of phytic acid and 2-6 parts of N-dodecyl-N,N-dimethylglycine. The tensile strength of the package film provided by the invention is greater than 15MPa, the elongation at break is greater than 155% and the water absorption is less than 4.0%, so that the package film has good tensile strength, elongation at break, impact resistance and low water absorption, and the durability of the packaging film is improved. Meanwhile, the raw materials used by the package film are green, environmentally friendly and free of pollution, and the main materials are easy to degrade, so that the package film have a wide application prospect in the field of environment-friendly packaging films.

Owner:苏州纳贝通环境科技有限公司

Compound degradable waterproof paper with film with waterproofness and heat resistance enhanced by polylactic acid

InactiveCN106801363AHigh strengthImprove wet strengthWater-repelling agents additionPaper coatingHeat resistanceChloroform

The invention discloses compound degradable waterproof paper with a film with waterproofness and heat resistance enhanced by polylactic acid. Polylactic acid is dissolved in chloroform to form a polylactic acid solution, the toughness and temperature resistance of polylactic acid are enhanced by means of plasticization of polycaprolactone, and an impregnated product is subjected to coating, so that the waterproofness and the tensile strength of the paper can be further enhanced, and meanwhile, the heat resistance is greatly improved. The waterproof paper which is extremely good in waterproof property and tensile strength is obtained by way of secondary coating, and meanwhile, as the paper is coated with polylactic acid, the heat resistance of the product is enhanced, so that the product can be used for manufacturing products such as disposable packaging articles and advertising boards, and the waterproof paper is wide in application range, and does not cause burdens to the environment as being biodegradable.

Owner:李宗飞

Large-section nodular cast iron and cast parts and preparation method thereof

The invention discloses large-section nodular cast iron and cast parts and a preparation method thereof. Based on 100 parts by weight, the large-section nodular cast iron contains the elements in parts by weight: 3.6-3.8 parts of carbon, 2.5-2.8 parts of silicon, 0.5-0.6 part of manganese, 0.005-0.015 part of sulfur, 0.04-0.06 part of phosphorus, 0.03-0.04 part of magnesium, 0.028-0.035 part of strontium, 0.01-0.03 part of calcium and the balance of ferrum and unavoidable microelements. The cast parts prepared from the large-section nodular cast iron have excellent mechanical properties.

Owner:WUHU GUODING MACHINERY MFG

Fiber-reinforced wear-resistant polyamide composite material, and preparation method and application thereof

The invention discloses a fiber-reinforced wear-resistant polyamide composite material and a preparation method thereof. The fiber-reinforced wear-resistant polyamide composite material is prepared from polyamide, glass fibers, butadiene-styrene-vinyl pyridine rubber, silicone powder, N,N-dimethylformamide, polyethersulfone, a poly-alpha-methylstyrene resin, tritolyl phosphate, epoxy soybean oil, polyethylene wax, a lubricant TAF, nano diamond, antioxidant 168, methylphenyl silicone oil, glass microspheres, decabromo diphenylethane, tantalum carbide and zirconite powder. By using the polyamide as the base material and the glass fibers as the reinforcer and adding the inorganic filler, antioxidant and other modifiying raw materials, the polyamide composite material has favorable tensile strength, bending modulus and notch impact strength. The added butadiene-styrene-vinyl pyridine rubber, poly-alpha-methylstyrene resin, polyethersulfone, nano diamond, tantalum carbide, zirconite powder, lubricant TAF, methylphenyl silicone oil, polyethylene wax and the like improve the impact resistance of the polyamide, lower the friction factor of the material and enhance the wear resistance of the material.

Owner:曹高煜

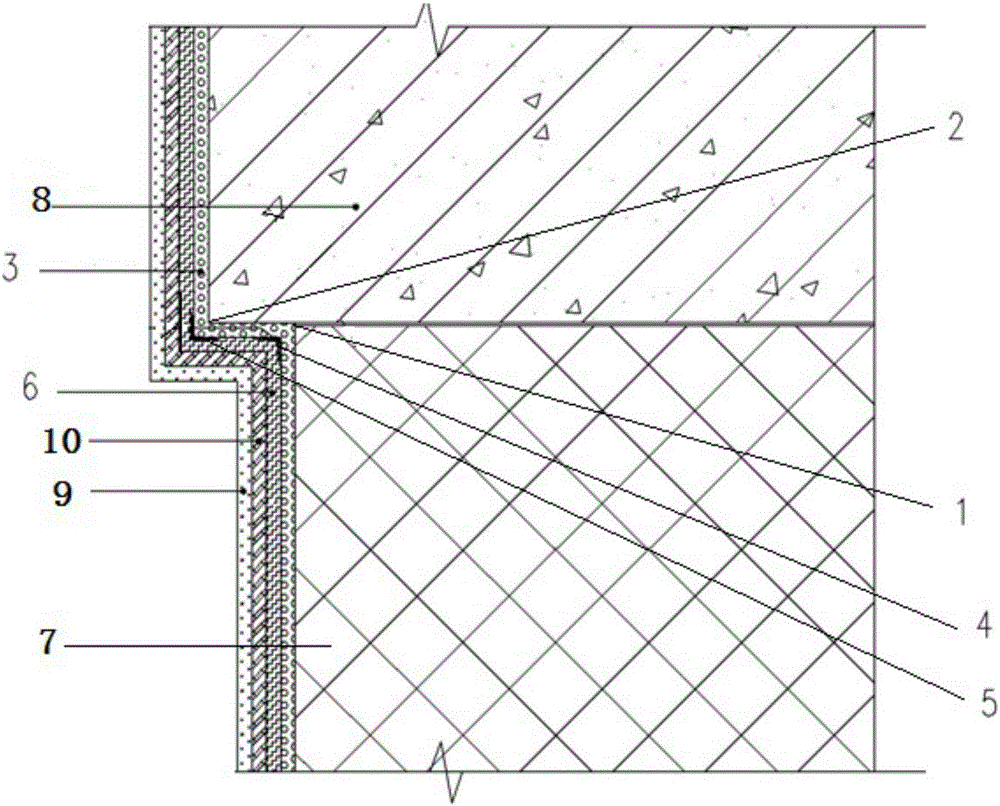

Building wall surface plastering-free anti-crack technology

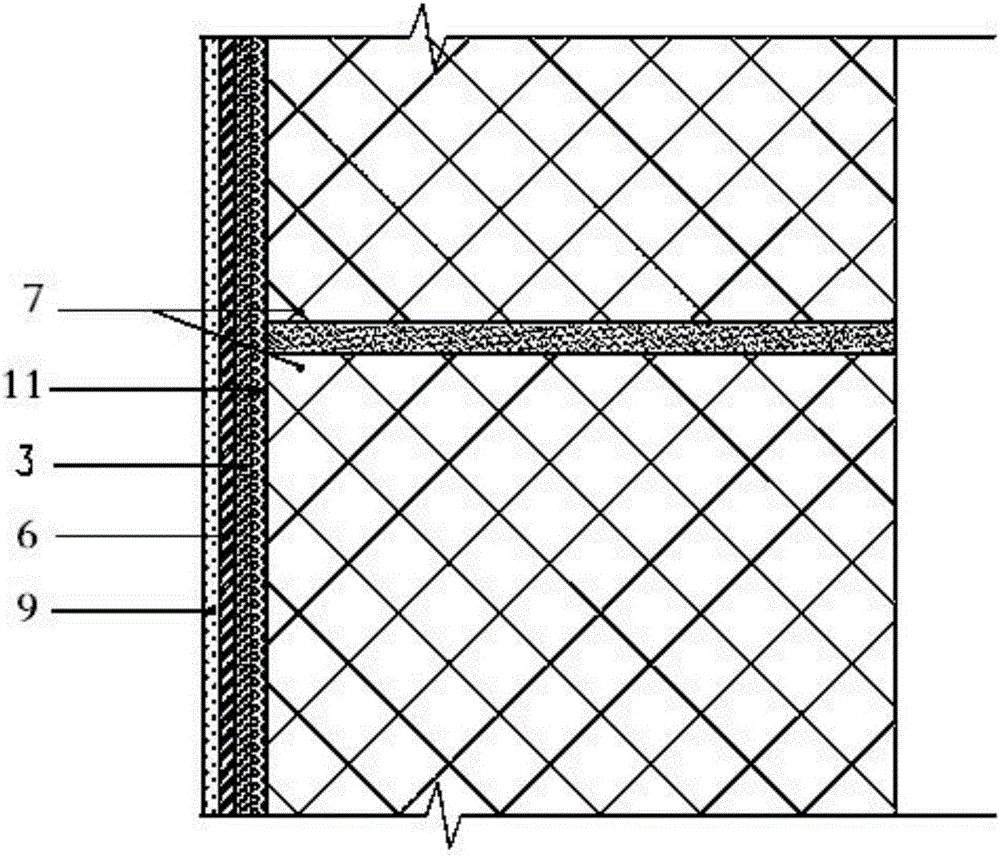

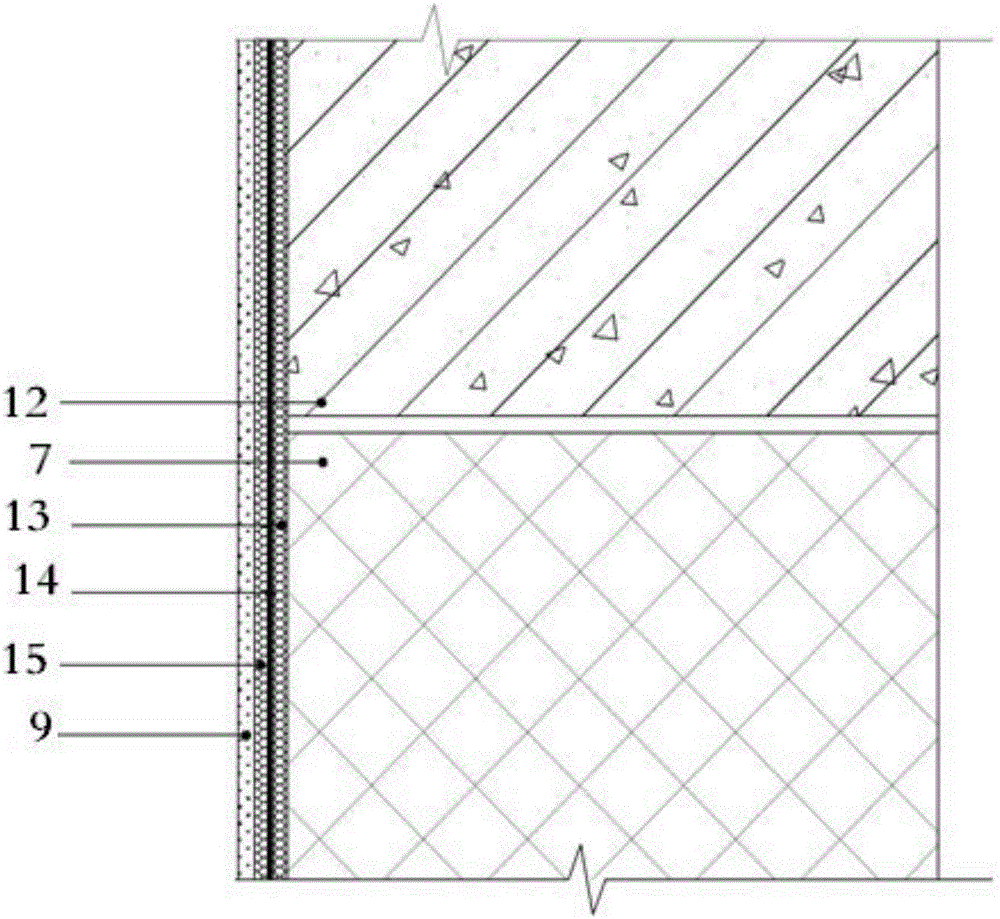

InactiveCN106193485AGood tensile strengthStrong acid and alkali corrosion resistanceCovering/liningsEngineeringTextile

The invention discloses a building wall surface plastering-free anti-crack technology. The technology is characterized in that different constriction processed are adopted at an internal corner and an external corner of a building, a brickwork wall surface and joints between concrete and brickwork respectively, an internal corner strip (4) and an external corner strip (5) with L-shaped cross sections are installed inside the internal corner (1) and the external corner (2) on a bottom anti-crack putty layer (3) respectively in a fillet mode, the internal corner strip and the external corner strip are coated with a surface layer leveling anti-crack putty layer (6), the brickwork wall surface built by building blocks (7) is coated with jointing anti-crack putty (11), and then the whole wall surface is sequentially coated with the bottom anti-crack putty layer (3) and the surface layer leveling anti-crack putty layer (6); the wall surface portion where the concrete (12) and the building blocks (7) are connected is directly coated with a bottom high-elasticity putty layer (13), and an anti-alkali grid cloth (14) is pressed into the bottom high-elasticity putty layer and coated with a surface high-elasticity putty layer (15). The house wall surface quality problem can be effectively solved.

Owner:YUNNAN CONSTR ENG GENERAL CONTRACTING

Non-wovens incorporating avian by-products

InactiveUS20080003914A1Mild scrub actionGood tensile strengthLayered productsWoven fabricsFiber typeEngineering

The present invention relates to a non-woven web comprising fibers and feathers for use as a substrate for cleaning articles. The non-woven web may be created using a variety of non-woven processing techniques and bonding treatments to bond the fibers. The non-woven web is made by combination of variety of fiber types and feathers in varying proportions which create non-woven webs with varying levels of loft, weight, tensile strength, absorbency and abrasiveness.

Owner:THE CLOROX CO

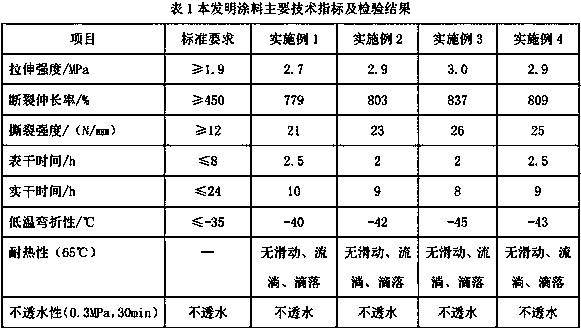

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN107892868AGood tensile strengthFast curingPolyurea/polyurethane coatingsIsocyanateChemistry

The invention relates to a two-component polyurethane waterproof coating. The two-component polyurethane waterproof coating is prepared by mixing a component A and a component B in a mass ratio of 1:1to 1.5; the component A is mainly made of, by mass, 40 to 100 parts of polyether polyol, 30 to 60 parts of isocyanate and 0.7 to 8 parts of modifier; the component B is mainly made of, by mass, 15 to20 parts of water, 0.5 to 1 parts of dispersant, 0.5 to 2 parts of antioxidant, 0.1 to 1 part of CO2 absorbent, 3 to 10 parts of plasticizer, 0.1 to 1 part of leveling agent, 30 to 55 parts of fillers and 0.1 to 1.5 parts of defoaming agent. The polyurethane waterproof coating has no addition of organic solvents and no pollution to the environment, is harmless to the health of staff in productionand construction, and has excellent tensile strength, elongation at break, tear strength, flexibility at low temperature and heat resistance; a paint film is less affected by the humidity of the environment and can be quickly cured, and the construction performance is good.

Owner:洛阳双瑞防腐工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com