Patents

Literature

142 results about "Tritolyl Phosphates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mixture of isomeric tritolyl phosphates. Used in the sterilization of certain surgical instruments and in many industrial processes.

Low-carbon fuel oil and preparation method thereof

InactiveCN103484172APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a low-carbon fuel oil and a preparation method thereof. The low-carbon fuel oil comprises methanol or a modified complex thereof, and an additive, and the additive is prepared through a certain process of an oleic acid-Span series-Tween series (or OP-10) compounded three-in-one emulsifier, a sodium petroleum sulfonate and barium petroleum sulfonate combined pH buffer pair, isobutanol, tritolyl phosphate, an organic solvent, isooctyl nitrate, an emulsification dispersion aid and an antioxidant. The low-carbon fuel oil prepared through the method has the advantages of high cetane number, high flash point, low corrosivity, low emission and low cost, can be compounded with or dissolved in routine diesel oil for use, can be used in the fields of boilers, cars and boats by substituting the routine diesel oil, and has substantial energy saving and emission reduction effects.

Owner:东莞恒量新能源科技有限公司 +1

Coloured transparent glass paint and its preparation method and application

The present invention discloses a colored transparent glass paint, its preparation method and application. Its composition includes (by weight portion) 6-9 portions of nitro-cotton, 9-12 portions of polyketone resin, 15-25 portions of castor oil modified alkyd resin, 8-12 portions of thermoset acrylic resin, 1-2 portions dibutyl phthatate, 1-2 portions of tritolyl phosphate, 5-7 portions of solvent-type metal complex dyestuff and proper quantity of volatile mixed solvent. Said paint can be coated on the glass surface, under the condition of 120-150 deg.C it can be baked for 3-5 min and can be solidified to form film.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of polyvinyl chloride hose

InactiveCN105860341AHigh temperature resistantGood oil resistanceTubular articlesPolyvinyl chlorideTemperature resistance

The invention discloses a preparation method of a polyvinyl chloride hose. The polyvinyl chloride hose is prepared from 90-110 parts of polyvinyl chloride resin, 8-15 parts of dioctyl phthalate, 35-45 parts of tritolyl phosphate, 1-3 parts of lead stearate, 1-3 parts of calcium stearate, 0.1-0.5 part of stearic acid, 35-45 parts of nitrile rubber, 3-5 parts of modifier, 2-5 parts of tribasic lead sulfate, 1-3 parts of chlorinated paraffin, 1-3 parts of polyethylene wax, 2-5 parts of chlorinated polyethylene and 3-8 parts of light calcium carbonate. The preparation method of the polyvinyl chloride hose comprises the following steps: adding the heat stabilizer, plasticizer, lubricant, modifier and filler into the polyvinyl chloride resin, and carrying out high-speed mixing, granulation, extrusion, cooling for setting, drawing, cutting and detection to prepare the polyvinyl chloride hose. The polyvinyl chloride hose has the characteristics of high temperature resistance, favorable oil resistance, aging resistance, high strength, high toughness, corrosion resistance, long service life and favorable flame retardancy.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

Graphene-oxide-modified polypropylene composite material

The invention discloses a graphene-oxide-modified polypropylene composite material which is prepared from graphene-oxide-modified polypropylene, ethylene propylene diene monomer rubber, a butadiene-acrylonitrile copolymer, a silane coupling agent, zinc borate, magnesium hydroxide, pentaerythritol, epoxy soybean oil, tritolyl phosphate, pentaerythritol stearate, yttrium oxide, nano mica powder, talcum powder, silicon micropowder, 1,3,2,4-di(3,4-dimethylbenzylidene)sorbitol, an ethylene-octylene copolymer and 2-hydroxy-4-n-octyloxy diphenyl ketone. The graphene-oxide-modified polypropylene composite material has the advantages of high strength, excellent heat resistance, excellent flame retardancy and favorable heat stability.

Owner:ANHUI LANTONG TECH CO LTD

Nano conveyor belt and preparation method thereof

InactiveCN101927893AImprove mechanical propertiesAvoid pollutionConveyorsRubber layered productsPolyvinyl chlorideChlorinated paraffins

The invention discloses a nano conveyor belt which consists of tyre fabrics or canvas and a high polymer composite material covered on the fabrics or the canvas, wherein the high polymer composite material comprises the following raw materials in parts by weight: 20-40 parts of chloroprene rubber, 5-10 parts of nitrile rubber, 5-10 parts of natural rubber, 5-15 parts of polyvinyl chloride, 10-20 parts of diocty phthalate, 2-5 parts of chlorinated paraffin, 2-5 parts of antimonous oxide, 2-5 parts of tritolyl phosphate, 0.1-0.3 part of tetraisopropyl titanate, 0.1-0.5 parts of hydroquinone dibenzyl ether, 0.1-0.5 parts of tetramethylthiuram disulfide, 0.3-0.6 part of sulphur, 2-5 parts of carbon black and 1-3.6 parts of nano particles. The nano conveyor belt prepared of the invention is characterized in that the surface resistivity is 1.5*105 omega, and the body resistivity is 3.0*1.3 omega.m; the combustion time is 1.3 second, and the smoldering time is 0 second; and after the nano conveyor belt is soaked in water for 70 hours, the antistatic performance and flame resistance thereof have no obvious change.

Owner:ZHONGYUAN ENGINEERING COLLEGE

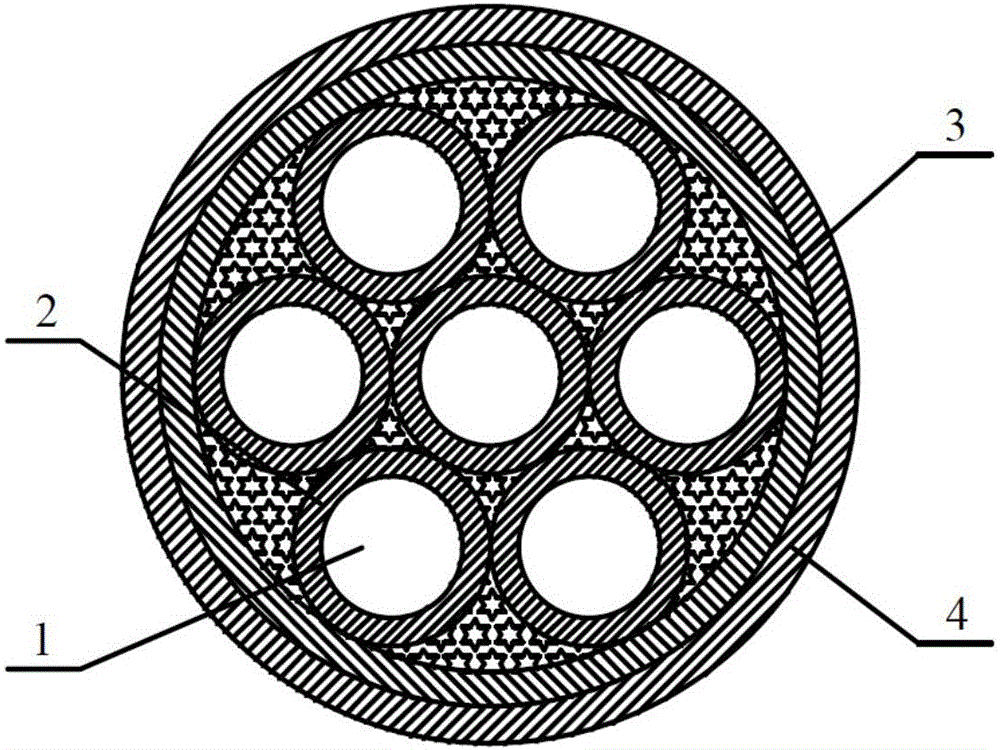

High-flame-retardation, electricity-resistant and aging-resistant cable

InactiveCN105006286AHigh strengthImprove aging resistanceInsulated cablesInsulated conductorsLow-density polyethyleneEPDM rubber

The invention discloses a high-flame-retardation, electricity-resistant, and aging-resistant cable. The cable comprises cable cores, each cable core comprises a conductor positioned at the central part and an insulating layer wrapping the outer part of the conductor, the outside of the cable cores is provided with an inner sheath layer, the outside of the inner sheath layer is provided with an outer sheath layer, the outer sheath layer is made of high-flame-retardation modified polyethylene materials, and raw materials of the high-flame-retardation modified polyethylene materials comprise low-density polyethylene, EPDM rubber, magnesium hydroxide particles, zinc borate, tritolyl phosphate, organic modified montmorillonite, organic modified nanometer magnesium oxide, modified nanometer silicon dioxide, ethylene-butyl acrylate copolymer, calcium stearate, epoxidized soybean oil, dicumyl peroxide, trimethylol-propane trimethacrylate, triallyl isocyanurate, anti-oxidant, and silane coupling agent. According to the high-flame-retardation, electricity-resistant, and aging-resistant cable, the intensity is high, the electricity resistance and aging resistance are good, the flame retardation performance is excellent, and the service lifetime is long.

Owner:ANHUI HONGHAI CABLE

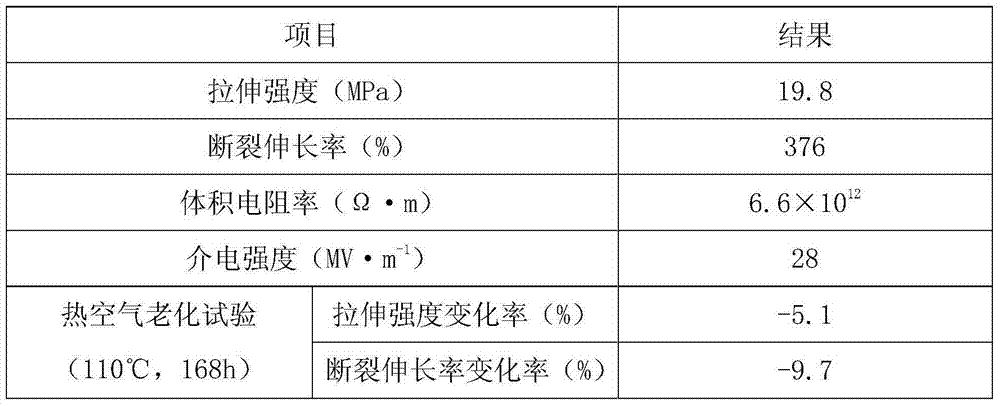

Cable sheath material containing modified methyl vinyl silicone rubber and preparation method thereof

ActiveCN103289415AImprove mechanical propertiesHigh insulation resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolystyrene

The invention discloses a cable sheath material containing modified methyl vinyl silicone rubber and a preparation method thereof. The cable sheath material comprising raw materials of: the modified methyl vinyl silicone rubber, impact-resistant polystyrene, calcium carbonate, diatomite, aluminium nitride, accelerant DM, accelerant TMTD, Bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, calcium ricinoleate, diphenylamine, tributyl citrate and tritolyl phosphate. The cable sheath material containing the modified methyl vinyl silicone rubber and the preparation method thereof employ the modified methyl vinyl silicone rubber as a main material; the mechanical properties of the modified methyl vinyl silicone rubber are greatly modified by modifying the methyl vinyl silicone rubber; the cable sheath material has better mechanical properties, and has the characteristics of low smoke, being free of halogen and high insulation resistance; and calcium carbonate is used as a reinforcing agent in raw materials, and diatomite and aluminium nitride are used as filling materials.

Owner:HUBEI XINHAIHONG CHEM

Formula of enhanced flame retardant nylon 6

The invention discloses a formula of enhanced flame retardant nylon 6, which comprises the components of nylon 6, a flame retardant, a compatilizer, a flexibilizer, a plasticizer and a filler. The flame retardant is tritolyl phosphate and zinc borate, the compatilizer is a polypropylene mixed bidirectional graft, the flexibilizer is an ethylene-vinyl acetate copolymer, the plasticizer is tolylbutyl ester phthalate, and the filler is glass fiber. According to the formula of the enhanced flame retardant nylon 6, the enhanced flame retardant nylon 6 has the effects of good flame retarding performance, high strength, good plasticity, strong rigidity and high impact toughness and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

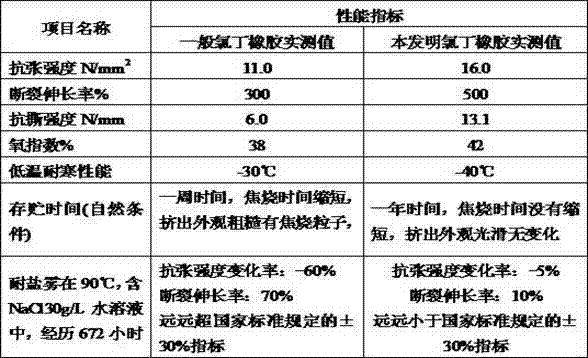

High-performance freezing-resistant and flame-retardant chloroprene rubber covering material

ActiveCN103113640AImprove cold resistanceExtended storage timeRubber insulatorsInsulated cablesMicrocrystalline waxPolymer science

The invention discloses a high-performance freezing-resistant and flame-retardant chloroprene rubber covering material which comprises the following raw materials in parts by weight: chloroprene rubber CR3221, zinc oxide, magnesium oxide, accelerator TMTD, accelerator DM, accelerator NA-22, stearic acid, microcrystalline wax, anti-aging agent ODA-40, antimony trioxide, tritolyl phosphate, 2500-mesh talcum powder, N550 carbon black, dioctyl sebacate, bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, N,N'-m-phenylenedimaleimide and modified meerschaum. The freezing resistance of the high-performance freezing-resistant and flame-retardant chloroprene rubber covering material is high, and the low temperature resistance can reach -40 DEG C, while common chloroprene rubber has the freezing resistance of only -30 DEG C and can not be applicable to movable cables in cold areas.

Owner:安徽龙庵电缆集团有限公司

Brown corundum resin grinding wheel and preparation method thereof

ActiveCN102814758ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesMaterials scienceCorundum

The invention discloses a brown corundum resin grinding wheel and a preparation method of the chrome corundum resin grinding wheel. The brown corundum resin grinding wheel is prepared from the following components by weight, 50-60 parts of brown corundum grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of diamond grinding material, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of tritolyl phosphate, 5-10 parts of nano celestite powder, 5-10 parts of bauxite, 2-5 parts of borax and 2-5 parts of copper powder. According to the brown corundum resin grinding wheel, as the ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, cracks formed by rigid grinding are reduced, and the use efficiency and service life of the resin grinding wheel are improved further; in addition, as the copper power is added, fast heat dissipation effect is achieved, a great deal of heat generated in the cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is lowered.

Owner:台山市恒讯研磨科技有限公司

Special corrosion-resistant high-flame-retardancy paint for chemical equipment

The invention discloses a special corrosion-resistant high-flame-retardancy paint for chemical equipment, which is prepared from a water-based polyurethane-acrylate composite emulsion, a water-based epoxy resin emulsion, a boric acid modified organic silicon resin, ammonium polyphosphate, pentaerythritol, melamine phosphate, hydroxyethyl methacrylate phosphate, tritolyl phosphate, carbon nanotubes, nano aluminum hydroxide, ceramic hollow microbeads, expanded perlite, modified attapulgite, fatty group polyisocyanate, an amino resin, N-phenyl-N'-cyclohexyl p-phenylenediamine, polyvinyl butyral, a film-forming assistant, a cosolvent, water, a coupling agent, carboxymethyl cellulose and assistants. The special corrosion-resistant high-flame-retardancy paint for chemical equipment has the advantages of favorable corrosion resistance, favorable high temperature resistance, high adhesive force and excellent flame retardancy. When being used in chemical equipment, the paint can not easily shed, has favorable protective effect, and can prolong the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

High-impact-resistance PVC (polyvinyl chloride) sheath material for cables and preparation method thereof

InactiveCN103571089AImprove impact resistanceIncrease stressPlastic/resin/waxes insulatorsInsulated cablesEpoxyPolyvinyl chloride

The invention discloses a high-impact-resistance PVC (polyvinyl chloride) sheath material for cables and a preparation method thereof. The high-impact-resistance PVC sheath material is prepared from the following raw materials in parts by weight: 80-100 parts of SG-5 PVC resin, 10-15 parts of MABS (methyl methacrylate-acrylonitrile-butadiene-styrene) resin, 5-10 parts of BOVC, 2-3 parts of dioctyltin dilaurate, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 3-5 parts of oxidized polyethylene wax, 10-15 parts of barium sulfate, 15-25 parts of carbon black N220, 3-6 parts of white oil, 1-2 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 4-8 parts of butyl epoxy stearate, 5-10 parts of triphenyl phosphite, 3-6 parts of tritolyl phosphate, 8-12 parts of pulverized asbestos, 4-6 parts of calcium sulfate whisker and 3-5 parts of composite filler. On the premise of keeping higher strength and favorable flexibility, the toughness of the sheath material disclosed by the invention is enhanced, and the sheath material with excellent toughness enhances the impact resistance and environmental stress crack resistance of the sheath, can effectively resist impact effect of external force so as not to deform or rupture, and prolongs the service life of the sheath.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Chlorinated polyethylene cable sheath for coal mine

InactiveCN104788834AInhibition of lysisImprove liquidityPlastic/resin/waxes insulatorsInsulated cablesMethacrylatePolymer science

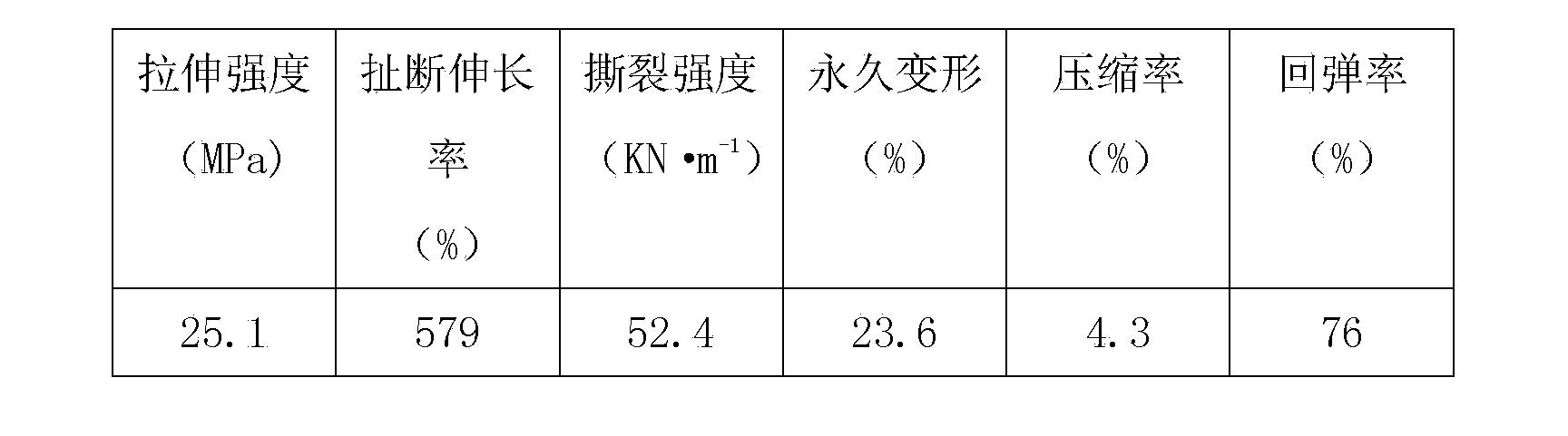

The invention discloses a chlorinated polyethylene cable sheath for a coal mine. The chlorinated polyethylene cable sheath comprises the following raw materials by weight: 100 parts of chlorinated polyethylene 135B, 3 to 5 parts of a vulcanizing agent 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 1 to 1.5 parts of a co-vulcanizing agent trimethylol trimethacrylate, 3 to 5 parts of a calcium-zinc stabilizing agent, 10 to 15 parts of precipitated white carbon black, 20 to 30 parts of potter's clay, 3 to 4 parts of oxidized polyethlene wax, 8 to 12 parts of magnesium oxide, 2 to 5 parts of chlorinated paraffin, 15 to 20 parts of magnesium hydroxide, 1 to 3 parts of tritolyl phosphate, 1.2 to 1.3 parts of an auxiliary crosslinking agent TAIC, 2 to 5 parts of paraffin, 20 to 30 parts of powdered steatile and 50 to 60 parts of nanometer kaolin. The chlorinated polyethylene cable sheath provided by the invention has excellent heat resistance and flame retardation performance, high hardness, good resilience and small permanent compression set.

Owner:ANHUI TIANCAI CABLE GRP

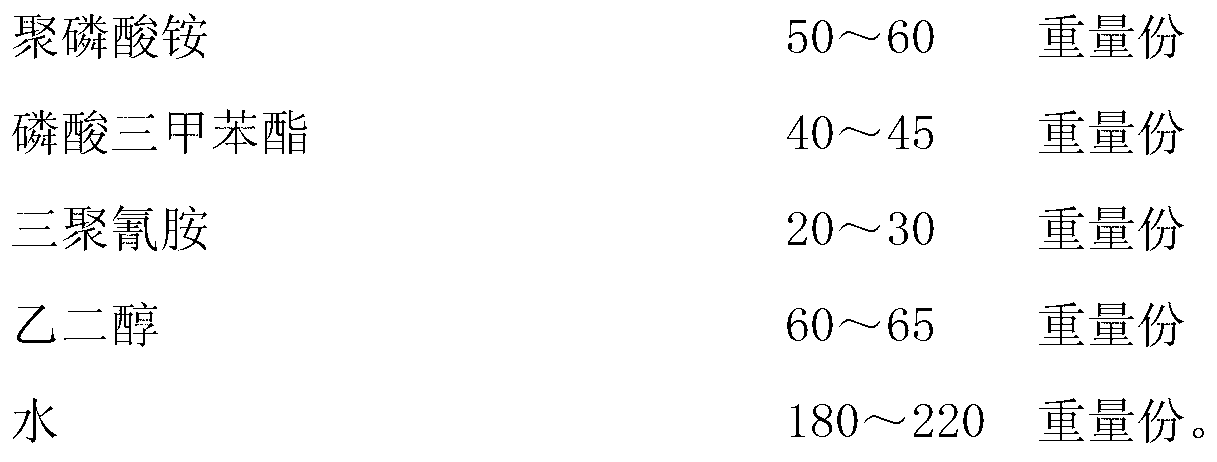

Flame retardant for filter paper of filter, and preparation method and application thereof

ActiveCN103343484AWon't happenParty economyNon-fibrous pulp additionPaper coatingPolymer sciencePhosphoric acid

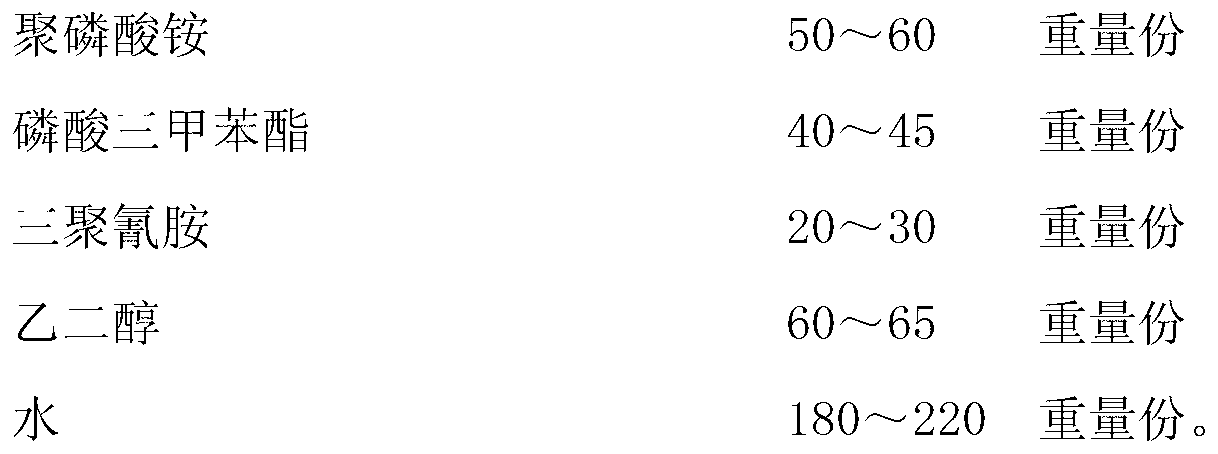

The invention provides a flame retardant for the filter paper of a filter and a preparation method and application thereof. The flame retardant comprises, by weight, 50 to 60 parts of ammonium polyphosphate, 40 to 45 parts of tritolyl phosphate, 20 to 30 parts of melamine, 60 to 65 parts of glycol and 180 to 220 parts of water. The flame retardant has the advantages of economic composition, a good flame retardation effect and long-lasting action. The preparation method is a traditional mixing and heated stirring method and has the advantages of simple process and a small amount of used equipment. The application of the flame retardant is as follows: three traditional methods consisting of electrostatic spraying, dip-coating and brush coating are utilized for coating the flame retardant on the surface of the filter paper of the filter so as to form a layer of flame retardant membrane, process temperature is 110 to 120 DEG C, and process time is 10 to 30 s. The membrane enables the filter paper of the filter to have good flame resistance and the service life of the filter to be prolonged accordingly.

Owner:JIANGSU HUAYANG NYLON

Purified cotton textile scouring agent

InactiveCN106381713AEfficient removalBiochemical treatment with enzymes/microorganismsVegetal fibresPectinaseAdditive ingredient

The invention discloses a purified cotton textile scouring agent which is composed of the following ingredients in parts by weight: 2-5 parts of fatty acyl amide polyoxyethylene ether mono succinate sodium sulfonate, 1-3 parts of red ginseng extract, 1-2 parts of endoglucanase, 3-5 parts of n-hexyl trimellitate, 3-5 parts of alkyl ethoxy polyglycosides, 1-3 parts of Chinese wolfberry extract, 5-8 parts of tritolyl phosphate, 1-2 parts of alkaline pectinase, 1-3 parts of a fibrous protector, 8-10 parts of benzoin ethyl ether, 5-8 parts of a penetrating agent, 1-3 parts of camphor extract, 1-2 parts of citrus aurantifolia juice and 10-12 parts of water. Through the mode, the purified cotton textile scouring agent is capable of effectively removing weaving sizing agents on purified cotton textiles.

Owner:无锡市华誉日用品厂

High-wear-resistance rubber sealing gasket and preparation method thereof

The invention discloses a high-wear-resistance rubber sealing gasket and a preparation method thereof. The high-wear-resistance rubber sealing gasket is prepared from the following raw materials in parts by weight: 50-70 parts of nitrile-butadiene rubber, 20-30 parts of cis-1,4-polybutadiene rubber, 10-15 parts of ABS (acrylonitrile-butadiene-styrene) high rubber powder, 3-5 parts of dibutyl ester of nylon acid, 2-3 parts of tributyl citrate, 4-6 parts of tritolyl phosphate, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of barium stearate, 3-4 parts of zinc oxide, 2-3 parts of magnesium oxide, 10-15 parts of modified barite powder, 5-10 parts of nano silicon carbide, 10-15 parts of high-wear-resistance carbon black N330, 1-2 parts of 2-thiolbenzoimidazole, 2-3 parts of bis-peroxycarbamate, 1-2 parts of anti-aging agent DNP, 1-2 parts of accelerator TMTD and 1-2 parts of accelerator TETD. Tungsten carbide, zirconium fluoride and the like are utilized to inorganically modify barite, thereby obviously enhancing the mechanical strength and wear resistance of the rubber material; and isopropyldistearoyloxy aluminate and the like are utilized to organically modify the barite, thereby enhancing the compatibility of the barite with the rubber material.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Flame-retardant bromocarbon phenolic aldehyde adhesive and preparation method thereof

InactiveCN101519521AOvercome the disadvantage that it cannot be used for casting under high temperature conditionsHigh strengthFoundry mouldsFoundry coresGlass fiberAdhesive

The invention discloses a flame-retardant bromocarbon phenolic aldehyde adhesive and a preparation method thereof. The adhesive comprises the following compositions in percentage by mass: 35.0 to 60.0 percent of bromocarbon phenolic aldehyde resin, 2.0 to 10.0 percent of tritolyl phosphate, 1.0 to 3.0 percent of organic silane coupling agent, 2.0 to 8.0 percent of mica powder, 5.0 to 15.0 percent of glass fiber, and 25.0 to 35.0 percent of solvent. The preparation method comprises the following steps: placing the bromocarbon phenolic aldehyde resin, the tritolyl phosphate, the organic silane coupling agent, the mica powder, the glass fiber, and the solvent into an enamel jar; dispersing the mixture at high speed for 3 to 5 minutes; grinding and dispersing the mixture for 2 times in a cone mill; and obtaining the flame-retardant bromocarbon phenolic aldehyde adhesive.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Drawing lube cooling oil of aluminum-coated red copper metal bar and its production

InactiveCN101029266AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherOleic Acid Triglyceride

A dual-metal rod pulling lube cooling oil of copper aluminum-coated consists of motor oil 20-30wt%, oleic acid 8-9wt%, tritolyl phosphate 20-30wt%, benamide azole trinitride 0.8-0.9wt%, anhydrous alcohol 1-2wt%, sulfur-phosphorus butanoctyl-zinc salt 20-30wt%, poly-n-butyl vinyl ether 13.5-14.5wt% and bactericide 0.2-0.3wt%. The process is carried out by dissolving benamide azole trinitride by anhydrous alcohol, adding motor oil into reactor, heating to 80-90degree, adding into tritolyl phosphate and oleic acid successively, agitating at 550-650 / min for 0.5-1.5hrs, lowering temperature to 40-50degree, adding benamide azole trinitride ethanol solution and bactericide into mixed solution, agitating for 0.5-1.5hrs, cooling, adding into sulfur-phosphorus butanoctyl-zinc salt and poly-n-butyl vinyl ether successively and agitating at 25-35 / min for 0.5-1.5hrs. It has excellent finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

High-efficiency energy-saving diesel fuel additive

InactiveCN104987902AIncrease profitImprove protectionLiquid carbonaceous fuelsIsobutanolOil additive

A high-efficiency energy-saving diesel fuel additive is prepared from the following raw materials in parts by weight: 4-8 parts of sodium carboxymethylcellulose, 2-7 parts of 2-methyl cellosolve, 4-6 parts of tritolyl phosphate, 5-8 parts of calcium peroxide, 20-26 parts of ethyl alcohol, 5-7 parts of ferrocene, 3-7 parts of petroleum ether, 5-7 parts of zinc primary alcohol dialkyl thiophosphate, 4-6 parts of graphite, 5-7 parts of N,N-disulfoxide salicyl propane diamine, 4-7 parts of isobutanol, 8-12 parts of ethelene glycol alkyl monophenyl ether, 3-7 parts of 3-hydroxybutyraldehyde, 4-8 parts of cyclopentane, 2-6 parts of triethyl orthoacetate, 4-7parts of ortho aminophenol, 2-4 parts of a modified additive and 4-6 parts of spermine. The high-efficiency energy-saving diesel fuel additive has the benefits that the utilization ratio of diesel oil is improved, an excellent protective effect is played for a fuel oil system, the heat efficiency is improved, the oil consumption is effectively reduced, and an efficient energy-saving effect can be played.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

Rubber composite material, composite board prepared from material and board technique

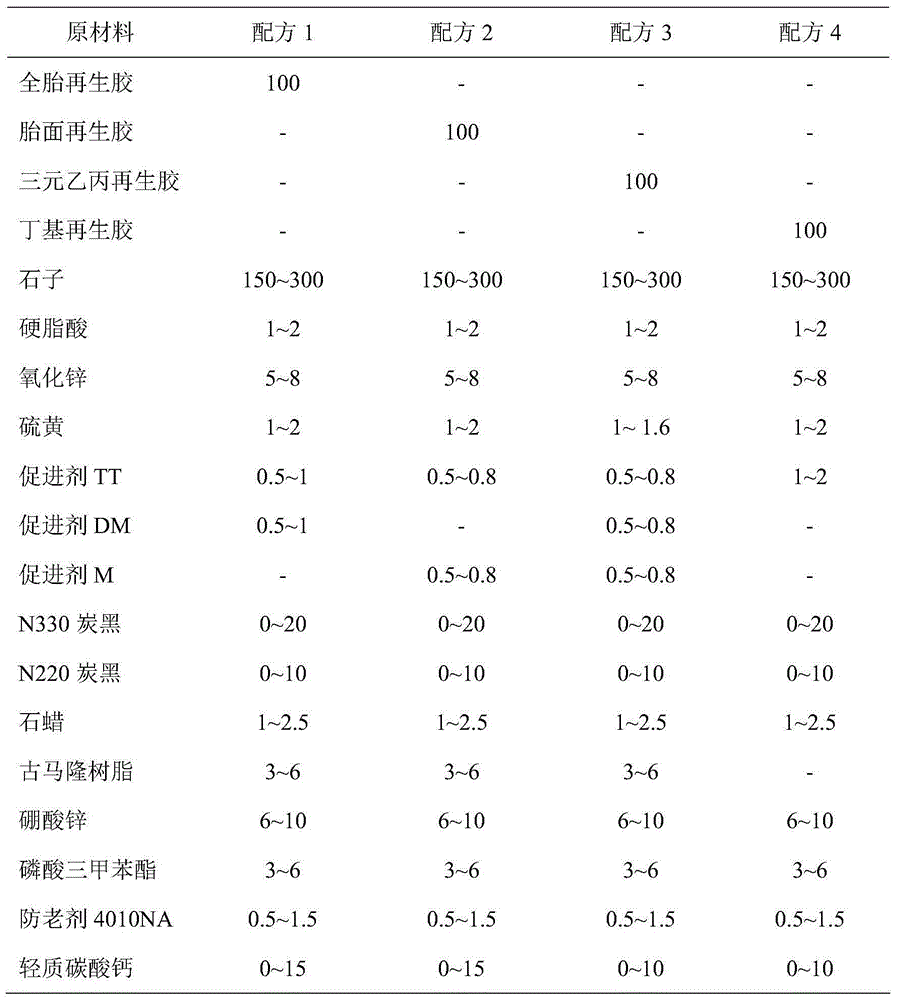

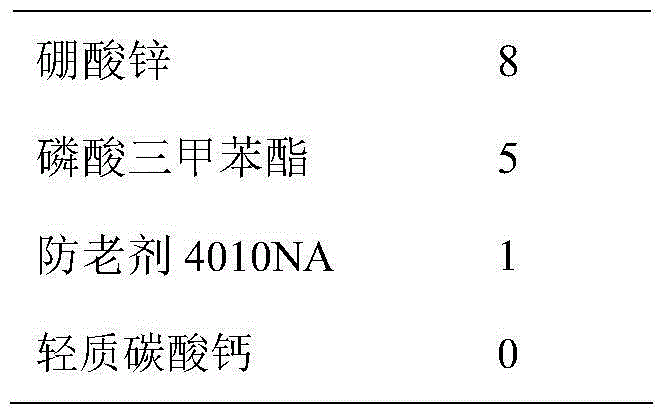

The invention relates to a rubber composite material, a composite board prepared from the material and a board technique. The rubber composite material contains the following substances in parts by weight: 100 parts of regenerated rubber, 150-300 parts of gravel and 18.5-85 parts of rubber ingredient. The regenerated rubber is any one of whole tire regenerated rubber, tire tread regenerated rubber, ethylene propylene diene monomer regenerated rubber and butyl regenerated rubber. The rubber ingredient is a combination of at least 11 of stearic acid, zinc oxide, sulfur, accelerator TT, accelerator DM, accelerator M, N330 carbon black, N220 carbon black, paraffin, coumarone indene resin, zinc borate, tritolyl phosphate, anti-aging agent 4010NA and light calcium carbonate. By using the regenerated rubber and gravel as the main raw materials, the rubber composite material has the advantages of low price and low production cost. The regenerated rubber can adopt the whole tire regenerated rubber and tire tread regenerated rubber, thereby effectively changing waste tires into valuable substances and lowering the environmental pollution caused by the waste tires.

Owner:BEIJING DALUYITONG ENVIRONMENTAL PROTECTION TECH CO LTD

Transparent fireproof paint used for lost foam

The invention discloses a transparent fireproof paint used for lost foam, which comprises the following components by weight part: 30-40 parts of methylated amino resin, 20-30 parts of pentaerythritol triacrylate, 8-12 parts of amino acid sodium phosphate resin, 20-30 parts of melamine, 15-20 parts of ammonium polyphosphate, 2-4 parts of inorganic sodium phosphate, 1-3 parts of smog inhibitor, 10-20 parts of titanium dioxide, 5-7 parts of sulfate tritolyl phosphate and 7-9 parts of dispersant. The obtained fireproof paint has the advantages of no irritation, no pollution, good cohesiveness when being coated on the surface of the lost foam, beauty, stable chemical performance, excellent acid and alkali resistance and corrosivity, the paint coating with thickness of lower than 3mm has fireproof effect for 60-80 minutes, flame resistance is greatly increased, and usage life of the lost foam is prolonged.

Owner:QINGDAO DAYUN MACHINERY

Production formula and preparation method for halogen-free flame-retarding HIPS resin

InactiveCN101914258AImprove flame retardant performanceHigh impact strengthChemical industryZinc borate

The invention belongs to the technical field of chemical industry and relates to a production formula and a preparation method for a halogen-free flame-retarding HIPS resin. The formula consists of an HIPS resin, a polyurethane resin, a thermoplastic elastomer (SBS) resin, microencapsulated red phosphorus, tritolyl phosphate, zinc borate, ethylene bisstearamide (EBS), calcium stearate, a silane coupling agent, titanium dioxide, an antioxidant 1010, an antioxidant 168, UV-770 and UV-327. The preparation method of the invention comprises the following steps of: adding the HIPS resin, the polyurethane resin, the SBS resin, the silane coupling agent, the tritolyl phosphate and the microencapsulated red phosphorus into a high-speed mixer in turn; starting the high-speed mixer for mixing for 5 to 10 minutes and then stopping the high-speed mixer; adding the zinc borate, the EBS, the calcium stearate, the titanium dioxide, the antioxidant 1010, the antioxidant 168, the UV-770 and the UV-327 into the mixer again in turn and uniformly mixing; and feeding into a twin-screw extruder to obtain the halogen-free flame-retarding HIPS resin. The resin has the characteristics of high flame retarding performance, high impact strength and low production cost, and has high market competitive power.

Owner:深圳市一塑科技有限公司

Method for preparing anti-fouling paint for ship bottom

InactiveCN102408763AGood water permeabilityPrevent adhesionAntifouling/underwater paintsPaints with biocidesToxic materialSilicon dioxide

The invention discloses a method for preparing an anti-fouling paint for ship bottom. The method comprises the following steps: mixing the following components of 175-180 parts of xylene, 52-56 parts of toluene, 50 parts of pyrolyzed silica, 14-16 parts of methyl isobutyl ketone, 36 parts of iron oxide red, 24 parts of chlorinated rubber, 50-54 parts of tritolyl phosphate and 15-17 parts of styrene; stirring and heating to the temperature of 50 DEG C, heating at constant temperature for 3 hours, filtering to obtain the product. According to the invention, the industrial test for paints provesthat the paint has good water penetration, stable and gradual exsudation of toxic materials in the paint film can be ensured, so that the adhesion of marine animals can be prevented; the paint of theinvention has good adhesive force with a rust-resisting paint. The anti-fouling paint for ship bottom has good sea water impact-resistance.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

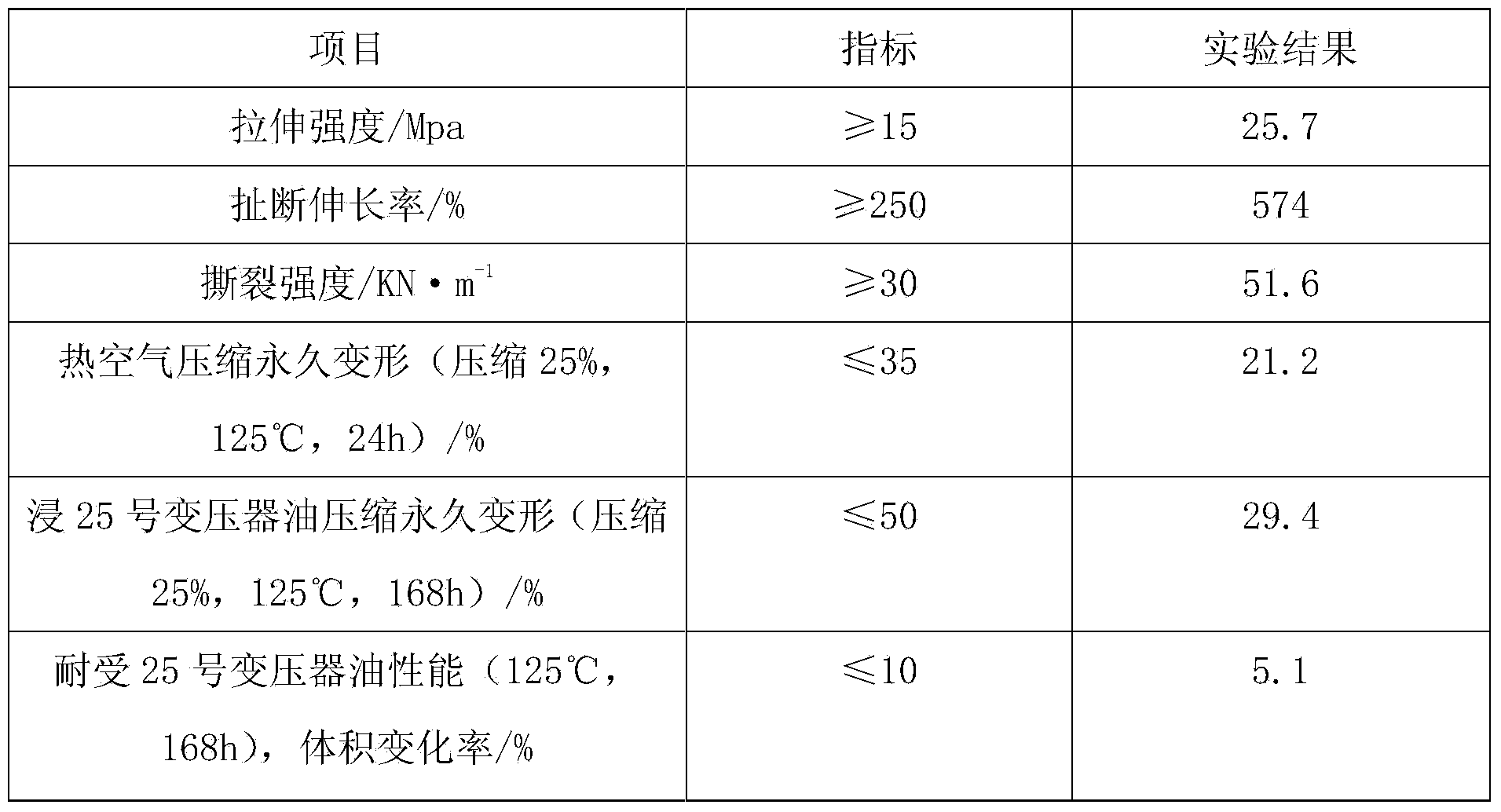

Ultraviolet-resistant sealing gasket for outdoor transformers and preparation method thereof

InactiveCN103509216AExcellent light aging performanceHigh mechanical strengthUltraviolet lightsPhosphoric acid

The invention discloses an ultraviolet-resistant sealing gasket for outdoor transformers and a preparation method thereof. The ultraviolet-resistant sealing gasket for the outdoor transformers is prepared from the raw materials in parts by weight: 65-85 parts of chloroprene rubber, 25-35 parts of styrene-butadiene rubber, 5-10 parts of SEBS, 10-15 parts of dicapryl phthalate, 8-12 parts of tritolyl phosphate, 10-15 parts of No. 30 engine oil, 3-5 parts of zinc oxide, 2-4 parts of magnesium oxide, 1-2 parts of stearic acid , 20-30 parts of carbon black N220, 2-3 parts of insoluble sulphur, 3-4 parts of diethylene glycol dimethacrylate, 5-10 parts of nanometer aluminium nitride, 10-15 parts of powdered steatile, 4-8 parts of nanometer barite, 3-5 parts of a composite filling material, 1-2 parts of antiager 264, 0.5-1 part of antiager MBZ, 1-2 parts of promoter DZ and 1-2 parts of ultraviolet light absorber UV-9. The sealing gasket of the invention is excellent in ultraviolet light illumination aging resistance, good in performances of mechanical strength, compression resilience, acid-base resistance, impact resistance, wear resistance, oil resistance, heat resistance and the like, is capable of resisting hit of ultraviolet light in sunlight, enabling the transformers to have no cracks and guaranteeing effective seal, and is long in service life.

Owner:ANHUI KELIN ELECTRONICS

Self-repairing waterborne marine anticorrosive paint and preparation method thereof

ActiveCN106928764AImprove good performanceAccelerated corrosionAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesivePolymer

The invention relates to a self-repairing waterborne marine anticorrosive paint, which comprises the following raw materials (by weight): 50-70 parts of anticorrosive resin, 10-30 parts of microcapsules, 5-10 parts of a diluent, and 1-10 parts of a thickening agent. The microcapsules are prepared from a capsule material and a core material. The capsule material is polymer porous microspheres, and the core material is a self-repairing underwater adhesive. The particle size of the microspheres is 5-20 microns. The thickening agent is a combination of one or more components selected from carboxymethyl cellulose, hydroxymethyl cellulose, hydroxyethyl cellulose, tritolyl phosphate and dibutyl phthalate, and of one or two components selected from modified bentonite and modified attapulgite. The waterborne marine anticorrosive paint can achieve rapid self-recognition and self-repairing of corrosion in a marine environment.

Owner:北京中科力信科技有限公司

High-flame-retardance polyvinyl chloride resin and preparation method thereof

The invention discloses a high-flame-retardance polyvinyl chloride resin, and belongs to the technical field of resin preparation. The high-flame-retardance polyvinyl chloride resin comprises: a polyvinyl chloride resin, an epoxy resin, a phenolic resin, poly(phenylene oxide), an EVA resin, diethylene glycol phthalic anhydride polymer, ethylene-vinyl acetate copolymer, trioctyl trimellitate, styrene, dicumyl peroxide, tritolyl phosphate, polycaprolactone, talcum powder, zinc stearate, cerium oxide, antimonous oxide, wood fiber powder, glass fiber, aluminium triphosphate, zinc borate, chlorinated paraffin, epichlorohydrin, maleic anhydride, magnesium hydroxide, a silicane coupling agent KH-560, and a flame-retardant modification auxiliary agent. The high-flame-retardance polyvinyl chlorideresin is made through base material preparation, modification material preparation, and mixing of base materials and modification materials. The prepared polyvinyl chloride resin is excellent in flameretardance.

Owner:HWASU

ABS (acrylonitrile-butadiene-styrene) composite material applicable to 3D printing and preparation method thereof

The invention discloses an ABS (acrylonitrile-butadiene-styrene) composite material applicable to 3D printing and a preparation method thereof. The preparation method comprises the following steps: adding 3-aminopropyltrimethoxy silane into acetone, standing at room temperature, sequentially adding hydroquinone, tritolyl phosphate and methyl 2-cyanoacrylate, stirring at room temperature, adding ABS particles, and continuing stirring at room temperature to obtain the ABS composite material applicable to 3D printing. The content of the ABS is 40-60%, the content of the methyl 2-cyanoacrylate is 5-30%, the content of the tritolyl phosphate is 1-5%, the content of the acetone is 20-30%, the content of the 3-aminopropyltrimethoxy silane is 0.2-0.5%, and the content of the hydroquinone is 0.1-0.5%. The composite material disclosed by the invention can be used for 3D printing within the temperature range of 30-50 DEG C, and overcomes the defect that the conventional 3D printing needs to melt the high-molecular polymers under high-temperature conditions; and the preparation method has the advantages of simple technique and low production cost.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

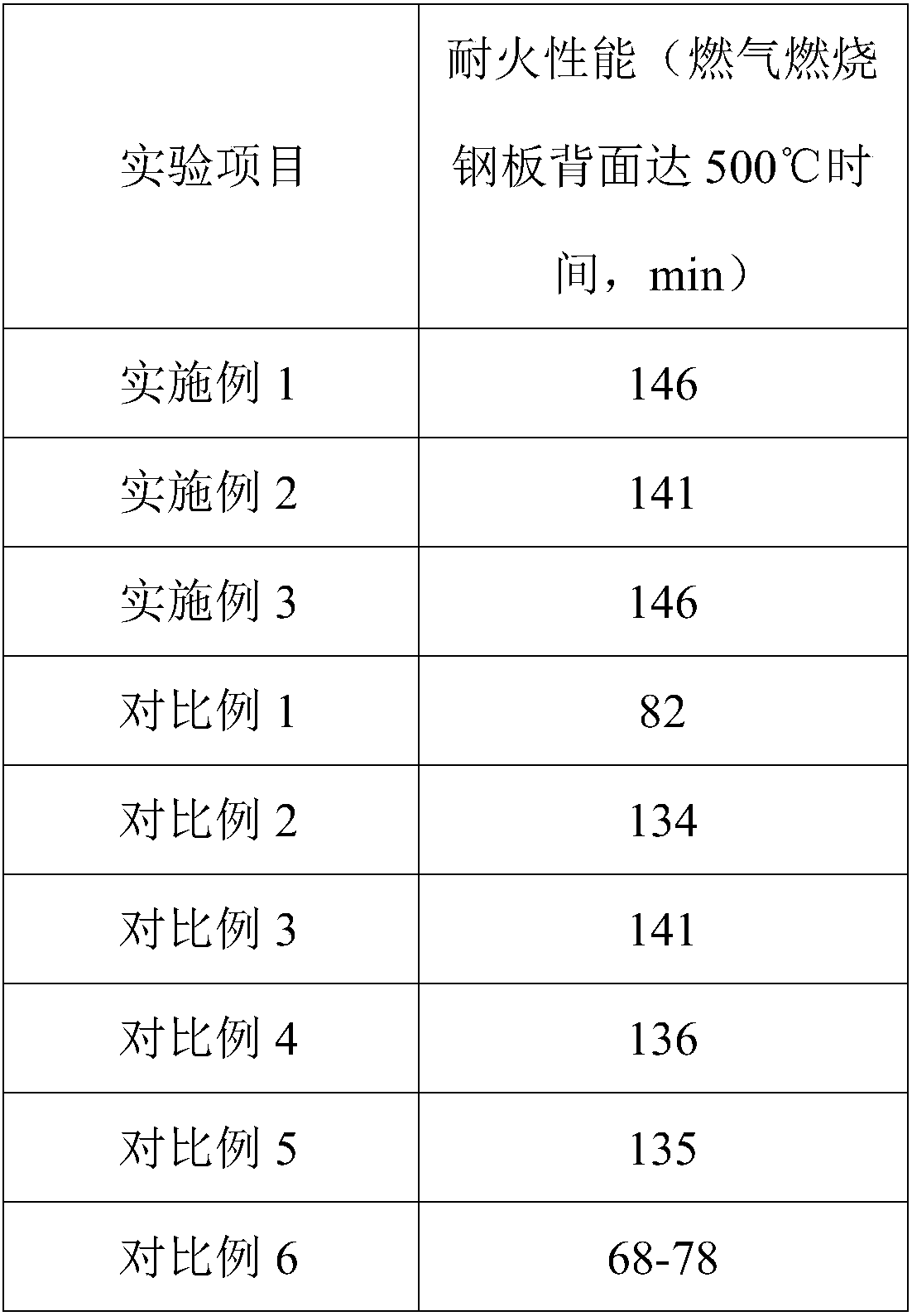

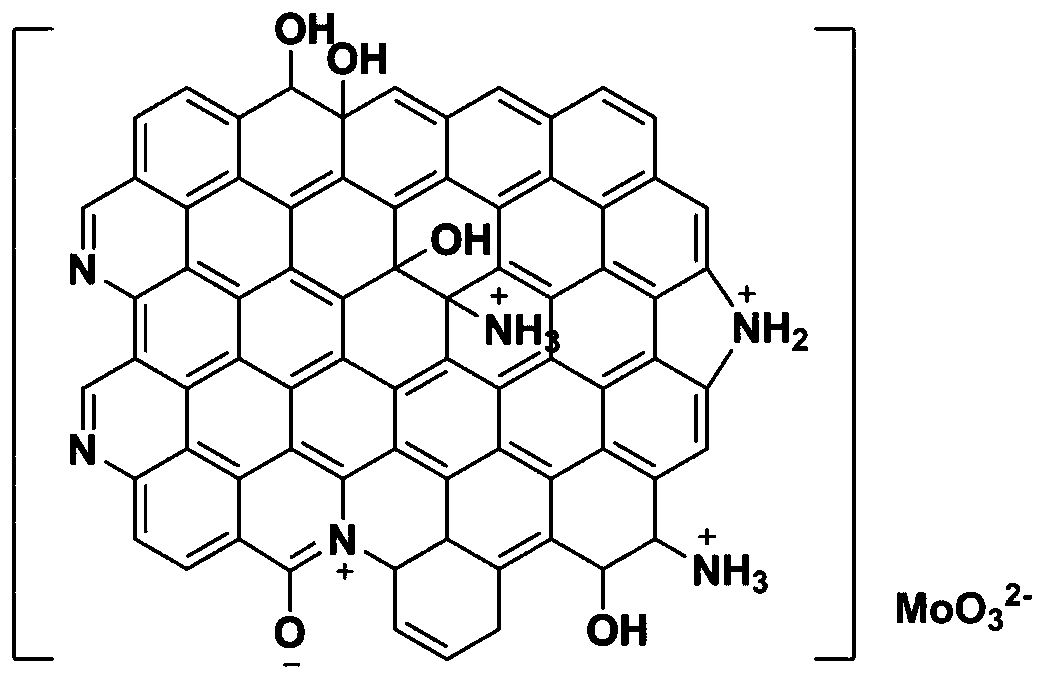

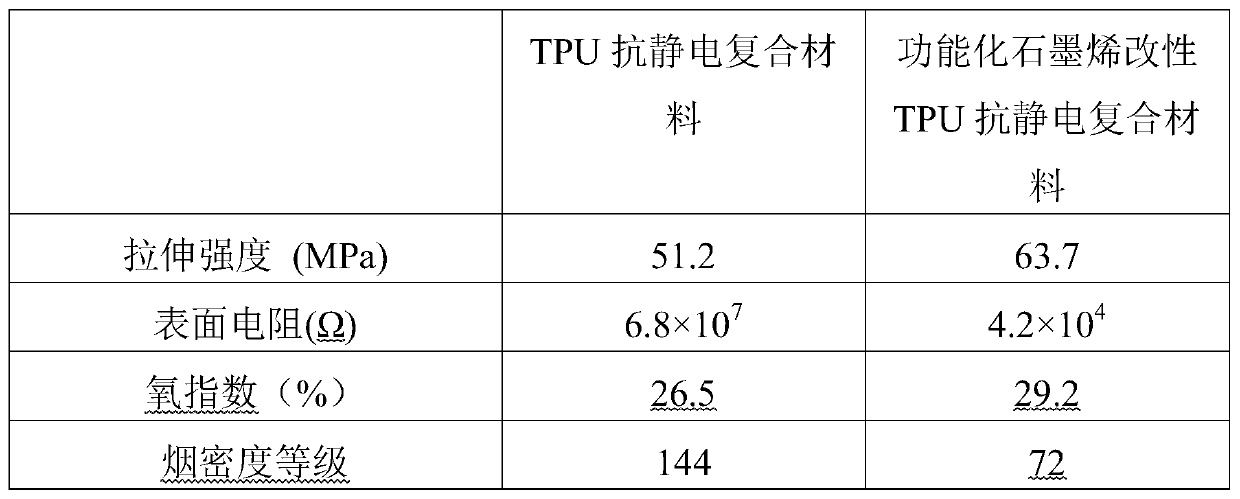

Flame-retardant smoke-suppressing thermoplastic polyurethane antistatic composite material and preparation method thereof

The invention discloses a flame-retardant smoke-suppressing thermoplastic polyurethane antistatic composite material and a preparation method thereof. The antistatic composite material is prepared from the following raw materials: TPU resin, tritolyl phosphate, melamine polyphosphate, functionalized graphene, an antioxidant 1076, an ultraviolet light absorber UV-24, conductive carbon black, stearic acid and 8-hydroxyquinolinone, wherein the surface of the functionalized graphene is doped with nitrogen and is modified by molybdate radicals chemically, thus good dispersity of the functionalizedgraphene in TPU under high addition amount can be realized, and meanwhile the smoke suppression performance and the mechanical property of the TPU antistatic composite material can be improved. The preparation method is simple in preparation process and low in production cost, and energy consumption and pollutant emission are reduced; and the composite material is suitable for popularization and application in industries such as electronic appliances, automobiles, buildings and precision instruments.

Owner:TAIZHOU BRT PLASTICS ELECTRONICS

Montmorillonite-modified ethylene propylene diene monomer tubing

The invention discloses a montmorillonite-modified ethylene propylene diene monomer (EPDM) tubing, raw materials of which comprise EPDM, cis-polybutadiene, silicone rubber, styrene butadiene rubber, epoxy resin, liquid nitrile-butadiene rubber, 1,2-polybutadiene, stearic acid, zinc oxide, 1,4-bis(1-(tert-butylperoxy)-1-methylethyl)-benzene, bis(diisopropyl)DIPDIS, sulphur, modified montmorillonite, magnesium hydroxide, magnesium methacrylate, carbon nanotube, attapulgite, polyacrylonitrile fibre, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, ammonium polyphosphate, tritolyl phosphate, castor oil, a silane coupling agent, 2-mercaptobenzothiazole, sodium dimethyldithiocarbamate and an anti-aging agent. The montmorillonite-modified EPDM tubing of the invention has advantages of high strength, good oil resistance, good heat resistance, good ageing resistance, excellent flame resistance and long service life.

Owner:安徽都邦电器有限公司

Methyl vinyl silicone rubber cable sheath material of modified nanocarbon, and preparation method thereof

InactiveCN103525096AHigh tensile strengthHigh elongation at breakRubber insulatorsInsulated cablesLow-density polyethylenePolymer science

The invention discloses a methyl vinyl silicone rubber cable sheath material of modified nanocarbon, and a preparation method thereof. Raw material composing the sheath material comprise methyl vinyl silicone rubber, low density polyethylene, nano-clay, modified nanocarbon, antimony trioxide, an accelerant DM, 2-mercaptobenzimidazole, vinyltri(beta-methoxyethoxy)silane, a rare earth stabilizer, resorcinol, fatty alcohol polyoxyethylene ether and tritolyl phosphate. The sheath material is based on the methyl vinyl silicone rubber, so the tensile strength, the elongation at break, the elongation at break after ageing and the insulation rate of a cable sheath are excellent; and the modification treatment of the filler nanocarbon enhances the internal connection of the cable sheath, so the break of the cable sheath can be effectively prevented, and the service life of the cable sheath is prolonged.

Owner:ANHUI MINGDU ELECTRIC WIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com