Patents

Literature

180results about How to "Low baking temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft ceramic mud and preparation method thereof

The invention discloses a soft ceramic mud and method for preparation, which is prepared by polyvinylchloride pasty resin 15-40 parts by weight, dioctyl phthalate 20-55 parts by weight, calcium carbonate 15-35 parts by weight, plasticizer 0.1-0.4 parts by weight, toner 0.5-0.15 parts by weight, and trace moisture and impurity. The invention also discloses a method for preparation, which comprises steps as follows, each component is weighed proportionally and is placed into stirrer to stir until all components doesn't display nodular powder to be kneaded together evenly and the color is uniform, the evenly stirred mud is placed in the molder to squeeze and mould. The invention provides the soft ceramic mud which is hard and fine in texture under normal temperature, low in softening temperature to soften by hand temperature, low in toasting temperature and short in time, and the toasted material is as hard as ceramic without any odor, further protecting environment.

Owner:东莞市汇欣工贸有限公司

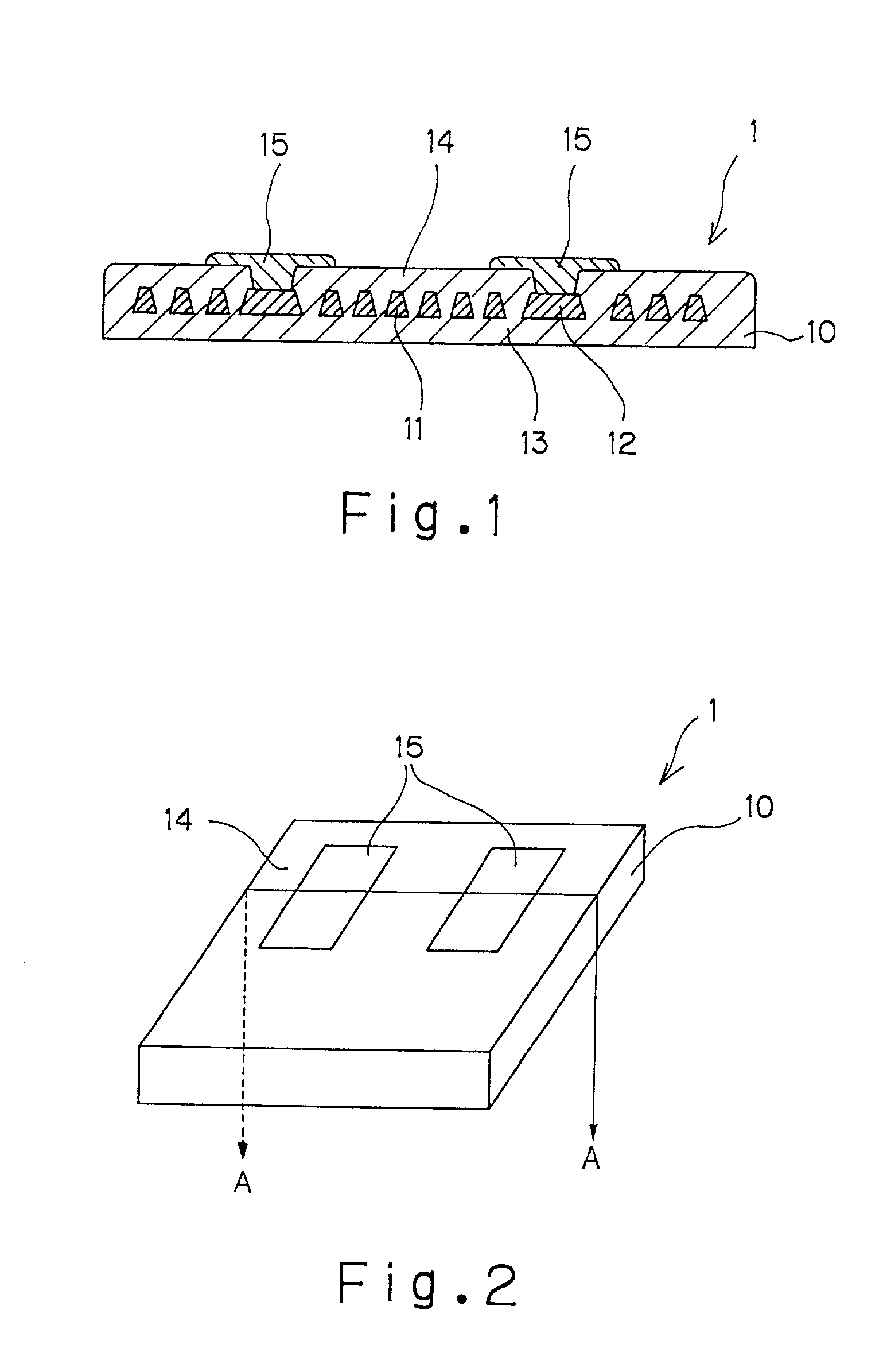

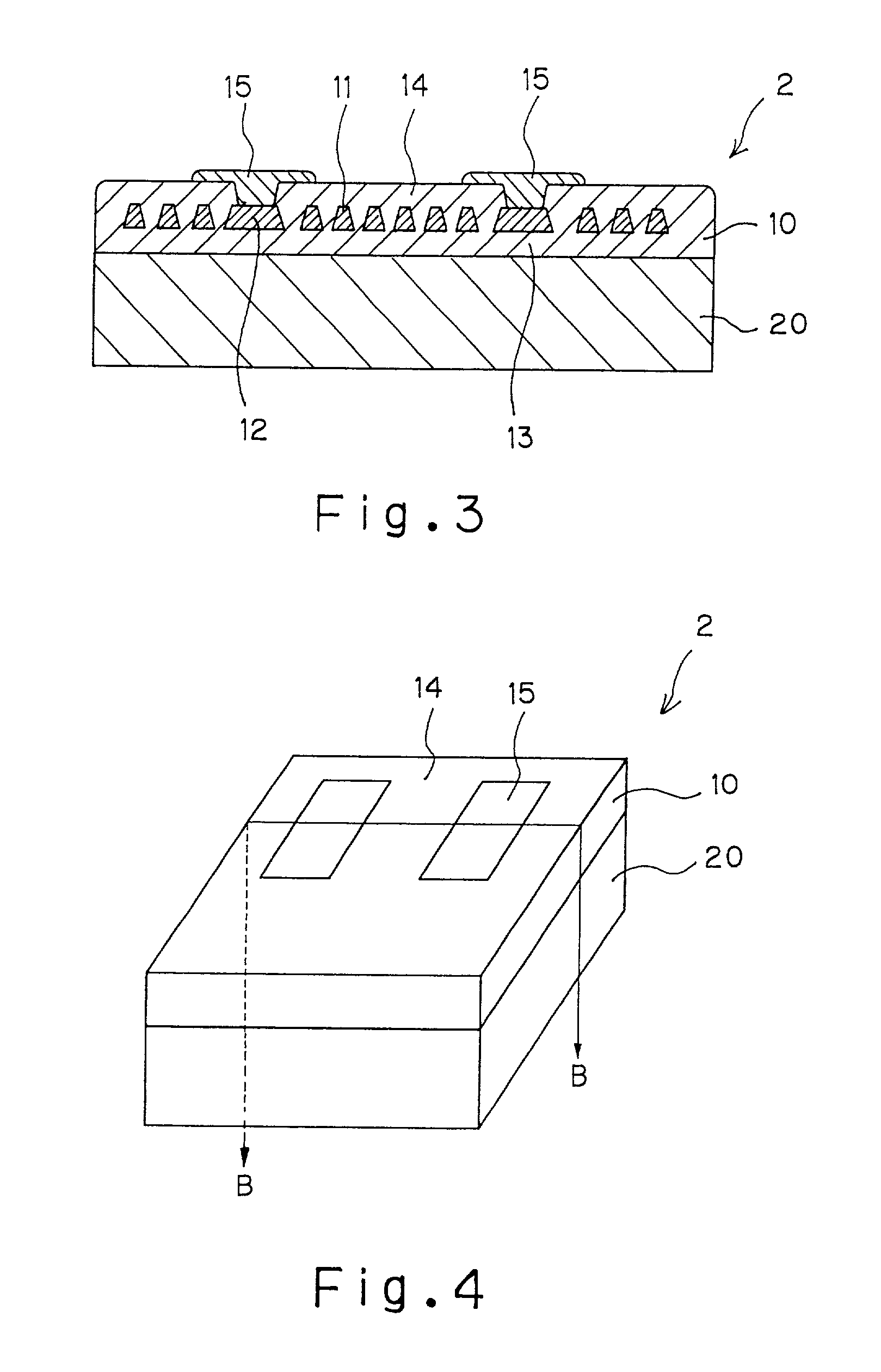

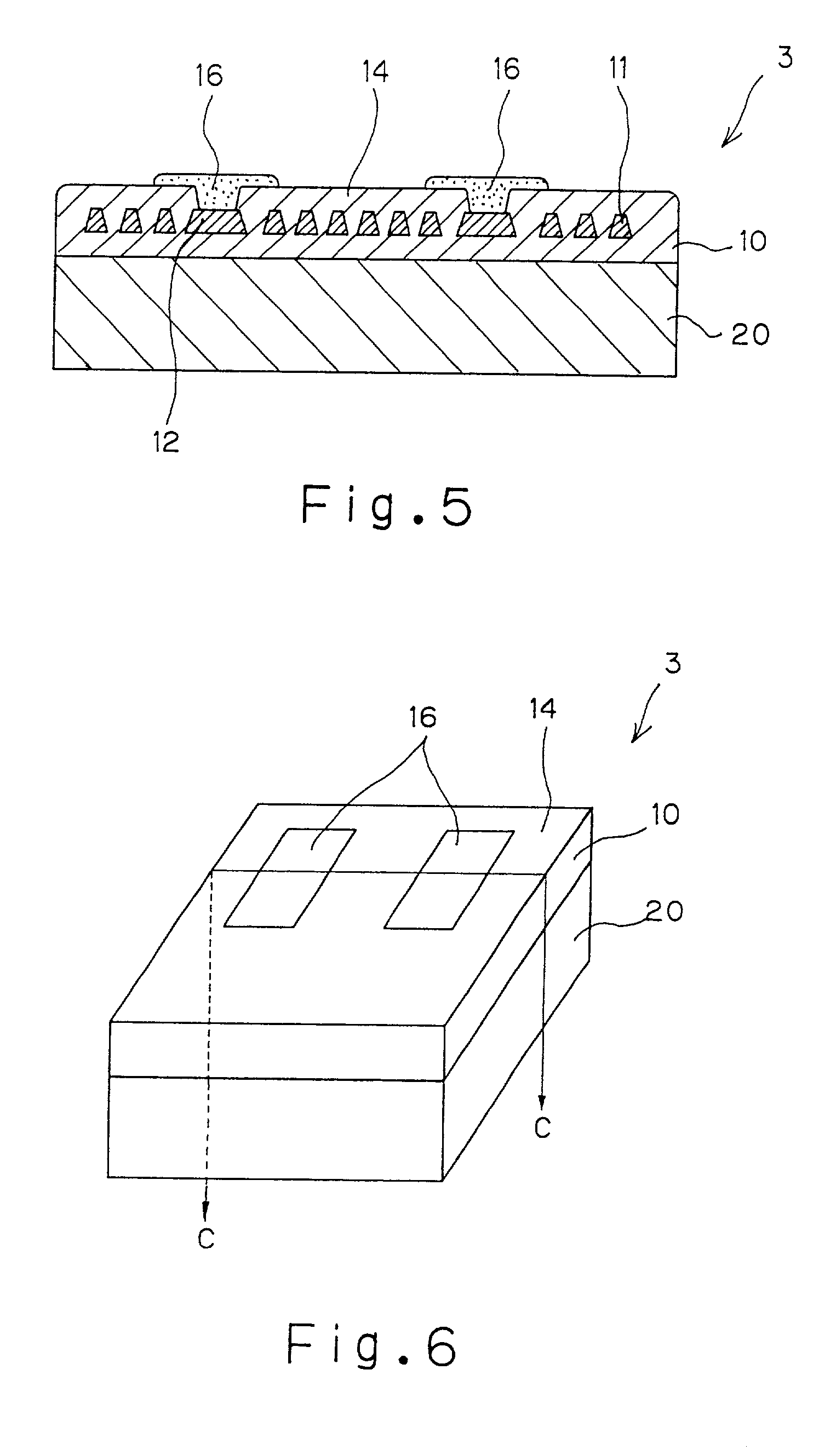

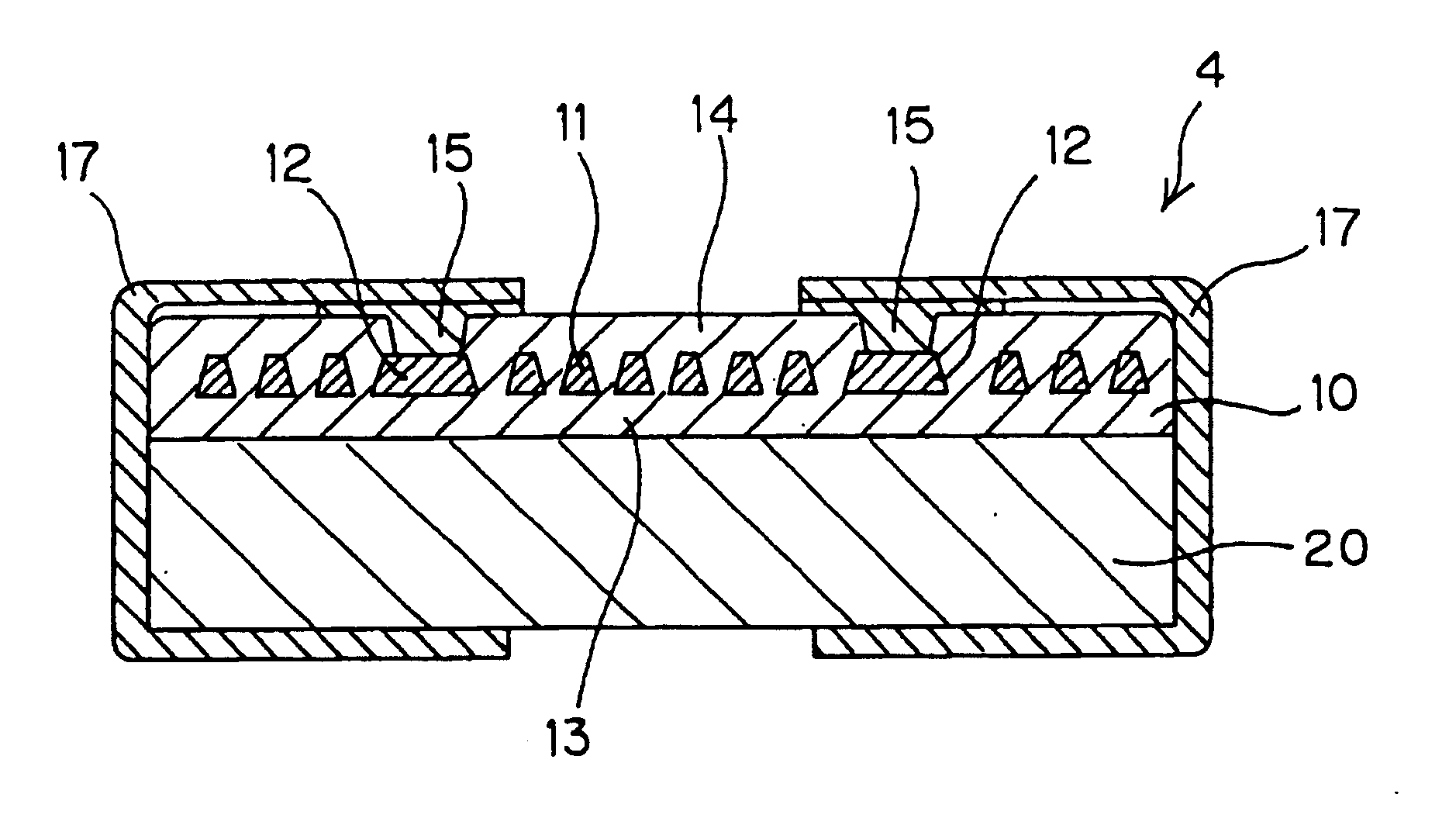

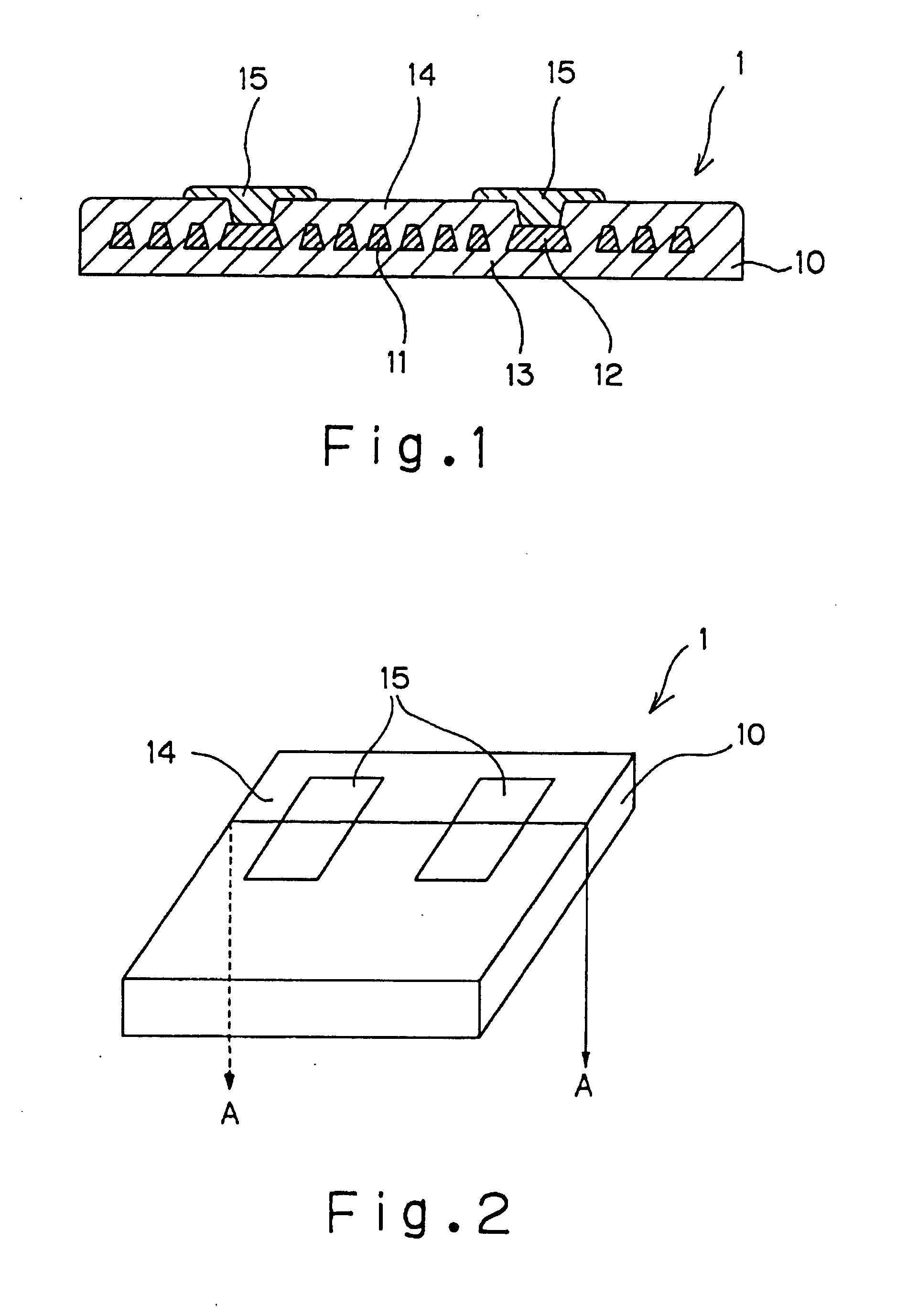

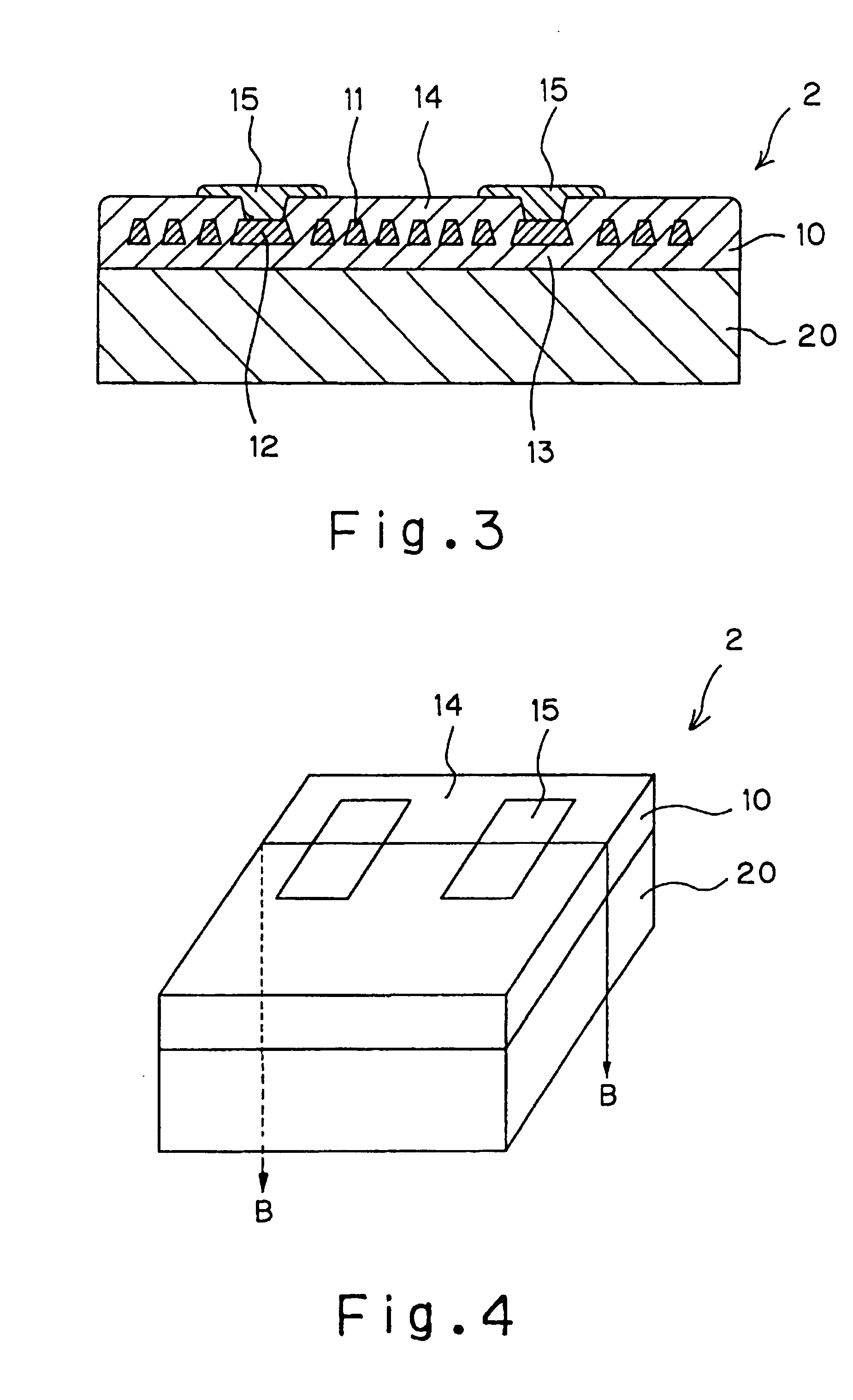

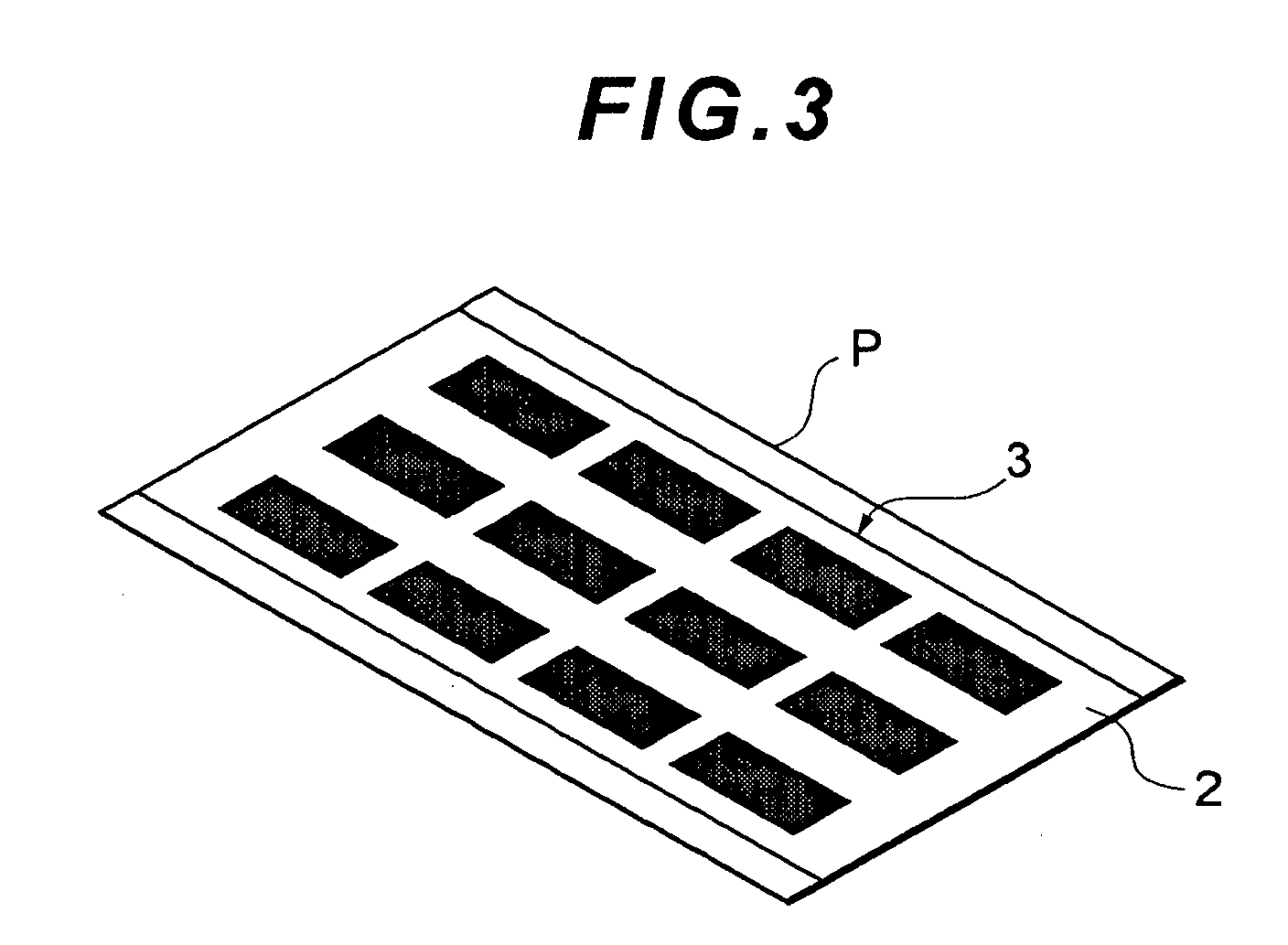

Surface mounting type planar magnetic device and production method thereof

InactiveUS20010024739A1Reduce loss by DC resistance of the coilIncrease the sectionTransformers/inductances coils/windings/connectionsRecord information storageSurface mountingEngineering

This invention provides a surface mounting type planar magnetic device comprised of upper ferrite magnetic film, lower ferrite magnetic film and a planar coil interposed therebetween. For applying surface mount technology, an opening is formed in the upper ferrite magnetic film above a coil terminal portion and then, an external electrode conductive with the coil terminal portion through the opening is formed on the upper ferrite magnetic film. Further, this surface mounting type planar magnetic device is of a thin structure and can be mounted on the surface of a printed board. Its power loss is small, its inductance is large, its frequency characteristic is excellent, the disparity of the characteristic is small and its reliability is excellent.

Owner:KK TOSHIBA +1

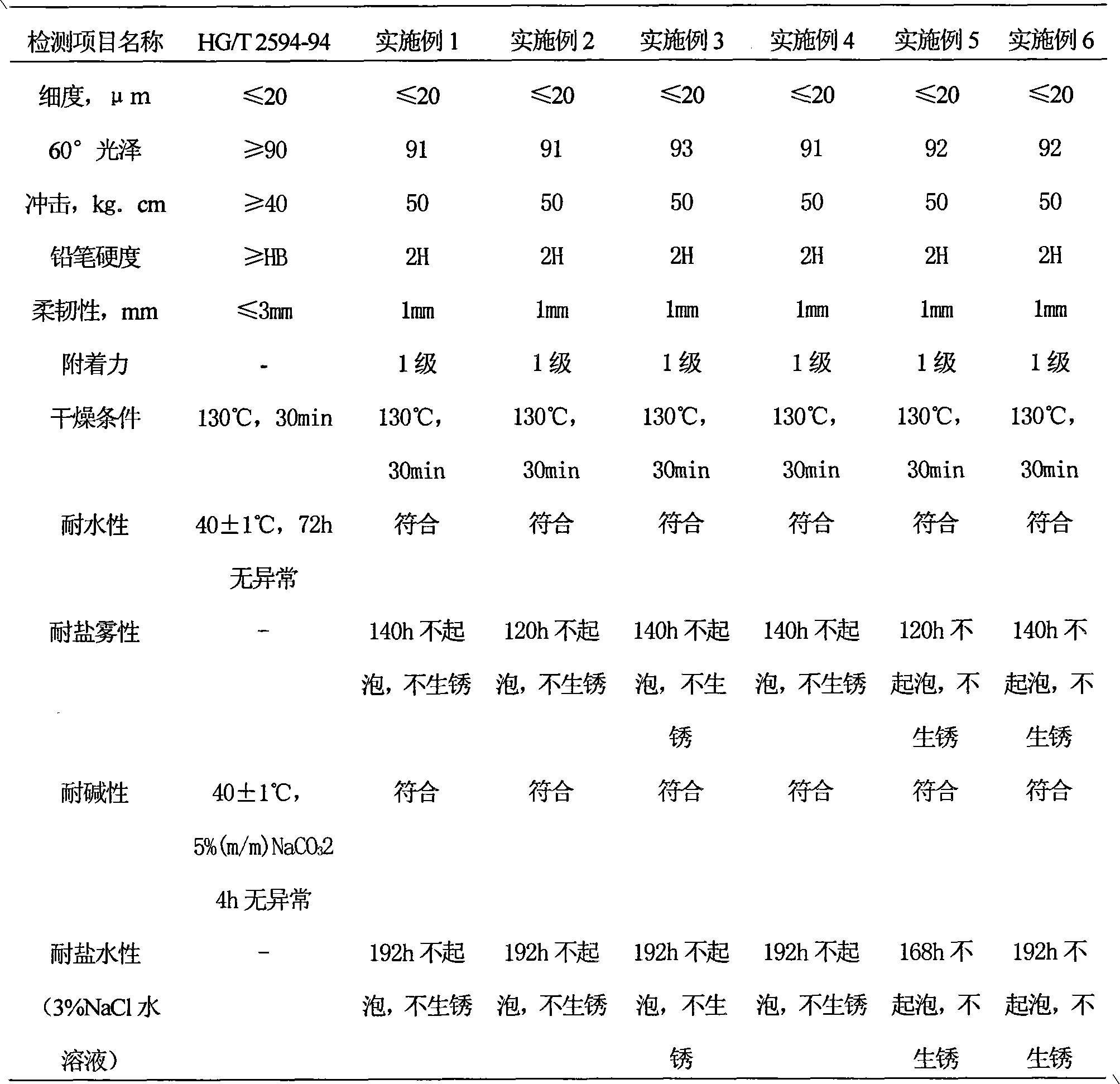

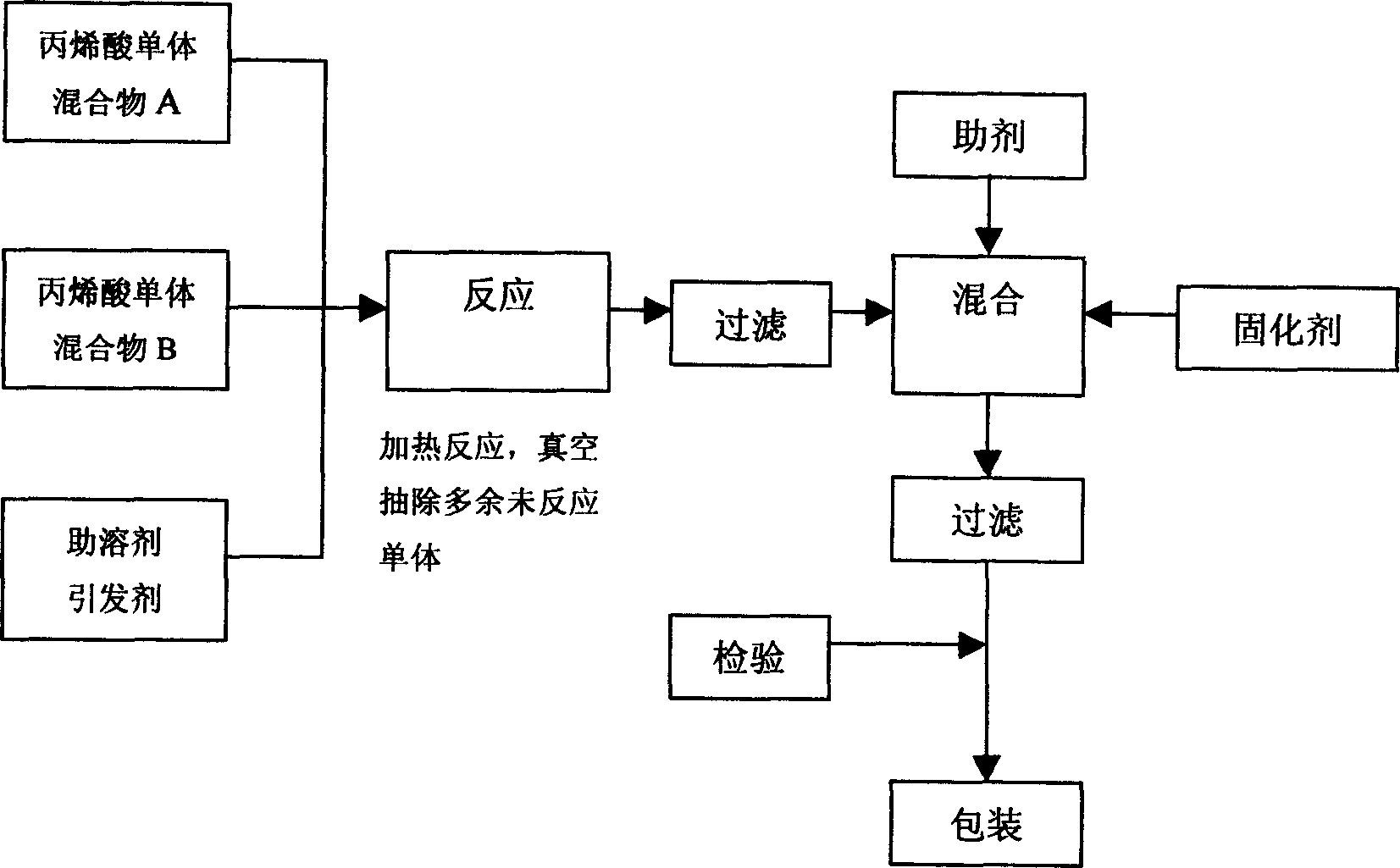

Mono-component aqueous metal baking paint and preparation method thereof

The invention discloses a mono-component aqueous metal baking paint and a preparation method thereof. The mono-component aqueous metal baking paint consists of the following components by weight: 40 to 57 percent of tap water, 28 to 34 percent of aqueous acrylic modified polyester resin, 7 to 8.5 percent of amino resin, 1.12 to 1.36 percent of amine modifier, 0.1 to 0.3 percent of wetting dispersing agent A, 0.1 to 0.3 percent of wetting dispersing agent B, 0.01 to 0.1 percent of defoaming agent, 0.5 to 1.2 percent of thickening agent, and 0.2 to 0.6 percent of levelling agent. The mono-component aqueous metal baking paint uses water as a solvent without adding an alcohol / ether cosolvent so that environmental protection is excellent; because of mono-component, the construction is simple and convenient, and the performance is stable; and a paint film is plumpy, the luster is high, the mechanical property is excellent, and the adhesive force is good. The mono-component aqueous metal baking paint is applicable to metal surface corrosion protection and decoration, and can be used as a finishing paint, a priming paint or a coating varnish; and when used for bottom surface integral coating, the mono-component aqueous metal baking paint still has excellent surface effect and protective action.

Owner:GUANGZHOU JOINTAS CHEM

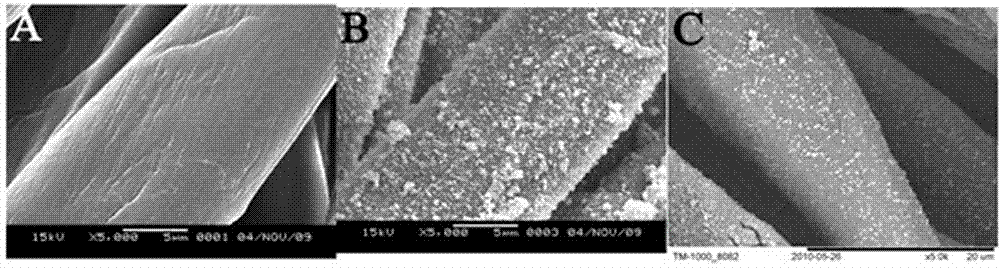

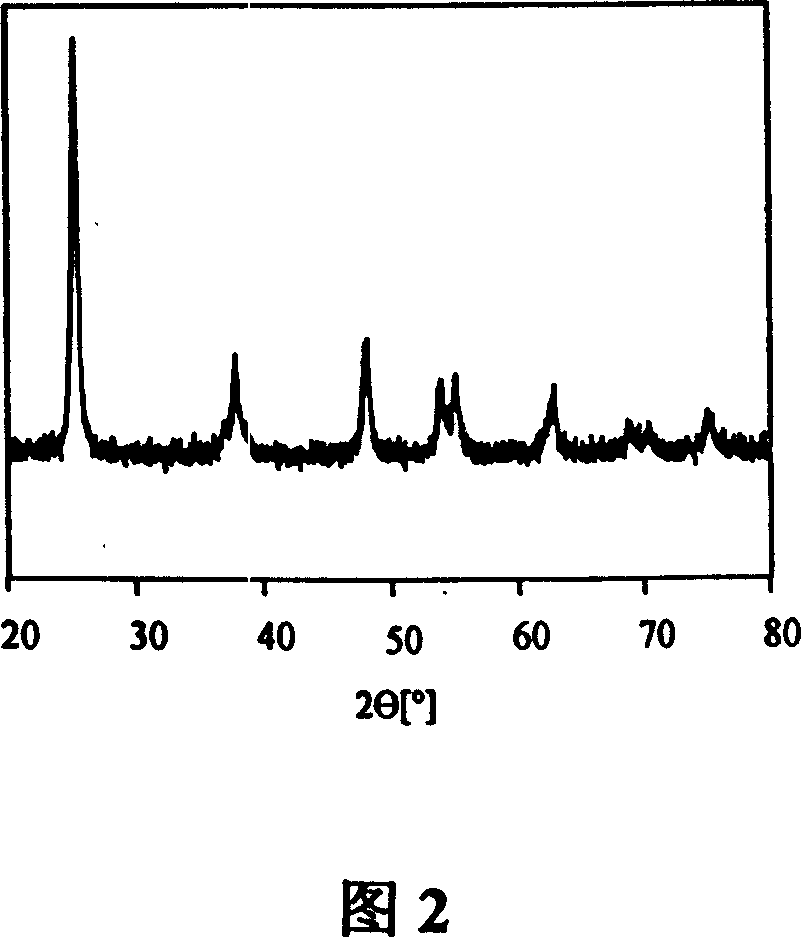

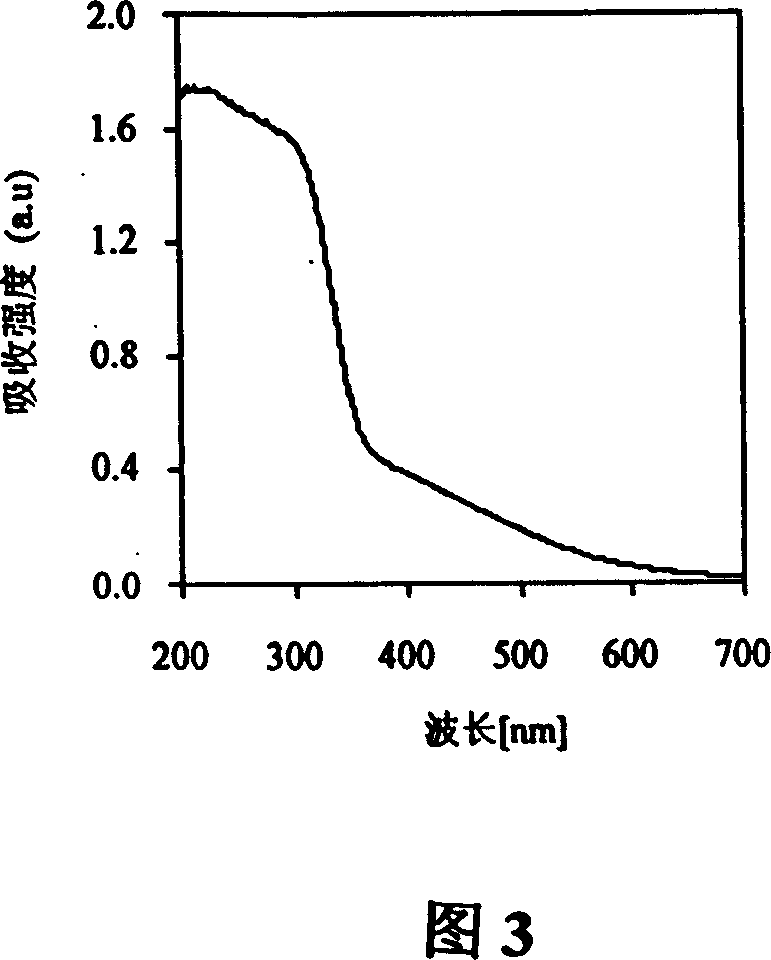

Collosol-gel ultraviolet-proof finishing liquid and its use for preparing ultraviolet-proof textile

InactiveCN1614133ALow baking temperatureEnhance absorption and reflection abilityFibre treatmentLiquid/gas/vapor textile treatmentAcetic acidPolymer science

An anti-ultraviolet finishing liquid for fabric is prepared from tetrabutyl titanium, organic solvent, hydrochloric acid, acetic acid and water. It can be used to prepare the anti-ultraviolet fabric through preparing TiO2 sol and using it to finish the fabric for generating the TiO2 gel nanoparticles on the surface of fabric.

Owner:DONGHUA UNIV

Resin dispersion, coating materials, laminates, and process for production of the same

InactiveUS20090092847A1Good dispersionAvoid bleedingSynthetic resin layered productsSpecial tyresPolymer sciencePolyolefin

To provide an aqueous dispersion of a resin wherein dispersed particles are stable with fine particle sizes and whereby bleeding out is suppressed, which is thus useful as e.g. a surface treating agent, an adhesive or a coating material for a polyolefin substrate.A resin dispersion having, dispersed in water with a 50% particle diameter of at most 0.5 μm, a polymer (C) having a hydrophilic polymer (B) or an acidic group bonded to a propylene / α-olefin copolymer (A) as a copolymer of propylene with an α-olefin other than propylene, wherein the copolymer (A) has a propylene content of at least 50 mol % and less than 100 mol %, and the copolymer (A) has a weight average molecular weight Mw of at least 10,000 and a molecular weight distribution Mw / Mn of at most 3.5; and the resin dispersion has a surfactant content of at most 15 parts by weight per 100 parts by weight of the polymer (C); and a coating material or laminate, made by using such a dispersion.

Owner:MITSUBISHI CHEM CORP

Surface mounting type planar magnetic device and production method thereof

InactiveUS6831543B2Little power lossLarge inductanceTransformers/inductances coils/windings/connectionsMagnetic layersSurface mountingEngineering

A surface mounting type planar magnetic device comprised of upper ferrite magnetic film, lower ferrite magnetic film and a planar coil interposed therebetween. For applying surface mount technology, an opening is formed in the upper ferrite magnetic film above a coil terminal portion and then, an external electrode conductive with the coil terminal portion through the opening is formed on the upper ferrite magnetic film. Further, this surface mounting type planar magnetic device is of a thin structure and can be mounted on the surface of a printed board. Its power loss is small, its inductance is large, its frequency characteristic is excellent, the disparity of the characteristic is small and its reliability is excellent.

Owner:KK TOSHIBA +1

Nano metal titanium dioxide sol negative oxygen ion finishing method for fabric

InactiveCN101481874ASimple operation processLow baking temperatureVegetal fibresAnimal fibresAnhydrous ethanolOxygen ions

The invention relates to a finishing method of fabric by nano-metal titanium dioxide sol negative oxygen ions. The finishing method comprises the following steps: (1) dissolving butyl titanate in 2 / 3 of ethanol, mixing evenly, adding ethanol aqueous solution dropwise, and adjusting pH value to 2 by concentrated inorganic acid after finishing adding dropwise, and continuing to stir for 2h to obtain transparent nano-TiO2 sol, wherein, the butyl titanate, an inhibitor, an anhydrous ethanol and water are at a mol ratio of 1:1:10-30:2-4; and (2) soaking the fabric in the sol finishing agent for 3min, then predrying at the temperature of 80 DEG C, baking at the temperature of 120 DEG C for a plurality of 150s, washing and drying at the temperature of 80 DEG C. The method has simple operation process and low baking temperature of 100-180 DEG C and can help realize industrial production.

Owner:DONGHUA UNIV

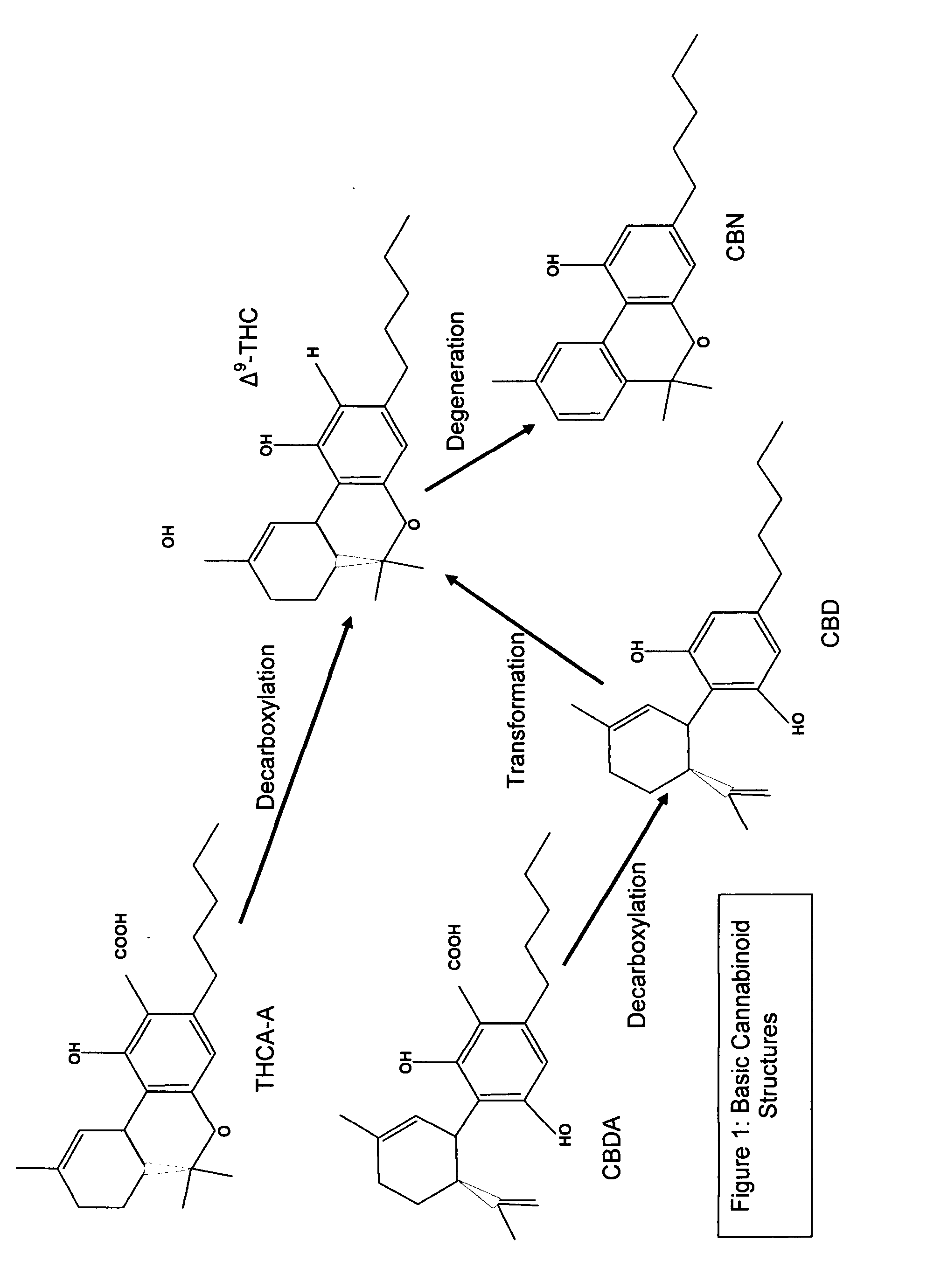

Medicinal cannabis uniform in food

InactiveUS20120095088A1Low baking temperatureExtend the baking timeBiocideNervous disorderCannabinoidMedicine

The invention is a product and a process wherein cannabinoids such as Medicinal Δ9-THC and / or other substances associated with medicinal cannabis, including yet not necessarily limited to cannbidiols, cannabigerol are contained or processed into foodstuffs or medicinal compounds in controlled ways and with specific characteristics. First a medicinal substance with a known about of medicinal cannabis is mixed into a foodstuff such that the medicinal cannabis is distributed uniformly in the foodstuff. Foodstuffs consistent with this invention include baked goods, hard candies, ice cream, bases, ice cream, and yogurt. The product is characterized by a controlled amount of cannabinoids per unit volume of the foodstuff. Another provision of the invention is providing controlled amounts or ratios of Δ9-THC as compared to CBD in a foodstuff.

Owner:HOSPODOR ANDREW DAVID

Conductive silver paste with low halogen content

ActiveCN101650982ALow baking temperatureLow resistivityConductive materialNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention relates to a conductive silver paste with low halogen content. The conductive silver paste comprises the following components by weight percent: 1-25% of vibrin, 20-55% of silver powder,0.1-9% of dispersant, 0.1-8% of adhesion promoter, 0-6% of flatting agent, 0-8% of graphite powder and 20-60% of organic solvent. Compared with the prior conductive silver paste, the conductive silver paste has low halogen content, meets the European Union requirements for environmental protection, and is an environmental-protection product. The silver paste requires a low baking temperature, hasa strong adhesion to PET films, has the advantages of low specific resistivity, moderate bending performance and moderate hardness, and therefore, is a preferable material for making environmental-protection printed circuits.

Owner:湘潭市泽宇新材料科技有限公司

Ceramic ink-jet printing ink and its use methods

The invention relates to a ceramic ink-jet printing ink and its use methods, and concretely relates to a selection method of a ceramic pigment, five formula schemes of the ceramic ink-jet printing ink, and two use methods of the ceramic ink-jet printing ink. A preparation method of the ceramic ink-jet printing ink is optimized, and a printing device is arranged according to the different physical and chemical indexes of the ceramic ink-jet printing ink, so the cost using a ceramic ink-jet technology is reduced.

Owner:鲁继烈

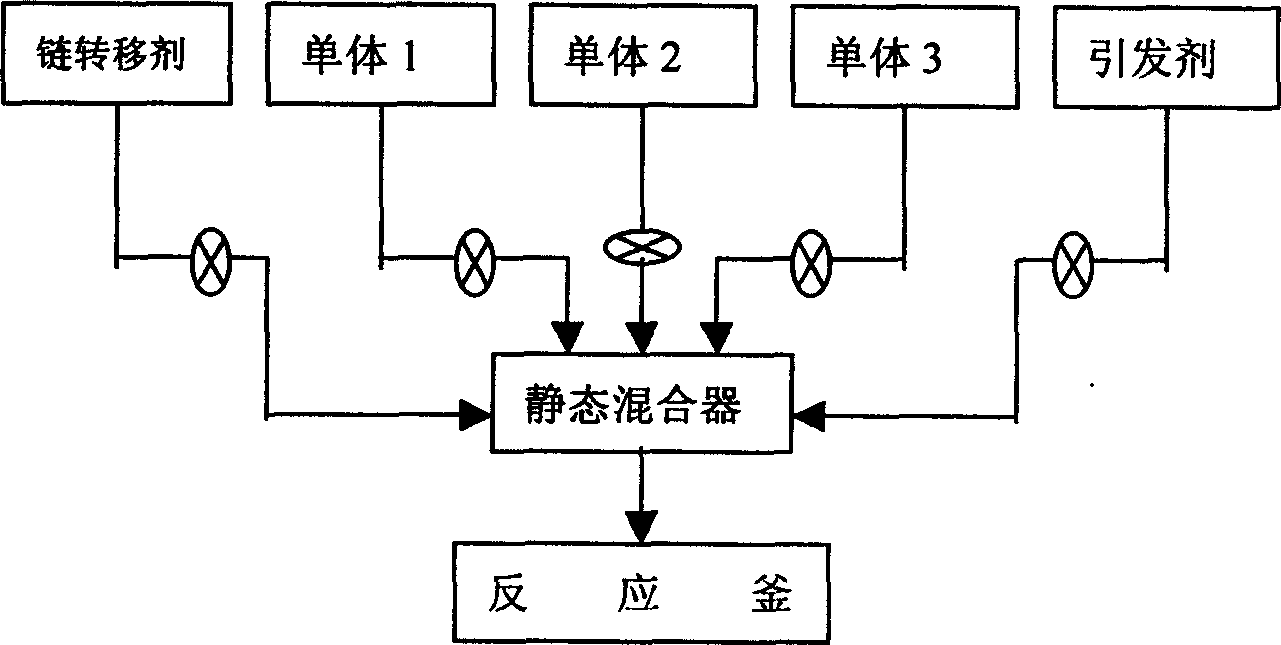

Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

InactiveCN1807528AControl molecular weightIncrease the degree of effective responsePaints for electrolytic applicationsMethacrylateSurface-active agents

The invention relates to an acroleic acid / polyurethane transparent anode electrophoresis coating and its preparation method, comprising the following raw materials (by weight ratio): cationic acrylic polymer 52-85, closed isocyanate cross linking agent 14.5-23.5, non-ionic or / and cationic surface active agent 4.6-8, catalyst 0.6-1.1, chain-transferring agent 0.5-0.8, deionized water 26-51. The cationic acrylic polymer comprises the following raw materials (by weight portions): isobutyl methacrylate 35-55, methyl acrylic ester 23-43, methyl methacrylic hydroxyl propyl ester 15-26, dimethyl amido propyl ester methacrylamide 13.5-23, 2-ethylhexyl methacrylate 13-28, azo-diisobutyronitrile 0.5-1.2, and dimethyl carbinol 35-89.

Owner:冯国贤

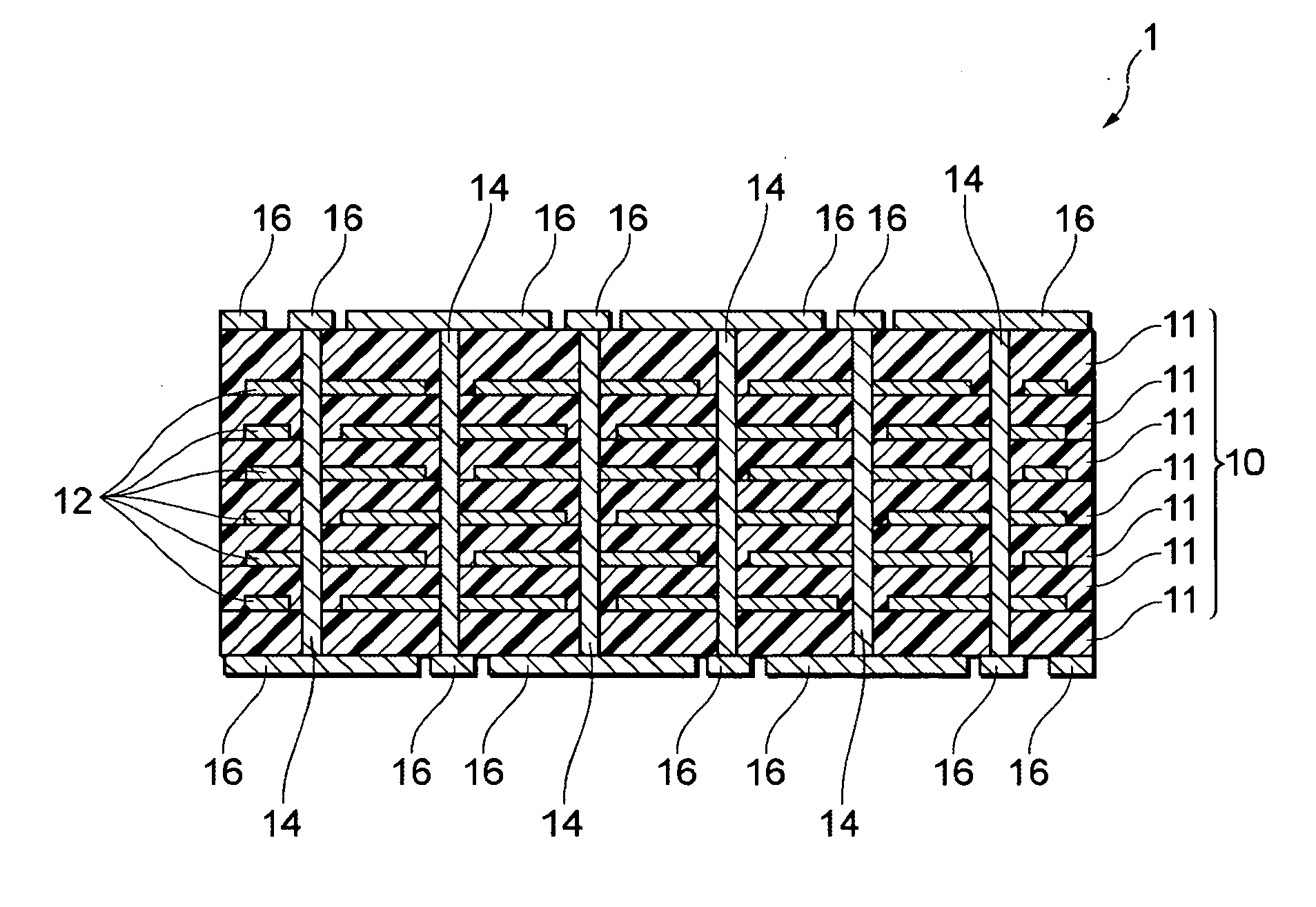

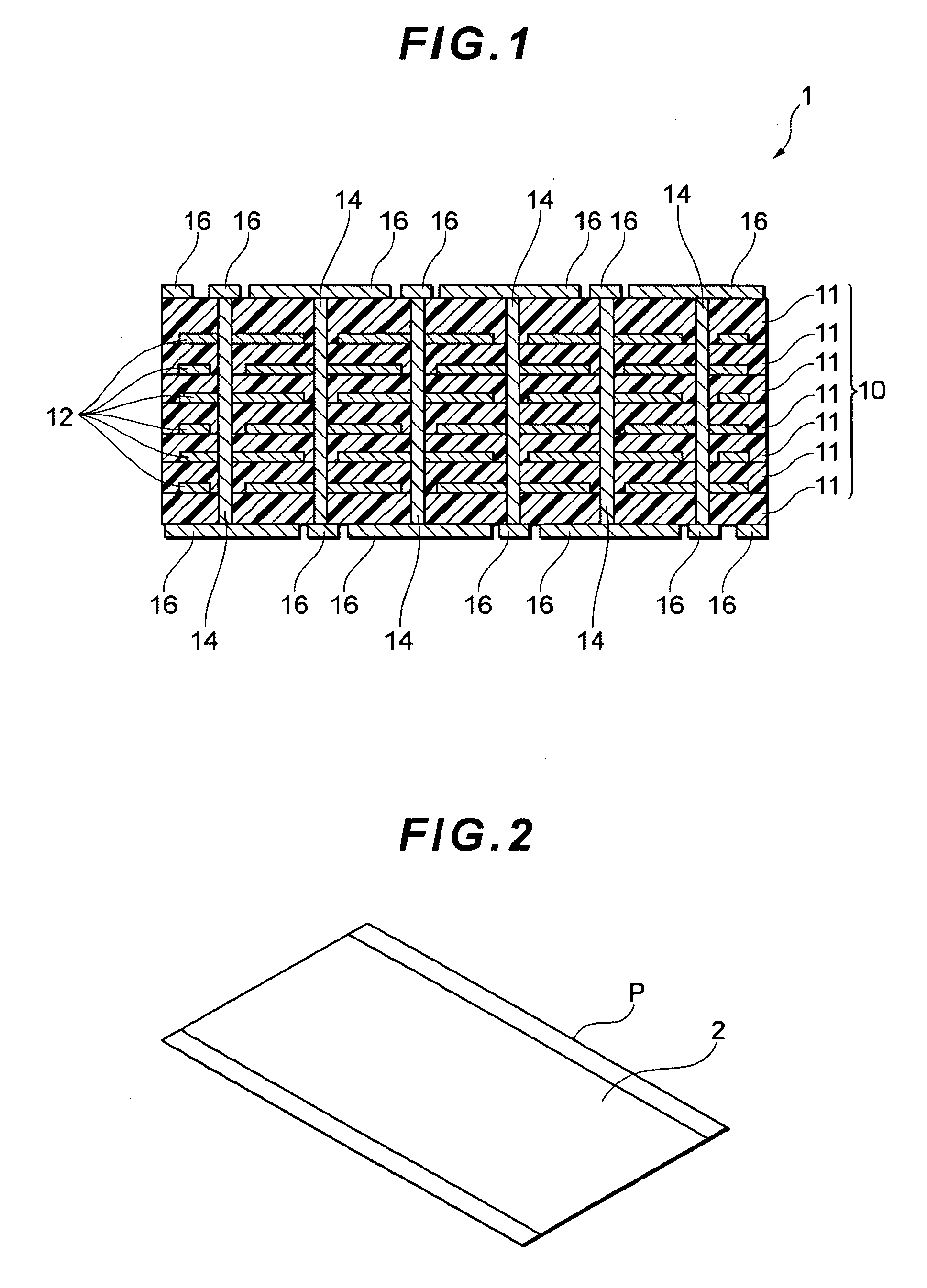

Layered ceramic electronic component and manufacturing method therefor

InactiveUS20100038120A1Minimize expansion/contraction degreeDegree of reductionSemiconductor/solid-state device detailsStacked capacitorsConductive pasteCeramic capacitor

Provided is a manufacturing method of a layered ceramic electronic component capable of preventing appearance of a gap between a dielectric layer and a via electrode to achieve reliable conduction between the via electrode and an internal electrode and at the same time, capable of effectively preventing occurrence of structural defects in the dielectric layer and the like.In a layered (multilayer) ceramic capacitor, dielectric layers and internal electrodes are stacked alternately. Of the internal electrodes, those placed opposite to each other via the dielectric layer are connected through the via electrode. The layered (multilayer) ceramic capacitor is produced by forming a via hole in stacked layers of a ceramic green sheet for forming the dielectric layer and a conductive paste for forming the internal electrode, followed by firing to obtain stacked layers having the dielectric layers and the internal electrodes formed therein. A conductive paste for forming the via electrode is filled in the via hole of the stacked layers and then baked to form the via electrode.

Owner:TDK CORPARATION

Baking varnish composition

The invention discloses a baking varnish composition, the main contents of which by weight percentages are: thermosetting acrylic resin: 50-57.5, high imino resin: 10-12.6, n-butyl ether amino resin: 8-11.4, epoxy resin: 2-2.8, solvent: 8-13.2, flatting agent: 0.2-0.5 and adhesion promoter: 0.5-1. The thermosetting acrylic resin, the high imino resin, the n-butyl ether amino resin and the epoxy resin are main film forming matters and the solvent is ethylene glycol monobutyl ether, n-butanol and xylene. The varnish of the invention has low baking temperature, high hardness, strong adhesion, as well as little energy consumption and excellent corrosion resistance and impact resistance.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

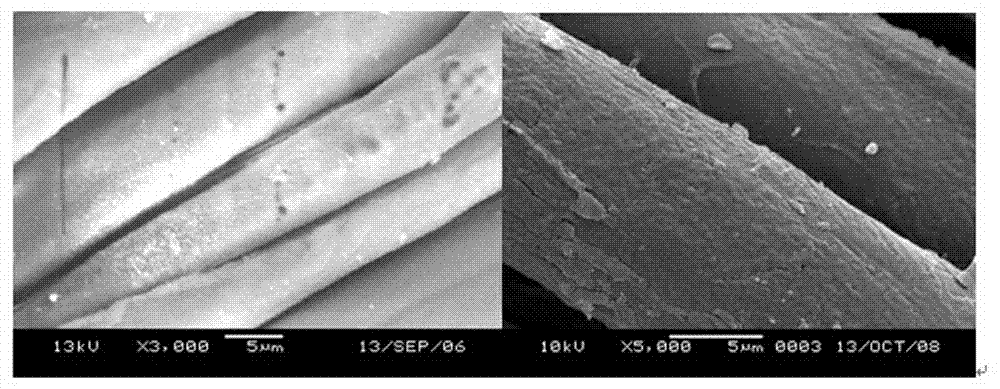

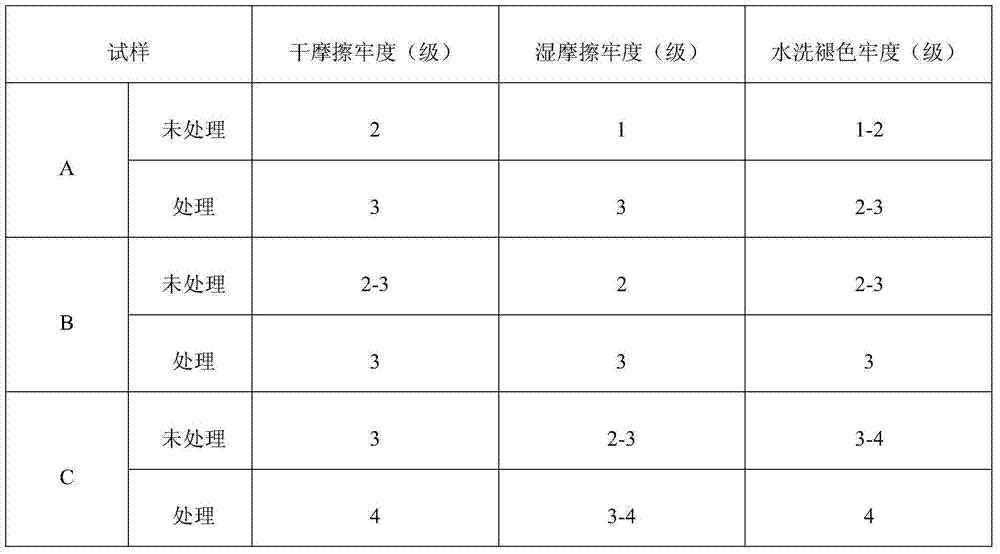

Sol-gel color fixing method

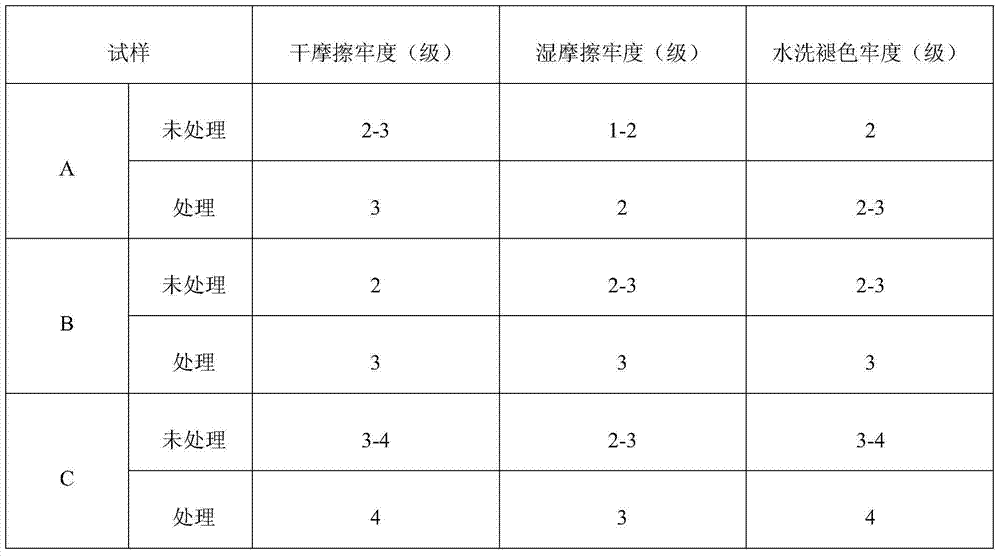

The present invention belongs to the field of chemical technology and is a kind of sol-gel color fixing method. Reagent capable of producing chemical combination with fabric fiber is selected as material for sol finishing liquid to finish fabric at 100-180 deg.C. Thn and transparent complicated network film is formed on the inner and outer surface of fiber to fix the dye on the fabric and to raise the color fastness of fabric.

Owner:DONGHUA UNIV

Continuous hot melting dyeing technology for polyester fiber fabric

InactiveCN103668829AReduce consumptionLow baking temperatureSucessive textile treatmentsDyeing processDisperse dyeHot melt

The invention aims at providing a continuous hot melting dyeing technology for a polyester fiber fabric. The traditional pad dyeing technology of carrying out rolling, drying and baking in sequence on the polyester fiber fabric is changed into the technology of carrying out steaming, rolling, drying and baking in sequence. Before padding, a polyester fiber is steamed through negative pressure saturation steam so that the expansion degree of the polyester fiber can be improved, the dyeing speed, the dye utilization ratio and the level dyeing degree of dyes can be improved, and the effects of shaping the polyester fiber and improving the quality of the fiber can be achieved. In the padding process, the dyeing speed and the dyeing uptake of disperse dyes are further improved by utilizing the function of a dyeing assistant, and the liquid rate and the level dyeing effect of two-immersing and two-rolling technology can be achieved by adopting the one-immersing and one-rolling technology. After pre-drying is carried out through high-frequency infrared rays, the temperature of the baking and drying is reduced to 180 DEG C to 190 DEG C from 210 DEG C to 220 DEG C by adopting the low-temperature dyeing technology. By means of the technology, dyeing and printing enterprises can greatly reduce energy consumption, and meanwhile, high quality dyed fabrics with the superior performance can be obtained.

Owner:YANCHENG INST OF IND TECH

Process for preparing low temperature baking silver mirror back lacquer

InactiveCN1900189ALow baking temperatureShort baking timeInstrumentsPolyester coatingsOrganic solventLacquer

The lower temperature baked silver mirror back lacquer consists of priming lacquer and finishing paint. The priming lacquer consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, and organic solvent in certain weight proportion. The finishing paint consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, leveling agent and organic solvent in certain weight proportion. The present invention has silver mirror back lacquer with baking temperature lowered to 100 deg.c, raised adhesion, high wet head resistance, high temperature change tolerance, high salt fog resistance, high salt water resistance, high corrosion resistance and good post finishing property.

Owner:SHANGHAI JIAO TONG UNIV

Amino stoving varnish capable of being cured quickly at low temperature

ActiveCN103087603ALow baking temperatureReduce baking timeEpoxy resin coatingsPolyester coatingsComposite materialAntifoam agent

The invention relates to amino stoving varnish, and in particular to amino stoving varnish capable of capable of being cured quickly at a low temperature. The amino stoving varnish comprises the following components in parts by weight: 50-60 parts of hydroxy acrylic resin or alkyd resin, 10-20 parts of amino resin, 1-5 parts of functional auxiliary, 0.1-0.5 part of flatting agent, 0.1-0.5 part of antifoaming agent and 10-20 parts of diluent. A preparation method of the amino stoving varnish provided by the invention is simple, and the prepared product has strong applicability and good quality.

Owner:浙江德尚化工科技有限公司

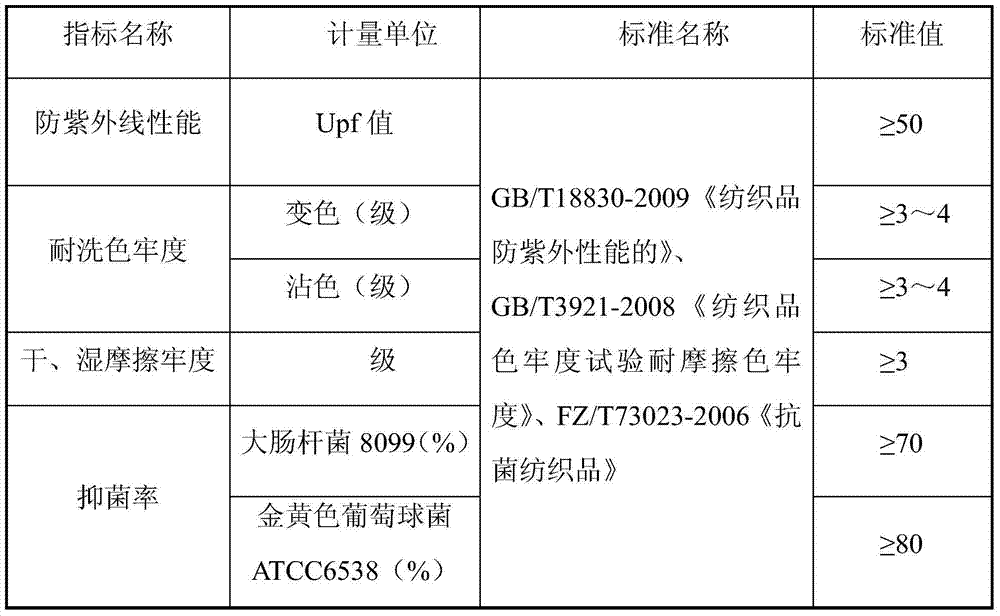

Nano TiO2/ZnO-doped composite hydrosol, and preparation method thereof and finishing method of textile

InactiveCN103498331AGood antibacterial effectImprove antibacterial propertiesZinc oxides/hydroxidesFibre treatmentTextile technologyCooking & baking

The invention belongs to the technical field of intersection of a chemical technology and a textile technology, and particularly relates to a nano TiO2 / ZnO-doped composite hydrosol, and a preparation method of the nano TiO2 / ZnO-doped composite hydrosol and a finishing method of a textile. The composite hydrosol comprises the following components: ZnO hydrosol, TiO2 hydrosol, and Ag<+> or La<3+> of which the mass percent is 0.1-1%, wherein the quantity ratio of the TiO2 hydrosol to the ZnO hydrosol is 1:(0-5), namely TiO2, ZnO and La<3+> or Ag<+> are compounded in nanoscale at a sol dissolving stage by a sol-gel method; the doped hydrosol containing a plurality of components is prepared on the same transparent medium; the prepared doped hydrosol is used for functional finishing of the textile; an organic solvent is removed in a baking manner; a layer of oxide gel mask with a porous structure is formed at the surface of the textile; better irregular tightness is directly formed by the oxide gel mask and the fiber surface; the multi-functionality of the textile is endowed.

Owner:JINHUA JIELING HOUSE WARES CO LTD

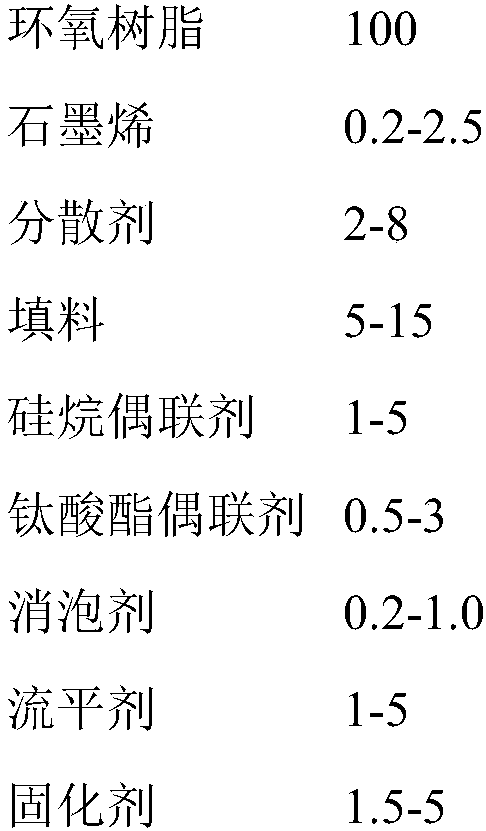

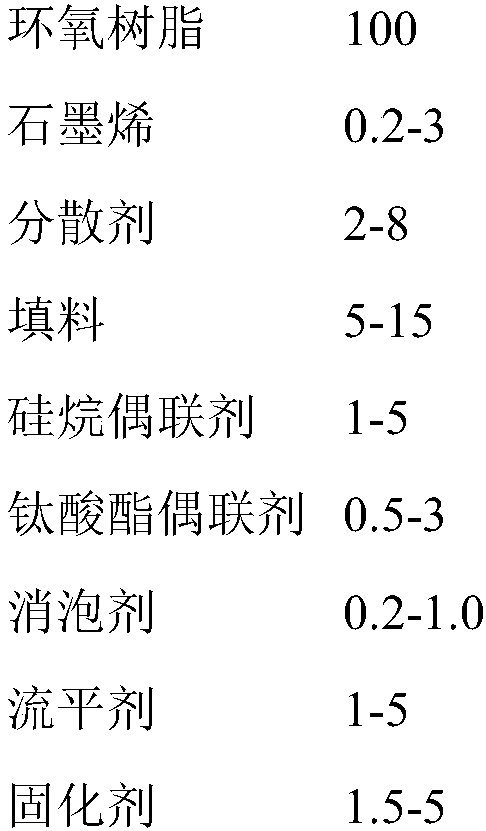

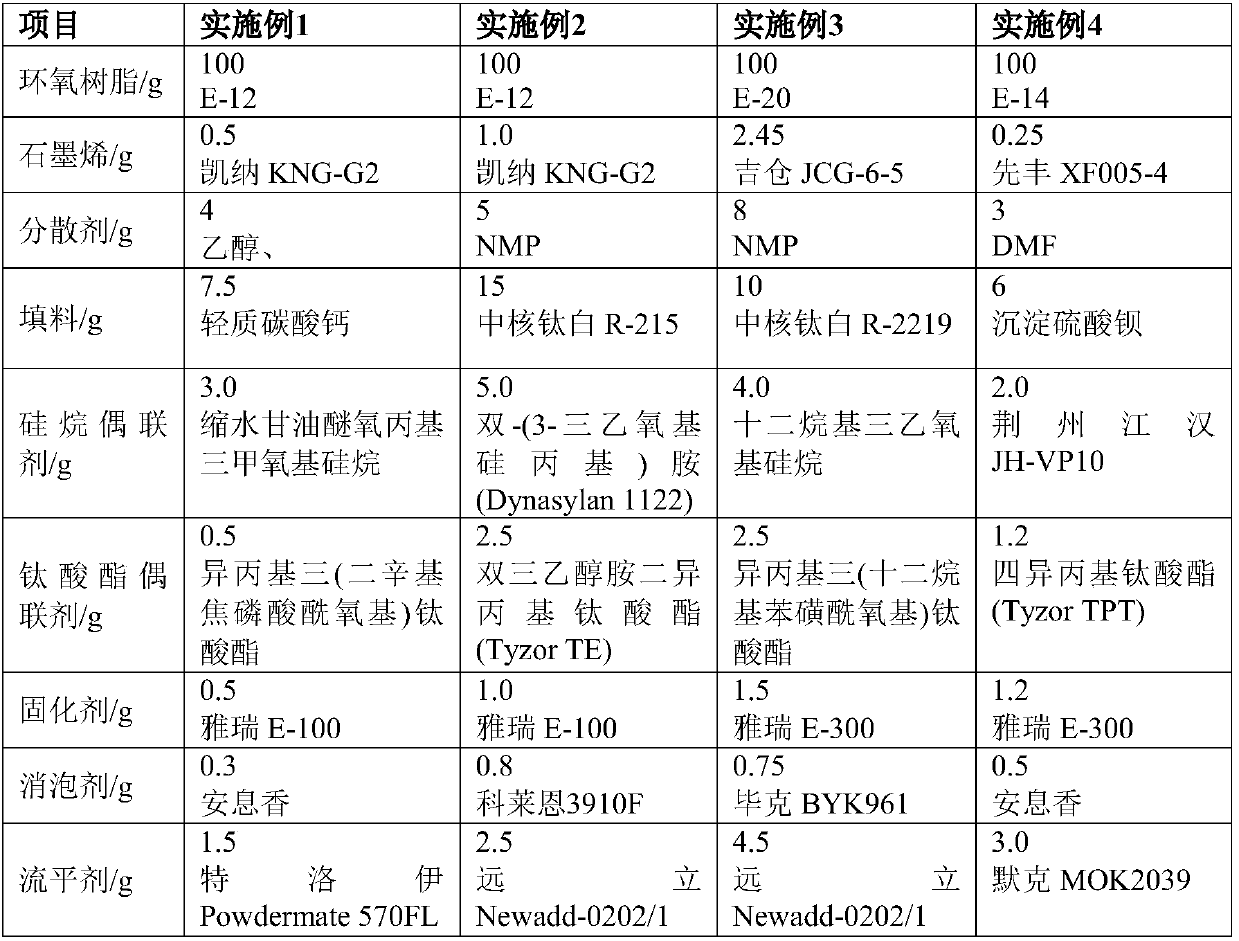

Graphene conductive powder coating before wooden product coating as well as preparation and application thereof

InactiveCN107760164AAvoid bloomingHigh strengthPowdery paintsEpoxy resin coatingsEpoxyConductive coating

The invention provides a graphene conductive powder coating before wooden product coating as well as preparation and application thereof. The conductive powder coating is composed of the following components: epoxy resin, graphene, a dispersing agent, a filler, a silane coupling agent, a coupling agent of organic titanate, a flatting agent, a curing agent, an antifoaming agent and the like. The conductive powder coating can be applied to conductive treatment before wooden product coating, and the wooden product is treated and dried and cured to form a flat and dense conductive coating on the surface. The conductive powder coating is capable of closing pores on the surface of the wooden product base material and does not diffuse and permeate on the surface, so that the conductivity performance on the surface of the base material is improved, the electrostatic spraying coating quality of the wooden product is improved, phenomena such as pinholes, bubbles and cracking occurring in the coating flatting and curing process are avoided, and the adhesive force between the wooden product base material and the coating is promoted. The graphene conductive powder coating is excellent in hardness and resistance, is capable of improving the durability of the wooden products and can be widely applied to coating treatment industries of the wooden products.

Owner:杭州五源科技实业有限公司 +2

Coloured transparent glass paint and its preparation method and application

The present invention discloses a colored transparent glass paint, its preparation method and application. Its composition includes (by weight portion) 6-9 portions of nitro-cotton, 9-12 portions of polyketone resin, 15-25 portions of castor oil modified alkyd resin, 8-12 portions of thermoset acrylic resin, 1-2 portions dibutyl phthatate, 1-2 portions of tritolyl phosphate, 5-7 portions of solvent-type metal complex dyestuff and proper quantity of volatile mixed solvent. Said paint can be coated on the glass surface, under the condition of 120-150 deg.C it can be baked for 3-5 min and can be solidified to form film.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving color fastness of photochromic fabric

InactiveCN103572621AFormaldehyde freeColor becomes smallerDyeing processColour fastnessTextile fiber

The invention relates to a method for improving the color fastness of a photochromic fabric. The method comprises the following steps: (1), at the room temperature, mixing tetraethoxysilane and glutamic-pyruvic transamine with ethyl alcohol, stirring until uniform mixing, then dripping hydrochloric acid drop by drop under stirring, and stirring unceasingly for 5 hours so as to obtain a finishing liquor; (2), at the room temperature, carrying out two times of soaking and two times of rolling to the photochromic fabric in the finishing liquor, then drying, and finally baking the photochromic fabric. The method provided by the invention has the advantages that the color fixing is convenient, the consumed time is short, the cost is low, pollutions to the environment are small, and the effect in improving the color fastness of the photochromic fabric is obvious; an agent capable of being in reaction with and combined with textile fiber is selected as a raw material to prepare a colloidal sol finishing liquor, when finishing is performed on the photochromic fabric, overhigh temperature is not required, not only can the effect of improving the color fastness of the photochromic fabric be improved, but also damage to fabrics can be prevented.

Owner:DONGHUA UNIV

Laminated aluminium-base cover board for PCB drilling and preparation method of cover board

ActiveCN103937387AReduce processing energy consumptionIncrease productivityPolyether coatingsPolyester coatingsEmulsionPolyvinyl alcohol

The invention provides a laminated aluminium-base cover board for PCB drilling and a preparation method of the cover board. The method is characterized by taking 30-50 parts by weight of both unsaturated polyester and adjuvants as components A1, then taking 42-60 parts by weight of two or more than two of polyoxyethylene, polyethylene glycol, glycerol, vinyl acetate and polyvinyl alcohol to form components A2, then taking 2-8 parts by weight of auxiliaries, mixing the components A1 and A2 and the auxiliaries to form emulsion, spraying the emulsion onto the surface of an aluminium foil and drying the surface, thus preparing the finished product. Compared with the existing laminated aluminium cover boards, the laminated aluminium cover board has the beneficial effects that the hardness of a base resin layer on the surface of the laminated aluminium cover board is higher, thus improving the hardness difference between the base resin layer and the aluminium foil and improving the drilling precision; the base resin layer has higher curing speed and lower braking temperature, so that the laminated aluminium cover board is lower in machining energy consumption and has higher production efficiency.

Owner:SHENZHEN NEWCCESS IND

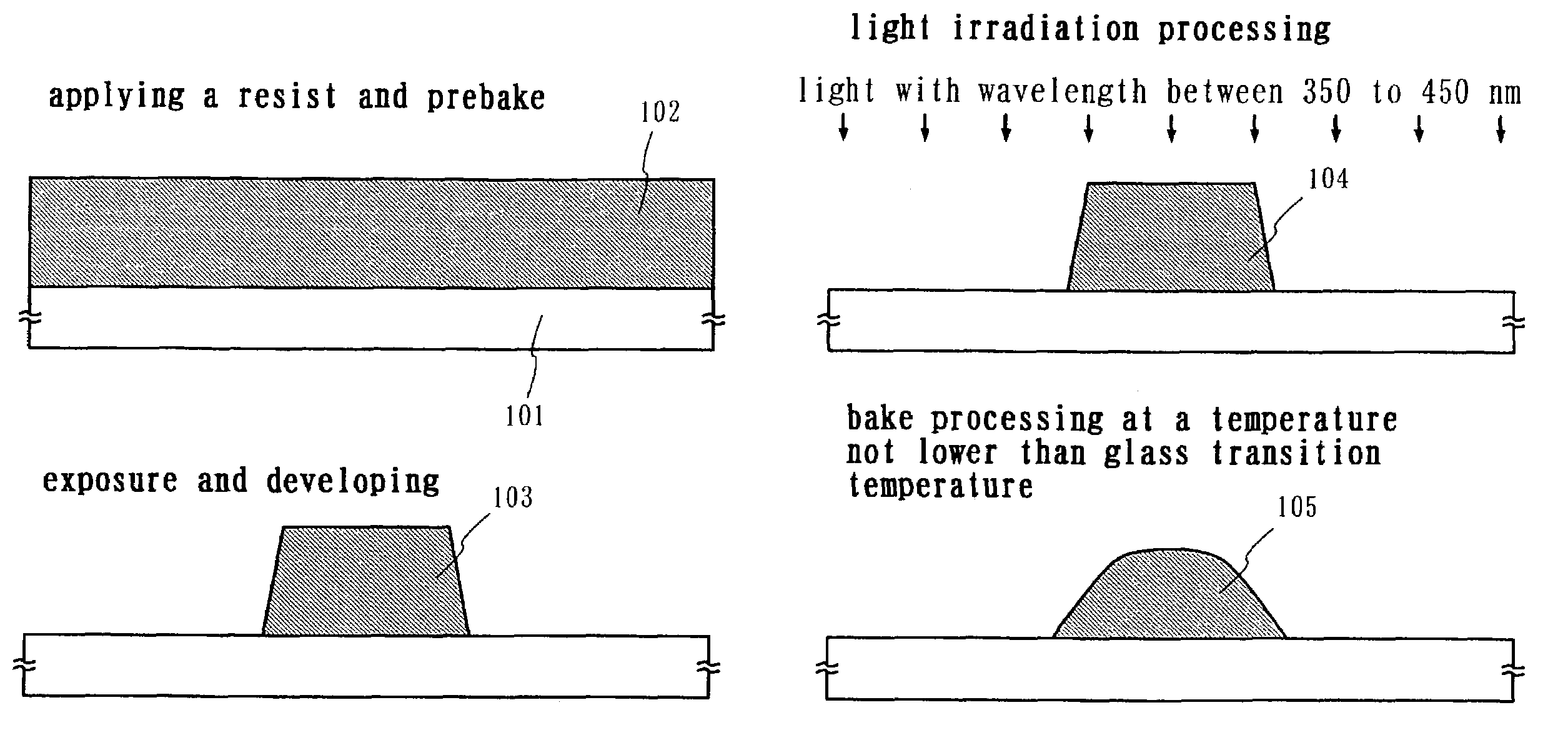

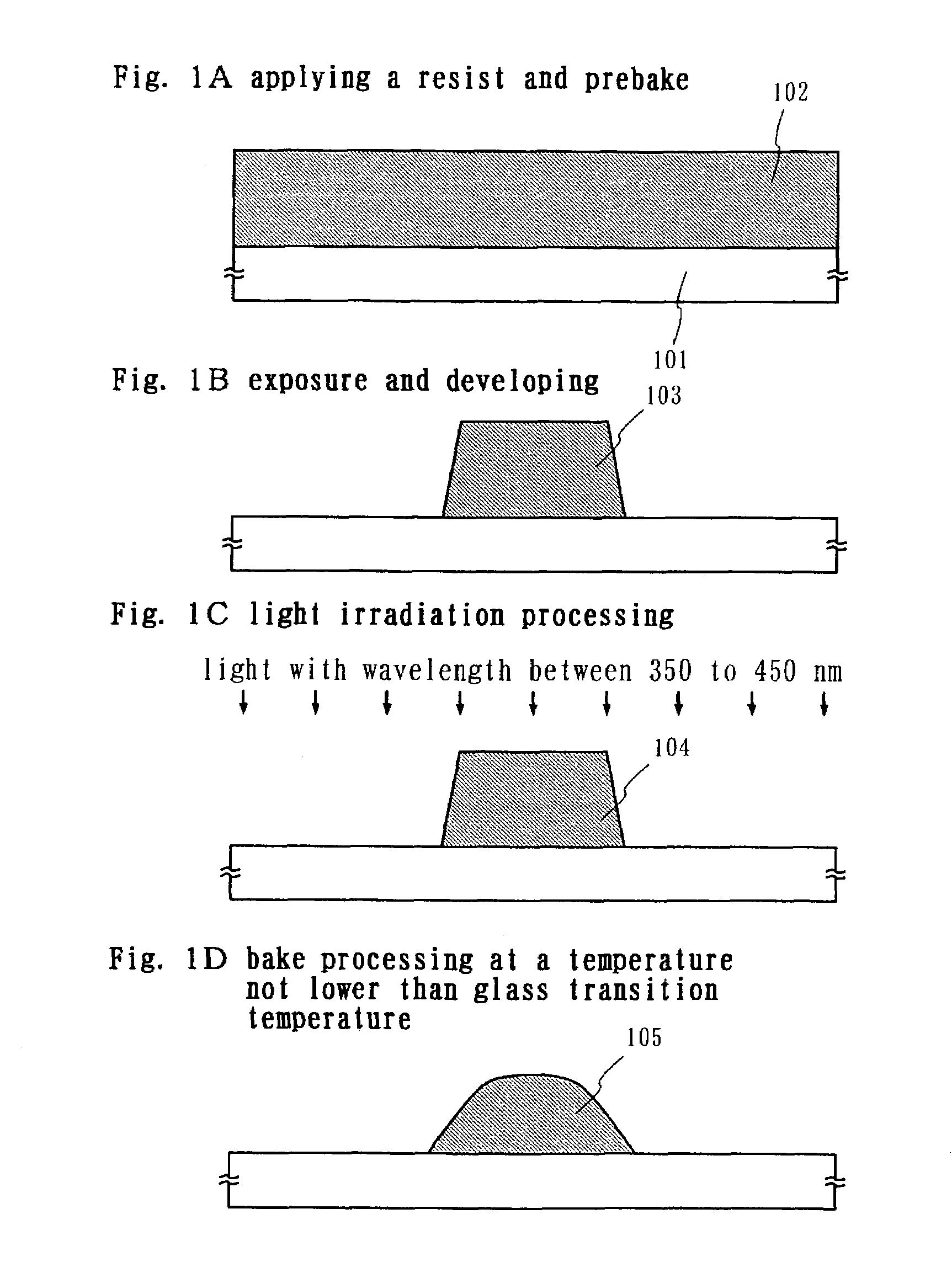

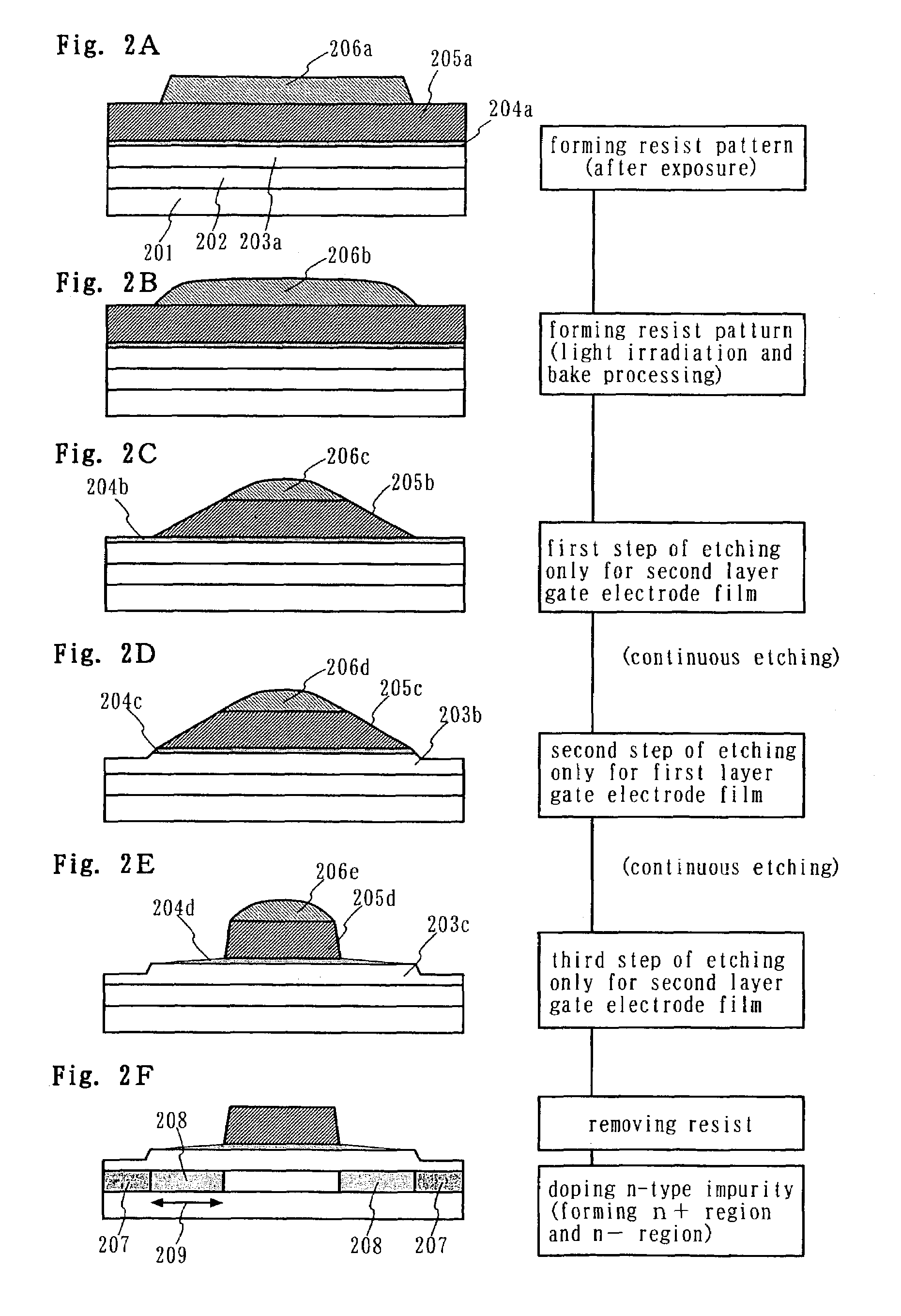

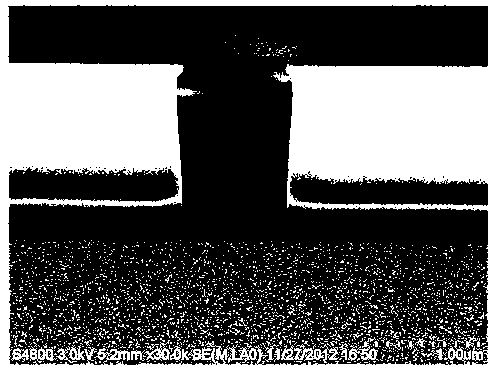

Method of fabricating semiconductor device, and developing apparatus using the method

InactiveUS7344825B2High-throughput processingImprove solubilityTransistorSolid-state devicesVitrificationResist

In a resist pattern forming method in which bake processing is performed at a temperature not lower than a glass transition temperature in order to obtain the desired sidewall angle, resist removable is difficult. Accordingly, in the resist pattern forming method of performing bake processing at a temperature not lower than a glass transition temperature, a process margin for resist removability cannot be ensured, so that there is the problem that it is impossible to compatibly realize both the formation of a resist pattern having the desired sidewall angle and the resist removability of the resist pattern. The invention aims to solve the problem. A resist pattern including a diazonaphthoquinone (DNQ)-novolac resin type of positive resist is formed, and the resist pattern is irradiated with light within the range of photosensitive wavelengths of a DNQ photosensitizer to perform bake processing on the resist pattern at a temperature not lower than the glass transition temperature of the resist pattern.

Owner:SEMICON ENERGY LAB CO LTD

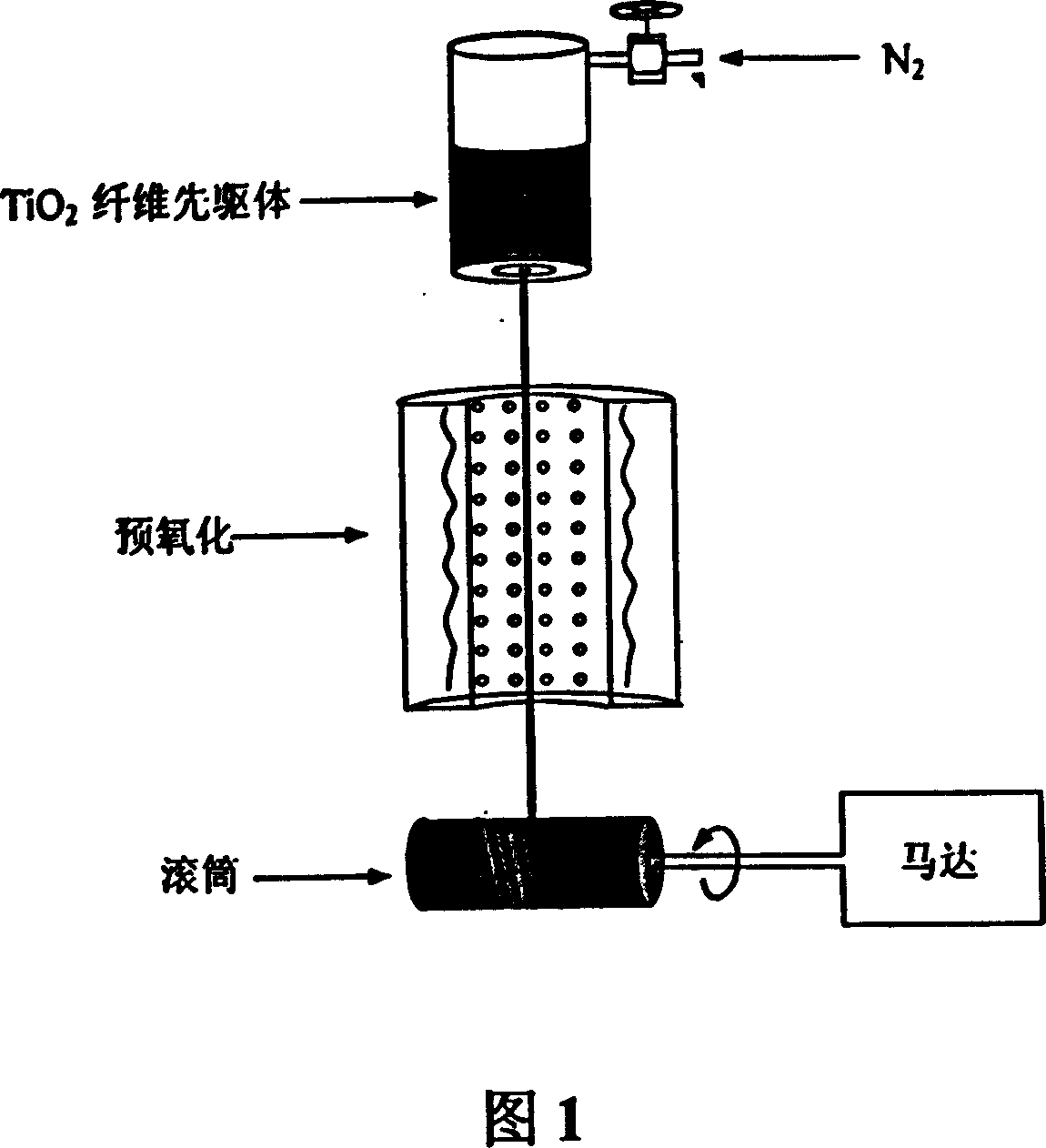

Continuous poriferous titanium dioxide fiber and the technique of preparing the same

InactiveCN101041127ALarge specific surface areaHigh strengthPhysical/chemical process catalystsTitanium dioxideFiberOrganic solvent

The invention relates to a continuous porous titanium dioxide fiber and the preparing technology. Sol-gel method is used to prepare the continuous porous titanium oxide fiber. First, TiO2 sol with low molecular weight is compounded; by evaporating organic solvent and adding polymer, TiO2 fiber precursor with high molecular weight is prepared. Then by extruding and extending the continuous porous TiO2 fiber is compounded. The outstanding characteristic of method is that by using sol-gel method the continuous porous TiO2 fiber with new structure and good physical and chemical property is prepared so as to provide a new path for studying continuous inorganic fiber material. At the same time, the technology is simple and it is easy to industrial production. It makes active contribution to developing theory, technology and method of sol-gel filature.

Owner:CHANGSHA UNIVERSITY

Sol-gel negative ion finshing method for fabric

InactiveCN1587497ALow baking temperatureOvercome the shortcomings of easy aggregation, easy migration, and uneven dispersionFibre treatmentLiquid/gas/vapor textile treatmentCellulosePolyester

The present invention performs negative ion finishing of fabric by means of sol-gel technology, and in a rolling-stoving-roasting process with silicate ester as precursor for preparing stable transparent nanometer sol. During the negative ion finishing of cellulose, silk and other natural fiber and polyamide, polyester and other synthetic fiber, adhesive and softening agent are used to endow fabric with excellent and lasting negative ion performance and excellent hand feeling and comfort.

Owner:DONGHUA UNIV

Paste-like thermally expandable filler

InactiveUS20130280451A1Avoid wind noiseHigh foaming capabilitySynthetic resin layered productsThin material handlingQuinonePlasticizer

A paste-like thermally foaming filler contains 2 to 20 parts by weight of an uncrosslinked synthetic rubber. 5 to 30 parts by weight of a partially crosslinked rubber, 0.1 to 5 parts by weight of a quinone-based vulcanizing agent, 0.2 to 1 parts by weight of thermally expandable balloons, 1 to 10 parts by weight of a thermoplastic resin, 20 to 50 parts by weight of a plasticizer, 15 to 50 parts by weight of an inorganic filler, and 2 to 15 parts by weight of a chemical foaming agent. The paste-like thermally foaming filler exhibits high foaming capability even at low temperatures.

Owner:SUNSTAR GIKEN KK

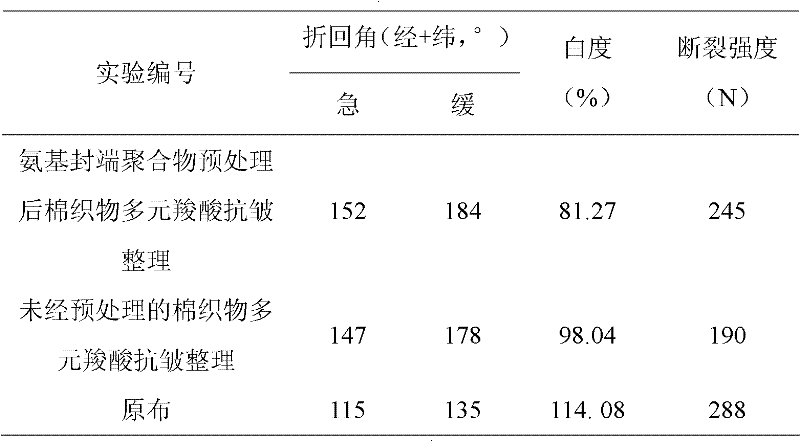

Polycarboxylic acid anti-crease finishing technology for low-strength damaged cotton fabric

InactiveCN102517897AImprove wrinkle resistanceStrong retention rateVegetal fibresCarboxylic acidPre treatment

The invention discloses a polycarboxylic acid anti-crease finishing technology for low-strength damaged cotton fabric. The technology comprises the following steps of: steeping the scoured and bleached cotton fabric in preprocessing liquid, steeping twice and rolling twice, and drying, wherein the rolling residual rate is 90-100%, the preprocessing liquid consists of 2-8 g / L amino-blocked polymerand the balance of water; and steeping and rolling the preprocessed cotton fabric in anti-crease finishing liquid, steeping twice and rolling twice, drying and baking at high temperature, wherein therolling residual rate is 80%, and the anti-crease finishing liquid consists of 2-10% of citric acid by weight, 2-10% of sodium monophosphate by weight and the balance of water. Through the invention,the major problem, i.e. strength damage in the anti-crease processing of polycarboxylic acid can be solved; the processed fabric not only has excellent crease resistance, but also has high strength retention rate; the bottleneck limiting the application of polycarboxylic acid in the anti-crease processing is broken through; and meanwhile, the baking temperature and the dosage of polycarboxylic acid can be reduced, thereby being favorable for lowering the production cost.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA +1

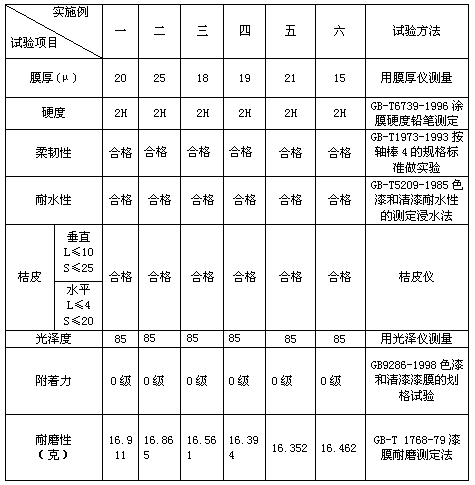

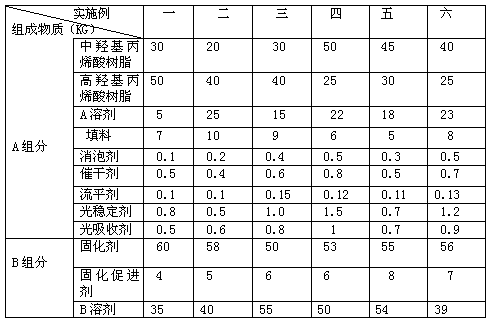

Low-temperature quick-drying dual-component automotive trim paint

The invention relates to low-temperature quick-drying dual-component automotive trim paint, which is used for solving the problems of long baking time, high baking temperature and low hardness in the conventional automobile plastic trim paint. The low-temperature quick-drying dual-component automotive trim paint consists of a component A and a component B, wherein a mass ratio of the component A to the component B is 4:1; the component A consists of the following substances in part by mass: 60 to 80 parts of hydroxy acrylic resin mixture, 5 to 25 parts of solvent A, 5 to 10 parts of filler, 0.1 to 0.5 part of defoamer, 0.1 to 0.15 part of flatting agent, 0.4 to 0.8 part of drier, 0.5 to 1.5 parts of light stabilizer and 0.5 to 1 part of light absorber; and the component B consists of the following substances in part by mass: 50 to 60 parts of curing agent, 4 to 8 parts of curing accelerator and 35 to 55 parts of solvent B. According to an automotive interior trim part sprayed by the automotive trim paint, the baking time can be reduced by nearly 50 percent, the baking temperature is reduced by about 20 DEG C, and the hardness of pencils is improved to 2H; and the low-temperature quick-drying dual-component automotive trim paint has the characteristics of improving production efficiency and quality of products along with energy conservation.

Owner:GREAT WALL MOTOR CO LTD

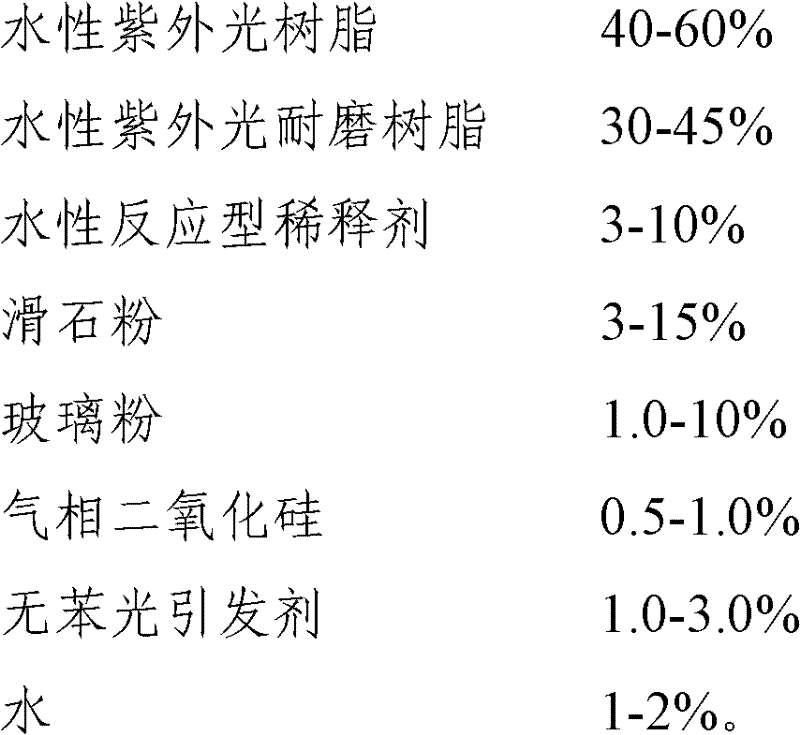

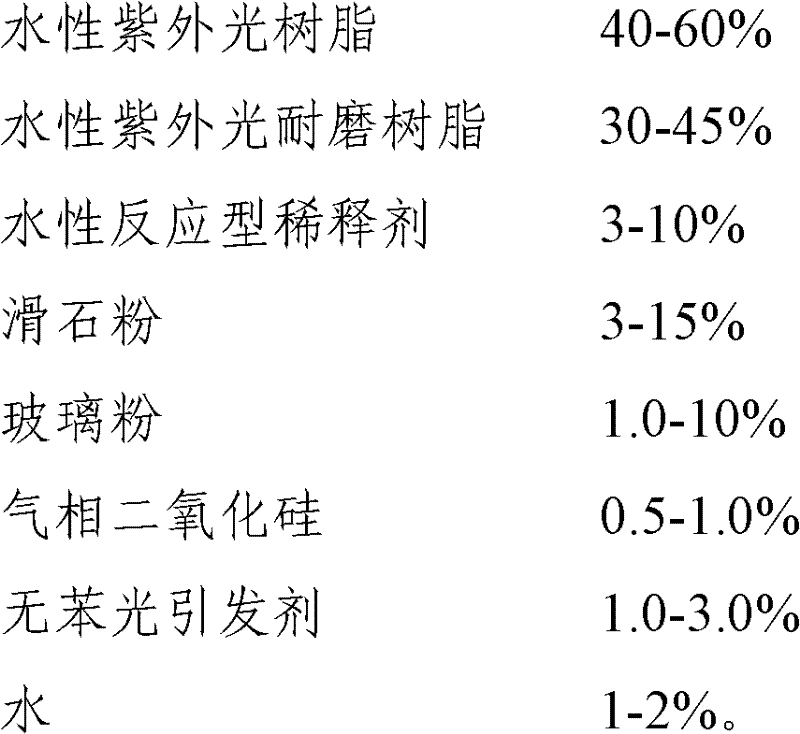

Aqueous ultraviolet-curing transparent prime coat and preparation method thereof

ActiveCN102408827ASmall shrinkageImprove toughnessAntifouling/underwater paintsPaints with biocidesThree levelGas phase

The present invention relates to an aqueous ultraviolet-curing transparent prime coat and a preparation method thereof. The transparent prime coat comprises the following components, by weight, 40-60% of an aqueous ultraviolet resin, 30-45% of an aqueous ultraviolet wear resistance resin, 3-10% of an aqueous reaction type diluent agent, 3-15% of talc powder, 1-10% of glass powder, 0.5-1.0% of fumed silica, 1.0-3.0% of benzene-free photoinitiator and 1-2% of water. According to the present invention, the transparent prime coat of the present invention is a functional product with excellent environmental protection performance, wherein the benzene content is low before or after the transparent prime coat construction; the transparent prime coat of the present invention is odorless, can be directly diluted with the water, and can be applicable for the spray coating process and the roller coating process; the hardness of the transparent prime coat is more than 3H, and the water resistanceof the transparent prime coat meets requirements of the three-level water in GB\T6682.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

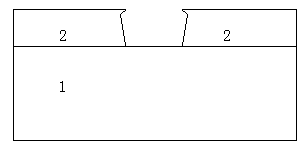

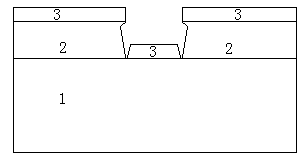

Single-layered positive photoresist photoetching method applied to metal stripping

InactiveCN103293850ALow baking temperatureShort baking timePhotomechanical exposure apparatusPhotosensitive material processingSolventChemistry

The invention provides a single-layered positive photoresist photoetching method applied to metal stripping. The single-layered positive photoresist photoetching method comprises the following steps of: (1) coating a positive photoresist layer 2 on a semiconductor base plate 1; (2) after gelatinizing of the photoresist layer 2, carrying out baking treatment to remove a part of a solvent; (3) carrying out positive photoresist developing solution treatment on the photoresist layer 2; (4) exposing the photoresist layer 2; (5) exposing the photoresist layer 2 and carrying out the baking treatment; (6) developing the photoresist layer 2, wherein a developing solution is a positive photoresist developing solution; and (7) after the photoresist layer 2 is developed, carrying out the baking treatment. The single-layered positive photoresist photoetching method disclosed by the invention has the advantages that a photoetching profile pattern with an olecranon-shaped opening is obtained so as to prevent metal of a photoresist surface layer from being connected with metal at the bottom of a photoresist pattern in an evaporation process, thereby being good for the metal stripping. Compared with a process of adopting a plurality of layers of glue to realize the metal stripping, the single-layered positive photoresist photoetching method is simple; meanwhile, the single-layered positive photoresist photoetching method has better pattern resolution than using negative photoresist, and can realize a small-line-width image stripping process.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com