Patents

Literature

104results about How to "Avoid blooming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Construction heat-insulating mortar

InactiveCN101279833AImprove adhesionImprove toughnessSolid waste managementCalcium formateMaterials science

The invention belongs to the building material technique field, in particular relates to a building thermal insulating mortar. The building thermal insulating mortar is characterized in that the mortar is composed of dry powder and water, the dry powder and water are present in a weight ratio of 1:1.3, when in use, the dry powder is added to the water and agitated evenly; and the dry powder is mixed by materials of modified cement, modified fly ashes, a re-dispersible latex powder, wood fibers, polypropylene fibers, calcium formate, hydroxypropyl methylcellulose, hydrophobic agent, multi-functional auxiliary agent and modified expanded perlite, materials of the dry powder include: 500 parts of modified cement, 160 parts of modified fly ashes, 25 parts of re-dispersible latex powder, 3 parts of wood fibers, 1 part of polypropylene fiber, 5 parts of calcium formate, 6 parts of hydroxypropyl methylcellulose, 1 part of hydrophobic agent, 3 parts of multi-functional auxiliary agent and 300 parts of modified expanded perlite by weight. The building thermal insulating mortar has advantages of strong heat preservation, firm bonding with wall bodies, compression resistance, superior tensile performance, good weathering resistance, environmental protection, and excellent waterproofing, anti-cracking and shedding prevention properties.

Owner:QIUSHI HUBEI PAINT

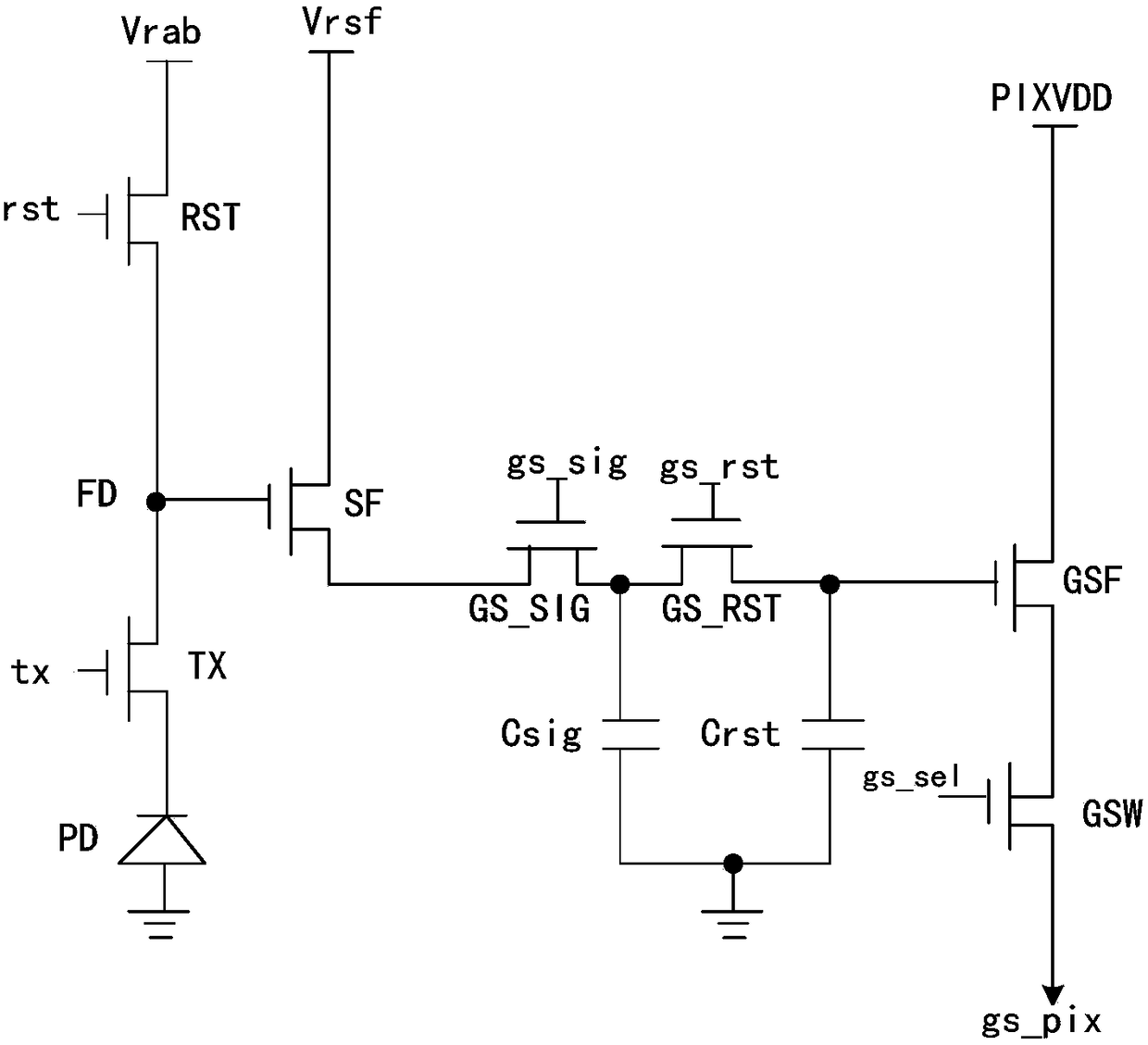

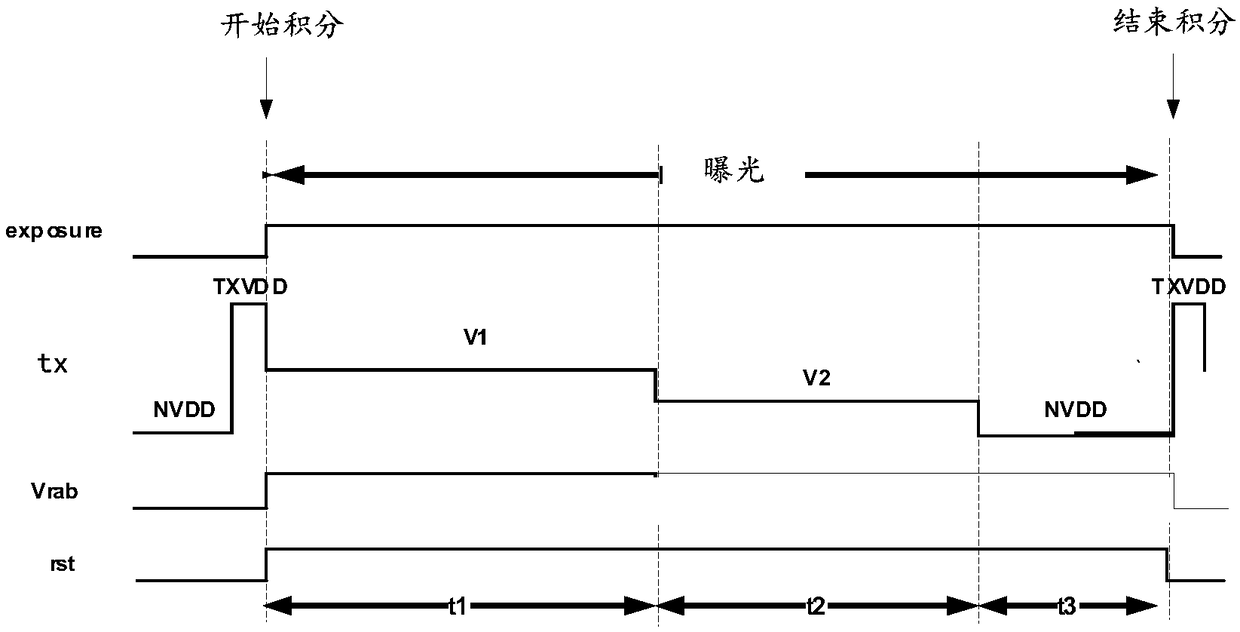

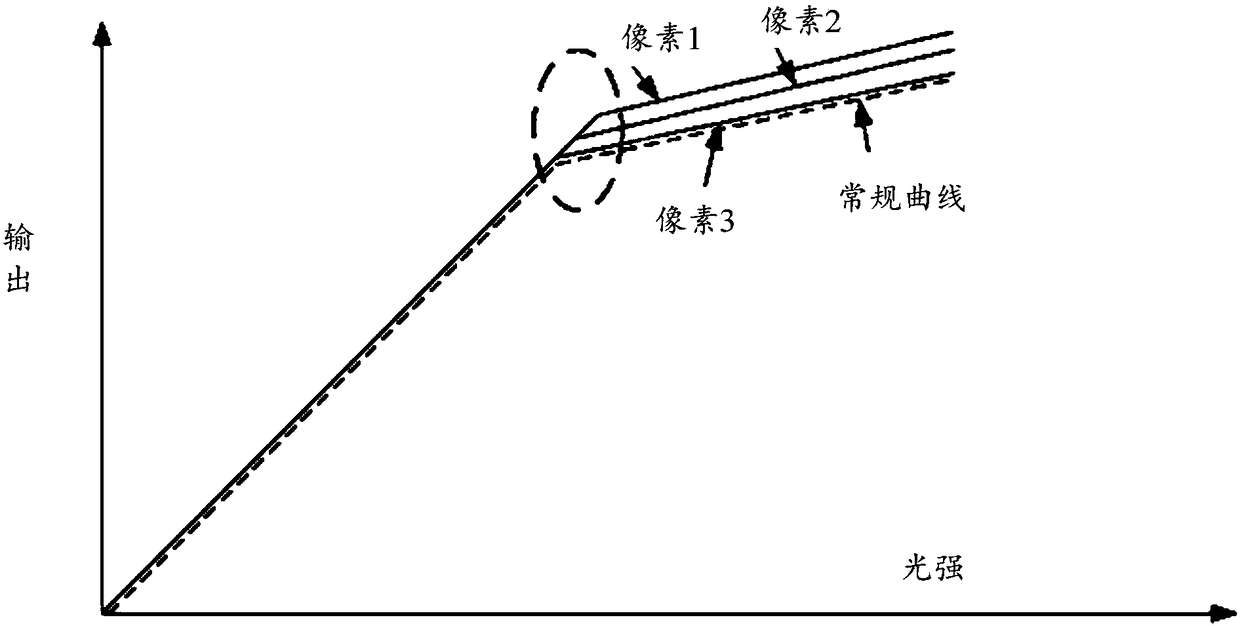

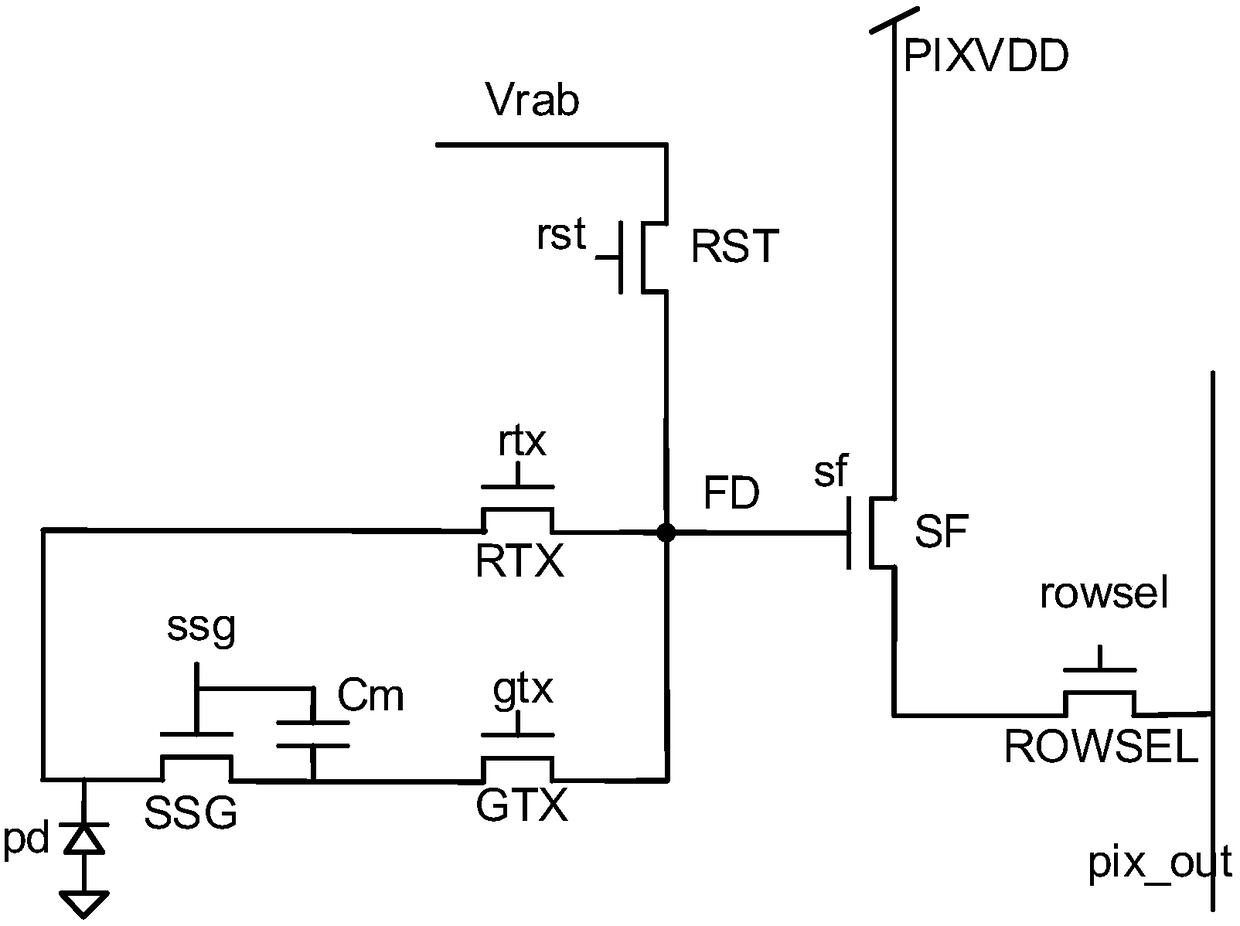

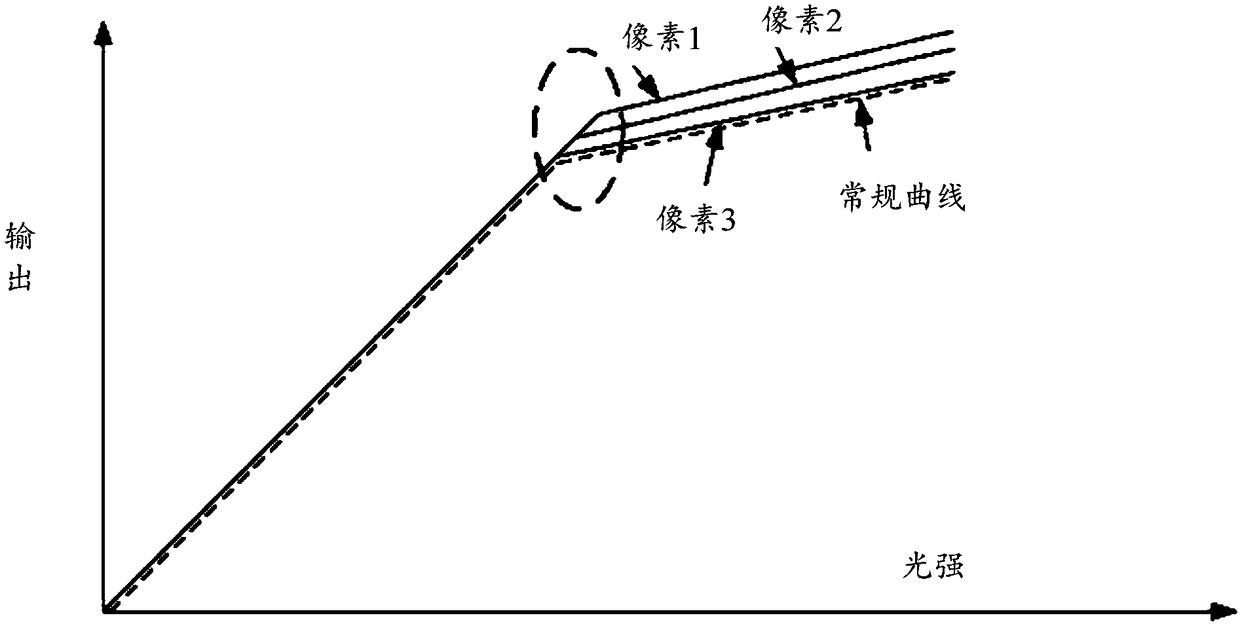

HDR image sensor pixel structure and imaging system

ActiveCN108470742AHigh dynamic range characteristicsPrevent bloomingTransistorTelevision system detailsPower flowEngineering

The invention discloses an HDR image sensor pixel structure and an imaging system. A reset transistor of the pixel structure is coupled between a floating diffusion node and a first voltage source; aphotodiode is coupled to the floating diffusion node through a transmission unit; and the floating diffusion node is coupled to a column output line through a first output unit, a signal storage unit,and a second output unit in sequence. Because the transmission unit can provide a balancing current during the exposure process of the photodiode to control a full well charge, the signal transmission gain is changed, so that the pixel structure has the high dynamic range characteristic.

Owner:思特威(上海)电子科技股份有限公司

Odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and preparation method thereof

The invention belongs to the field of coatings and particularly relates to an odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and a preparation method thereof. The odorless and wear-resisting smooth UV matt finish paint coating comprises components in percentage by weight as follows: 25%-50% of hexa-functional polyurethane acrylate prepolymers, 15%-50% of trifunctional modified polyurethane acrylate prepolymers, 15%-50% of acrylate monomers, 1%-10% of a photoinitiator, 0.2%-2% of a wetting dispersant, 0.2%-1% of a leveling agent, 0.2%-0.5% of a defoaming agent and 1%-15% of a matting agent. According to the odorless and wear-resisting smooth UV matt finish paint coating, the technical problems that a pungent smell is left, wetting of the matting agent is difficult, matting is difficult, a paint film is prone to floating and the like after curing of a conventional UV matt finish paint coating are solved, and meanwhile, the defect of crispness of the paint film caused by improvement of the wear resistance of the conventional UV matt finish paint coating is overcome.

Owner:AODA KOALA PAINT HUIZHOU

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

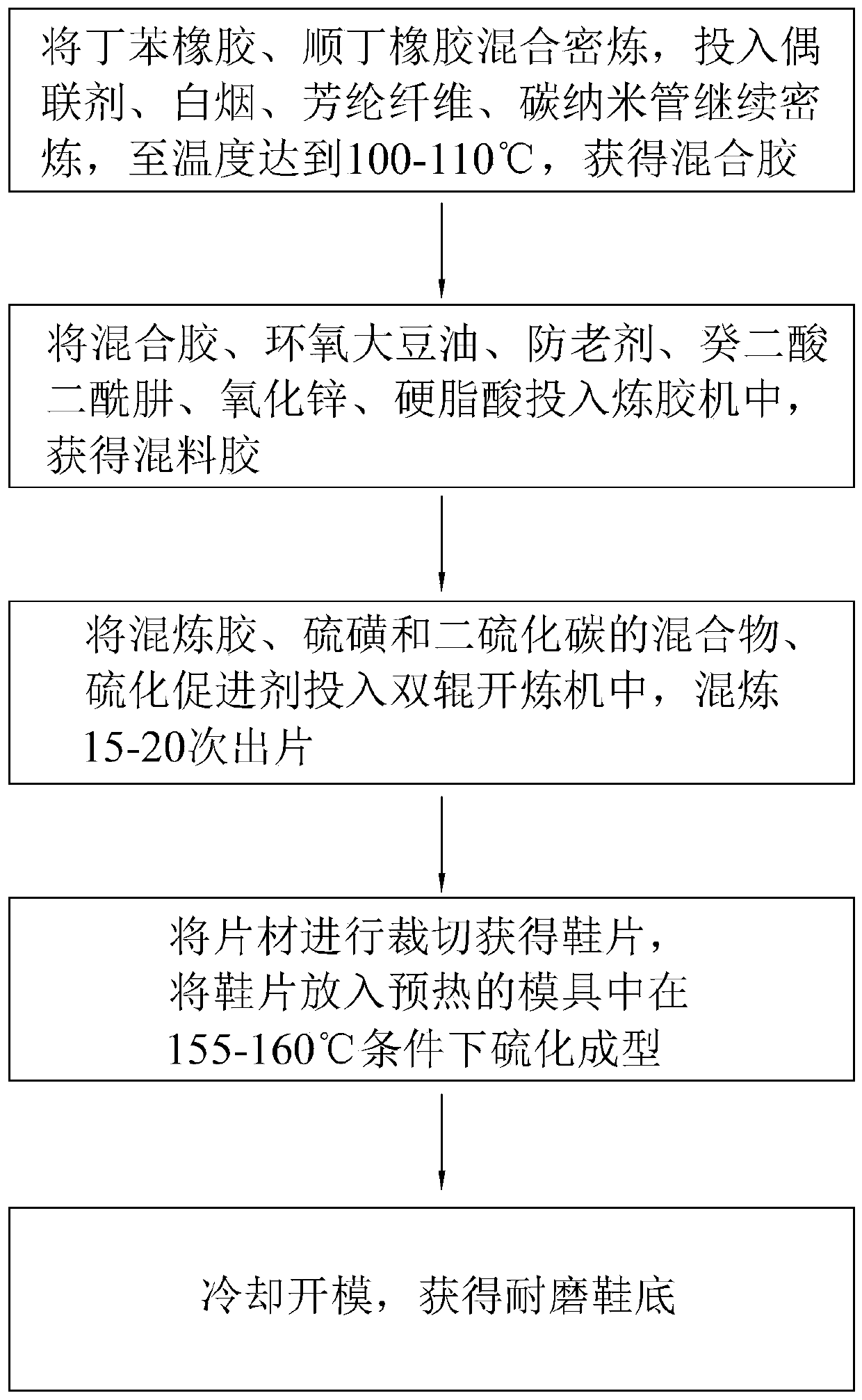

Wear-resistant rubber sole and preparation method thereof

The invention discloses a wear-resistant rubber sole. The wear-resistant rubber sole comprises the following raw materials in parts by weight: 30 parts of natural rubber, 30 parts of butadiene styrene rubber, 150 parts of butadiene rubber, 150 parts of white carbon black, 90 parts of oil, 12 parts of zinc carbonate, 2.8 parts of stearic acid, 3 parts of DM, 0.75 parts of M, 0.26 parts of TMTM, 3.8 parts of insoluble sulfur, 2 parts of an anti-aging agent, 1.5 parts of anti-fogging agent, 3 parts of tackifying resin and 14 parts of PEG. The invention further provides a preparation method of the wear-resistant rubber sole. Compared with the prior art, the wear-resistant rubber sole has the advantages as follows: the formulation is environment-friendly; the amount of various components can be adjusted; through the addition of the anti-fogging agent, a protective film is formed on the surface of the wear-resistant rubber sole, thus effectively preventing a blooming phenomenon and delaying the aging of the rubber sole; through the addition of the butadiene rubber as well as through reasonable matching of the natural rubber, the butadiene rubber and the butadiene styrene rubber, not only is the wear resistance improved, but also the cost is reduced, thus obtaining good physical properties and economic benefits.

Owner:ANHUI HONGXIANG SHOES

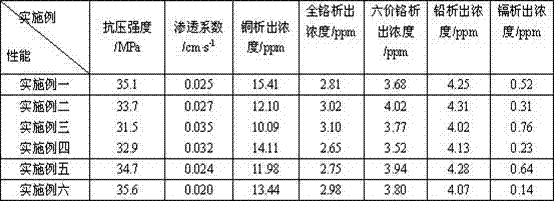

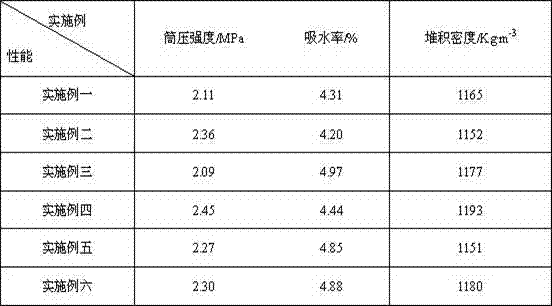

Environment-friendly water-permeable brick and production method thereof

InactiveCN106892617AAchieve reductionRealize harmless treatmentSolid waste managementCeramicwareBrickExpanded clay aggregate

The invention relates to a water-permeable brick and a production method thereof. Granulating and secondary 'pelletizing' moulding technologies are adopted for preparing raw materials, by carrying out high temperature calcining, most of heavy metals in pellets are fused with silicate glass formed in a high temperature roasting stage, a stable solid solution is formed, and the mobility of the heavy metals is reduced. Meanwhile, by virtue of quick cooling, vitrification on clay coated on the surfaces of ceramsites is completed, so that dual effects of preventing heavy metal ions from leaching out and preventing scum are achieved. The water-permeable brick made by mixing the ceramsites with cement mortar and maintaining has the characteristics of high compressive strength, good durability, no dissolution of heavy metal ions, high water penetration and water conserving function.

Owner:内蒙古科韵环保材料股份公司

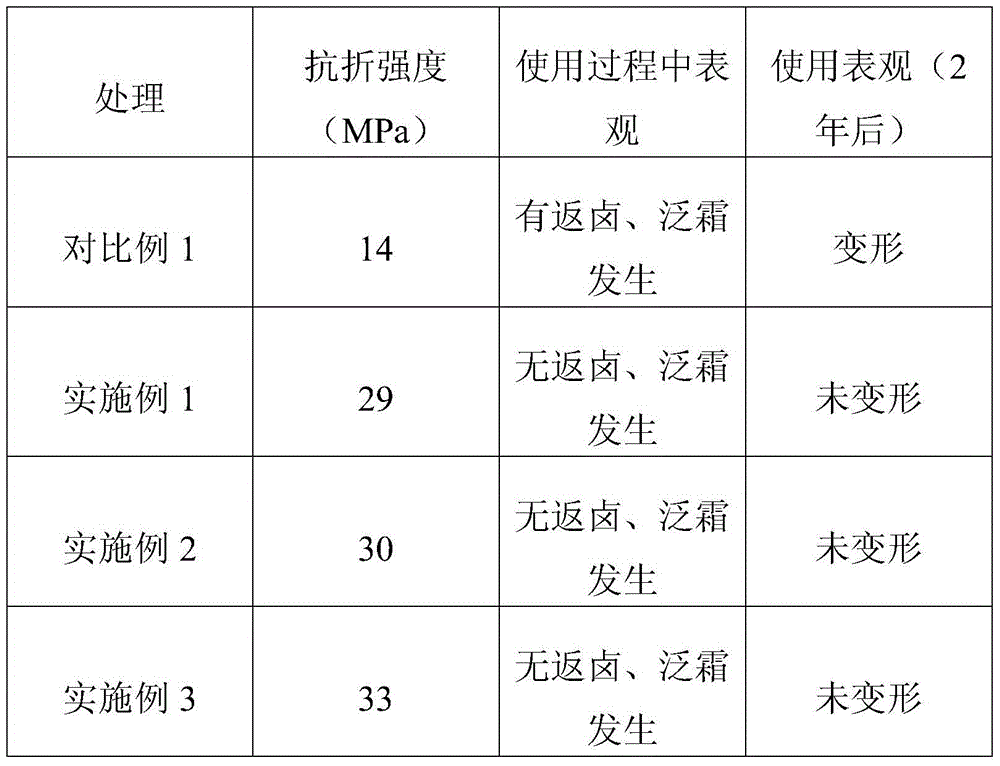

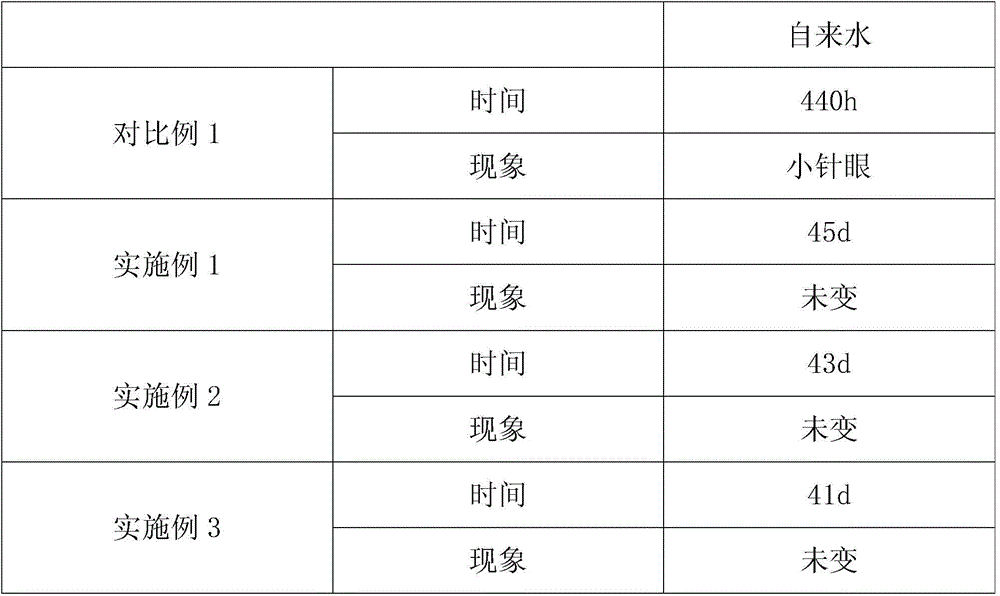

Magnesium oxysulfate cement plate and preparation method thereof

The invention belongs to the technical field of building materials and particularly relates to a magnesium oxysulfate cement plate and a preparation method thereof.The magnesium oxysulfate cement plate is characterized by comprising the following components according to parts by weight: 60-75 parts of magnesium oxide, 30-40 parts of magnesium sulfate solution, 8-10 parts of coarse wood flour, 6-8 parts of fine wood flour, 3-6 parts of reinforcing material, and 0.2-0.5 part of a modifier.The magnesium oxysulfate cement plate has a reasonable formula, is convenient to use, good in breaking strength and good in water resistance; the magnesium oxysulfate cement plate of the invention is free of scumming during usage and never deforms during long-term usage.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Water-soluble ink compositions, their manufacturing method and use

This invention relates a water soluble ink that utilizes dyes, protective glue, dispersant, leveling agent, emulsifier and water absorbing resin to prepare. This invention also relates to the making method of the water soluble ink and its utilization in printing, watercolor and paper keir. The product of this invention can overcome the oxidation decoloring phenomenon of colorful paper and rice paper when meeting water or ultraviolet irradiation; the decoloring phenomenon of traditional Chinese painting and watercolor painting; the ink marks of the characters are bright, the color is proper and the writing is smooth, the intensity is proper, the fragrance is moderate and it is dry quickly and decreases the environmental pollution.

Owner:李联江

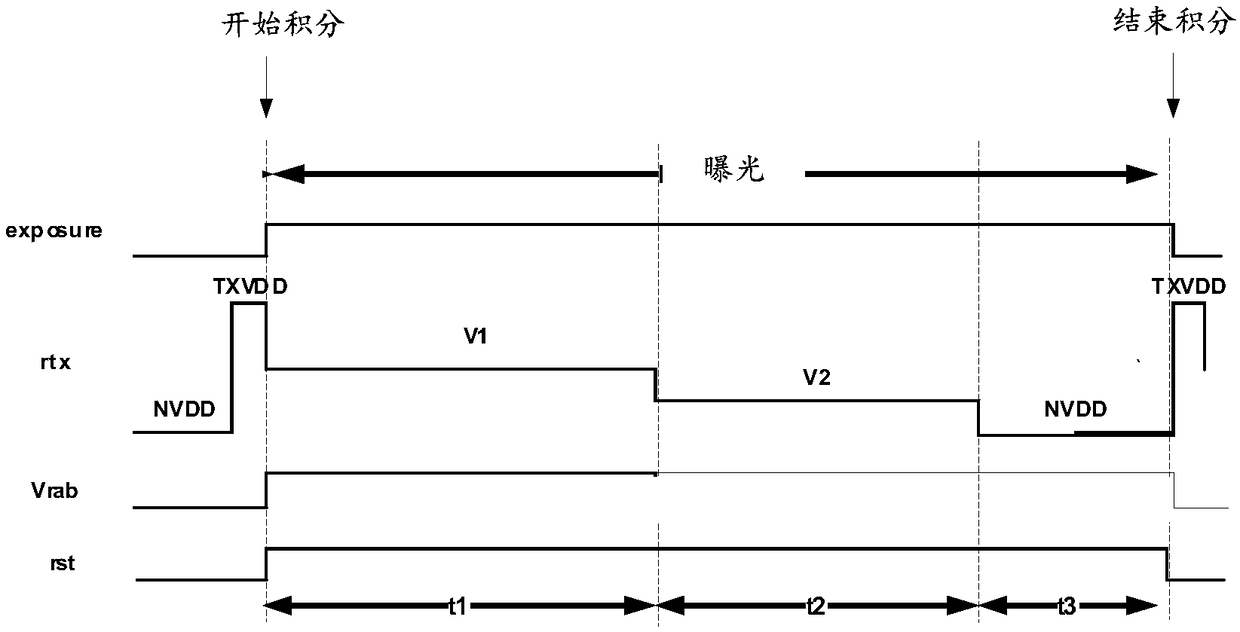

Inflection point-based HDR image sensor pixel structure and imaging system

ActiveCN108419033AHigh dynamic range characteristicsAvoid bloomingTelevision system detailsColor television detailsPower flowFloating diffusion

The invention discloses an inflection point-based HDR image sensor pixel structure and an imaging system. A reset transistor of the pixel structure is coupled between a floating diffusion node and a first voltage source, a photodiode of the pixel structure is coupled to the floating diffusion node through a rolling exposure transmission unit and a global exposure transmission unit separately, andthe rolling exposure transmission unit can be used for providing a balance current in exposure of the photodiode so as to control full well electric charge amount. Two exposure modes of transmission unit are used to transfer electric charge, so that the pixel structure can support multiple exposure modes; the rolling exposure transmission unit can be used for providing a balance current in exposure of the photodiode so as to control full well electric charge, so that the signal transmission gain is changed, and the pixel structure has a characteristic of high dynamic range.

Owner:思特威(上海)电子科技股份有限公司

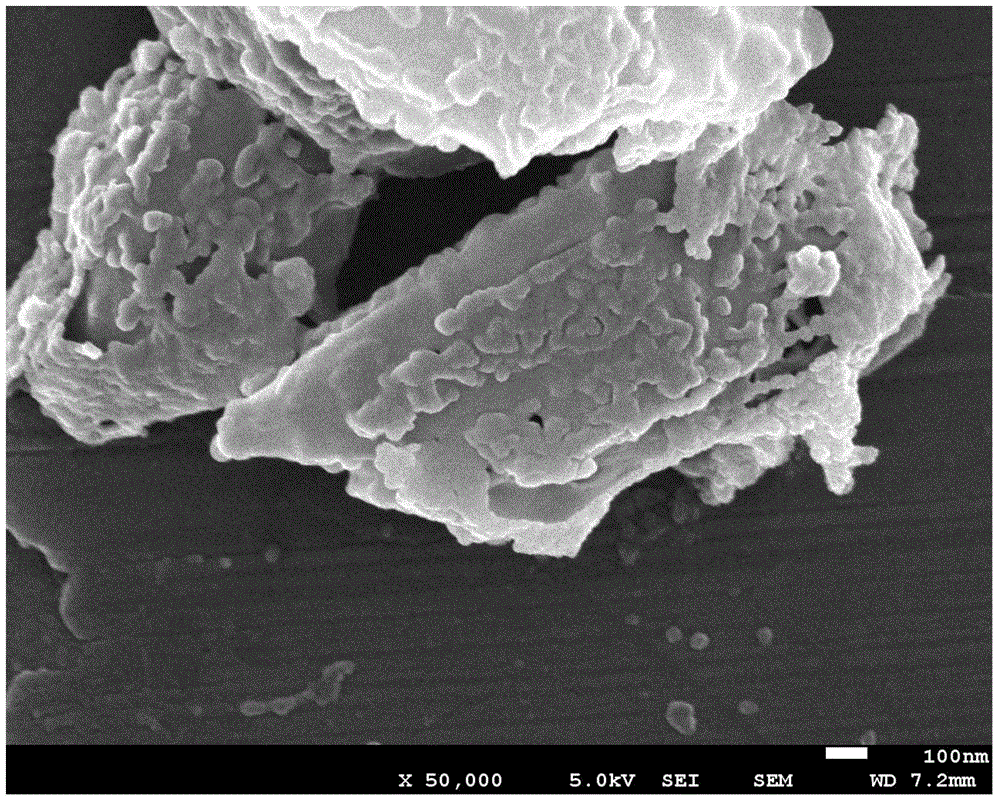

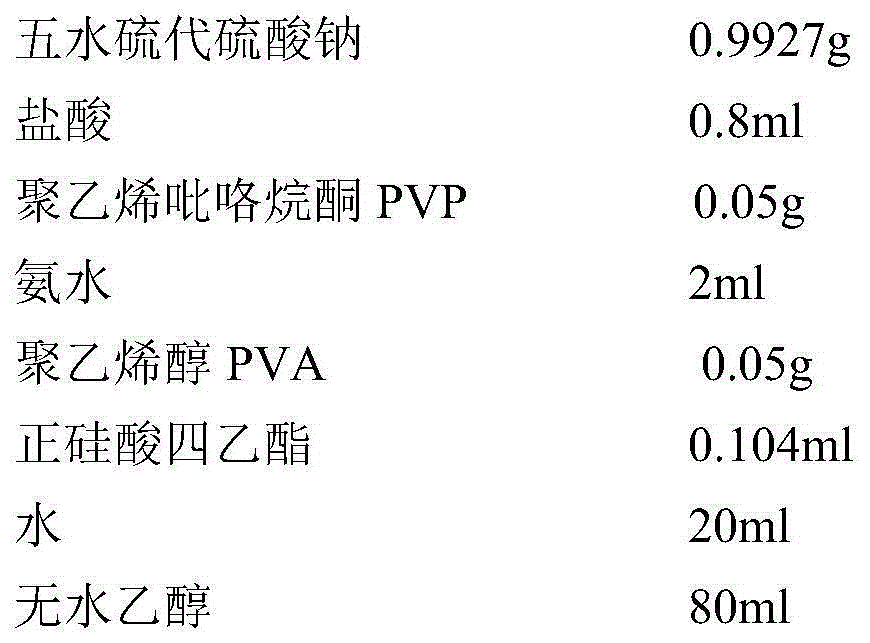

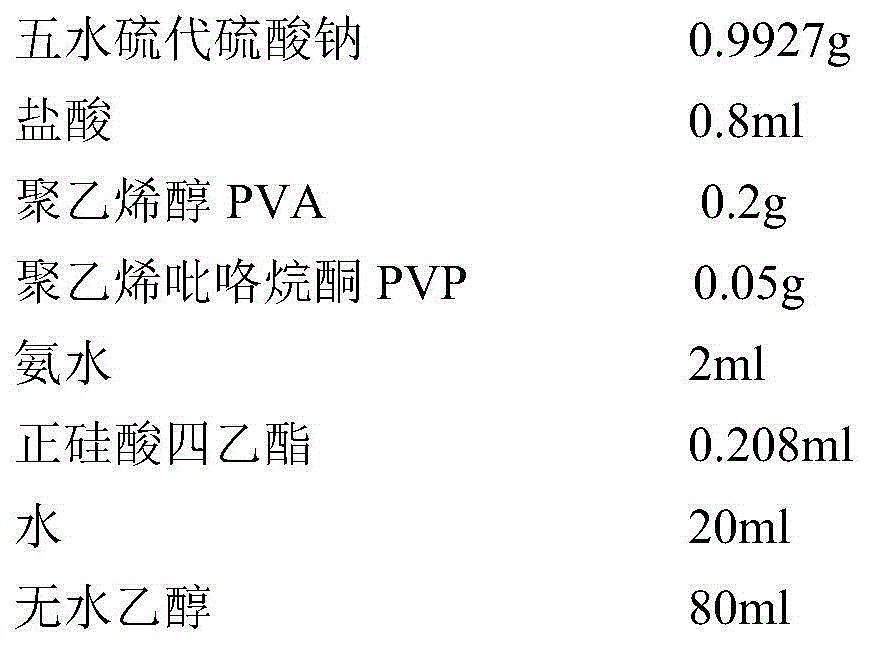

Preparation method of silicon-dioxide-coated sulfur microcapsules

ActiveCN105037802ASimple processOperational securityMicroballoon preparationMicrocapsule preparationFilm materialChemistry

The invention discloses a preparation method of coated sulfur. By using synthetic sulfur as a core and an inorganic high-polymer material as a film material, the coated sulfur microcapsules are prepared by in-situ modification. Coated sulfur with different film thicknesses and different surface shapes is prepared. The product can be uniformly dispersed during rubber compounding. The compounded rubber can not have the phenomenon of blooming in the parking stage, and can release sulfur at proper speed at curing temperature to participate in crosslinking. The microcapsules have the advantages of simple preparation technique and lower cost, and are a novel vulcanizing agent which is worthy of development.

Owner:QINGDAO UNIV OF SCI & TECH

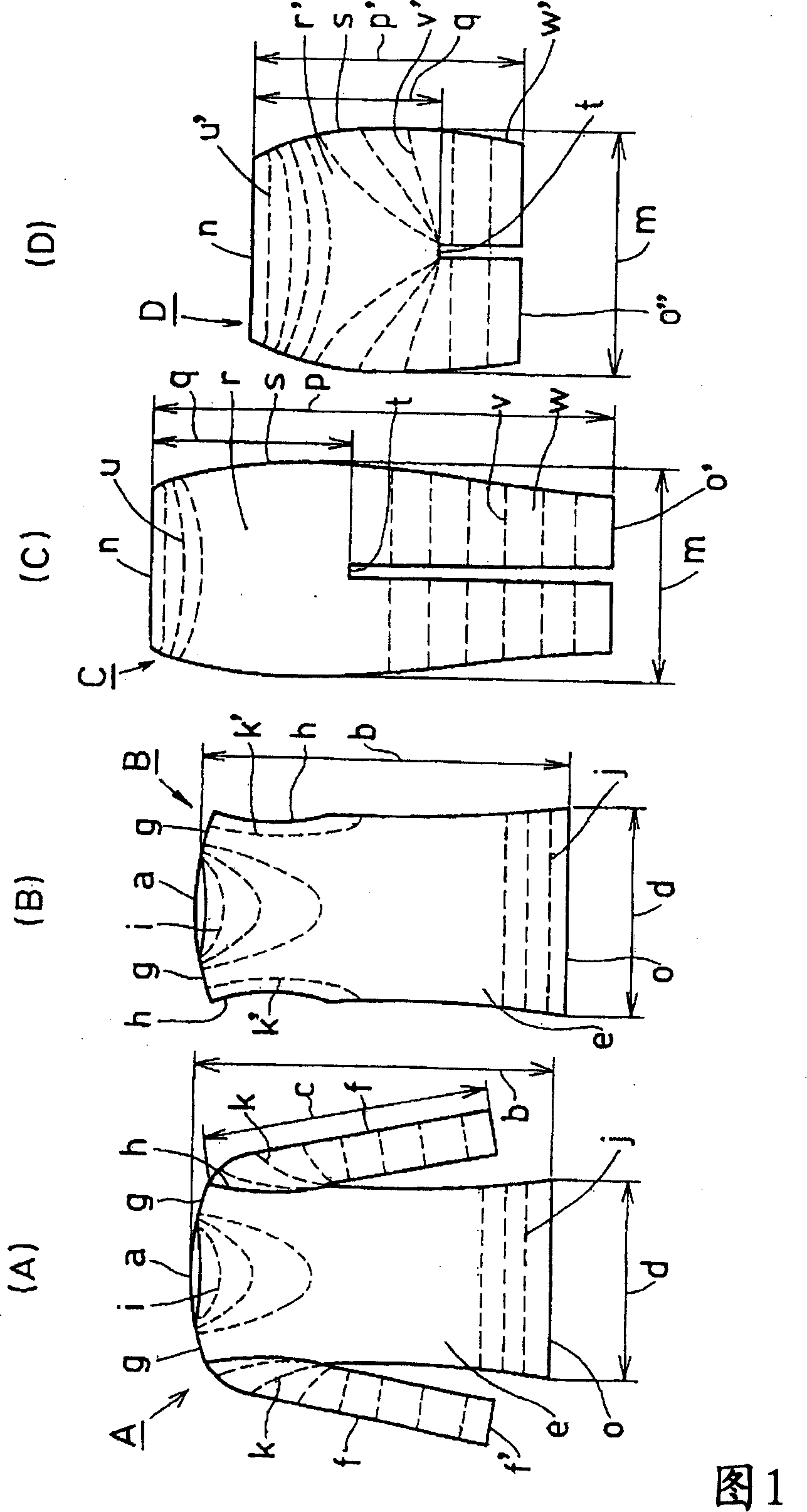

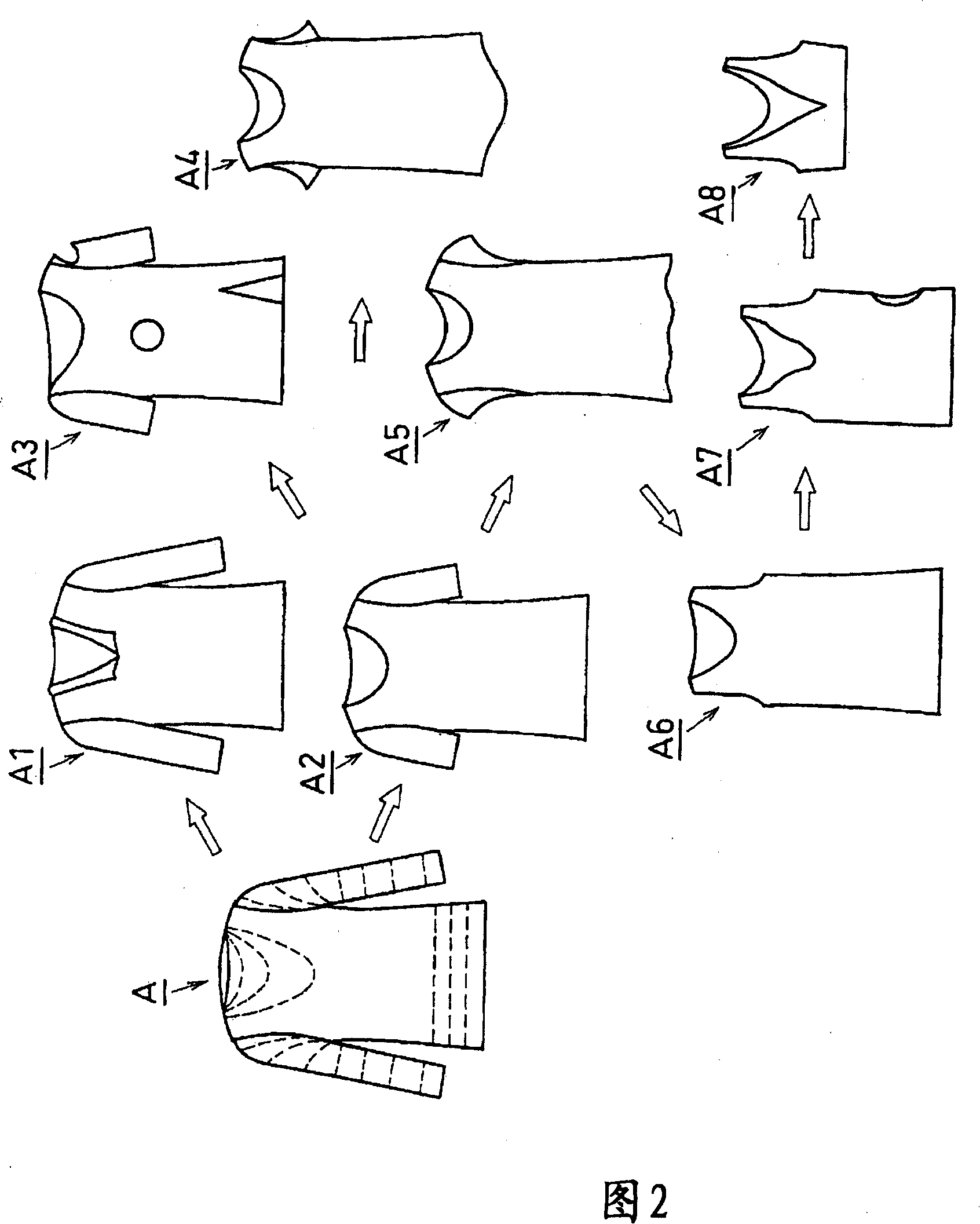

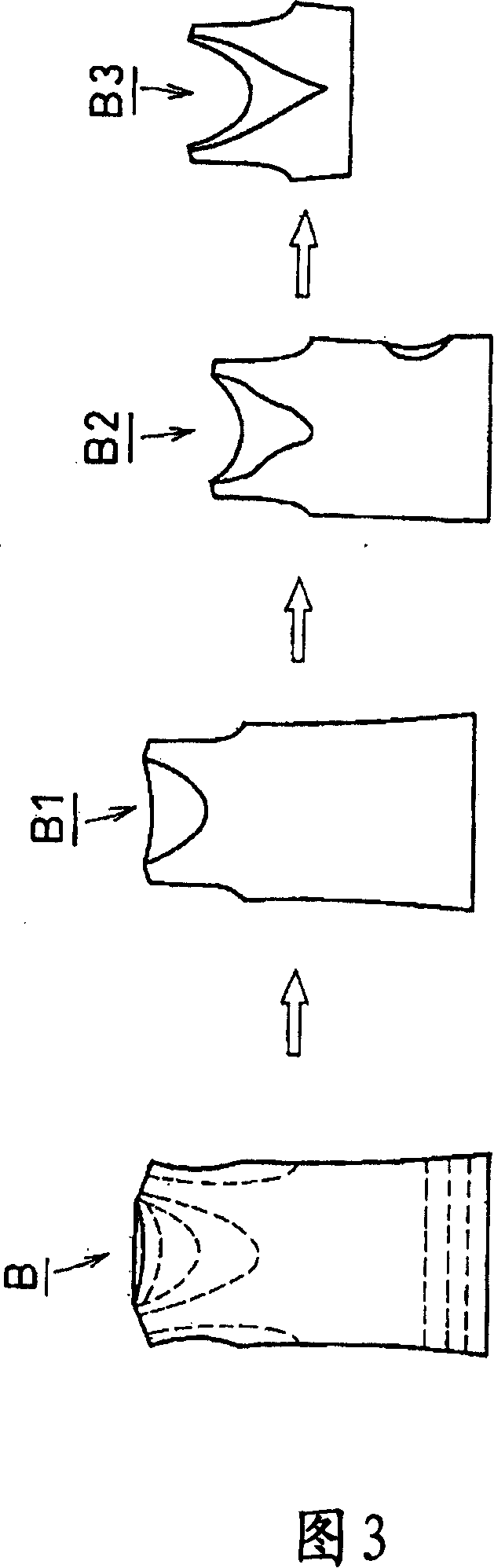

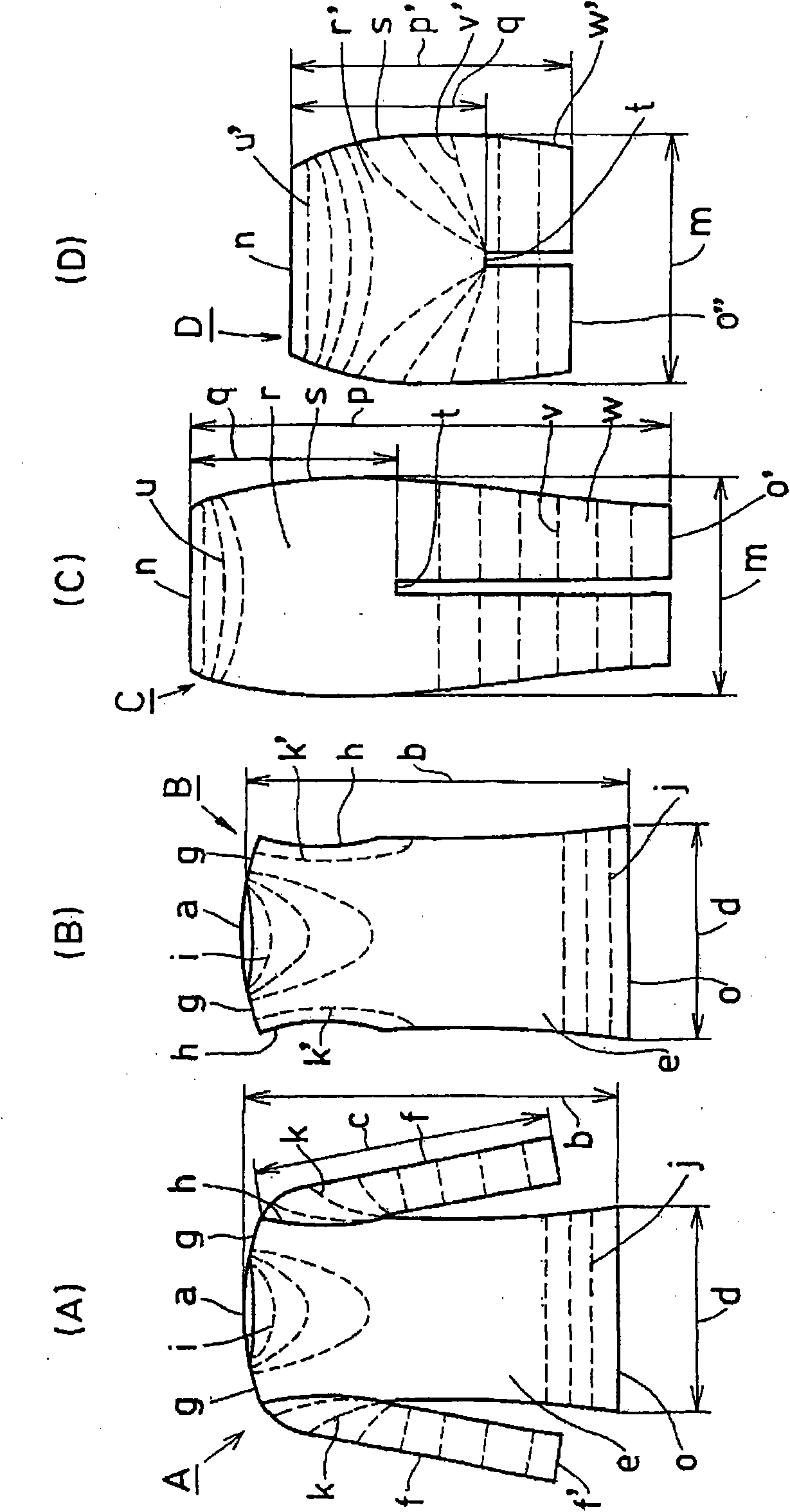

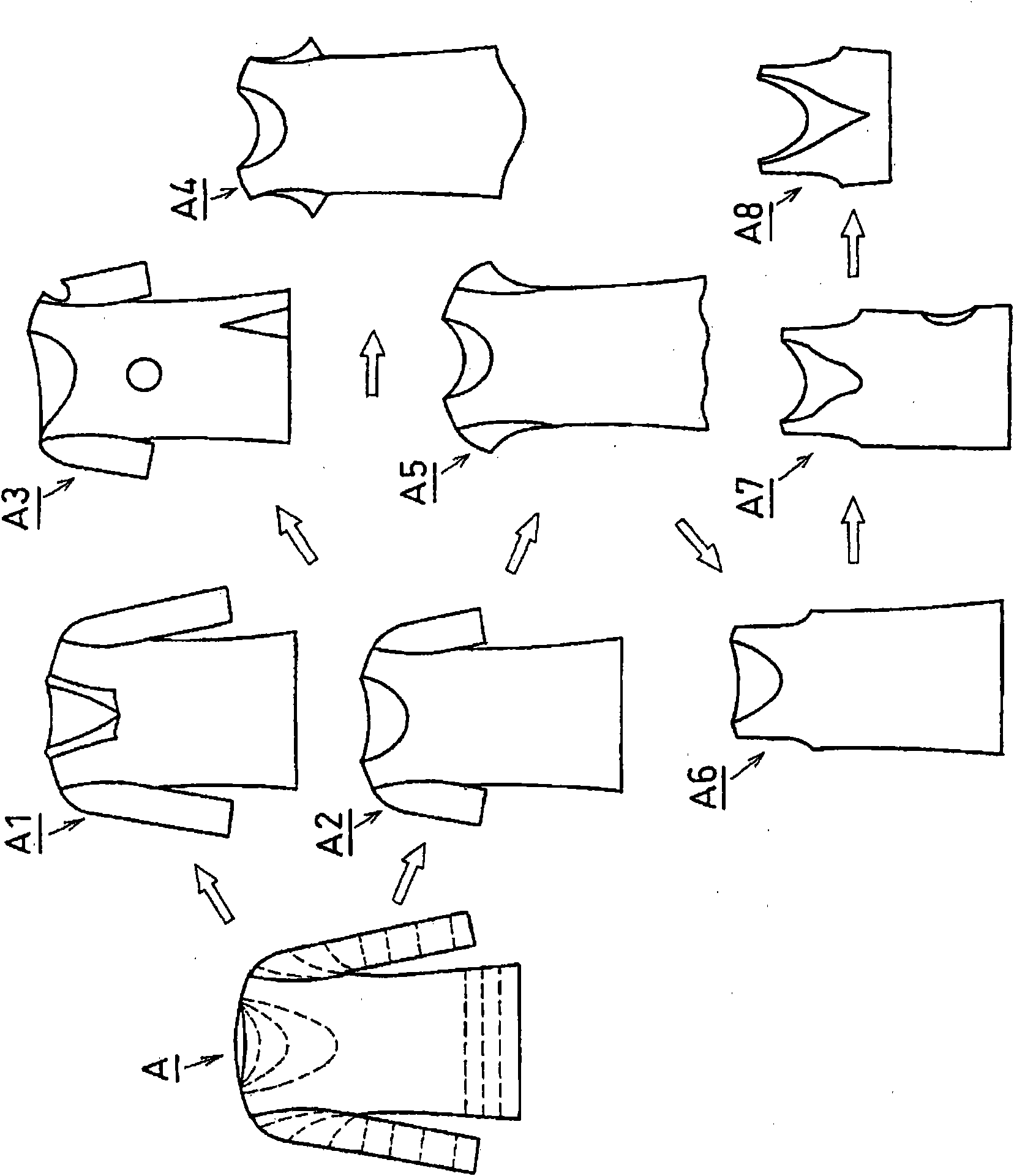

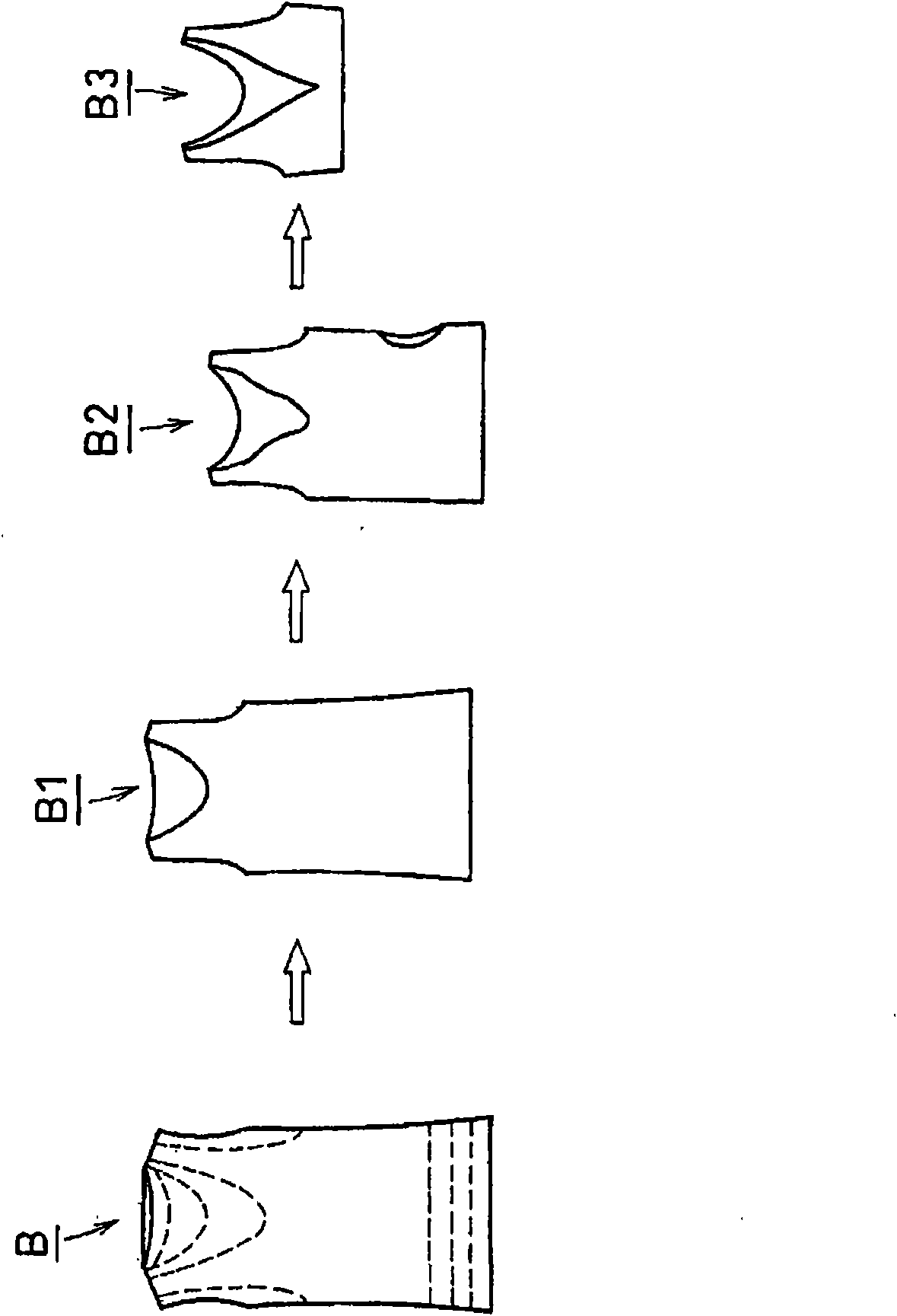

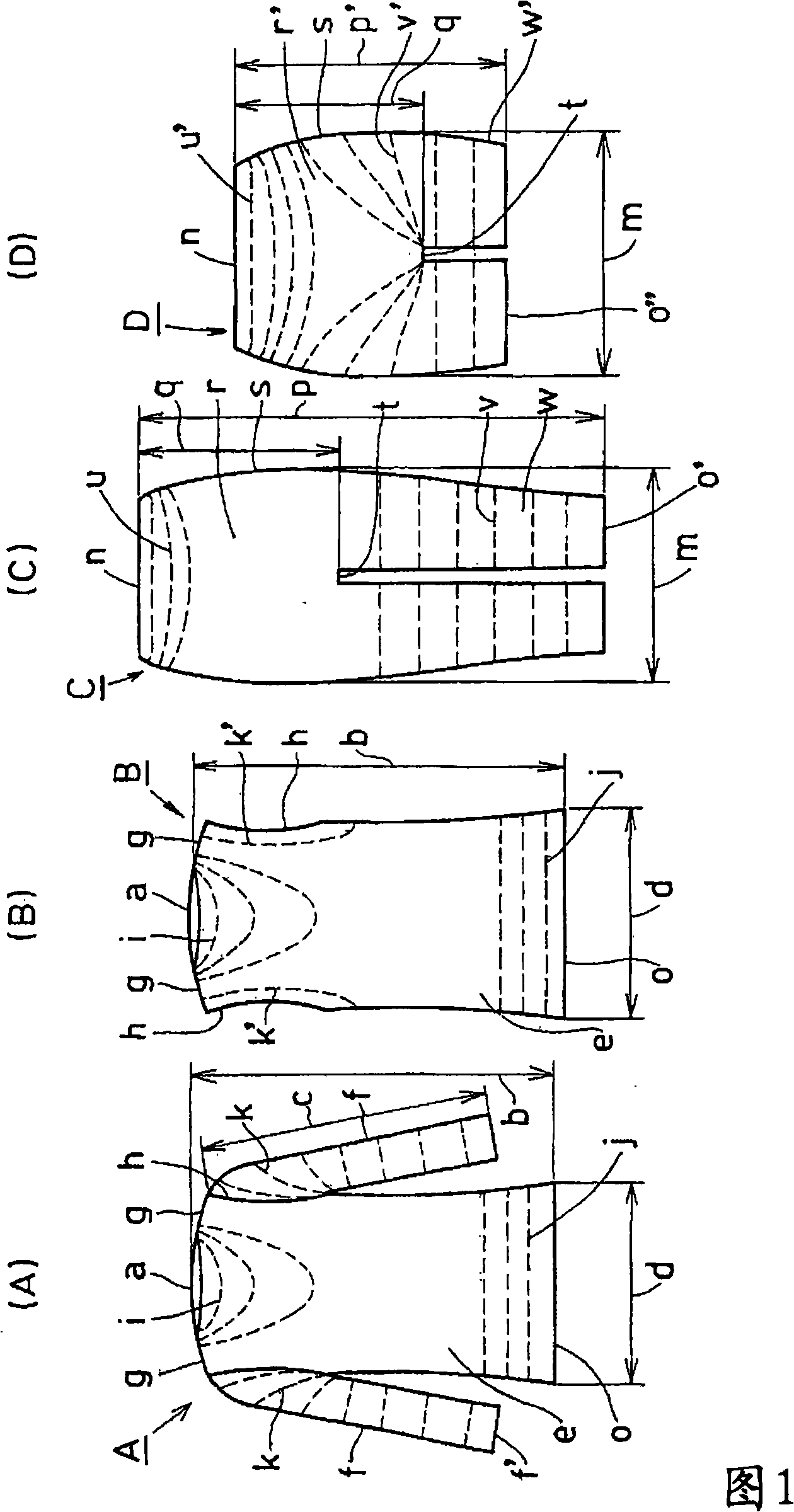

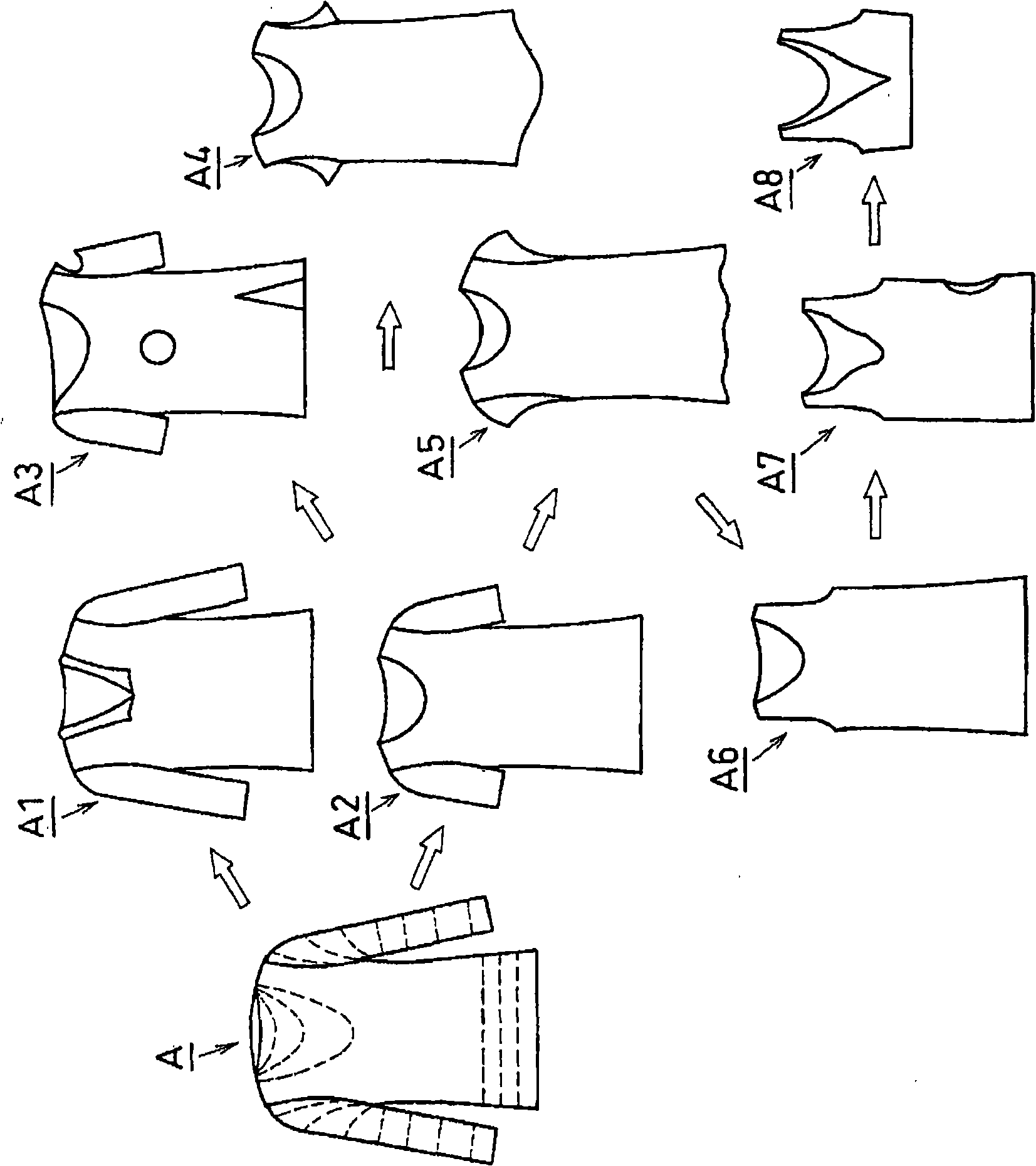

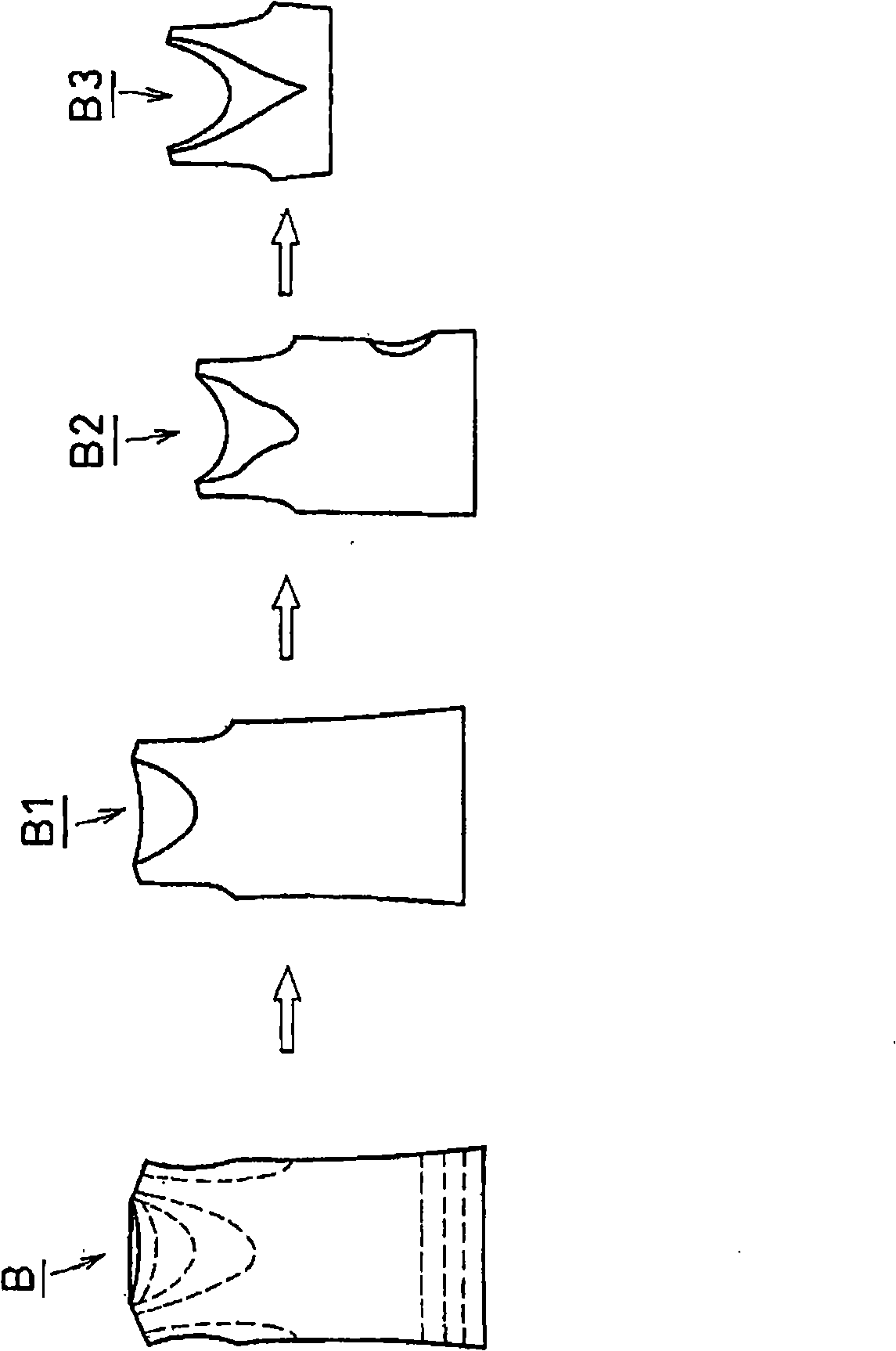

Clothing capable of being cut freely

InactiveCN101146461AAvoid bulking upImprove wearing feelingConvertible garmentWeft knittingYarnEngineering

A garment is provided which a purchaser can freely cut after purchase into any design shape and then wear, and also which has a cut-off part requiring no high-level cutting and sewing processing techniques. The garment is formed of a fray-preventing knitted fabric woven with heat-welding elastic yarn. Sizes of opening parts of the neck, side, and bottom of the garment are smaller than those of a standard product; a total length and sleeve length of the garment are larger than those of the standard product; and a body width, cuff, waist, and lower bottom edge of the garment are equal to those of the standard product. The garment can be cut into any design shape and can be used with the opening parts left cut-off.

Owner:GUNZE LTD

Preparation method of multifunctional water-borne woodenware close primer

The invention relates to a preparation method of a multifunctional water-borne woodenware close primer. A basic recipe of the primer is as follow: 40 percent-70 percent of emulsion, 2 percent-10 percent of coalescing agents, 0.1 percent-0.5 percent of antifoaming agents, 0.2 percent-1 percent of flatting agents, 0.1 percent-1 percent of base material moistening agent, 0.2 percent-1.5 percent of thickening rheological agents, 0.1 percent-0.3 percent of bacteriacide, 0.1 percent-1 percent of PH regulation agents, and 25 percent-40 percent of deionized water. The water-borne woodenware close primer has strong permeability, and excellent water resistance and closure, gallotannic acid in woods can be prevented from seeping to cause floating of colored paint, the adhesion between a base material and a coating is increased, and moisture in putty can be also prevented from being absorbed by the woods untimely to cause difficulty in coating the putty. The water-borne woodenware close primer is suitable for closed coating of surfaces of various dyeing plates, medium-fibrousness plates, artificial lagging boards, woods containing vegetable oil or gallotannic acid and the like.

Owner:UNION FOSHAN CHEM

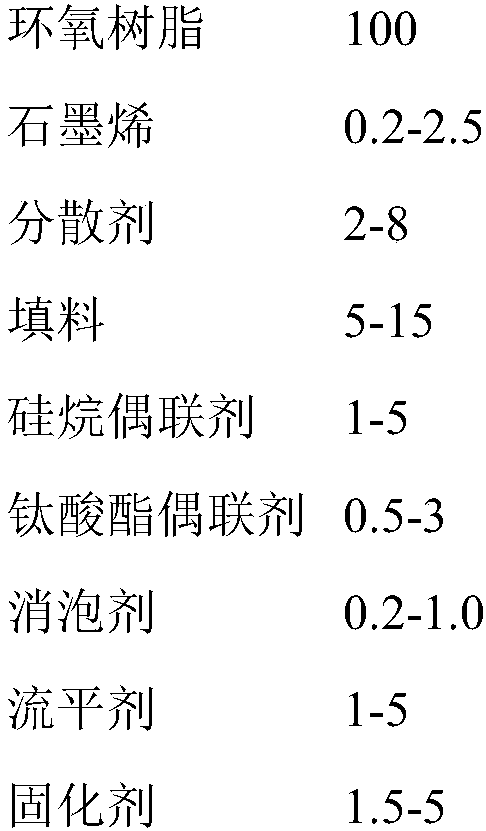

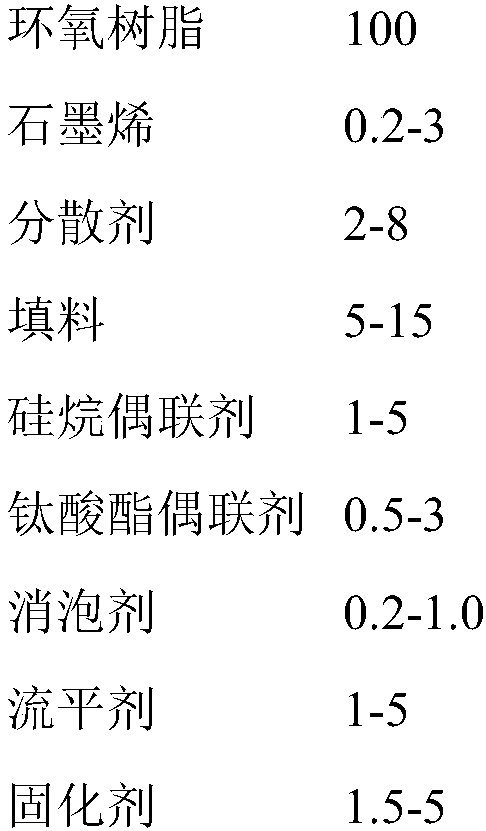

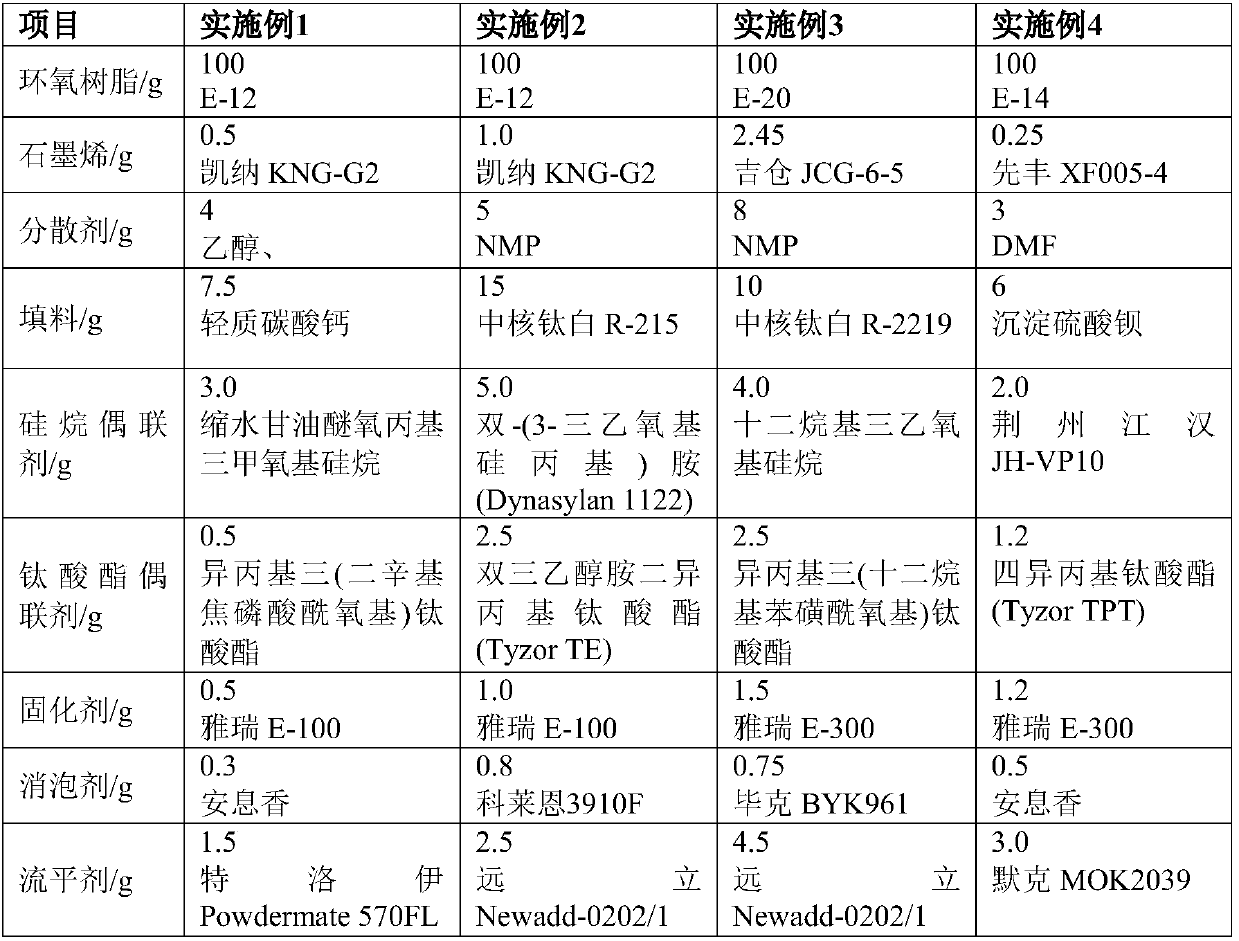

Graphene conductive powder coating before wooden product coating as well as preparation and application thereof

InactiveCN107760164AAvoid bloomingHigh strengthPowdery paintsEpoxy resin coatingsEpoxyConductive coating

The invention provides a graphene conductive powder coating before wooden product coating as well as preparation and application thereof. The conductive powder coating is composed of the following components: epoxy resin, graphene, a dispersing agent, a filler, a silane coupling agent, a coupling agent of organic titanate, a flatting agent, a curing agent, an antifoaming agent and the like. The conductive powder coating can be applied to conductive treatment before wooden product coating, and the wooden product is treated and dried and cured to form a flat and dense conductive coating on the surface. The conductive powder coating is capable of closing pores on the surface of the wooden product base material and does not diffuse and permeate on the surface, so that the conductivity performance on the surface of the base material is improved, the electrostatic spraying coating quality of the wooden product is improved, phenomena such as pinholes, bubbles and cracking occurring in the coating flatting and curing process are avoided, and the adhesive force between the wooden product base material and the coating is promoted. The graphene conductive powder coating is excellent in hardness and resistance, is capable of improving the durability of the wooden products and can be widely applied to coating treatment industries of the wooden products.

Owner:杭州五源科技实业有限公司 +2

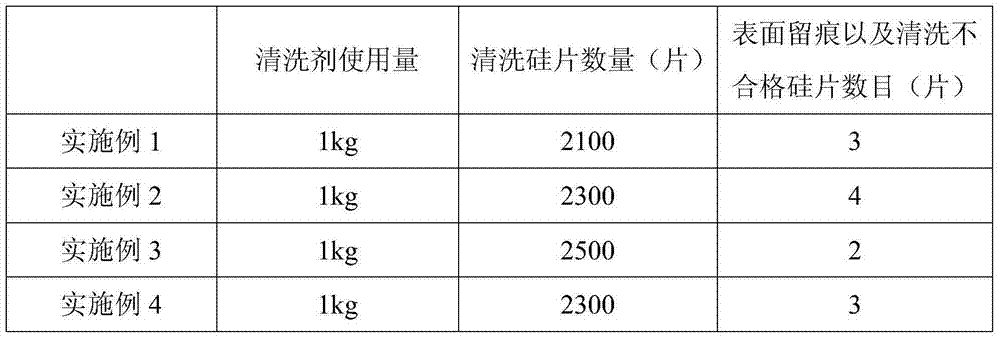

Cleaning agent for solar energy monocrystalline silicon wafer

ActiveCN103710179AReduce corrosionIncrease acid and alkali consumptionSurface-active non-soap compounds and soap mixture detergentsPotassium hydroxideCleansing Agents

The invention discloses a cleaning agent for a solar energy monocrystalline silicon wafer. The cleaning agent comprises the following components of potassium hydroxide, a surfactant, a penetrating agent and a chelating agent. The cleaning agent has a good cleaning effect for the monocrystalline silicon wafer and is low in use cost. Compared with other silicon wafer-cleaning agents, the cleaning agent provided by the invention can simplify a cleaning process, does not pollute the environment and has no harm to human health.

Owner:长沙艾森设备维护技术有限公司

Clothes capable of being freely cut

The invention provides clothes with cut opening part, which can be freely cut into various design shape and wore, and does not need skillful cutting technology and sewing processing technology. The clothes use knitting cloth wove with heat fusion elastic yarn with dissilient effect, size of opening parts such as neck circumference, side sheet and lower hem is smaller than standard matter, body length and sleeve length of the clothes are larger than the standard matter, body width, cuff, waistline part and lower hem opening of the clothes are same to the standard matter. The clothes can be cut into various design shape and used under state that the opening part is cut.

Owner:GUNZE LTD

Clothes of cut open part

The invention provides a coat with a cut opening which can be freely cut into any designed shape by a purchaser without high cutting technique or sewing processing technique. The coat is made of knitted fabric of heat welded elastic yarn which has slip prevention effect, thus the sizes of opening parts such as a neck circumference, a side edge, a skirt of the coat are less than the standard sizes, the lengths of a body and a sleeve is longer than the standard products; and the sizes of the body, the sleeve opening, waistline and the skirt opening are the same as the sizes of the standard product. The coat can be cut into any designed shape and the opening part can be used after being cut.

Owner:GUNZE LTD

Temperature-sensitive wallpaper coating

A temperature-sensitive wallpaper coating comprises 30-40% of water, 30-40wt% of a silicon acrylic emulsion, 1-3wt% of a film forming agent, 4-6wt% of pearl powder, 3-5wt% of thermochromic material, 6-10wt% of a thickening agent, 10-15wt% of superfine wollastonite powder, 0.05wt% of a wetting agent, 0.2wt% of a dispersant and 0.15wt% of a film forming agent. The thermochromic material has a cool tone at a high temperature and has a warm tone at a low temperature, and gives people a comfortable feeling, the dispersant used in the invention is a copolymer containing an acid anchoring group, makes the dispersion effect of the pearl powder good and avoids moldy spot appearing, and the wetting agent can effectively prevent flooding, and prevents pigment floating and settlement through controlling flocculation.

Owner:QINGDAO XINGGUO PAINT CHEM

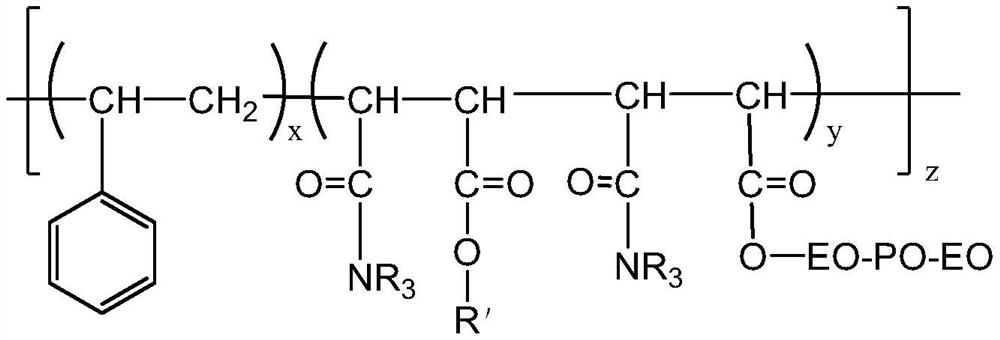

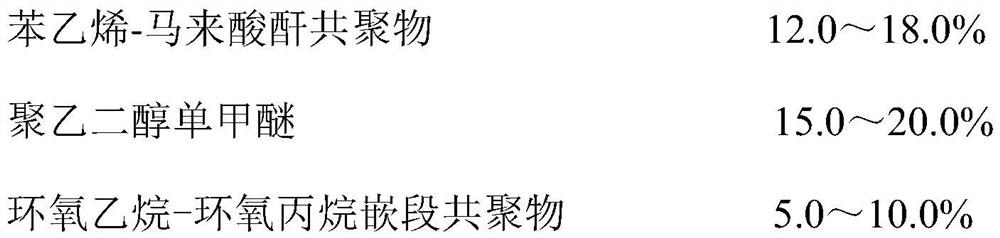

Preparation method and application of hyperbranched polymer water soluble dispersant

PendingCN113527695APrevent flocculationPrevent flocculation and sedimentationOrganic dyesAnti-corrosive paintsMaleic anhydrideEthylene glycol monomethyl ether

The invention relates to a preparation method of a hyperbranched polymer water soluble dispersant and application of the dispersant in water-based color paste. The dispersant is poly (styrene-co-maleic anhydride)-g-(methoxypolyethylene glycol + EO-PO-EO + NR3), is biodegradable and does not contain alkylphenol. According to the preparation method of the hyperbranched polymer water soluble dispersant, the dispersant has an anionic nonionic-multi-branched-chain comb-shaped structure, the molecular structure contains aromatic rings, carboxyl, hydroxyl, amido, polyether and other pigment adsorption groups, and pigment particles are prevented from flocculating and settling by utilizing steric hindrance. The dispersant has excellent viscosity-reducing dispersibility, improves tinting strength, prevents floating and flooding, can be used for preparing resin-free / resin-system high-solid-content low-viscosity pigment concentrated slurry dispersions such as organic red, yellow and purple pigments, inorganic pigments and matting powder, can also be used for mixing and dispersing organic pigments, anti-rust pigments and fillers, and is suitable for water-based systems such as water-based color paste, water-based industrial paint, water-based ink, water-based anti-corrosion and anti-rust primer and the like.

Owner:GUANGZHOU JOINTAS CHEM

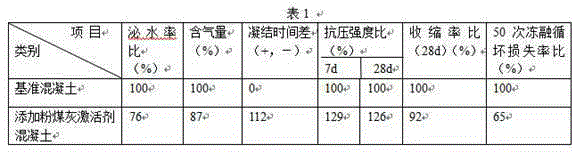

Coal ash activating agent and low-cost cement prepared through same

ActiveCN105330189AGood activation functionSimple manufacturing processCement productionShrinkage crackingUltimate tensile strength

The invention belongs to the technical field of mortar concrete preparation, and particularly relates to a coal ash activating agent for cement added with coal ash. The coal ash activating agent is prepared from, by weight, 20-40 parts of anhydrous sodium sulphate, 40-60 parts of aluminum potassium sulfate, 3-6 parts of triethanolamine, 3-6 parts of sodium gluconate, 1-2 parts of citric acid and 20-40 parts of silica powder. The raw materials are evenly mixed, smashed and screened through a screen with the mesh number of 200, and the coal ash activating agent is obtained. The invention further relates to the low-cost cement prepared through the coal ash activating agent. The low-cost cement is prepared from, by weight, 40-50 parts of ordinary Portland cement, 45-50 parts of the coal ash and 6-10 parts of the coal ash activating agent. As for concrete poured through the low-cost cement, the early strength of the concrete is hardly affected, and the later strength is obviously increased; hydration heat of the concrete can be reduced, and shrinkage cracking of the concrete can be relieved; the phenomena of bleeding and disintegration of the concrete can be prevented; the corrosion resistance of the concrete can be improved, and chlorine ion penetration can be relieved.

Owner:甘肃土木工程科学研究院有限公司

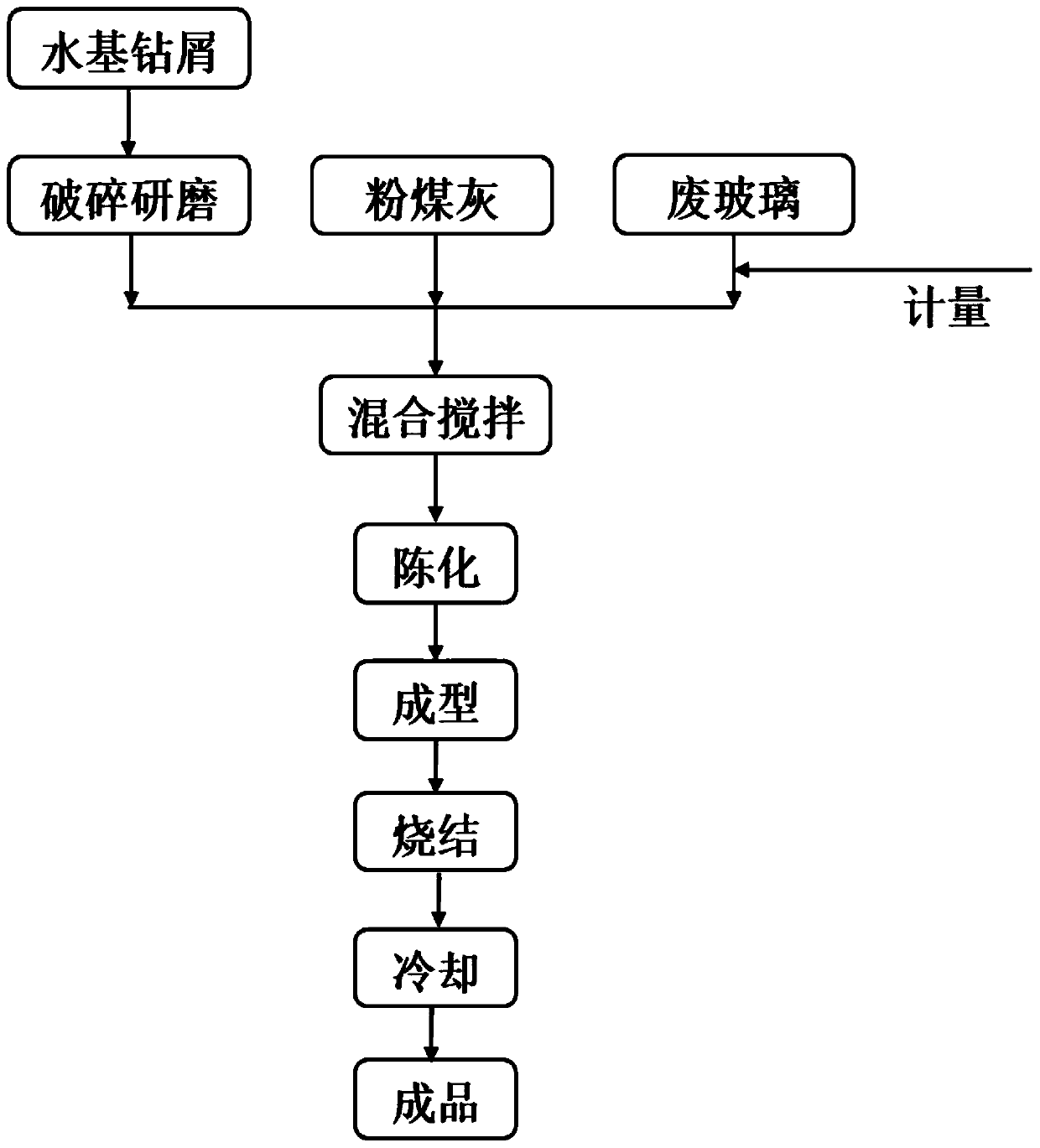

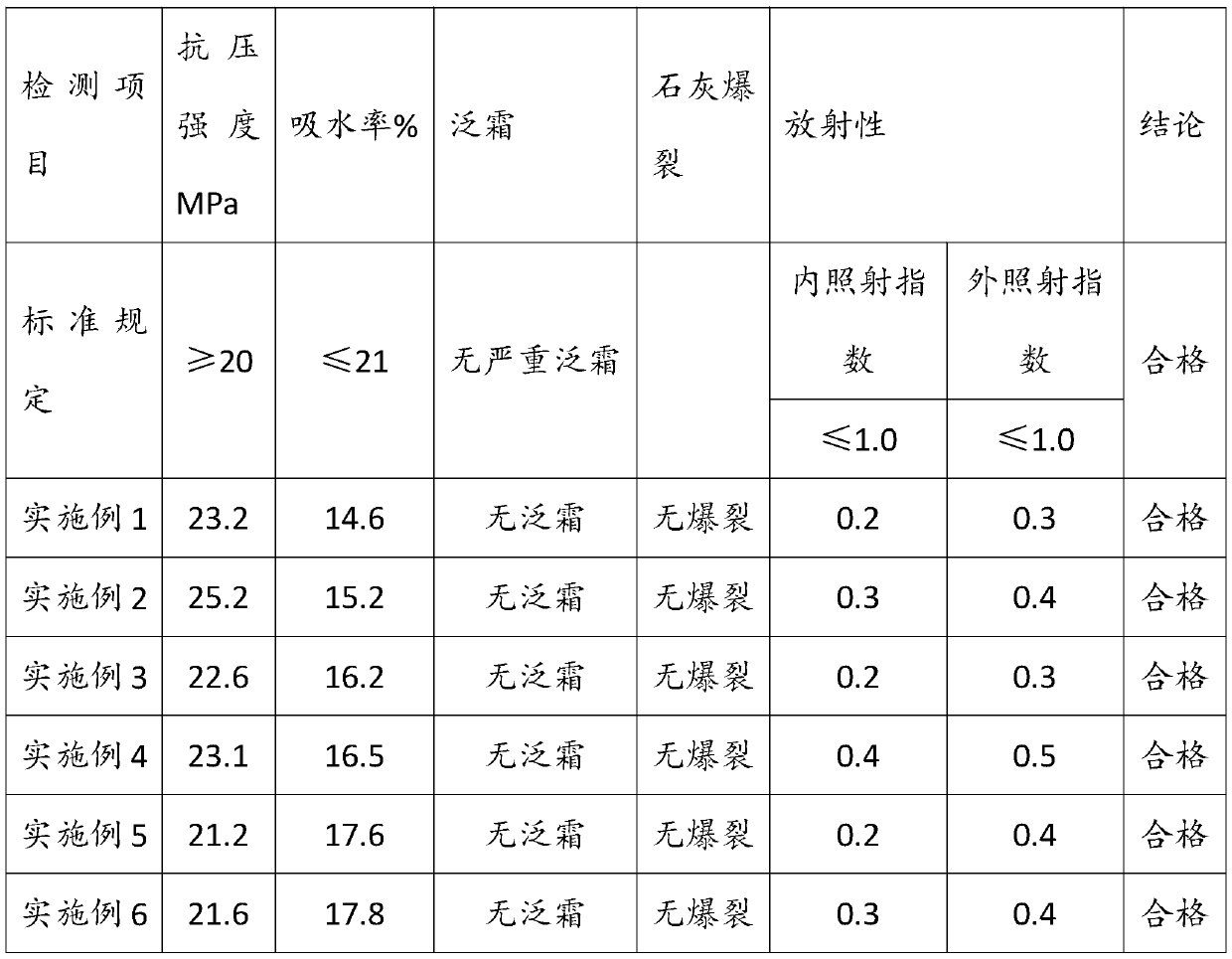

Method for preparing sintered brick from shale gas water-based drilling waste

InactiveCN110683836AReduce governance costsGood economic and environmental benefitsCeramic materials productionClaywaresShale gasDrill cuttings

The invention discloses a method for preparing a sintered brick from shale gas water-based drilling waste. The method comprises the following steps: crushing, grinding and sieving water-based drillingcuttings to obtain water-based drilling cutting powder with fineness of lower than 2 mm; uniformly mixing the water-based drilling cutting powder, fly ash and waste glass in proportion under stirringto obtain a mixed material; adding water into the mixed material, uniformly stirring the material, carrying out ageing for 24 h, and pressing the aged material into a green brick; and drying the molded green brick at 105 + / -5 DEG C for 4 h, heating the green brick to 850-900 DEG C at a heating rate of 1-4 DEG C / min, carrying out high-temperature sintering, carrying out heat preservation for 2 h,and then performing cooling and drawing to obtain a finished sintered brick product. According to the invention, the waste glass is used for tempering the water-based drilling cuttings, so the contentof silicon dioxide in the water-based drilling cuttings can be increased, the content of calcium oxide and the content of SO3 are reduced, the raw materials are allowed to meet the component requirements of the sintered brick, and therefore the phenomena of frosting, cracking and the like of a brick body are avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Environmentally-friendly coating capable of purifying air, and preparation method thereof

InactiveCN108250809ABroaden applicationFlat surfaceAntifouling/underwater paintsPaints with biocidesCellulosePhysical well being

The invention discloses an environment-friendly coating capable of purifying air, and a preparation method thereof, and relates to the technical field of environment-friendly materials. The environment-friendly coating is prepared from the following raw materials in parts by weight: 10-18 parts of seaweed mud, 10-15 parts of quartz powder, 8-16 parts of ash calcium powder, 5-12 parts of coarse whiting powder, 10-18 parts of calcium-magnesium powder, 9-16 parts of wollastonite in powder, 4-10 parts of titanium dioxide, 3-8 parts of anion powder, 1-5 parts of liquid sodium silicate, 1-5 parts ofdispersible gelatine powder, 1-3 parts of cellulose and 1-5 parts of accessory ingredient. The preparation method comprises the following steps: (1) weighing raw materials; (2) smashing materials; (3) mixing the materials; (4) adding the accessory ingredient. The environmentally-friendly coating capable of purifying air has the advantages of easiness in smearing, smooth and even surface,an d small possibility of cracking and falling, in addition, indoor harmful substances, including formaldehyde, benzene series and the like, can be adsorbed, and indoor air is purified so as to be beneficial for body health. The preparation method has the advantages of simpleness in operation and low production cost and is already popularized and used.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

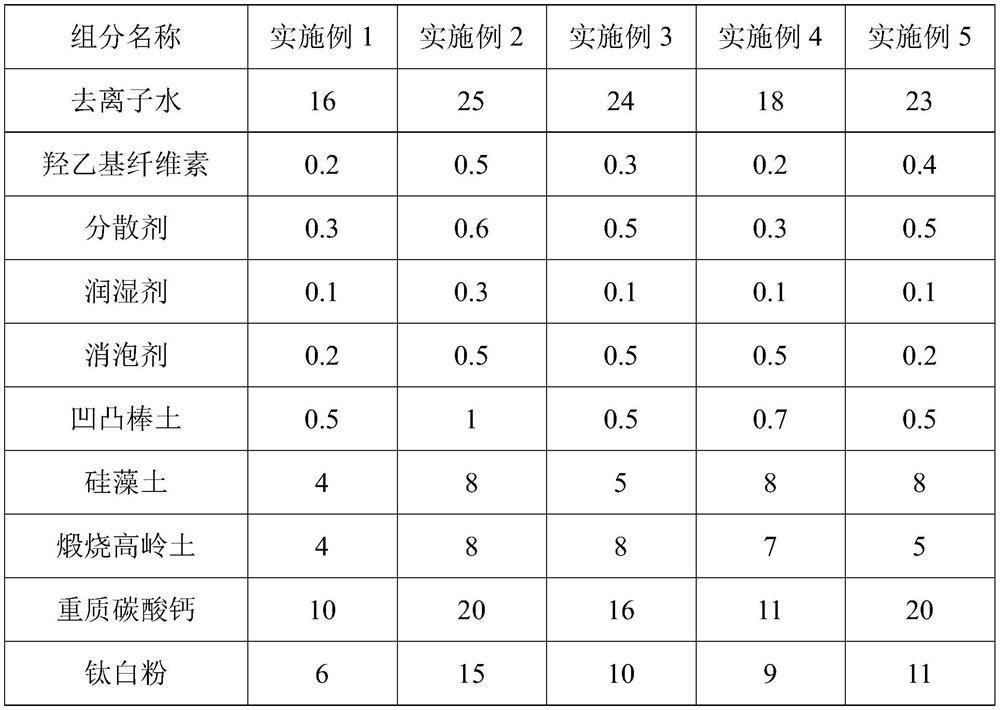

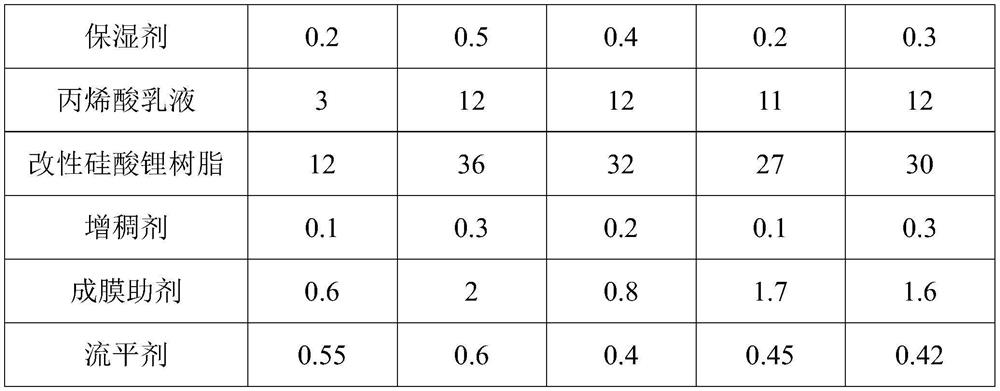

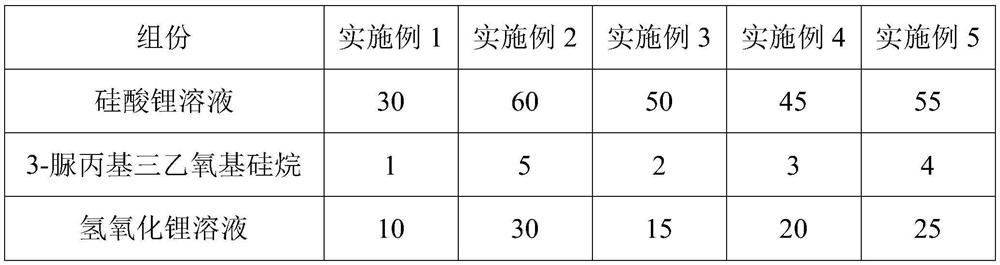

Lithium silicate interior and exterior wall coating and preparation method thereof

PendingCN114716852AGood self-cleaning effectImprove stain resistanceAlkali metal silicate coatingsCelluloseWeather resistance

The invention discloses a lithium silicate interior and exterior wall coating and a preparation method thereof. The lithium silicate interior and exterior wall coating is prepared from the following raw materials: water, hydroxyethyl cellulose, a dispersing agent, a wetting agent, a defoaming agent, attapulgite, diatomite, calcined kaolin, ground calcium carbonate, titanium dioxide, a humectant, an acrylic emulsion, modified lithium silicate resin, a thickening agent and a coalescing agent. And the modified lithium silicate resin is modified lithium silicate resin subjected to silane coupling and hydrolysis, and has the characteristics of high strength, high strength and self-drying film formation, so that the floating phenomenon caused by saltpetering on the wall surface due to the coating is fundamentally avoided. The lithium silicate-based inorganic coating produced by taking the emulsion as a base material comprehensively reaches various performance indexes of the inorganic coating, the attractive effect of a wall surface is remarkably improved, and the weather resistance and the stability of the coating can also be improved. The preparation method of the coating is simple in step, mild in reaction condition and suitable for large-scale production and preparation.

Owner:中山葆信涂料科技有限公司 +1

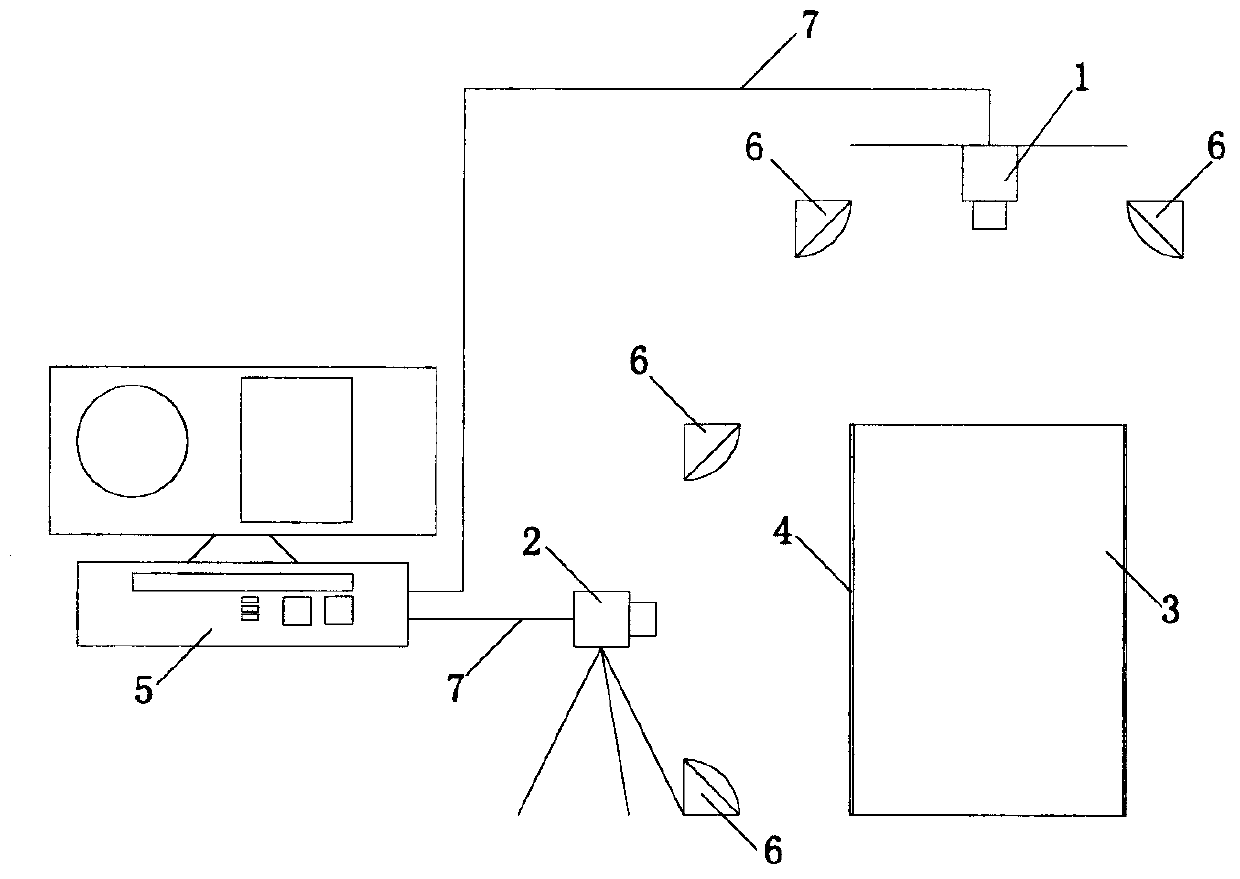

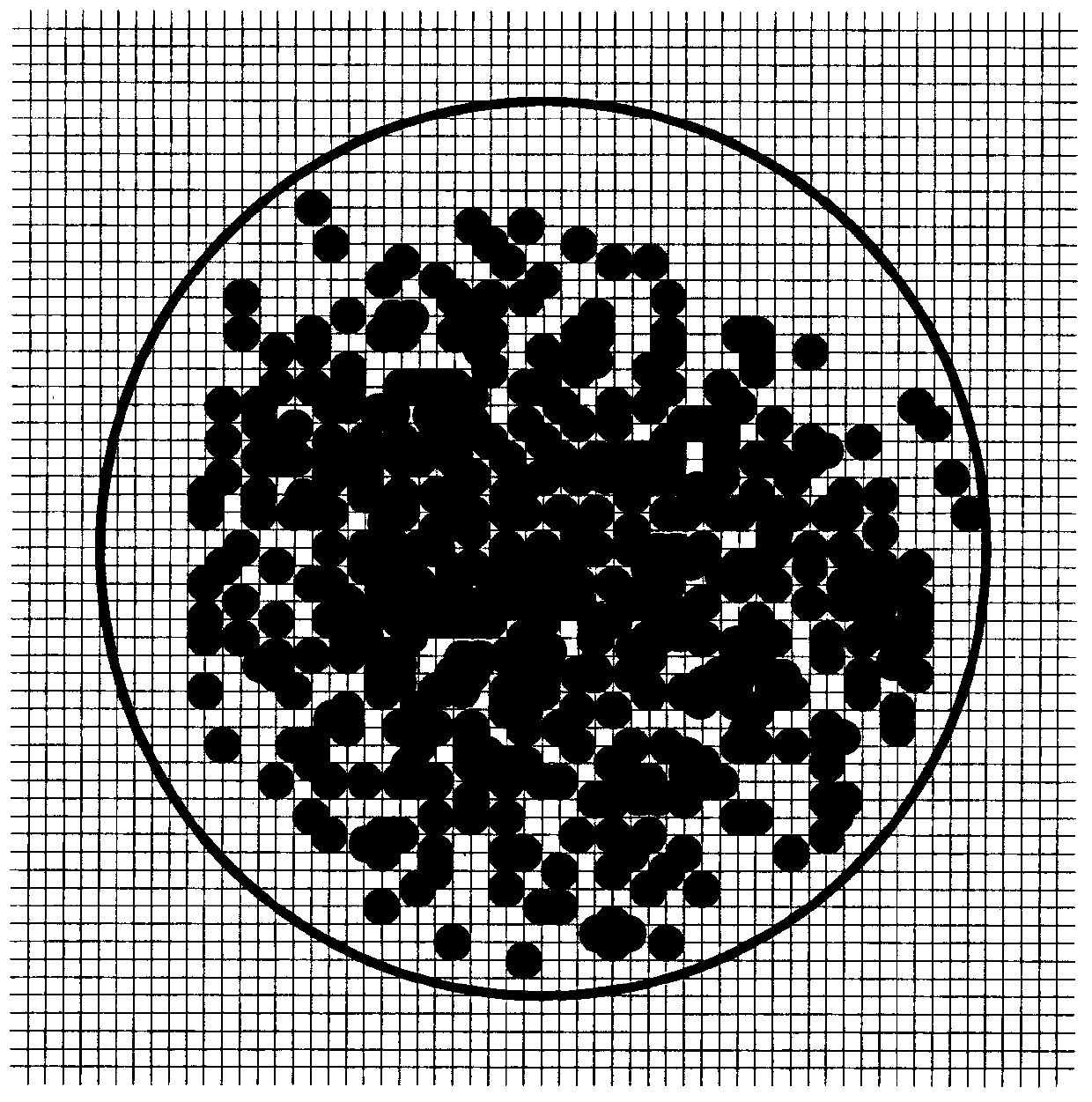

Test system and method for asphalt foaming performance

ActiveCN109655459AGood accuracy and reproducibilityEliminate too much subjectivityMaterial analysis by optical meansData transmissionHalf-life

The invention discloses a test system for asphalt foaming performance. The test system comprises a foam asphalt containing device, a foaming image collecting system and a foaming image analyzing system. The foam asphalt containing device is a bucket body made from a high temperature resistance temperature preservation transparent glass steel material; the foaming image collecting system is composed of two high speed industrial cameras, four white direct current light sources, a data transmission line and an electronic computer; the foaming image analyzing system is composed of an electronic computer and built-in digital image analyzing software. The invention discloses a test method for the asphalt foaming performance. The digital image processing technology is combined, the size distribution rule of asphalt foams can be acquired, and foaming performance evaluation indexes of the expansion rate, the half-life period and the like can be accurately measured. The test result has better accuracy and reproducibility, the equipment source is wide, the operation is simple, the cost is lower, and the universality is higher.

Owner:NANJING FORESTRY UNIV

Ethylene-propylene-diene monomer (EPDM) flame-retardant rubber for automobile and preparation method thereof

The invention relates to the field of rubber and rubber processing, in particular to flame-retardant rubber for an automobile and a preparation process thereof. The flame-retardant rubber comprises the following components in percentage by weight: 50 to 60 percent of crude rubber EP330, 8 to 20 percent of carbon black, 0.5 to 1 percent of silicon dioxide; 2 to 5 percent of zinc oxide, 0.8 to 1.5 percent of silicon 69, 8 to 15 percent of antimony trioxide, 18 to 35 percent of decabromodiphenyl, and 1.5 to 3.5 percent of vulcanizing accelerator DCP. Compared with the conventional formula, the formula of the ethylene-propylene-diene monomer (EPDM) flame-retardant rubber reduces a plurality of accelerators, vulcanizers and flowable agents and introduces the DCP to replace all accelerators and vulcanizers so as to reduce the cost, simplify the preparation process, ensure simple and fast operation and avoid the blooming phenomenon; and the prepared flame-retardant rubber has high performance and attractive appearance.

Owner:惠州市成琳橡胶制品有限公司

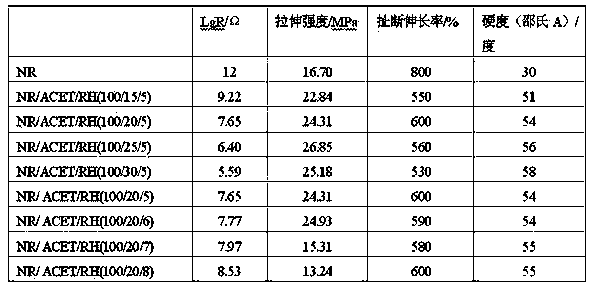

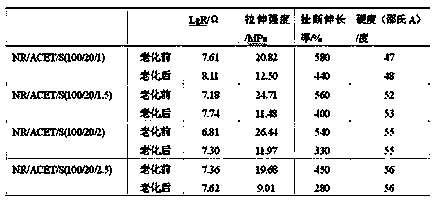

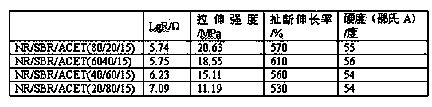

Rubber/acetylene black conductive material as well as preparation method and application thereof

ActiveCN103539969ASimple processEasy to operate and controlNon-conductive material with dispersed conductive materialElectrographic process apparatusConductive materialsAcetylene

The invention discloses a rubber / acetylene black conductive material as well as a preparation method and application thereof. The rubber / acetylene black conductive material consists of the following materials in parts by weight: 100 parts of rubber, 2-20 parts of acetylene black, 0-10 parts of a modifier and 0.5-5 parts of a vulcanizing agent. The preparation method of the composite material disclosed by the invention is simple and is easy to operate and control, and an existing rubber processing method and device can be adopted; the conductive performance of the conductive composite material is stable, and blooming can be effectively avoided; the conductive composite material has good mechanical property and excellent aging resistance on the premise of keeping the conductive performance.

Owner:苏州瑞力博新材科技有限公司

High-gloss glazed tile and production process thereof

The invention discloses and provides a high-gloss glazed tile which is low in production difficulty and suitable for large-scale stable production and a production process of the highlight glazed tile. The high-gloss glazed tile comprises a tile blank body, ground coat and surface coat are sprayed outside the tile blank body in sequence, and the ground coat is prepared from, by percentage, 40%-50%of albite, 3%-8% of calcite, 6%-10% of calcined talc, 2%-6% of aluminum oxide, 3%-7% of wollastonite, 3%-7% of dolomite, 4%-8% of kaolin, 8%-12% of black mud powder and 8%-12% of zirconium silicate;The surface glaze comprises the following components in percentage: 15%-25% of potassium feldspar, 25%-35% of albite, 20%-30% of calcite, 8%-12% of black mud powder, 3%-7% of calcined talc, 3%-7% of quartz powder and 3%-7% of zinc oxide. The method is suitable for the field of production and manufacturing of high-gloss glazed tiles.

Owner:珠海市斗门区旭日陶瓷有限公司

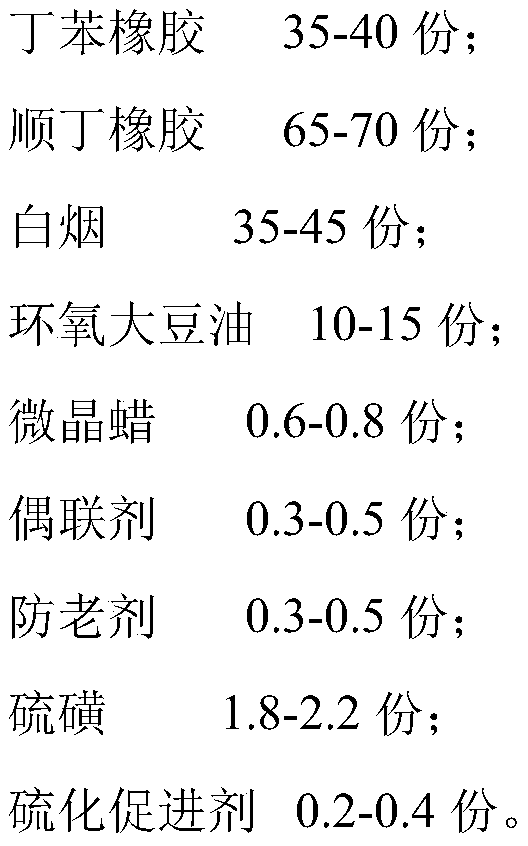

Wear-resistant sole of male boot and preparation method thereof

The invention discloses a wear-resistant sole of a male boot and a preparation method thereof, and relates to the technical field of shoes, the wear-resistant sole comprises the following raw materials in parts by weight: 35 to 40 parts of styrene butadiene rubber; 65 to 70 parts of butadiene rubber; 25 to 35 parts of white smoke; 10 to 15 parts of epoxidized soybean oil; 15 to 20 parts of aramidfiber; 0.3 to 0.5 part of a coupling agent; 0.3 to 0.5 part of an anti-aging agent; 1.8 to 2.2 parts of sulfur; and 0.2 to 0.3 part of a vulcanization accelerator. The butadiene styrene rubber has good wear resistance, heat resistance and aging resistance, and the butadiene rubber has good elasticity, cold resistance and flexing resistance; the white smoke, namely hydrated silicon dioxide, can provide good mechanical properties and wear resistance for the system. By adding the aramid fiber, the wear resistance of the sole can be effectively improved, and by adding the coupling agent, the compatibility of the aramid fiber and a rubber system can be effectively improved. Epoxidized soybean oil is a plasticizer with extremely low toxicity, can improve the physical properties of a rubber system and prolong the aging time, and improves the wear resistance of the system to a certain degree.

Owner:浙江荣威鞋业有限公司

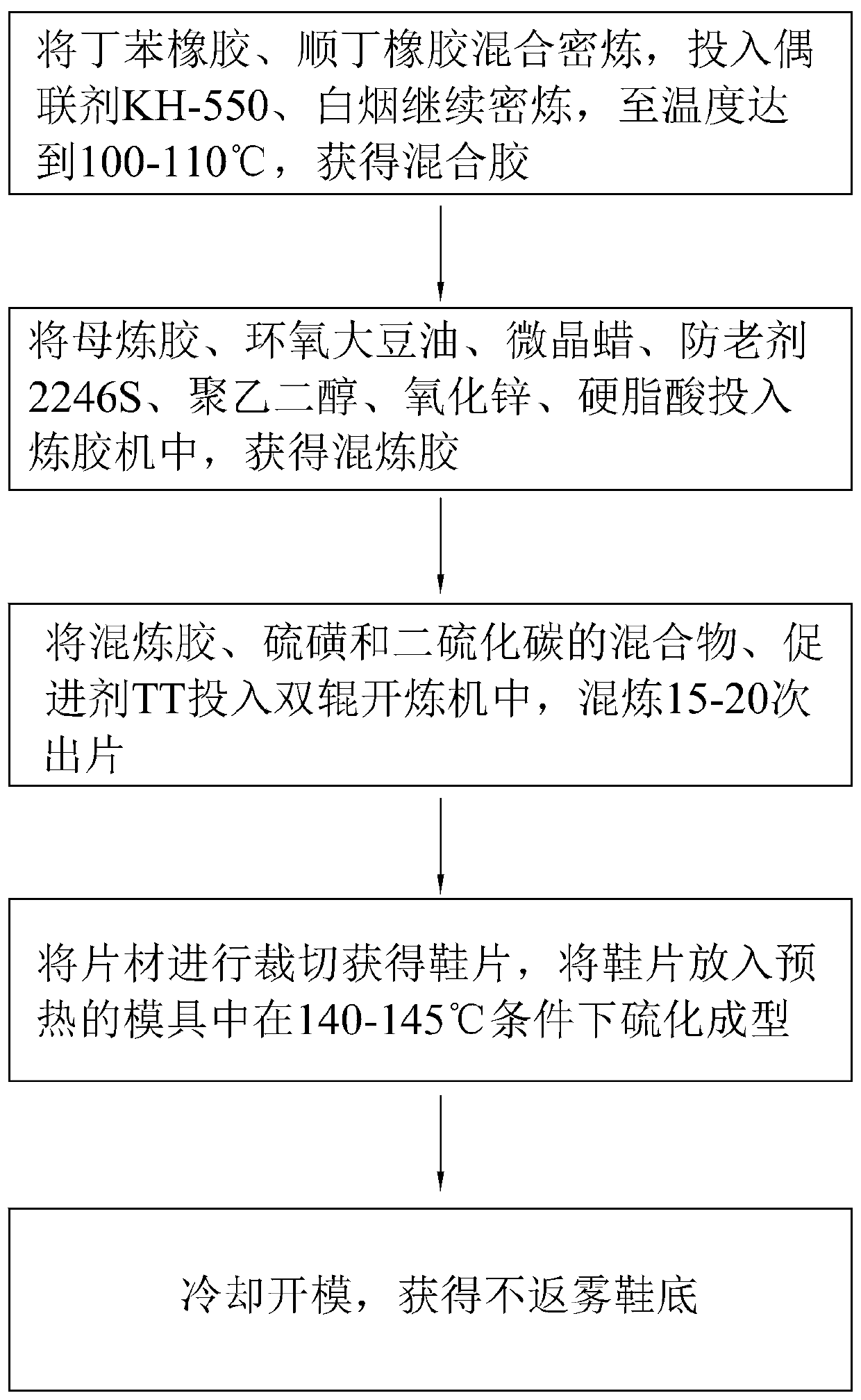

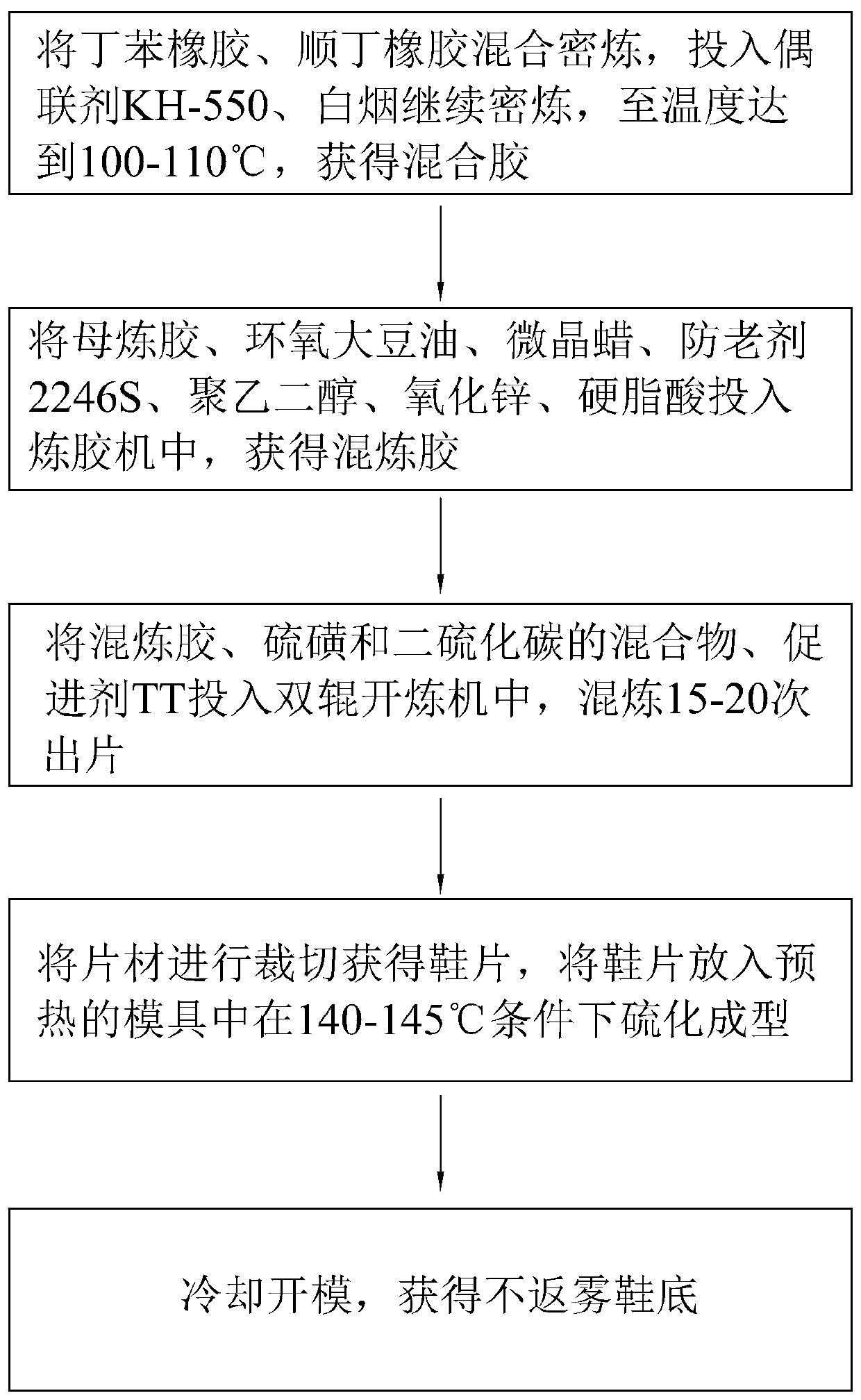

Anti-fogging sole for male boots and preparation method thereof

ActiveCN111138734AImprove wear resistanceImprove heat resistanceSolesPolymer scienceMicrocrystalline wax

The invention discloses an anti-fogging sole for male boots and a preparation method thereof, and relates to the technical field of shoes. The anti-fogging sole comprises the following raw materials (by weight): 35-40 parts of styrene butadiene rubber; 65-70 parts of butadiene rubber; 35-45 parts of white smoke; 10-15 parts of epoxidized soybean oil; 0.6-0.8 part of microcrystalline wax; 0.3-0.5 part of a coupling agent; 0.3-0.5 part of an anti-aging agent; 1.8-2.2 parts of sulfur; and 0.2-0.4 part of a vulcanization accelerator. Styrene butadiene rubber has good wear resistance, heat resistance and aging resistance, is easy to combine with sulfur, and has a good vulcanization effect. Butadiene rubber has good elasticity, cold resistance and flexing resistance. White smoke is hydrated silicon dioxide and can provide good mechanical properties for the system. Epoxidized soybean oil is a plasticizer with extremely low toxicity, and can improve the physical properties of a rubber system and prolong the aging time. The microcrystalline wax has a good dissolving effect on non-polar substances in the system so as to achieve the effect of preventing components from migrating out, and themicrocrystalline wax is matched with the formula proportion of the system so as to effectively inhibit the return fog of the rubber system.

Owner:浙江荣威鞋业有限公司

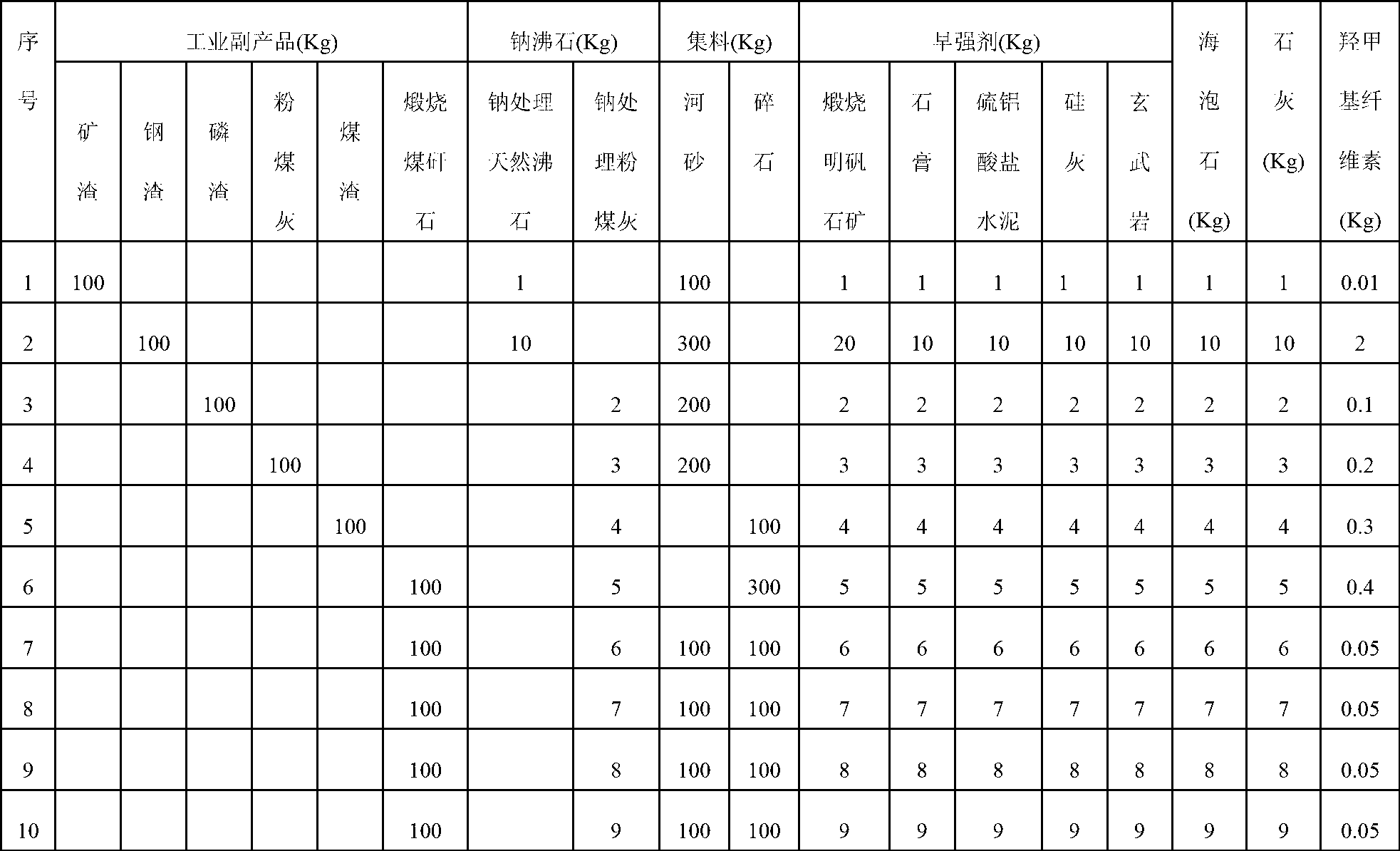

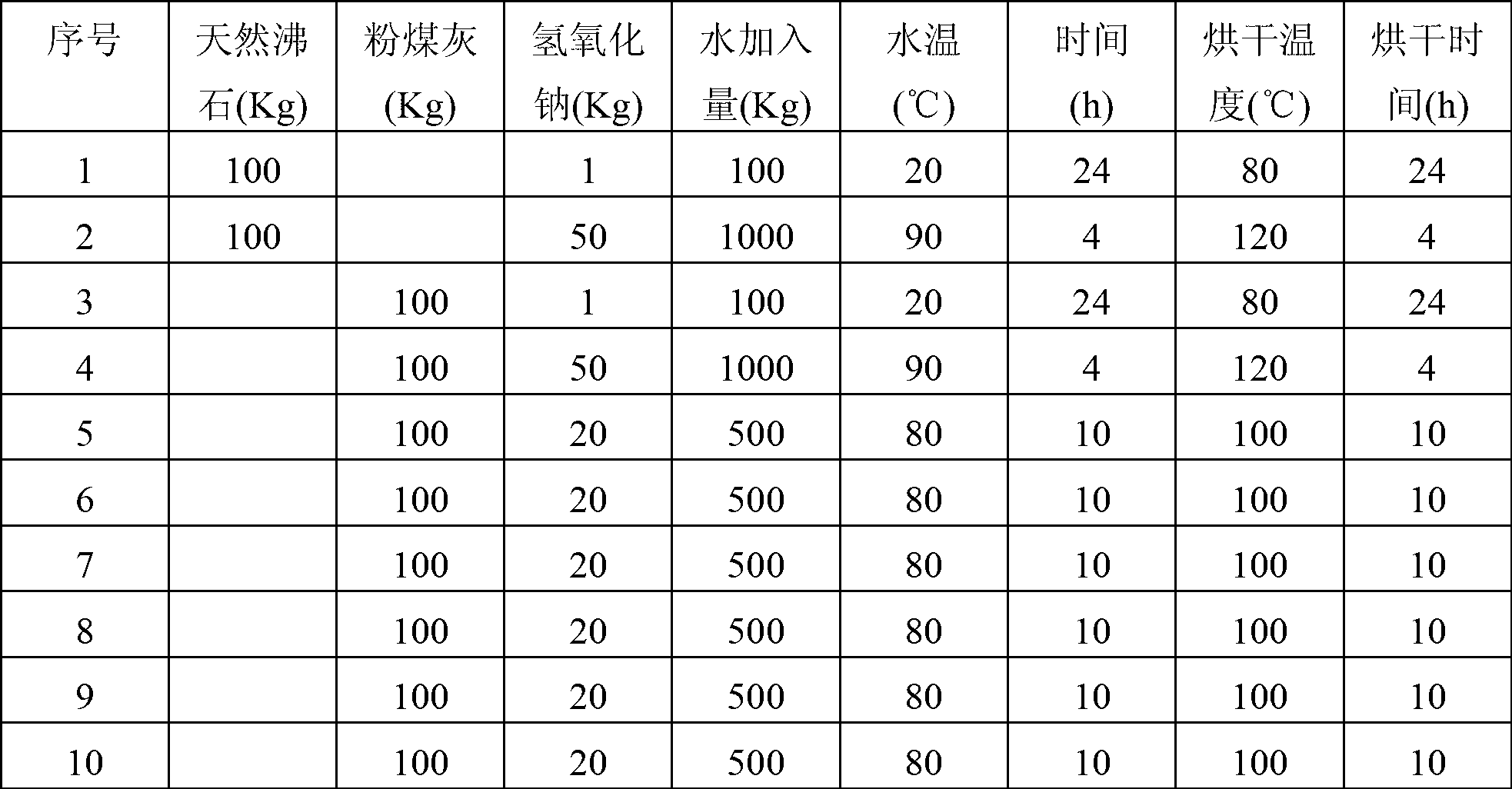

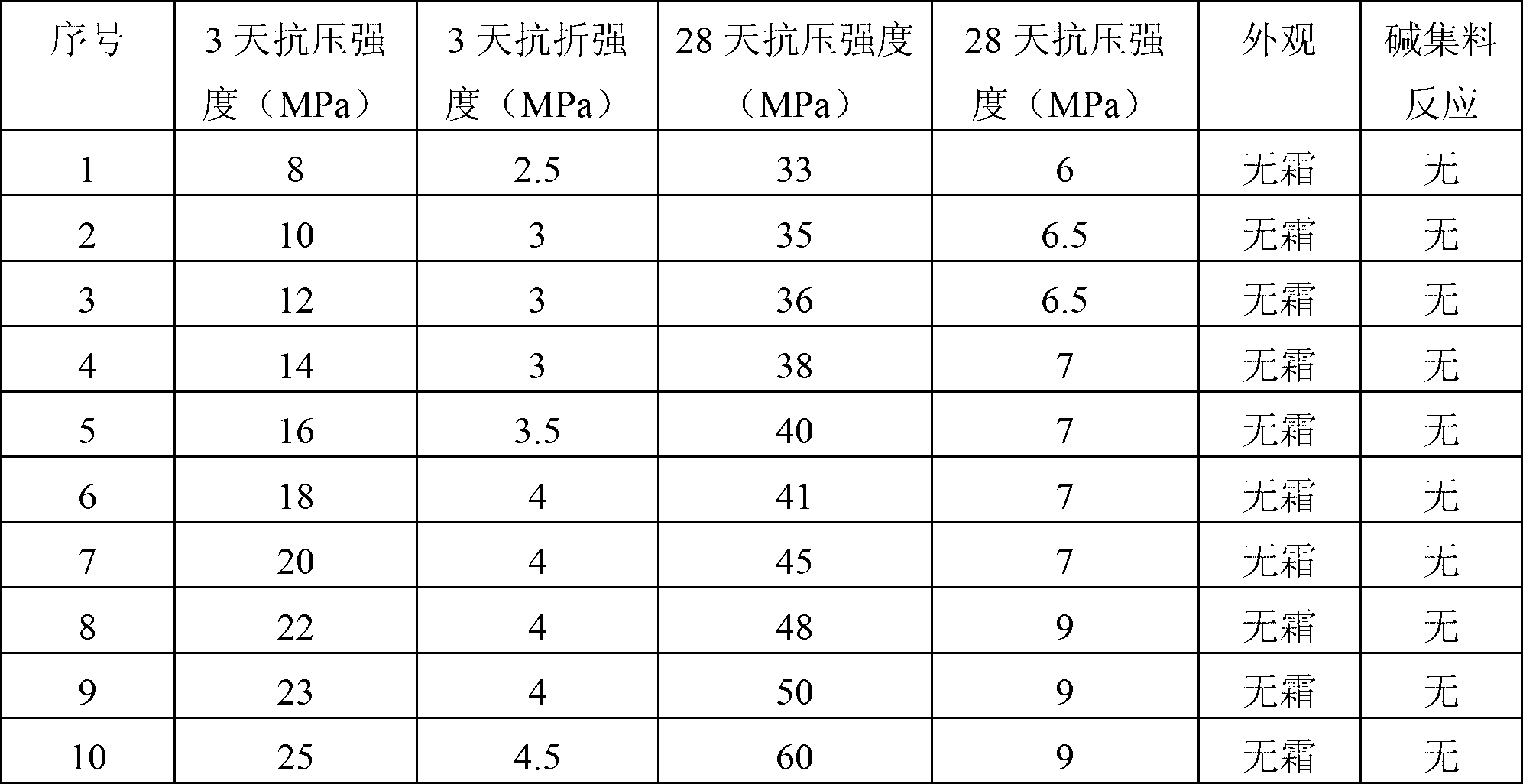

Preparation process of natrolite inorganic artificial stone

InactiveCN103011743AImprove utilization efficiencyPerformance is not affectedNatroliteArtificial stone

The invention discloses a preparation process of a natrolite inorganic artificial stone. The process is characterized by: adding natrolite, aggregate, an early strength agent, sepiolite, lime, and hydroxymethyl cellulose into an industrial by-product, and stirring them evenly to obtain natrolite inorganic artificial stone precursor powder, adding water into the natrolite inorganic artificial stone precursor powder, stirring them uniformly, pouring the mixture into a die, and performing natural curing for 28d, thus obtaining the natrolite inorganic artificial stone, which has the characteristics of high early strength, no frosting, and no alkali-aggregate reaction.

Owner:SHAANXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com