Environment-friendly water-permeable brick and production method thereof

A manufacturing method and technology of permeable bricks are applied in the field of building materials, which can solve the problems of dissolving heavy metal ions and polluting the environment, and achieve the effects of no heavy metal ion dissolution, reduced mobility, and high compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

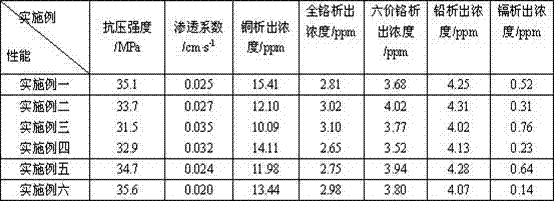

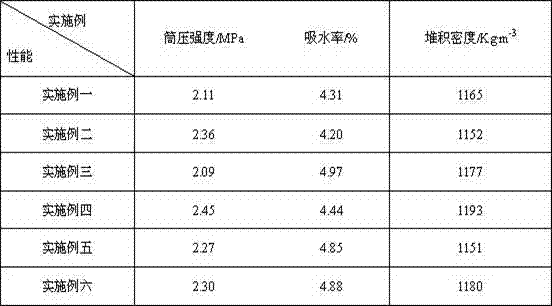

Examples

Embodiment 1

[0024] 1. In parts by weight, the components and dosage of the ceramsite mixture (100 parts by total weight, the same below) are: 40 parts of gold tailings, 20 parts of iron tailings, 20 parts of red mud, 20 parts of clay, Ball milling in a ball mill until the particle size of the mixture is 200 mesh;

[0025] 2. Add water with a weight percentage of 20% in the mixture as a granulating agent, and granulate it through a drum granulator to make the particle size reach about 3mm~4mm, and then dry it after sieving to control its moisture content below 5%. , put the granulated blank into clay powder, continue to roll and granulate, wrap the blank in the middle, and cover the outer layer with a layer of ceramsite about 1-2mm thick.

[0026] 3. Put the ceramsite raw material into the drying equipment and keep it warm at 110°C for 48 hours to remove the natural water. Directly put the ceramsite raw material into a gas-fired rotary kiln for calcination at 1150°C-1250°C for 2 hours, an...

Embodiment 2

[0029] 1. In parts by weight, the components and dosage of ceramsite mixture (100 parts by total weight, the same below) are: 20 parts of gold tailings, 30 parts of iron tailings, 20 parts of dried sludge, 20 parts of red mud part, 10 parts of clay, ball milled in a ball mill until the particle size of the mixture is 200 mesh;

[0030] 2, with embodiment one step.

[0031] 3. Put the ceramsite raw material into the drying equipment and keep it warm at 110°C for 48 hours to remove the natural water. The ceramsite raw meal was directly put into a gas-fired tunnel kiln for calcination at 1200°C for 3 hours, and rapidly cooled to room temperature at a cooling rate of 30°C / min.

[0032] 4. Select 5~20mm vitrified ceramsite as aggregate, use 42.5 grade Portland cement, water cement ratio 0.3, bone ash ratio 4.5, lignosulfonate water reducer mass fraction 2.5%, use cement slurry pre The mixing method is static pressure molding after mixing, and then 28 days of sealing and wet curin...

Embodiment 3

[0034] 1. In parts by weight, the components and dosage of ceramsite mixture (100 parts by total weight, the same below) are: 30 parts of molybdenum tailings, 30 parts of iron tailings, 10 parts of dried sludge, 30 parts of clay, ball milled in a ball mill until the particle size of the mixture is 200 mesh;

[0035] 2, with embodiment one step.

[0036] 3. Put the ceramsite raw material into the drying equipment and keep it warm at 110°C for 48 hours to remove the natural water. Put the ceramsite raw material directly into the gas-fired rotary kiln for calcination at 1250°C for 2 hours, and rapidly cool to room temperature at a cooling rate of 50°C / min.

[0037]4. Select 5~20mm vitrified ceramsite as aggregate, use 42.5 grade Portland cement, water cement ratio 0.3, bone ash ratio 5.0, lignosulfonate water reducing agent mass fraction 2.5%, use cement slurry pre The mixing method is static pressure molding after mixing, and then 28 days of sealing and wet curing to make envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com