Kitchen waste on-site treatment method

The technology of a kitchen waste and a treatment method is applied in the field of in-situ treatment of kitchen waste, which can solve the problems of high temperature process energy consumption, large moisture and grease, the growth and reproduction of food waste treatment bacteria, and the like, so as to improve efficiency and resources. The effect of rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

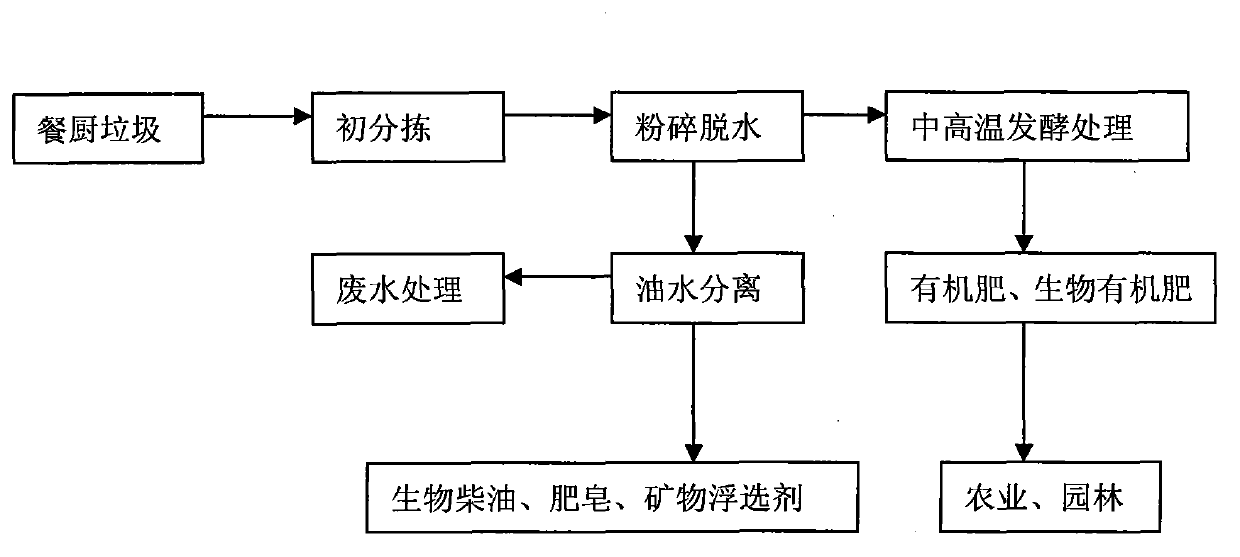

[0018] A method for treating food waste in situ, comprising the following steps:

[0019] 1) Initial sorting of food waste: when collecting food waste, sort hard waste such as plastic, metal, porcelain, and big stick bones to avoid damage to equipment in subsequent processing;

[0020] 2) Grinding and dehydration: The pre-sorted food waste enters the crushing and dehydration system, and the water and grease in the food waste are separated through the screw extrusion drainage system, and then enters the oil-water separation system, and the solid matter in the food waste is separated Carry out crushing and enter the fermentation treatment system;

[0021] 3) Medium and high temperature fermentation treatment: transport the solid matter extruded and pulverized in step 2) into the fermentation bin, add a food waste degradation composite microbial agent with a weight ratio of 2‰, adjust the moisture content of the material to 50% by weight, and the initial temperature at Above 35°...

Embodiment 2

[0026] A method for treating food waste in situ, comprising the following steps:

[0027] 1) Initial sorting of food waste: when collecting food waste, sort hard waste such as plastic, metal, porcelain, and big stick bones to avoid damage to equipment in subsequent processing;

[0028] 2) Grinding and dehydration: The pre-sorted food waste enters the crushing and dehydration system, and the water and grease in the food waste are separated through the screw extrusion drainage system, and then enters the oil-water separation system, and the solid matter in the food waste is separated Carry out crushing and enter the fermentation treatment system;

[0029] 3) Medium and high temperature fermentation treatment: transport the solid matter extruded and pulverized in step 2) into the fermentation bin, add a food waste degradation composite bacterial agent with a weight ratio of 2‰, adjust the moisture content of the material to 40% by weight, and the initial temperature at 25°C, pro...

Embodiment 3

[0034] A method for treating food waste in situ, comprising the following steps:

[0035] 1) Initial sorting of food waste: when collecting food waste, sort hard waste such as plastic, metal, porcelain, and big stick bones to avoid damage to equipment in subsequent processing;

[0036] 2) Grinding and dehydration: The pre-sorted food waste enters the crushing and dehydration system, and the water and grease in the food waste are separated through the screw extrusion drainage system, and then enters the oil-water separation system, and the solid matter in the food waste is separated Carry out crushing and enter the fermentation treatment system;

[0037] 3) Medium-high temperature fermentation treatment: transport the solid matter extruded and pulverized in step 2) into the fermentation bin, add a food waste degradation composite bacterial agent with a weight ratio of 2‰, adjust the moisture content of the material to 45% by weight, and the initial temperature at Above 30°C, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com