Patents

Literature

314results about How to "Improve cracking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

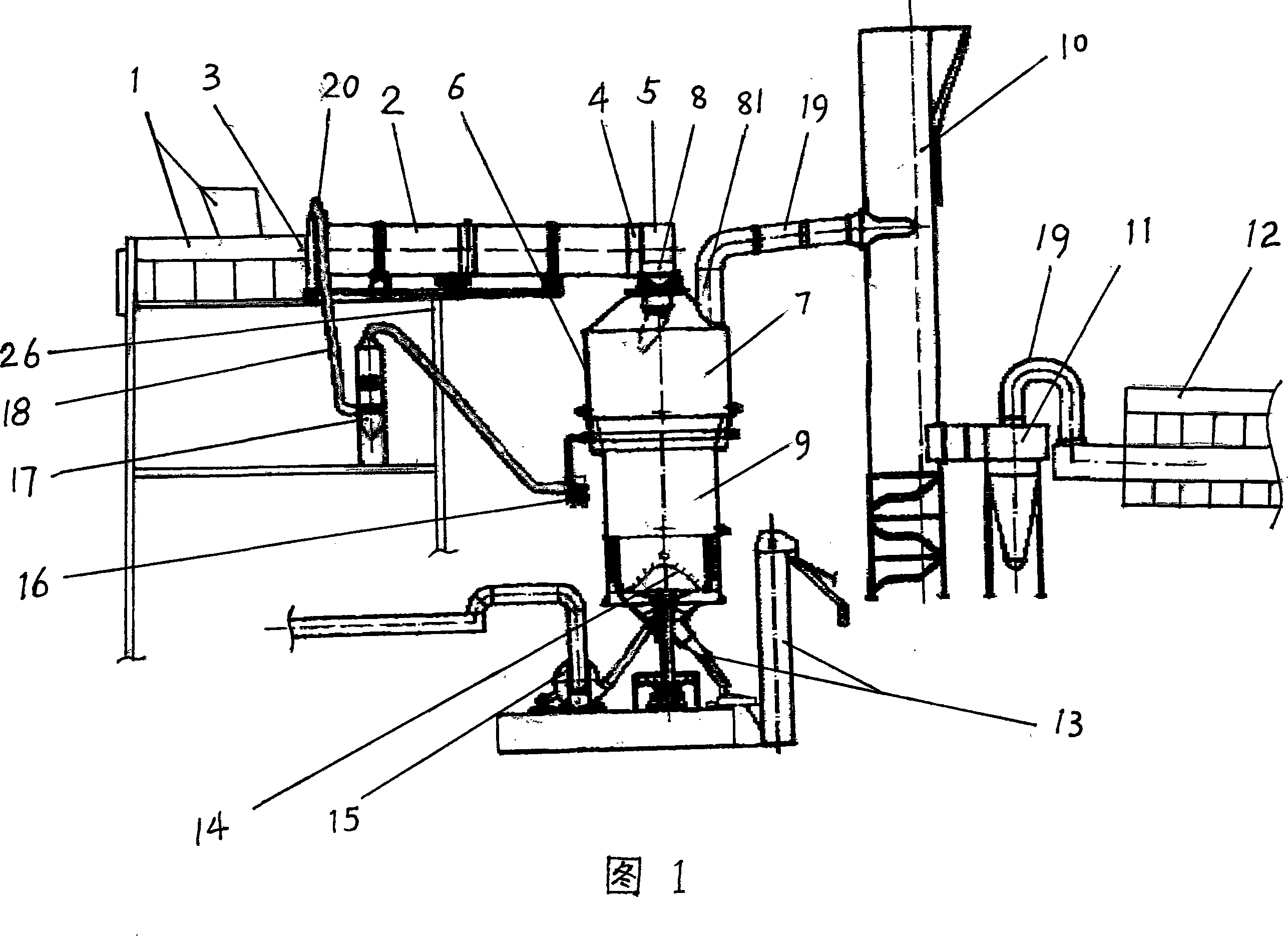

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

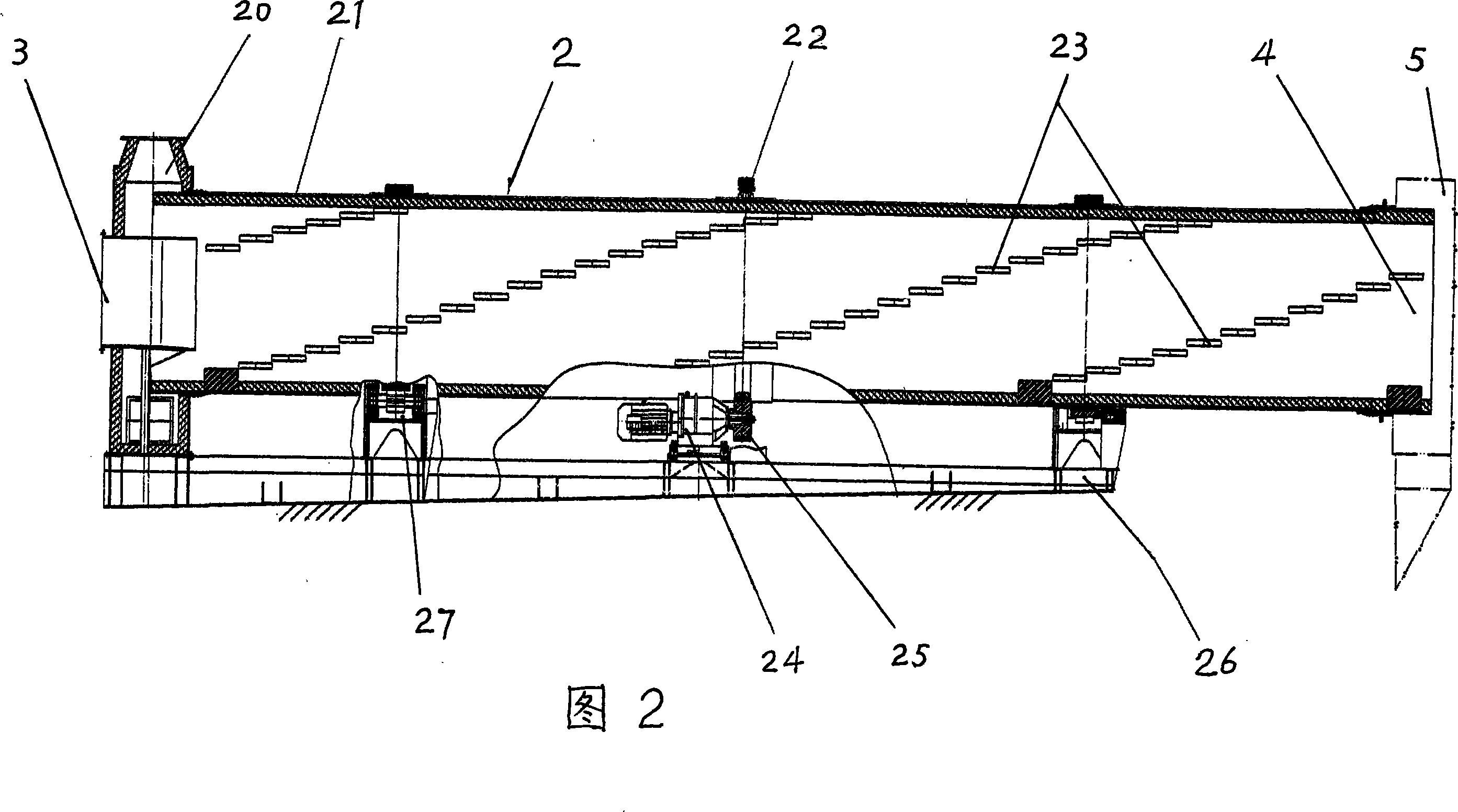

Method for producing liquid organic fertilizer by using organic fertilizer

InactiveCN101037354AImprove cracking efficiencyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningClimate change adaptationUltrafiltrationHumic acid

The invention discloses method of producing liquid organic fertilizer by organic belonging to solid wastes disposal field, including: co-treating the residual sludge with 98 percent moisture content by ultrasound and sodium hydroxide to make the organic matters dissolve out; getting concentrated sludge and supernatant fluid after centrifugation; dehydrating the concentrated sludge after neutralization in a routine method; sand leaching and ultrafiltration treating the supernatant fluid twice after centrifugation to get a concentrated liquid containing macromolecule organic matter such as humic acid and the filtrate containing low molecular organic matter; the filtrate entering into the sewage treating plant for a primary treatment. Disposed dehydrated sludge cake has 70-80 percent moisture content and a reduction of the content of organic matter of 30-50%. The concentrated liquid by ultrafiltration is mainly composed of macromolecule organic matter and with a low content of heavy metal, and can be an organic liquid fertilizer, and complies the rule of using green food fertilizer. The invention is suitable for the sludge with a high organic matter content such as residual sludge and digested sludge.

Owner:TSINGHUA UNIV

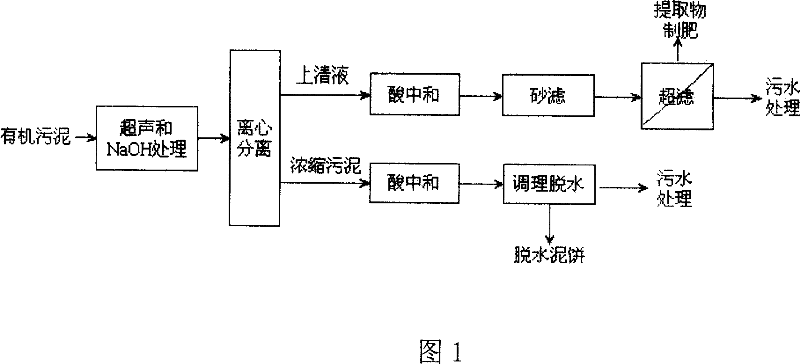

Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

InactiveCN106499376AEmission reductionAchieve emissionsConstructionsFluid removalReaction rateHeater Rod

The invention provides a technology method for comprehensive oil production and in-situ improvement of super heavy oil, oil shale, kerogen and medium and low-maturity shale oil reservoirs. The technology method is characterized in that a novel shaft electric heating in-situ cracking improvement technology is adopted, and is assisted by an air injection technology; by drilling a production well group into an oil bearing reservoir or adjusting the existing well network, a heating well, an air injection well and a production well are reasonably arranged; air is injected into the reservoir, and a heating cable in a heating well shaft is connected with an electric heating bar to heat the oil bearing reservoir, so as to realize the improvement of underground cracking of crude oil. The technology method has the advantages that by combining the advantages of shaft electric heating and air injection technologies, the problems of single heat transfer type, insufficient driving energy and the like in a single shaft electric heating mode are solved; by utilizing the heat effect of crude oil and oil oxidizing reaction, the stratum temperature is increased, the cracking temperature of the crude oil is decreased, the reaction rate of in-situ cracking is accelerated, the recovery efficient of the crude oil is improved, and the consumption of water resources and carbon emission are decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

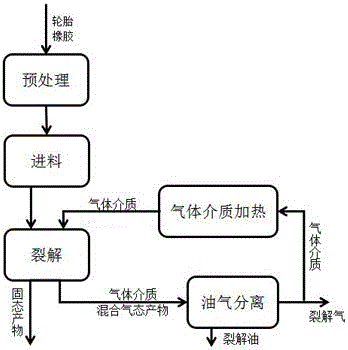

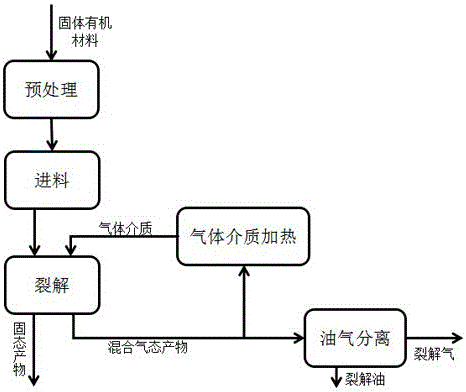

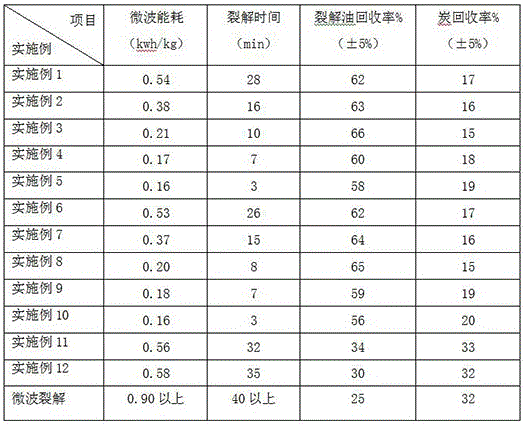

Tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves

ActiveCN105733644AStrong process controllabilityImproved microwave absorption propertiesProductsReagentsMicrowaveProduct gas

The invention provides a tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves. The method includes the steps of A, preprocessing tire rubber; B, feeding the preprocessed tire rubber into a composite pyrolysis cavity; C, using a gas heating device to heat gas media to 350-700 DEG C; D, continuously feeding the heated gas into the composite pyrolysis cavity, and allowing the heated gas and the microwaves to jointly act on the tire rubber so as to perform pyrolysis to obtain solid products and mixed gas products; E, performing oil-gas separation on the mixed gas products to remove pyrolysis oil; F, partially feeding the gas obtained after the oil-gas separation in the step E into the gas heating device of the step C, and heating the gas to 350-700 DEG C for the circulation pyrolysis of the step D. By the tire rubber pyrolysis method, pyrolysis energy consumption and pyrolysis time can be reduced and cost is saved.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

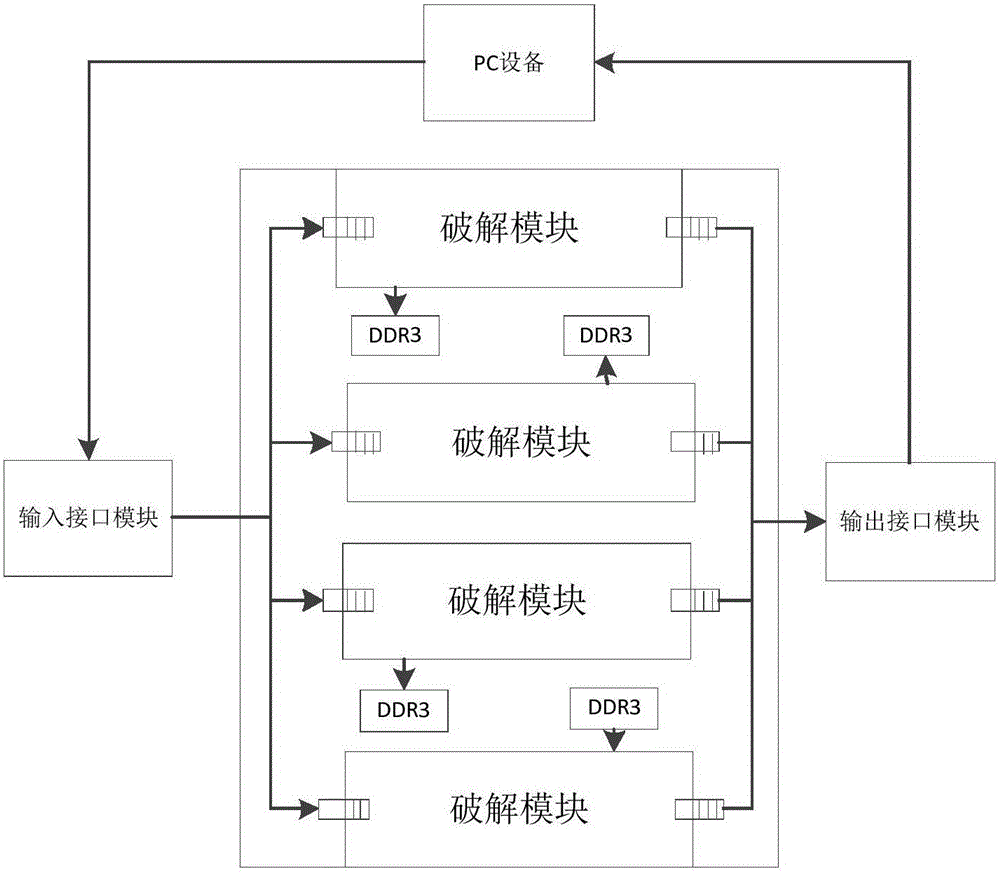

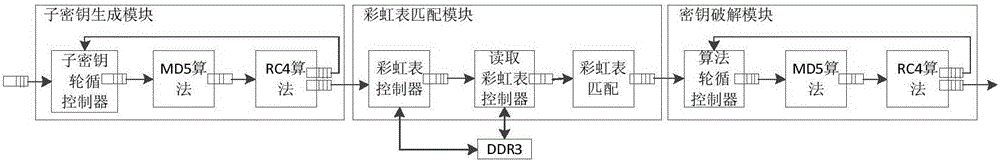

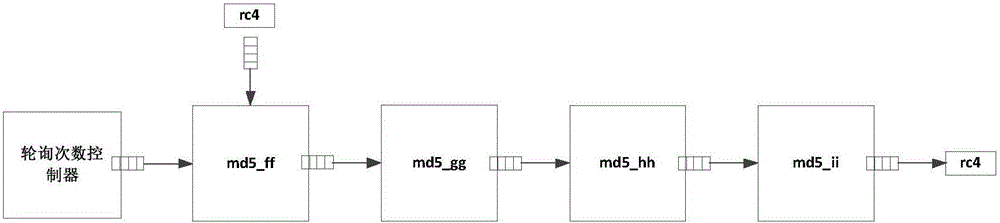

Word2003 document cracking system based on FPGA hardware and method

ActiveCN106357384AImprove cracking efficiencyDelayed cracking timeData stream serial/continuous modificationResource consumptionComputer module

The invention discloses a word2003 document cracking system based on FPGA hardware and a method. The system comprises a PC, an input interface module, a crack module and an output interface module which are connected sequentially, and the PC is connected with the output interface module. The crack module comprises a sub-key generation module, a rainbow table matching module and a key cracking module which are connected sequentially. The sub-key generation module includes sub-key round robin controller, MD5 algorithm module and RC4 algorithm module which are connected sequentially. The key cracking module consists of algorithm round robin controller, MD5 algorithm module and RC4 algorithm module. The system achieves document cracking by using the time and space folding algorithm of the rainbow table, thus improving the crack efficiency and reducing the cracking time. On the basis of considering the technical characteristics of the rainbow table and the FPGA, the appropriate rainbow table is used for cracking, thus solving the contradiction between cracking time and resource consumption.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

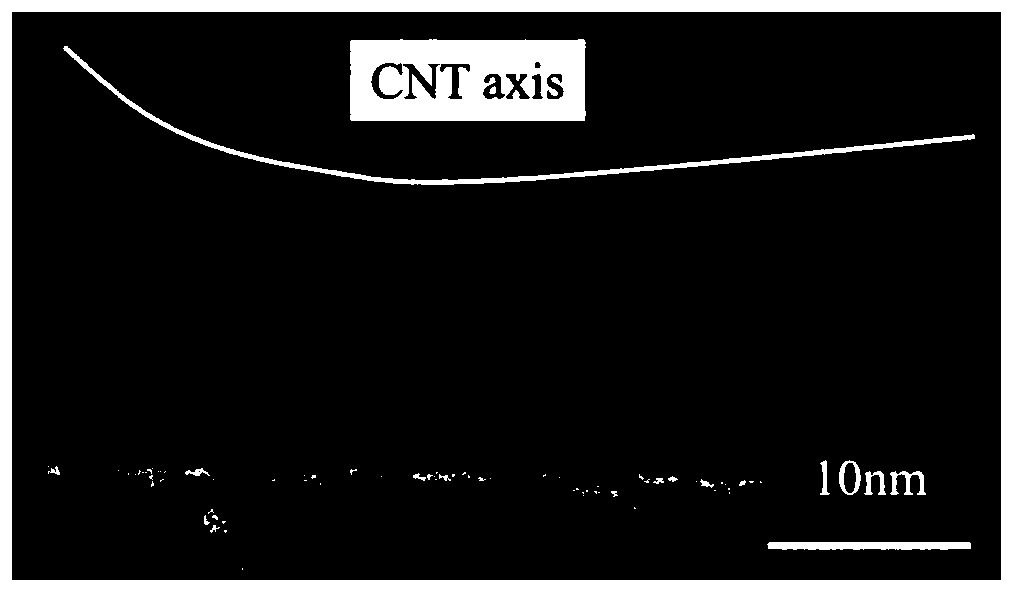

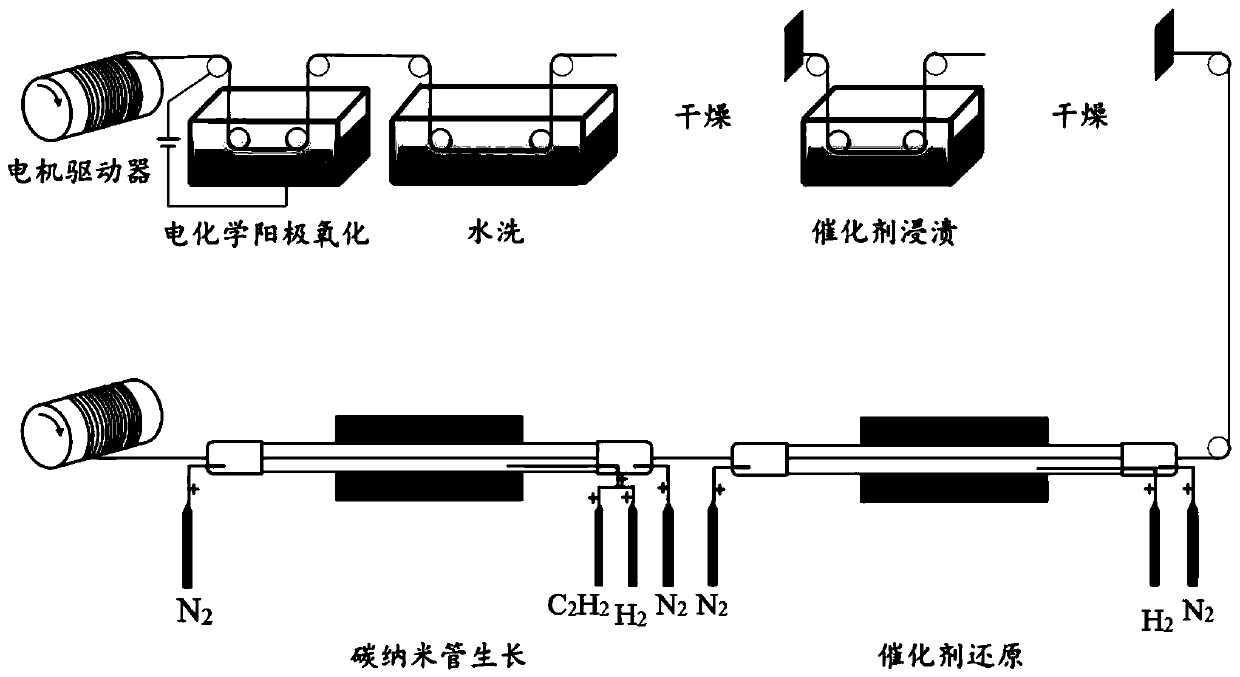

Preparation method for on-thread and continuously growing carbon nanotubes on surface of carbon fiber

ActiveCN109797540AImprove surface activityImproved through-thickness performanceCarbon fibresCarbon fiber reinforced polymersTube furnace

The invention relates to a preparation method for on-thread and continuously growing carbon nanotubes on the surface of carbon fiber. The method specifically comprises the steps of performing surfaceelectrochemical anodic oxidation treatment on the carbon fiber, then immersing the treated carbon fiber in Co(NO3)2 solution, inletting hydrogen into a tube furnace to reduce metal salts on the surface of the carbon fiber into elementary metals, then placing the reduced carbon fiber into a chemical vapor deposition furnace, and under protection of hydrogen, performing acetylene pyrolysis at 500-800 DEG C and producing the carbon nanotubes on the surface of the carbon surface with the catalysis of the elementary metals to obtain a carbon fiber-reinforced polymer composite material with the surface loaded with the carbon nanotubes. The carbon nanotubes are multi-walled and the tube walls are basically parallel to the axes of the nanotubes, the multi-walled carbon nanotubes are composed of layered graphite structures, the spacing between the tube walls is small, and the carbon nanotubes of the carbon fiber are uniform in distribution and intertwined with one another to increase the layering resistance and the penetration thickness.

Owner:SHANDONG UNIV

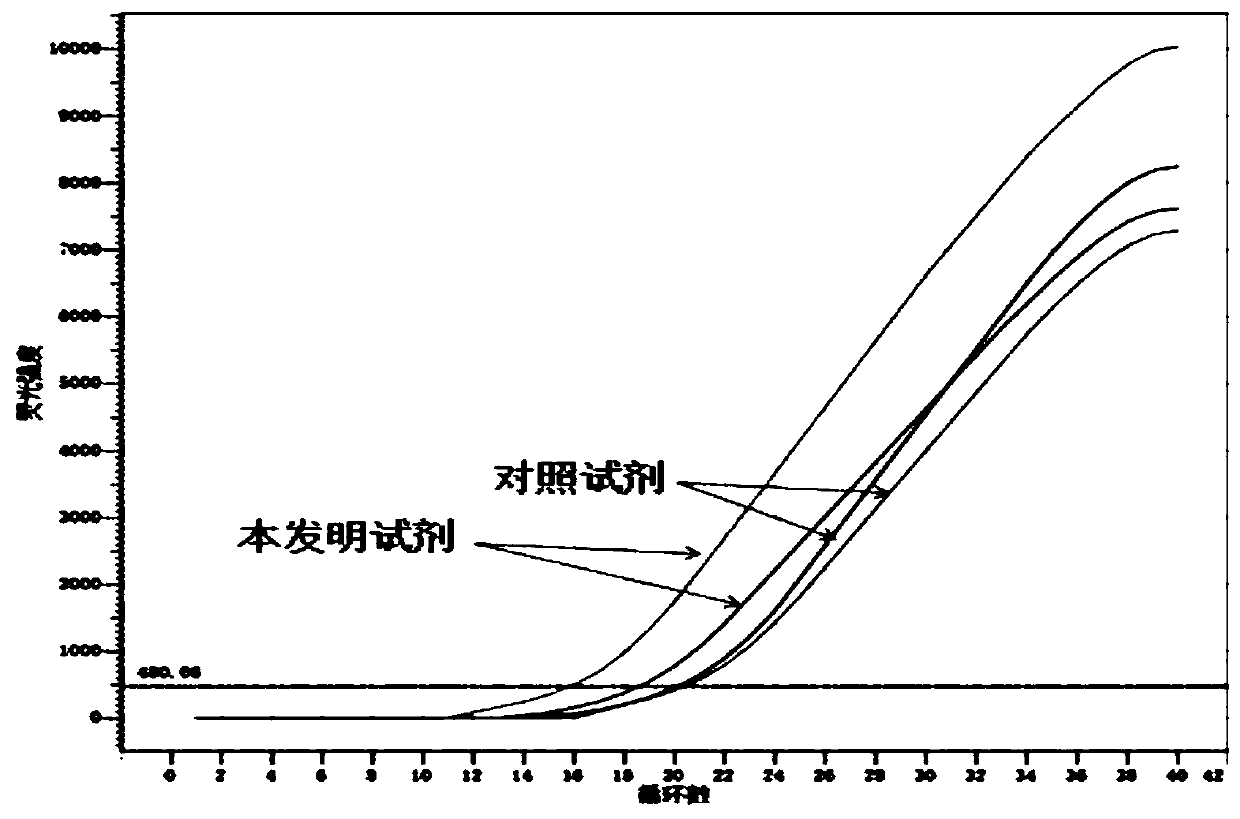

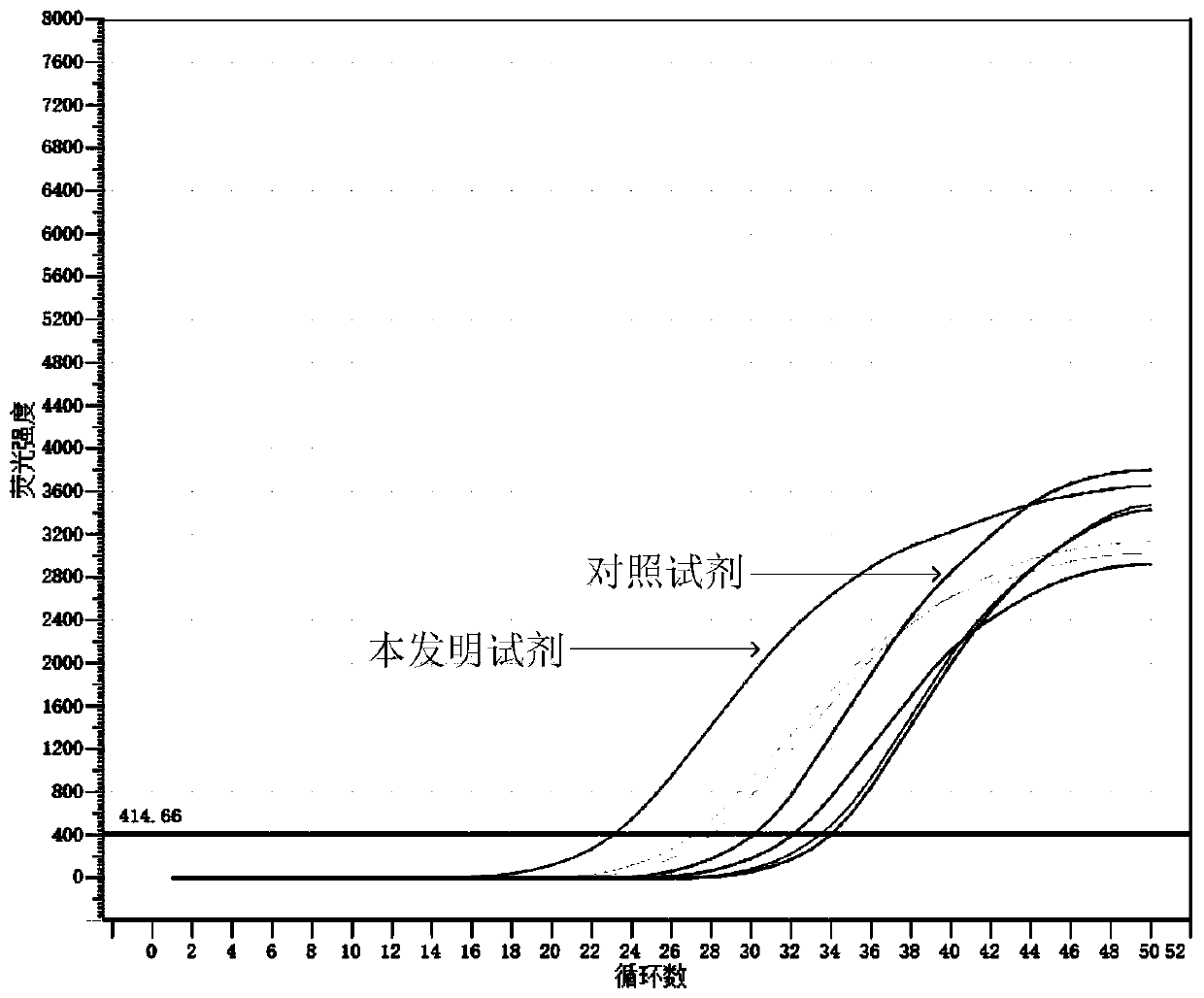

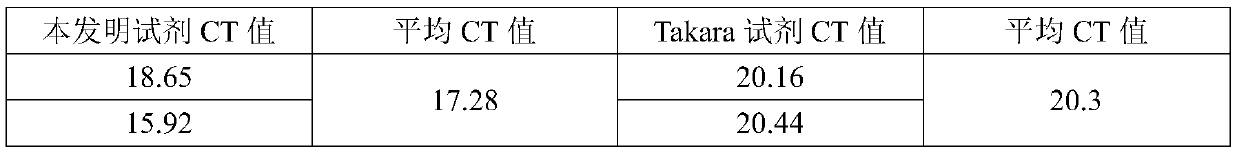

Lysate, nucleic acid extraction kit, and nucleic acid extraction method for nucleic acid extraction

ActiveCN110684764AReasonable ratioFully lysedMicrobiological testing/measurementDNA preparationLysisActive agent

The invention discloses a lysate, nucleic acid extraction kit, and nucleic acid extraction method for nucleic acid extraction. The lysate for the nucleic acid extraction is prepared from 0.5 to 2M ofsodium salt, 2 to 5M of guanidine salt, 1 to 5mM of a metal ion complexing agent, 0.25% to 1% of a nonionic surfactant, and 1% to 3% of PEG, and the molecular weight of the PEG is 6000 to 10000 Da, preferably 8000 Da. The lysate has a reasonable ratio, cells can be fully and effectively lysed, the lysis efficiency is high, so that the nucleic acids in the cells can be fully released, and the nucleic acids with higher concentration and purity can be obtained, and the quality and extraction efficiency of the nucleic acids are improved advantageously; and according to the lysate and the kit, digestion and removal of protein can be conducted without the aid of proteinase K during the entire nucleic acid extraction process, alcohols are not usedfor precipitate the nucleic acids,the obtained nucleic acids have high purity, and fragments are complete.

Owner:HANGZHOU BIGGER FISH BIOTECHNOLOGY CO LTD

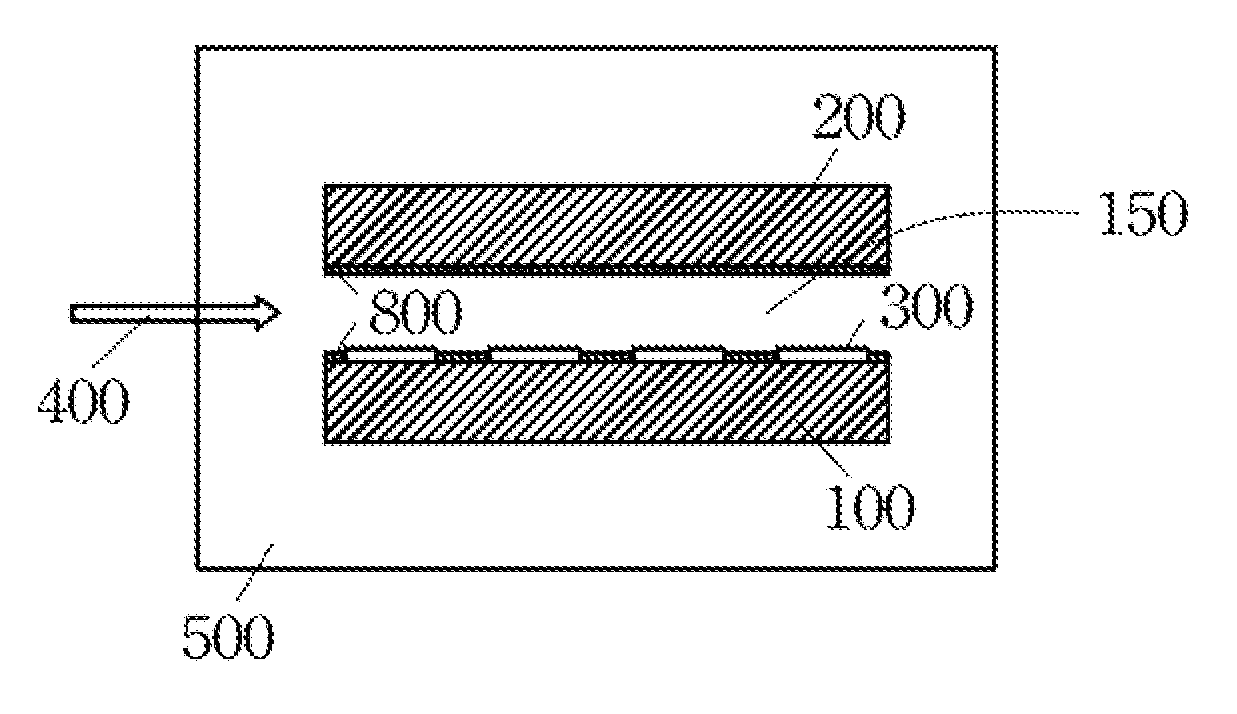

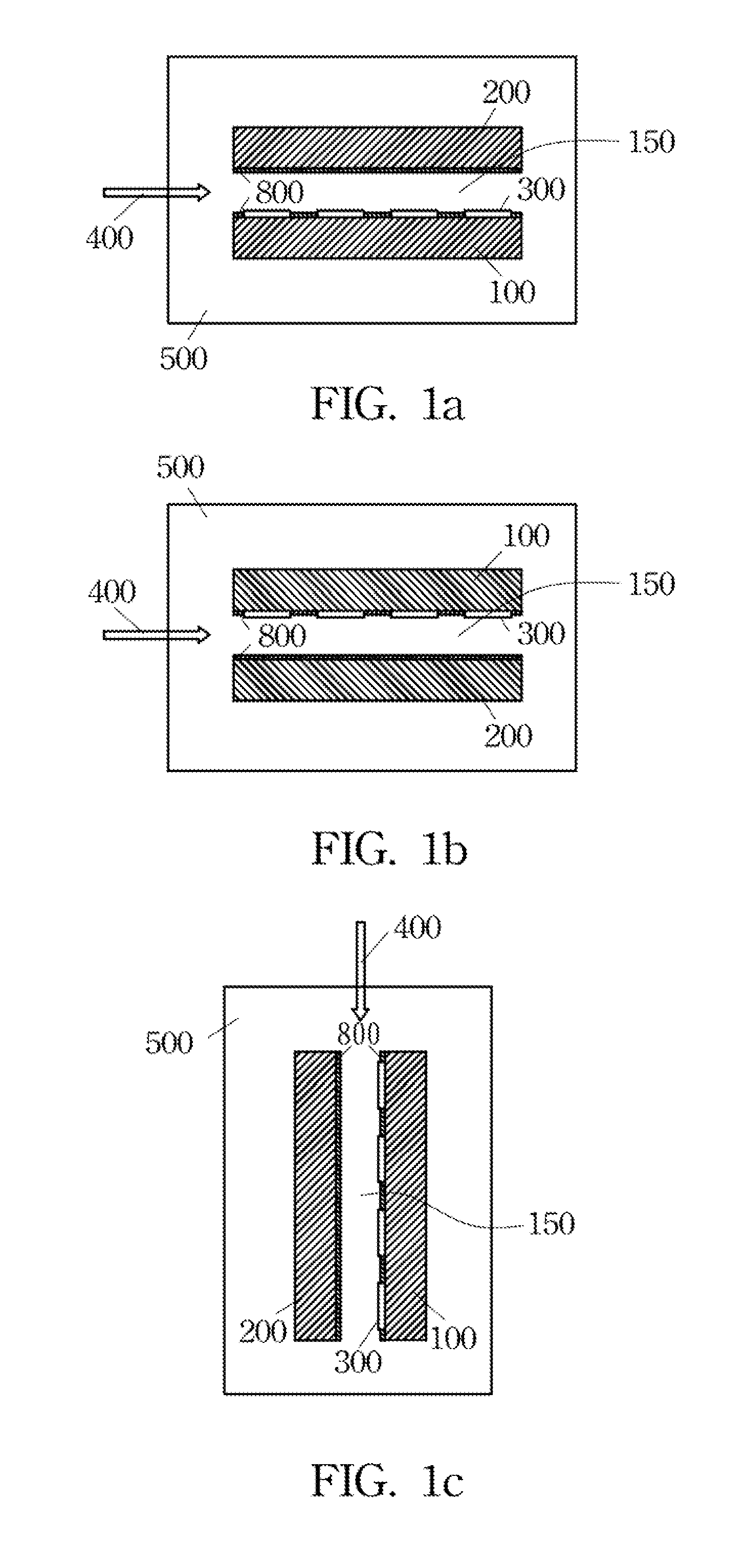

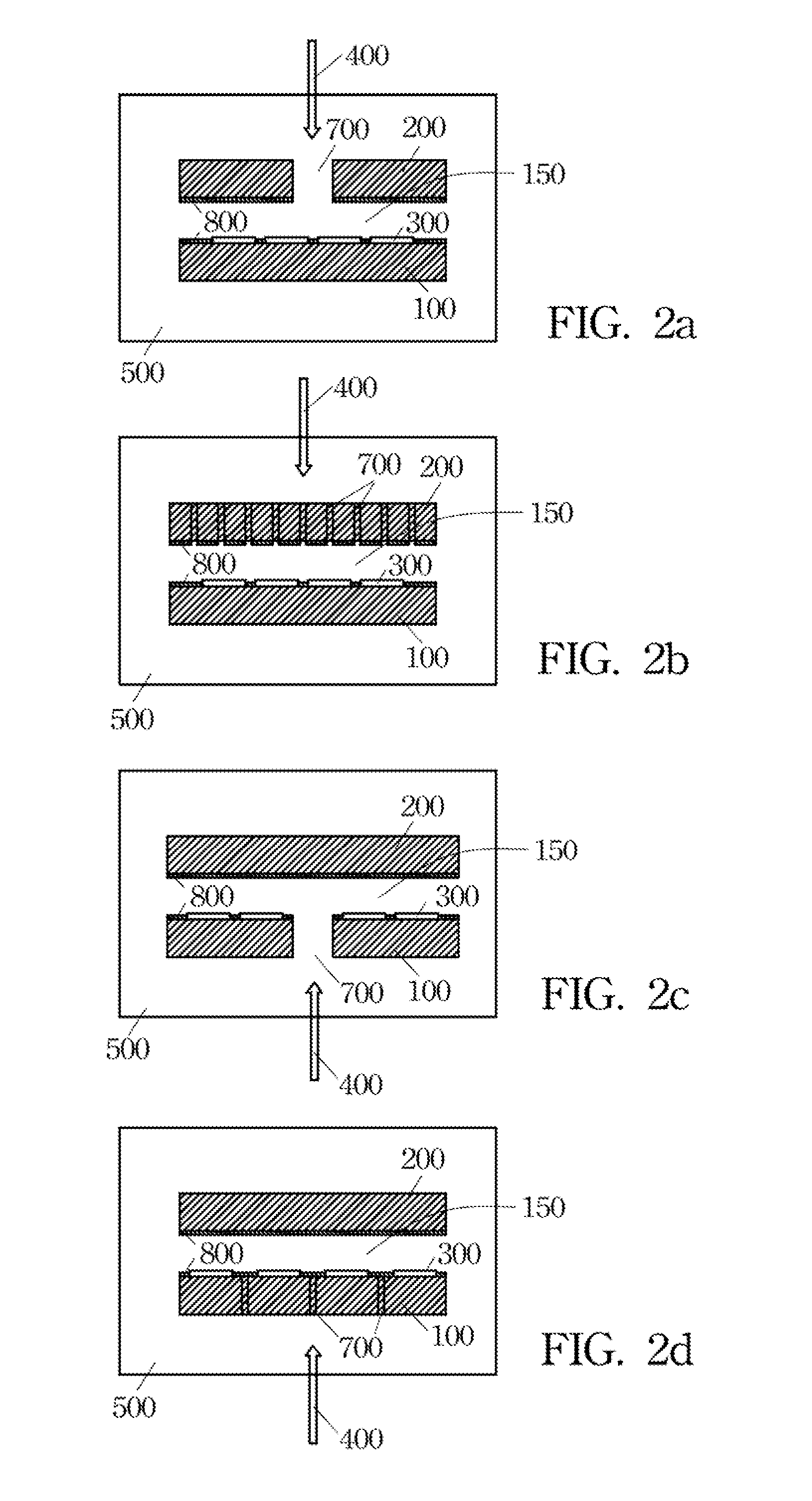

Reactor, chemical vapor deposition reactor, and metalorganic chemical vapor deposition reactor

InactiveUS20110155061A1Efficient preparationQuality improvementSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringChemical vapor deposition

A reactor for film deposition having a first heating unit and the second heating units is described. The temperature of each heating unit is controlled individually by heating and / or cooling means. The first heating unit and the second heating unit are disposed face-to-face to each other to form a reaction region therein, and their inner sides are placed with an inclined angle. At least one substrate is disposed on the inner surface of the first heating unit. The temperature of the second heating unit can be adapted to a temperature higher than the temperature of the first heating unit to improve the thermal decomposition efficiency of input reactants so that a low-temperature film deposition can be accomplished.

Owner:NAT CHIAO TUNG UNIV

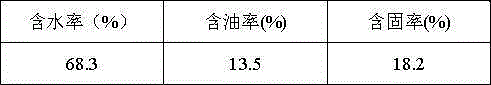

Low energy consumption drying treatment technology of residual activated sludge

InactiveCN106698886AImprove dehydration efficiencyDehydration fastSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeActivated sludge

The invention discloses a low energy consumption drying treatment technology of residual activated sludge. The treatment technology comprises the following steps: sending the residual activated sludge to a high speed shearing homogenizing tank, adding a treatment agent to the homogenizing tank, shearing and homogenizing the residual activated sludge and the treatment agent at 0-20 DEG C for 0.5-1 h, sending the obtained mixture to a sludge dehydrating machine, dehydrating the mixture to obtain a dehydrated sludge cake and sewage, sending the sewage to a sewage plant, further treating the sewage, sending the dehydrated sludge to a molding machine, extruding the dehydrated sludge to form strips, allowing the strips to enter a solar multilayer mesh belt type low temperature drying box through a conveyor belt, and drying the strips to obtain dried sludge with the water content being less than 15%. The technology decreases the water content of the residual sludge to 15% or less from 97% or above, and greatly reduces the volume of the sludge, and the dried sludge can be used as a further recycling raw material, or can be burnt.

Owner:CHINA PETROLEUM & CHEM CORP +1

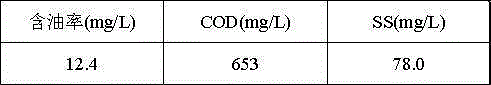

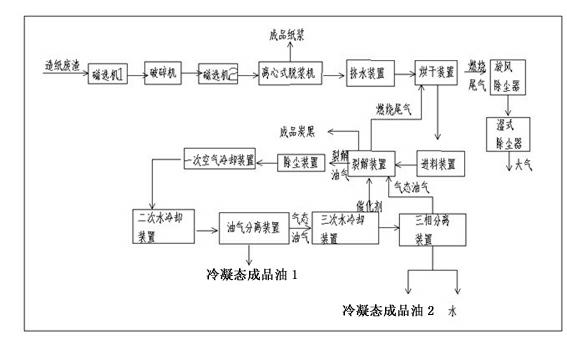

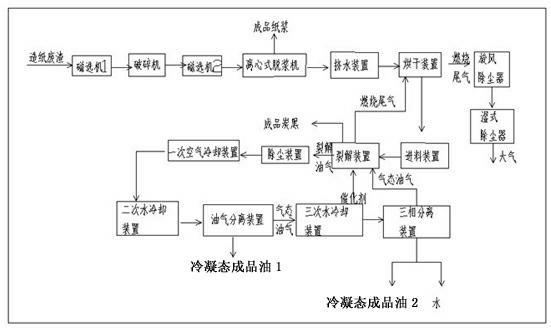

Method for recycling papermaking waste residues

InactiveCN102366756ASmall sizeAvoid destructionSolid waste disposalPaper recyclingPulp and paper industryCracking reaction

The invention discloses a method for recycling papermaking waste residues, belonging to the technical field of papermaking waste residue treatment. The method comprises the following steps: magnetic separation, stave processing, centrifugal deslurrying, squeezing water, drying, cracking and cracking oil-gas separation. The method fully utilized various ingredients of waste residues, can achieve the purpose of recycling the papermaking waste residues, and can eliminate the damage of papermaking waste residue to the environment.

Owner:仁精科技(昆山)有限公司

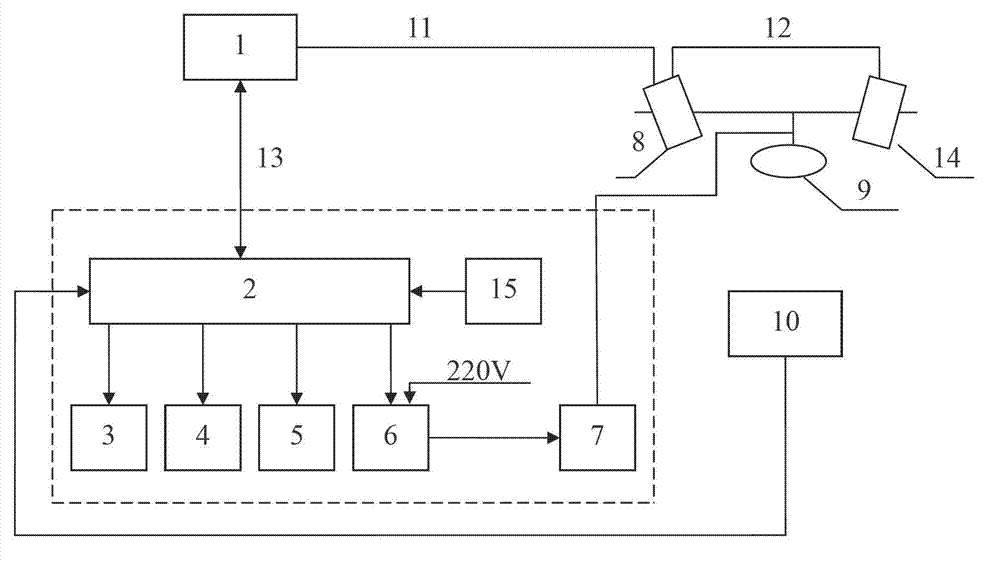

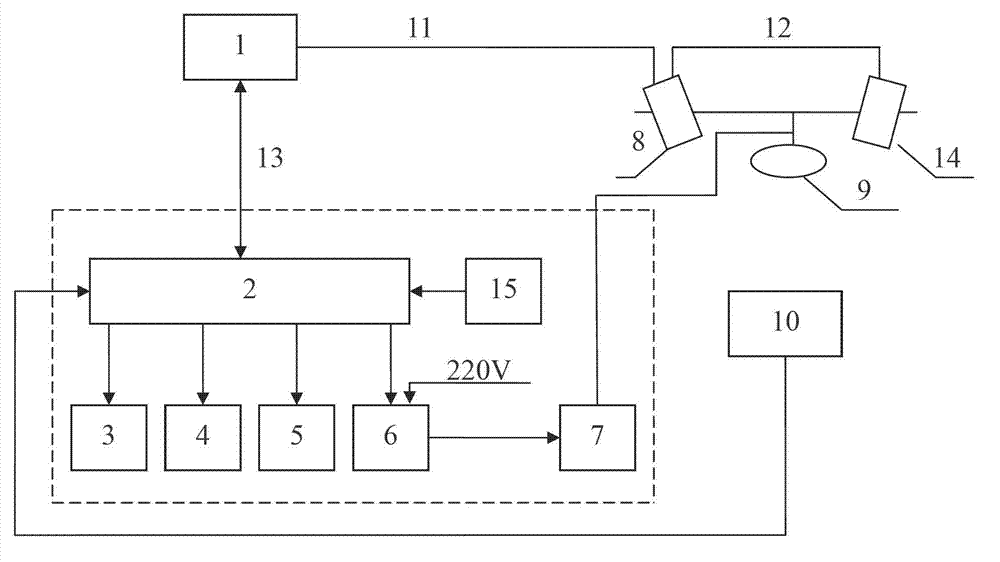

System for detecting fracture splitting notch of connecting rod of automobile based on machine vision

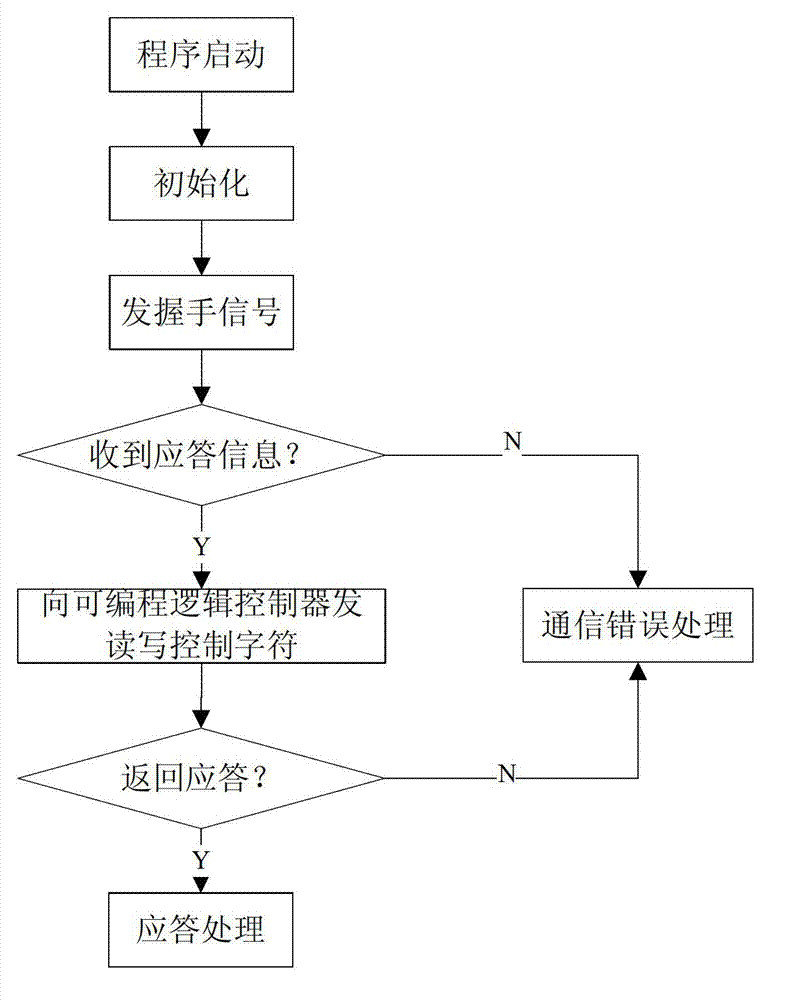

InactiveCN102967888AImprove cracking efficiencyReduce workloadOptical detectionMachine visionProgrammable logic controller

The invention discloses a system for detecting a fracture splitting notch of a connecting rod of an automobile based on machine vision, which intends to overcome the problem that the connecting rod with the facture cracking trough not processed is cracked. The system comprises a computer, a programmable logic controller, an output success indicator light, an output failure indicator light, an output alarming light, a relay, a light source controller, a No. 1 camera, a light source, a photoelectric switch, a No. 2 camera and a power supply, wherein the No. 1 camera is connected with the computer through a camera line; the No. 2 camera is connected with the No. 1 camera through the camera line; the computer is connected with the programmable logic controller by a communication line; the light source is connected with the light source controller by a wire; the photoelectric switch is connected with a first input port I 0.0 of the programmable logic controller by the wire; the relay is connected with the light source controller by the wire; the programmable logic controller is connected with the power supply by the wire; and control pins of the output success indicator light, the output failure indicator light, the output alarming light and the relay are sequentially connected with the output ports Q 0.0, Q 0.1, Q 0.2 and Q 0.3 of the programmable logic controller by the wires.

Owner:JILIN UNIV

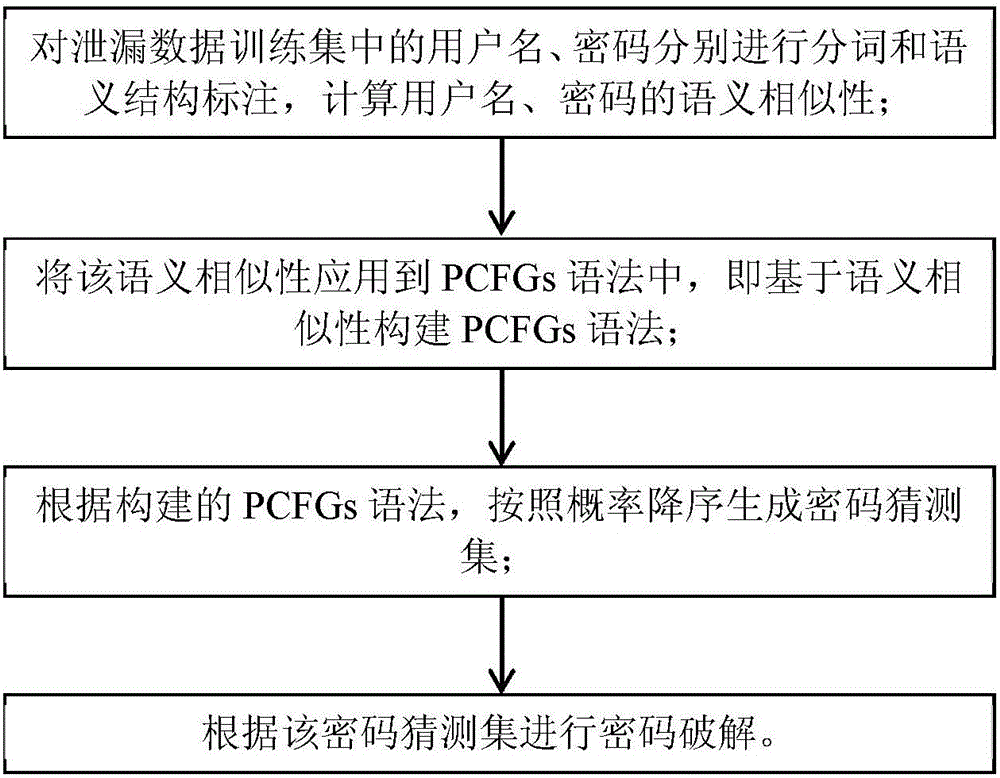

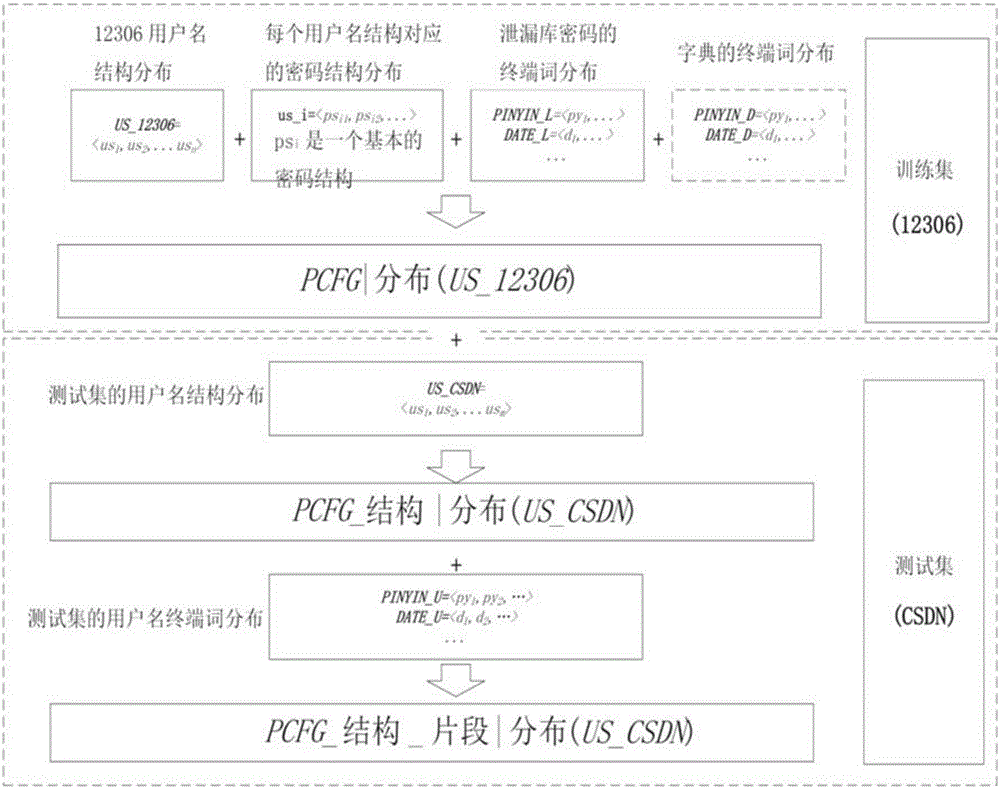

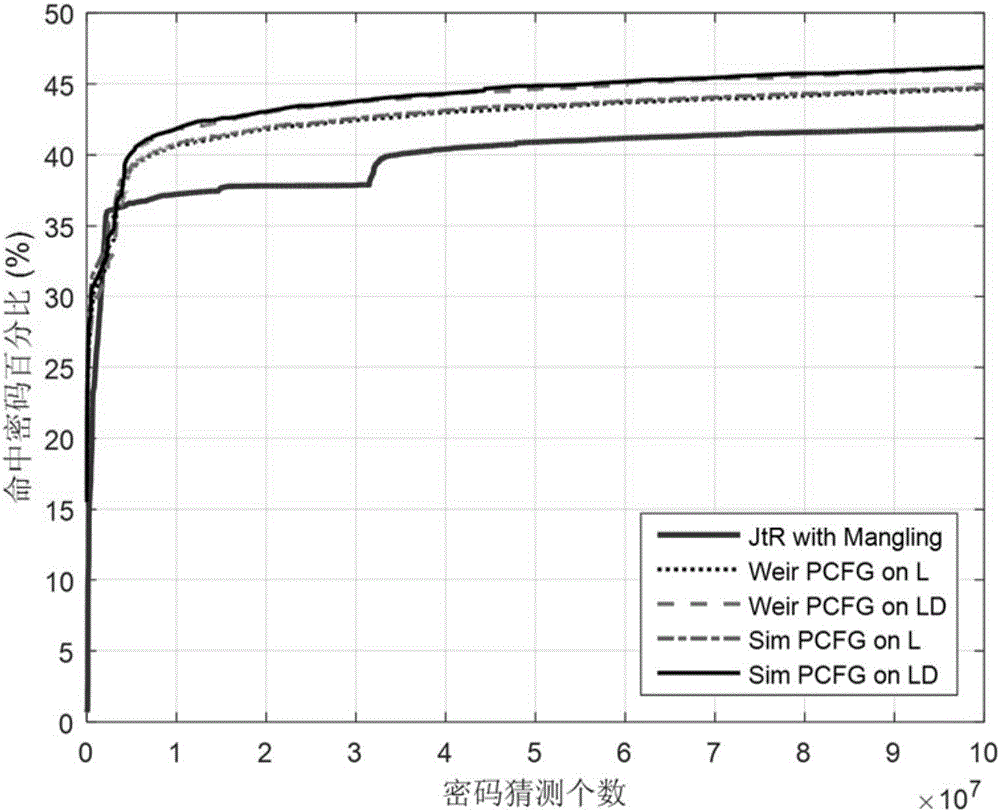

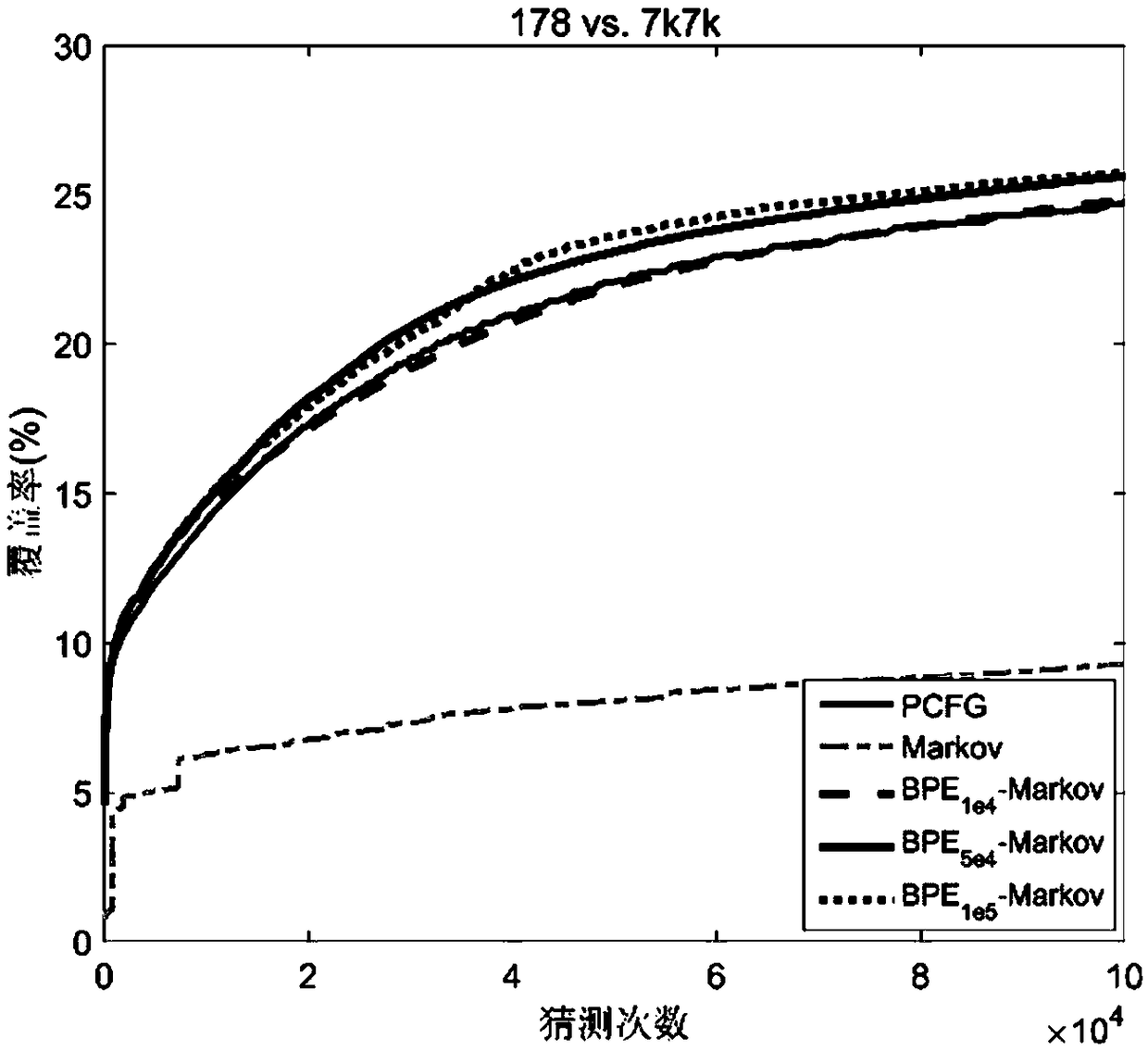

Password guessing set generating method and password cracking method based on user name information

InactiveCN106803035AImprove cracking efficiencyHigh guessing success rateDigital data protectionDigital data authenticationPasswordLabelling

The invention discloses a password guessing set generating method and a password cracking method based on user name information. The password cracking method comprises the steps of: 1) labelling user names and passwords of a data training set leaked according to word segmentations and semantic structures, calculating the semantic similarity of the user names and passwords, wherein the semantic similarity comprises semantic structure similarity and semantic portion similarity; 2) applying the semantic similarity to PCFGs grammar, in another word, PCFGs grammar is built based on the semantic similarity; 3) building PCFGs grammar according to step 2), generating a password guessing set according to the probability of descending; 4) cracking the password according to the password guessing set. The password guessing set generating method and password cracking method have the advantages of utilizing the portion similarity and the structure similarity of the usernames and passwords, understanding the constitution semantic of the password, generating the password guessing set, and improving the password cracking efficiency.

Owner:INST OF INFORMATION ENG CAS

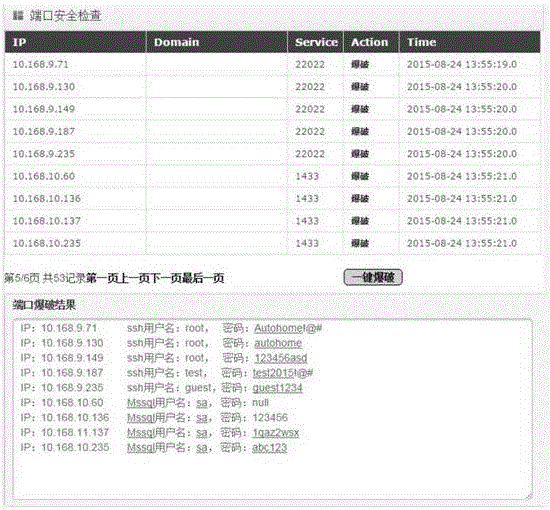

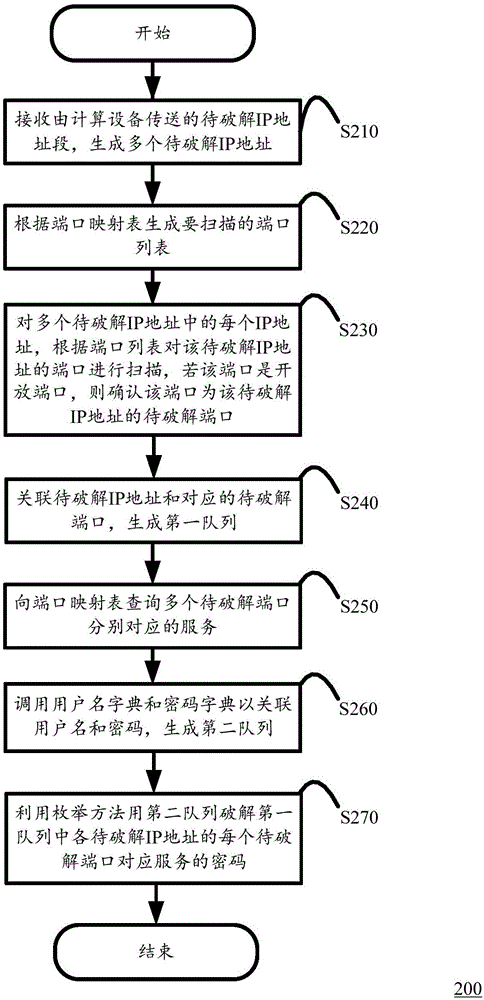

Port security check method, device and system

InactiveCN105721472AImprove security inspection efficiencyImprove cracking efficiencyCryptographic attack countermeasuresOpen portPassword

The invention discloses a port security check method executed in a server. A mapping relationship of ports and services as a port mapping table is stored in the server. The port security check method comprises the following steps of: receiving an IP address segment to be cracked transmitted by calculation equipment to generate a plurality of IP addresses to be cracked; generating a port list to be scanned according to the port mapping table; scanning the port of each IP address in the plurality of IP addresses to be cracked according to the port list, and determining that the port is the port to be cracked of the IP address if the port is an open port; associating the IP address with the corresponding port to be cracked so as to generate a first queue; inquiring services respectively corresponding to the plurality of ports to be cracked from the port mapping table; associating a user name and a password by invoking a user name dictionary and a password dictionary so as to generate a second queue; and cracking passwords of services corresponding to various ports to be cracked of various IP addresses in the first queue by using the second queue through an enumerative method. The invention further provides a corresponding device and system.

Owner:BEIJING CHESHANGHUI SOFTWARE

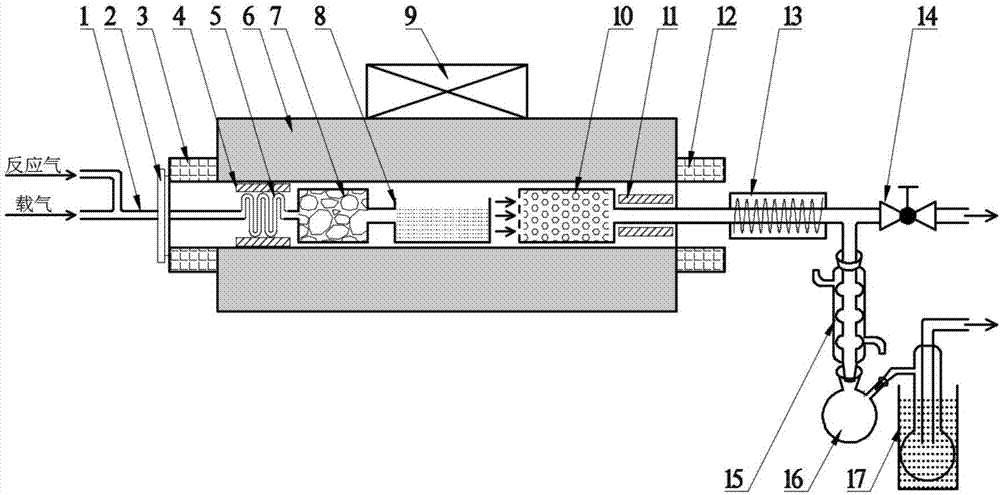

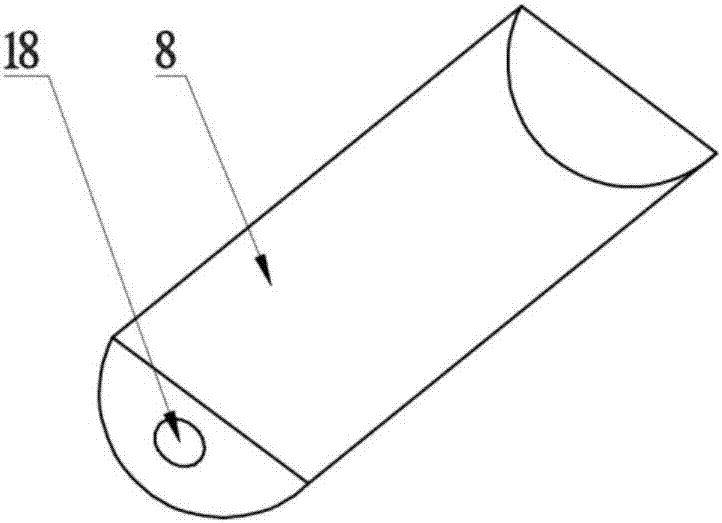

Device and method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization

ActiveCN107987866ARealize online catalytic reformingAchieve hierarchical enrichmentLiquid hydrocarbon mixture productionCatalytic pyrolysisLiquid product

The invention discloses a device and a method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization. The device comprises a gas inlet system for providing reaction gas and carrier gar, wherein an outlet end of the gas inlet system is connected with a preheating system, an outlet end of the preheating system is connected with a thermal-insulation filtration system, an outlet end of the thermal-insulation filtration system is connected with a reaction system, an outlet end of the reaction system is connected with a product collecting system, a productthermal insulation system is arranged on a pipeline between the reaction system and the product collecting system, and the outer sides of the preheating system, the thermal-insulation filtration system and the reaction system are sleeved with a microwave generation system. Solid waste can be converted into high-value liquid product bio-oil and solid product pyrolytic carbon in an efficient reduction, harmless and recycling manner with a two-stage conversion method of microwave depolymerization and catalytic pyrolysis.

Owner:临沂市新大环保科技有限公司

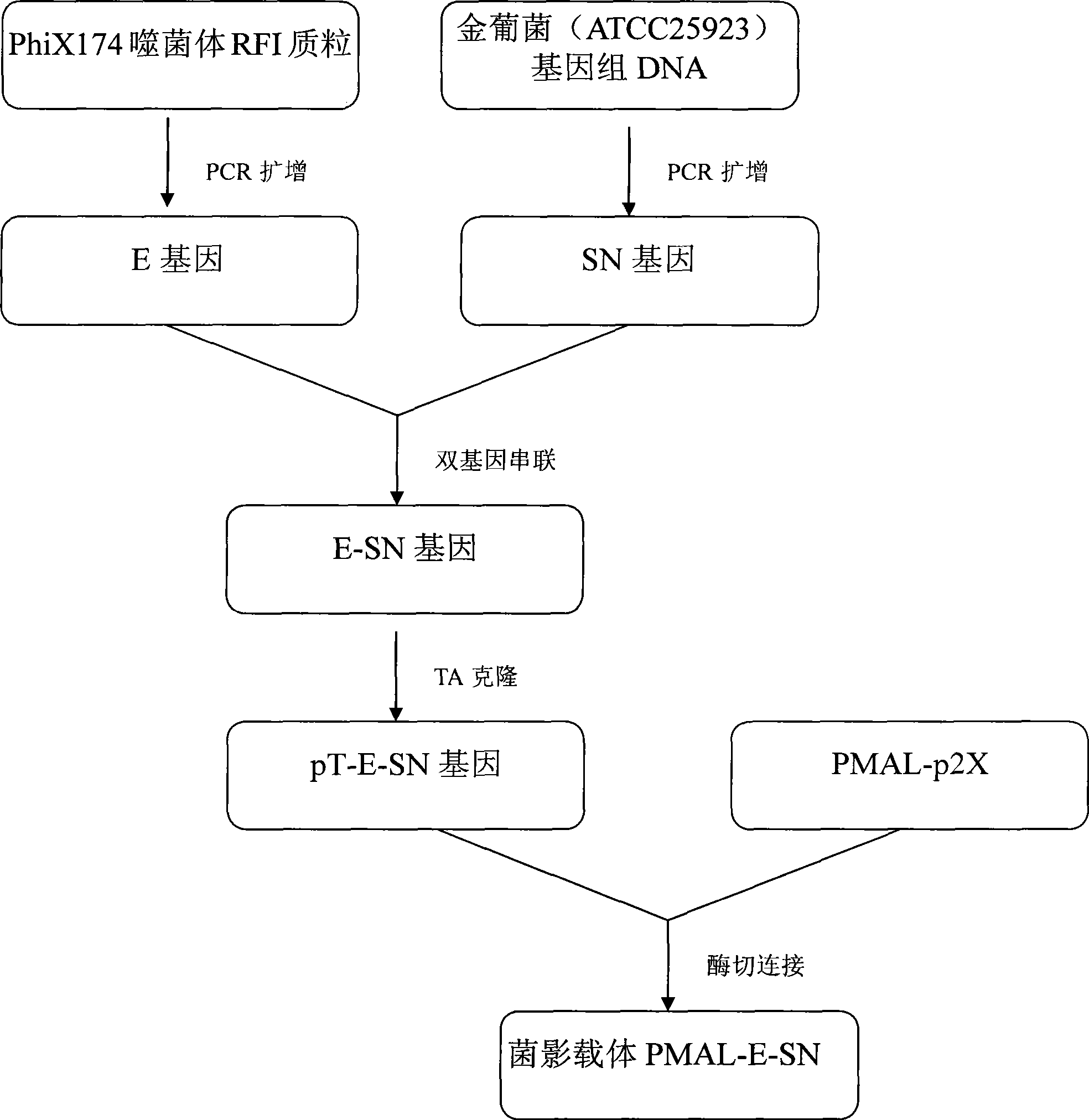

Construction of bacteria ghost vector PMAL-E-SN and its application in bacillus coli

InactiveCN101457231ASame protection rateImprove cracking efficiencyBacteriaFermentationEscherichia coliStaphylococcus cohnii

The invention discloses a bacterial ghost vector PMAL-E-SN construction and application thereof in an escherichia coli comprising an E gene obtained by PCR amplification using a PhiX174 phage RFI plasmid as a template; an SN gene obtained by PCR amplification using a staphylococcus aureus standard strain ATCC25923 genome DNA as a template; an E-SN gene obtained by serial connecting the E gene and the SN gene by the Linker of the fifteen flexible amino acids; a positive plasmid pT-E-SN sequencing screened by coupling an E-SN gene PCR amplification outcome and a pMD18-T vector and the bacterial ghost vector PMAL-E-SN constructed by the recombinant plasmid pT-E-SN with right sequencing and the plasmid vector PMAL-p2X. The bacterial ghost vector PMAL-E-SN of the invention enables the E gene and the SN gene to obtain the high efficiency expression through a ''tac'' strong promoter and a malE start signal, successfully prepares the escherichia coli bacterial ghost and the degradation efficiency can reach 99.99 The invention induces a secondary killing gene SN, obtains good effect by combining the E gene and the SN gene to a high efficiency expression vector PMAL-p2X and is widely used in preparation of the escherichia coli bacterial ghost.

Owner:JILIN UNIV

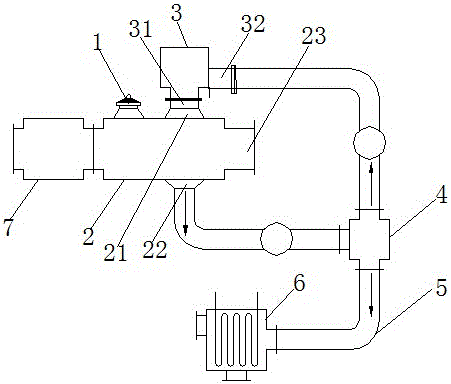

Solid organic material cracking method and system

ActiveCN106338066AImproved microwave absorption propertiesStrong process controllabilityProductsReagentsMicrowaveProduct gas

The invention provides a solid organic material cracking method and system. The method comprises the following steps of: A, pre-treating a solid organic material; B, sending the pre-treated solid organic material into a cracking device; C, heating a gas medium to 350-700 DEG C; D, continuously importing the heated gas medium into the cracking device to act on the solid organic material with microwave, so as to carry out cracking to obtain a solid product and a mixed gaseous product; and E, importing a part of the obtained mixed gaseous product into a gas heating device in the step C so as to heat the mixed gaseous product to 350-700 DEG C to be circularly used for the cracking in the step D. The process can effectively decrease the cracking energy consumption and the cracking time, and can save the cost.

Owner:成都德理克新材料科技有限公司

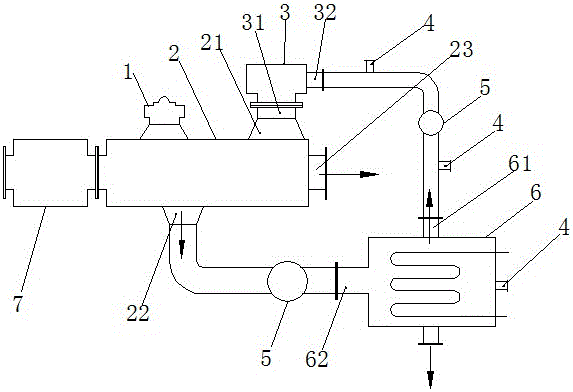

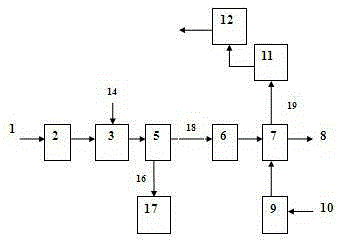

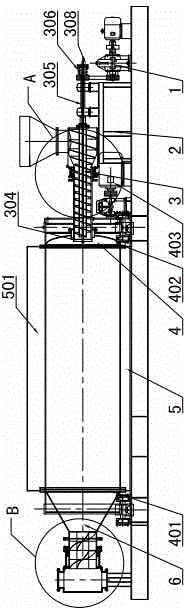

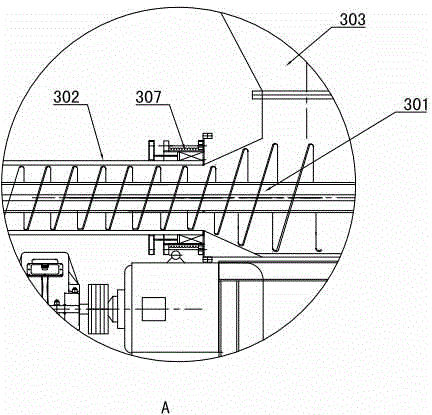

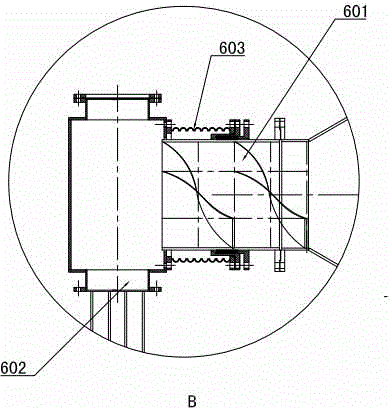

Special oil-sludge cracking device and oil-sludge cracking process

InactiveCN104449795ANo adhesionImprove cracking efficiencySludge treatment by pyrolysisLiquid hydrocarbon mixture productionOil sludgeFuel oil

The invention relates to a special oil-sludge cracking device and an oil-sludge cracking process, belonging to the technical field of equipment and processes for preparation of fuel oil from oil sludge. The special oil-sludge cracking device comprises a feeding system, a cracking furnace (4), a heating system (5) and a discharging system (6). The special oil-sludge cracking device is characterized in that the feeding system comprises a driving device (1) and a screw feeding mechanism (3), the screw feeding mechanism (3) comprises a conical screw propeller (301), the conical screw propeller (301) is provided with a conical screw section of which the diameter is decreased gradually, a feeding cylinder (302) which adapts to the conical screw propeller (301) is sleeved by the conical screw propeller (301), one end of the conical screw propeller (301) is used for driving through the driving device (1), the other end of the conical screw propeller (301) is extended into the cracking furnace (4), and the upper part of the conical screw propeller (301) is provided with a hopper (303). The special oil-sludge cracking device and the oil-sludge cracking process have the advantages that automatic and continuous feeding and discharging can be realized, oil and gas leakage can be prevented, and the efficiency is high.

Owner:冯强

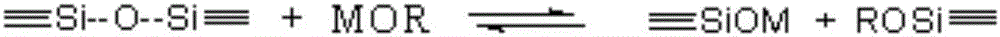

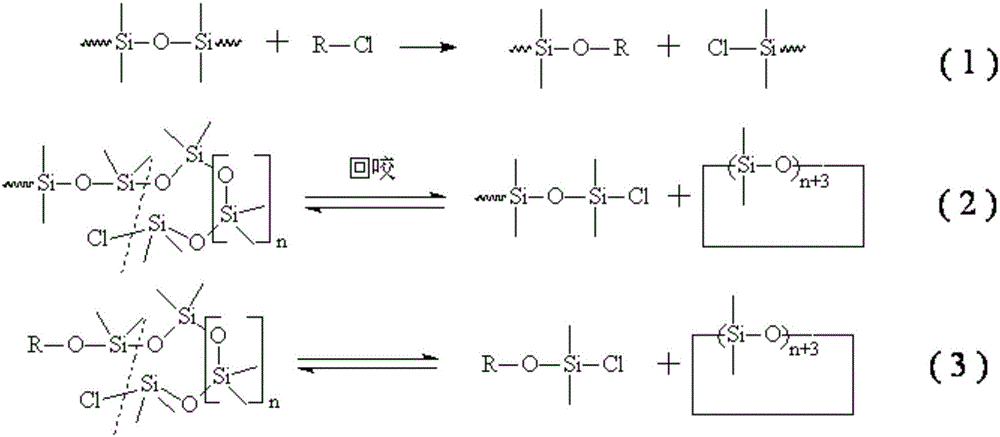

Method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances

The invention relates to a method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances. The method comprises the following steps: a chemical reaction of an organosilicon halogenation agent and a polysiloxane main chain in silicone rubber is carried out to break the polysiloxane main chain into polysiloxanes with silicon-chlorine bonds, and the polysiloxanes with silicon-chlorine bonds undergo a series of back-biting reactions and are degraded into an organosilicon micro-molecule and organosilicon cyclic compound mixture; and organosilicon micro-molecules and organosilicon cyclic compounds obtained after cracking undergo a rearrangement reaction to obtain highly pure D4 used for synthesizing various organosilicon polymers and materials as a basic raw material.

Owner:SHANDONG UNIV

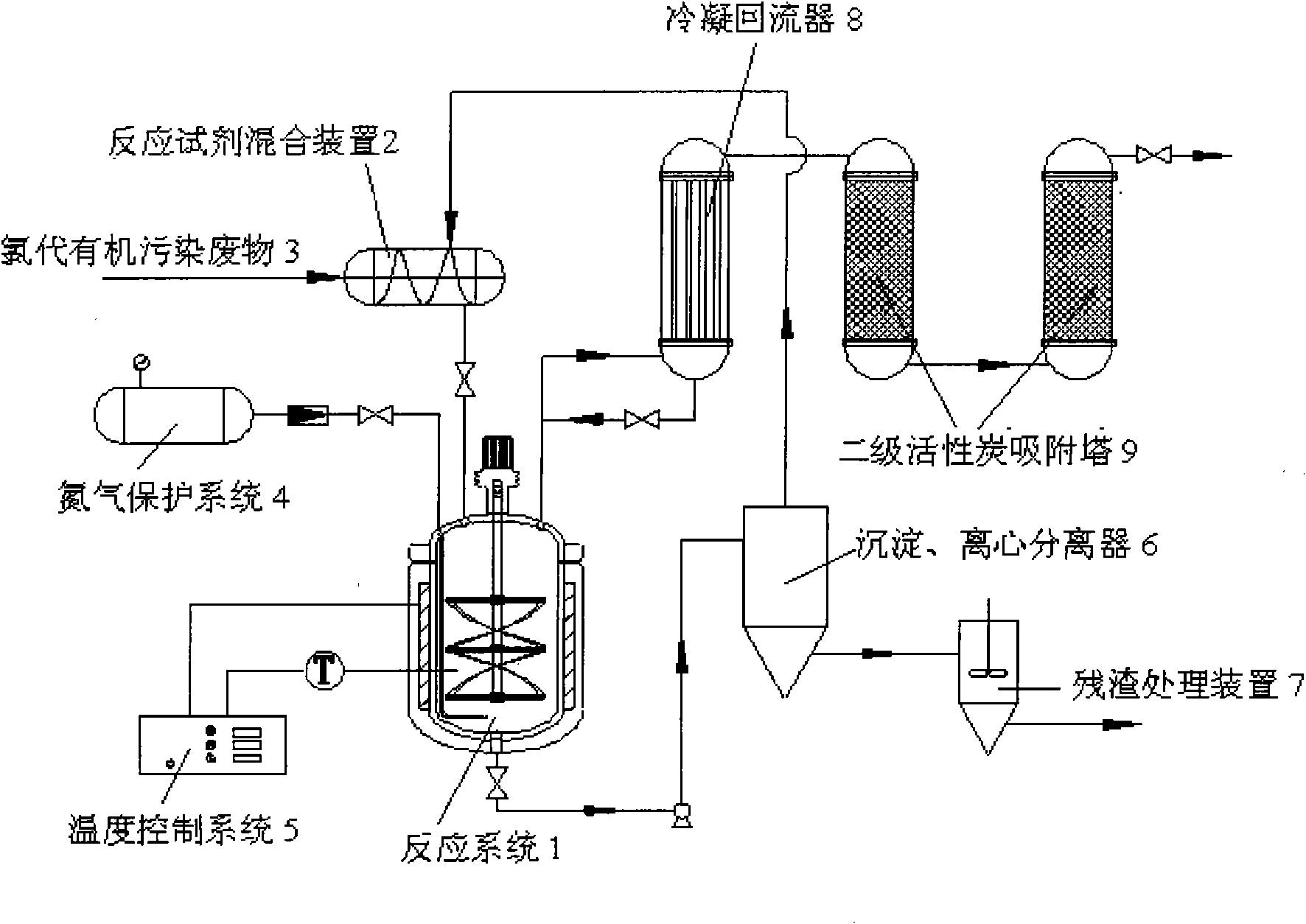

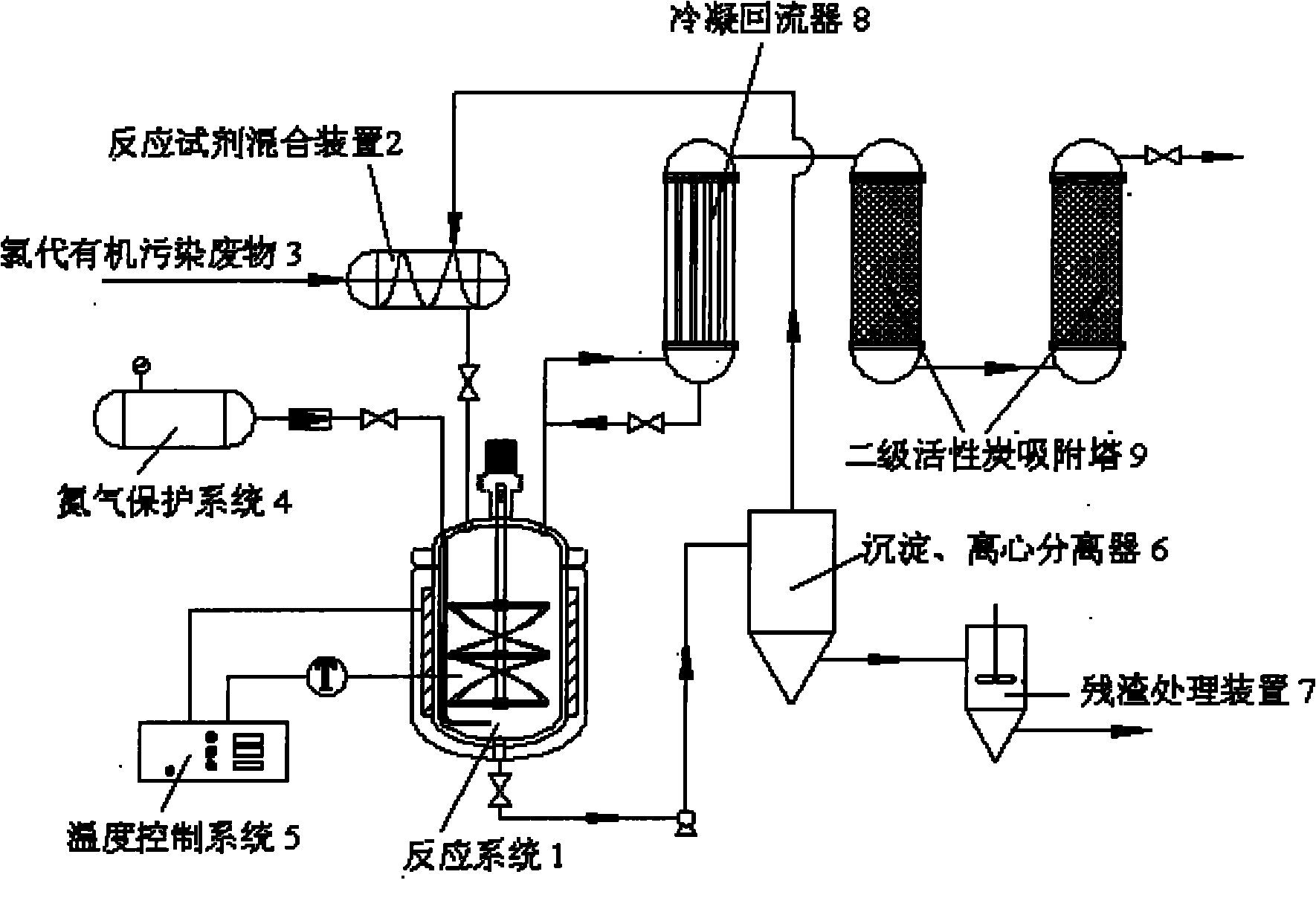

Base-catalyzed decomposition device and method for industrial waste containing chlorinated organic compound

InactiveCN102058953AHigh viscosityIncrease solid contentChemical protectionReaction rateDecomposition

The invention relates to a base-catalyzed decomposition device and method for industrial waste containing a chlorinated organic compound. A reaction system of the device is communicated with chlorinated organic polluting waste via a reaction reagent mixing device, communicated with a nitrogen gas protection system, connected with a temperature control system, communicated with a residue processing device via a deposition and centrifugal separator, and communicated with a secondary activated carbon absorption tower via a condensing reflux device, tail gas from the secondary activated carbon absorption tower is released into the atmosphere, and the deposition and centrifugal separator is communicated with the pipeline of the reaction reagent mixing device; and the decomposition method comprises the following steps of: firstly, adding the chlorinated organic pollutant, the hydrogen donors from the reaction reagent mixing device and the like into the reaction system; secondly, starting the nitrogen gas protection system; and finally, heating and stirring to realize base-catalyzed dechlorination decomposition of the pollutant. The decomposition method has the advantages of high reaction rate, low reaction temperature, small temperature fluctuation of the reaction system, large actual reaction quantity of the pollutant and small risk of secondary pollution.

Owner:TSINGHUA UNIV

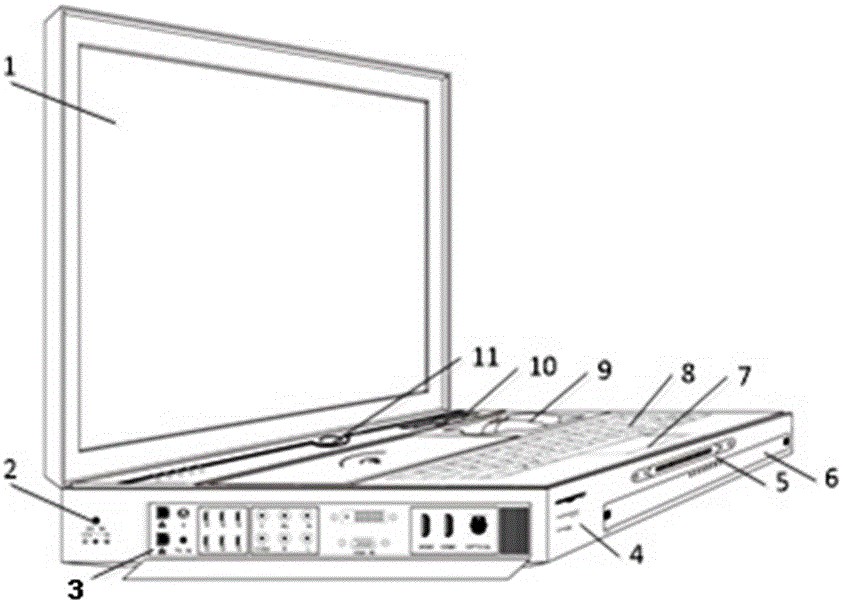

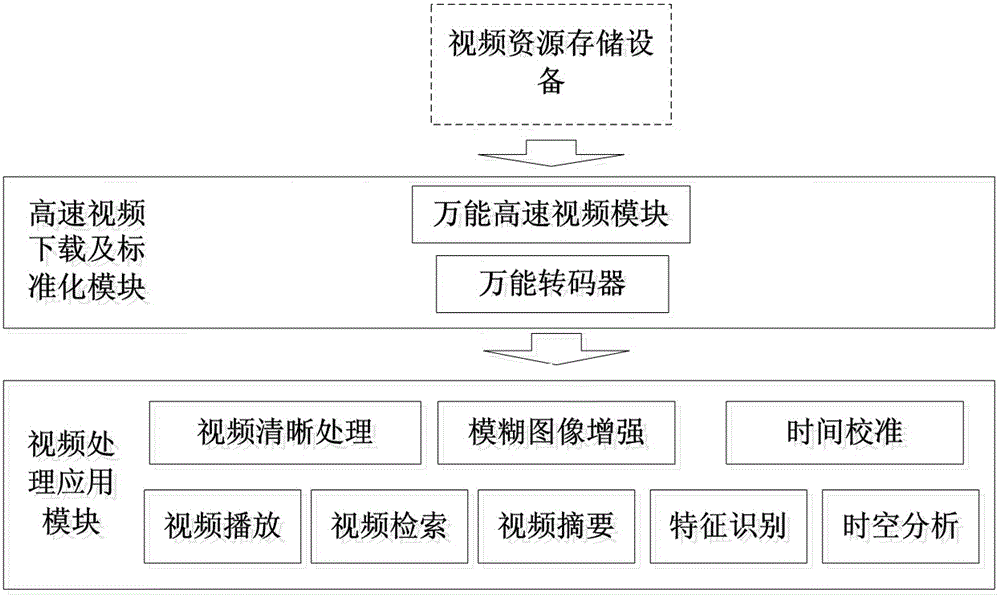

Portal mobile image investigation device

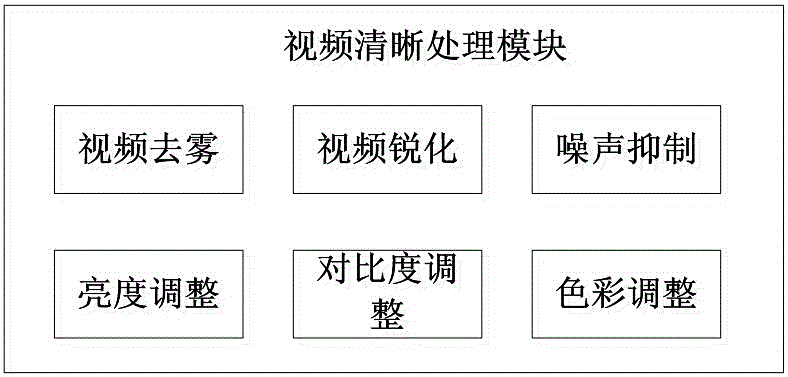

InactiveCN105141909AEasy accessImprove convenienceTelevision system detailsColor television detailsComputer graphics (images)Video processing

The invention relates to a portal mobile image investigation device. The portal mobile image investigation device comprises a box with a built-in video processing module; a display screen serves as the upper cover of the portal mobile image investigation device and is hinged to the box; an interface module for connection with an external video resource storage device and a slot matched with a compound card reader are arranged on the outer side of the box; the video processing module is composed of a high-speed video downloading and standardizing module and a video processing application module. The portal mobile image investigation device is capable of realizing fast access of various video resource storage devices and realizing high-speed downloading of video data and standard conversion of video file formats via the internal video processing module of the system; a plurality of video and image sharpening tools are provided while video downloading and format standardization are completed, and therefore, the quality of videos and images is improved; the portal mobile image investigation device, integrated in the portal box, is high in integrated level, small in volume and convenient for carrying.

Owner:ANHUI SUN CREATE ELECTRONICS

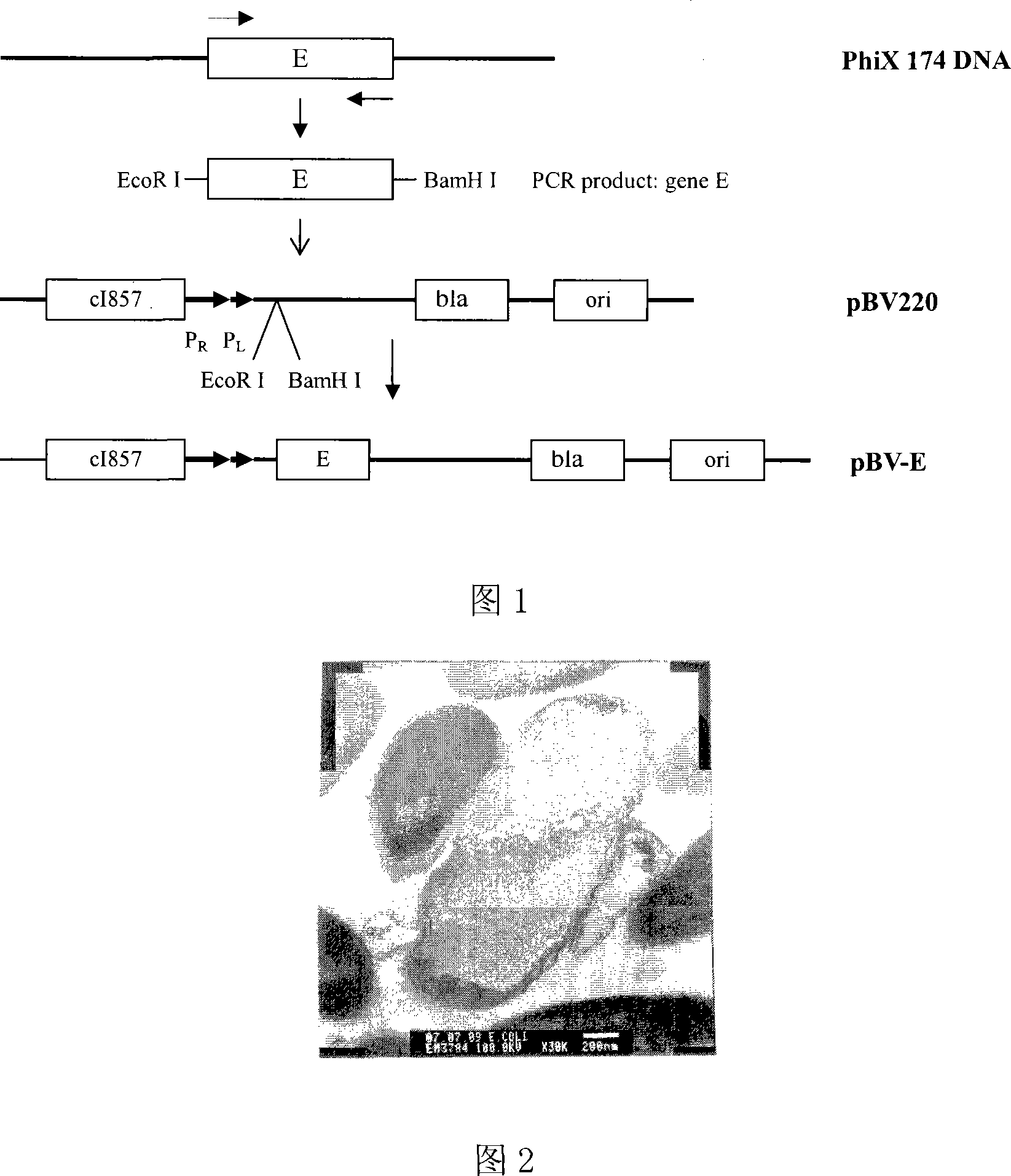

Bacillus coli perforating plasmid vector, construction method thereof and applications in bacterial ghost preparation

InactiveCN101182538AImprove cracking efficiencyBacteriaVector-based foreign material introductionDecompositionBiology

The invention discloses a colon bacillus perforated plasmid vector p BV-E and a construction method thereof; the invention also discloses the purpose of the colon bacillus perforated plasmid vector in the process of preparing the ghost of the colon bacillus, which belongs to the gene engineering field. The colon bacillus perforated plasmid vector of the invention adopts two promoters of pR and pL serial double promoters to express E gene and successfully prepares the ghost of the colon bacillus; the decomposition rate can reach 99.9613 percent which is 3 magnitudes higher than of the present perforated plasmid vector with pR or pL single promoter.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

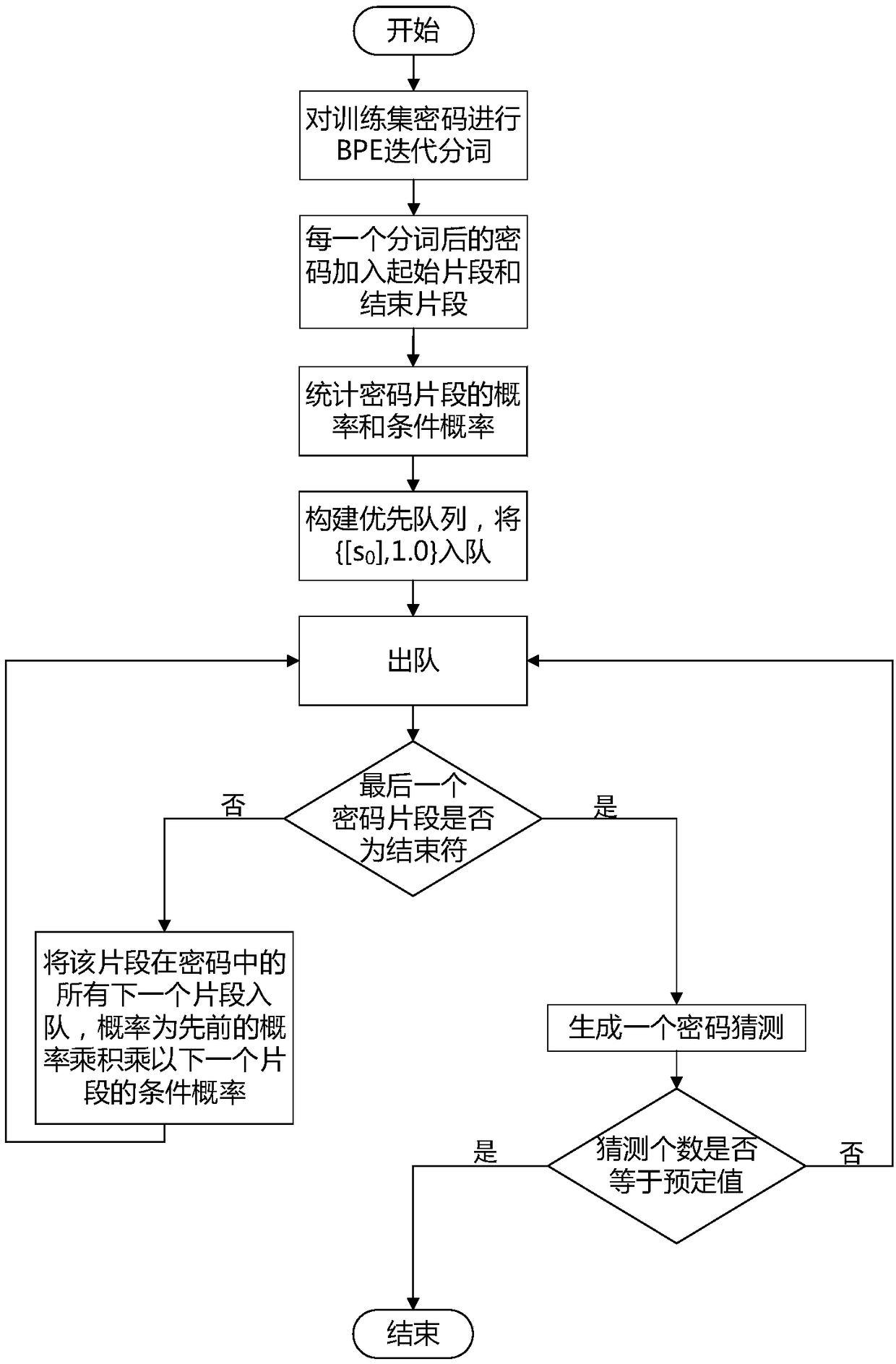

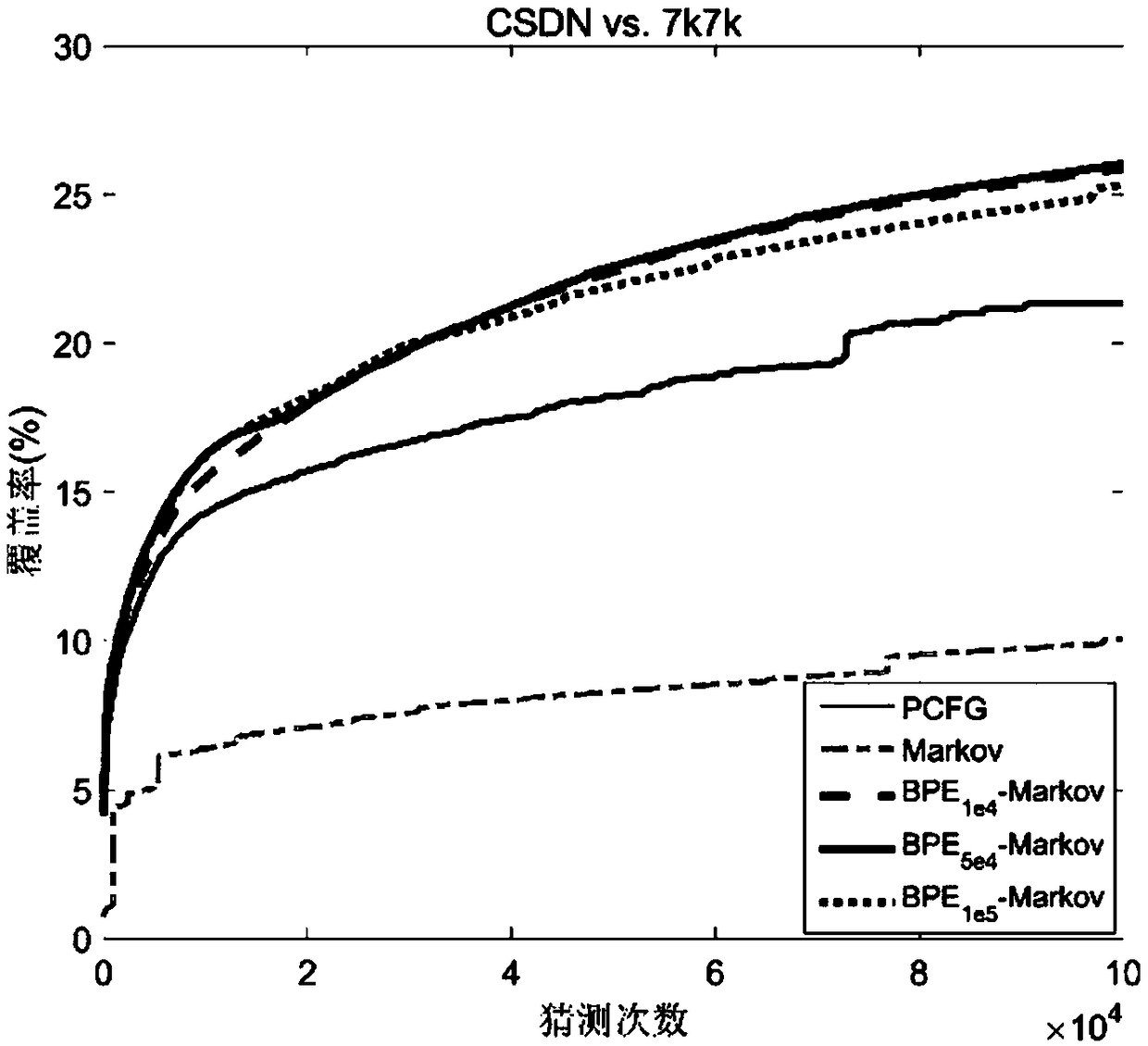

Password guessing set generation method based on byte pair encoding, password cracking method and device

ActiveCN109145582AImprove guessworkImprove efficiencyDigital data protectionDigital data authenticationPlaintextDecoding methods

The invention relates to a password guessing set generation method based on byte pair encoding, a password decoding method and a device. Firstly, byte pair encoding is used to segment the cipher of training set, and then Markov model is used to generate the cipher guess set according to the result of word segmentation. Further, the plaintext password is decoded by string matching using the password guess set. The invention fully utilizes the idea of statistical probability to segment the cipher, and uses Markov model to explore the correlation between the cipher components, thereby improving the cipher guess effect and the cipher decoding efficiency. The password guessing set generated by the invention is directly used for string matching, so that the password guessing set can be better generated and the security strength of the password can be evaluated.

Owner:INST OF INFORMATION ENG CAS

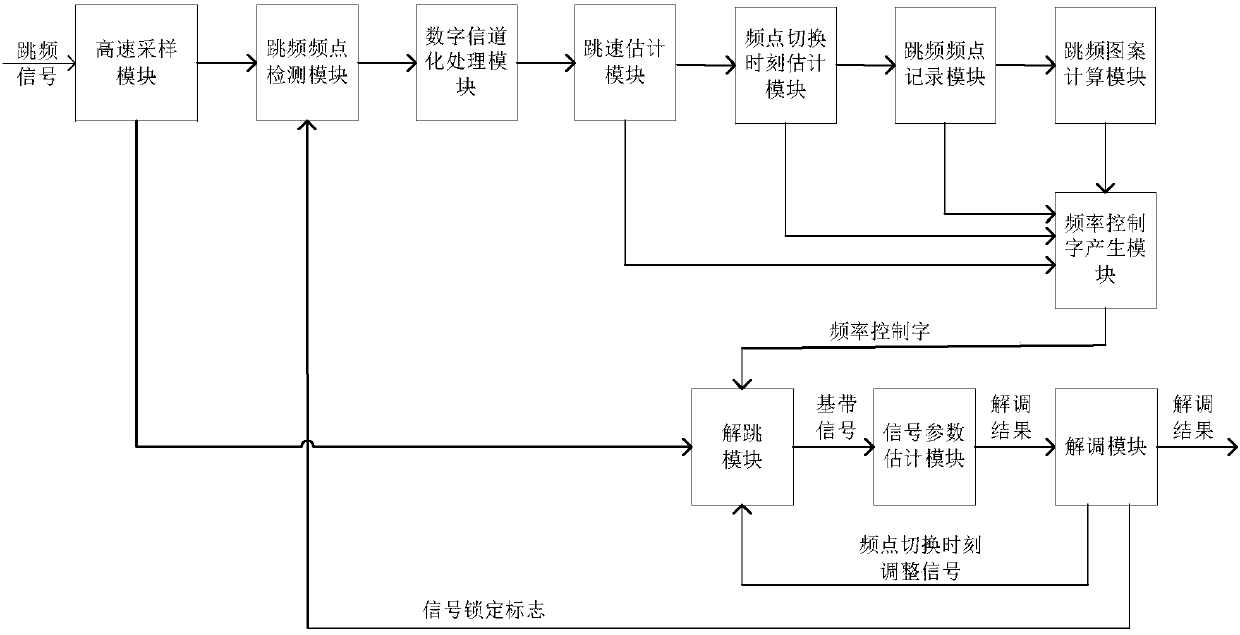

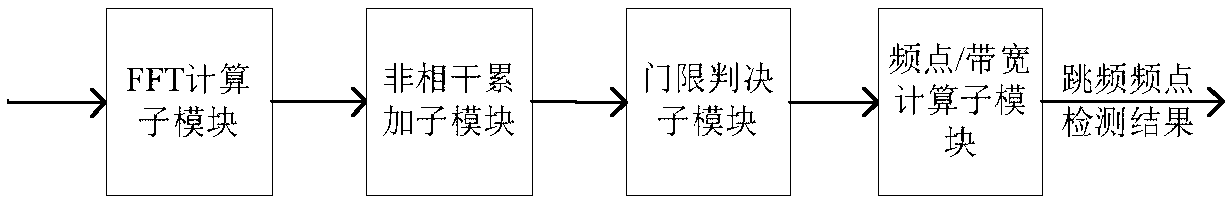

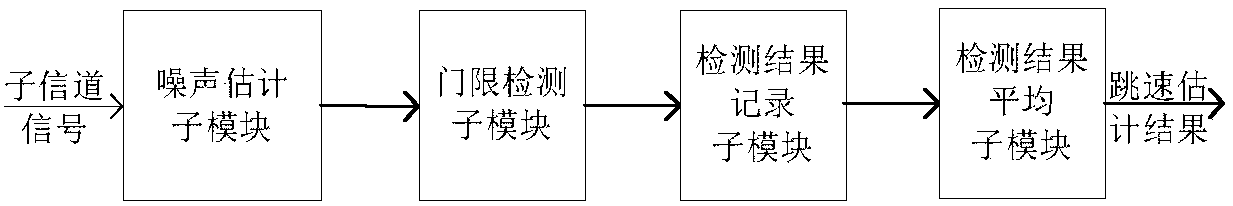

Non-cooperative frequency hopping signal deciphering method

ActiveCN107835036AImprove cracking efficiencyHigh success rate of crackingTransmissionFrequency spectrumFast algorithm

The invention provides a non-cooperative frequency hopping signal deciphering method. The non-cooperative frequency hopping signal deciphering efficiency can be obviously improved by using the methodprovided by the invention. The method is realized through the following technical schemes: firstly sampling the frequency band located by a frequency hopping signal through a frequency hopping signaldeciphering circuit, obtaining the spectrum through a FFT fast algorithm, and performing incoherent accumulation on N FFT results; estimating a core parameter of the frequency hopping signal by adopting a frequency hopping point estimation circuit, a hopping speed estimation circuit and a frequency hopping pattern estimation circuit, wherein the frequency hopping point estimation circuit initiallyestimates the signal bandwidth on each frequency hopping point to obtain the hopping speed of the frequency hopping signal, and estimates the frequency point switching moment of the frequency hoppingsignal; recording the frequency hopping points of the signal crossing more than two complete frequency hopping periods according to the time order, and determining the frequency hopping period; performing the de-hopping of the frequency hopping signal by the frequency hopping pattern estimation circuit according to the estimated frequency hopping point, the frequency hopping pattern and the hopping speed, and demodulating the frequency hopping signal according to the estimated parameter, and outputting a demodulation signal.

Owner:10TH RES INST OF CETC

Rearranged bacterial virus E gene, perforating plasmid vector containing the same and use thereof

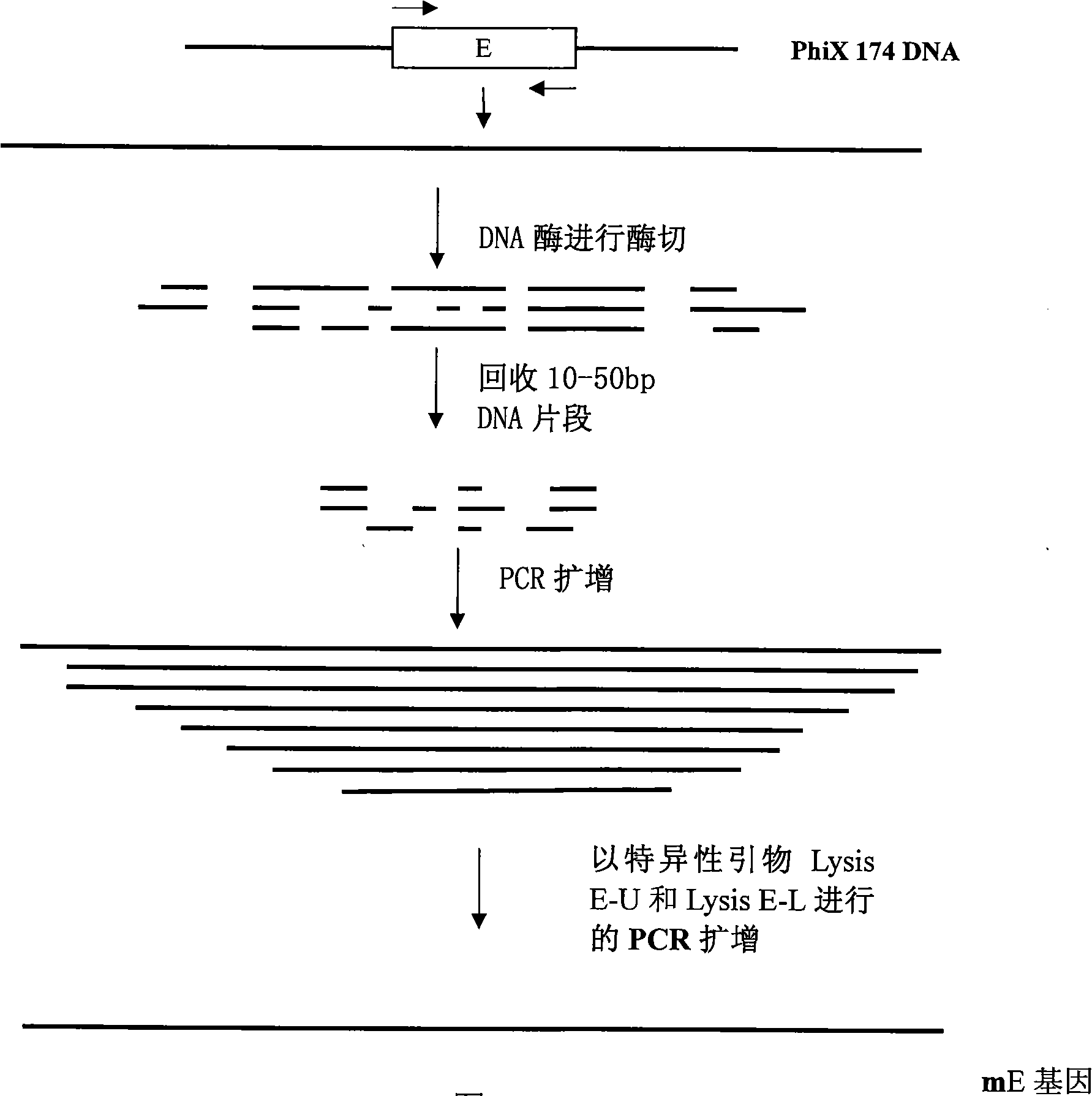

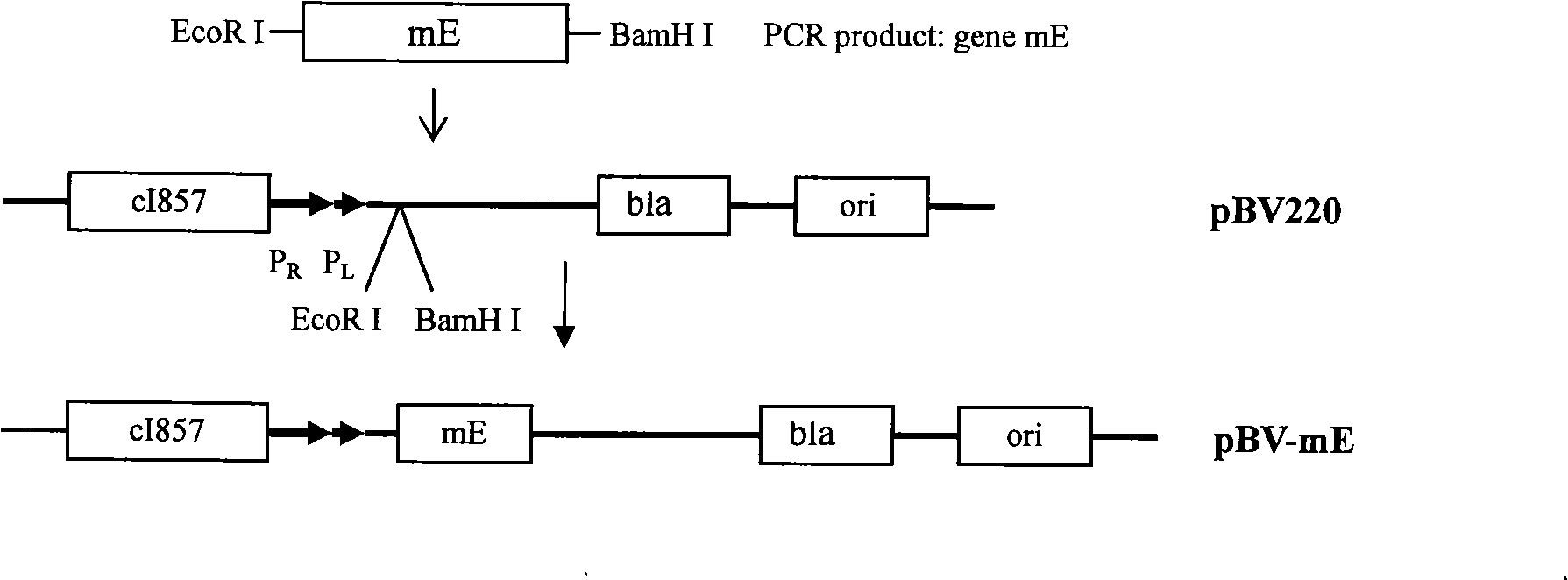

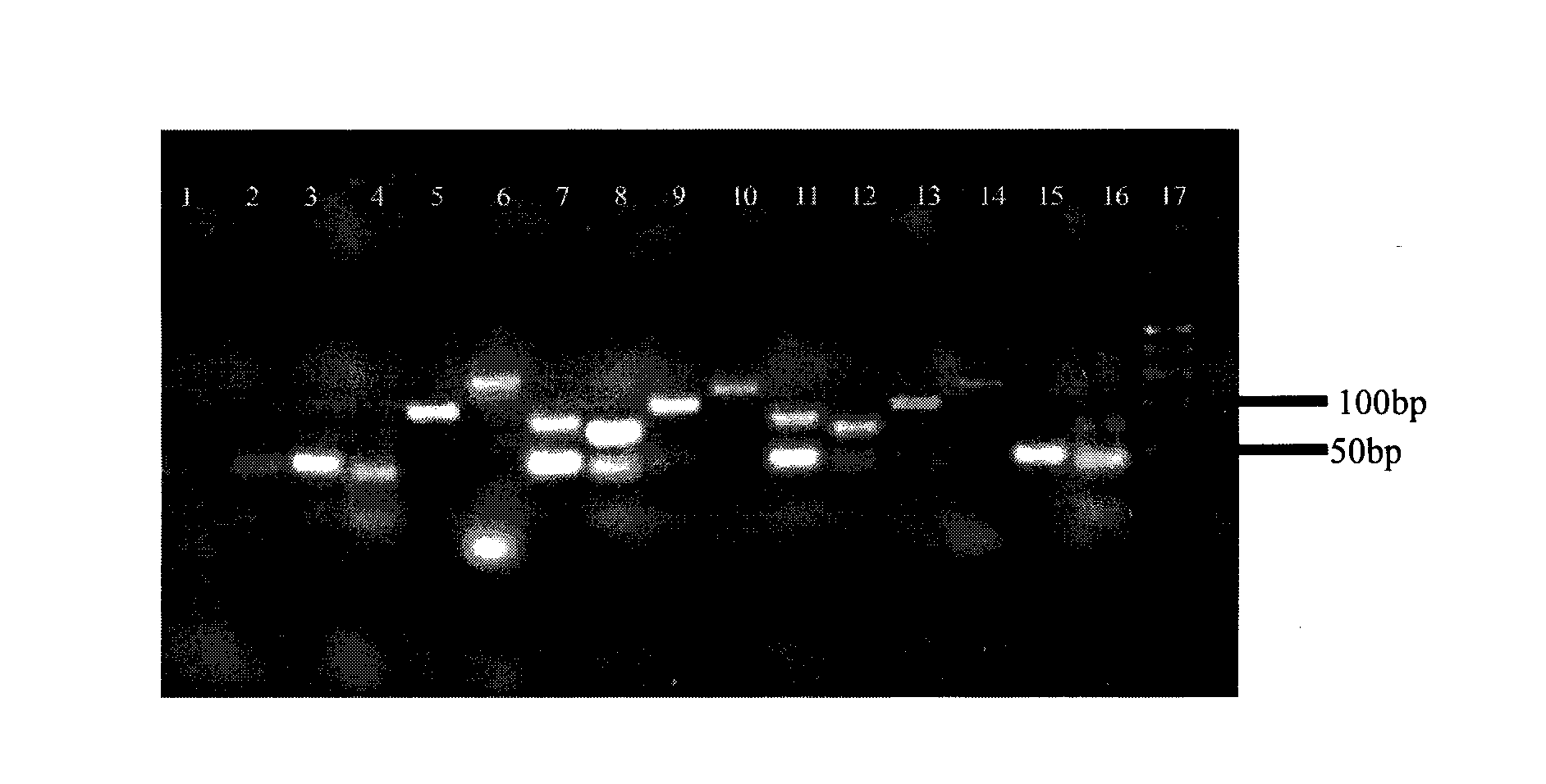

InactiveCN101302527AImprove drilling efficiencyImprove cracking efficiencyBacteriaMicroorganism based processesBacterial virusEscherichia coli

The invention discloses a PhiX174 bacterial virus mE gene obtained by gene rearrangement and a perforating plasmid vector containing the gene as well as a method for building the same. The invention further relates to an application of the perforating plasmid vector for making bacterial ghost, belonging to the gene engineering field. The PhiX174 bacterial virus E gene is rearranged by using the gene rearrangement technology so that a reading frame with E containing 276 nucleotides is mutated as a reading frame with mE (from ATG at the 76th site) containing 201 nucleotides by deleting A of an initial codon ATG at the first site. The made mE gene is maneuverably connected with pBV 220 vector to perforate the vector pBV-mE, and the vector pBV-mE can effectively improve perforation efficiency of the cell and lysis efficiency is up to 99.9613 percent. Compared with the prior perforating plasmid vector, the lysis efficiency of homophytic escherichia coli is more than three orders of magnitude.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

Method and apparatus for preparing low-carbon olefins through cracking of crude oil

ActiveCN109694739ASimple structureReduce volumeTreatment with hydrotreatment processesHydrocarbon oils treatment productsLiquid stateAlkene

The invention belongs to the field of preparation of low-carbon olefins, and discloses a method and an apparatus for preparing low-carbon olefins through cracking of crude oil. The method comprises: 1) feeding crude oil into the first pipe group of a convection section, pre-heating, and carrying out gas-liquid separation on the pre-heated crude oil by a first cyclone separator to form a first steam phase and a first liquid phase; 2) carrying out hydrogenation processing on the first liquid phase, and mixing with a liquid-state hydrocarbon to obtain a mixture; 3) feeding the mixture into the first pipe group of the convection section of the cracking furnace, pre-heating, and carrying out gas-liquid separation on the pre-heated mixture by a second cyclone separator to form a second steam phase and a second liquid phase; 4) feeding the first steam phase and the second steam phase into the second pipe group of the convection section of the cracking furnace, heating to achieve a crossover temperature, directly feeding into a radiation section, and cracking to form cracking gas containing low-carbon olefins; and 5) making the second liquid phase contact the superheated steam of the convection section, and carrying out steam stripping. With the method of the present invention, the crude oil cracking efficiency can be effectively improved, and the yield of the olefin product can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting DNA from formalin fixed hair

InactiveCN101492486AQuality improvementIncrease concentrationSugar derivativesDNA preparationWater bathsReactive site

The invention discloses a method of extracting DNA from formalin-fixed hair stems. After washing and pretreatment, the hair stems are put into a homogenizer full of 0.01mmol / L sodium citrate solution for grinding under 0 to 10 DEG C, then put in boiling water bath for 5 to 15min and be restored; ethanol is added for stewing, then eccentrically collected and deposited; hair digestive fluid and proteinase K solution are added into the deposition, and continuously digested for 1 to 2 hours in water bath at the temperature of 37-57 DEG C; DNA is extracted after digestion. The invention restores hair stem samples so as to totally or partially recover the activity of the protein active site. In addition, the preparation of the digestive fluid takes the characteristics of hair stem crack into full consideration so as to greatly improve the efficiency of hair stem crack and shorten the time of hair digestion. The method is used to extract not only the genome in the hair stem soaked in formalin but also the genome in the ancient hair stem.

Owner:CENT SOUTH UNIV

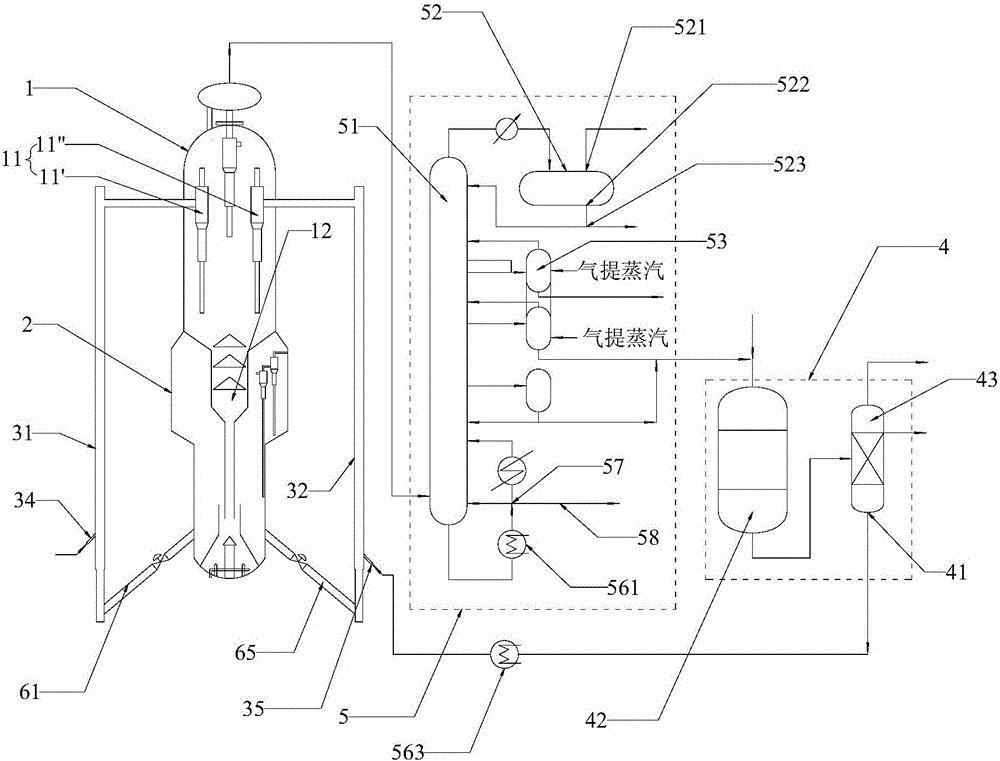

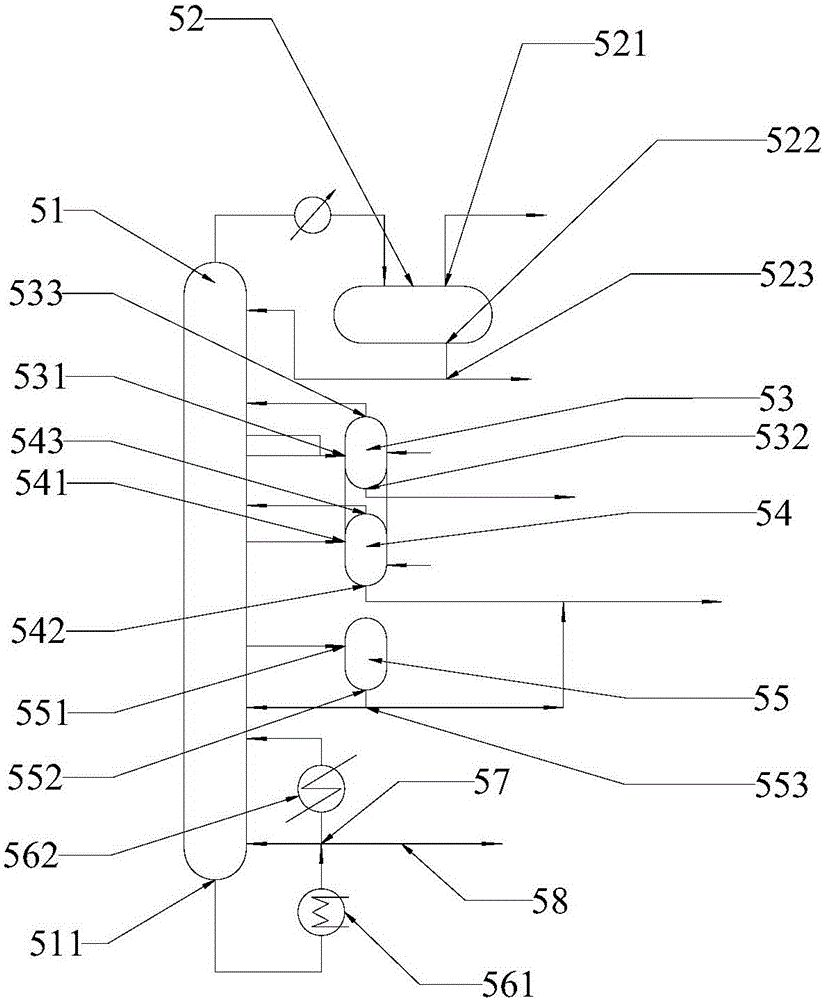

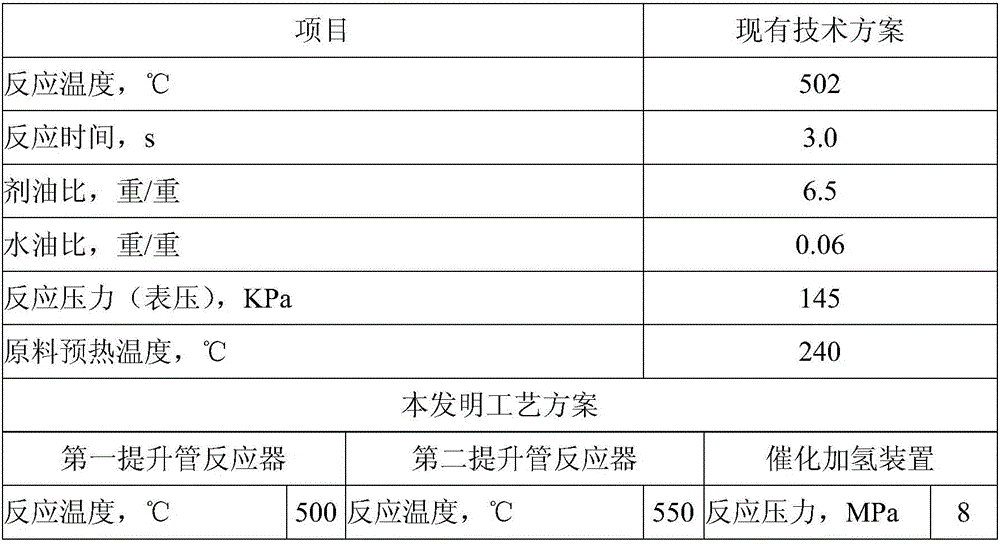

Method and device for converting catalytic cracking cycle oil in classified and divisional manner

ActiveCN105802663AImprove cracking efficiencyAvoid mutual interferenceHydrocarbon oils treatment productsRefining to eliminate hetero atomsFractionationProcess engineering

The invention provides a method and a device for converting catalytic cracking cycle oil in a classified and divisional manner, wherein the device comprises a settler (1), a regenerator (2), a first riser reactor (31), a second riser reactor (32), a catalytic hydrogenation device (4) and a fractionation device (5); the regenerator is arranged at the bottom of the settler; the first riser reactor and the second riser reactor are arranged in a way of parallel connection; the tops of the two riser reactors are respectively connected with a gas-solid separation device (11) in the settler; the bottoms of the two riser reactors are respectively connected with the bottom of the regenerator by a first inclined tube (61) and a second inclined tube (62); the top of the settler is connected with the fractionation device; the fractionation device is connected with the catalytic hydrogenation device; a raw oil inlet (34) is formed in the first riser reactor (31); a cycle oil inlet (35) is formed in the second riser reactor (32) and is connected with a cycle oil outlet (41) of the catalytic hydrogenation device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

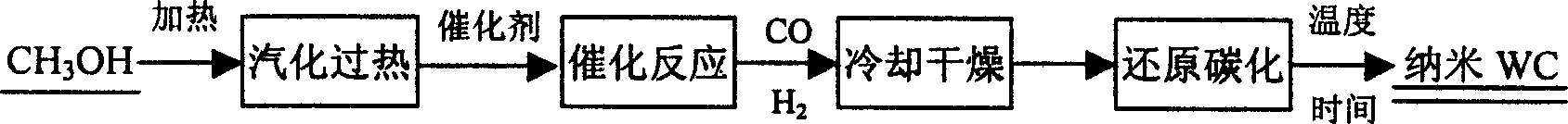

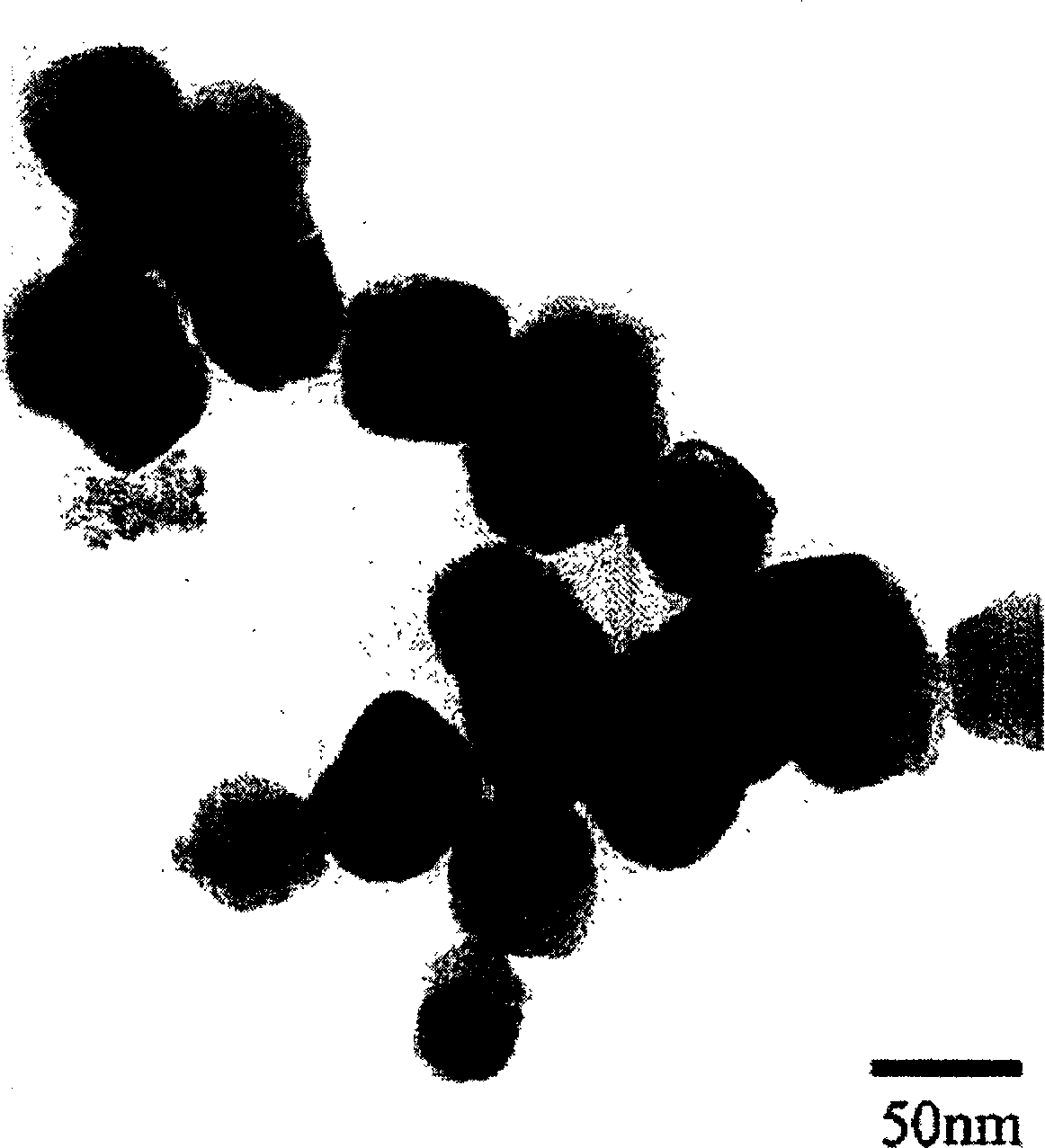

Method for preparing nanometer tungsten carbide powder by methyl alcohol cracking

The present invention provides methanol cracking and low temperature vapor carbonizing process of preparing nanometer WC powder. The WO3 powder of average size 21 nm and specific surface area 54 sq m / g as main material and methanol as carbon source are reacted at 450-950 deg.c for 1.5-4 hr in the presence of Co / Fe catalyst to obtain nanometer level WC. Methanol is first made to pass through liquid pump, flow meter and pre-heating pipe at 300-420 deg.c to gasify, and the methanol gas is catalytically cracked in the cracking device at 420-550 deg.c to obtain required reacting gas CO and H2. CO and H2 are made to react with nanometer WO3 powder to produce nanometer level WC. The present invention has the advantages of low cost, high cracking efficiency, and controllable, homogeneous and stable WC granularity.

Owner:UNIV OF SCI & TECH BEIJING

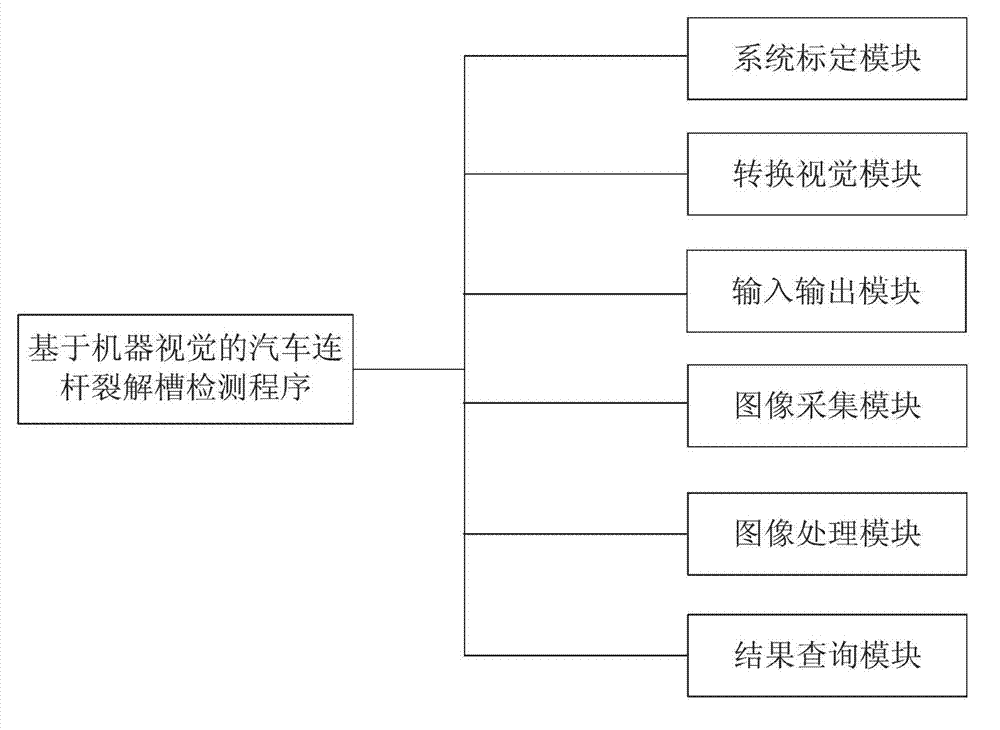

Method for detecting fracture splitting notch of connecting rod of automobile based on machine vision

The invention discloses a method for detecting a fracture splitting notch of a connecting rod of an automobile based on machine vision, which intends to overcome the problem in the prior art that the existence of the fracture splitting notch on the connecting rod cannot be accurately detected, and the qualification of the fracture splitting notch also cannot be accurately detected. The method for detecting the fracture splitting notch of the connecting rod of the automobile based on machine vision comprises the following steps: 1, calibrating by a system; 2, receiving an input signal; 3, acquiring the image: converting the images acquired by two cameras from analog signals into digital signals by an image acquiring module, and inputting the digital signals into a computer memory; 4, processing images: filtering the digital images of the fracture splitting notches on the left side and the right side, detecting the edges, distinguishing based on the characteristics of the fracture splitting notches, and determining whether the fracture splitting notches exist and whether the fracture splitting notches are qualified, thus obtaining the detection result; and 5, outputting and searching the results, wherein a result searching module is arranged and provides the function of searching the data relative to the detection process, including detecting time, number of detecting images, quantity of detected connecting rods, quantity of qualified connecting rods, quantity of unqualified connecting rods, and the qualification of the detection results, and also provides the function of printing.

Owner:JILIN UNIV

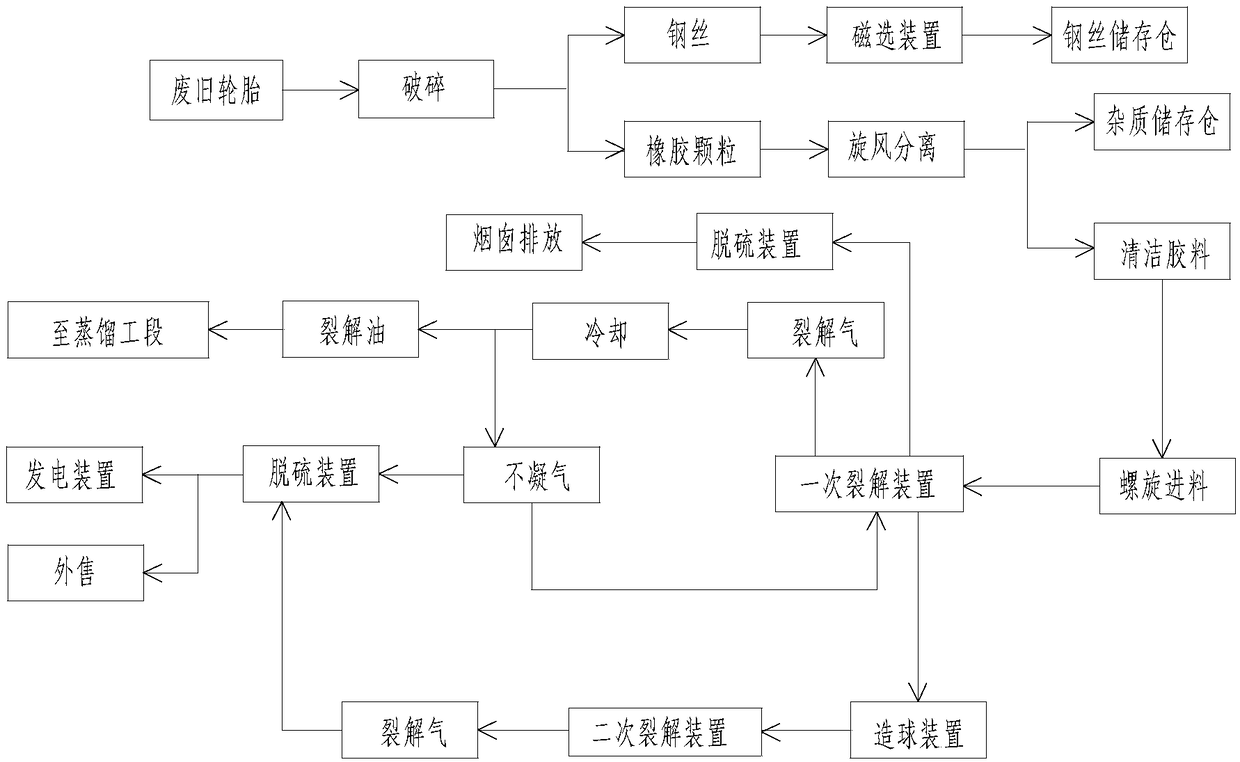

Method for catalytic cracking treatment of waste/used tires

InactiveCN108342215AFast heating rateSolve the problem of poor cracking efficiency aloneLiquid hydrocarbon mixture productionDistillationPre treatment

The invention discloses a method for catalytic cracking treatment of waste / used tires and belongs to the technical field of reutilization of the waste / used tires. The method is used for solving the problems in the prior art that the recovery rate is low, carbon black granules are large in size, and the pollution is heavy. The method for the catalytic cracking treatment of the waste / used tires comprises the procedures of raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization, wherein the secondary cracking means adding a solid-state cracked product produced from primary catalytic cracking into a secondary cracker for secondary cracking, subjecting produced cracked gas to dedusting and desulfurizing, and then, storing up the cracked gas. The method can be applied to the catalytic cracking treatment of the waste / used tires.

Owner:山东铂铠环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com