Base-catalyzed decomposition device and method for industrial waste containing chlorinated organic compound

A technology for chlorinated organic matter and industrial waste, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of reduced reaction amount of chlorinated organic pollutants, environmental risks, large temperature fluctuations in the system, etc., and achieves easy reuse and residues. safe disposal, reduce the risk of secondary pollution, and avoid the reduction of cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

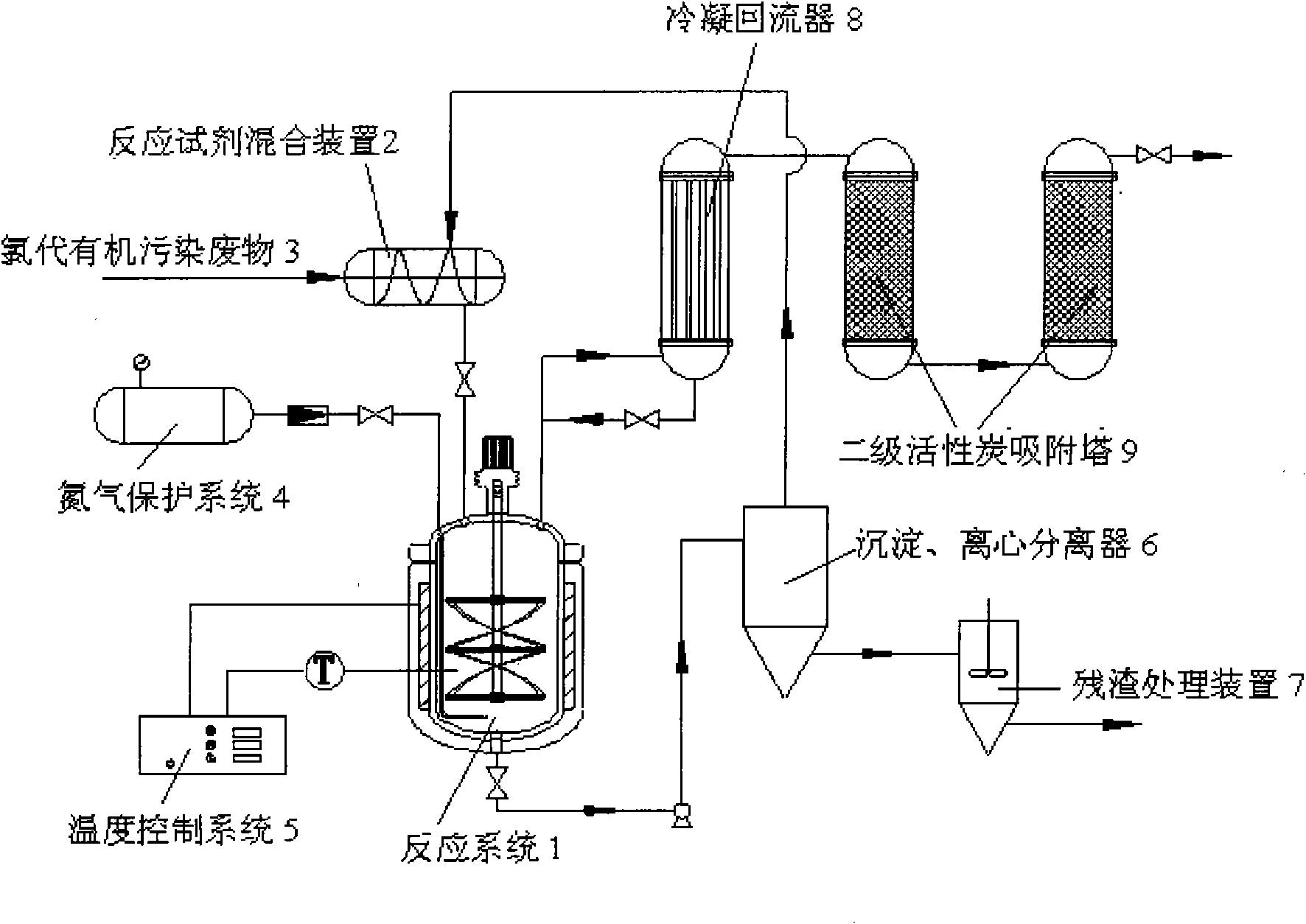

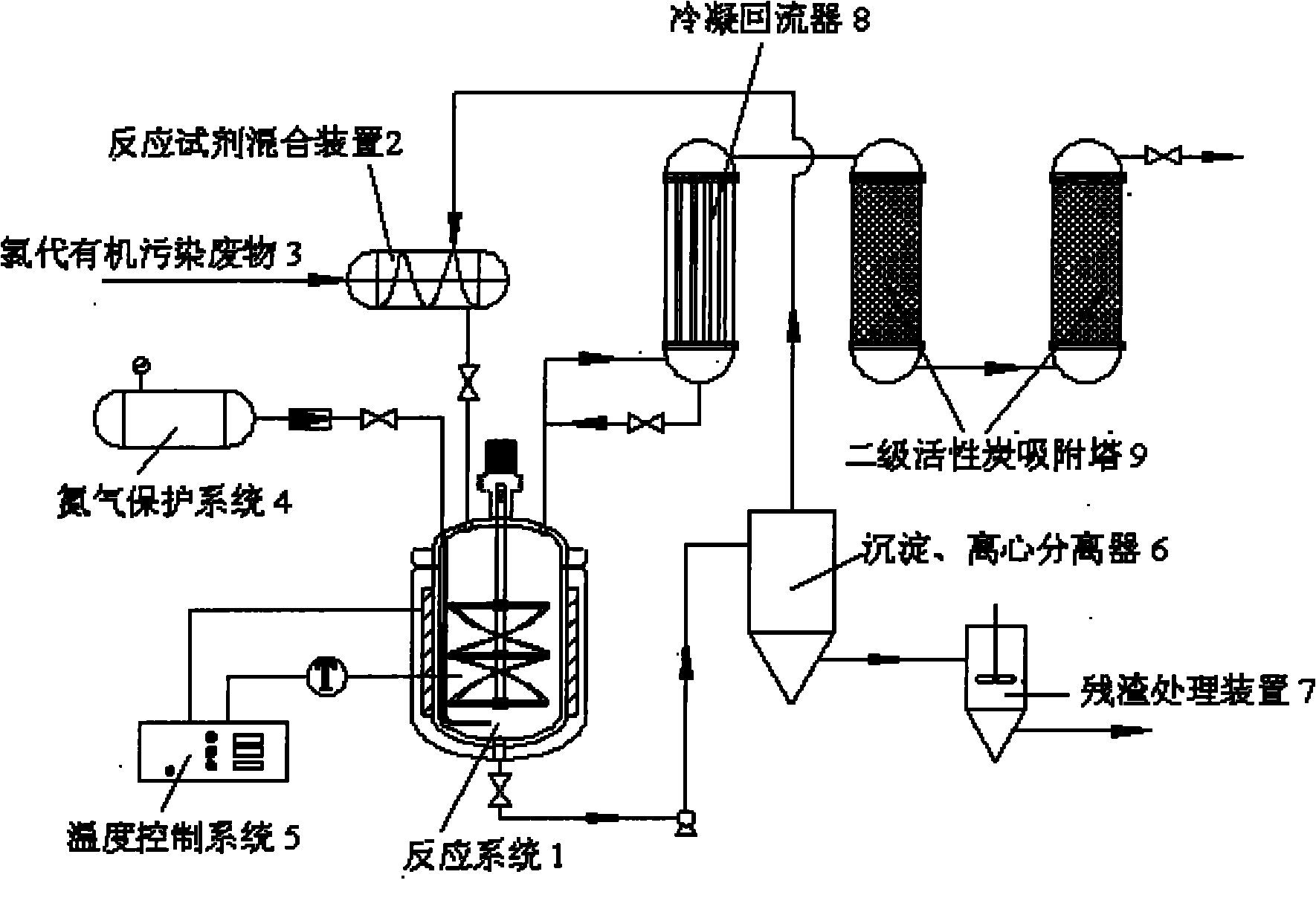

[0020] With reference to accompanying drawing, a kind of alkali-catalyzed decomposition device of industrial waste containing chlorinated organic matter comprises reaction system 1, and the feed port of reaction system 1 is communicated with the pipeline communication of reaction reagent mixing device 2 and chlorinated organic pollution waste 3, and reaction system 1 The gas regulating port of the reaction system is connected with the nitrogen protection system 4, the heating device and the temperature measuring port of the reaction system 1 are connected with the temperature control system 5, and the discharge port of the reaction system 1 is connected with the sedimentation, centrifugal separator 6 and residue treatment device 7, and the reaction The tail gas outlet of the system 1 is communicated with the secondary activated carbon adsorption tower 9 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com