Patents

Literature

36results about How to "Delayed cracking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

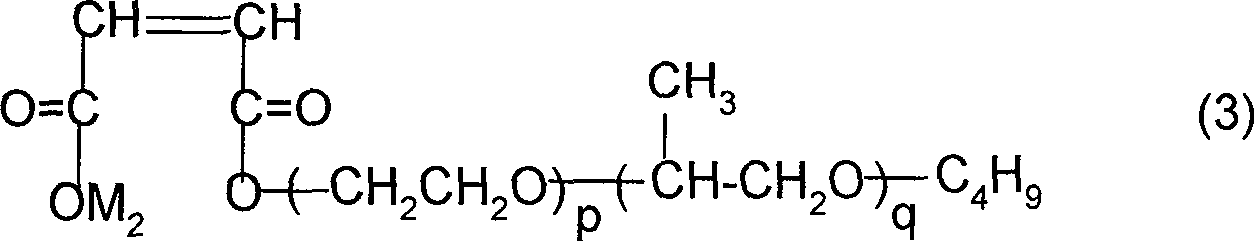

Reduction-reducing crack-resisting concrete superplasticizer of graft copolymer and method for preparing the same

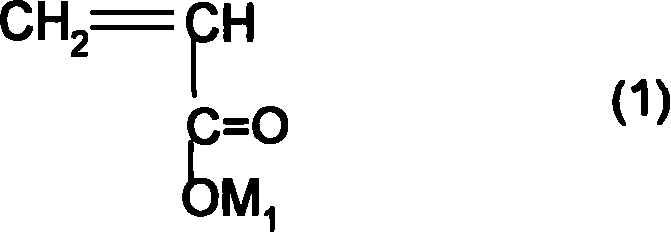

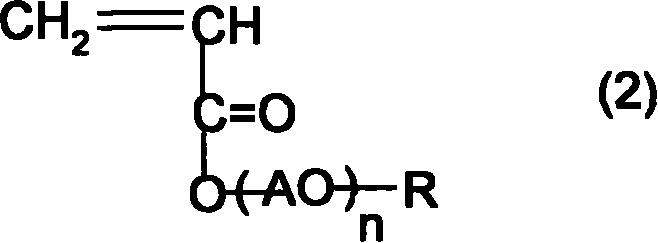

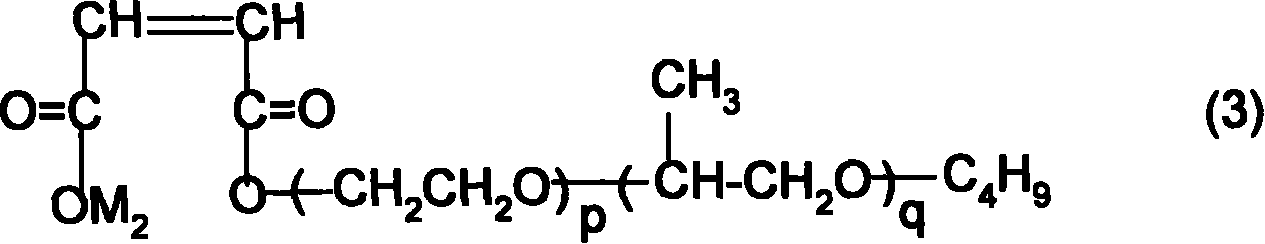

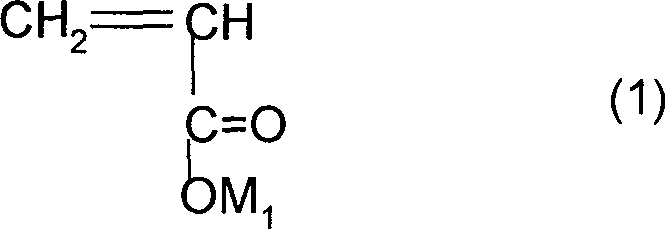

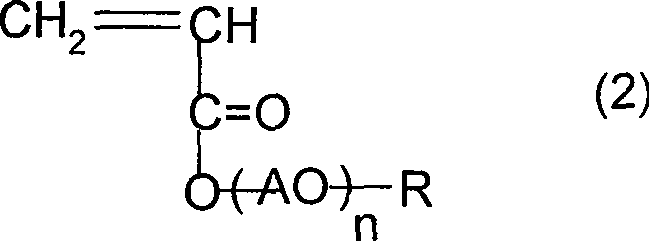

Disclosed is a shrinkage-reduction anti-cracking type grafted copolymer concrete superplasticiser, which is prepared from monomer a of acroleic acid or salts, monomer b of alkoxy polyether monoacrylate, monomer c of maleic anhydride hemiester or its salts, monomer d of alpha-propenol omega-methyl polyether and monomer e of phenylethene through free radical copolymerization reaction, wherein the molar ratio of the monomer a, b, c, d and e being 1 : 0.2-0.5 : 0.10-0.25 : 0.10-0.20 : 0-0.10.

Owner:JIANGSU SOBUTE NEW MATERIALS

Preparing method for polycarboxylate water reducing agent

ActiveCN103159899AIncrease profitNarrow down the range of molecular weight fluctuationsHydrogenRoom temperature

The invention provides a preparing method for polycarboxylate water reducing agent. The polycarboxylate water reducing agent composed of, by weight, 30%-55% of deionized water, 35%-50% of polyoxyethylene ether, 5%-10% of carboxylic acid derivatives monomer, 0.0005%-0.002% of catalyst, 1.5%-4.5% of initiator, 0.2%-0.8% of chain transfer agent, 1.0%-2.5% of structure modifying agent and 4.5%-8.5% of alkali liquor. Under the temperature of 20-35 DEG C, the deionized water and the polyoxyethylene ether are enabled to be put in a reaction still to be dissolved, after the deionized water and the polyoxyethylene ether are fully dissolved, the carboxylic acid derivatives monomer, the catalyst, the initiator, the chain transfer agent and the structure modifying agent are enabled to be added in sequence, after stirring for 28-32 minutes, the mixed liquor still standings for 4-6 hours under room temperature, the alkali liquor is added in under a state of stirring, a potential of hydrogen (PH) value is adjusted to be 6.0-7.5, and then products are achieved.

Owner:XINJIANG DELAND

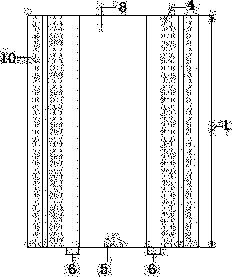

All-wet-joint precast prestressed underground continuous wall and construction method thereof

The invention provides an all-wet-joint precast prestressed underground continuous wall and a construction method of the all-wet-joint precast prestressed underground continuous wall. The continuous wall is formed by sequentially connecting a plurality of wall segments (1). The middle of the section of each wall segment (1) is provided with a cavity (4). Concave groove segments (8) are arranged at the center of the wall segments (1) in the length direction. Semi-conical holes (5) are formed in the upper connection parts and the lower connection parts of the wall segments (1). The semi-conical holes (5) are communicated with the cavities (4) and the concave groove segments (8). Water-proof wet joints are formed by pouring concrete in the semi-conical holes (5). According to the continuous wall, all the wall segments are connected through the wet joints, so that the problem of leakage at the connection parts of the wall segments is solved. By exerting prestressing force between the wall segments, the flexural rigidity, the anti-cracking ability and the lasting quality of the underground continuous wall are improved. Due to the fact that the underground continuous wall is connected with reinforcing mesh pieces, the shear-resistant performance between the wall segments is strengthened. As the wall segments are constructed on the ground, the quality of the continuous wall is easy to guarantee.

Owner:SOUTHEAST UNIV

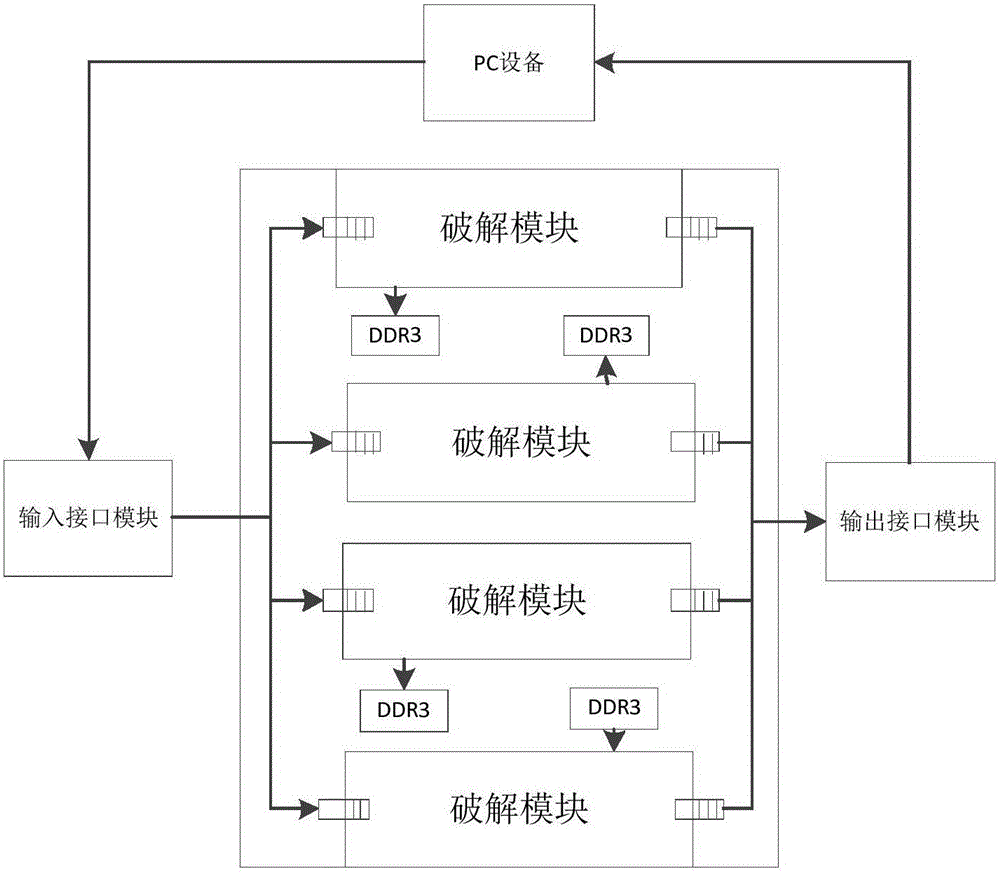

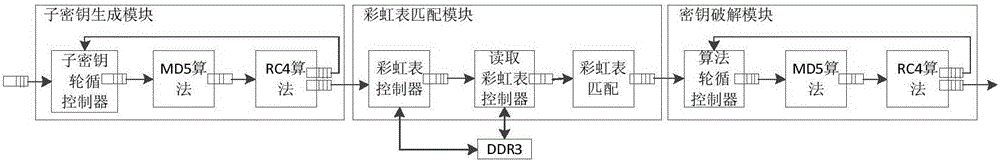

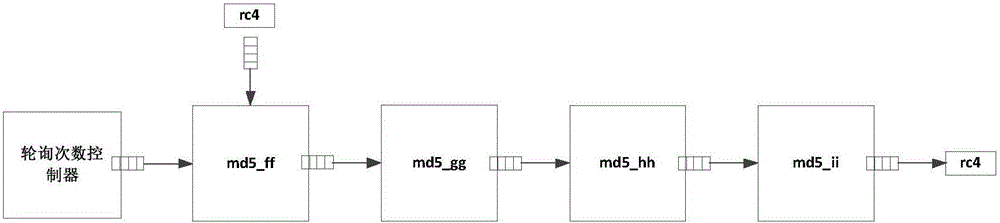

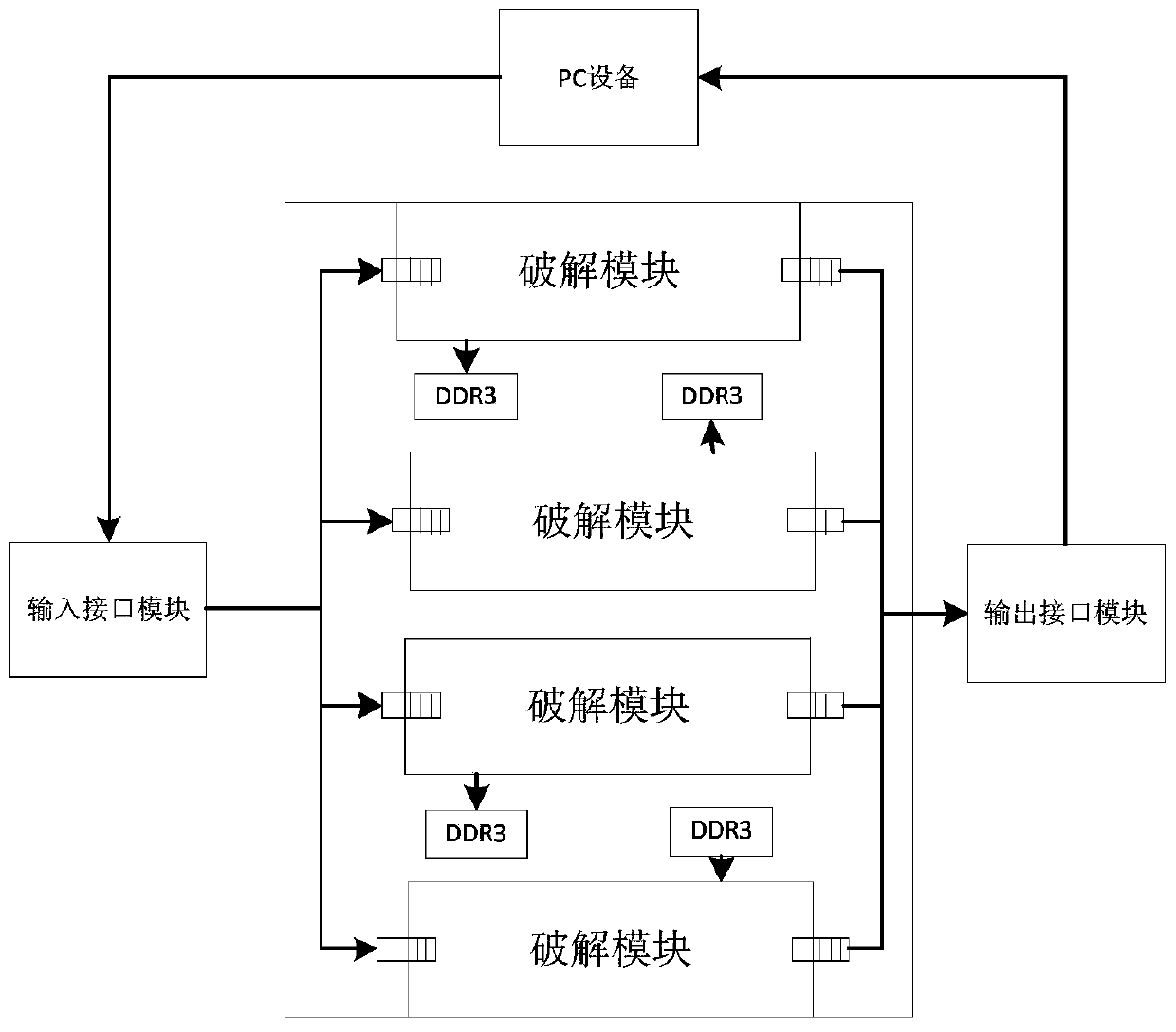

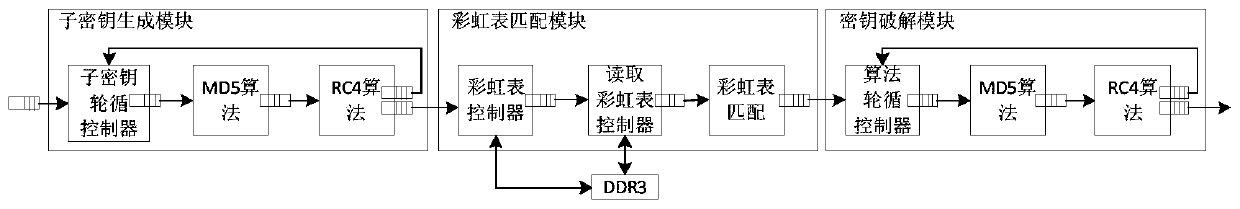

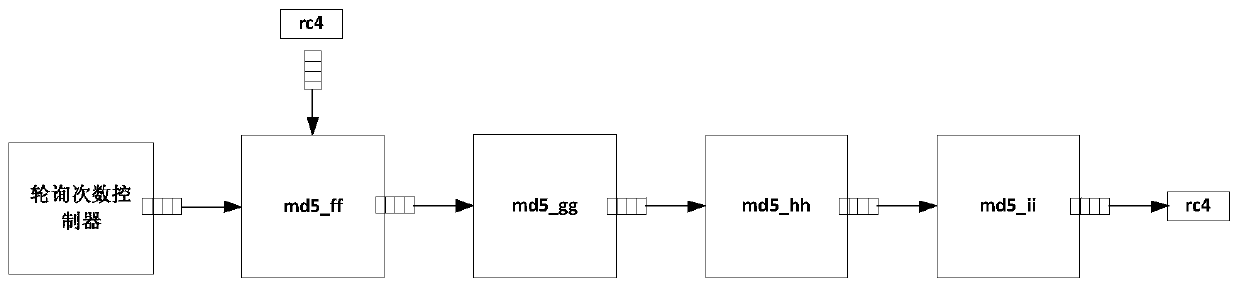

Word2003 document cracking system based on FPGA hardware and method

ActiveCN106357384AImprove cracking efficiencyDelayed cracking timeData stream serial/continuous modificationResource consumptionComputer module

The invention discloses a word2003 document cracking system based on FPGA hardware and a method. The system comprises a PC, an input interface module, a crack module and an output interface module which are connected sequentially, and the PC is connected with the output interface module. The crack module comprises a sub-key generation module, a rainbow table matching module and a key cracking module which are connected sequentially. The sub-key generation module includes sub-key round robin controller, MD5 algorithm module and RC4 algorithm module which are connected sequentially. The key cracking module consists of algorithm round robin controller, MD5 algorithm module and RC4 algorithm module. The system achieves document cracking by using the time and space folding algorithm of the rainbow table, thus improving the crack efficiency and reducing the cracking time. On the basis of considering the technical characteristics of the rainbow table and the FPGA, the appropriate rainbow table is used for cracking, thus solving the contradiction between cracking time and resource consumption.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

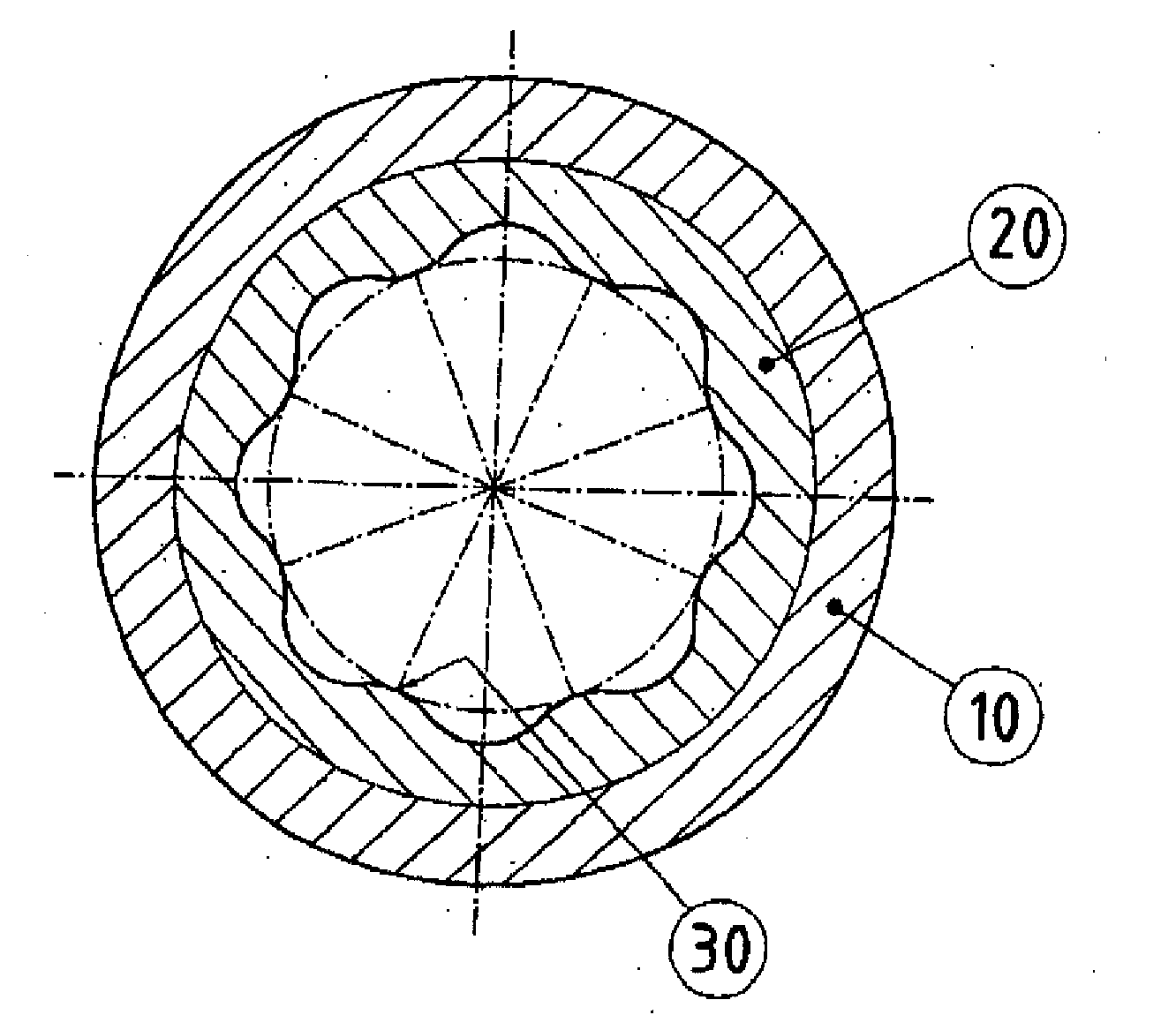

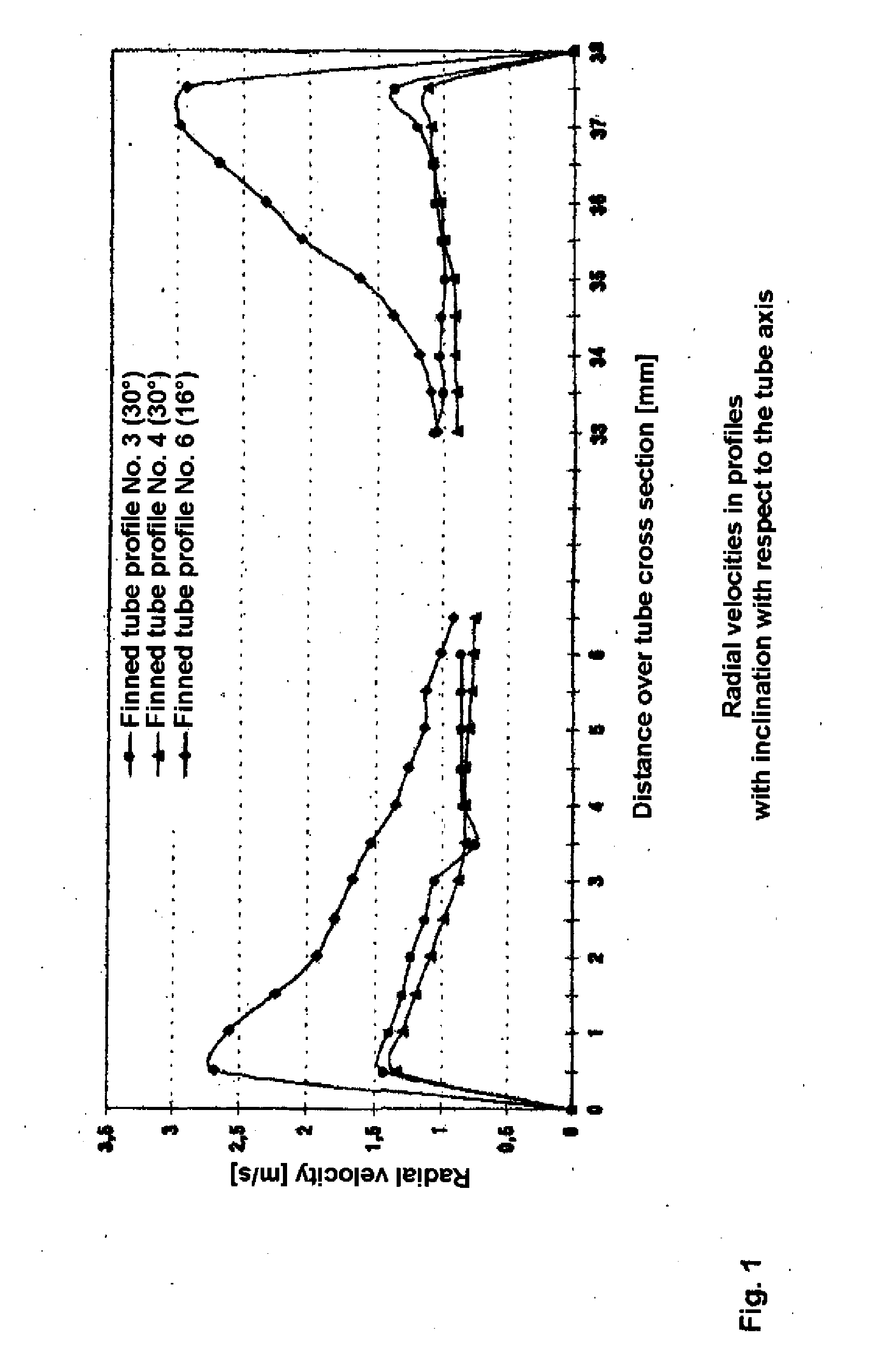

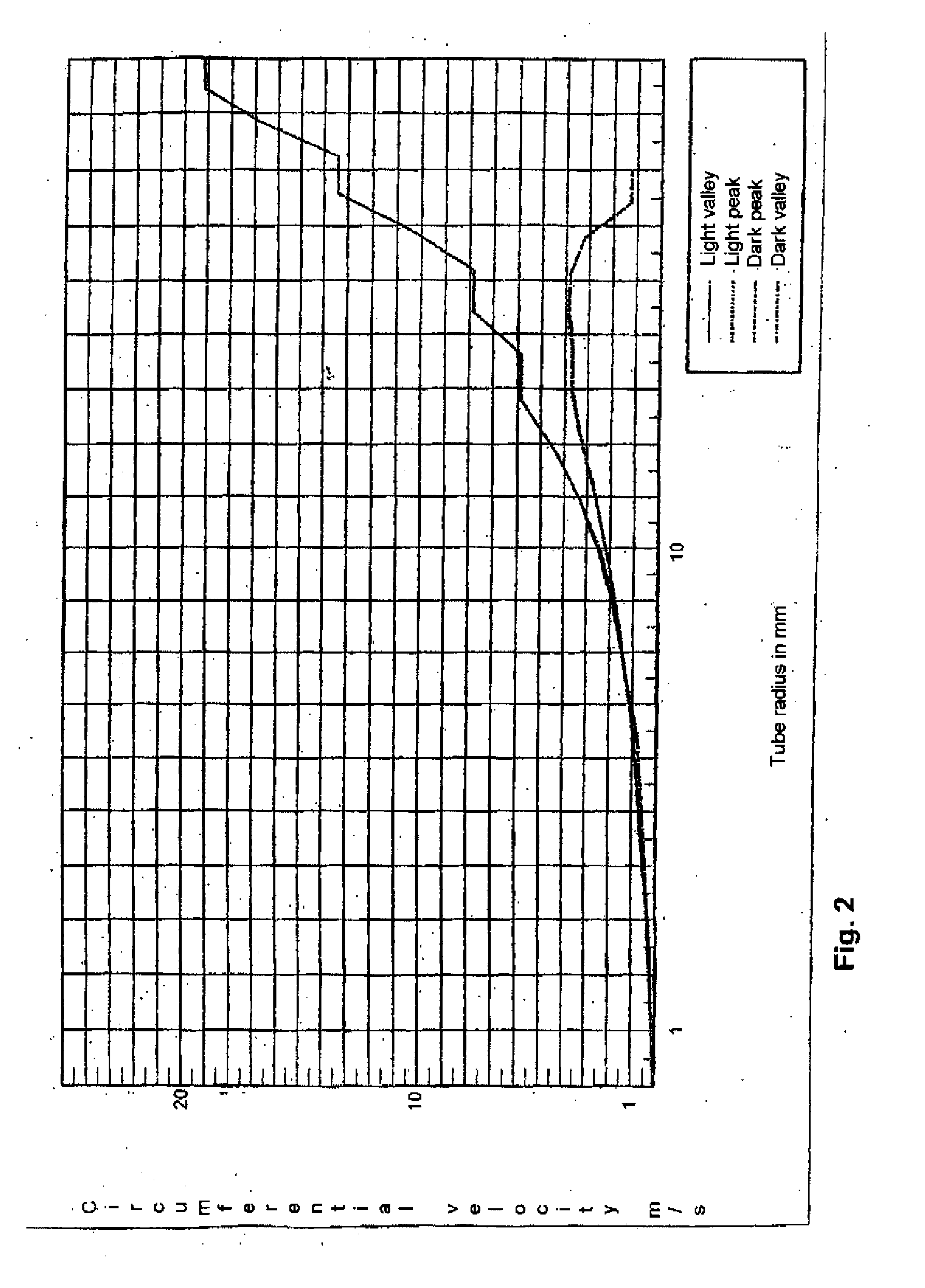

Composite tube, method of producing for a composite tube, and use of a composite tube

InactiveUS20080014342A1Reduce riskExtended service lifeThermal non-catalytic crackingLiquid surface applicatorsHydrogenApplication areas

To provide a tube which is particularly well matched to the specific demands imposed in special application areas, such as for example hydropyrolysis, the invention proposes a composite tube having a first part-tube and a second part-tube, in which—one part-tube is arranged in the other part-tube,—the first part-tube is a centrifugally cast tube, and—the second part-tube has been produced by pressure treatment from a powder.

Owner:SCHMIDT CLEMENS

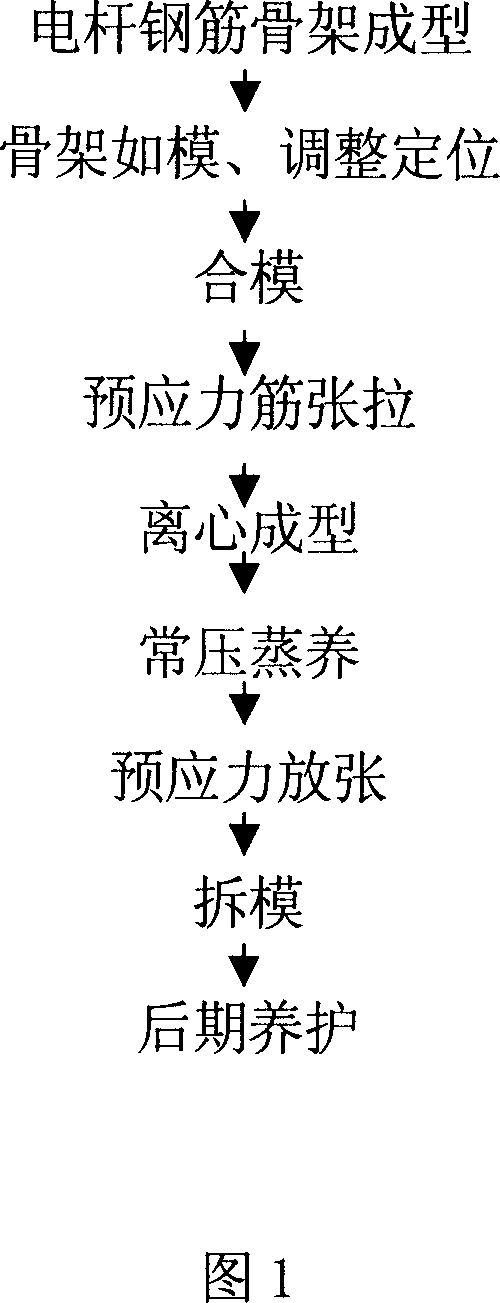

Method for manufacturing wire pole from steel fiber concrete with no bracing wire

InactiveCN1958261AImprove crack resistancePrevent sudden increase in centrifugal forceMixing operation control apparatusCeramic shaping apparatusRebarEmulsion

A method for manufacturing the electric transmission line post without pull cable A high-strength antiwear composite wood-plastics board is composed of an artificial core board with two adhesive layers on its both surface, and two veneers adhered respectively onto said two adhesive layers. Said veneer is chosen from high-density plywood, polyhydroamine solution immersed paperboard, and PCC plate. Said adhesive is chosen from MVF adhesive, high-adhesion emulsion adhesive and universal adhesive. Proportionally mixing cement, water, sand, broken stone and steel fibers, binding a skeleton with reinforcing bars, loading the skeleton in a mould, pouring said mixture in said mould, closing the mould, centrifugal shaping at a gradually increased rotation speed, and ordinary-pressure steam curing. Its product has no cracking.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

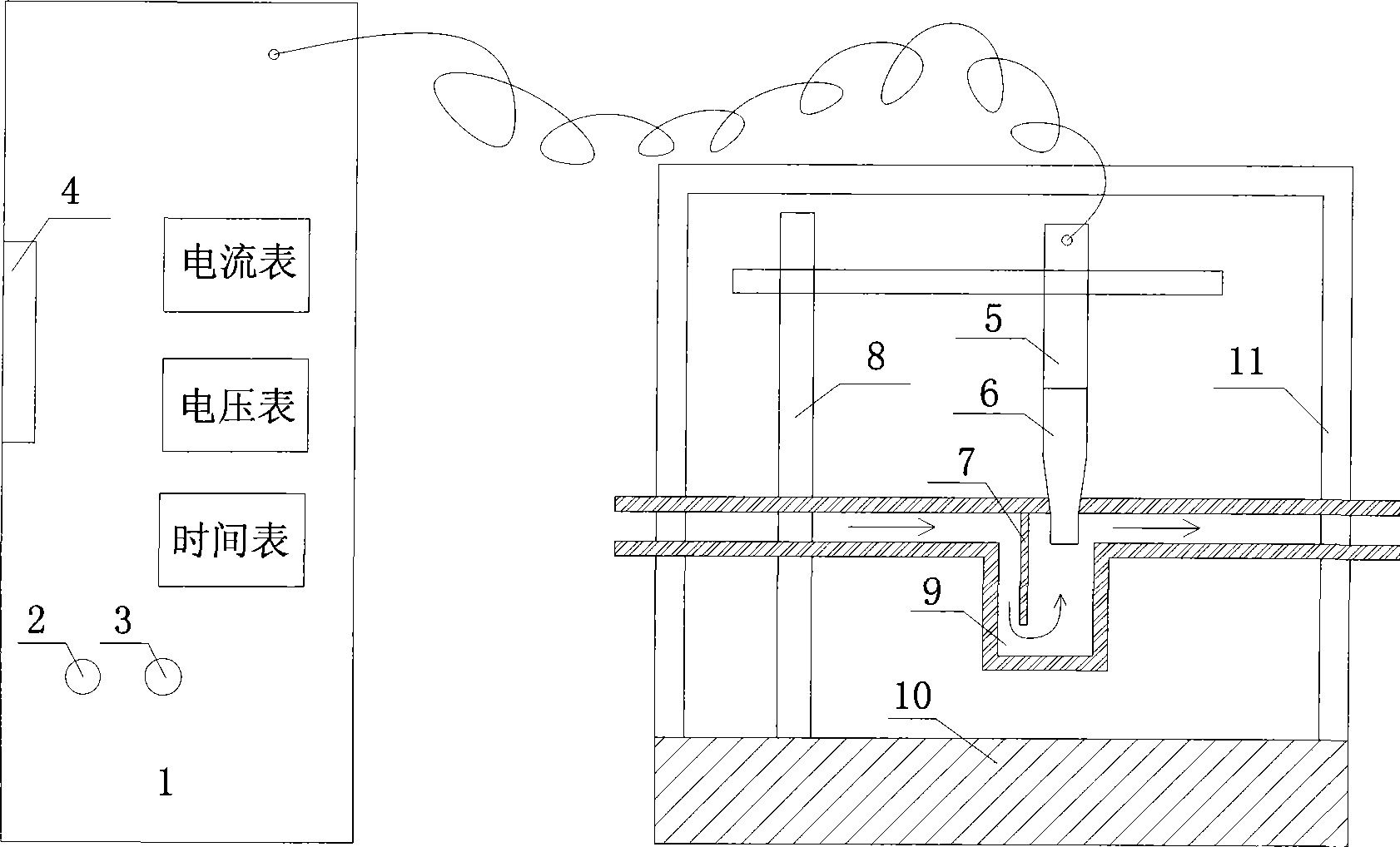

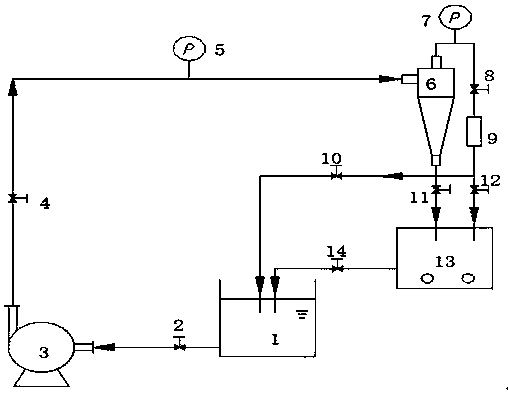

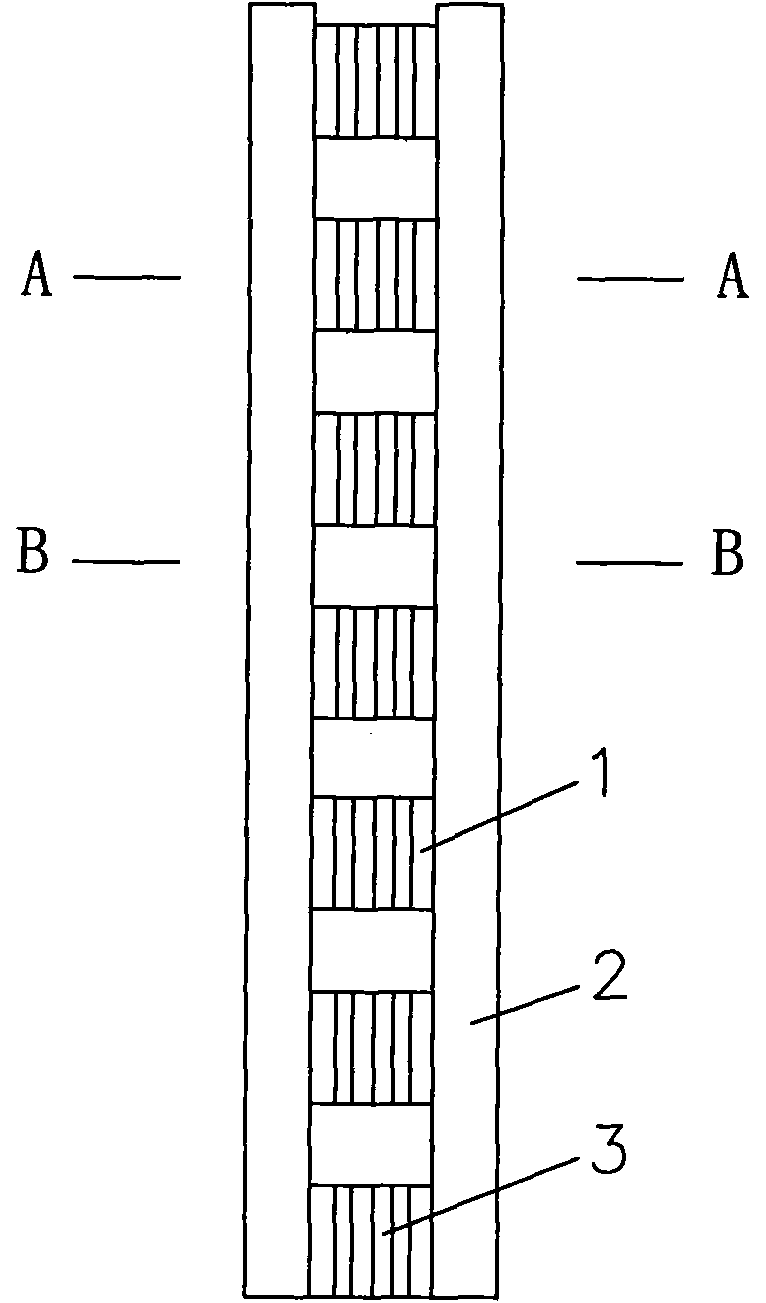

Probe type ultrasonic device for breaking sludge

InactiveCN101531447AGuaranteed continuous conveying operationExtended staySludge treatmentPower controllerProbe type

The invention provides a probe type ultrasonic device for breaking sludge, which consists of a sound energy generator, an energy transducer, an ultrasonic probe, a vertical chute and a soundproof box. The sound energy generator has a box body structure, is connected with the energy transducer, and comprises a cooling system, a power controller and a time controller. The energy transducer has a stainless steel cylindrical structure, while the ultrasonic probe has a titanium alloy MS73 cylindrical structure, one end of the probe is connected with the energy transducer, while the other end is positioned in the vertical chute. The front end of the vertical chute is a sludge inlet and the back end is a sludge outlet, and the front end in the chute is provided with a sludge baffle plate to increase the staying time of the sludge in the chute. The whole energy transducer, the ultrasonic probe and the vertical chute are completely arranged and sealed in the soundproof box. The soundproof box is connected with a support to form an airtight fixing device for the convenience of carrying and displacement.

Owner:SUN YAT SEN UNIV +1

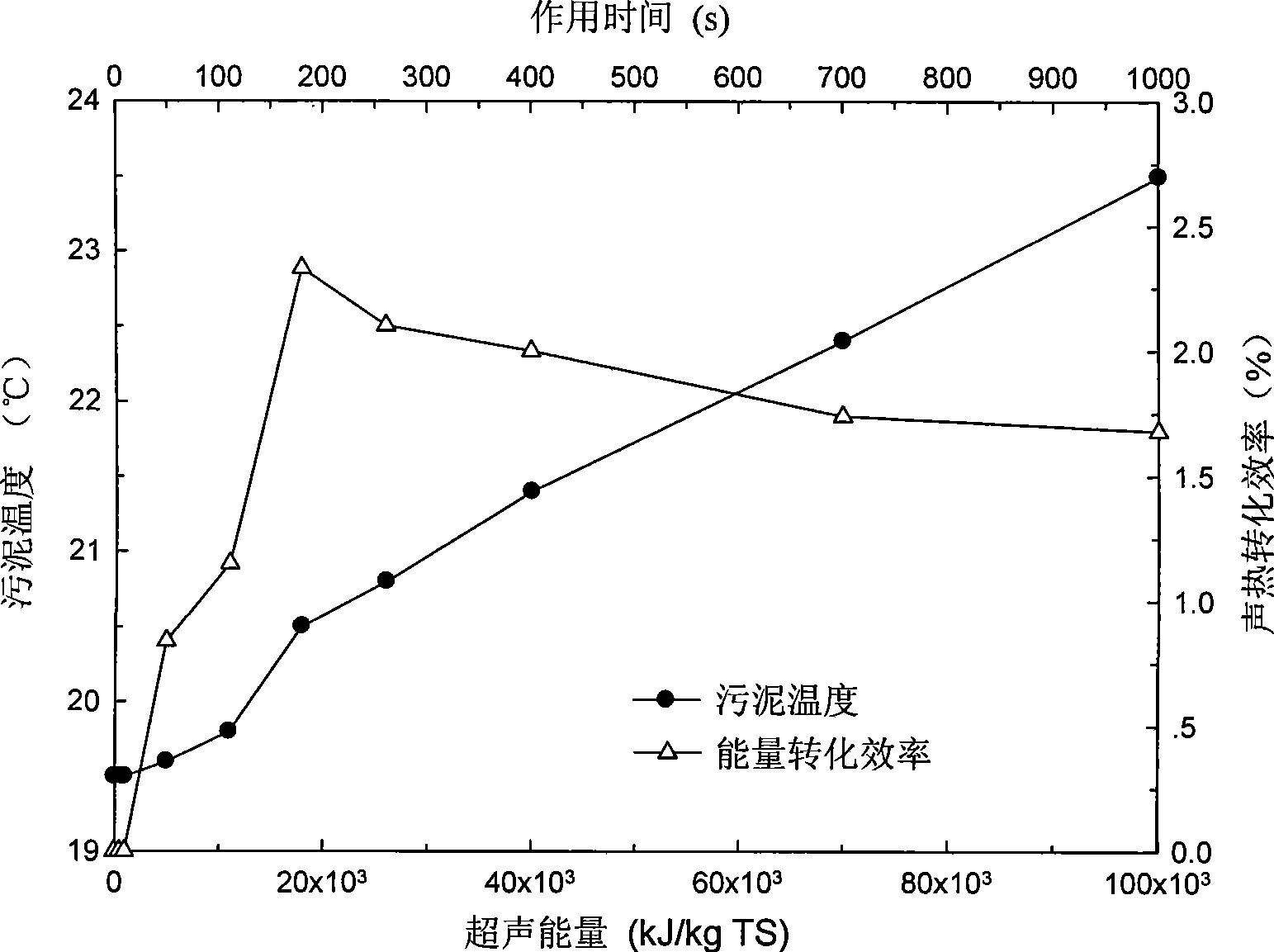

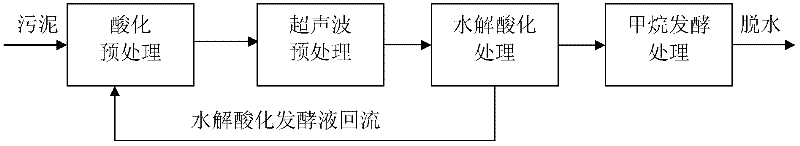

Method for pretreating sludge by reflux of fermentation liquor and application of method

InactiveCN102583913AHigh speedImprove efficiencyWaste based fuelBiological sludge treatmentAcoustic energyRetention time

The invention discloses a method for pretreating sludge by the reflux of fermentation liquor. The method comprises the following steps of: pretreating the sludge by using an ultrasonic wave in an ultrasonic treater, and hydrolyzing and acidizing the sludge in a hydrolytic acidification tank; and performing methane fermentation on the hydrolyzed and acidized sludge in a methanogenesis tank, wherein the fermentation liquor obtained by hydrolysis and acidification flows back to a sludge pretreatment tank and is mixed with sludge which is not subjected to ultrasonic pretreatment to perform acidizing pretreatment, and the mixture is subjected to subsequent ultrasonic pretreatment. According to the method, the acidizing pretreatment and the ultrasonic treatment are combined, so that the gas production rate can be improved effectively, the retention time of the sludge can be reduced, and the volume of a digestion tank can be reduced; and the density of required ultrasonic acoustic energy is reduced substantially, and energy consumption is reduced effectively, so that a pretreatment process can be applied to methane production practically.

Owner:TIANJIN UNIV

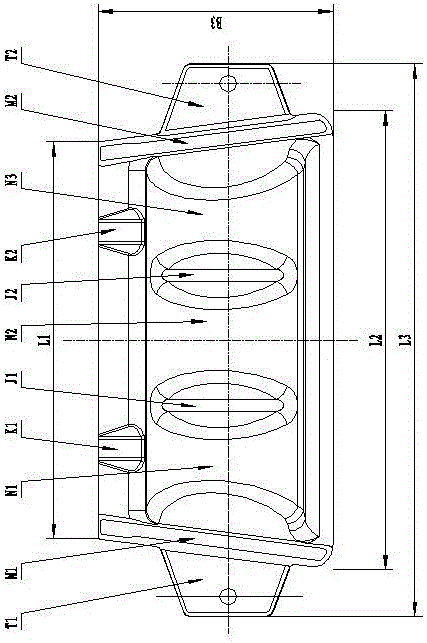

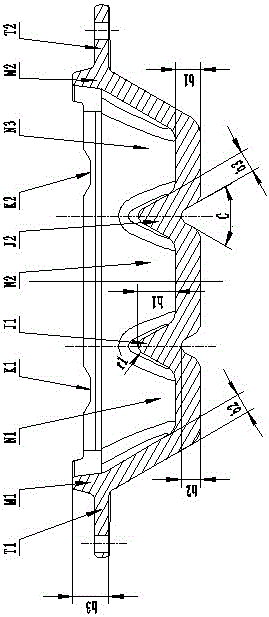

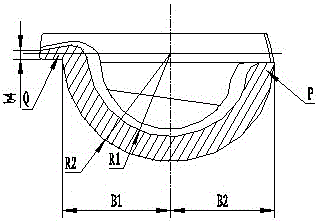

Long-service-life, safe and reliable forging cast iron die for pig casting machine and manufacturing method thereof

ActiveCN103769552AReduce carbon contentImprove ductilityPig casting plantsThermal fatigueCasting defect

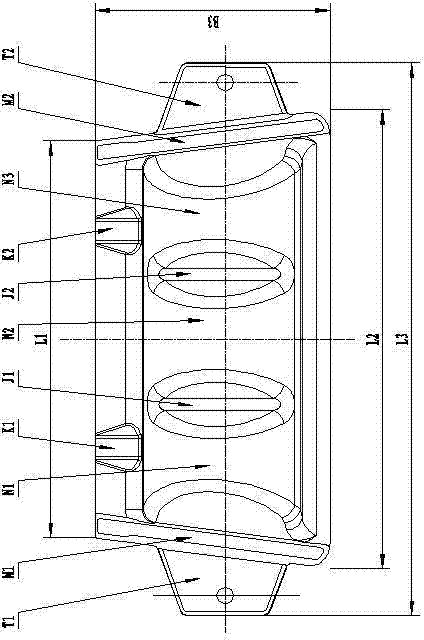

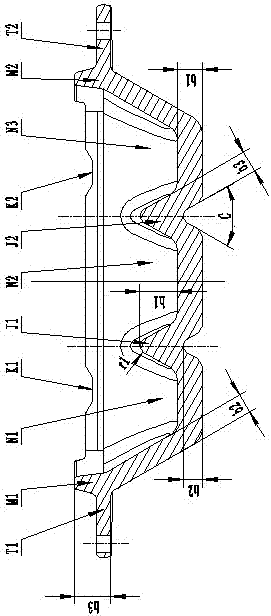

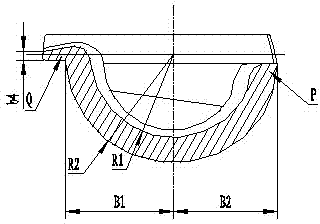

The invention discloses a long-service-life, safe and reliable forging cast iron die for a pig casting machine and a manufacturing method of the long-service-life, safe and reliable forging cast iron die. The forging cast iron die is integrally formed based on a forging technology, at least two separating ribs lower than a high-temperature molten iron liquid face are arranged in the forging cast iron die, an inner die cavity of the forging cast iron die is divided into at least three forming die cavities by the separating ribs, a lap joint mouth Q used for being in lap joint with an adjacent forging cast iron die is arranged at the lower end of the forging cast iron die, a cast iron die tail P corresponding to the lap joint mouth at the lower end of the adjacent forging cast iron die is arranged a the upper end of the forging cast iron die, at least two overflow openings are formed in the lap joint mouth Q, and molten iron protection edges M1 and M2 and lug portions T1 and T2 connected with a chain plate are arranged on the two sides of the forging cast iron die. The poor cast condition metallographic structure and various forging defects of a forging forming cast iron die are avoided and overcome through the forging cast iron die, the thermal fatigue resisting strength of the cast iron die is effectively improved, the safe reliability of the cast iron die is improved, and the service life of the cast iron die is prolonged.

Owner:SHILIN LUOHE METALLURGY EQUIP +1

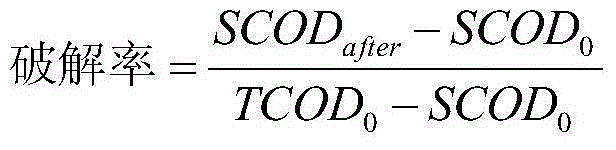

Method for disintegrating excess sludge through combination of ultrasonic waves and modified eggshells

InactiveCN105174681AOdorlessRealize harmless resource utilizationSludge treatment by de-watering/drying/thickeningEggshellSludge

The invention relates to a method for disintegrating excess sludge through combination of ultrasonic waves and modified eggshells. The method comprises steps as follows: firstly, in terms of 0.05-0.4 g of modified eggshells added to the excess sludge per ml, the modified eggshells are added to the excess sludge, the modified eggshells and the excess sludge are mixed uniformly, and sludge slurry is prepared; the sludge slurry is subjected to ultrasonic treatment through the ultrasonic waves, and the excess sludge is disintegrated. With the adoption of the modified eggshells, the waste eggshells are changed to be wealthy, the environmental pollution is reduced, the problem about disposal and treatment of the eggshells is solved effectively, further, an effective chemical for disintegrating the excess sludge is obtained, the chemical cost for sludge treatment is saved, and the treatment cost of the excess sludge is reduced; with the introduction of the ultrasonic waves in a disintegrating experiment, the sludge cell disintegrating speed is increased greatly, the disintegrating time of the excess sludge is shortened effectively, the treatment efficiency is improved, besides, the disintegrating effect of the excess sludge is remarkable, the settling property is improved perfectly, and the disintegrated sludge is free of foul smell.

Owner:YULIN UNIV

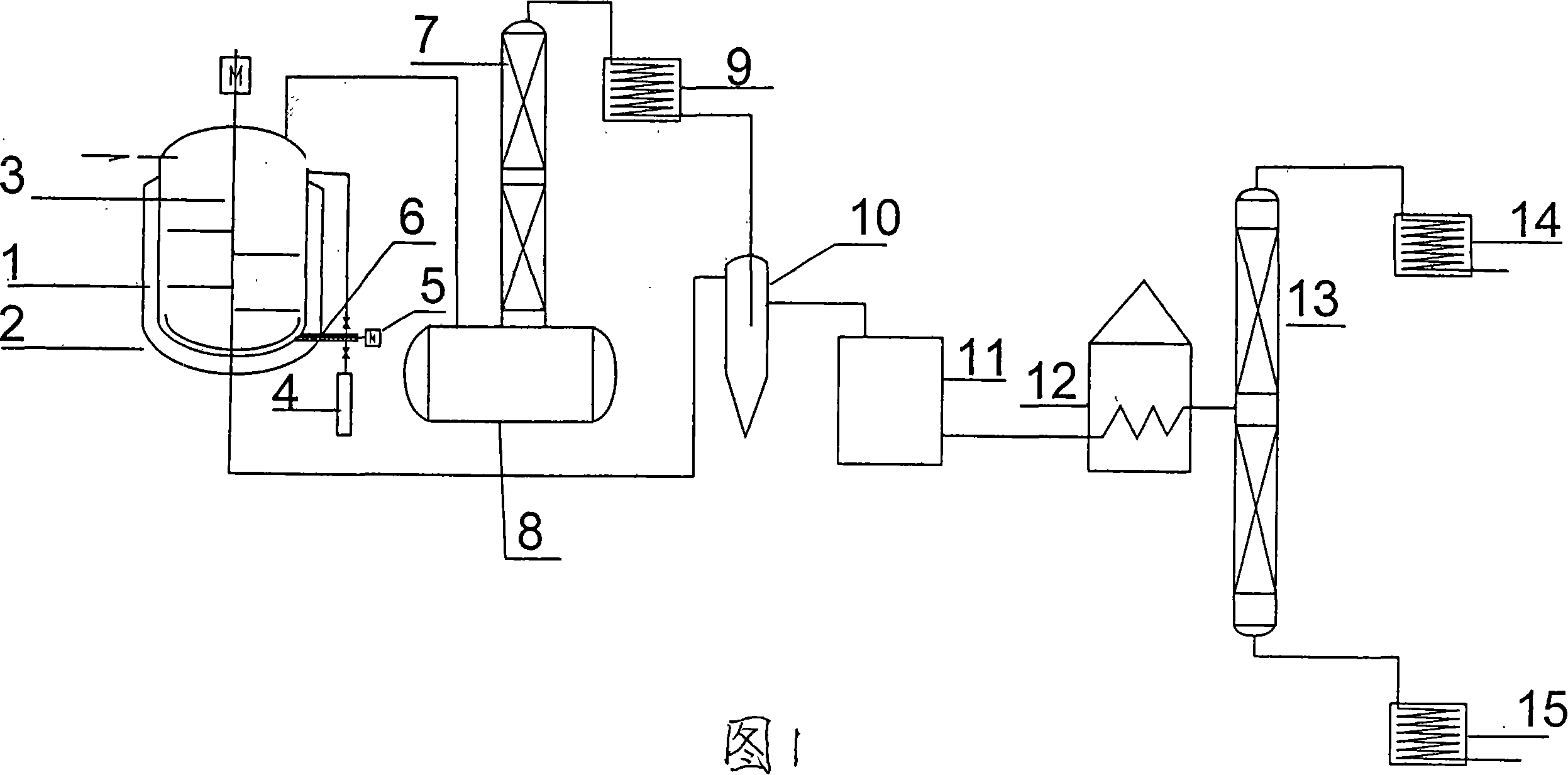

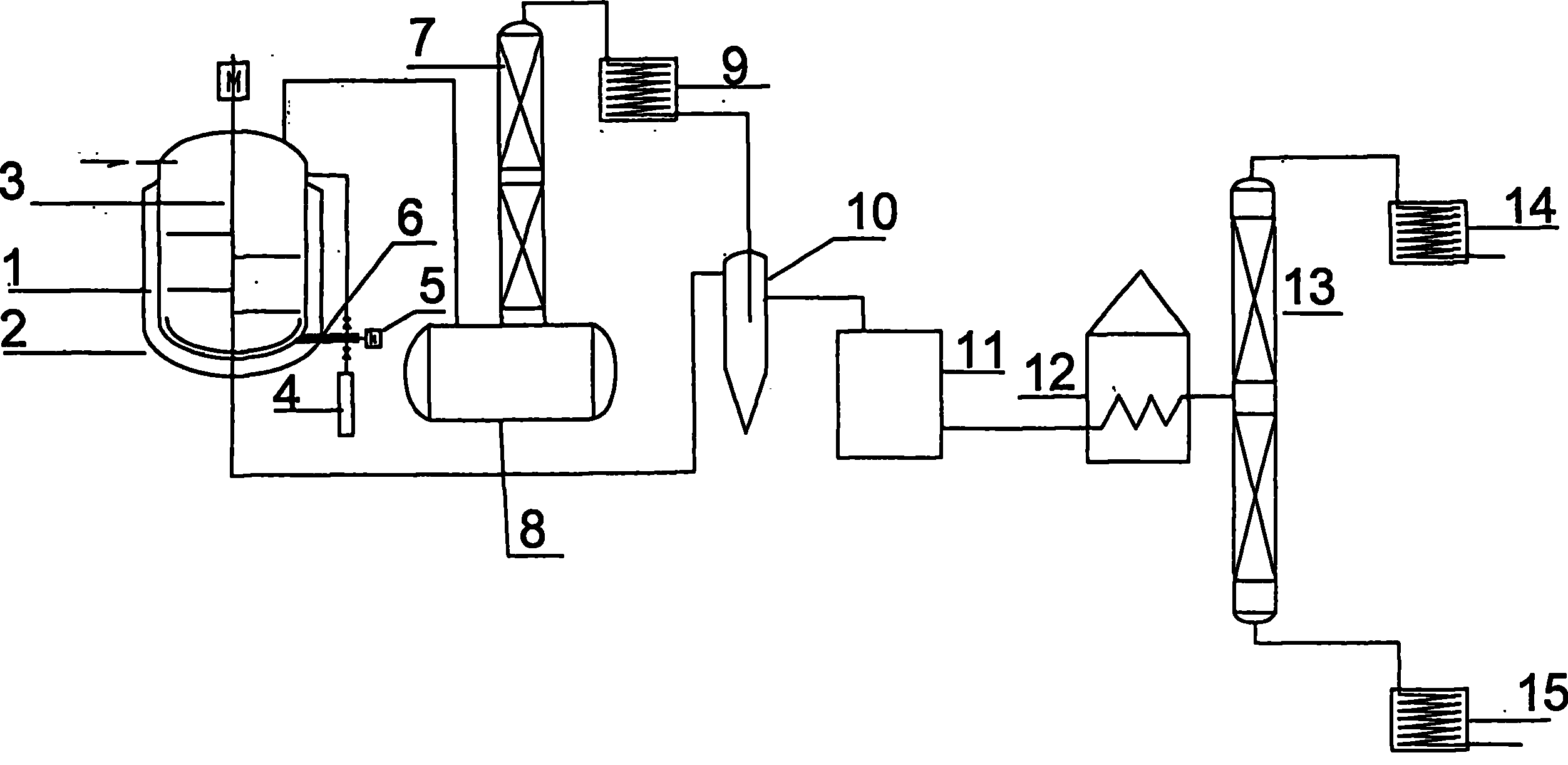

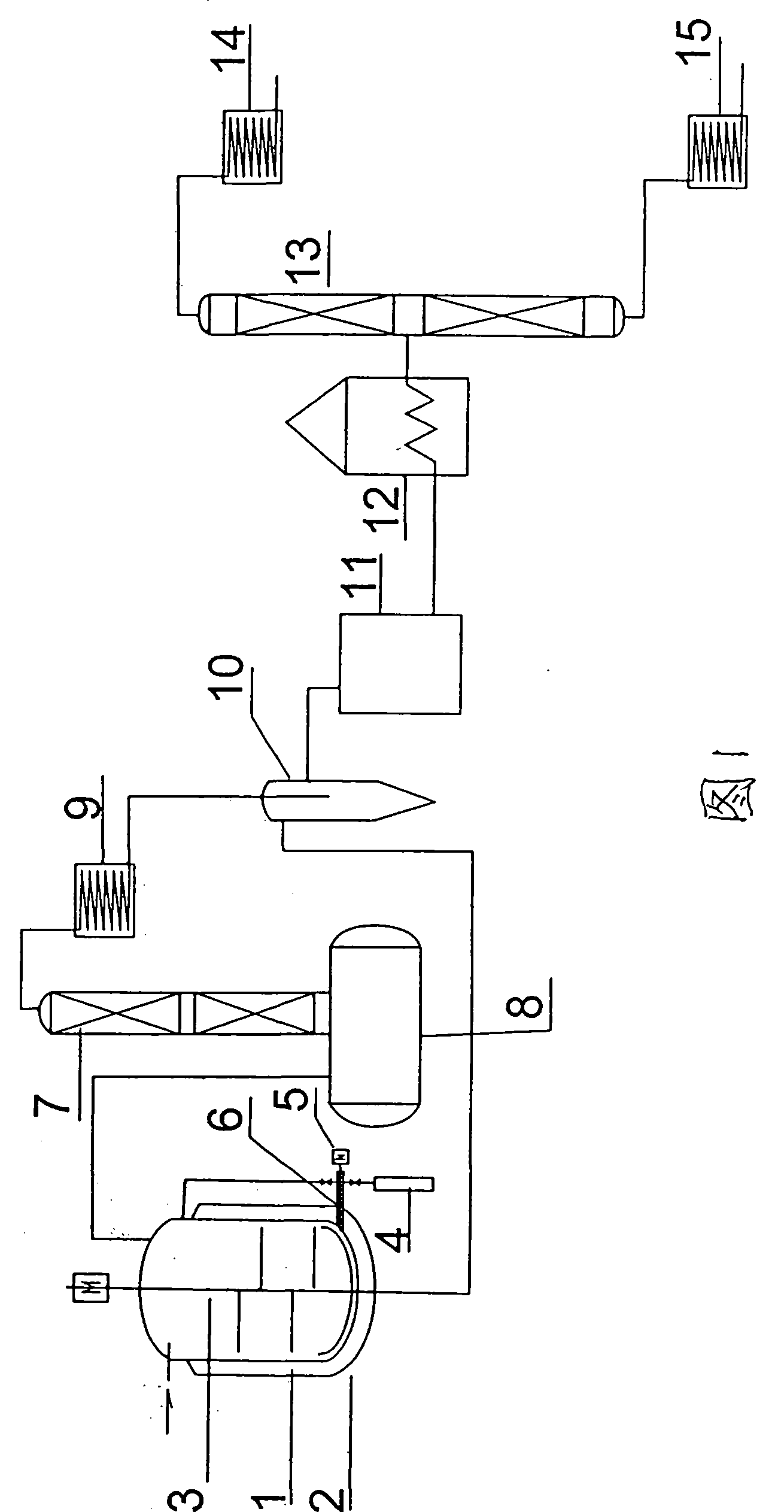

Industrialized method for producing fuel oil by using waste plastics

InactiveCN101117585AIncrease heat absorption areaImprove conversion rateLiquid hydrocarbon mixture productionDistillationHeat conducting

The present invention relates to an oil refining technology by utilizing waste plastic, in particular to an industrialized fuel oil producing method by utilizing the waste plastic. The present invention solves the shortcoming existed in the prior art that the effect for using the waste plastic to produce the fuel oil is bad. The steps includes: dehydrated mineral oil is used as the medium of liquidized waste plastic to be put into a reactor, the mineral oil being used for liquidizing the waste plastic is preheated in the reactor, the waste plastic is put into the reactor, the waste plastic in the reactor is stably heated and time-lapsed cracked, gaseous hydrocarbon produced from the reaction is fed into a flash distillation column, light distillated oil produced from the flash distillation column is distilled in the normal atmosphere. The present invention adopts molten salt as the heat-conducting medium, so as to enable the plastic being heated evenly, the operation temperature is controlled at 500 DEG C, the liquid liquidoid temperature inside the reactor is controlled at 370 DEG C for delaying the cracking operation and stabilizing the cracking temperature, the liquid inside the reactor is cracked under the stable condition, so as to overcome disadvantages in the prior art that using the coal fire to burn directly, the stability of the oil product is bad and the yield of the liquid is low.

Owner:党德润

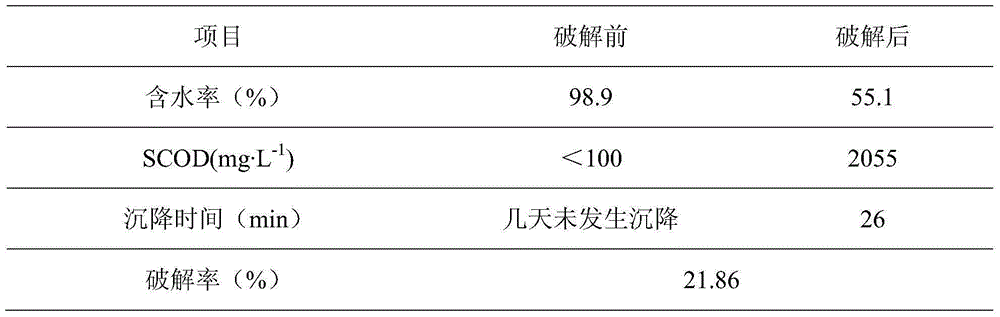

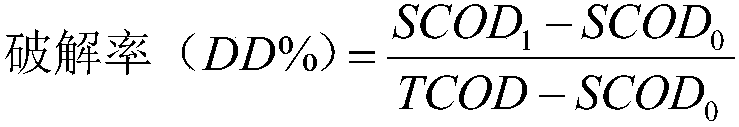

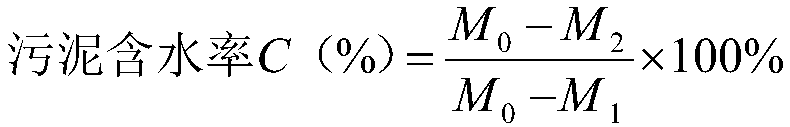

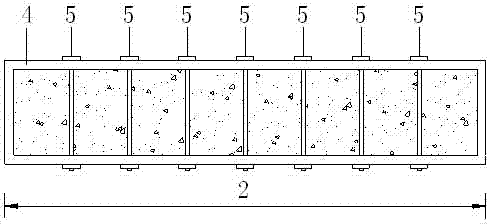

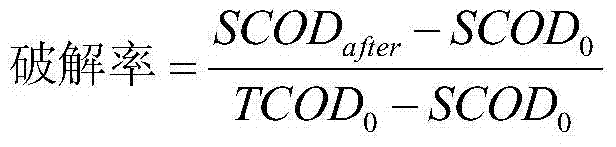

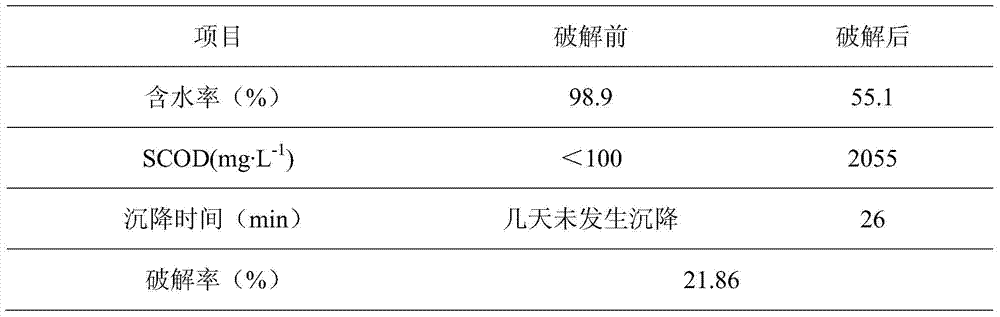

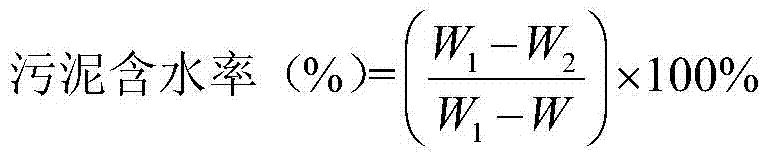

Combined ultrasonic whirl and disintegration process for surplus sludge

InactiveCN108046550AReduce moisture contentDelayed cracking timeSludge treatment by de-watering/drying/thickeningUltrasonic cavitationShear flow

The invention relates to the technical field of municipal domestic wastewater and sludge treatment and specifically discloses a combined ultrasonic whirl and disintegration process for surplus sludge.The process comprises the following steps: after carrying out gravity sedimentation and concentration on surplus sludge generated by a secondary sedimentation tank of a municipal sewage treatment plant, disintegrating the surplus sludge under the action of a strong whirl shear flow field to form small flocs; then, realizing the crushing of microorganism cell walls under the action of ultrasonic cavitation; and releasing intercellular and extracellular polymers and intercellular organic matters into a water body to facilitate the subsequent recycle of a carbon source, so that the reduction ofthe surplus sludge is realized. By using the combined ultrasonic whirl and disintegration process, the disintegration rate of the sludge is increased, the disintegration time of the surplus sludge isshortened, the problem that the overmuch surplus sludge is difficult to treat is effectively solved, the transportation cost of the sludge is reduced, the operation costs of sludge treatment and sewage treatment are reduced as a whole, and the combined ultrasonic whirl and disintegration process has high environmental and economic benefits.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Underground continuous wall with prefabricated concrete-filled steel tube composite structure and method for constructing underground continuous wall

ActiveCN103924581AFast constructionHigh tensile strengthExcavationsBulkheads/pilesSteel tubeSteel plates

The invention discloses an underground continuous wall with a prefabricated concrete-filled steel tube composite structure and a method for constructing the underground continuous wall. The underground continuous wall comprises a plurality of prefabricated connecting wall sections. The prefabricated connecting wall sections are vertically sequentially connected with one another and comprise concrete-filled steel tube composite members and external cast-in-place box-type concrete structures, rectangular steel tubes are arranged on the outsides of the concrete-filled steel tube composite members, concrete is arranged inside each concrete-filled steel tube composite member, the steel tubes are provided with binding bars at certain intervals, the binding bars are made of high-strength bolts, the protruded concrete-filled steel tube composite members of the wall sections are connected with one another by bolts, high-strength non-shrink grouting materials are poured in joints to form bond zones, prestressed steel strands are arranged inside the box-type concrete structures, slits are formed in the middle or two sides of each end of each connecting wall section, connecting steel plates are embedded among slit sections, slurry is poured in the wall sections after the wall sections are washed, and then the wall sections are integrally connected with one another. The underground continuous wall with the concrete-filled steel tube composite structure and the method have the advantages of good mechanical property, leakage resistance, reliability in connection, capability of implementing industrial production, and the like.

Owner:SOUTHEAST UNIV

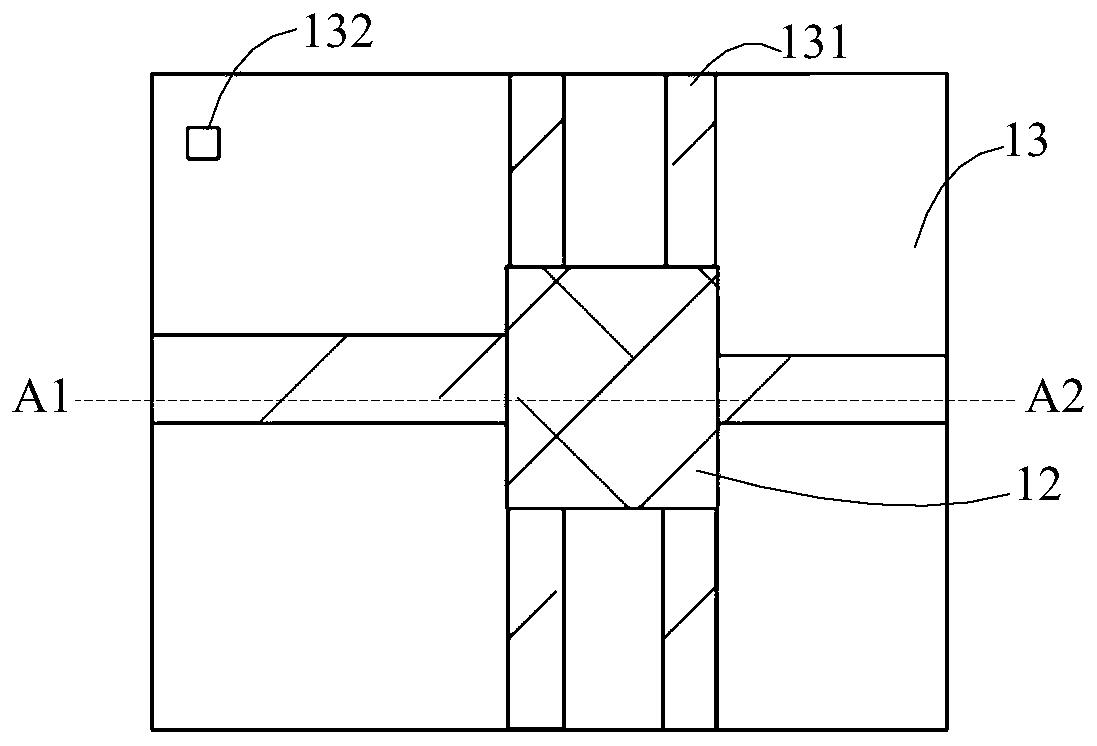

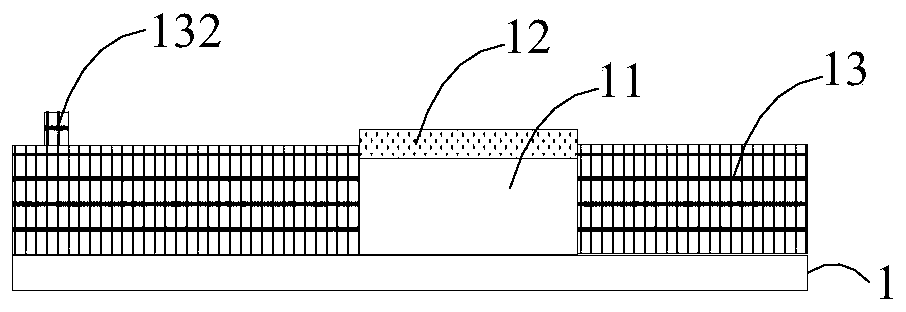

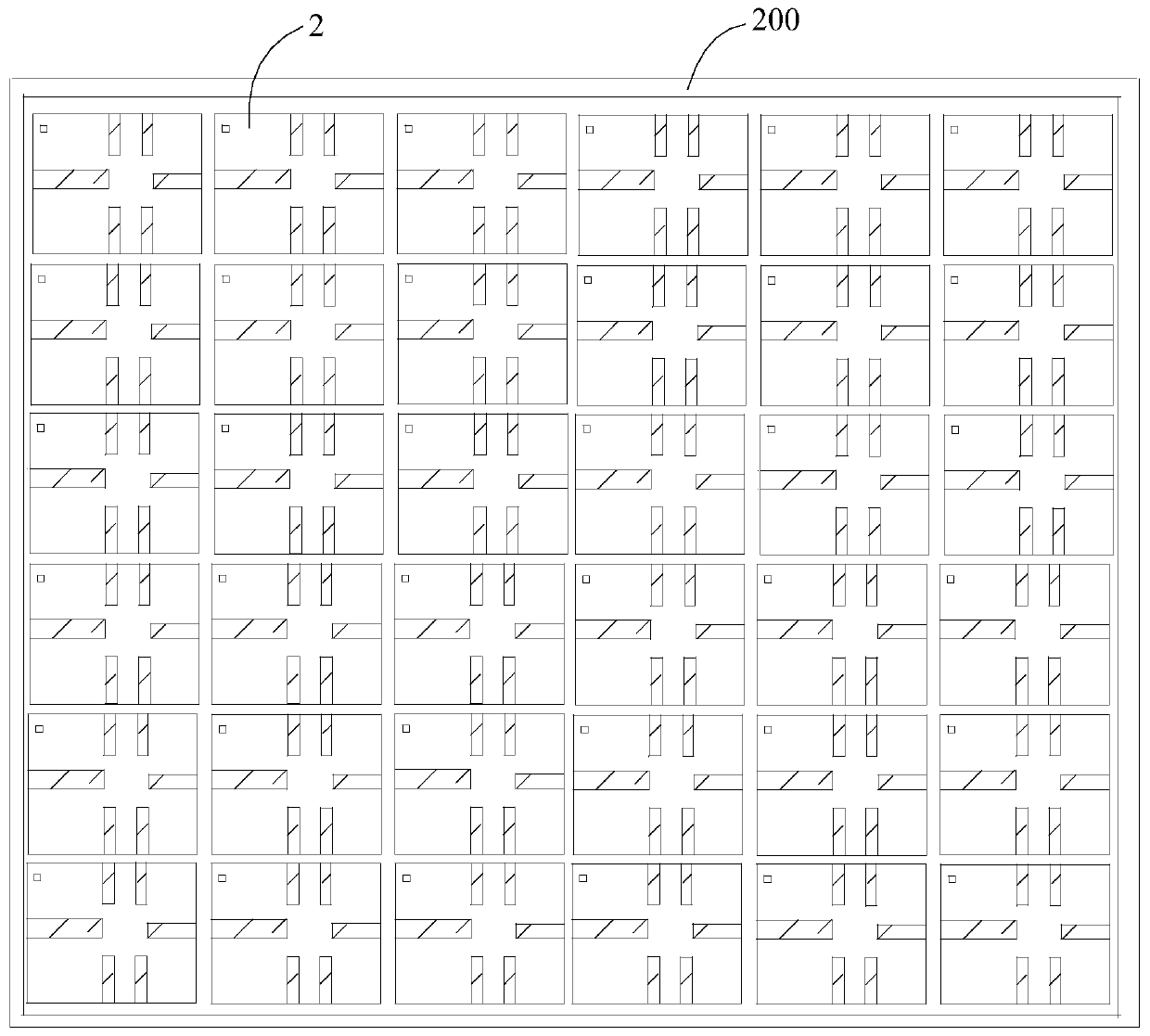

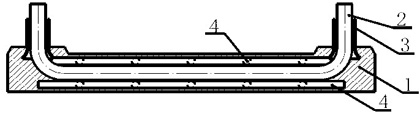

Package substrate, semiconductor device and manufacturing method thereof

PendingCN109801902AExtended service lifeRelieve heat stressSolid-state devicesSemiconductor devicesThermal expansionEngineering

The invention discloses a package substrate, a semiconductor device and a manufacturing method thereof. The semiconductor device comprises a die bonding substrate, an LED chip disposed on the die bonding substrate, a fluorescent sheet disposed on the LED chip, and a white glue layer disposed around the LED chip and fluorescent sheet; the top of the white glue layer is flush with the upper surfaceof the fluorescent layer; at least one groove is formed in the upper surface of the white glue layer; the at least one groove passes through the inner wall and outer wall of the white glue layer; andthe groove extension direction of the at least one groove is perpendicular to the side of the LED chip. With the semiconductor device and the manufacturing method thereof of the invention adopted, thethermal stress of the white glue layer can be effectively alleviated, the adaptability of the white glue layer to heat-induced expansion and cold-induced contraction displacement can be improved, andtherefore, the cracking time of the white glue layer can be delayed, and the service life of the semiconductor device can be prolonged.

Owner:APT ELECTRONICS

Preparation method of static cracking agent

InactiveCN111039598ARegulation stabilityPromote fragmentationFibre typesConjugated synthetic polymer artificial filamentsSpinningNanofiber

The invention discloses a preparation method of a static cracking agent, and belongs to the technical field of cracking agent preparation. According to the invention, organic macromolecular substancesand the like are used for spinning to prepare a nano-fiber net component so as to improve the cracking effect; the hydrogen storage effect is improved by blending a plurality of metal powders and matching the metal powders with the imitating nano-liposome; the breaking strength and effect can be improved by burst of hydrogen during subsequent application; different levels of auxiliary expansion cracking effects are formed by combining a plurality of substances which are expanded when meeting water, and the hydrogen burst degree can be adjusted and the breaking effect is stably improved; by adding a compound mixture composed of bentonite, sepiolite, starch and the like, the static cracking effect can be improved through multi-level expansion of the compound mixture, release and burst of hydrogen are controlled within a controllable range, large expansion pressure is provided, the cracking time is shortened, and cracking can be better completed. The invention solves the problems of lowexpansion pressure, long cracking time and poor cracking effect of a current common static cracking agent.

Owner:陈超超

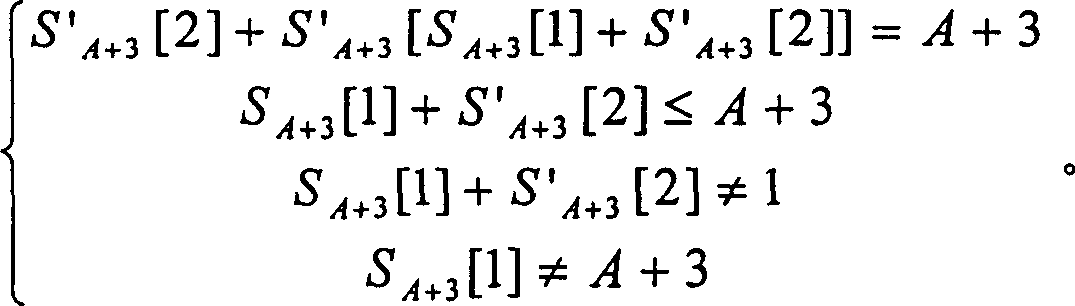

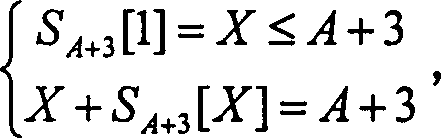

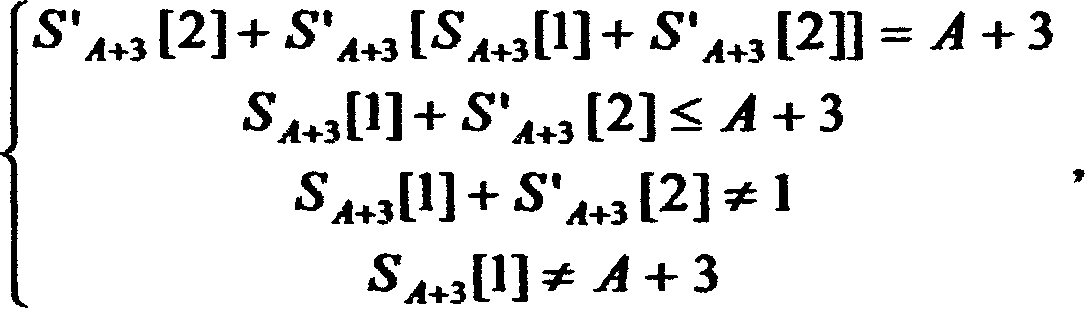

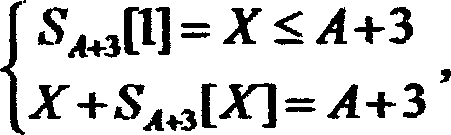

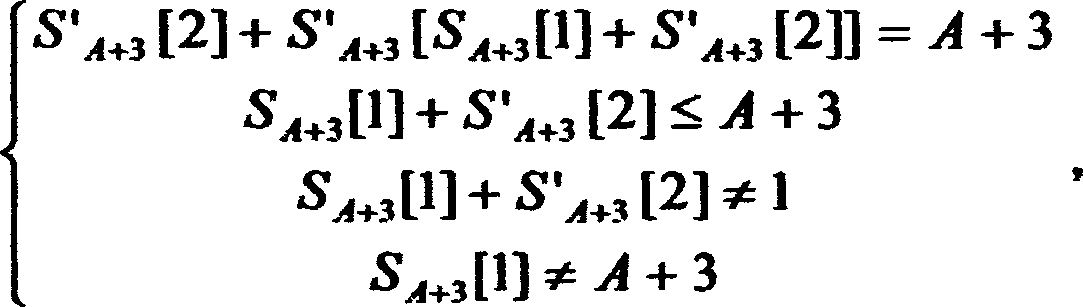

Method of deciphering wired cipher in the same privacy

InactiveCN1441567AImprove accuracyDelayed cracking timeMultiple keys/algorithms usageUser identity/authority verificationRC4Byte

Owner:SOUTHEAST UNIV

A kind of online welding method of circulating fan impeller

ActiveCN106181087BExtended service lifeAdd depthWelding/cutting auxillary devicesAuxillary welding devicesImpellerEngineering

Owner:PANGANG GRP ENG TECH

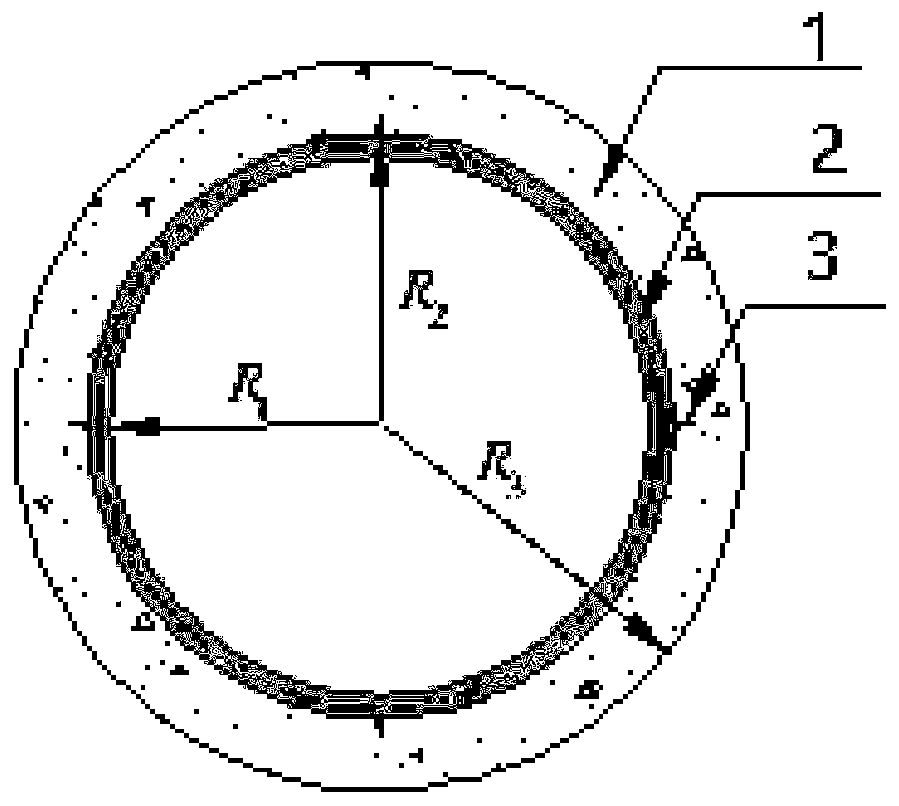

Improved test method for determining crack resistance of concrete under condition of restrained shrinkage

PendingCN109917114AEliminate driveDelayed cracking timeMaterial testing goodsCrack resistanceStrain gauge

The invention, which belongs to the technical field of crack resistance research of early-age concrete, provides an improved test method for determining the crack resistance of concrete under the condition of restrained shrinkage. On the basis of reasonable improvement of the restrained ring test recommended by the American Society for Testing and Materials, the influence on the shrinkage crackingby the own constraining effect is reduced and the crack resistance of early-age concrete under restricted shrinkage condition is accurately evaluated. A corresponding initial crack is formed at the annular inner side of concrete by pasting a pre-fabricating crack at the outer side of a steel ring. The bottom of the pre-fabricating crack is flush with the bottom of a ring-shaped test piece in a height direction; and the top of the pre-fabricating crack is higher than the top of the test piece by no less than 10mm. With consideration of the influence of the dispersion on the concrete material,the numbers of the initial cracks is set to be 3 to 5 and the initial cracks are distributed uniformly at the annular inner side of the concrete. No strain gauge needs to be pasted at the inner side of the steel ring and the crack time of the test piece can be determined clearly by observing the expansion of the outer ring surface at the initial crack position of the concrete.

Owner:DALIAN UNIV OF TECH

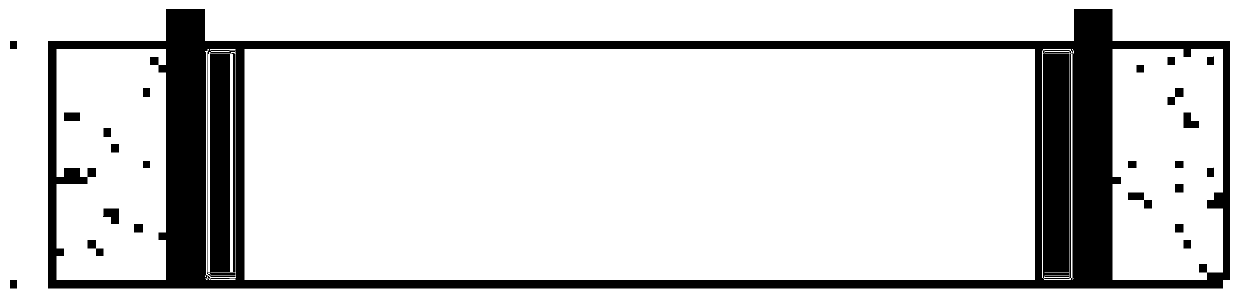

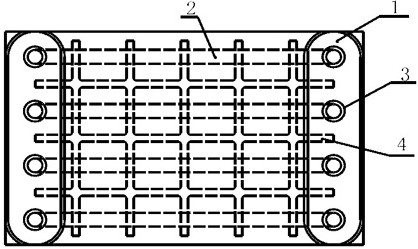

Water pipe reinforcing rib type cooling wall

InactiveCN113913573AHigh tensile strengthExtended service lifeCooling devicesThermodynamicsMechanical engineering

The invention relates to a water pipe reinforcing rib type cooling wall. The cooling wall is provided with a cooling water pipe, the cooling water pipe is arranged on a cooling wall body, a protection pipe is arranged at an inlet and an outlet of the cooling water pipe, and net-shaped reinforcing ribs are fixedly laid above and below the cooling water pipe and are respectively an upper-layer net-shaped reinforcing rib and a lower-layer net-shaped reinforcing rib; and the net-shaped reinforcing ribs are composed of a plurality of longitudinally-arranged ribs and a plurality of transversely-arranged ribs, the longitudinal ribs and the transversely-arranged ribs intersect with each other, and the intersection points are fixedly connected. The upper-layer net-shaped reinforcing ribs and the lower-layer net-shaped reinforcing ribs are laid above and below the cooling water pipe, the effect of fixing the water pipe is achieved, the tensile strength of the cooling wall body is improved, and the cooling wall body can bear large force without cracks; and the cracking time of the cooling wall is delayed in the using process of a blast furnace, an internal water pipe is protected against small strain stress, so that the service life of the cooling wall is prolonged, and the overall service life of the blast furnace is prolonged.

Owner:SHANGHAI BAOSTEEL CASTING

Long-life, safe and reliable forging cast iron mold for iron casting machine and manufacturing method thereof

ActiveCN103769552BImprove thermal fatigue strengthImprove safety and reliabilityPig casting plantsThermal fatigueCasting defect

The invention discloses a long-service-life, safe and reliable forging cast iron die for a pig casting machine and a manufacturing method of the long-service-life, safe and reliable forging cast iron die. The forging cast iron die is integrally formed based on a forging technology, at least two separating ribs lower than a high-temperature molten iron liquid face are arranged in the forging cast iron die, an inner die cavity of the forging cast iron die is divided into at least three forming die cavities by the separating ribs, a lap joint mouth Q used for being in lap joint with an adjacent forging cast iron die is arranged at the lower end of the forging cast iron die, a cast iron die tail P corresponding to the lap joint mouth at the lower end of the adjacent forging cast iron die is arranged a the upper end of the forging cast iron die, at least two overflow openings are formed in the lap joint mouth Q, and molten iron protection edges M1 and M2 and lug portions T1 and T2 connected with a chain plate are arranged on the two sides of the forging cast iron die. The poor cast condition metallographic structure and various forging defects of a forging forming cast iron die are avoided and overcome through the forging cast iron die, the thermal fatigue resisting strength of the cast iron die is effectively improved, the safe reliability of the cast iron die is improved, and the service life of the cast iron die is prolonged.

Owner:SHILIN LUOHE METALLURGY EQUIP +1

Preparing method for polycarboxylate water reducing agent

ActiveCN103159899BIncrease profitNarrow down the range of molecular weight fluctuationsHydrogenRoom temperature

The invention provides a preparing method for polycarboxylate water reducing agent. The polycarboxylate water reducing agent composed of, by weight, 30%-55% of deionized water, 35%-50% of polyoxyethylene ether, 5%-10% of carboxylic acid derivatives monomer, 0.0005%-0.002% of catalyst, 1.5%-4.5% of initiator, 0.2%-0.8% of chain transfer agent, 1.0%-2.5% of structure modifying agent and 4.5%-8.5% of alkali liquor. Under the temperature of 20-35 DEG C, the deionized water and the polyoxyethylene ether are enabled to be put in a reaction still to be dissolved, after the deionized water and the polyoxyethylene ether are fully dissolved, the carboxylic acid derivatives monomer, the catalyst, the initiator, the chain transfer agent and the structure modifying agent are enabled to be added in sequence, after stirring for 28-32 minutes, the mixed liquor still standings for 4-6 hours under room temperature, the alkali liquor is added in under a state of stirring, a potential of hydrogen (PH) value is adjusted to be 6.0-7.5, and then products are achieved.

Owner:XINJIANG DELAND

Reduction-reducing crack-resisting concrete superplasticizer of graft copolymer and method for preparing the same

A shrinkage-reducing, crack-resistant graft copolymer concrete superplasticizer consists of monomer A: acrylic acid or its salt, monomer B: alkoxy polyether monoacrylate, monomer C: maleic anhydride half ester or its Salt, monomer D: α-allyl alcohol ω-methyl polyether and monomer E: styrene are prepared by free radical copolymerization, the aforementioned monomer A: monomer B: monomer C: monomer D: The molar ratio of the monomer E is 1:0.2-0.5:0.10-0.25:0.10-0.20:0-0.10. Its preparation method includes 1) preparing monomer B by esterification reaction of monoalkoxy polyether and acrylic acid in the presence of water-carrying agent, acid catalyst and polymerization inhibitor; Polyether and maleic anhydride undergo esterification reaction under the condition of catalyst to prepare monomer C; 3) carry out free radical copolymerization reaction of each monomer under the condition of free radical initiator to obtain finished product. The invention has the advantages of simple production technology, high water reducing rate, good reinforcing effect, low drying shrinkage rate, good crack resistance and low price.

Owner:JIANGSU SOBUTE NEW MATERIALS

Industrialized method for producing fuel oil by using waste plastics

InactiveCN101117585BIncrease heat absorption areaReduce the temperatureLiquid hydrocarbon mixture productionDistillationHeat conducting

The present invention relates to an oil refining technology by utilizing waste plastic, in particular to an industrialized fuel oil producing method by utilizing the waste plastic. The present invention solves the shortcoming existed in the prior art that the effect for using the waste plastic to produce the fuel oil is bad. The steps includes: dehydrated mineral oil is used as the medium of liquidized waste plastic to be put into a reactor, the mineral oil being used for liquidizing the waste plastic is preheated in the reactor, the waste plastic is put into the reactor, the waste plastic inthe reactor is stably heated and time-lapsed cracked, gaseous hydrocarbon produced from the reaction is fed into a flash distillation column, light distillated oil produced from the flash distillation column is distilled in the normal atmosphere. The present invention adopts molten salt as the heat-conducting medium, so as to enable the plastic being heated evenly, the operation temperature is controlled at 500 DEG C, the liquid liquidoid temperature inside the reactor is controlled at 370 DEG C for delaying the cracking operation and stabilizing the cracking temperature, the liquid inside the reactor is cracked under the stable condition, so as to overcome disadvantages in the prior art that using the coal fire to burn directly, the stability of the oil product is bad and the yield of the liquid is low.

Owner:党德润

Ultrasonic combined with modified eggshell method to crack excess sludge

InactiveCN105174681BOdorlessRealize harmless resource utilizationSludge treatment by de-watering/drying/thickeningEggshellSlurry

The invention relates to a method for disintegrating excess sludge through combination of ultrasonic waves and modified eggshells. The method comprises steps as follows: firstly, in terms of 0.05-0.4 g of modified eggshells added to the excess sludge per ml, the modified eggshells are added to the excess sludge, the modified eggshells and the excess sludge are mixed uniformly, and sludge slurry is prepared; the sludge slurry is subjected to ultrasonic treatment through the ultrasonic waves, and the excess sludge is disintegrated. With the adoption of the modified eggshells, the waste eggshells are changed to be wealthy, the environmental pollution is reduced, the problem about disposal and treatment of the eggshells is solved effectively, further, an effective chemical for disintegrating the excess sludge is obtained, the chemical cost for sludge treatment is saved, and the treatment cost of the excess sludge is reduced; with the introduction of the ultrasonic waves in a disintegrating experiment, the sludge cell disintegrating speed is increased greatly, the disintegrating time of the excess sludge is shortened effectively, the treatment efficiency is improved, besides, the disintegrating effect of the excess sludge is remarkable, the settling property is improved perfectly, and the disintegrated sludge is free of foul smell.

Owner:YULIN UNIV

Device and method for directional fracture of rocks

InactiveCN101726223BEfficient and accurate fractureBreak accuratelyBlastingShape-memory alloyStructural engineering

The invention discloses a device and a method for directional fracture of rocks. The fracture device consists of a pressure transfer body, a plurality of shape memory alloy bodies and a spacing body. The inner side of the pressure transfer body is provided with symmetrical grooves, and the outer side of the pressure transfer body is arc-shaped; and the cross sections of the shape memory alloy bodies are cross, the left and right ends of the shape memory alloy bodies are embedded in the grooves of the pressure transfer body, and the front and rear ends of the shape memory alloy bodies are embedded with hard straight blades. The method comprises the following steps: putting the directional fracture device into a borehole, adjusting the straight blades towards the predetermined fracture direction, then heating the shape memory alloy bodies to be stretched along the cross direction, forming primary shear fracture on the hole wall firstly through the driven straight blades, and then expanding the cracks through the combined action of extrusion forces of the straight blades and the pressure transfer body so as to cause rock fracture. The rock fracture surface is regular, the fracture efficiency is high, the reuse rate is high, the cost is low, and the method and the device are suitable for stone exploitation, blasting operations of tunnels, side slopes and the like and other pre-splitting blasting and demolition blasting.

Owner:CHINA UNIV OF MINING & TECH

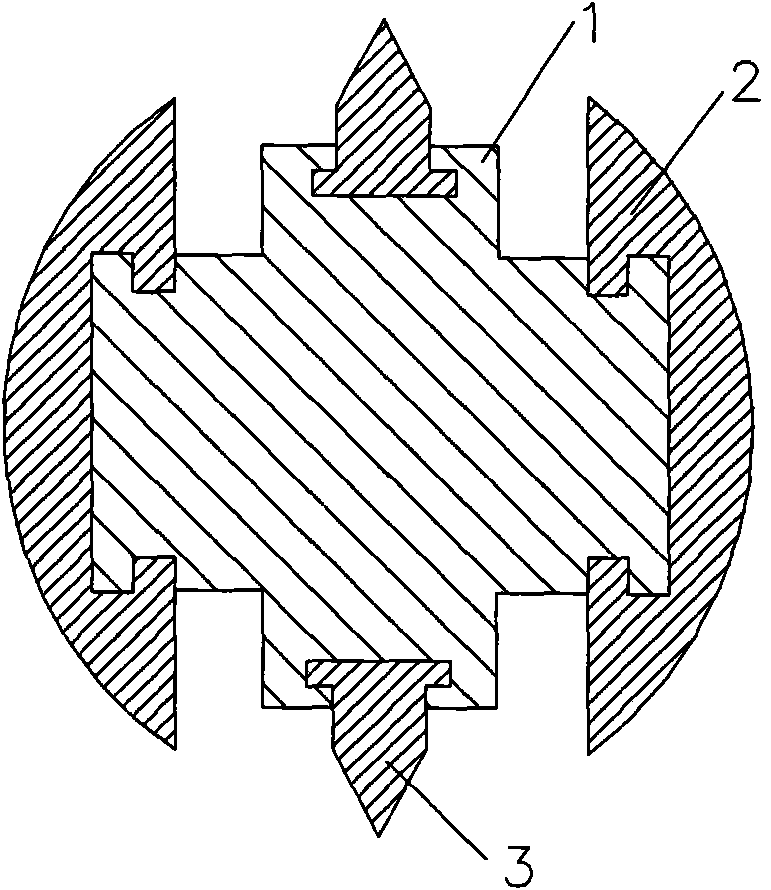

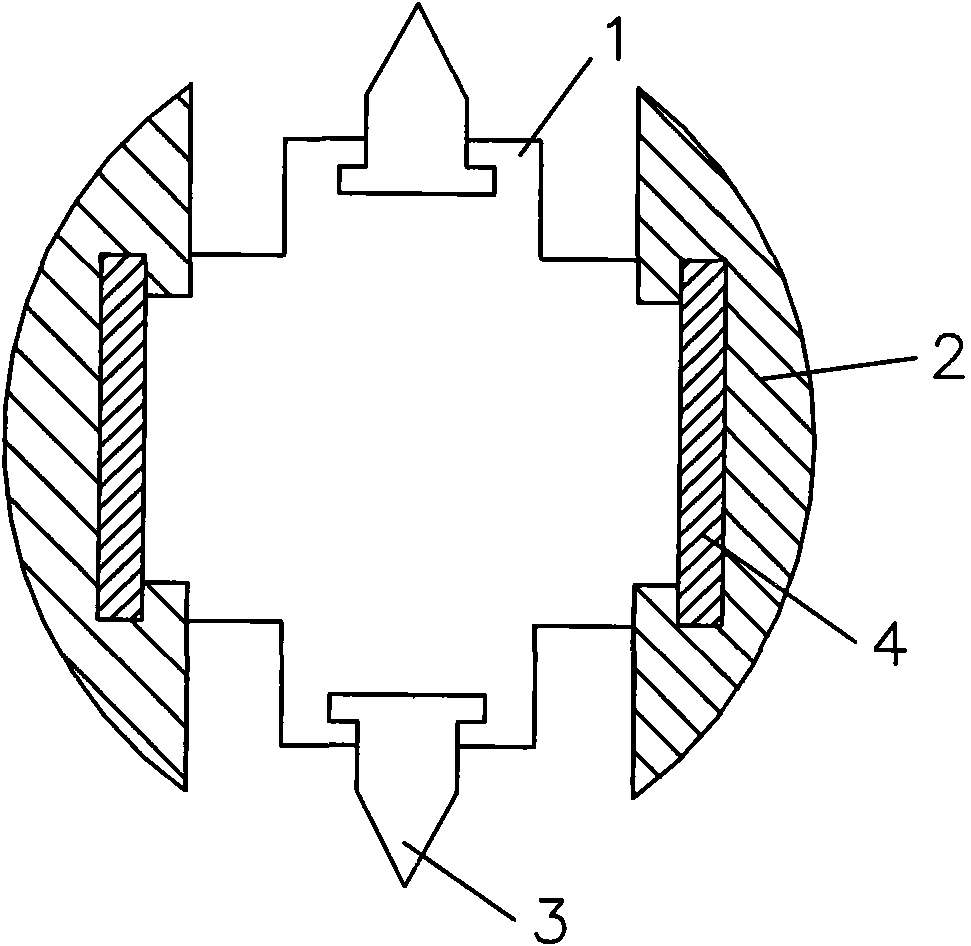

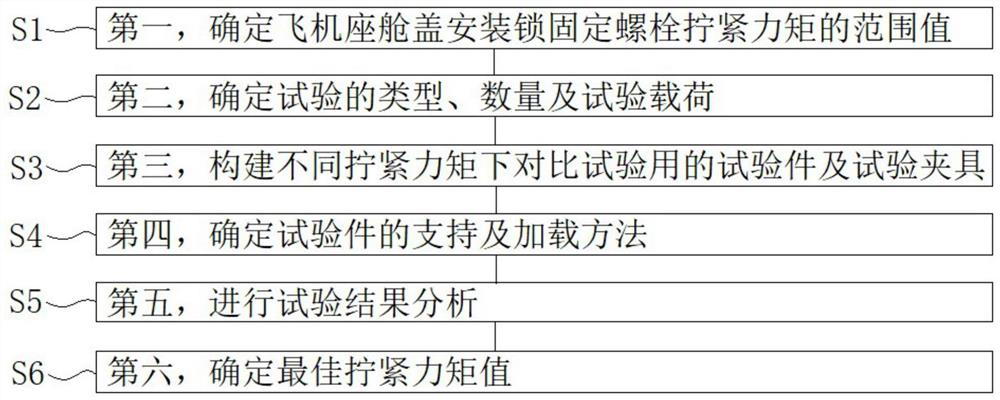

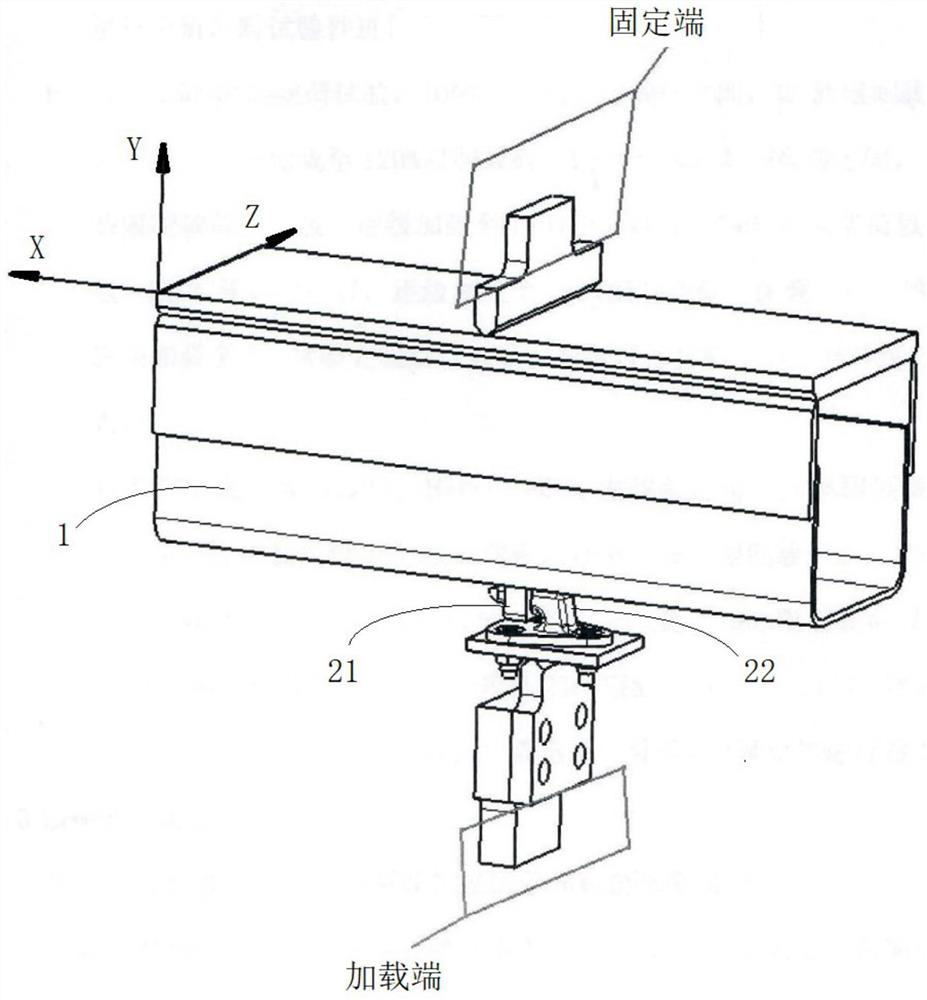

Method for determining tightening torque value of aircraft canopy mounting lock

ActiveCN113834596ADelayed cracking timeExtended service lifeSustainable transportationMeasurement of torque/twisting force while tighteningStructural engineeringMechanical engineering

The invention provides a method for determining the tightening torque value of an aircraft canopy mounting lock. The method comprises the steps that: the range value of tightening torque of a fixing bolt is determined according to the diameter of the fixing bolt; a test type is determined as a fatigue test, a test group at least comprises three groups of test pieces with different tightening torques, and a test load is the maximum use load of the aircraft canopy mounting lock; test pieces and test fixtures for contrast tests under different tightening torques are constructed according to a load transfer route and a boundary condition requirement; supporting and loading modes of test equipment and the test pieces are determined according to the load transfer route and boundary conditions in a full-size aircraft structure; the mechanical property influence of the bolt hole of the aircraft canopy mounting lock under different tightening torques is obtained through contrast test results under the different tightening torques; and according to the longest median life of the bolt hole of the canopy mounting lock under the different tightening torques, the optimal tightening torque value of the canopy mounting lock isdetermined.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Method of deciphering wired cipher in the same privacy

InactiveCN1202636CImprove accuracyDelayed cracking timeMultiple keys/algorithms usageUser identity/authority verificationRC4Password

Owner:SOUTHEAST UNIV

System and method for cracking word2003 document based on fpga hardware

ActiveCN106357384BImprove cracking efficiencyDelayed cracking timeEncryption apparatus with shift registers/memoriesResource consumptionComputer module

The invention discloses a word2003 document cracking system based on FPGA hardware and a method. The system comprises a PC, an input interface module, a crack module and an output interface module which are connected sequentially, and the PC is connected with the output interface module. The crack module comprises a sub-key generation module, a rainbow table matching module and a key cracking module which are connected sequentially. The sub-key generation module includes sub-key round robin controller, MD5 algorithm module and RC4 algorithm module which are connected sequentially. The key cracking module consists of algorithm round robin controller, MD5 algorithm module and RC4 algorithm module. The system achieves document cracking by using the time and space folding algorithm of the rainbow table, thus improving the crack efficiency and reducing the cracking time. On the basis of considering the technical characteristics of the rainbow table and the FPGA, the appropriate rainbow table is used for cracking, thus solving the contradiction between cracking time and resource consumption.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

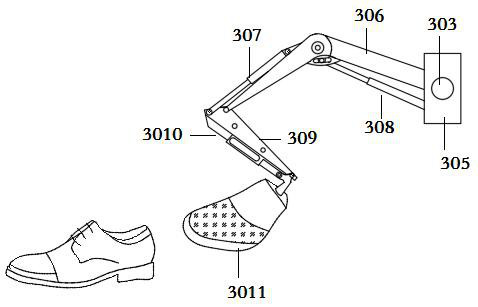

A smart shoe cabinet with automatic wiping uppers for household use

ActiveCN113558550BReduced service lifeDelayed cracking timeWardrobesFootwear cleanersBristleDrive wheel

The invention relates to an intelligent shoe cabinet with automatic wiping of shoe uppers for household use, comprising a shoe cabinet body, a shoe upper wiping mechanism and a shoe support deformation prevention mechanism are respectively arranged in the shoe cabinet body, and the shoe support deformation prevention mechanism is arranged on the shoe upper shoes Above the surface wiping mechanism, the shoe upper wiping mechanism includes a first wiping rotating rod and a second wiping rotating rod. The first wiping rotating rod and the second wiping rotating rod are horizontally arranged below the inner cavity of the shoe cabinet body. The outer side walls of the two wiping rods are both sleeved with the bristle installation plate, and the outer walls of the two sets of bristle installation boards are evenly inserted with wiping bristles. The first wiping rod and the second wiping rod rotate through the side wall of the shoe cabinet body and are respectively socketed There are a synchronous driving wheel and a synchronous driven wheel, and the synchronous driving wheel and the synchronous driven wheel are sleeved with each other through a rotating belt. The upper and lower ends of the shoes are rotated and wiped.

Owner:LUOYANG STEELITE STEEL CABINET CO LTD

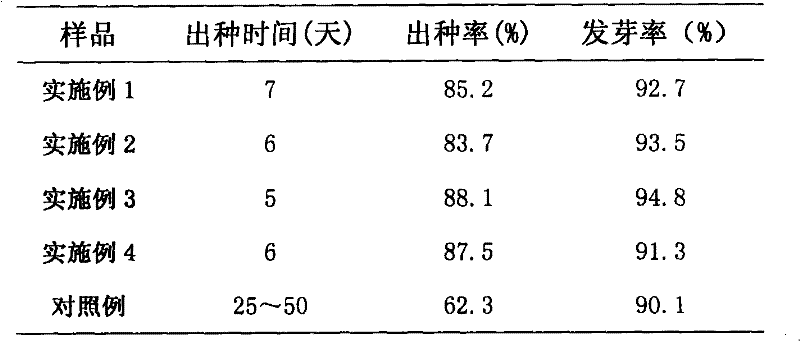

Method for processing strobili of pinus massoniana

ActiveCN102124836BDelayed cracking timeNeat openingSeed and root treatmentAdverse weatherPinus massoniana

Owner:GUANGXI FORESTRY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com