Method for pretreating sludge by reflux of fermentation liquor and application of method

A technology of pretreatment and fermentation liquid, applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problem of high energy consumption, and achieve the effects of increasing gas production, shortening cracking time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

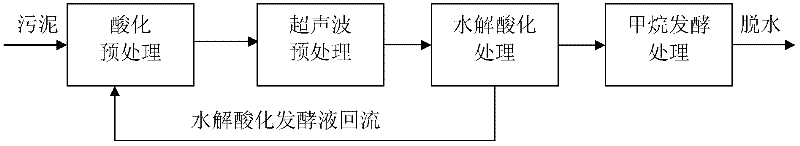

Image

Examples

Embodiment 1

[0019] The fermented liquid obtained in the hydrolysis and acidification treatment step is returned to the sludge pretreatment tank through the sludge pump, and the solid content of the sludge in the pretreatment tank is controlled to 2.5%, the reflux ratio of the fermented liquid is 50%, and the mechanical agitation mixes the sewage After the mud and fermentation broth are uniform, acidification pretreatment is carried out, and the pretreatment time is 14 hours. After pretreatment, TCOD in the sludge liquid phase increased by 1340mg / L. The sludge is transported by the sludge pump to a multi-probe ultrasonic processor for ultrasonic cracking, in which the frequency of the ultrasonic reactor is 20kHz, the diameter of the probe is 20mm, and the acoustic energy density is 0.2kW / m 3 , the solid content of the sludge is 2.1%, and the cracking time is 1min. After cracking, the TCOD in the sludge liquid phase increased by 950mg / L. After the ultrasonic treatment, the sludge enters t...

Embodiment 2

[0021] The fermented liquid obtained in the hydrolysis and acidification treatment step is refluxed into the sludge pretreatment tank through the sludge pump, and the solid content of the sludge in the sludge pretreatment tank is controlled to 2.5%, the reflux ratio of the fermented liquid is 55%, and the mechanical stirring After the mixed sludge and fermented liquid are homogeneous, acidification pretreatment is carried out, and the pretreatment time is 24 hours. After pretreatment, TCOD in the sludge liquid phase increased by 1453mg / L. The sludge is transported by the sludge pump to a multi-probe ultrasonic processor for ultrasonic cracking, in which the frequency of the ultrasonic reactor is 20kHz, the diameter of the probe is 20mm, and the acoustic energy density is 0.42kW / m 3 , the solid content of the sludge is 2.1%, and the cracking time is 3 minutes. After cracking, TCOD in the sludge liquid phase increased by 1023mg / L. After the ultrasonic treatment, the sludge ent...

Embodiment 3

[0023] The fermented liquid obtained in the hydrolysis and acidification treatment step is refluxed into the sludge pretreatment tank through the sludge pump, and the solid content of the sludge in the sludge pretreatment tank is controlled to 2.9%, the reflux ratio of the fermented liquid is 67%, and the mechanical stirring After the mixed sludge and fermentation broth are evenly mixed, acidification pretreatment is carried out, and the pretreatment time is 36 hours. After pretreatment, TCOD in the sludge liquid phase increased by 2142mg / L. The sludge is transported by the sludge pump to a multi-probe ultrasonic processor for ultrasonic cracking. The frequency of the ultrasonic reactor is 28kHz, the diameter of the probe is 25mm, and the sound energy density is 0.65kW / m 3 , the solid content of the sludge is 2.4%, and the cracking time is 5 minutes. After cracking, TCOD in the sludge liquid phase increased by 1987mg / L. The ultrasonically treated sludge enters the hydrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com