Industrialized method for producing fuel oil by using waste plastics

A technology for waste plastics and fuel oil, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures. It can solve the problems of poor thermal conductivity of plastics, achieve the effects of increased heat absorption area, high liquid conversion rate, and reduced carbonization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

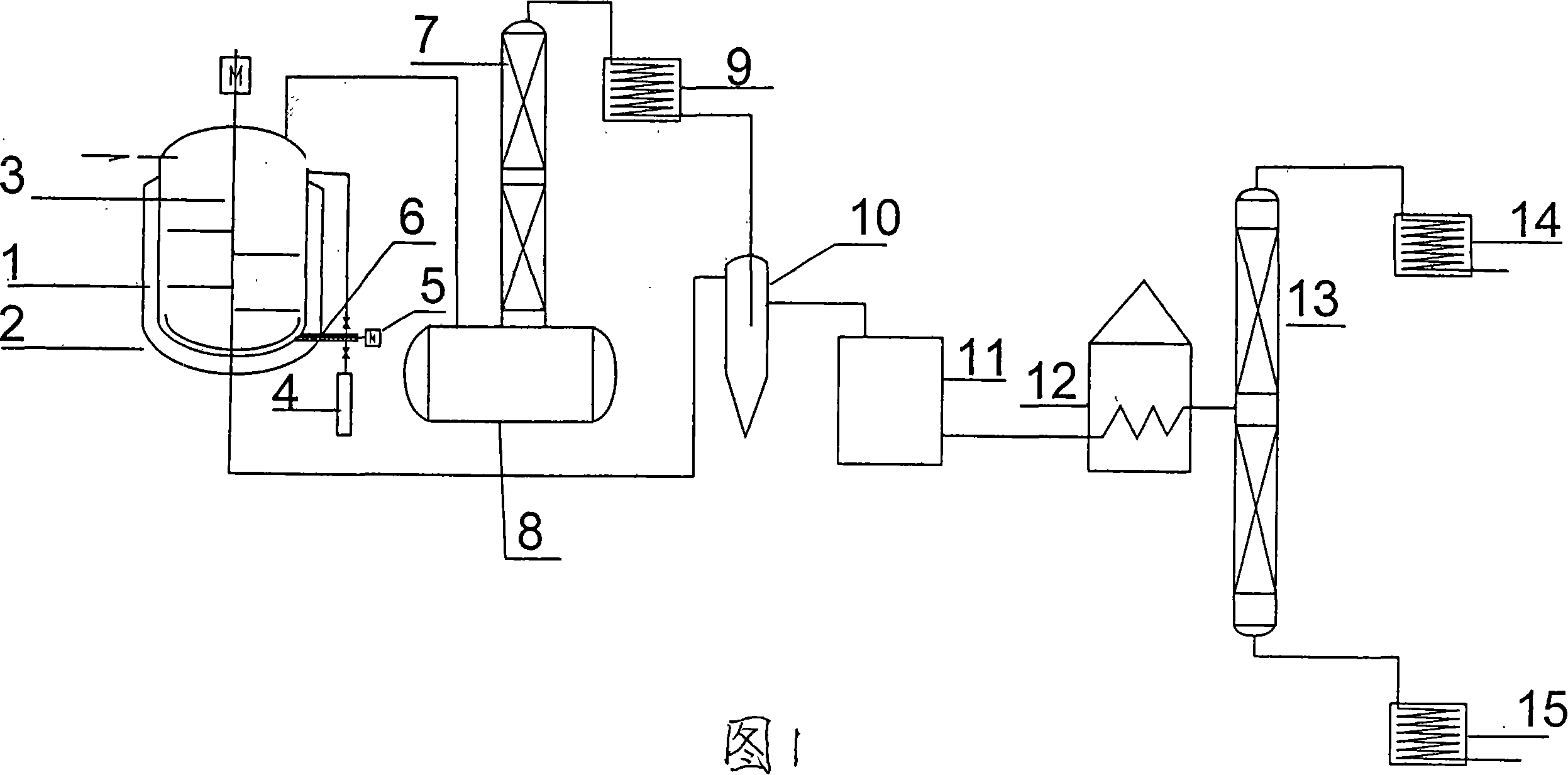

[0022] Below in conjunction with accompanying drawing the present invention will be further described,

[0023] A method for industrially producing fuel oil from waste plastics, comprising the following steps:

[0024] 1. Select dehydrated waste mineral oil as the liquefied waste plastic medium and put it into the reciprocating linkage agitator 3 inside, and the molten salt on the outside for heat conduction Medium molten salt jacketed 2 reactors. The input amount of waste mineral oil is three-fifths of the capacity of the liquid phase section of the reactor. The function of the compound linkage agitator 3 is mainly to stir and remove coke on the inner wall.

[0025] 2. Preheat the waste mineral oil put into the reaction kettle. The temperature of the molten salt in the molten salt jacket 2 is 350°C-400°C, and the temperature of the waste mineral oil in the reaction kettle is 250°C-300°C.

[0026] 3. Put the waste plastic PE, PP, PS mixture into the reactor with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com