Patents

Literature

616results about How to "Conducive to industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

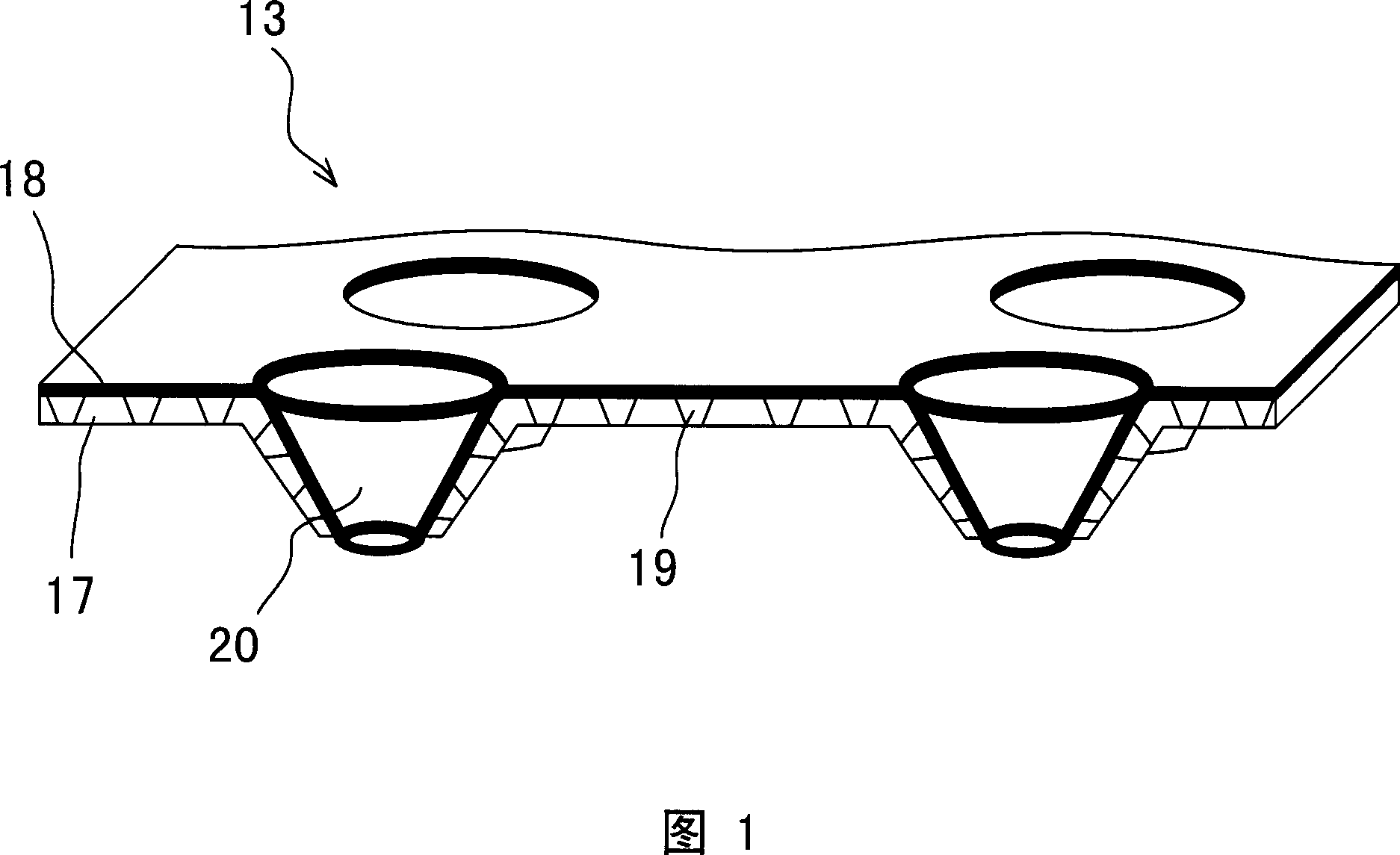

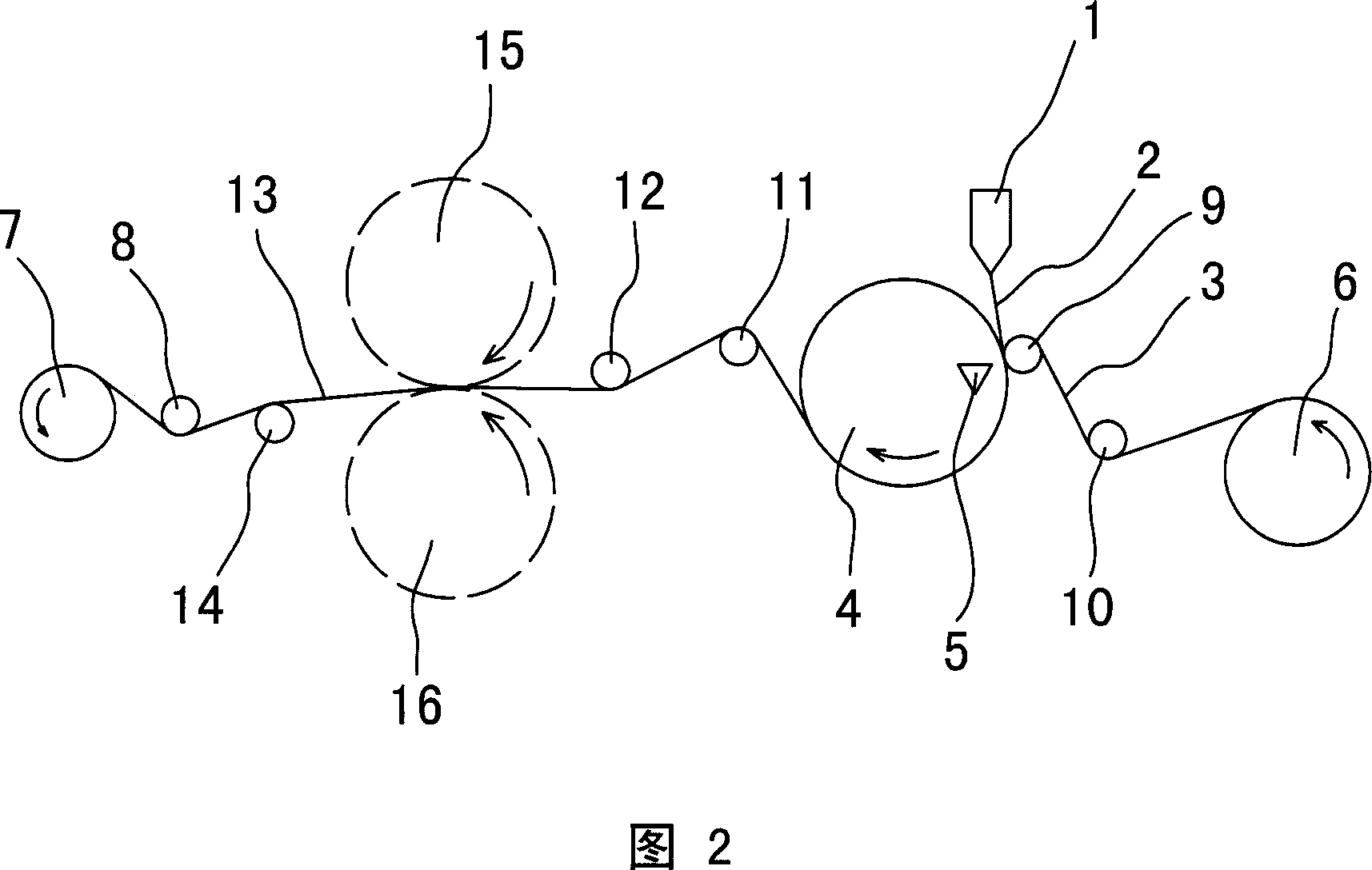

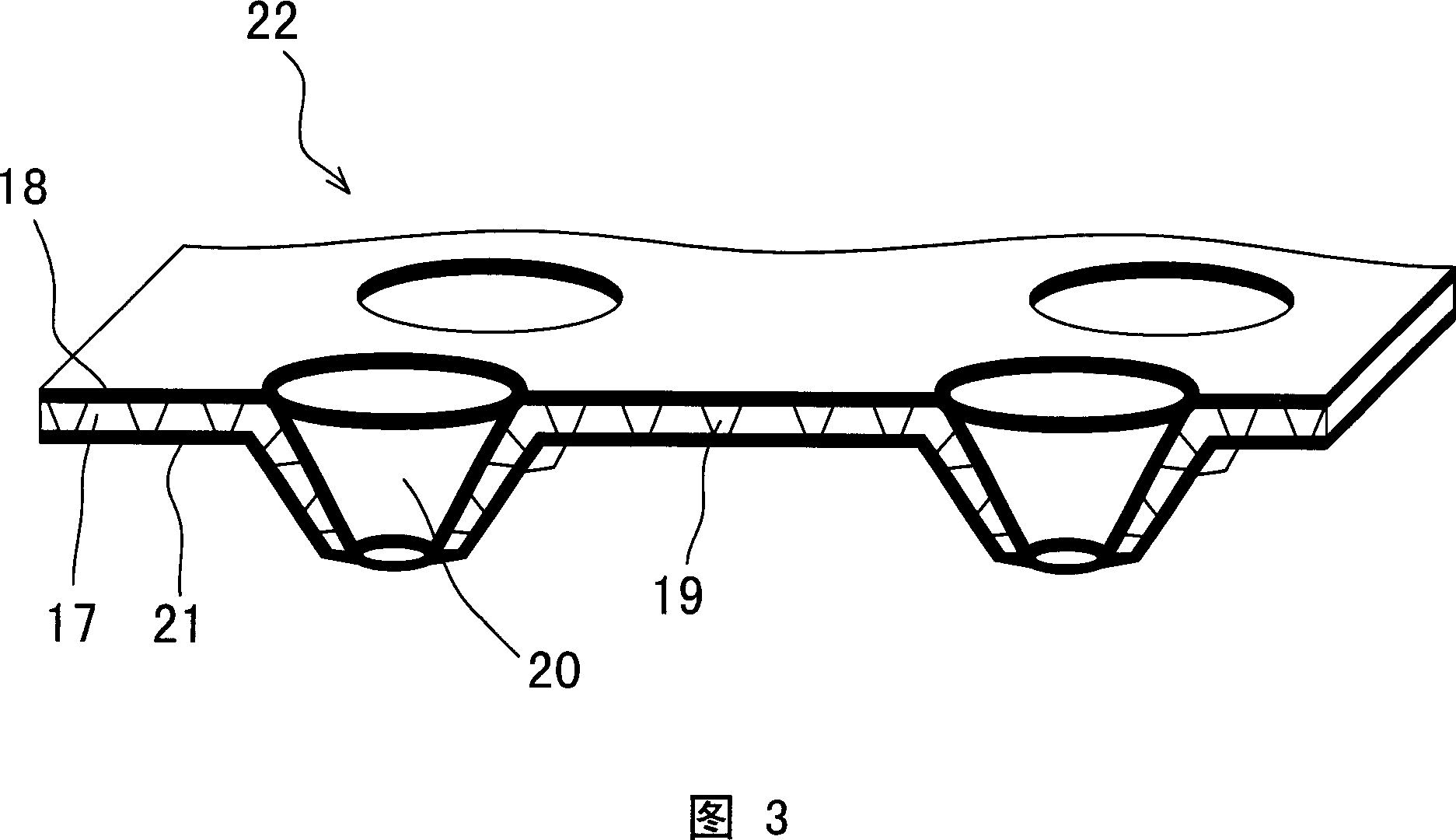

Composite punching film and its producing method

InactiveCN1943530AImprove breathabilityHigh porositySynthetic resin layered productsLaminationPunchingVolumetric Mass Density

A compound punching film and preparation thereof, said punching film consisting of a layer of plastic film and one or two side compound non-woven fabrics. On plastic film is of evenly spread tiny mesh, density thereof is 170-500 mesh / C sqm ,perforating rate is 10-35%. Said whole compound film is perforated of evenly big mesh , aperture thereof greater than that of tiny mesh two times, the shape of big mesh is of funnel, thereof protruding to one side and on the surface of awl is of tiny mesh. Said invention combines PE film technique and punching one, making compound of a layer of non-woven fabric and cast film with the help of high melting temp. of cast film, also making use of mesh cage through vacuum suction nozzle punching tiny mesh, thereafter punching big mesh by pressure roller machine, thus to prepare new compound punching film with good permeability, softness and strong third dimension.

Owner:蔡子辛 +1

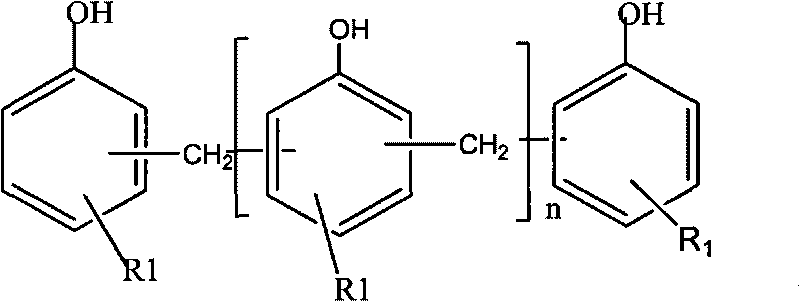

Epoxy resin composition, preparation method thereof, laminated material and copper-clad laminated board manufactured by adopting epoxy resin composition

ActiveCN101735562AImprove heat resistanceExcellent dielectric propertiesGlass/slag layered productsWoven fabricsEpoxyHeat resistance

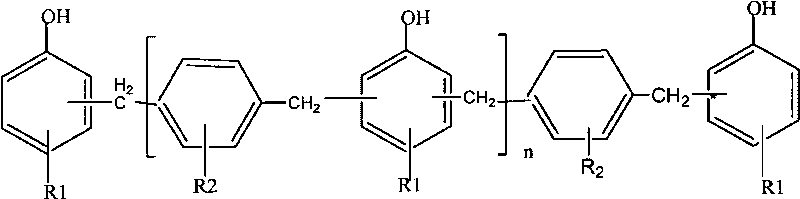

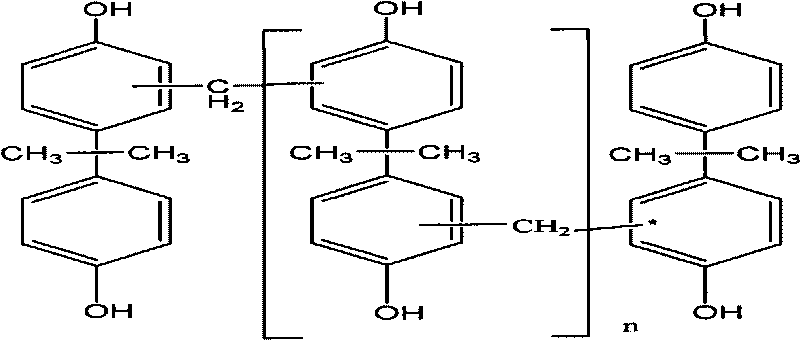

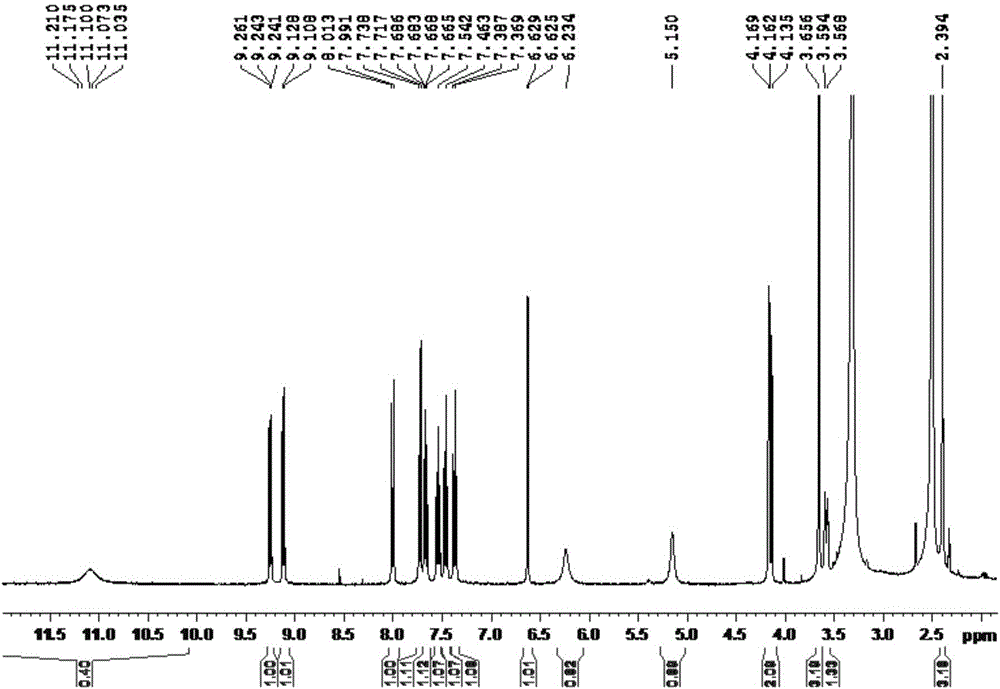

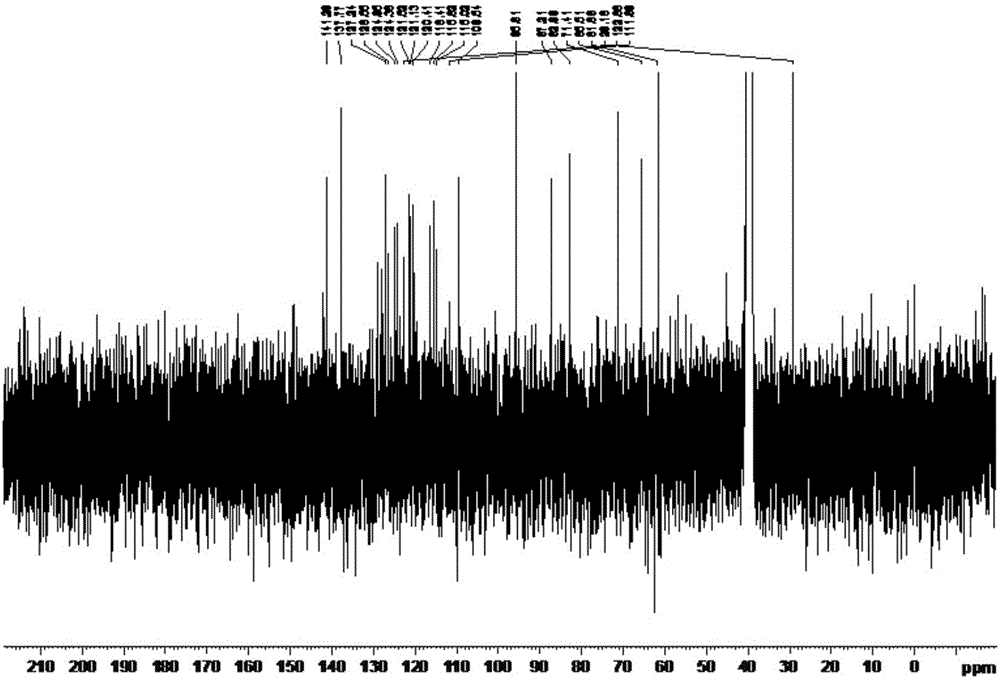

The invention relates to an epoxy resin composition, a preparation method thereof, a laminated material and a copper-clad laminated board manufactured by adopting the epoxy resin composition. The epoxy resin composition comprises the following components in part by mass: 30 to 80 parts of epoxy resin, 20 to 50 parts of polyphenyl ether resin with a novel structure, 0 to 50 parts of filler and 1 to 20 parts of assistant, wherein the polyphenyl ether resin is obtained through redistribution reaction of polyphenyl ether and phenolic resin in the presence of a reaction initiator, and the number-average molecular weight of the polyphenyl ether resin is 1,000 to 5,000. The epoxy resin composition provided by the invention not only has good heat resistance and dielectric property, but also has simple and convenient preparation process and is favorable for industrialized large-scale production; and in addition, the laminated material and the copper-clad laminated board manufactured by using the epoxy resin composition are applied to a printed circuit board, have good heat resistance, dielectric property and machining property, and are favorable for signal transmission of a high-frequency circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

Compound with protein kinase inhibiting activity as well as preparation method and application of compound

ActiveCN106831898AConducive to industrial mass productionNervous disorderSugar derivativesDiseaseEthyl acetate

The invention discloses a compound with protein kinase inhibiting activity as well as a preparation method and application of the compound. The compound has a structure shown as a formula I, a formula II and a formula III. The compound provided by the invention can be used for medicines for treating cancers related with kinase inhibition, such as acute and chronic leukemia, lymphoma, breast cancer, lung cancer and sarcoma, and diseases including acquired immunodeficiency syndrome and Alzheimer's disease and the like. The invention further discloses the preparation method of the compound with the protein kinase inhibiting activity; the compound is produced through solid fermentation on rice by utilizing actinomyces; a fermented product is extracted through ethyl acetate and then is subjected to silica-gel column chromatography, gel column chromatography and reversed-phase chromatography separation and purification to obtain a product; the preparation method is easy to operate and implement. (The formula I, the formula II and the formula III are shown in the description.).

Owner:浙江美新控股有限公司

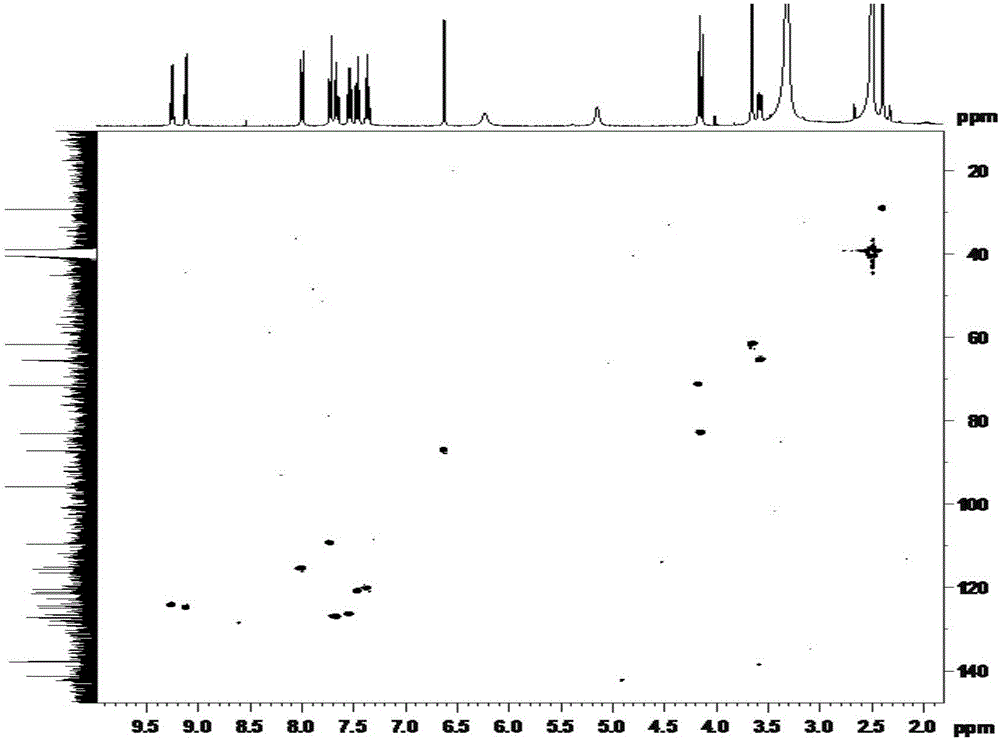

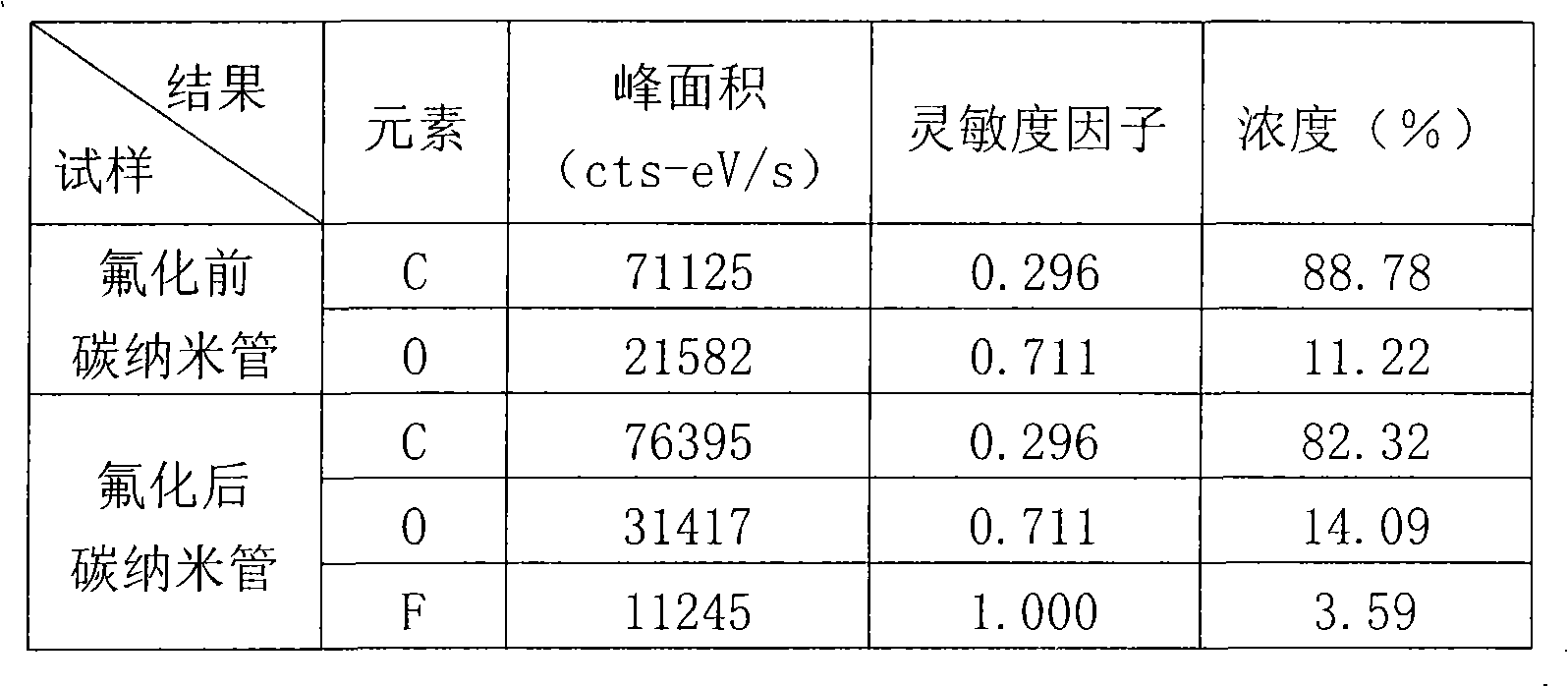

Carbon fluoride nanotube and method for making same

InactiveCN101284659AImprove securityExtended service lifeNanostructure manufacturePolyvinylidene fluorideMuffle furnace

The invention relates to a perfluorocarbon nanotube and a preparation method thereof. The method is technically characterized in that the nanotube and organic fluorine are mechanically ground, fully and evenly mixed, then placed in a reactor, sealed and then immediately put into a muffle furnace; the heating temperature is maintained at 100 to 600 DEG C; the heating is stopped after the reaction time for 1 to 10 hours; then the reactor is opened after being cooled to the room temperature; and then the perfluorocarbon nanotube is obtained after grinding. The nanotube is a multi-walled carbon nanotube or a single-walled carbon nanotube. The organic fluoride is the organic fluoride of solid powders or liquids such as polyfluortetraethylene, fluorinated ethylene propylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, tetrafluoroethylene and perfluoroalkyl vinyl ether copolymer, dodecafluoroheptyl heptanol or derivants of dodecafluoroheptyl heptanol. The method overcomes the shortcomings of low safety, short apparatus service life and high product cost of the prior fluorization methods, and has the advantages of long service life, simple process, low production cost and no pollution, so as to be suitable for mass production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

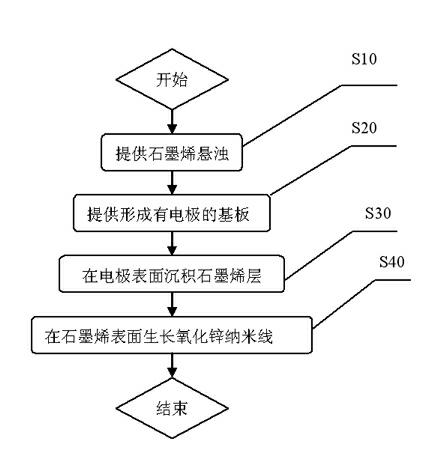

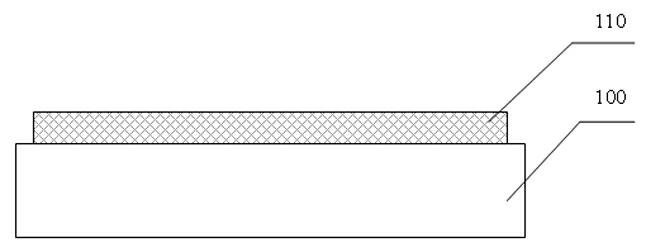

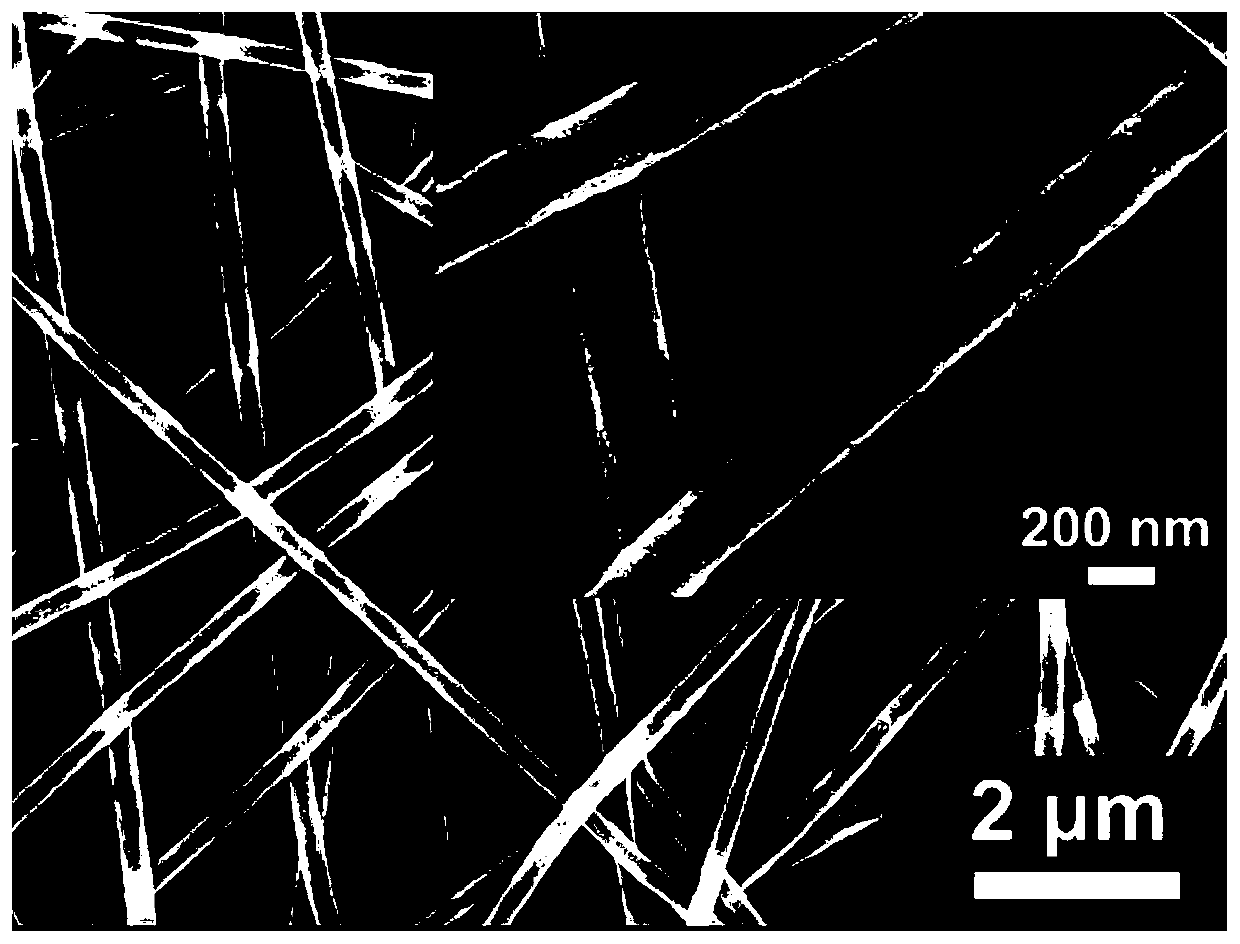

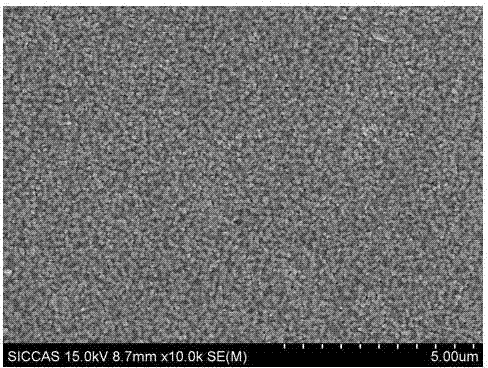

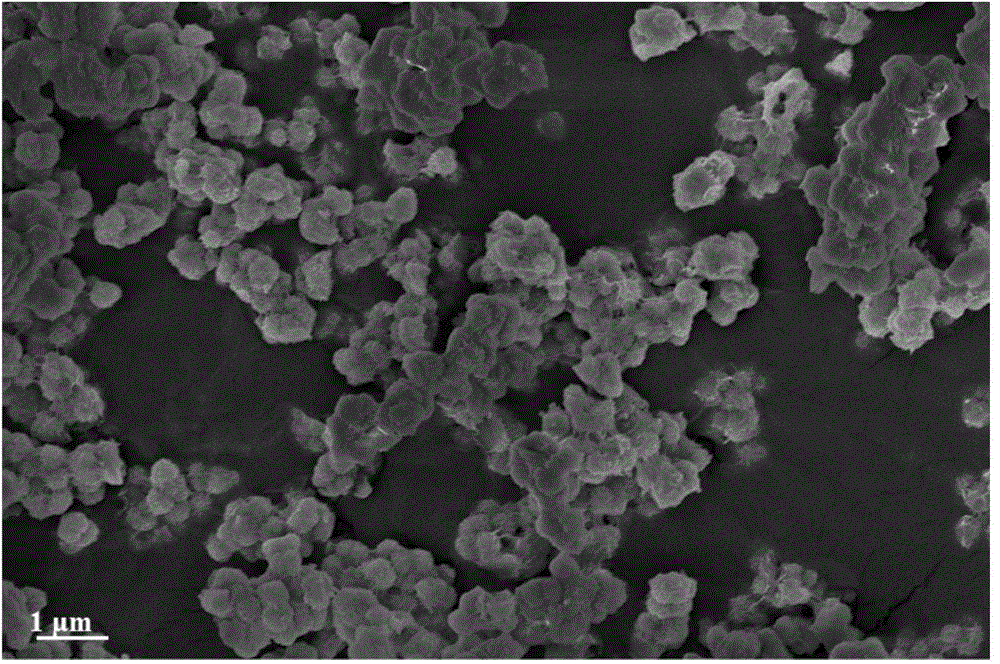

Emitting cathode based on composite material of graphene/zinc oxide nanowire and preparation of same

ActiveCN102157315AReduce the turn-on electric fieldIncreased emission current densityDischarge tube/lamp detailsCold cathode manufacturePower flowElectron source

The invention relates to a field electron emitting cathode based on the composite material of graphene / zinc oxide nanowire, comprising a conductive electrode and the composite material of graphene / zinc oxide nanowire, wherein the composite material of graphene / zinc oxide nanowire is positioned on the surface of the electrode, and consists of the graphene with the size ranging from 2 to 10 micronsand the zinc oxide nanowire with the length ranging from 1 to 2 microns and the diameter being 100 nanometers; and the turn-on field is lower than or equal to 1.7 volt / microns, and the threshold field is lower than or equal to 4 volt / microns. The filed emission electron source has the advantages of lower turn-on field, low threshold field, high emission current density, stable emission, easy preparation method and easy realization of industrialized volume production.

Owner:FUZHOU UNIV

Method for preparing bivalirudin through solid-liquid combination

ActiveCN104031127ASolve difficult coupling problemsReduce contentPeptide preparation methodsFluid phaseEngineering

The invention belongs to the field of polypeptide synthesis and relates to a method for preparing bivalirudin through solid-liquid combination. The bivalirudin is prepared by adopting a method for combining a liquid phase and a solid phase, impurity peptides can be well avoided, the purity of crude peptides is improved, and the production cost is reduced. The method comprises the following steps: synthesizing a fragmental hexapeptide Fmoc-Arg(pbf)-Pro-Gly-Gly-Gly-Gly-OH by adopting a liquid phase method, and connecting peptides onto the solid phase. By utilizing the method, impurity peptides Biv+ / -Gly and Biv+ / -2Gly can be avoided, and the problem that the peptides are difficultly completely coupled during solid phase Arg connection is avoided. By utilizing the synthesis process, the purity of the crude peptides can be over 90 percent, and the purification difficulty is reduced, so that the purity of the final product exceeds 99.5 percent, and the production cost is further reduced. Compared with the prior art, the method disclosed by the invention is simple in operation and low in synthesis cost, and is conductive to large-scale industrial production.

Owner:JINAN KANGHE MEDICAL TECH

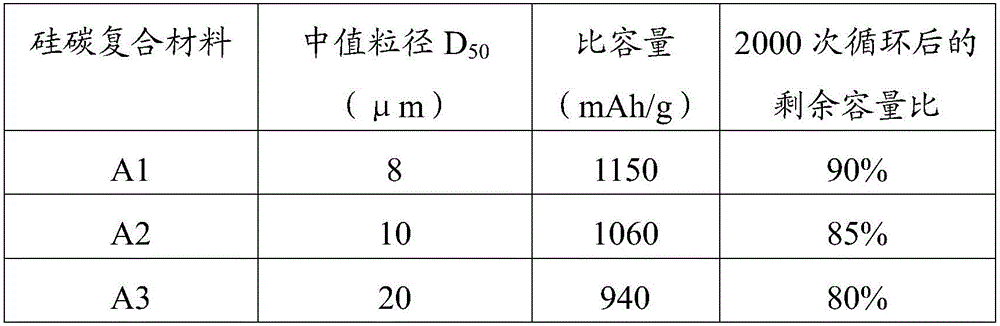

Silicon carbon composite material, fabrication method thereof, anode material and battery

ActiveCN105742599AConducive to industrial mass productionIncrease profitCell electrodesCarbon compositesMetal silicide

The invention relates to a silicon carbon composite material. The silicon carbon composite material comprises a three-layer core-shell structure, wherein a silicon material is arranged at the innermost layer, a metal compound is arranged at the intermediate layer, a carbon material is arranged at the outermost layer, and the silicon material is selected form one or more of silicon, a silicon oxide and a metal silicide. In the above silicon carbon composite material, the intermediate layer of the metal compound is further arranged between the silicon material and the carbon material, the interface contact between the silicon material and the carbon material is effectively improved, so that the silicon carbon composite material is more stable during the application process. The conductivity of the silicon carbon composite material is improved, and the energy density is also improved. The silicon carbon composite material is easier to be bonded with a current collector during the subsequent preparation and application process, and is difficult to be agglomerated or drop, and the cycle performance of the silicon carbon composite material is improved. The fabrication method is low in process difficulty, the device is simple, and the industrial production is facilitated. The invention also discloses a fabrication method of the above silicon carbon composite material, an anode material and a battery.

Owner:SUZHOU GCLSI SCI & TECH IND APPL RES INST CO LTD +3

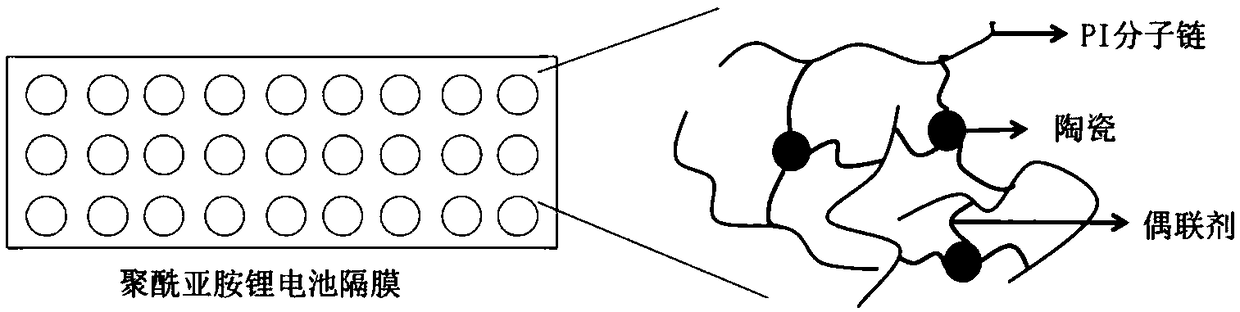

A polyimide lithium battery diaphragm, a preparation method thereof, and a lithium battery comprising the diaphragm

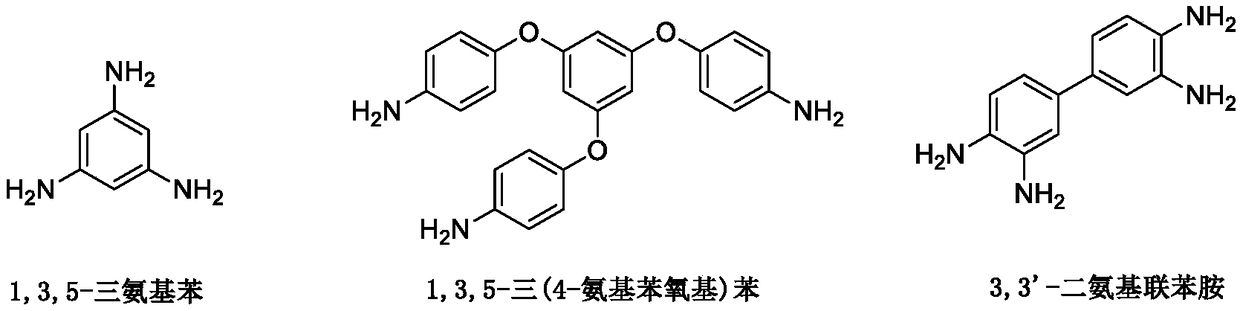

InactiveCN109119572AHigh mechanical strengthImprove puncture strengthCell component detailsCross-linkCoupling

The present application relates to the field of lithium ion battery materials. Disclosed are a polyimide lithium battery diaphragm, a preparation method thereof, and a lithium battery comprising the diaphragm. The polyimide lithium battery diaphragm comprises: 30-50 parts of diorganic amine, 30-50 parts of dibasic organic anhydride, 2-5 parts of a polyamino crosslinking agent and 5-20 parts of polyimide formed by reaction of amino coupling agent surface modified ceramic powder and imidization. The polyimide diaphragm can form cross-linking between polymer molecular chains in the subsequent imidization process by adding polyamino crosslinking, which greatly enhances the mechanical strength; by ceramic powder added with the surface-modified coupling agent, the puncture strength of polyimidediaphragm can be greatly improved, and the pore size of diaphragm can be ensured to be small, the distribution is uniform, and the leakage current problem of a battery can be solved. At the same time,the polyimide lithium battery diaphragm has high production efficiency and is favorable for industrial large-scale production.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

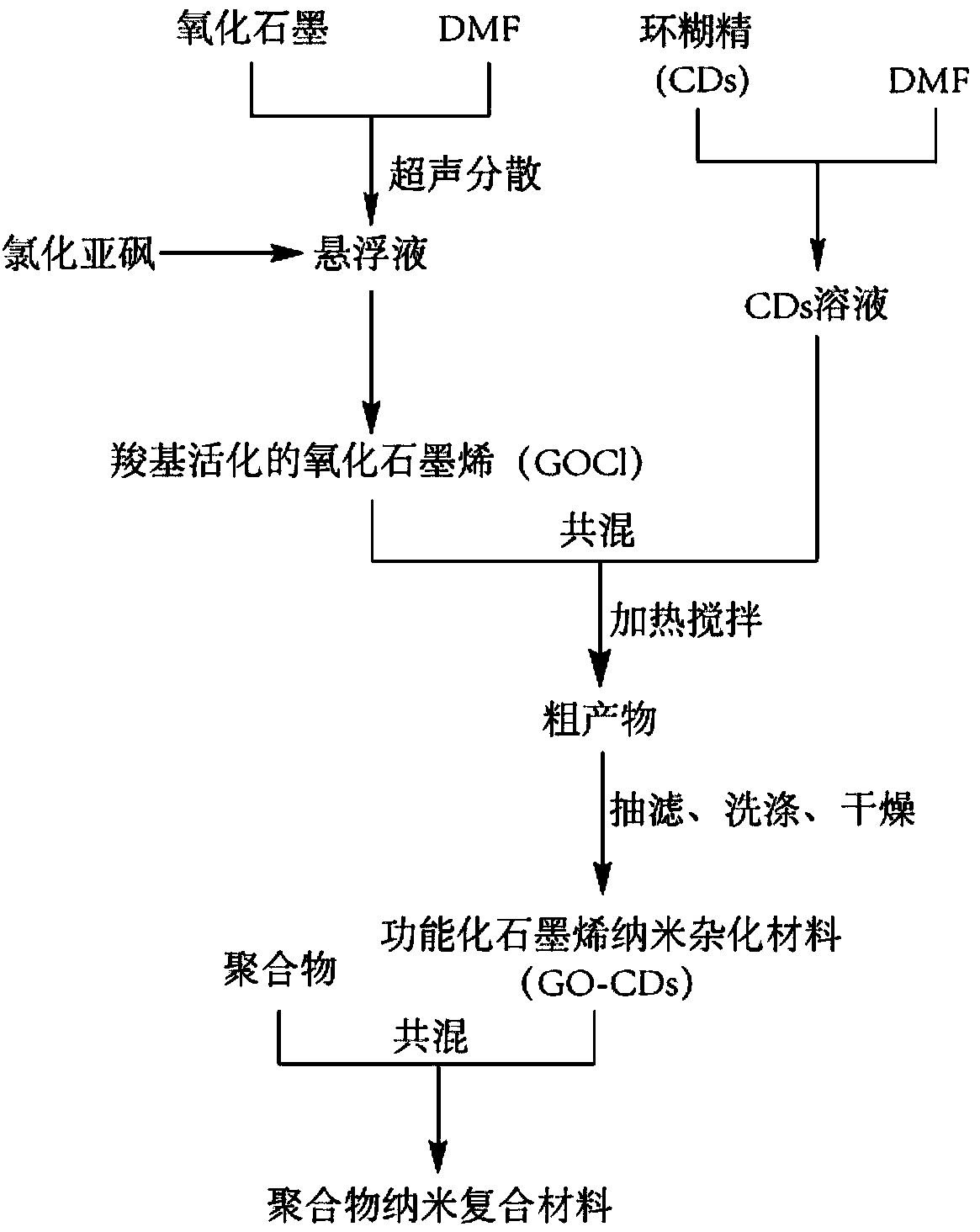

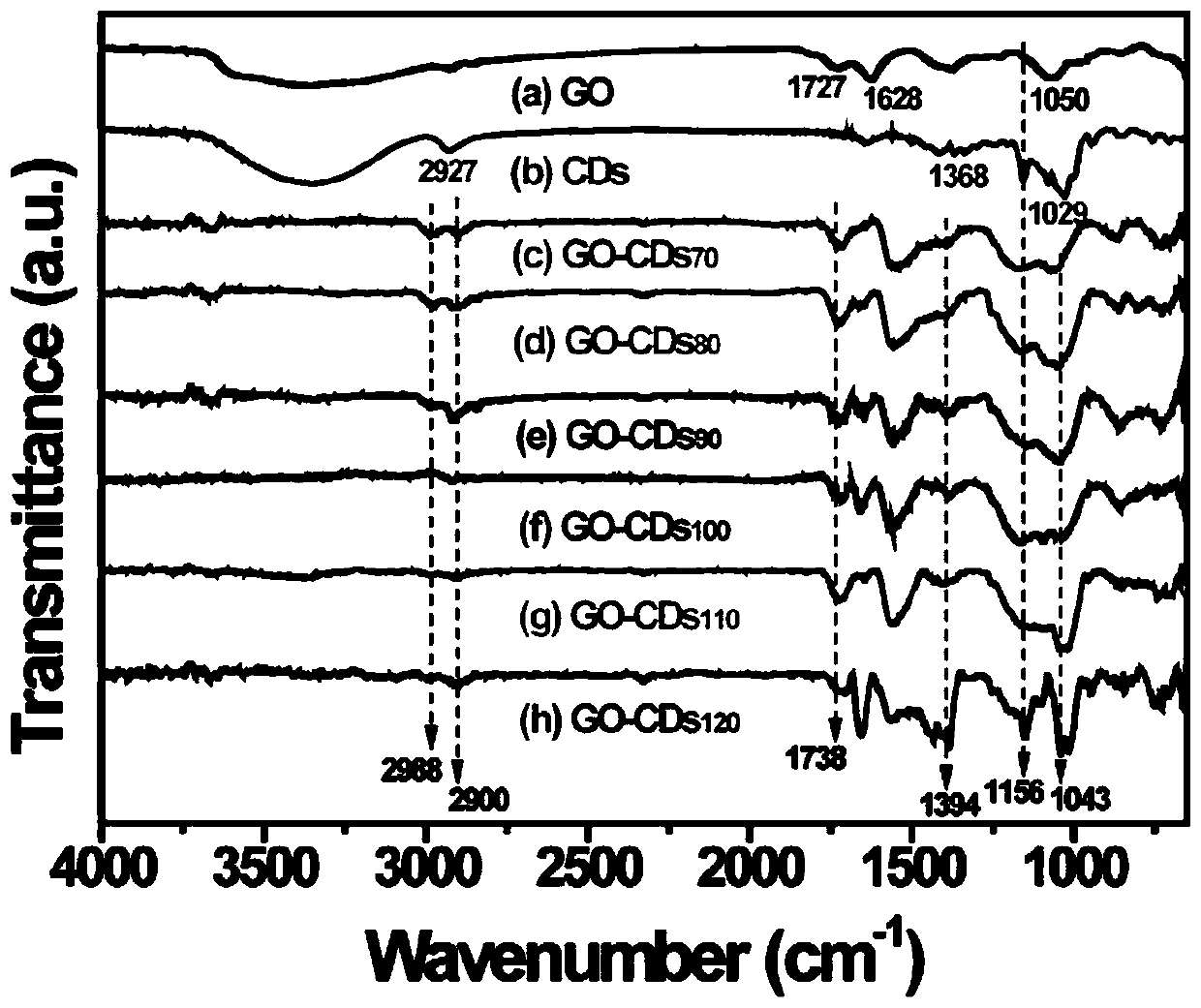

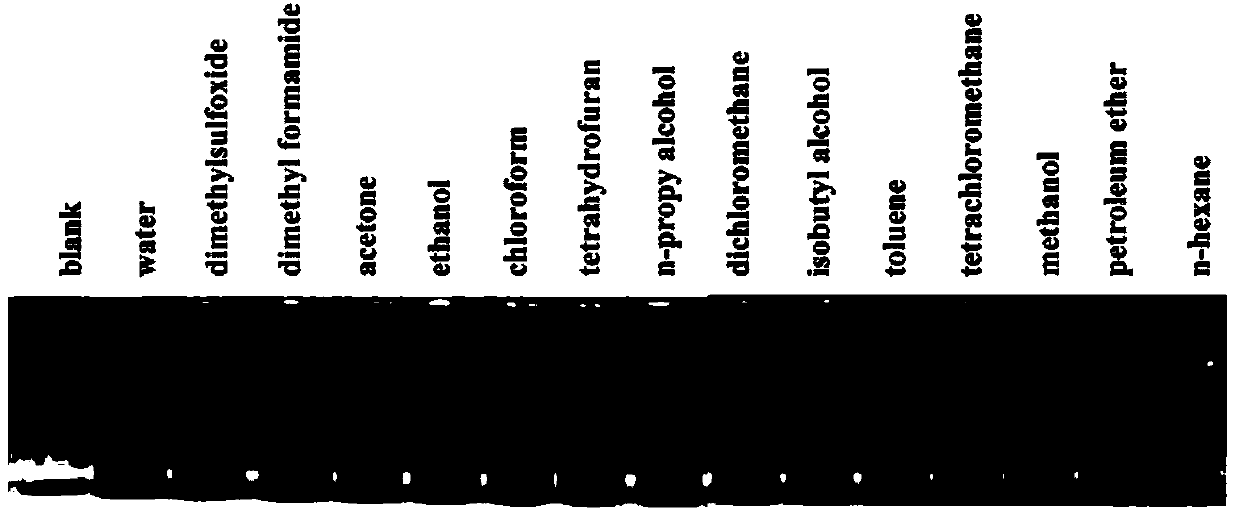

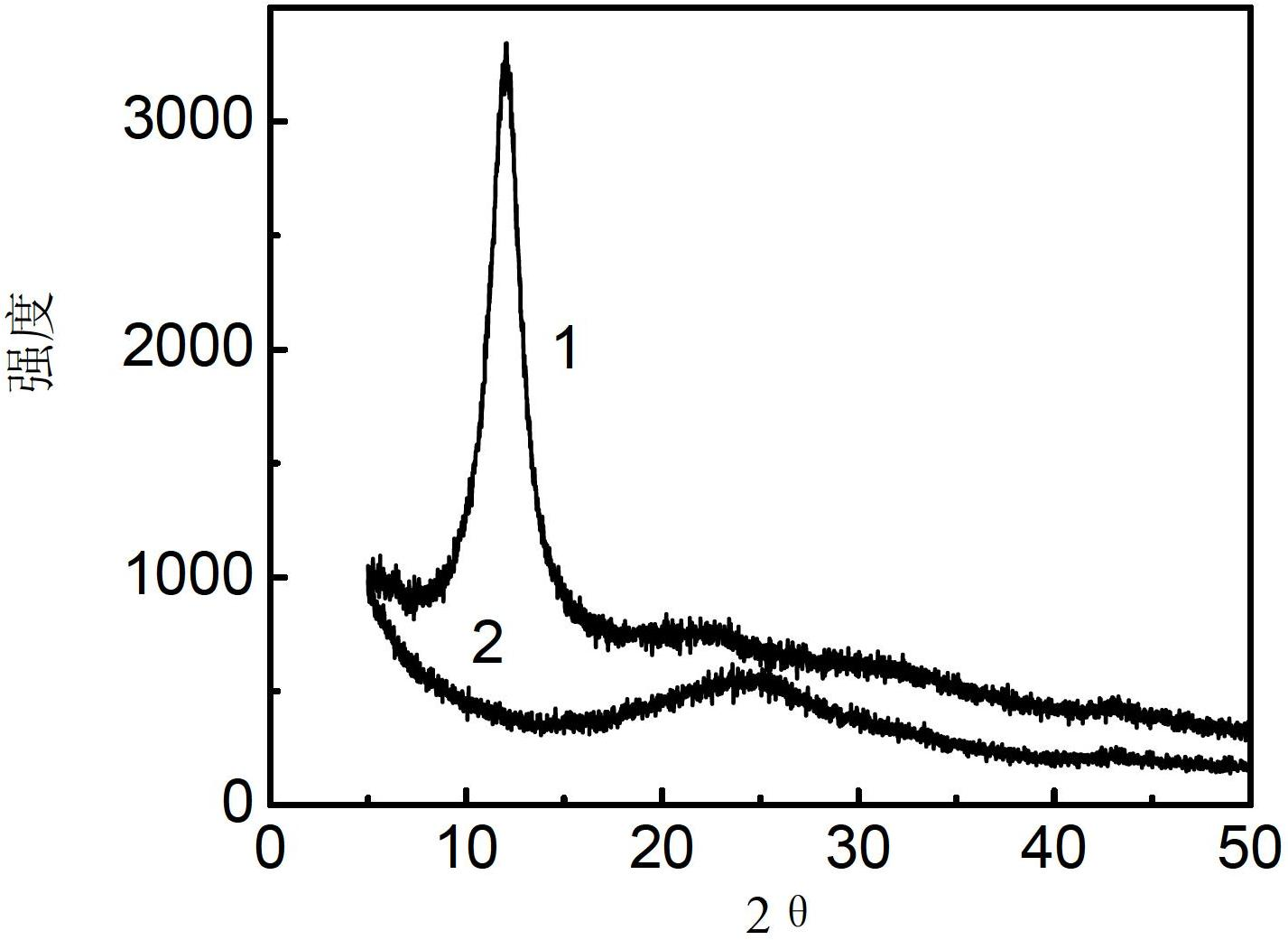

Polymer based nanocomposite and preparing method thereof

The invention discloses a polymer based nanocomposite and a preparing method thereof. According to the invention, an organic covalent modification technology is adopted, polyhydroxy cyclodextrin molecules are anchored on a graphene oxide nanosheet through a coupling agent, excellent dispersion in various solvents is realized through utilizing the hydroxyl on the cyclodextrin to simulate the characteristic that the graphene oxide is enriched with oxygen species, the capacity of cyclodextrin on the graphene oxide is controlled through adjusting the reaction temperature, further the solvent dispersing performance and thermal stability of functionalized hybrid materials can be effectively regulated and controlled; besides, the solvent blending technology is adopted, the cyclodextrin functionalized grapheme based nano hybrid materials are used as fillers to prepare different-polymer based nanocomposite; through the adoption of the method, the intermolecular and intramolecular interfacial interaction are further enhanced so as to improve the thermal stability of the functionalized nano materials and polymer based nanocomposite adopting the nano materials as fillers, besides, the synthetic steps are simple and efficient, the aftertreatment is simple and concise, and large-scale preparation is facilitated.

Owner:NANJING UNIV OF SCI & TECH

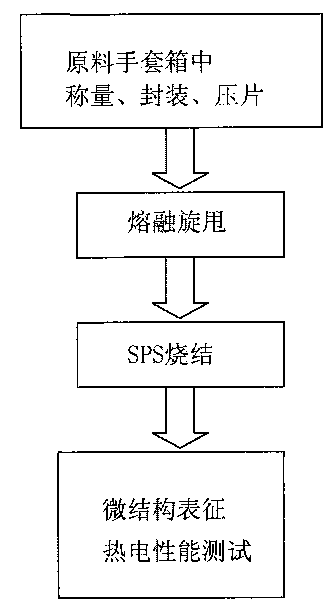

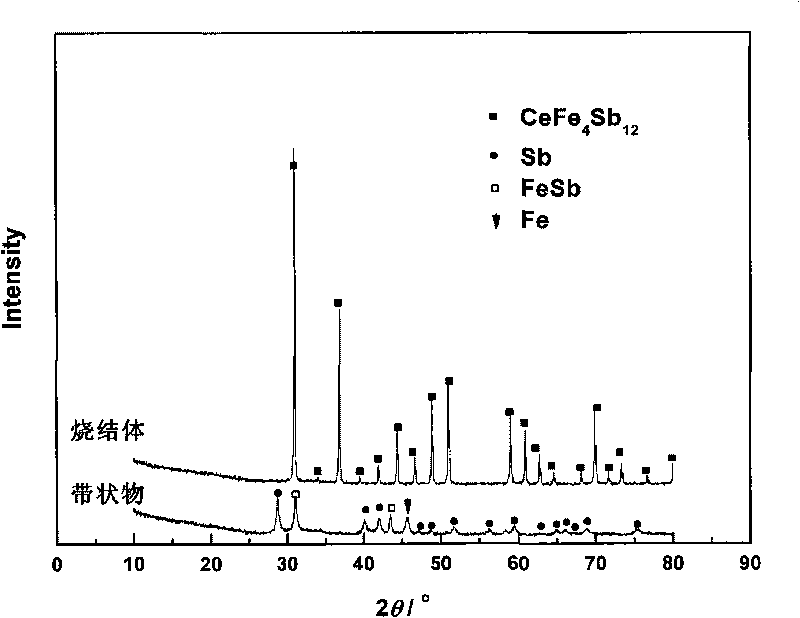

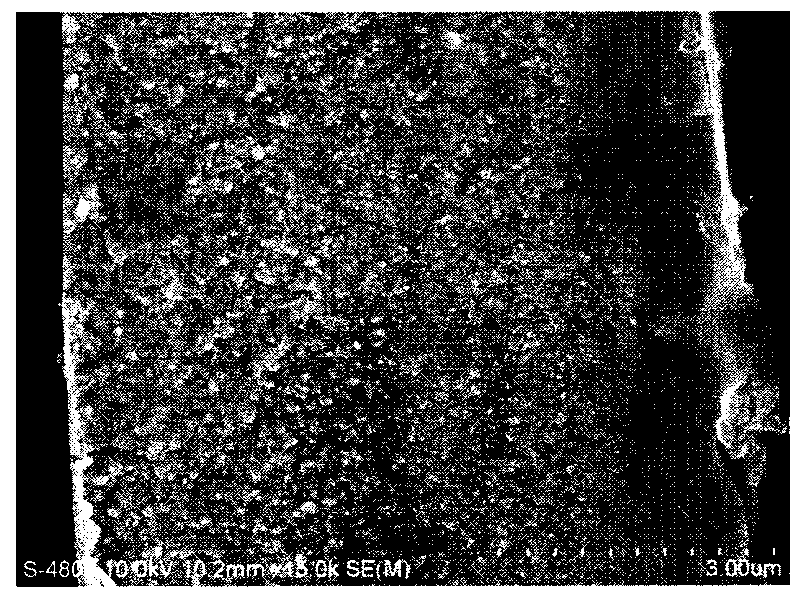

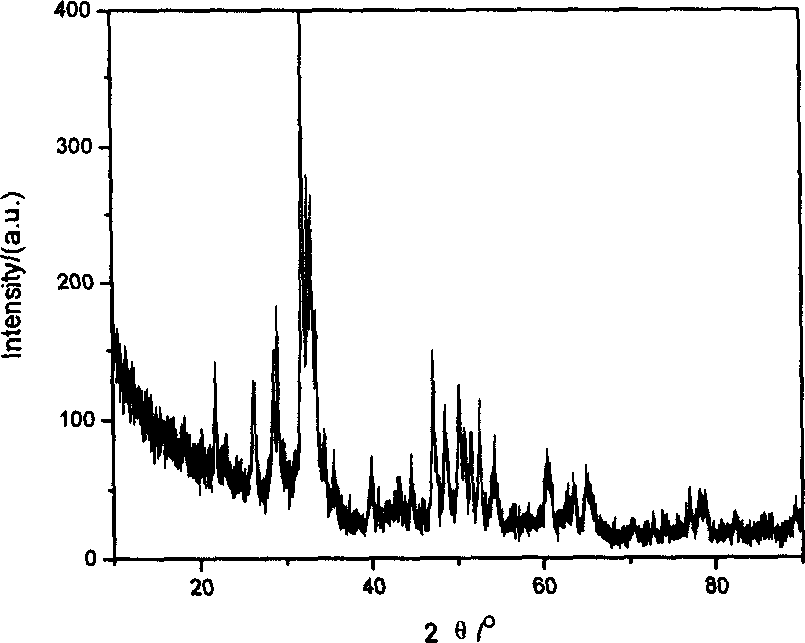

Method for preparing p-type filling type skutterudite compound thermoelectric material

InactiveCN101693962AOmit premeltingPrevent deviationThermoelectric device junction materialsSkutteruditeArgon atmosphere

The invention belongs to the field of new energy materials, and particularly relates to a method for preparing filling type skutterudite thermoelectric compound. A method for preparing the p-type filling type skutterudite compound thermoelectric material comprises the following steps: firstly, taking high-purity granule type M, Fe, Co and Sb as starting reaction materials, weighing reaction raw materials in an Ar gas glove box according to the chemical formula MFe4-xCoxSb12+y, wherein 0<=x<=3, 0<=y<=1.0, mixing the high purity granule type M, Fe, Co and Sb, then, pressing into columnar blocks under the pressure of 300 to 400MPa, secondly, melting columnar blocks, swinging melted welding flux in argon atmosphere, obtaining belt-shaped products, thirdly, sintering in vacuum through a discharge plasma sintering method after coarsely grinding and pressing the belt-shaped products tightly, and obtaining single-phase compact p-type filling type skutterudite compound thermoelectric material. The method for preparing p-type filling type skutterudite compound thermoelectric material has the characteristics of simple technique, short reaction time, low energy consumption, excellent repeatability, and the like.

Owner:WUHAN UNIV OF TECH

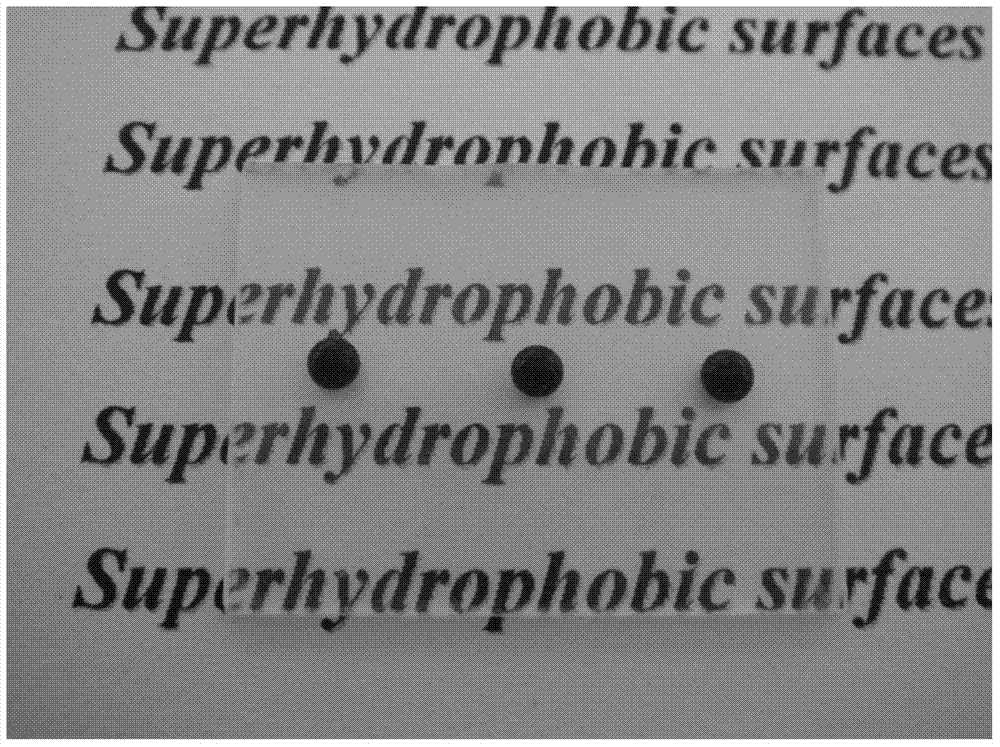

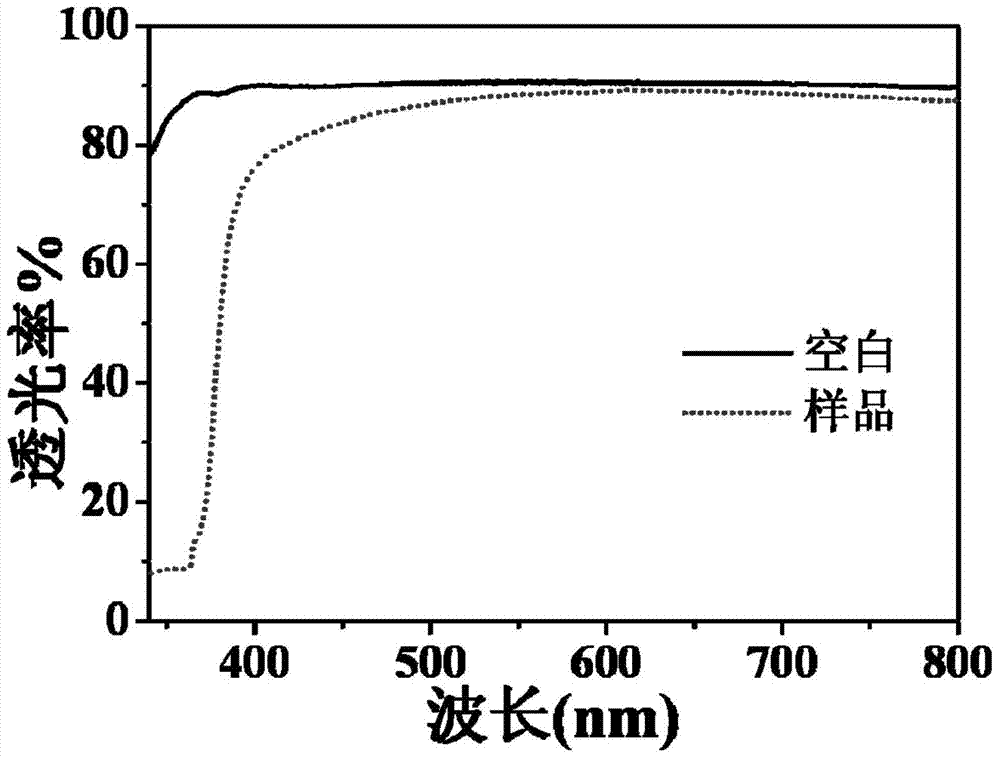

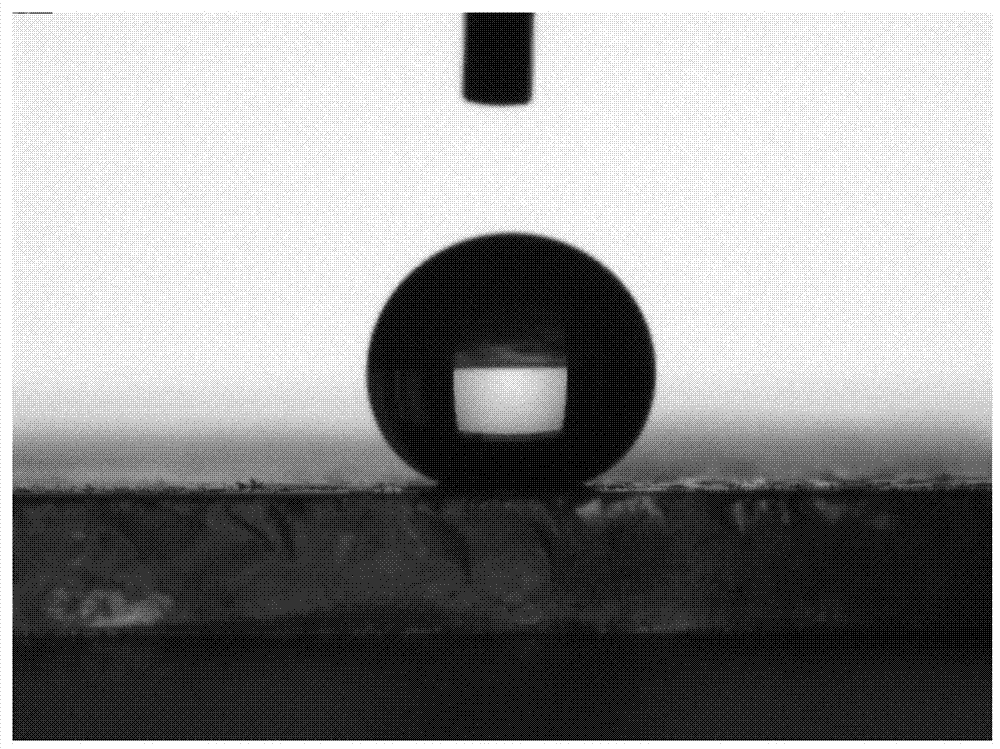

Preparation method of transparent super-hydrophobic zinc oxide coating

The invention relates to a preparation method of a transparent super-hydrophobic zinc oxide coating on a glass substrate. The preparation method comprises the following steps of a, substrate pretreatment; b, zinc oxide solution preparation; c, zinc oxide coating preparation; and d, zinc oxide coating surface modification. Compared with the prior art, the preparation method has the beneficial effects of simple equipment process, low cost and mild reaction condition and is beneficial to large-scale industrial production. The transparent super-hydrophobic zinc oxide coating prepared by using the method has excellent hydrophobicity and transparency; the contact angle is larger than 160 degrees, the rolling angle is smaller than 8 degrees, and water drops can freely roll on the coating, so that the transparent super-hydrophobic zinc oxide coating has relatively good self-cleaning performance; and the light transmittance is approach to 90% which is close to that of blank glass, so that the transparent super-hydrophobic zinc oxide coating has favorable visible light transmittance. A surface modifier used in the preparation method is an alkyl silane coupling agent instead of a fluorinated compound, so that the cost is low, the environment pollution is relatively low, and the modified coating is relatively stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

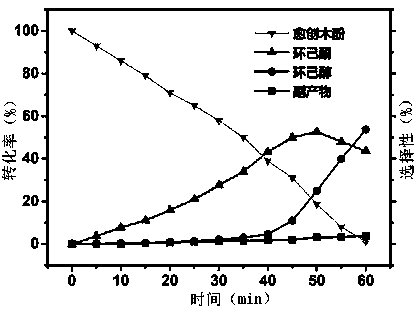

Method for preparing KA oil and derivatives of KA oil by electrocatalytic hydrogenation of lignin-based phenolic compounds

ActiveCN108660479AImprove conversion rateGood choiceElectrolytic organic productionChemical recyclingElectricityPlatinum

The invention relates to a method for preparing KA oil and derivatives by electrocatalytic hydrogenation of lignin-based phenolic compounds. According to the method, an H-shaped electrolytic cell is used as a container, in a negative pole chamber of the electrolytic cell, carbon fiber cloth is coated with a supported composite catalyst as a working electrode, and the lignin-based phenolic compounds are used as reaction substrates to be dissolved in an acidic solution as a negative pole solution; and a positive pole chamber uses a platinum sheet as a counter electrode and the acidic solution aspositive pole liquid, an electrocatalytic hydrogenation reaction is carried out at the temperature of 30-90 DEG C for 0.5-2 hours, and the KA oil and the derivatives of the KA oil are obtained afterpost-treatment. By the adoption of the method, by adopting the composite catalyst, the service life of the catalyst is greatly prolonged, and the conversion rate of the lignin-based phenolic compoundsreaches over 90-99%, the selectivity of the KA oil and the derivatives of the KA oil reaches over 90-95%, the Faraday efficiency can reach 80-90%, the cost is low, environmental protection is realized, the technological process is simple, the supported composite catalyst is recyclable, the production cost lowered, and the method has the high industrial value.

Owner:ZHEJIANG UNIV OF TECH

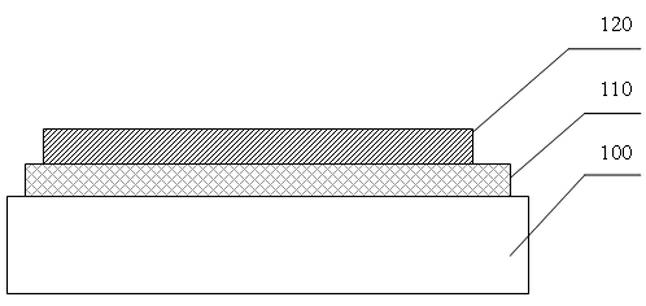

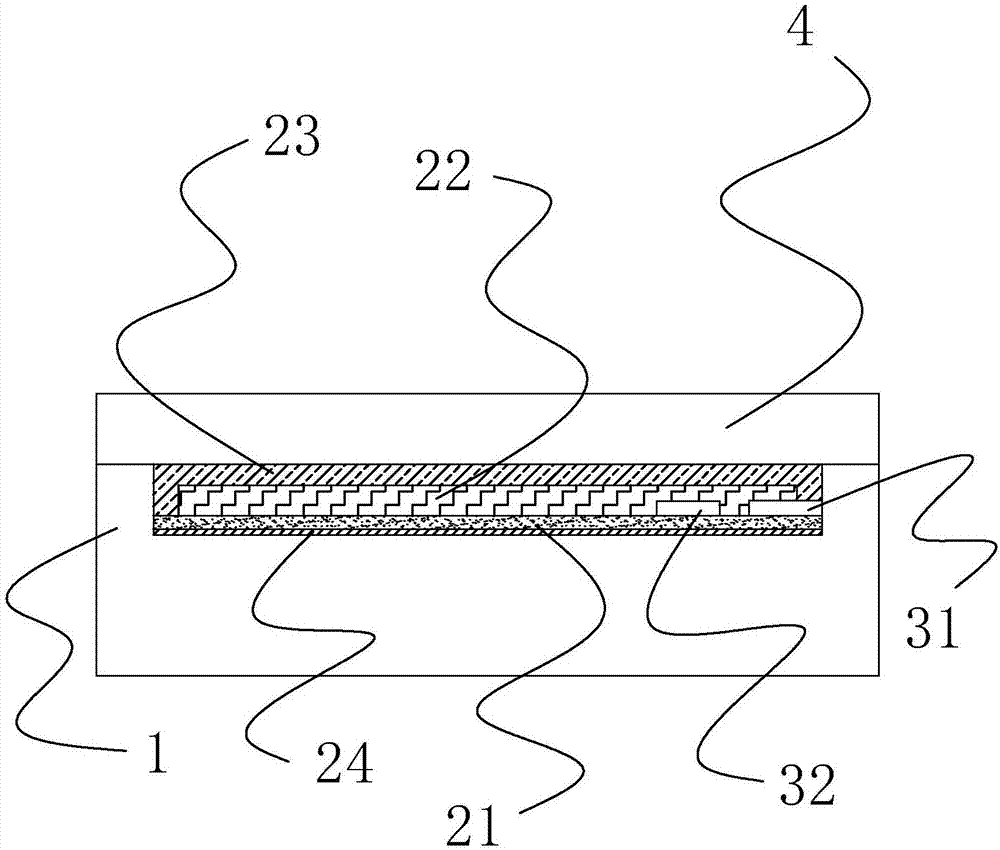

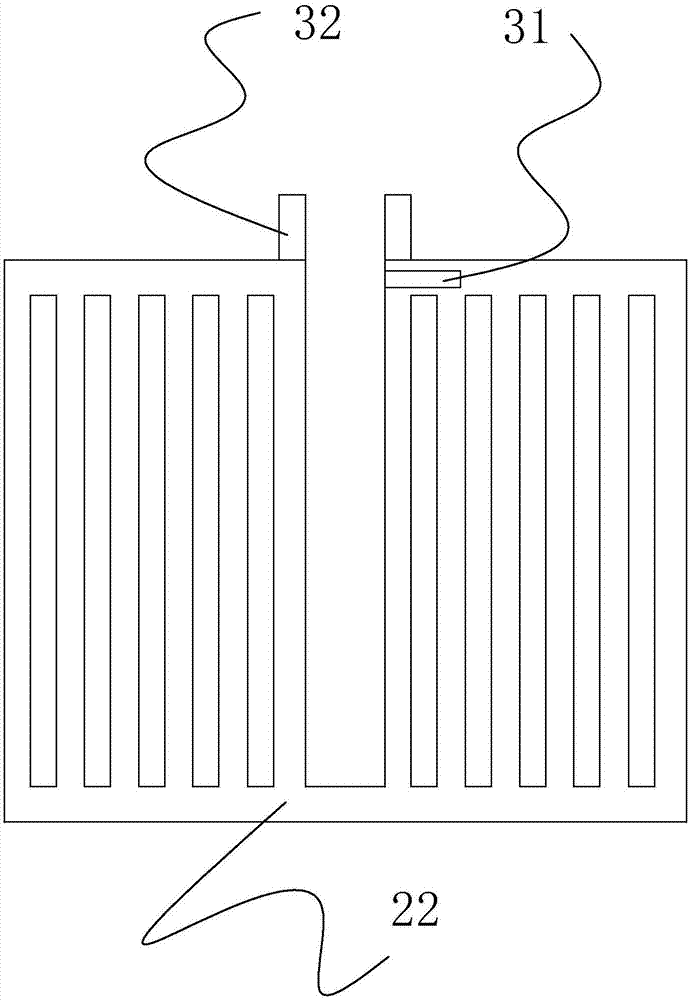

Ceramic tile with heating function and preparation method thereof

InactiveCN107097478APrevents heat transfer downwardsImprove heating efficiency and thermal insulation performanceConstructions elementsCeramic layered productsThermal insulationCeramic tiles

The invention discloses a ceramic tile with a heating function. The ceramic tile is prepared by fitting a ceramic tile layer with a ceramic tile base layer with a cavity, wherein the cavity is located on one side of the fitting surface; the cavity is filled with an insulating layer, a heating layer and an insulating sealing heat conducting layer overlapped in turn from bottom to top; a metal electrode and a temperature sensor are arranged in the heating layer. According to the ceramic tile disclosed by the invention, a cavity for filling a heating function composite layer is arranged on one side of the fitting surface between the ceramic tile layer and the ceramic tile base layer, and the layer structure of the composite layer is further limited; by adding a near-infrared inorganic heat reflecting layer, the heat emitted by the heating layer is efficiently transferred to the ceramic tile layer and effectively prevented from being transferred downward, and the heating efficiency and thermal insulation property of the ceramic tile are greatly improved. The invention also discloses a preparation method of the ceramic tile, which has the advantages of simple preparation technology, low production cost and high operability and facilitates industrial large-scale production.

Owner:FOSHAN OCEANO CERAMICS

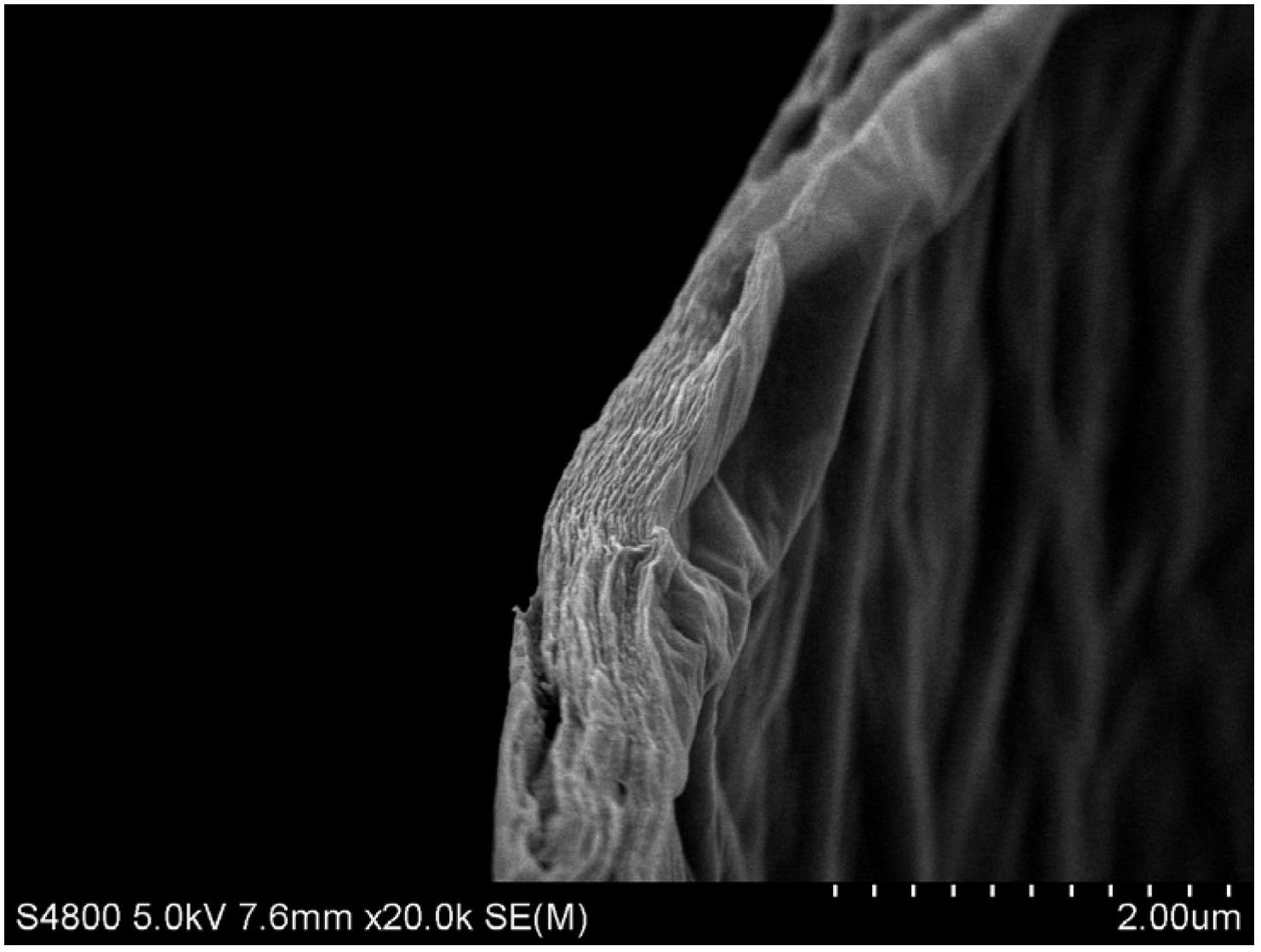

Beta-FeOOH/polyacrylonitrile composite nanofiber membrane, preparation method thereof and application of membrane

ActiveCN110205748ALarge specific surface areaImprove adsorption capacityNon-woven fabricsComposite nanofibersNanofiber

The invention provides a beta-FeOOH / polyacrylonitrile composite nanofiber membrane, a preparation method thereof and an application of the membrane, and belongs to the technical field of materials. The preparation method of the beta-FeOOH / polyacrylonitrile composite nanofiber membrane includes the steps: polyacrylonitrile nanofiber membrane preparation: preparing a polyacrylonitrile nanofiber membrane by electrostatic spinning; stabilizing treatment: performing gradient heating treatment on the polyacrylonitrile nanofiber membrane; biological mineralization treatment: preparing ferric chloridesolution and hydrochloric acid according to the volume ratio of 2:1, placing the stabilized polyacrylonitrile nanofiber membrane into mixed solution and stirring the mixed solution for 1-3 minutes, performing reaction under the condition of 55-65 DEG C for 10-14 hours, and then cleaning and drying the polyacrylonitrile nanofiber membrane to prepare the beta-FeOOH / polyacrylonitrile composite nanofiber membrane. The beta-FeOOH / polyacrylonitrile composite nanofiber membrane has good stability, mechanical performance, super-hydrophilic-underwater super-oleophobic properties and high adsorption efficiency and can be recycled.

Owner:成都石大力盾科技有限公司

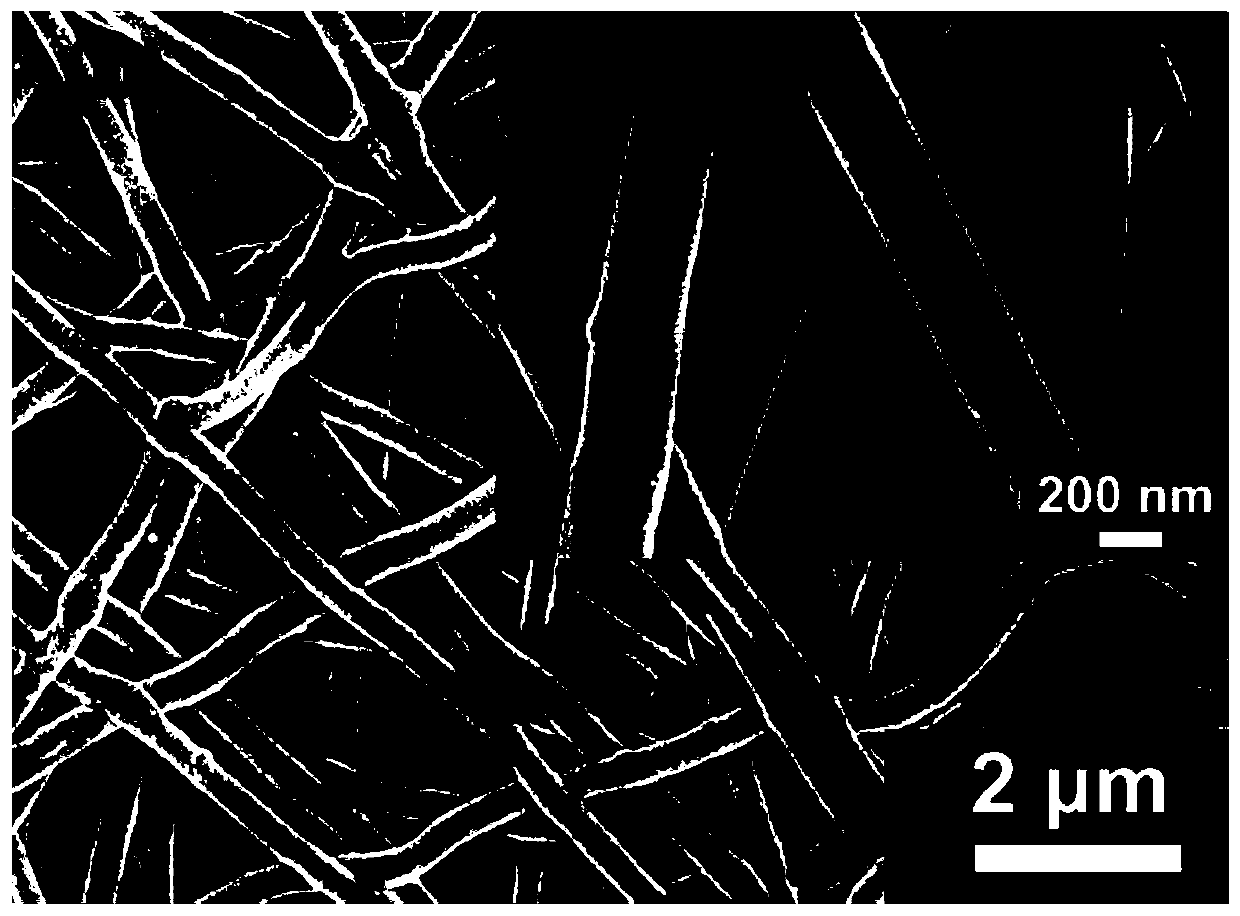

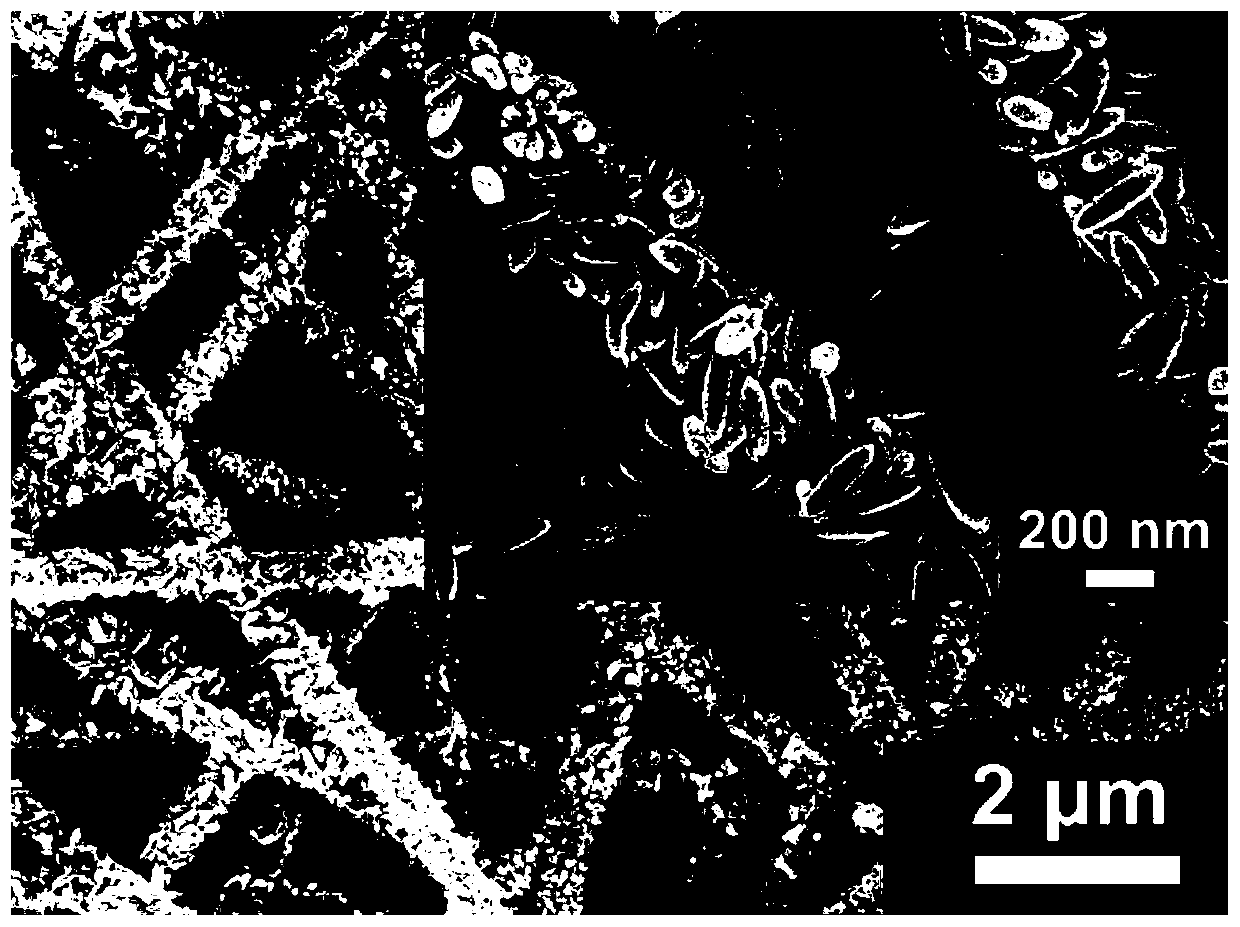

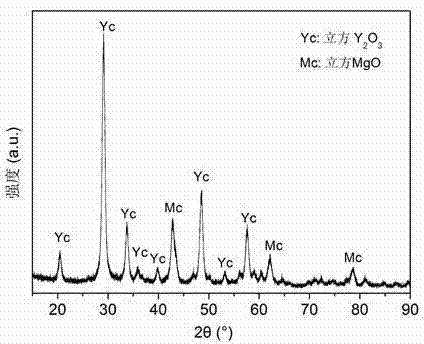

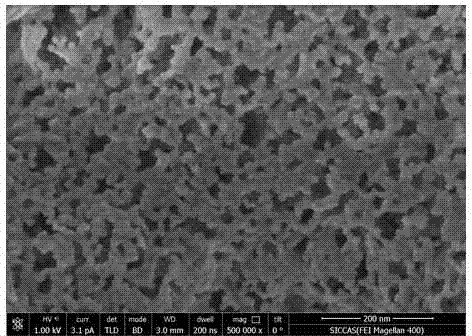

Y2O3-MgO nano-composite ceramic and preparation method thereof

The invention relates to a Y2O3-MgO nano-composite ceramic and a preparation method thereof. The Y2O3-MgO nano-composite ceramic is shown as xY2O3.(1-x)MgO, wherein x is the percentage of the mole number of Y2O3 to the total mole number of Y2O3 and MgO; the value of x is more than or equal to 0.01 and less than or equal to 0.99. The method comprises the following steps: preparing Y2O3-MgO nano-composite powder by adopting a sol-gel method; sintering the sieved composite powder by virtue of discharge plasma sintering or hot isostatic pressing sintering to obtain the infrared transparent Y2O3-MgO nano-composite ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

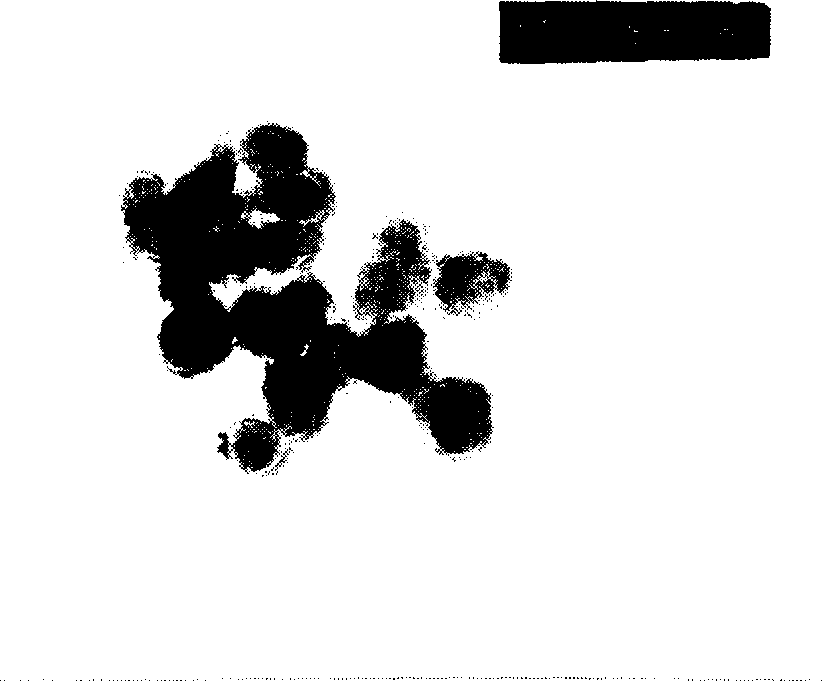

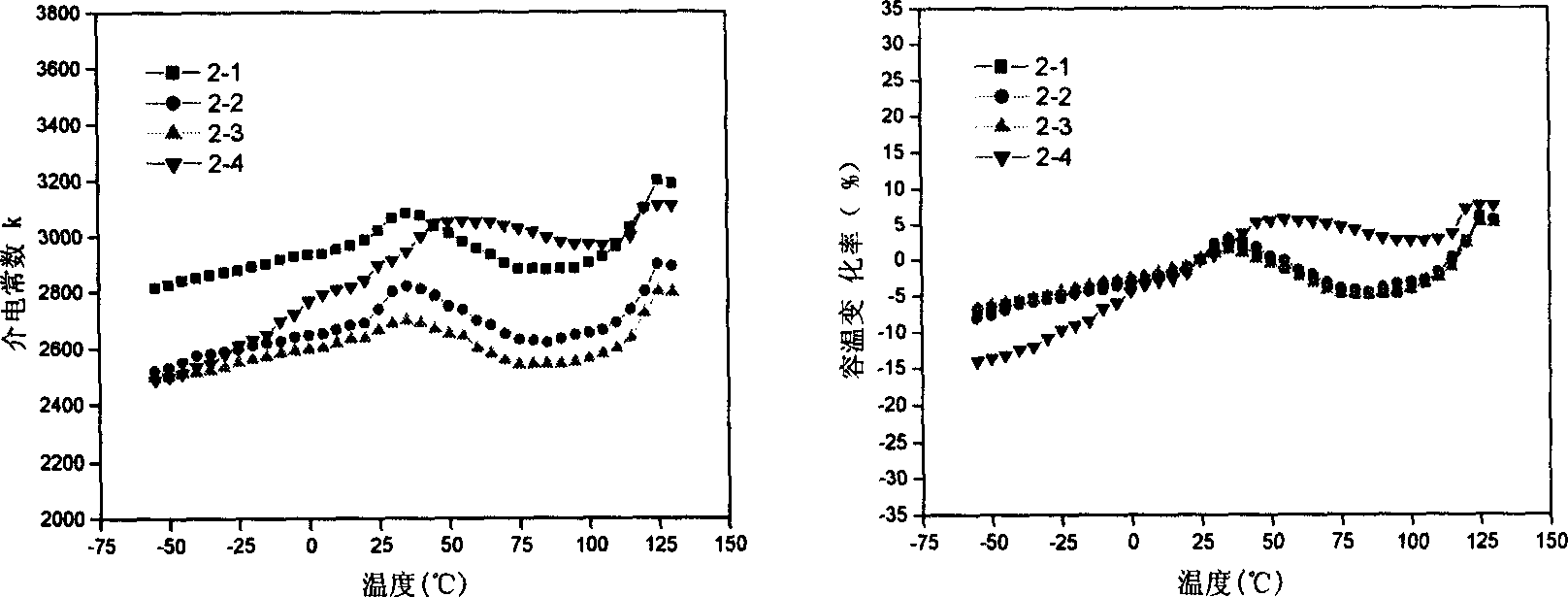

Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

InactiveCN1854105APromote lowerMeet miniaturizationFixed capacitor dielectricPiezoelectric/electrostrictive/magnetostrictive devicesDopantCeramic capacitor

A nanometer ceramic material dopant, medium material of ceramic capacitor and their production are disclosed. The formula of the dopant consists of aA.bB.cC.dR2 O3.eSiO2; A contains Na2O; B contains one or multiple of MgO and CaO; C contains one or multiple of MnO2 and Co3O4; R contains one of multiple of Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, among them a, b, c, d and e are coefficient, by computing mol%, 0<=a<=10%, 0<=b<=25%, 0<=c<=15%, 20%<=d<=60%, 10%<=e<=50% and b and c can't be zero at same time. Its advantages include large capacity, adjustable material formula, low sintering temperature, less medium loss, high dielectric constant and better reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

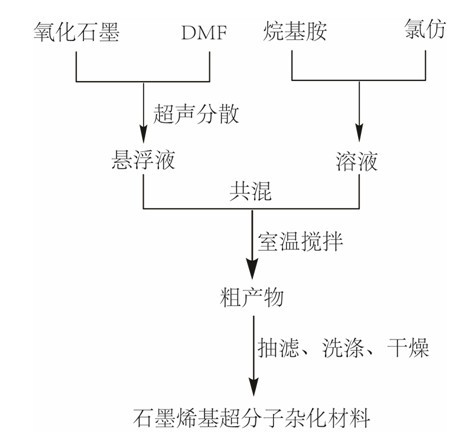

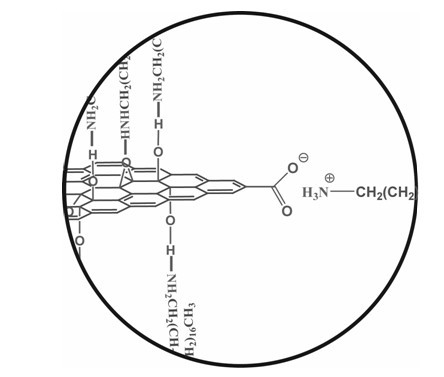

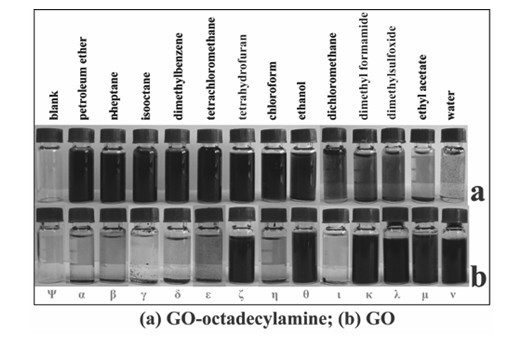

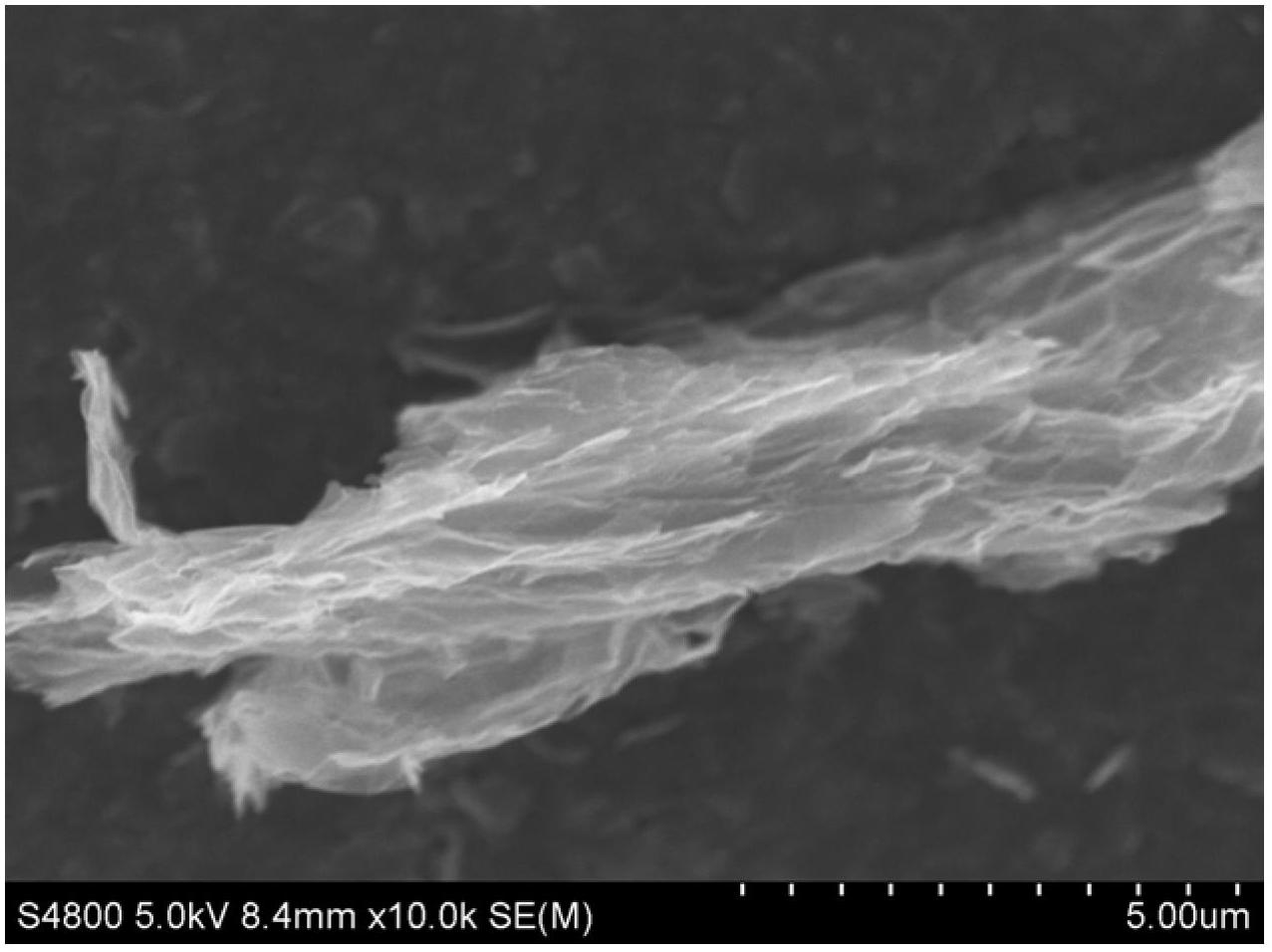

Graphite alkenyl supermolecule hybridization material with strengthened heat stability and preparation method thereof

InactiveCN102491316AGood dispersionImprove thermal stabilityMaterial nanotechnologyGrapheneMaterials preparationOrganic solvent

The invention discloses a graphite alkenyl supermolecule hybridization material with strengthened heat stability and a preparation method thereof. The graphite alkenyl supermolecule hybridization material with strengthened heat stability is in a nanometer structure constructed on the basis of supermolecule self-package technique. The preparation process includes three steps of graphite oxide preparation, reduced graphene oxide preparation and graphite alkenyl supermolecule hybridization material preparation. Relative to unmodified reduced graphene oxide, the hybridization material combined inthe method can be easily dispersed in organic solvent with low polarity and the heat stability is greatly improved. Simultaneously, the hybridization material can serve as a nanometer material to improve the heat stability of a polymer composite material. The combining steps are simple and high in efficiency, so that the hybridization material can be prepared in a large amount and has better application prospect and economical benefit.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing graphene/polymer composite material based on infrared irradiation

The invention discloses a method for preparing a graphene / polymer composite material based on infrared irradiation. The method comprises the following steps: 1) mixing a graphite oxide solution with a polymer solution or polymer emulsion to obtain a mixed solution, casting or spinning, and drying until the weight percentage of the total solvent is less than or equal to 50 percent so as to obtain a composite product; and 2) removing the solvent from the composite product under the irradiation of an infrared heating lamp, and performing reduction reaction of graphite oxide to obtain the graphene / polymer composite material. By the preparation method, the graphene / polymer composite material is prepared under the irradiation of the infrared heating lamp, the process is simple and convenient, the production cost is low, the method is suitable for large-scale industrial production, different polymers can be selected for preparing different graphene / polymer composite materials so as to meet the production and use requirements, and the graphene / polymer composite material has a wide application prospect in the fields such as conductive polymer composite materials, films and fibers.

Owner:ZHEJIANG UNIV

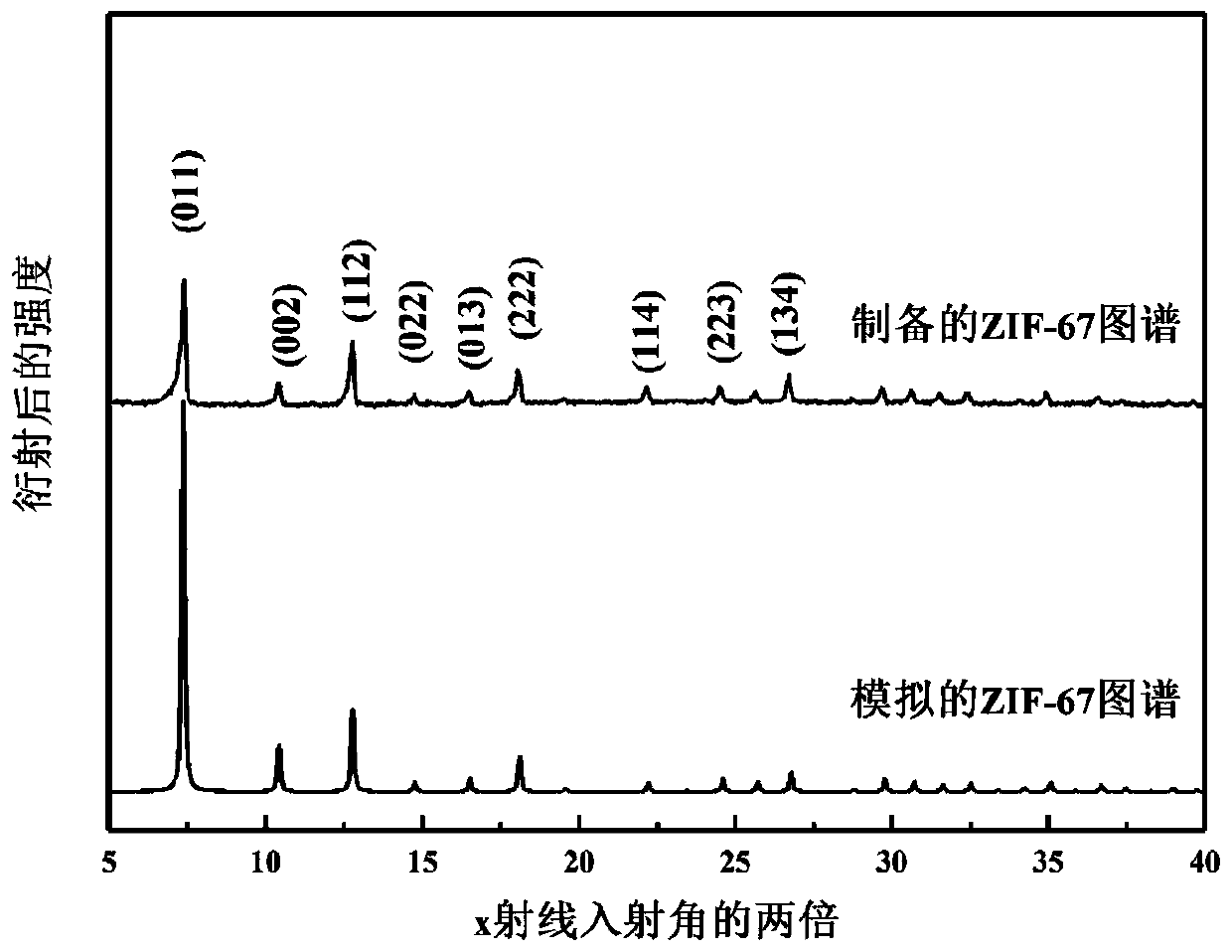

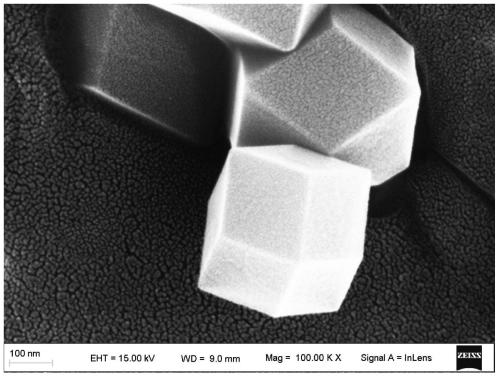

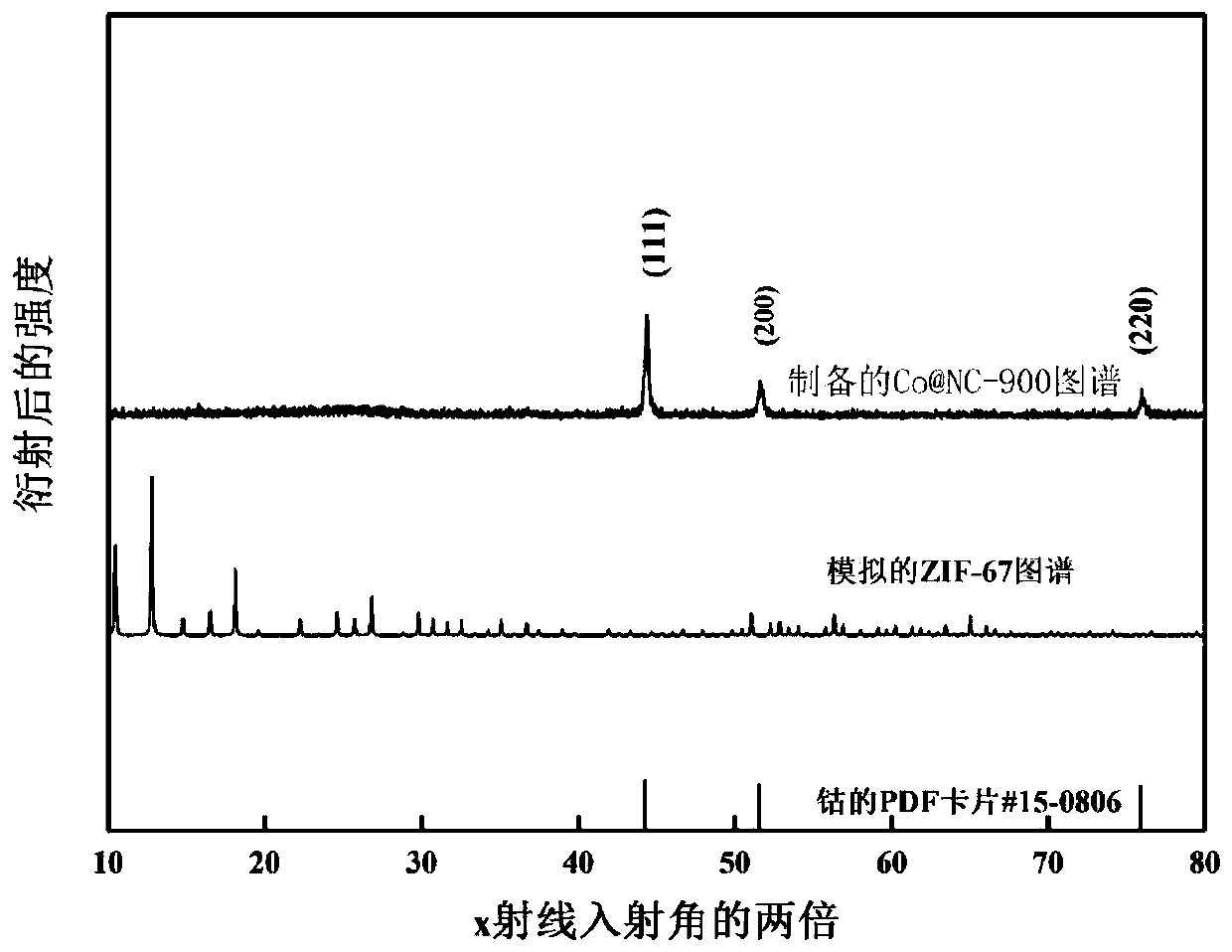

Cobalt sulfide-based composite material as well as preparation method and application thereof

ActiveCN111370707AUniform particle sizeGood lookingMaterial nanotechnologyCobalt sulfidesElectrical batteryLithium–air battery

The invention provides a cobalt sulfide-based composite material as well as a preparation method and application thereof. The cobalt sulfide-based composite material is CoS2NC, the preparation methodof the cobalt sulfide-based composite material comprises the following steps: (1) synthesizing a ZIF-67 precursor by using a precipitation method; (2) transferring the ZIF-67 precursor into a tubularfurnace, and calcining the ZIF-67 precursor in an inert gas environment to obtain a nitrogen-doped carbon-coated cobalt-based nano material CoNC; and (3) taking the nitrogen-doped carbon-coated cobalt-based nano material CoNC as a Co source, taking sulfur powder as a sulfur source, fully mixing the Co source and the sulfur source, and carrying out secondary calcination under the protection of inert gas to obtain the cobalt sulfide-based composite material. The cobalt sulfide-based composite material prepared by the method is good in electrochemical performance, high in specific surface area and good in crystallinity; when applied to the lithium-air battery, the material has high specific capacity and cycle performance, and the preparation method is simple and suitable for large-scale production.

Owner:东北大学秦皇岛分校

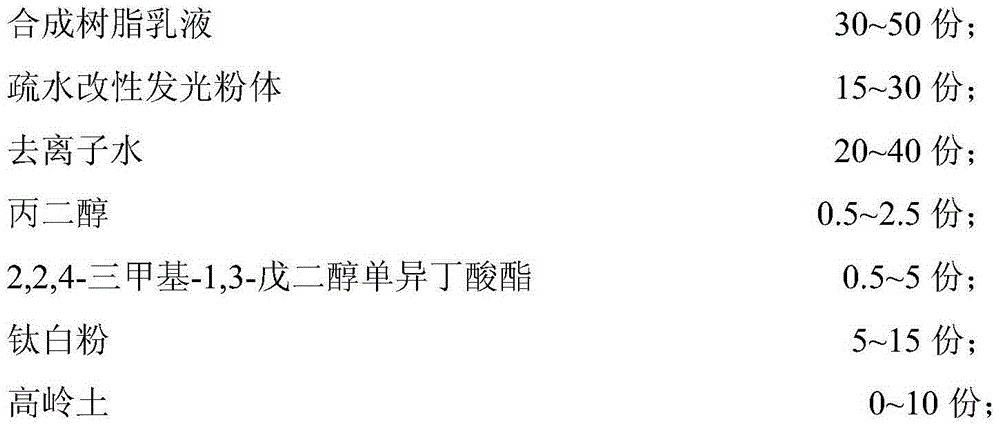

Long-lasting phosphorescent waterborne coating and preparation method thereof

InactiveCN104861812AEasy to prepareLow cost of industrializationLuminescent paintsPolyurea/polyurethane coatingsEmulsionSynthetic resin

The invention relates to functional building coating technologies and aims to provide a long-lasting phosphorescent waterborne coating and a preparation method thereof. The coating is prepared by mixing the following raw materials in parts by weight: 30-50 parts of synthetic resin emulsion, 15-30 parts of hydrophobic modified luminescent powder, 12-30 parts of pigments and fillers, 6.5-8 parts of an assistant and 20-40 parts of de-ionized water. The luminescent powder is subjected to hydrophobic modification to obtain the hydrophobic modified luminescent powder which is stable for a long term (more than 6 months) in a waterborne environment and emits light for 12 hours. The hydrophobic modified luminescent powder is introduced into the coating, so that a film-forming material has the functions of being stable for a long term (more than 6 months) in the waterborne coating and emitting light for 12 hours. At the same time, the preparation method is simple, convenient and favorable for reducing the industrialized production cost. According to the preparation method, the raw materials are ground, stirred and dispersed to prepare the coating; the preparation process is simple, easy to implement, simple and convenient to operate and favorable for large-scale industrialized production, and reduces the industrialized production cost.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

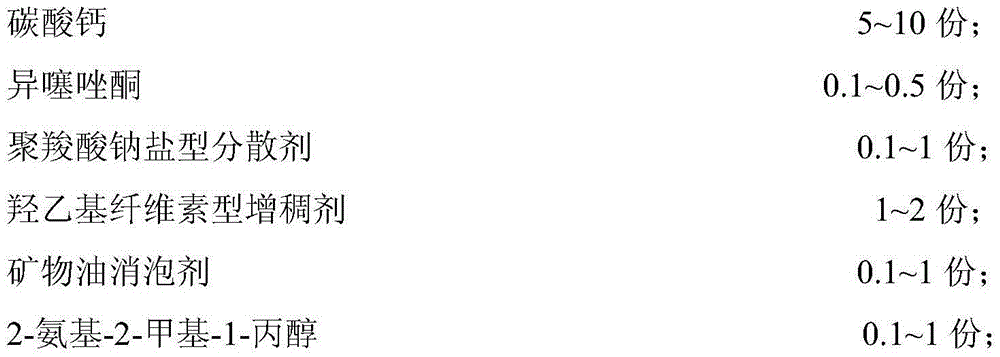

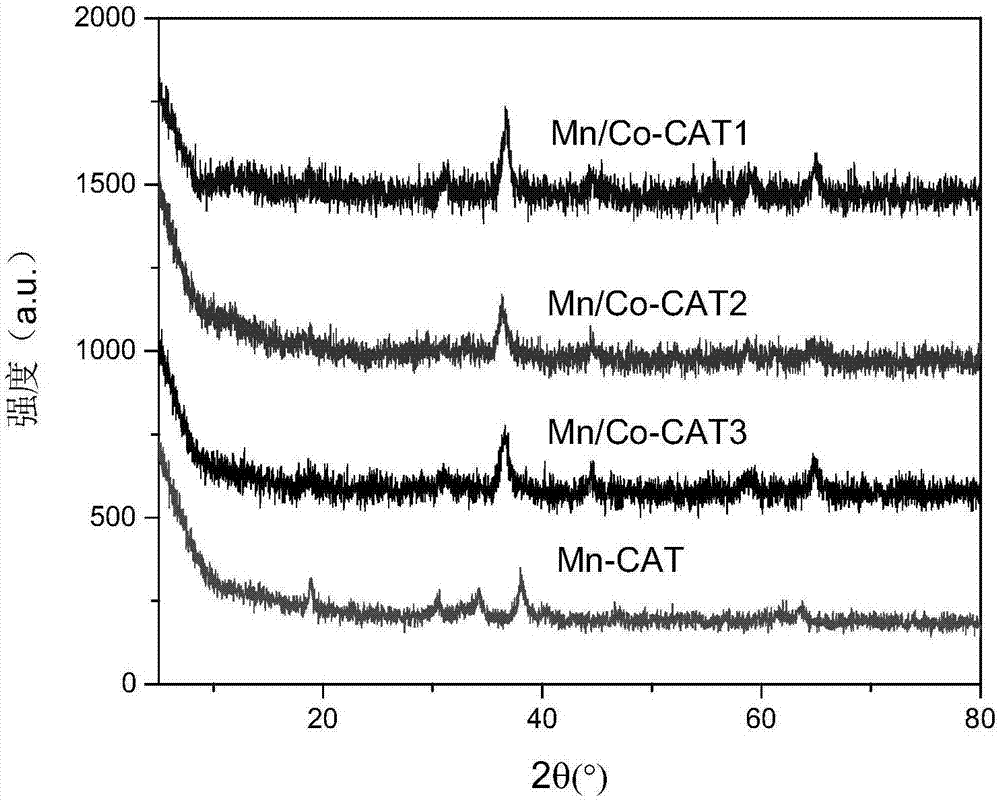

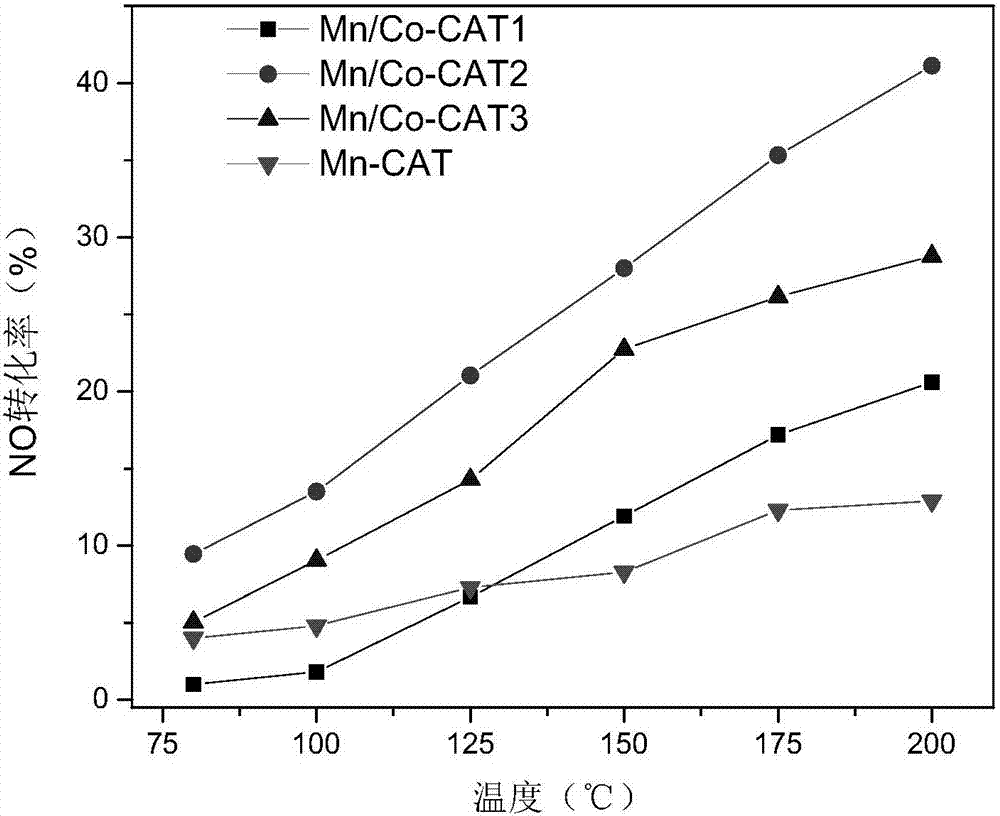

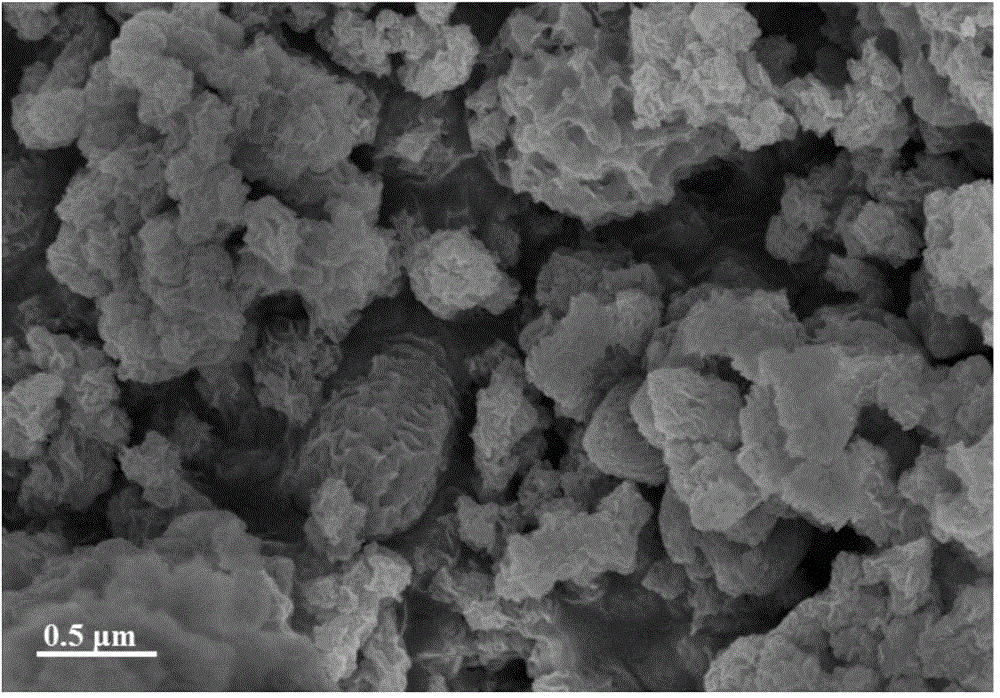

Mn/Co-based low-temperature SCO catalyst and preparation method thereof

ActiveCN107362807AHigh porosityStable structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseMetal-organic framework

The invention discloses a Mn / Co-based low-temperature SOC catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving manganese-containing metal salt and cobalt-containing metal salt in dimethylformamide, adding an organic ligand and water, and magnetically stirring and uniformly mixing the components to obtain a mixed solution; and (2) carrying out hydrothermal reaction on the obtained mixed solution in a reactor, reacting to obtain Mn / Co double-metal organic framework crystal, soaking the Mn / Co double-metal organic framework crystal in the dimethylformamide and activating the Mn / Co double-metal organic framework crystal, and then purifying, filtering and roasting the activated crystal to obtain the Mn / Co-based low-temperature SCO catalyst. The Mn / Co-based low-temperature SCO catalyst has good low-temperature denitration activity. Compared with an existing low-temperature denitration catalyst, the Mn / Co-based low-temperature SOC catalyst has the advantages that the conversion rate of catalyzed NO is greatly increased, at the low temperature of 150-200 DEG C, the catalyzed conversion rate of NO can reach 50% or above, and existing industrial requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

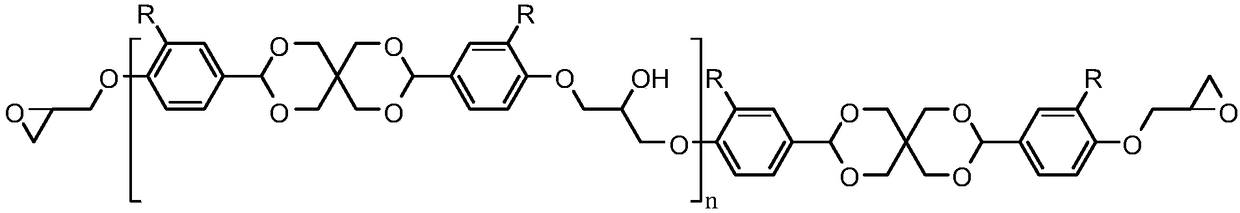

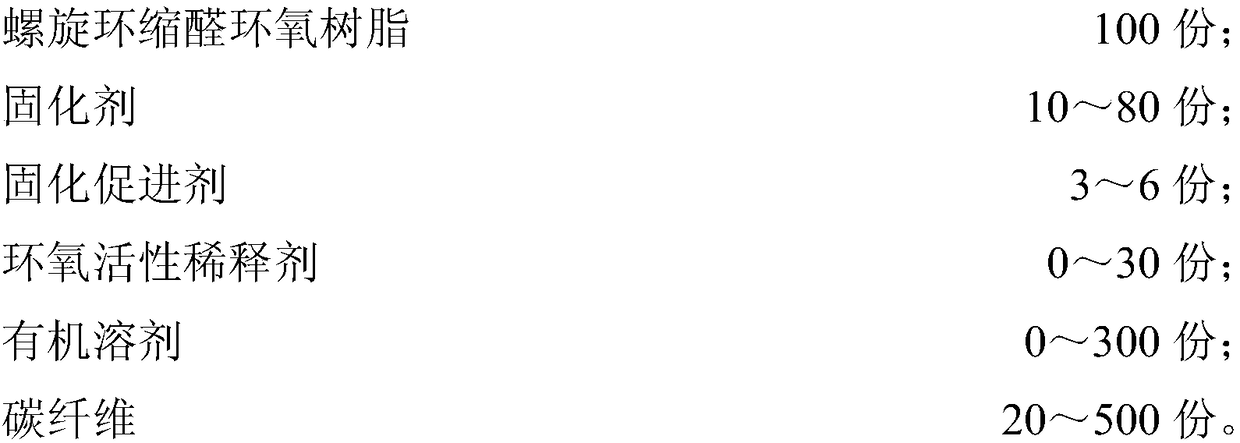

Easily-recoverable carbon fiber composite material based on spiral cyclic acetal epoxy resin

The invention specifically discloses an easily-recoverable carbon fiber composite material based on spiral cyclic acetal epoxy resin, belonging to the field of polymers and composite materials. The composite material is composed of, by mass, 100 parts of spiral cyclic acetal epoxy resin, 5 to 100 parts of a curing agent, 0 to 6 parts of a curing accelerator, 0 to 30 parts of an epoxy reactive diluent, 0 to 300 parts of an organic solvent and 20 to 500 parts of carbon fibers. Compared with conventional epoxy resin / carbon fiber composite materials, the easily-recoverable carbon fiber composite material based on the spiral cyclic acetal epoxy resin can remove matrix resin bonding with carbon fibers under mild conditions, allows the carbon fibers to be well recycled and enables the recycled carbon fibers to maintain original excellent performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

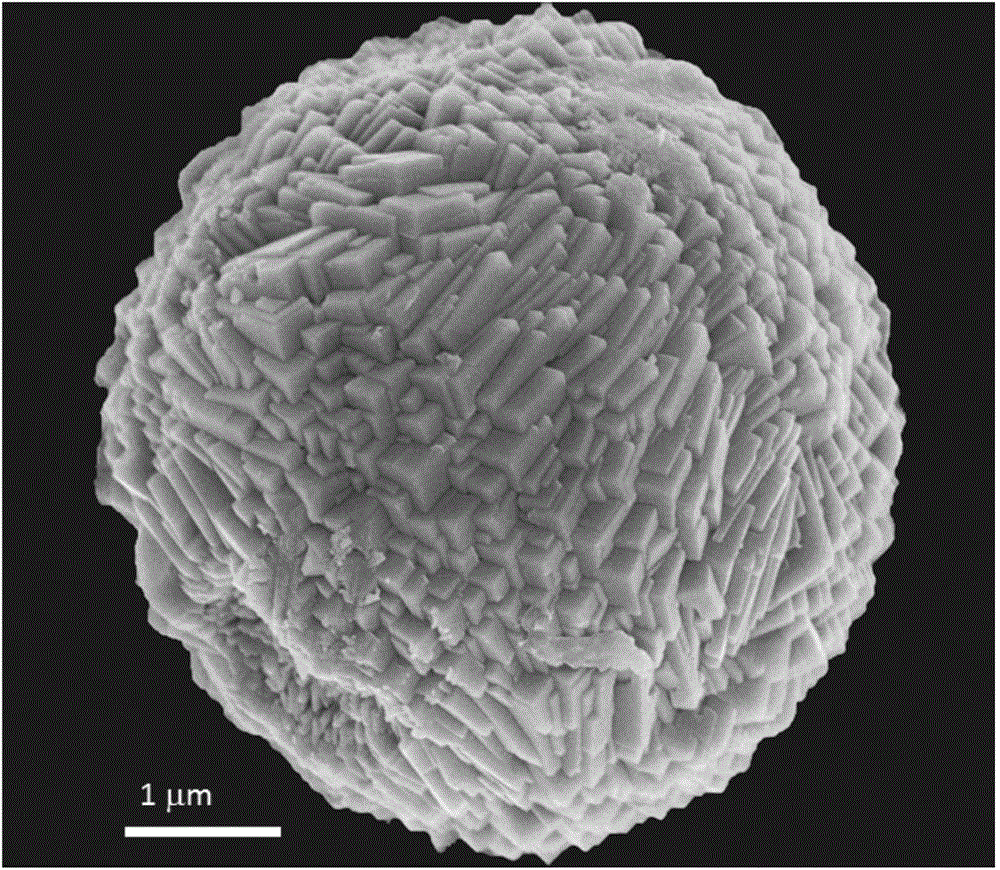

Hollow porous spherical mixed oxide for lithium ion battery negative electrode and preparation method of hollow porous spherical mixed oxide

ActiveCN104466108AEasy to prepareConducive to industrial mass productionCell electrodesNanotechnologyManganeseSpherical shaped

The invention relates to hollow porous spherical mixed oxide for a lithium ion battery negative electrode and a preparation method of the hollow porous spherical mixed oxide. The material is a uniform nano-mixture of Mn2O3 and NiMn2O4, and a specific chemical formula is NixMn<1-x>O<1.5-0.5x> (x is more than 0 and less than 1 / 3). The preparation method of the hollow porous spherical mixed oxide comprises the steps that based on complexing action of ammonia water and nickel ions, the precipitation speed of nickel carbonate is reduced, so that a spherical structure of the manganese carbonate cannot be destroyed by the nickel carbonate and has a certain modification function on a spherical structure of the manganese carbonate to form a uniform spherical mixture (NixMn<1-x>CO3, x is more than 0 and less than 1 / 3) of the nickel carbonate and the manganese carbonate; the prepared hollow porous spherical mixed oxide for the lithium ion battery negative electrode is obtained by using a high-temperature segmental roasting process. Compared with the prior art, the method is easy to operate and suitable for industrial large batch production; by utilizing the hollow porous spherical mixed oxide, the large-current charging / discharging performance of the lithium ion battery negative electrode can be effectively improved, and the and the cycle life of the lithium ion battery negative electrode can be effectively prolonged.

Owner:SHANGHAI JIAO TONG UNIV

Production of L-aspartase calcium

InactiveCN1817855AShort reaction timeConducive to industrial mass productionOrganic compound preparationAmino-carboxyl compound preparationCalcium hydroxideCalcium crystals

Production of L-aspartyl-calcium is carried out by taking L-asparagic acid and calcium hydroxide as raw materials, furnishing in proportion 3.4-3.8:1, putting it into mixer, adding into water while agitating to obtain soliquoid, heating the soliquoid, inducing into colloid mill and high-pressure fluid nanometer mill to obtain L-aspartyl-calcium liquid, inducing L-aspartyl-calcium into agitating container, adding into 45% alcohol, agitating, laying aside to obtain L-aspartyl-calcium crystal, adding into 55% alcohol, agitating, laying aside, centrifugal separation depositing, vacuum drying deposit and screening to obtain final product. It has short reactive time, higher purity and more yields.

Owner:JIANGSU XINGCHI BIOTECH

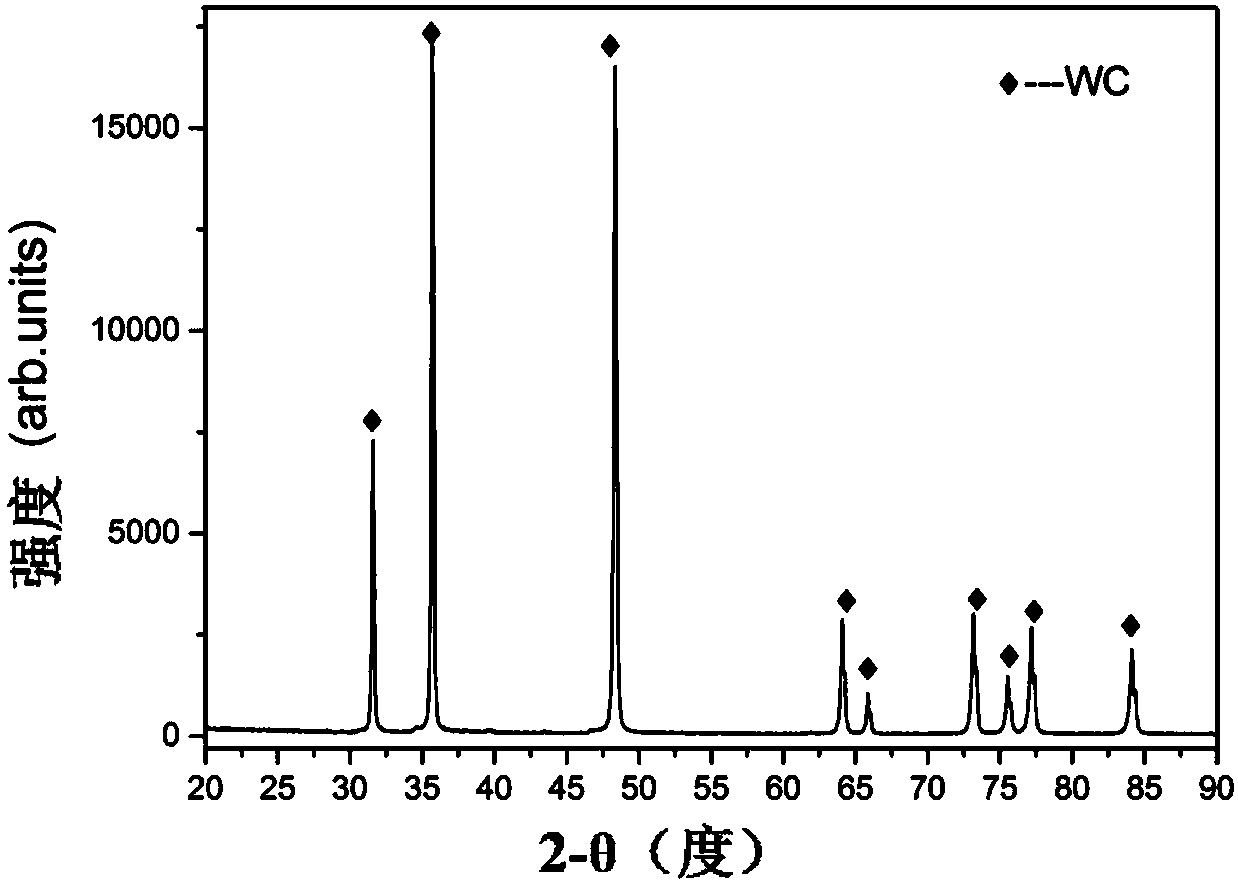

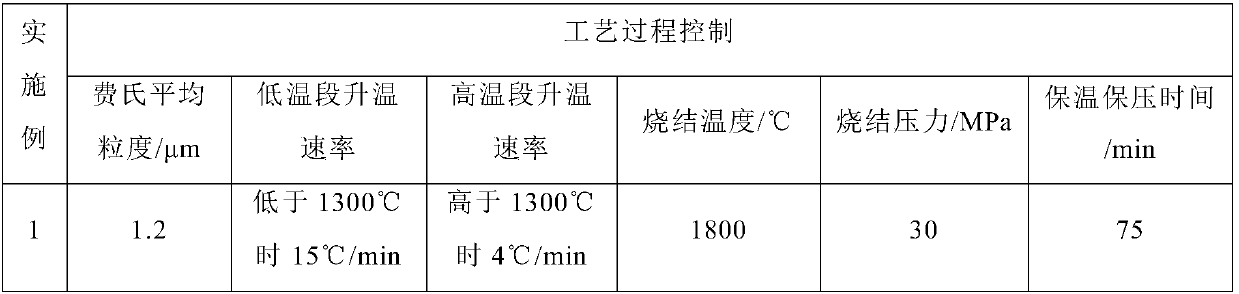

Preparation method for non-bonding-phase pure-carbonation tungsten target material

ActiveCN107620049AReduce surface defectsSimple preparation processVacuum evaporation coatingSputtering coatingDiamond-like carbonSuperficial mass

The invention provides a preparation method for a non-bonding-phase pure-carbonation tungsten target material. The method comprises the steps that pure-carbonation tungsten raw material powder is screened firstly to obtain pure-carbonation tungsten powder with the even particle size; then a mould is evenly filled with the pure-carbonation tungsten powder, hot-pressing sintering treatment is conducted under the vacuum condition, cooling is conducted, and then mould release is conducted to obtain a sintered blank; and finally, the sintered blank is machined to obtain the non-bonding-phase pure-carbonation tungsten target material meeting the size and surface-quality requirements. According to the preparation method for the non-bonding-phase pure-carbonation tungsten target material, the technique is simple, the forming effect is good, and industrialized large-scale production is facilitated; the target material does not contain any bonding phase component, grains are even, the average grain size is 5 [mu]m or below, the compactness can reach 99% or more, and the purity is 99.9% or more; and according to the target material, the arc starting discharging phenomenon in the sputtering process is reduced, the surface defects of a prepared film layer are few, a coating is more compact, the target material can be used for preparing an adulteration phase of diamond-like carbon (DLC) coating and a transitional layer, and coating mechanical performance and tribological performance are improved.

Owner:北京安泰六九新材料科技有限公司 +1

Preparation process of bicomponent castor oil polyurethane waterproof coating

ActiveCN102417779AImprove low temperature flexibilityImprove statusCoatingsPolymer sciencePtru catalyst

A preparation process of a bicomponent castor oil polyurethane waterproof coating is characterized in that the coating is obtained by interpenetrating a component A of polyurethane prepolymer and a component B of a colorful color paste system under the action of an initiator and a catalyst; wherein the component A is obtained by allowing castor oil and 2,4-toluene diisocyanate to react in an organic solvent dissolved with an initiator; the component B is obtained by mixing a blending agent, a solid pigment and / or a solid filler with a coupling agent, milling, orderly adding a alkene monomer, a catalyst, a polymerization inhibitor, and a light stabilizer, and stirring uniformly. The coating of the invention has excellent waterproofness, a good apparent state, abundant colors, good decorative effect, adjustable curing time, adjustable film flexibility and hardness, and simple operations.

Owner:湖北蓝盾之星科技有限公司 +1

Method for preparing light ceramsites by subway rail residue soil

InactiveCN106145996ASmall bulk densityHigh strengthCeramic materials productionCeramicwareFiberThermal insulation

The invention discloses a method for preparing light ceramsites by subway rail residue soil. The method includes the steps: drily grinding the subway rail residue soil by a ball grinder, then sieving the dry grinded residue soil by a sieve with100 meshes, uniformly mixing the sieved residue soil and coal ash according to a weight percentage, and preparing a mixed slurry according to water-solid ratio; performing granulation for the mixed slurry by a granulator to form balls, selecting the balls with grain diameters of 15-25mm and 10-15mm, and placing the selected balls into a constant temperature air blast drying oven with the temperature of 105 DEG C to dry by constant temperature for 4 hours or more than; tiling the dried balls on a ceramic fiber board, placing the tiled balls in a silicon-molybdenum box-type resistance furnace, increasing the temperature to 500 DEG C from the indoor temperature by the heating speed of 8-10 DEG C per minute, preheating for 20 minutes, then increasing the temperature to 1160-1250 DEG C by the heating speed of 8-10 DEG C per minute, roasting for 15 minutes, placing roasted ceramsites in a ventilated kitchen to naturally cool to the indoor temperature, and sieving the roasted ceramsites to obtain the light ceramsites. The weight percentage of the residue soil and the coal ash is 50%-85%:15%-50%, and the water-solid ratio is 15%-30%. The prepared ceramsites meet standard requirements of artificial lightweight aggregates in GB / T17431.1-2010 and GB / T17431.2-2010 and has the excellent advantages of high strength, multiple hole, high temperature resistance and the like and can serve as high-efficiency support agents for precast concrete components and thermal insulation materials of walls.

Owner:TIANJIN CHENGJIAN UNIV

Preparation method of iron-based amorphous nanocrystalline soft magnetic alloy for industrial production

The invention discloses a preparation method of an iron-based amorphous nanocrystalline soft magnetic alloy for industrial production. The preparation method comprises the following steps: firstly, preparing master-alloy raw materials; smelting the master-alloy raw materials repeatedly, and casting into an alloy ingot; smashing the alloy ingot, re-smelting, and covering the molten alloy with a steel-making slag forming agent; preparing an amorphous ribbon through quenching by using a single roller; putting the obtained amorphous ribbon into a vacuum annealing furnace, annealing isothermally, and crystallizing; and cooling the amorphous ribbon to room temperature in the vacuum annealing furnace to obtain the iron-based amorphous nanocrystalline soft magnetic alloy. The amorphous ribbon can be wound into a magnetic core with the sizes of 13.2mm*21.5mm*10mm before being nano-crystallized. Because the preparation method adopts low-cost industrial raw materials, the cost of the iron-based amorphous nanocrystalline soft magnetic alloy can be reduced greatly. The prepared iron-based amorphous nanocrystalline soft magnetic alloy has high magnetic conductivity and low loss.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

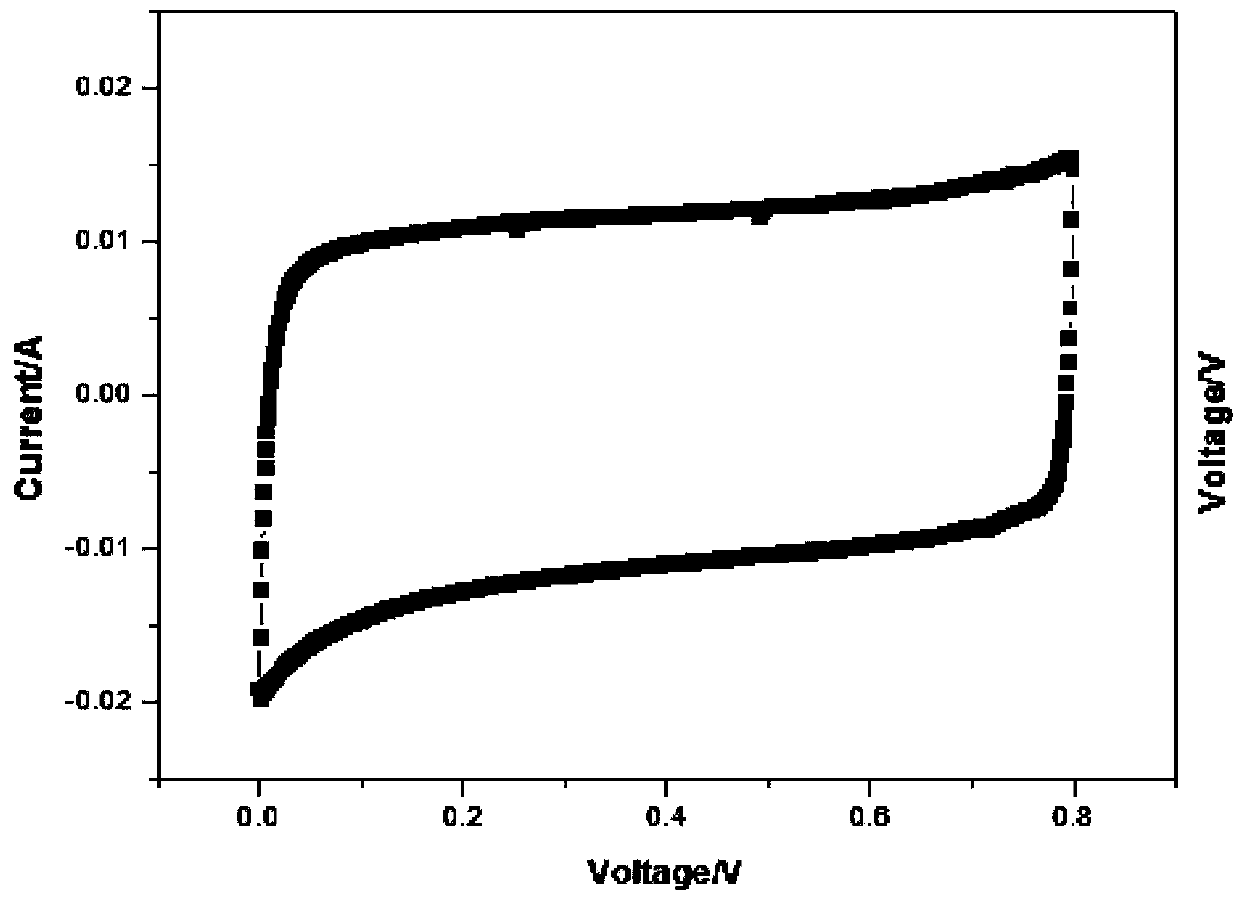

Method for preparing nano MnO2 composite electrode for high-conductivity super-capacitor

InactiveCN103440999ALower requirementSimple and fast operationNanotechnologyHybrid/EDL manufactureElectrolytic agentCarbon nanotube

A method for preparing nano MnO2 composite electrode for a high-conductivity super-capacitor includes the steps of taking a multi-walled carbon nanotube, adding the multi-walled carbon nanotube to mixed acid formed by sulfuric acid and nitric acid, wherein the molar ratio of the sulfuric acid and the nitric acid is 3:1, heating the mixed acid to 60 DEG C and stirring the mixed acid in a centrifugal mode, washing the mixed acid repeatedly with deionized water until the PH value of supernatant is 7, drying the multi-walled carbon nanotube for use, preparing electrolyte with the concentration between 0.1g / L and 2g / L, using stainless steel net electrodes as a cathode and an anode, applying direct-current voltage of 0.05-1V / cm2 across the cathode and the anode, depositing for 10-50min, obtaining a stainless steel net absorbing the multi-walled carbon nanotube, preparing a MnSO4 solution or a MnNO3 solution of 0.1mol / L as electrolyte, taking the stainless steel net to prepare an electrode, wherein the electrode serves as a positive pole and a platinum electrode serves as a negative pole, carrying out electrodeposition at a constant current of 0.5-50mA / cm2, keeping the temperature at 90 DEG C, and obtaining the nano MnO2 composite electrode after depositing for 5-30min. The method can conveniently and accurately control current density, electrolysis time, the type, components, the concentration, the PH value and other parameters of the electrolyte, and has the advantages of being simple to operate and low in cost.

Owner:NANCHANG HANGKONG UNIVERSITY

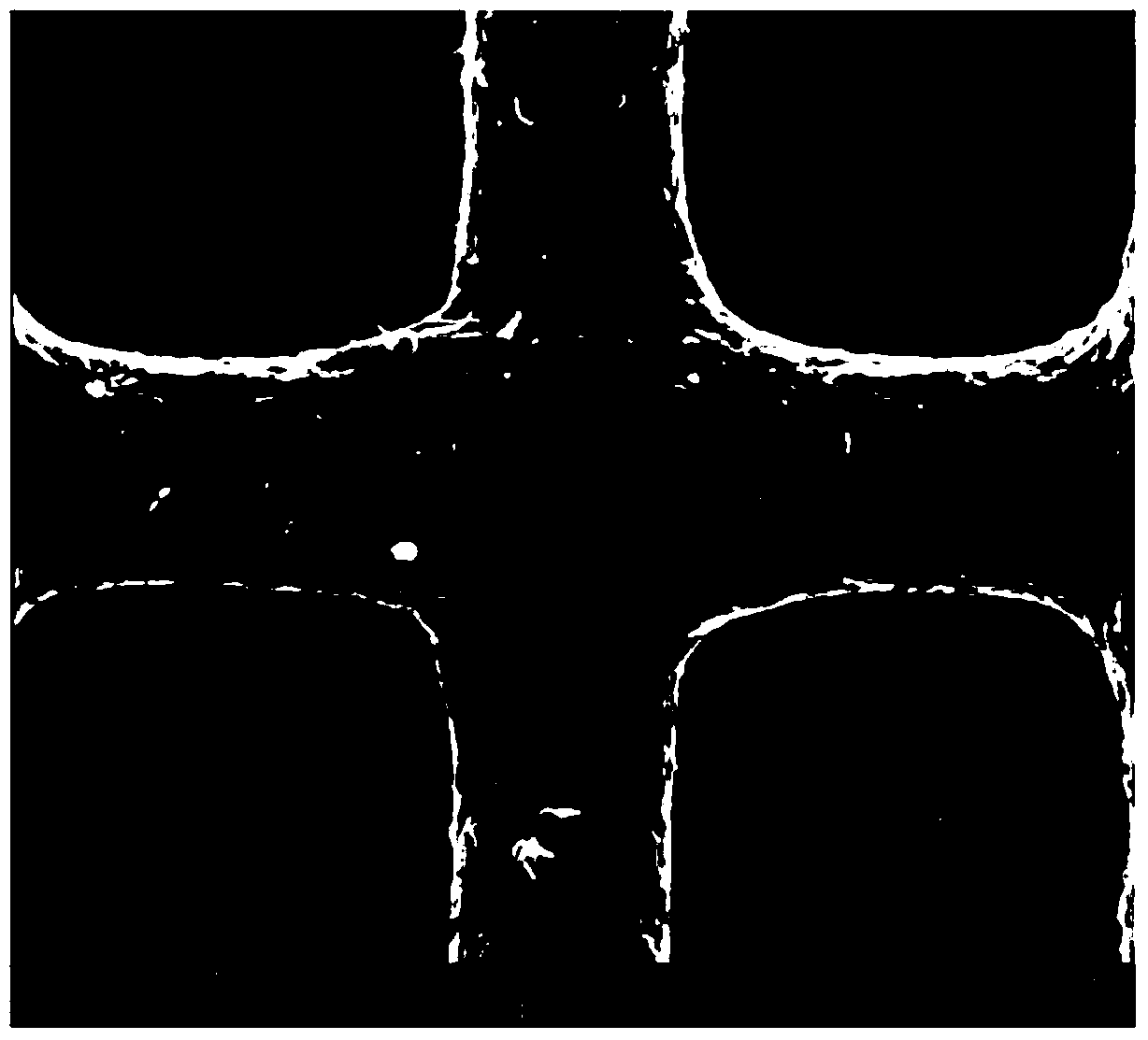

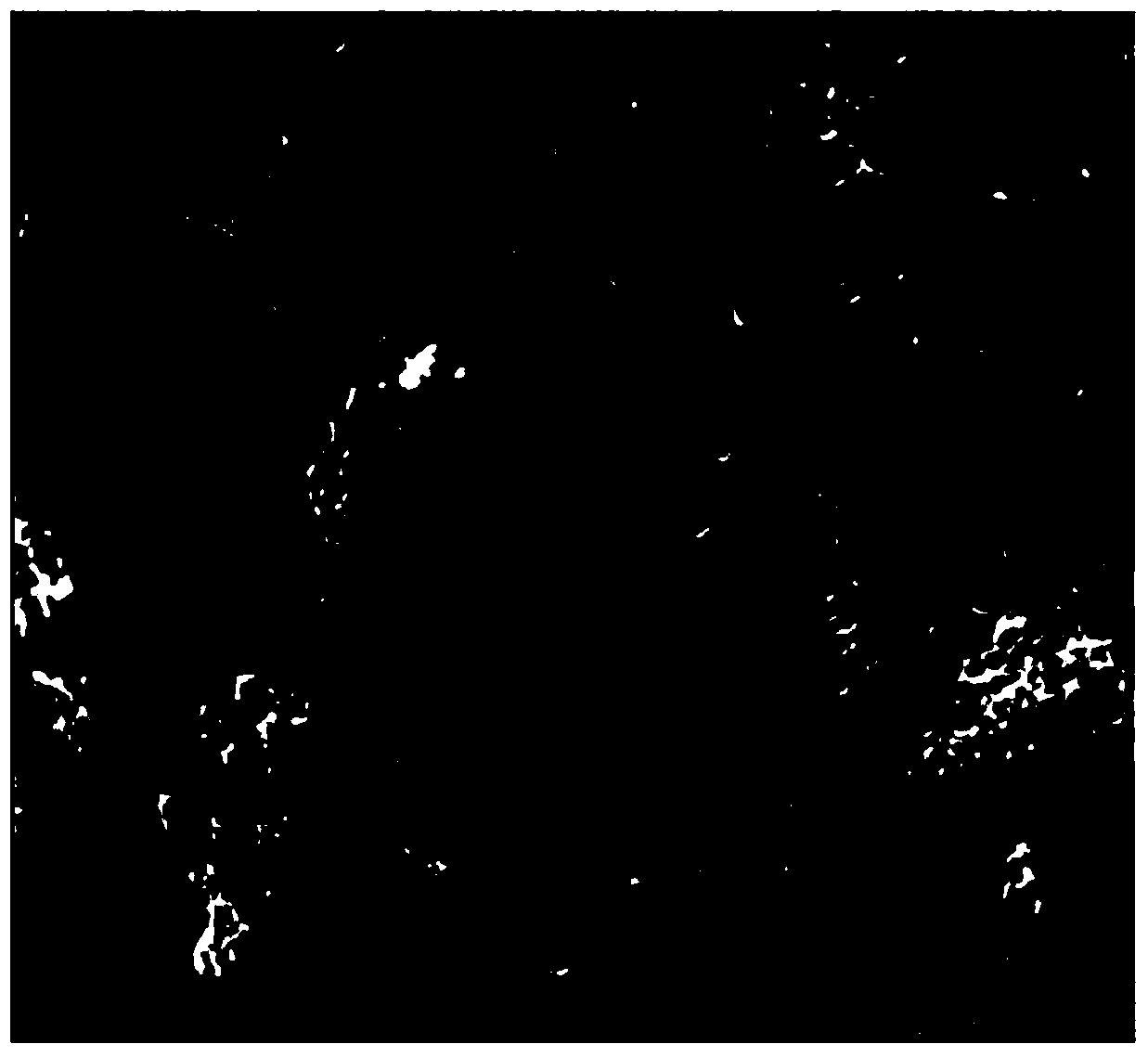

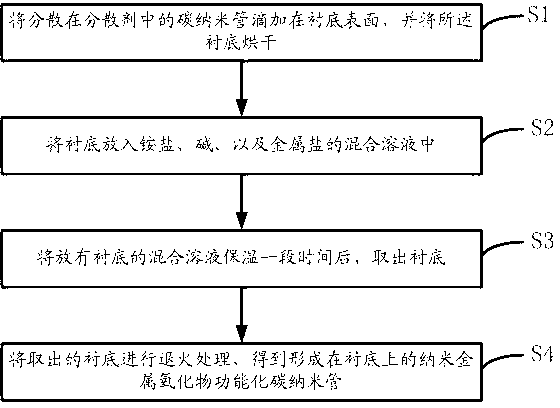

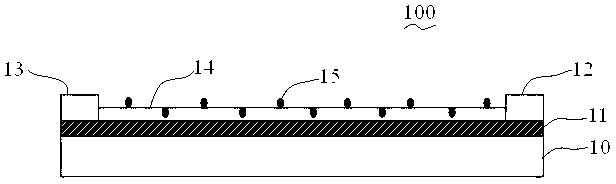

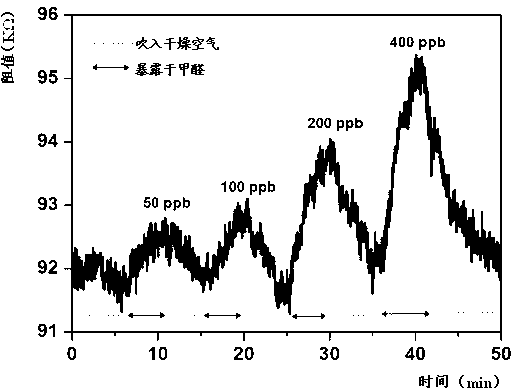

Preparation method of nano metal oxide functionalized carbon nanotubes and gas sensor

The invention discloses a preparation method of nano metal oxide functionalized carbon nanotubes and a gas sensor. The method comprises the following steps of: dropping carbon nanotubes which are dispersed in a dispersant to the surface of a substrate, and drying the substrate; placing the obtained substrate into a mixing solution of ammonium salt, alkali and metal salt; preserving the heat of the mixing solution containing the substrate for a certain duration, and taking out the substrate; and annealing the substrate which is taken out, to obtain nano metal oxide functionalized carbon nanotubes formed on the substrate. The method is comparatively simple in preparation process, free from strict reaction condition, favorable for industrial mass production and comparatively low in cost; and the nano metal oxide functionalized carbon nanotubes prepared by the method disclosed by the invention, in preparing the gas sensor, can detect some special gases, in particular formaldehyde, and precision is comparatively high.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com