Preparation method of transparent super-hydrophobic zinc oxide coating

A zinc oxide, super-hydrophobic technology, applied in the field of functional coating preparation, can solve the problems of high cost, complex equipment, harsh reaction conditions, etc., and achieve the effects of low pollution, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

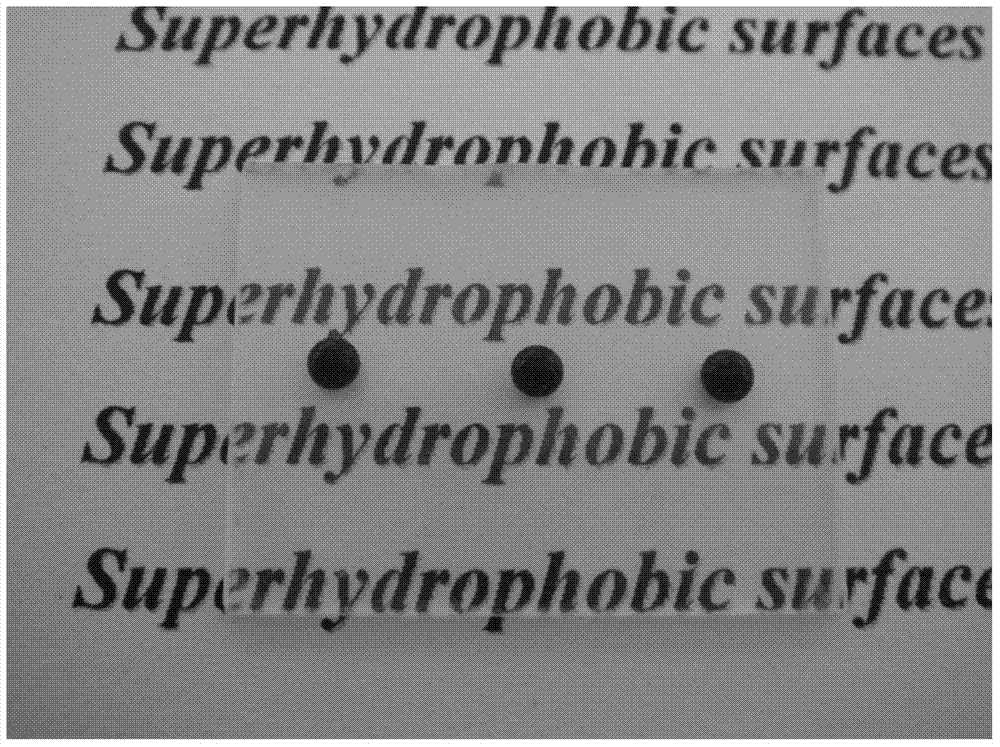

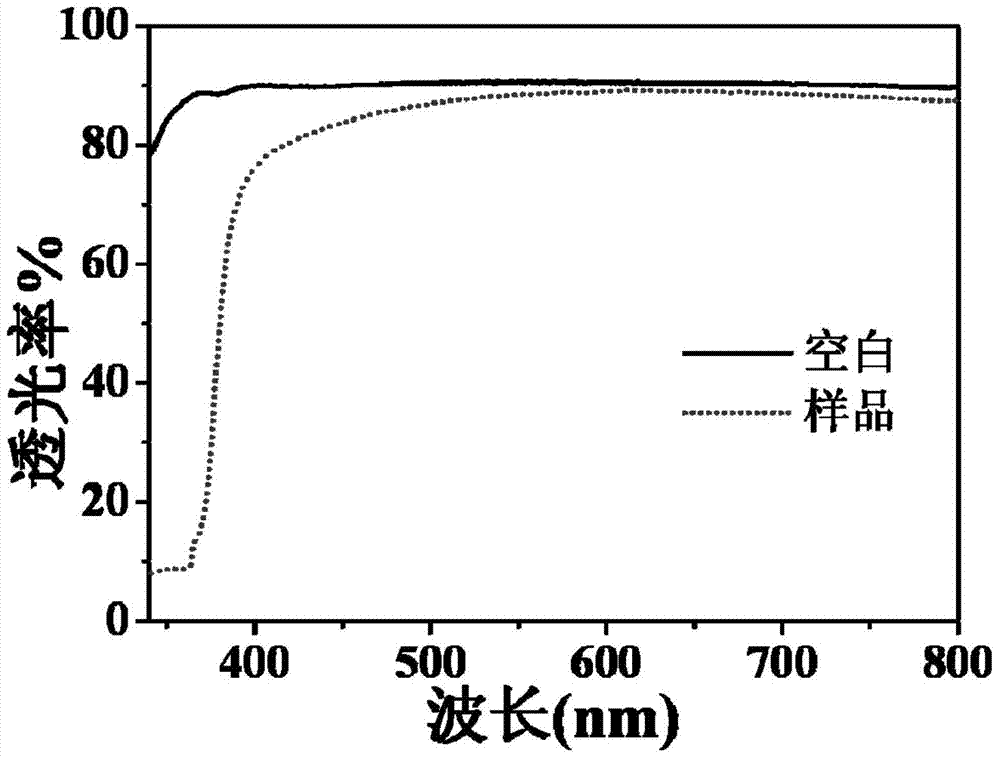

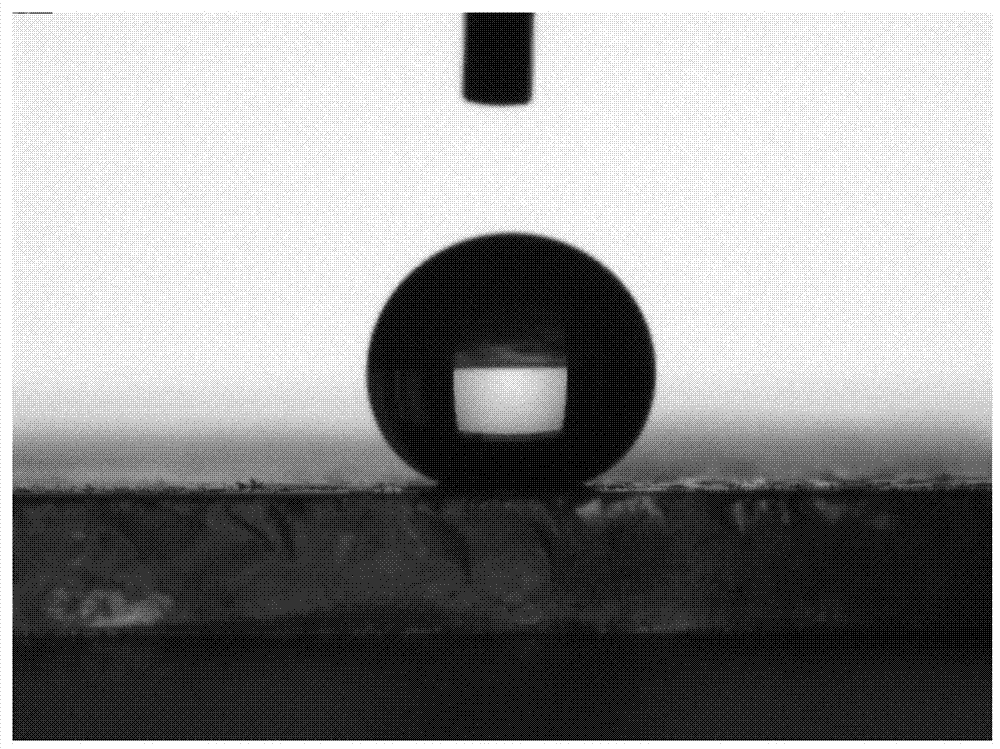

Examples

Embodiment 1

[0039] The preparation method of embodiment 1 transparent superhydrophobic zinc oxide coating, comprises the following steps:

[0040] a. Substrate pretreatment

[0041] Soak ordinary glass in hot Piranha solution (concentrated sulfuric acid: 30% hydrogen peroxide solution = 3:1, V / V), let it stand for 15 minutes, take it out and rinse it with plenty of water until the washing solution is neutral, then dry it ,spare.

[0042] b. Preparation of zinc oxide sol

[0043] Weigh 2.634g of zinc acetate dihydrate and 0.4374g of cetyltrimethylammonium bromide (CTAB) and dissolve them in 10mL of isopropanol, ultrasonically disperse them evenly for 5min, then slowly add 720μL of ethanolamine dropwise to make ethanolamine, acetic acid The molar ratio of zinc and surfactant was 1:1:0.1, and the reaction was stirred at 70°C for 2 hours to obtain a clear transparent sol with a concentration of 1.2mol / L.

[0044] c. Preparation of zinc oxide coating

[0045] The transparent sol was aged f...

Embodiment 2

[0052] The preparation method of embodiment 2 transparent superhydrophobic zinc oxide coatings, comprises the following steps:

[0053] a. Substrate pretreatment

[0054] Soak ordinary glass in hot Piranha solution (concentrated sulfuric acid: 30% hydrogen peroxide solution = 3:1, V / V), let it stand for 20 minutes, take it out and rinse it with plenty of water until the washing solution is neutral, then dry it ,spare.

[0055] b. Preparation of zinc oxide sol

[0056] Weigh 1.317g of zinc acetate dihydrate and 0.2187g of cetyltrimethylammonium bromide (CTAB) and dissolve them in 10mL of isopropanol, ultrasonically disperse them evenly for 5min, then slowly add 360μL of ethanolamine dropwise to make ethanolamine, acetic acid The molar concentration ratio of zinc and surfactant was 1:1:0.1, and reacted at 80°C for 1 h under stirring condition to obtain a clear transparent sol with a concentration of 0.6 mol / L.

[0057] c. Preparation of zinc oxide coating

[0058] The transp...

Embodiment 3

[0063] The preparation method of embodiment 3 transparent superhydrophobic zinc oxide coatings, comprises the following steps:

[0064] a. Substrate pretreatment

[0065] Soak the ITO glass in hot Piranha solution (concentrated sulfuric acid: 30% hydrogen peroxide solution = 3:1, V / V), let it stand for 30 minutes, take it out and rinse it with plenty of water until the washing solution is neutral, then dry it ,spare.

[0066] b. Preparation of zinc oxide sol

[0067] Weigh 3.512g of zinc acetate dihydrate and 0.583g of cetyltrimethylammonium bromide (CTAB) and dissolve them in 10mL of absolute ethanol, ultrasonically disperse them evenly for 5min, then slowly add 960μL of ethanolamine dropwise to make ethanolamine, acetic acid The molar concentration ratio of zinc and surfactant was 1:1:0.1, and the reaction was carried out at 70°C for 1 h under stirring condition to obtain a clear transparent sol with a concentration of 1.6 mol / L.

[0068] c. Preparation of zinc oxide coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com