Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

A technology of ceramic capacitors and ceramic materials, which is applied in the direction of fixed capacitor dielectrics, fixed capacitor parts, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of lead being unfavorable to environmental protection, and achieve low cost and uniformity Good, the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

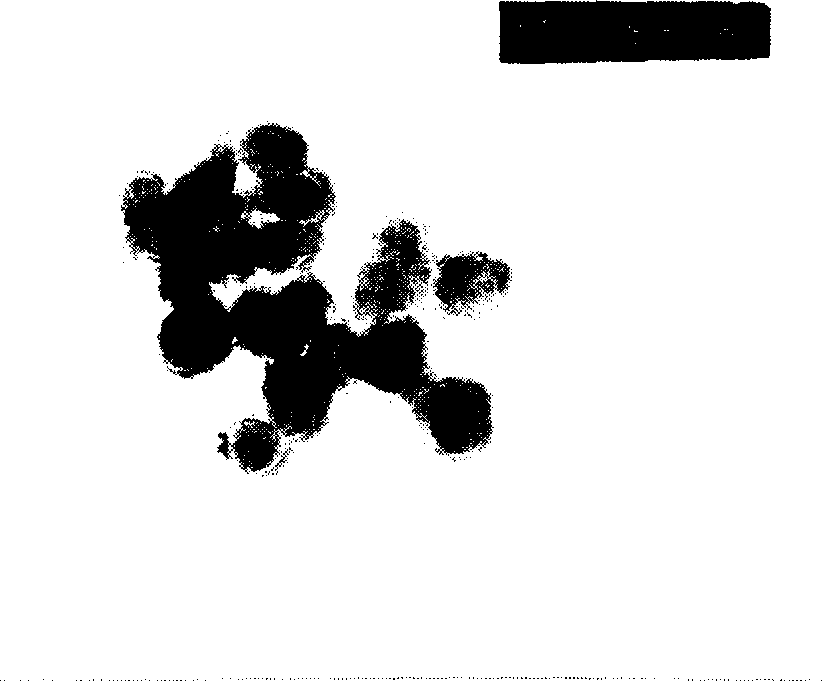

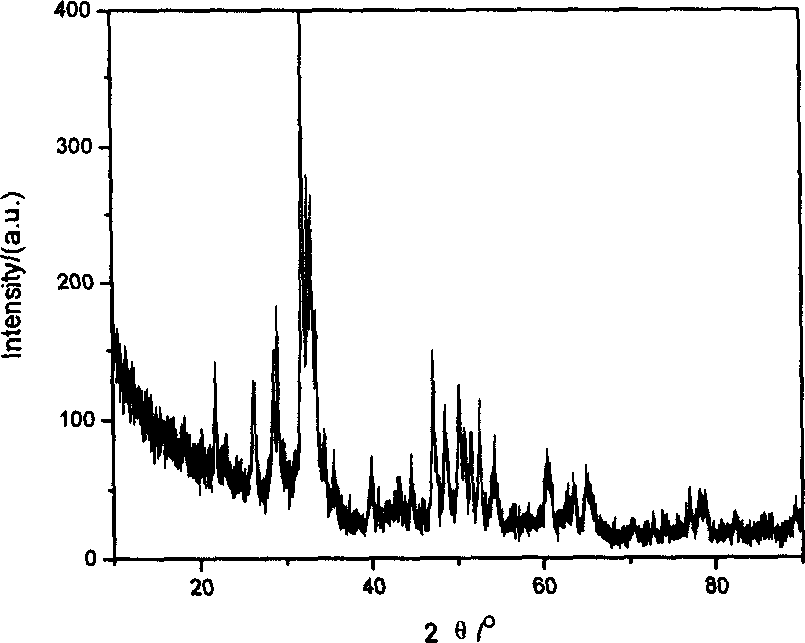

[0057] Example 1: Nanoscale ceramic material dopants N1-N4 were prepared by process method 1, as shown in Table 1. Take the preparation of N3 as an example to specify as follows: 12.5mol% magnesium carbonate (MgCO 3 ), 12mol% calcium carbonate (CaCO 3 ), 11.5mol% manganese oxide (MnO 2 ), 1mol% tricobalt tetroxide (Co 3 o 4 ), 33mol% yttrium oxide (Y 2 o 3 ) is dissolved in nitric acid; 30 mol% tetraethyl orthosilicate is mixed with acetylacetone, absolute ethanol and polyethylene glycol in a volume ratio of 3:1:3:1 to form an organic solvent. The sol-gel is prepared by the process method 1, dried at 50-100° C. to obtain a xerogel, heat-treated at 750° C. for 1 hour, and then ground into a powder. The obtained nanoscale ceramic material dopant was observed with a transmission electron microscope (TEM) for its microscopic morphology and particle size distribution. figure 1 A TEM photograph of the sample magnified 100,000 times is given. According to XRD analysis, after ...

Embodiment 2

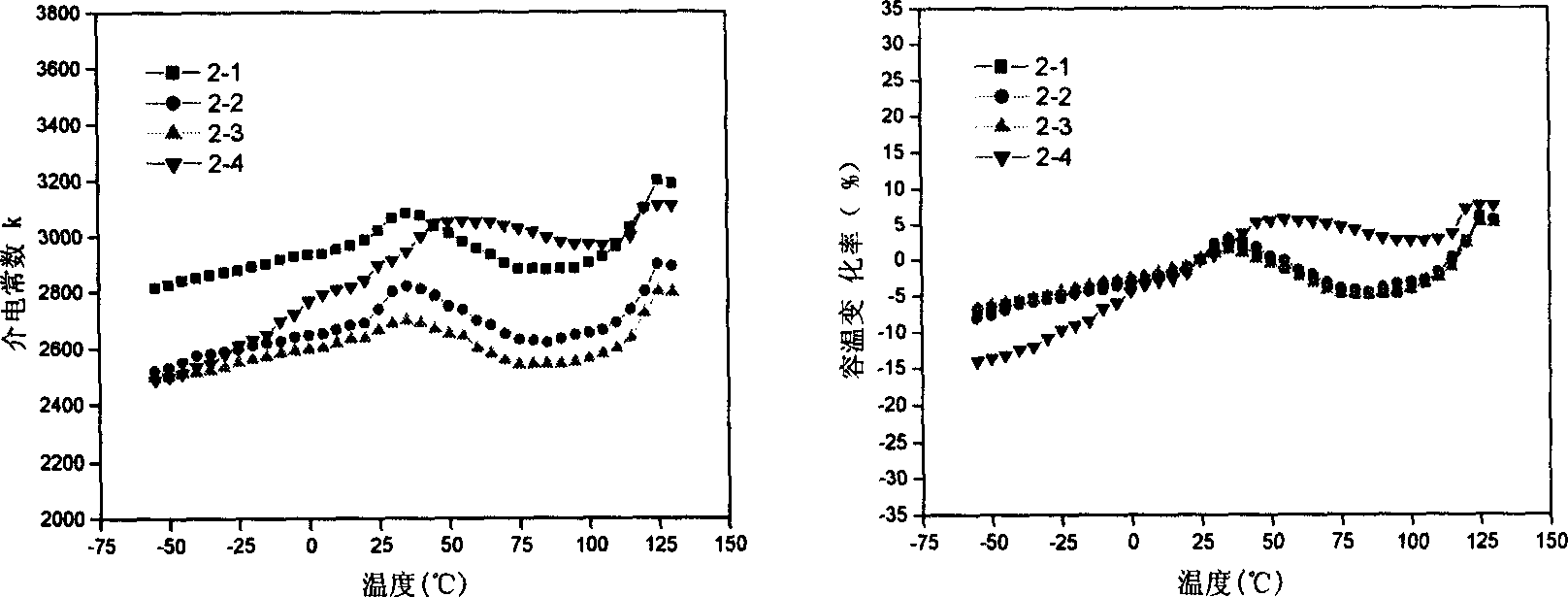

[0059] Embodiment 2: Using process method 2 to prepare an ultra-fine temperature-stable anti-reduction multilayer ceramic capacitor dielectric material. BaTiO with an average particle size of 0.3 μm synthesized by hydrothermal method in the formula 3It is the base material, accounting for 97% of the total mass of the dielectric material; the dopant is the nanoscale ceramic material dopant N1-N4 prepared in Example 1 of the present invention, accounting for 3% of the total mass of the dielectric material. After the medium material obtained by mixing and ball milling is dried, add 10wt% PVA to mix and granulate, and press to form a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 10Mpa. Coating nickel internal electrode paste on both sides, and then placed in N 2 / H 2 Reducing atmosphere (oxygen partial pressure P(O 2 )=10 -12 Pa) for sintering, the sintering temperature is 1200 ° C for 4 hours, in a weak oxygen atmosphere (oxygen partial pressure P(O ...

Embodiment 3

[0061] Example 3: Using process method 2 to prepare an ultra-fine temperature stable anti-reduction multilayer ceramic capacitor dielectric material. BaTiO with an average particle size of 0.5 μm synthesized by hydrothermal method in the formula 3 It is the base material, accounting for 92-99.5% of the total mass of the dielectric material; the dopant is the nanoscale ceramic material dopant N1 prepared in Example 1 of the present invention, accounting for 0.5%-8.0% of the total mass of the dielectric material. After the medium material obtained by mixing and ball milling is dried, add 10wt% PVA to mix and granulate, and press to form a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 10Mpa. Coating nickel internal electrode paste on both sides, and then placed in N 2 / H 2 Reducing atmosphere (oxygen partial pressure P(O 2 )=10 -12 Pa) for sintering, the sintering temperature is 1220 ° C for 3 hours, in a weak oxygen atmosphere (oxygen partial pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com