Patents

Literature

128results about How to "Less adulterated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

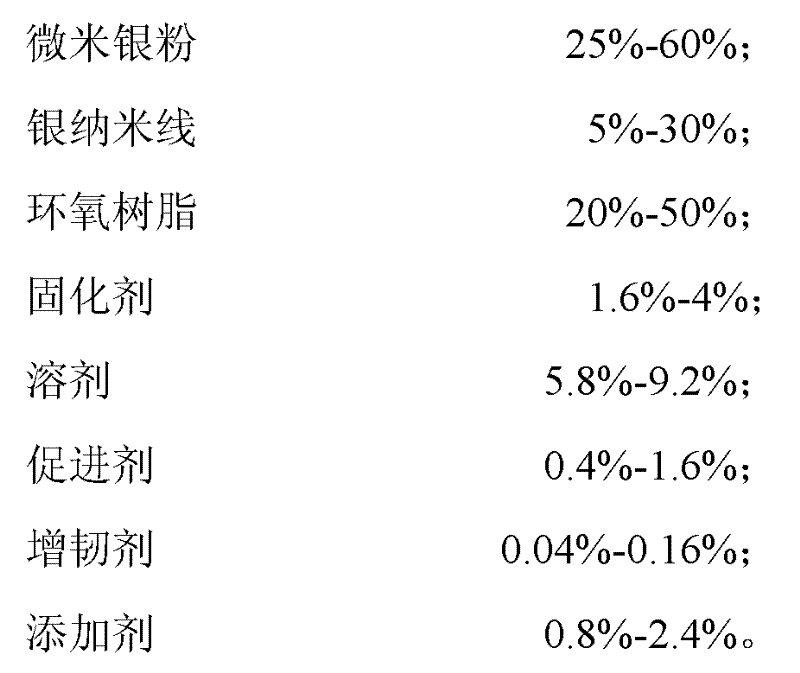

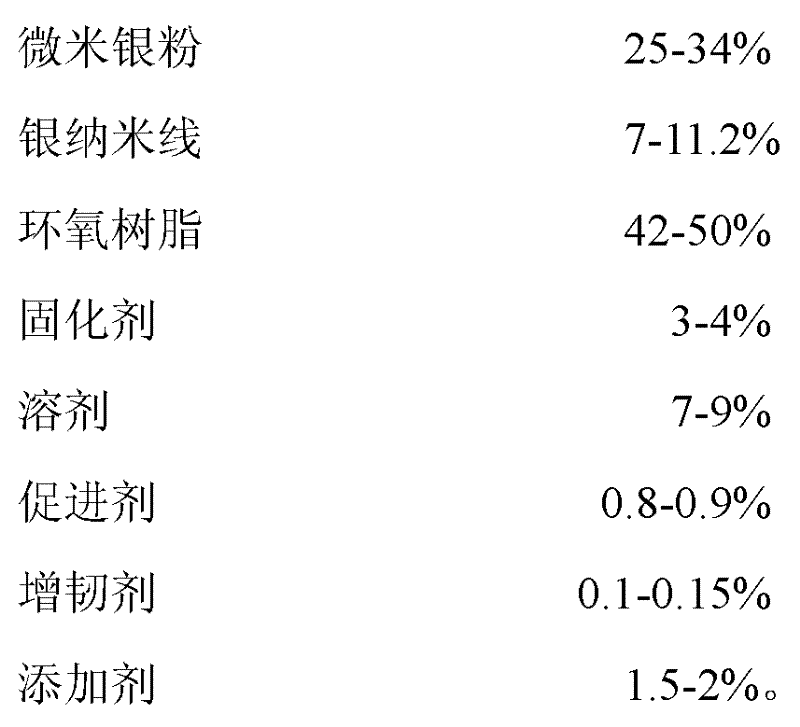

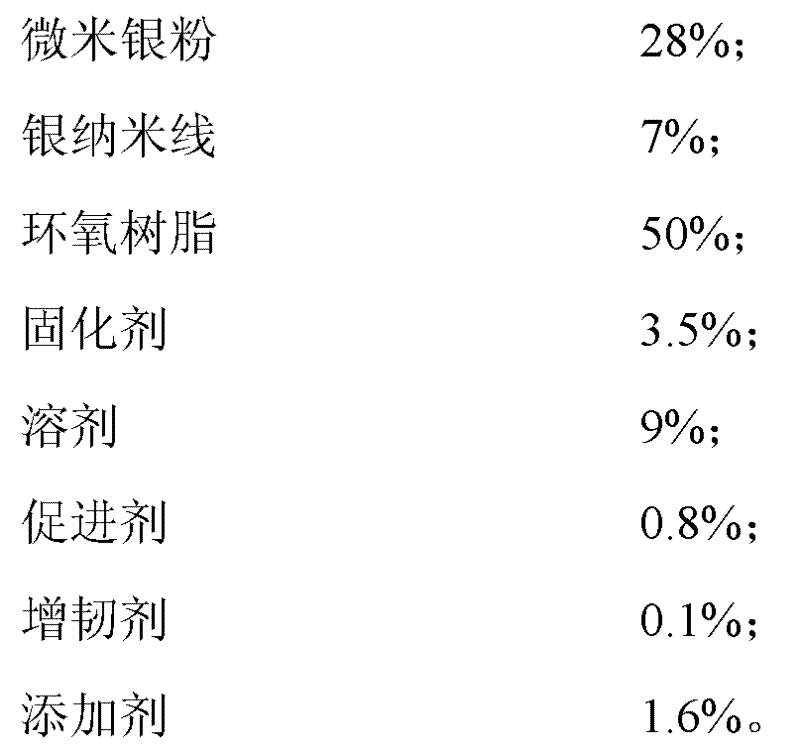

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

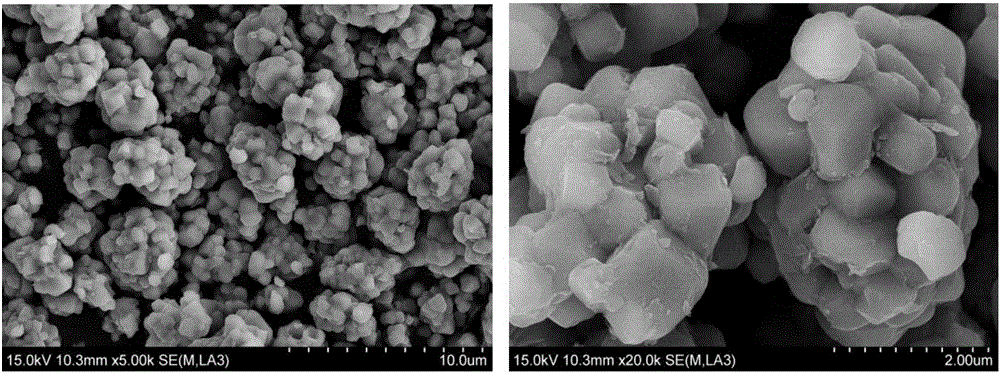

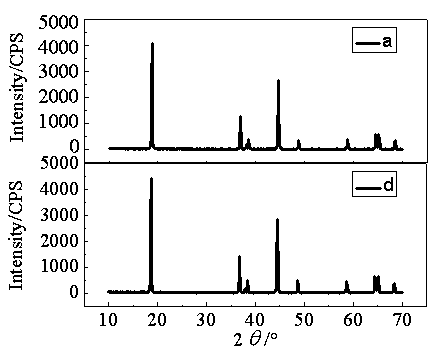

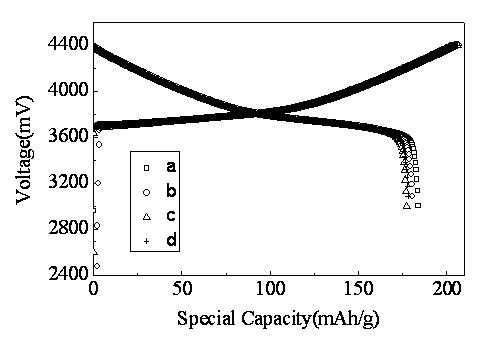

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

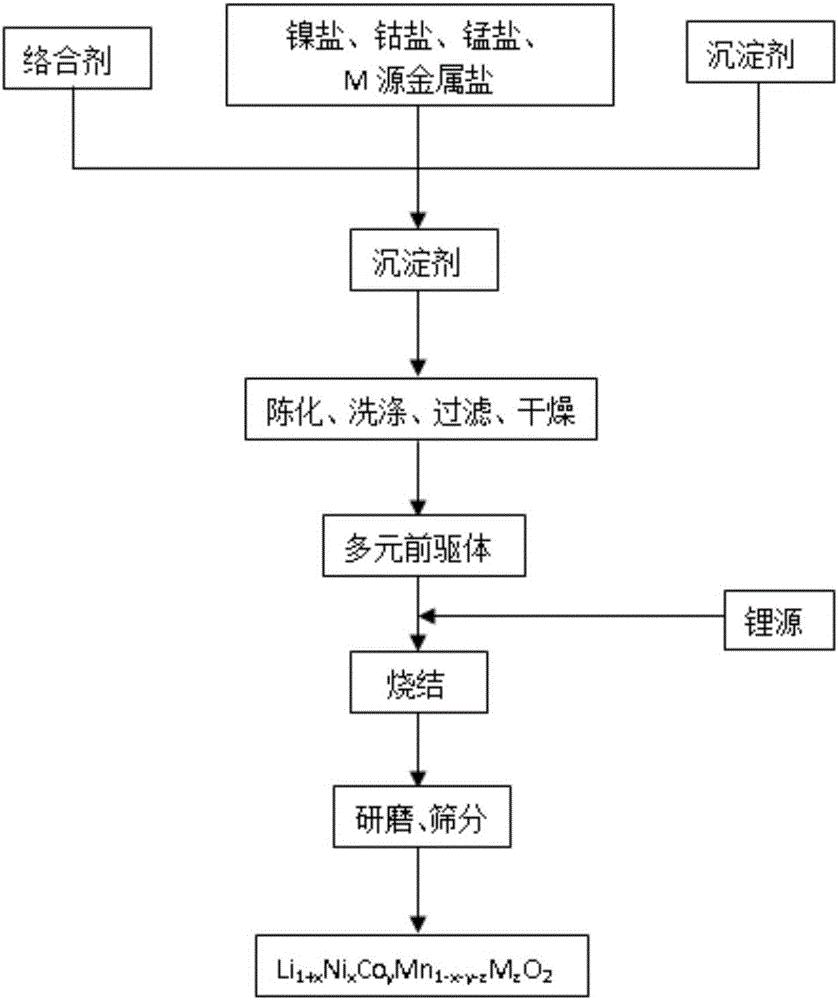

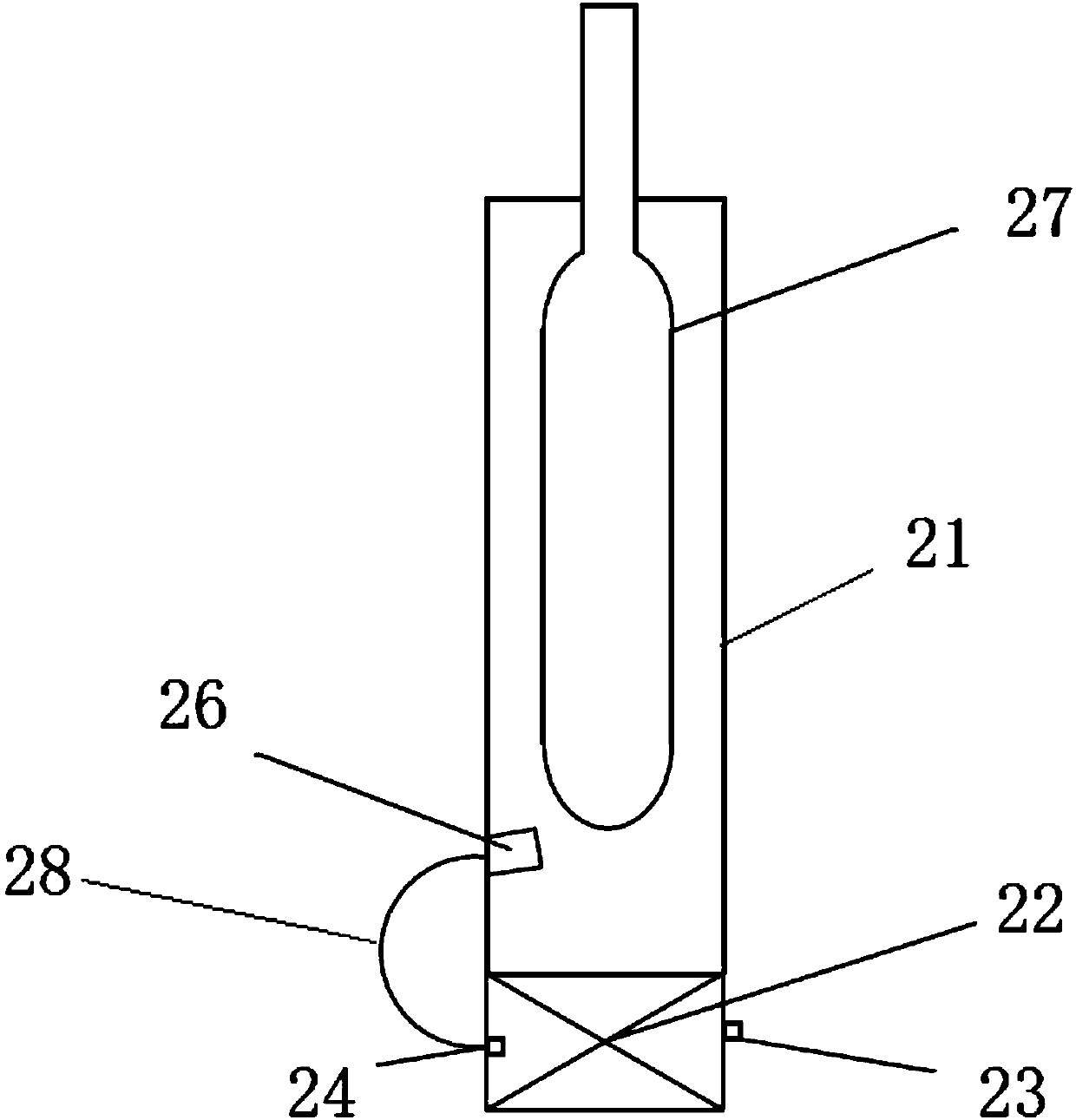

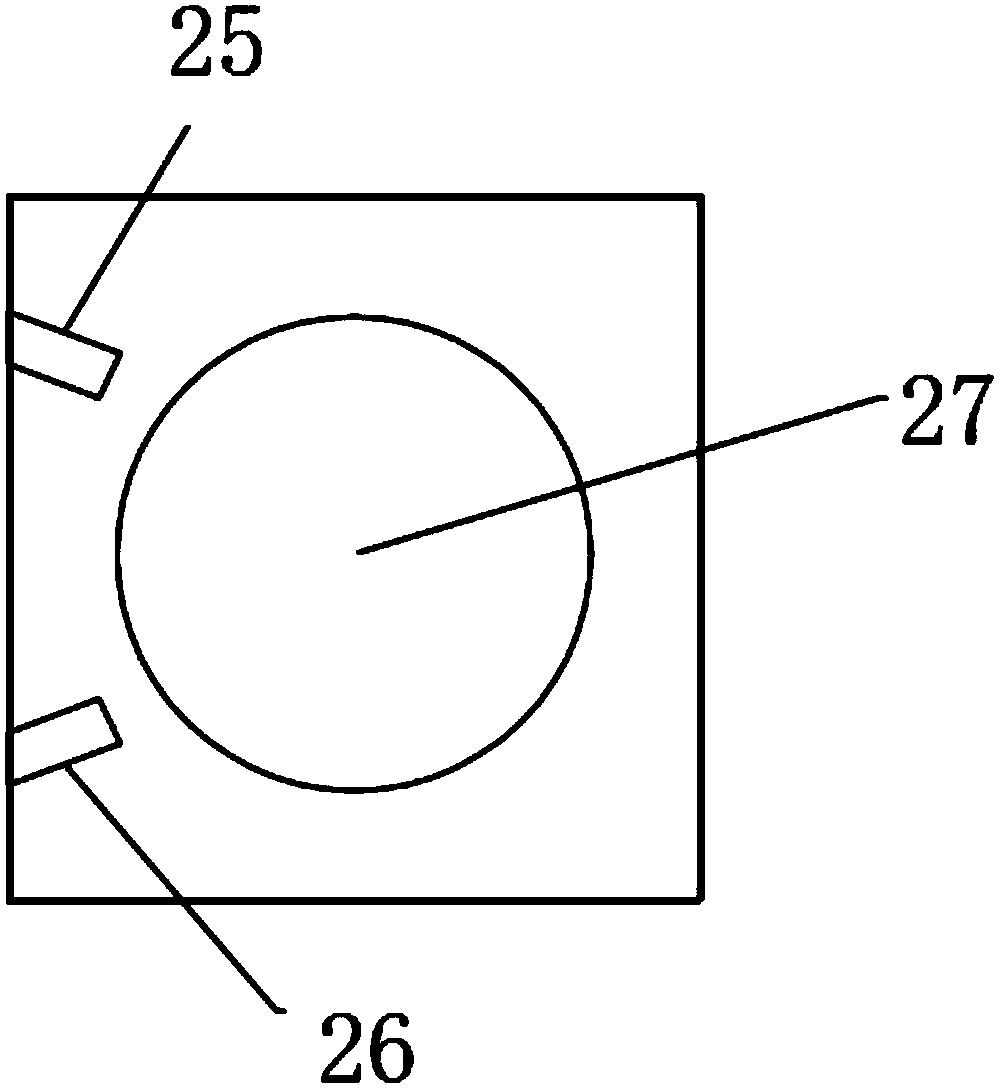

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

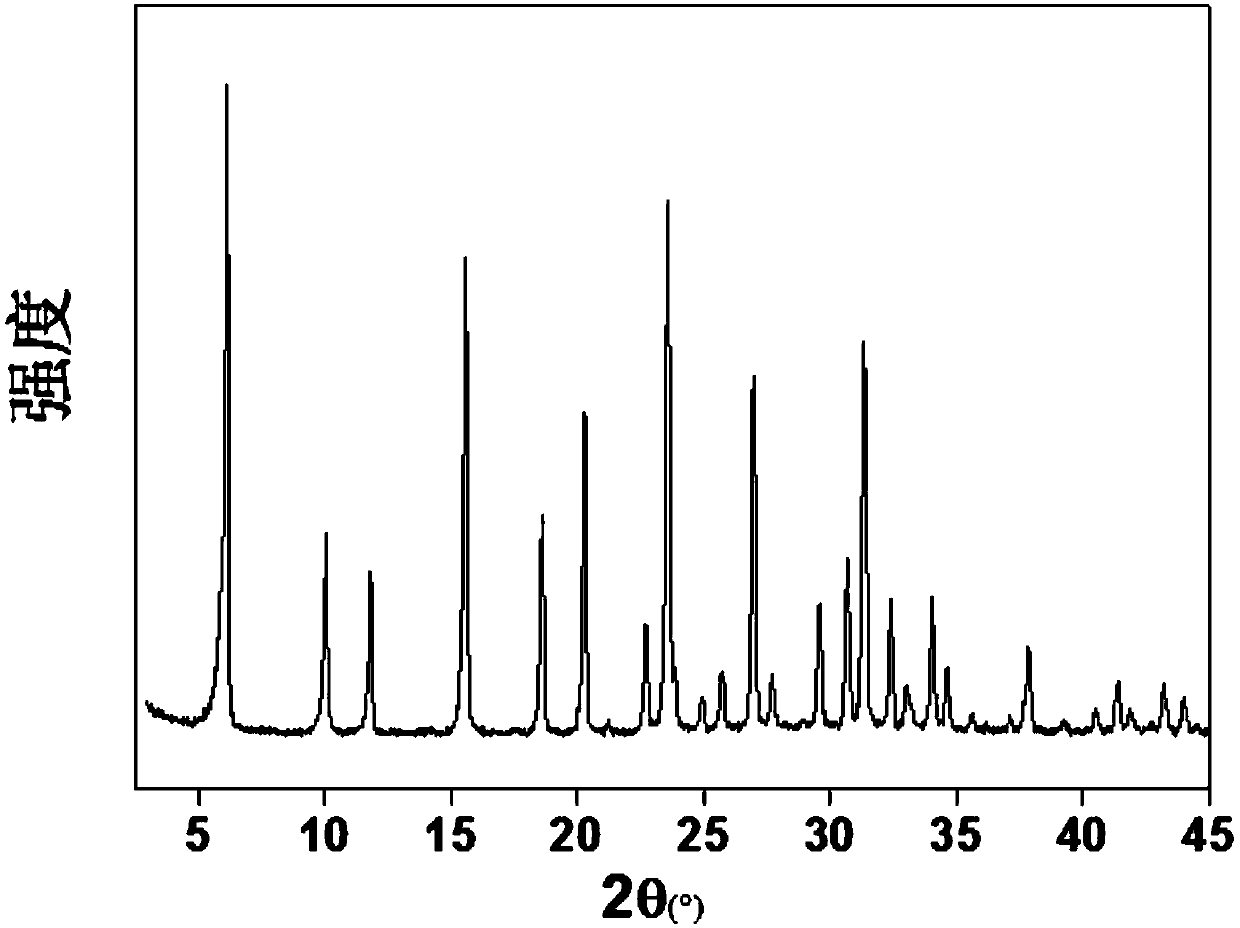

Preparation method of hierarchically porous Y-type molecular sieve

ActiveCN107555446AHarm reductionEmission reductionFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method of a hierarchically porous Y-type molecular sieve. The method comprises the following steps: mixing a silicon source and an aluminium source at 5-60 DEG C,and standing and aging the mixture to prepare seed crystal glue; mixing the silicon source, the seed crystal glue and the aluminium source at 15-70 DEG C, and stirring the mixture to obtain sol; mixing the sol, a co-structure- directing agent and a template agent, stirring the mixture for 0.5-8 h, heating the obtained sol to 90-120 DEG C, crystallizing the sol for 6-72 h, and performing filtering, washing, drying and roasting to obtain the hierarchically porous Y-type molecular sieve. The co-structure directing agent and the template agent adopted in the preparation method are cheap, available and small in dosage and are easily separated from volume phase; the obtained hierarchically porous Y-type molecular sieve is high in relative crystallinity, mesoporous channels are regular, microporous channels and mesoporous channels intersect, and mesoporous diameter distribution is uniform.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

F, Mn codoped deposit nano SnO2 transparent thermal-insulation film

The invention discloses an F, Mn co-doping deposition nano-SnO2 transparent heat insulating thin film, wherein the F, Mn element co-doping effect is utilized to increase the number charge carriers in the thin film material, thus increasing the index of thin film reflection to infrared rays. The invention can prevent the excess doping of one single element, it can be applied to chemical CVD or supersonic spraying thermal dissociation deposition.

Owner:雷智 +1

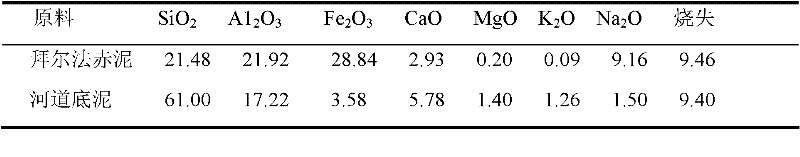

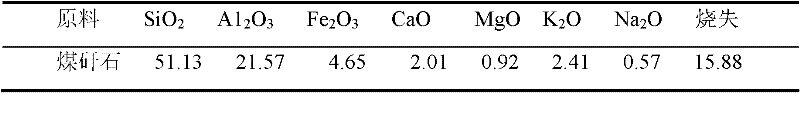

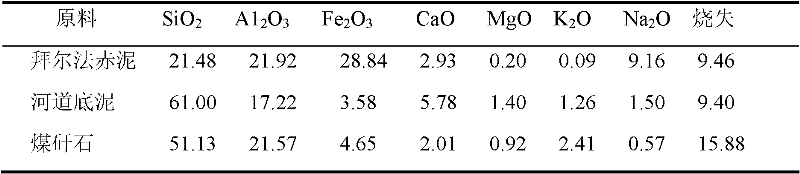

Preparation method of ceramsite filter material for water treatment

The invention provides a preparation method for a ceramsite filter material for water treatment. The method is characterized by comprising the following steps: (1) mixing Bayer red mud powder in aluminum manufacturers in Shangdong province, river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province, gangue powder and a pore forming agent according to a mass ratio of 40-50:40-50:0-5:5-10 to obtain a mixture; (2) putting the mixture into a pan granulator and adding water, the mass of which is 20 to 25% of the mixture, for granulation into spherical particles with phi being 3 to 10 mm; (3) sintering and cooling the spherical particles after drying so as to obtain the ceramsite filter material. According to the invention, Bayer red mud powder in aluminum manufacturers in Shangdong province and river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province are used as the main raw materials and added at an equal or substantially equal amount, and a small amount of the pore forming agent is blended for the preparation of the ceramsite filter material; therefore, low cost is realized, the problem of flood passage capability of rivers is overcome, and environment pollution and land occupation caused by accumulation of Bayer red mud are simultaneously eliminated.

Owner:SHANDONG UNIV OF TECH

Multi-element anode lithium battery material suitable for high voltage and preparation method for material

The invention provides a multi-element anode lithium battery material suitable for high voltage, and a preparation method for the material. The multi-element anode lithium battery material has the feature of a single-particle structure, and the particle size distribution is within the range of 0.5-15 mum; the chemical formula of the nickel-cobalt-manganese multi-element lithium battery anode material with composite doping elements is LiNiXCoyMnzMaNbO2, wherein the value range of x, y and z is that: x is not smaller than 0.2 and not larger than 0.9, y is not smaller than 0 and not larger than 0.4, z is not smaller than 0.1 and not larger than 0.5, 1-x-y-z equals to a+b, is larger than 0, and is not larger than 0.05, M is any one selected from titanium, aluminum, ferrum, vanadium, silicium, fluorine, lanthanide and actinide elements, and N is any one selected from calcium, magnesium, aluminum, zirconium, ferrum and titanium. Based on the preparation of the single-particle multi-element lithium battery anode material, the method of compositing specific doping elements is adopted, the structural stability under high voltage charge and discharge is improved and the cycle performance of the material is effectively improved without changing the electrochemical performance of the material.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

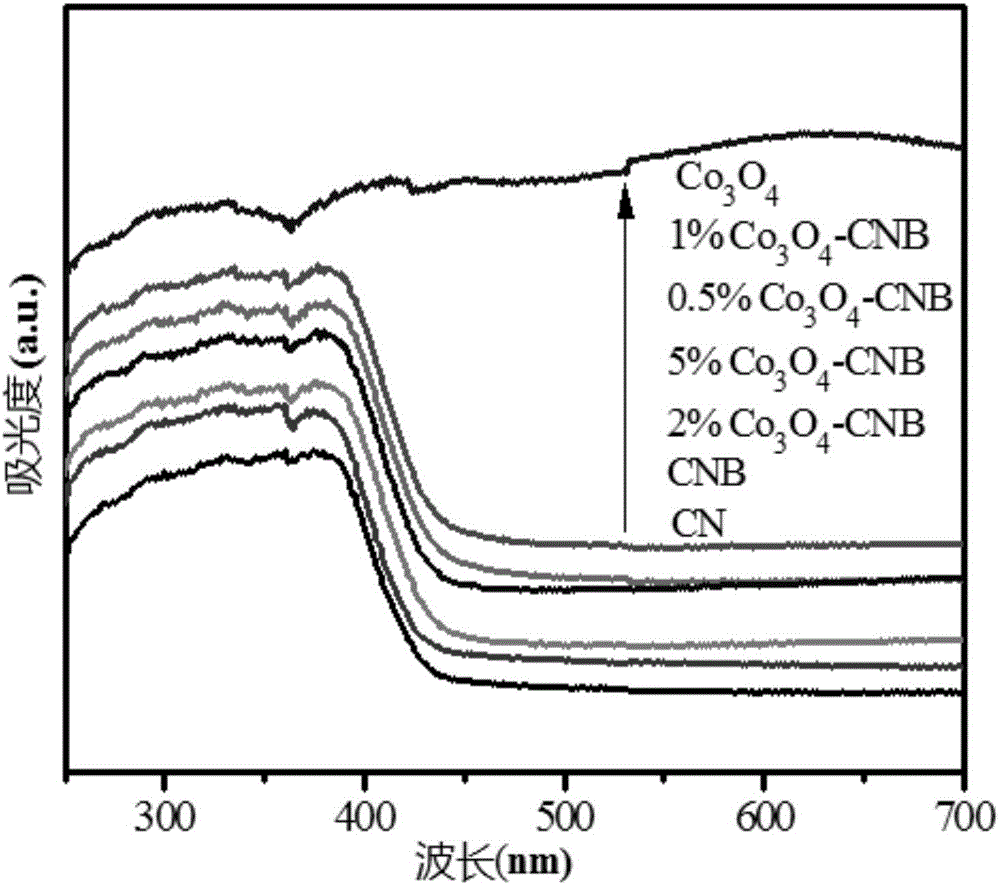

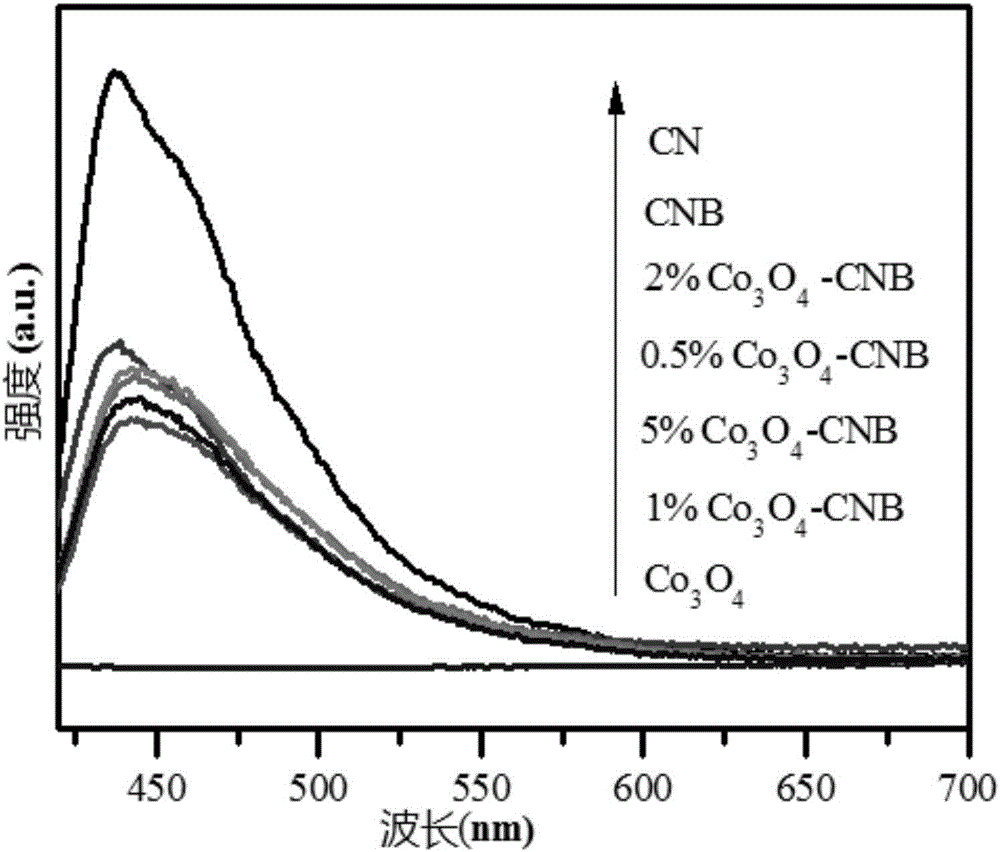

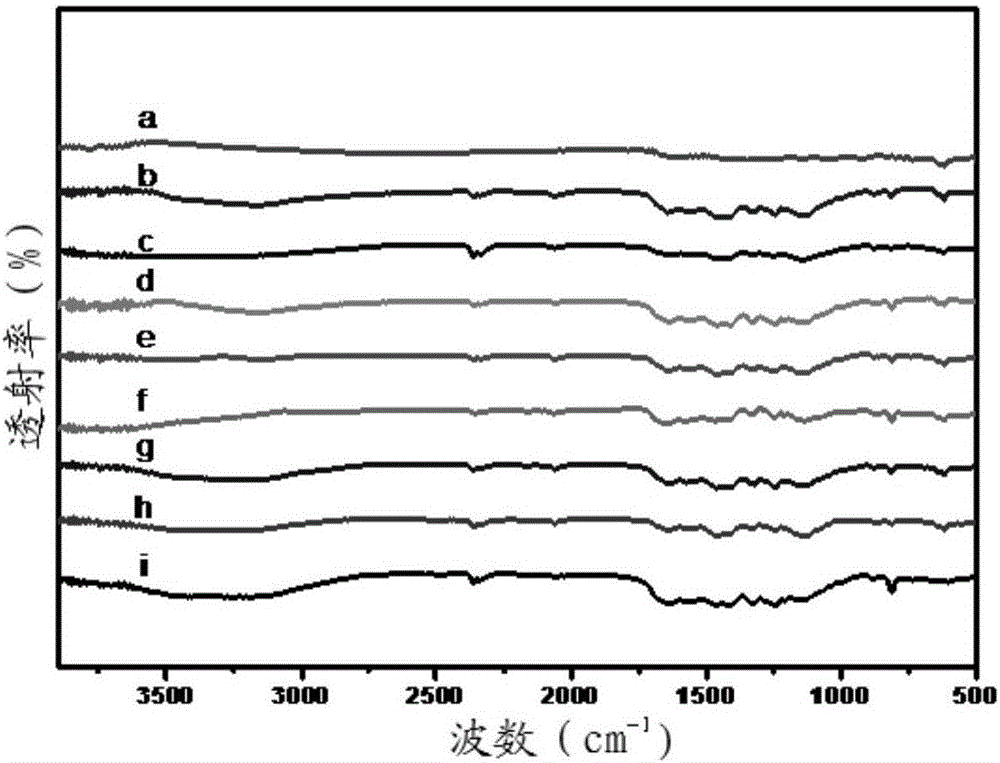

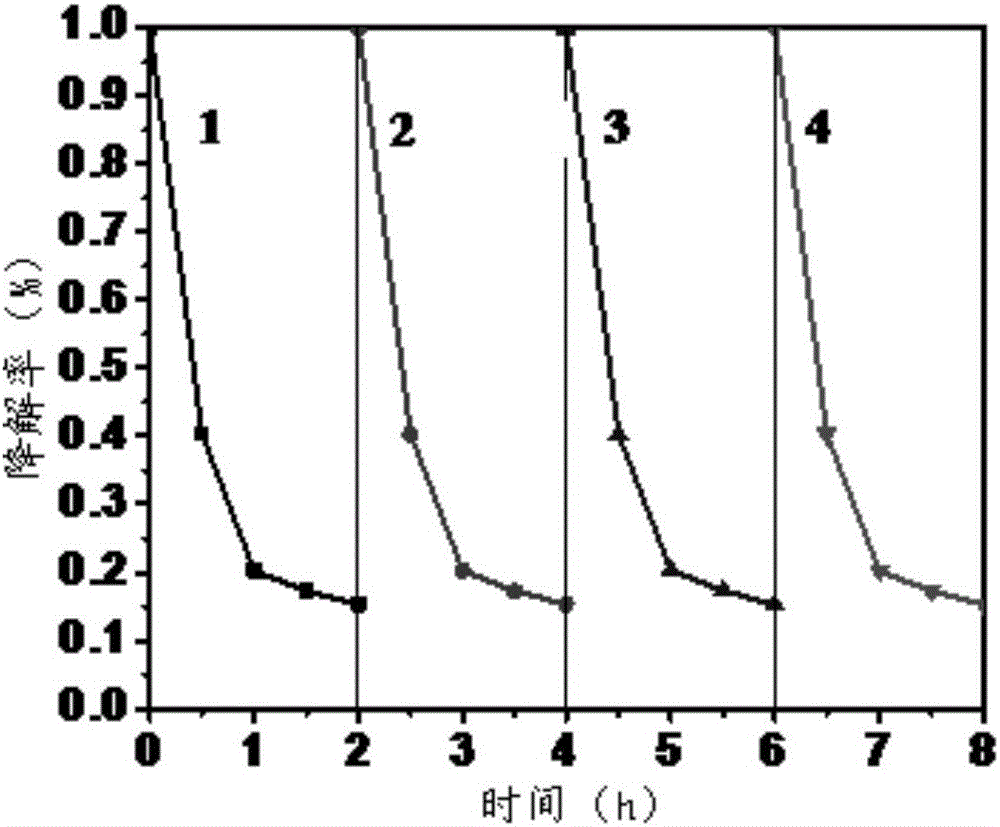

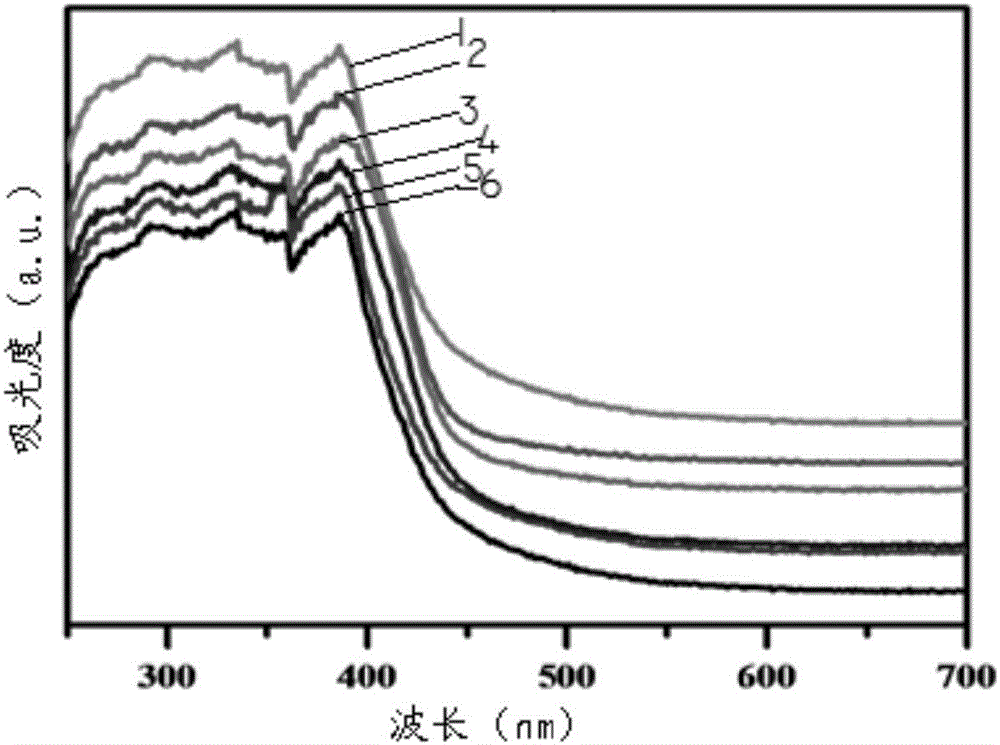

Transition metal oxide composite CNB photocatalyst and preparation method thereof

InactiveCN106540734ALess adulteratedLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeUltraviolet lights

The invention provides a transition metal oxide composite CNB photocatalyst. The photocatalyst is formed by compositing CNB and a transition metal oxide with carbon, has good photocatalytic degradation effect on organic dyes, especially azo dyes or anthraquinone dyes, under ultraviolet light, and has the degradation rate on methyl orange reaching more than or equal to 75% especially after being radiated in the ultraviolet light for 1 h. The invention also provides a preparation method for the photocatalyst; the method comprises the steps of preparing CNB by doping a boron element in graphite-phase carbon nitride and then composting the CNB with the transition metal oxide, to prepare the composite photocatalyst; the method is simple and feasible to implement; the yield of preparation of the photocatalyst is high.

Owner:FUYANG NORMAL UNIVERSITY

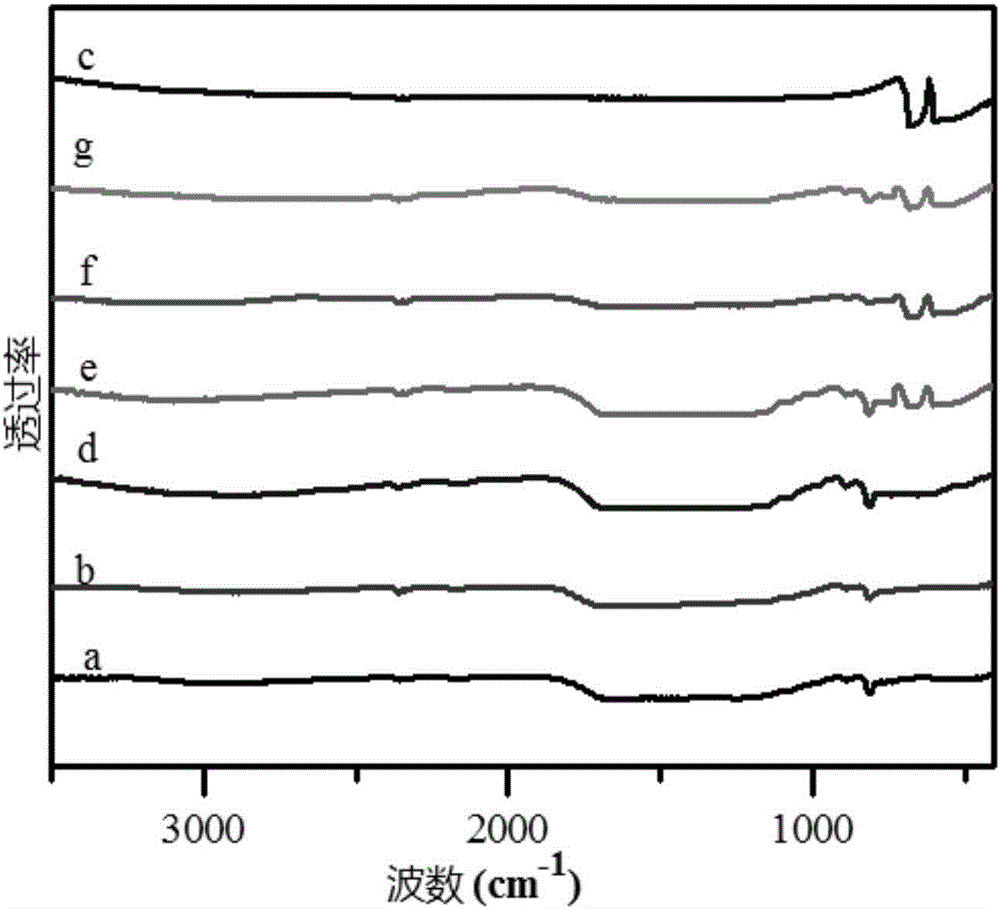

PBI-based polysiloxane and phosphonic acid high-temperature proton exchange film and preparation method thereof

InactiveCN104485467AReduce exudationLess adulteratedSolid electrolyte fuel cellsFuel cell detailsPolymer scienceFuel cells

The invention belongs to the technical field of fuel batteries, and relates to a PBI-based polysiloxane and phosphonic acid high-temperature proton exchange film and a preparation method thereof. The PBI-based polysiloxane and phosphonic acid high-temperature proton exchange film disclosed by the invention is prepared through the following method: dispersing polysiloxane and phosphonic acid in dimethylacetamide, and preparing to obtain a polysiloxane and phosphonic acid gel; then dissolving PBI in dimethylacetamide to obtain PBI polymer solution; then uniformly mixing the polysiloxane and phosphonic acid gel with the PBI polymer solution, then preparing by a tape-casting film-forming technique to obtain the PBI-based polysiloxane and phosphonic acid high-temperature proton exchange film. The doping amount of phosphonic acid is low and phosphonic acid is not liable to exude when the high-temperature proton exchange film prepared by the preparation method disclosed by the invention achieves a certain proton conductivity, and the high-temperature proton exchange film has a high proton conductivity under a high-temperature and low-humidity condition; moreover, the medium-temperature proton exchange film is good in flexibility, high in mechanical strength, and good in durability in a high-temperature fuel battery.

Owner:WUHAN UNIV OF TECH

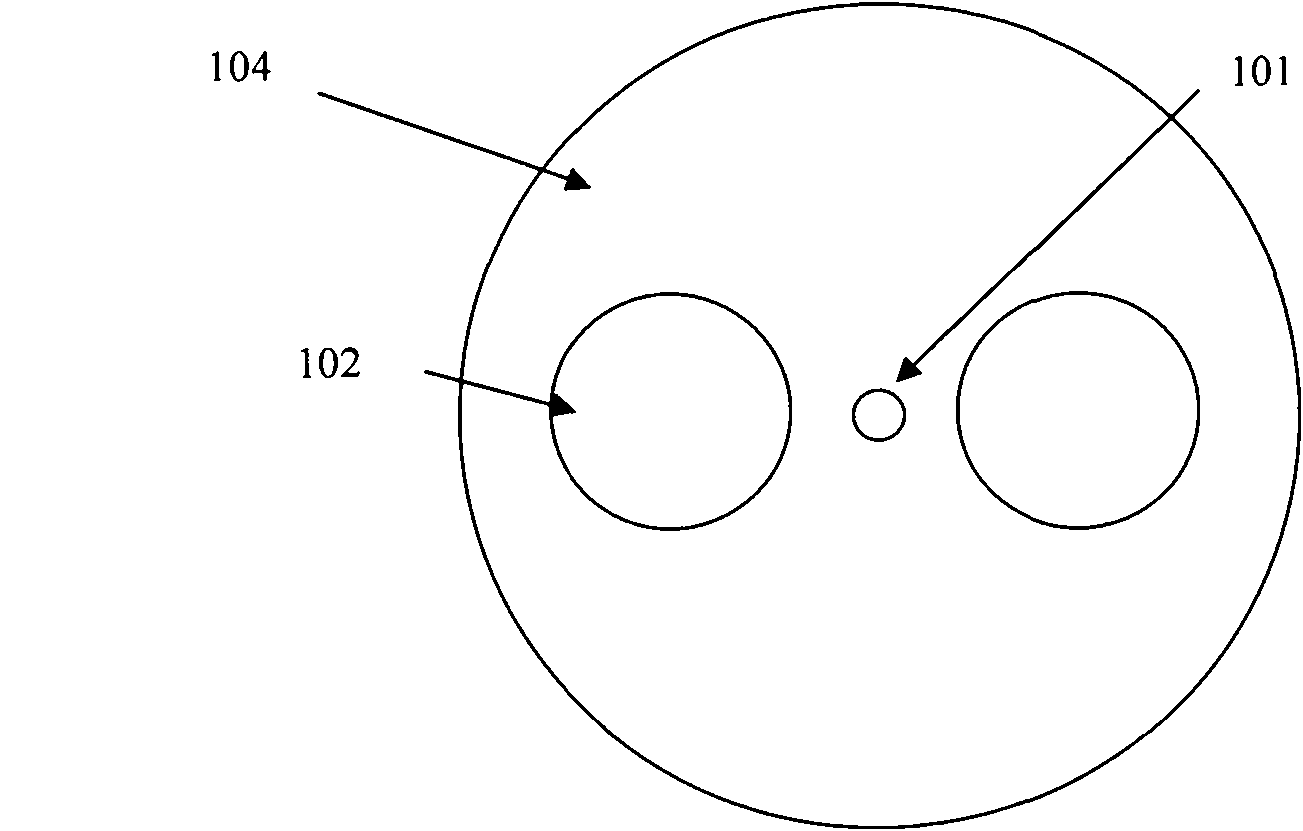

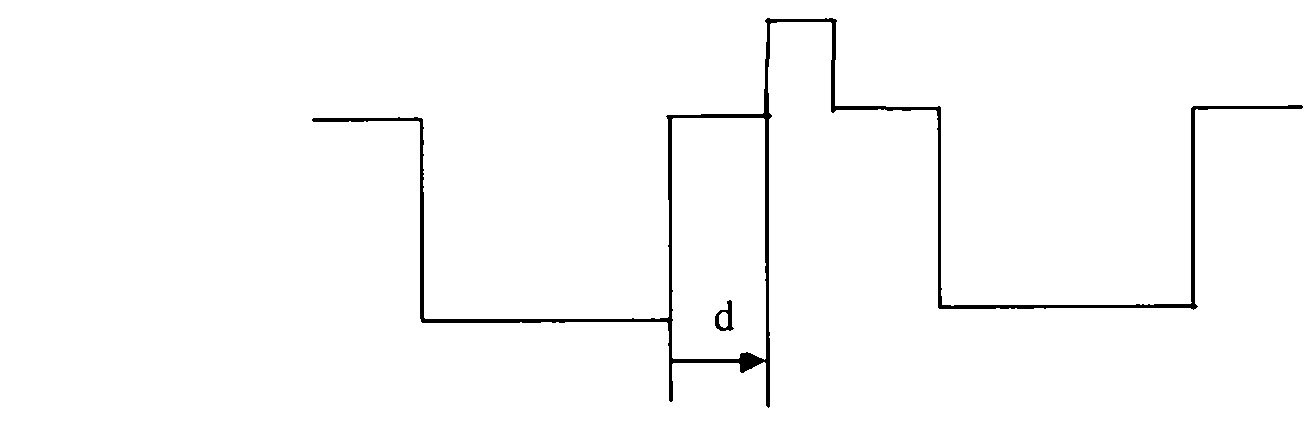

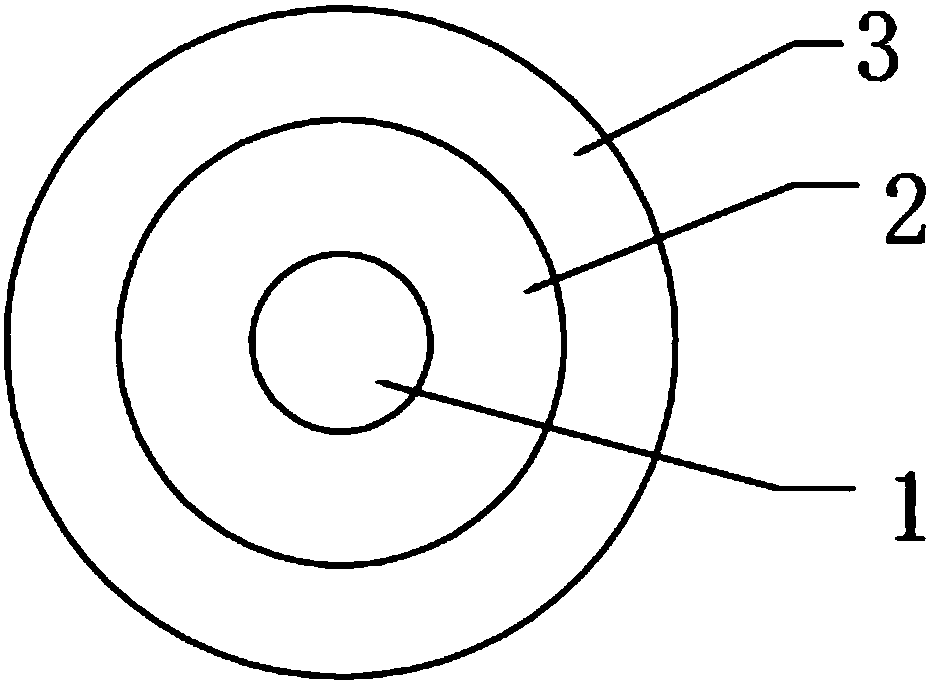

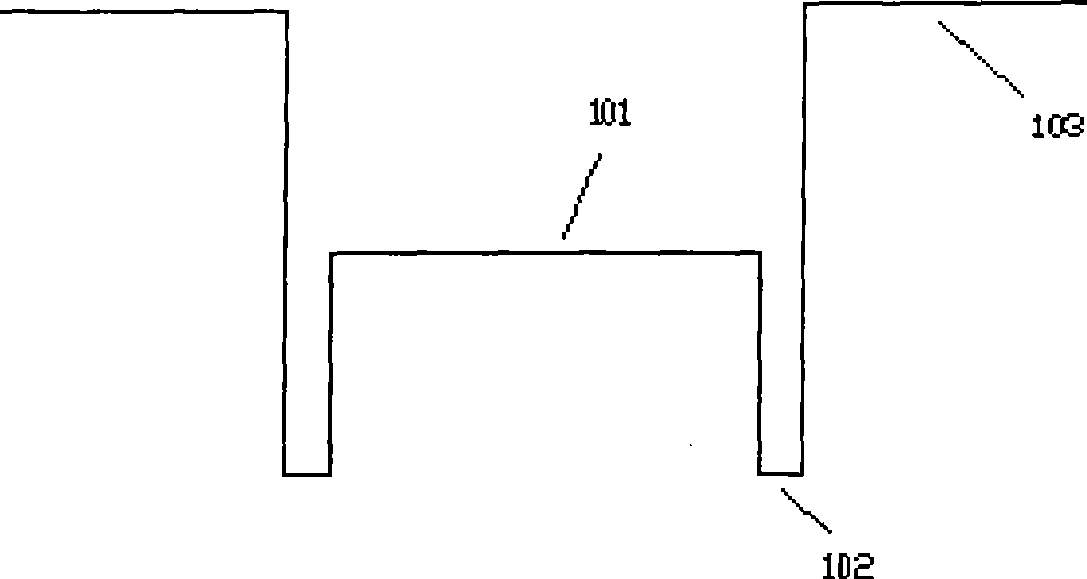

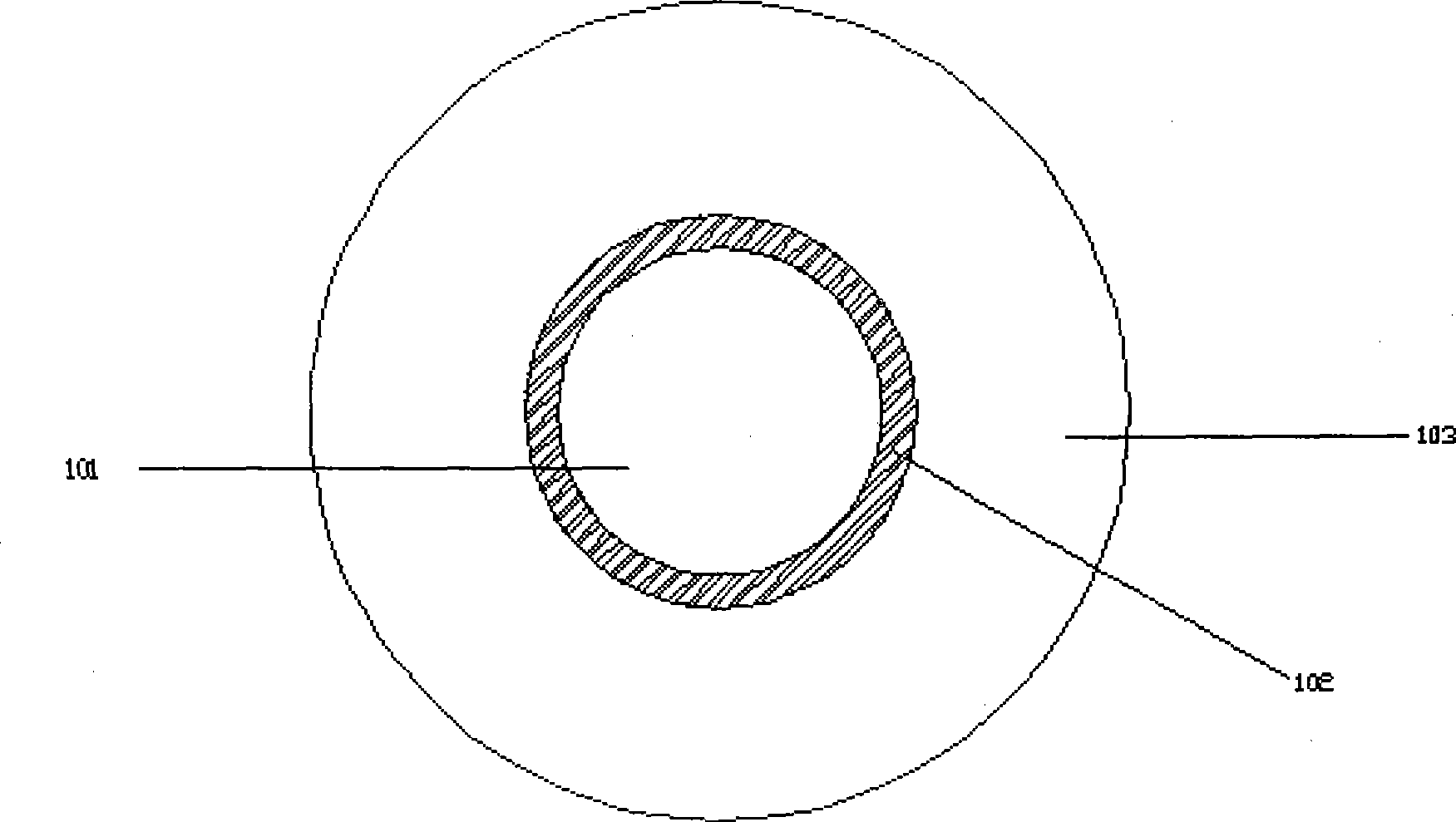

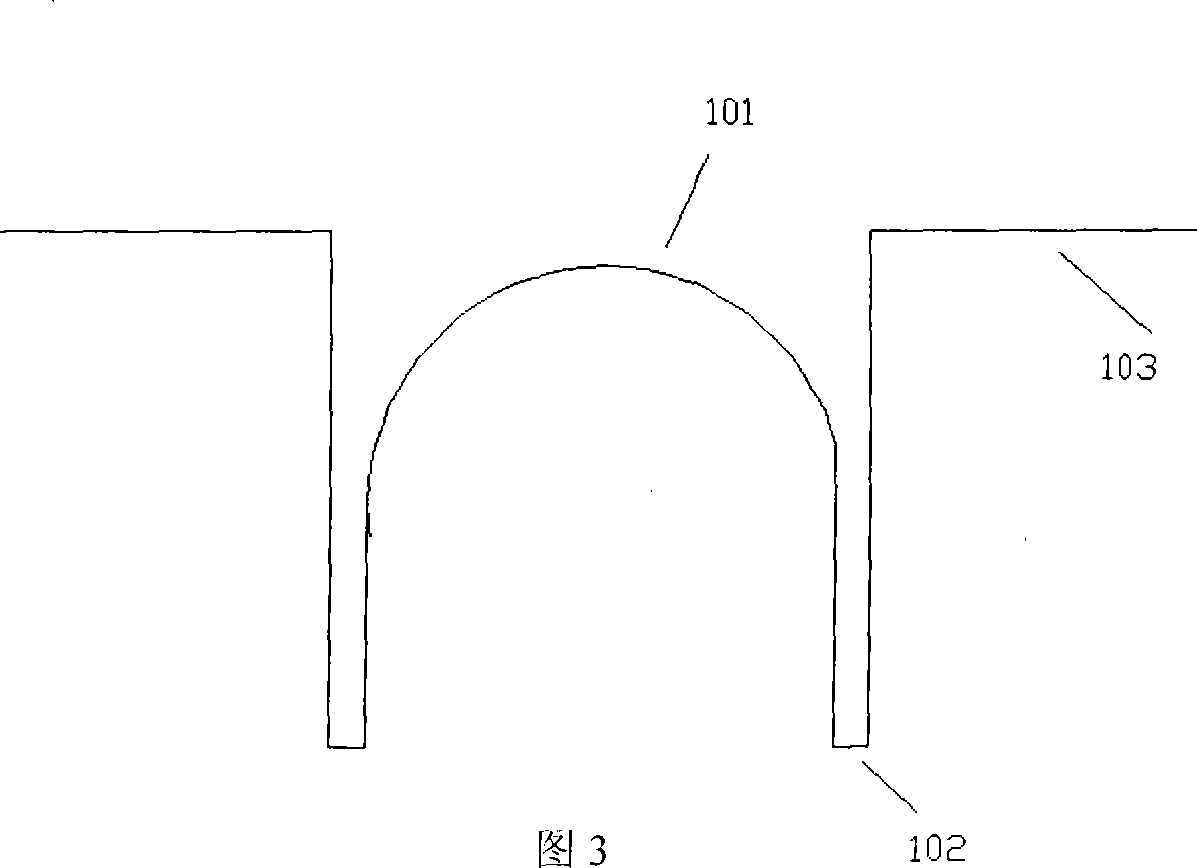

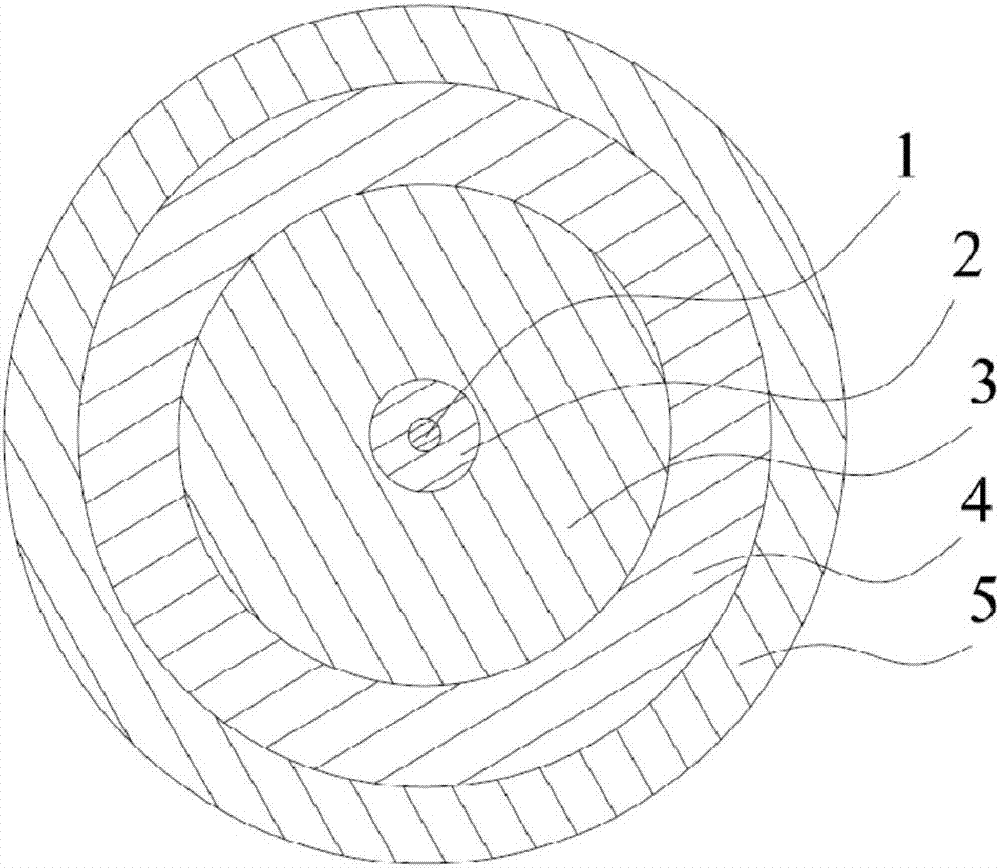

Panda type polarization maintaining optical fiber

ActiveCN101825738AIncrease stressLess adulteratedOptical fibre with polarisationOptical fibre with multilayer core/claddingStress concentrationPunching

The invention relates to a panda type polarization maintaining optical fiber for use in the field of optical fiber guidance and sensing, which comprises a core layer and a pure quartz cladding, wherein stress zones are symmetrically arranged at the two sides of the core layer in the pure quartz cladding. The panda type polarization maintaining optical fiber is characterized in that a depressed inner cladding is arranged outside the core layer, and the space between the boundaries of the stress zones and the boundary of the core layer is reduced, so that the space d between the boundaries of the stress zones and the boundary of the core layer keeps 3-7mu m. The birefringent property of the panda type polarization maintaining optical fiber can be improved by the invention to meet the performance requirements of a high-precision gyro, and the introduction of the depressed inner cladding can effectively reduce the burst probability of the prefabricated core layer in the process of punching in the stress zones under the condition of not increasing the difficulty of process preparation; the depressed inner cladding adopts viscosity doping and matching design, and further reduces the burst probability of the prefabricated core layer caused by the external mechanical stress in the process of punching in the stress zones; and one side of the stress zones and the depressed inner cladding have an overlapped region so as to prevent the mechanical stress from acting on an intrinsic boundary stress concentration point.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

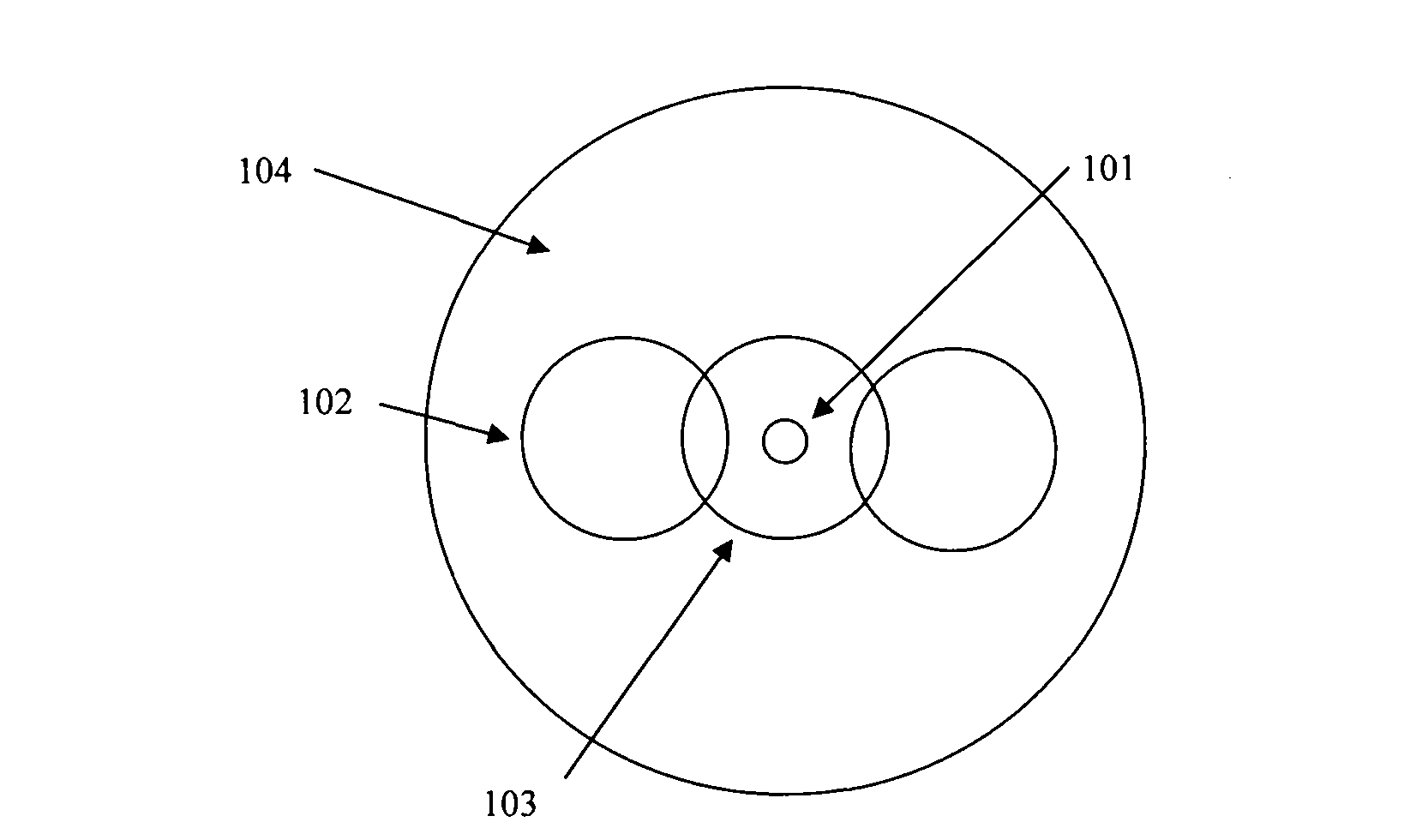

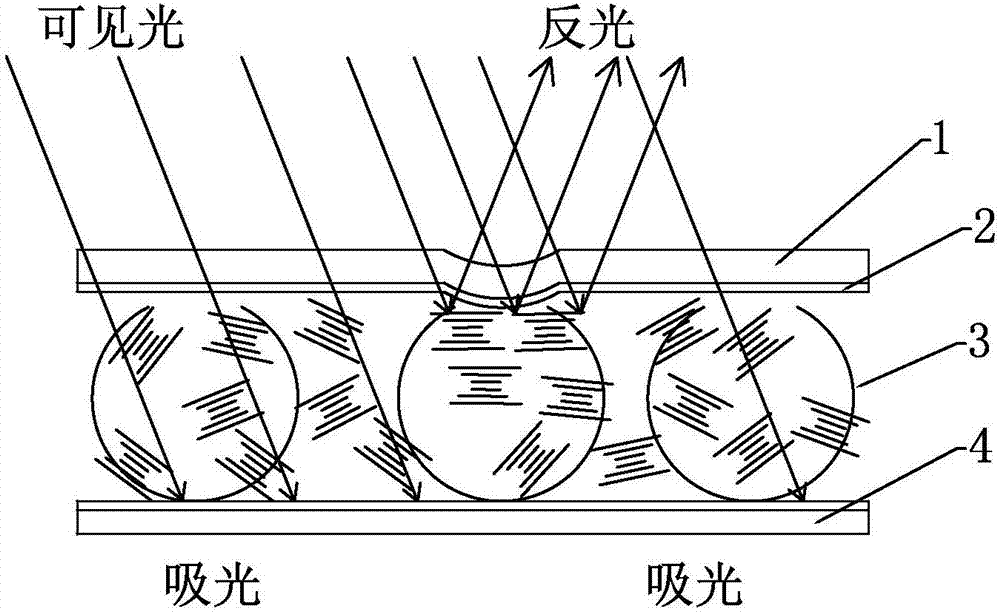

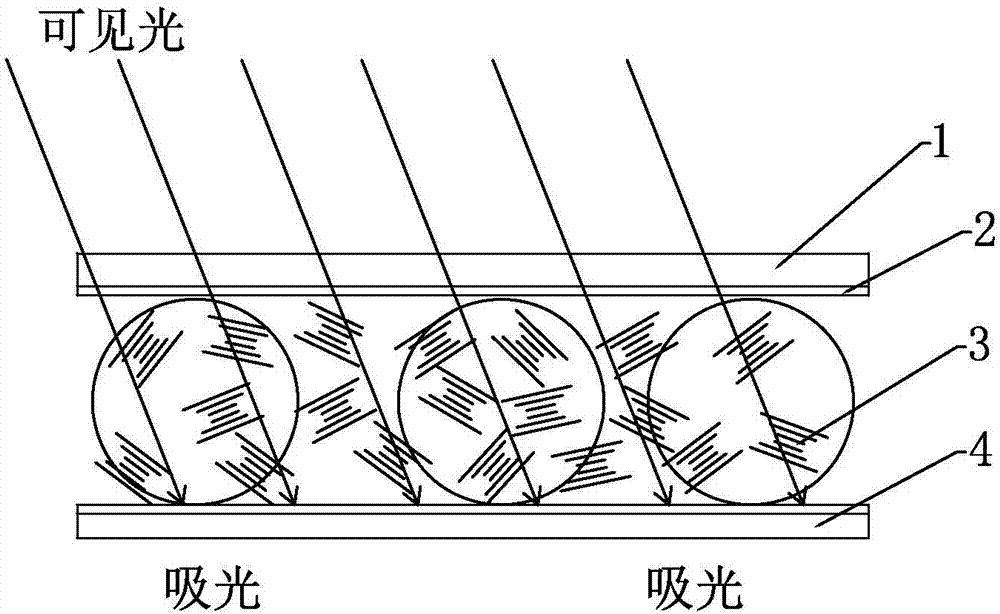

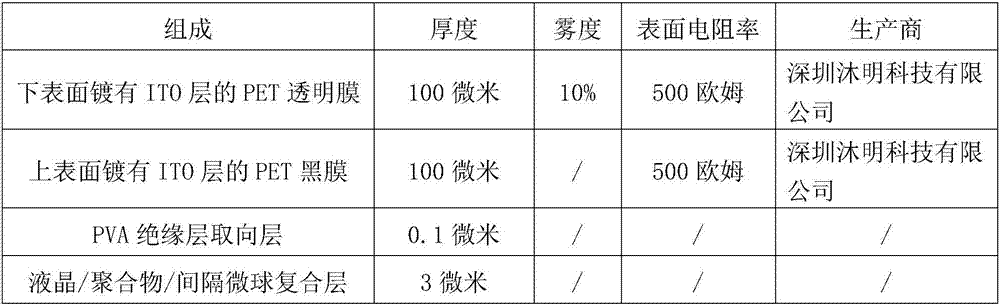

Liquid crystal composite film with writing display function and preparation method thereof

ActiveCN107300818ABig advantageIncrease frictionNon-linear opticsComposite filmLiquid-crystal display

The invention belongs to the field of liquid crystal display and particularly discloses a liquid crystal composite film with a writing display function and a preparation method thereof. The liquid crystal composite film with the writing display function comprises a PET transparent film, a PVA insulating orientation layer, a liquid crystal / polymer / interval microsphere composite layer and a PET black film sequentially from top to bottom. The lower surface of the PET transparent film is coated with an ITO layer, and the upper surface of the PET black film is coated with an ITO layer. The liquid crystal composite film with the writing display function and the preparation method thereof have advantages that due to addition of the PVA insulating orientation layer, short circuit risks of two conductive layers are avoided, and accordingly the rate of finished products is sharply increased, service lives of the products are greatly prolonged, production cost is reduced, and the driving voltage of the liquid crystal film is lowered to increase key technical indexes such as brightness and contrast ratio of the film.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP +1

Pholocatalyst for metallic oxide doping and preparation method thereof

InactiveCN106492870ALess adulteratedLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationMethyl orangeOxide

The invention provides a pholocatalystfor metallic oxide doping and a preparation method of the pholocatalyst. The method comprises the steps of doping non-metal elements in g-C3N4 to form the g-C<3>N<4> doped with non-metal elements, doping metallic oxide especially the second transition metallic oxide to obtain the codope g-C3N4 pholocatalyst. The pholocatalyst possesses an obviously enhanced degradation rate of azo dyes under visible spectrum. As an example, helianthin B is under degradation in ultraviolet with the help of the pholocatalyst, and one hour later the degradation rate can reach over 80%.

Owner:FUYANG NORMAL UNIVERSITY

Preparation of ultra-low loss optical fiber preform rod and optical fibers by axial vapor deposition method

InactiveCN107721149ALow viscosityReduce internal stressGlass making apparatusOptical fibre with multilayer core/claddingFiberUltrasound attenuation

The invention discloses ultra-low loss optical fibers. Alkali metal elements are added during the VAD deposition technological process to reduce the viscosity of a core layer, enable the core layer tobe more matched with an inner cladding layer and an outer cladding layer, and reduce the internal stress, so that the ultra-low loss fibers with low transmission attenuation can be manufactured. A preparation method of the ultra-low loss optical fibers, disclosed by the invention, is based on the traditional VAD deposition process. A small amount of alkali metal is doped in the deposition process, and the doping amount is small and the gas flow rate is small, so that the normal deposition process is not affected too much, and doping is finished while depositing, and therefore, the productioncycle is prolonged, and then the production stability can be ensured, the production process is not complex, and the preparation method can be used in large-scale production. By the adoption of the invention, optical fiber attenuation can be optimized to ultra-low loss standards, and relay stations can be reduced in high speed transmission with long distance and low attenuation to lower the cost and improve the transmission quality.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

Cathode material for lithium ion battery and preparation method thereof, cathode and lithium ion battery

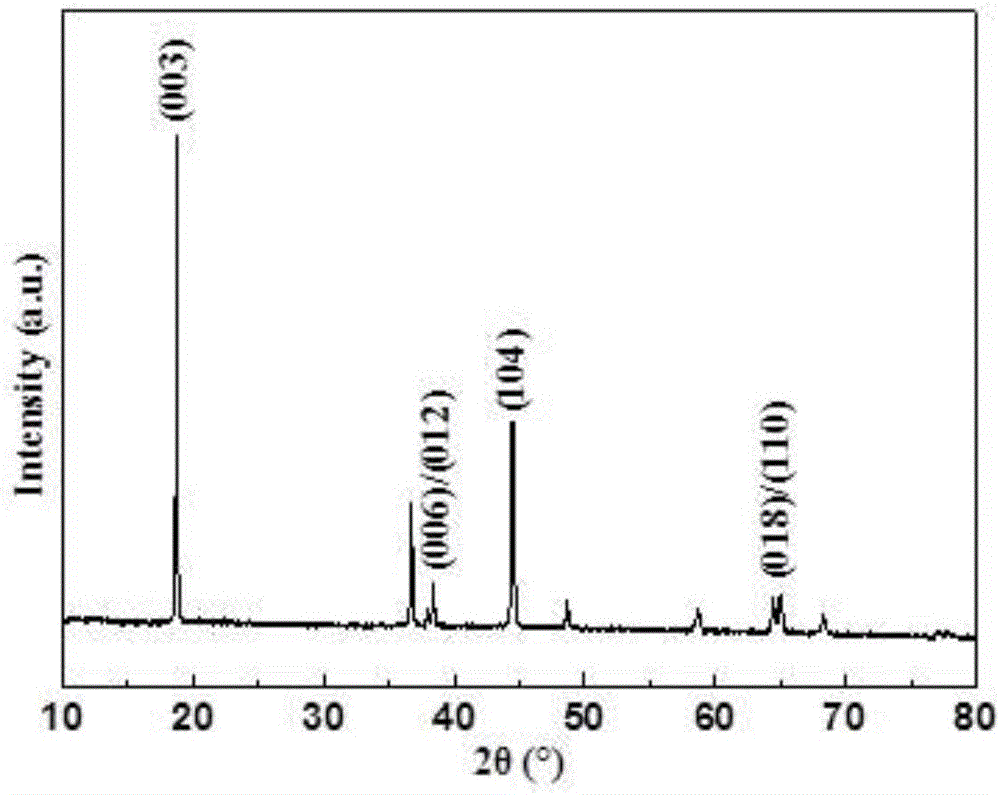

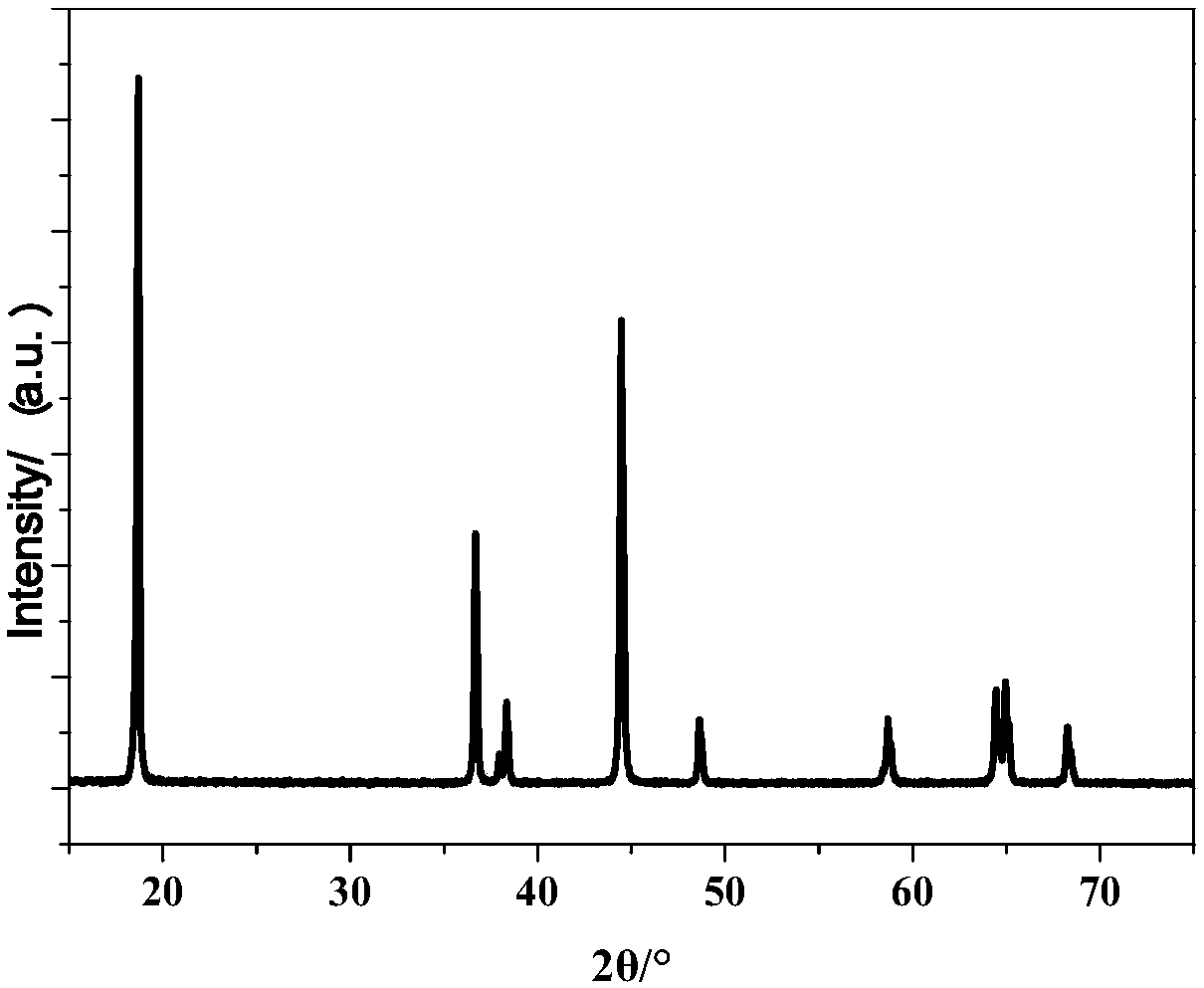

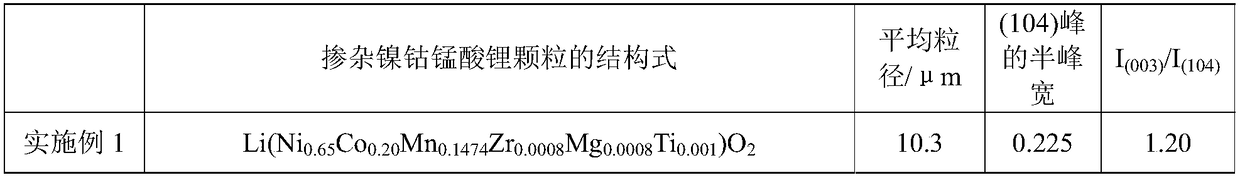

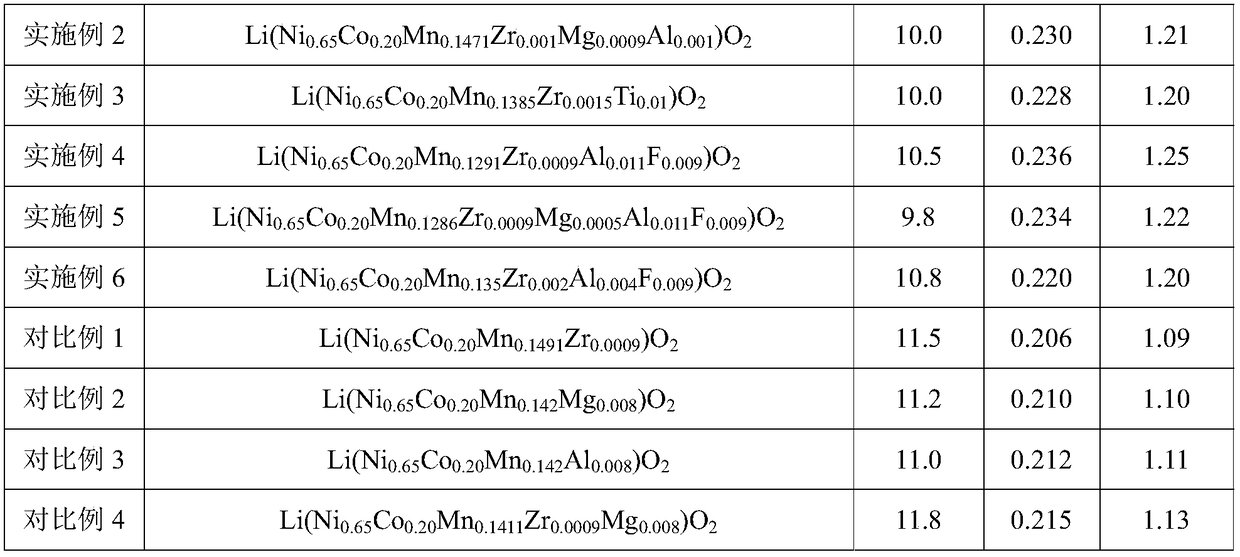

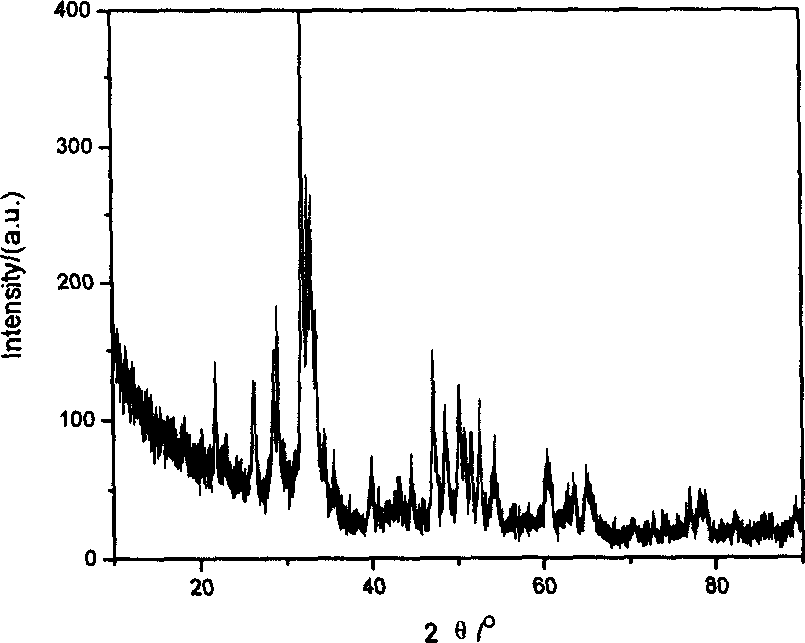

ActiveCN109244365AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsFull width at half maximumManganate

The invention relates to a lithium ion battery cathode material and a preparation method thereof, a cathode and a lithium ion battery. The cathode material comprises doped lithium nickel cobalt manganate particles, wherein the structural formula of the doped lithium nickel cobalt manganate particles is Li (NixCoyMn1-x-y-p-qM1pM2q)O2, M1 is a metal element comprising Zr and / or Mg, M2 is Al, Ti, La,B, F or Mo, or a combination of two or three or four of them, wherein 0.6<=x<=0.8, 0.1<=y<= 0.2, 0.0006<=p<= 0.0018, 0.0055<=q<=0.013; The ratio of the peak intensity I (003) of the peak (003) and the peak intensity I (104) of the peak (104) of the XRD spectrum of the doped nickel cobalt manganate lithium particles is 1.20<=I (003) / I (104)<= 1.30; The (104) diffraction peak of the doped lithium nickel cobalt manganate particles has a full width at half maximum of 0.22 to 0.25. The cathode material of the lithium ion battery disclosed by the invention has high specific capacity, and also improves the rate performance, cycle performance and safety performance of the cathode material. The method disclosed by the invention has the advantages of small doping amount, simple operation, easy control and low production cost, and is suitable for industrial large-scale production.

Owner:WANHUA CHEM GRP CO LTD

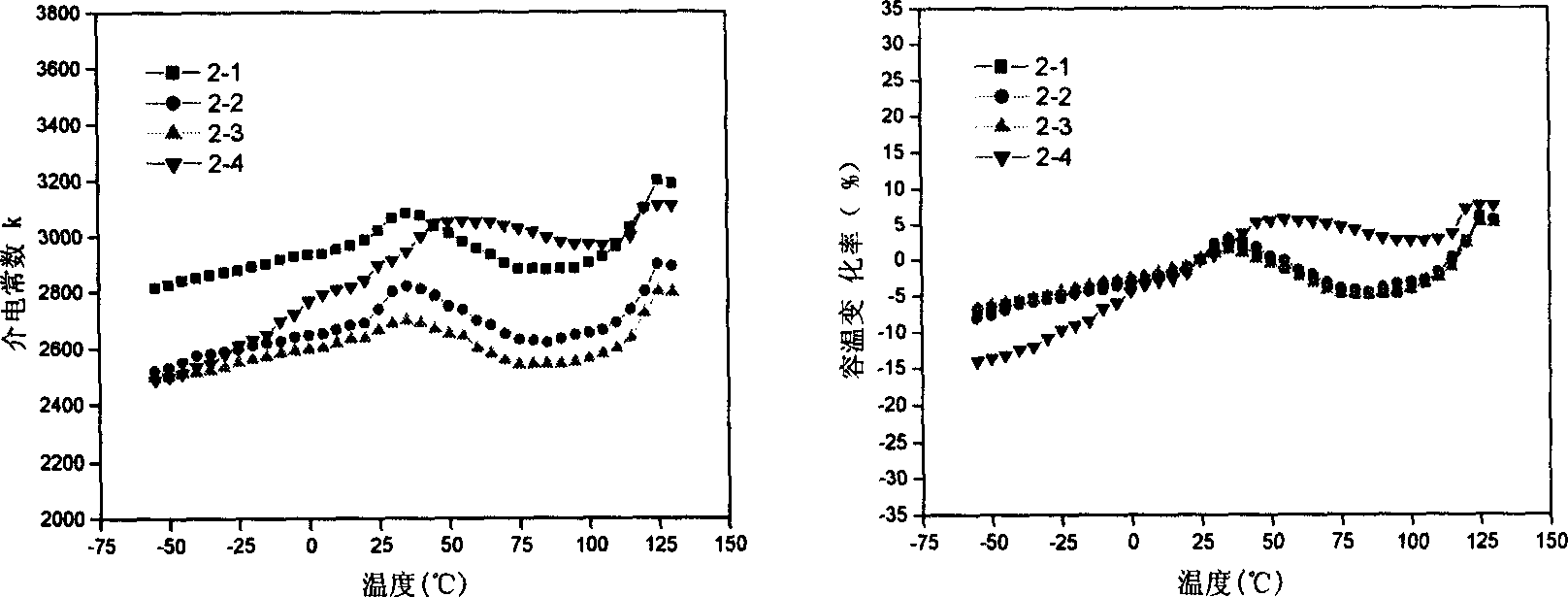

Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

InactiveCN1854105APromote lowerMeet miniaturizationFixed capacitor dielectricPiezoelectric/electrostrictive/magnetostrictive devicesDopantCeramic capacitor

A nanometer ceramic material dopant, medium material of ceramic capacitor and their production are disclosed. The formula of the dopant consists of aA.bB.cC.dR2 O3.eSiO2; A contains Na2O; B contains one or multiple of MgO and CaO; C contains one or multiple of MnO2 and Co3O4; R contains one of multiple of Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, among them a, b, c, d and e are coefficient, by computing mol%, 0<=a<=10%, 0<=b<=25%, 0<=c<=15%, 20%<=d<=60%, 10%<=e<=50% and b and c can't be zero at same time. Its advantages include large capacity, adjustable material formula, low sintering temperature, less medium loss, high dielectric constant and better reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Catalyst for catalyzing methane dry-reforming reaction as well as preparation method and application of catalyst

InactiveCN107282086AImprove stabilityEfficient preparationHydrogenMolecular sieve catalystsSyngasGas phase

The invention belongs to the field of chemical engineering and catalyst preparation and relates to a catalyst for catalyzing a methane dry-reforming reaction as well as a preparation method and an application of the catalyst. The catalyst for catalyzing the methane dry-reforming reaction adopts oxide as a carrier C to carry metals A and B with an impregnation method and a redox replacement method, and a B-A / C catalyst is obtained. The invention further provides the preparation method and the application of the catalyst for catalyzing the methane dry-reforming reaction. The B-A / C catalyst performs reforming catalysis for CH4 and CO2 in a gas phase, and synthesis gas of H2 and CO is produced. The B-A / C catalyst prepared with the impregnation-replacement method shows an obvious effect on catalysis of the methane dry-reforming reaction, the obtained H2 / CO content is higher than 80%, and the yield of hydrocarbon in a follow-up Fischer-Tropsch reaction is increased; the conversion rate of a reactant is increased and the stability of the catalyst is enhanced.

Owner:NANJING UNIV

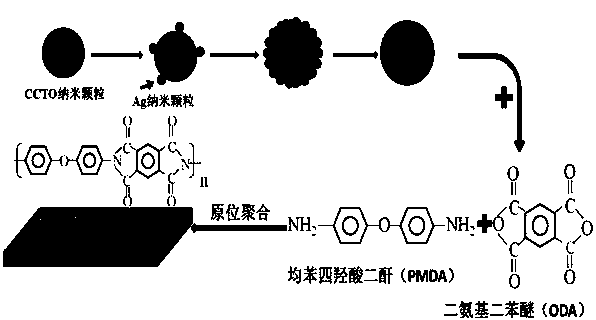

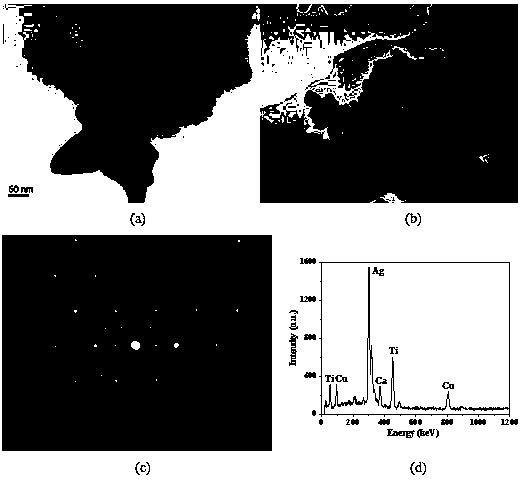

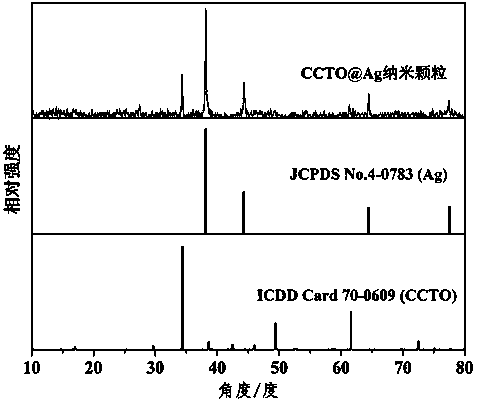

Preparation method of polyimide/copper calcium titanate coated silver nanoparticle composite material

InactiveCN103755958APromote recombinationImprove electric field distributionIn situ polymerizationHigh energy

The invention discloses a preparation method of polyimide / CCTO@Ag nanoparticle composite material with high dielectric and low loss. According to the method, polyimide is used as matrix, the prepared CCTO@Ag nanoparticles are ultrasonically dispersed in absolute ethyl alcohol, then is blended with polyimide monomer in solvent, then in situ polymerization reaction is carried out on the monomer at room temperature to simultaneously realize copolymerization of polyimide and intercalation recombination with the CCTO@Ag nanoparticles, obtained stock solution is subjected to gradient annealing according to a coating method to finally obtain the polyimide / CCTO@Ag nanoparticle composite film. Compared with pure polyimide, the polyimide / CCTO@Ag nanoparticle composite material prepared according to the preparation method has the dielectric constant (103) increased by 30 times, also has low dielectric loss (0.006) and can be widely applied in fields of high energy storage capacitors, artificial organs, high speed integrated circuits, and the like.

Owner:WUHAN UNIV

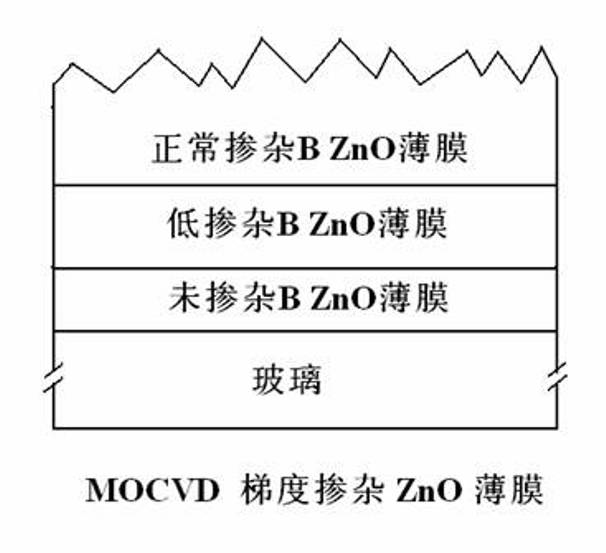

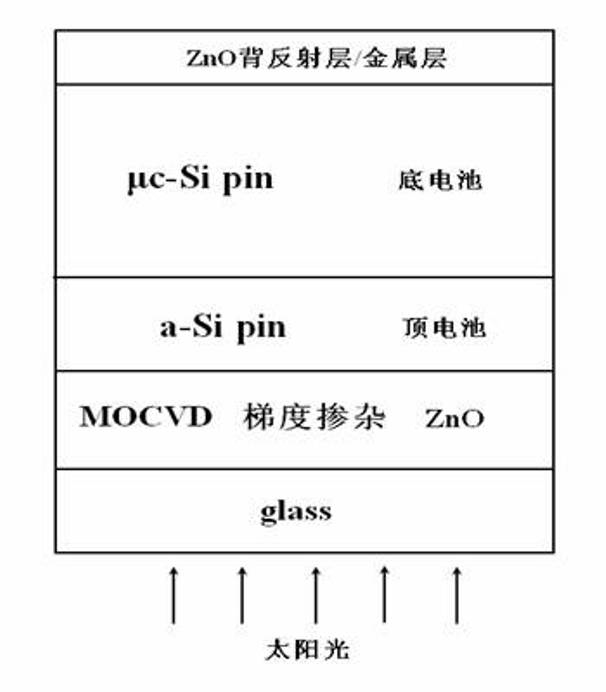

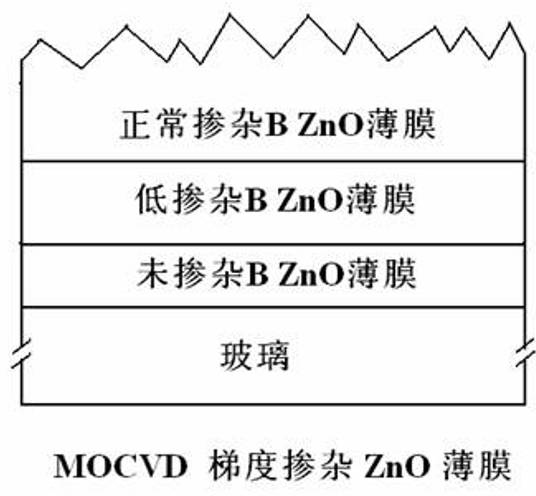

ZnO:B film grown by utilizing MOCVD (Metal Organic Chemical Vapor Deposition) gradient doping technology and application

InactiveCN102168256ARefine the grain sizeReduce absorptionFinal product manufactureChemical vapor deposition coatingPhysical chemistryThin membrane

The invention relates to a ZnO:B film grown by utilizing an MOCVD (Metal Organic Chemical Vapor Deposition) gradient doping technology. By utilizing the MOCVD technology, using a glass base sheet as a substrate, using diethylzinc and water as raw materials and using borane as doping gas, a ZnO transparent conducting film without doping B or doping less B grows on the glass base sheet; then, ZnO grows by sectional gradient doping on the basis of the film by utilizing the MOCVD technology as well to prepare the glass base sheet / undoped B or low B doped ZnO / normal B doped ZnO transparent conducting film. The invention has the advantage of realizing the ZnO film with large grain size and high visible light and near-infrared transmissivity by growing undoped or low B doped ZnO film at the initial period and then adopting doping under the normal condition. The film is suitable for being applied to a p-i-n type Si-based film solar cell, especially an a-Si / muc-Si laminated film solar cell andcan further improve the performance of an Si film cell.

Owner:NANKAI UNIV

Technique for preparing porous ceramicite loaded Ag/N-TiO2 nano film

InactiveCN101209422AAchieve hybrid dopingLess adulteratedWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveExpanded clay aggregate

The invention provides a preparation technique for porous porcelain granules loaded with Ag / N-TiO2 nanometer film, which comprises the preparation of the porous porcelain granules and the manufacture of film on the porous porcelain granules, and is characterized in that: (1) -100 meshes of fly ash and quicklime and -200 meshes of kaolin and glass powder are adopted as raw materials, which are mixed according to the weight ratio of 70: 6: 10:14; TiO2 that accounts for 0.5-1 percent of the total weight of the raw materials, NH4HCO3 that accounts for 20-30 percent of the total weight of the raw materials and water that accounts for 60-65 percent of the total weight of the raw materials, are all added into the mixture mixed by the four raw materials; the new mixture is stirred uniformly to prepare granules with the particle size of 1-2cm, which is immediately placed under microwave for foaming and drying for 1-5min so as to prepare porous porcelain granule billets with the diameter of 2-5cm, and then the billets are sintered for 1h under 1100DEG C to prepare the porous porcelain granules; (2) Ag / N-TiO2 sol is prepared by adopting sol-gel method and the sol is coated on the porous porcelain granules by adopting dipping method, thus obtaining the porous porcelain granules loaded with Ag / N-TiO2 nanometer film after drying and calcining. The sol is evenly coated on the porous porcelain granules, so active constituent does not lose effectiveness under low temperature, thus having good visible light degradation and relatively strong bactericidal effect.

Owner:SHANDONG UNIV OF TECH

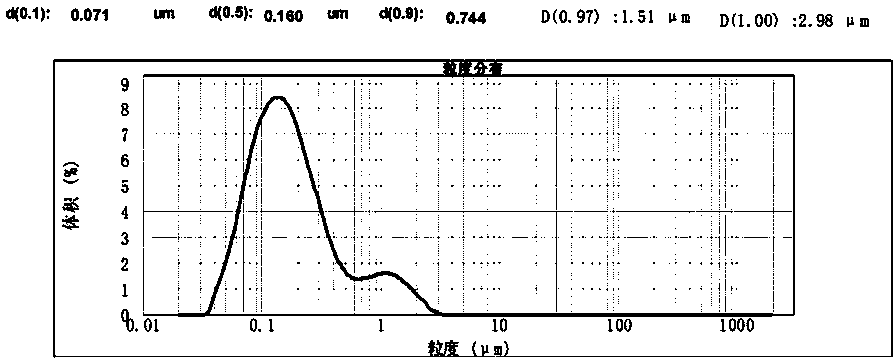

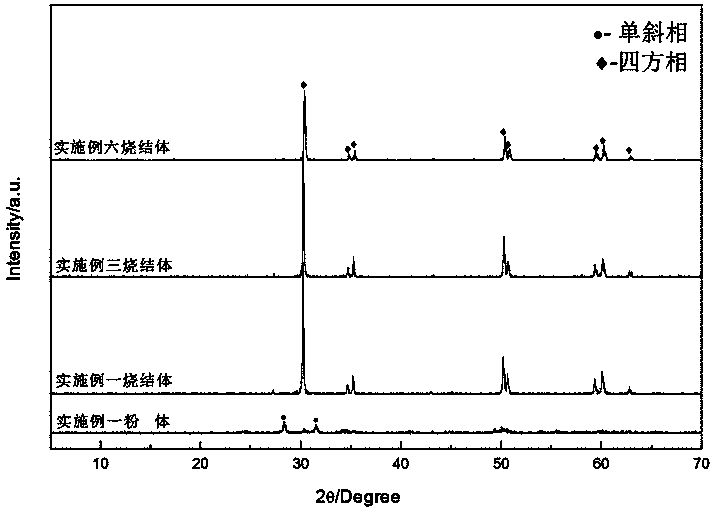

Powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics and preparation method of powder material

The invention discloses a powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics. The powder material is prepared from zirconia and yttrium oxide, wherein the content of the yttrium oxide is 1.4-2.6mol% of the total amount of Zr<4+>; and the average grain size of raw crystal of the powder material is 50-110nm. Moreover, the invention further discloses a preparation method of the powder material. According to the zirconia powder material, the doping amount of yttrium is reduced, the tetragonal polycrystal ceramics prepared by using the powder are capable of realizing full tetragonal phase stable existence of zirconia at room temperature to guarantee the characteristic of high strength, activating the tetragonal phase in TZP (tetragonal zirconia polycrystalline), improving the transformation toughening performance and further optimizing the fracture toughness of TZP ceramics. The preparation method is safe and reliable, has the advantages of wide raw material source, low energy consumption and remarkable effect on energy conservation and emission reduction, is convenient for popularization and application, is suitable for industrial large-scale production, and can be used for effectively promoting application and development of zirconia materials.

Owner:江西赛瓷材料有限公司 +1

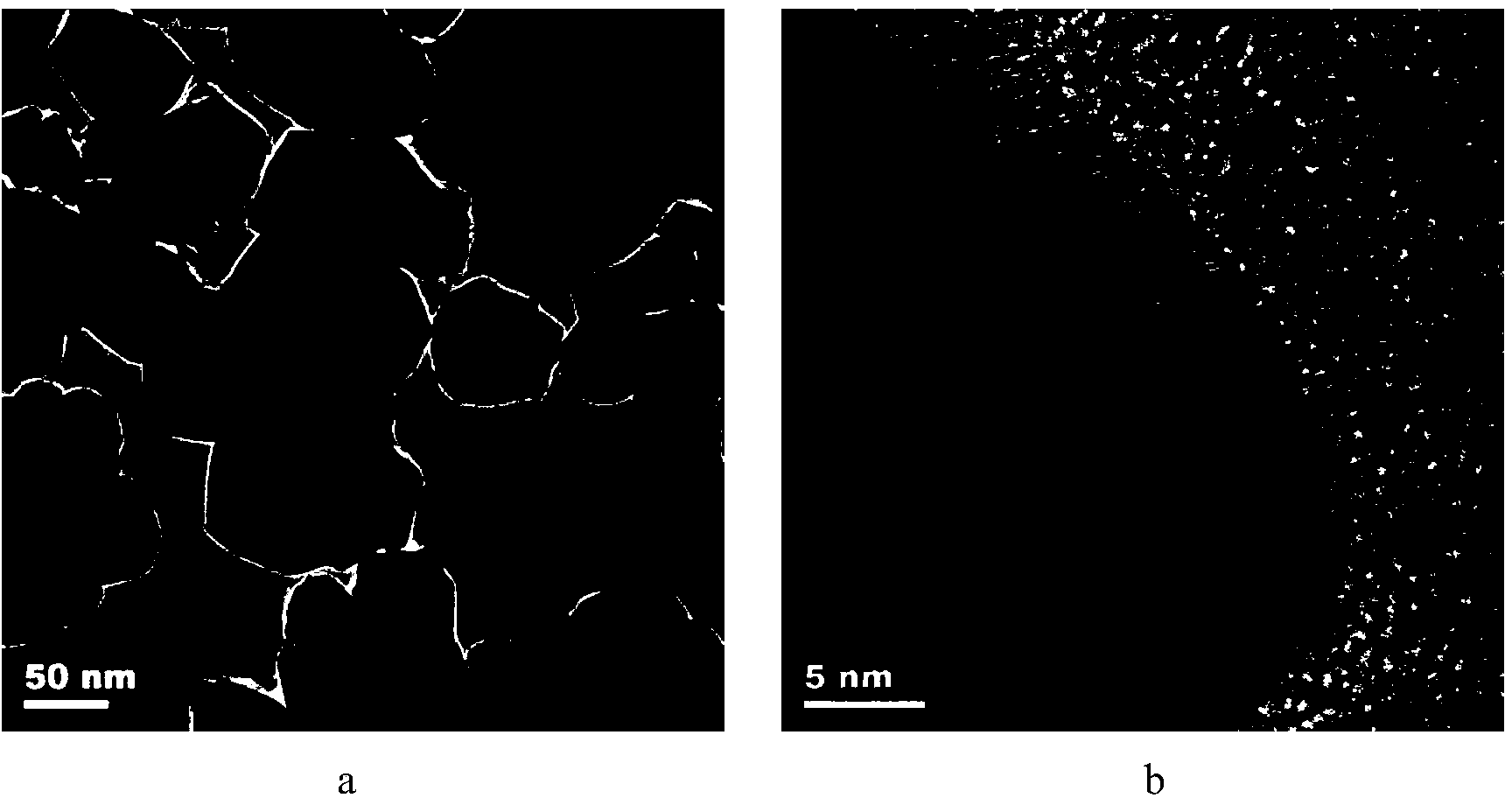

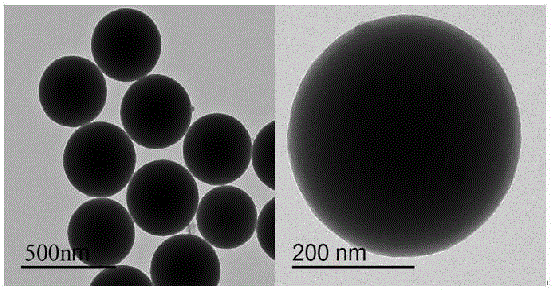

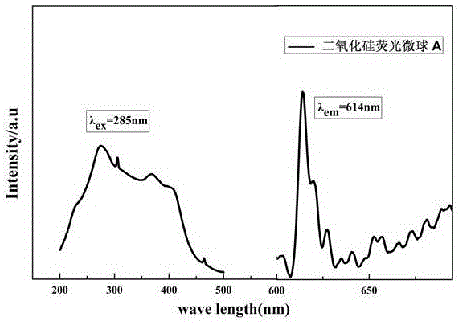

Preparation method of monodisperse silicon dioxide fluorescent microspheres

InactiveCN106221692ASimple preparation processLess adulteratedLuminescent compositionsChemical compositionSeed nucleus

The invention discloses chemical composition and a preparation method of monodisperse silicon dioxide fluorescent microspheres. The general chemical formula of the fluorescent microspheres is SiO2@SiO2:Ln(L)3, wherein SiO2 represents silicon dioxide of the main part of the fluorescent microspheres, Ln represents a rare earth metal element serving as a luminescence center, and L represents an organic ligand serving as the enhanced fluorescence performance. The preparation method of the fluorescent microspheres is an organic ligand sensitization fluorescence enhancement-sol seed method, that is to say, silicon dioxide is taken as seed nucleuses, and a silicon dioxide-doped rare earth complex is taken as a surface coating substance. The preparation method is simple, and the obtained silicon dioxide fluorescent microspheres are good in sphericility, monodispersity, stability and luminescence property have a wide application prospect on photoelectric materials, fluorescent markers, drug targeting and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Novel plastic cladding optical fiber

InactiveCN101363941ALarge numerical apertureReduce transmission lossOptical fibre with multilayer core/claddingOptical waveguide light guideOpto electronicOptical communication

The invention relates to a novel plastic cladding optical fiber in the fields of optical fiber communication, industrial control and optical fiber sensing. The novel plastic cladding optical fiber comprising a quartz core layer and a plastic ultraviolet cured clad is characterized in that the shear modulus of the plastic clad is not smaller than 150 Mpa; the thickness of the plastic clad is 10 Mum-20 Mum; the relative difference value Delta of the refractive index between the plastic clad and a pure quartz material is 2.5 percent-7.5 percent; the value of the numerical aperture NA of the optical fiber is 0.35-0.5; and the optical fiber can be used in a 850 nm window. The optical fiber has the advantages that the large numerical aperture and the low transmission loss enable the optical fiber to be applied in the short-distance and medium-distance data communications, the industrial control and the medical photoelectric products.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A process for preparing solar-grade N-type monocrystalline

InactiveCN109023509ALess adulteratedConcentration increases rapidlyPolycrystalline material growthBy pulling from meltSeed crystalGallium alloy

A process for preparing solar-grade N-type monocrystalline is disclosed. The process includes (1) adding a silicon raw material into a quartz crucible put into a monocrystalline furnace, adding an N type master alloy and gallium to the middle position of the silicon raw material; (2) closing the monocrystalline furnace, vacuumizing the furnace to detect leakage, heating the furnace for a melting purpose, adding the silicon raw material with a repeated feeder and heating the furnace for a melting purpose; (3) cooling the furnace, stabilizing the temperature, finding out power, melting seed crystal, seeding, crowning, shouldering, bodying and tailing to obtain a first monocrystalline rod, pulling the monocrystalline rod to an auxiliary chamber of the monocrystalline furnace to be cooled, andmaintaining the temperature of the residual solution in the monocrystalline furnace; (4) taking the monocrystalline rod out after the monocrystalline rod is cooled and weighing the monocrystalline rod; (5) adding a material for repeated addition into the repeated feeder, and adding an N type master alloy and gallium to the middle position of the silicon raw material; and (6) heating the furnace for a melting purpose, cooling and stabilizing the furnace, finding out power, melting seed crystal, seeding, crowning, shouldering, bodying, tailing, and cooling the product to obtain a second monocrystalline rod. A proper amount of the gallium is added in the initial material addition to neutralize phosphorus better and to effectively improve the degree of centralization of the specific resistance of the N-type monocrystalline, thus increasing the percent of pass of solar resistance.

Owner:包头美科硅能源有限公司

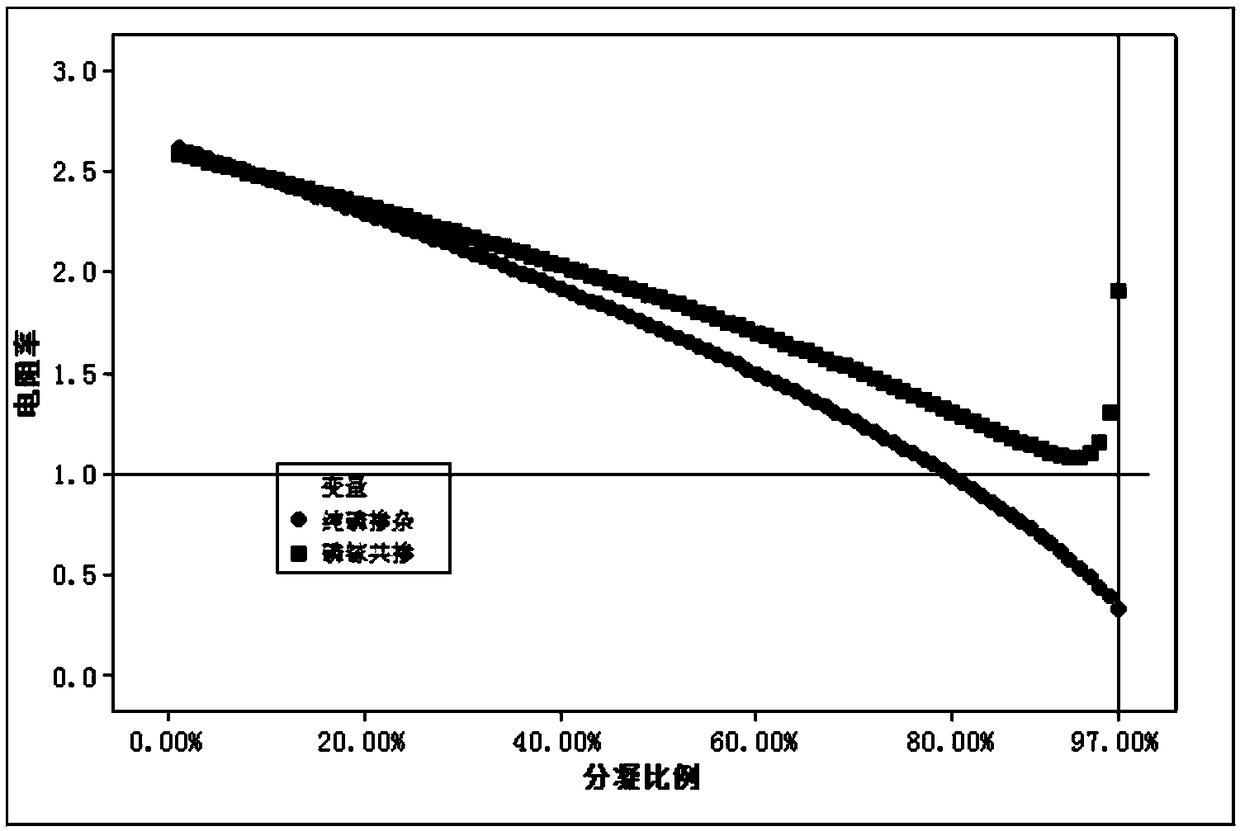

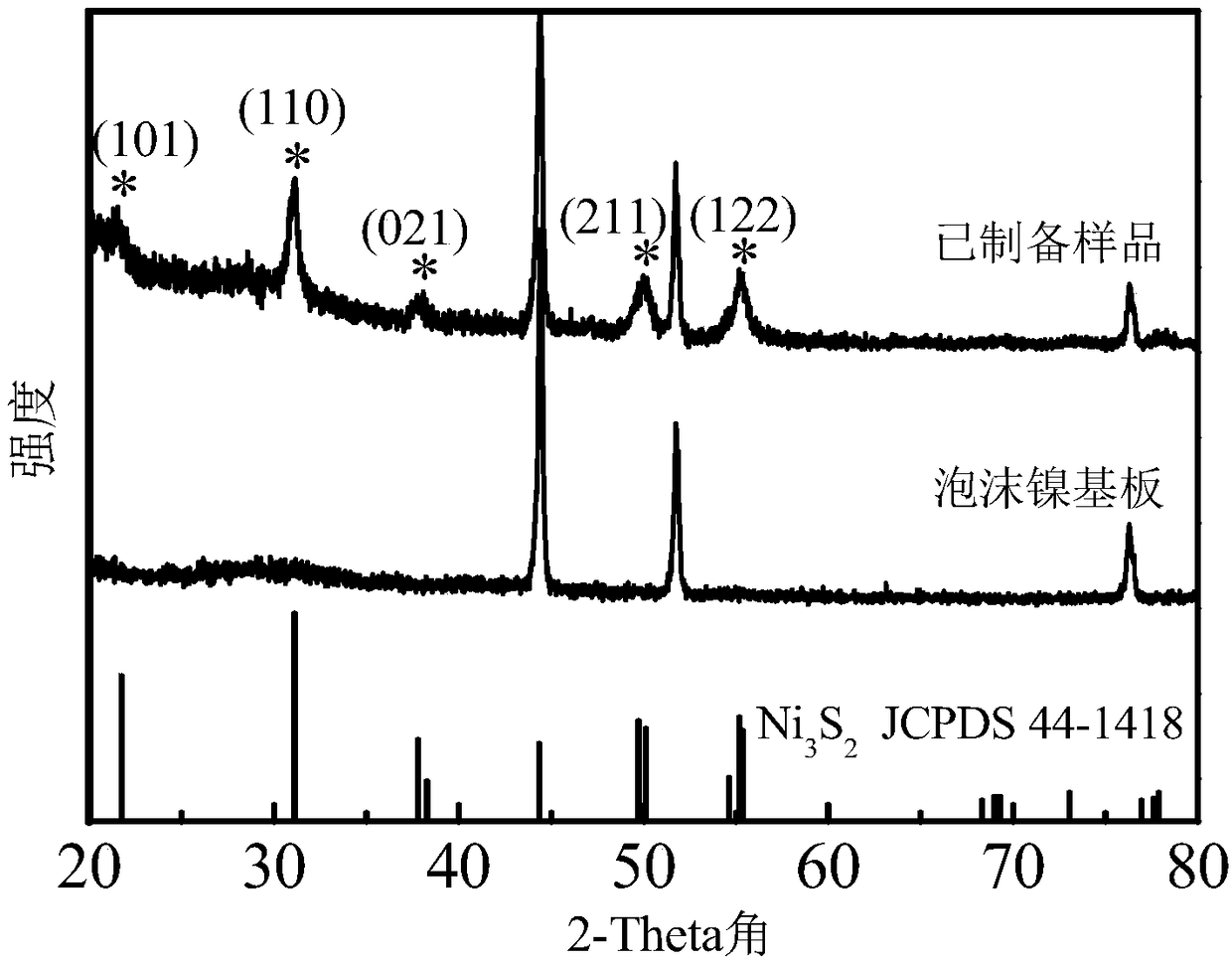

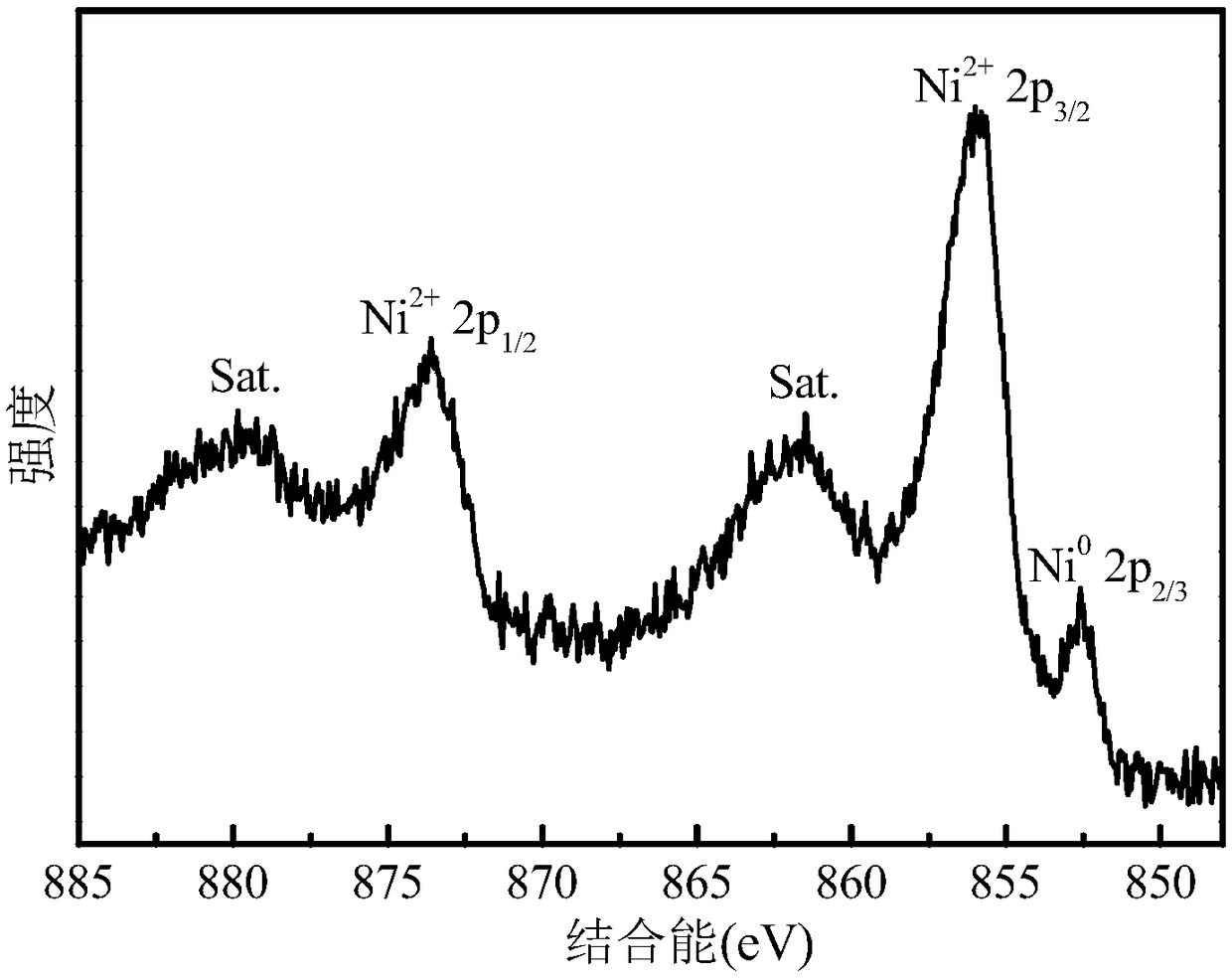

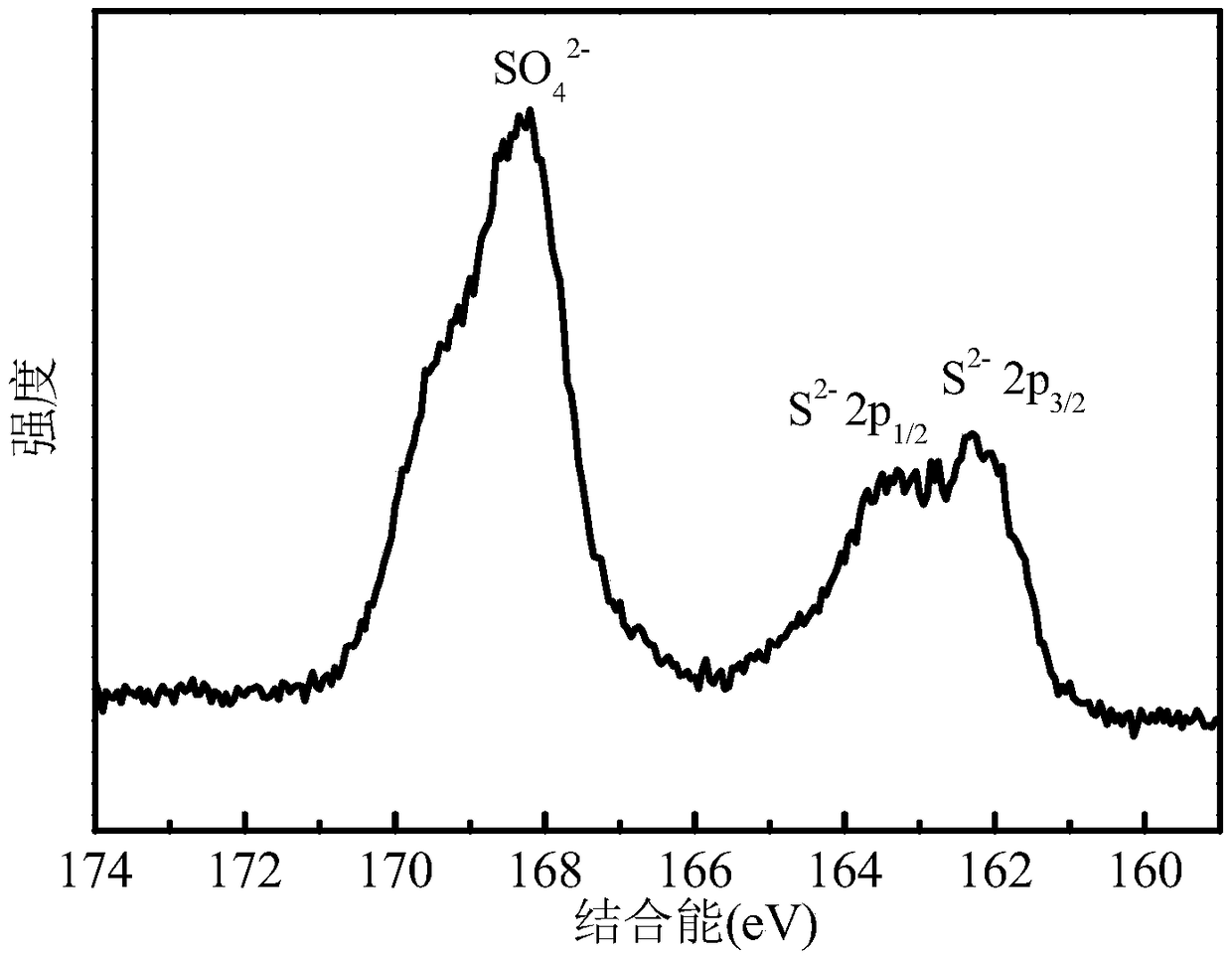

Trace iron (III) ion-doped nickel disulfide catalyst for oxygen evolution reaction of electrolysis water

ActiveCN109112566ALess adulteratedLow costElectrolytic inorganic material coatingElectrodesIonIron(II) chloride

The invention discloses a trace iron (III) ion-doped nickel disulfide catalyst for oxygen evolution reaction of electrolysis water. The trace iron (III) ion-doped nickel disulfide catalyst is characterized in that the molar content of iron element only accounts for 0.5% to 3% of the total molar quantity of iron, sulfur and nickel elements; the catalyst is prepared by taking a water solution containing nickel chloride, ferrous chloride, sodium thiosulfate, thiourea, PEG-100 and boric acid as an electrodeposition solution by a one-step electrodeposition method, wherein the sodium thiosulfate andthe thiourea are used as sulfur sources of the catalyst, the PEG-100 is used as a surfactant, and the boric acid is used as a pH (potential of hydrogen) buffer solution. The prepared trace iron (III)ion-doped nickel disulfide catalyst has the advantages that a nanosheet-shaped structure is adopted; by doping trace iron (III) ion, the catalyzing activity of the nickel disulfide catalyst in the oxygen evolution reaction is greatly improved, and the oxygen evolution over-potential is lower; the efficiency is high, the cost is low, and noble metal is not used.

Owner:SHAANXI NORMAL UNIV

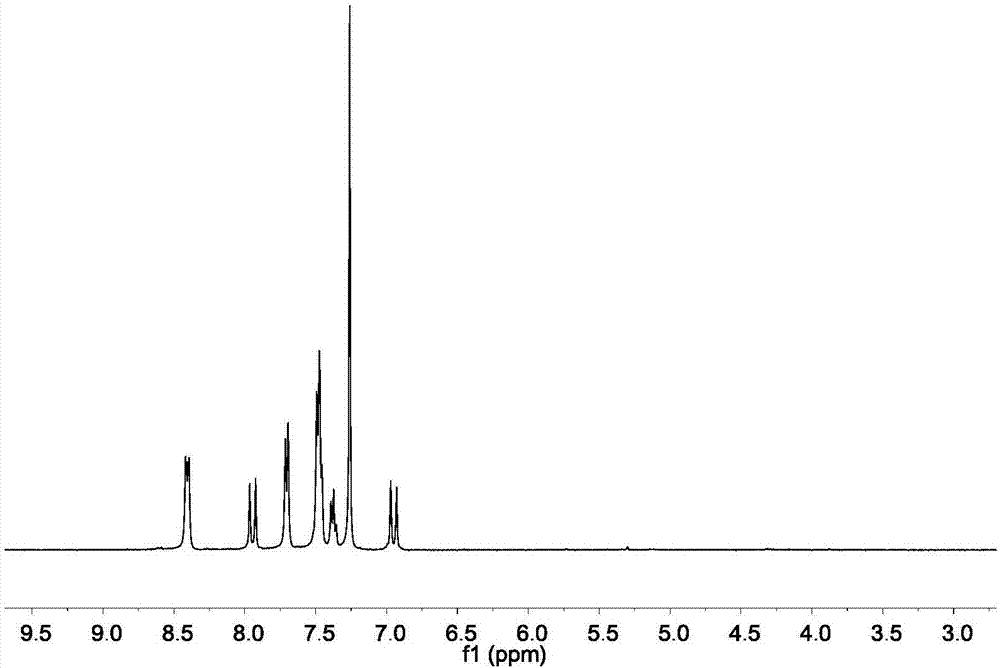

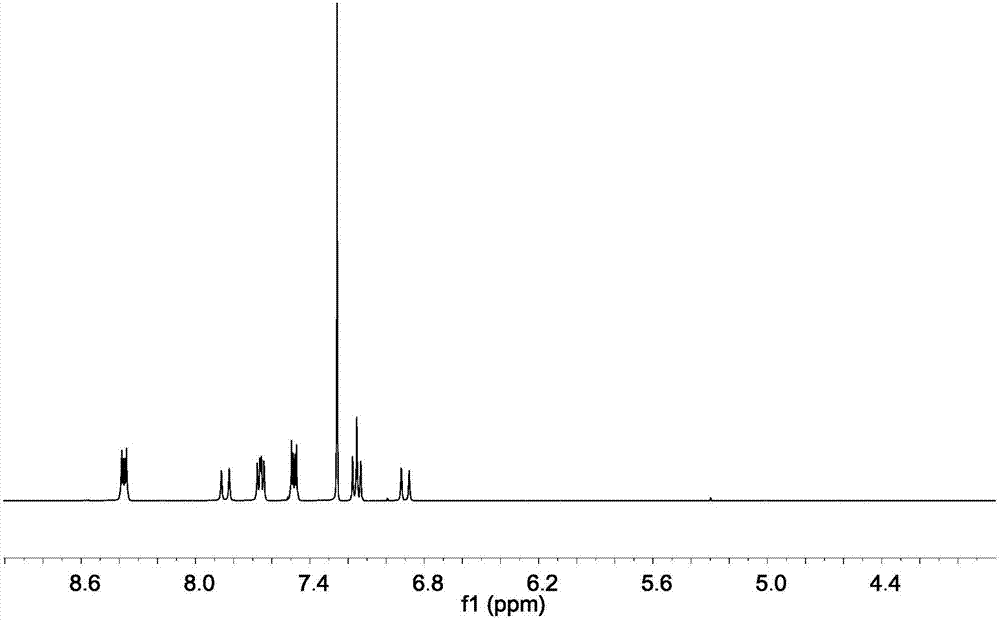

Solid-state upconversion light emitting material based on triplet state-triplet state annihilation and preparation method thereof

ActiveCN107573928AHigh fluorescence quantum yieldSolve the self-quenching problemLuminescent compositionsQuantum yieldUpconversion luminescence

The invention discloses a solid-state upconversion light emitting material based on triplet state-triplet state annihilation, and relates to the technical field of photon upconversion. The solid-stateupconversion light emitting material comprises a photosensitive agent and an annihilation agent with a 9,10-diphenyl vinyl anthracene structure, wherein the annihilation agent has AIE (aggregation-induction emission) effect. The solid-state upconversion light emitting material is formed by physically doping the annihilation agent into the photosensitive agent, and has the advantages that becausethe annihilation agent has regular structure in the solid state, the fluorescence quantum yield is high in the solid state, the energy transfer in the annihilation is favorably performed, the self-quenching of conversion light emitting is avoided, and the problem of self-quenching of the annihilation agent in the solid due to aggregation is certainly solved; the quick energy transfer among the triplet states of the annihilation agent in the solid is favorable for realizing the triplet state-triplet state annihilation of the molecules of the annihilation agent, and is further favorable for improving the upconversion light emitting efficiency.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

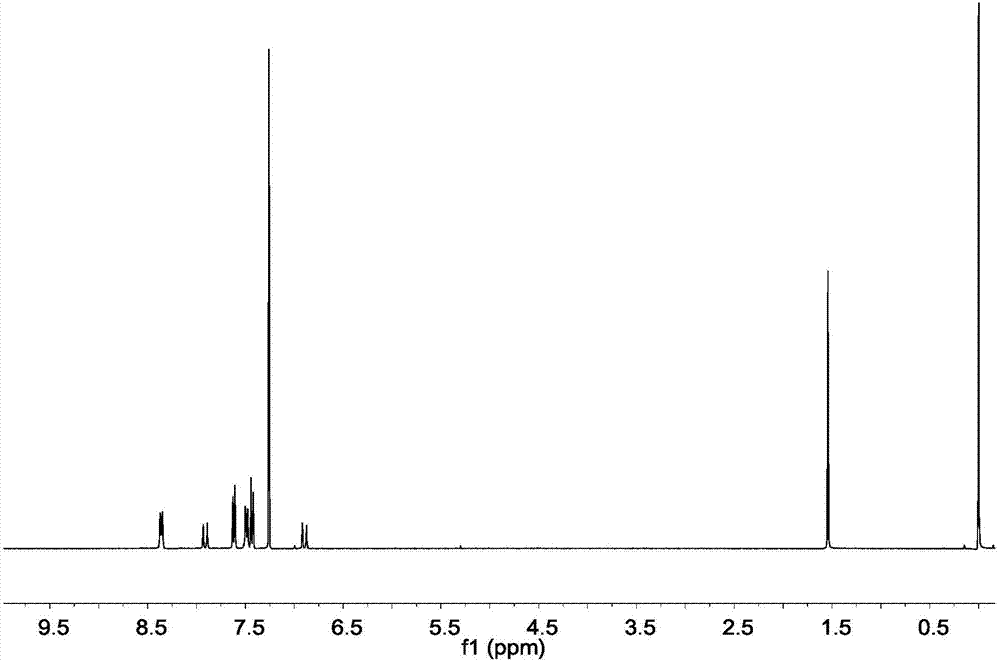

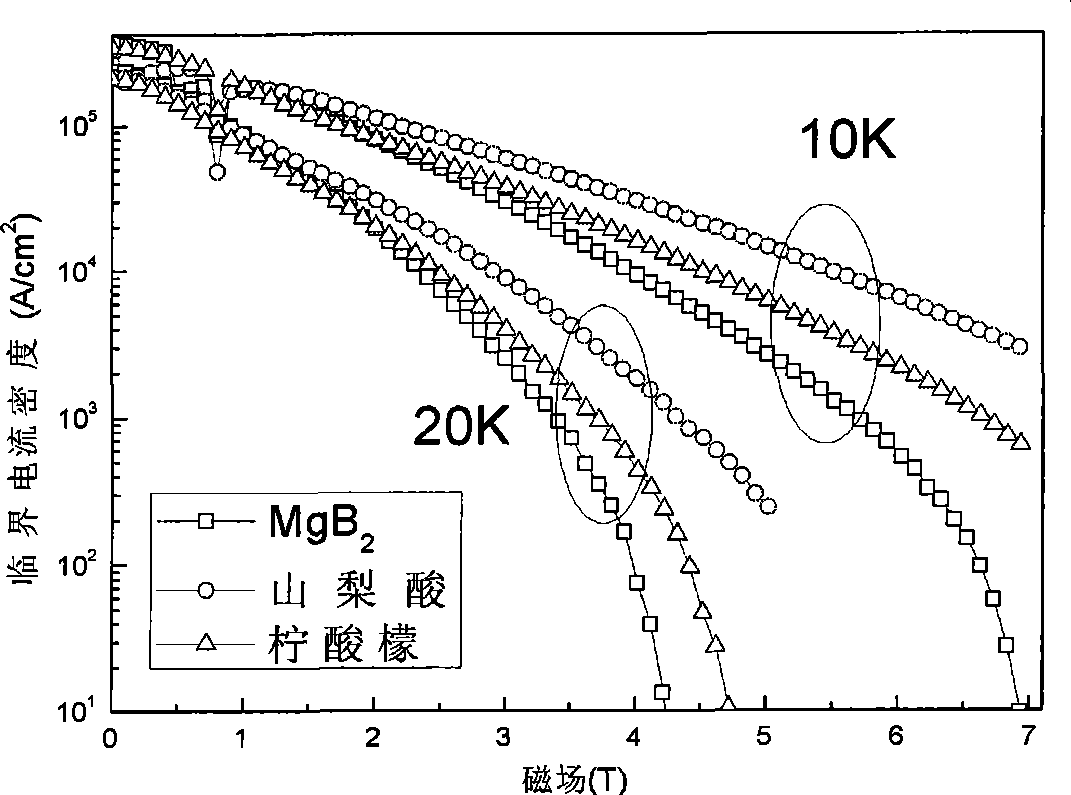

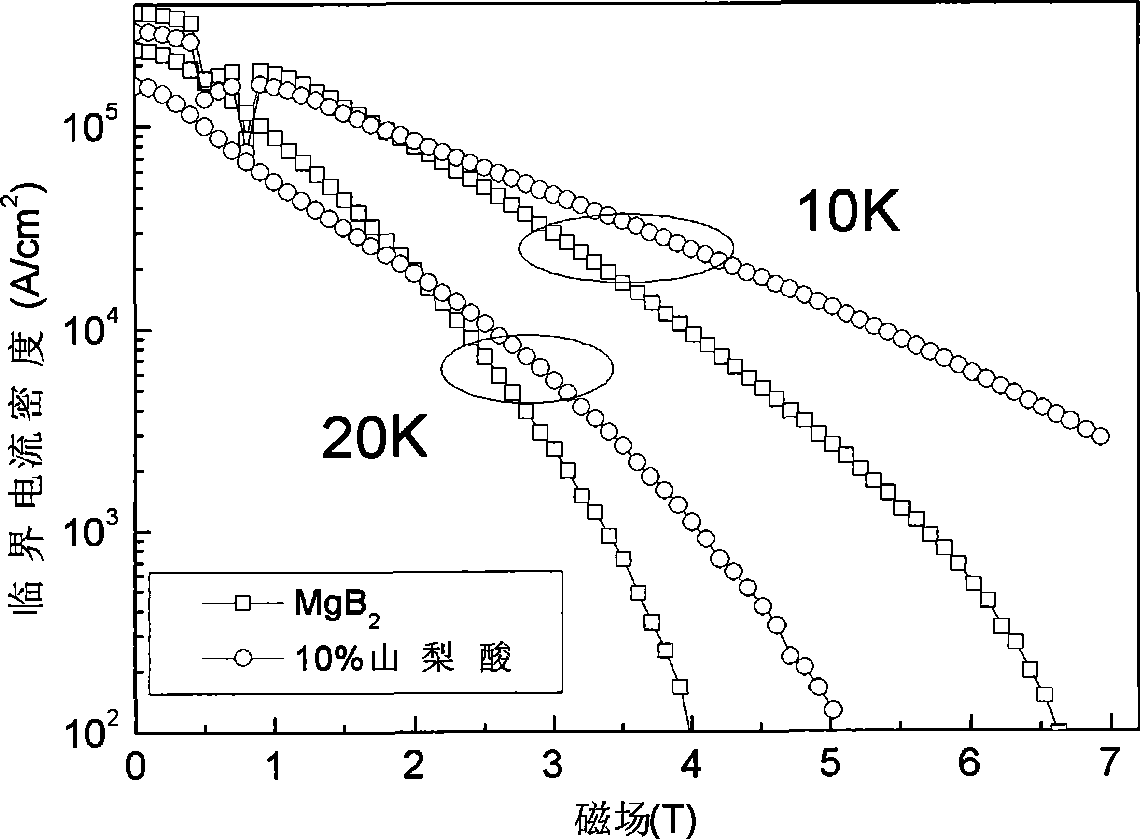

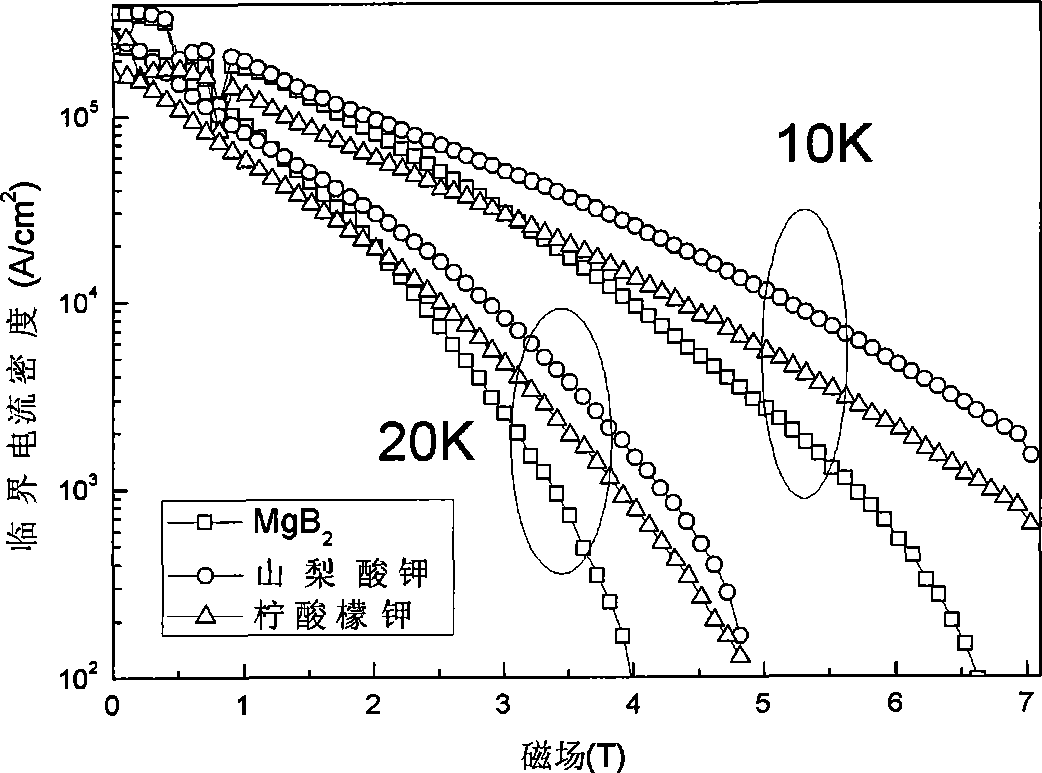

Preparation of magnesium boride doped superconduction material

InactiveCN101462881ALow reaction temperatureShorten the timeSuperconductors/hyperconductorsSuperconductor devicesDopantArgon atmosphere

A preparation method of a magnesium diboride-doped superconducting material comprises the following steps: respectively weighing magnesium powder and boron powder based on a mol ratio of 1:0.7-2.5; weighing a dopant based on the ratio of the total mass of the magnesium powder and the boron powder to the mass of the dopant of 1:0.01-1, wherein, the dopant is one of sorbic acid or sorbate; evenly mixing the magnesium powder, the boron powder and the dopant powder to obtain mixed powder; and sintering the mixed powder under the protection of argon atmosphere at the sintering temperature of 600 DEG C-1200 DEG C, and keeping the temperature for 0.5-12 hours, thus obtaining the superconducting material. The method has the advantages of short preparation time, low reaction temperature, high efficiency and low cost, and is especially suitable for industrialized production. The magnesium diboride superconducting material obtained by the method has obviously increased critical current density especially very high critical current density in a high magnetic field, which is beneficial to the application of the superconducting material to the high magnetic field; and the superconducting material has strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

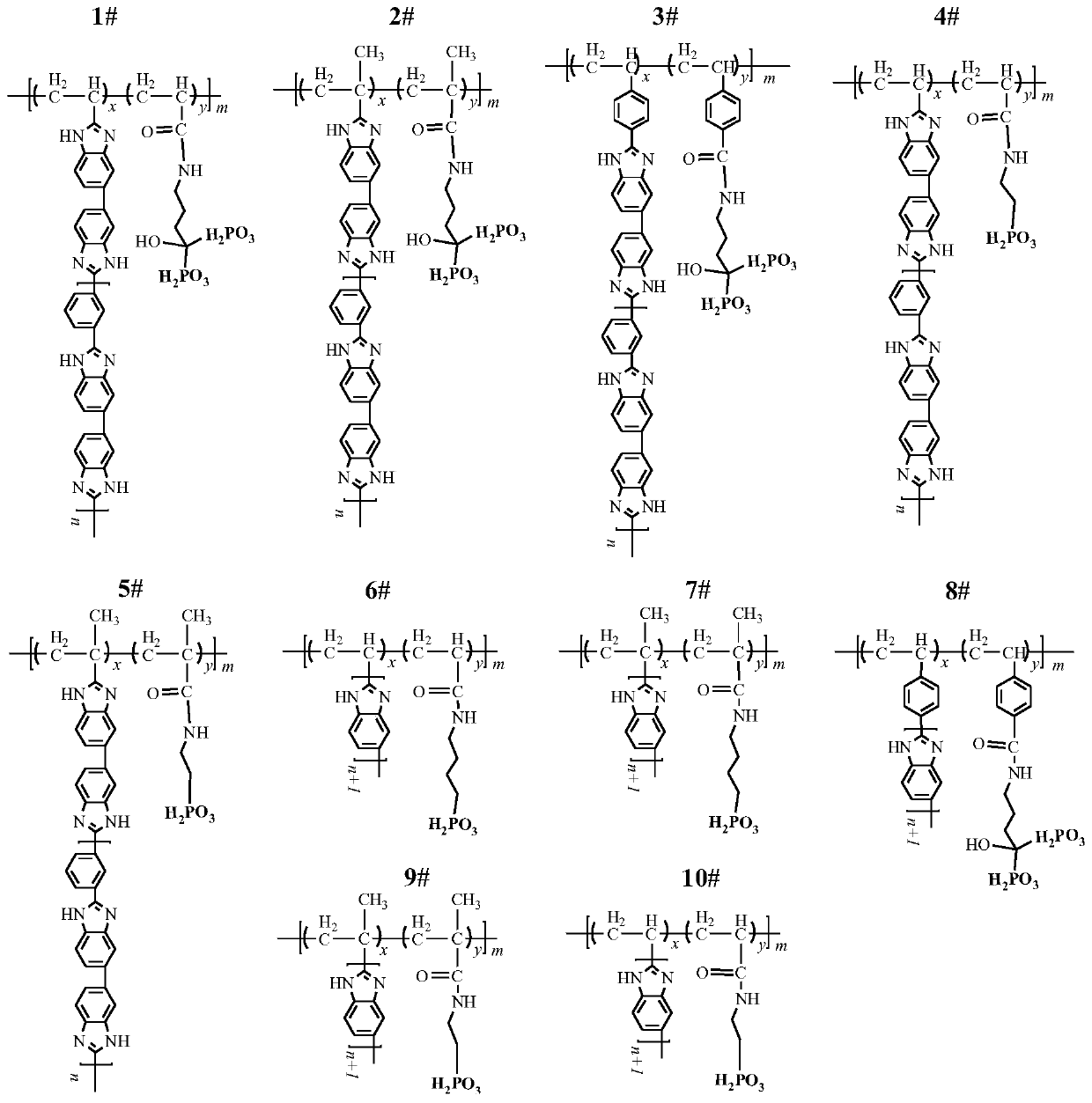

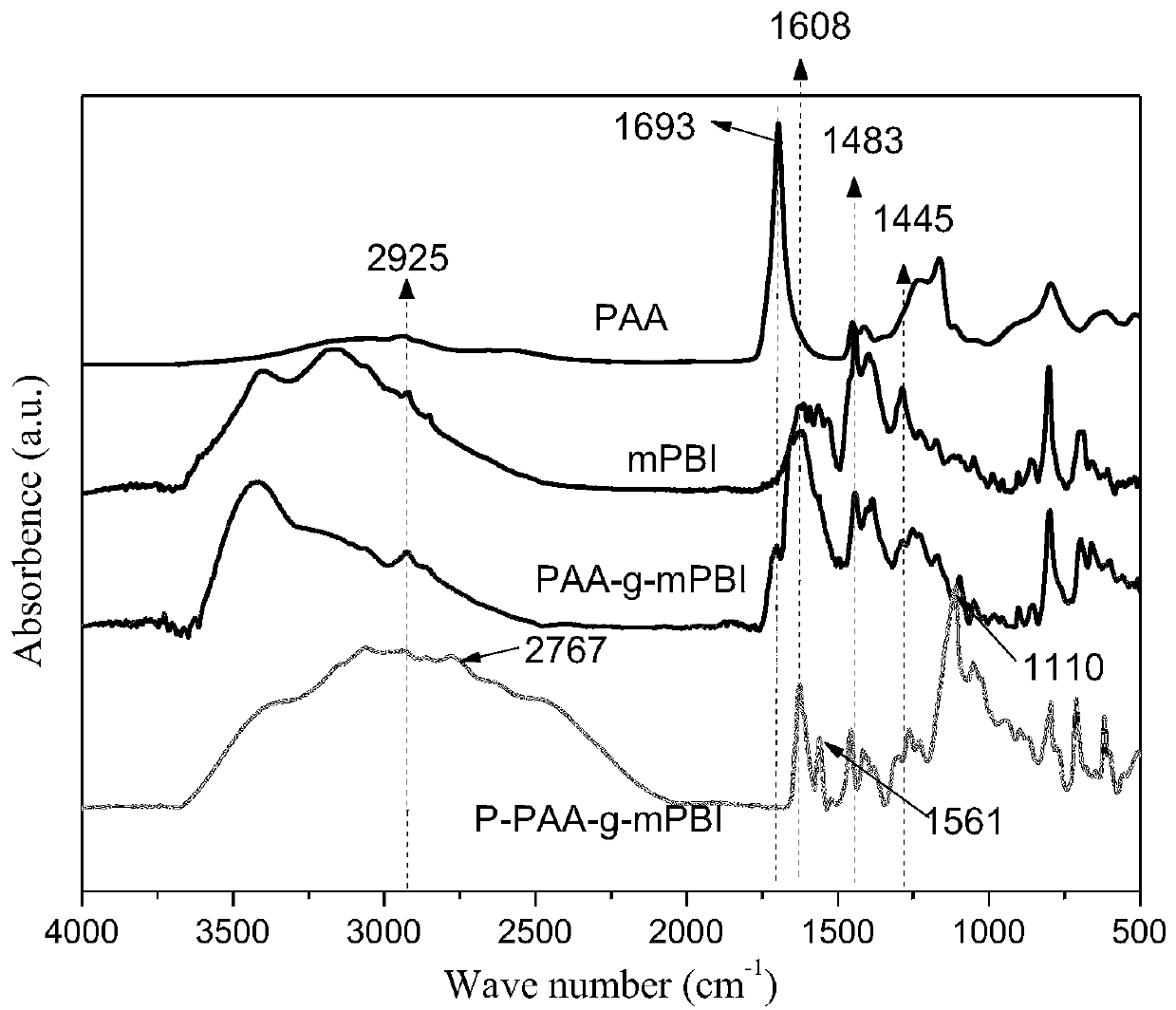

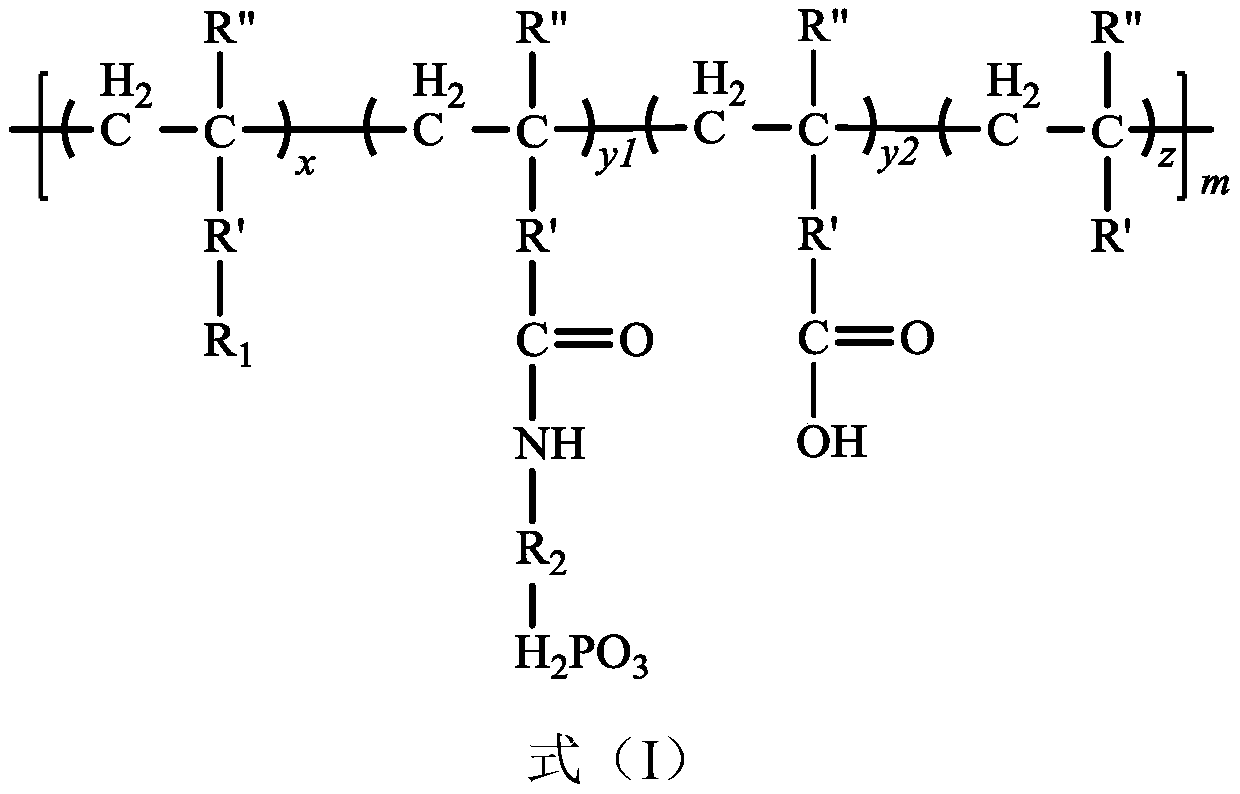

Phosphorylated(polyolefin-g-polybenzimidazole) graft copolymer as well as preparation method and application thereof

ActiveCN110982081ALower activation energy for migrationPromote migrationFuel cellsPolymer sciencePolyolefin

The invention relates to a phosphorylated(polyolefin-g-polybenzimidazole) graft copolymer as well as a preparation method and application thereof. According to the graft copolymer, soft polyolefin isused as a main chain, rigid PBI is used as a branched chain, and the phosphorylated graft copolymer which contains phosphonic acid and has a soft-hard chain segment is further prepared through amino-containing phosphonic acid grafting. The polymers with two properties are subjected to microcosmic phase separation to construct a proton transmission channel, so that the proton conductivity is improved. In addition, the flexible main chain drives the PBI branched chain to move so as to reduce proton migration activation energy, promote migration of phosphoric acid or protons and improve proton conductivity. The grafted amino-containing phosphonic acid can reduce the doping amount of inorganic phosphoric acid, so that the loss of phosphoric acid in the use process is reduced, and the proton conductivity retention rate of the membrane is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

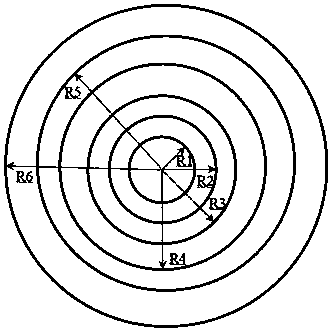

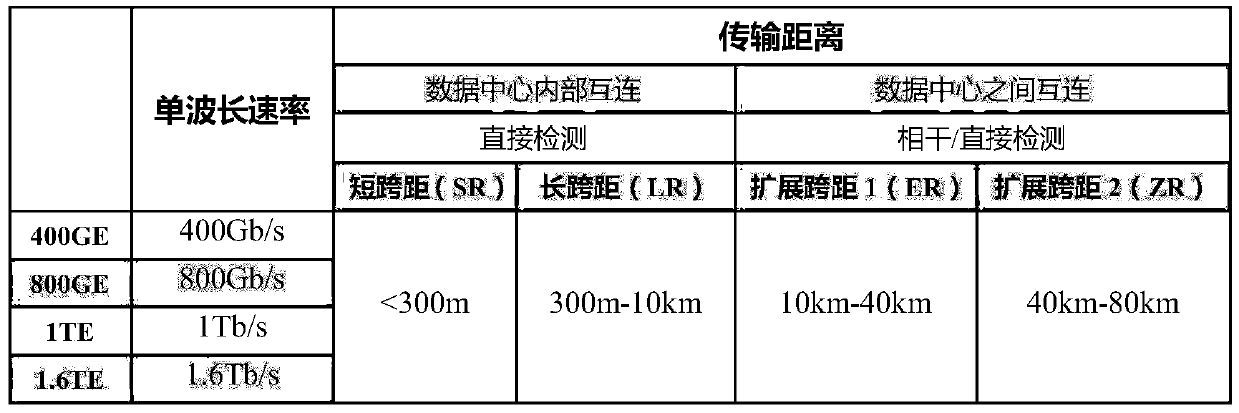

Low attenuation gradient orbital angular momentum fiber

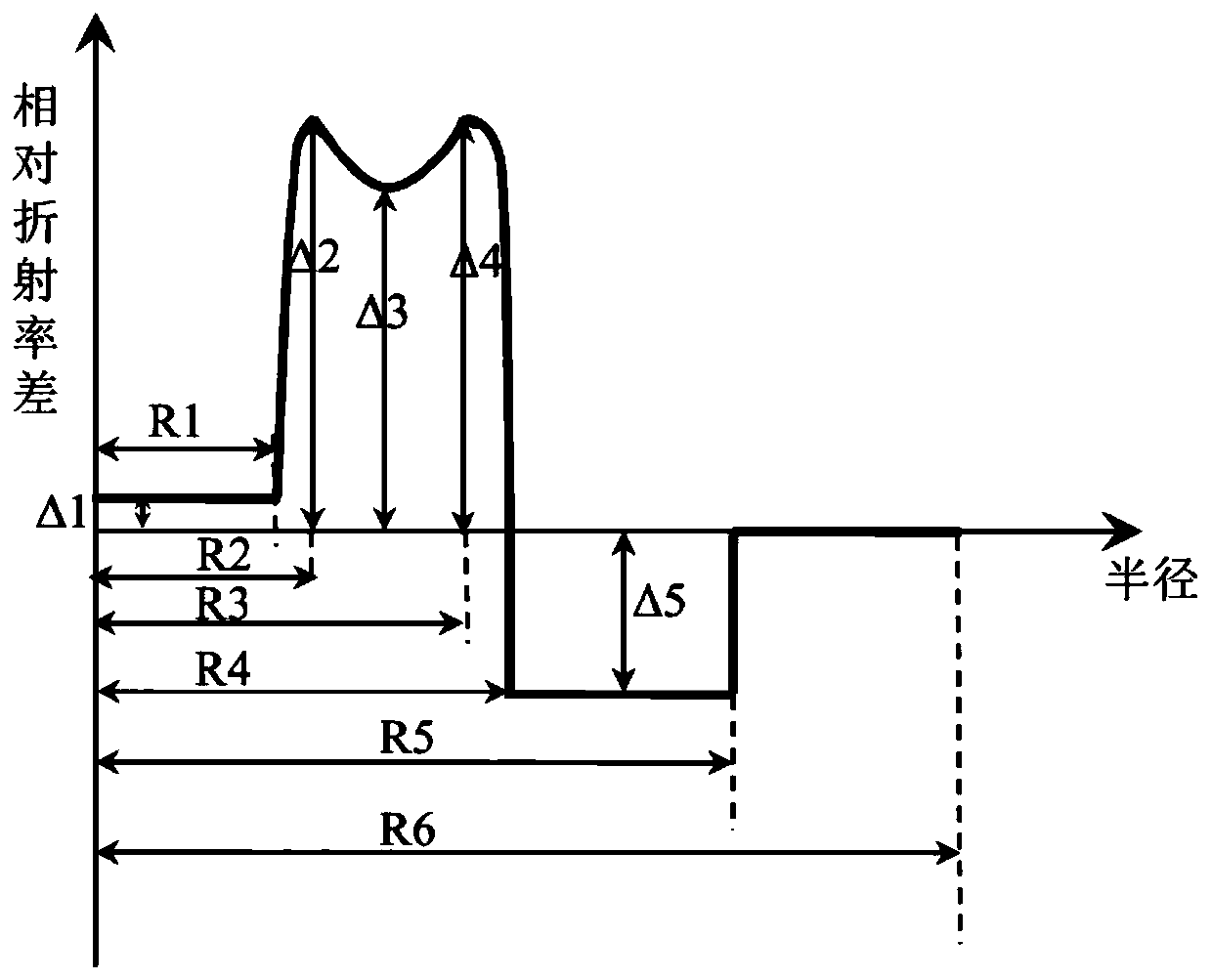

ActiveCN110333572AReduce defectsReduce the attenuation factorOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingUltrasound attenuationMomentum

The invention relates to a low attenuation gradient orbital angular momentum fiber. The low attenuation gradient orbital angular momentum fiber includes a core layer and a cladding layer; the core layer radius R1 is 3.5 [Mu]m to 5.5 [Mu]m, and the [Delta]1 is -0.08% to 0.08%; the core layer is covered by a ring core layer, a depressed cladding layer and an outer cladding layer; the ring core layerhas a gradual shape, and the top portion has a gradual concave shape, and is successively divided into an inner ring layer, a lower concave layer and an outer ring layer from the inside to the outside; the inner ring layer has a radius R2 of 4.5 [Mu]m to 6.5 [Mu]m and a [Delta]2 of 0.7% to 1%; the lower concave layer radius R3 is 8 [Mu]m to 13 [Mu]m, and the [Delta]3 is 0.6% to 0.9%; the outer ring layer has a radius R4 of 9[Mu]m to 15[Mu]m and a [Delta]4 of 0.7% to 1%; and the depressed cladding layer radius R5 is 11 [Mu]m to 16 [Mu]m, and the [Delta]5 is 0.6% to 0.3%; the relative refractive index difference is the relative refractive index difference between each layer of the fiber and the outer cladding layer; and the outer cladding layer is an outer cladding layer with a negative refractive index relative to a pure silicon dioxide layer. The low attenuation gradient orbital angular momentum fiber not only can support long-distance signal transmission with low attenuation of fourmode groups, but also has good comprehensive performances in crosstalk of the optical fiber, macro-bend and micro-bend loss of each mode and the like.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

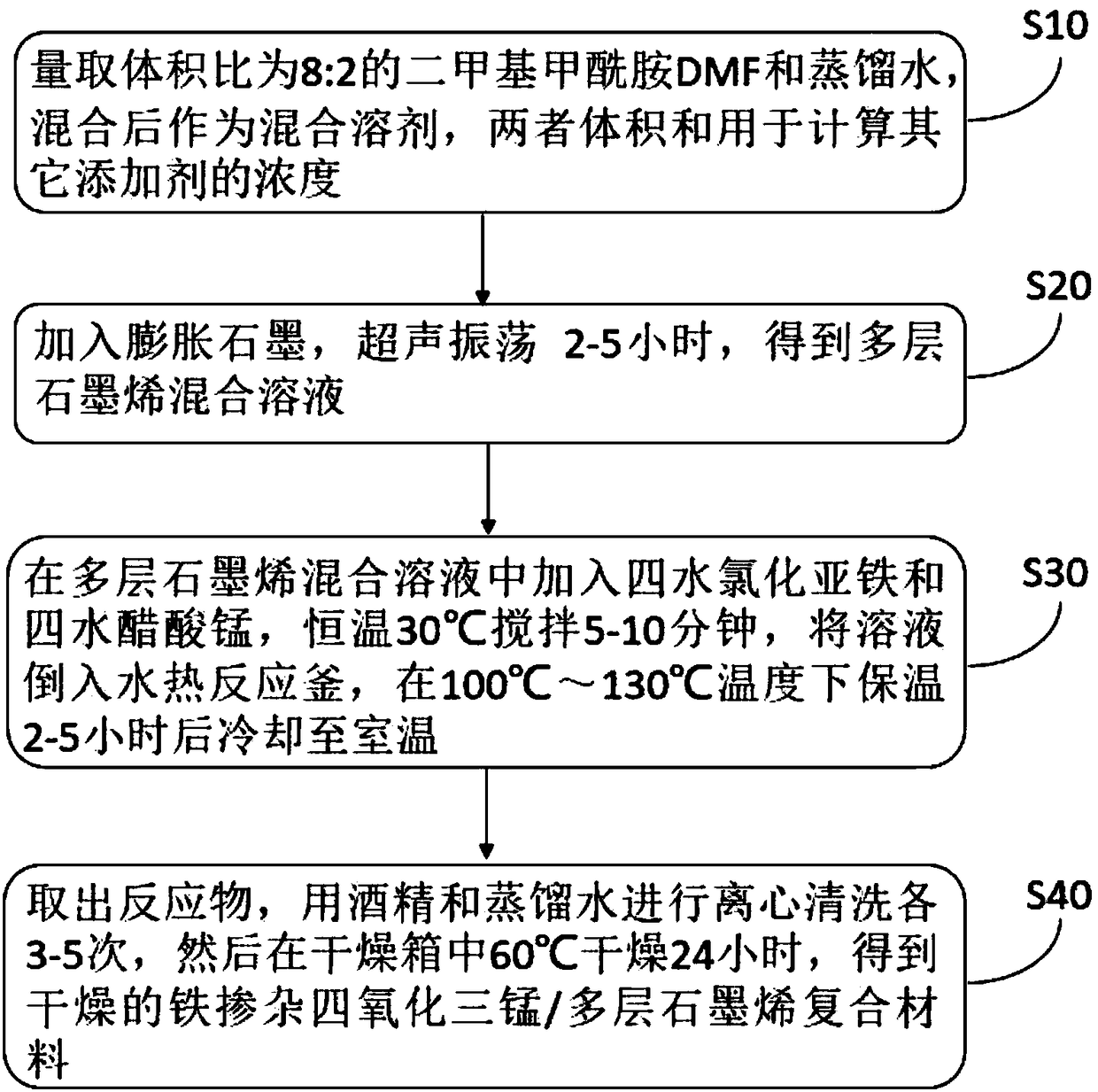

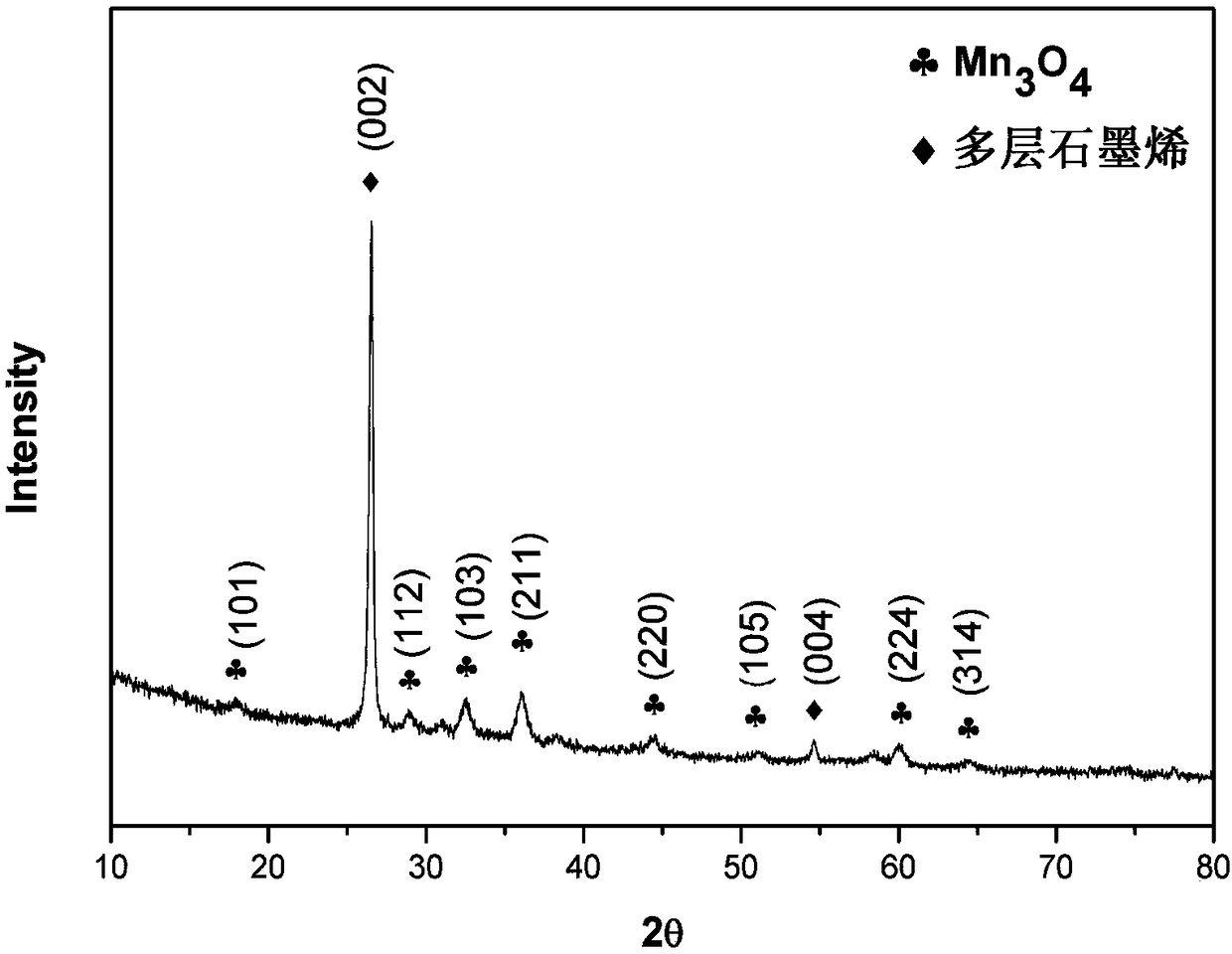

Iron ion-doped nanometer manganous-manganic oxide/multilayer graphene composite material and preparation method thereof, and lithium battery using same

ActiveCN108365182AImprove distributionEasy to prepareCell electrodesLi-accumulatorsMANGANESE ACETATEMANGANESE ACETATE TETRAHYDRATE

Embodiments of the invention disclose an iron ion-doped nanometer manganous-manganic oxide / multilayer graphene composite material and a preparation method thereof, and a lithium battery using the composite material. The preparation method comprises the following steps: measuring DMF and distilled water in a volume ratio of 8: 2, and carrying out mixing to obtained a mixed solvent; adding expandedgraphite and carrying out ultrasonic vibration for 2-5 hours to obtain a multilayer graphite flake; adding manganese acetate tetrahydrate and ferrous chloride tetrahydrate in a certain ration into themixed solution, carrying out stirring at a constant temperature of 30 DEG C for 10-15 minutes, pouring the solution into a hydrothermal reaction kettle, carrying out hydrothermal treatment at a temperature of 100 to 130 DEG C for 1-5 hours, and then carrying out cooling to room temperature; subjecting a reactant of the previous step to centrifugal washing with alcohol and water 3-5 times respectively; and carrying out drying in a drying oven with a temperature of 60-80 DEG C to obtain the composite material. According to the invention, through doping of a reaction solution with iron ions, thedispersibility of manganous-manganic oxide nanoparticles is improved, and gaps among the nanoparticles are increased, so buffering is provided for volume effect during the charging and discharging process of the oxide and the electrochemical performance of the composite material is improved.

Owner:嘉善县国创新能源研究院

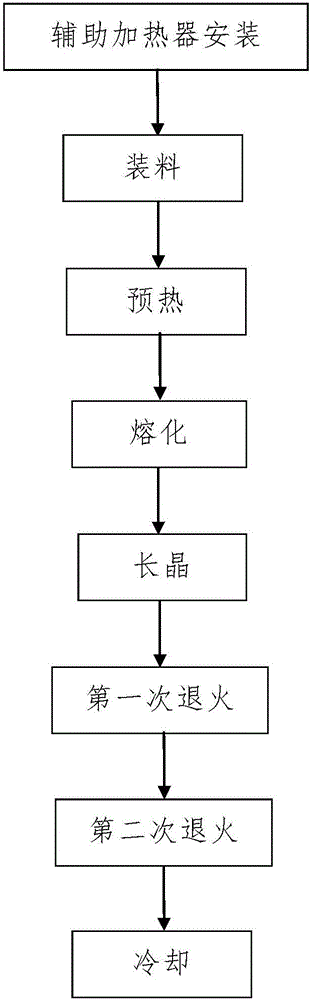

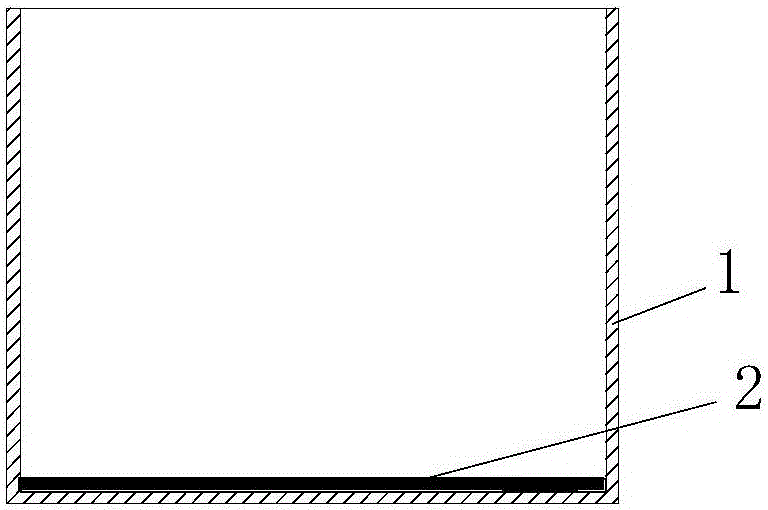

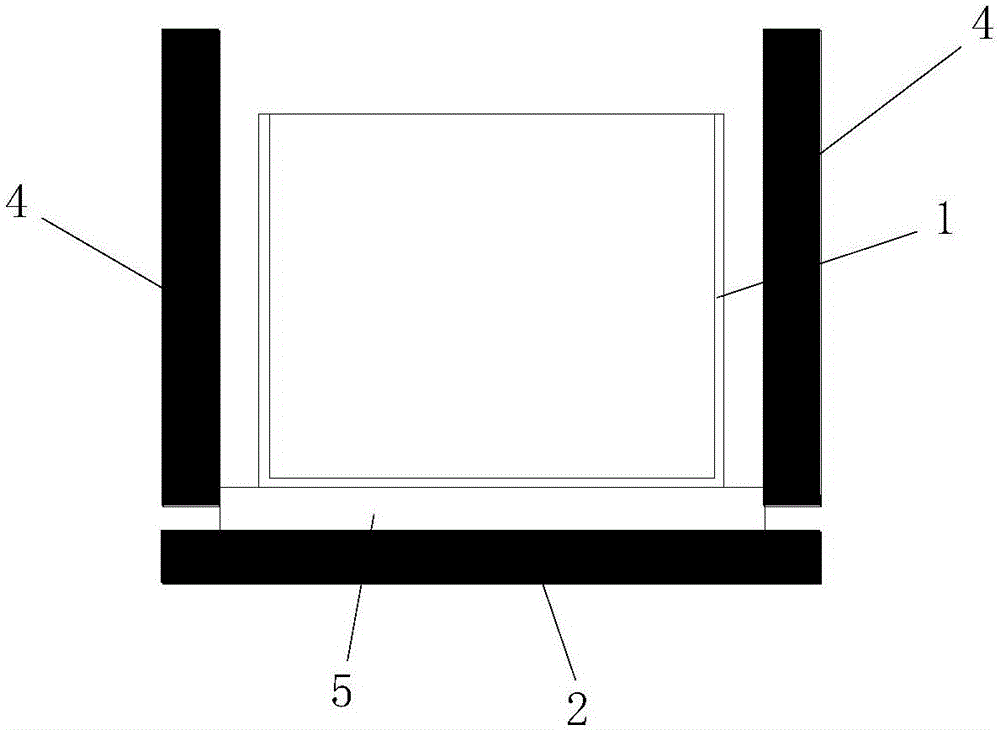

Method for polycrystalline silicon ingot casting

InactiveCN106087053AThe method steps are simpleReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a method for polycrystalline silicon ingot casting. The method comprises a first step of installation of an auxiliary heater, wherein the auxiliary heater is installed in a polycrystalline silicon ingot furnace, the auxiliary heater is a bottom heater below a crucible, and the auxiliary heater forms a six-side heating device together with a top heater and four side heaters; a second step of charging; a third step of preheating; a fourth step of melting: six-side heating melting, fifth-side heating melting and follow-up melting; a fifth step of crystal growth; a sixth step of annealing and cooling which comprise primary annealing, secondary annealing and cooling, wherein during the primary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T4 and heat insulation is performed for 2-3 h, and T4=1250-1280 DEG C; during the secondary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T5 and heat insulation is performed for 2-3 h, and T5=900-950 DEG C. The method is simple in steps, reasonable in design, convenient to implement and good in using effect. The six-side heating device is adopted for heating, the oxygen content of the bottom of the crucible can be effectively reduced; the annealing process is adjusted, and the quality of a finished ingot can be effectively improved.

Owner:XIAN HUAJING ELECTRONICS TECH

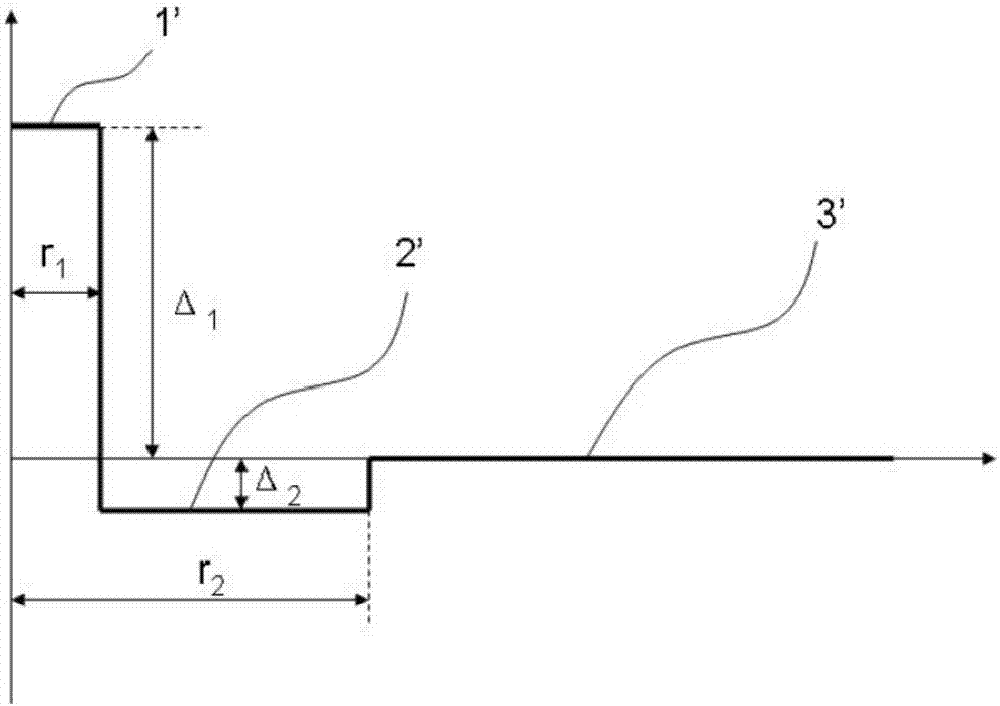

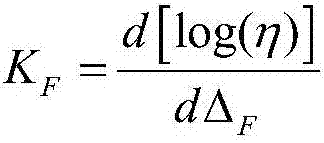

Large effective area optical fiber

InactiveCN107132614AReduce lossReduce complexityOptical fibre with multilayer core/claddingOptical waveguide light guideDopantMicrometer

The invention discloses a large effective area optical fiber. The large effective area optical fiber is provided with a core layer, an inner cladding layer and an outer cladding layer from center to outside, wherein the core layer and the inner cladding layer are made of silica dioxide as a base material and doped with a dopant; the outer cladding layer is a pure silicon dioxide layer; the radius of the core layer is 4.5-6.5 micrometers, and the relative refractive index difference delta 1 of the core layer is 0.23%-0.35%; the radius of the inner cladding layer is 16.0-32.5 micrometers, and the relative refractive index difference delta 2 of the inner cladding layer is (-0.09%)-(-0.02%); the absolute value of the difference value between the core layer and inner cladding layer viscosity logarithms is not more than 0.105. The optical fiber achieves the matching of the core layer and inner cladding layer viscosity at a simple structure and a lower cost, and the absolute value of the difference value between the core layer and inner cladding layer viscosity logarithms is not more than 0.105.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com