Patents

Literature

94 results about "MANGANESE ACETATE TETRAHYDRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

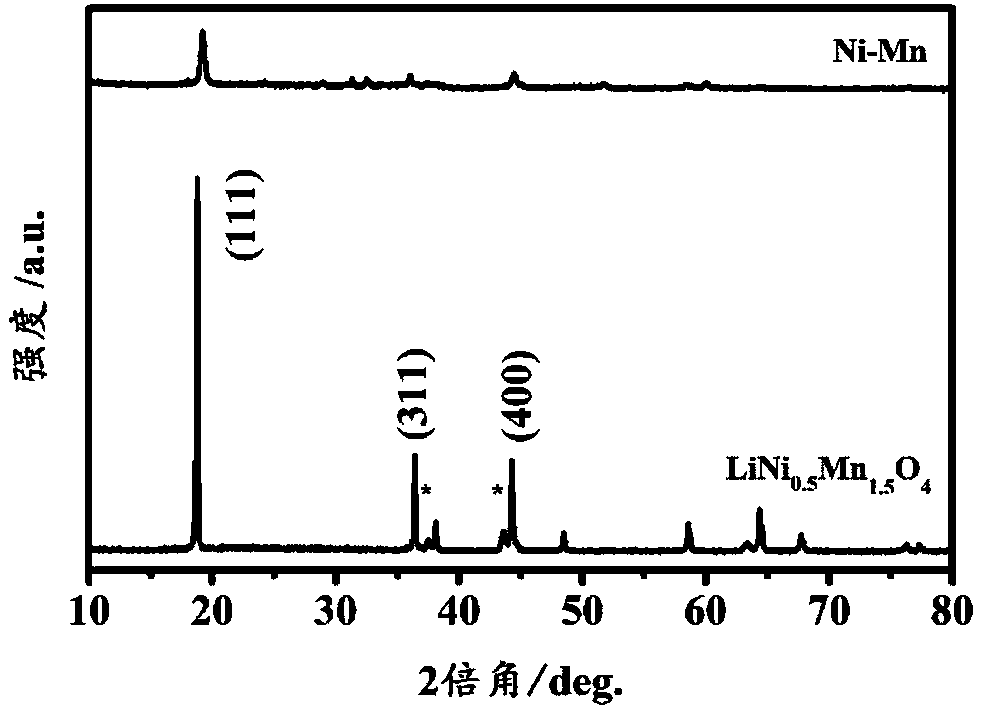

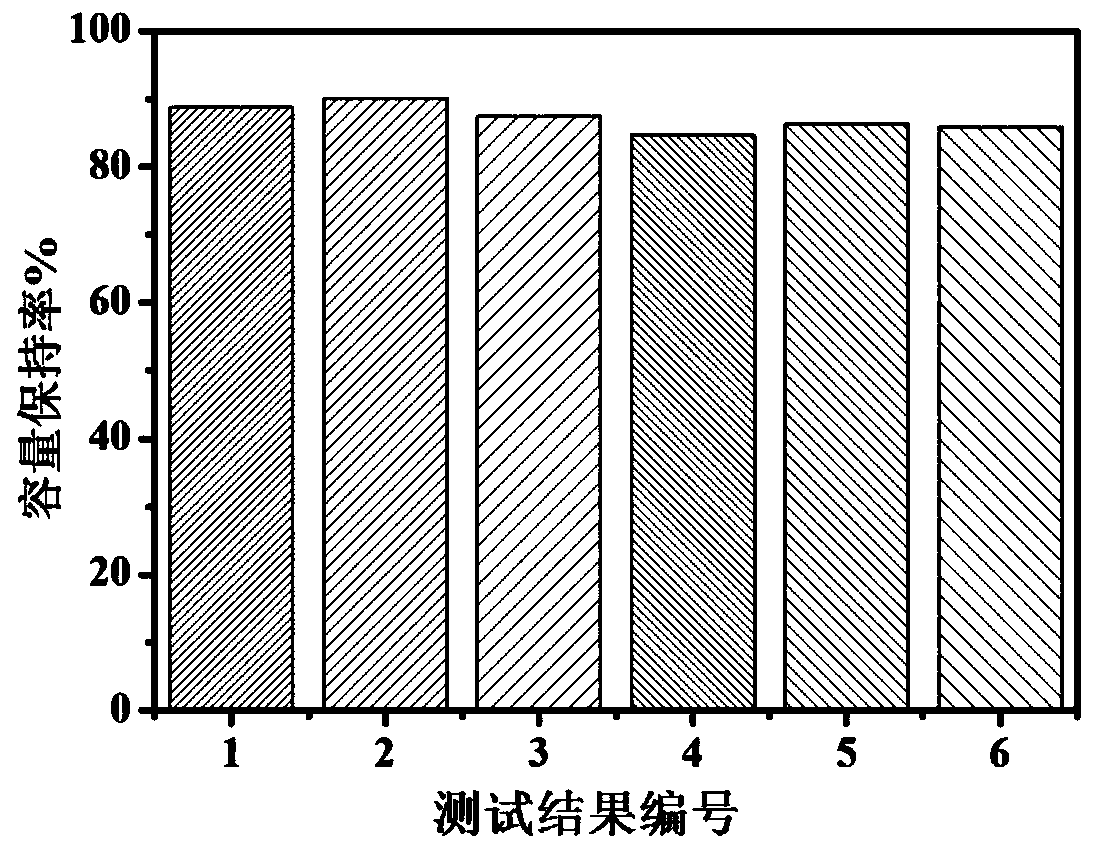

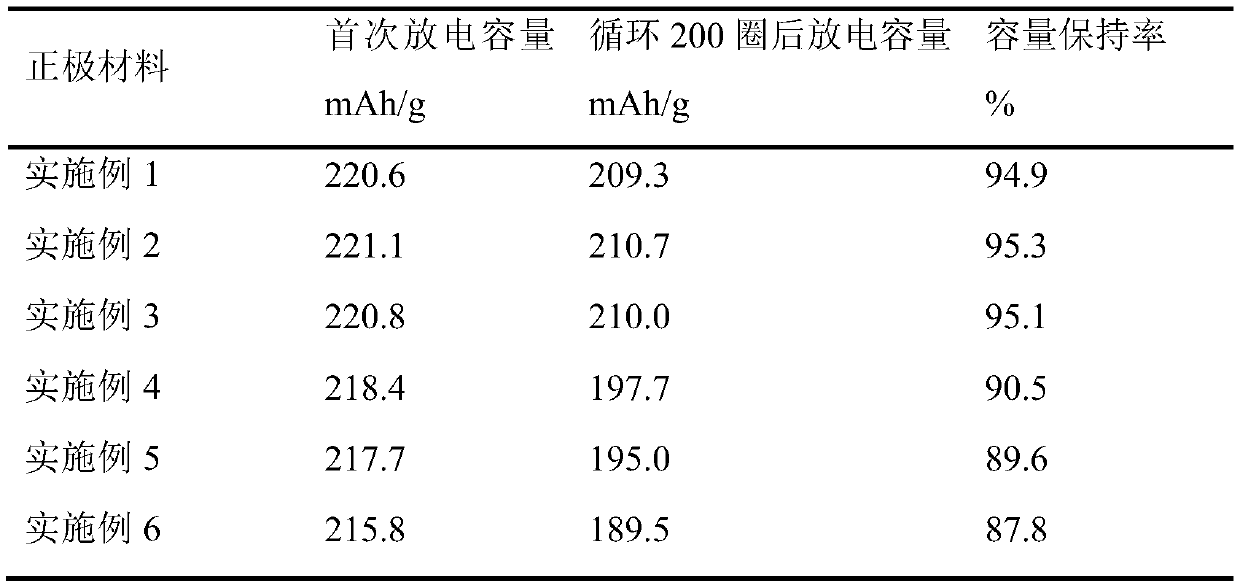

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

InactiveCN106356509AInhibition of dissolutionIncrease contentCell electrodesSecondary cellsMANGANESE ACETATE TETRAHYDRATENickel acetate tetrahydrate

The embodiment of the invention discloses modified lithium manganate coated based on a sol-gel method, and a preparation method thereof. The preparation method comprises the steps of preparing a nickel-doped lithium manganate material with the sol-gel method by firstly, weighing lithium hydroxide monohydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate and citric acid according to a certain stoichiometric ratio, adding deionized water, and uniformly mixing, wherein the citric acid is used as a chelating agent; mixing the prepared nickel-doped lithium manganate with cobalt acetate tetrahydrate; grinding, and calcining in a tube furnace to obtain a cobaltosic oxide coated and modified nickel-doped lithium manganate composite material. The composite material prepared by using the technical scheme has excellent cycling stability, rate capability and high-temperature performance.

Owner:EAST CHINA UNIV OF SCI & TECH

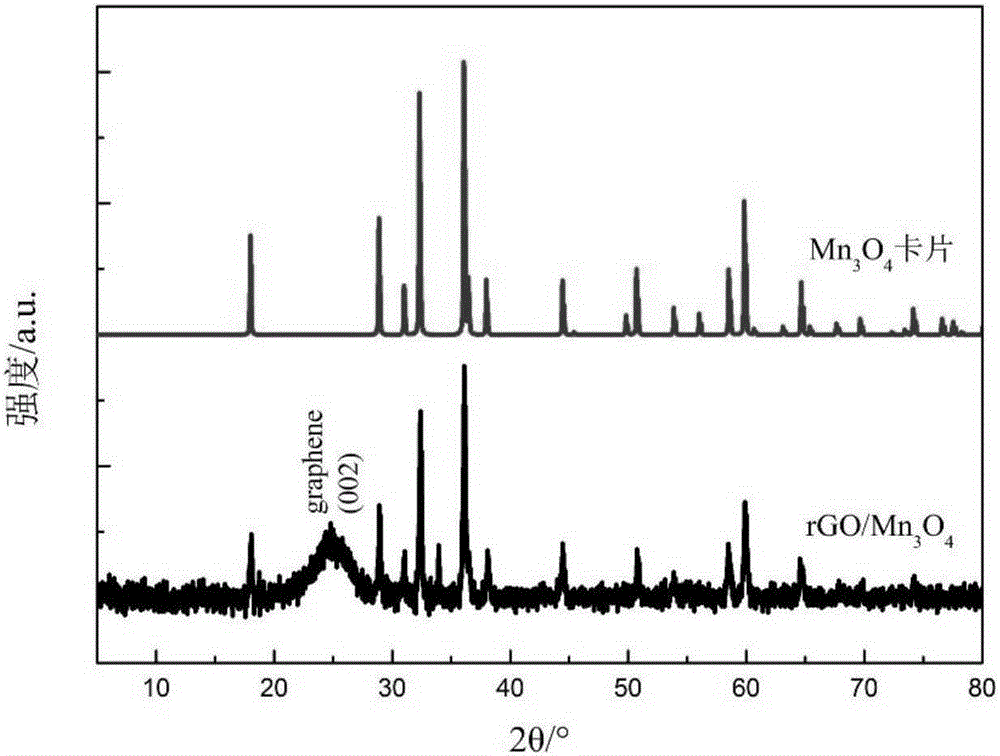

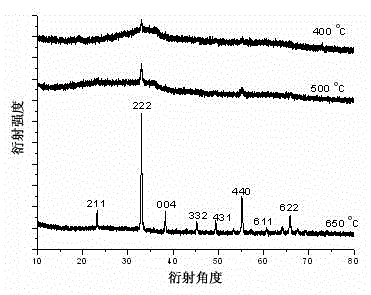

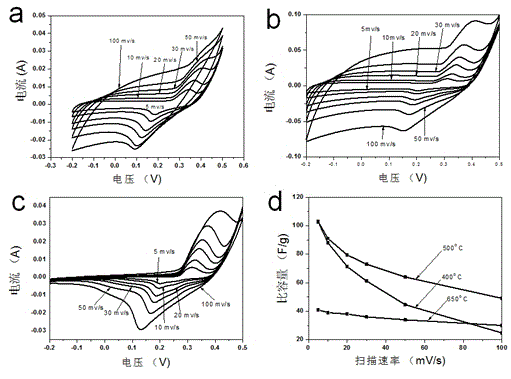

Graphene and manganous-manganic oxide composite material and preparation method thereof

ActiveCN105347334ASimple processEasy to operateHybrid capacitor electrodesManganese oxides/hydroxidesMANGANESE ACETATE TETRAHYDRATEManganous-manganic oxide

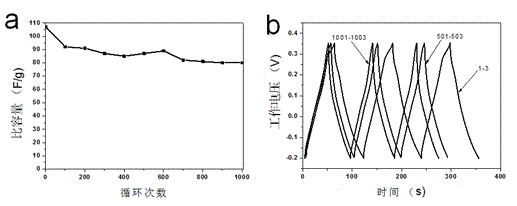

The invention relates to a graphene and manganous-manganic oxide composite material and a preparation method thereof. The graphene and manganous-manganic oxide composite material is characterized in that graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and manganese acetate tetrahydrate are used as matrix materials, the advanced Hummers' method is adopted for preparing oxidized graphene, and a solvothermal method is adopted for further preparing the graphene and manganous-manganic oxide composite material. The preparation method comprises the steps that 1-2 g of the graphite powder and 20-40 mL of the concentrated sulfuric acid are mixed, 100-200 mg of the sodium nitrate is added into the mixture, stirring is performed, a water bath is performed, 1-3 g of the potassium permanganate is added, the oxidized graphene dispersion liquid of the concentration being 4.00-5.00 mg / mL is dispersed in an ethyl alcohol-water mixed solvent, the mass ratio of the oxidized graphene to the manganese acetate tetrahydrate is 1:1-1:30, and then a reaction is performed for 8-12 h at the temperature of 160-200 DEG C. The method is easy to operate and low in cost, has no special requirement for equipment, and can be applied in the fields of supercapacitors, batteries, automobiles, military facilities and the like.

Owner:WUHAN UNIV OF TECH

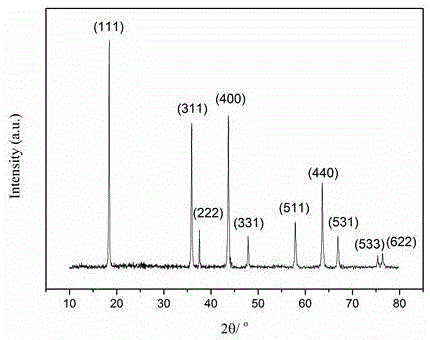

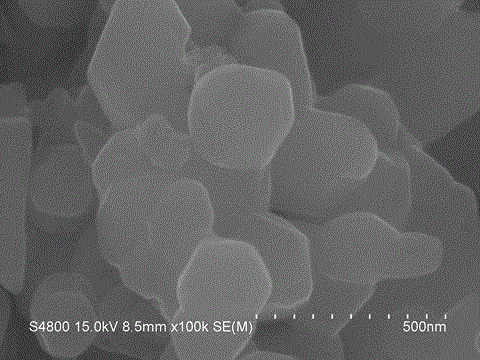

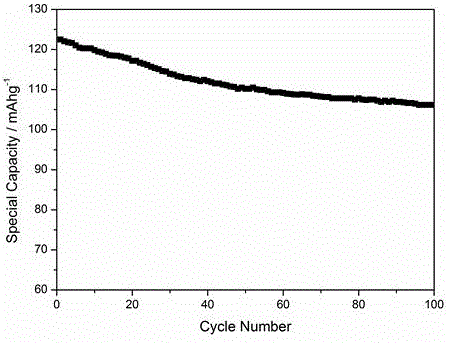

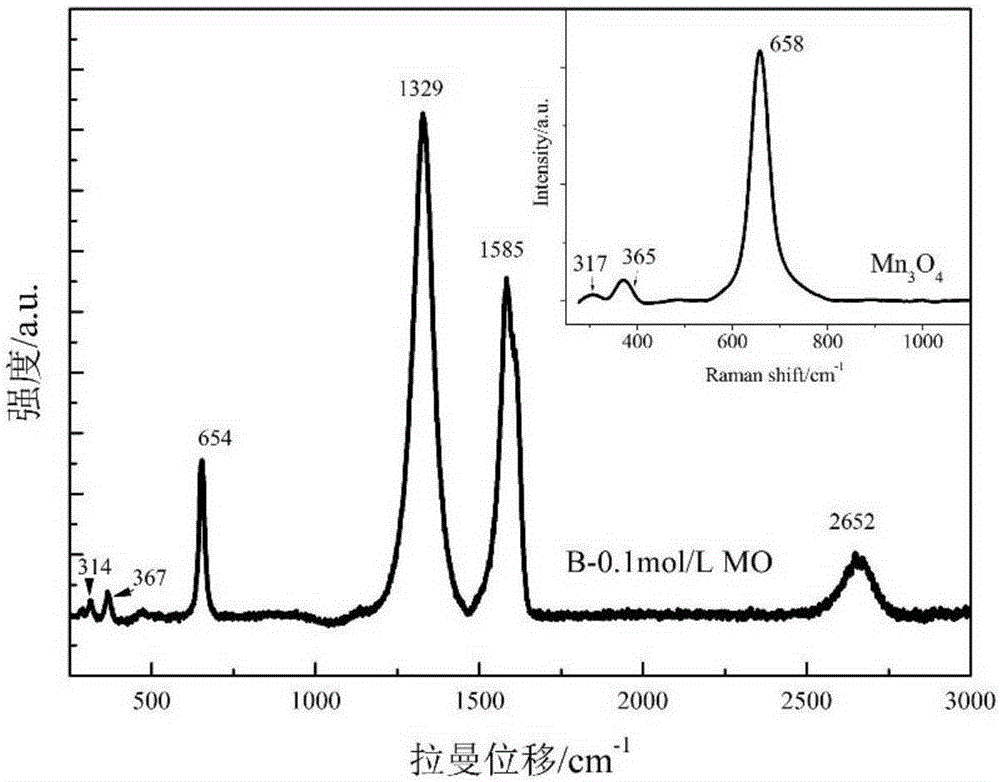

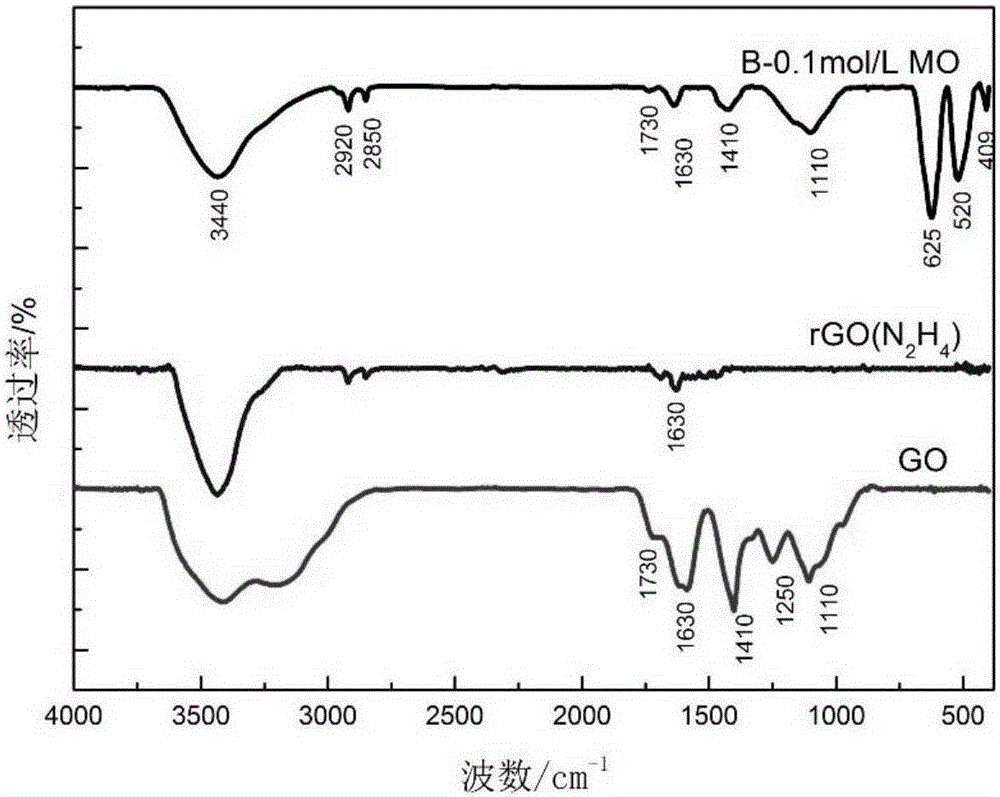

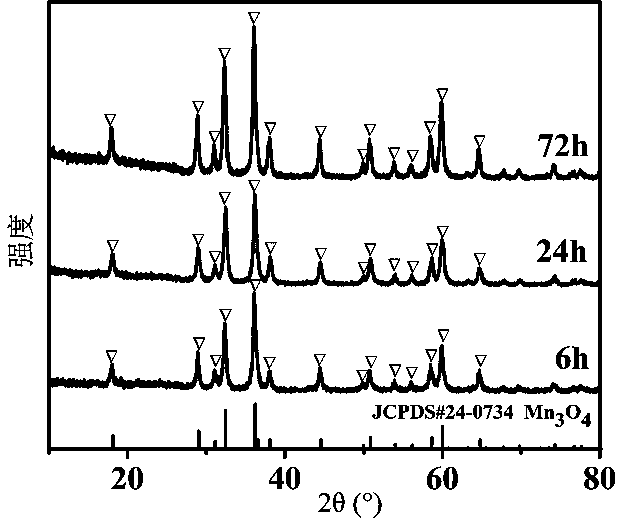

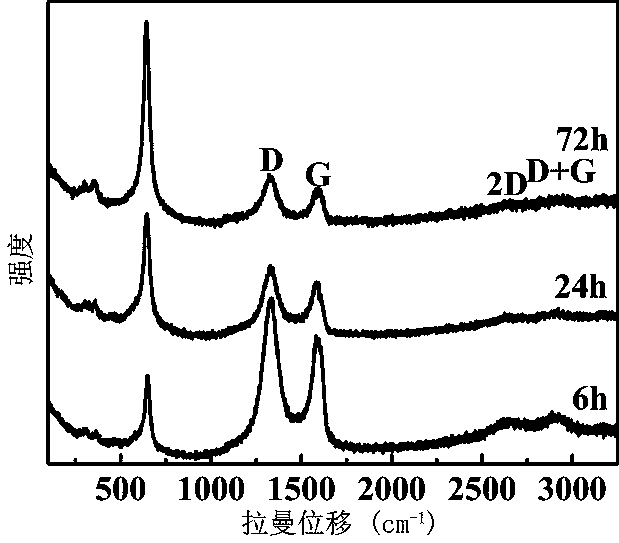

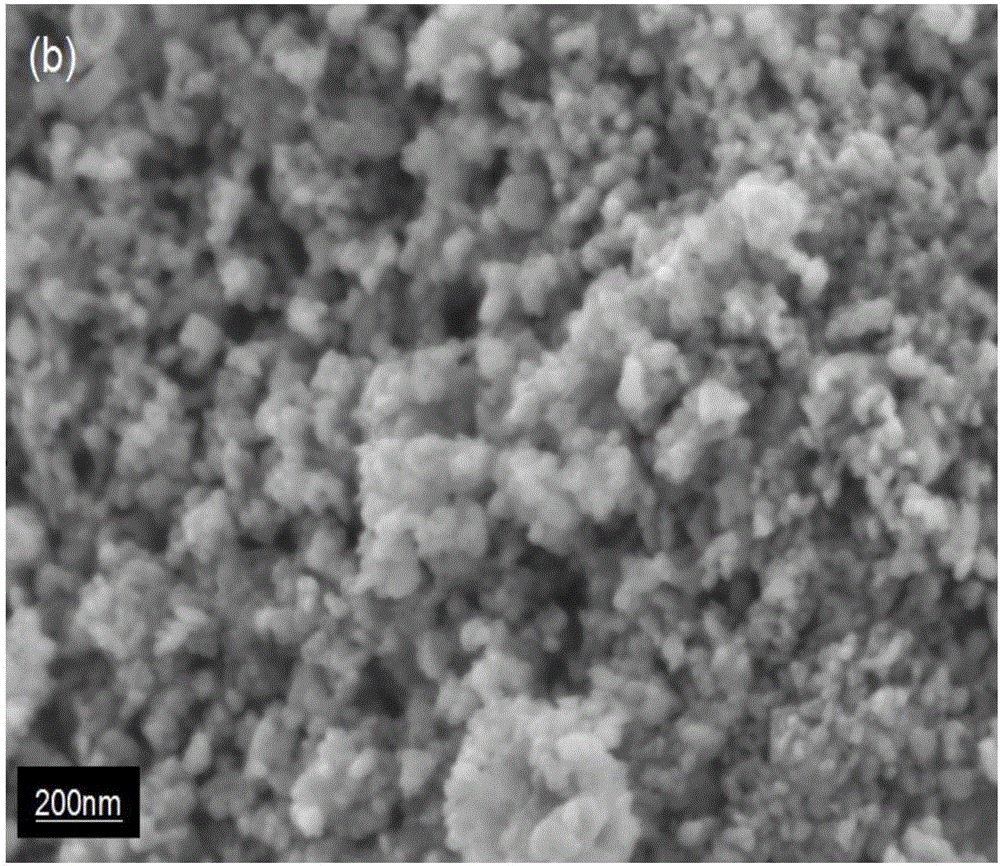

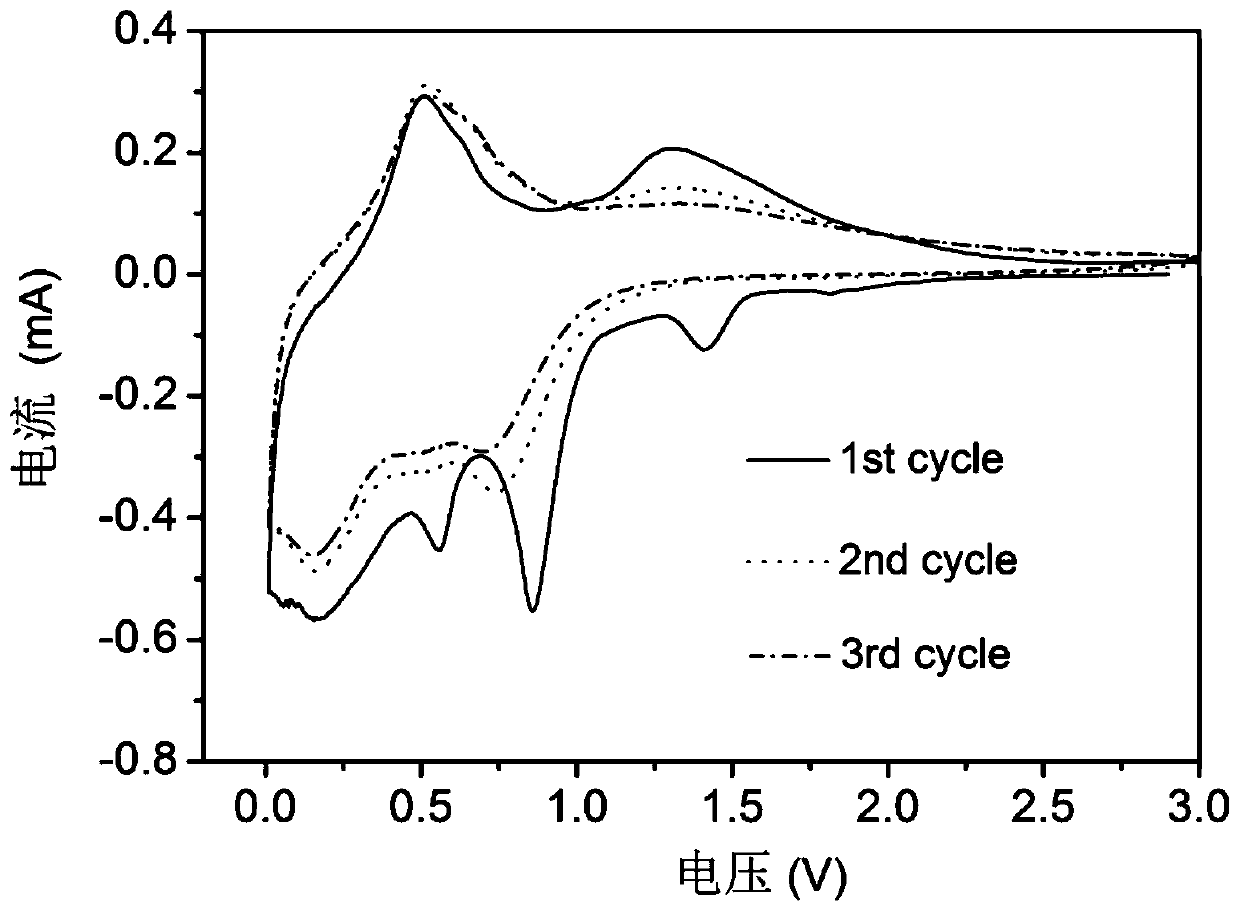

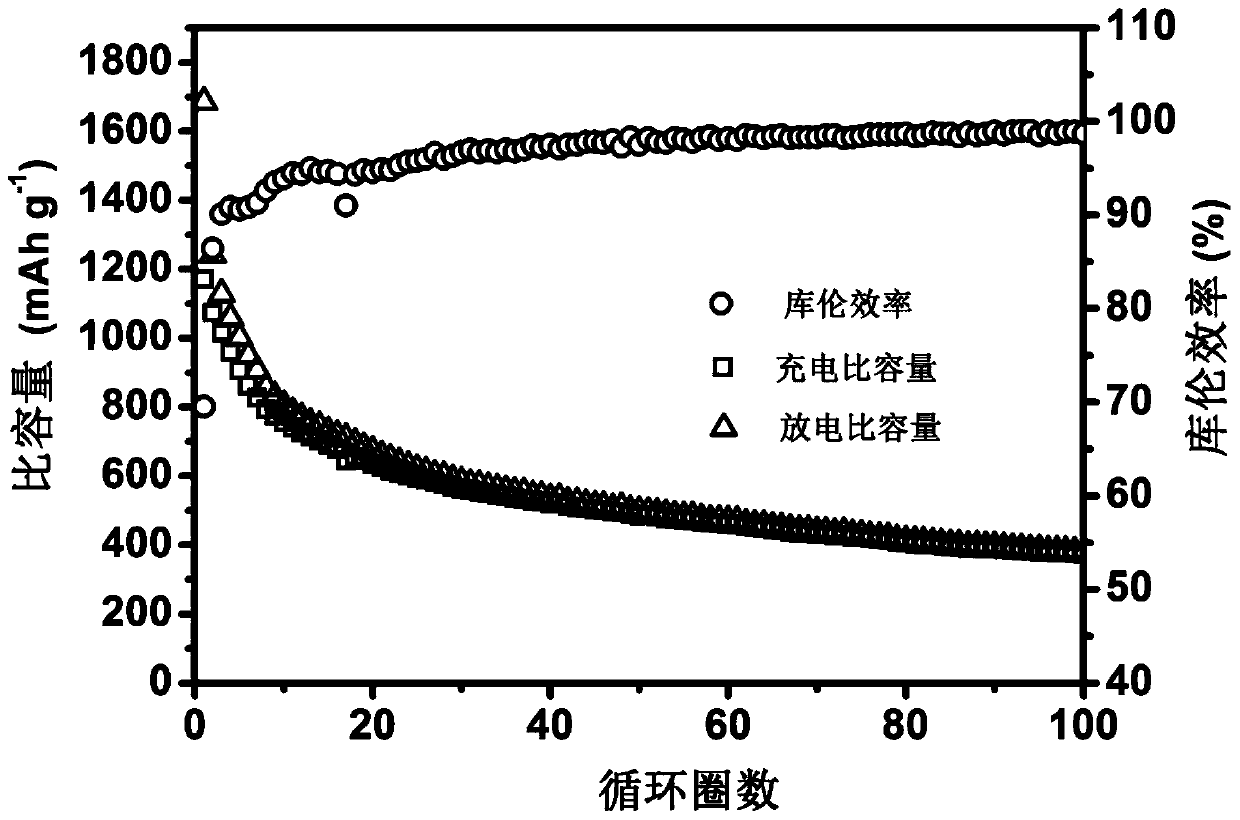

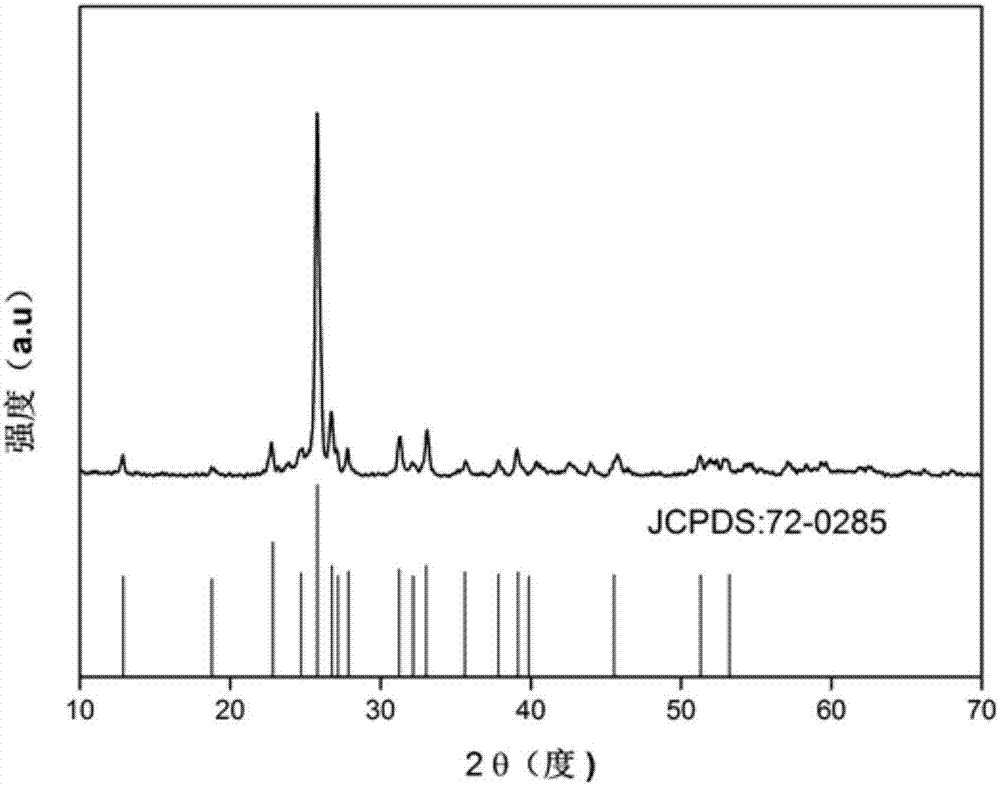

Preparation method of Mn3O4/RGO nanocomposite used as anode material of lithium ion battery

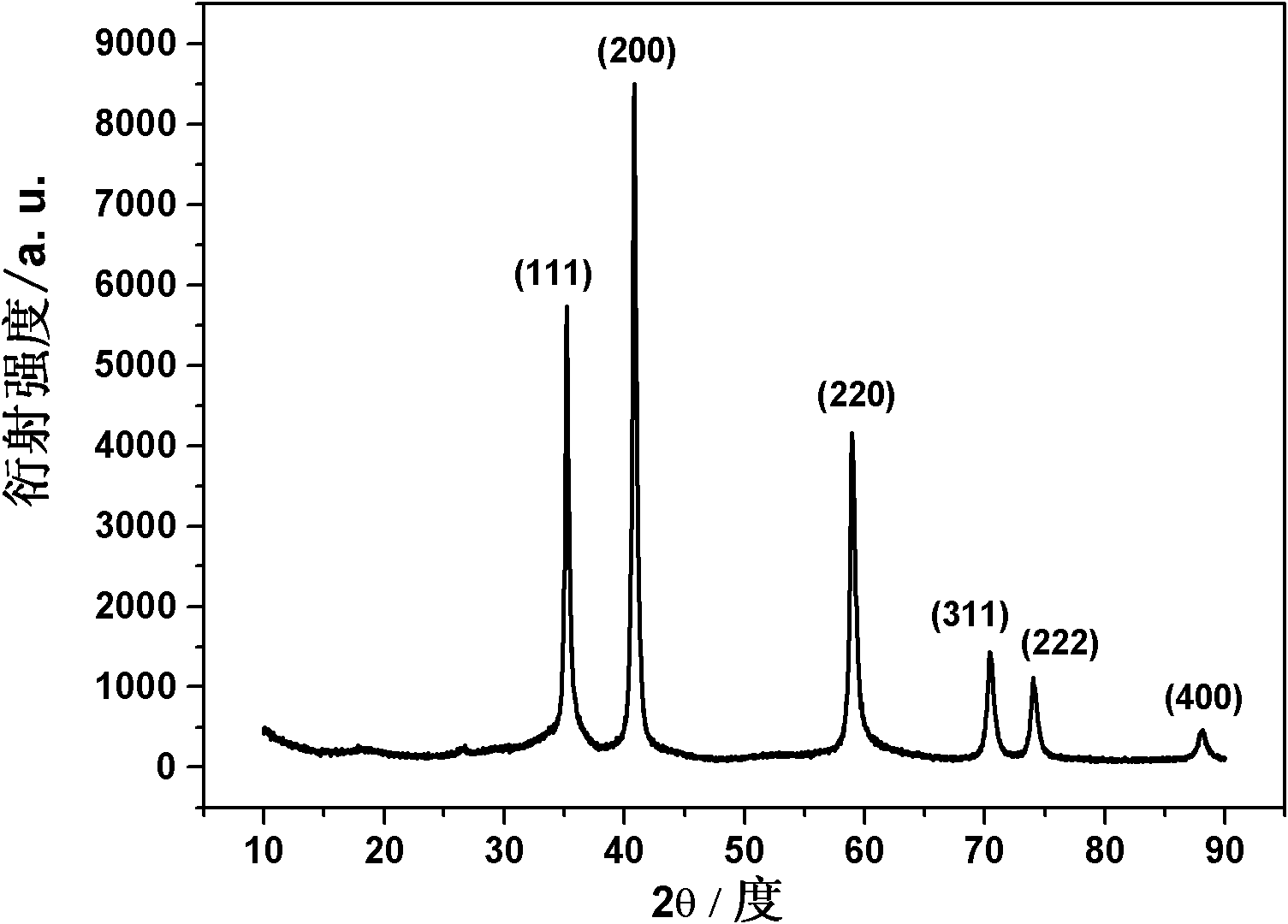

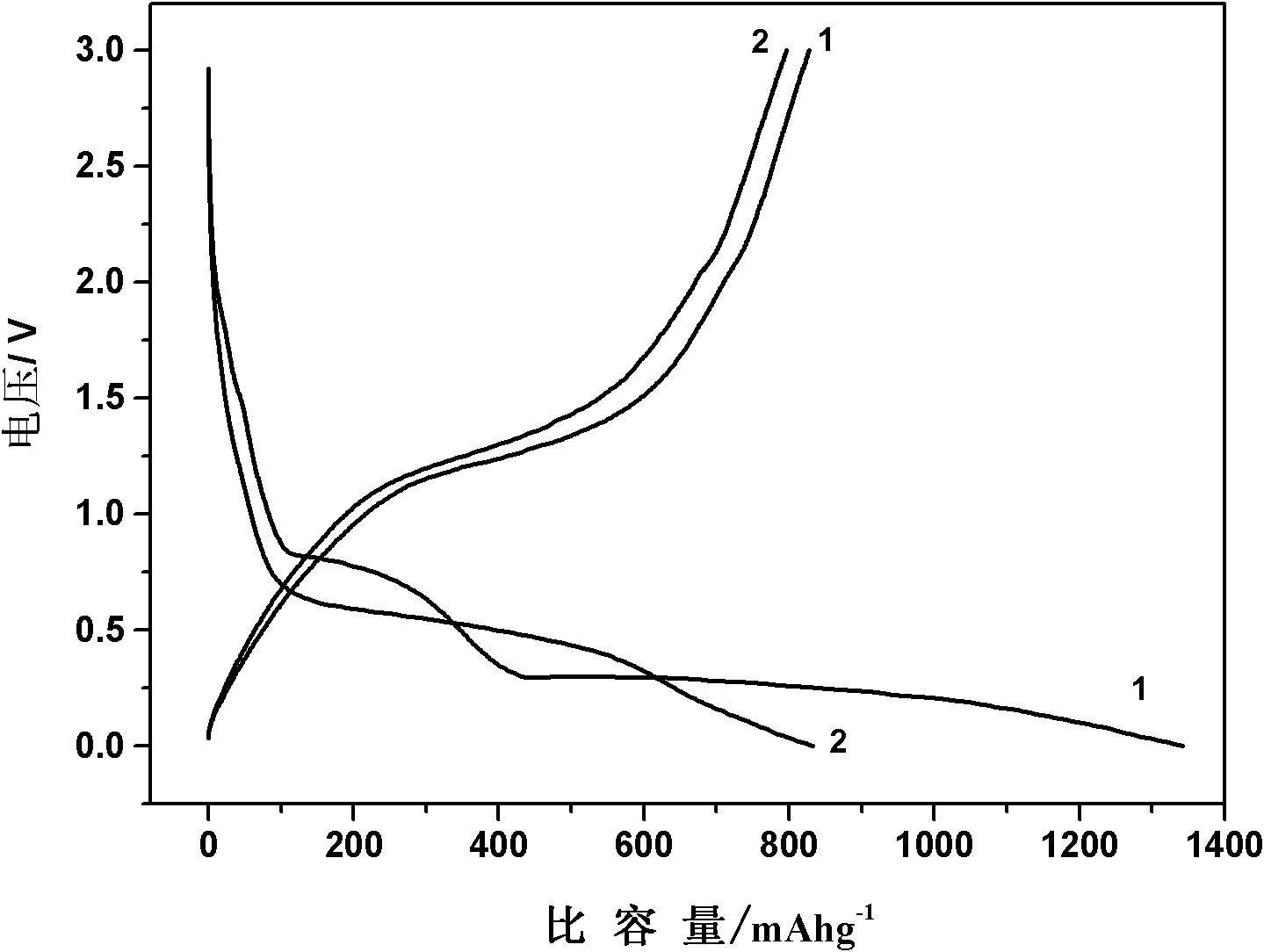

InactiveCN105514363AMaterial nanotechnologyCell electrodesMANGANESE ACETATE TETRAHYDRATECrystallinity

The invention relates to a preparation method of Mn3O4 / RGO nanocomposite used as an anode material of a lithium ion battery and belongs to the field of composite functional materials. The preparation method is simple in operation, mild, controllable, energy-saving and environment-friendly. The preparation method mainly comprises steps as follows: oxidized graphene is prepared with an improved Hummers method, then the oxidized graphene and manganese acetate tetrahydrate have a reaction with a hydrothermal method, and the Mn3O4 / RGO nanocomposite with excellent performance is directly prepared. The preparation process is simple, tests show that the crystallinity of Mn3O4 in the Mn3O4 / RGO composite is improved, and the Mn3O4 / RGO nanocomposite serving as the anode material of the lithium ion battery has good electrochemical performance due to the synergistic effect of the oxidized graphene and manganese acetate tetrahydrate. The product has potential application value in the field of composite functional materials, especially in the fields of energy storage of a lithium ion battery, a capacitor and the like.

Owner:SHANGHAI UNIV

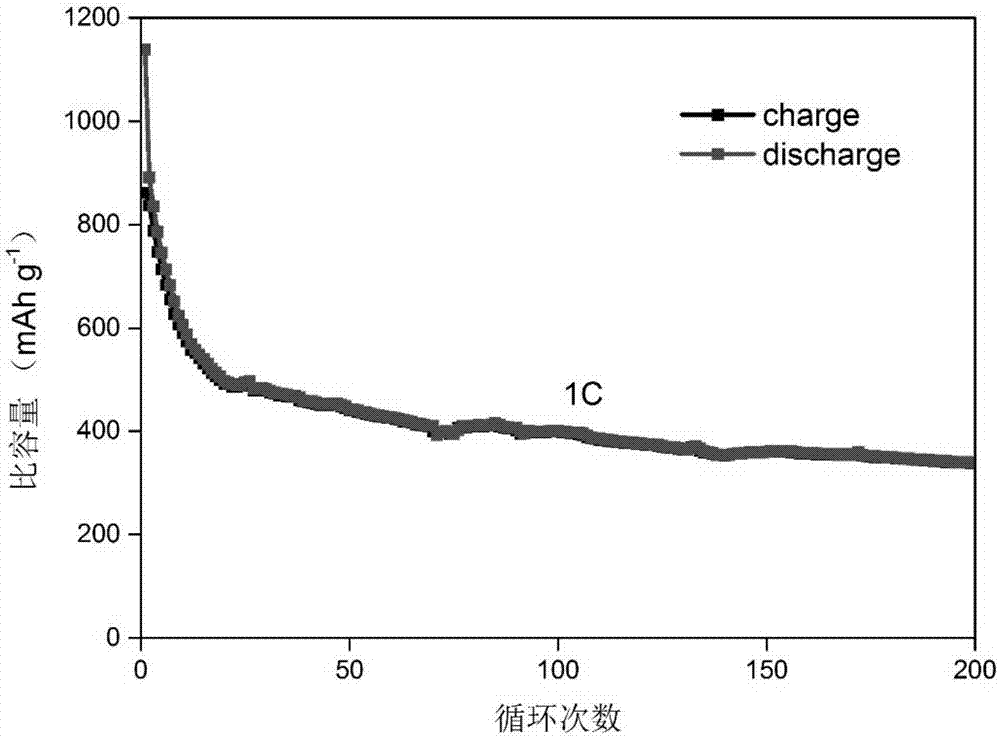

Preparation method for nano MnO of negative electrode material of lithium ion battery

InactiveCN102157727ASimple manufacturing methodLow requirements for production equipmentCell electrodesNanotechnologyMANGANESE ACETATE TETRAHYDRATECitrinin hydrate

The invention discloses a preparation method for nano MnO of a negative electrode material of a lithium ion battery, which belongs to the technical field of lithium ion battery material and electrochemistry. The method comprises the following steps of: firstly dissolving polyvinylpyrrolidone K30 in glycol under the condition of magnetic stirring, wherein the concentration of the polyvinylpyrrolidone K30 is 2.0 to 4.0 g / L; then adding citric acid monohydrate with the concentration of 8.4 to 42.0 g / L; adding manganese acetate tetrahydrate when the adding citric acid monohydrate is dissolved completely, wherein the molar ratio of the citric acid monohydrate to the manganese acetate tetrahydrate is between 0.3 and 1.6; and then subjecting the mixture to magnetic stirring, heating the mixture between 140 DEG C and 180 DEG C to evaporate the solvent; transferring the red-brown sticky material obtained into an over of 140 to 180 DEG C to dry for 3 to 5 hours; and finally subjecting the product dried to thermal treatment of 600 to 1000 DEG C for 1 hour in H2 / Ar mixed atmosphere to obtain nano MnO of a negative electrode material of a lithium ion battery. The preparation method for nano MnO of a negative electrode material of a lithium ion battery provided by the invention has the advantages that the specific capacity of the nano MnO negative electrode material prepared by means of themethod provided by the invention is high, the cycle performance is stable, the security performance is good, the preparation method is simple and easy, the production conditions are mild, and the preparation method is suitable for large-scale production.

Owner:BEIJING UNIV OF TECH

Preparation method of porous carbon coated MnO nanocrystalline composite material and application of porous carbon coated MnO nanocrystalline composite material in lithium battery

InactiveCN107394183AThe process steps are simpleSimple processMaterial nanotechnologyCell electrodesPorous carbonMANGANESE ACETATE TETRAHYDRATE

The invention discloses a preparation method of a porous carbon coated MnO nanocrystalline composite material. The method comprises the following steps: (a1) in a temperature environment of 20-25DEG C, dripping mixed solution of ethyl alcohol of trimesic acid and water into a mixed solution of manganese acetate tetrahydrate, ethyl alcohol of polyvinylpyrrolidone and water, stirring evenly, standing for 20-30h, and carrying out centrifugalization to obtain a precursor Mn-BTC micro-sphere; (a2) putting the precursor Mn-BTC micro-sphere into a tube-type crucible furnace, raising the temperature to 500-700DEG C at a rate of 7-13DEG C / min in inert gas, then, calcining at the temperature for 1-3h, and naturally cooling to 20-25DEG C to obtain the porous carbon coated MnO nanocrystalline composite material. The preparation method has the advantages that a complex is directly calcined in nitrogen to prepare the carbon coated MnO composite material, and technical steps for preparing the carbon coated MnO composite material are effectively simplified. In addition, the preparation method has the advantages of simple and efficient preparation technology, safety, easiness in realization and short synthesis period, and is hopefully subjected to popularization and industrial production.

Owner:ANQING NORMAL UNIV

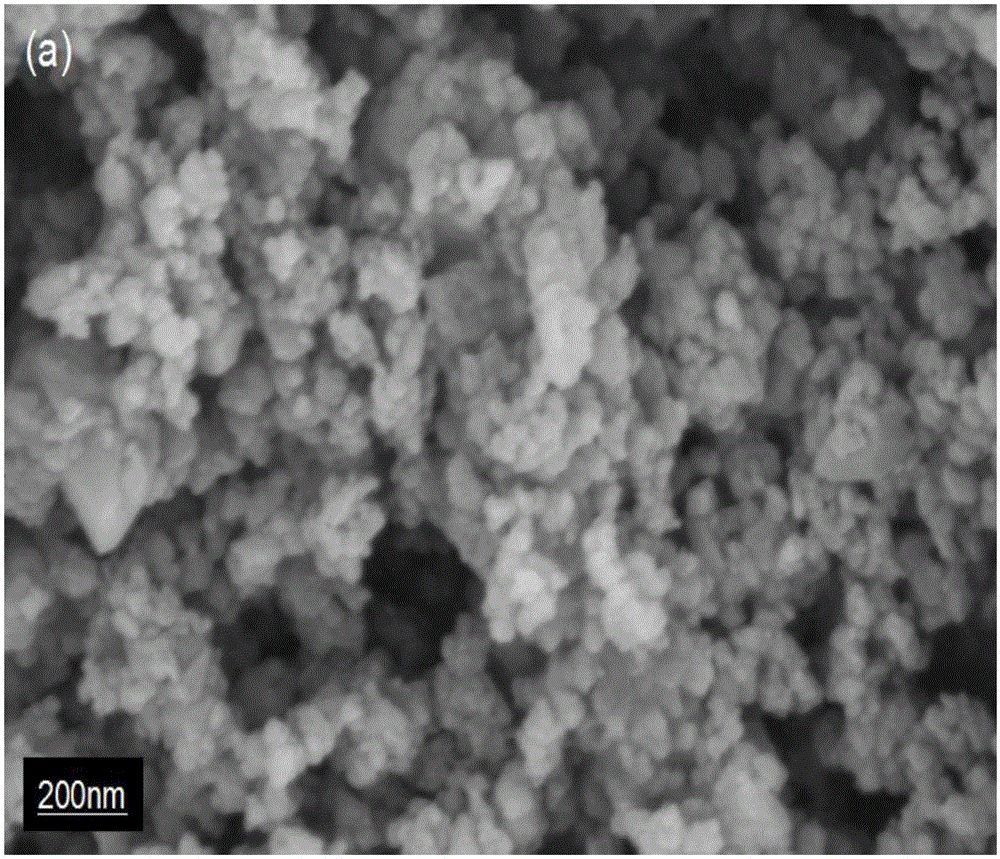

Lithium manganese phosphate nanoparticles and preparation method thereof

InactiveCN104183845AGood dispersionFacilitated DiffusionMaterial nanotechnologyCell electrodesArgon atmospherePhosphoric acid

The invention discloses lithium manganese phosphate nanoparticles. The nanoparticles have the size of 50-100nm. A preparation method of the nanoparticles comprises the steps that a solvent, required for solvent thermal reaction, is prepared from ethylene glycol, manganese acetate tetrahydrate, lithium acetate dihydrate and phosphoric acid are taken as reacting materials, P123 is taken as a surfactant, so as to influence nucleation and growth, heat treatment is carried out at high temperature and high pressure, then, segmented calcining is carried out at the temperature of 300-400 DEG C and 550-650 DEG C under the protection of a nitrogen or argon atmosphere, and then, the lithium manganese phosphate nanoparticles are obtained. The lithium manganese phosphate nanoparticles and the preparation method thereof have the advantages that the product is stable in quality, high in purity and good in particle dispersibility and is beneficial to the diffusion of lithium ions and the improvement of the electrochemical properties of a lithium-ion battery, and the preparation process is simple in process, easy to control and low in cost and is pollution-free, so that the large-scale production is facilitated.

Owner:ZHEJIANG UNIV

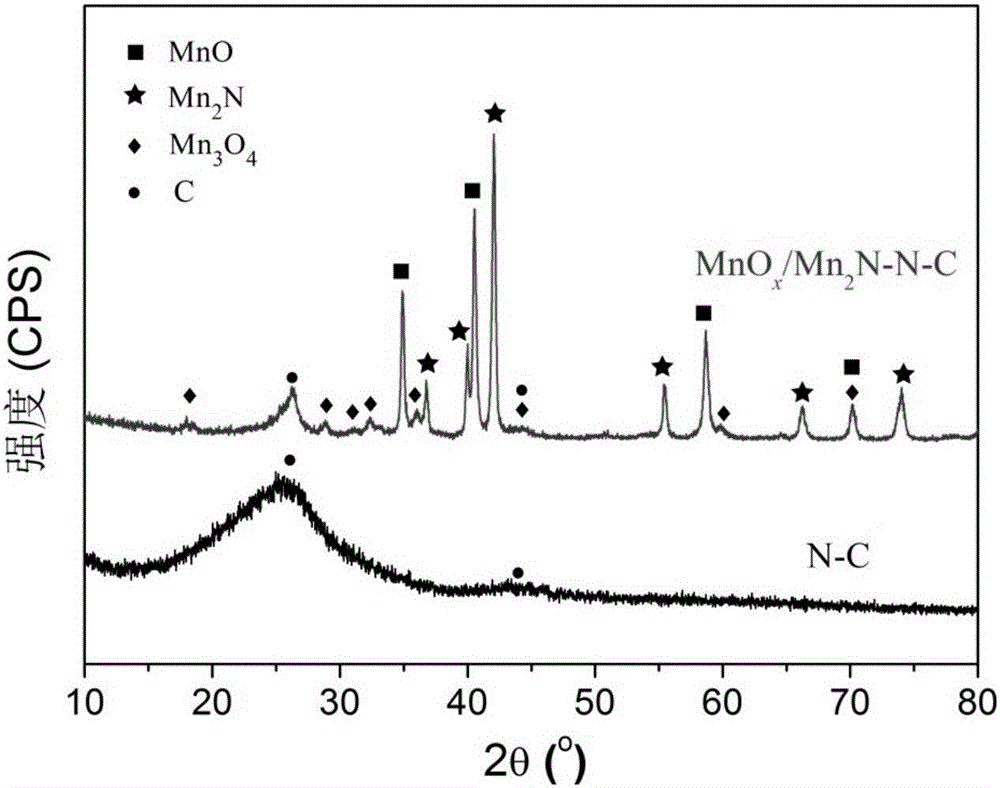

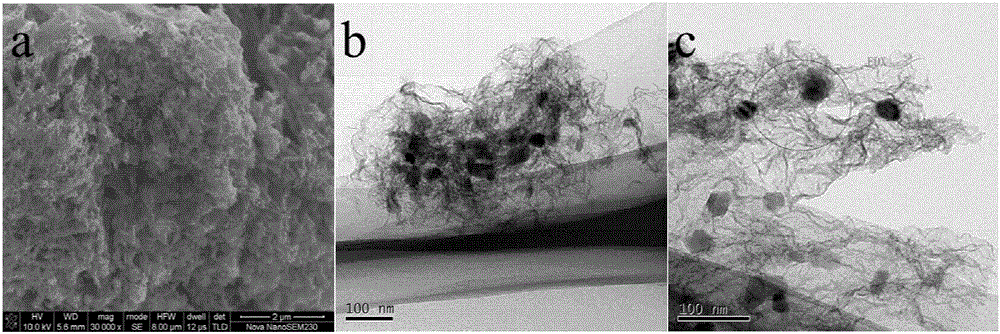

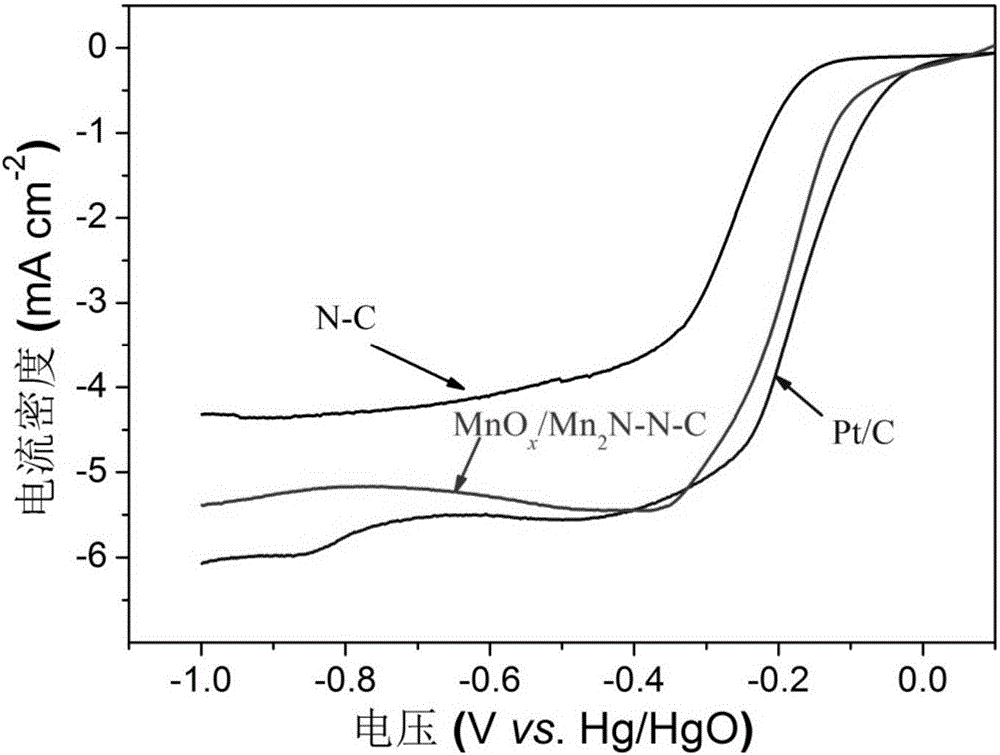

High-performance oxygen reduction catalyst MnOx/Mn2N-N-C composite catalyst and preparation method and application thereof

ActiveCN105810959AGood synergyHigh catalytic activityMaterial nanotechnologyCell electrodesDoped grapheneMANGANESE ACETATE TETRAHYDRATE

The invention discloses a high-performance oxygen reduction catalyst MnOx / Mn2N-N-C composite catalyst and a preparation method and an application thereof. The composite catalyst is formed by loading MnOx (MnO and Mn3O4) nanoparticles and Mn2N nanoparticles on three-dimensional porous N-doped graphene; and the preparation method comprises the following steps: evaporating and drying a water solution containing urea, glucose and manganese acetate tetrahydrate; and carrying out high-temperature thermal treatment on the obtained mixture in a protective atmosphere and cooling the mixture to obtain the MnOx / Mn2N-N-C composite catalyst. The preparation method is simple, low in cost and beneficial to industrial production; and the prepared MnOx / Mn2N-N-C composite catalyst has the characteristics of high activity and good stability when applied to a fuel cell and has better overall performance and better application prospect than commercial 20wt% of Pt / C.

Owner:CENT SOUTH UNIV

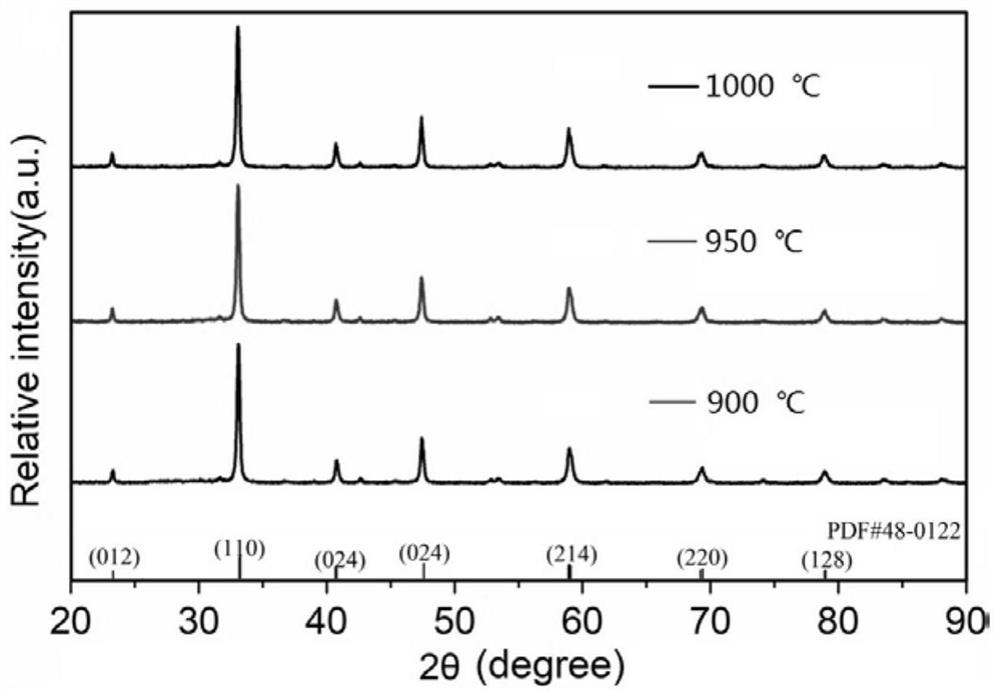

Perovskite type catalyst prepared by sol-gel weak oxidation calcination and method

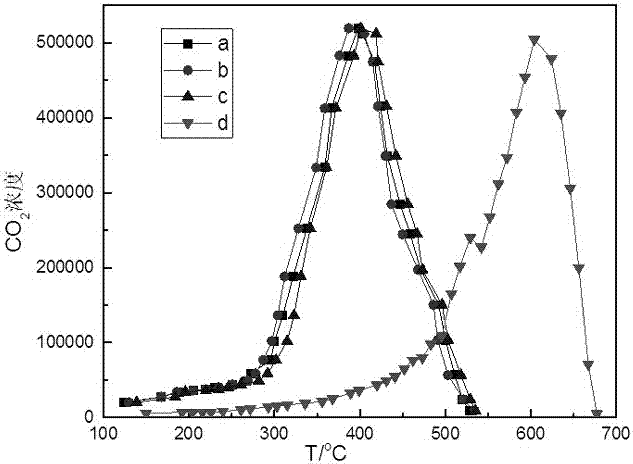

PendingCN112058272AWell mixedThe right concentration of oxygen vacanciesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a perovskite type catalyst prepared by sol-gel weak oxidation calcination and a method. The method comprises the following steps of: dissolving lanthanum nitrate, strontium acetate hemihydrate, cobalt nitrate hexahydrate, manganese acetate tetrahydrate, a composite complexing agent ethylenediaminetetraacetic acid and citric acid with deionized water to prepare sol, and adjusting the pH value by using an adjusting agent in the sol forming process to make the pH value in a range of 6-7; evaporating sol moisture through heating or water bath to form gel, and drying the gelat 250 DEG C for 5 hours to obtain dry gel; and calcining the dry gel for 4-6 hours at 900-1000 DEG C under a weak oxidation condition, cooling, taking out, and grinding into powder, thereby obtaining the perovskite (La0.5Sr0.5) (Co0.8Mn0.2)O3-lambda oxide catalyst. The preparation process is simple, damage to equipment and the environment is small, and the prepared catalyst has excellent, stableand reliable catalytic activity.

Owner:TIANJIN UNIV

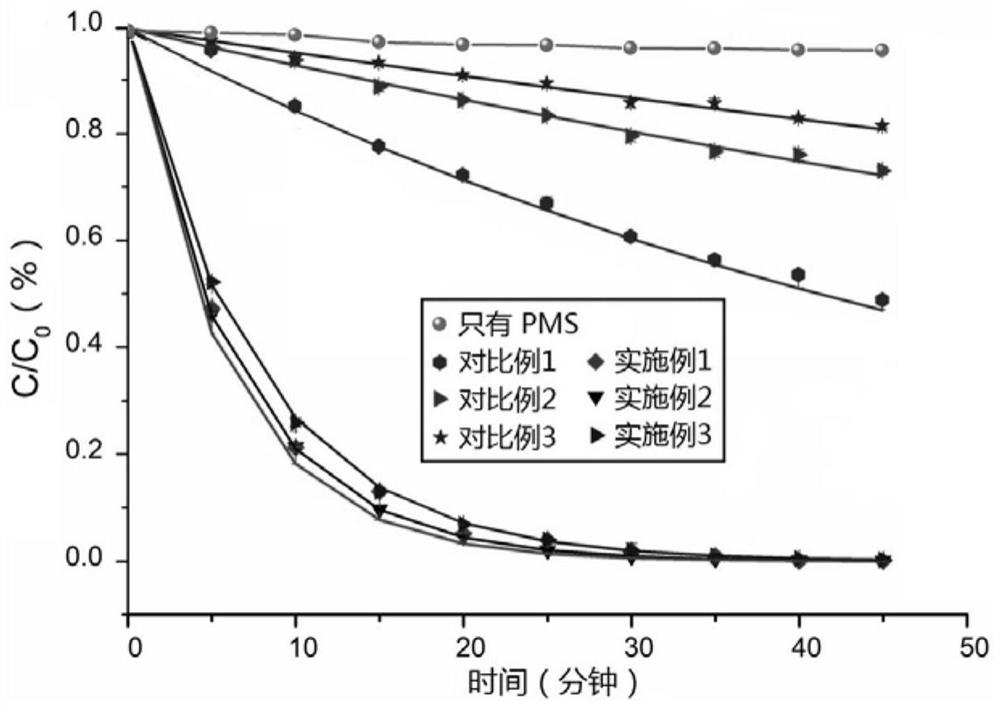

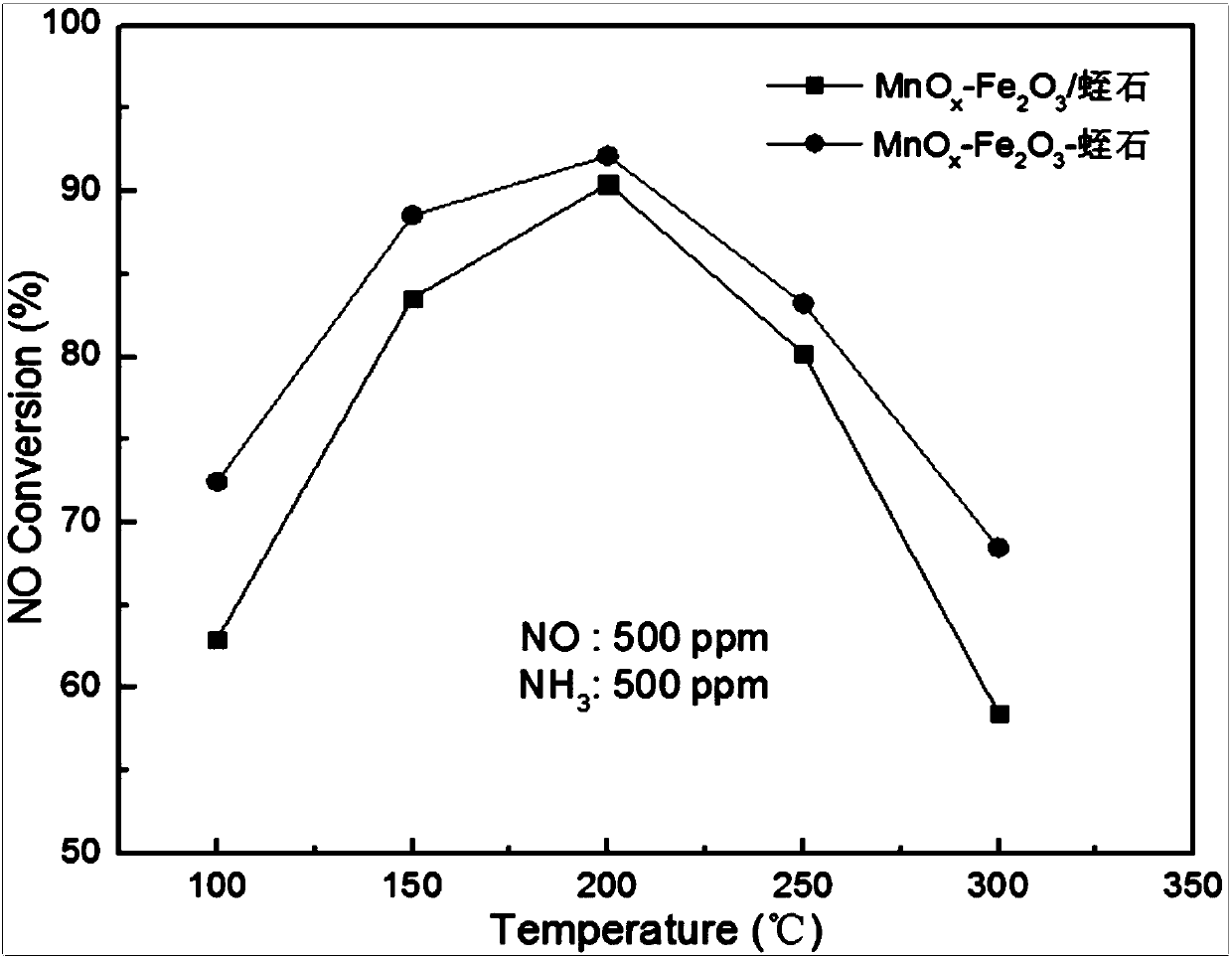

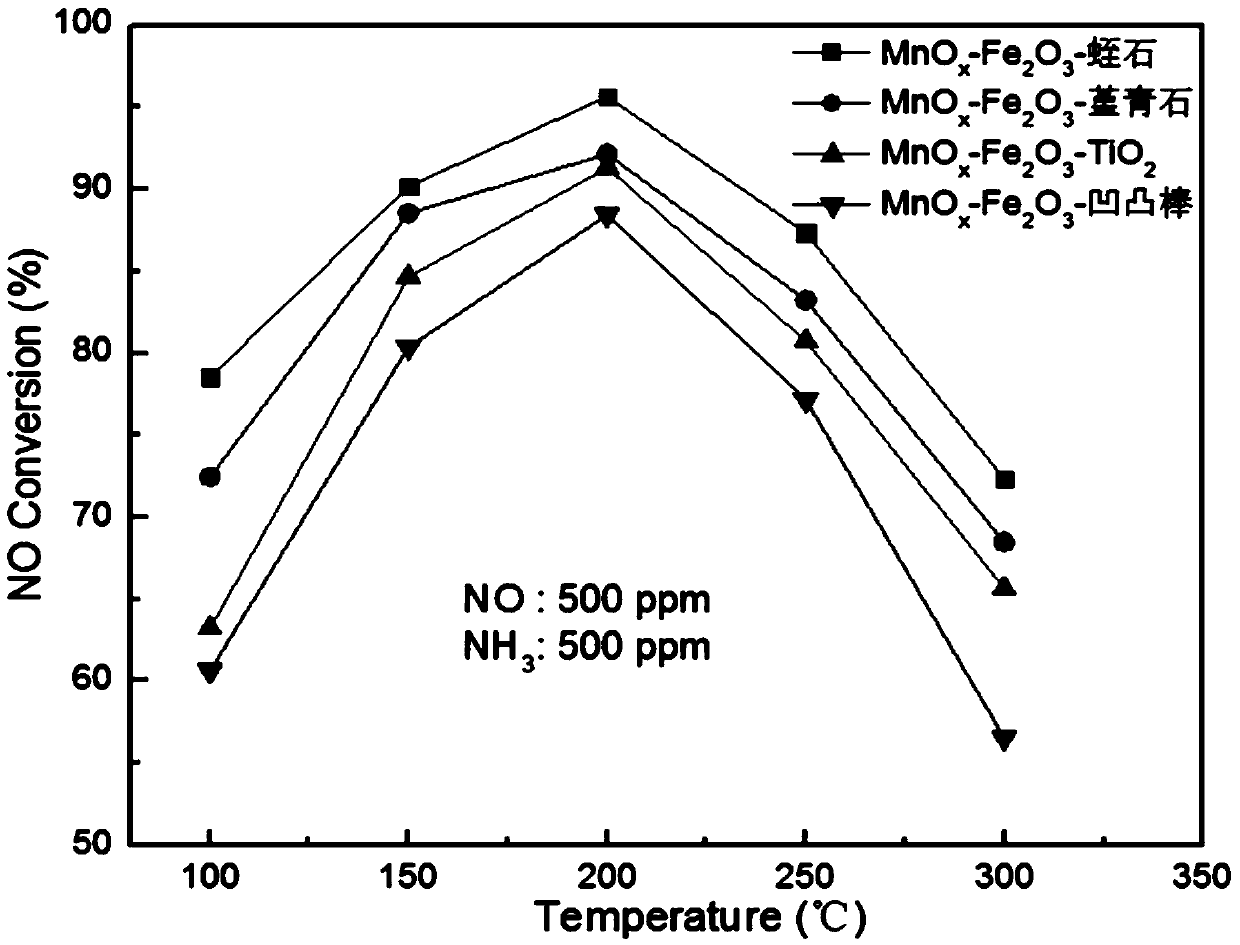

Honeycomb type denitration catalyst and preparation method thereof

InactiveCN107824197AWide variety of sourcesLow priceGas treatmentDispersed particle separationSodium BentonitePolyvinyl alcohol

The invention belongs to the field of catalysts and in particular relates to a honeycomb type denitration catalyst and a preparation method thereof. The honeycomb type denitration catalyst comprises acarrier, an active component, an adhesive, a plasticizer, a toughening agent and a lubricant, wherein the carrier is one of cordierite, attapulgite, TiO2 and expanded vermiculite; the active component is manganese acetate tetrahydrate and ferric sulfate nonahydrate; the adhesive is one of bentonite, silica sol, clay and polyvinyl alcohol; the toughening agent is a glass fiber or quartz cotton; the plasticizer is carboxymethylcellulose or PMMA (Polymethyl Methacrylate) microspheres; the lubricant is glycerinum or ethanolamine. The invention further discloses a preparation method of the catalyst. The honeycomb type denitration catalyst and the preparation method thereof provided by the invention are low in raw material price, short in preparation cycle, simple in process procedure and low in catalyst molding preparation cost, and the obtained honeycomb type denitration catalyst is good in denitration property and good in stability.

Owner:SHIHEZI UNIVERSITY

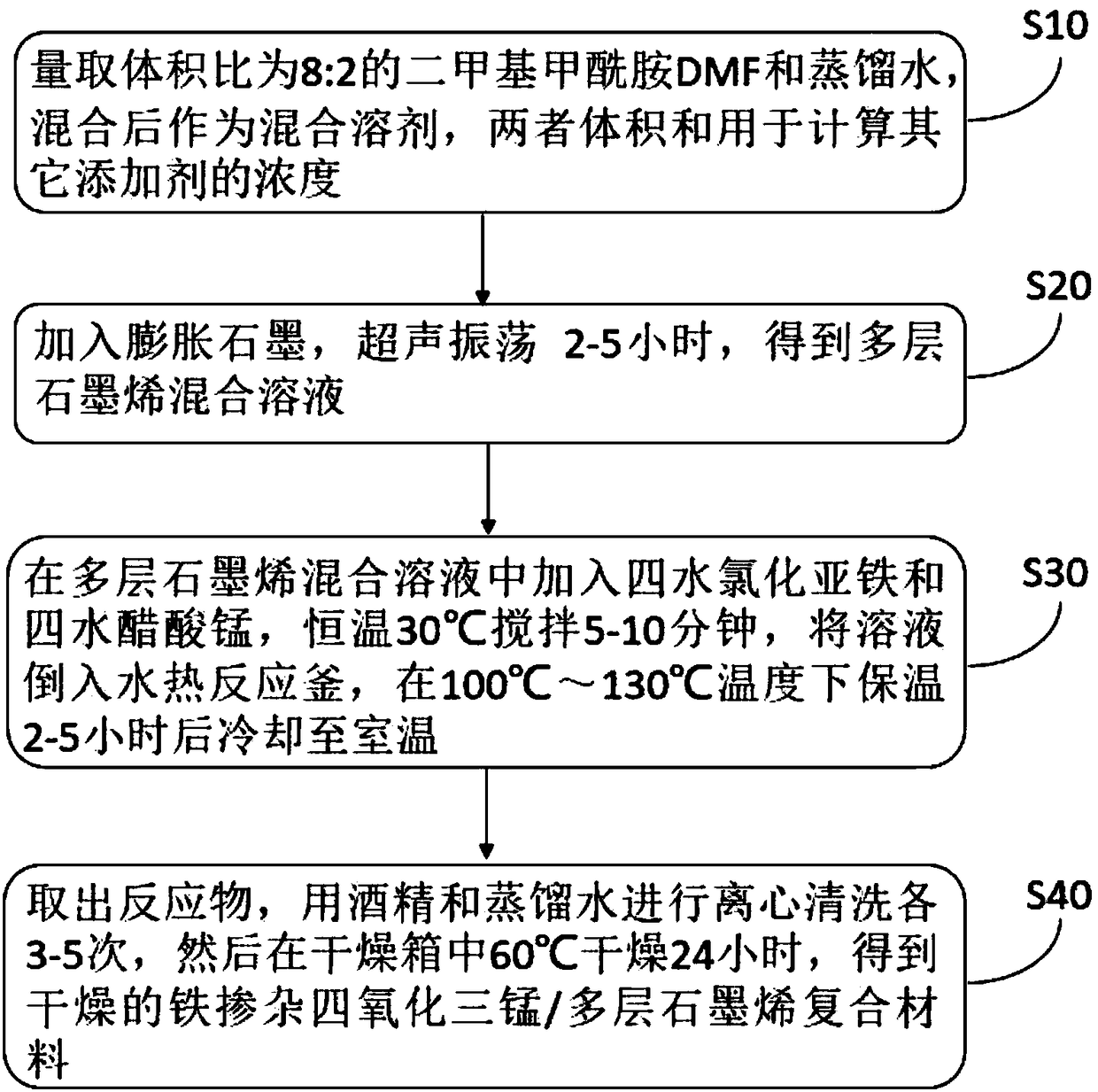

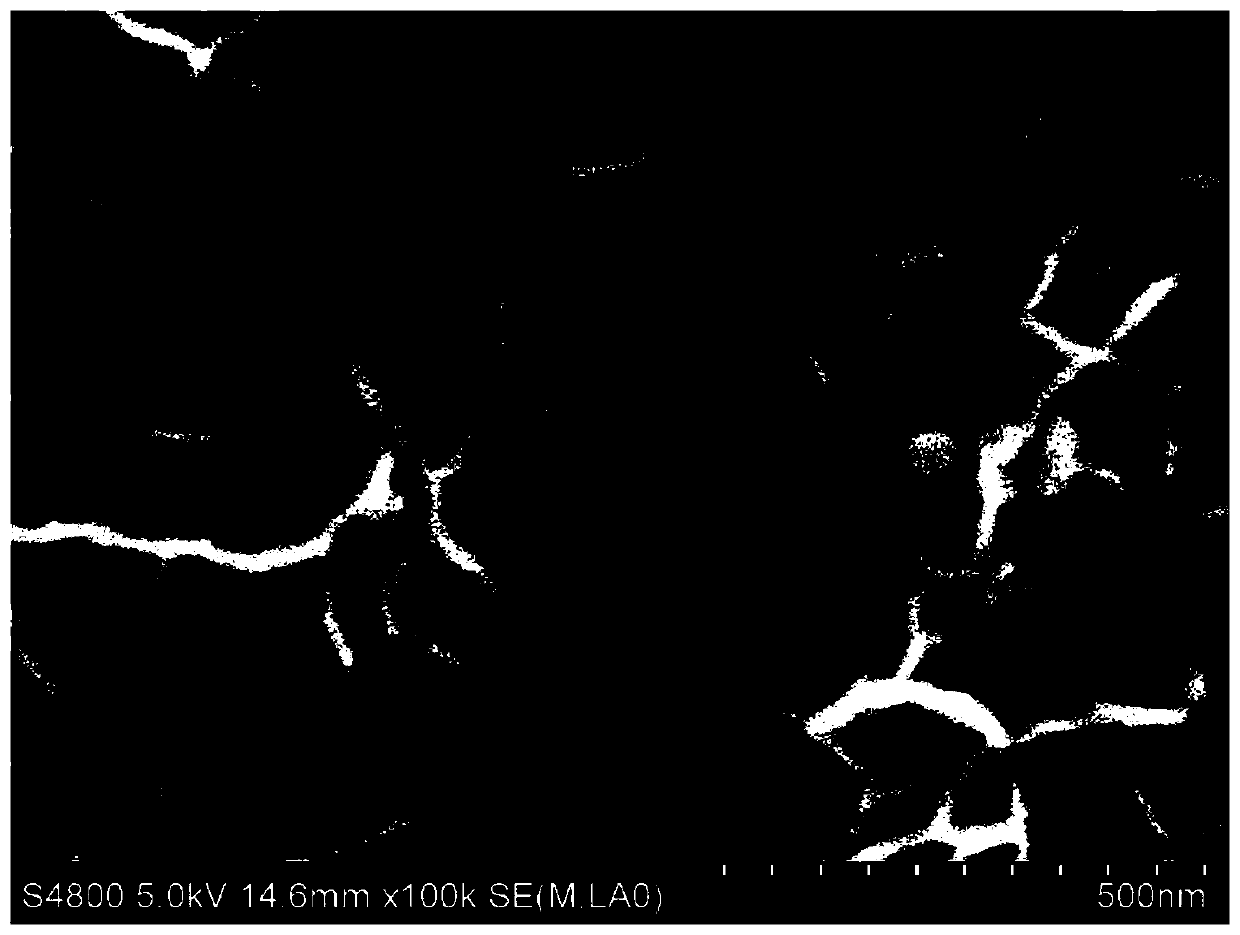

Iron ion-doped nanometer manganous-manganic oxide/multilayer graphene composite material and preparation method thereof, and lithium battery using same

ActiveCN108365182AImprove distributionEasy to prepareCell electrodesLi-accumulatorsMANGANESE ACETATEMANGANESE ACETATE TETRAHYDRATE

Embodiments of the invention disclose an iron ion-doped nanometer manganous-manganic oxide / multilayer graphene composite material and a preparation method thereof, and a lithium battery using the composite material. The preparation method comprises the following steps: measuring DMF and distilled water in a volume ratio of 8: 2, and carrying out mixing to obtained a mixed solvent; adding expandedgraphite and carrying out ultrasonic vibration for 2-5 hours to obtain a multilayer graphite flake; adding manganese acetate tetrahydrate and ferrous chloride tetrahydrate in a certain ration into themixed solution, carrying out stirring at a constant temperature of 30 DEG C for 10-15 minutes, pouring the solution into a hydrothermal reaction kettle, carrying out hydrothermal treatment at a temperature of 100 to 130 DEG C for 1-5 hours, and then carrying out cooling to room temperature; subjecting a reactant of the previous step to centrifugal washing with alcohol and water 3-5 times respectively; and carrying out drying in a drying oven with a temperature of 60-80 DEG C to obtain the composite material. According to the invention, through doping of a reaction solution with iron ions, thedispersibility of manganous-manganic oxide nanoparticles is improved, and gaps among the nanoparticles are increased, so buffering is provided for volume effect during the charging and discharging process of the oxide and the electrochemical performance of the composite material is improved.

Owner:嘉善县国创新能源研究院

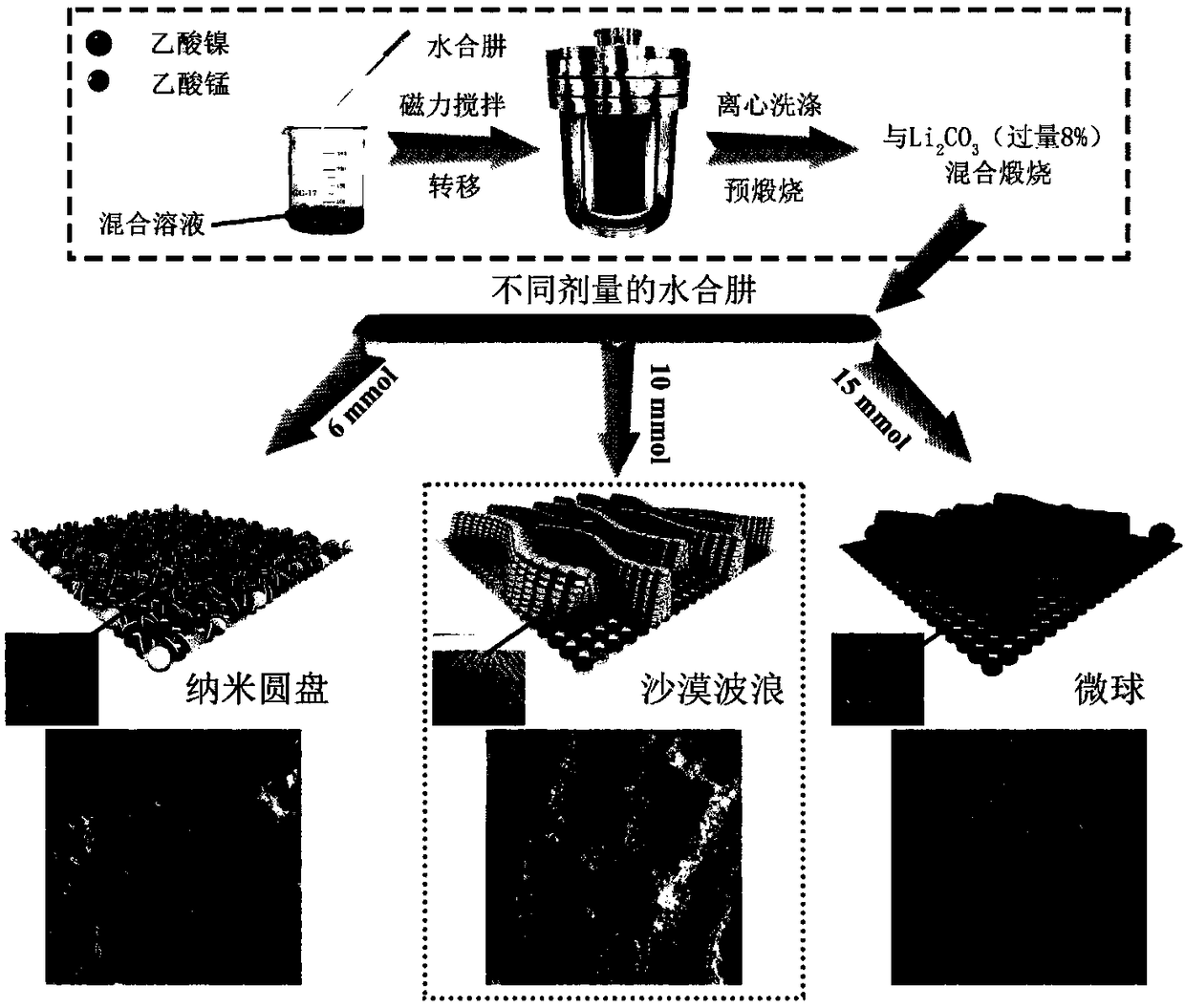

Lithium nickel manganese oxide anode material of three-dimensional desert wave structure and preparing method and application of lithium nickel manganese oxide anode material

ActiveCN108565454AQuick migrationUnhindered transmissionCell electrodesMANGANESE ACETATEElectrical battery

The invention provides a preparing method of a lithium nickel manganese oxide anode material of a three-dimensional desert wave structure, and belongs to the field of anode materials for lithium ion batteries. According to the preparing method, tetrahydrate nickel acetate and tetrahydrate manganese acetate serve as raw materials, ethylene glycol serves as an end-capping agent and a chelating agent, and hydrazine hydrate serves as a morphology guiding agent; based on the synergistic effect of hydrazine hydrate and ethylene glycol in a hydrothermal reaction, a precursor is synthesized; then through pre-roasting and control over roasting in the process of mixing lithium carbonate, preparation of the three-dimensional lithium nickel manganese oxide anode material can be achieved, and rich anddiversified morphology and performance are provided for the end product. The prepared lithium nickel manganese oxide anode materials of the three-dimensional desert wave structure are connected mutually, from the whole aspect, the wide and uninterrupted three-dimensional desert wave structure is conducive to quick transfer of electrons, and barrier-free electron transfer can be achieved; from thepartial aspect, uniform and quasi-circular nanometer discs can shorten the diffusion distance of lithium ions, an uninterrupted electricity-conductive network is formed, and excellent electricity conductivity and a high transfer rate are provided.

Owner:HUBEI UNIV

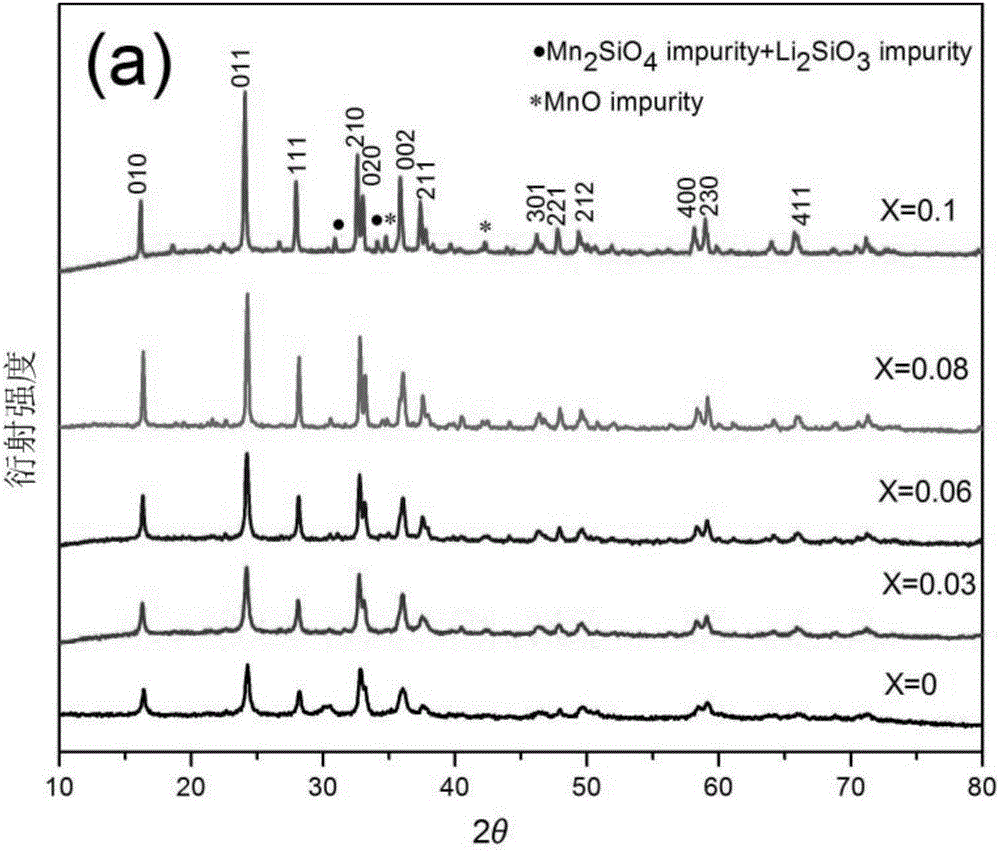

Hybrid polyanion-type lithium manganese silicate positive electrode material and preparation method thereof

InactiveCN106252640AImprove cycle stabilityImproved magnification performanceCell electrodesSecondary cellsShielding gasMANGANESE ACETATE TETRAHYDRATE

The invention provides a hybrid polyanion-type lithium manganese silicate positive electrode material, and a molecular formula of the hybrid polyanion-type lithium manganese silicate positive electrode material is Li<2+x>MnB<x>Si<1-X>O<4> / C, wherein x=0.03-0.1. The invention further provides a preparation method of the positive electrode material. The method comprises the steps of weighing lithium acetate dihydrate, manganese acetate tetrahydrate, a boric acid and a citric acid in a container; adding deionized water for dissolving, adding a mixed solution of absolute ethyl alcohol and tetraethyl orthosilicate to the solution, stirring evenly and carrying out ultrasonic oscillation; forming white emulsion sol through a thermostatic waterbath in a closed reverse-flow system, heating the white emulsion sol until a solvent is evaporated to become sticky sol; carrying out drying to obtain white crystalline dry gel, grinding the dry gel and then burning; carrying out heat preservation under the condition of a protective gas, and then naturally cooling to a room temperature in a furnace to obtain a precursor; and carrying out grinding to obtain hybrid polyanion-type lithium manganese silicate. Through an electrochemical performance test, the rate capability and the cycling stability of the positive electrode material of a lithium-ion battery are better improved in comparison with those of pure-phase lithium manganese silicate.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

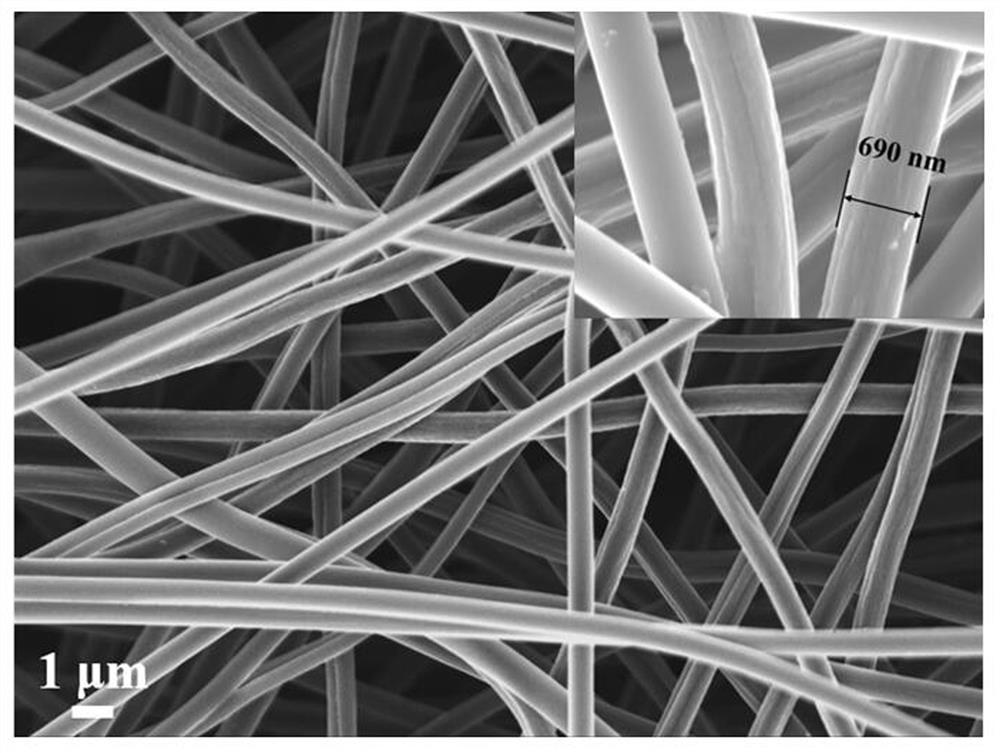

Preparation method of cobalt oxide-modified carbon-doped tin-manganese composite oxide nanofibers

ActiveCN110854381AAlleviate the volume expansion effectImprove conductivityMaterial nanotechnologyCell electrodesMANGANESE ACETATESpinning

The invention discloses a preparation method of cobalt oxide-modified carbon-doped tin-manganese composite oxide nanofibers, which comprises the steps of dissolving a certain amount of manganese acetate tetrahydrate and di-butyltin oxalate and a proper amount of polyacrylonitrile in a certain volume of N,N-dimethylformamide to obtain a faint yellow mixture solution precursor; then carrying out electrostatic spinning under the atmosphere of certain voltage, flow rate and certain relative humidity, sequentially soaking dried spinning products in a methanol solution containing Co<2+> ions, then soaking the spinning products in a methanol solution containing 1,2-dimethylimidazole, sintering in a nitrogen atmosphere in a tubular furnace to obtain the cobalt oxide modified carbon-doped tin-manganese composite oxide nanofibers. The nanofiber material has good electrochemical performance when being used as a lithium ion battery negative electrode material. In the whole preparation process ofthe material, the operation is simple, the cost of raw materials is low, the equipment investment is low, and batch production is facilitated.

Owner:NINGBO UNIV

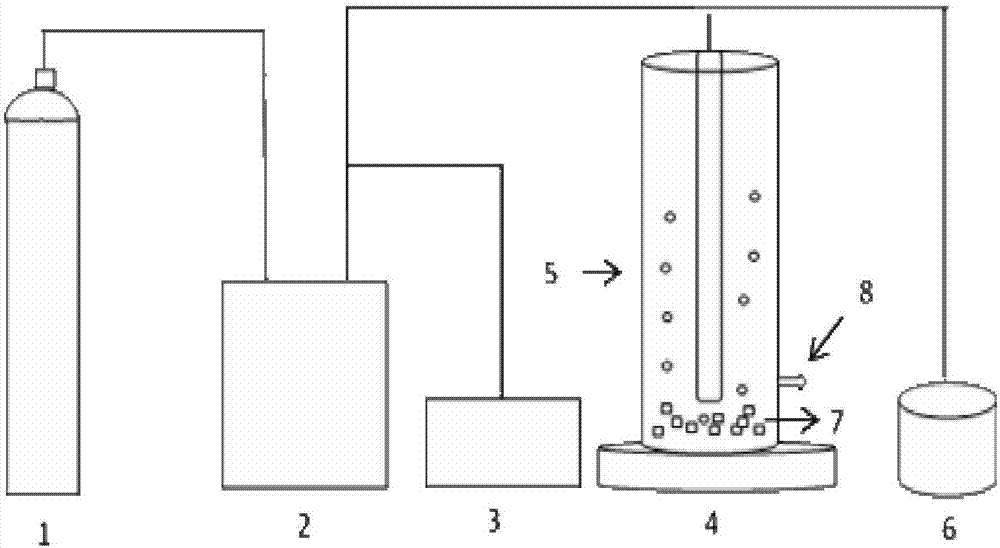

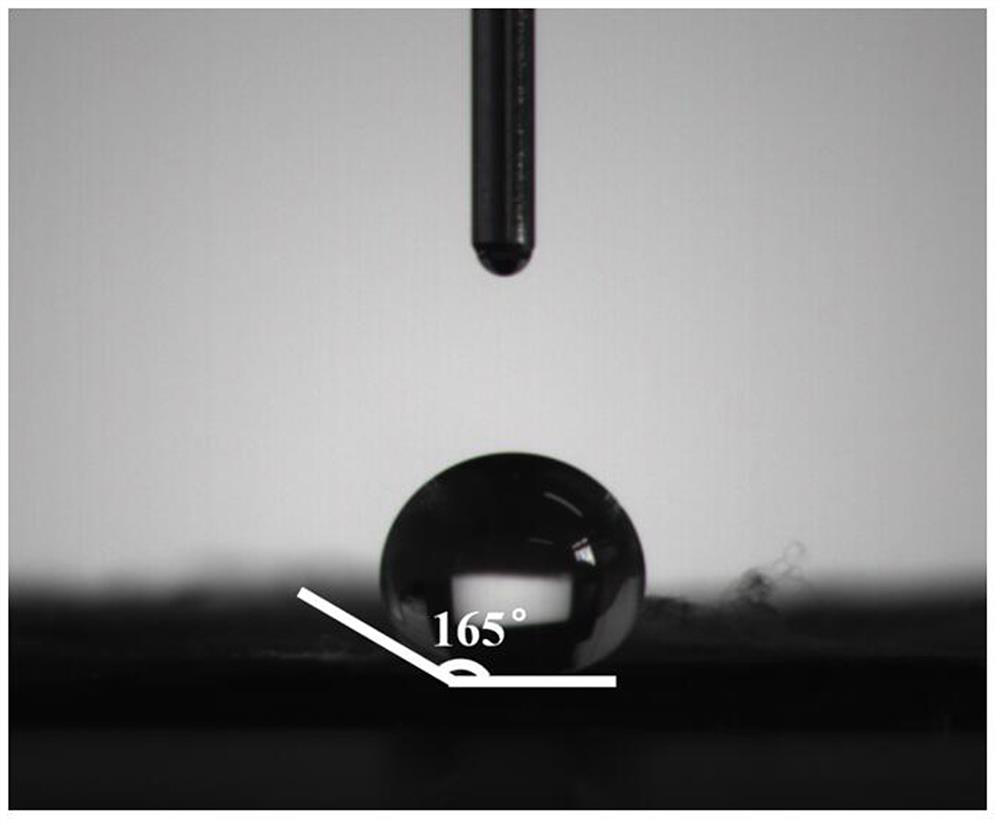

Preparation method of manganese oxide-carbon nano fibrous composite catalytic membrane

InactiveCN107398268AExcellent catalytic ozonation effectEasy to operateWater contaminantsCatalyst activation/preparationMANGANESE ACETATECarbonization

The invention discloses a preparation method of a manganese oxide-carbon nano fibrous composite catalytic membrane. The preparation method comprises the following steps of A, preparation of casting membrane solution, mixing 8wt% to 15wt% of polymer and 85wt% to 92wt% of organic solvent, sufficiently agitating at normal temperature, so that a uniform polymer casting membrane solution is obtained; in a continuous agitation process, adding manganese acetate tetrahydrates with different masses, sufficiently agitating to obtain a dark-red homogeneous casting membrane solution, and de-aerating for later use; B, spinning of a fibrous membrane: injecting the casting membrane solution into an electrostatic spinning propeller, and spraying a liquid drop to be a filament under the action of a high-voltage electric field, so that a Mn(oAc)2 / polymer nano fibrous composite membrane is formed; C, carbonization of the composite membrane: subjecting the fibrous composite membrane to pre-oxidation in air, and then entering an inert-gas protective medium to carry out high-temperature carbonization, so that the manganese oxide-carbon nano fibrous composite catalytic membrane is formed.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

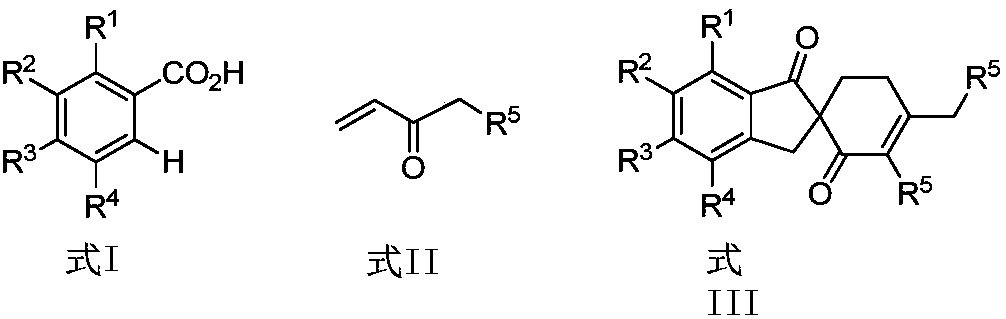

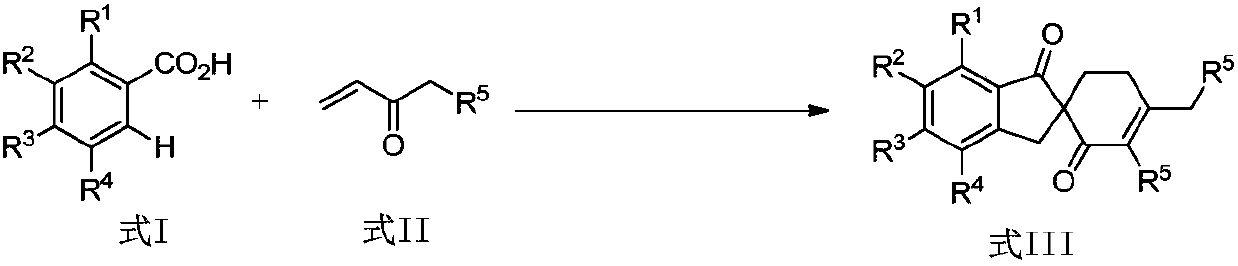

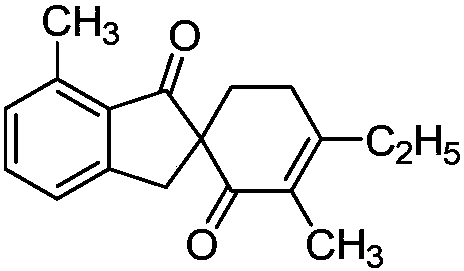

Synthetic method of spirocyclic compound containing 1-indanone skeleton

ActiveCN108047007AAtom utilization is highEasy to operateOrganic compound preparationCarbonyl group formation/introductionPentamethylcyclopentadieneMANGANESE ACETATE

The invention discloses a synthetic method of a spirocyclic compound containing 1-indanone skeleton. The method comprises the following steps: taking aromatic carboxylic acid and alpha, beta-unsaturated ketone as raw materials, taking any of p-cymene ruthenium chloride dimer, pentamethylcyclopetadienyl rhodium chloride dimmer, tris(acetonitrile)(pentamethylcyclopentadienyl)rhodium bis(hexafluoroantimonate) as a catalyst, taking any of anhydrous manganese acetate, manganese acetate tetrahydrate, anhydrous zinc acetate and zinc acetate as an additive, and thus synthesizing the spirocyclic compound containing 1-indanone skeleton by adopting a one-step method. The reaction comprises four steps such as conjugate addition reaction of aromatic carboxylic acid ortho-position C-H bond and alpha, beta-unsaturated ketone, intramolecular dehydration, Michael addition with second molecular alpha,beta-unsaturated ketone and intramolecular aldol condensation. The synthetic method has the characteristics that the raw materials are low in price and easy to obtain, the efficiency is high, the atom utilization rate is high, the reaction operation is simple and four new C-C bonds are constructed by adopting the one-step method.

Owner:SHAANXI NORMAL UNIV

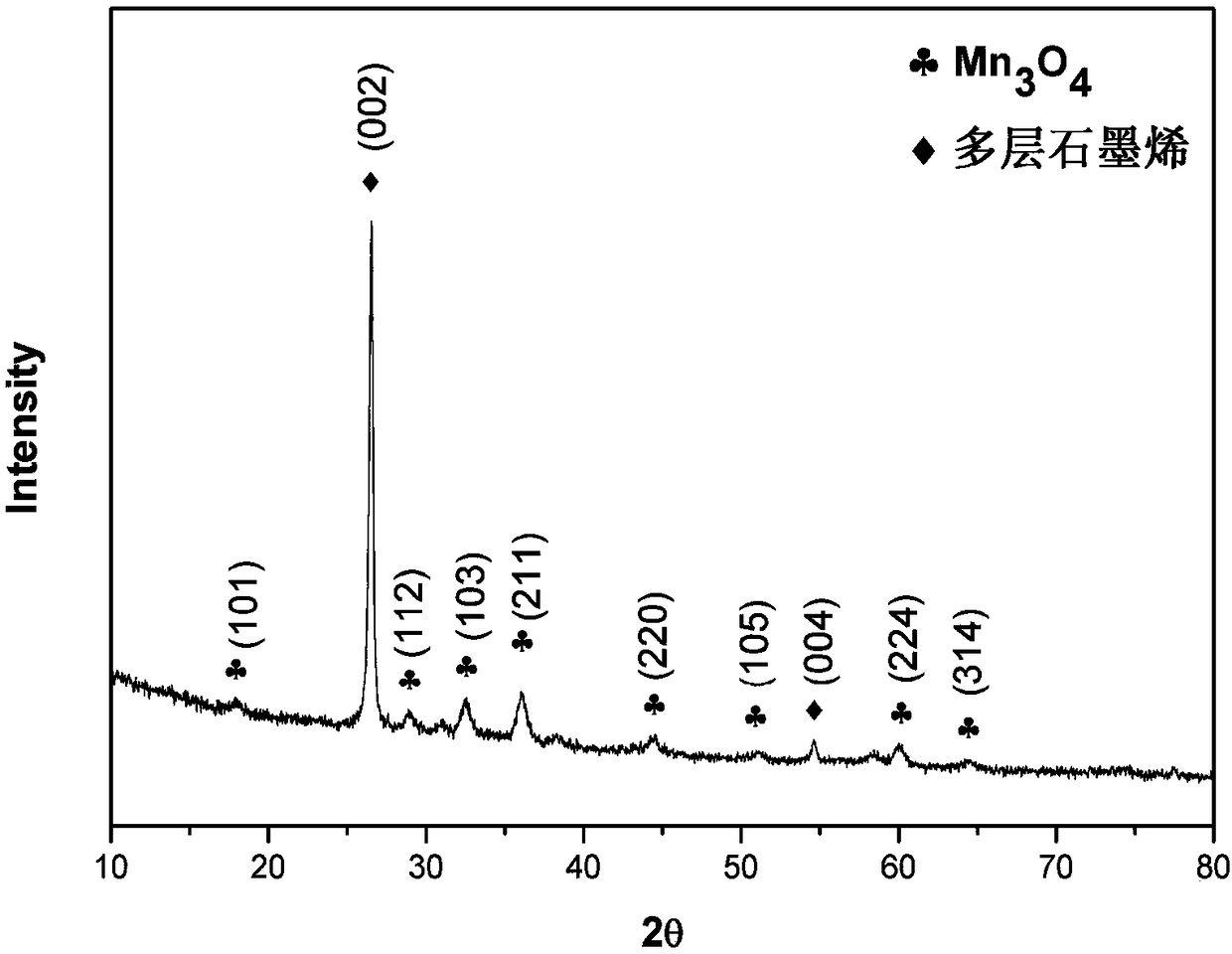

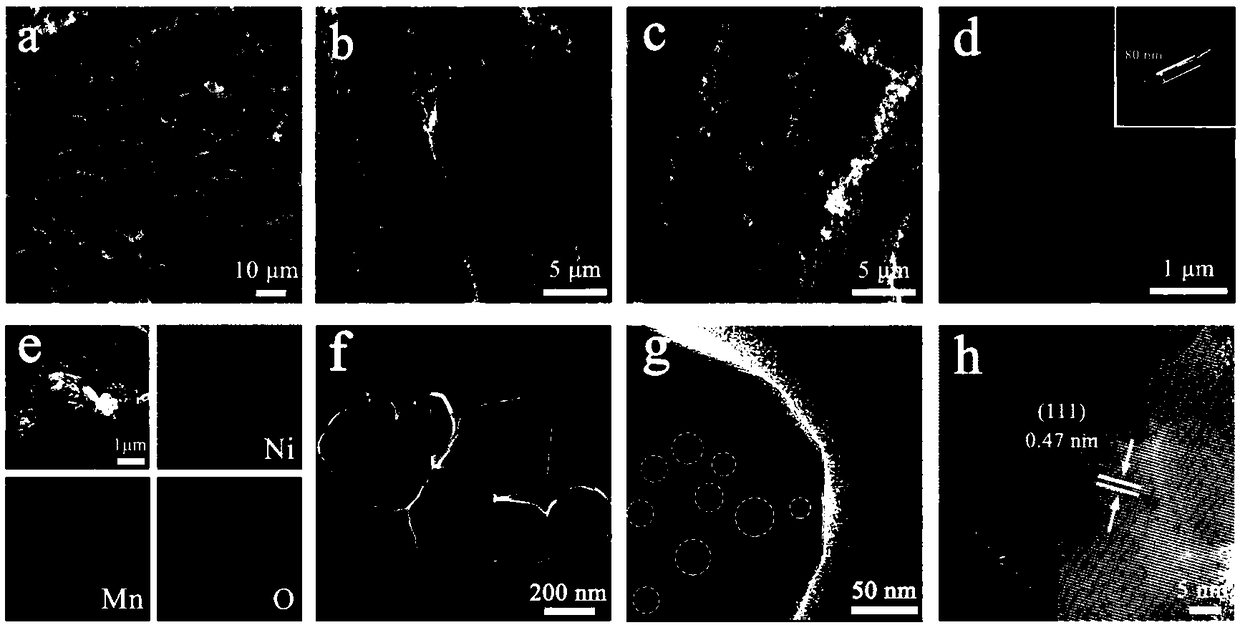

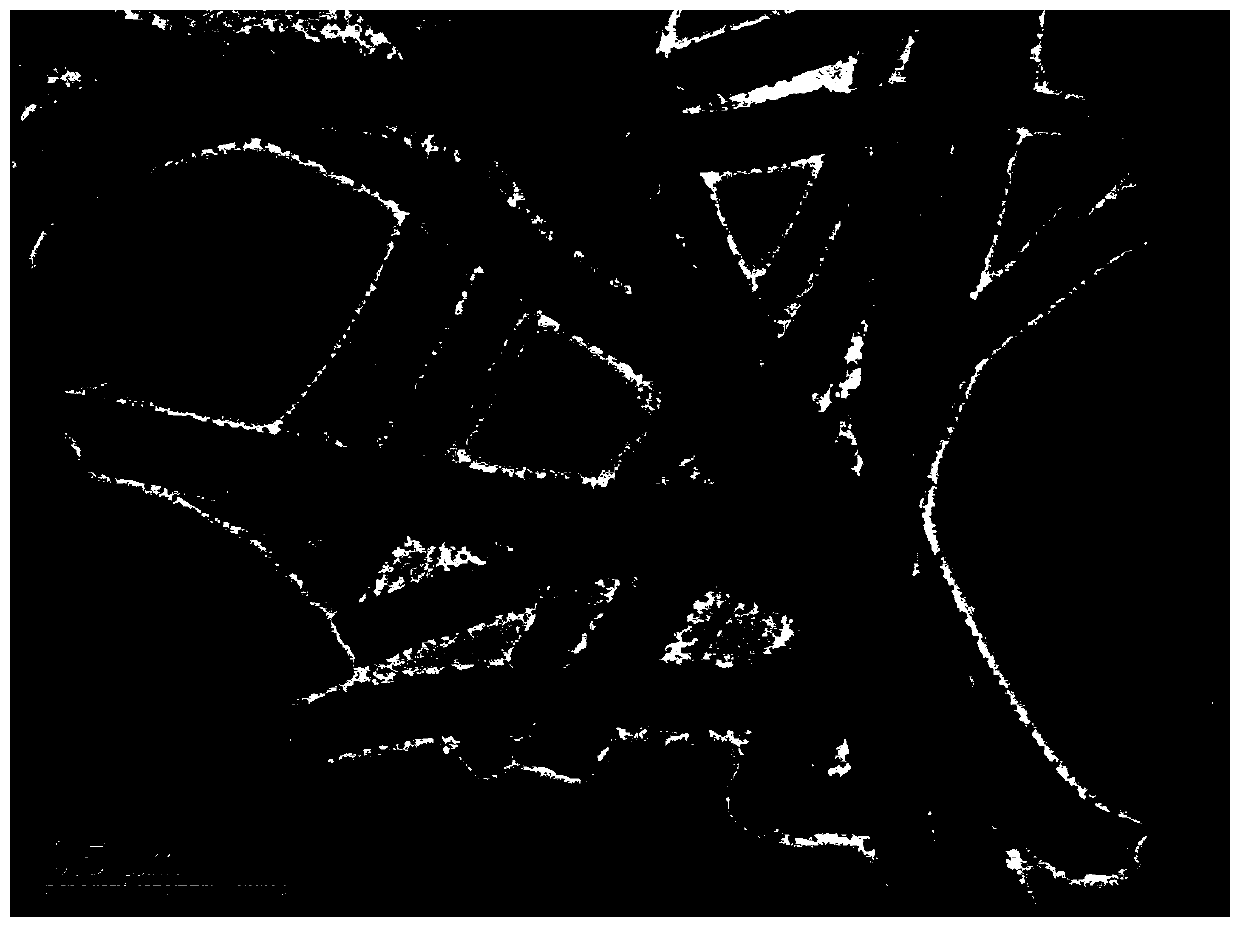

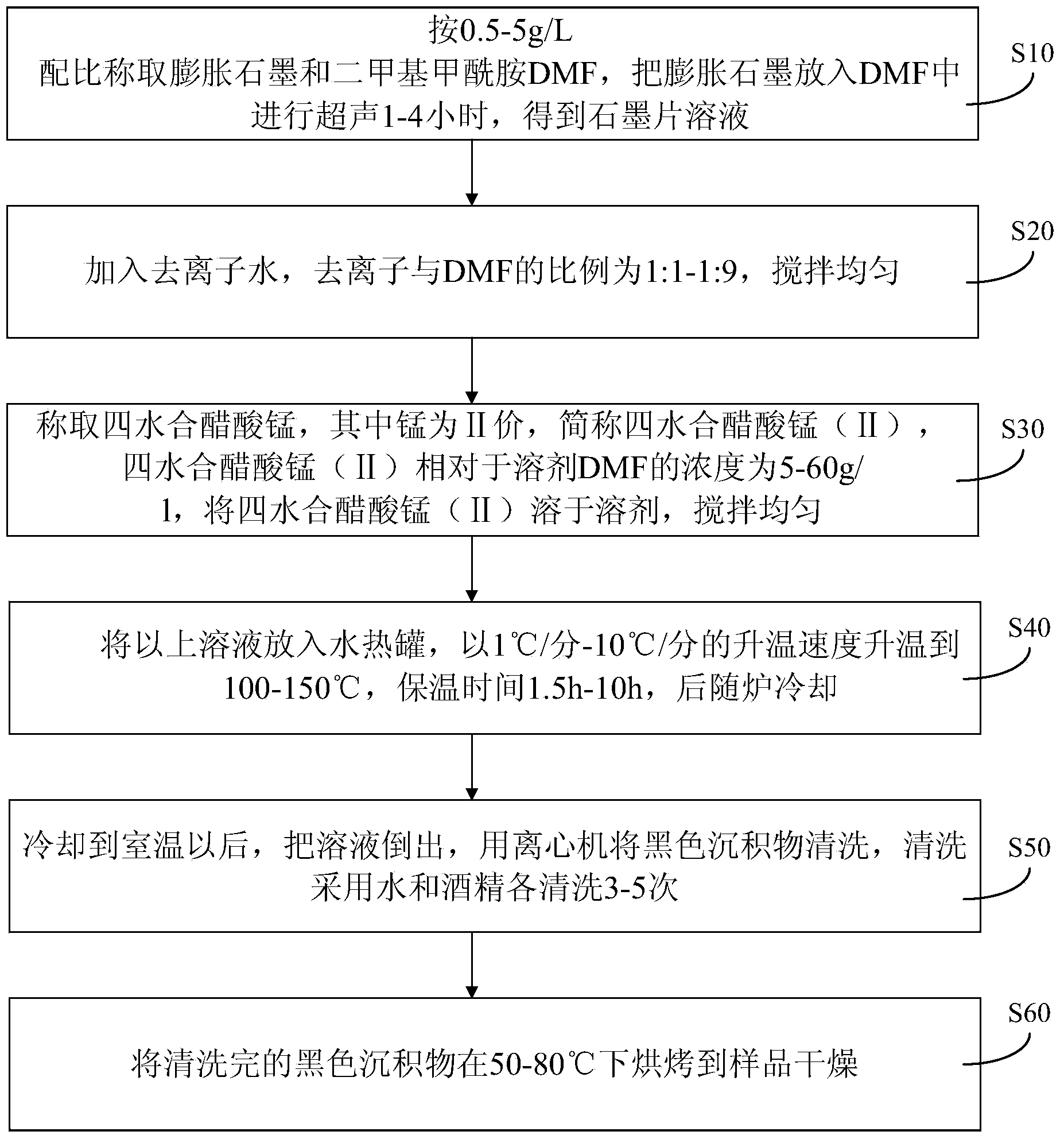

Graphite flake /trimanganese tetroxide composite nano-material with sandwich structure, its preparation method, and lithium ion battery using it

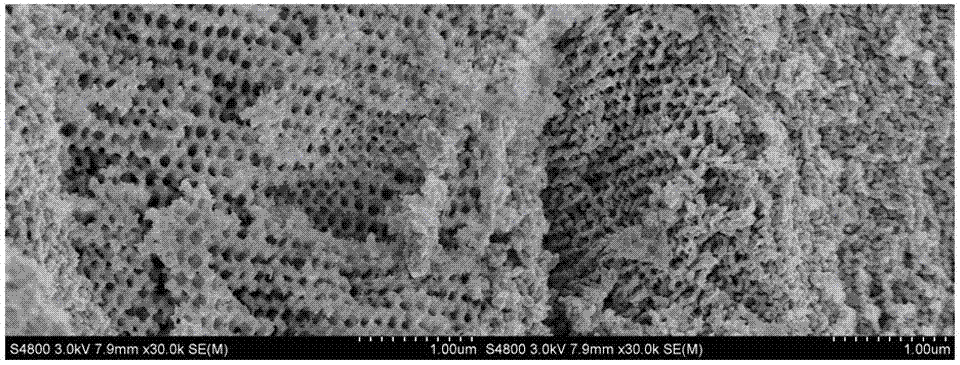

ActiveCN104167532AAvoid re-stackingAvoid reunionMaterial nanotechnologyCell electrodesMANGANESE ACETATE TETRAHYDRATERoom temperature

The invention discloses a graphite flake / trimanganese tetroxide composite nano-material with a sandwich structure, its preparation method, and a lithium ion battery using it. The method comprises the following steps: weighing expanded graphite and DMF according to a ratio of 0.5-5g / L, putting the expanded graphite in the DMF, and carrying out ultrasonic treatment for 1-4h to obtain a graphite flake solution; adding deionized water according to a ratio of deionized water to the DMF of 1:1-1:9, and uniformly stirring; weighing manganese (II) acetate tetrahydrate according to a ratio of the manganese acetate tetrahydrate to the solvent DMF of 5-60g / L, dissolving the manganese acetate tetrahydrate in the solvent, and uniformly stirring; adding the above obtained solution into a hydrothermal tank, heating, carrying out heat insulation, and carrying out furnace cooling; cleaning a black sediment by using a centrifuge after the above obtained material is cooled to room temperature; and baking the cleaned black sediment at 50-80DEG C until the obtained sample is dry. The method for obtaining a uniform Mn3O4 nanoparticle film on the surface of a non-oxidized graphite flake is simple, and is suitable for mass production.

Owner:浙江东信昆辰科技股份有限公司

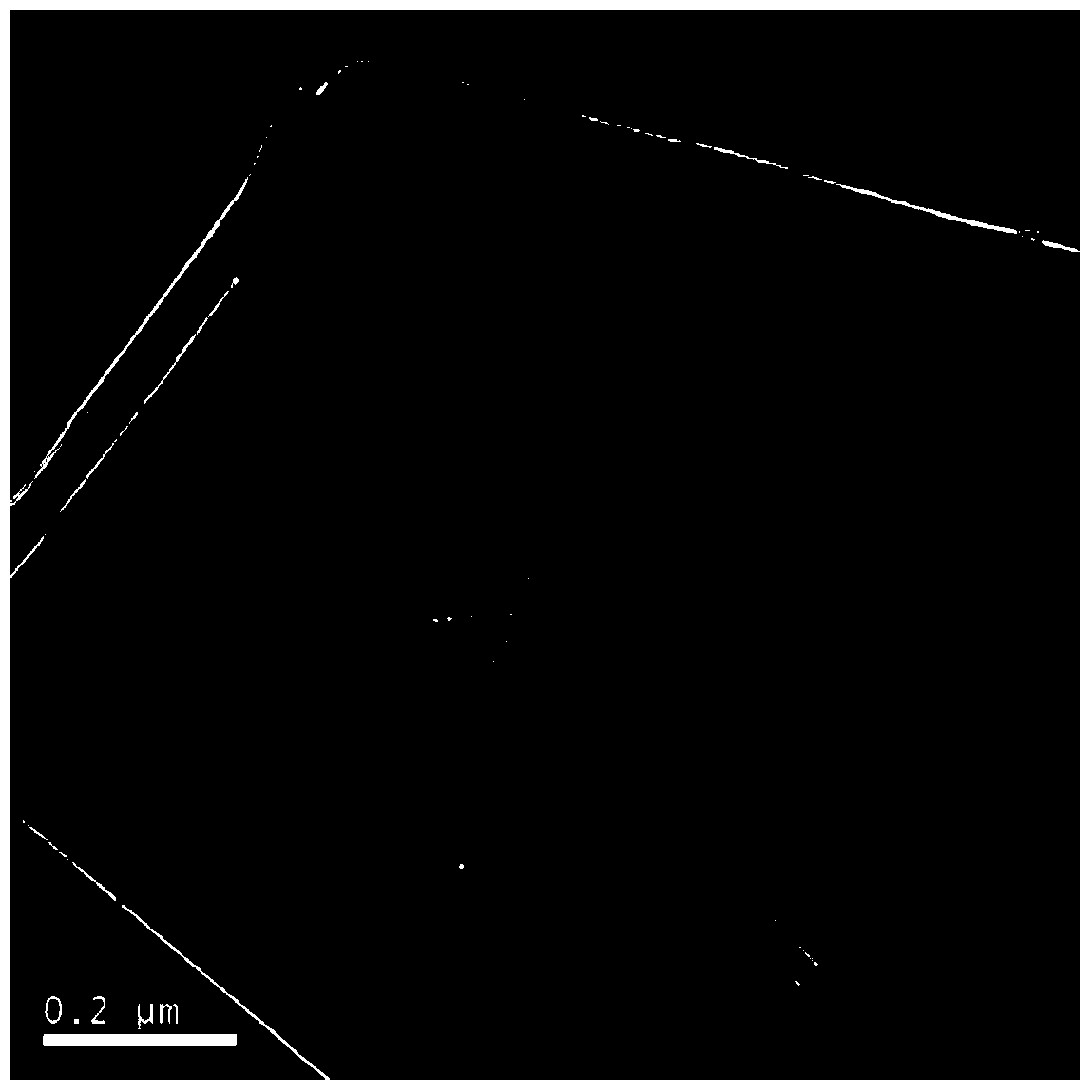

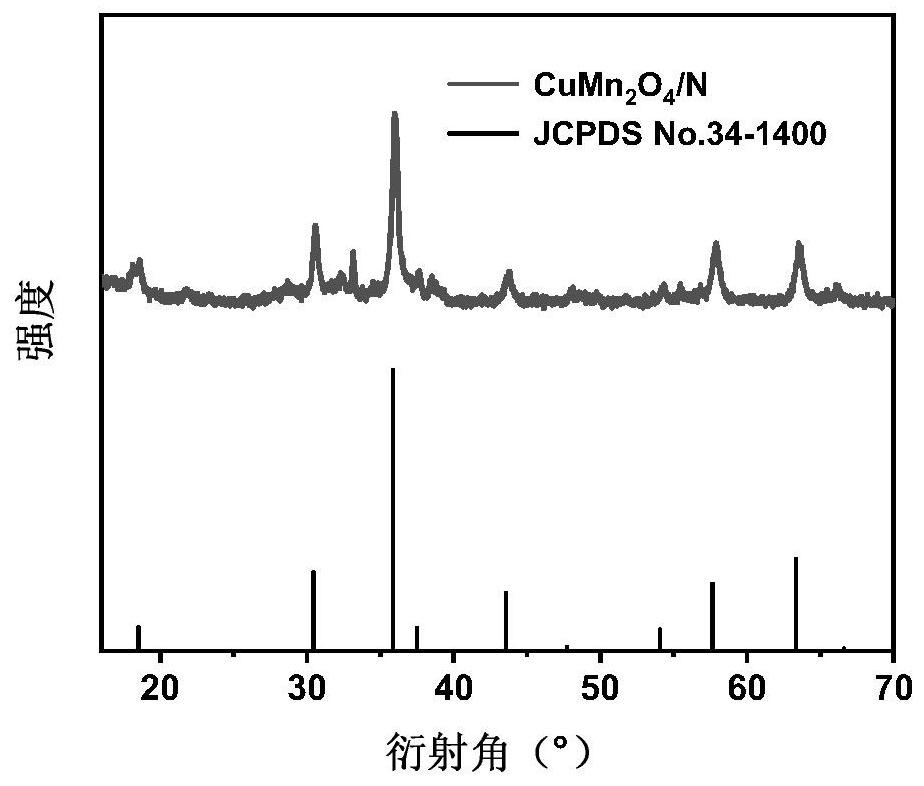

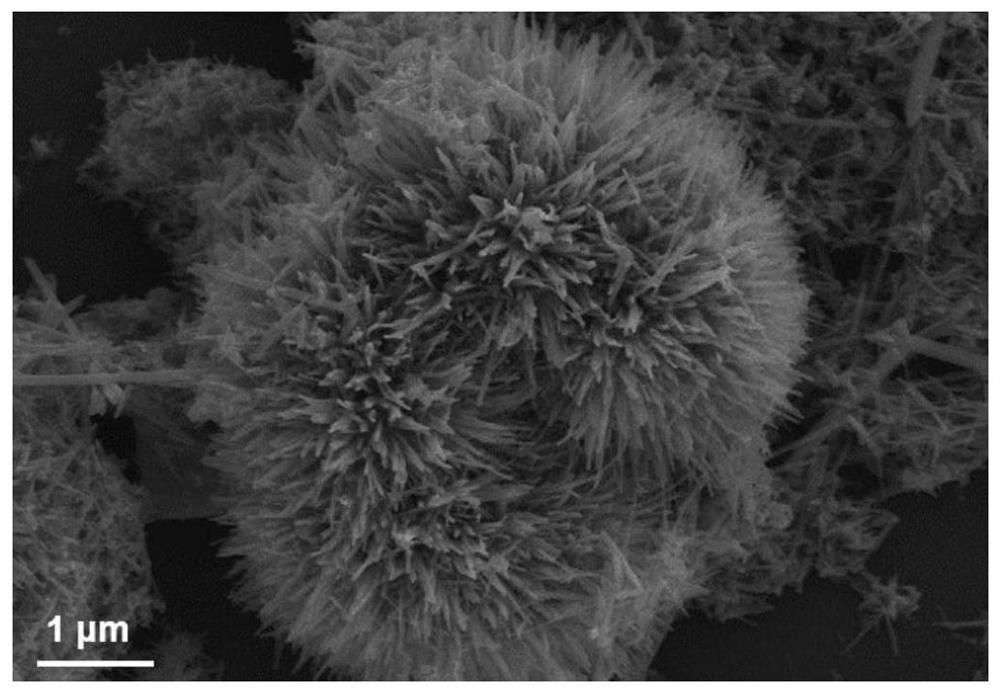

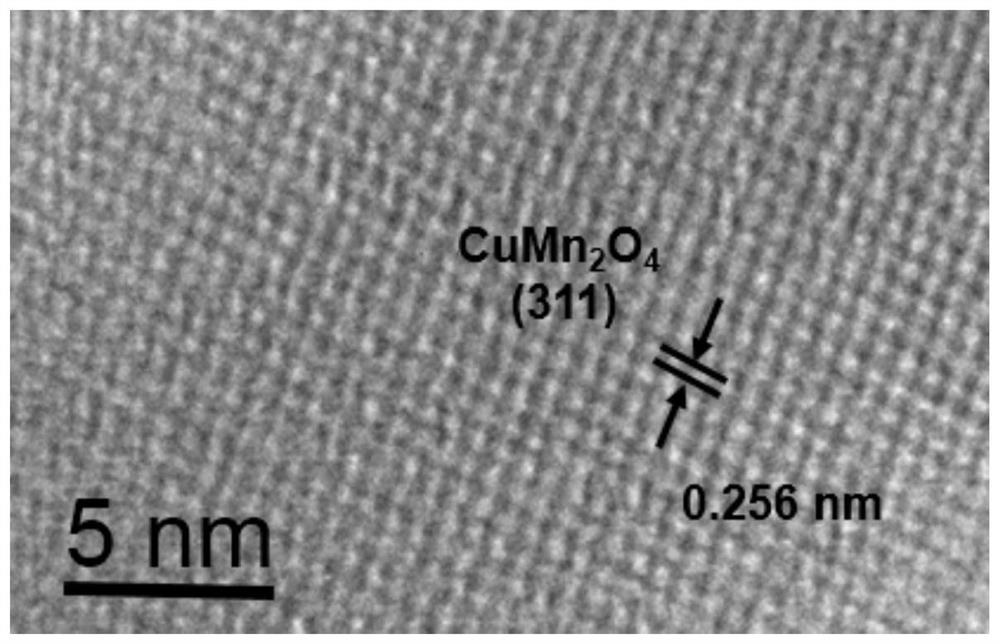

Ammonia-etched sea-urchin-shaped spherical structure copper-manganese spinel material, preparation method and application thereof

ActiveCN113046778AEasy transferLower adsorption energyElectrolytic organic productionElectrodesFuranFuraldehyde

The invention provides an ammonia-etched sea-urchin-shaped spherical structure copper-manganese spinel material, a preparation method and application thereof. The preparation method comprises the following steps: dissolving copper acetate monohydrate, manganese acetate tetrahydrate, urea, potassium bromate and ammonium fluoride in deionized water, uniformly mixing, and carrying out hydrothermal treatment and calcination to obtain precursor powder; and soaking in ammonia water to obtain the ammonia-etched copper-manganese spinel material CuMn2O4 / N. According to the invention, the chemical formula of the ammonia etching copper-manganese spinel material is shown as CuMn2O4 / N, the ammonia etching copper-manganese spinel material is of a sea urchin-shaped spherical structure, each spherical structure is composed of a nanoneedle structure which grows in the radial direction from a central core, the length of the nanoneedle is 100-150 nm, and the average diameter of the sea urchin-shaped spherical structure is 6-10 [mu]m; and when the material is used as an electrode material for generating furandicarboxylic acid through electro-catalytic oxidation of 5-hydroxymethylfurfural, excellent electro-catalytic performance is achieved.

Owner:BEIJING UNIV OF CHEM TECH

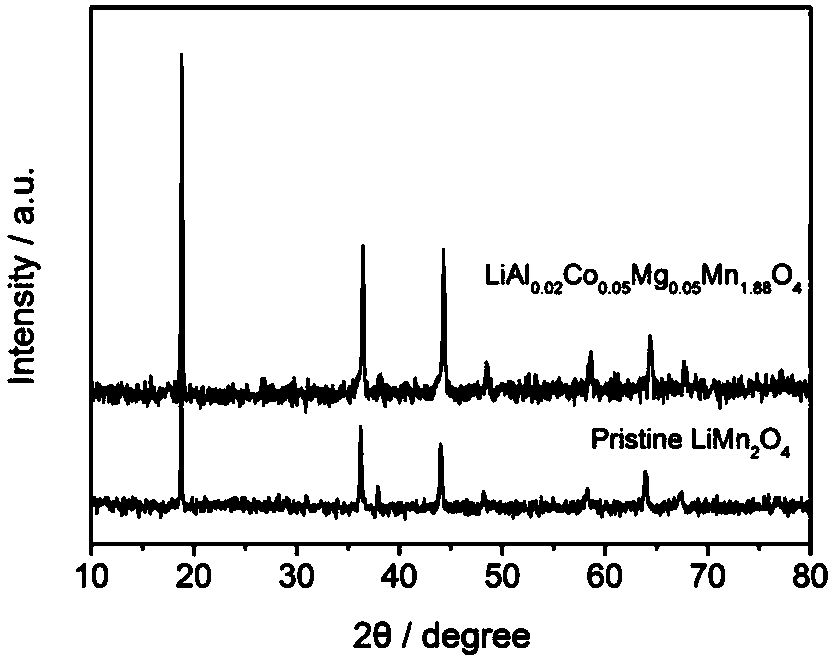

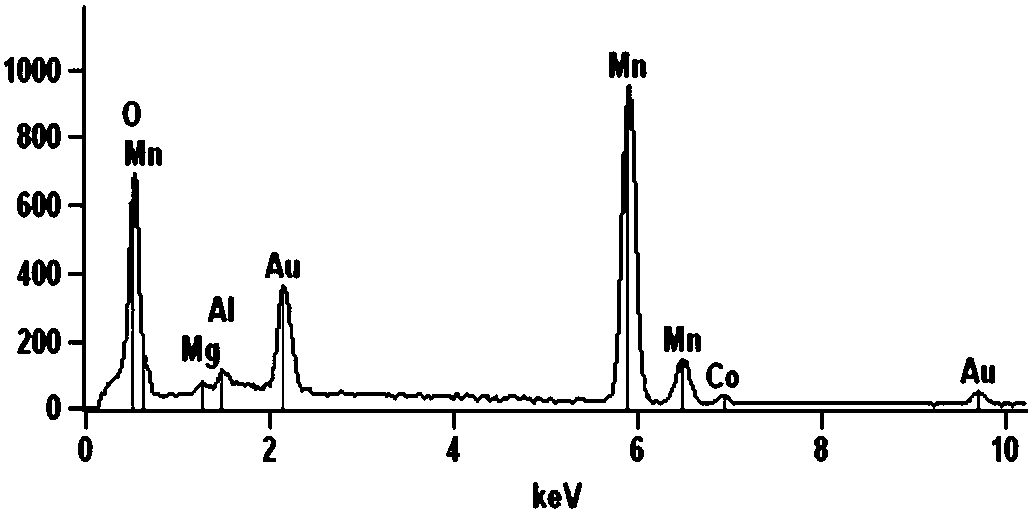

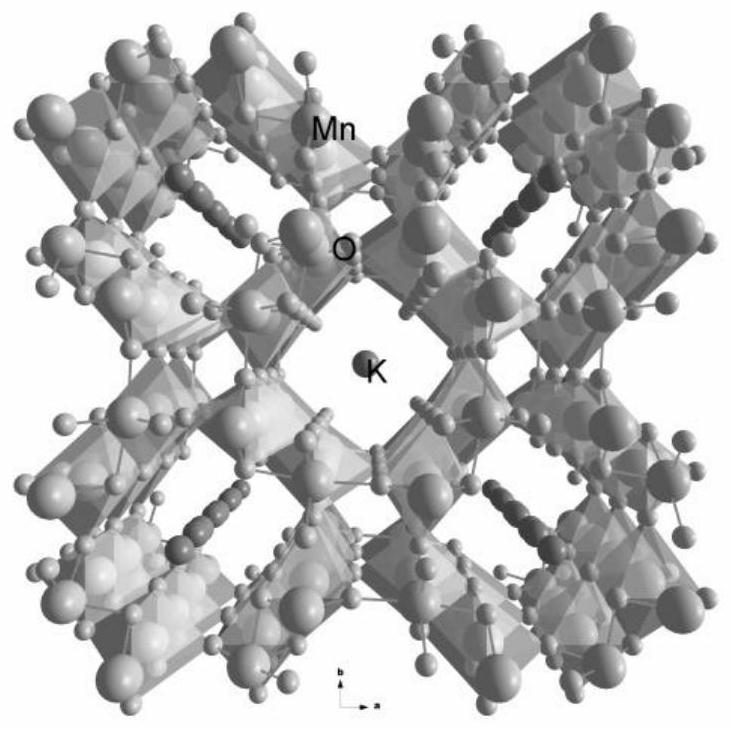

Method for preparing multi-element co-doped lithium manganate composite material

InactiveCN108539159AStable structureInhibition of Ginger-Taylor EffectCell electrodesSecondary cellsMagnesium Acetate TetrahydrateMANGANESE ACETATE TETRAHYDRATE

The invention discloses a method for preparing a multi-element co-doped lithium manganate composite material. The method adopts a sol-gel method, firstly, a mixed solution of manganese acetate tetrahydrate, aluminum nitrate nonahydrate, magnesium acetate tetrahydrate, and cobalt acetate tetrahydrate is slowly added dropwise to a lithium hydroxide monohydrate and citric acid mixed solution under stirring, an ammonia solution is added to adjust the pH of the solution, and the mixture is heated and stirred until a sol is formed, the sol is dried to obtain a dry gel, and the dry gel is calcined and ground into powder, and finally calcined to obtain the aluminum-cobalt-magnesium three-element co-doped lithium manganate composite material. The method has the advantages of simple process, wide source of raw materials, large output, low cost and easy control, and is favorable for large-scale industrial production, and the prepared lithium ion battery positive electrode material has excellent rate charge and discharge performance and excellent cycle service life.

Owner:NANJING UNIV OF SCI & TECH

Aqueous zinc ion battery positive electrode material and matched electrolyte

ActiveCN112886004AImprove structural stabilityAdd reactive sitesCell electrodesSecondary cellsElectrolytic agentMANGANESE ACETATE TETRAHYDRATE

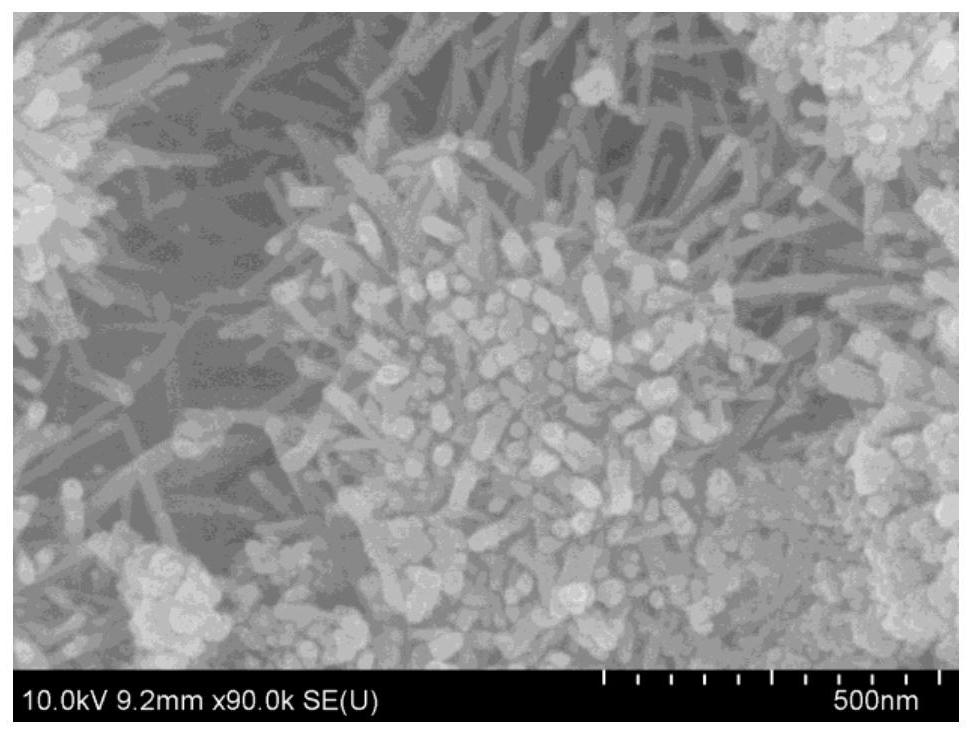

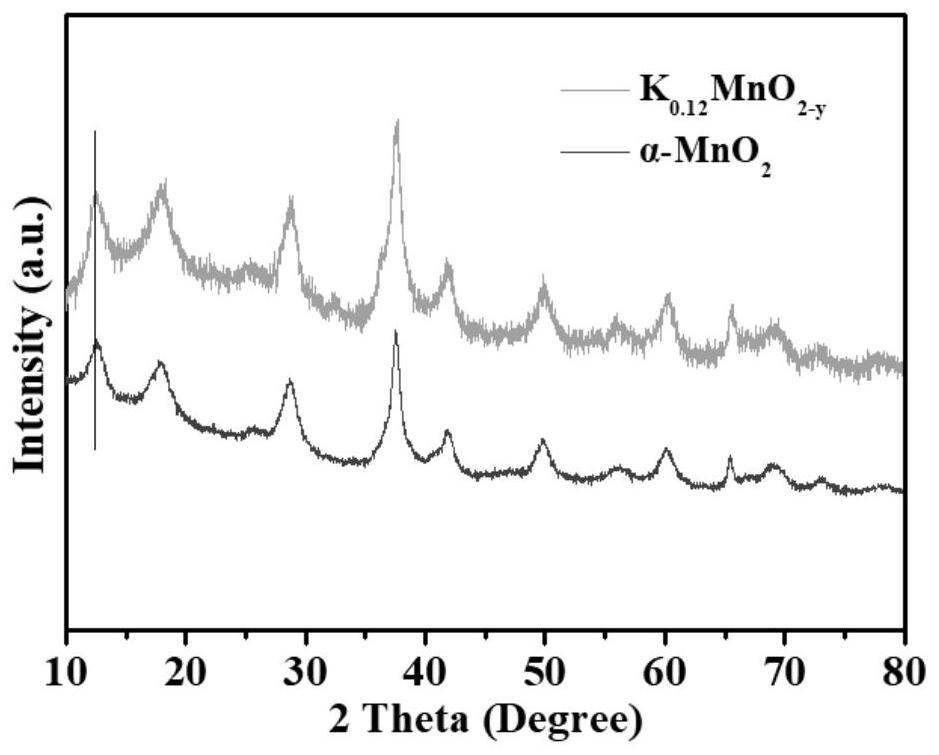

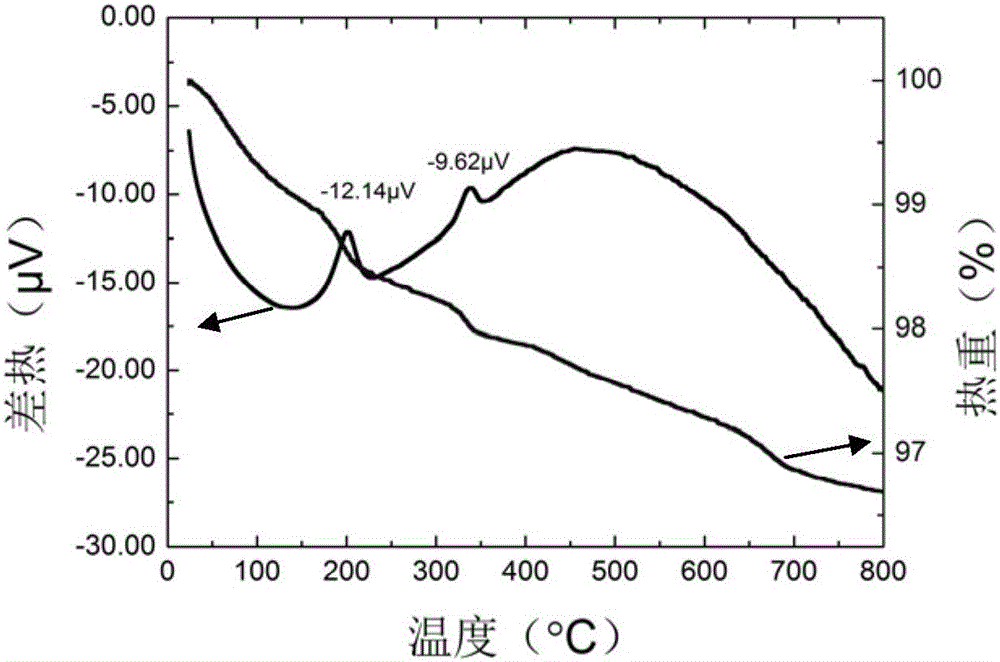

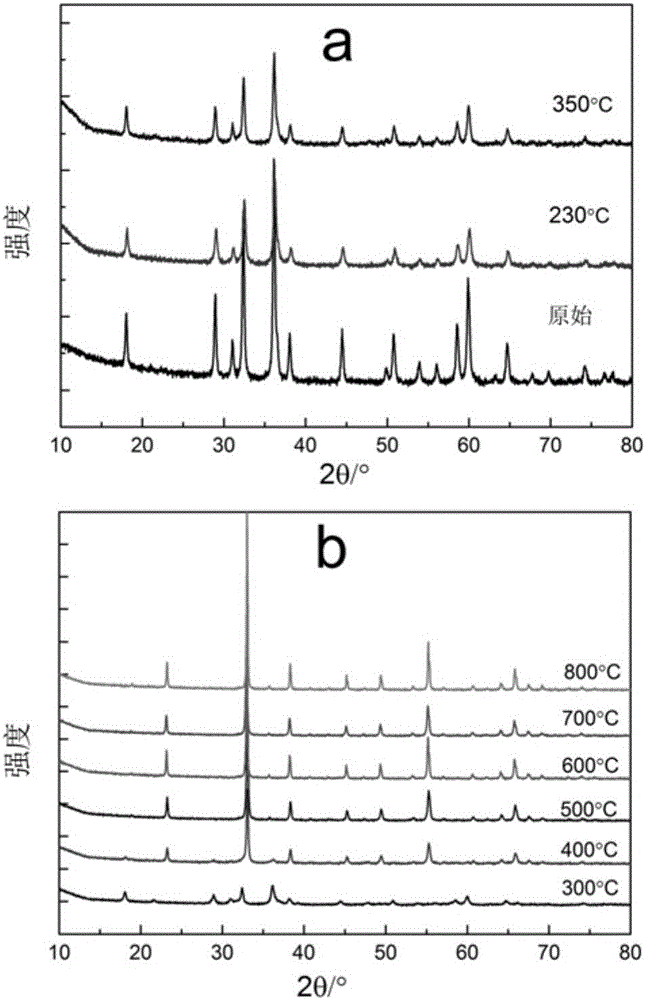

The invention relates to an aqueous zinc ion battery positive electrode material and a matched electrolyte. A chemical formula of the positive electrode material is RxKyMn1-xO2-z, wherein x is greater than or equal to 0 and less than or equal to 0.1, y is greater than or equal to 0 and less than or equal to 0.5, z is greater than 0 and less than 0.1, and R is a metal cation. A preparation process comprises the following steps: grinding and uniformly mixing potassium permanganate, manganese acetate tetrahydrate and metal salt, then putting a mixture into a tubular furnace, carrying out heat treatment under a protective atmosphere, washing an obtained product with deionized water, carrying out suction filtration for several times, and then drying the product in a drying oven to obtain the RxKyMn1-xO2-z positive electrode material. According to the invention, K<+> is successfully pre-embedded into a tunnel structure of a manganese dioxide crystal through one-step heat treatment, metal cations are doped into the manganese dioxide crystal, and oxygen vacancies are introduced into the surface of the manganese dioxide crystal so that the structural stability of manganese dioxide is improved, active sites are increased, and the conductivity is improved. The material is low in production cost, simple in process, mild in reaction condition and easy for large-scale preparation. The positive electrode material has a high specific capacity, a high rate capability and excellent cycling stability; and the matched and compatible aqueous electrolyte further prolongs the long cycle life of the positive electrode material.

Owner:UNIV OF SCI & TECH BEIJING

Method for easily and conveniently preparing Mn3O4 nanopowder and product of method

InactiveCN106006747AAvoid generatingEasy to operateMaterial nanotechnologyManganese oxides/hydroxidesWater bathsMANGANESE ACETATE TETRAHYDRATE

The invention discloses a method for preparing Mn 3 o 4 The method of the nano powder, comprising: (1) taking manganese salt and deionized water and mixing to obtain a manganese salt solution, stirring in a water bath until the manganese salt is completely dissolved; the manganese salt is selected from manganese chloride tetrahydrate or manganese acetate tetrahydrate, The concentration of the manganese salt solution is 0.167-0.333mol / L; the temperature of the water bath heating is 60-100°C; (2) the hydrogen peroxide and the ammonia water are respectively diluted with deionized water and then mixed to obtain a mixed solution, which is added dropwise to the step In the manganese salt solution of (1), continue to react for 1 to 3 hours under stirring, and obtain the Mn after standing, washing and drying. 3 o 4 The molar ratio of nanometer powder, manganese salt, hydrogen peroxide and ammonia water is 1:0.25-3:1-3. The present invention prepares Mn through one-step method 3 o 4 Nano powder, simple process, low cost, convenient for industrial production; the prepared Mn 3 o 4 The yield and purity of the nanopowder are high.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for one-step preparation of manganese phthalocyanine crystal through solvothermal reaction

The present invention relates to a method for one-step preparation of a manganese phthalocyanine crystal through a solvothermal reaction. The method comprises: adding phthalonitrile and manganese acetate tetrahydrate to a reaction kettle according to a molar ratio of 4:1, adding an anhydrous ethanol solution, uniformly stirring, sealing the reaction kettle, carrying out a solvothermal reaction for not less than 1 h at a temperature of 180-200 DEG C, stopping heating after completing the reaction, naturally cooling to a room temperature, taking out the prepared sample, adopting hot water and hot ethanol to repeatedly wash the remaining reactant adsorbed on the manganese phthalocyanine crystal surface, and drying to obtain the manganese phthalocyanine crystal. According to the present invention, the manganese phthalocyanine crystal prepared by using the method has the regular crystal appearance, and the whole preparation process has characteristics of simple operation, low cost, no harmful pollutant generation and easily controllable reaction process, and meets actual production requirements.

Owner:XUCHANG UNIV

Preparation method of nickel-cobalt-manganese-aluminum composite positive electrode material co-coated with lithium manganese vanadium phosphate and carbon

ActiveCN110518206ASimple manufacturing methodSuppress shufflingSecondary cellsPositive electrodesMANGANESE ACETATE TETRAHYDRATECobalt

The invention relates to a preparation method of a nickel-cobalt-manganese-aluminum composite positive electrode material co-coated with lithium manganese vanadium phosphate and carbon, which comprises the steps of (1) ultrasonically dispersing nickel-cobalt-manganese-aluminum LiNi0.89Co0.05Mn0.05Al0.01O2 in deionized water, adding vanadium pentoxide and citric acid, heating and stirring; (2) adding manganese acetate tetrahydrate, lithium acetate and ammonium dihydrogen phosphate, and continuously stirring until gel is formed; and (3) drying the gel in vacuum, and calcining in a protective gasto obtain the nickel-cobalt-manganese-aluminum positive electrode material co-coated with lithium manganese vanadium phosphate and carbon co-coated. The method is simple in process and easy to operate, raw materials are cheap and easy to obtain, and the prepared cathode material is excellent in electrochemical performance. The method has the advantages of simple process, easy operation and cheapand easily-obtained raw materials, and the prepared positive electrode material is excellent in electrochemical performance.

Owner:湖北锂诺新能源科技有限公司

Preparation method of FeMnO3 hollow nanospheres

InactiveCN103551092AUniform shapeNarrow size distributionNanotechnologyIron compoundsAir atmosphereCalcium Chloride Hexahydrate

The invention discloses a preparation method of FeMnO3 hollow nanospheres, and the preparation method comprises the following steps: (1) dissolving manganese(II) acetate tetrahydrate and iron(III) chloride hexahydrate in the molar ratio of 1:1 in absolute ethanol; (2) adding carbon nanospheres with the diameter of 100-500nm for ultrasonic dispersion; (3) with mixing, adding full dose of an ammonia aqueous solution to completely precipitate manganese ions and iron ions; (4), centrifuging and washing the precipitate, and then drying to obtain black powder; (5) calcining the black powder in the air or oxygen atmosphere at 400-800 DEG C to obtain the FeMnO3 hollow nanospheres. The new FeMnO3 hollow nanospheres can be used as an electrode material for a supercapacitor.

Owner:NORTHWEST UNIV

Preparation of three-dimensionally ordered macroporous MnCo2O4 spinel-type composite oxide

ActiveCN107999087AHigh activityImprove contact effectIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsBüchner funnelMANGANESE ACETATE TETRAHYDRATE

The invention relates to preparation of a three-dimensionally ordered macroporous MnCo2O4 spinel-type composite oxide. The preparation comprises the following manufacturing steps: a first step, weighing manganese acetate tetrahydrate and cobalt nitrate hexahydrate; a second step, adding methanol or mixed liquor of ethylene glycol and water to dissolve at room temperature; a third step, weighing glucose according to a ratio, adding into the solution of the second step and continuing to stir; a fourth step, adding a polymethyl methacrylate template and impregnating; a fifth step, pouring the impregnated mixed liquor into a buchner funnel for suction filtration, washing, and drying; a sixth step, placing a dried sample in a tube furnace, raising temperature from room temperature for multipletimes, and then dropping to room temperature. The preparation of the three-dimensionally ordered macroporous MnCo2O4 spinel-type composite oxide has the beneficial effects that a prepared catalyst hasa regular pore structure, a larger pore size, a higher specific surface area, the preparation of the three-dimensionally ordered macroporous MnCo2O4 spinel-type composite oxide can increase a comparative area of the catalyst, and improve contact performance between the catalyst and soot particles, in addition, by adding glucose, combustion temperature of the soot particles can be reduced, and activity of the catalyst can be increased.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

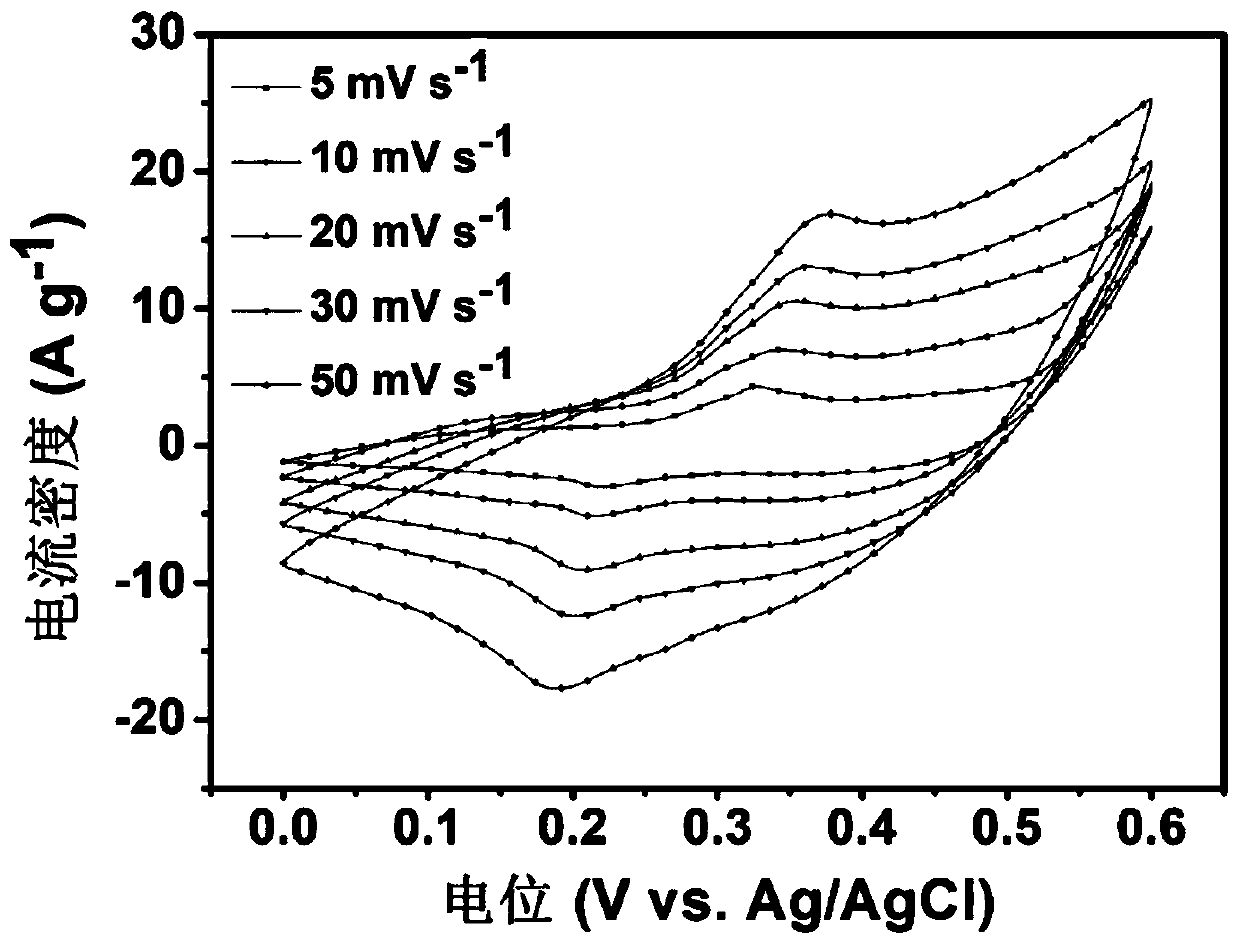

Preparation method and application of Mn-Co-S/Co-MOF nano material

ActiveCN110415993AExcellent pseudocapacitive performanceAlleviate volume changesMaterial nanotechnologyHybrid capacitor electrodesCobalt acetateMANGANESE ACETATE TETRAHYDRATE

The invention relates to a preparation method of a Mn-Co-S / Co-MOF nano material, and the method comprises the following steps: S1: sequentially dissolving manganese acetate tetrahydrate, cobalt acetate tetrahydrate, carbon disulfide and pentamethyldiethylenetriamine in methanol to obtain a solution A, and dissolving 2-methylimidazole in methanol to obtain a solution B; S2, adding the solution B into the solution A, and transferring a mixed solution of the solution B and the solution A into a reaction kettle for reaction; S3, performing centrifuging, washing and drying to obtain the Mn-Co-S / Co-MOF nano material. Compared with the prior art, the preparation method disclosed by the invention is environment-friendly, simple in process and convenient for large-scale production, and the obtainedMn-Co-S / Co-MOF nanosheet can obtain excellent electrochemical performance when being applied to an electrode material.

Owner:SHANGHAI INST OF TECH

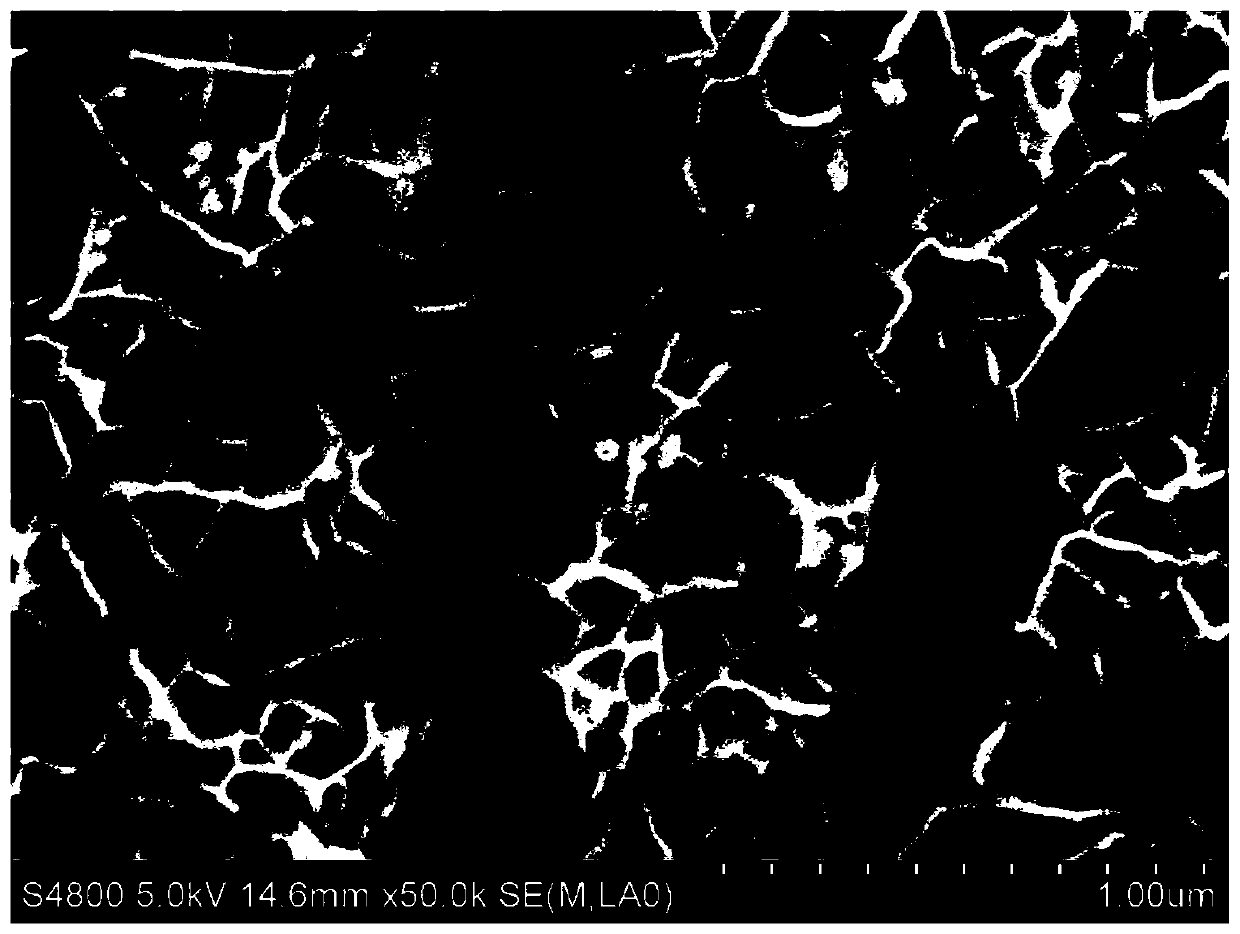

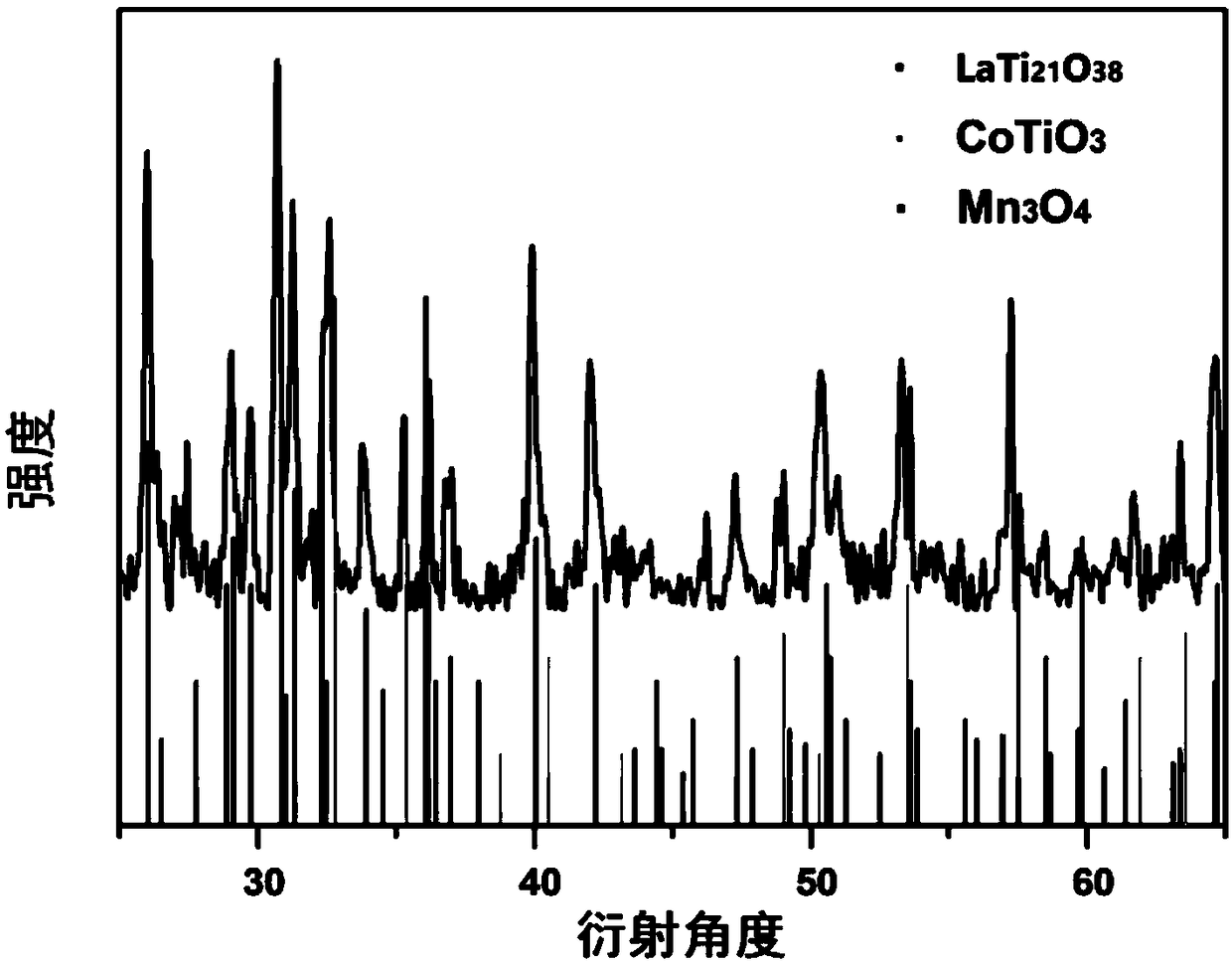

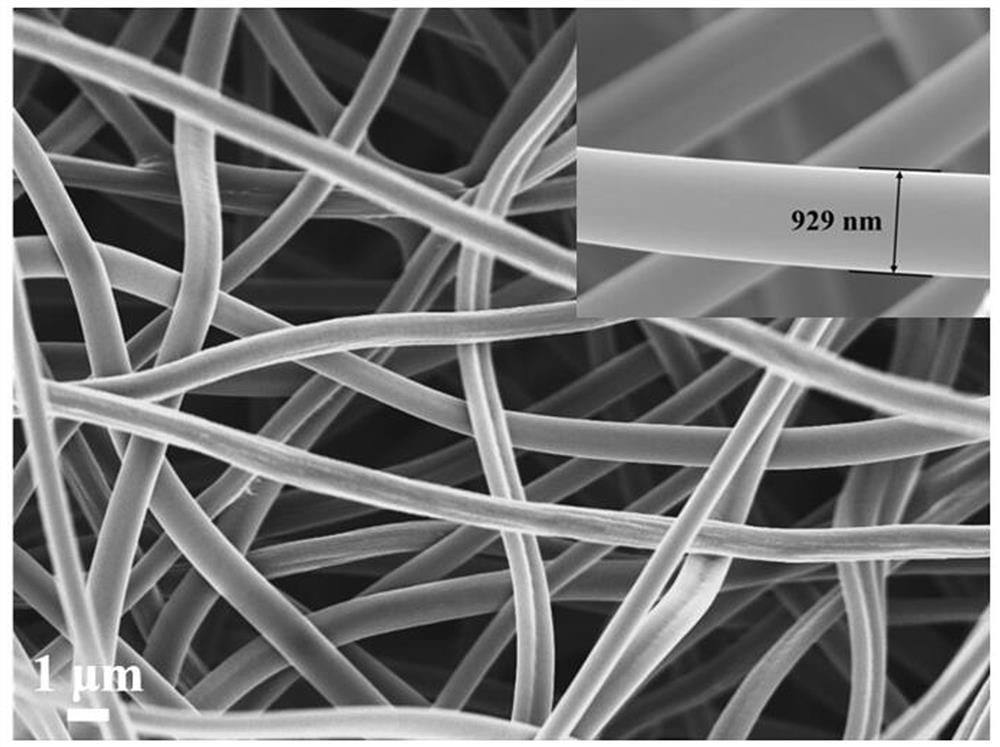

Preparation method of LaTi<21>O<38>CoTi<3>Mn<3>O<4> composite nanowires

ActiveCN108649200AUniform particle sizeImprove stabilityCell electrodesSecondary cellsNanowireN dimethylformamide

The invention discloses a preparation method of LaTi<21>O<38>CoTi<3>Mn<3>O<4> composite nanowires. According to the invention, a certain amount of tetrabutyl titanate, cobalt acetate tetrahydrate, manganese acetate tetrahydrate and lanthanum acetate hydrate are used as principal raw materials to be dissolved in a mixed solvent of N, N-dimethylformamide and isopropanol of a certain volume by meansof the electrospinning technology; then a suitable amount of polyvinylpyrrolidone is added to obtain a precursor mixture solution; the electrospinning is carried out under certain voltage, flow rate and certain relative humidity atmosphere; then the spinning products is sintered to obtain the LaTi<21>O<38>CoTi<3>Mn<3>O<4> composite nanowires. The composite nanowires prepared by the invention havegood electrochemical properties and can be applied to the electrode materials of lithium ion batteries. In the whole preparation process, the operation is simple, the raw material cost is low, the equipment investment is few, and it is suitable for mass production.

Owner:宁波市大学科技园发展有限公司

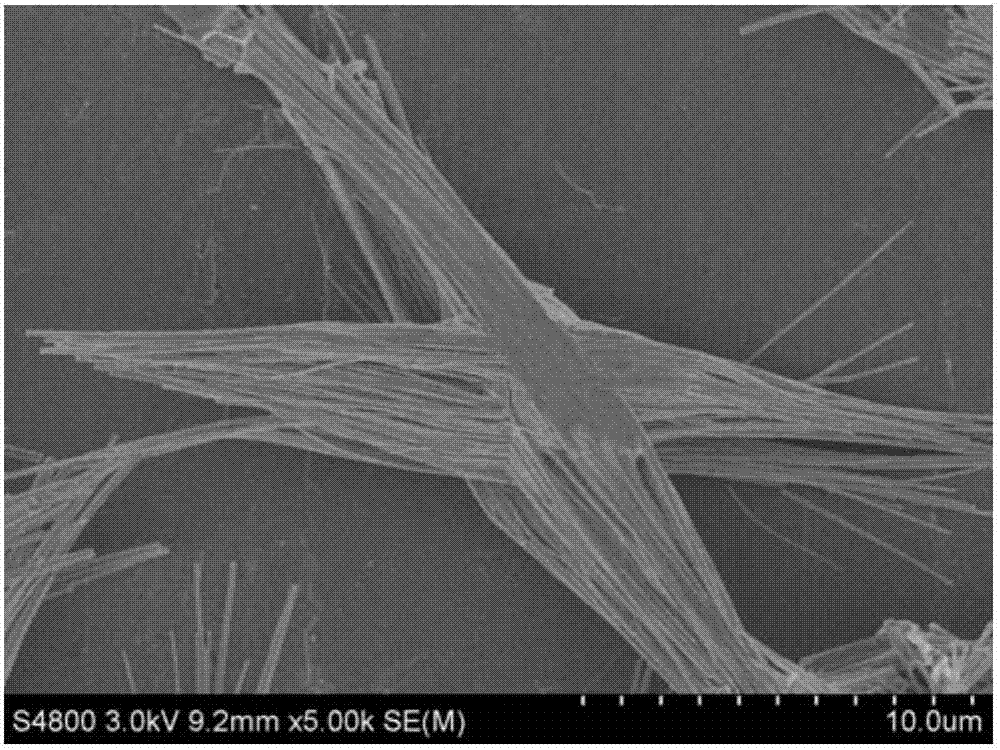

Manganese molybdate micro-nano bundle and method for preparing same

ActiveCN107032406ALarge specific surface areaImprove electrochemical performanceManganese compoundsMicro nanoMolybdate

The invention provides a manganese molybdate micro-nano bundle and a method for preparing the same. The method includes steps of firstly, preparing manganese acetate tetrahydrate aqueous solution with the concentration of 0.1-3 mol / L; secondly, preparing sodium molybdate dihydrate solution with the concentration of 0.05-0.2 mol / L; thirdly, mixing the manganese acetate tetrahydrate aqueous solution and the sodium molybdate dihydrate solution with each other according to a volume ratio of 1:(1-2), uniformly stirring the manganese acetate tetrahydrate aqueous solution and the sodium molybdate dihydrate solution, then pouring the manganese acetate tetrahydrate aqueous solution and the sodium molybdate dihydrate solution into a reaction kettle and carrying out sufficient hydrothermal reaction to obtain intermediate products; fourthly, placing the intermediate products in a tube furnace, calcining the intermediate products in argon atmosphere for 3-5 h, and then cooling the intermediate products until the temperatures of the intermediate products reach the room temperature to obtain the manganese molybdate micro-nano bundle. The manganese molybdate micro-nano bundle and the method have the advantages that the manganese molybdate micro-nano bundle prepared by the aid of the method has microscopic morphology of X-shaped structures and has large specific surface areas, and accordingly the electrochemical performance of manganese molybdate can be improved; the manganese molybdate micro-nano bundle is low in cost and high in purity, the method is simple, and accordingly the manganese molybdate micro-nano bundle has a potential market prospect in the field of nano-electronic devices.

Owner:合肥名龙电子科技有限公司

ACNFs@Ni-Mn-P nanosheet array composite material as well as preparation method and application thereof

PendingCN113539699ASimple processing routeLow costMaterial nanotechnologyHybrid capacitor electrodesCapacitanceSpinning

The invention discloses an ACNFs@Ni-Mn-P nanosheet array composite material which is prepared by the following steps of: by taking polyacrylonitrile, N, N-dimethylformamide, manganese acetate tetrahydrate, nickel acetate tetrahydrate, urea, ammonium fluoride and sodium hypophosphite as initial raw materials, firstly preparing a carbon nanofiber precursor through an electrostatic spinning method, then obtaining activated carbon nanofibers through low-temperature pre-carbonization, high-temperature carbonization and activation, and finally, carrying out hydrothermal reaction and calcining. The overall diameter is 6-7 microns. The thickness of the Ni-Mn-P nanosheets ranges from 30 nm to 40 nm, and the surfaces of the Ni-Mn-P nanosheets are rough. The preparation method comprises the following steps of: preparing a carbon nanofiber precursor; preparing and activating active carbon nanofibers; and preparing ACNFs@Ni-Mn-OH and the ACNFs@Ni-Mn-P. When the material is used as a supercapacitor electrode material, the material is charged and discharged within the range of 0-0.45 V. When the discharge current density is 1 A g <-1 >, the specific capacitance can reach 1000-1100 F g <-1 >; and when the discharge current density is 10A g <-1 >, the cycling stability after 5000 cycles is 88.53%, and the coulombic efficiency is 100%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

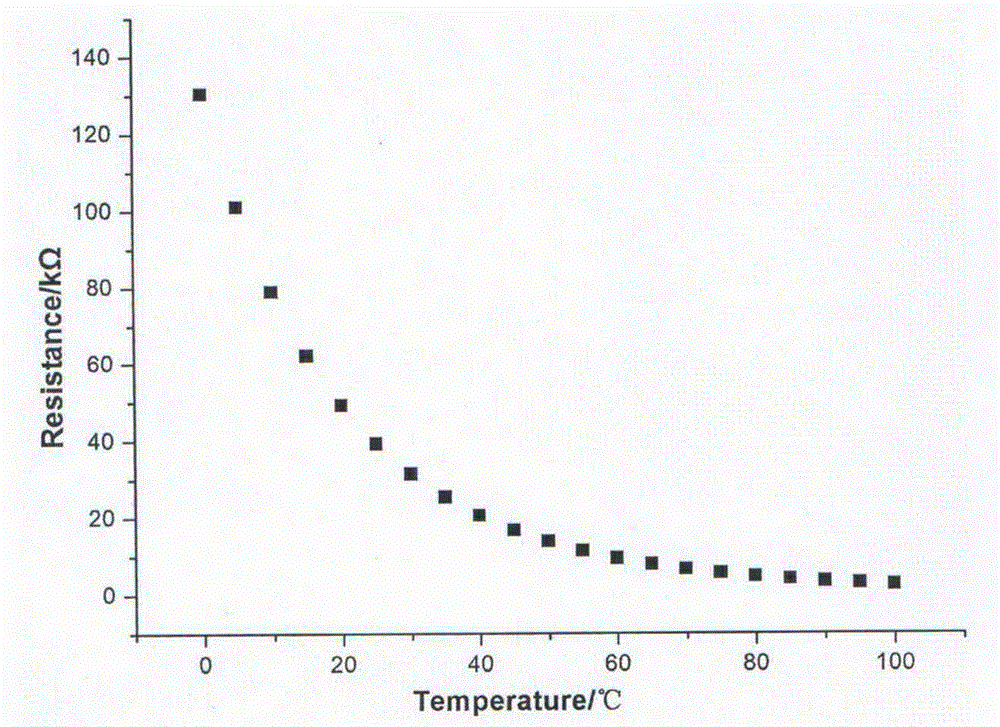

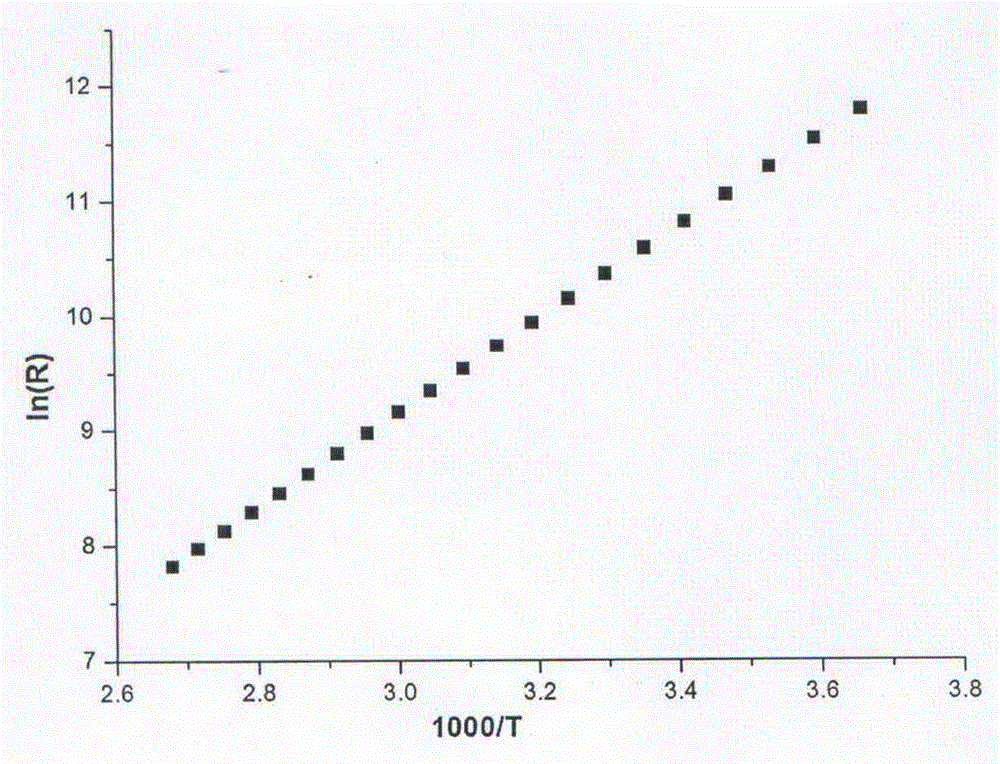

Method for preparing NTC (negative temperature coefficient) thermosensitive ceramic material through two-step solid-phase chemical reaction

InactiveCN104649681AIncrease the resistance valueImprove consistencyMANGANESE ACETATE TETRAHYDRATEComposite oxide

The invention relates to a method for preparing an NTC (negative temperature coefficient) thermosensitive ceramic material through two-step solid-phase chemical reaction. The method comprises the following steps: by taking manganese acetate tetrahydrate, nickel nitrate hexahydrate, magnesium nitrate hexahydrate, aluminium nitratenonahydrate and ammonium citrate as raw materials, carrying out solid-phase chemical reaction at room temperature, calcining the reaction product at a high temperature to obtain composite oxide powder with uniform size and good dispersibility, prepressing the composite oxide powder, pressing isostatically, and calcining to obtain the NTC thermosensitive ceramic material. The NTC thermosensitive ceramic material can be made into an NTC thermosensitive resistor by adopting a conventional method according to the procedures of slicing, coating with electrodes, scribing, welding and encapsulating. The NTC thermosensitive resistor has good consistent resistance value and B value, interchangeability, stability and repeatability and can be widely used for controlling and detecting the temperature of induction cookers, electric pressure cookers, electric rice cookers, electric ovens, disinfection cabinets, water dispensers, microwave ovens, electric heaters and other household appliances.

Owner:XINJIANG ZHONGKE SENSING CO LTD

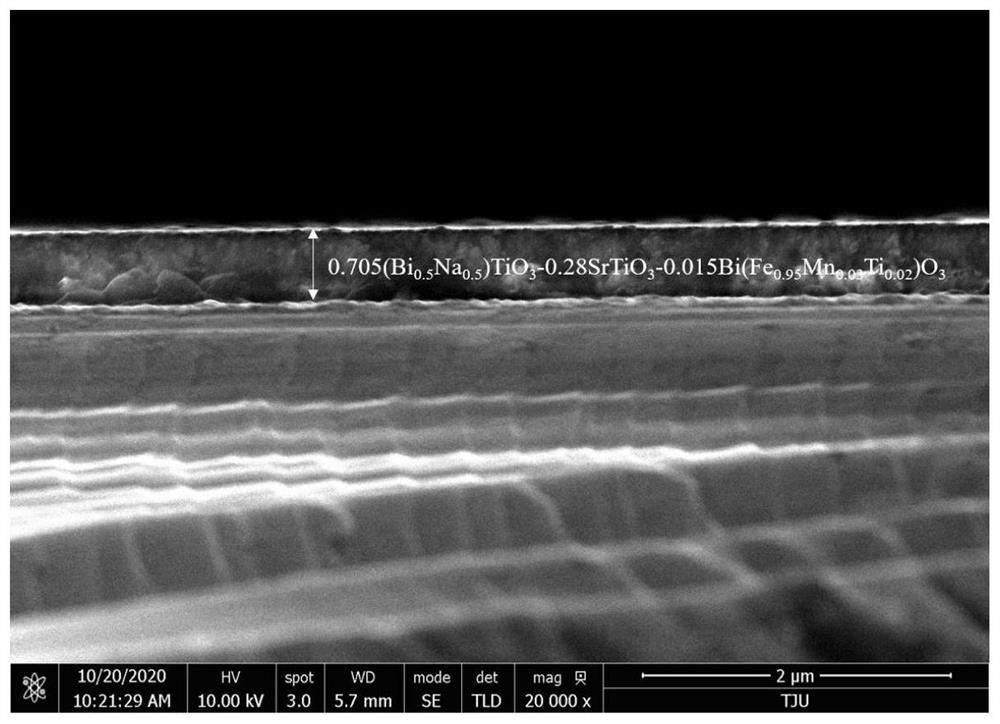

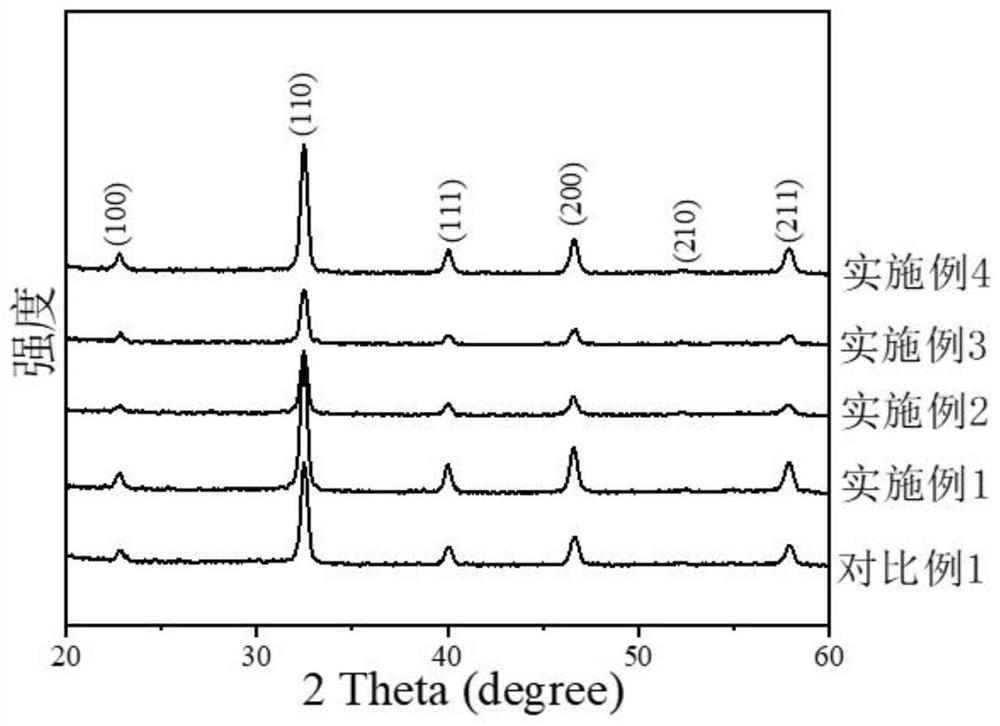

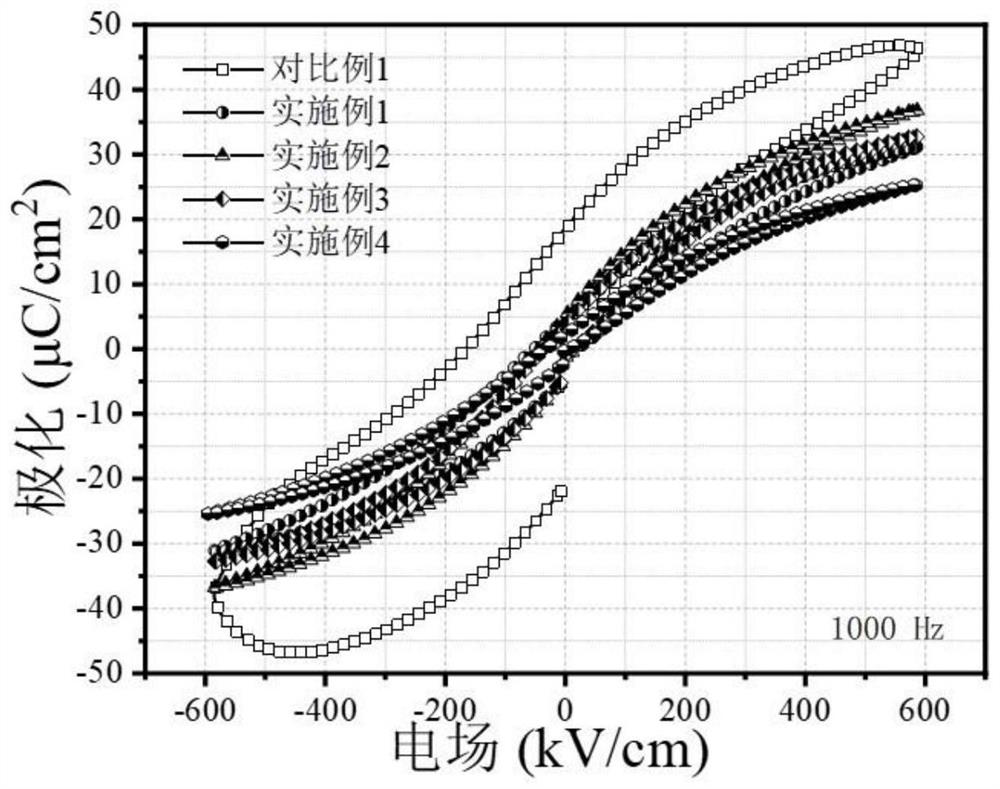

Sodium bismuth titanate-based lead-free piezoelectric film and preparation method thereof

ActiveCN113213920AHigh polarizationTypical perovskite structureSodium acetateMANGANESE ACETATE TETRAHYDRATE

The invention relates to a sodium bismuth titanate-based lead-free piezoelectric film and a preparation method thereof, and belongs to the field of electronic functional materials and devices. The preparation method provided by the invention comprises the following steps: step 1, adding bismuth nitrate, sodium acetate and strontium acetate into a solvent, and stirring to obtain a solution A; step 2, dissolving acetylacetone, tetrabutyl titanate, ferric nitrate nonahydrate and manganese acetate tetrahydrate in a solvent, stirring and heating to obtain a solution B; step 3, mixing the solution A with the solution B, and performing pretreatment to obtain a mixed solution C; and step 4, coating a treated substrate with the mixed solution C by using a spin coating method, and performing high-temperature treatment to obtain the (0.72-x)(Bi0. 5Na0. 5) TiO3-0. 28SrTiO3-xBi (Fe0. 95Mn0.03Ti0.02)O3 ternary system sodium bismuth titanate-based lead-free piezoelectric film. Therefore, the piezoelectric film prepared by the method is flat and smooth in surface, has a typical perovskite structure, relatively high polarization intensity and excellent piezoelectric performance; and meanwhile, the inverse piezoelectric coefficient can reach 179.7 picometer / volt to the maximum, and the method has very important significance for developing a high-performance lead-free piezoelectric film.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com