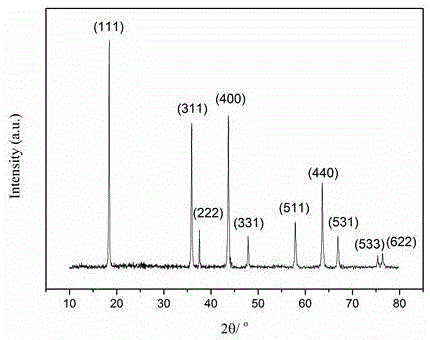

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

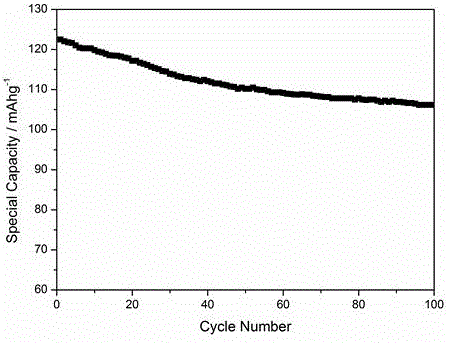

A technology of three cobalt tetroxide and lithium heteromanganate, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of poor cyclability and high temperature, and achieve the effect of preventing dissolution and improving cycle performance and high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

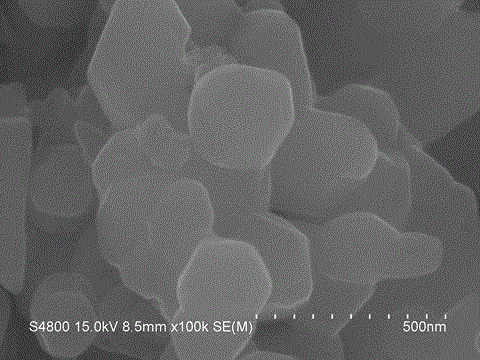

[0019] Weigh 0.5245g lithium hydroxide monohydrate, 1.0507g citric acid, 0.0933g nickel acetate tetrahydrate and 6.0353g manganese acetate tetrahydrate, add 40mL deionized water and stir for half an hour, transfer to an oil bath and heat to 80 ℃, adjust the pH to 7.5 and keep it warm for a period of time until a brown oily gel is obtained, then dry the gel in microwave to obtain a white dry gel, and then grind it to obtain a precursor powder. The xerogel was ground into powder and placed in a tube furnace in an air atmosphere at a heating rate of 5°C to 750°C for 10 hours, then cooled naturally to obtain a nickel-doped lithium manganate material. The nickel-doped lithium manganese oxide material obtained above is mixed with cobalt acetate tetrahydrate in a certain metering ratio, and ground. Among them, nickel-doped lithium manganate is 0.7070 g, and cobalt acetate tetrahydrate is 0.1085 g. Add the resulting mixture to anhydrous ethanol and sonicate for 30 minutes, then place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com