Patents

Literature

130results about How to "Uniform grain distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

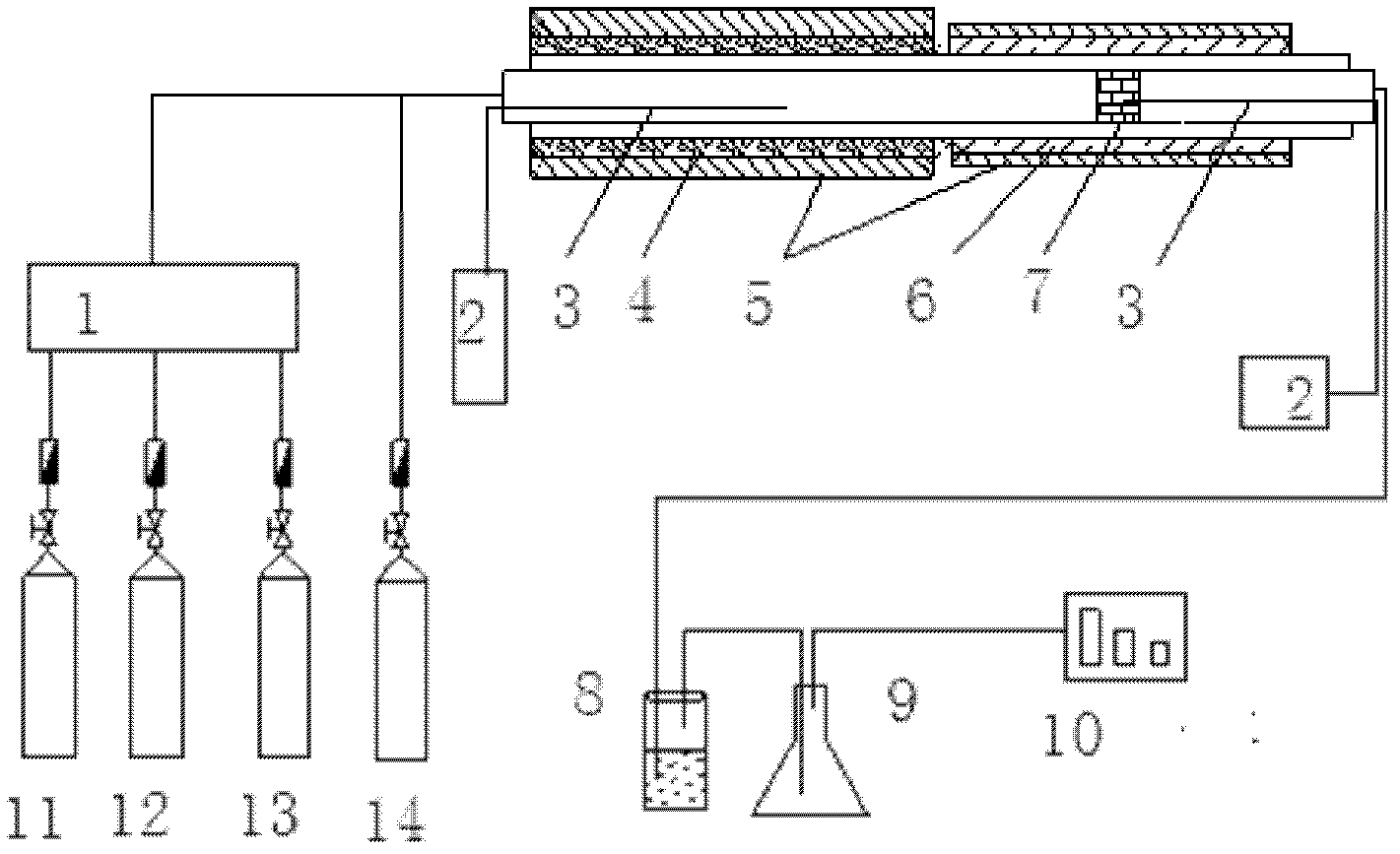

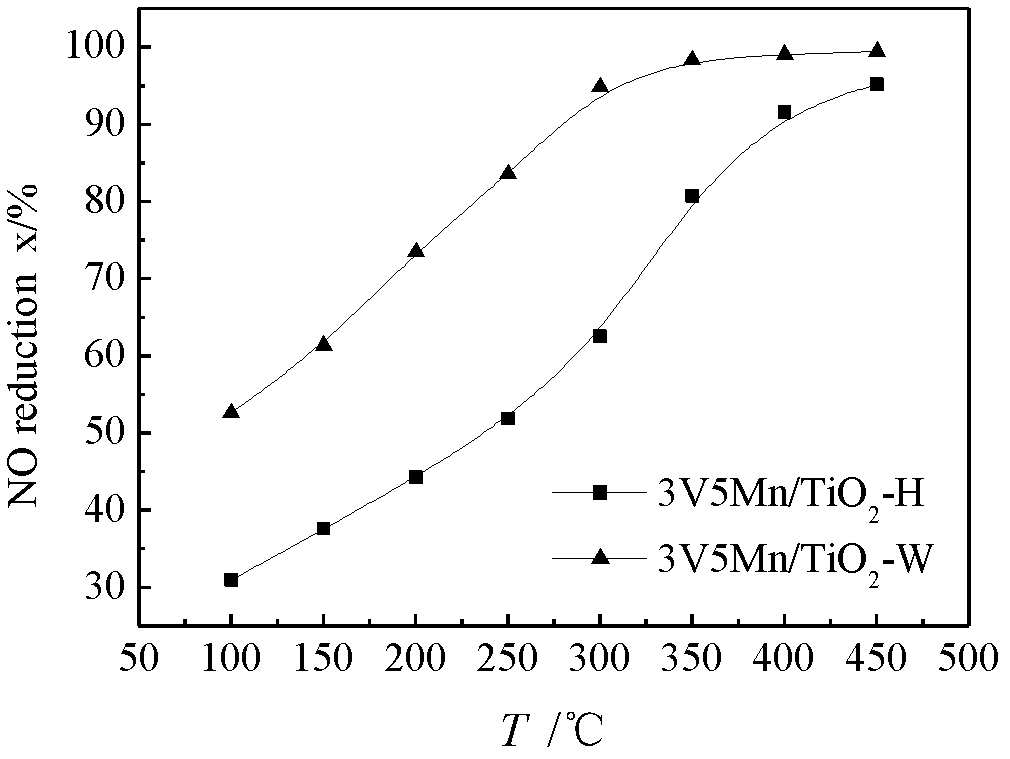

Method for preparing flue gas SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN102553574AShorten drying timeReduce energy consumptionDispersed particle separationCatalyst activation/preparationWater bathsAmmonium metavanadate

The invention relates to a method for preparing a flue gas SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: mixing ammonium metavanadate, oxalic acid, manganese salt and water for preparing a mixture solution, adding titanium dioxide powder into the mixture solution, heating in water bath and stirring, and obtaining mixed sol by standing at room temperature; putting the mixed sol into a microwave oven, heating and drying by utilizing microwave radiation; and putting dried solid into a muffle furnace for burning. According to the method disclosed by the invention, a temperature window of the SCR catalyst can be broadened to a low-temperature direction, the problems of low denitration efficiency at low temperature and narrow temperature window of a commercial catalyst are solved; compared with the traditional drying method, the microwave radiation heating and drying method has the advantages that low-temperature SCR denitration activity of the composite catalyst can be increased to a large extend, when the activity temperature is up to 250 DEG C, the denitration efficiency of the catalyst prepared by the traditional drying method is up to 51.9%, and the denitration efficiency of the catalyst can be increased by 31.7 percentage points and can be up to 83.6% by the microwave radiation heating and drying method.

Owner:SHANDONG UNIV

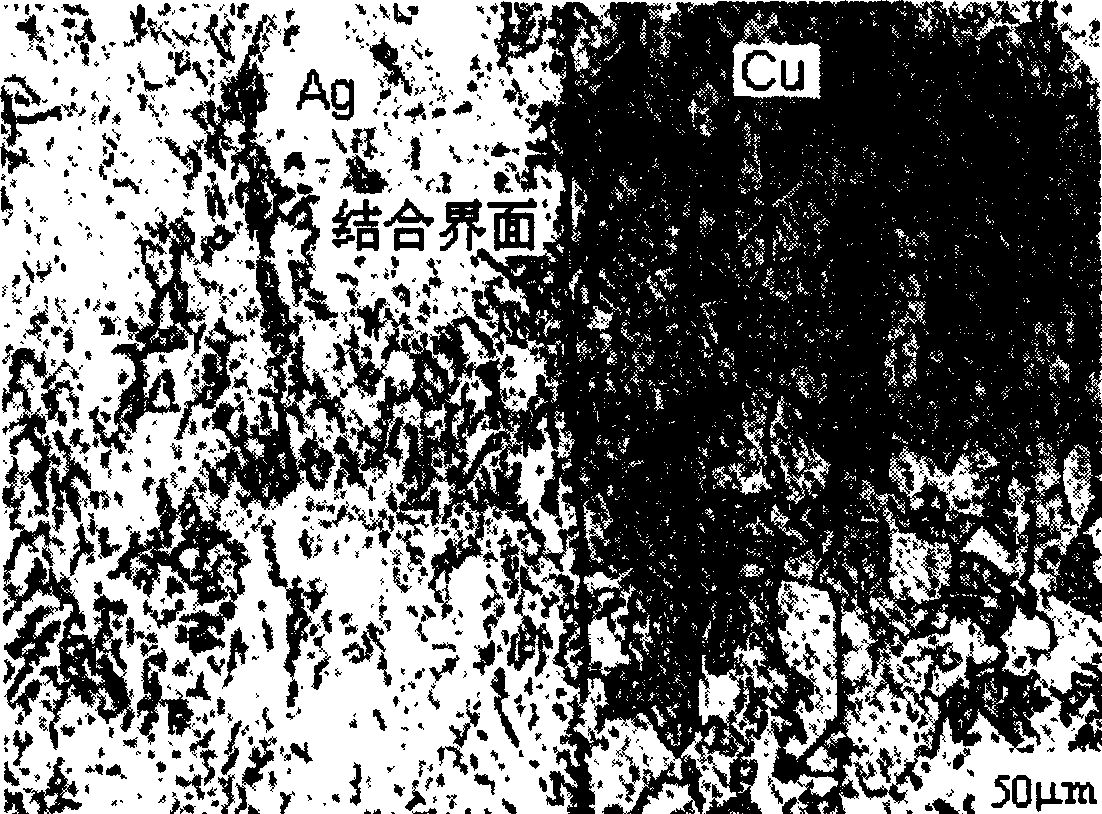

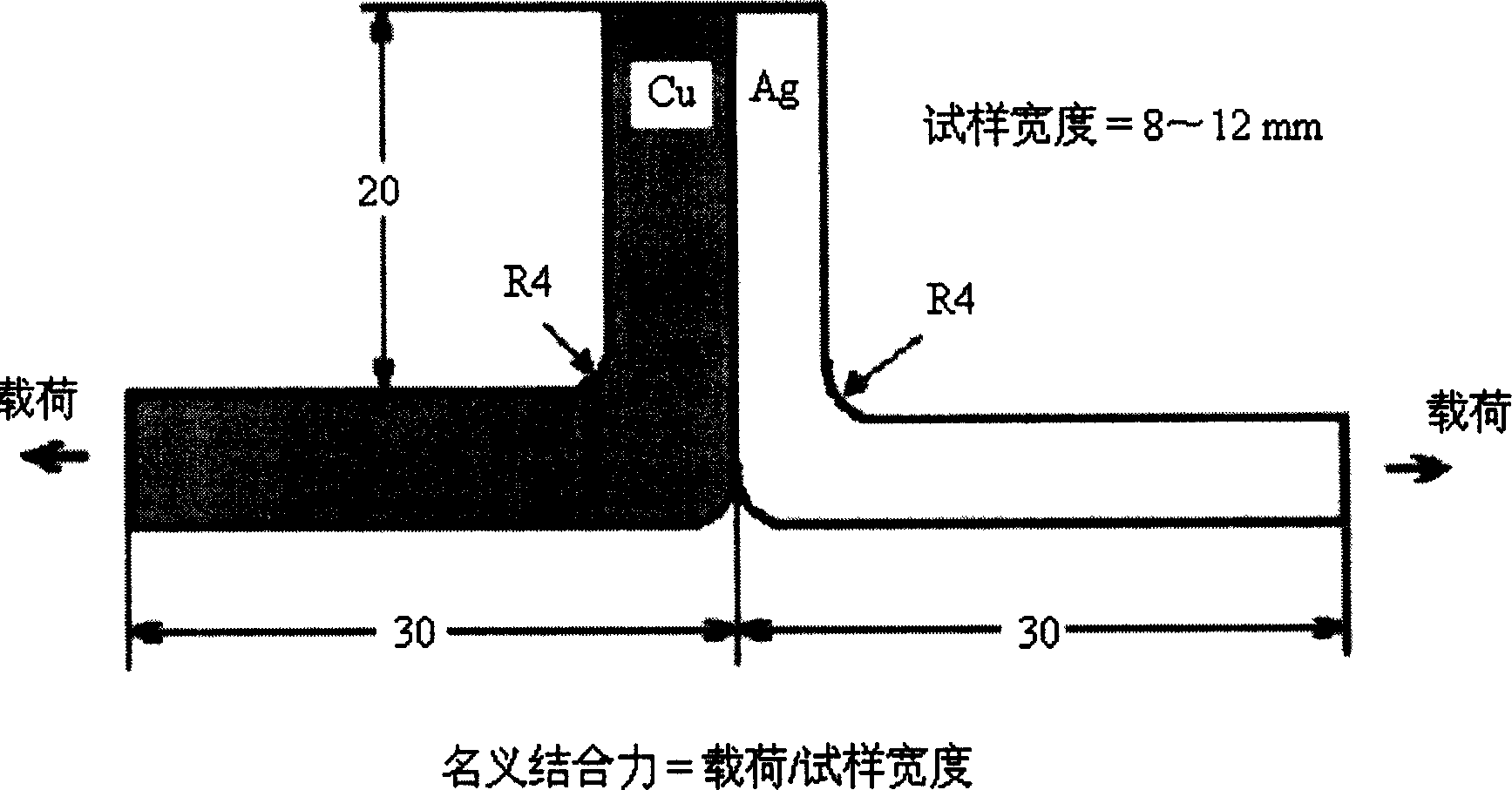

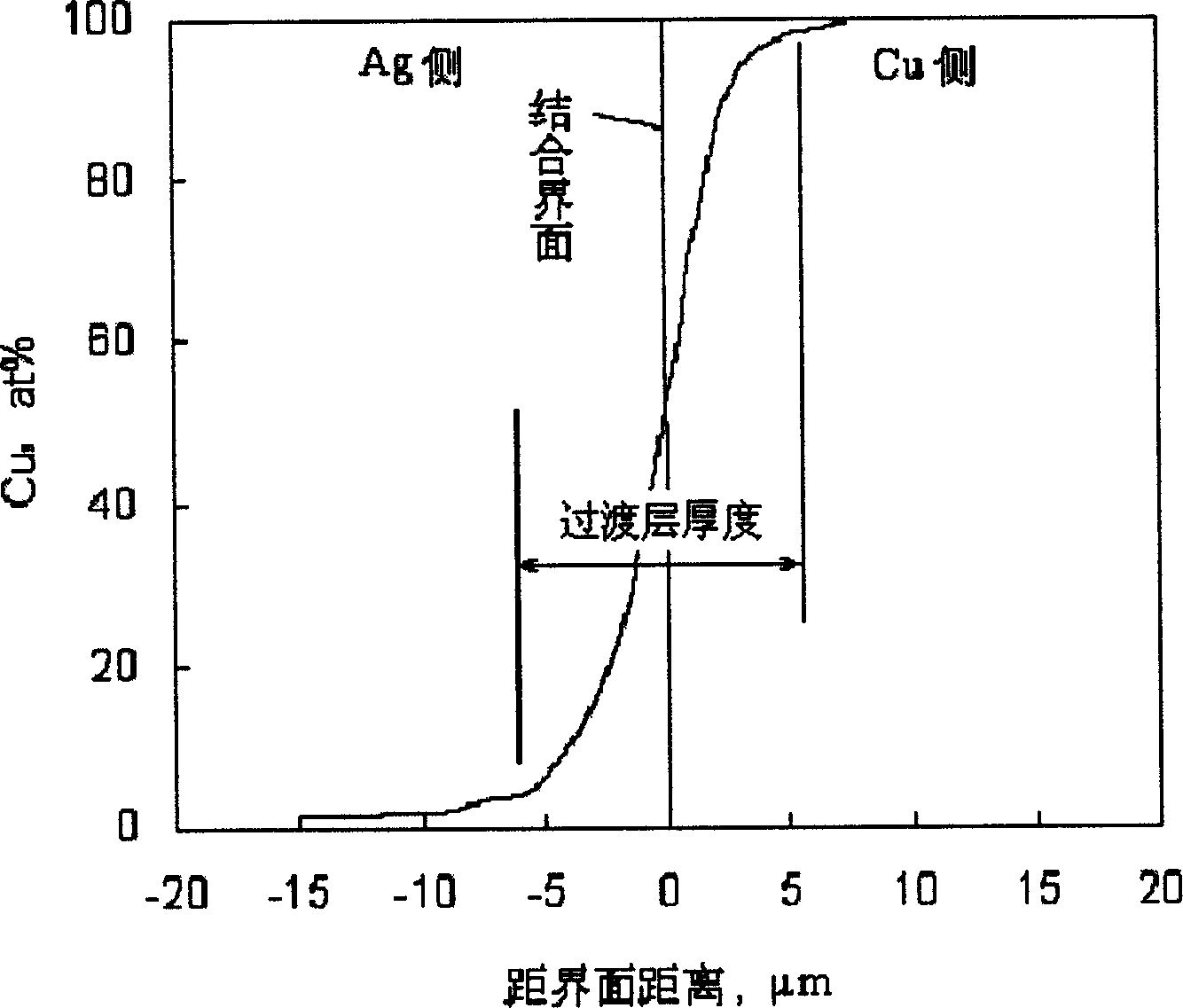

Bimetallic compound Cu/Ag plate making process

InactiveCN1739913AGood for mechanical engagementGood initial composite stateOther manufacturing equipments/toolsBinding forceTransition layer

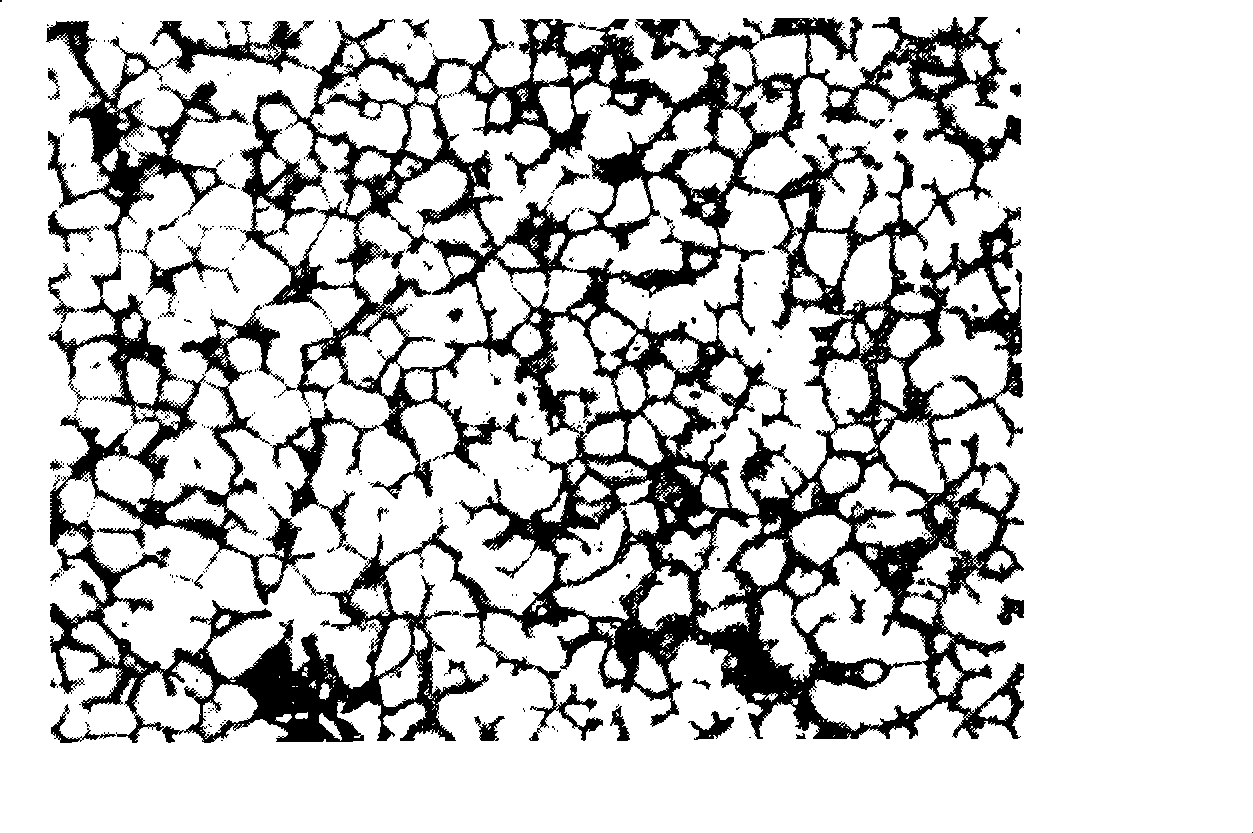

The bimetallic compound Cu / Ag plate making process includes the following steps: annealing hard industrial pure Cu and Ag base material at 250-300 deg.c, pre-tension straining, mechanically grinding to form composite surface of roughness Ra 12.5-50 micron, cold rolling for deformation of 5 % and pre-compounding, rolling at normal temperature or 200 deg.c for deformation of 70-80 % and physical compounding, and annealing and diffusion compounding at 400-450 deg.c for 2-4 hr. The prepared compound plate has nominal interface binding force of 40-45 N / mm, diffusion transition layer in the thickness of 10-14 micron, homogeneous structure and close interface binding. In addition, the present invention has also the effects of obvious technological stages, convenient parameter control, etc.

Owner:ZHEJIANG UNIV

Isothermal normalizing technology of carburized gears steel forging

The invention discloses an isothermal normalizing process of a carburized gear steel forging stock, which relates to the technical field of metal heat treatment. The process is carried out on a bright isothermal normalizing production line under a preevacuated and fully electrically heated roller bottom protective atmosphere. The heating, heat preservation, fast cooling, isothermy and water cooling in the protective atmosphere are automatically completed by a PLC control. The normalizing heating temperature of the forging stock is Ac3 plus (100-150) DEG C, and the temperature is kept for 36-45min, and the forging stock is quickly cooled to 560-600 DEG C within 10min by high-purity nitrogen gas blown by an electric fan. The normalizing process has the advantages of normative operation, high production efficiency, and can ensure that the forging stock is not oxidized and decarburized in the heat treatment process, and austenite crystals in the forging stock are evenly distributed, which avoids the appearance of banded structures and causes the forging stock to have good and stable quality with small hardness fluctuation.

Owner:JIANGSU PACIFIC PRECISION FORGING

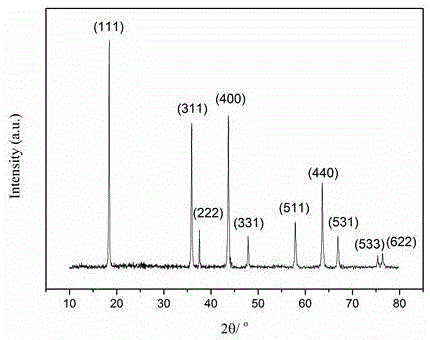

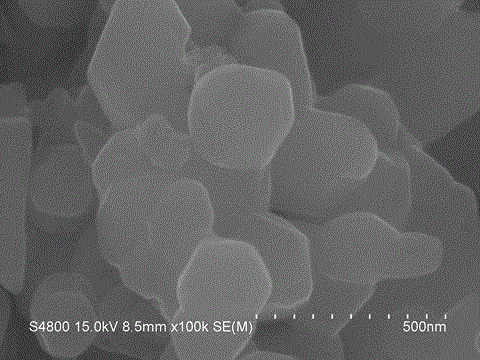

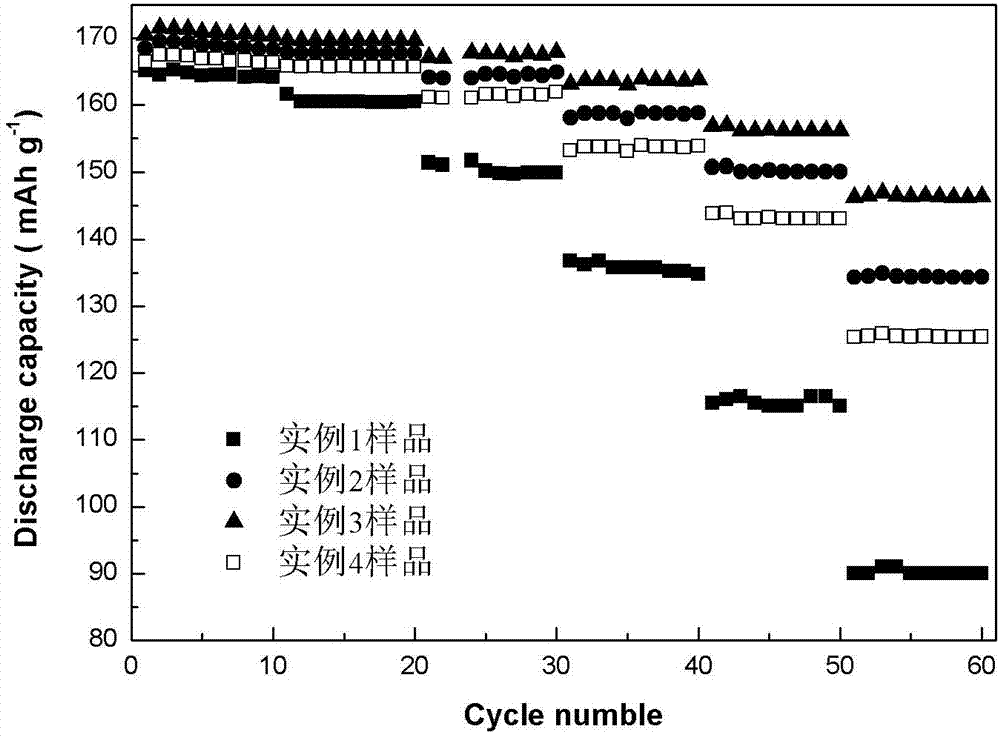

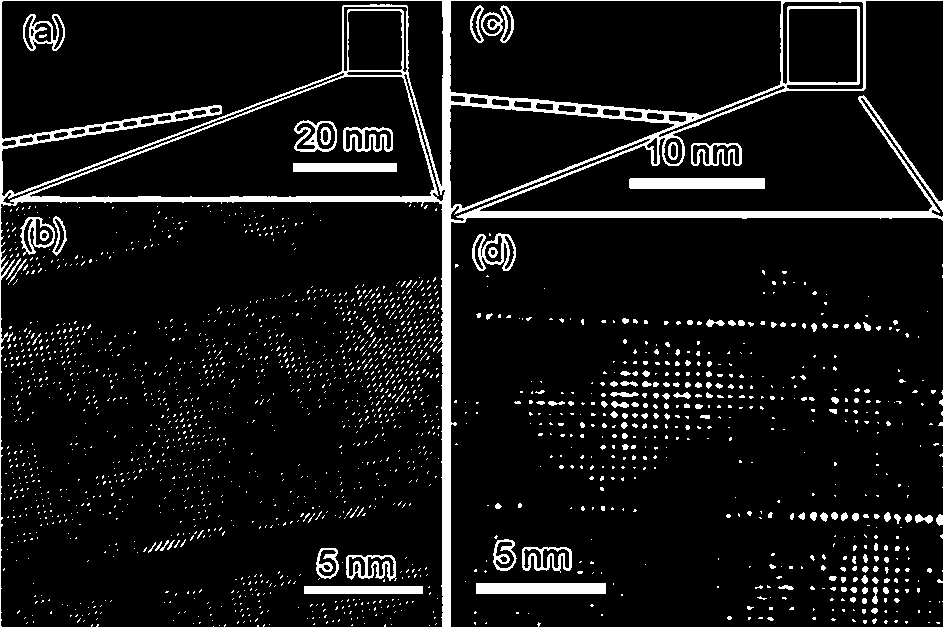

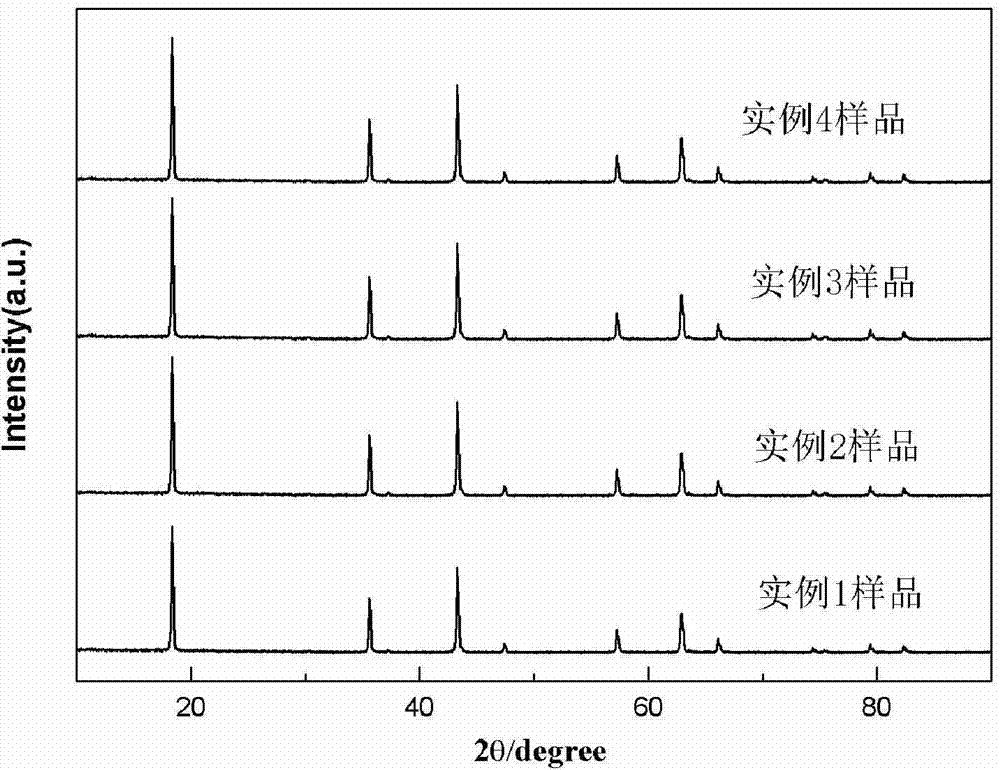

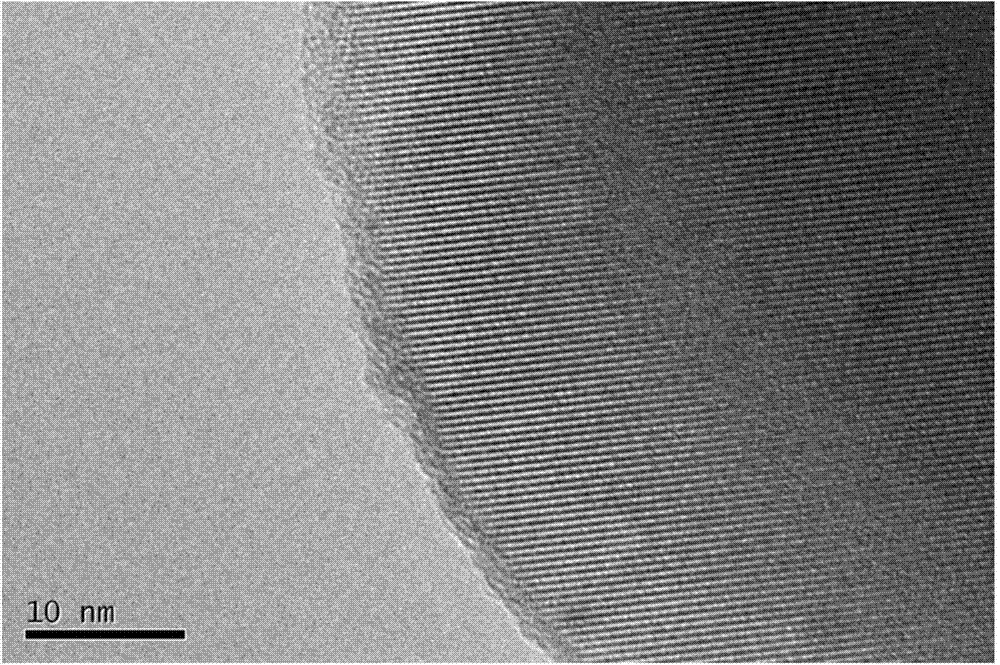

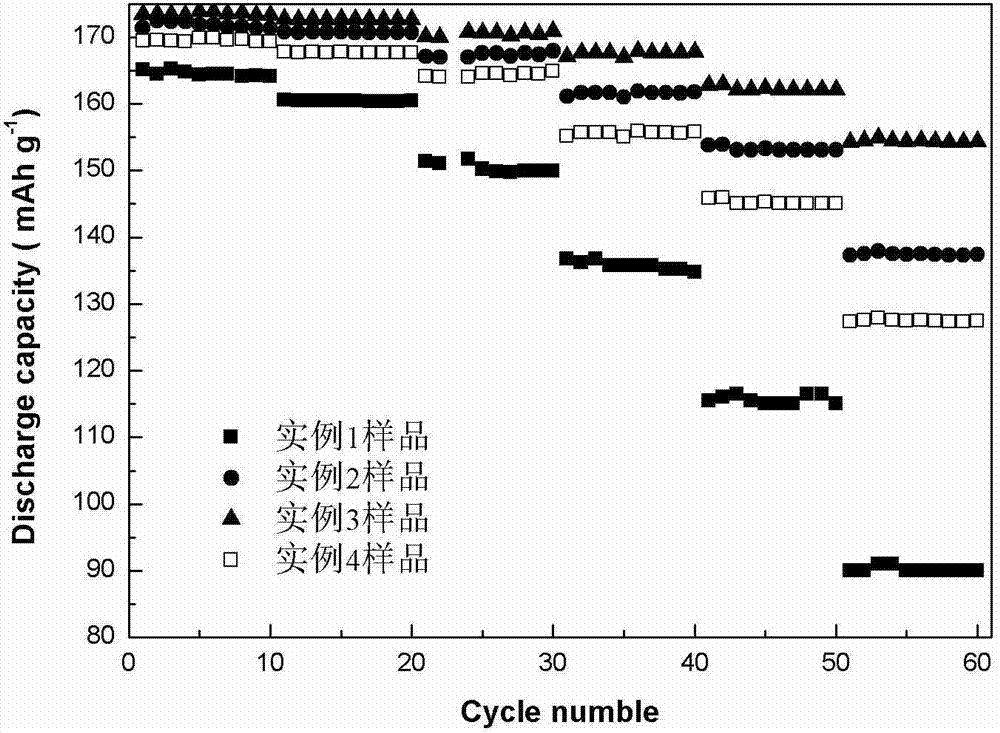

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

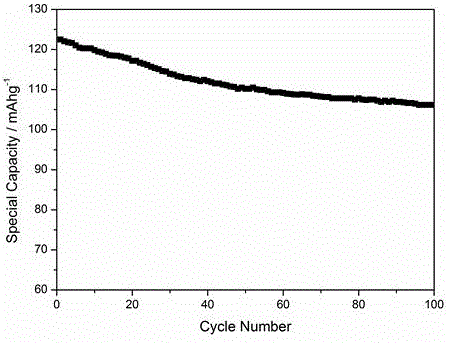

InactiveCN106356509AInhibition of dissolutionIncrease contentCell electrodesSecondary cellsMANGANESE ACETATE TETRAHYDRATENickel acetate tetrahydrate

The embodiment of the invention discloses modified lithium manganate coated based on a sol-gel method, and a preparation method thereof. The preparation method comprises the steps of preparing a nickel-doped lithium manganate material with the sol-gel method by firstly, weighing lithium hydroxide monohydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate and citric acid according to a certain stoichiometric ratio, adding deionized water, and uniformly mixing, wherein the citric acid is used as a chelating agent; mixing the prepared nickel-doped lithium manganate with cobalt acetate tetrahydrate; grinding, and calcining in a tube furnace to obtain a cobaltosic oxide coated and modified nickel-doped lithium manganate composite material. The composite material prepared by using the technical scheme has excellent cycling stability, rate capability and high-temperature performance.

Owner:EAST CHINA UNIV OF SCI & TECH

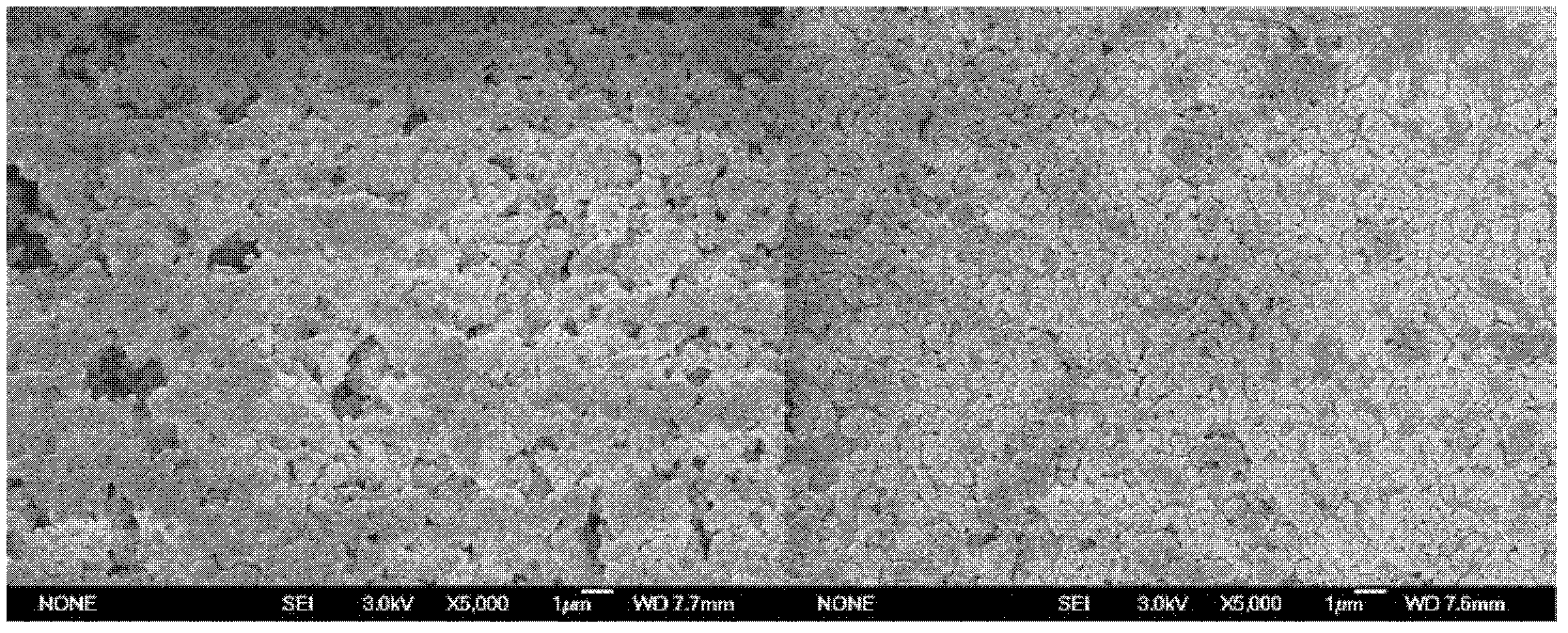

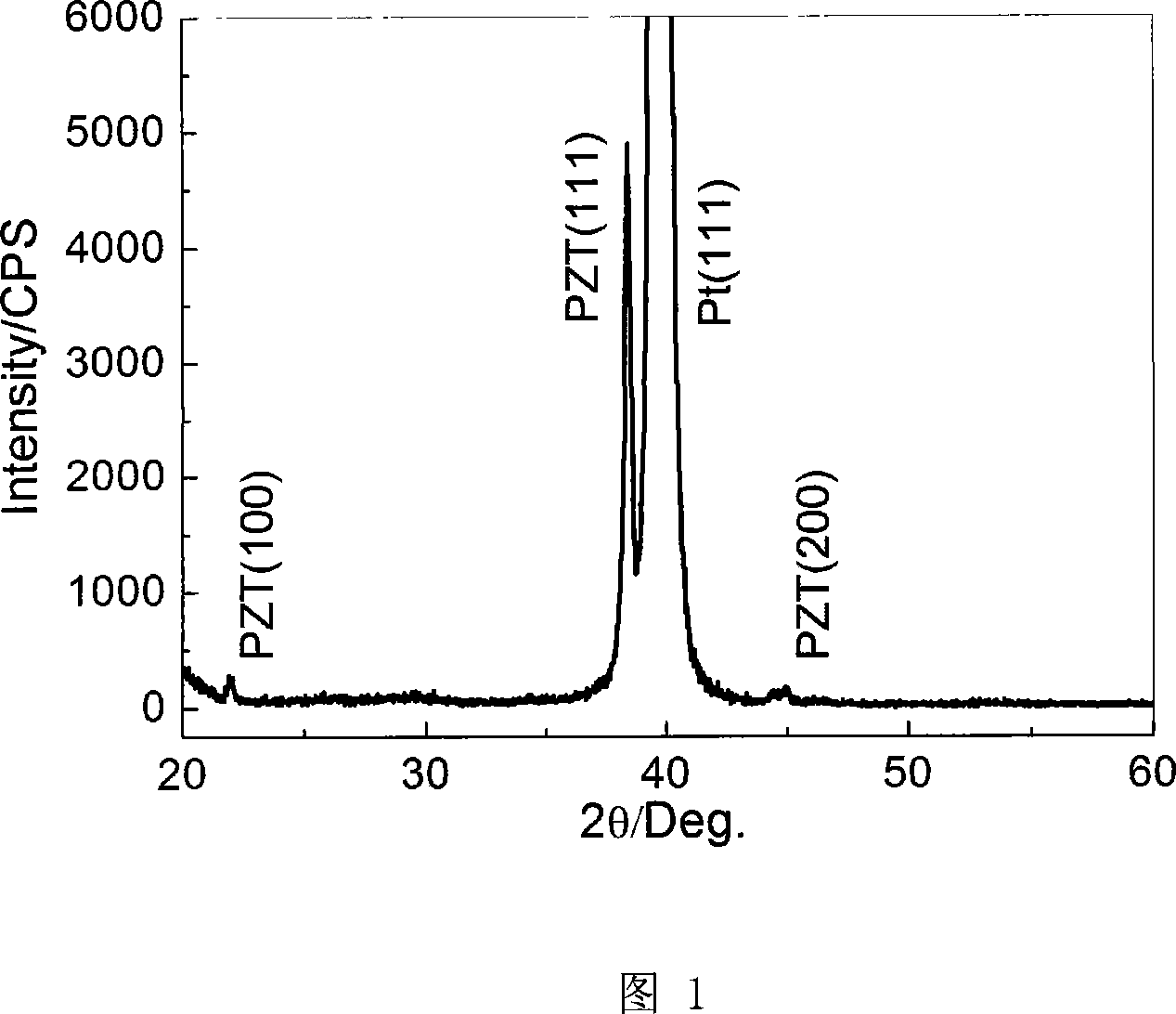

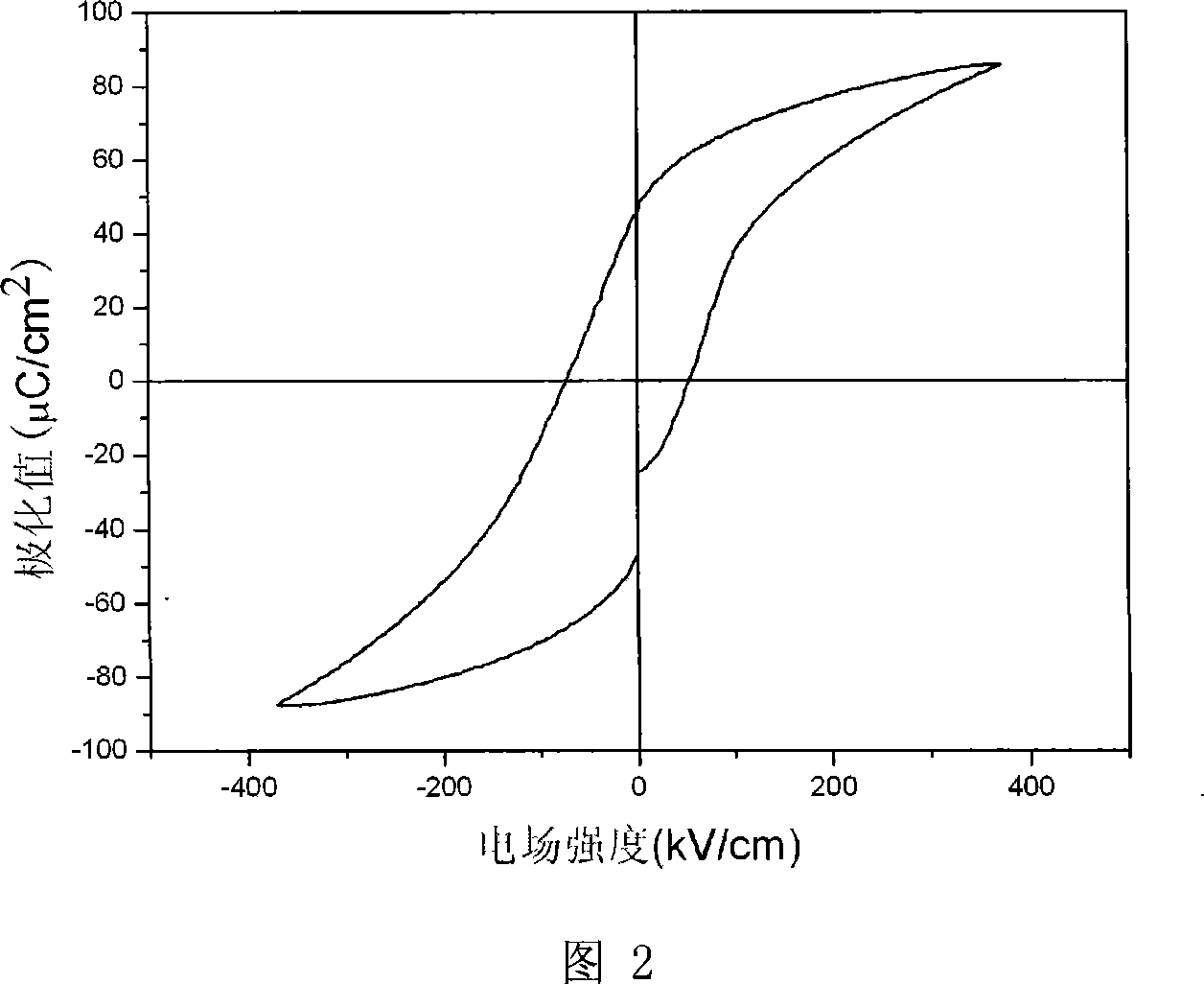

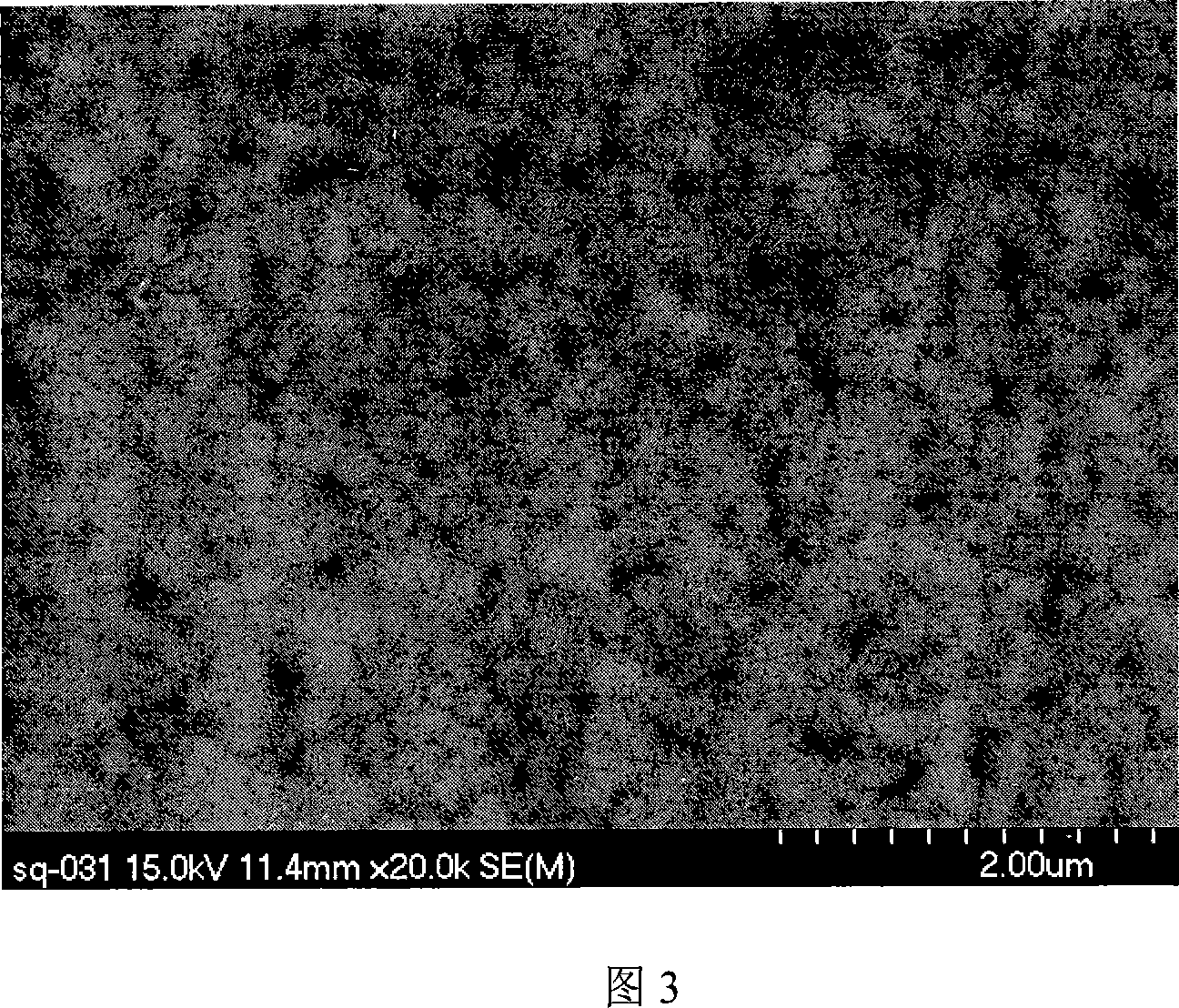

Method for fabricating film of aluminum zirconate titanate with high orientating (111)

InactiveCN101050119AFlat and dense surfaceUniform compositionCeramicsLead zirconate titanateZirconate

This invention discloses a method for preparing highly (111)-oriented PZT thin film. The method can solve the problems of complex process and low repeatability faced by sol-gel method. The method comprises: preparing PZT sol, depositing PZT thin film, pre-crystallizing PZT thin film, and crystallizing PZT thin film. The method is simple. The obtained PZT thin film has compact and smooth surface, uniform thickness, uniform grain sizes, high residual polarization value (43-60 muC / cm2), low coercive field (60-75 kV / cm), and high saturated polarization value.

Owner:HARBIN INST OF TECH

Method for preparing palladium carbon catalyst of high activity

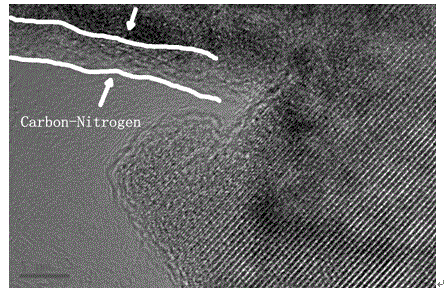

InactiveCN101433839AUniform grain distributionPrevent self-aggregation from overlappingMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHigh activity

The invention provides a method for preparing a high active palladium-carbon catalyst. The method comprises the following steps: palladium chloride is dissolved by hydrochloric acid to be prepared into a solution with certain concentration, then the solution is added into pretreated activated carbon along with an auxiliary agent to ensure that palladium is evenly dispersed on the surface and the subsurface of carbon, and then the high active palladium-carbon catalyst is obtained through the reduction of a reducing agent.

Owner:CHANGSHA RONGXING NOBLE METAL

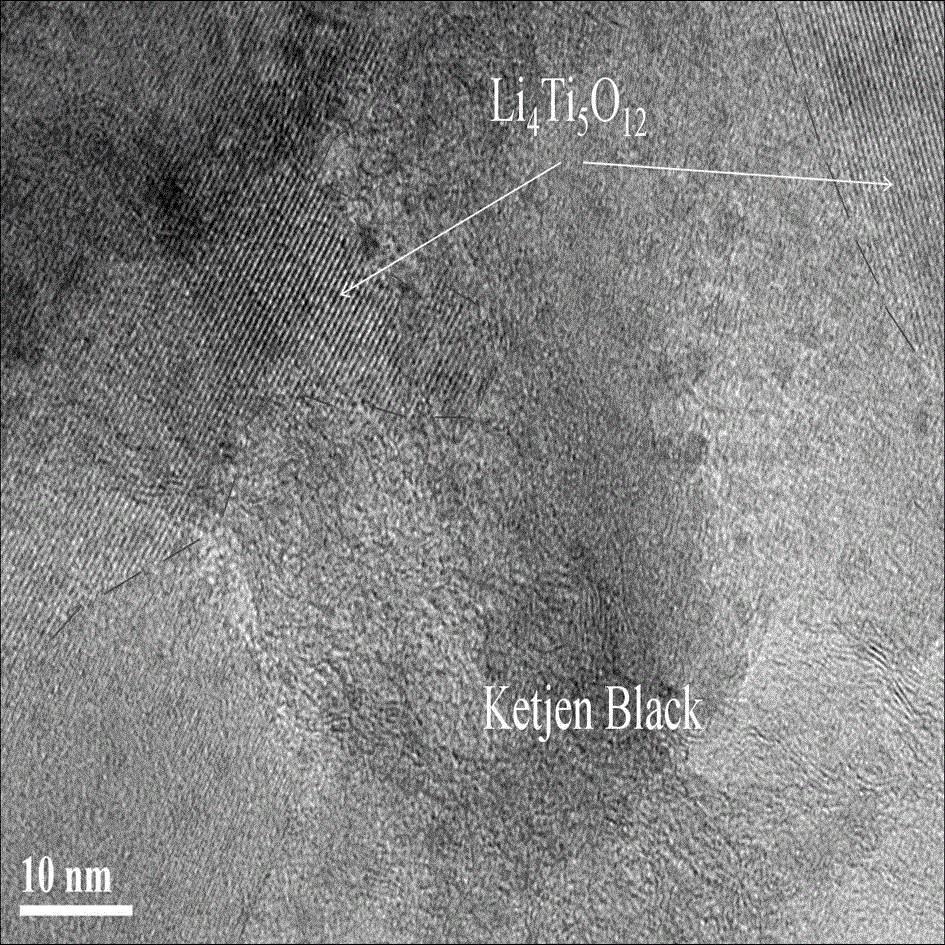

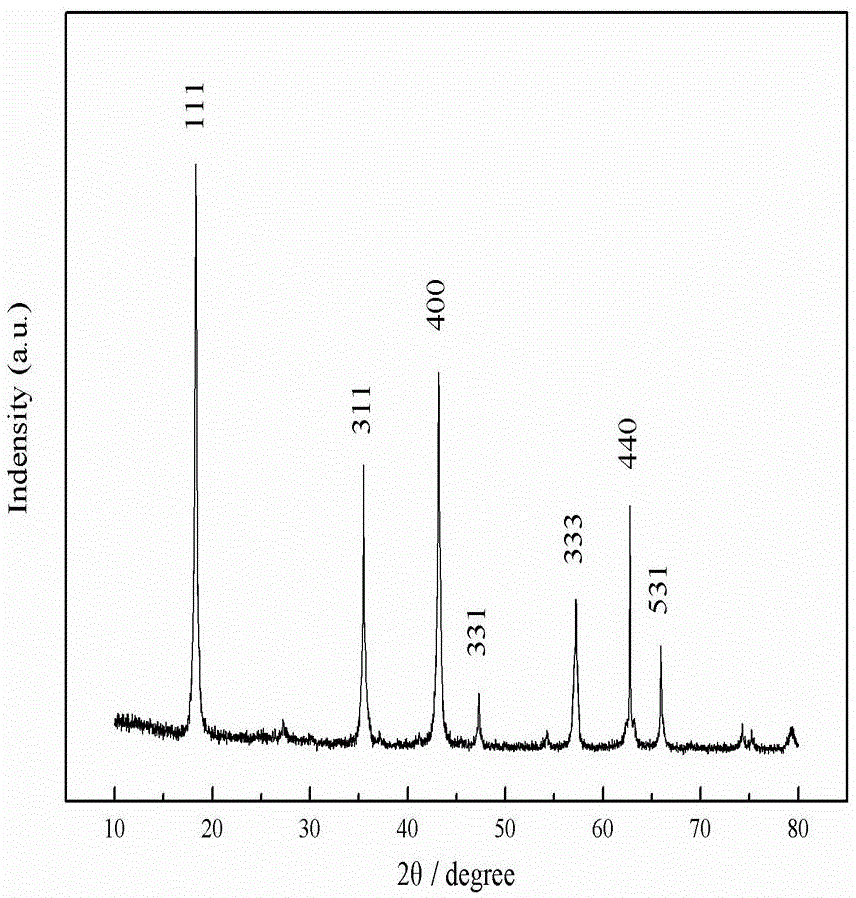

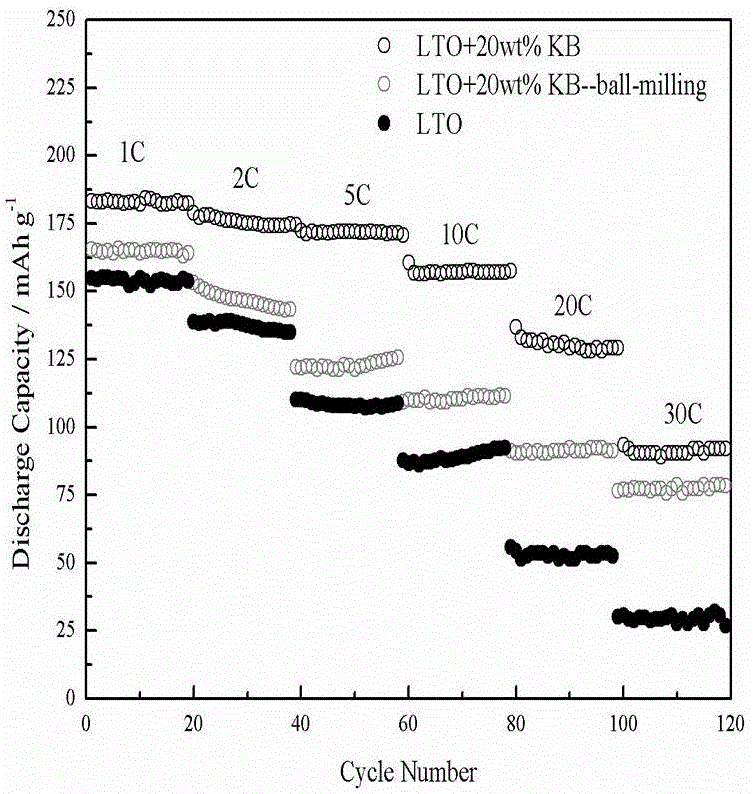

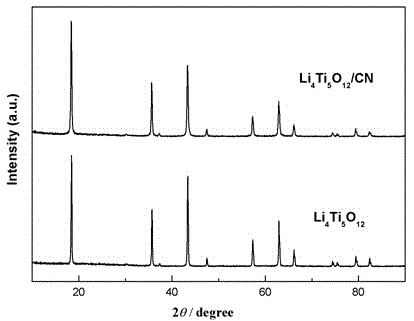

Lithium titanate/porous carbon composite material and preparation method of lithium titanate/porous carbon composite material

InactiveCN105789582AImprove electronic conductivityIncrease the diffusion coefficientCell electrodesSecondary cellsCarbon compositesHydration reaction

The invention discloses a lithium titanate / porous carbon composite material. The invention further discloses a preparation method of the lithium titanate / porous carbon composite material. The prepapration method comprises the following steps: weighing lithium hydroxide monohydrate, tetrabutyl titanate and porous carbon according to a certain stoichiometric ratio; adding ethanol and de-ionized water and uniformly mixing; transferring a stirred suspension solution into a hydrothermal reaction kettle and reacting at 180 DEG C for 24h to 48h to obtain precursor slurry; drying and crushing the precursor slurry to obtain precursor powder; treating the precursor powder in an inert atmosphere at the temperature of 500 DEG C to 700 DEG C for 5 to 10 hours to obtain the lithium titanate / porous carbon composite material. The composite material prepared by the technical scheme provided by the invention has excellent rate performance and low-temperature property.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of polycrystalline silicon ingot

InactiveCN104711673AImprove photoelectric conversion efficiencyIngot casting process requirements are lowPolycrystalline material growthSingle crystal growth detailsVacuum pumpingSpray coating

The invention relates to a preparation method of a polycrystalline silicon ingot. The method comprises the following steps: (1) a binding agent, a dispersing agent, and silicon particles of which the purity is above 99.9 percent and the diameter is between 1 [mu]m and 5,000 [mu]m, are added into deionized water, a pulp is obtained after uniform mixing, and the mass percentage of the silicon particles in the pulp is not less than 50 percent; (2) in a quartz crucible with a silicon nitride coating on the inner surface, the pulp is applied on the surface of the silicon nitride coating through spray coating, roller coating or brush coating, so as to form a pulp layer with a thickness between 1 mm and 10 mm; the crucible with a silicon coating is obtained after drying; (3) the crucible with the silicon coating is sent into a polycrystalline silicon ingot furnace after being loaded with silicon materials, the silicon materials are heated after vacuum pumping, a silicon material melt is cooled for polycrystalline silicon growth after the silicon materials are completely molten, and the polycrystalline silicon ingot is obtained through annealing cooling after the polycrystalline silicon growth is completed. The polycrystalline silicon ingot obtained through the method can be used for the manufacturing of a solar battery, so that the average battery efficiency of a silicon wafer exceeds 18 percent.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

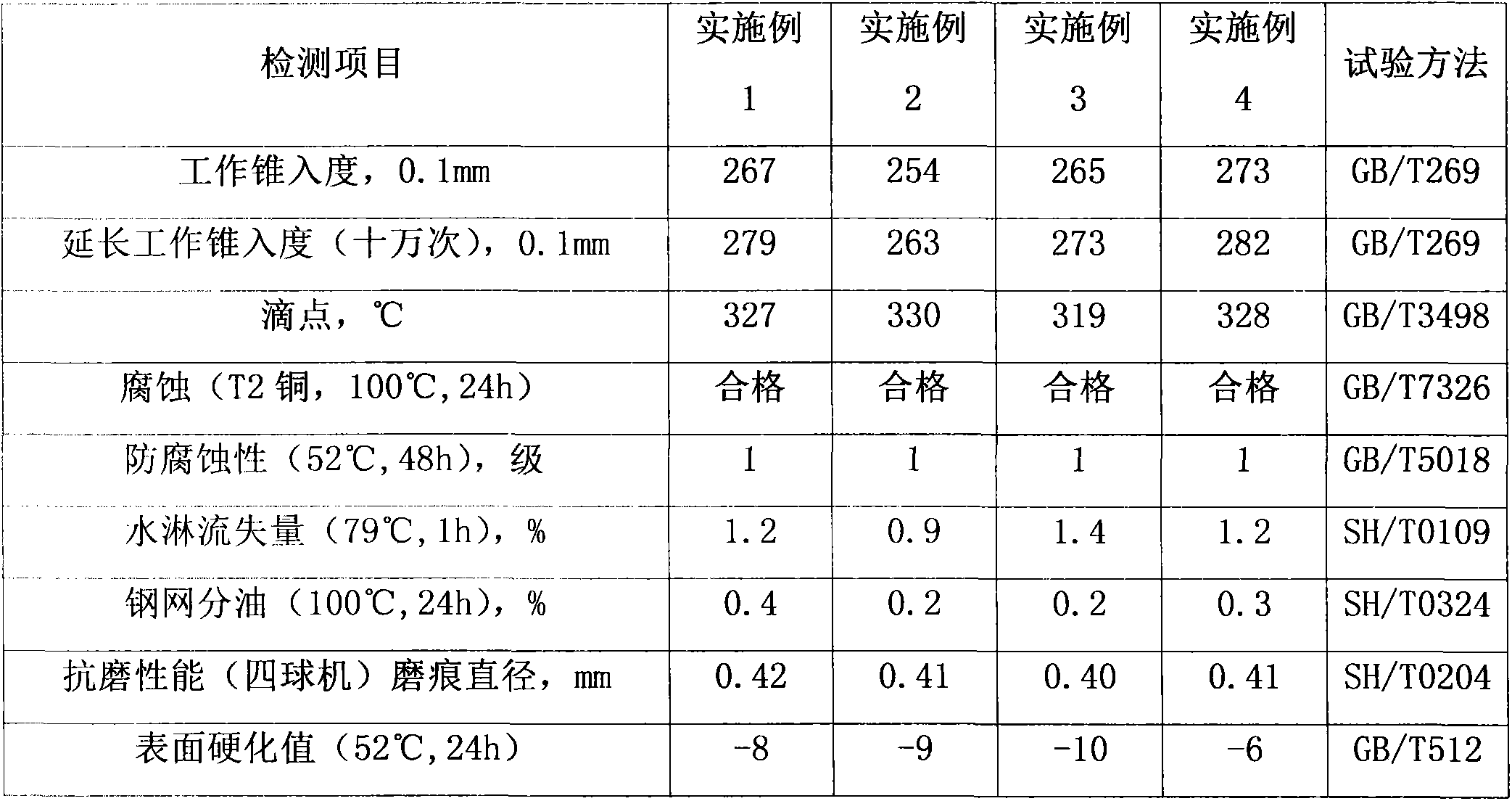

High-performance calcium sulfonate complex grease and preparation method thereof

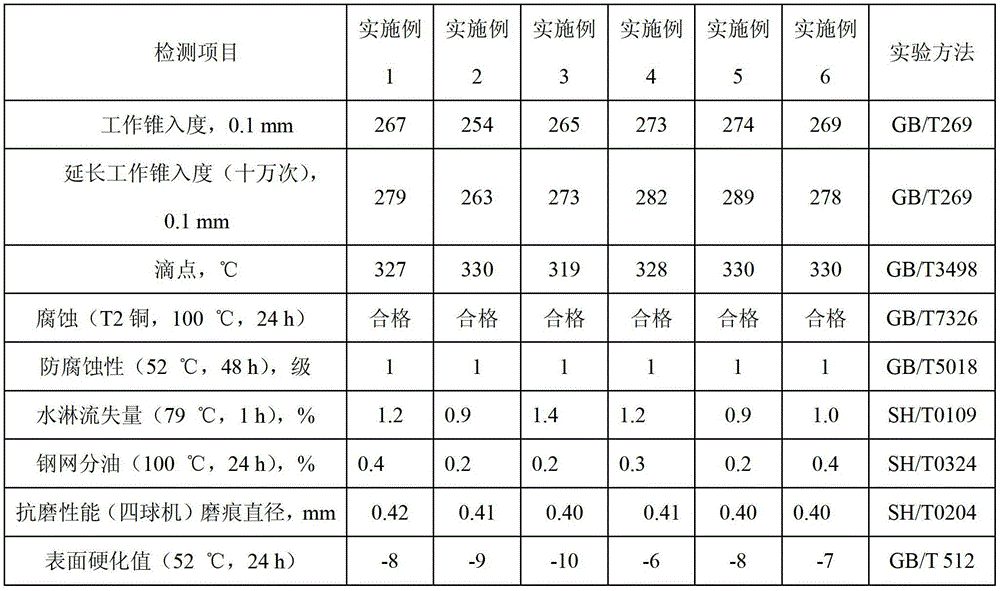

InactiveCN103952215AHigh temperature resistantWater resistantLubricant compositionSulfonateCalcium hydroxide

The invention relates to high-performance calcium sulfonate complex grease and a preparation method thereof. The calcium sulfonate complex grease is prepared from the following raw materials: high-base-number calcium sulfonate, base oil, lauric acid, low-molecular-weight alcohol, high-purity water, boric acid, calcium hydroxide, an antioxidant, and an HL functional additive. The high-performance calcium sulfonate complex grease has the characteristics of being resistant to high temperature, resistant to water, and outstanding in extreme-pressure antiwear property, particularly realizing the uniform distribution of converted calcium carbonate crystal grain, ensuring stable structure, and also solving the problem of surface hardening.

Owner:青州市东能润滑油脂有限公司

Microwave method for synthesizing nickel phosphates cobalt microporous material

InactiveCN101249969AOvercome timeOvercome uniformity issuesMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesNickel phosphateMicrowave method

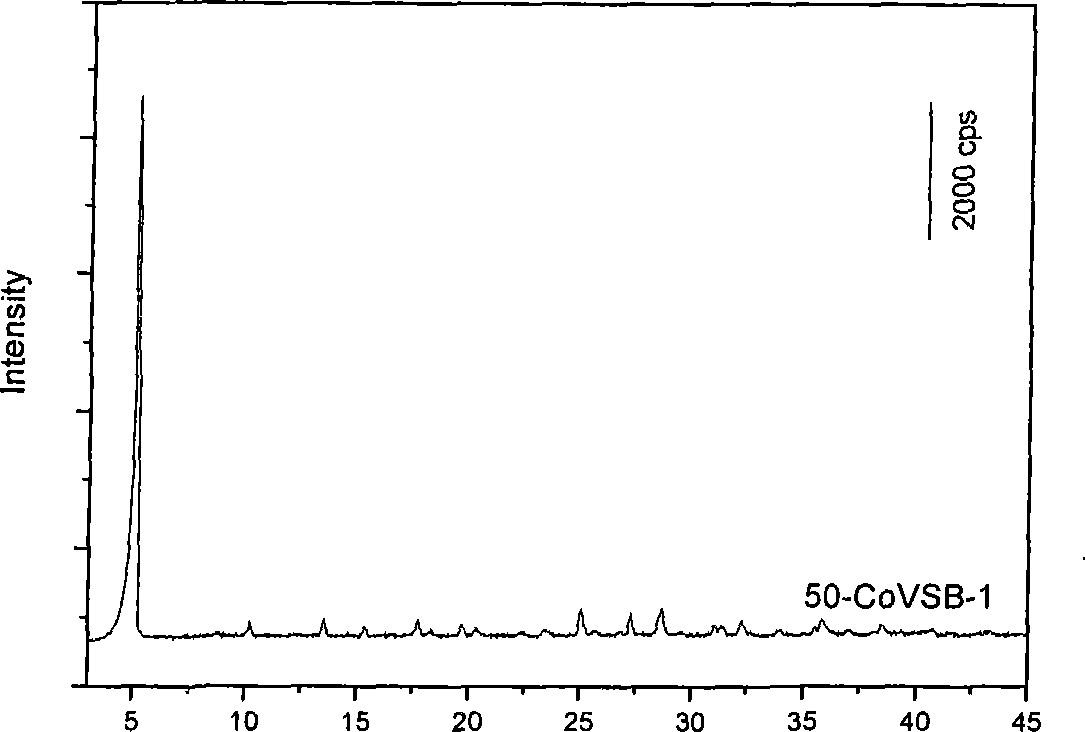

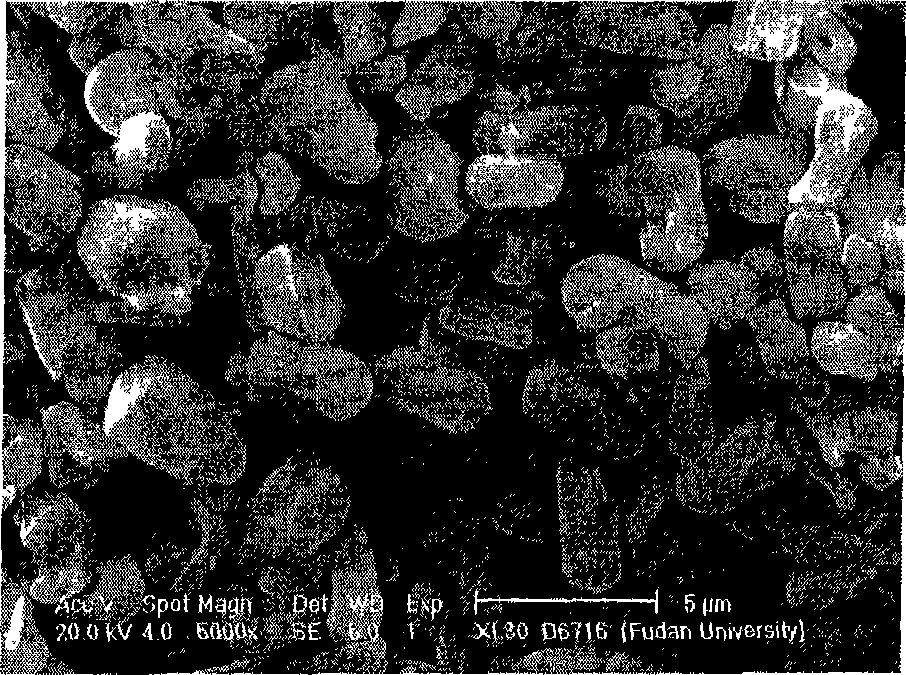

Disclosed is a microwave synthesis method of nickel phosphates cobalt cellular materials. The steps comprise preparing nickel source substance, cobalt source substance, phosphorus source substance, template, mineralizer and water according to oxide molecular ratio, initially dissolving the nickel source and the cobalt source in the water, adding with the phosphorus source when stirring, then adding with the template and the mineralizer and continuing to stir evenly, moving the reaction solution into a microwave synthesis reactor, irradiating for 3-360 minutes step by step under the temperature of 130-180 DEG C, then centrifugal separating, washing and freeze-drying, and thereby the nickel phosphates cobalt CoVSB-1 materials is obtained. The frequency of the microwave is 2450 megahertz, and the power is 400-1000 watt. A microwave is heated by employing the temperature controlling mode. Compared with the conventional hydro-thermal method, the synthesis time of the invention is shorter, the grain size distribution is more uniform, and the reducing of the size of crystal grain is in favor of the increasing of the catalytic performance of the product.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

High-performance composite calcium sulfonate based lubricating grease and preparation method thereof

ActiveCN103146465AHigh temperature resistantWater resistantLubricant compositionCalcium hydroxideSulfonate

The invention relates to high-performance composite calcium sulfonate based lubricating grease and a preparation method thereof. The composite calcium sulfonate based lubricating grease is prepared from the following raw materials: high-alkali-value calcium sulfonate, base oil, lauric acid, low-molecular alcohol, high-purity water, boric acid, calcium hydroxide, antioxidant and HL-functional agent. The composite calcium sulfonate based lubricating grease provided by the invention has the characteristic of excellent high-temperature resistance, water resistance and extreme pressure wear resistance; and in particularly, the converted calcium carbonate is uniform in crystalline grain distribution, so that the product is very stable in structure, thus solving the problem of the surface hardening of the composite calcium sulfonate-based lubricating grease.

Owner:天津市津冠科技发展有限公司

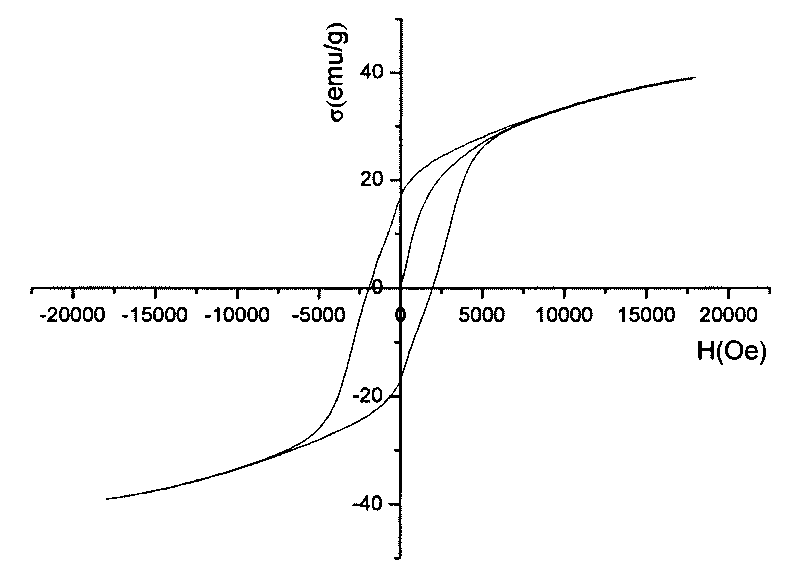

Method for synthesizing presintering hard ferrite material

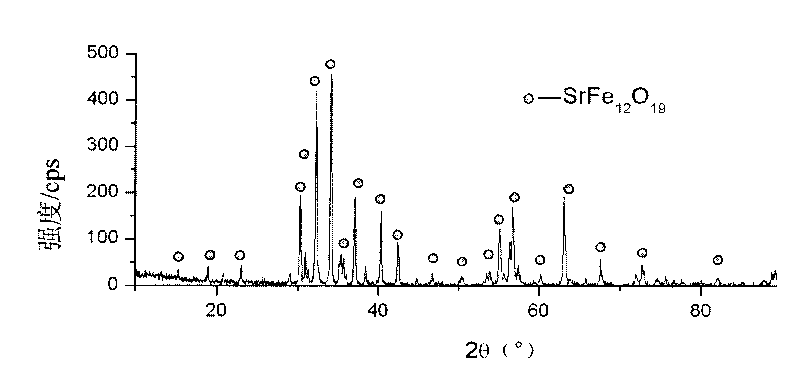

InactiveCN101712556AUniform grain distributionGood molding effectInorganic material magnetismMicrowavePhysical field

The invention discloses a method for synthesizing a presintering hard ferrite material, which takes one or more of oxide or carbonate of ferrite cations and other additives such as CaO, Al2O3 and the like as raw materials, and comprises the following steps: ball milling and tempering, drying, heating by a microwave physical field with the frequency of 300-3,000MHz, raising the temperature to 1,150-1,350 DEG C at the heating-warming speed of 20-80 DEG C / min, and preserving the temperature for 30-180min to obtain the single-phase presintering hard ferrite material with the grain size being about 0.2-2 mu m. Compared with the traditional method for synthesizing presintering materials, the method in the invention has the advantages of short presintering time, low energy consumption, fine and uniform grains of the presintering materials, good moldability and stable magnetic performance, and can be used for preparing sintering bodies by wet compression moulding and dry compression moulding.

Owner:SHANGHAI INST OF TECH

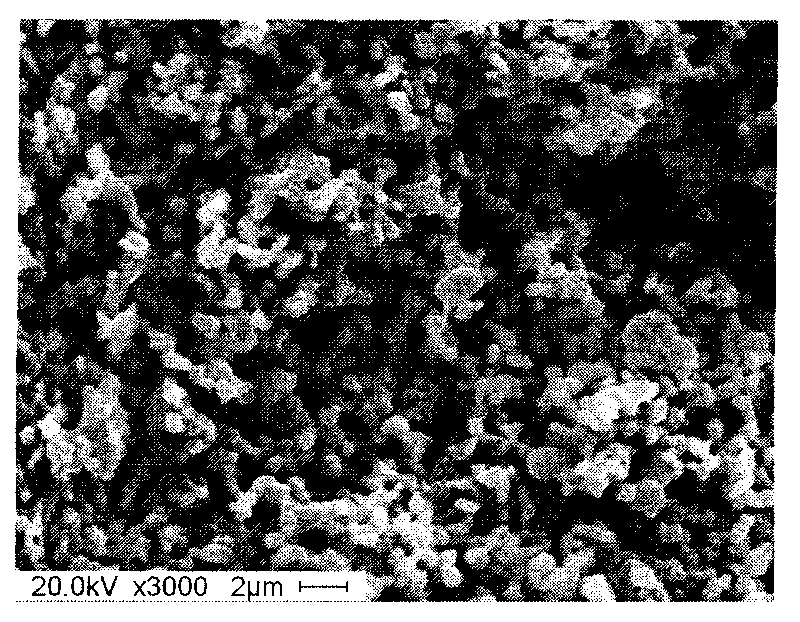

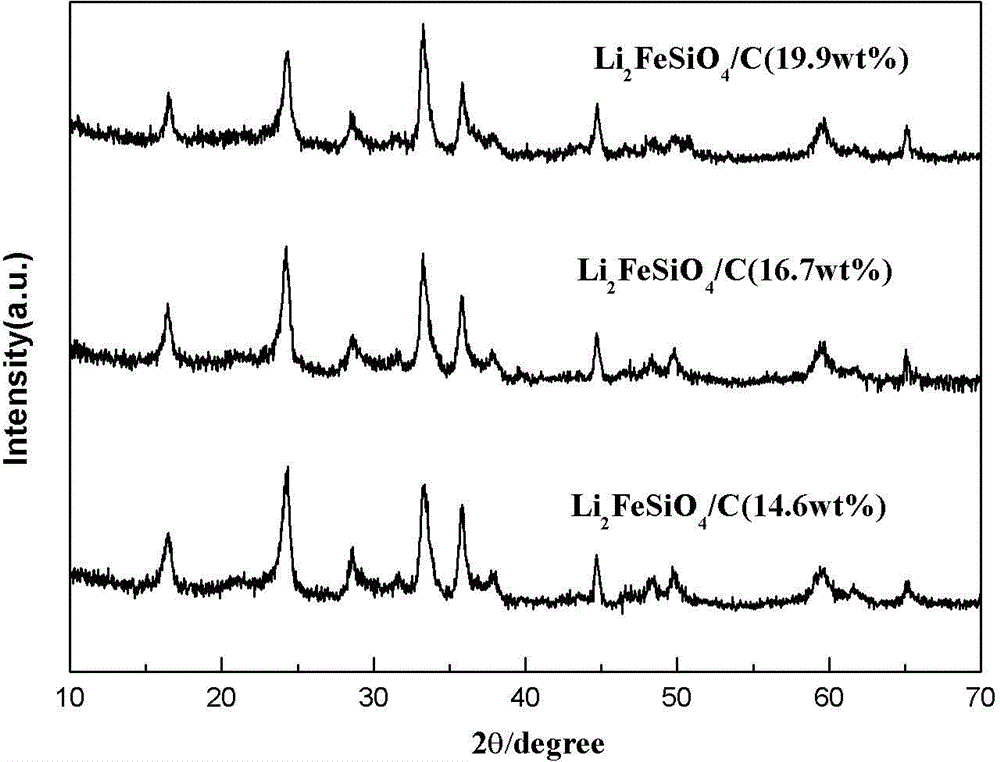

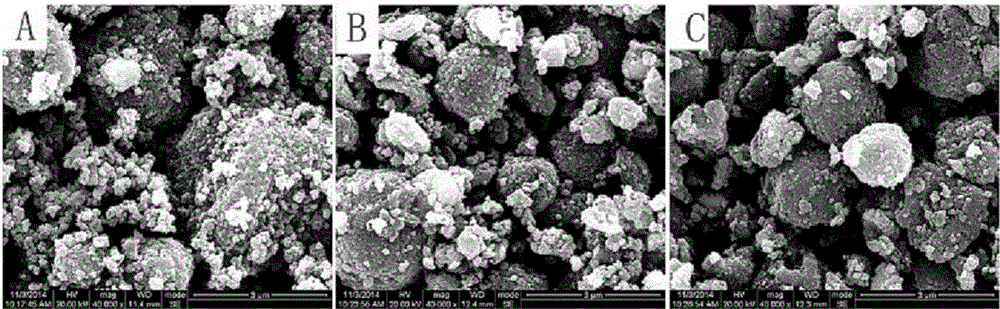

Method for preparing ferrous silicate lithium/carbon composite positive pole material with micropore spherical structure

ActiveCN104362318AImprove electronic conductivityImprove conductivityCell electrodesCarbon compositesOxalate

The invention discloses a method for preparing a ferrous silicate lithium / carbon composite positive pole material with a micropore spherical structure. The method particularly comprises the following steps of (1) adding citric acid and lithium hydroxide into water, and stirring for dissolution; adding ferrous oxalate, regulating the pH of a solution to 6-8, carrying out oil bath at 80-95 DEG C, and keeping temperature for 24-72 hours to form a deep green solution; adding nanometer silicon dioxide, carrying out ultrasonography for 20-60 minutes, and stirring at room temperature for 1-3 hours to prepare gel; (2) spray-drying the gel at 100-120 DEG C to obtain a ferrous silicate lithium / carbon composite precursor; (3) calcining the ferrous silicate lithium / carbon composite precursor in argon at 600-800 DEG C for 8-12 hours to obtain the ferrous silicate lithium / carbon composite positive pole material with the micropore spherical structure. The method disclosed by the invention is simple and safe in process and low in cost. The obtained ferrous silicate lithium / carbon composite positive pole material has the advantages of fine granules, uniformity in distribution, excellent microstructure and preferable electrochemical property.

Owner:HUNAN UNIV OF ARTS & SCI

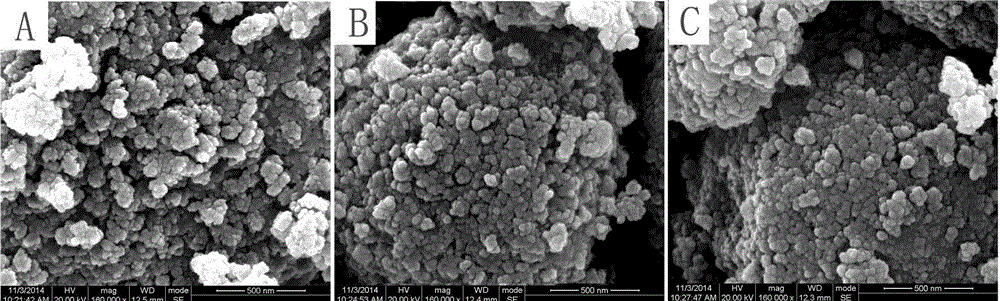

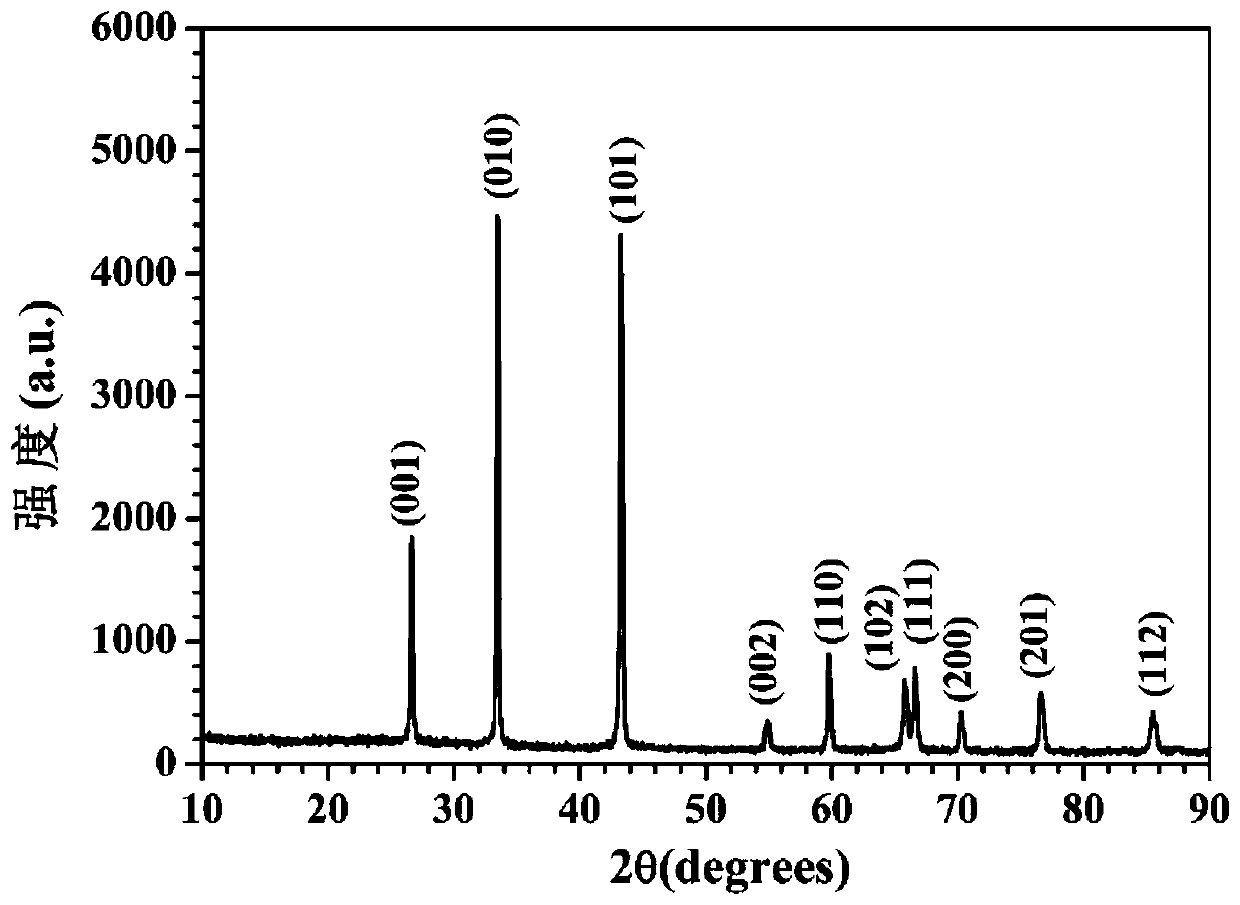

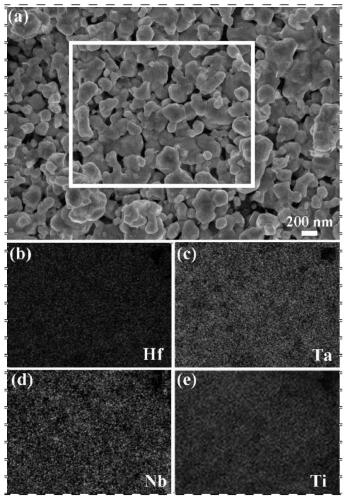

(Hf,Ta,Nb,Ti)B2 high-entropy ceramic powder and preparing method thereof

The invention discloses (Hf,Ta,Nb,Ti)B2 high-entropy ceramic powder and a preparing method thereof. The preparing method comprises the steps of 1, weighing HfO2 powder, TiO2 powder, Nb2O5 powder, Ta2O5 powder, B4C powder and C powder as raw materials, then mixing the raw materials, and grinding the raw materials to obtain mixed powder; 2, sintering the mixed powder obtained in step 1, introducinginert gas in the sintering process, conducting cooling after sintering is finished, and finally, obtaining the (Hf,Ta,Nb,Ti)B2 high-entropy ceramic powder. The method has the advantages that the process is simple, the production cost is low, the synthesized powder is fine in crystal grain, uniform in distribution and high in purity, and the oxygen content is lower than 0.53 wt%, all of which endowthe method with the potential of developing large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

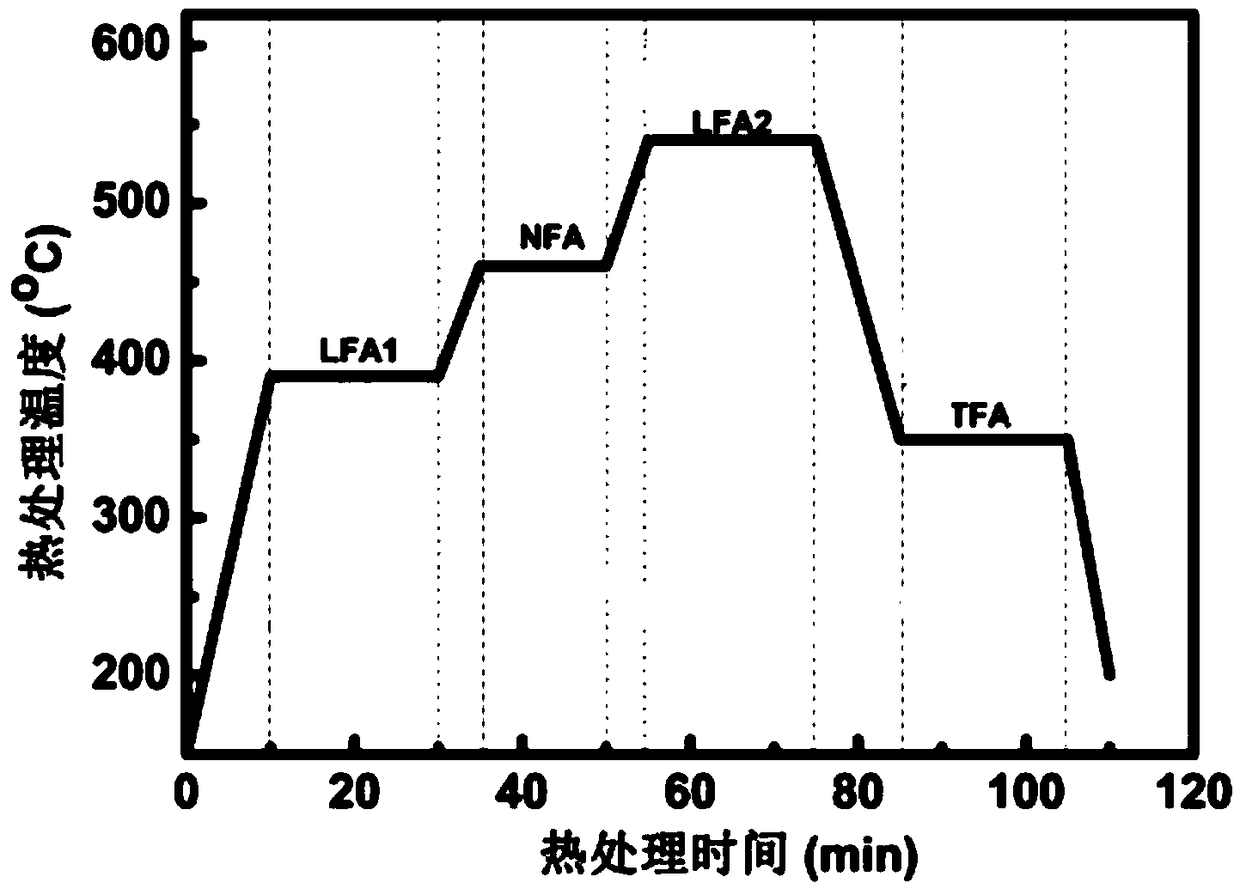

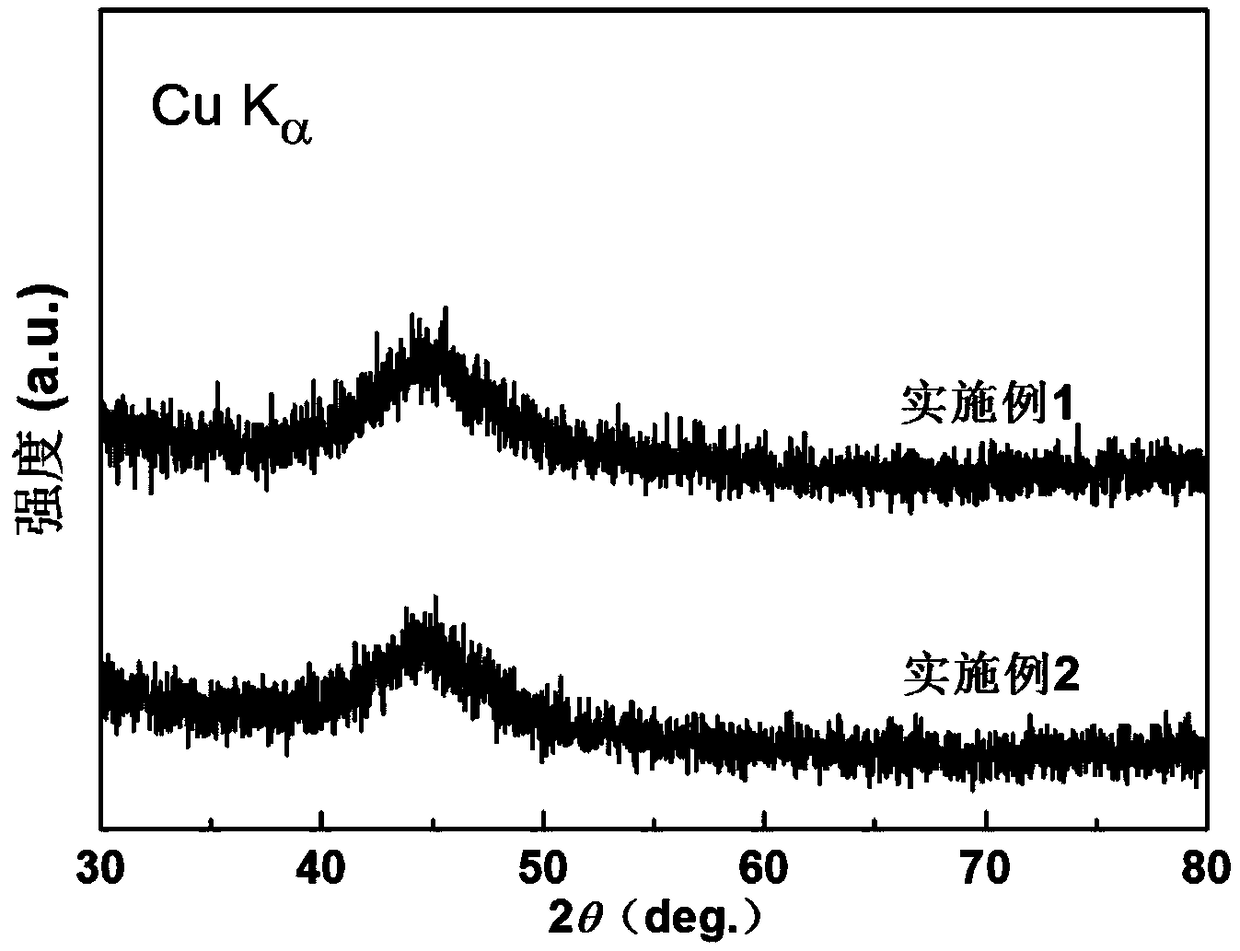

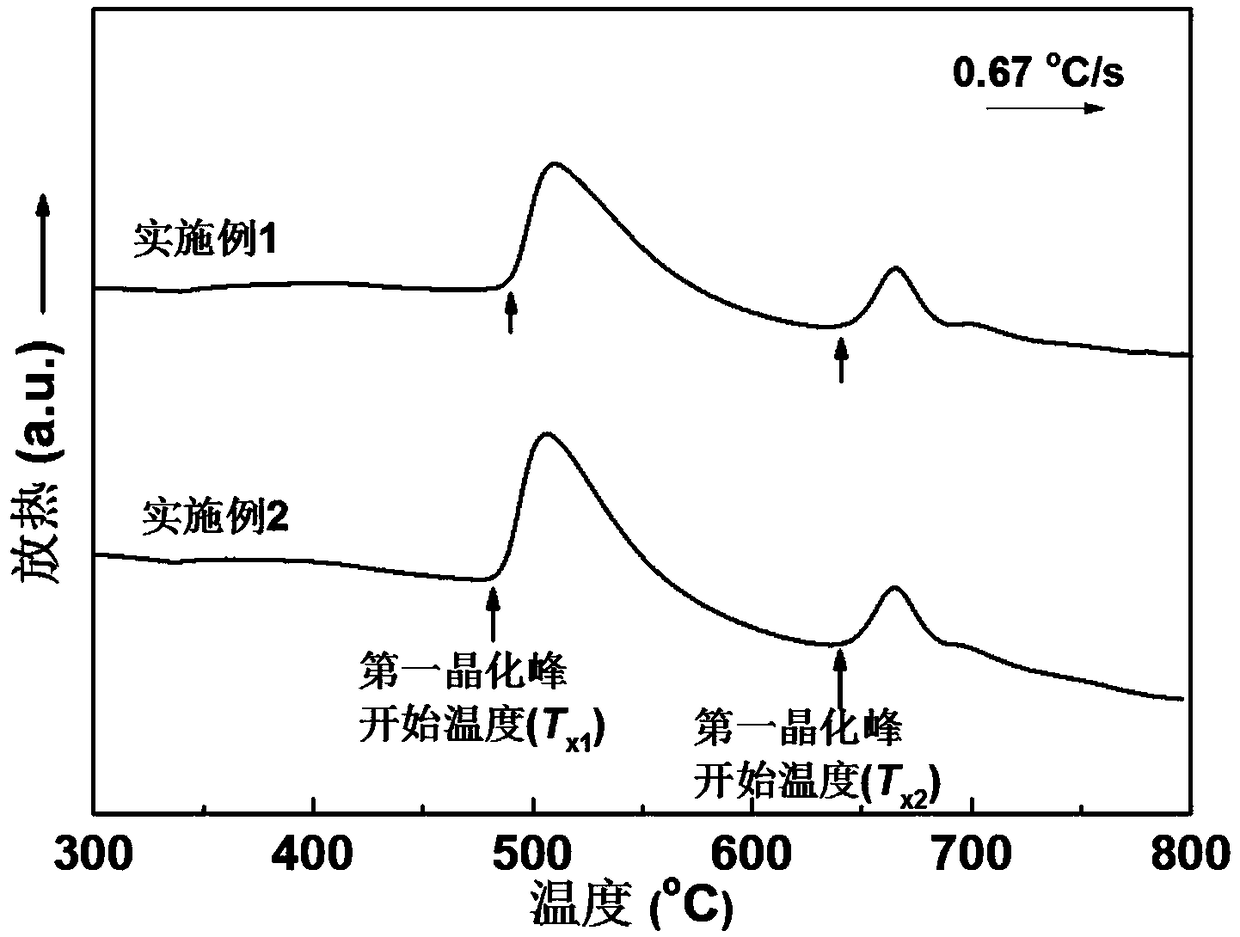

Preparation method of low-loss nano crystal soft magnetic alloy

ActiveCN109234628AIncrease nucleation rateRefine grain sizeFurnace typesInductances/transformers/magnets manufactureThermal insulationCopper

The invention provides a preparation method of low-loss nano crystal soft magnetic alloy. In the method of the invention, when crystallization heat treatment is performed on a strip obtained in a quenching technology, a heat treatment process is divided into four steps: step I, applying a magnetic field for thermal insulation in a copper cluster precipitation temperature zone along a length direction of an alloy strip; step II, performing thermal insulation in an optimum potential heat release temperature zone under a magnetic-field-free condition; step III, applying the magnetic field for thermal insulation in an optimum crystallization and growth temperature zone of alpha-Fe-phase nano crystal grains; and finally, applying the magnetic field for thermal insulation at a temperature less than the copper cluster precipitation temperature along a width direction of the strip. Compared with an existing heat treatment method, the method can reduce the high-frequency loss of the nano crystal soft magnetic alloy and can improve the comprehensive performance of the nano crystal soft magnetic alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD +2

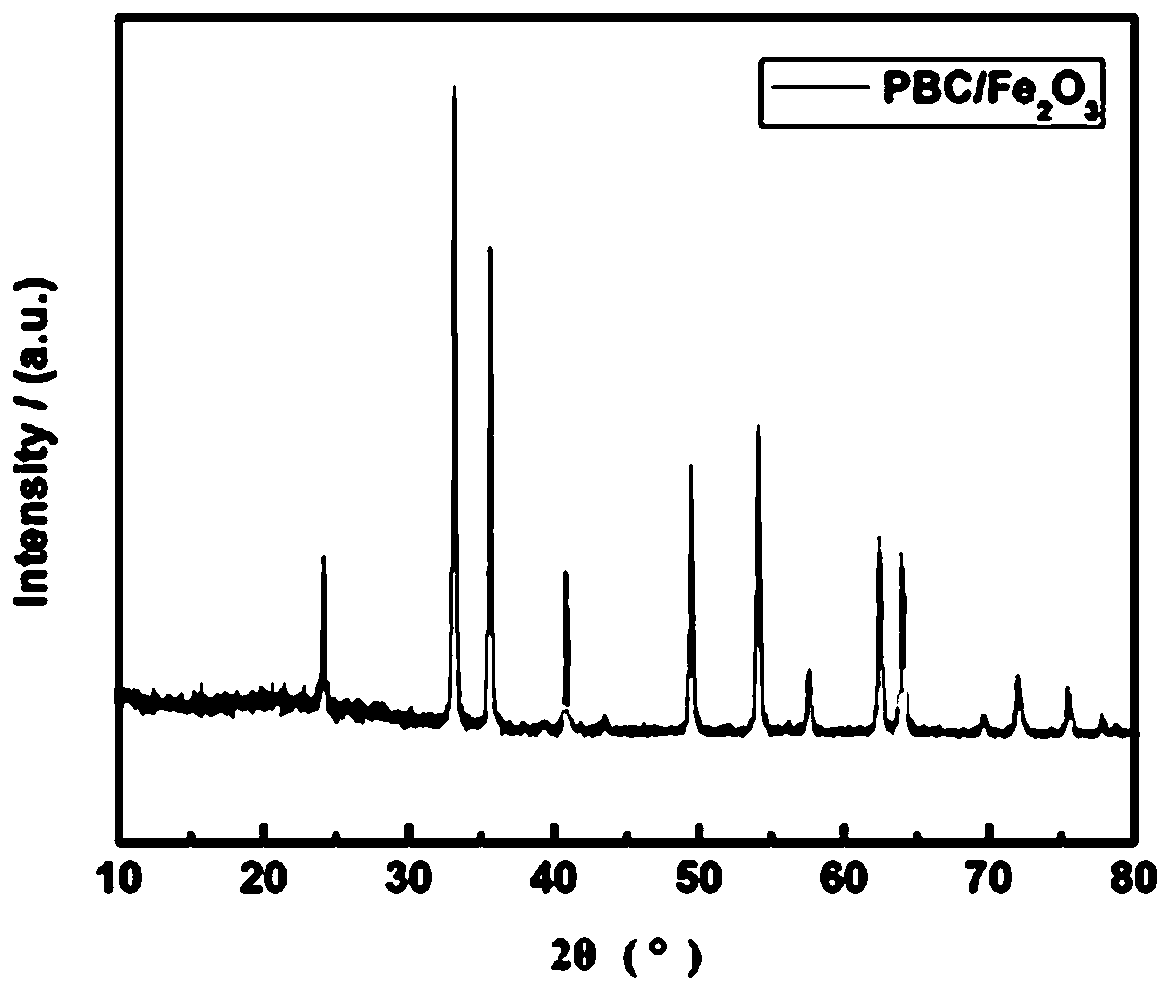

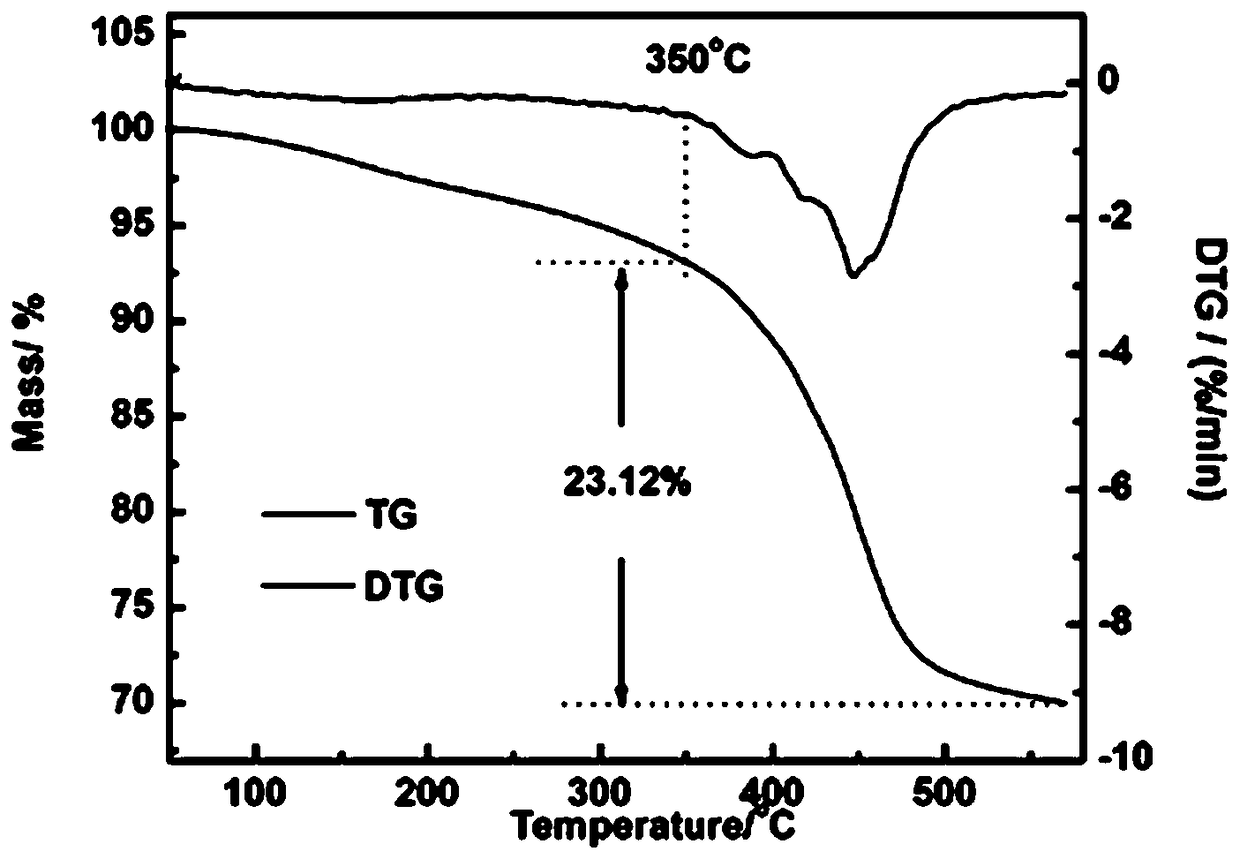

Biomass charcoal/iron oxide composite material and preparation method thereof

The invention discloses a biomass charcoal / iron oxide composite material for a lithium battery negative electrode, and a preparation method thereof in order to solve the problems of large volume expansion ratio and poor cycle performance of a lithium battery negative electrode material iron oxide. The preparation method comprises the following steps: carbonizing leaves, barks, wood chips and / or animal hair to prepare biomass charcoal, compounding the biomass charcoal with iron oxide by a forced hydrothermal process in order to obtain a porous biomass charcoal-coated iron oxide precursor, and performing microwave treatment on the precursor to change the crystallinity of the iron oxide in order to obtain the biomass charcoal / iron oxide composite material. The biomass charcoal / iron oxide composite material prepared in the invention has a low cost, can be directly applied to the electrode materials of lithium ion battery negative electrodes, and has wide practical application values and industrial production prospects.

Owner:SHANGHAI INST OF QUALITY INSPECTION & TECHN RES

Production process of specially-shaped pipe

The invention discloses a production process of a specially-shaped pipe. The production process of the specially-shaped pipe comprises the following steps: selecting a pipe, grinding ends of the pipe, annealing for a first time, pickling with acid for a first time, washing for a first time, phosphatizing for a first time, washing for a second time, saponifying for a first time, cold drawing for a first time, annealing for a second time, pickling with acid for a second time, washing for a third time, phosphatizing for a second time, washing for a fourth time, saponifying for a second time, cold drawing for a second time, straightening and carrying out antirust treatment. The production process of the specially-shaped pipe is characterized by firstly cold drawing a billet pipe in inner and outer circular dies so as to reduce the outer diameter of the wall thickness of the billet pipe, so that the inner and outer surfaces of the billet pipe are more smooth; the quality during cold drawing for the second time is improved; grains in the billet pipe subjected to cold drawing for the first time are unevenly distributed in the presence of stress; through annealing, the grains in the billet pipe are evenly distributed and the stress is removed, so that the breakage of the billet pipe when the billet pipe is subjected to cold drawing for the second time is avoided.

Owner:ZHEJIANG JIUDING MACHINERY CO LTD

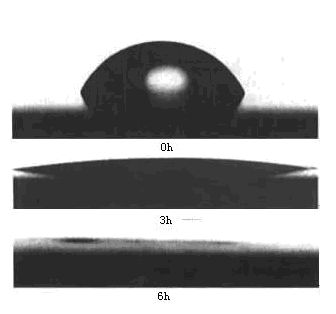

Novel nanometer titanium dioxide self-cleaning fluorine-carbon aluminum single sheet as well as low-temperature preparation method and application thereof

InactiveCN102433978AAvoid uneven dispersionEvenly distributedCovering/liningsBridge structural detailsUltraviolet lightsSILICONE DIOXIDE

The invention discloses a novel nanometer titanium dioxide self-cleaning fluorine-carbon aluminum single sheet as well as a low-temperature preparation method and application thereof. The surface of the fluorine-carbon aluminum single sheet is coated with a self-cleaning nanometer titanium dioxide film or a nanometer titanium dioxide and silicon dioxide composite film; the film is uniformly distributed on the surface of the fluorine-carbon aluminum single sheet, and thickness of the film is 1-3 micrometers; and after being irradiated by ultraviolet light, the nanometer titanium dioxide film has super-hydrophilic property and photocatalytic property, thus, the self-cleaning effect is realized. The novel nanometer titanium dioxide self-cleaning fluorine-carbon aluminum single sheet related in the invention has the following advantages: (1) the thickness of the titanium dioxide film is uniform, nanometer titanium dioxide crystal particles are uniformly distributed, and the titanium dioxide film has super-hydrophilic property and a better self-cleaning function; (2) the film has photocatalytic property, so that residual organic pollutants on the surface of the film can be decomposed, and the self-cleaning effect is further improved; and (3) the original performances, such as weatherproof performance, chemical corrosion resistance and the like, of the fluorine-carbon aluminum single sheet are retained.

Owner:NANCHANG UNIV

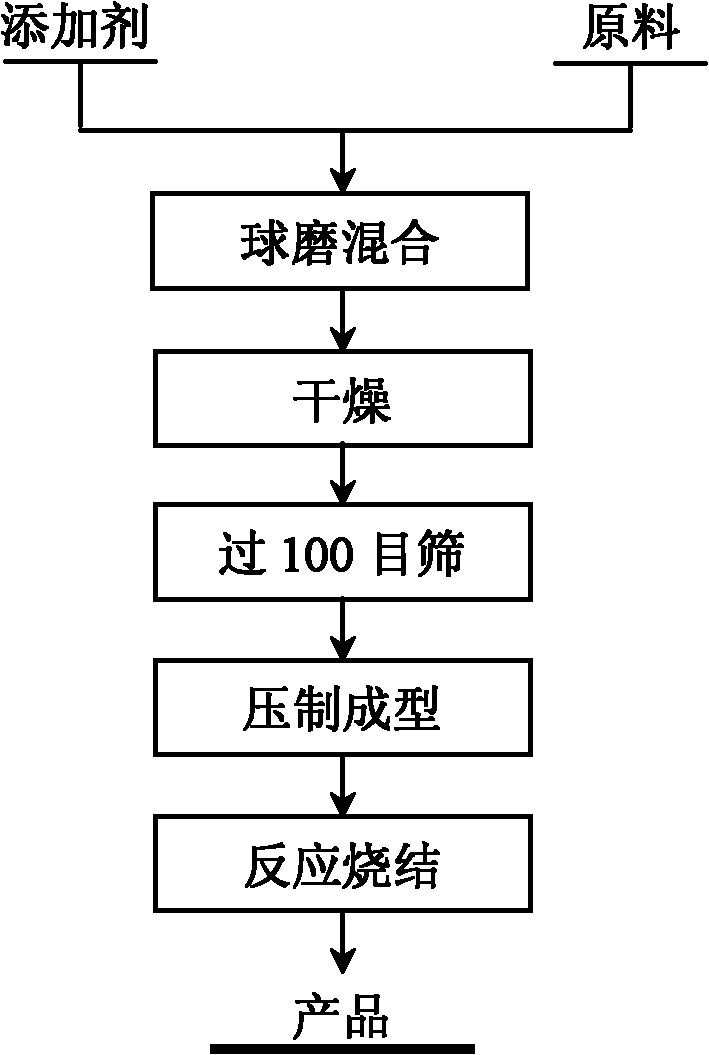

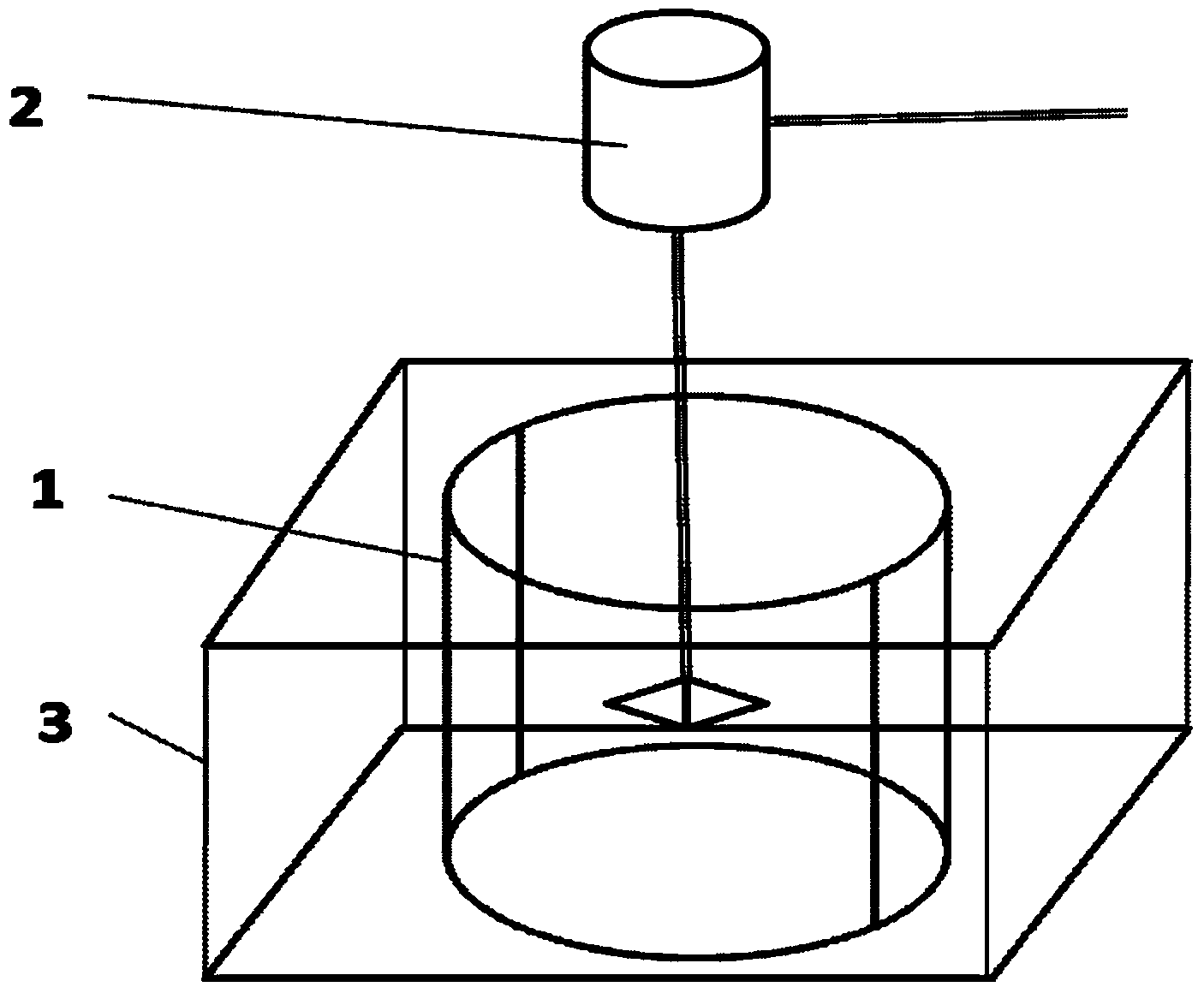

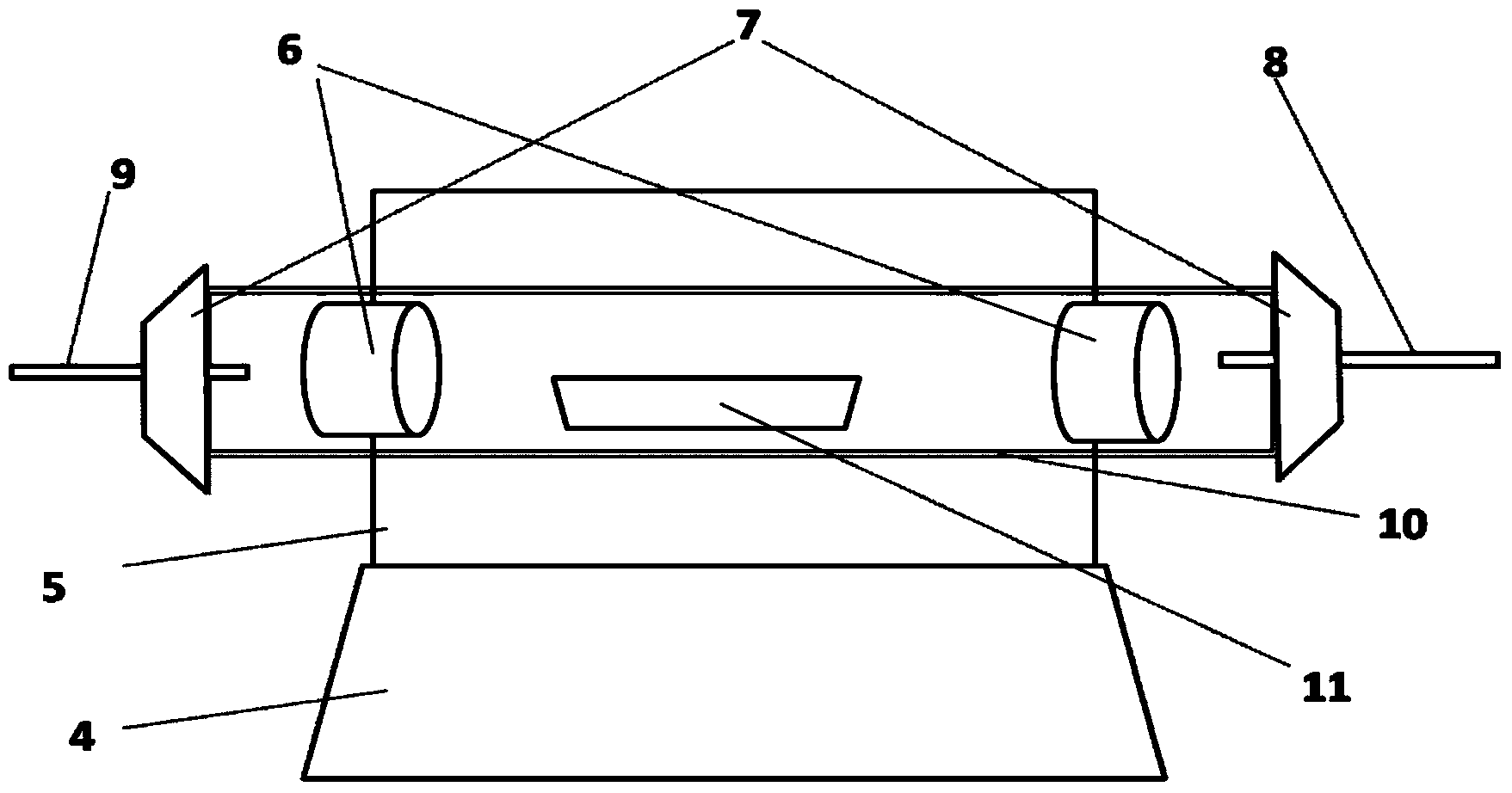

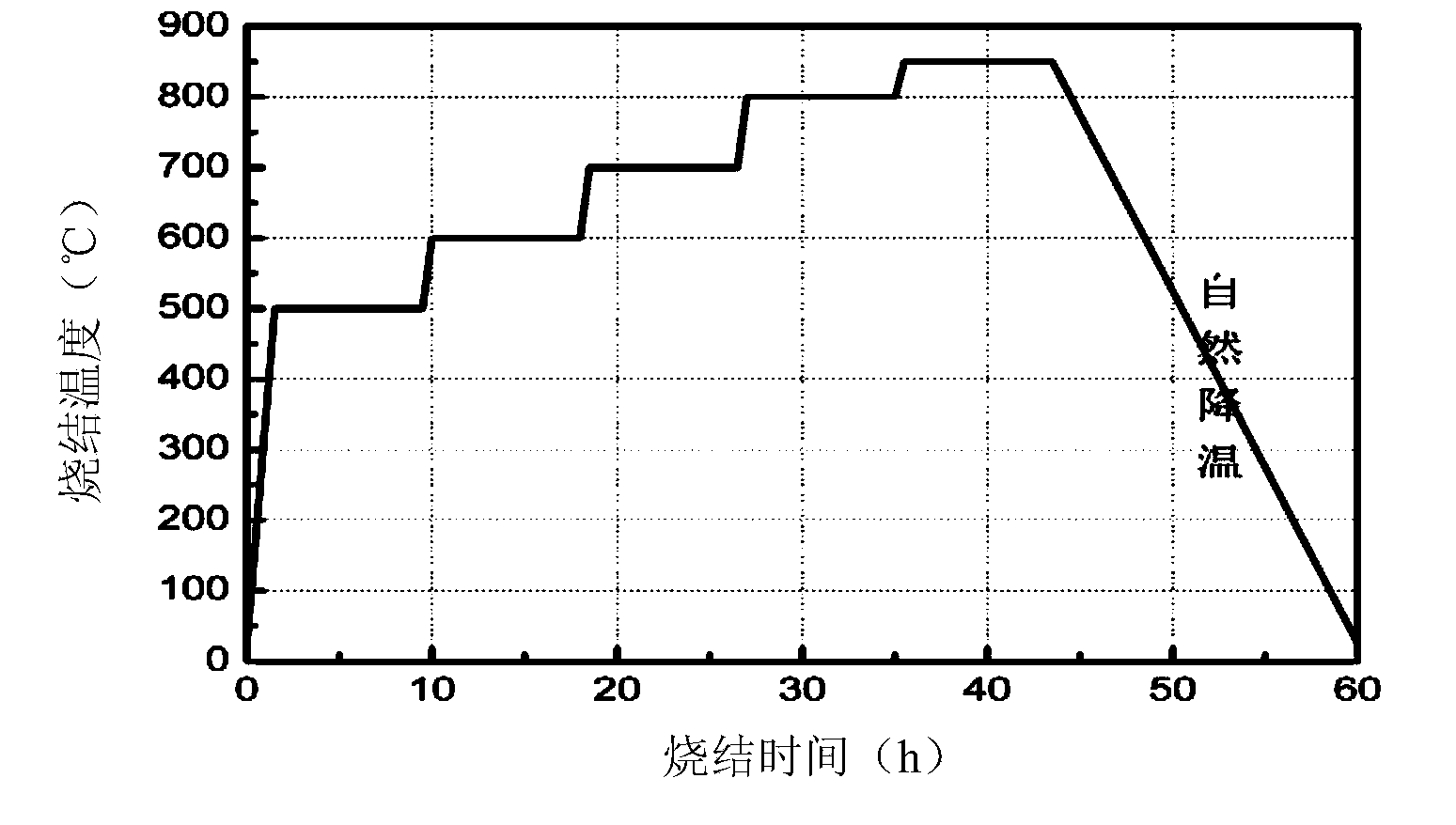

Niobium zinc barium-based microwave medium ceramic and preparation method thereof

InactiveCN101830708AReduce pollutionImprove production efficiencyCeramicsCompression moldingMicrowave

The invention relates to the field of microwave medium ceramic of material science, in particular to Ba(Zn1 / 3Nb2 / 3)O3(BZN)-based microwave medium ceramic sintered by low-temperature reaction and a preparation method thereof. The method comprises the following steps of: adding the following additives in percentage by mass into a Ba(Zn1 / 3Nb2 / 3)O3(BZN) base material: 0.5 to 1.5 percent of CuO, 0.5 to 1.5 percent of Li2CO3, 0.5 to 1.5 percent of V2O5 and 1.5 to 4.5 percent of ZnO-B2O3; and performing common ball-milling and mixing, drying, screening and compression molding on the mixture, and then obtaining a dense ceramic product by reacting and sintering the mixture, wherein the sintering temperature can be reduced to 950 DEG C. The microwave medium ceramic has good microwave performance, and reduces the energy consumption and the cost.

Owner:江苏兴云新能源有限公司

Nanometer tungsten powder and method for preparing nanometer tungsten powder by adoption of sol-gel hydrogen reduction method

The invention discloses nanometer tungsten powder and a method for preparing the nanometer tungsten powder by the adoption of a sol-gel hydrogen reduction method. Ammonium tungstate and citric acid are utilized to generate a complex, and hydrogen low temperature sintering is carried out on the complex to be restored. The method comprises the steps that the ammonium tungstate, the citric acid and distilled water are mixed, and after mixing and regulating of the pH value, constant-temperature concentration is carried out to form wet gel; the wet gel is dried in a drying box to form dry gel; the dry gel is sintered in a muffle furnace to obtain a predecessor; the predecessor is sintered and restored according to a preset sintering temperature in a vacuum sintering furnace with argon and hydrogen mixed gas protection to obtain the nanometer tungsten powder. The preparation method is simple in operation, low in temperature, capable of regulating the yield according to the size of a chamber of the furnace, and good in temperature stability of a tungsten powder room.

Owner:BEIHANG UNIV

Isothermal die forging technology for large-size high-strength aluminum alloy parts

InactiveCN105964849AImprove plasticityImprove malleabilityMetal-working apparatusLarge deformationLarge size

The invention relates to an isothermal die forging technology for large-size high-strength aluminum alloy parts, and belongs to the technical field of aluminum alloy machining. According to the isothermal die forging technology, large-size aluminum alloy forging cake blanks undergo isothermal die forging formation in one step after being heated and thermally insulated for obtaining forge pieces, the forge pieces are taken out and cooled, and finally finished products are obtained; in the isothermal die forging process, the descending speed of upper dies is 0.1-0.2 mm / s. By selecting raw materials and strictly controlling forging parameters, continuous large deformation is realized on the condition that alloy crystal grains do not grow, and the large-size and high-performance aluminum alloy parts can be prepared with high efficiency and low cost. The isothermal die forging technology has the advantages that the operation is easy, the production efficiency is high, the product quality is high and the practicability is high, thereby being suitable for industrialized use and popularization.

Owner:SHANDONG NANSHAN ALUMINUM

Method for preparing CsPbX3 perovskite quantum dot film through one-step crystallization

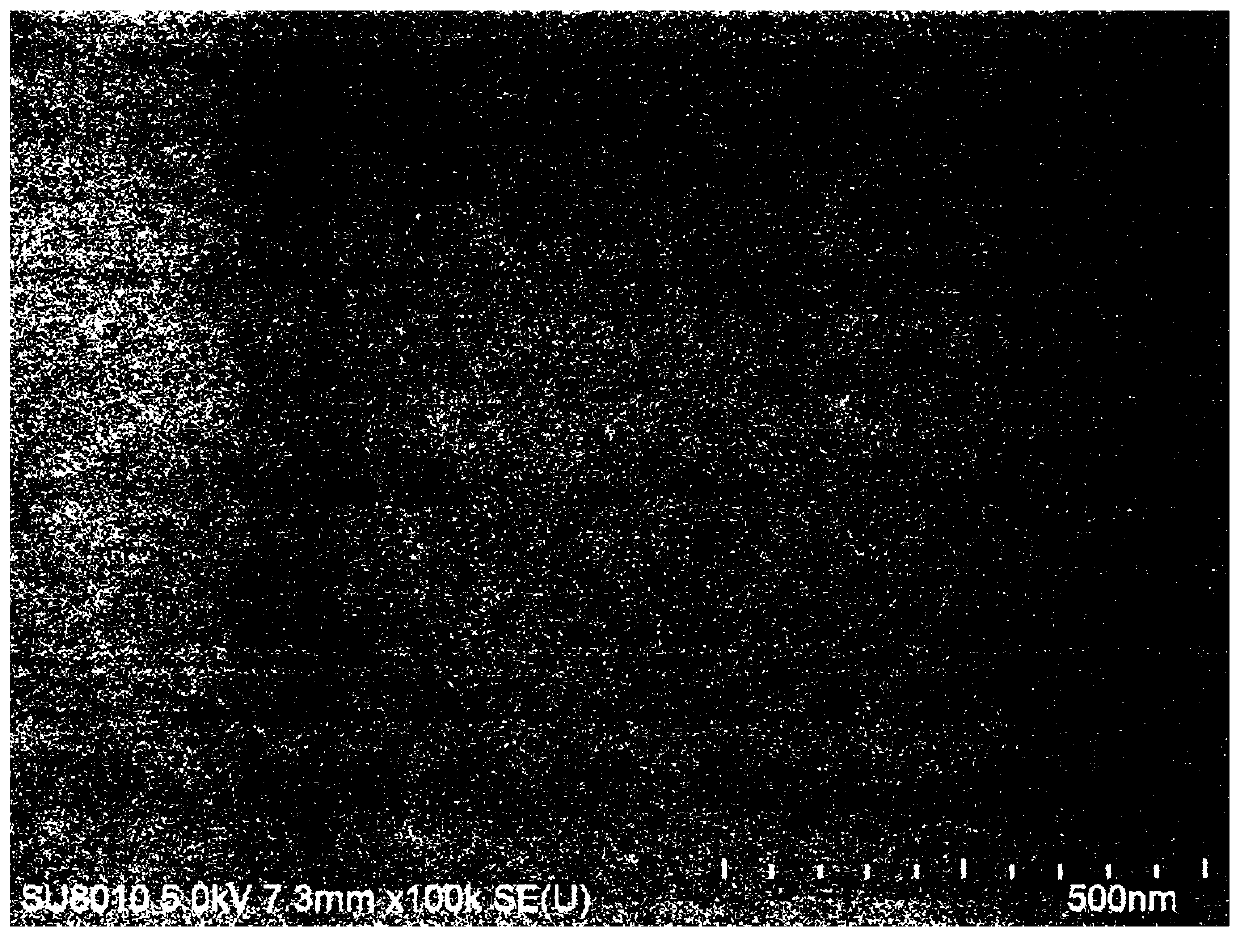

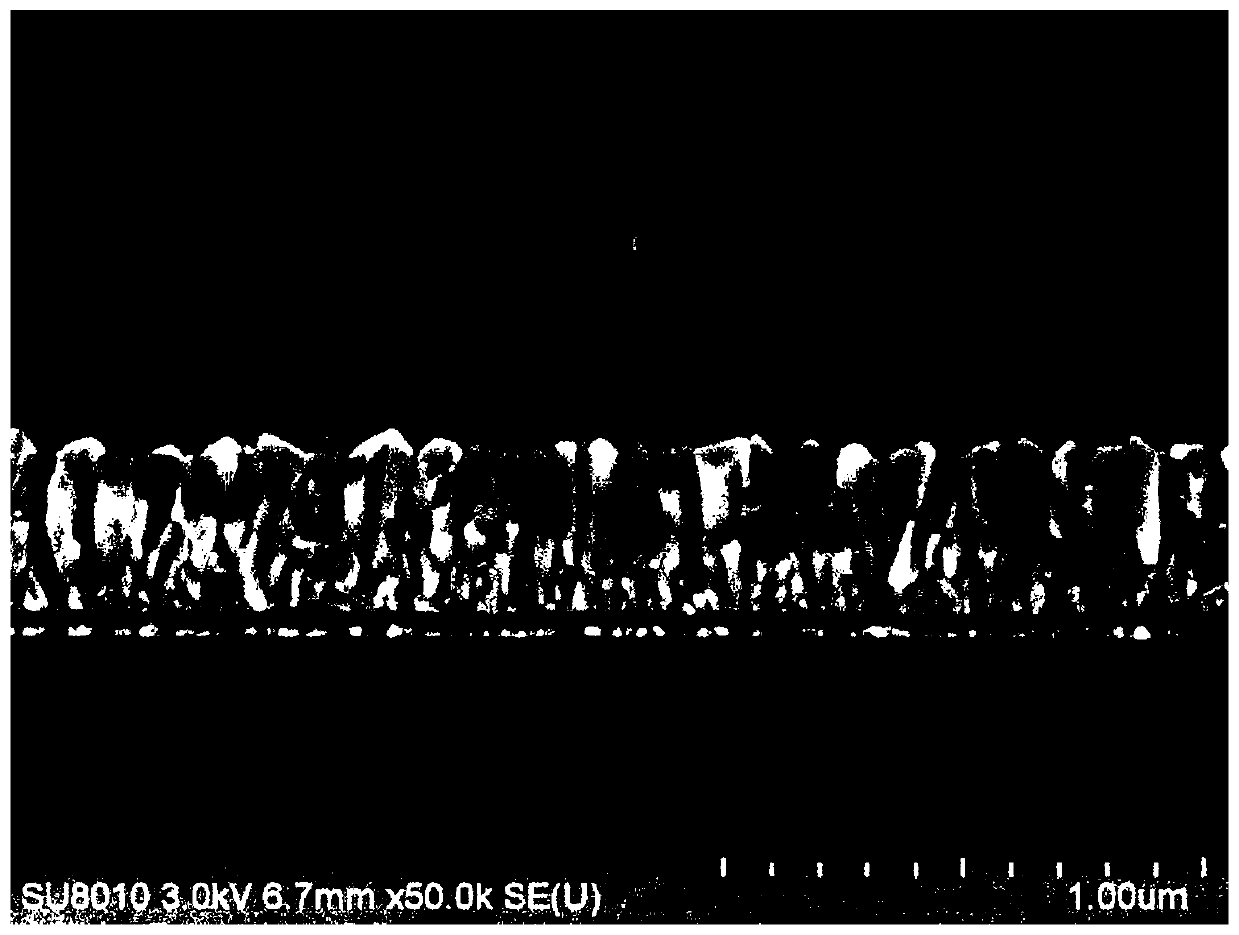

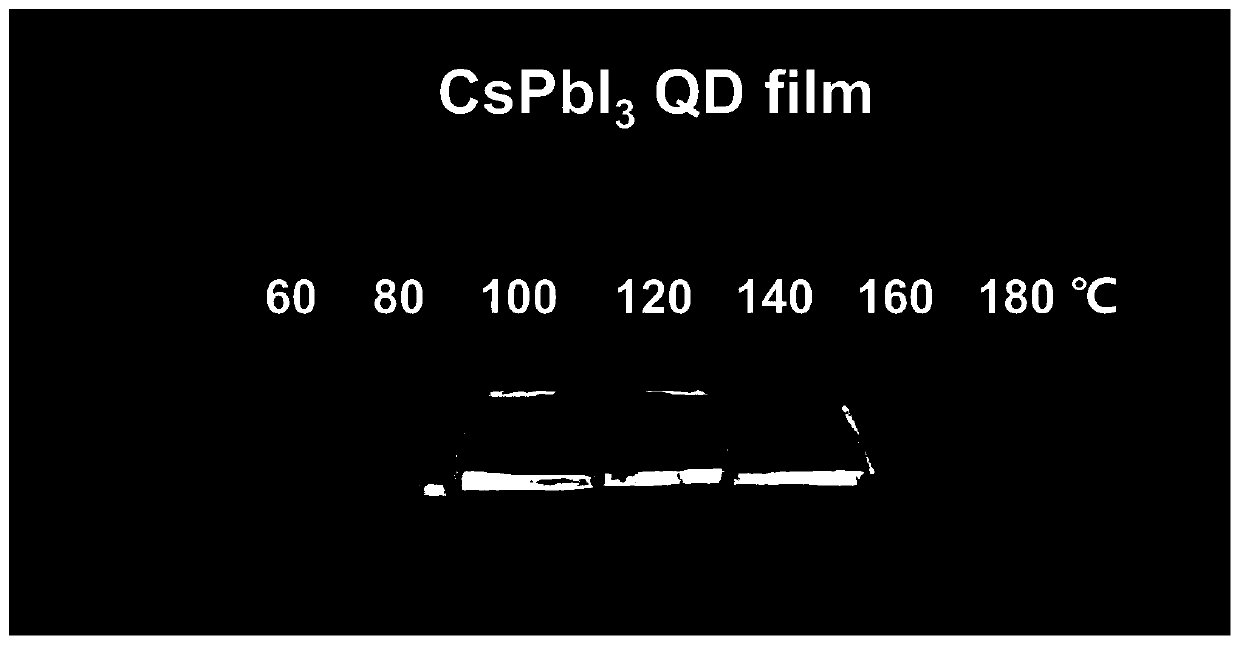

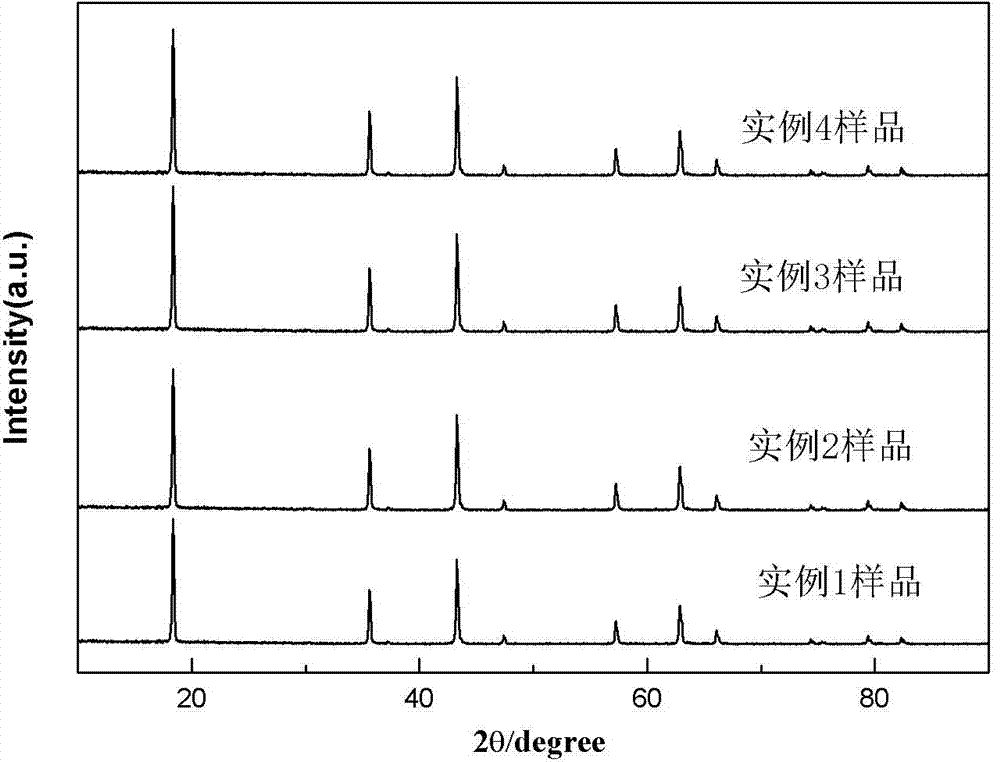

ActiveCN110615466ALow costGood repeatabilityMaterial nanotechnologyLiquid surface applicatorsFluorescenceQuantum dot

The invention provides a method for preparing a perovskite quantum dot film through one-step crystallization, and belongs to the technical field of perovskite quantum dot materials. Adamantane methylamine and haloid acid are used as ligands, cesium halide, lead halide, the ligands and a solvent are mixed to obtain a precursor solution, the precursor solution is then deposited on a substrate, and the CsPbX3 perovskite quantum dot film is obtained after heating. The adamantane methylamine and the haloid acid are used as ligands, can rapidly cover perovskite, and are coordinated with CsPbX3 perovskite, and perovskite quantum dots are directly formed through a strong three-dimensional effect; meanwhile, the method is easy to operate and low in cost, the high-quality perovskite quantum dot filmwith the thickness larger than 500 nm can be directly obtained through one-step crystallization, and the obtained perovskite quantum dot film is high in repeatability, high in stability, good in fluorescence performance and uniform in grain distribution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

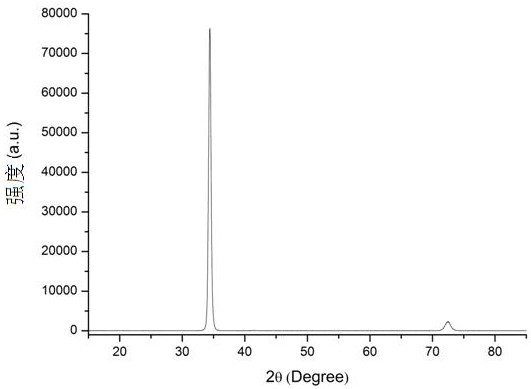

Method for preparing molybdenum dioxide coated lithium titanate negative electrode material

ActiveCN104733699AUniform grain distributionImproved magnification performanceCell electrodesAir atmosphereSolvent

The invention relates to the technical field of lithium ion battery manufacturing, and particularly relates to a method for preparing a molybdenum dioxide coated lithium titanate negative electrode material. The method comprises the following steps: dissolving lithium acetate and polyvinylpyrrolidone in distilled water, adding nano titanium dioxide, and carrying out magnetic stirring for 1 h so as to obtain a slurry; carrying out spray drying on the slurry so as to obtain a lithium titanate precursor; roasting the precursor for 8 h at a temperature of 750 DEG C in an air atmosphere so as to obtain a pure lithium titanate negative electrode material; dissolving ammonium molybdate and a tartaric acid in distilled water, adding the pure lithium titanate negative electrode material, and carrying out magnetic stirring for 1 h; after solvents are dried by distillation at a temperature of 100 DEG C, carrying out vacuum drying on the obtained object for 1 h at a temperature of 80 DEG C, so that a molybdenum dioxide coated lithium titanate precursor is obtained; and roasting the molybdenum dioxide coated lithium titanate precursor for 6 h at a temperature of 600 DEG C in an argon atmosphere, so that a molybdenum dioxide coated lithium titanate negative electrode material is obtained. The method disclosed by the invention is simple and safe in process, and low in cost, and the obtained molybdenum dioxide coated lithium titanate negative electrode material has good electrochemical properties.

Owner:CHANGZHOU UNIV

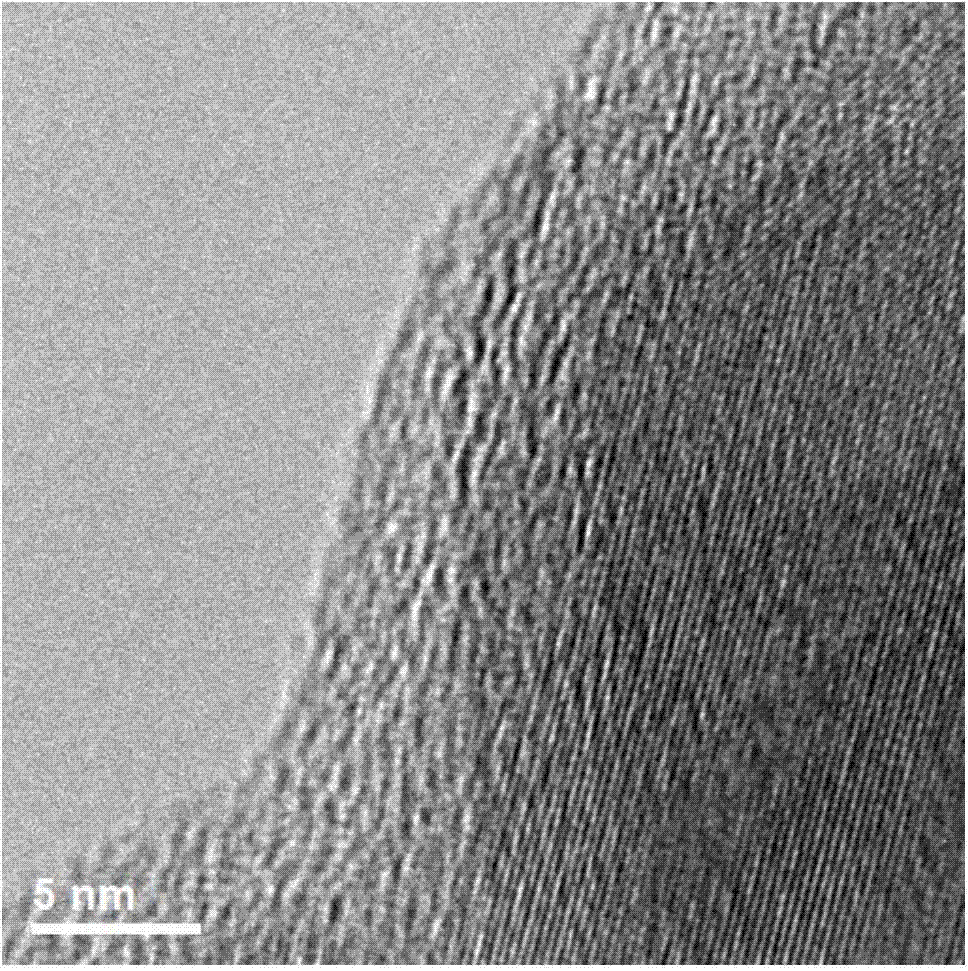

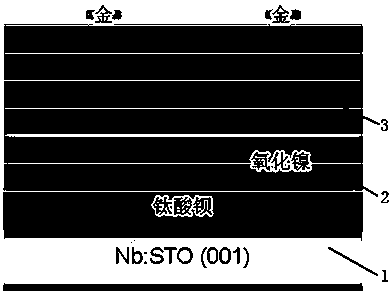

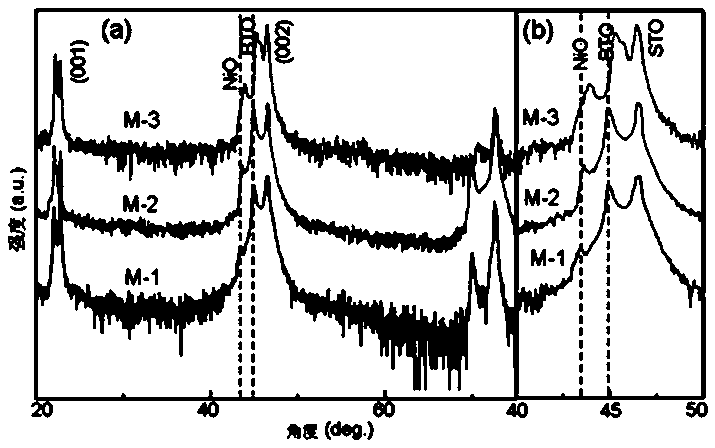

Nickel oxide and barium titanate nano composite ferroelectric film material and preparation method and application thereof

InactiveCN107604310APrecise and controllable thicknessUniform grain distributionVacuum evaporation coatingSputtering coatingComposite filmBarium titanate

The invention provides a nickel oxide and barium titanate nano composite ferroelectric film material and a preparation method and application thereof. A film has the (001) face crystal orientation andcomprises, by volume percentage, 10-30% of nickel oxide and 70-90% of barium titanate. The preparation method comprises the steps of preparing the barium titanate, the nickel oxide and a nickel oxideand barium titanate composite target material through a solid phase deposition method; and then adopting a pulsed laser deposition method, and preparing the nano layered nickel oxide and barium titanate nano composite ferroelectric film, the nano columnar nickel oxide and barium titanate nano composite ferroelectric film and the nano granulated nickel oxide and barium titanate nano composite ferroelectric film by controlling deposition parameters. The nickel oxide and barium titanate nano composite ferroelectric film material and the preparation method and application thereof are simple in process. The obtained nano composite film has the beneficial effects that the microstructure is continuous and adjustable; nanoscale crystalline grains are distributed uniformly; the film thickness canbe controlled precisely; and crystal orientation extends outwards. Ferroelectric performance of the composite film material is effectively improved; dielectric performance is enhanced; the obtained high-performance material can be applied to the fields of ferroelectric storage devices, supercapacitors, crystalline field effect tubes, acoustic surface wave devices and the like; and the applicationscope is wide.

Owner:HEBEI UNIVERSITY

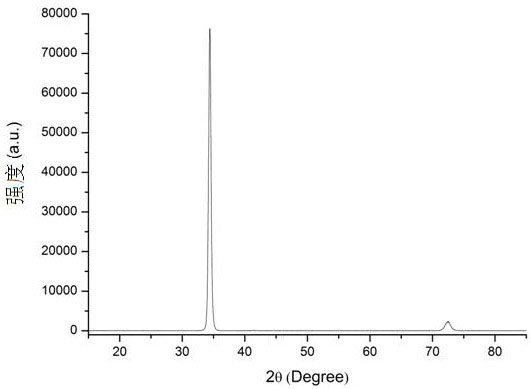

Method for preparing vanadium trioxide coated lithium titanate negative electrode material

ActiveCN104733698AImprove electronic conductivityImproved magnification performanceCell electrodesAir atmosphereManufacturing technology

The invention relates to the technical field of lithium ion battery manufacturing, and particularly relates to a method for preparing a vanadium trioxide coated lithium titanate negative electrode material. The method comprises the following steps: dissolving lithium acetate and polyvinylpyrrolidone PVP in 500 ml of distilled water, adding nano titanium dioxide, carrying out magnetic stirring for 1 h so as to obtain a slurry, and carrying out spray drying on the slurry so as to obtain a lithium titanate precursor; carrying out heat treatment on the precursor in an air atmosphere until the reaction is completed, so that a pure lithium titanate negative electrode material is obtained; dissolving ammonium metavanadate and glycine in distilled water, adding the pure lithium titanate negative electrode material, carrying out magnetic stirring for 1 h, and after solvents are dried by distillation, carrying out vacuum drying on the obtained object so as to obtain a vanadium trioxide coated lithium titanate precursor; and carrying out heat treatment on the precursor in an argon atmosphere until the reaction is completed, so that a target product vanadium trioxide coated lithium titanate negative electrode material is obtained.

Owner:CHANGZHOU UNIV

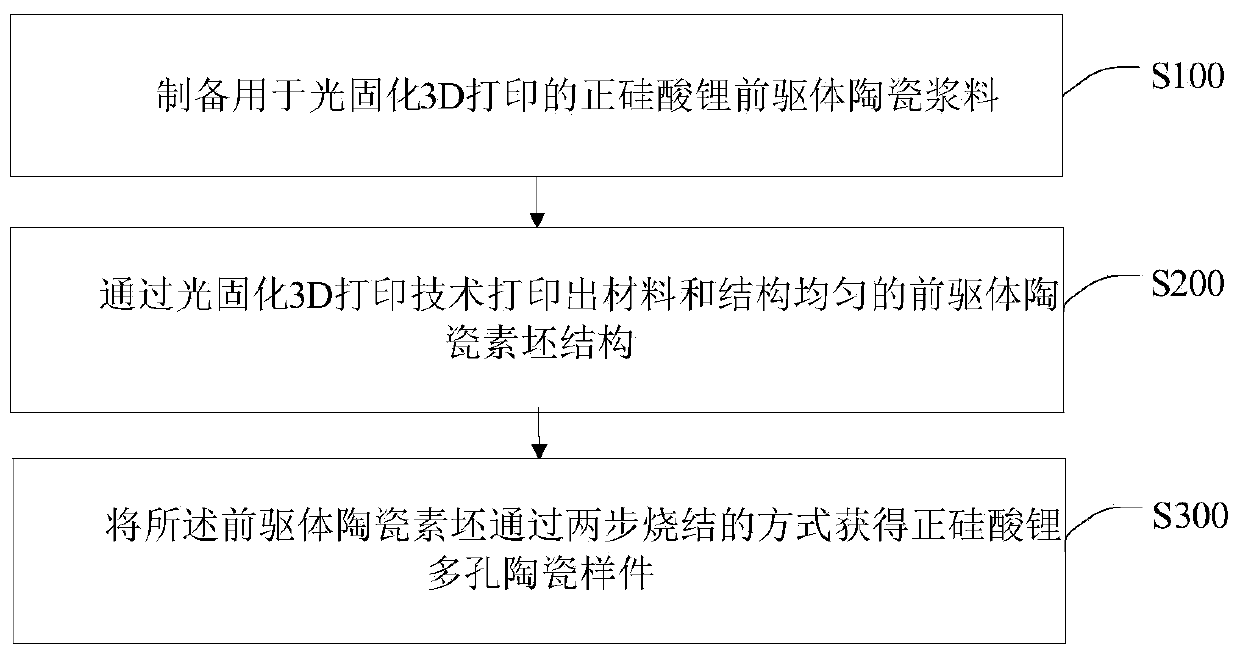

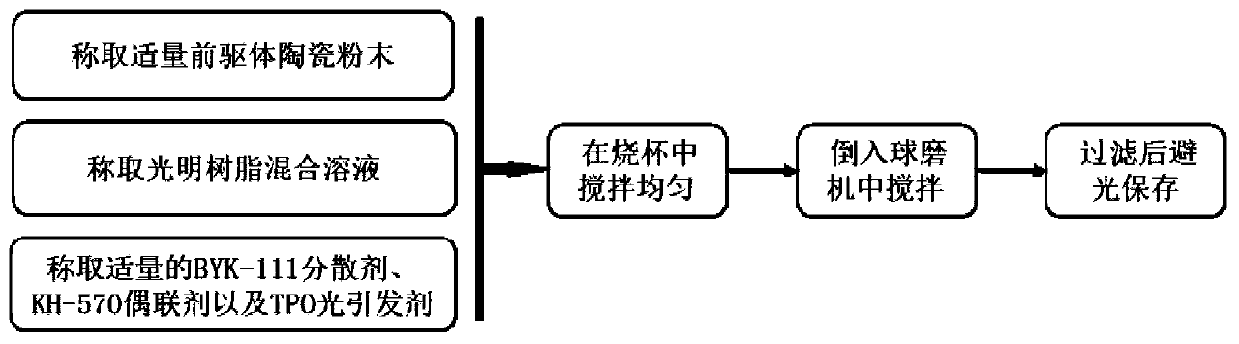

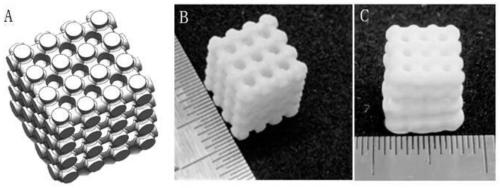

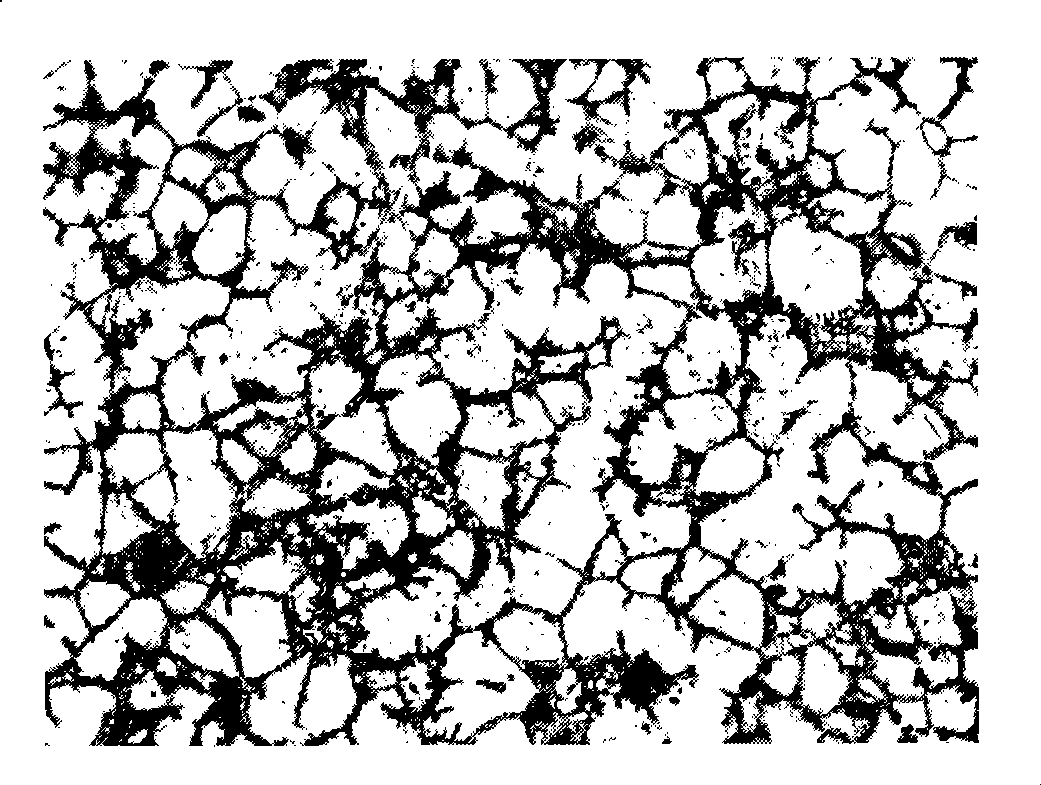

Ceramic precursor slurry and 3D printing reaction forming method of porous ceramic part

ActiveCN111548137AHigh purityUniform grain distributionAdditive manufacturing apparatusCeramicwareGrain distributionPorous ceramics

The invention discloses a ceramic precursor slurry and a 3D printing reaction forming method of a porous ceramic part. The method comprises the following steps: preparing a lithium orthosilicate precursor ceramic slurry for photocuring 3D printing; printing a precursor ceramic biscuit structure with uniform material and structure through a photocuring 3D printing technology; and carrying out two-step sintering on the precursor ceramic biscuit to obtain a lithium orthosilicate porous ceramic sample piece. According to the invention, the lithium orthosilicate ceramic part is prepared by a 3D printing technology, without expensive and difficult-to-obtain lithium orthosilicate powder; instead, the precursor powder with low price is subjected to 3D printing and high-temperature sintering reaction to generate the porous ceramic structure of the lithium orthosilicate material; therefore, the prepared lithium orthosilicate ceramic is high in purity and uniform in grain distribution, and any complex structure can be realized, so that a larger specific surface area is realized, the tritium production efficiency of a tritium breeding ceramic part is improved, and the service life of the tritium breeding ceramic part is prolonged.

Owner:SHENZHEN UNIV

Rotary pouring manufacture method of AZ91D magnesium alloy semisolid slurry

The invention relates to a method for preparing AZ91D magnesium alloy semi-solid sizing agent by rotating pouring, which is characterized in that AZ91D magnesium alloy is melted and refined in a smelting maintaining furnace, then cooled to 630-650 DEG C, and insulated for 10-30 minutes; a stainless steel rotating pouring tube is preheated to 60-80 DEG C, with the rotating speed of the pouring tube controlled at 0-105r / min, and the inclination of the rotating pouring tube being 20-30 degrees; then the AZ91D magnesium alloy melt is poured into the rotating tube through a deflection tube; a crystallizer is preheated to 470-500 DEG C; the AZ91D magnesium alloy melt enters the crystallizer through the rotating pouring tube, and insulated for 5-15 minutes. The method for preparing the AZ91D magnesium alloy semi-solid sizing agent by rotating pouring has a simple device, low cost, convenient operation, high practicality; the prepared AZ91D magnesium alloy semi-solid sizing agent has fine grain organization and even distribution; in addition, the process flow is short, the energy consumption is low, the efficiency is high, the equipment is simple, the structure is compact, the applicability is high, and the method is especially applicable to small and medium-sized enterprises of China.

Owner:NANCHANG UNIV

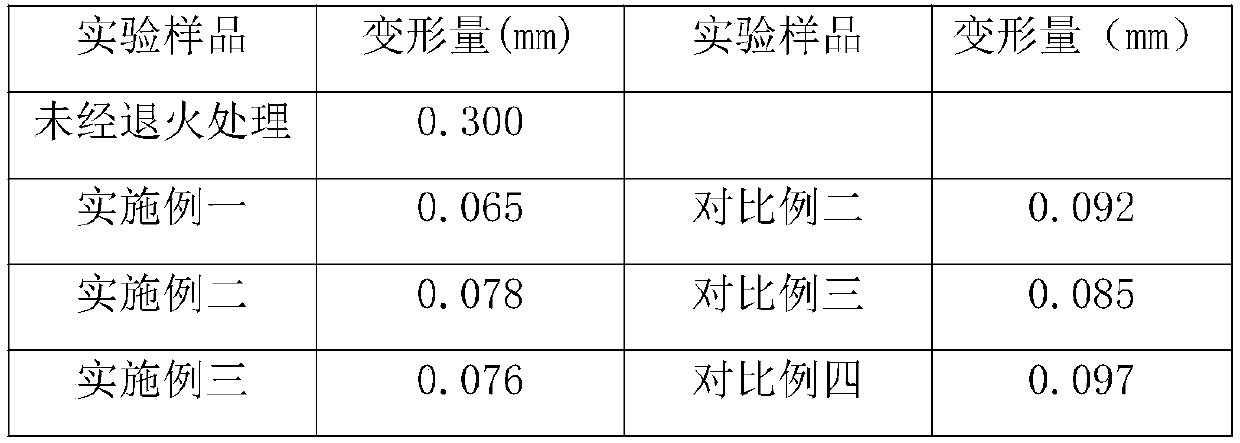

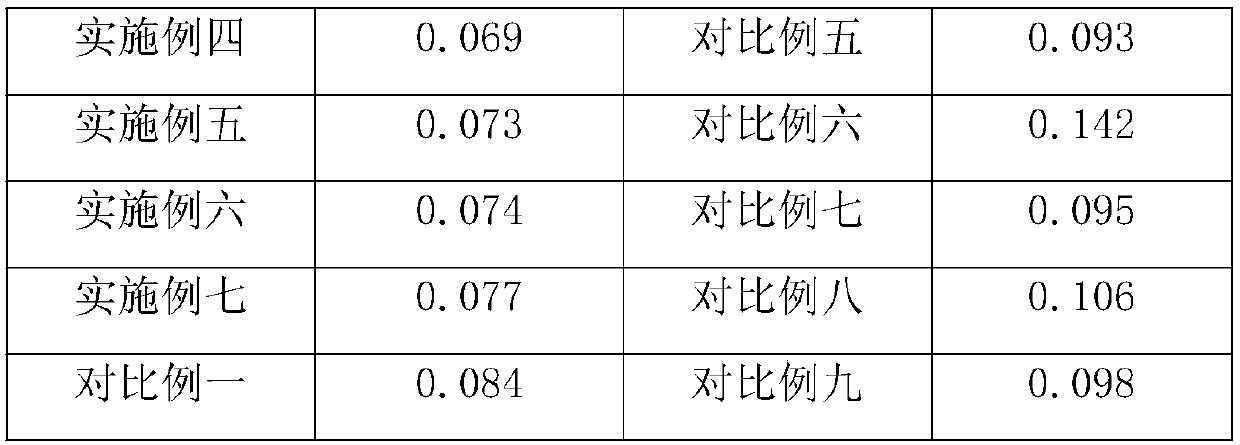

Annealing method of ceramic rear cover

InactiveCN107698278AUniform grain distributionArrangement structure is reasonableTelephone set constructionsInteraction forcesTwo temperature

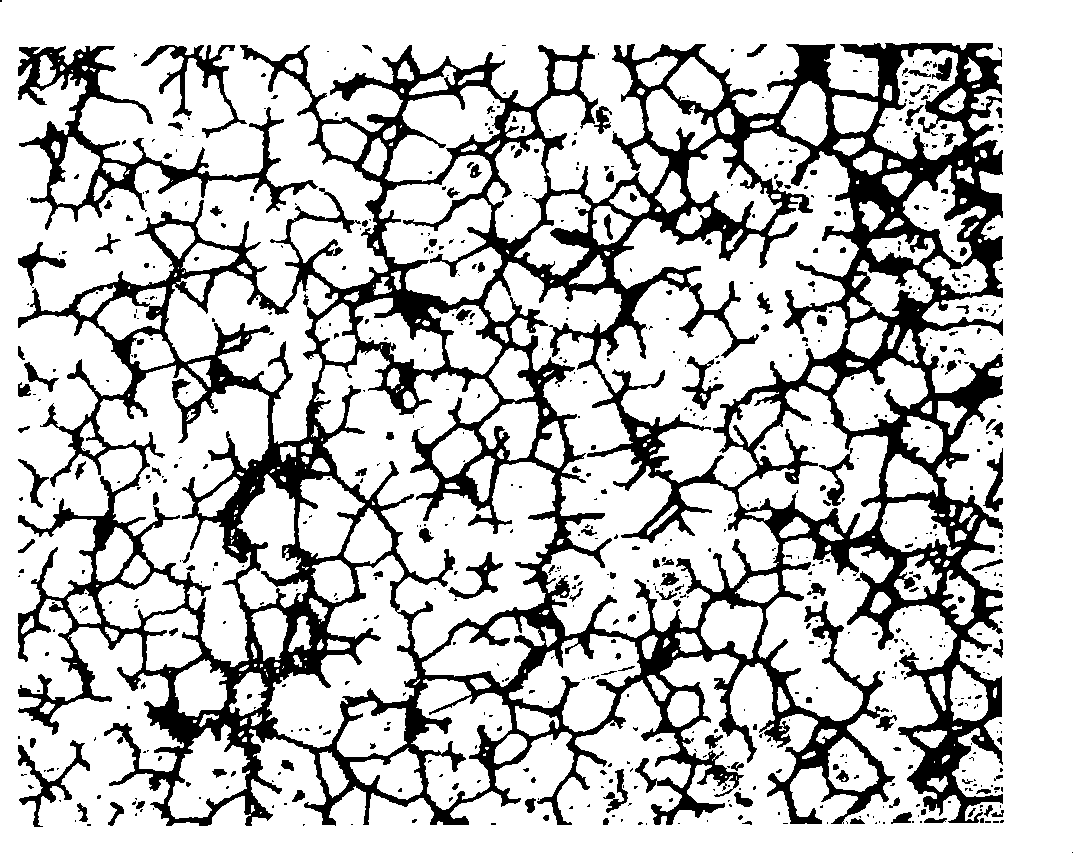

The invention discloses an annealing method of a ceramic rear cover, and belongs to the field of ceramic rear cover machining. The method comprises the following steps: putting the ceramic rear coverinto an annealing furnace, rising the temperature to a 600 to 800 DEG C medium temperature zone, and performing heat preservation for 1 to 2 hours; rising the temperature to a 1000 to 1200 high temperature zone after heat preservation is performed in the medium temperature zone, and performing heat preservation for 3 to 4 hours in the high temperature zone; reducing the temperature to 800 to 900 DEG C after high temperature preservation is performed, and ensuring that the time is controlled to be 1 to 2 hours; naturally cooling the ceramic rear cover to the room temperature, and then discharging the ceramic rear cover, so as to accomplish annealing. The method has the benefits that a gradient temperature rising and reducing technology is adopted; through twice time rise and twice temperature reduction, the ceramic rear cover is kept in the two temperature zones for a certain period of time, then crystal particles inside the ceramic rear cover are grown by stages, interaction force among the crystal particles is fully released, the crystal particles are more uniformly distributed, and an arrangement structure among the crystal particles is more stable, so that stress produced duringfine carving of the ceramic rear cover is effectively reduced, the fact that the deformation of the ceramic rear cover is below 0.08mm after annealing treatment is ensured, and the assembly requirement of mobile phones is met.

Owner:湖北天宝光电科技有限公司

Preparation method of oriented ZeTe nanocrystals

InactiveCN102586880AChange in growth habitReduce manufacturing costPolycrystalline material growthFrom condensed vaporsAdhesiveCrystal orientation

The invention discloses a preparation method of oriented ZeTe nanocrystals, which includes the following steps: synthesizing a ZnTe alloy material in vacuum by taking metals Ze and Te having purities higher than 99.99% as raw materials, cleaning the alloy material with deionized water, bonding on an object stage of pulsed laser deposition equipment with conducting silver glue adhesive to obtain a sputtering target material, sputtering the ZeTe target material at a room temperature with a pulsed laser energy density of 2-5J / cm<2>, and carrying out in-situ annealing treatment of the sputtered film at 30-400 DEG C to obtain the oriented ZeTe nanocrystals, wherein the distance between the target material and a substrate is set to be 5cm, the sputtering substrate is glass, sapphire, monocrystalline silicon and the like. The obtained oriented ZeTe nanocrystals have a grain size of about 20-60nm, and have orientations (110, 111). Compared with the traditional preparation method, the preparation method disclosed by the invention can realize oriented growth of the ZeTe nanocrystals through controlling the annealing temperature after sputtering and controlling the substrate.

Owner:SHANGHAI INST OF TECH

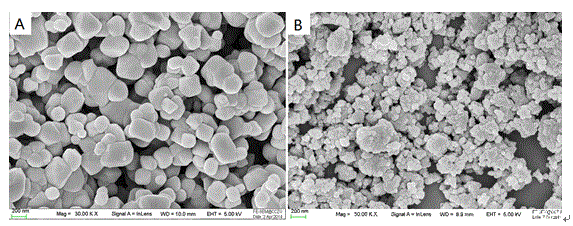

Method for preparing nitrogen-carbon co-coated lithium titanate anode material

InactiveCN104409714AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsCarbon compositesMelamine formaldehyde resin

The invention discloses a method for preparing a nitrogen-carbon co-coated lithium titanate anode material. The method specifically comprises the following steps: 1) ball-milling lithium carbonate, titanium dioxide and melamino-formaldehyde in acetone for 6 hours, uniformly mixing, transferring into a vacuum drying box at the temperature of 100 DEG C, and drying to obtain a lithium titanate / nitrogen-carbon composite precursor; 2) roasting the lithium titanate / nitrogen-carbon composite precursor in argon at 750 DEG C for 8 hours to obtain the nitrogen-carbon co-coated lithium titanate anode material. The method is simple and safe in process and low in cost, and the prepared nitrogen-carbon co-coated lithium titanate anode material is fine and uniform in granule and relatively good in electrochemical property.

Owner:HUNAN UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com