Patents

Literature

64results about How to "Flat and dense surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

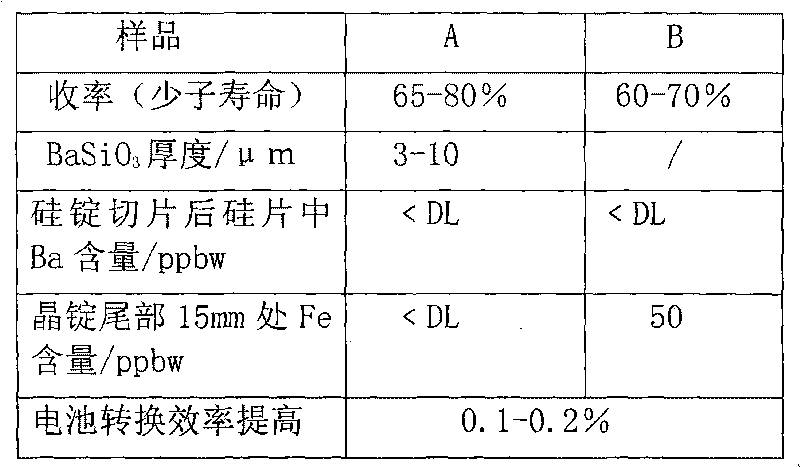

Method for producing polycrystal ingot

InactiveCN101696514AIncrease profitImprove efficiencyPolycrystalline material growthBy pulling from meltBarium saltShielding gas

The invention relates to a method for producing a polycrystal ingot, which comprises the following steps: preparing a solution of barium hydroxide or a barium salt serving as a coating solution; preheating a quartz ceramics crucible; uniformly coating the coating solution of the solution of the barium hydroxide or the barium salt on the inner surface of the preheated quartz ceramics crucible; baking the quartz ceramics crucible; spraying silicon nitride on the inner surface of the quartz ceramics crucible after baking and rotating the quartz ceramics crucible; filling a silicon material into the quartz ceramics crucible; putting the quartz ceramics crucible into a polycrystal furnace; vacuumizing the polycrystal furnace and adding a protective gas to the polycrystal furnace; heating the silicon material to smelt the silicon material; gradually crystallizing the melted silicon material from the bottom to the top by directional solidification; at last performing high temperature annealing to form the polycrystal ingot used for making a battery through slicing; slicing a crystal ingot into silicon slices; making the silicon slices into battery plates by making herbs into wool, diffusing, etching edges, PECVD filming, screen painting and sintering; and testing and grading the battery plates. The coating in the crucible prevents impurities in the crucible from diffusing to the silicon material, and improves the lifetime of minority carrier close to the crucible, the utilization rate of the crystal ingot and the battery conversion efficiency.

Owner:TRINA SOLAR CO LTD

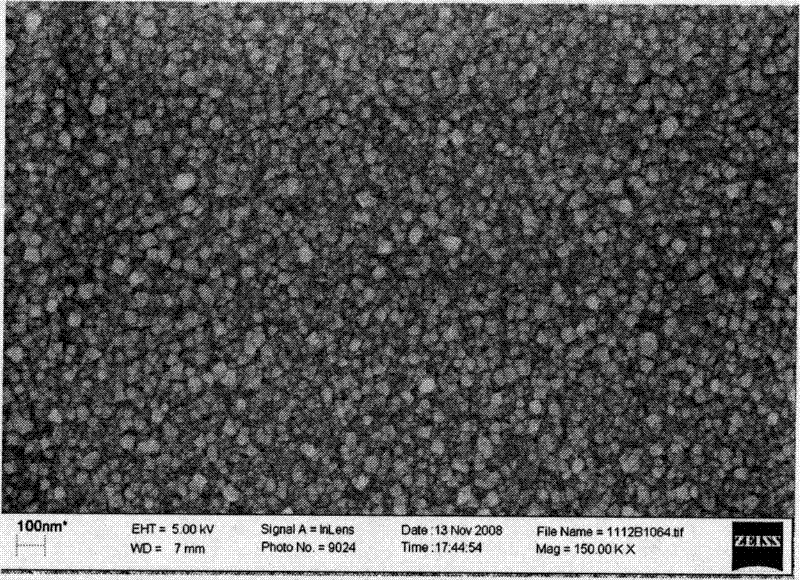

Preparation method for copper zinc tin sulfide thin film material

InactiveCN102496659AFlat and dense surfaceReduce usageFinal product manufactureSemiconductor devicesEvaporationCopper foil

The invention discloses a preparation method for a copper zinc tin sulfide thin film material. The preparation method comprises the following steps of: performing oil removal, electrochemical polishing and activation pretreatment on the surface of a copper foil substrate; depositing metallic zinc and tin by using one of a magnetron sputtering method, an evaporation method, a pulsed laser deposition method and an electrodeposition method to form a metallic preformed layer; annealing the metallic preformed layer in a sulfur-containing protective atmosphere at high temperature; and placing the annealed metallic preformed layer in an alkaline KCN solution for etching. By the preparation method, a copper belt is adopted as a flexible substrate and a back contact conductive material, so that the usage of expensive metallic molybdenum is greatly reduced, and production cost is decreased; and a Cu-S phase formed by excessive copper is favorable for the growth of copper zinc tin sulfide crystal grains, reduces charge carrier recombination centers and improves photoelectric conversion efficiency. The copper zinc tin sulfide thin film material prepared by the method is easy to produce in large scale, and can be popularized and applied in a thin film solar cell industry.

Owner:CENT SOUTH UNIV

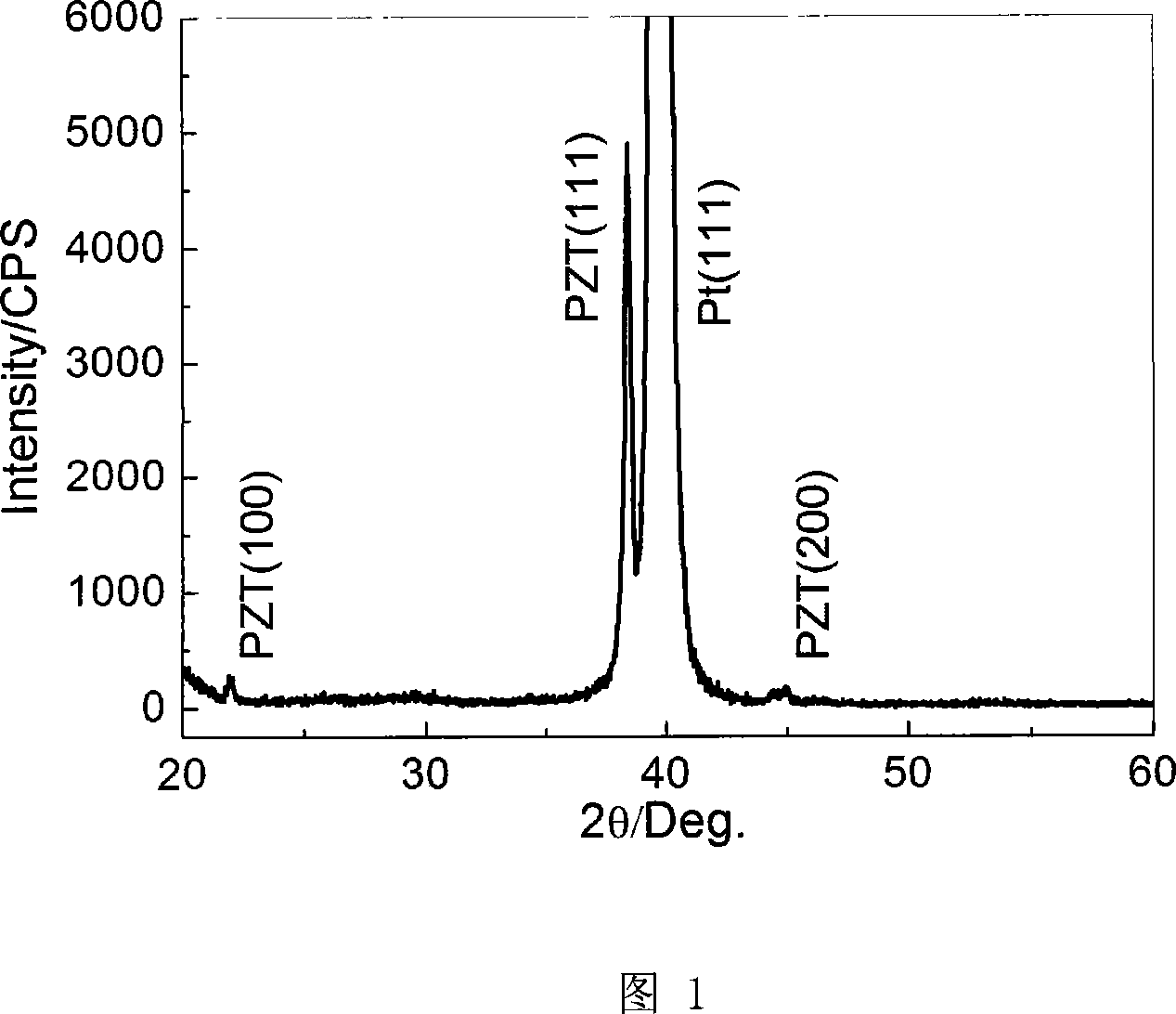

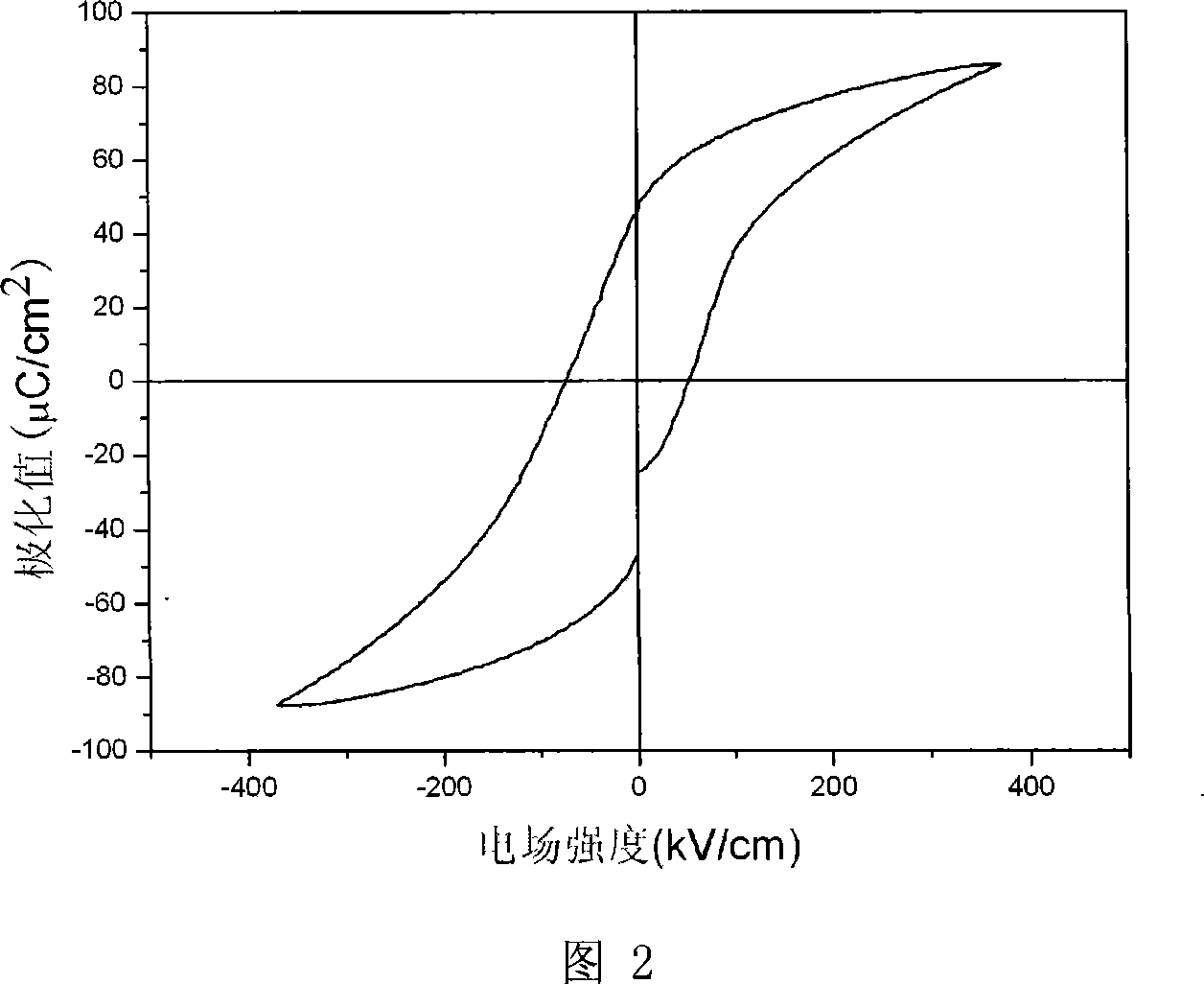

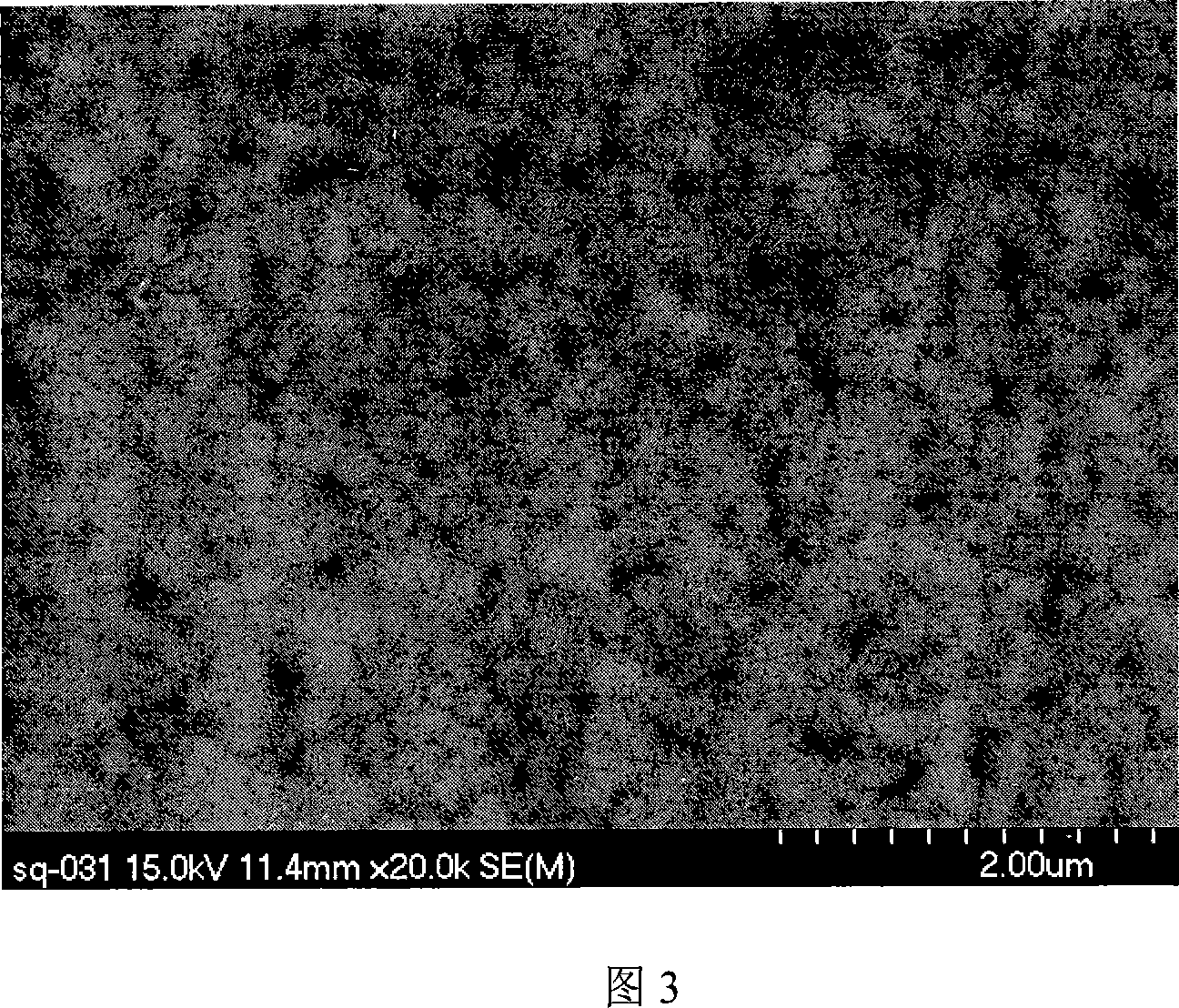

Method for fabricating film of aluminum zirconate titanate with high orientating (111)

InactiveCN101050119AFlat and dense surfaceUniform compositionCeramicsLead zirconate titanateZirconate

This invention discloses a method for preparing highly (111)-oriented PZT thin film. The method can solve the problems of complex process and low repeatability faced by sol-gel method. The method comprises: preparing PZT sol, depositing PZT thin film, pre-crystallizing PZT thin film, and crystallizing PZT thin film. The method is simple. The obtained PZT thin film has compact and smooth surface, uniform thickness, uniform grain sizes, high residual polarization value (43-60 muC / cm2), low coercive field (60-75 kV / cm), and high saturated polarization value.

Owner:HARBIN INST OF TECH

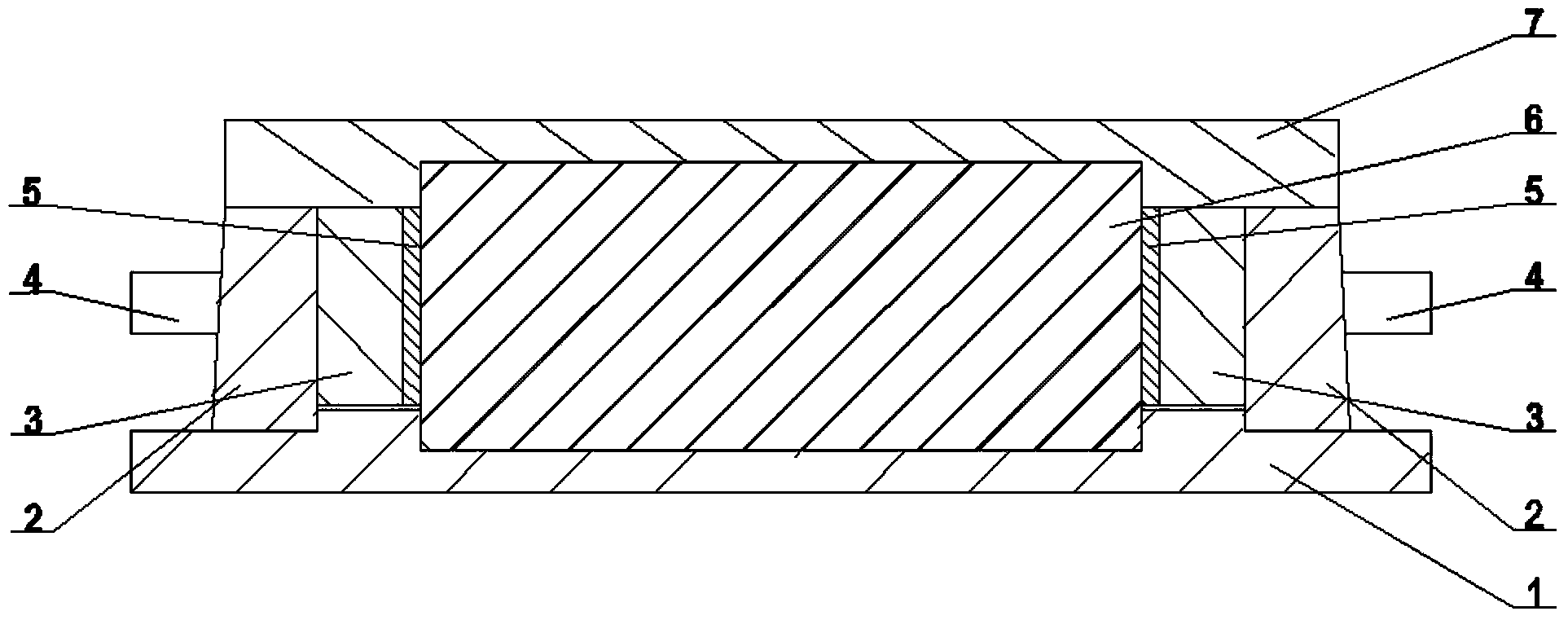

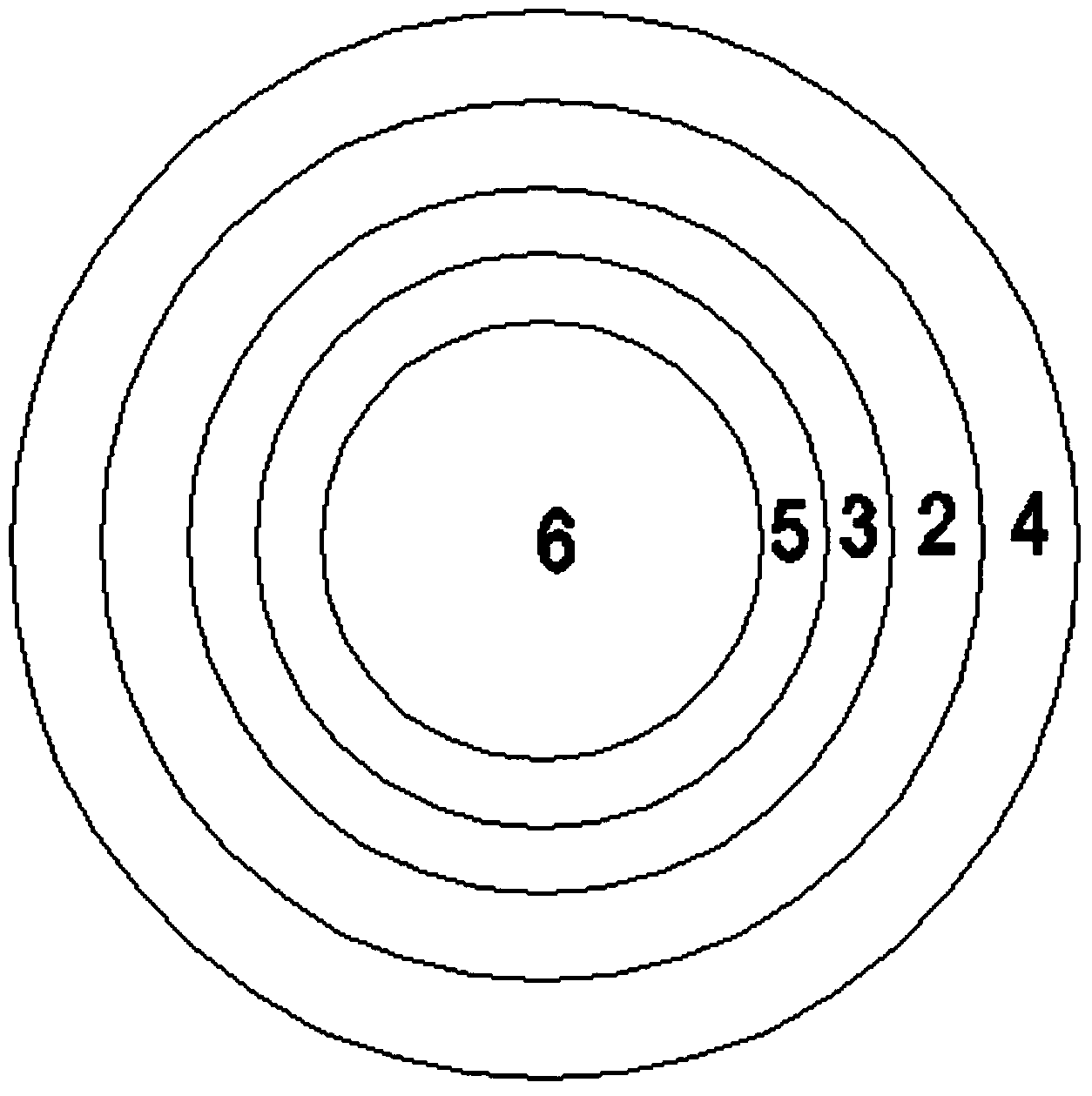

Method for forming composite material by matched mold

The invention discloses a method for forming a composite material by a matched mold, aiming to solve the problems that a composite material formed by an existing method is uneven in surface and insufficient in compactness. The method comprises the following steps: firstly, laying a prepreg layer of the composite material on the surface of an inner mold on a lower mold of a metal mold, and laying expansion rubber uniformly on the outer layer of the prepreg layer of the composite material; secondly, combining an outer mold with the outer layer of the expansion rubber, and combining the outer mold closely at the outer side of the outer mold by a mold combining ring, and covering the upper mold tightly, thereby obtaining the packaged mold; and thirdly, putting the packaged mold in the second step into a curing furnace, curing, then taking the mold out, cooling to room temperature, and demolding, thereby obtaining the formed composite material. The method is used for forming the composite material.

Owner:HARBIN FRP INST

Heat dissipation circuit board embedded with ceramic and preparation method of circuit board

ActiveCN107708315AGood cooling performanceFlat and dense surfaceSuperimposed coating processCircuit precursor manufactureCopper platingElectroplating

The invention relates to the manufacturing field of a circuit board, and specifically relates to a heat dissipation circuit board embedded with ceramic and a preparation method of the circuit board. The preparation method of the heat dissipation circuit board embedded with ceramic at least comprises the following steps of a, processing of copper-clad plates: putting a prepreg between two one-sidedcopper-clad plates and then performing fixation by a rivet, and processing windows in the one-sided copper-clad plates; b, processing of a ceramic substrate: plating a titanium layer on the upper andlower surfaces of the ceramic substrate through a first sputtering process separately, then plating a first copper layer through a second sputtering process, next, plating a second copper layer by afirst electroplating process, and finally cutting into ceramic blocks, wherein the dimensions of the ceramic blocks are matched with those of the windows; and c, lamination: embedding the cut ceramicblocks into the widows and then performing lamination; d, hole drilling: processing conductive holes in the one-sided copper-clad plates; and e, copper plating: depositing a third copper layer in theconductive holes through a chemical copper plating way and then plating a fourth copper layer through a second electroplating process.

Owner:江苏贺鸿电子有限公司

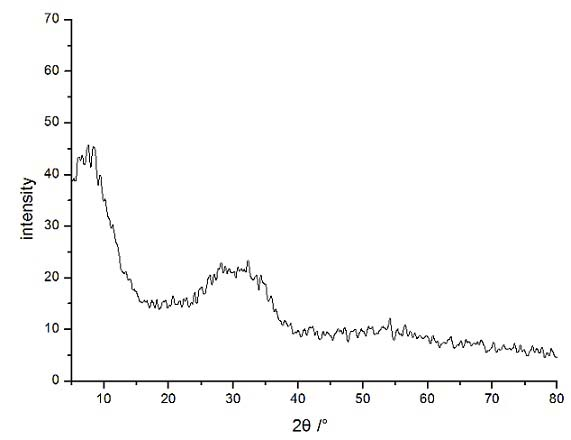

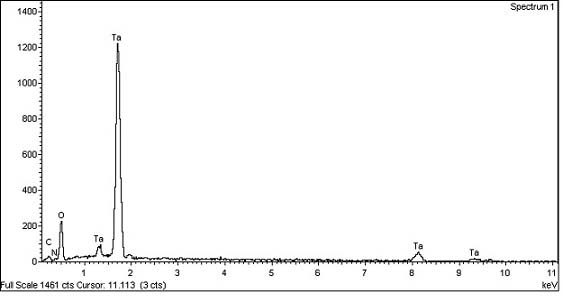

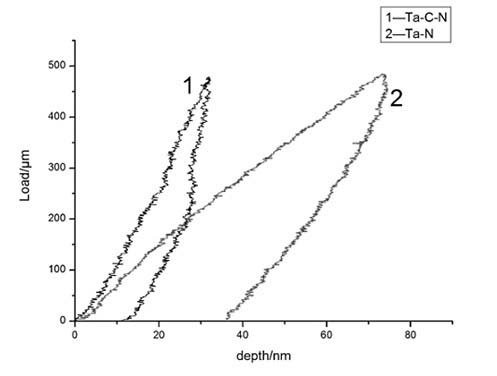

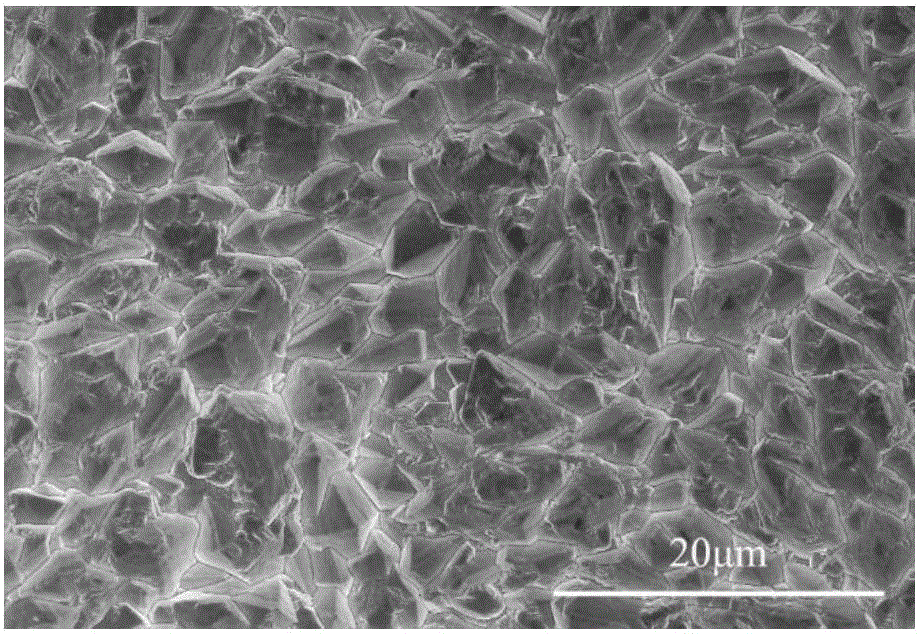

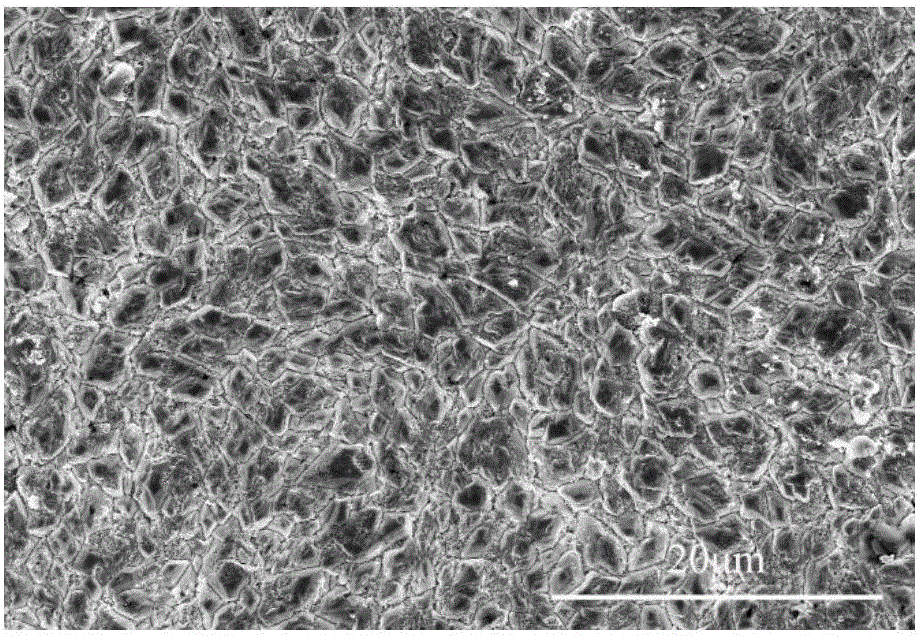

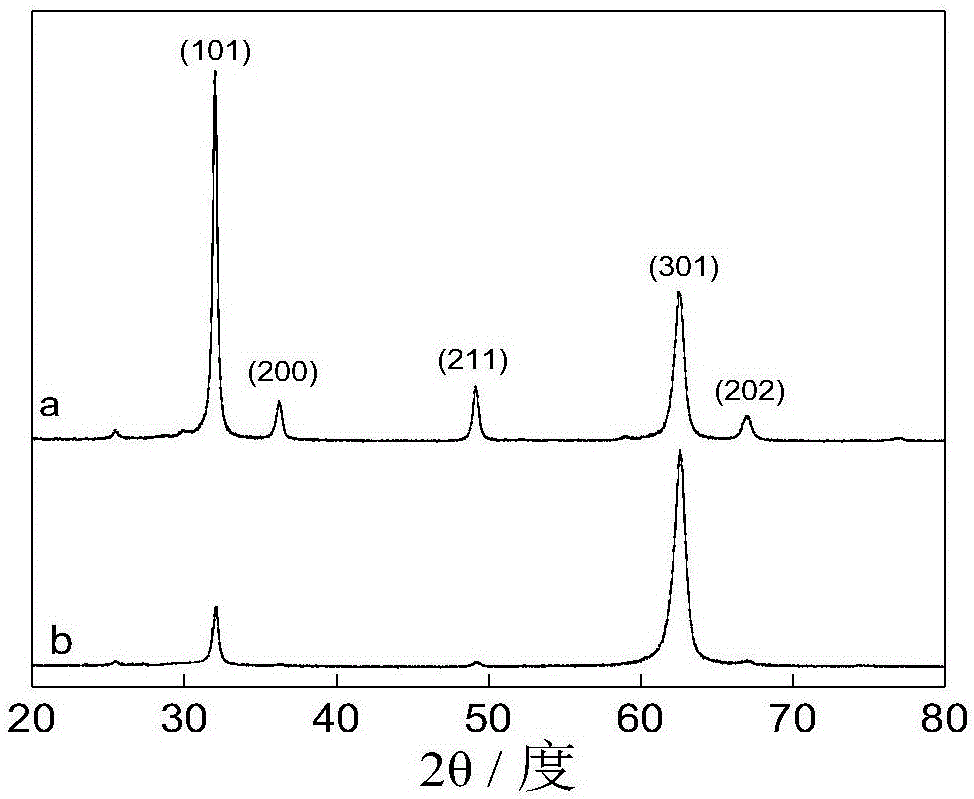

Preparation method of Ta-C-N thin-film

InactiveCN102127743AFlat and dense surfaceSurface mean square roughness is smallVacuum evaporation coatingSputtering coatingTest samplePhysical chemistry

The invention relates to the technical field of thin-film preparation, particularly relates to a preparation method of a Ta-C-N thin-film, which comprises the following steps: performing surface activation on a monocrystalline silicon substrate by using a conventional process, separately placing a Ta target, a graphite target and the silicon substrate into a main sputtering chamber and a sample injection chamber, vacuumizing the sputtering chamber and the sample injection chamber, and pre-sputtering the Ta target and the graphite target to remove surface impurities; adjusting the ratio of nitrogen gas flow to argon gas flow (sccm) to 1:(10-100); adjusting the distance between the substrate and the targets to 5-10 centimeters; regulating the Ta target sputtering power to 80-150 W to do firing sputter, regulating the graphite target sputtering power to 100-200 W to do firing sputter, and producing the thin film by adopting simultaneous sputtering and layered sputtering process; and taking the test sample out from the main sputtering chamber to obtain the non-crystalline Ta-C-N ternary thin-film. The preparation method provided by the invention has the characteristics of simple process, short synthesis time, and on the like and is easy to implement.

Owner:JIANGSU UNIV

Preparation method and application of titanium dioxide modified lead dioxide electrode

InactiveCN106745526ALarge active surface areaFlat and dense surfaceWater contaminantsWater/sewage treatmentIonLead plate

The invention relates to a preparation method and application of a titanium dioxide modified lead dioxide electrode, and belongs to the technical field of electrode materials. The method comprises the following steps: cleaning a titanium plate, then roughening the titanium plate, steeping the titanium plate into an oxalic acid aqueous solution to remove an oxide layer, finally cleaning the titanium plate with deionized water, and blowing the titanium plate to dry; coating the treated titanium plate with a solution containing tin ions and antimony ions, carrying out sintering, and repeating the coating and sintering processes for multiple times to obtain a titanium plate with a coated middle layer; carrying out electro-deposition by using a lead plate as a negative electrode, the titanium plate as a positive electrode with the coated middle layer and a TiO2 particle-containing Pb(NO3)2 and NaF mixed solution as an electro-deposition solution, thus obtaining the electrode. The electrode preparation process is simple, convenient to operate and low in comprehensive cost; the prepared electrode fully develops the photoelectric synergistic catalytic action of TiO2 and PbO2, is outstanding in effect of degrading an azo-organic dye, and is long in service life.

Owner:HEBEI ZHISHENG GREEN TECH

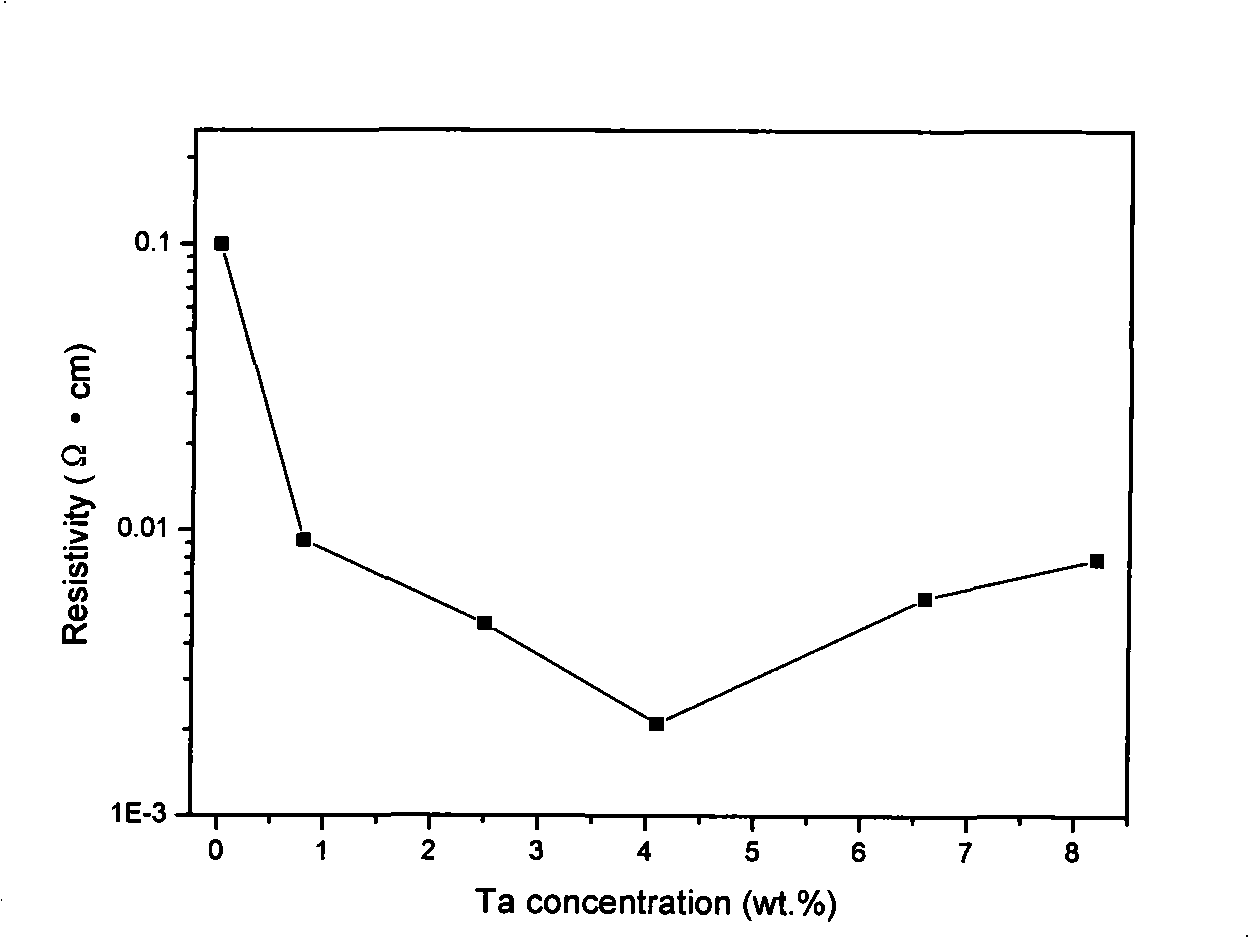

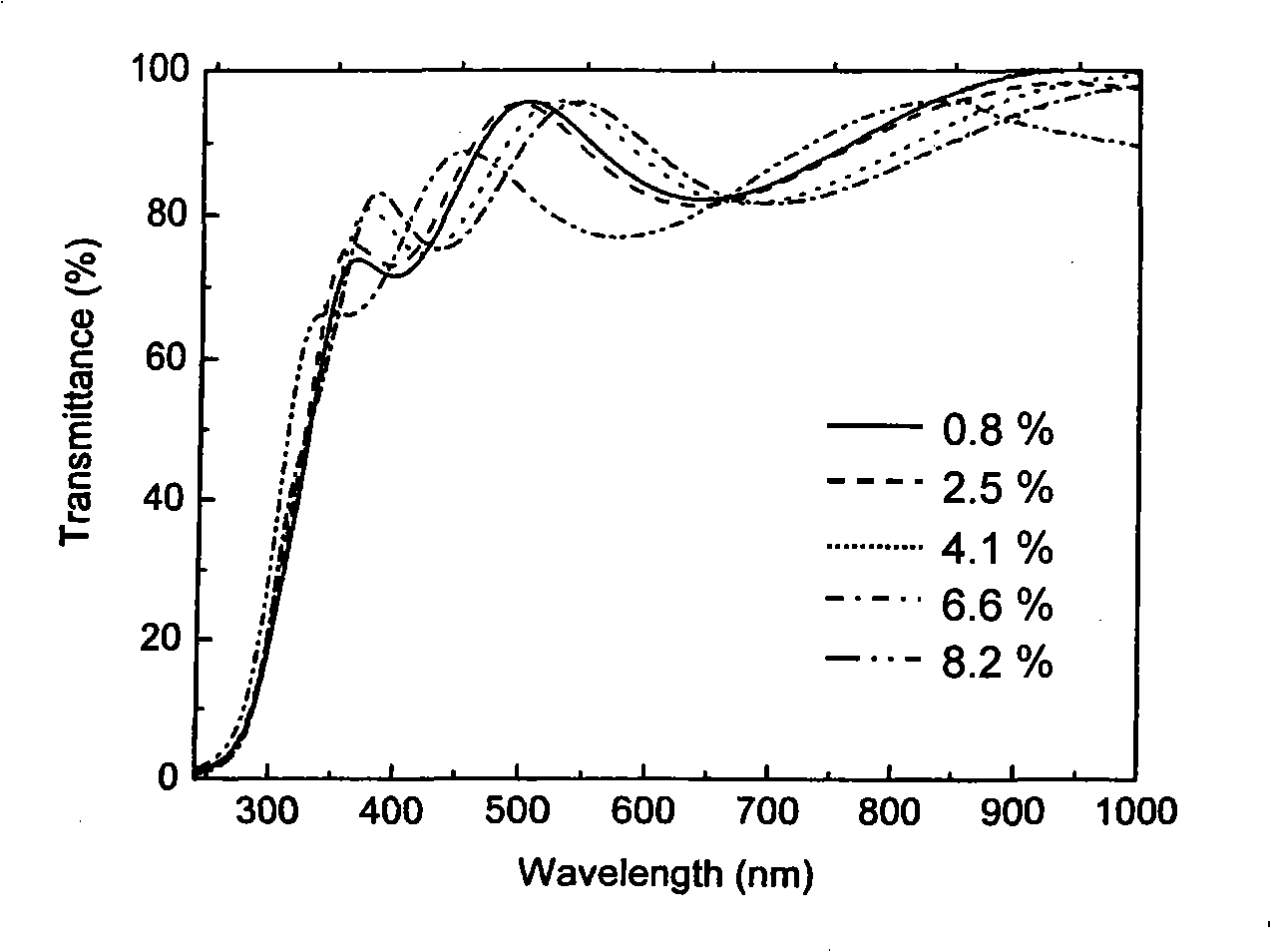

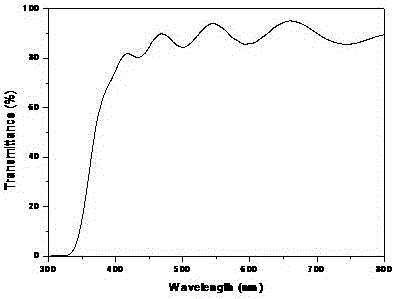

Method for preparing tantalum doping tin oxide transparent conductive film

InactiveCN101260512AImprove photoelectric performanceExcellent chemical durabilityVacuum evaporation coatingSputtering coatingBiocompatibility TestingElectromagnetic shielding

The invention relates to a method for preparing tantalum jewellers putty-doped transparent conductive film. The method is characterized in that Ta2O5 powder and SnO2 powder with 99.99 percent purity quotient are fully mixed according to weight ratio between 1:99 to 10:90, pressed, molded and sintered into a tantalum jewellers putty-doped sputtering target material under the temperature between 1500 DEG C and 1650 DEG C, then a jewellers putty-doped transparent conductive film with different tantalum contents is prepared by a magnetron sputtering method. The prepared film has the characteristics of smooth and compact surface, uniform film thickness, excellent photoelectric performance, simple preparation technology, low cost and easy realization of industrialized production, etc. and also has good mechanical performance, chemical durability, high-temperature thermal stability and biocompatibility. The film can not only be used for a flat-panel dispaly, a solar battery, a transparent electromagnetic shielding and antistatic device but also used for a resistance type touch screen, a biosensor, etc. which have special needs on the toxicity and biocompatibility of the film.

Owner:KUNMING UNIV OF SCI & TECH

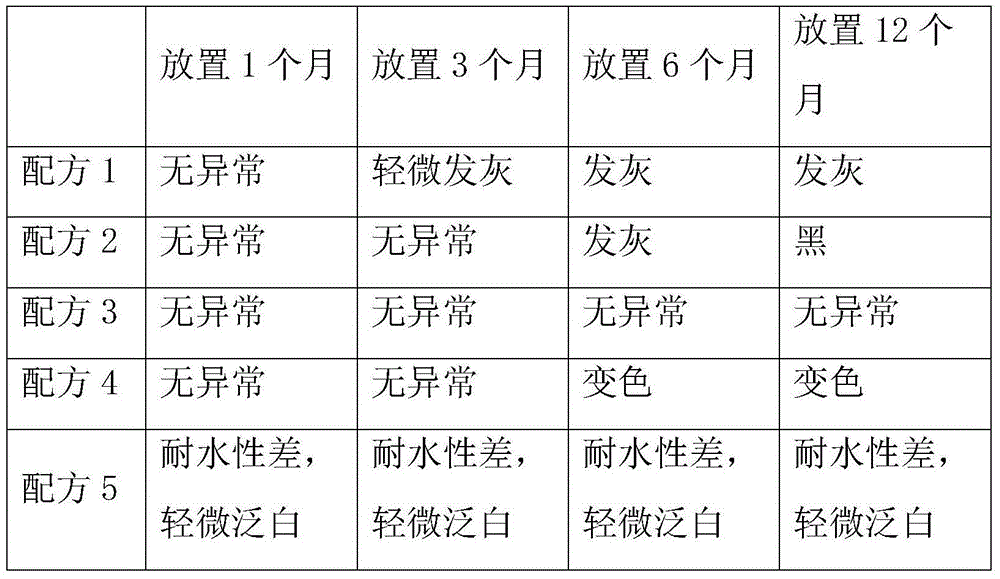

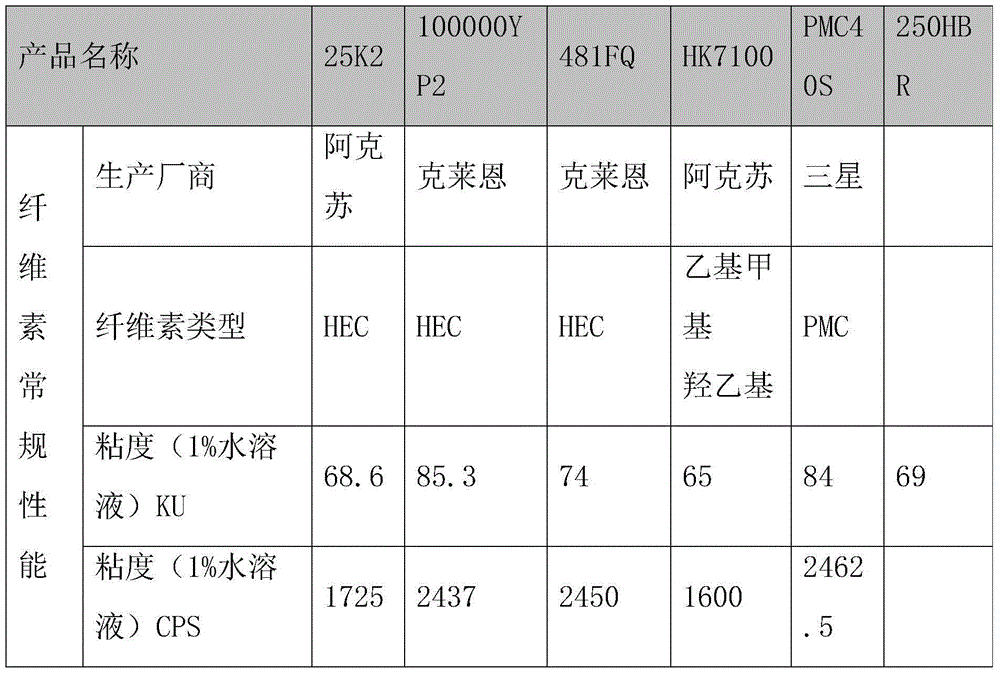

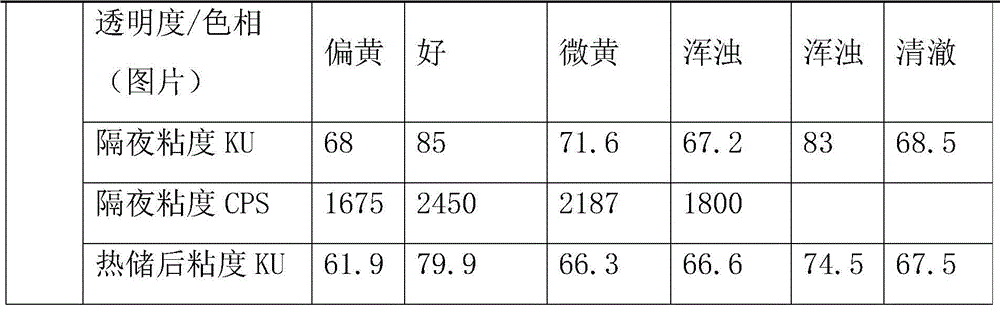

Safe and environment-friendly type abrasion-resistant self-cleaning latex paint and preparation method thereof

InactiveCN106883688ALower minimum film forming temperatureLow film forming temperatureAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceCellulose

The invention relates to a safe and environment-friendly type abrasion-resistant self-cleaning latex paint and a preparation method thereof. The latex paint is prepared from the following components in parts by weight: 390 to 420 parts of emulsion, 20 to 30 parts of film forming additive, 5 to 50 parts of silicon sol, 2 to 4 parts of multifunctional ammine additive, 5 to 10 parts of hydrophobic agent, 2 to 5 parts of wetting agent, 7 to 8 parts of dispersant, 2 to 5 parts of defoaming agent, 1 to 3 parts of cellulose, 2 to 4 parts of thickener, 240 to 260 parts of inorganic filler, 250 to 270 parts of water, 2 to 4 parts of preservative, 1 to 2 parts of anti-mildewing agent and 15 to 20 parts of propylene glycol. Compared with the prior art, the latex paint has the advantages that the compactness of a paint film is good, the hardness is high, the abrasion-resistant property is good, static electricity is not produced, and various dust in air is difficult to adhere; the preparation method is simple, the controllability is good, the green and environment-friendly effect is achieved, the technical defect of poor dirt resistance in a latex paint is effectively overcome, the service life of the latex paint is prolonged, the economy is good, the industrialized expanding production is easy, and the application prospect is good.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

Painted ceramic stone and production technology thereof

The invention provides a building decoration coating painted ceramic stone and a production technology thereof. The coating painted ceramic stone adopts 40-80 mesh ceramic sands, the thickness of the coating layer of the above product is 2mm, and the disadvantages of single color, easy efflorescence, insufficient thickness and no crack resistance function of traditional emulsion paints are overcome; the color of the ceramic sands can be sintered arbitrarily, and is stable, so the painted ceramic stone has the advantages of grittiness of texture coatings, no need of any color paste, no color fading risk, uniform particle size, and great reduction of the lapping defect generation; and silica sol is introduced in the formula of the painted ceramic stone, a film composite base material is arrayed in a spherical or subglobular manner, and the surface is flat and compact and has few apertures, so fine dust particles cannot intrude the apertures, and cannot adhere, thereby the coating layer has good contamination resistance.

Owner:上海贝塔建筑科技有限公司

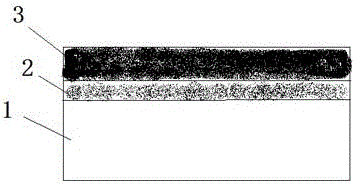

Sputtering deposition method of flexible AZO transparent conductive film at room temperature

InactiveCN106119778APromote crystallizationImprove photoelectric performanceVacuum evaporation coatingSputtering coatingRoom temperatureUltraviolet lights

The invention relates to a sputtering deposition method of a flexible AZO transparent conductive film at room temperature. The method comprises the following steps of (1) cleaning a substrate; (2) presputtering; (3) preparing a homogeneous buffer layer; (4) assisting to sputter a main body layer of the AZO film by ultraviolet light. According to the sputtering deposition method, the homogeneous buffer layer which is sputtered with low power at room temperature is introduced, so that the subsequent preparation of the high-quality main body layer of the AZO film is facilitated, and damages of sputtered particles to the organic flexible substrate are reduced. The AZO film prepared by utilizing the sputtering deposition method has the advantages of good crystallization performance, compact and smooth surface and simplicity in technological operation and is suitable for industrial production.

Owner:HENAN ANCAI HI-TECH

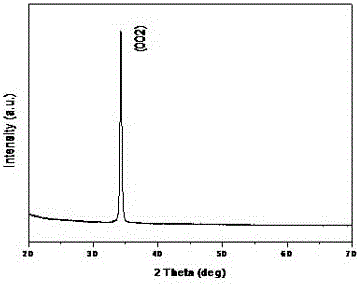

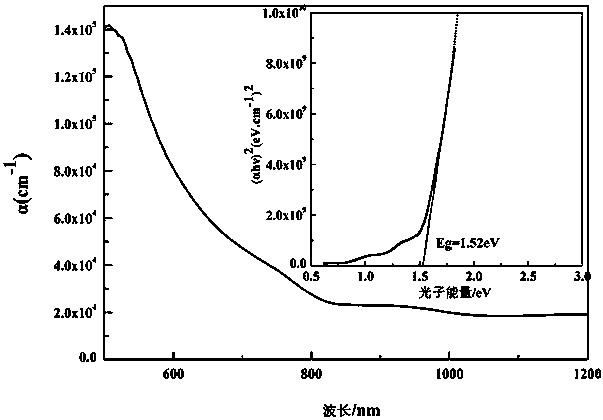

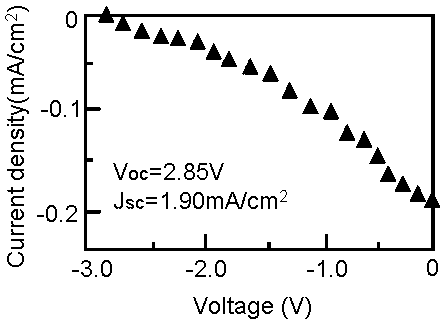

Preparation method of copper antimony sulfur film material

ActiveCN107829071AHigh purityFlat and dense surfaceVacuum evaporation coatingSputtering coatingSulfurCopper

The invention discloses a preparation method of a copper antimony sulfur film material. The preparation method of the copper antimony sulfur film material comprises the following steps: the surface ofa substrate is cleaned; the co-sputtering deposition of a Cu-Sb-S prefabricated layer is performed on the cleaned surface of the substrate through a radio-frequency or direct-current reaction; the substrate deposited with the Cu-Sb-S prefabricated layer on the surface is put in a reactive atmosphere for high-temperature annealing treatment; and the surface of the Cu-Sb-S prefabricated layer afterhigh-temperature annealing treatment is etched to obtain the copper antimony sulfur film material. The preparation method of the copper antimony sulfur film material has the advantages of low cost, easy control and adjustment of film components, good reproducibility, large-area growth of films and the like; and the prepared films achieve excellent component controllability and uniformity and excellent crystallization quality and properties.

Owner:CENT SOUTH UNIV

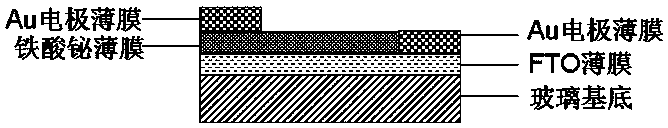

Method for preparing high-quality bismuth ferrite ferroelectric photovoltaic films by magnetron sputtering

InactiveCN108085650AImprove performanceThe preparation process is highly controllableVacuum evaporation coatingSputtering coatingLanthanideSolar cell

The invention provides a method for preparing high-quality bismuth ferrite (BFO) ferroelectric photovoltaic films. The method comprises the specific steps of adopting BFO ceramic targets mixed with lanthanide, placing a cleaned FTO / glass substrate into a vacuum chamber, and adjusting the distance between a sample stage and a target stage to be 50-150 mm; introducing O2 and Ar according to the gasflow ratio O2 / Ar of 1 / 10-1 / 4 when the background vacuum degree is higher than 8x10<-4> Pa, making the working pressure reach 1-10 Pa, setting the power of a radio frequency power supply to be 10-100 W, the rotation speed of the sample stage to be 5-15 rpm, and the pre-sputtering time to be 5-15 min separately, and setting the sputtering time according to the thickness of the BFO film; and continuously introducing Ar insert protective gas upon completion of sputtering for in-situ annealing treatment to the BFO film, wherein the heating temperature is 300-600 DEG C, and the holding time is 30-180 min. The method provided by the invention is a physical vapor deposition method, and the BFO ferroelectric photovoltaic films are prepared by a conventional magnetron sputtering system, and are highin technological controllability and applicability, and easy to produce on a large scale; and a new way is opened up for development of solar cells based on the BFO ferroelectric photovoltaic films.

Owner:YUNNAN NORMAL UNIV

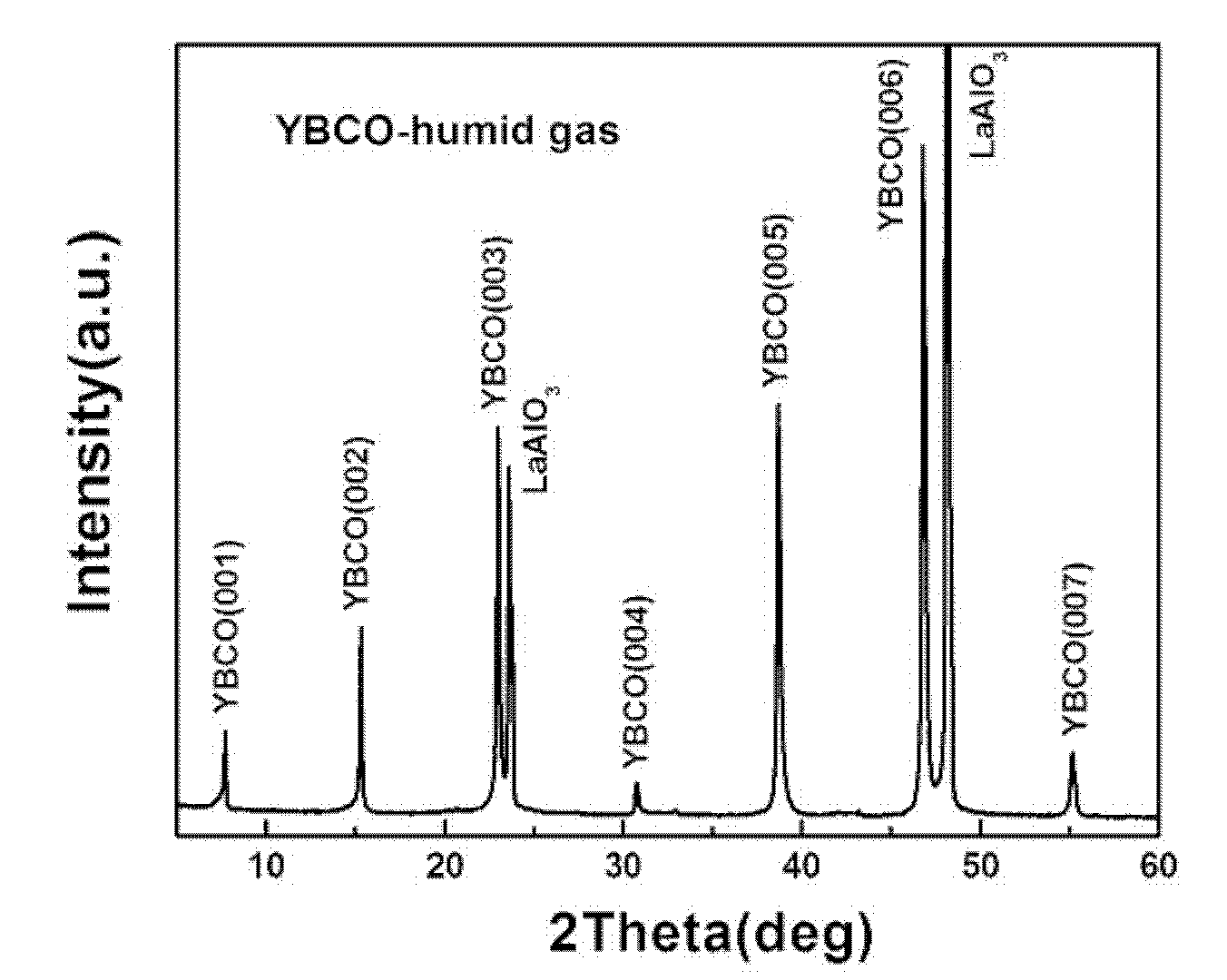

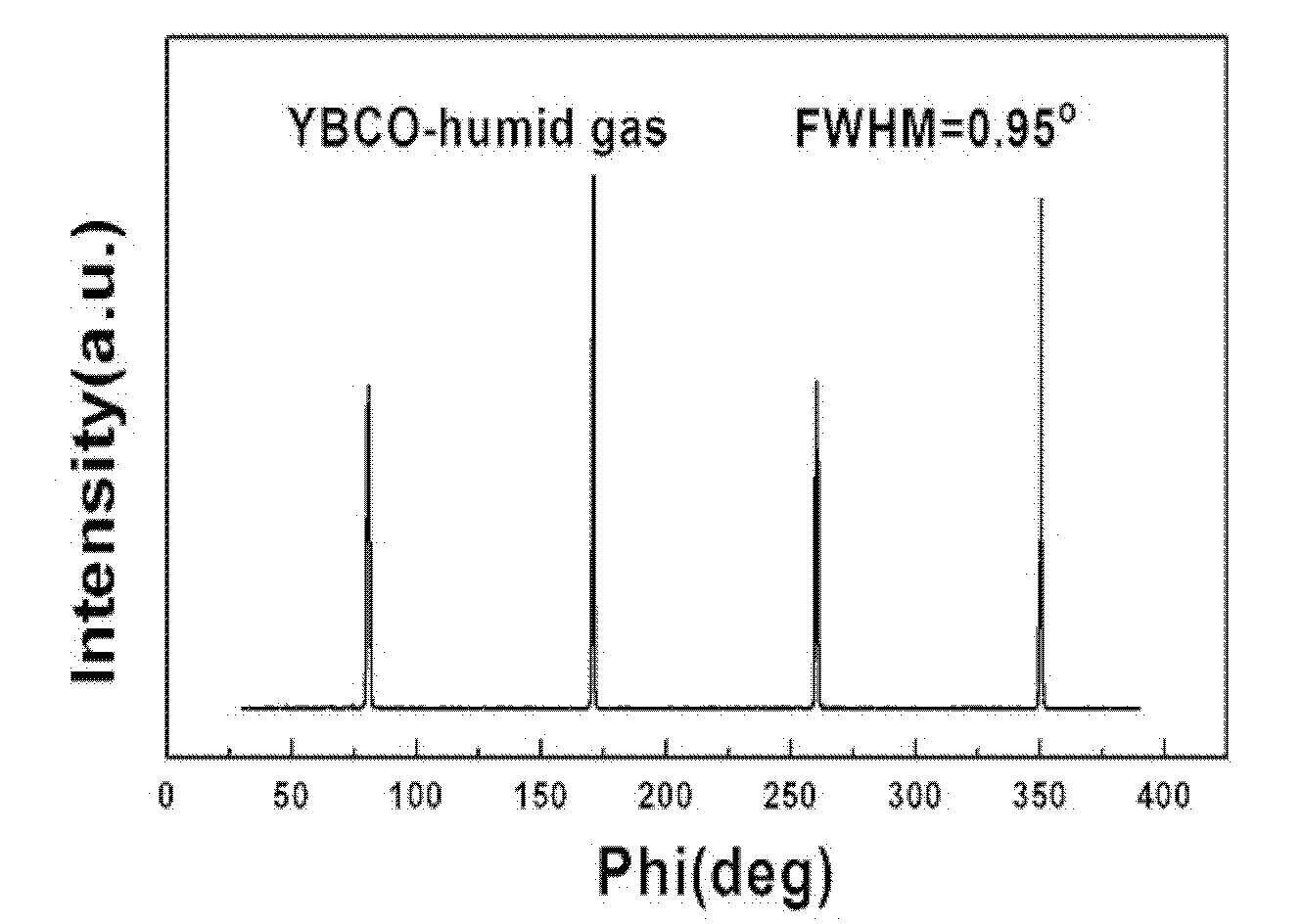

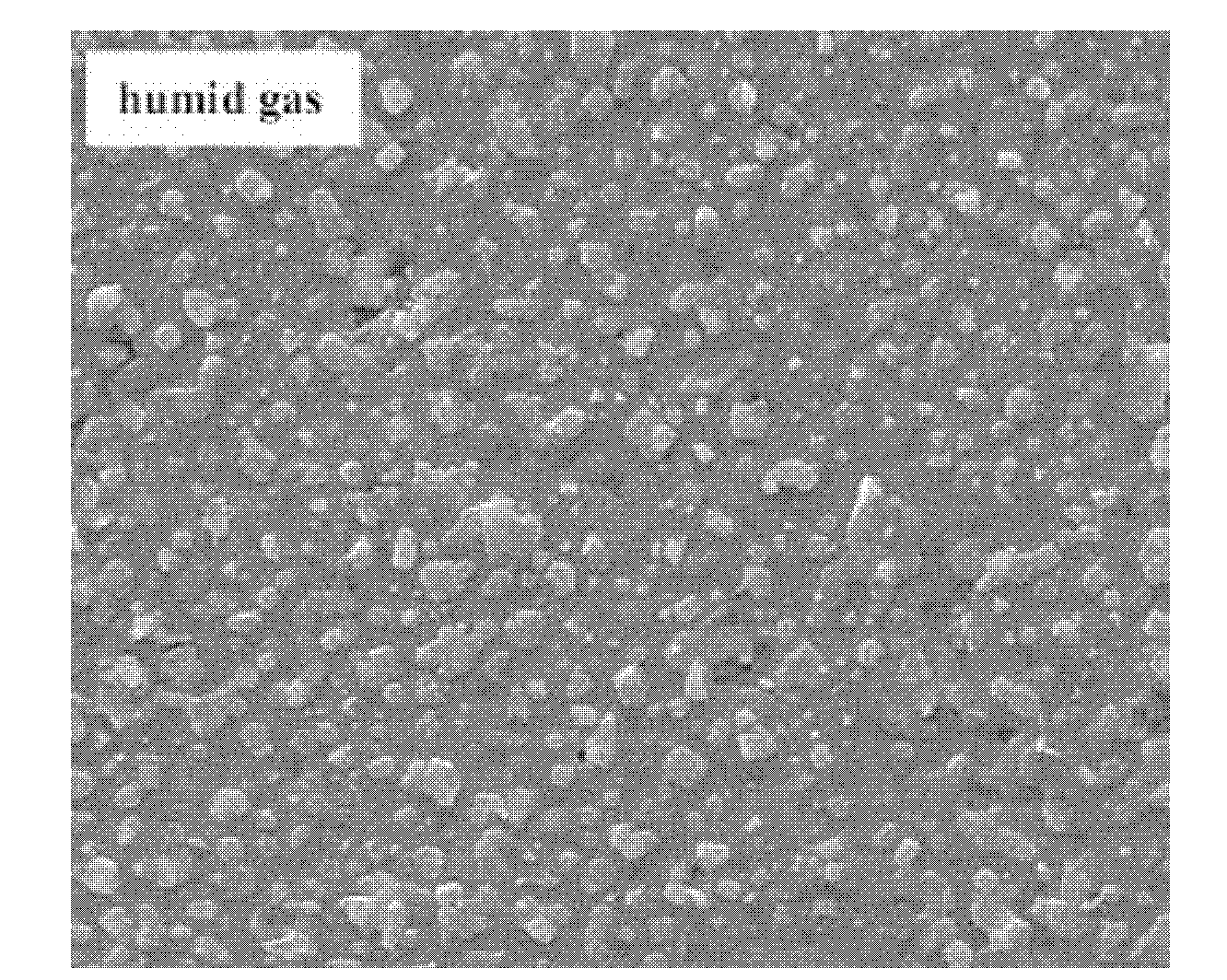

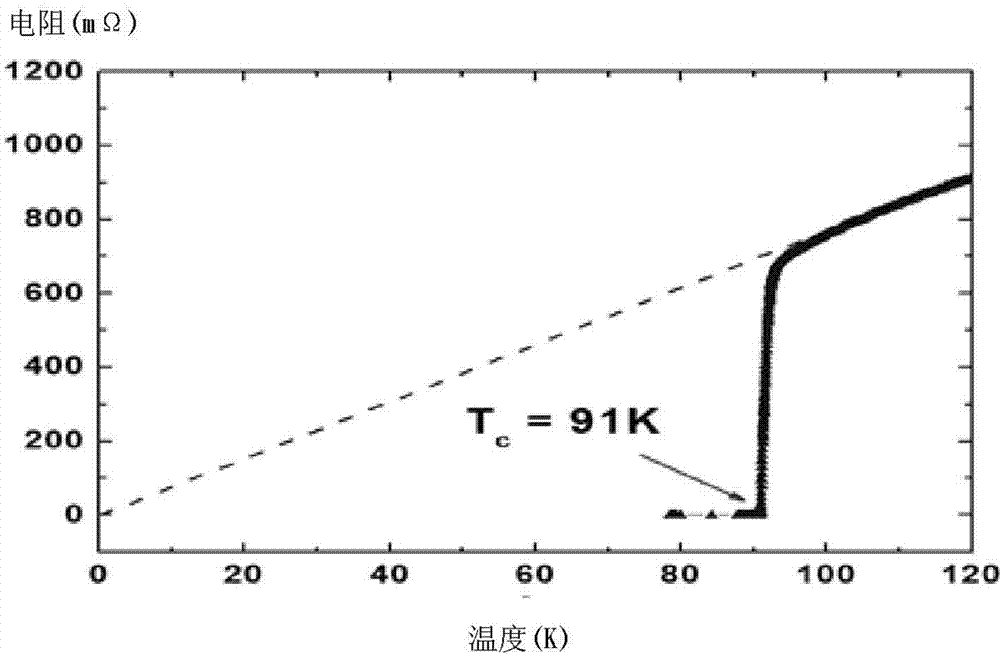

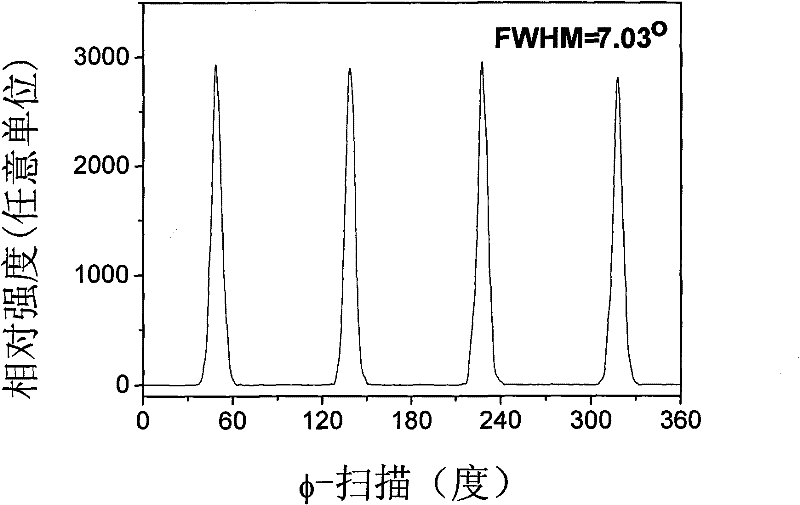

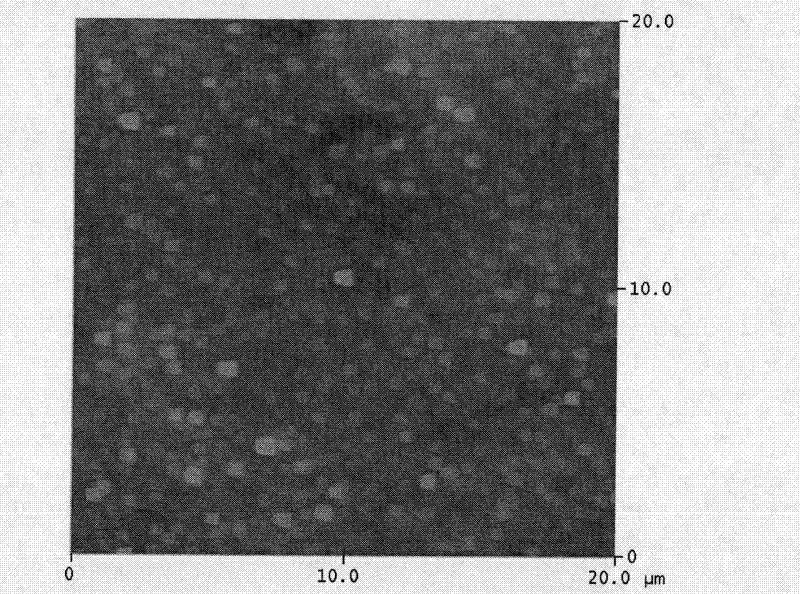

Method for preparing superconducting layer of high-temperature superconducting coated conductor by depositing fluorine-free chemical solution

InactiveCN101857429AReduced current carrying capacityStable stateSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorPhase formation

The invention discloses a method for preparing a superconducting layer of a high-temperature superconducting coated conductor by depositing fluorine-free chemical solution. The method comprises the following steps of: a, preparation of precursor solution; b, the preparation of coating colloid; c, coating and drying; d, wet-type decomposition heat treatment, namely placing a substrate with a film into a tubular finance; rising the temperature to be between 100 and 150 DEG C from room temperature at the speed of 1-5DEG C / min under the protection of an argon atmosphere; introducing a mixed gas of water vapor and argon with the dew point of between 10 to 20 DEG C into the furnace to form a wet argon protective atmosphere; rising the temperature to be between 450 and 500 DEG C at the speed of 0.25 to 1.5DEG C / min; keeping the temperature for 0.5 to 2 hours; cooling to the room temperature in the argon atmosphere; and e, phase formation and heat treatment to obtain the superconducting layer. The critical current density of the superconducting layer of the high-temperature superconducting coated conductor prepared by the method is up to the same magnitude order as the that of the superconducting layer prepared by a fluorine-containing method; the superconducting layer has a high-degree biaxially texture and a flat and dense surface; and the method is easy to prepare a thicker superconducting layer and has the characteristics of low cost, simple process and suitability of large-scale industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

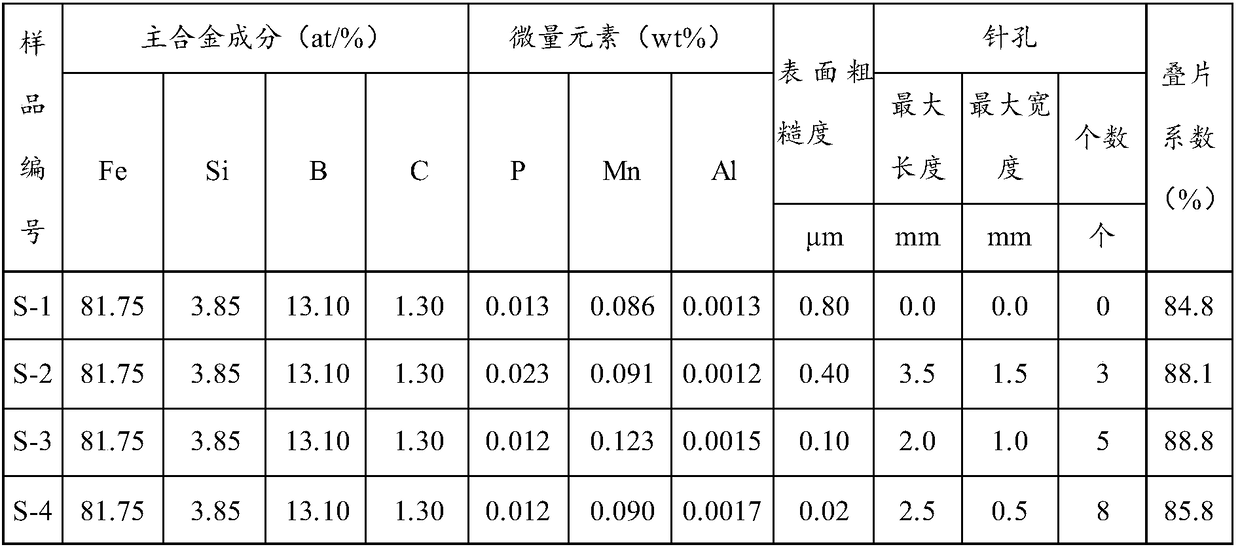

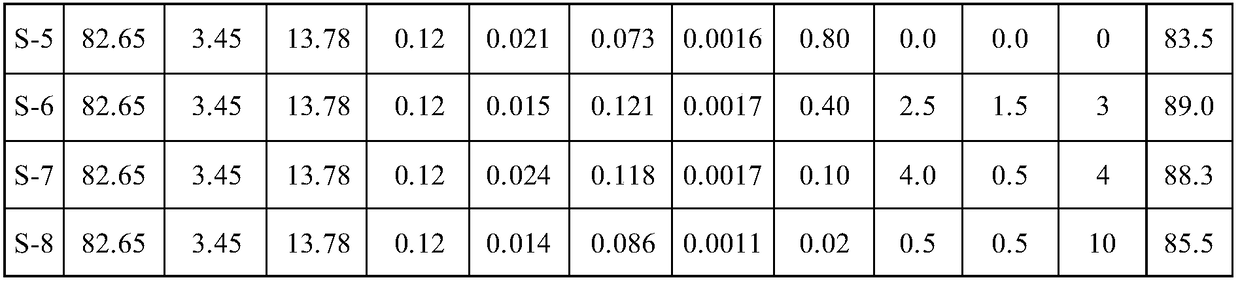

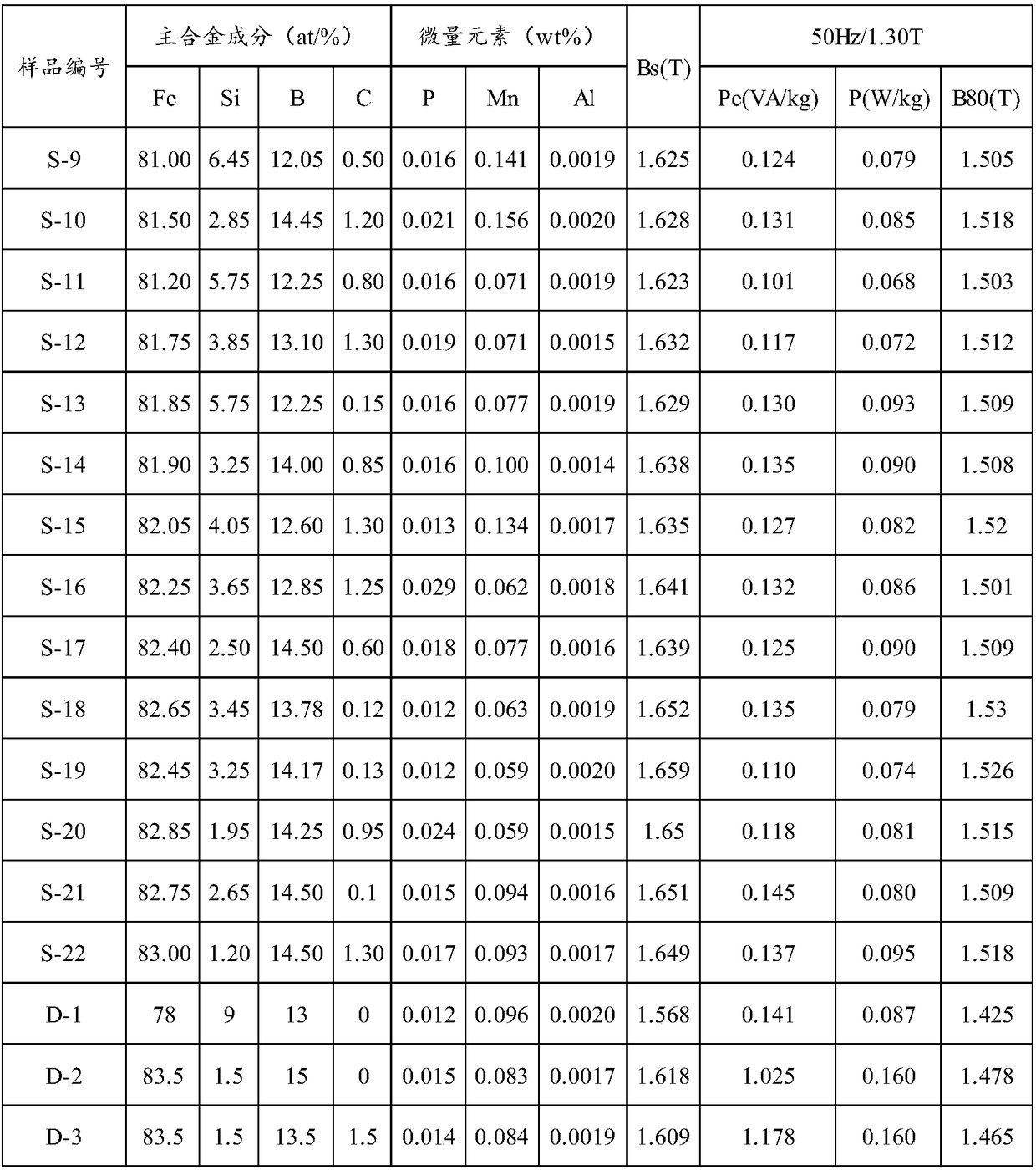

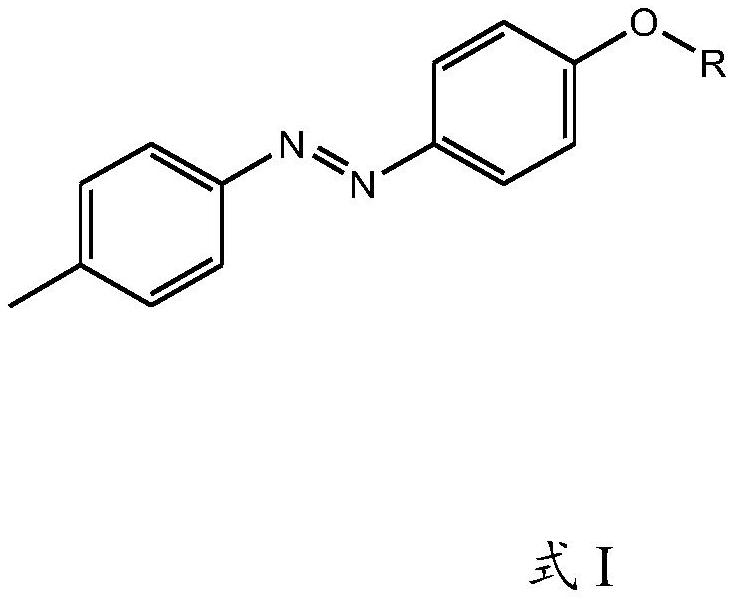

Iron-based amorphous alloy strip and preparation method thereof

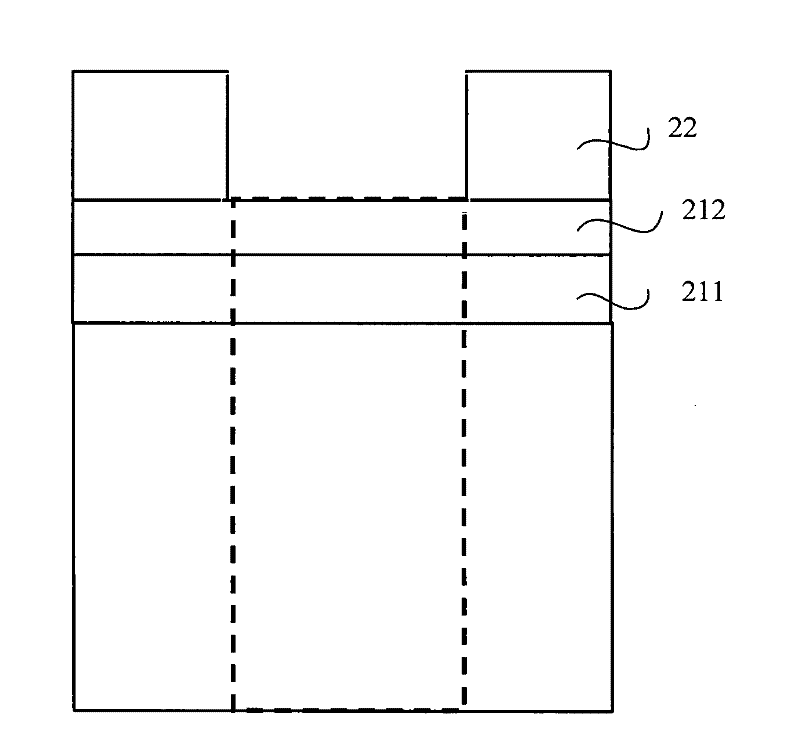

ActiveCN109504924AFlat and dense surfaceHigh saturation magnetic inductionFurnace typesMagnetic materialsAlloyMolten steel

The invention provides an iron-based amorphous alloy strip as shown in a formula (1). The pinhole length of the iron-based amorphous alloy strip is greater than 0 and is smaller than or equal to 4 mm,the pinhole width is greater than 0 and smaller than or equal to 2 mm, and the number of pinholes in a strip with the length being 2 m does not exceed 5. The invention further provides a preparationmethod of the iron-based amorphous alloy strip. The method comprises the following steps that A) after ingredients of a shown iron-based amorphous alloy are prepared, smelting and refining are performed so as to obtain molten steel; and B) the molten steel is subjected to single-roll rapid quenching, then heat treatment is performed, and the iron-based amorphous alloy strip is obtained. Accordingto the iron-based amorphous alloy strip and the preparation method thereof, the surface quality of the iron-based amorphous alloy strip is controlled by optimizing the alloy ingredients and the preparation technology, so that the iron-based amorphous alloy strip with the high saturation flux density, high lamination coefficient, low loss and high tenacity is obtained.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

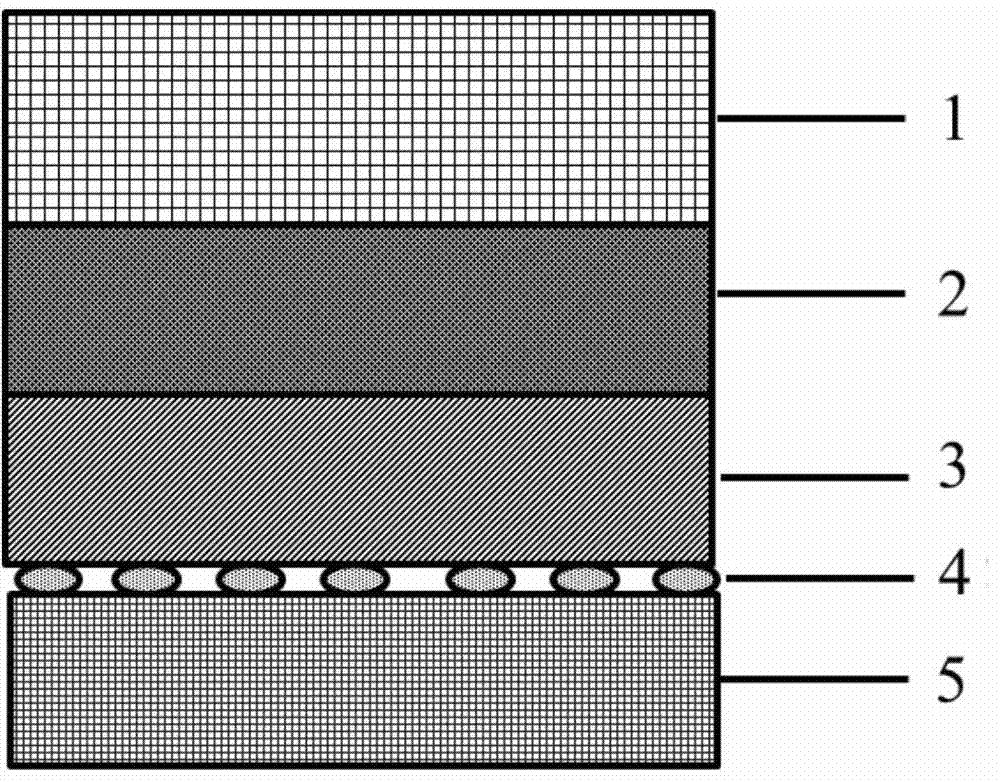

Composite superconducting material

InactiveCN105551680AFlat and dense surfaceImprove superconductivitySuperconductors/hyperconductorsSuperconductor devicesComposite filmMetal

The invention discloses a composite superconducting material, which comprises a superconducting base material and a superconducting film, wherein the superconducting film coats the surface of the superconducting base material; the thickness of the superconducting film is 0.2-1.0micron; the superconducting film is a YBCO composite film; the YBCO composite film comprises at least two YBCO superconducting layers; and a conductive metal oxide layer is arranged between two adjacent YBCO superconducting layers. The composite superconducting material disclosed by the invention is compact and smooth in surface and excellent in superconducting property.

Owner:常熟市东方特种金属材料厂

Method for enlarging metal interconnected lithography process window

InactiveCN102194734AHigh surfaceFlat and dense surfaceSemiconductor/solid-state device manufacturingMetal interconnectLithography process

The invention discloses a method for enlarging a metal interconnected lithography process window. The metal interconnection is realized through a dual-damascenes structure which comprises through holes and grooves. The grooves are formed from a hard mask by a lithography process. The hard mask comprises a low-temperature oxide layer and an organic bottom antireflection coating which is formed above the low-temperature oxide layer, wherein after the low-temperature oxide layer is formed by a deposition process, the surface of the low-temperature oxide layer is processed by using active gas plasmas so as to improve the adhesion between the low-temperature oxide layer and the organic bottom antireflection coating.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

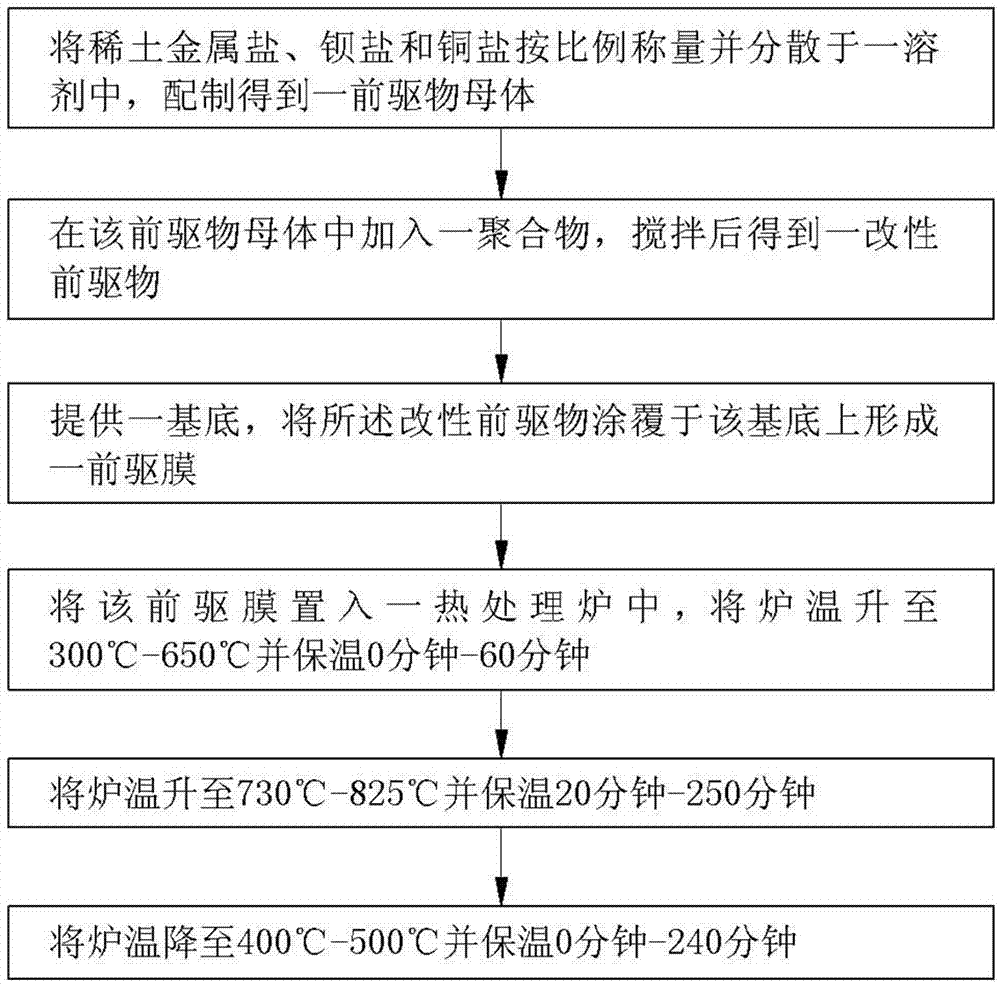

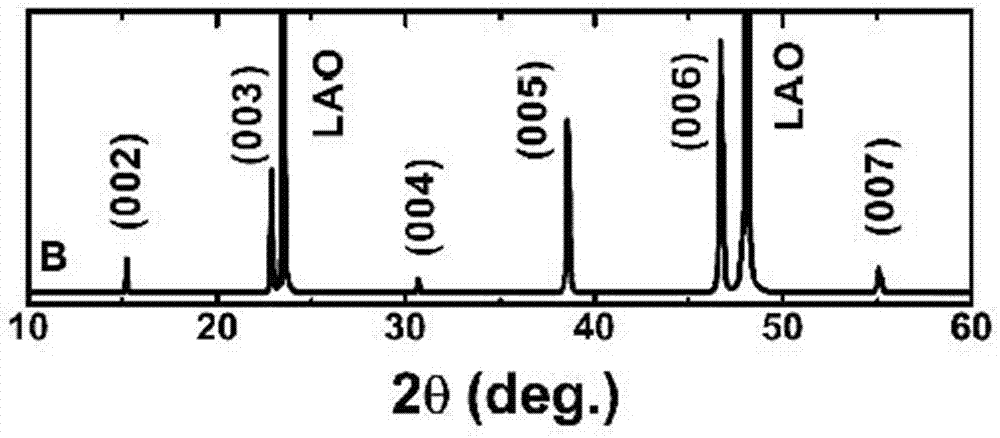

Preparation method of high temperature superconducting film

ActiveCN103086722AImprove diffusion abilityImprove mechanical propertiesFurnace temperatureHigh-temperature superconductivity

The invention relates to a preparation method of a high temperature superconducting film. The preparation method comprises the specific steps of weighting rear earth metal salt, barium salt and copper salt according to a proportion and dispersing in a solvent so as to prepare and obtain a precursor parent; adding a polymer to the precursor parent and stirring so as to obtain a modified precursor; providing a substrate and coating the modified precursor on the substrate so as to form a precursor film; placing the precursor film in a thermal treatment furnace, raising the furnace temperature to 300 DEG C-650 DEG C rapidly and holding the temperature for 0-60 minutes; raising the furnace temperature to 730 DEG C-825 DEG C and holding the temperature for 20-250 minutes; and lowering the furnace temperature to 400 DEG C-500 DEG C and holding the temperature for 0-240 minutes. According to the preparation method, not only can the high temperature superconducting film which has a compact and smooth surface and excellent superconductivity be prepared, but also the preparation rate of the high temperature superconducting film can be greatly improved.

Owner:TSINGHUA UNIV +1

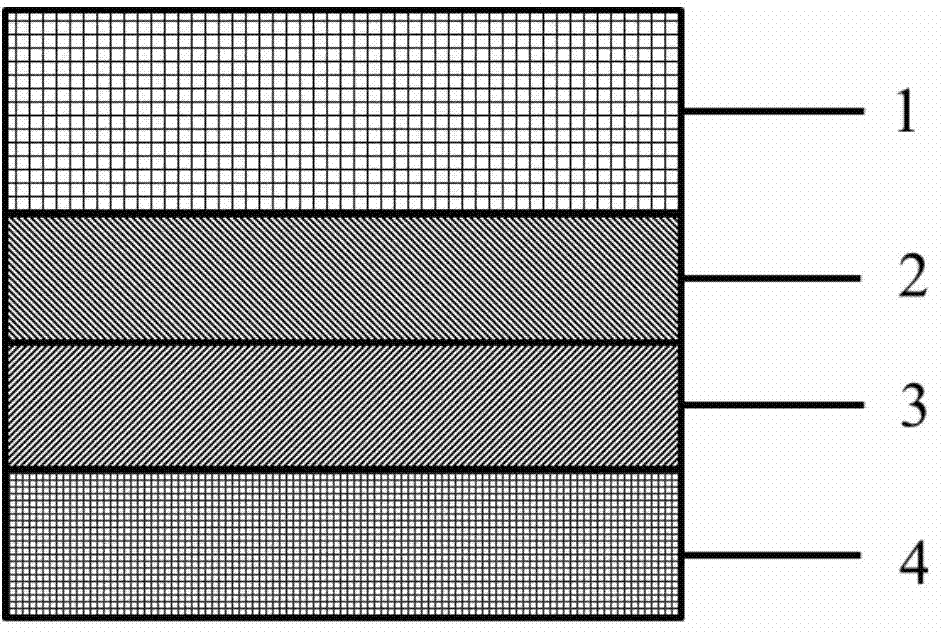

La2Zr2O7 transition-layer gradient film structure, preparation and application thereof

ActiveCN103922738ASimple structureRealize integrationLiquid surface applicatorsCoatingsHigh-temperature superconductivityLattice constant

A La2Zr2O7 transition-layer gradient film structure, preparation and application thereof belong to the technical field of a high-temperature superconductive coating material. According to the La2Zr2O7 transition-layer film provided by the invention, the lower layer is a La2Zr2-xTixO7 film doped with Ti<4+> having small ionic radius, wherein x is less than or equal to 1.8 and greater than or equal to 0.2; and the upper layer is a La2Zr2-yYyO7 film doped with Y<3+> having large ionic radius, wherein y is less than or equal to 1.8 and greater than or equal to 0.2. Through different doping contents, 100% matching between the film and a substrate Ni and a superconducting layer YBCO is realized, and the transition-layer structure of lattice constant gradient change is realized. In addition, the transition layer is the same bulk material and has more stable performance. Lattice constants of the La2Zr2-xTixO7 film and the La2Zr2-yYyO7 film are accurate and adjustable. Integration of multiple transition-layer functions is achieved, and complexity of a present transition-layer structure is minimized.

Owner:深创超导(深圳)科技有限公司

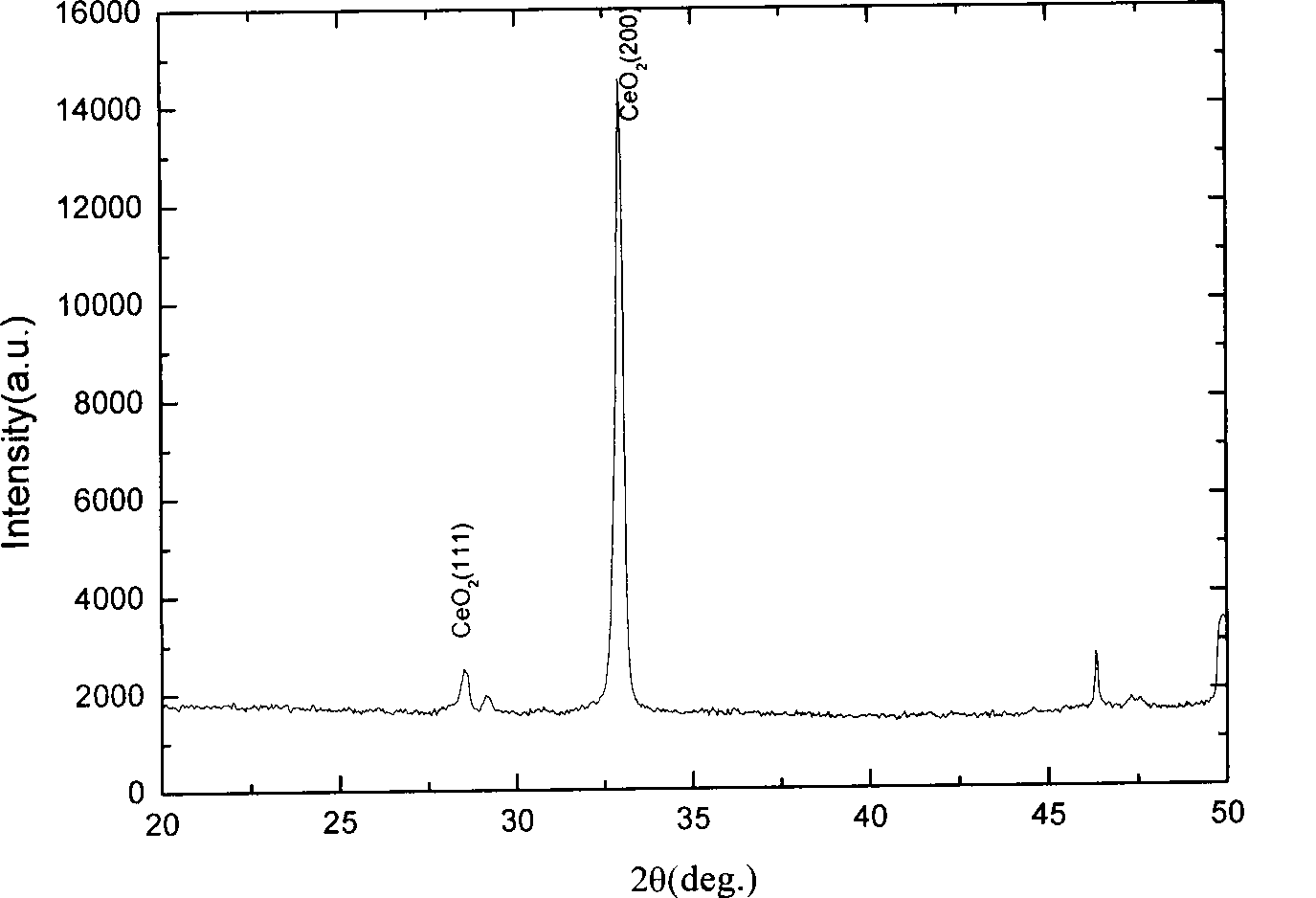

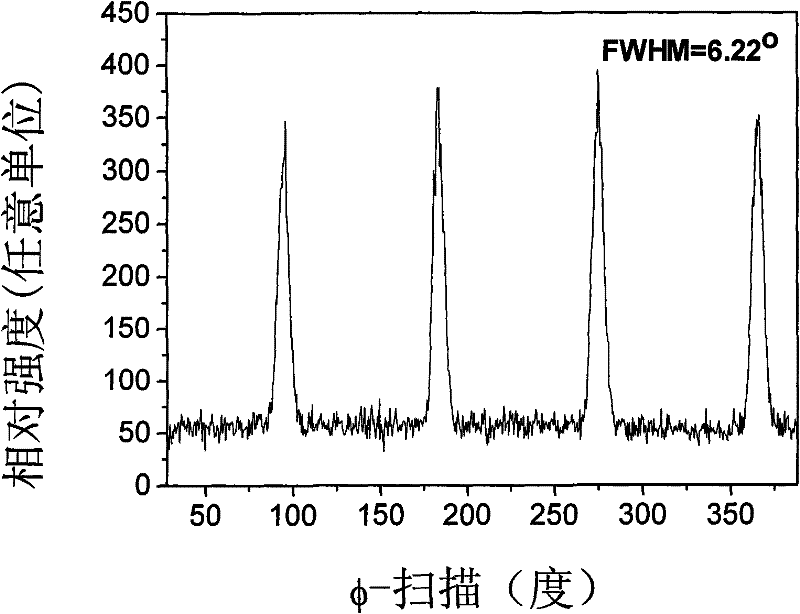

Method for continuously preparing two-sided texture high-temperature superconduction bibasic strip transition layer

InactiveCN101414497AGood orientationEnsure consistencySuperconductors/hyperconductorsSuperconductor devicesN dimethylformamideRare earth

The invention discloses a method for continuously preparing a second generation high-temperature superconducting tape transition layer with double-side texture. The method comprises the following steps: cerous nitrate or rare-earth nitrate is dissolved in N,N-dimethylformamide (DMF) to obtain precursor solution; polyacrylic acid (PPA) or polymethacrylic acid is added to the precursor solution to prepare colloid; Ni alloy base band is wound to pass through the prepared colloid, and after the base band is taken out, the colloid is evenly dipped and coated on the surface of the base band and then dried; and finally, the base band is placed in a sintering furnace for molding. The method helps realize the continuous preparation and the high preparation efficiency of the high-temperature superconducting transition layer, and is suitable for mass industrialized production; meanwhile, the prepared double-side tape transition layer film has the advantages of good consistency, good evenness, high degree of orientation and high surface smoothness; and the critical thickness of the transition layer is thick.

Owner:SOUTHWEST JIAOTONG UNIV

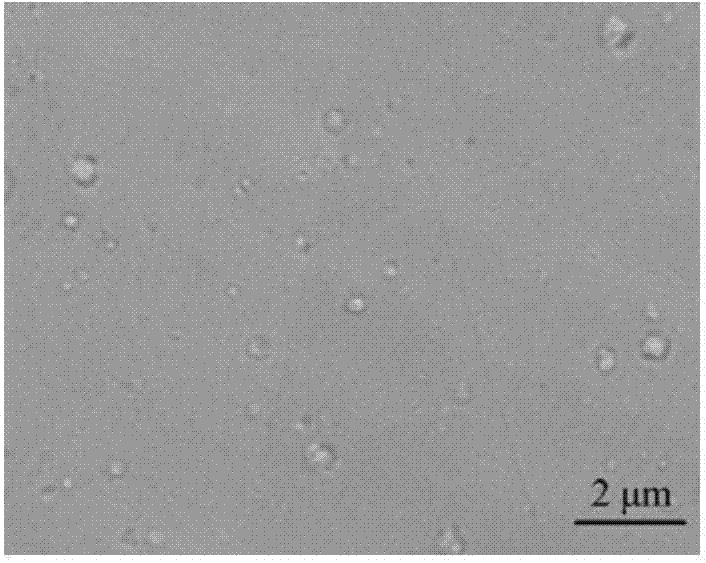

A kind of La-doped CeO2 transition layer thin film and preparation method thereof

InactiveCN101624286BPrecisely adjustable lattice constantThe role of isolation interactionsSuperconductor device manufacture/treatmentChemical solutionCerium

A La-doped CeO2 transition layer film and a preparation method thereof belong to the technical field of preparation of high-temperature superconducting materials. The La-doped CeO2 transition layer film provided by the present invention is composed of Ce1-xLaxO2 composite oxide solid solution, wherein, 0.1≤x≤0.3; the thickness of the transition layer film is 30-250nm. In the present invention, the organic cerium salt is used as the precursor salt, lanthanum acetylacetonate is used as the lanthanum source, and after the chemical solution method is used to prepare the precursor solution, the precursor solution is coated on the metal substrate by spin coating or dip coating, and then the heat treatment process is carried out. The La-doped CeO2 transition layer film was prepared. The invention has the advantages of low preparation cost, precise and adjustable lattice constant of the Ce1-xLaxO2 transition layer film, and can realize the integration of various transition layer functions, reduce the existing complex transition layer structure, and the like.

Owner:BEIJING UNIV OF TECH

Transition layer film with Gd mixed with CeO<2> and preparation method thereof

The present invention relates to a transition layer film with Gd mixed with CeO2 and a preparation method thereof, belonging to the technical field of high temperature superconduction material preparation. The transition layer film with Gd mixed with CeO2 provided by the invention consists of Ce1-xGdxO2 composite oxide sosoloid, wherein, x is more than or equal to 0.1 and less than or equal to 0.5; and the thickness of the transition layer film is 30-250nm. The invention takes cerium acetate as precursor and gadolinium acetate as gadolinium source, uses chemical solution method to prepare precursor solution, coats the precursor solution on metal base bands by a spin coating or dip coating method, and prepares the transition layer film with Gd mixed with CeO2 by thermal treatment process. The transition layer film with Gd mixed with CeO2 and the preparation method thereof provided by the present invention has the advantages of simple preparation process, low cost, large thickness but no crack of the film, level, even and compact surface of the texture through which the film is capable of extending the base of the film, the role in separating mutual reaction between the superconduction layer and the base material, etc.

Owner:BEIJING UNIV OF TECH

Matte type high-staining-resistance coating varnish and preparation method thereof

InactiveCN109897490AImprove surface strengthImprove flatnessAntifouling/underwater paintsPaints with biocidesAdhesiveDefoaming Agents

The invention relates to matte type high-staining-resistance coating varnish and a preparation method thereof. The matte type high-staining-resistance coating varnish comprises, by weight, 5-10 partsof butyl acrylate, 2-5 parts of styrene, 15-25 parts of methyl methacrylate, 2-5 parts of 2-ethylhexyl acrylate, 20-30 parts of emulsion, 10-30 parts of deionized water, 0.1-0.3 part of pH regulator,0.1-0.3 part of mildew preventive, 0.1-0.2 part of defoaming agent, 0.6-2 parts of coalescing agent, 0.8-1.5 parts of anti-freezing agent, 0.3-1 part of thickening agent, 8-12 parts of compound inorganic adhesive and 0.5-2.0 parts of nano staining-resisting agent. Compared with the prior art, the matte type high-staining-resistance coating varnish and the preparation method thereof have the advantages that the nano staining-resisting agent and the compound inorganic adhesive are added into traditional waterborne matte coating varnish using acrylate copolymer resin as the main component, and the staining resistance of the varnish is improved greatly by the synergistic effect of the nano staining-resisting agent and the compound inorganic adhesive.

Owner:浙江来往新材料有限公司

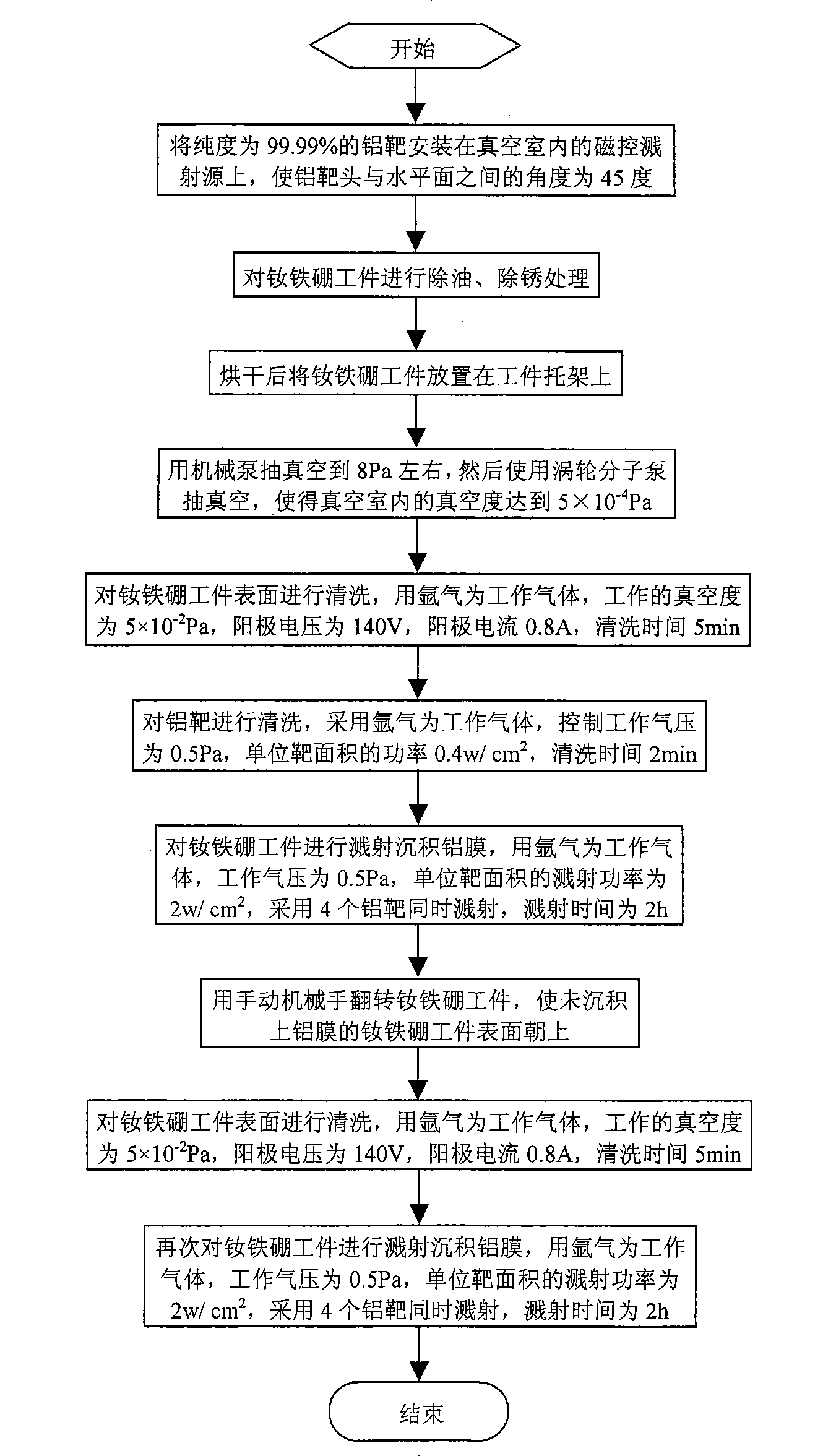

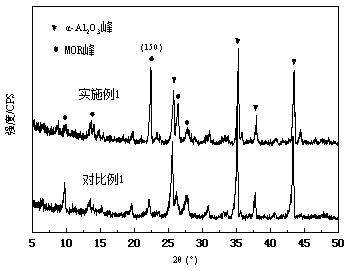

Method for magnetron sputtering deposition of aluminum film for surface protection of NdFeB workpiece

ActiveCN101724820BFlat and dense surfaceThickness is smooth and denseVacuum evaporation coatingSputtering coatingVacuum pumpingWorking pressure

The invention relates to a method for magnetron sputtering deposition of an aluminum film for surface protection of an NdFeB workpiece, which is characterized in that the method comprises the following steps: (1) mounting an aluminum target with the purity being more than 98% in a vacuum chamber, and leading the angle between the aluminum target and the horizontal line to be 45 degrees-90 degrees; (2) carrying out de-oiling and derusting treatment on the NdFeB workpiece; (3) placing the NdFeB workpiece on a bracket of the workpiece; (4) carrying out vacuum-pumping, and leading the vacuum degree in the vacuum chamber to be not more than 1 multiplied by 10-3Pa; (5) carrying out the magnetron sputtering deposition of the aluminum film on the NdFeB workpiece, adopting inert gas as working gas, keeping the working pressure at 0.1-10Pa, leading the sputtering power of unit target area to be 1-6w / cm2, adopting at least one aluminum target for carrying out the sputtering on the NdFeB workpiece and keeping the sputtering time to be 1-5h; (6) adopting a manual mechanical hand to overturn the NdFeB workpiece; and (7) carrying out the sputtering deposition on the NdFeB workpiece, adopting theinert gas as the working gas, keeping the working pressure at 0.1-10Pa, leading the sputtering power of the unit target area to be 1-6w / cm2, adopting at least one sputtering target for carrying out the sputtering on the NdFeB workpiece, and keeping the sputtering time to be 1-5h.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

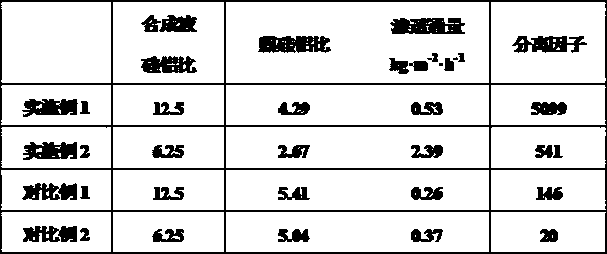

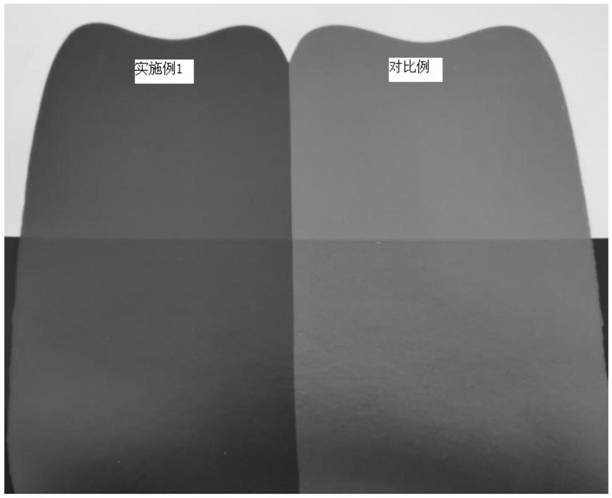

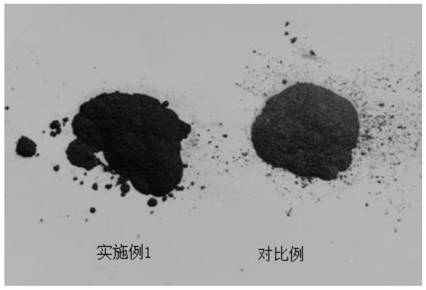

Simple preparation method for mordenite membrane with low silica-alumina ratio

ActiveCN110898685AAvoid enteringFlat and dense surfaceSemi-permeable membranesMordenite aluminosilicate zeoliteMordeniteAqueous ethanol

The invention provides a simple preparation method for a mordenite membrane with a low silica-alumina ratio. The invention mainly aims to solve the problems of poor membrane surface hydrophilicity andlow permeation flux due to high silica-alumina ratio of a zeolite membrane. The simple preparation method is mainly characterized by comprising the following steps: loading large and small seed crystals onto a macroporous alpha-Al2O3 carrier tube so as to prepare a seed crystal tube with flat surface, then pre-adsorbing deionized water onto a seed crystal layer and a ceramic tube supporting layeron the seed crystal tube through the action of capillary coacervation, and synthesizing the mordenite membrane through a secondary growth method. The method provided by the invention effectively reduces the silica-alumina ratio of the surface of the mordenite membrane, increases the compactness of the membrane, and reduces the thickness of the membrane at the same time. In an ethanol / aqueous solution with a concentration of 92 wt.%, the membrane shows excellent separation performance and is significantly improved in permeation flux; meanwhile, the mordenite membrane shows good acid resistancein an HCl or acetic acid solution with a concentration of 1 mol / L.

Owner:CHANGZHOU UNIV

Carbon-coated titanium pearlescent pigment and preparation method thereof

ActiveCN113105756AAvoid unordered aggregates from growing largeGuaranteed uniformityPigment treatment with macromolecular organic compoundsPigment physical treatmentMaterials sciencePolymerization

The invention relates to the technical field of pearlescent pigments, and in particular, relates to a carbon-coated titanium pearlescent pigment and a preparation method thereof. The preparation method of the carbon-coated titanium pearlescent pigment comprises the step that a polymer monomer is added into a reaction system of titanium oxychloride and carbonate, so that the polymer monomer is subjected to a polymerization reaction. A polymer monomer is added into the reaction system in which titanium oxychloride and carbonate react to form titanium dioxide, so that when titanium oxychloride and carbonate react, the polymer monomer also has a polymerization reaction to form a polymer, and then the polymer can coat the formed titanium dioxide, so that disordered aggregation and enlargement of particles are avoided, the uniformity of titanium dioxide particles formed by reactivity is ensured, then the finally formed pearlescent pigment is bright and uniform in color, and the surface is flat and compact.

Owner:FUJIAN KUNCAI MATERIAL TECH

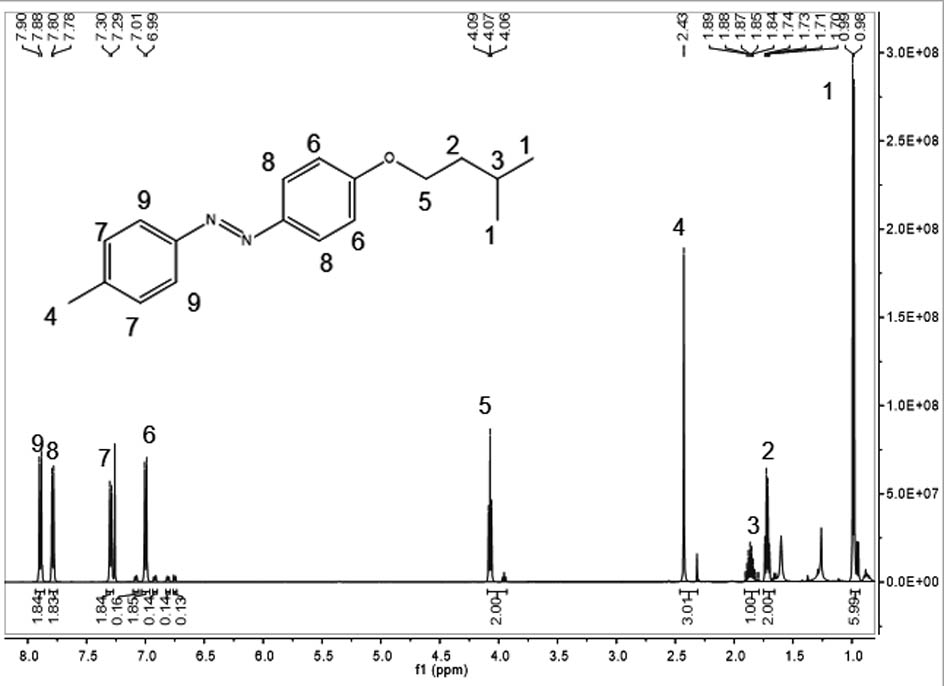

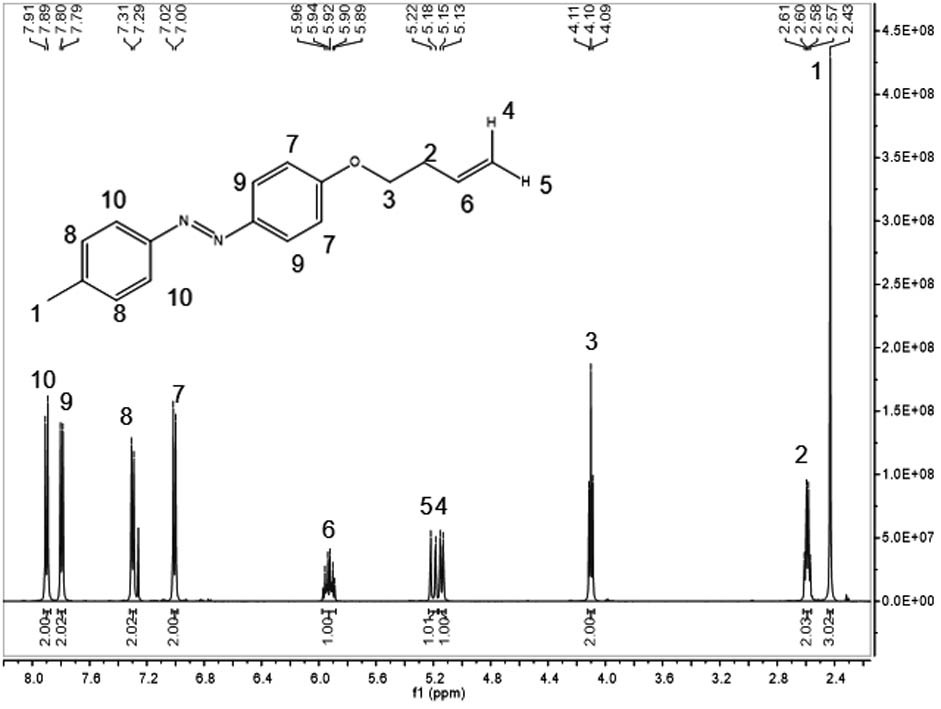

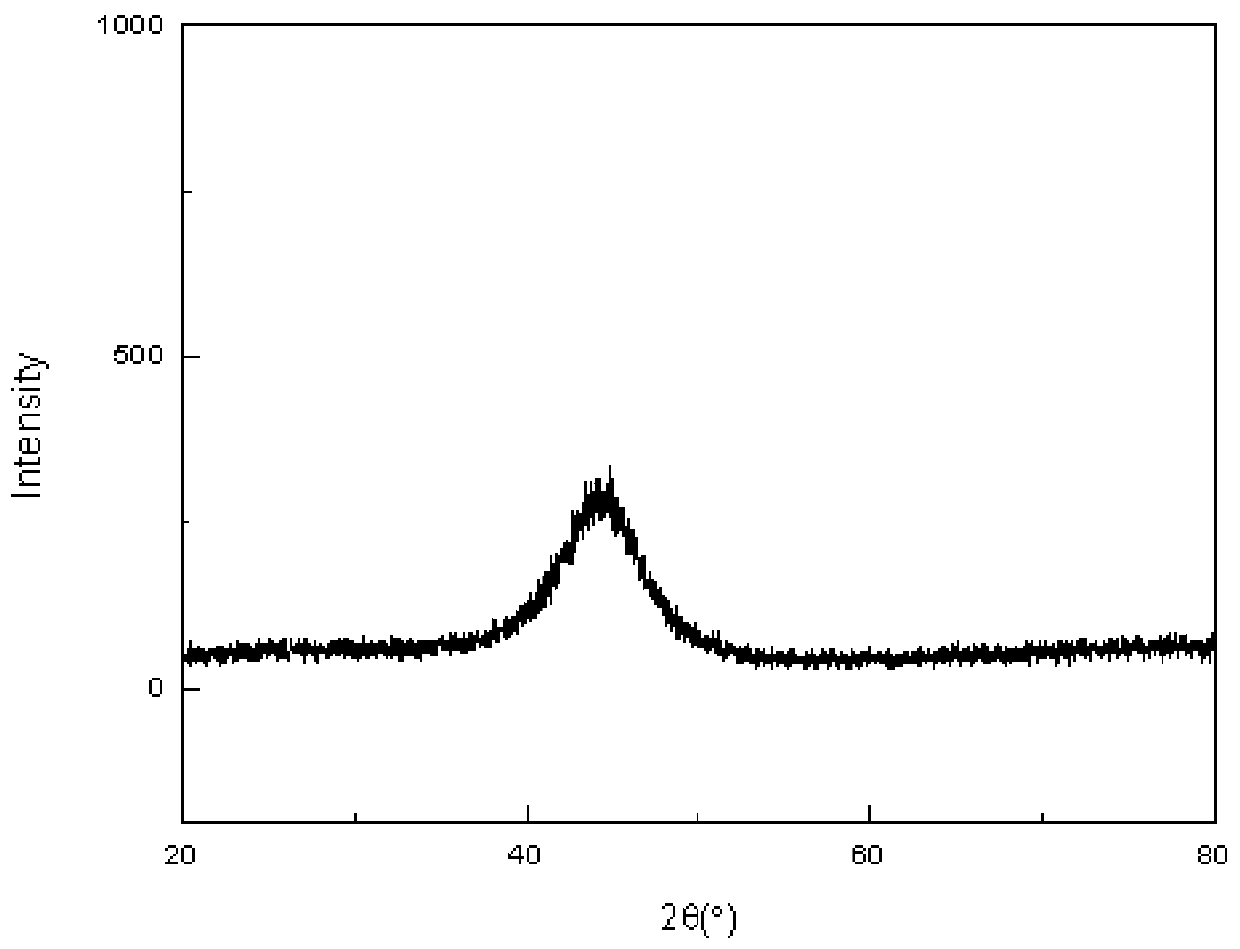

Azobenzene derivative, solar thermal energy fuel film composite material and preparation method and application thereof

ActiveCN112552206AHigh energy storage densityFlat surfaceSolar heating energyOrganic chemistryPhotoisomerizationStored energy

The invention relates to an azobenzene derivative, a solar thermal energy fuel film composite material and a preparation method and application thereof, discloses a series of azobenzene derivatives, and provides a method for preparing a photo-induced phase change ready-to-use solar thermal energy fuel film through the azobenzene derivatives. The prepared solar thermal energy fuel composite film has good mechanical flexibility, photoisomerization effect and energy storage capacity. The composite film can rapidly generate cis-trans isomerization to store energy under the irradiation of an ultraviolet lamp, the stored energy is gradually increased along with the prolonging of irradiation time, the full state can be achieved within about 2 hours, the energy density can reach 200 J / g or above,and the temperature of the composite film can be continuously increased by about 5 DEG C. The charging / discharging process has very good reversibility, and no obvious attenuation exists after the energy is circularly charged / discharged for more than 5 times. The composite material has the advantages of simple preparation process, environmental friendliness, easily available materials, large heat release amount, good mechanical flexibility, strong acid and alkali corrosion resistance, good recycling performance and the like.

Owner:QINGDAO UNIV OF SCI & TECH

A method of electrodepositing tungsten alloy

ActiveCN105350036BImprove electrodeposition efficiencyStrong hardnessElectrolysisConcentration ratio

The invention discloses a tungsten alloy electro-deposition method. According to the method, a boric acid solution is prepared, then sodium tungstate, cobalt sulfate and nickel sulfate are added to be stirred and dissolved, and a salt solution with the molecular concentration ratio of tungsten ions to cobalt ions to nickel ions being 3:1:1 is formed; then a compound complexing agent of citric acid and succinic acid is added, and the molecular concentration ratio of citric acid to succinic acid is 3:1; finally, a sodium dodecyl sulfate solution is added and fully stirred; and the final using amount of citric acid in an electrolyte is 58-116 g / L, the final using amount of a wetting agent of sodium dodecyl sulfate is 0.1 g / L, the final using amount of sodium tungstate is 30-99 g / L, and the final using amount of boric acid is 4-6 g / L. Tungsten alloy is electrically deposited in a constant-current manner, a negative electrode is formed by a stainless steel plate, and a positive electrode is formed by a dual-graphite plate; the negative electrode and the positive electrode are placed in an electrolysis tank in parallel, electrolysis time is 1-5 h, electrolysis temperature is 40-80 DEG C, the current intensity is 500-750 mA / dm<2>, and pH is 5-7. The electrolyte is stable, an amorphous tungsten alloy coating can be obtained, the surface is compact and flat, and the hardness of the coating is high.

Owner:BEIJING UNIV OF TECH

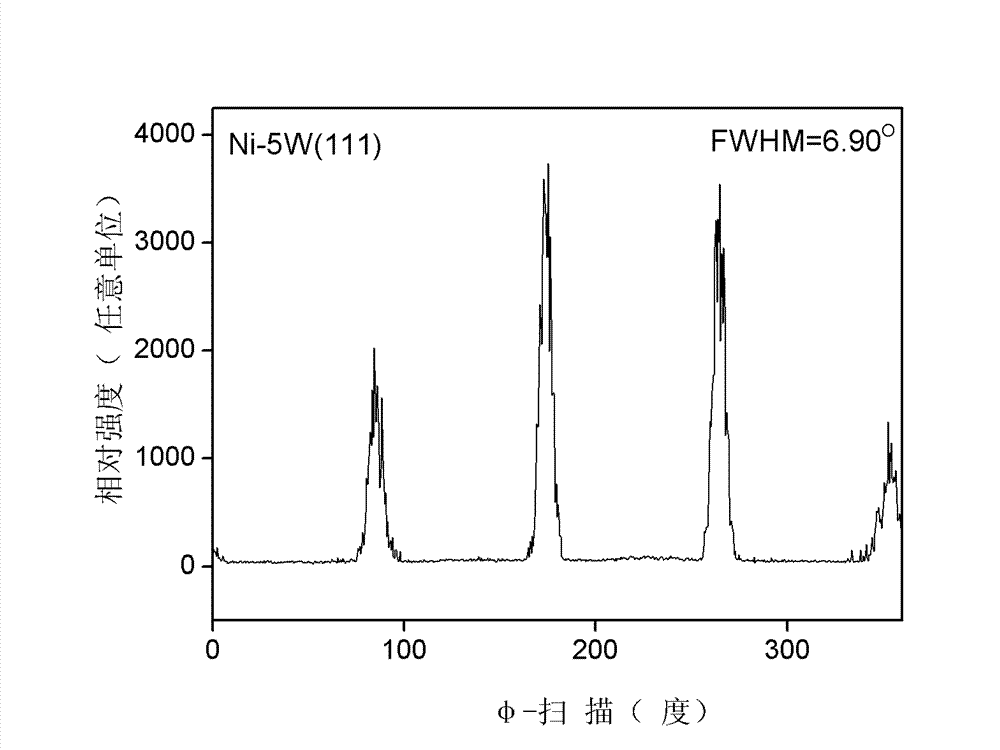

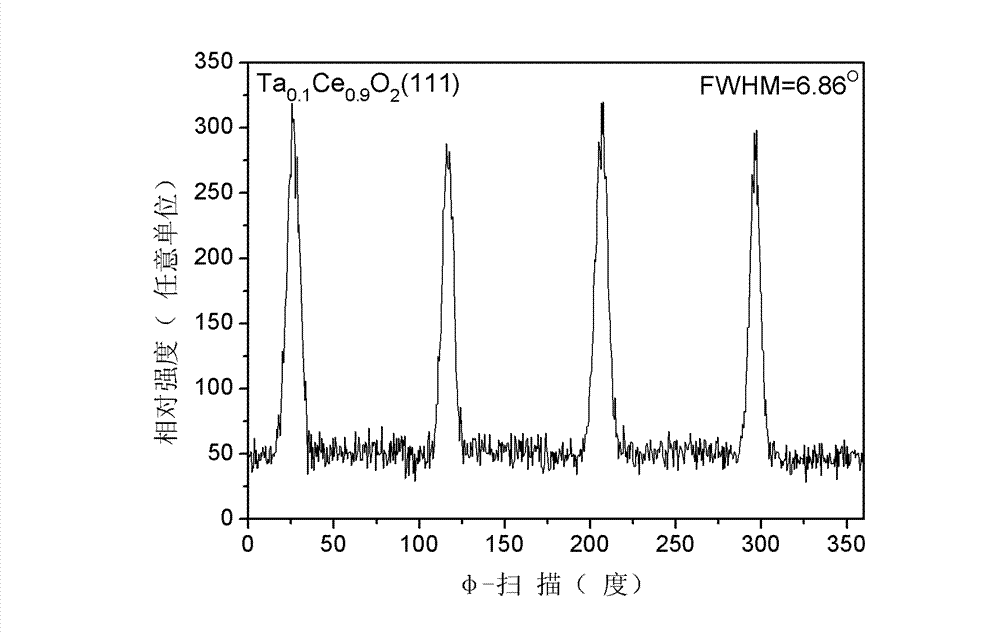

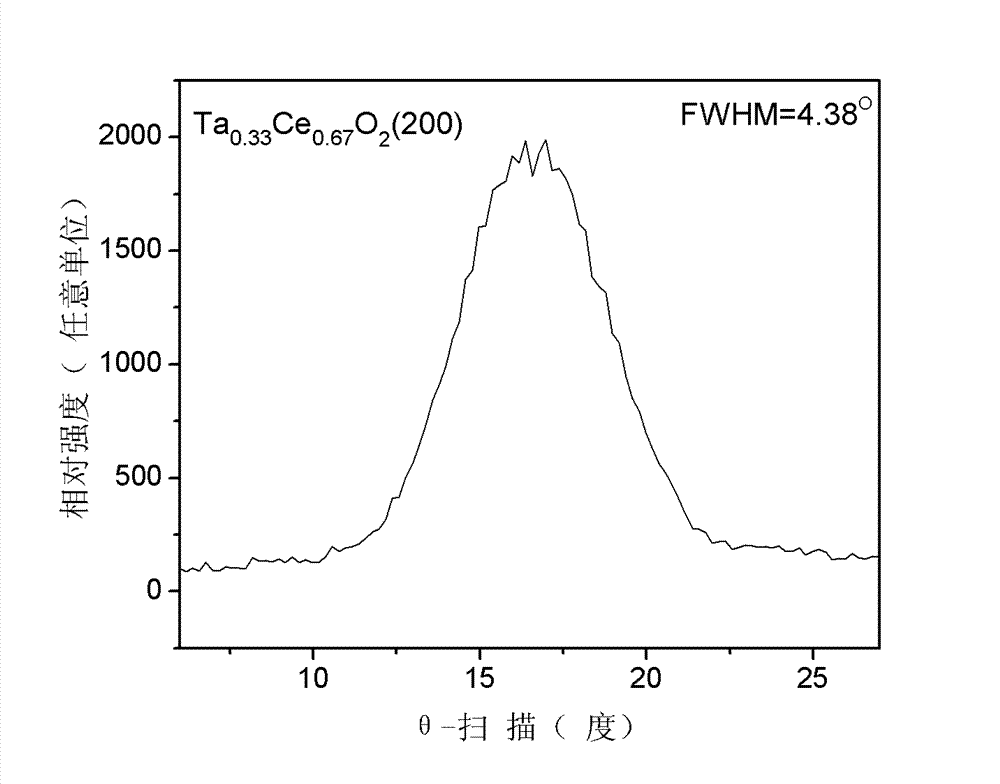

Ta doped CeO2 depletion layer film and preparation method thereof

The invention discloses a Ta doped CeO2 depletion layer film and a preparation method thereof, belonging to the technical field of high-temperature coating superconducting materials. In the TaxCe1-xO2 film provided by the invention, the thickness of the depletion layer film is about 30-240nm. The preparation method comprises the following steps: dissolving Ta salt and Ce salt in methanol and propionic acid to obtain a precursor solution, wherein a cation molar ratio of Ta salt to Ce salt is x:(1-x), and x is larger than or equal to 0.1 and less than or equal to 0.25; then depositing the precursor solution on a Ni-5W base plate with a spin method; carrying out high temperature sintering in a protective atmosphere to obtain the TaxCe1-xO2 film. According to the invention, the preparation process is simple, cost is low, and the prepared film has the advantages of large thickness, good structure and less cracks and can isolate a superconducting layer to prevent it from reacting with a base material while extending texture.

Owner:BEIJING UNIV OF TECH

A preparation method of a solar cell thin film

InactiveCN109088004AEvenly distributedLarge particle sizeSolid-state devicesSemiconductor/solid-state device manufacturingPotassium hydroxideZno nanoparticles

The invention discloses a preparation method of a solar cell thin film, belonging to the field of solar cell materials. Zinc acetate and potassium hydroxide are taken as raw material, the nano zinc oxide particles are introduced into the thin film, lead iodide is added, tin tetrachloride is doped, and the substrate is formed by annealing, thereby effectively suppressing recombination of electron-hole pairs at the interface between a perovskite layer and ZnO, and greatly improving the electron transport efficiency and the photoelectric conversion efficiency. On the basis of the formation of theperovskite structure solar cell thin film, the halogen atom loss of the thin film will produce Pb<2 +> and a recombination center is formed, so that the probability of carrier recombination is increased, the interface properties are improved, and the nano-scale phase separated aggregation structure is maintained; the charge transfer is accelerated and the conversion efficiency is improved in theprocess of photoelectric conversion. The invention solves the problems of low photoelectric conversion rate and poor stability of the conventional solar cell thin film.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com