Azobenzene derivative, solar thermal energy fuel film composite material and preparation method and application thereof

A technology of azobenzene derivatives and hydroxymethyl azobenzene is applied in the fields of processing and molding to prepare solar thermal fuel film composite materials, photothermal energy storage and solar energy utilization, and can solve the problems of inconvenient use, short energy storage life, and storage problems. For problems such as low energy capacity, it achieves the effects of fast response, good mechanical flexibility and rich sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 p-hydroxymethyl azobenzene

[0047] Mix p-methylaniline (10mmol, 1equiv) and high-concentration hydrochloric acid (37%, 2.5mL) in a 100mL round bottom flask, then add distilled water (10mL), put the round bottom flask into ice water and stir. Weigh NaNO 2 (690mg, 10mmol, 1equiv) was put into a 50mL beaker, and 1.5mL of distilled water was added to dissolve it, and then the solution was slowly poured into the above-mentioned round bottom flask and stirred for 4h. Then weigh phenol (940mg, 10mmol, 1equiv), Na 2 CO 3 (1.092mg, 10.3mmol, 1.03equiv) and sodium hydroxide (400mg, 10mmol, 1equiv) in a 50mL beaker, add 10mL of distilled water to dissolve, then add drop by drop in the round bottom flask, and stir at room temperature for 4 Hour. After adjusting the pH to 7 with hydrochloric acid, the precipitated product was filtered off, washed with water (3×20 mL), and dried under vacuum at room temperature for 24 hours. Then put the dried so...

Embodiment 2

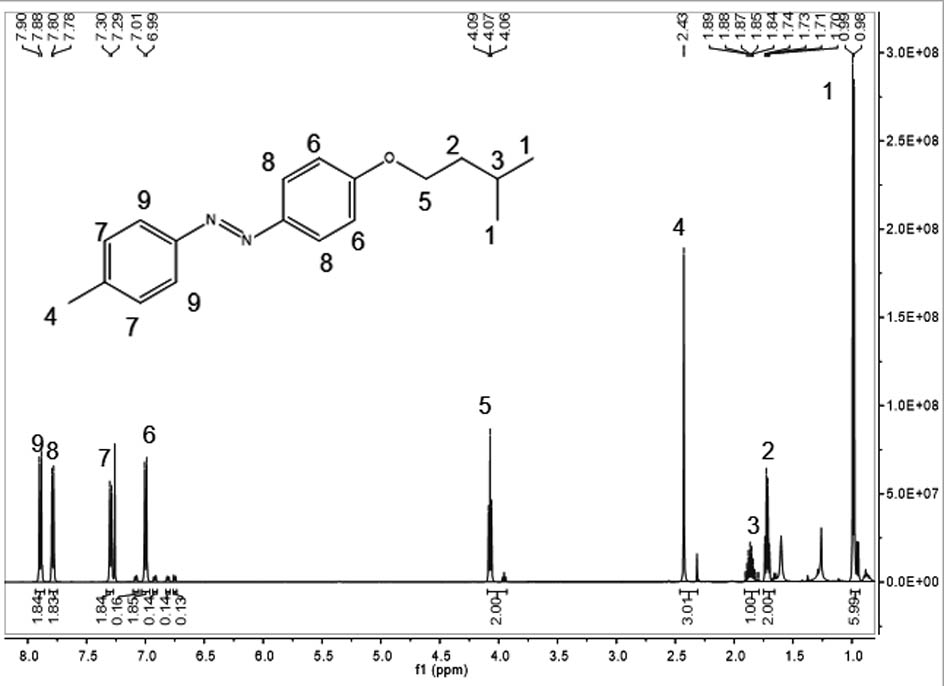

[0048] Example 2 1-(4-(isoamyloxy)phenyl)-2-(p-tolyl)diazene (C 18 h 22 N 2 O) Preparation

[0049]

[0050] Weigh p-hydroxymethylazobenzene (1060mg, 5mmol, 1equiv), 1-bromo-3-methylbutane (2266mg, 15mmol, 3equiv) and sodium hydroxide (400mg, 10mmol, 2equiv) in a 100mL round bottom flask , and then add 45mL of absolute ethanol and 5mL of distilled water to it, then put the round bottom flask into an oil bath and heat it to 70°C, circulate the condensed water, and stir for 24h. Then add an appropriate amount of silica gel and rotary steam to form a solid, put it into a chromatography column, use dichloromethane:petroleum ether=1:3 to pass through the product point, and rotary steam to obtain 1-(4-(isoamyloxy)phenyl) -2-(p-Tolyl)diazene, yield 71%, MS (m / z) 282.1. 1 H NMR (500MHz, CDCl 3 ,δ):7.91-7.87(d,2H,Ar-H),7.81-7.77(d,2H,Ar-H),7.32-7.28(d,2H,Ar-H),7.02-6.98(d,2H ,Ar-H),4.09-4.05(t,2H,O-CH 2 ),2.44-2.41(s,3H,-CH 3 ),1.91-1.79(m,1H,-CH),1.75-1.69(q,2H,-CH 2 ),1.0...

Embodiment 3

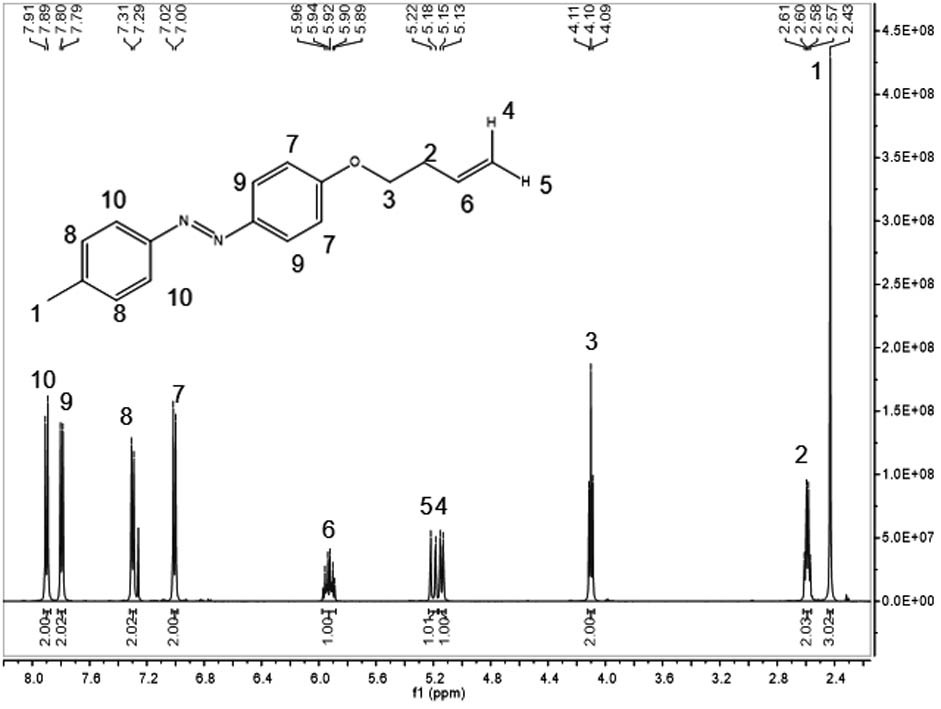

[0051] Example 3 1-(4-(2-methylbutoxy)phenyl)-2-(p-tolyl)diazene (C 18 h 22 N 2 O) Preparation

[0052]

[0053] Weigh p-hydroxymethylazobenzene (1060mg, 5mmol, 1equiv), 1-bromo-2-methylbutane (2266mg, 15mmol, 3equiv) and sodium hydroxide (400mg, 10mmol, 2equiv) in a 100mL round bottom flask Add 45mL of absolute ethanol and 5mL of distilled water to it, then put the round bottom flask into an oil bath and heat it to 70°C, circulate the condensed water, and stir for 24h. Then add an appropriate amount of silica gel and rotary steam to form a solid, put it into a chromatography column, pass through the product point, and rotary steam to obtain 1-(4-(2-methylbutoxy)phenyl)-2-(p-tolyl) Diazene, yield 63%, MS (m / z) 282.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com