Polymer matrix composite and preparation method thereof

A composite material and polymer technology, which is applied in the field of polymer-based composite materials with high energy storage density and high discharge efficiency and its preparation, can solve the problem of low energy storage density of composite materials, resistance to breakdown field strength of sacrificial composite materials, low Energy storage density and other issues, to achieve the effects of low cost, improved energy storage performance, and increased energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

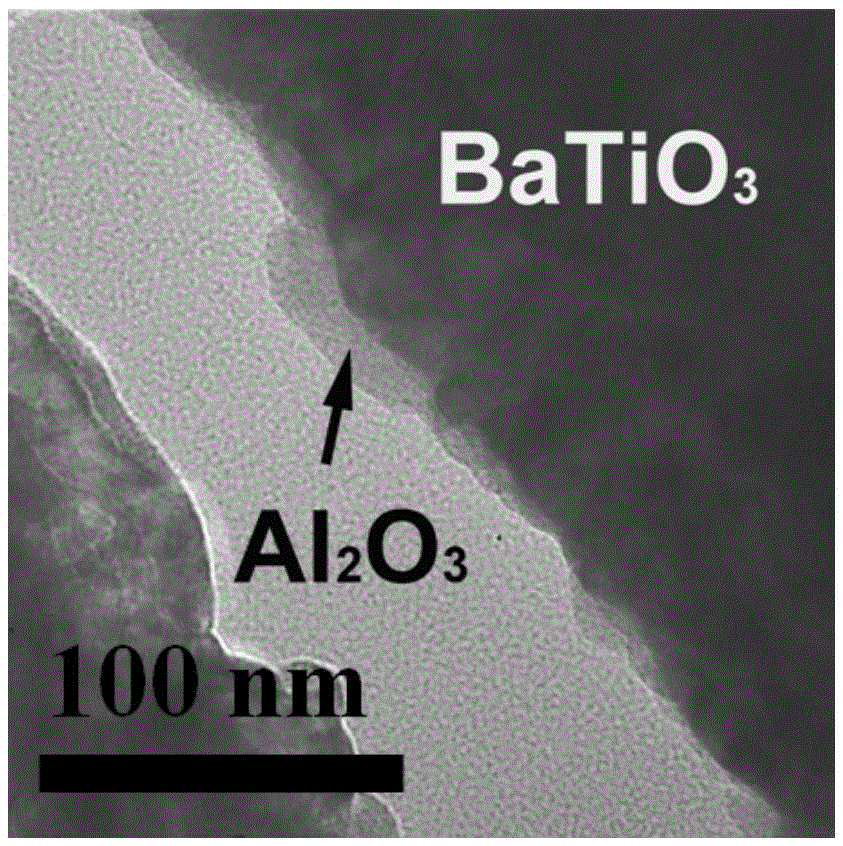

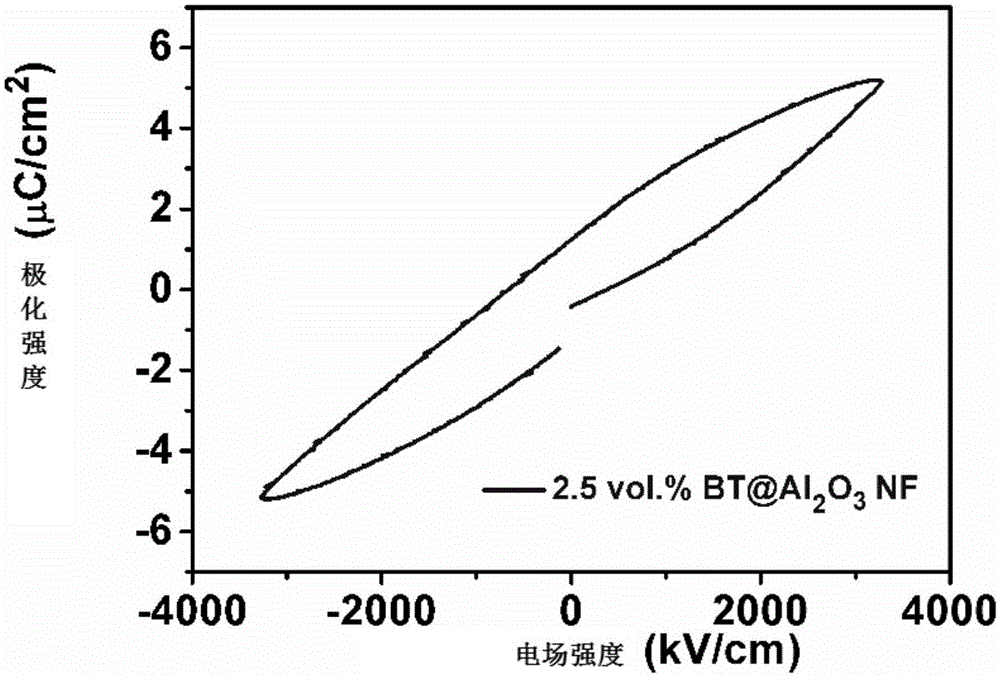

[0034] Preparation of BaTiO by Electrospinning 3 nano ceramic fiber, 1.5gBaTiO 3 The nano-ceramic fibers were placed in a mixed solution of aluminum nitrate, PVP and ethanol, the mass ratio of aluminum nitrate, PVP and ethanol was 1:0.02:5, stirred in a water bath at 40°C for 2 hours, the stirring speed was 400r / min, after centrifugation, ethanol Wash, dry, and sinter at 600°C for 2 hours to obtain a nanofiber material with a core-shell structure. The core is barium titanate nano-ceramic fiber, and the shell layer is an alumina coating layer; 3-aminopropyltriethoxysilane (APS) coupling agent, stirred at 100°C for 5 hours, washed with deionized water and absolute ethanol three times, and dried at 80°C for 12 hours, APS surface-modified nanofibrous materials were obtained, and then the modified BaTiO 3 al 2 o 3 Fibers are added to the PVDF / DMF mixture (BaTiO 3 al 2 o 3 The volume ratio of PVDF and PVDF is 2.5:97.5), stirred for 8 hours until evenly mixed, poured the mixtu...

Embodiment 2

[0038] The method is the same as above, except that the BaTiO 3 al 2 o 3 The volume ratio of nanofibrous material to PVDF / DMF is 5:95, and the polymer-based composite film can be prepared.

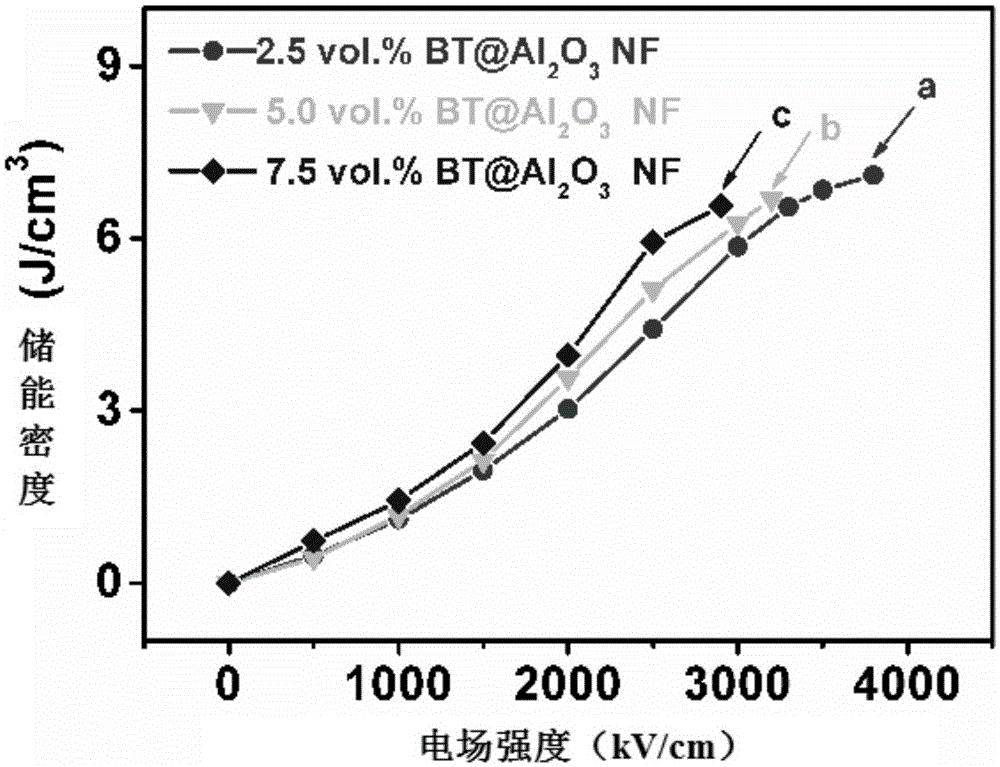

[0039] The energy storage density of the composite film is as image 3 As shown, it is 6.6J / cm 3 .

Embodiment 3

[0041] The method is the same as above, except that the BaTiO 3 al 2 o 3 The volume ratio of nanofibrous material to PVDF / DMF is 7.5:92.5, and the polymer-based composite film can be prepared.

[0042] The energy storage density of the composite film is as image 3 As shown, it is 6.4J / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com