Aramid paper compounded with aramid nanometer fiber thin film and preparation method thereof

A nanofiber, para-aramid fiber technology, applied in special paper, synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, etc. Problems such as problems occur to achieve the effects of improving mechanical properties and insulation properties, large aspect ratio and specific surface area, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

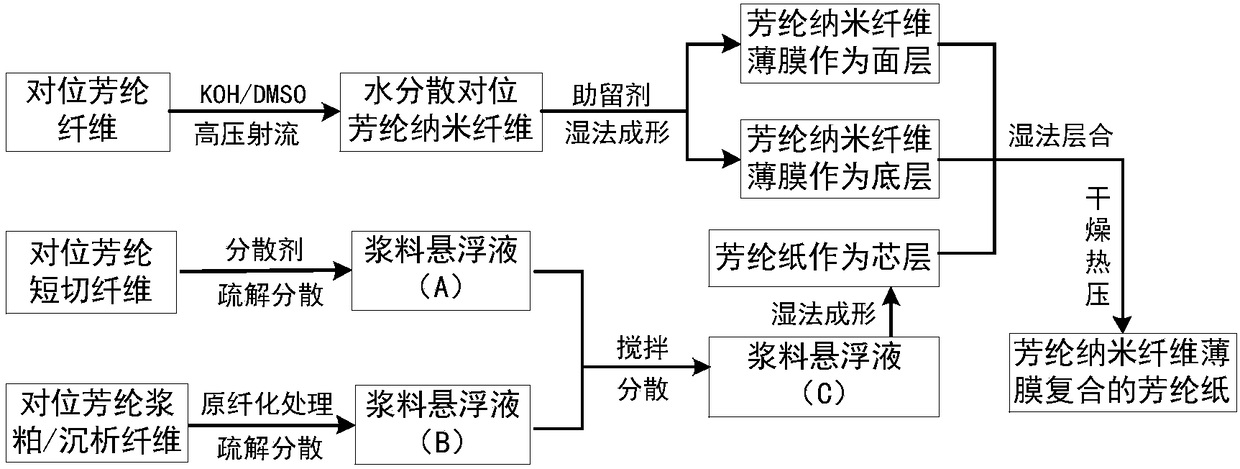

[0048] A preparation method of the above-mentioned aramid nanofiber film composite aramid paper, comprising the following steps:

[0049] Step 1: Disperse and disperse para-aramid chopped fibers for 10,000 to 30,000 r, add polyethylene oxide with a molecular weight of 5 million as a dispersant, and use an amount of 0.1 to 0.5 of the absolute dry mass of para-aramid chopped fibers %, made slurry suspension A;

[0050] Step 2: fibrillating para-aramid pulp fibers or para-aramid fibrid fibers until the degree of beating reaches 45-60°SR, and then dissolving and dispersing for 10000-20000r to obtain slurry suspension B;

[0051] Step 3: Stir and mix the slurry suspension A and slurry suspension B obtained in step 1 and step 2 at a speed of 500-1500 rpm for 5-30 minutes to obtain slurry suspension C;

[0052] Step 4: Add a dispersant to the water-dispersed aramid nanofiber, wherein the dispersant is a cationic polyacrylamide, and the dosage of the cationic polyacrylamide is 0.01 t...

Embodiment 1

[0057] An aramid paper composited with aramid nanofiber film, wherein the aramid paper composited with aramid nanofiber film is composed of a surface layer, a core layer and a bottom layer through wet papermaking lamination, without any adhesive bonding; The above-mentioned surface layer, core layer and bottom layer, in terms of dry fiber weight parts, the ratio between them is 5:90:5; the surface layer and bottom layer are all made of water-dispersed aramid fiber nanofibers. Aramid nanofilm, the core layer is aramid paper prepared from para-aramid chopped fibers and para-aramid pulp fibers, and the quality of para-aramid chopped fibers and para-aramid pulp fibers The ratio is 3:7.

[0058] Wherein, water-dispersed aramid fiber nanofiber is made by following preparation steps:

[0059] Step (1): 1.0g para-aramid yarn fiber, 1.5g potassium hydroxide (KOH) and 500ml dimethyl sulfoxide (DMSO) are placed in a container, and stirred at a temperature of 30°C under sealed conditions...

Embodiment 2

[0072] An aramid paper composited with aramid nanofiber film, wherein the aramid paper composited with aramid nanofiber film is composed of a surface layer, a core layer and a bottom layer through wet papermaking lamination, without any adhesive bonding; The surface layer, the core layer and the bottom layer, in terms of dry fiber weight parts, the ratio between them is 8:84:8; the surface layer and the bottom layer are all made of aramid nanofibers. film, the core layer is an aramid paper prepared from para-aramid chopped fibers and para-aramid fibrids, and the mass ratio of para-aramid chopped fibers and para-aramid fibrids is 3.5:6.5.

[0073] Wherein, water-dispersed aramid fiber nanofiber is made by following preparation steps:

[0074] Step (1): 1.0g of para-aramid chopped fiber, 1.5g of potassium hydroxide (KOH) and 500ml of dimethyl sulfoxide (DMSO) are placed in a container, and stirred at a temperature of 40°C under sealed conditions After 7 days, the aramid nanofi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com