Patents

Literature

696results about "Dispersing agents addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite conductive paper of carbon fiber

InactiveCN101003956AHigh porosityImprove conductivityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The present invention discloses a composite conductive carbon fiber paper. Its preparation process includes the following steps: using acrylonitrile carbon fiber and other carbon material as raw material, adopting polyphenylamine, conventional polyvinyl alcohol and water-soluble phenolic resin and mixing them, and using their mixture as adhesive, the polyphenylamine is conductive high-molecular polymer; mixing sodium alginate and conventional dispersing agent; adopting wet-process paper-making technique to make paper; vacuum drying the obtained carbon paper, then using Teflon emulsion whose concentration is 5%-20% to make treatment; finally, introducing nitrogen gas and making carbonization, carbonization temperature is higher than 1000 deg.C, so as to obtain the invented composite conductive carbon fiber paper. Said composite conductive carbon fiber paper mainly is used in fuel cell field.

Owner:DONGHUA UNIV

Carbon nanotube/short-fiber composited nano-carbon paper and continuous preparation method thereof

InactiveCN102877367AGuaranteed FeaturesOvercoming the lack of brittlenessSpecial paperPaper/cardboardNanostructured carbonNonwoven fabric

The invention provides a kind of carbon nanotube / short-fiber composited nano-carbon paper and a continuous preparation method thereof. The nano-carbon paper mainly comprises disordered carbon nanotubes and short fibers, and is in a non-woven form. The preparation method of the nano-carbon paper comprises the following steps that: the disordered carbon nanotubes are dispersed in a solvent so as to form a dispersion liquid; then, mixing and dispersing the short fibers so as to form a size; preparing an initial film through vacuum assisted flow-casting film-forming; and then, removing polymers in the initial film through subsequent processing so as to obtain a target product. The composited nano-carbon paper disclosed by the invention integrates the huge specific surface areas, superior conductivity and functional characteristics of the carbon nanotubes and the enhancement effect of the short fibers on the strength and flexibility of the carbon paper, therefore, the composited nano-carbon paper is good in self-supporting property and flexibility; meanwhile, through the direct film-forming implemented by using a flow-casting method, the continuous film-forming of the nano-carbon paper is realized, therefore, the nano-carbon paper has the advantages of high efficiency, rapidness and easy large-scale preparation. The composited nano-carbon paper disclosed by the invention has a wide application prospect in the fields of energy electrodes, catalytic carriers, environmental management, static resistance, electromagnetic shielding, wave-absorbing camouflage, and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

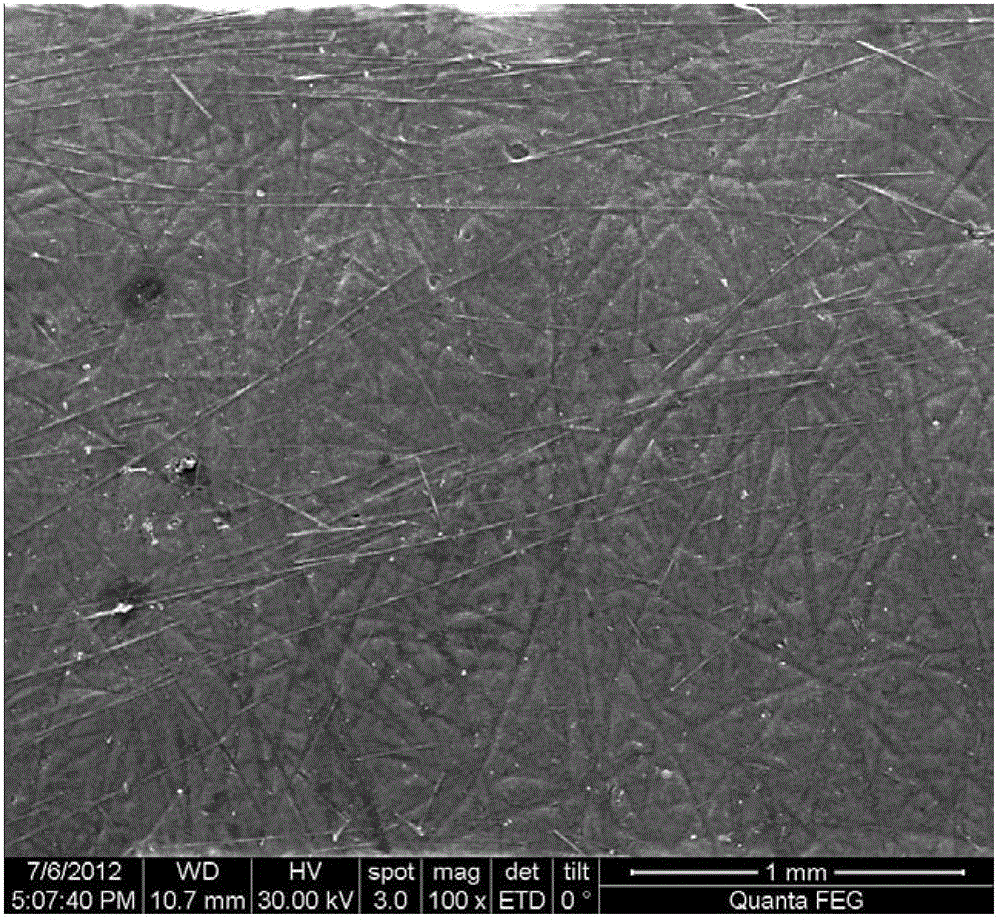

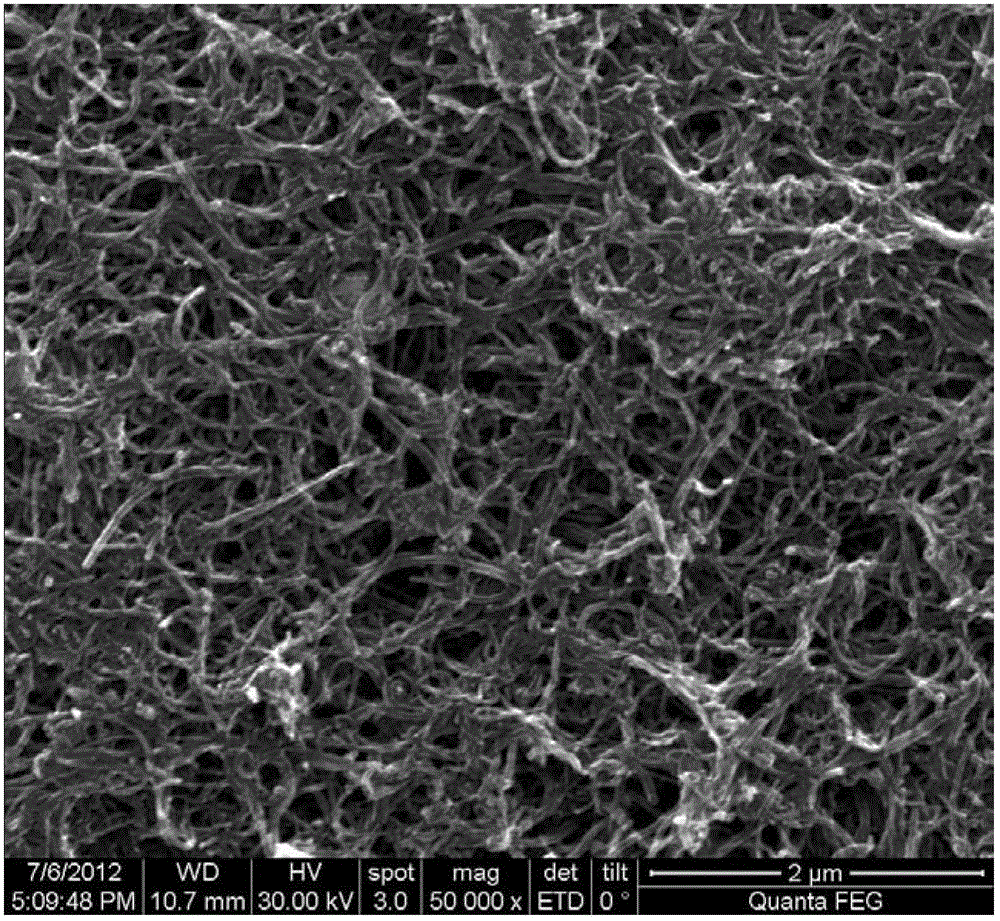

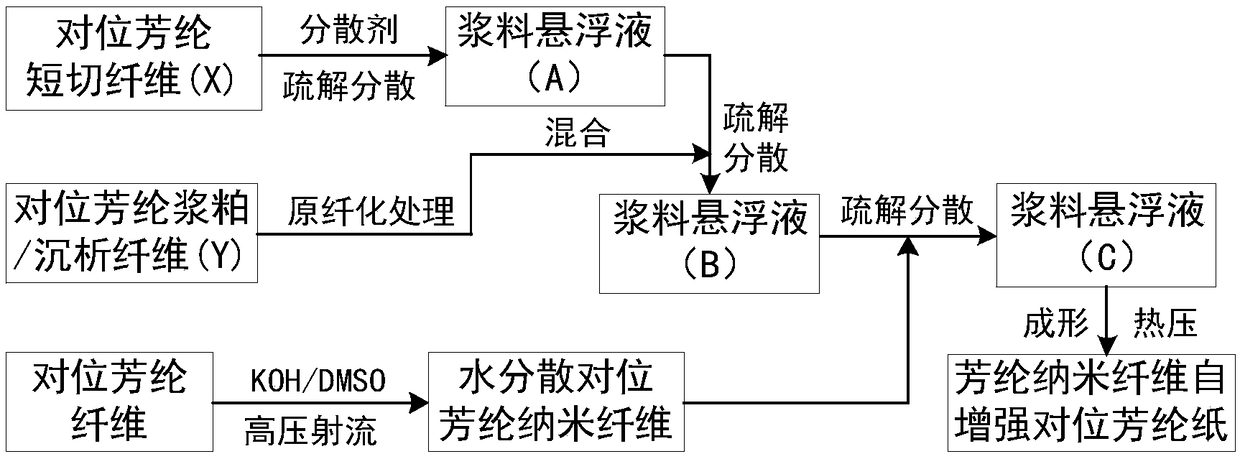

PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

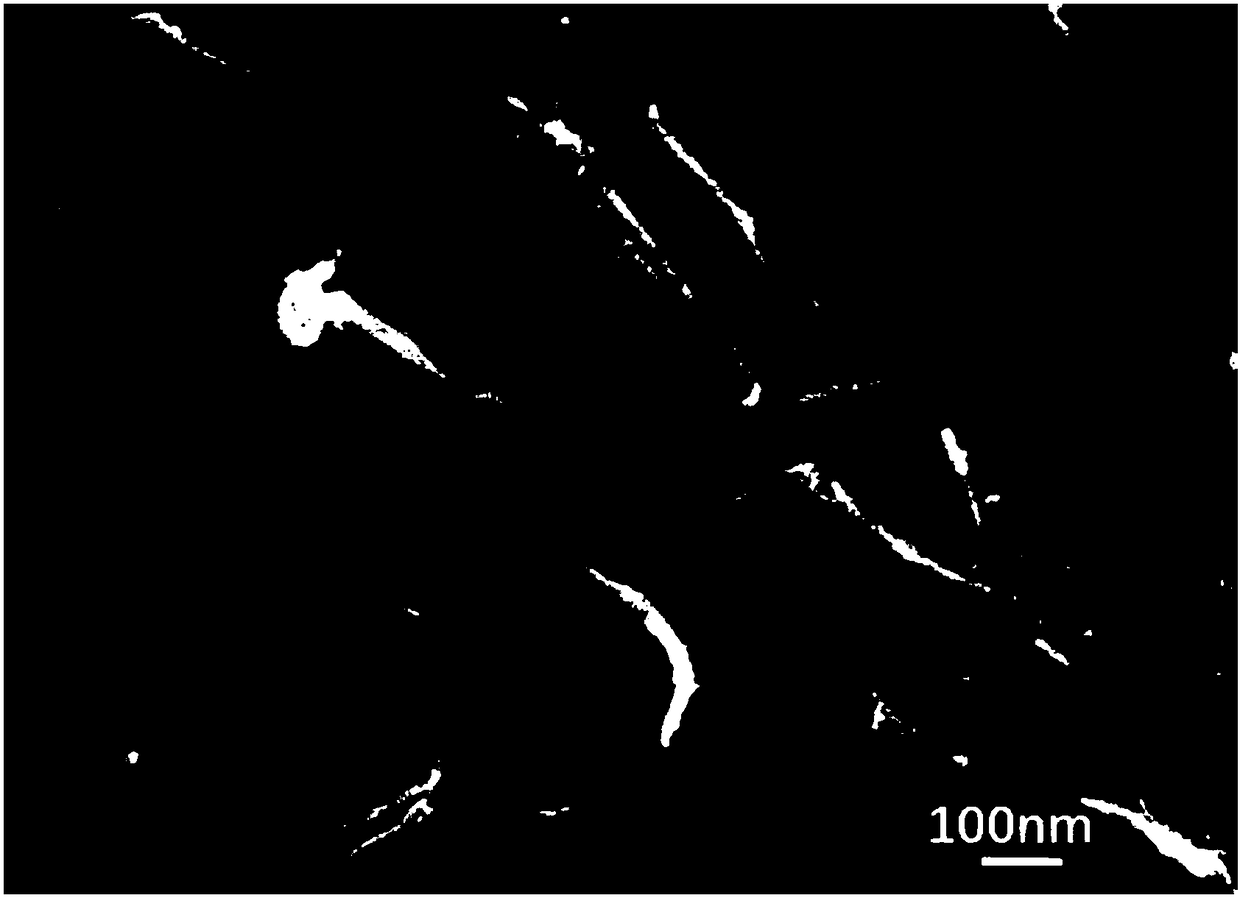

ActiveCN108265566AUnique nanoscale structureLarge aspect ratioSpecial paperPaper/cardboardNano structuringHigh surface

The invention discloses a PPTA paper using aramid nanofiber for self-reinforcement and a preparation method thereof. The preparation method includes: utilizing para-aramid paper nanofiber with the advantages of special nano-structure, small fiber diameter, large length-diameter ratio, high surface activity, excellent heat resistance and the like as the self-reinforcement material of para-aramid paper, conducting mixing, defibering and dispersion on aramid chopped fiber, pulp or fibrid and aramid nanofiber to make a uniform suspension, carrying out papermaking shaping, squeezing and drying, andfurther performing hot-pressing on a hot press to obtain aramid paper. The introduced aramid nanofiber enables nanoscale aramid fiber and an aramid nanofilm formed thereby to reach the good interfacefilling, coating and enhancement effects, provides more binding sites for the combination of components, at the same time reduces the pores and holes between components, significantly improves the bonding strength between the aramid paper components, and greatly enhances the mechanical and insulation properties.

Owner:SHAANXI UNIV OF SCI & TECH

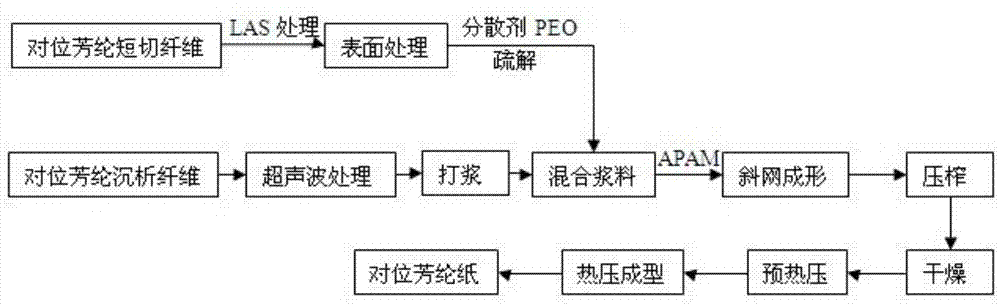

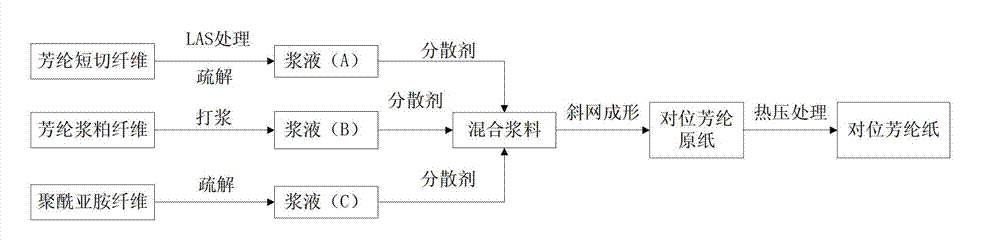

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

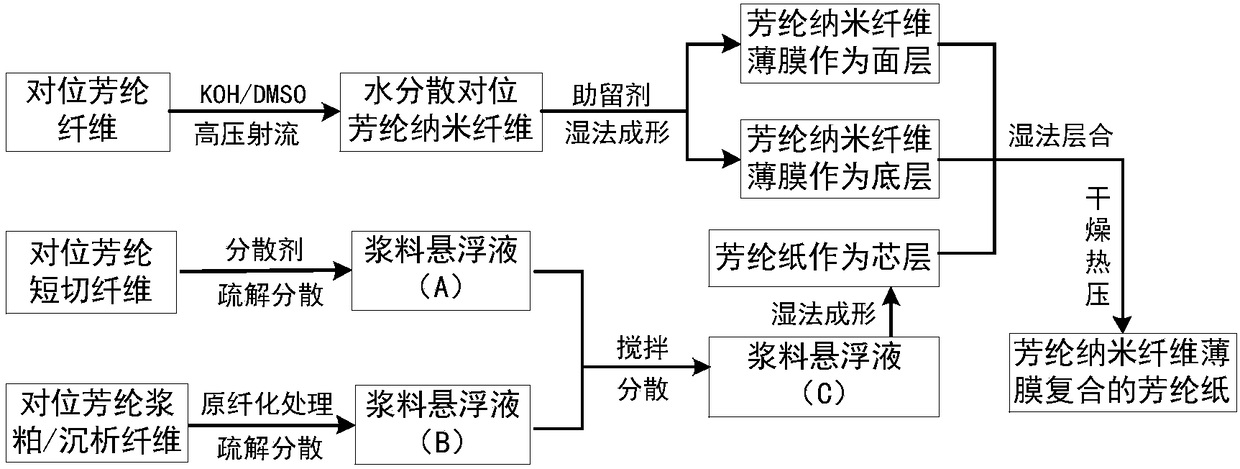

Aramid paper compounded with aramid nanometer fiber thin film and preparation method thereof

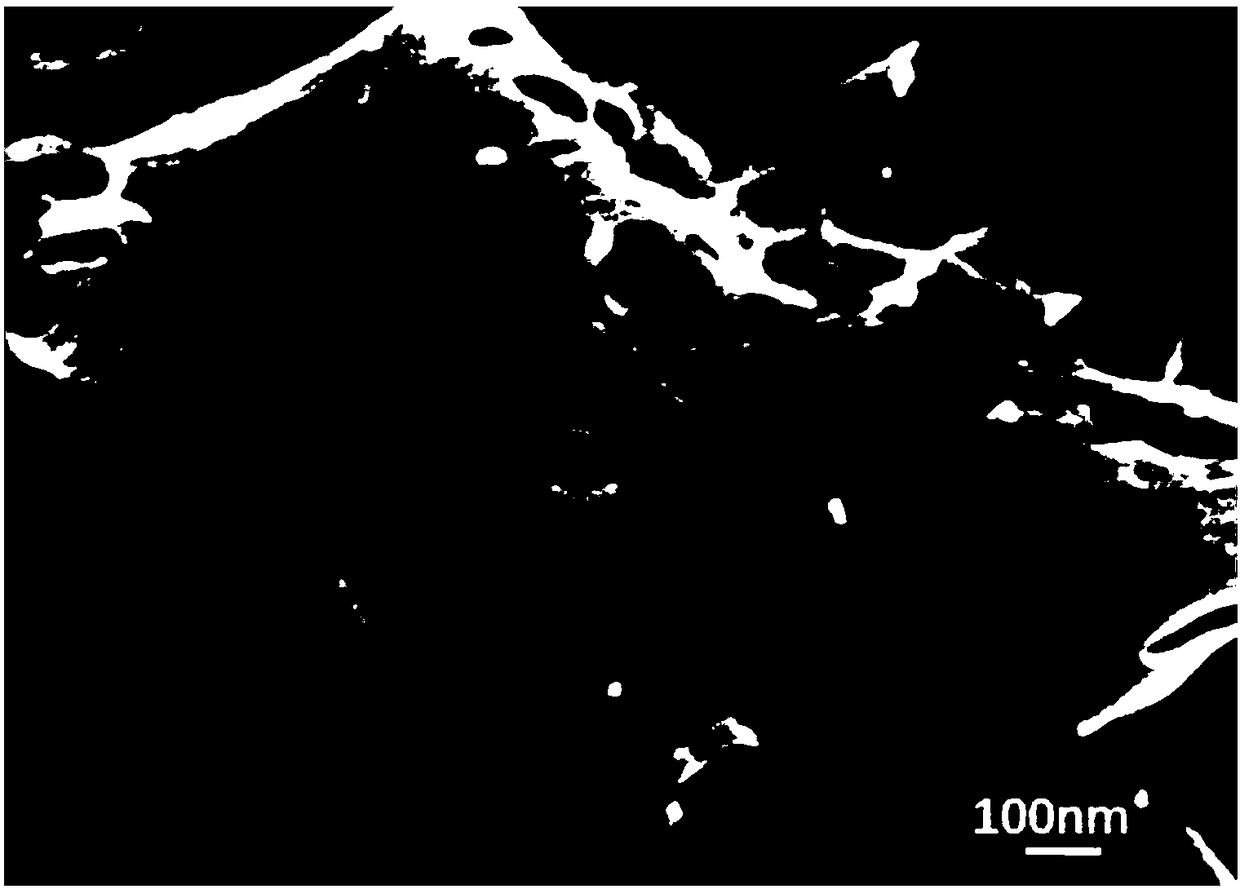

ActiveCN108316056AUnique nanoscale structureLarge aspect ratioSpecial paperSynthetic resin layered productsSurface layerPapermaking

The invention discloses an aramid paper compounded with an aramid nanometer fiber thin film and a preparation method thereof. The aramid paper is compounded by a surface layer, a core layer and a bottom layer through a wet type papermaking laminating method, wherein the ratio of the surface layer to the core layer to the bottom layer is (5 to 20):(60 to 90):(5 to 20) in parts by weight of absolutedry fiber; the surface layer and the bottom layer respectively adopt aramid nanometer films which are prepared from aramid nanometer fibers; the core layer adopts the aramid paper which is prepared from one of aramid chopped fibers and aramid pulp fibers or aramid precipitated fibers. The aramid paper has the advantages that because of excellent strength property and dense thin film structure ofthe aramid nanometer fiber film, more bonding sites are provided for bonding with the fiber components of the aramid paper, and the larger pores can be filled and coated; the comprehensive property ofthe final product is greatly improved, and the aramid paper is favorably widened to the high-end application field.

Owner:SHAANXI UNIV OF SCI & TECH

Chemical mechanical pulping method for cotton haulm raw material

InactiveCN101016702AHigh whitenessHigh yieldPaper/cardboardPulping with inorganic basesChemical reactionUltimate tensile strength

The invention discloses a chemical mechanical pulping method which uses cotton stalk as material, wherein the invention processes the first grinding after the first screw protrusion pre-immersion to replace present APMP technique which comprises two screw protrusion immersion followed with at least two sections of grinding, then holds the pulp after first grinding process for some time to process chemical reaction, at the same time, the invention uses novel additive to replace traditional metal ion chelating agent, Na2SiO3 and MgSO4. Compared with present APMP technique, the invention has low cost and high strength to be used to produce high-level paper.

Owner:SOUTH CHINA UNIV OF TECH

Water-based calcium stearate dispersion for papermaking and preparation method thereof

InactiveCN102094356AImprove performanceSmall particle sizeDefoamers additionCoatings with pigmentsWater basedRoom temperature

The invention relates to a water-based dispersion and a preparation method thereof, wherein the water-based dispersion takes calcium stearate as the main component and is used for papermaking; and the dispersion is mainly used as an auxiliary, a functional auxiliary and a coating lubricant in the papermaking and coating processes. The dispersion is formed by processing the calcium stearate, an emulsifier A, an emulsifier B, an auxiliary, a dispersing agent, a defoamer, a fungicide and water; and the production comprising the steps of: adding the calcium stearate, the emulsifier A, the emulsifier B, the auxiliary, the dispersing agent, the defoamer, the fungicide and the water into a high-pressure reaction kettle according to a certain proportion; sealing the high-pressure reaction kettle and heating to 160-190DEG C; mixing the materials at a constant temperature for 1h; and then rapidly cooling to the room temperature so as to obtain the target product. According to the proportion and the method, the viscosity range of the prepared water-based calcium stearate dispersion is 90-680mPa.S, the particle size range is 0.45-5.0 microns and the solid content is 39-75wt%. The water-based calcium stearate dispersion has the advantages of simple process, high efficiency, no color reversion of the product, no odor, no pollution and the like; and the particle size, the solid content and the viscosity are adjustable.

Owner:DONGGUAN CHNV TECH CO LTD

Coated craft paper and production method thereof

ActiveCN102912691AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentPulp and paper industry

The invention discloses coated craft paper and a production method thereof. The coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: manufacturing paper through a paper layer by taking the UKP pulp, the non-deinked waste paper pulp or the mixture of the UKP pulp and the non-deinked waste paper pulp as the pulp to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

Carbon fiber heating paper and preparation method thereof

ActiveCN102182100AImprove conductivityImprove thermal efficiencyPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperCarbon fibersGraphene

The invention provides a carbon fiber heating paper. The carbon fiber heating paper contains 5 to 60 percent of carbon fibers and 0.01 to 0.50 percent of graphene based on the total weight. A preparation method of the carbon fiber heating paper comprises the following steps of: mixing and pulping the graphene and the polyacrylonitrile-based carbon fibers, putting the mixture into paper pulp, beating the pulp, manufacturing paper with the pulp, and drying the paper to form the carbon fiber heating paper. The carbon fiber heating paper is applied in the field of electric heating paper; and compared with the common carbon fiber heating paper without the graphene, the heating efficiency of the carbon fiber heating paper is improved by nearly 90 percent, and the uniformity of the carbon fiber heating paper is greatly improved.

Owner:WUHAN SAIYANG INDOOR CLIMATE

Production method for base wallpaper

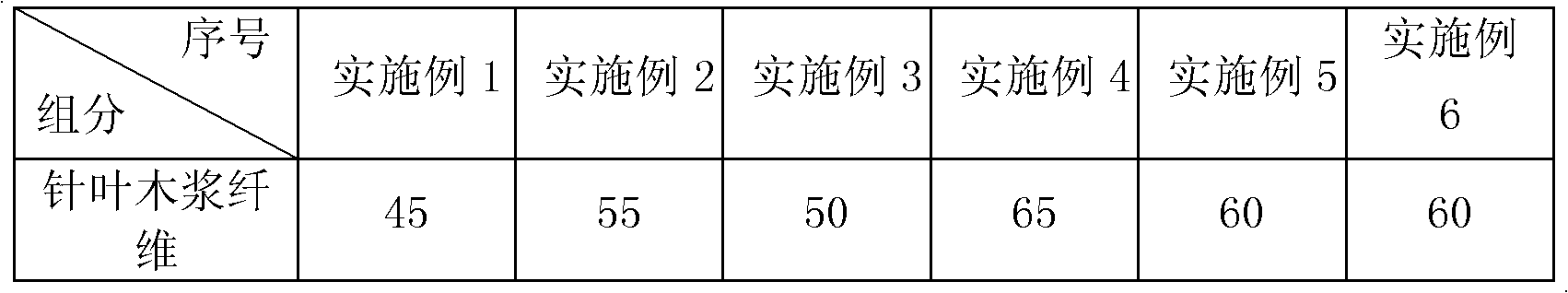

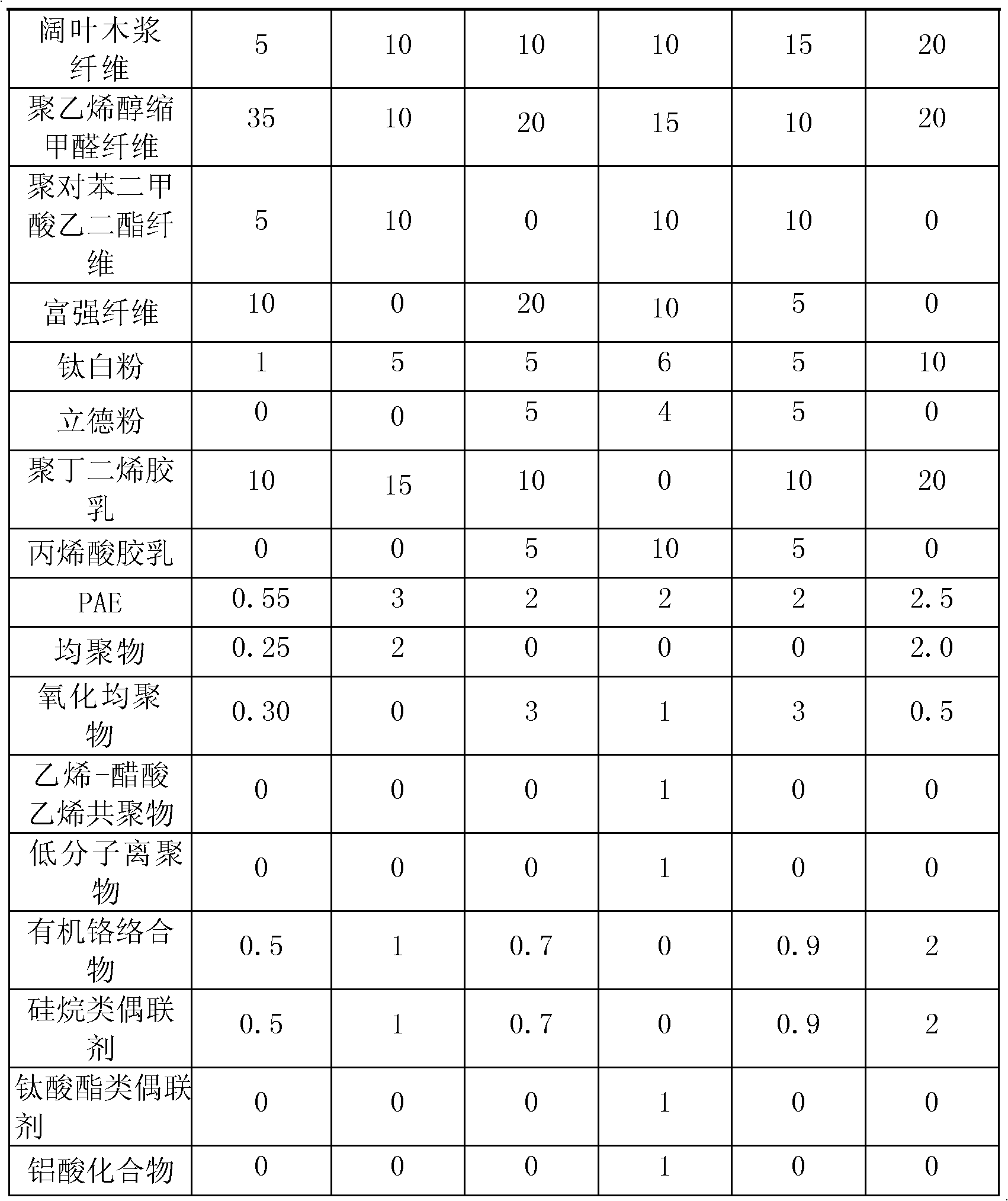

InactiveCN102978995AImprove performanceImprove resource utilizationReinforcing agents additionPaper/cardboardPolyesterFiber

The invention relates to papermaking technology and especially to a production method for base wallpaper. The production method for base wallpaper comprises the following steps: A, mixing chemically bleached needle wood pulp, chemically bleached bamboo fiber pulp, polyester fiber pulp and bleached recycled pulp to obtain pulp I; B, adding an inorganic filling material and a chemical auxiliary agent for batching to form base paper pulp; C, subjecting the base paper pulp to paper making and drying with a fourdrinier; D, mixing the chemically bleached needle wood pulp and the polyester fiber pulp to obtain pulp II; E, adding the inorganic filling material and the chemical auxiliary agent for batching to form surface paper pulp; F, subjecting the surface paper pulp to paper making and drying with the fourdrinier; G, coating a layer of a paper binder on semi-finished base paper, applying semi-finished surface paper on the layer of the paper binder and carrying out compacting; and H, dipping semi-finished composite paper in mixed liquor of a surface conditioning agent and latex, subjecting a surface coating to drying and gelling and carrying out surface mechanical calendering and reeling.

Owner:福建希源纸业有限公司

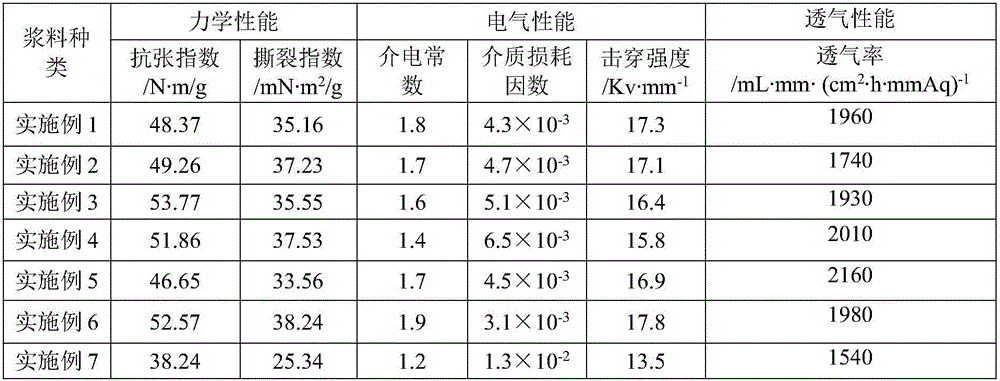

Preparation method of polyimide fiber paper

ActiveCN106436441AHigh surface energyIncrease roughnessDefoamers additionPaper/cardboardFiberPapermaking

The invention discloses a preparation method of polyimide fiber paper, and belongs to the field of paper-making industries and materials. The method comprises the steps that polyimide chopped fiber is treated by a chemical reagent, the treated fiber is washed to be neutral, then, the fiber, a binder and a dispersing agent M are mixed according to a certain mass ratio, the fiber raw materials are dispersed into a pulp suspension, papermaking is performed through a paper making machine to obtain raw polyimide fiber paper, and finally hot pressing is performed through a hot press to obtain the polyimide fiber paper. According to the preparation method, the fiber is subjected to modification treatment, fiber surface active groups are added, the fiber surface energy and roughness are improved, the binding force of components in paper pages can be improved, the binder flows in the paper pages to achieve the effect of viscose fiber through hot pressing and melting, the preparation method can remarkably reduce chemical auxiliaries added in the polyimide fiber raw paper making process, environmental pollution caused in the paper making process can be reduced, and the mechanical performance, the electrical performance and the gas permeability of the polyimide fiber paper can be effectively improved.

Owner:JIANGNAN UNIV +2

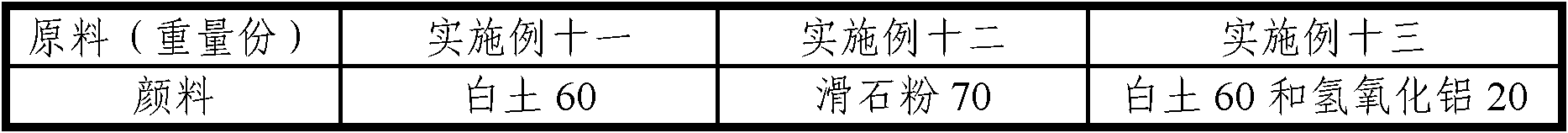

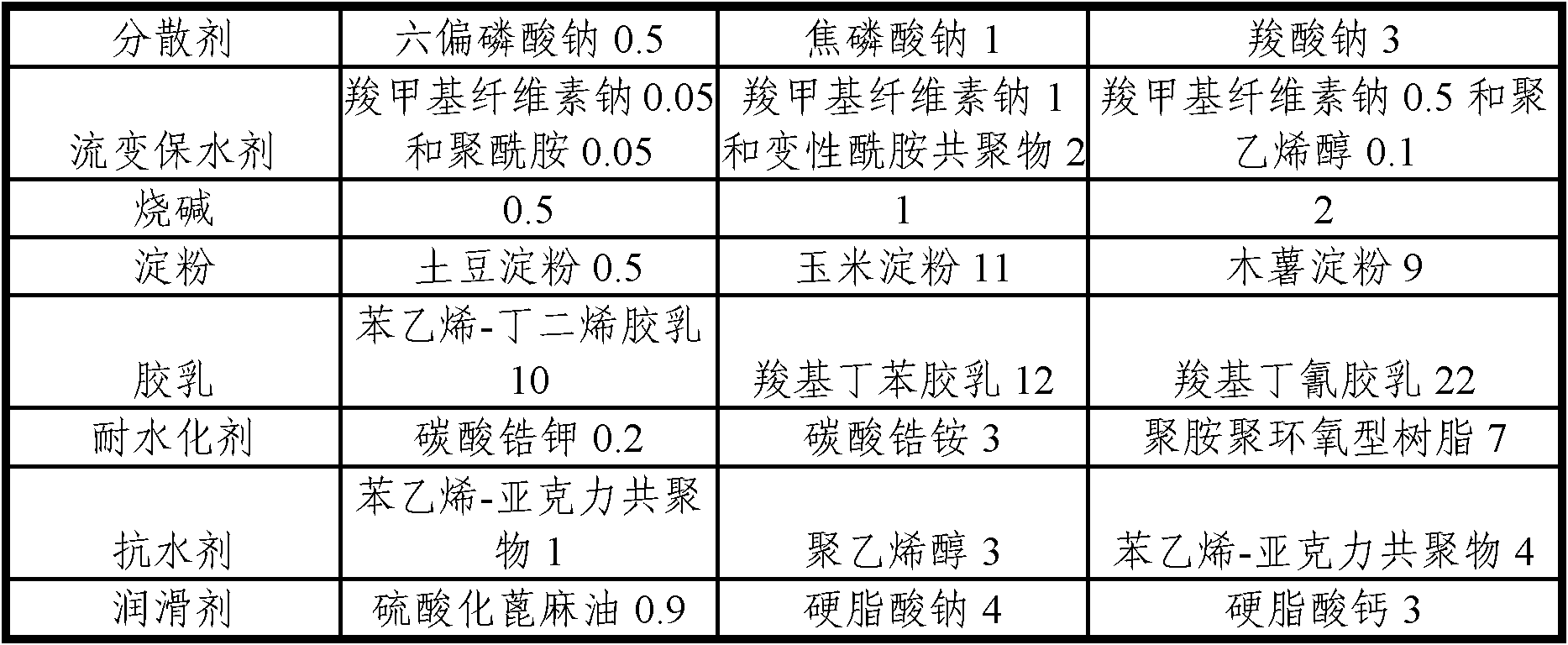

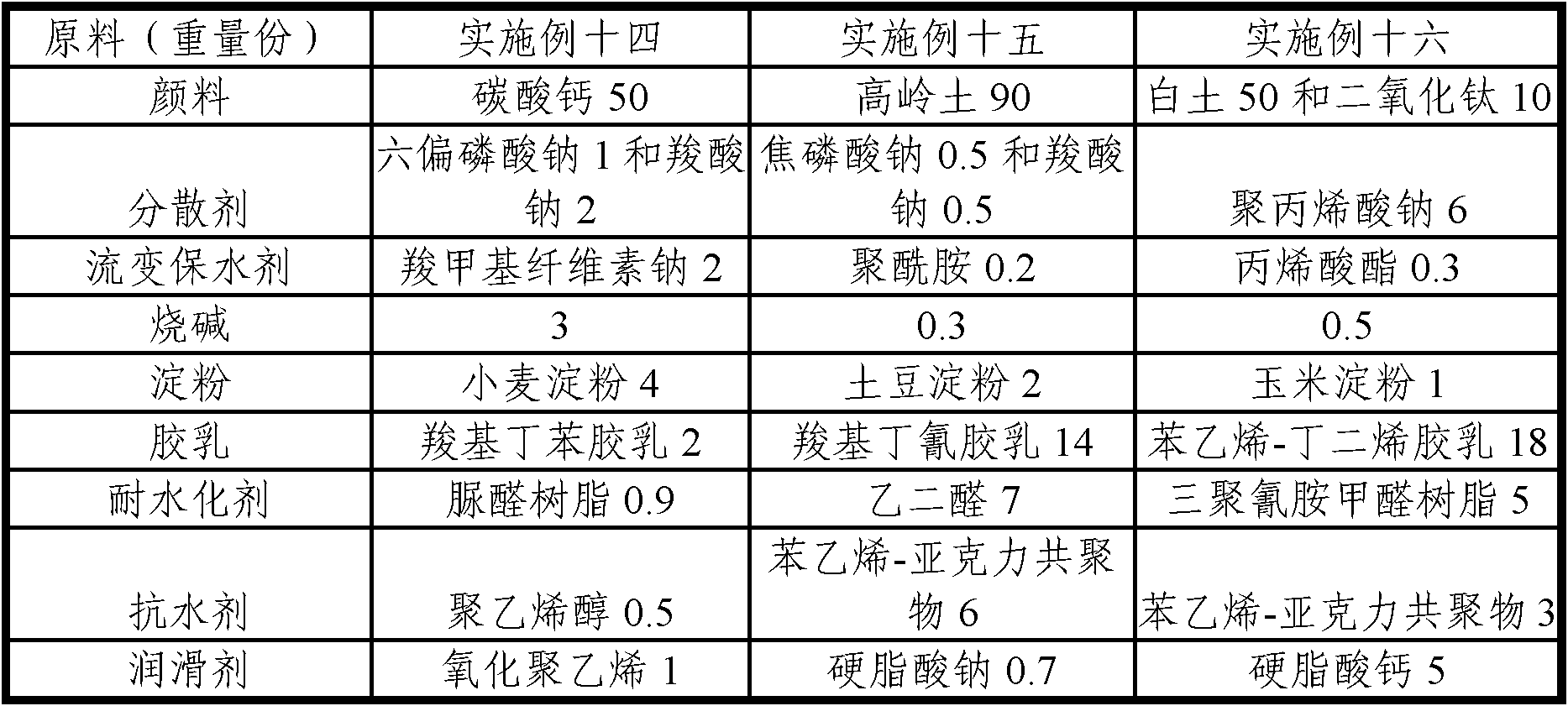

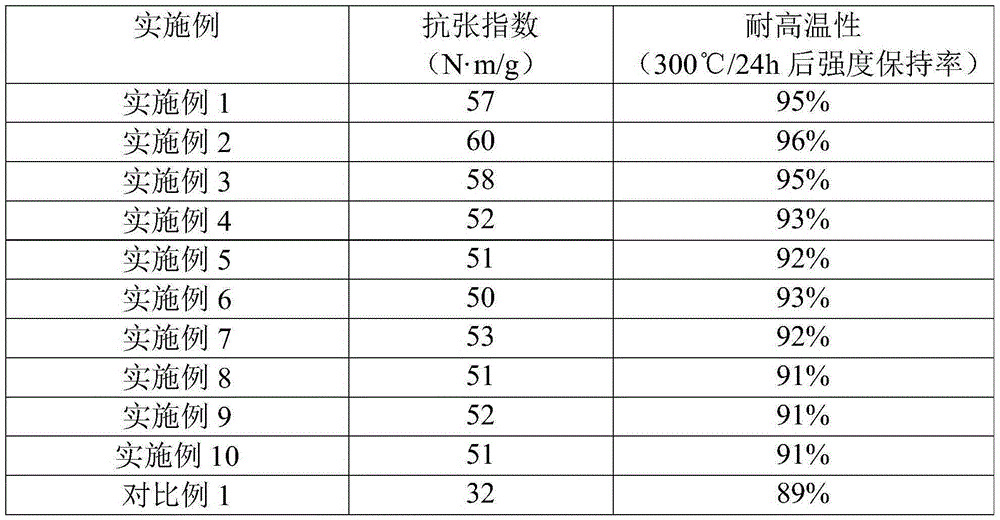

Copperplate board coating

ActiveCN102321997AHigh solid contentLose weightCoatings with pigmentsPaper/cardboardPapermakingSlurry

The present invention provides a new copperplate board coating. The copperplate board coating comprises the following raw materials, by weight, 5-100 parts of a pigment, 0-20 parts of starch, 0.2-5 parts of caustic soda, 0.05-3 parts of a rheology and water retaining agent, 1-30 parts of latex, 0.1-10 parts of a hydration resistant agent, 0.1-10 parts of a water repellent agent, 0.1-10 parts of alubricant and 0.1 to 8 parts of a dispersing agent. With the formula of the high solid content coating provided by the present invention, the gram weight of the base paper can be reduced in the context of production of the copper board with the same specification, such that the ratio of the base paper in the copper board is reduced, the slurry cost is decreased, the requirement of wood is reduced, the economic benefits and the social benefits are significantly improved; due to the reduction of the gram weight of the base paper, the speed can be improved during the base paper papermaking, the machine efficiency and the productivity can be improved; with the improvement of the coating amount, the paper covering and the smoothness are improved, such that the final product has a better printing effect.

Owner:HAINAN JINHAI PULP & PAPER

Polyimide paper and preparation method thereof

ActiveCN106638114ALow dielectric constantEnhanced physical entanglementPlastic/resin/waxes insulatorsPaper/cardboardFiberTemperature resistance

The invention relates to a preparation method of polyimide paper. The method includes the steps: (1) performing surface treatment for polyimide chopped fibers and polyimide fiber pulp; (2) dispersing products obtained in the step (1) in water solution with dispersing agents; (3) sequentially performing papermaking, rolling and drying products obtained in the step (2); (4) dipping or coating the surfaces of the products obtained in the step (3) with solution or dispersing liquid of resin binders. The invention further relates to polyimide paper prepared by the method. According to the method, the polyimide fibers and the polyimide fiber pulp directly serve as raw materials, and the method can solve the problems that the polyimide fibers need to be used instantly after preparation as the polyimide fibers are degraded when being stored for a long time, and inner stress of paper surfaces is generated as shrinkage ratio is excessive when the polyimide fibers are imidized and formed. The polyimide paper prepared by the method sufficiently keeps good high-temperature resistance and insulation performance of polyimide materials and has good mechanical strength.

Owner:BEIJING UNIV OF CHEM TECH

Coating and coating used coated paper

ActiveCN103590282AHigh glossReduce the risk of bad printsDefoamers additionCoatings with pigmentsStrong acidsPaper sheet

The invention provides a coating used in the papermaking field. The coating contains nanometer microcrystalline cellulose, a pigment, a latex, an assistant and water, and the nanometer microcrystalline cellulose is highly-crystallized cellulose having a length of 100-500nm and a width of 3-100nm obtained by hydrolyzing a cellulose raw material in a strong acid; and the bone dry mass parts of the nanometer microcrystalline cellulose, the pigment, the latex, the assistant and water in the coating are 0.02-10, 75-95, 5-15 and 0.35-10 respectively. The invention also provides a coated paper made by using the coating. The coating is coated on the surface of paper to effectively improve the glossiness, the post-print glossiness and the roughness of the coated paper in order to improve the paper quality.

Owner:GOLD EAST PAPER JIANGSU

Environment-friendly high-printability non-woven wallpaper base and preparation method thereof

ActiveCN102619127ASoft touchSmooth to the touchSpecial paperPaper coatingEnvironmental resistanceFiber

The invention relates to an environment-friendly high-printability non-woven wallpaper base and a preparation method thereof, belongs to the field of processing of non-woven fabric and mainly relates to the environment-friendly high-printability non-woven wallpaper base and the preparation method thereof. The environment-friendly high-printability non-woven wallpaper base comprises the following components in percentage by weight: 50-80 parts of wood pulp fiber, 20-50 parts of chemical fiber, 1-19 parts of inorganic filler, 10-20 parts of latex, 1.1-5 parts of chemical additives and 1-4 parts of surface treating agent, wherein the wood pulp fiber is of a mixture formed by mixing softwood pulp fiber and hardwood pulp fiber according to the weight ratio of 3-9: 1. The environment-friendly high-printability non-woven wallpaper base disclosed by the invention has the advantages of uniform ink absorption, strong color spreading capability, lower flexibility, higher softness, good printability, economy and environment-friendly property.

Owner:ZIBO OU MU SPECIAL PAPER

Production method of base paper of tipping paper used by cigarettes with high natural air permeability

InactiveCN103103859AGood operating strengthGood flexibilityPulp beating methodsReinforcing agents additionWet strengthRaw material

The invention relates to a production method of tipping paper of base paper used by cigarettes with high natural air permeability and aims to provide the production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU. The production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability is characterized by comprising the following steps: a, beating section, beating is conducted on needle pulp and eucalyptus pulp through fibrillation and cut of a millstone mill to reach the effects that the beating degree of the needle pulp is 20-300SR, the wet weight of the needle pulp is 9-10g, the beating degree of the eucalyptus pulp is 20-220SR, and the wet weight of the eucalyptus pulp is 1-2g, b, preparation of pulp. Raw material components of pulp material comprises, by weight, 20-30 of needle pulp, 70-80 of eucalyptus pulp, 50-80 calcium carbonate and 0.2-0.4 wet strength agent. The produced tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU uses high natural holes to bring a large quantity of are into the main stream smoke of the cigarettes and enables injurious ingredients in the main stream smoke to be greatly reduced.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

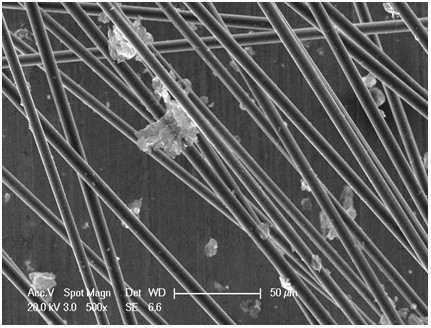

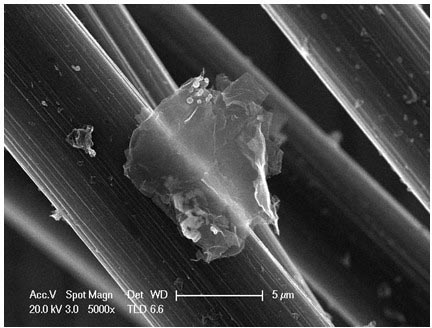

Carbon fiber shielding paper preparing process

InactiveCN101265676AImprove shielding effectGuaranteed lightweightDefoamers additionPaper/cardboardCarbon fibersPlant fibre

A process for preparing carbon fiber screening paper is provided. The invention includes the following steps: mixing chopped carbon fiber and plant carbon fiber in a certain proportion, adding certain amounts of a dispersant and a defoaming agent, dispersing on a fluffer, and papermaking in a paper former. While the light weight of material is guaranteed, the paper is endowed with good screening performance and easy process, which make full use of the advantages of large scale production in the papermaking industry. Furthermore, the paper electric conductive screening performance can be controlled by adjusting and quantifying the amount of the carbon fiber. The carbon fiber screening paper, which is an electric conductive material with high performance, replaces the conventional electric conductive screening material and covers the shortages thereof. The prepared screening paper has good screening performance of electromagnetic waves, the screening effectiveness at 100KHz-1500MHz is more than 30dB and the maximum is 50dB, thereby being generally applicable to radiation protection and anti-interference of common commercial or electronic products.

Owner:SHAANXI UNIV OF SCI & TECH

Method for improving removal effect of stickies in waste paper pulp

InactiveCN101725064AGood removal effectThe removal effect is significantly improvedSurfactants additionPaper recyclingPulp and paper industryHot melt

The invention discloses a method for improving a removal effect of stickies in waste paper pulp. The method comprises the steps of: breaking waste paper comprising the stickies accounting for less than or equal to 10 percent of the weight of the waste paper at the temperature of between 40 and 60 DEG C first; placing pulp obtained after the breaking into a pulp screen, and screening the pulp under the condition that the screening water temperature is between 40 and 60 DEG C; and diluting accepts obtained after the screening until the weight concentration of the paper pulp is between 0.8 and 1.5 percent, adding 0.01 to 0.5 percent of nonionic surfactant into the pulp based on the absolute dry mass of the paper pulp, adding 0.0025 to 0.5 percent of anionic dispersant, and floating at the temperature of between 40 and 50 DEG C after the mixture is stirred uniformly, wherein the anionic dispersant is one of anionic polyacrylamide, polyacrylate and polymethacrylate. The method has a more remarkable effect on the removal of the stickies such as pressure-sensitive adhesives and hot melt adhesives in most of waste paper pulp comprising an ONP, an OMG, an MOW and the like.

Owner:SOUTH CHINA UNIV OF TECH

Silver-loaded antibacterial paper and preparing method thereof

InactiveCN105780590AFast and good bactericidalFast and good bacteriostasisWater-repelling agents additionReinforcing agents additionPaper productionBleach

The invention discloses silver-loaded antibacterial paper.The silver-loaded antibacterial paper is prepared from a silver-loaded antibacterial agent, a softening agent, a dry strength agent, a wet strength agent, a drying agent, a retention agent, a sizing agent, an antibacterial agent, a dispersing agent and a decolorizer additive.The invention further discloses a preparing method of the silver-loaded antibacterial paper.The method comprises the following steps that pulping, pulp dispersing, pulp milling and pulp beating are carried out, the silver-loaded antibacterial agent is added into the pulp sizing agent, the sizing agent is conveyed, pulp is fed onto a net to be shaped and pressed into paper, pressing is carried out, and dry dehydration and paper forming are carried out.Compared with the prior art, the antibacterial paper and the antibacterial paper production method have the advantages that prebiotics and the antibacterial agent are used in the antibacterial paper in a combined mode, it is ensured that the antibacterial paper has the fast and good sterilization and bacteriostasis effects, can well restrain breeding and growth of microorganisms of the antibacterial paper, the damage to the quality of the antibacterial paper due to breeding of the microorganisms is avoided, and the quality of the antibacterial paper is ensured.

Owner:上海渊泉集币收藏品有限公司

Composite plant fiber aramid paper and preparation method thereof

ActiveCN105648830AWide variety of sourcesLow costPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPhosphoric acidSlurry

The invention discloses composite plant fiber aramid paper which is prepared from the following components in percentage by mass: 82%-97% of an aramid fiber and 3%-20% of a plant fiber, wherein the sum of the components is 100%. The invention further discloses a preparation method of the composite plant fiber aramid paper. The method comprises the following steps: treating one of a meta-aramid chopped fiber and a para-aramid chopped fiber through phosphoric acid to prepare a slurry suspension; modifying the plant fiber with a NaOH solution to prepare a slurry suspension; preparing the slurry suspension from at least one of a para-aramid precipitation fiber, a para-aramid pulp fiber and a meta-aramid precipitation fiber; and mixing the three slurry suspensions, adding cationic polyacrylamide, and carrying out squeezing, drying, dipping, pre-pressing and hot-pressing processes to prepare the composite plant fiber aramid paper. According to the production technology, the synergistic effect and composite excellent performance of the hybrid fiber are developed on the premise of ensuring the paper making property of the composite aramid paper, the production cost of the aramid paper is reduced, and thus the method is suitable for large-scale production of the composite aramid paper.

Owner:SHAANXI UNIV OF SCI & TECH

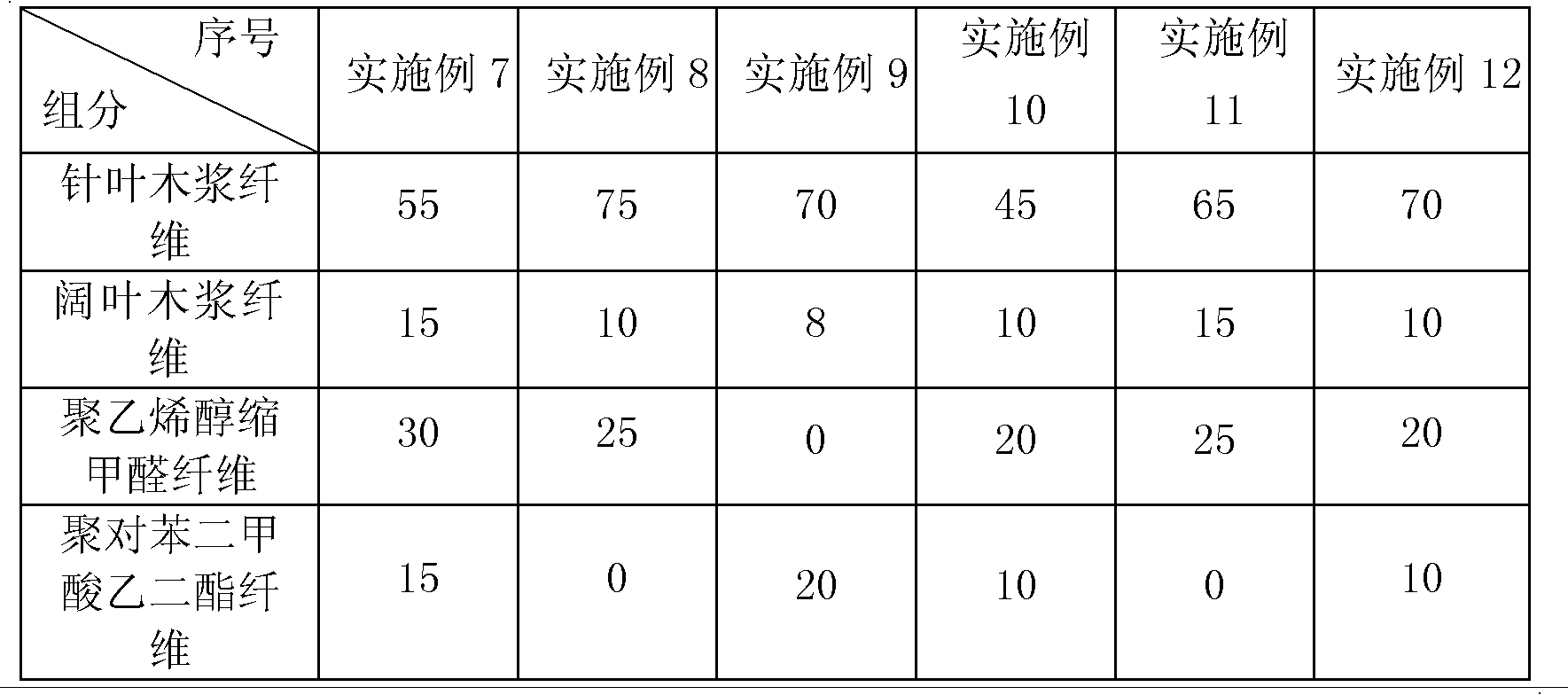

Carbon nanofiber paper and preparation method thereof

ActiveCN103015256AControl the degree of hydrophilicityHigh mechanical strengthPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberSurface finish

The invention discloses carbon nanofiber paper and a preparation method for the carbon nanofiber paper. According to the invention, the carbon nanofiber paper is prepared by adopting nanoscale carbon fiber, and the carbon nanofiber is combined with van der waals force therebetween relying on hydrogen bonds. The preparation method for the carbon nanofiber paper comprises the procedures of surface finish of carbon fiber, dispersing, flocculating, filtering and squeezing and drying. The carbon nanofiber paper, disclosed by the invention, has the advantages of large specific surface area, electrical conductivity, air permeability and hydrophilia; and the preparation method for the carbon nanofiber paper is applied to low-cost and large-scale industrial production.

Owner:KUNMING NATAI TECH CO LTD

Para-position aramid fiber paper used for cellular material and preparation method thereof

ActiveCN102899959AReduce water repellencyImprove dispersion compatibilityPulp beating methodsPaper/cardboardPolyesterPapermaking

The invention discloses a para-position aramid fiber paper used for a cellular material and a preparation method thereof. The preparation process comprises the following steps: adding polyimide fibers, defibering and dispersing; papermaking together with para-position aramid fiber, wherein the papermaking proportion in parts by weight is as follows: 20-50% of para-position aramid short cut fiber, 35-60% of para-position aramid pulp fiber and 5-30% of polyimide fiber; and squeezing, drying and carrying out hot press moulding.. According to the preparation method, tear strength, temperature resistance and fire resistance of the para-position aramid fiber paper can be obviously improved, paper breaking during papermaking is reduced, operating speed of a paper machine and production efficiency are improved, and negative effects on properties of a paper sheet as a cohesive fiber such as a polyester fiber is introduced can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

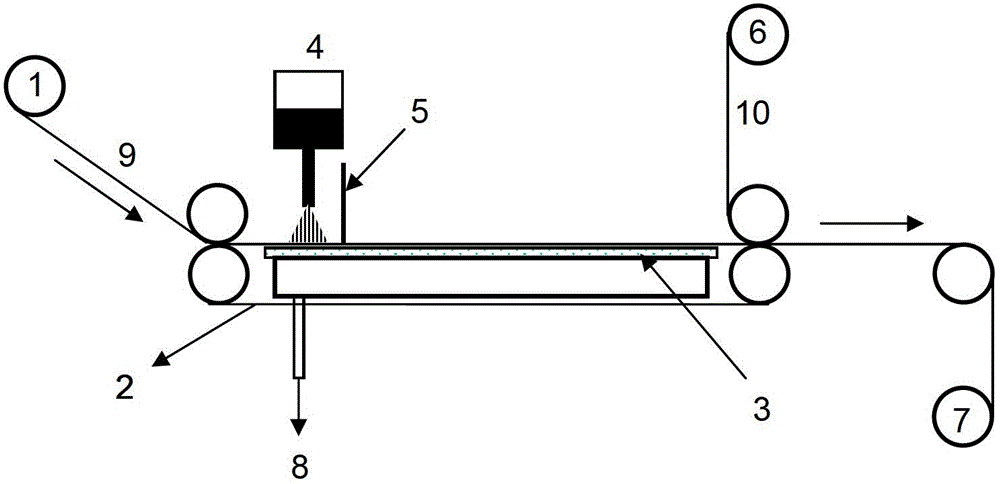

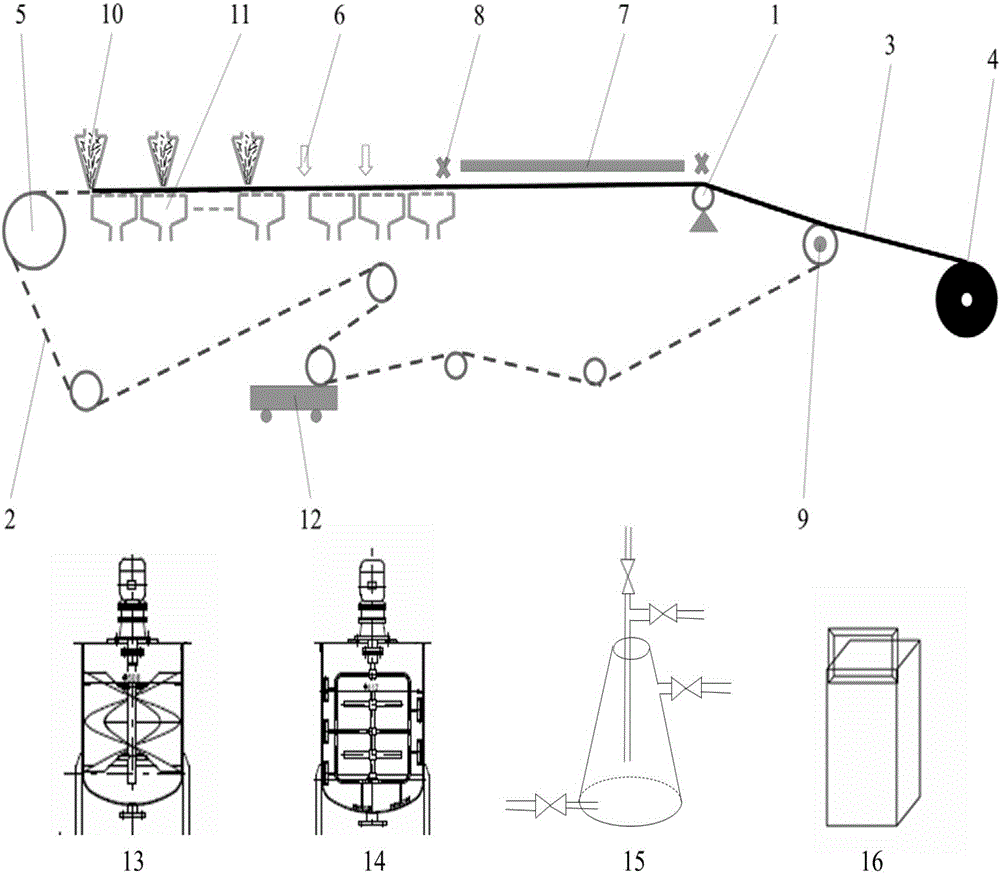

Method and device for preparing chopped fiber continuous orientation felt

ActiveCN106758481AIncreasing the thicknessIncrease widthPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiber suspensionControllability

The invention provides a method for preparing chopped fiber continuous orientation felt and belongs to the field of fiber fabric. The method comprises the following processes: dispersion, orientation, separation, drying and rolling, wherein in the orientation process: a chopped fiber suspension dispersed in a storage device is introduced into reducing orientation nozzles and is spread on conveying mesh belt running continuously after passing through the reducing orientation nozzles; in the separation process: moisture and a dispersant in the chopped fiber suspension on the conveying mesh belt are separated by negative pressure suction box located below the conveying mesh belt, and wet chopped fiber continuous orientation felt is obtained after washing. The device has high degree of automation, the prepared chopped fiber continuous orientation felt is high in controllability of thickness, width, length and fiber content, the orientation degree of chopped fibers in the chopped fiber continuous orientation felt is high, and the orientation structure is uniform; the device is energy-saving, environment-friendly, high-quality and efficient, the problems of low production efficiency and the failure in continuous and large-scale production are solved, and technical guarantee is provided for industrial application of the chopped fiber orientation felt.

Owner:BEIJING UNIV OF CHEM TECH

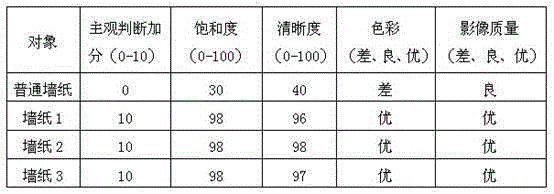

Wallpaper and preparation method thereof

ActiveCN105178110AIncrease reflectionImproved viewing angle balanceDefoamers additionCovering/liningsFiberCyclohexanone

The present invention discloses a wallpaper and a preparation method thereof, wherein the wallpaper comprises 40-80 parts of paper pulp, 10-15 parts of tree bark powder, 1-2 parts of borosilicate, 0.4-0.8 part of nanometer powder, 2-4 parts of calcium hypochlorite, 4-7 parts of polycarbonate, 3-6 parts of polyethylene terephthalic acid ester, 3-5 parts of 2,6-dibenzylidene cyclohexanone, 2-4 parts of carbon fibers, 3-6 parts of diethyl phthalate, 2-5 parts of glass fiber filament, 1-3 parts of carboxymethyl cellulose, 2-4 parts of polyacrylic acid fibers, 0.4-1 part of an anti-forming agent, 8-10 parts of a film forming agent, and 1-3 parts of a dispersant. The wallpaper has characteristics of high reflective property, visual angle balance improving and gain increasing so as to provide high projection effect, good image saturation degree and high definition, and further has characteristics of green environmental protection, wear resistance and good stability.

Owner:香山红叶集团有限公司

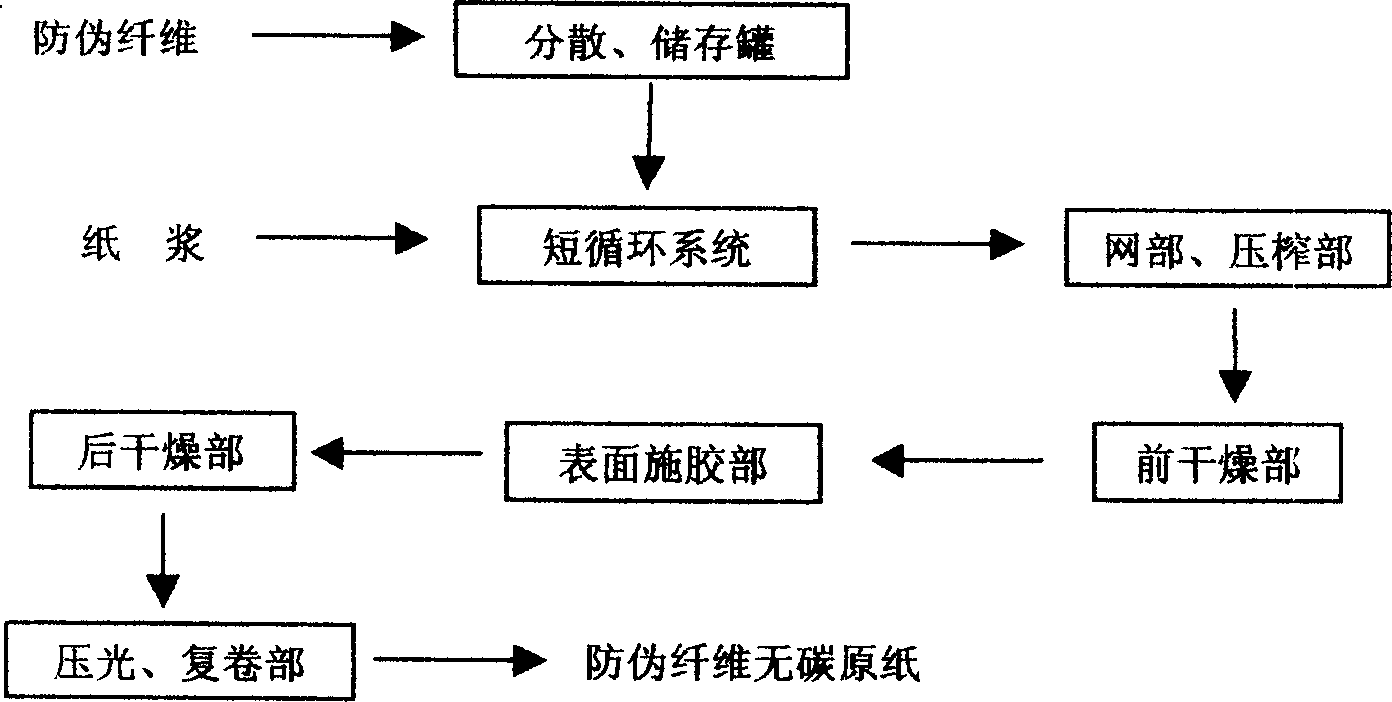

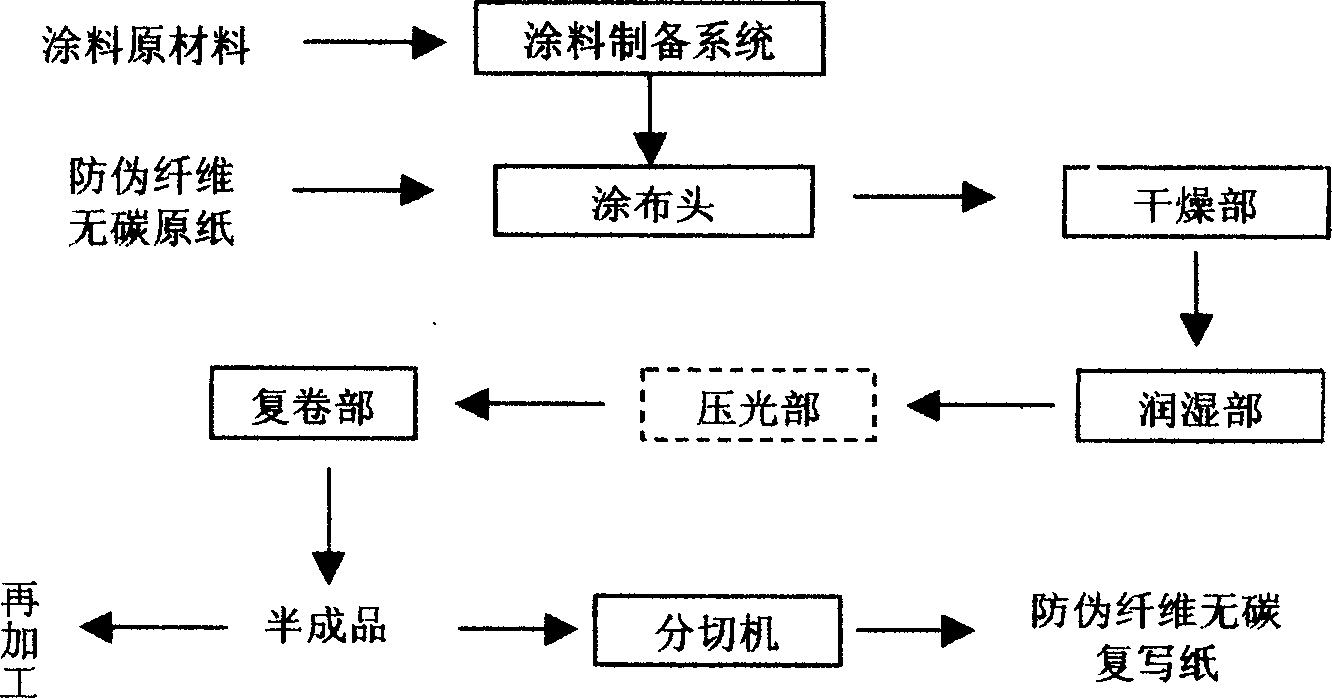

Anticounterfeit fiber carbor-free copy paper and its production method

ActiveCN1580396AGood anti-counterfeiting functionImprove yieldSpecial paperPaper coatingFiberPulp and paper industry

This invention relates to an anti-false fiber noncarbon paper and its production method aiming at overcoming the shortcoming of not anti-false of the current bills made of carbon copy paper which is made by adding a certain quantites of anti-false fiber original paper to produce primary anti-false then to be specially coated to produce the noncarbon paper with anti-false function.

Owner:GUANGDONG GUANHAO HIGH TECH

Preparing method for AKD (Alkyl Ketene Dimer) latex

ActiveCN102535248ASizing properties are not compromisedSizing performance damageWater-repelling agents additionPaper/cardboardCardboardPolyamide

The invention discloses a preparing method for AKD (Alkyl Ketene Dimer) latex. The method comprises the following steps: taking AKD as a raw material, carrying out pre-dispersion under the action of dispersing agent (modified polyamide) and protective colloid, and carrying out homogeneous treatment, so as to obtain the AKD latex. The AKD latex prepared according to the method can serve as an internal sizing agent and a surface sizing agent, so as to greatly improve the water resistance of paper and paper boards, and has the characteristics of high sizing effect and slaking speed, low impact on paper strength, environmental protection, high efficiency and the like.

Owner:广州星业科技股份有限公司

Production process of low molecular weight polysodium acrylate as papermaking dispersant

InactiveCN1986581AIncrease profitEnhanced mass transferPaper/cardboardDispersing agents additionAqueous solutionEnergy consumption

The present invention discloses production process of low molecular weight polysodium acrylate as papermaking dispersant. The process includes the following steps: dissolving ammonium persulfate of 20 kg in water of 120 kg to obtain water solution of ammonium persulfate; adding water of 200 kg in reactor and heating to 75+ / -2deg.c; stirring, dropping industrial pure acrylic acid in 275 kg, water solution of ammonium persulfate and mercapto ethanol in 4-6 wt% of acrylic acid monomer, and reaction at 75-85 deg.c for 2 hr; and maintaining at 80+ / -2 deg.c for 0.5 hr and adding 40 % concentration water solution of NaOH to regulate pH to 7-8 and obtain the product. The present invention adopts mercapto ethanol as molecular weight regulator, and has raised reaction apparatus utilizing rate and raised heat transfer and mass transfer efficiency, simple operation low production process, short production period and low power consumption.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

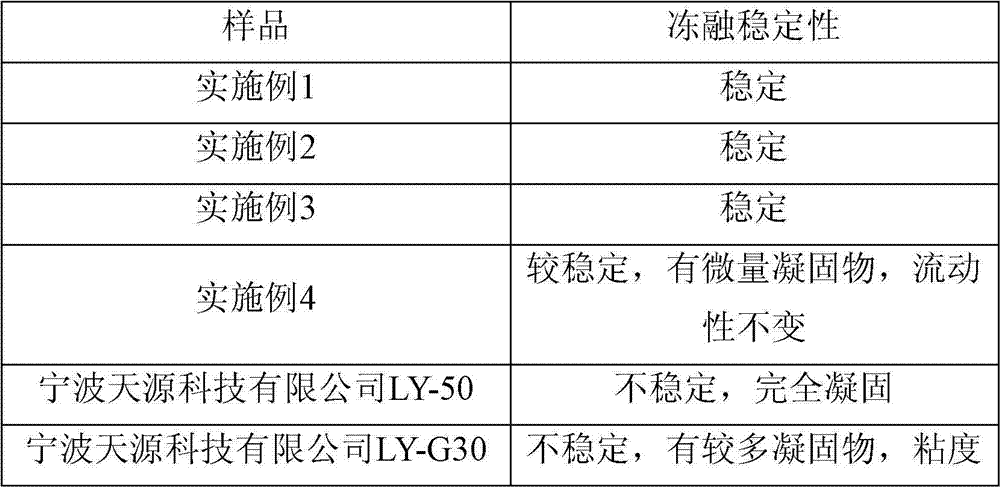

Calcium stearate dispersing liquid for papermaking and preparation method thereof

InactiveCN102828440AGood storage stabilityImprove mechanical stabilityDefoamers additionPaper coatingFreeze thawingPolyvinyl alcohol

The invention discloses a calcium stearate dispersing liquid for papermaking and a preparation method thereof. The liquid comprises, by weight percent, 30 to 60 % of water, 30 to 60 % of stearic acid, 5 to 15 % of calcium hydrate, 0.8 to 3.2 % of a dispersant, 1 to 2.5 % of an emulsifier A, 1 to 4 % of an emulsifier B, 0.3 to 0.6 % of an emulsification auxiliary agent, 0.1 to 0.8 % of an stabilizing agent, 0.4 to 3 % of a catalyst, 0.3 to 0.5 % of an antifoaming agent, and 1 to 2.8 % of a modified polyvinyl alcohol aqueous solution. The invention further discloses a preparation method of the calcium stearate dispersing liquid for papermaking. The calcium stearate dispersing liquid for papermaking and the preparation method thereof are simple to operate and suitable for industrial production, and the prepared calcium stearate dispersing liquid for papermaking is good in stability, and has greatly improved freeze-thaw stability especially.

Owner:ZHEJIANG HEXIN TECH

Method for improving removal effect of ink in waste paper pulp

InactiveCN101725069AGood removal effectGood deinking effectPaper recyclingPaper/cardboardDeinkingFiber

The invention discloses a method for improving a removal effect of ink in waste paper pulp. The method comprises the steps of: breaking waste paper, and diluting obtained pulp; then relative to the absolute dry mass of the paper pulp, adding 0.0025 to 0.5 percent of nonionic deinking agent into the pulp; at the same time, adding an anionic dispersant with a dispersion effect, wherein the consumption of the anionic dispersant is 0.001 to 0.3 percent of the absolute dry mass of the paper pulp; and floating at the temperature of between 40 and 50 DEG C after the mixture is stirred uniformly to remove the ink in the waste paper pulp, wherein the anionic dispersant is anionic polyacrylamide, or is one of polyacrylate and polymethacrylate. The method adopts the cheaper dispersant to compound the deinking agent with higher cost for floatation, which promotes deinking effect, and also solves the problems of cost increase caused by overhigh consumption of the deinking agent and the decrease of economic benefit caused by excessive fiber loss.

Owner:SOUTH CHINA UNIV OF TECH

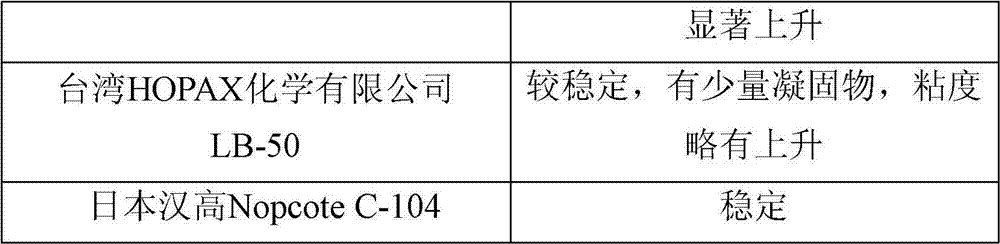

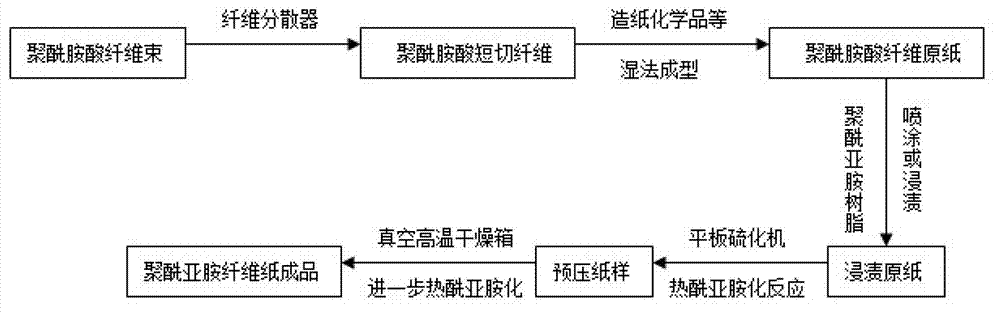

Method for preparing polyimide fiber paper

ActiveCN102926270AHigh strengthInnovativePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiber bundleUltimate tensile strength

The invention discloses a method for preparing polyimide fiber paper, and the method comprises the following steps: firstly, carrying out dispersing treatment on a polyamide acid fiber bundle by using a standard fiber disperser, adding a fiber dispersant and a fiber binder, and then manufacturing a certain amount of polyamide acid fiber body paper in a standard paper sheet former; carrying out spraying or impregnating treatment on the polyamide acid fiber body paper by using a 1-10wt% of polyimide resin liquid, so that the polyimide resin liquid is uniformly distributed on the surface of the body paper, and drying the body paper; prepressing the body paper; and treating the body paper for 15-60 minutes at a temperature of 300-420 DEG C, and cooling the obtained product so as to obtain polyimide fiber paper. The method for preparing the polyimide fiber paper disclosed by the invention can be used for facilitating the reduction of consumption for beating and the improvement of paper evenness; and through the heat treatment on paper, a crosslinking reaction is generated among fibers, so that the binding force among fibers is increased, the strength properties of the paper are improved, and the application requirements of the paper in special fields are met.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com