Patents

Literature

169results about "Bleaching agents addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ligno cellulosic materials and the products made therefrom

ActiveUS20060260773A1Reducing functional groupGood drainage propertyBiocidePaper after-treatmentCelluloseHypochlorite

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

Pulp and paper having increased brightness

InactiveUS20070193707A1Natural cellulose pulp/paperSpecial paperPulp and paper industryBrightness perception

Owner:INT PAPER CO

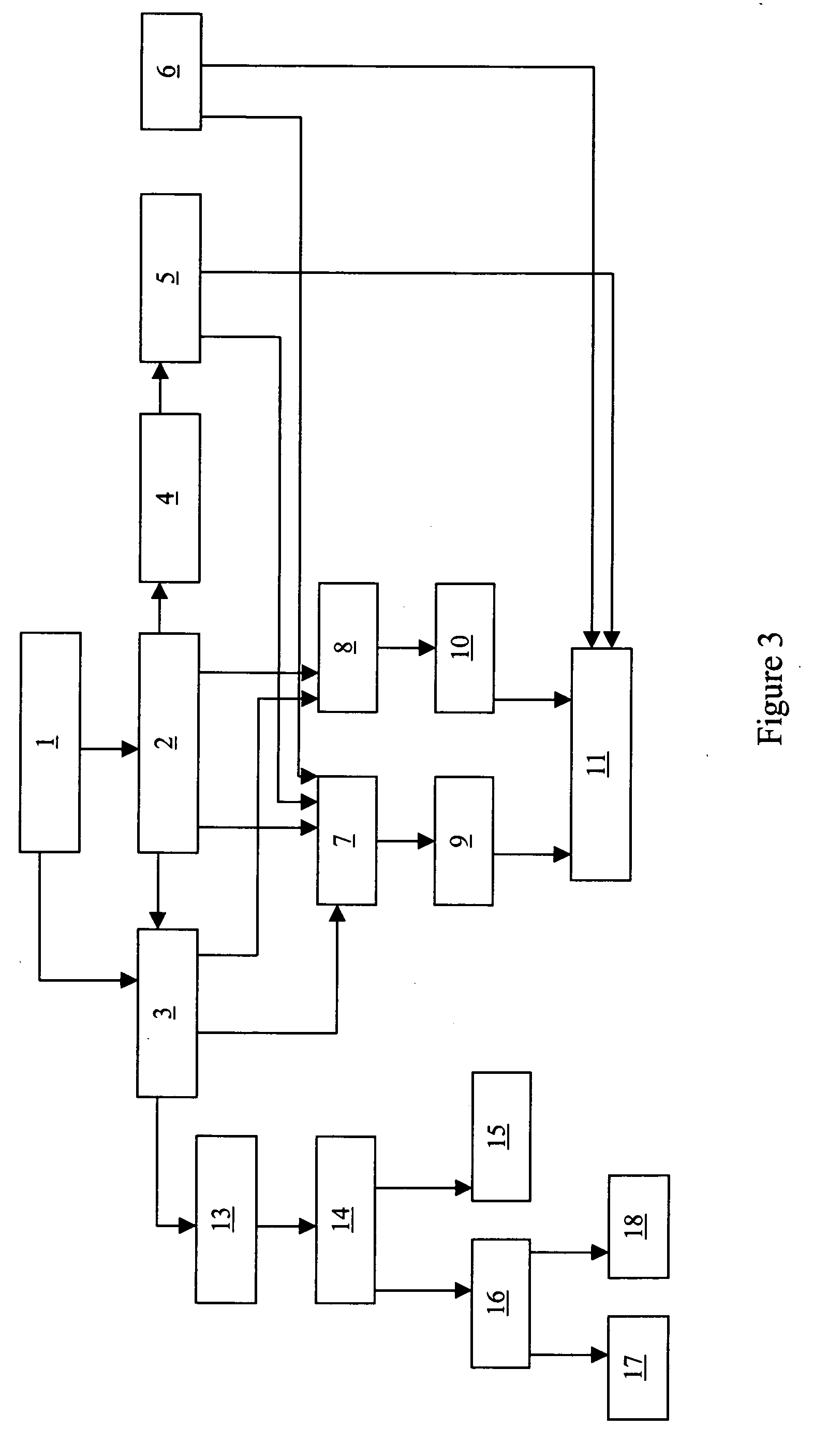

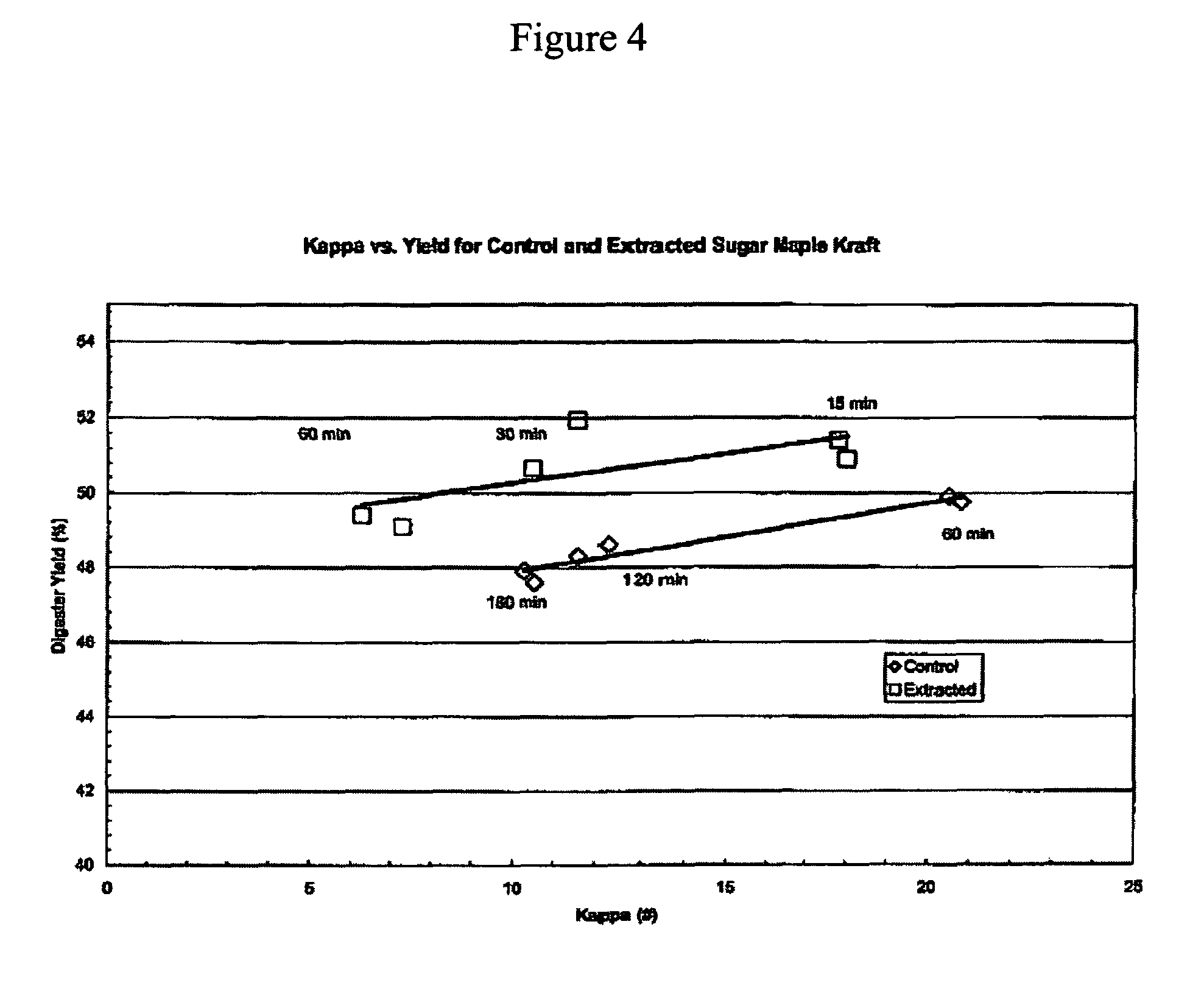

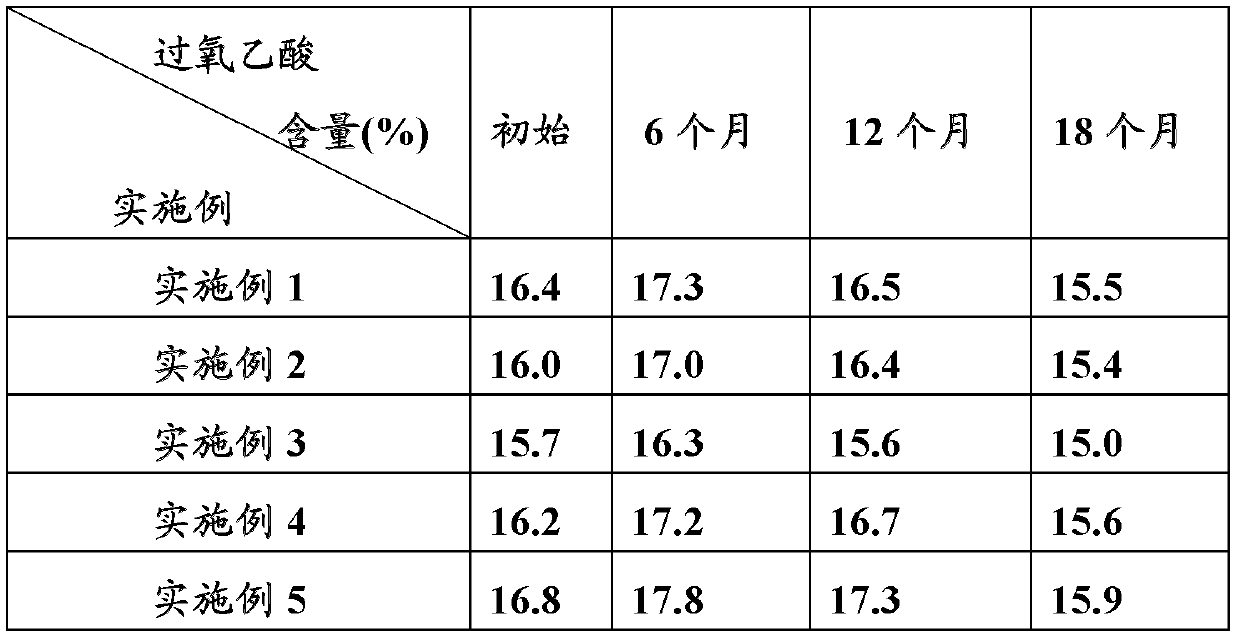

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Compositions and processes for paper production

ActiveUS20080017337A1Avoid brightness lossIncrease brightnessNatural cellulose pulp/paperSpecial paperPaper productionPapermaking

Oxidative compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The oxidative composition and method maintains and / or enhances brightness, prevents yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the oxidative agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

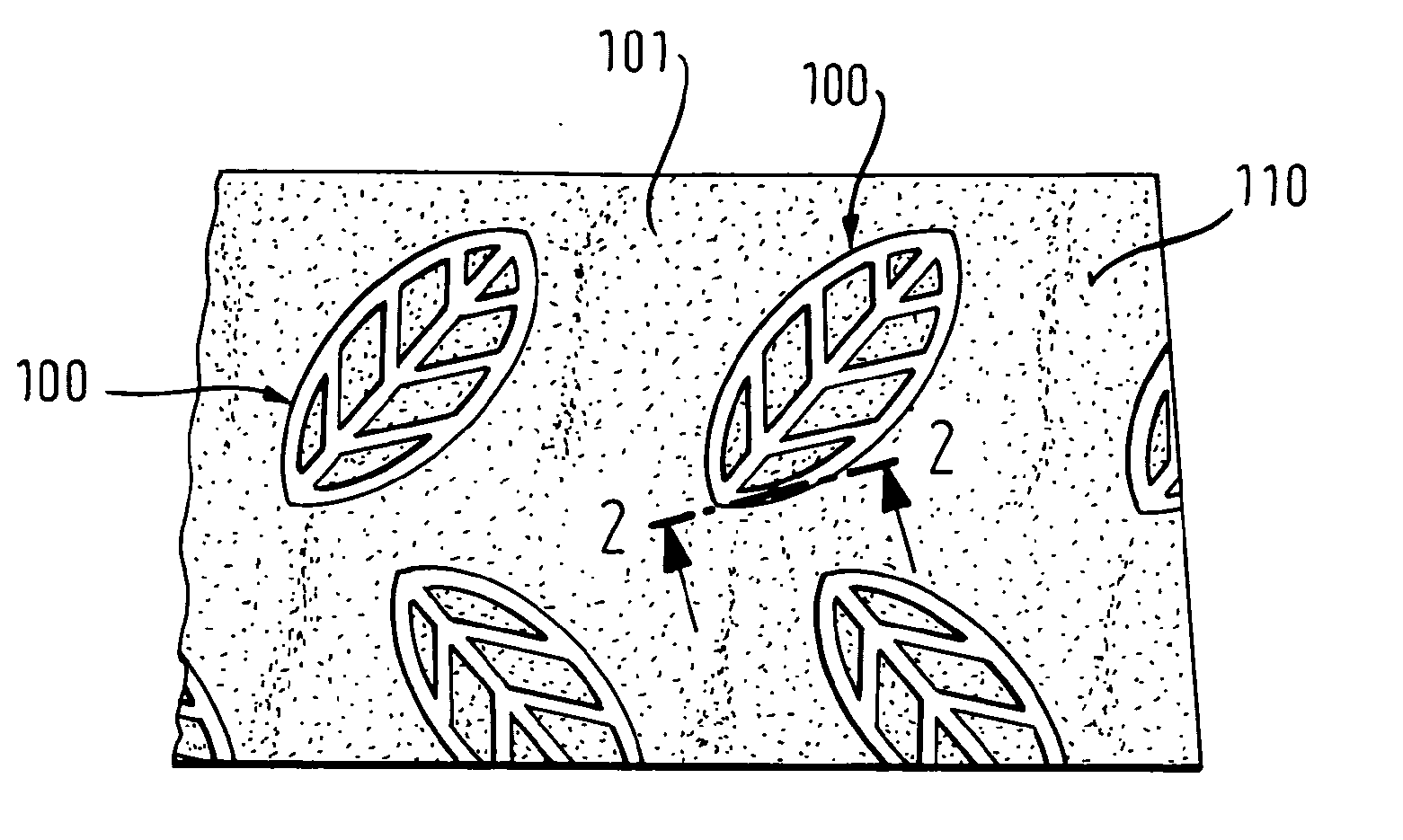

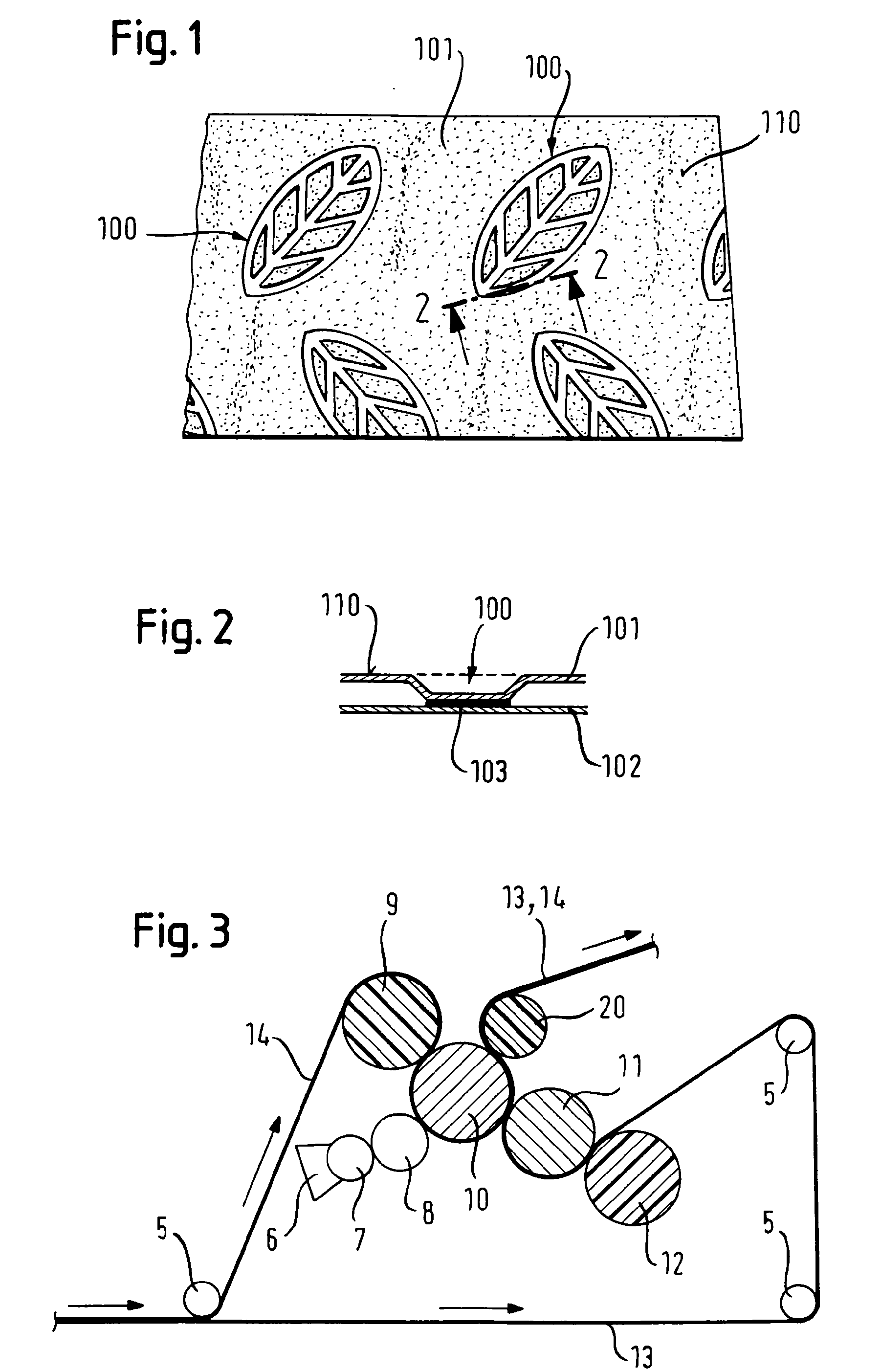

Hygiene or wiping product comprising at least one patterned ply and method for patterning the ply

InactiveUS20110027545A1Prevent precipitationLamination ancillary operationsDecorative surface effectsCellulose fiberEngineering

A hygiene or wiping product includes at least one ply of a fibrous web containing cellulose fibers and having a graphical pattern of at least first and second areas. The ply contains a coloring compound providing a coloration of the ply in the first area. The coloring compound is at least partly chemically destroyed in the second area so that the ply is less colored in the second area than in the first area. A method for producing such a ply includes the steps of providing a fibrous web containing a coloring compound, which provides a uniform coloration in at least a portion of the web, and applying a bleaching agent to a part of the colored portion of the web to at least partly decolor the web in the part generating a pattern of at least first colored and second less colored areas.

Owner:SCA HYGIENE PROD AB

Lignocellulosic materials and the products made therefrom

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

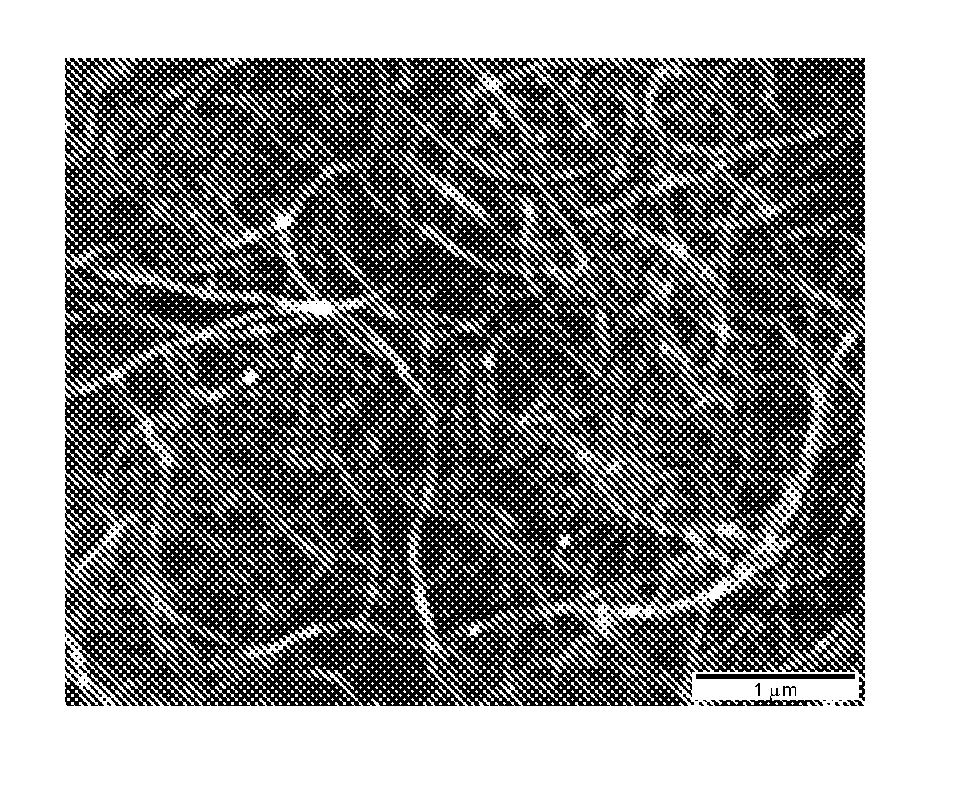

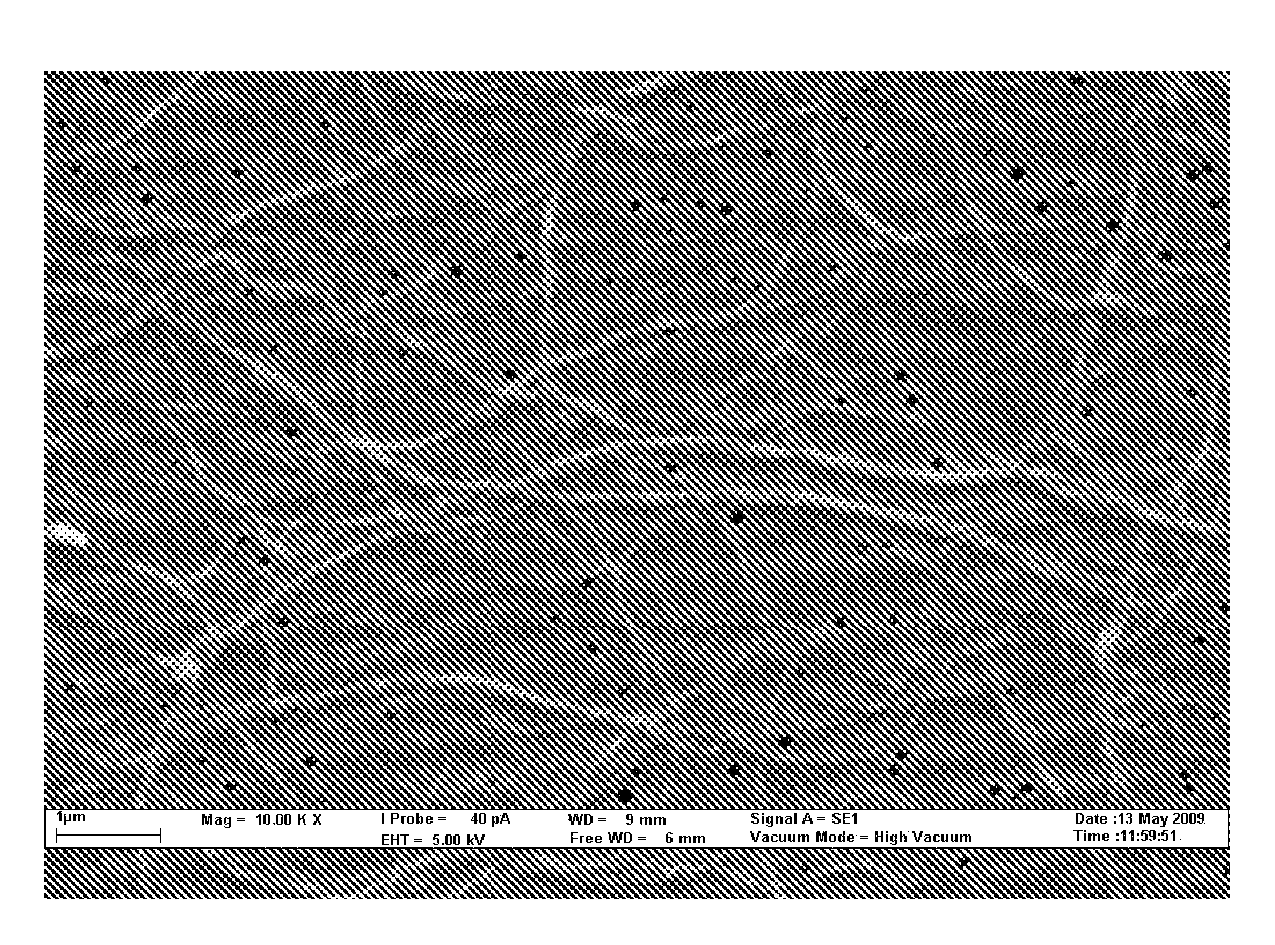

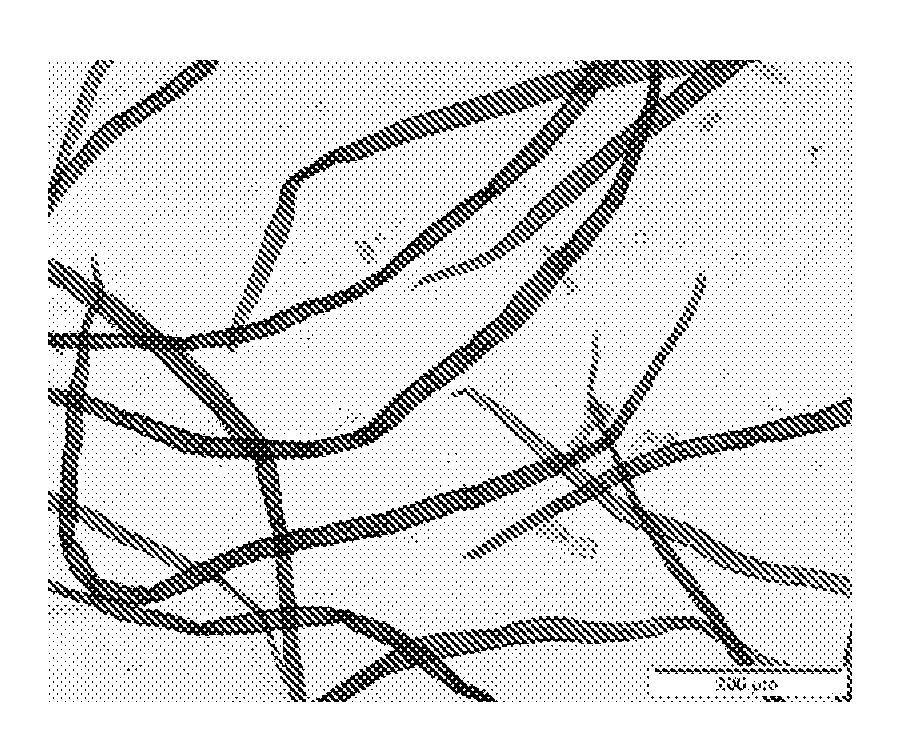

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

InactiveUS20130000855A1Increase productivityPrevents hydrogen bondPulp properties modificationLuminescent/fluorescent substance additionPaper manufacturingPulp and paper industry

Owner:UPM-KYMMENE OYJ

Compositions and processes for paper production

ActiveUS20070062653A1Increase brightnessIncrease resistanceCellulosic pulp after-treatmentNatural cellulose pulp/paperPapermakingPaper production

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

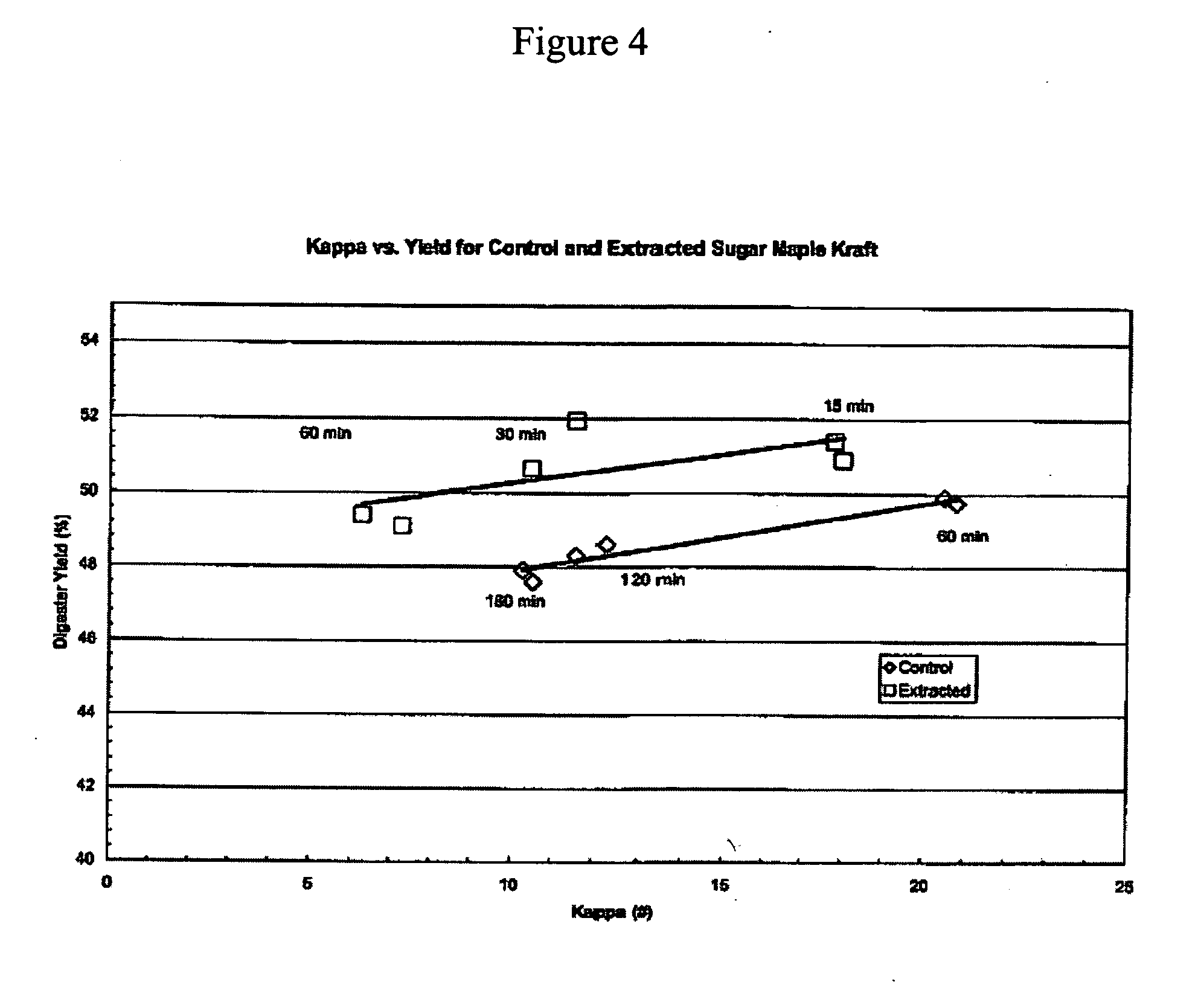

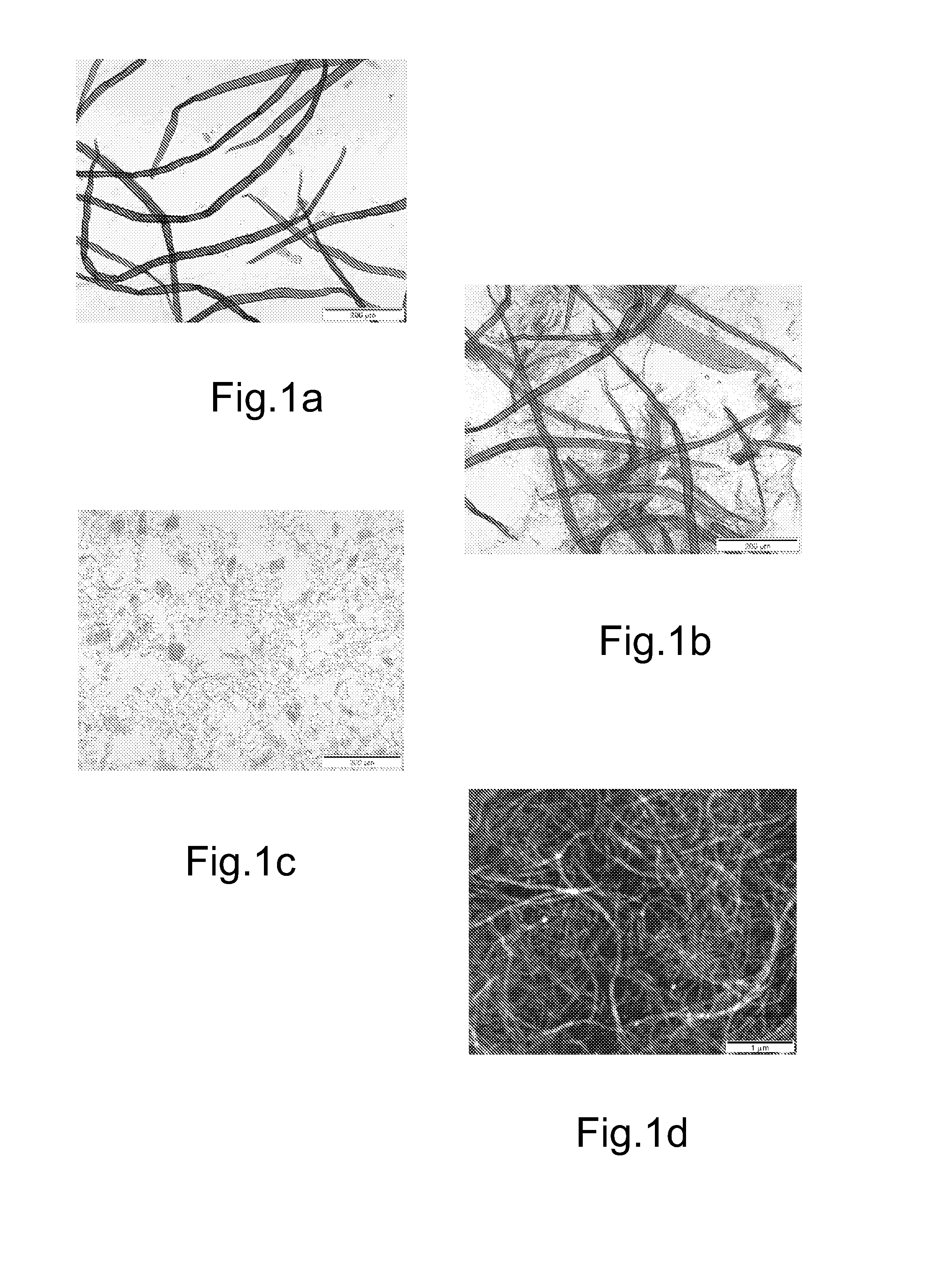

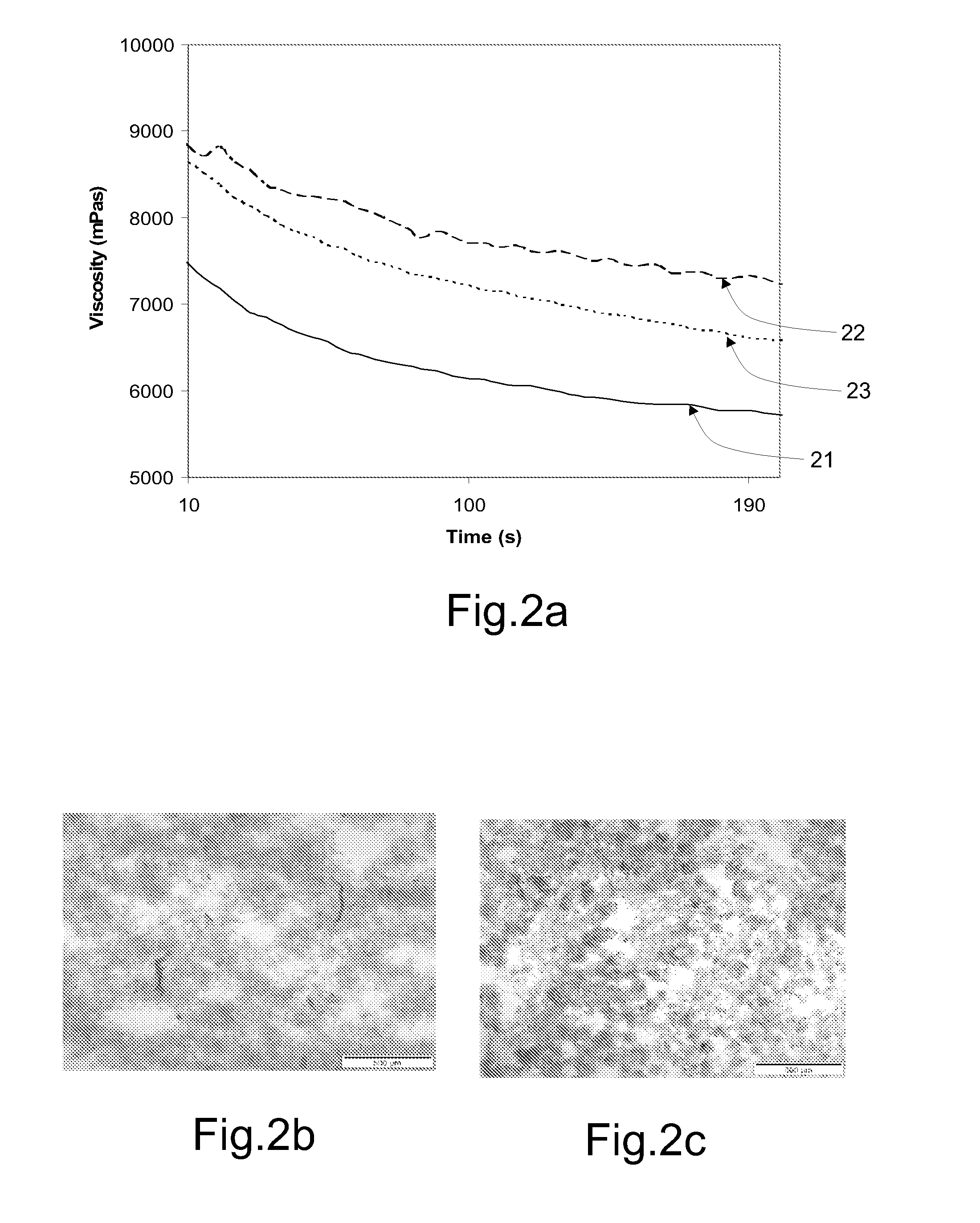

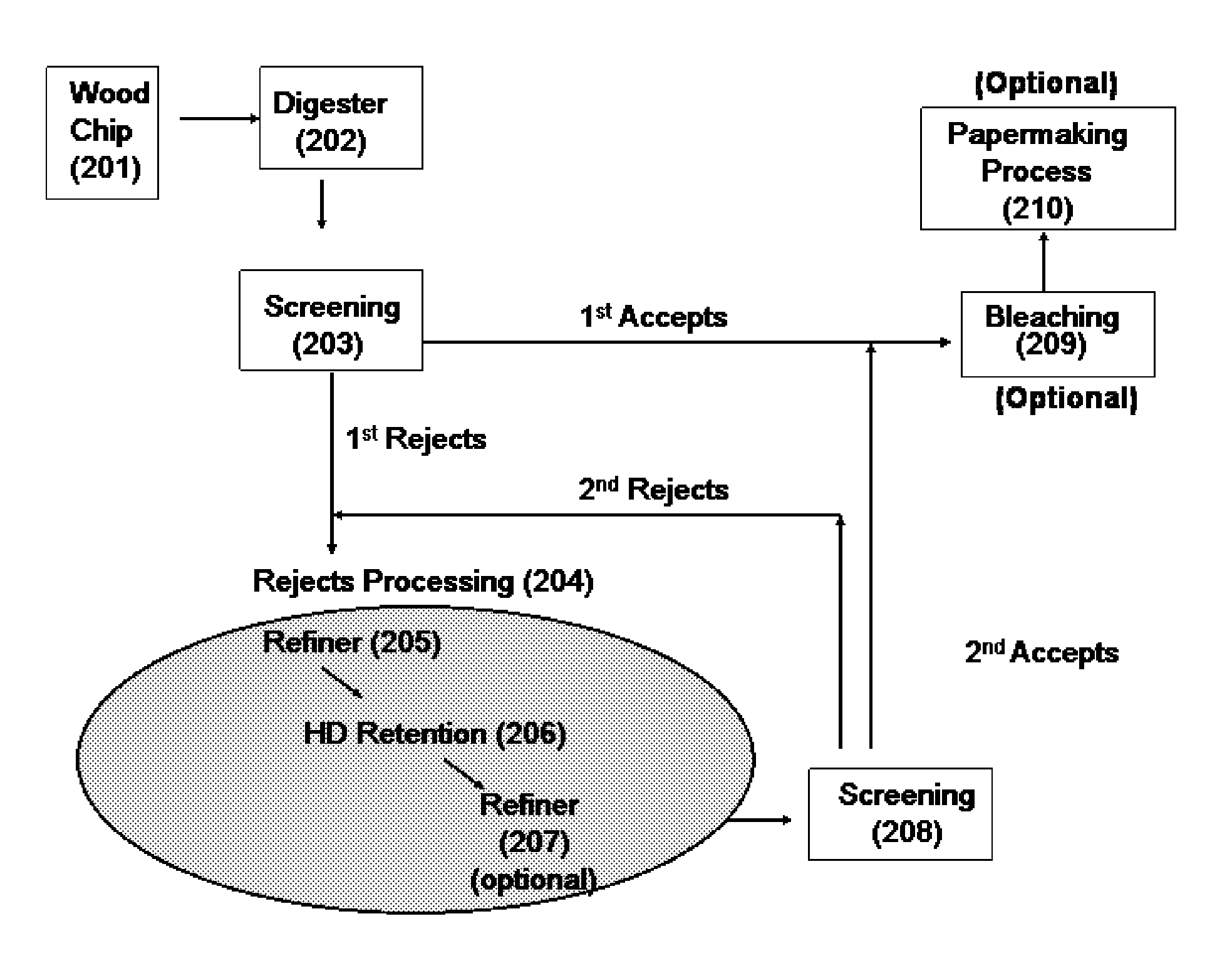

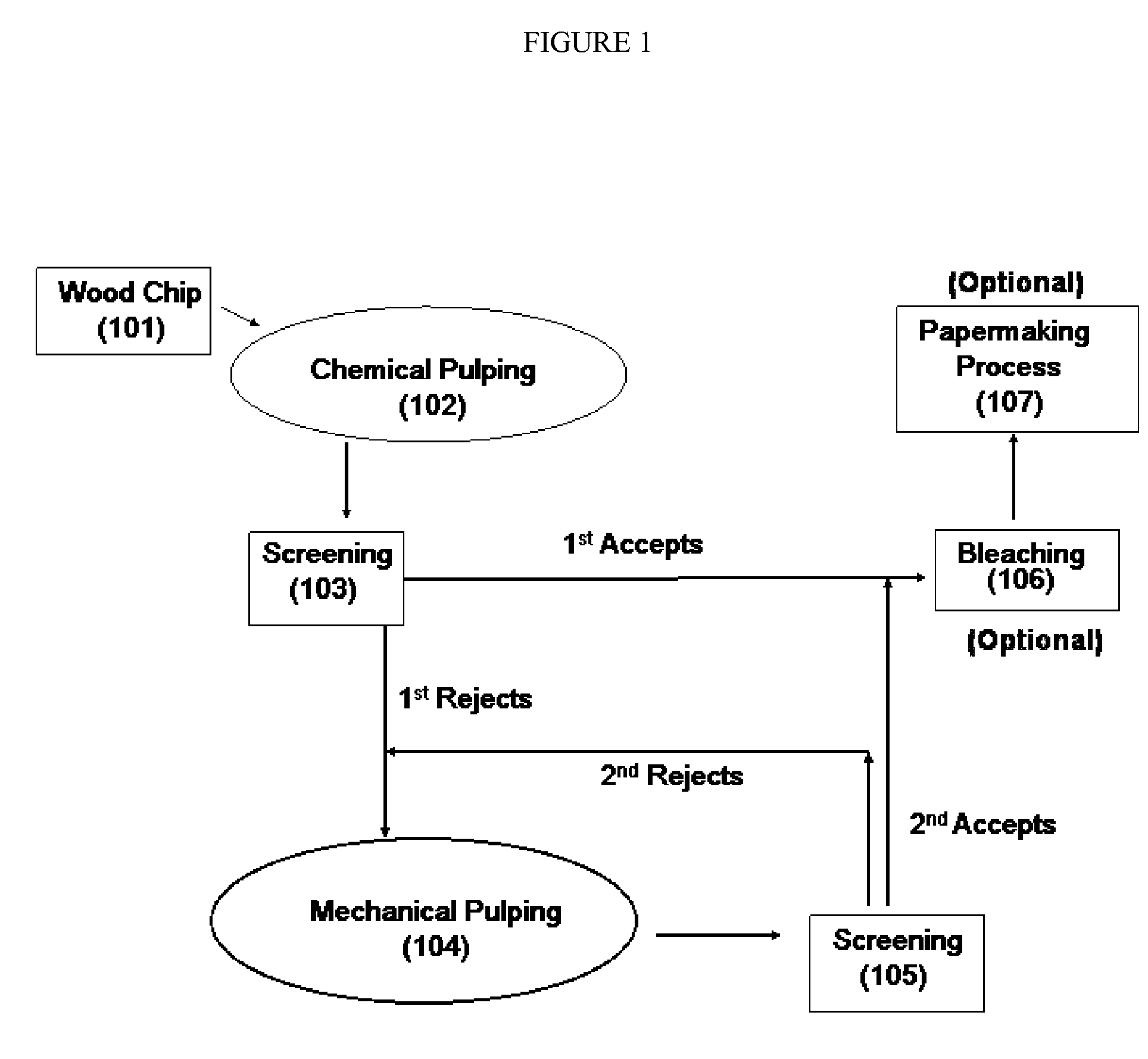

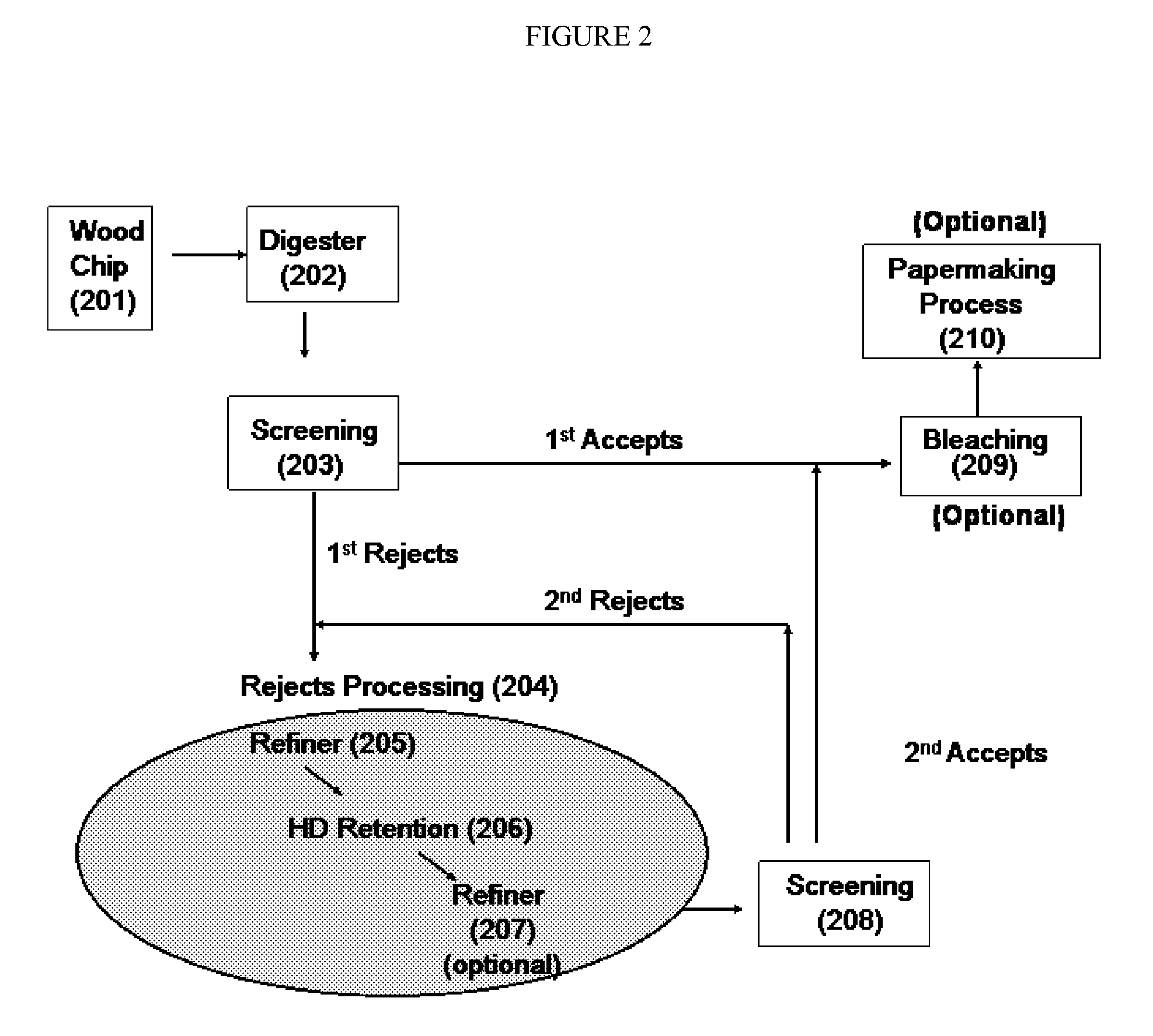

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

Ligno cellulosic materials and the products made therefrom

ActiveUS20110287275A1Maintain good propertiesHigh strengthBiocideAnimal repellantsCellulosePolymer science

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

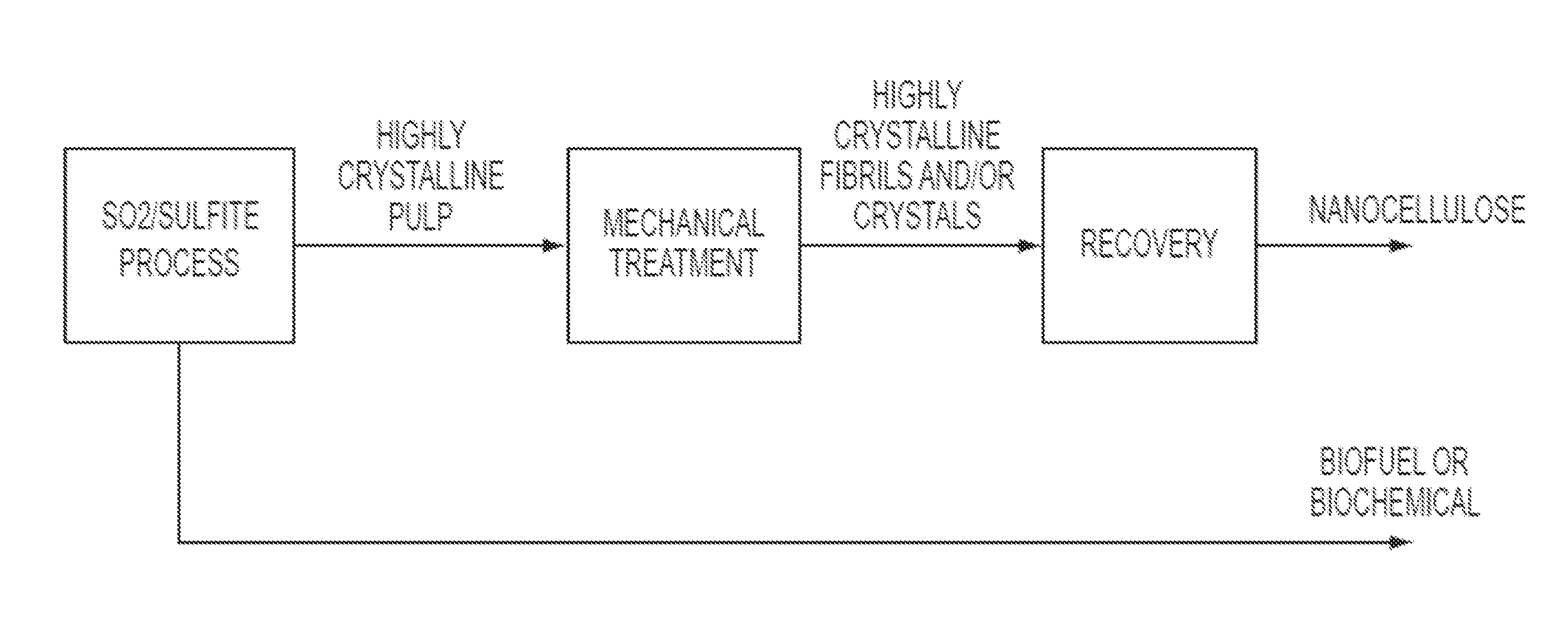

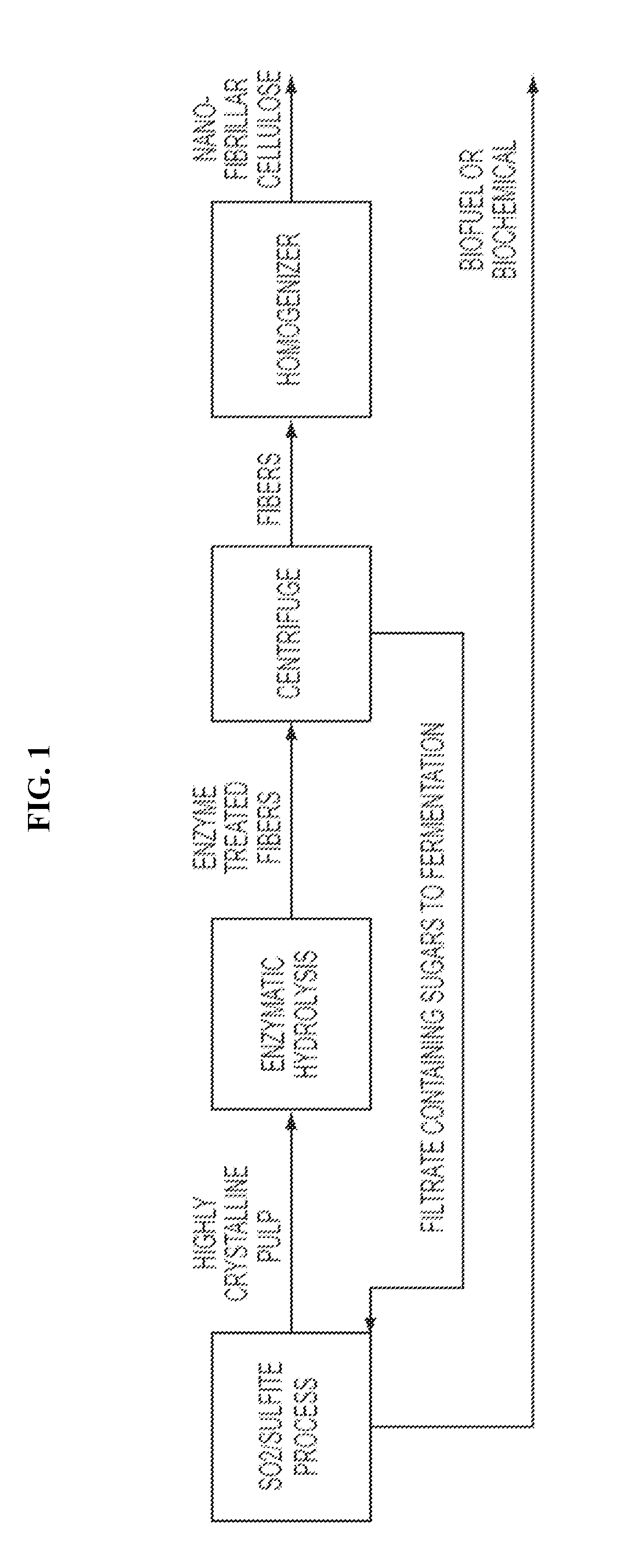

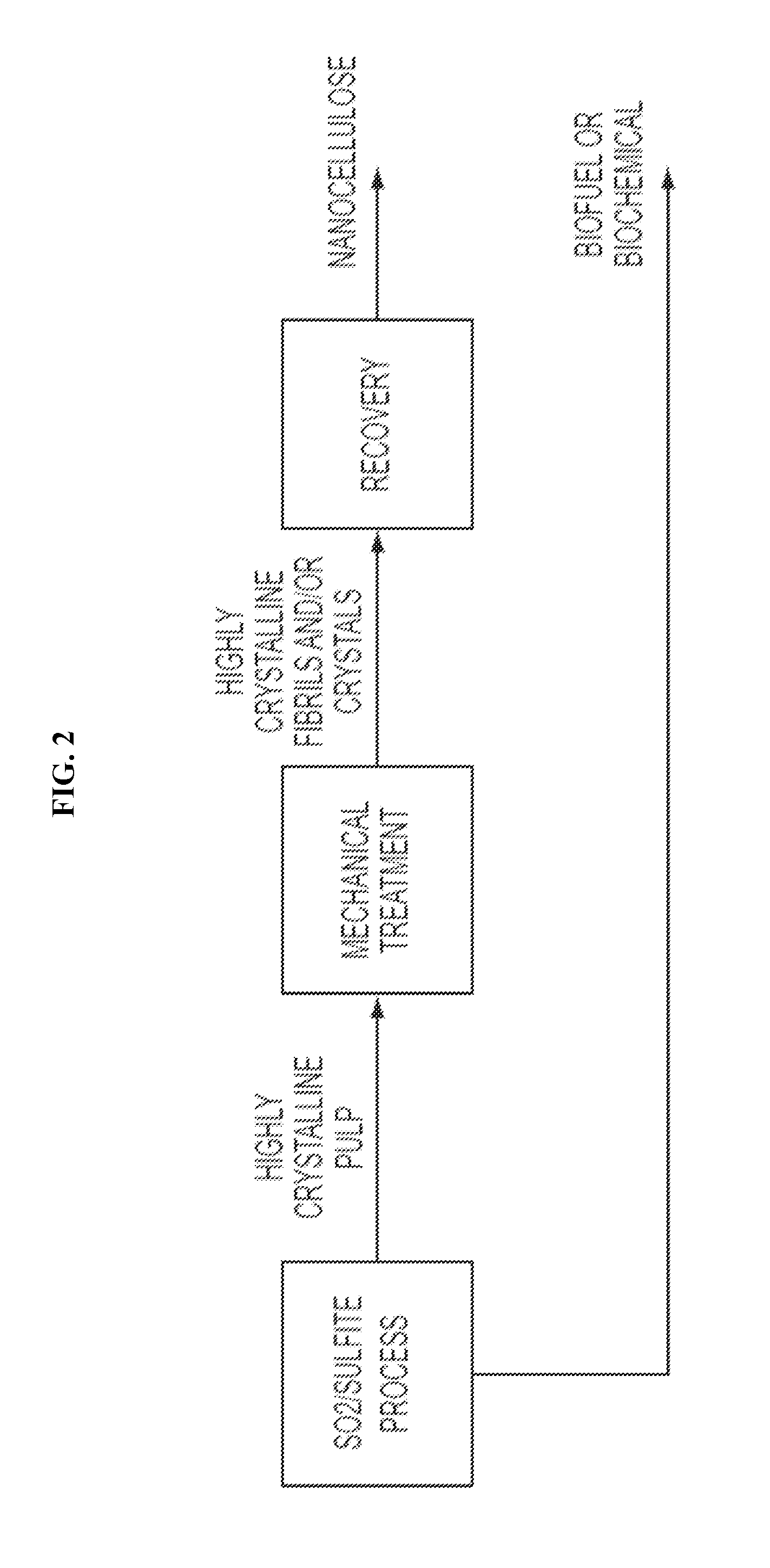

Sulfite-based processes for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with low mechanical energy input. In some variations, the process includes fractionating biomass with sulfur dioxide or a sulfite compound and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Articles of manufacture made from pulp composition

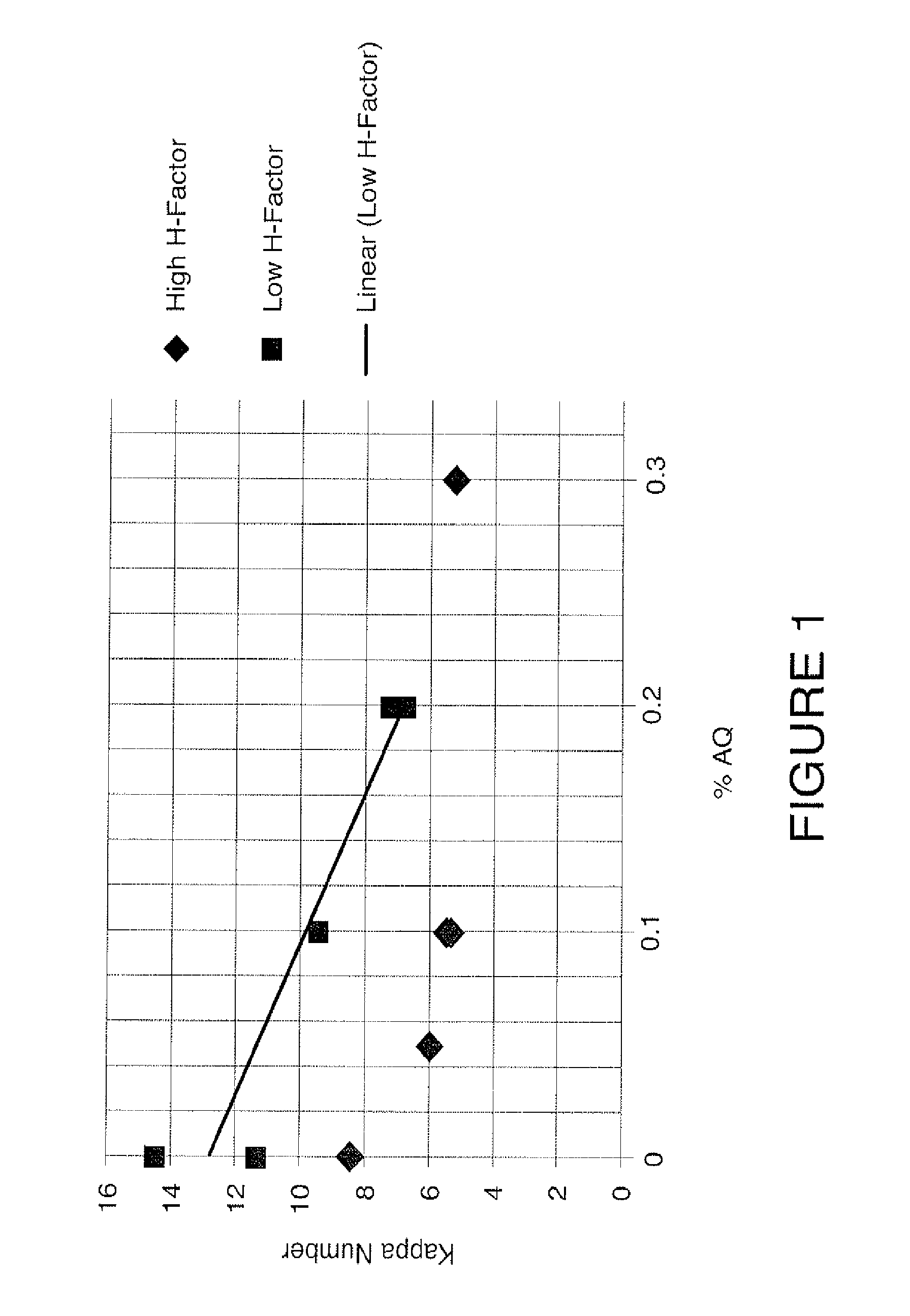

InactiveUS20140205777A1Strength parameter sufficientSynthetic resin layered productsPulp bleachingFiberKappa number

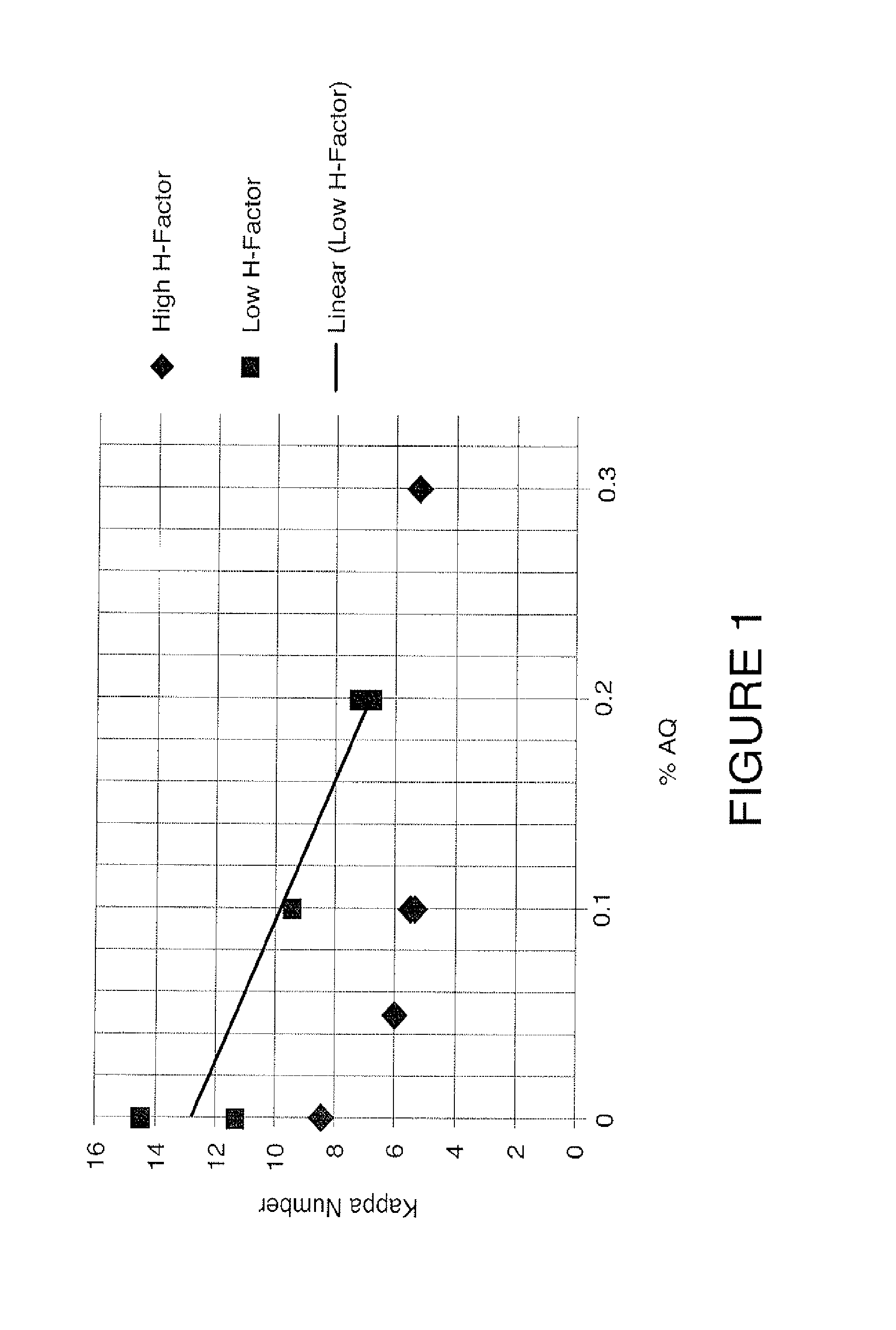

One aspect of the invention relates to an article of manufacture made from a pulp composition comprising an ARF pulp. In one embodiment, the pulp composition made from agricultural renewable fibers (ARF) having low Kappa number with unexpected quality sufficient for papermaking (e.g., high strength parameters and high freeness). In another embodiment, the ARF pulp has ISO brightness of 60% or higher, and unexpected quality sufficient for papermaking (e.g. high strength.parameters and high freeness). In another embodiment, the ARF pulp is made from a pulping process comprising using a high concentration of anthraquinone (AQ).

Owner:CARGILL INC

Chemical mechanical pulping method for cotton haulm raw material

InactiveCN101016702AHigh whitenessHigh yieldPaper/cardboardPulping with inorganic basesChemical reactionUltimate tensile strength

The invention discloses a chemical mechanical pulping method which uses cotton stalk as material, wherein the invention processes the first grinding after the first screw protrusion pre-immersion to replace present APMP technique which comprises two screw protrusion immersion followed with at least two sections of grinding, then holds the pulp after first grinding process for some time to process chemical reaction, at the same time, the invention uses novel additive to replace traditional metal ion chelating agent, Na2SiO3 and MgSO4. Compared with present APMP technique, the invention has low cost and high strength to be used to produce high-level paper.

Owner:SOUTH CHINA UNIV OF TECH

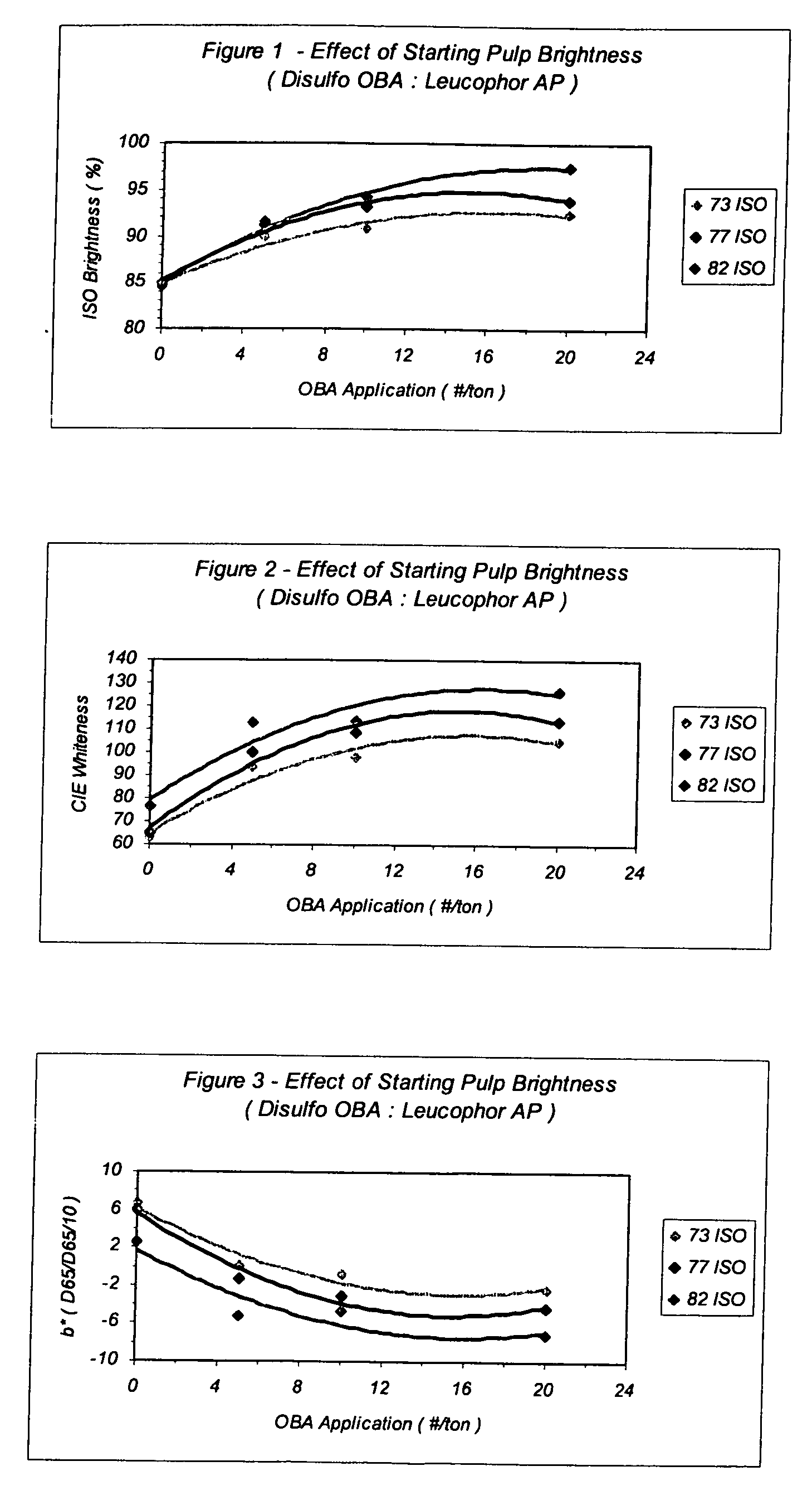

Methods for enhancing brightness and resistance to thermal yellowing of bleached kraft pulp and paper

ActiveUS8246780B2Improve the immunityImproving and stabilizing brightnessCellulosic pulp after-treatmentSpecial paperFluorescencePapermaking

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

Whiten method for preparing bamboo chemical dissolving pulp and application thereof

InactiveCN101446053AIncrease contentImprove physical strengthWashing/displacing pulp-treating liquorsPulp bleachingMaterial consumptionDissolving pulp

Aiming at current situations of cotton and wood dissolving pulp, characters of bamboo material and many disadvantages existing in the existing whiten method for preparing dissolving pulp, the invention provides a whiten method for preparing bamboo material chemical dissolving pulp. The chemical dissolving pulp produced by the invention can be widely applied to derivant industry of celluloses, such as spinning viscose fiber, cellulose nitrate, acetate fiber, etc. The whiten method in the invention uses element-free chlorine bleaching or total chlorine free bleaching, thereby solving the problems existing in the whiten method of bamboo material chemical dissolving pulp and preparing bamboo material chemical dissolving pulp high-efficiently with low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

Improved paper pulp bleaching process

The invention discloses an improved pulp bleaching technique for reed pulp paper-making, which comprises: first, using deoxylignin for bleaching, wherein, slurry concentration 8-20%, temperature 85-130Deg, oxygen consumption quanity 1-4.5Kg per ton slurry, NaOH consumption quanity 1-4Kg per ton slurry, and MgSO4 consumption quantiy 0.1-1.0%; second, using biological enzyme for bleaching, wherien, enzyme adding quanity 20-80g per ton slurry, temperature 30-80Deg, slurry concentration 5-16%, pH value 5-12, slurry hardness 2-8(KMnO4), and time 0.5-4h; third, adding hypochlorite for bleaching. This invention can reduce bleachability and back-yellow value, improves yield and slurry hardness, and decreases pollution to environment.

Owner:XINJIANG BOHU REED IND

Raw paper and production method and application thereof

A raw paper prepared by a mixed pulp including straw pulp, which can be used to prepare textbooks, writing papers and office paper with good performance, and the producing method of said raw paper are provided. The weight proportion of the straw pulp in the mixed stock is from 10% to 100%, and the straw pulp has a hardness of KMnO4 value 10-17, an average fiber length of 0.1-2.5 mm, a tensile index of 23-57 Nm / g, a tearing index of 3.0-6.0 mN·m2 / g, a folding endurance index of 2-6 kPa·m2 / g and a whiteness of 28-50%. Either, the L value of the hue of said raw paper is 65-95, a value is 0-5, and b value is 0-40. The KMnO4 value of hardness of the pulp after oxygen delignification is 10-14. The method includes: adding grass-series raw material into a digester, then adding cooking liquor, heating the cooking liquor to 100-200°, pressurizing to 0.3-0.9 MPa, cooking for 150-250 min, extruding the pulp, washing and obtaining the straw pulp. The amount of the ammonium sulfite of the cooking reagent is 5-20% of the absolute dry material, and the amount of the sodium hydroxide is 0-15% of the absolute dry material, the liquor ratio is 1:2-15.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

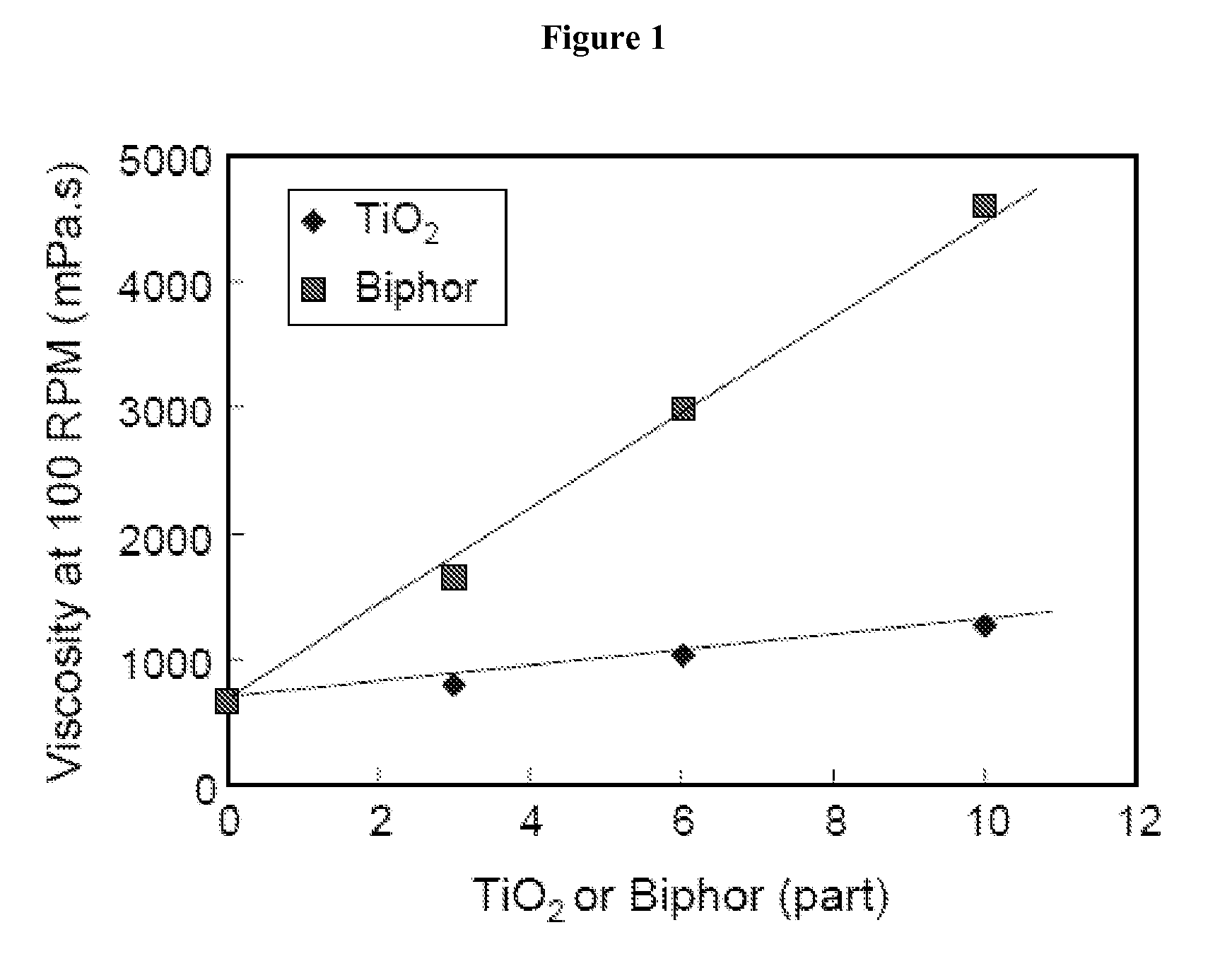

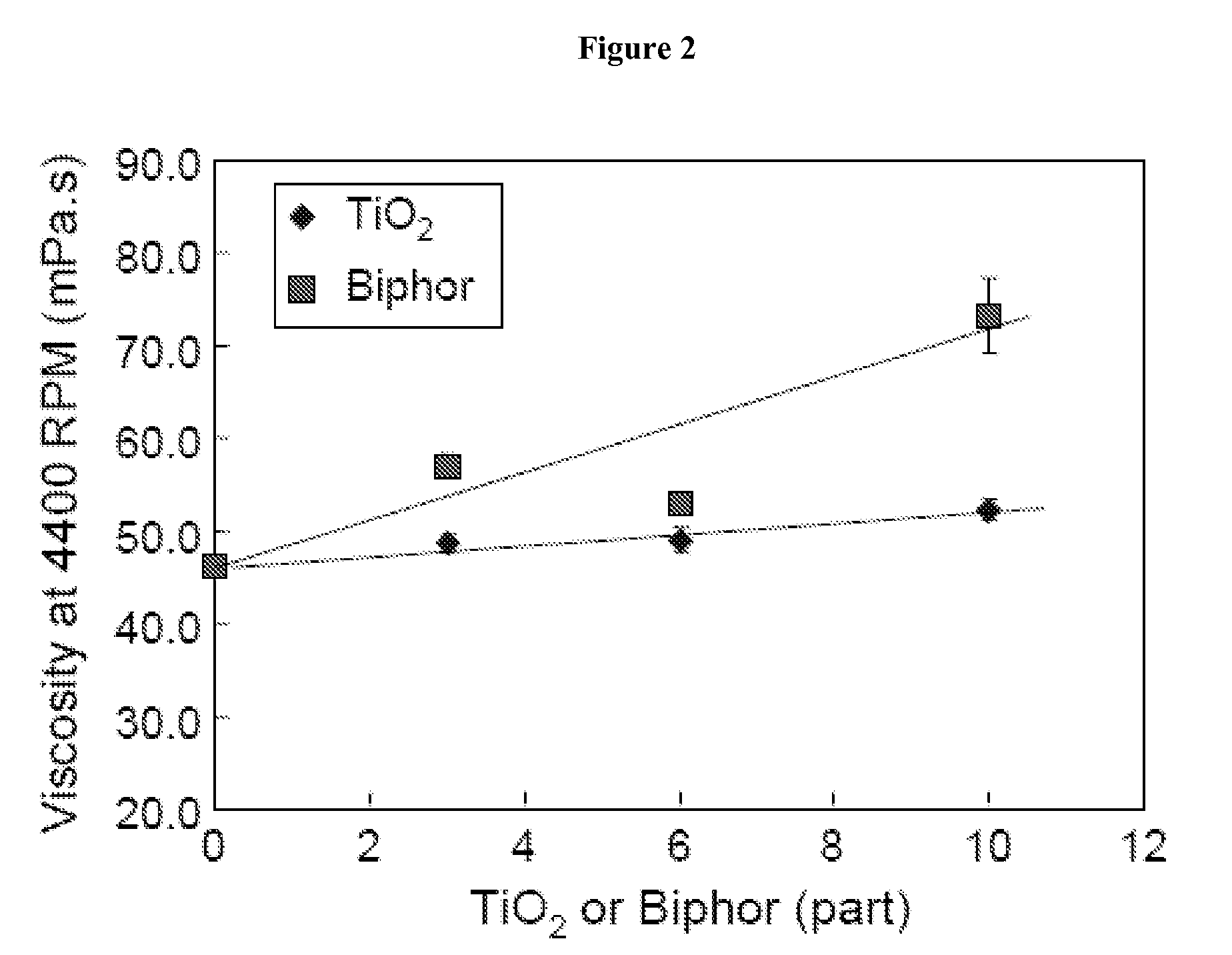

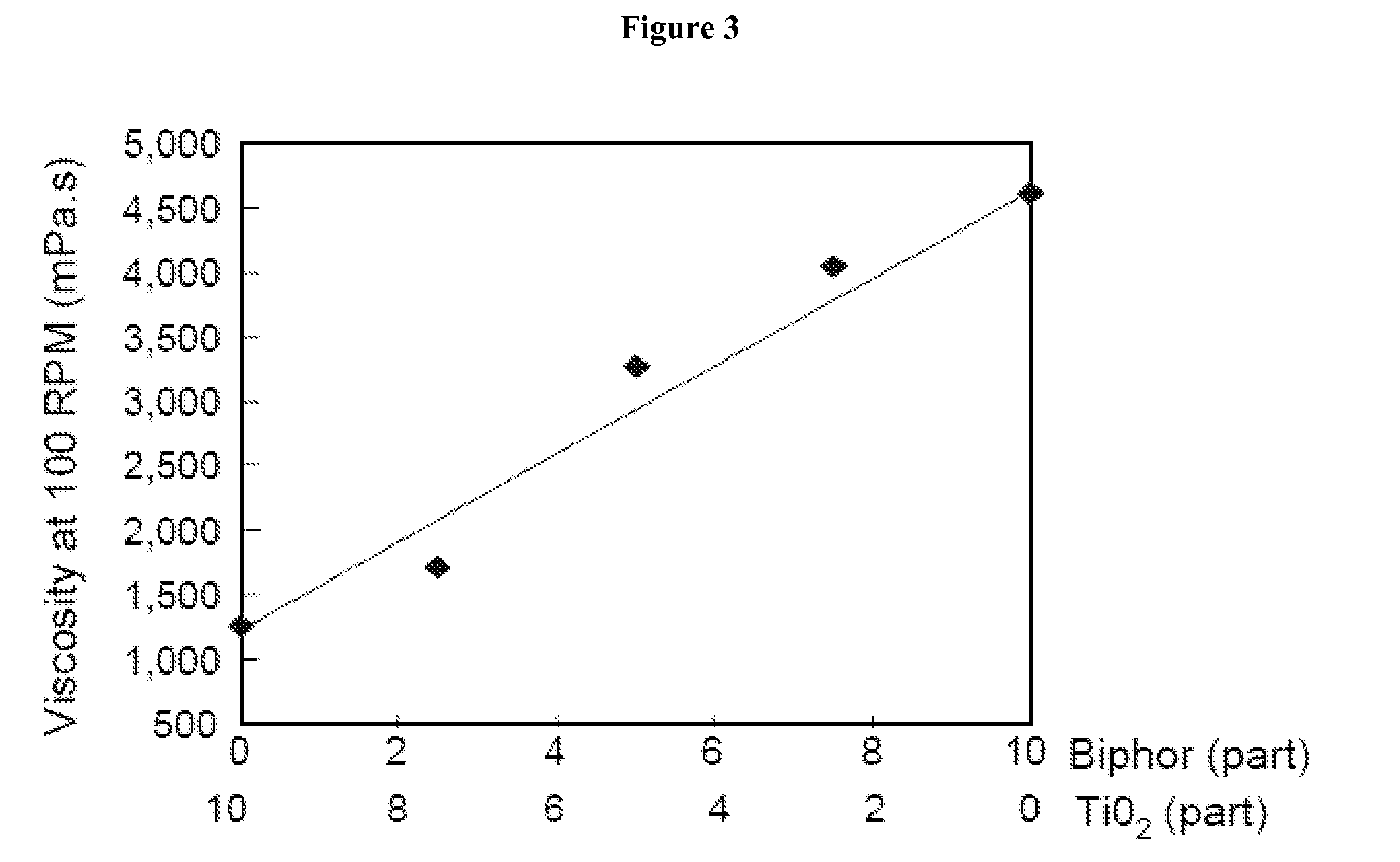

Use of Aluminum Phosphate, Polyphosphate and Metaphosphate Particles in Paper Coating Applications

InactiveUS20100203318A1Avoid smudgingSimple compositionDefoamers additionCoatings with pigmentsMetallurgyPolyphosphate

Provided herein are coating compositions for paper comprising aluminum phosphate, aluminum metaphosphate, aluminum orthophosphate and / or aluminum polyphosphate pigments. Methods of making and using the compositions are described.

Owner:BUNGE AMORPHIC SOLUTIONS +1

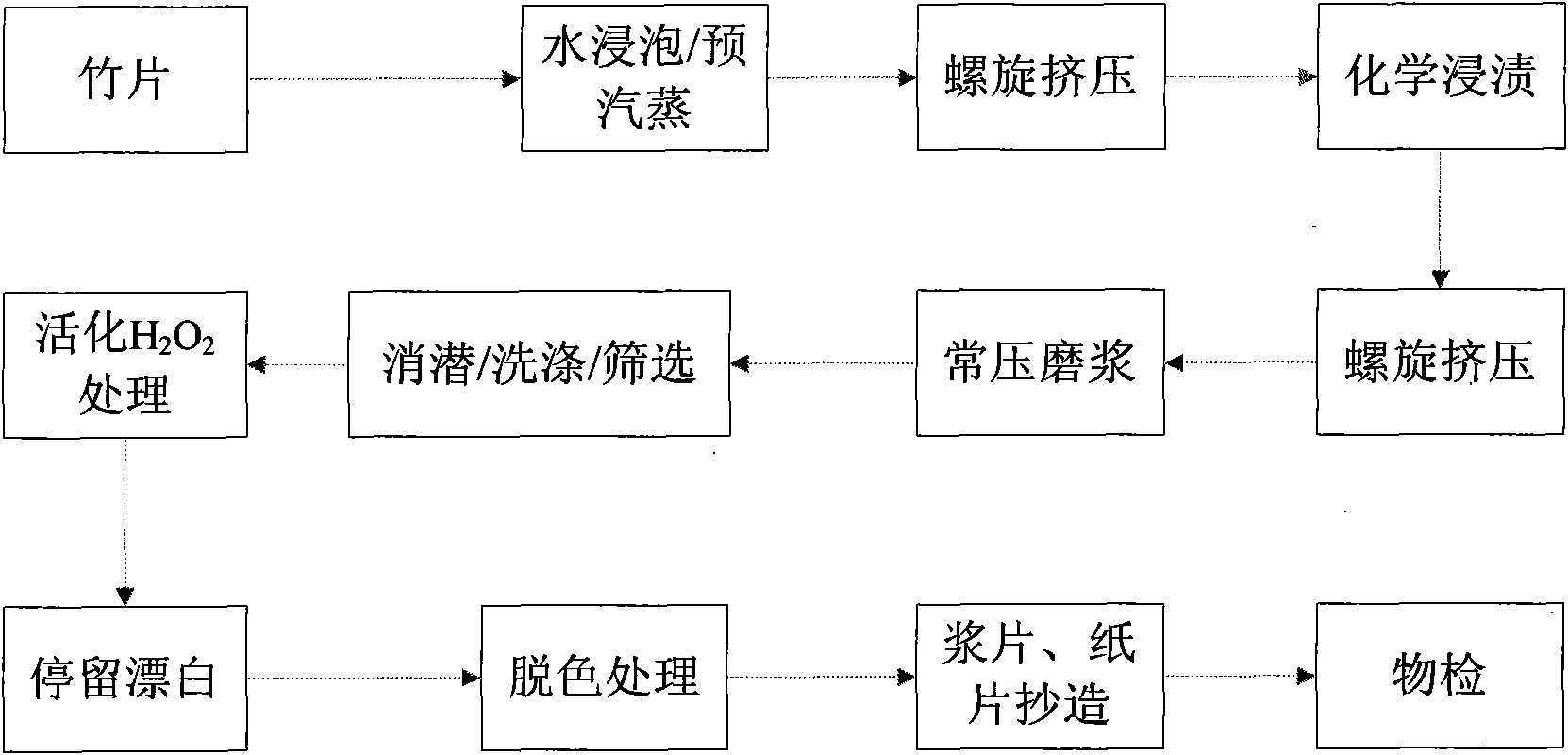

High-whiteness bleaching method for high-yield bamboo wood pulp

ActiveCN101638859AReduce dosageImprove bleaching efficiencyNon-macromolecular organic additionPulp bleachingHigh concentrationPre treatment

The invention discloses a high-whiteness bleaching method for high-yield bamboo wood pulp. The high-whiteness bleaching method comprises the following steps: firstly, using an extruder to carry out enhanced mechanical treatment on pretreated bamboo sheets; using a transition metal ion remover and the like to carrying out chemical impregnating treatment on extruded cizu materials; then, carrying out secondary spiral extrusion before pulping, straightening and screening; secondarily, using a peroxide activating agent and peroxide to carry out the activating treatment of 20 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 30-60 minutes; thirdly, using a chlorine-free bleaching medicine H2O2 to carry out high-concentration rested bleaching of 10-30 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 60-180 minutes; and using a decoloring agent of thiourea dioxide to decolour the bamboo pulp, remove a ground color, adjust a color phase and improve the bleaching white content. The invention forcefully and mechanically treats the bamboo sheets, synchronously realizes pulping, the removal of transition metal ions and deep extractionsand the break of complex cells, reduces the consumption of the bleaching medicine and improves the bleaching efficiency.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Water hyacinth fibre paste and preparation method thereof

InactiveCN101105017AGood papermaking effectLuminescent/fluorescent substance additionChemical/chemomechanical pulpFiberCalcium hydroxide

A water hyacinth fiber pulp used as fibrous raw material for paper making is provided, which is made from fibers of water hyacinth plant of the Pontederiaceae family by paper pulp process technique. The water hyacinth fiber pulp is characterized in that the fiber pulp contains water hyacinth fibers, calcium hydroxide, talc powder, kaolin and titanium dioxide. The water hyacinth contains high-quality fibers and the fiber pulp processed from water hyacinth is used as chemical raw material for paper making and cellulose production. The invention utilizes water hyacinth fibers as raw material, which is improvement of the prior art, and helps to protect environment and restore ecological balance and simultaneously solves the problem that the water hyacinth enrichment causes the blockage of water transport, resulting in the hazard to global traffic. The invention changes waste water hyacinth to a new resource for human beings. The invention has significant social value as well as economic value.

Owner:梁浩东 +2

Product and processes from an integrated forest biorefinery

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method and chemical composition to improve efficiency of mechanical pulp

InactiveUS20100224333A1Improved papermaking processReduce energy consumptionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpChemical compositionBrightness perception

The invention provides a composition of matter and a method, which enhance the process of mechanically pulping paper precursors. The composition of matter includes a small quantity of a reducing agent and a source of alkali. When added to the pulped material, e.g., wood chips, before or during mechanical pulping, the composition reduces the energy cost of the operation. In addition, not only does the composition also does not reduce the brightness of pulp, the composition can also enhance the effectiveness of subsequent bleaching processes.

Owner:ECOLAB USA INC

Stable peroxyacetic acid solution

The invention discloses a stable peroxyacetic acid solution, a preparation method of the stable peroxyacetic acid solution, and a stabilizer for preparation of the stable peroxyacetic acid solution. The stabilizer comprises a component A and a component B. The component A is a diethylene triamine penta (methylene phosphonic acid) aqueous solution having the concentration of 45 to 55 wt% or an amino trimethylene phosphonic acid aqueous solution having the concentration of 45 to 55 wt% or a mixture of the diethylene triamine penta (methylene phosphonic acid) aqueous solution and the amino trimethylene phosphonic acid aqueous solution. The component B is a sodium hydroxide aqueous solution which has the concentration of 10 to 15 wt% and is added with 50 to 100ppm of complexation components. The stable peroxyacetic acid solution comprises 5 to 25% of peroxyacetic acid, 15 to 25% of hydrogen peroxide, 0.04 to 0.06% of the component A, 0.15 to 0.25% of the component B and the balance water.The stable peroxyacetic acid solution can be stored at a normal temperature for 18 months or more, has good stability, and effectively solves the safety and economy problems of the existing peroxyacetic acid solution. The stable peroxyacetic acid solution has a simple formula, does not contain components of lead, arsenic and sulfates limited by the GB19104-2003 standard, and has environmental benefits.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

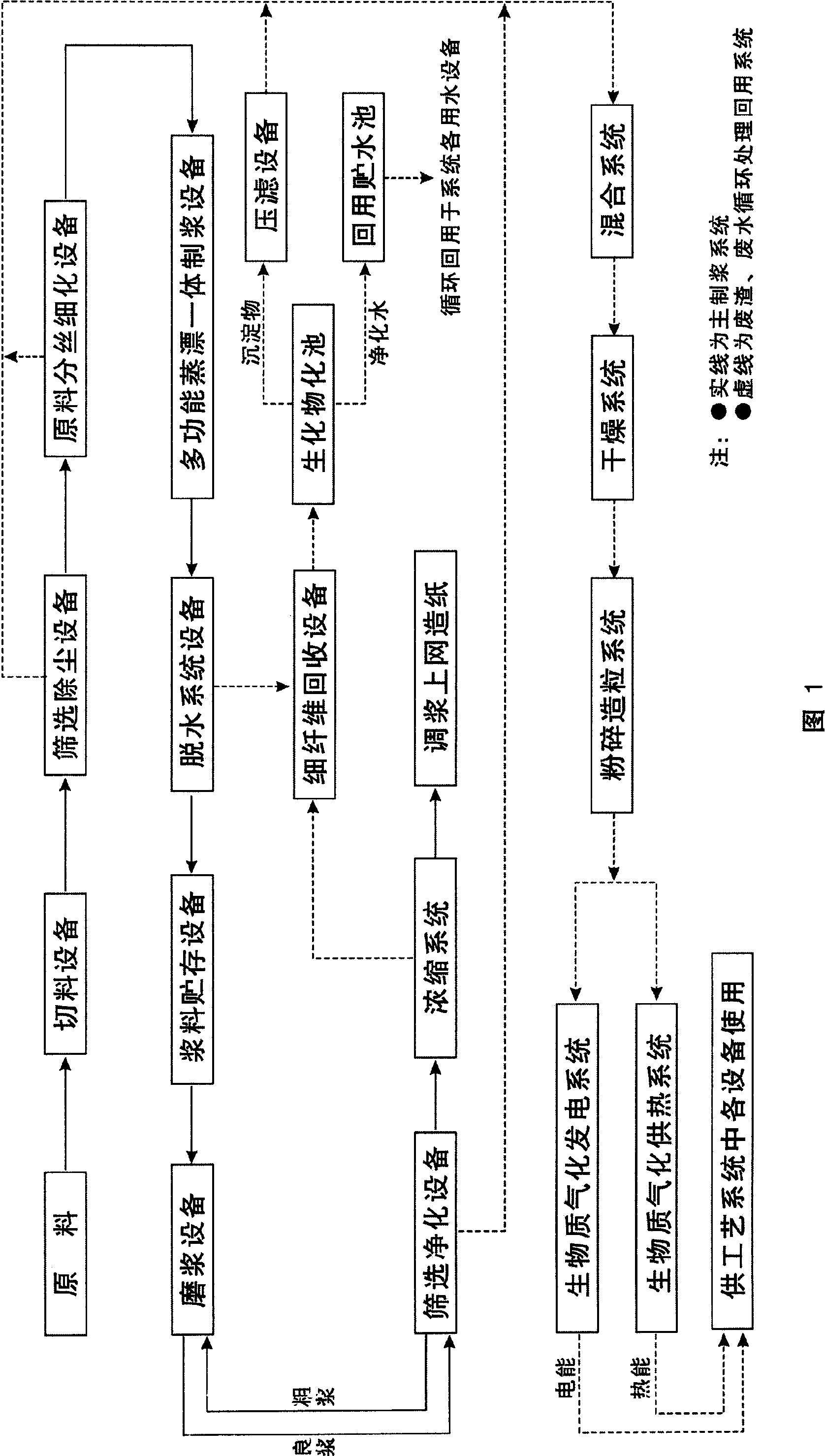

Environment friendly energy-saving circulation type non-pollution pulping process and its system apparatus

InactiveCN101319471ASolve pollutionSolve the problem of energy consumptionPretreatment with alkaline reacting compoundsPretreatment with acid reacting compoundsElectricityBlack liquor

The invention relates to an environment-friendly energy-saving cyclic-type pollution-free pulping process and a system device thereof. The process comprises the following procedures of cutting material, screening, dedusting, thinning raw material, integrating steaming with bleaching, grinding pulp, screening, purifying, concentrating, treating water, granulating, supplying heat and generating electricity through biomass gasification, etc. The procedure of integrating steaming with bleaching comprises the following processes of presoaking, steaming, cooking and bleaching the raw material, wherein a presoaking agent is added to carry out presoaking for 30-60 min at a temperature between 50 and 100 DEG C; a steaming- cooking agent is added after presoaking, and oxygen is supplied to carry out steaming- cooking delignification reaction at the same time, with oxygen pressure kept between 0.1 and 0.3 MPa, for 45-90 min, at a temperature between 60 and 100 DEG C; bleaching agent is added after steaming- cooking, and the oxygen pressure continues to be kept, and bleaching reaction is carried out for 45-120 min at a temperature between 60 and 100 DEG C. The pulping process solves the pollution problems of lack liquor from pulping, especially straw pulping, washing sewage, discharged waste residue, etc., and solves the problem that is complex working procedure and serious pollution widely exist in the prior pulping in a real sense.

Owner:李刚荣

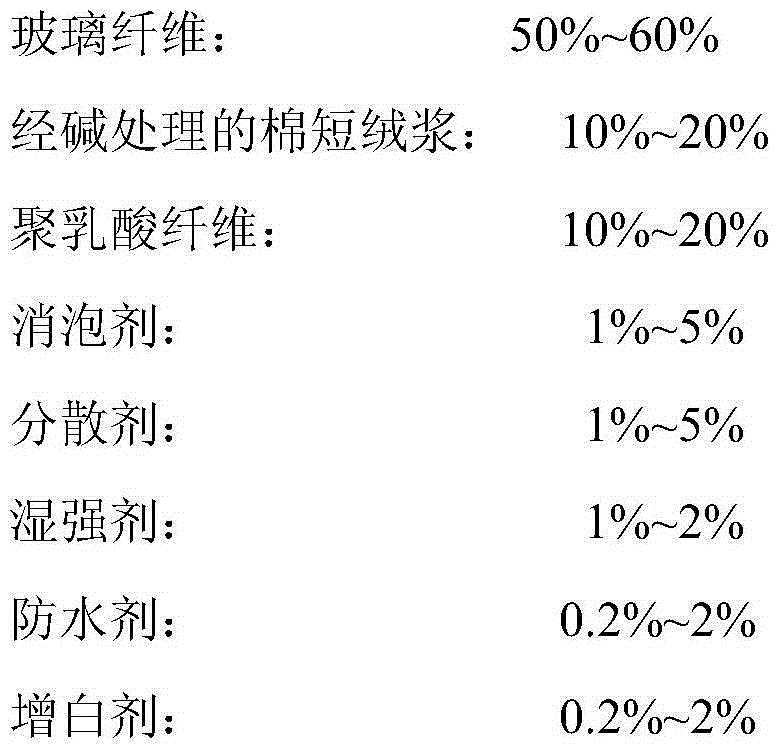

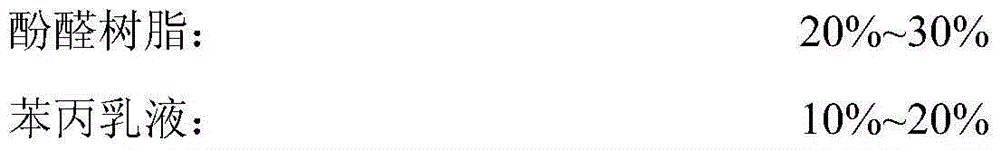

Flame-retardant air filter paper, preparation method therefor and application thereof

InactiveCN104894913AHigh porositySmall apertureCellulosic pulp after-treatmentDefoamers additionFiberAir filter

The invention discloses air flame-retardant air filter paper which comprises raw paper and an imprgnant for impregnating the raw paper, wherein the raw paper comprises glass fibers, cotton linter pulp treated by alkali, polylactic acid fibers, a defoaming agent, a dispersant,a wet strength agent, a water-proofing agent and a brightening agent; the imprgnant comprises phenolic resin, styrene-acrylic emulsion, normal hexane, methanol, N-hydroxymethyl acrylamide, a wetting agent, a flame retardant N, N '-piperazinetetra(phenol) phosphoramidate and a flame retardant decabromodiphenyl ethane. The invention further discloses a preparation method for the flame-retardant air filter paper. The air filter paper prepared by the preparation method is remarkable, high and lasting in flame retardant efficiency, has no great effect on the mechanical performance of the filter paper, and can be widely applied to the field of engines.

Owner:杭州特种纸业有限公司

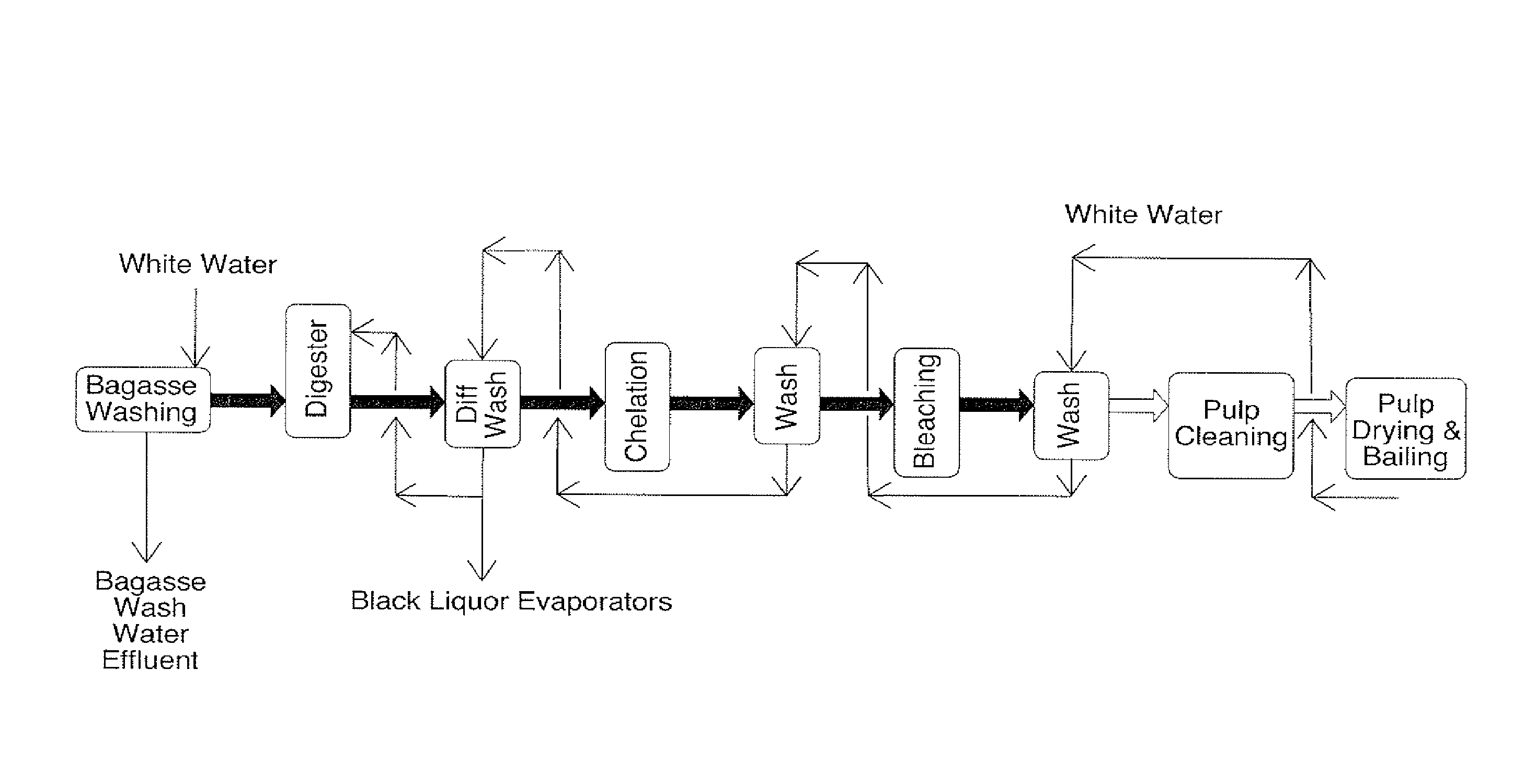

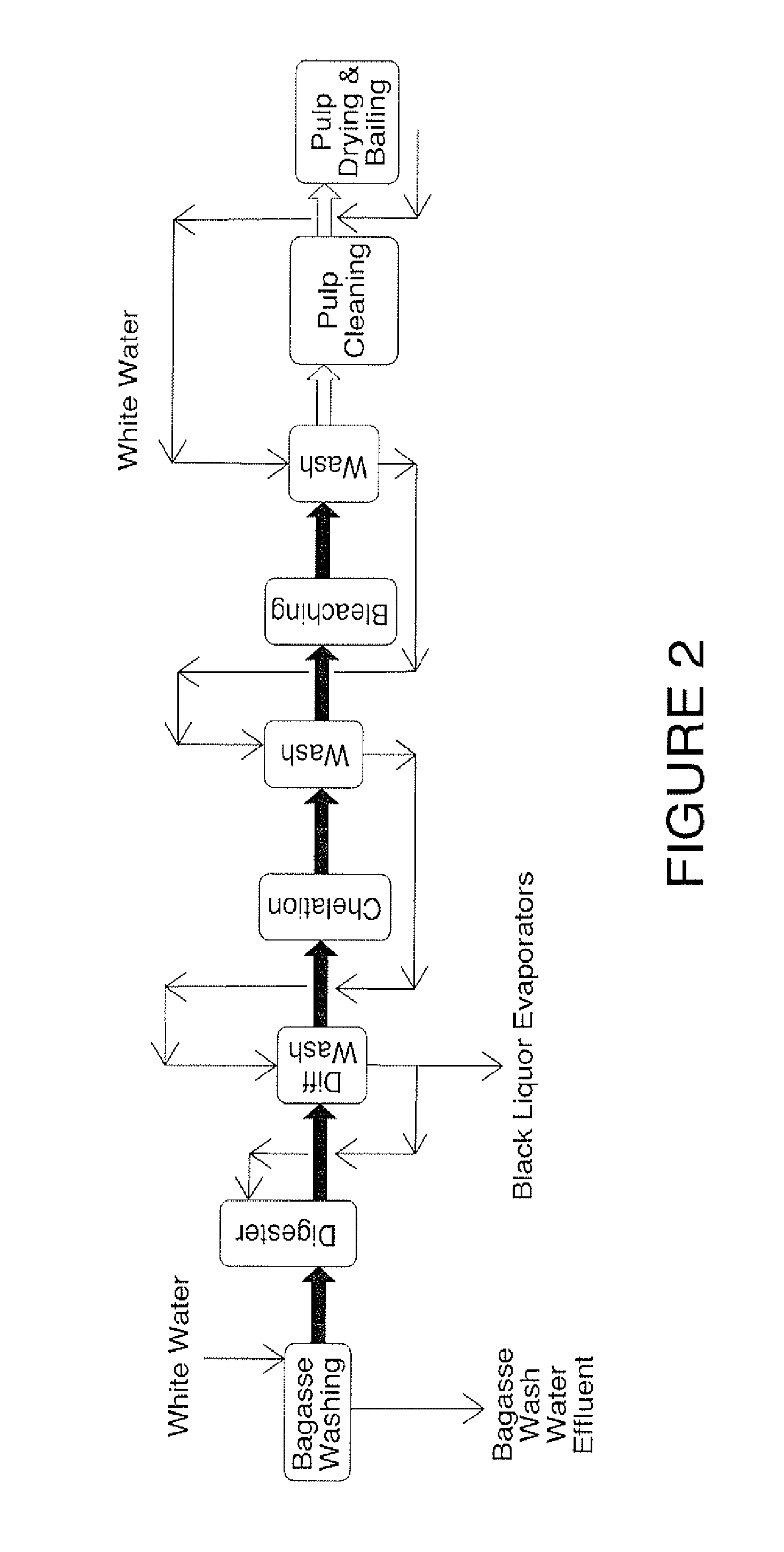

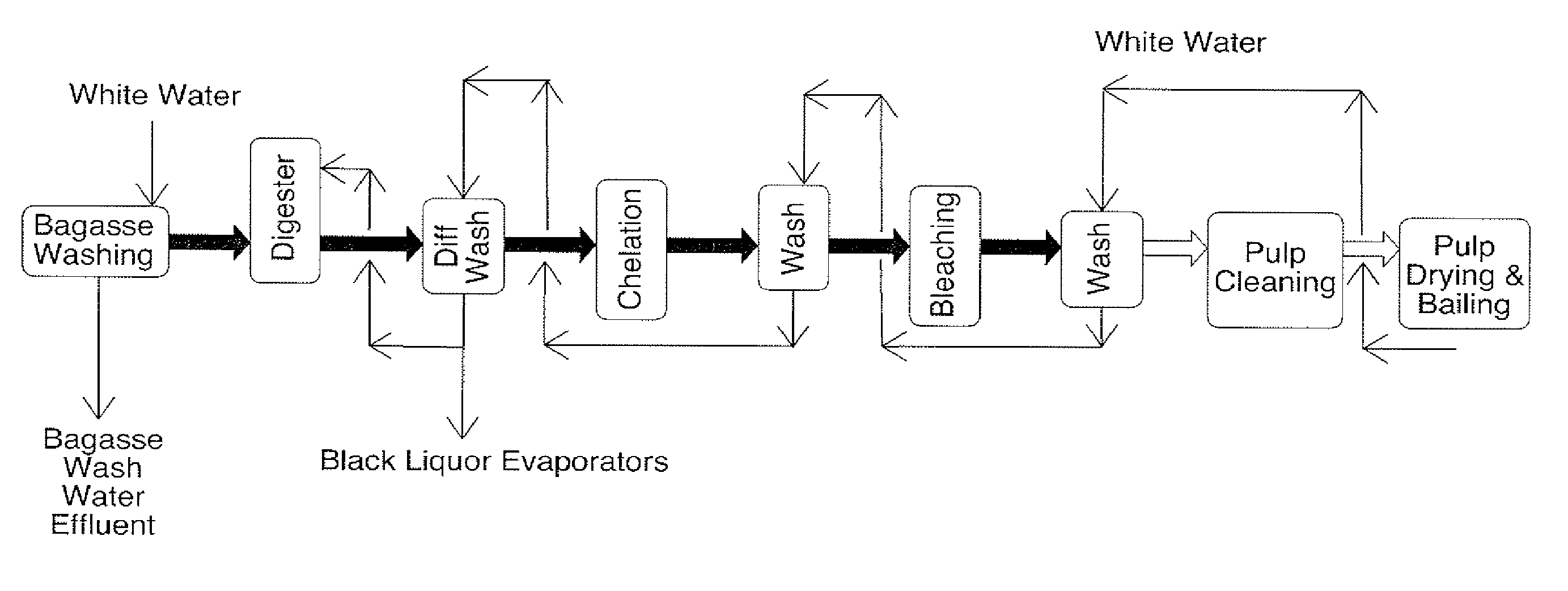

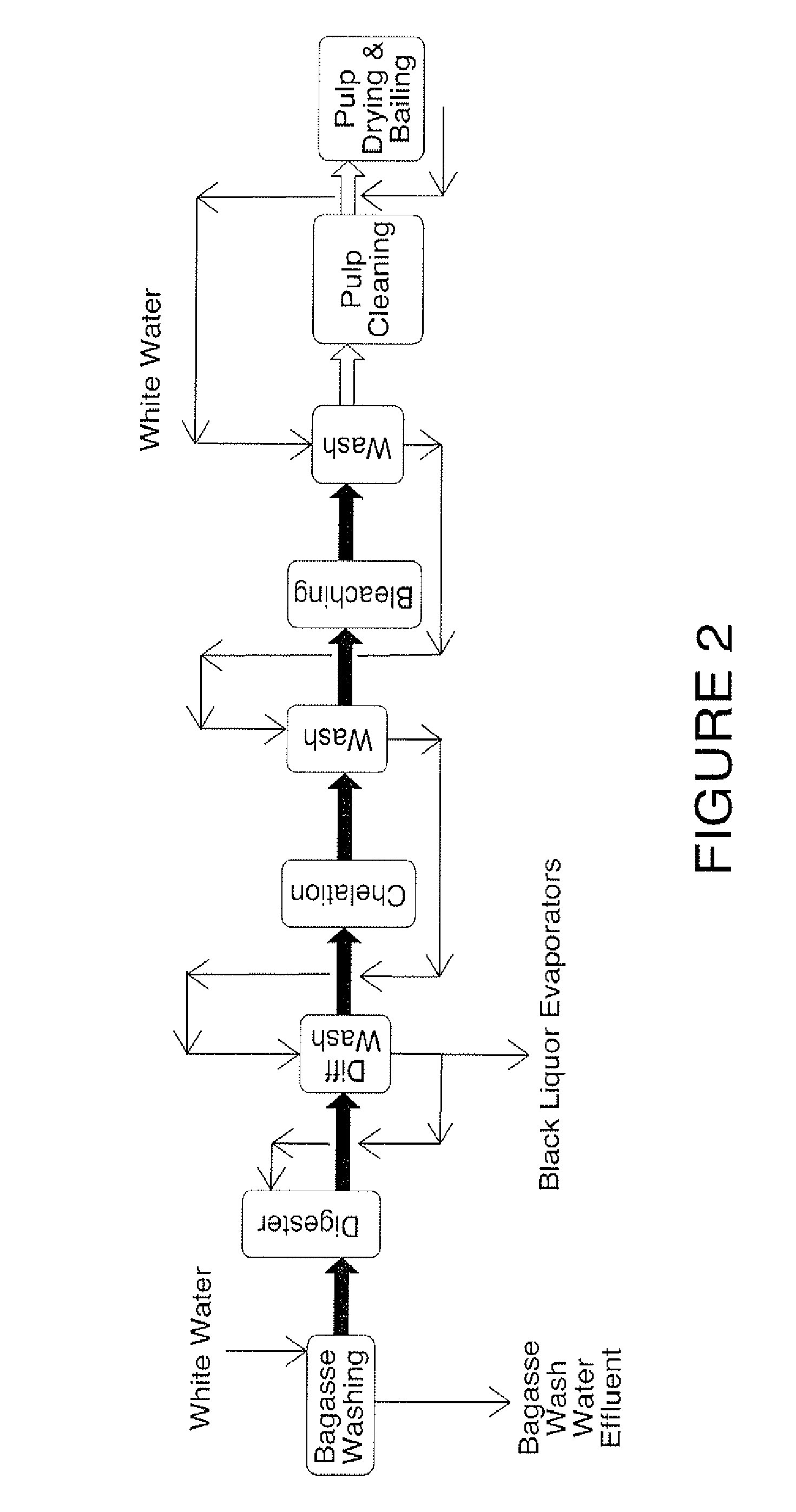

Pulp composition

One aspect of the invention relates to a pulp composition made from agricultural renewable fibers (ARF) having low Kappa number with unexpected quality sufficient for papermaking (e.g., high strength parameters and high freeness). Another aspect of the invention relates to an ARF pulp having ISO brightness of 60% or higher, and unexpected quality sufficient for papermaking (e.g. high strength parameters and high freeness). Another aspect of the invention relates to a pulp composition made from a pulping process comprising using a high concentration of anthraquinone (AQ). The pulping process can use wood or nonwood fibers (e.g., bagasse and corn stover) to provide pulp having good paper-making quality.

Owner:CARGILL INC

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

InactiveCN102686799APulp properties modificationLuminescent/fluorescent substance additionPaperboardPaper manufacturing

The invention relates to a method for manufacturing pulp. The manufactured pulp contains at least 30 w-% nanofibrillated cellulose material measured from the dried pulp. The method comprises the following stages: introducing raw material to a system which raw material includes cellulose, dosing at least one type of an optical brightening agent as a refining additive to the system, and refining the raw material in the presence of the dosed optical brightening agent in at least one pre-refining stage or fibrillation stage in order to form fibrillar cellulose material. The invention further relates to a use of the produced pulp in nanofibrillated cellulose composites or in paper or paperboard manufacturing including base paper production and finishing stages, including, for example, paper and paperboard coatings.

Owner:UPM-KYMMENE OYJ

Process for manufacturing pulp, paper and paperboard products

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

High-gloss and waterproof photographic paper and preparation method thereof

InactiveCN106555364AScratch resistantHas an isolation effectDefoamers additionCoatings with pigmentsPhotographic paperHardness

The invention discloses high-gloss and waterproof photographic paper. The high-gloss and waterproof photographic paper comprises an ink-absorbing layer, a lustering layer, raw paper and a back coating. A preparation method of the high-gloss and waterproof photographic paper comprises a preparation method of ink-absorbing coating liquid, a preparation process of lustering coating liquid, a preparation process of back-coating coating liquid and a preparation process of the high-gloss and waterproof photographic paper. According to the high-gloss photographic paper produced by the method, the glossiness can reach above 80 percent and is far more than that of photographic paper with the glossiness being 40 to 60 percent in the market; meanwhile, the high-gloss photographic paper has scratch resistance and the surface hardness of the photographic paper reaches level 7; the back side is coated with polymer emulsion, so the isolating effect and the anti-curl effect are achieved; and the surface tension of the back side is less than 25 dynes, so water cannot be spread on the surface. The flatness reaches the level of coated paper. The ink-absorbing drying rate is high, the effect that the paper is dry once being discharged out of a machine is achieved, and the drying rate is greatly increased compared with the drying rate, that the coated photographic paper is dry 2 minutes later when being discharged out of the machine, of the coated photographic paper.

Owner:JIANGSU GEMEIGAO DEV CO LTD

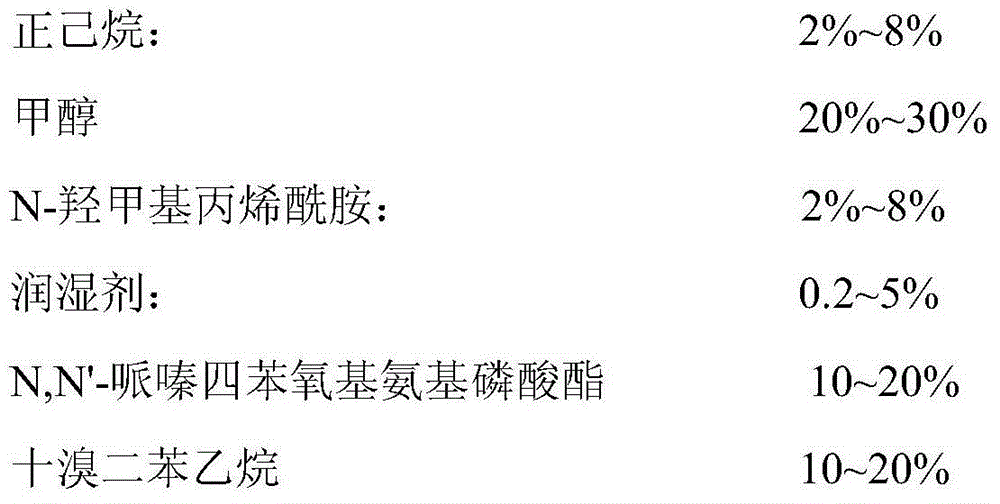

Hydrogen peroxide stabilizer composition in paper pulp bleaching

InactiveCN101265678AReduce decomposition rateAvoid it happening againPulp bleachingBleaching agents additionFiberDecomposition

A hydrogen peroxide stabilizer composition in paper pulp bleaching contains the following materials by the weight percentages: ethylenediaminetetraacetic acid 8%-10%, polyacrylic acid 3%-5%, nitrilortiacetic acid 5%-10%, hydroxy ethylidene-1, 1-diphosphonic acid 5%-8%, sodium hydroxide in suitable amount and the rest of deionized water,. The preparation method includes: mixing the materials in the material ratio, adjusting the pH value to 6.8-7.1 with the sodium hydroxide and adding the deionized water to 100%. The inventive hydrogen peroxide stabilizer composition in the paper pulp bleaching can reduce the decomposition rate of the hydrogen peroxide to less than 20%, prevent the fouling from generating and dispersing pulp fibers and chelating metal ions.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com