Patents

Literature

743results about How to "Improve physical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacture and use of hybrid anion exchanger for selective removal of contaminating ligands from fluids

ActiveUS20050156136A1Reduce needSuperior material propertyOther chemical processesWater contaminantsArsenatePhosphate

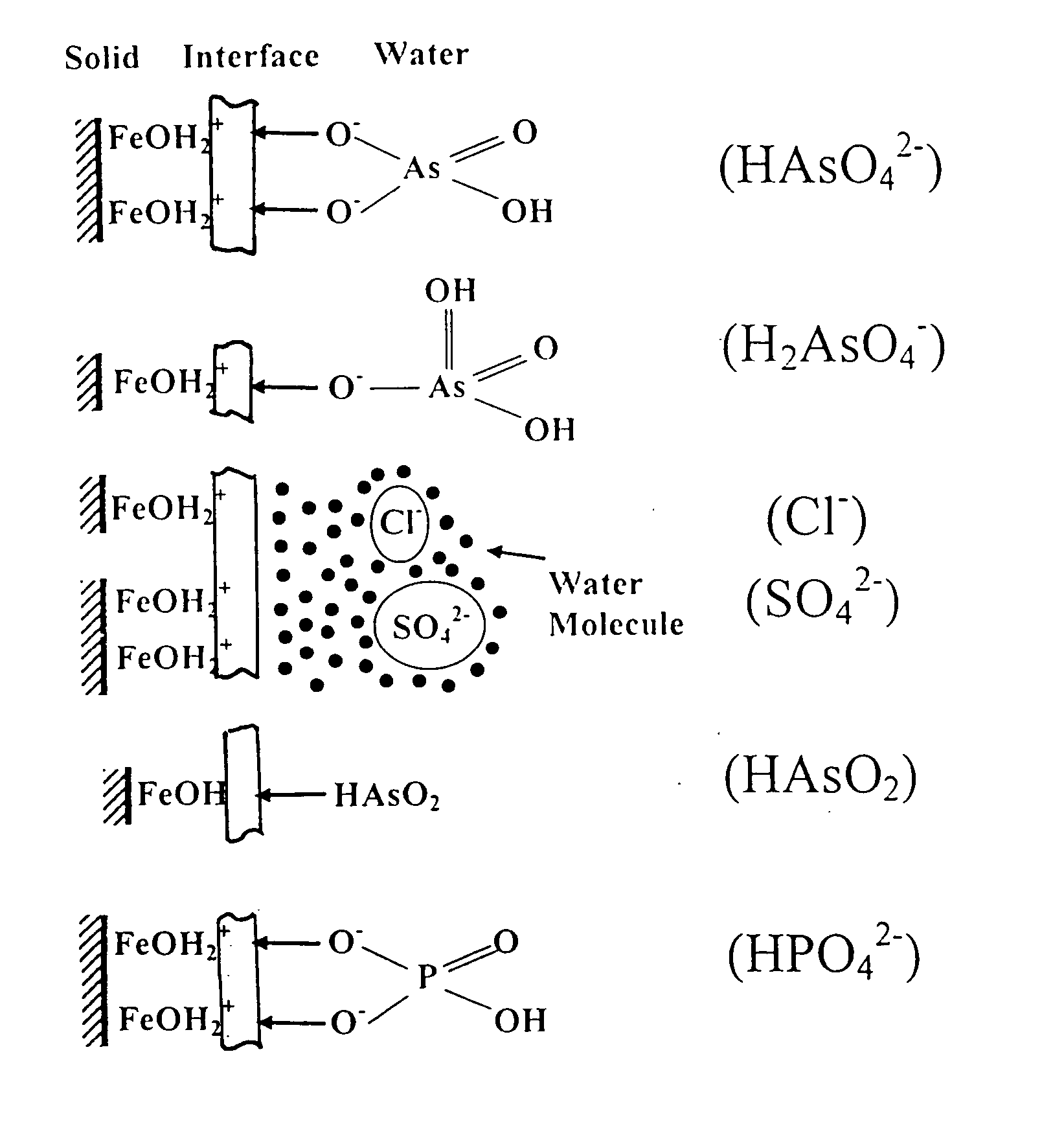

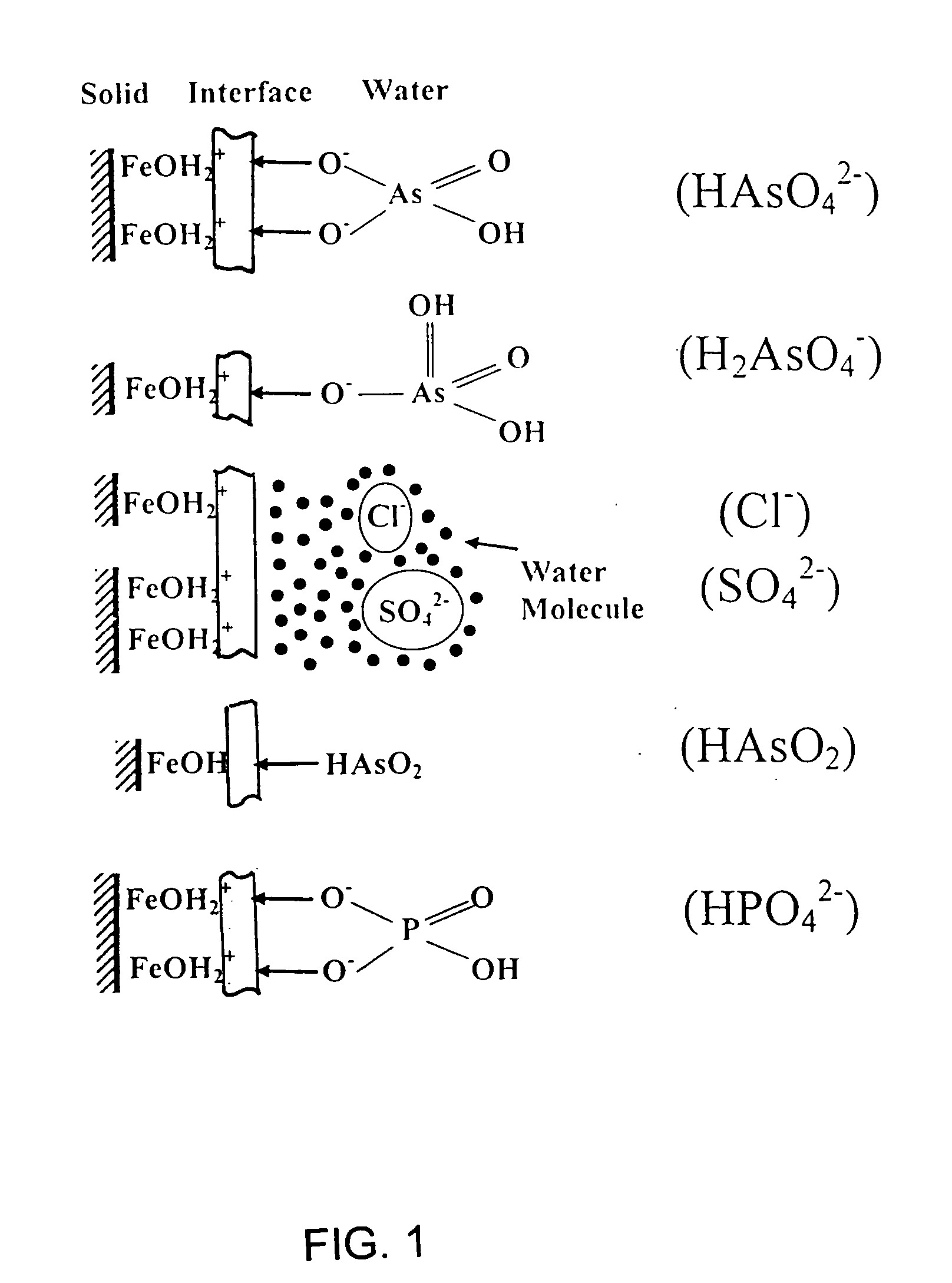

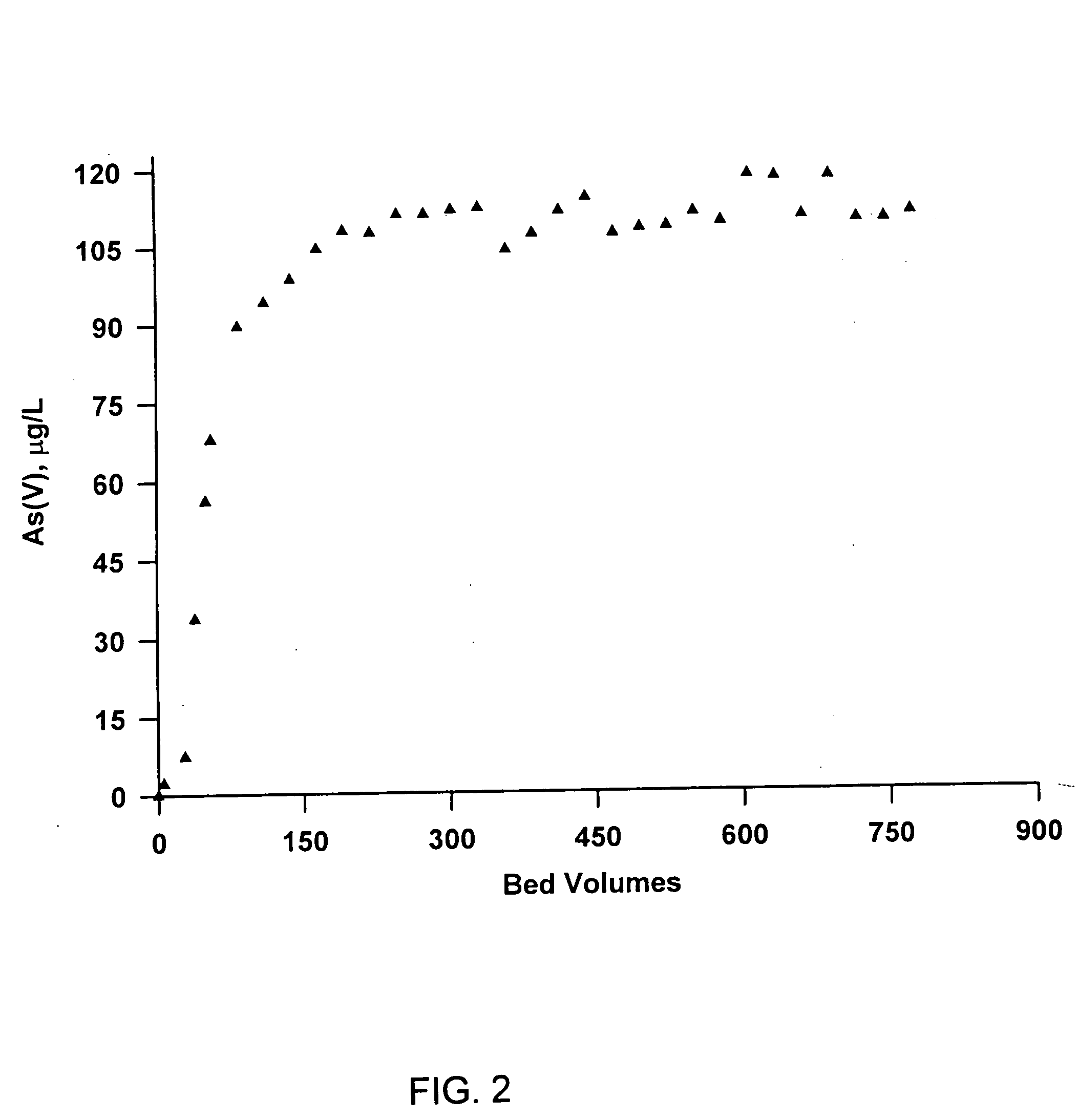

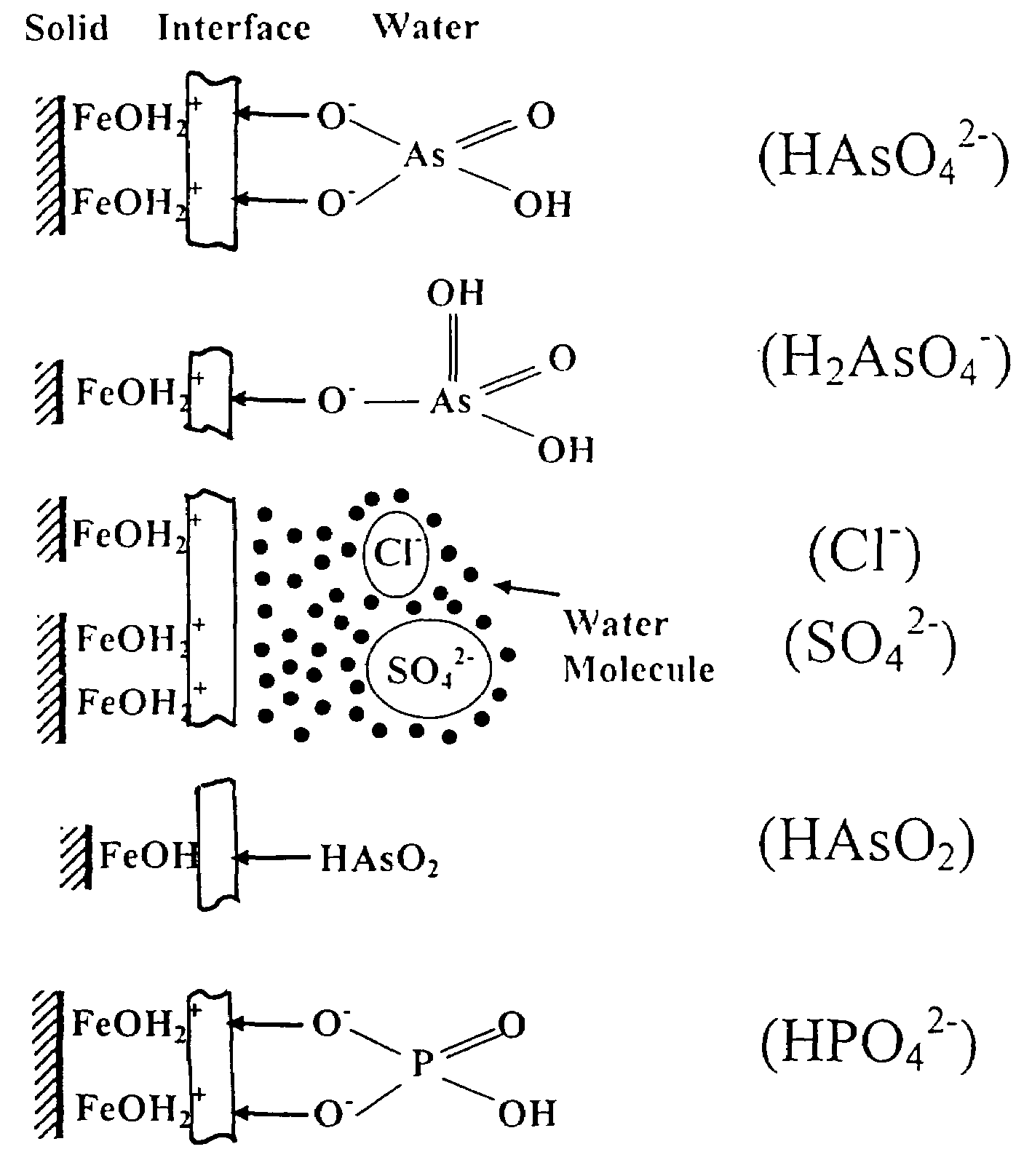

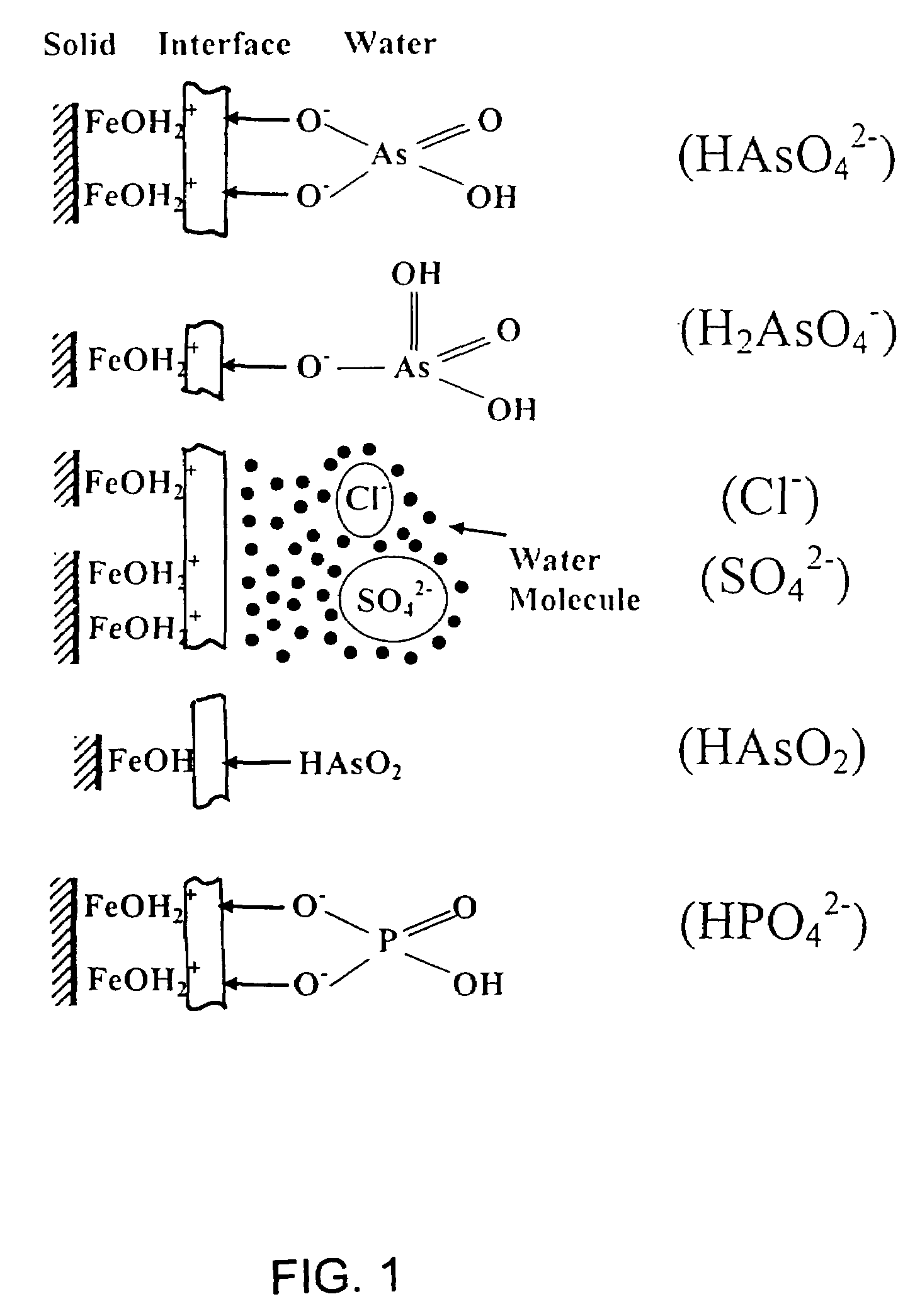

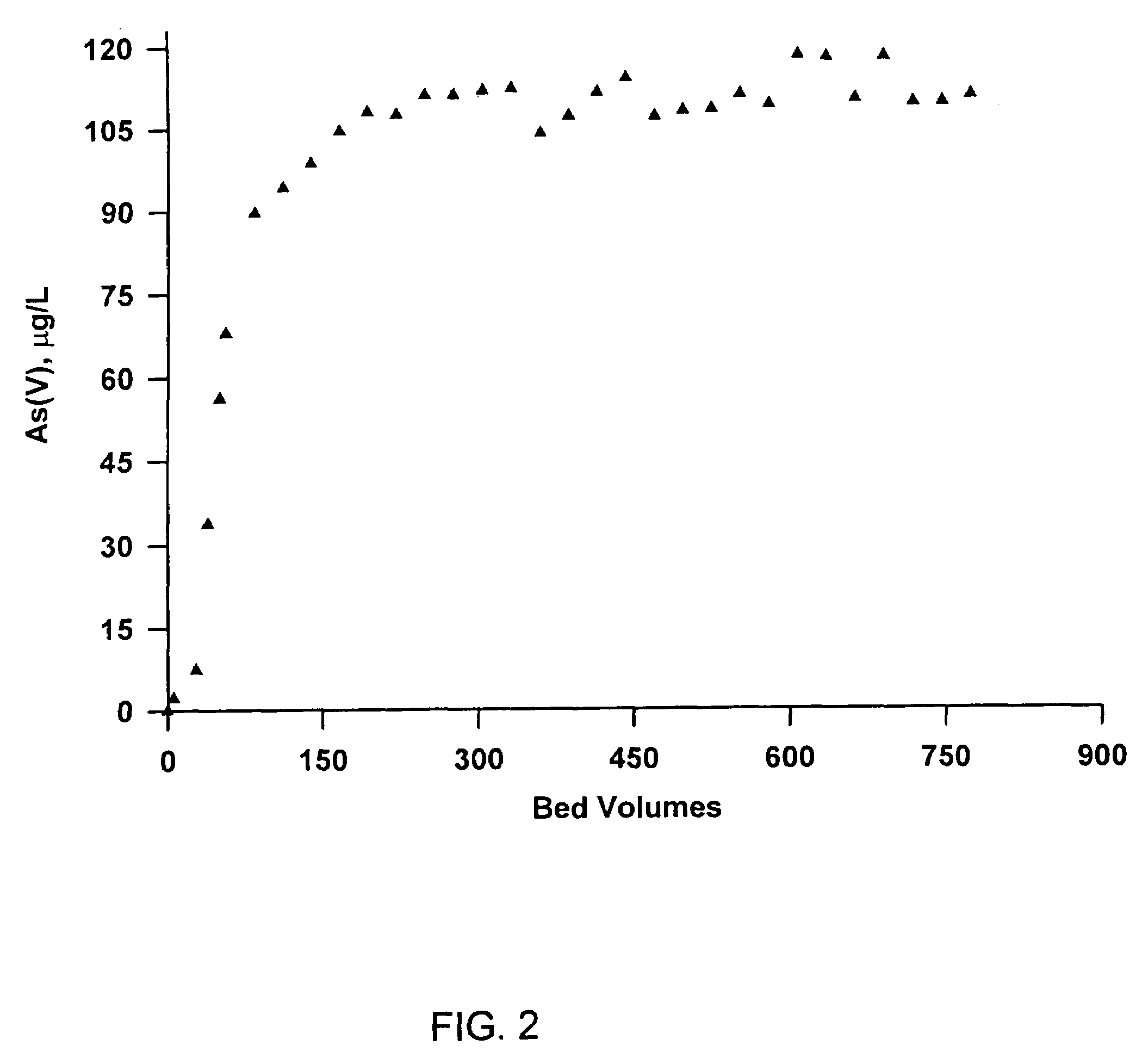

Polymeric anion exchangers are used as host materials in which hydrated Fe(III) Oxides (HFO) are irreversibly dispersed within the exchanger beads. Since the anion exchangers have positively charged quaternary ammonium functional groups, anionic ligands such as arsenates, chromates, oxalates, phosphates, phthalates can permeate in and out of the gel phase and are not subjected to the Donnan exclusion effect. Consequently, anion exchanger-supported HFO micro particles exhibit significantly greater capacity to remove arsenic and other ligands in comparison with cation exchanger supports. Loading of HFO particles is carried out by preliminary loading of the anion exchange resin with an oxidizing anion such as MnO4− or OCl−, followed by passage of a Ferrous Sulfate solution through the resin.

Owner:ARUP K SENGUPTA

Hybrid anion exchanger for selective removal of contaminating ligands from fluids and method of manufacture thereof

ActiveUS7291578B2Improve material performanceImprove physical strengthOther chemical processesWater contaminantsPhosphateIon-exchange resin

Owner:ARUP K SENGUPTA

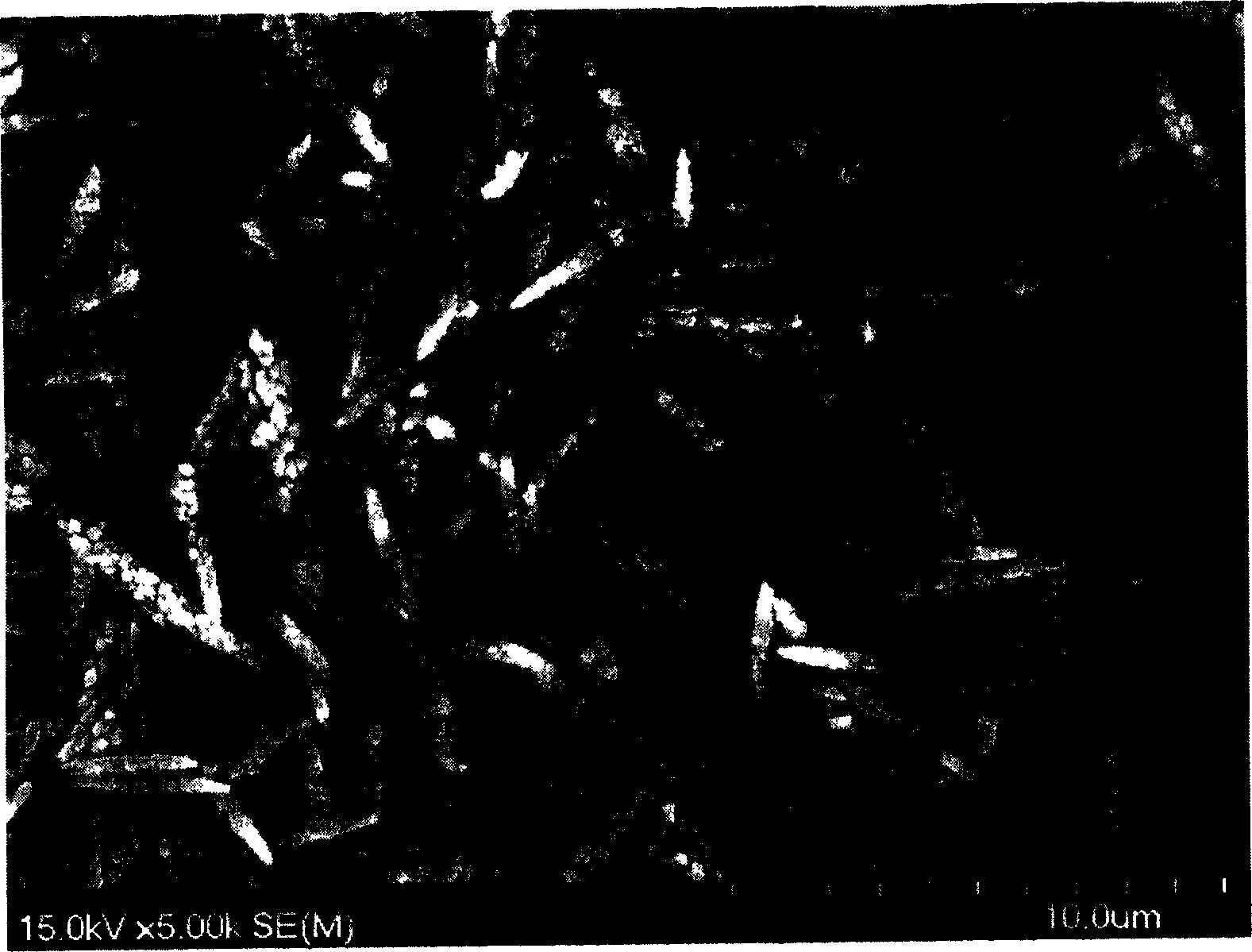

Single dispersing micron chopped fiber-like aragonite type calcium carbonate and preparation method thereof

InactiveCN1631792ASimple methodThe method is simple and controllableCalcium/strontium/barium carbonatesSolubilityPrinting ink

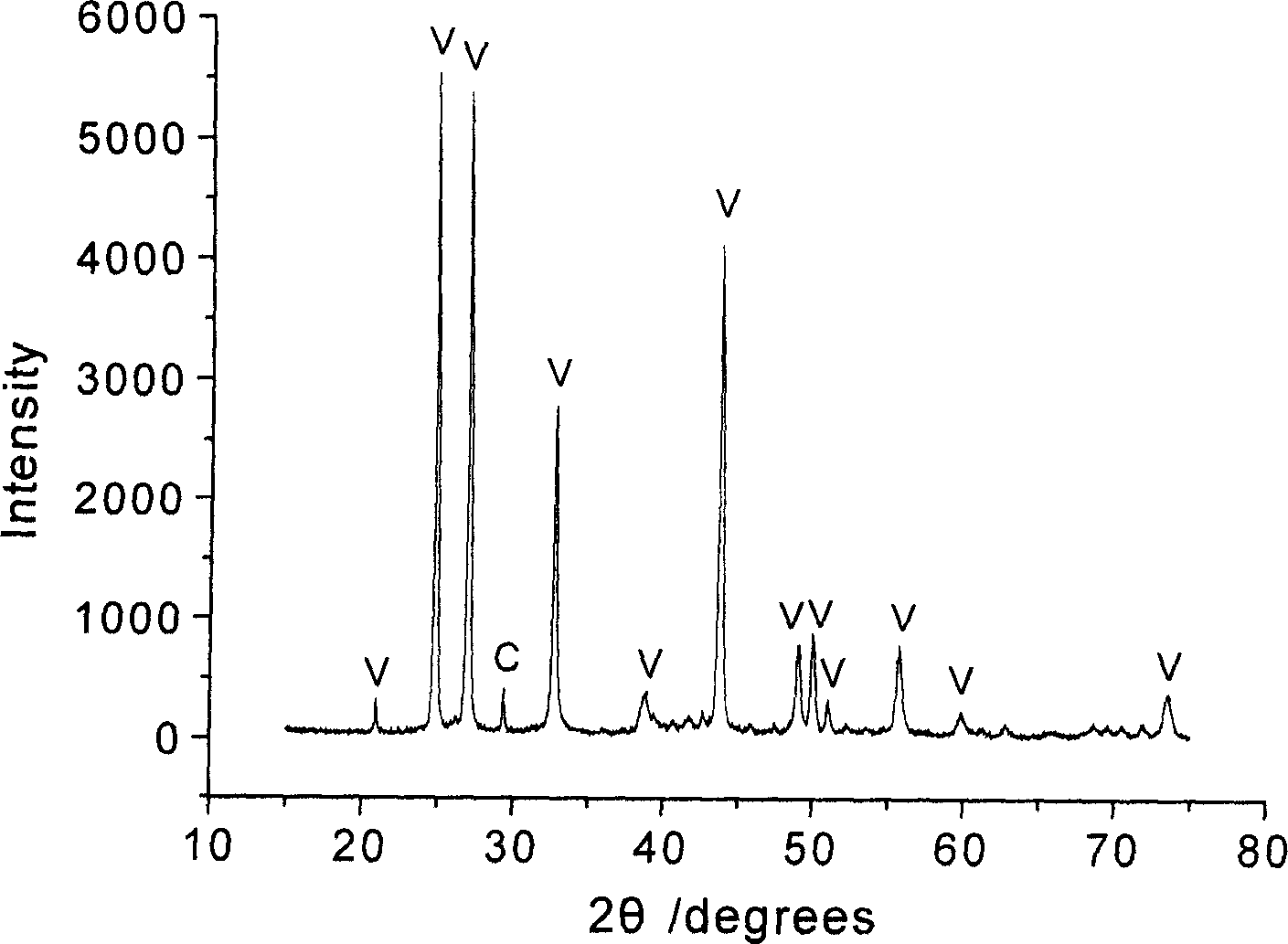

The invention relates to a single-distributive micron short fiber-typed vaterite calcium carbonate and its preparing method. The calcium carbonate crystal is needle short fiber-typed, its length is 2-8 micron and width is 0.3-1.5 micron, the ratio of length and diameter is 5-10, its content of vaterite calcium carbonate is larger than 90% with small particle on the surface of. The preparing method includes mix the aqueous solution of carbonate containing water soluble organic solvent with aqueous solution of calcium salt also containing that, make use of the different dissolubility of carbonate and calcium salt in water soluble organic solvent and water, and the different solvation to calcium ion, compound the product. The calcium carbonate has remarkable single distribution, large ratio of length and diameter, high activity of surface, suitable for coating on paper, filling plastic, coating, printing ink and paper, as well as the raw material for calcium preparations.

Owner:ZHEJIANG UNIV

High temperature gas seals

A flexible seal for use in a solid oxide fuel cell stack is formed from a ceramic fibre matrix impregnated with a plurality of metallic or semi-metallic particles which are then converted to a corresponding ceramic particle, such as by oxidation. The seal may be formed by dipping the fibre matrix into a slurry, suspension or sol-gel of the particles in an alcohol, and then firing the seal to oxidize the metal particles. The seal may also be formed by tape casting a slurry formed from metallic or semi-metallic particles, ceramic fibres and / or ceramic particles.

Owner:FUELCELL ENERGY LTD

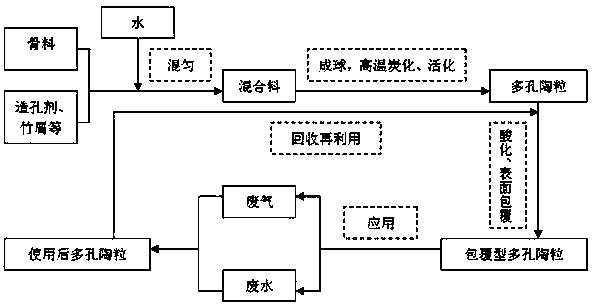

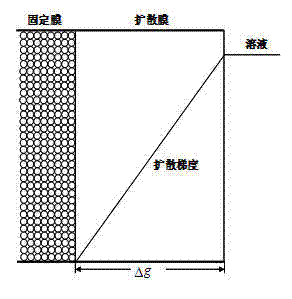

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

Biodegradable bag

ActiveUS6984426B2Improve physical strengthEnhanced durability propertyFlexible coversWrappersPoly l lactic acidBiodegradable bag

A biodegradable film formable into biodegradable bags includes the blended product of polylactic acid and a suitable biodegradable polymeric resin. The blended product includes from about 5% to about 50% by weight polylactic acid.

Owner:CORTEC

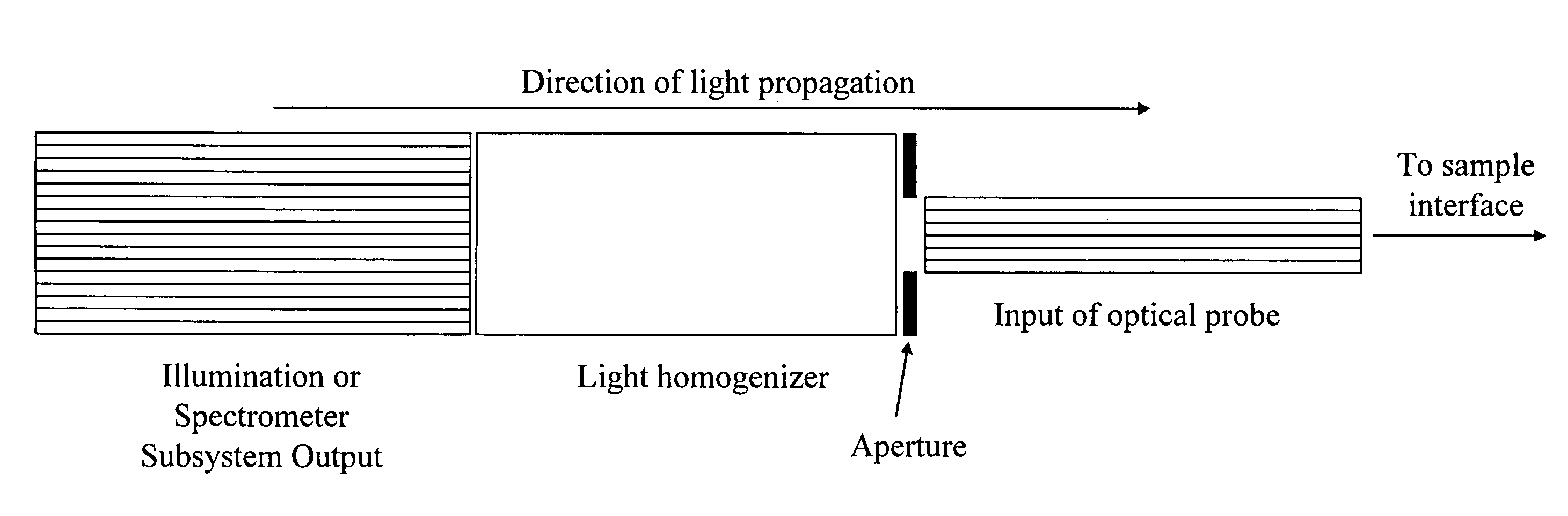

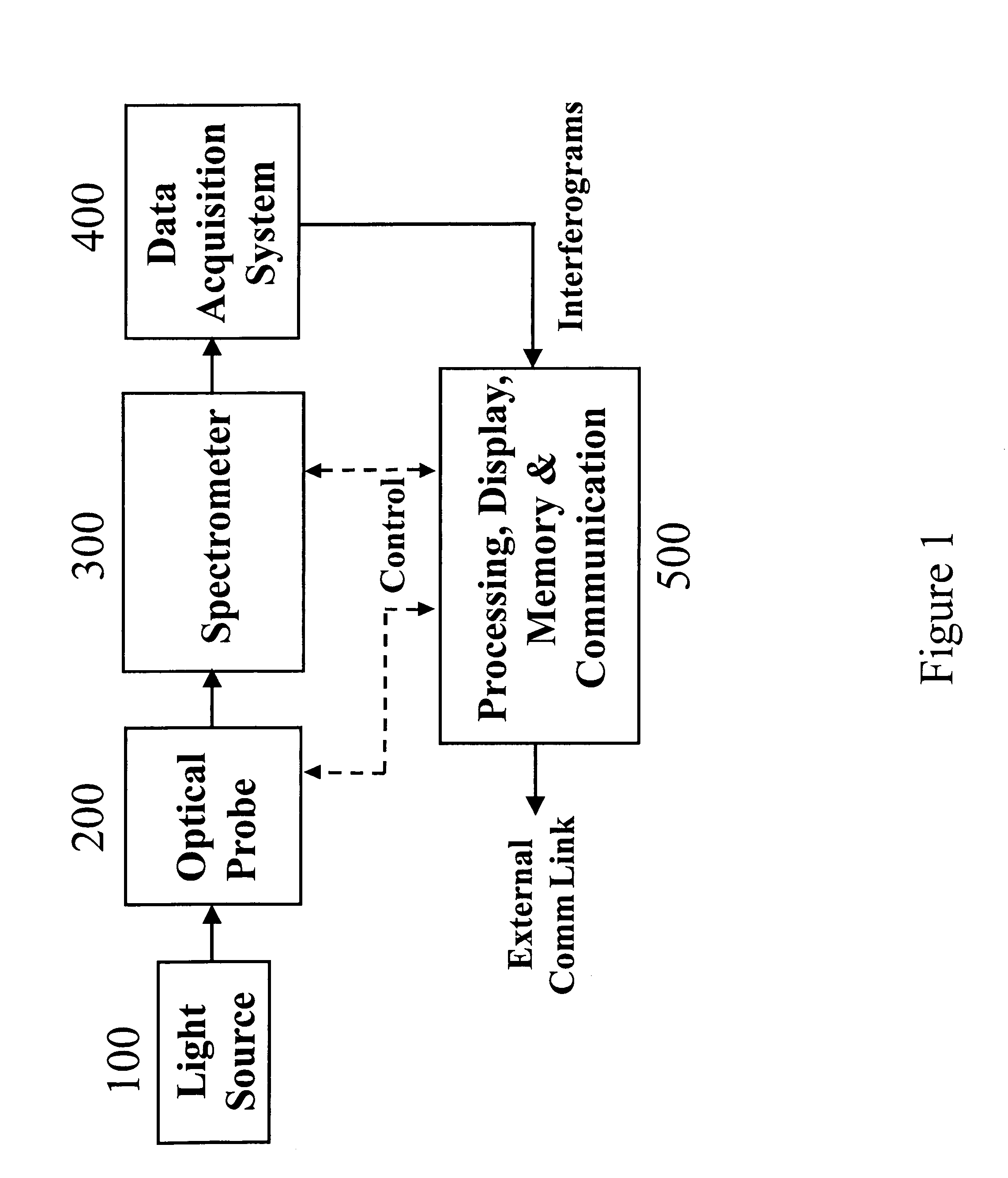

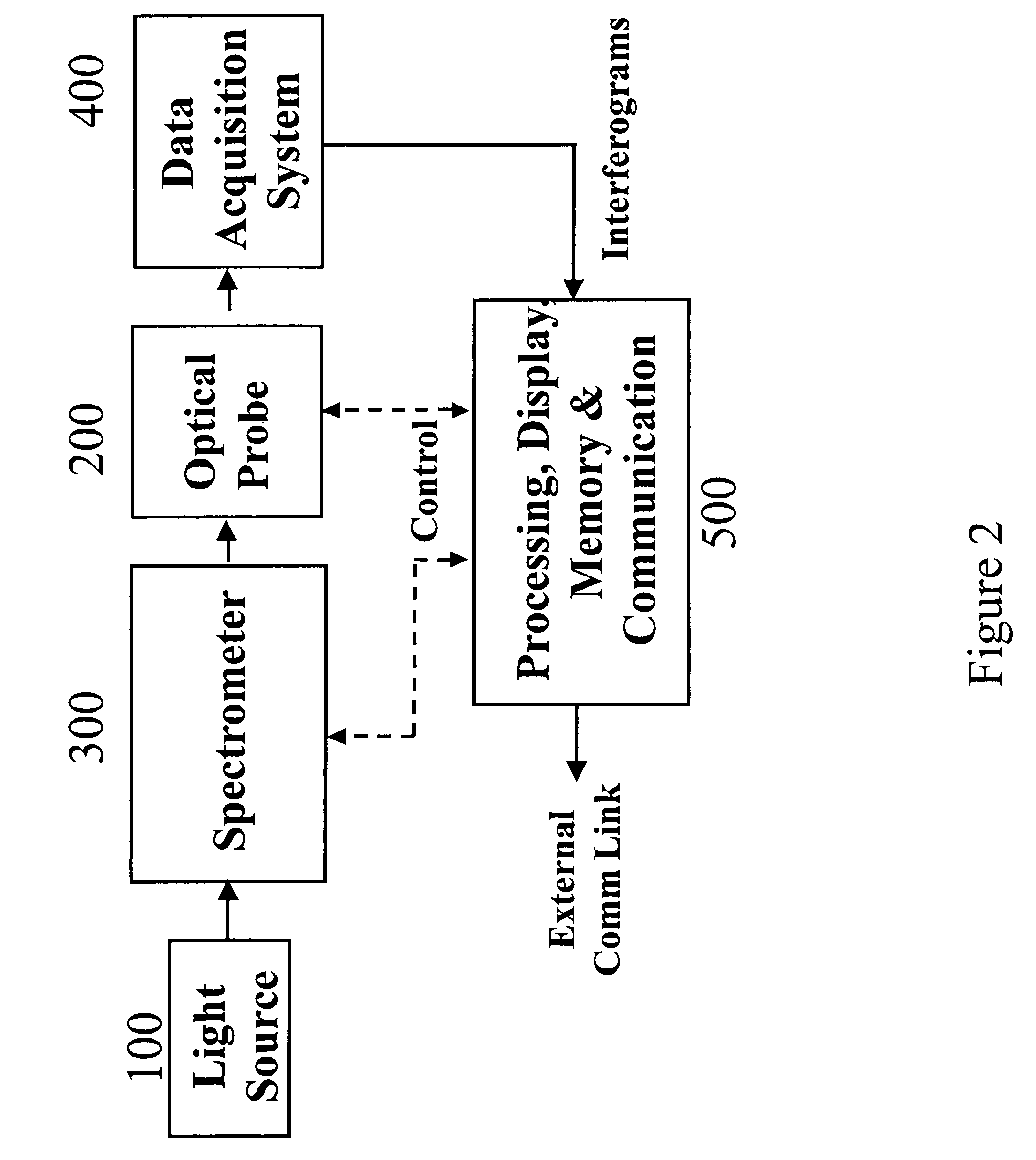

Method of making optical probes for non-invasive analyte measurements

ActiveUS7848605B2Improve physical strengthBig advantageScattering properties measurementsDiagnostic recording/measuringFiberAnalyte

An optical probe for non-invasively measuring an analyte property in a biological sample of a subject, comprises a plurality of illumination fibers that deliver source light from an optical probe input to a sample interface, a plurality of collection fibers that deliver light returned from the sample interface to an optical probe output, and wherein the illumination and collection fibers are oriented substantially perpendicular to the sample interface and the illumination and collection fibers are stacked in a plurality of linear rows to provide a stack of fibers arranged in a rectangular pattern. The optical probe is amenable to manufacturing on a scale consistent with a commercial product. Methods of making such probes are described.

Owner:ROCKLEY PHOTONICS LTD

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

Process for biologically pulping

InactiveCN1616758AReduce pollution loadQuality improvementNon-woody plant/crop pulpCellulose material pulpingFiberPre treatment

The biologically pulping process includes the following steps: pre-treating cotton fiber material with polyxylose enzyme to obtain pulp material; and normal pressure and low temperature steaming and rinsing of the pre-treated pulp material with alkali and H2O2. The said pulping process has low cost of eliminating impurity from the material, lowered bleaching chemical liquid consumption and raised paper pulp quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

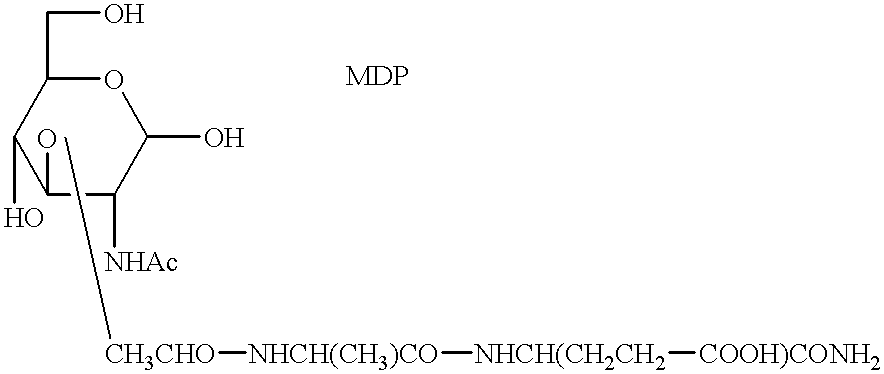

Compositions and methods for treating viral infections

InactiveUS6258599B1Neutralize and inactivate essential stepReduce infectivityPeptide/protein ingredientsVirus peptidesEpitopeImmunodeficiency virus

Owner:PROBE INT

Method for preparing high molecule emulsifying agent for ASA

InactiveCN101397353ASolve easy foamingFix stability issuesWater-repelling agents additionTransportation and packagingEmulsion polymerizationColloid

The invention discloses a preparation method for a macromolecule emulsifier used in ASA. The invention solves the problem that cationic starch and a micromolecule emulsifier added in the traditional ASA latex have poor gluing effect, and the prepared latex easily forms bubbles and has poor stability. The method chooses appropriate oil-soluble vinyl monomers, water-soluble vinyl monomers and cation monomers under the action of a macromolecule stabilizing colloid; the macromolecule emulsifier used in ASA is prepared under the action of an evocating agent by seed emulsion polymerization. On one hand, the macromolecule emulsifier can overcome the shortcoming that the cationic starch easily goes bad at high temperature and in the process of the long term storage to cause that the ASA latex has poor gluing effect and poor stability; on the other hand, the reserving performance and the anti-anion trash interference performance of the macromolecule emulsifier are greatly increased; the macromolecule emulsifier not only can increase water resistance of paper but also can increase the physical strength of paper; in addition, when the macromolecule emulsifier is used for ASA emulsification, additional pasting, dilution and high shear emulsifying plants are not needed.

Owner:SHAANXI UNIV OF SCI & TECH

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

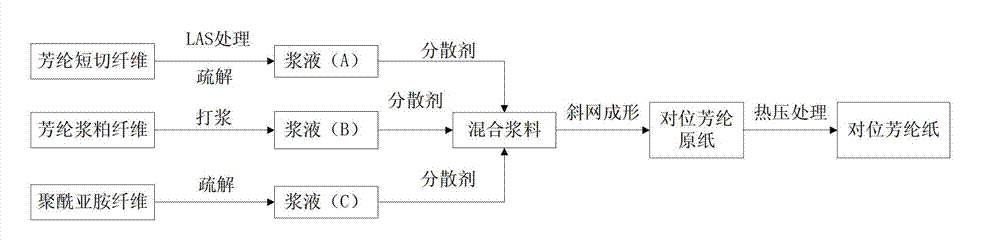

Preparation process for manufacturing insulated paper by para position fiber and meta position fiber

InactiveCN1884692AImprove evennessGood flexibilityPlastic/resin/waxes insulatorsSynthetic cellulose fibresManufacturing technologyPulp and paper industry

The invention discloses a manufacturing technology of copy-allocating insulated paper of para and meta aramid fiber, which comprises the following steps: adopting para-aramid chopped fiber and meta aramid pulp fiber to dispense insulated paper according to certain proportion; dispersing the fiber through PEC or congenic adjuvant; improving paper evenness and flexibility; proceeding heat pressing for para aramid fiber to modify physical strength and insulating property.

Owner:SHAANXI UNIV OF SCI & TECH

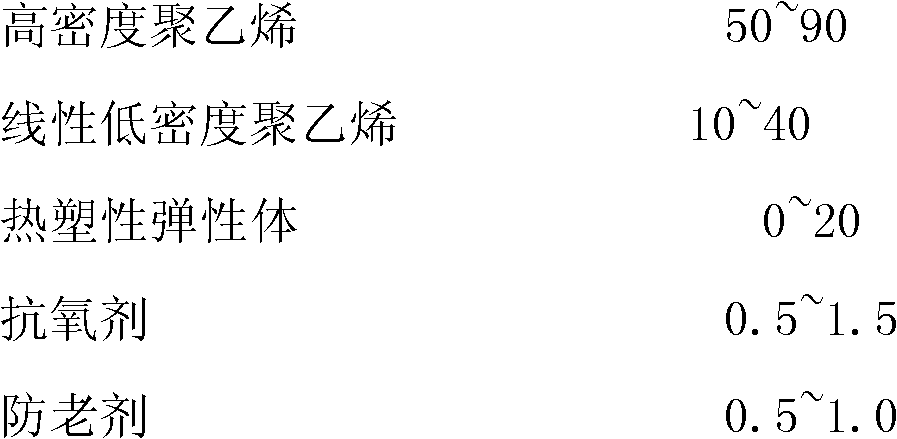

Composite macromolecular waterproof board and preparation method thereof

The invention discloses a composite macromolecular waterproof board, which consists of high density polyethylene, linear low density polyethylene, a thermoplastic elastomer, an antioxidant, an anti-ageing agent and a filler. The composite macromolecular waterproof board has high permeability resistance, high barrier property, high penetration resistance, resistance to acid, alkali and various chemical substances, high elongation and wear resistance, is free from chemical pollution, and can effectively improve the surface energy of polyethylene. The invention also discloses a method for preparing the composite macromolecular waterproof board.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

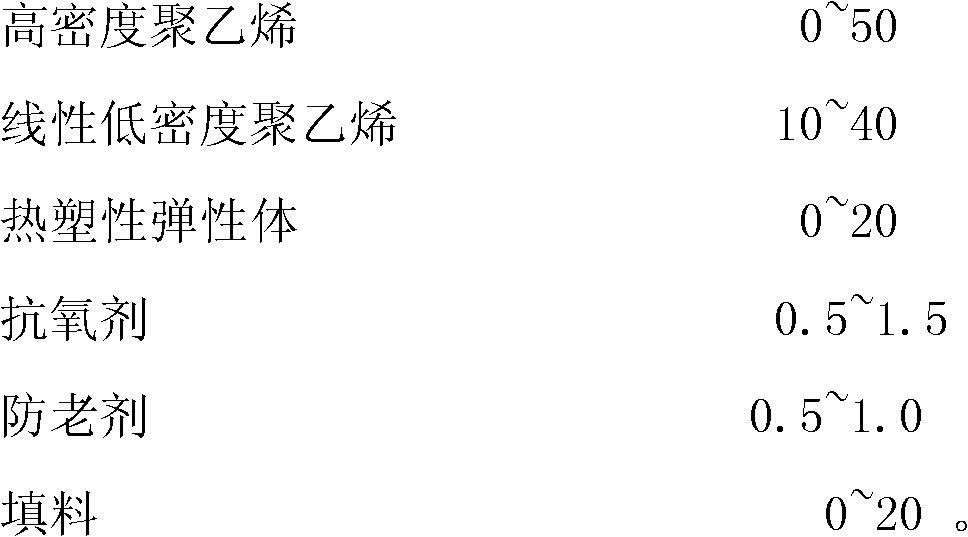

Improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement and preparation method thereof

InactiveCN102507388AImprove physical strengthLittle flexibilitySurface/boundary effectMoisturePolyacrylamide

The invention provides an improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement. The improved phosphorus fixing film is a polyacrylamide gel film containing zirconium dioxide (ZrO2) and is characterized in that ZrO2 particles of which the particle size is less than or equal to 5mu m are uniformly distributed on the surface of the phosphorus fixing film. A preparation method of the improved phosphorus fixing film comprises the following steps: uniformly mixing ZrO2 powder with the moisture content of 45-55% with an acrylamide solution at the weightmeasurement ratio of (1:3)-(1:6); grinding and then carrying out ultrasonication; standing for removing precipitates, adding tetramethylethylenediamine of which the volume is (1:1600)- (1:1400) of that of acrylamide and a 10% ammonium persulfate solution of which the volume is (1:60)-(1:40) of that of acrylamide, uniformly mixing and injecting into a glass mold; horizontally placing the glass mold at room temperature; After the zirconium powder is freely precipitated, raising the temperature to 40-60DEG C until the mixed solution forms a gel film; and soaking in de-ionized water for more than 12 hours, thus obtaining the phosphorus fixing film. The phosphorus fixing film provided by the invention can be used for maintaining high phosphorus ion adsorption capacity and simultaneously improving the resolution ratio of DGT in phosphorus analysis.

Owner:HOHAI UNIV

Production method of bamboo chemical dissolving pulp

ActiveCN101457494ASimple switching processHighly corrosiveWashing/displacing pulp-treating liquorsDigestersMaterial consumptionDissolving pulp

Aiming at the current situation of the cotton dissolving pulp and the wood dissolving pulp and the characteristics of the bamboo and the defects in the existing preparation of the dissolving pulp, the invention provides a method for preparing a chemical bamboo dissolving pulp. The chemical dissolving pulp produced can be widely applied in the cellulose derivative industries such as spinning viscose fiber, nitrocellulose and acetate fiber. The method comprises the following steps of: material preparation, cooking, screening, scrubbing, bleaching and paper making. The cooking procedure comprises two grades of cooking steps, wherein the primary cooking procedure is continuous cooking and the secondary cooking procedure is continuous cooking or intermittent cooking; and the bleaching procedure is elemental chlorine free bleaching or totally chlorine free bleaching. The invention solves the problems existed in the cooking and bleaching procedures. The chemical bamboo dissolving pulp can be prepared with high efficiency, low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

Preparation of cation polymer emulsifier for AKD

InactiveCN101302320AImprove waterproof performanceImprove physical strengthWater-repelling agents additionTransportation and packagingPolymer scienceInterference resistance

The invention discloses a method for preparing AKD cationic macromolecular emulsifier, comprising the following steps: adequate acrylic acid long-chain fatty esters and adequate vinyl monomers such as cationic monomers and so on are selected according to the physicochemical properties of binding compositions; free-radical nonsoap latex copolymerization is performed in water solution by adoption of the seeding polymerization method under the condition that modified polyvinyl alcohol exists; and the AKD cationic macromolecular emulsifier is obtained. The AKD cationic macromolecular emulsifier can replace micromolecular emulsifier added into the prior AKD latex; the problems of easy foaming of the latex, poor stability and sizing effect and so on are solved; simultaneously the adhesion property and the anionic waste interference resistance of the emulsifier are greatly improved; not only the waterproofness of paper can be improved but also the physical strength of the paper can be improved; and no cationic starch is required to be added for colloid protectant during the preparing process of the emulsifier, thereby overcoming the defect of poor sizing effect and stability of the AKD latex due to easy deterioration of the emulsifier during the high-temperature and long-term storage process.

Owner:SHAANXI UNIV OF SCI & TECH

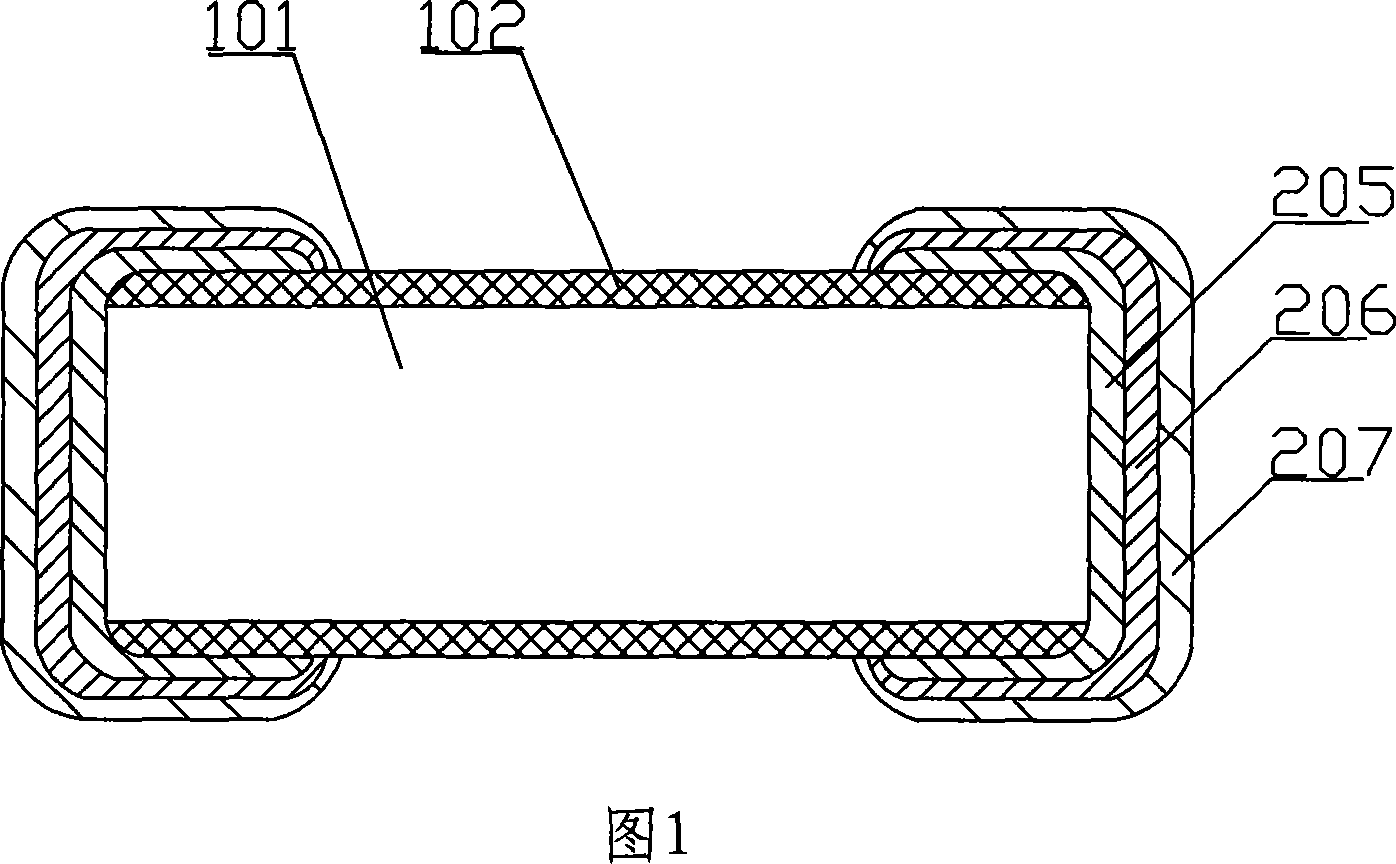

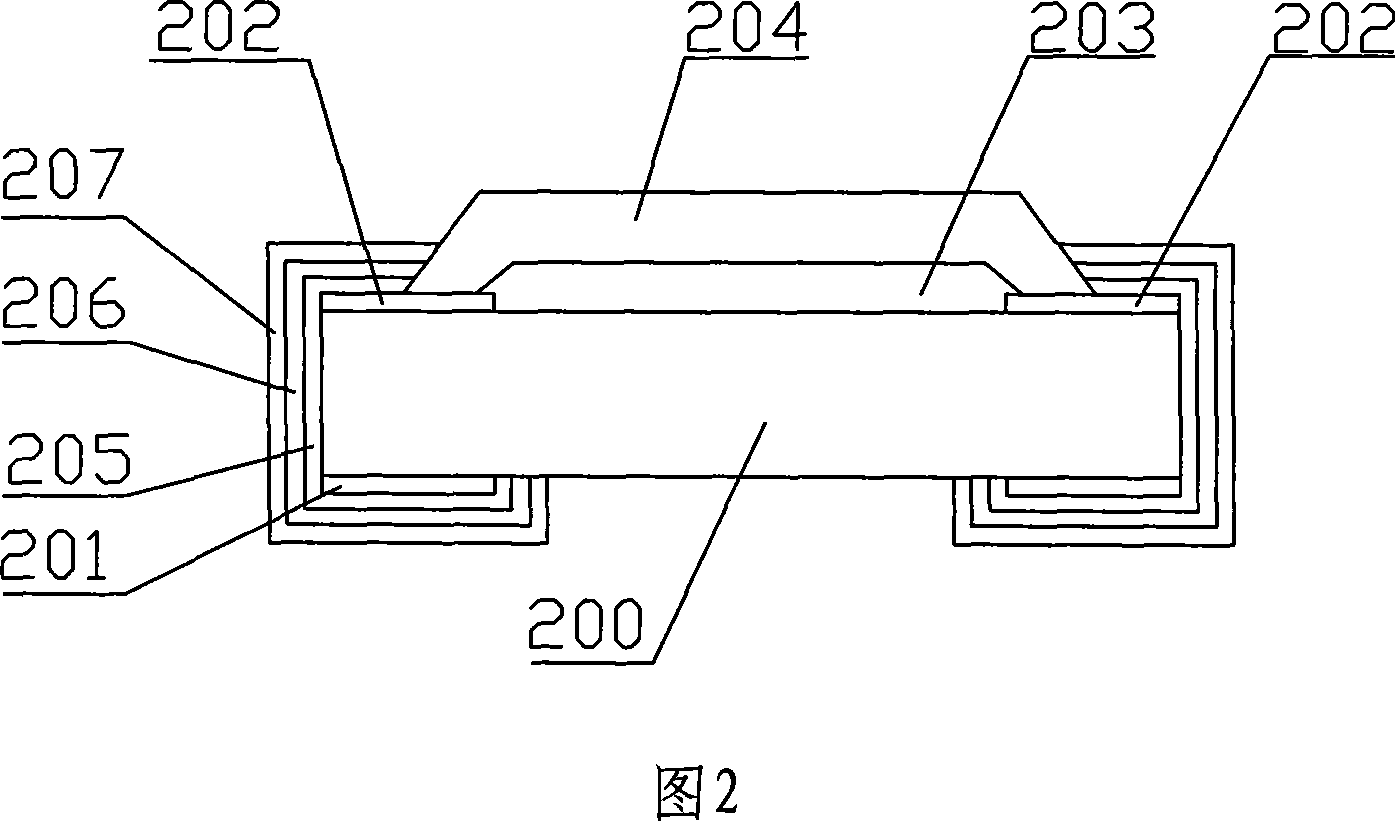

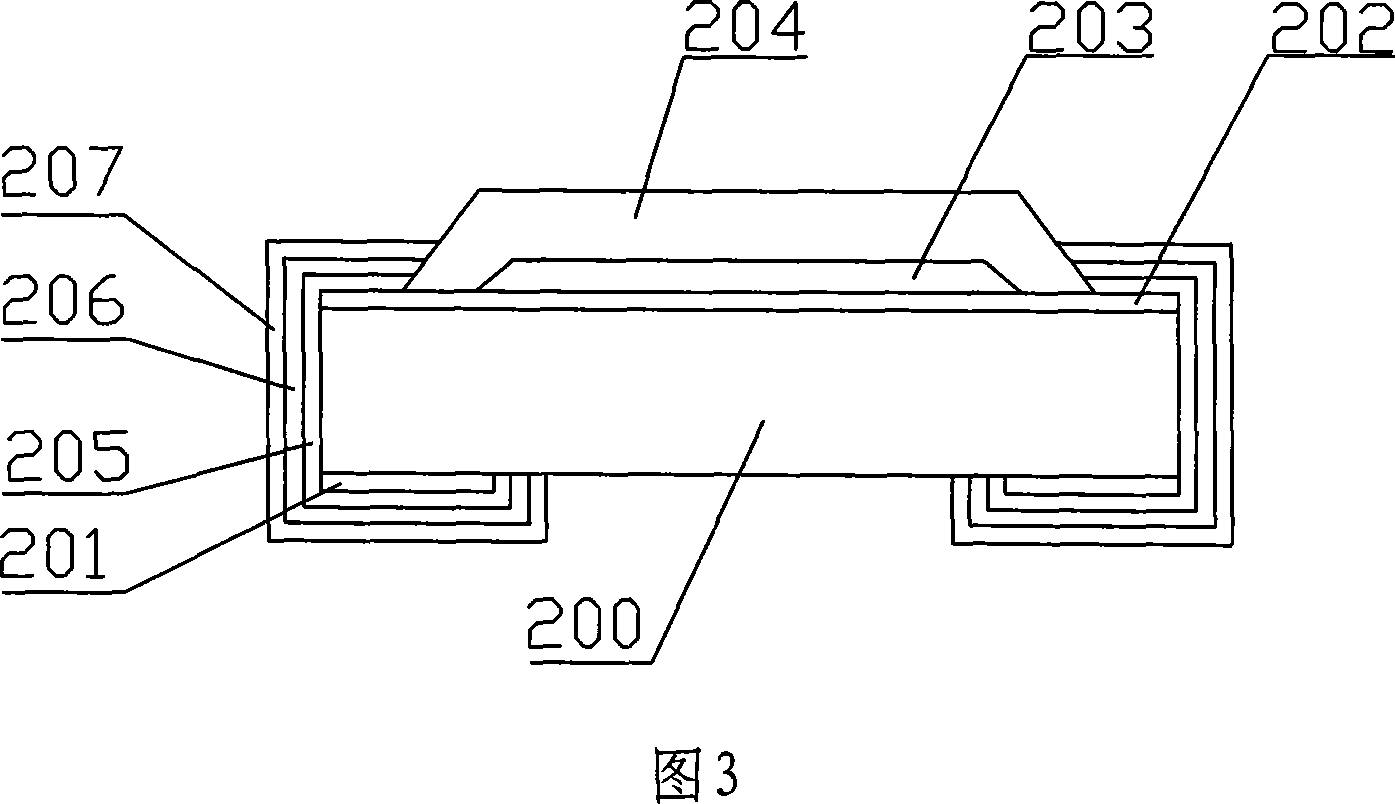

Method for producing sheet type thermosensitive resistor

InactiveCN101067981ASimplify the manufacturing processEasy to operateNegative temperature coefficient thermistorsResistor manufactureThermal resistorProtection layer

This invention discloses a manufacturing method for slice thermal resistors, which prints a back electrode on the back of a marked slot side of an insulated ceramic chip, prints a face electrode on the slot side, then prints a thermal resisting layer and a protection layer with a thick film silk screen, which can reduce the processing time of slice thermal resistors effectively.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

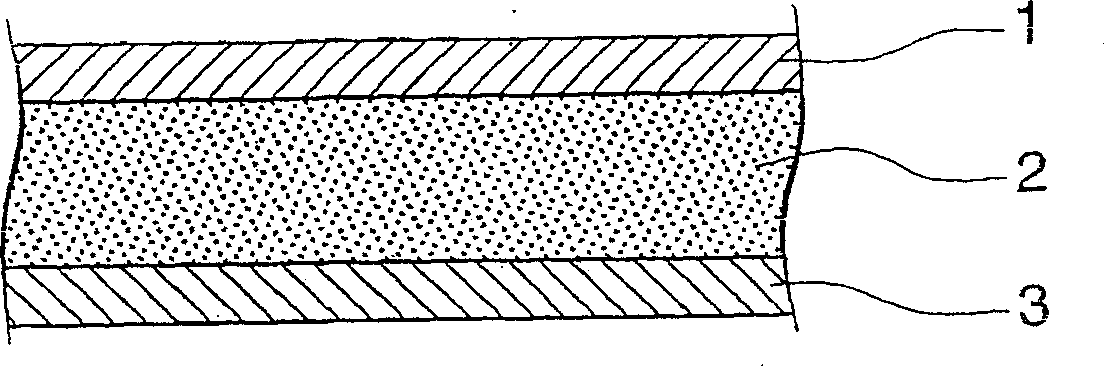

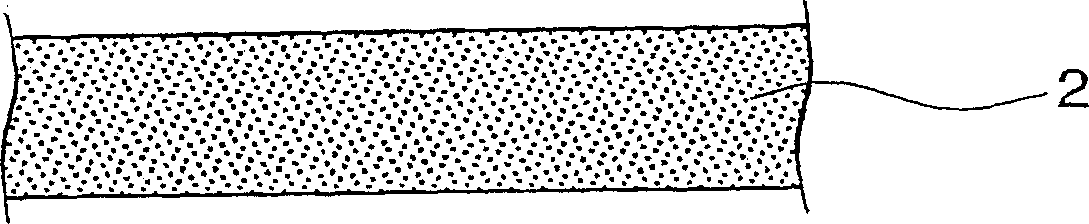

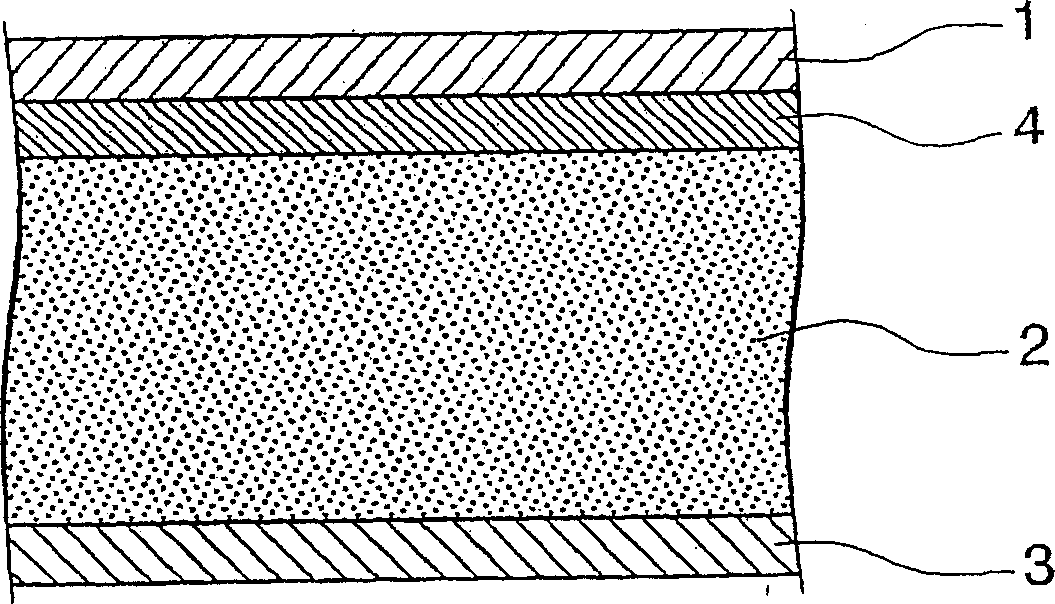

Manufacturing process of polyurethane foam sheet and layered sheet using the same

ActiveCN1732082AControllable shapeUniform shapeSynthetic resin layered productsLaminationWood veneerCushioning

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DIC CORP

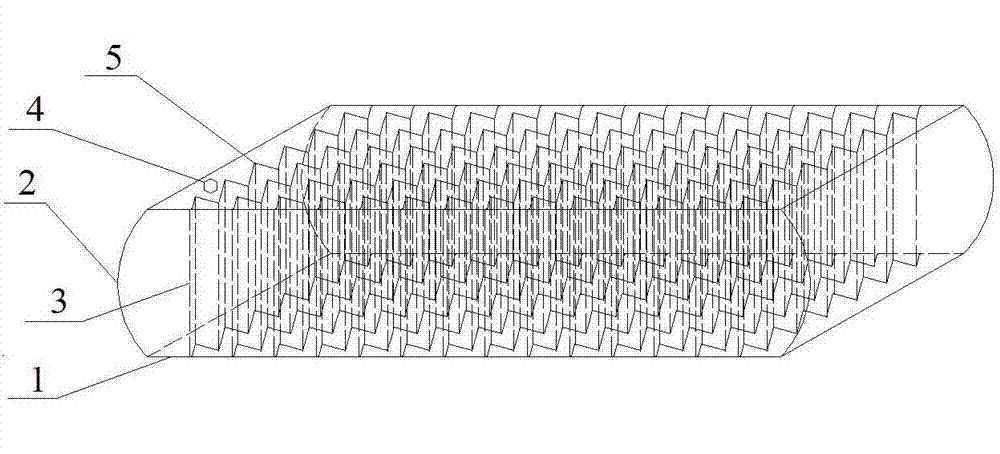

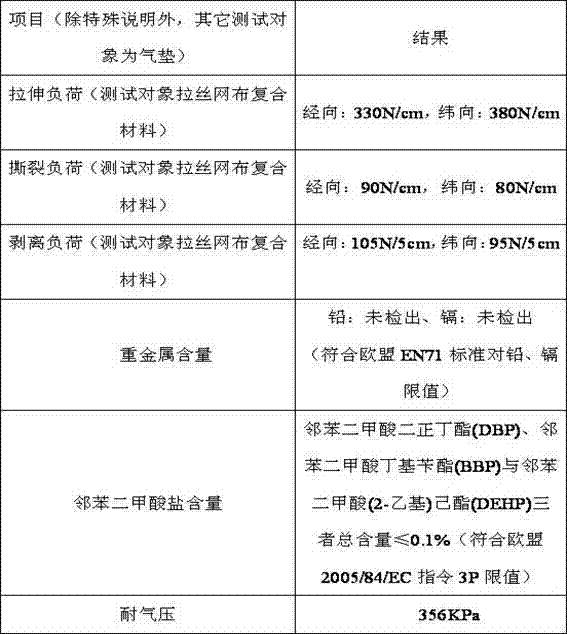

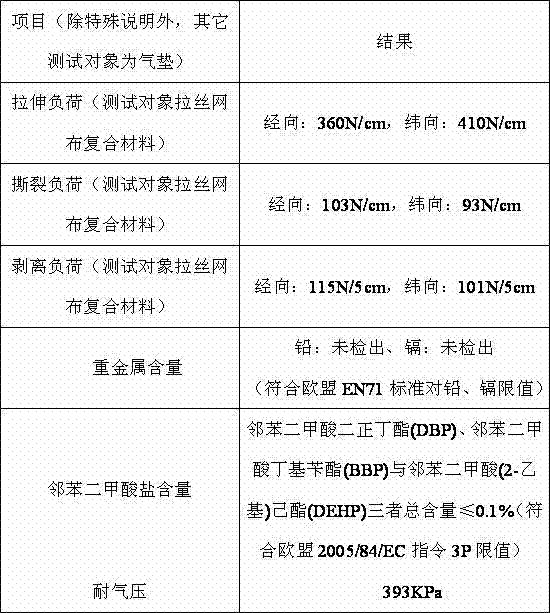

Production process of air cushion

ActiveCN102848688AHigh strengthGood dispersionLaminationLamination apparatusPolyesterWeather resistance

The invention relates to a production process of an air cushion. The production process comprises the following steps: (1) preparing drawbench net cloth; (2) preparing an anti-aging polyvinyl chloride (PVC) membrane and a convergence cloth special PVC membrane; (3) based on the drawbench net cloth prepared in step (1) as the framework material, gluing the anti-aging PVC membrane prepared in step (2) on both sides of the drawbench net cloth to prepare a drawbench net cloth composite material; (4) gluing the convergence cloth special PVC membrane prepared in step (2) on both sides of polyester weaving soaked with PVC paste resin slurry to obtain a convergence cloth composite material; and (5) gluing the edge of the drawbench net cloth composite material prepared in step (3) with the convergence cloth composite material prepared in step (4) to obtain the air cushion. The air cushion has the characteristics of high mechanical strength, function of cushion and strong absorption, and also has excellent performances of strong weather resistance, favorable tightness and elasticity, long service life, environmental friendliness and the like.

Owner:浙江华生科技股份有限公司

Method for preparing antibacterial paper on the basis of interlayer self-assembling technology

InactiveCN102587196AIncreased tensile indexHigh folding resistanceNon-fibrous pulp additionPaper/cardboardCelluloseFiber

The invention discloses a method for preparing antibacterial paper on the basis of an interlayer self-assembling technology. In the method, cationic polyelectrolyte chitosan biguanide hydrochloride (CGH) with an antibacterial function, and anionic polyelectrolyte carboxymethyl cellulose sodium (CMC) are alternately deposited on the surface of a bleached kraft hardwood fiber to prepare a layered ordered self-assembled multilayer ultrathin film, which can improve the strength property of a paper sheet while endowing the paper sheet with a good antibacterial performance. Through the change of the environment and the technical conditions of an interlayer self-assembling system, multilayer film structures with different properties can be obtained on the surface of the bleached kraft hardwood fiber, the retention of an antibacterial agent on the fiber is improved, and the antibacterial effect of the paper sheet is enhanced; a layered ordered self-assembled nano-film is prepared by taking a negatively-charged fiber as a matrix and controlling the adsorption process of a reverse-phase ion system,; the preparation method is simple in production process, less in equipment investment and high in adaptability; the prepared antibacterial paper has better antibacterial performance and strength property; and antibacterial requirements of household paper and food packaging paper can be met better.

Owner:ZHEJIANG SCI-TECH UNIV

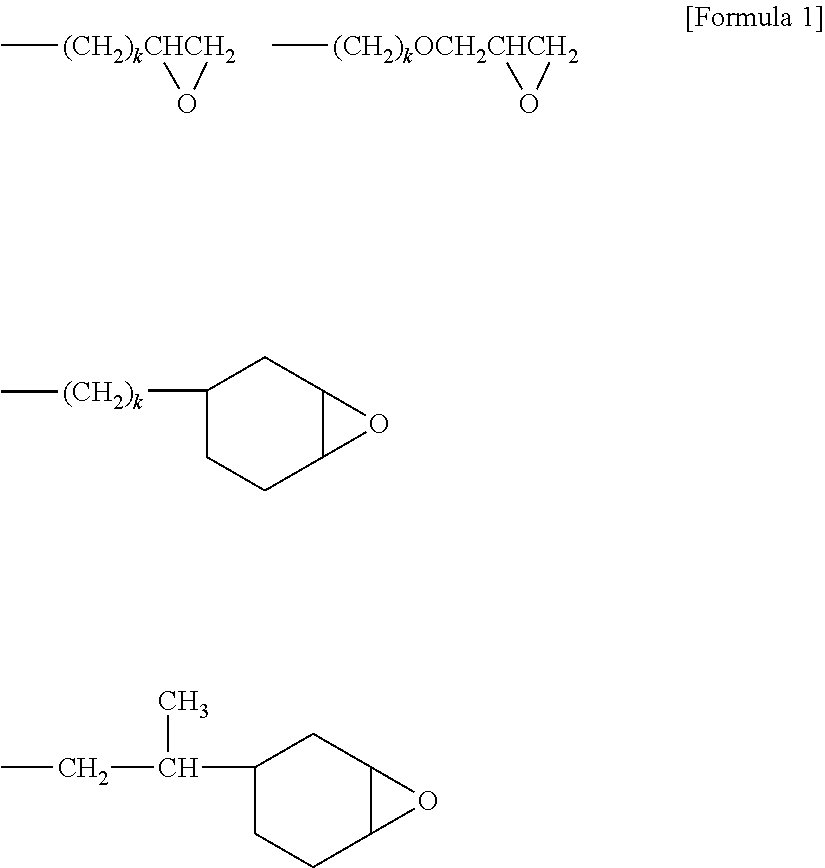

Light emitting diode (LED) encapsulation adhesive composition

ActiveCN102643627AHigh refractive indexHigh light transmittanceNon-macromolecular adhesive additivesOther chemical processesAlkeneOrganic chemistry

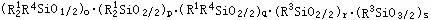

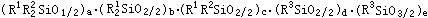

The invention relates to a light emitting diode (LED) encapsulation adhesive composition, which comprises the following components of polysiloxane A, polysiloxane B, a curing accelerator C and a solidification inhibitor D, wherein each molecule of the polysiloxane A comprises at least one alkylene and one aromatic group which are connected with silicon, each molecule of the polysiloxane B comprises at least two hydrogen atoms and aromatic groups, the at least two hydrogen atoms and aromatic groups are connected with the silicon, the composition comprises, by weight, 30-70 parts of the polysiloxane A, 30-70 parts of the polysiloxane B, 0.001-0.003 part of the curing accelerator C and 0.001-0.003 part of the solidification inhibitor D, and the molar mass of the aromatic groups which are connected with the silicon in the polysiloxane A and the polysiloxane B are over 40% of that of total groups. The LED encapsulation adhesive composition has the advantages of being high in index of refraction, transmittance and physical strength, anti-yellowing, anti-ultraviolet and heat aging resistant.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Light offset paper filled with synthetic calcium silicate and manufacturing method thereof

InactiveCN102912669ATake advantage ofReduce pollutionWater-repelling agents additionPaper/cardboardCalcium silicateFilling materials

The invention relates to light offset paper filled with synthetic calcium silicate and a manufacturing method thereof. The manufacturing method of the light offset paper includes the process of taking chemical softwood pulp and poplar PRC-APMP pulp as paper pulp raw materials, taking synthetic calcium silicate as filling material and then manufacturing the light offset paper with pulp. The produced light offset paper provided by the invention has high bulk, high opacity, no luster on the surface, excellent finishing and simple manufacturing technique, and filling material can be effectively added; and meanwhile, the calcium silicate filling material used in the invention comes from waste material of power plants, so that the manufacturing cost is reduced, and an output way with high added value is provided for the plenty of discharged fly ash in power plants.

Owner:DATANG INT POWER GENERATION +1

Para-position aramid fiber paper used for cellular material and preparation method thereof

ActiveCN102899959AReduce water repellencyImprove dispersion compatibilityPulp beating methodsPaper/cardboardPolyesterPapermaking

The invention discloses a para-position aramid fiber paper used for a cellular material and a preparation method thereof. The preparation process comprises the following steps: adding polyimide fibers, defibering and dispersing; papermaking together with para-position aramid fiber, wherein the papermaking proportion in parts by weight is as follows: 20-50% of para-position aramid short cut fiber, 35-60% of para-position aramid pulp fiber and 5-30% of polyimide fiber; and squeezing, drying and carrying out hot press moulding.. According to the preparation method, tear strength, temperature resistance and fire resistance of the para-position aramid fiber paper can be obviously improved, paper breaking during papermaking is reduced, operating speed of a paper machine and production efficiency are improved, and negative effects on properties of a paper sheet as a cohesive fiber such as a polyester fiber is introduced can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

Fireproof paint

The invention discloses a fireproof paint prepared by the following raw materials by the weight: 25-45% of acrylic emulsion, 10-20% of dipentaerythritol, 5-15% of expanded graphite, 5-15% of melamine, 2-10% of ammonium polyphosphate, 3-10% of aluminium hydroxide, 2-5% of zinc oxide, 1-5% of silica, 4-10% of carbon fiber, 5-10% of silicon nitride fiber and the balance of water. The fireproof paint is the water paint; organic solvent is not needed in the preparation process; and the formula does not include halogen, so the fireproof paint does not release toxic or harmful gases containing the halogen, therefore, the fireproof pain has the advantages of security, low pollution and environmental protection, and is widely applied to various steel structure buildings.

Owner:SHANDONG CHANGXING GROUP

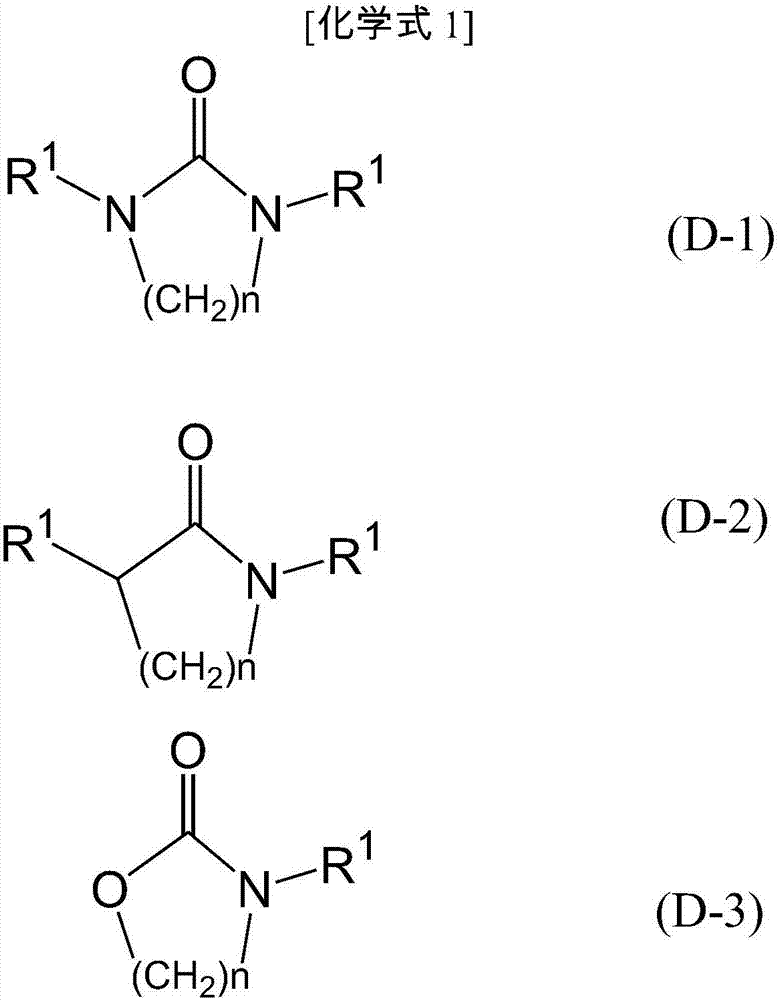

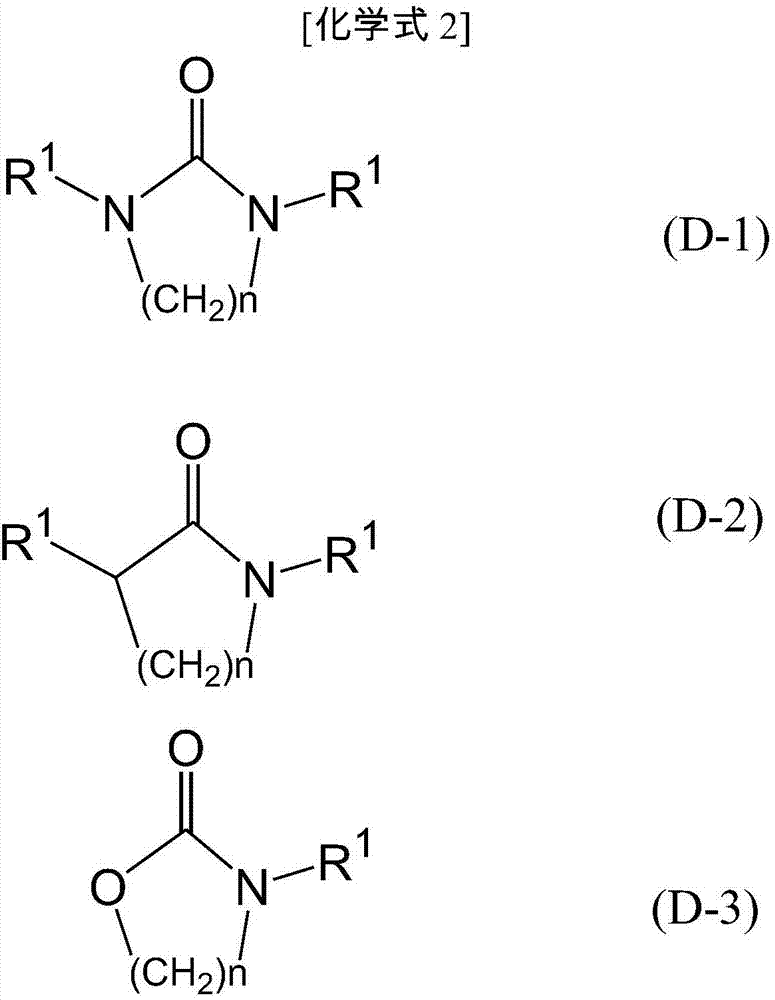

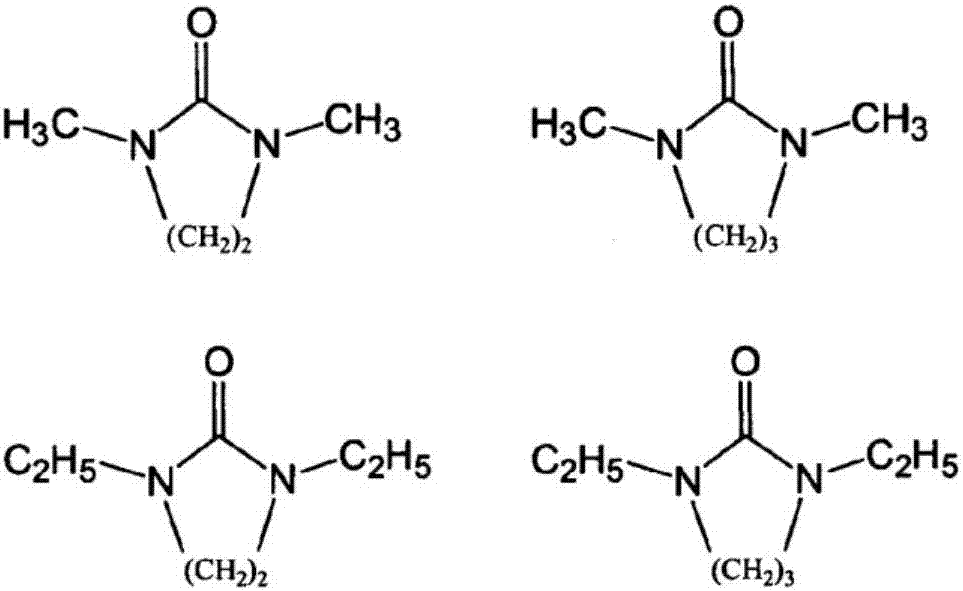

Water-based coating agent composition, water-based lubricating film paint composition comprising same, and member

ActiveCN107429116AInhibition of thickeningPrevent gelationAdditivesEmulsion paintsWater basedEmulsion

The present invention addresses the problem of providing a water-based coating agent composition (in particular, a water-based lubricating film paint composition that includes a solid lubricant) that suppresses the interaction of a curable resin and a surfactant, that suppresses thickening / disproportionation throughout a water-based coating agent, that has superior total fluidity, coating properties, and storage stability, and that can form a favorable coating film, and the problem of providing a member that is provided with said coating film, and a method for forming said coating film. Said problems can be solved by a water-based coating agent composition that includes (A) a curable resin in the form of a water-based emulsion, (B) a surfactant, (C) solid particles, (D) one or more nitrogen-containing heterocyclic compound, and (E) water. In particular, the (C) component preferably includes a solid lubricant, and for reasons of environmental regulations, it is particularly preferable that the (D) component be 1,3-dimethyl-2-imidazolidinone.

Owner:DUPONT TORAY SPECIALTY MATERIALS KK

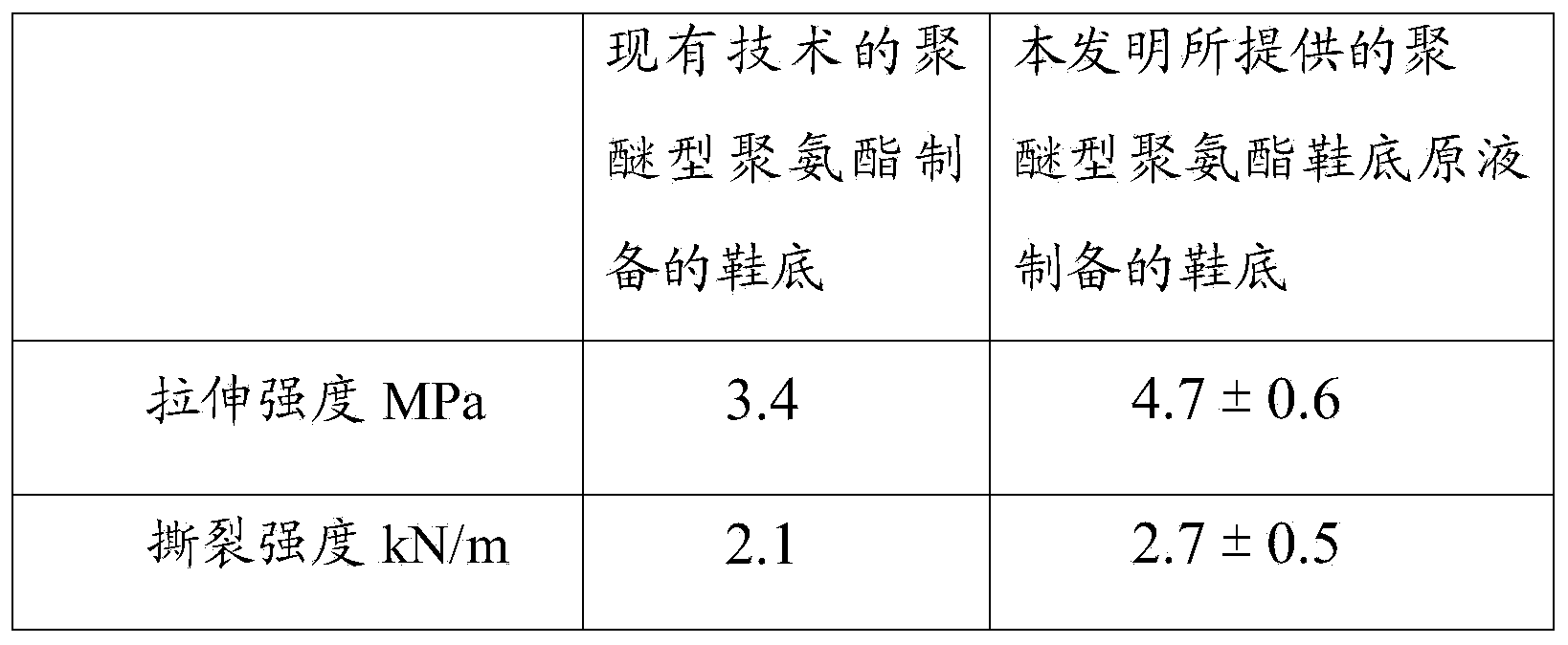

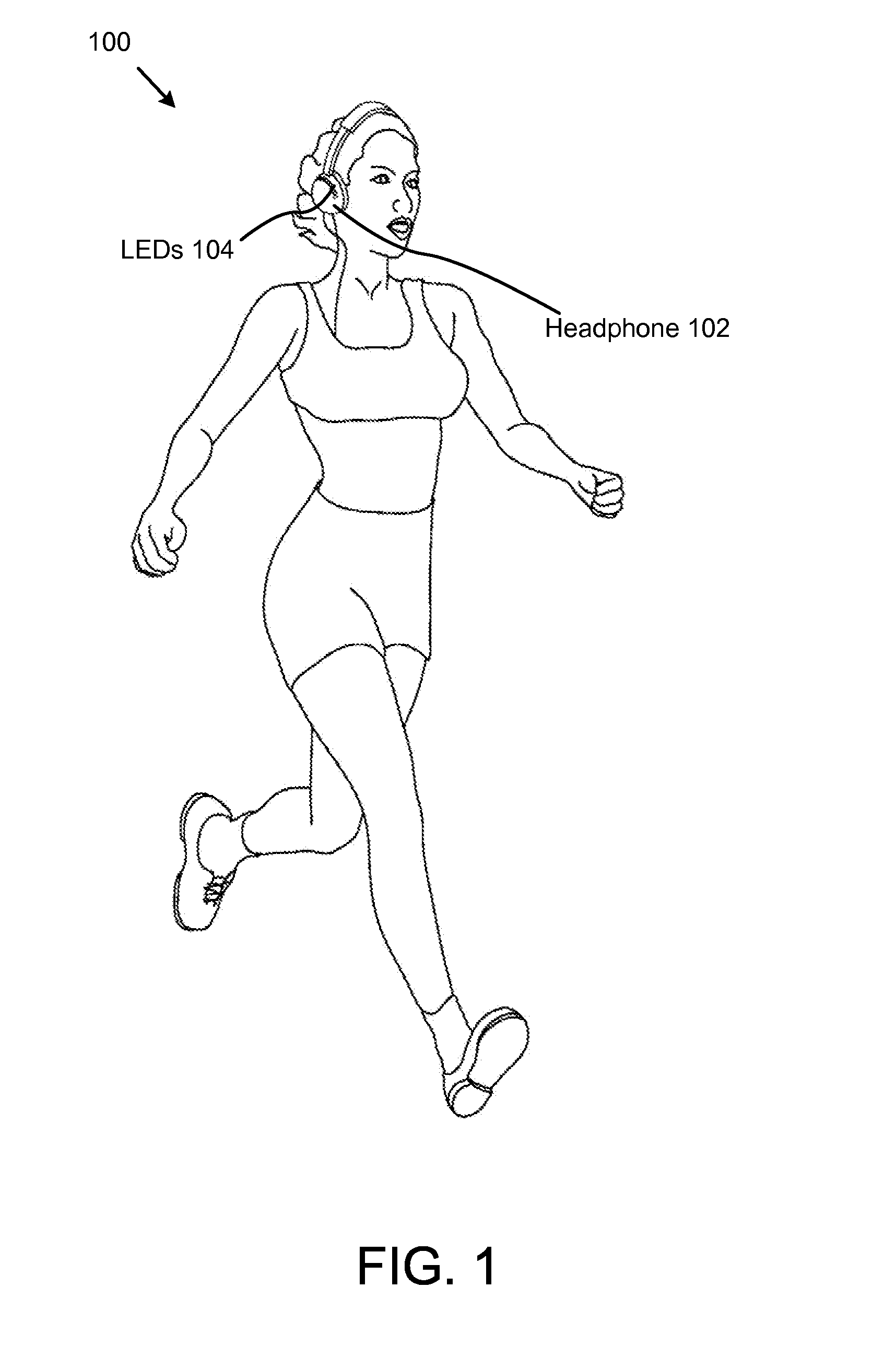

Polyether urethane shoe sole raw liquorbasic solution

The invention discloses a polyether urethane shoe sole raw liquorbasic solution. The polyether urethane shoe sole basic solutionraw liquor comprises a component A and a component B, wherein the raw material formula of the component A comprises polyether polyol, polymer polyol (POP), a chain extender, a strength improvement additive, a dispersing aid, a catalyst, a foaming agent and a foam stabilizer. The polyether urethane shoe sole basic solutionraw liquor is characterized in that the component B is an isocyanate prepolymer which is prepared by the reaction of isocyanate, polyether polyol and poly dimer acid glycol diethylene glycol ester polyhydric alcohol. The polyether urethane shoe sole basic solutionraw liquor provided by the invention has the advantages that the dimer acid type polyether polyol with a long molecular chain and excellent hydrolysis resistance is introduced to the component B, so that the hydrolysis resistance of the polyurethane product is not affected on the basis of improving the mechanical property of the polyurethane product; and organic modified silicon dioxide having relatively good compatibility with macromolecules and nanoscale calcium carbonate are adopted, so that the physical and mechanical property of the polyurethane product is improved.

Owner:XUCHUAN CHEM SUZHOU

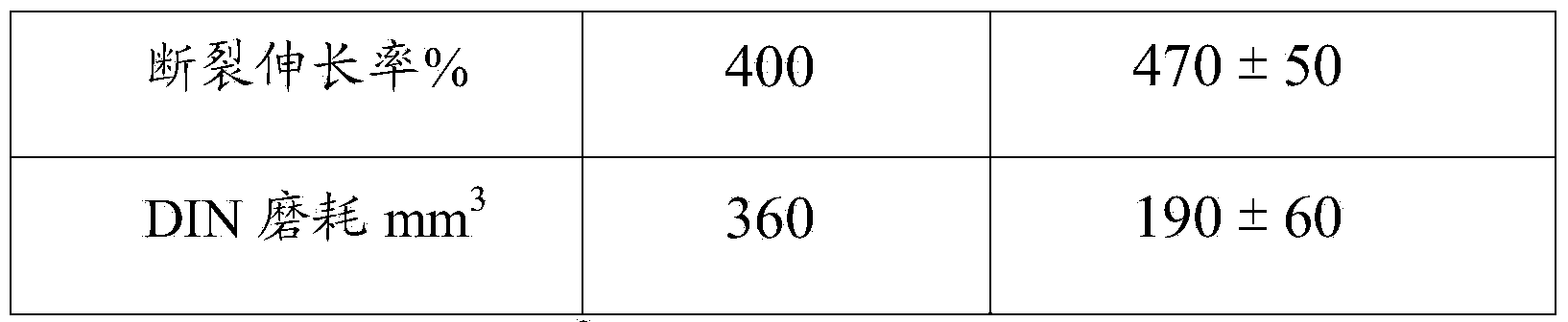

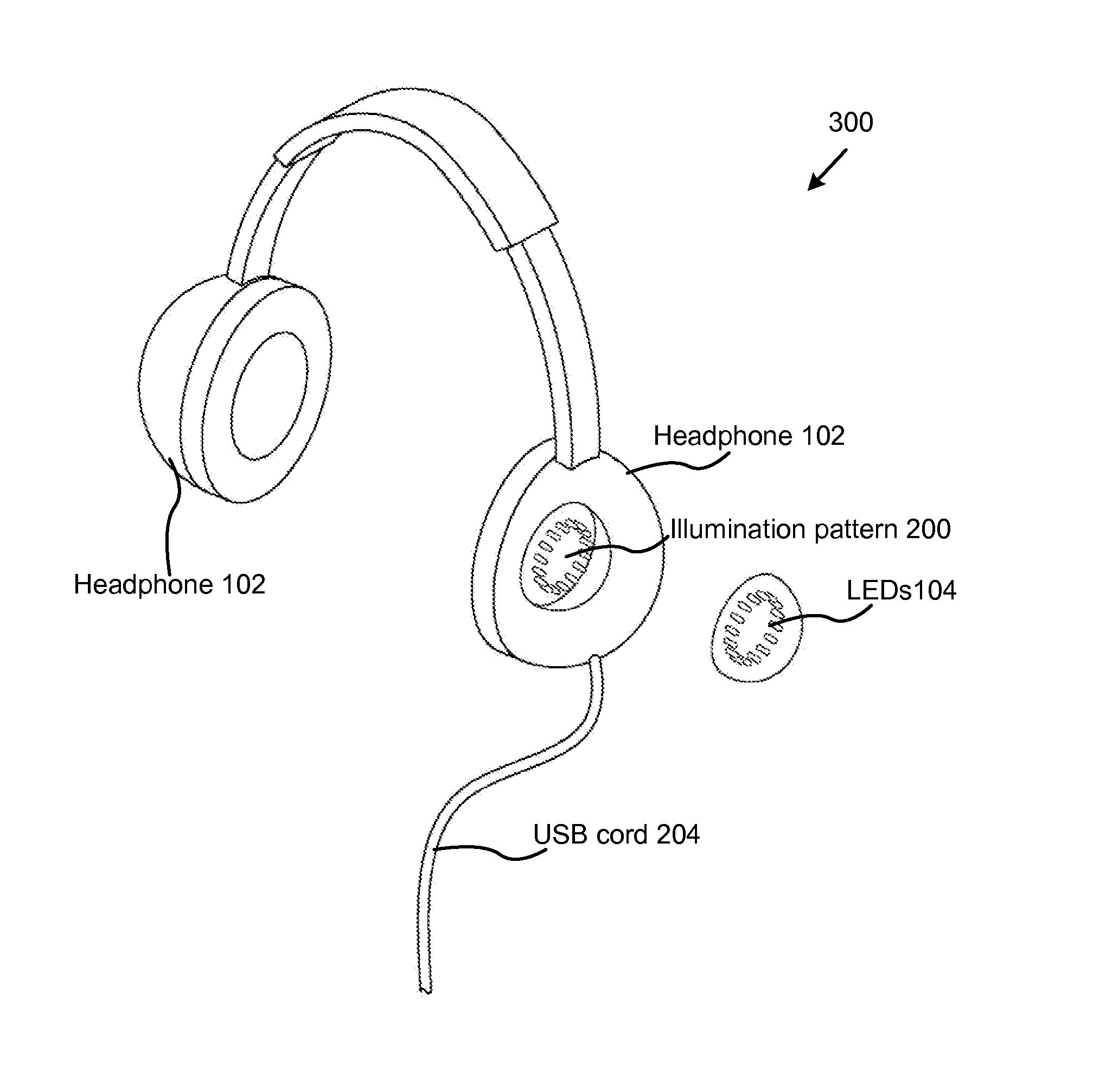

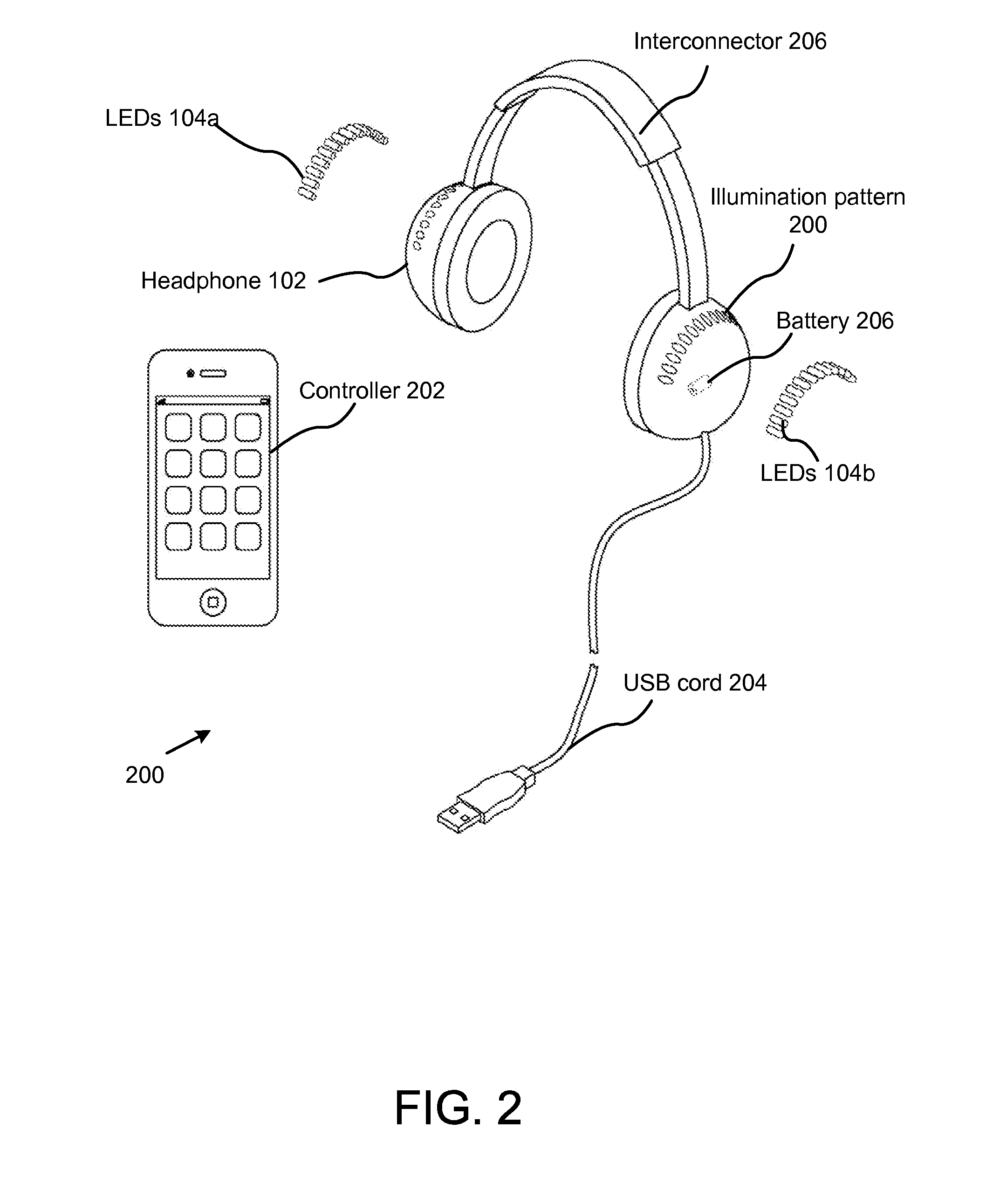

System and method for illuminating a headphone to indicate volume and/or beat

InactiveUS20150071456A1Reduce energy consumptionLong lastingHeadphones for stereophonic communicationSupra/circum aural earpiecesGraphicsData signal

A system, apparatus and method for illuminating a headphone to indicate the volume and / or rhythm of an audio signal emitting from the headphone through a flashing illuminated pattern of light emitting diodes visible to an observer. The pattern and synchronization of the illumination pattern provides an instantaneous, graphical indication of the volume, rhythm, intensity, and frequency of the audio signal. The invention includes a headphone. A plurality of light emitting diodes (LEDs) operably attach to the headphone(s). The LEDs form a pattern in, or on, the headphone(s) that is efficacious for prominently displaying the illumination. Various pattern shapes can be utilized. The illumination produced by the LEDs is efficacious for signaling the different variances of the audio signal. A USB cable may provides power and data signals for the headphone(s). A battery may provide power. A heat sink helps dissipate heat from the LEDs.

Owner:STEENKAMP SHANE CAMERON

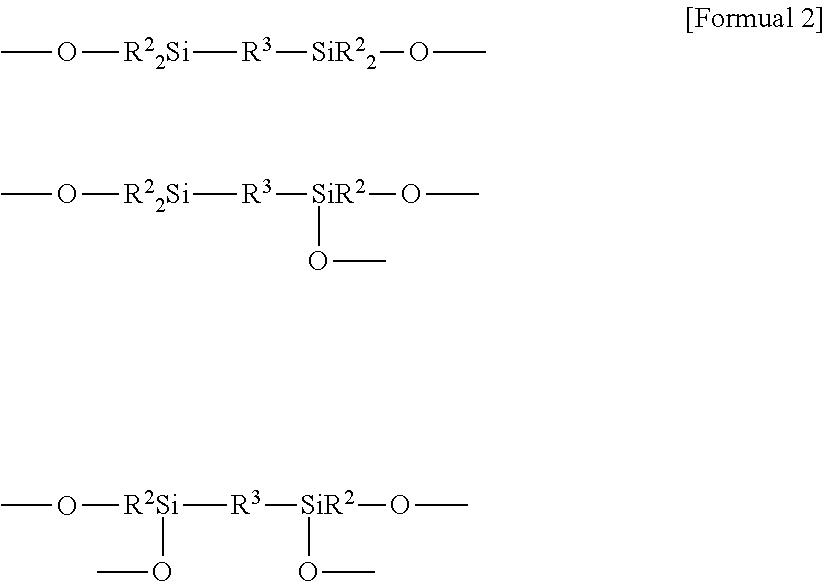

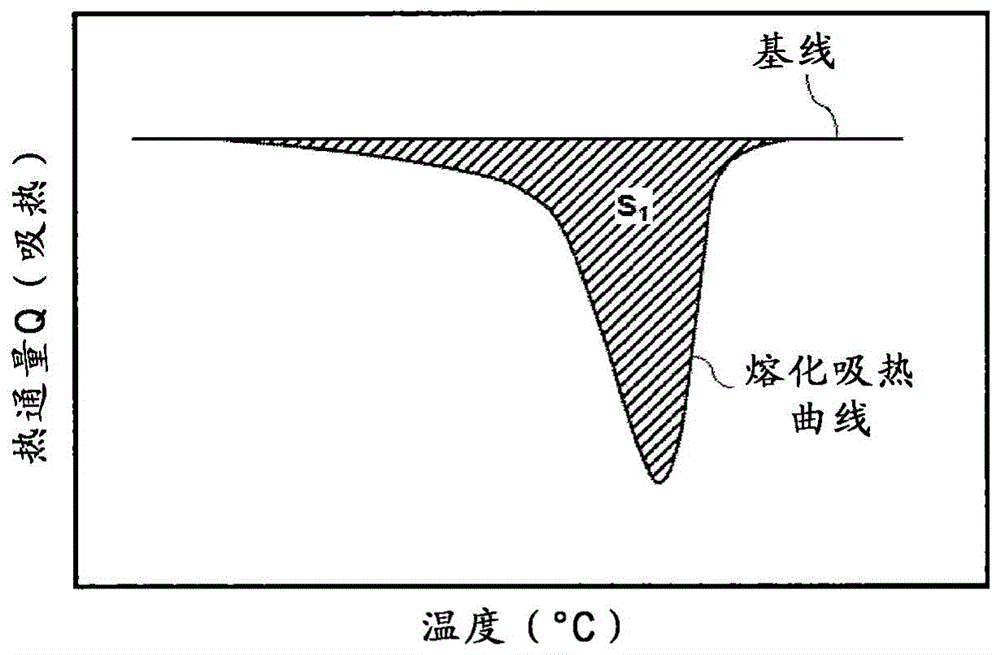

Curable organopolysiloxane composition, semiconductor sealant comprising same, and semiconductor device

ActiveUS20170355804A1Short timeGood staminaCoatingsGraft polymer adhesivesPolymer sciencePtru catalyst

Disclosed is a curable organopolysiloxane composition, comprising: (A) a curing reactive organopolysiloxane component formed by curing or semi-curing and reacting at least two or more types of organopolysiloxanes in the presence of one or more types of catalysts; and (B) a peroxide. The composition is a non-fluid at 25° C., and the melt viscosity at 100° C. is 8000 Pa·s or lower. A sealing agent comprising the curable organopolysiloxane composition and a cured product of the curable organopolysiloxane composition are also disclosed, along with a method of molding a cured product and a semiconductor device comprising the cured product.

Owner:DOW TORAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com