Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

An iron-coated and bamboo charcoal technology is applied in the field of coated bamboo charcoal porous ceramsite and its preparation, which can solve the problems of single type of pollutants, low physical strength of products, and high cost of production raw materials, and achieves simple production process conditions and high processing efficiency. The effect of good effect and low energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

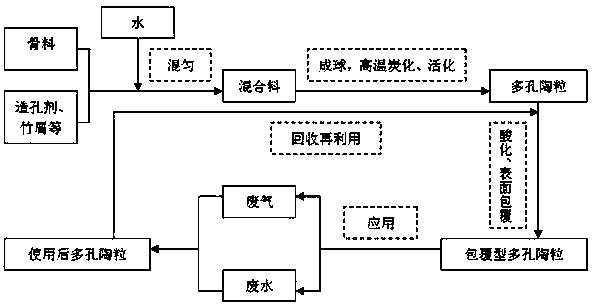

Method used

Image

Examples

Embodiment 1

[0038] 1. Raw materials and dosage

[0039] Bamboo chips: 12 kg

[0040] Surfactant: 8 kg

[0041] Porogen: 11 kg

[0042] Clay: 12kg

[0043] Bentonite: 13kg

[0044] α-Al 2 o 3 : 16 kg

[0045] Water: 15kg

[0046] Acidifier: 1 kg

[0047] Covering material: 8 kg

[0048] Coated reducing agent: 4 kg

[0049] 2. Process steps

[0050] (1) Surface activation: After crushing 12 kg of dried bamboo chips, put them into 8 kg of surfactant, stir at 80°C for 1 h, remove the moisture by suction filtration, and obtain surface-activated bamboo chips after drying.

[0051] (2) Preparation: The surface-activated bamboo chips prepared in step (1), 16 kg α-Al 2 o 3 , 11 kg of pore-forming agent, 12 kg of clay, 13 kg of bentonite and 15 kg of water were mixed in proportion and formed into balls to obtain ceramsite with a particle size of 6 mm. After drying, carbonize at 400 °C for 0.5 h, activate at 600 °C for 1 h, cool to 50 °C, immerse in 1 kg of acidifier and stir for 1 h, ne...

Embodiment 2

[0058] 1. Raw materials and dosage

[0059] Bamboo chips: 13.5 kg

[0060] Surfactant: 6.5 kg

[0061] Porogen: 10 kg

[0062] Clay: 13kg

[0063] Bentonite: 13kg

[0064] α-Al 2 o 3 : 16 kg

[0065] Water: 15kg

[0066] Acidifier: 1.5 kg

[0067] Covering material: 7.5 kg

[0068] Coated reducing agent: 4 kg

[0069] 2. Process steps and parameters

[0070] (1) Surface activation: After crushing 13.5 kg of dried bamboo chips, put them into 6.5 kg of surfactant, stir at 85°C for 1 h, remove the moisture by suction filtration, and obtain surface-activated bamboo chips after drying.

[0071] (2) Preparation: The surface-activated bamboo chips prepared in step (1), 16 kg α-Al 2 o 3 , 10 kg of pore-forming agent, 13 kg of clay, 13 kg of bentonite and 15 kg of water were mixed in proportion and formed into balls to obtain ceramsite with a particle size of 6 mm. After drying, carbonize at 400°C for 0.5 h, activate at 600°C for 2 h, cool to 60°C, immerse in 1.5 kg of ac...

Embodiment 3

[0078] 1. Raw materials and dosage

[0079] Bamboo chips: 13.5 kg

[0080] Surfactant: 6.5 kg

[0081] Porogen: 10.5 kg

[0082] Clay: 12.5kg

[0083] Bentonite: 12kg

[0084] α-Al 2 o 3 : 15kg

[0085] Water: 17kg

[0086] Acidifier: 1.5 kg

[0087] Wrapping material: 6.5 kg

[0088] Coated reducing agent: 5 kg

[0089] 2. Process steps and parameters

[0090] (1) Surface activation: 13.5 kg of dried bamboo chips were crushed, put into 6.5 kg of surfactant, stirred at a constant temperature of 90 °C for 1.5 h, filtered to remove water, and surface-activated bamboo chips were obtained after drying.

[0091] (2) Preparation: The surface-activated bamboo chips prepared in step (1), 15 kg α-Al 2 o 3 , 10.5 kg of pore-forming agent, 12.5 kg of clay, 12 kg of bentonite and 17 kg of water were mixed in proportion and formed into balls to obtain ceramsite with a particle size of 6 mm. After drying, carbonize at 400°C for 1 h, activate at 600°C for 1.5 h, cool to 90°C, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com