Water-based coating agent composition, water-based lubricating film paint composition comprising same, and member

A technology of composition and coating agent, applied in the direction of lubricating composition, base material, coating, etc., can solve the problem of water-based coating agent stability without any description, solution without any suggestion, mixed solvent without any record and Suggestions and other problems, to achieve the effect of excellent workability, low friction coefficient, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0119] [Preparation method of composition]

[0120] The preparation method of the composition of the present invention is not particularly limited, and it can be obtained by uniformly mixing and dispersing the above-mentioned components (A) to (E) and other water-soluble optional components by using mechanical force, and can also be obtained by using a concentration adjustment agent if necessary. It is prepared by mixing and dispersing water and any other additives. There are no restrictions on its mixing method and mixing order.

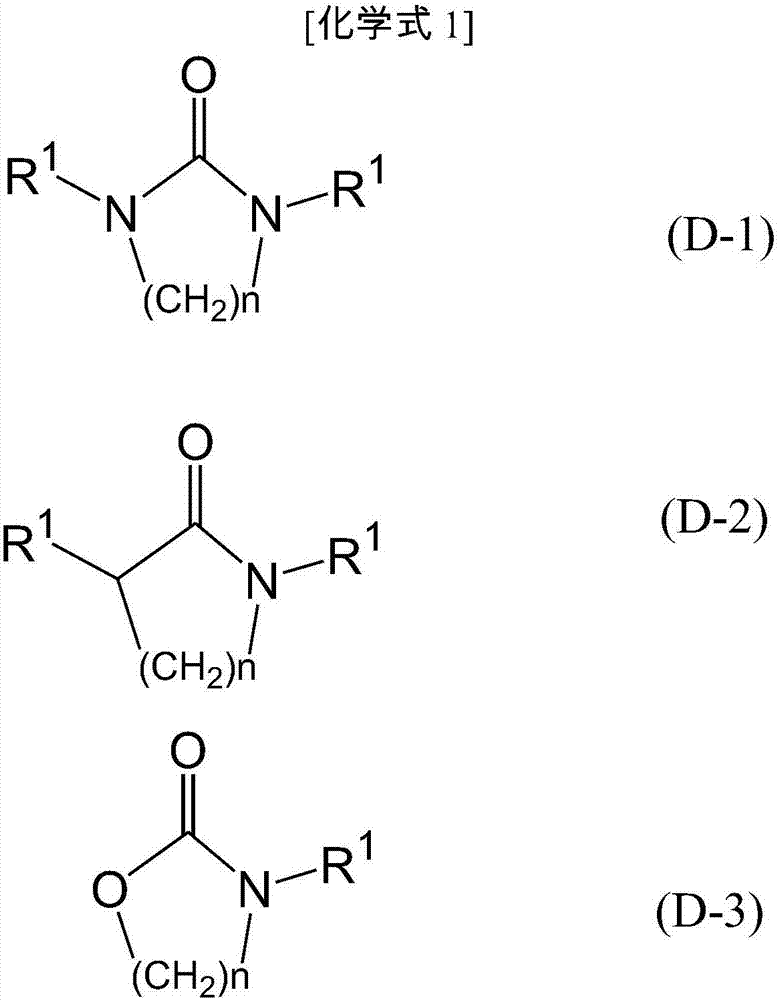

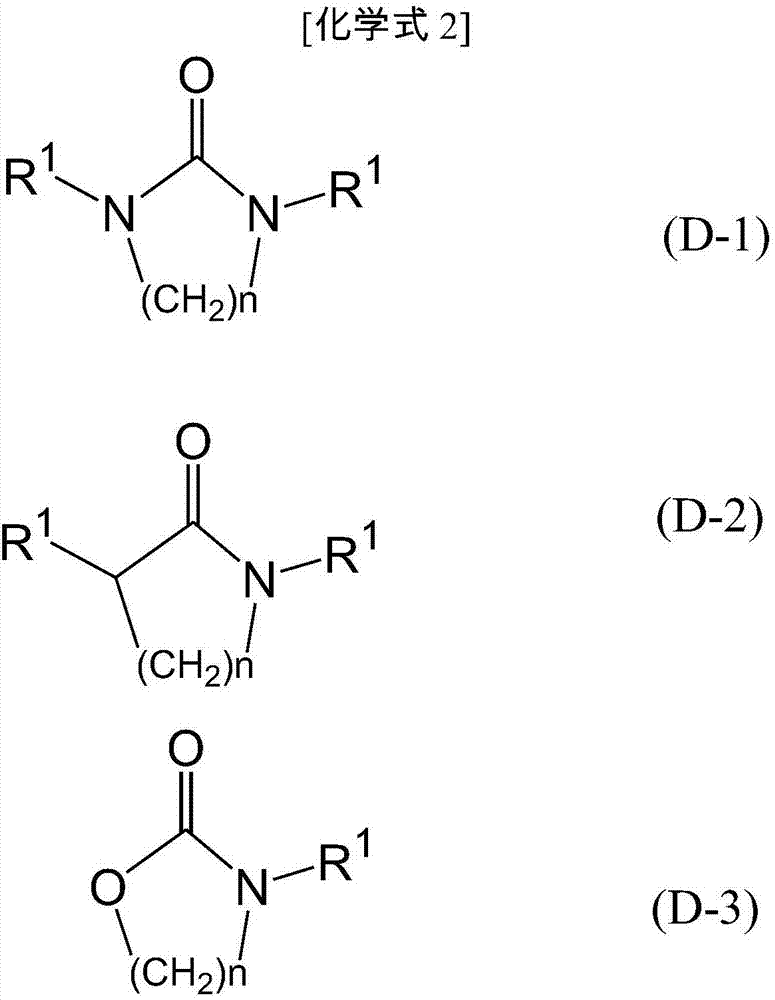

[0121] On the other hand, it is preferable to prepare (A) an emulsion of curable resin in the form of an aqueous emulsion by emulsion polymerization using an ionic or nonionic surfactant, etc. One or more nitrogen-containing heterocyclic compounds are added as the component (D) to plasticize or stabilize the curable resin in the form of an aqueous emulsion. In this state, by using mechanical force to uniformly mix and disperse other surfactants,...

Embodiment 1~7 and comparative example 1~8

[0145] Each component was mixed in the ratio shown in Table 1 and Table 2, and the water-based coating agent (water-based coating composition for lubricating coatings) of Examples 1-7 and Comparative Examples 1-8 was obtained.

[0146] In addition, the numerical value shown in Table 1 and Table 2 represents a mass part. Further, the water-based polyurethane resin / water-based polyolefin resin in the table is used as the binder of (A) component of the present invention, and is described in the form of mass parts (100 parts by mass) of the solid content, and the water in the water-based emulsion form is included in (E ) is recorded in the water component.

[0147] [Flow Stability]

[0148] The flow stability of the coating agent was determined on the basis of the following criteria, and is shown in Table 1 (Examples 1 to 7) and Table 2 (Comparative Examples 1 to 8).

[0149] ◎: very stable

[0150] ○: Stable but thickened

[0151] Δ: Viscosification and saponification after 2...

Embodiment 1

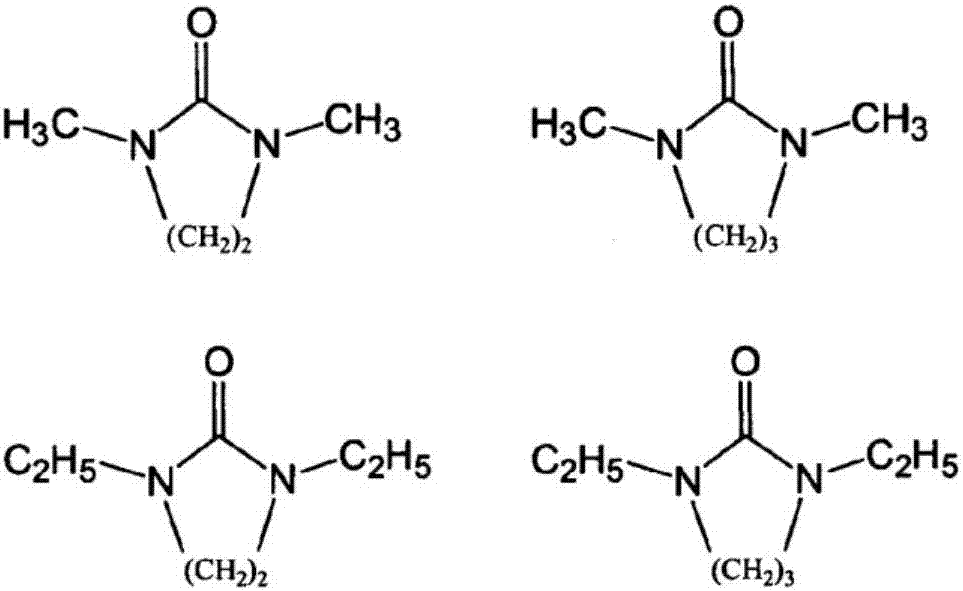

[0171] 1,3-Dimethyl-2-imidazolidinone was added as a solvent to a water-based polyurethane resin emulsion (resin solid content: 40%) at a compounding ratio shown in Table 1, and stirred and mixed for dissolution. Then, sodium dodecylbenzenesulfonate as an anionic surfactant was added and dissolved while stirring, and then PTFE powder as a solid lubricant was dispersed. After adding the antifoaming agent, the obtained mixture was mixed and stirred at 600 rpm for 30 minutes to obtain a water-based coating agent composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com