Patents

Literature

198results about How to "Prevent gelation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite materials and methods of making the same

InactiveUS20090169867A1Reduce slurry viscosityLow viscosityProtein adhesivesFibre treatmentEmulsionFormaldehyde free

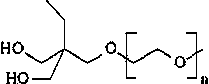

The present invention provides composite materials that contain formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size and polymer particles of at least one emulsion (co)polymer. Preferably, the defatted soy flour is present as an aqueous dispersion, or is in denatured form. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

Soy composite materials comprising a reducing sugar and methods of making the same

InactiveUS20100129640A1Reduce slurry viscosityLow viscosityLayered productsPretreated surfacesEmulsionSoy flour

The present invention provides composite materials derived from formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, and one or more reducing sugar. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

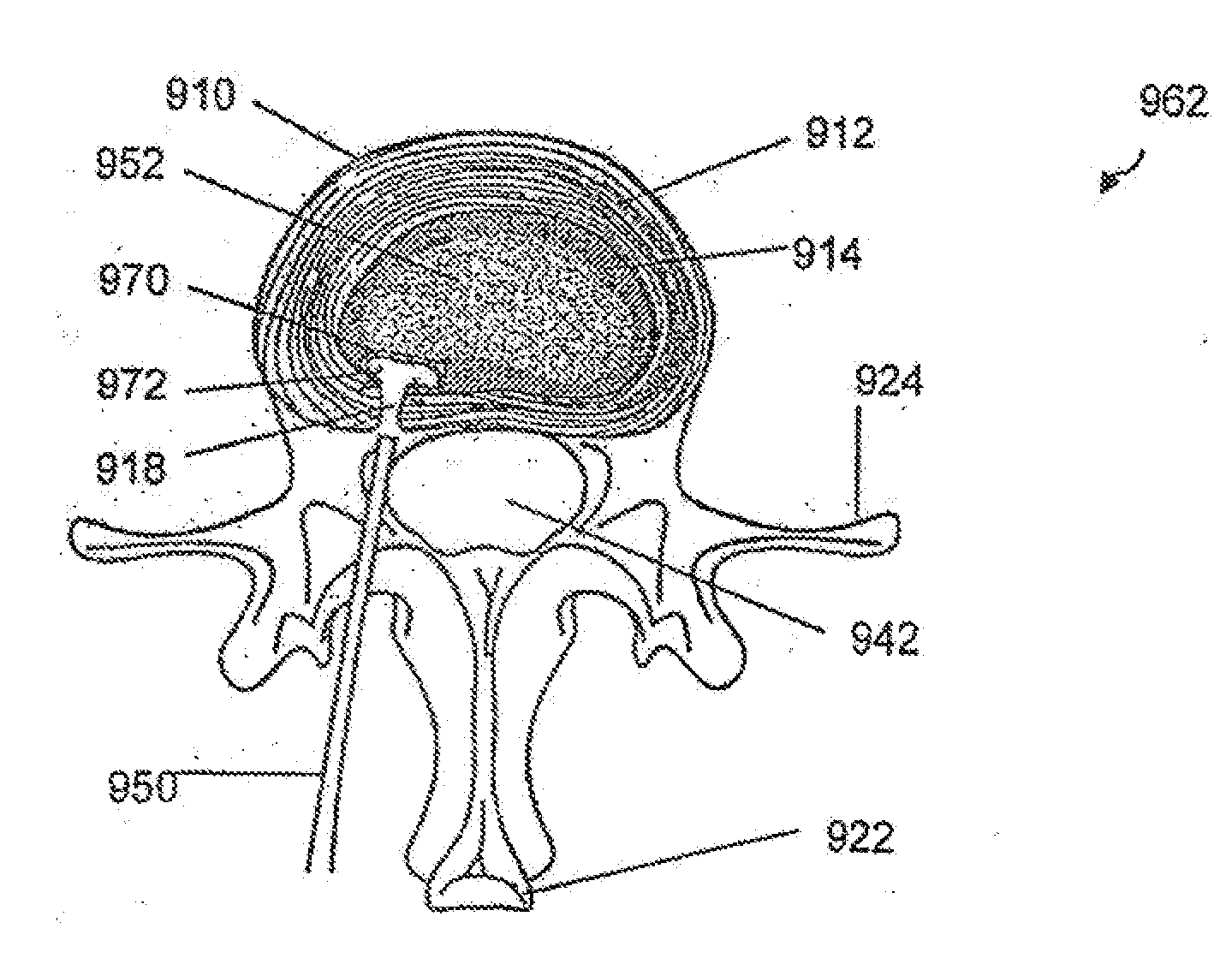

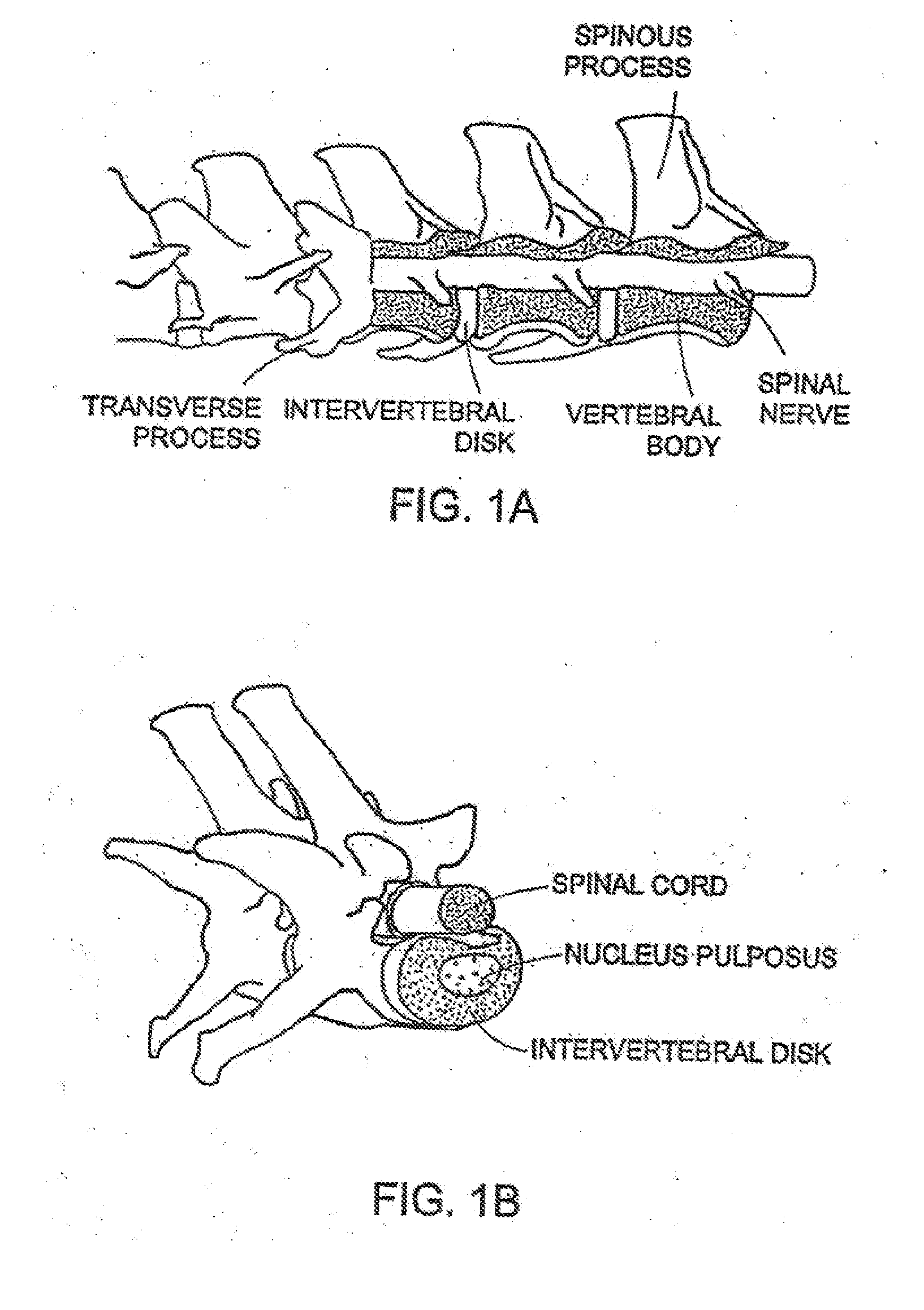

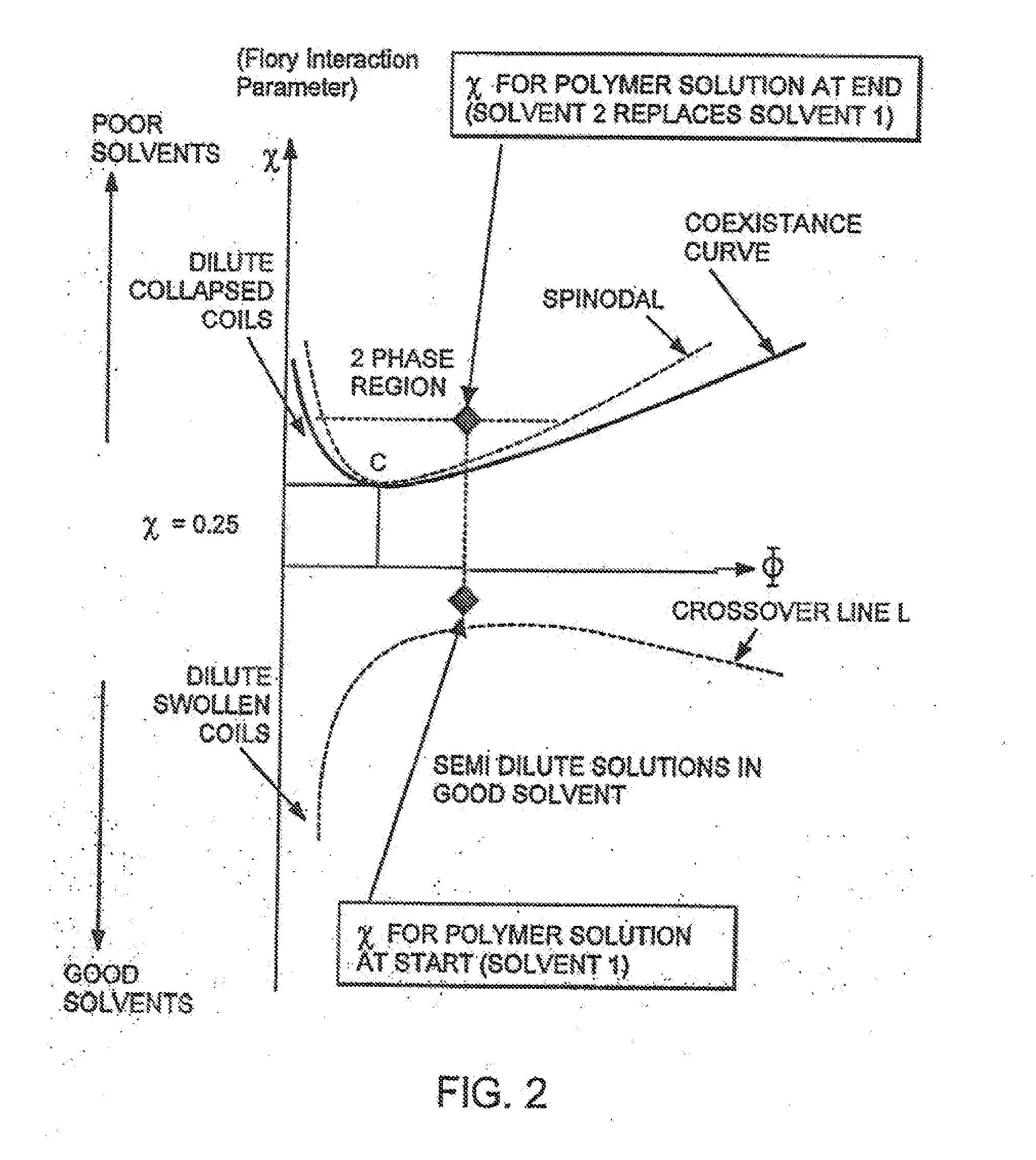

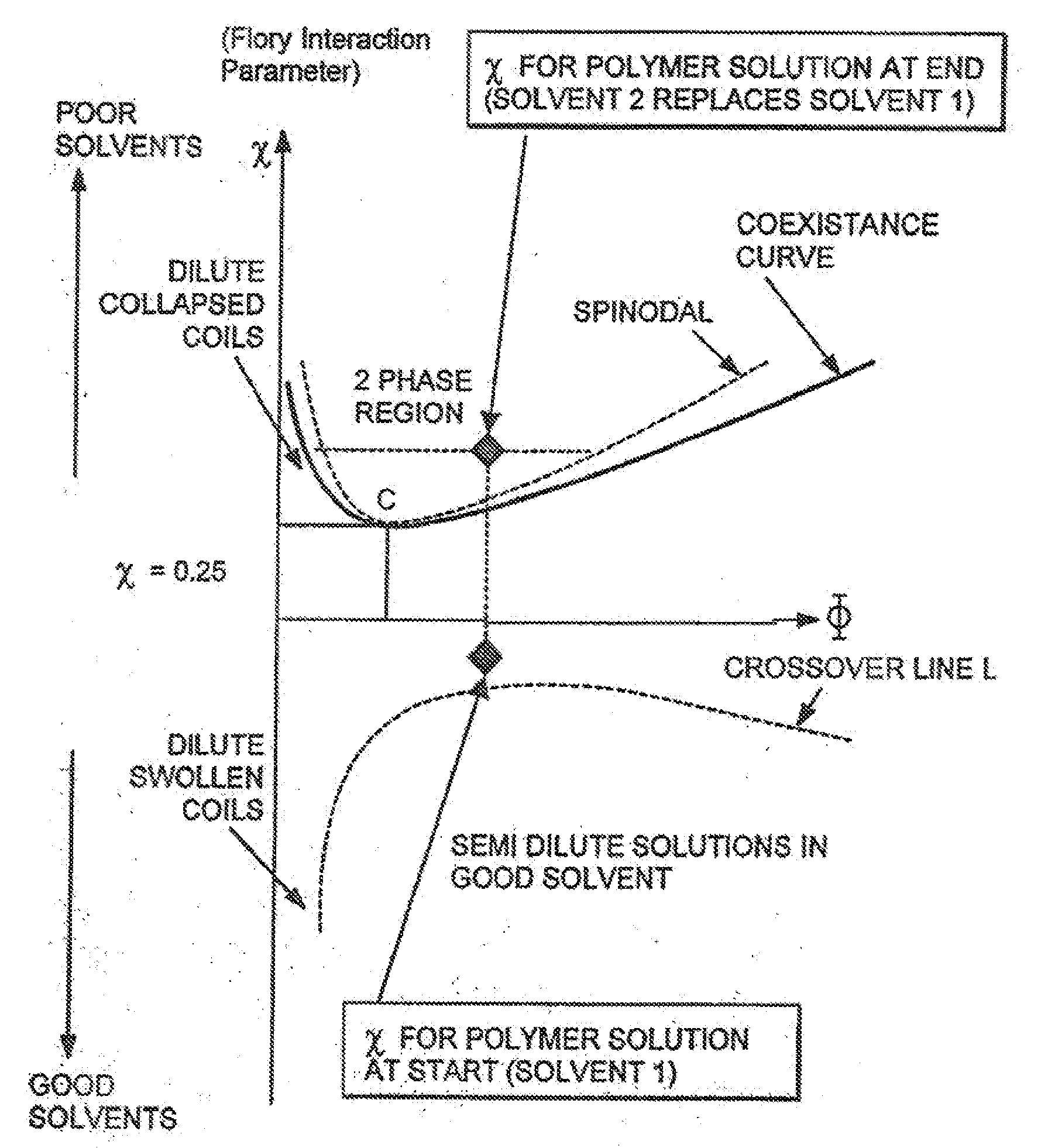

Systems and methods for controlling and forming polymer gels

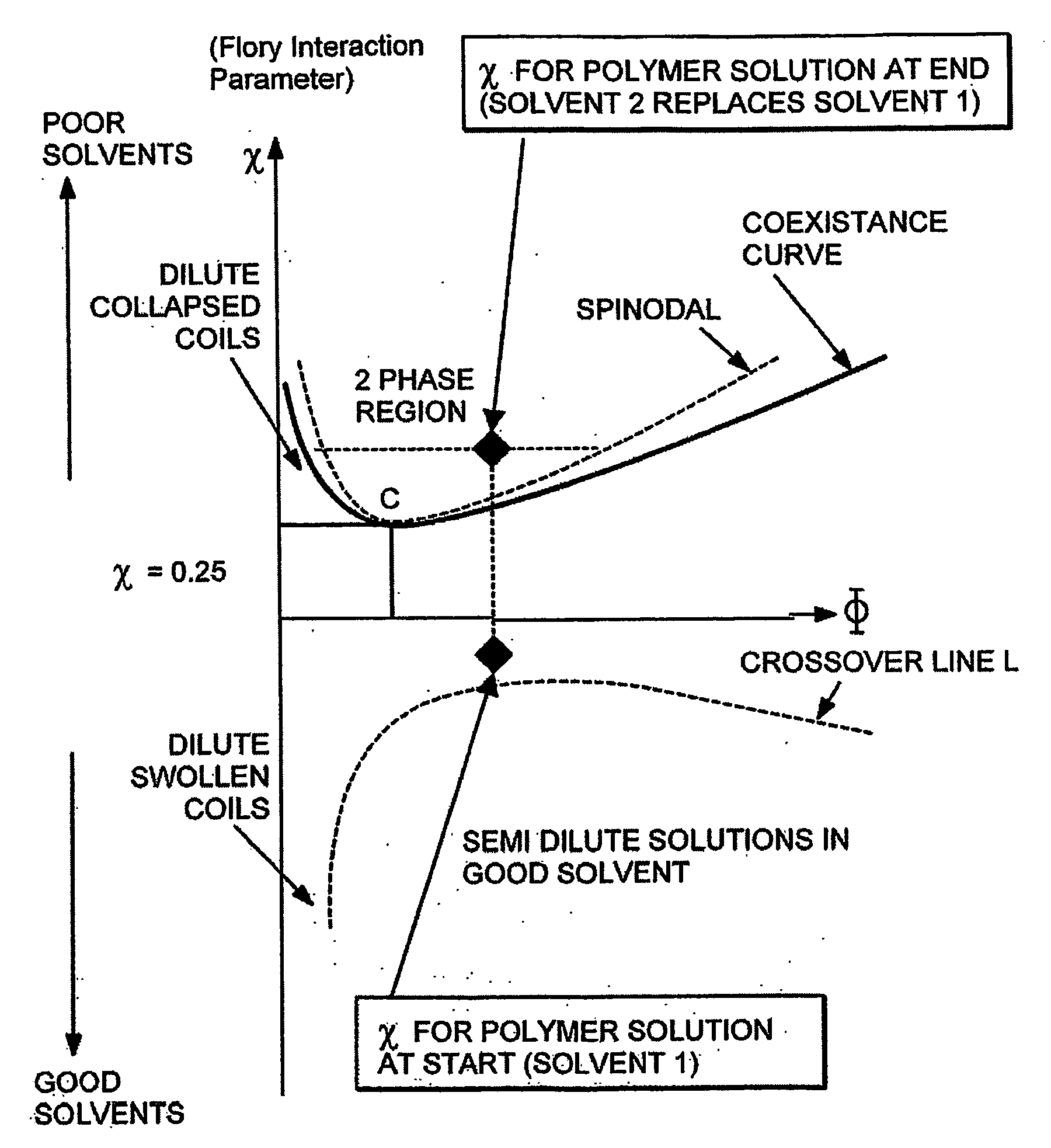

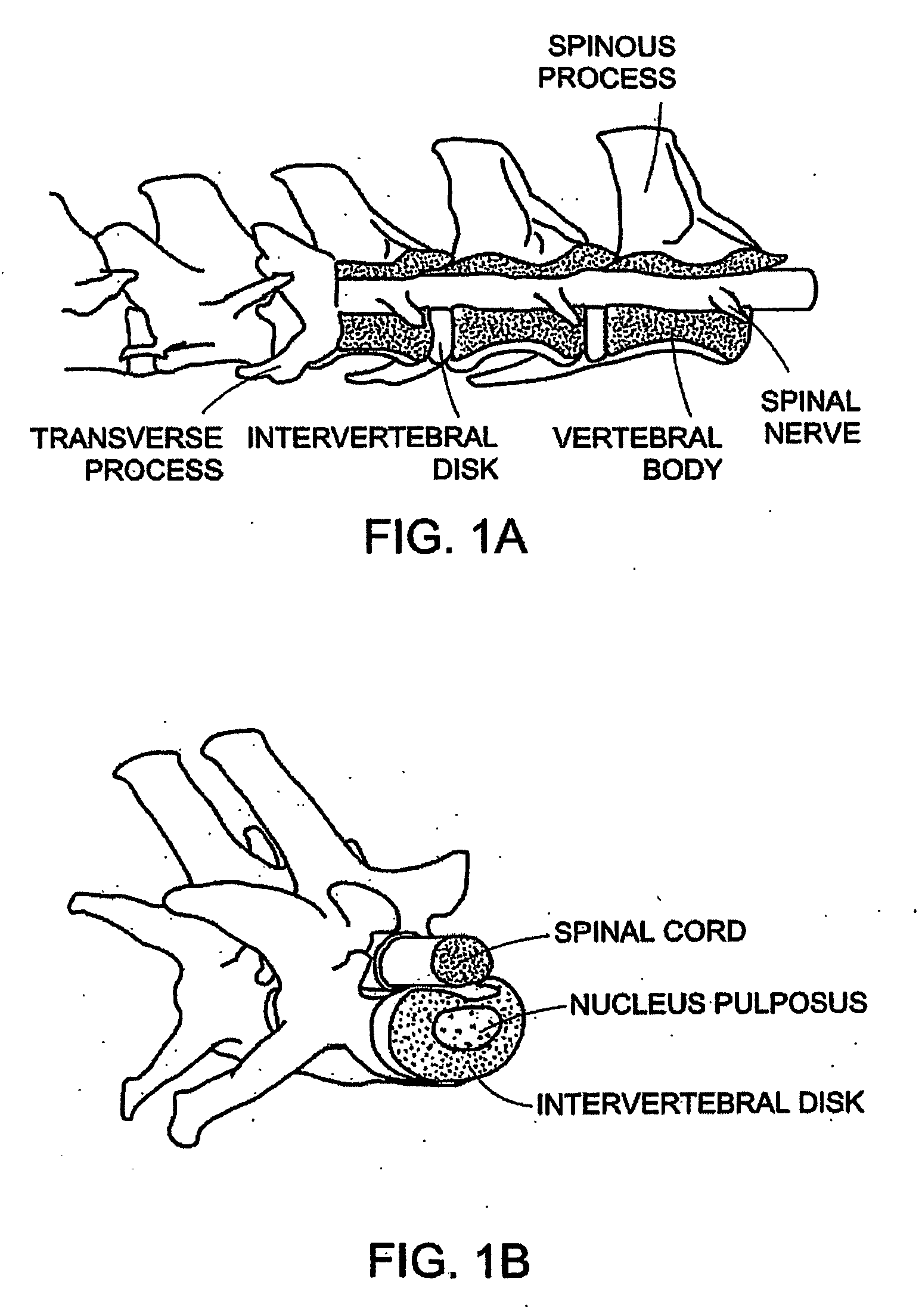

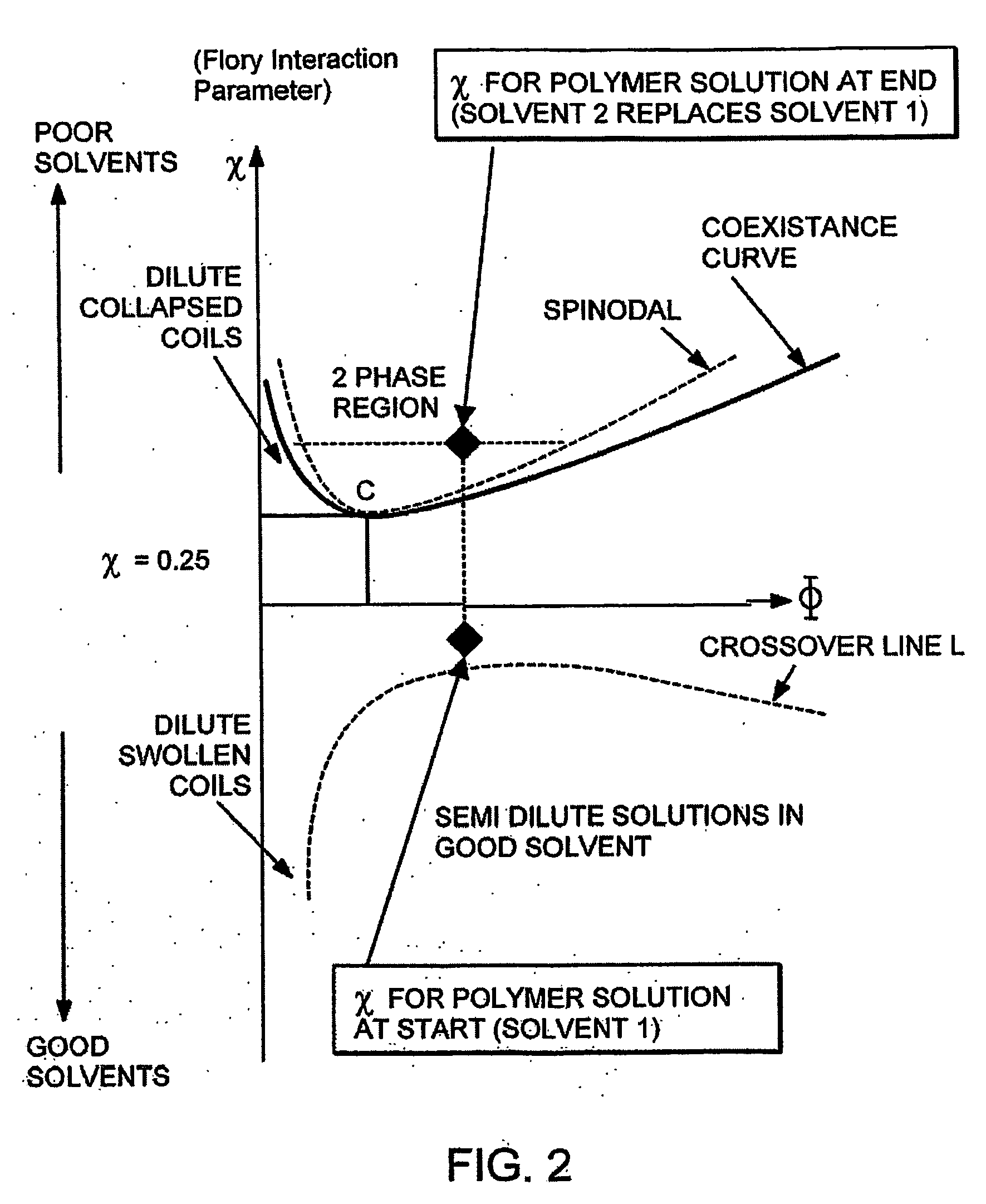

InactiveUS20070167541A1Minimizing damageHigh Flory interaction parameterInksGranular deliveryCross-linkViscoelastic Solutions

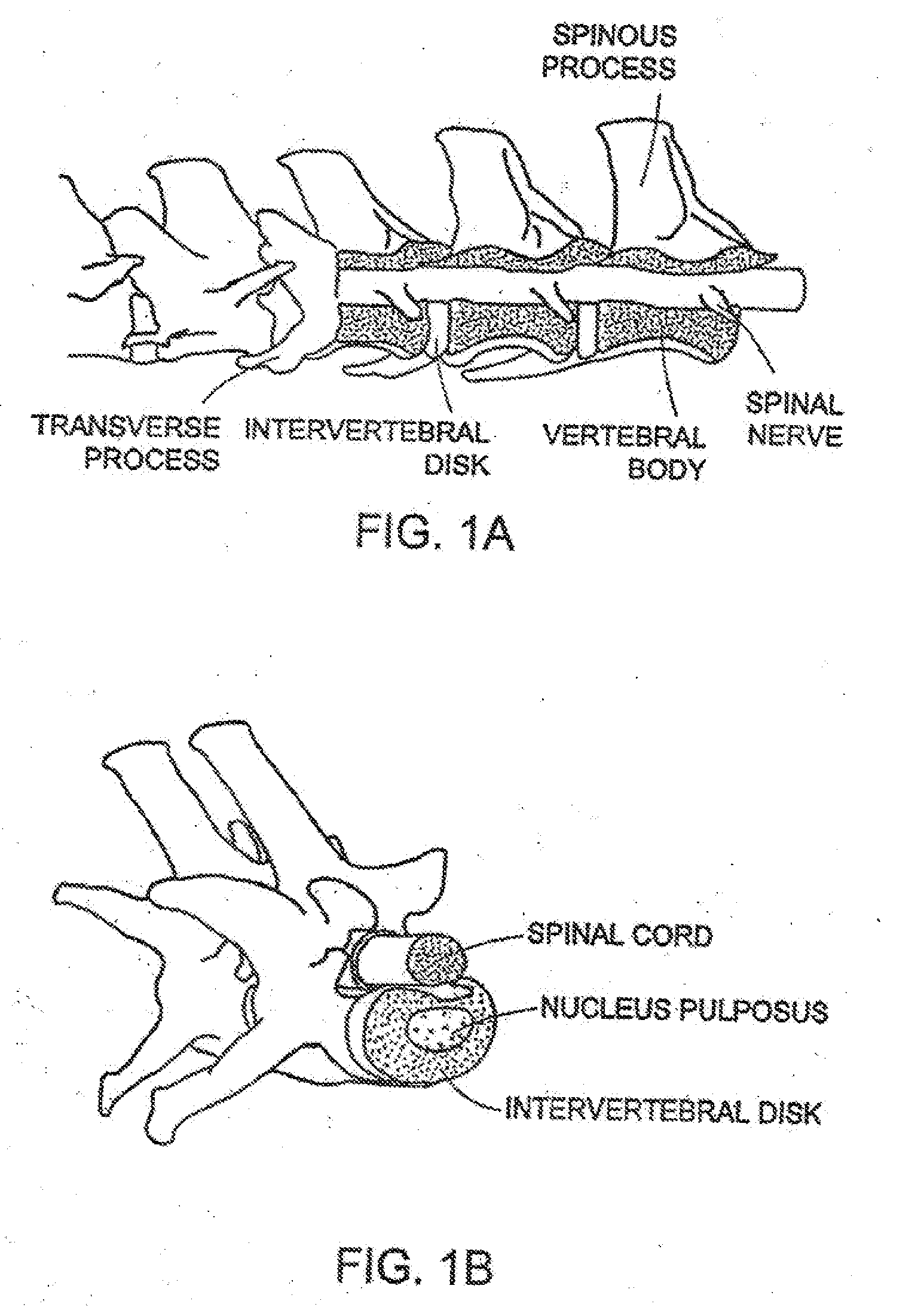

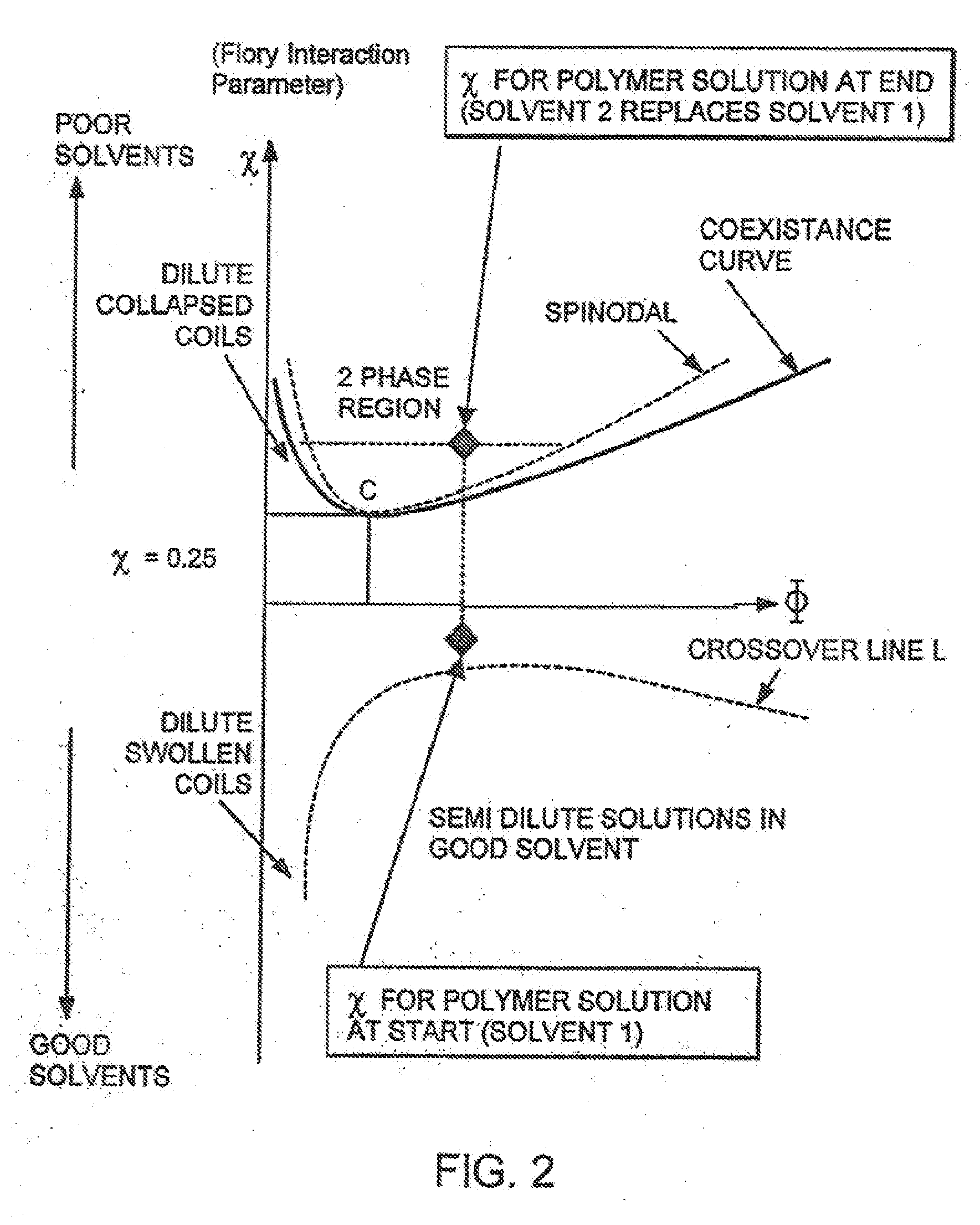

In preferred embodiments, the present invention provides methods of controllably making a vinyl polymer hydrogel having desired physical properties without chemical cross links or radiation. The gelation process is modulated by controlling, for example the temperature of a resultant vinyl polymer mixture having a gellant or using active ingredients provided in an inactive gellant complex. In accordance with a preferred embodiment the method of manufacturing a vinyl polymer hydrogel includes the steps of providing a vinyl polymer solution comprising a vinyl polymer dissolved in a first solvent; heating the vinyl polymer solution to a temperature elevated above the melting point of the physical associations of the vinyl polymer, mixing the vinyl polymer solution with a gellant wherein the resulting mixture has a higher Flory interaction parameter than the vinyl polymer solution: inducing gelation of the mixture of vinyl polymer solution and gellant; and controlling the gelation rate to form a viscoelastic solution wherein workability is maintained for a predetermined period thereby making a vinyl polymer hydrogel having the desired physical property. In further preferred embodiments the present invention provides physically crosslinked hydrogels produced by controlled gelation of viscoelastic solution wherein workability is maintained for a predetermined period. In another aspect, the present invention provides kits for use in repairing intervertebral disks or articulated joints including components that form the vinyl polymer hydrogel and a dispenser.

Owner:CAMBRIDGE POLYMER GROUP

Resin composition and multilayer structure

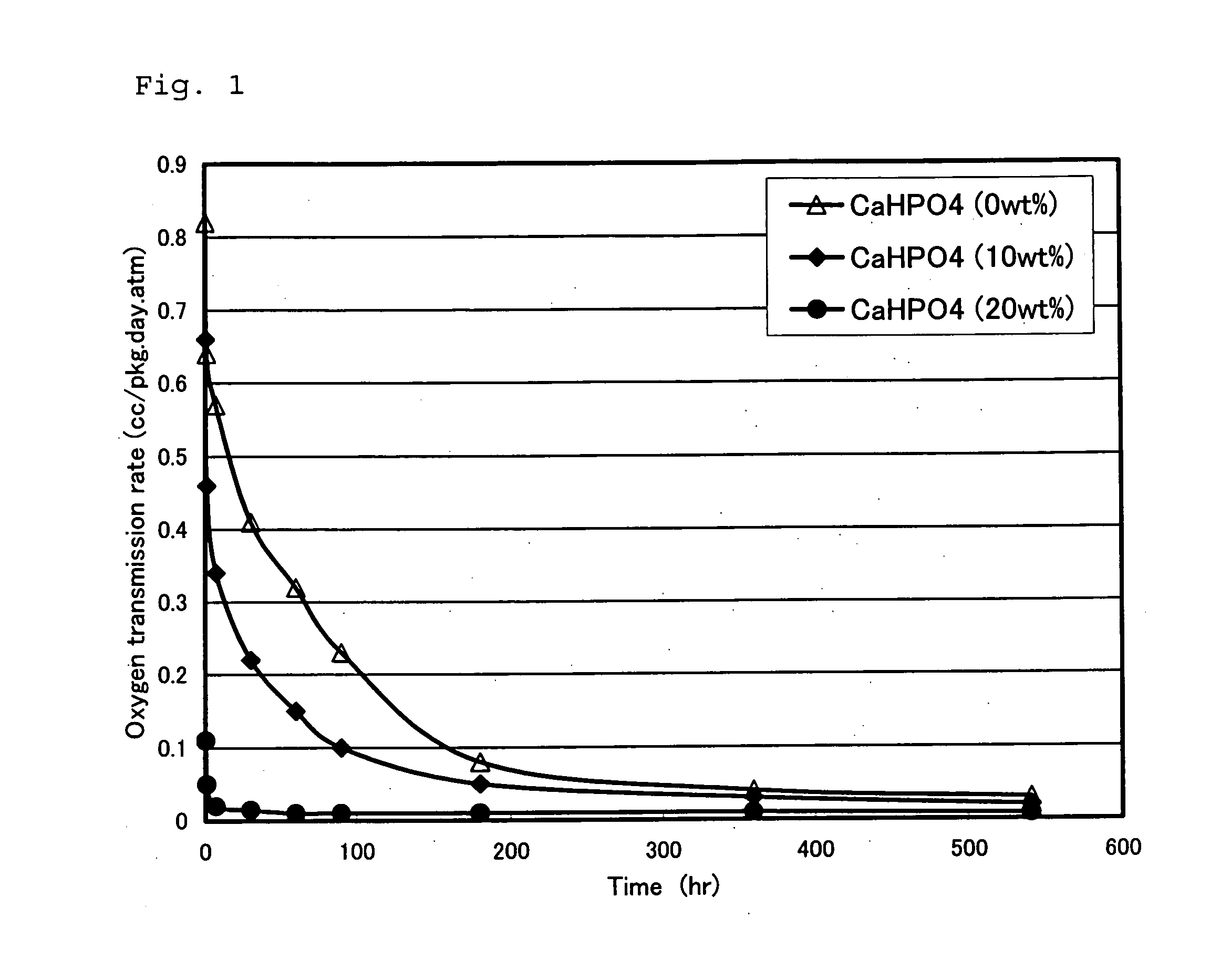

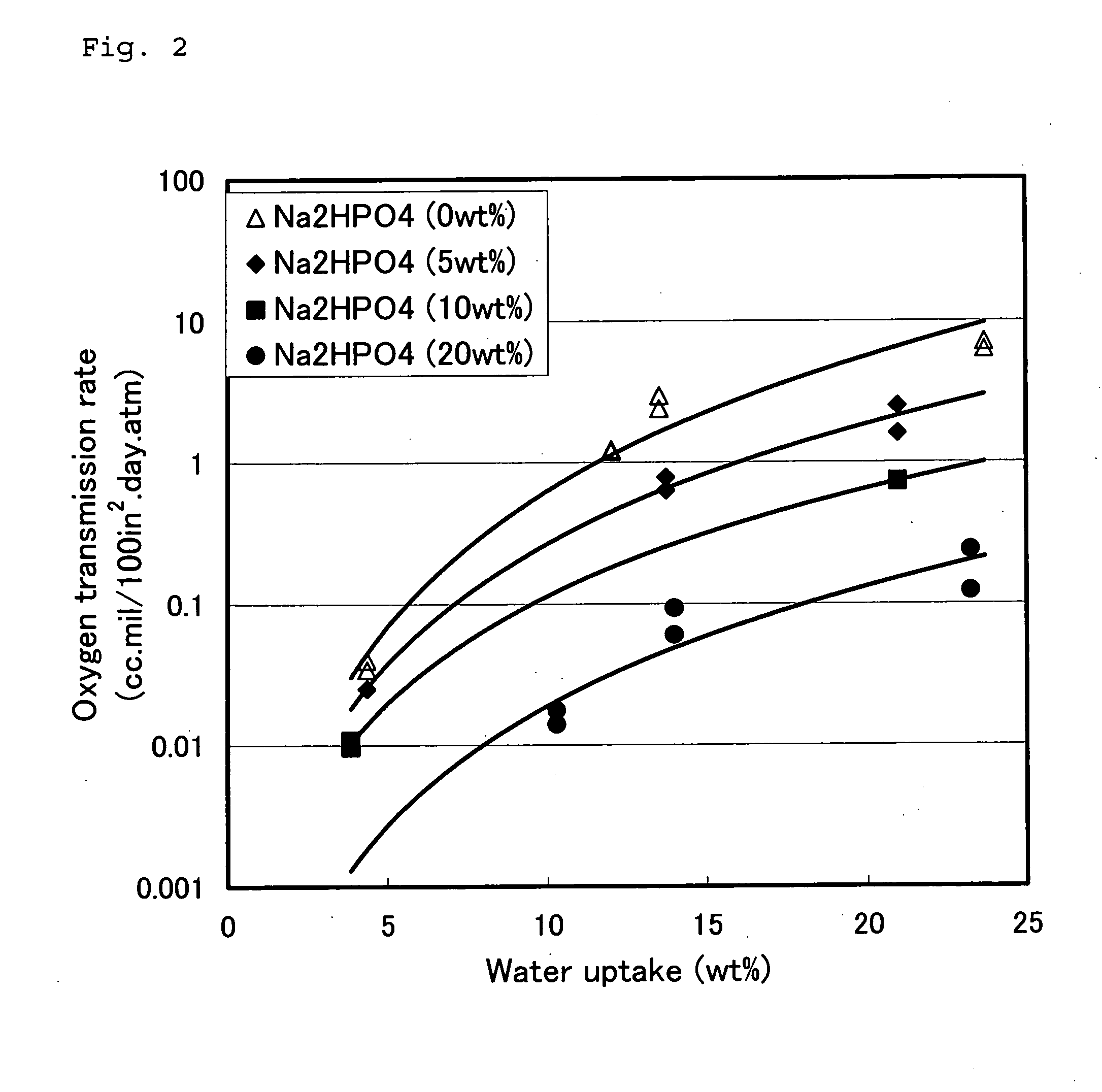

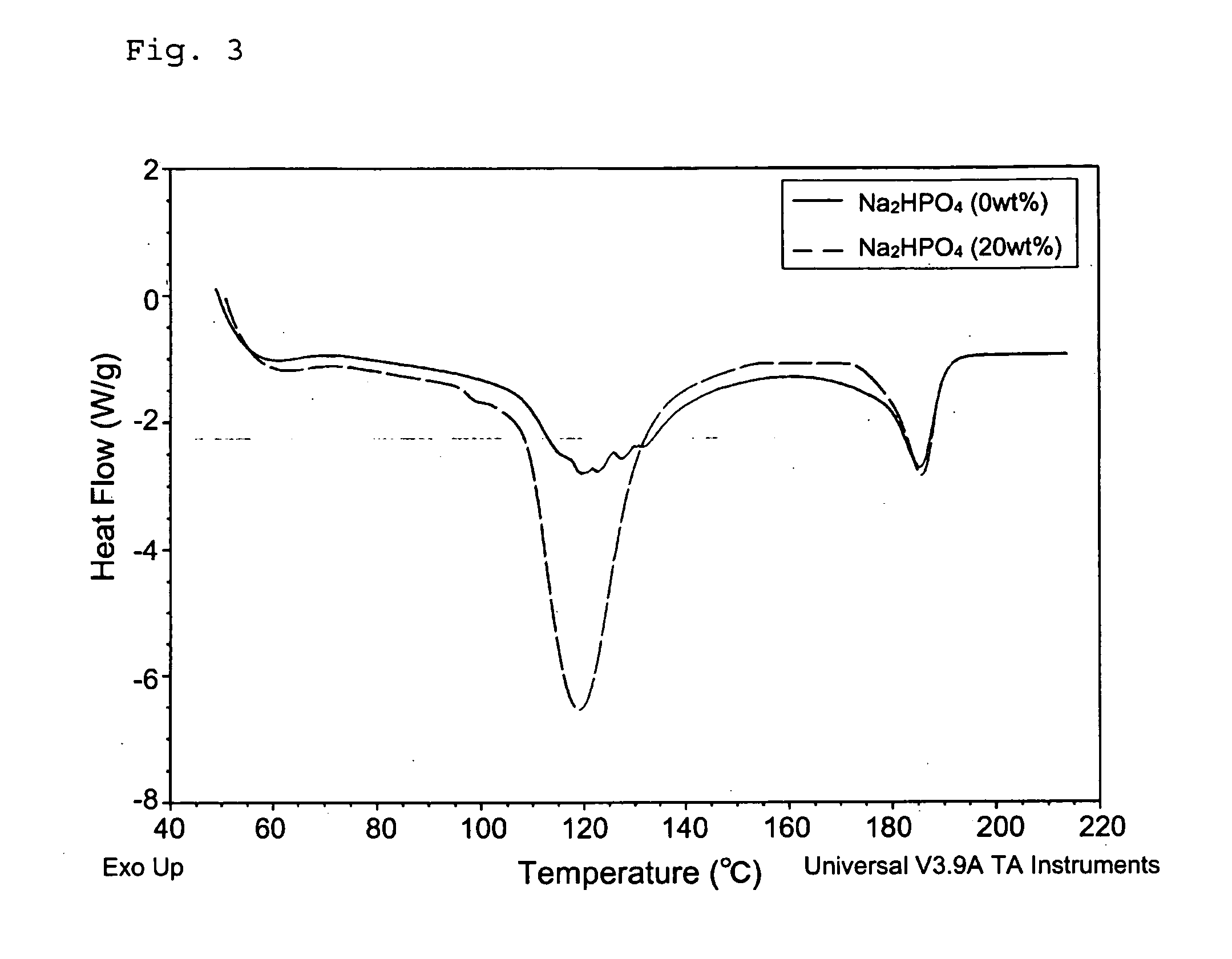

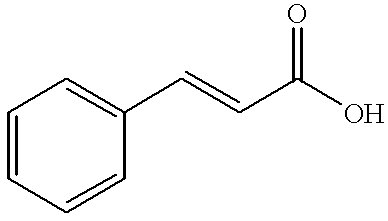

InactiveUS20070275197A1Excels in gas barrier property and moisture resistanceMultilayer structure being prevented from deterioration in gas barrier propertiesSynthetic resin layered productsOrganic dyesPhosphoric acidMoisture resistance

To provide a resin composition including: an ethylene-vinyl alcohol copolymer (A) having an ethylene content of from 15 to 65 mol % and a saponification degree of at least 95 mol %, a phosphoric acid salt (B) which can form a hydrate, and a conjugated polyene compound (C) having a boiling point of at least 150° C., wherein the resin composition comprises from 50 to 99 parts by weight of (A), from 1 to 50 parts by weight of (B) and from 0.00001 to 1 parts by weight of (C), based on 100 parts by weight of the total amounts of (A) and (B). This resin composition excels in gas barrier property and also in moisture resistance at high temperatures and high humidities. Therefore, it is suitable for food packaging containers to be retorted.

Owner:KURARAY CO LTD

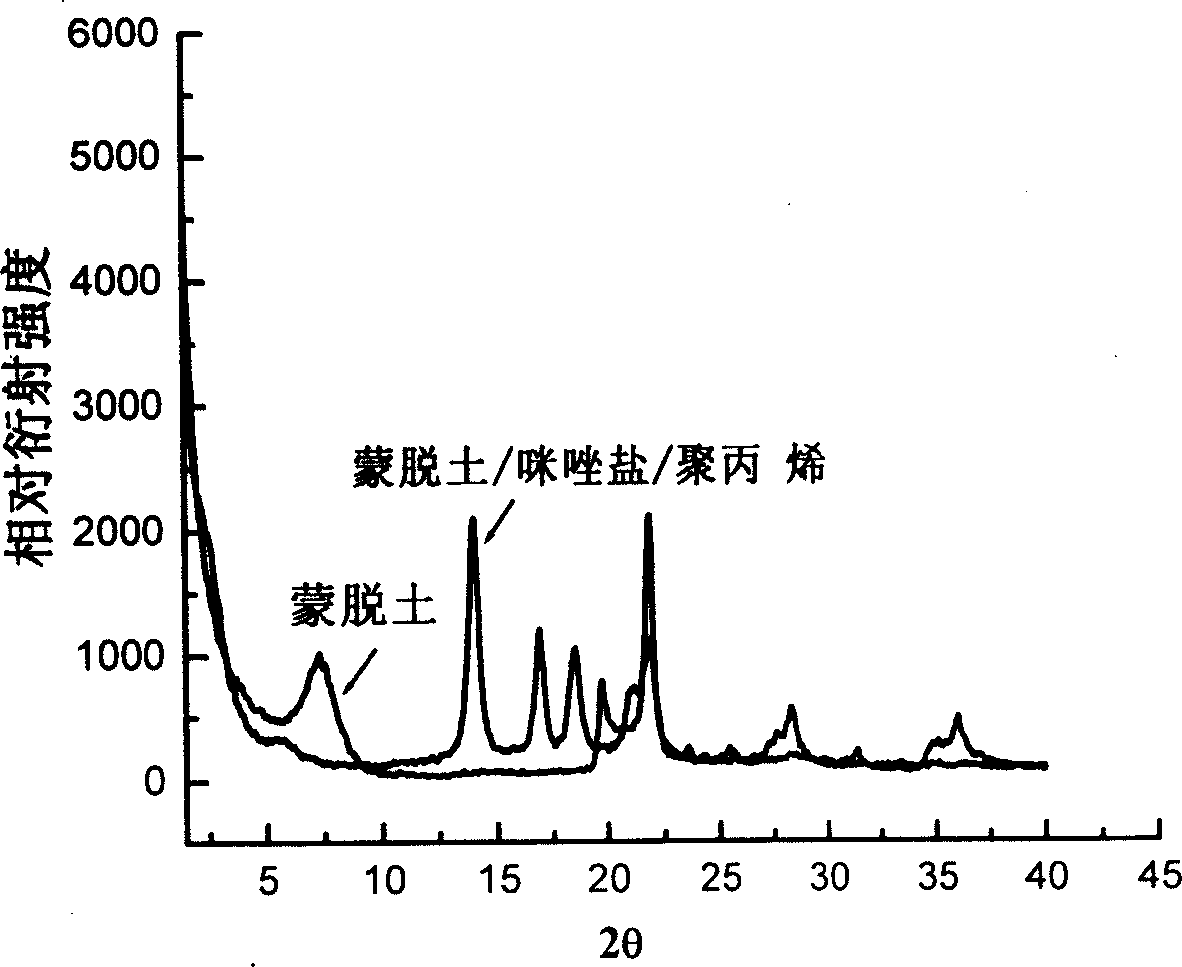

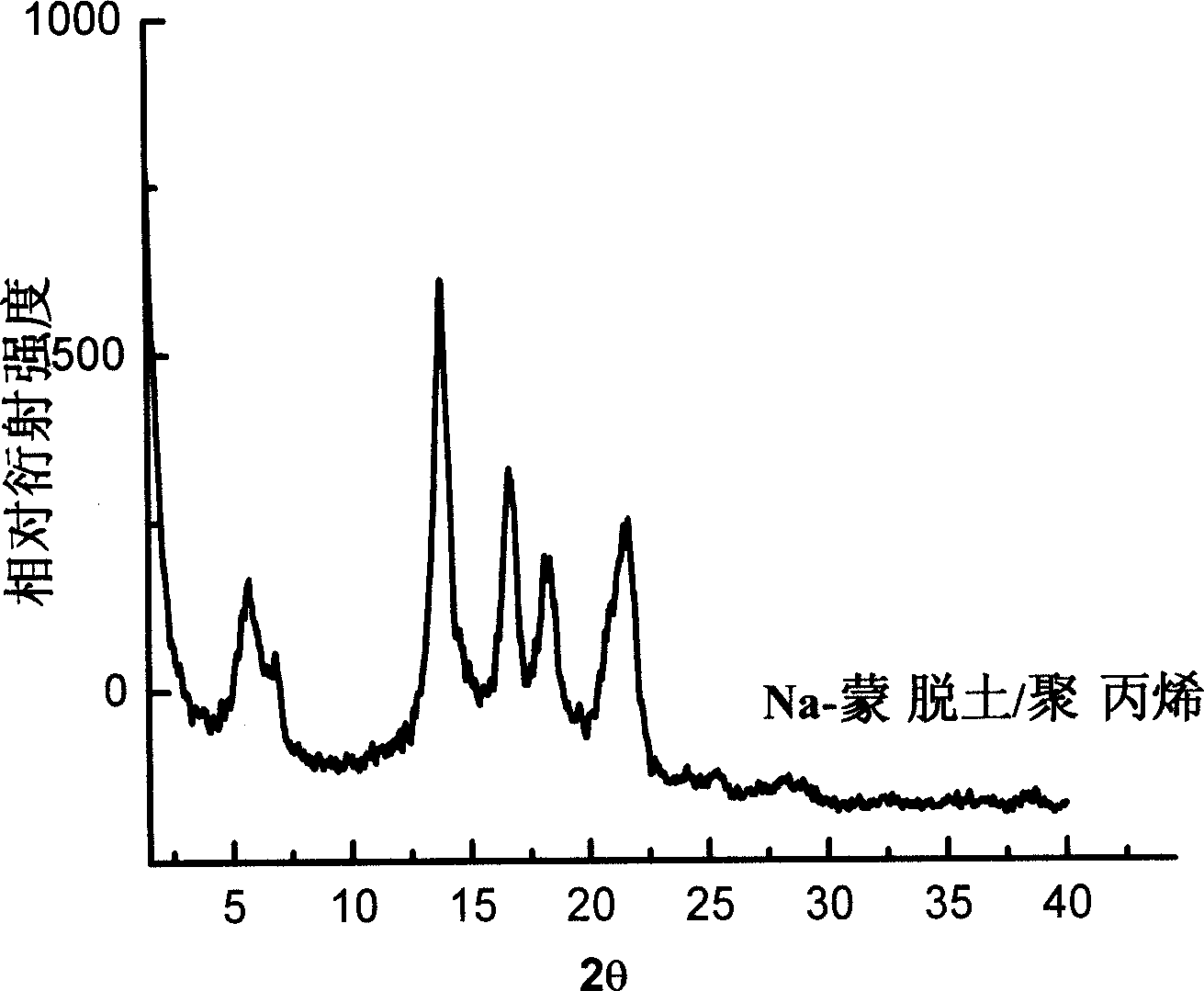

Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

A process for preparing composite polymer / montmorillonite nanoparticles by in-situ organizing of montmorillonite features that the imidazole-type or pyridine-type organic salt is used in non-water solvent to obtain organic modifier for organizing and dispersing the montmorillonite, resulting in the colloidal solution of its nanoparticles. The solvents with different properties and the organic salts with different molecular structures can be chosen for preparing the nanoparticles with relative performance. Its advantages are high thermal stability and high compatibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Stabilized glucagon solutions

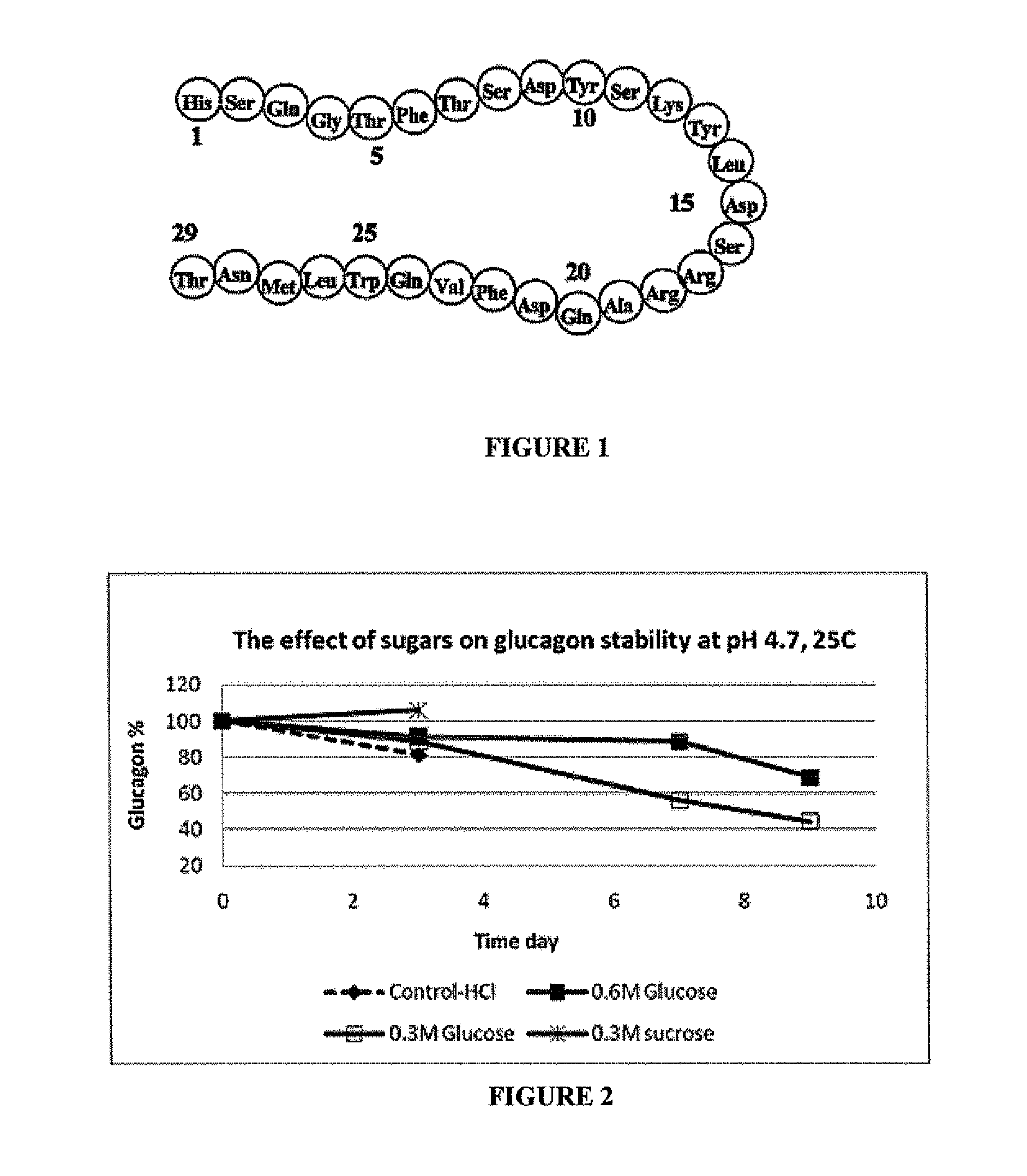

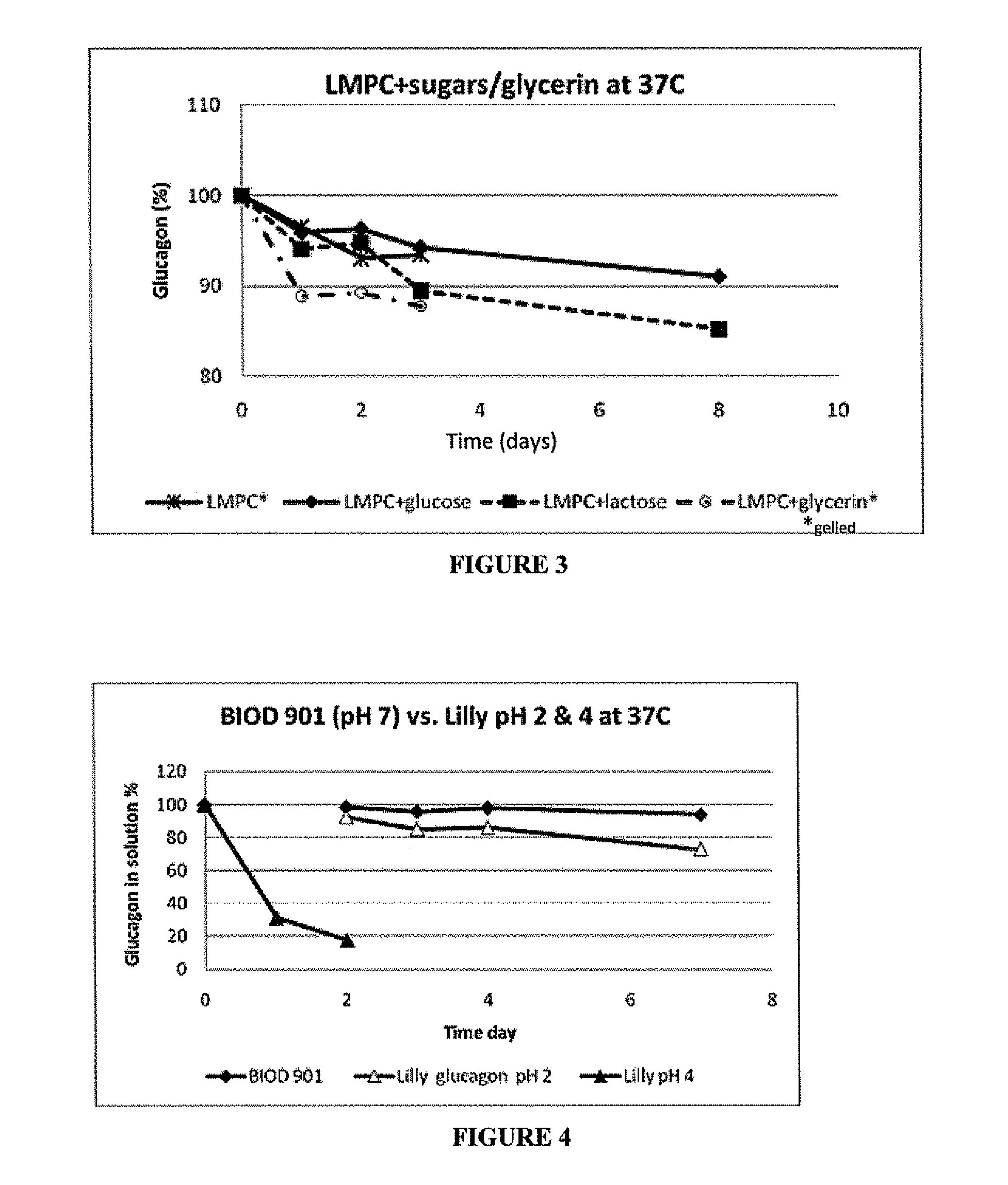

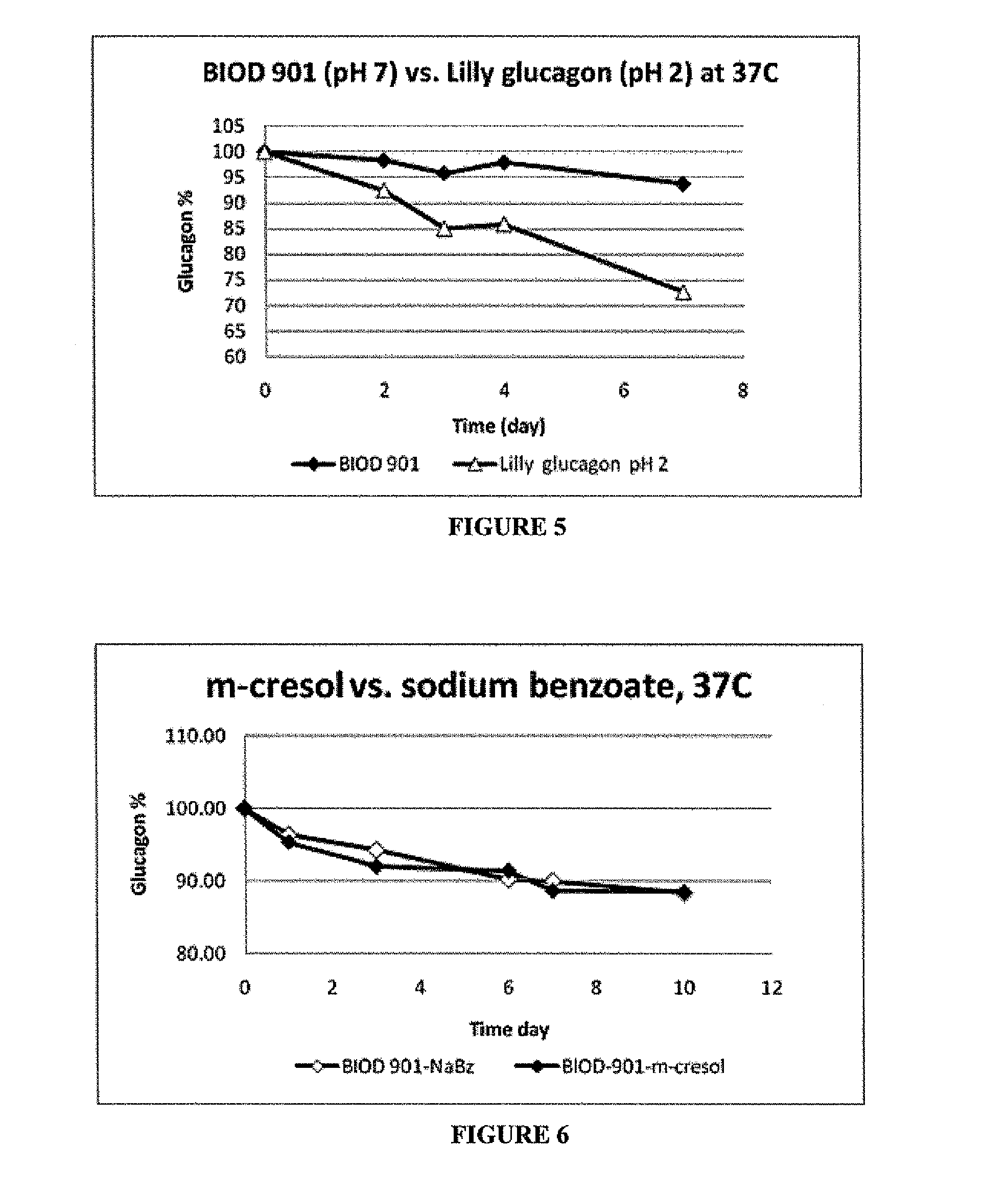

InactiveUS20110237510A1Prevent gelationAssist in stabilityPeptide/protein ingredientsMetabolism disorderIrritationSimple sugar

A formulation composed of a sugar such as glucose and a surfactant such as myristoyl lysophosphocholine (LMPC) has been designed to stabilize both hydrophilic and hydrophobic portions of the glucagon molecule, under prolonged physiological conditions, in a formulation that is sufficiently similar to the pH and osmolarity of plasma so as not to induce or to minimize site irritation. The combination of a simple sugar and an surfactant stabilizes the glucagon molecule in an aqueous solution for seven days at 37° C.

Owner:ALBIREO PHARMA INC

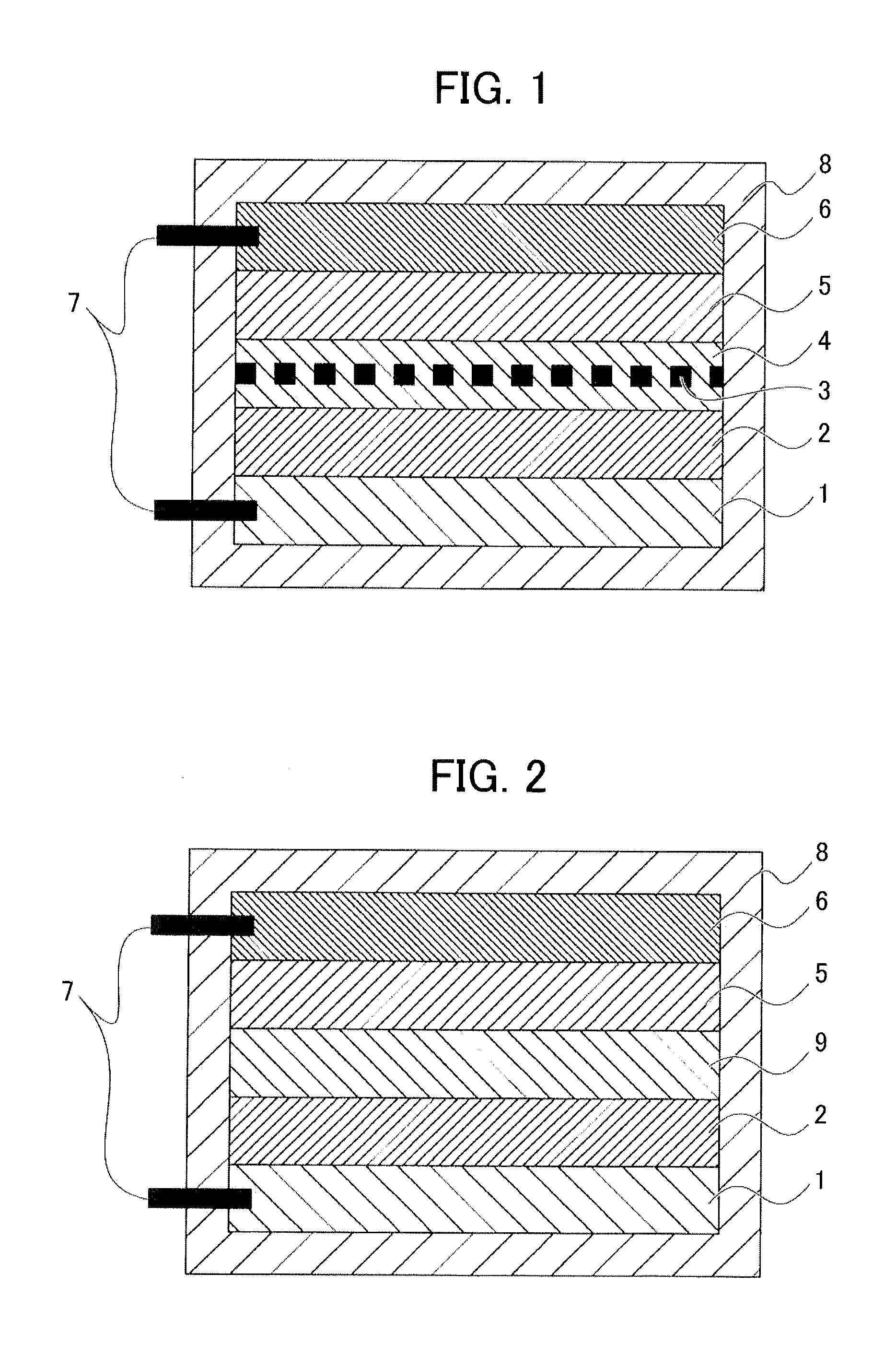

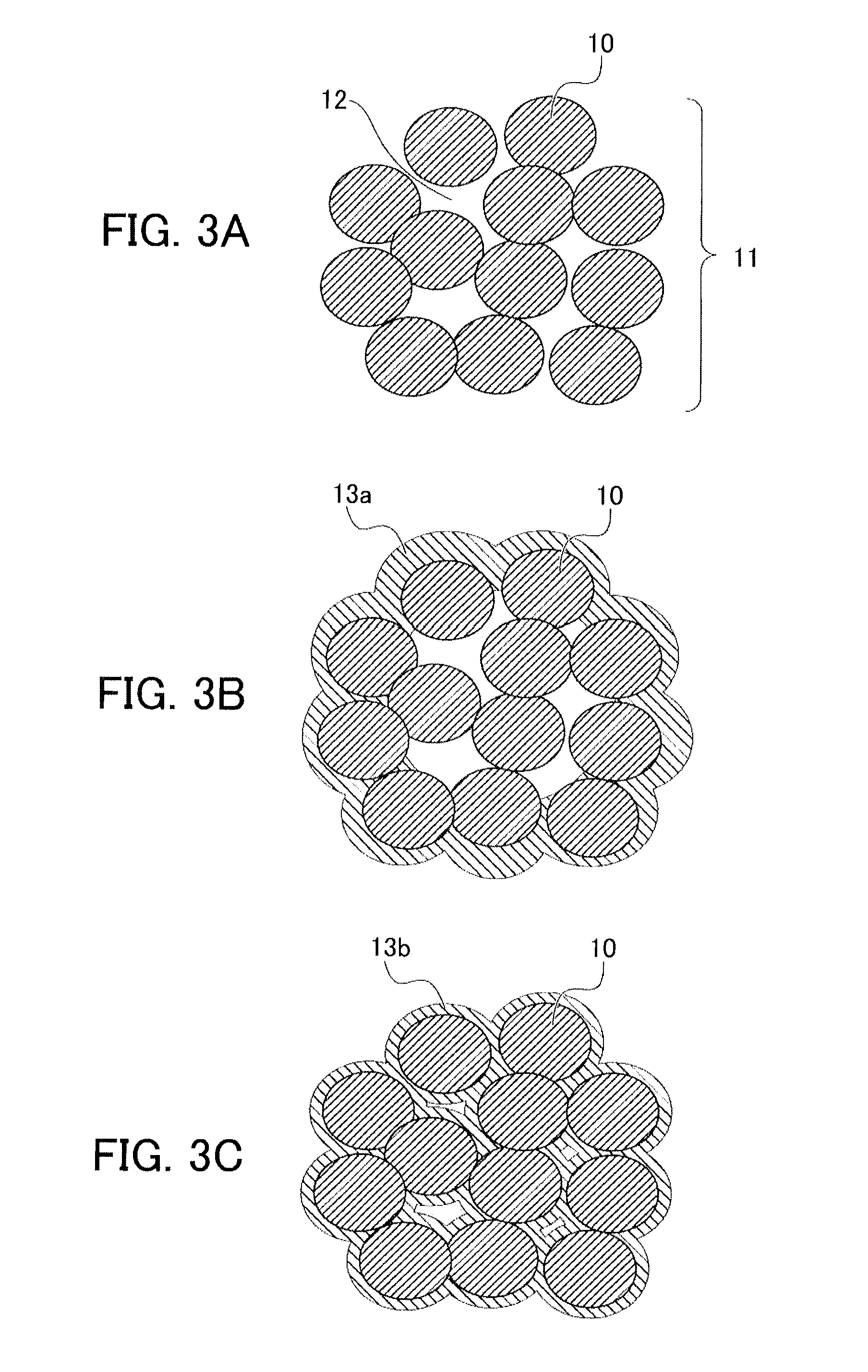

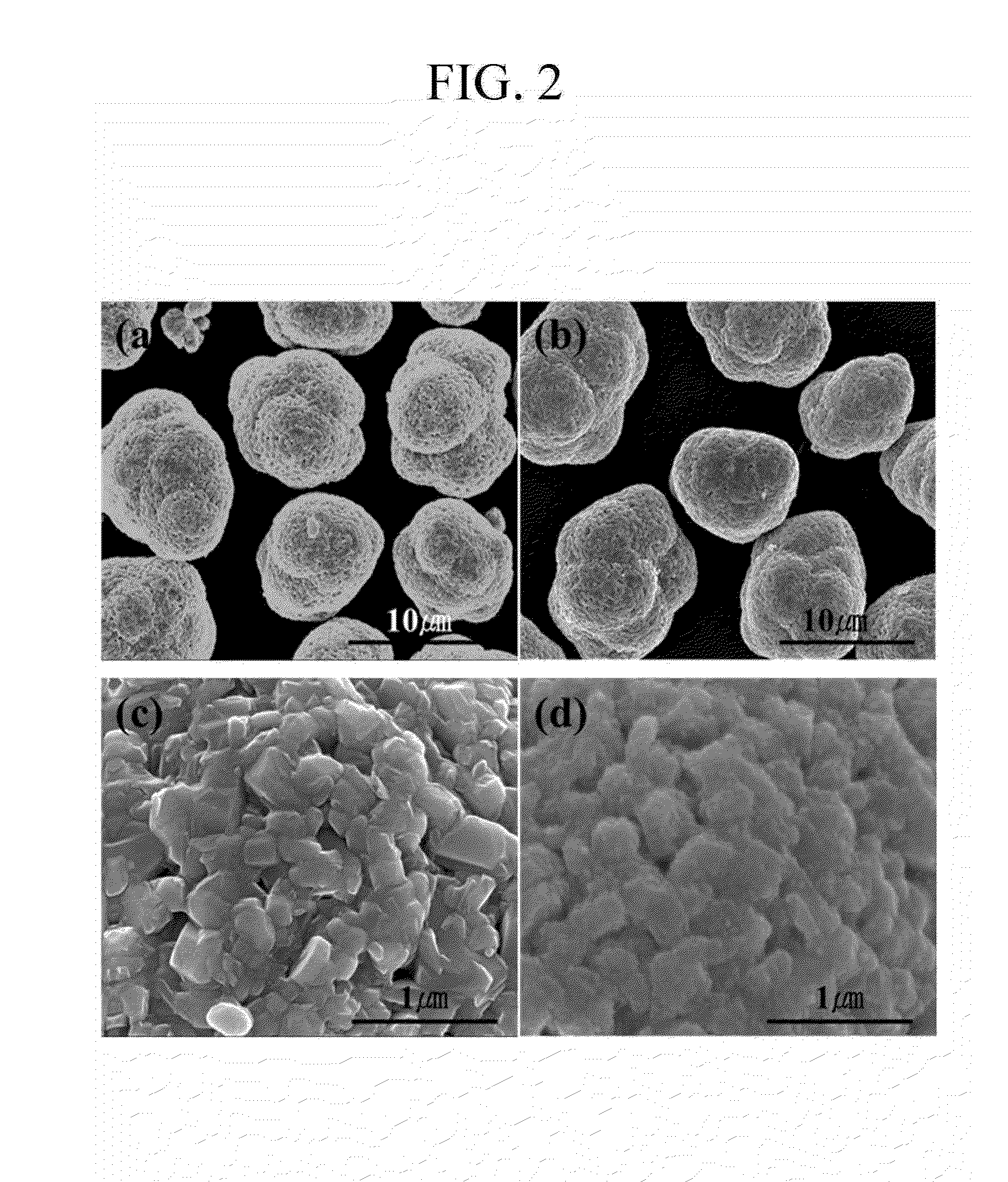

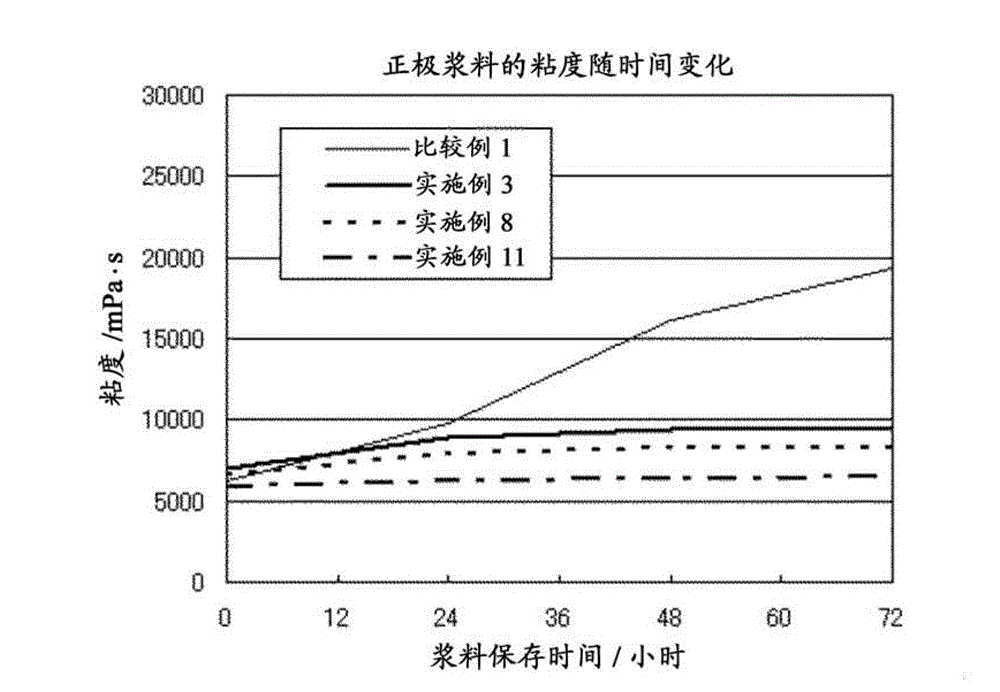

Cathode active material, method of preparing the same, and cathode and lithium battery applying the material

ActiveUS20060204850A1Prevent gelationElectrode manufacturing processesFinal product manufactureHigh rateSlurry

Composite cathode active materials comprising a composite oxide and an acid treated with an organic solvent are provided. The composite cathode active materials are prepared by treating mixtures of nickel-based composite oxides and organic acids with organic solvents. The active materials suppress gelation of the electrode slurries for a long period of time, even when the active materials are mixed with fluorine-based polymers, by decreasing the basicity of the slurries and the amount of lithium present on the surfaces of the active materials. As a result, electrode slurries having high stability can be prepared. Cathodes and lithium batteries comprising the slurries have excellent charge-discharge characteristics, including high capacity and excellent high rate discharge characteristics.

Owner:SAMSUNG SDI CO LTD

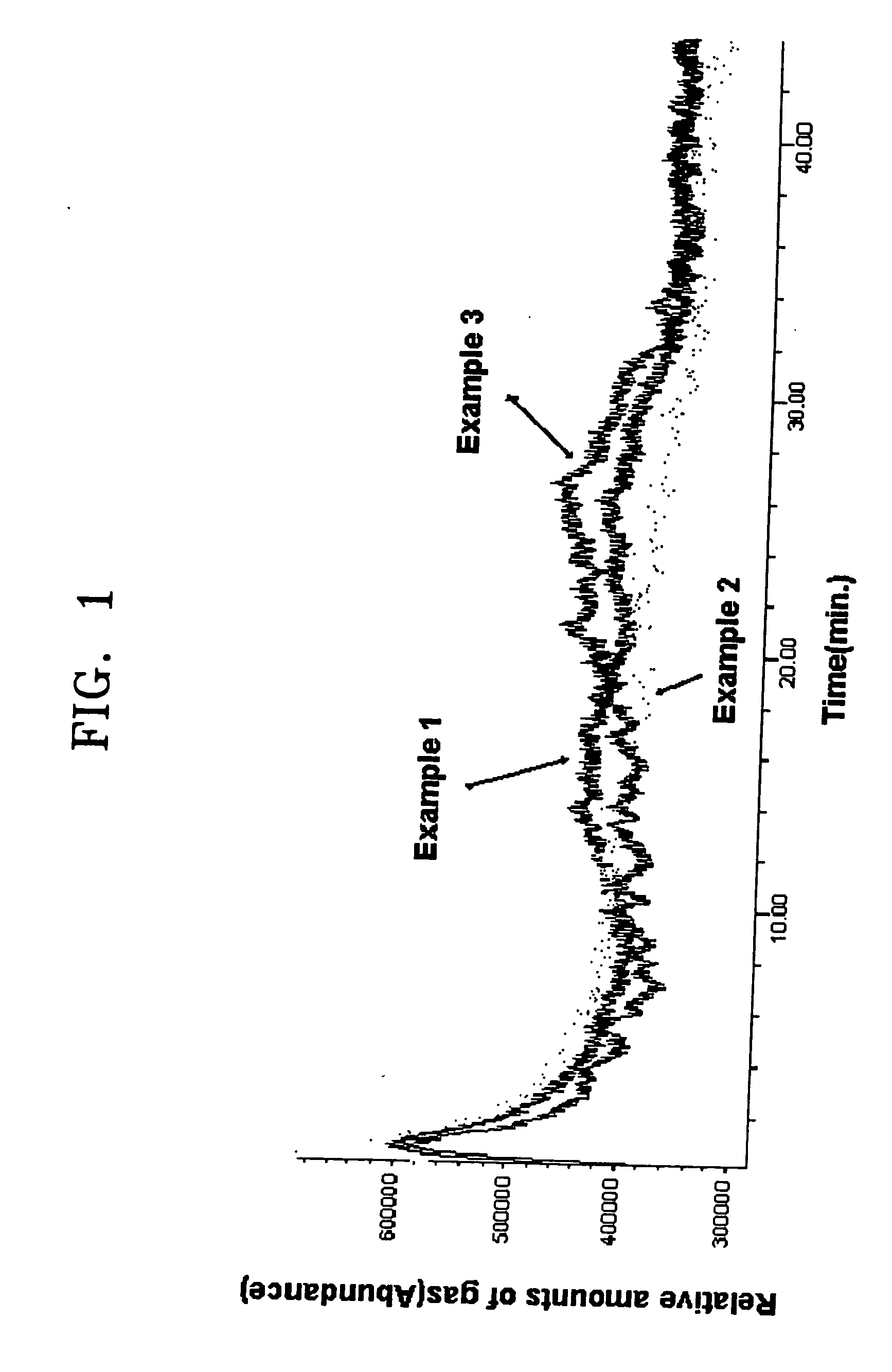

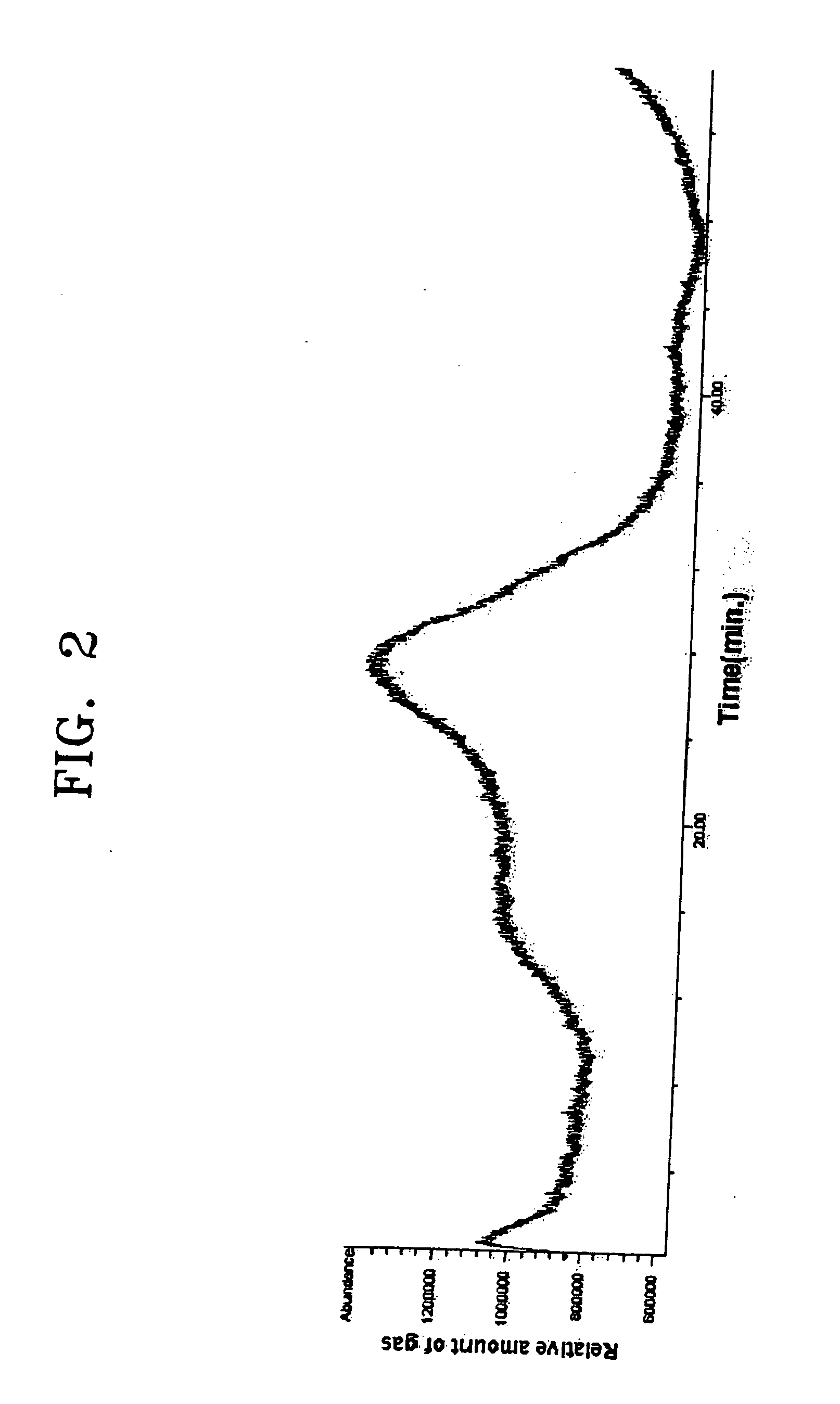

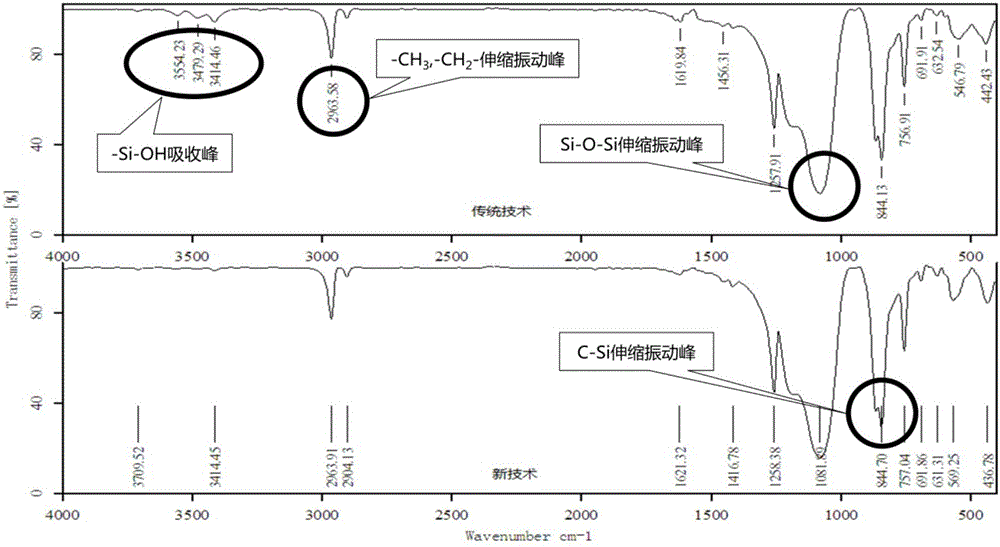

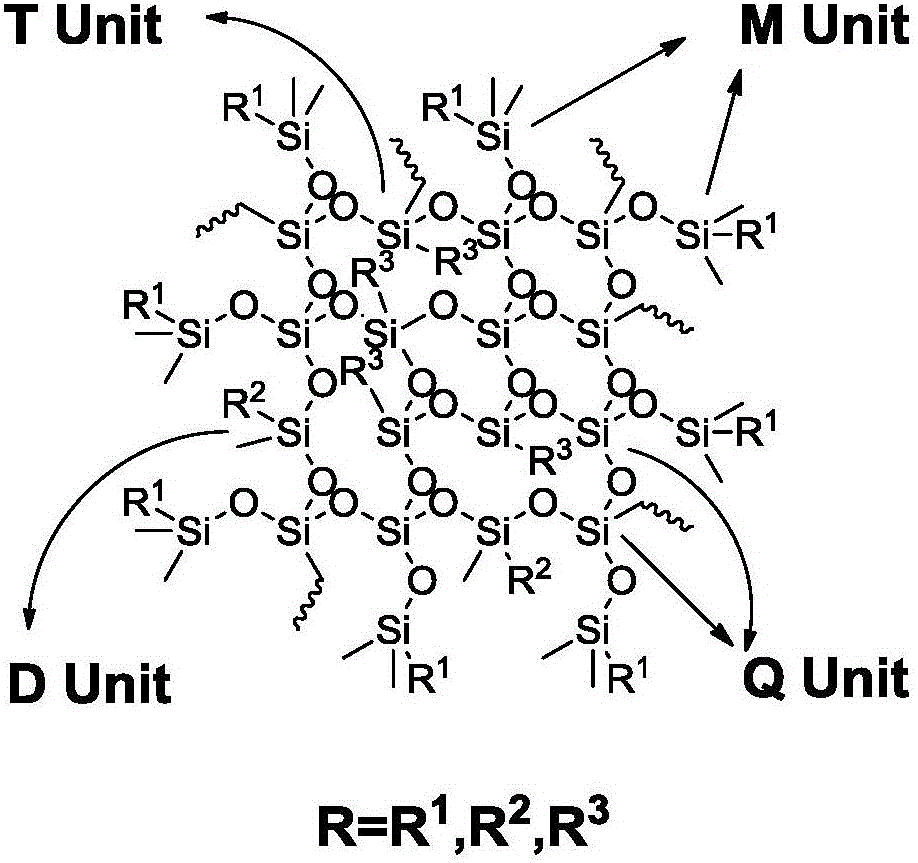

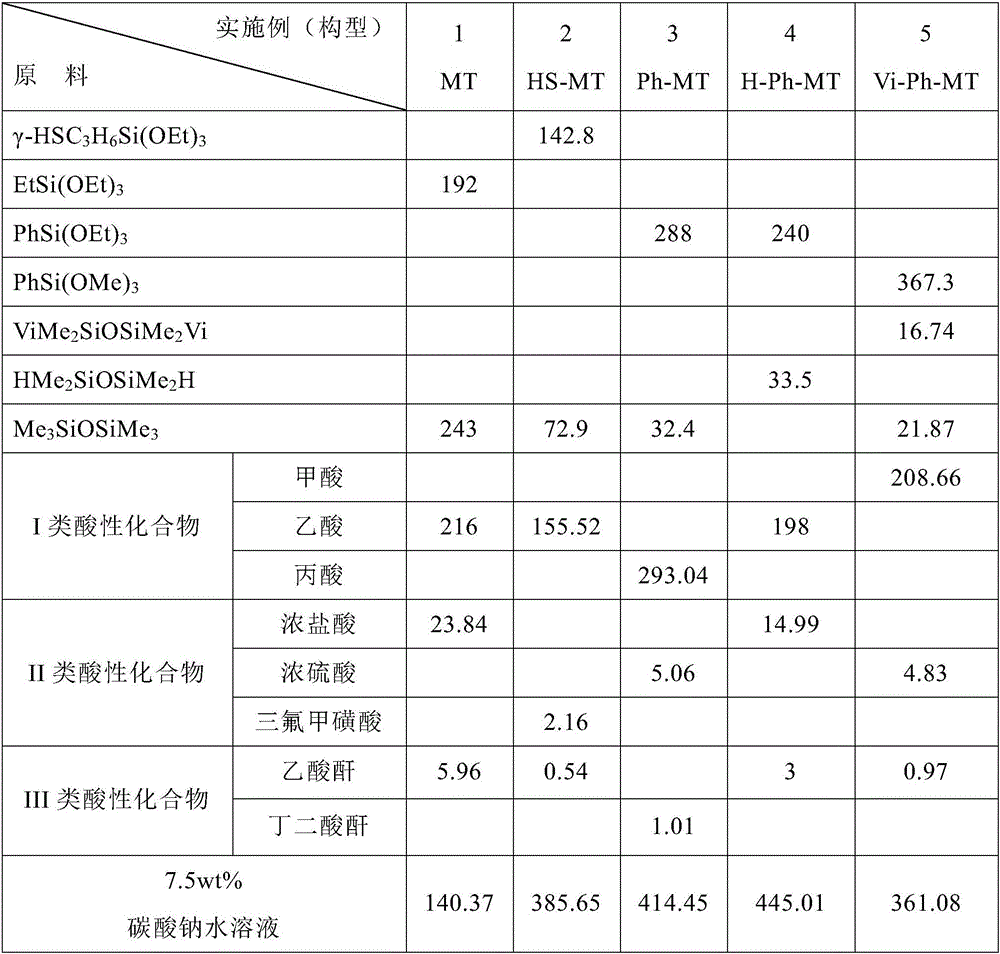

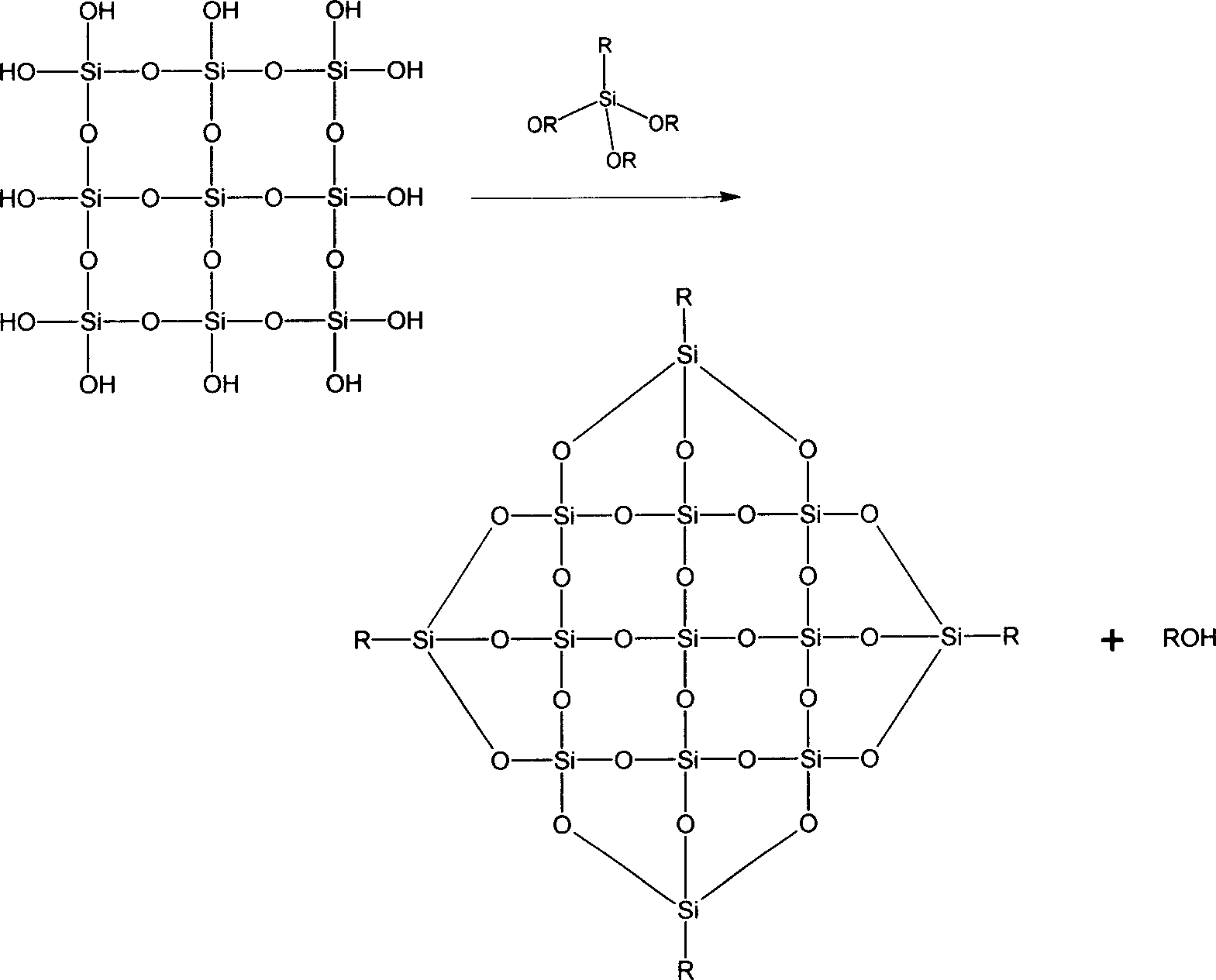

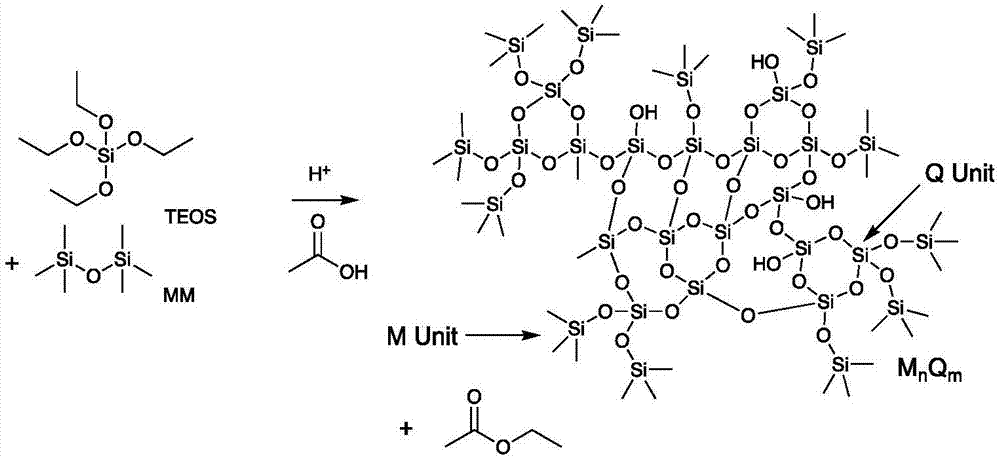

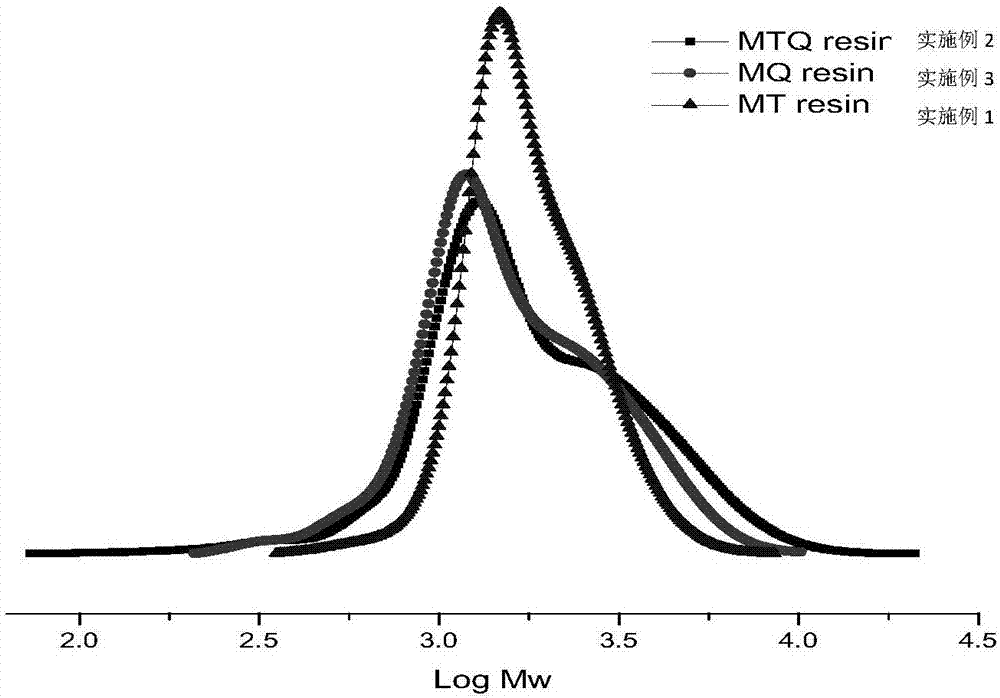

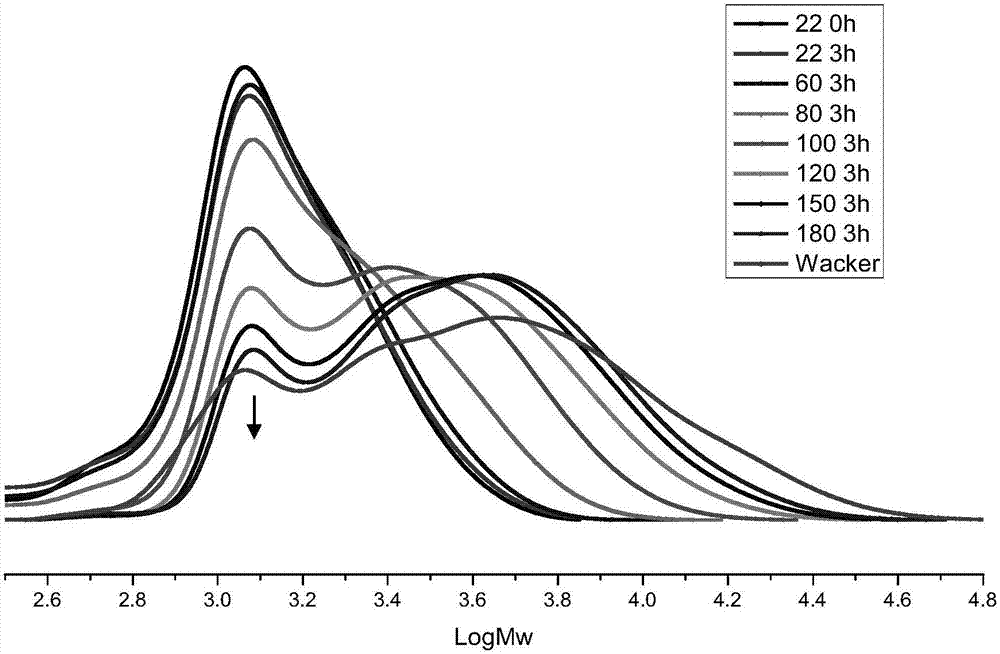

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

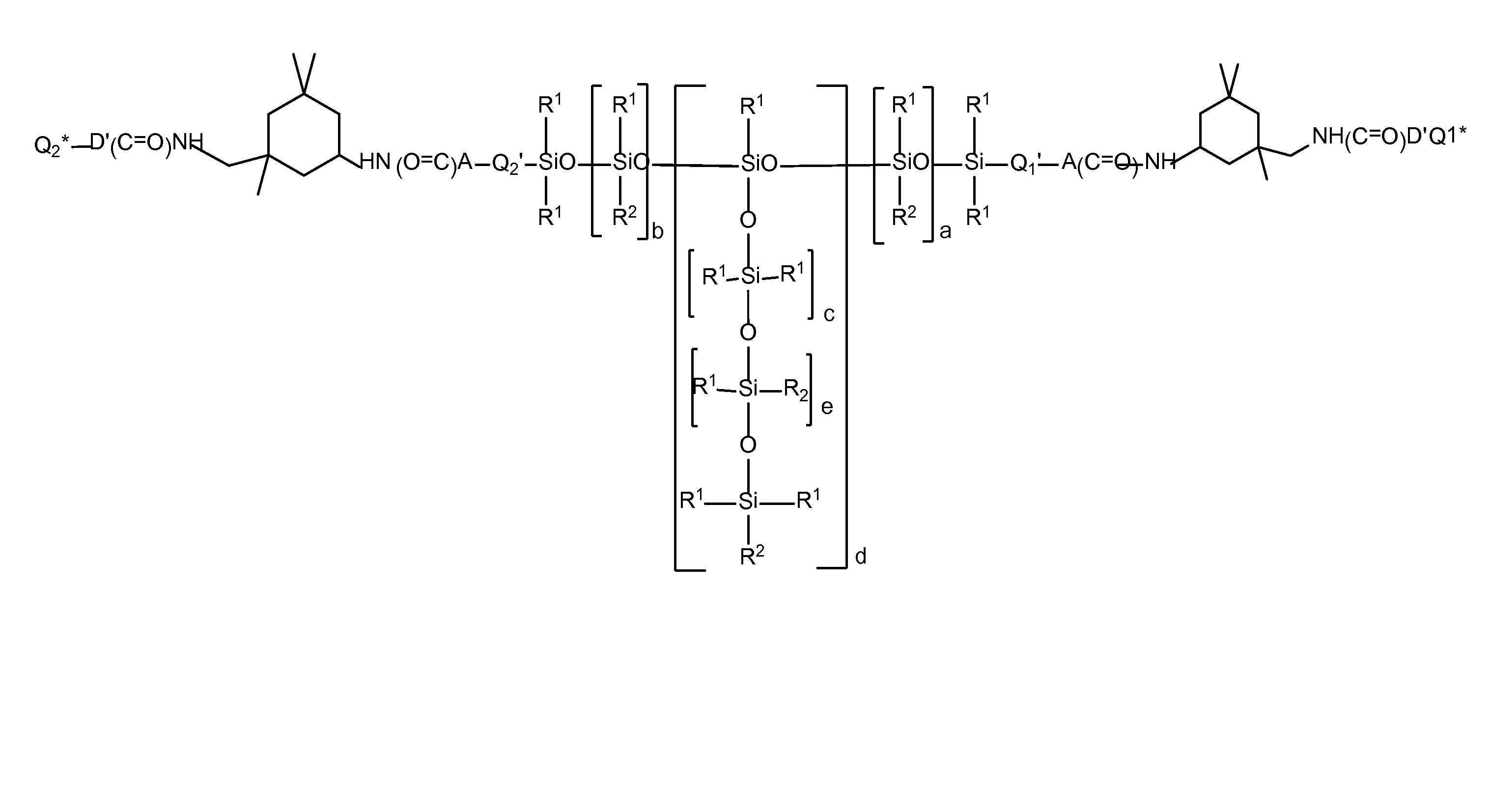

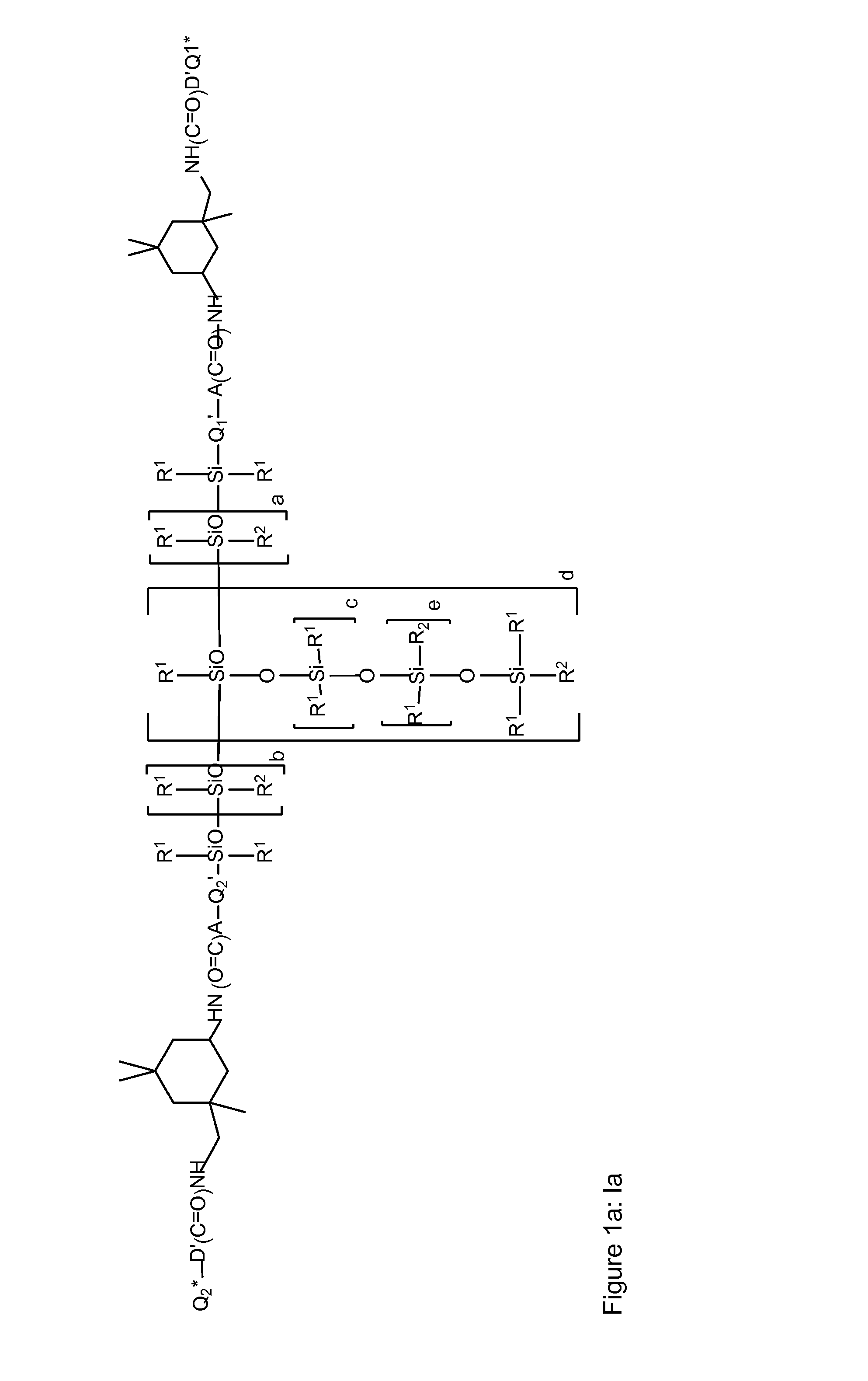

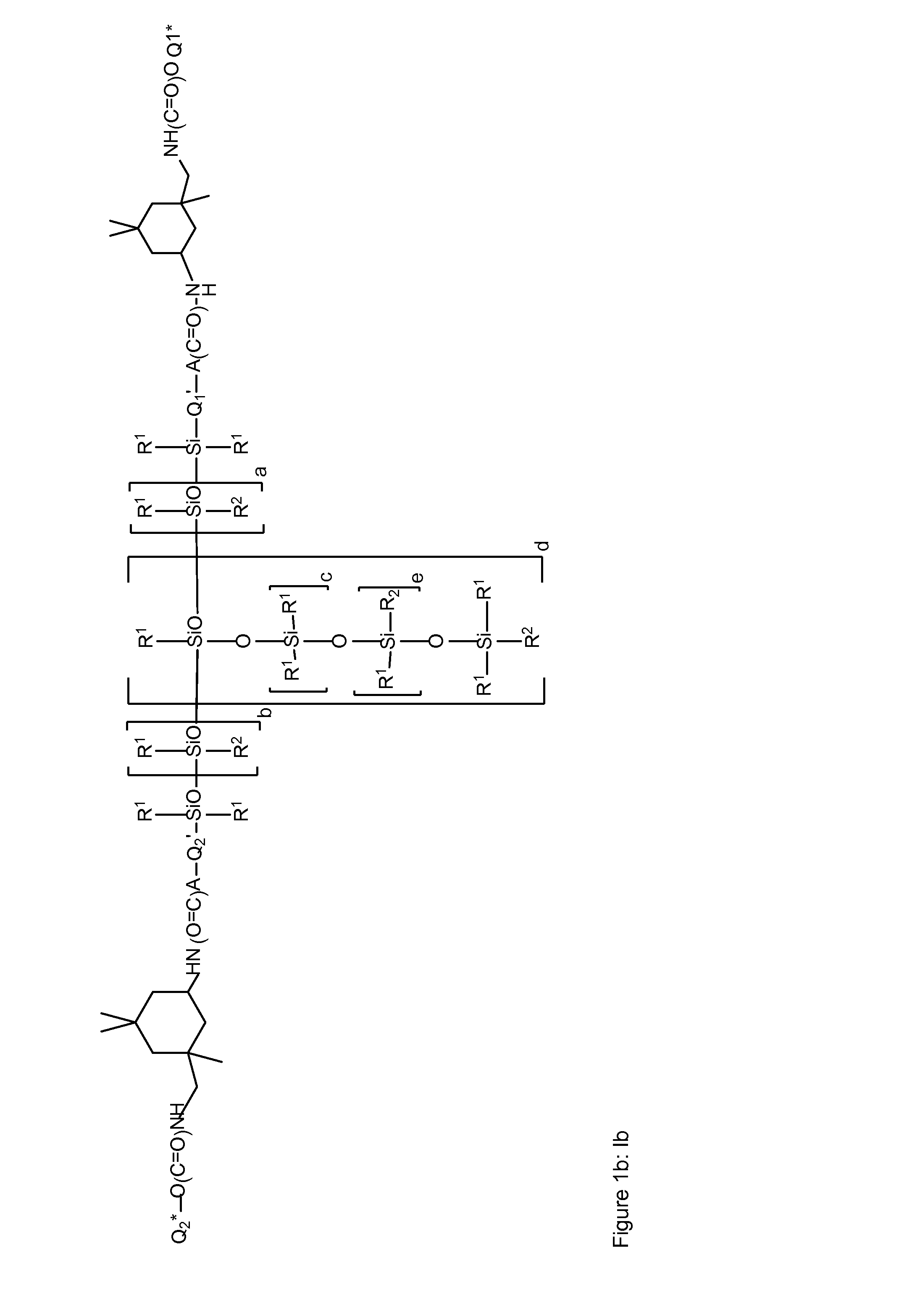

Siloxane polymers with a central polysiloxane polymer block with organofunctional radicals each having at least two bivalent groups selected from urea and/or carbamate groups and at least one UV/vis chromophore as radical

InactiveUS20150004112A1Reduces UV damageSmooth care effectCosmetic preparationsHair cosmeticsPolymer scienceCarbamate

The invention relates to siloxane polymers comprising a central polysiloxane polymer block B with organofunctional radicals bonded terminally or laterally to the polymer block and based on IPDI and UV / Vis chromophores or derivatives, in particular UV chromophores, which are covalently bonded via a hydrophobic or hydrophilic linker group Q1′, Q2′, and compositions comprising these siloxanes. Also disclosed are processes for their preparation and their use.

Owner:EVONIK IND AG

Systems and methods for controlling and forming polymer gels

ActiveUS20060270781A1Change qualityPrevent gelationNon-fibrous pulp additionDiagnosticsCross-linkViscoelastic Solutions

In preferred embodiments, the present invention provides methods of controllably making a vinyl polymer hydrogel having desired physical properties without chemical cross links or radiation. The gelation process is modulated by controlling, for example, the temperature of a resultant vinyl polymer mixture having a gellant or using active ingredients provided in an inactive gellant complex. In accordance with a preferred embodiment, the method of manufacturing a vinyl polymer hyrodgel includes the steps of providing a vinyl polymer solution comprising a vinyl polymer dissolved in a first solvent; heating the vinyl polymer solution to a temperature elevated above the melting point of the physical associations of the vinyl polymer, mixing the vinyl polymer solution with a gellant, wherein the resulting mixture has a higher Flory interaction parameter than the vinyl polymer solution; inducing gelation of the mixture of vinyl polymer solution and gellant; and controlling the gelation rate to form a viscoelastic solution, wherein workability is maintained for a predetermined period, thereby making a vinyl polymer hydrogel having the desired physical property. In further preferred embodiments, the present invention provides physically crosslinked hydrogels produced by controlled gellation of viscoelastic solution wherein workability is maintained for a predetermined period. In another aspect, the present invention provides kits for use in repairing intervertebral disks or articulated joints including components that form the vinyl polymer hydrogel and a dispenser.

Owner:CAMBRIDGE POLYMER GROUP

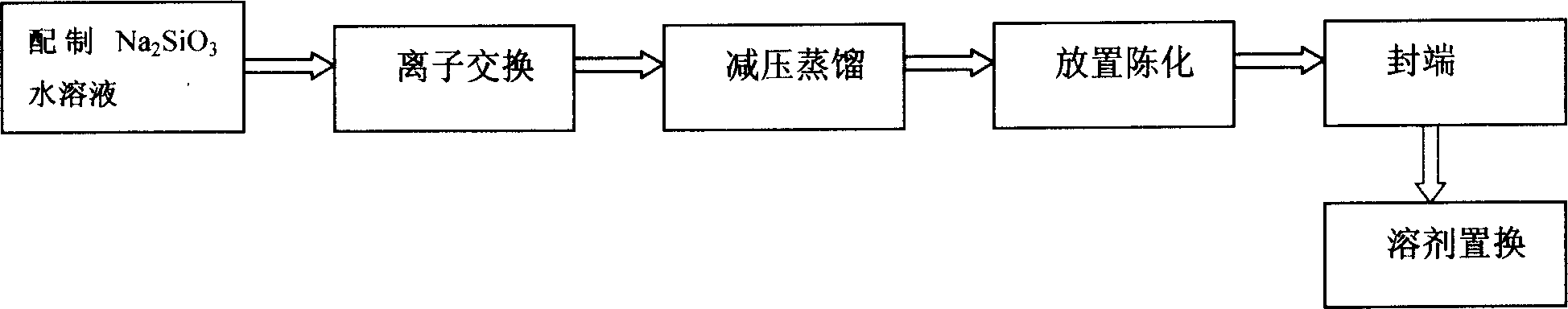

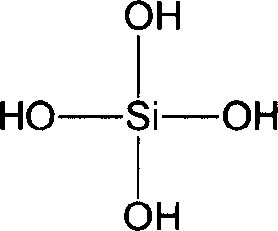

Nano organic solvent silicasol and preparation method thereof

InactiveCN1699166AAppearance is clear and transparentImprove stabilitySilicon compoundsOrganic solventBoiling point

The invention discloses a nano organic solvent silicasol and preparation method, which mainly comprises SiO2 particles, organic solvent and end blocking agent by the proportion of SiO2 particles 5-15%, organic solvent 94.5-83.5%, end blocking agent 0.5-1.5%.The grain diameter of SiO2 is between 10-100 nanometer, the pH of the sol system be between 6-9. The sol is prepared through the conventional method for organic solvent silicon oxide sol with a boiling point higher then that of water. The preparation method employs sodium silicate as the raw material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

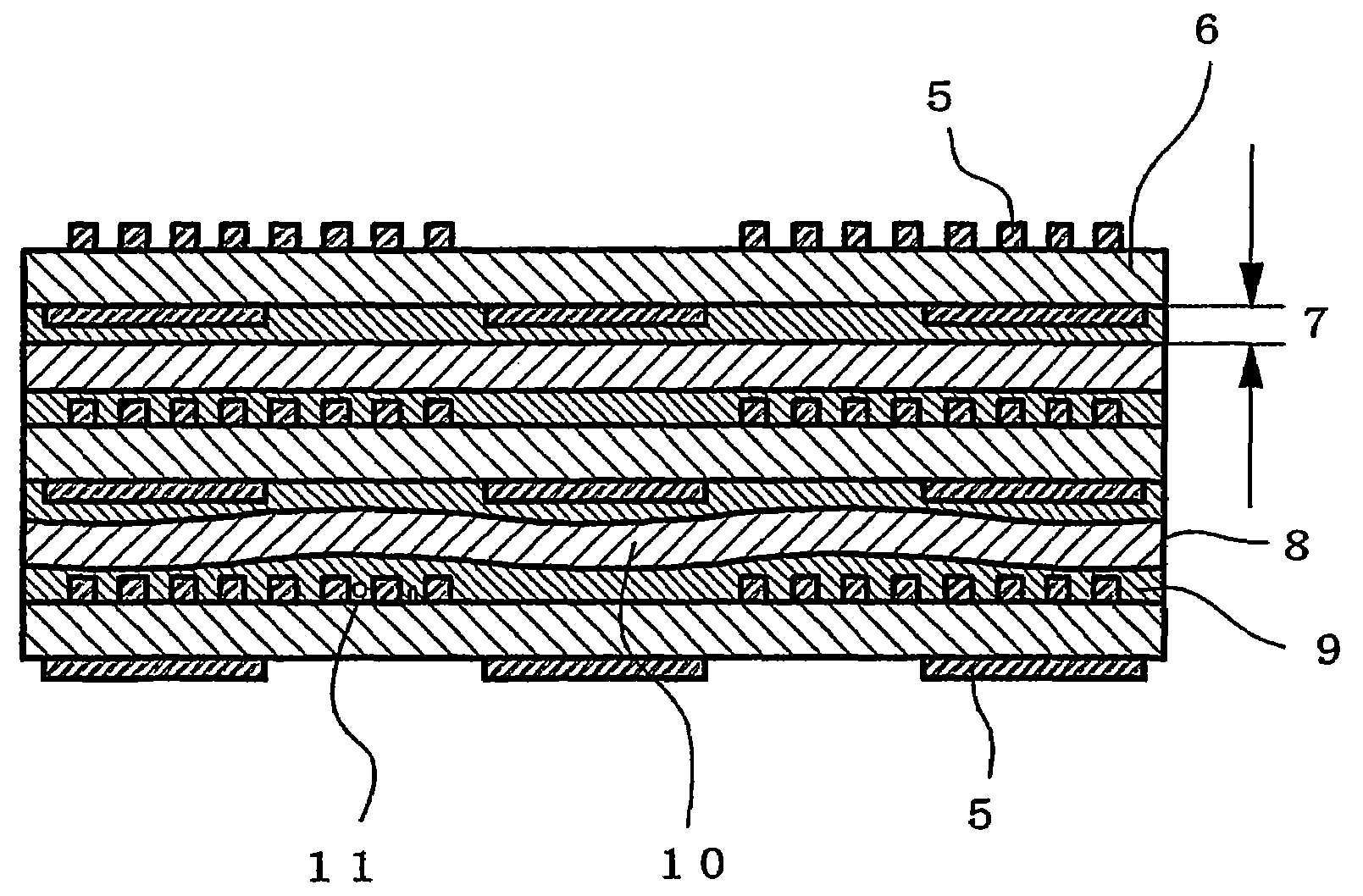

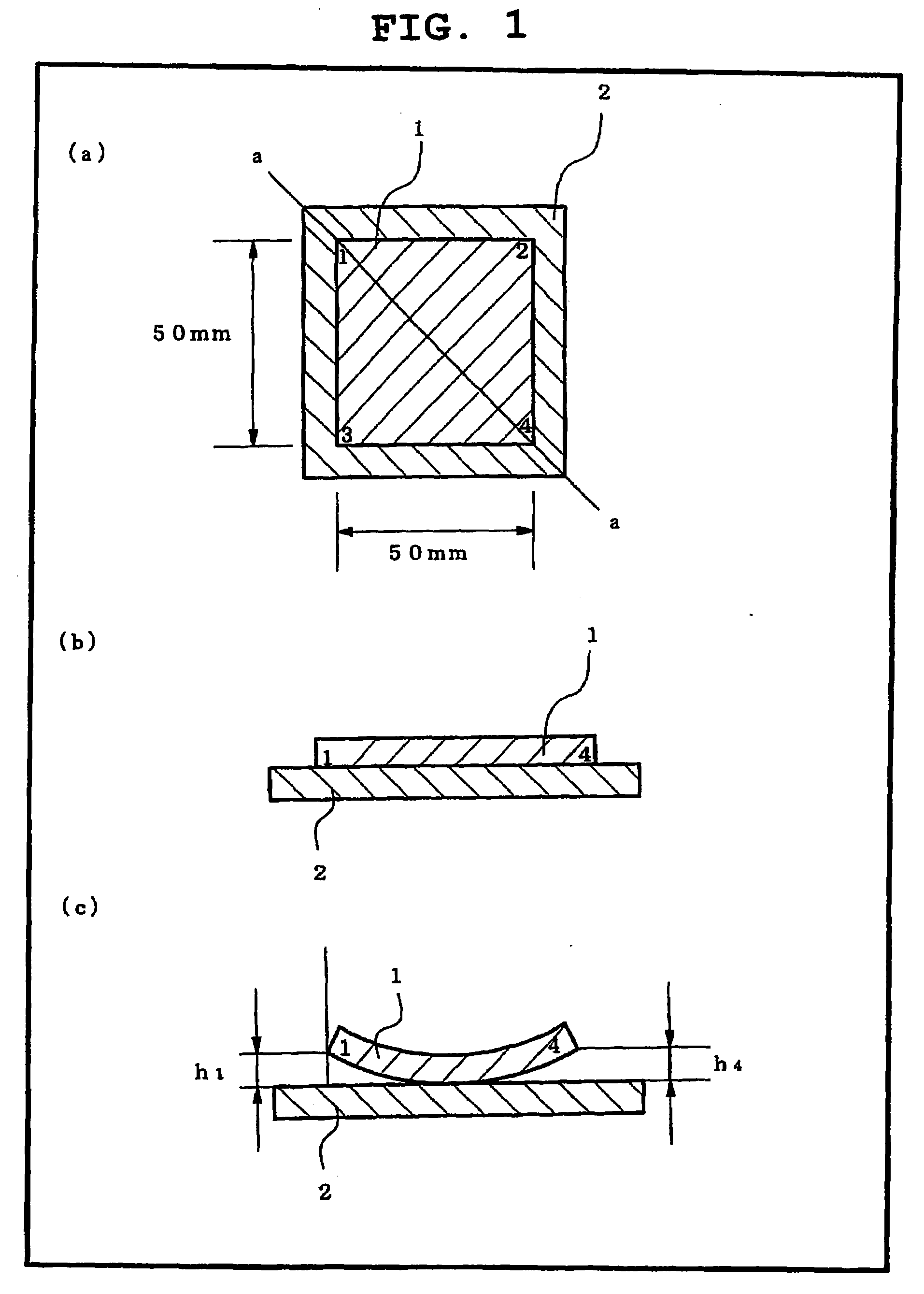

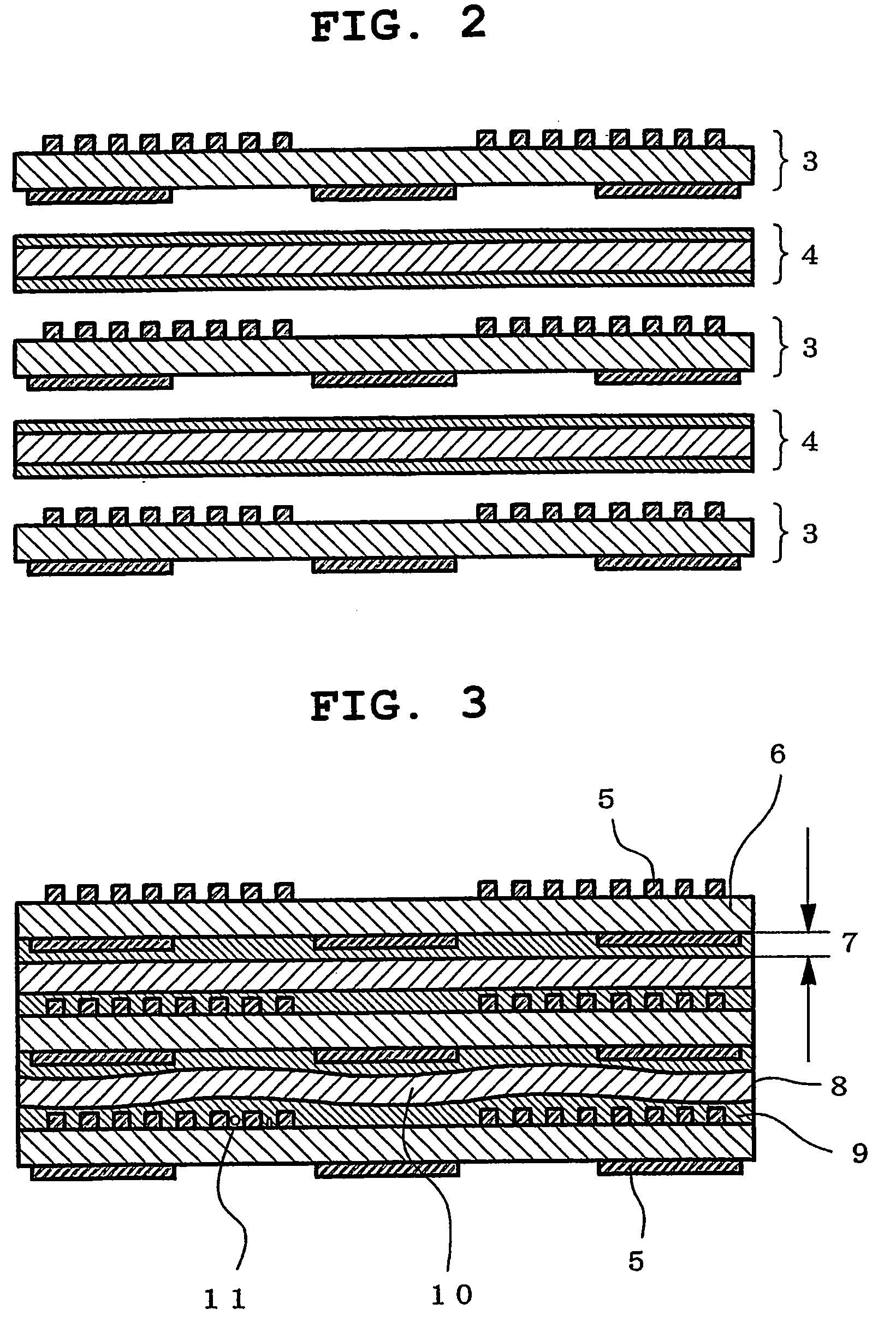

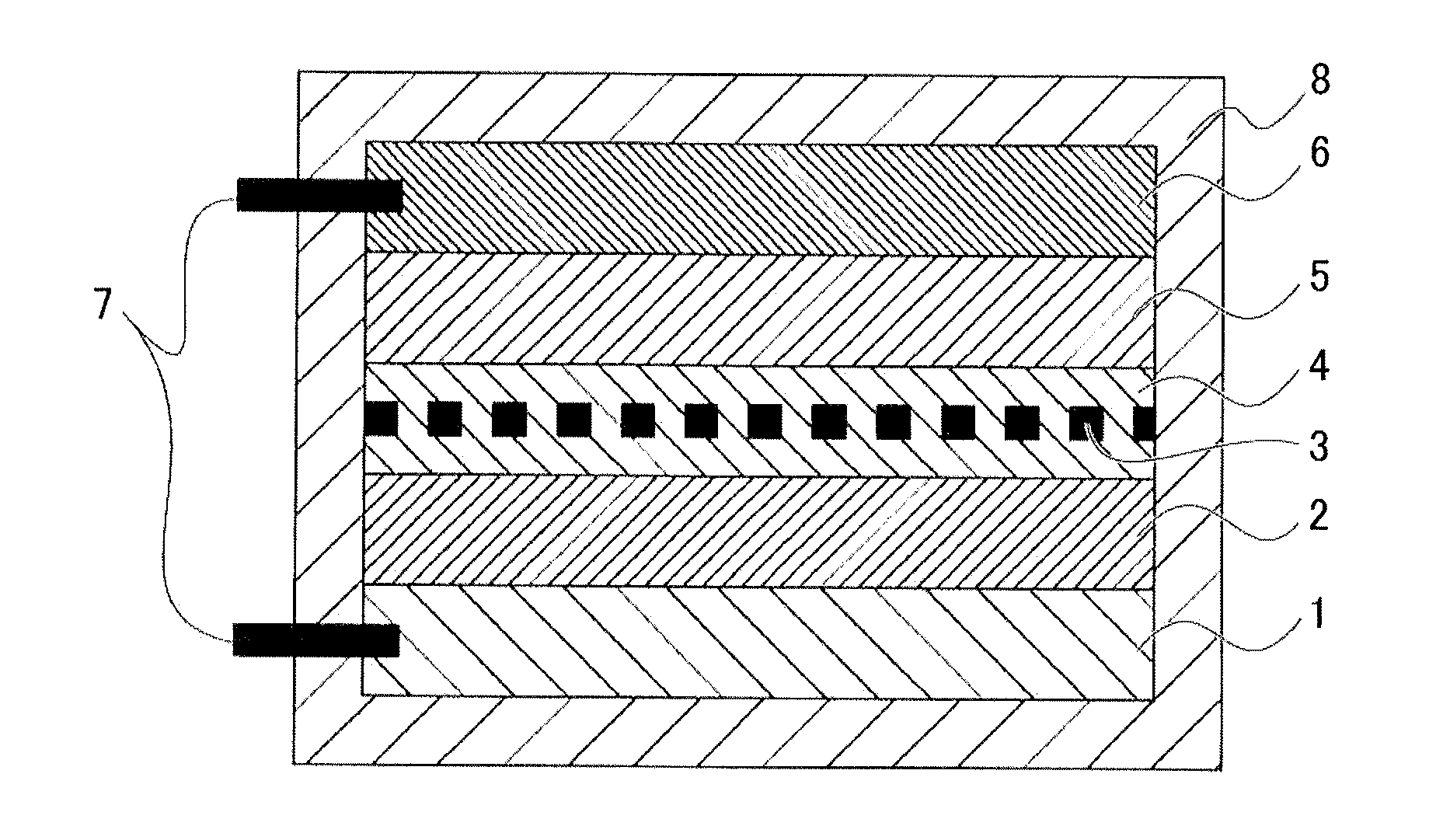

Adhesive sheet, metal-laminated sheet and printed wiring board

InactiveUS20090056995A1Reduced adhesion strengthPrevent gelationPrinted circuit detailsPrinted circuit aspectsEngineeringPolyimide membrane

The adhesive sheet contains a substrate film and an adhesive layer formed at least on one surface of the substrate film. The substrate film is made of a polyimide film showing a degree of curl after a heat treatment at 300° C. of not more than 10%. The adhesive sheet of the present invention can be used for electronic parts and the like exposed to high temperature particularly because warpage and distortion thereof caused by a high temperature treatment are suppressed, and can improve quality and yield of electronic parts and the like.

Owner:TOYOBO CO LTD

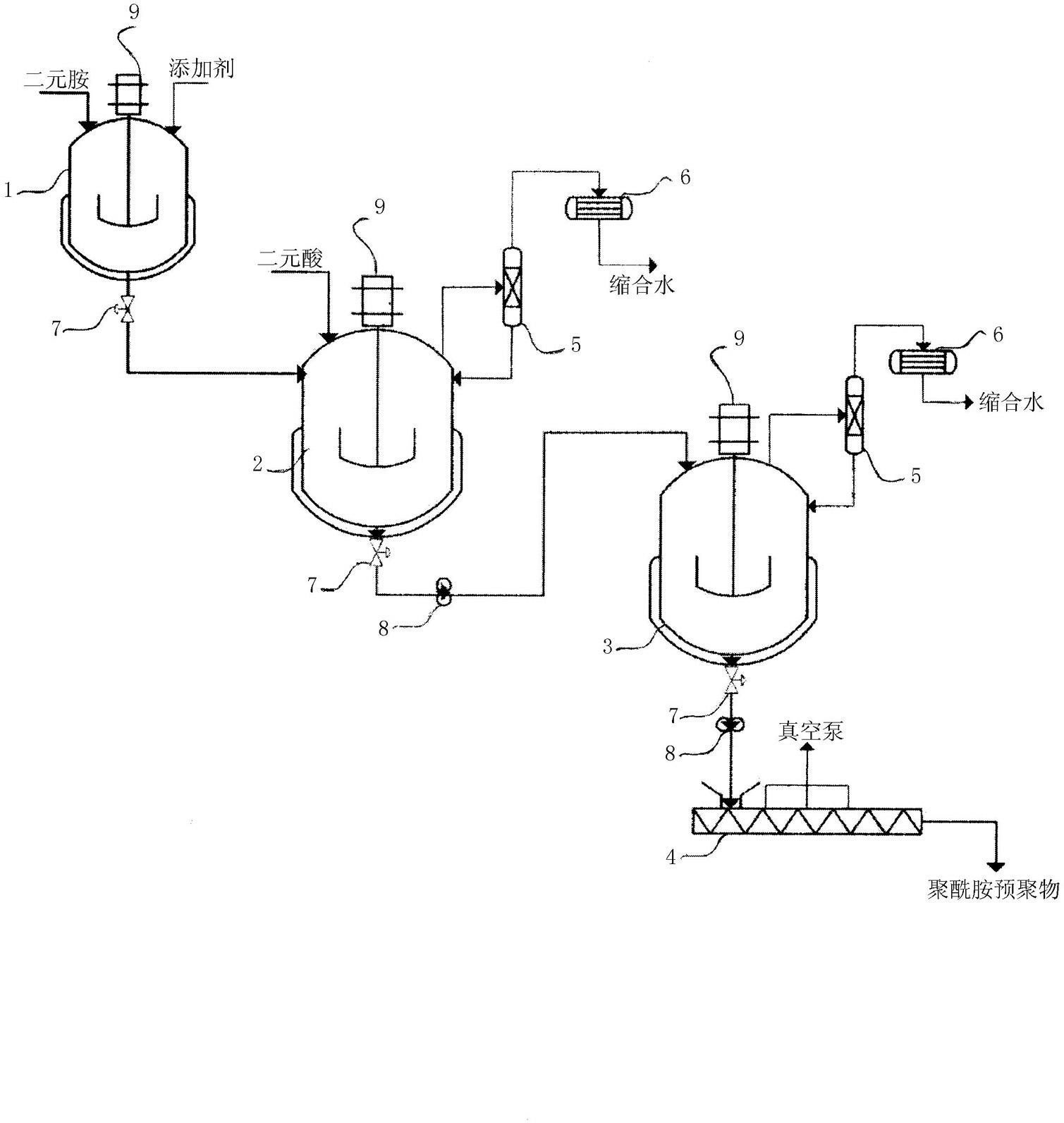

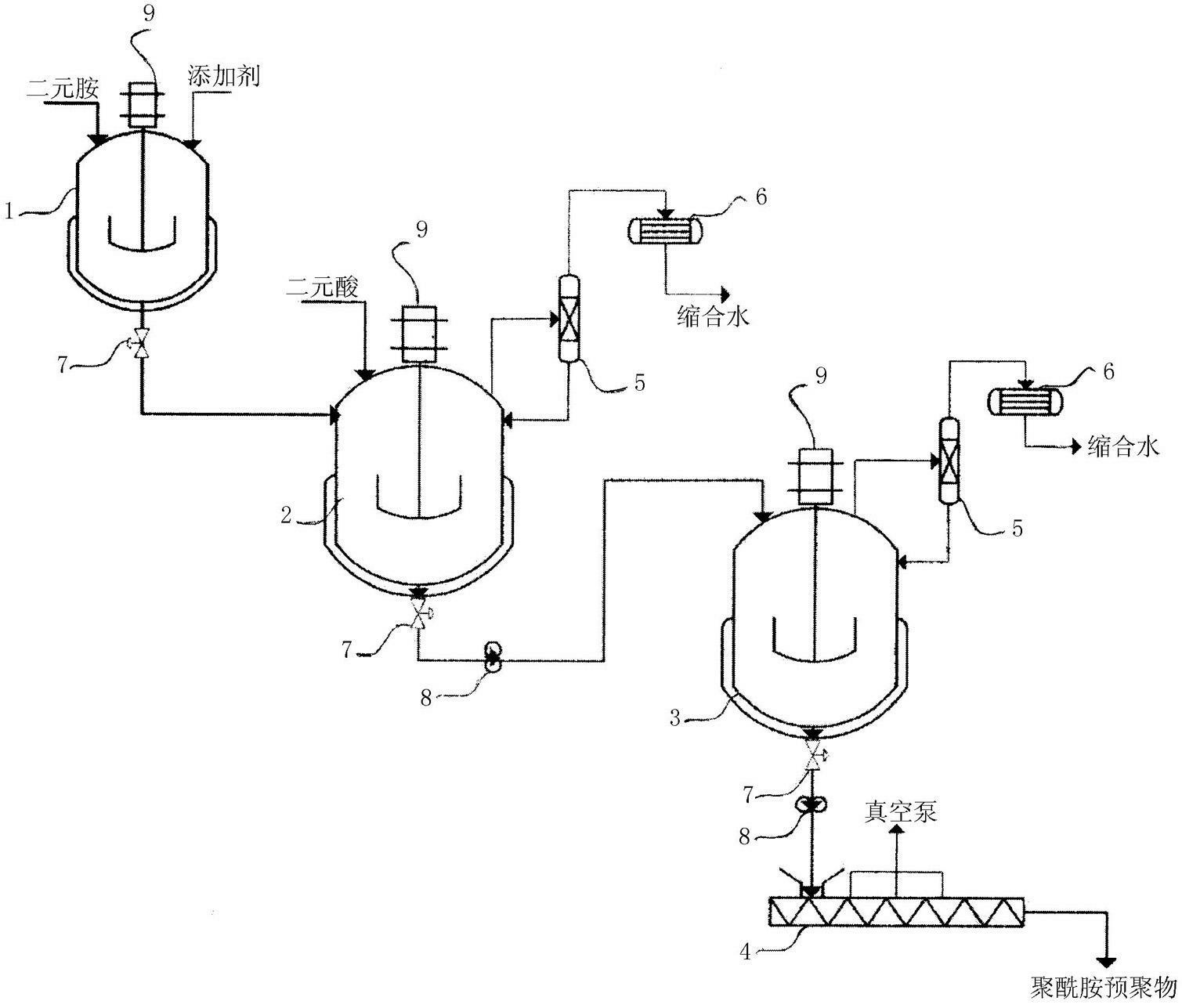

Method for producing polyamide

The invention discloses a method for producing polyamide. The method comprises the following steps: 1, adding a molten diamine to a solid dicarboxylic acid without a solvent, forming a mixed solution of the dicarboxylic acid and the diamine or a suspension with good fluidity in a first polymerization reactor, and forming a prepolymer of polyamide with the inherent viscosity of 0.3-0.7dl / g in a second polymerization reactor; and 2, granulating the prepolymer with a double screw extruder with at least two vent holes, adding prepolymer particles to a solid phase polymerization reactor of a fixedbed, heating the prepolymer particles with hot nitrogen with a certain flow and a certain temperature, reacting for 1-15h to obtain products of polyamide with the inherent viscosity of 1.0-2.5dl / g. Compared with previous polyamide polymerization methods, extra energy costs needed by solvent removal are reduced and the operation cost is reduced because polycondensation is carried out without the solvent; energy consumption in the melting process is reduced and possible problems of raw material oxidation and the like caused by a high melting temperature are avoided because cases that the diamine and the diacid for polyamide production have different melting points and the melting point of the diamine is low, and the molten diamine is added to the solid diacid are skillfully used in the method of the present invention.

Owner:卢建国

Method for producing surface-treated oxide particles, and oxide particles produced by said production method

ActiveUS20160301063A1Low costImprove propertyFinal product manufactureSecondary cellsComposite oxideSurface finishing

Provided is a method for producing surface-treated oxide particles which can be used in an active-material layer for a positive electrode or a negative electrode in a storage battery. Oxide particles in which an alkaline compound is contained in a part or the whole area of the surface of each of the particles are brought into contact with a gas containing a volatile acidic compound to produce a neutralization product by a gas phase reaction, thereby producing surface-treated oxide particles in which the neutralization product is contained. The alkaline compound comprises at least one compound selected from compounds respectively containing lithium (Li), sodium (Na) and magnesium (Mg), the volatile acidic compound comprises at least one compound selected from compounds respectively containing boron (B), phosphorus (P) and silicon (Si), and the oxide particles comprise an alkali-composited oxide containing at least one transition metal selected from manganese, cobalt, nickel, iron and titanium.

Owner:SUMITOMO METAL MINING CO LTD

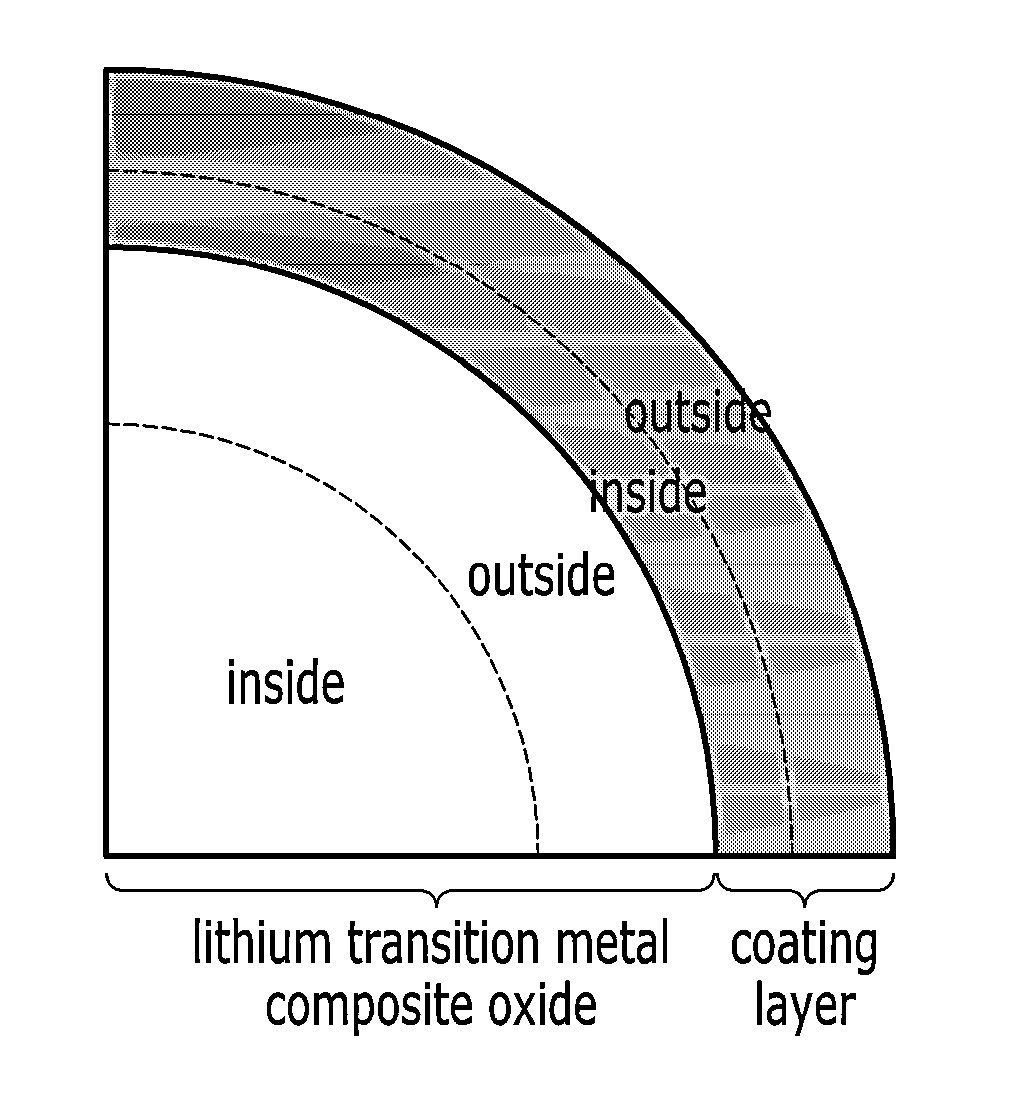

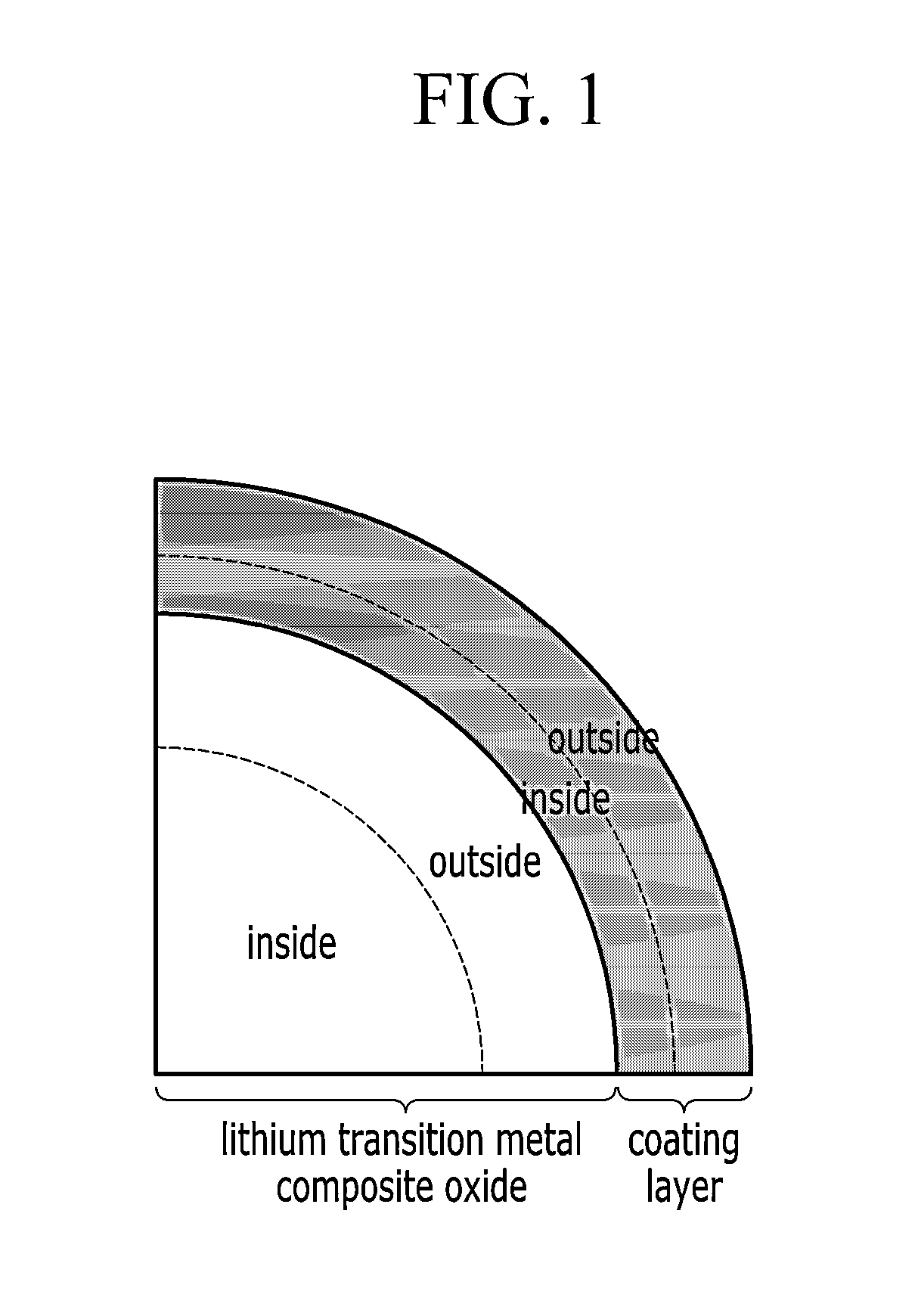

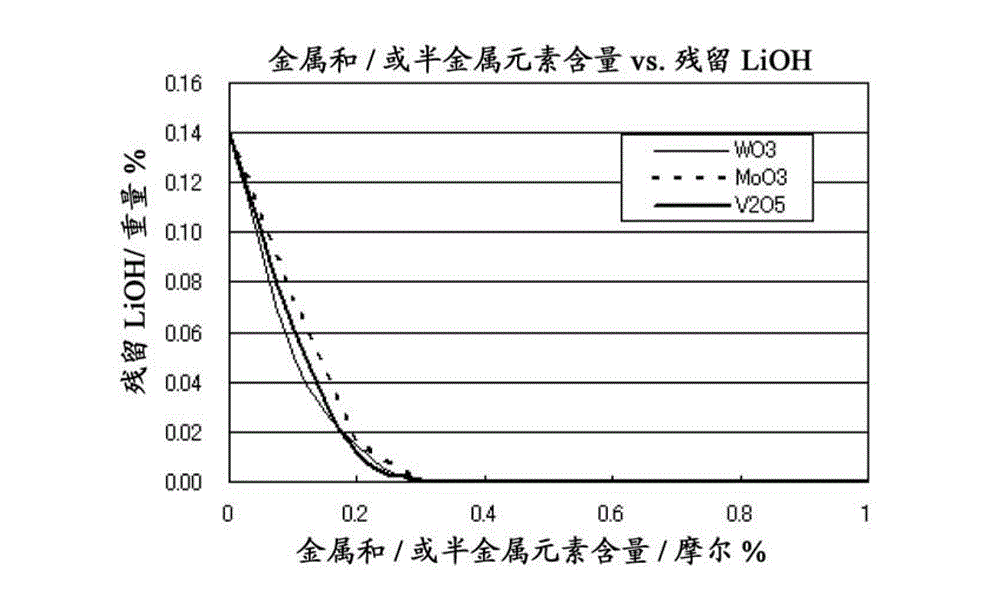

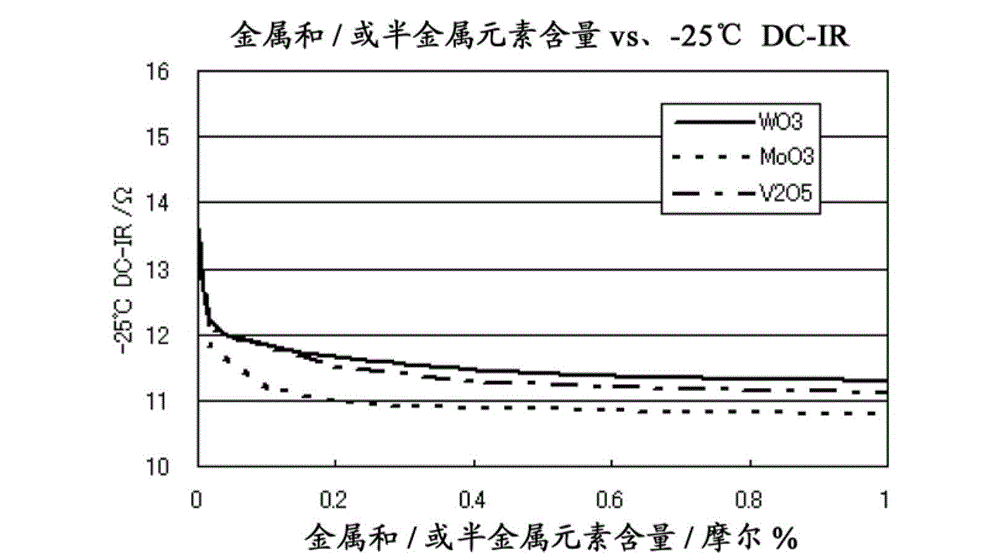

Positive active material for rechargeable lithium battery, method for manufacturing the same, and rechargeable lithium battery including the same

ActiveUS20150228969A1Improve stabilityImprove rate characteristicsElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesPhysical chemistryVanadium oxide

Disclosed are a positive active material for a rechargeable lithium battery including a nickel-containing lithium transition metal composite oxide and a coating layer positioned on the surface of the lithium transition metal composite oxide, wherein the coating layer includes vanadium oxide, lithium vanadium oxide, or a combination thereof, a method of manufacturing the same, and a rechargeable lithium battery including the same.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

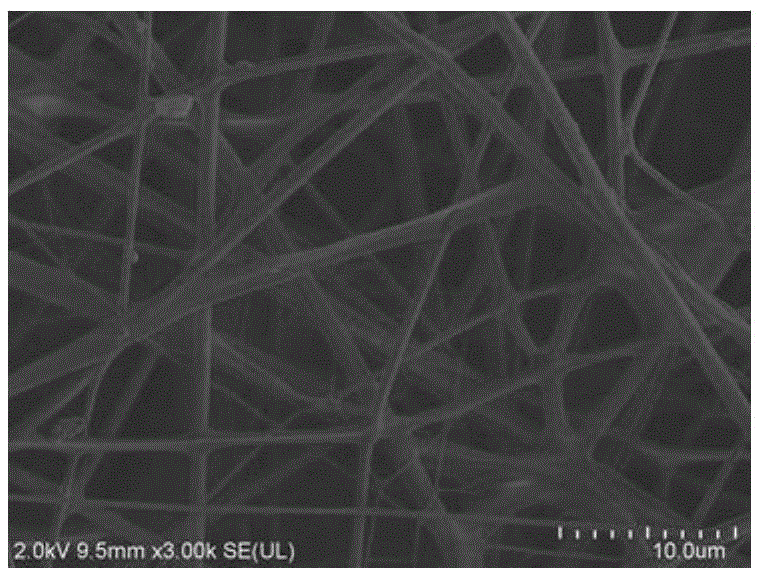

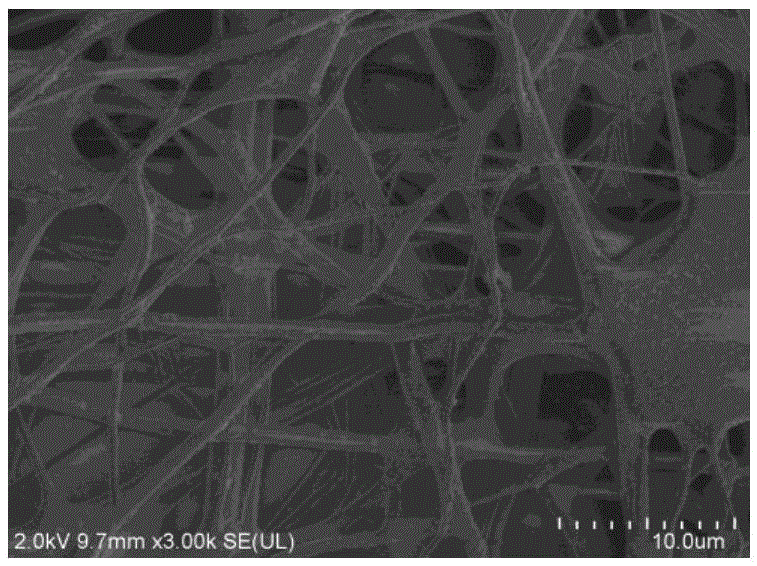

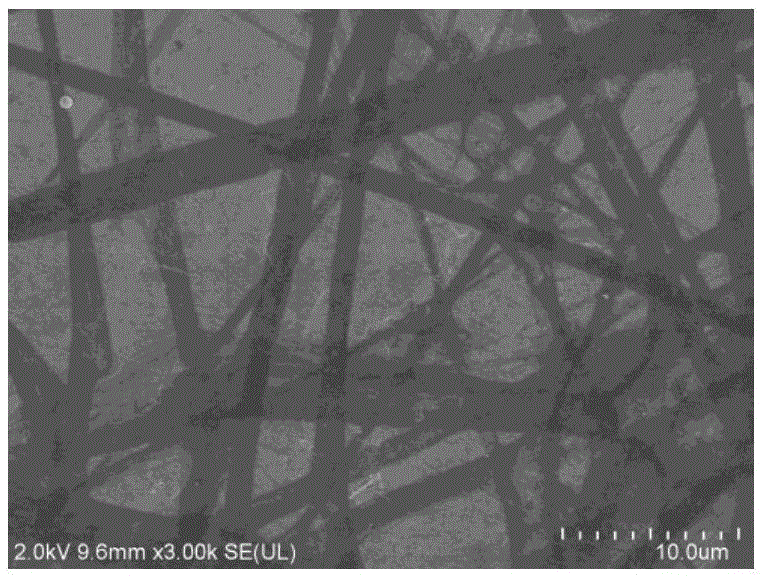

Waterproof polyvinyl alcohol nanofiber membrane and preparation method thereof

ActiveCN105648653ASimple processImprove spinning efficiencyHeating/cooling textile fabricsNon-woven fabricsSolventChemistry

The invention discloses a polyvinyl alcohol nanofiber membrane good in water resistance and a preparation method thereof. In the method, ionized water, organic acid, alcohols, polyvinyl alcohol, a crosslinking agent and a catalyst serve as main raw materials for electrostatic spinning solution; and the degree of crosslinking of the polyvinyl alcohol nanofiber membrane is improved through heat treatment after electrostatic spinning. A disclosed process is green and environmentally friendly. Compared with a conventional nanofiber filtering material, the polyvinyl alcohol nanofiber membrane is free of solvent recovery and solvent residue problems and free of toxic and side effect, and the prepared polyvinyl alcohol nanofiber membrane has excellent water resistance and can serve as a medical dressing or an air filtering material.

Owner:刘丽娟

Full-dull polyamide 6 fibre and method for producing the same

ActiveCN101463506AAvoid yellowingImprove structural uniformityFilament/thread formingHeating/cooling textile fabricsYarnPolymer science

The invention relates to a chemical fiber and a manufacturing method thereof, in particular to a full-dull daiamid 6 fiber added with titanium dioxide and a manufacturing method thereof. The full-dull daiamid 6 fiber and the manufacturing method thereof which have less polymer degradation, even yarn levelness, less filoplume and uniform dyeing aim at solving the disadvantages of easy degradation of high polymer fusant, poor evenness of the yarn levelness, high fluctuation of oiling rate, easy occurrence of more filoplume, bad uniformity of dyeing, etc. The invention mainly has the technical proposal that daiamid 6 particle with more than or equal to 1.6% of TiO2 is taken as raw material, treated by melt spinning and cross air blasting through twice of rectification and oiling, and is wound; finally, the full-dull daiamid 6 fiber is obtained.

Owner:YIWU HUADING NYLON

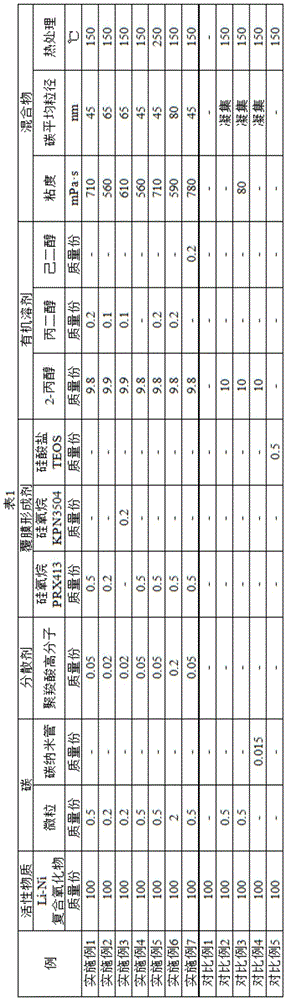

Method for producing positive electrode active material for nonaqueous electrolyte secondary batteries, positive electrode active material for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN105594024AEasy to operateIncrease internal resistanceElectrode thermal treatmentFinal product manufactureOrganic solventFilm-forming agent

To provide: a method for producing a positive electrode active material, which is capable of improving water resistance of the positive electrode active material and suppressing gelation of a positive electrode mixture paste without deteriorating the original battery performance of the positive electrode active material; and the like. A method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, which is provided with: a mixing step for preparing a mixture that contains fine carbon particles, an organic dispersant, a hydrophobic coating film-forming agent, an organic solvent and positive electrode active material particles; a drying step for drying the mixture so as to obtain a mixture in which the content of the organic solvent is reduced; and a heat treatment step for subjecting the mixture, in which the content of the organic solvent is reduced, to a heat treatment so as to obtain a coated positive electrode active material.

Owner:SUMITOMO METAL MINING CO LTD

High temperature stabilization of UV systems

ActiveUS20050043450A1Improve high temperature stabilityReduced stabilityImpression capsInksGreek letter betaOligomer

A composition comprising one or more radiation curable monomers and / or oligomers and one or heat stable composition comprising at least one radiation-curable alpha, beta-ethylenically unsaturated compound, at least one phenolic stabilizer, and at least one non-phenolic stabilizer selected from the group consisting of hydroperoxide decomposers and free radical traps. The compositions and methods are useful in applications such as radiation curable ink jet systems where viscosity is reduced by heating.

Owner:ARKEMA FRANCE SA

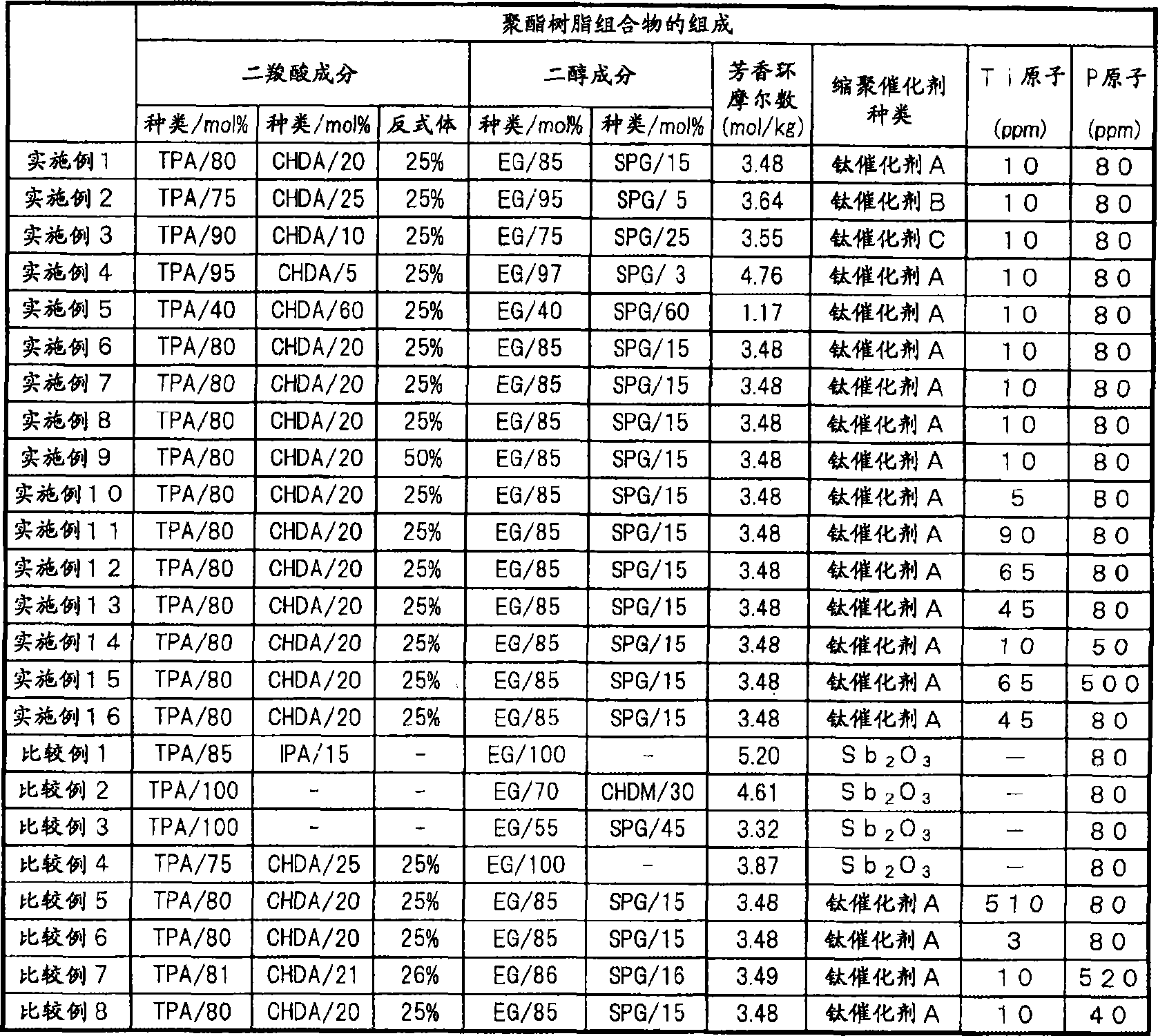

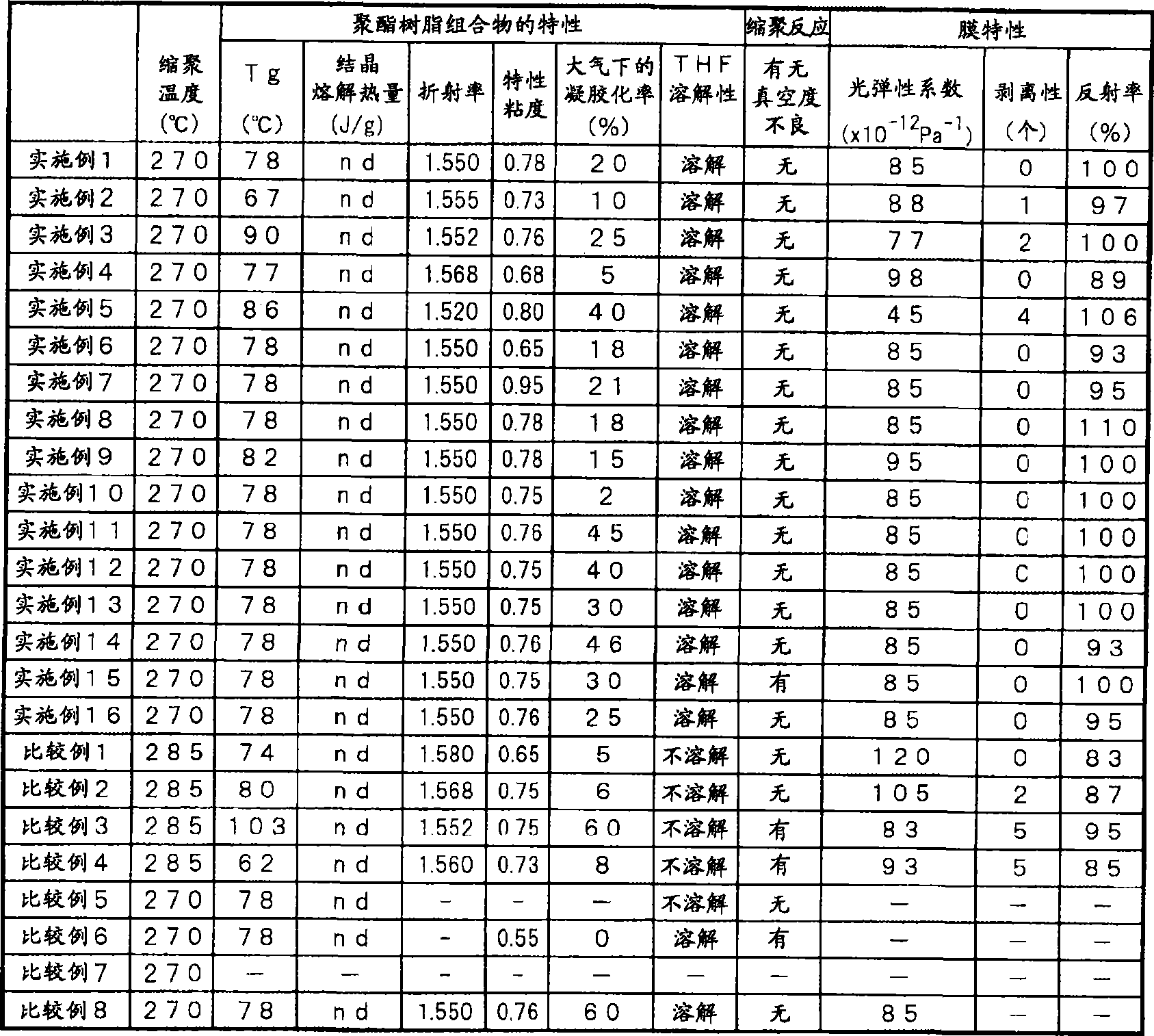

Polyester resin composition, process for production thereof, and laminated polyester film

ActiveCN101511907ALow refractive index and photoelastic coefficientGood thermal stabilitySynthetic resin layered productsOptical elementsTitaniumForeign matter

The present invention is a composition containing a polyester resin containing at least an alicyclic dicarboxylic acid component and an alicyclic diol component, and it is a polyester resin composition which satisfies that a glass transition temperature is 65 DEG C or more and 90 DEG C or less, a refractive index at sodium D line is 1.500 or more and 1.570 or less, a titanium element content is 5 ppm or more and 500 ppm or less, a phosphorus element content is 50 ppm or more and 500 ppm or less and a gel fraction is 50% or less. By the present invention, it is possible to obtain a polyester resin composition having a low refractive index and photoelastic coefficient, and in which a thermally degraded foreign substance is reduced.

Owner:TORAY IND INC

Cathode active material, method of preparing the same, and cathode and lithium battery applying the material

ActiveUS7547491B2Prevent gelationElectrode manufacturing processesFinal product manufactureHigh rateCharge discharge

Composite cathode active materials comprising a composite oxide and an acid treated with an organic solvent are provided. The composite cathode active materials are prepared by treating mixtures of nickel-based composite oxides and organic acids with organic solvents. The active materials suppress gelation of the electrode slurries for a long period of time, even when the active materials are mixed with fluorine-based polymers, by decreasing the basicity of the slurries and the amount of lithium present on the surfaces of the active materials. As a result, electrode slurries having high stability can be prepared. Cathodes and lithium batteries comprising the slurries have excellent charge-discharge characteristics, including high capacity and excellent high rate discharge characteristics.

Owner:SAMSUNG SDI CO LTD

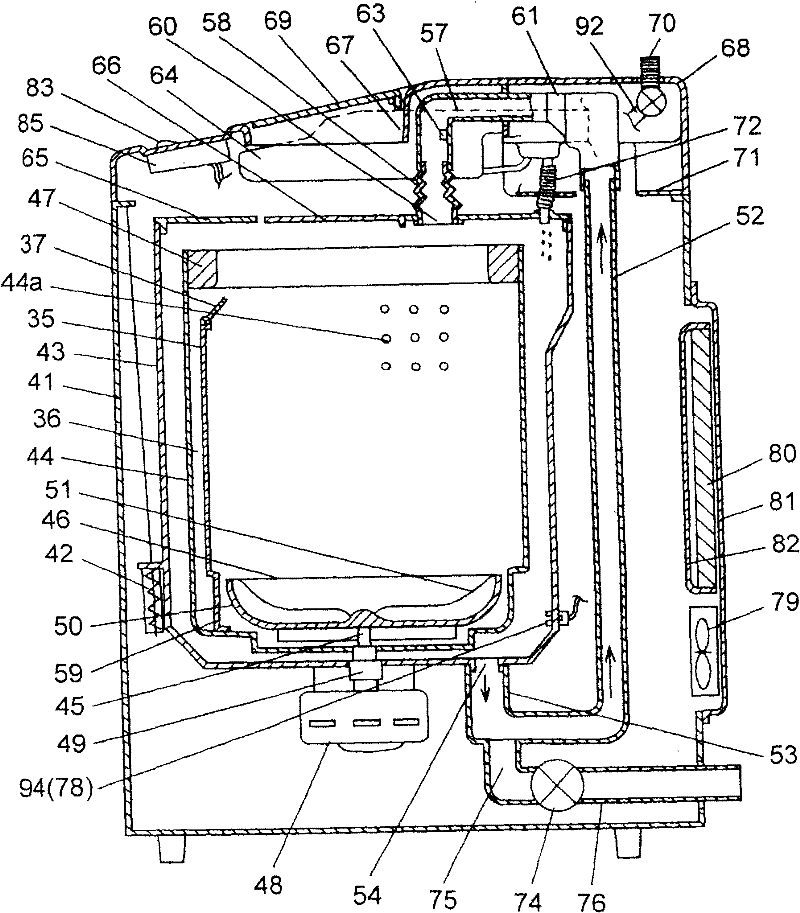

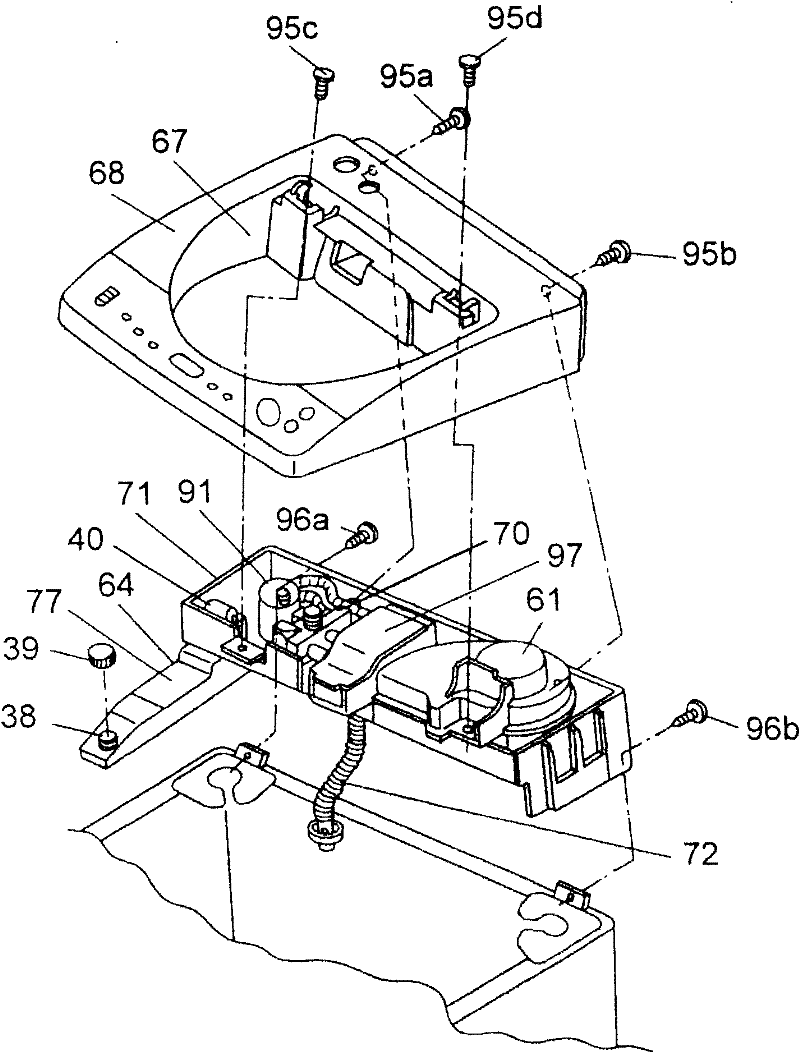

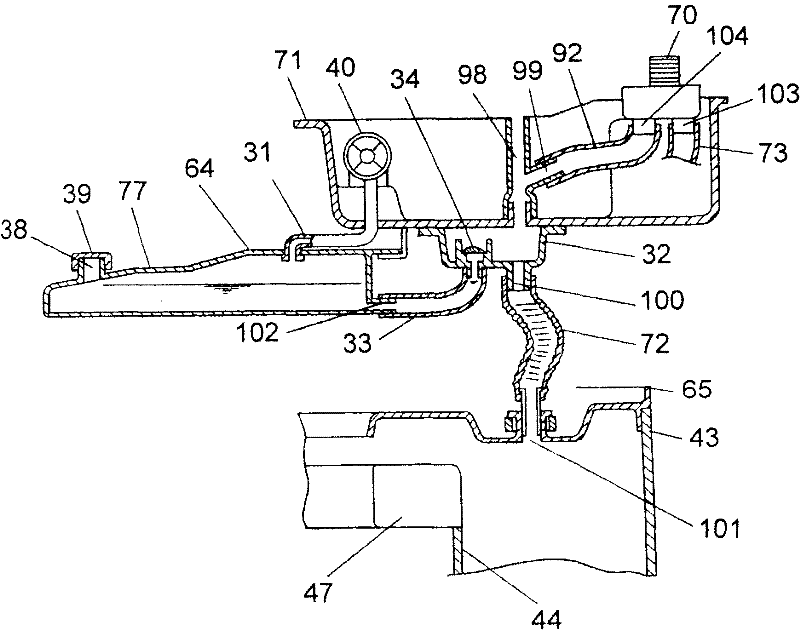

Washing machine

InactiveCN102191666AAvoid residuePrevent gelationOther washing machinesControl devices for washing apparatusInlet valveEngineering

The invention discloses a washing machine, which comprises a water inlet valve installed on a supporting component, an automatic liquid detergent feeding device arranged on the supporting component and consisting of a detergent tank, an air pump and a detergent containing part, an opening arranged above the detergent containing part and communicated with the detergent containing part, the water inlet valve and the air, a detergent filling hose connected between the detergent containing part and an upper cover of an outer bucket, and a control part for controlling a series of processes. The control part controls the air pump to act so as to put the liquid detergent into the outer bucket from the detergent tank via the detergent containing part and the detergent filling hose, then the control part controls the water inlet valve to act so as to put water into the outer bucket via the opening, the detergent containing part and the detergent filling hose; the detergent containing part and the detergent filling hose are internally washed so as to prevent the gelatinization of the liquid detergent, so that the liquid detergent can have specified performances.

Owner:PANASONIC CORP

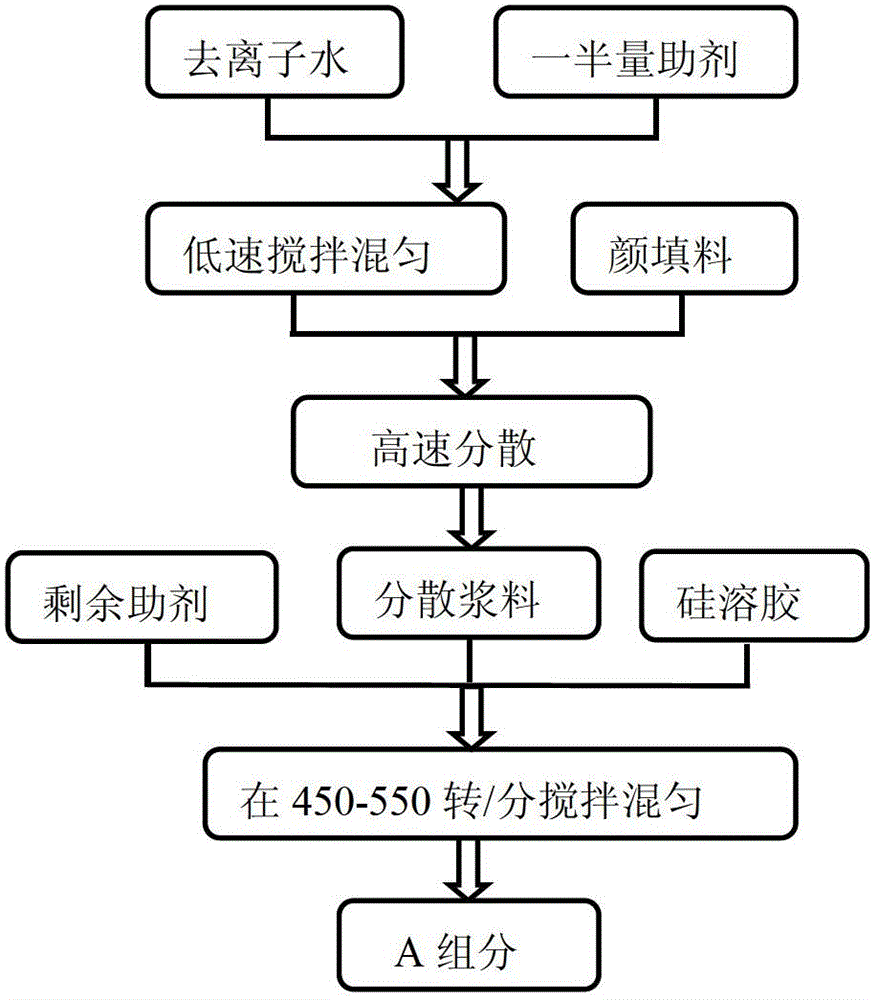

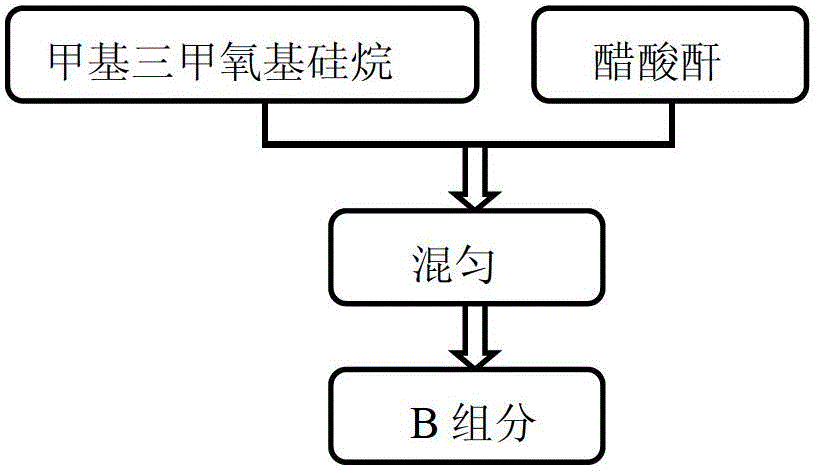

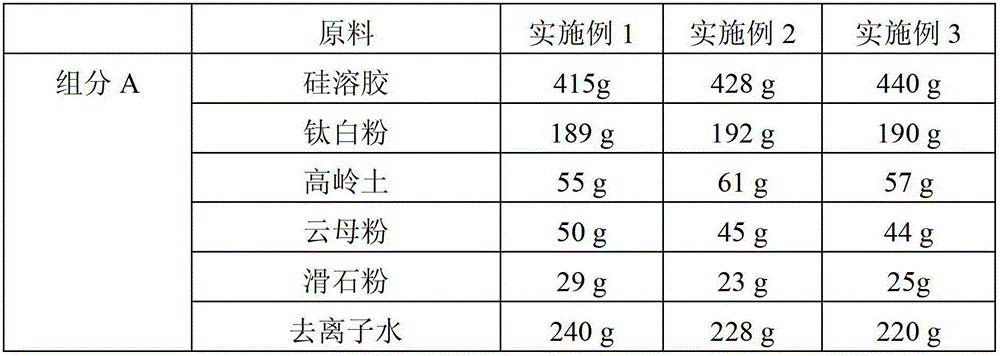

Environment-friendly high temperature-resistant inorganic insulated paint and preparation method thereof

InactiveCN102719120AExtend construction timeNo change in viscosityCoatingsEnvironmental resistanceAcetic anhydride

The invention relates to environment-friendly high temperature-resistant inorganic insulated paint and a preparation method thereof and belongs to the field of preparation of coatings. The environment-friendly high temperature-resistant inorganic insulated paint consists of a component A and a component B, wherein the component A consists of the flowing raw materials in percentage by mass: 41 to 44 percent of silica sol, 18.5 to 19.8 percent of inorganic pigment, 5.3 to 6.3 percent of kaolin, 4.4 to 5.0 percent of mica powder, 2.2 to 3.0 percent of talcpowder, 22 to 24 percent of deionized water, and 2.1 to 2.2 percent of aid; and the component B consists of the following raw materials in percentage by mass: 1.0 to 1.2 percent of acetic anhydride and 98.8 to 99.0 percent of methyltrimethoxysilane. During use, the component A and the component B are stirred and mixed in a ratio and cured; and then a mixture is subjected to air spraying onto metal base materials such as aluminum alloy, stainless steel and the like which are treated. The paint has the advantages of environment-friendliness, high temperature resistance and insulativity, acid and alkali resistance, long normal temperature quality guarantee period, long construction time and the like, and can be cured at normal temperature.

Owner:DALIAN JIAOTONG UNIVERSITY

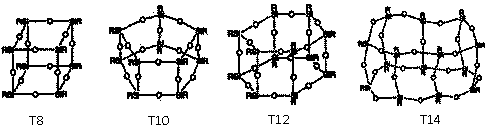

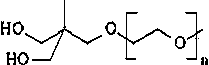

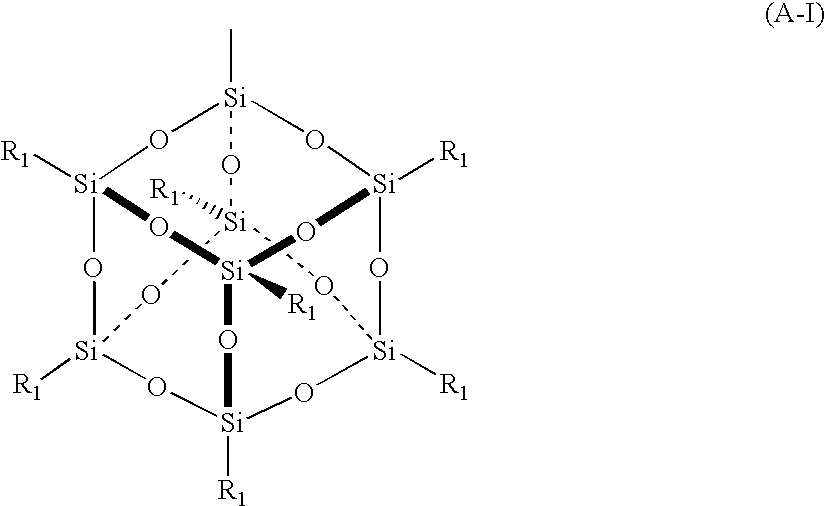

Preparation method of waterborne polyurethane with excellent freeze-thawing stability

The invention discloses a preparation method of waterborne polyurethane with excellent freeze-thawing stability. The preparation method specifically comprises the steps of: at 20-80 DEG C, adding amino type polyhedral oligomeric silsesquioxane into acetone of excessive isocyanate monomer, reacting to be clear, setting the temperature to be 60 DEG C, adding ethyoxyl-terminated polymer glycol, diol and polyol, and catalyst di-n-butyl tin dilaurate, reacting for one to two hours, and controlling the R value to be 1.50-3.00 in the prepolymerization reaction; then increasing the temperature to be 70-90 DEG C, continuously reacting for one to two hours, then cooling to room temperature, adding water for dispersion, adding a chain extender at 30-50 DEG C to conduct chain extension reaction for two to four hours, and cooling to room temperature to obtain waterborne polyurethane. Through tests, the waterborne polyurethane has favorable wear resistance property and bonding strength, as well as excellent freeze-thawing stability.

Owner:JIANGSU HUAXIA PAINT MAKING

Soy composite materials comprising an amino resin and methods of making the same

InactiveUS20120149813A1Reduce slurry viscosityLow viscosityOrganic detergent compounding agentsFibre treatmentEmulsionSoy flour

The present invention provides composite materials derived from aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, one or more amino resin, and, optionally, one or more reducing sugar. Also provided are methods of making and using composite materials containing the binder compositions.

Owner:ROHM & HAAS CO

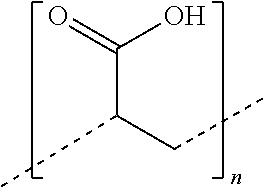

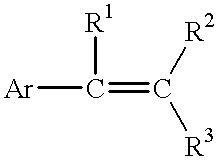

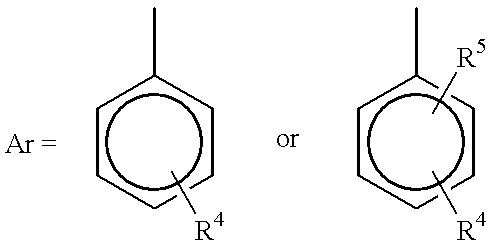

Process for reducing mono-functional and non-functional by-products during aralkylation of phenolics

Phenol aralkyistion polymers can be prepared by reaction among a phenolic monomer, at least one styrenic monomer and an aryl diolefin. A phenolic monomer can be initially aralkylated in the presence of an acid catalyst with a first portion of at least one styrenic monomer to obtain an aralkylated phenol. The aralkylated phenol thereafter can be reacted with an aryl diolefin to obtain a phenol aralkylation polymer. Optionally, (though preferably) the phenol aralkylation polymer is further aralkylated with a second portion of at least one styrenic monomer. By employing specific catalyst concentrations, reactant concentrations, reaction temperatures, and reaction times, the formation of mono-functional and non-functional by-products is substantially reduced.

Owner:GEORGIA PACIFIC CHEM LLC

Positive-electrode composition for a nonaqueous-electrolyte secondary battery and method for manufacturing a positive-electrode slurry using said positive-electrode composition

ActiveCN102947983ANo gelationImprove output characteristicsCell electrodesSecondary cellsParticulatesManganese

Disclosed is a positive-electrode composition that improves output characteristics, is low-cost, is easy to handle when fabricating positive electrodes, and has improved yield. Said positive-electrode composition, which is used in positive electrodes, comprises: a positive-electrode active material comprising a lithium / transition-metal composite oxide represented by the general formula Li[1+x]NiyCozM[1-y-z-w]LwO2 (with 0<=x<=0.50, 0.30<=y<=1.0, 0<=z<=0.5, 0<=w<=0.1, 0.30<y+z+w<=1, M being manganese and / or aluminum, and L being at least one element selected from the group comprising zirconium, titanium, magnesium, and tungsten); and a particulate additive comprising acidic oxide particles.

Owner:NICHIA CORP

Method for anhydrous synthesis of organosiloxane resin and product thereof, and application of product

The invention discloses an organosiloxane resin product prepared through anhydrous synthesis. The product is prepared by subjecting alkoxy silane, an end-capping reagent and an acidic compound in a mol ratio of 1: (0-2): (2-10) to a reaction, wherein the alkoxy silane is trifunctional and / or tetrafunctional alkoxy silane, and the acidic compound comprises organic carboxylic acid and an acidic catalyst. The organosiloxane resin provided by the invention has high regularity, narrower molecular weight distribution and PDI of less than 1.8. The invention also provides a preparation method for the organosiloxane resin. According to the method, an anhydrous one-step synthesis process is employed; and changes of the molecular weight parameters of polymers can be induced in a predicted way by controlling a pH value during quenching and the temperature of pressure-reduced distillation. The invention also provides application of the product. Since the organosiloxane resin product has good regularity, the organosiloxane resin product has good application prospects in silicone rubber, adhesives, lubricants, release agents and personal care products.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Systems and methods for controlling and forming polymer gels

ActiveUS20070054990A1Minimizing damageHigh Flory interaction parameterPowder deliverySpinal implantsCross-linkViscoelastic Solutions

In preferred embodiments, the present invention provides methods of controllably making a vinyl polymer hydrogel having desired physical properties without chemical cross links or radiation. The gelation process is modulated by controlling, for example, the temperature of a resultant vinyl polymer mixture having a gellant or using active ingredients provided in an inactive gellant complex. In accordance with a preferred embodiment, the method of manufacturing a vinyl polymer hydrogel includes the steps of providing a vinyl polymer solution comprising a vinyl polymer dissolved in a first solvent; heating the vinyl polymer solution to a temperature elevated above the melting point of the physical associations of the vinyl polymer, mixing the vinyl polymer solution with a gellant, wherein the resulting mixture has a higher Flory interaction parameter than the vinyl polymer solution; inducing gelation of the mixture of vinyl polymer solution and gellant; and controlling the gelation rate to form a viscoelastic solution, wherein workability is maintained for a predetermined period, thereby making a vinyl polymer hydrogel having the desired physical property. In further preferred embodiments, the present invention provides physically crosslinked hydrogels produced by controlled gelation of viscoelastic solution wherein workability is maintained for a predetermined period. In another aspect, the present invention provides kits for use in repairing intervertebral disks or articulated joints including components that form the vinyl polymer hydrogel and a dispenser.

Owner:CAMBRIDGE POLYMER GROUP

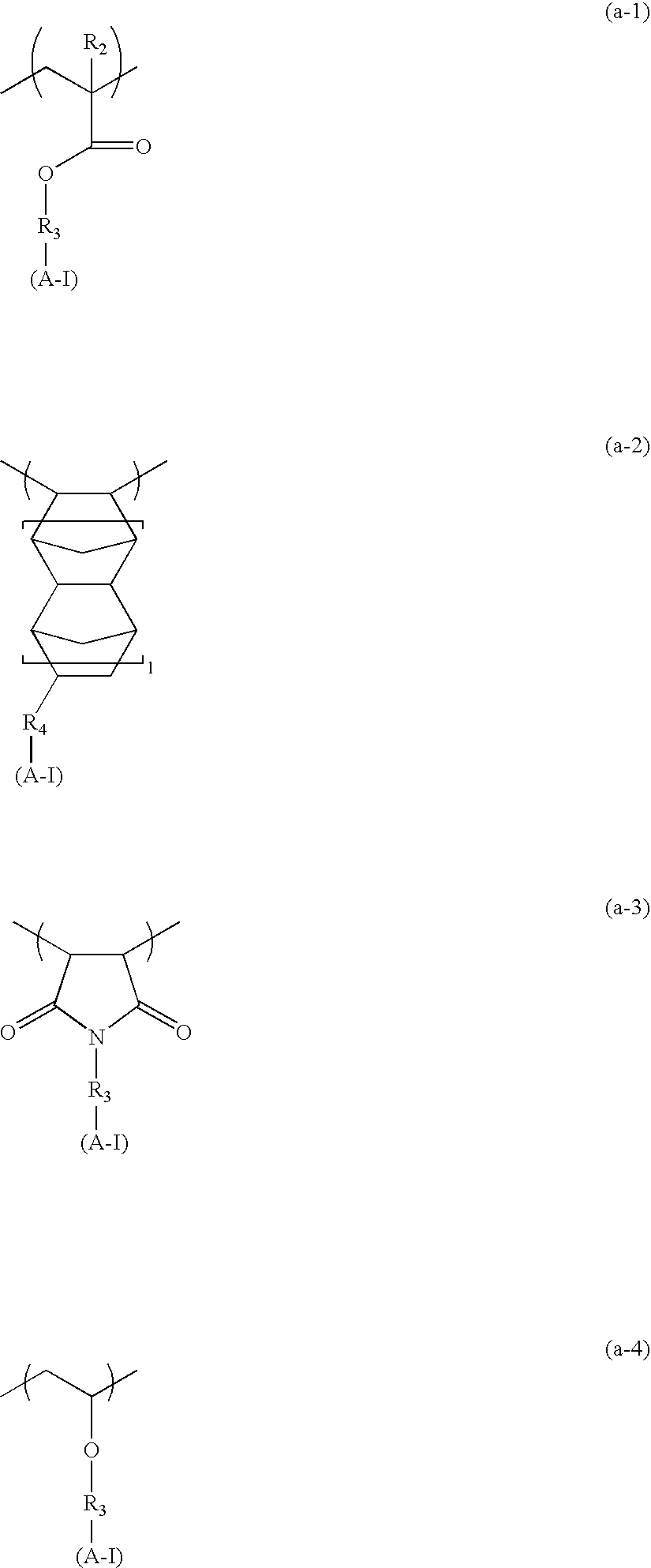

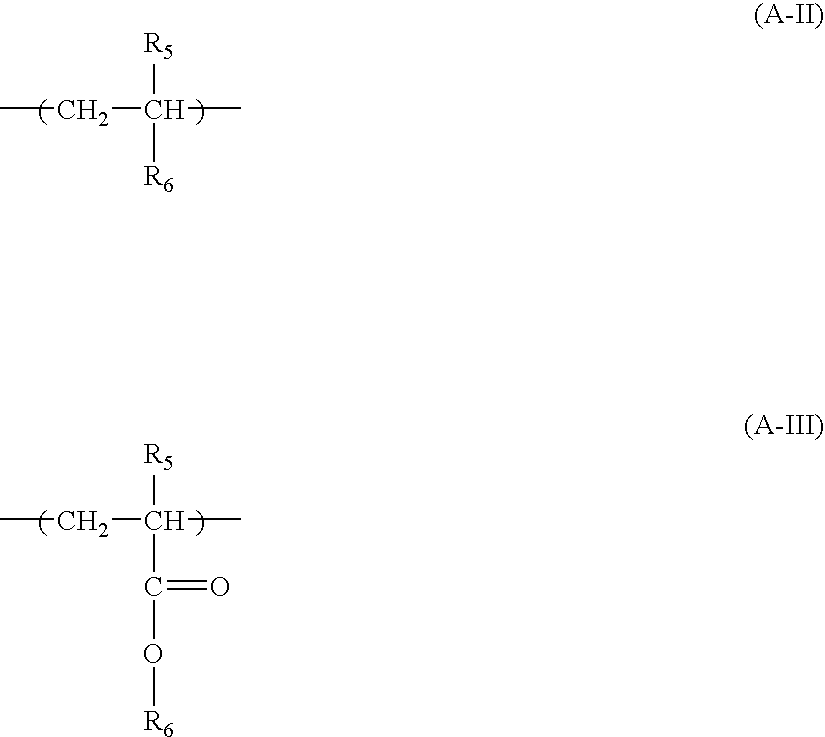

Intermediate layer material composition for multilayer resist process and pattern formation process using the same

InactiveUS20040053162A1Prevent gelationPhotosensitive materialsRadiation applicationsChemistrySide chain

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com