Method for anhydrous synthesis of organosiloxane resin and product thereof, and application of product

A technology for organosiloxane and dimethyldisiloxane, which is applied in the field of anhydrous synthesis of organosiloxane resins, can solve the problems of poor environmental protection performance, poor process reproducibility, low yield and the like, and avoid gelation. The effect of sizing and narrowing the molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

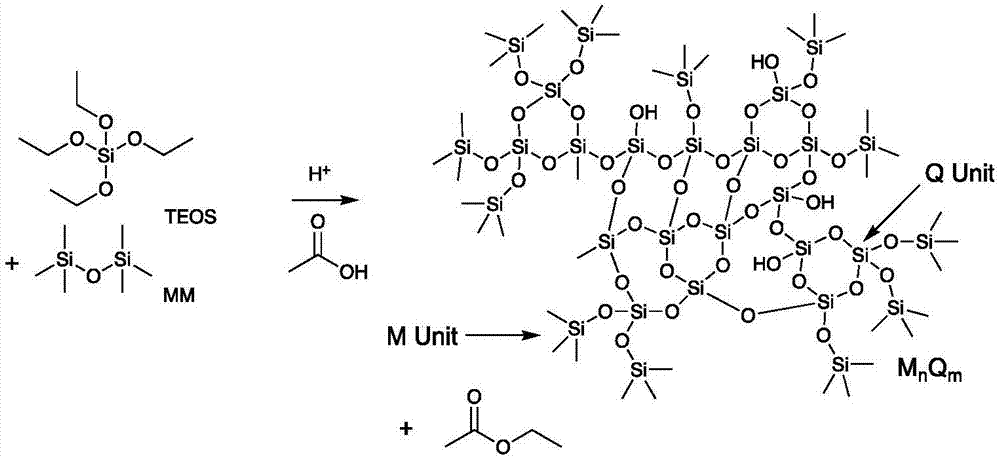

[0059] The invention provides the synthetic method of this product, comprising:

[0060]1) Take alkoxysilane, capping agent and acidic compound according to the molar ratio of 1:(0-2):(2-10), mix and stir evenly, and stir at 40-100°C for 0.3-20h;

[0061] Alkoxysilanes are trifunctional and / or tetrafunctional alkoxyorganosilanes, and acidic compounds include organic carboxylic acids and acidic catalysts;

[0062] 2) cooling, adjusting the pH to 1-12, standing for stratification, and removing the water phase;

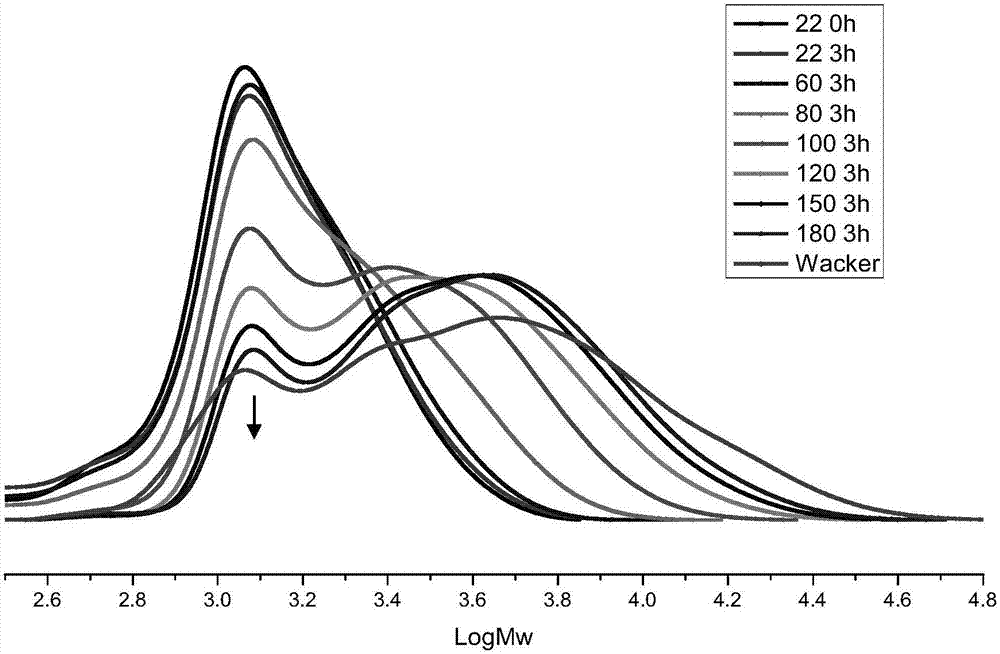

[0063] 3) After drying and filtering, distill under reduced pressure at 20-180°C to obtain a silicone resin.

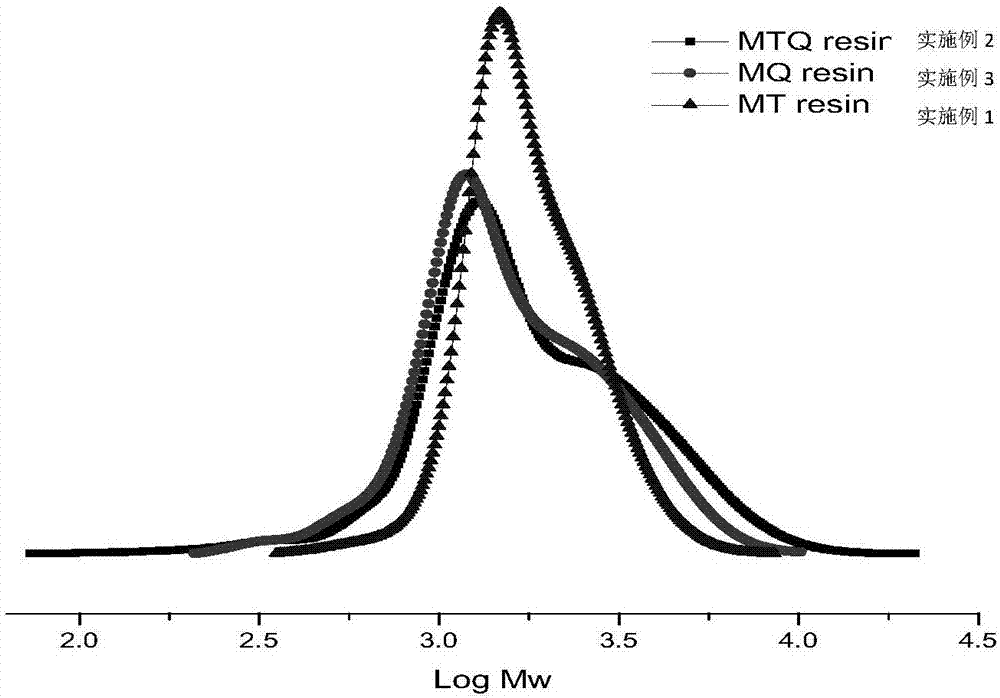

[0064] This method prepares higher quality silicone resin by avoiding the use of water in the synthesis process. Compared with the cohydrolysis polycondensation method, the silicone resin obtained by this method has a narrower molecular weight distribution and more controllable molecular weight. This method can be applied to MT Synthesis of resins, MQ and MTQ ...

Embodiment 1

[0068] Embodiment 1 provides the synthesis method of methacryloxypropyl MT silicone resin, the specific operations are as follows: octyltriethoxysilane (138.25g, 0.5mol), hexamethyldisiloxane (4.06g, 0.025mol), glacial acetic acid (99.08g, 1.65mol) and 98wt% sulfuric acid (1.4g) were added into a round bottom flask, stirred evenly, and heated to 78°C for 4 hours under reflux. After cooling to room temperature, the resulting reaction mixture was neutralized to pH=7 with aqueous sodium carbonate solution (15 wt%, 198.29 g). The organic phase was separated by decantation, and the organic solvent was removed under reduced pressure at 80 °C to obtain a viscous liquid resin. GPC measurement showed that Mn=1554, Mw=1829 and PDI=1.1770 of the resin.

Embodiment 2

[0070] Embodiment 2 provides the synthetic method of methacryloxypropyl MTQ silicone resin, and concrete operation is as follows: Tetraethoxysilane (10.42g, 0.05mol), hexamethyldisiloxane (4.06g, 0.025mol ), 3-methacryloxypropyltrimethoxysilane (3.72g, 0.015mol), glacial acetic acid (14.70g, 0.245mol) and 98wt% sulfuric acid (0.18g, 110ul) were stirred in a round bottom flask, Heat to 50°C for 4 hours. After cooling to room temperature, the resulting mixture was neutralized to pH=7 with aqueous sodium carbonate solution (20 wt%, 3.42 g). The organic phase was separated by decantation, and the organic solvent was removed under reduced pressure at 60 °C to obtain a viscous liquid resin. The product has Mn=1462, Mw=2328, PDI=1.59.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com