Preparation method of waterborne polyurethane with excellent freeze-thawing stability

A water-based polyurethane, freeze-thaw stability technology, applied in the field of preparation of water-based polyurethane, can solve the problems of water-based polyurethane resin, such as low strength, insufficient viscosity and wear resistance, application limitations, etc., to improve adhesion and performance Superior, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

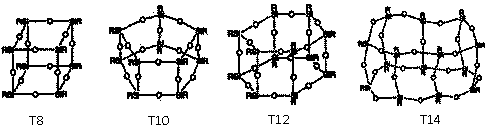

[0035] (1) At 70° C., add 88.00 g of amino cage silsesquioxane T8 to 174.00 g of toluene diisocyanate in acetone (750.00 g), and react until clear.

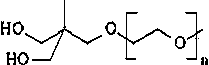

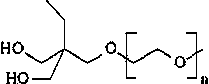

[0036] (2) Add 75.00g of 2,2-Dimethylolbutoxyethylene glycol (20EO, see structural formula (II), where n=20) methyl ether (ethoxy-terminated polymer glycol) , 200.00g of polyglycol 1000, 4.60g of glycerol and 2.71g of catalyst di-n-butyltin dilaurate, reacted at 60°C for 2h; then heated to 85°C and continued to react for 2h before returning to room temperature.

[0037] (3) Add 300 g of deionized water to the mixture after it has dropped to room temperature to disperse at 25°C.

[0038] (4) After dispersion, add 29.81g of ethylenediamine at 40°C to carry out chain extension reaction for 3h, then cool to room temperature to obtain waterborne polyurethane with good freeze-thaw stability. The solid content is determined to be 33.35%, and the particle size is 323.6nm.

[0039] The reaction conditions and parameters of each step in Examples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com