Waterproof polyvinyl alcohol nanofiber membrane and preparation method thereof

A nanofiber membrane, polyvinyl alcohol technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of poor water resistance of polyvinyl alcohol nanofibers, improve polyvinyl alcohol nanofibers, and cannot mask filter materials Use and other problems to achieve the effect of improving spinning efficiency, no toxic side effects, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

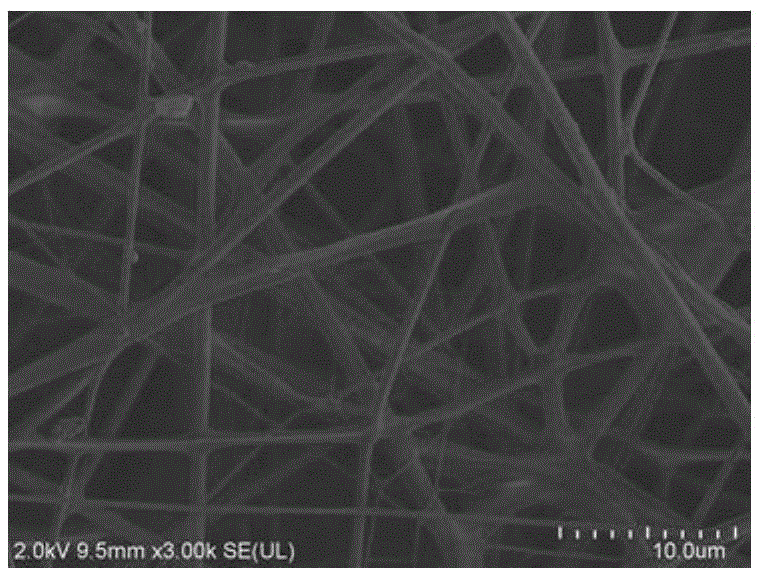

Image

Examples

Embodiment 1

[0030] A method for preparing polyvinyl alcohol nanofibers with excellent water resistance, comprising the steps of:

[0031] 1) First add 5 parts by weight of formic acid to 100 parts by weight of water to prepare a mixed solvent, then add 8.5 parts by weight of polyvinyl alcohol PVA1799 and 3.2 parts of glutaraldehyde in sequence, mechanically stir at 80°C for 3 hours, and prepare a spinning stock solution.

[0032] 2) Use a 20mL needle to absorb the feed liquid, cover with a needle with an inner diameter of 0.8mm, and squeeze out air bubbles; use the needle as the positive electrode and tinfoil (15cm*30cm) as the negative electrode, and start spinning. The spinning conditions are: 15°C; relative humidity: 50 -55%; spinning voltage 20KV; spinning current 0mA; injection speed 1mL / min; needle plate distance 17.8cm.

[0033] 3) After the spinning is completed, put the polyvinyl alcohol nanofiber membrane into a blast drying oven for 20 minutes at 150° C. for drying.

[0034] T...

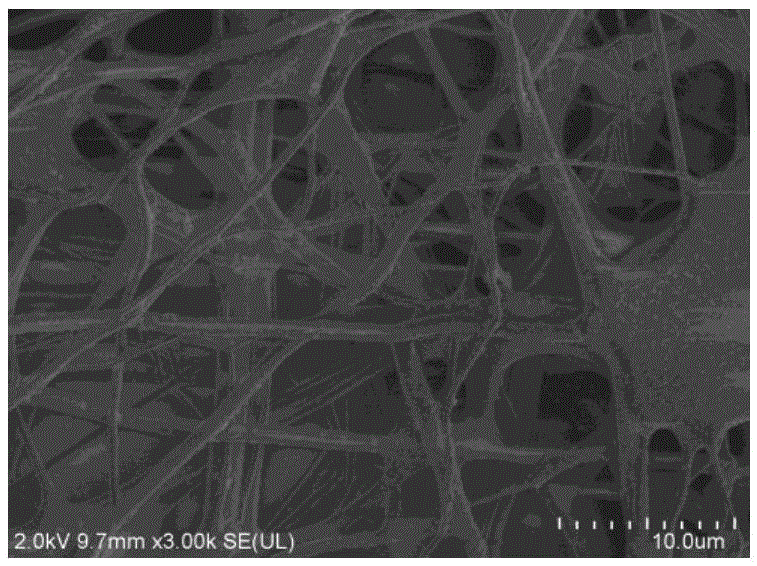

Embodiment 2

[0036] A method for preparing polyvinyl alcohol nanofibers with excellent water resistance, comprising the steps of:

[0037] 1) First add 18 parts by weight of acetic acid and 8.5 parts by weight of ethanol to 100 parts by weight of water to configure a mixed solvent, then add 11.5 parts by weight of polyvinyl alcohol PVA1799, 1.6 parts of glutaraldehyde and 0.3 parts by weight of ammonium persulfate, Stir mechanically at 85°C for 5 hours, and configure it as a spinning stock solution.

[0038] 2) Use a 20mL needle to absorb the feed liquid, cover with a needle with an inner diameter of 0.8mm, and squeeze out air bubbles; use the needle as the positive electrode and tinfoil (15cm*30cm) as the negative electrode, and start spinning. The spinning conditions are: 18°C; relative humidity: 50 -55%; spinning voltage 20KV; spinning current 0mA; injection speed 1.1mL / min; needle-plate distance 18cm.

[0039] 3) After the spinning is completed, put the polyvinyl alcohol nanofiber mem...

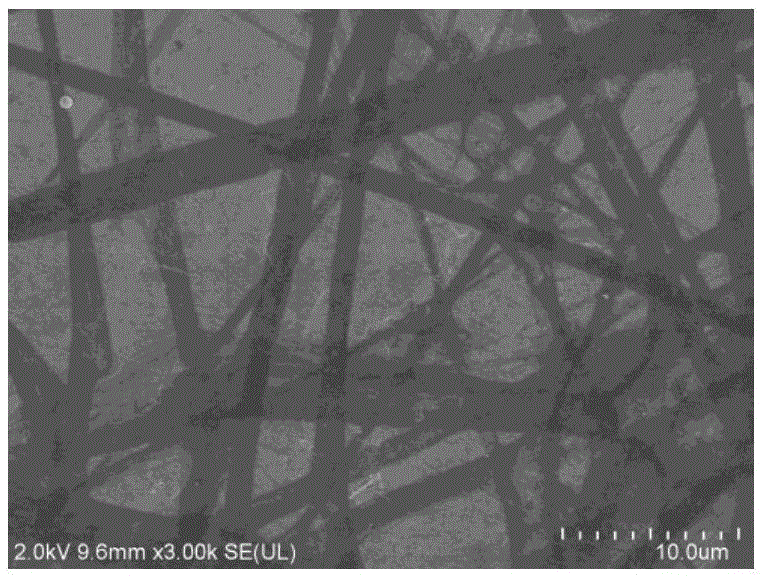

Embodiment 3

[0041] A method for preparing polyvinyl alcohol nanofibers with excellent water resistance, comprising the steps of:

[0042] 1) First add 20 parts by weight of propionic acid to 100 parts by weight of water to prepare a mixed solvent, then add 14 parts by weight of polyvinyl alcohol PVA1799 in sequence, mechanically stir at 90°C for 4 hours, and prepare a spinning stock solution.

[0043] 2) Use a 20mL needle to absorb the feed liquid, cover with a needle with an inner diameter of 0.8mm, and squeeze out air bubbles; use the needle as the positive electrode and tinfoil (15cm*30cm) as the negative electrode, and start spinning. The spinning conditions are: 20°C; relative humidity: 50 -55%; spinning voltage 20KV; spinning current 0mA; injection speed 1.1mL / min; needle-plate distance 18cm.

[0044] 3) Put the polyvinyl alcohol nanofiber membrane obtained in step 3) into a YN-280 glutaraldehyde fumigation cabinet (Yaohua Medical Instrument Factory) to carry out glutaraldehyde fumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com