Patents

Literature

385results about How to "Improve spinning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

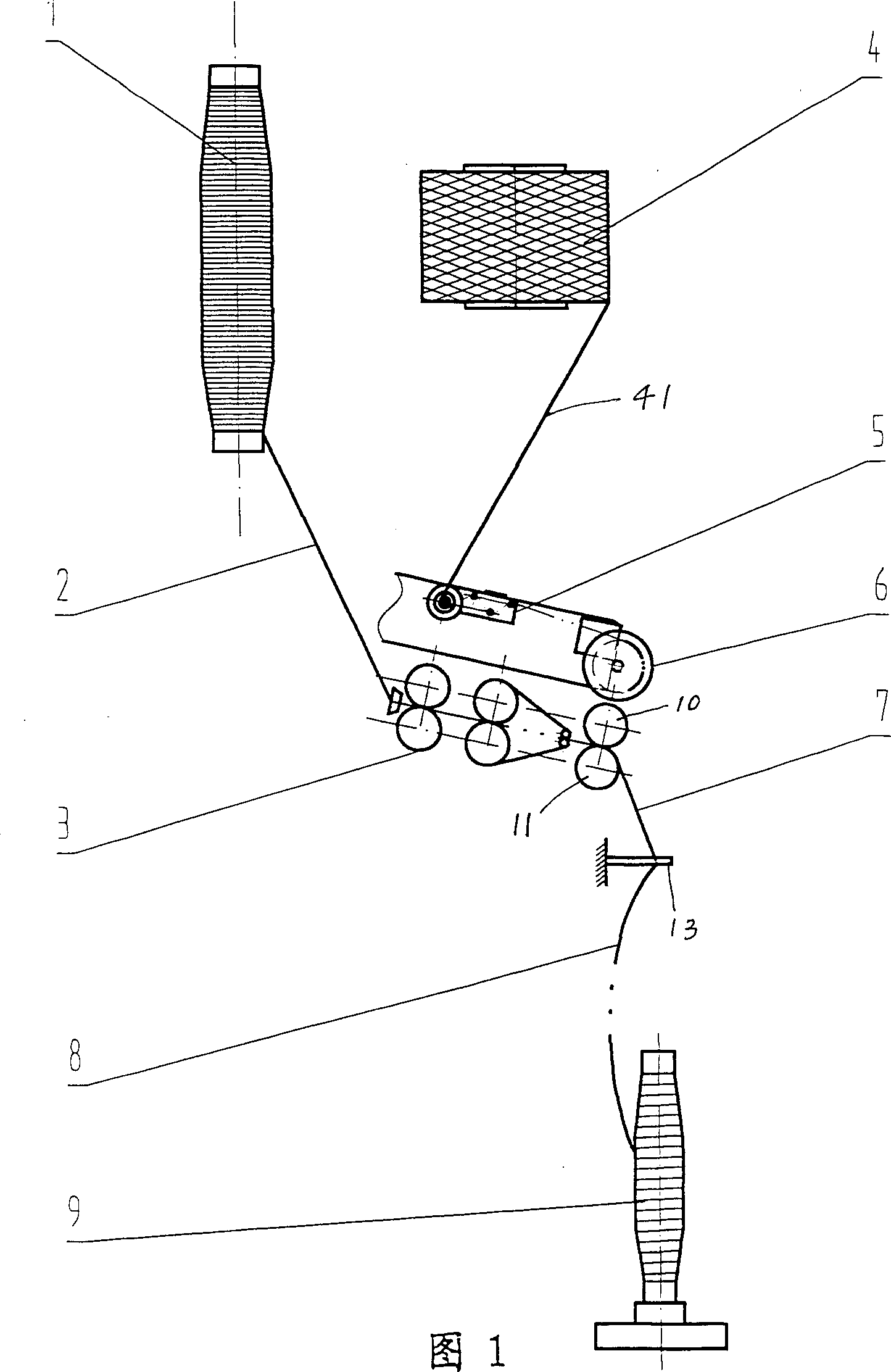

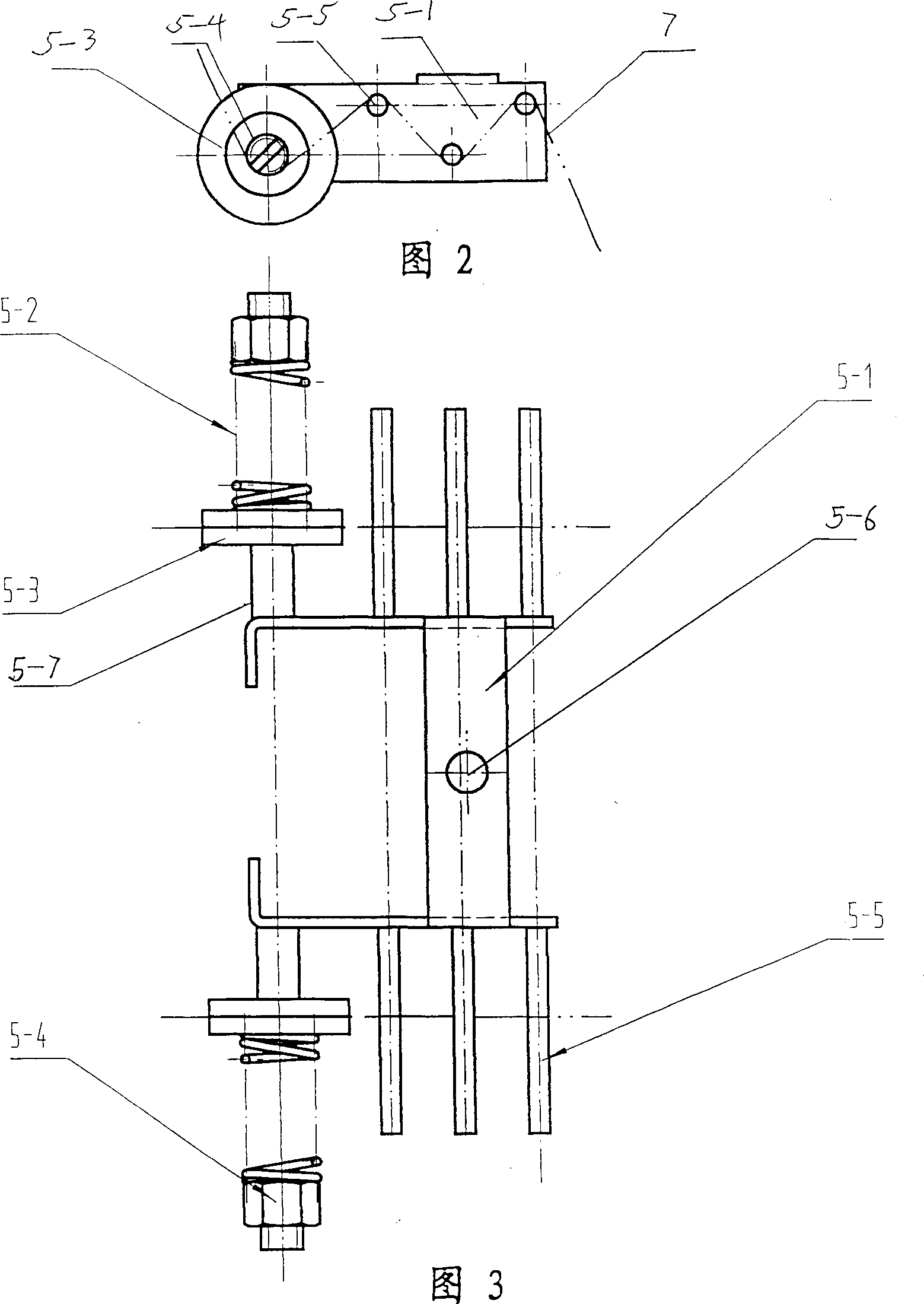

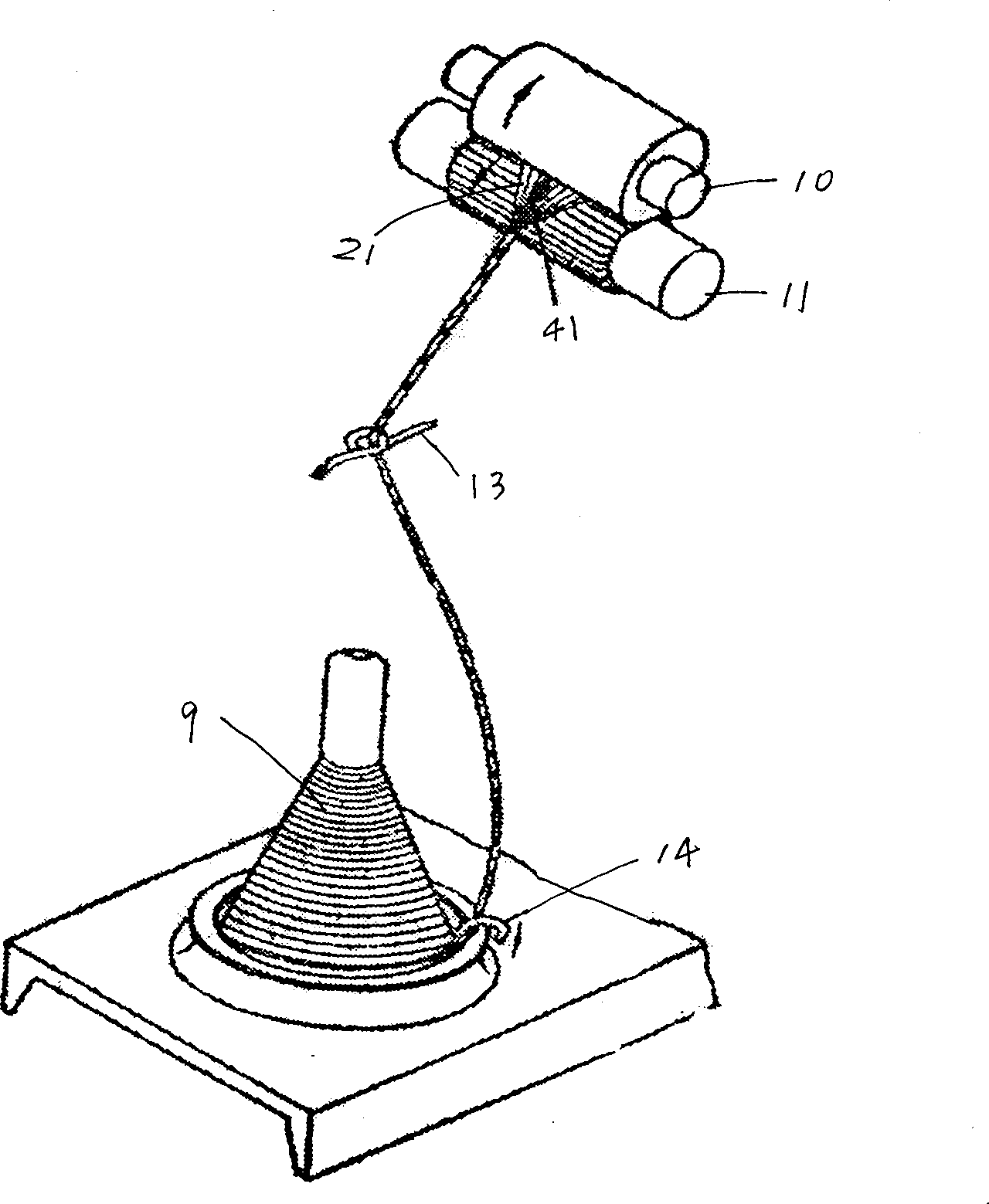

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

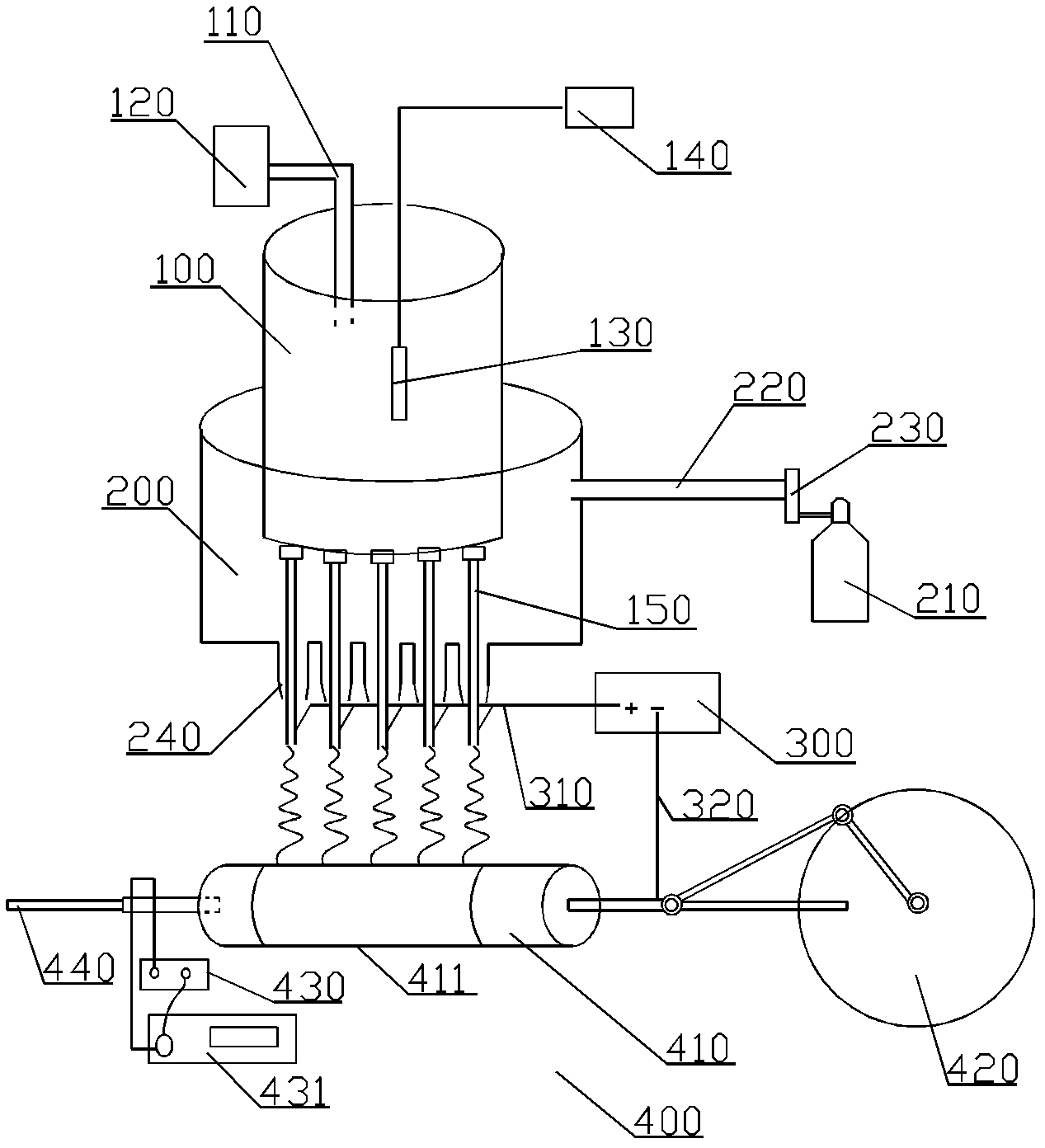

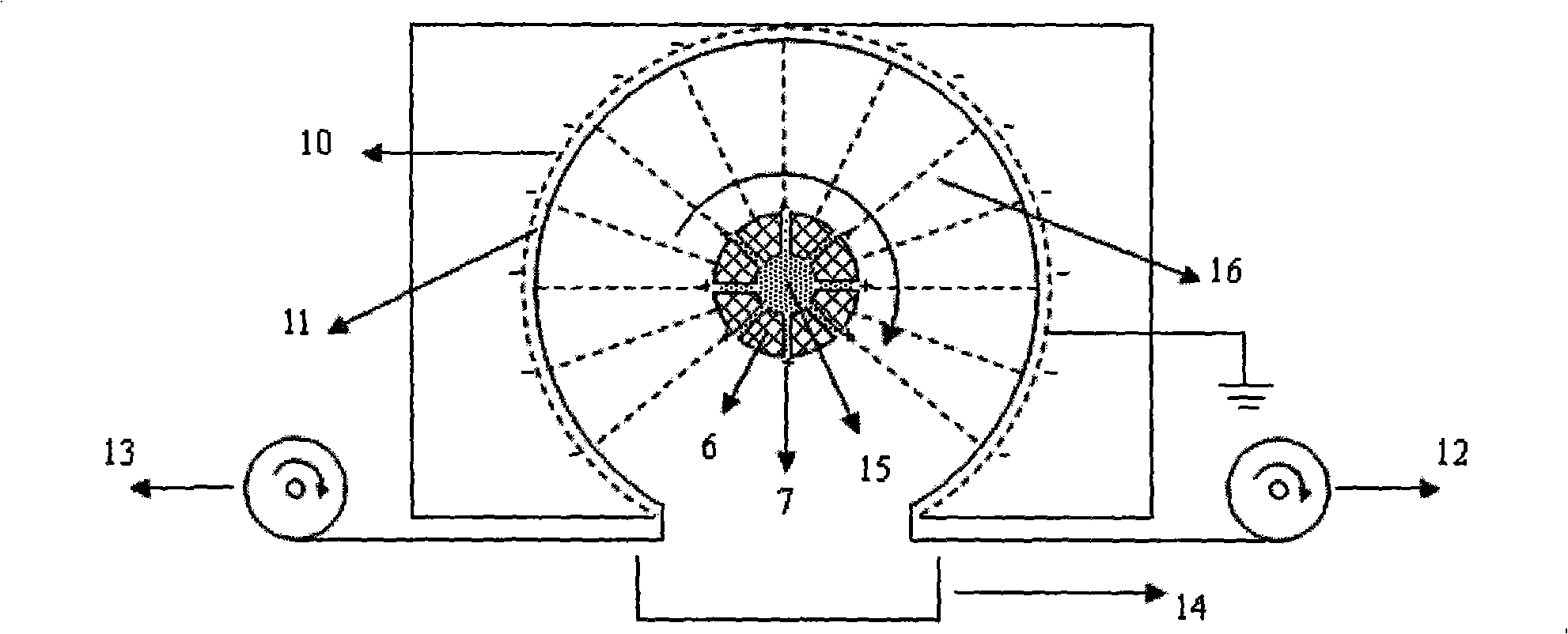

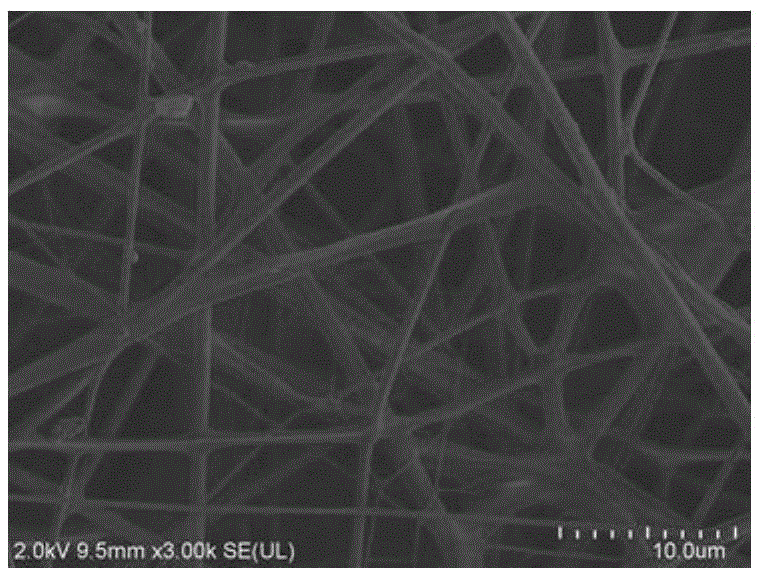

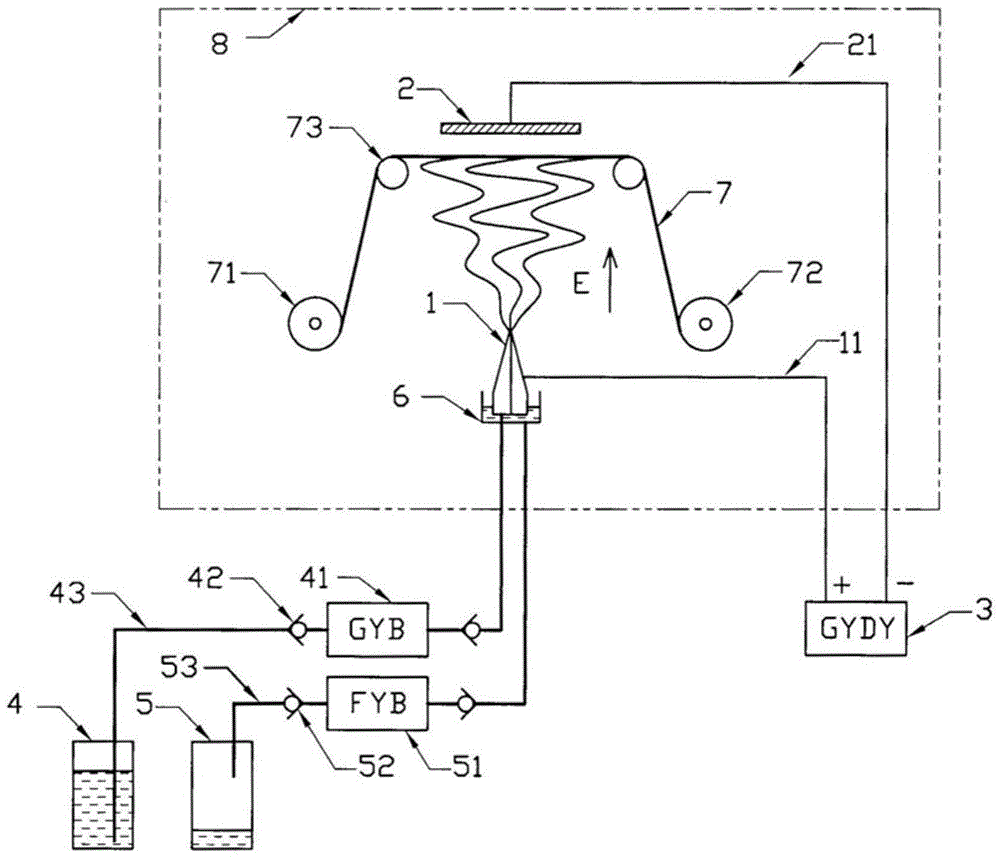

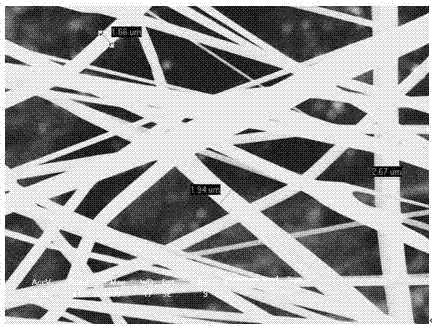

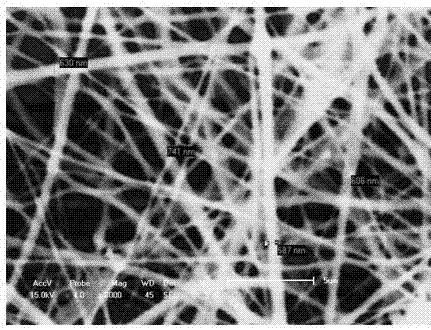

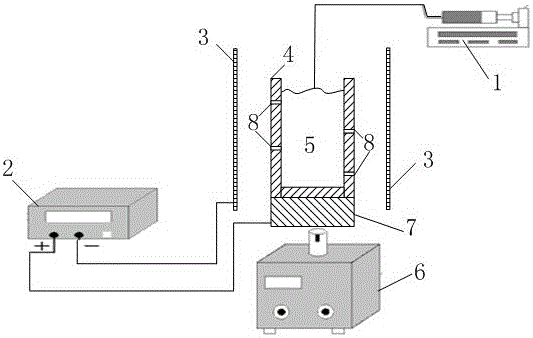

Device and method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination

ActiveCN102534822AOvercome surface tensionLarge specific surface areaStretch-spinning methodsFiberElectrospinning

The invention discloses a device and a method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination. The device comprises a liquid storage tank, an air chamber, an electrostatic generator and a receiving device, a plurality of spinnerets are arranged at the bottom of the liquid storage tank, the air chamber is arranged outside the liquid storage tank, air outlets in the number equal to that of the spinnerets at the bottom of the liquid storage tank are arranged at the bottom of the air chamber, the spinnerets are arranged inside the air outlets, an electrode with multiple pins are led from the positive electrode of the electrostatic generator to be connected with the spinnerets, and a lead is led from the negative electrode of the electrostatic generator to be connected with the receiving device. The method includes steps of combining the airflow method and the electrostatic spinning method effectively to prepare the polysulfonamide nanometer fiber nets. By the device and the method for preparing the polysulfonamide nanometer fiber nets, the specific surface area of the polysulfonamide nanometer fibers is enlarged greatly, the problem of blockage of existing electrostatic spinning needles due to inflow of the airflow is alleviated greatly, and spinning efficiency is improved. Besides, nanometer fibers can be prepared at the normal temperature directly, so that production procedures are simplified and production cost is saved.

Owner:SHANGHAI UNIV OF ENG SCI

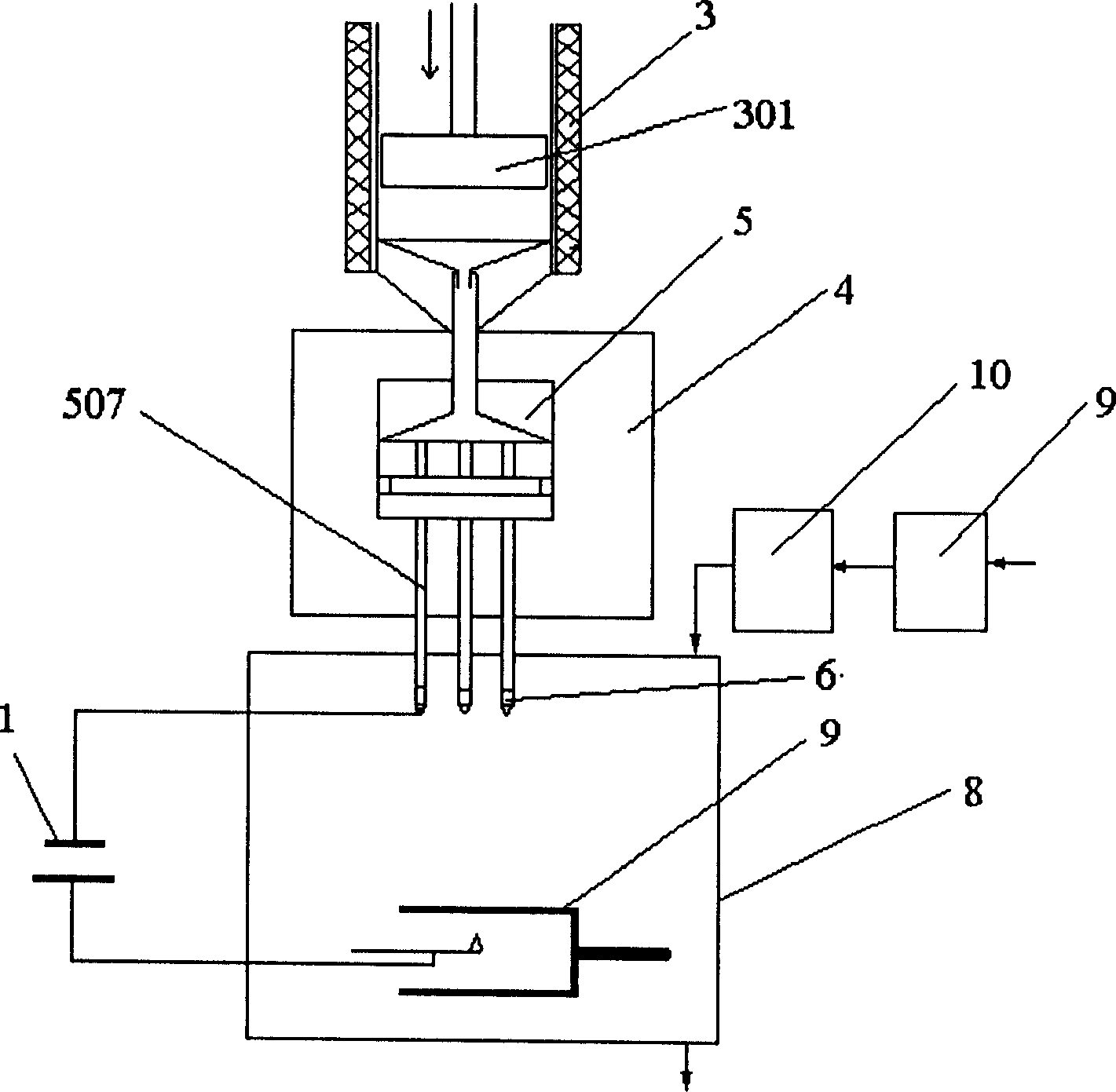

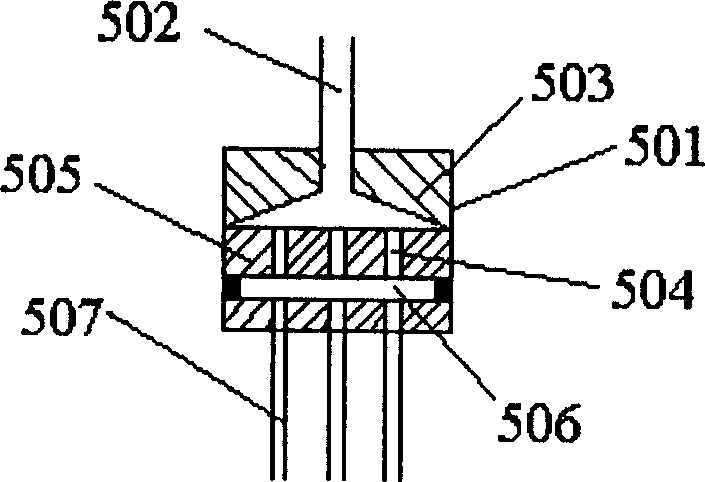

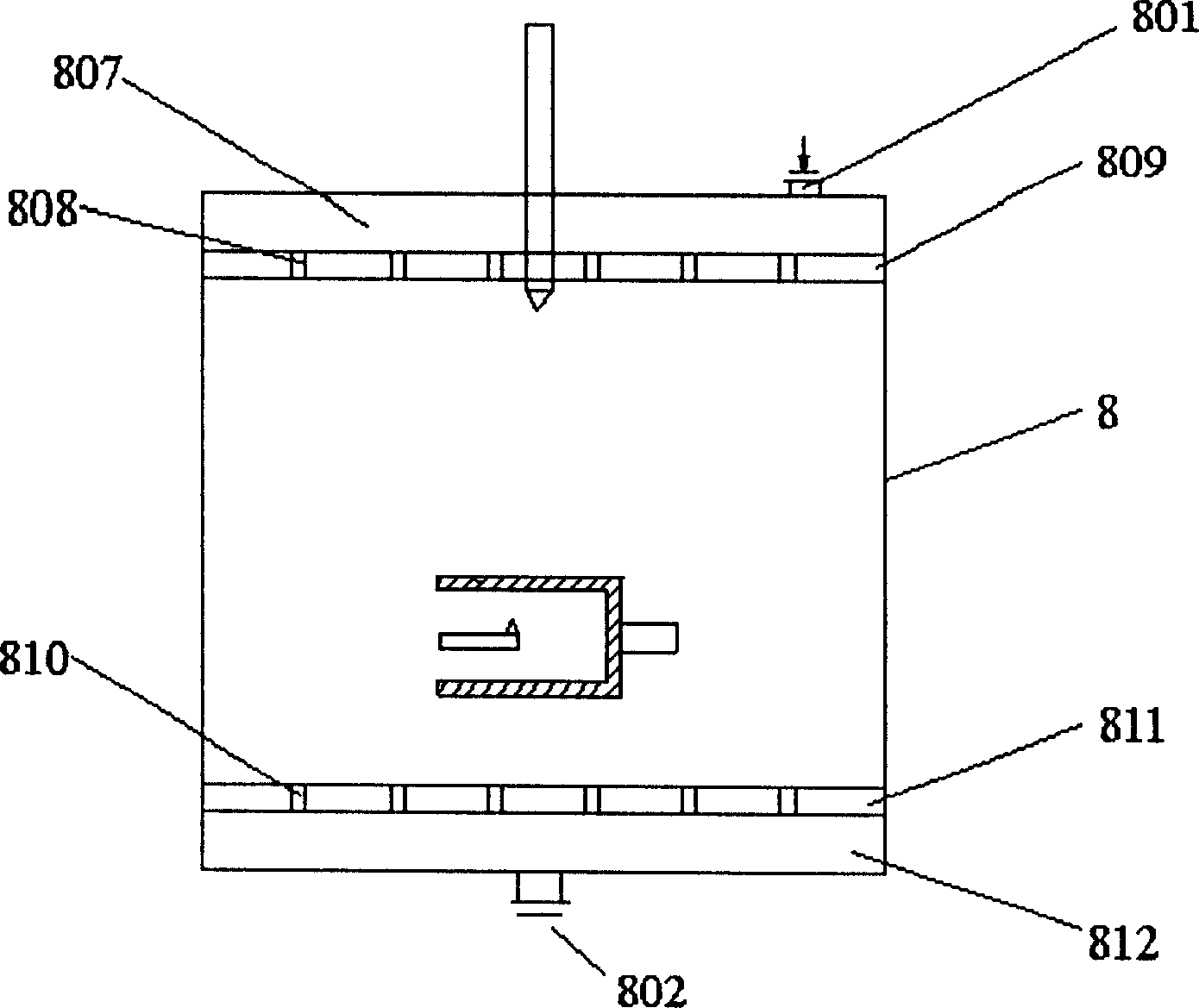

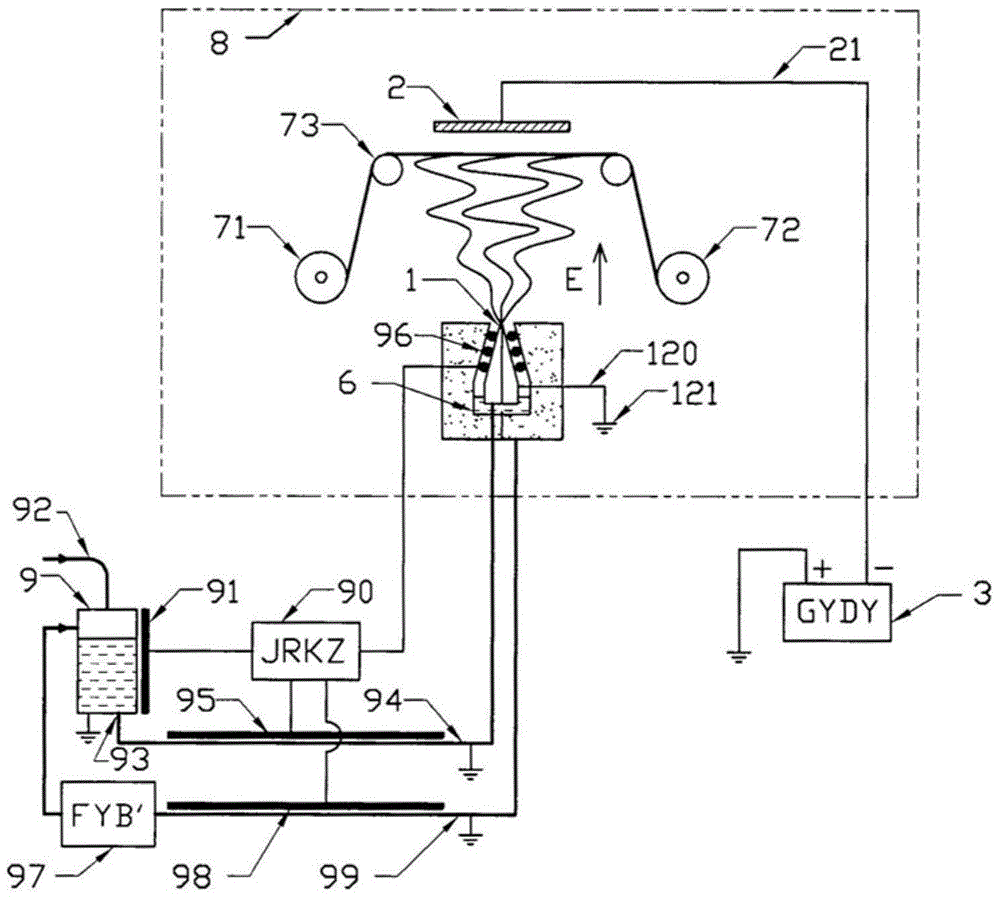

Atmosphere controllable static spinning device and industrial application thereof

InactiveCN1876902AImprove efficiencyImprove qualityMonocomponent protein artificial filamentSpinnerette packsElectrospinningSolvent

The invention discloses an atmospherecontrolled electrostatic spinning apparatus and its industry application, and the said electrostatic spinning apparatus includes statitron (1) with material chamber(3) of prograding piston (301), incubator (4), blow head (6), electrostatic spinning surgetank (8), receiver (9), high-voltage electrostatic field electrode and material dispatcher(5) installed in incubator (4). The invention improves the electrostatic spinning method and largely improves the spinning rate by adopting a plurality of spray caps, and the invention can distinctively improve the quality of the electrostatic shaped article, control the solvent volatilization speed, stabilize the environmental factor in electrostatic forming process, increase the raw material and solvent species used for electrostatic figuration and improve the electrostatic spinning deliverability. The invention extremely reduces the unit cost of the electrostatic spinning and widens the application foreground.

Owner:DONGHUA UNIV

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

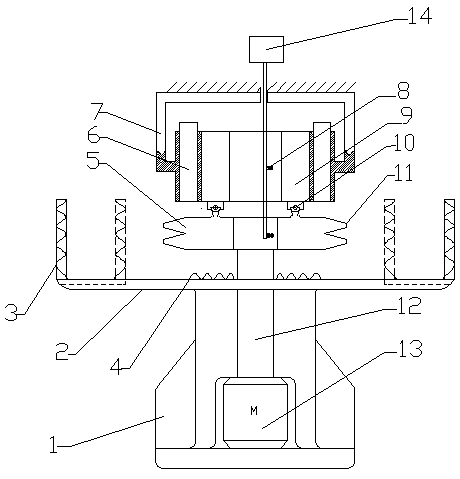

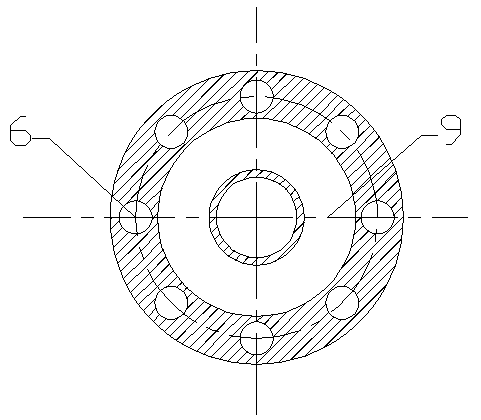

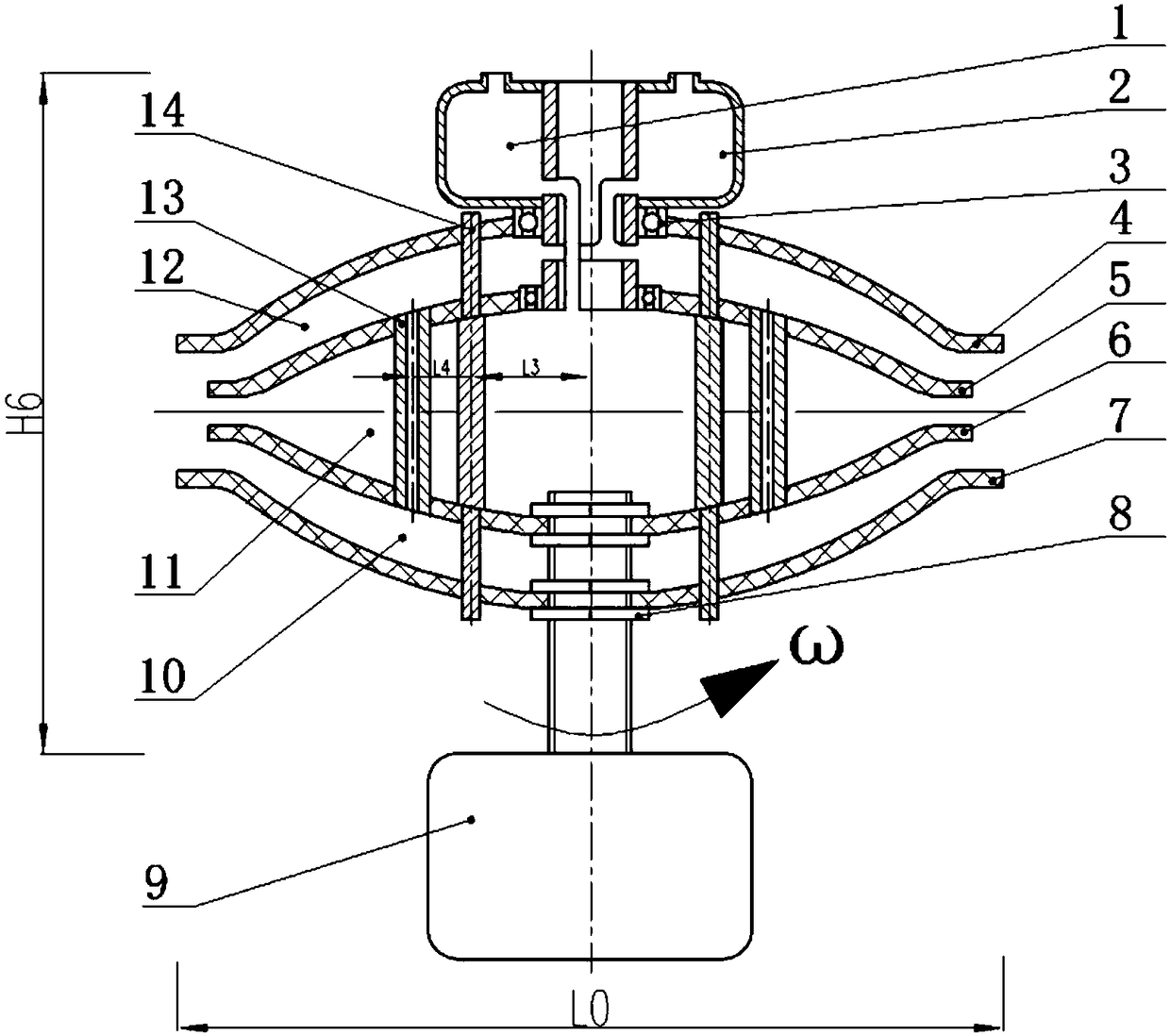

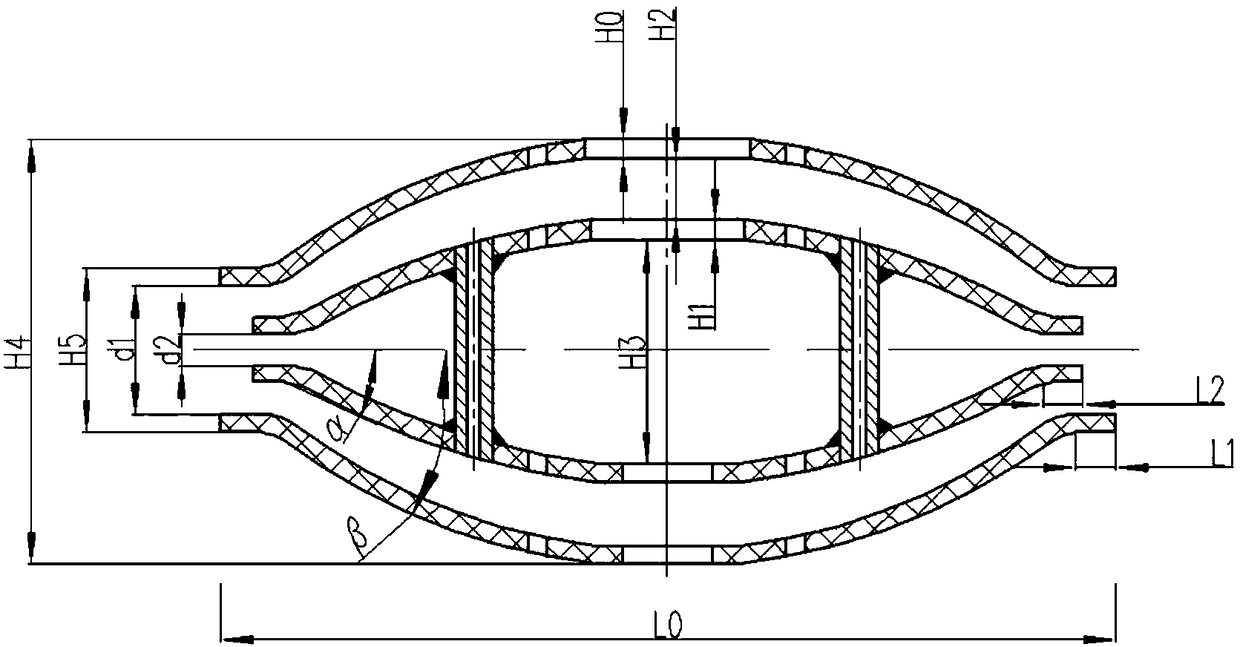

Novel centrifugal melt electrostatic spinning device

ActiveCN103215666ARealize continuous spinningRealize industrial productionFilament/thread formingFiberCollection system

The invention discloses a novel centrifugal melt electrostatic spinning device and belongs to the field of electrostatic spinning. The whole set of the device comprises a supporting and power system, a material supplying and temperature controlling system, a spinning sprayer and a collection system. The novel centrifugal melt electrostatic spinning device utilizes the common effect of high-voltage electric field force and high-speed centrifugal force, so that a nano superfine fiber is spun by using a macromolecular melt; materoals can be discontinuously added into a charging room to realize continuous spinning of the whole device; and a plurality of layers of shower nozzles not only can greatly improve the spinning efficiency, but also can obtain a fiber membrane with the certain width, being good for realizing industrial production.

Owner:BEIJING UNIV OF CHEM TECH

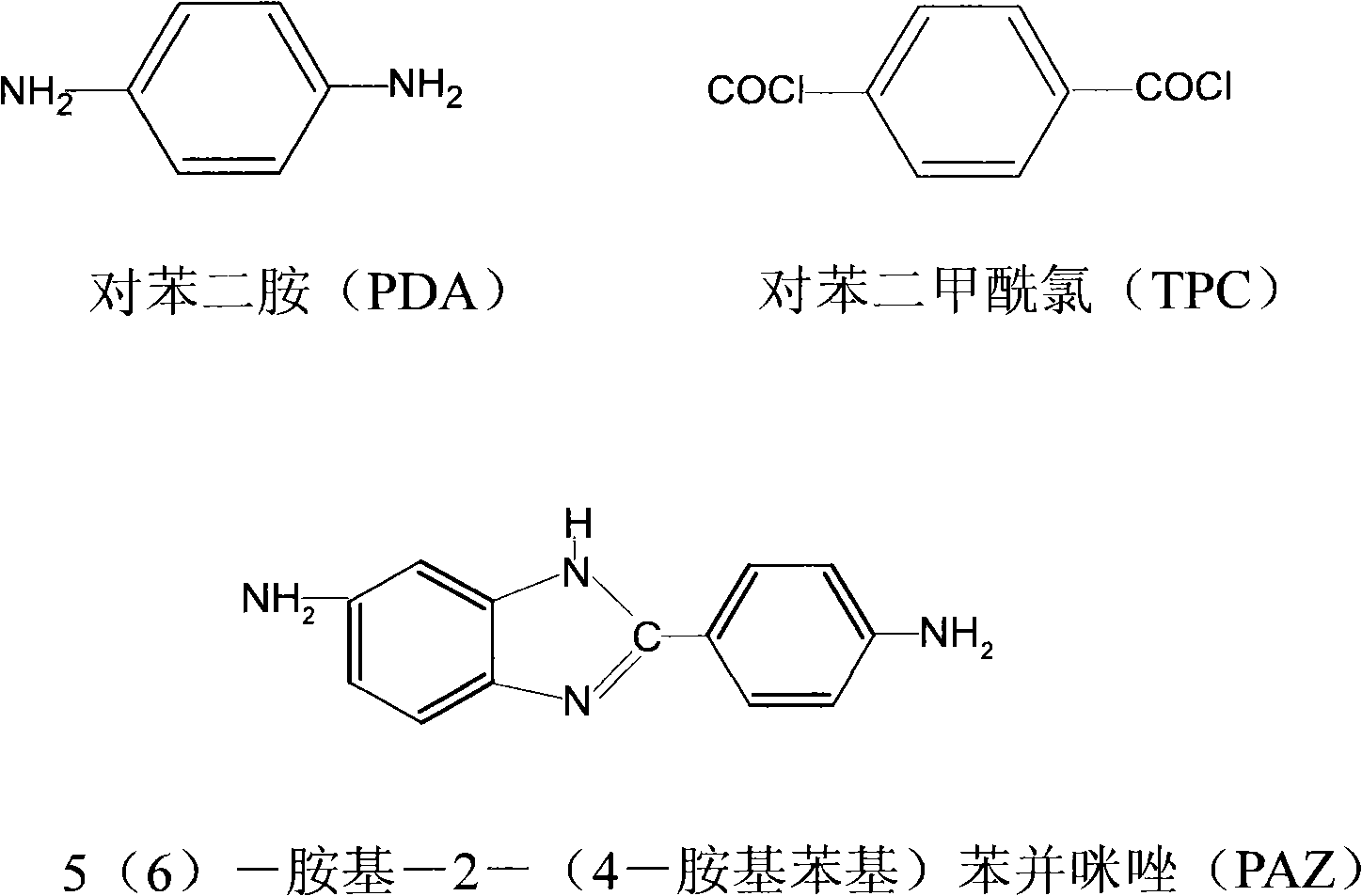

Method for preparing aramid IIII fiber

InactiveCN101851809AImprove spinning efficiencyLow investment costMonocomponent copolyamides artificial filamentDry spinning methodsYarnLithium chloride

The invention relates to a method for preparing an aramid IIII fiber, which comprises the following steps of: (1) synthesizing a spinning stock solution, carrying out low-temperature copolymerization by adopting three monomers of p-phenylenediamine, paraphthaloyl chloride and 5(6)-amido-2-(4-amidophenyl)benzimidazole as raw materials and adopting dimethylacetylamide / lithium chloride as a solvent; (2) spinning by adopting a dry method spinning process, i.e. leading the spinning stock solution obtained in the previous step to pass through a spinneret and directly enter a hot inert gas channel and evaporating and removing the solvent in the spinning stock solution by utilizing a hot inert gas to obtain cured raw yarn; and (3) carrying out water washing and heat treatment on the raw yarn and winding to obtain the aramid IIII fiber. The method has high solid content of the spinning stock solution, high spinning speed, great improvement of spinning efficiency, obvious reduction of fiber manufacturing cost, improved mechanical performance of the manufactured aramid IIII fiber and wide application prospect.

Owner:SINOSELEN HI TECH

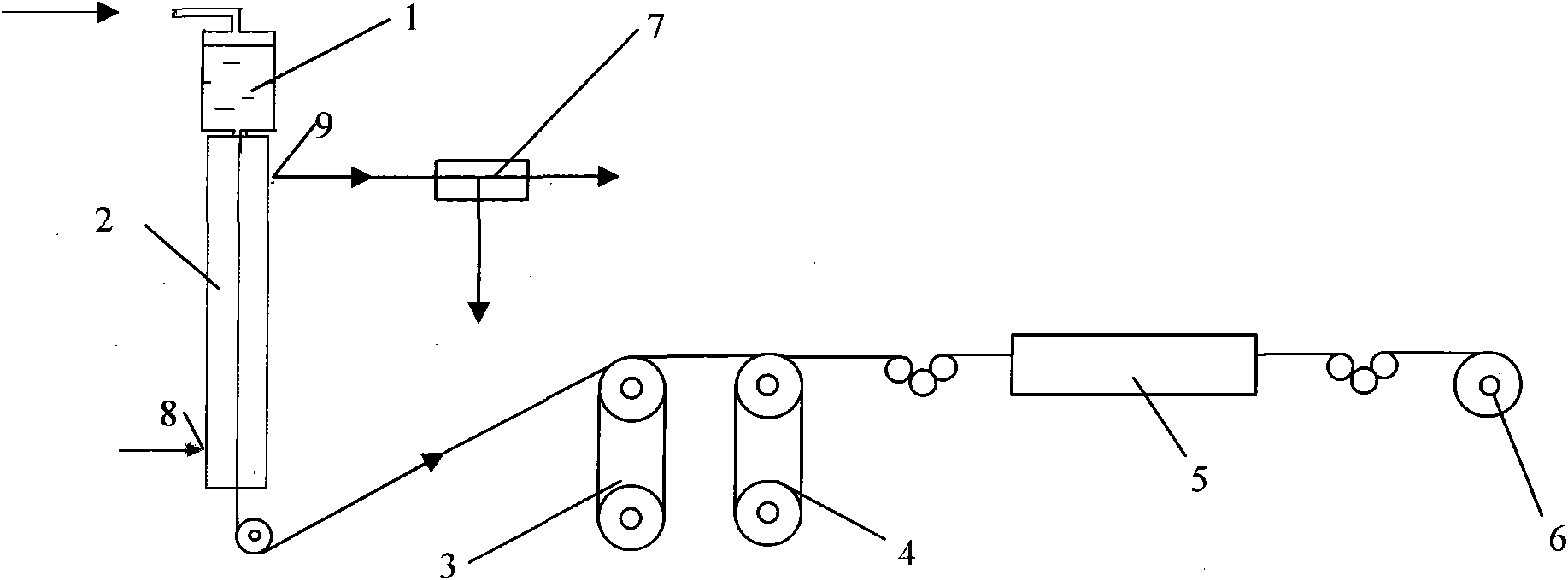

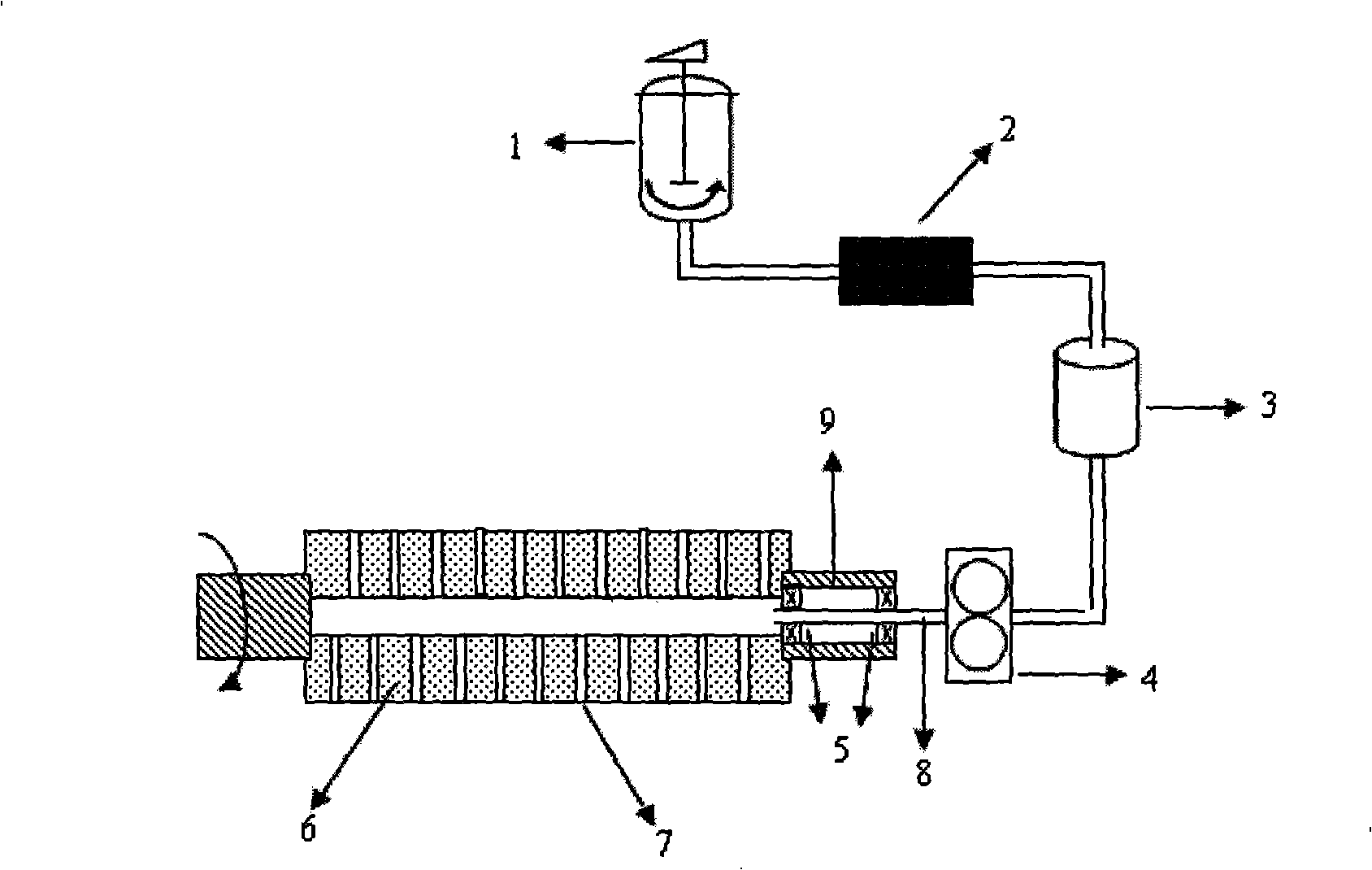

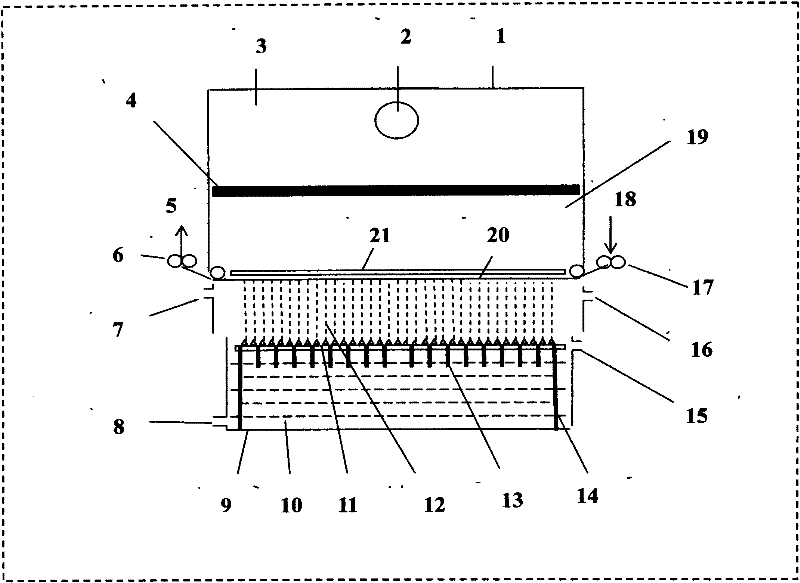

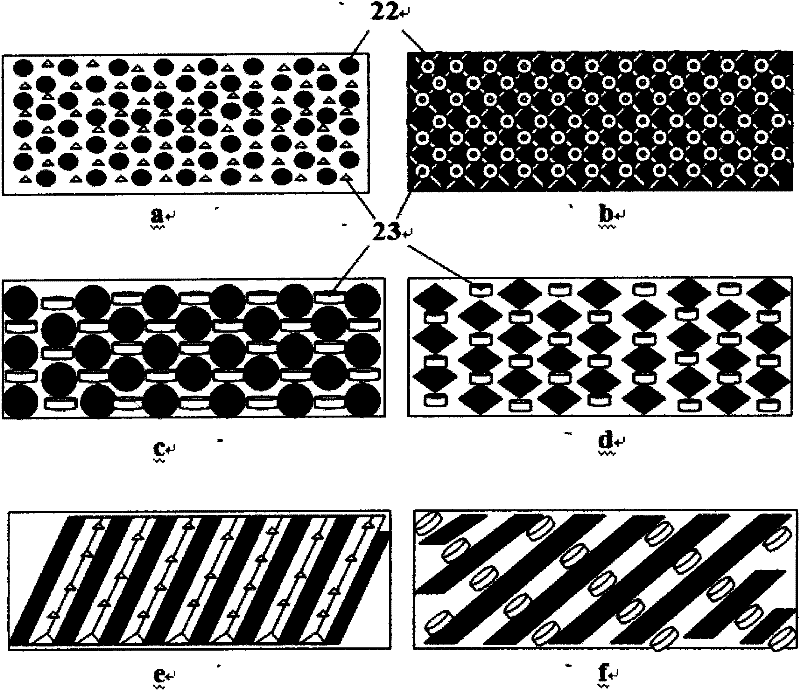

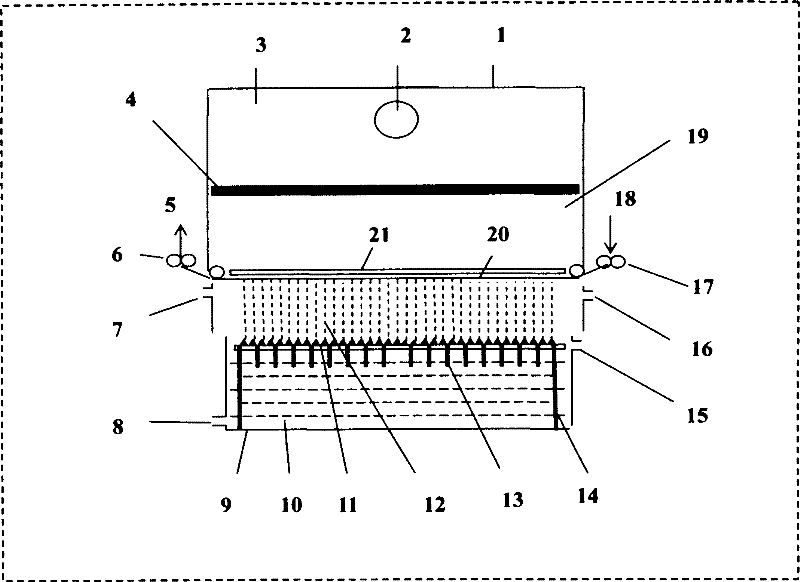

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

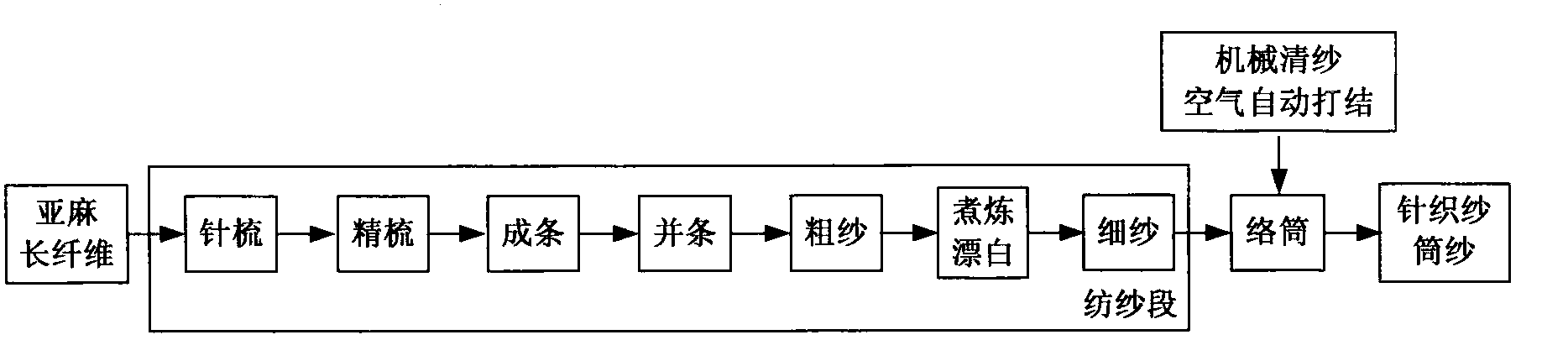

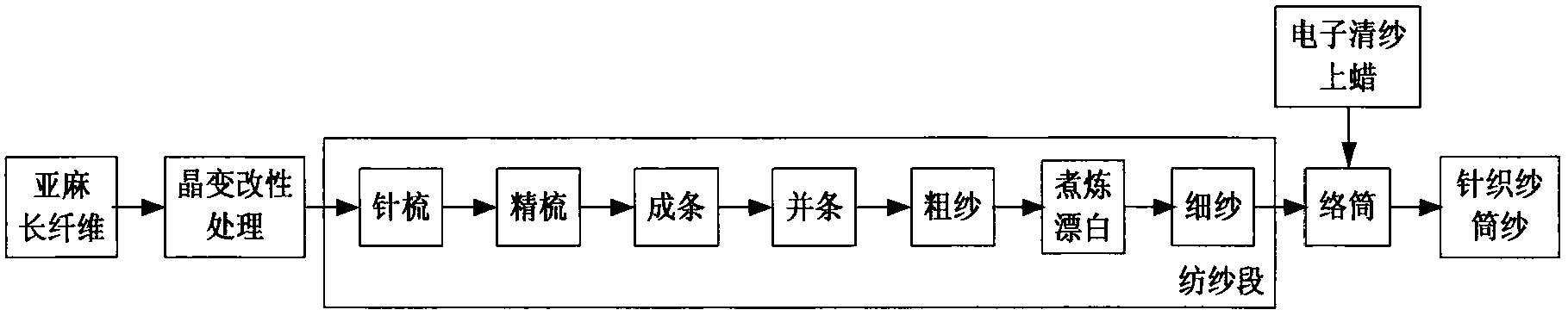

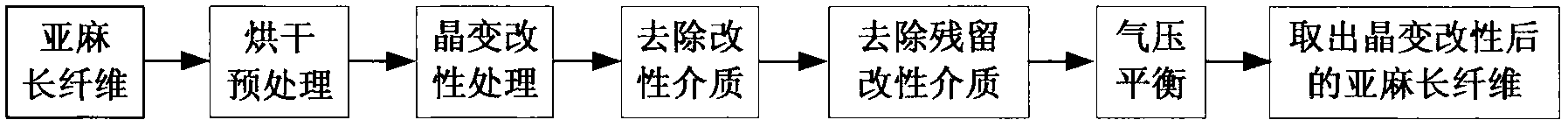

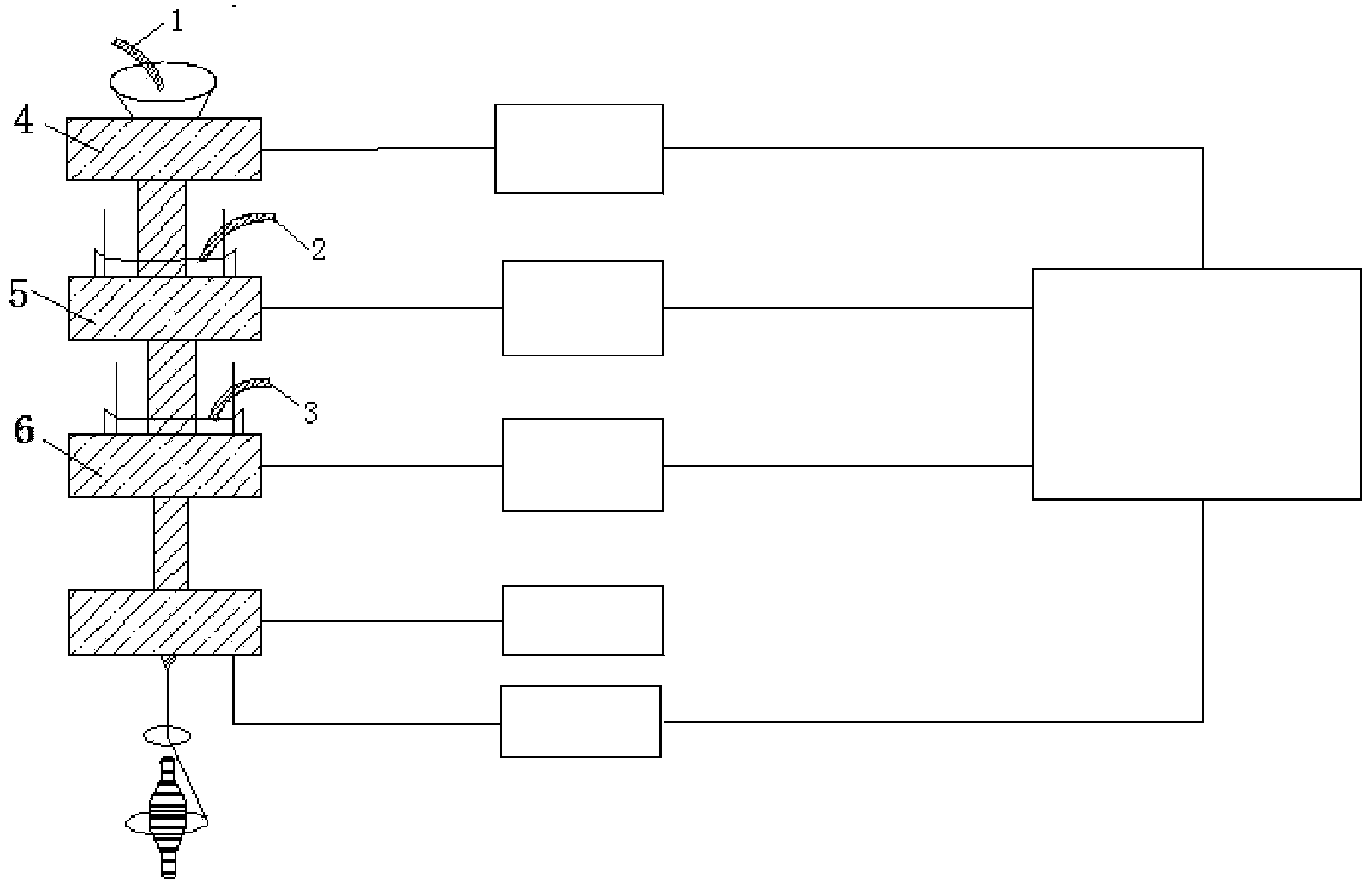

Method for spinning high-grade knitting yarns by using long flax fibers

InactiveCN102704095ASoft textureImproved drying uniformityFibre treatmentYarnYarnPulp and paper industry

The invention provides a method for spinning high-grade knitting yarns by using long flax fibers. The method comprises the steps of: carrying out crystallization modification treatment on the long flax fibers, carrying out gilling, combing, slivering, drawing, roving, boiling-off, bleaching and spinning operations sequentially, and carrying out electronic yarn clearing and waxing simultaneously in a spooling process, thereby forming the knitting yarns. According to the method provided by the invention, the crystallization modification treatment is carried out on the long flax fibers, so that the fibers are soft in texture and have an improved uniformity for dry adjustment, therefore a foundation for spinning the high-grade knitting yarns is laid; and electronic yarn clearing and waxing operations are simultaneously carried out in the spooling process owing to the facts that the fibers are soft in texture and have an improved uniformity for dry adjustment after the crystallization modification treatment is carried out on the long flax fibers, therefore the spinning efficiency is improved, and the knitting yarn quality is improved.

Owner:DONGHUA UNIV +1

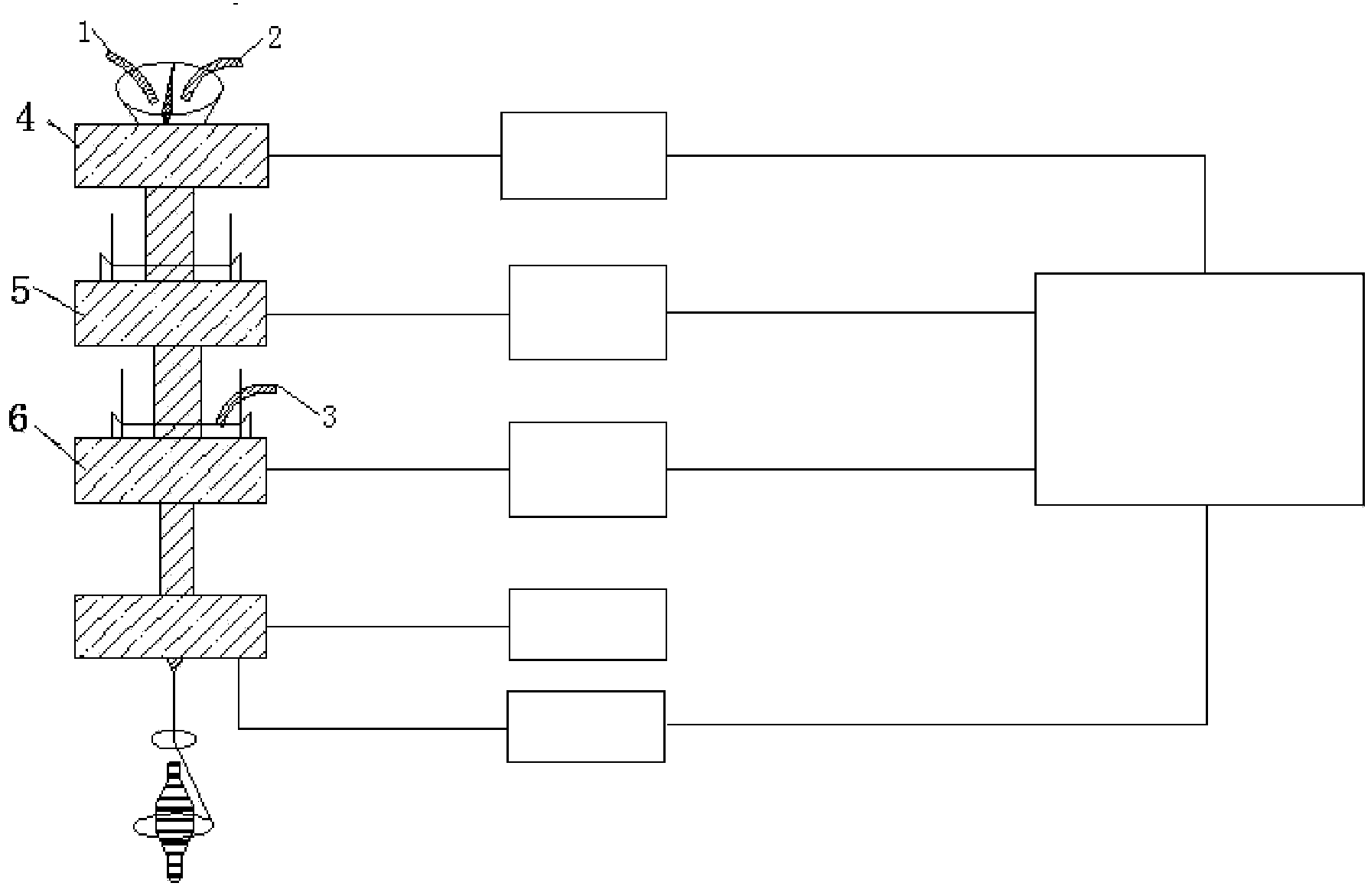

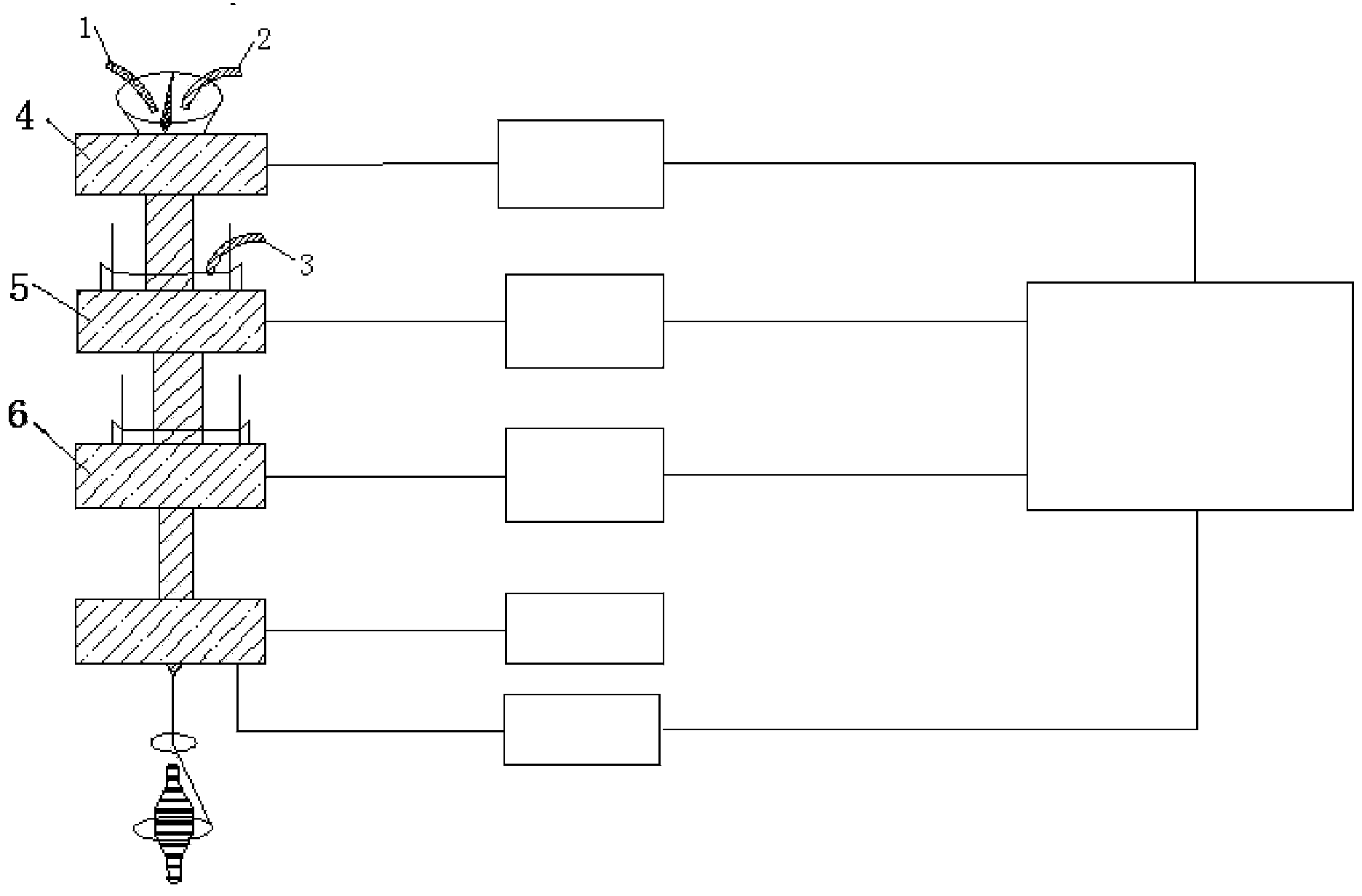

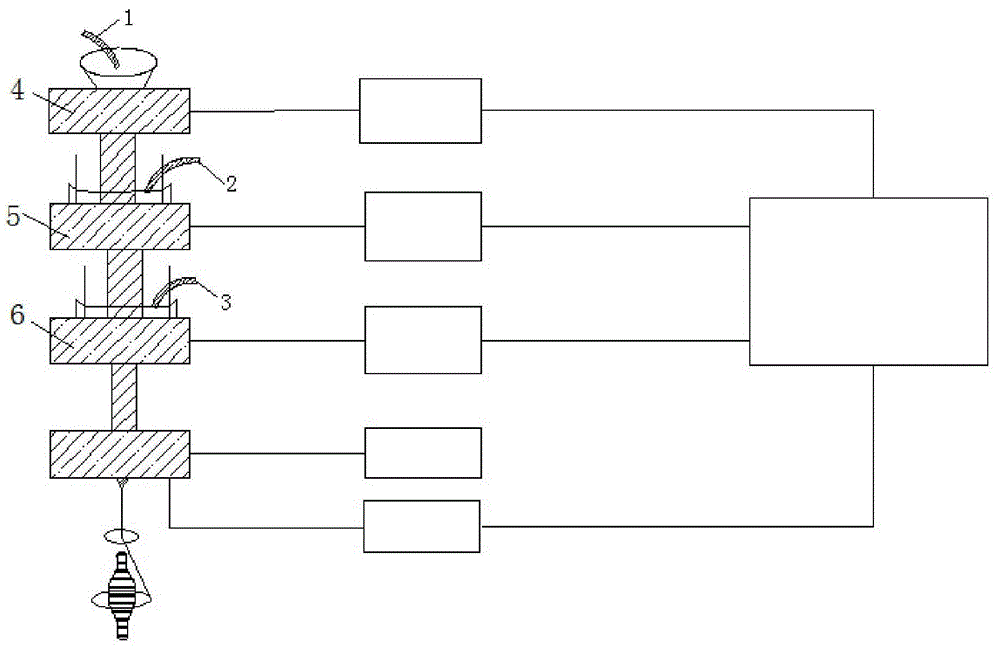

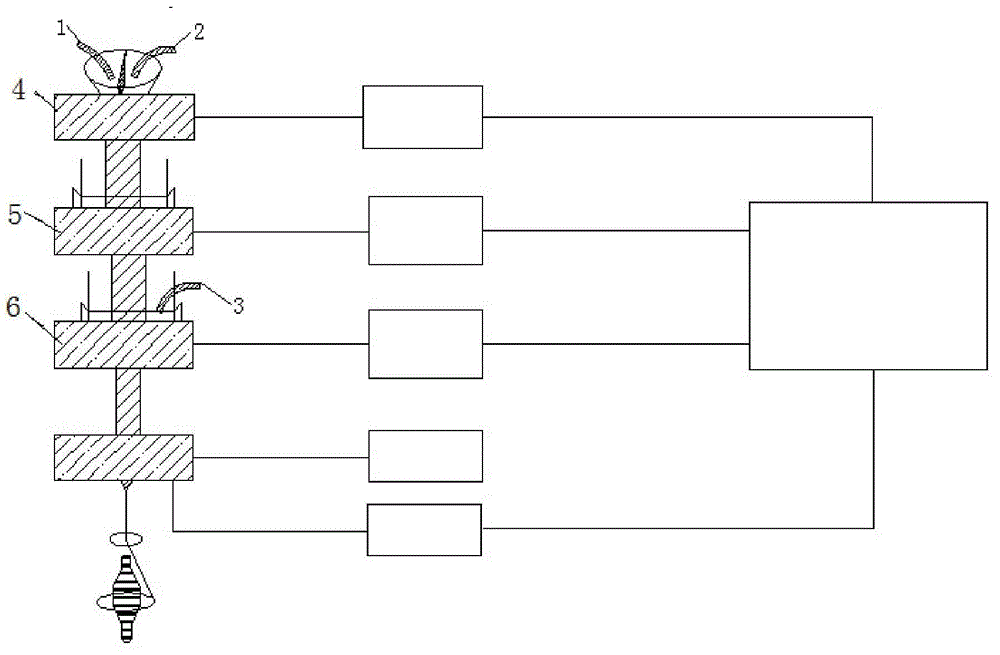

Spinning method of multi-component multi-segment color yarns

The invention discloses a spinning method of multi-component multi-segment color yarns. In the spinning procedure, three roves at least in one color and one material are simultaneously fed into a super-large drafting spinning machine which is formed by four rollers and four aprons and which operates in a three-region drafting mode. The spinning method has the advantages that according to the feeding mode of the three roves, the multi-component segmental color yarns with three different colors can be produced, the color yarns in different styles can be produced, and yarn added value is increased; in the spinning procedure, 30 to 300 times of super-large drafting can be realized through the four rollers and the four aprons in the three-region drafting mode, foundation for simultaneously feeding three roves is established, spinning efficiency is improved effectively, and meanwhile, spinning-compatibility and yarn quality of the color yarns are improved.

Owner:江苏泗水纺织有限公司

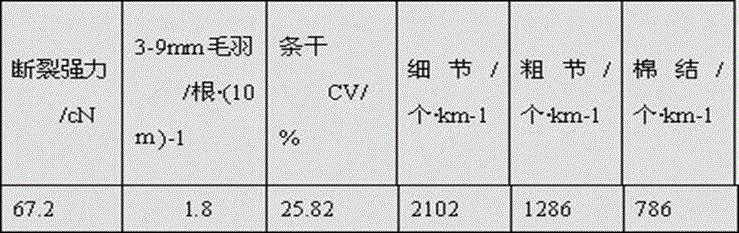

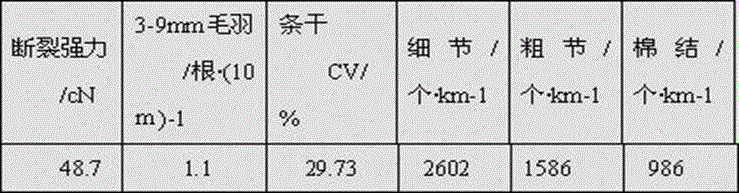

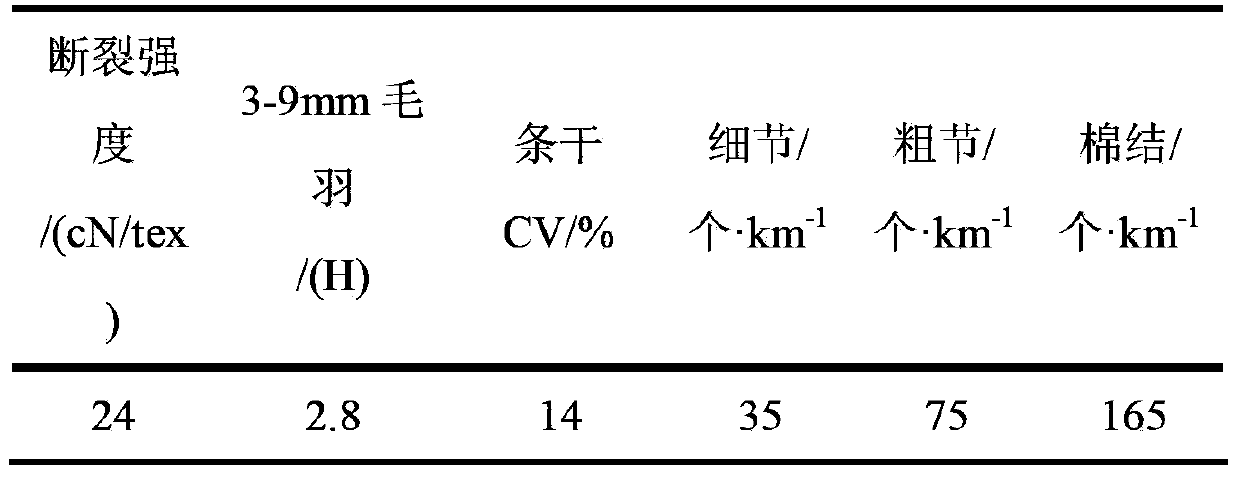

Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

ActiveCN103334190APromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

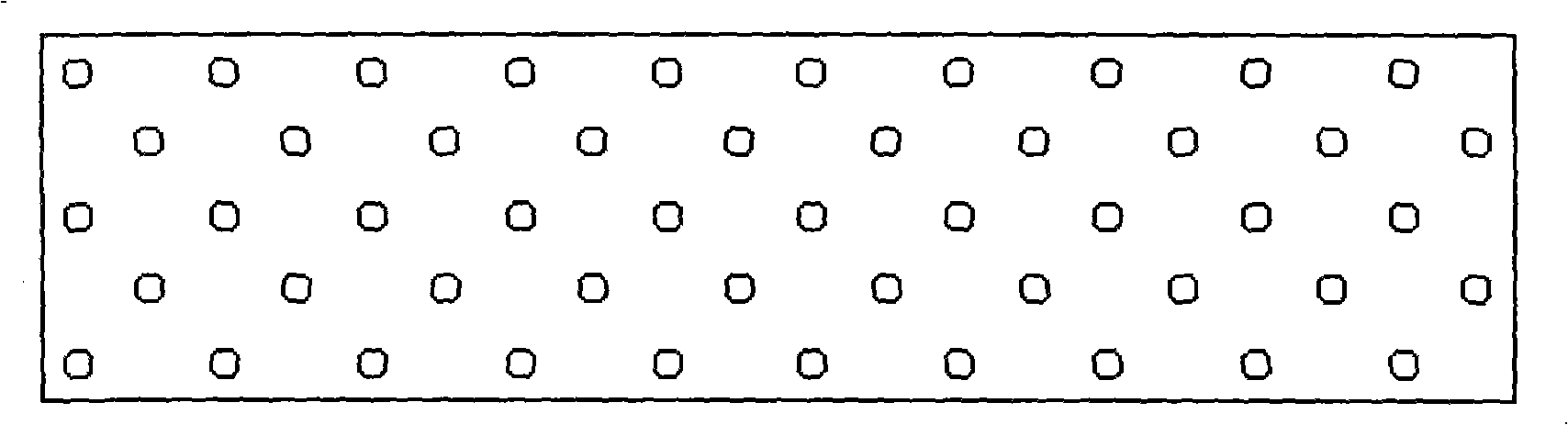

Continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes

InactiveCN102650095AImprove driftOvercoming electrostatic repulsionFilament/thread formingNon-woven fabricsElectrospun nanofiberNanofiber

The invention relates to a continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes. The method comprises the following steps: (1), electrified electrodes are kept in a vibrating state to drive polymer liquor to a plurality of protrusions on the upper surfaces of the electrified electrodes, so as to form a Taylor cone, and ensure that the whole upper surfaces become spinning surfaces, which obtains high spinning production capacity; (2), air in the space between two electrodes is sucked to the back side of a counter electrode to generate an air flow, so that stressed drift of nanofiber is accelerated, and the nanofiber is sucked to be laid on a continuous receiving screen to form a membrane; and (3) the air flow is heated dry hot air. The equipment comprises a polymer container, the vibrating electrified electrodes, the continuous receiving screen, the counter electrode and a negative pressure chamber, wherein the upper surfaces of the vibrating electrified electrodes are approximately in accordance with the liquid level; the counter electrode is made of a metal mesh or a porous metal plate; the negative pressure chamber comprises a hood, a rear air chamber, a balancing plate and an air suction pump; each vibrating electrified electrode is a metal mesh-shaped plane or a porous metal flat plate; innumerous holes and innumerous small protrusions are formed on the plane; and the small protrusions are regularly arranged and higher than the plane. The invention facilitates mass production of the electrospun nanofiber membranes.

Owner:谢维

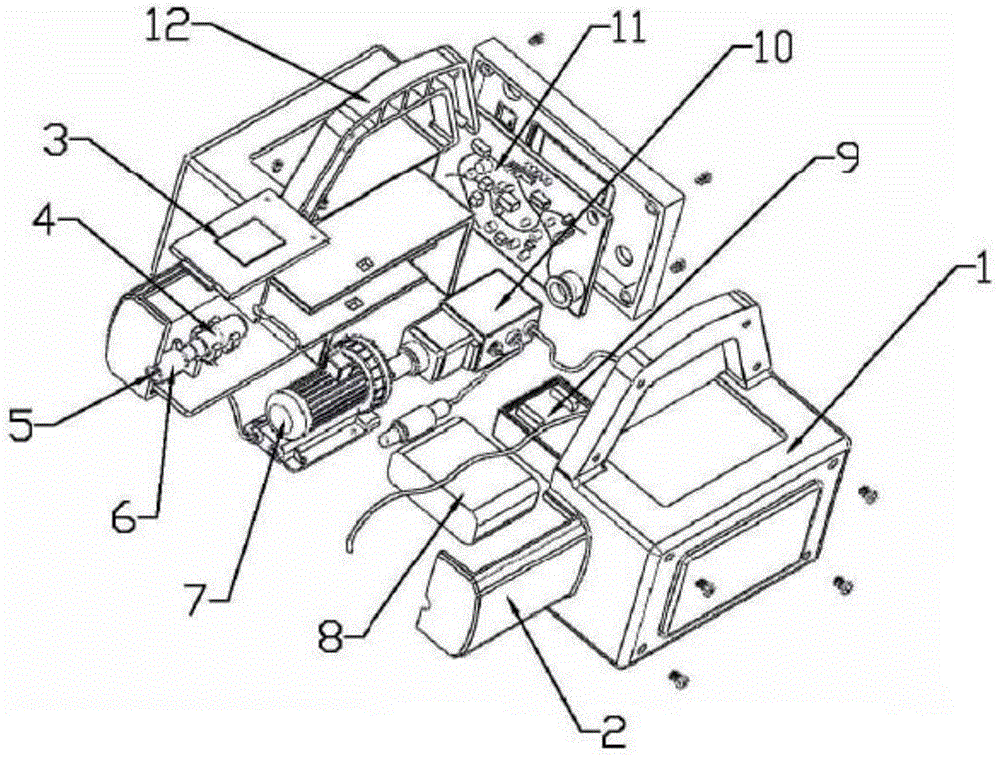

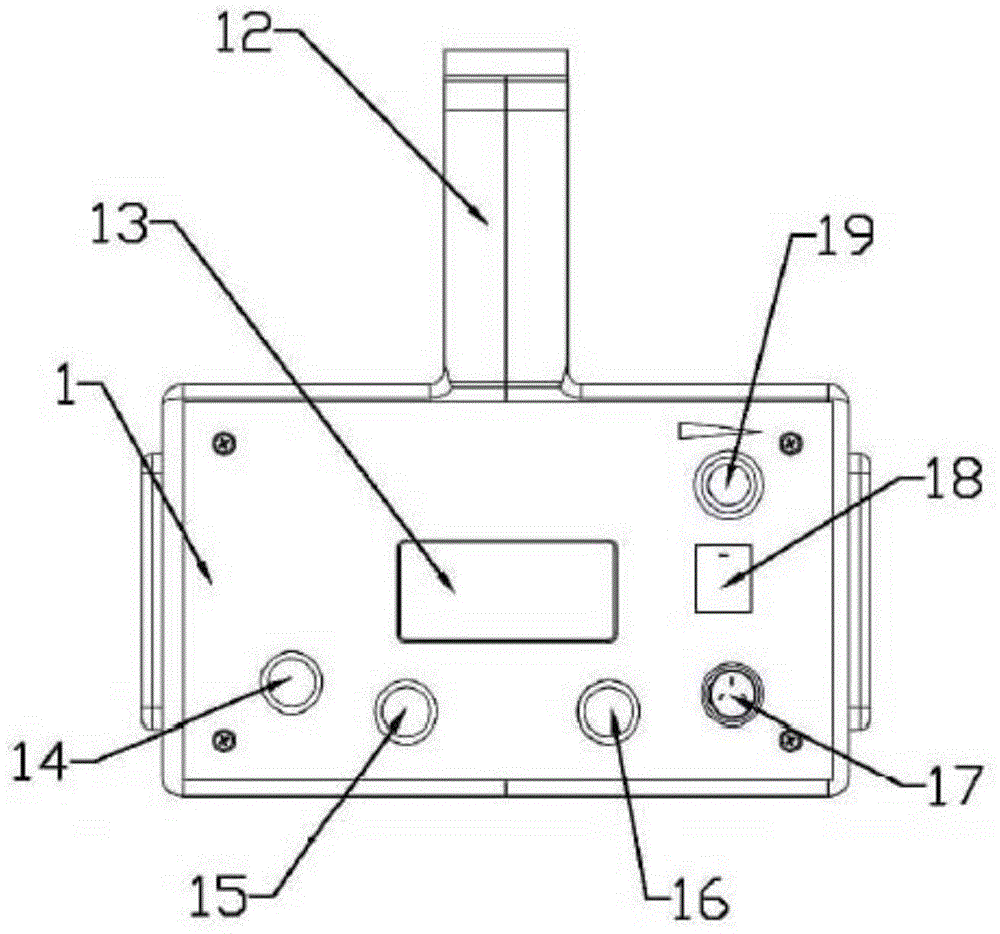

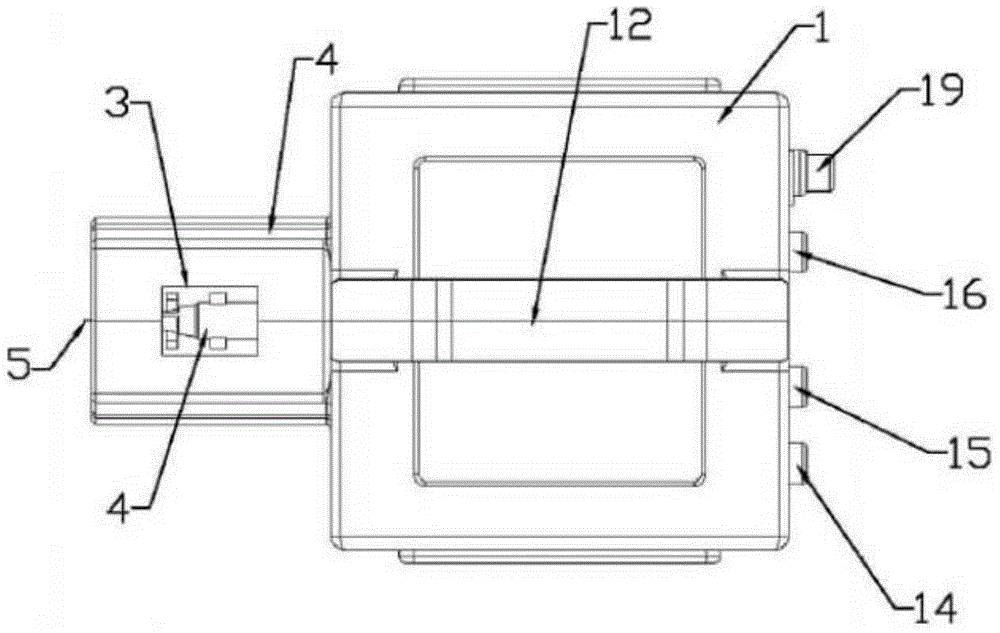

Portable electrostatic spinning equipment and using method thereof

ActiveCN104790049AAchieve directional depositionLight in massSpinning head liquid feederFilament/thread formingElectrical batteryVoltage regulation

The invention discloses portable electrostatic spinning equipment and a using method thereof. The equipment comprises a dry battery power source, a high-voltage electrostatic generator, a gas generator and a spinning ejection device. According to the equipment, a dry battery arranged in a battery bin is used as the power source, the high-voltage electrostatic generator comprises a DC-high voltage DC inverter and a voltage regulation circuit. The voltage provided by the dry battery is increased by the DC-high voltage DC inverter to be used as spinning voltage, the airflow auxiliary spinning technology is used, a spinning nozzle is sleeved with an airflow guide pipe connected with the gas generator, and the flow direction of airflow guided into the airflow guide pipe by the gas generator is the same as the spinning jet injection direction. The equipment is low in mass, small in size and convenient to carry, can be used with no external power source, is not limited by using environment, can precisely control and adjust spinning parameters, is convenient to use and wide in application range and can better achieve orientated fiber deposition.

Owner:QINGDAO KANGYUAN JULI BIOTECH CO LTD

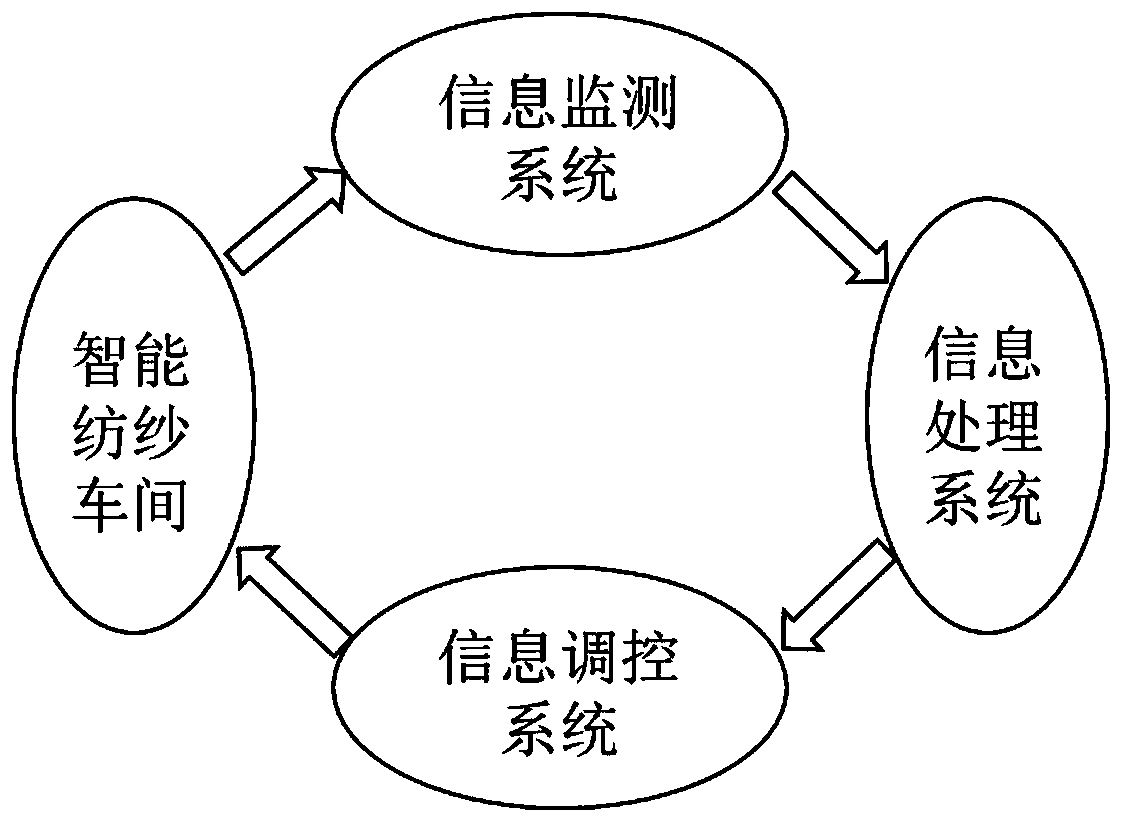

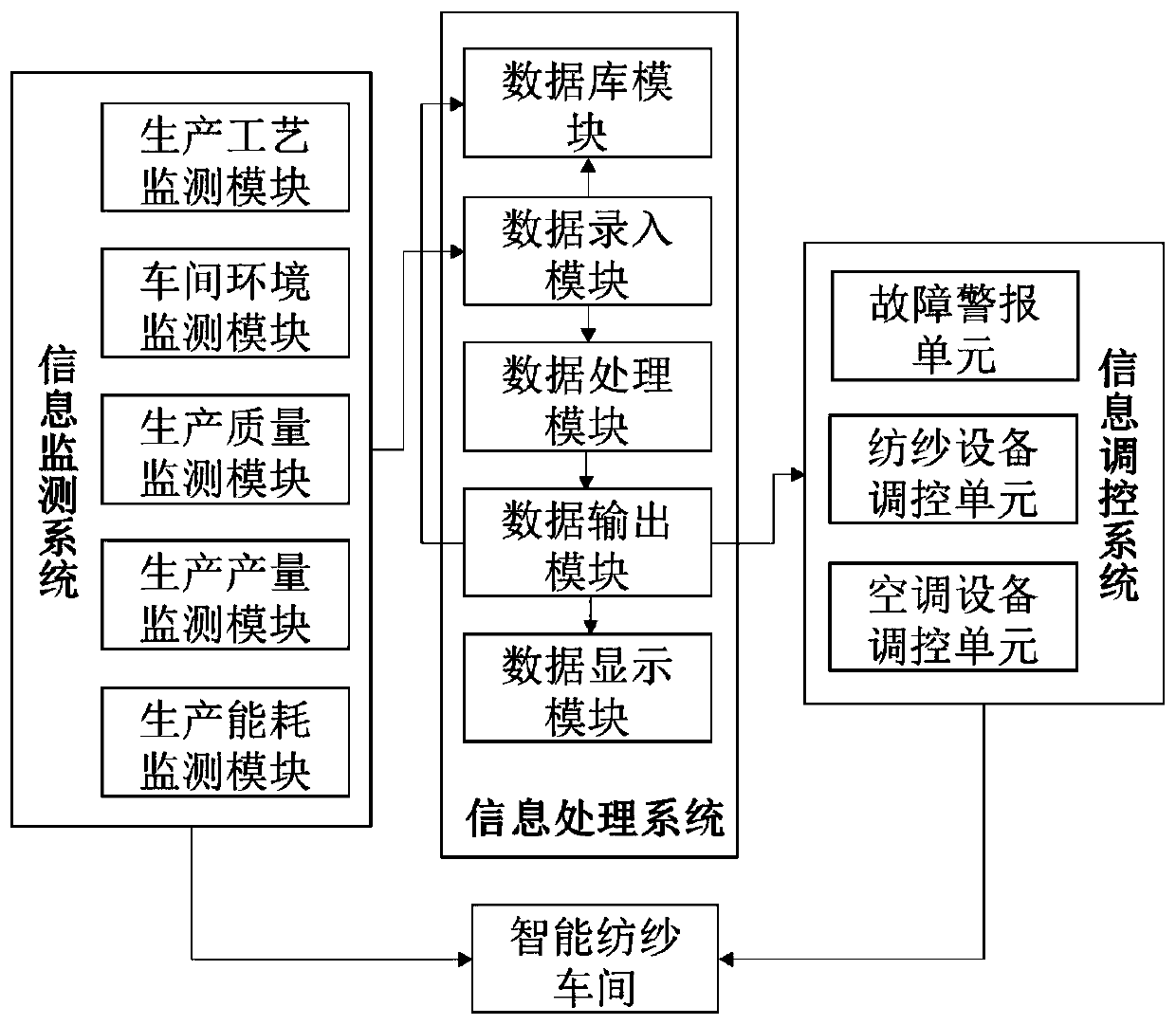

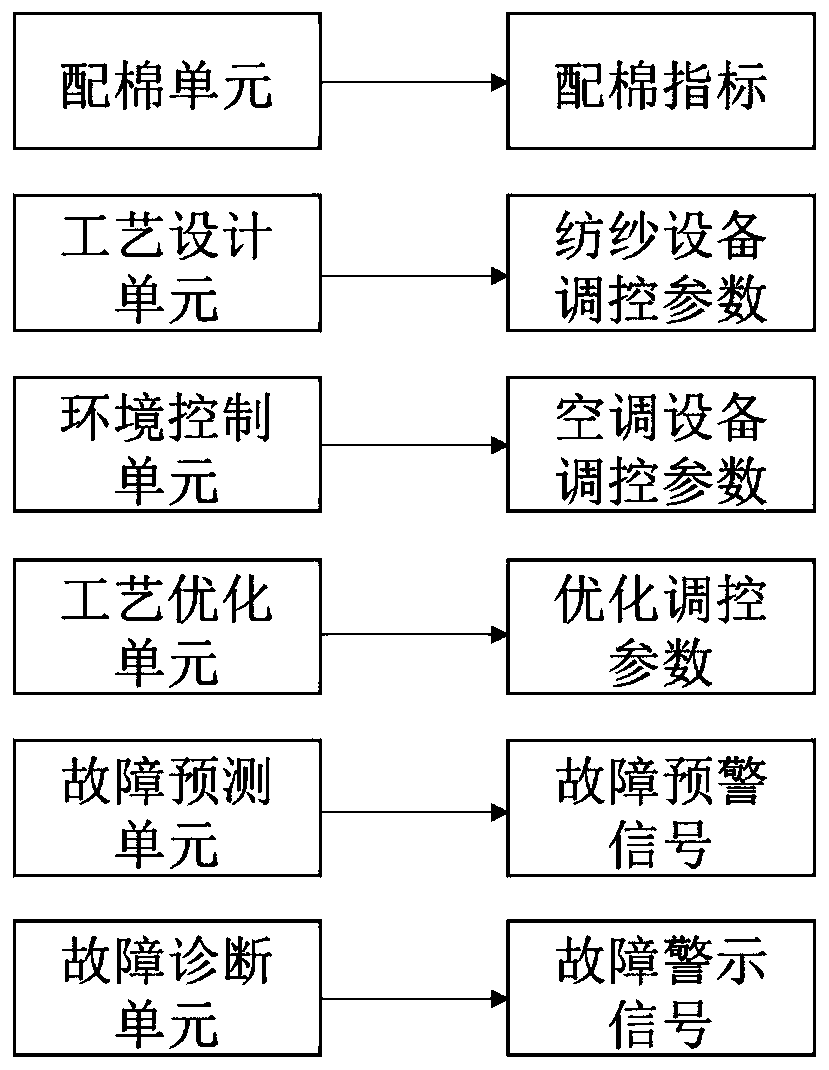

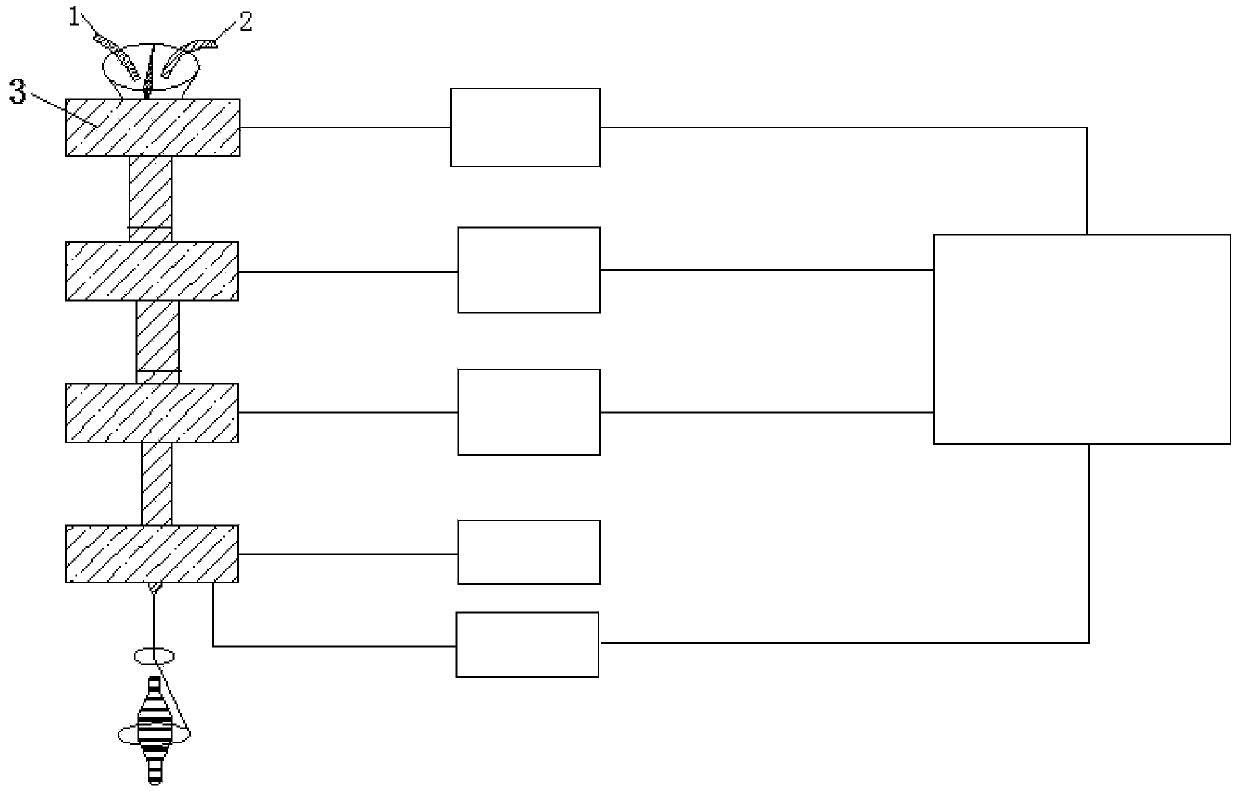

Intelligent management system for intelligent spinning workshop

ActiveCN110427004AIncrease production capacityEasy to controlTotal factory controlProgramme total factory controlInformation processingInformatization

The invention discloses an intelligent management system for an intelligent spinning workshop. The intelligent management system comprises an information monitoring system, an information processing system and an information regulation system. Data of the whole spinning workshop is monitored by the information monitoring system in real time, then data in the spinning workshop is processed by the information processing system to obtain regulation parameters of the intelligent spinning workshop, and finally, running of equipment in the intelligent spinning workshop is regulated by the information regulation system. The intelligent management system for the intelligent spinning workshop achieves automatic production and transportation control from raw materials to finished products and onlinemonitoring and control over the quality and yield of the products through an informatization network technology, a fusion sensor technology, frequency-conversion speed regulation and the like, the product quality and the production efficiency are significantly improved, the production cost is reduced, and the intelligent management system has the advantages of modernization, scientification and standardization.

Owner:武汉裕大华纺织有限公司

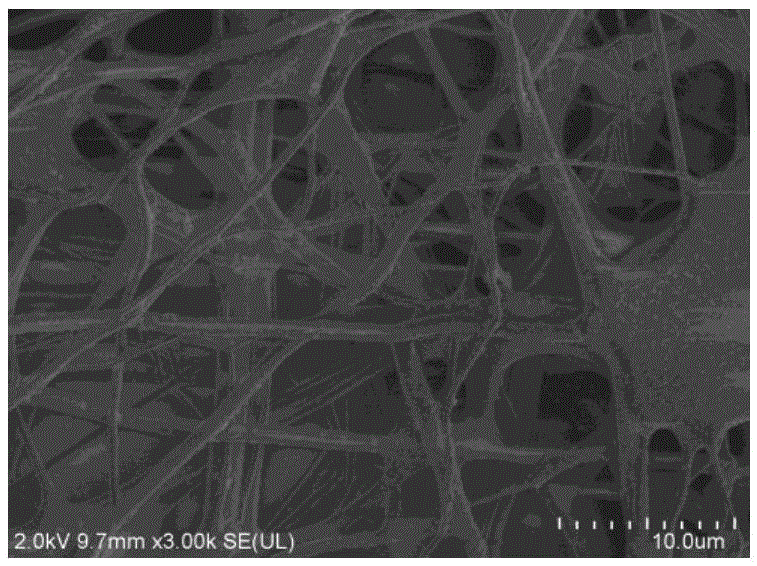

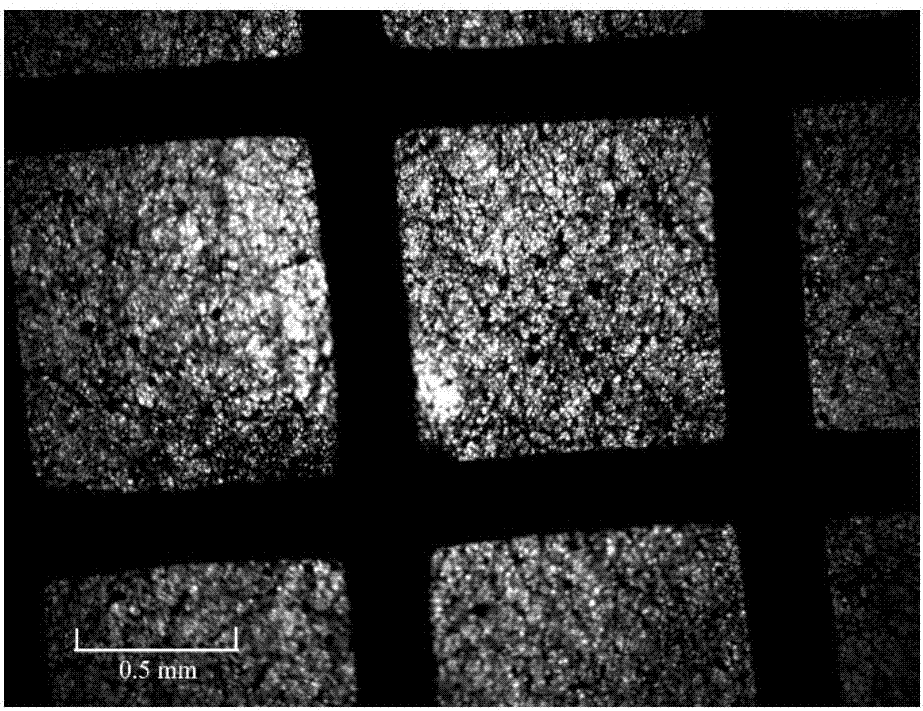

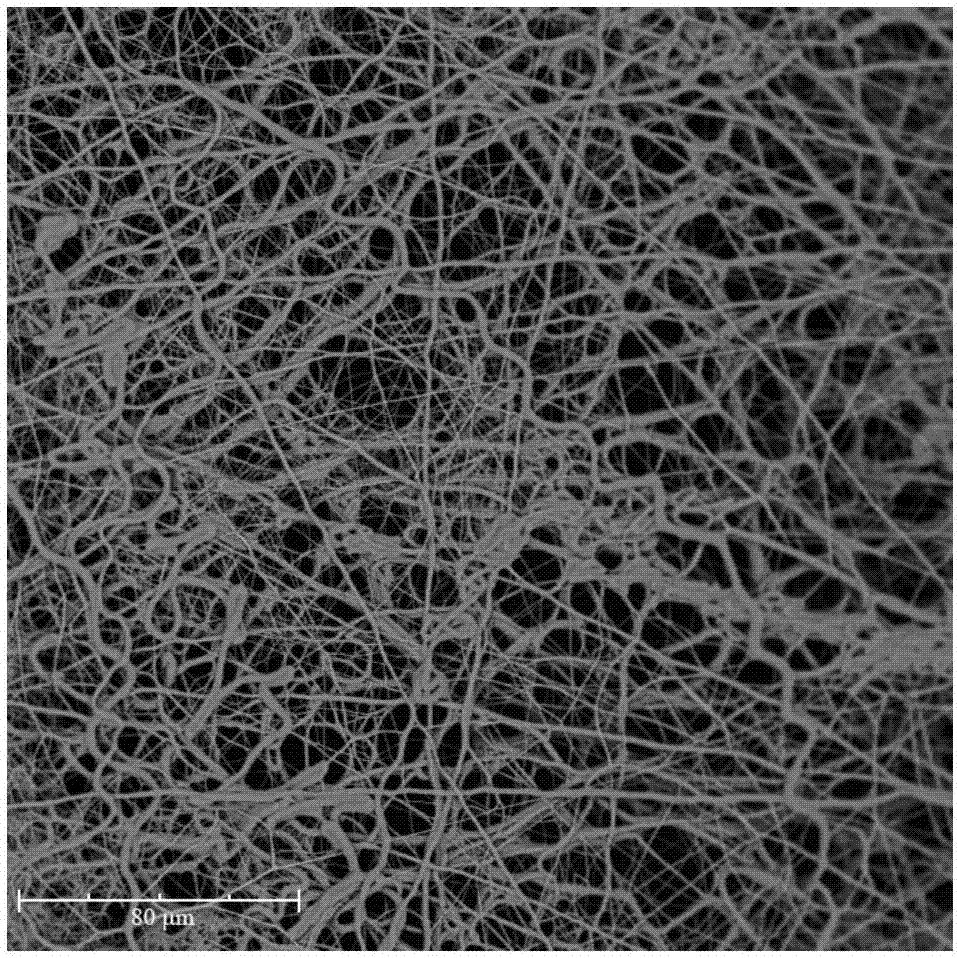

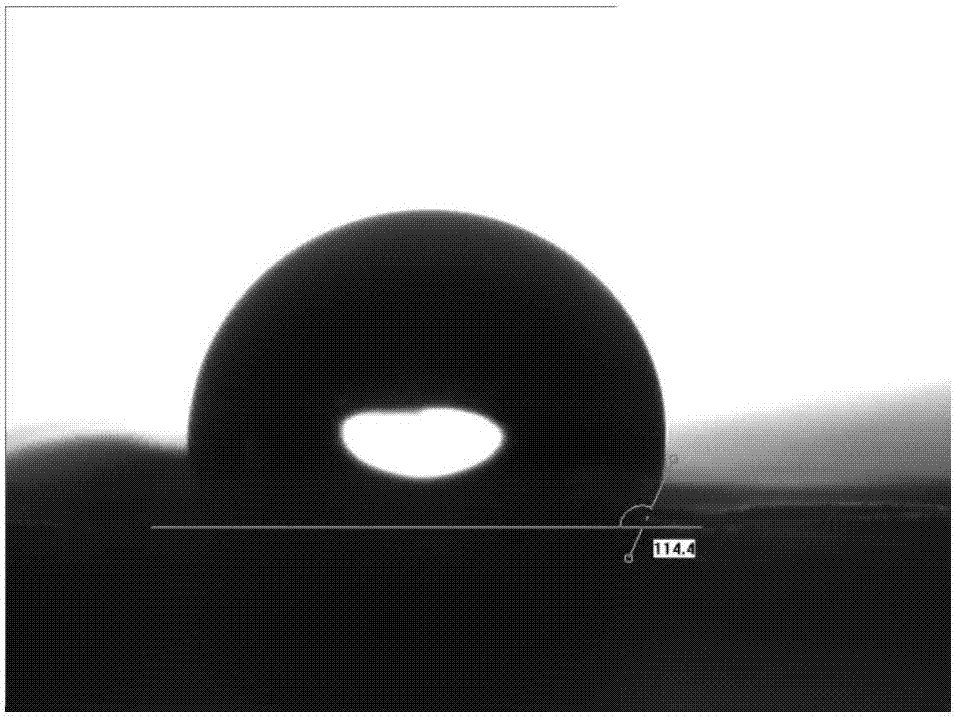

Waterproof polyvinyl alcohol nanofiber membrane and preparation method thereof

ActiveCN105648653ASimple processImprove spinning efficiencyHeating/cooling textile fabricsNon-woven fabricsSolventChemistry

The invention discloses a polyvinyl alcohol nanofiber membrane good in water resistance and a preparation method thereof. In the method, ionized water, organic acid, alcohols, polyvinyl alcohol, a crosslinking agent and a catalyst serve as main raw materials for electrostatic spinning solution; and the degree of crosslinking of the polyvinyl alcohol nanofiber membrane is improved through heat treatment after electrostatic spinning. A disclosed process is green and environmentally friendly. Compared with a conventional nanofiber filtering material, the polyvinyl alcohol nanofiber membrane is free of solvent recovery and solvent residue problems and free of toxic and side effect, and the prepared polyvinyl alcohol nanofiber membrane has excellent water resistance and can serve as a medical dressing or an air filtering material.

Owner:刘丽娟

Needleless electrostatic spinning device

ActiveCN104790048AEasy to disassembleEasy to cleanArtificial thread manufacturing machinesElectro-spinningFiberElectrospinning

The invention relates to a needless electrostatic spinning device. The needless electrostatic spinning device is composed of a spinning jet, a reception electrode, a high voltage power supply, a solution tank used for storing polymer solution, a waste fluid slot, base materials, a winding system of the base materials and the like, or the needless electrostatic spinning device is composed of the spinning jet, the reception electrode, the high voltage power supply, the solution tank used for storing polymer solution, the waste fluid slot, base materials, the winding system of the base materials, a heating device, an electric heating control device thereof and the like. The spinning jet adopts a slit-type spinning jet. The spinning jet is integrally constituted through the tight fitting of a left semi-spinning jet and a right semi-spinning jet, and the left semi-spinning jet and the right semi-spinning jet are fastened through a threaded connector, or the spinning jet is constituted by a left spinning jet component, a right spinning jet component and a flow-equalizing grid plate clamping piece arranged between the left spinning jet component and the right left spinning jet component. According to the needless electrostatic spinning device, the slit-type spinning jet is adopted, assembly, disassembly and cleaning are convenient, nano fibers can be produced continuously and effectively, and the spinning efficiency is improved greatly; the needless electrostatic spinning device can be applied both to the electrostatic spinning of the polymer solution and to the electrostatic spinning of the polymer molten mass.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

High voltage static power shuttle nano-spinning device

ActiveCN103898620AReduce intertwiningReduce generationFilament/thread formingSiphonLiquid storage tank

The invention relates to a high voltage static power shuttle nano-spinning device. The device is composed of a spinneret nozzle, a liquid storage cavity, a metal valve needle, an adjusting cap, a liquid supply tank, a multifunctional high voltage static generator, a cavitation machine, a cavitation machine deckle rod, a positive pressure power pump, a positive pressure power pipe, a siphon type feed pipe, a net structure electrode, a receiving substrate, an unwinding roller, a winding roller, nanofiber, a constant temperature system, a ventilating system, an illuminating system and an environment isolation box. A high voltage static power shuttle body is formed by the spinneret nozzle, the liquid storage cavity, the metal valve needle, the adjusting cap and a shell. A high voltage static power shuttle is jointly formed by the spinneret nozzle, the liquid storage cavity, the metal valve needle, the adjusting cap, the shell, the multifunctional high voltage static generator, a liquid storage tank, the siphon type feed pipe, the positive pressure power pipe, the cavitation machine, the cavitation machine deckle rod, an output line, the ventilating system, the illuminating system, a humidity and temperature regulator and the box. Through the establishment of the high voltage static power shuttle and the adjustment of the size of the spinneret nozzle, the static field intensity, the pressure and the frequency of the cavitation machine, the spinning speed and the diameter of the nanofiber can be adjusted, and the high voltage static power shuttle nano-spinning device has the advantages of being high in spinning efficiency, free of blocking, easy to clean, safe, reliable, easy and convenient to operate, environmentally friendly and the like.

Owner:盐城迈迪科技有限公司

Sandwich microcapsule composite antibacterial nonwoven fabric and preparation method and application thereof

ActiveCN106609421ALarge specific surface areaGo greenBiochemical fibre treatmentElectro-spinningSurface layerNanofiber

The invention belongs to the technical field of nonwoven fabrics, and discloses sandwich microcapsule composite antibacterial nonwoven fabric and a preparation method and application thereof. The sandwich microcapsule composite antibacterial nonwoven fabric comprises an intermediate layer and a first surface layer and a second surface layer which are arranged at the two sides of the intermediate layer. The composition of the intermediate layer is antibacterial microcapsules. The first surface layer and the second surface layer are nanofiber membranes prepared by electrostatic spinning. The microcapsules are prepared by using natural herbal antibacterial components, and the electrostatic spinning technology is adopted so that the disadvantages that the microcapsules are poor in stability, liable to lose and low in acting efficiency can be overcome. The prepared sandwich microcapsule composite antibacterial nonwoven fabric is green, environment-friendly and stable and has great antibacterial effect.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

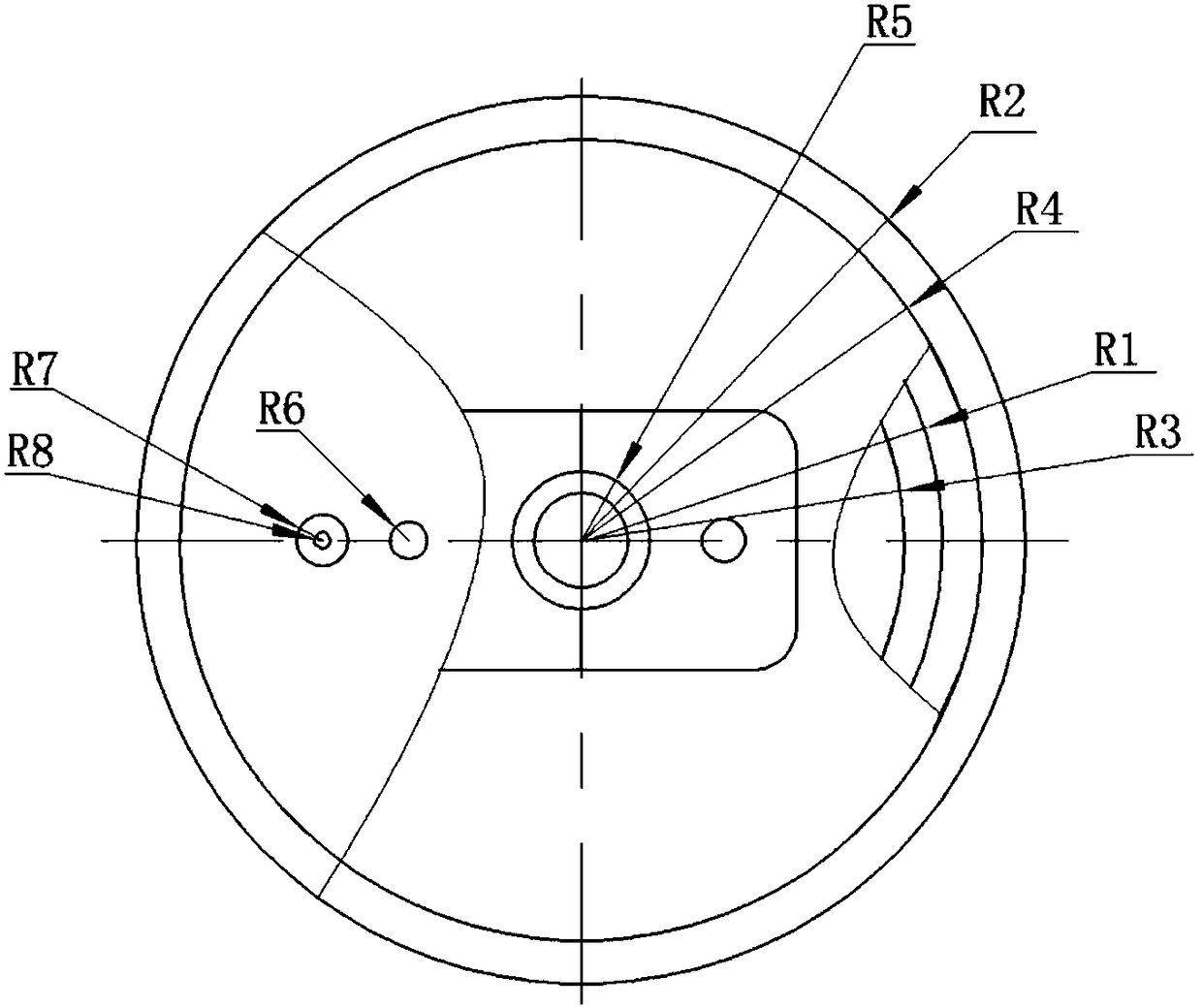

Free-surface coaxial centrifugal electrostatic spinning spinneret

ActiveCN108385175AEnables high-volume preparationSimple preparation processFilament/thread formingFiberEngineering

The invention discloses a free-surface coaxial centrifugal electrostatic spinning spinneret which comprises a first liquid inlet cavity, a second liquid inlet cavity, a first spinning cavity, a secondspinning cavity, a third spinning cavity, communication channels, a motor and connection columns. A first folding sheet and a second folding sheet are arranged at intervals to form the first spinningcavity; the second folding sheet and a third folding sheet are arranged at intervals to form the second spinning cavity; the third folding sheet and a fourth folding sheet are arranged at intervals to form the third spinning cavity; the first spinning cavity and the third spinning cavity are arranged on the upper side and the lower side of the second spinning cavity, and the communication channels are fixed onto the second folding sheet and the third folding sheet; the first folding sheet and the second folding sheet are connected with the third folding sheet and the fourth folding sheet by the connection columns. The free-surface coaxial centrifugal electrostatic spinning spinneret has the advantages that the problems of complicated influence factors of common coaxial pinhead electrostatic spinning processes, difficulty in cleaning devices, easiness in blocking spray orifices and the like can be solved by the aid of the free-surface coaxial centrifugal electrostatic spinning spinneret; the spinning efficiency and the spinning stability can be improved, and composite fiber materials with skin-core structures can be effectively prepared by the aid of the free-surface coaxial centrifugal electrostatic spinning spinneret on a large scale.

Owner:SOUTH CHINA UNIV OF TECH +1

Four-roller ultra-large drafting siro spinning AB yarns and production method thereof

The invention discloses four-roller ultra-large drafting siro spinning AB yarns, which are characterized in that A coarse yarns comprise 50% weight percent of Xinjiang long stapled cotton and 50% weight percent of cashmere fibers; and B coarse yarns comprise 55% weight percent of viscose, 20% weight percent of chinlon and 25% weight percent of bamboo fibers. A production method for the four-roller ultra-large drafting siro spinning AB yarns comprises the steps of feeding the A and B coarse yarns, processed and machined according to a ratio, into rear rollers by a dual-horn port, and obtaining the four-roller ultra-large drafting siro spinning AB yarns through four-roller three-area ultra-large drafting. The four-roller ultra-large drafting siro spinning AB yarns and the production method thereof can comprehensively utilize excellent properties of various fibers, realize the excellent comfort and antibacterial function of the blending yarns, realize the multifunctional demands of the yarns, and meet actual demands; and meanwhile, the ultra-large drafting is realized by adopting the four-roller four-leather ring three-area drafting, thus improving the spinning suitability and the finished yarn quality of the yarns.

Owner:DAFENG WANDA TEXTILE

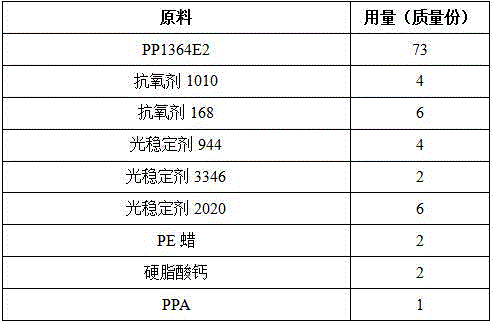

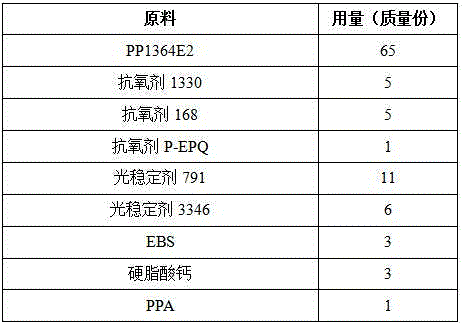

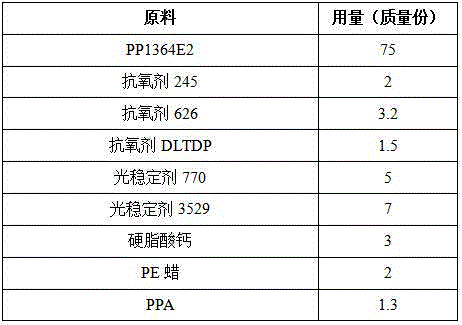

Ageing resisting master batche for spinning polypropylene material and products and preparation method for ageing resisting master batche

InactiveCN104558839AInhibition of thermal degradationEasy to processMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceSpinning

The invention discloses ageing resisting master batche for spinning polypropylene material and products and a preparation method for the ageing resisting master batche. The ageing resisting master batche is prepared from the following raw materials in parts by weight: 65-80 parts of polypropylene resin, 2-5 parts of a hindered phenol anti-oxidant, 3.5-6 parts of an auxiliary anti-oxidant, 8-17 parts of a light stabilizer, 3-6 parts of a dispersing agent, and 1-2 parts of a processing additive. The preparation method comprises the following steps: (1) mixing all the raw materials uniformly; (2) conducting melt extrusion and pelletization. The prepared ageing resisting master batche can effectively restrain the thermal degradation of polypropylene in a spinning manufacturing process, remarkably delays photooxidation aging and thermo-oxidative aging of spinning polypropylene products in outdoor using environment, remarkably prolongs the service life, and has the functions of improving the processability of resin, removing accumulation at die head and improving spinning efficiency.

Owner:广州合成材料研究院有限公司

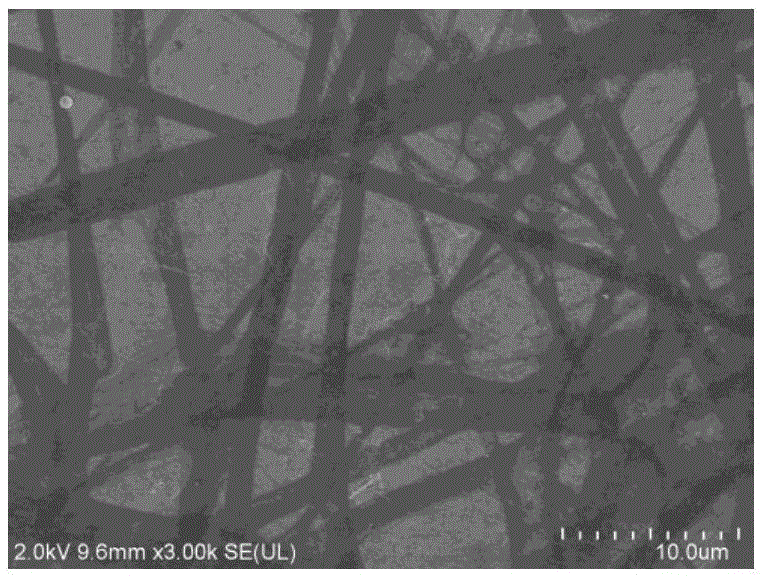

Nano filtering membrane containing silk fibroin and preparation method thereof

The invention relates to a nano filtering membrane containing silk fibroin consisting of complex fibers formed by silk fibroin and nano carbon, wherein the membrane contains 70-95wt% of silk fibroin and 3-30wt% of carbon nanospheres in unit area, the filtering membrane is 0.05-5 microns thick, has high specific area of fiber, strong adsorption effect and high strength, and is durable. The preparation method of the nano filtering membrane comprises the following steps: (1) putting silk into a sodium carbonate solution, boiling for degumming, and filtering to obtain coarse silk fibroin; (2) putting the obtained coarse silk fibroin into a calcium chloride solution for dissolution, thus obtaining an initial liquid of silk fibroin; (3) desalting the obtained initial liquid of silk fibroin to obtain a silk fibroin fluid; (4) adding carbon nanospheres into the obtained silk fibroin fluid, and performing ultrasonic dispersion uniformly to obtain a spinning solution; and (5) performing electrostatic spinning on the obtained spinning solution to obtain the nano filtering membrane.

Owner:汤氏(湖州)商业管理有限公司

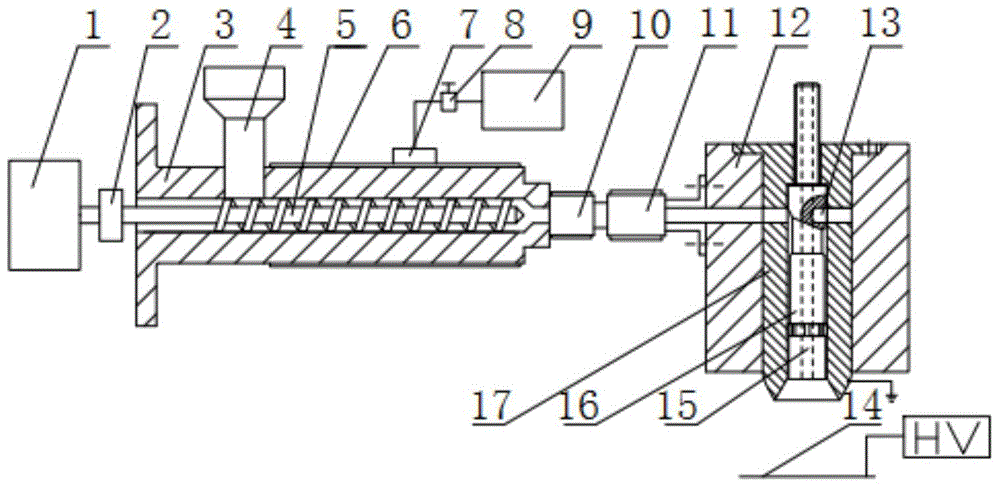

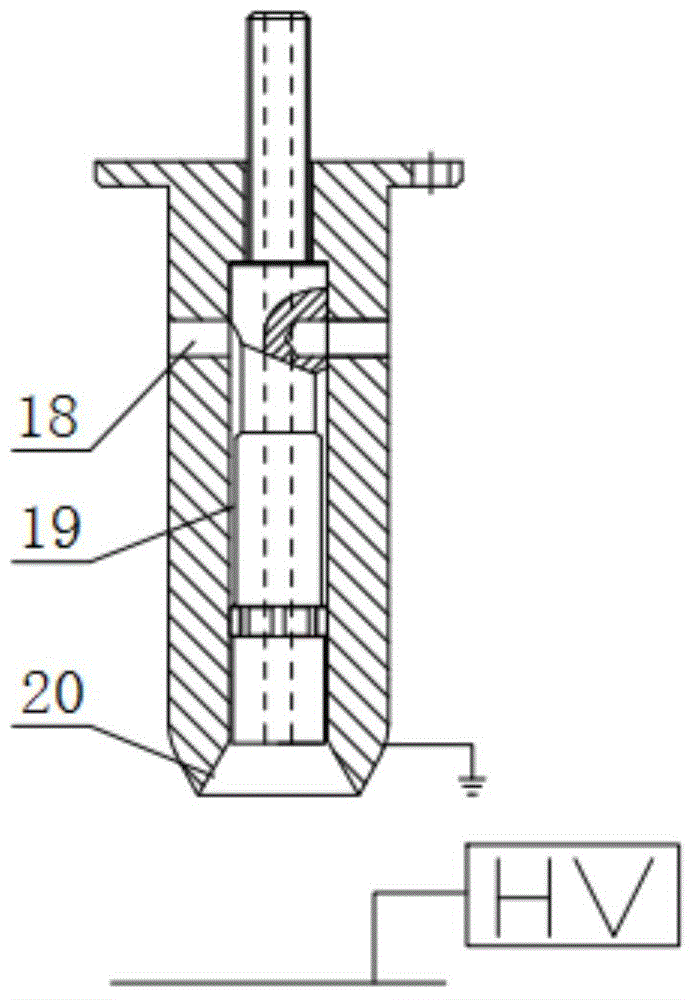

Melt electro-spinning device and technology capable of mixing supercritical gas

InactiveCN104894664AImprove uniformitySmooth feedingFilament forming substance formingArtificial thread manufacturing machinesFiberMolten state

The invention relates to a melt electro-spinning device and technology capable of mixing supercritical gas. The device comprises a power device, an extruding device, a supercritical gas generator and a melt electro-spinning device body. The technology comprises the steps that polymer is firstly added into a charging barrel, heated to a melt state, and mixed with supercritical gas conveyed by the supercritical gas generator; the mixture is conveyed to a static mixer, and the polymer and the supercritical gas form a gas / polymer homogeneous system through the static mixer; the mixture is fed to the melt electro-spinning device body, the polymer is blown, pulled and thinned under the action of high-speed hot gas flow input in an electric field between a spray nozzle and a receiving device and a gas flow channel, and finally the mixture is deposited on the receiving device to obtain fibers. According to the melt electro-spinning device and technology capable of mixing supercritical gas, the extruding device and the melt electro-spinning device body are combined, and therefore nanofibers with good uniformity can be prepared continuously and stably.

Owner:NINGBO GMF TECH

A spinning method of multi-component multi-color segment colored yarn

The invention discloses a spinning method of multi-component multi-segment color yarns. In the spinning procedure, three roves at least in one color and one material are simultaneously fed into a super-large drafting spinning machine which is formed by four rollers and four aprons and which operates in a three-region drafting mode. The spinning method has the advantages that according to the feeding mode of the three roves, the multi-component segmental color yarns with three different colors can be produced, the color yarns in different styles can be produced, and yarn added value is increased; in the spinning procedure, 30 to 300 times of super-large drafting can be realized through the four rollers and the four aprons in the three-region drafting mode, foundation for simultaneously feeding three roves is established, spinning efficiency is improved effectively, and meanwhile, spinning-compatibility and yarn quality of the color yarns are improved.

Owner:江苏泗水纺织有限公司

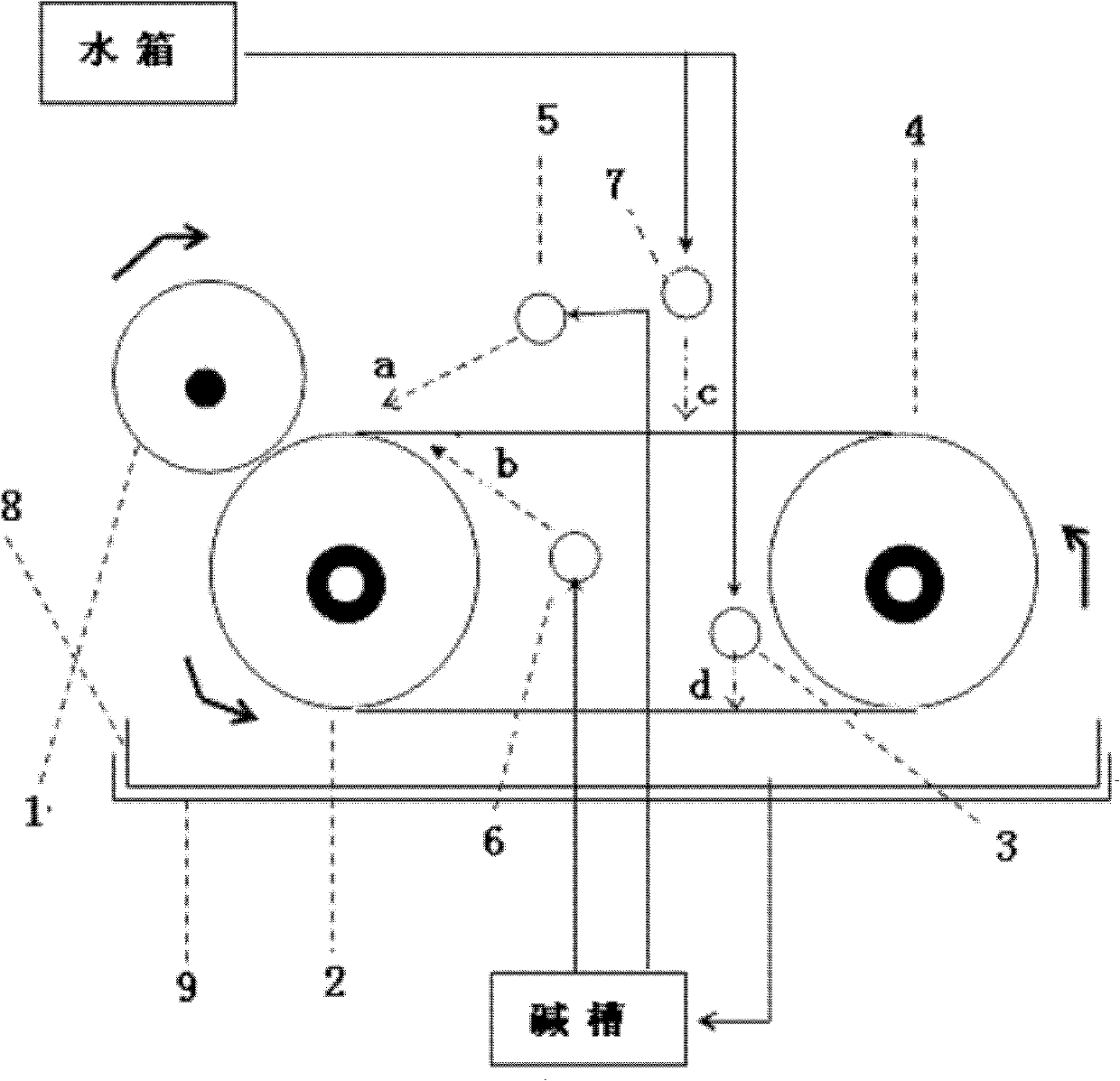

Cotton sliver mercerizing process and mercerizing device utilizing same

InactiveCN102704225AImprove spinning efficiencyHigh glossMercerising of yarns/threads/filamentsMercerising of sliversComposite materialPolymer chemistry

Disclosed are a cotton sliver mercerizing process and a mercerizing device utilizing the same, which belong to the technical field of textile technology. The cotton sliver mercerizing process includes: a, cotton sliver pretreatment step including dewing cotton slivers and dewatering the same or squeezing water out of the same to form wet cotton slivers with certain liquid content; b, a cotton sliver reeling step including reeling the wet cotton slivers on a reeling machine and fixing the cotton slivers by lay bands; c, a covering step including wrapping the reeled cotton slivers with the wrapping cloth integrally; and d, a mercerizing step realized by concentrated spraying and instant squeezing. The sliver cottons are mercerized effectively by dewing to reinforce and by means of concentrated spraying and instant squeezing, and alkali content of the cotton slivers is controlled all the time, so that the cotton slivers cannot be dissolved due to excessive swelling, and the difficult problem of failure in mercerizing the cotton slivers without twist is solved. In addition, the mercerized cotton slivers are bright, smooth and fluffy, and dye color yield is increased by 20%-30%.

Owner:WUXI NON SIZING TECH

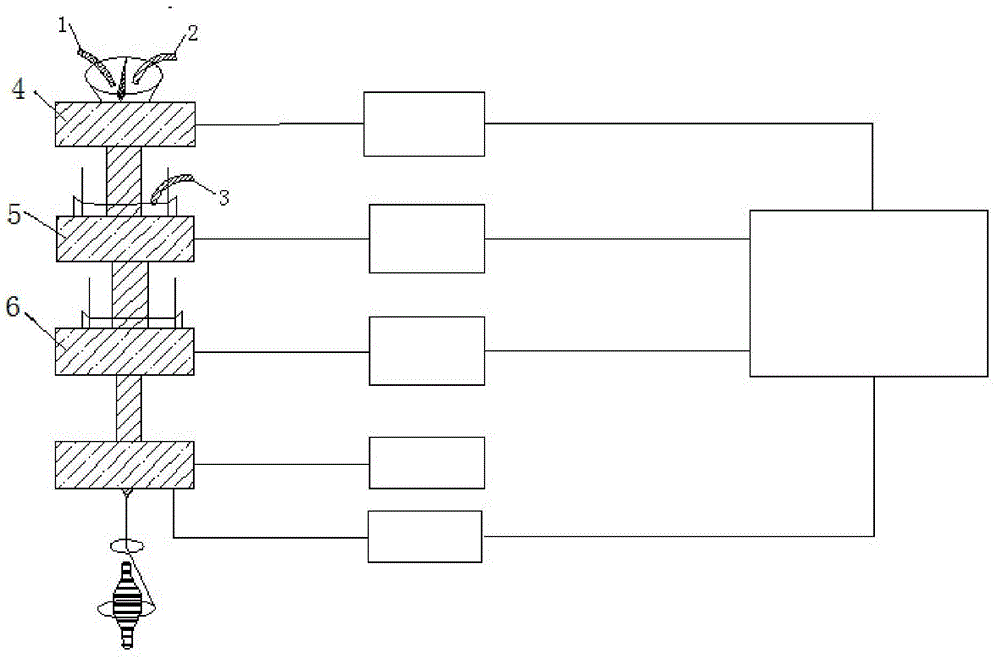

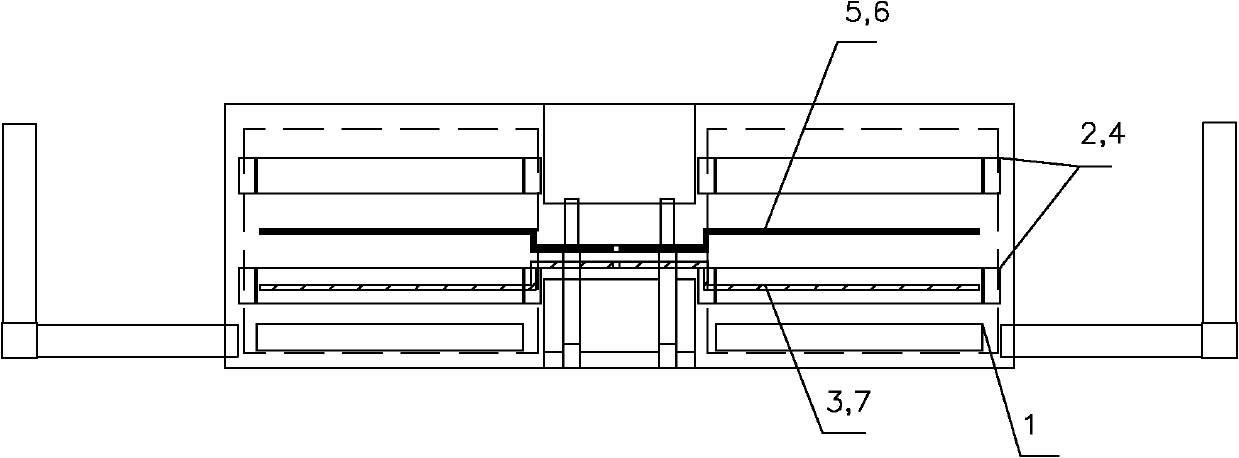

Synchronous and anti-clockwise twist spinning device and synchronous and anti-clockwise twist spinning method

ActiveCN106757568AImprove yarn qualityImprove spinning efficiencyDrafting machinesContinuous wound-up machinesYarnFiber

The invention provides a synchronous and anti-clockwise twist spinning device and a synchronous and anti-clockwise twist spinning method. The synchronous and anti-clockwise twist spinning device comprises a drafting mechanism and a winding mechanism, a yarn guiding device is arranged between the drafting mechanism and the winding mechanism, a false twist device is arranged between the drafting mechanism and the yarn guiding device, an upper side band and a lower side band are respectively contacted with fiber strands which are drafted and outputted through a front roller draft pair, a working face of pre-adding twist and a working face of balance twist are respectively formed, the working faces respectively generate twists opposite in twisting direction and identical in size with the fiber strands contacted with the working faces, the drafted double-fed strands are synchronously twisted through the twist generated from speed difference of a bobbin of a bead ring and the reverse twist synchronously generated from upper and lower working faces of the yarn guiding device, the final twist on yarn forming is unaffected by twist effect generated from a yarn forming area by the false twist device, double strands drafted are directed converged and twisted into yarn without changing final twist in yarn forming, quality in yarn forming is improved, and spinning efficiency is improved.

Owner:湖州菱创科技有限公司

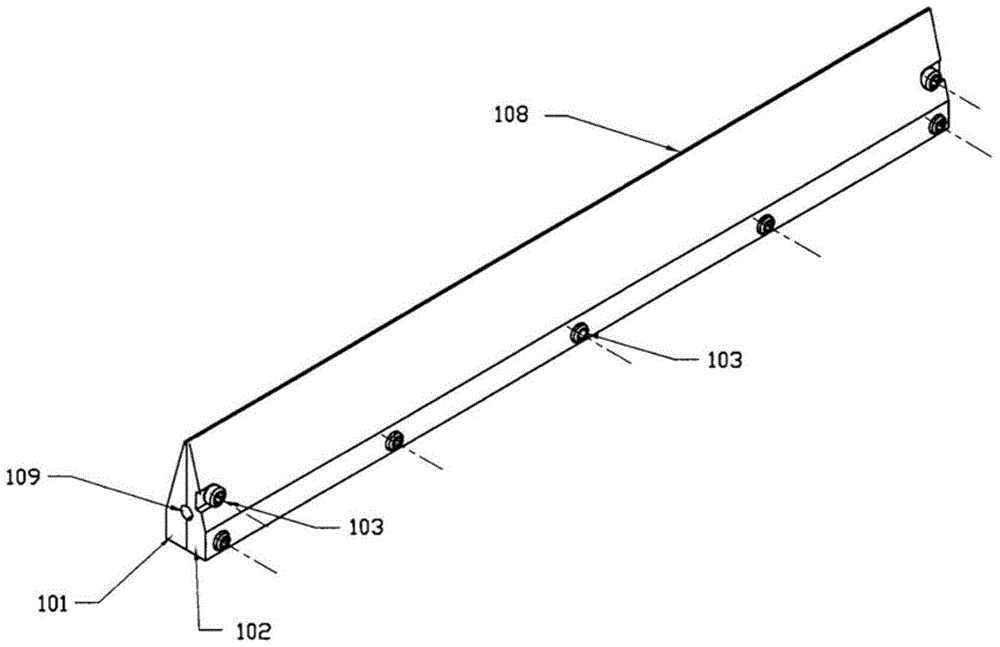

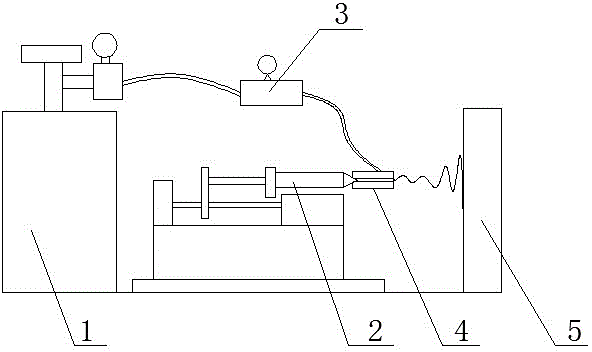

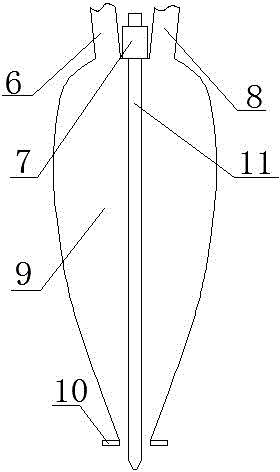

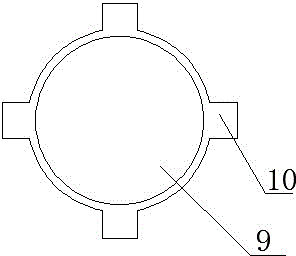

Detachable adjustable long shuttle type nozzle for solution jet spinning and application method thereof

ActiveCN104532368AImprove spinning efficiencyChange structure parametersSpinnerette packsArtificial thread manufacturing machinesFiberDiameter ratio

The invention discloses a detachable adjustable long shuttle type nozzle for solution jet spinning. The nozzle comprises an airflow inlet branch pipe A, an airflow inlet branch pipe B, a rubber plugging sleeve, a needle head, a long shuttle type airflow pipeline and a nozzle outlet adjusting device; the airflow inlet branch pipe A and the airflow inlet branch pipe B are communicated with the long shuttle type airflow pipeline with a certain angle; the rubber plugging sleeve is fixed between the airflow inlet branch pipe A and the airflow inlet branch pipe B and can adjust the distance of the needle head extending out of the outlet; the long shuttle type airflow pipeline can be retracted in a certain length-diameter ratio; the nozzle outlet adjusting device can adjust the section area o the outlet. Compared with other solution jet nozzles, the nozzle has the advantages that the mounting and the dismounting are convenient, the change of an airflow field in the jet solution spinning can be effectively adjusted, related technical parameters in the jet solution spinning can be effectively adjusted, the stretching airflow field in which fibers are positioned can be improved, and therefore, micro-nanofibers can be obtained conveniently.

Owner:JIAXING UNIV

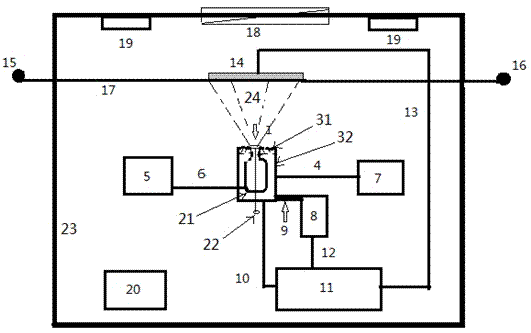

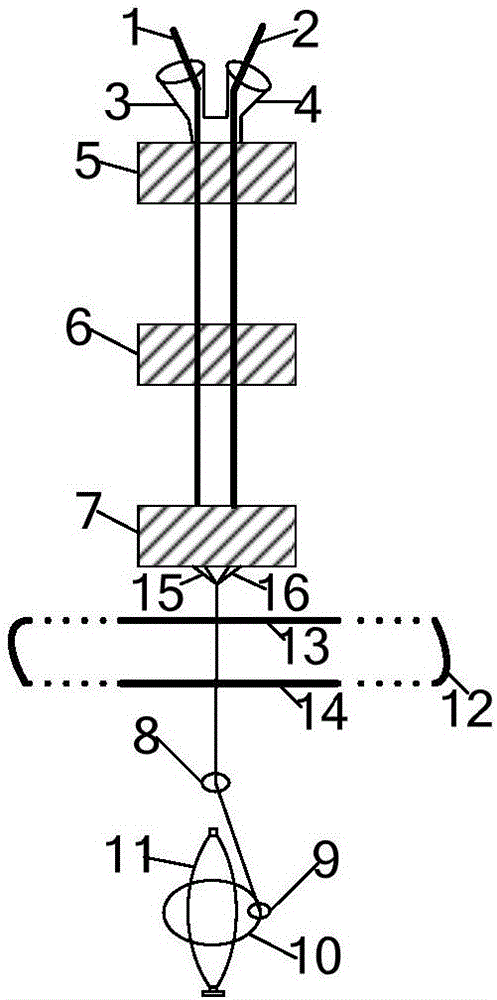

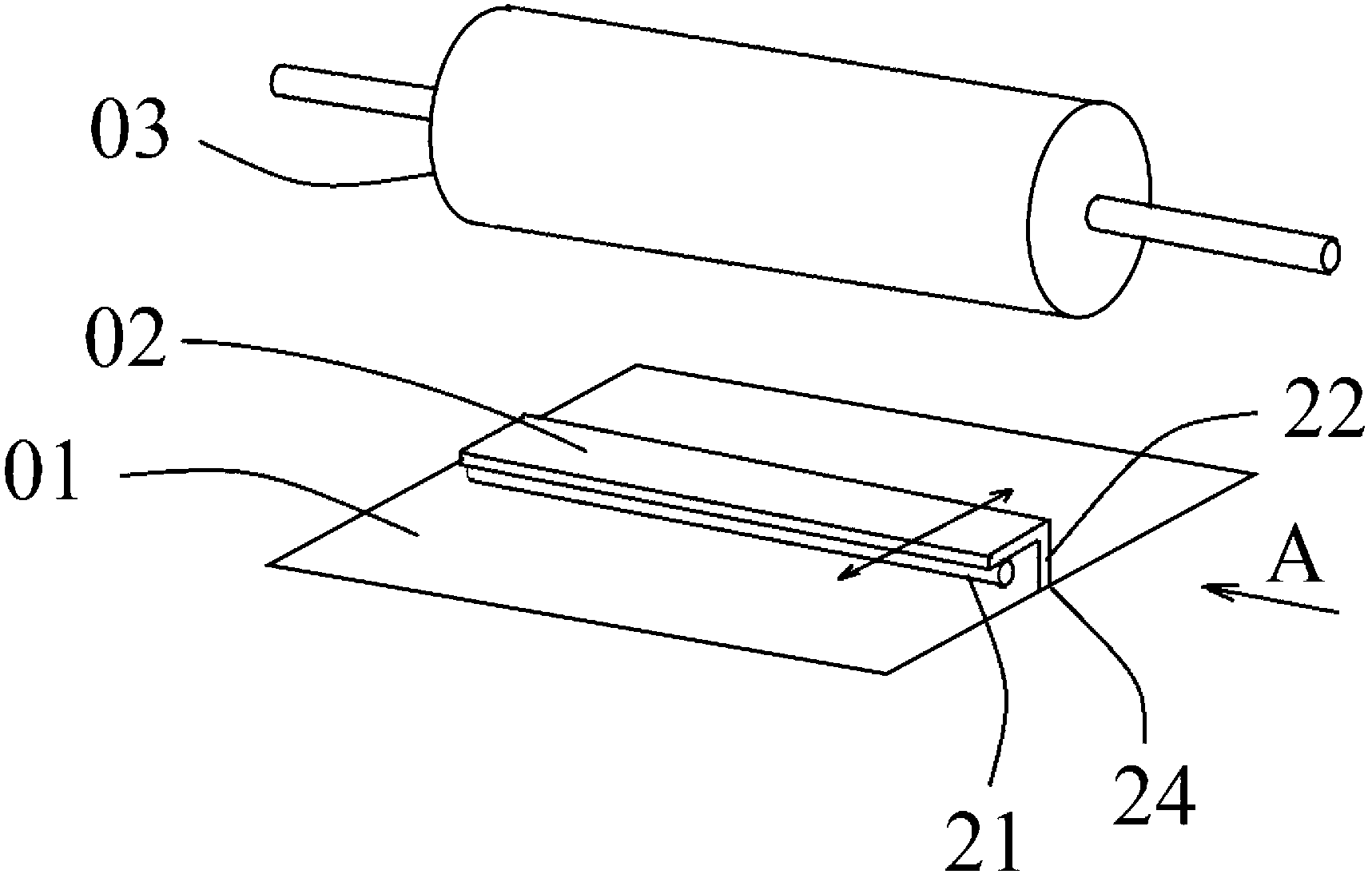

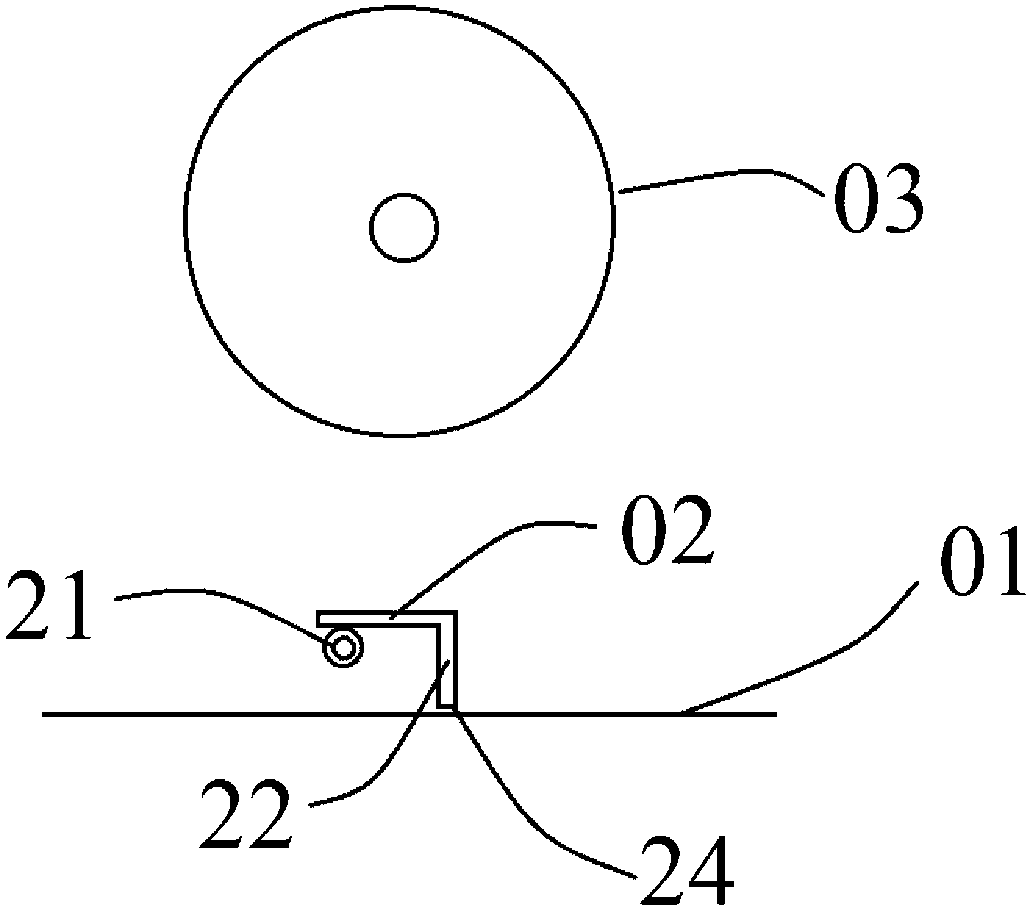

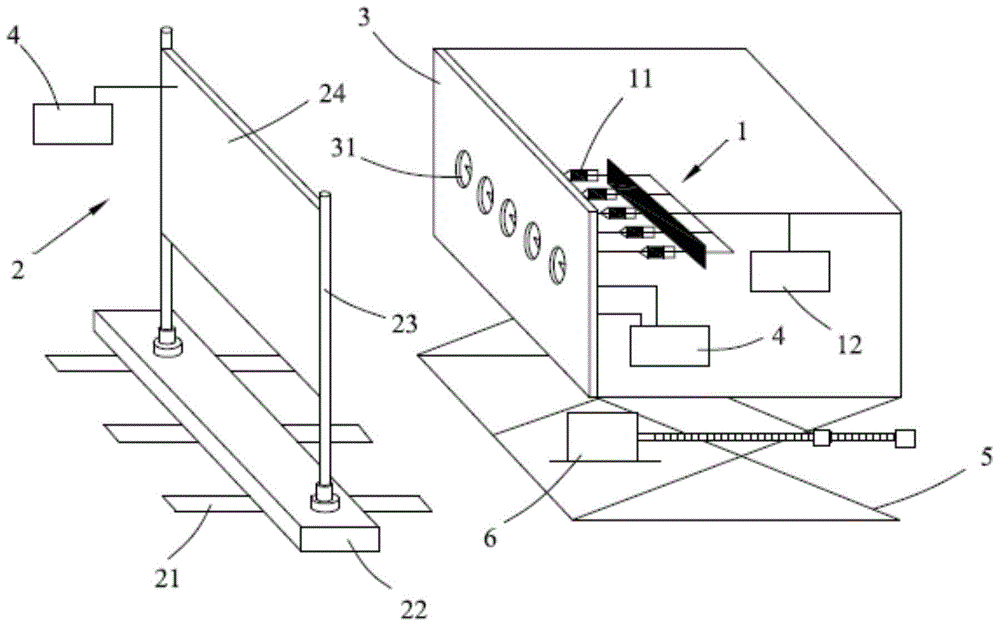

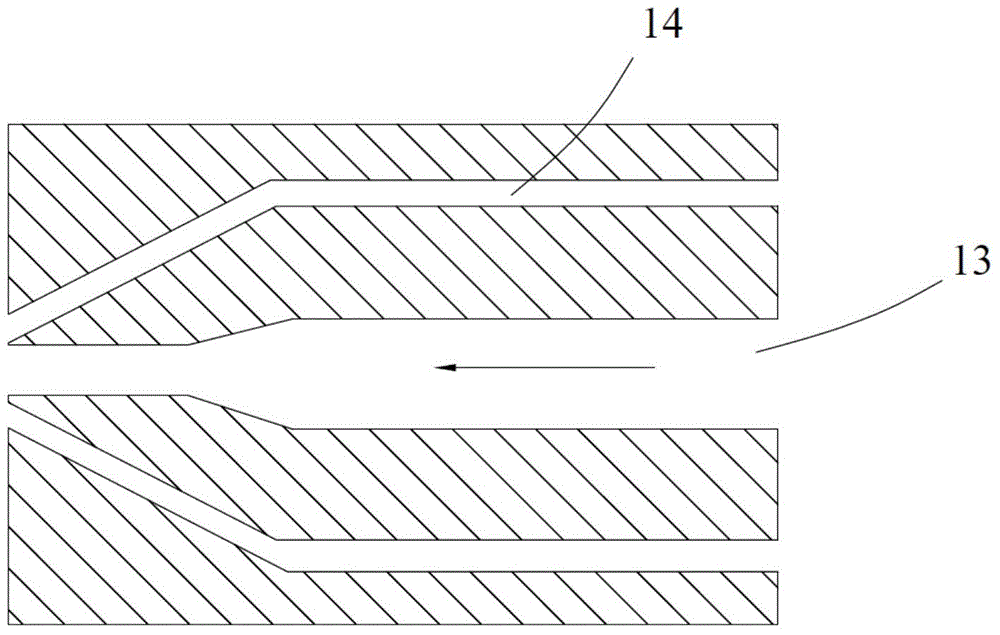

Polymer solution electrostatic spinning component, device and method

ActiveCN103194806AImprove spinning efficiencyOvercome technical issues that limit spinning efficiencyFilament/thread formingBiochemical engineeringPolymer solution

The invention provides a polymer solution electrostatic spinning component, a device and a method. The spinning component comprises a first electrode, a second electrode which is placed opposite to the first electrode, and a spraying mechanism which is positioned between the first electrode and the second electrode, wherein the first electrode is a plate electrode; and the spraying mechanism is used for spraying solution to the surface of the first electrode and is provided with a flat plate and a scraping cutter. Because the first electrode with a large area is used, a large-area spinning region can be formed, and the spinning efficiency is greatly improved. The flat plate in the spraying mechanism is used for flatly spraying a newly-sprayed spinning solution, and the scraping cutter can be used for removing the residual old solution of the previous spinning to prevent a new solution from being mixed with the old solution, so that the spinning quality is improved.

Owner:杨宝麟

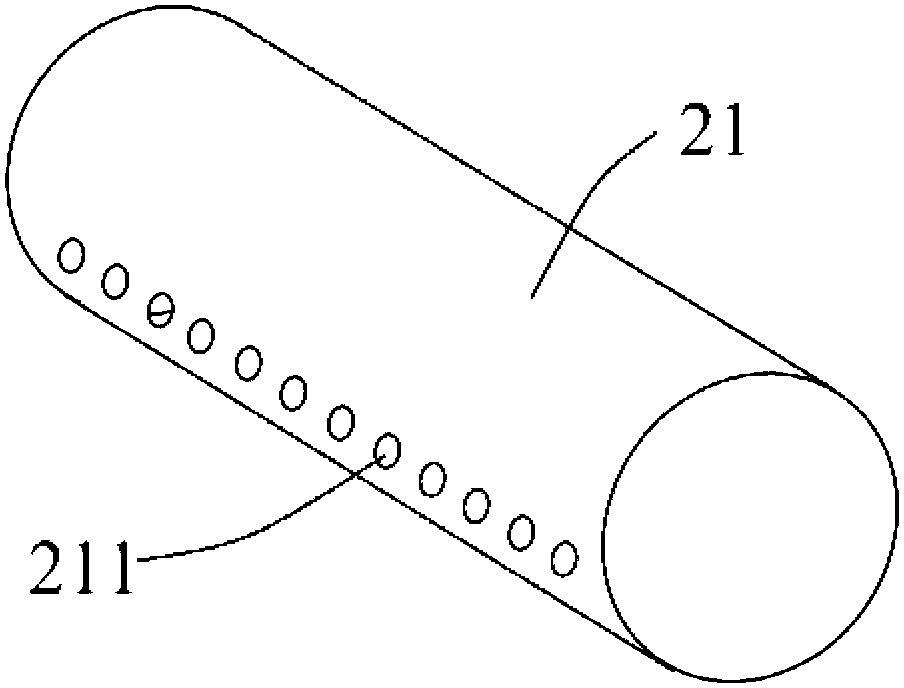

Electro-spinning micro-nanofiber device and method for preparing micro-nanofiber

InactiveCN106012053AImprove convenienceEnsure manufacturing stabilityFilament/thread formingFiberEngineering

The invention provides an electro-spinning micro-nanofiber device and a method for preparing a micro-nanofiber and belongs to the field of biological materials and tissue engineering. The electro-spinning micro-nanofiber device comprises a high-voltage power supply, receiving devices, a porous spinning jet and a rotary motor, wherein the porous spinning jet is of a hollow cylindrical structure, and the hollow part is an electro-spinning stock solution storage groove capable of accommodating an electro-spinning stock solution; a plurality of spray orifices are formed in the surface of the porous spinning jet; one pole of the high-voltage power supply is connected with the receiving devices, and the other pole of the high-voltage power supply is connected with the porous spinning jet; the rotary motor drives the porous spinning jet to rotate. By virtue of the porous device, the yield can be improved, and micro-nanofibers with uniform directivity are obtained. Meanwhile, the required application voltage can be greatly reduced, and the method for adjustment and control of the more uniform spinning directivity through a single step is also provided.

Owner:ZHEJIANG UNIV

Multi-nozzle static spinning device

InactiveCN104060336AEffective isolationBalanced working electric fieldFilament/thread formingFiberAir pump

The application discloses a multi-nozzle static spinning device which comprises a plurality of spinning nozzles, a collecting device and high voltage power supplies, wherein a spinning solution flow passage is formed in each spinning nozzle in the axial direction; warm air flow passages are formed in the periphery of each spinning solution flow passage; the warm air flow passages are communicated with an air pump; a heating device is arranged between the air pump and the warm air flow passages. According to the invention, the warm air flow passages are formed in the periphery of each spinning solution flow passage, through the stretching function of the warm air flow passage, the diameter of the fiber can be further reduced, the unstability of the static spinning process can be improved, the landing direction of fibers can be guided, and the efficiency of the static spinning technology can be improved; through the utilization of the combined action of airflow stretching and electrostatic force stretching, the controllability and yield of nanofiber preparation can be improved, and the yield is improved by times to dozens of times as compared with the standard electrospinning technology.

Owner:张家港市宏盛贸易有限公司

Anti-haze screen window and preparing method thereof

ActiveCN107575151AImprove spinning efficiencyEfficient cycleInsect protectionFilament/thread formingParticulatesPolyethylene terephthalate glycol

The invention relates to an anti-haze screen window and a preparing method thereof. The anti-haze screen window is made of high polymer materials, titanium dioxide nanoparticles and screen window materials through an electrostatic spinning method. The high polymer materials are one or more of polyvinylidene fluoride, poly methyl methacrylate, thermoplastic polyurethane, polyacrylonitrile and polyethylene terephthalate. According to the anti-haze screen window, the spinning efficiency is high, nano-fiber membranes are uniform and are in close fitting with the screen window, holes are dense, ventilation and breathability are achieved, the screen window can be anti-haze, anti-dust, anti-pollen and anti-mosquito, PM2.5 particulate matters are be effectively blocked, the PM2.5 filtering efficiency reaches more than 99%, clean air effective circulation indoor and outdoor is maintained, and exhaust gas pollution of automobile tail gas is effectively solved. The preparing method of the anti-haze screen window is simple, raw materials are easy to obtain, the cost is low, and scale production is easy.

Owner:HEBEI NAINUO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com